Patents

Literature

123results about How to "Play a role in separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spatial-spectral integrated hyperspectral remote sensing image classification method

InactiveCN103473557AContour smoothingPlay a role in separationCharacter and pattern recognitionSpectral domainSpectral space

The invention discloses a spatial-spectral integrated hyperspectral remote sensing image classification method. A conventional hyperspectral image classification technology mainly focuses on how to use the classification information of spectral spaces better, but ignores the information of image spatial domains. According to the invention, in the process of carrying out self spectral feature classification by using data, spectral classification results are supplemented by using effective spatial domain information combining a region growing method with a binary morphology method. According to the invention, an SVM (support vector machine) based classification method is adopted for carrying out spectral domain classification on data firstly; then, effective spatial domain information is introduced by using the region growing method and the binary morphology method so as to correct spectral classification results. According to the invention, information contained in hyperspectral data is used more fully, and the precision of hyperspectral image classification is improved.

Owner:HANGZHOU DIANZI UNIV

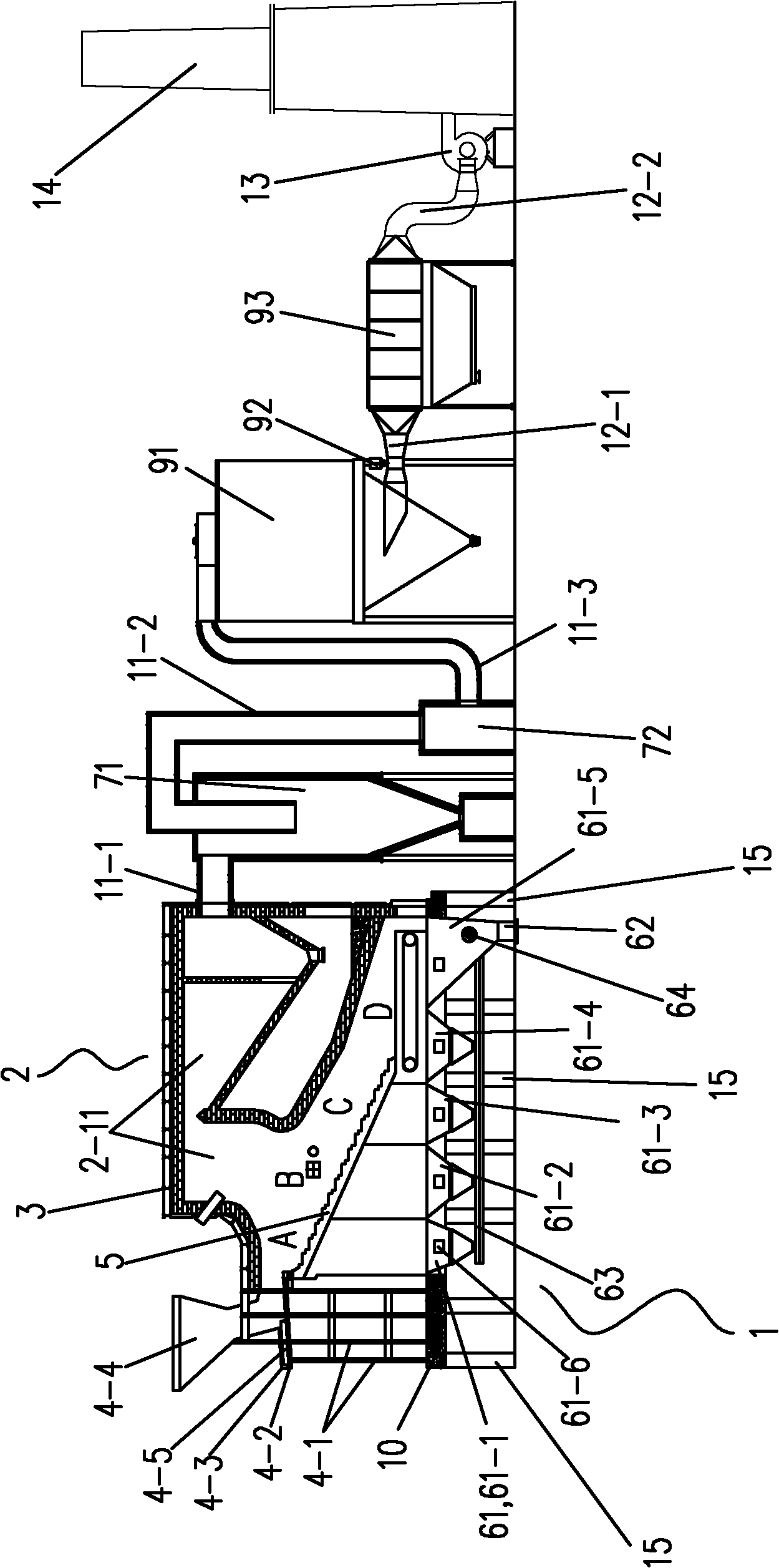

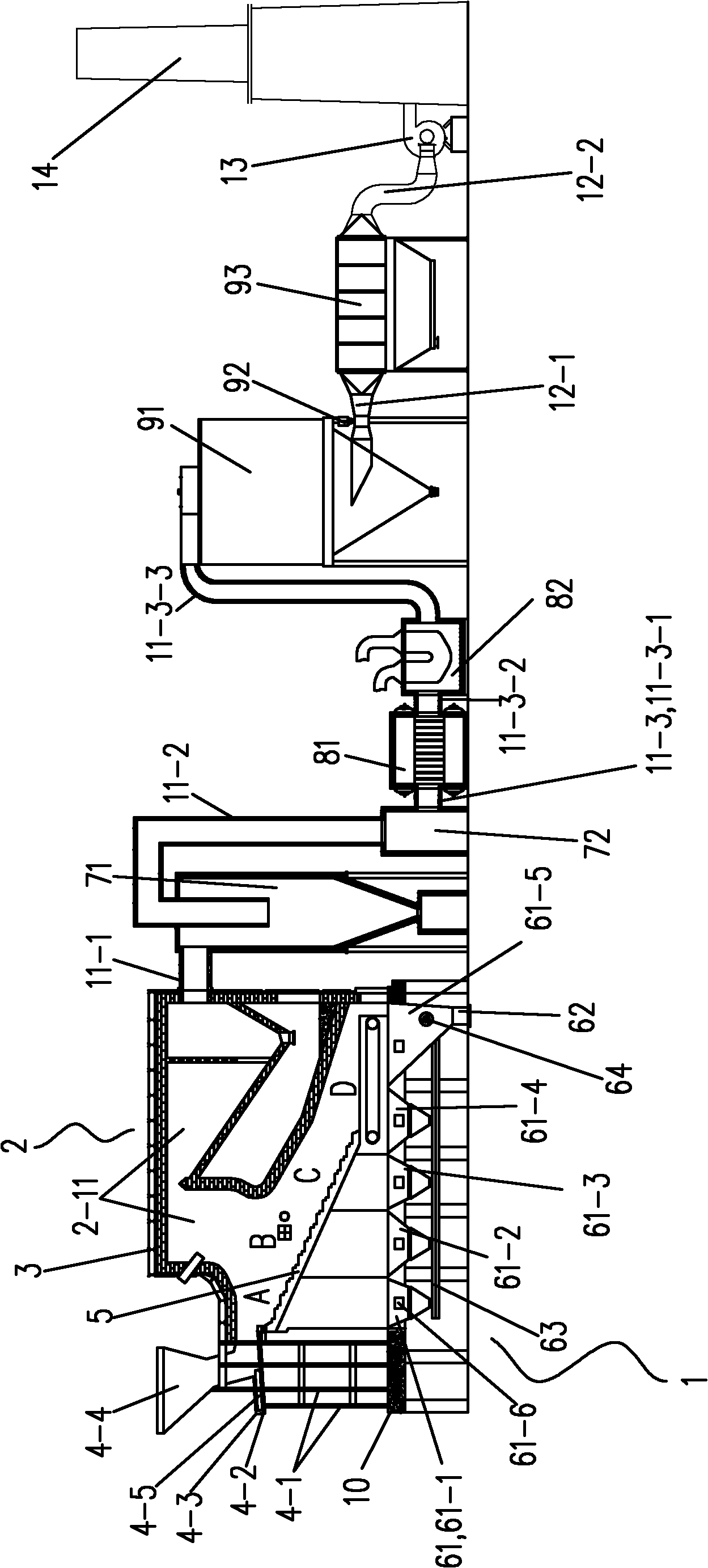

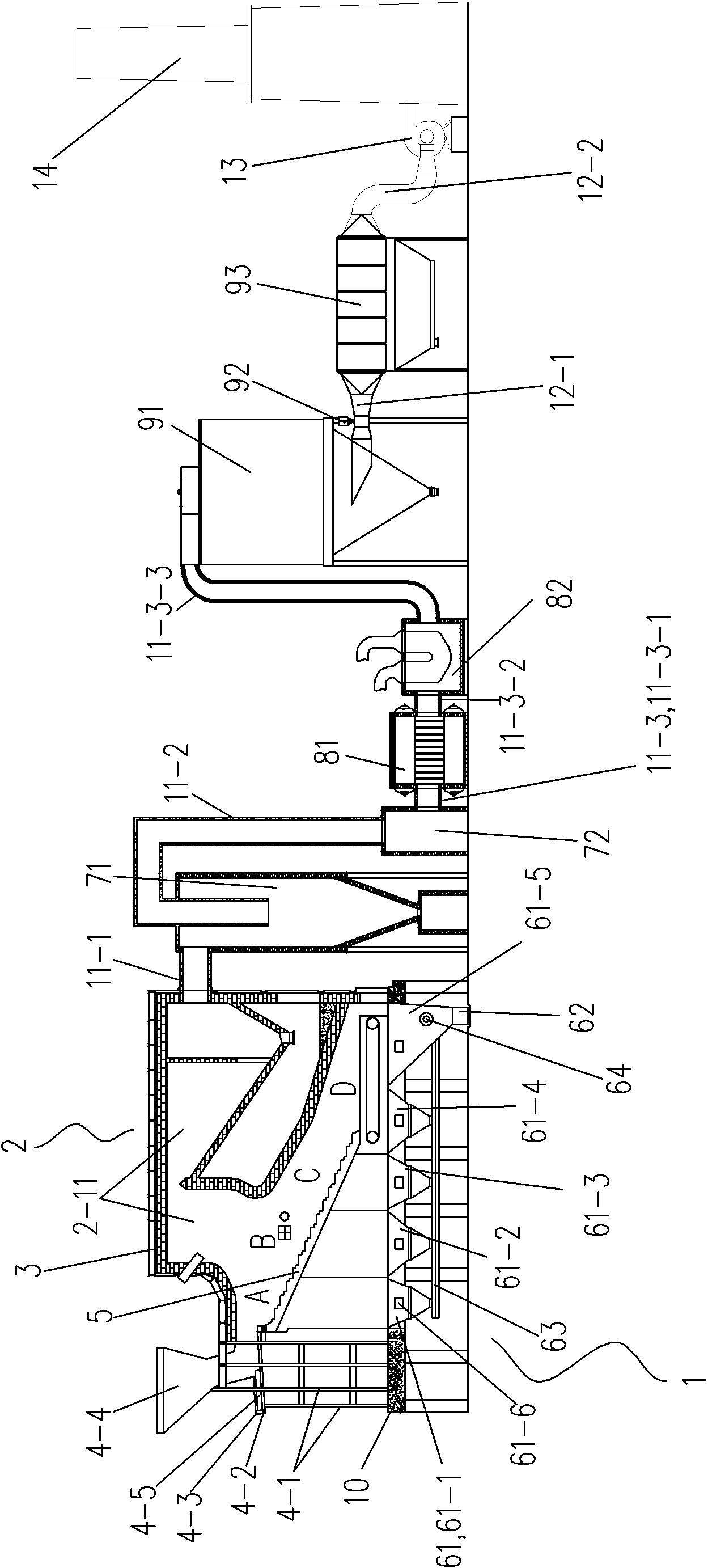

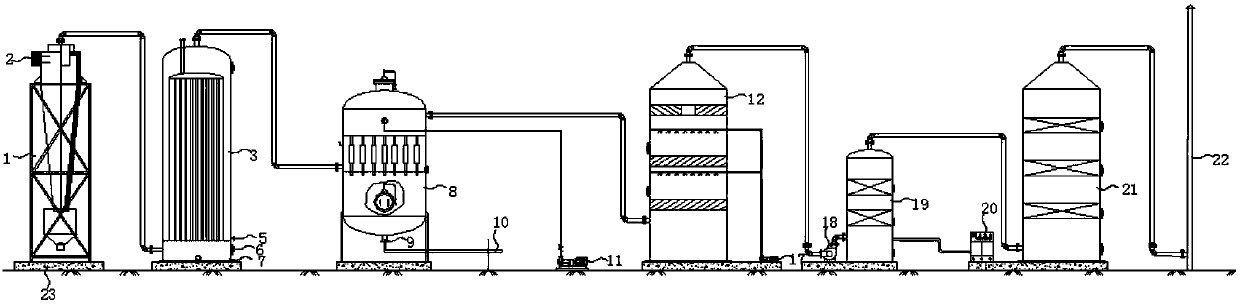

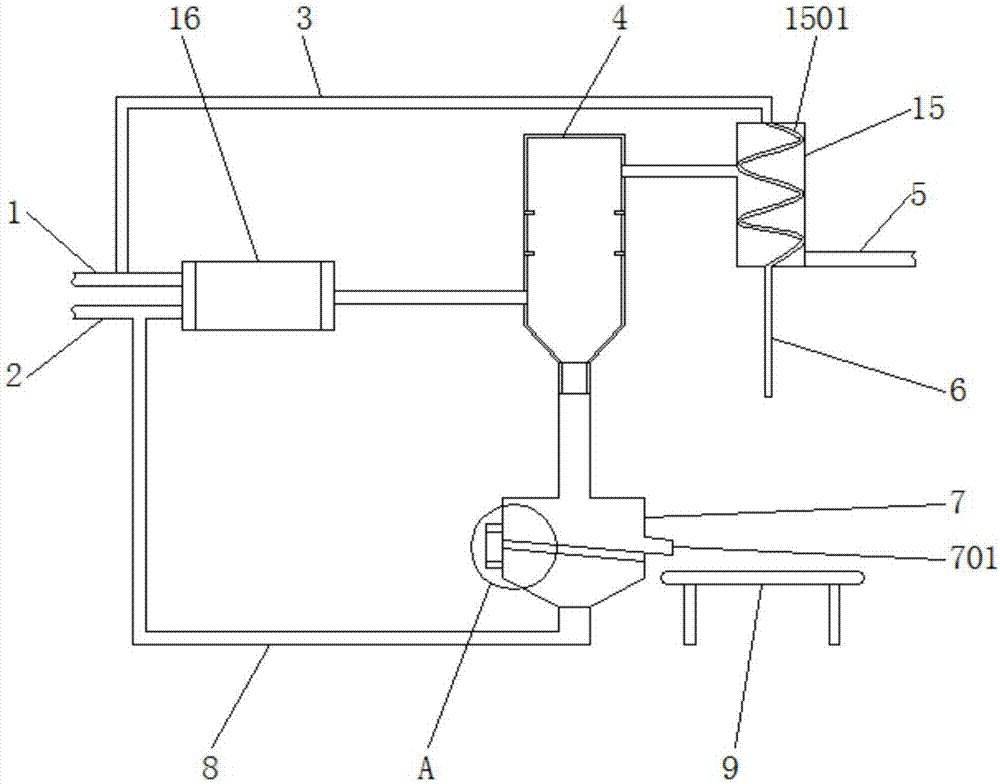

Household garbage incineration and flue gas processing system and method for processing household garbage

InactiveCN102042597ALow costPlay a role in separationCombination devicesIncinerator apparatusCycloneCombustion chamber

The invention discloses a household garbage incineration and flue gas processing system and a method for processing household garbage. The system comprises a household garbage incinerator, a draught fan, a chimney, a high-temperature flue and a low-temperature flue. The key point is that the system also comprises an ultrahigh-temperature cyclone dust collector, a flue gas settling chamber, an intermediate-temperature semidry neutralizing reaction tower, an activated carbon ejector and a bag-type dust collector. The main combustion chamber and secondary combustion chamber of the household garbage incinerator allow dioxin and other noxious substances to be decomposed completely at the high temperature; the ultrahigh-temperature cyclone dust collector and the flue gas settling chamber can remove fly ash, dust, heavy metals, and precursors, carriers and catalysts, which are likely to form dioxin, such as C and Cu; the intermediate-temperature semidry neutralizing reaction tower can remove precursors such as chloride ions, which are likely to form dioxin; and harmful substances such as dioxin are removed by utilizing the activated carbon ejector and the bag-type dust collector, so that the discharge of the dioxin harmful substances is less than 0.1 ng / m<3> finally.

Owner:江苏金陵环保科技有限公司

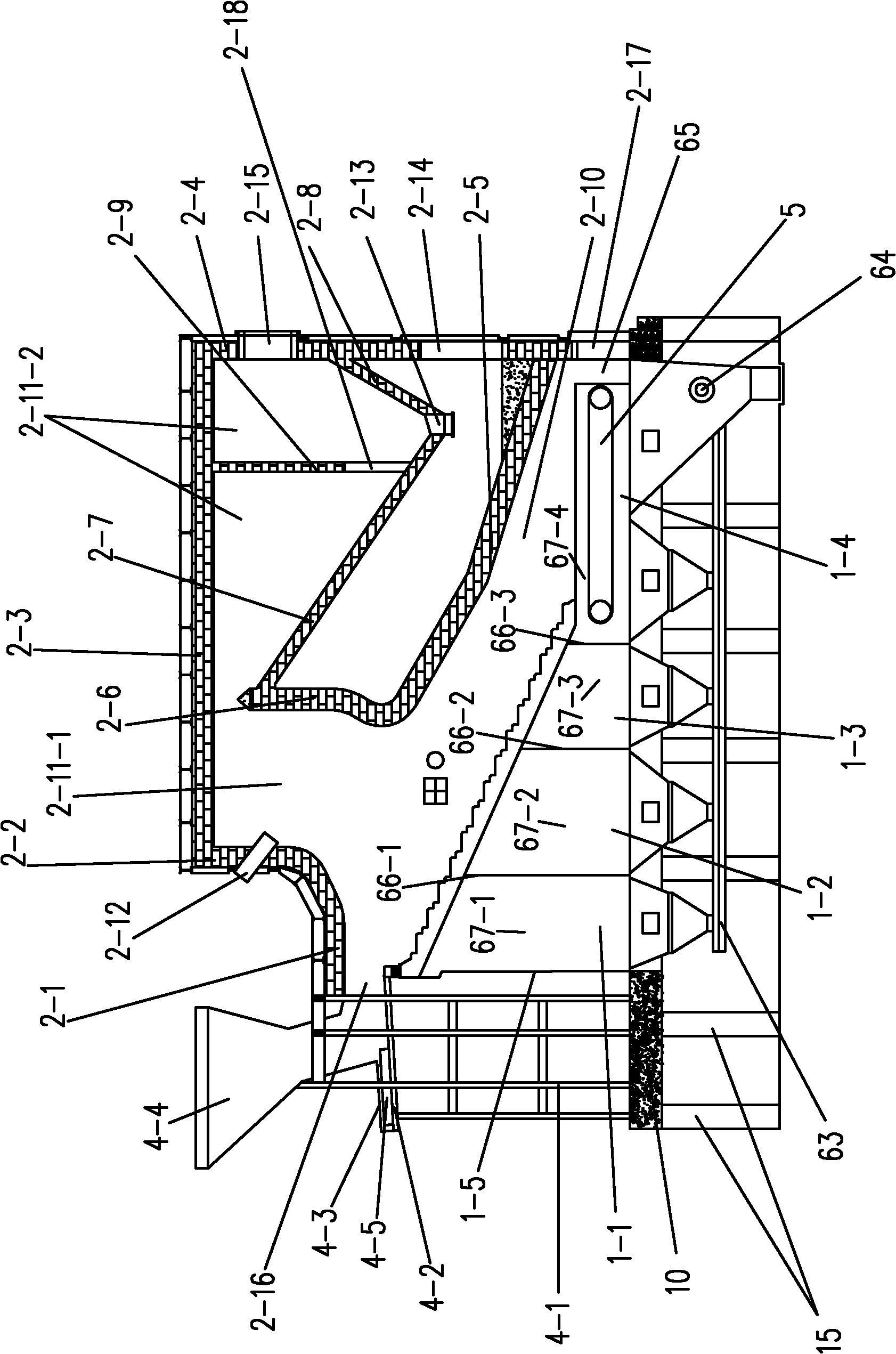

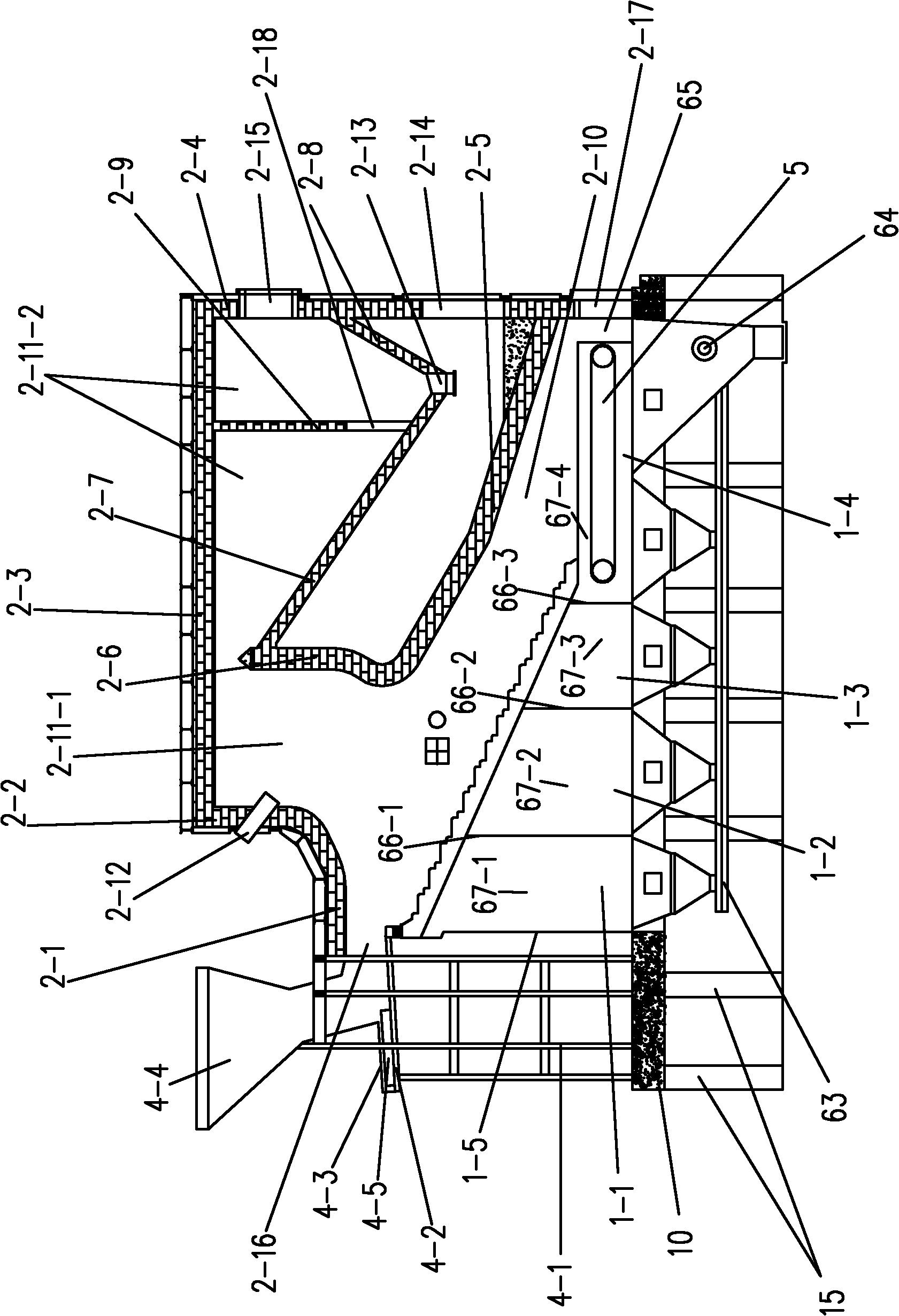

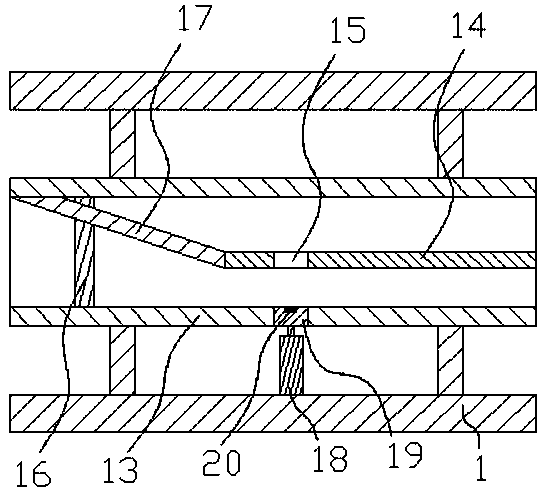

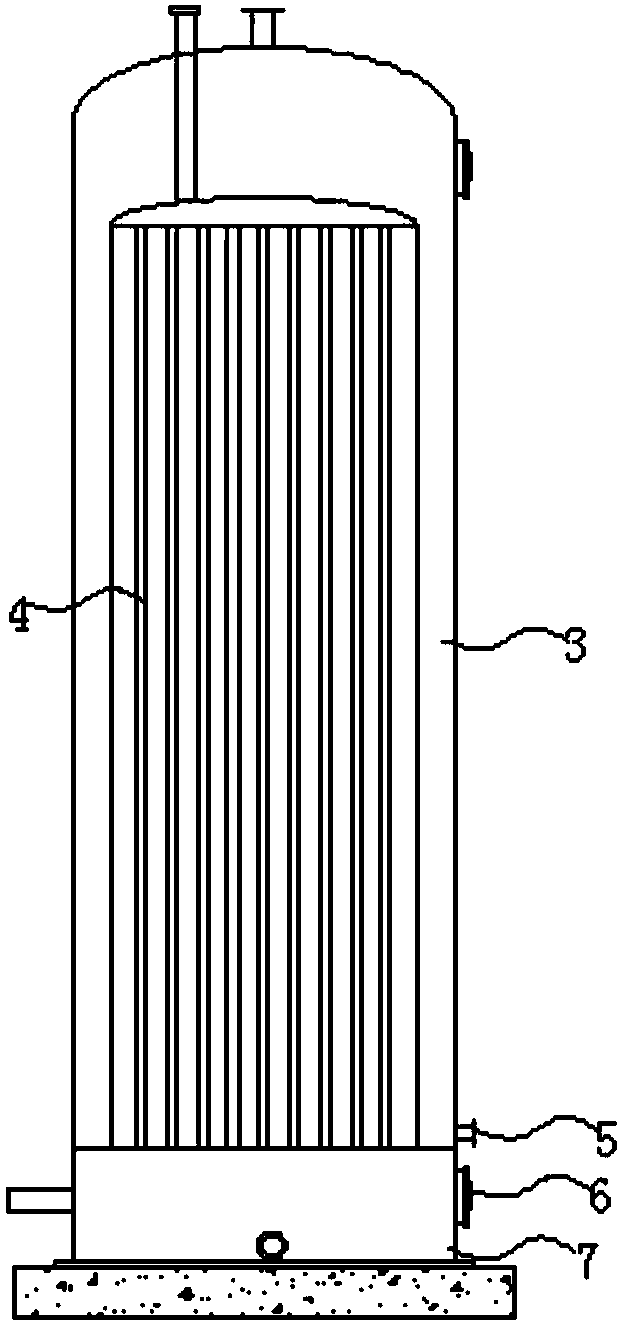

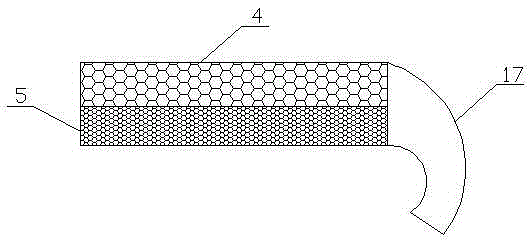

Domestic garbage incinerator and method for treating domestic garbage

InactiveCN102003714AExtension of timeAchieve emissionsIncinerator apparatusBottom ashCombustion chamber

The invention discloses a domestic garbage incinerator. The incinerator is characterized by comprising a foundation base, a furnace base, a hearth body, a furnace frame, a feeding device, a combined fire grate mechanism, a furnace bottom ash outlet hopper, a slag outlet hopper, an ash outlet mechanism, a slag breaking mechanism, a slag fall channel, air cabin plates and a cold and hot air device, wherein the furnace base comprises a front base, a back base and a left end sealing plate; each air cabin plate is arranged between the front seat and the back seat of the furnace base; a corresponding air cabin is formed between the front and back seats of the furnace base and a corresponding air cabin plate and a corresponding sealing plate; a space between each wall body of the hearth body and the combined fire grate mechanism forms a corresponding main combustion chamber and a secondary combustion chamber; hot air entering the air cabin through the cold and hot air device passes through the combined fire grate mechanism and enters the main combustion chamber so as to play a role in drying the domestic garbage and assisting combustion; the middle part of the left side wall of the hearth body is provided with a secondary air inlet; and air entering the secondary combustion chamber from the secondary air inlet can play a role in producing vortex flow and assisting combustion, so that complete decomposition of dioxin and other harmful substances at a high temperature is promoted and CO, C<+> and the like are burnt out completely at a high temperature.

