Upper flange component and compressor

A component and flange technology, which is applied in the field of upper flange components and compressors, can solve problems such as adverse effects of heat exchangers and affect the performance of air conditioning systems, and achieve the effect of avoiding oil volume decline and reducing oil output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

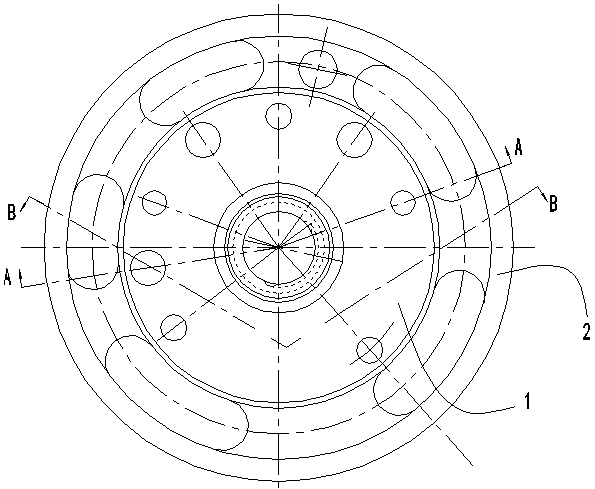

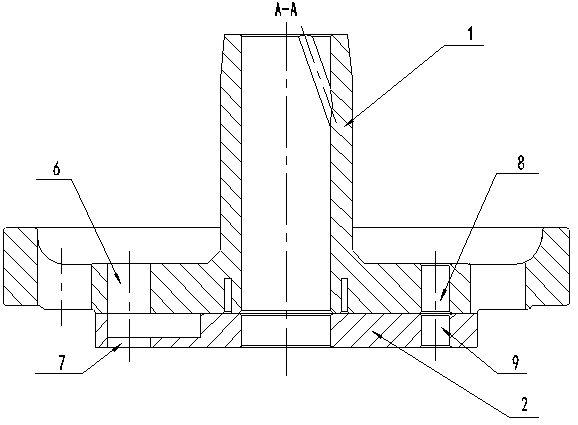

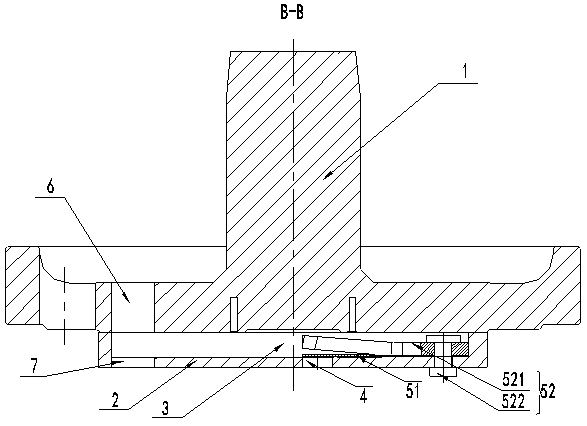

[0026] Such as Figure 1-3 As shown, an upper flange assembly includes a bearing 1 and an exhaust baffle 2, the exhaust baffle 2 is bolted to the lower end of the bearing 1, an air flow channel 3 is opened on the exhaust baffle 2, and the lower end of the air flow channel 3 There is an exhaust hole 4 communicating with the airflow channel 3, and an exhaust valve assembly 5 for controlling the opening and closing of the exhaust hole 4 is fixed in the airflow channel 3, and a bearing exhaust channel 6 communicating with the airflow channel 3 is opened on the bearing 1 The end of the exhaust partition 2 away from the exhaust hole 4 is also provided with a partition exhaust passage 7 communicating with the air flow passage 3 . When the compressor is working, after the high-pressure chamber reaches the exhaust pressure, the exhaust valve assembly 5 is squeezed open by the pressure, so that the oil-air mixture is discharged through the exhaust hole 4, and then the through-flow air p...

Embodiment 2

[0034] Such as Figure 6 As shown, the difference between the present embodiment and the first embodiment is that the air flow passage 3 is inclined to the axis line of the exhaust partition 3, and at the same time, there is a The small hole 17 communicates with the air flow channel.

[0035] The advantage of this embodiment is that the channel wall of the airflow channel 3 can be inclined, so that the refrigerated oil can flow into the oil pool from the exhaust hole 4 and the small hole along the airflow channel 3 .

[0036] The beneficial effects of the present invention are as follows: due to the arrangement of bearings and exhaust baffles, when the compressor is working, after the high-pressure chamber reaches the exhaust pressure, the exhaust valve assembly is squeezed and opened by the pressure, so that the oil-gas mixture passes through the exhaust hole It is discharged, and then discharged from the bearing exhaust passage to the upper cavity of the compression mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com