Patents

Literature

223results about How to "Automatic speed adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

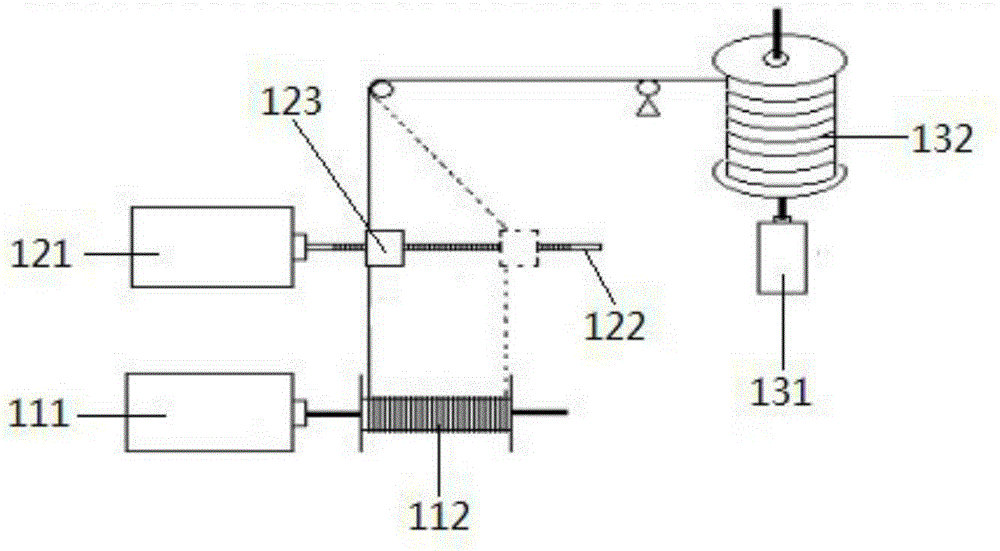

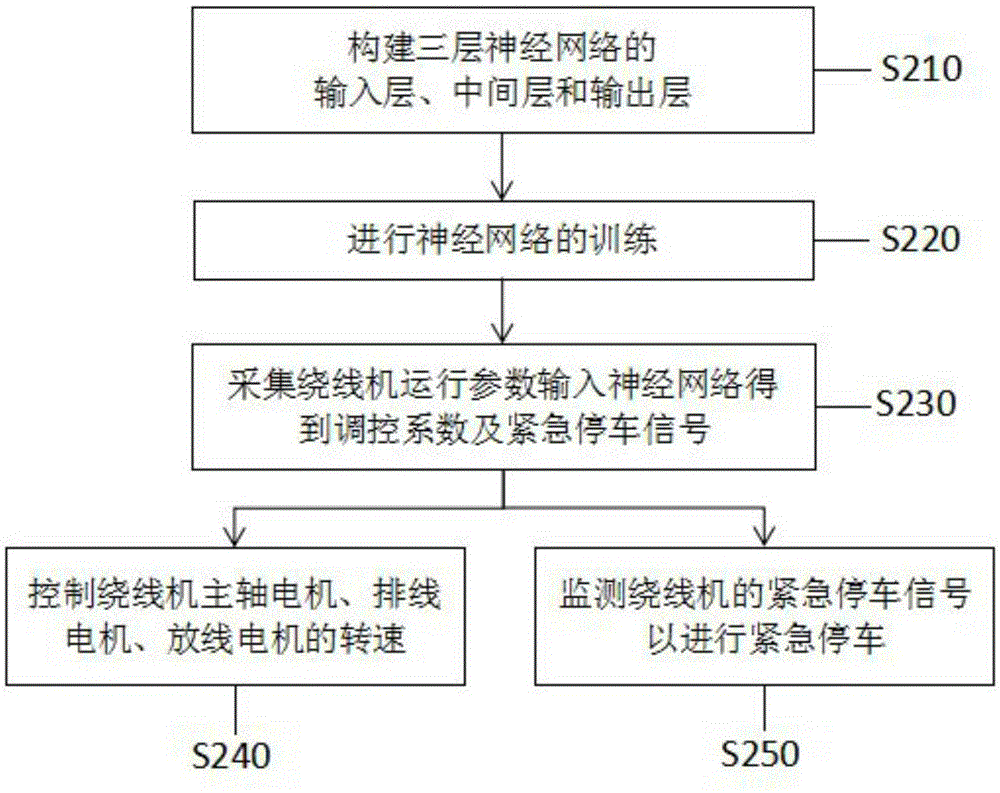

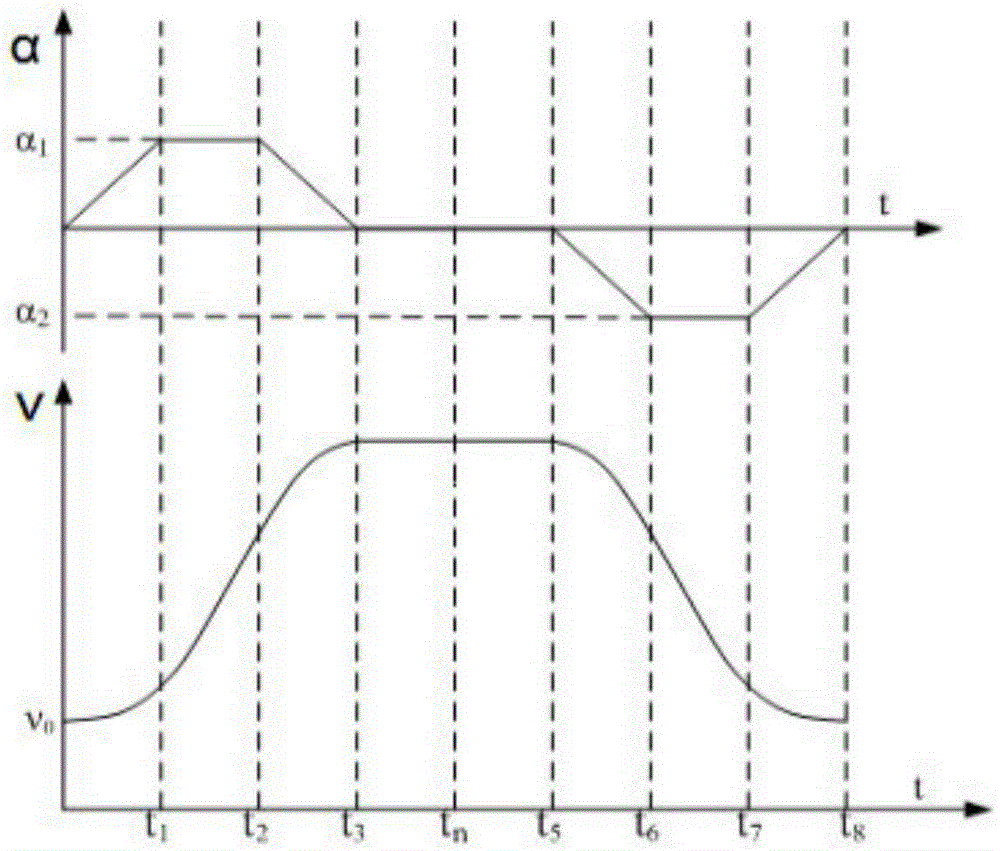

Coil winding machine control method based on BP nerve network, and coil winding machine

InactiveCN105404153AReduce disconnection frequencyAutomatic speed adjustmentCoils manufactureAdaptive controlWinding machineNerve network

The invention discloses a coil winding machine control method based on a BP nerve network. The method comprises the following steps: step one, determining an input-layer vector, an intermediate-layer vector and an output-layer vector of a three-layer nerve network; step two, according to historical data, obtaining a training sample, and training the nerve network; step three, according to a certain sampling period, measuring an internal temperature T, a vibration rate U, stress F between a wire arrangement device and a coiling frame, a main shaft motor rotating speed omega a, a wire arrangement motor rotating speed omega b and a wire laying motor rotating speed omega c of a coil winding machine by use of a sensor, and normalizing the parameters to obtain the input-layer vector and the output-layer vector; step four, controlling the main shaft motor rotating speed, the wire arrangement motor rotating speed and the wire laying motor rotating speed; and step five, according to emergency shutdown signals in the intermediate-layer vector, determining an operation state of the coil winding machine. According to the invention, the coiling line breaking frequency can be reduced, the product quality is improved, the machine mean time between failures is increased, and the realistic significance is great.

Owner:JILIN UNIV

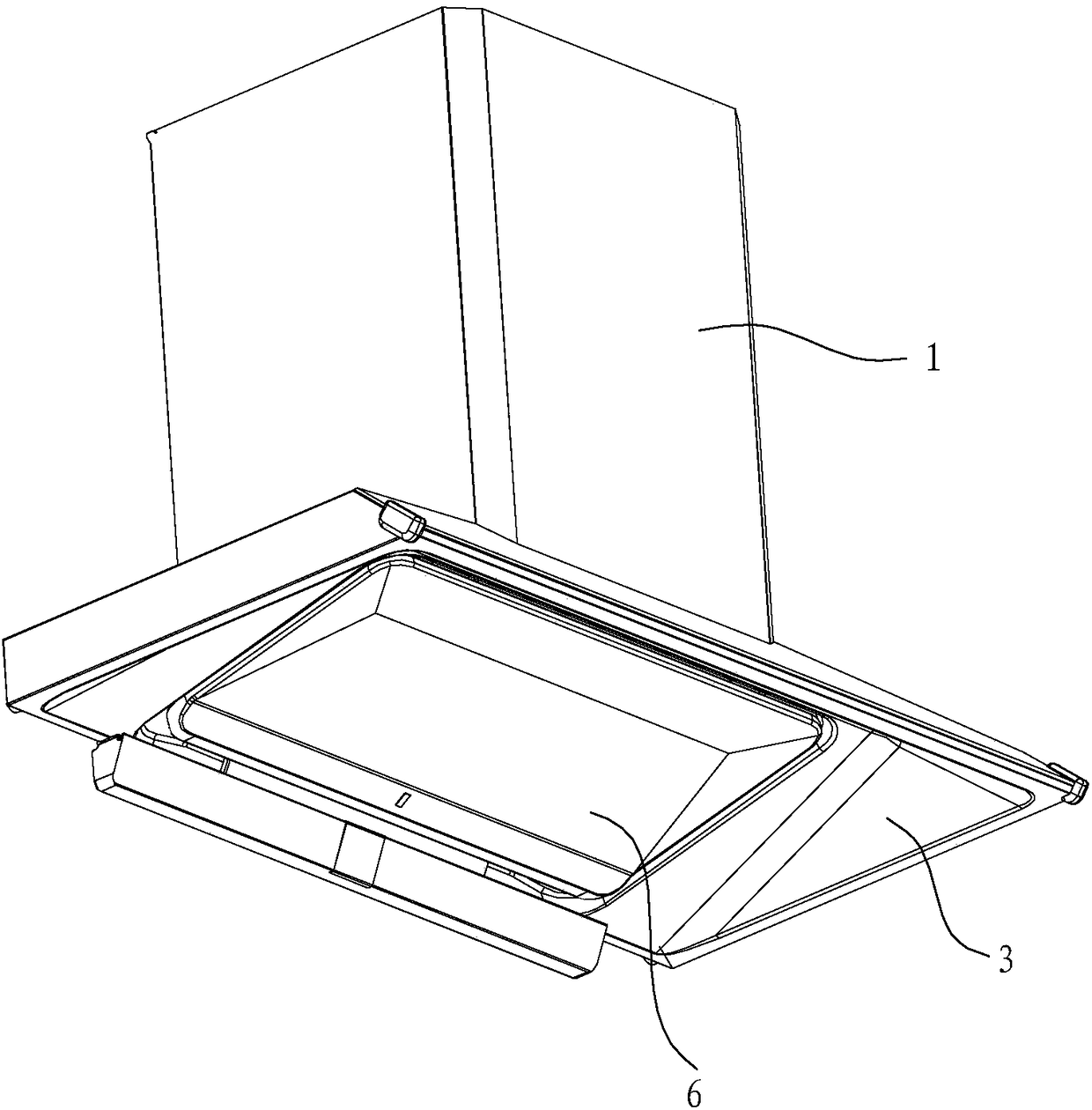

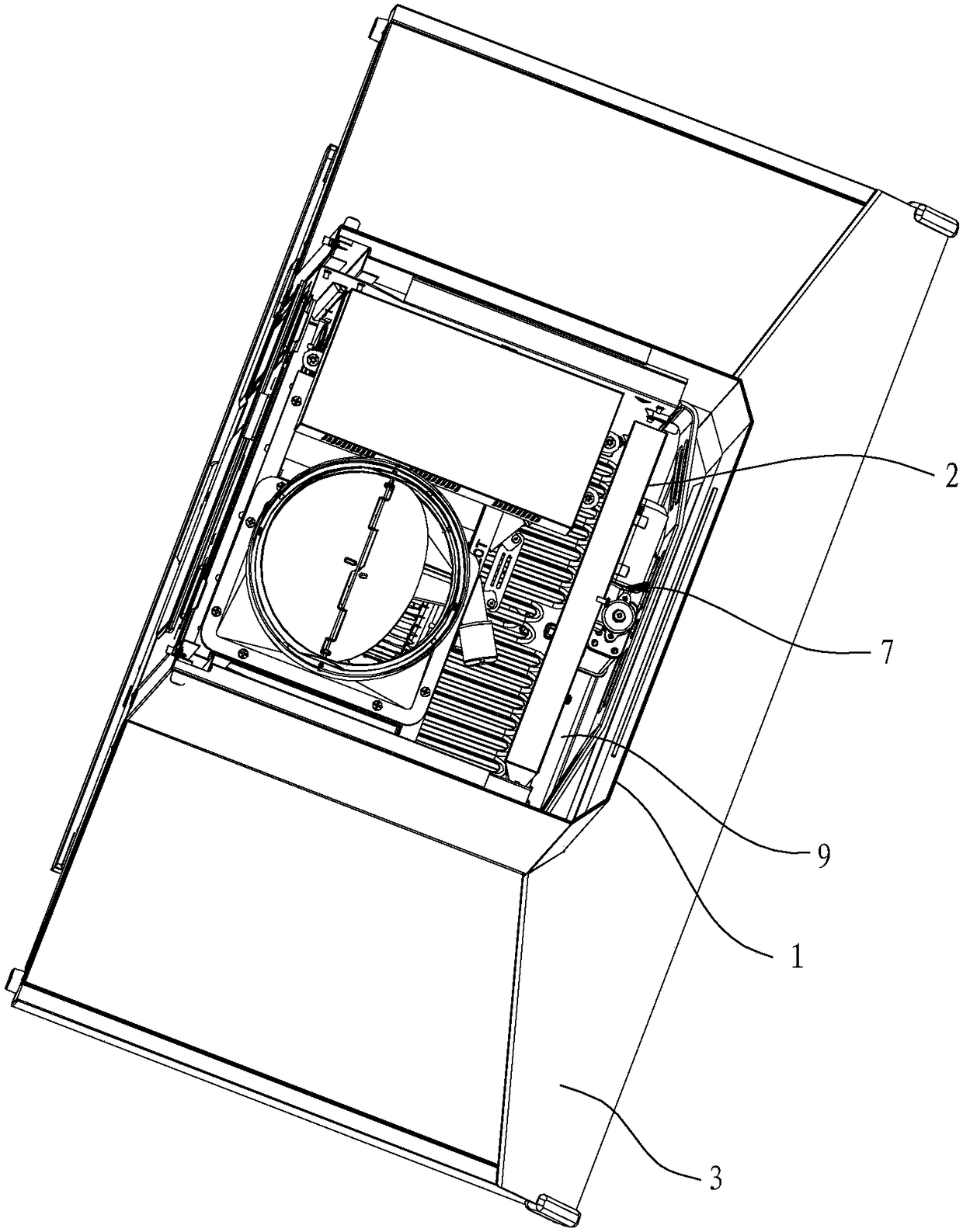

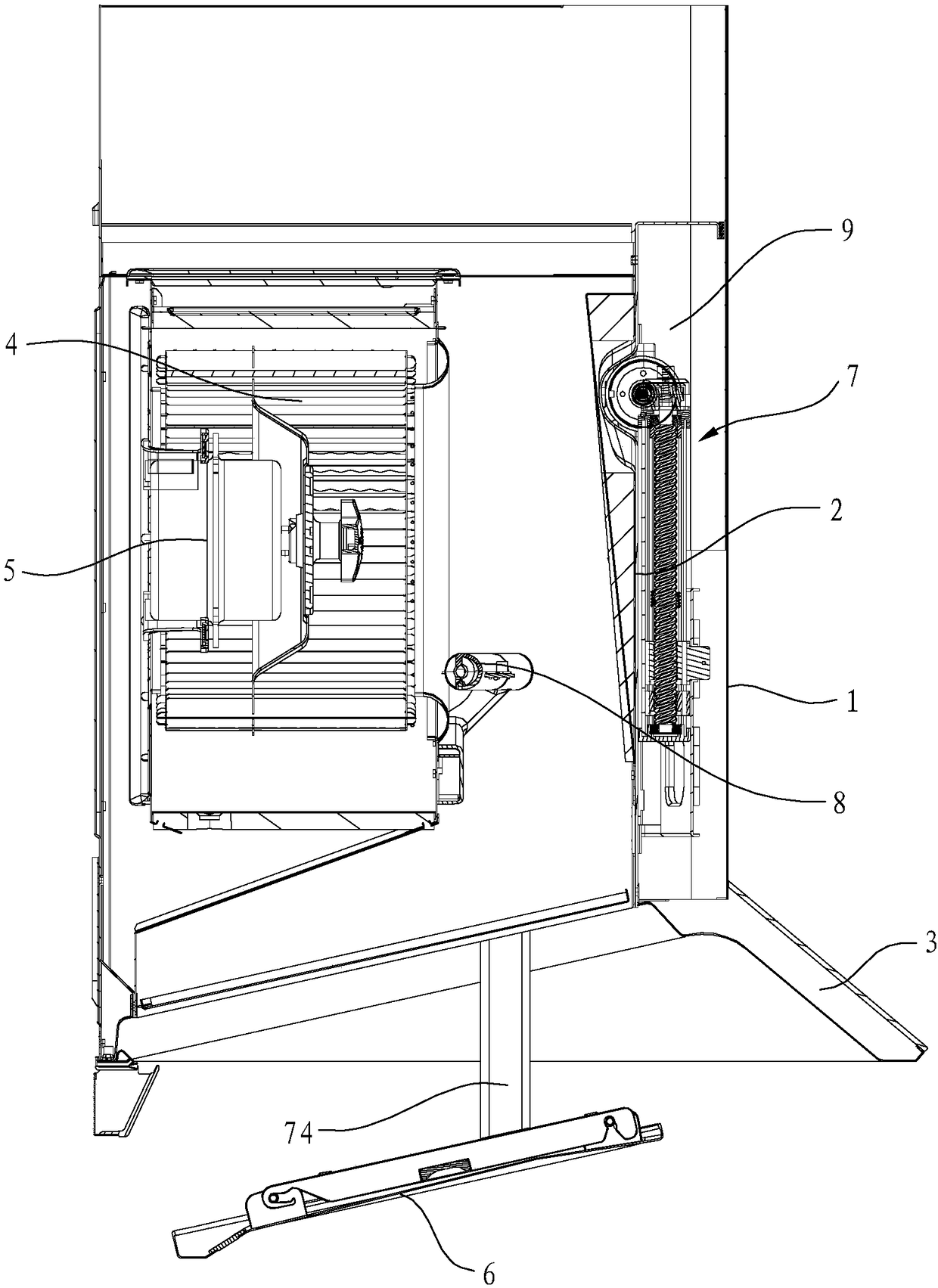

Intelligent extractor hood and control method thereof

ActiveCN108253474AAutomatic speed adjustmentDomestic stoves or rangesLighting and heating apparatusAir volumeExhaust fumes

Provided are an intelligent extractor hood and a control method thereof. The intelligent extractor comprises a machine shell, a fan located in the machine shell, an exhaust fume collecting hood located below the machine shell and an exhaust fume guide plate arranged below the exhaust fume collecting hood; and a push rod mechanism for driving the exhaust fume guide plate to ascend and descend is installed inside the machine shell. The intelligent extractor hood is characterized by further comprising a controller and a sensor for detecting the cooking fume and / or vapor concentration inside or outside the machine shell, the signal output end of the sensor is in electric signal connection with the signal input end of the controller, and the controller controls the rotation speed of a fan motorand the lifting position of the exhaust fume guide plate according to a received output signal of the sensor. In the working process, the sensor senses the cooking fume and / or vapor concentration inside or outside the machine shell, the controller can adjust the rotation speed of the fan motor automatically according to the output signal of the sensor in order to make the air volume of the fan bematched with the working condition of the extractor hood in real time, and the controller can further adjust the air intake area and the distance between a negative pressure area and a fume source automatically by ascending or descending the exhaust fume guide plate to adapt to change of the working conditions.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