Owner:江苏金陵环保科技有限公司

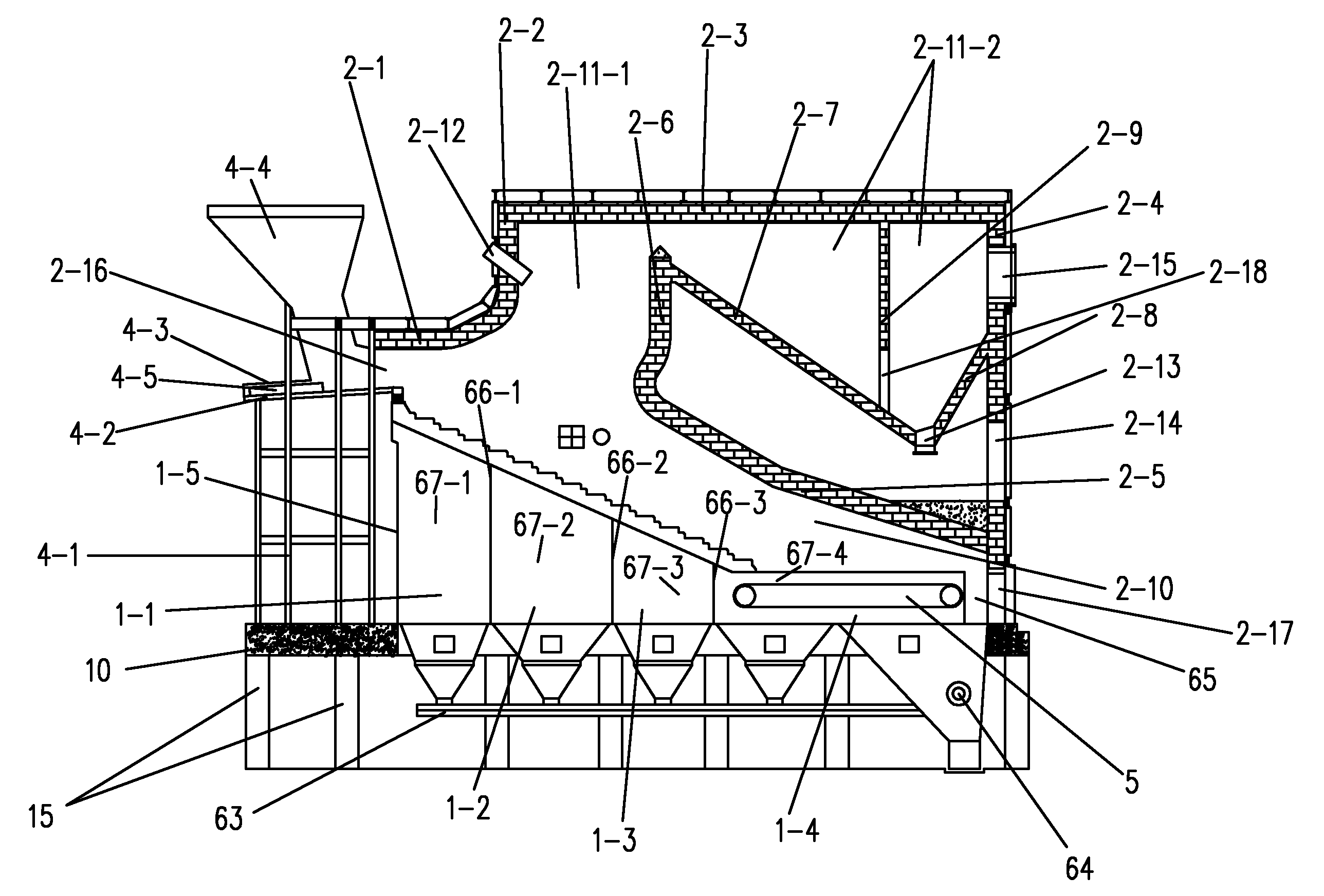

Preparing method for oil-contamination adsorbing material

InactiveCN108636384AEasy to fillFacilitated DiffusionOther chemical processesAlkali metal oxides/hydroxidesGas phaseGlucose effect

The invention discloses a preparing method for an oil-contamination adsorbing material, and belongs to the technical field of oil contamination governance. In the preparing method, ferroferric oxide is modified through N-beta(aminoethyl)-gamma-aminopropyl-trimethoxysilane, graphene oxide is subjected to the effect of glucose for preparing and reducing graphene foam, and the graphene oxide is frozen and dried to be subjected to hydrazine hydrate steam reduction to obtain vapor-phase-reduction graphene foam; flexible polyurethane foam serves as a base material, sodium alginate and polyethyleneimine solutions are added and applied to the surface of the flexible polyurethane foam, and are mixed into soaking liquid and quickly soaked into polyurethane foam, and the water-phase environment is shown in a three-dimensional open hole inside the polyurethane foam; due to the gravity effect and the capillary effect, water penetrates a foam base body, crude oil is separated on an oil-water-separator foam sample through the lipophobic property shown by the polyurethane foam after water is wet, the oil-water separation effect is achieved, and the good oil-water selectivity is achieved; the problems that an existing oil-contamination adsorbing material is small in adsorbing capacity and poor in oil-water selectivity are solved.

Owner:高阳

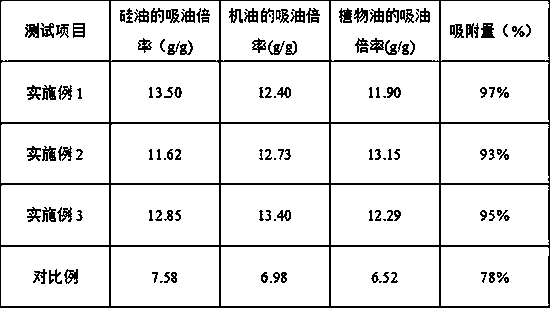

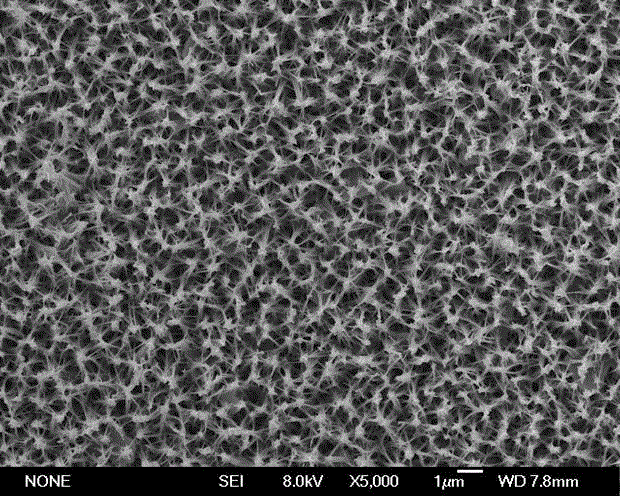

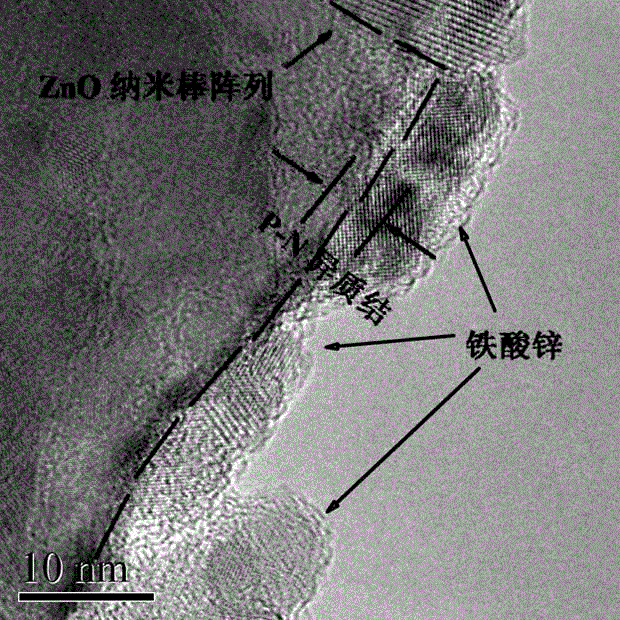

Composite photo anode and preparation method thereof

The invention relates to a novel composite photo anode used for producing hydrogen and oxygen by splitting water with sunlight, and belongs to the technical field of preparation of electrode materials. The composite photo anode comprises a substrate, a ZnO nano rod array and ZnFe2O4 nano fibers. The substrate is fluoro-doped tin dioxide conductive glass (FTO glass), wherein the ZnO nano rod array is vertically dispersed on the surface of the substrate. The ZnFe2O4 nano fibers are amorphously deposited on the surface of ZnO nano rods, thereby forming a three-dimensional network structure with the ZnO nano rod array. The photo anode can effectively absorb visible light which is repeatedly diffracted in the three-dimensional network structure formed on the surface of the electrode. Meanwhile, a p-n junction electric field formed in the interface of the composite material has separation effect on photo-induced electron-cavity, so that photoelectric conversion performance in sunlight splitting water can be optimized as more as possible.

Owner:JINAN LEINUO NEW ENERGY TECH CO LTD

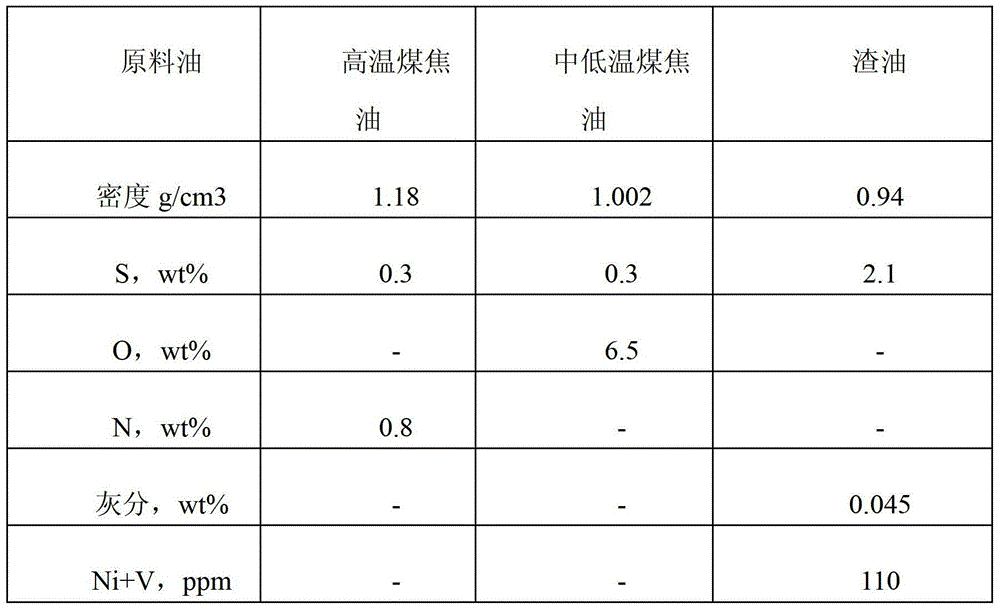

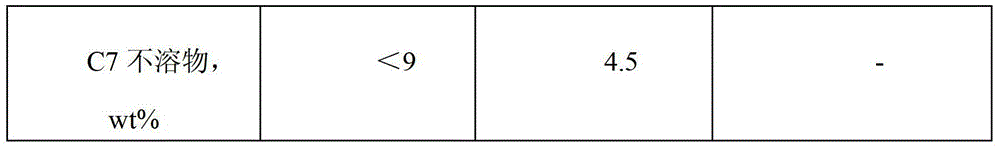

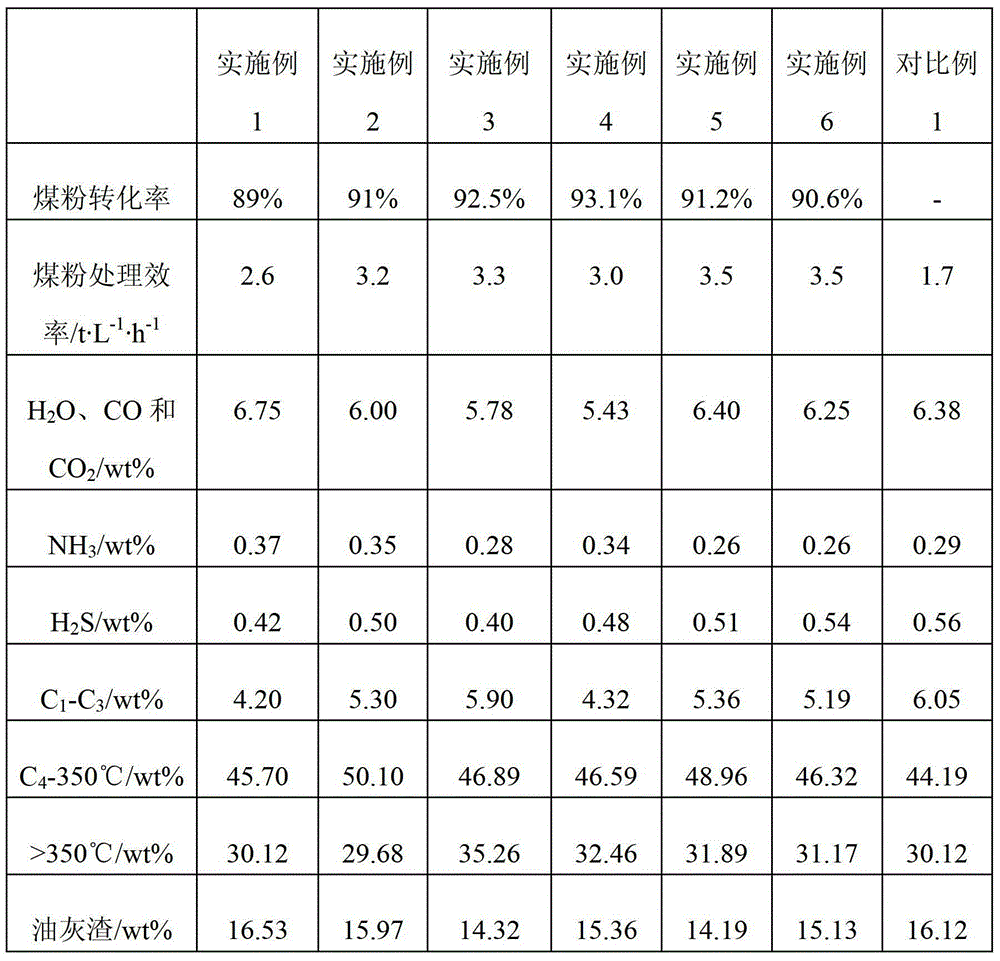

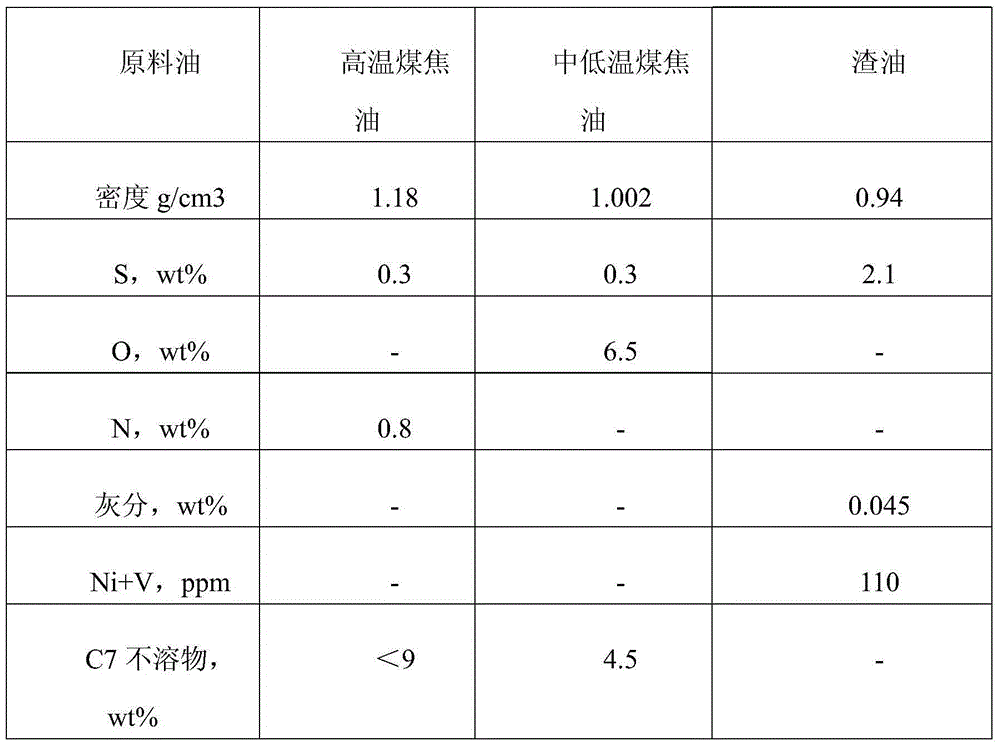

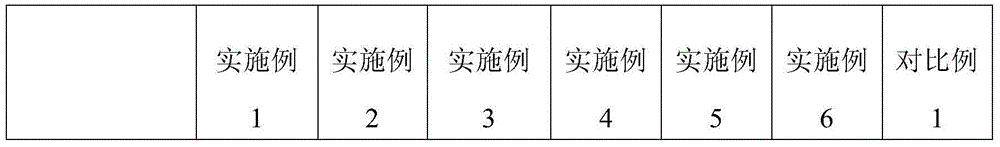

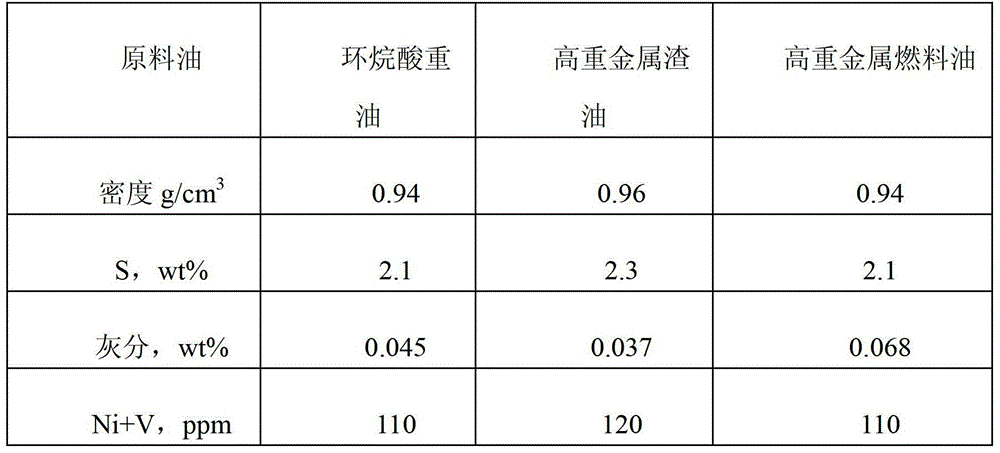

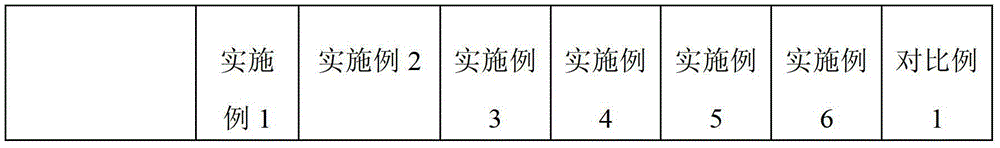

Direct liquefaction process of coal mixed with high temperature coal tar

ActiveCN104419437AImprove qualityIncrease cetane numberLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesGas phaseReaction temperature

The invention discloses a direct liquefaction process of coal mixed with high temperature coal tar. The process comprises the following steps: carrying out purification treatment on the high temperature coal tar, carrying out vacuum distillation or atmospheric distillation on the high temperature coal tar subjected to purification treatment, and cutting the factions into light oil fractions at a temperature lower than 350 DEG C and heavy oil fractions at a temperature higher than 350 DEG C; subjecting a coal oil mixture obtained by mixing pulverized coal with the heavy oil fractions at a temperature higher than 350 DEG C, hydrogen and a catalyst to reaction in a primary reactor at a reaction temperature of 420-460 DEG C, sending a primary reaction product to the upper part of a secondary reactor, enabling a gas phase component in the primary reaction product to flow out from the top of the secondary reactor, enabling solid and liquid components in the primary reaction product to flow down in the secondary reactor to carry out countercurrent contact reaction with hydrogen flowing up at a reaction temperature of 430-480 DEG C, and carrying out fractional distillation after the reaction ends. The process has the effects of obviously improving the production efficiency of direct coal liquefaction and improving the quality of naphtha and diesel products, and is suitable for the large-scale direct coal liquefaction industry.

Owner:任相坤

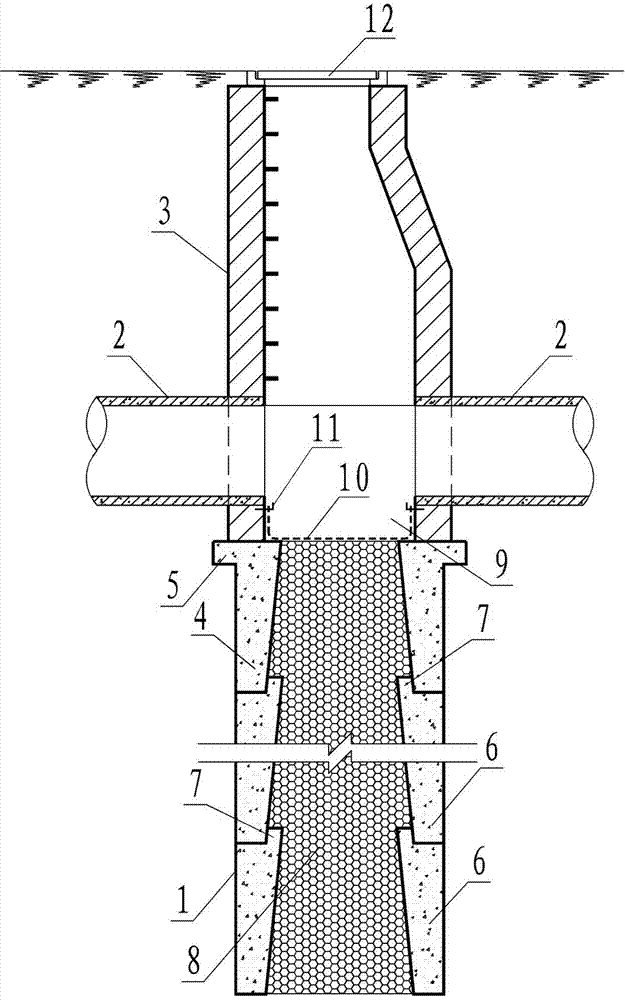

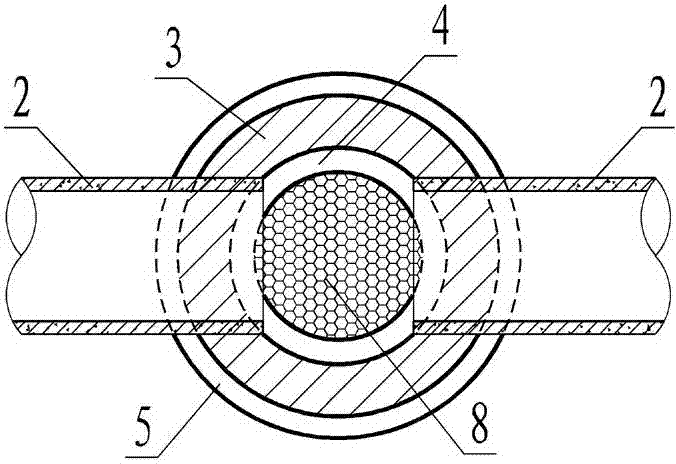

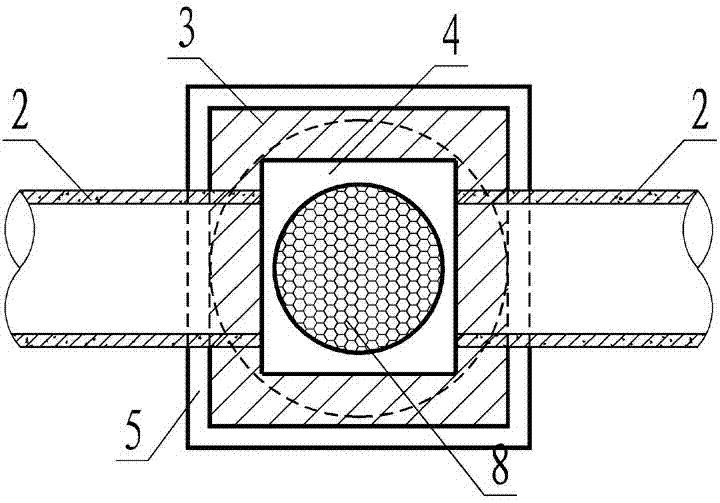

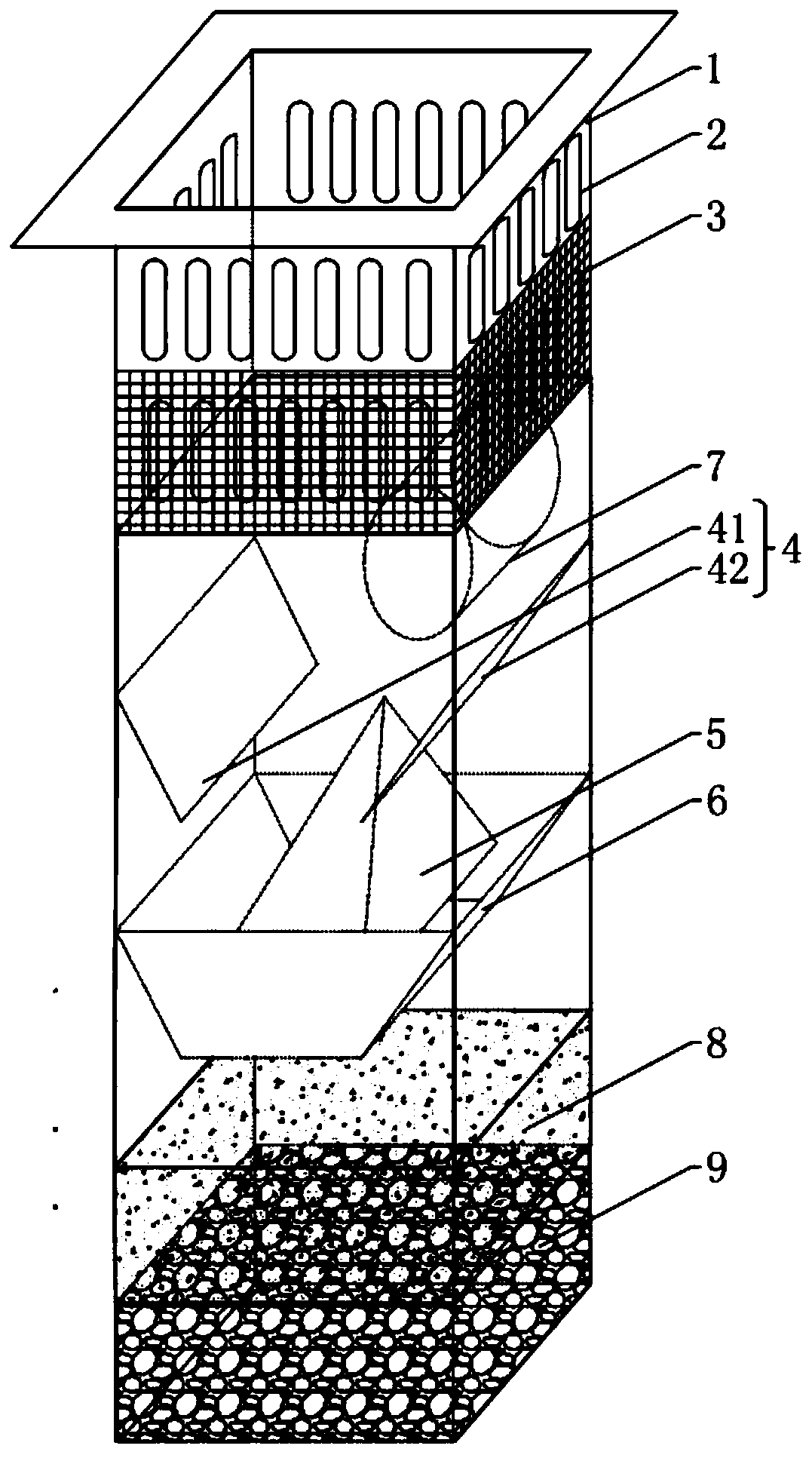

Combined rainwater seepage well and construction method

ActiveCN104499560AReduce trafficPlay the role of staggered peak regulation and storageSewerage structuresPipeflowFilter material

