Assembly type automobile brake disc

A brake disc and assembly technology, applied in the field of brake discs, can solve problems such as insufficient braking force, impact on driving safety, unsatisfactory heat dissipation of brake discs, etc., and achieve the best heat dissipation efficiency and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

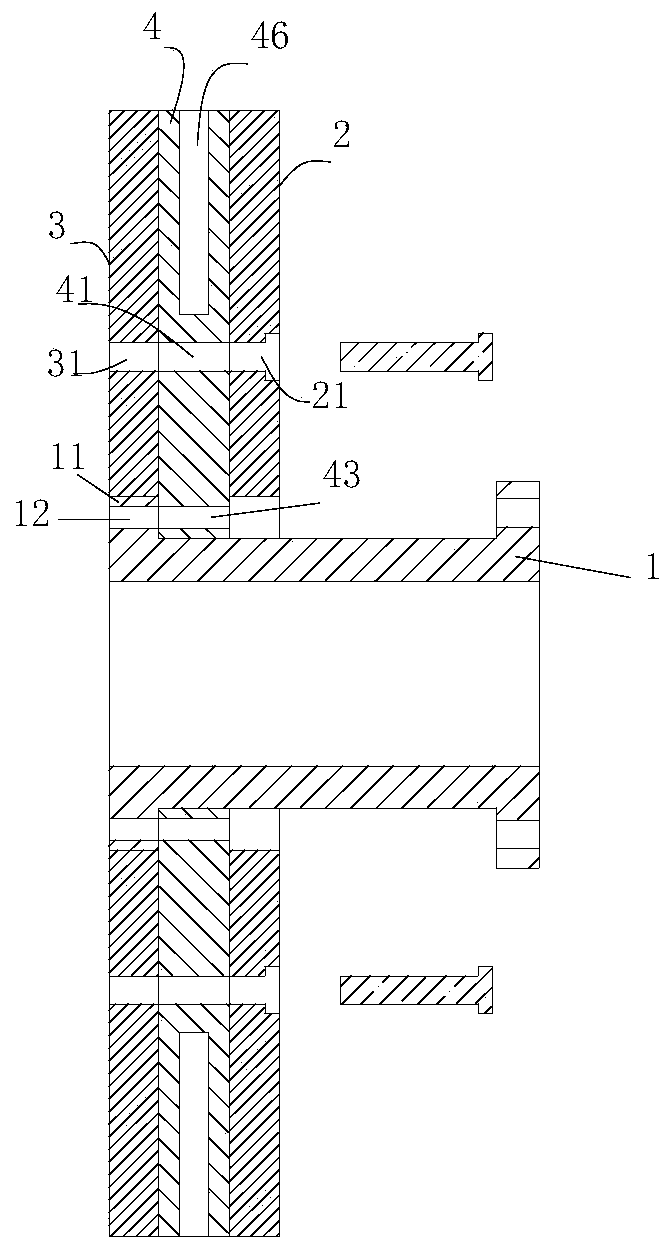

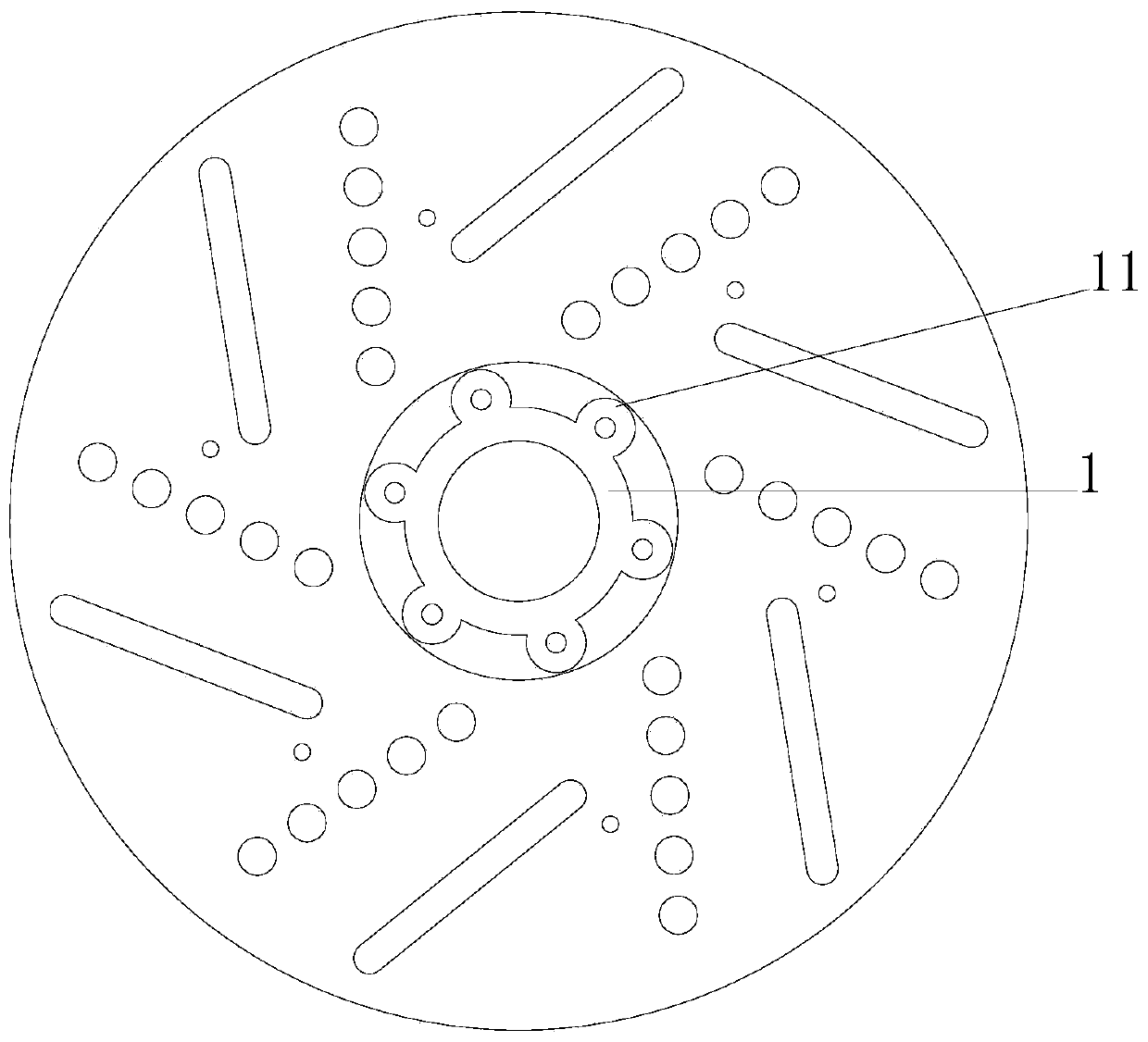

[0022] refer to Figure 1-Figure 8 , the present invention proposes an assembled brake disc for automobiles, including a brake disc and a connecting sleeve 1; wherein:

