Patents

Literature

121results about How to "Reduce oil output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

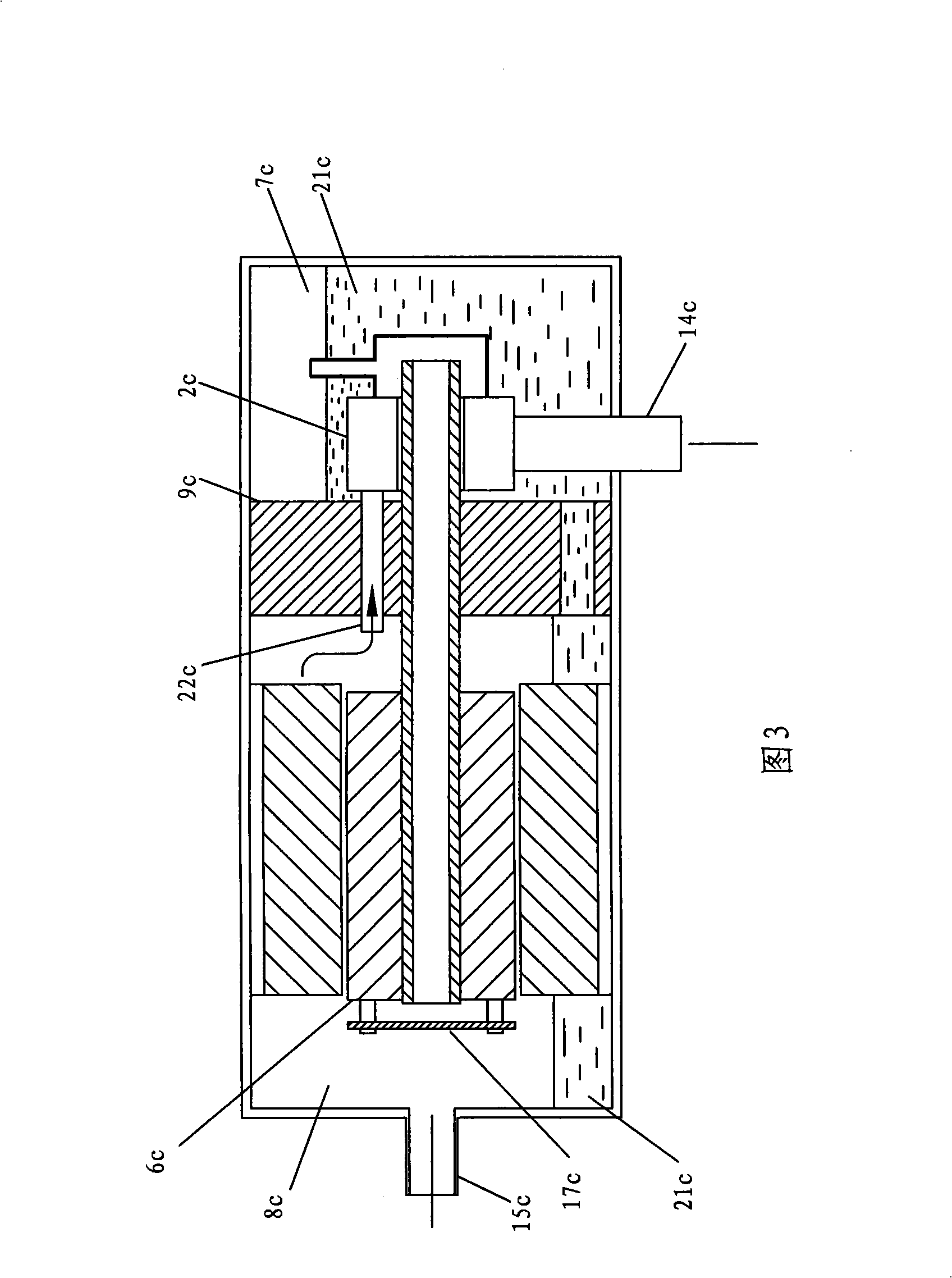

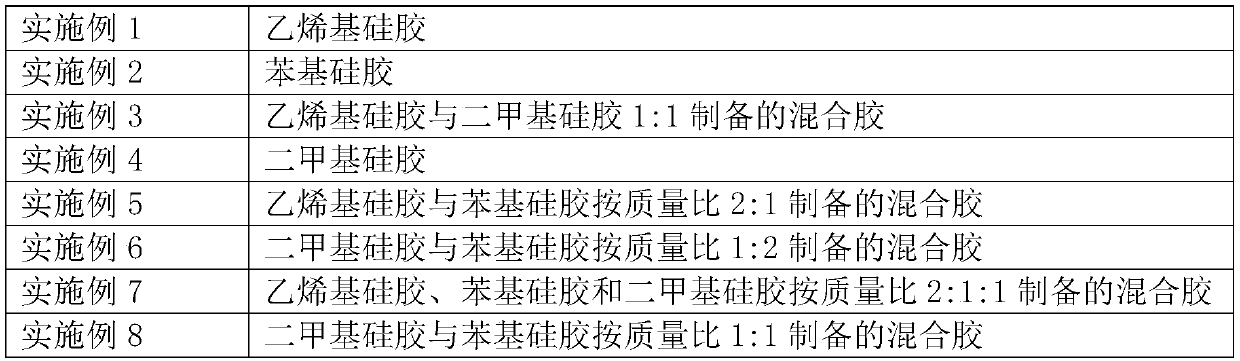

Rotation-type compressor with housing low pressure, control mode of coolant and oil return and applications thereof

ActiveCN101158352AProduction cost advantageEasy to useCompression machines with non-reversible cycleRotary piston pumpsControl mannerEngineering

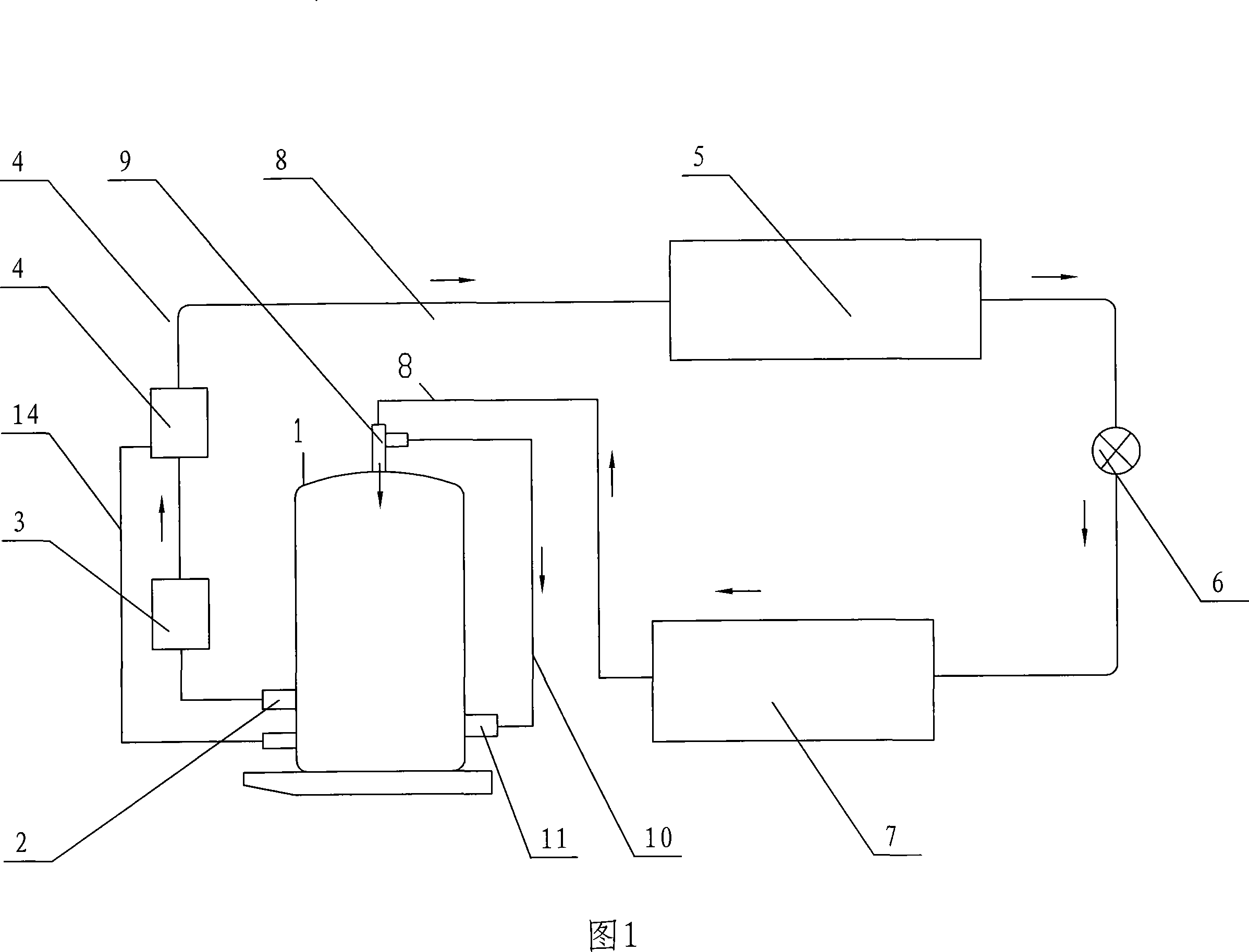

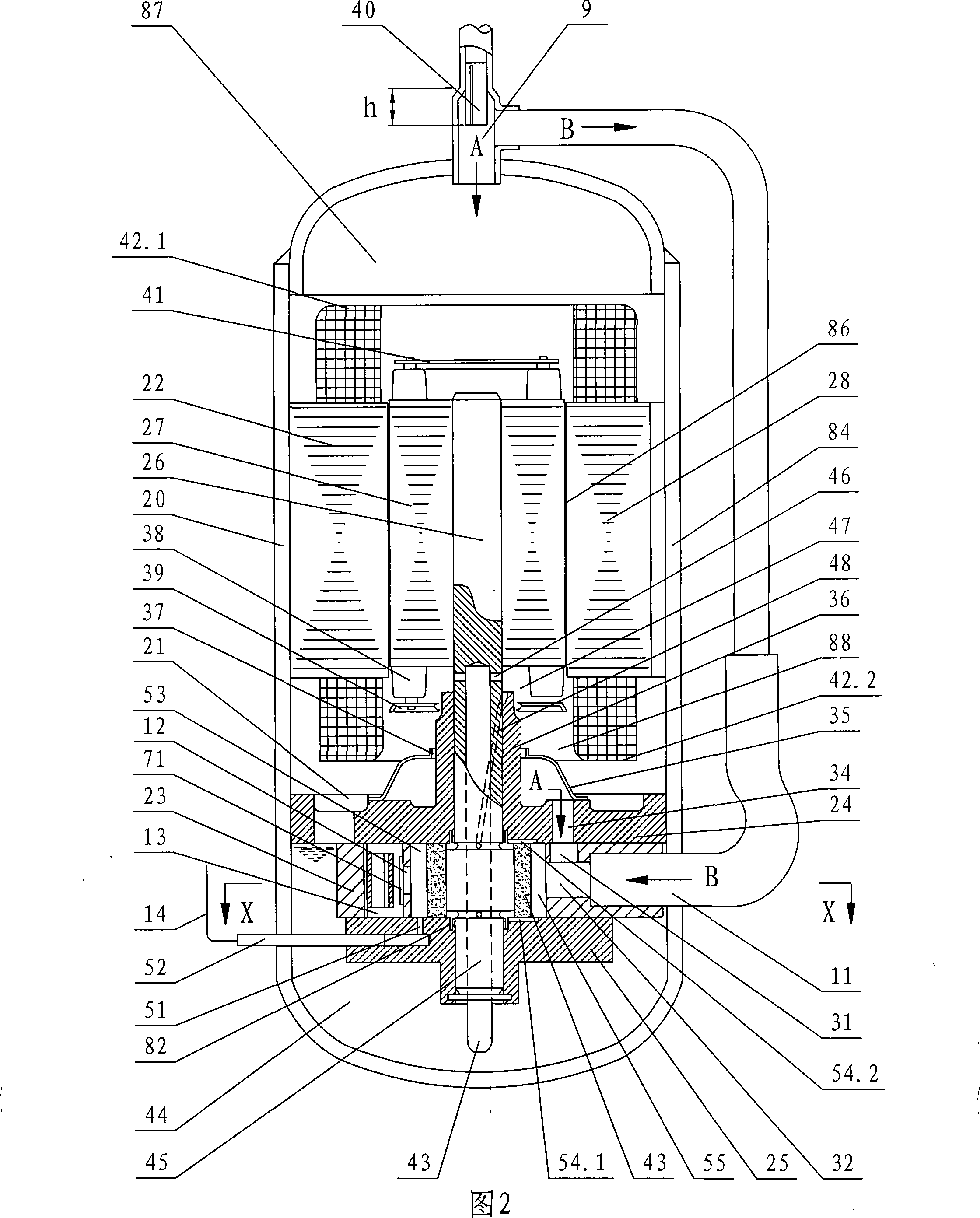

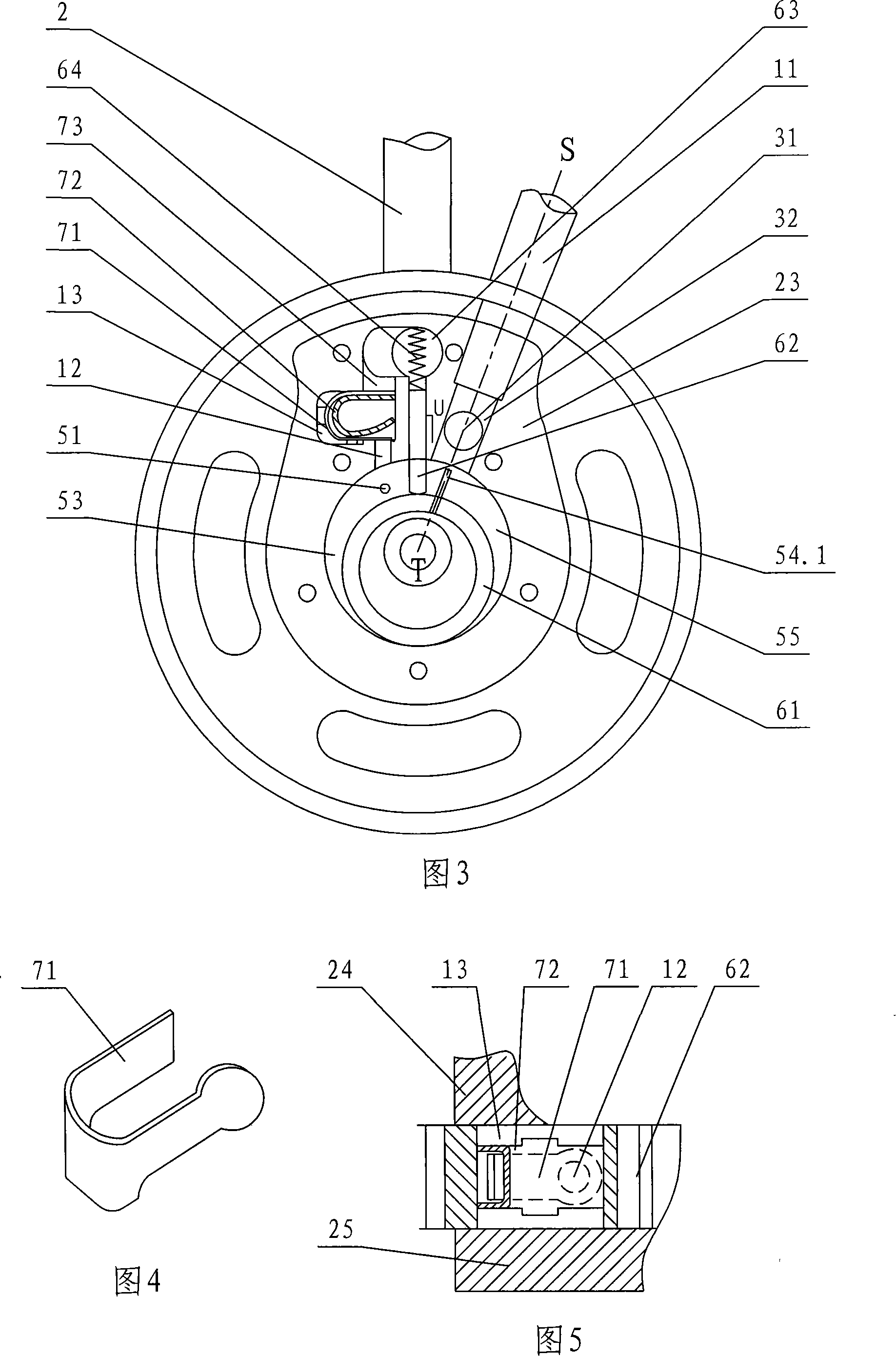

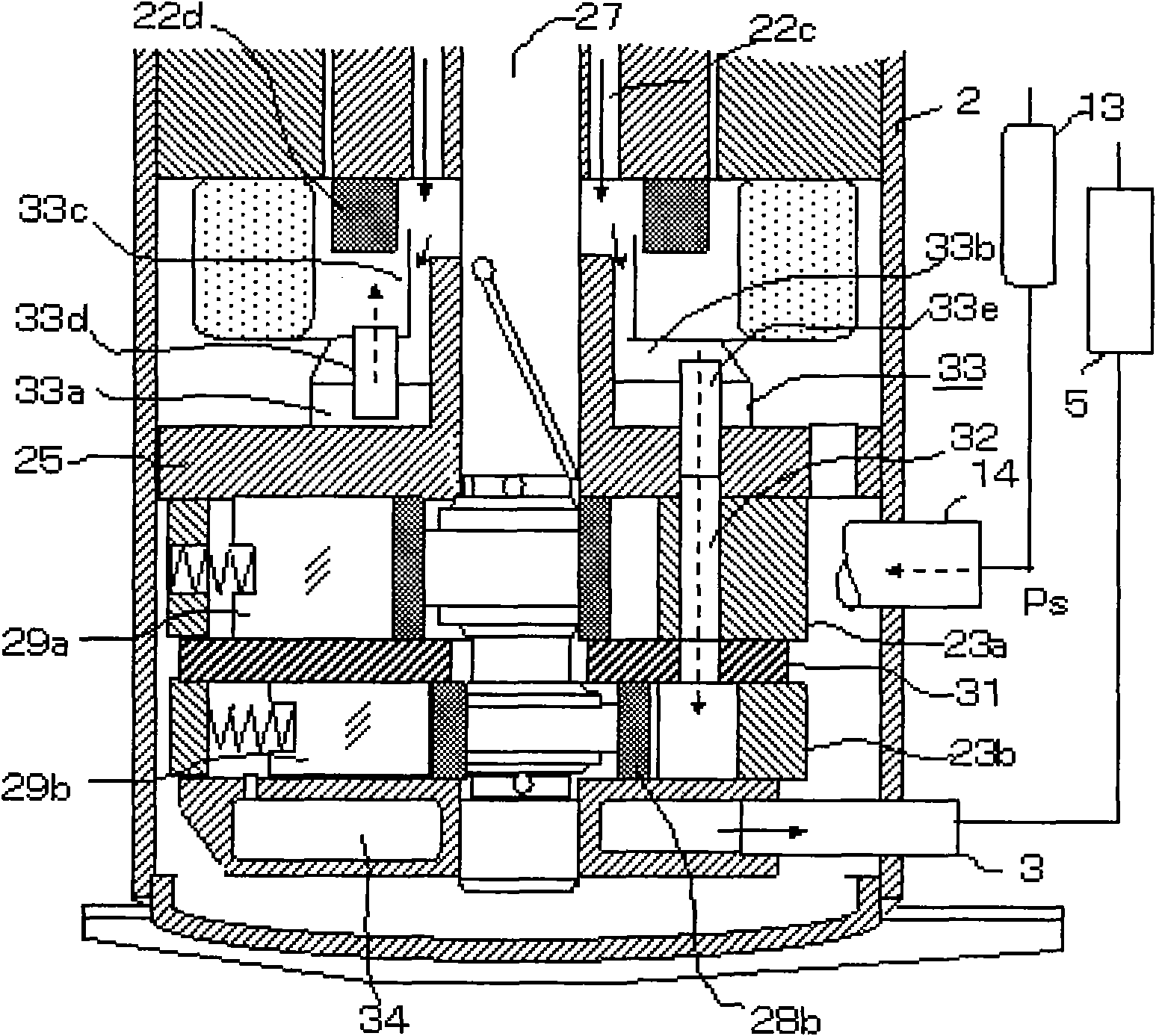

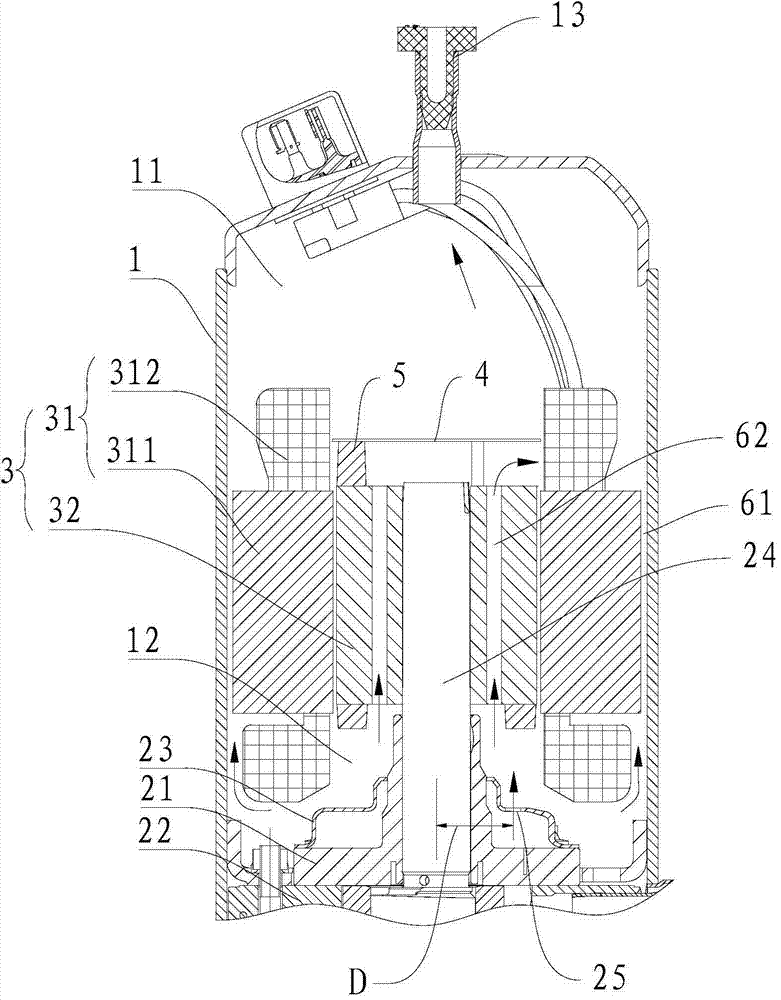

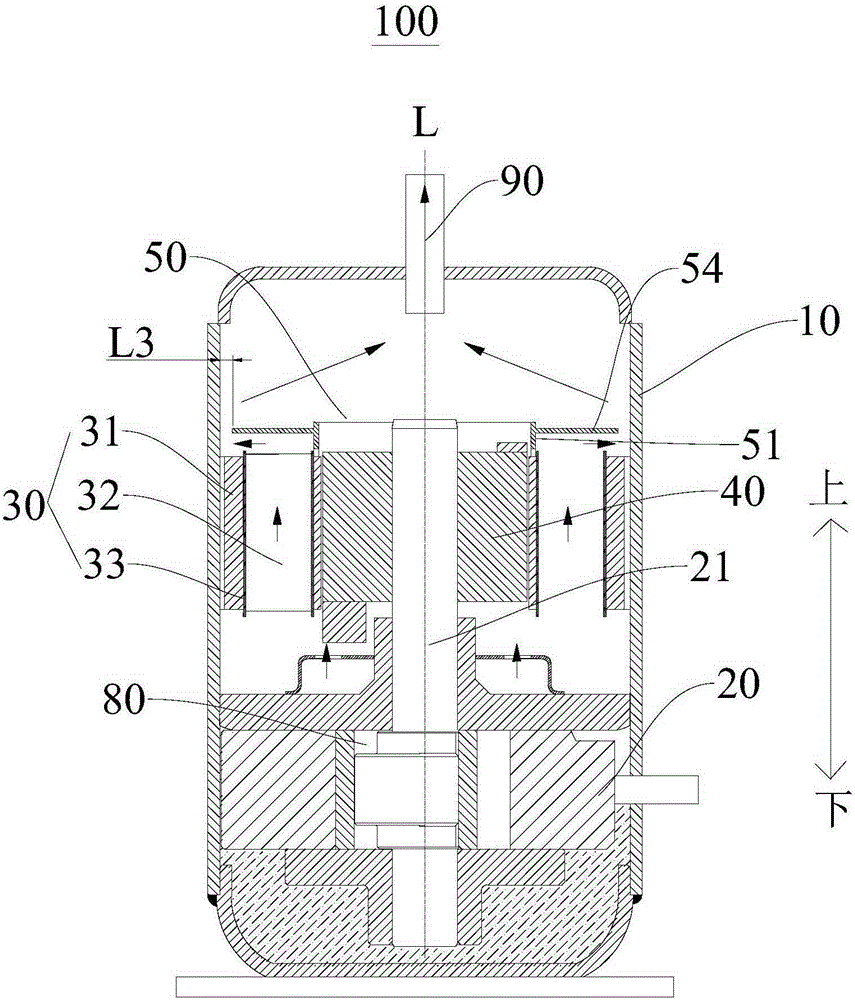

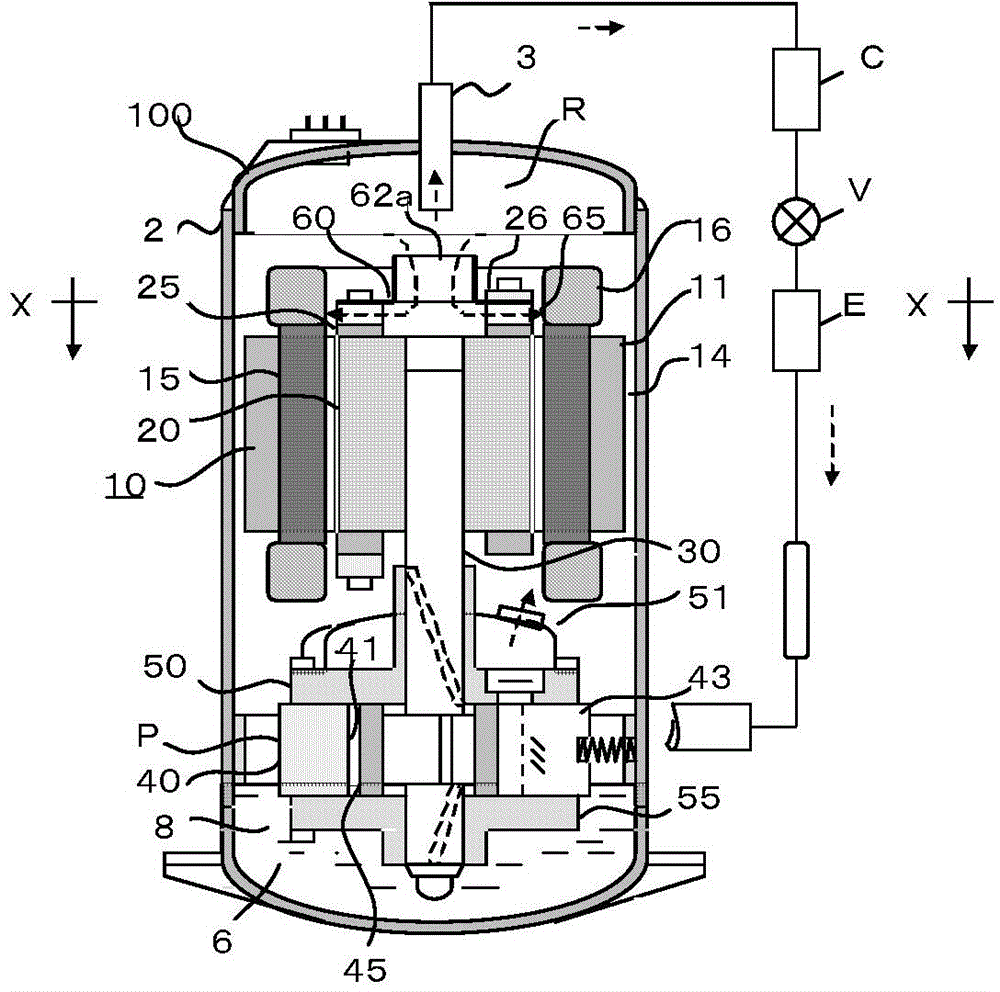

A shell low-pressure rotary compressor and a control type and application for refrigerant and oil return of the compressor comprise a compression component and a motor component arranged in the shell. The compression component comprises one and more cylinders, pistons arranged in the cylinders, sliding pieces arranged in sliding piece trough of the cylinder, an eccentric crankshaft driving the piston and an upper bearing and a lower bearing supporting the eccentric crankshaft; the motor component comprises a motor rotor, and a motor stator; the shell is provided with a refrigerant diffluence device which is arranged on top or side surface of the shell; the refrigerant diffluence device comprises a diffluence pipe which is internally provided with a spring pipe which adjusts the diffluence rate. An air suction muffler is arranged between the motor component and the compression component; a radial spacing is arranged between the air suction muffler and a main bearing, and / or the motor rotor or the eccentric crankshaft or the upper bearing which is provided with a round plate. The invention has the advantages of high safety degree, low manufacture cost, smart operation, good lubrication performance, little oil consumption, high compression efficiency, and long service life.

