Patents

Literature

682results about How to "Improve internal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

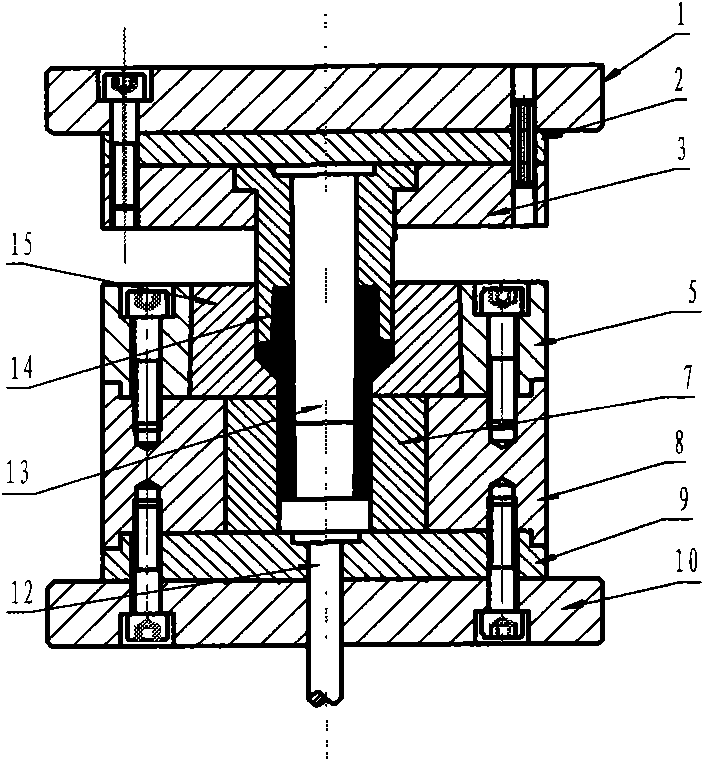

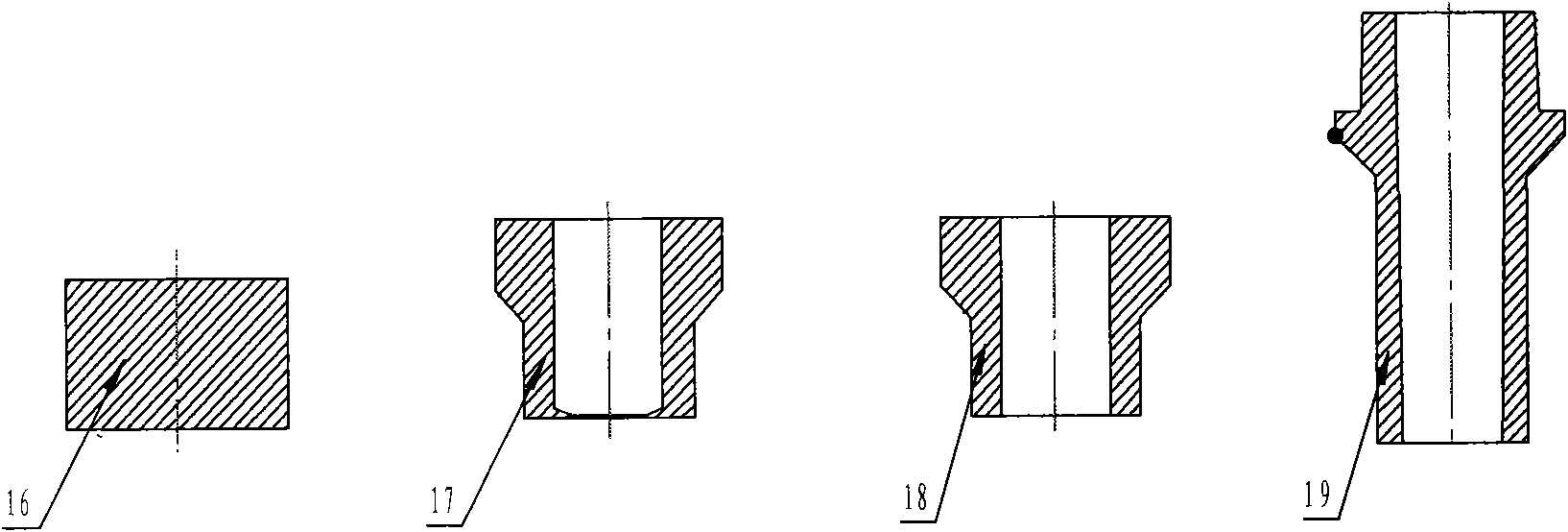

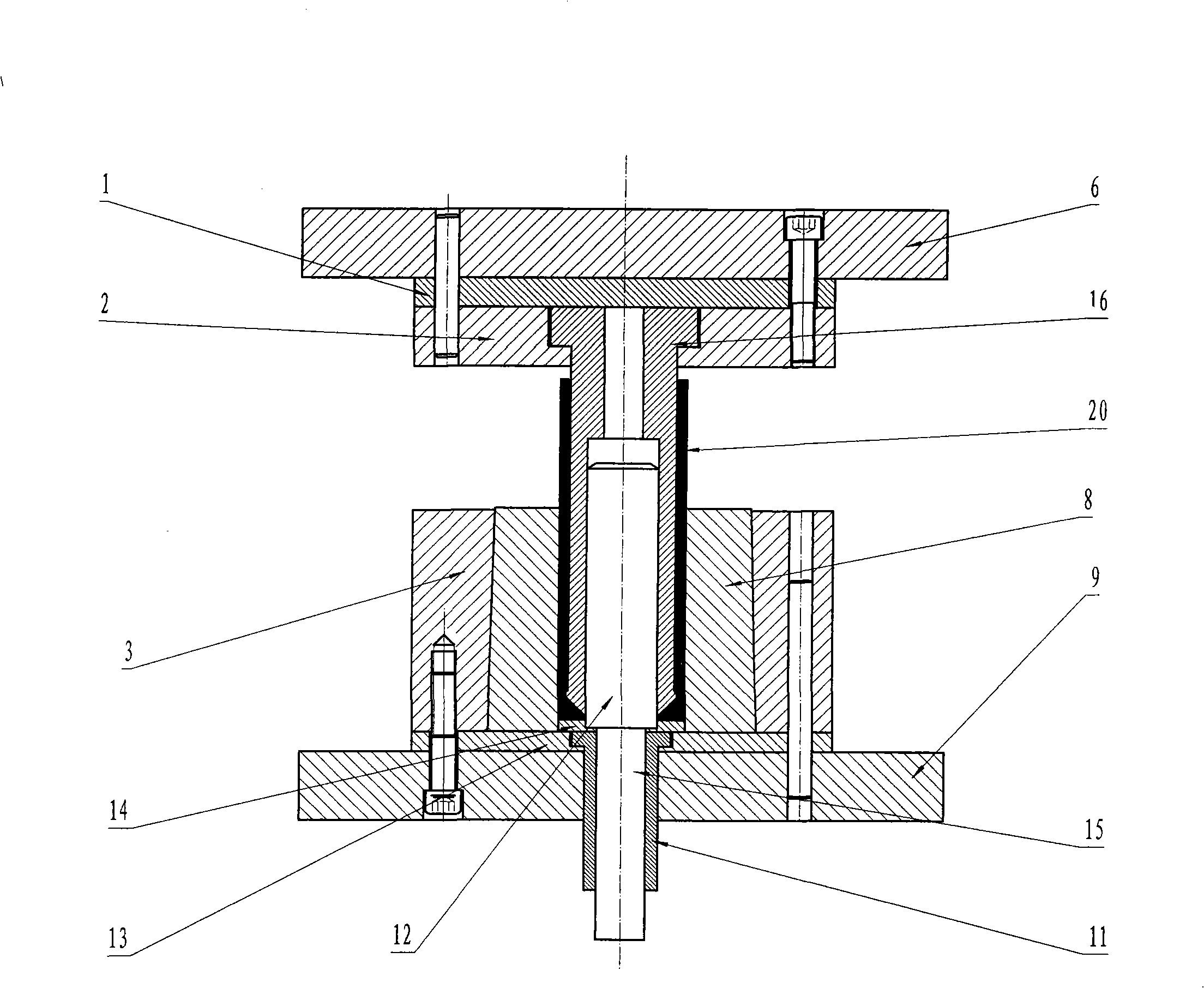

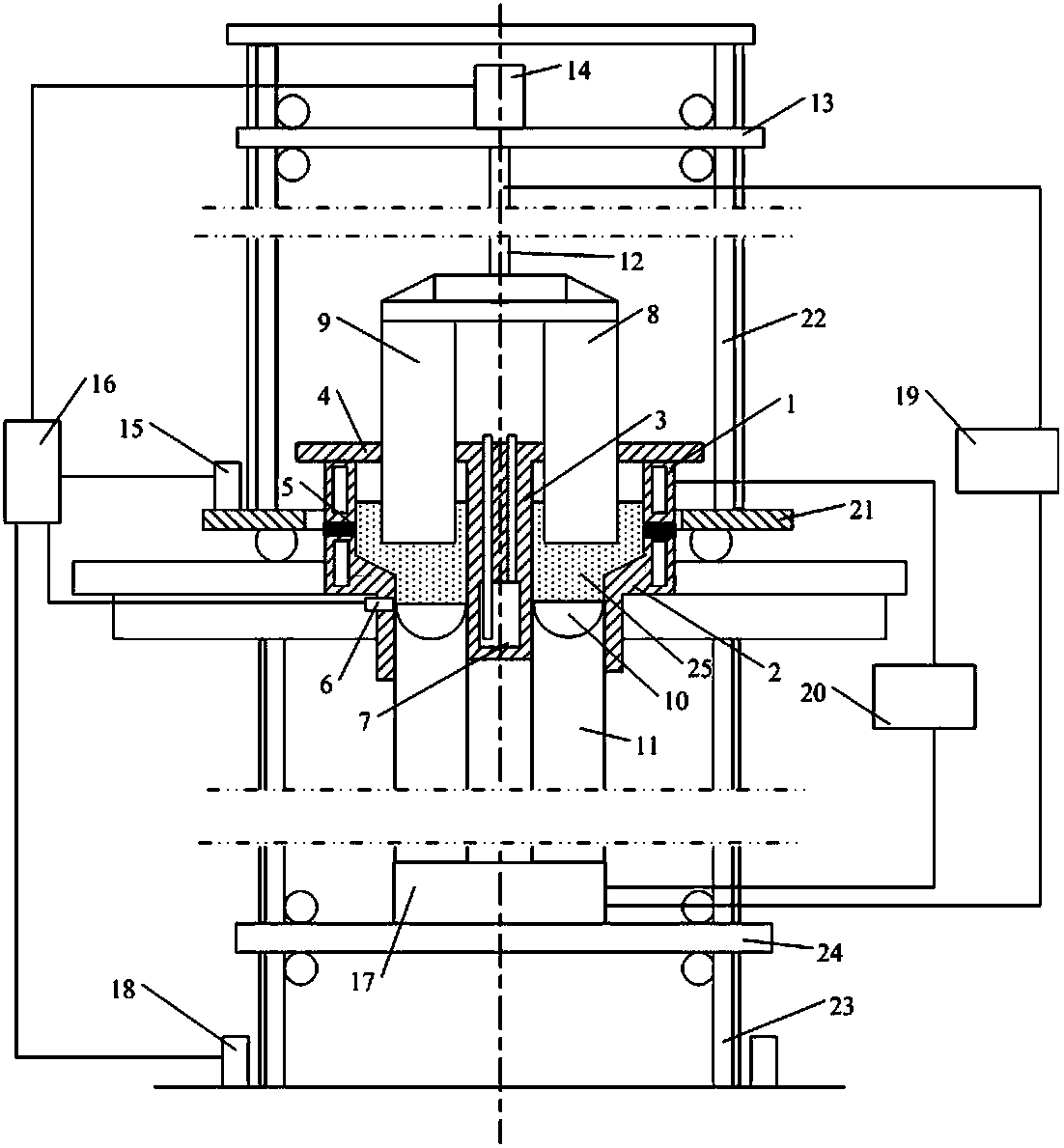

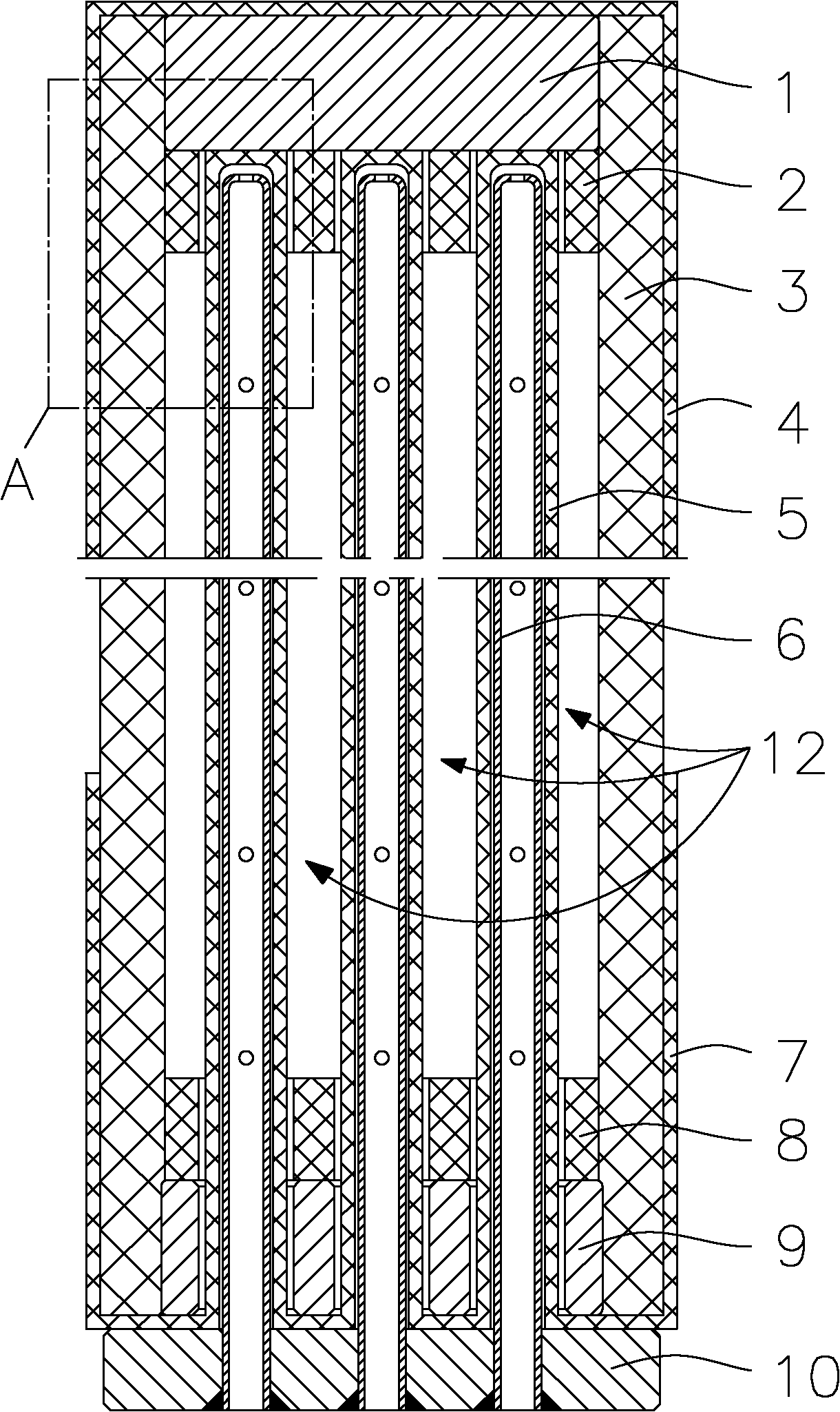

Extrusion forming process of thin-wall long pipe-shaped part blank with flange and mould

InactiveCN101829698AImprove internal qualityHigh dimensional accuracyExtrusion diesMaterials scienceForming processes

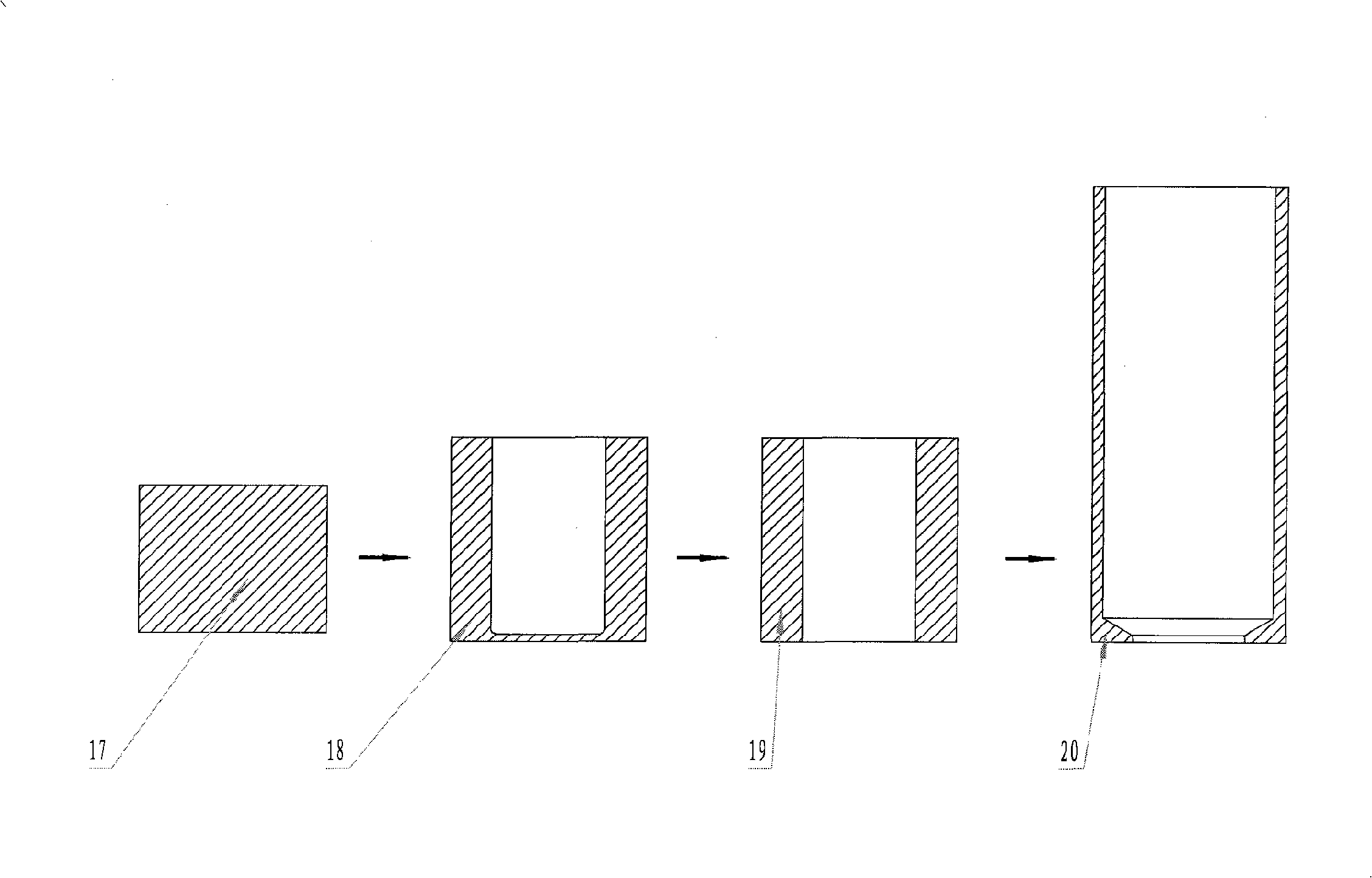

The invention belongs to extrusion forming technologies for non-ferrous metal materials and relates to a precise extrusion forming process of a thin-wall long pipe-shaped part blank with a flange. The forming process comprises two steps of primary backward extrusion and secondary forward extrusion, wherein in the step of primary backward extrusion, a primary backward extrusion convex mould (6) is utilized to match with a primary backward extrusion concave mould to together with a piece pusher (11) as an auxiliary for obtaining a primary backward extrusion pipe blank (17) with a web; a secondary forward extrusion convex mould consisting of a forward extrusion convex mould (14) and a mandrel (13) and a secondary forward extrusion concave mould (15) are utilized to carry out the secondary forward extrusion; and the secondary forward extrusion convex mould is placed into a primary backward extrusion pipe blank (18) and moves downwards to extrude the primary backward extrusion pipe blank (18) to obtain a secondary forward extrusion pipe blank (19) so as to finish a secondary forward extrusion process. The internal quality, the size precision and the material utilization rate of the produced thin-wall long pipe-shaped part blank with the flange are greatly improved; and meanwhile, the production efficiency is improved, and the production cost is reduced.