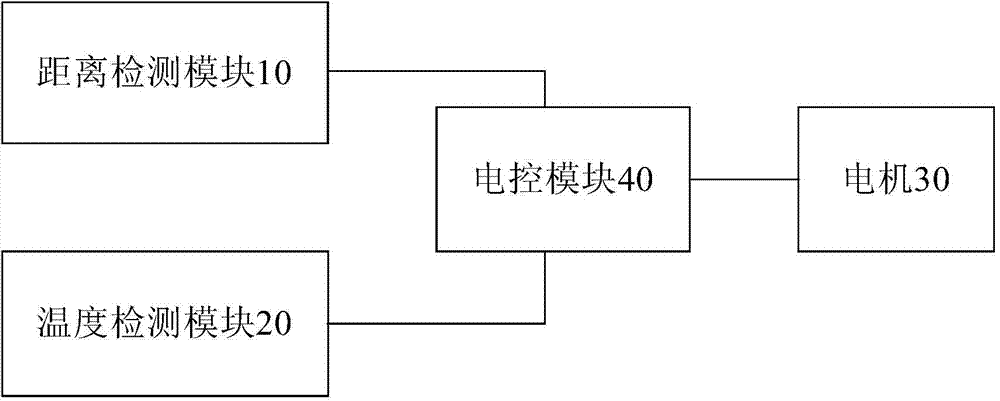

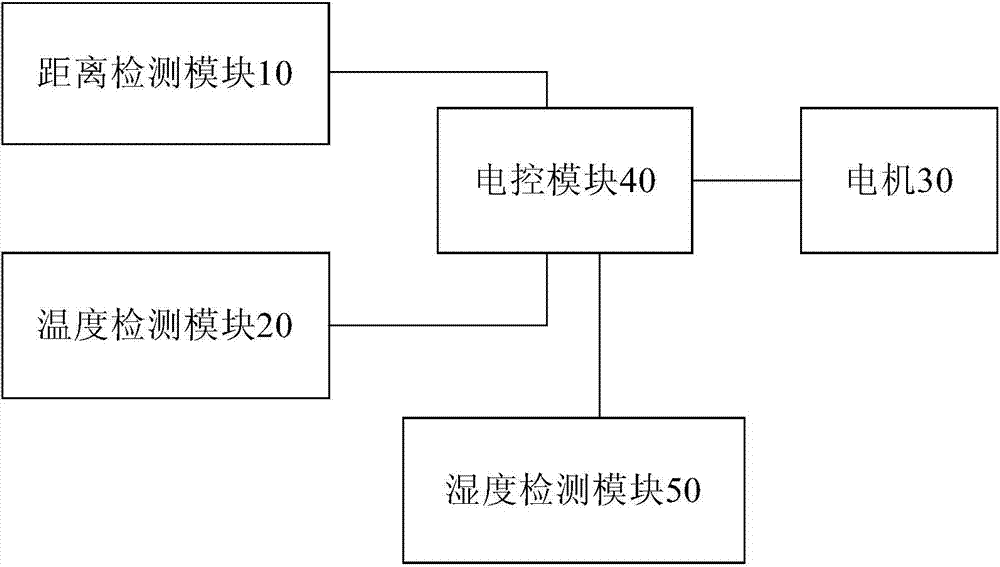

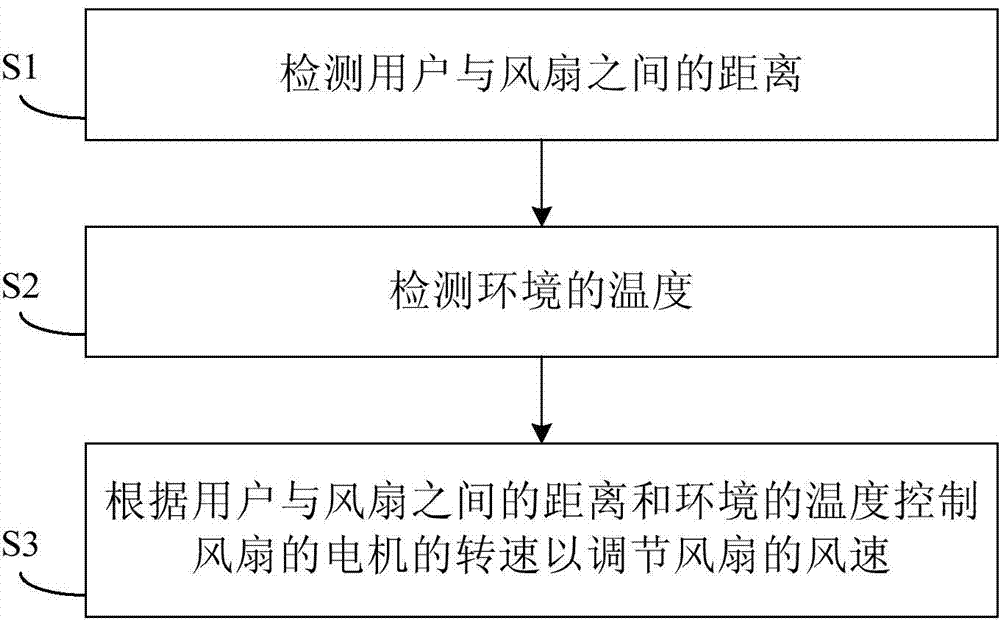

Fan and control method of fan

InactiveCN104514736AImprove comfortFully meet the needsPump controlPump installationsTemperature controlDistance detection

The invention discloses a fan; the fan comprises a distance detection module, a temperature detection module, an electric motor, and an electric control module; the distance detection module is used for detecting the distance between a user and the fan; the temperature detection module is used for detecting the environmental temperature; the electric control module is respectively connected with the distance detection module, the temperature detection module and the electric motor; the electric control module controls the rotation speed of the electric motor based on the distance between the user and the fan as well as the environmental temperature, so as to regulate the wind speed of the fan. The fan is able to automatically adjust the rotation speed of the electric motor based on the distance between people and the fan as well as the environmental temperature, so as to achieve an intelligent switchover, thereby enabling the wind speed to change with the change of the distance between people and the fan, and also change with the change of the environmental temperature, enable the user to feel the most comfortable wind speed, thereby increasing the comfort level of the user and completely meeting the requirements of the user. Additionally, unnecessary electric energy waste can be avoided in the premise of meeting the requirement of cooling, thus effectively saving the electric energy. The invention further discloses a control method of the fan.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

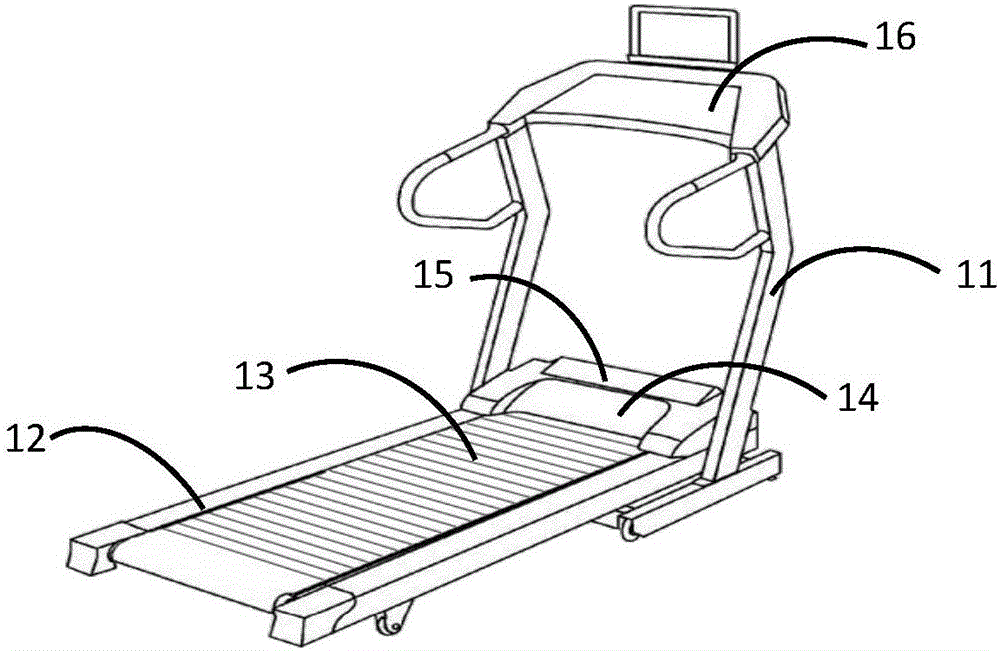

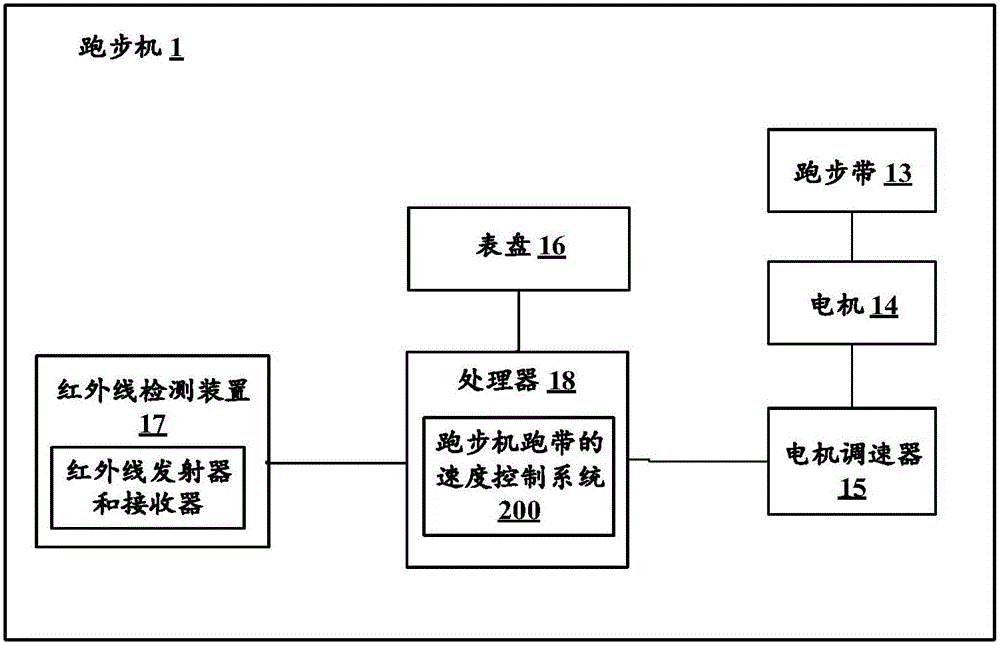

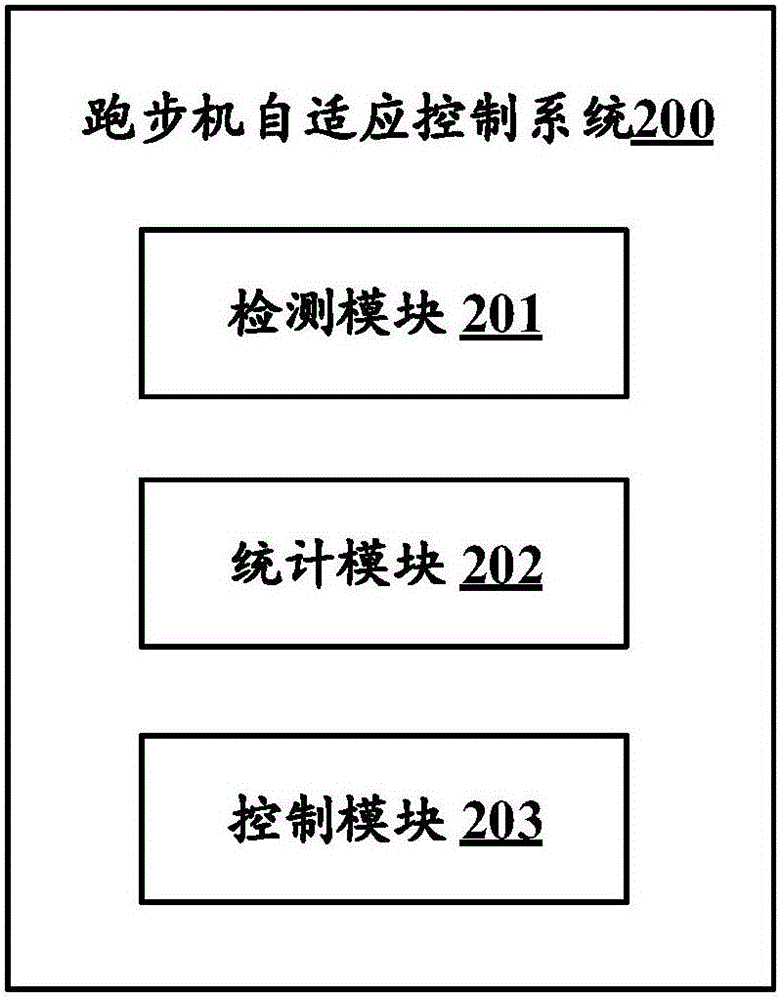

Treadmill, and speed control method and system of running belt of treadmill

InactiveCN105920784AAutomatic speed adjustmentImprove experienceMovement coordination devicesCardiovascular exercising devicesSpeed control systemControl system

The invention relates to a speed control method of a running belt of a treadmill. The method comprises the following steps of detecting the foot pedaling positions of a user on the running belt of the treadmill; determining a foot pedaling region of the user on the running belt of the treadmill according to the foot pedaling positions detected in the preset time; and regulating the speed of the running belt of the treadmill according to the foot pedaling region of the user on the running belt of the treadmill. By using the method provided by the invention, the function of automatic adaptation of the treadmill to the speed of a sportsman is realized; the user experience of the treadmill is improved; and the user can decide the running speed according to the self feeling. The invention also relates to a speed control system of the running belt of the treadmill, and the treadmill using the speed control system of the running belt of the treadmill.

Owner:SHENZHEN YISHI TECH CO LTD

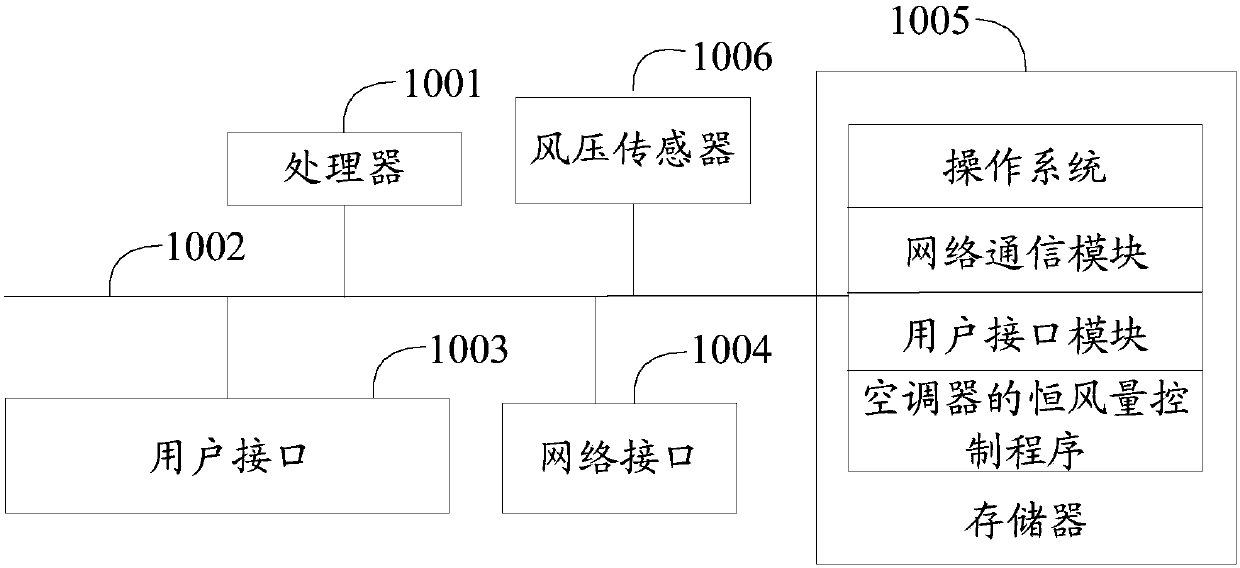

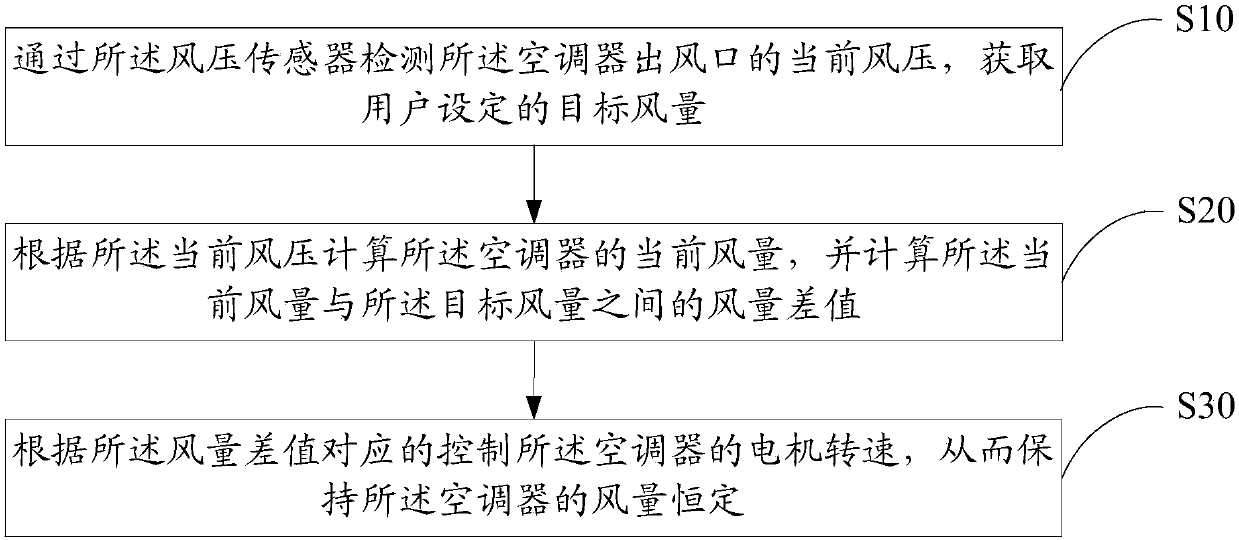

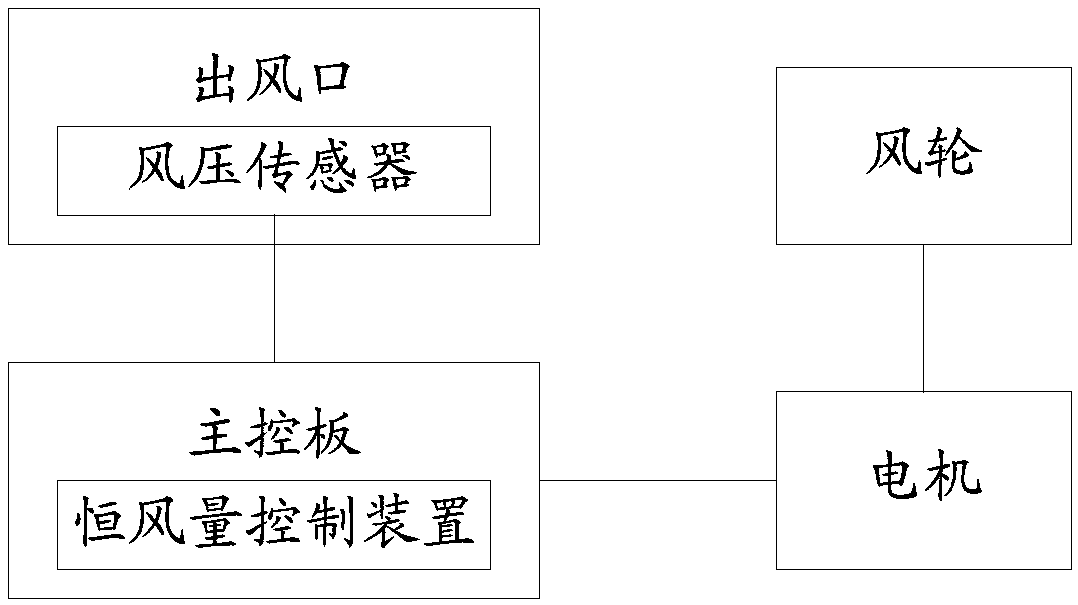

Constant air volume control method of air conditioner, air conditioner and computer readable storage medium

InactiveCN107781957AConstant air volumeImprove cooling and heating effectMechanical apparatusSpace heating and ventilation safety systemsAir volumeEngineering

The invention discloses a constant air volume control method of an air conditioner. The air conditioner comprises an air pressure sensor; the constant air volume control method of the air conditionerincludes steps of detecting current air pressure of an air outlet of the air conditioner through the air pressure sensor, acquiring the target air volume set by a user; calculating the current air volume according to current air pressure, and calculating the air volume differential value between the current air volume and the standard air volume; correspondingly controlling the motor rotate speedof the air conditioner according to the differential value of the air volume, thereby keeping the constant air volume of the air conditioner. The invention further discloses an air conditioner and a computer readable storage medium. According to the constant air volume control method of the air conditioner, the air conditioner and the computer readable storage medium, the constant air volume control of an indoor air conditioner is realized, and the cooling and heating effects of the air conditioner are improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