Owner:GUANGDONG MEIZHI COMPRESSOR

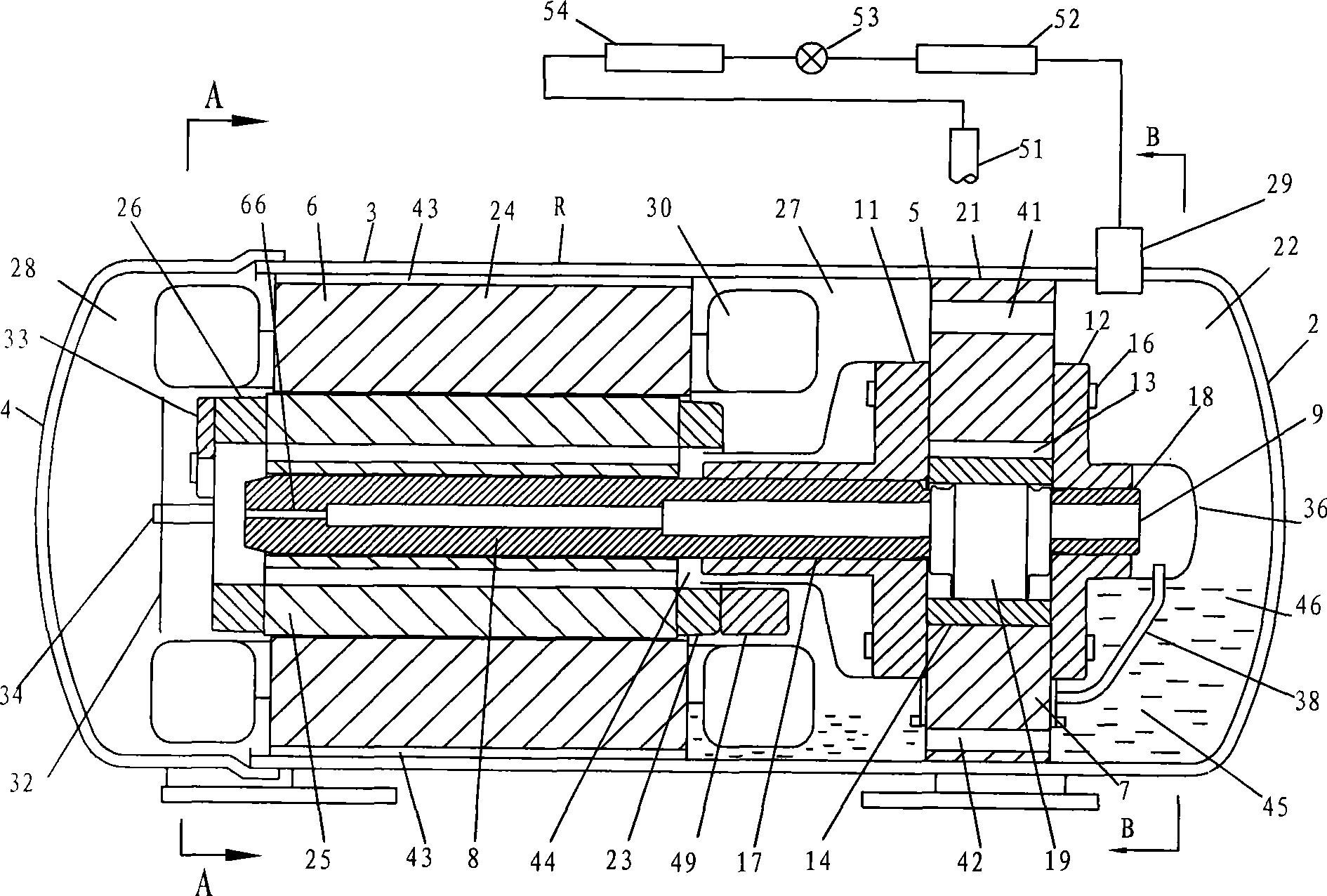

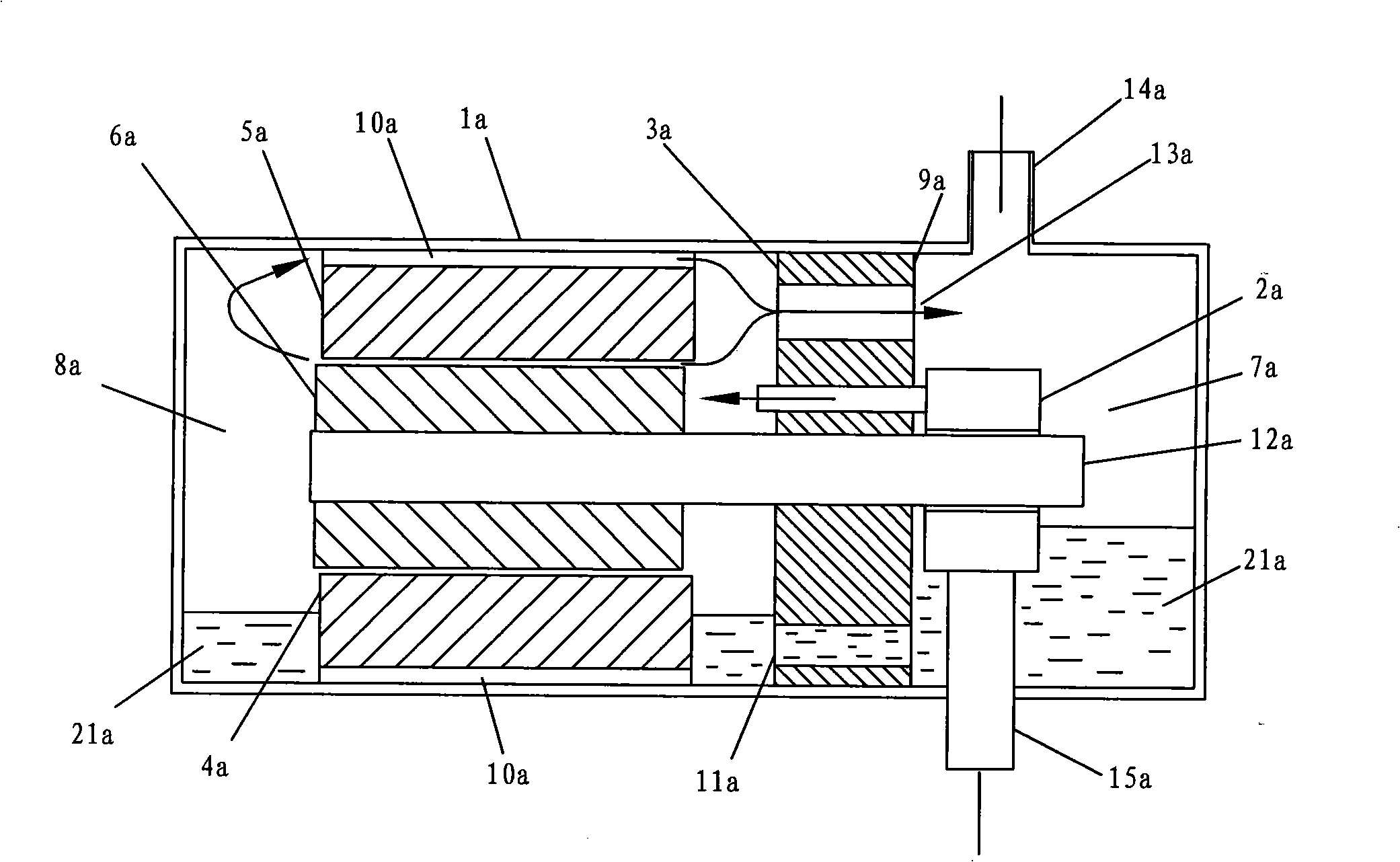

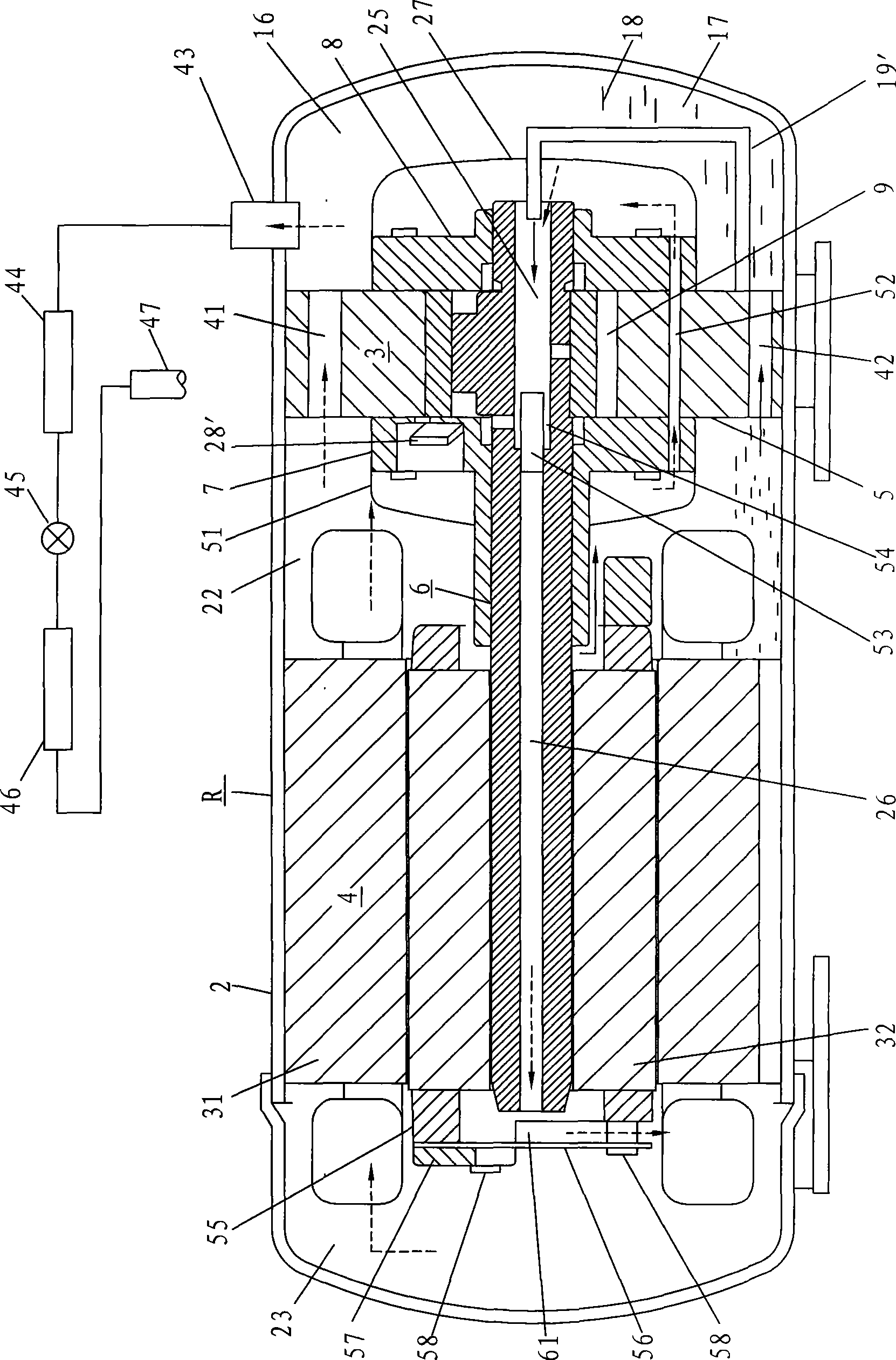

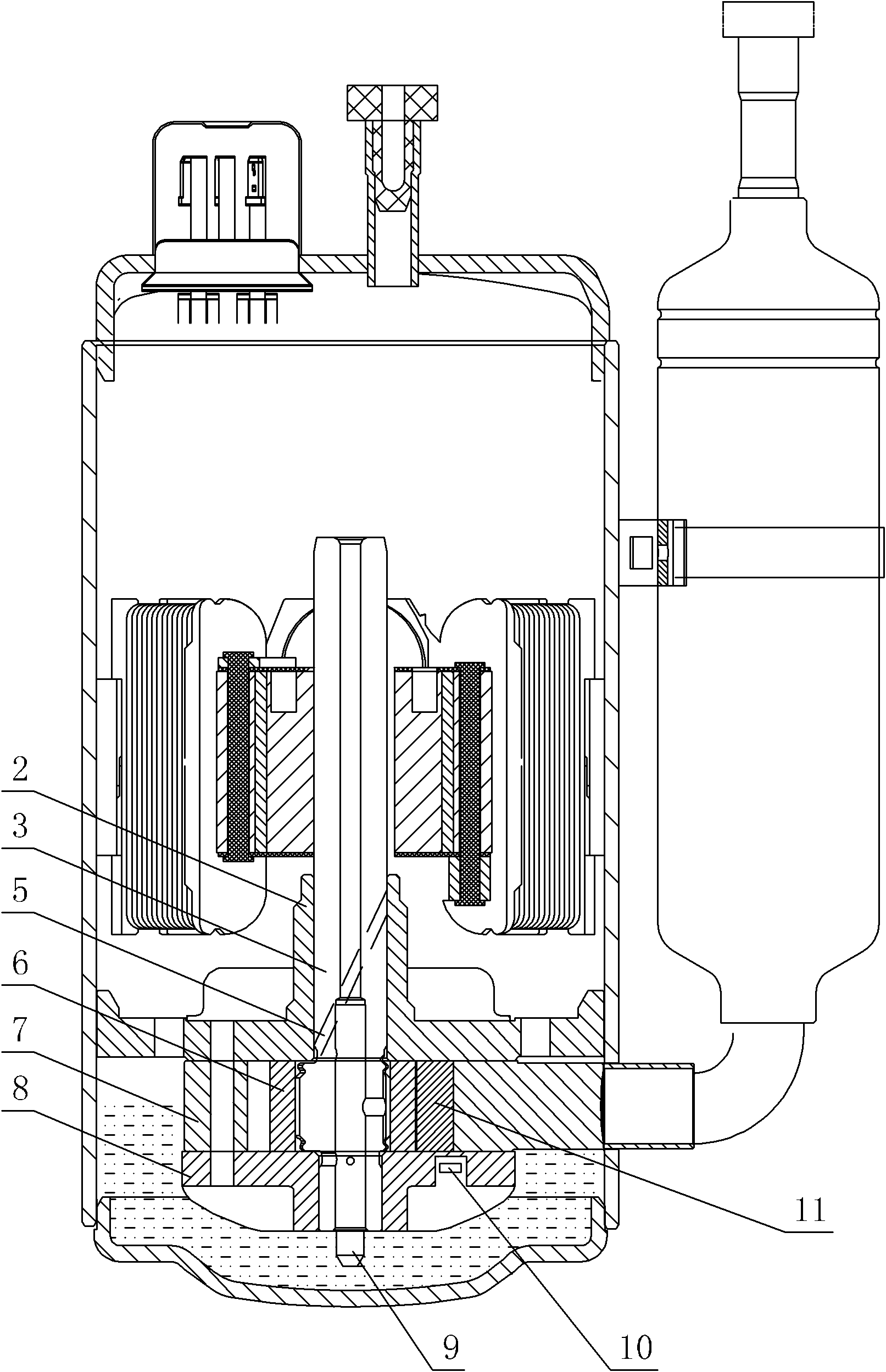

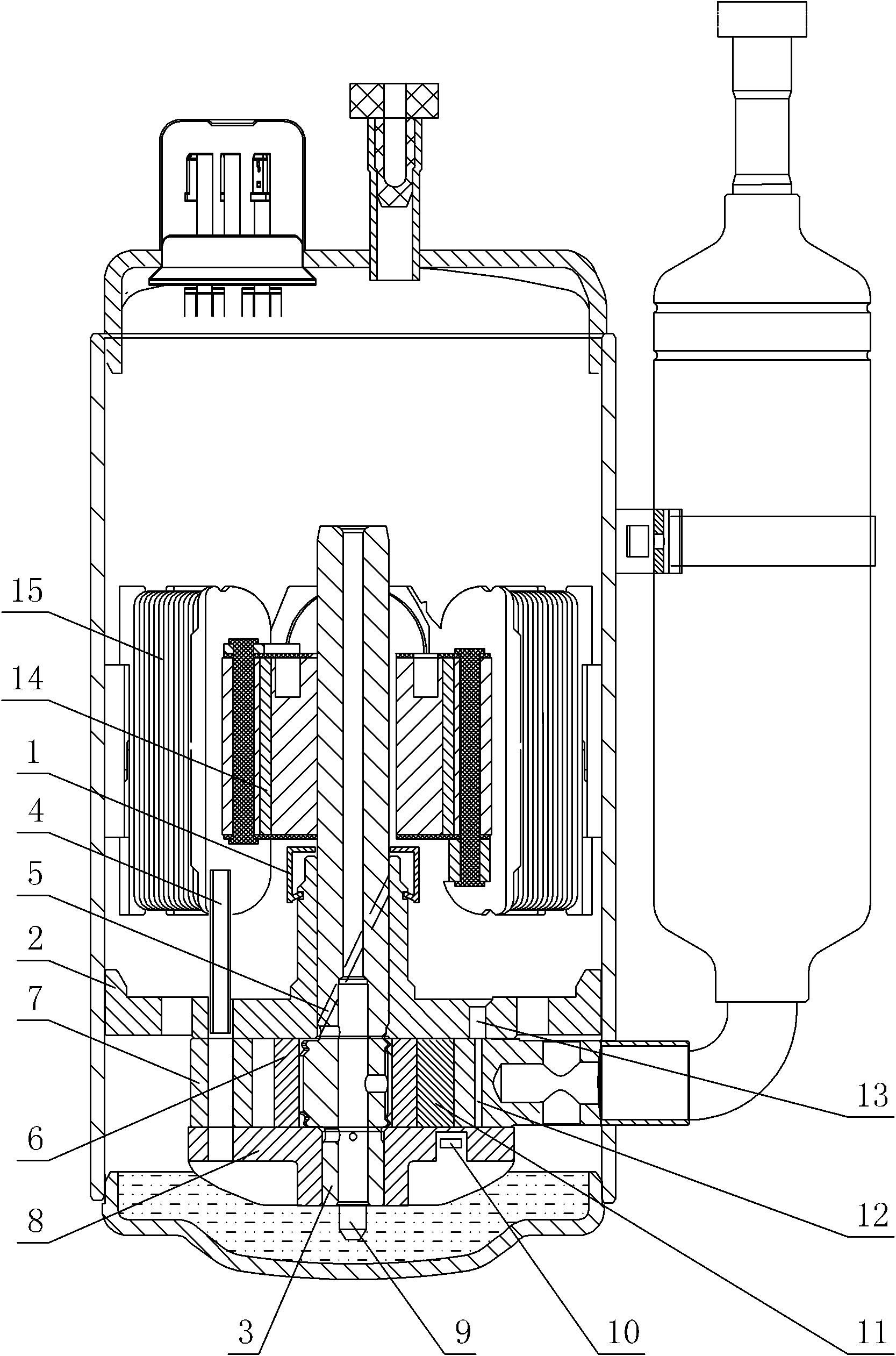

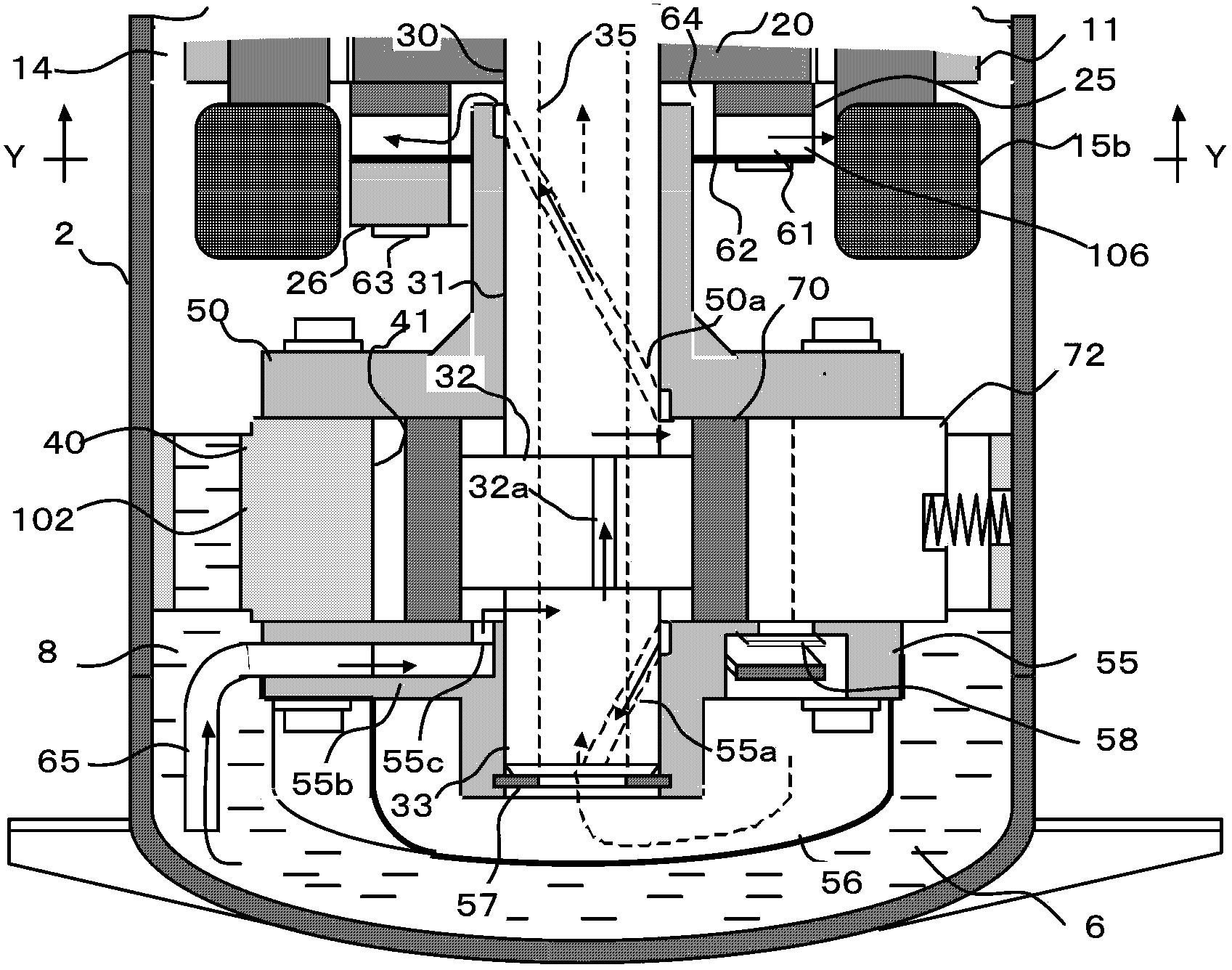

Lubrication apparatus of horizontal rotary compressor and control method thereof

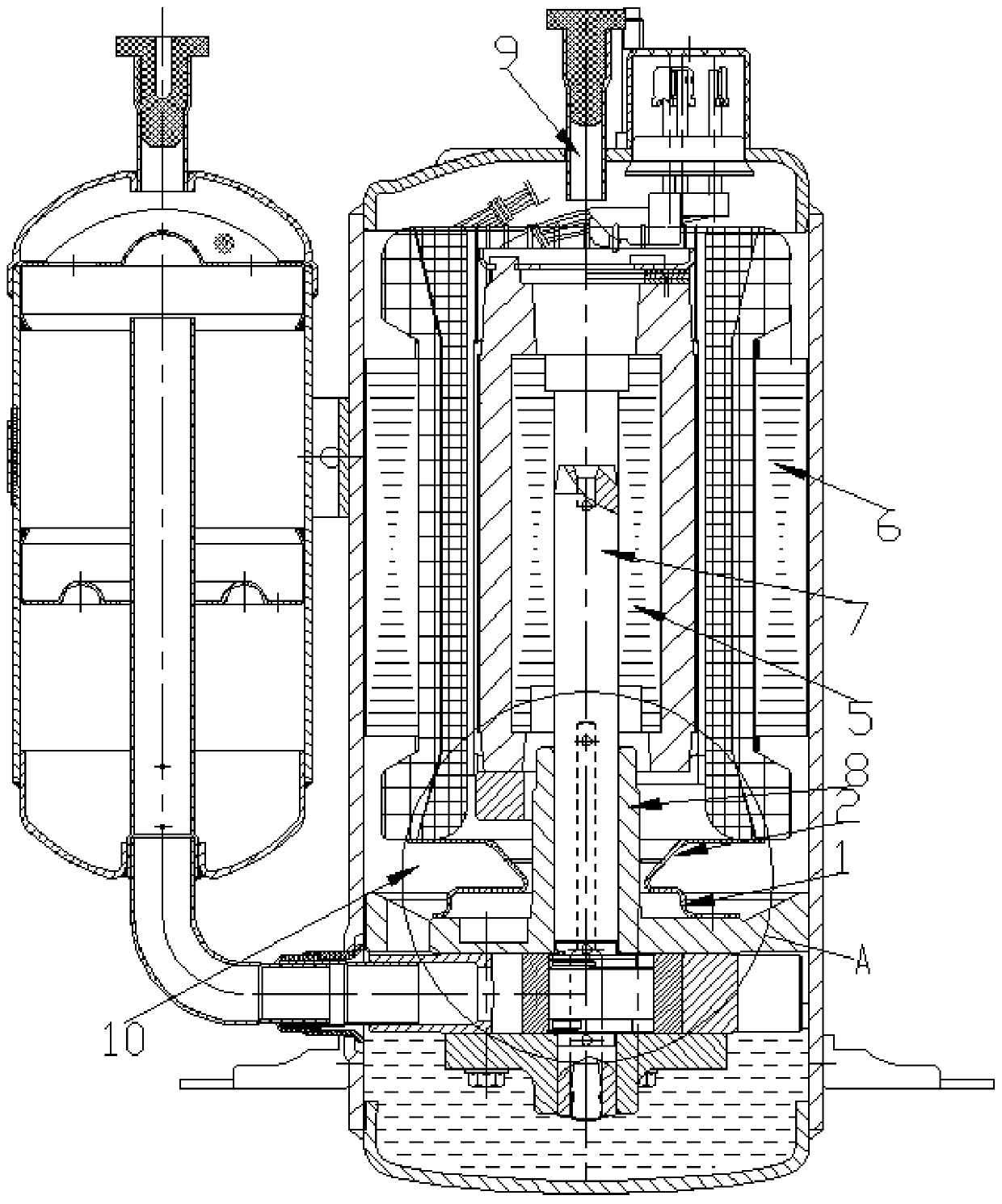

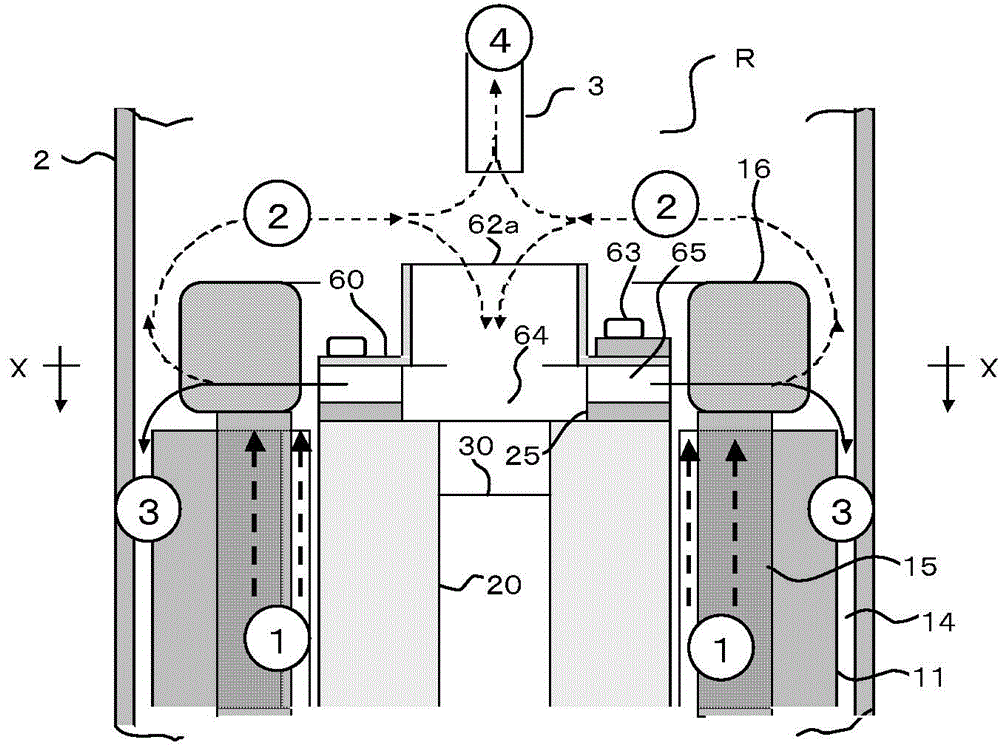

ActiveCN101440811ACool evenlyReduce oil outputRotary piston pumpsRotary piston liquid enginesExhaust gasLubrication

