Patents

Literature

117results about How to "Contour smoothing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

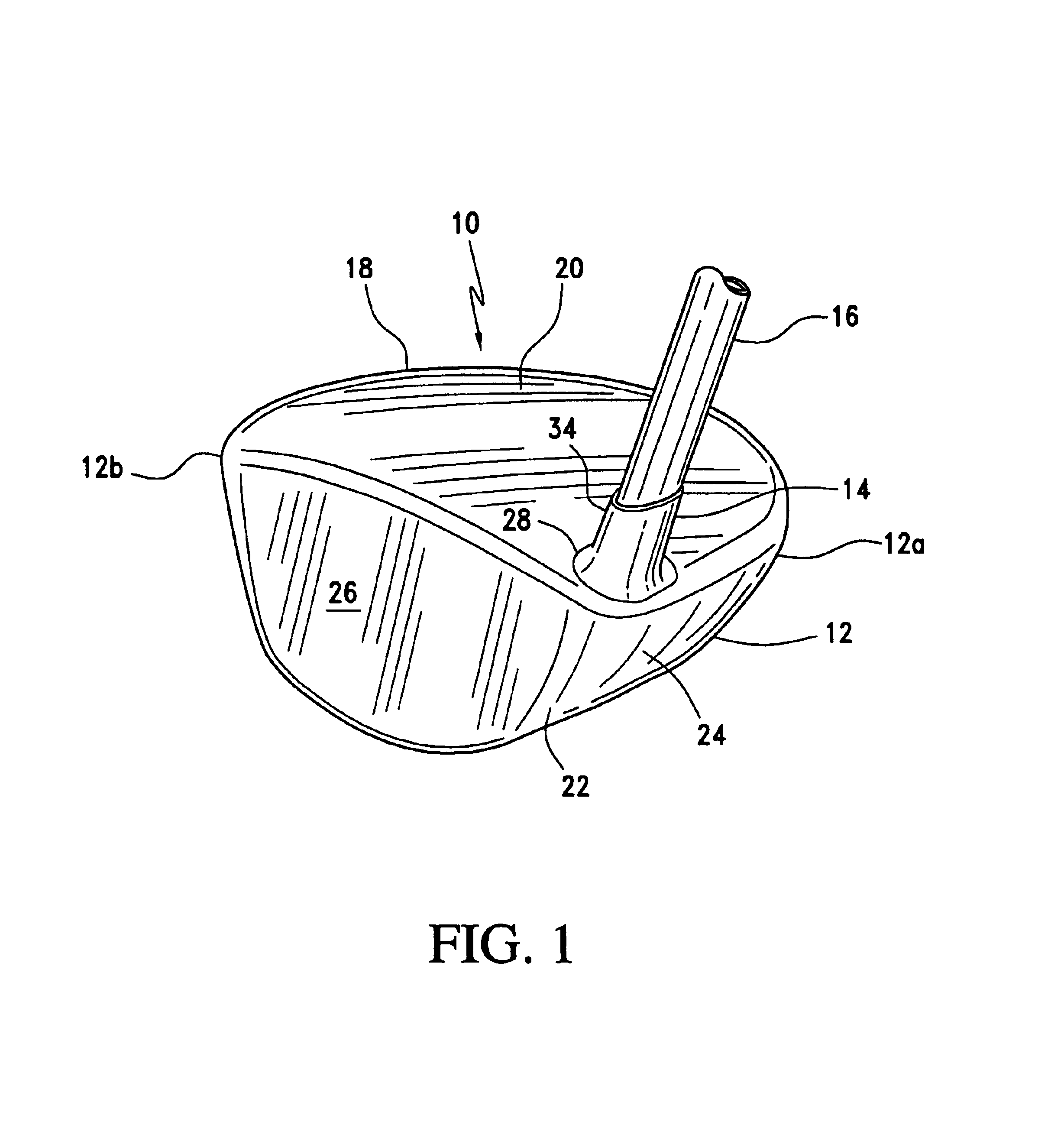

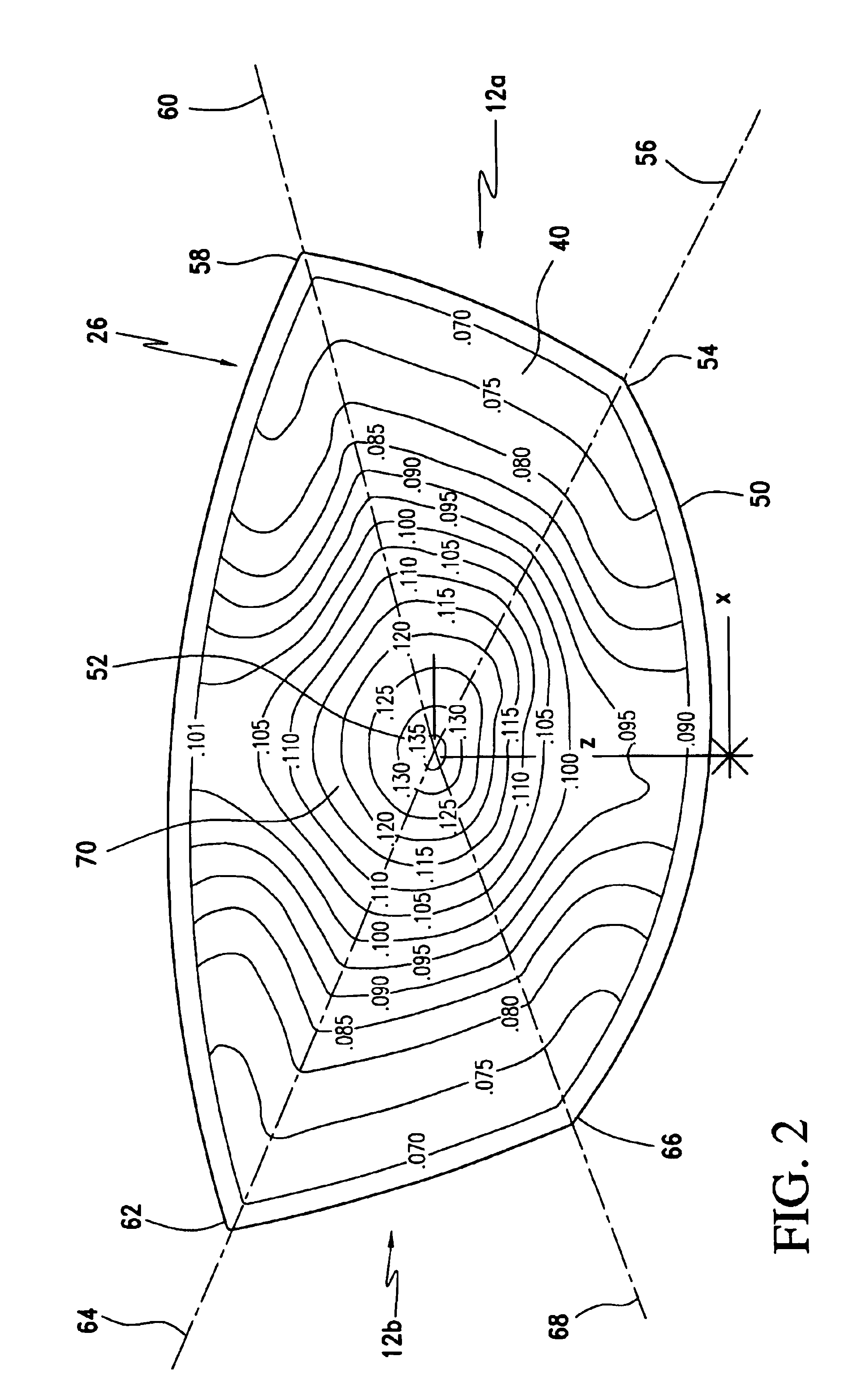

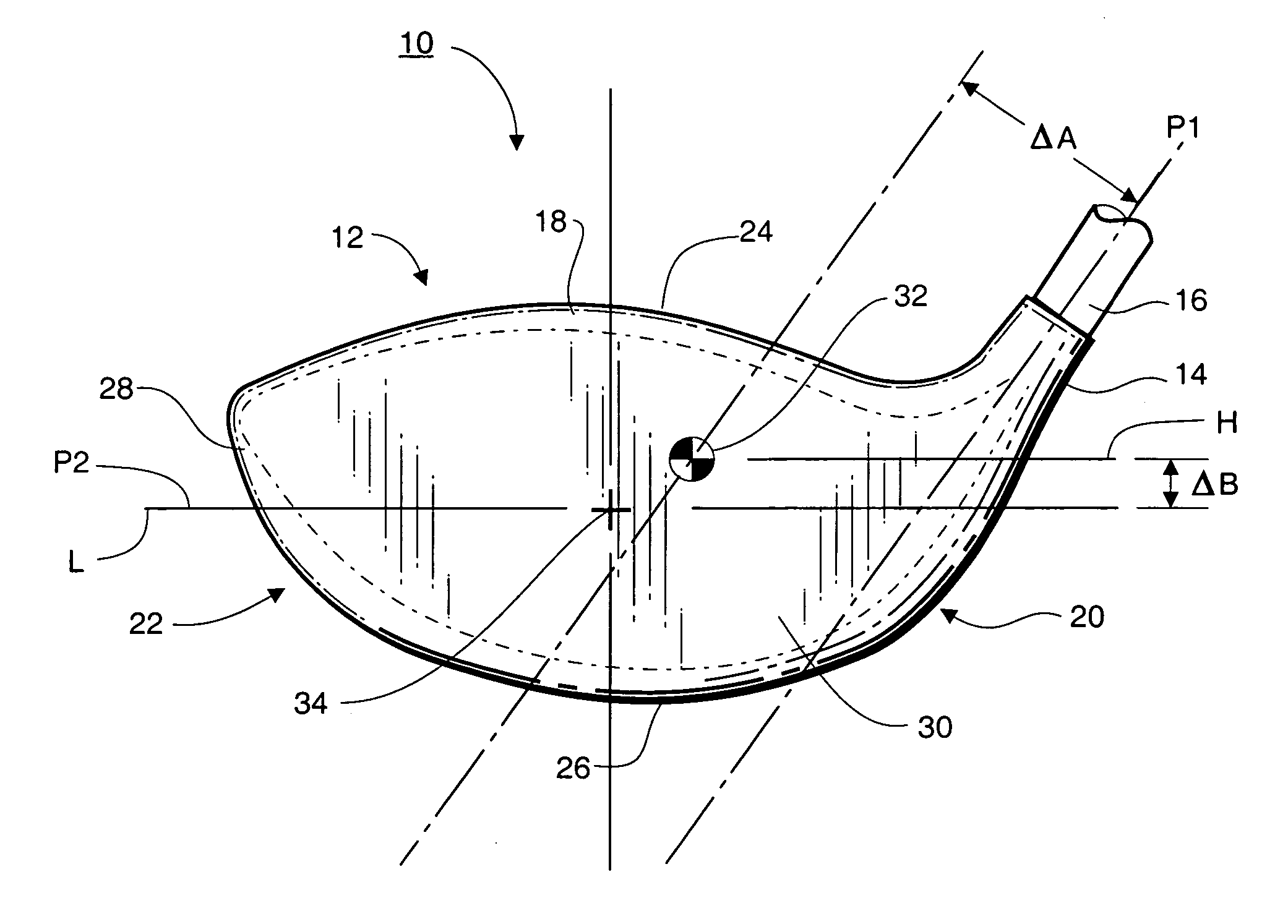

Golf club head with high center of gravity

ActiveUS6939247B1Contour smoothingSufficient backspinGolf clubsRacket sportsGravity centerEngineering

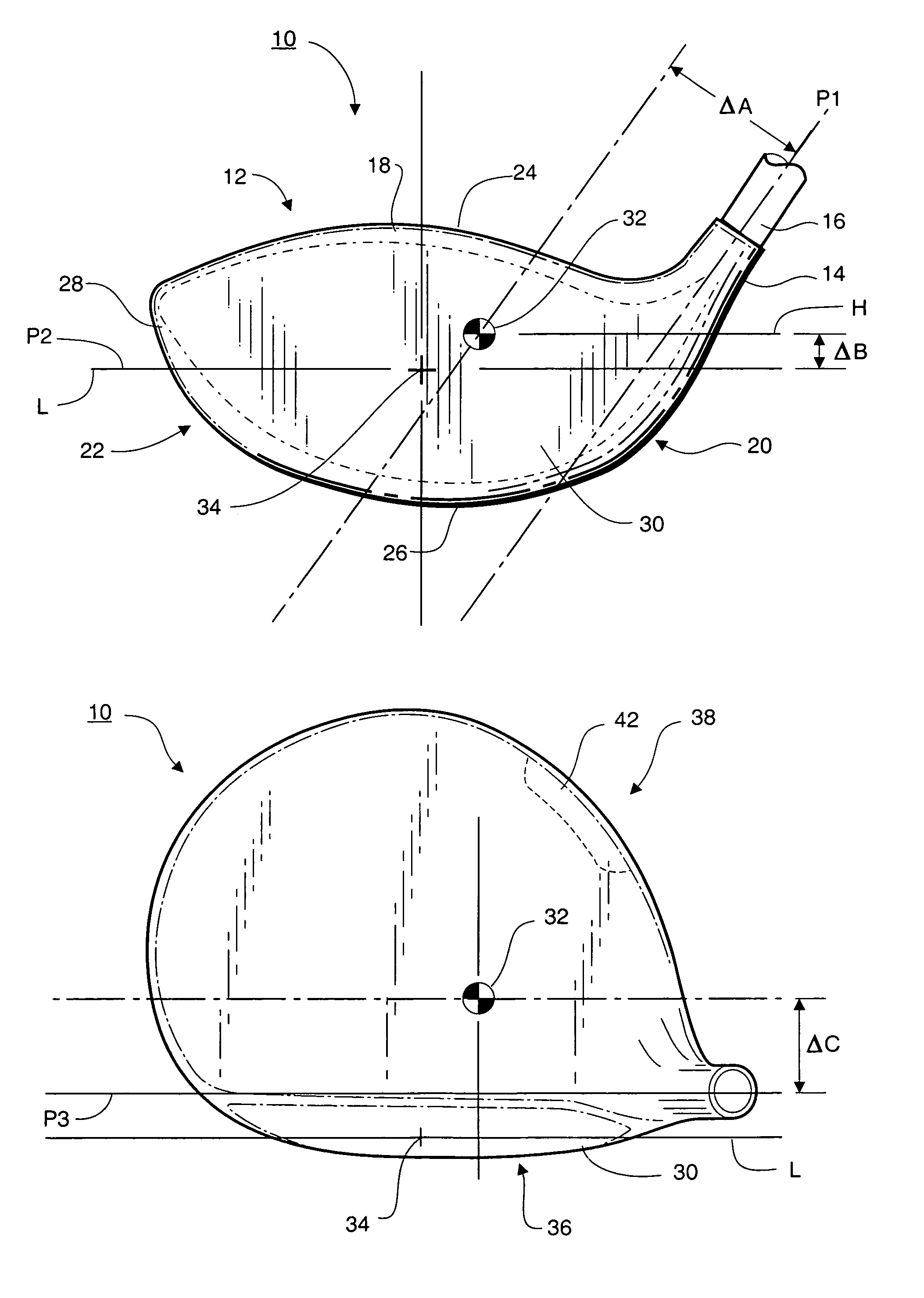

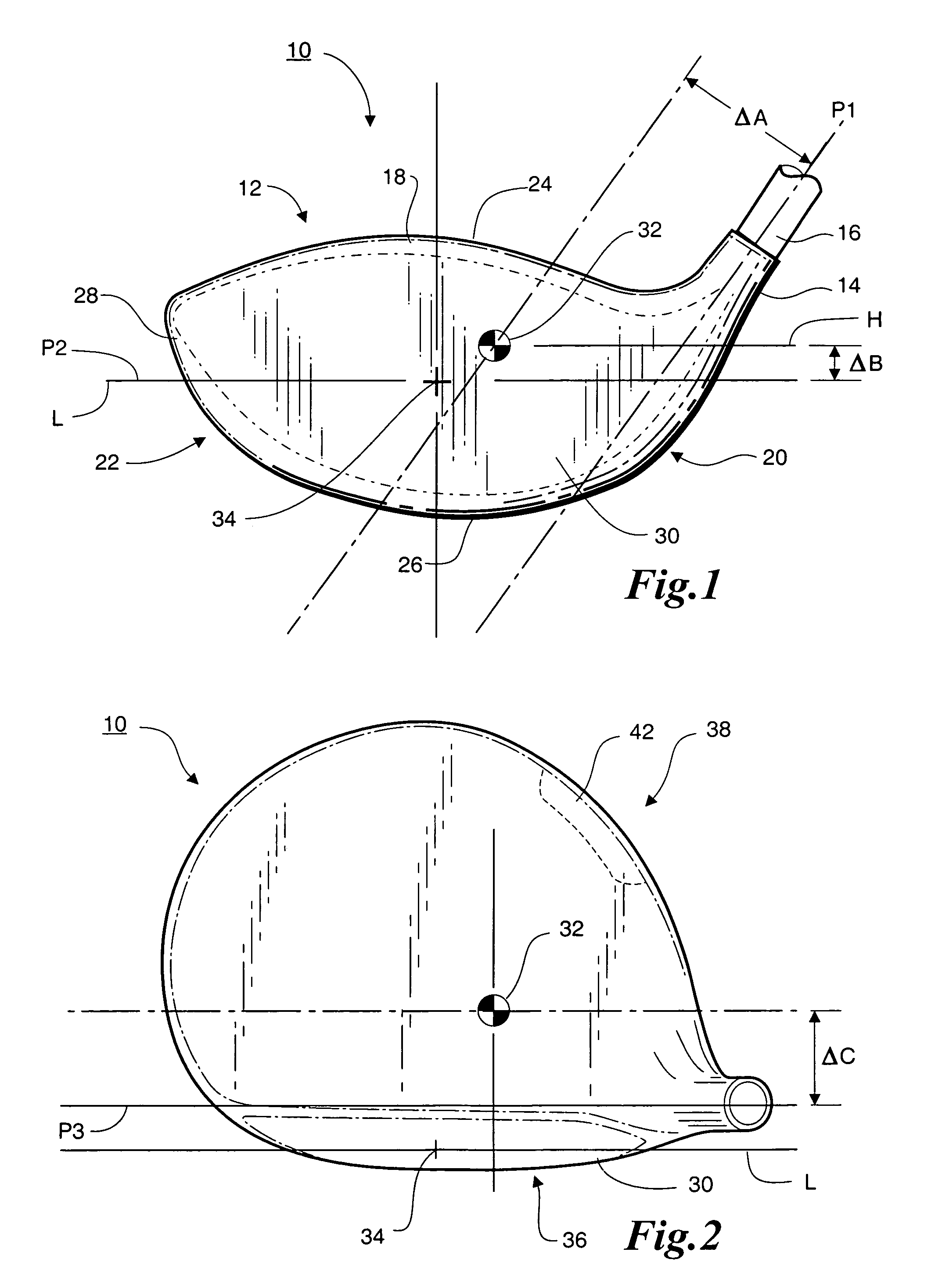

A golf club head is formed of a hollow metal body having a center of gravity that is above the geometric center of the club face. The hollow metal body of the club head has a sole plate that is smoothly contoured and devoid of any inefficient structures such as weight pads or other mass concentrations. By avoiding the use of inefficient structures such as weight pads, more material is available for the structural walls of the club head body while maintaining the club head within acceptable weight limitations. Moreover, placement of the center of gravity above the center line of the face ensures that sufficient backspin will be imparted to the golf ball when struck by the club.

Owner:KARSTEN MFG CORP

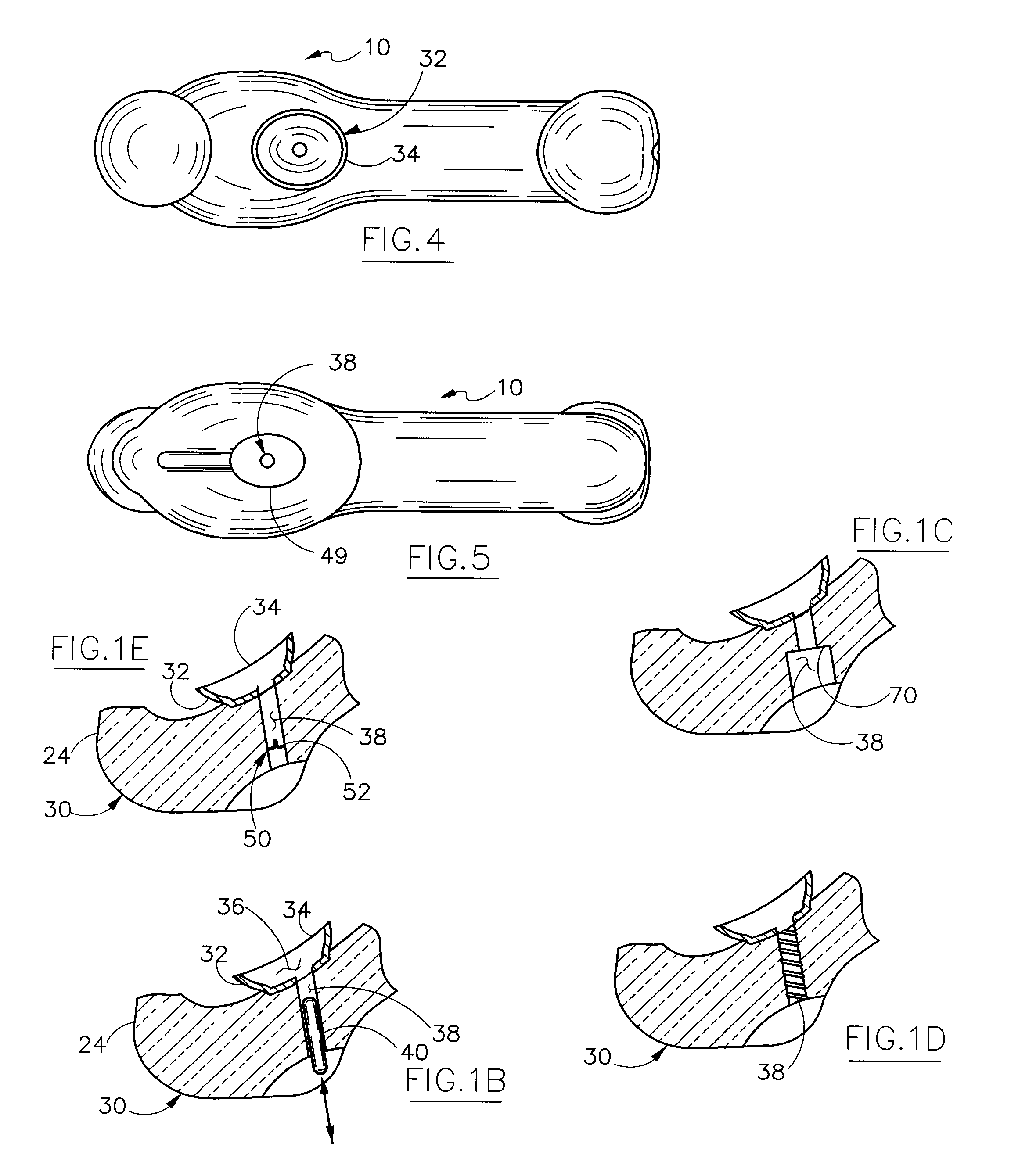

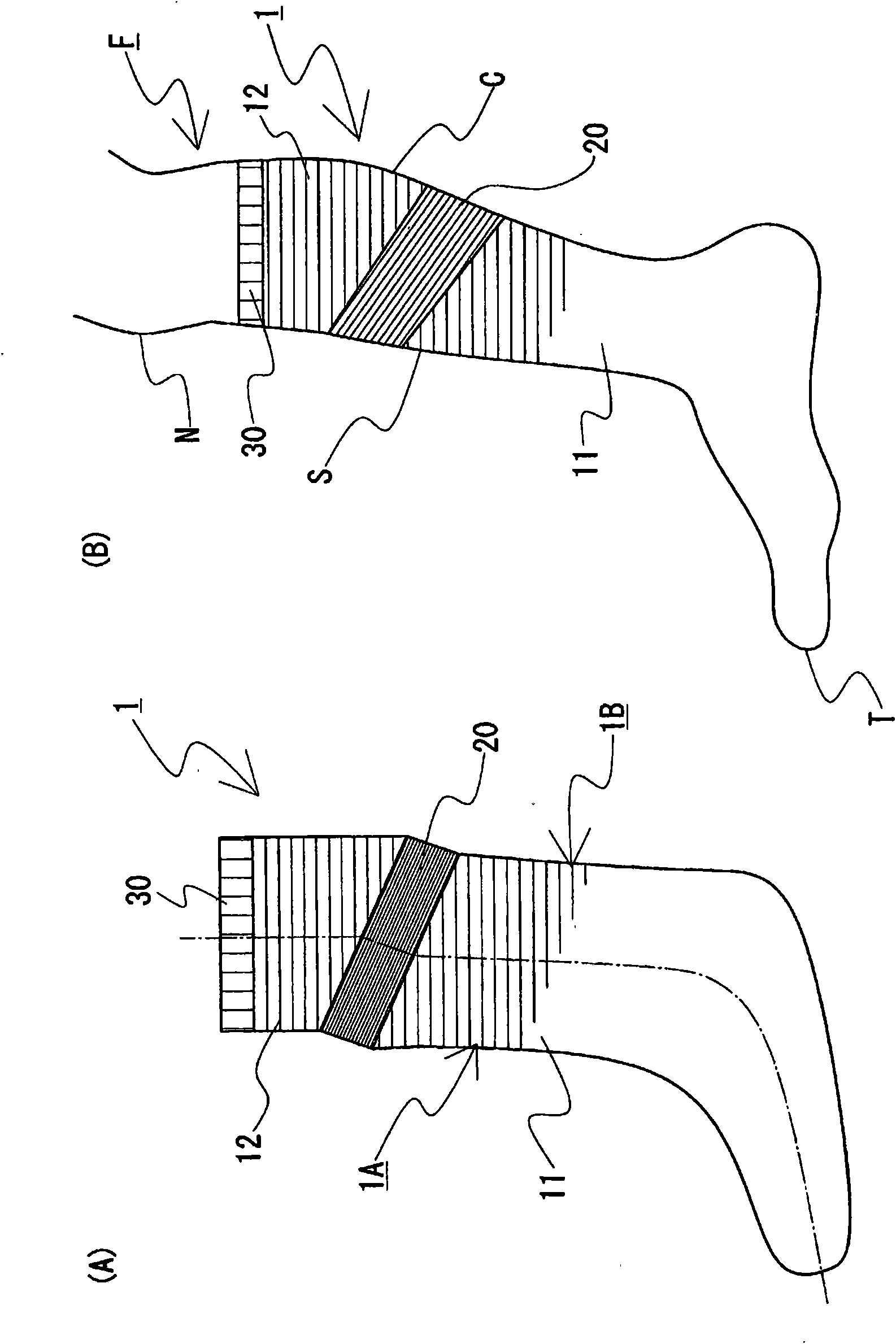

Golf club with diagonally reinforced contoured front wall

InactiveUS6926618B2Convenient lengthEfficient transferGolf clubsRacket sportsStress distributionFour quadrants

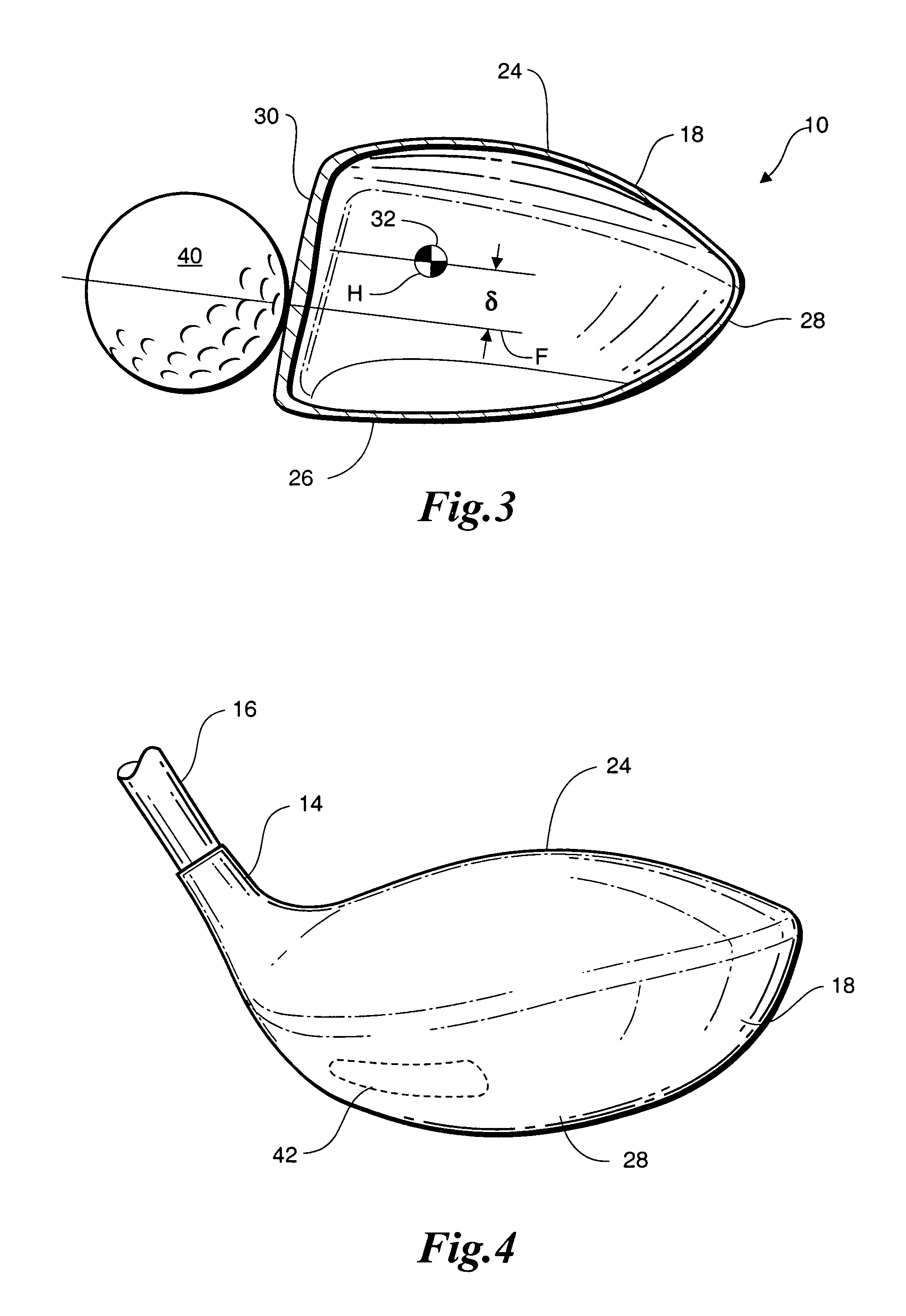

A golf club head composed of a forged metal material has a striking surface that is supported by diagonal stiffening regions that extend from a central region of the face toward the heel-sole quadrant, heel-crown quadrant, toe-crown quadrant, and toe-sole quadrants of the face. The diagonal stiffening regions are smoothly contoured to blend into the back surface of the face so as to avoid any stress concentrations. By extending the stiffening regions diagonally from the center of the club face to the four quadrants, a more uniform stress distribution can be obtained and therefore more uniform performance. Additionally, since the diagonal stiffening regions are greater in length than vertical or horizontal stiffening region could be made, the center of the face can deflect a greater amount without exceeding the yield strength of the material and, therefore, there is a more efficient transfer of energy from the club head to the ball.