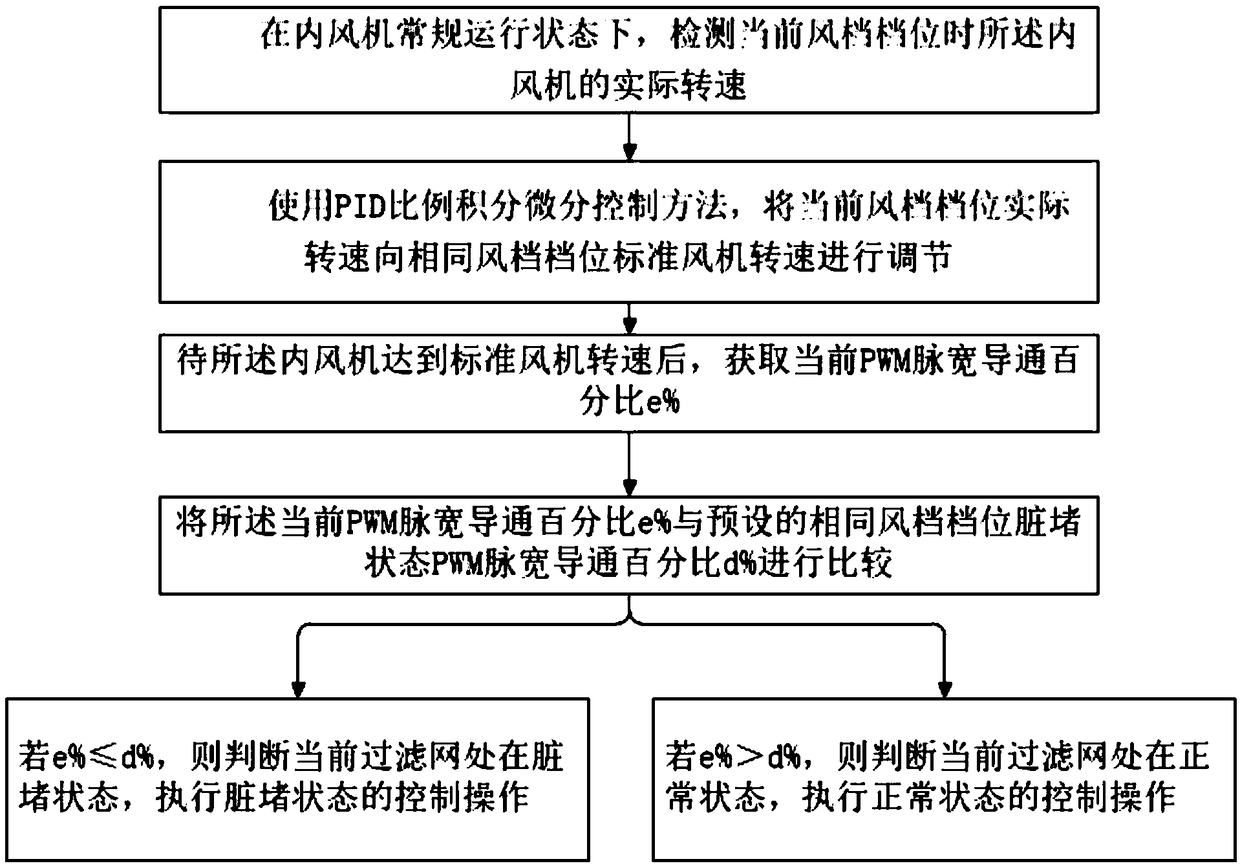

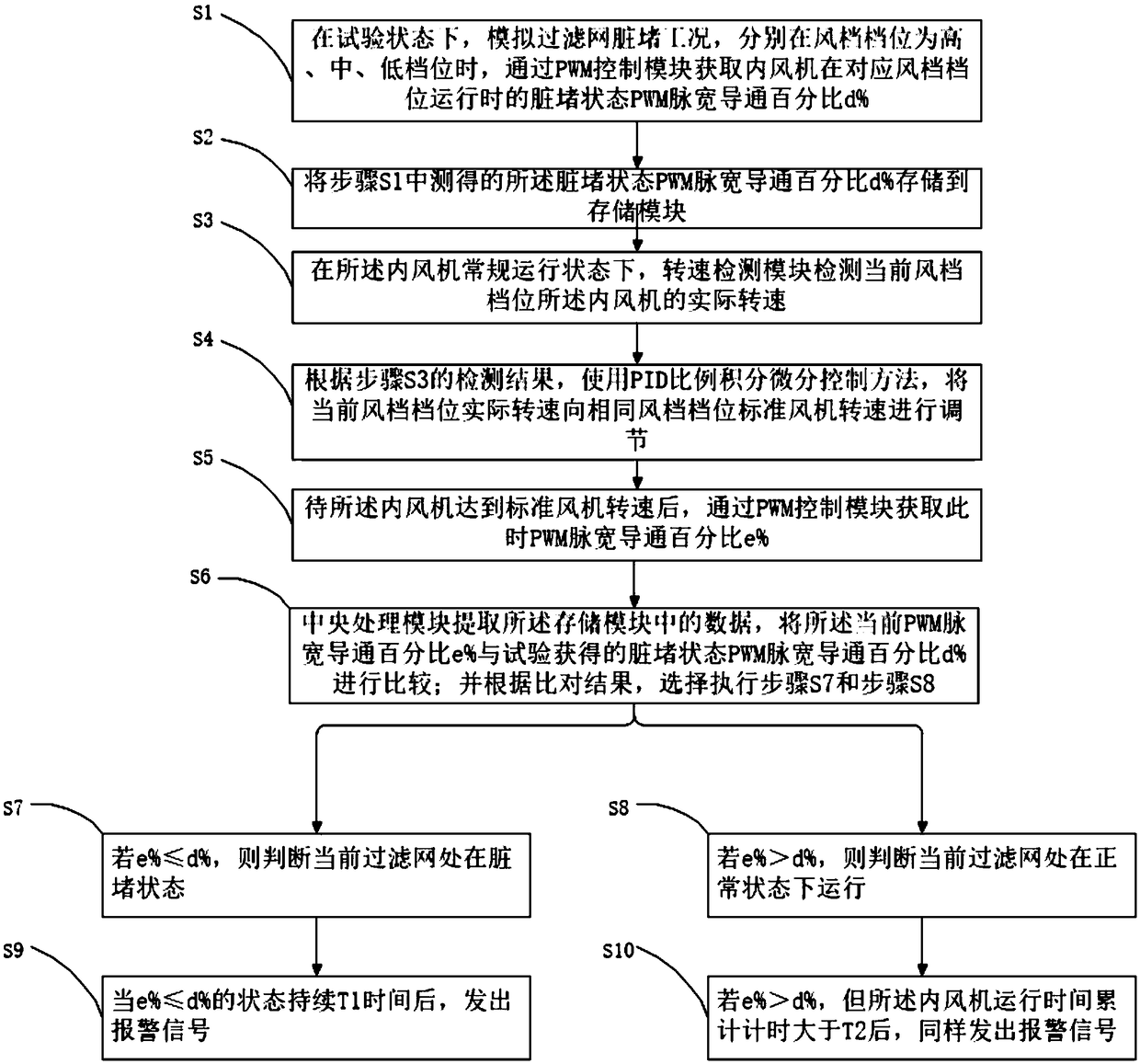

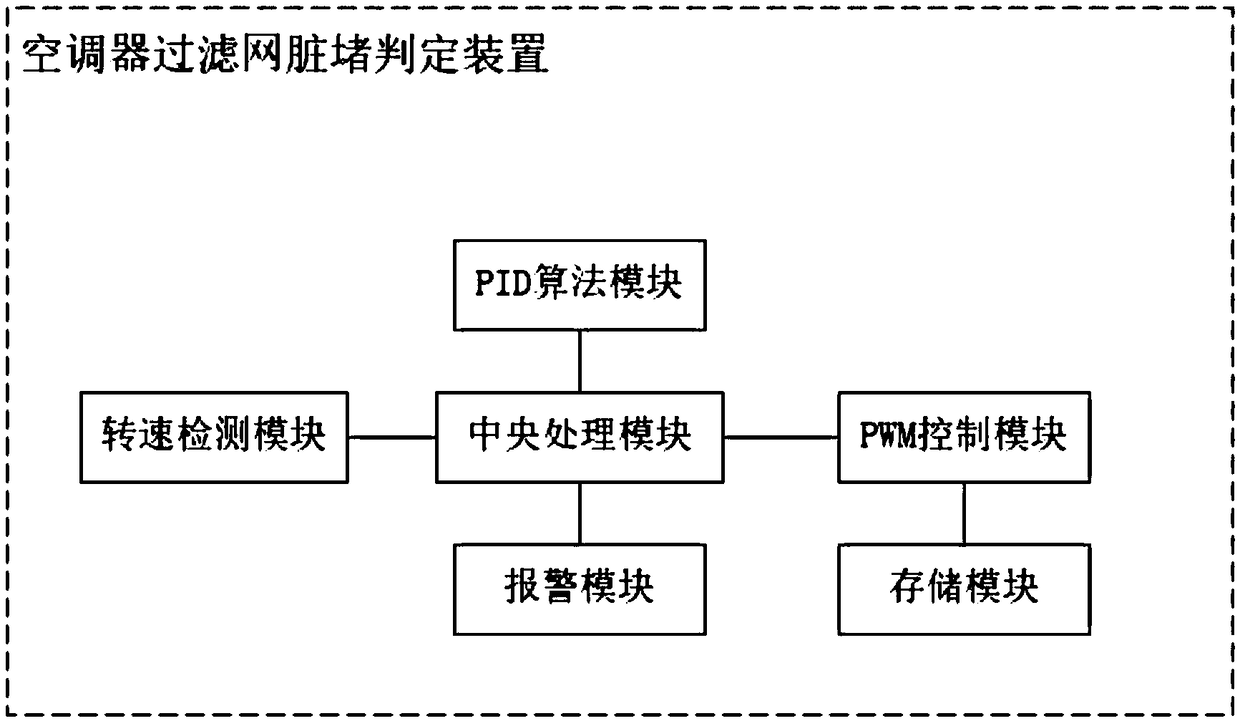

Air conditioner filter screen filth blockage judgment method and device and air conditioner

ActiveCN109028460AReal-time judgment of dirt and blockageAutomatic speed adjustmentMechanical apparatusProportion integration differentiationComputer module

The invention provides an air conditioner filter screen filth blockage judgment method and device and an air conditioner. The air conditioner filter screen filth blockage judgment method comprises thesteps of adjusting the air damper gear actual speed into the standard fan speed by using a proportion integration differentiation (PID) algorithm through a PID control module; after an inner fan reaches the standard fan speed, acquiring current pulse-width modulation (PWM) pulse width conduction percentage e percent; comparing the current PWM pulse width conduction percentage e percent with preset PWM pulse width conduction percentage d percent under the air damper gear filth blockage state; if the e percent is less than or equal to the d percent, judging that a current filter screen is at the filth blockage state, and carrying out the control operation of the filth blockage state; and if the e percent is larger than the d percent, judging that the current filter screen is at the normal state, and carrying out the control operation of the normal state, wherein the air damper gear is one of a high gear, a middle gear and a low gear. According to the air conditioner filter screen filthblockage judgment method provided by the invention, the filter screen filth blockage situation can be judged in real time according to the actual use environment, and a warning is sent to a user in time.

Owner:NINGBO AUX ELECTRIC

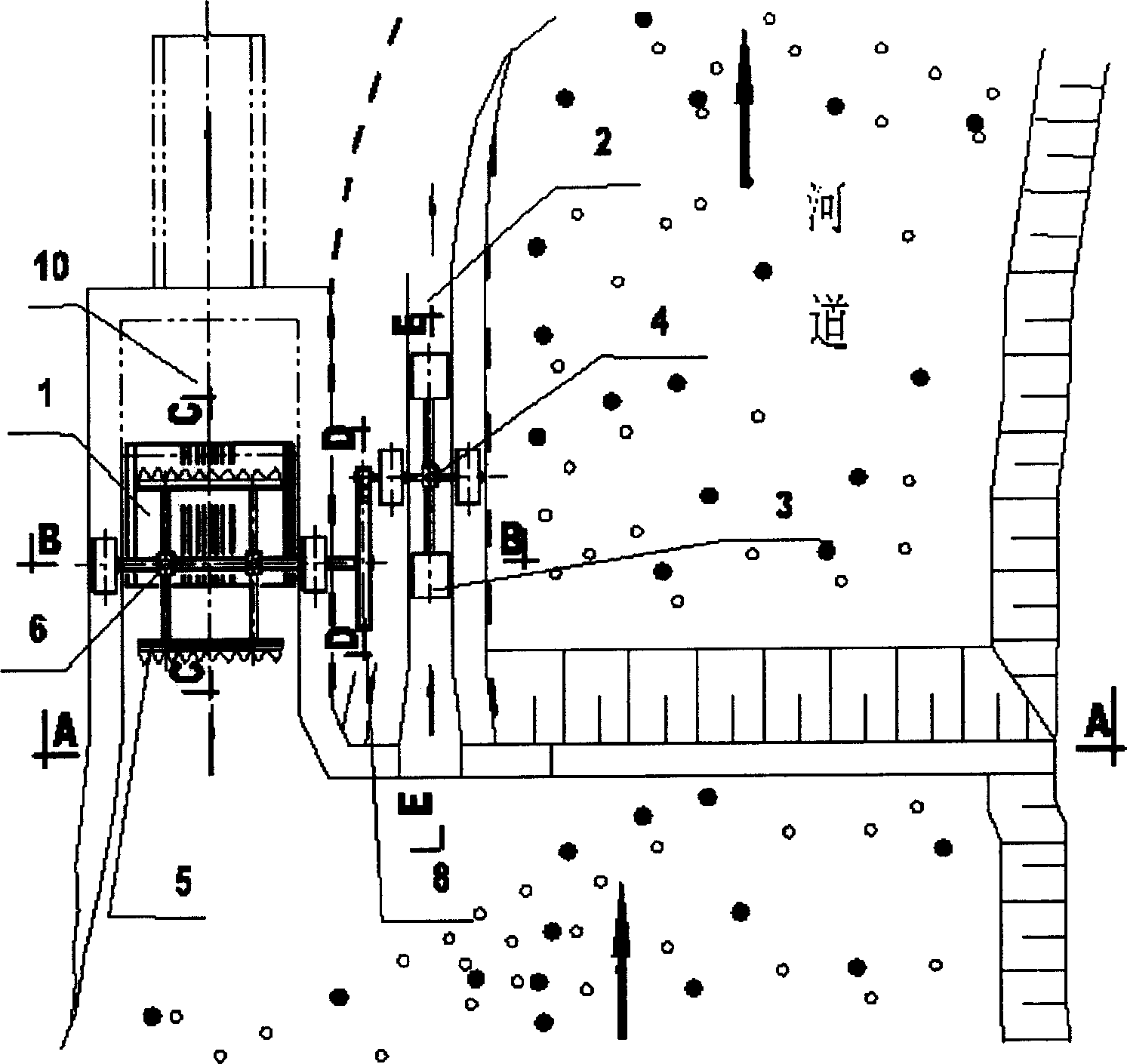

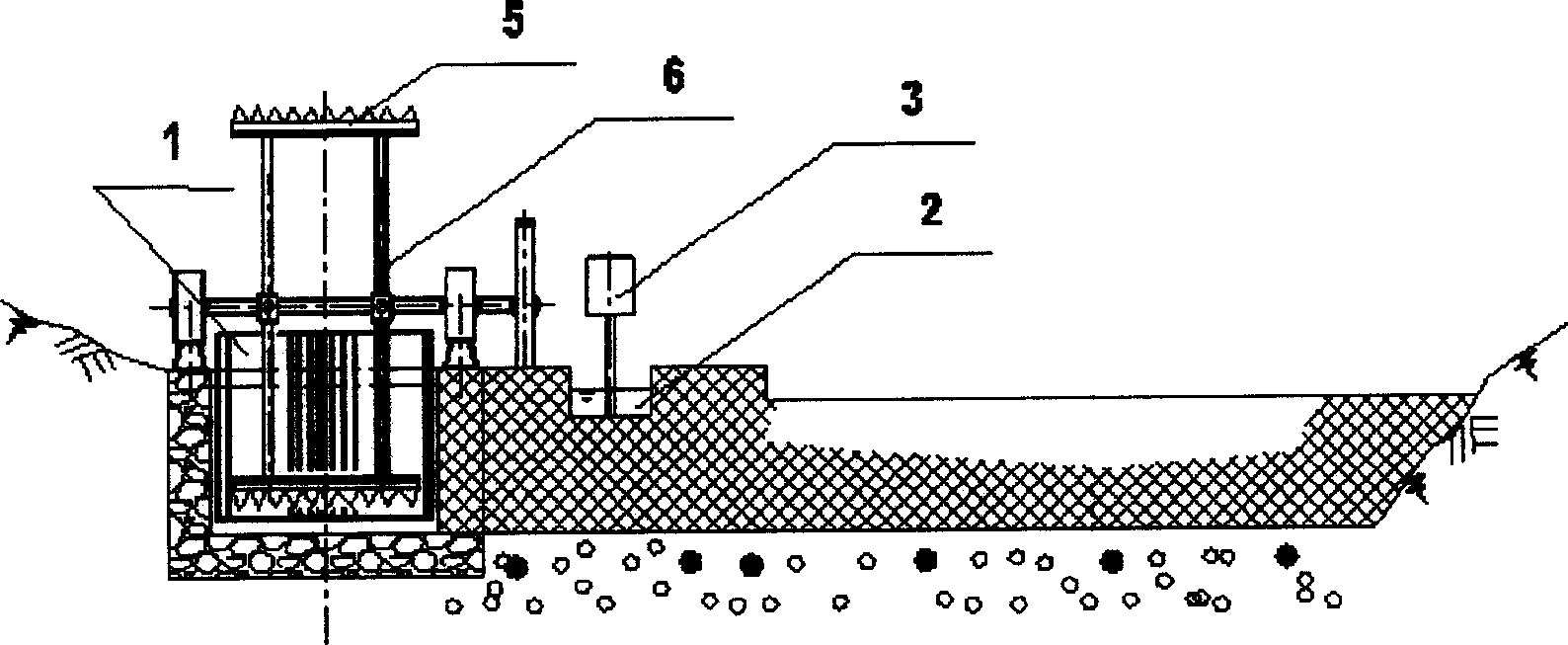

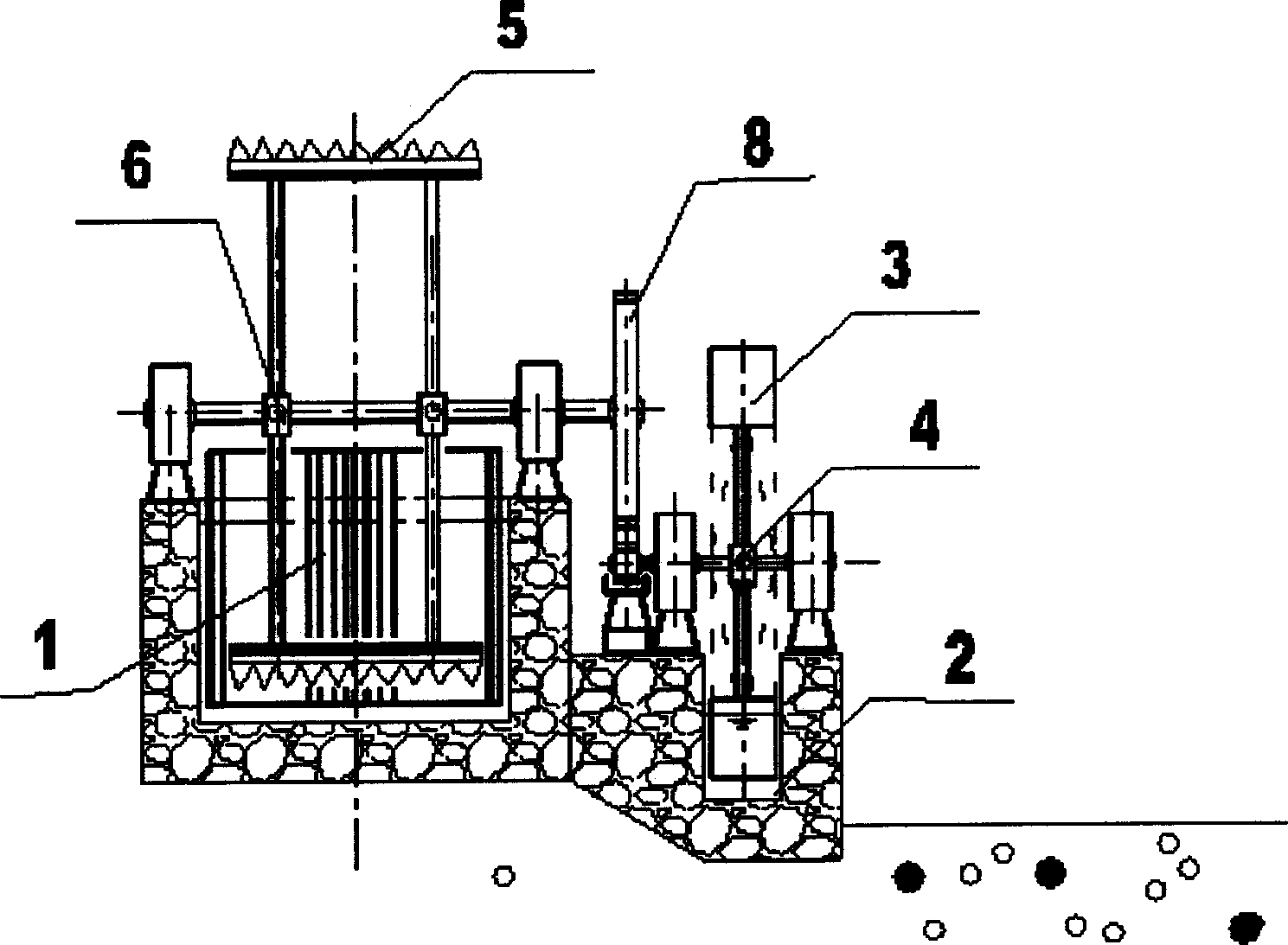

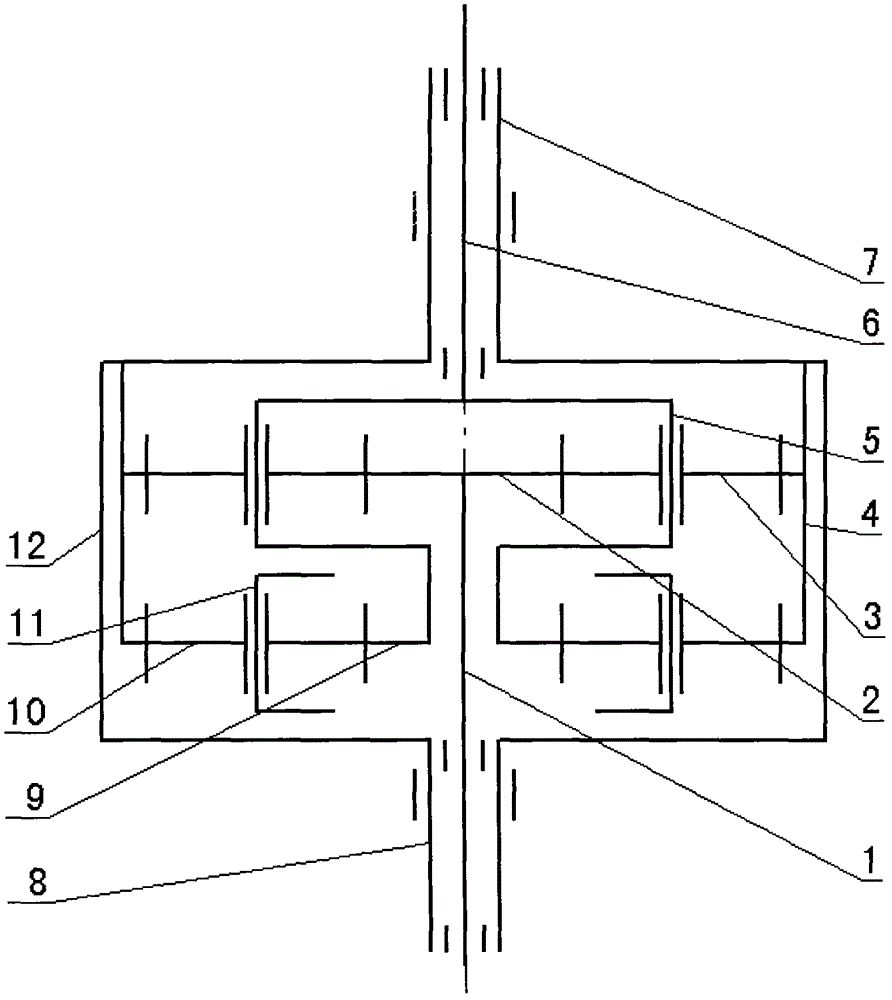

Method and device for automatically removing sewage in grid of water intake of river channel

The invention discloses an auto-clearing estuary water intake grid sewage method and device, which is characterized by the following: the gutter is installed on the barrage beside water intake, which can let a river flow and the floor have difference in elevation; the rotation device is installed on the gutter, which can be attacked by the current its pulpboard to rotate; the rotation gear with scumming rake is installed before the grid at intake; using river flowing in the gutter motivates pulpboard of rotating device and make rotating device rotate; scumming rake removals the sewage from the grid by rotating device makes the rotation gear rotate. The invention reduces the cost, which simplifies the structure.