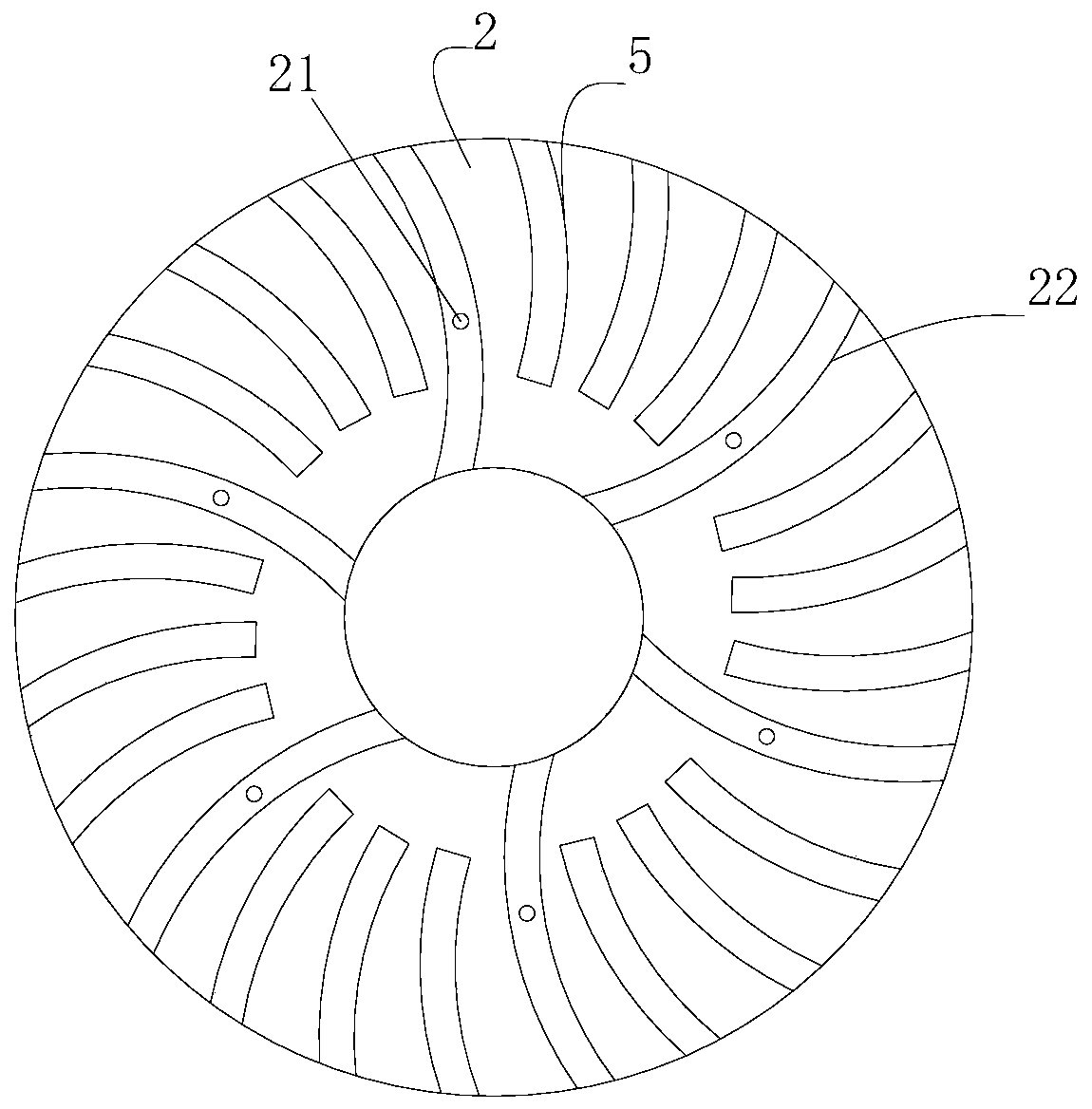

[0023] The brake disc includes a first disc body 2 and a second disc body 3 arranged in parallel and opposite to each other. The first plate body 2 is provided with a plurality of first assembly holes 21 penetrating and distributed in a circle, and the second plate body 3 is provided with a plurality of second assembly holes 31 penetrating and distributed in a circle. The central axes of 21 coincide with the central axes of the plurality of second assembly holes 31 respectively.

[0024] A plurality of circumferentially distributed first connectors 4 are arranged between the first disc body 2 and the second disc body 3, and a gap is left between any two adjacent first connectors 4 to form a heat dissipation channel. Connecting bodies 4 are respectively provided in one-to-one correspondence with a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com