The invention discloses a combined rainwater seepage well and a construction method, belongs to the field of drainage projects, and particularly relates to a structure for discarding initial rainwater, adjusting the rainwater and supplying underground water by seeped rainwater. The combined rainwater seepage well mainly comprises a shaft, a pipe and a well body, wherein the shaft is positioned on the lower portion of the well body; and the pipe is connected with the well body. Seepage wells are arranged on a rainwater pipe at intervals of 1-3 inspection wells, rainwater is collected through the pipe during raining and seeps into the ground through the seepage well, the flow of the rainwater is reduced at the source, an effect of shifting peaks and adjusting storage is achieved, and waterlogging caused by accumulated water on the ground is reduced. The shaft is filled with filter materials, a slime pit is arranged on the bottom of the well body, a filter screen is arranged on the bottom of the slime pit, and the rainwater is filtered by the filter materials, seeps into the ground and supplements the underground water. The seepage well is constructed in a combined mode, the well body on the upper portion of the seepage well is constructed by using a down-top method, different sections of the shaft on the lower portion of the seepage well are constructed one by one by using a top-down method, and the construction difficulty and the manufacturing cost are greatly reduced.

Owner:洛阳城市建设勘察设计院有限公司 +1

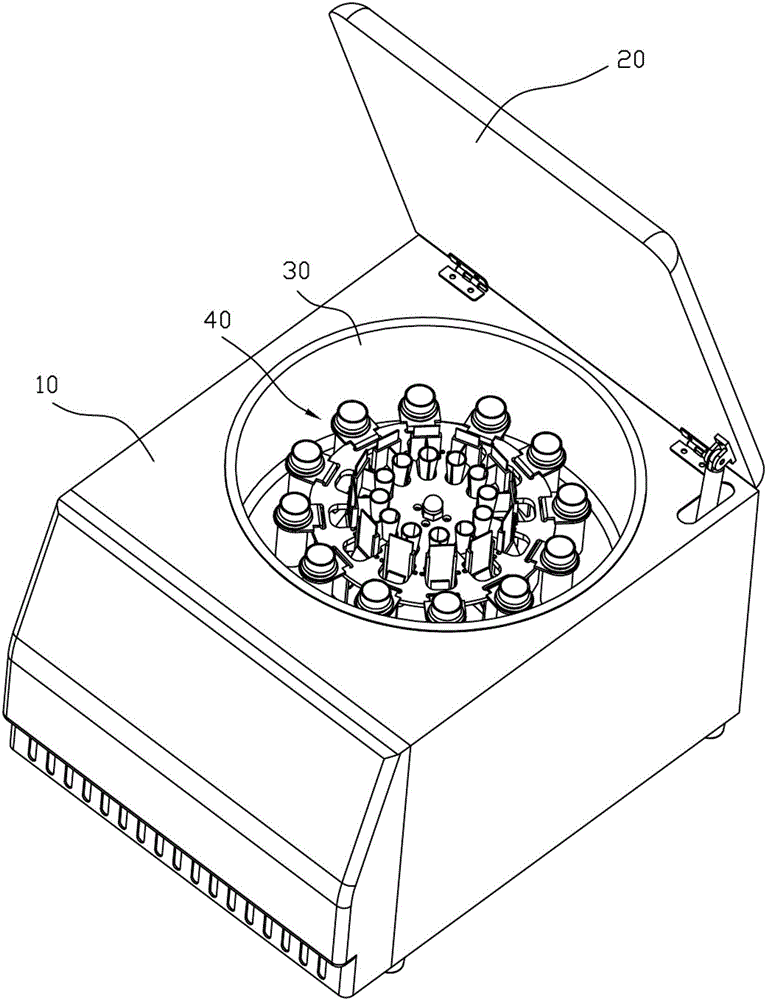

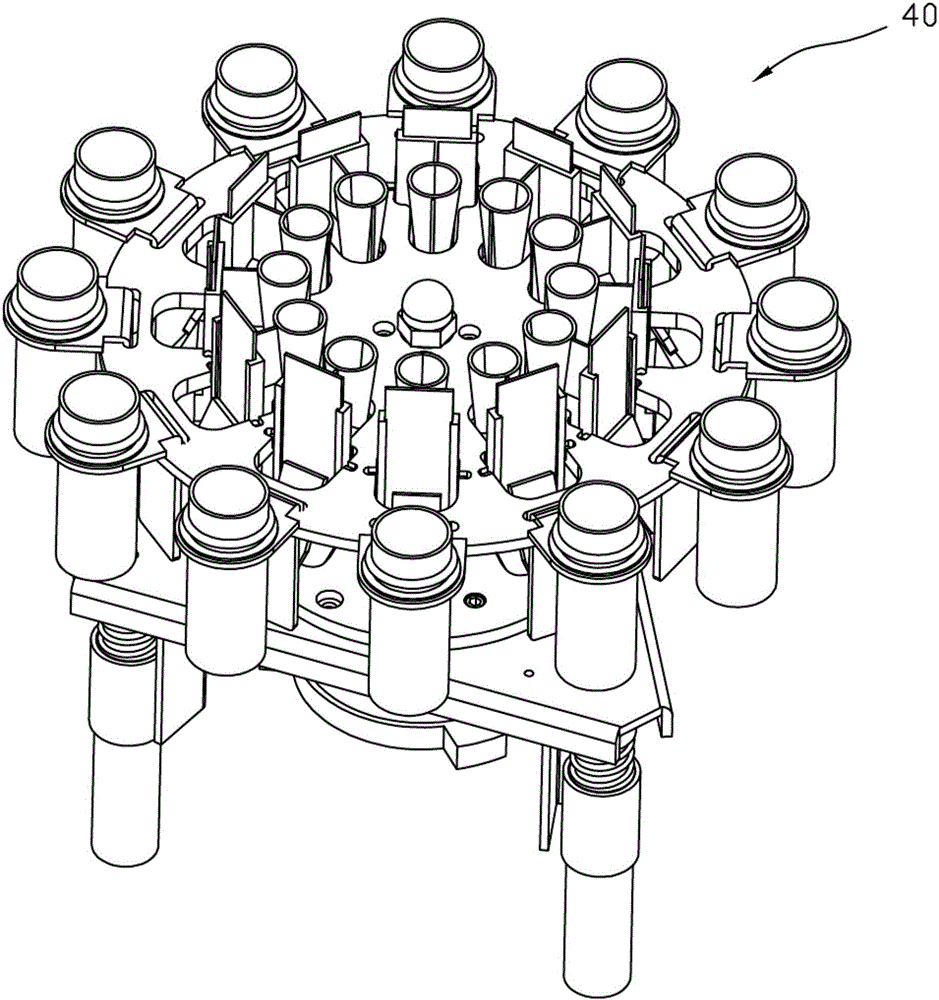

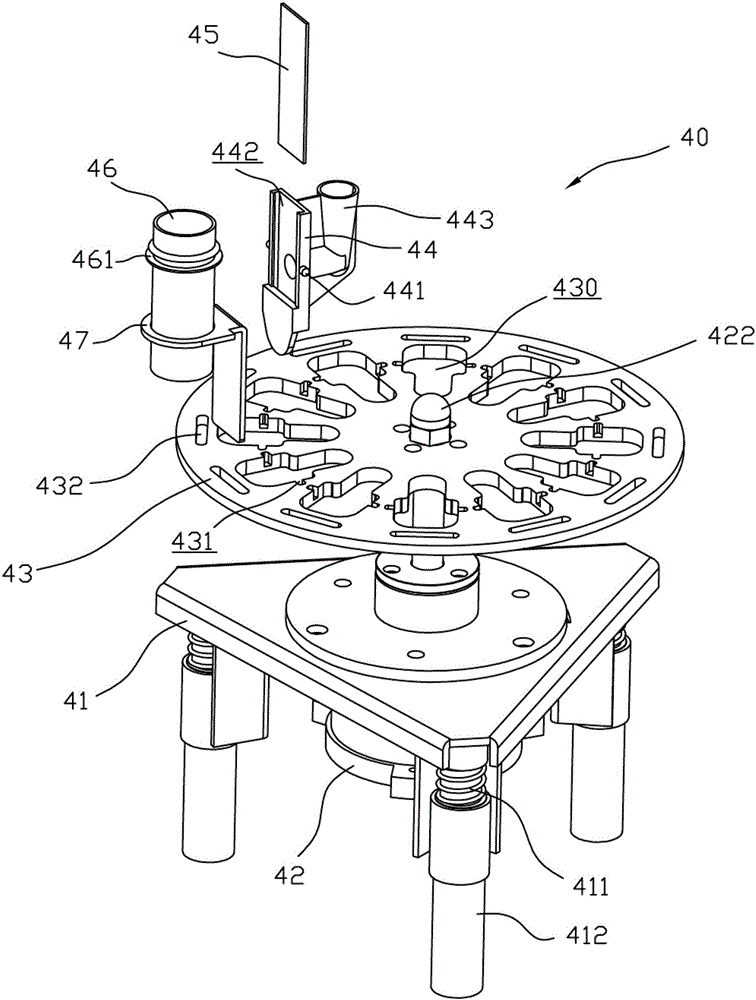

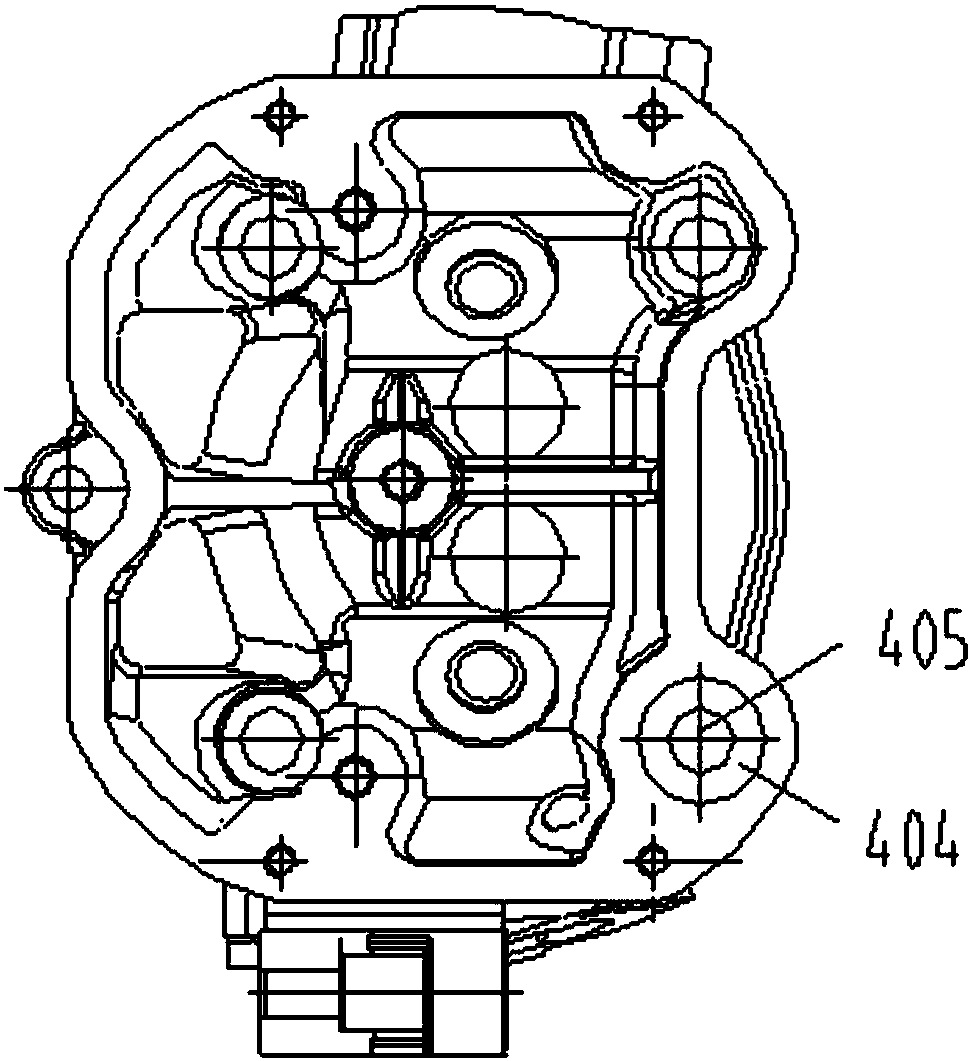

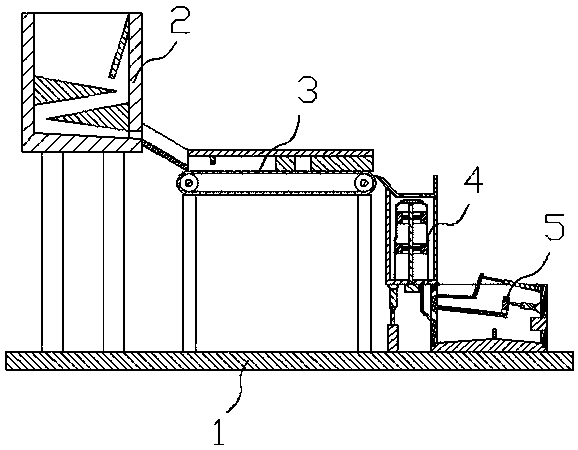

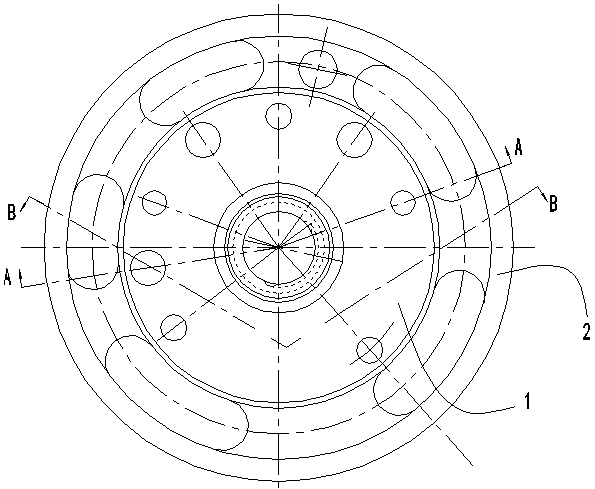

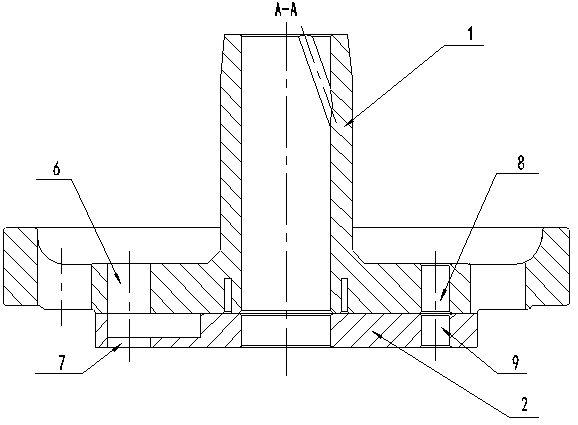

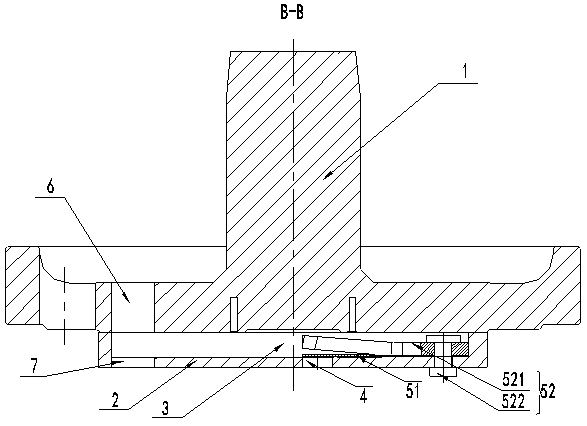

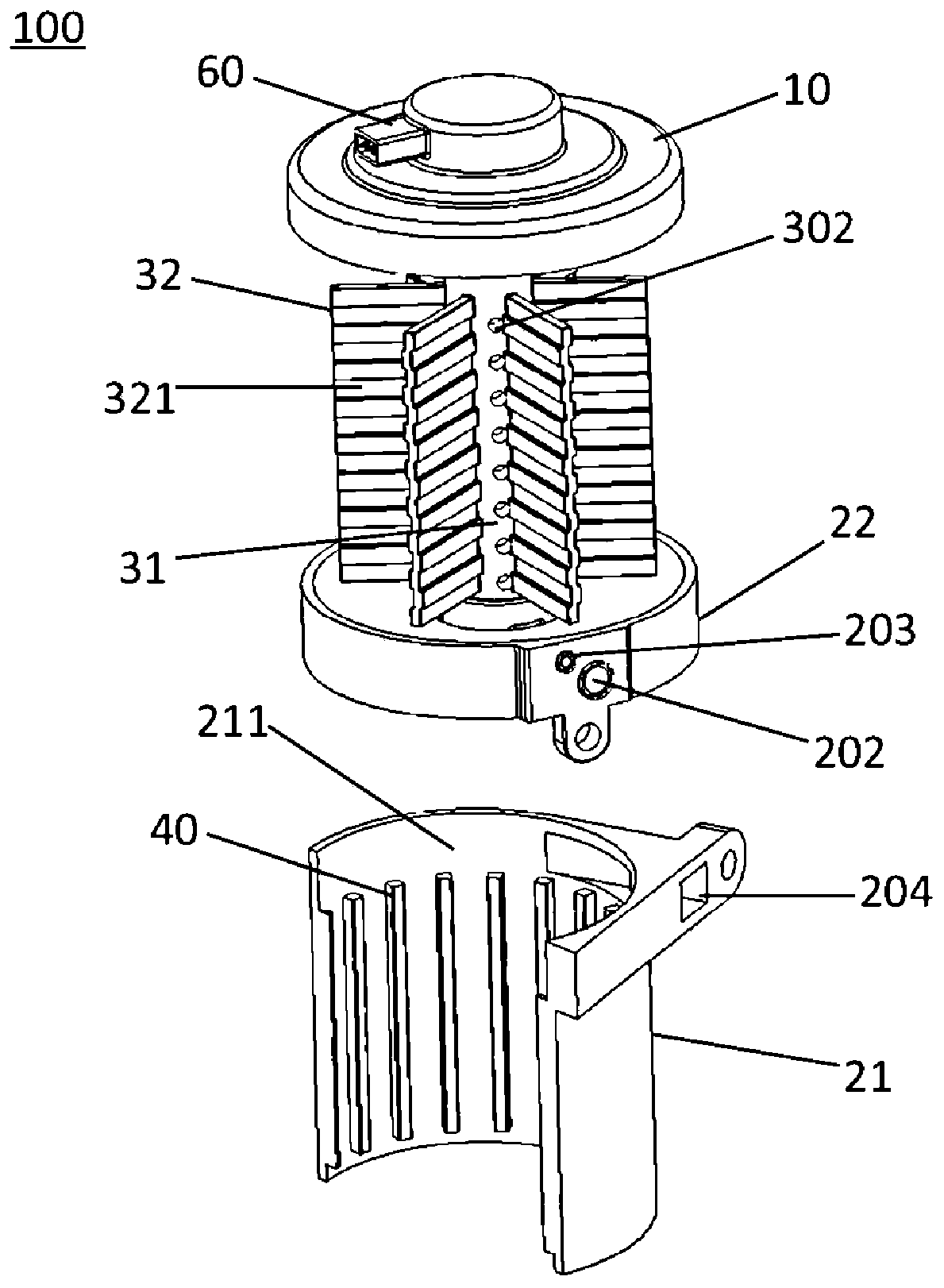

Portable medical blood centrifugal machine

ActiveCN106475235APlay a buffer rolePlay a role in separationCentrifugesDesign improvementEngineering

The invention discloses a portable medical blood centrifugal machine which comprises a base. An inner container is arranged in the base, and a centrifugal assembly is arranged in the inner container. A cover is arranged at the top of the base and hinged to the base. The centrifugal assembly comprises a triangular plate, springs are arranged under the triangular plate, the springs are fixed in spring seats, and the spring seats are fixed in the inner container. A motor is arranged under the triangular plate, a rotating shaft is arranged at the output end of the motor, a rotating plate is arranged at the top of the rotating shaft, a first cup and a second cup are arranged in the rotating plate, and the first cup and the second cup are both sealed. According to the portable medical blood centrifugal machine, an existing medical centrifugal machine is subjected to design improvement, and the triangular plate and three spring structures of the centrifugal assembly can achieve the effects of stabilization and buffering; the two blood containers can be placed in the rotating plate, and thus the number of samples detected at a time is increased; and the machine is reasonable in structure, and the weight of the machine can be effectively reduced.

Owner:江苏耀坤医疗器械有限公司

Direct liquefaction process of coal mixed with medium and low temperature coal tar

ActiveCN104419438AImprove conversion rateReduce effective reaction spaceLiquid hydrocarbon mixture productionGas phaseReaction temperature

The invention discloses a direct liquefaction process of coal mixed with medium and low temperature coal tar. The process comprises the following steps: carrying out purification treatment on the medium and low temperature coal tar, carrying out vacuum distillation or atmospheric distillation on the medium and low temperature coal tar subjected to purification treatment, and cutting the factions into heavy oil fractions and light oil fractions, wherein the temperature range of the cut point is 320-380 DEG C; subjecting a coal oil mixture obtained by mixing pulverized coal with the heavy oil fractions higher than the cut point, hydrogen and a catalyst to reaction in a primary reactor at a reaction temperature of 420-460 DEG C, sending a primary reaction product to the upper part of a secondary reactor, enabling a gas phase component in the primary reaction product to flow out from the top of the secondary reactor, enabling solid and liquid components in the primary reaction product to flow down in the secondary reactor to carry out countercurrent contact reaction with hydrogen flowing up at a reaction temperature of 430-480 DEG C, and carrying out fractional distillation after the reaction ends. The process has the effects of obviously improving the production efficiency of direct coal liquefaction, increasing the conversion rate of pulverized coal and improving the quality of naphtha and diesel products, and is suitable for the large-scale direct coal liquefaction industry.