Owner:GUIYANG AL-MG DESIGN & RES INST

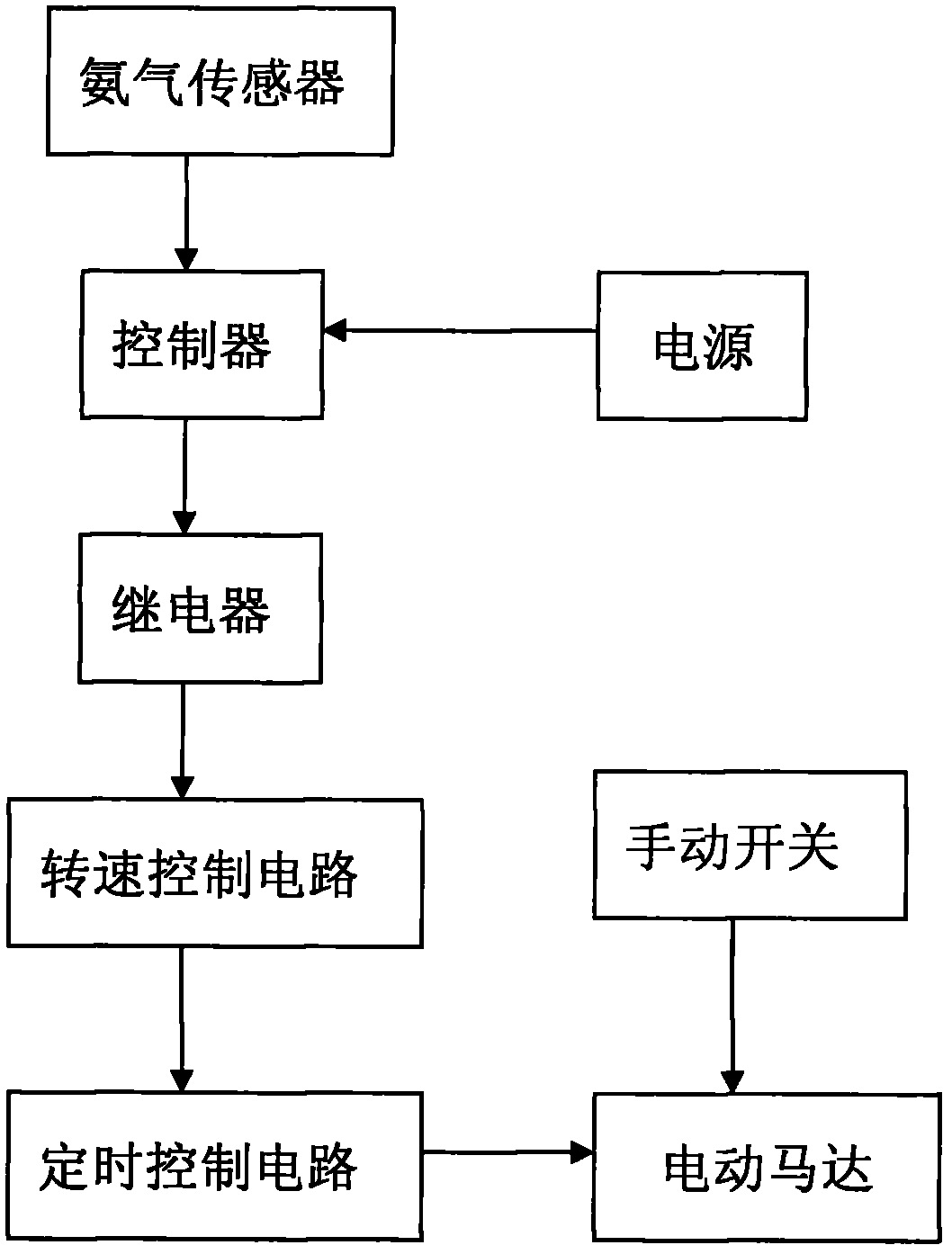

Intelligent exhaust fan for washrooms

InactiveCN102562634ALive healthyAutomatic speed adjustmentPump controlNon-positive displacement fluid enginesAgricultural engineeringFan blade

The invention discloses an intelligent exhaust fan for washrooms, which belongs to the technical field of intelligent household appliances and comprises a casing. A guide cover is mounted in the front of the casing, a hand-operated switch is mounted at the lower end of the casing, fan blades and an electric motor are mounted in the casing, and an ammonia gas detection control circuit comprising a power source, an ammonia gas sensor, a controller, a relay, a timing control circuit and a revolution speed control circuit is arranged on the back side of the electric motor. The intelligent exhaust fan for washrooms has the advantages that the exhaust fan can be turned on automatically according to the detected ammonia gas volume in washrooms, the revolution speed of the exhaust fan can be regulated automatically, and the exhaust fan can be controlled automatically or manually and can create a healthy home life for people.

Owner:李臣华

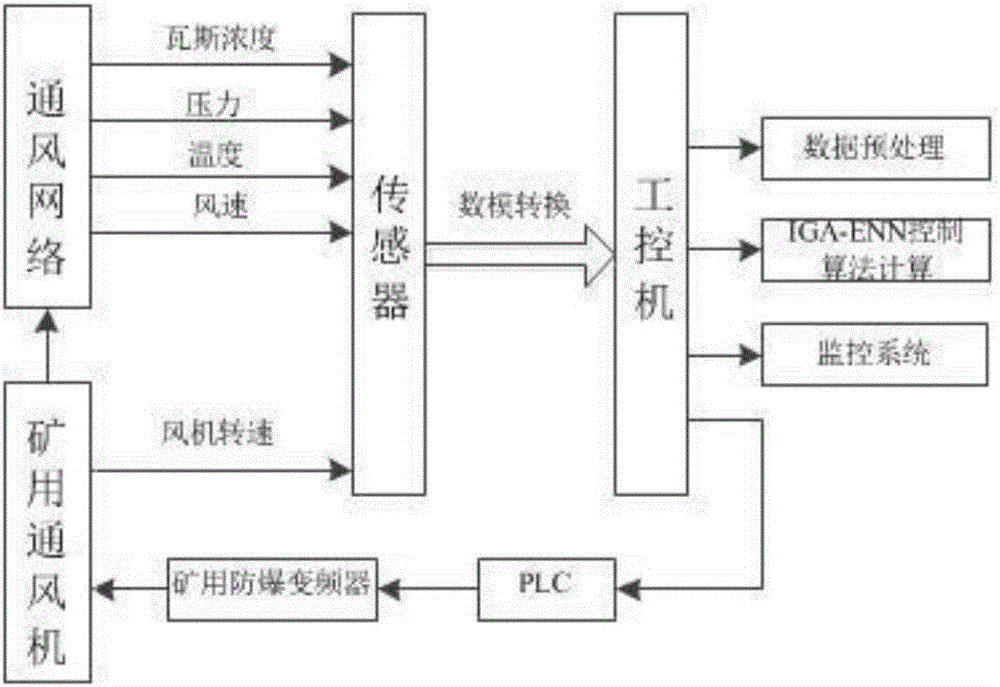

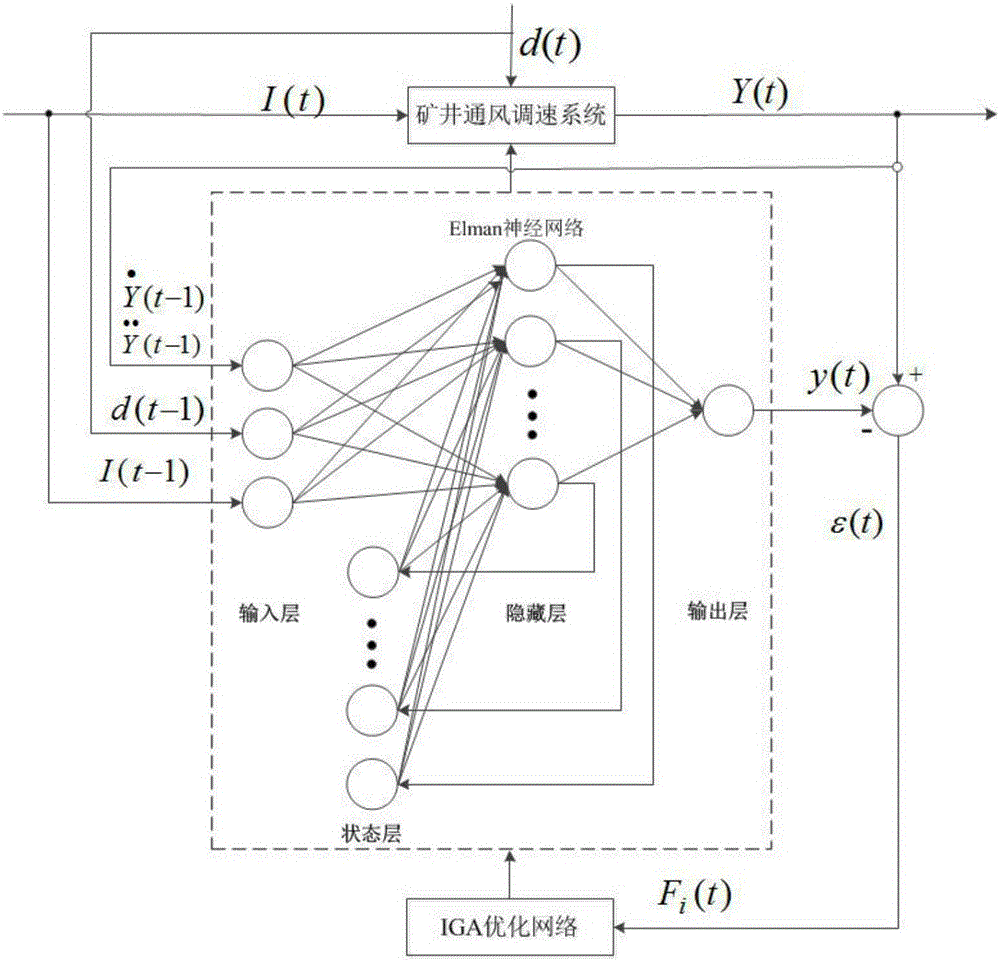

Adaptive speed regulation method of neural network for mine ventilator

ActiveCN106779071AAutomatic speed adjustmentReasonable controlSpecial data processing applicationsNeural learning methodsNerve networkEngineering

The invention relates to an adaptive speed regulation method of a neural network for a mine ventilator. The method comprises the following steps that: utilizing a gas concentration sensor, a pressure sensor and a laser tachometer to independently measure fan blast capacity influence parameter information including tunnel gas concentration, wind pressure, the revolving speed of a motor and the like, good nonlinear mapping capability of the neural network is utilized for establishing a nonlinear mapping relationship between a blast capacity influence factor and the revolving speed of the ventilator, and the adaptive control model of the mine ventilator is obtained. By use of the technical scheme of the invention, an Elman neural network and an adaptive genetic optimization method are applied and are combined with a variable-frequency speed regulation technology to realize the accurate control of the blast capacity of the mine ventilator. The method has the advantages of being high in rate of convergence, high in accuracy and good stability, and energy is effectively saved while the required blast capacity is achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

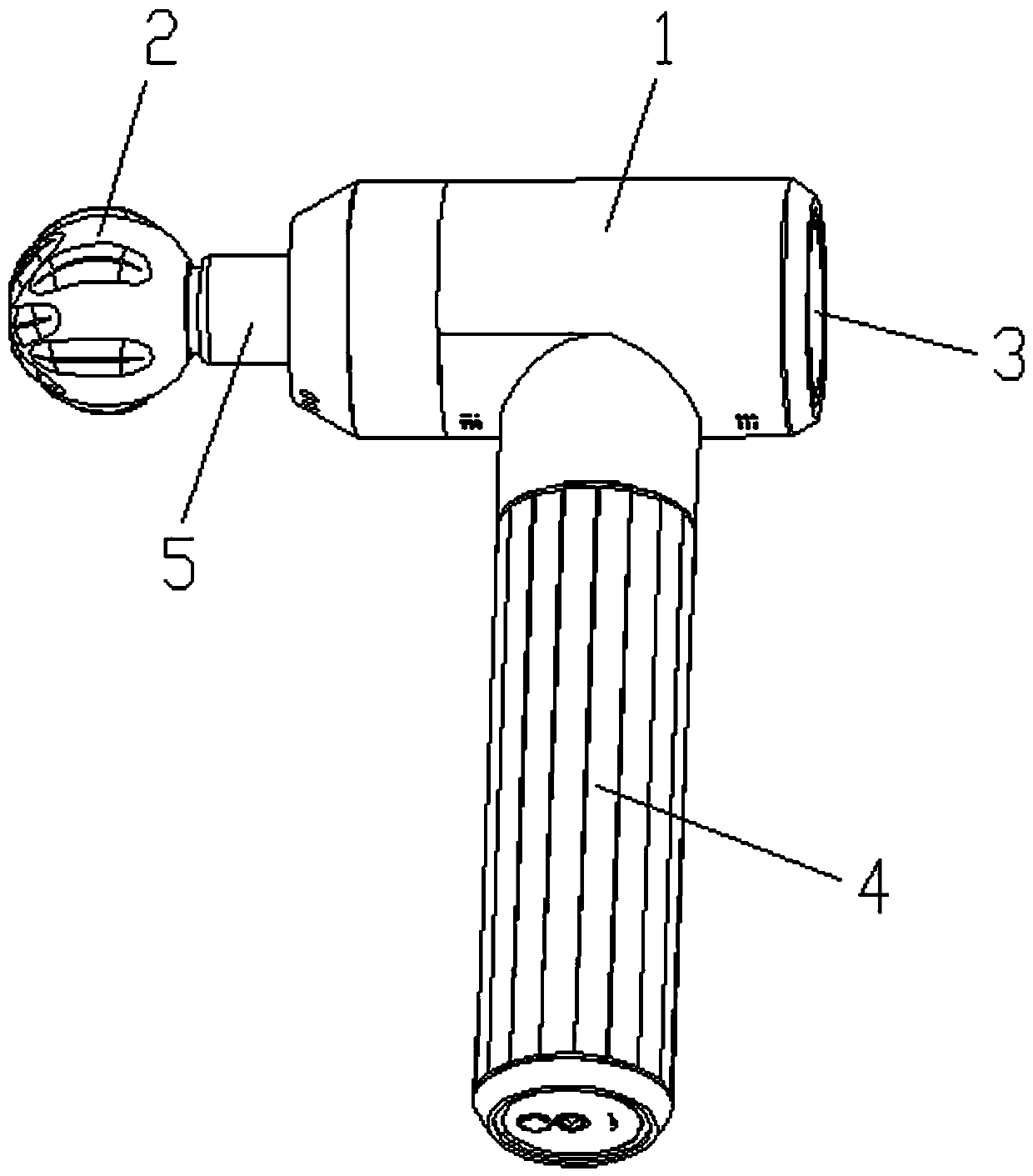

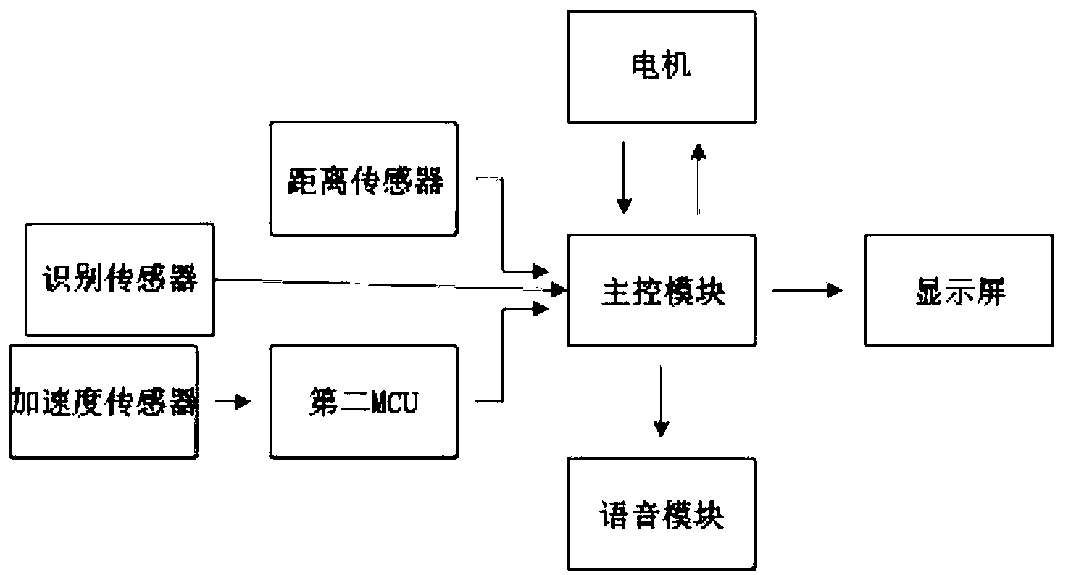

Automatic identification system for fascia gun

InactiveCN111297668AAutomatic speed adjustmentBody partsVibration massageHuman bodyPhysical medicine and rehabilitation

The invention discloses an automatic identification system for a fascia gun. The fascia gun comprises a shell, a massage head arranged at one end of the shell and a motor driving the massage head to reciprocate through a transmission mechanism. The automatic identification system comprises a main control module for controlling the running state of the motor and a detection assembly connected to the main control module, the detection assembly comprises an identification sensor for identifying the model of the massage head and / or a distance sensor for sensing the human body, and the main controlmodule adjusts the rotating speed of the motor according to signals fed back by the detection assembly. The system can intelligently identify the massage head, automatically adjust the rotating speedof the motor according to different massage heads, intelligently identify whether the massage head is close to the human body or not, and adjust the rotating speed of the motor to a preset idling mode when the massage head is far away from the human body, thereby saving more energy and electricity.

Owner:SHENZHEN FITTOP HEALTH TECH

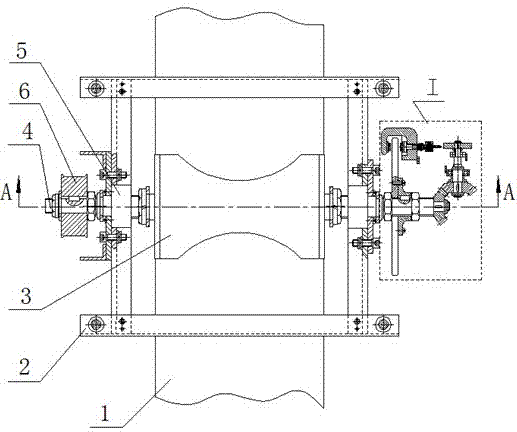

Reduction gear for impeller type washing machine

ActiveCN102797131ALow costEasy to assembleOther washing machinesTextiles and paperImpellerGear wheel

The invention relates to the technical field of impeller type washing machines, in particular to a reduction gear for an impeller type washing machine and overcomes the defects of high cost and inconvenience in assembly in the prior art. The reduction gear mainly comprises an input shaft, an output shaft, an output shaft sleeve, an input shaft sleeve and a brake wheel; the output shaft is arranged in the output shaft sleeve; the lower end of the output shaft sleeve is arranged in the brake wheel; double planetary gear mechanisms consisting of input shaft gears, upper planetary gears, inner gears, upper planetary carriers, central wheels, lower planetary gears and lower planetary carriers are arranged in the brake wheel; the brake wheel is fixedly connected with the output shaft sleeve and the inner gears respectively; the lower planetary gears are arranged on the floating lower planetary carriers; and the rotation directions of the output shaft and the output shaft sleeve are opposite to each other, and the rotation speed can be automatically adjusted according to the load magnitude. By adopting the technical scheme, the reduction gear is low in cost and convenient to assemble; a good washing effect can be achieved; double-direction water flow is formed; and clothes are not damaged.

Owner:NINGGUO JULONG IND

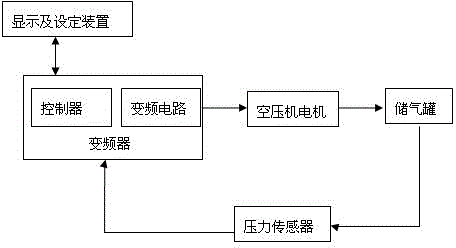

Air compressor control device and method

InactiveCN104373330AAutomatic speed adjustmentReduce loadPump controlPositive-displacement liquid enginesFrequency changerAtmospheric pressure

The invention relates to an air compressor control device and method. The device comprises an air compressor motor and an air compressor air storage tank. The device is characterized in that a pressure sensor is disposed in the air compressor air storage tank, one end of the air compressor motor is connected with a frequency converter, and the pressure sensor is connected with the frequency converter. Due to the fact that the air compressor control device is provided with the frequency converter, soft starting and soft stopping of the air compressor motor are achieved, starting impact is reduced, and equipment service life is prolonged. Due to the fact the operation frequency of the motor is variable, motor rotation speed of an air compressor can be automatically adjusted according to air using amount, frequent motor loading and unloading is reduced, operation power of the motor is reduced greatly, the air pressure of an air supply system is kept constant, and energy conservation is achieved.

