Gas distribution garment

- Summary

- Abstract

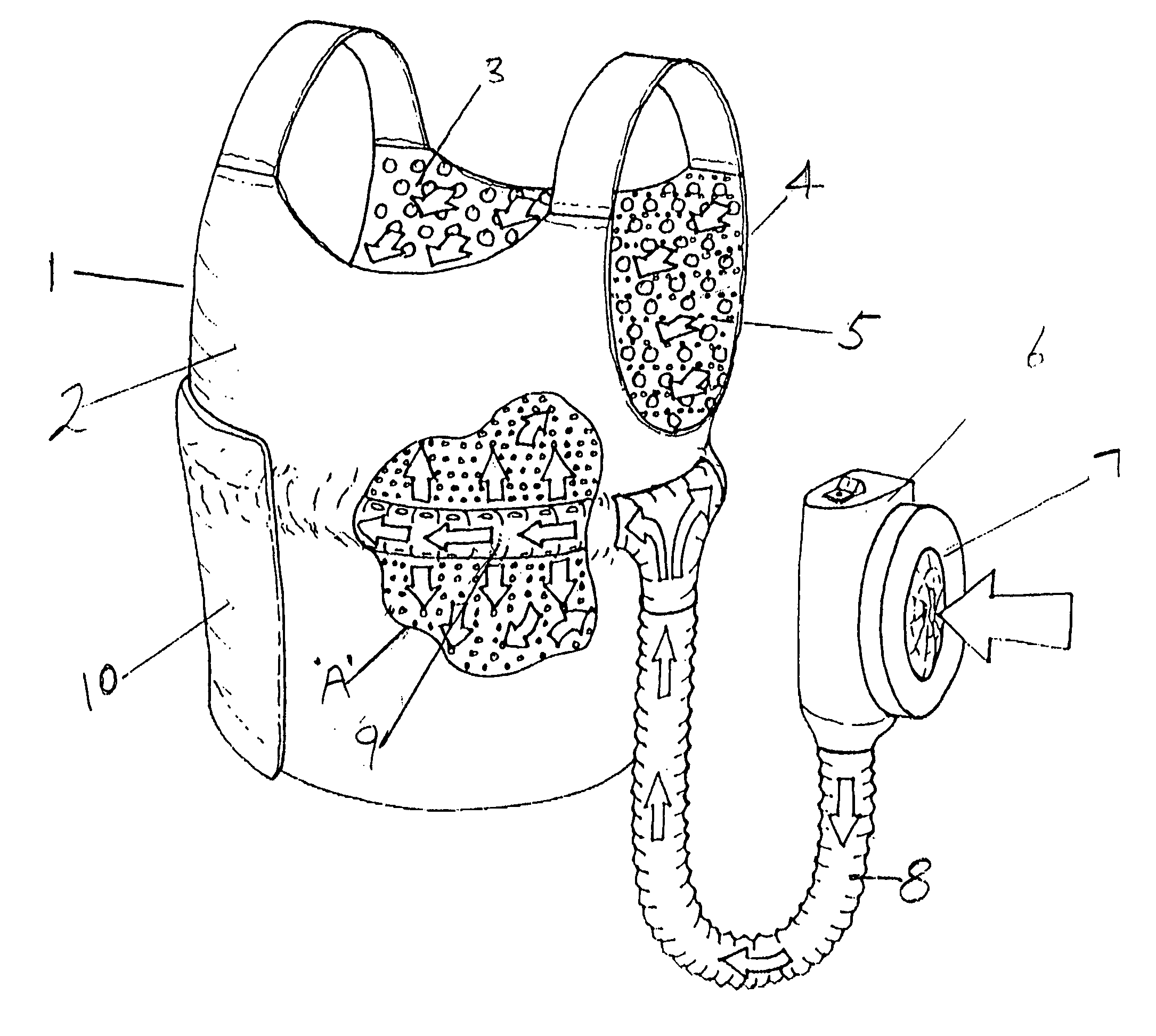

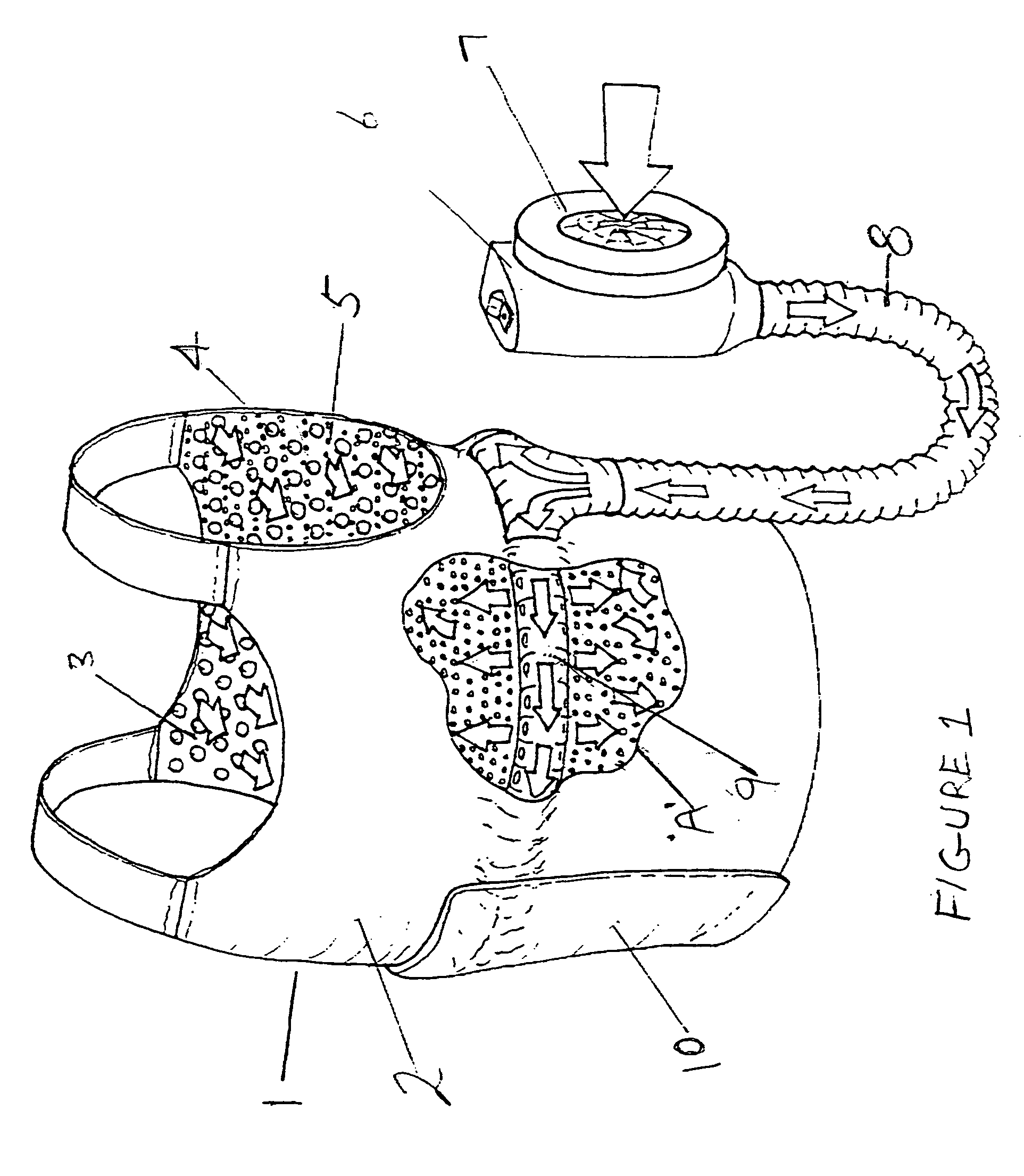

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0046] To demonstrate the efficacy of an embodiment of the invention a garment was constructed according to the teaching of this specification and its cooling effectiveness evaluated whilst being worn by a human subject walking on a tread-mill.

[0047] The first and second substrates comprised a laminate of Basofil® spun bonded non-woven textile and expanded polytetrafluoroethylene having an air-impermeable water vapour permeable coating with a plurality of foamed silicone rubber protrusions uniformly distributed on the Basofil® surface. The laminate is available from W.L.Gore and Associates GmbH, Putzbrunn, Germany under the trade name Airlock® Part No. AIRL 002000. The silicone rubber protrusions are approximately 3 mm in height and cover an area of approximately 13% of the surface of the laminate.