Owner:KARSTEN MFG CORP

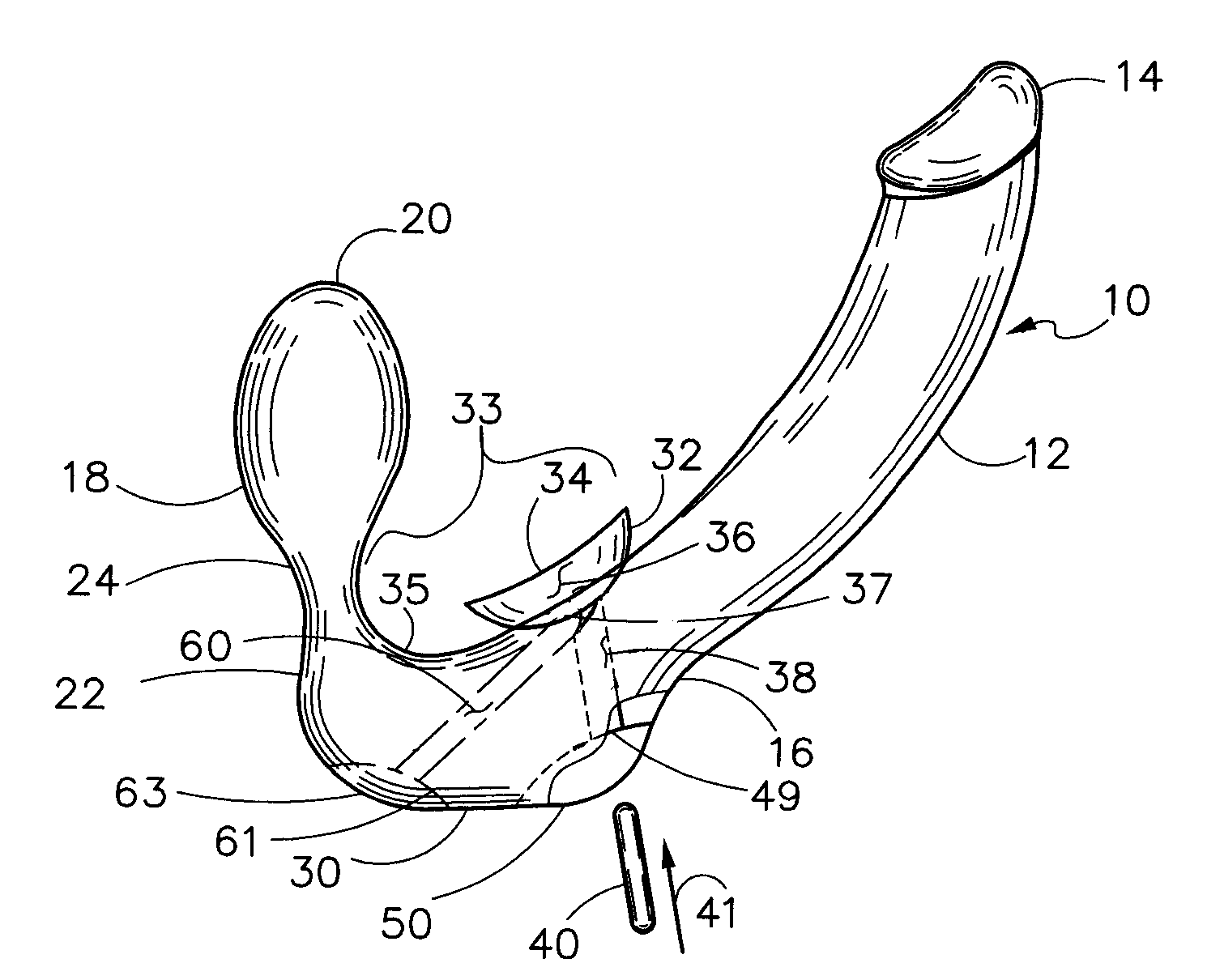

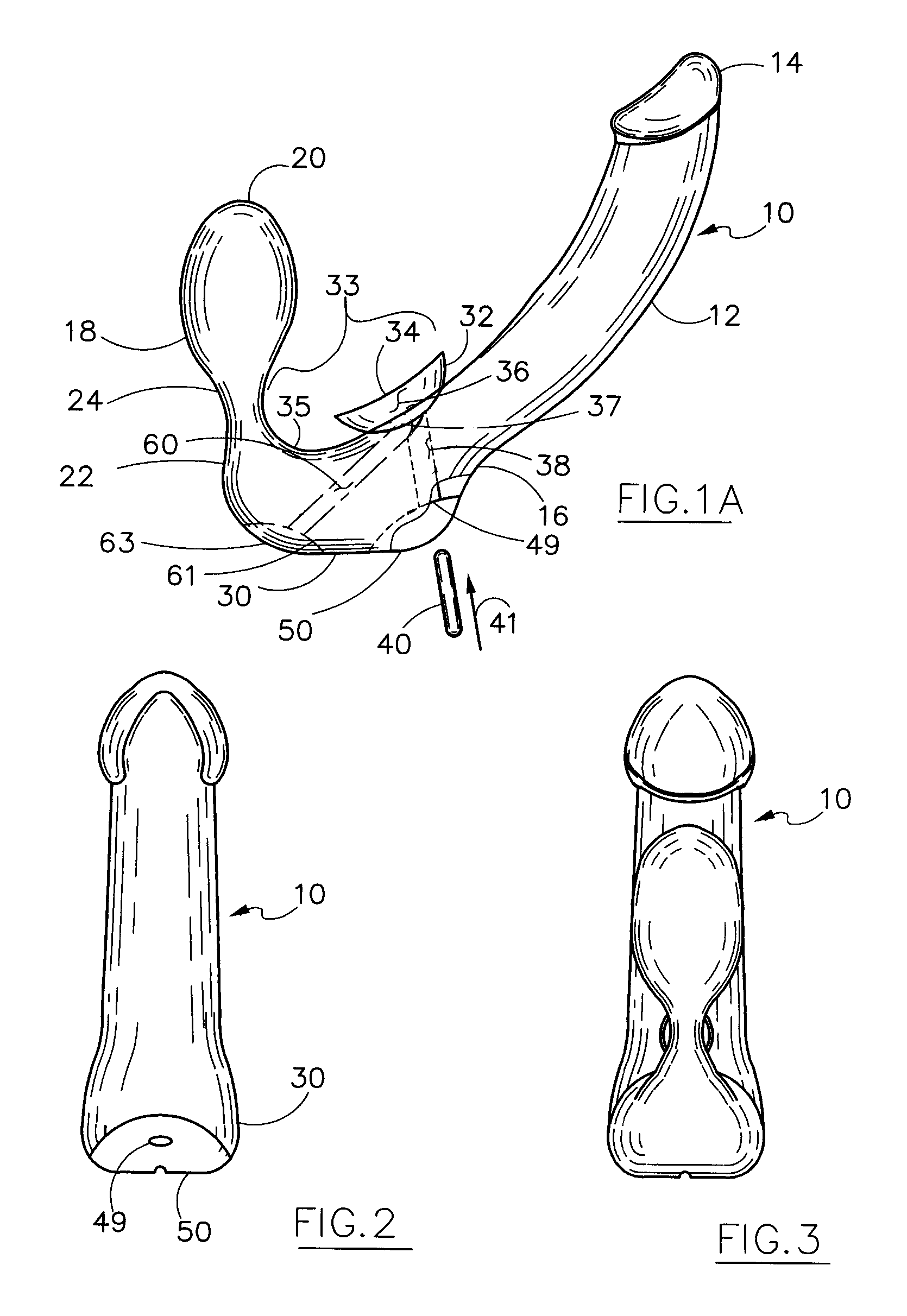

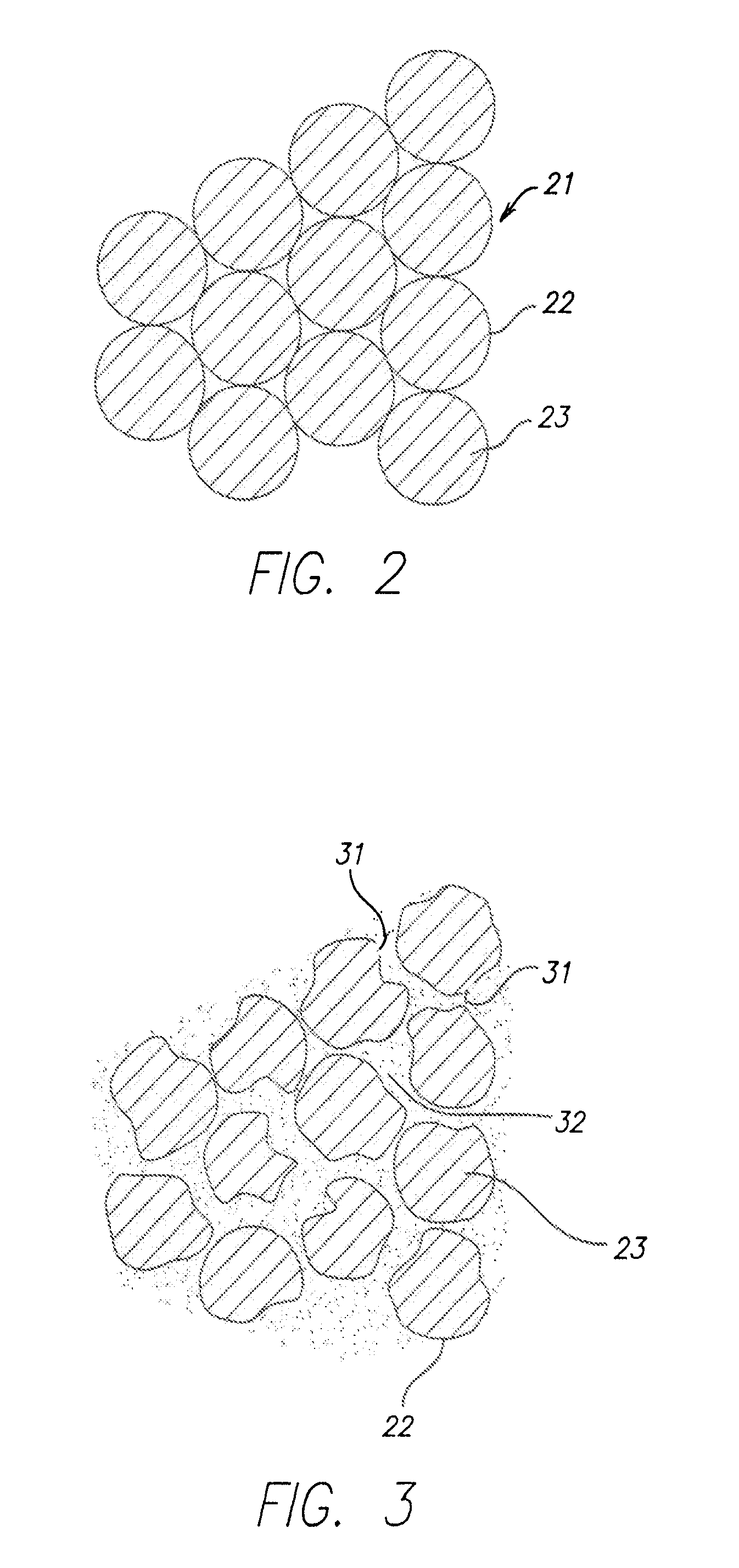

Erogenic stimulator

ActiveUS7530944B1Stimulating areaDelay and discomfortPneumatic massageCavity massageEngineeringSpherical form

The erogenic stimulator includes a first resilient end region (phallic) extending from a base and a second resilient bulbous end region extending therefrom. The bulbous end is connected via a reduced diameter neck to the base. The base and first and second ends form a truncated substantially U-shaped stimulator. A concave suction element is formed on the base in the curved portion of the U-shape. A passageway may be included from the concave suction element through the base into which may be inserted either a plug or a vibratory element. The plug / vibratory element closes the base end of the passageway thereby permitting expansion and contraction of the passageway dependent upon a predetermined condition at the suction opening of the passageway. If the suction element contacts the skin or an erogenous region and blocks the passageway, the rocking stimulator suctions and evacuates, alternatively, air through the suction opening of the passageway.

Owner:KAIN MELISSA MIA MS

Spatial-spectral integrated hyperspectral remote sensing image classification method

InactiveCN103473557AContour smoothingPlay a role in separationCharacter and pattern recognitionSpectral domainSpectral space

The invention discloses a spatial-spectral integrated hyperspectral remote sensing image classification method. A conventional hyperspectral image classification technology mainly focuses on how to use the classification information of spectral spaces better, but ignores the information of image spatial domains. According to the invention, in the process of carrying out self spectral feature classification by using data, spectral classification results are supplemented by using effective spatial domain information combining a region growing method with a binary morphology method. According to the invention, an SVM (support vector machine) based classification method is adopted for carrying out spectral domain classification on data firstly; then, effective spatial domain information is introduced by using the region growing method and the binary morphology method so as to correct spectral classification results. According to the invention, information contained in hyperspectral data is used more fully, and the precision of hyperspectral image classification is improved.

Owner:HANGZHOU DIANZI UNIV

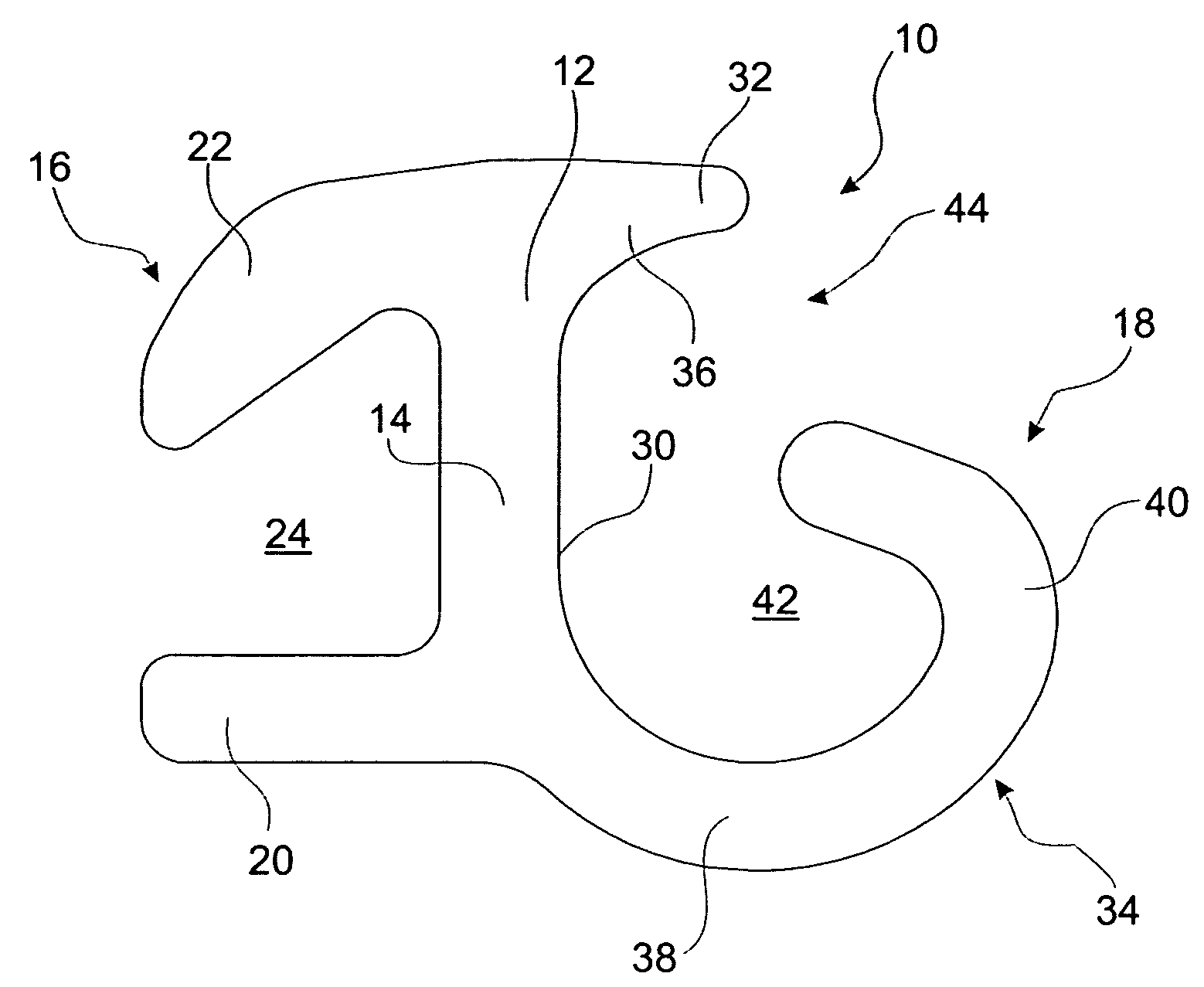

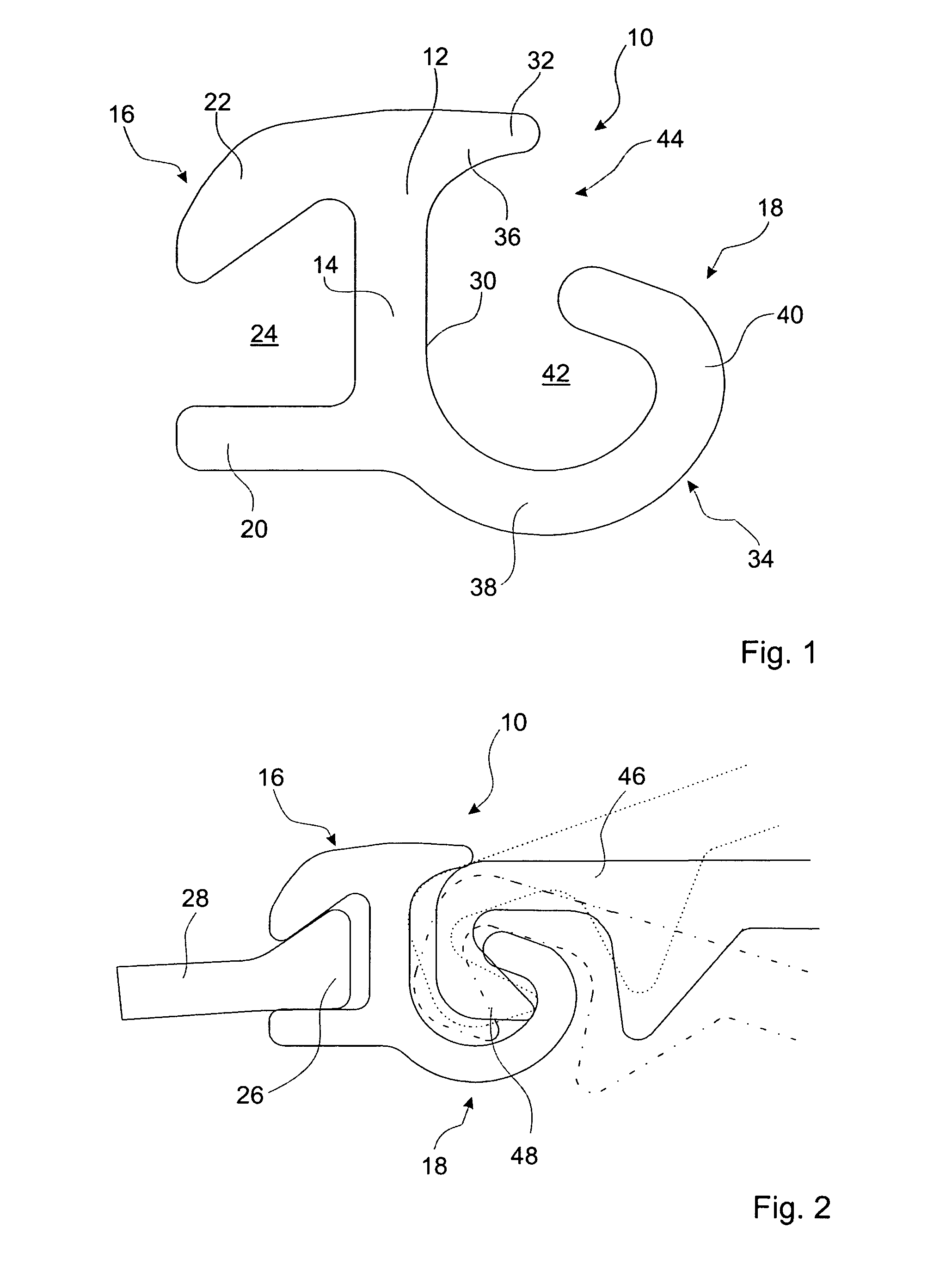

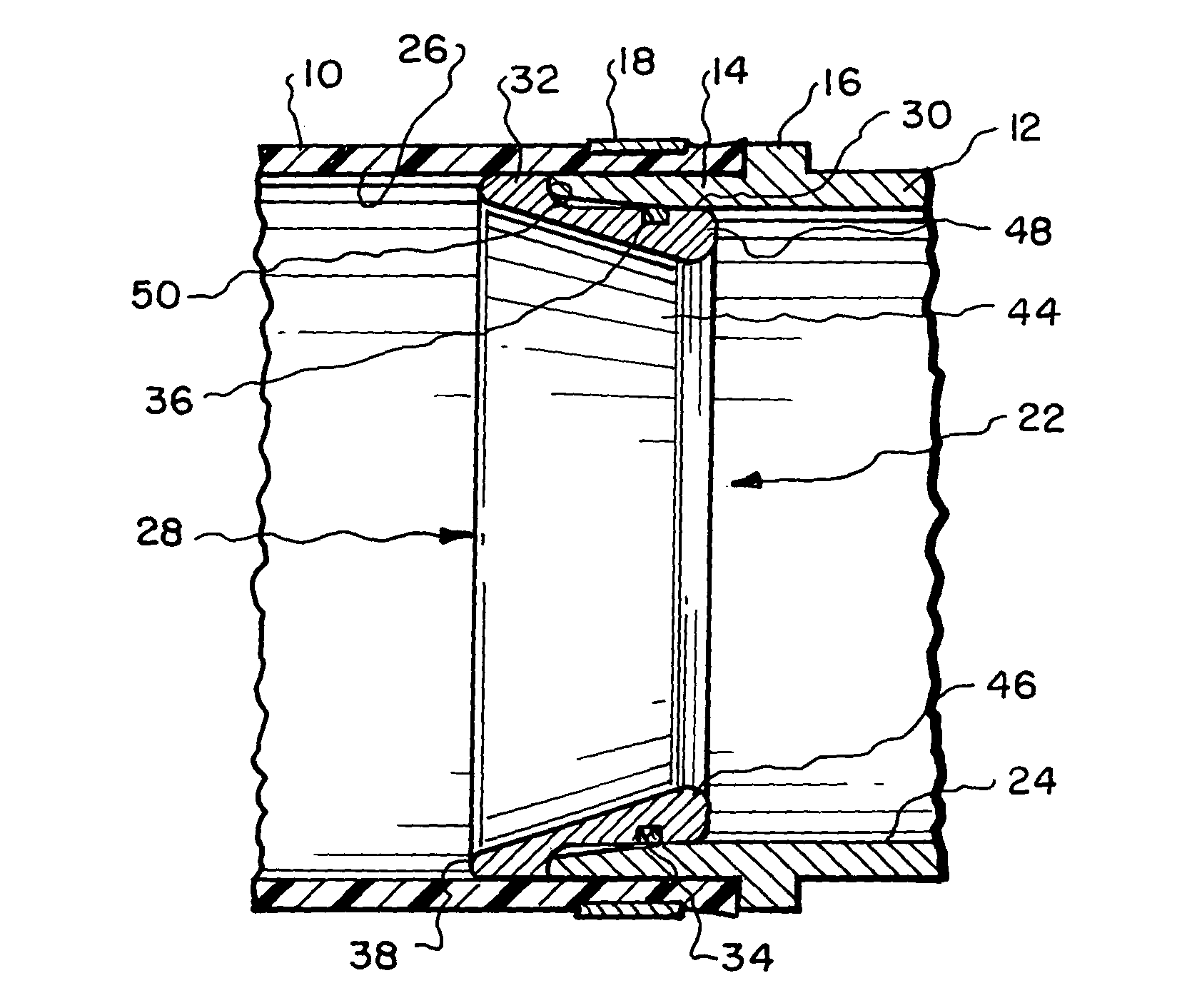

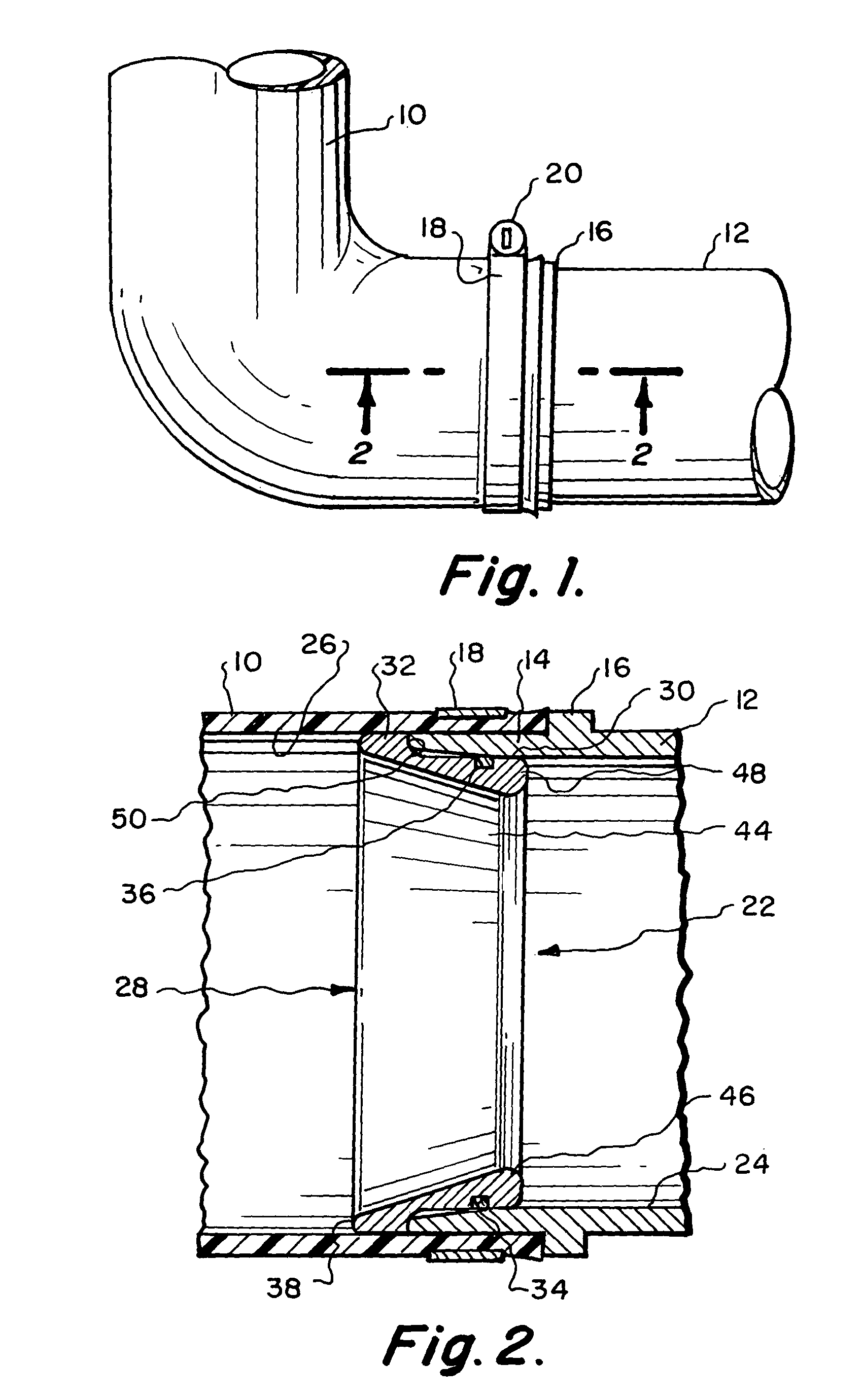

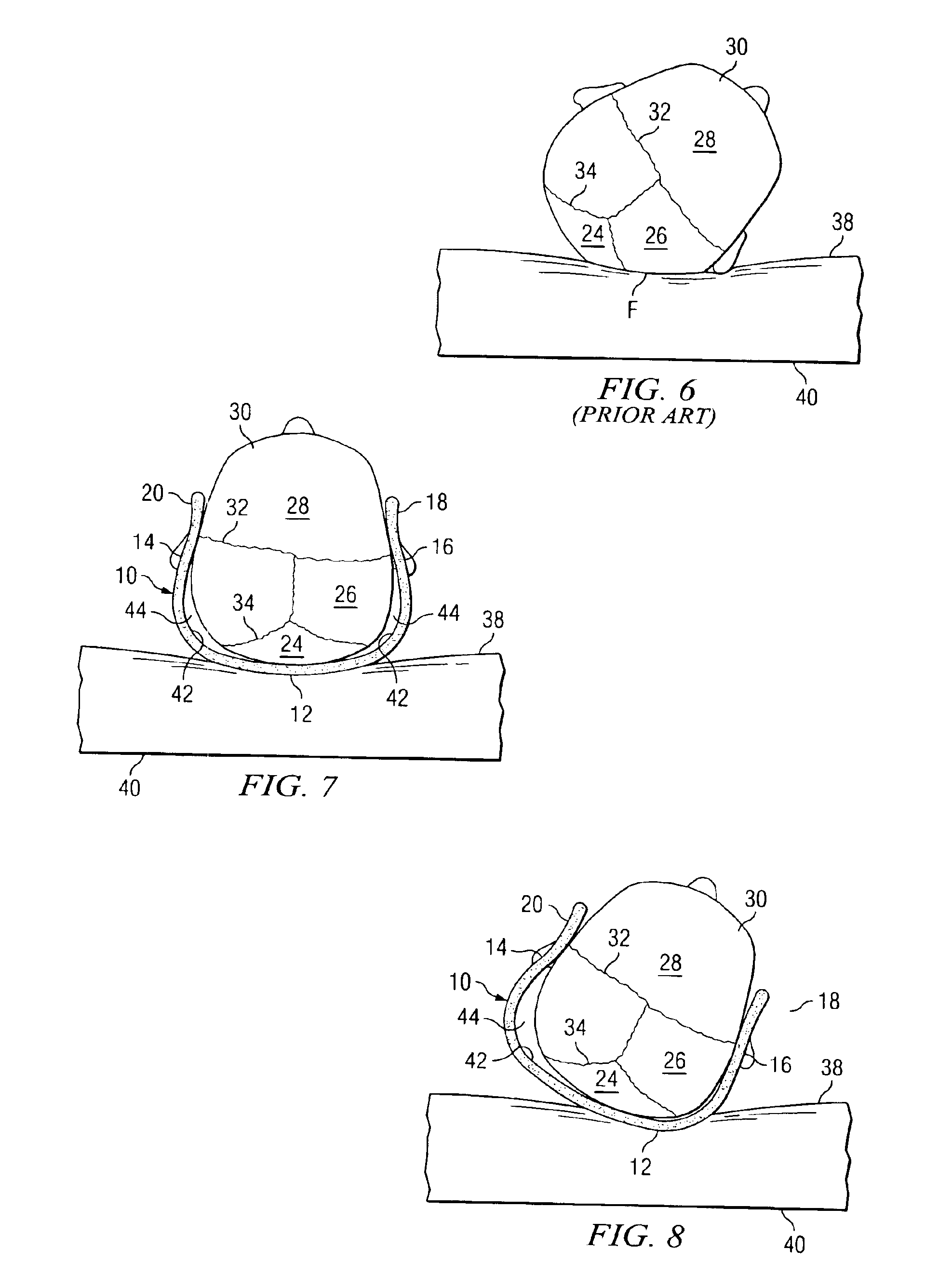

Connecting profiled element for connecting sheet piles to carrier elements

ActiveUS7527456B2Erected more easilyEasy erectionArtificial islandsScaffold connectionsEngineeringSheet pile

A rod-type connecting profiled element (10) for connecting sheet piles to carrier elements comprises a central strip (12) that separates two opposing connecting profiled elements (16, 18), each of which respectively forms a saw (24, 42). One connecting profiled element is embodied as a plug-in profiled element (16) for the carrier element and the other connecting profiled element is embodied as a receiving profiled element (18) for connecting a sheet pile. The central strip (12) comprises, on the side of the receiving profiled element (18), a central section (14) having a straight plane inner wall (30) to which a first short end section (32) is connected on one side, said short end section protruding past the central section (14) at an angle of approximately 90°, and being connected thereto by means of a transition section (36) having an inner wall with a cross-section that follows a quadrant. A hook strip (34) is arranged on the other side of the plane central section (14) as a second end section oriented in the same direction as the first end section (32).

