Lubrication apparatus of horizontal rotary compressor and control method thereof

A technology of rotary compressors and lubricating devices, which is applied in the direction of rotary piston machinery, components of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, etc., which can solve the problem of sacrificing cooling and reducing reliability , the motor is easy to burn out, etc., to achieve the effect of balanced cooling and reduced oil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

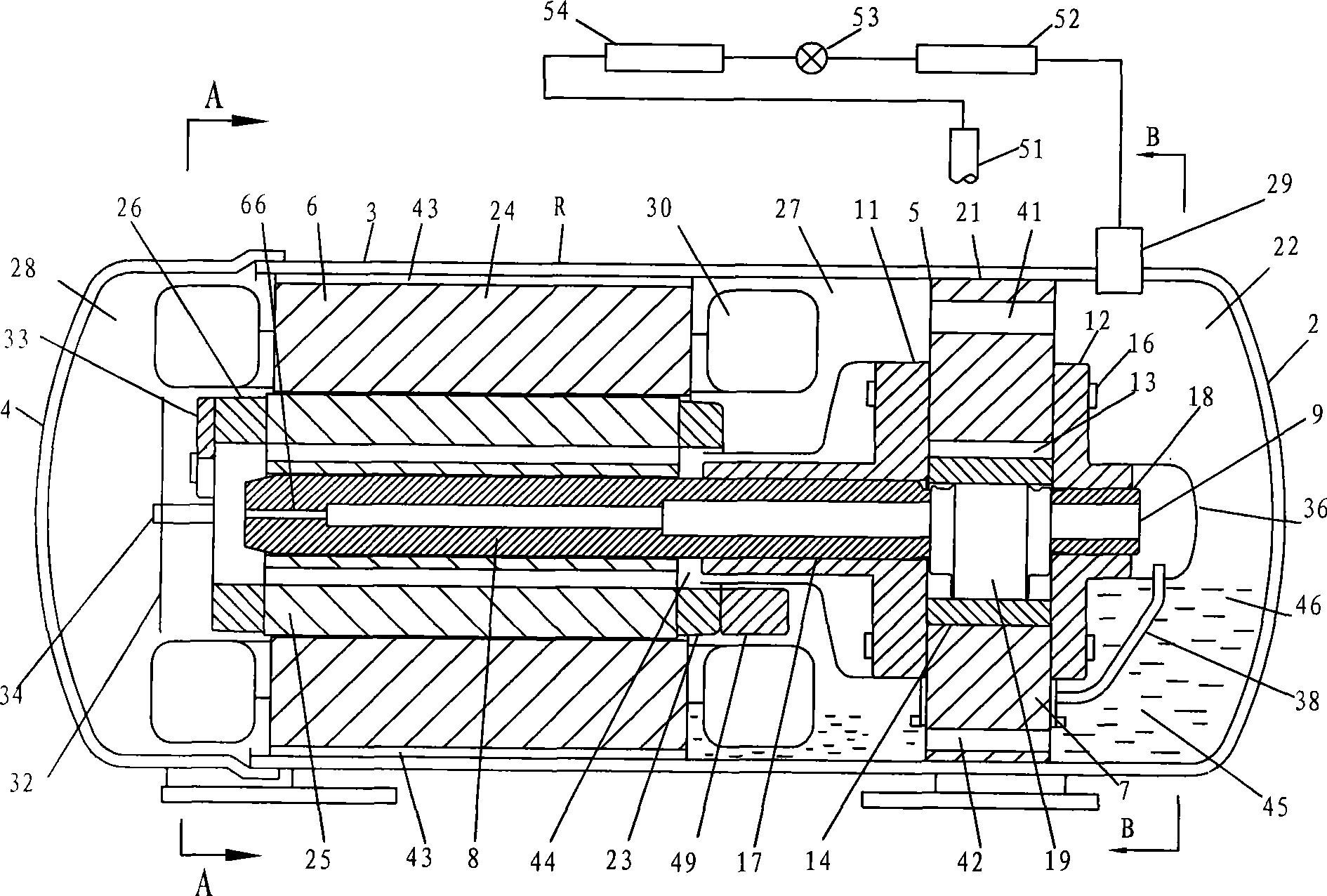

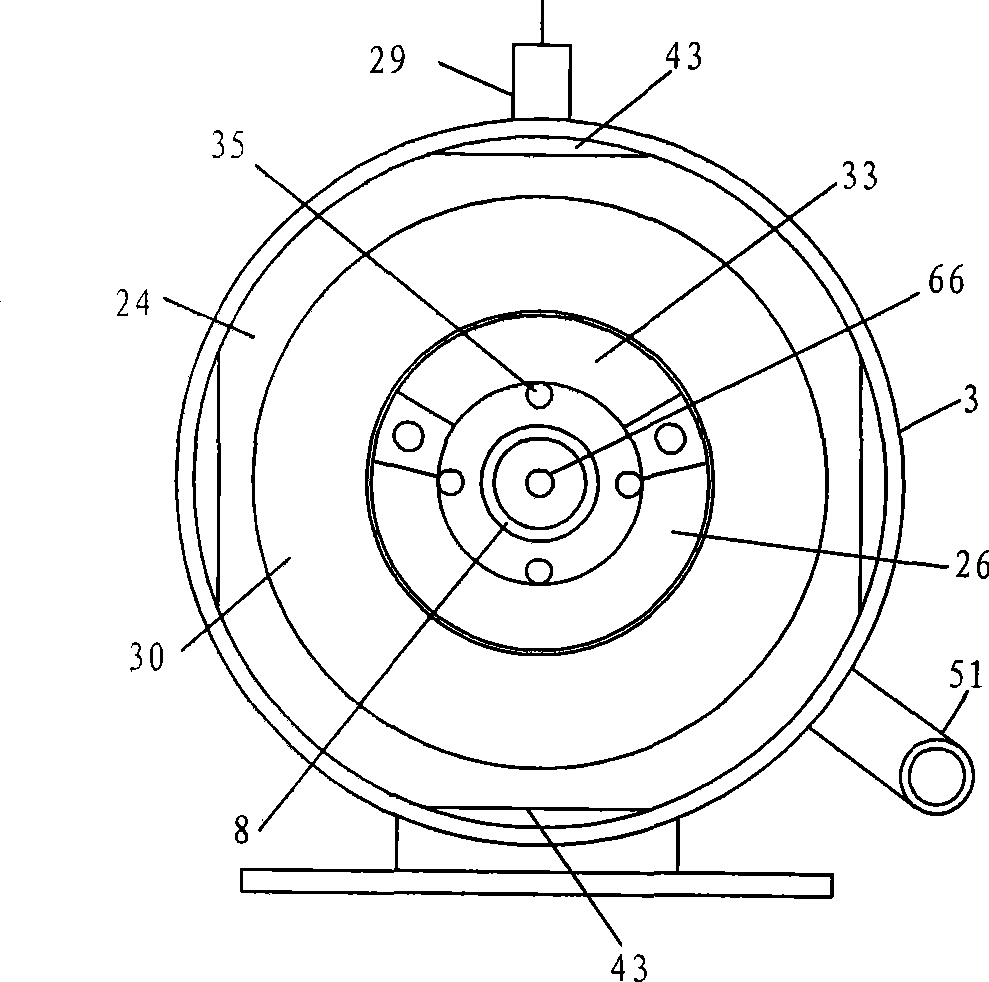

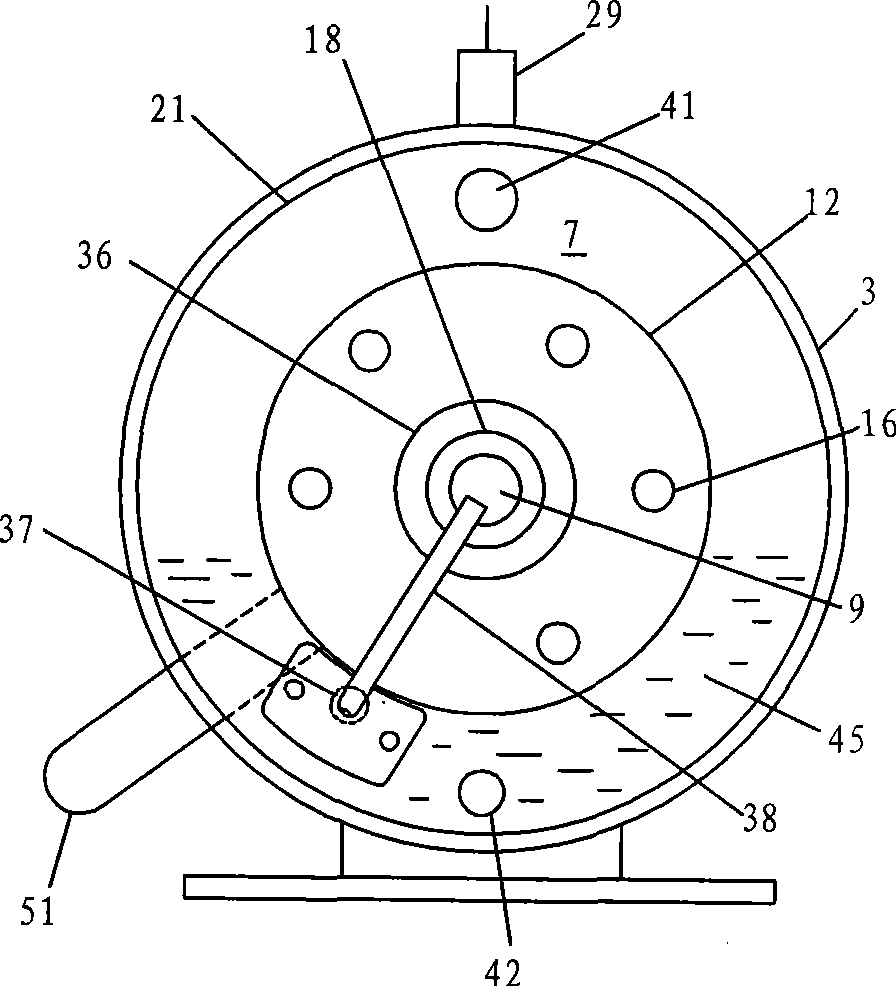

[0022] see Figure 1-Figure 4 , The airtight casing 2 of the horizontal rotary compressor R is composed of a main casing 3 and a side casing 4 , and the compressor assembly 5 and the motor 6 are fixed and accommodated in the inner cavity of the main casing 3 .