Owner:HENAN UNIV OF SCI & TECH

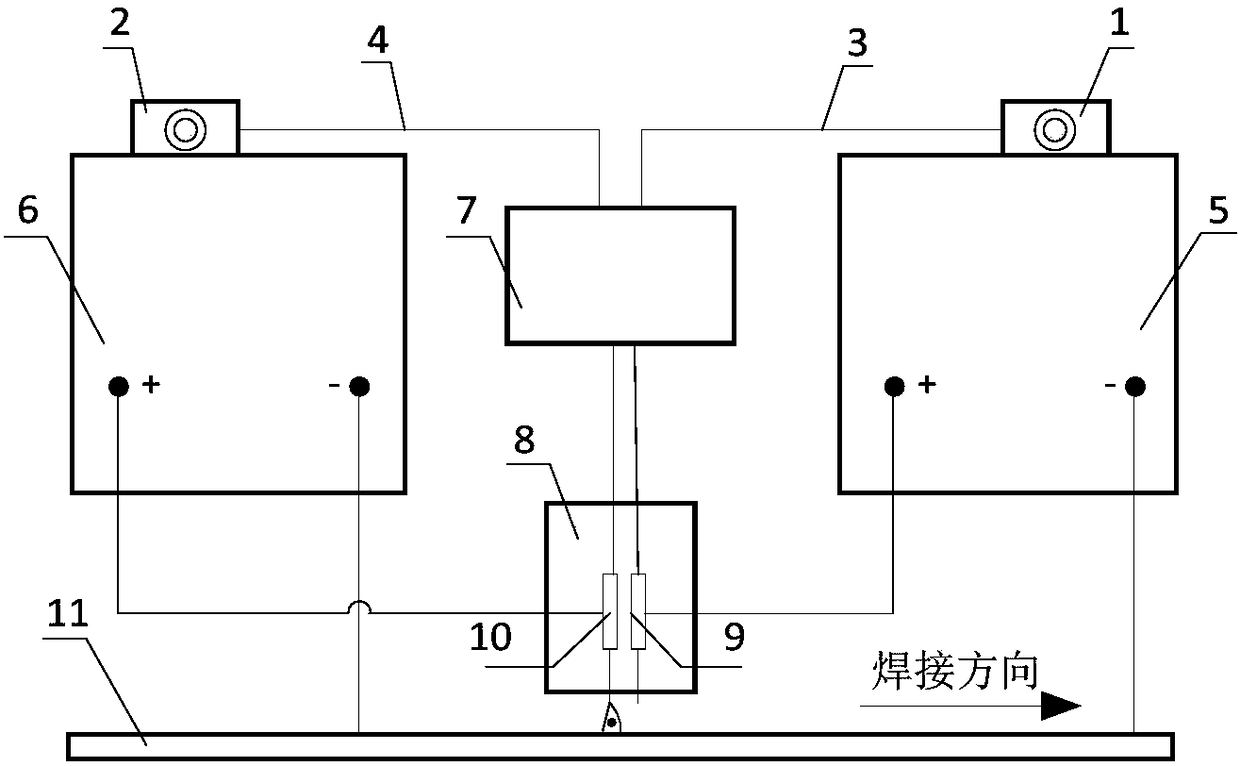

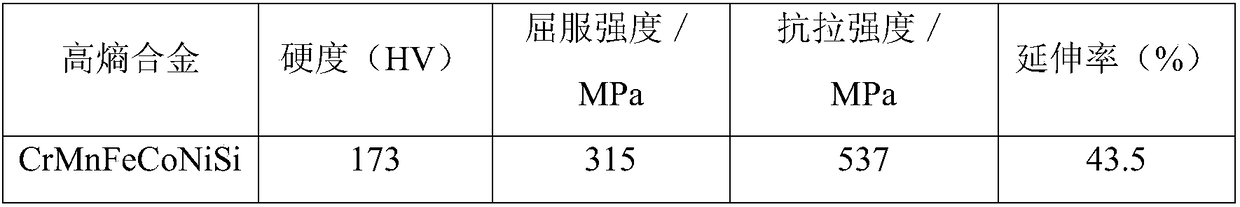

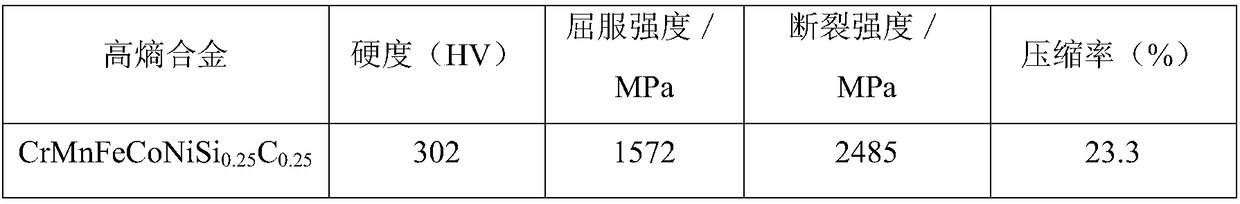

Double-arc fuse collaborative additive manufacturing method of high-entropy alloy

ActiveCN108326427AEasy to adjust ingredientsEasy to adjust grain sizeAdditive manufacturing apparatusLaser beam welding apparatusManufacturing technologyHigh entropy alloys

The invention relates to the technical field of high-entropy alloys, and specifically discloses a double-arc fuse collaborative additive manufacturing method of a high-entropy alloy. The method is characterized in that raw materials are supplied based on a formula of the high-entropy alloy, wherein the raw materials include an alloy strip and flux core powder; the alloy strip and the flux core powder are prepared into a flux cored welding wire; and then a double-arc fuse collaborative additive manufacturing method is carried out to obtain a part or a blocky alloy as requirement. The method isstable in processes, high in cladding efficiency, high in preparation efficiency, wide in heat input adjusting range, low in cost, convenient to adjust the components of the alloy and the size of crystal grains; in addition, the method is applicable to manufacturing of massive high-entropy alloys as well as precise high-entropy alloy parts.

Owner:SHIJIAZHUANG TIEDAO UNIV

Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

ActiveCN103586433AImprove internal qualityImprove the qualified rate of flaw detectionMetallurgyContinuous casting

The invention discloses a method for increasing the flaw detection yield of a continuous casting sheet head billet and a tail billet. The flaw detection yield of the head billet and the tail billet is increased by improving internal quality of casting billets in the casting process and after the casting stopping process and optimizing technological operation. According to the method, through technological optimization and control under the unstable state condition, the internal quality of the head billet and the internal quality of the tail billet are improved, and then the flaw detection yield of steel sheets is increased. The method is suitable for the field of sheet billet continuous casting, and has significant economical value and practical significance in improving the quality of the casting billets under the continuous casting billet unstable state condition, and especially in improving the quality of variety steel and the material yield.