Owner:SHEET PILE LLC

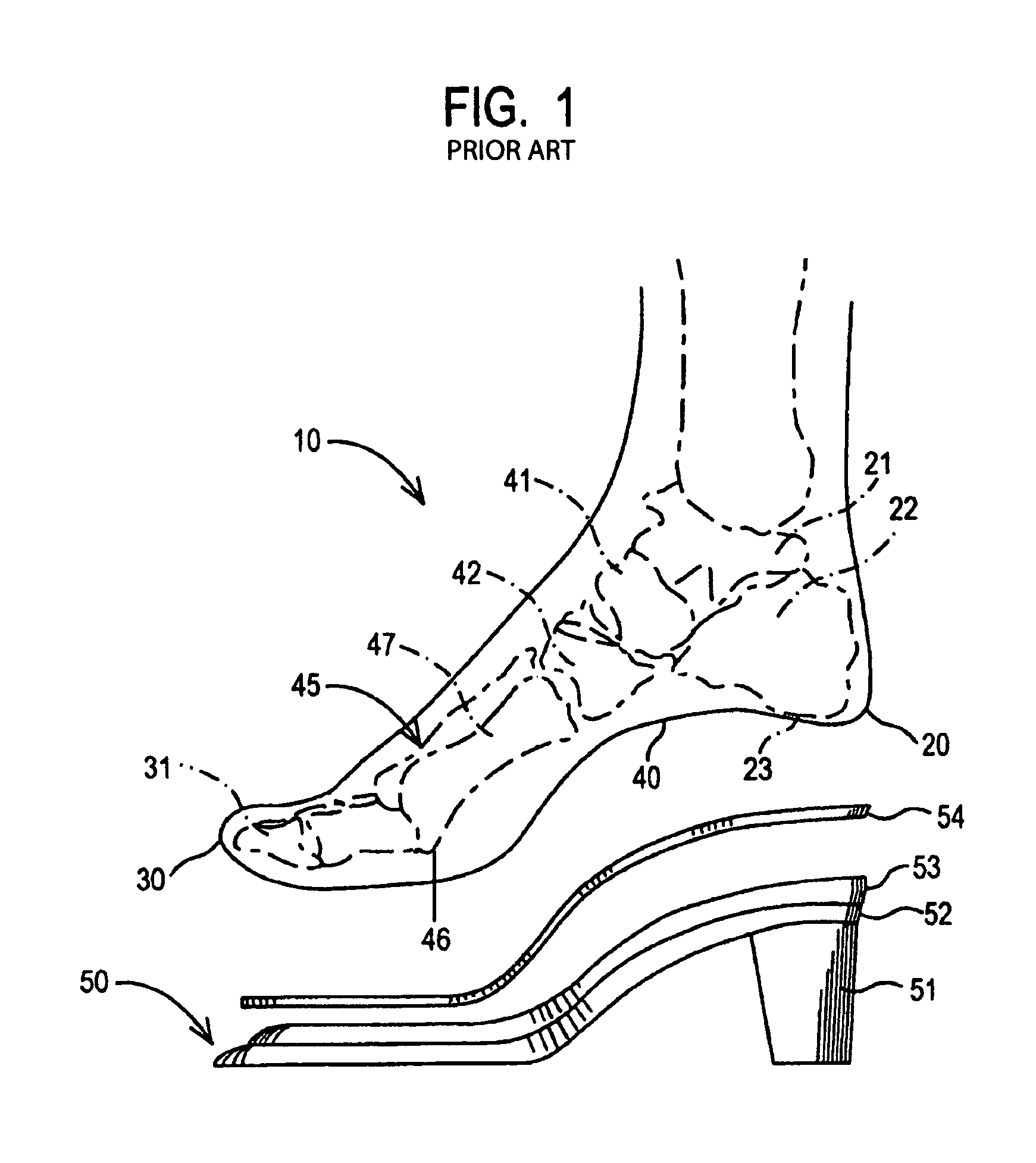

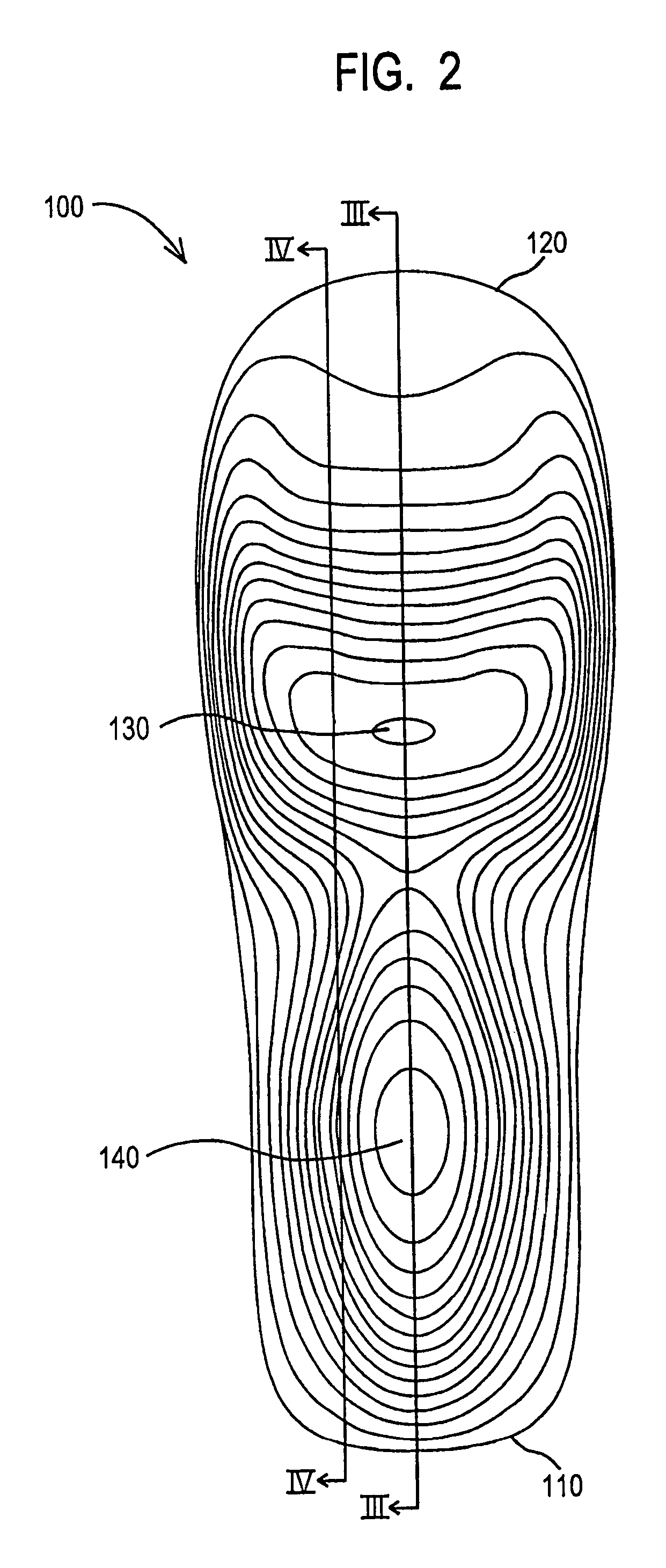

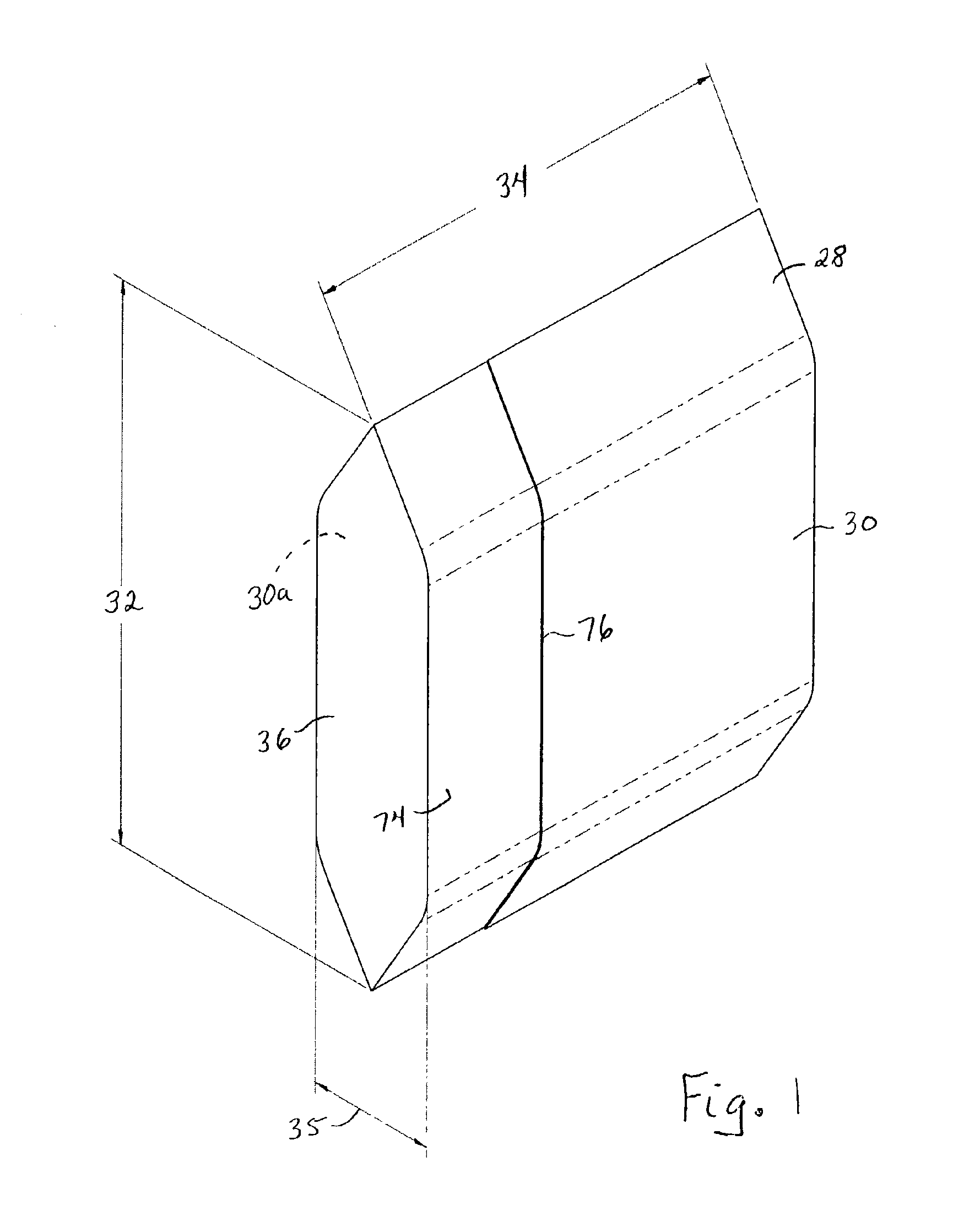

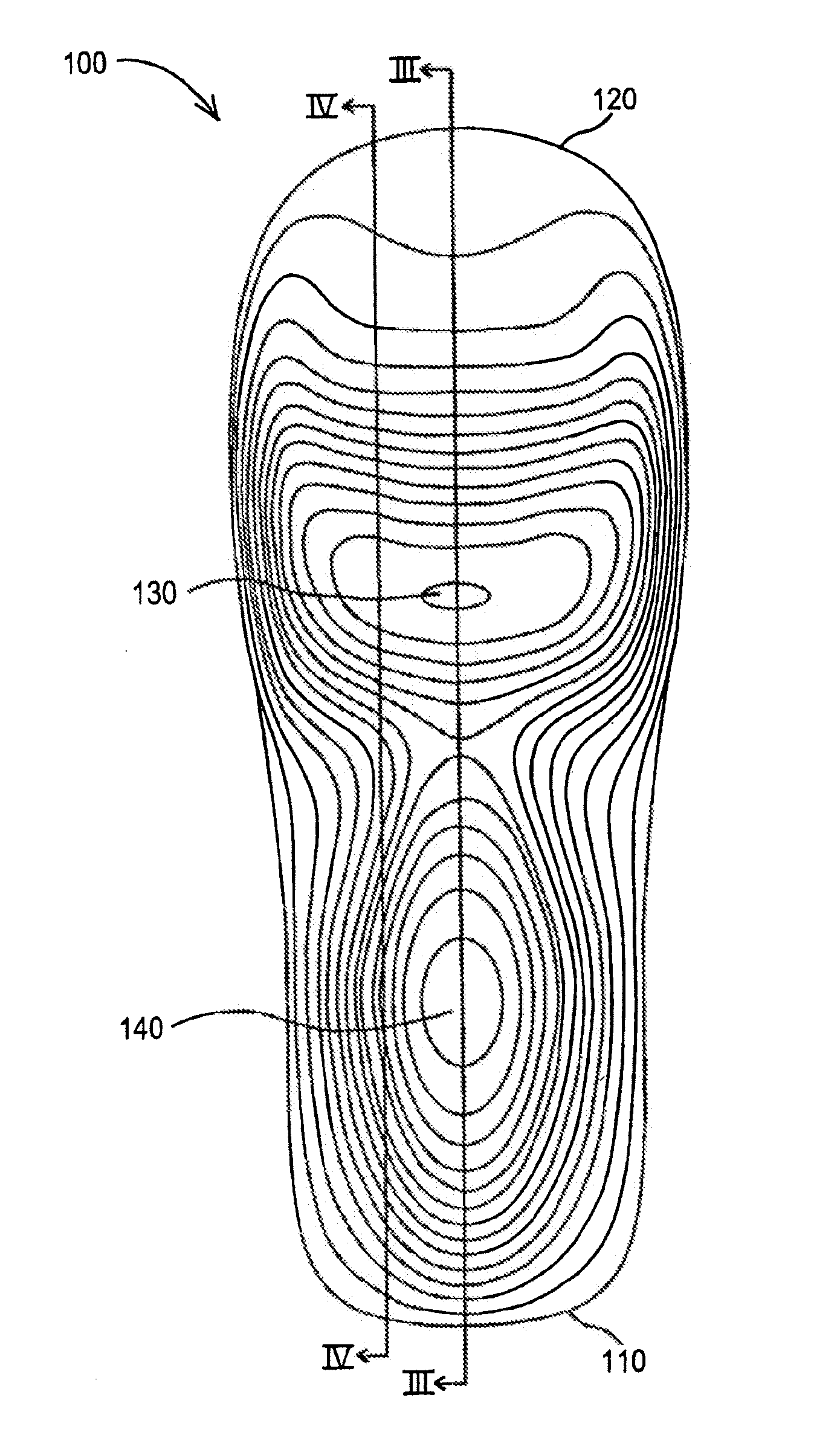

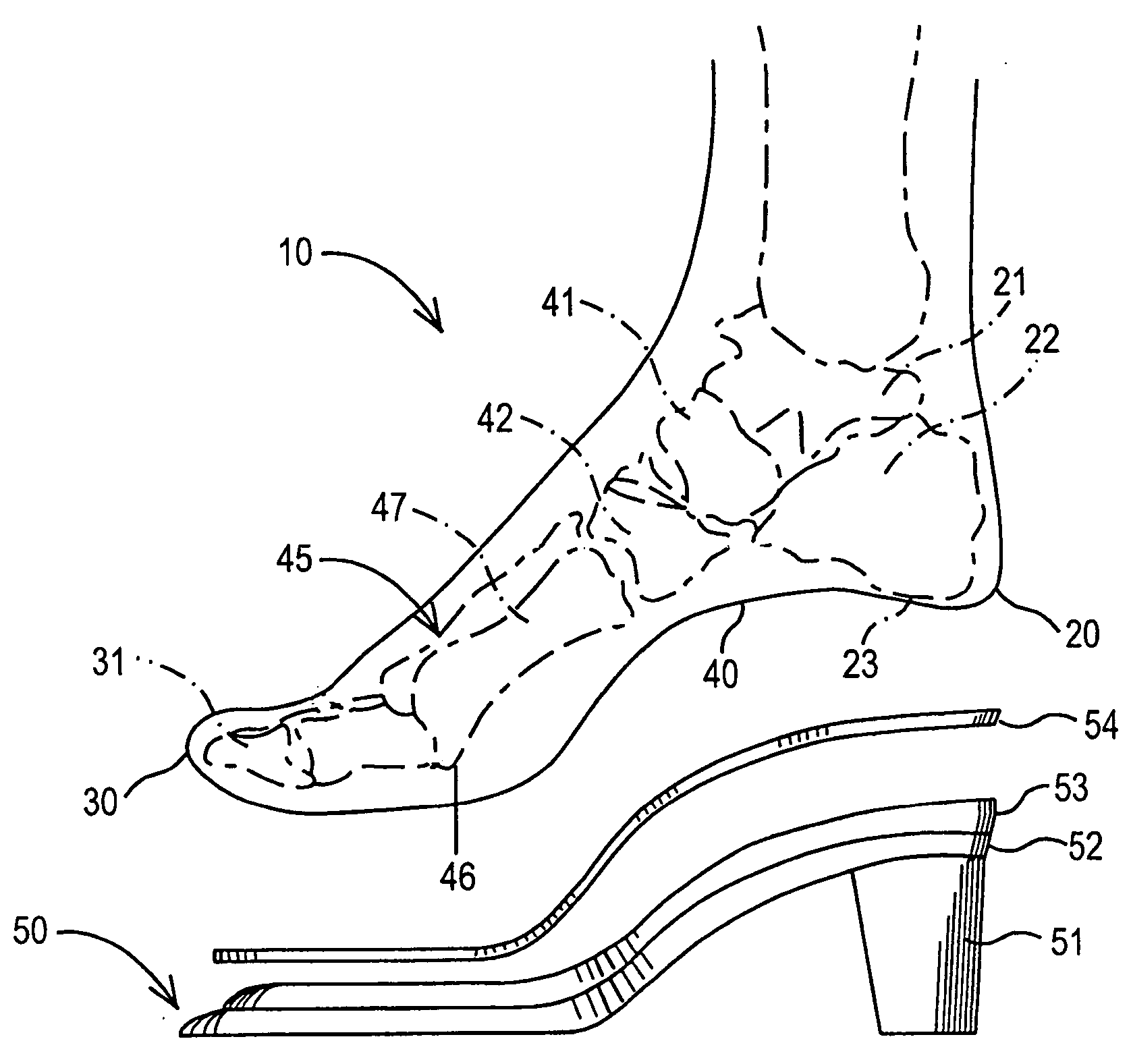

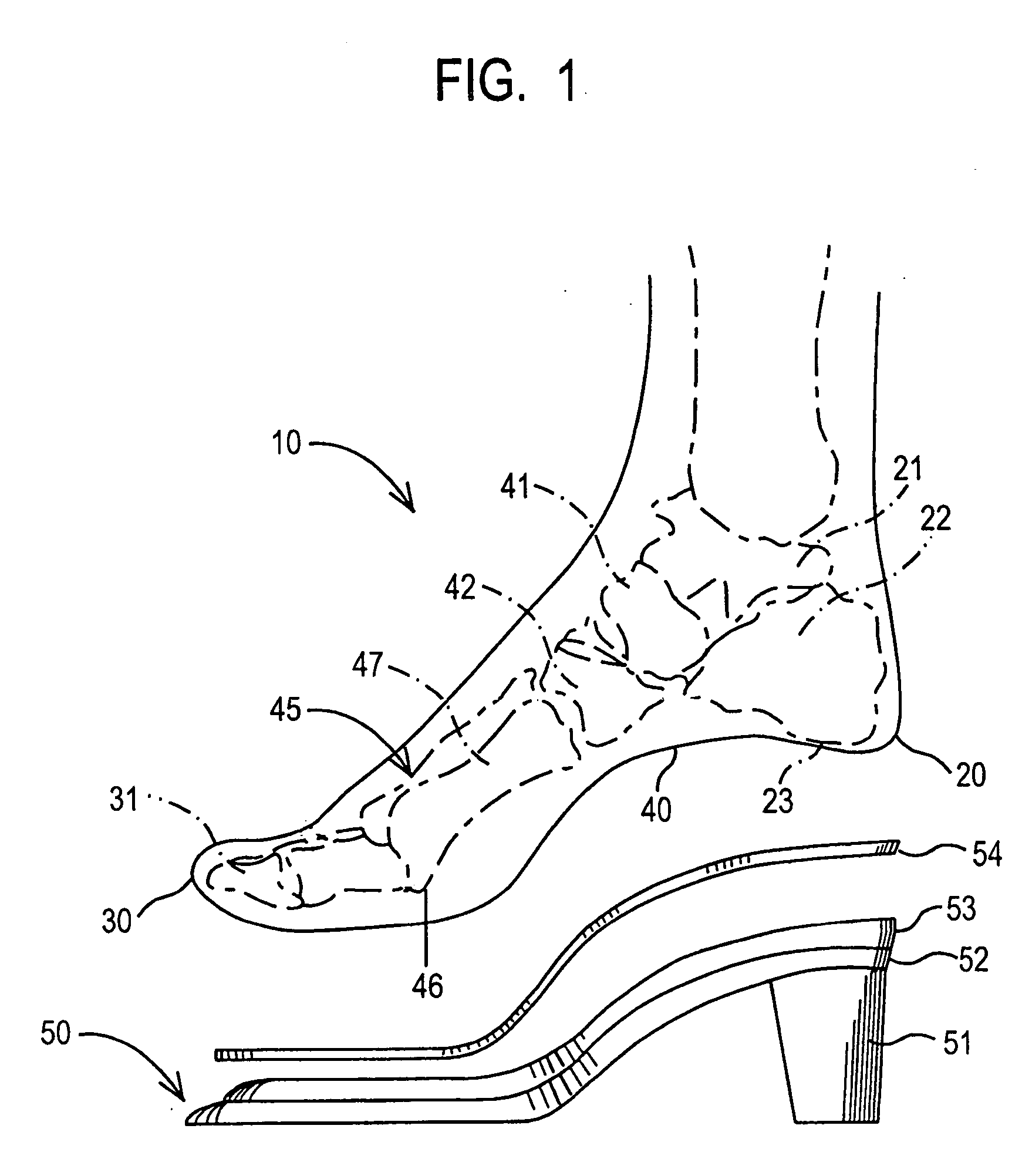

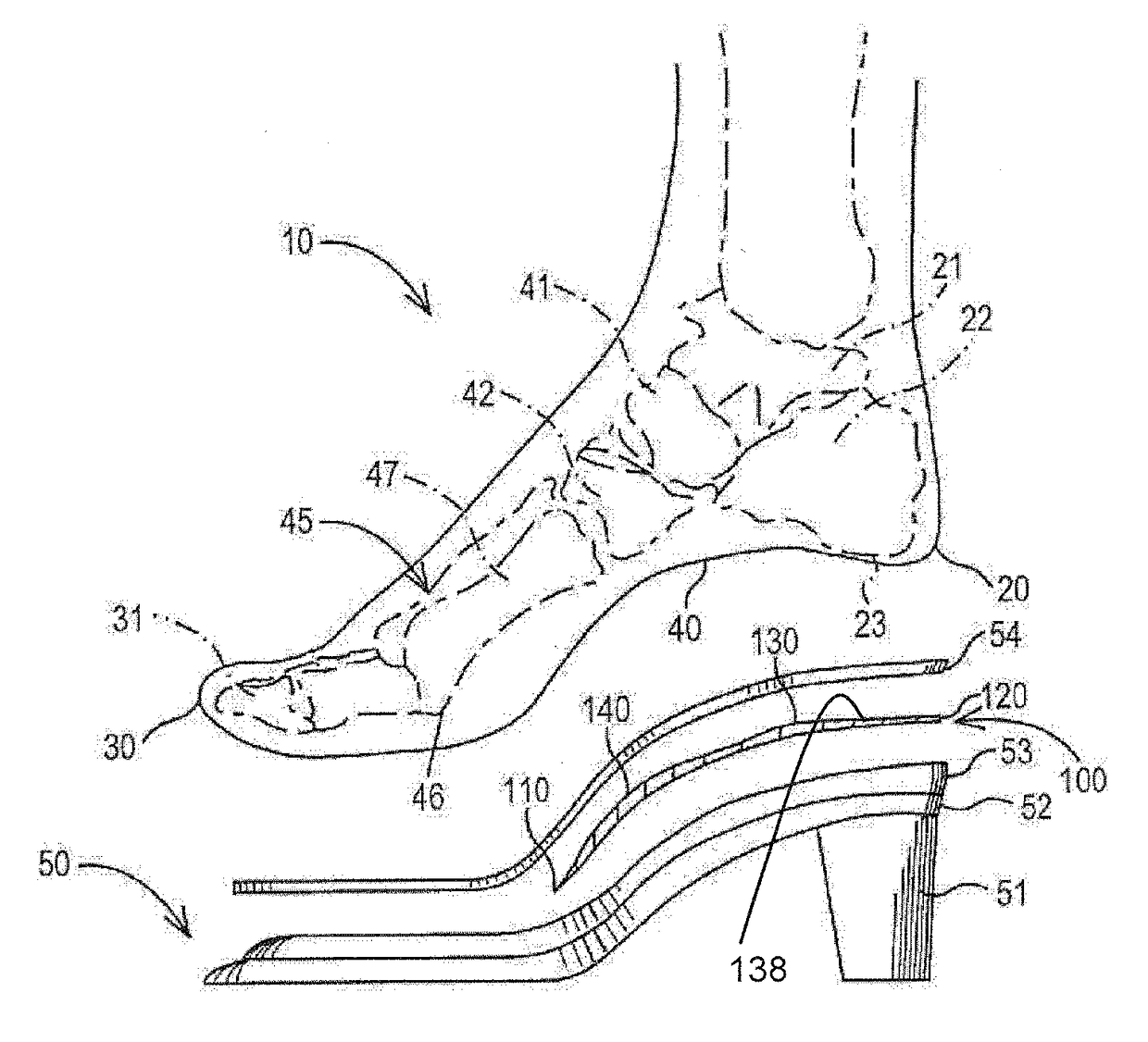

Device for high-heeled shoes and method of constructing a high-heeled shoe

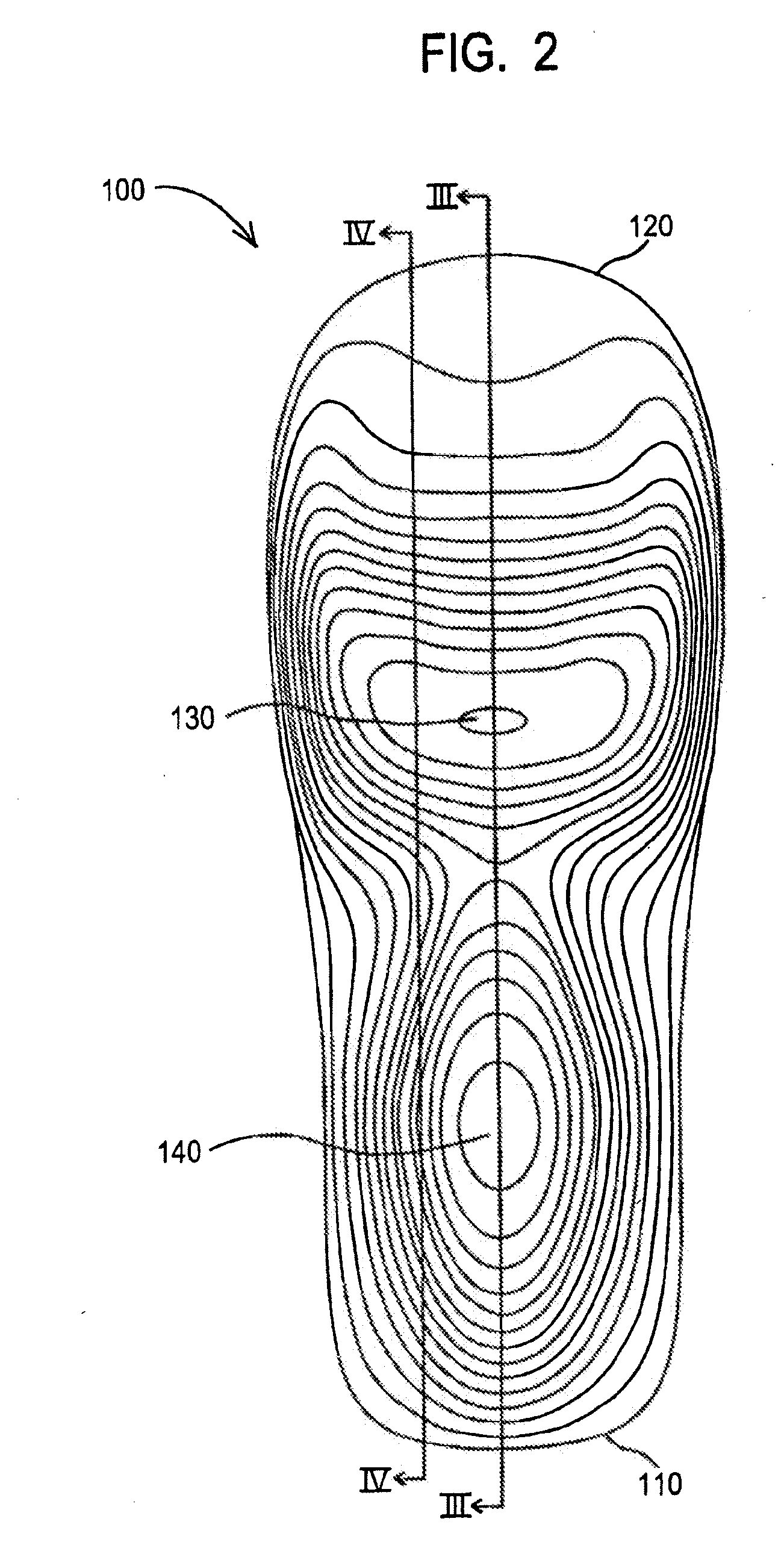

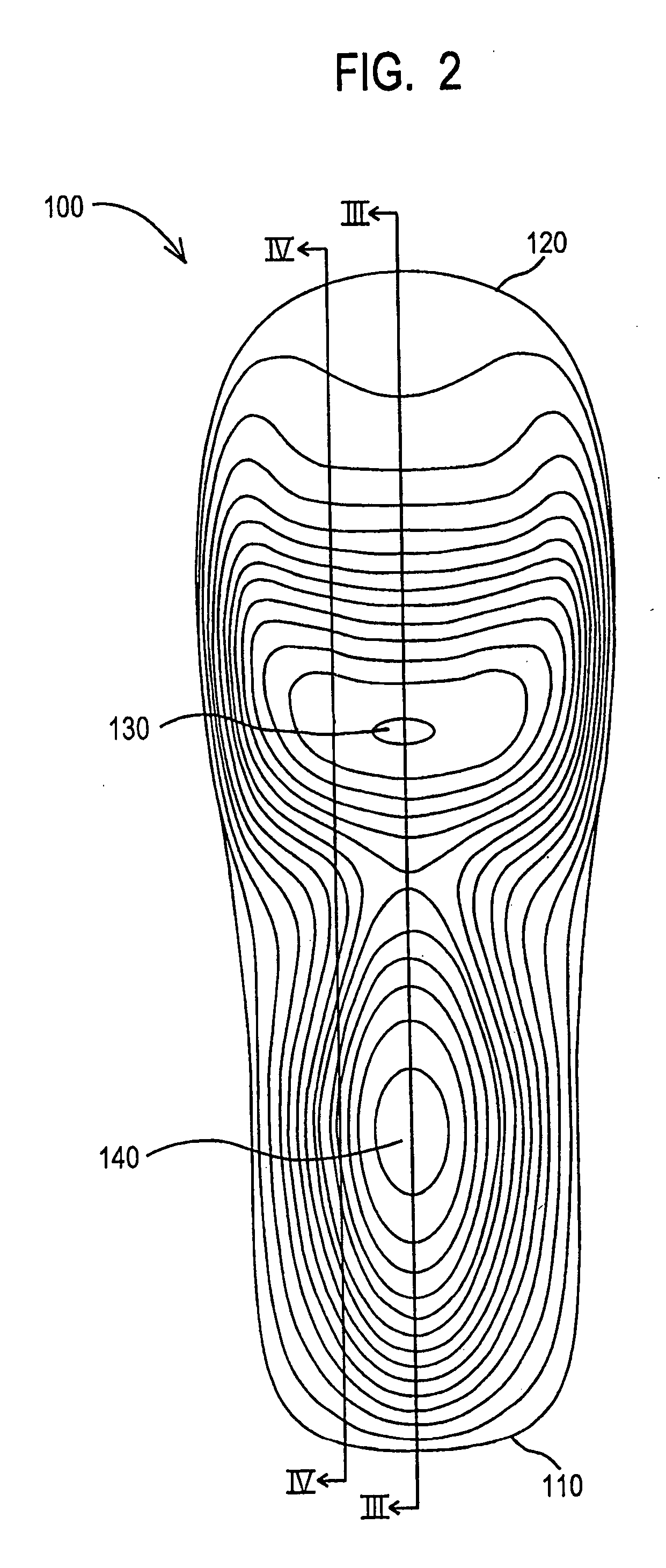

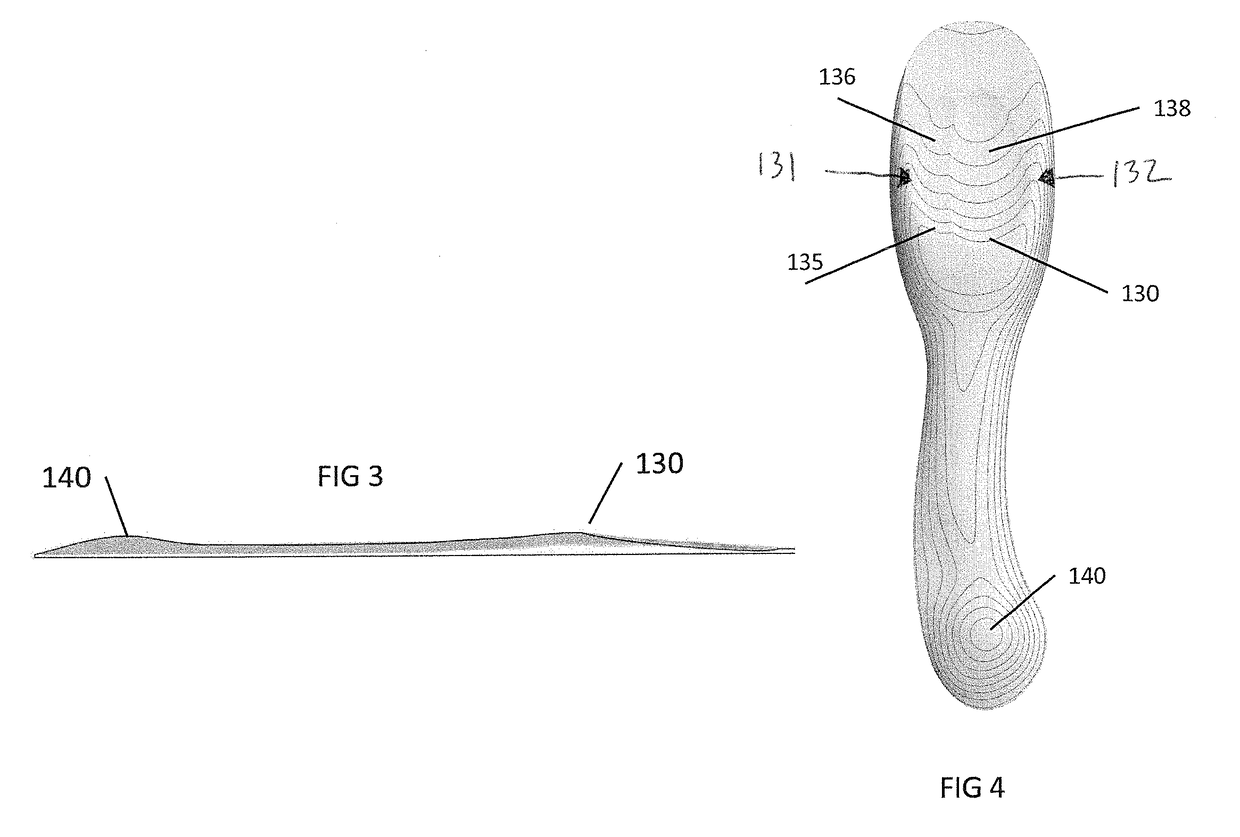

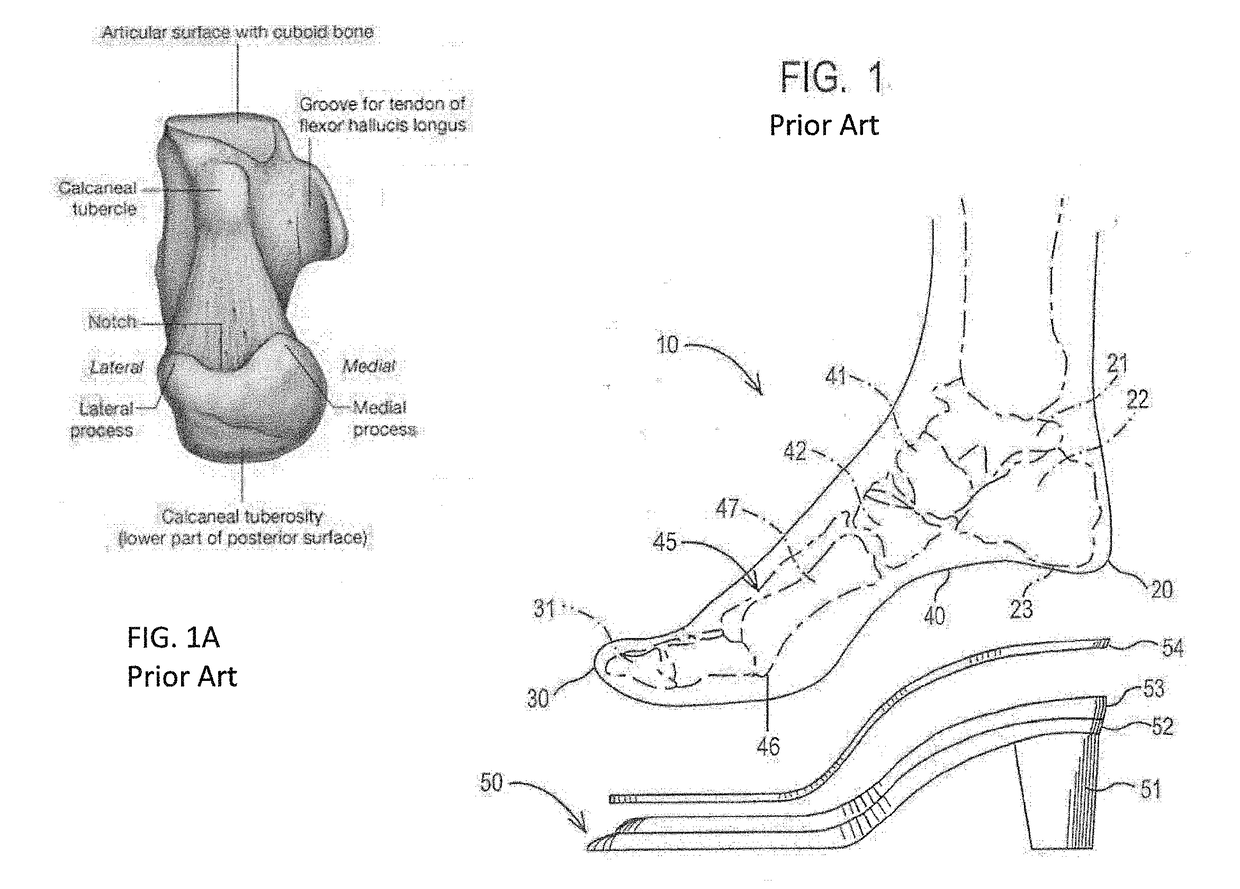

ActiveUS7322132B2Contour smoothingInsolesNon-surgical orthopedic devicesLeading edgeBiomedical engineering

A device for insertion in a high-heeled shoe has a first crescent shaped raised area in a region underlying the forward edge of a wearer's heel bone and a second raised area underlying the metatarsals of the wearer is described. Also described is a method for constructing a shoe using the device and the resulting shoe.

Owner:HBN SHOE LLC

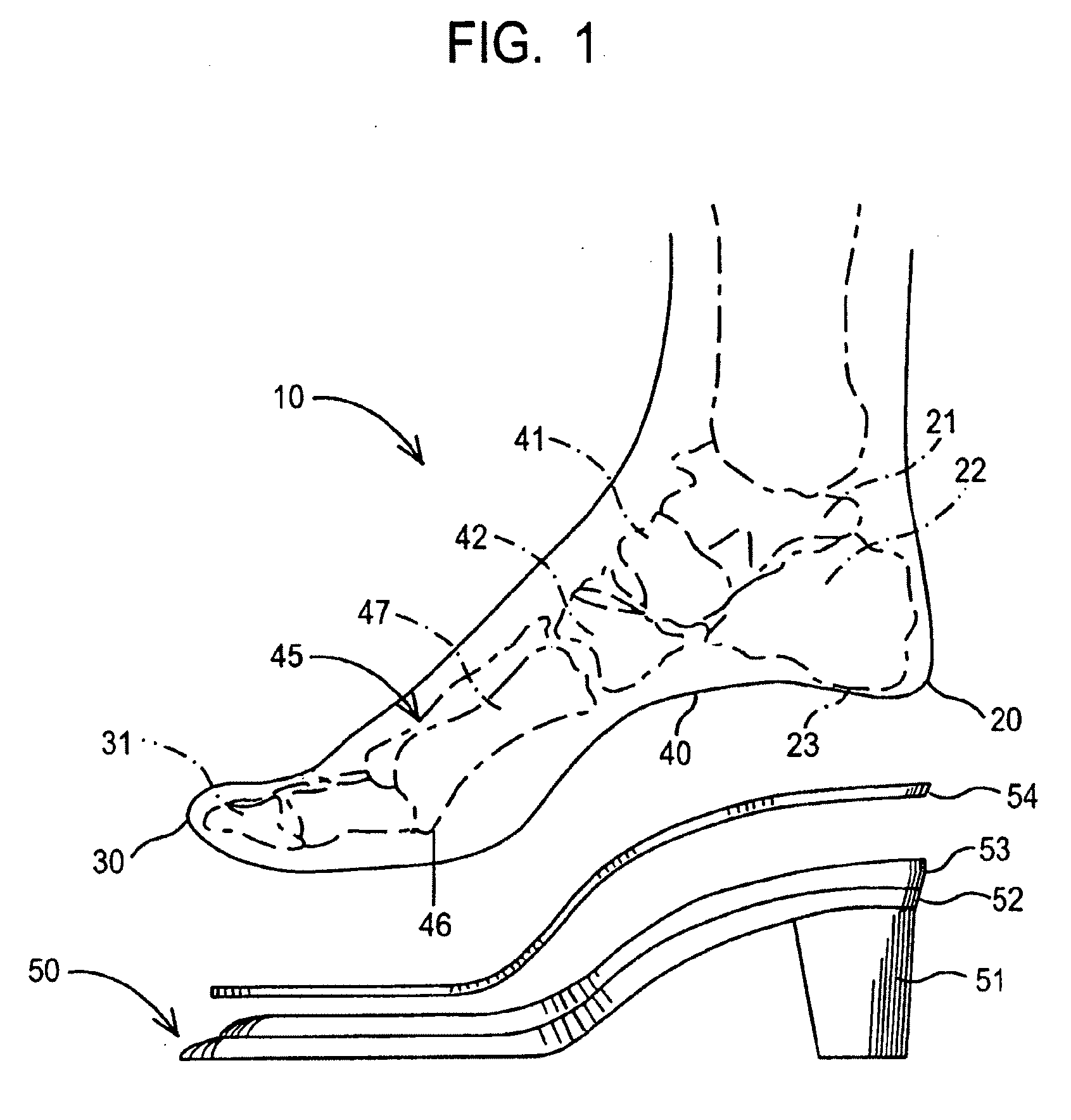

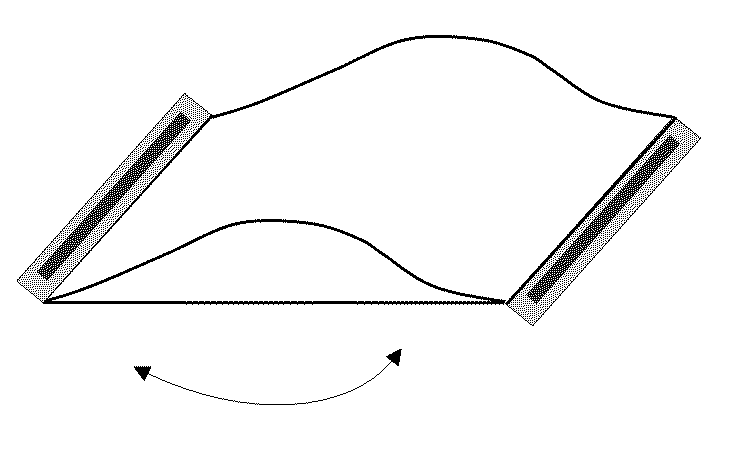

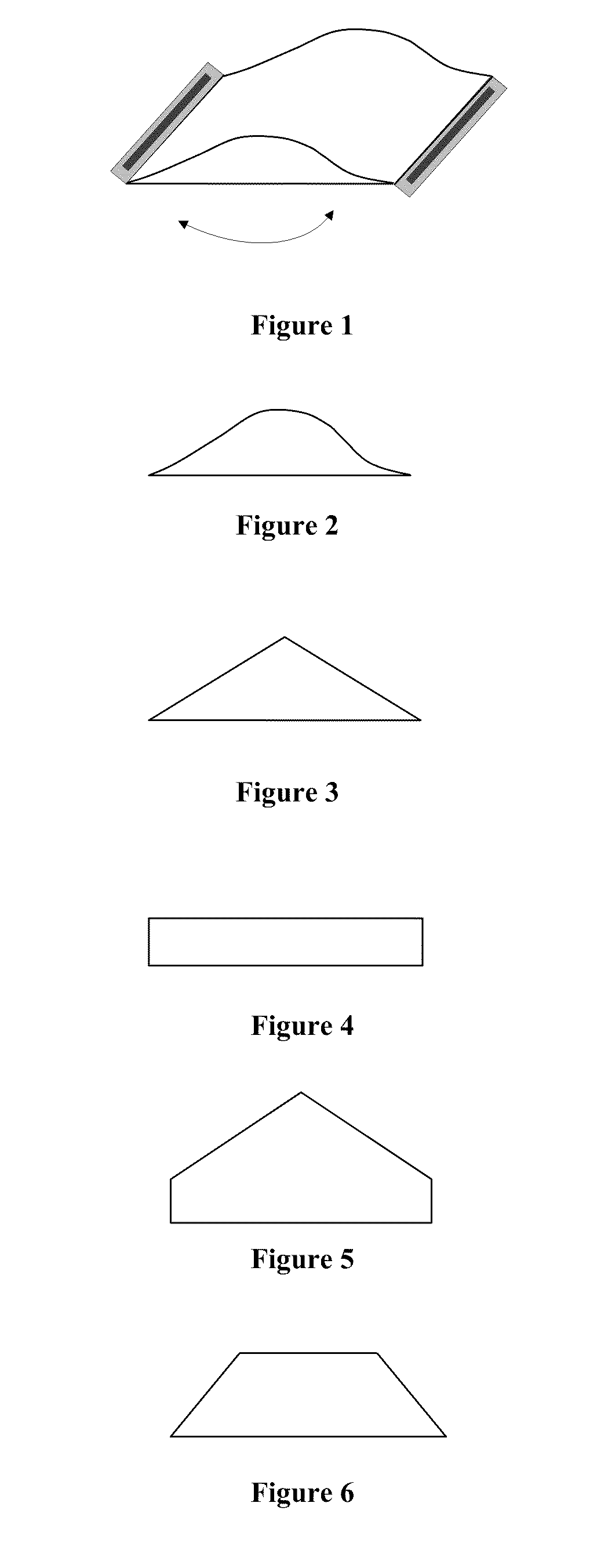

Bioreactors

InactiveUS20110151551A1Prevent and minimize formationContour smoothingBioreactor/fermenter combinationsBiological substance pretreatmentsWrinkle skinEngineering

The present invention relates to improved single-use bioreactors comprising disposable plastic bags for cell cultivation. The invention provides an inflatable bioreactor bag for cell cultivation comprised of a top and a bottom sheet of polymer material that are joined along their edges to form a sealed bag, wherein two opposing edges are formed as clamping edges to allow clamping of the bioreactor bag to a rocker type bioreactor, and wherein the bioreactor bag is provided with a wrinkle preventing structure at each end of the clamping edges. The bag avoids formation of undesired wrinkles or creases which otherwise lead to fatigue of the plastic and eventually fracture.