[0023] The compressor assembly 5 includes a cylinder 7, the main bearing 11 and the auxiliary bearing 12 are installed on the surface of both sides of the cylinder 7, and support the crankshaft 8, the circular piston 14 located in the center of the cylinder and accommodated in the cylinder compression chamber 13, and the piston 14 The outer periphery of the sliding plate is in relative sliding contact, and the sliding plate is not shown in the figure. Above each parts are combined by cylinder screw 16. The crankshaft 8 is composed of a main shaft 17 , a counter shaft 18 and an eccentric shaft 19 . The piston 14 is mounted on the eccentric shaft 19 and revolves in the cylinder compression chamber 13 . The cylinder out...

no. 2 example

[0038] see Figure 5-Figure 6 , with respect to the first embodiment, the second embodiment has the following three alternatives: enlarge the outer circumference of the main bearing 11, fix it on the inner diameter of the main housing 3, and also support the entire compressor assembly 5; and add Utilize the pressure-reducing means of the second end ring 26 of the rotor 25, that is, form a pressure difference through its high-speed rotation, so that the high-pressure gas of the exhaust muffler 39 can easily flow out to the second motor chamber 28; The connection method of one end ring 23.

[0039] The outer circumference of the main bearing 11 is almost equal to the inner diameter of the main casing 3, and the compressor assembly 5 is fixed on the outer circumference. An auxiliary plate 61 having an L-shaped inner diameter cylindrical portion is installed on the first end ring 23 , and the first balance weight 49 is installed on it. When the gap between the muffler exhaust ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com