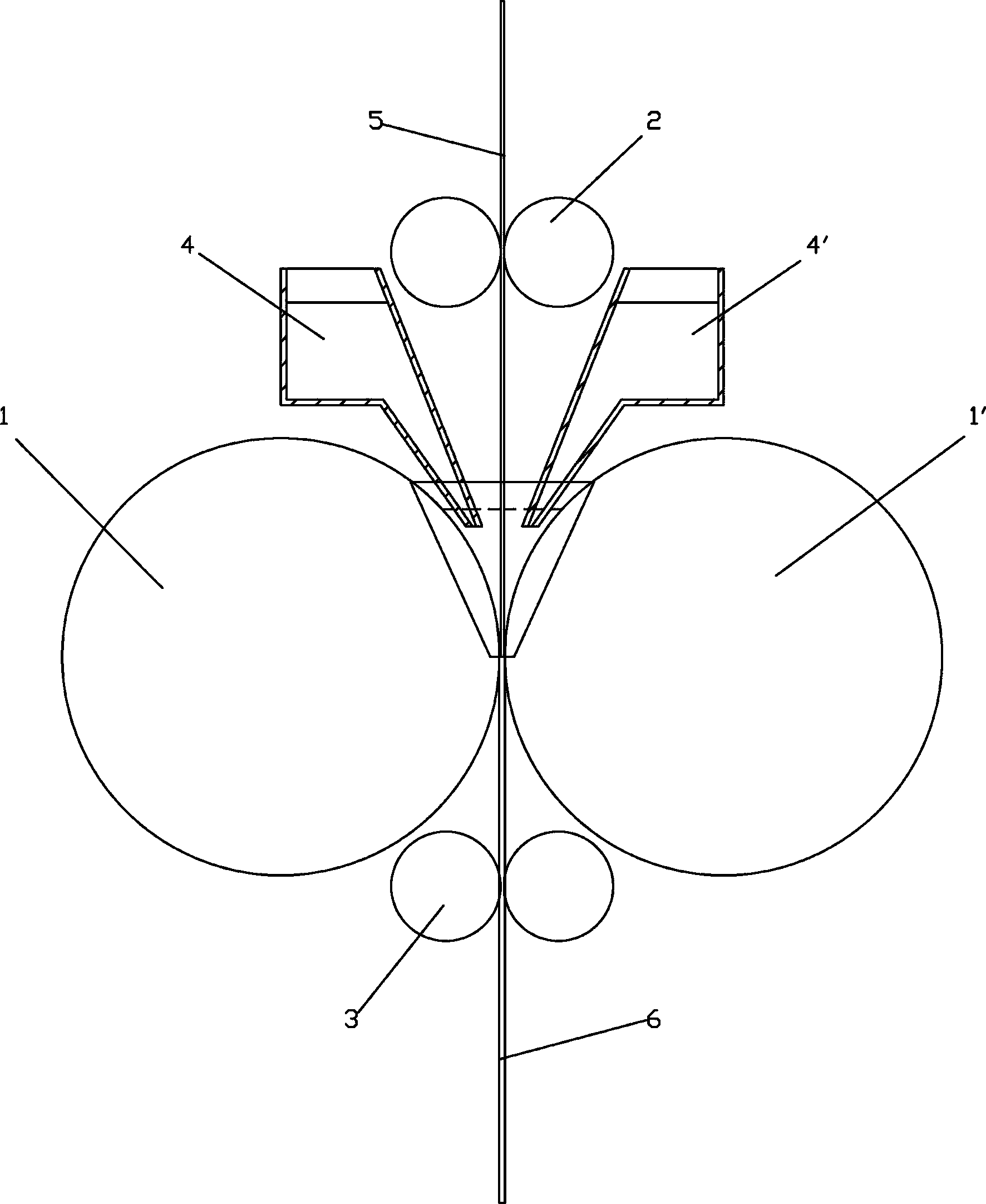

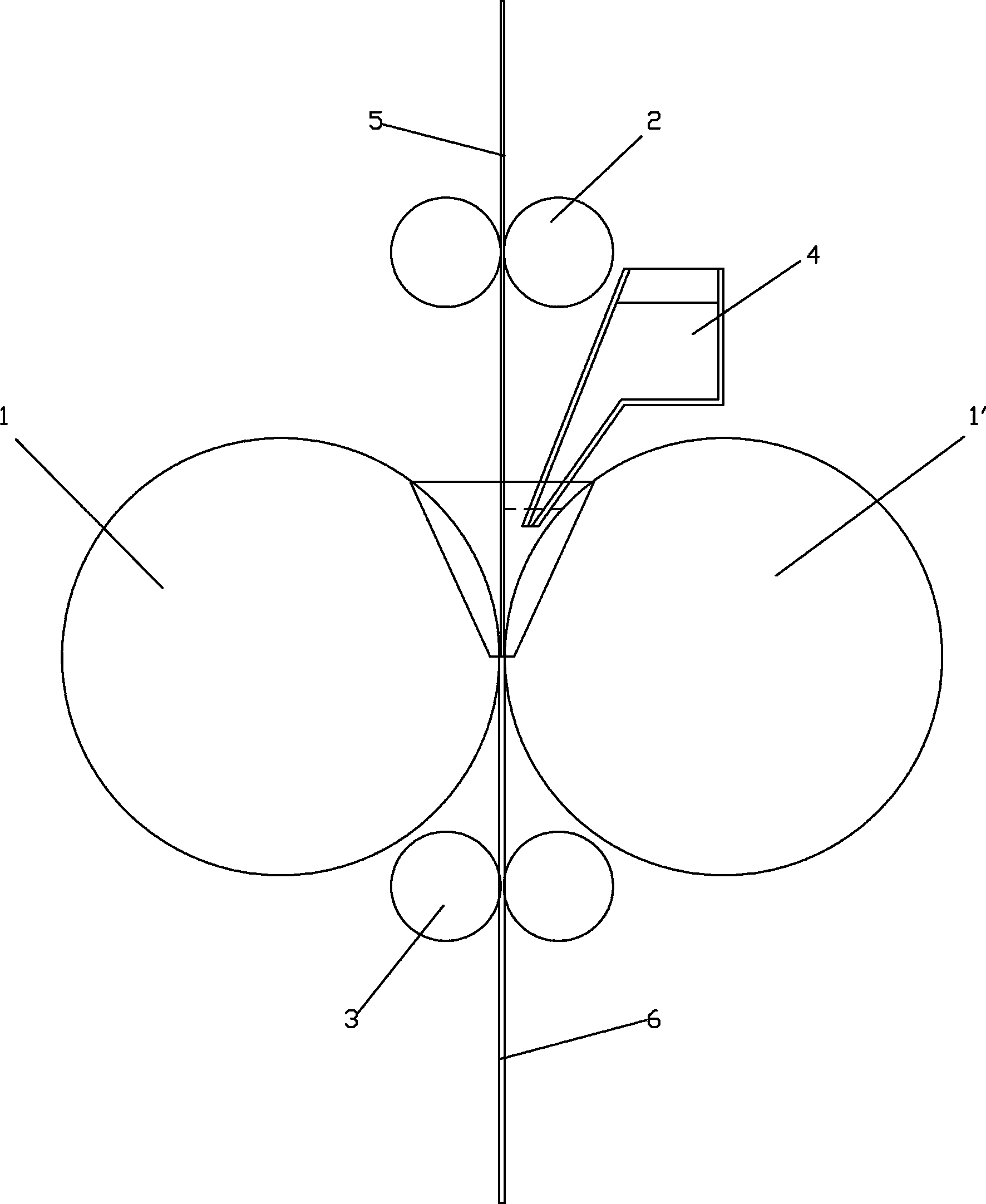

Preparation method for double roller thin strips of clad plate strip

A composite strip and twin-roll thin strip continuous casting technology, which is applied in the field of twin-roll thin strip continuous casting, can solve the problems of high labor intensity, long production cycle and complicated process, so as to improve the density and internal quality and reduce porosity And the formation of cracks, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The thickness of the middle strip is 2mm, and the thickness of the composite metal on both sides is 1mm. In the actual composite process, first adjust the roll gap between the composite metal and the composite metal, and then start the control roller of the middle strip to make it pass The crystallization roller, the intermediate strip is preheated at 550°C, during which the molten metal in the tundish starts to be cast, and the threading speed of the intermediate strip, the liquid level and the superheat of the composite metal liquid are controlled within the following ranges: the threading speed: 45m / min, Composite metal liquid level: 80mm, superheat: 23°C.

Embodiment 2

[0034] The thickness of the middle strip is 3mm, and the thickness of the composite metal on both sides is 1.5mm. In the actual composite process, first adjust the roll gap between the composite metal and the composite metal, and then start the control roller of the middle strip to make it pass through. After passing through the crystallization roller, the intermediate strip is preheated to 600°C. During this period, the molten metal in the tundish starts to be cast, and the threading speed of the intermediate strip, the liquid level and superheat of the composite metal liquid are controlled within the following ranges: Strip threading speed: 60m / min , Composite metal liquid level: 110mm, superheat: 26 ℃.

Embodiment 3

[0036] The thickness of the middle strip is 5mm, and the thickness of the composite metal on both sides is 2.5mm. In the actual composite process, firstly adjust the roll gap between the composite metal and the composite metal, and then start the control roller of the middle strip to make it pass through. After passing through the crystallization roller, the intermediate strip is preheated to 700°C. During this period, the molten metal in the tundish starts to be cast. The threading speed of the intermediate strip, the liquid level and superheat of the composite metal liquid are controlled within the following ranges: Strip threading speed: 80m / min , Composite metal liquid level: 150mm, superheat: 33 ℃.

[0037] Composite materials are artificially compounded by matrix materials and composite materials by a special method. It gives full play to the physical and chemical properties of the materials and forms a new type of material with excellent comprehensive performance. It is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com