Owner:GE HEALTHCARE BIO SCI CORP

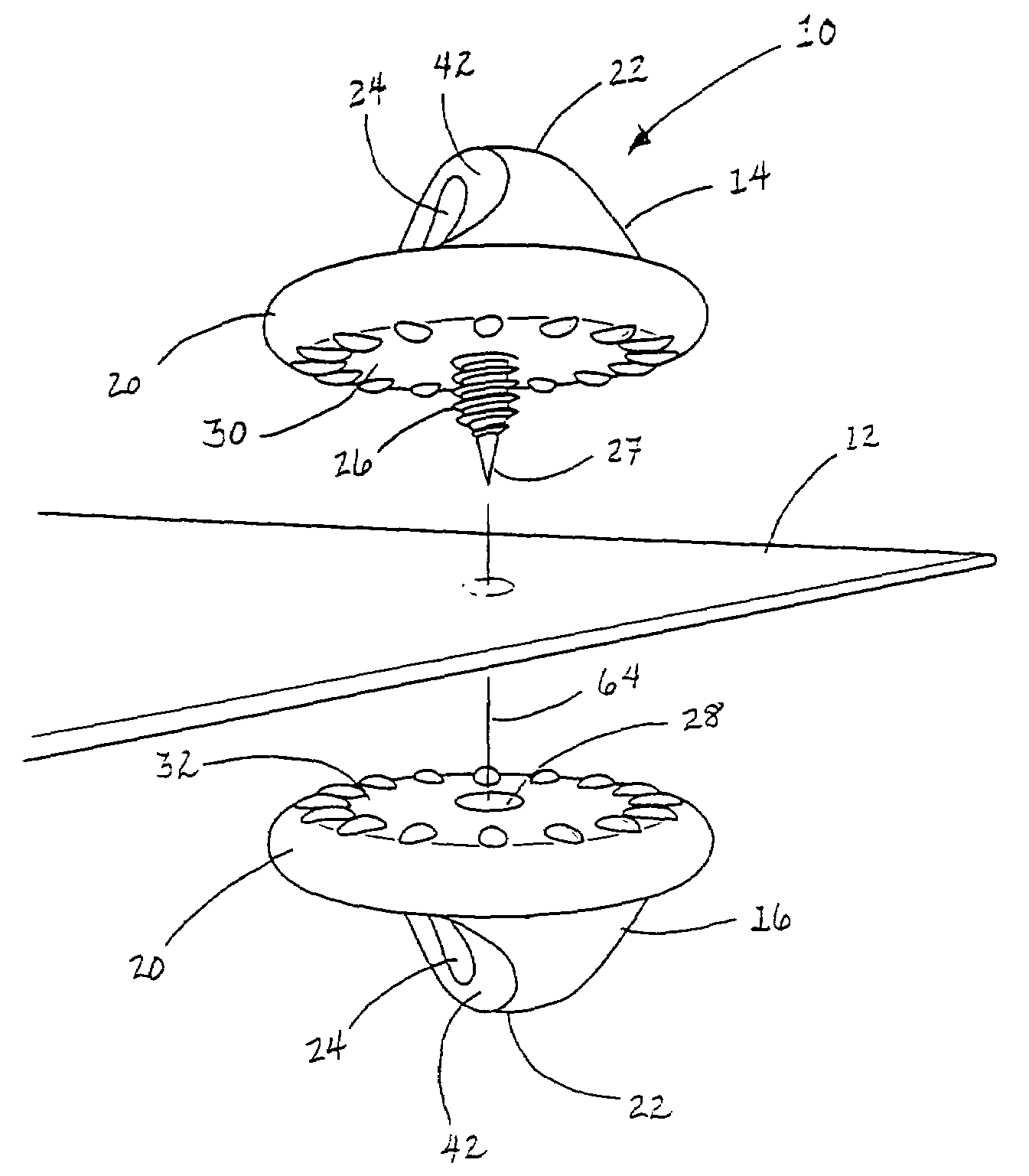

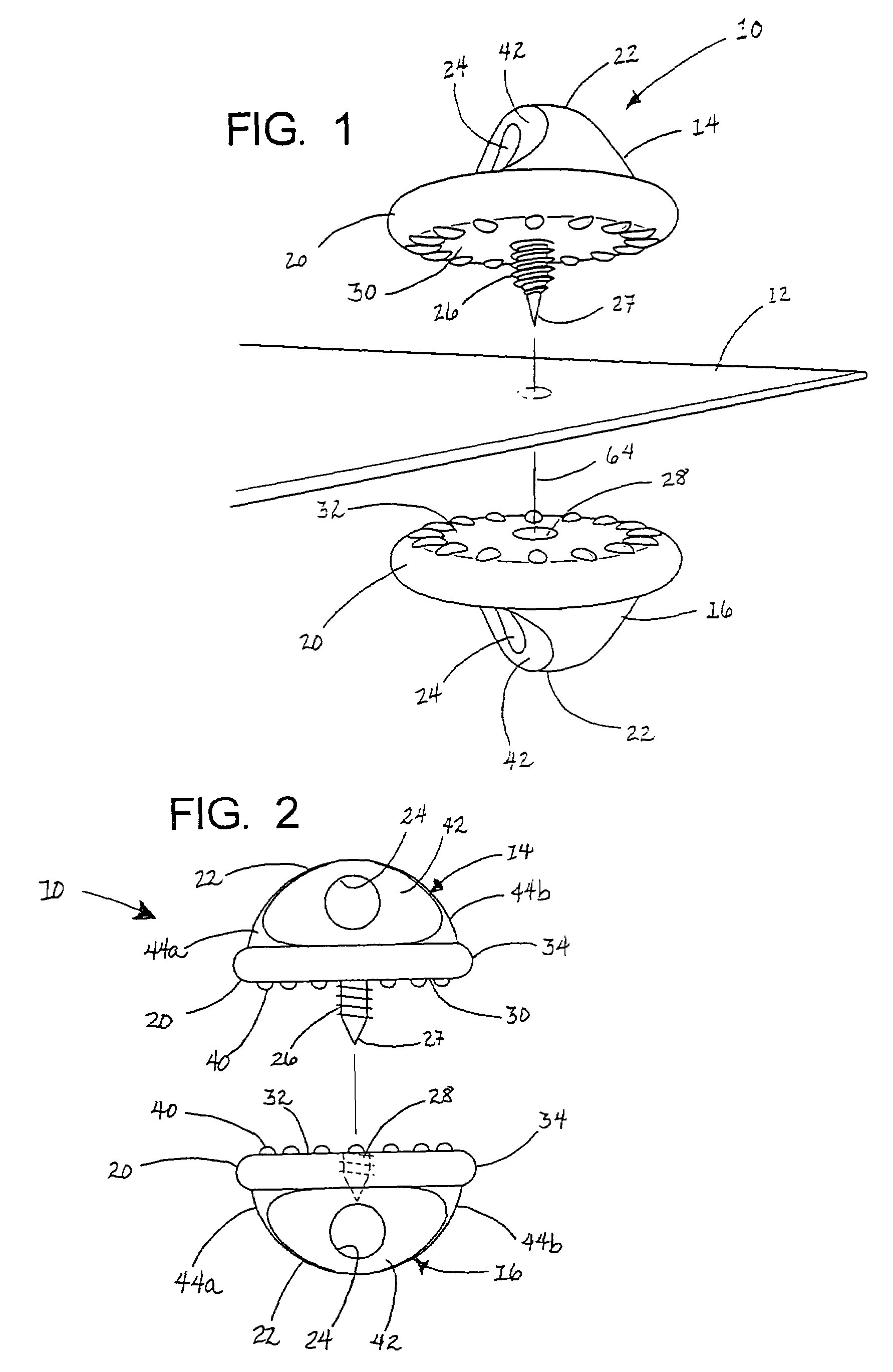

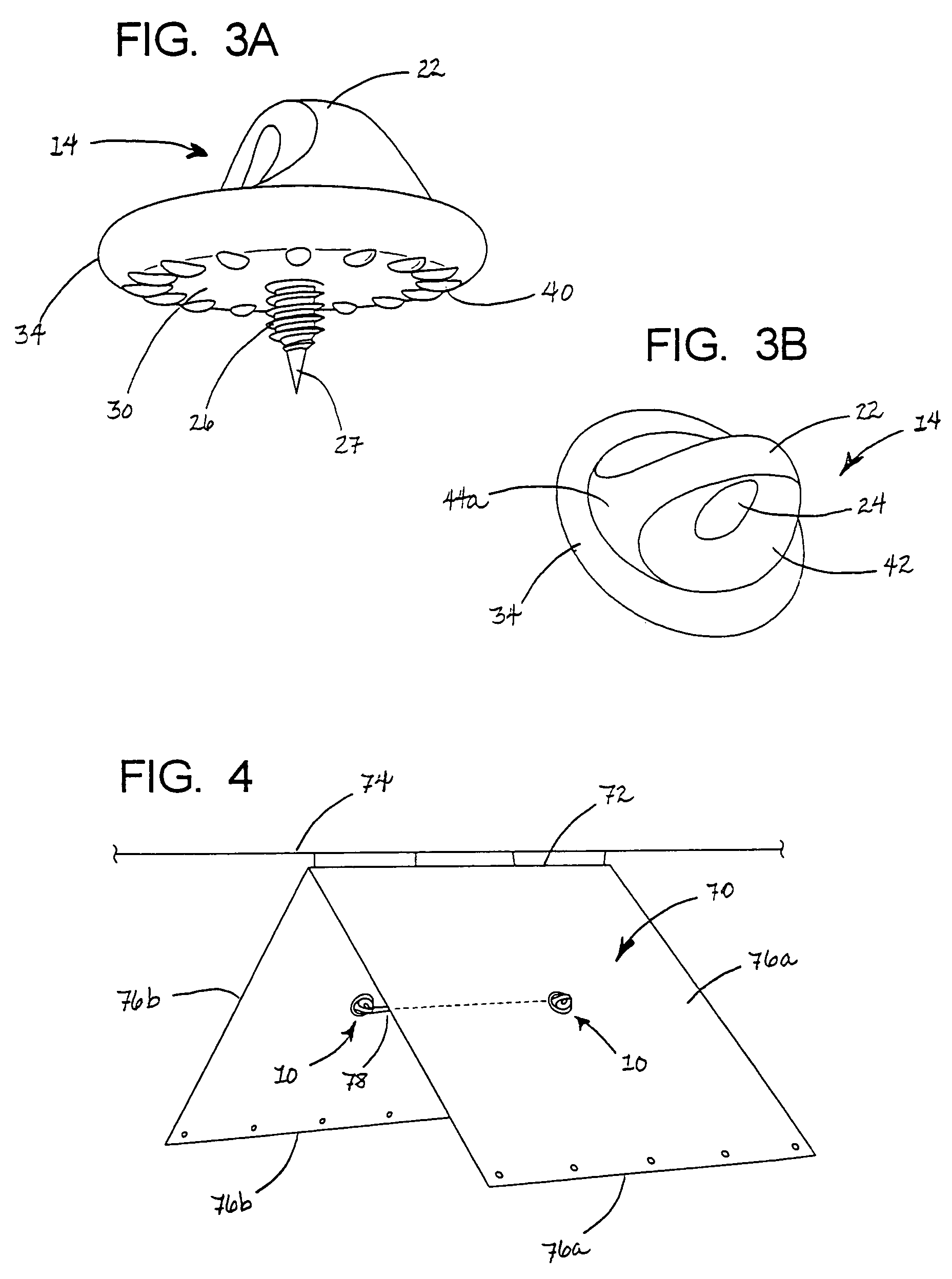

Tarp connector

InactiveUS7189024B2Prevent accidental looseningPrevent tears from propagatingSnap fastenersBucklesEngineeringScrew thread

A connector assembly that enables a rope or other load to be attached to a tarp or other sheet material. The assembly includes male and female connector members having broad, flat base surfaces for engaging the material of the tarp from opposite sides. The male connector member has a sharply pointed screw portion for penetrating through the material of the tarp, and the female connector member has a threaded socket for receiving the screw portion of the male connector member. At least one of the connector members includes a projecting flange portion having an opening or hook for attachment of the rope or other load. The flange portions are flattened for being gripped between the thumb and forefinger when tightening / loosening the assembly. The grip faces of the connector members include raised protuberances that prevent accidental loosening during use.

Owner:NEVADA NORTH COAST LIMTIED

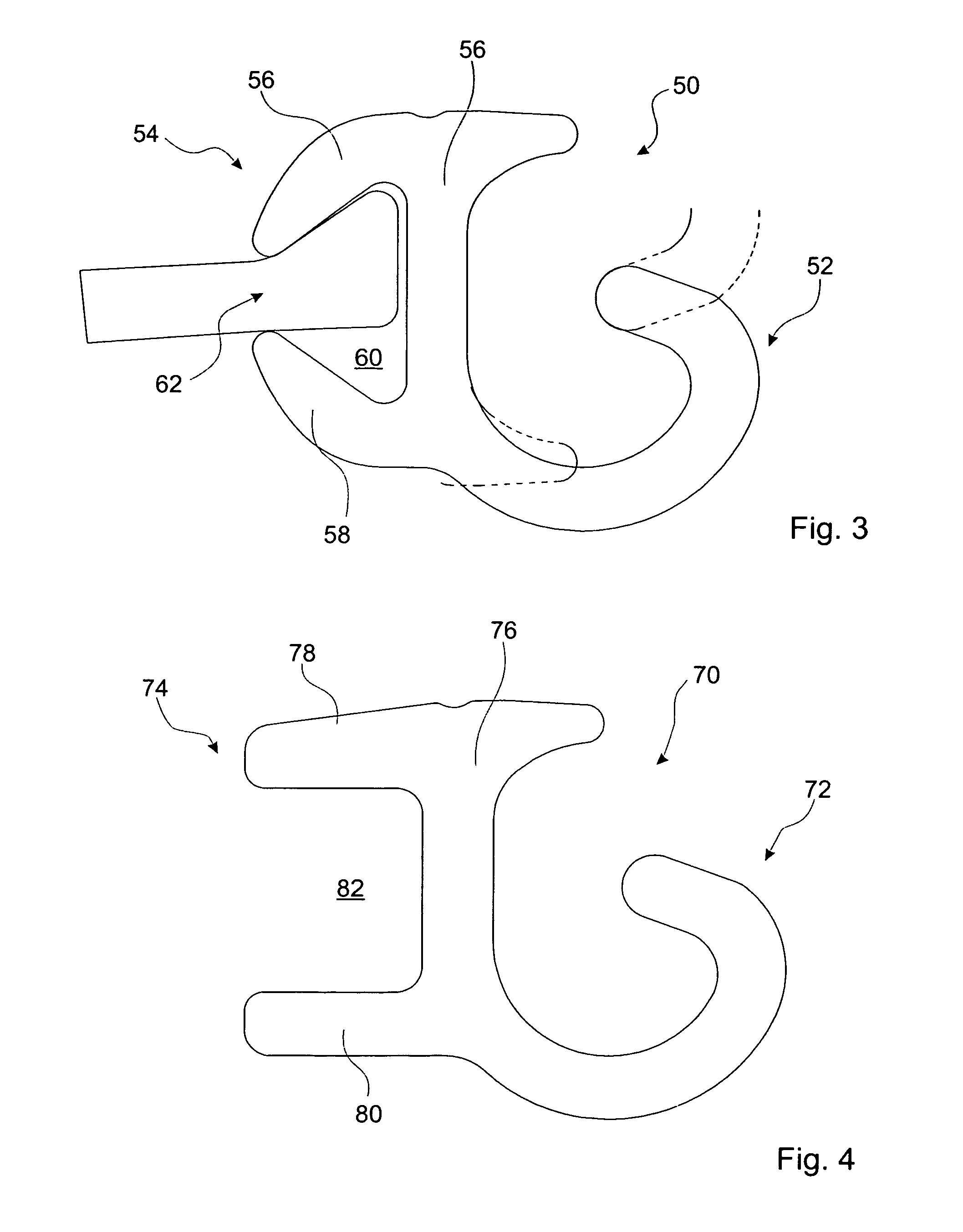

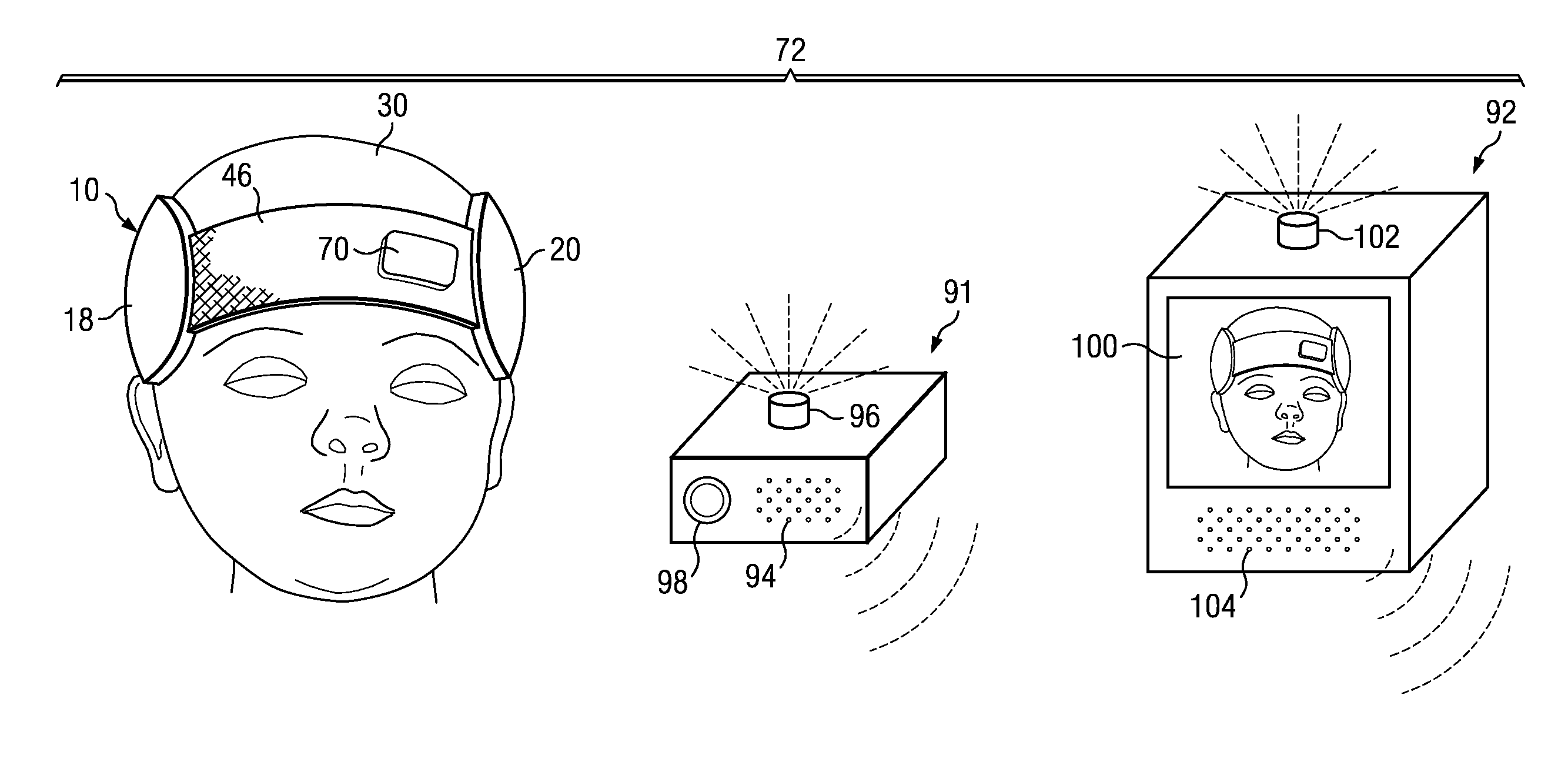

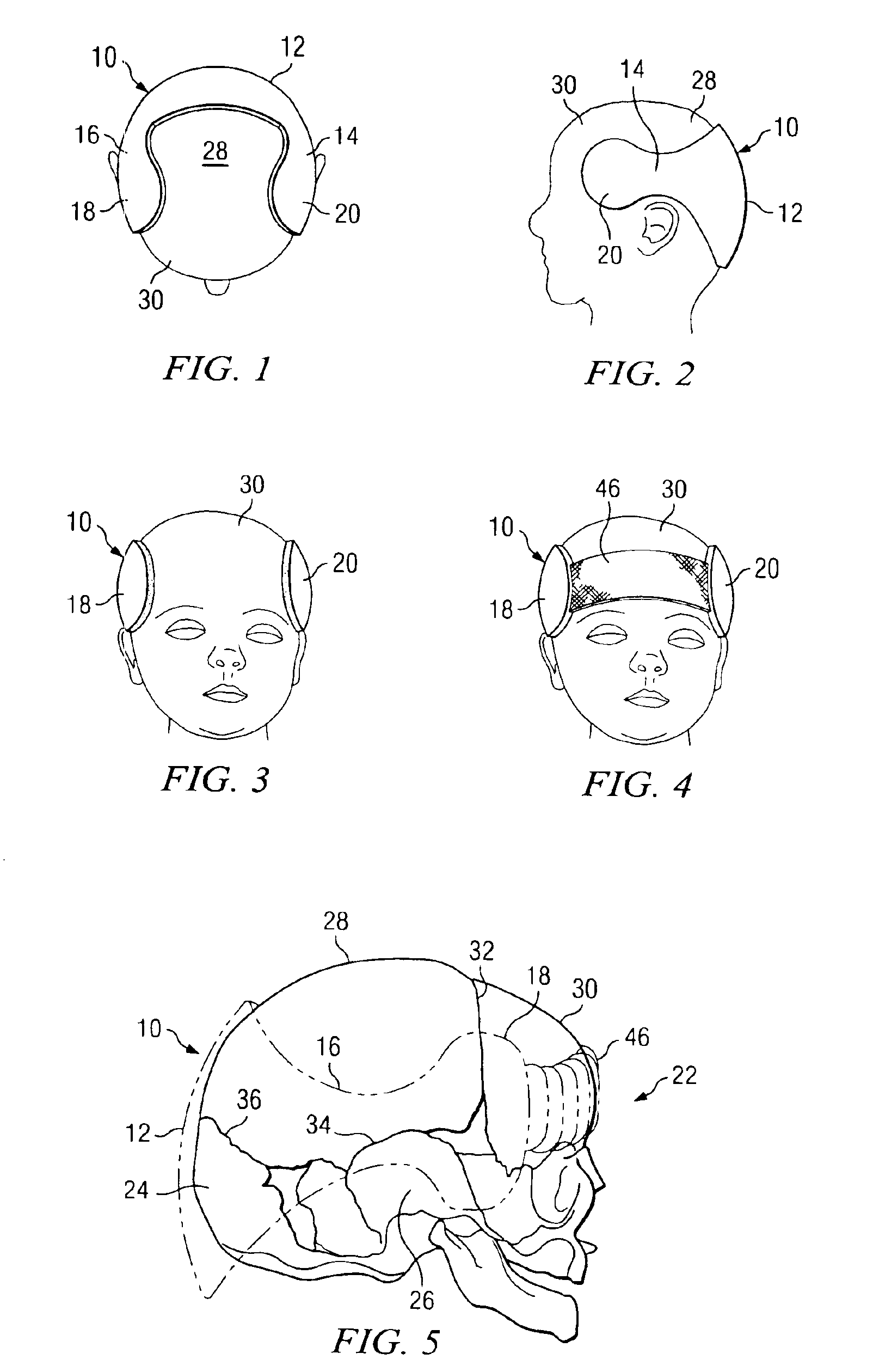

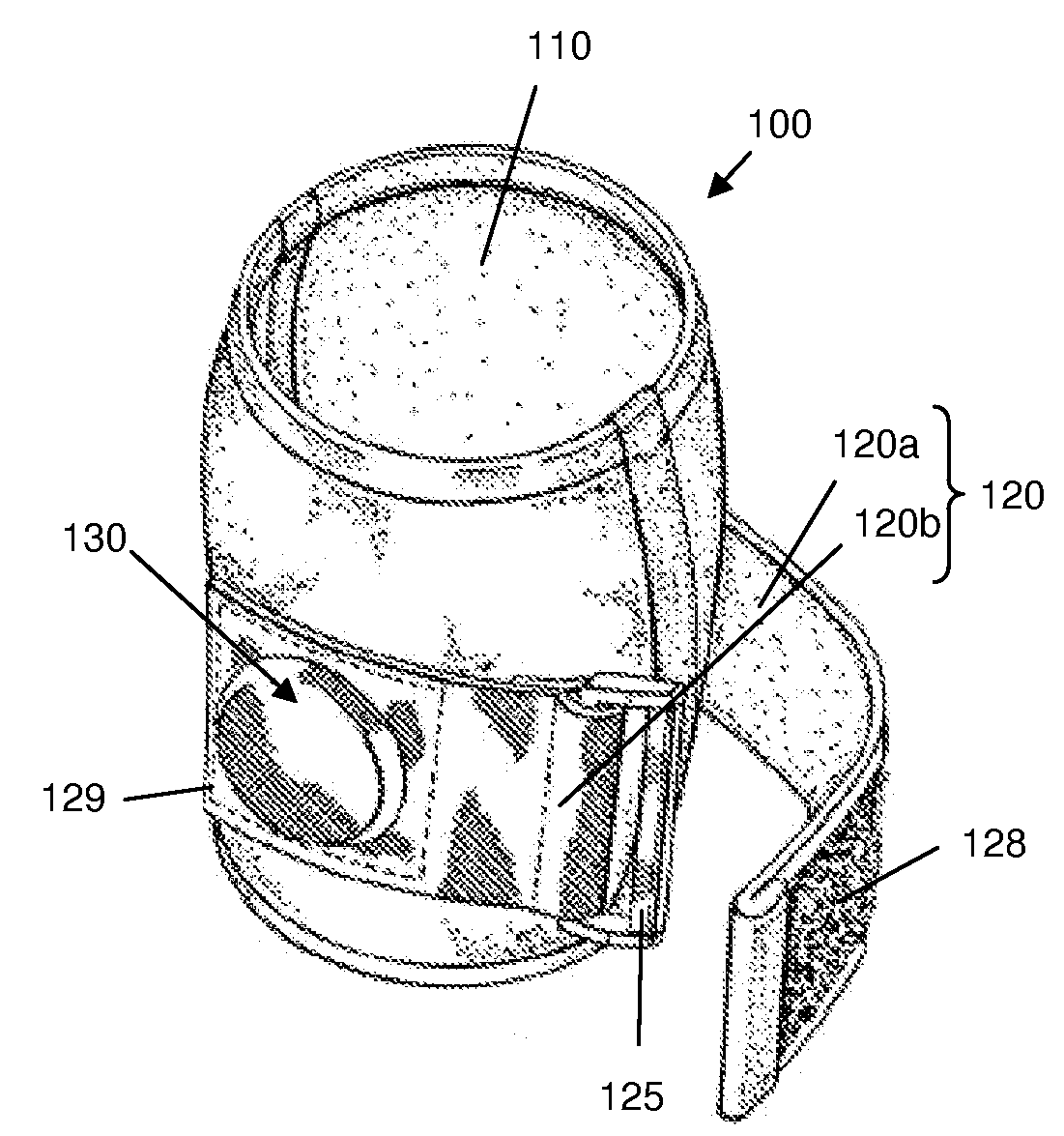

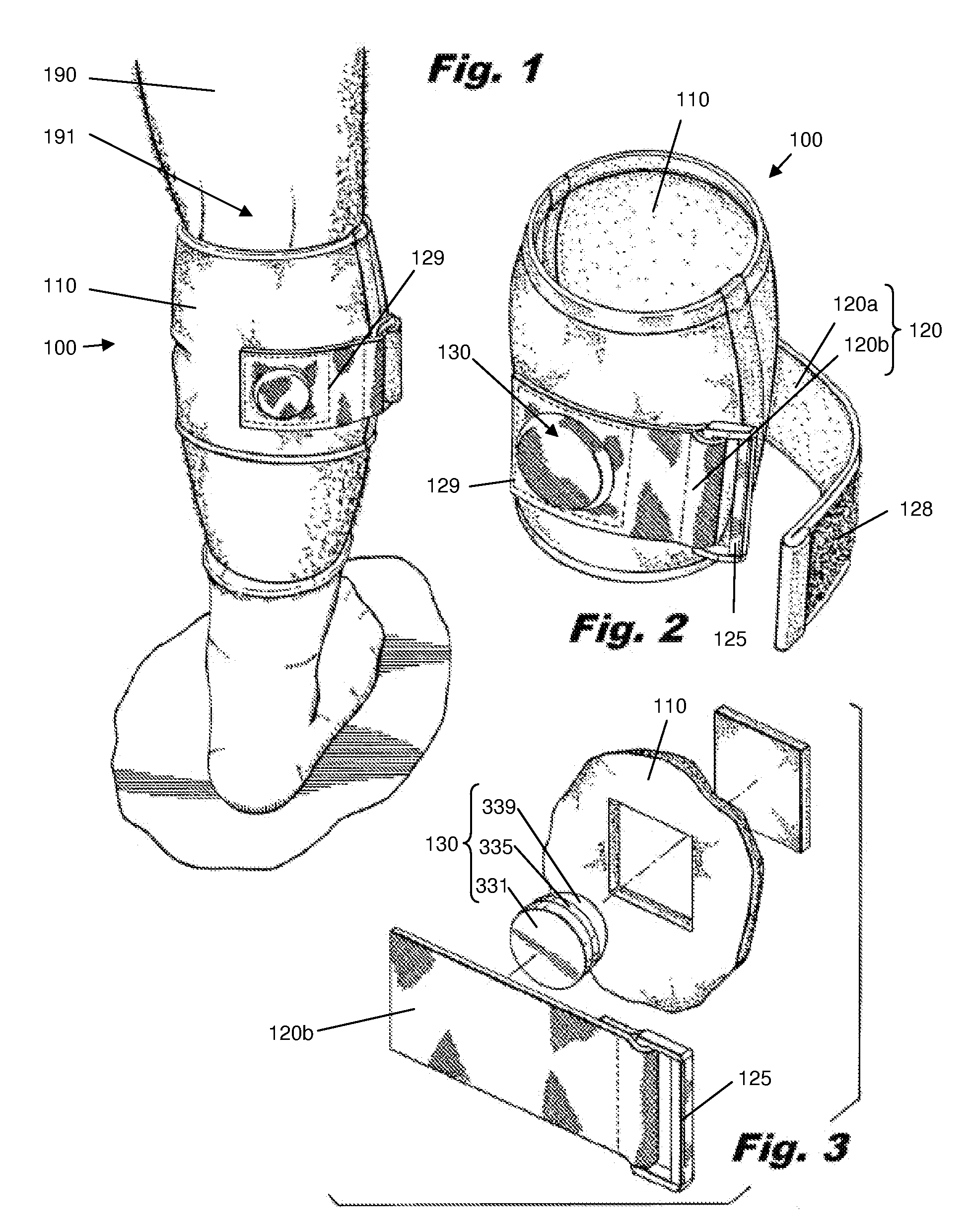

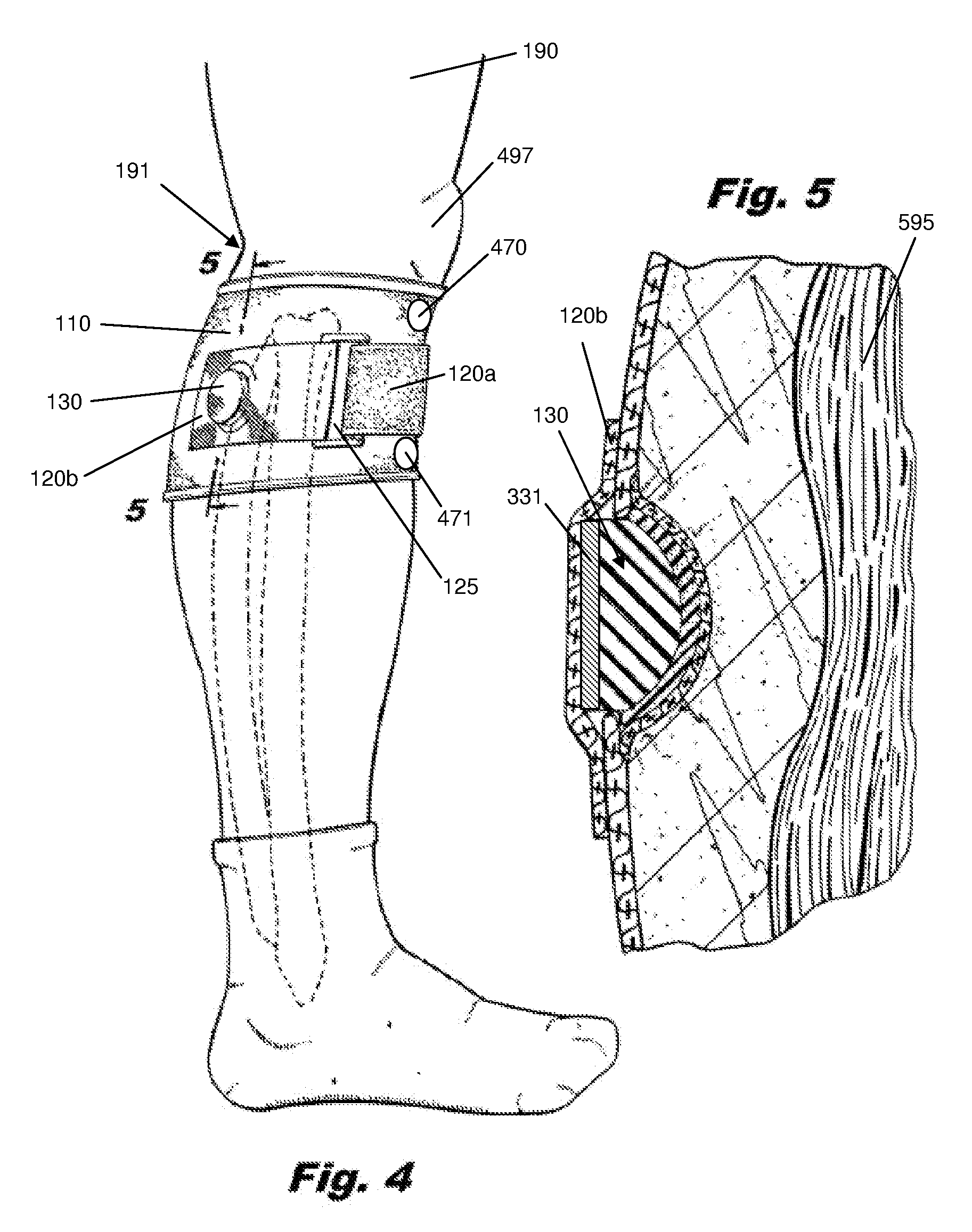

System for Monitoring a Person Wearing Head Gear

InactiveUS20110273286A1Increase air circulationImprove heat transfer performanceAlarmsFractureCRANIAL DEFORMITYCranial vault

A cranial orthosis includes a sensor to monitor one or more conditions of an infant wearing the cranial orthosis. The cranial orthosis is preferably contoured to match the curvature of the fronto-temporal, parietal and occipital areas of an infant's cranial vault to provide protection against the acquisition of postural cranial deformities as a result of the infant's sleeping in the supine position. The orthosis is designed to be of universal fit, as determined by the infant's fronto-occipital head circumference (FOC) measurement. The interior dimensions of the orthosis can be enlarged to accommodate growth of the infant's head without requiring replacement. The sensor may detect oxygen saturation, pulse, temperature, or any other measureable condition or combination of conditions. The system includes an alarm that is triggered when a sensed condition crosses a selected threshold level.

