Forging and heat treatment process of marine anticorrosion pull rod duplex stainless steel forge piece

A duplex stainless steel, forging heating technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of metallographic structure prone to intergranular precipitate grains, complex manufacturing process, and high product scrap rate, and improve the All aspects of performance, grains are more uniform and refined, and the effect of eliminating the as-cast structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

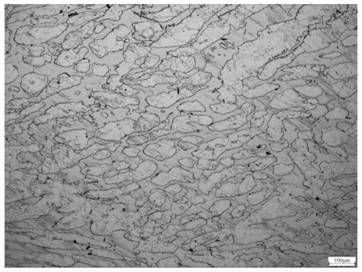

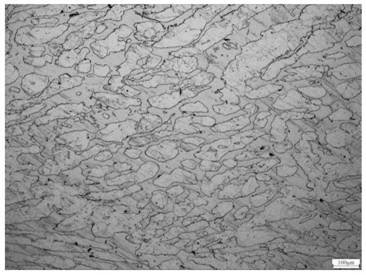

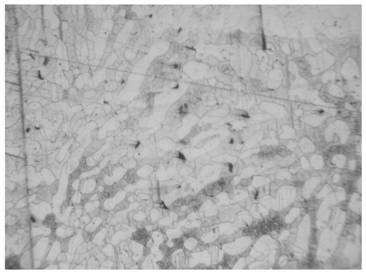

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of forging and heat treatment process of the duplex stainless steel forging of anti-corrosion tie rod for marine, such as figure 1 shown, including the following steps:

[0033] S1. Smelting the raw materials to obtain steel ingots: the raw materials are sent to the electric arc furnace for smelting, then the raw materials are refined out of the furnace, and finally the raw materials are electroslag remelted to obtain steel ingots.

[0034] S2. Steel ingot forging and heating, including the following steps:

[0035] (1) Furnace loading; the temperature of steel ingot loading furnace is ≤400℃.

[0036] (2) Heating: According to the maximum heating power, the temperature is raised to 400-800°C, and then the temperature is evenly raised to the holding temperature.

[0037] (3) Heat preservation: heat preservation is carried out in stages. The heat preservation temperature of the first stage is 860°C; the heat preservation temperature of the second st...

Embodiment 2

[0050] Embodiment 2: A forging and heat treatment process of a marine anti-corrosion tie rod duplex stainless steel forging. Its different steps from Embodiment 1 are:

[0051] S3. Steel ingots are forged to obtain forgings. Forging includes three steps:

[0052] 1. The first firing: the steel ingot is heated up to the forging temperature, and the forging temperature is 1150°C, and then the steel ingot is drawn, upset, and drawn out in sequence to ensure that the final forging temperature is ≥ 650°C, and the total drawing length ratio is > 2.2; total upsetting Rough ratio > 2.2. Then put the steel ingot into the forging heating furnace for heating, the heating temperature is 1140°C, the heating time is positively related to the thickness of the steel ingot, and the steel ingot with a thickness of 200mm is heated for 1-1.2h.

[0053] 2. The second firing: the steel ingot is heated up to the forging temperature, and the forging temperature is 1130°C. After the forging is heated...

Embodiment 3

[0057] Embodiment 3: A forging and heat treatment process of a marine anti-corrosion tie rod duplex stainless steel forging. Its different steps from Embodiment 1 are:

[0058] S3. Steel ingots are forged to obtain forgings. Forging includes three steps:

[0059] 1. The first firing: the steel ingot is heated up to the forging temperature, and the forging temperature is 1160°C, and then the steel ingot is drawn, upset, and drawn out in sequence to ensure that the final forging temperature is ≥ 650°C, and the total drawing length ratio is > 2.2; total upsetting Rough ratio > 2.2. Then put the steel ingot into the forging heating furnace for heating, the heating temperature is 1150°C, the heating time is positively related to the thickness of the steel ingot, and the steel ingot with a thickness of 200mm is heated for 1-1.2h.

[0060] 2. The second firing: the steel ingot is heated up to the forging temperature, and the forging temperature is 1140°C. After the forging is heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com