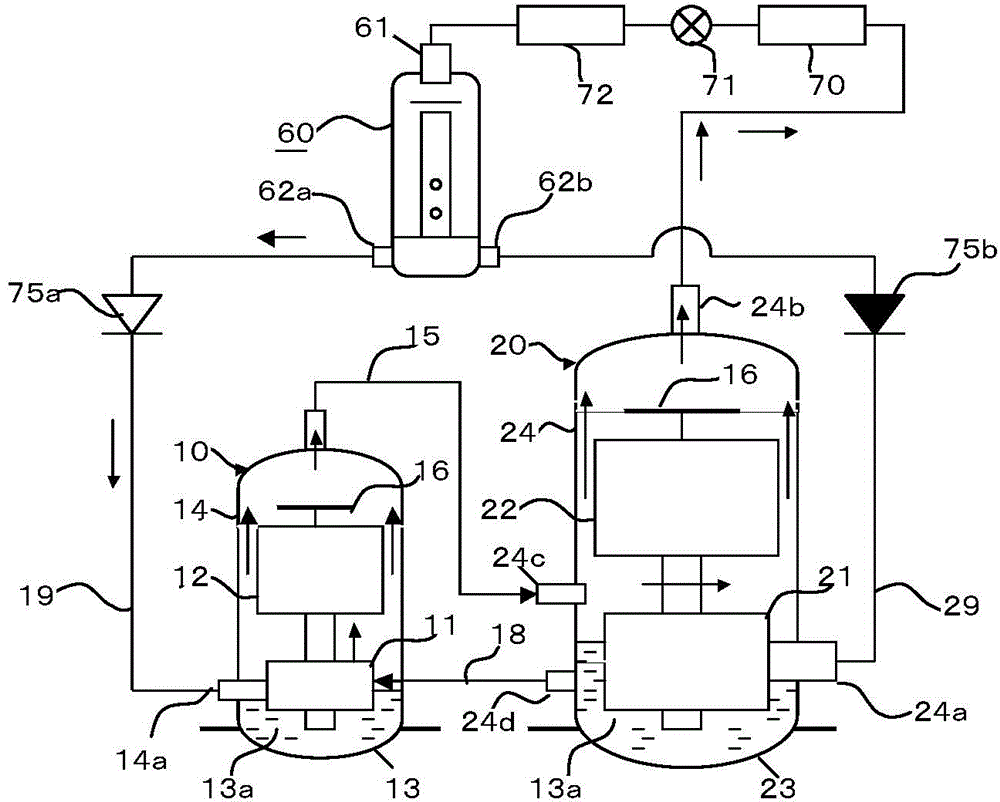

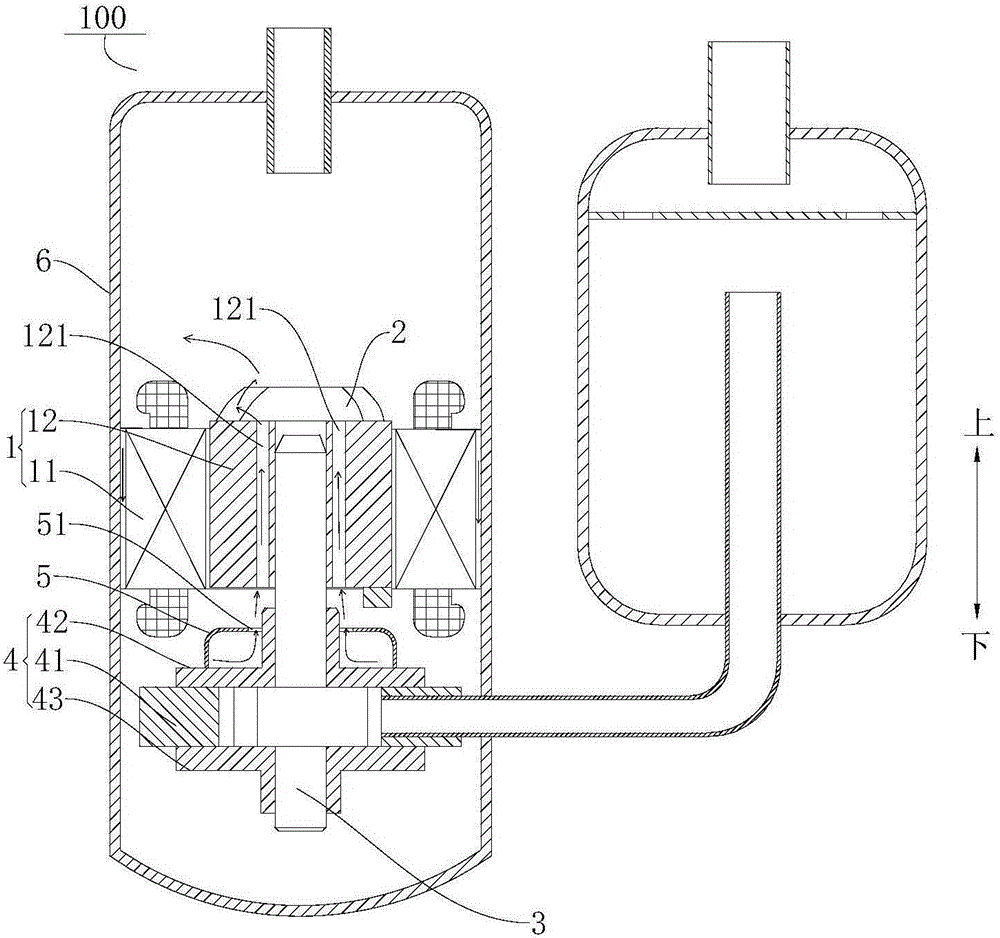

The invention discloses a lubrication device of a horizontal rotary compressor and a control method thereof. The lubrication device comprises a compression component and a motor which are fixed in a closed shell through the periphery thereof respectively; the shell and the motor are divided into an oil chamber, a first motor chamber and a second motor chamber through a cylinder and a main bearing or an auxiliary bearing; the compression component is provided with an exhaust silencer; a rotor is provided with an axially through rotor air hole; an outlet of the exhaust silencer is communicated with the first motor chamber; and one end of the rotor air hole is communicated with the first motor chamber, while the other end is communicated with the second motor chamber. The adoption of the technical proposal can ensure that oil diffused into the closed shell can be mostly recovered and stored in the oil chamber in any working condition of the compressor, thereby continuously supplying oil for the compression component. Moreover, when exhaust gas containing small amount of oil is moved from the second motor chamber to the first motor chamber, the oil can be separated out, so the bleeding oil amount is reduced, and a motor winding can be evenly cooled.