Owner:青岛海普润机械有限公司

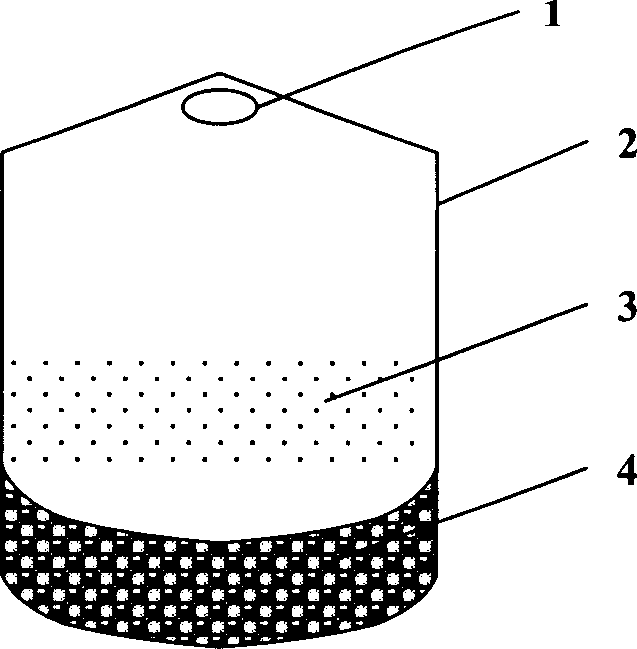

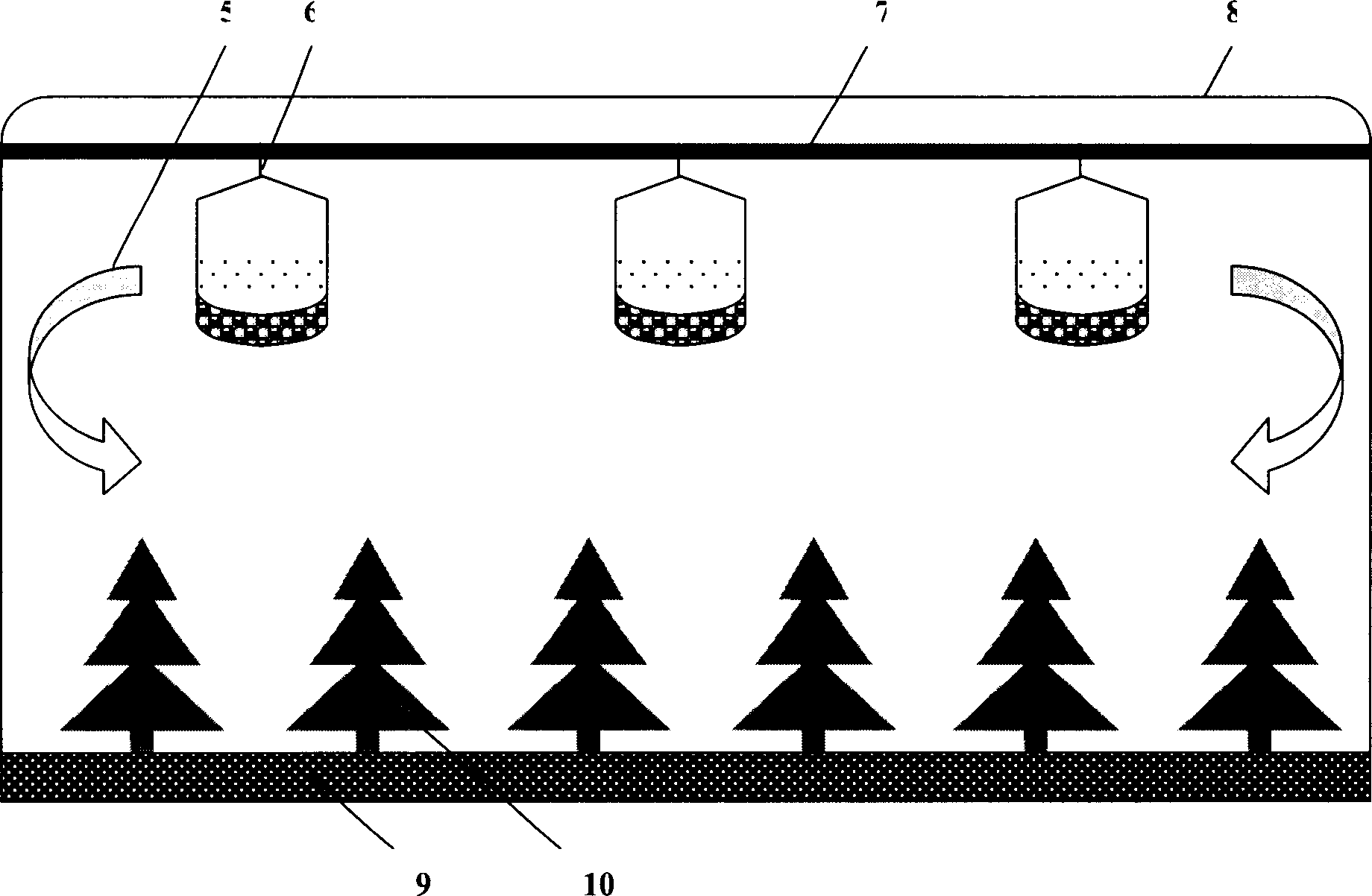

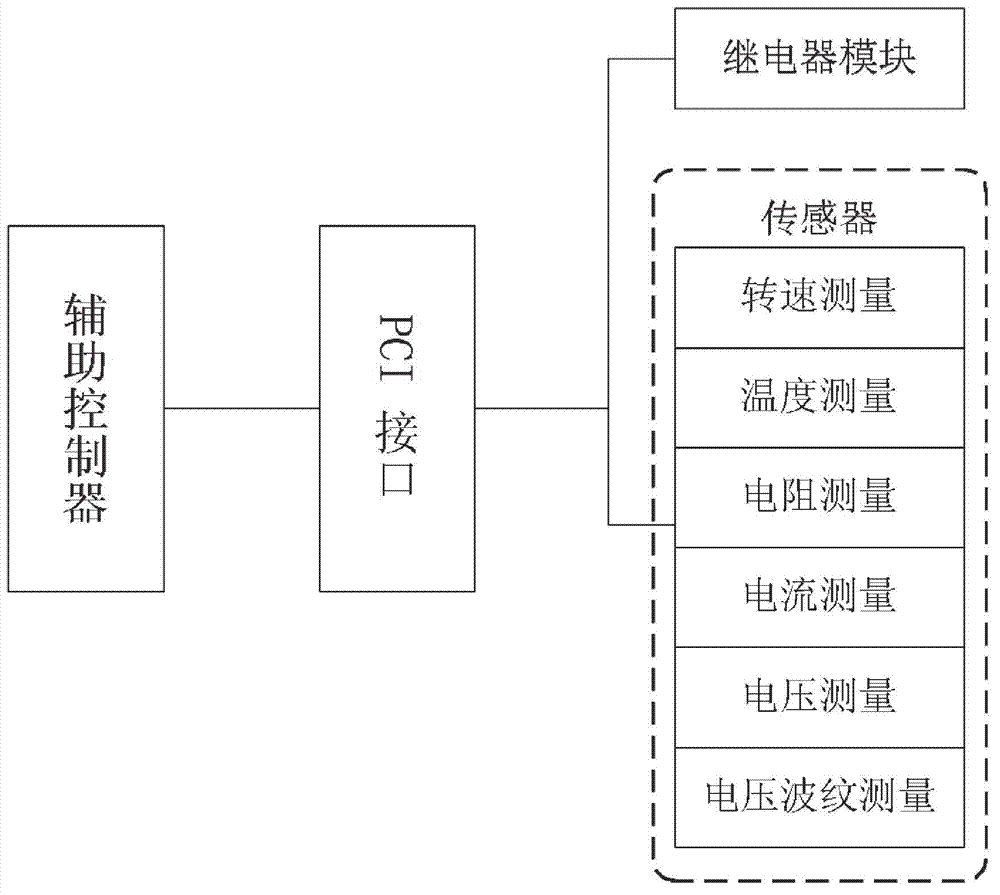

CO2 slow-release gas-fertilizer of two-component solid hanging-bag type and production method

InactiveCN1849870ASave raw materialsRaw material environmental protectionHorticulture methodsAmmonium salt fertilisersSolid componentSolid mass

The present invention discloses a double-component solid bag-hanging carbon dioxide delayed release gas fertilization agent. Said invention includes two solid components of delayed release agent and solid carbonate, they are chemically-modified diatomite and ammonium hydrogen carbonate respectively. Said invention also provides its concrete preparation method and its application method.

Owner:石磊 +1

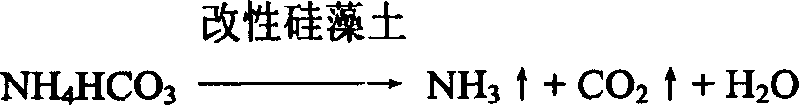

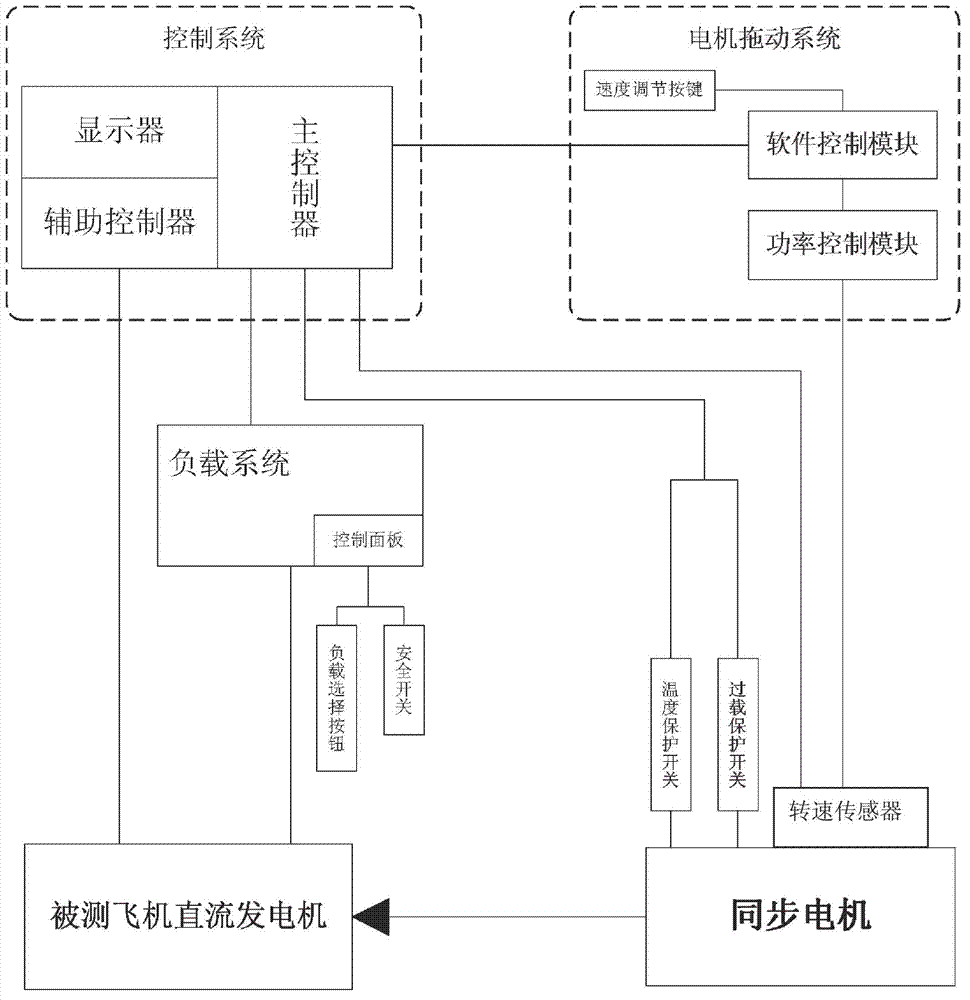

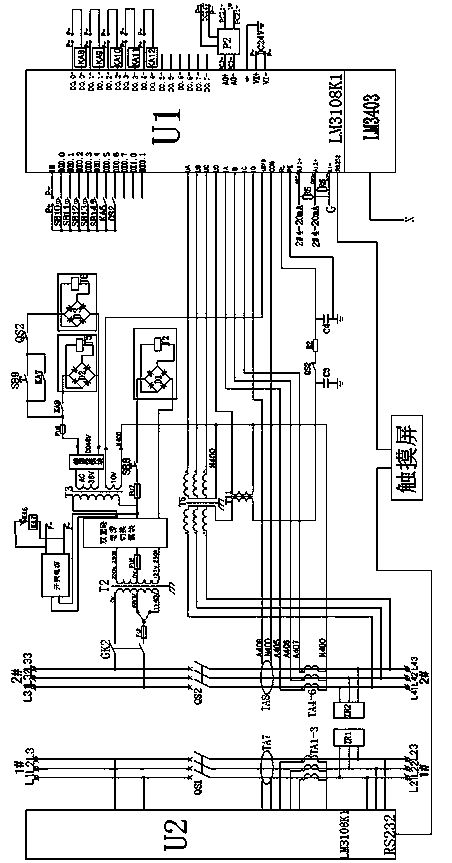

General testing system of airplane direct-current generator

InactiveCN103197244AEasy to monitor manuallyImprove applicabilityDynamo-electric machine testingSynchronous motorAirplane

The invention discloses a general testing system of an airplane direct-current generator. The general testing system of the airplane direct-current generator comprises a synchronous motor, a motor dragging system, a load system, and a control system, wherein the synchronous motor is used for driving a tested airplane direct-current generator, the motor dragging system is used for controlling the synchronous motor in a speed-control mode, the load system is used for providing load for the tested airplane direct-current generator, and the control system is used for controlling testing conditions of the tested airplane direct-current generator and detecting a test result of the tested airplane direct-current generator. The control system is respectively connected with the synchronous motor, the motor dragging system, the load system and the tested airplane direct-current generator. The load system is connected with the tested airplane direct-current generator. The motor dragging system is connected with the synchronous motor. The tested airplane direct-current generator is installed on the synchronous motor. The general testing system of the airplane direct-current generator can achieve a general test of various airplane direct-current generators.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

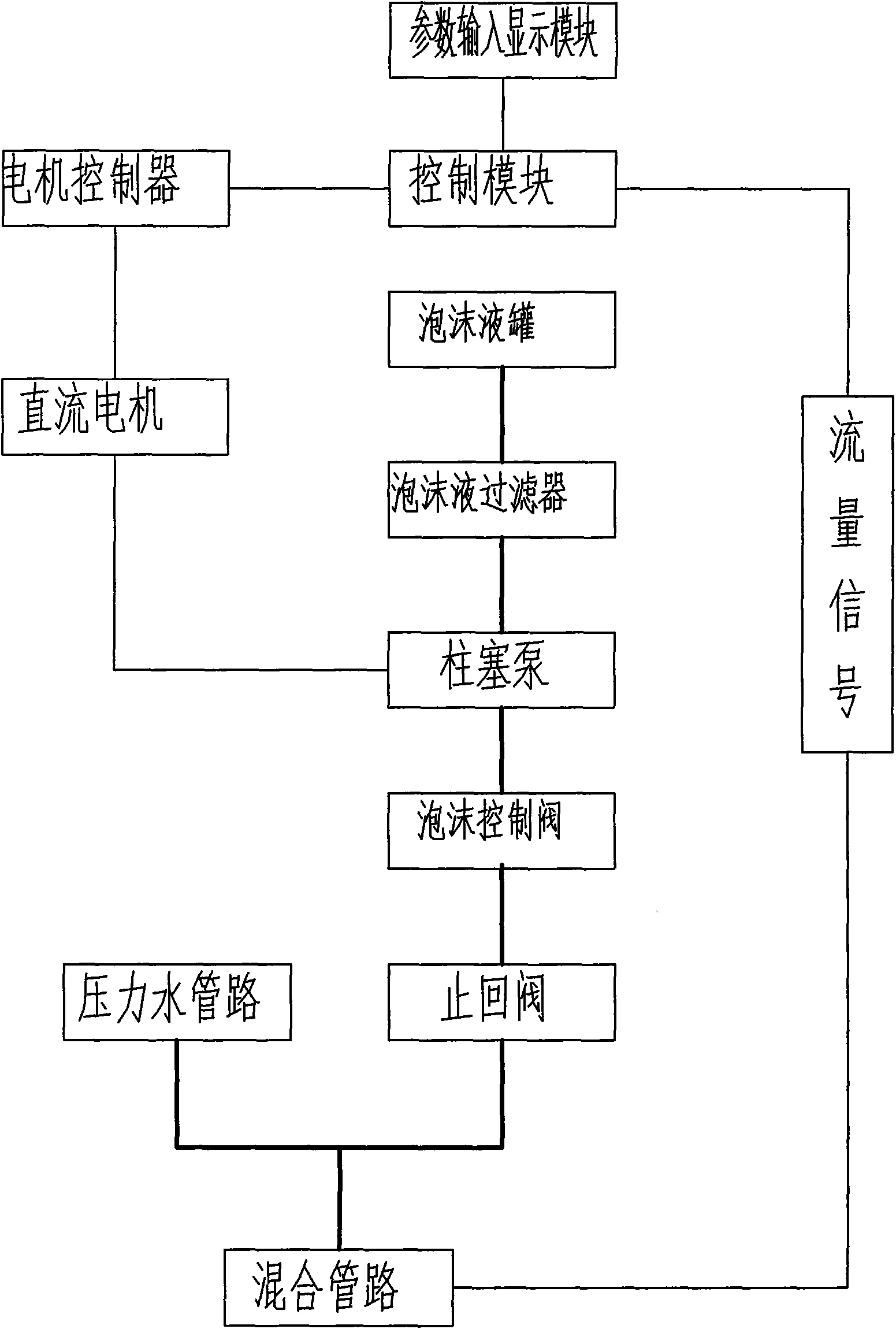

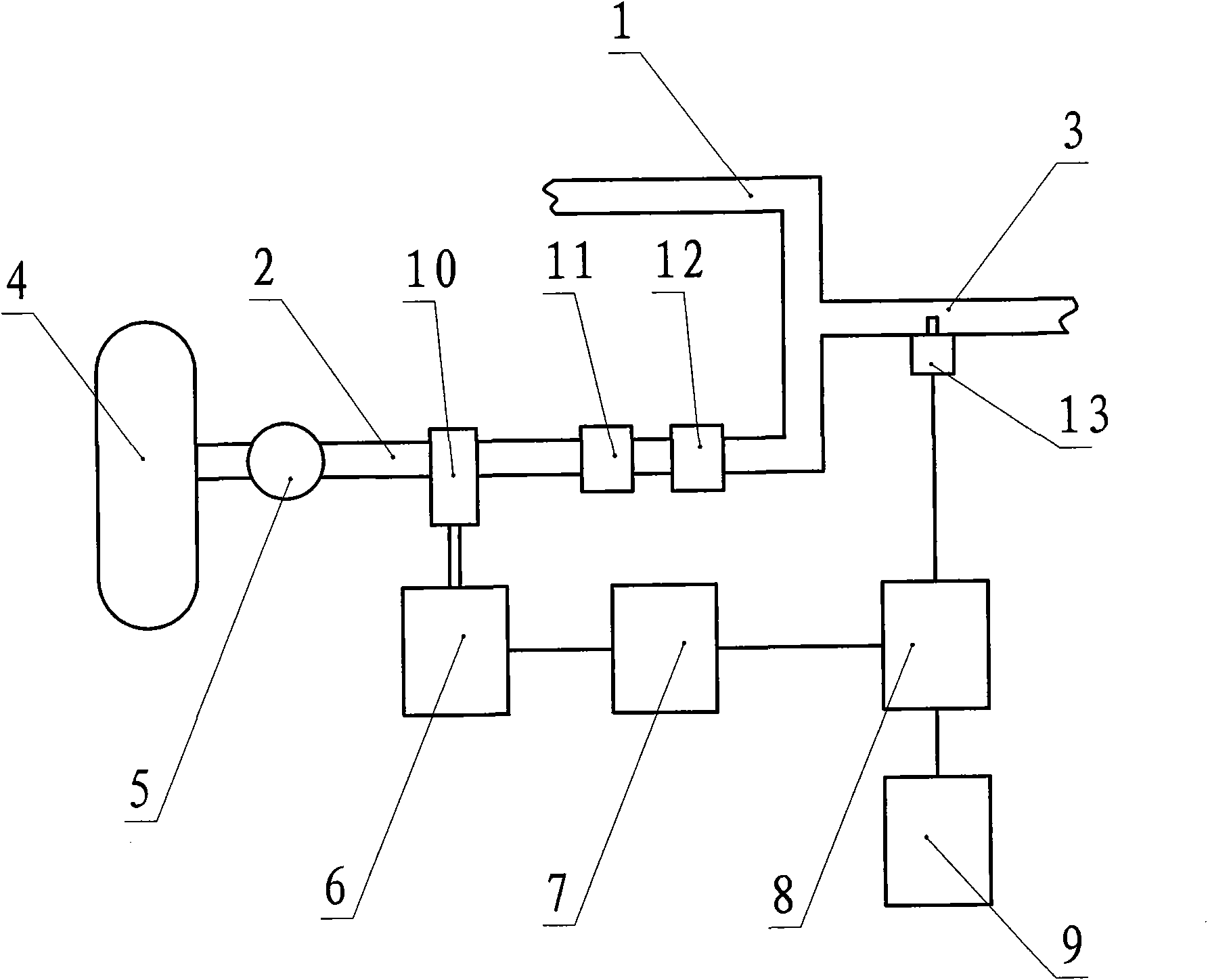

Positive-pressure automatic spume proportionality mixer systems

ActiveCN101549193ARun accuratelyEasy to operateControlling ratio of multiple fluid flowsFire rescuePipingAutomatic control

A positive-pressure automatic spume proportionality mixer systems includes pressure water pipeline, spume pipeline and mixer pipeline. There are at least spume tank, spume purification apparatus, ram-type pump, spume application valve ball and back valve setup at the spume pipeline with spume tank at the beginning, the out spout pipeline of back valve joins with pressure water pipeline to mixer pipeline. A flow rate sensor is set at the aforementioned mixer pipeline and connects to control module with wires, the control module connects with parameter input and display module and machine controller connecting with electric motor drive ram-type pump. The system can implement whole automatic control spume mixing proportion with simple operation, accurate adjustment, stabilizing and reliable operation activity.

Owner:BEIJING FIREFEND EQUIP

Water cooling system for battery pack of new energy vehicle

InactiveCN110224202AImprove cooling effectAutomatic speed adjustmentSecondary cellsVehicular energy storageNew energyWater cycling

The present invention discloses a water-cooling heat dissipation system for a battery pack of a new energy vehicle. The system includes a vehicle body. A battery is fixedly disposed in the vehicle body. A heat-dissipating copper plate is fixed on a top surface of the battery. A heat dissipating cavity is arranged on a top side of the heat-dissipating copper plate. A first heat dissipating device for cooling is disposed in the heat dissipating cavity. When the battery starts to be charged or discharged, the water pump is turned on, water in a water tank is circulated, so that heat is absorbed through the heat dissipating copper plate, and then condensing is performed by using a condensation tube, and then cooling is performed by using a cooling plate. The device cools the battery pack of the new energy vehicle by combining air cooling with water cooling. At the same time, two sets of cooling devices are used to cool the water while cooling the battery, so that an effect of cooling for the battery is more remarkable, and the device contains a speed that automatically adjusts a fan according to changes in a temperature of the battery.

Owner:嘉兴喜格丽服装有限公司

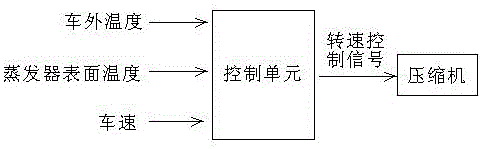

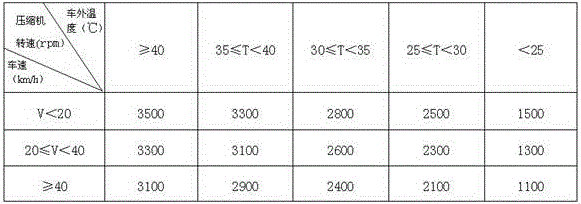

Electric car manual air conditioning system and control method thereof

InactiveCN106183710AAutomatic speed adjustmentIncrease costAir-treating devicesVehicle heating/cooling devicesAir conditioningRefrigeration

The purpose of the present invention is to propose a manual air-conditioning system for electric vehicles and its control method, so that the traditional manual air-conditioning can meet the needs of customers for cooling comfort without major changes, and can also effectively save the cost of the entire vehicle. Electric energy consumption, thereby prolonging the cruising range of electric vehicles. The electric vehicle manual air-conditioning system of the present invention includes an air-conditioning body and a control system. The air-conditioning body includes a compressor, an evaporator, and a control panel. The key point is that the control system is composed of an outside temperature sensor, a vehicle speed sensor, and a control unit. The control unit is respectively connected with the outside temperature sensor, vehicle speed sensor, evaporator surface temperature sensor and compressor. The key to the control method is: during the working process of the compressor, the control unit controls the speed of the compressor according to the outside temperature and the vehicle speed. The specific control principle is as follows: the higher the outside temperature, the higher the compressor speed; the higher the vehicle speed, the higher the speed of the compressor. The lower the compressor speed is.

