Closed cold-temperature precision forging die for straight-tooth bevel gear

A bevel gear and precision forging technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of complex structure, difficult to form structural parts, high production cost, etc., and achieve strength And high precision, easy control, good surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

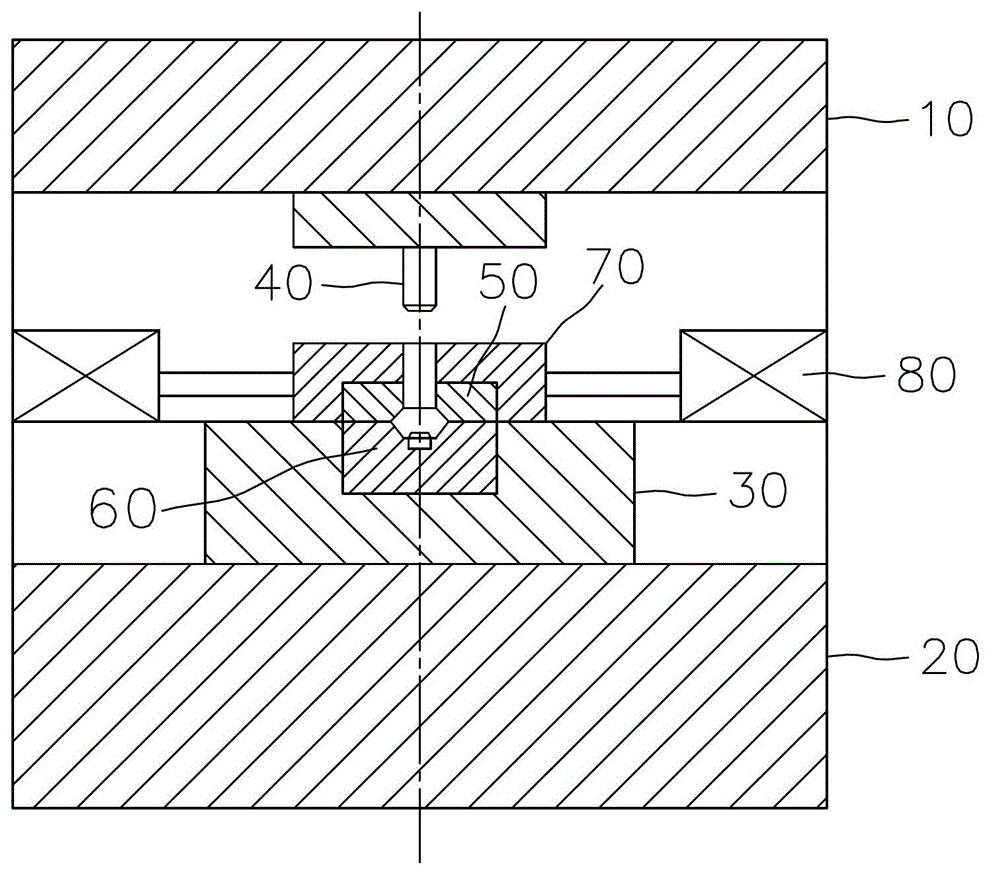

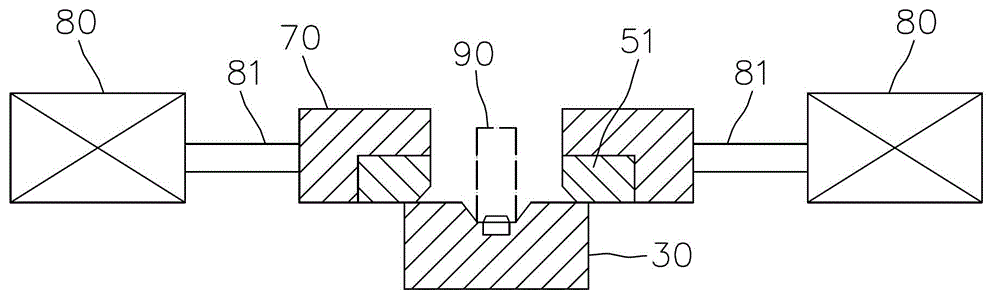

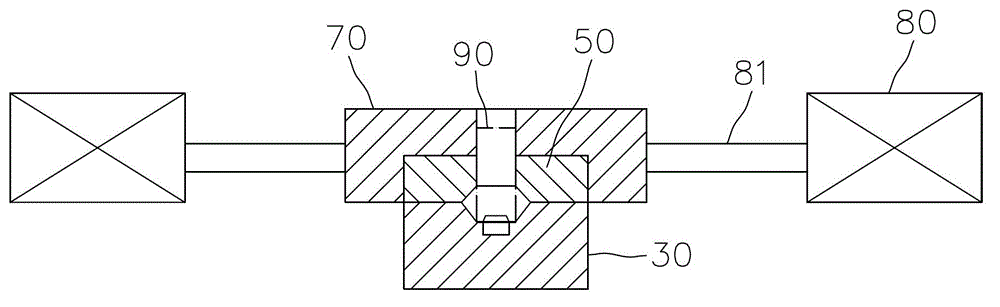

[0027] like figure 1 A closed-type cold and warm precision forging die for straight bevel gears is shown, comprising a precision forging upper die 50, a precision forging lower die 60 and an upper punch 40, and the precision forging upper die 50 is composed of several upper die units 51, and each upper die unit 51 is provided with a corresponding drive mechanism, and the upper die units 51 are connected to each other and enclosed by the drive of the drive mechanism to form the precision forging upper die 50 and are scattered in order to facilitate Take out the two states of the forging 90; the upper ends of the upper die units 51 connected to each other are provided with passages for the upper punches 40 to pass through.

[0028] Preferably, the parting surface between the precision forging upper die 50 and the precision forging lower die 60 is a plane, and each upper die unit 51 constituting the precision forging upper die 50 translates along the parting surface under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com