Owner:INFA SAFE

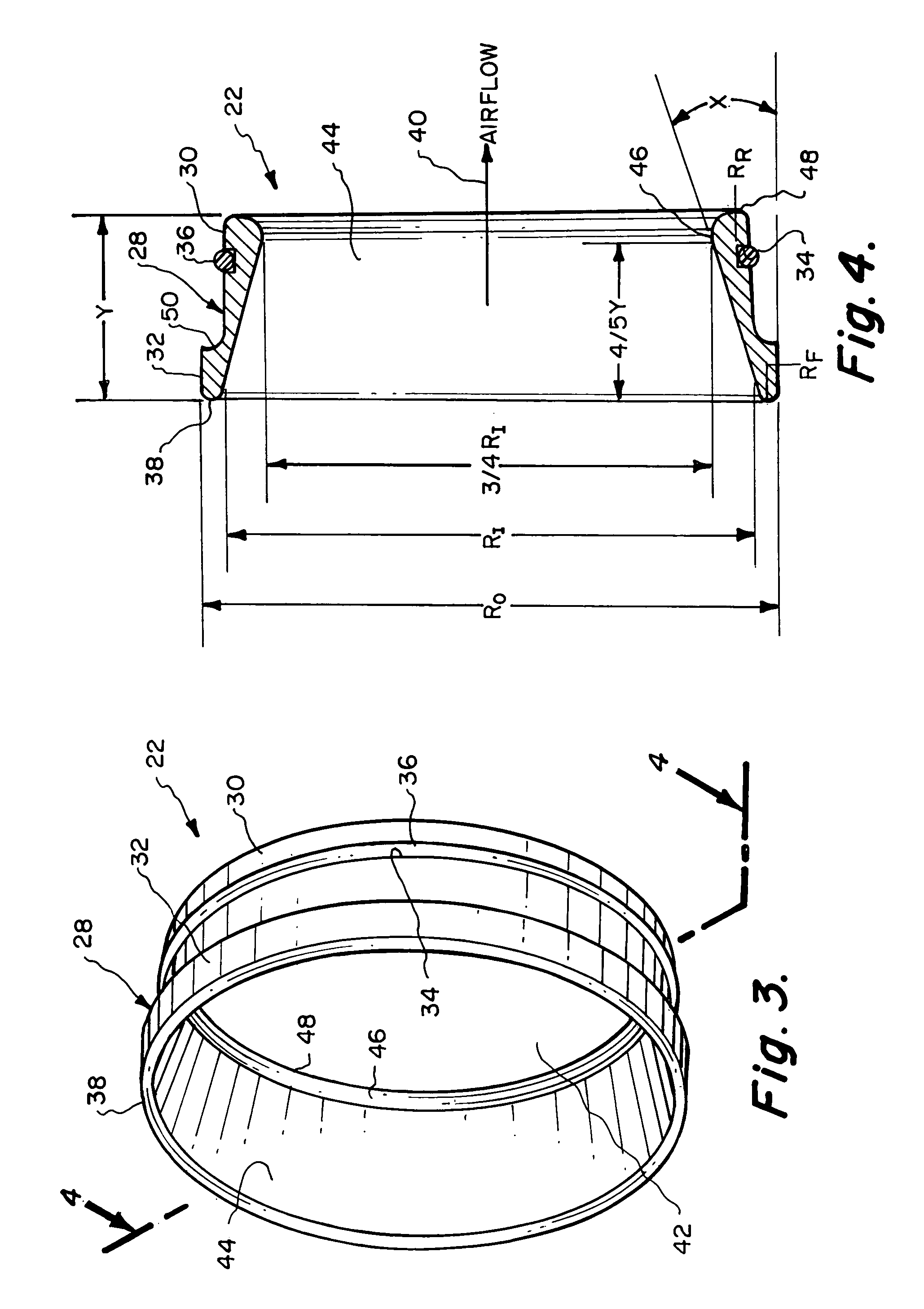

Ring insert for an air intake conduit for an internal combustion engine

InactiveUS7942139B1Increase air velocityDecrease air pressureMixing methodsGas modification by gas mixingInternal combustion engineLeading edge

A ring insert for an air intake conduit for an internal combustion engine comprising a sleeve-shaped body which is tightly mounted within the air intake conduit. The body has an inner surface which includes an annular surface in the shape of a truncated cone defining an annular inclined surface that is narrower at the forward edge of the body than at the rearward edge forming a venturi directly adjacent the rearward edge. The forward edge of the body is smoothly contoured and the rearward edge of the body is smoothly contoured.

Owner:MILE EDGE PLUS

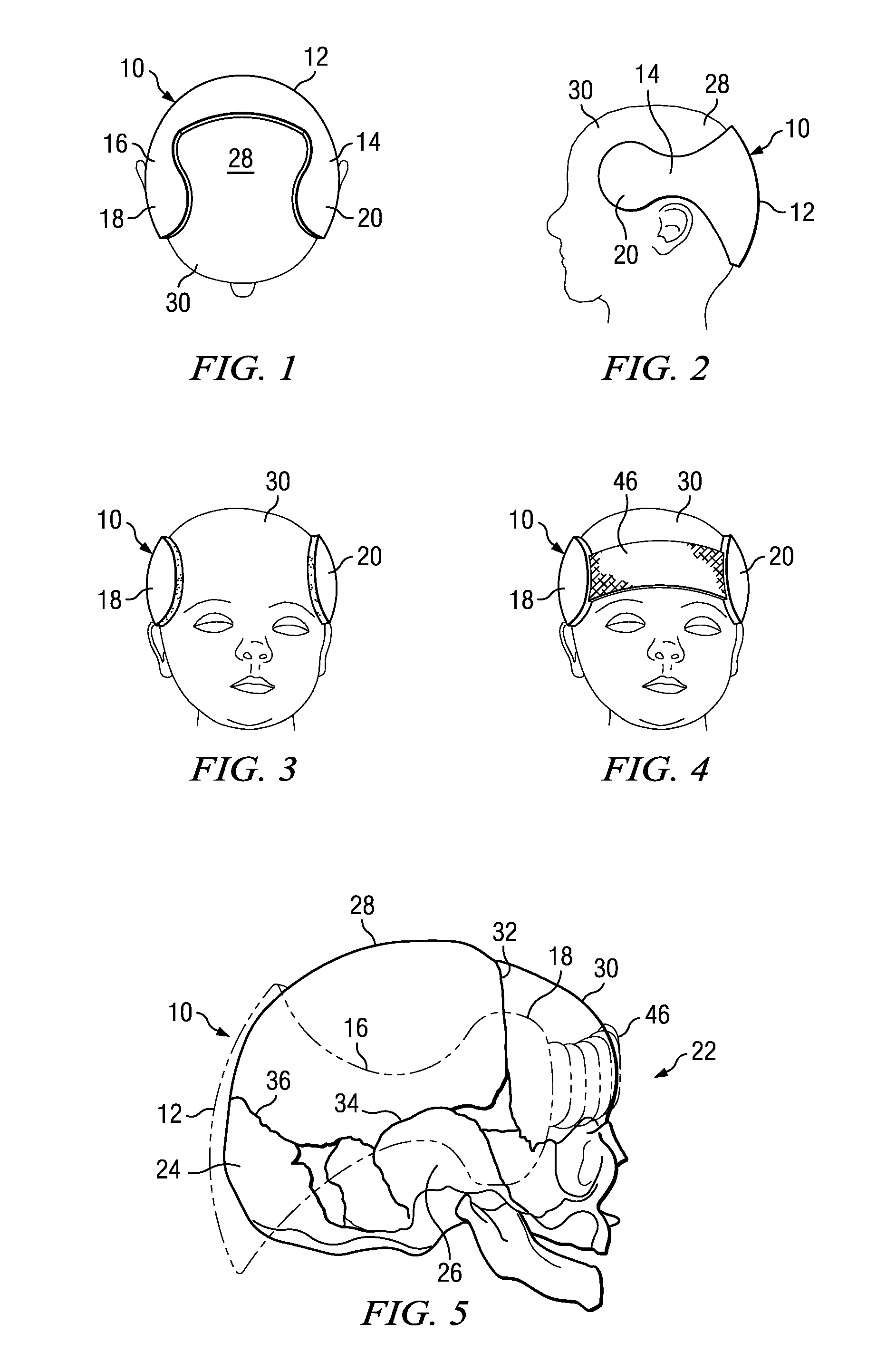

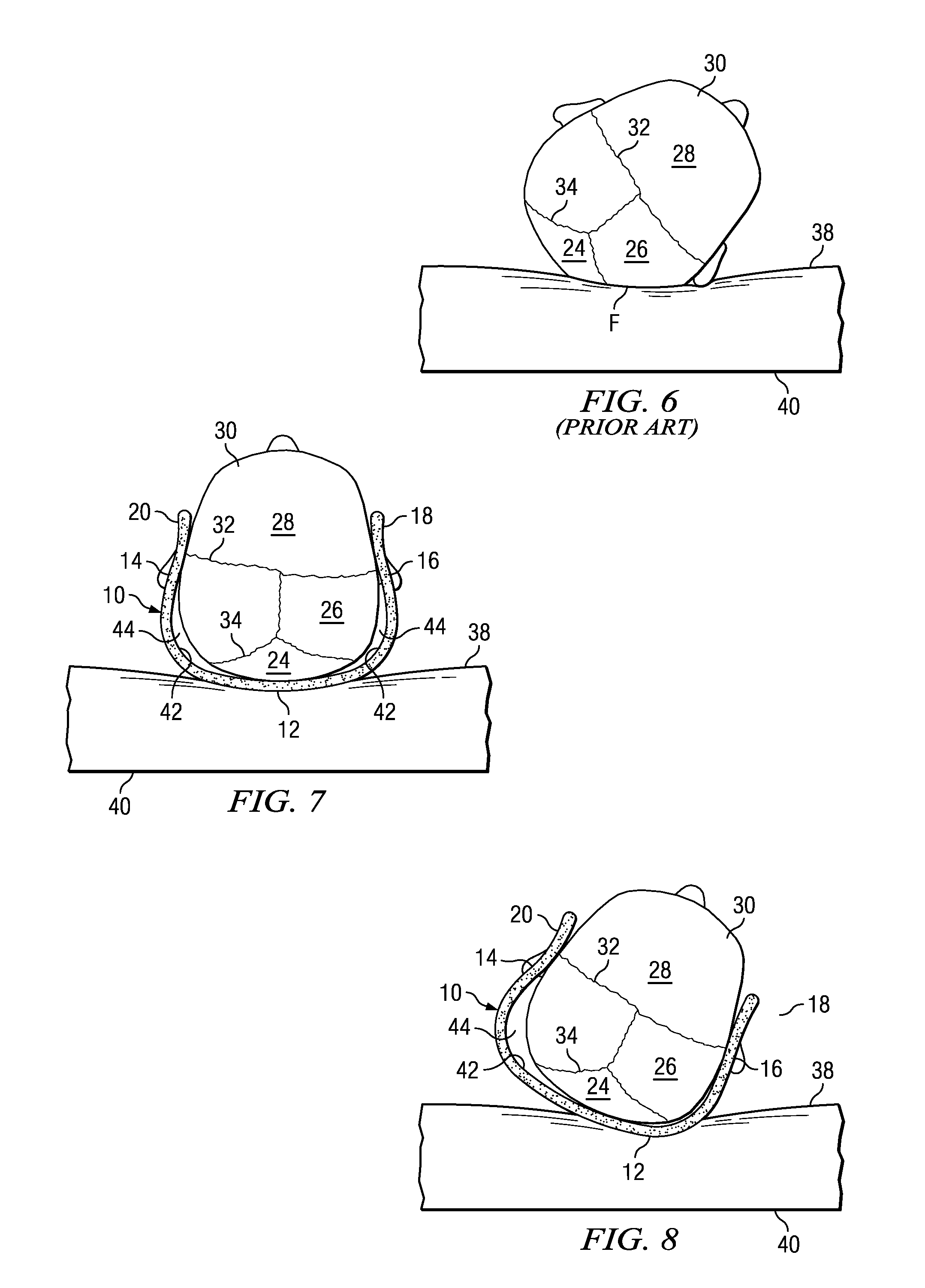

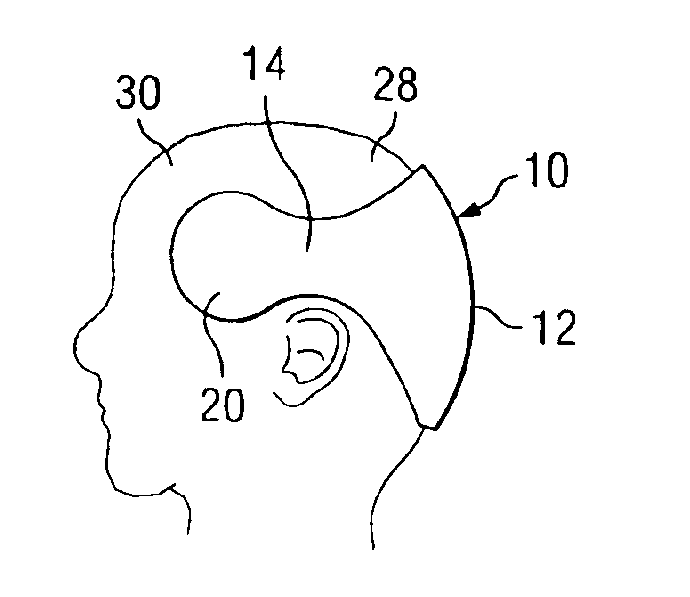

Cranial orthosis for preventing positional plagiocephaly in infants

InactiveUS6939316B2Increase air circulationImprove heat transfer performanceHead bandagesEar treatmentCRANIAL DEFORMITYCranial vault

A cranial orthosis is contoured to match the curvature of the fronto-temporal, parietal and occipital areas of an infant's cranial vault to provide protection against the acquisition of postural cranial deformities as a result of the infant's sleeping in the supine position. The orthosis is designed to be of universal fit, as determined by the infant's fronto-occipital head circumference (FOC) measurement. Moreover, the interior dimensions of the orthosis can be enlarged to accommodate growth of the infant's head without requiring replacement. The orthosis is a molded plastic appliance in the form of a shell, headband or helmet having interior surfaces that are smoothly contoured to conform in shape to the surface curvature of the occipital, temporal and parietal areas of a healthy human infant having normal cranium size, shape and symmetry. The cavity is sized to provide a close, non-interfering fit of the conformed interior surfaces in facing relation to the occipital, fronto-temporal and parietal areas of the infant's cranial vault, thereby allowing the the infant's head weight forces to spread substantially uniformly across one or more of the conformed interior surfaces while the infant is resting on a sleep surface in the supine position.

Owner:INFA SAFE

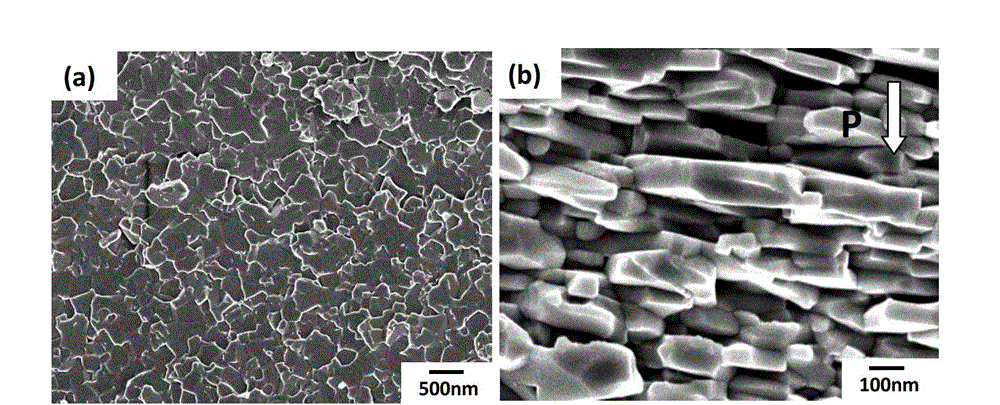

Additive for producing low-profile electrolytic copper foil and production process

The invention relates to low-profile electrolytic copper foil, particularly relates to an additive for producing the low-profile electrolytic copper foil, and also relates to a production process. The additive for producing the low-profile electrolytic copper foil is mixed by the following components: 0.2-0.4 part of sodium 3-mercapto-1-propanesulfonate; 0.8-1.2 part of polyvinyl alkylimine or polyethyleneimine alkyl compounds; 1.0-2.0 parts of polyethylene glycol 8000; 0.08-0.12 part of N,N-diethyl thiourea; and 20 parts of pure water. Electrolytic copper foil produced by the additive and the production process of the invention can not only maintain a low profile tolerance and low impedance, but also maintain high peel strength, and also is suitable for the manufacture of interior and exterior lines.

Owner:惠州联合铜箔电子材料有限公司

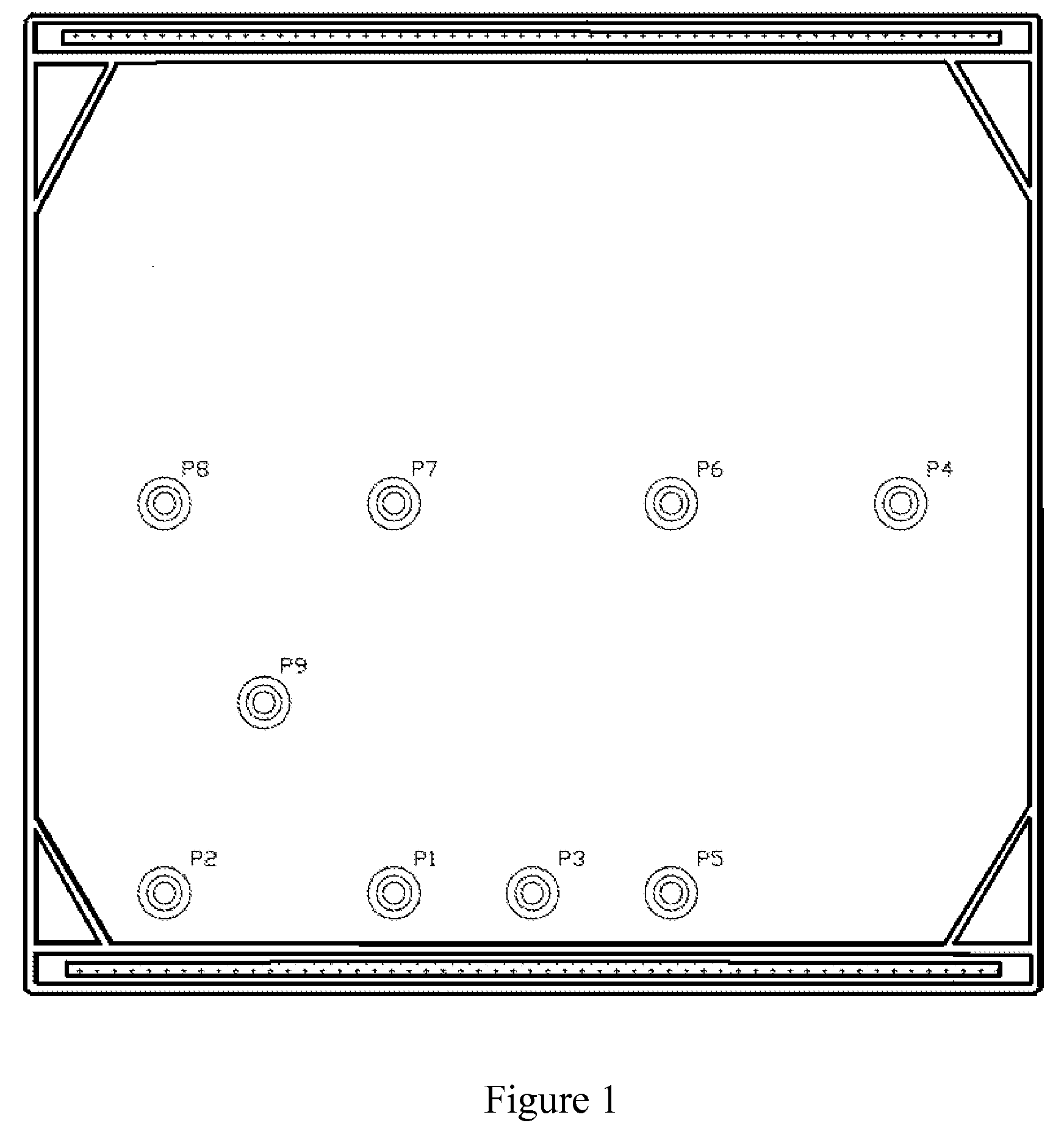

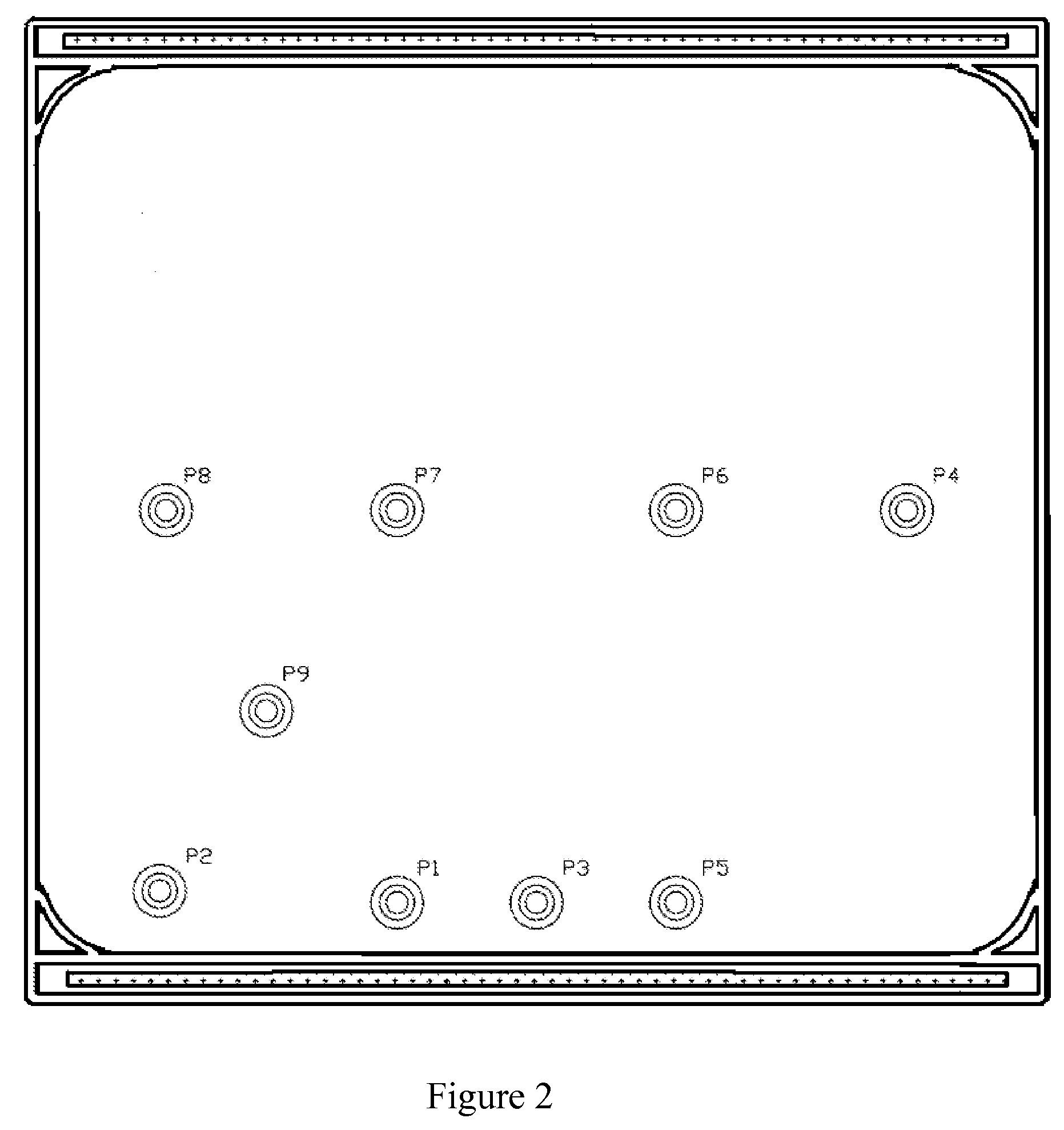

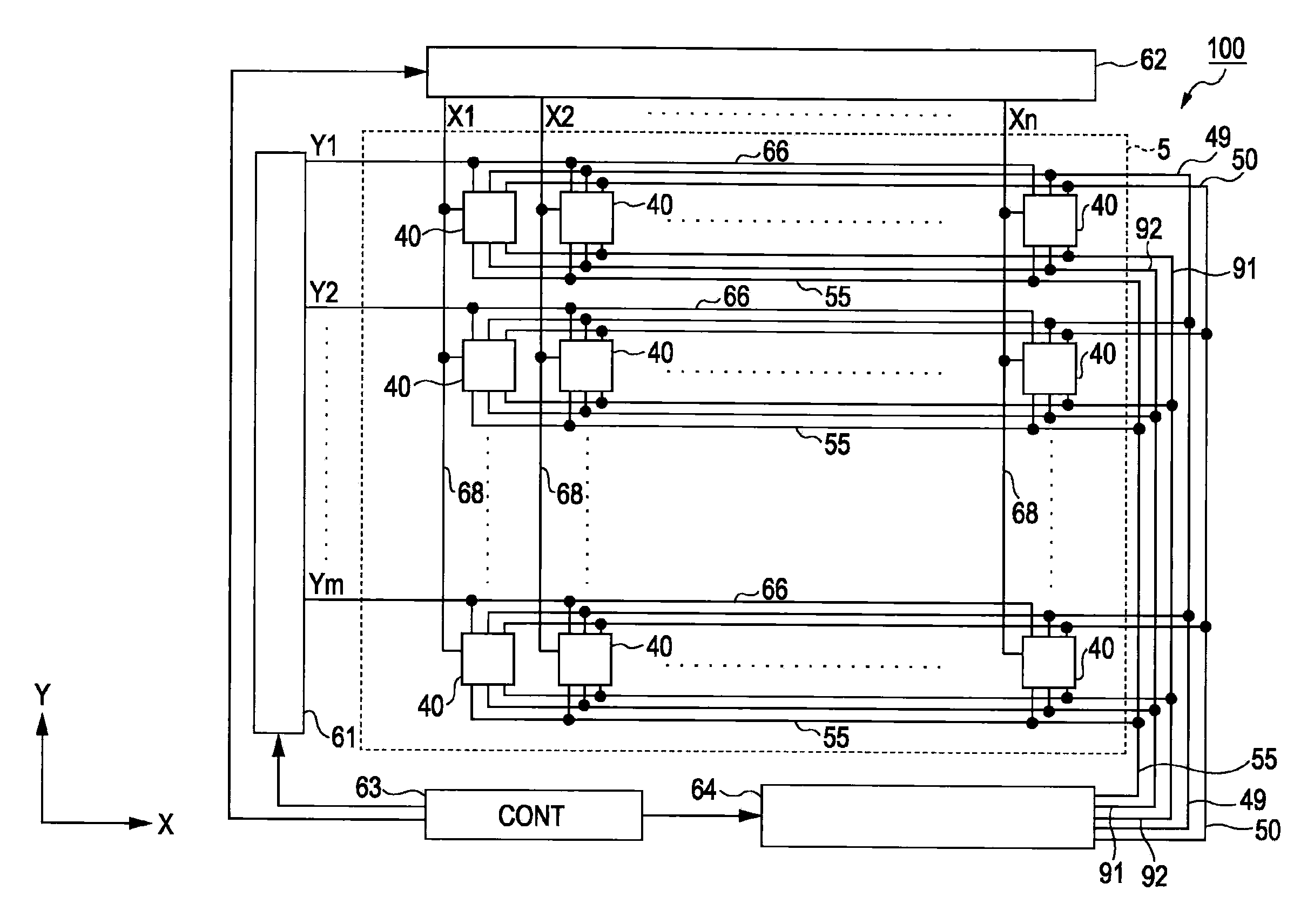

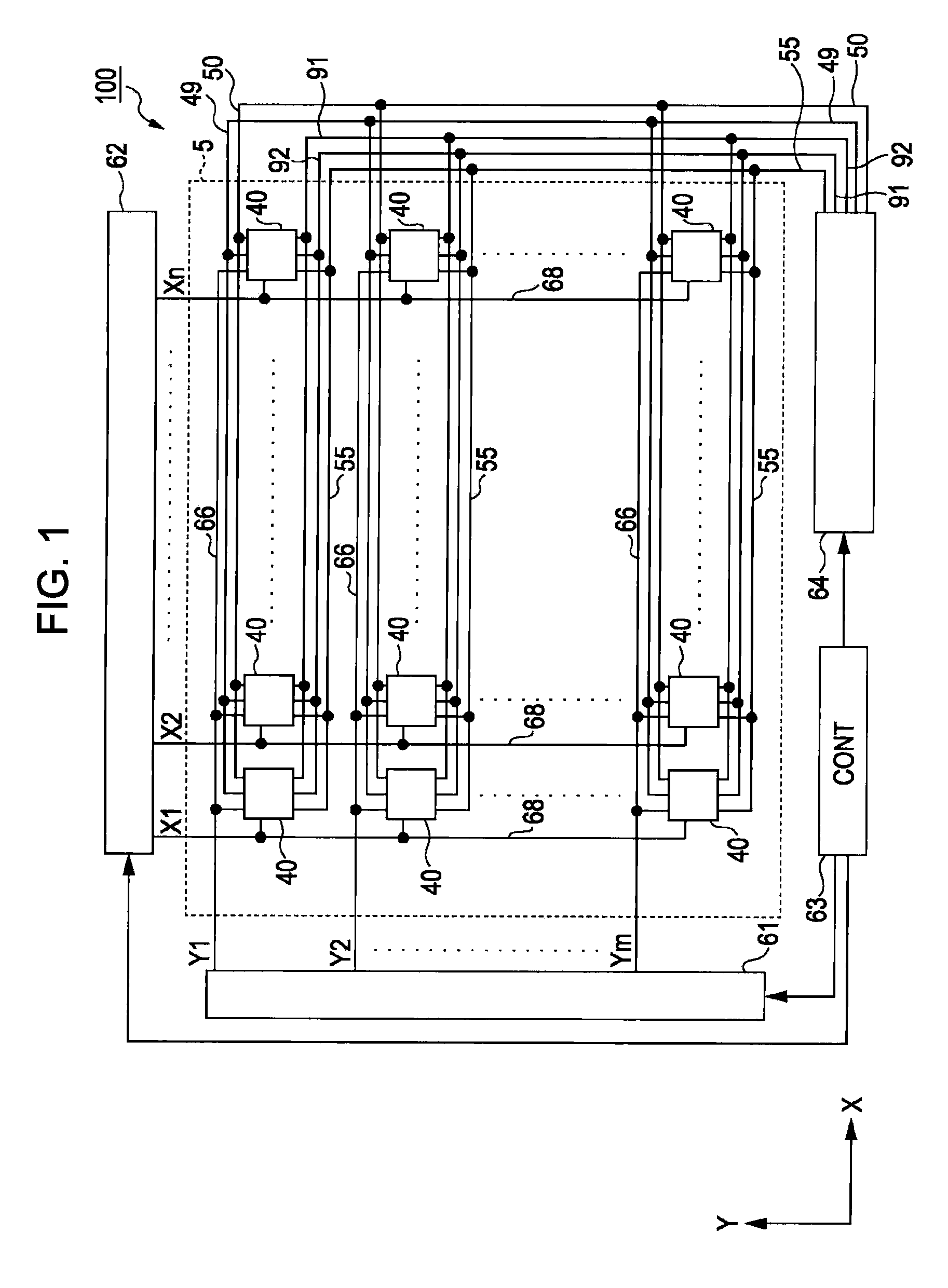

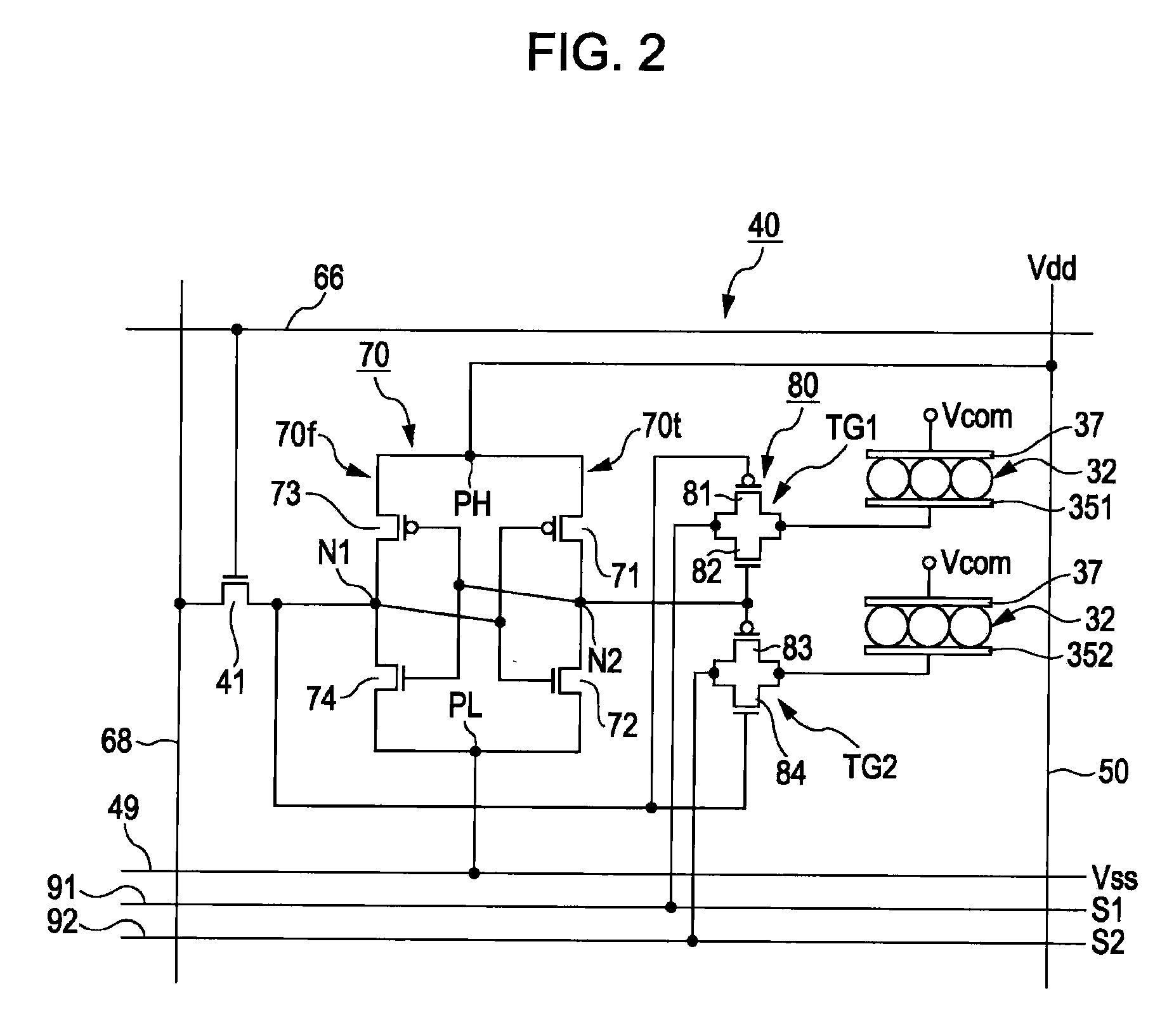

Electrophoretic display device and electronic apparatus

ActiveUS20100001946A1Suppress generationContour smoothingStatic indicating devicesNon-linear opticsDisplay deviceControl line

An electrophoretic display device includes a first substrate and a second substrate that face each other, an electrophoretic element disposed between the first substrate and the second substrate, the electrophoretic element including electrophoretic particles, a display unit that has a plurality of pixels including the electrophoretic element, a common electrode that is formed on an electrophoretic element side of the second substrate, and a first control line and a second control line that are formed in either the first substrate or the second substrate. Each of the plurality of pixels includes a pixel switching element, a memory circuit that is connected to the pixel switching element, a switching circuit that is connected to the memory circuit, and a first pixel electrode and a second pixel electrode that are connected to the switching circuit and are disposed to face the common electrode. The switching circuit includes a first switch that controls a conductive state between the first control line and the first pixel electrode in accordance with an output signal of the memory circuit and a second switch that controls a conductive state between the second control line and the second pixel electrode in accordance with the output signal of the memory circuit.