Owner:CHERY AUTOMOBILE CO LTD

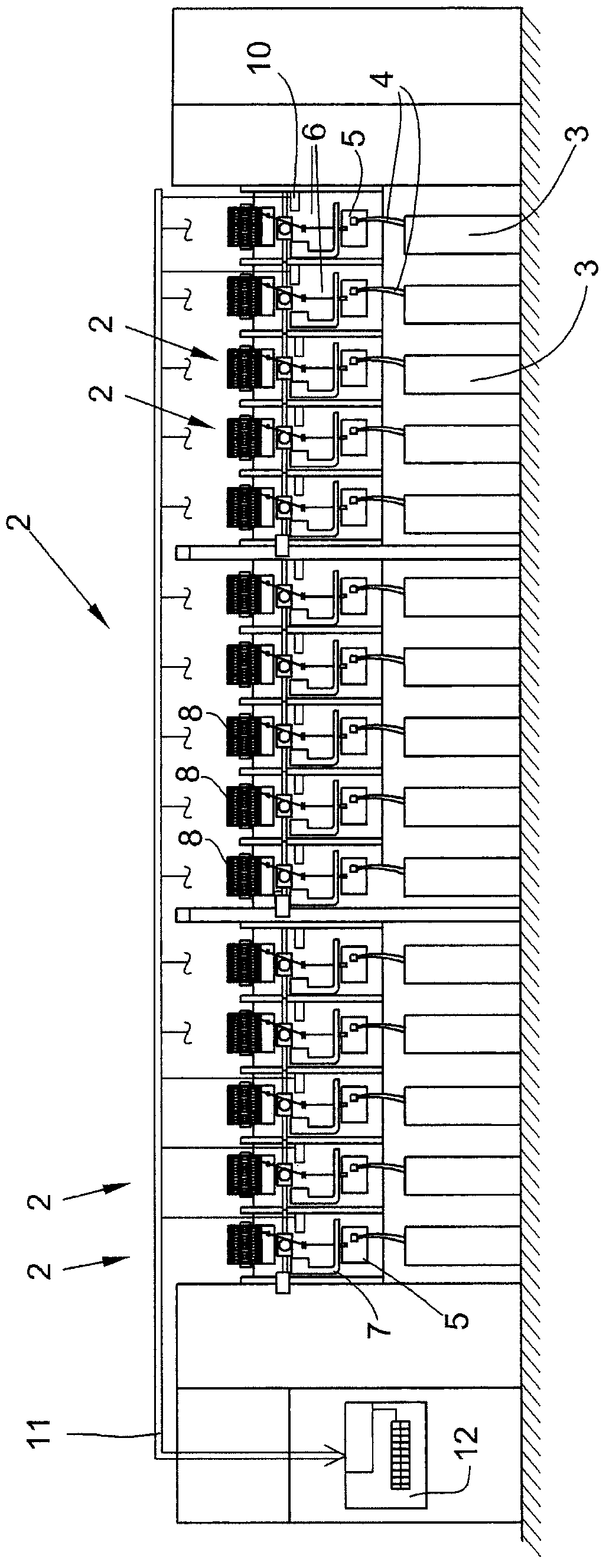

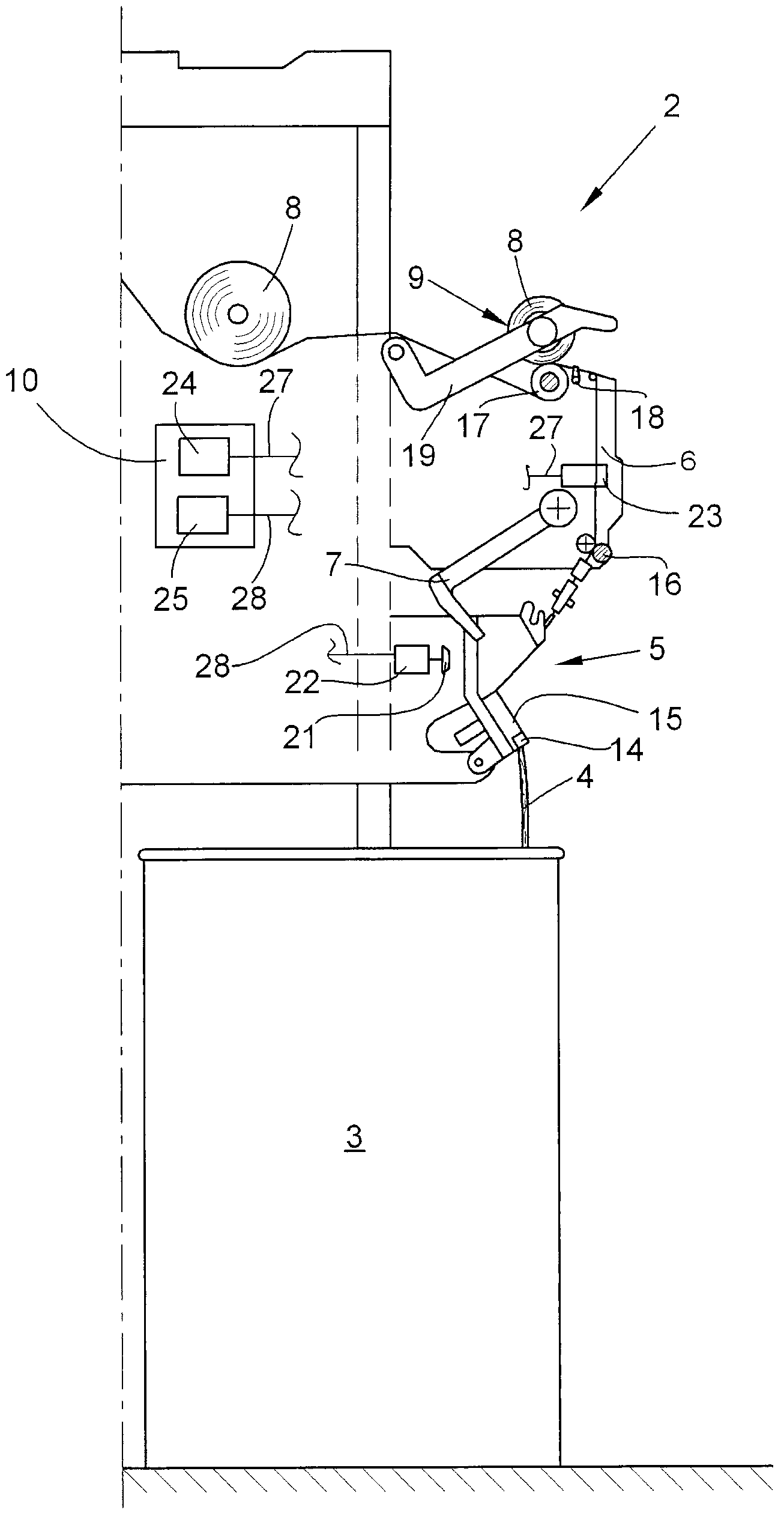

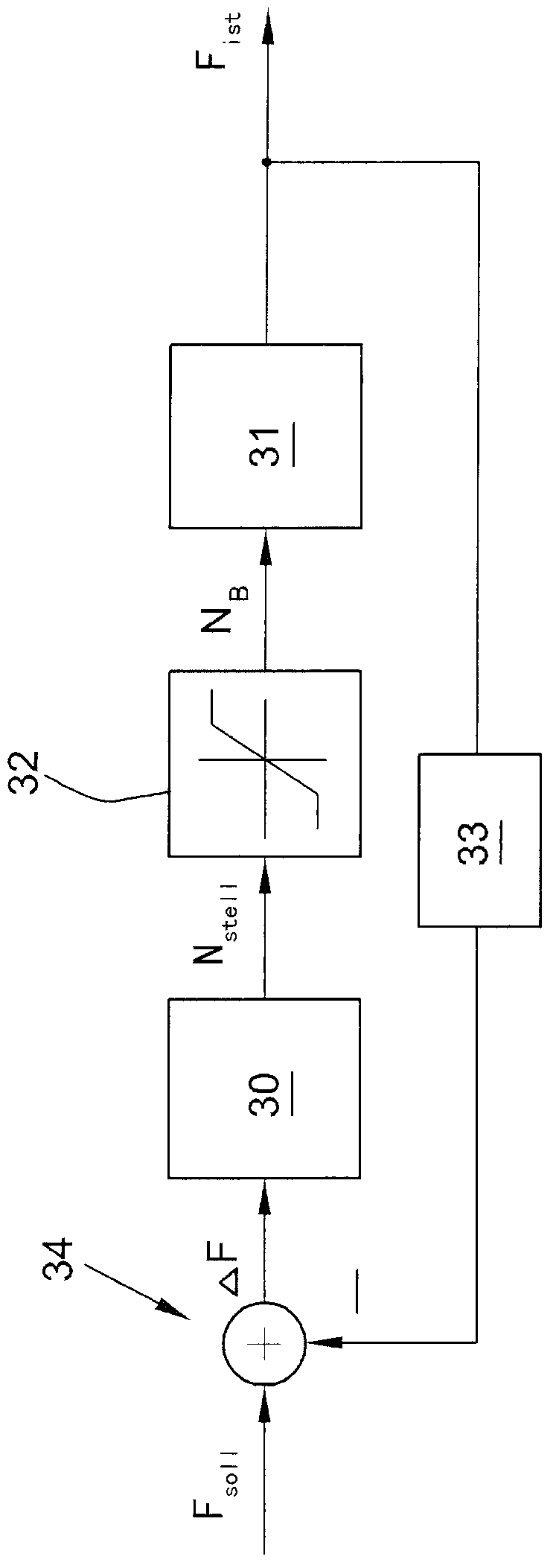

Rotor spinning machine

ActiveCN102978754AAutomatic speed adjustmentOptimum speed adjustmentContinuous wound-up machinesOpen-end spinning machinesYarnBreakage rate

The invention relates to a rotor spinning machine (1) which comprises several work stations (2), each having a spinning rotor (21). A drive unit (22) performs variable-speed drive of the spinning rotor. A measuring unit (23) detects the thread breaks, and an evaluation unit (24) detects the yarn breakage rate. According to the invention, the rotor spinning machine comprises a control unit (25) which is configured to be used for adjusting the speed of spinning rotors (21) automatically in dependence on the respectively determined yarn breakage rate, and thus controlling the yarn breakage rate, so that the yarn breakage rate is below a predetermined maximum yarn breakage rate.

Owner:SAURER GERMANY GMBH & CO KG

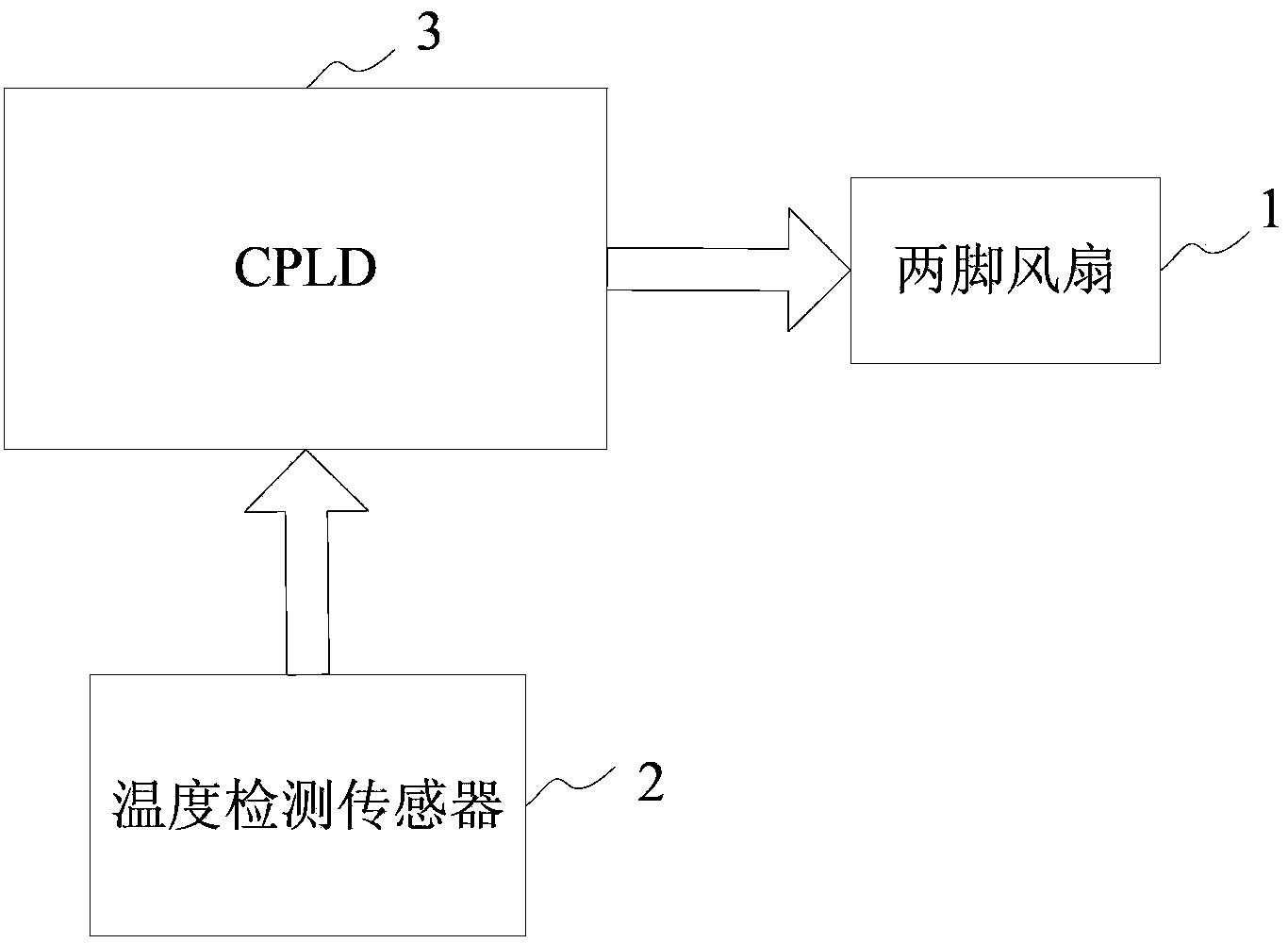

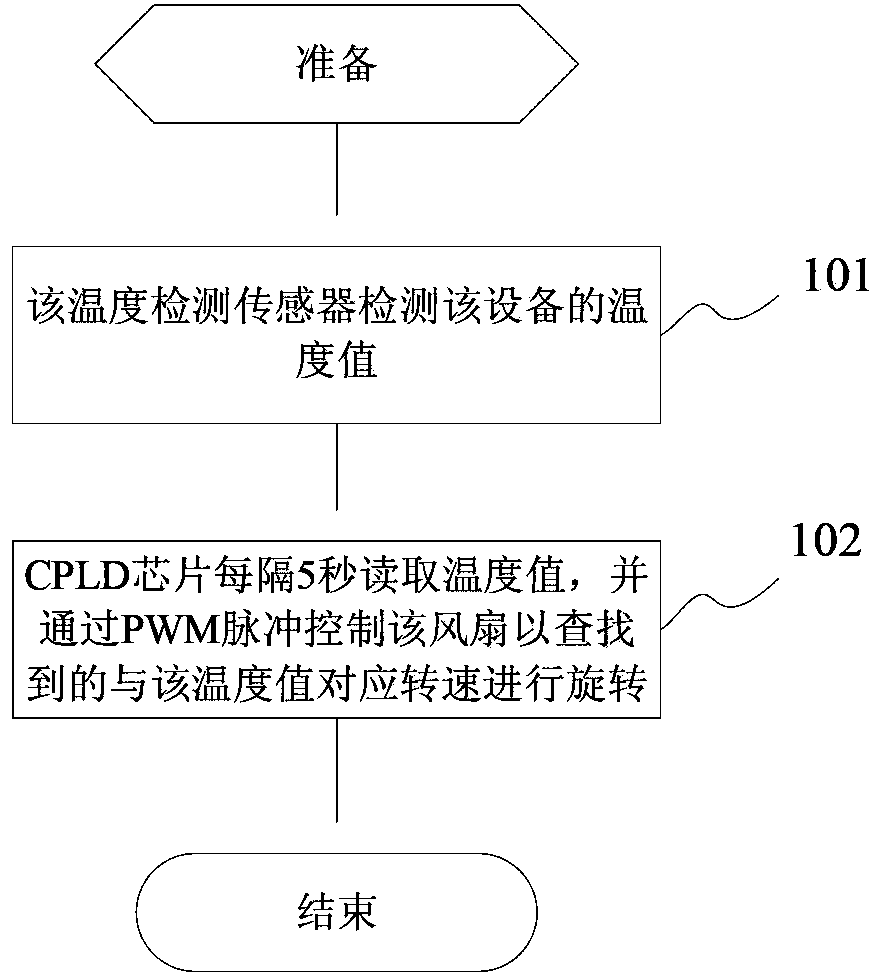

Fan heat dissipation device and method

InactiveCN103687424AAutomatic speed adjustmentFlexible designPump controlCooling/ventilation/heating modificationsEngineering

Owner:PHICOMM (SHANGHAI) CO LTD

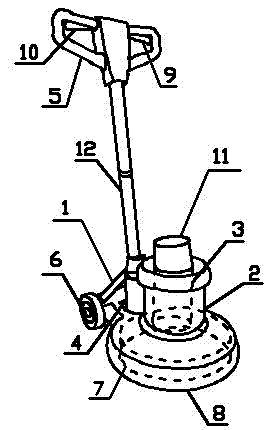

Novel polisher

InactiveCN102825530AReduce labor intensityReduce inhalationGrinding machinesGrinding/polishing safety devicesPhysical healthFrequency conversion

The invention discloses a novel polisher, comprising a rack, a housing, a motor, a frequency conversion device, a dust collection device, an expansion link, and a handle, wherein the housing is connected with the rack, the motor is arranged in the housing, the frequency conversion device is connected with the motor and is used for controlling running of the motor, the dust collection device is arranged on a side surface of the housing, the expansion link is arranged on the rack, and the handle is arranged on the top of the expansion link; a plurality of wheels are arranged at the bottom of the rack; and the bottom of the motor is connected with a plurality of grinding wheels. Compared with the prior art, the polisher disclosed by the invention can trim and polish a large-area plane, can treat the dusts generated in the polishing process by using the dust collection device, so as to avoid air and environment pollution and reduce the dust which are likely to be breathed by workers during working, thereby protecting physical health, and can automatically adjust a rotation speed of the motor according to a condition of a polished plane surface when a plane is polished.

Owner:苏州天盛电线电缆有限公司

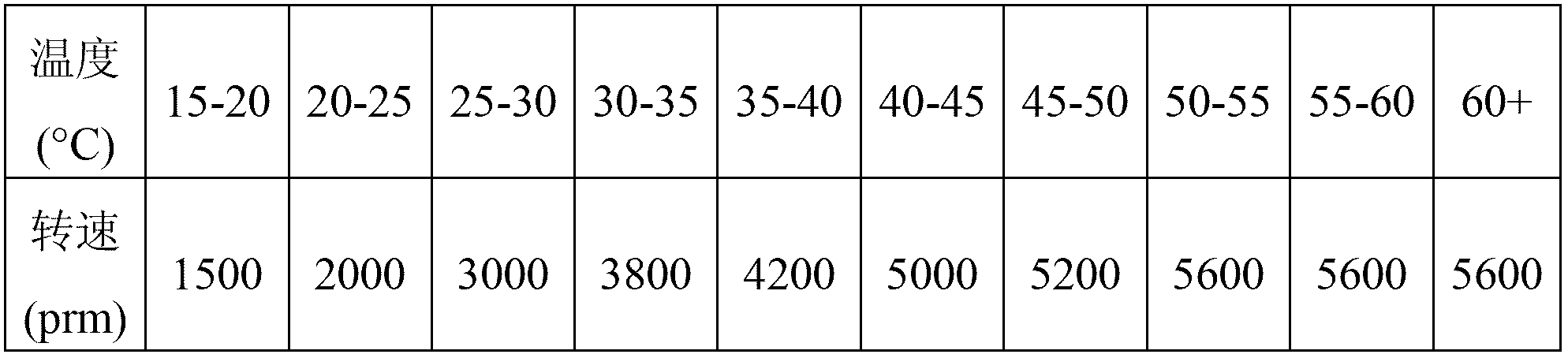

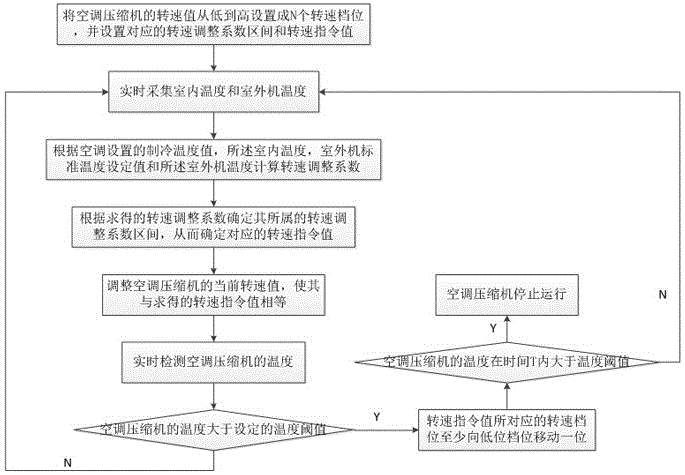

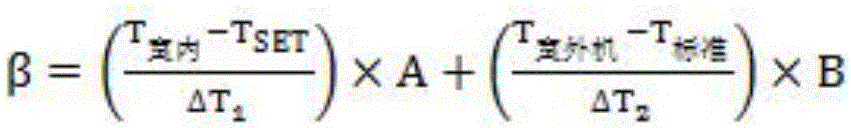

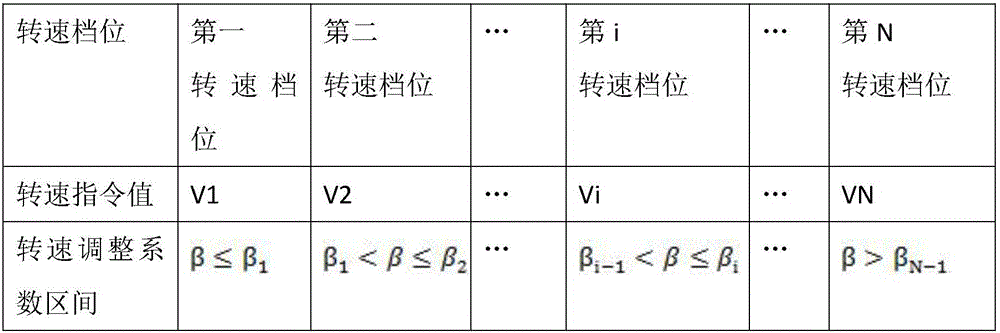

Rotation speed control method for air conditioner compressor

ActiveCN106839319AAdjust the speedAvoid long-term high-speed operationMechanical apparatusSpace heating and ventilation safety systemsValue setCooling effect

The invention relates to a rotation speed control method for an air conditioner compressor, which comprises the following steps: setting the rotation speed value of an air conditioner compressor into N rotation speed shifts from low to high, and setting a corresponding rotation speed adjusting coefficient interval and a rotation speed instruction value; acquiring indoor temperature and outdoor machine temperature in real time; according to a cooling temperature value set for an air conditioner, the indoor temperature, an outdoor machine standard temperature setup value and the outdoor machine temperature, calculating a rotation speed adjustment coefficient; according to the calculated rotation speed adjustment coefficient, confirming the rotation speed adjustment coefficient interval, confirming a corresponding rotation speed instruction value; adjusting a current rotation speed value of the air conditioner compressor to be equal to the calculated rotation speed instruction value. By adopting the rotation speed control method for the air conditioner compressor, the service life of the air conditioner compressor can be prolonged, and the cooling effect of the air conditioner compressor can be improved.