Owner:NANJING IRON & STEEL CO LTD

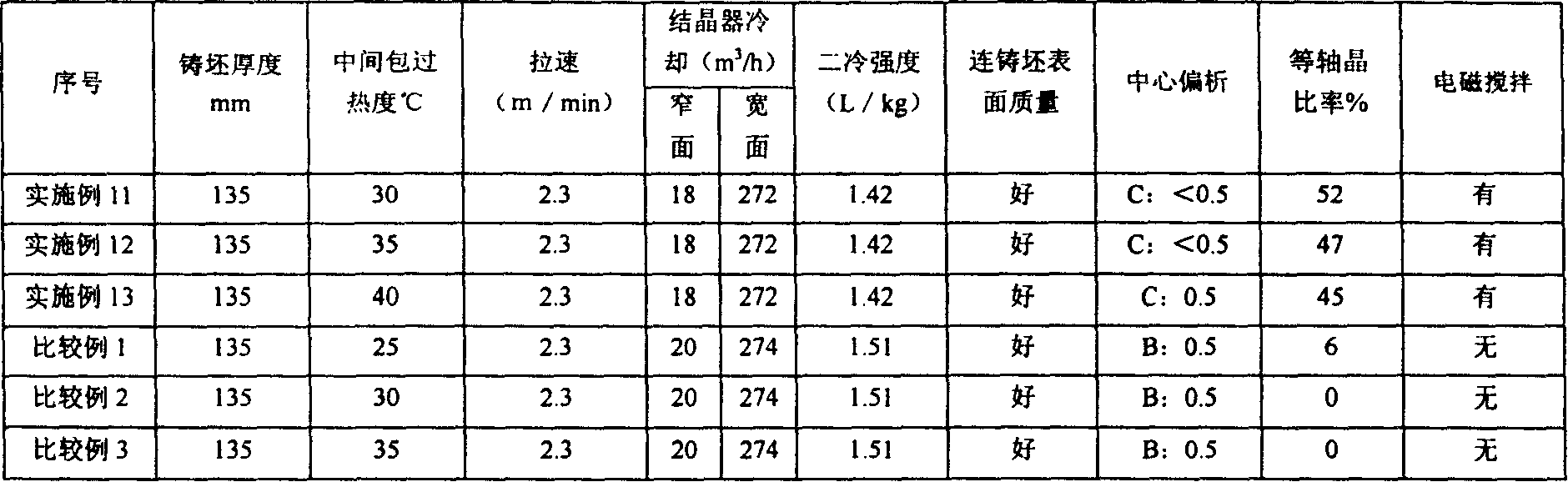

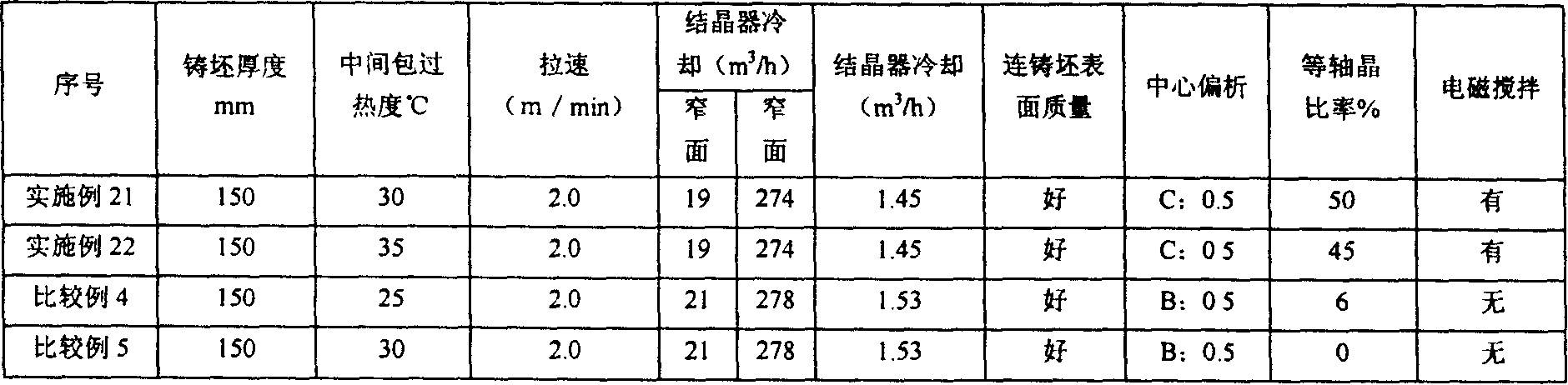

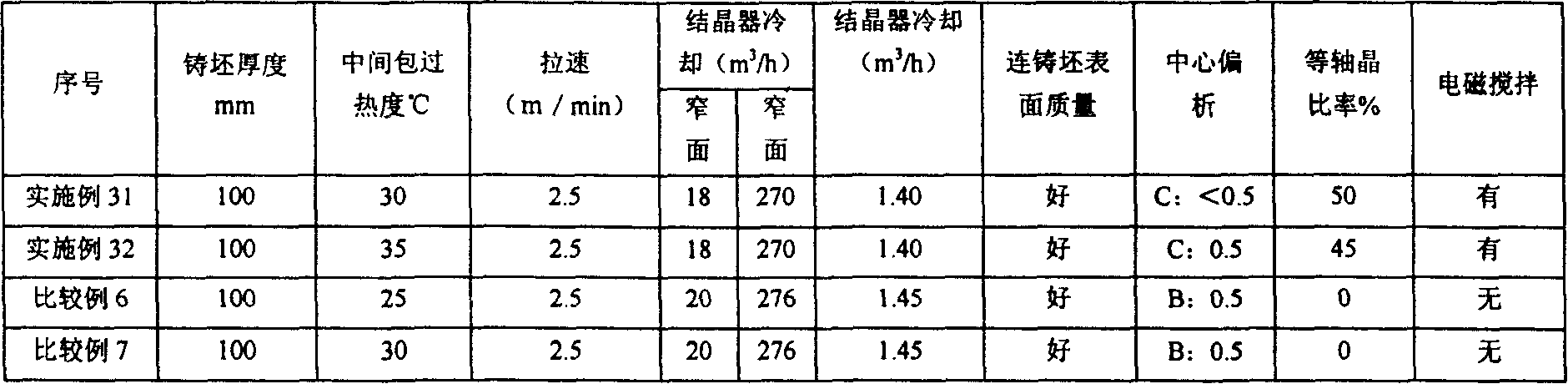

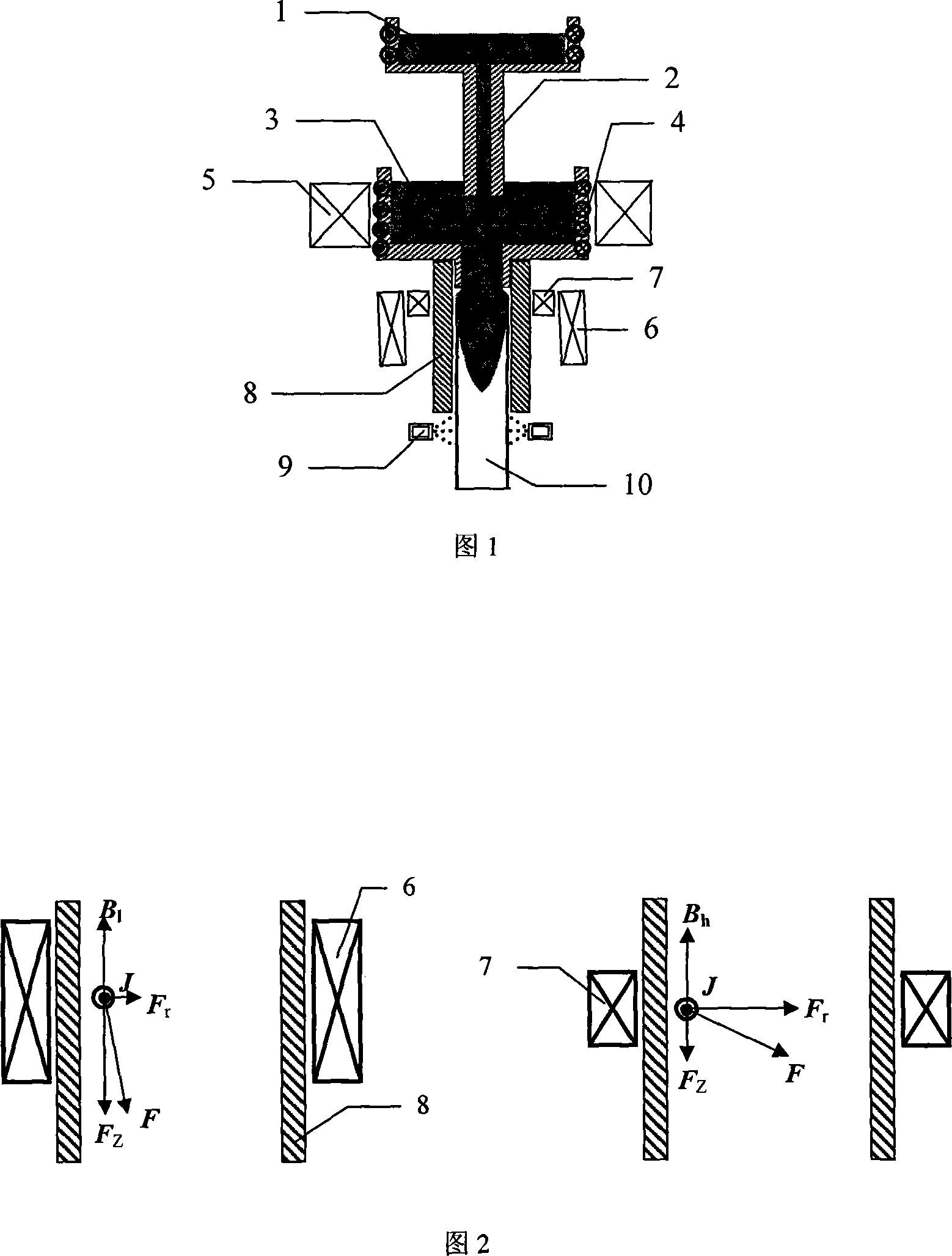

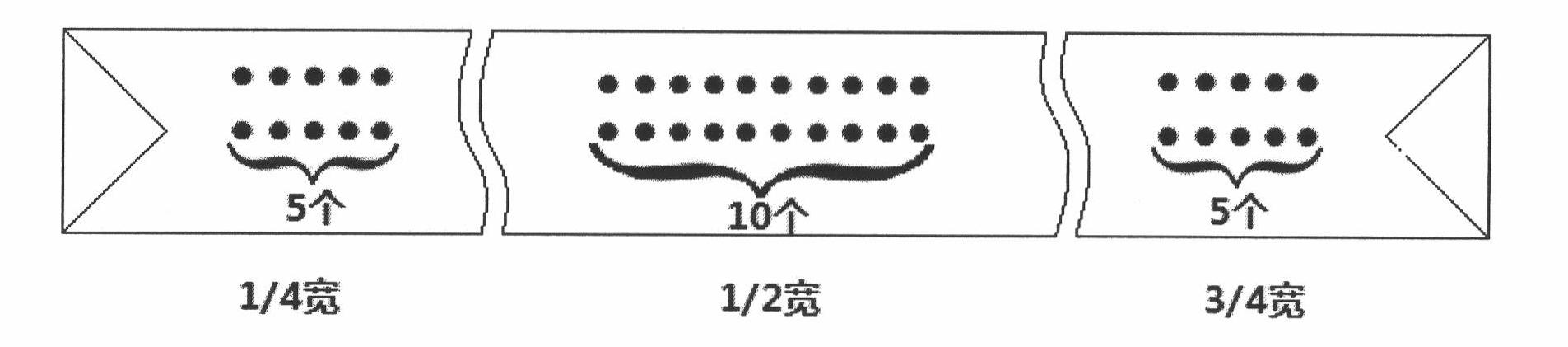

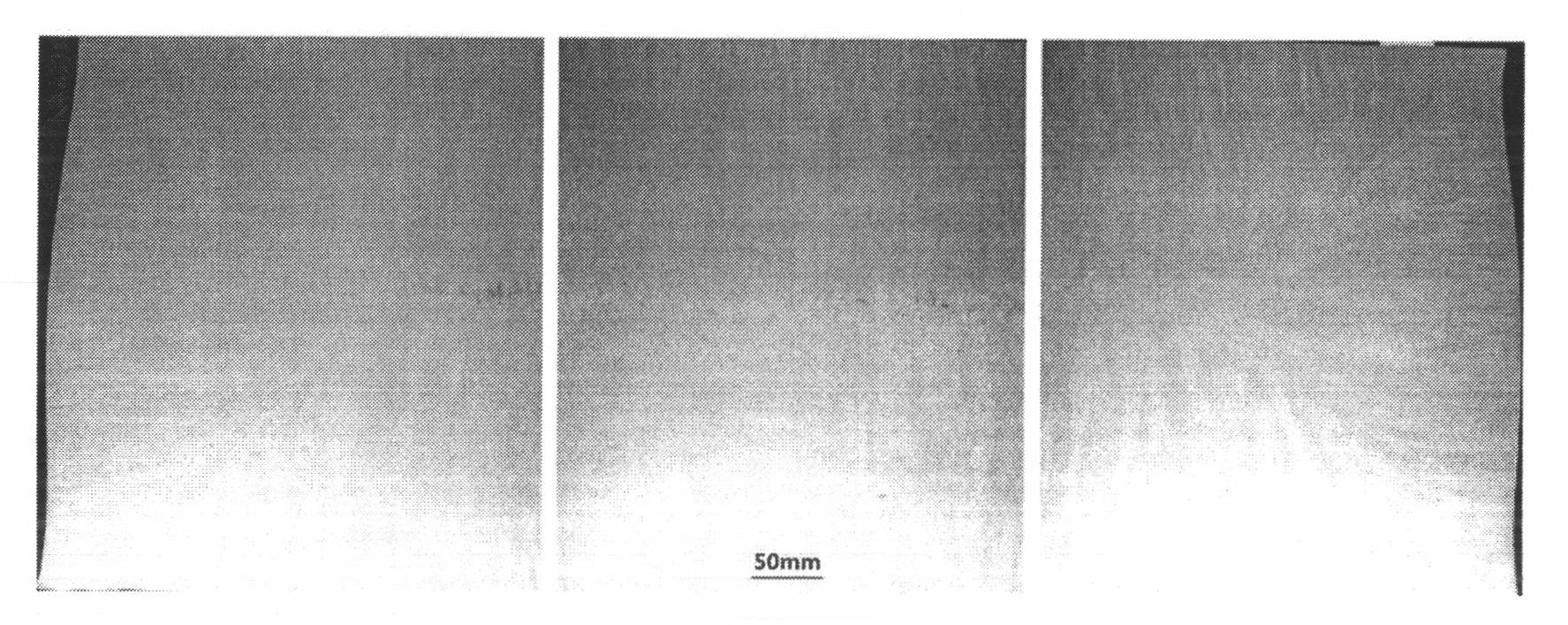

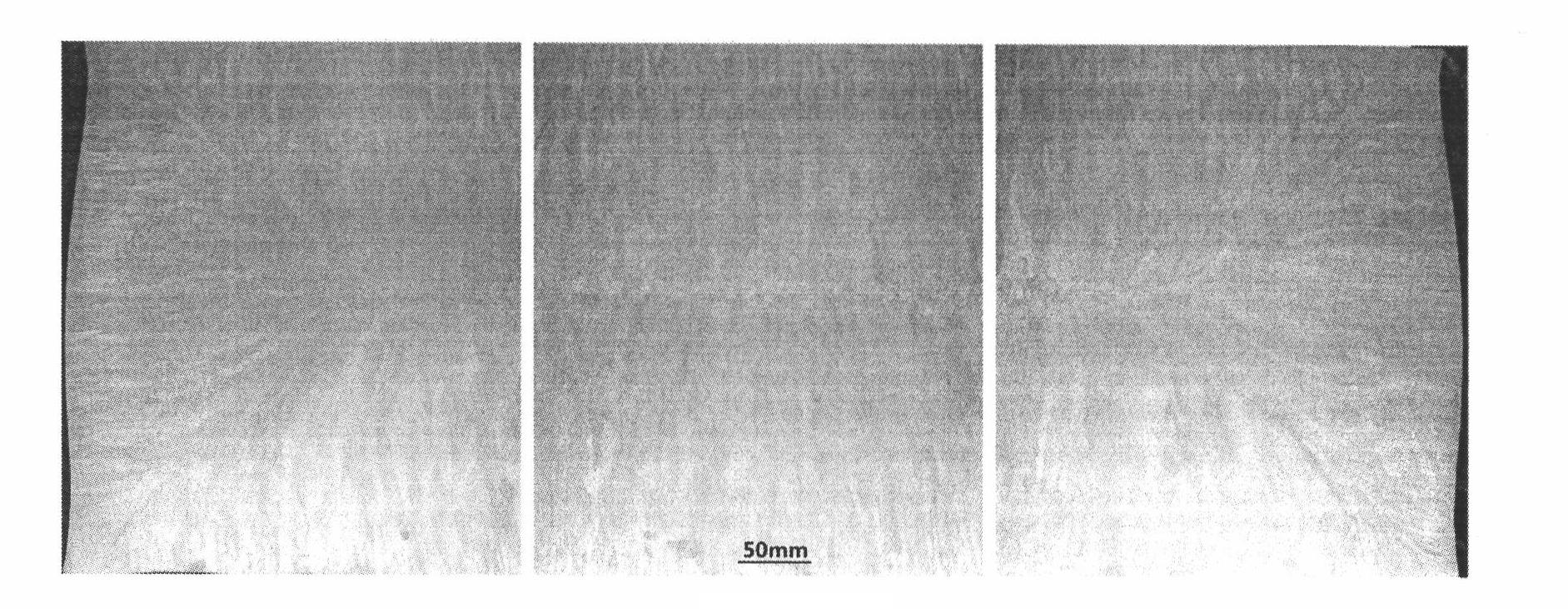

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

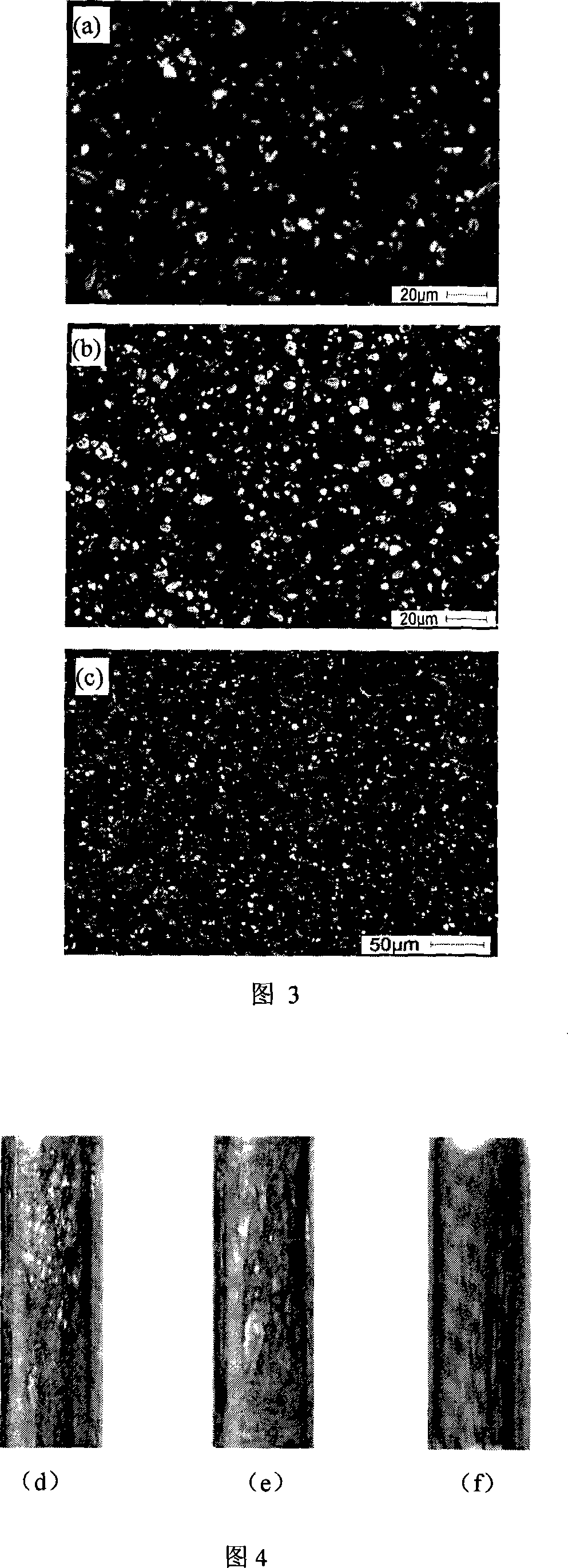

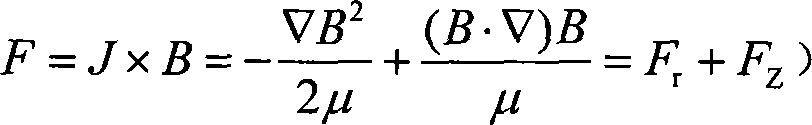

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

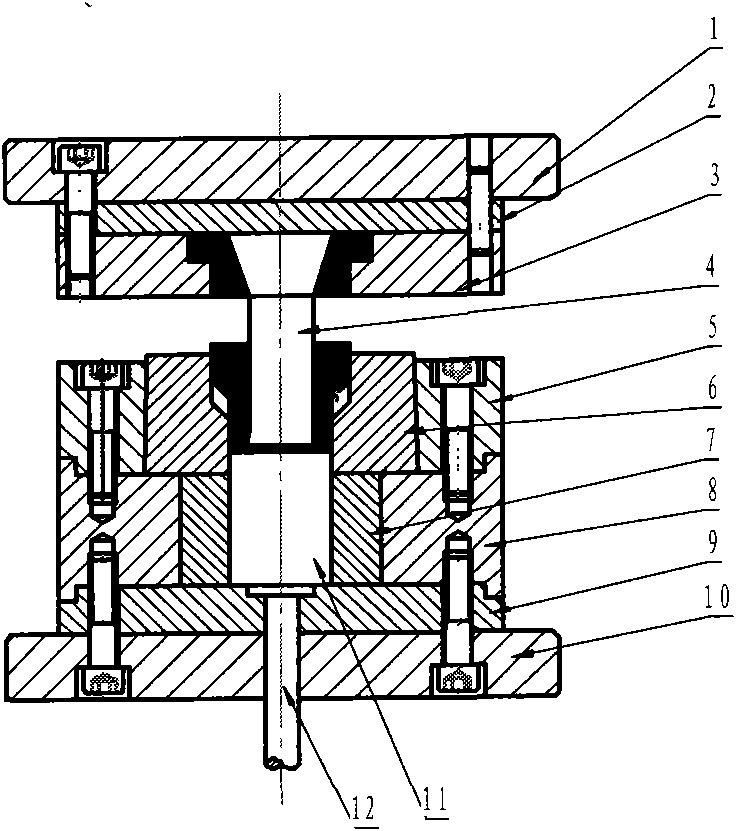

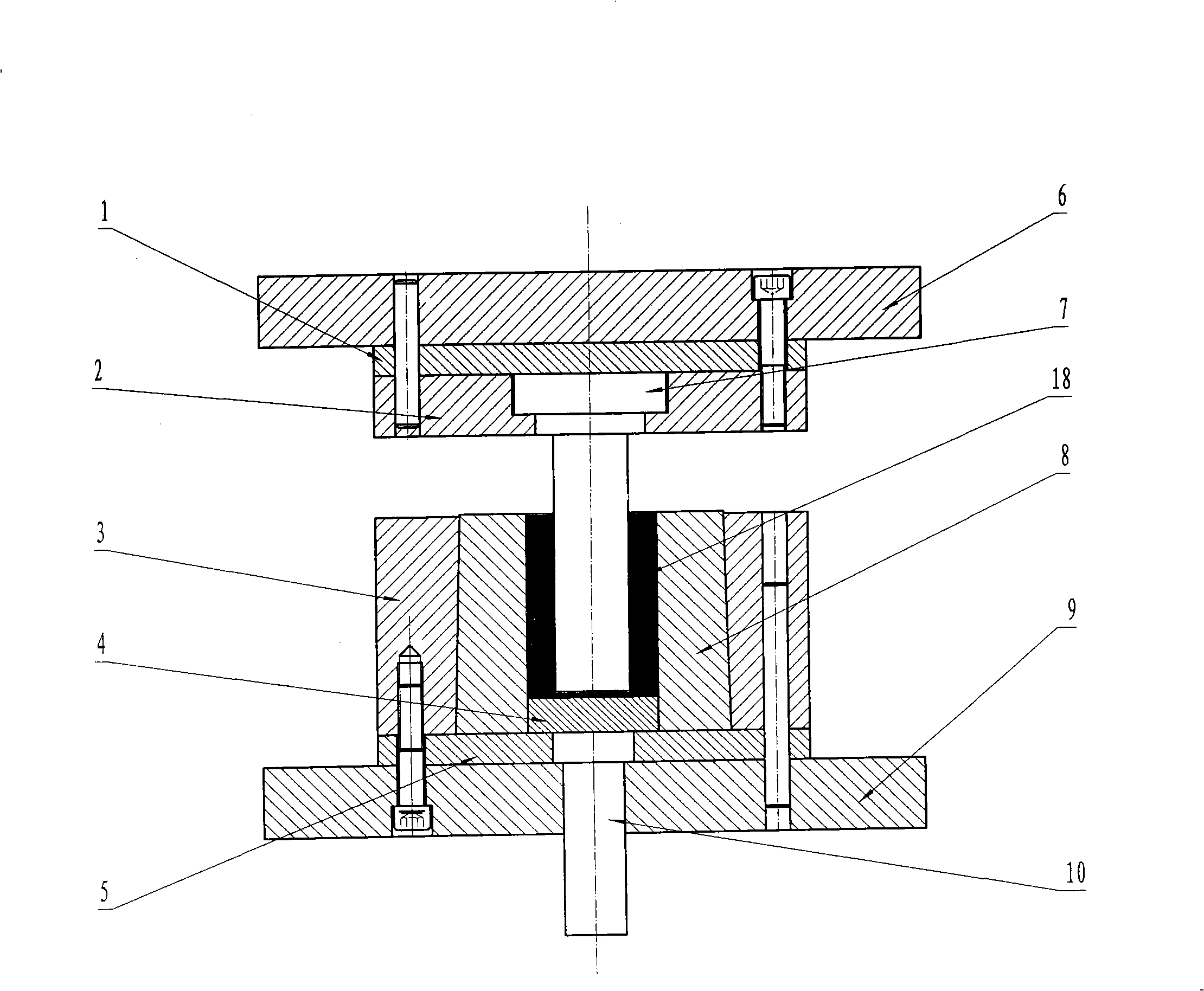

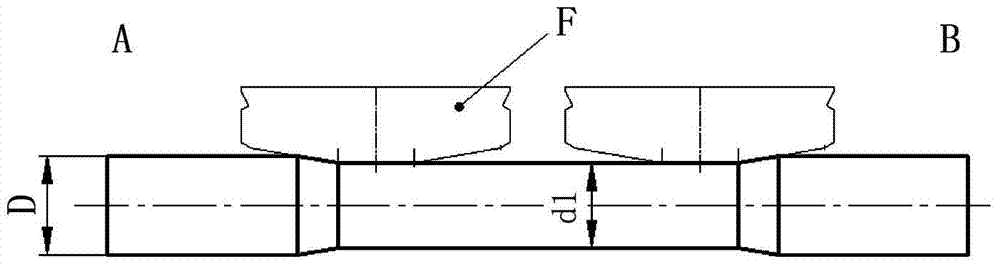

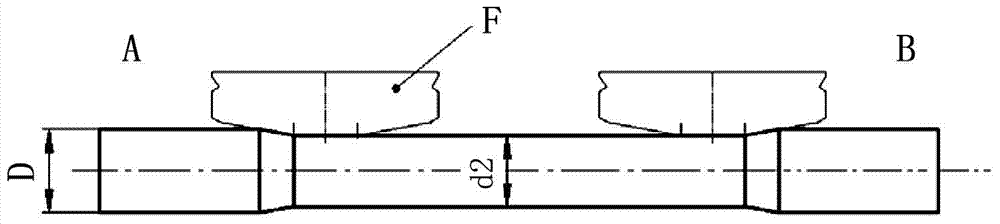

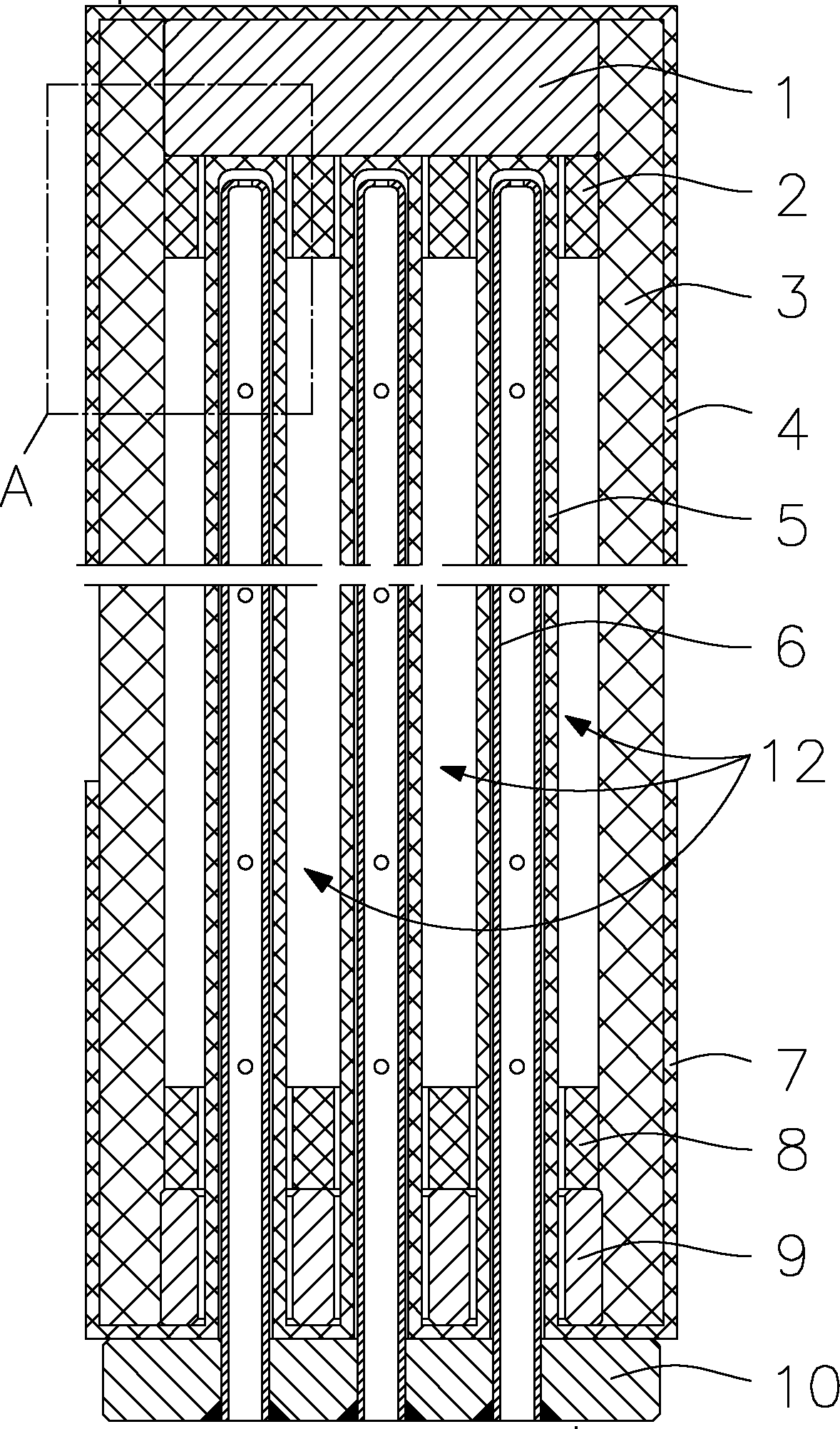

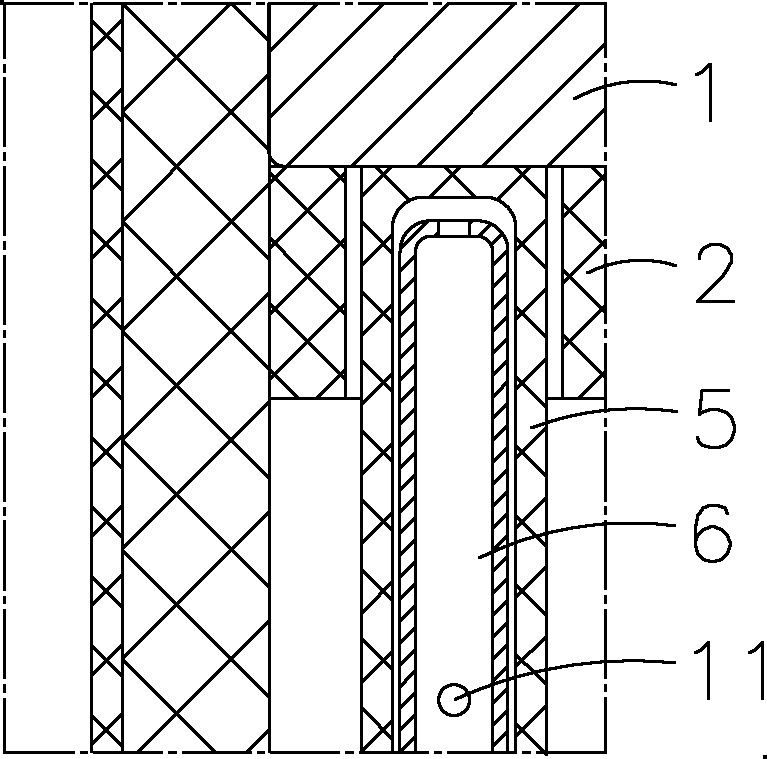

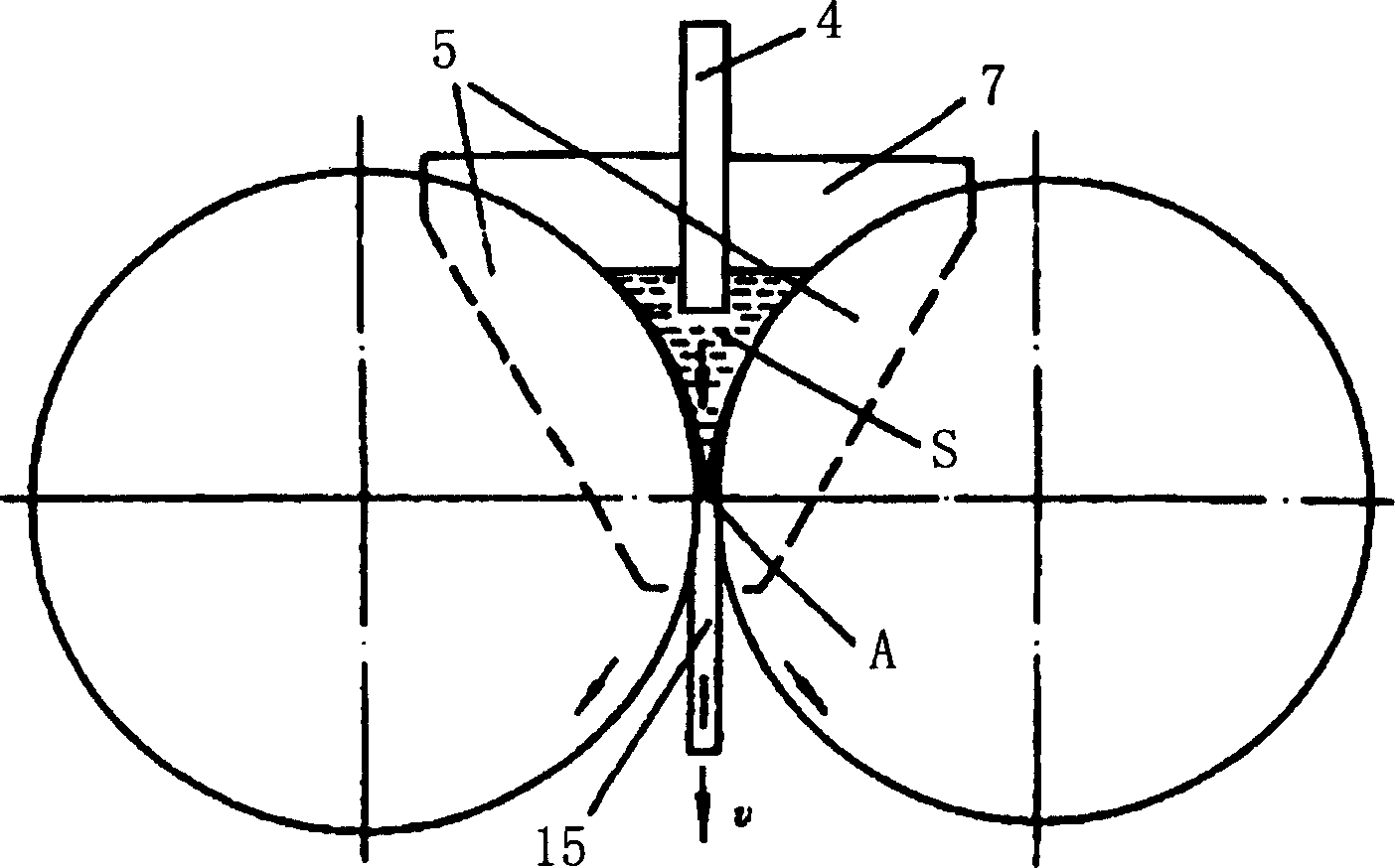

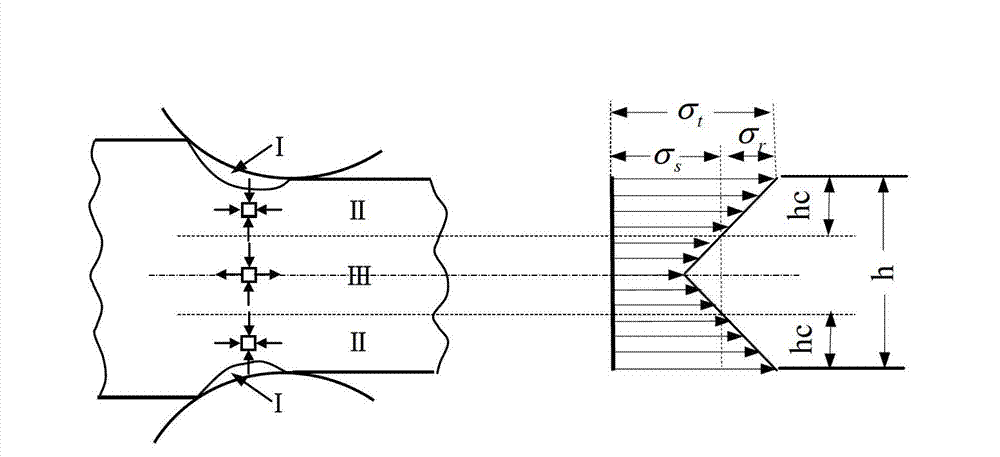

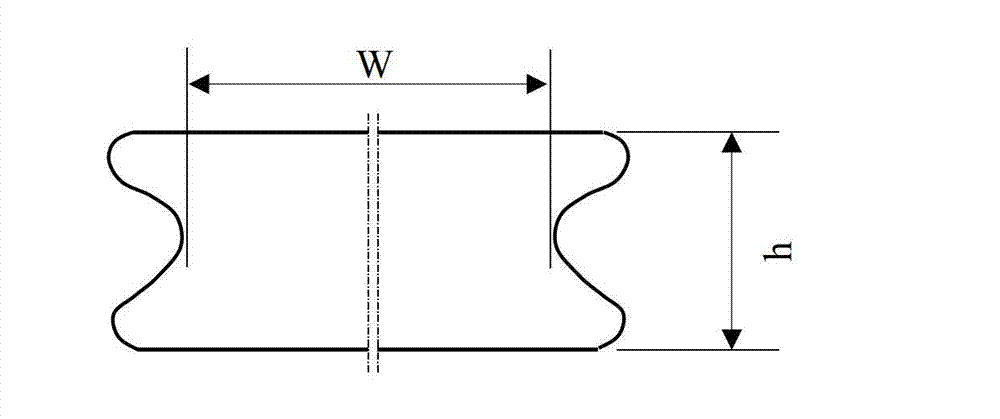

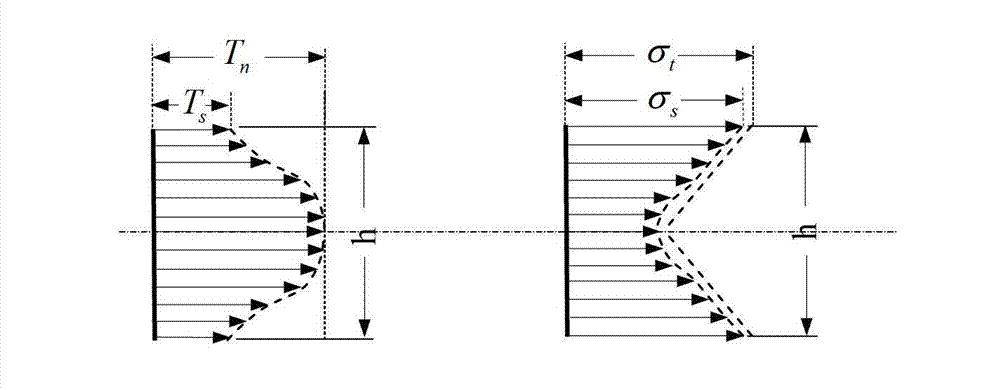

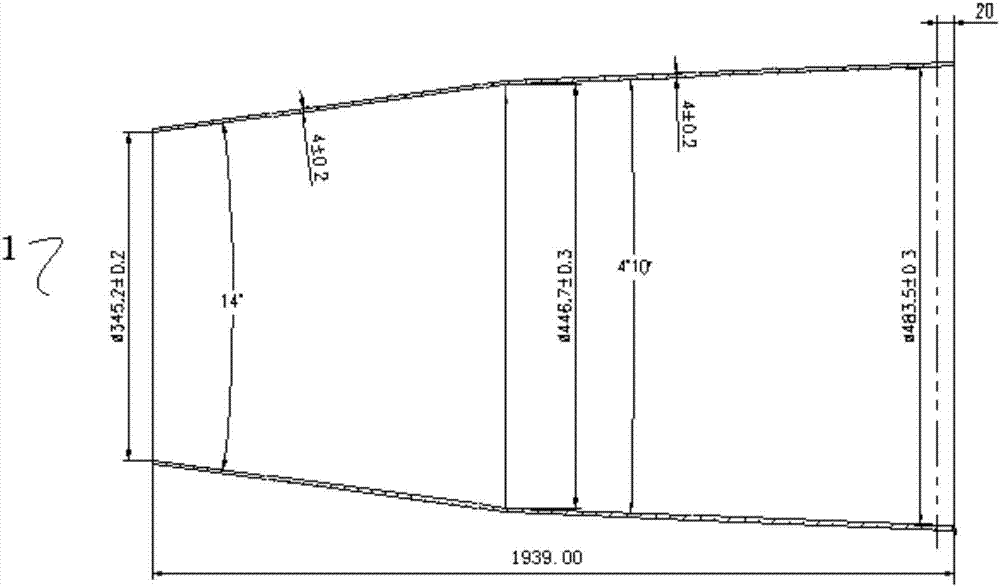

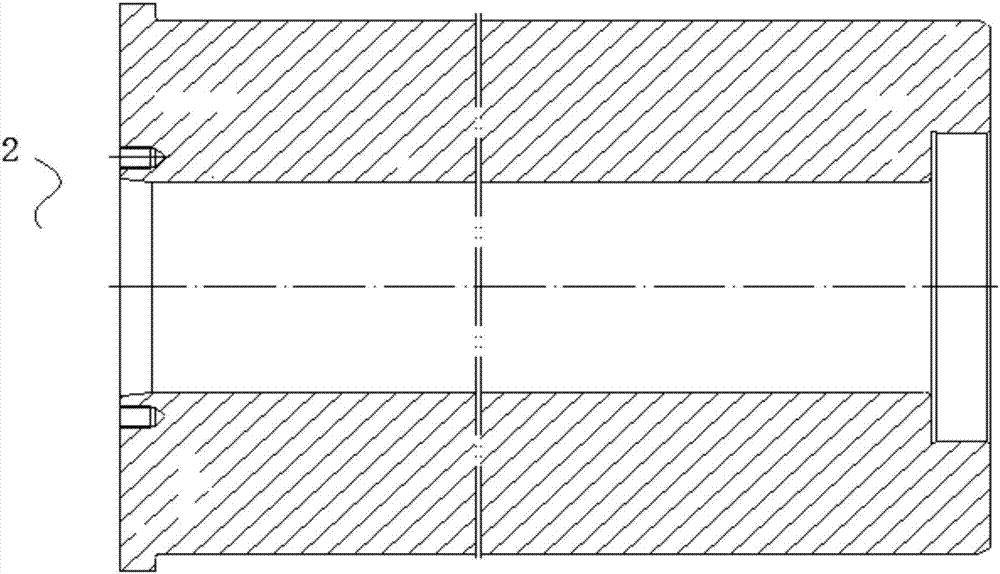

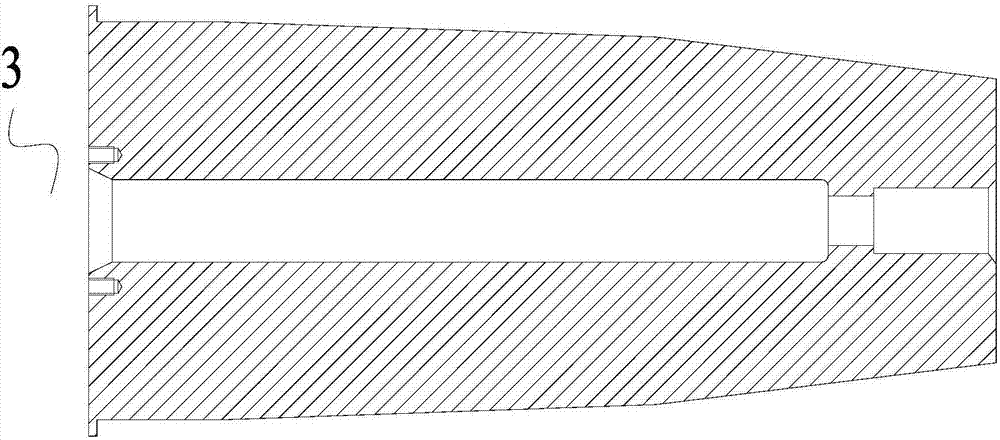

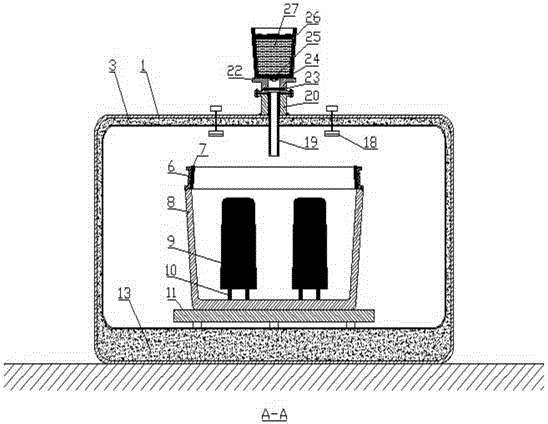

Precise extrusion molding method of thin wall long-pipe shaped parts bland and special mould

InactiveCN101332476AIncreased dimensional accuracy and material utilizationIncrease productivityExtrusion diesThin walledNonferrous metal

The invention belongs to an extrusion forming technique of non-ferrous materials. The precise extrusion forming technique of a thin-wall long-tube part blank comprises two procedures, namely, a primary reverse extrusion and a secondary reverse extrusion; the primary reverse extrusion obtains a primarily extruded tube blank (18) by adopting a primary male die (7) and a primary concave die (8) by virtue of a primary backing-out punch (4), the secondary reverse extrusion is carried out by adopting a secondary fixed male die (16), a secondary movable male die (12), a secondary concave die (6) by virtue of a secondary backing-out punch (14); the secondary movable male die (12) is placed into the primarily extruded tube blank (18), the secondary fixed male die (16) moves downward along the