Owner:GUANGDONG MEIZHI COMPRESSOR

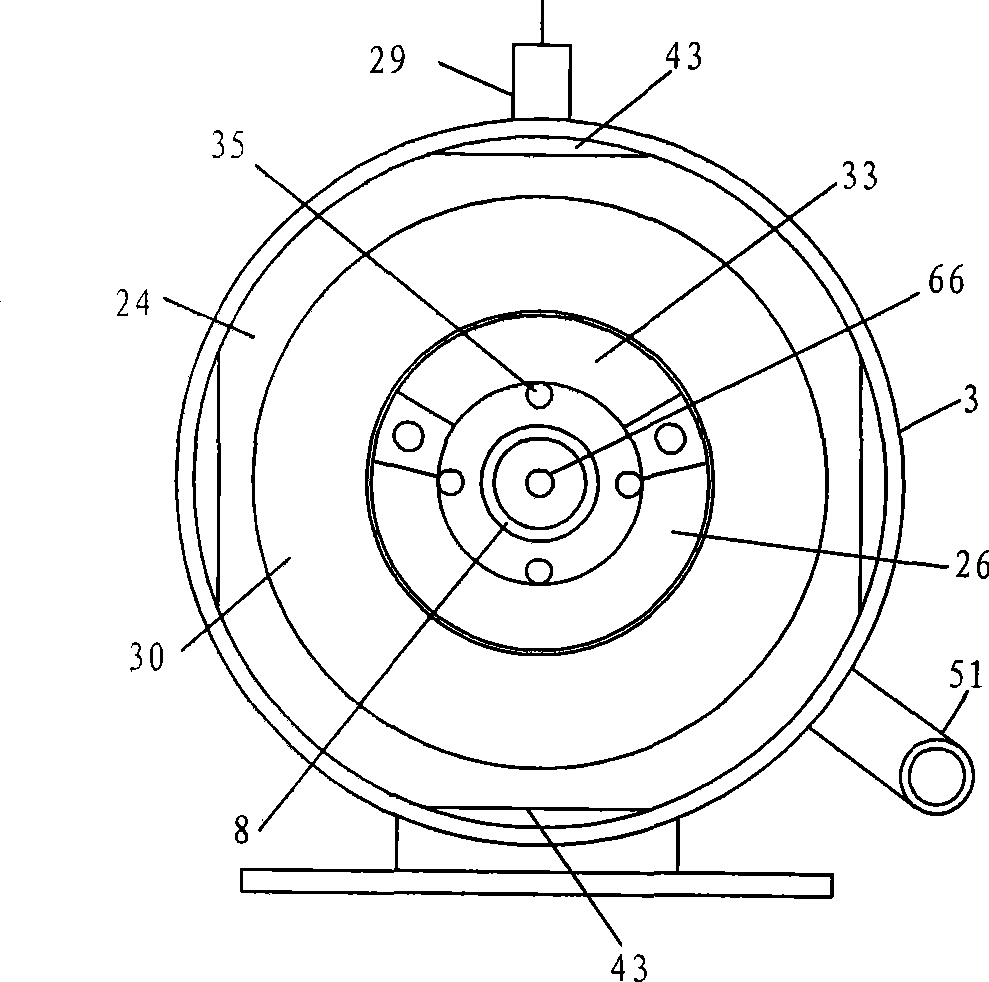

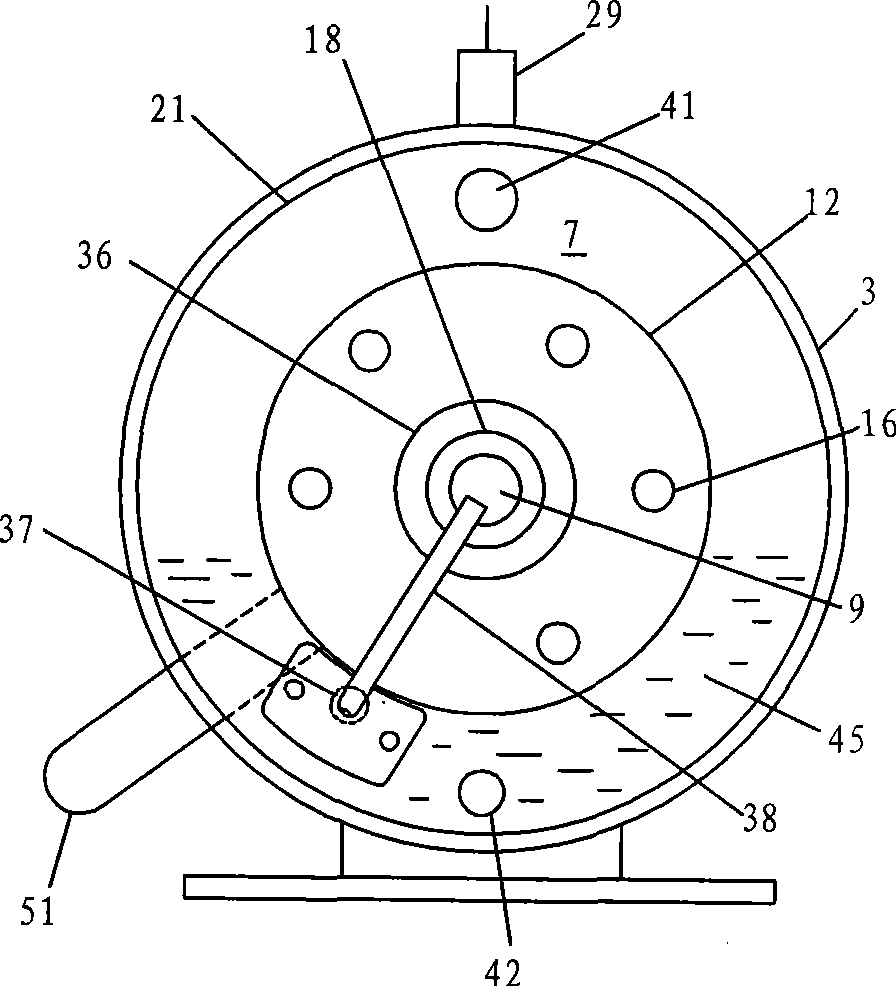

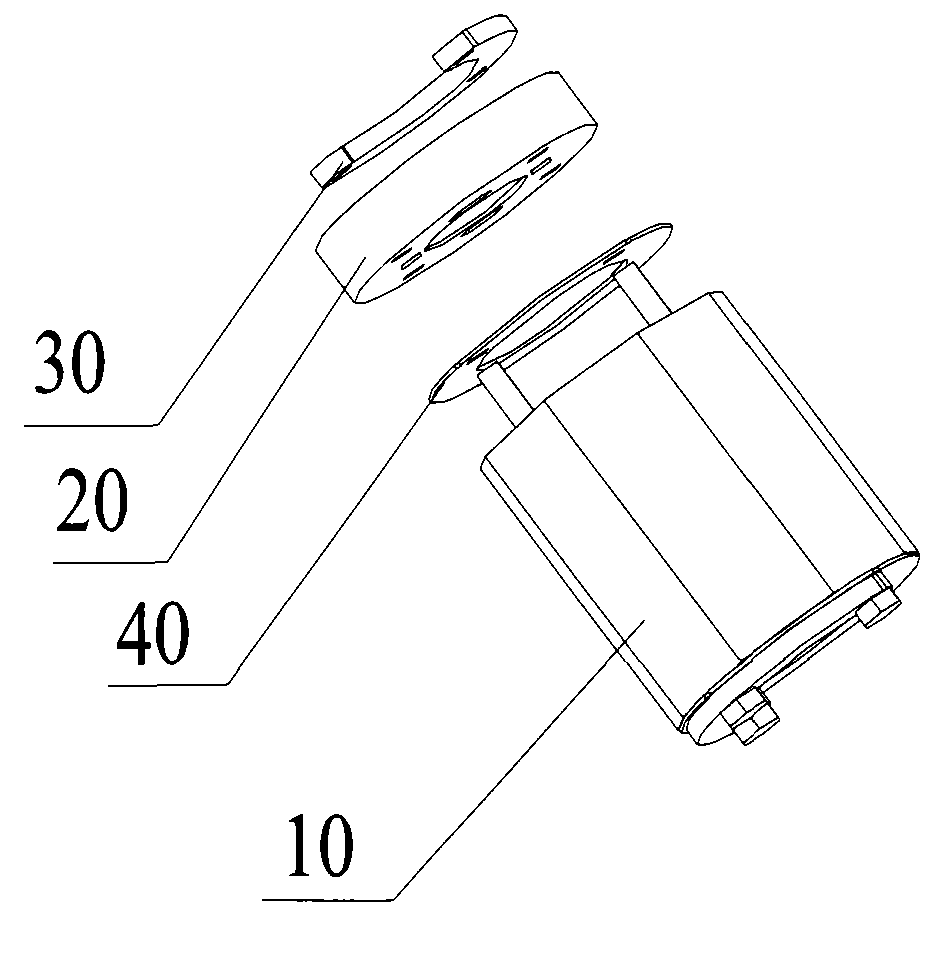

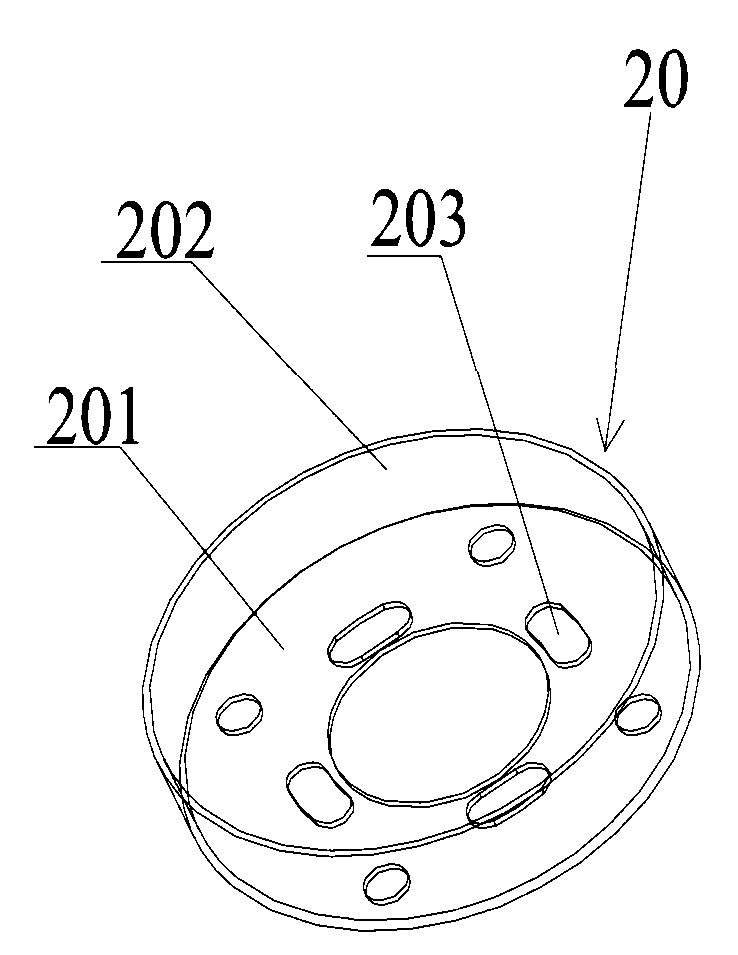

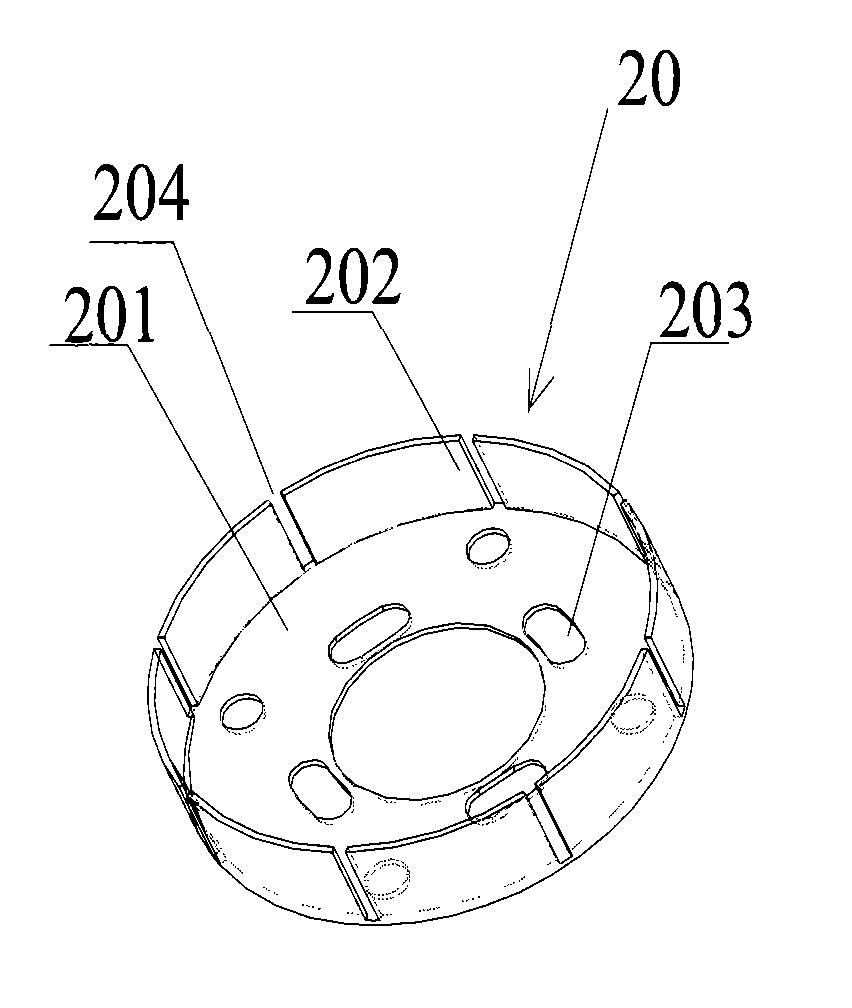

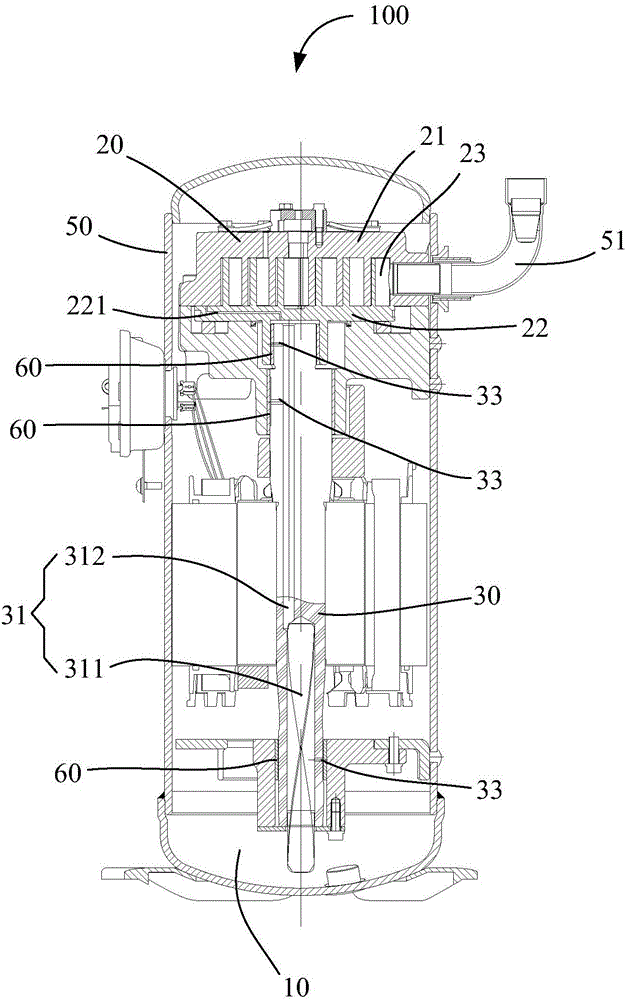

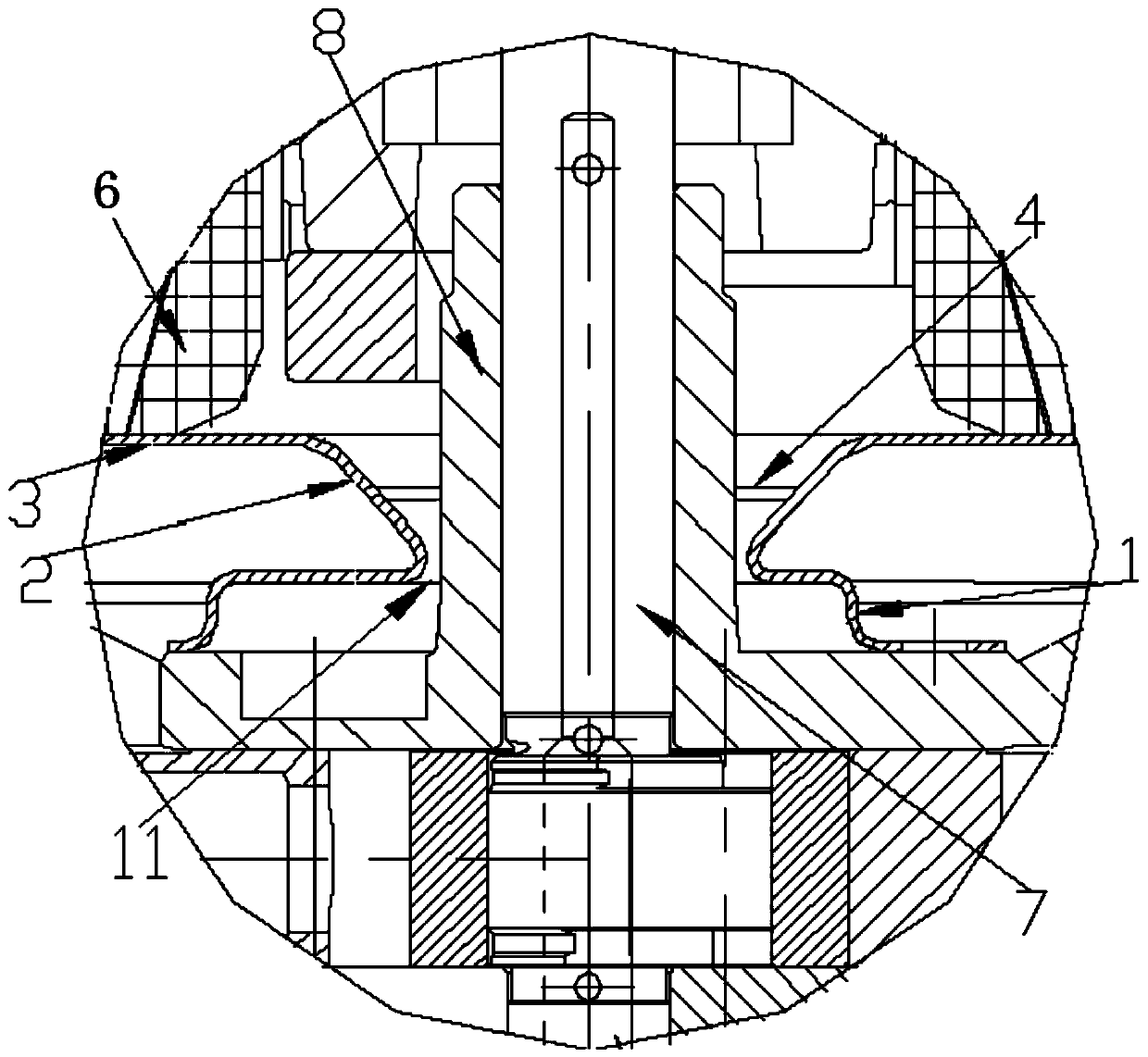

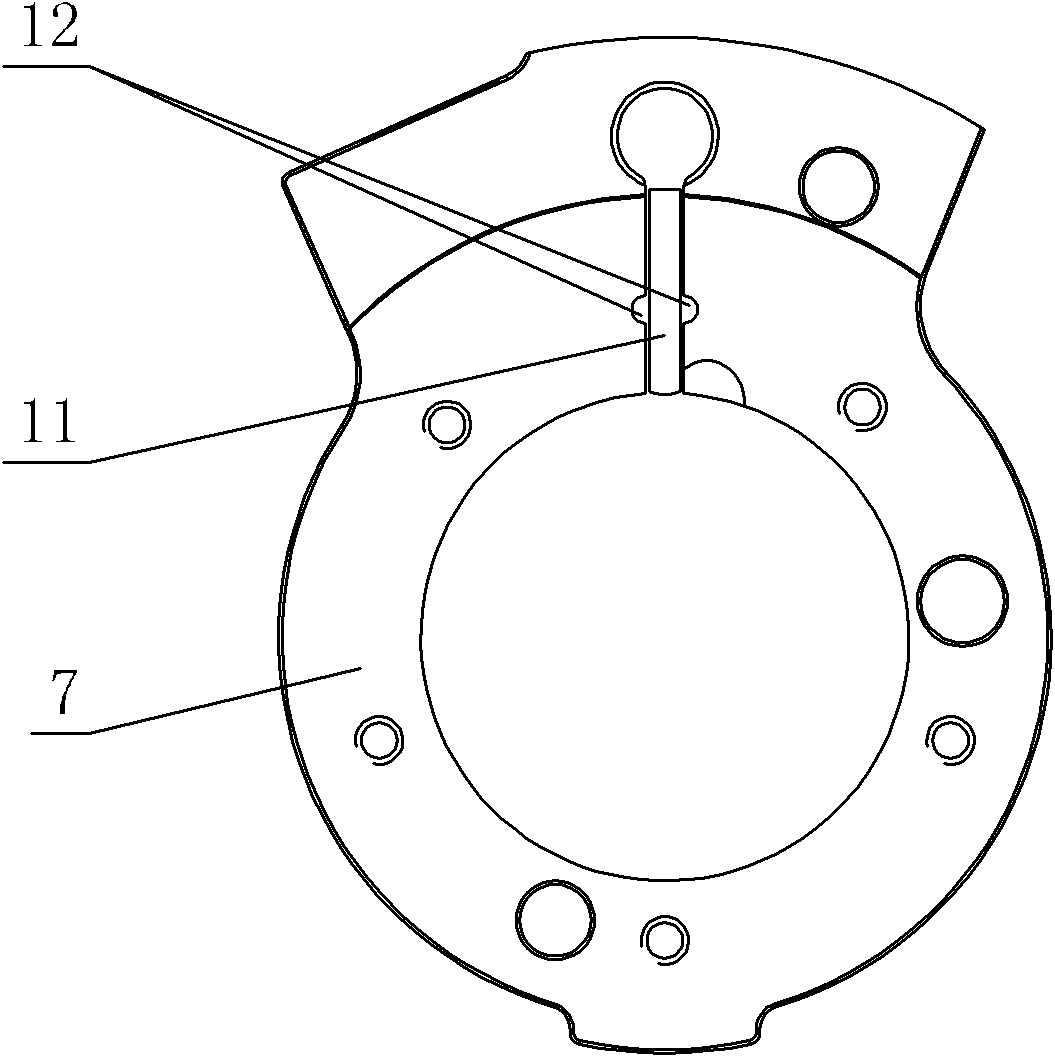

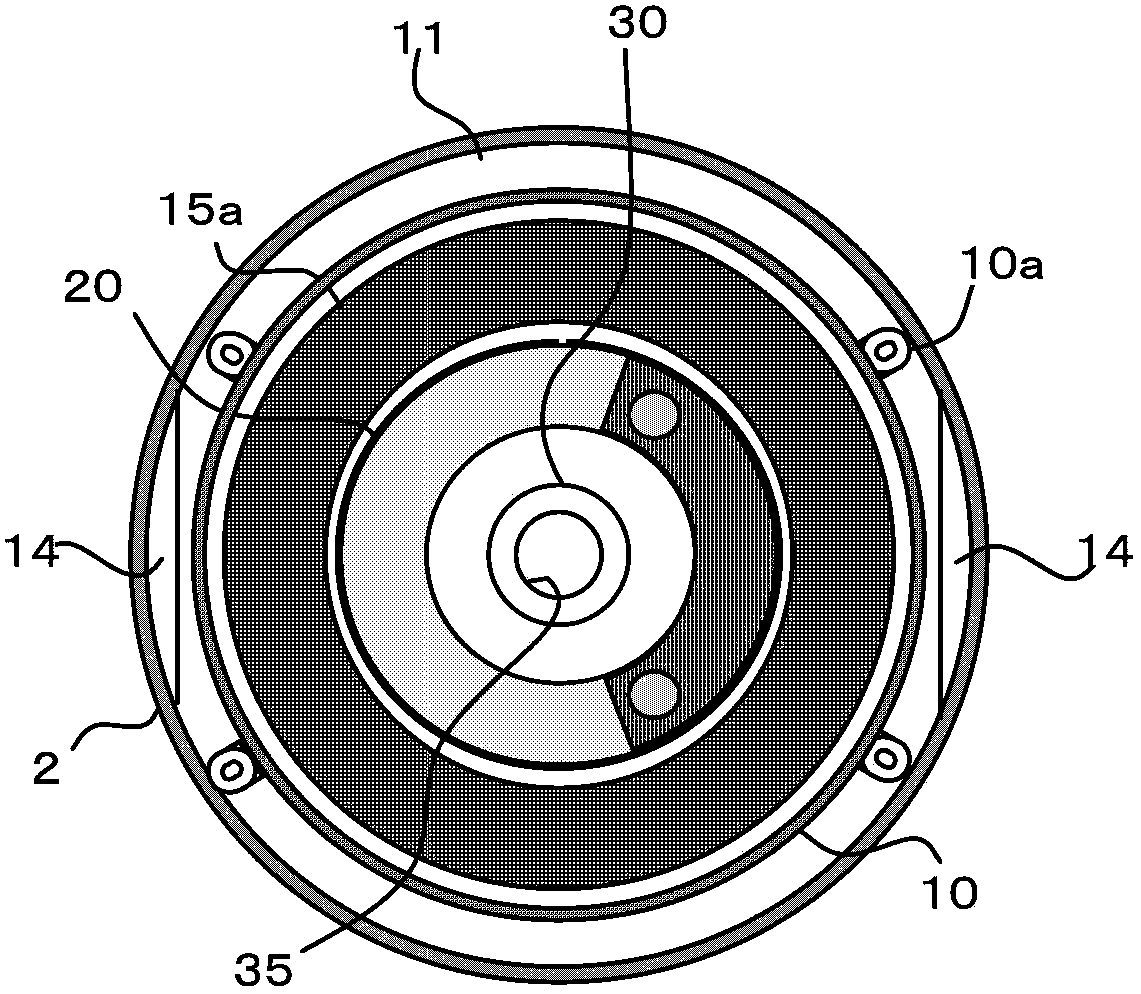

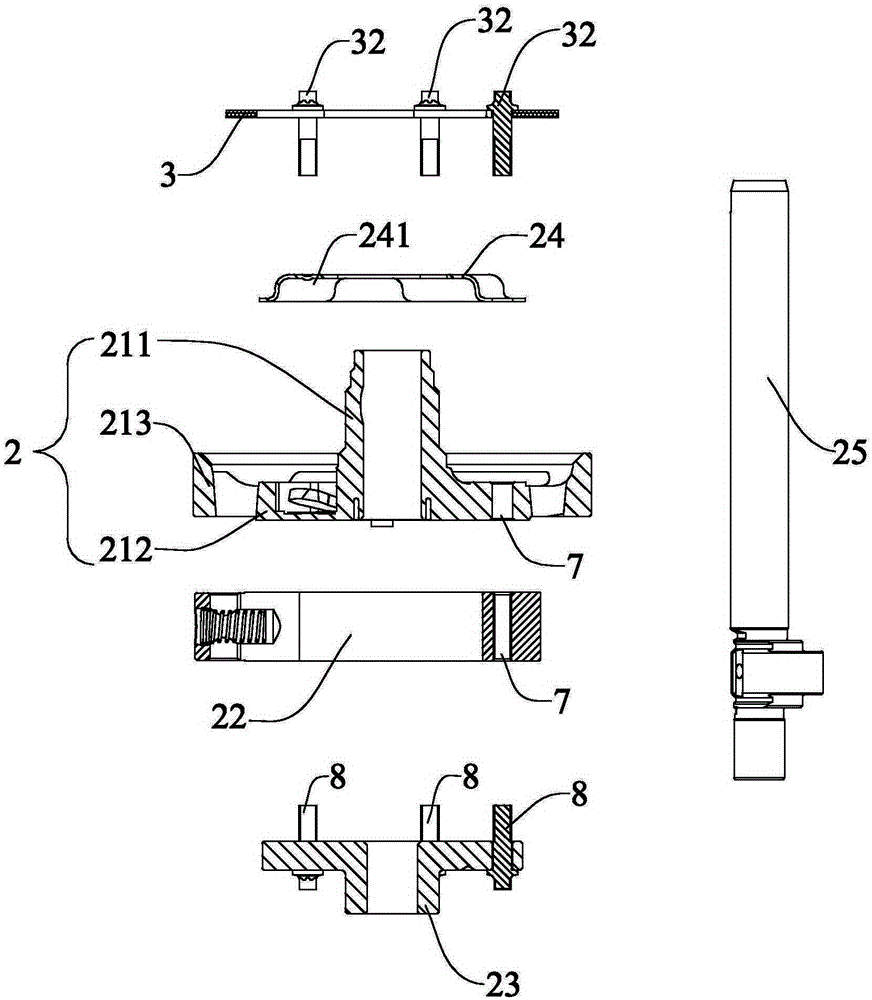

Oil baffle assembly and rotary compressor with same

ActiveCN102251966ASimple structureReduce oil outputRotary piston pumpsRotary piston liquid enginesPetroleum engineeringHigh Frequency Waves

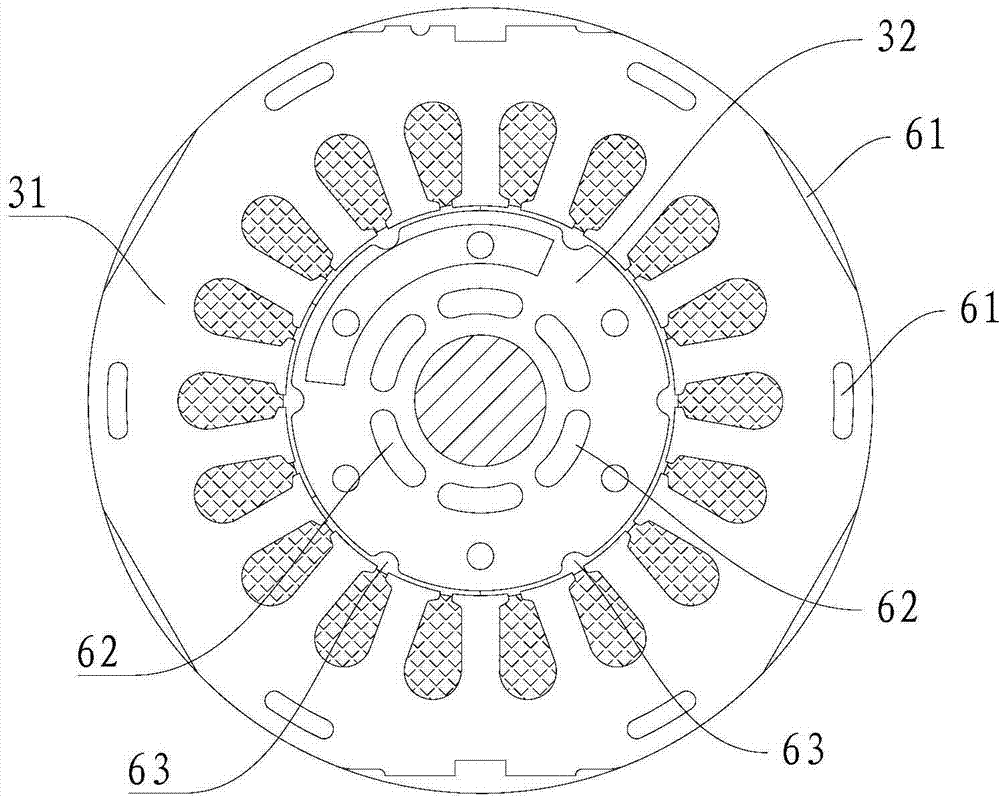

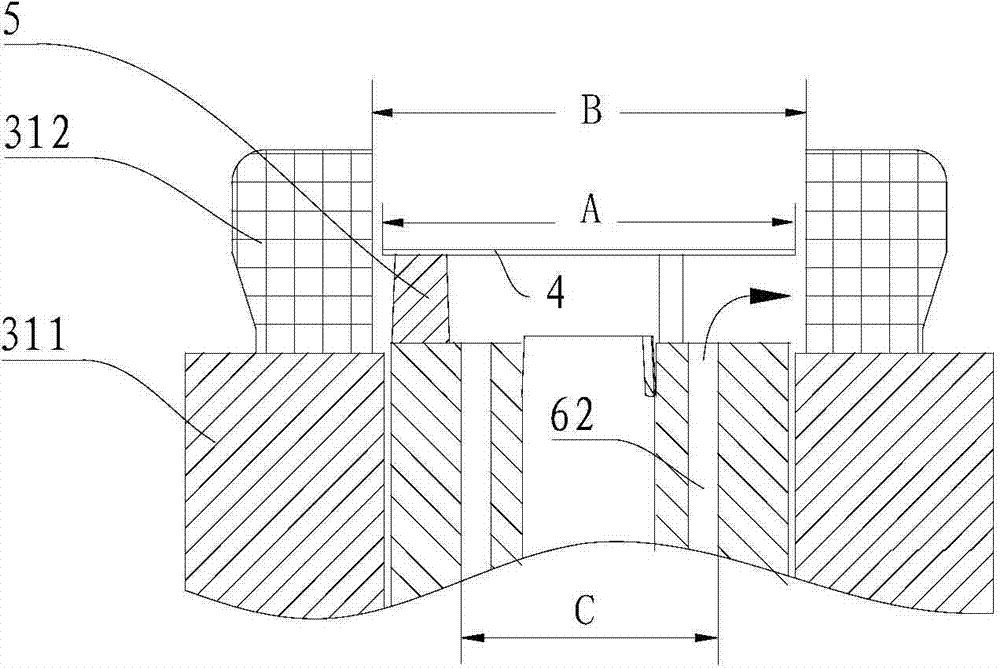

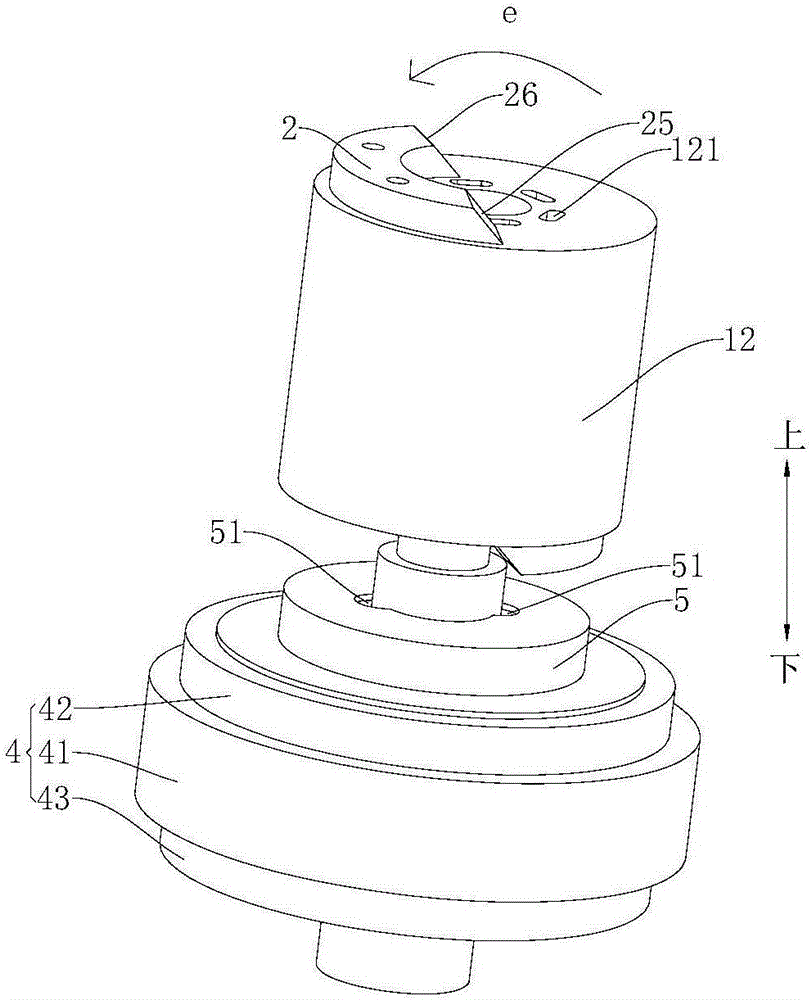

The invention provides an oil baffle assembly which comprises a rotor and an oil baffle plate; the oil baffle plate is connected with the rotor; the oil baffle plate comprises a base plate and a side plate which is surrounded on the base plate; and the base plate is provided with a plurality of through holes. The invention also provides a rotary compressor, and the oil baffle assembly is adopted. In the oil baffle assembly and the rotary compressor with the same, the rotor is connected with the oil baffle plate, the oil baffle plate is of a special structure, frozen oil can be effectively controlled in the compressor, the oil effluence of the compressor can be reduced greatly, and especially when the compressor operates at a high frequency, the effect is more obvious; and furthermore, the discharged frozen oil from the compressor can be reduced by adopting the oil baffle plate, and the reliability of the compressor is improved.

Owner:ZHUHAI LANDA COMPRESSOR

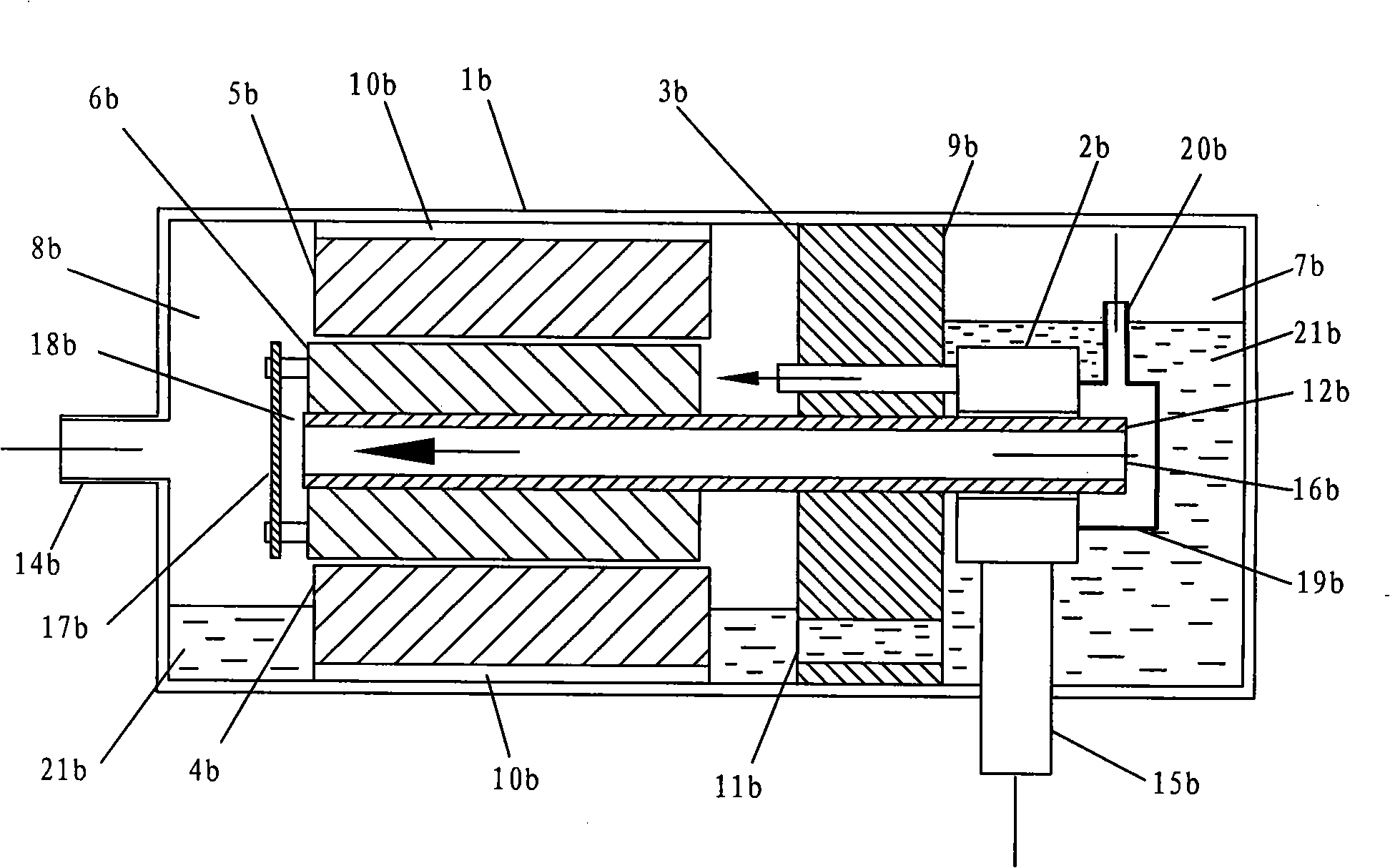

Lubrication system of horizontal rotary compressor, its control method and application

ActiveCN101403385AImprove reliabilityImprove efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsElectric machineEngineering

The invention relates to a lubricating system of a horizontal and rotary type compressor, a control method and application thereof. A sealed shell of the lubricating system of the horizontal and rotary type compressor is sealed with oil and is internally provided with a compression component which is at least composed of an eccentric crank shaft, a steam cylinder, a bearing, a piston and a sliding sheet and an electric motor component which is at least composed of a stator and a rotor; the outer diameter of the stator is provided with one or more plane(s) with a notch; the rotor is arranged on the eccentric crank shaft; the internal part of the shell is divided into an oil storage cavity and an electric motor cavity at least by a dividing part which is provided with an oil channel communicated with the oil storage cavity and the electric motor cavity; the eccentric crank shaft is axially provided with an air channel which leads from the oil storage cavity to the electric motor cavity; and the end part of one side of the rotor in the electric motor cavity is provided with a decompression device of the air channel. The invention has simple and reasonable structure, good effects of oil supplying and lubrication, stable oil level control in the compressor and higher reliability and working efficiency.

Owner:GUANGDONG MEIZHI COMPRESSOR

Nutritional breakfast and preparation method beneficial to calcium supplement and stomach nourishing of the elderly

The invention involves a nutritional breakfast beneficial to calcium supplement and stomach nourishing of the elderly. The raw materials include totally 30 food materials in six kinds of grain, beans, fruit, vegetables, nuts and fiber. The specific form is nutrition rice slice and fruit and vegetable particle. The invention also refers to the preparation of the nutritional breakfast beneficial to calcium supplement and stomach nourishing of the elderly. The described nutritional breakfast is of comprehensive nutrition easy to absorb and convenient to carry with and blew. The effect to replenish calcium and strengthen the bone is achieved by adding the rice, soybeans, red beans and red dates which are rich in calcium. The breakfast also has the effect of nourishing stomach, enhancing the heart, reinforcing the vitality and reducing the blood pressure and cholesterol by adding the millet, barley, pumpkin, oats, buckwheat, potato, carrot, lotus seed, banana, grapes, broccoli, pearl barley and gorgon fruit, etc.