Owner:KEHUA DATA CO LTD

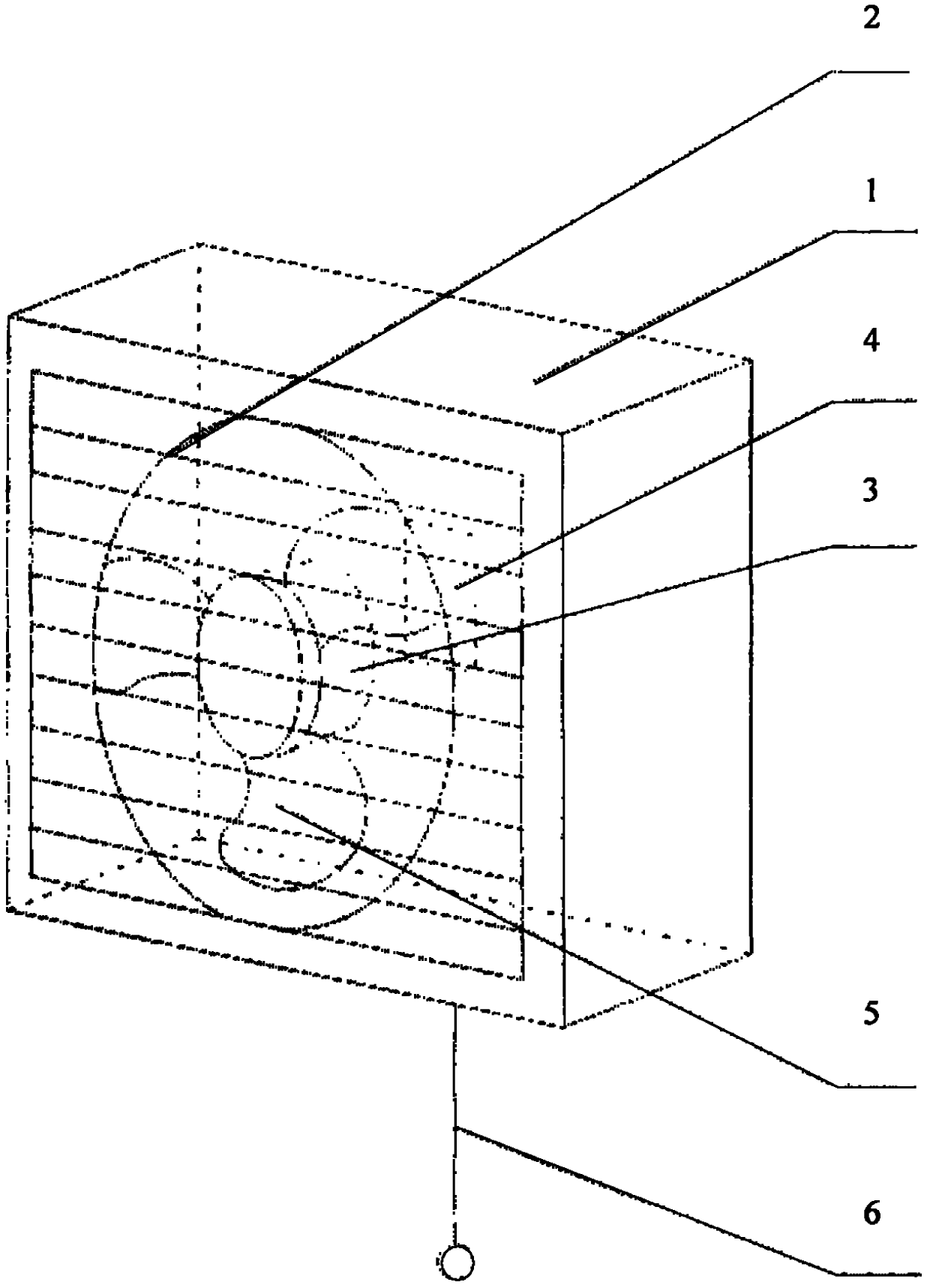

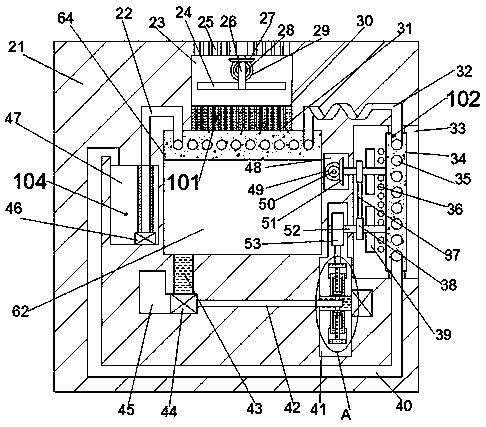

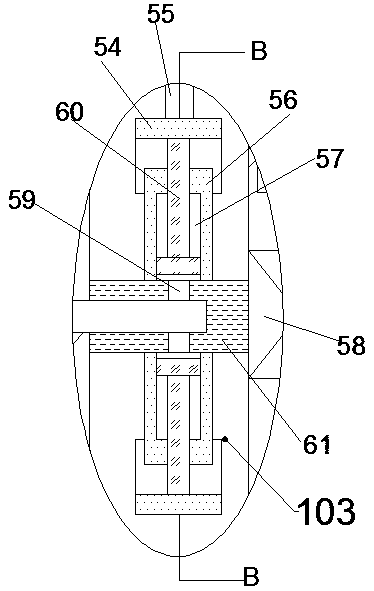

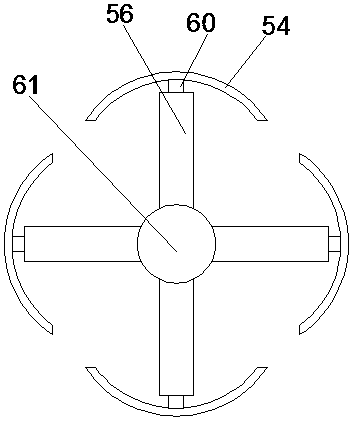

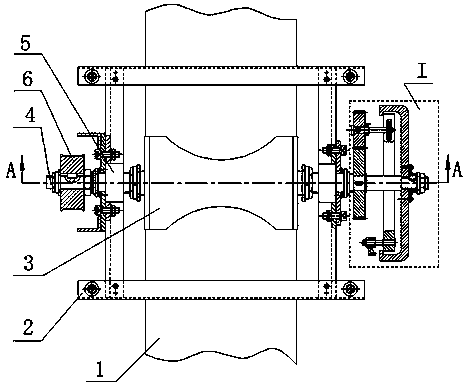

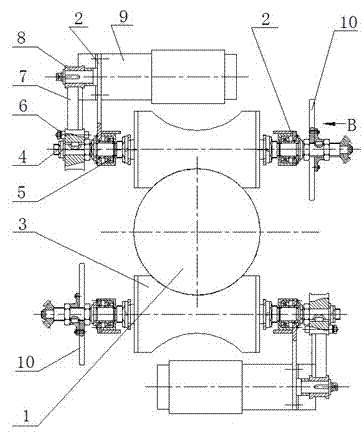

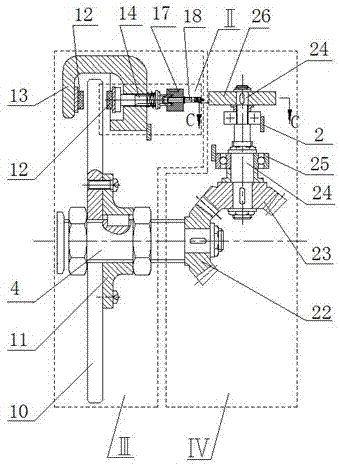

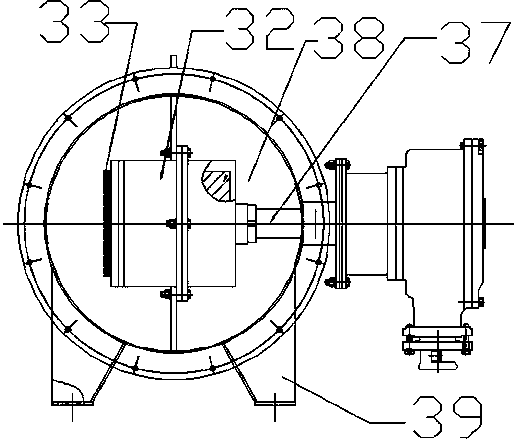

Automatic speed adjustment type cable robot

The invention discloses an automatic speed adjustment type cable robot and belongs to the field of special robots. The cable robot comprises a frame, a roller wheel, a main shaft, a rolling bearing A, a synchronous belt wheel A, a synchronous belt, a synchronous belt wheel B, a synchronous motor and a return stroke mechanism, wherein the return stroke mechanism comprises a speed increment mechanism and an internal expansion block type brake mechanism; the speed increment mechanism comprises a transmission shaft, a rolling bearing B, a gear B and a gear A; the internal expansion block type brake mechanism comprises a brake wheel, a flange plate, a brake shoe, a cam, a tension spring, a rotary shaft and a shaft sleeve. The cable robot solves the problems that an existing cable robot hardly and automatically returns to the ground in case of unexpected power outage and a large amount of energy is consumed and the speed is not easy to adjust automatically when the robot normally returns to the ground, and has the advantages of reasonable design and simplicity for manufacturing.

Owner:平湖市中劢磁业股份有限公司

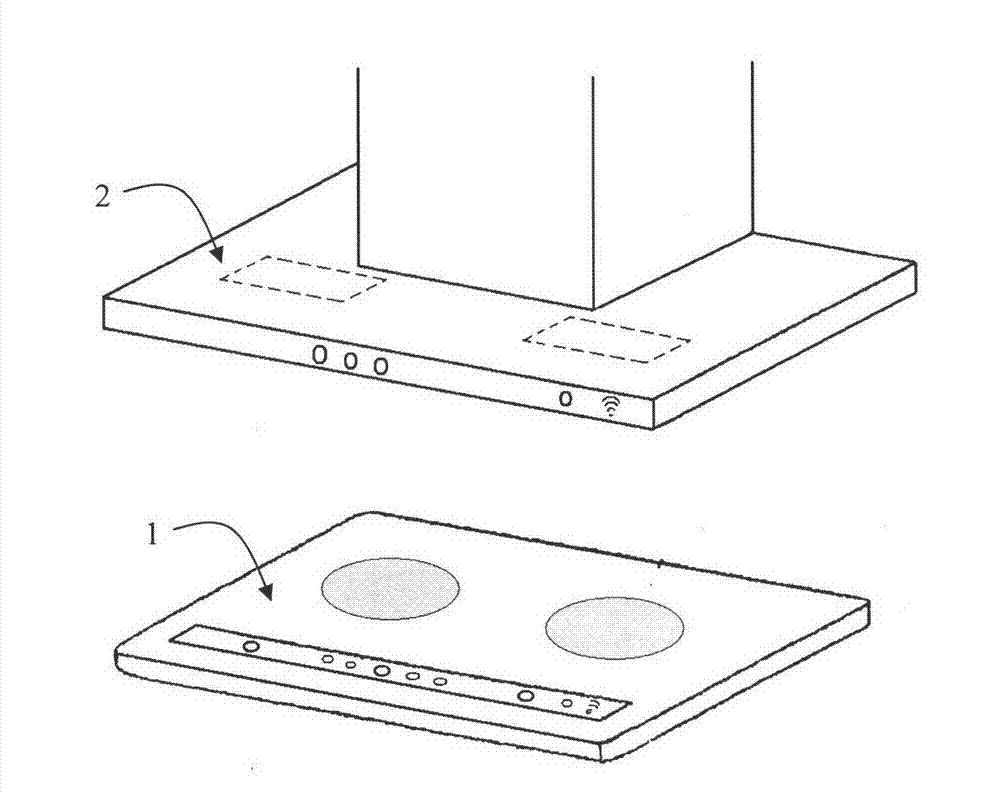

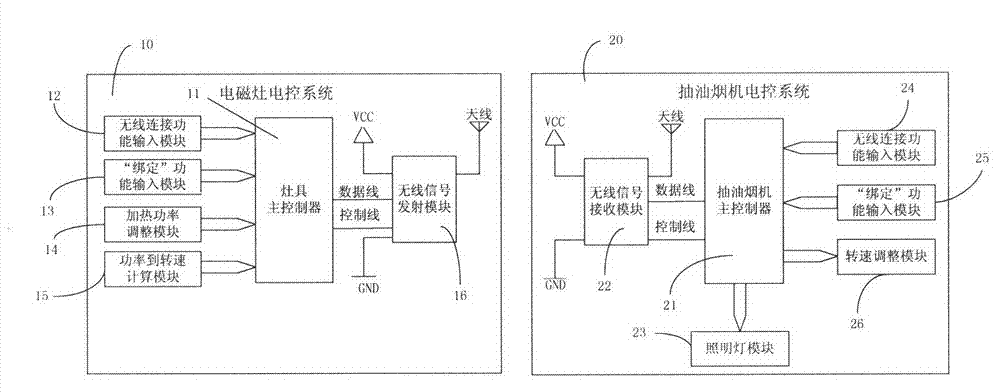

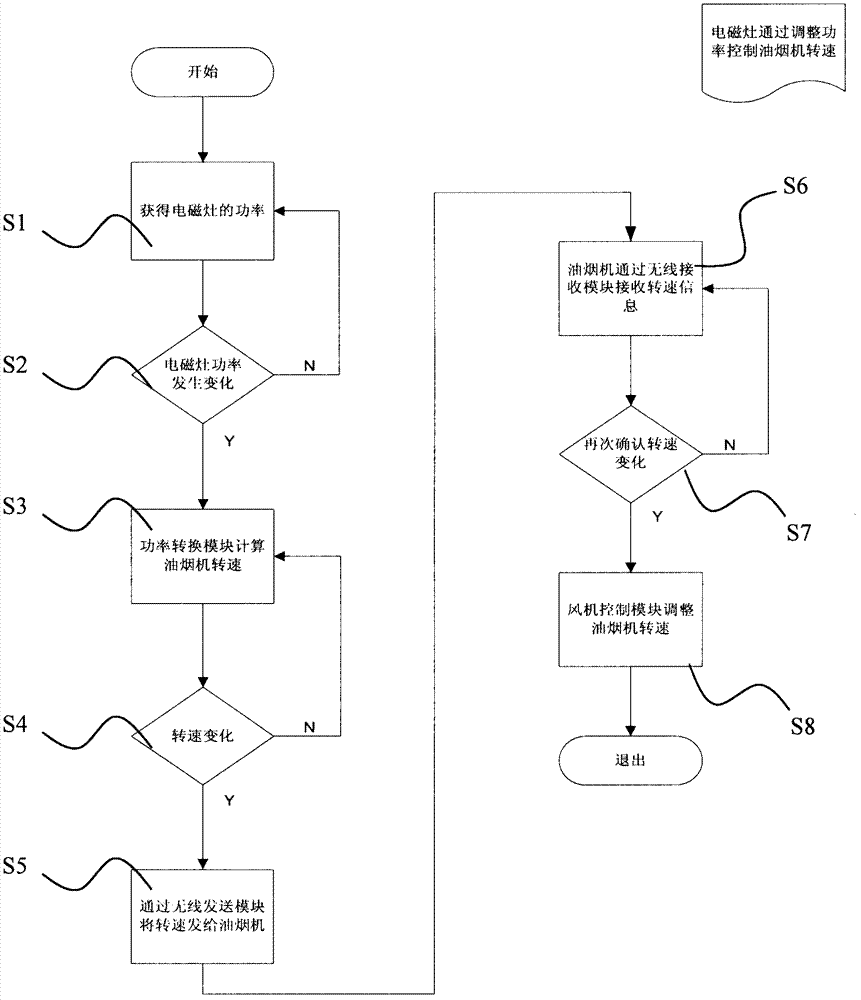

Combination of electromagnetic stove and range hood and control method thereof

InactiveCN102954508AAutomatic speed adjustmentDomestic stoves or rangesTransmission systemsEngineeringHeating power

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

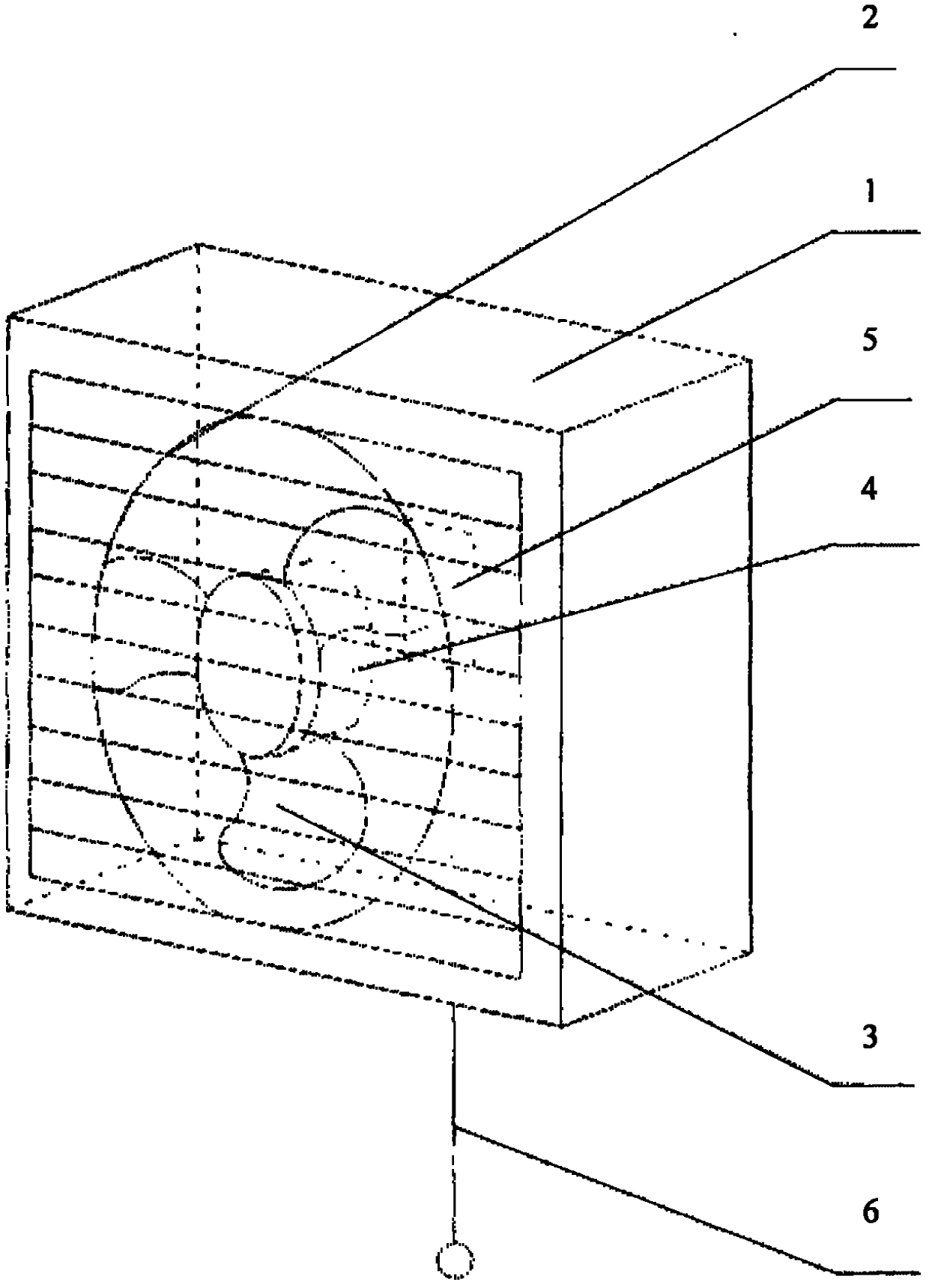

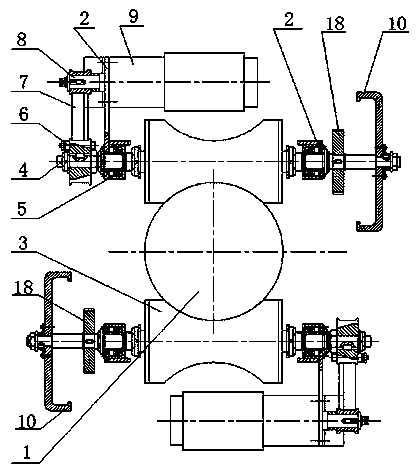

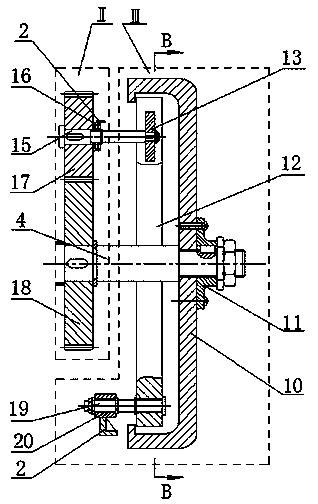

Cable climbing robot

ActiveCN103692436AHigh output speedIncrease working frequencyProgramme-controlled manipulatorBridge erection/assemblyAuto regulationSynchronous motor

The invention discloses a cable climbing robot and belongs to the field of specialized robots. The cable climbing robot comprises racks, rollers, spindles, rolling bearings A, synchronous wheels A, synchronous belts, synchronous wheels B, synchronous motors and a return stroke mechanism. The return stroke mechanism is formed by a clearance brake mechanism and an acceleration transmission mechanism. The clearance brake mechanism is composed of a brake disc, a flange disc, a friction block, a brake caliper, a brake shaft, an adjusting spring, an adjusting nut A, an adjusting block, an adjusting shaft, an adjusting nut B, a roller and a roller shaft. The acceleration transmission mechanism is composed of a conical gear A, a conical gear B, a transmission shaft, a rolling bearing B and a cam. By means of the cable climbing robot, the problems that returning of prior cable climbing robots to the ground is difficult during accidental outage and when the cable climbing robots return to the ground normally, a large amount of energy is consumed, and the speed is difficult to adjust automatically are solved, the design is reasonable, and manufacturing is facilitated.