secondary movable male die (12) to extrude the primarily extruded tube blank (18), therefore, the secondary reverse extrusion is completed. The thin-wall long-tube part blank produced by adopting the technique of the invention has the advantages that the internal quality, dimensional accuracy and the utilization ratio of materials are greatly improved, and the production efficiency is improved and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

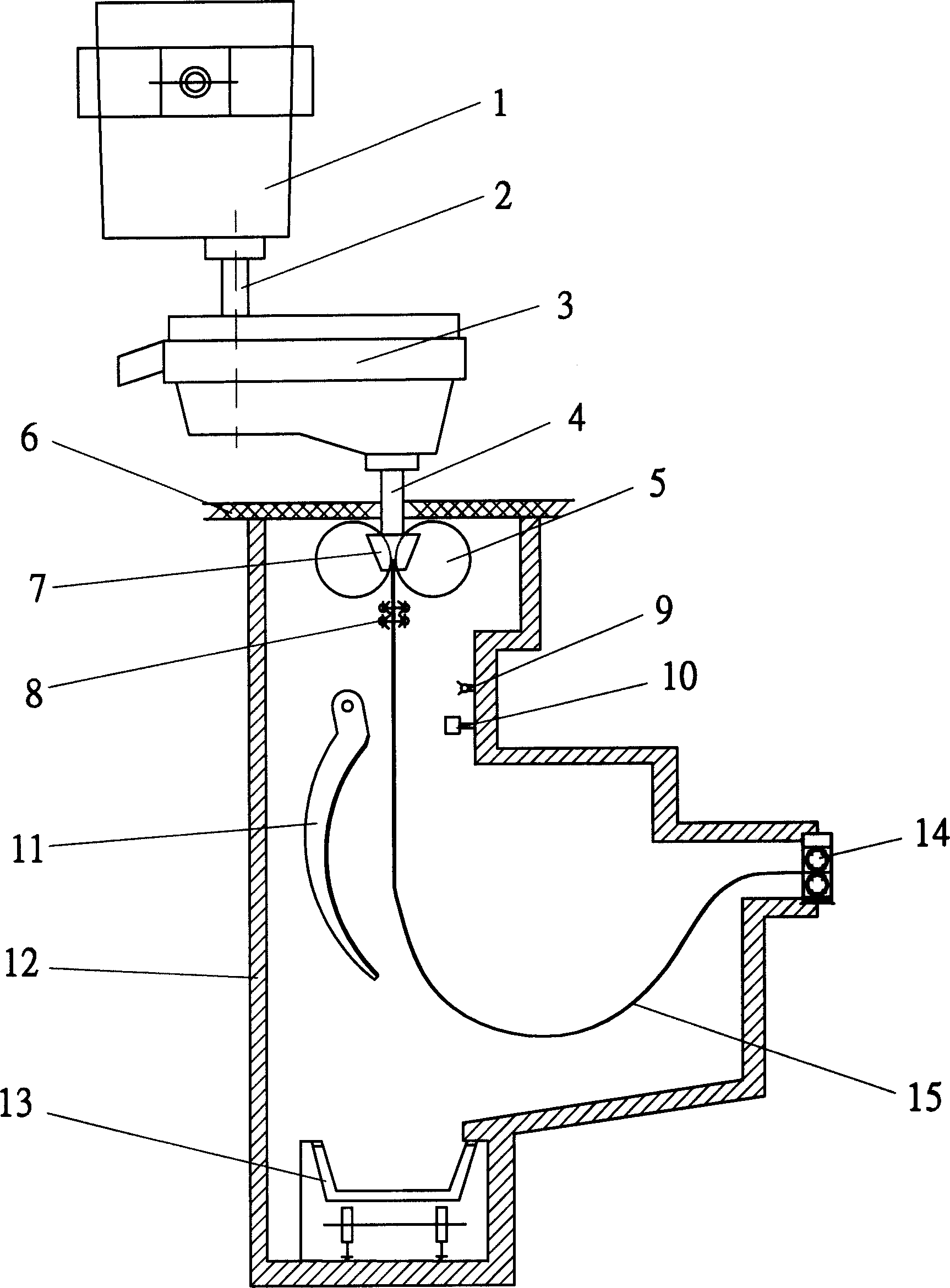

Molten aluminum refining degassing and slag-removing device

The invention relates to a molten aluminum refining degassing and slag-removing device. The molten aluminum refining degassing and slag-removing device comprises a heat insulation furnace and a bracket, wherein the heat insulation furnace is provided with a cover body which is connected with a hoisting plate by a connection rod; the hoisting plate is connected with the bracket by a hydraulic retractable rod; the lower end of the cover body is connected with an agitating shaft; a driving motor is arranged at the upper end of the cover body; the upper end of the agitating shaft vertically penetrates through the cover body and is connected with the driving motor; the lower end of the agitating shaft is arranged in the heat insulation furnace and is further connected with a graphite rotor; an air vent is formed in the surface of the graphite rotor; the agitating shaft is a hollow shaft and is internally provided with an air ventilation pipeline; one end of the air ventilation pipeline stretches out of the agitating shaft to be connected with a nitrogen generator; the other end of the air ventilation pipeline is communicated with the air vent of the graphite rotor. According to the molten aluminum refining degassing and slag-removing device, hydrogen and non-metal impurities in molten aluminum can be removed and the molten aluminum is purified; scrap caused by needle holes and the non-metal impurities after the molten aluminum is cast into a casting is reduced; the inner quality of the casting is improved greatly and the market competitiveness of products is improved.