Owner:湖南益百年健康科技有限公司

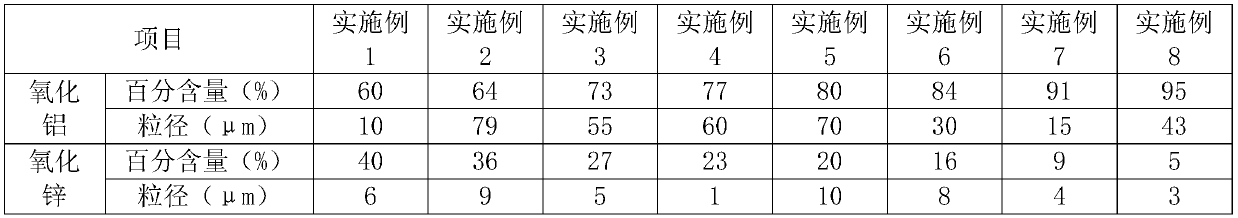

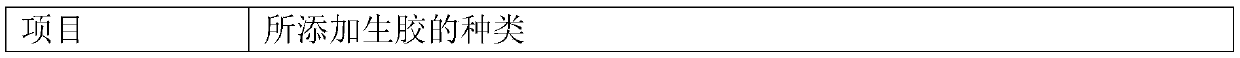

Heat-conducting gel with high heat conductivity and low oil output performance and preparation process thereof

InactiveCN111171575AImprove cooling effectImprove cooling efficiencyHeat-exchange elementsPtru catalystCommunication industry

The invention relates to the technical field of heat-conducting interface materials for the intelligent communication industry, in particular to a heat-conducting gel with high heat conductivity and low oil output performance and a preparation process of the heat-conducting gel. The heat-conducting gel comprises the following components in parts by mass: 65-95 parts of a powder; 5-30 parts of silicone oil; 0.01 to 10 parts of a raw rubber; 0.1-5 parts of a curing agent; 0.1 to 3 parts of a coupling agent; and 0.5 to 1 part of a catalyst; wherein the powder is a mixture of aluminum oxide and zinc oxide powder; wherein the powder comprises, by mass, 60-95% of aluminum oxide; and 5%-40% of zinc oxide; in the powder, the particle size of aluminum oxide is 10-80 microns, and the particle size of zinc oxide is 1-10 microns. Theheat-conductinggel can form a uniform dispersion system, has high thermal conductivity and good fluidity; the heat dissipation efficiency of the heat-conducting gel isincreased greatly, the service life is prolonged greatly, anda strong practical value is achieved.

Owner:广东桑泰科技有限公司

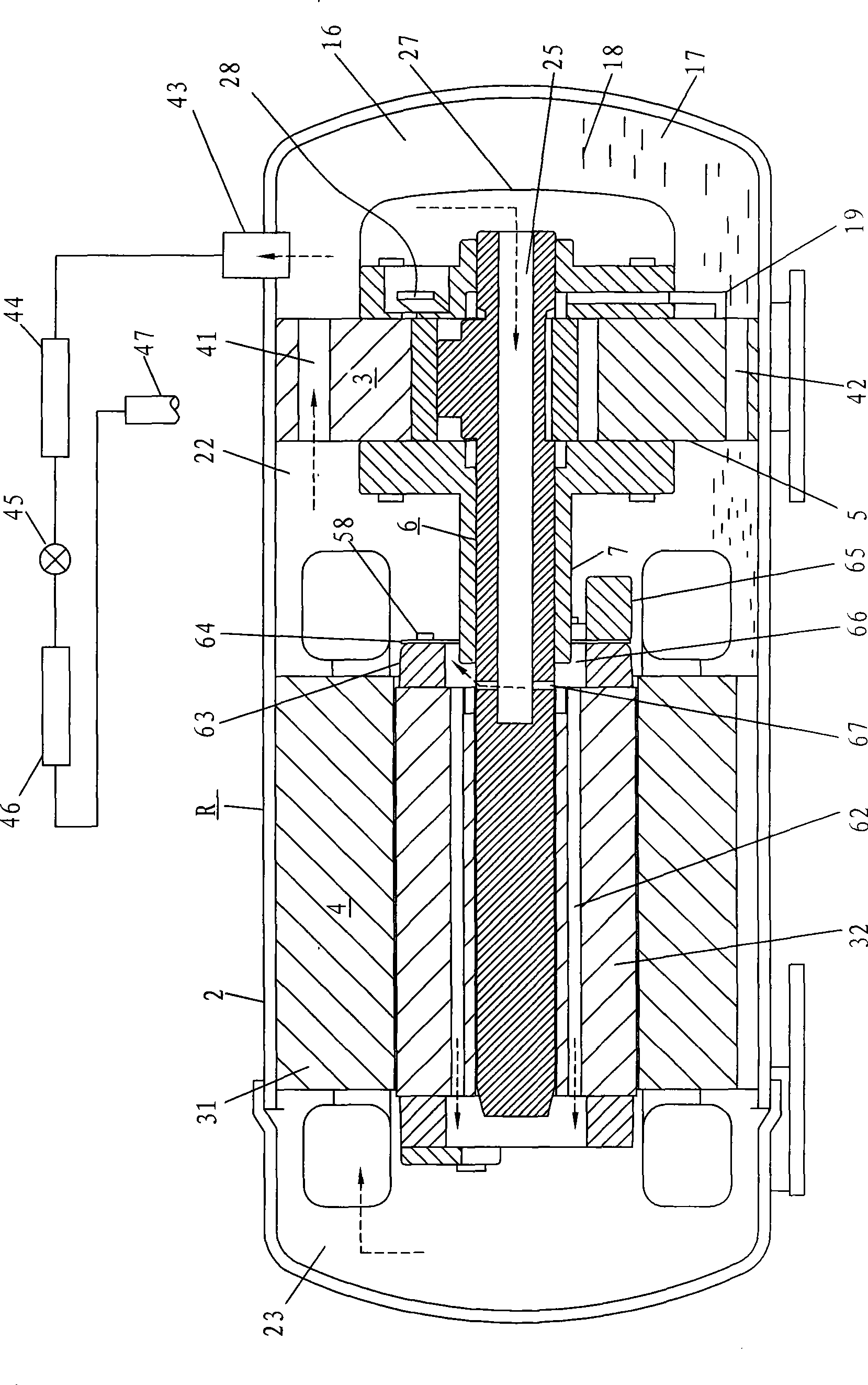

Horizontal rotary compressor

InactiveCN101463820ACool evenlyReduce oil outputRotary piston pumpsRotary piston liquid enginesInternal pressureEngineering

The invention relates to a horizontal rotary compressor, comprising a housing, wherein, the inner pressure of the housing is high, and a compression component and an electric motor are arranged in the housing; the compression component and the periphery of the electric motor are respectively fixed on the inner diameter of the housing and divide the interior of the housing into three cavity chambers, i.e. a crank shaft penetration oil cavity, a first electric motor cavity and a second electric motor cavity; more than one incision gaps are arranged between the bottom of a rotor and the inner diameter of the housing, both ends of each incision gap are respectively provided with holes on the first electric motor cavity and the second electric motor cavity, the upper part of an air cylinder is provided with an air passage, the lower part is provided with an oil passage, and the air passage and the oil passage are respectively provided with holes on first electric motor cavity and the oil cavity; and an exhaust muffler is arranged on a main bearing or a supplementary bearing, one end of a communication channel is provided with a hole on the exhaust muffler, the other end is provided with a hole on the second electric motor cavity, and high pressure air and oil exhausted from the compression component are led into the second electric motor cavity by the communication channel. The horizontal rotary compressor can reduce the oil discharge volume, uniformly cool the machine winding and greatly improve the reliability of the compressor.

Owner:GUANGDONG MEIZHI COMPRESSOR

Rotary compressor and control method thereof

ActiveCN102251964AReduce oil outputNo reliability issuesRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringAir conditioning

The invention relates to a rotary compressor and a control method thereof, and the rotary compressor comprises a motor part and a two-stage compression type compression mechanism part which are arranged in a sealed housing, wherein the motor part comprises a stator and a rotor, the compression mechanism part comprises a first cylinder, a second cylinder, a crankshaft for driving a first piston and a second piston to rotate eccentrically in a first cylinder compression cavity and a second cylinder compression cavity, a main bearing and an auxiliary bearing, the main bearing and the auxiliary bearing are used for supporting the crankshaft, the end parts of a first sliding sheet and a second sliding sheet are connected with the peripheries of the first piston and the second piston respectively, and gas which is spitted from the first cylinder compression cavity into the sealed housing is sucked into the second cylinder compression cavity. A cooling medium injection device communicated with the second cylinder compression cavity is arranged on the second cylinder compression cavity. The rotary compressor has the characteristics of high air-conditioning ability, high efficiency, safety, reliability and a wide application range and can be popularized and applied to heat pump type air conditioners.

Owner:GUANGDONG MEIZHI COMPRESSOR

Heat conductive silicone grease composition and preparation method thereof

InactiveCN106519691AReduce oil outputImprove lipophilicityHeat-exchange elementsHydrogenSilicone grease

The invention discloses a heat conductive silicone grease composition and a preparation method thereof. The heat conductive silicone grease composition includes (A) base silicone oil, which is linear organopolysiloxane, has a monovalent hydrocarbonyl group having 1-18 carbon atoms and bonded with silicon in the molecular structure, and has a kinematic viscosity of 50-1500mpa.s at 25DEG C; (B) a heat conductive filler, which has hydroxyl on the surface; and (C) an oil suppression additive, which is organopolysiloxane containing a hydrogen group connected to silicon, and has a kinematic viscosity of 10-1500mpa.s at 25DEG C. The heat conductive silicone grease prepared from the composition provided by the invention has the characteristics of high heat conduction coefficient, good insulation performance and low oil yield, and can effectively improve the use reliability of heat conductive silicone grease.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

Natural shampoo

InactiveCN107157855AReduce allergiesRelieve itchingCosmetic preparationsHair cosmeticsSide effectAllergy

The invention discloses a natural shampoo. The shampoo consists of the following components in parts by weight: 10-30 parts of beeswax, 15-35 parts of a rosemary extract, 10-20 parts of lanolin oil, 8-18 parts of an old ginger extracting solution, 5-15 parts of lavender essential oil, 3-10 parts of soybean saponin, 2-8 parts of citric acid, 8-15 parts of honeysuckle flowers, 4-12 parts of herba taraxaci, 2-10 parts of cortex phellodendri, 5-12 parts of an extracting solution of radix sophorae flavescentis and 1-4 parts of chestnut. The shampoo provided by the invention is simple in preparation method; the prepared shampoo can relieve such symptoms as scalp allergy, pruritus, oily scalp, excessive dandruff and the like; the shampoo is free from toxic and side effects; and the shampoo is especially suitable for pregnant women, children and people of skin allergy.

Owner:BEIJING JUNXIU CONSULTATION CO LTD

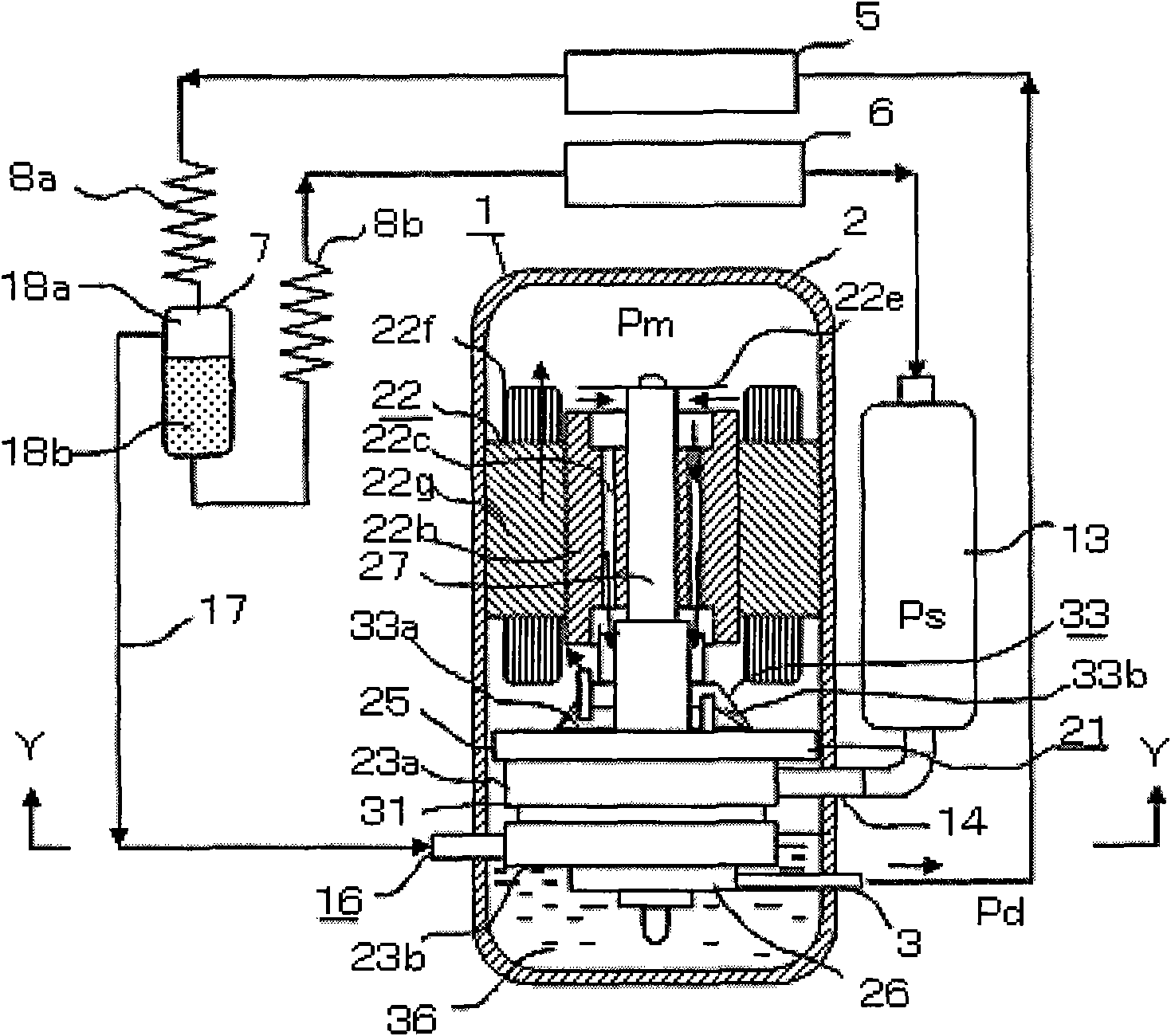

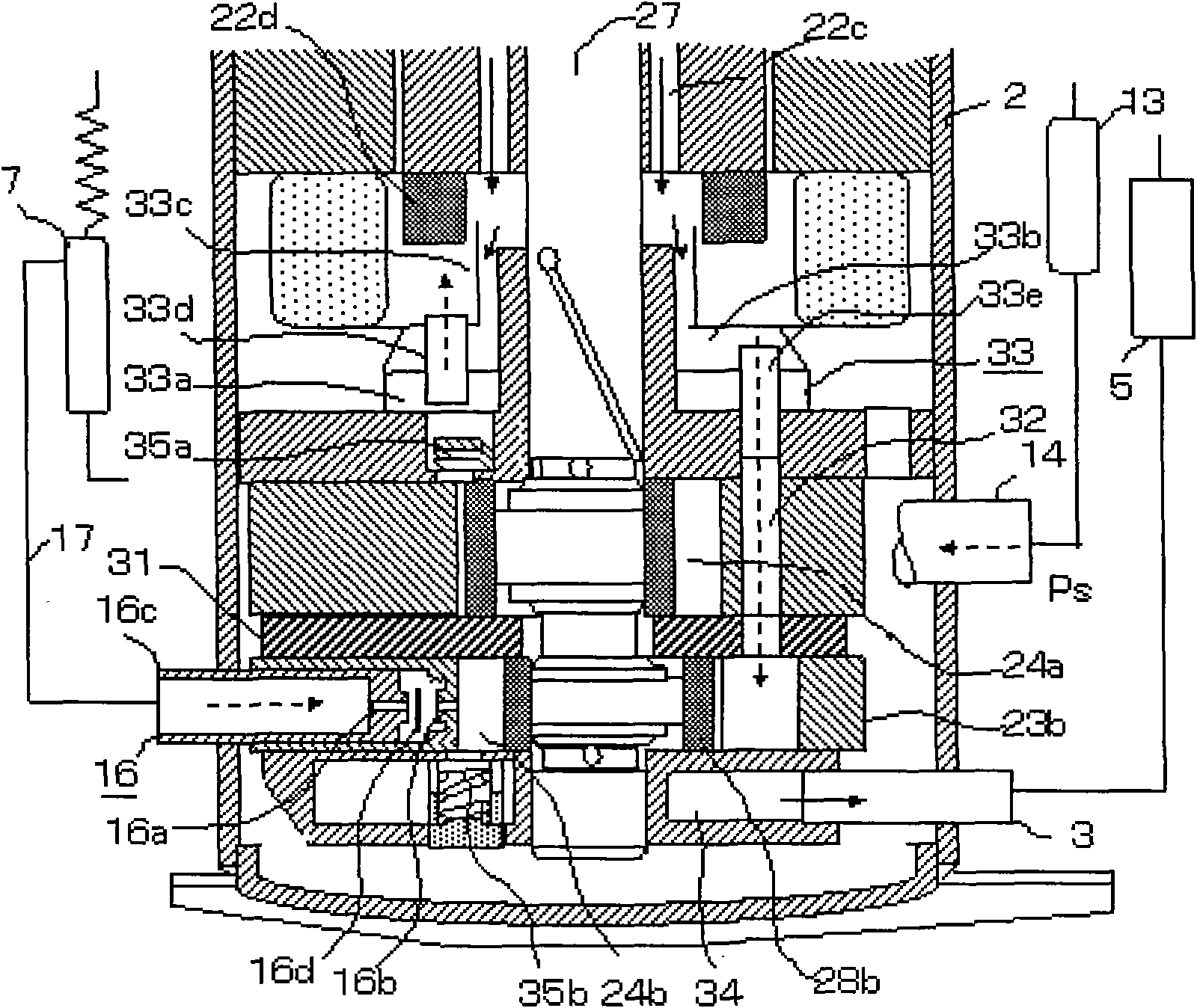

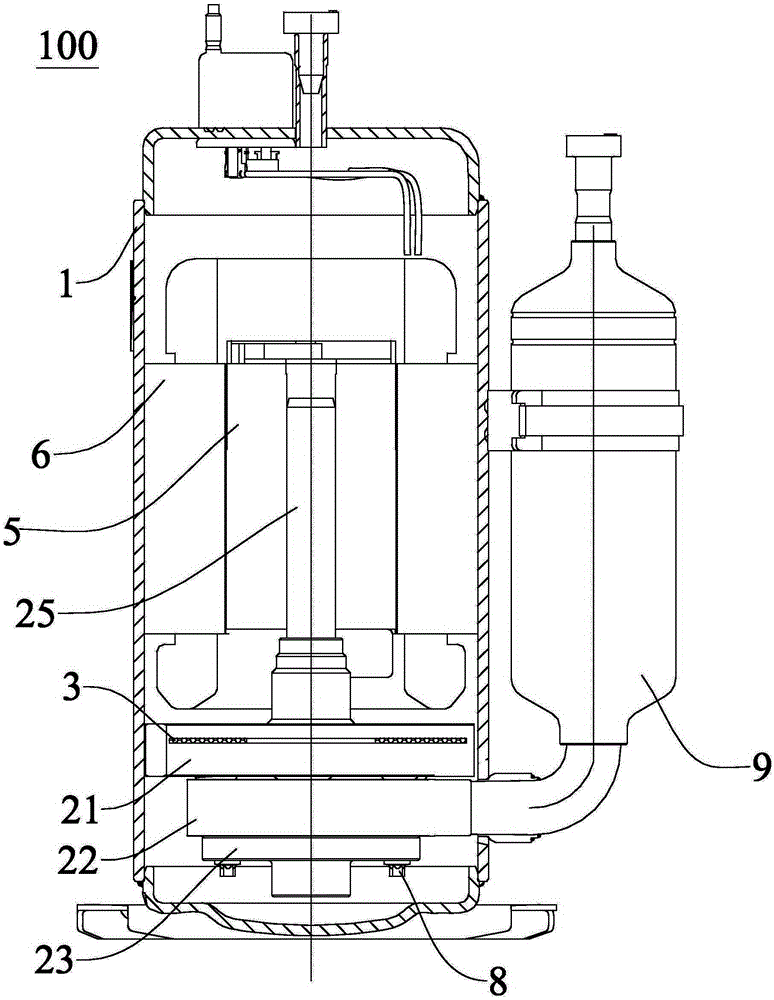

Refrigerating cycle device

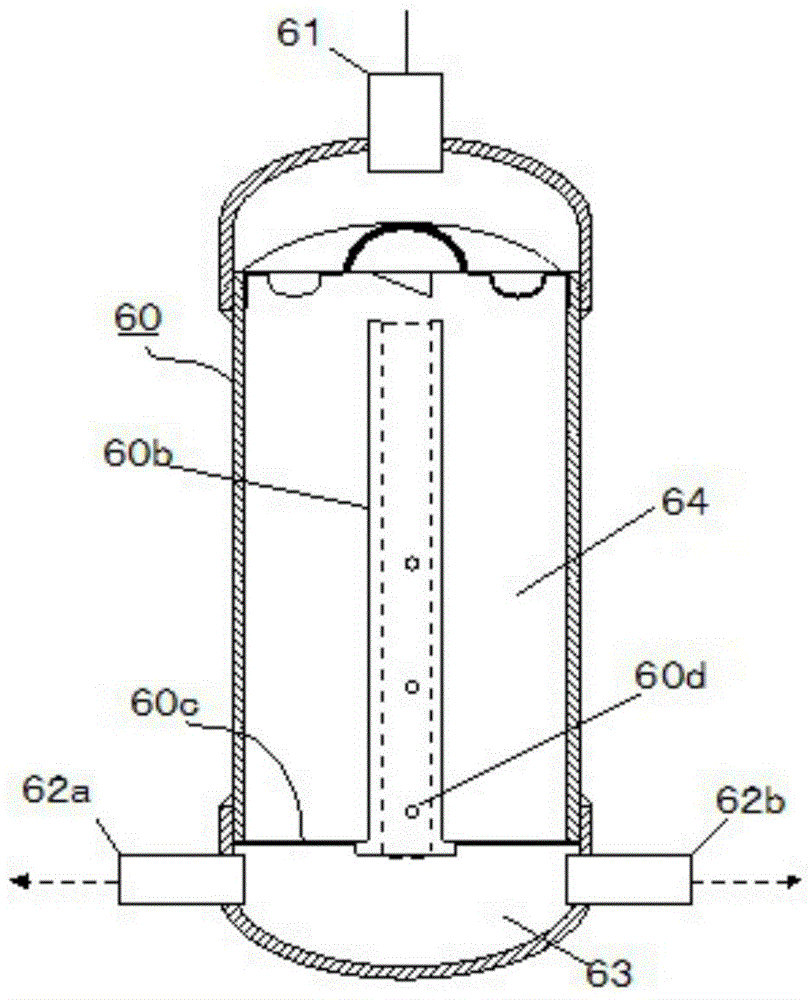

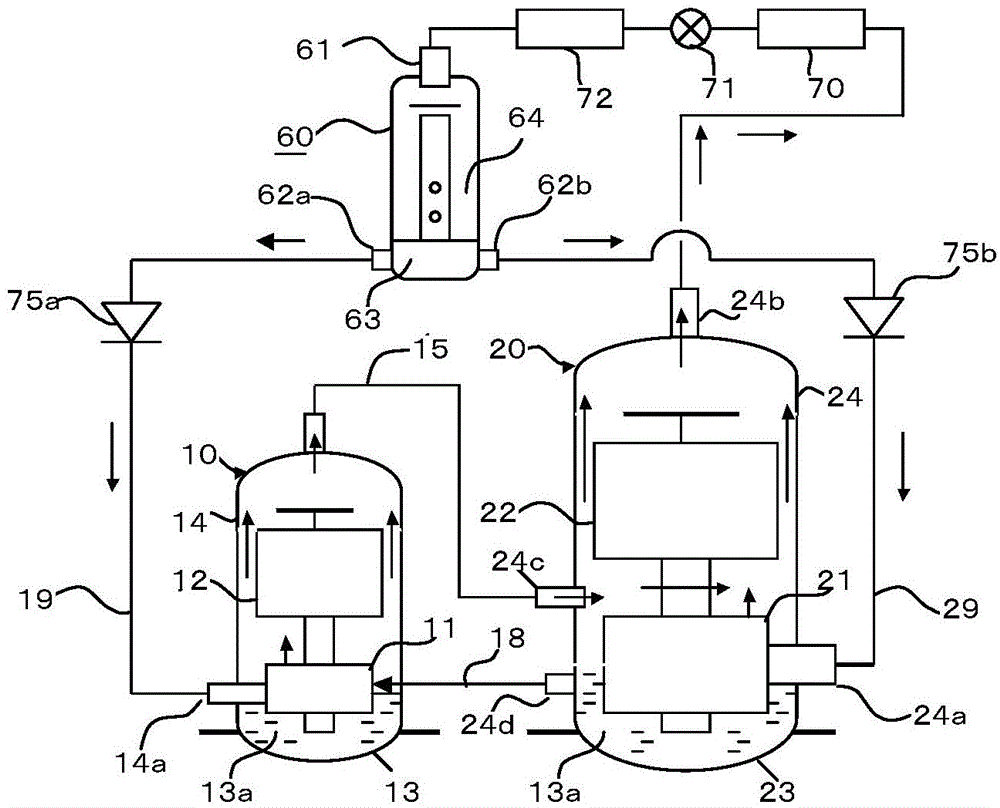

ActiveCN104930738AReduce oil outputThe amount of refrigerant in action is stableCompressorCompression machines with non-reversible cycleEngineeringEvaporator

The invention discloses a refrigerating cycle device which is at least composed of a condenser, an expansion valve, an evaporator and a plurality of compressors. A sealed shell of each compressor is provided with a rotating type compression mechanism part communicated with a low-pressure loop of the evaporator and a motor part for driving the compression mechanism part. Each compressor is further provided with an oil storage cavity. An exhaust loop of at least one compressor is connected with the sealed shell of another compressor. According to the refrigerating cycle device, stopped compressors play the role of an oil separator part in the operating compressors, the oil discharge amount of the operating compressors in refrigerating cycle can be reduced, the stopped compressors are heated, no liquid refrigerant exists in the stopped compressors, and thus the action refrigerant amount of refrigerating cycle can be stable.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