Owner:任相坤

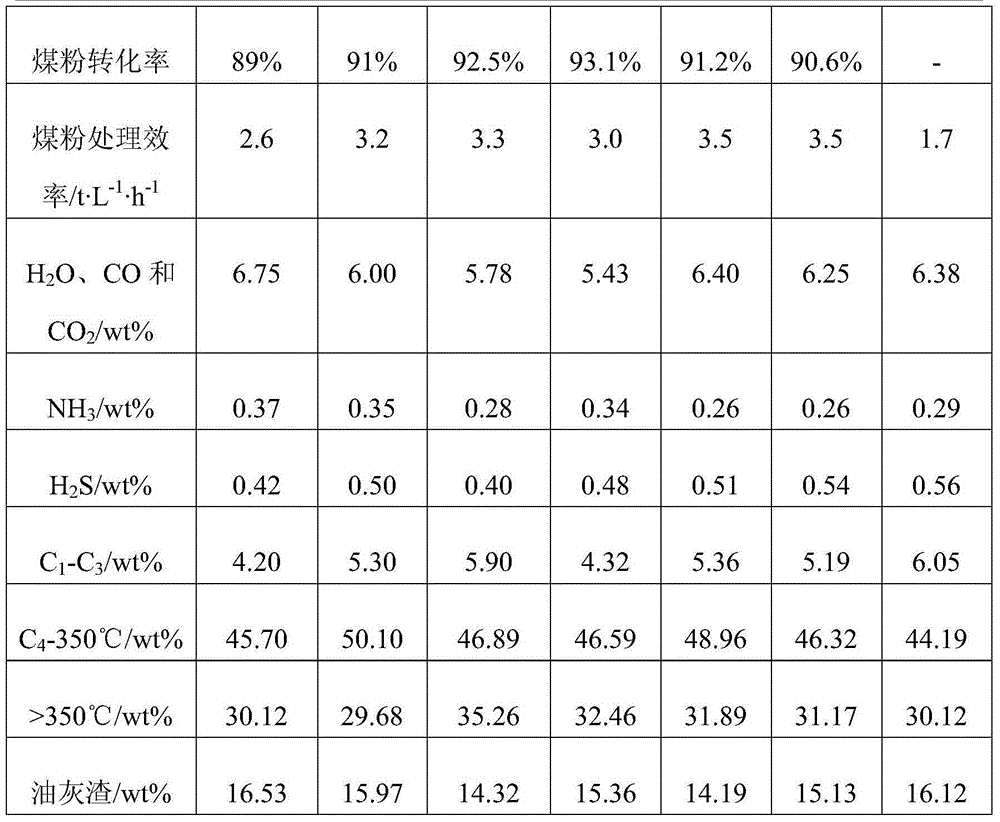

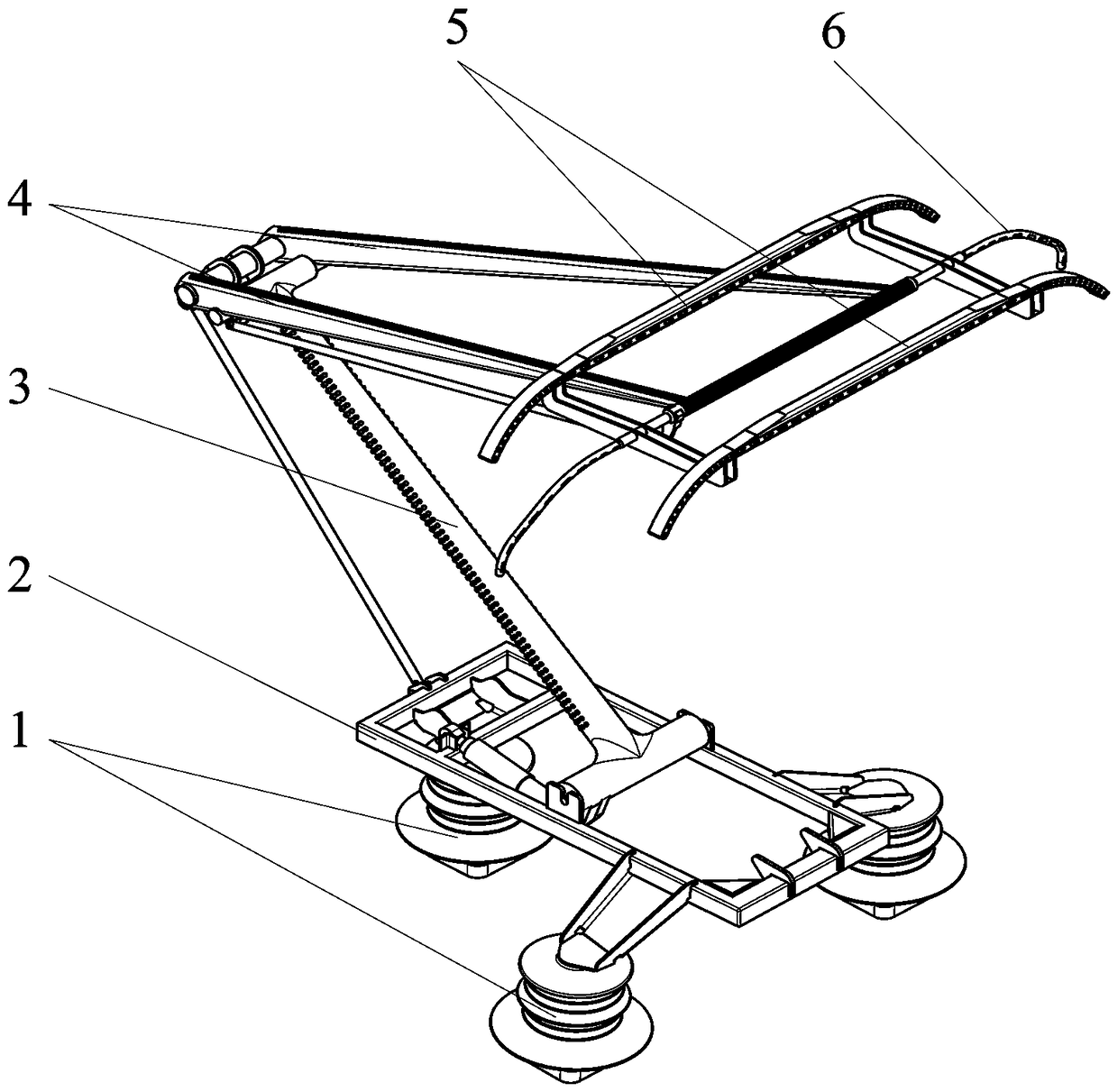

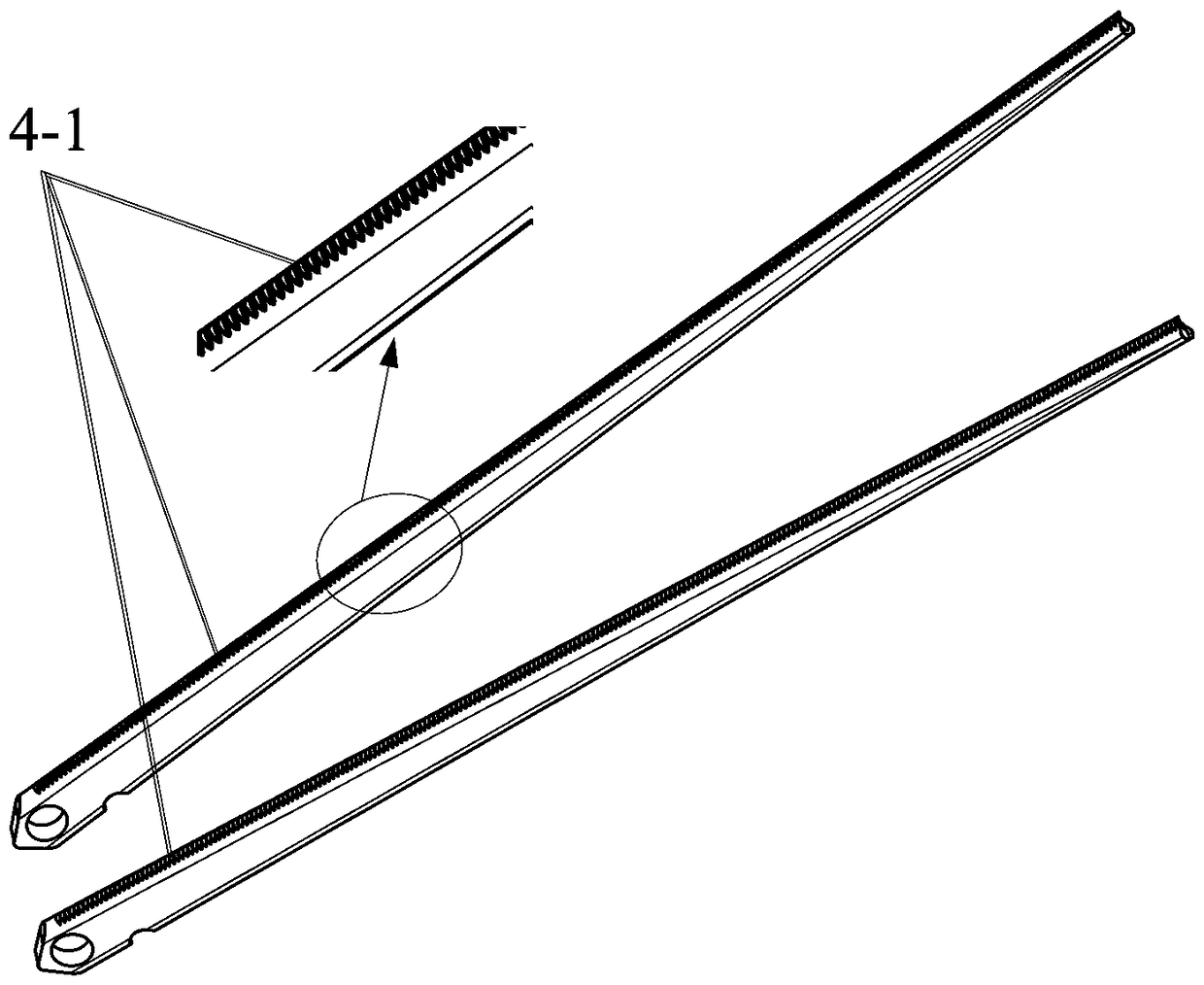

Drag and noise reducing high-speed train pantograph based on multi-factor coupling bionics

PendingCN108859771AReduce resistanceReduce aerodynamic noiseRailway vehiclesPower current collectorsCouplingEngineering

The invention discloses a drag and noise reducing high-speed train pantograph based on multi-factor coupling bionics. The drag and noise reducing high-speed train pantograph mainly consists of an insulator, an underframe, a lower arm lever, an upper arm lever, a pantograph head and a support lever, wherein spherical protuberance structures are distributed on two side surfaces around the flow of the lower arm lever; sawtooth groove structures are distributed on the surface of the windward side of the upper arm lever; columnar protuberance structures are distributed on the forward windward surface of the straight part of the pantograph; flat through hole structures are distributed between adjacent columnar protuberance structures; a circular through hole structure is arranged at the bent pantograph horn part; sawtooth stripe structures are distributed on the whole lower surface of the pantograph head; annular sawtooth structures are distributed on the middle straight lever of the supportlever, and non-uniform penetration structures are arranged on the bent lever parts on two sides. According to the drag and noise reducing high-speed train pantograph disclosed by the invention, by adopting a plurality of bionic coupling element structures, mutual coupling between the bionic units realizes the effects of rectification and control of boundary layer separation on the pantograph surface so as to remarkably reduce air resistance and aerodynamic noise.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Filter screen cleaning device for petroleum filtering processing

InactiveCN110898506AEffectively fixedAvoid shakingRefining by filtrationStationary filtering element filtersMechanical engineeringPetroleum engineering

The invention discloses a filter screen cleaning device for petroleum filtering processing. The filter screen cleaning device comprises a box body, wherein supporting columns are fixedly connected with and arranged at four corners of the lower surface of the box body; a box door is hinged on the box body; a sealing gasket is fixedly connected with and arranged on the box door; a water inlet pipe is fixedly connected with and arranged above one side of the box body, and communicates with the interior of the box body; the upper surface of the box body is fixedly connected with a water pump; thewater outlet end of the water pump is fixedly connected with a water outlet pipe which longitudinally penetrates through the box body and is fixedly connected with a spraying head; the water inlet endof the water pump is fixedly connected with the water inlet pipe; the other end of the water inlet pipe is fixedly connected with one side of the bottom end of the box body, and the interior of the water inlet pipe is communicated with the interior of the box body; a U-shaped placement seat is respectively arranged at two sides of the inner cavity of the box body; and two rotating seats are symmetrically and fixedly connected with and arranged at the upper part and the lower part of one side, corresponding to the U-shaped placement seats, of the inner cavity of the box body. The filter screencleaning device provided by the invention avoids manual cleaning, improves the washing speed and the working efficiency, reduces the labor intensity of personnel and is simple in structure and convenient in use.

Owner:安徽省睿斯达石油有限公司

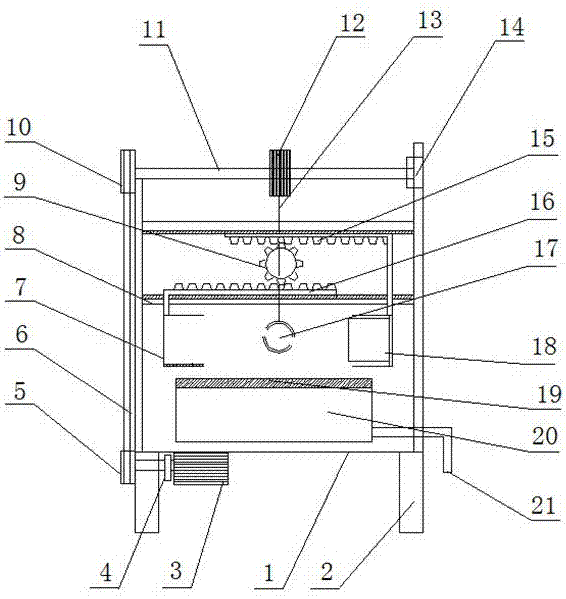

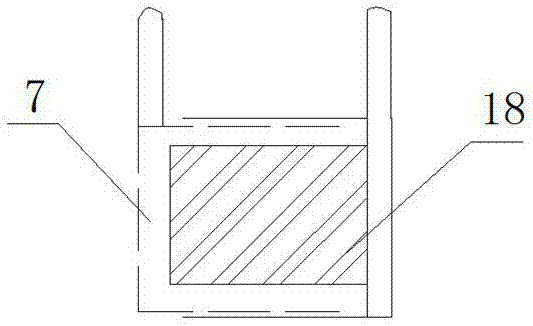

Traditional Chinese medicine dreg extrusion device

The invention discloses a traditional Chinese medicine dregs extruding device, which comprises a frame, a supporting leg, a servo motor, a reducer, a driving wheel, a belt, a concave pressing plate, a fixed frame, a gear, a driven wheel, a rotating shaft, a reel, and a string , bearings, spur rack 1, spur rack 2, balloon, convex briquetting block, filter screen, liquid medicine collection box and pipeline, the fixed frame is fixedly connected to the frame, and the fixed frame is respectively equipped with The first spur rack and the second spur rack, and the first spur rack and the second spur rack are meshed with the gears installed in the fixed frame respectively, and vertical gears are respectively arranged on the first spur rack and the second spur rack plate, a convex pressure block is fixedly connected to the vertical baffle of the spur rack one, and a concave pressure plate is fixedly connected to the vertical baffle of the spur rack two, and the liquid medicine collection box is arranged on the front of the fixed frame Below, a filter screen is provided on the top of the liquid medicine collection box, a liquid medicine outlet is opened at the bottom of the liquid medicine collection box, and the other end connected to the liquid medicine outlet pipeline is arranged outside the frame.

Owner:石雪芳

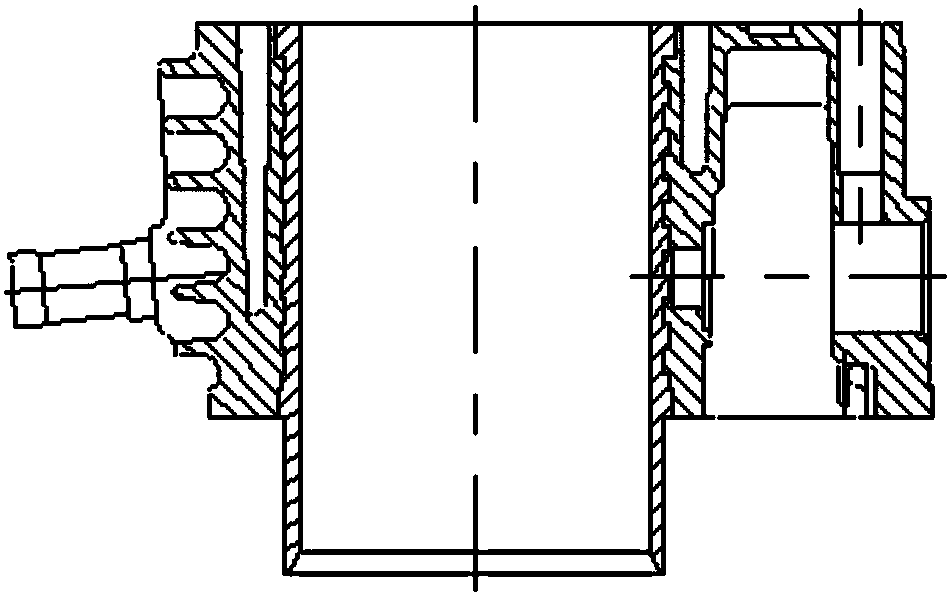

Motorcycle water cooling engine

PendingCN107725208APlay a role in separationAvoid wear and tearCasingsLubrication of auxillariesCylinder headEngineering

The invention discloses a motorcycle water cooling engine. An annular closed cylinder water way surrounding a cylinder hole is formed in an air cylinder body, a water inlet nozzle is arranged on the side face of the air cylinder body, and a cylinder body water outlet is formed in the upper end face of the air cylinder body. The water inlet nozzle and the cylinder body water outlet communicate withthe cylinder body water way. The upper end of the outer-layer inner wall, away from the cylinder hole, of the cylinder body water way so that the cross section area of the upper end of the cylinder body water way can be larger than the lower end cross section area, and the cylinder body water outlet is close to the outer edge of the upper end of the cylinder body water way. The corresponding design is conducted on the cylinder head water way and the water inlet in the air cylinder head. According to the structure, the volume of the water way is increased, and the amount of cooling water in the cylinder body and the cylinder head is increased. After the water way is expanded outwards, the cylinder body water outlet and the cylinder head water inlet are correspondingly moved outwards, so that ablation of an air cylinder pad due to high-temperature and high-pressure gas influences is not likely to happen, and circulation water is prevented from entering the engine.

Owner:力帆科技(集团)股份有限公司

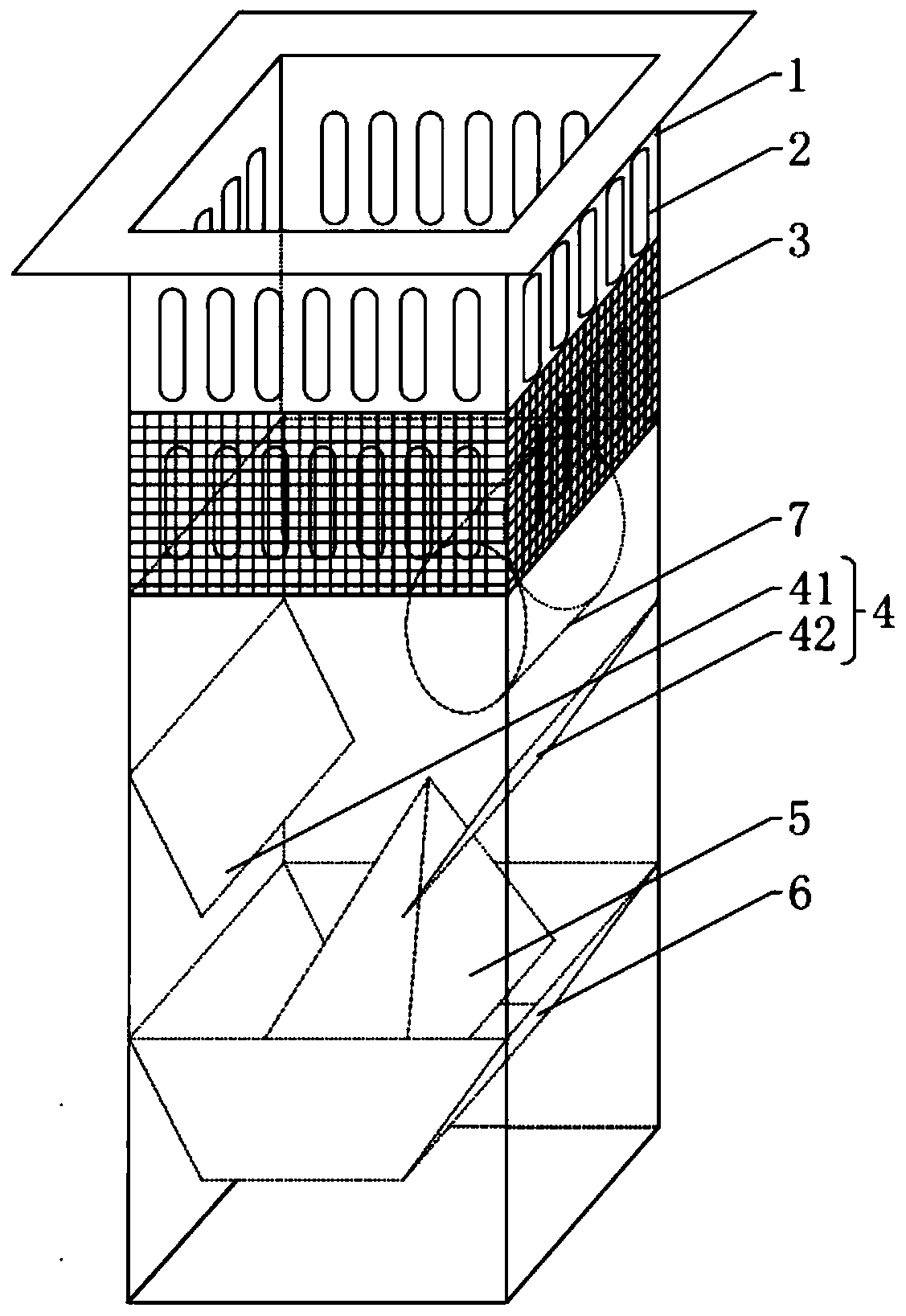

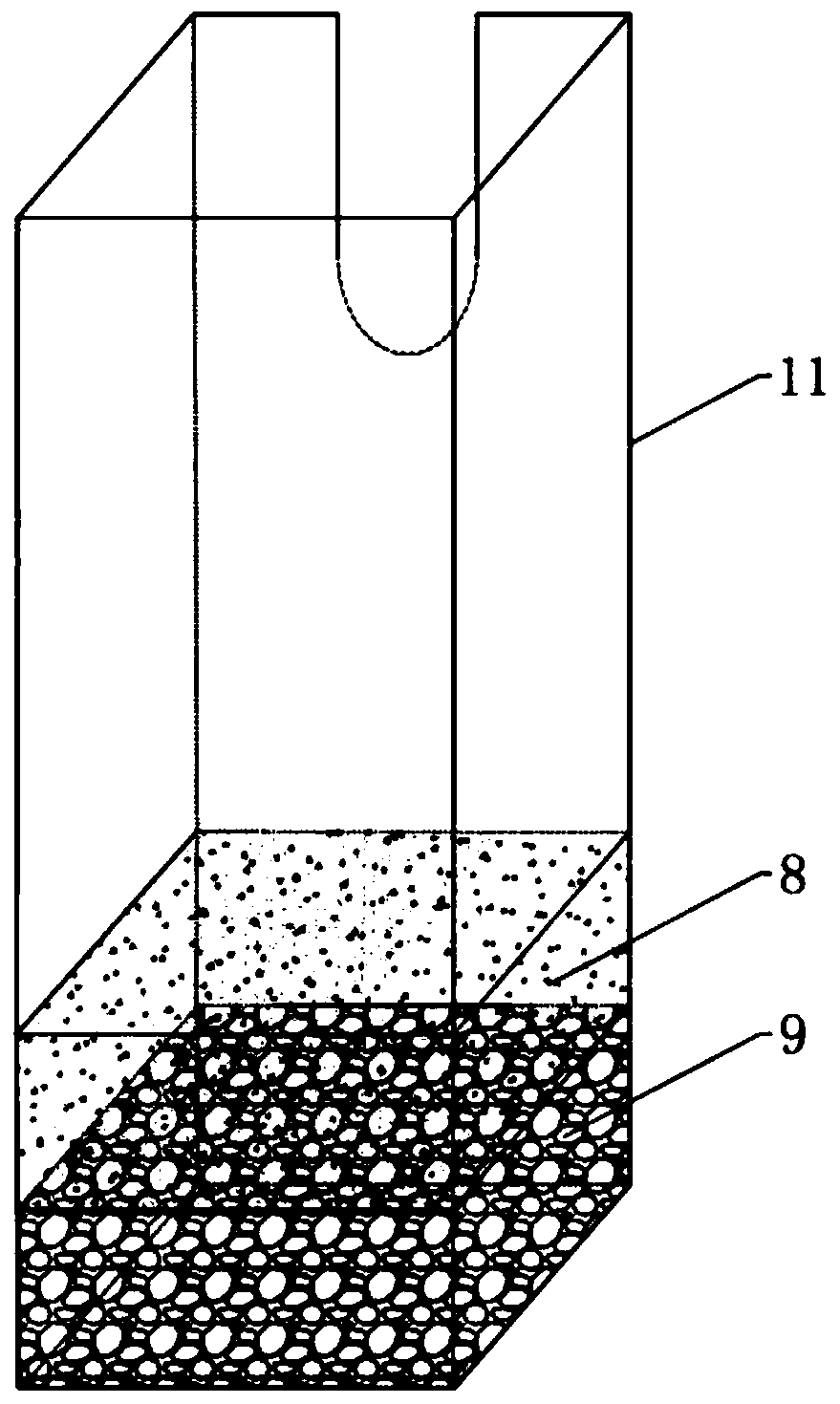

Efficient sewage interception device and efficient sewage interception operation method for urban road gutter inlets

InactiveCN109797839AReduce pollutionEasy to assembleFatty/oily/floating substances removal devicesSewerage structuresPollutantSewage

The invention relates to an efficient sewage interception device and an efficient sewage interception operation method for urban road gutter inlets. The efficient sewage interception device comprisesa collecting well body and a water collecting pipe, wherein the collecting well body comprises an upper collecting well body and a lower collecting well body which are detachably connected into a whole vertically by insertion, and the bottom of the lower collecting well body is provided with a microorganism filler layer. A vertically two-section rainwater grate of a hanging-basket structure is mounted at the upper end of the upper collecting well body, and a vertical-flow sand settling device is arranged in the upper collecting well body and comprises a splayed reflecting component, a silt interception component of a rectangular pyramid and an anti-sludge resuspension component of an inverted square frustum structure which are arranged from top to bottom. The efficient sewage interceptiondevice integrating a gutter inlet sewage interception modification technology, the vertical-flow sand settling device and the bottom microorganism filler layer can intercept large solid pollutants, silt and other particles and can ecologically degrade the sludge deposited at the bottom.