Owner:LUOYANG ANLUN ALUMINUM PROD

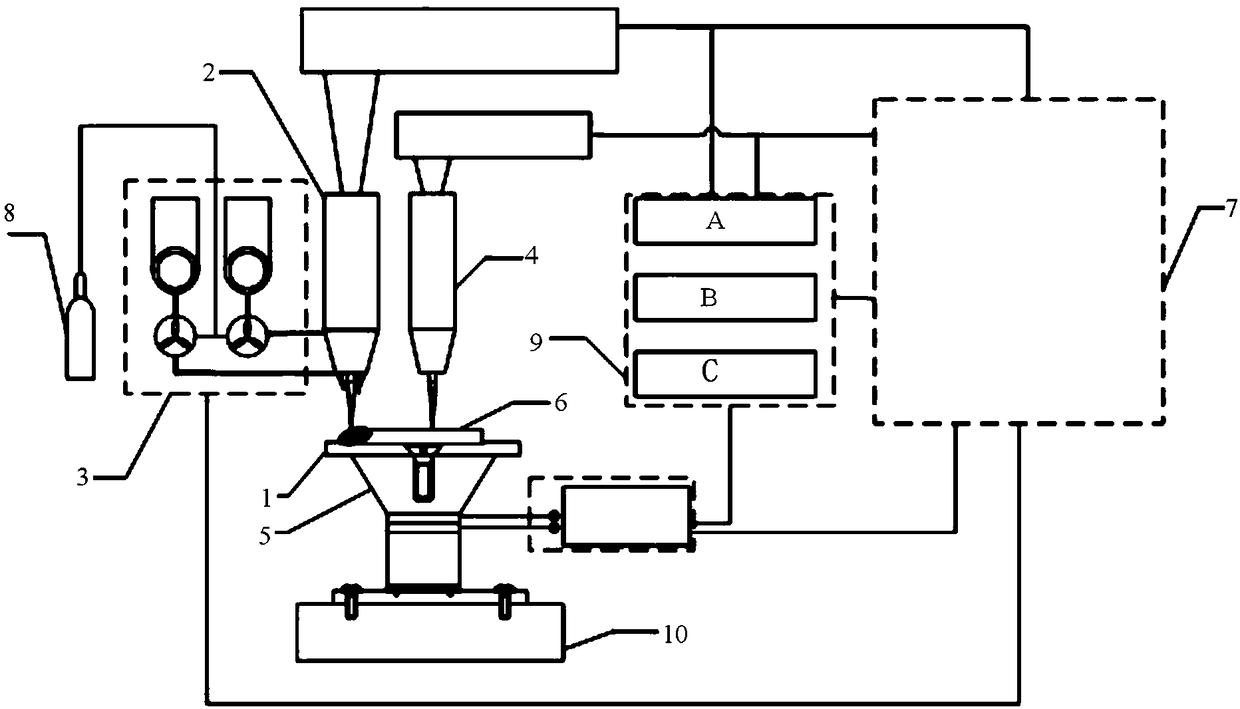

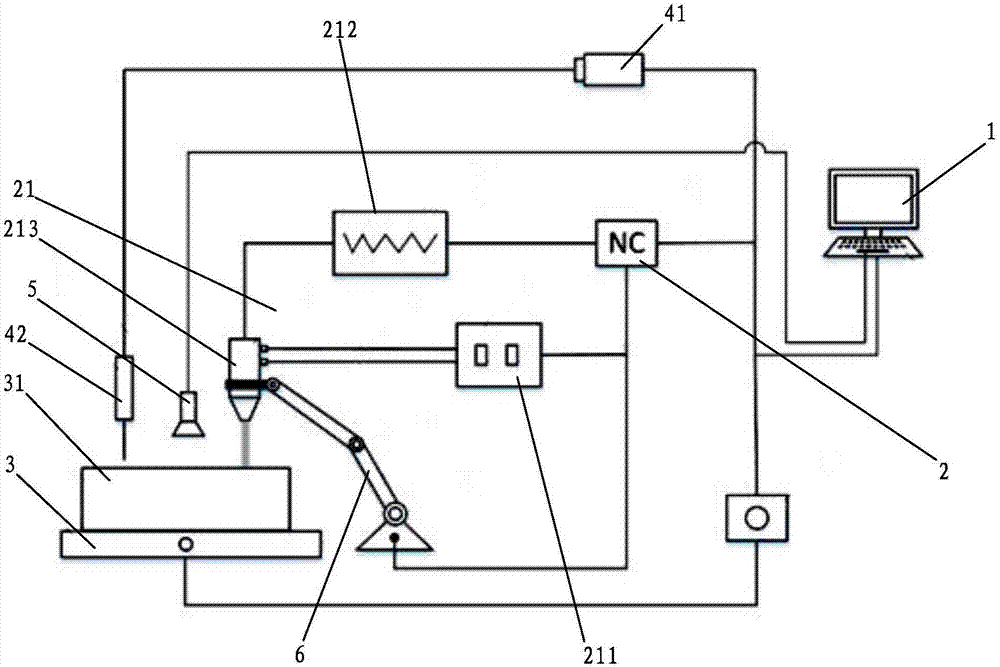

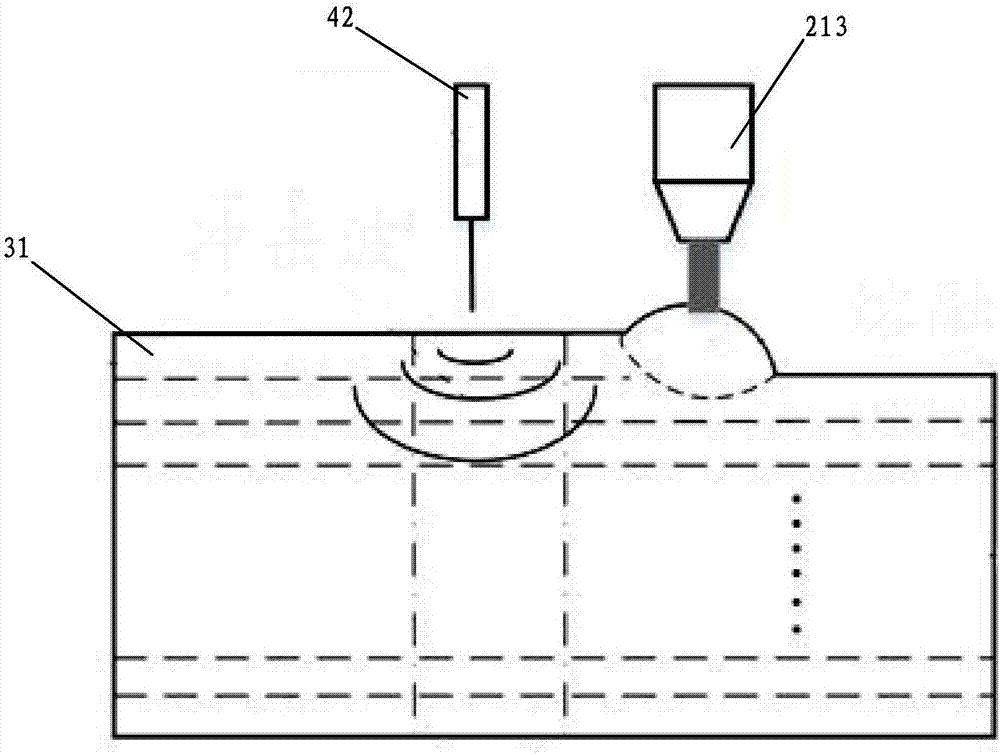

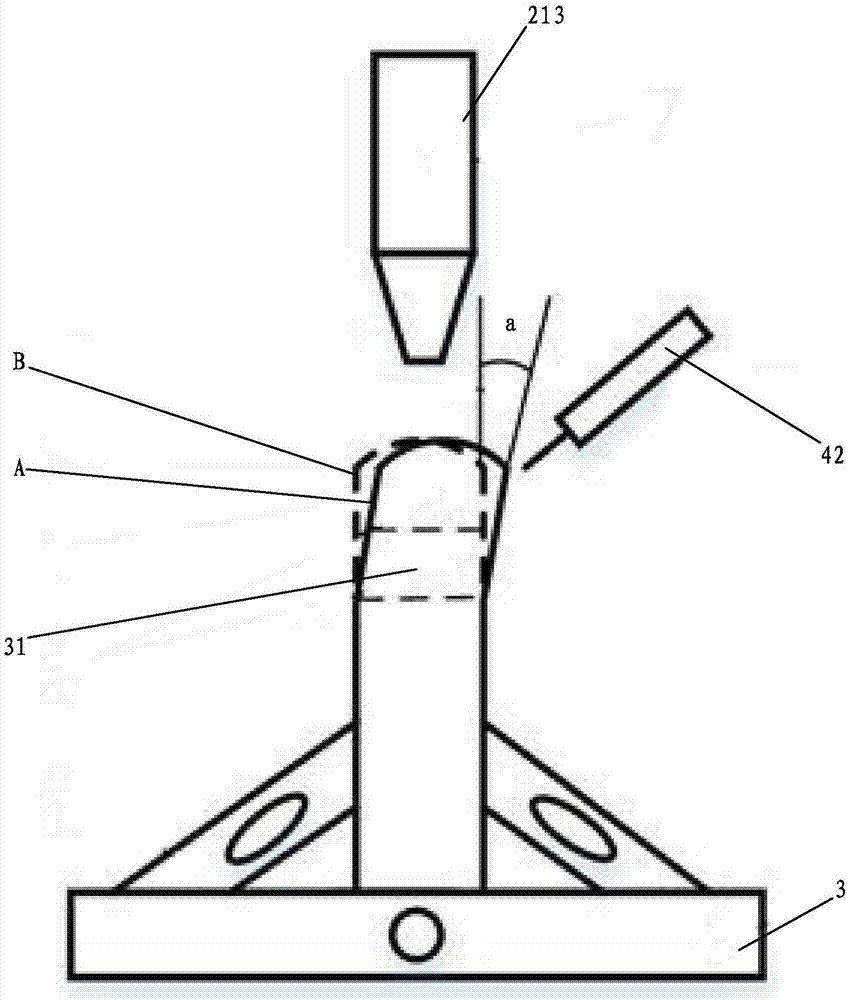

Method and device for carrying out 3D (Three-Dimensional) printing and composite manufacturing on metal

PendingCN108176857AImprove internal qualityImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyShock waveUltrasonic vibration

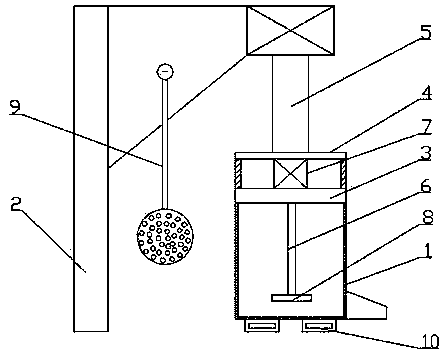

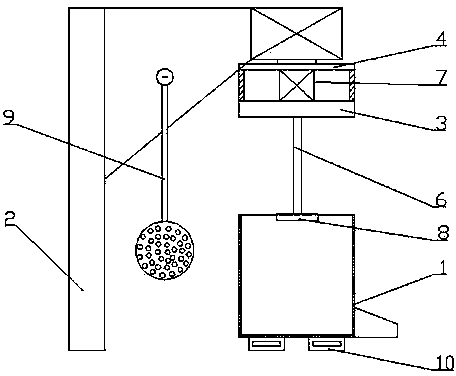

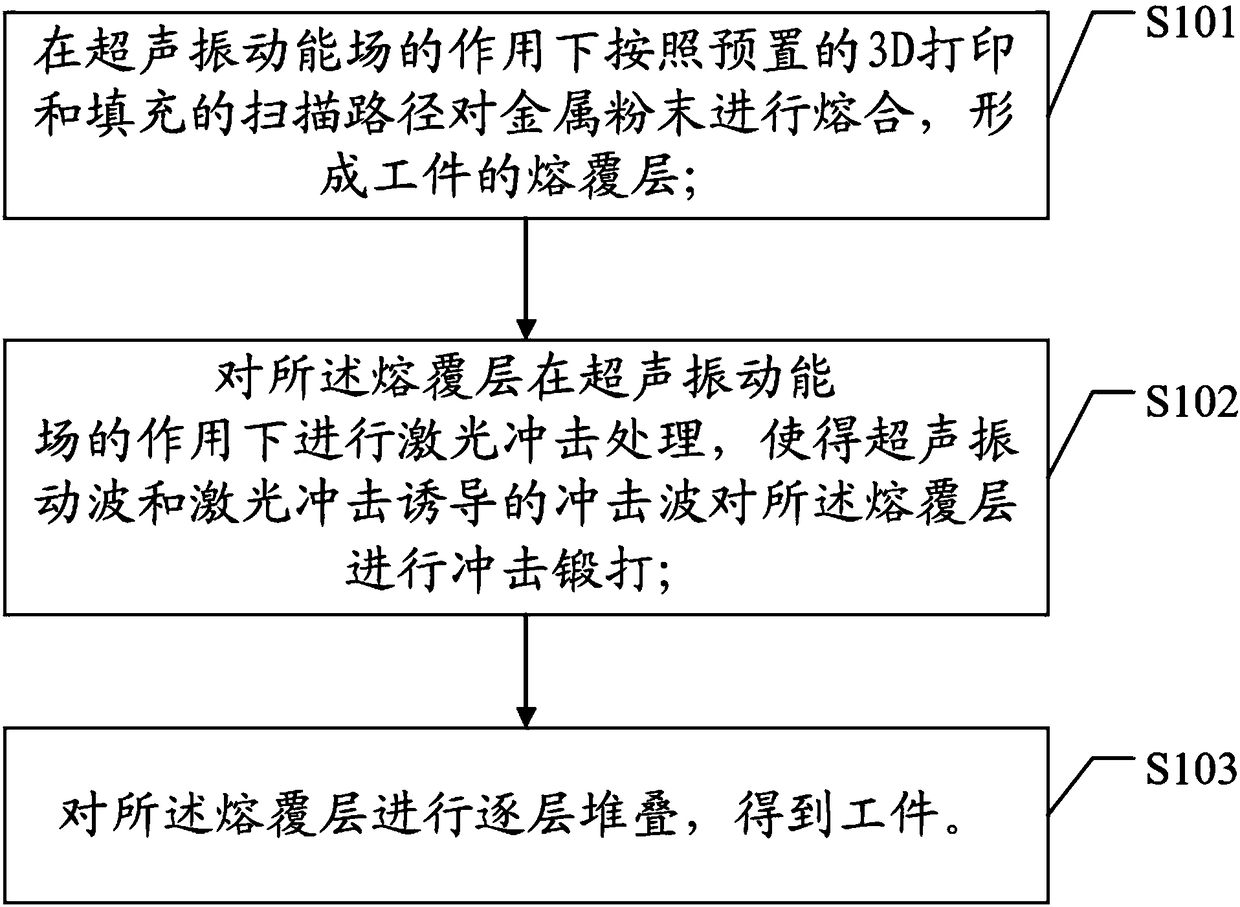

The invention belongs to the technical field of 3D (Three-Dimensional) printing, and particularly relates to a method and a device for carrying out 3D printing and composite manufacturing on metal. The method for carrying out the 3D printing and the composite manufacturing on the metal comprises the following steps: S101, fusing metal powder under the action of an ultrasonic vibration energy fieldaccording to a preset 3D printing and filling scanning path, thus forming cladding layers of a workpiece; S102, simultaneously carrying out laser shock processing on the cladding layers under the action of the ultrasonic vibration energy field, and impacting and forging the cladding layers through ultrasonic vibration waves and shock waves induced by laser shock; S103, stacking the cladding layers layer by layer, thus obtaining the workpiece. Aiming at the problem existing when an existing metal 3D printing technology is used for manufacturing metal parts, the method disclosed by the invention has the advantages that internal defects of pores, poor fusion, shrinkage porosity and cracks of metal cladding layers and thermal stress can be removed to the maximum, the internal quality and themechanical dynamical comprehensive performance of the metal parts can be increased, and the problems of macroscopic deformation and cracking can be effectively controlled.

Owner:GUANGDONG UNIV OF TECH

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

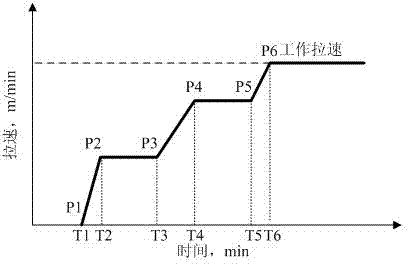

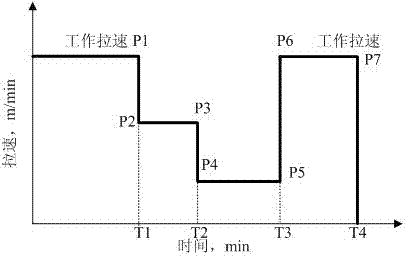

Radial forging method for high temperature alloy step shaft

The invention provides a radial forging method for a high temperature alloy step shaft. The method includes: upsetting and drawing out a steel ingot, and providing a blank to a forging machine; forging the blank in multiple passes, and pre-forging to form a first step shaft; forging the middle of the first step shaft in multiple passages so as to form a middle step shaft, and forming a transition section between the first step shaft and the middle step shaft, wherein pulling speed for forming the first step shaft is controlled to be 3-5.5m / min, deformation of each pass for forming the middle step shaft is controlled to be 10-25%, and pulling speed for forming the middle step shaft is controlled to be 3-5.5m / min. By control on forging frequency, reduction in pass and pull speed of the radial forging method and by control on final forging temperature, the property structure of a step shaft product is controlled, quality stability and structure property uniformity of the product are improved greatly while comprehensive yield and qualified rate of the product are increased greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

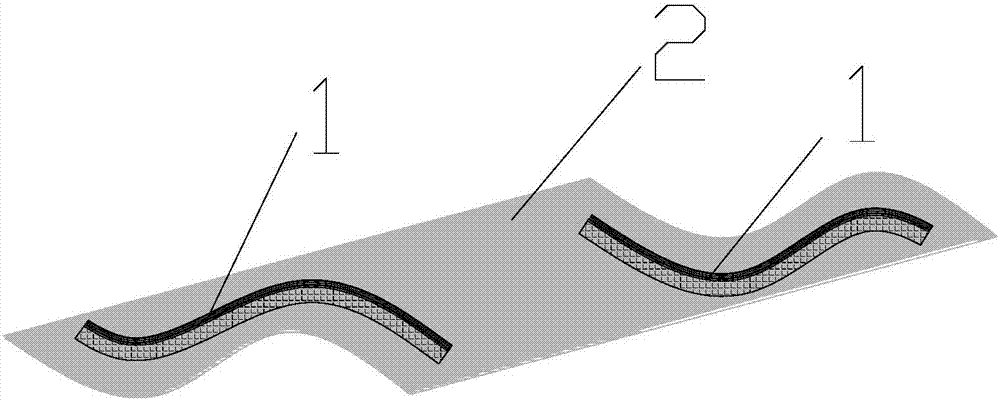

Co-curing forming technological method of variable-curvature composite stiffened wall plate

The invention belongs to the technical field of composite manufacturing and relates to a co-curing forming technological method of a variable-curvature composite stiffened wall plate. The co-curing forming technological method of the variable-curvature composite stiffened wall plate comprises the following steps of manufacturing a flexible long purlin core mold, conducting laying and pasting on a composite wall plate skin and a long purlin, assembling a long purlin green body and the skin and conducting packaging and curing formation. According to the co-curing forming technological method of the variable-curvature composite stiffened wall plate, the flexible long purlin core mold is used as the forming core mold, the flexibility of rubber and the rigidity, low density and other features of a fiber composite are combined, the composite flexible long purlin core mold is used for replacing a metal core mold and formed into a continuous structure, the rigidity of the core mold is controlled by adjusting the ratio of rubber in the flexible long purlin core mold, the long purlin green body with the composite part is laid and pasted to a laying and pasting mold, then the long purlin green body is transferred to a flexible long purlin mold, the long purlin is located to a skin blank through a long purlin locating clamping plate, the co-curing technological method is adopted to manufacture the stiffened wall plate of a variable-curvature structure, and during operation, the stiffened wall plate of the variable-curvature structure is easy to attach to a technology piece and is not influenced by curvature and shape.