Owner:长沙猎空智能科技有限公司

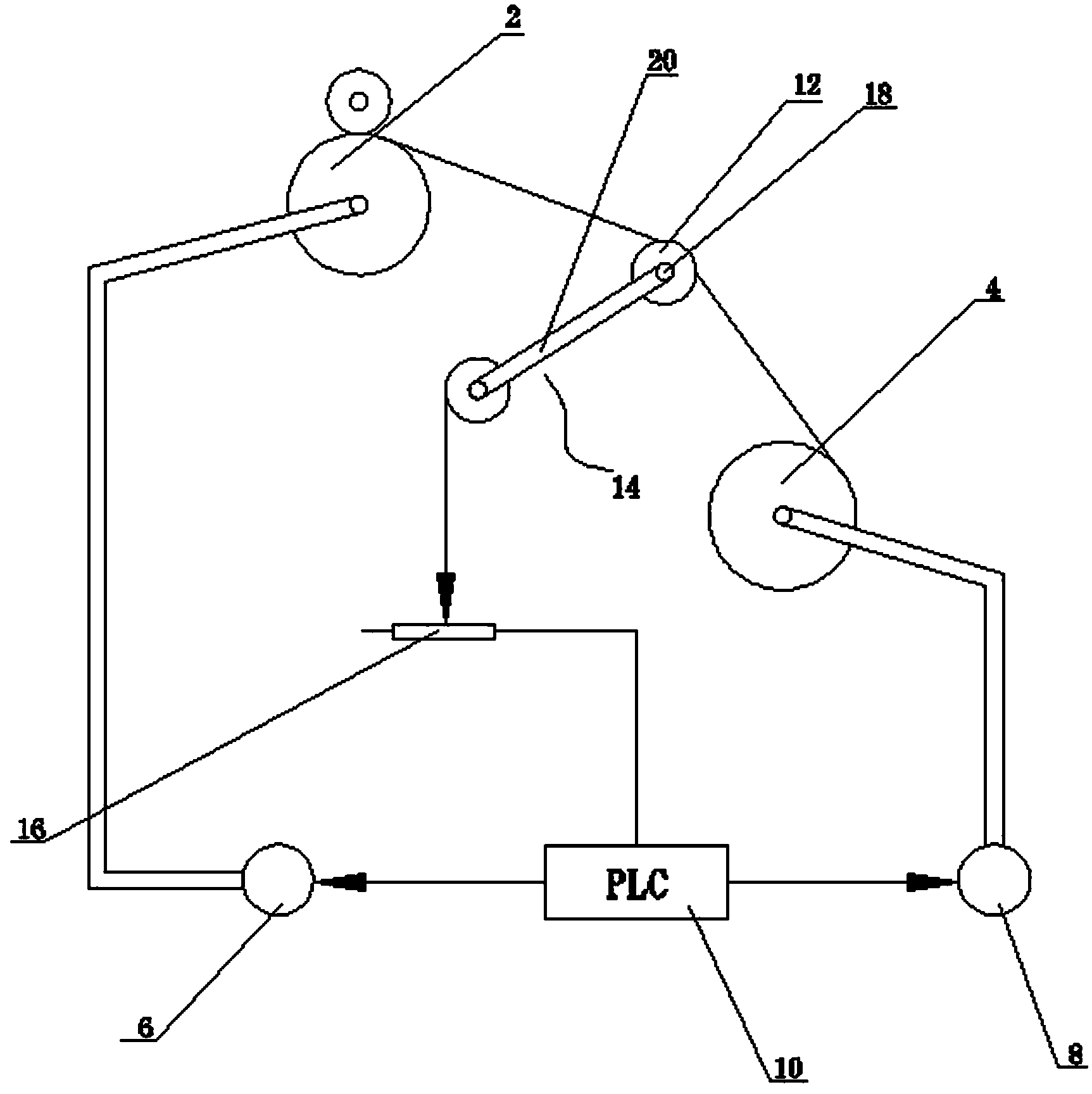

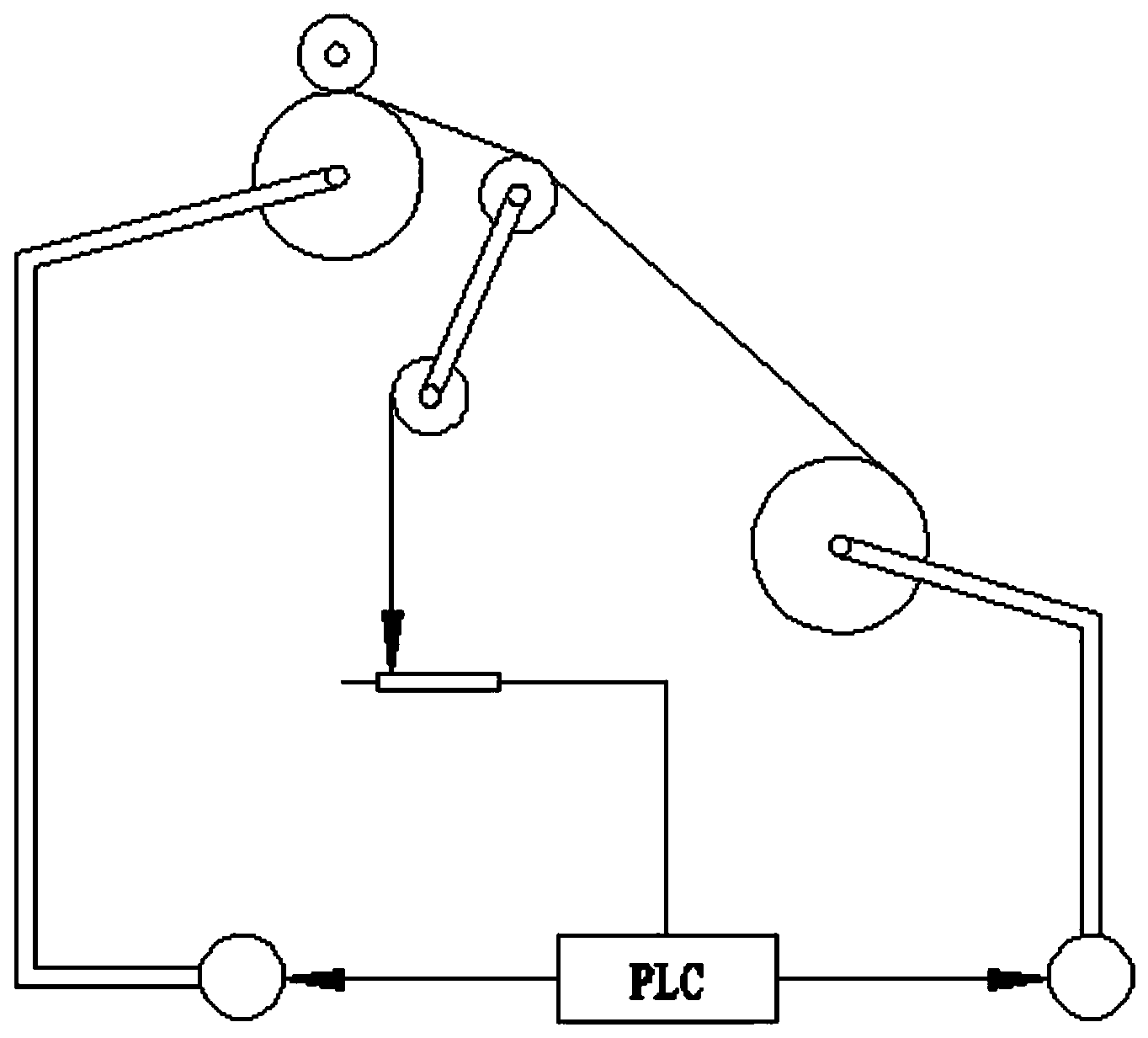

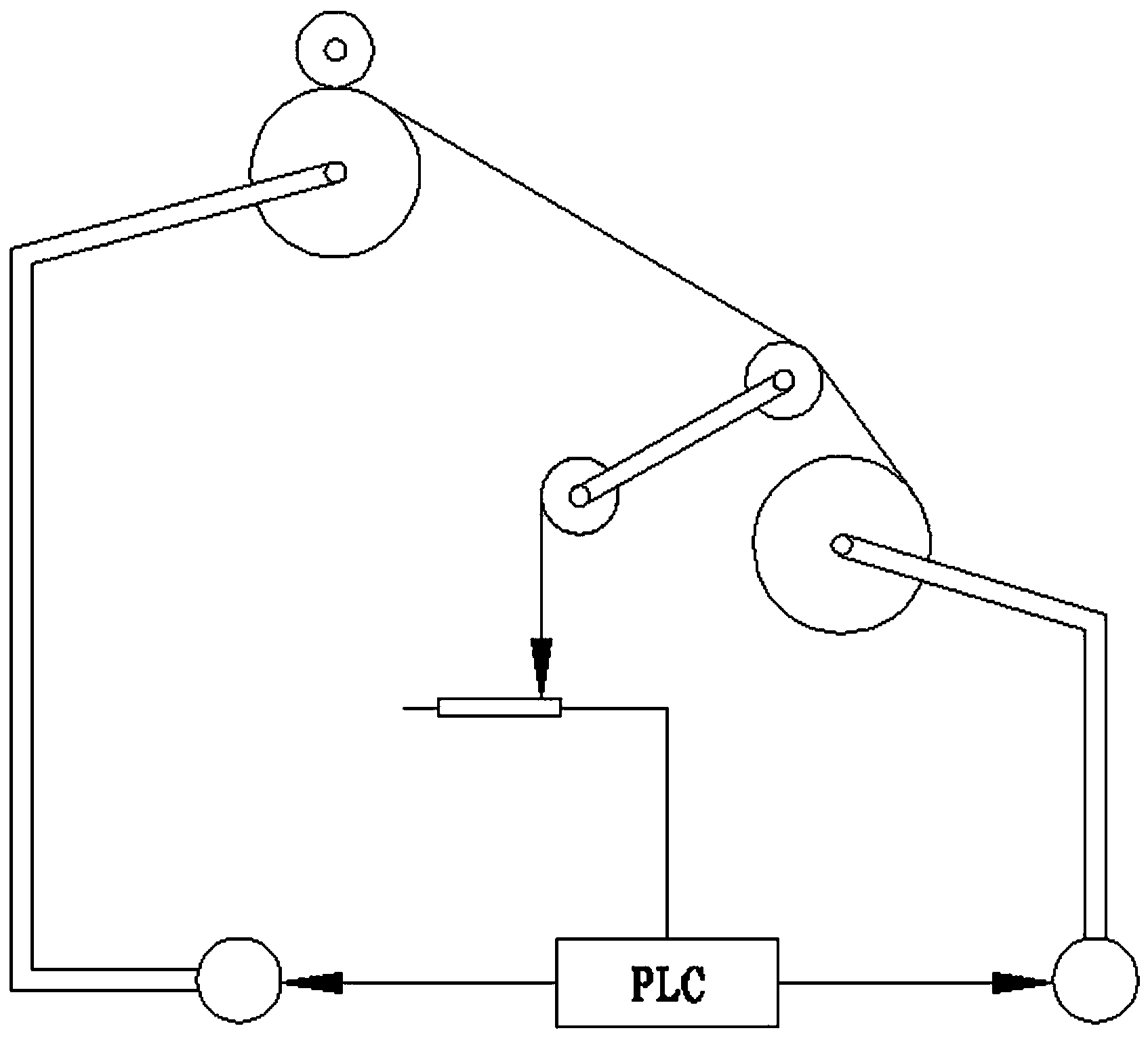

Device for automatically adjusting spinning part winding tension

InactiveCN103510253AAutomatic speed adjustmentWinding tension real-time adjustmentLoomsElectric machineEngineering

The invention provides a device for automatically adjusting spinning part winding tension. The device comprises a pulling traction roller, a winding roller, a first motor, a second motor and a PLC, wherein the pulling traction roller and the winding roller work independently, the first motor and the second motor drive the pulling traction roller and the winding roller respectively, and the PLC is used for electrically connecting the first motor and the second motor and controlling the rotation speed of the first motor and the rotation speed of the second motor. The device is characterized in that a tension roller is arranged between the pulling traction roller and the winding roller, a tension detector is arranged on the tension roller, and the signal output end of the tension detector is electrically connected with the PLC through a potentiometer. After the winding tension of the tension roller changes, the variable quantity of tension is converted into the voltage change of the potentiometer through the tension detector, the PLC converts the voltage change into an output signal and sends the output signal to the first motor or the second motor, the rotation speed of the pulling traction roller or the rotation speed of the winding roller is adjusted automatically to enable the winding tension to return to the set constant value, and the purpose of adjusting the winding tension in real time is achieved.

Owner:WUJIANG WEIQI FABRIC

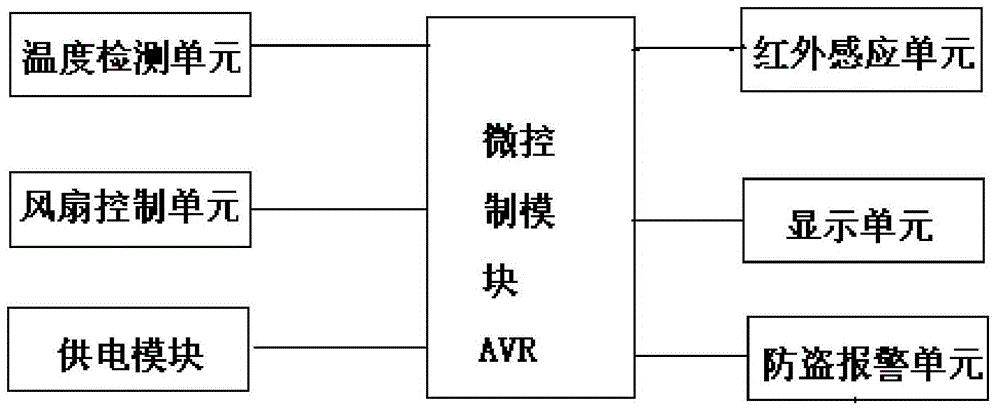

Fan control system with intelligent temperature control and antitheft control functions

InactiveCN104405668ASimple structureEasy to implementPump controlNon-positive displacement fluid enginesTemperature controlControl system

The invention discloses a fan control system with intelligent temperature control and antitheft control functions. The fan control system comprises a micro control module which is arranged on a fan, and a temperature detection unit, a speed governing unit, a power supply module, an infrared sensing unit and an alarm module which are connected with the micro control module, wherein the micro control module comprises a first parameter comparison unit, a first control unit, a second parameter comparison unit and a second control unit. The fan control system with intelligent temperature control and antitheft control functions has the advantages that the structure is simple and the realization is easy; not only can the revolving speed of the fan be automatically adjusted according to ambient temperature, but also whether people exist in the surrounding environment can be detected in real time to control the power-off of the fan, so that electric energy is saved.

Owner:SUZHOU YOURUI TESTING TECH

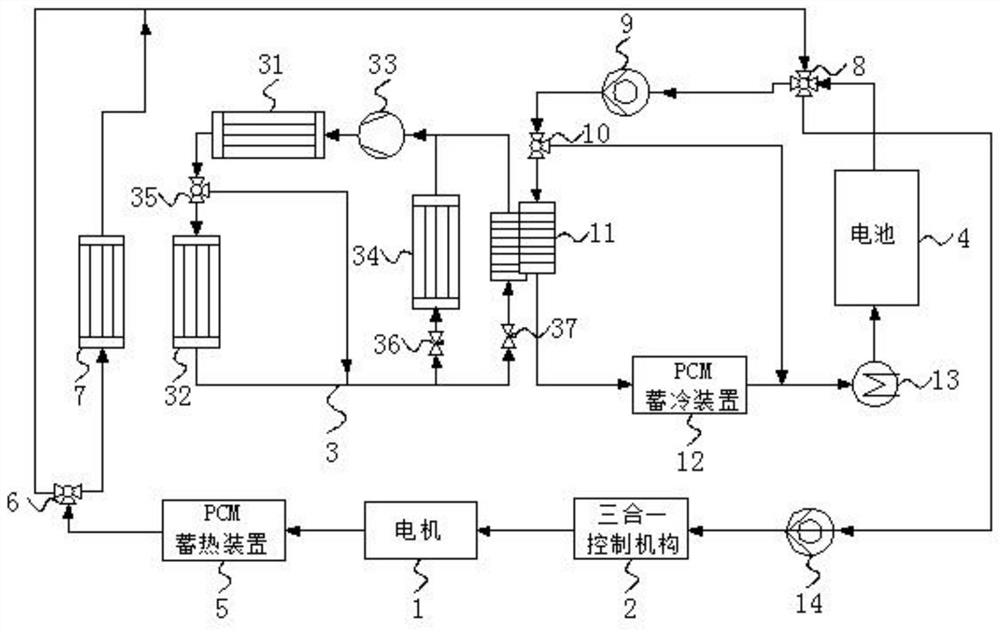

Electric vehicle heat management system with waste heat recycling function

ActiveCN111845269ASolve the mileageAvoid lossAir-treating devicesHeat recovery systemsElectrical batteryThermal management system

The invention discloses an electric vehicle heat management system with a waste heat recycling function. The system comprises a motor, a three-in-one control mechanism, an air conditioner loop systemand a battery. A heat dissipation port of the three-in-one control mechanism is connected with an inlet of the motor through a pipeline; and a heat dissipation opening of the motor is connected with an inlet of a heat storage device through the pipeline, a heat dissipation opening of the heat storage device is connected with an inlet of a temperature control valve through the pipeline, and an outlet of the temperature control valve is connected with a low-temperature radiator and an inlet of a four-way reversing valve through the pipelines. The electric vehicle heat management system with thewaste heat recycling function relates to the technical field of thermal management system. A motor cooling loop and a battery cooling loop are connected through the four-way reversing valve, waste heat of the motor can be used as a supplementary heat source of a battery and a heat pump air conditioning system, the function of recycling the waste heat of motor electric control is achieved, an energy utilization rate of the whole vehicle is increased, and an endurance mileage can be effectively improved.

Owner:HUBEI RADIATECH COOLING SYSTEM CO LTD

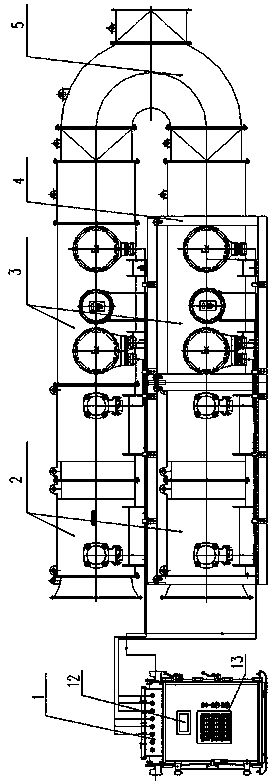

Intelligent coal mine local ventilation system

ActiveCN103591041AAutomatic speed adjustmentImprove safety and reliabilityTunnel/mines ventillationPump controlAuto regulationComputer module

The invention discloses an intelligent coal mine local ventilation system which comprises a mining flame-proof type two-circuit feeder switch, two passageway type anti-explosion frequency converters and two local ventilation machines. The mining flame-proof type two-circuit feeder switch is connected with an information collecting module under a coal mine, supplies power for the two anti-explosion frequency converters respectively and controls the two anti-explosion frequency converters to work. The two anti-explosion frequency converters are connected with the two local ventilation machines respectively, and air flow automatic switching devices are further arranged at air outlets of the two local ventilation machines. Under the control of the mining flame-proof type intelligent two-circuit feeder switch, rotation speed of a fan is automatically adjusted, air is supplied according to needs, gas is intelligently exhausted, energy is saved, consumption is reduced, disasters are prevented, and safety and reliability of the local ventilation system are improved.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

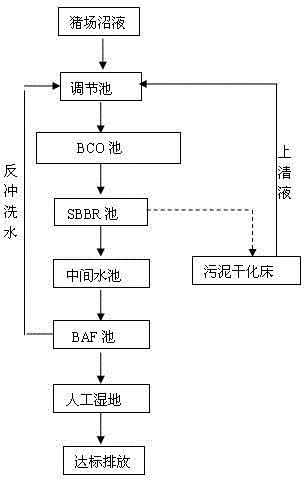

BCO-SBBR-BAF-CW combination technology for processing pig farm biogas slurry

InactiveCN103951137AGuaranteed continuityFlexible operationMultistage water/sewage treatmentBiogasPig farms

The invention discloses a BCO-SBBR-BAF-CW combination technology for processing pig farm biogas slurry. Specifically, the pig farm biogas slurry is successively processed by a regulating tank, a bio-contact oxidation tank (BCO), a sequential batchbiofilm reactor (SBBR), a middle tank, a biological aerated filter (BAF) and constructed wetland (CW), and finally reaches the standard and is discharged. The technology is flexible in operation manner, simple in operation, relatively small in occupation area, and low in operation cost.

Owner:NANCHANG UNIV

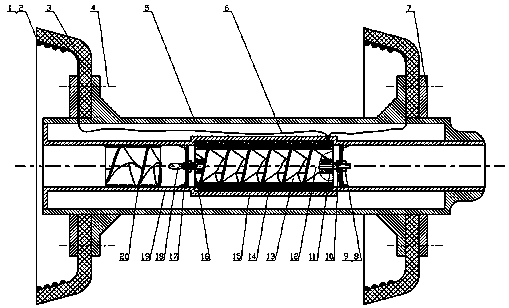

Self-blockage-removing speed-regulating pipe cleaner

PendingCN111036627AAutomatic speed adjustmentRealize automatic adjustmentHollow article cleaningRubber CupImpeller

The invention provides a self-blockage-removing speed-regulating pipe cleaner, which comprises actuators, actuator protective sleeves, rubber cups, a pipe cleaner outer body, lead wires, a distance adjusting ring, a bearing, a mandrel, an impeller, magnetic poles, a coil, a supporting ring, a pipe cleaner inner body and a guide wheel, wherein the rubber cups are arranged at the two ends of the pipe cleaner outer body, the pipe cleaner inner body is arranged in the pipe cleaner outer body, and the pipe cleaner inner body, the pipe cleaner outer body and the rubber cups form a hollow structure;and the coil is fixed in an annular groove of the pipe cleaner inner body, the impeller is arranged in the coil, and the magnetic poles are arranged on the outer circumferential surface of the impeller. Electric energy generated by rotation of the impeller is converted into heat energy by means of an electric heating wire on the artificial muscle, crude oil can be heated when the pipe cleaner works normally, wax on a pipeline can be removed conveniently, and the actuators drive the rubber cups to deform to a certain degree due to temperature changes, so as to control a friction force between the pipe cleaner and the pipeline, and achieve the purpose of adjusting the speed of the pipe cleaner.

Owner:XIAN CHANGQING TECH ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com