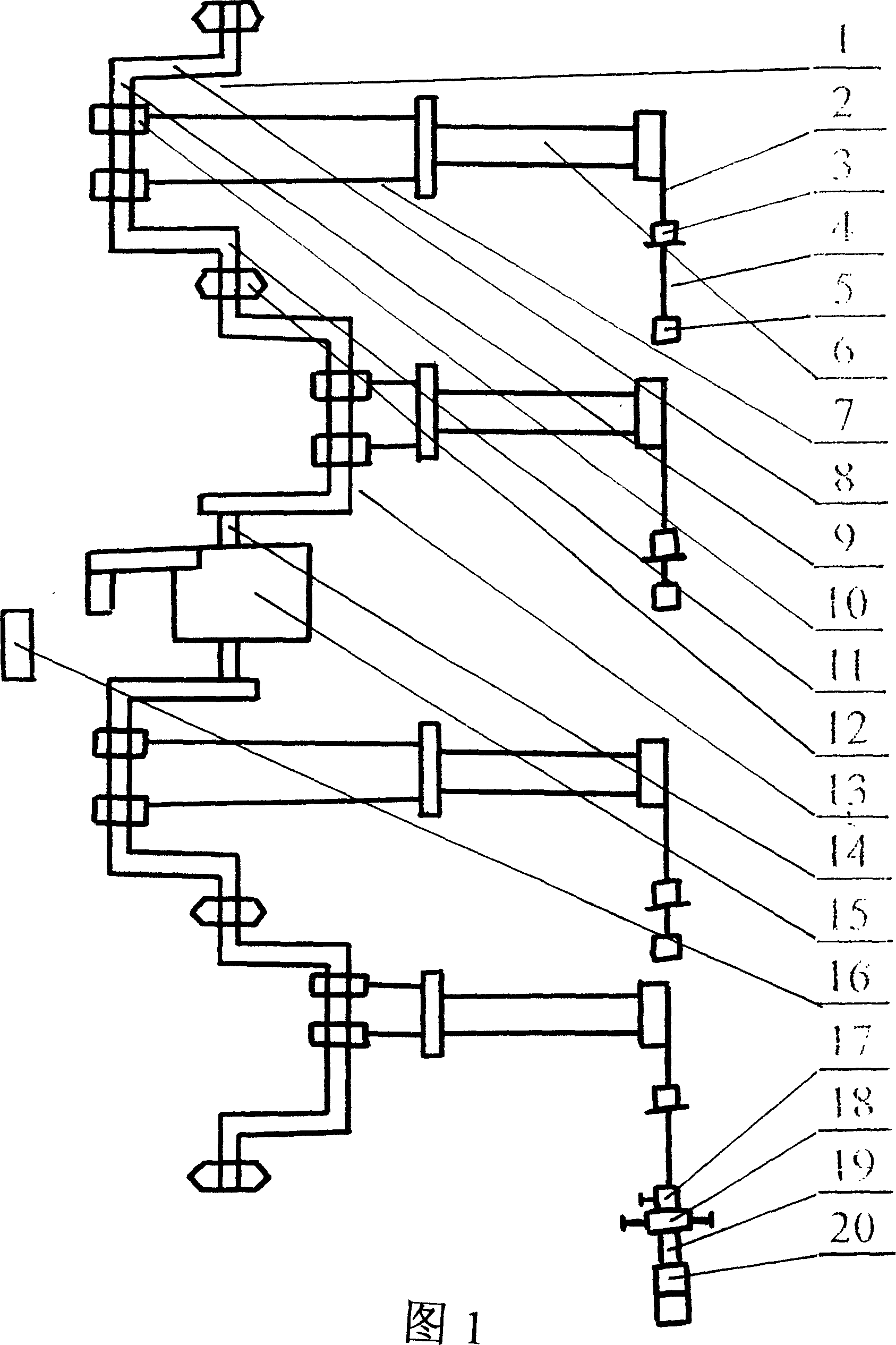

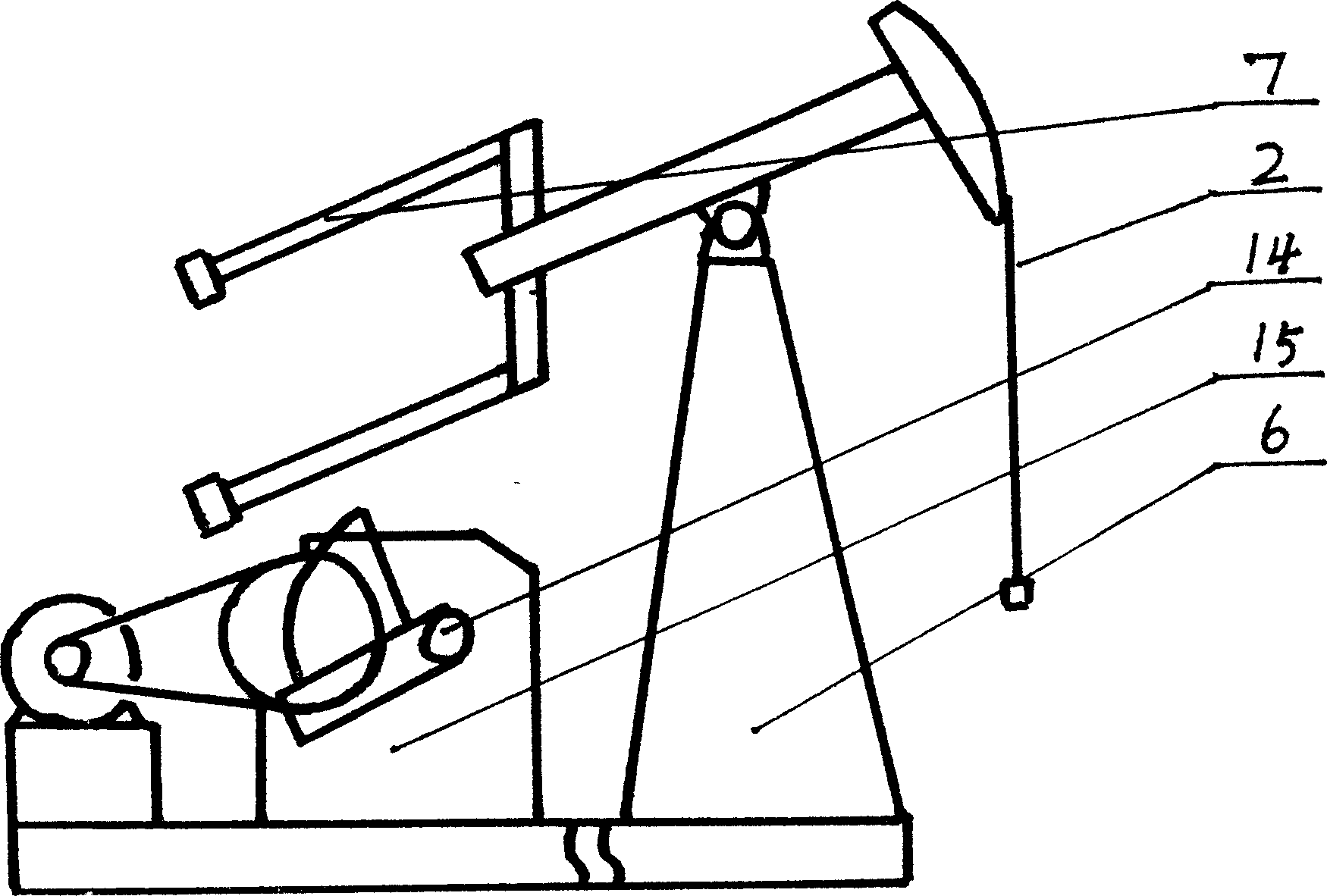

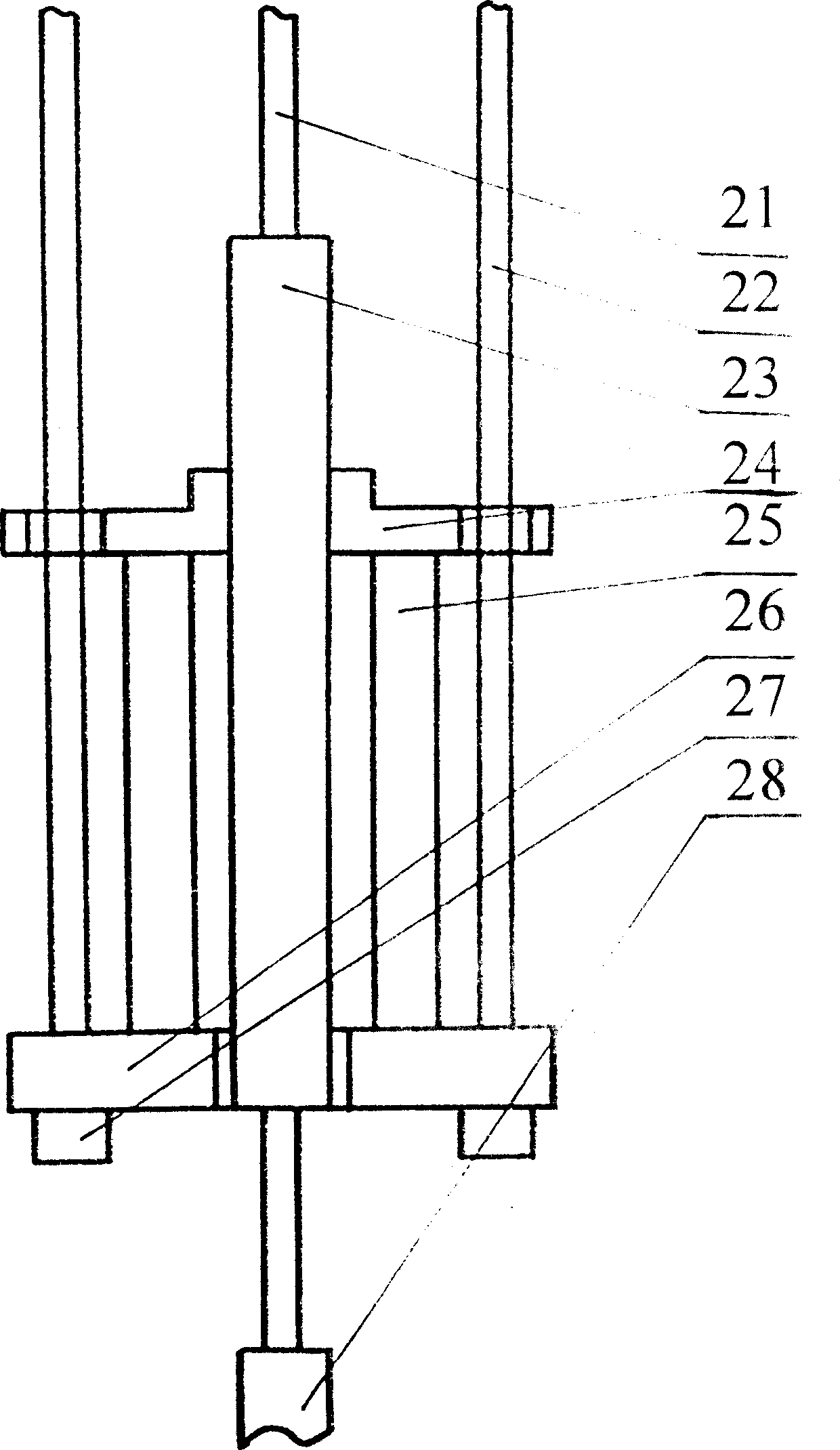

Method and equipment for equipotential self-balancing pumping unit in cluster wells

An equipotential self-balance petroleum pumping unit for cluster well is disclosed, which is suitable for the beam-type pumping unit. Its advantages are low cost, long service life and high reliability. The methods and apparatus for the contacting shaft with pump, the multifunctional sealing of bare rod sealer, exchanging said sealer without stopping production, regulating the horizontal angle of said sealer, and recovering leaked oil and preventing blowout are also disclosed.

Owner:王福成

Wintersweet shampoo soap and production method thereof

The invention provides a wintersweet shampoo soap and a production method thereof. The wintersweet shampoo soap is prepared from the following raw materials: 25-55 parts of sodium lauryl acyl glutamate, 2-15 parts of sodium lauryl sulfate, 1-10 parts of cocamidopropyl DEA, 0.5-5 part(s) of cocamidopropyl betaine, 1-10 part(s) of ciruela extract, 0.1-2 part(s) of cocoa butter, 0.2-2 part(s) of PEG-100 stearate, 1-12 part(s) of propylene glycol, 0.5-10 part(s) of glycerol, 0.2-5 part(s) of beewax, 0.02-0.2 part of methyl parahydroxybenzoats, 0.01-0.1 part of propyl p-hydroxybenzoate, 0.1-2 part(s) of butter resin, 0.1-1 part of cetyl stearyl alcohol ether, 0.5-5 part(s) of monoglyceric stearate, 0.5-5 part(s) of stearate, 0.1-1 part of oil-soluble lanolin, 0.1-3 part(s) of jojoba ester, 0.1-1 part of sodium chloride and 0.5-1 part of dry wintersweet petals. The wintersweet shampoo soap brings the medicinal value of wintersweet into full play, can clean a scalp and hairs well, and can soothe nerves, resist bacteria, relieve itching and make the scalp healthy.

Owner:CHONGQING PUPU BIOTECH

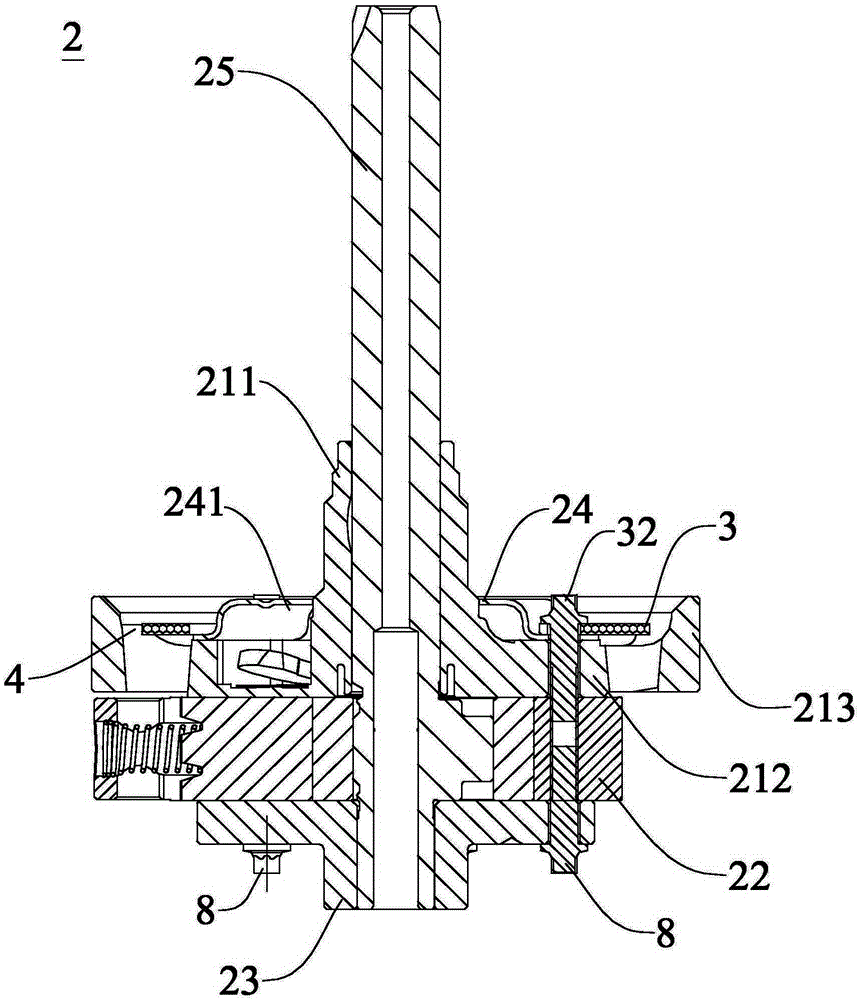

Compressor and air conditioner

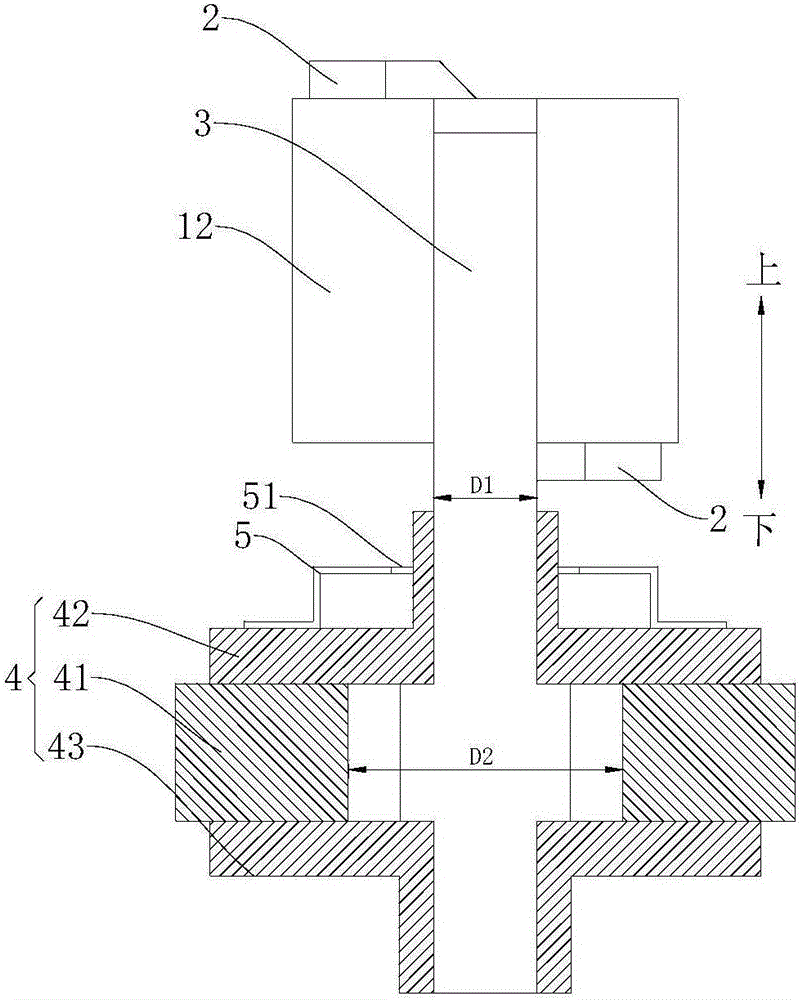

InactiveCN106499636AReduce energy consumptionImprove energy efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsCrankshaftSump

The invention discloses a compressor and an air conditioner applying the same. The compressor comprises an oil sump, a compression component and a crankshaft which is connected to the compression component and drives the compression component to move; an oil supply channel is arranged in the crankshaft; a compression cavity is arranged in the compression component; the oil supply channel communicates with the oil sump and the compression cavity; the crankshaft is further provided with an oil return assembly; and the oil return assembly communicates with the oil supply channel and is put through in the direction from the oil supply channel to the oil sump under the pressure of oil. According to the technical scheme, the oil return assembly is arranged on the crankshaft of the compressor, so that the pressure of lubricating oil in the oil supply channel in the crankshaft is increased in the high-frequency running process of the compressor, the oil return assembly is put through in one direction, the lubricating oil can flow back to the oil sump through the oil return assembly, and the amount of the oil supplied to the compression component is not too large, so that the oil output amount and the power consumption of the compressor are reduced.