Owner:TIANJIN WATER RESOURCES RES INST

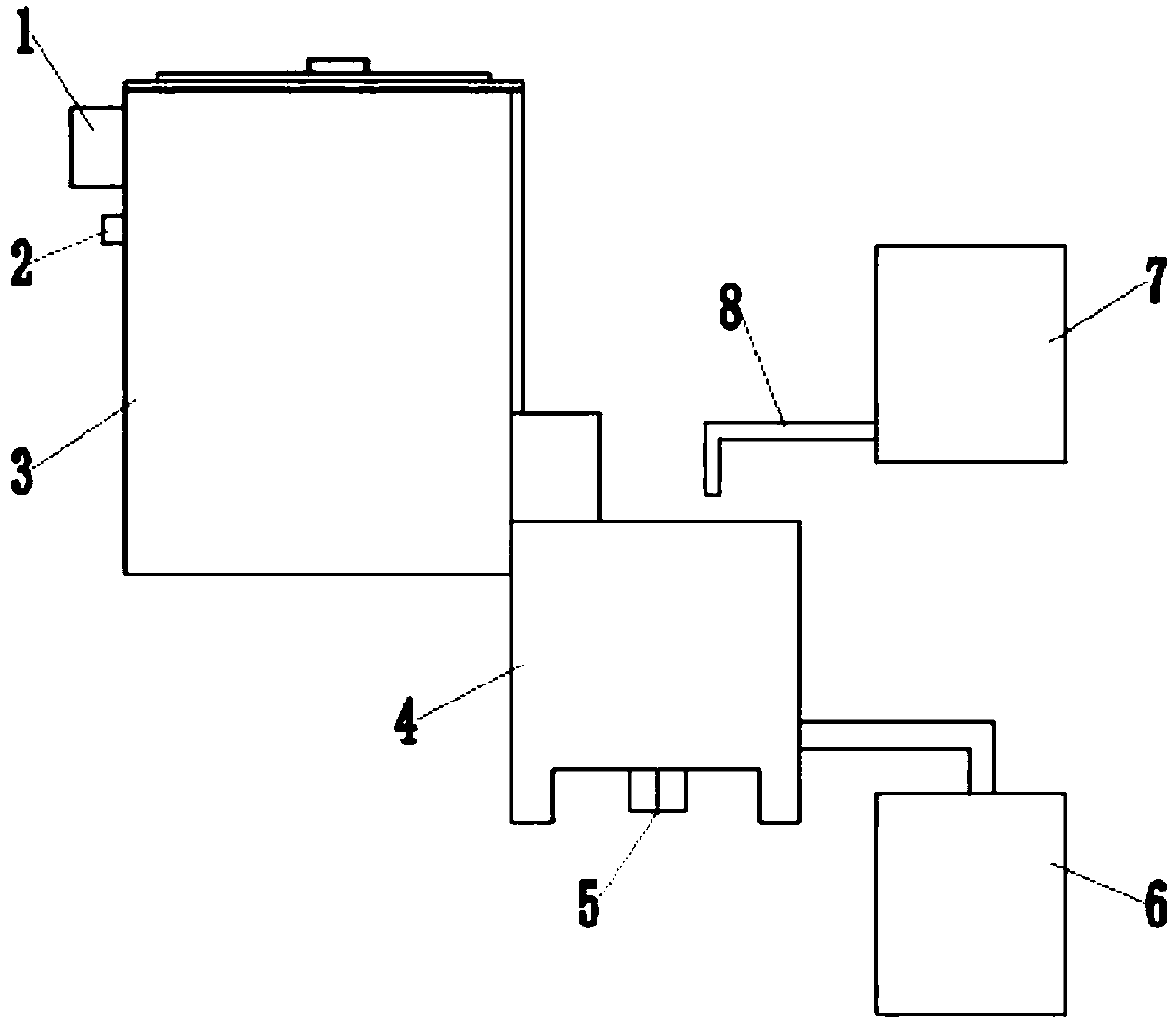

Waste lithium battery cool type splash-proof electrolyte recovery device

ActiveCN109560342AAvoid environmental pollutionProtect healthSolid waste disposalWaste accumulators reclaimingSolventOpen structure

The invention discloses a waste lithium battery cool type splash-proof electrolyte recovery device. The waste lithium battery cool type splash-proof electrolyte recovery device comprises a compressor,a crushing box, a filter box, a liquid collection box and a solvent box, wherein a refrigerator is arranged inside the crushing box; a condenser is wound on the outer side of the refrigerator; the compressor is arranged on the outer side of the crushing box; the condenser is connected with the compressor; a partition door is arranged at the lower end of the refrigerator; crushing teeth are arranged below the partition door; a sliding plate is arranged below the crushing teeth; the sliding plate is arranged slantly; an outlet is formed in one side of the crushing box; the lower end of the sliding plate is connected with the outlet; the upper end of the filter box is of an open structure; the outlet is connected with an opening in the upper end of the filter box through a connecting plate;the filter box is internally provided with a centrifugal cylinder; a centrifugal motor is arranged at the lower end of the filter box; the centrifugal motor is connected with the centrifugal cylinder;a liquid inlet pipe is arranged on the solvent box; the outlet end of the liquid inlet pipe is arranged above the filter box; and the liquid collection box is connected with the filter box through apipeline.