Owner:E INK CORPORATION

Golf club head with high center of gravity

ActiveUS20050215353A1Contour smoothingSufficient backspinGolf clubsRacket sportsEngineeringGravity center

A golf club head is formed of a hollow metal body having a center of gravity that is above the geometric center of the club face. The hollow metal body of the club head has a sole plate that is smoothly contoured and devoid of any inefficient structures such as weight pads or other mass concentrations. By avoiding the use of inefficient structures such as weight pads, more material is available for the structural walls of the club head body while maintaining the club head within acceptable weight limitations. Moreover, placement of the center of gravity above the center line of the face ensures that sufficient backspin will be imparted to the golf ball when struck by the club.

Owner:KARSTEN MFG CORP

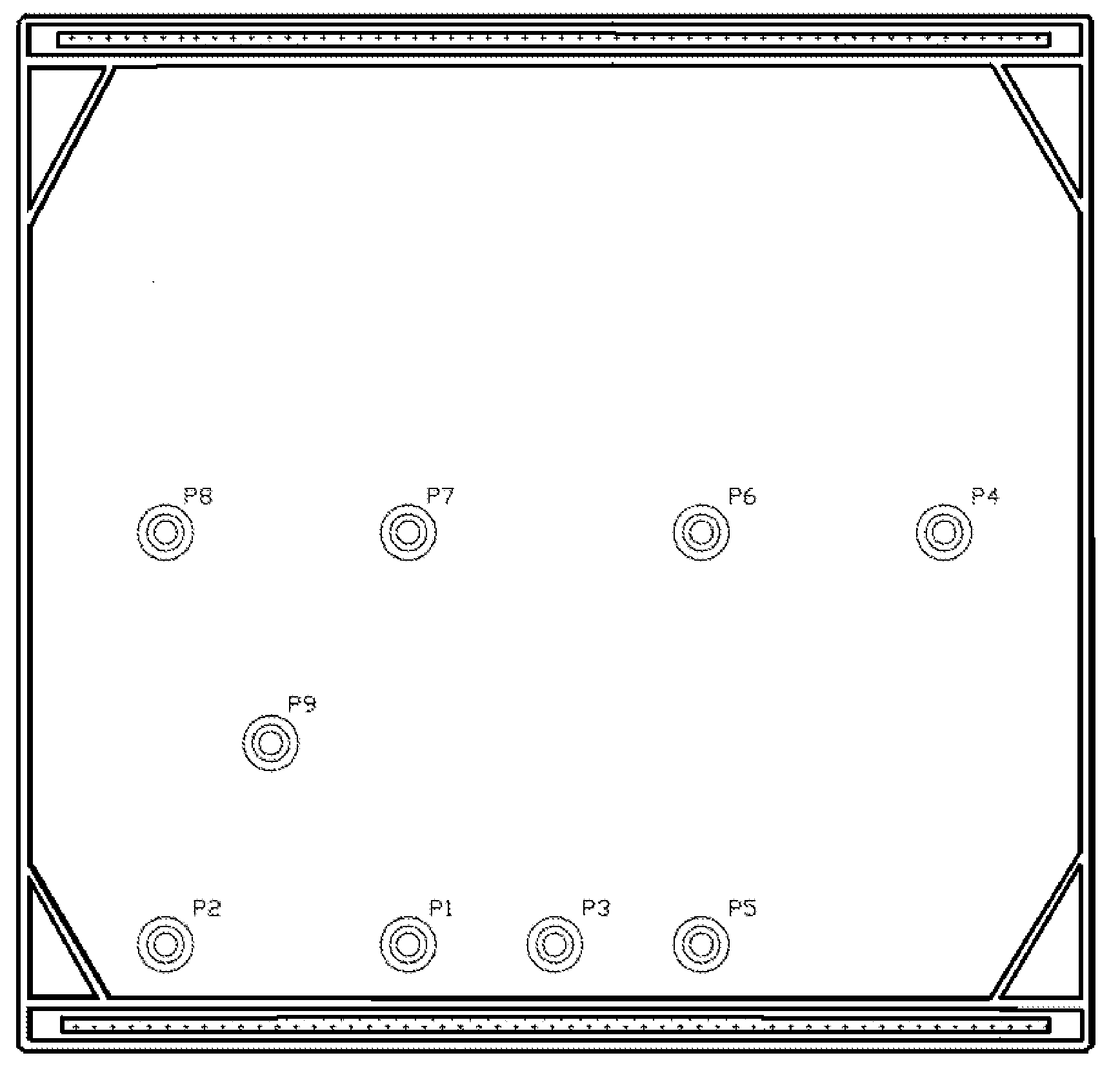

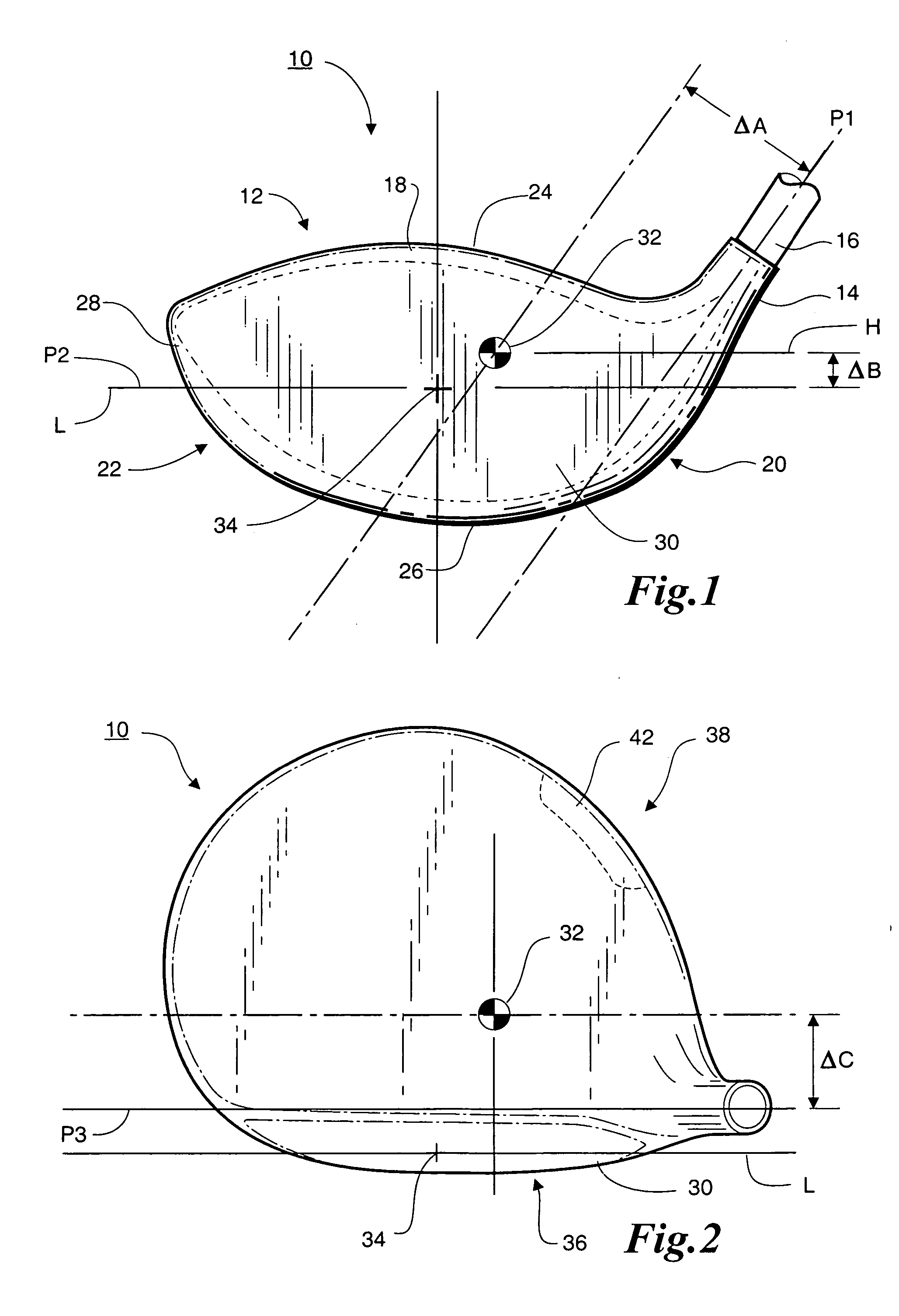

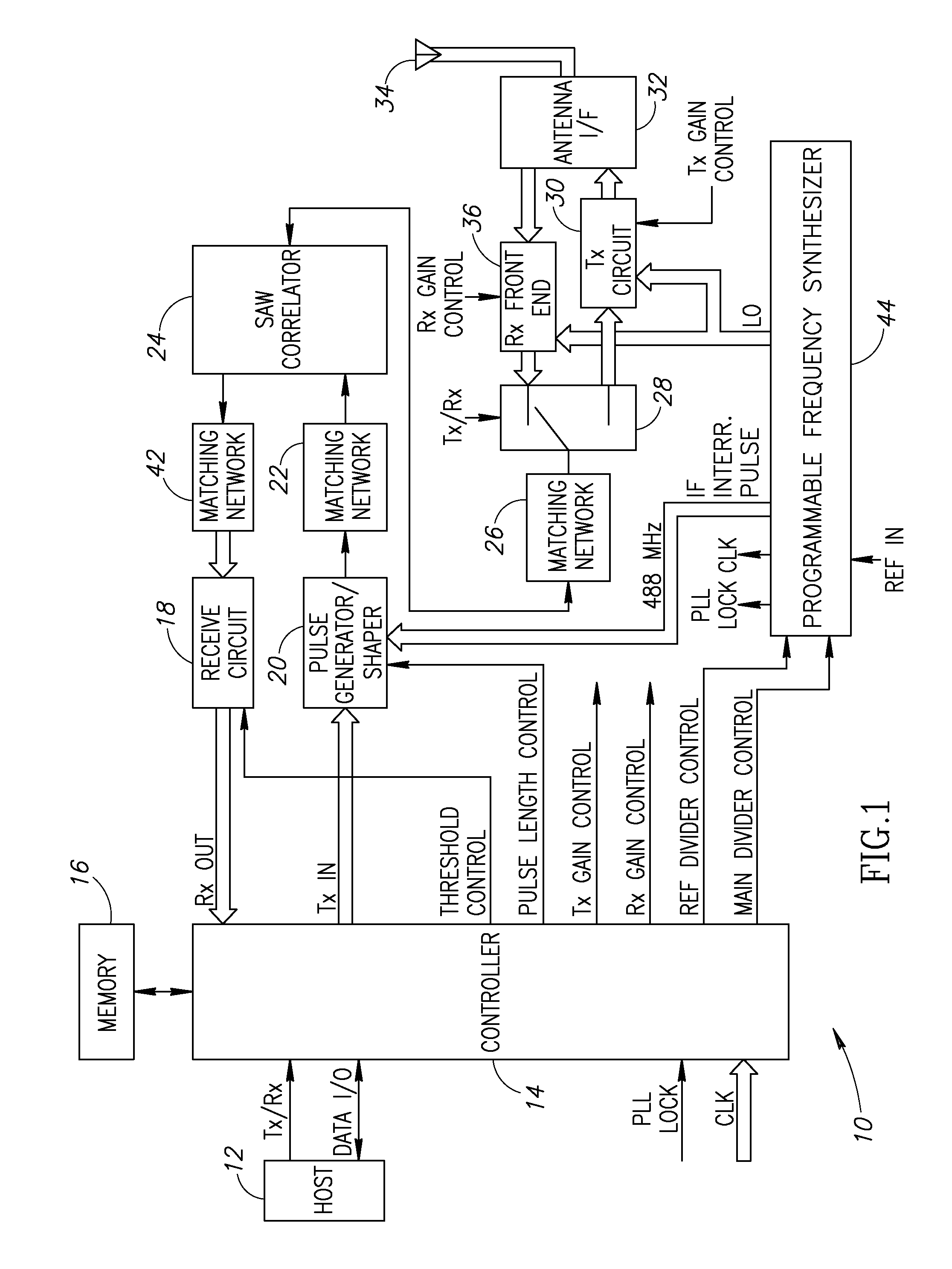

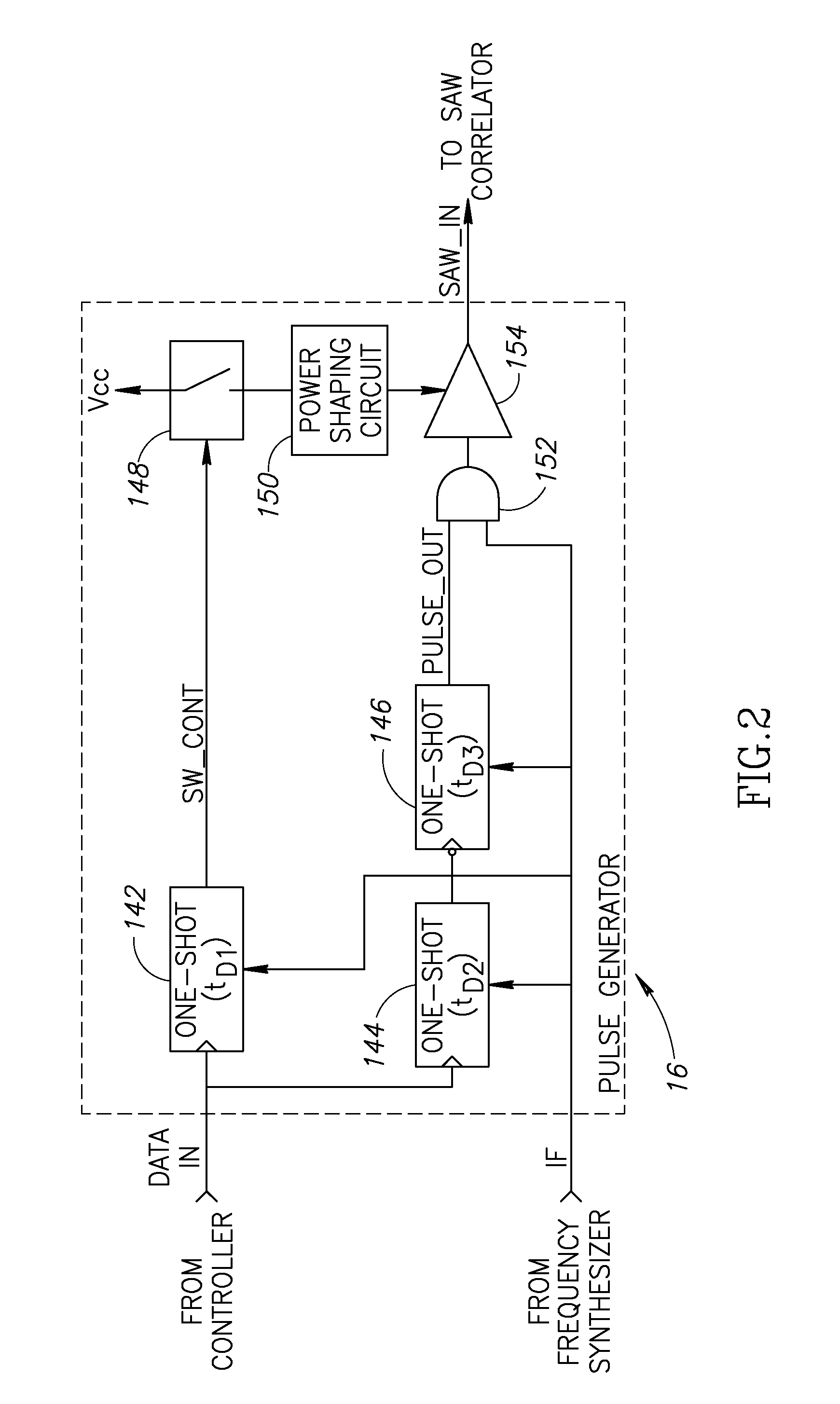

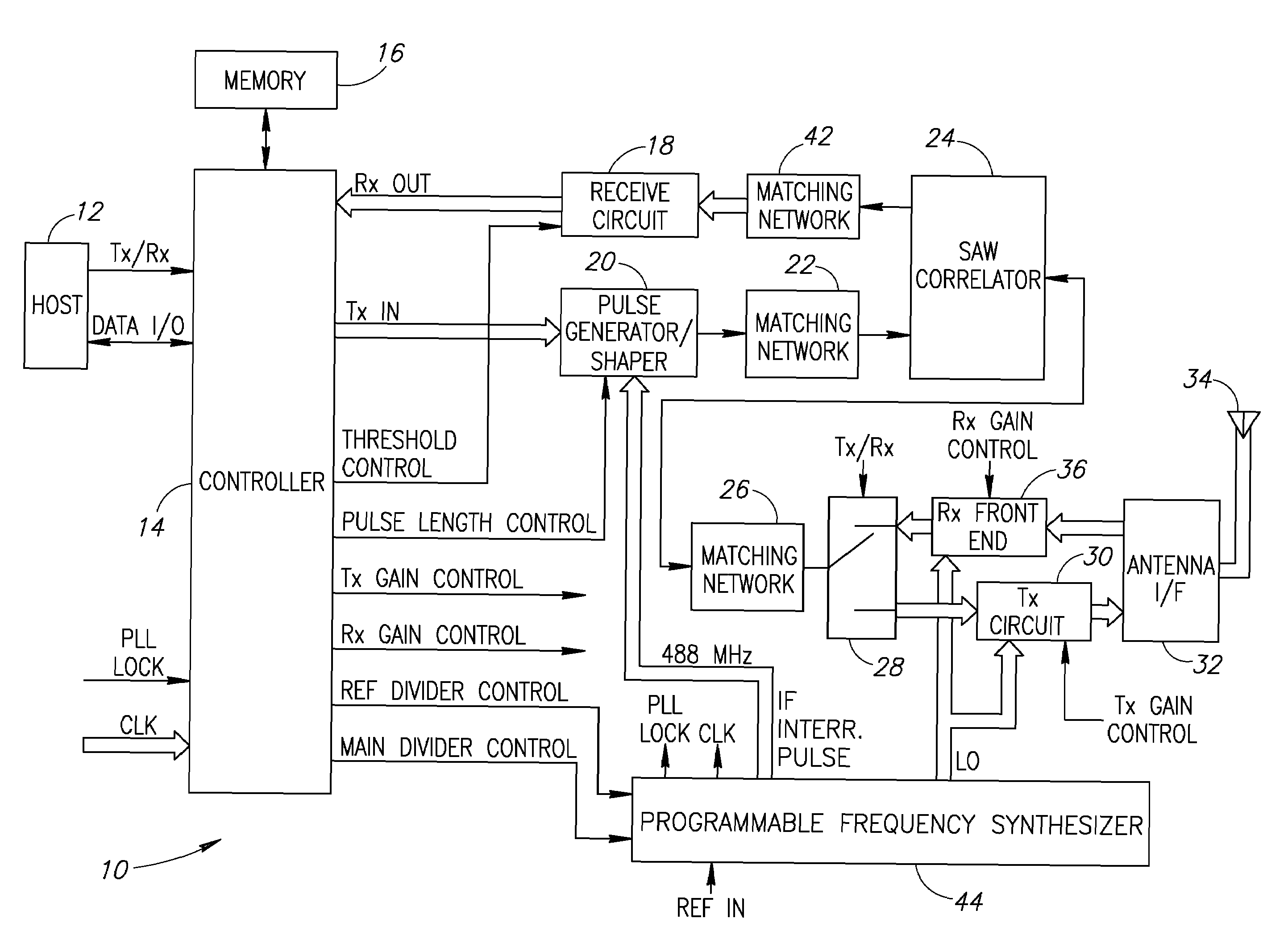

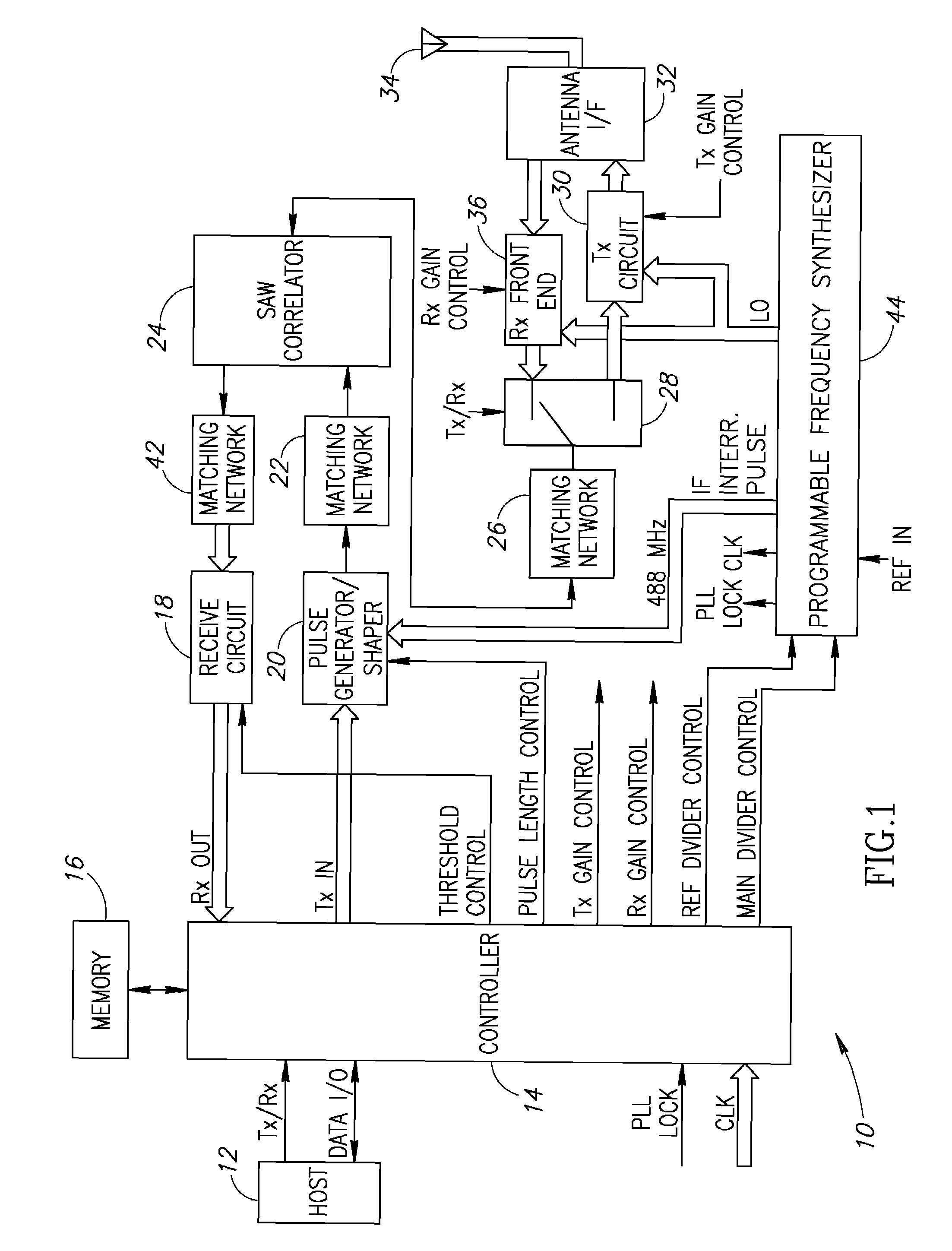

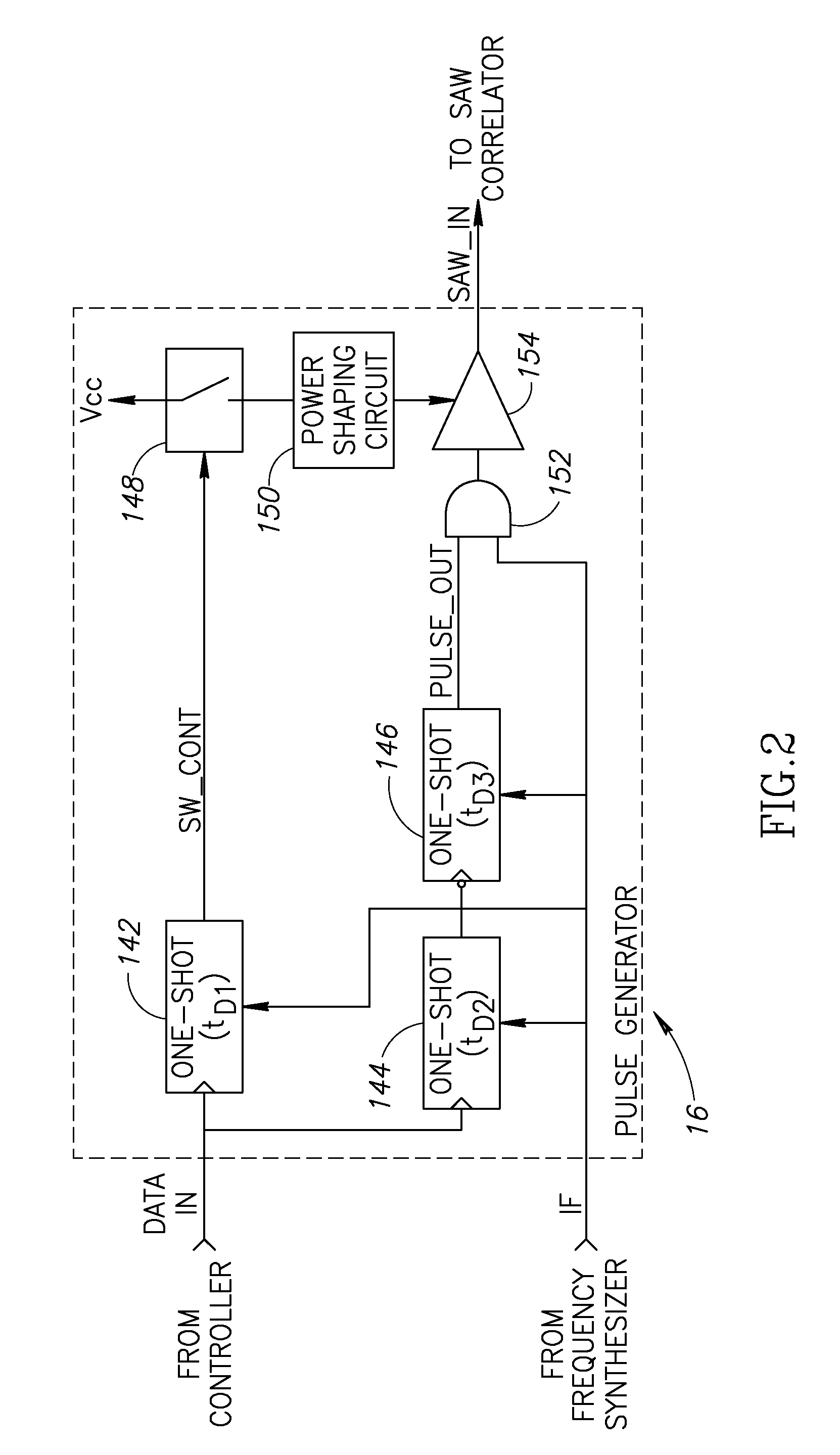

RF modem utilizing saw device with pulse shaping and programmable frequency synthesizer

InactiveUS20070291823A1Low implementation costReduce manufacturing costMultiplex communicationFrequency/rate-modulated pulse demodulationFrequency changerModem device

A bidirectional direct sequence spread spectrum half-duplex RF modem. The RF modem can be applied to transmit and receive numerous types of analog and digital pulse modulation. The modem incorporates a SAW based correlator for performing the spreading and de-spreading functions in the transmitter and receiver. A programmable frequency synthesizer provides the frequency source for various signals in the modem including the local oscillator (LO), IF interrogating pulse and clock signals. An upconverter / downconverter provides frequency translation to the desired frequency band. Pulse gating and interrogating pulse shaping are employed to reduce the spectral side bands of the transmitted spread pulse. The RF modem operates as a analog or digital pulse transmitter and receiver. It is adapted to be generic and is versatile enough to be used in many different types of data communication systems, such as OOK, PWM and PPM. The RF modem can be used as the physical (PHY) layer in a layered communication system such as the ISO OSI communication stack. In an alternative embodiment, the transmission bit rate is increased by using a plurality of correlators wherein each is configured with a unique function (i.e., code) that is orthogonal to the other functions.