Owner:GUANGDONG MIDEA ENVIRONMENTAL TECH CO LTD

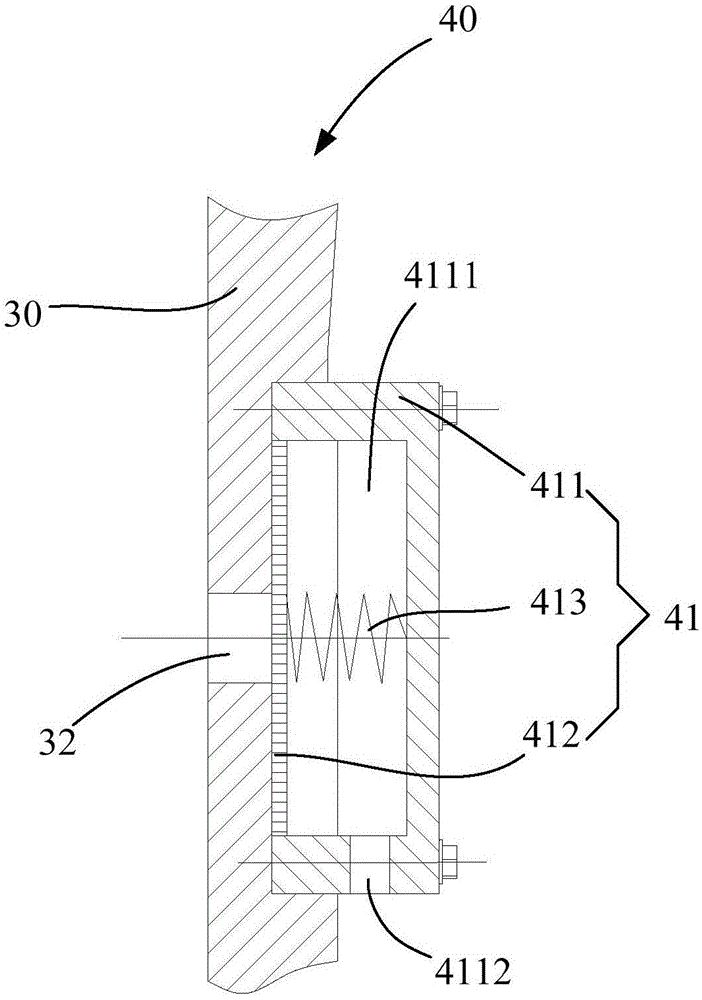

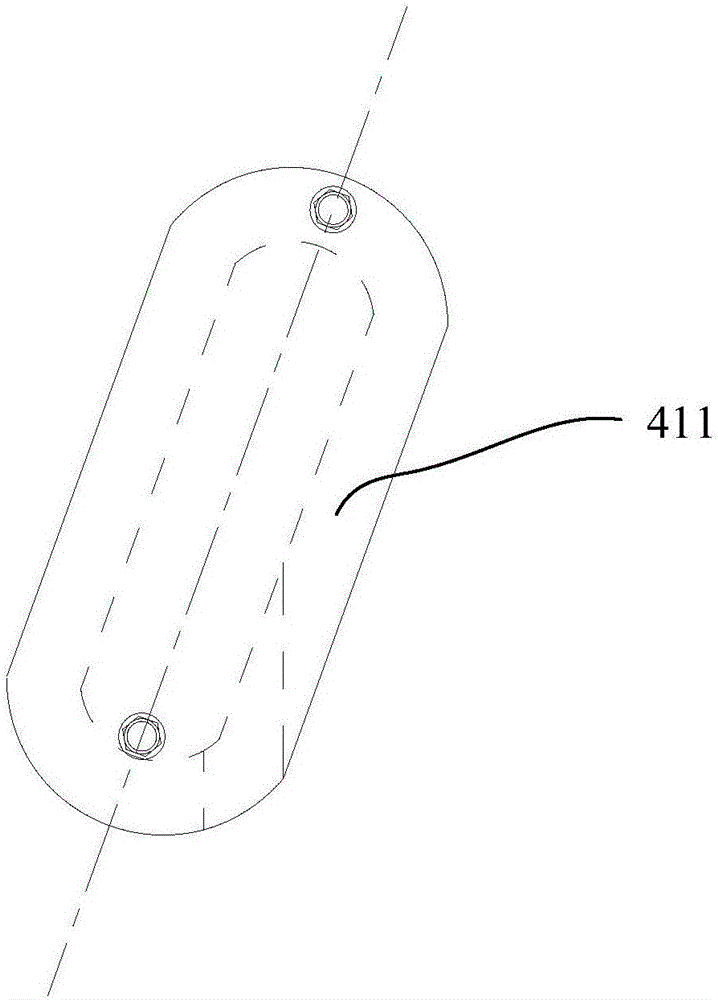

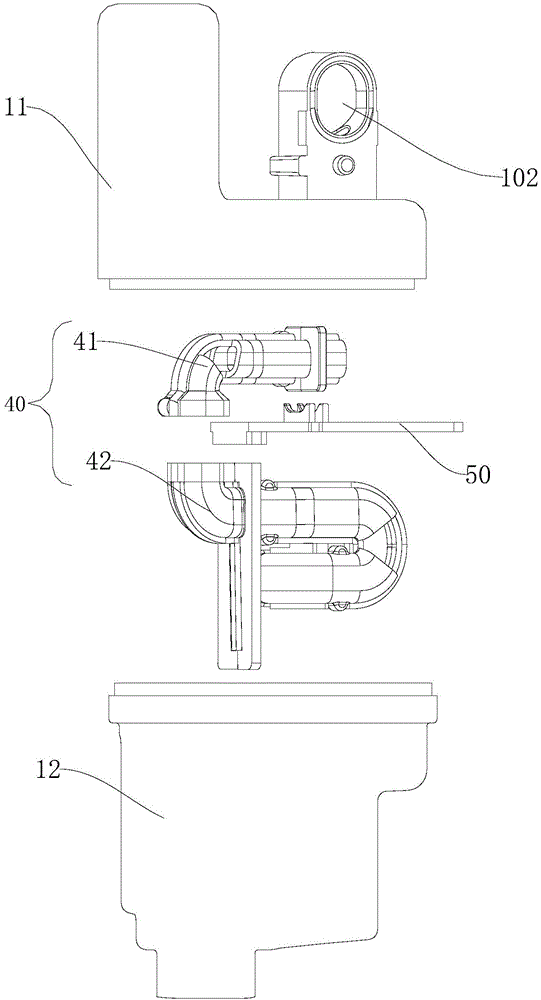

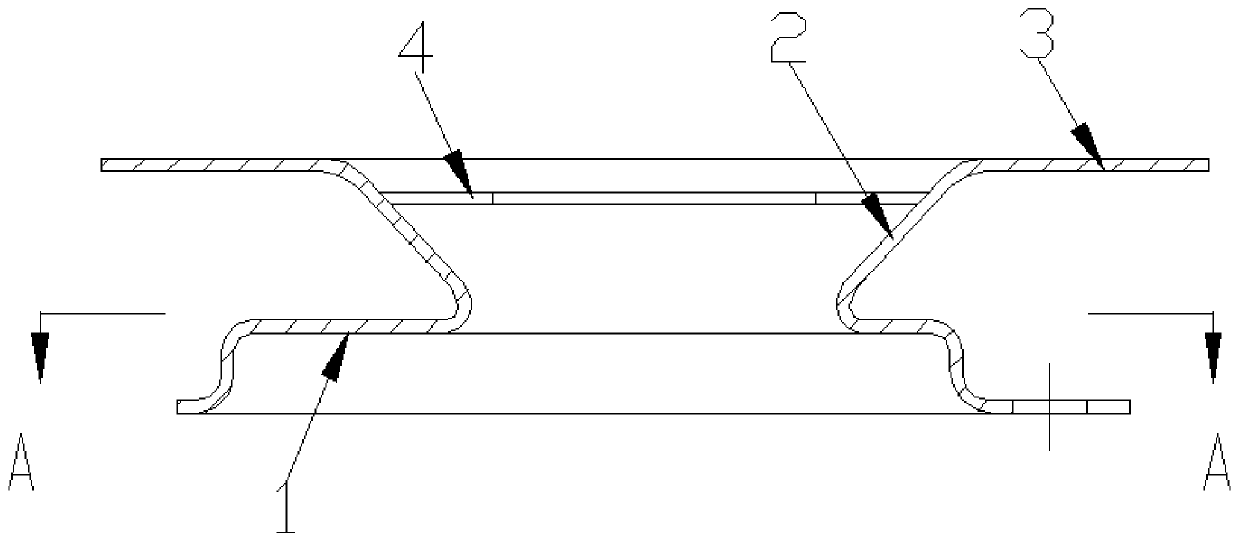

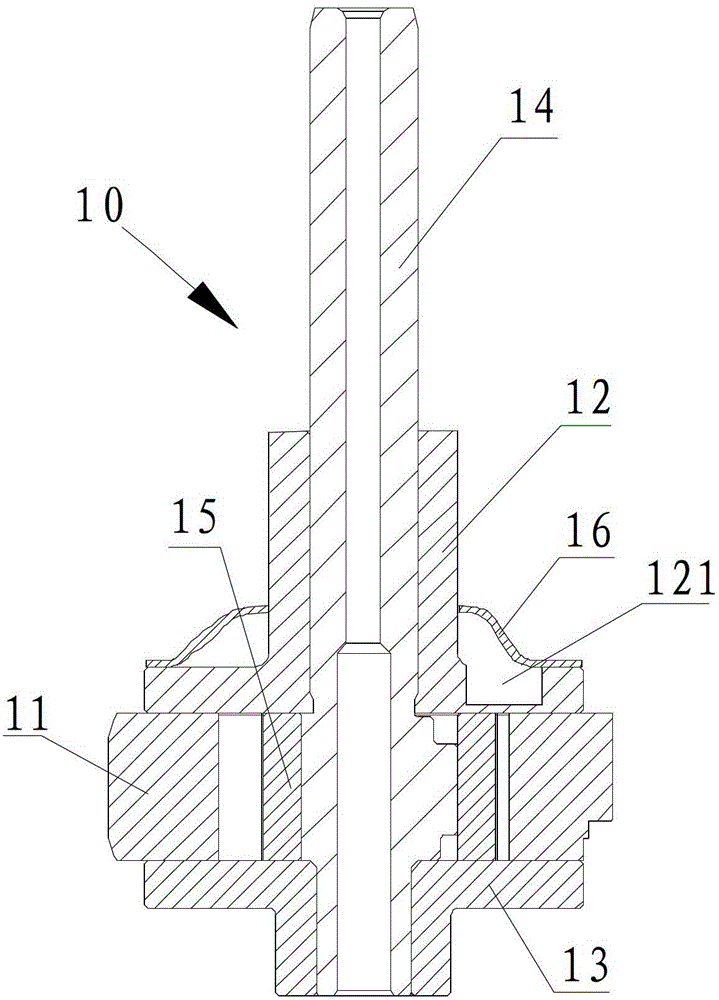

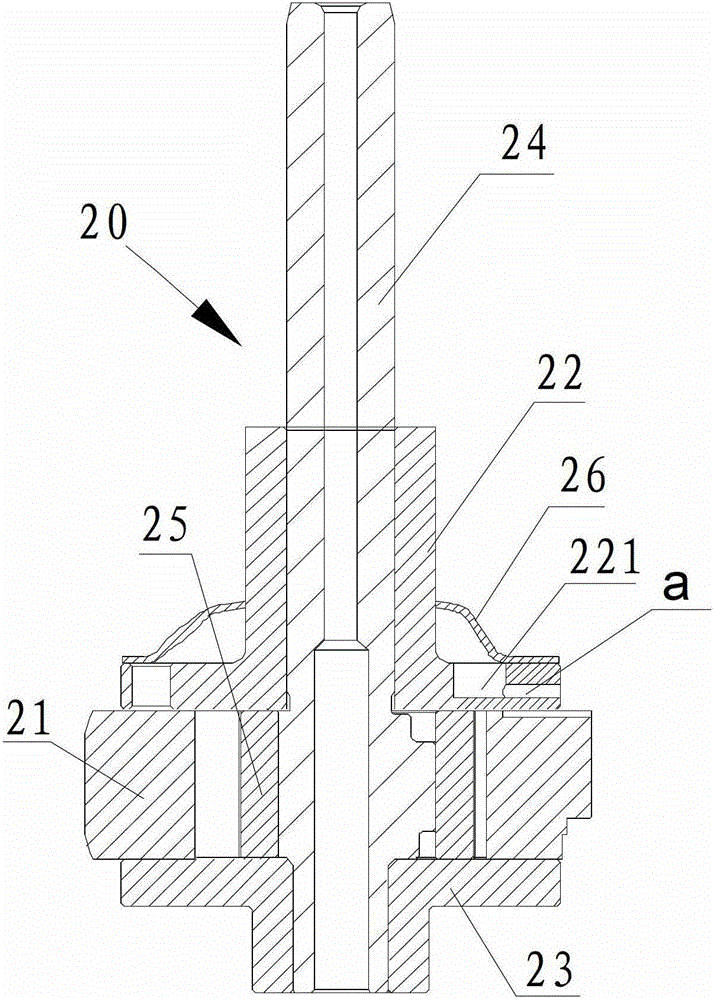

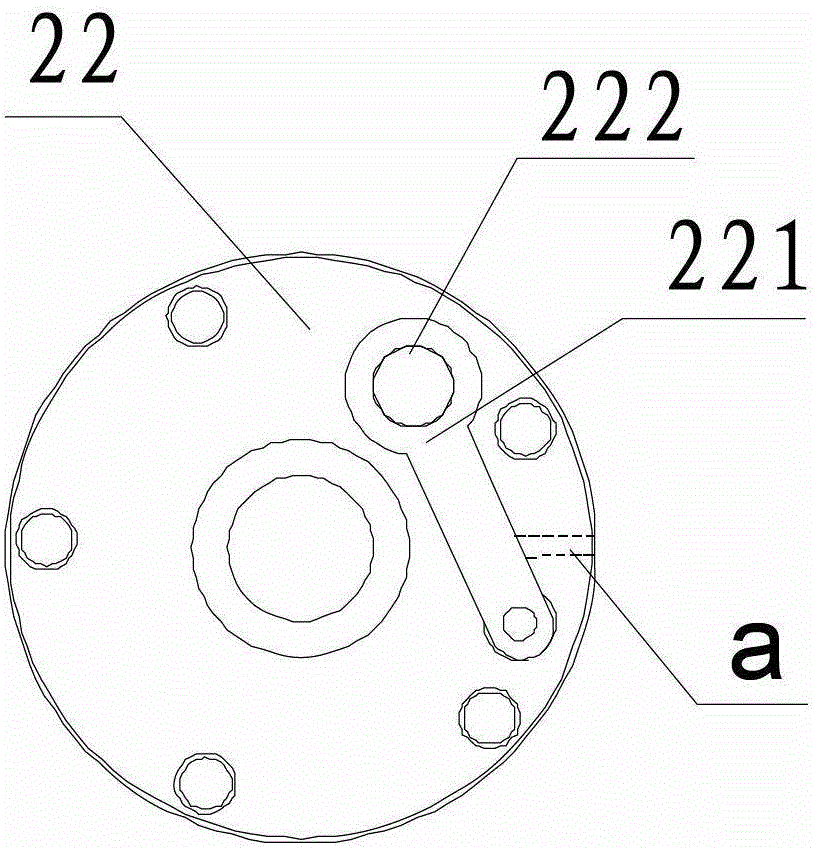

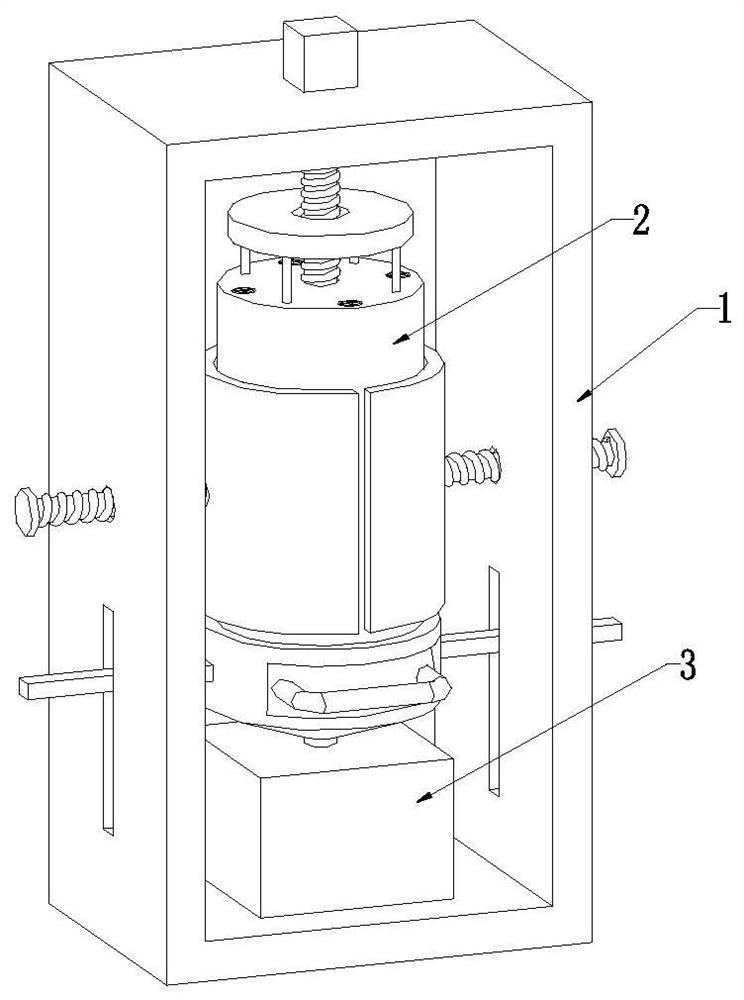

Air suction muffler and compressor provided with same

ActiveCN104879288ANot easy to bring inLess quantityPositive displacement pump componentsPositive-displacement liquid enginesRefrigerantRefrigerated temperature

The invention discloses an air suction muffler and a compressor provided with the same. The air suction muffler comprises a casing and an oil baffle element, wherein the casing is provided with an air suction port and an air exhaust port, and an airflow channel communicated with the air suction port and the air exhaust port is formed in the casing; the oil baffle element is arranged on the casing, bulges out of the outer wall surface of the casing and extends outwards, and at least part of the oil baffle element is located right above the air suction port. According to the air suction muffler disclosed by the embodiment, refrigerator oil is not easily carried into the air suction muffler by a refrigerant from the air suction port, so that the quantity of the refrigerator oil flowing into a compression chamber along with the refrigerant is reduced greatly, the oil puff quantity of the compressor is reduced, and the safe reliability is improved.

Owner:ANHUI MEIZHI COMPRESSOR +1

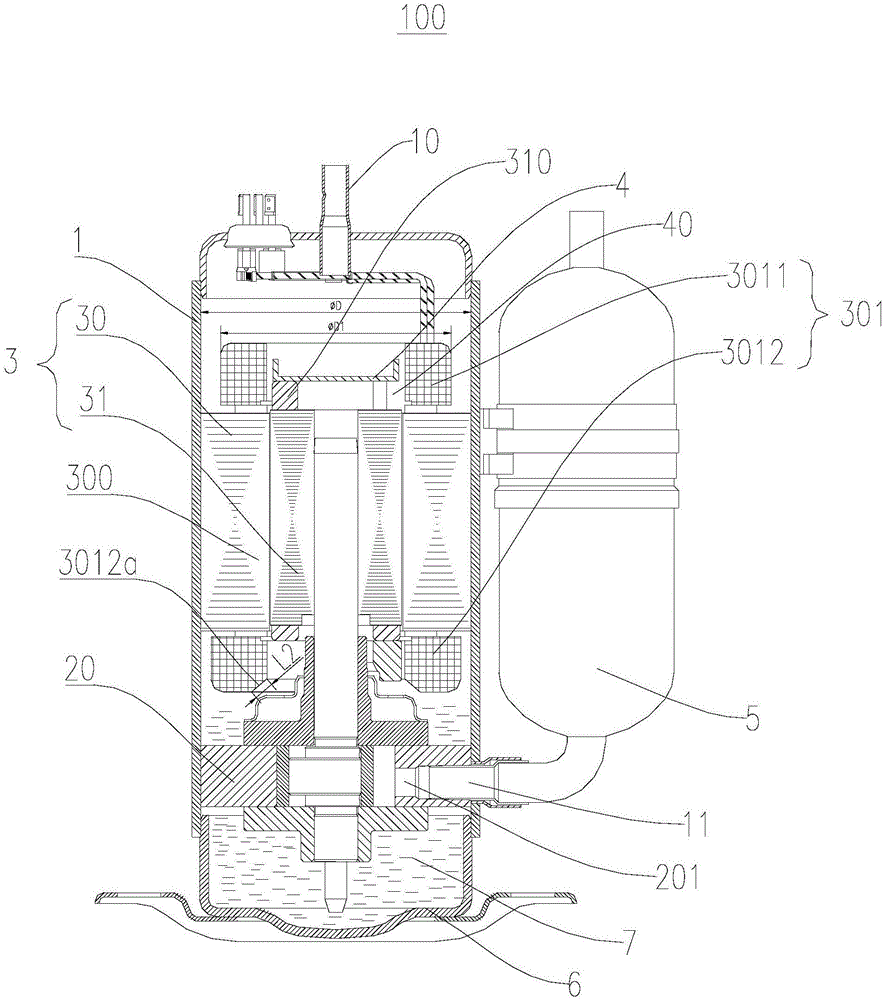

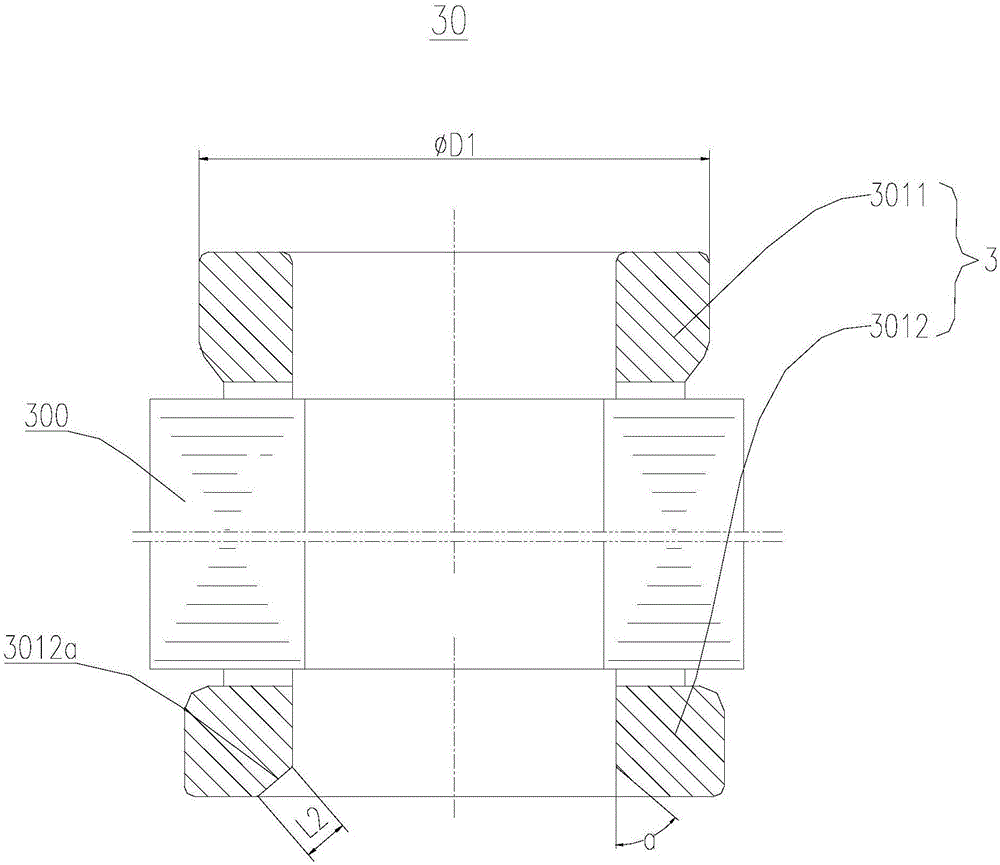

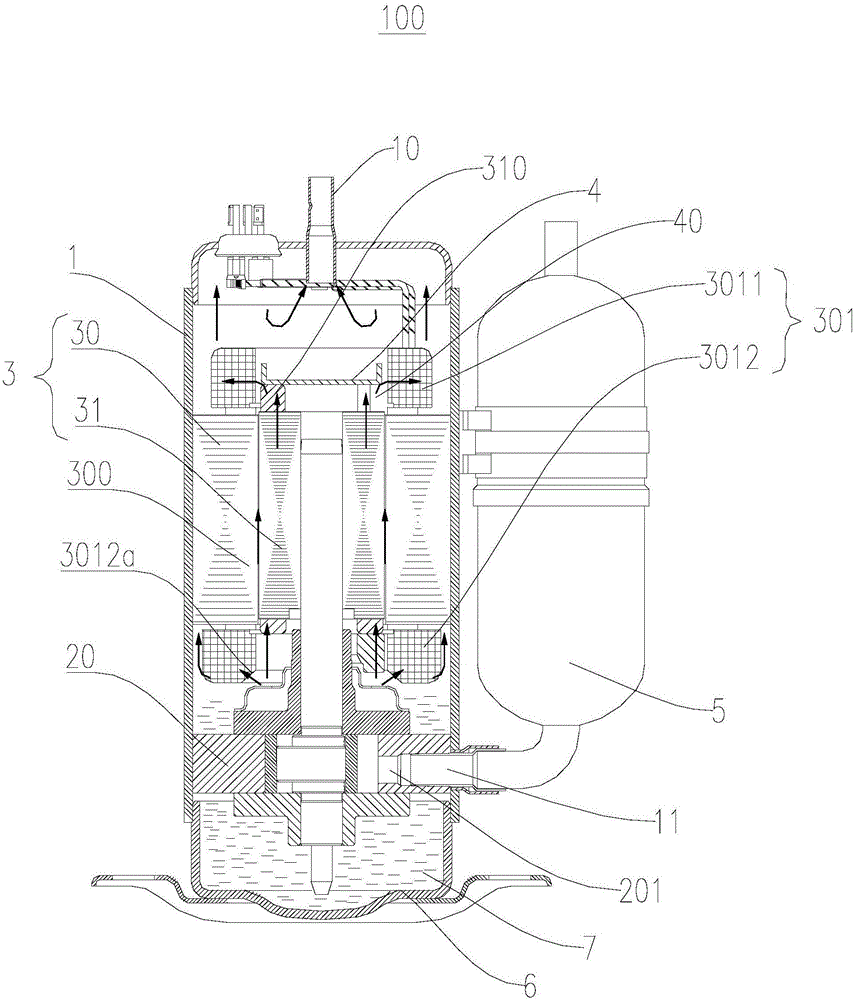

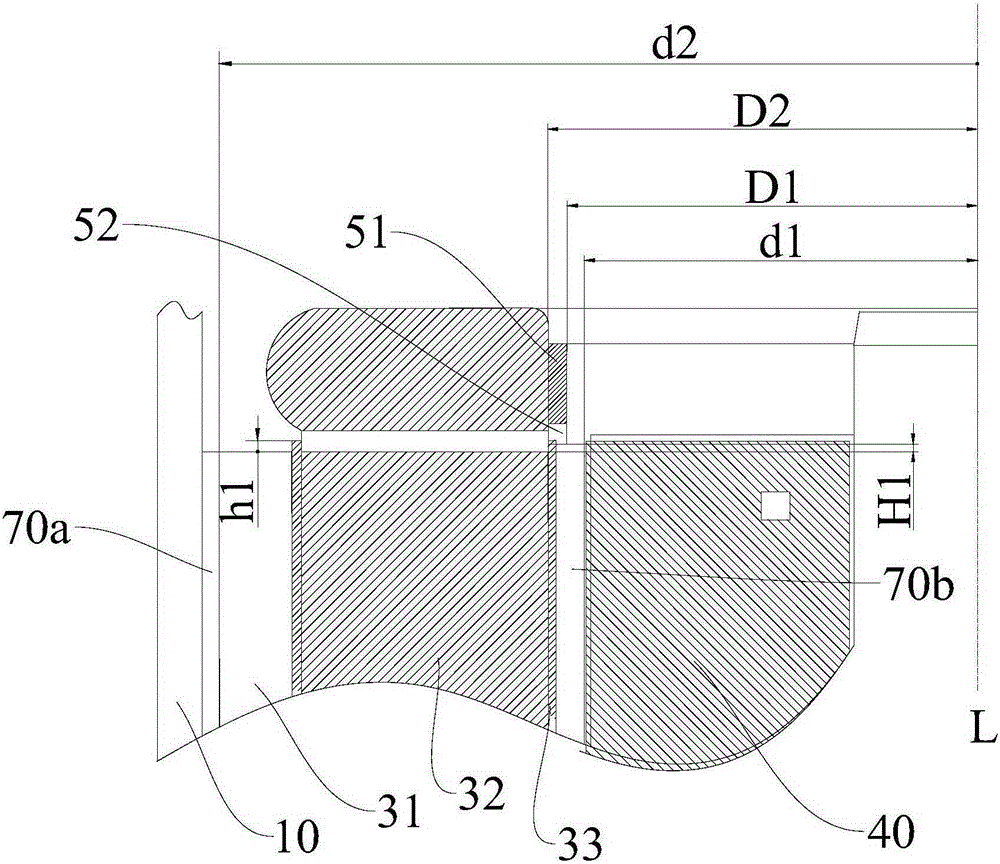

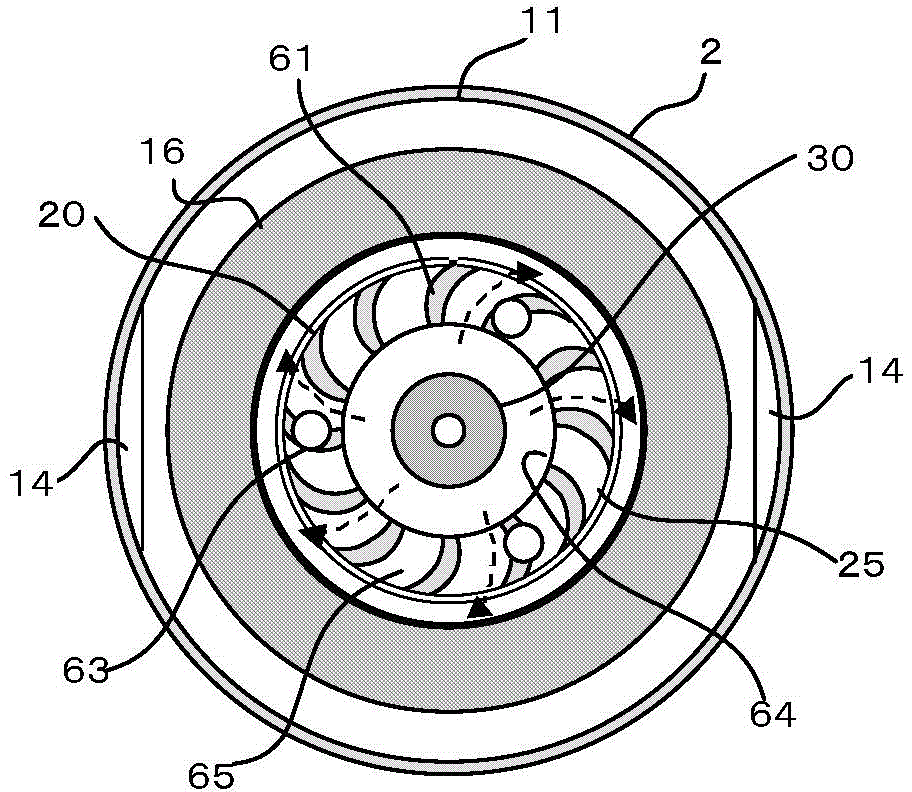

Compressor

ActiveCN106382228AImprove oil and gas separation efficiencyReduce oil outputRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsStatorOil film

The invention discloses a compressor which comprises a housing, a compression mechanism part and a motor part, wherein the compression mechanism part comprises an air cylinder with an exhaust port and an intake port; the motor part comprises a stator and a rotor which are fixedly arranged on the inner peripheral wall of the housing; the stator comprises a stator iron core and a coil winding; the part, positioned on the upper end surface of the stator, of the coil winding is a first coil; the part, positioned on the lower end surface of the stator, of the coil winding is a second coil; the inner peripheral wall of the second coil is connected with the lower end surface of the second coil through an inclined section; the inclined section extends downwards in an inclined mode in an outward direction; length of the inclined section is L2, the inner diameter of the housing is D, and the outer diameter of the first coil is D1, wherein L2, D and D1 at least meet one of the following relationships: D1 greater than or equal to 0.92 D, and L2 greater than or equal to 10 mm. According to the compressor disclosed by the invention, oil throughput capacity of the compressor is reduced, and the problem that heat exchange of a heat exchanger is affected due to the fact that frozen machine oil forms an oil film on the heat exchanger is avoided.

Owner:GUANGDONG MEIZHI PRECISION MFG

Rotary compressor

ActiveCN103573640AImprove oil spit phenomenonIncrease the circulation areaRotary/oscillating piston pump componentsLiquid fuel engine componentsHigh energyElectric machine

The invention discloses a rotary compressor. The rotary compressor comprises a shell, a motor, a compressing mechanism and an oil separation device, wherein the motor is arranged in the shell and separates the interior of the shell into an upper chamber and a lower chamber; the motor comprises stators and rotors; first refrigerant channels are formed in the stators and / or on the peripheries of the stators; second refrigerant channels are formed in the rotors; third refrigerant channels are defined between the rotors and the stators; the upper end of each refrigerant channel is communicated with the upper chamber and the lower end of each refrigerant channel is communicated with the lower chamber; the total areas of the cross sections of the first, second and third refrigerant channels are respectively S1, S2 and S3; S1, S2 and S3 at least satisfy one of the following relational expressions: (S2+S3) / (S1+S2+S3) is not less than 0.45; S2 / S3 is not less than 1; the compressing mechanism is arranged in the lower chamber and below the motor and is provided with a crankshaft and exhaust outlets for exhausting; the oil separation device is arranged at the top of the crankshaft or the rotors. The rotary compressor can reduce oil discharge and ensure higher energy efficiency and long service life.