Owner:贵州中伟资源循环产业发展有限公司

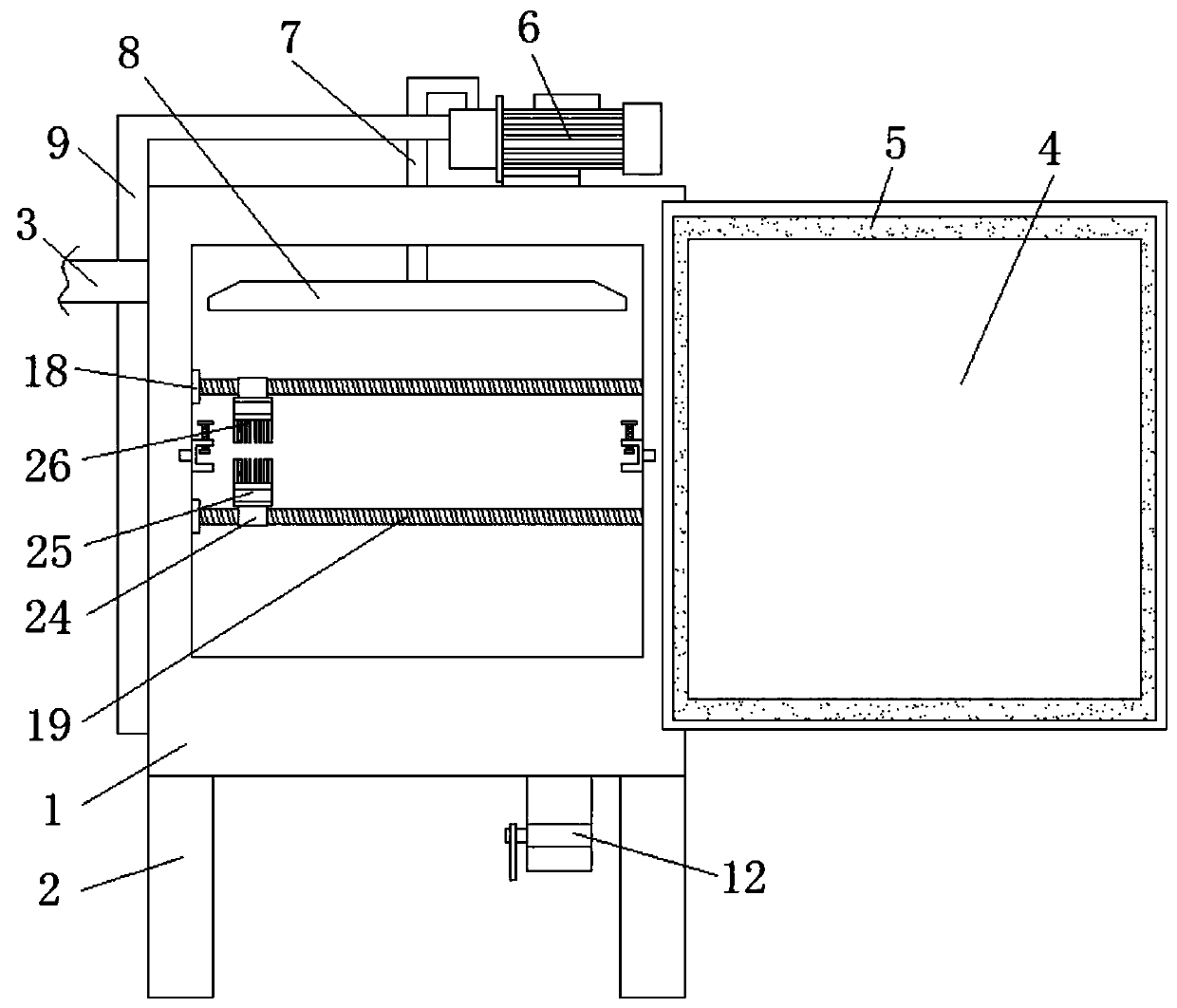

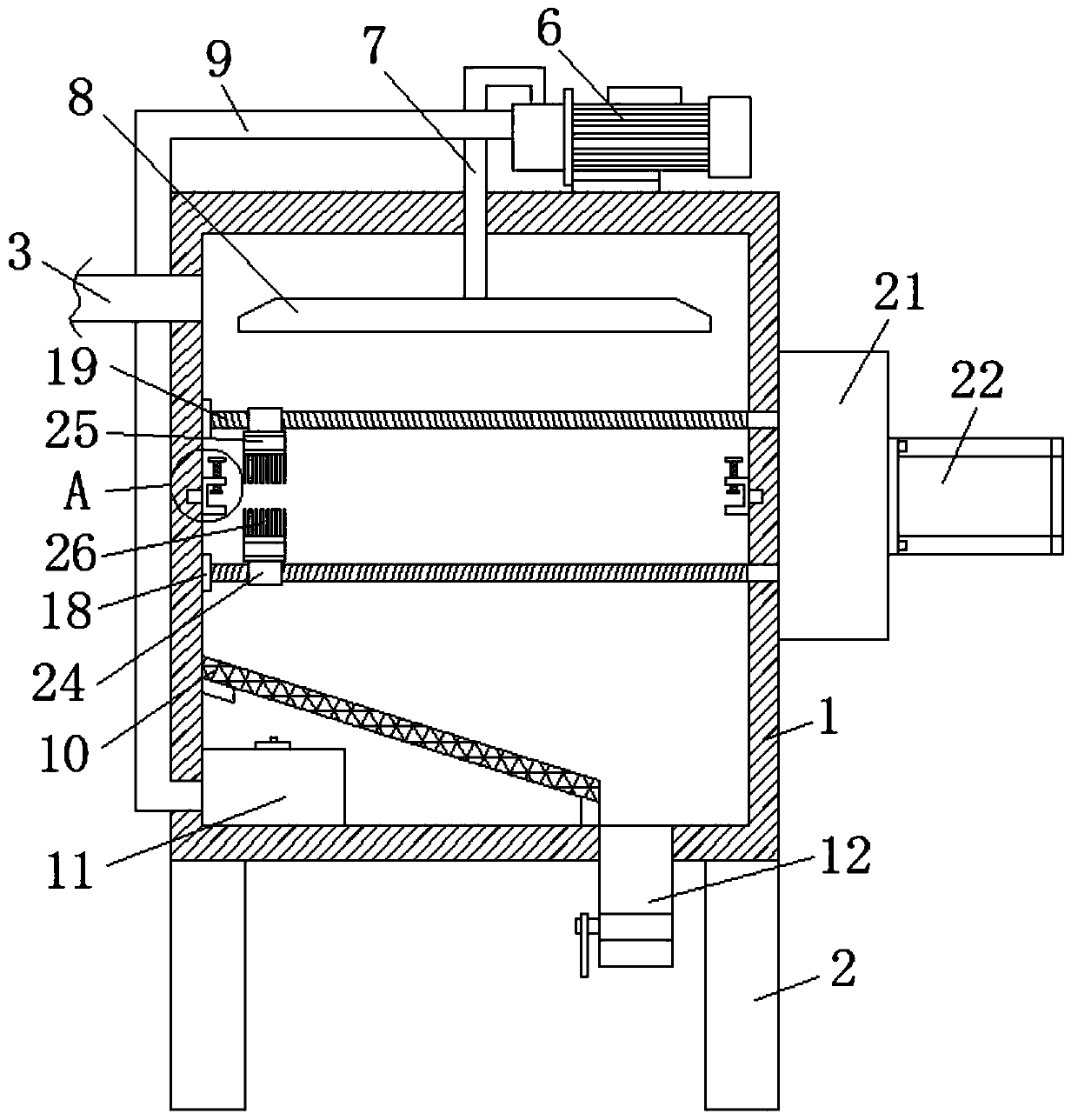

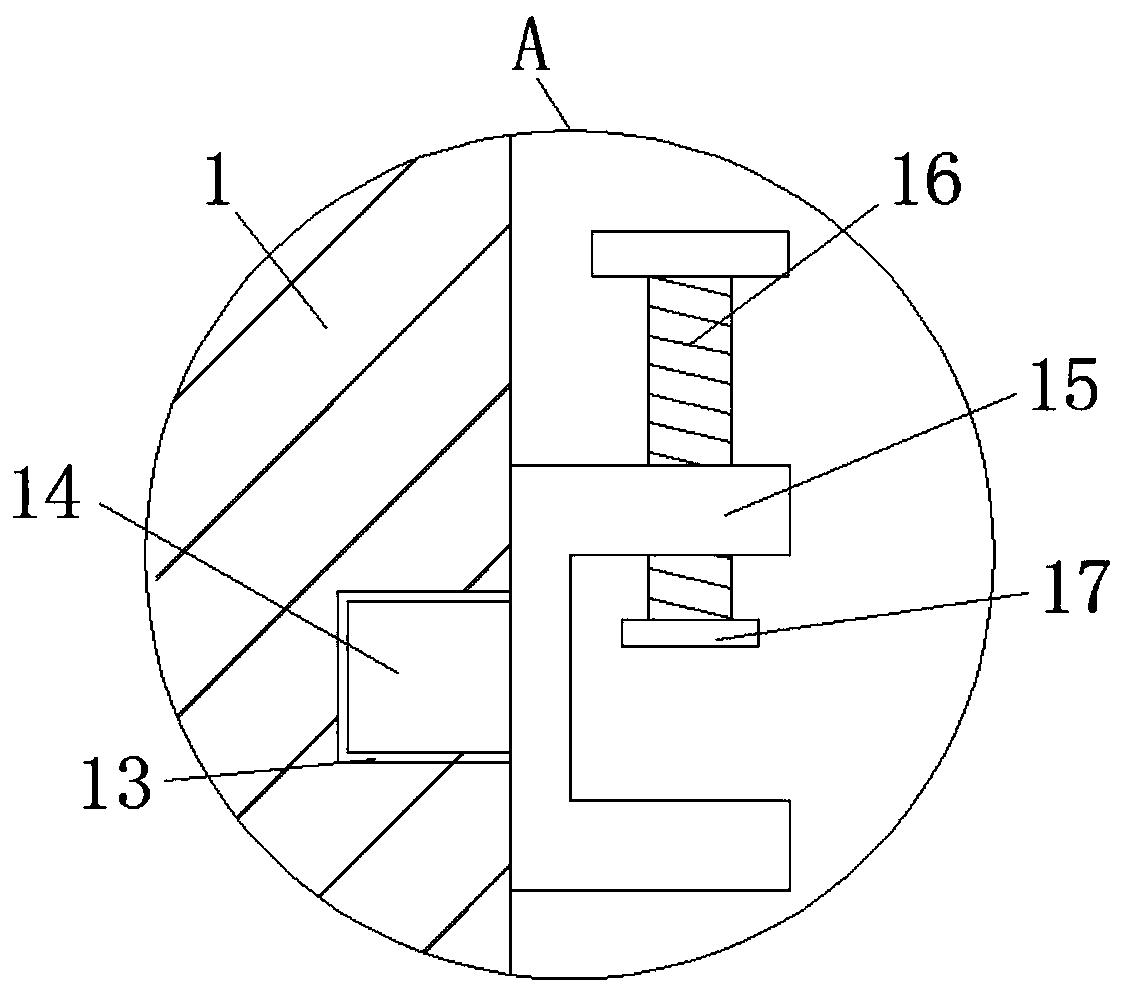

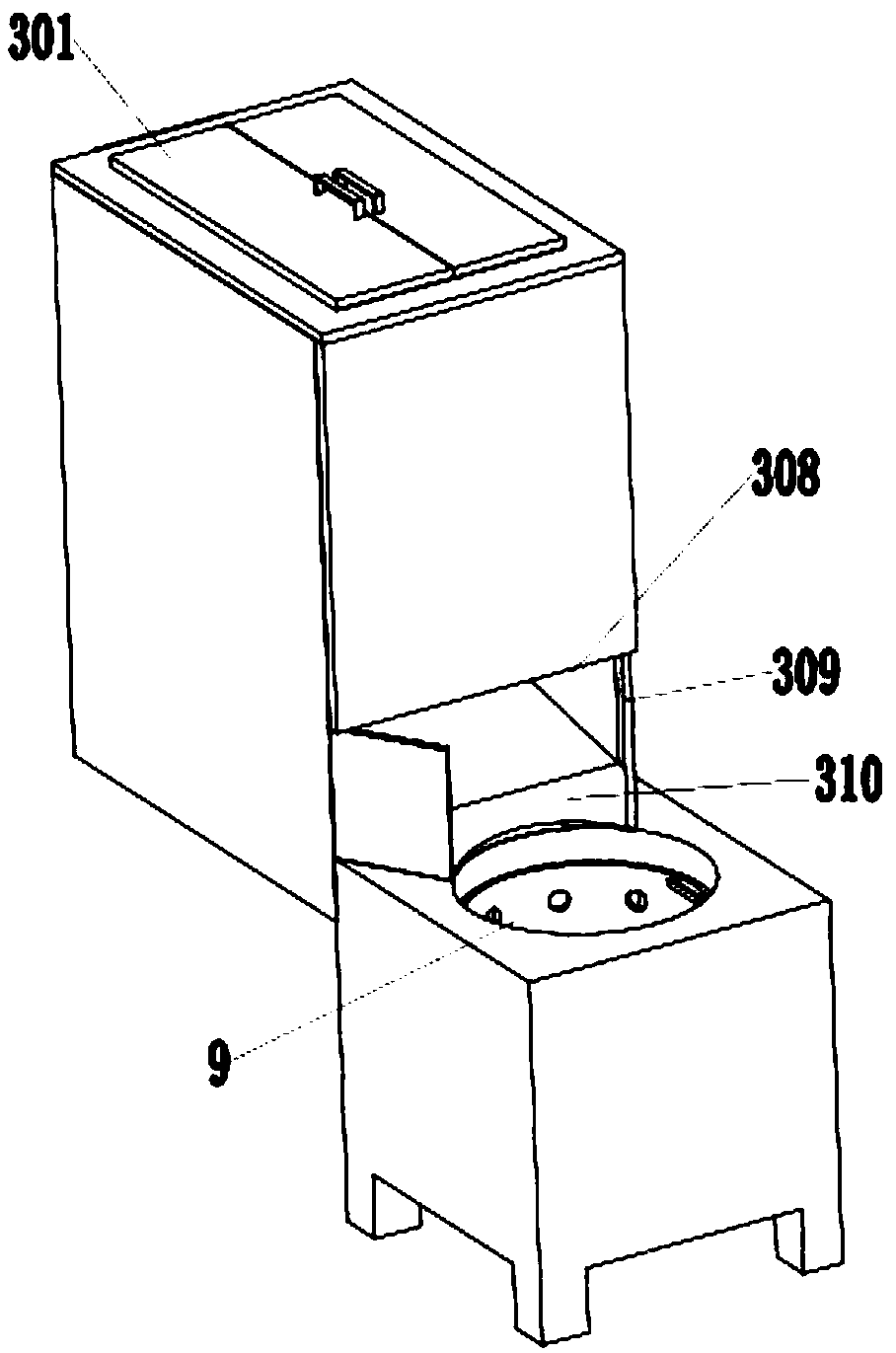

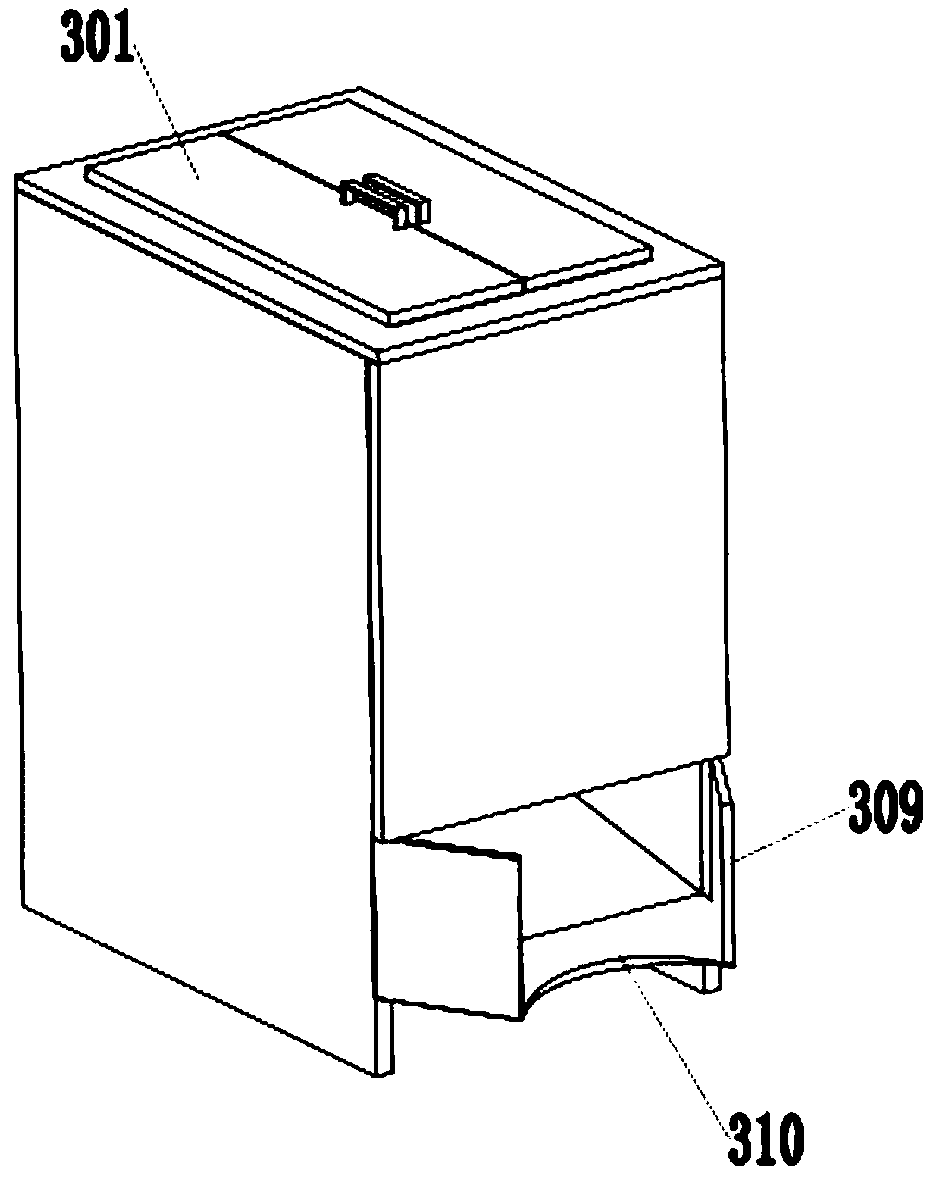

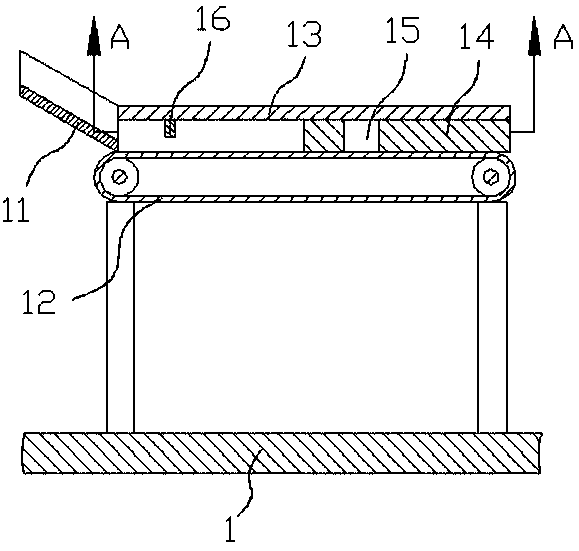

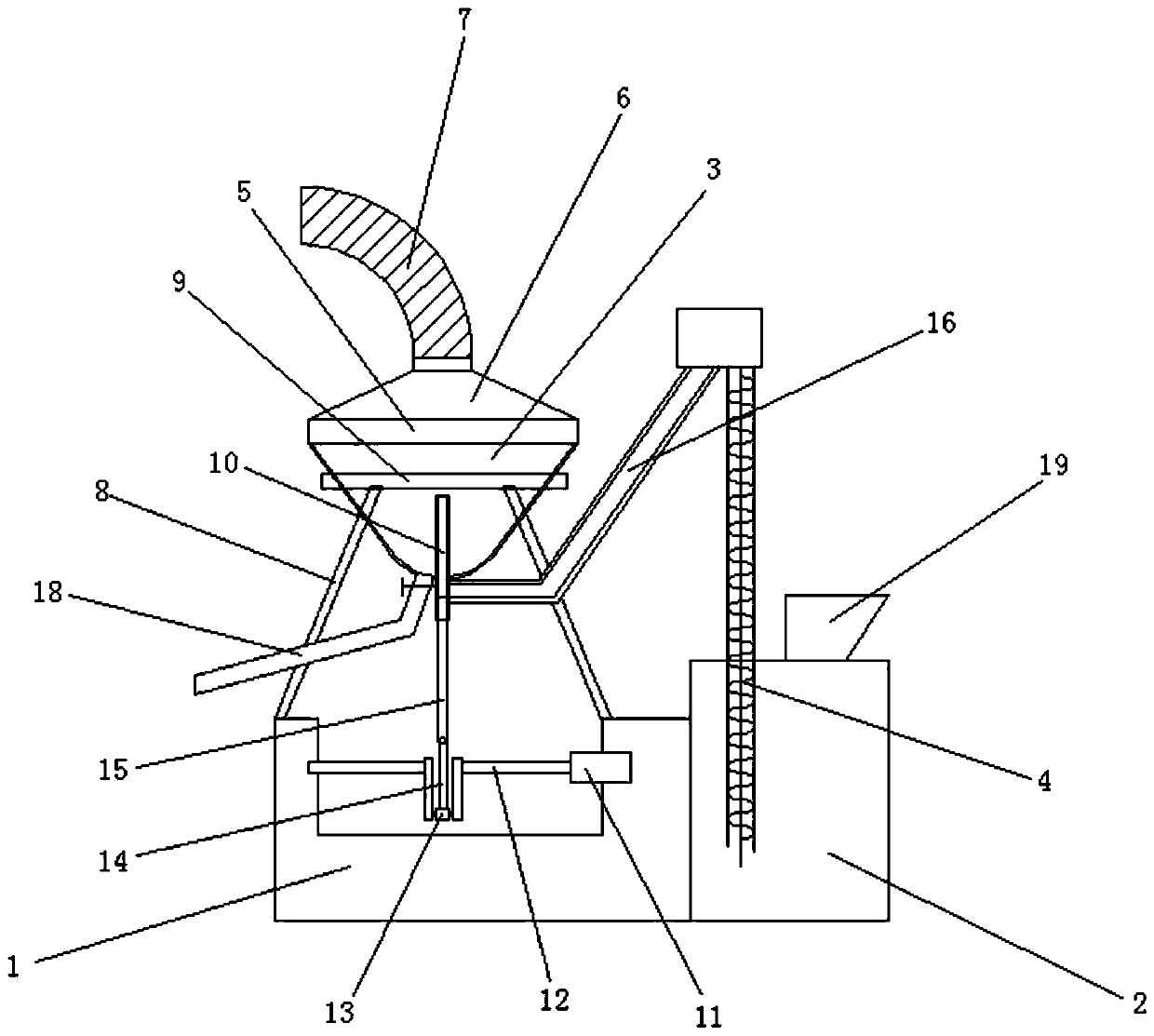

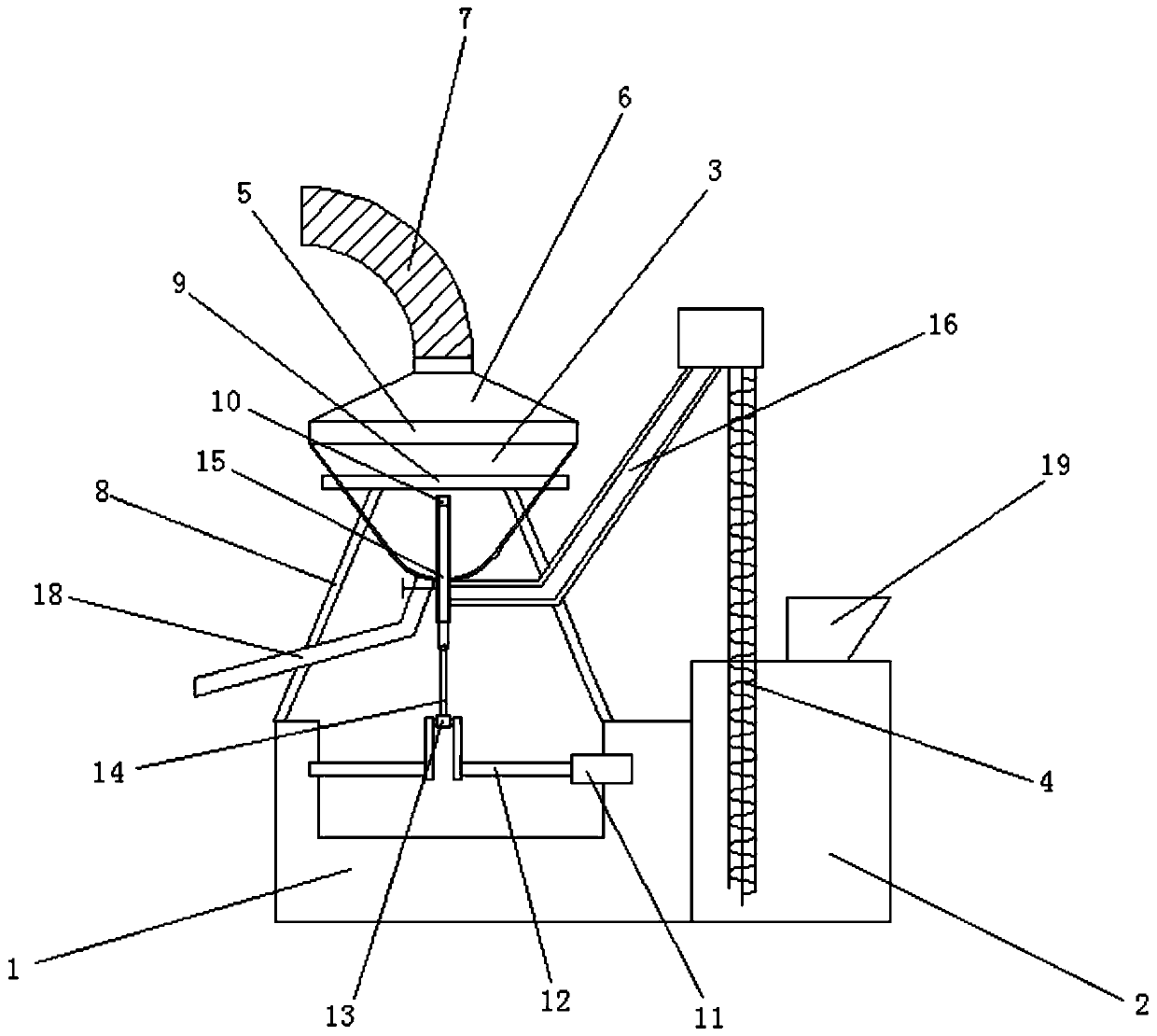

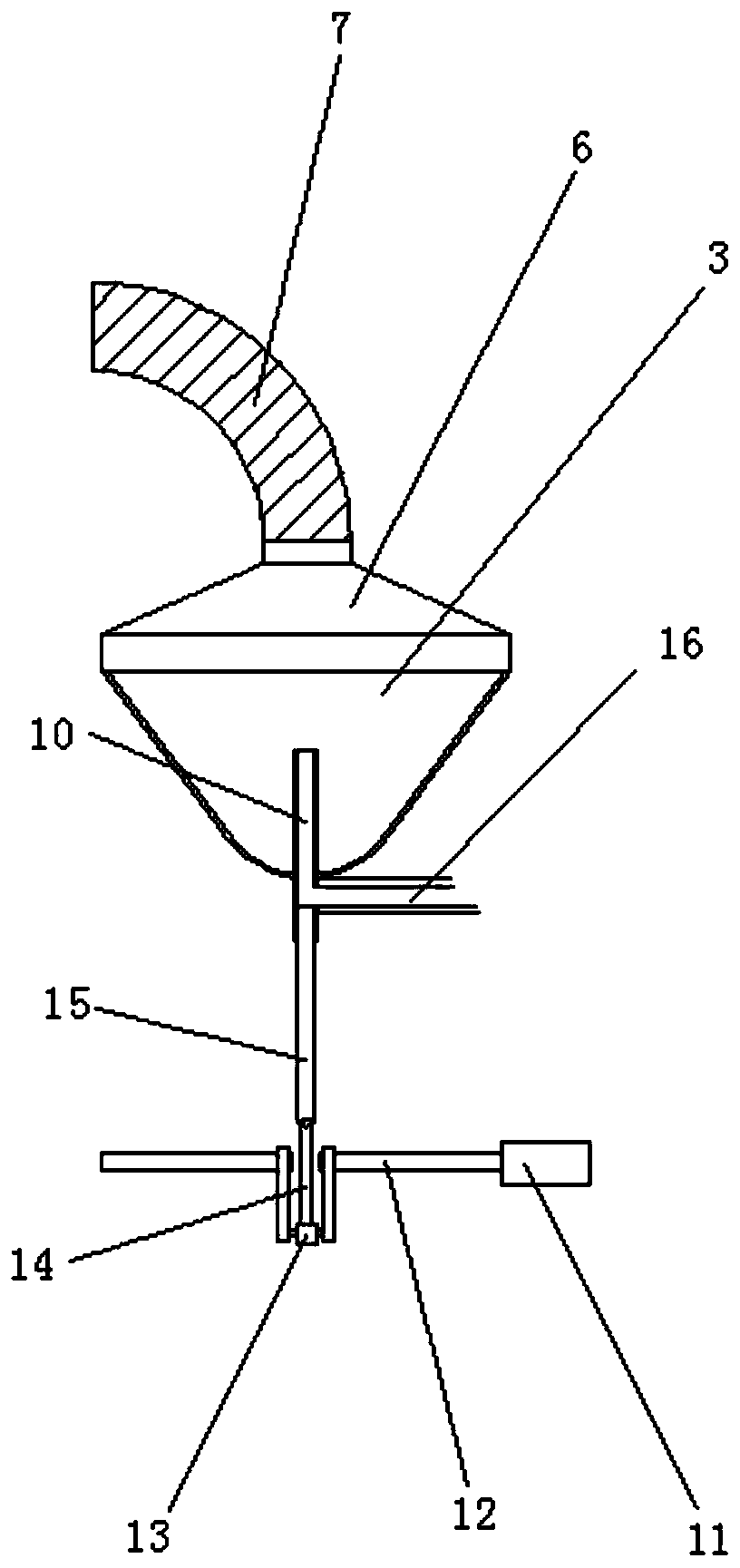

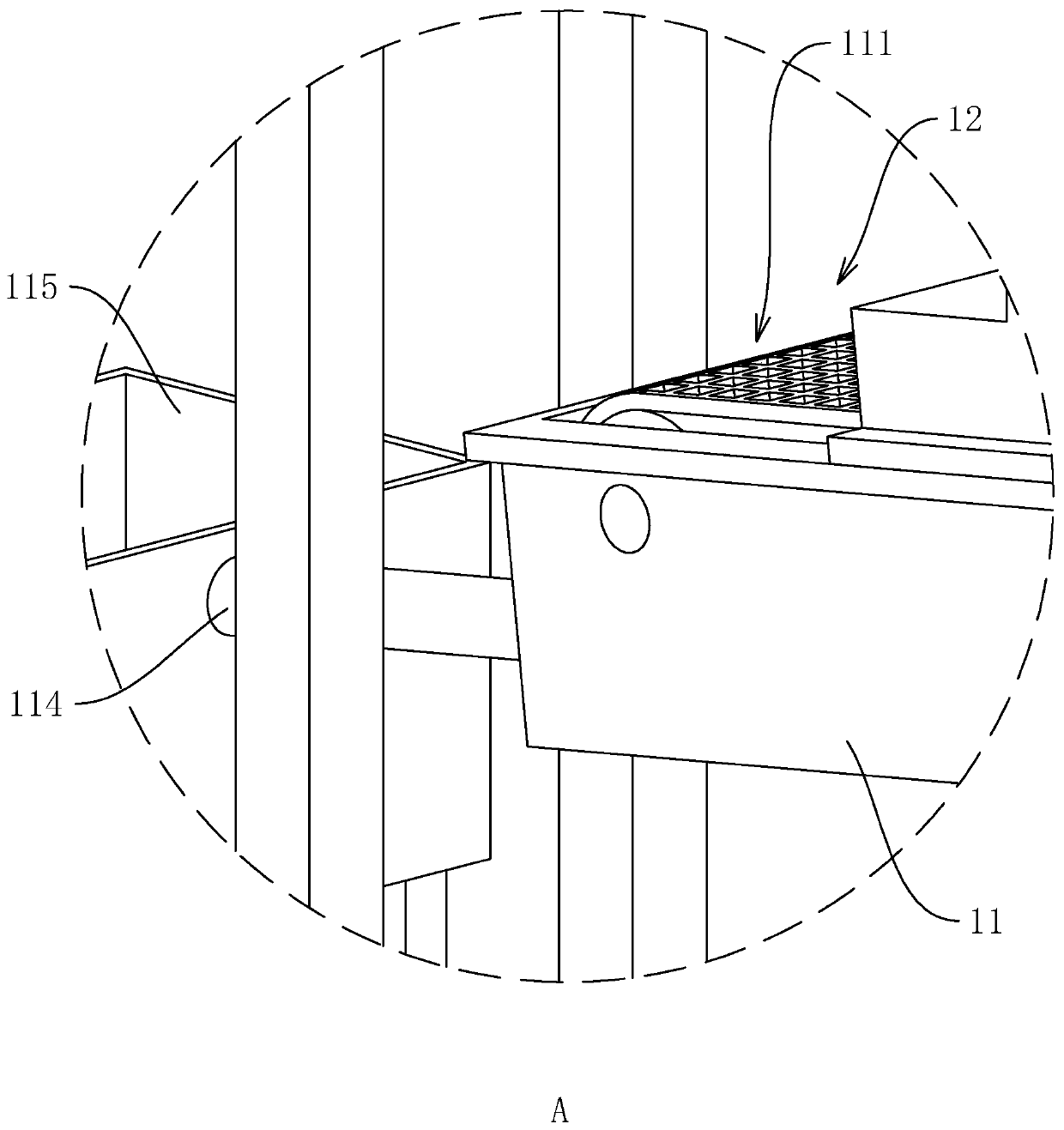

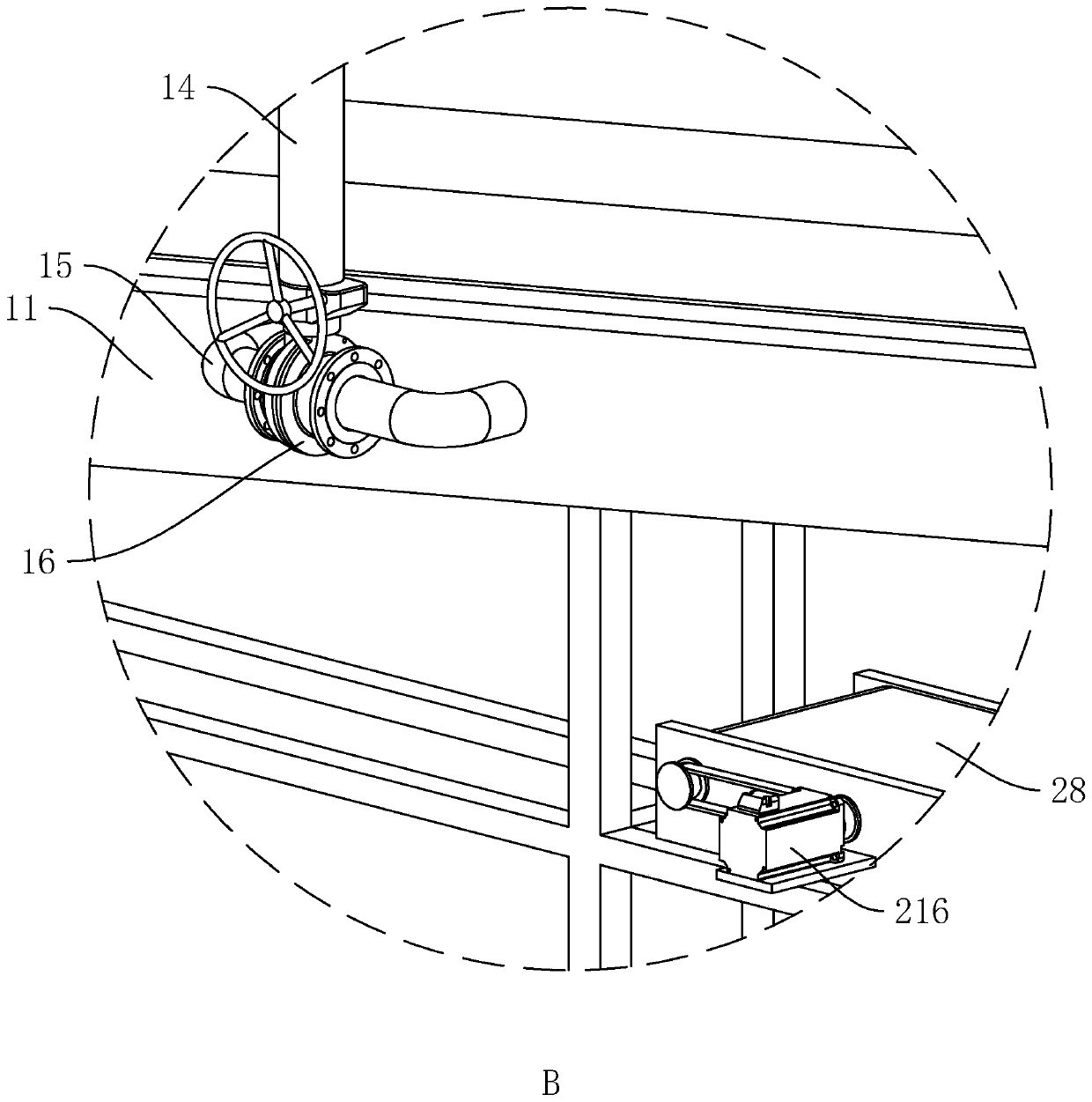

Shell breaking separating integrated machine for camellia oleifera seeds

InactiveCN108851098AGood separation effectGood cracking effectGas current separationFatty-oils/fats productionEngineeringCamellia oleifera

The invention relates to a shell breaking separating integrated machine for camellia oleifera seeds. The machine comprises a frame, a discharging device, a shell breaking device and a shell breaking separating device, the shell breaking separating device comprises a shell breaking separating bottom plate arranged on the frame, the shell breaking separating bottom plate is provided with a shell breaking separating side plate and is in inserting sleeve matching with a separating inserting slot by a separating inserting block, the middle of the shell breaking separating bottom plate is provided with a shell breaking separating partition plate, the shell breaking separating side plate on the left side is provided with a separating second screen mesh and a separating first screen mesh from topto bottom in sequence, the separating second screen mesh is in a break angle shape, meshes are larger than seed kernels, the separating first screen mesh tilts backwards and downwards, meshes are smaller than seed kernels, and separation fans are embedded in the shell breaking separating side plate on the right side with horizontal wind direction from right to left; the machine adopts the classification fans to cooperate with two layers of the screen meshes, broken shells lager and smaller than the seed kernels are screened and separated through the screen meshes, the seed kernels and the broken shells with the same size as the seed kernels are separated by the fans, and complete separation of the seed kernels and the broken shells is achieved.

Owner:DONGGUAN UNIV OF TECH

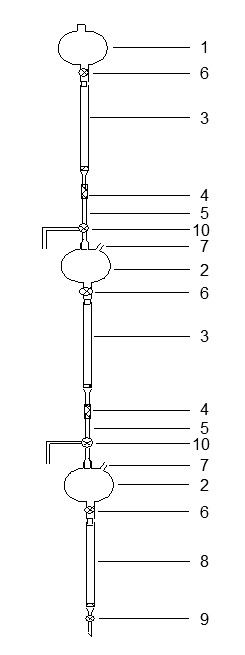

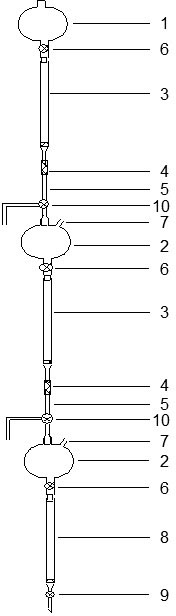

Multi-segment chromatographic column

InactiveCN102527089ALower the liquid levelReduce volumeSolid sorbent liquid separationEngineeringMulti segment

A multi-segment chromatographic column comprises a main liquid storage bottle and a plurality of auxiliary liquid storage bottles connected the main liquid storage bottle. The bottoms of the main liquid storage bottle and the plurality of auxiliary liquid storage bottles are all provided with throttling valves. Packing columns are arranged between the main liquid storage bottle and the auxiliary liquid storage bottles and among the auxiliary liquid storage bottles. T-shaped three-way tubes are arranged below the packing columns, each t-shaped three-way tube is provided with a three-way valve, each auxiliary liquid storage bottle is provided with a dissolvent filling port, a tail-segment packing column is arranged below the last auxiliary liquid storage bottle, and a valve is arranged at the lower end of the tail-segment packing column. According to actual needs, the quantity of the packing columns, packing, and packing of the ail-segment packing column can be changed flexibly, multi-stage separation of a complex mixture can be achieved, the packing columns have separation functions, the liquid storage bottles can bring convenience to addition of eluent, and the eluent does not need to be added manually and constantly. The multi-segment chromatographic column is simple in structure, convenient in use and good in effect.