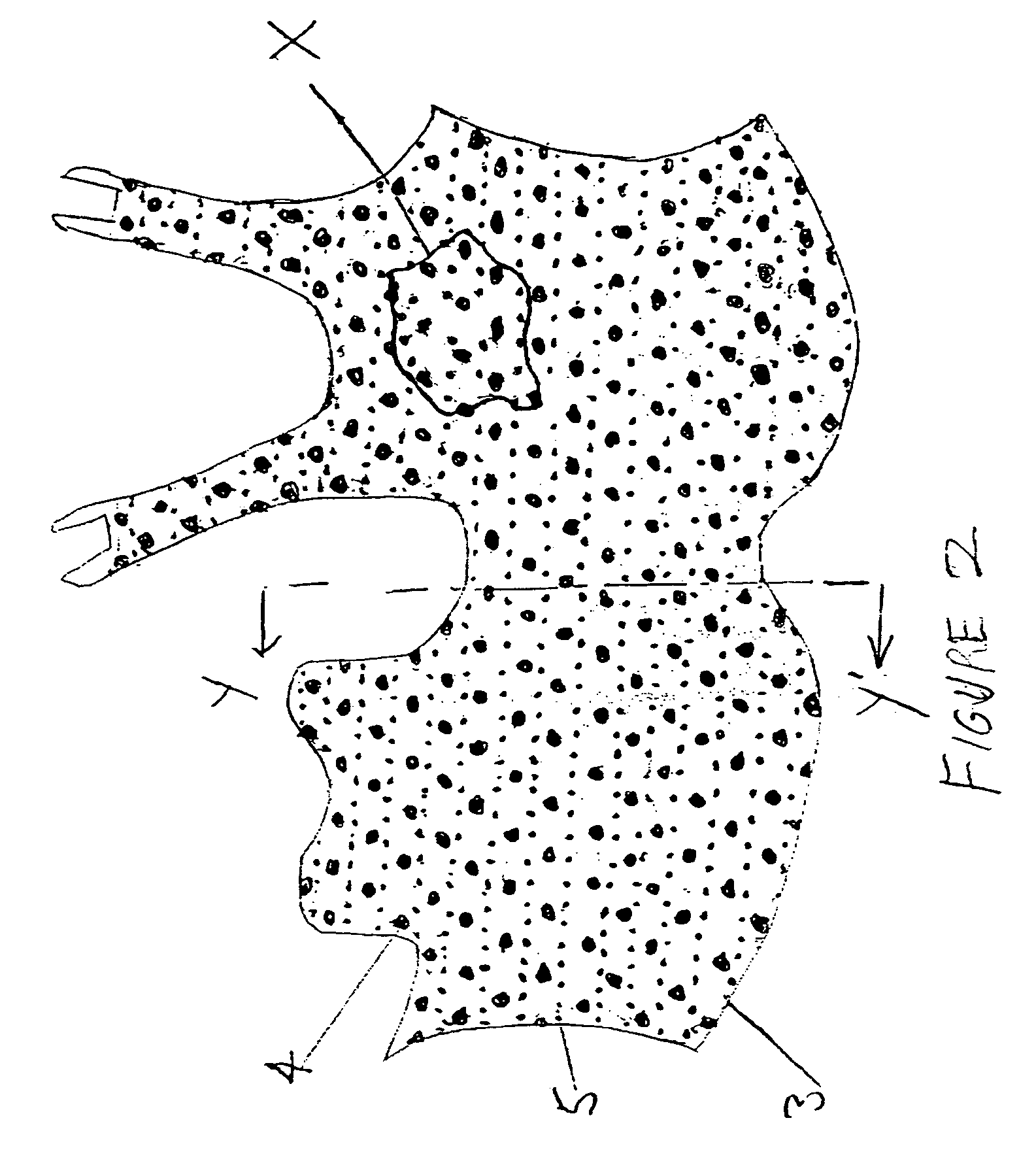

[0048] Two pieces of Airlock® AIRL 002000 laminate were cut and sized according to FIG. 2 to give a body coverage of about 0.45 m2. The laminate corresponding to the second substrate of ...

example 2

Cooling

[0061] To evaluate the cooling power of the cooling garment prepared substantially according to Example 1, it was subject to Thermally Instrumented Manikin testing by The Cord Group Ltd., Dartmouth, Nova Scotia, Canada. The cooling garment was tested in combination with a standard British Army Mk IV protective suit as used in the foregoing Example 1 and under the various conditions as detailed in the following Table 1. Testing was carried out in a temperature and humidity controlled room with an ambient temperature set at 35° C. and relative humidity set 50%. Details of the test methodology are as follows.

Test Method

[0062] The evaluation of cooling vest prototypes using UK standard suit ensemble was conducted using a Thermal Instrumented Manikin Test System. During the testing, environment temperature, skin temperature and power consumption were recorded.

[0063] The Thermal Manikin Test System consists of a hollow aluminum manikin equipped with temperature sensors and el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com