Owner:AVIC BASIC TECH RES INST

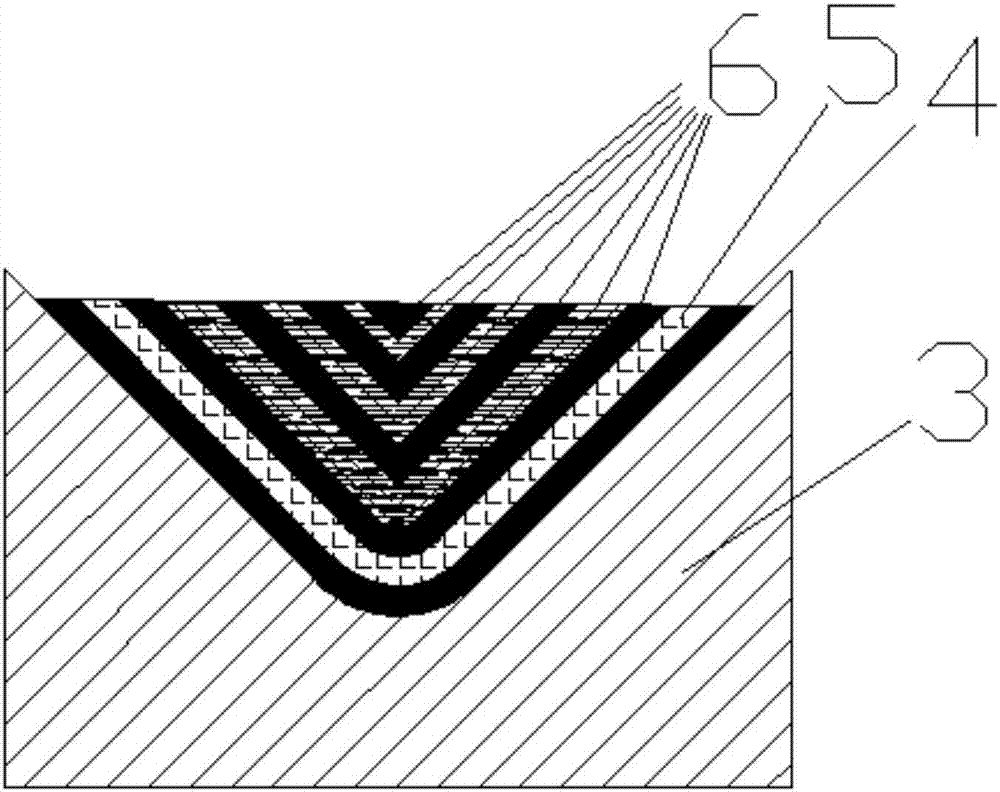

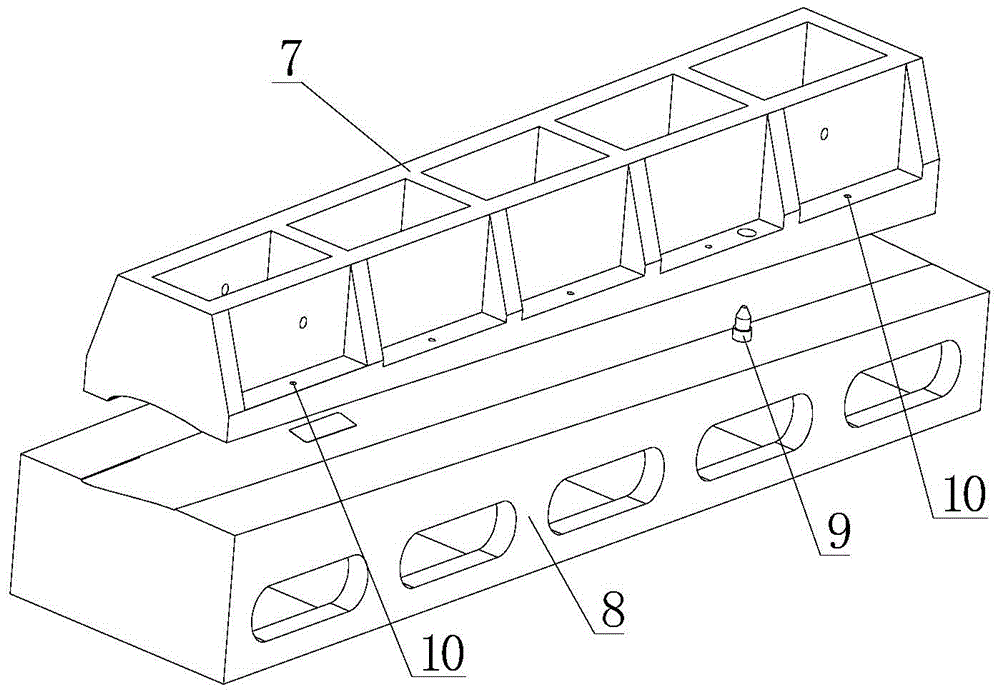

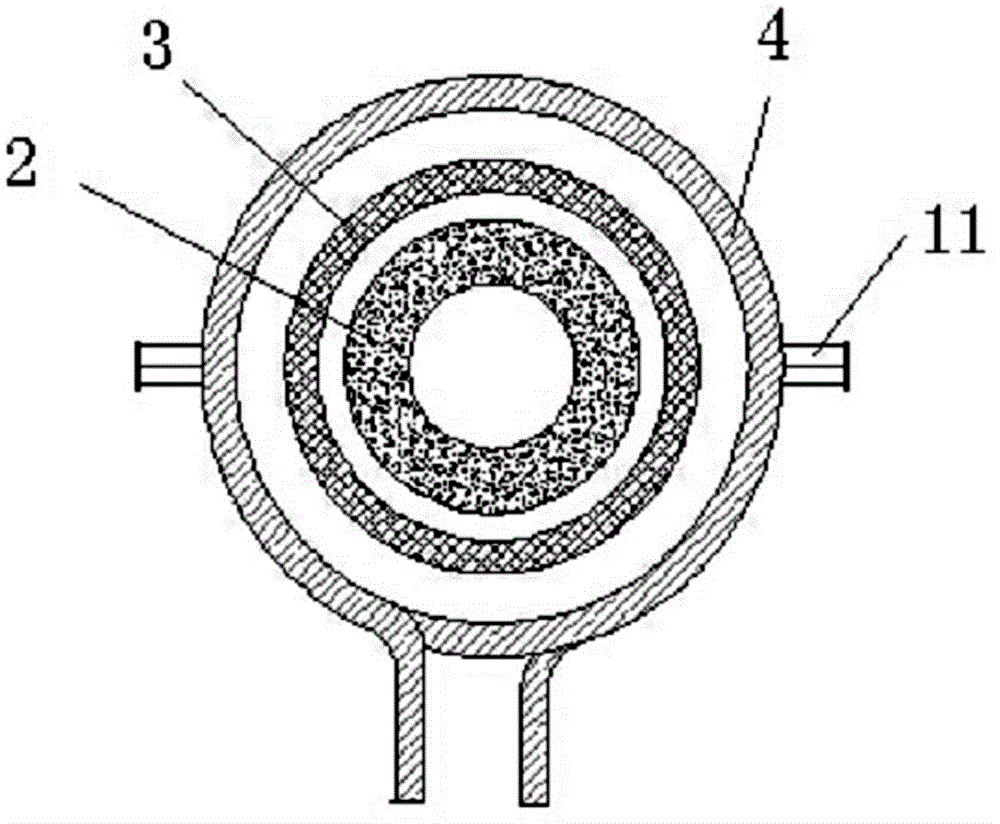

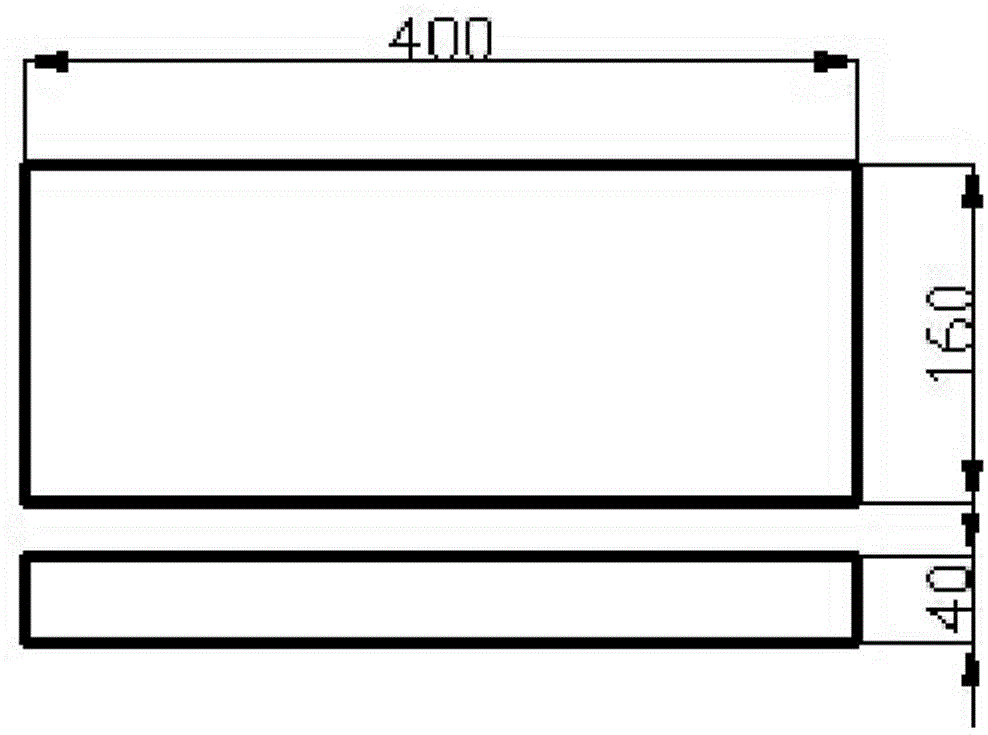

Cold isostatic compaction mould for multi-channel filter elements and method for producing multi-channel filter elements made of intermetallic compounds

ActiveCN102133768AUniform product densityImprove internal qualityCeramic shaping mandrelsCeramic shaping coresMulti materialEngineering

The invention discloses a cold isostatic compaction mould for multi-channel filter elements and a method for producing multi-channel filter elements made of intermetallic compounds by using the mould. The mould comprises an external rubber sleeve and a plurality of core rods, wherein the two ends of the external rubber sleeve are sealed, and the core rods are axially inserted and fixed in the external rubber sleeve from an end of the external rubber sleeve; each core rod is composed of a supporting tube and an internal expanding sleeve sleeved on the supporting tube; and the wall of the supporting tube sleeved with the internal expanding sleeve is provided with a plurality of through holes, at least one end of each core rod is an opening end communicated with the outside of the mould. Because the external rubber sleeve and the internal expanding sleeve extrude powder simultaneously in the process of cold isostatic compaction, the pressure can be evenly applied on the whole internal and external surfaces of a product, so that the density of the product is evener, and the internal quality of the product is higher; and in the process of demoulding, the external rubber sleeve and the internal expanding sleeve are simultaneously separated from the surface of the product, which is more beneficial for demoulding. The mould disclosed by the invention is applicable for the forming of various materials such as ceramic powder, metal powder or intermetallic compound materials. By using the method disclosed by the invention, multi-channel filter elements made of intermetallic compoundscan manufacture by cold isostatic compaction.

Owner:CHENGDU INTERMENT TECH

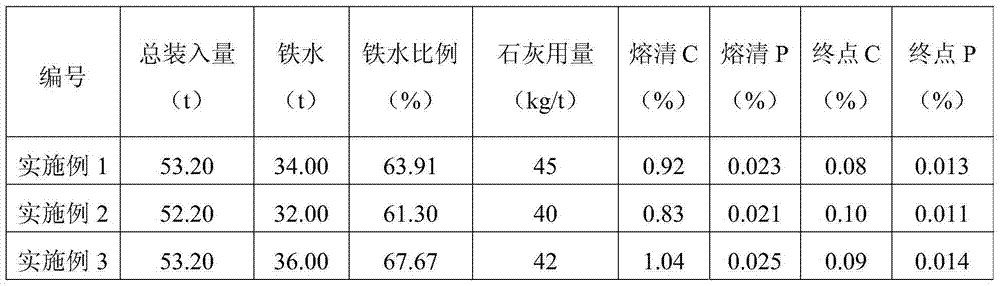

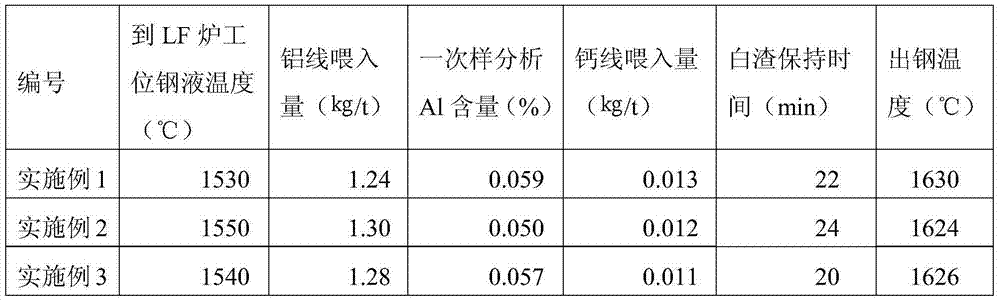

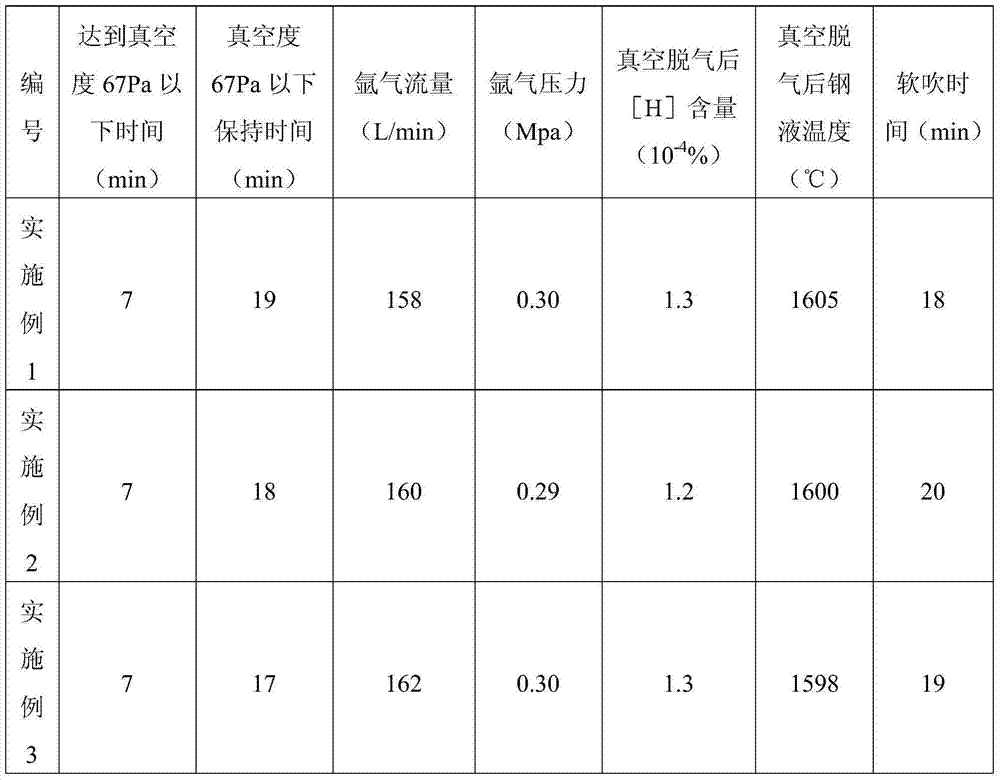

Smelting method for low-carbon low-silicon wire-welding steel

ActiveCN104862443AGood welding performanceSolve the problem of nodulation in submerged nozzlesManufacturing convertersOxygen contentRegular Production

The invention discloses a smelting method for low-carbon low-silicon wire-welding steel. The process flow of the smelting method comprises the following procedures: pretreatment and desulphurization of molten iron; treatment in a converter; LF refining; and continuous casting of small square billet with a size of 150 mm * 150 mm. With the smelting method, carbon content is stably controlled to be less than or equal to 0.08%; silicon content is stably controlled to be less than or equal to 0.027%; total oxygen content is no more than 0.0040%; the problem of nozzle clogging is overcome; and surface and internal quality of a casting blank is greatly improved. The process flow of the smelting method is simple and has low cost; and equipment used in the smelting method is conventional production equipment for iron and steel manufacture, is simple to operate, has good versatility and saves energy.

Owner:QINGDAO SPECIAL STEEL CO LTD

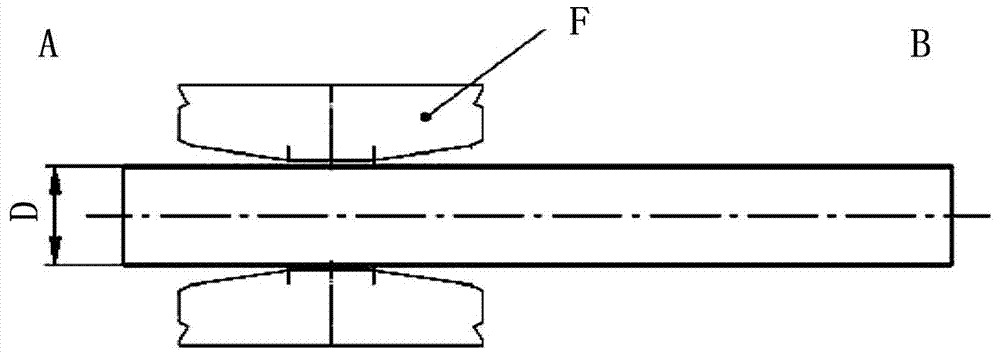

Thin-belt continuous casting method and apparatus

InactiveCN1472019AFlexible process controlEasy to operateMetal rolling arrangementsProduction rateMolten bath

A conticasting technology for thin steel band includes such steps as filling molten steel in the molten bath formed by crystallizing rollers, cooling and slight rolling by crystallizing rollers, blowing gas onto both surfaces of cast band for forced cooling, hot rolling, controlled cooling and winding. Its apparatus is composed of two blowing mechanisms, connecting-rod driver unit and synchronizing unit. Its advantages are high quality of product and high productivity.