Owner:VISHAY INTERTECHNOLOGY INC

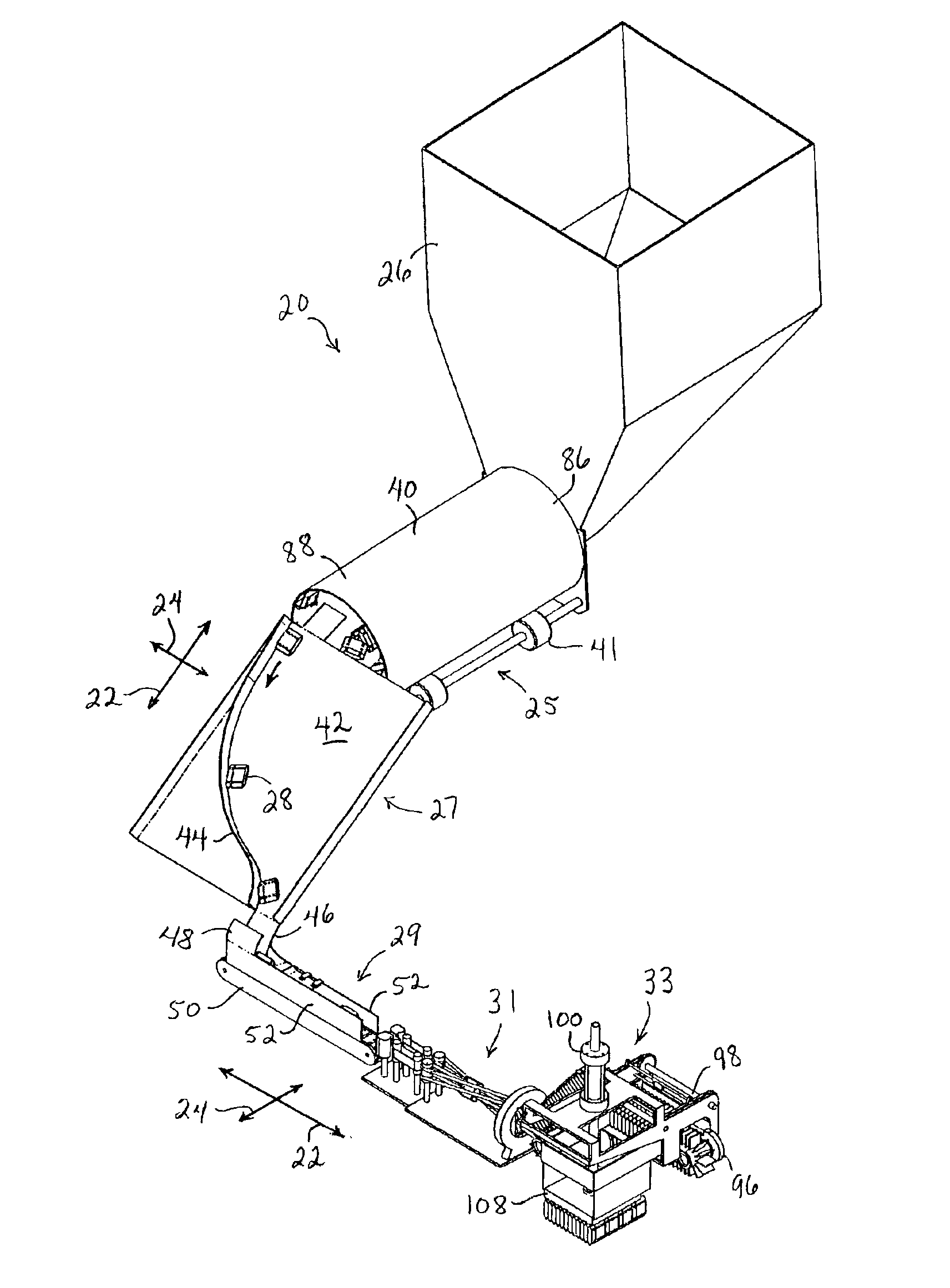

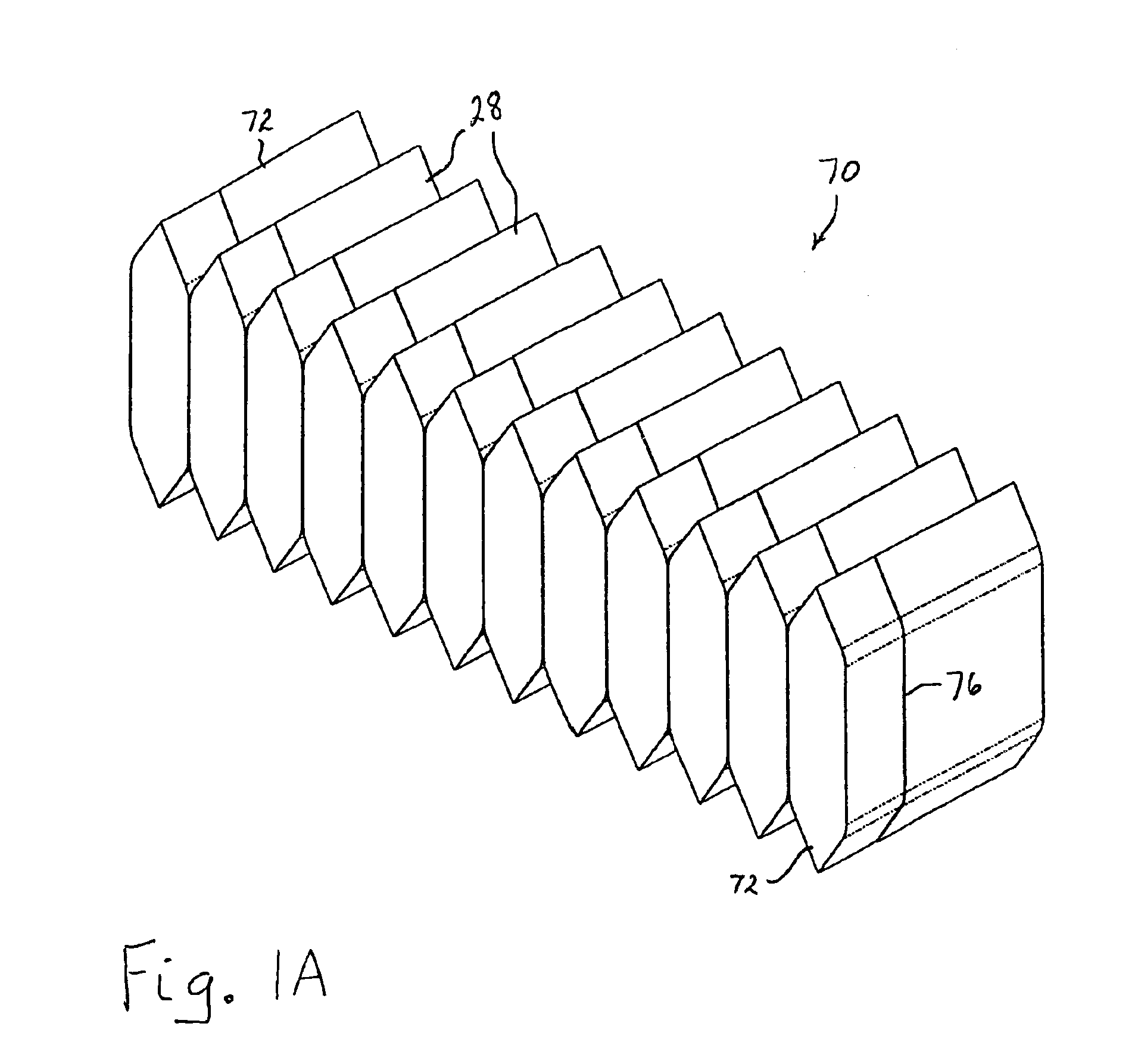

Positioning system for an automatic accumulation system

InactiveUS6884016B2Contour smoothingEasy to placeStorage devicesIndividual articlesEngineeringMechanical engineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

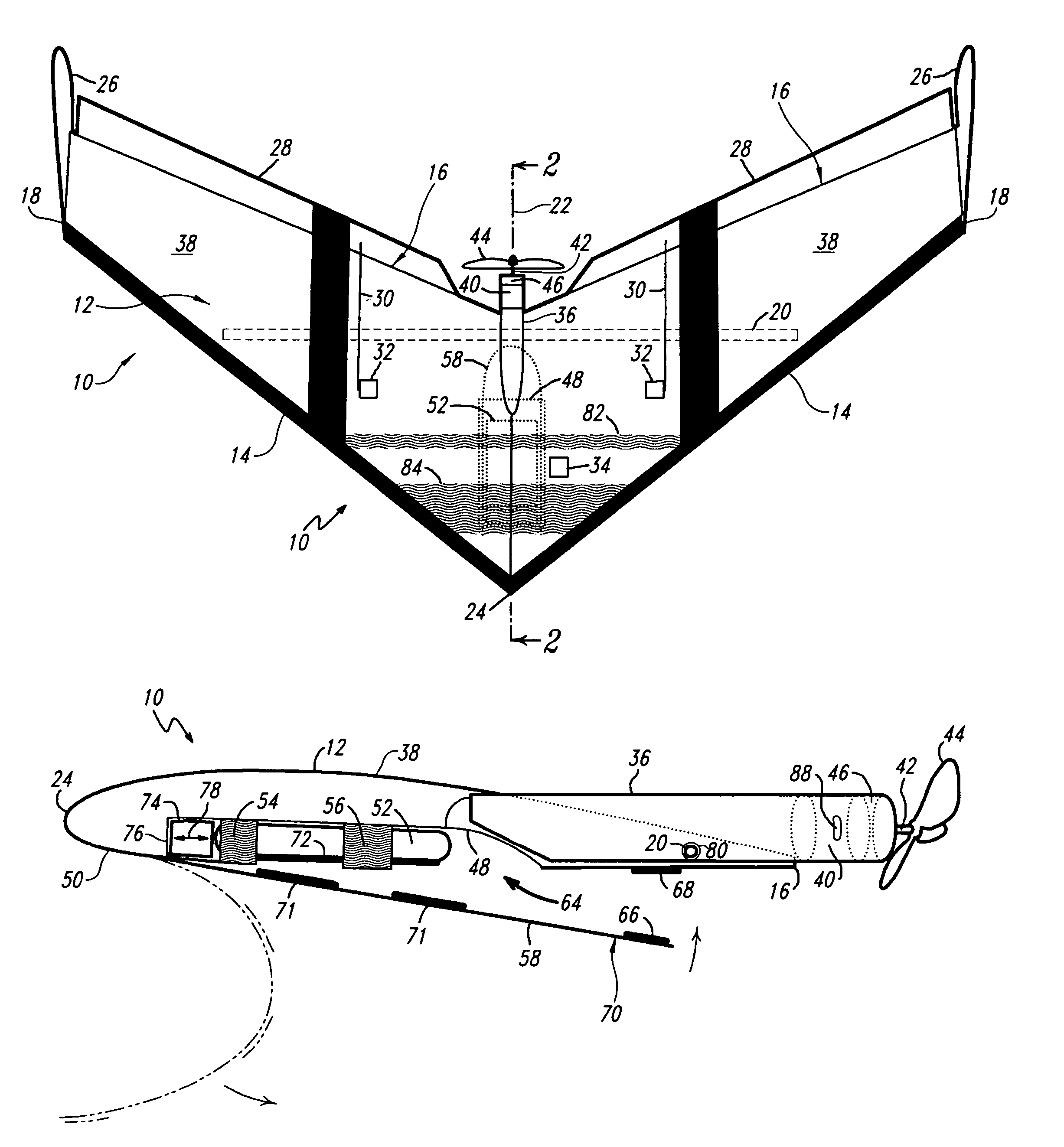

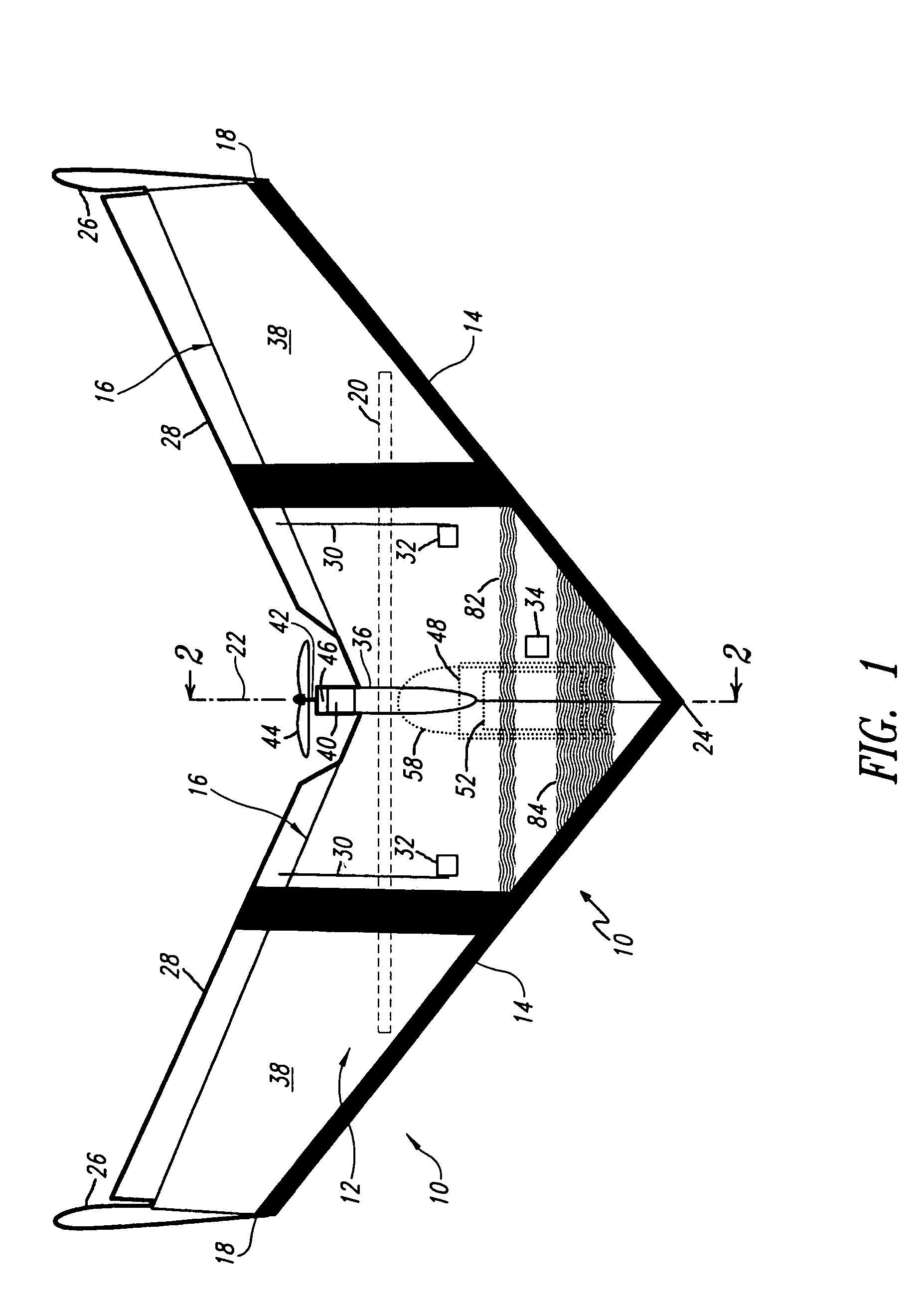

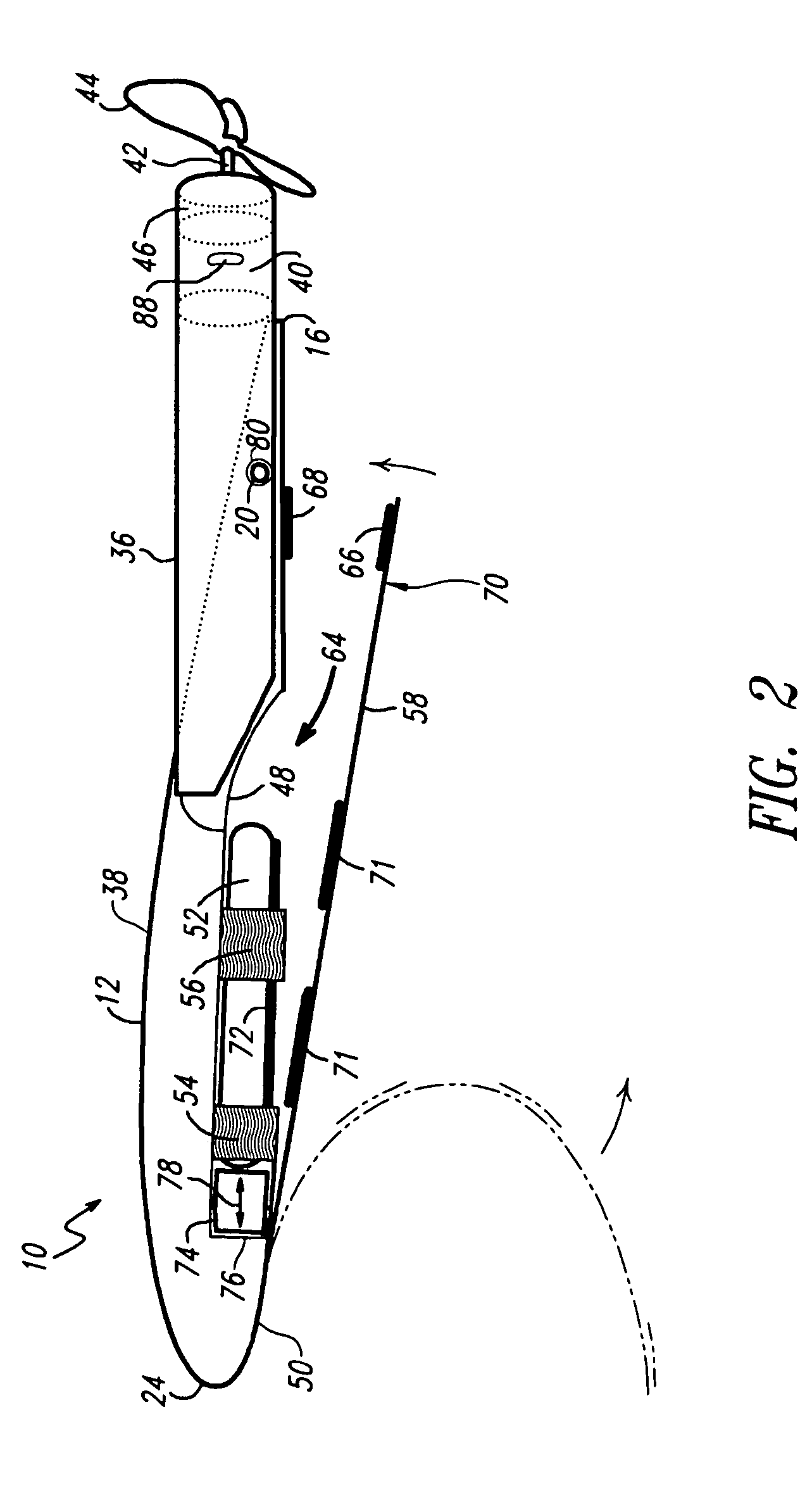

Electric powered flying wing toy

InactiveUS7377832B2Less thrustImprove efficiencyActuated automaticallyToy aircraftsPropellerTrailing edge

A radio-controlled electrically-powered model flying wing aircraft having a pusher propeller at the rear wing root powered by an electric motor mounted in a streamlined electric motor housing that extends into the wing and blends smoothly into the wing surface at the center wing chord. The motor housing, motor and propeller extend beyond the wing trailing edges to ensure efficient propeller operation and to reduce propeller-induced noise. A battery is secured in a resilient pouch and protected completely inside the wing root, serviceable from the bottom wing surface by removing a quick release flap. Major structural elements are composed of impact resistant, flexible, and resilient materials.

Owner:CHAMBERLAIN MARK SPENCER

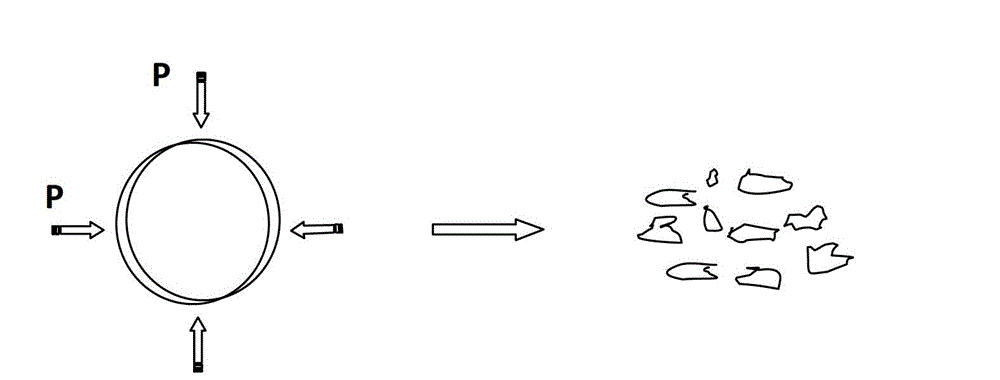

Method for preparing anisotropic neodymium iron boron magnetic powder through directionally breaking thermal deformed magnet

ActiveCN103151161AImprove coercive forceHigh energy productInductances/transformers/magnets manufactureMagnetic materialsThermal deformationRoom temperature

The invention discloses a method for preparing anisotropic neodymium iron boron magnetic powder through directionally breaking a thermal deformed magnet. The method comprises the following steps: (1) preparing a full-densification isotropic neodymium iron boron magnet; (2) preparing a thermal deformation anisotropic neodymium iron boron magnet; (3) directionally breaking the thermal deformation magnet: directionally breaking the round-cake-shaped anisotropic neodymium iron boron magnet, prepared in the step (2), by applying a symmetrical and circulating applied force along a radial direction at room temperature under the protection of argon, wherein the breaking force is 600-700MPa, so as to obtain a lamellar magnetic sheet; and (4) breaking the magnetic sheet in a regularized way: carrying out regularized breaking on the magnetic sheet prepared in the step (3) under the protection of the argon by adopting a rolling minding method, so as to obtain the anisotropic neodymium iron boron magnetic powder.

Owner:SICHUAN UNIV

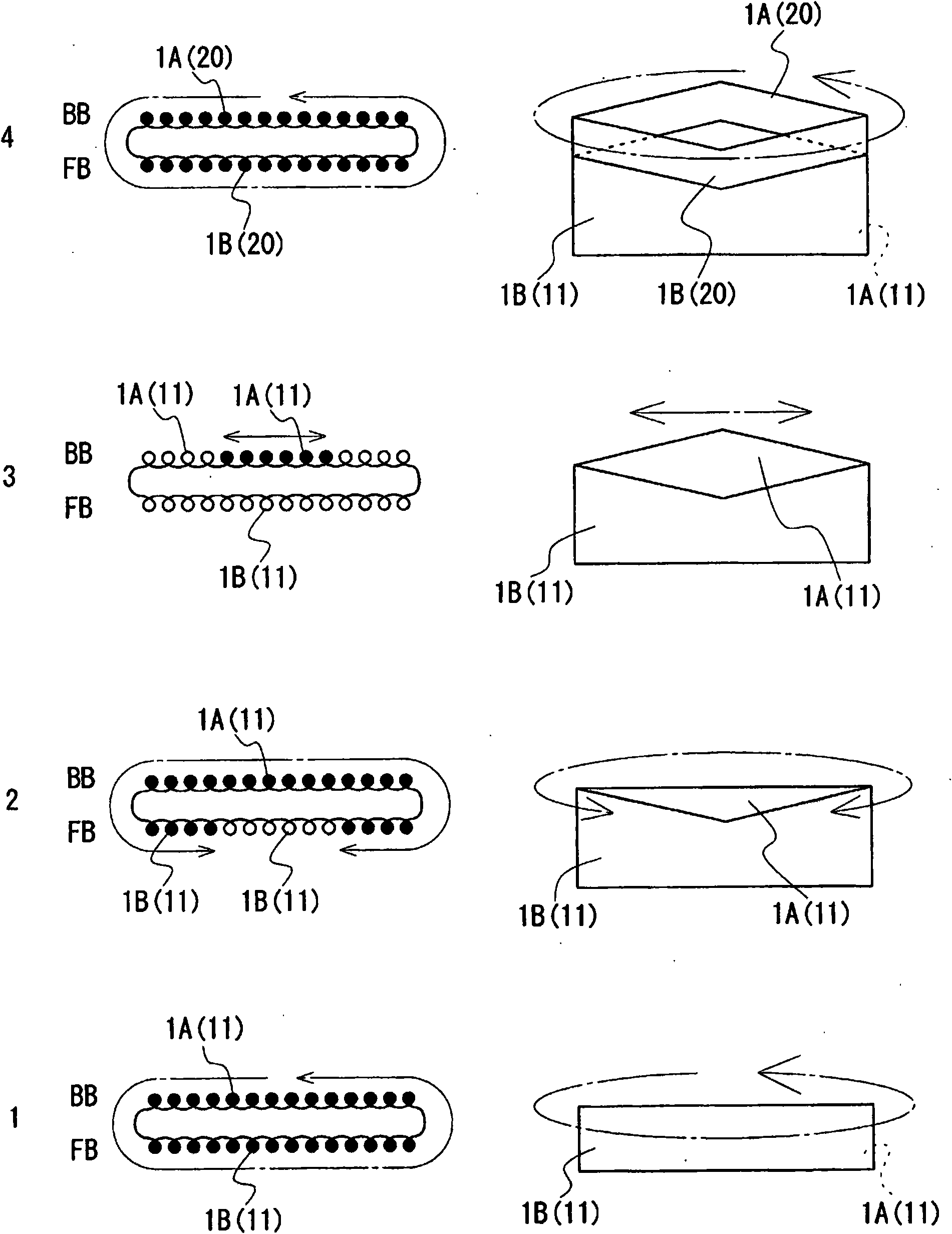

Knitting method for tubular knitted fabric and tubular knitted fabric

A tubular knitted fabric with annular obliquely arranged elastic knitted fabric area that ensures effective shrinkage along the circling direction of the elastic knitted fabric area; and a knitting method for the tubular knitted fabric. The tubular knitted fabric is obtained by knitting with the use of a flat knitting machine equipped with at least a pair of needlebeds extending in a horizontal direction and facing each other in an anteroposterior direction. The tubular knitted fabric comprises an annular elastic knitted fabric area (20) provided in a direction sloping with respect to the axial direction of the tubular knitted fabric; a first base knitted fabric area (11) coupled to a knitted stitch line appearing on a one edge side in the axial direction of the elastic knitted fabric area(20); and a second base knitted fabric area (12) coupled to a knitted stitch line appearing on the other edge side in the axial direction of the elastic knitted fabric area (20). The elastic knittedfabric area (20) has a course along the circling direction thereof.

Owner:SHIMA SEIKI MFG LTD

RF modem utilizing saw device with pulse shaping and programmable frequency synthesizer

InactiveUS7620095B2Reduce the amount requiredProviding frequency agilityMultiplex communicationFrequency/rate-modulated pulse demodulationFrequency changerFrequency spectrum

A bidirectional direct sequence spread spectrum half-duplex RF modem. that can be applied to transmit and receive numerous types of analog and digital pulse modulation. The modem incorporates a SAW based correlator for performing the spreading and de-spreading functions in the transmitter and receiver. A programmable frequency synthesizer provides the frequency source for various signals in the modem including the local oscillator (LO), IF interrogating pulse and clock signals. An upconverter / downconverter provides frequency translation to the desired frequency band. Pulse gating and interrogating pulse shaping are employed to reduce the spectral side bands of the transmitted spread pulse. The RF modem operates as an analog or digital pulse transmitter and receiver. It is adapted to be generic and is versatile enough to be used in many different types of data communication systems, such as OOK, PWM and PPM. The RF modem can be used as the physical (PHY) layer in a layered communication system such as the ISO OSI communication stack. In an alternative embodiment, the transmission bit rate is increased by using a plurality of correlators wherein each is configured with a unique function (i.e., code) that is orthogonal to the other functions.

Owner:VISHAY INTERTECHNOLOGY INC

Pain-alleviating orthopaedic appliance

ActiveUS20090287124A1Reducing spasming of the soleus muscleRelieve symptomsRestraining devicesFeet bandagesPlastic surgerySurgical department

An orthopaedic appliance includes a body, a protrusion extending inwardly from the body, positioned on the body to apply pressure on a proximal portion of the soleus muscle, and means for applying pressure to the protrusion.

Owner:NATURES PILLOWS INC +1

Method and device for forming word stock

ActiveCN104346390AIncrease production costSolve the file is too largeCharacter and pattern recognitionSpecial data processing applicationsPersonalizationAlgorithm

The invention provides a method for forming a word stock. The method includes steps of 1) acquiring word scripts; 2) scanning the word scripts into script images; 3) digitally fitting the script images to form a character outline; 4) automatically processing the character outline so as to remove excessive outline curves in the character outline and excessive points on the outline curves; 5) forming the word stock and testing. Correspondingly, the invention further provides a device for forming the word stock. By the aid of the method and the device for forming the word stock, an individual word stock can be formed and is lower in data flow as compared with existing individual word stock.

Owner:新方正控股发展有限责任公司 +1

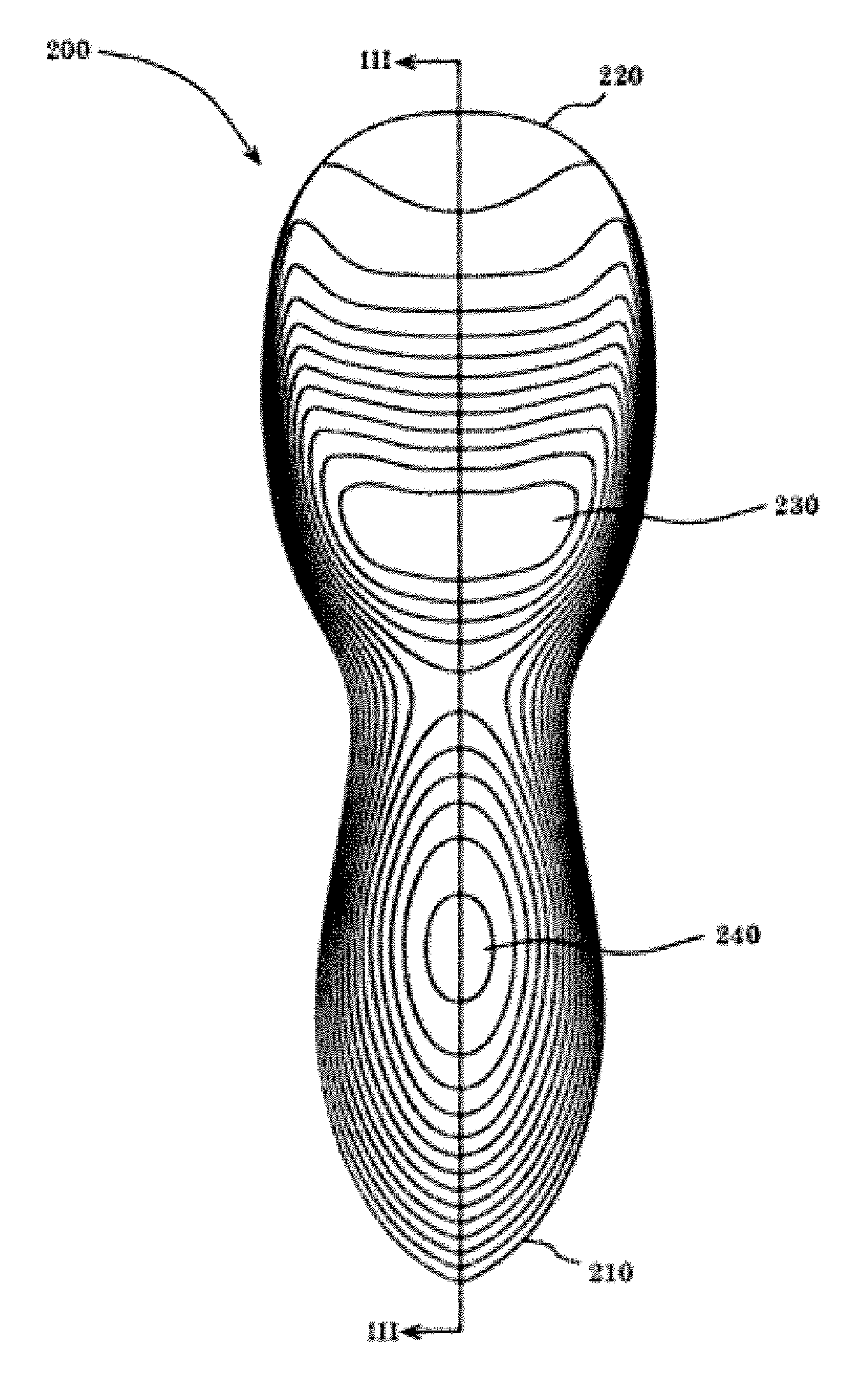

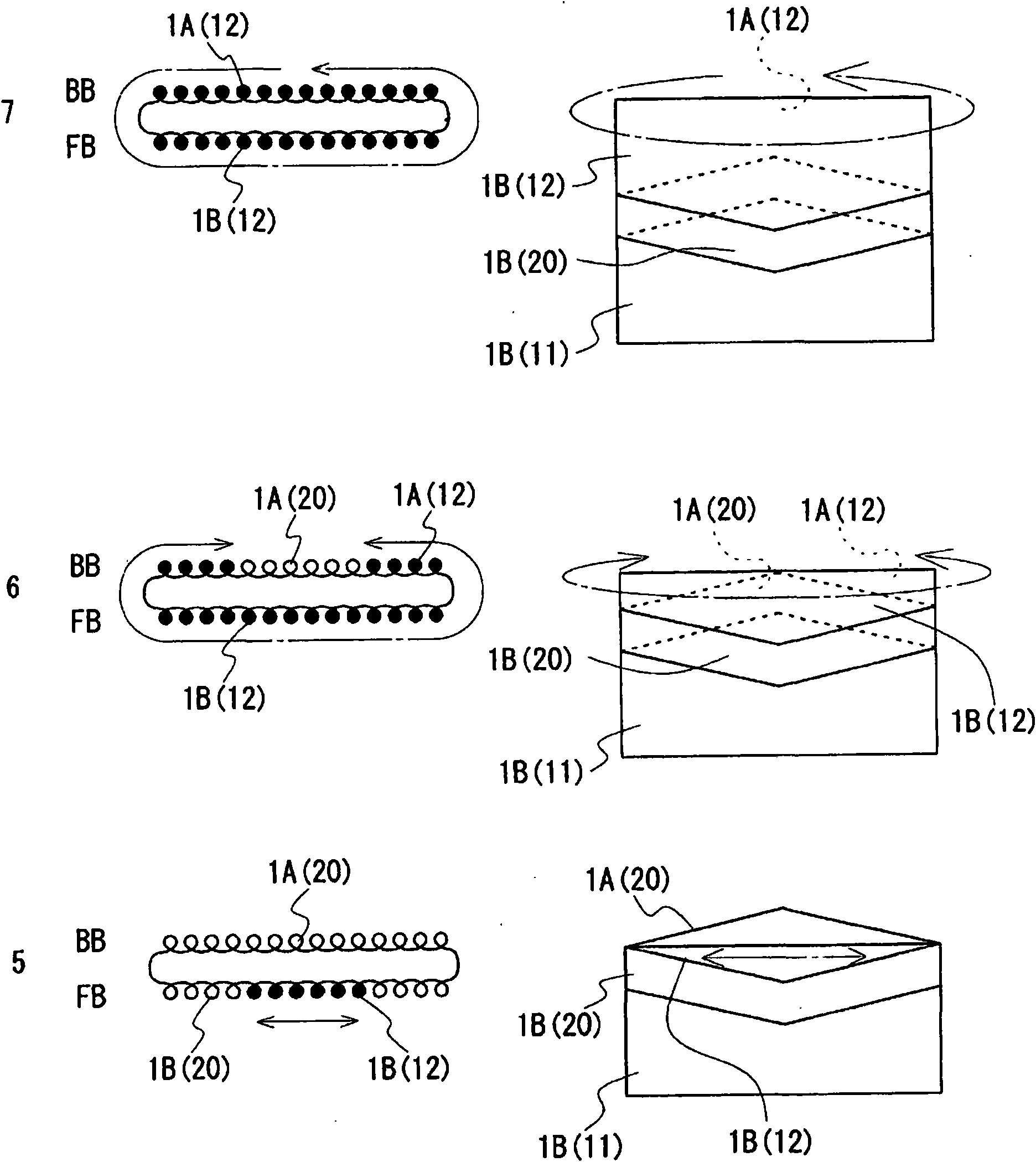

Device for high-heeled shoes and method of constructing a high-heeled shoe

A device for insertion in a high-heeled shoe has a first crescent shaped raised area in a region underlying the forward edge of a wearer's heel bone and a second raised area underlying the metatarsals of the wearer is described. Also described is a method for constructing a shoe using the device and the resulting shoe.