Owner:CHINA UNIV OF MINING & TECH

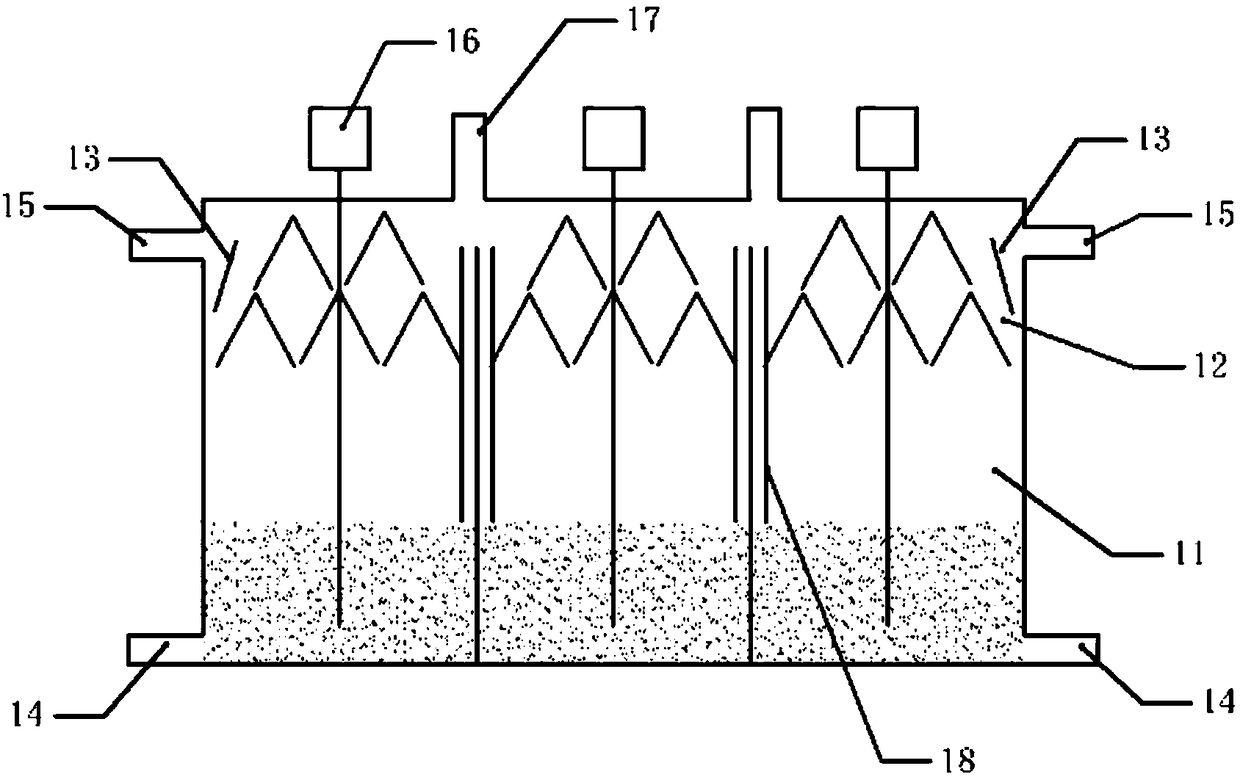

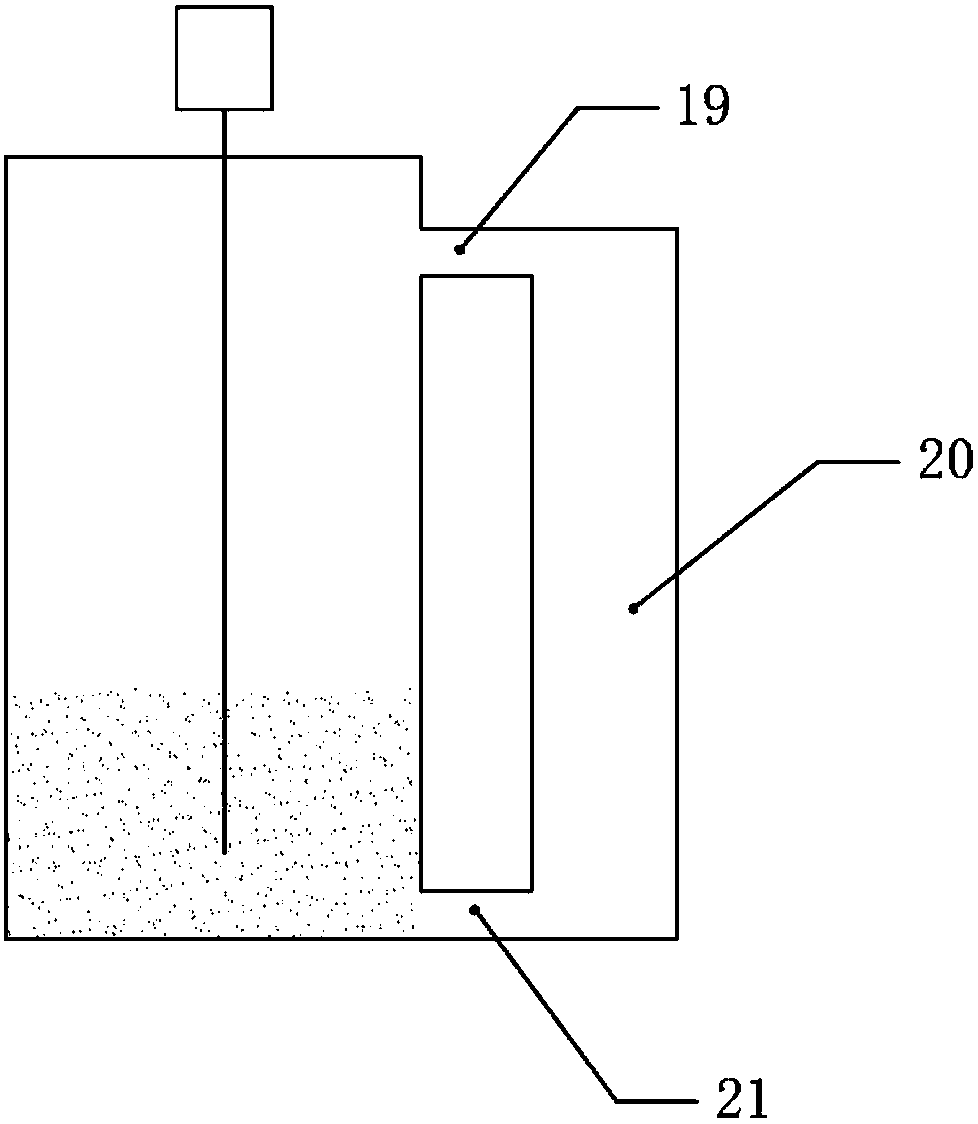

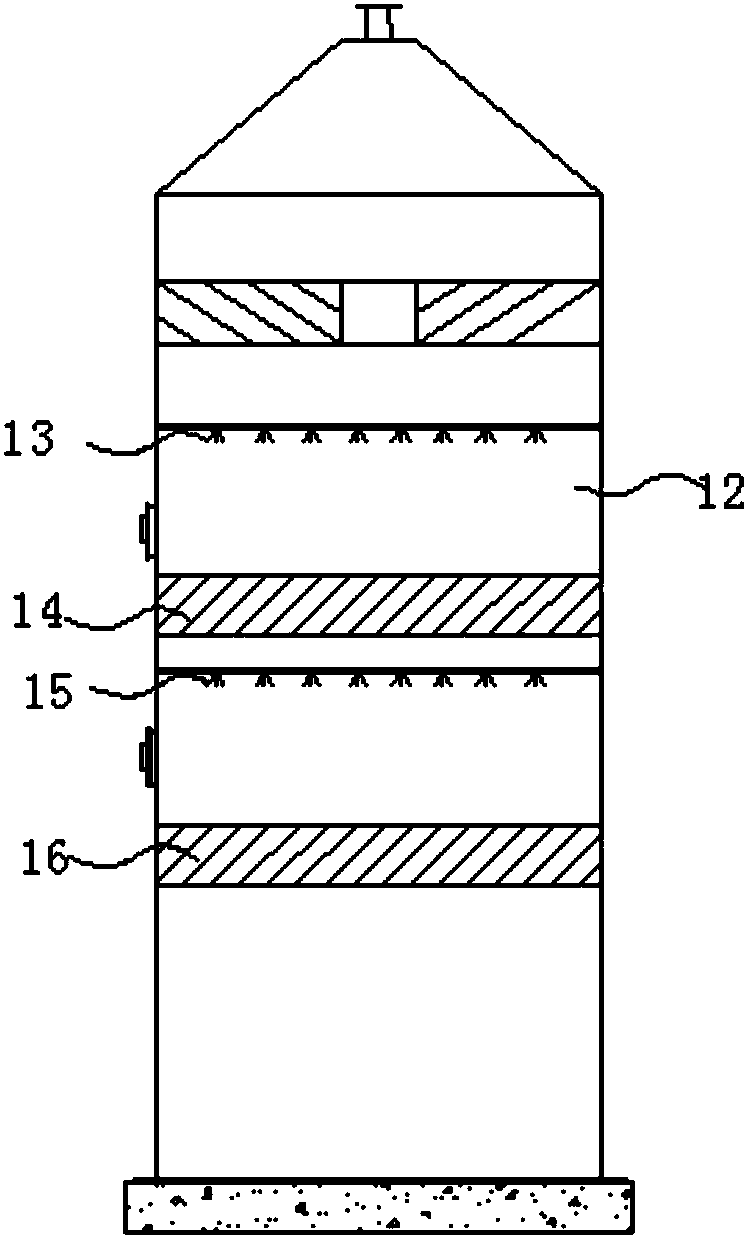

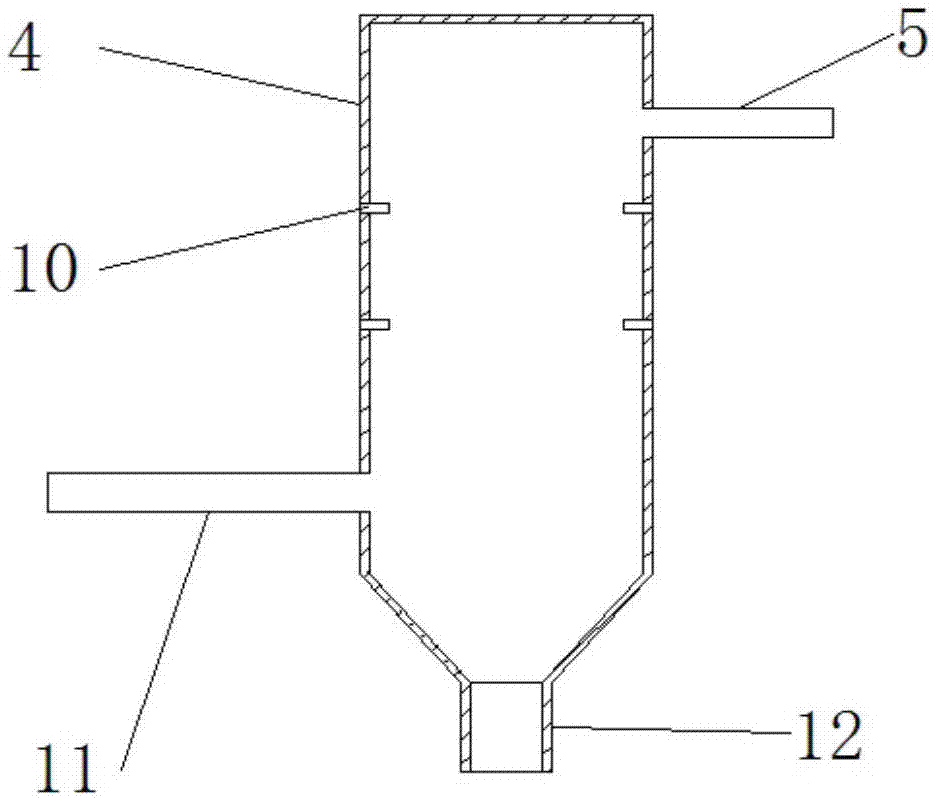

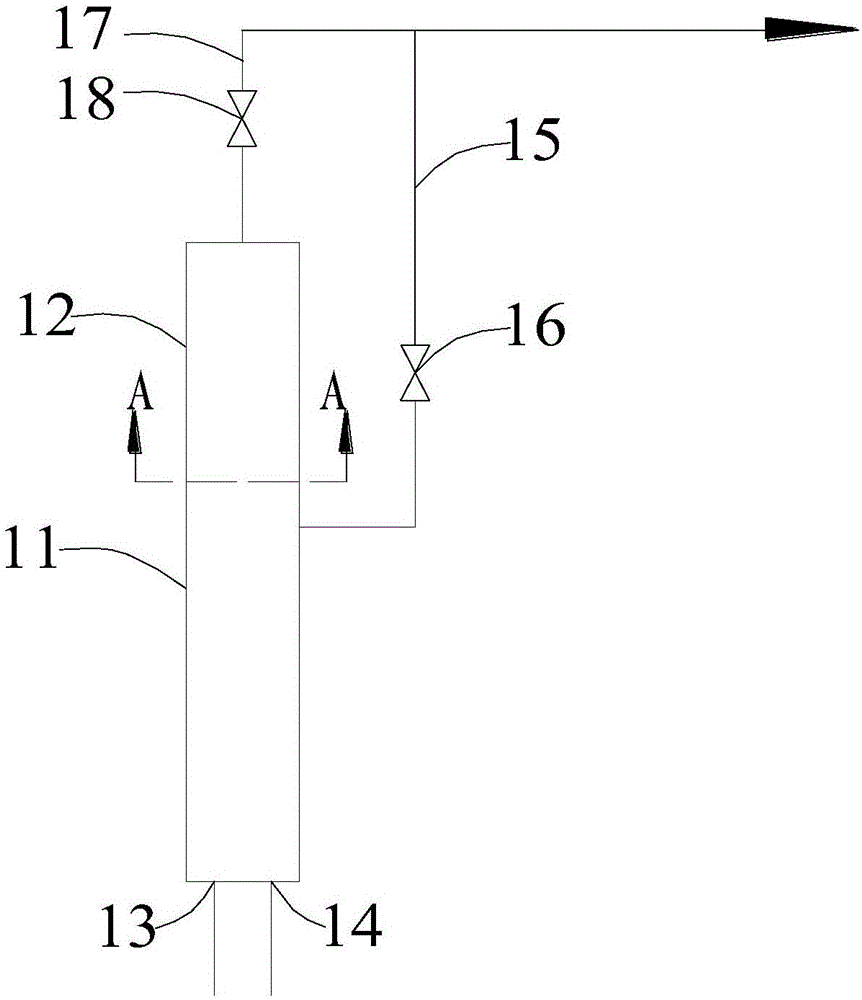

Upflow anaerobic reactor and organic wastewater treatment method thereof

PendingCN108147533AImprove precipitation effectCohesion effect is goodWater treatment parameter controlWater contaminantsThree-phaseAnaerobic reactor

The invention belongs to the technical field of sewage treatment and relates to an upflow anaerobic reactor and an organic wastewater treatment method thereof. The upflow anaerobic reactor comprises asludge bed reactor and a three-phase separator arranged at the inner top of the sludge bed reactor, a plurality of partition plates are arranged in the sludge bed reactor to partition the sludge bedreactor into a plurality of chambers, the chambers on two sides of the sludge bed reactor are provided with a water inlet and a water outlet respectively, the water outlet is positioned above the water inlet, and the upper portion of the sludge bed reactor is provided with a plurality of exhaust ports. A heating device is arranged on the outer side of each chamber, each chamber is provided with acirculation water inlet and a circulation water outlet, each heating device is communicated with the corresponding circulation water inlet and the corresponding circulation water outlet, and a circulating pump is mounted on each heating device. The problem of influences on organic wastewater treatment due to failure in normal operation of anaerobic reaction when the outdoor environment temperaturein northern China is below 0 DEG C for a long time in winter is effectively solved.

Owner:重庆鸿净环保科技开发有限公司

Gushing type circulating grain dust removing device

The invention relates to the field of grain processing, and discloses a gushing type circulating grain dust removing device which comprises a base. The bottom of the base is fixedly provided with a crankshaft rotating rod mechanism, the top of the base is rotatably hinged to an ejector rod, the top of the left side of a storage bin is fixedly provided with an elevator, the top of a dust removal hopper is fixedly provided with a negative pressure fan, the bottom of the dust removal hopper is fixedly connected with a grain spraying pipe, the tops of two sides of the base are provided with the dust removal hopper through supports and installation rings, a guide pipe is fixedly connected between the top of the elevator and the right side of the lower part of the grain spraying pipe, the guidepipe communicates with the grain spraying pipe, the ejector rod is movably sleeved with the bottom of the grain spraying pipe, and the left side of the bottom of the dust removal hopper is fixedly provided with a discharge pipe. The effect of controlling feeding can be achieved, grains are driven to be fluffy and uniformly distributed in the dust removal hopper in a gushing manner, dust and grainscan be separated easily, the function of circularly and repeatedly removing dust is achieved, and the dust removal effect is enhanced.

Owner:ANHUI JIESHOUSHI YUNLONG FOOD MACHINE ENG

Sludge incineration waste gas treatment system

InactiveCN107930335AImprove usabilityEasy to useHuman health protectionCombination devicesOzone generatorEmission standard

The invention discloses a sludge incineration waste gas treatment system. The sludge incineration waste gas treatment system comprises a cyclone dust collector, wherein the top part of the cyclone dust collector is connected with a heat exchange boiler through a pipeline; a heat exchange water pipe is mounted in an inner cavity of the heat exchange boiler; tail gas needing to be treated is conveyed into the inner cavity of the cyclone dust collector through a tail gas inlet; a mud-water separation opening and a mud-water separation groove are formed, so that tail gas residues are convenient torecycle; a first spraying nozzle, a second spraying nozzle, a first filtering screen and a second filtering screen re arranged so that tail gas is convenient to filter again and wash; an ozone oxidation device and an ozone generator are arranged so that the tail gas is conveniently subjected to sterilization and disinfection treatment; a biological deodorization device is arranged so that the tail gas is conveniently subjected to deodorization and the tail gas is discharged into atmosphere through a chimney, so that atmospheric pollutant emission standards of China are met; the utilization functionality of the sludge incineration waste gas treatment system is greatly improved and the sludge incineration waste gas treatment system is suitable for being widely popularized.

Owner:宜兴市吉星环保科技有限公司

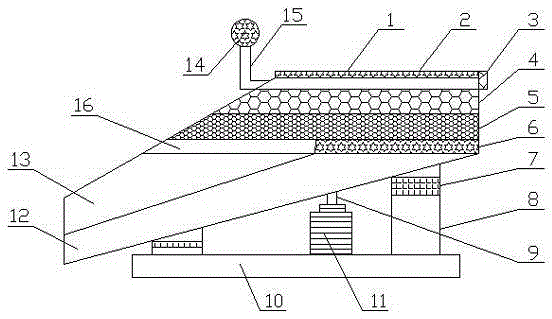

Environment-friendly mine vibrating screen

The invention belongs to the technical field of vibrating screens, and discloses an environment-friendly mine vibrating screen. The environment-friendly mine vibrating screen comprises a vibrating screen body, wherein the vibrating screen body comprises a base, support legs, a first screen, a second screen, an end cover and an air purifying device; the top of the base is connected with the support legs; a motor is arranged between the support legs, and is connected with the base; the tops of the support legs are connected with a second discharge port; a first discharge port is formed in the top of the second discharge port; the first discharge port and the second discharge port are connected with a guide device; the guide device is connected with a guide port; one side of the guide device is connected with a vibrator; the vibrator is connected with the second screen and the first screen; and a cover end is arranged at the top of the second screen. As the vibrating screen is combined with the air purifying device, materials can be screened, and dust generated in screening can be purified, the health of workers is protected, and the environment is protected.

Owner:HUZHOU JIASI MACHINERY TECH CO LTD

Sufficient combustion coal chemical industry gasification furnace slag decarburization device

The invention discloses a sufficient combustion coal chemical industry gasification furnace slag decarburization device. The sufficient combustion coal chemical industry gasification furnace slag decarburization device comprises a first water inlet pipe, a gasification furnace, flame spraying ports and a vibration motor. The first water inlet pipe is arranged on the left side of a coal mill, and a coal inlet pipe is arranged below the first water inlet pipe. The gasification furnace is in sealed connection to the right side of the coal mill through a feeding pipe. The lower end of a screening device is in sealed connection with the coal inlet pipe through a fine slag conveying device. The flame spraying ports are formed in the gasification furnace. The vibration motor is arranged on the left side of the screening device, a screen is arranged in the screening device, the upper portion of a condensation device is connected with the first water inlet pipe through a backflow pipe, and the lower portion of the condensation device is connected with a second water inlet pipe. According to the sufficient combustion coal chemical industry gasification furnace slag decarburization device, the gasification furnace is provided with the flame spraying ports which are arranged into double layers, the function of sufficient combustion of pulverized coal is achieved, and the decarburization efficiency of the sufficient combustion coal chemical industry gasification furnace slag decarburization device can be better improved.

Owner:开阳浩洋环保科技开发有限公司

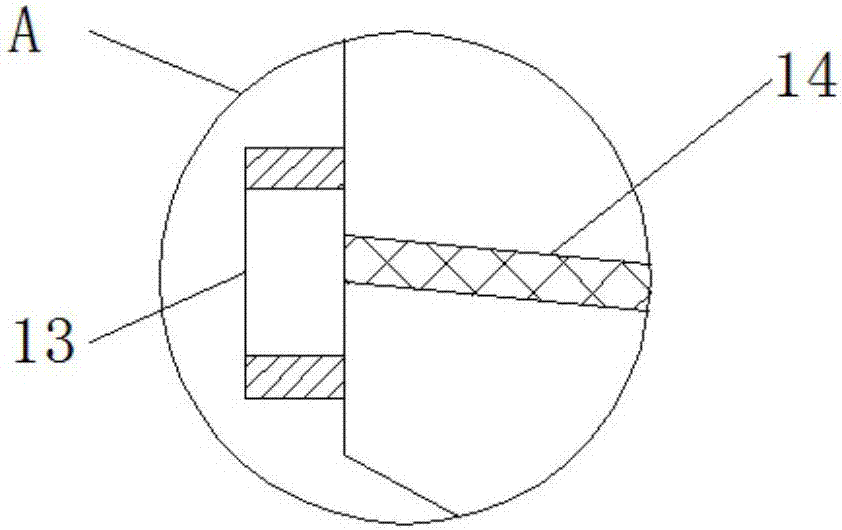

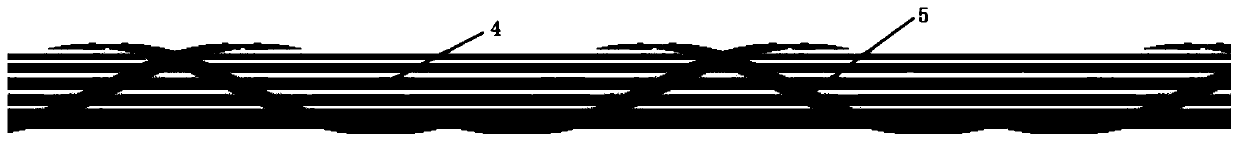

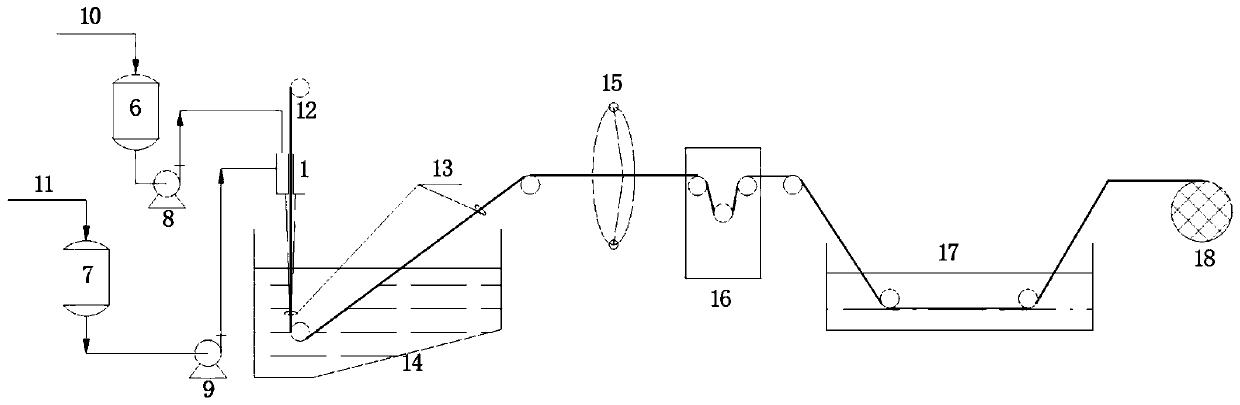

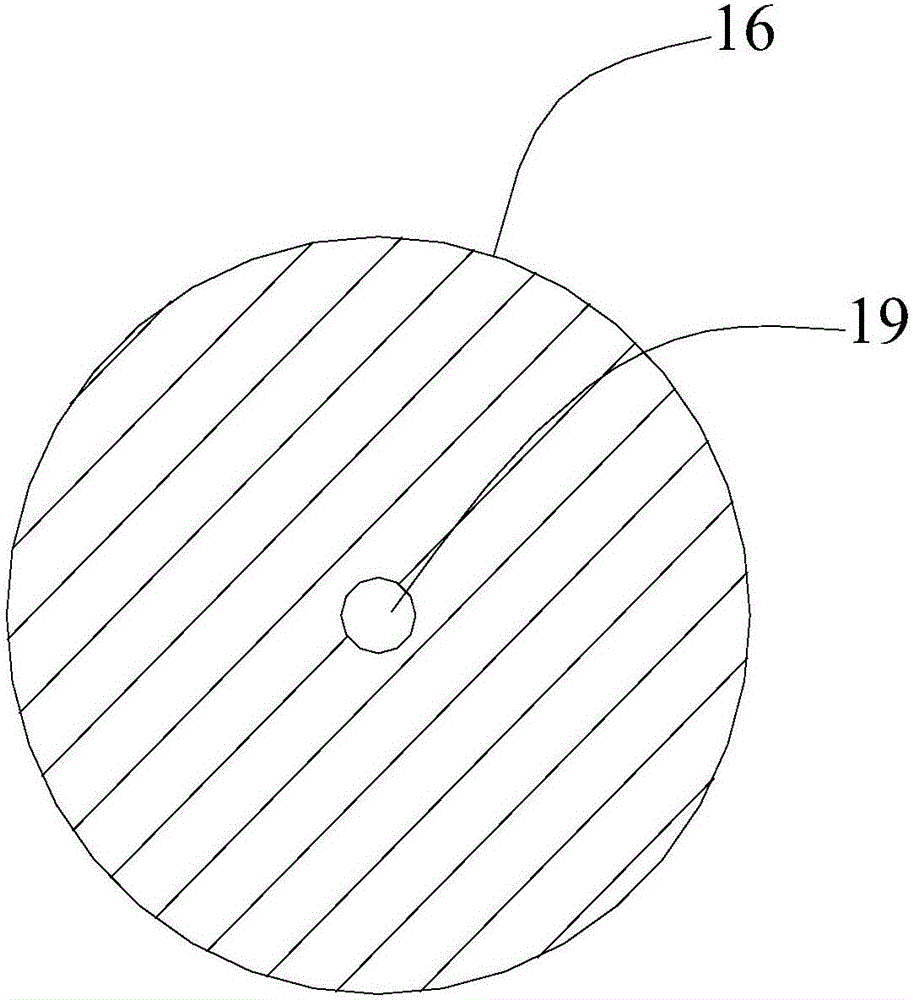

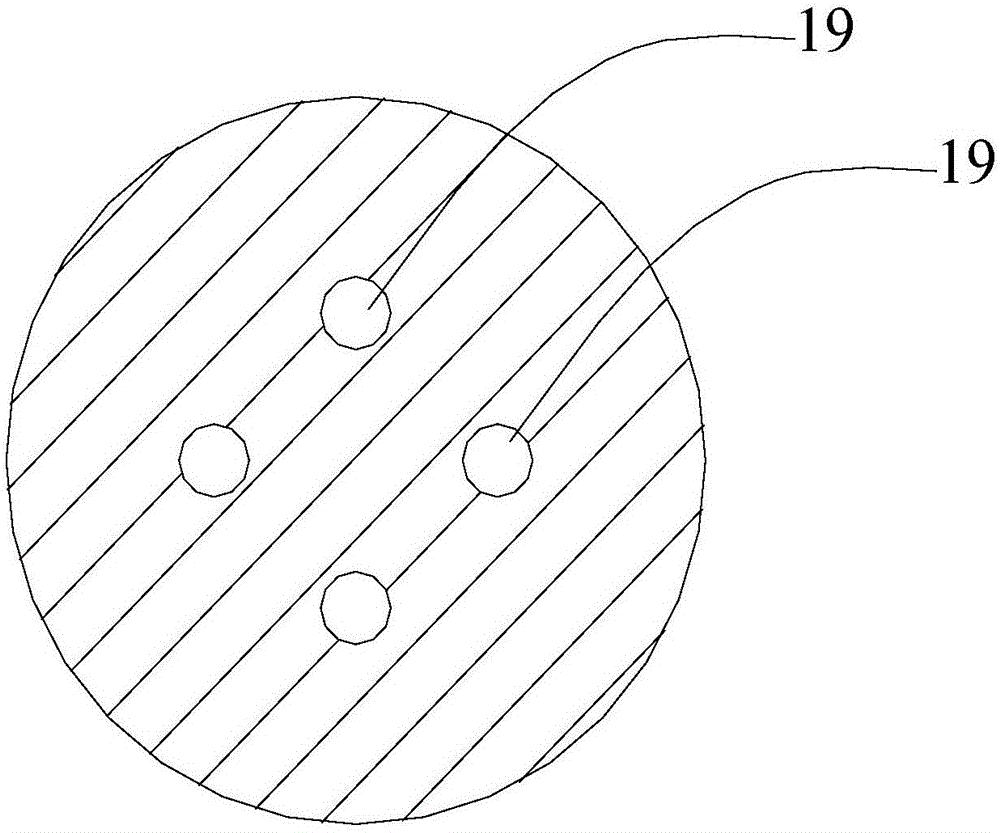

Reinforced hollow fiber membrane, preparation method and device

PendingCN110327787AHigh tensile strengthPlay a role in separationSemi-permeable membranesHollow fibre membraneFiber

The invention provides a novel reinforced hollow fiber membrane preparation device. The reinforced hollow fiber membrane comprises a braided rope supported at the center, membrane filaments distributed around the support rope and a winding tape binding the braided rope and the membrane filaments into a membrane bundle. The device comprises a feed liquid tank, a core liquid tank, a spinning metering pump, a pay-off rack, a special spinning head, a coagulation bath, a winding tape apparatus, a three-roller traction apparatus, a rinsing tank and a filament roll-up wheel. The beneficial effect ofinvention lies in that the invention provides the device for preparation of the reinforced hollow fiber membrane. The braided rope provides the tensile strength of the whole membrane filaments, and the membrane filaments provide the separation performance of the whole membrane bundle. Compared with the membrane filament of traditional outer diameter, the overall membrane bundle obtained by the device can have a larger separation specific surface area. At the same time, the device can prepare the one-time formed membrane bundle, and has the advantages of simple operation and high production efficiency.

Owner:南京久盈膜科技有限公司

Upper flange component and compressor

PendingCN110645179AReduce oil outputAvoid failureRotary/oscillating piston pump componentsLiquid fuel engine componentsExhaust valveEngineering

The invention provides an upper flange component. The upper flange component comprises a bearing and an exhausting partition plate; the exhausting partition plate is fixed to the lower end of the bearing and is provided with an air flow passage; the lower end of the air flow passage is provided with an exhaust vent which communicates with the air flow passage; an exhaust valve component used for controlling the opening and closing of the exhaust vent is fixedly arranged inside the air flow passage; the bearing is provided with a bearing exhaust passage which communicates with the air flow passage; and the end, far away from the exhaust vent, of the exhausting partition plate is further provided with a partition plate exhaust passage which communicates with the air flow passage. The upper flange component can reduce the oil output of the compressor in order to prevent the problem about compressor faults caused by reduction of oil amount inside the compressor and deficiency of oil supplypumpage, can also prevent refrigerant oil from entering a system so that oil films are not formed on the surface of a heat exchanger and reduces adverse effects generated on the heat exchanger of anair conditioner so that the performances of an air conditioning system are not affected.

Owner:ZHUHAI LANDA COMPRESSOR +1

Flash device and heat pump device including same

The invention discloses a flash device and a heat pump device including the flash device. The flash device comprises a first cavity, a second cavity and a valve assembly. The first cavity is provided with a two-phase freezing medium flow inlet and a liquid freezing medium flow outlet. The first cavity communicates with an air supplementing opening of a compressor through a first air supplementing pipe. The second cavity communicates with the first cavity through a refrigerant channel. The flow area of a refrigerant is increased when the refrigerant flows from the refrigerant channel to the second cavity. The second cavity communicates with the air supplementing opening of the compressor through a second air supplementing pipe. The valve assembly is used for controlling the first air supplementing pipe to be connected with or disconnected from the air supplementing opening and controlling the second air supplementing pipe to be connected with or disconnected from the first air supplementing pipe. By means of the arrangement, the flash device can ensure that the heat pump device runs in a good state, and then the reliability of a heat pump system is improved.

Owner:GREE ELECTRIC APPLIANCES INC

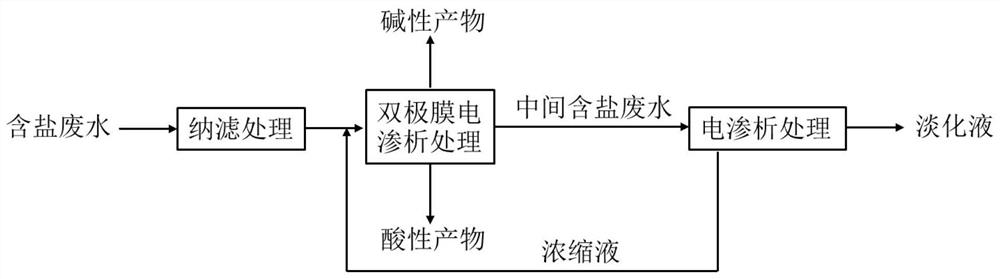

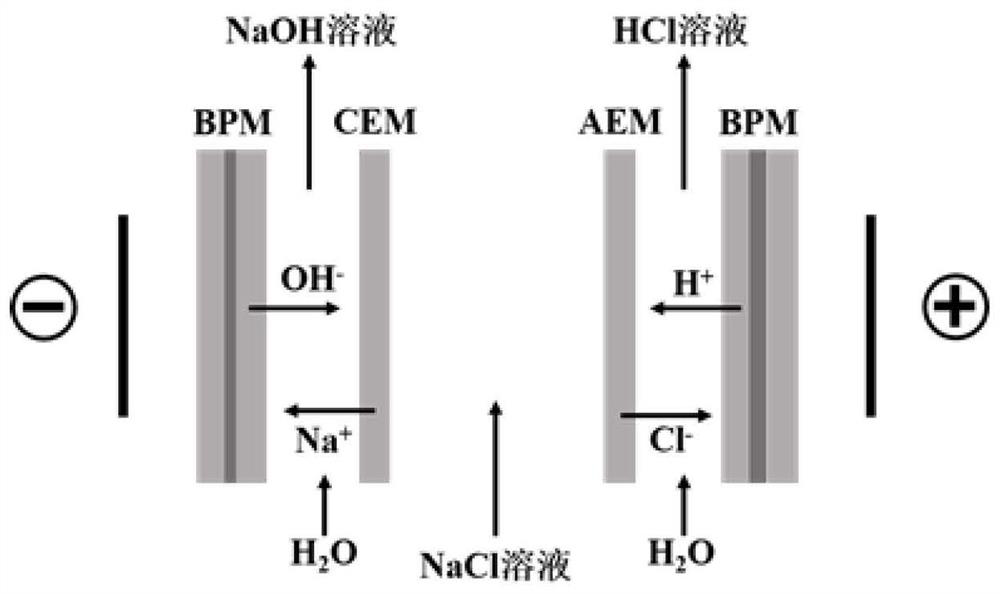

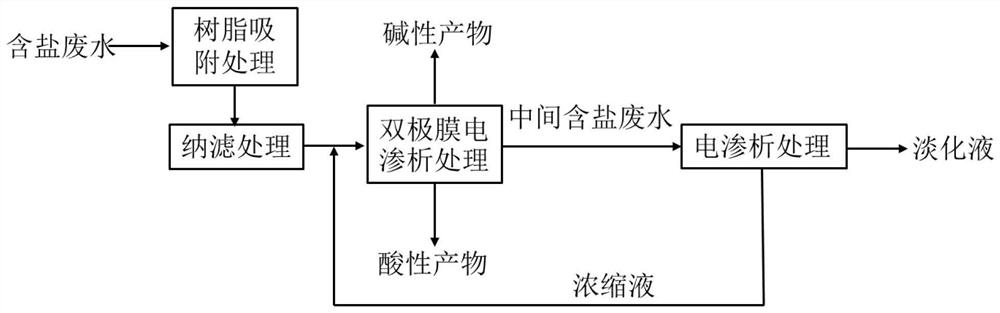

Salt-containing wastewater treatment method and treatment system

ActiveCN112811687AAvoid pollutionImprove stabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationNanofiltrationElectrodialysis

The invention provides a salt-containing wastewater treatment method, which comprises the following steps of: performing bipolar membrane electrodialysis treatment on salt-containing wastewater subjected to nanofiltration treatment to respectively obtain an acidic product, an alkaline product and intermediate salt-containing wastewater; and carrying out electrodialysis treatment on the intermediate salt-containing wastewater to obtain a desalted solution and a concentrated solution, and returning the concentrated solution to participate in bipolar membrane electrodialysis treatment. According to the salt-containing wastewater treatment method, efficient treatment of the salt-containing wastewater can be achieved with low energy consumption, industrial products can be obtained in the treatment process, the economic benefit of treating the salt-containing wastewater is improved, and the economic cost of treating the salt-containing wastewater is reduced.