Owner:BAOSHAN IRON & STEEL CO LTD

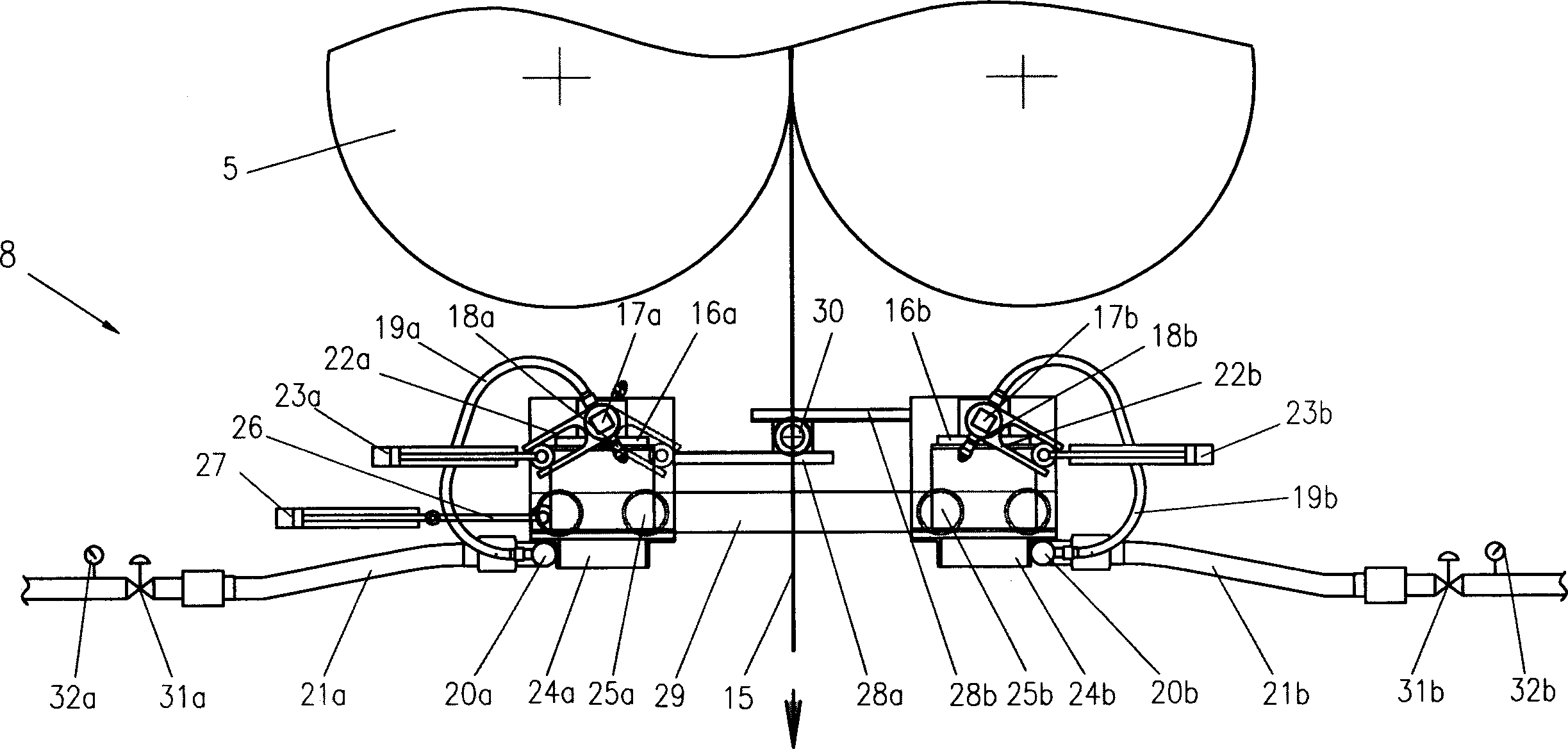

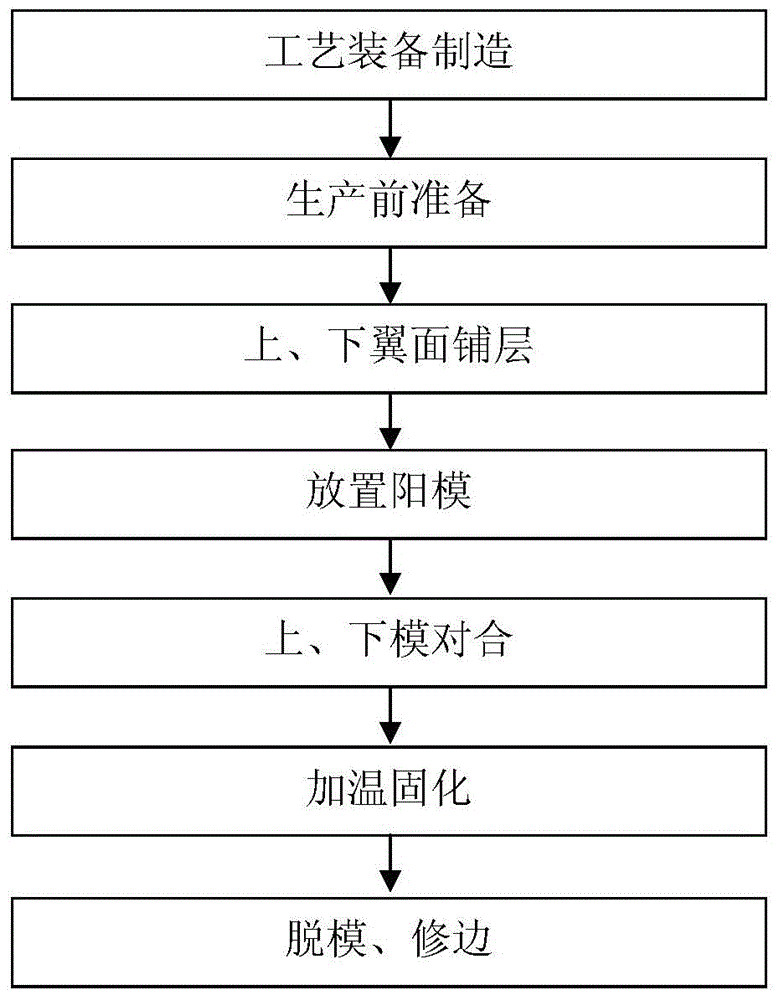

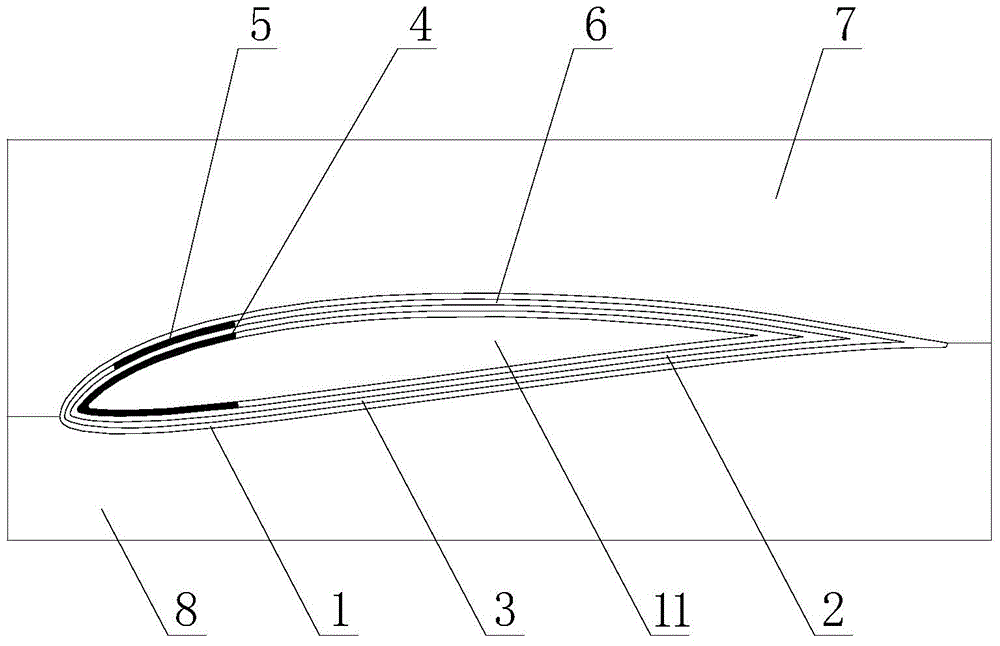

Composite material wing integral molding technological method and composite material wing integral molding tool

The invention discloses a composite material wing integral molding technology method and a composite material wing integral molding tool. A metal female mold and a silicon rubber male mold are assisted in molding. The composite material wing integral molding technology method comprises the following steps: firstly, manufacturing the female mold, and manufacturing a male mold by utilizing the female mold; cleaning a demolding agent sprayed on the upper and lower molded surfaces of the female mold; paving upper and lower wing panels of the composite material wing respectively on the upper and lower molded surfaces of the female mold; arranging the male mold and the wing front edge part on the lower wing panel of the wing; folding the upper mold and the lower mold of the female mold; putting the folded female mold and male mold and a composite material wing product into a hot pressing tank, and curing; demolding after curing, and trimming to obtain the composite material wing. Therefore, the composite material wing with relatively small size is molded integrally, the integral weight of the composite material wing is reduced, and the structure intensity of the composite material wing is improved. The integrally molded composite material wing is good in interior quality, the size of the external wing type molded surface is accurate, meanwhile the thickness of a paving layer of the composite material wing product can be strictly controlled, and the integral molding quality of the composite material wing is stable and reliable.

Owner:XIAN AISHENG TECH GRP +1

High-alkalinity mould flux used for niobium/vanadium/titanium-containing low alloy wide and heavy plate blank and manufacturing method thereof

The invention discloses a high-alkalinity mould flux used for niobium / vanadium / titanium-containing low alloy wide and heavy plate blanks and a manufacturing method thereof. The high-alkalinity mould flux is made from the following raw materials in percentage by weight: 35 to 45 percent of pre-melting materials, 11 to 14 percent of fluorite, 28 to 30 percent of wollastonite, 3 to 6 percent of flint clay, 3 to 6 percent of limestone, 2 to 4 percent of sodium carbonate, 1 to 3 percent of lithium carbonate, 1 to 3 percent of manganese carbonate, 2 to 4 percent of magnesium oxide, 2 to 4 percent of carbon black, 4 to 7 percent of graphite and 1 to 3 percent of binders. The mould flux has a good capability of absorbing Al (s), V, Ti, Nb and other metals and metal oxides or carbides thereof and nitride inclusions in molten steel, and remains unchanged after molten steel purification. Therefore, not only are the performances of the mould flux stable, but also the internal quality of casting blanks is improved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Method for improving center segregation of extra thick slab with thickness of 400mm

The invention relates to a method for improving center segregation of an extra thick slab with a thickness of 400mm, and belongs to the technical field of continuous casting of steelmaking. Degree of the center segregation of the extra thick slab with the thickness of 400mm is improved by a dynamic soft reduction technology, so that rating of the center segregation is free from above C2.0 so as to improve the inner quality of the extra thick slab. The specific steps are as follows: determining an optimal reduction position and an optimal rolling reduction: after determining the optimal reduction position, testing different rolling reductions in the reduction area: 5-6mm and 6-8mm and applying a certain rolling reduction of 0-0.5mm to a solid phase area; and combining lower power rating and C, S segregation ratios to determine the optimal rolling reduction.

Owner:SHOUGANG CORPORATION

Manufacturing method of super-thick steel plate

ActiveCN103111464AReduced compression ratio requirementsLarge amount of deformationTemperature control deviceMetal rolling arrangementsThick plateIndustrial engineering

The invention discloses a manufacturing method of a super-thick steel plate (thickness is 60 millimeters) and belongs to the steel plate production field of metallurgical industry. The manufacturing method of the super-thick steel plate comprises the following steps: firstly, sending a plate blank which is heated to a certain temperature and removed an oxide scale to cooling space to conduct forced cooling, surface temperature cooling a phase transition temperature of the super-thick plate material above Ar 1, then by short time temperature returning, the surface temperature rising to the range between 780 DEG C and 880 DEG C, and sending the plate bland to a rolling mill to roll as soon as possible; when the surface temperature of the plate blank being higher than 880 DEG C, needing to conduct the forced cooling again, and then conducting the subsequent rolling. A cooling-temperature returning-rolling process can be repeated for many times if needed till rolling to the needed thickness of the super-thick steel plate. The manufacturing method of a super-thick steel plate can increase dependent variable of the central area by increasing temperature difference between a surface layer and the central area and has the advantages of being beneficial to refining central organization and improving impact toughness, beneficial to removing center porosity of the super-thick plate, and capable of reducing double strand shape on lateral sides of the super-thick plates. The manufacturing method of a super-thick steel plate further has the advantages of being saving in investment, and flexible to operate.

Owner:UNIV OF SCI & TECH BEIJING

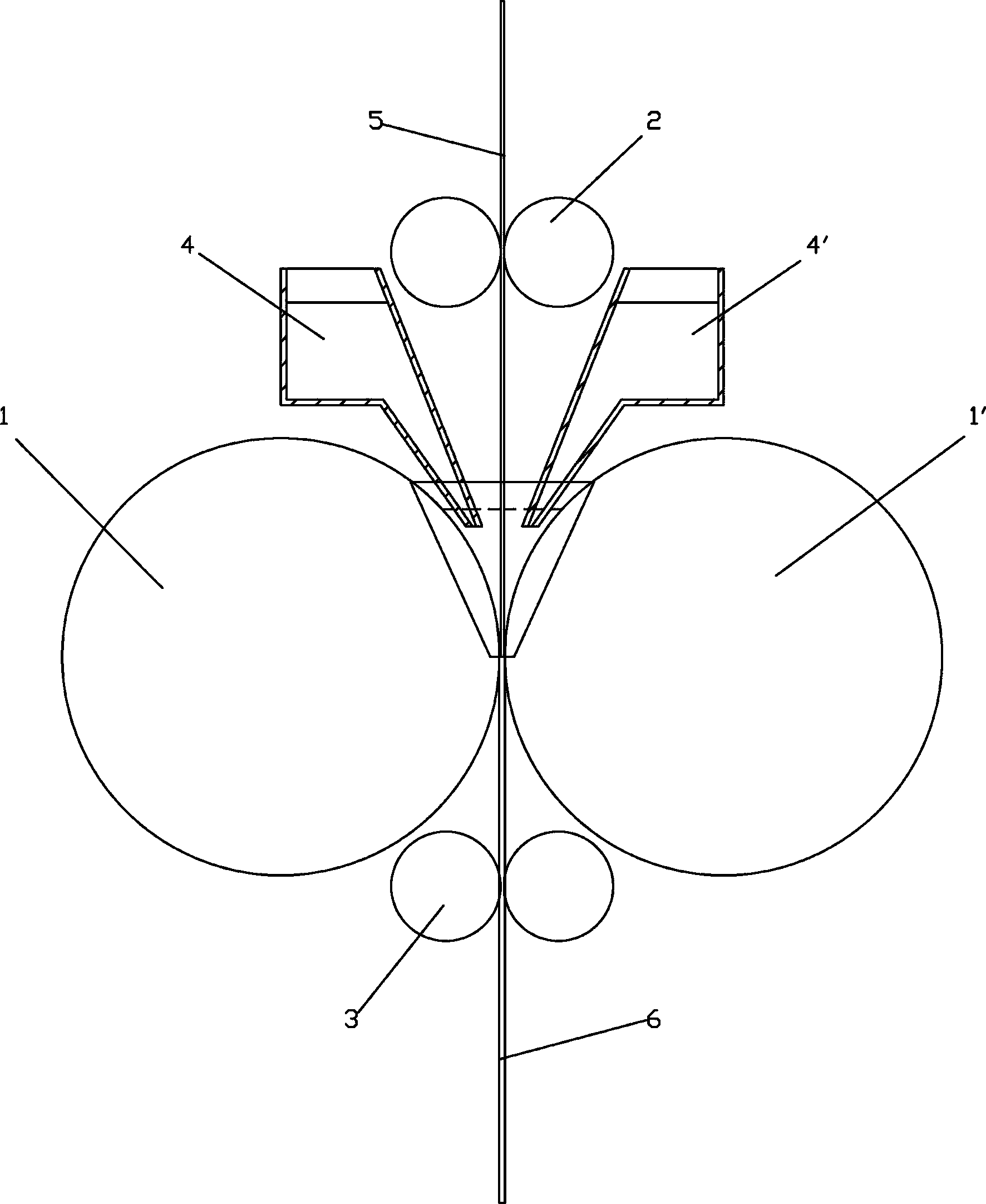

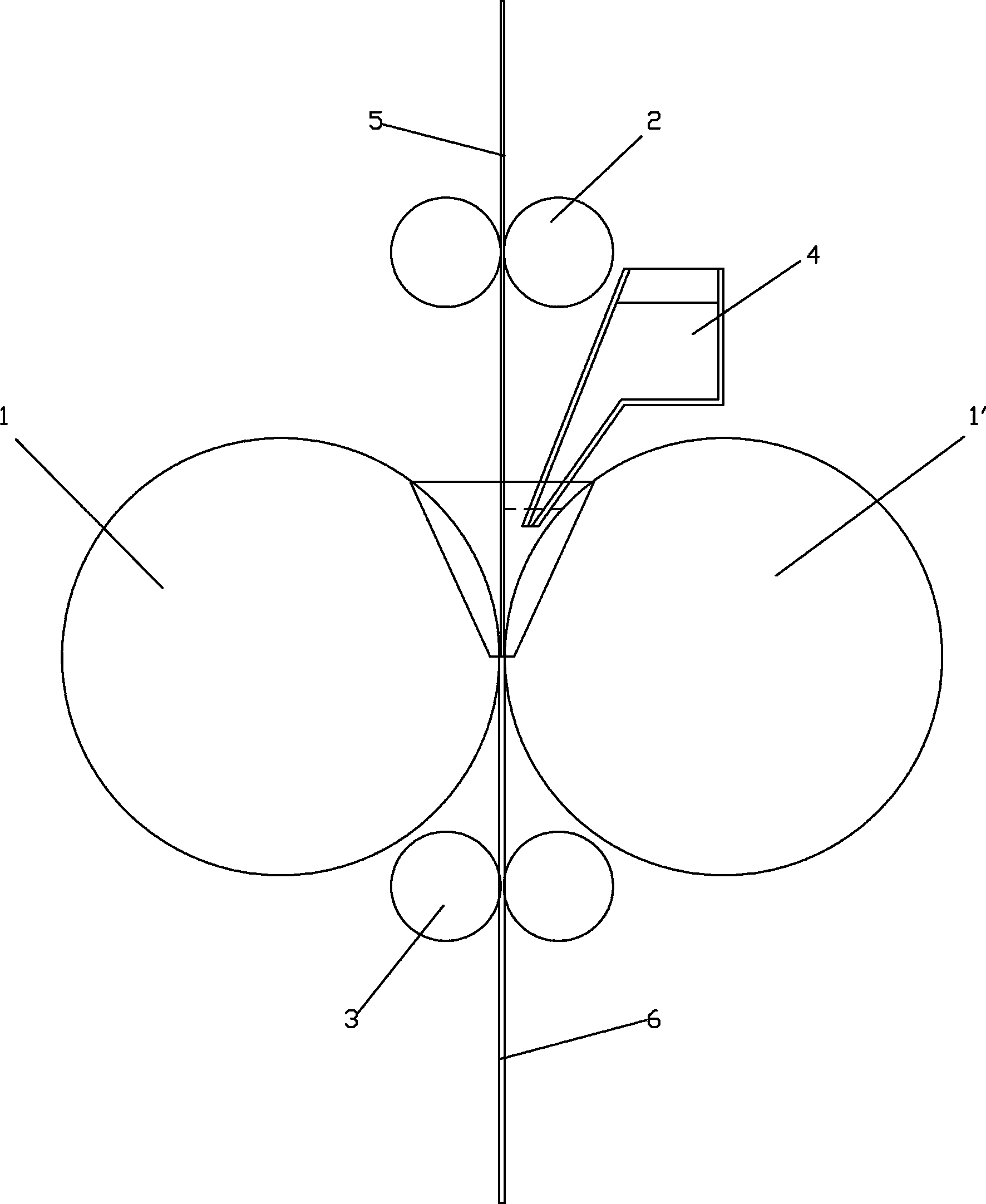

Preparation method for double roller thin strips of clad plate strip

The invention discloses a preparation method for double roller thin strips of a clad plate strip. A pair of pinch rollers and a pair of positioning rollers are arranged above and below two crystallization rollers rotating oppositely, namely double rollers, wherein a flow distribution device is also arranged above the double rollers; an outlet of the flow distribution device corresponds to a clearance formed between the double rollers; an intermediate plate strip enters a part between the double rollers through the rotating pinch rollers and then enters a part between the positioning rollers below the double rollers; molten metal to be clad is poured in the flow distribution device positioned above the crystallization rollers; the melting point of the molten metal is lower than that of the intermediate plate strip; the molten metal fills the clearance formed by the two crystallization rollers by virtue of the flow distribution device; molten pools are respectively established on one side or two sides of the intermediate plate strip; the outlet end of the flow distribution device is inserted to a position, which is 10-20mm below the liquid level of the molten pool between the double rollers; by using the cooling action of the crystallization rollers and the intermediate plate strip, the molten metal is quickly solidified; the molten metal and the surface of the intermediate plate strip act together at the occluded position of the two crystallization rollers; molten metal solidifying layers are formed on one side face or two side faces of the intermediate plate strip, so the clad plate strip is formed.