Owner:HBN SHOE

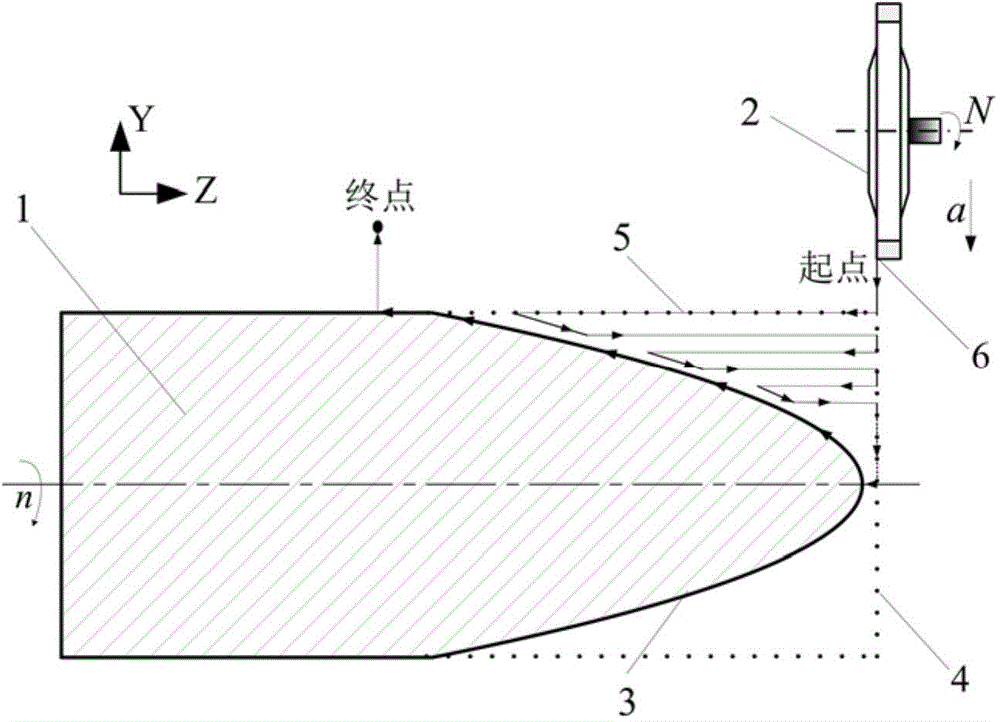

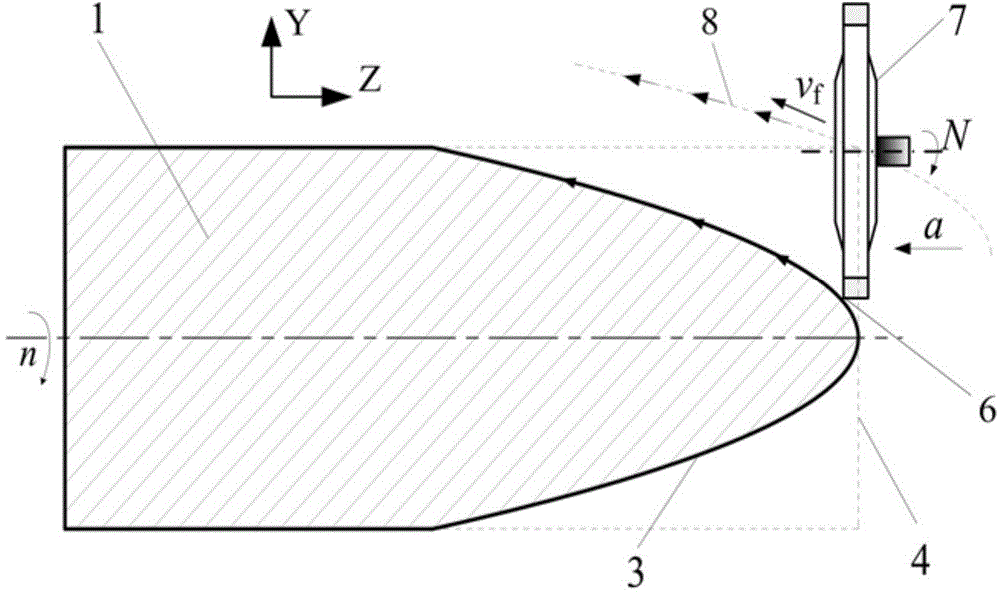

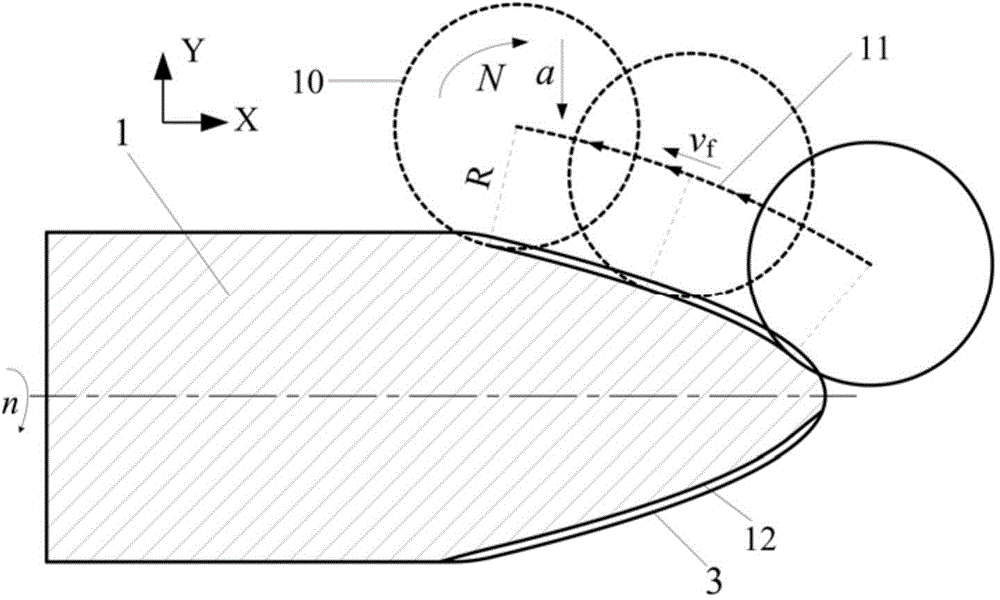

Flying body with curved-surface micro groove structures and manufacturing method of flying body

InactiveCN104647168AClear cornersNeat cornersGrinding machinesAir-flow influencersAerodynamic dragRadar

The invention discloses a flying body with curved-surface micro groove structures and a manufacturing method of the flying body. The flying body comprises a cylinder and a conical head, wherein multiple micro grooves are uniformly distributed at intervals along the axial section of the curved surface of the conical head, and the curved surface is a two-dimensional rotating surface in a parabolic surface or an elliptical surface. During machining, the manufacturing method comprises the steps of firstly machining a cylindrical material into the flying body which is provided with the conical head and has a rough curved surface with a curved surface profile; then machining the rough curved surface into a smooth curved surface along the curved surface profile by utilizing a corner of the annular end surface of a fine-grained diamond grinding wheel; finally axially steering the grinding wheel, enabling the grinding wheel to be vertical to a workpiece rotating shaft or to be in a certain inclination angle relative to the workpiece rotating shaft, enabling a workpiece to be fixed, and carrying out radial feeding along the radial direction of the smooth curved surface profile by utilizing a V-shaped pointed end of the diamond grinding wheel in high-speed rotation so as to machine the micro grooves in the curved surface. According to the manufacturing method disclosed by the invention, the smooth curved surface with the regular and controllable micro groove structures is machined on the flying body, the air resistance of the flying body can be reduced, the laser scattering can be enhanced, and resistance reduction and invisibility of flying can be finally realized.

Owner:SOUTH CHINA UNIV OF TECH

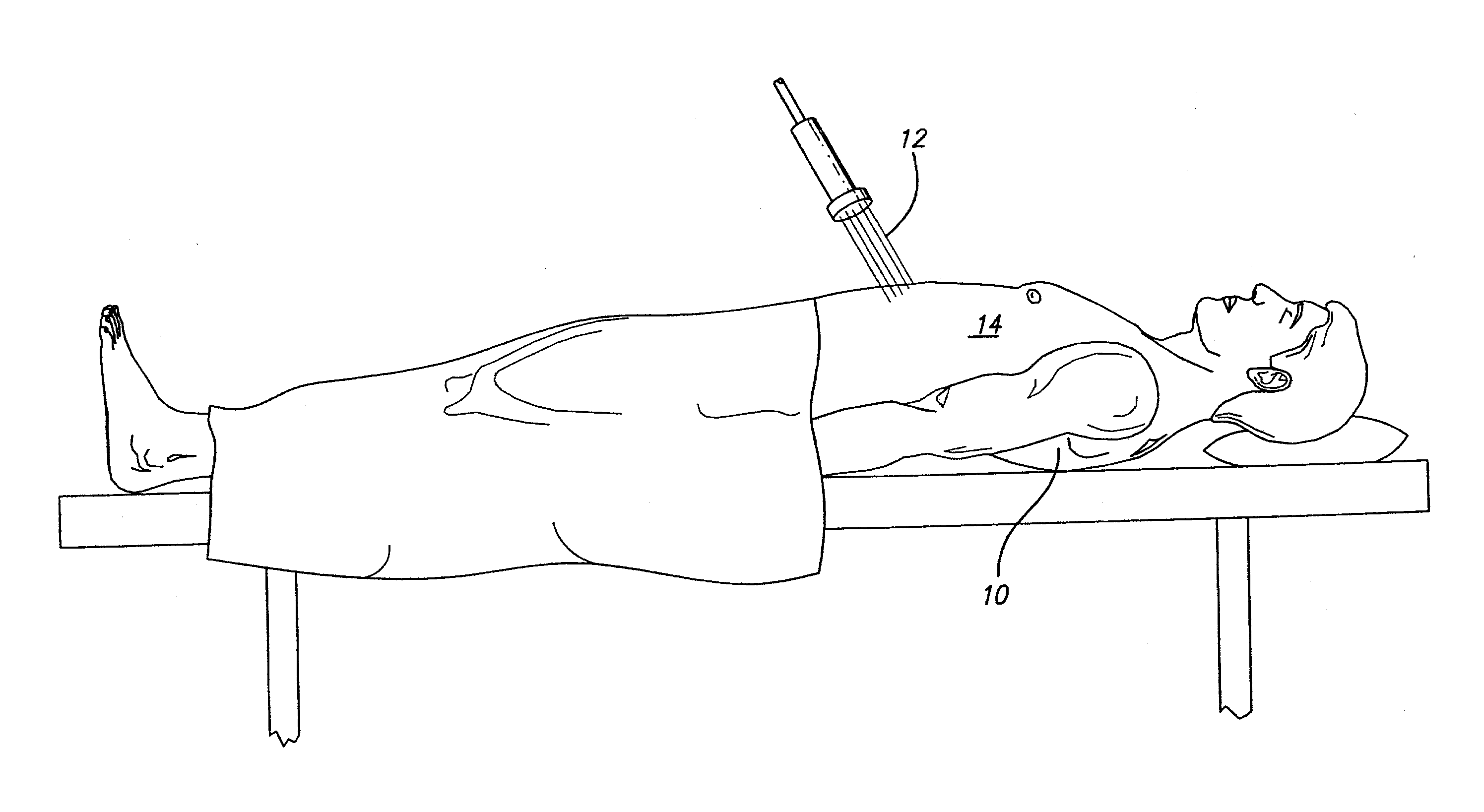

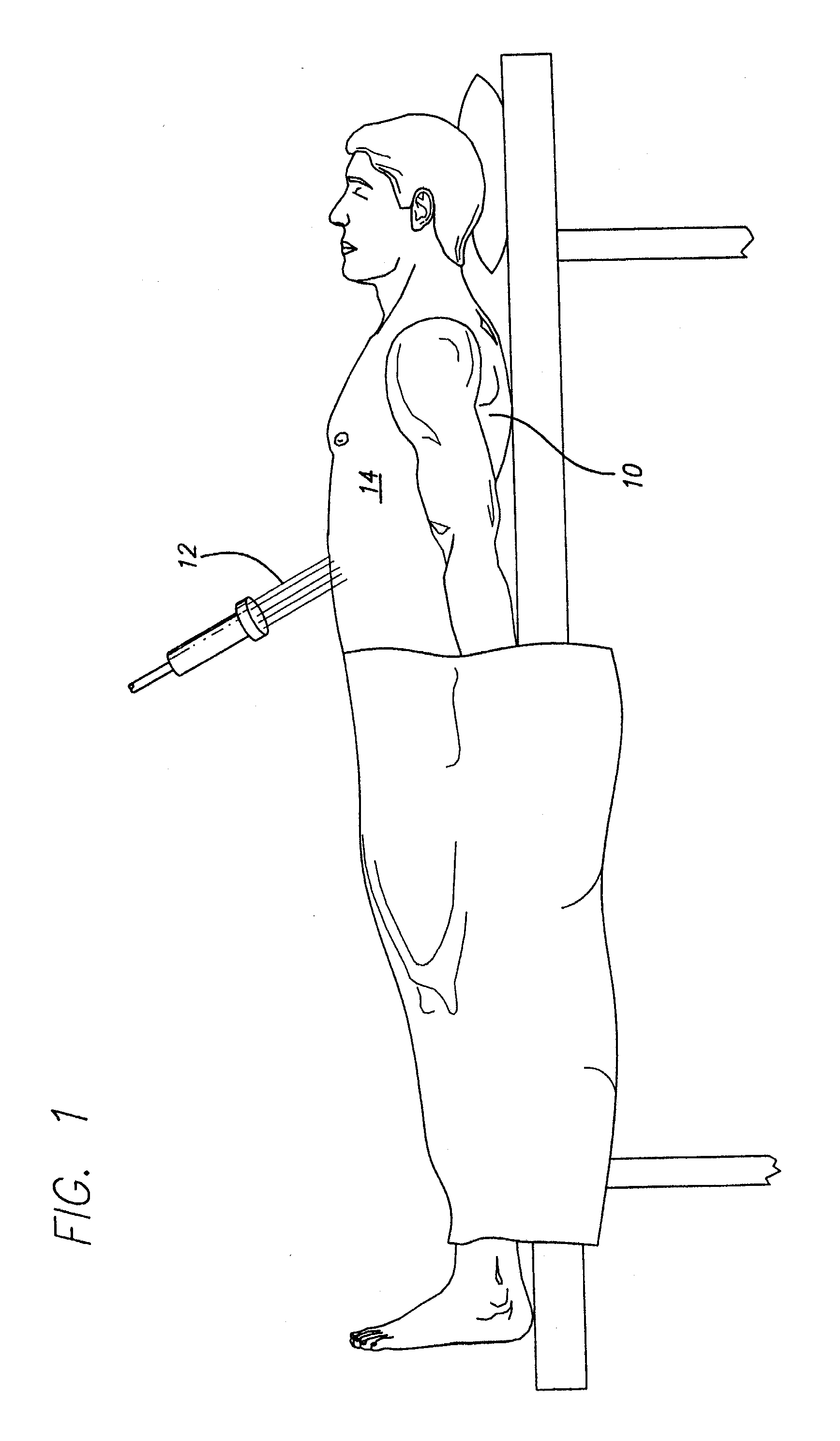

Fat Reduction Using External Laser Radiation and Niacin

InactiveUS20110295187A1Reduce fatReduce celluliteElectrotherapyTreatment involving filtrationPresent methodRadiology

The present invention is a non-invasive method for reducing fat or cellulite in a patient by administering a therapeutically effective amount of niacin and applying laser energy to targeted external regions of a patient's body. The present method helps create smooth contours.

Owner:ERCHONIA CORP

Bioreactors

InactiveUS20110151552A1Prevent and minimize formationIncrease pressureBioreactor/fermenter combinationsBiological substance pretreatmentsPolymer scienceEngineering

The present invention relates to improvements of bioreactor bags for cell cultivation. The invention provides an inflatable bioreactor bag for cell cultivation comprised of a top and a bottom sheet of polymer material that are joined along their edges to form a sealed bag, wherein two opposing edges are formed as clamping edges to allow clamping of the bioreactor bag to a rocker type bioreactor, wherein the top sheet is at least 5% longer than the bottom sheet between the clamping edges. The bioreactor bags provided by the invention avoid formation of undesired wrinkles or creases which otherwise may lead to fatigue of the plastic and eventually fracture.

Owner:GE HEALTHCARE BIO SCI CORP

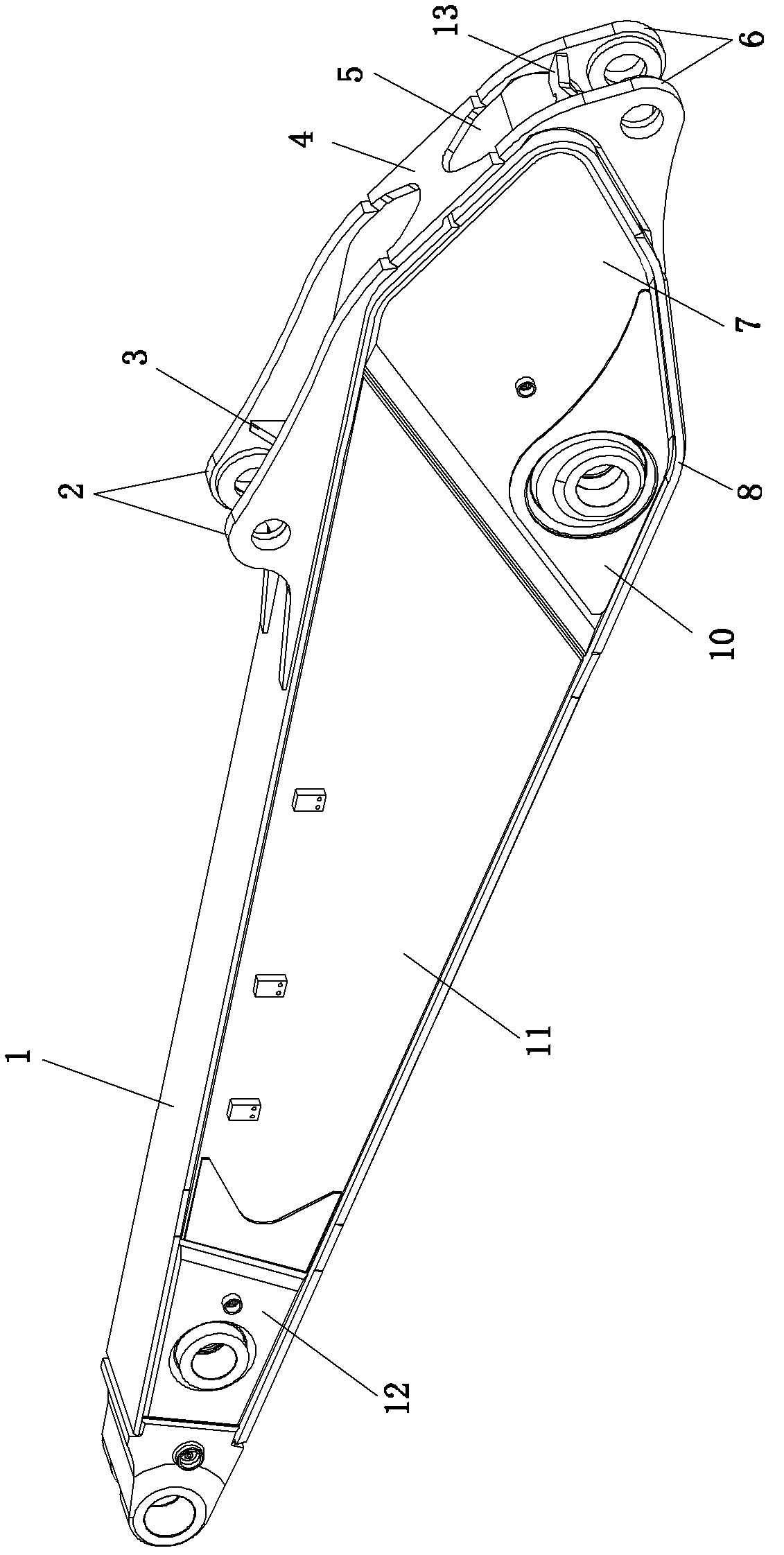

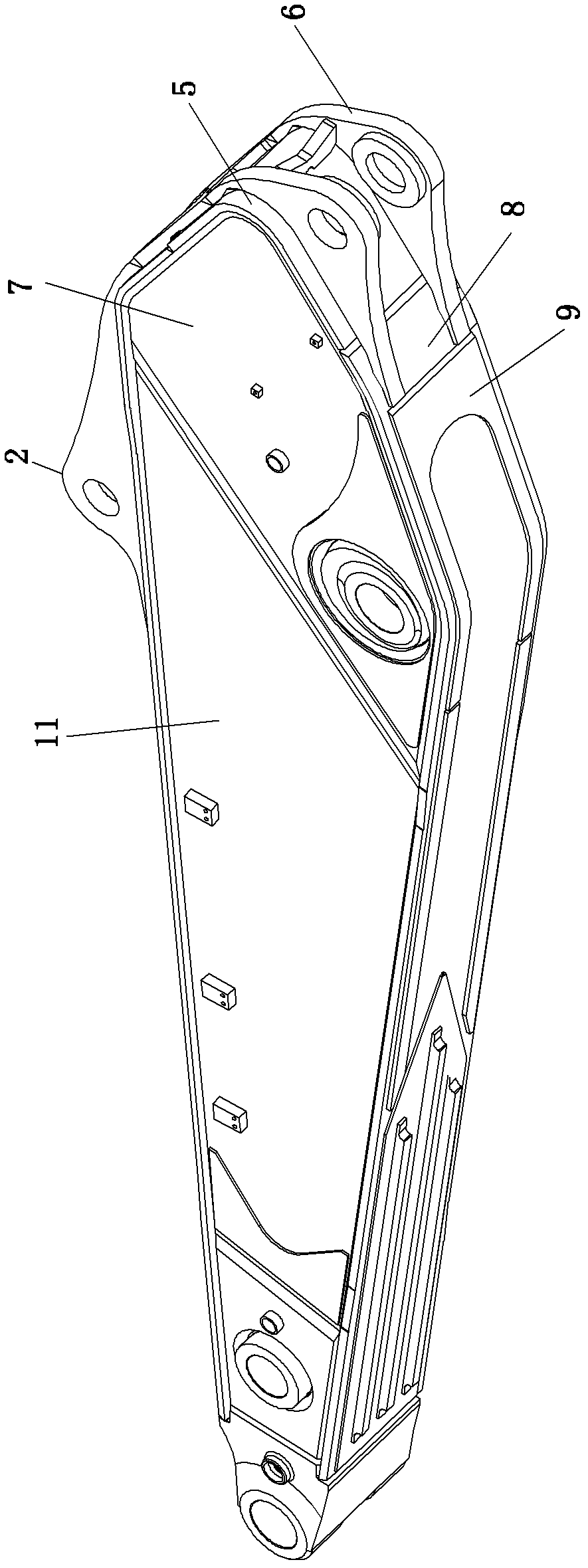

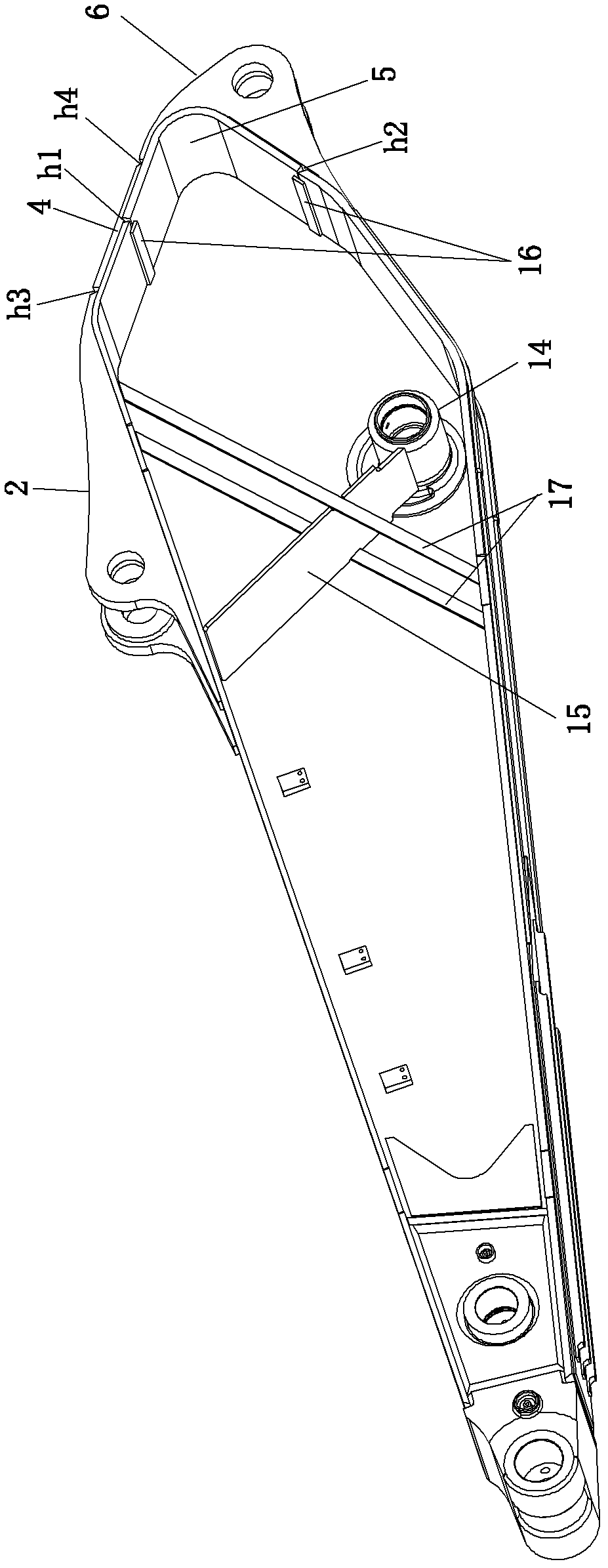

Bucket rod of excavator

ActiveCN102561427AMinimize wiggleHigh strengthMechanical machines/dredgersStress distributionArchitectural engineering

The invention discloses a bucket rod of an excavator. The bucket rod comprises a bucket rod main body consisting of two side plates and a surrounding plate; the bucket rod main body is provided with a pair of bucket cylinder supports and a pair of lug plates; each of the two side plates is formed by welding a front side plate, a middle side plate and a rear side plate; the surrounding plate is formed by welding an upper cover plate, a bent plate and a lower cover plate; the seam between the upper cover plate and the bent plate is opposite to the middle part of the upper plane of the rear side plate, and the seam between the bent plate and the lower cover plate is opposite to the lower part of the middle plane of the rear side plate; and a horizontal reinforcing plate is arranged between the two bucket cylinder supports and the two lug plates, an I type vertical reinforcing plate is welded on the upper cover plate and between the two bucket cylinder supports, and an II type vertical reinforcing plate is welded on the bent plate and between the two lug plates. Under equal conditions, the average stress of the bucket rod is low, the stress distribution of the bucket rod is uniform, and the strength of the bucket rod is improved; and by properly reducing the thickness of a part of plate, the bucket rod is lightened.

Owner:SINOMACH CHANGLIN CO LTD

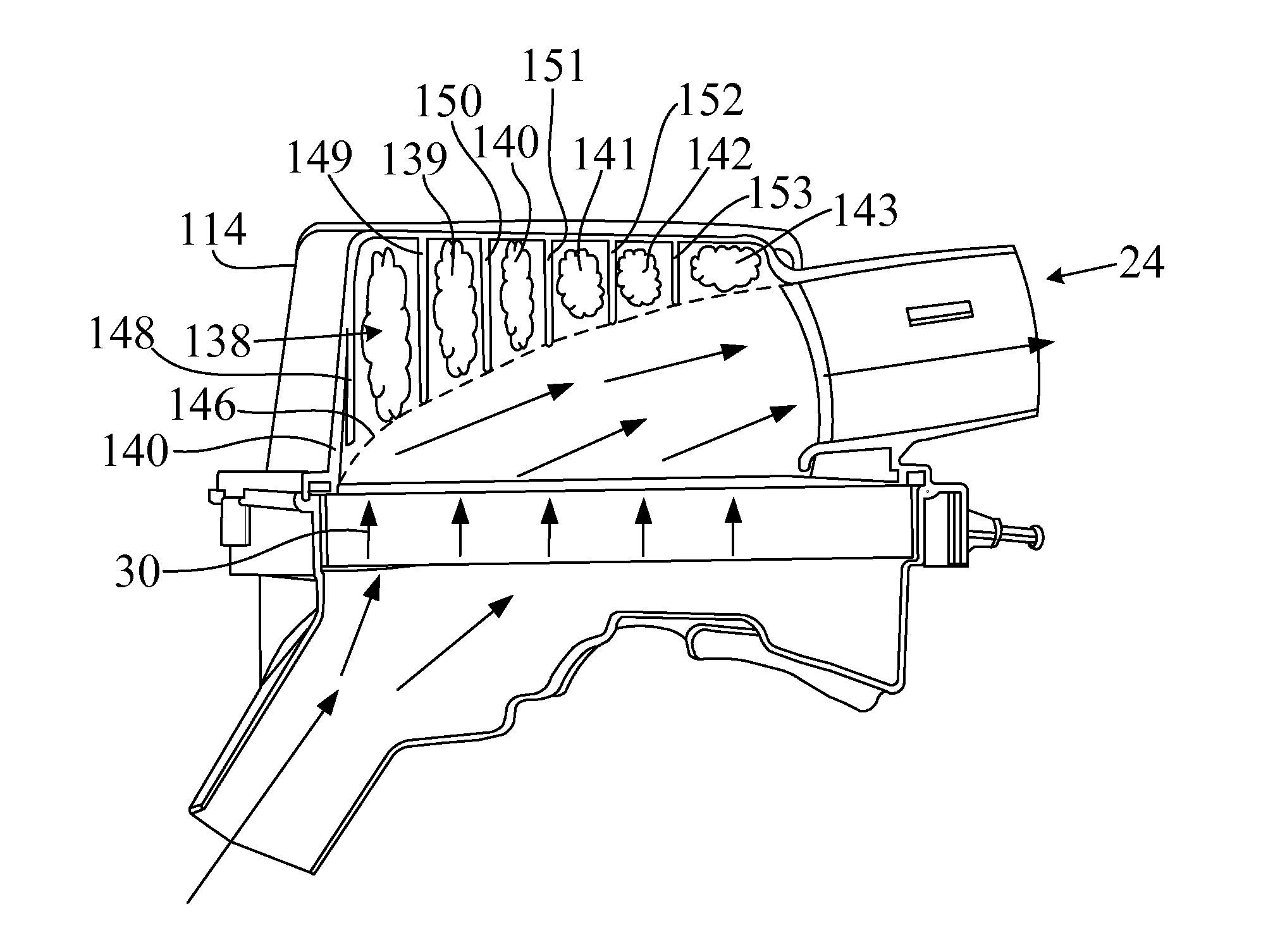

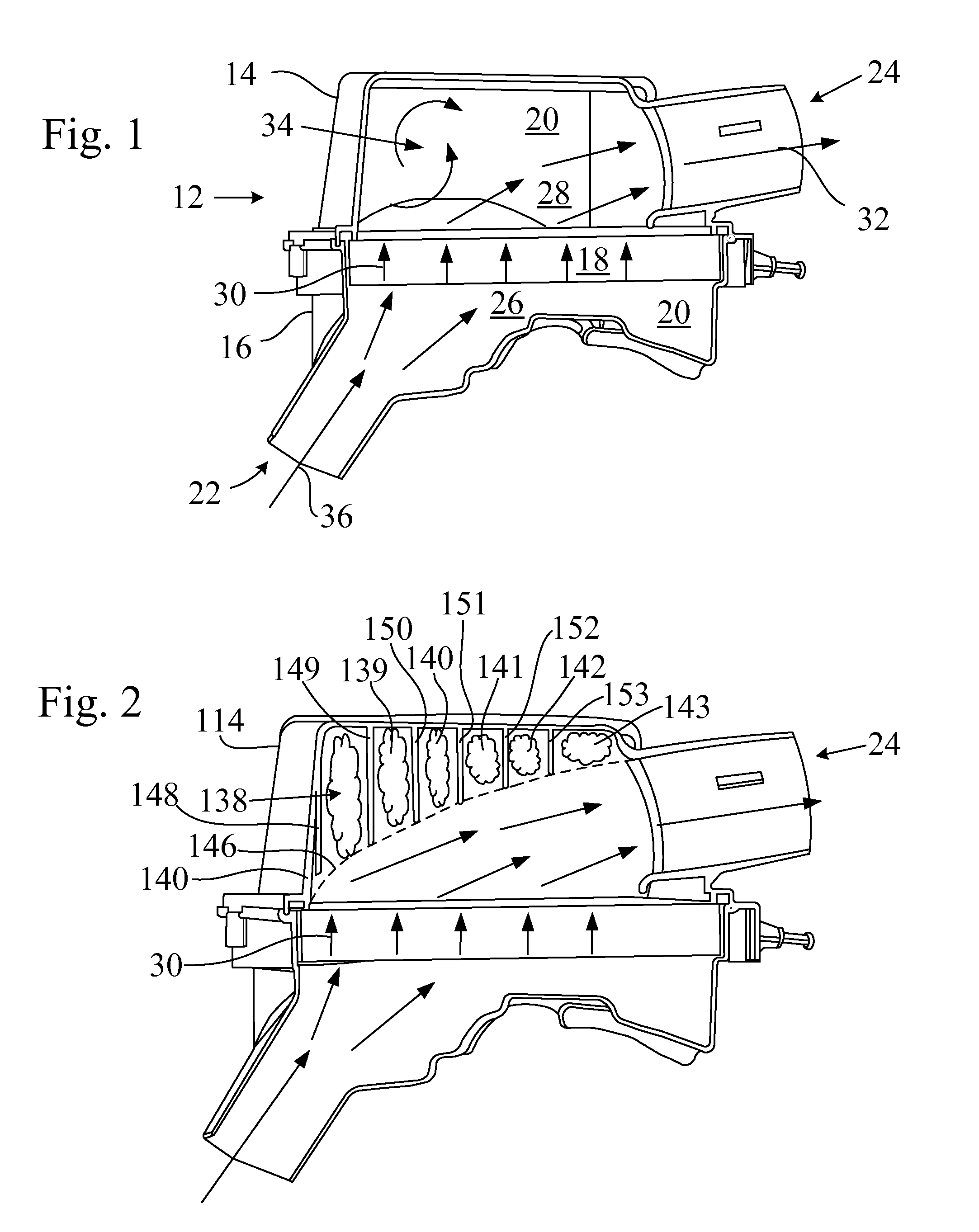

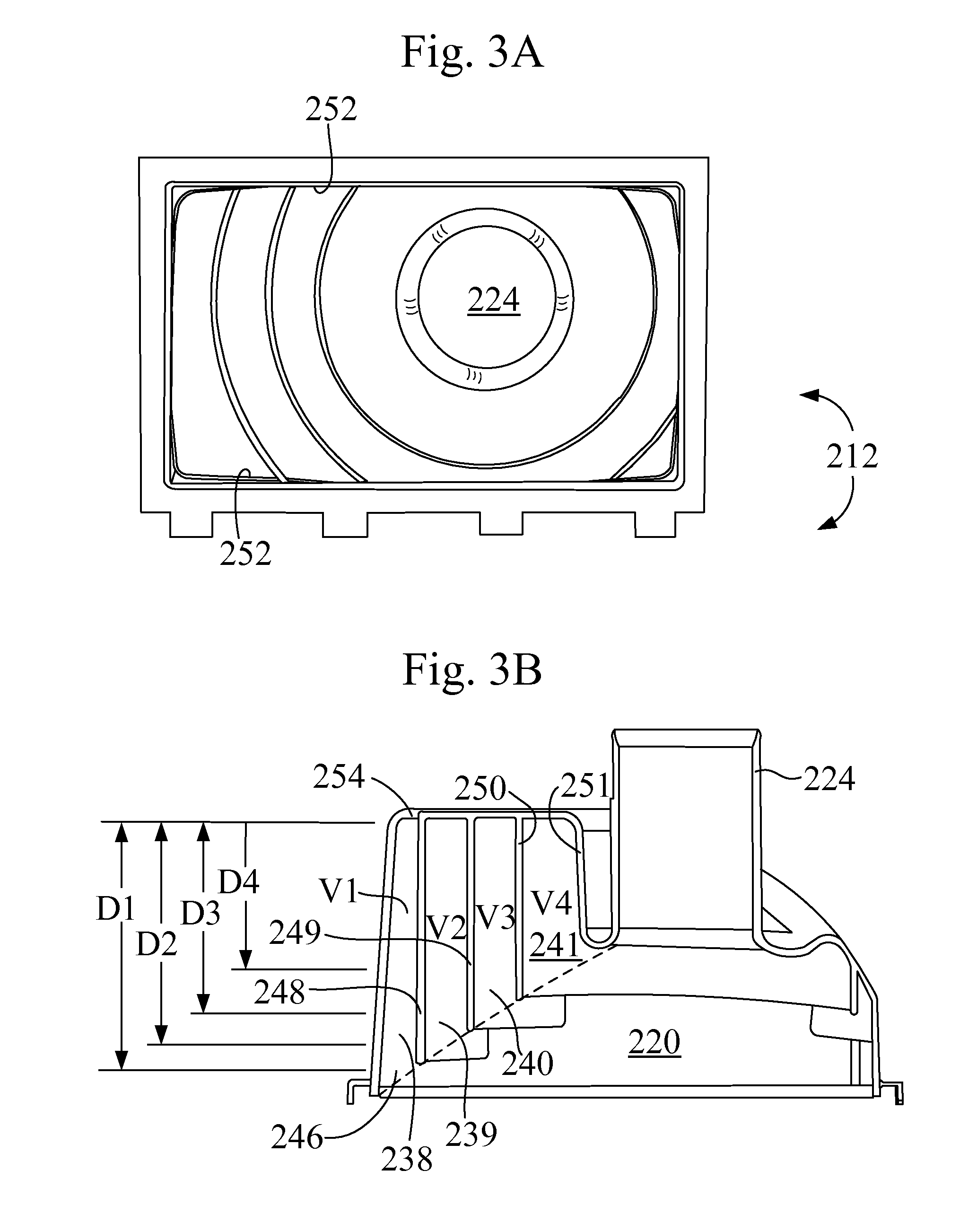

Air pillow flow guidance and acoustic countermeasure system for an air intake tract

InactiveUS20110139110A1Reduce flow restrictionReduce pressure dropCombination devicesGas treatmentAirflowEngineering

An air pillow system for an air intake tract includes a plurality of inwardly extending ribs arranged in a distally spaced arrangement and defining a plurality of peripherally closed air pillow pockets. Each pocket has an open end opening towards an airflow stream to be guided. Each rib is configured with an inwardly extending length selected to correlate with a boundary of a low-loss airflow glide path. The air pillows operate to guide the airflow stream along the low-loss airflow glide path with reduced airflow stream turbulence and airflow pressure loss.

Owner:MANN HUMMEL GMBH

Device for high-heeled shoes and method of constructing a high-heeled shoe

Provided is a device for insertion into a high heel shoe, having a rear region positioned to underlying a wearer's calcaneal tuberosity, the rear region being shaped to accommodate a planer surface of the wearer's calcaneal tuberosity, an upper surface of said rear region having a raised portion underlying an area of the wearer's calcaneus immediately forward of the wearer's calcaneus tuberosity; and a forward region positioned to underlie at least a portion of the shafts of the wearer's metatarsals, the second upper surface of said forward region having a raised portion which gradually rises to an apex position to underlie the shafts of the wearer's second and third metatarsals.

Owner:HBN SHOE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com