Owner:TSINGHUA UNIV

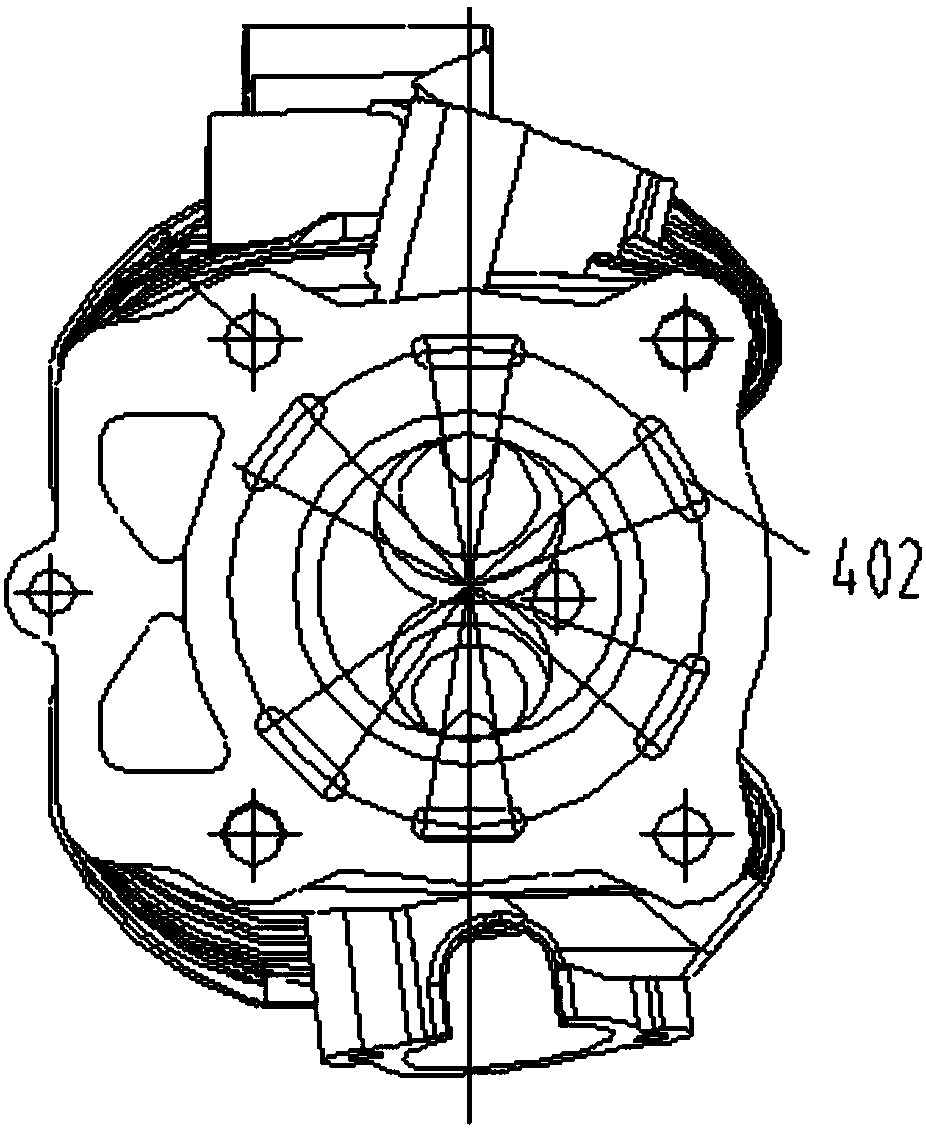

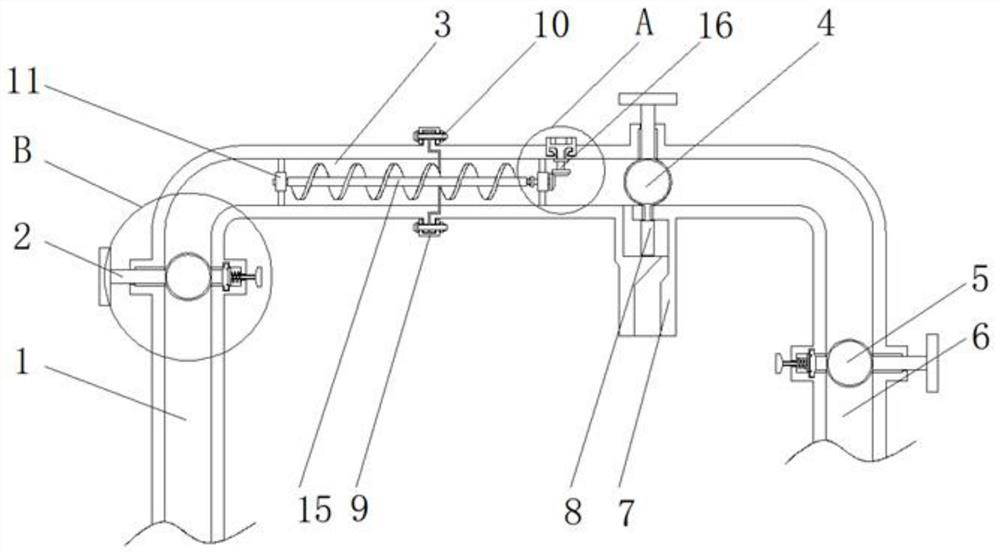

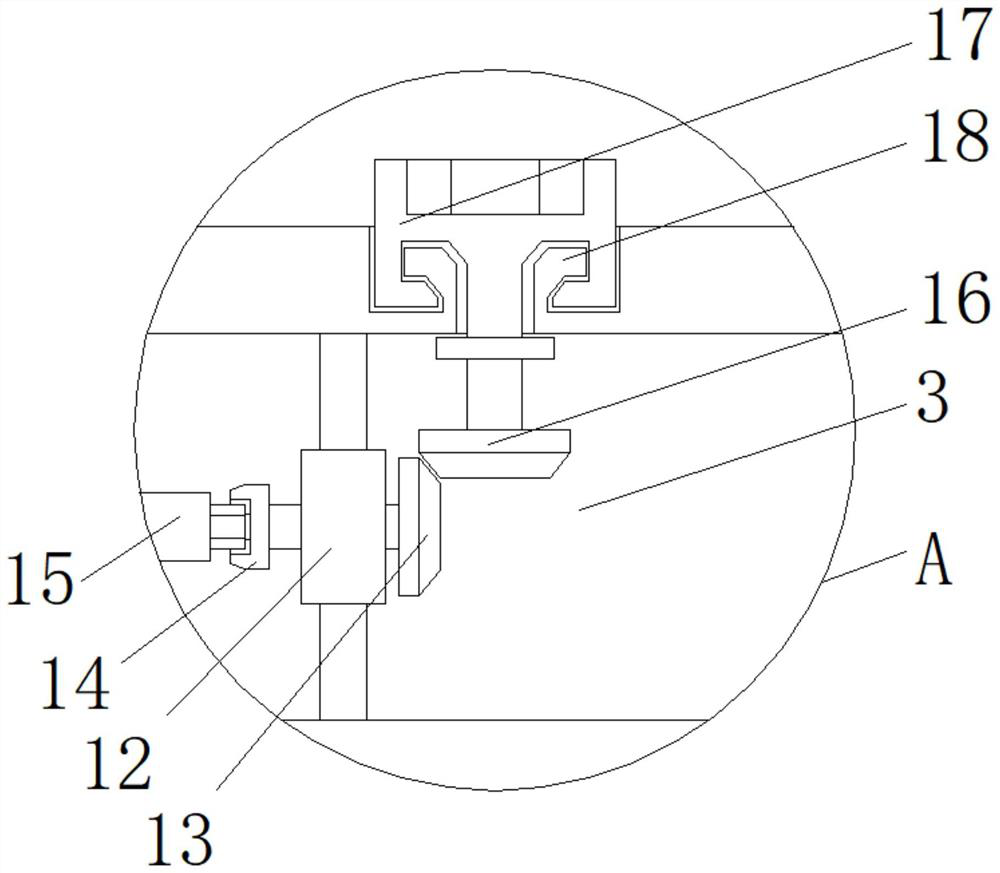

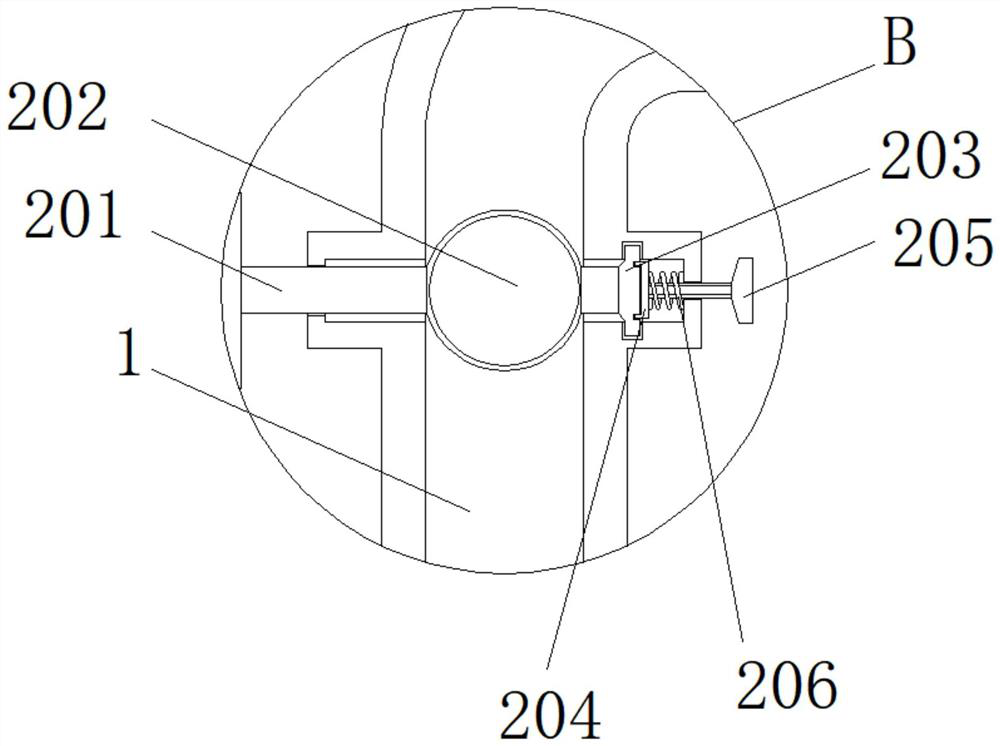

Ternary wellhead combination valve for water mixing process of oil well valve

ActiveCN112780223APlay a role in separationEasy to collectWell/borehole valve arrangementsSealing/packingGear wheelElectric machinery

The invention relates to the technical field of oil well valves, and discloses a ternary wellhead combination valve for a water mixing process of an oil well valve. The ternary wellhead combination valve comprises an oil inlet pipeline, wherein a master control valve is mounted in the oil inlet pipeline; and the other side of the oil inlet pipeline is fixedly connected with an oil conveying pipeline. According to the ternary wellhead combination valve for the water mixing process of the oil well valve, a device motor connecting piece and a motor connecting piece positioning sleeve are clamped and fixed, so that the connecting stability and sealing property of the device motor connecting piece can be driven; meanwhile, the outer part of the device motor connecting piece is connected with a motor, the motor is started to drive a device bevel gear II to rotate, and a device screw rod is driven to rotate through a linkage relation; and meanwhile, a spiral pipeline is mounted on the outer part of the screw rod, so that materials conveyed in the oil inlet pipeline can be continuously driven to move to the other side, the phenomenon that the materials are difficult to convey due to more impurities in an oil well is prevented, and the effect of increasing power during oil conveying is improved.

Owner:DAQING TIANDEZHONG PETROLEUM SCI & TECH CO LTD

Direct coal liquefaction process using inferior oil

ActiveCN104419436AImprove conversion rateIncrease cetane numberLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesGas phaseReaction temperature

The invention discloses a direct coal liquefaction process using inferior oil. The process comprises the following steps: carrying out purification treatment on inferior oil, carrying out vacuum distillation or atmospheric distillation on the inferior oil subjected to purification treatment, and cutting the factions into light oil fractions at a temperature lower than 230 DEG C and heavy oil fractions at a temperature higher than 230 DEG C; subjecting a coal oil mixture obtained by mixing pulverized coal with the heavy oil fractions at a temperature higher than 230 DEG C, hydrogen and a catalyst to reaction in a primary reactor at a reaction temperature of 420-460 DEG C, sending a primary reaction product to the upper part of a secondary reactor, enabling a gas phase component in the primary reaction product to flow out from the top of the secondary reactor, enabling solid and liquid components in the primary reaction product to flow down in the secondary reactor to carry out countercurrent contact reaction with hydrogen flowing up at a reaction temperature of 430-480 DEG C, and carrying out fractional distillation after the reaction ends. The process has the effects of obviously improving the production efficiency of direct coal liquefaction and improving the quality of naphtha and diesel products, and is suitable for the large-scale direct coal liquefaction industry.

Owner:任相坤

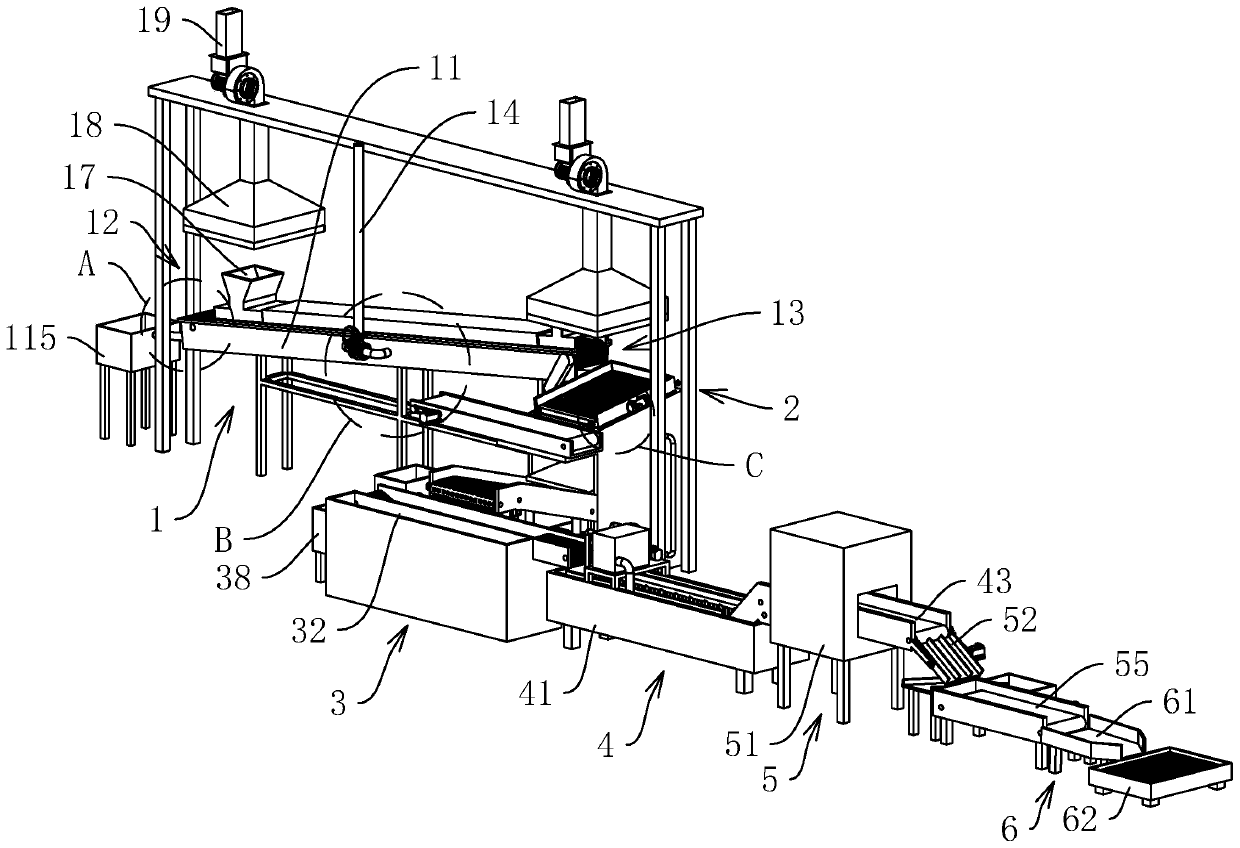

Clam meat processing production line

ActiveCN111194764AQuality improvementPlay a cleaning roleShellfish/bivalves grading/classificationFood shapingProcess engineeringClam shell

The invention relates to the technical field of clam meat processing equipment, and particularly relates to a clam meat processing production line. According to the technical scheme, the clam meat processing production line comprises a cooking machine, a clam meat and clam shell separation device, a clam meat blanching machine, a bubble machine, an X-ray screening machine and a receiving device which are arranged in sequence, the clam meat and clam shell separation device comprises a rack and a vibrating screen arranged on the rack, the vibrating screen is arranged at a discharging port of thecooking machine, a first driving piece used for driving the vibrating screen to vibrate is arranged on the rack, and a conveying device is arranged on the rack and located below the vibrating screen.The cooking machine body heats the clam at a high temperature through steam. The clam meat and the clam shells are separated through the vibrating screen, the clam meat and the clam shells can be further separated through the bleaching machine, the clam meat is deeply cleaned through the bubble machine, finally the clam meat is screened through the screening machine, and finally the screened clammeat is moved into the collecting device.

Owner:苏州泰进食品有限公司

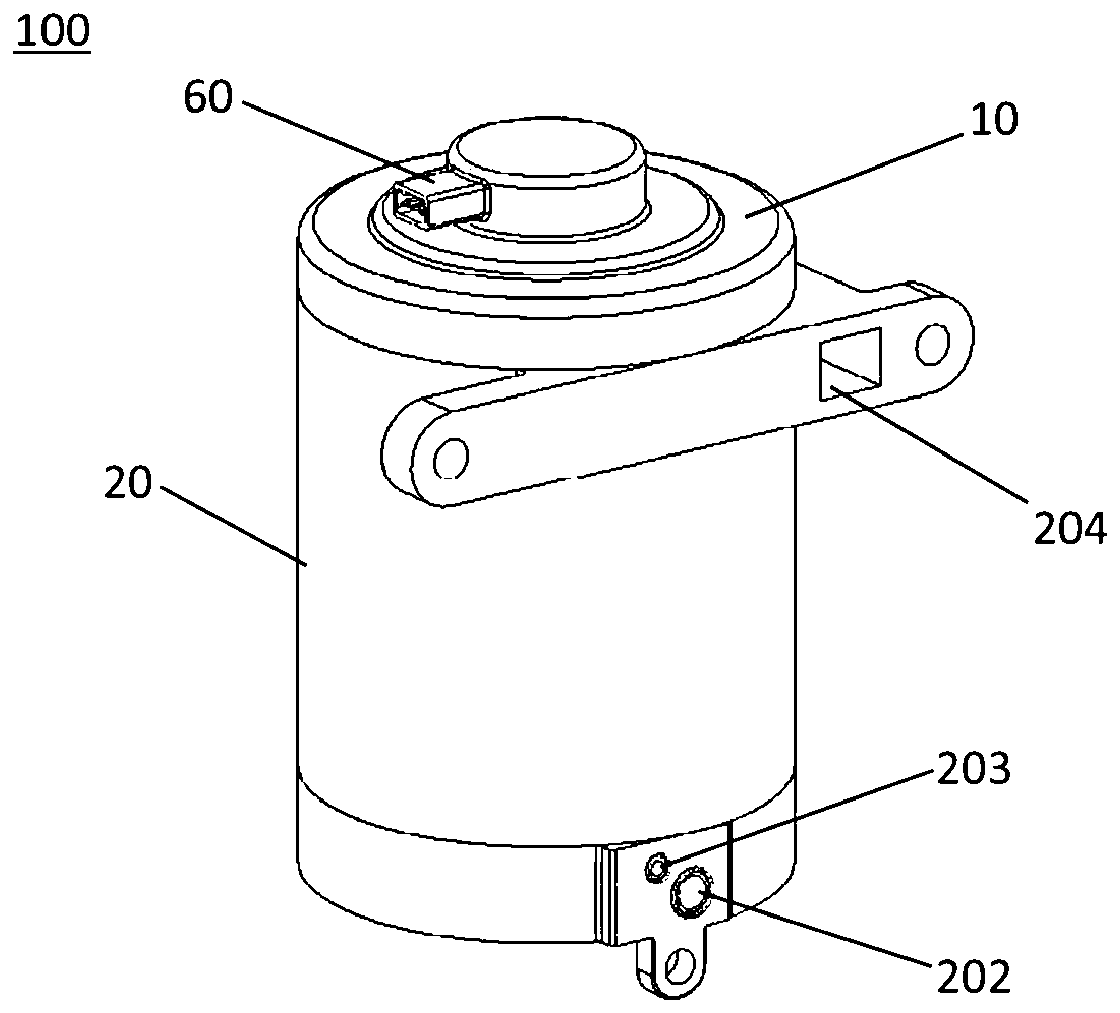

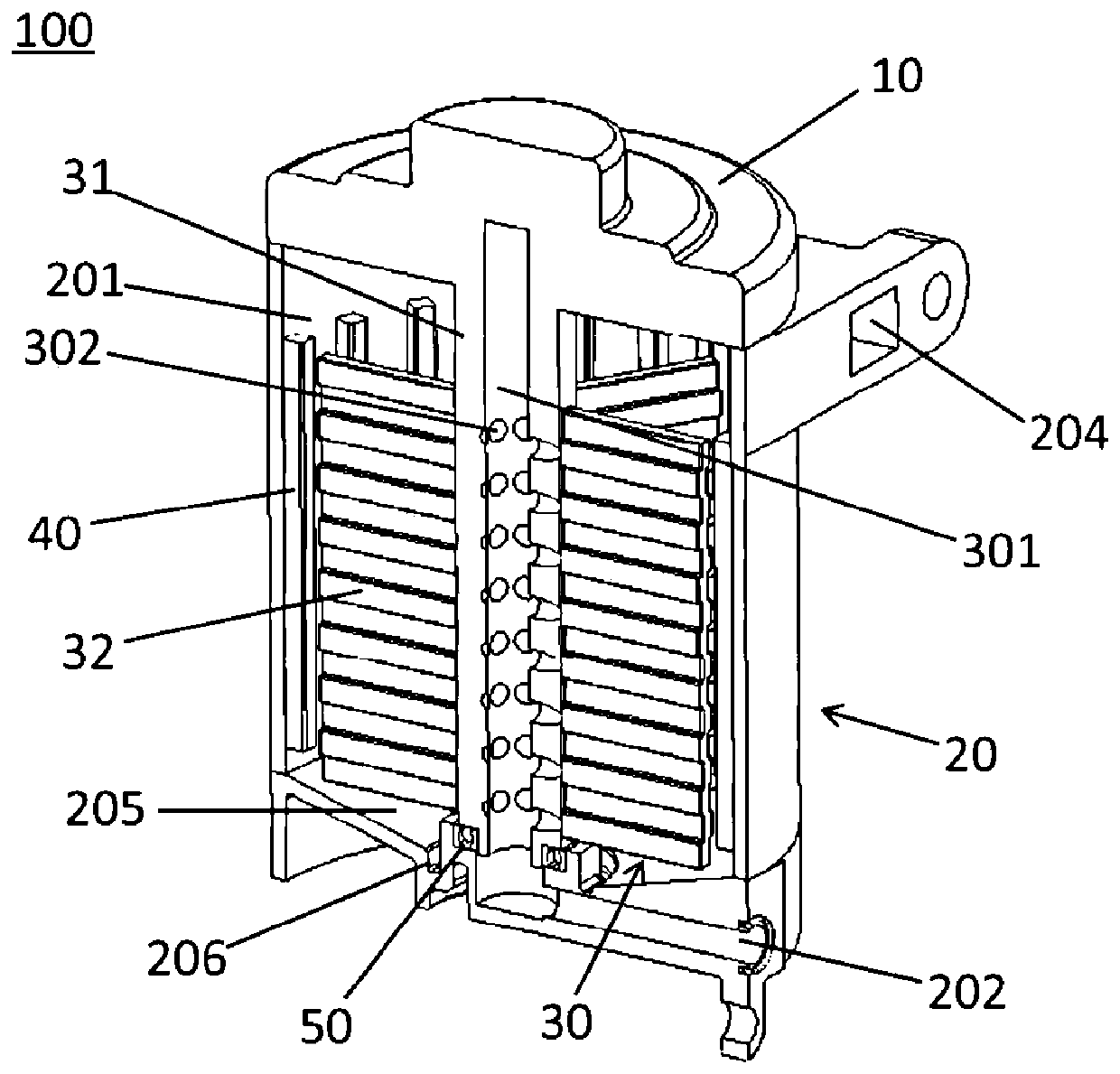

Active oil-gas separator

ActiveCN110173325APlay a role in separationIncrease centrifugal forceMachines/enginesCrankcase ventillationEngineeringCrankcase

The invention provides an active oil-gas separator, and belongs to the technical field of engines. The active oil-gas separator comprises a motor and a rotating device, wherein the motor comprises a body, a first storing cavity is formed in the body, an oil-gas inlet and an oil return opening located in the bottom of the first storing cavity are formed in the body, one end of the oil-gas inlet communicates with a crankcase of an engine, the oil returning opening is used for communicating with the first storing cavity and the crankcase of the engine, and a gas outlet is used for communicating with the first storing cavity and an air intake system of the engine; and the rotating device is arranged in the first storing cavity and comprises a rotating column and a plurality of blades extendingout of the rotating column in the radial direction, the rotating column is connected with the motor so as to drive the blades to rotate, a second storing cavity communicating with the oil-gas inlet is formed in the rotating column, and a plurality of oil-gas spraying openings communicating with the first storing cavity and the second storing cavity are formed in the side wall of the rotating column. The active oil-gas separator can effectively improve the efficiency of the oil-gas separation.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com