Owner:BAOSHAN IRON & STEEL CO LTD

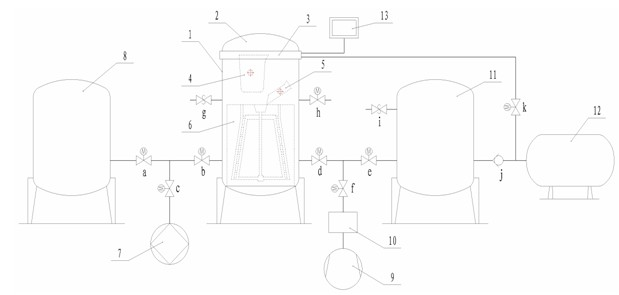

Device and process for manufacturing large-scale complex thin-wall aluminum alloy casting through vacuum pressurization casting

The invention relates to a device for manufacturing a large-scale complex thin-wall aluminum alloy casting through pouring and mold filling under vacuum and crystallization and solidification under pressure. The device comprises a vacuum pressurization casting chamber, a vacuum pumping system, an air pressurization system and an intelligent control system. The vacuum pressurization casting chamber is a high-pressure air-tight seal tank and adopts the vertical arrangement; a turnover seal cover driven by a cylinder and a locking ring for performing rotary seal are arranged at the upper part of the high-pressure air-tight seal tank; a pressure and vacuum detector is arranged on the seal cover; a ladle, a overturn casting drive device, a metal liquid diversion trench, a turnover temperature measuring device and the like are internally arranged in the chamber; a manual casting mechanism is arranged at the outer part of the chamber; the vacuum pumping system is composed of a vacuum pump, a vacuum storage cabin and a pipeline system; the air pressurization system is composed of an air compressor, a refrigeration drier, a pressure storage cabin, a circuit and a pipeline system; and the intelligent control system consists of a PLC (Programmable Logic Controller), an air bottle, a security caution light and an affiliated pipeline system, wherein the PLC is connected with the air bottle, the security caution light and the affiliated pipeline system, which collects and displays data of vacuum, pressure, temperature and the like to realize the intelligent control for the devices, so that the stages in the vacuum pressurization casting can be ensured to be performed sequentially, continuously and smoothly.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Composite material vacuum bag forming method

The invention belongs to the technical field of resin group composite material liquid moulding manufacture, and relates to a composite material vacuum bag forming method. According to the composite material vacuum bag forming method provided by the invention, a multilayer metal fiber mesh grid can be used as a rigid resin flow distributor, and technologic advantages such as resin film impregnation molding (RFI), vacuum auxiliary resin impregnation molding (VARI) and vacuum bag autoclave molding (Autoclave) are combined; the composite material vacuum bag forming method can be used for effectively promoting resin to flow along the thickness direction of a fiber perform body so as to guarantee the structural support of the preform body, and overcoming the disadvantages that a large-area composite material liquid moulding workpiece brought by the flexible distributor is low in superficial dimension precision and poor in thickness uniformity at present; and the moulding efficiency and dimensional accuracy of the composite material workpiece are improved, and a more rapid, more flexible and low-cost liquid molding technical scheme for manufacturing a high-performance composite material structure piece is provided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

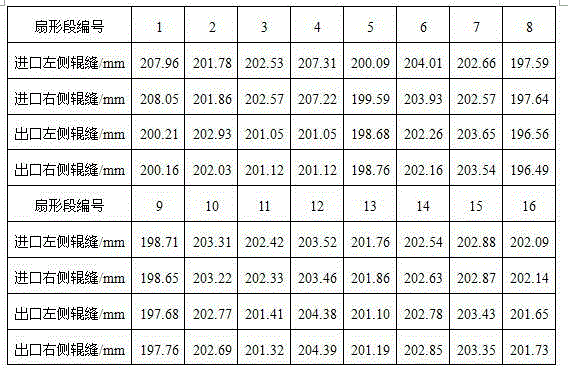

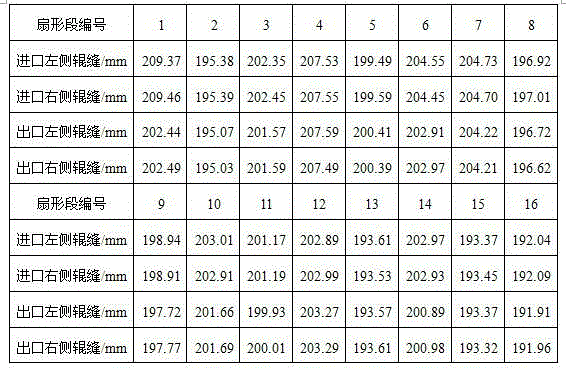

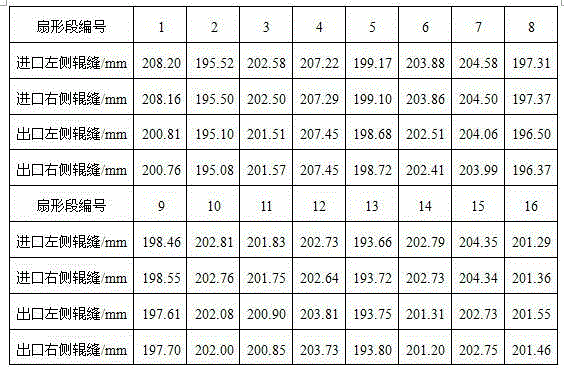

Method for calibrating sector sections of slab continuous casting machine online

The invention provides a method for calibrating sector sections of a slab continuous casting machine online, and belongs to the technical field of roll gap calibration methods of continuous casting machines. The method is used for calibrating the sector sections of the slab continuous casting machine online. According to the technical scheme, the method includes the steps that (1) two pairs of hydraulic cylinders at an inlet and an outlet of each sector section are leveled through gaskets respectively; (2) upper frames of the sector sections are pressed through pressure ranging from 800 kN to 4000 kN; (3) roll gap values of the inlets and the outlets of the sector sections are measured respectively; (4) displacement sensors in the hydraulic cylinders are calibrated according to the actually-measured roll gap values. By means of the method for calibrating the sector sections of the slab continuous casting machine online, the control precision of roll gaps of the continuous casting machine can be increased and reach 0.20 mm. The method can be used for calibrating all the sector sections at the same time, the calibrating efficiency is high, and the operating efficiency of the continuous casting machine can be improved. The hydraulic cylinders of the sector sections, calibrated through the method, of the continuous casting machine bear force uniformly, and the interior quality of casting blanks and the production stability of the continuous casting machine are improved. By means of the method, the labor intensity of workers can be greatly reduced.

Owner:HEBEI IRON AND STEEL

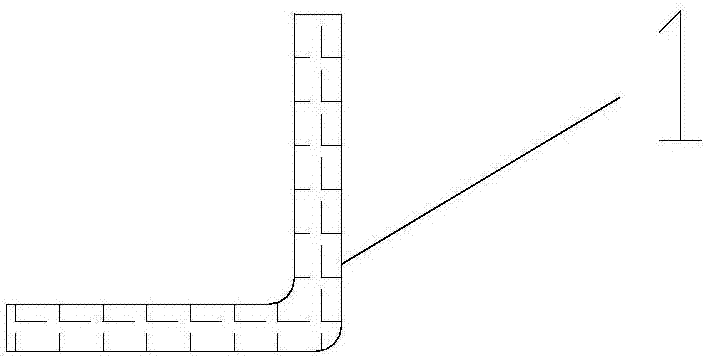

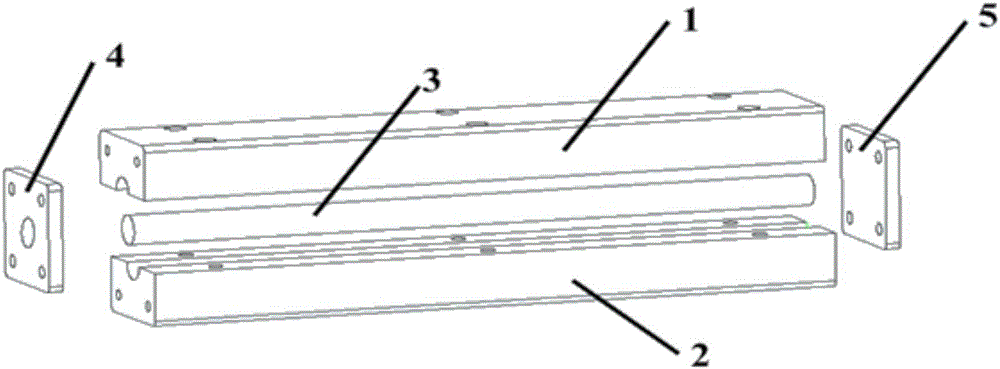

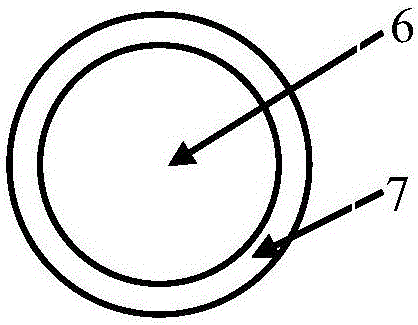

Forming mold and method for composite material pipe fitting

InactiveCN106182804AGuaranteed wall thickness uniformityGood internal qualityTubular articlesMetalProduct design

The invention provides a molding die and a molding method for composite material pipe fittings. The molding die includes a metal outer mold, a core mold and a connection structure arranged at both ends of the metal outer mold; a through hole is arranged in the middle of the metal outer mold, and the core The mold is arranged in the through hole; the metal outer mold is composed of an upper metal outer mold and a lower metal outer mold; the core mold includes a core material layer and a nylon bag film layer sleeved on the outer surface of the core material layer. Composite material pipe fittings prepared by the molding method of the present invention have lower production cost, higher internal quality, and better product thickness uniformity compared with traditional molding techniques, and can shape pipe fittings of various shapes according to product design drawings.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Spinning forming method for multi-angle tapered barrel body

The invention discloses a spinning forming method for a multi-angle tapered barrel body. The spinning forming method is characterized in that the multi-angle tapered barrel body is subjected to reversely compounded spinning forming, and two sections or multiple sections of the multi-angle tapered barrel body are integrally formed; compared with the conventional technological methods of part welding, machining and assembly welding forming, the spinning forming method has the advantages that processing efficiency is greatly improved, processing cost is greatly reduced, roundness requirements are met, and processing efficiency is effectively improved; and straight-side defects formed at longitudinal welding seam butt-joint parts of part welding forming are eliminated, and the problem that inner-profile circumferential welding seams at circumferential butt-joint welding seams are liable to sink is also eliminated, so that the integral processing precision, the appearance quality and the inner quality of the multi-angle tapered barrel body are effectively improved.

Owner:湖北三江航天江北机械工程有限公司

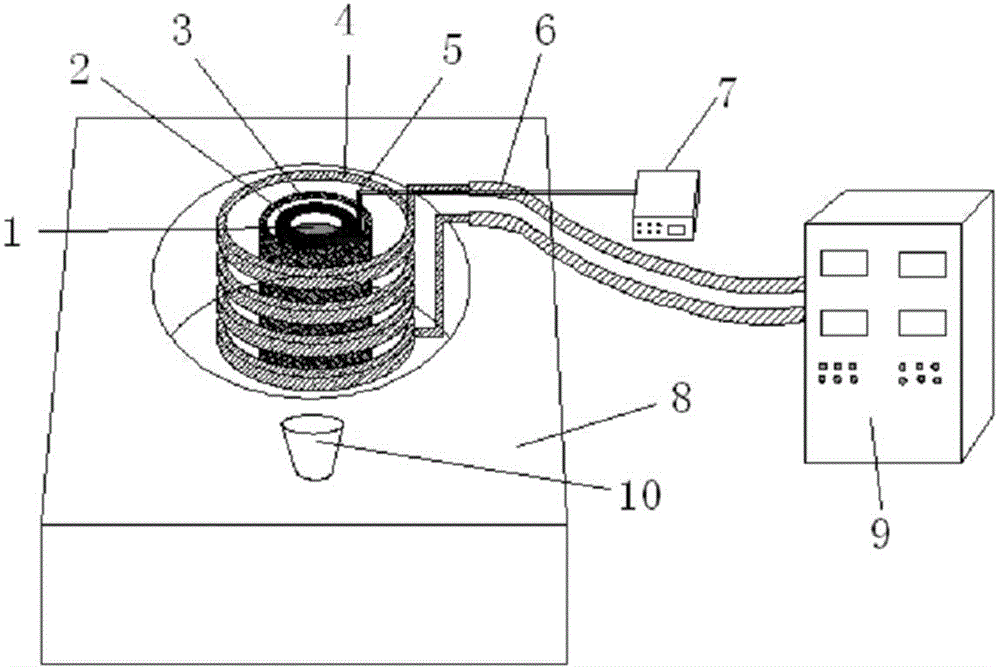

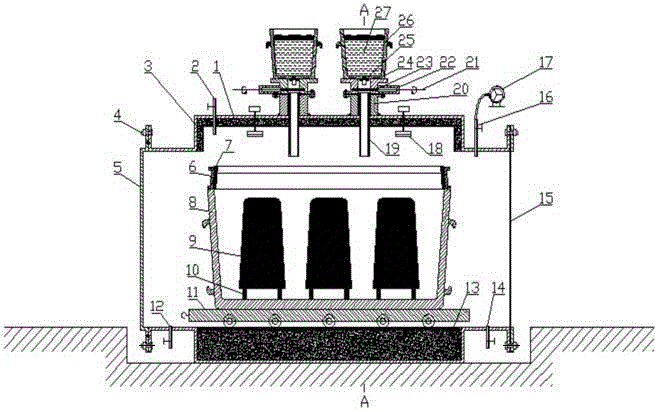

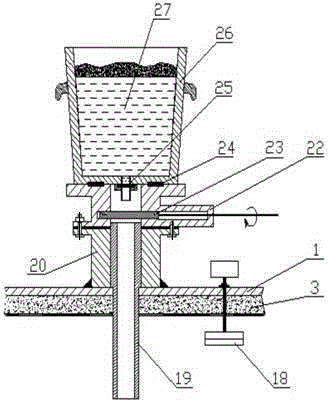

Casting riser induction heating device, and casting riser induction heating method

ActiveCN104826997AIncrease temperaturePlay a feeding roleFoundry mouldsFoundry coresEngineeringConductive materials

The invention discloses a casting riser induction heating device. The casting riser induction heating device comprises a riser sleeve; an annular sleeve prepared of graphite, steel, or other conductive materials; an induction coil; a thermoelectric couple; water cooled cables; a temperature recorder; and an induction heating power supply cabinet. Compared with conventional insulated risers and exothermic risers, the casting riser induction heating device possesses following advantages: riser setting time prolonging effect is more excellent than that of the conventional insulated risers and exothermic risers; real-time control on the temperature of molten metal in risers can be realized; recycling of induction heating risers can be realized; production cost is reduced; no environmental pollution is caused in using process; and environmental requirements are satisfied preferably.

Owner:SHENYANG POLYTECHNIC UNIV

Multi-core reducing multi-ladle co-casting method and device for casting large composite steel ingots

The invention discloses a multi-core reducing multi-ladle co-casting method and device for composite casting large composite steel ingots. The multi-core reducing multi-ladle co-casting method comprises the steps of selecting core blanks, regulating the temperatures of the core blanks, re-removing scales on the surfaces of the core blanks, assembling the core blanks and ingot molds, reducing oxide scales on the surfaces of the core blanks, casting and compositing and cooling composite ingots. The device adopted by the method comprises a tank body, a reducing gas inlet, a heat preservation layer, bolts, a bin door, risers, heat insulation plates, the steel ingot molds, the core blanks, shims, a trolley, an inert gas inlet, a bottom heat insulation layer, an exhaust port, an explosion-proof end cap, a vacuum exhaust valve, a vacuum pump, circulating fans, riser bricks, casting channels, sealing valve rods, sealing valve bodies, sealing valve plates, sealing asbestos, sliding nozzles and steel ladles. Large and ultra-large molded steel ingots which cannot be produced by means of an orthodox casting method can be manufactured. The steel ingots manufactured by means of the multi-core reducing multi-ladle co-casting method and device has the advantages of being low in production cost, high in solidification speed, small in internal segregation, even in components and high in finished product rate.

Owner:佛山市金禾精密模具有限公司

Technology for producing LS-CrNiMo30C steel forging for subsea oil production wellhead device through continuous casting billet

The invention relates to a technology for producing an LS-CrNiMo30C steel forging for a subsea oil production wellhead device through a continuous casting billet. The technology is characterized in that phi 300-400mm forged round steel is produced through a phi 600mm continuous casting round billet. The technology comprises the steps of smelting molten steel, continuously casting, forging, annealing, cooling, etc.; according to the grading in Appendix A of YB / T4149 Standard, a continuous casting billet macrostructure meets the following requirements: the center porosity is not greater than grade 2.0, the center cracks are not greater than grade 1.0, and the shrinkage cavity is not greater than grade 1.0; intermediate cracks, white points and skull patch defects are prohibited; the temperature increasing speed in casting billet heating during forging is not greater than 200 DEG C per hour; the forging heating temperature is 1200 to 1250 DEG C; the casting billet is completely burnt; the primary forging temperature is more than 1150 DEG C, and the final forging temperature is not less than 850 DEG C; after being removed from the production line, the forging is slowly cooled in a sand burying manner under the high temperature not less than 500 DEG C; after the temperature decreases to be less than 200 DEG C, the forging is removed from a sand pit for slowly cooling; the internal quality of the finished steel forging meets the requirement of D / d grade of Ultrasonic Testing SEP 1921 Standard, and the mechanical property meets the requirements of API SPEC 6A Standard.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Specific crystallizer casting powder for sulphur free-cutting steel and production method thereof

The invention discloses a specific crystallizer casting powder for sulphur free-cutting steel and production method thereof, mass percents of chemical components thereof are as follows: 29-35% of CaO, 25-30% of Sio2, 2-5% of MgO, 3-5% of Al2O3, 2-6% of Fe2O3, 5-11% of NaO?, 0-2% of Li2O, 5-9% of CaF2?, 0-5% of MnO, 0.5-2.0% of Al grey, 0-2% of B2O3, 5-11% of solid carbon, and allowance is building material adhesive and water. The sulphur free-cutting steel has low high-temperature strength and high crack sensitivity, and the casting powder should have properly high basicity. Basicity of a slag is improved, so that diffusion velocity is accelerated, and absorption of impurities in molten steel is benefited. So, improvement of basicity is an effective means for improving absorption of the impurities and control of surface longitudinal crack.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Steel for low-temperature and high-pressure pipeline connector and manufacturing method of continuous casting round billet thereof

InactiveCN103695785AImprove cleanlinessComposition is stableElectric furnaceProcess efficiency improvementMetallurgyHigh pressure

The invention relates to steel for a low-temperature and high-pressure pipeline connector and a manufacturing method of a continuous casting round billet thereof. The steel for the low-temperature and high-pressure pipeline connector disclosed by the invention comprises the following components by weight percent: 0.12-0.16% of C, 0.15-0.30% of Si, 1.20-1.45% of Mn, P not more than 0.025%, S not more than 0.015%, 0.15-0.25% of Cr, 0.04-0.10% of V, 0.02-0.05% of Nb, 0.015-0.040% of Alt, H not more than 2.0*10<-4>%, 120*10<-4>% to 260*10<-4>% of N, T.O not more than 15*10<-4>%, and the balance being Fe and inevitable impurities. The steel for the low-temperature and high-pressure pipeline connector provided by the invention has the advantages that the cleanliness is high, components are stable, the welding property is excellent, the strength, the tenacity and the low-temperature impact tenacity are high, and the like.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com