Owner:GUANGDONG MEIZHI COMPRESSOR

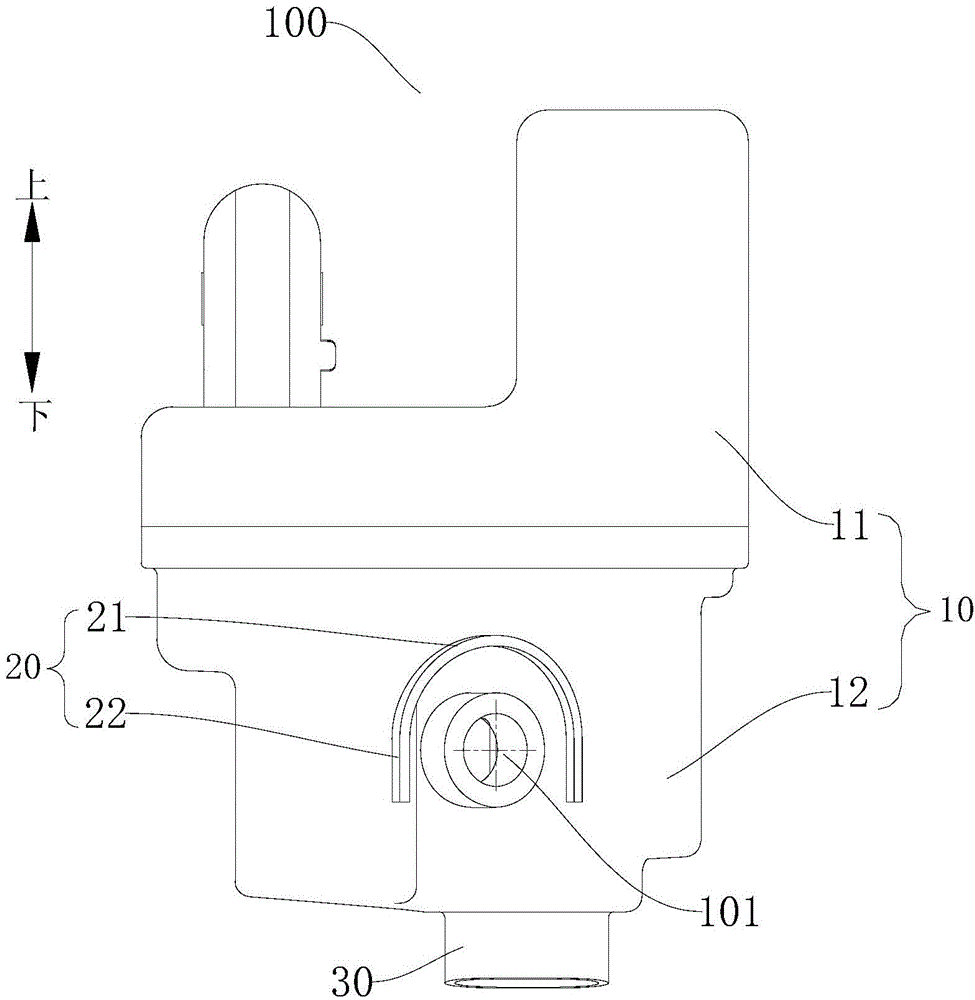

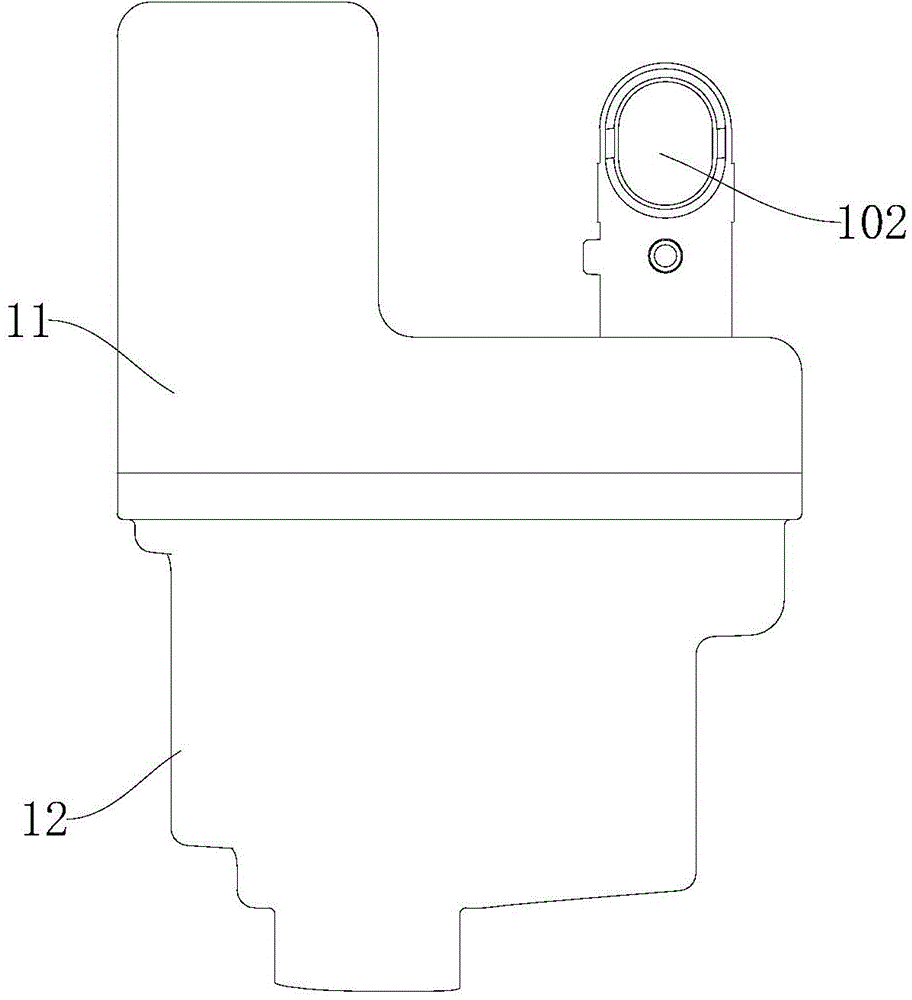

Silencer structure, compressor and air conditioner

PendingCN110285061AChange direction of motionAvoid accelerationRotary/oscillating piston pump componentsLiquid fuel engine componentsMufflerOil content

The invention provides a silencer structure, a compressor and an air conditioner and relates to the technical field of compressors. The technical problem in the prior art that the oil output of the compressor is relatively large is solved. The silencer structure comprises a silencer body and a flow guide structure connected with the silencer body, wherein an exhaust hole is formed in the silencer body; and a refrigerant discharged from the exhaust hole can flow to a motor of the compressor along the axis direction of the exhaust hole under the flow guidance of the flow guide structure. The silencer structure is used for reducing the oil content of the compressor exhaust.

Owner:ZHUHAI LANDA COMPRESSOR +1

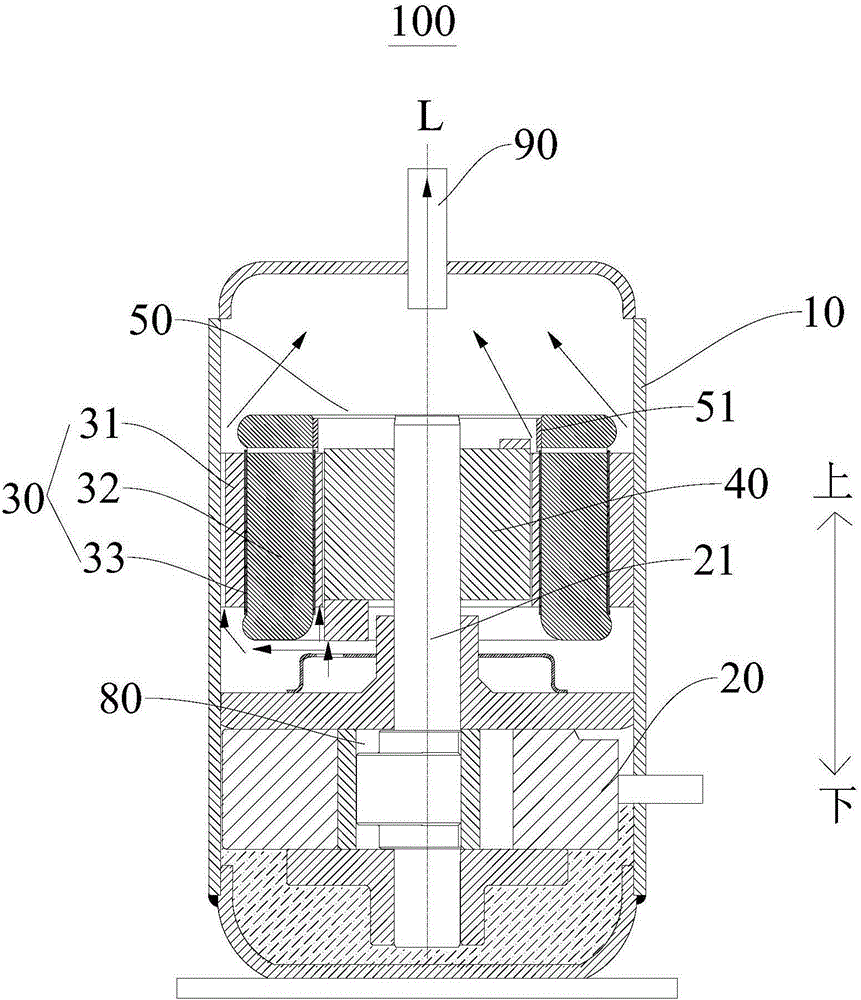

Rotary type compressor

ActiveCN105201846AImprove reliabilityReduce oilRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsStator coilOil separation

The invention discloses a rotary type compressor. The rotary type compressor comprises a shell, a compression mechanism which is arranged in the shell and possesses a crankshaft, a stator arranged above the compression mechanism, a rotor arranged in the stator, an oil separation device arranged at one side, far away from the compression mechanism, of the stator; the stator comprises a stator core and a stator coil reeling around the stator core; the crankshaft is arranged in the rotator and rotates under the driving effect of the rotator; and the oil separation device comprises a sleeve type main body, and the axis of the main body is coincident with the axis of the crankshaft. By arranging the oil separation device, lubricating oil is attached to the oil separation device, and the oil-spitting quantity of the rotary type compressor.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Compressor

ActiveCN106089726AReduce oil outputImprove energy efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringNoise reduction

The invention discloses a compressor. The compressor comprises a motor, a crankshaft, a compressing mechanism and a noise reduction cover, wherein the motor comprises a stator and a rotor, the stator is arranged on the rotor in a sleeving manner, an exhaust channel is arranged on the rotor, a balancing block is arranged on the upper end surface of the rotor and provided with a first end surface and a second end surface which are oppositely arranged, the first end surface is suitable for being connected with the rotor, the two ends in the extending direction of the balancing block are a windward end part and a leeward end part respectively, the windward end part is connected between the first end surface and the second end surface, and in the direction from the first end surface to the second end surface, the windward end part is inclined toward the leeward end part; the upper end of the crankshaft is connected with the rotor, and the exhaust channel is close to the crankshaft; the compressing mechanism is connected with the lower end of the crankshaft; and the crankshaft penetrates the noise reduction cover which is arranged on the upper end surface of the compressing mechanism in a covering manner, and a vent hole is formed in the noise reduction cover and is opposite to the exhaust channel. According to the compressor provided by the invention, the problem of oil accumulation and discharge is solved.

Owner:GUANGDONG MEIZHI COMPRESSOR

Rotary compressor

ActiveCN103334931AReduce oil outputImprove performanceRotary/oscillating piston pump componentsLiquid fuel engine componentsCompression PumpEngineering

The invention provides a rotary compressor which comprises a shell and a compression pump body arranged in the shell, wherein the bottom of the shell is provided with an oil pool used for storing lubricating oil; the compression pump body is provided with a valve seat concave part used for installing an air outlet valve plate; the compression pump body is also provided with an oil return channel, and the lubricating oil accumulated in the valve seat concave part can flow back into the oil pool at the bottom of the shell through the oil return channel; the inner end of the oil return channel is communicated with the valve seat concave part; the outer end of the oil return channel extends to the outer edge of the compression pump body. According to the rotary compressor, the lubricating oil accumulated in the valve seat concave part can flow back into the oil pool at the bottom of the shell of the rotary compressor through the oil return channel, so that the effects of reducing the viscous resistance of the air outlet valve plate and reducing the oil yield of the compressor can be achieved, and the performance of the rotary compressor can be improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

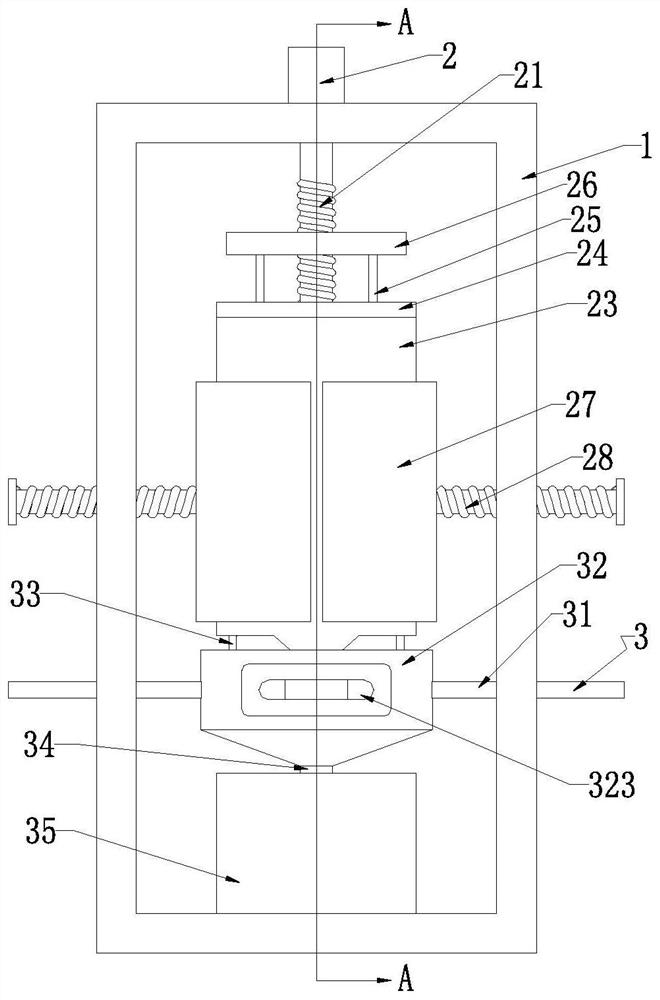

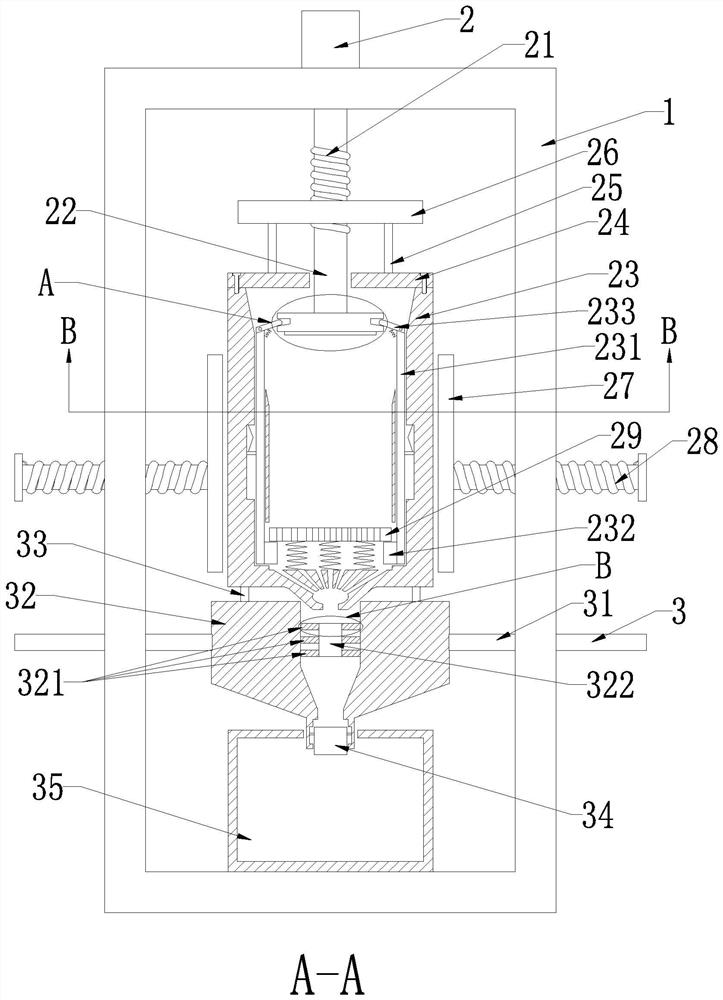

Edible sunflower seed oil squeezing processing treatment system and squeezing processing process

InactiveCN111909779AReduce oil outputPrevent stacking into blocksFatty-oils/fats refiningFatty-oils/fats productionEngineeringSunflower oil

The present invention relates to an edible sunflower seed oil squeezing processing treatment system and a squeezing processing process. The system comprises a material loading frame, a squeezing assembly and an oil discharging assembly, wherein the squeezing assembly and the oil discharging assembly are arranged in order from top to bottom in the loading frame. The system and the process can solvethe following problems that in the existing sunflower seed squeezing treatment process: a) sunflower seeds are frequently impacted multiple times to be broken and seep oil, but due to long-time impact, the sunflower seeds are often pushed to the bottommost end to be stacked into blocks, and therefore the oil yield of the sunflower seeds is reduced and the oil discharge efficiency is influenced; b), when existing sunflower seeds are subjected to squeezing and oil discharging treatment, a large amount of oil residues are often generated, so that the oil residues often enter a collecting vesselalong with oil during oil discharging, impurities of the oil in the collecting vessel are excessive, and the quality of the oil is influenced.

Owner:苏静雯

Slide plate lubricating structure of compressor

InactiveCN102828955AReduce the amount of encapsulationGuaranteed lubrication effectRotary/oscillating piston pump componentsLiquid fuel engine componentsSlide plateAir conditioning

The invention discloses a slide plate lubricating structure of a compressor. The compressor comprises a compression part and a motor part arranged in a closed housing, wherein the compression part comprises a cylinder, a piston arranged in the cylinder, a crankshaft driving the piston for eccentric rotation, a slide plate arranged in a slide plate groove of the cylinder, and a main bearing and an auxiliary bearing respectively arranged at two sides of the cylinder, and one end of the slide plate is connected with the periphery of the piston; and the motor part comprises a stator which is fixed on an inner wall of the closed housing and a rotor which is fixed on the crankshaft. The slide plate groove of the cylinder is longitudinally provided with an oil storage tank, and the main bearing is provided with an oil through hole corresponding to the oil storage tank. By reducing the oil from the end of the main bearing to mix with gaseous refrigerant, the oil is enabled to flow to and accumulate at the upper end surface of the main bearing, and then flows into the oil storage tank to lubricate the slide plate, so as to ensure lubrication effect of the slide plate under the situations of reduced oil output and low oil level. Meanwhile, based on the above structure, amount of refrigerant oil and sealed refrigerant of the compressor is reduced, and the efficiency of an air-conditioning system is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

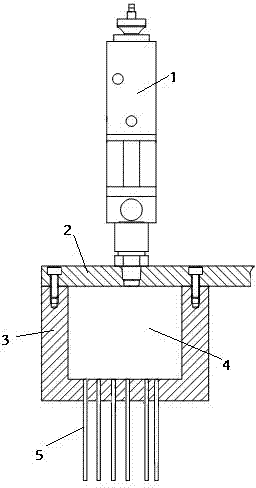

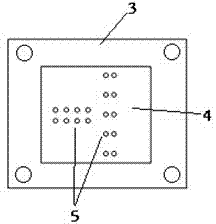

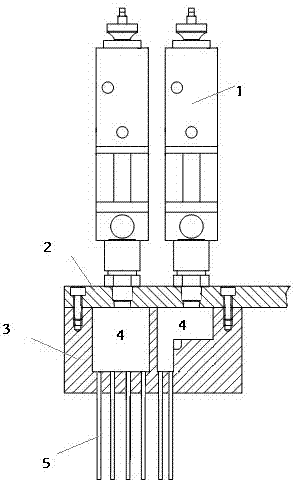

Oiling device for oiling machine

InactiveCN102921600AControl oiling qualityOil evenlyLiquid surface applicatorsCoatingsLarge distanceElectrical equipment

The invention discloses an oiling device for an oiling machine, comprising oil controllers (1), an oiling connection plate (2), an oil cavity plate (3), oil cavities (4) and an oiling pipe (5). According to the oiling device, the quantity of the oil cavities (4) and the oil controllers (1) is increased on the basis of the original oiling machine so that the oil cavities (4) correspond to the oil controllers (1) one by one; and meanwhile, the contour transition of the oil cavities (4) is machined into a fillet, and the volume of the cavity is smaller than the oil storage amount of the oil controller (1). The oiling device is reasonable in structure, fits for the characteristics of oiling positions and larger distance between oiling areas of automobile electric parts, and uniformly oils; and grease is difficultly hardened.

Owner:GUIZHOU GUIHANG AUTOMOTIVE COMPONENTS

Children's intelligence and vision development promoting fully nutritious breakfast and preparation method thereof

The present invention relates to children's intelligence and vision development promoting fully nutritious breakfast. The breakfast comprises the following six varieties of raw materials of cereals, beans, fruits, vegetables, nuts and fibers, a total of 31 edible materials. The specific form of the fully nutritious breakfast is nutritious rice slices and fruit and vegetable particles. The present invention also relates to a preparation method of the children's intelligence and vision development promoting fully nutritious breakfast. The fully nutritious breakfast is comprehensive in nutrition, easy to digest and absorb, and also easy to carry and convenient to brew. Besides, by adding carrots, grapes, blueberries and other edible materials, the breakfast supplements children needed anthocyanins, carotene, vitamin C and B family, and reaches the effects of protecting eyes and enhancing vision. By adding walnut kernels, millet, shii-take, red dates, bananas and other edible materials, the breakfast can reach a certain function of supplementing and tonifying brains.

Owner:湖南益百年健康科技有限公司

Making method of exfoliating toner

InactiveCN103099748AEasy to updateReduce surface temperatureCosmetic preparationsToilet preparationsVitamin CHamamelis virginiana

The invention discloses a making method of exfoliating toner. The making method is characterized by comprising the following steps of: firstly, adding 5ml of tartaric acid into 400ml of mineral water and uniformly stirring; secondly, adding 50ml of witch hazel extracting solution and uniformly stirring; thirdly, adding 3g of powder of vitamin C; and fourthly, sufficiently stirring to obtain a finished product. The product provided by the invention not only can be used for replenishing water, but also can be used for exfoliating, shrinking pores and promoting metabolism.

Owner:郭淑玲

Nutritional breakfast beneficial for working personnel to protect eyes, keep fit and strengthen spleen and stomach, and preparation method thereof

The invention relates to a nutritional breakfast beneficial for working personnel to protect eyes, keep fit and strengthen the spleen and the stomach. Raw materials of the nutritional breakfast include 30 food materials in six categories of cereals, beans, fruits, vegetables, nuts and fibers. The concrete form of the nutritional breakfast is nutritional rice slices and fruit and vegetable particles. The invention also relates to a preparation method of the nutritional breakfast beneficial for the working personnel to protect the eyes, keep fit and strengthen the spleen and the stomach. The nutritional breakfast disclosed by the invention is comprehensive in nutrition, easy to digest and absorb and convenient to carry and brew; the effects of protecting the eyes and enhancing vision are achieved through addition of blueberries, strawberries, applies, grapes and carrots; the effects of keeping fit and slimming are achieved through addition of apples, carrots, lentinus edodes, pumpkins, oats, buckwheat and sweet potatoes; and the effect of nourishing the spleen and the stomach is achieved through addition of rice, millet, barley, triticum aestivum, semen nelumbinis, pisum sativum, bananas, broccoli and brassica rapa.

Owner:湖南益百年健康科技有限公司

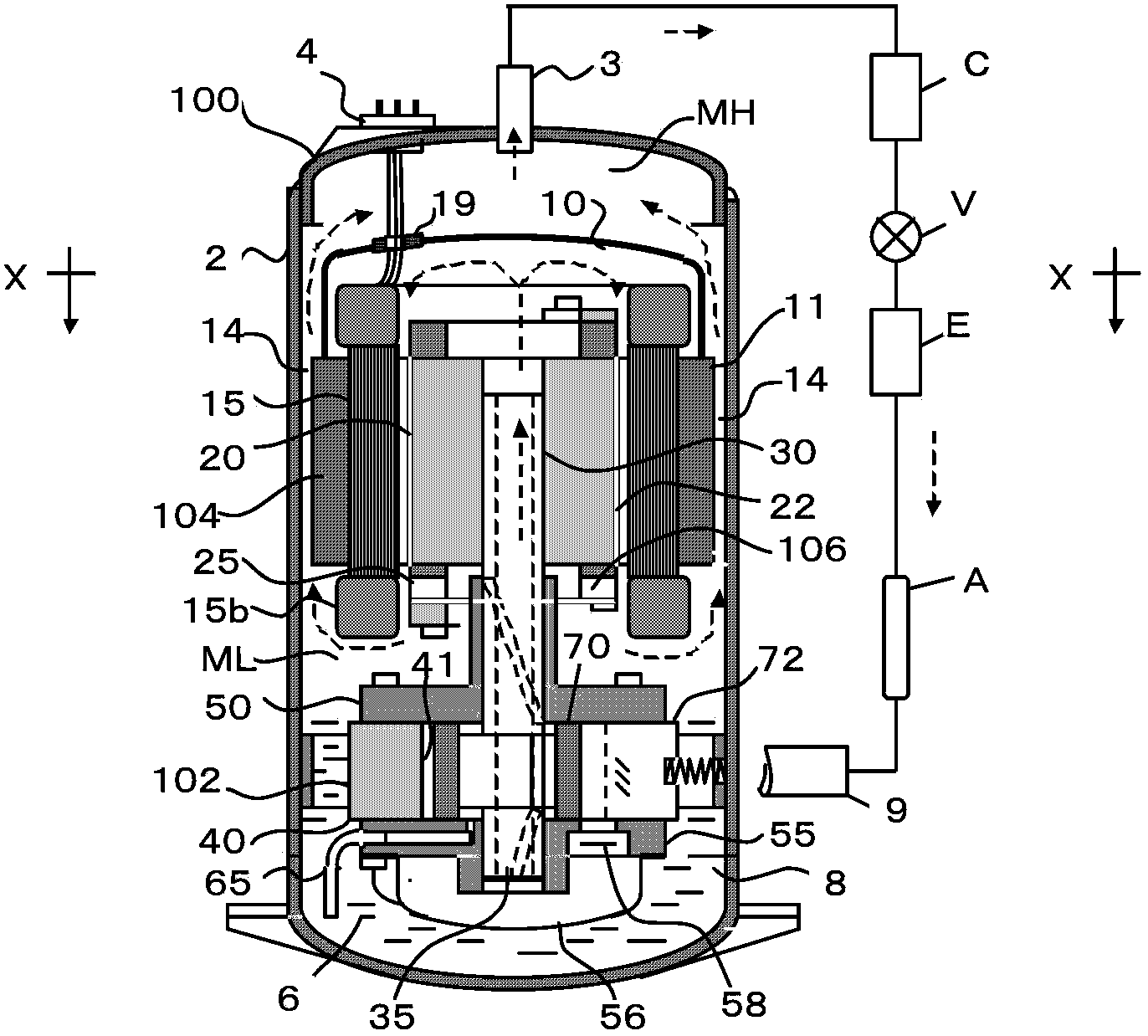

Rotary compressor

ActiveCN103557163AImprove reliabilityLow efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsCompression deviceOil separation

The invention discloses a rotary compressor comprising a seal housing. The seal housing comprises an electrodynamic motor formed by a motor stator with a motor winding, and a motor rotor arranged on the inner diameter of the motor stator; a rotary-type compression device which is arranged on the lower end of the motor and is driven by the motor; a rotor fan arranged on the upper end part of the motor rotor; and an exhaust pipe opening a hole to an oil separation chamber formed between the seal housing and the upper side of the motor. By running of the motor rotor, a fluid in the oil separation chamber passes through the rotor fan, and then flows to the inner circumference of the motor winding. According to the rotary compressor of the embodiment of the invention, by arrangement of the rotor fan, the oil discharge amount from the compressor to a refrigeration circulation system is reduced. Therefore, not only the reliability of the compressor is enhanced, also the efficiency reduction of a heat exchanger can be prevented. In addition, by arrangement of refrigerant cycle of the rotor fan, the motor winding temperature is decreased, so that faults caused by motor efficiency reduction and burning loss can be prevented.

Owner:GUANGDONG MEIZHI COMPRESSOR

Vertical rotary compressor

ActiveCN103511270AImprove efficiency and reliabilityImprove reliability issuesRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsStatorEngineering

The invention discloses a vertical rotary compressor. The vertical rotary compressor comprises a sealed housing provided with an exhaust pipe; an electrodynamic machine, a machine winding cover and a rotary compression unit are arranged in the sealed housing; the electrodynamic machine is composed of a motor stator provided with a machine winding, and a motor rotor surrounded by the motor stator; the top of the machine winding is covered by the machine winding cover; the rotary compression unit is arranged under the electrodtnamic machine, and is provided with a compression chamber and a crankshaft. Lubricating oil is stored in the sealed housing; refrigerant discharged from the compression chamber to the machine winding cover flows to a gap between the electrodynamic machine and the rotary compression unit through the inside of the motor stator. The vertical rotary compressor is capable of avoiding compressor reliability reduction caused by discharged oil amount, motor overheating , oil undercooling and the like, and improving efficiency by reducing motor temperature.

Owner:GUANGDONG MEIZHI COMPRESSOR

Rotary compressor

ActiveCN105402133AReduce oil outputImprove energy efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention discloses a rotary compressor. The rotary compressor comprises a shell, a compression mechanism and an oil pool partition plate. An oil pool is arranged at the bottom in the shell. The compression mechanism is arranged in the shell and comprises a main bearing, an air cylinder assembly and an auxiliary bearing. The main bearing is arranged on the top of the air cylinder assembly, and the auxiliary bearing is arranged at the bottom of the air cylinder assembly. The air cylinder assembly comprises at least one air cylinder. The oil pool partition plate is arranged in the shell and located at the upper portion of the compression mechanism. According to the rotary compressor, the oil pool partition plate is arranged in the shell, the oil spitting amount of the compressor is effectively reduced, and the energy efficiency of the compressor is improved.

Owner:ANHUI MEIZHI PRECISION MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com