Reduction gear for impeller type washing machine

A deceleration clutch and pulsator washing machine technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of high cost, inconvenient assembly, and gaps, and achieve low cost, convenient assembly, and good washing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

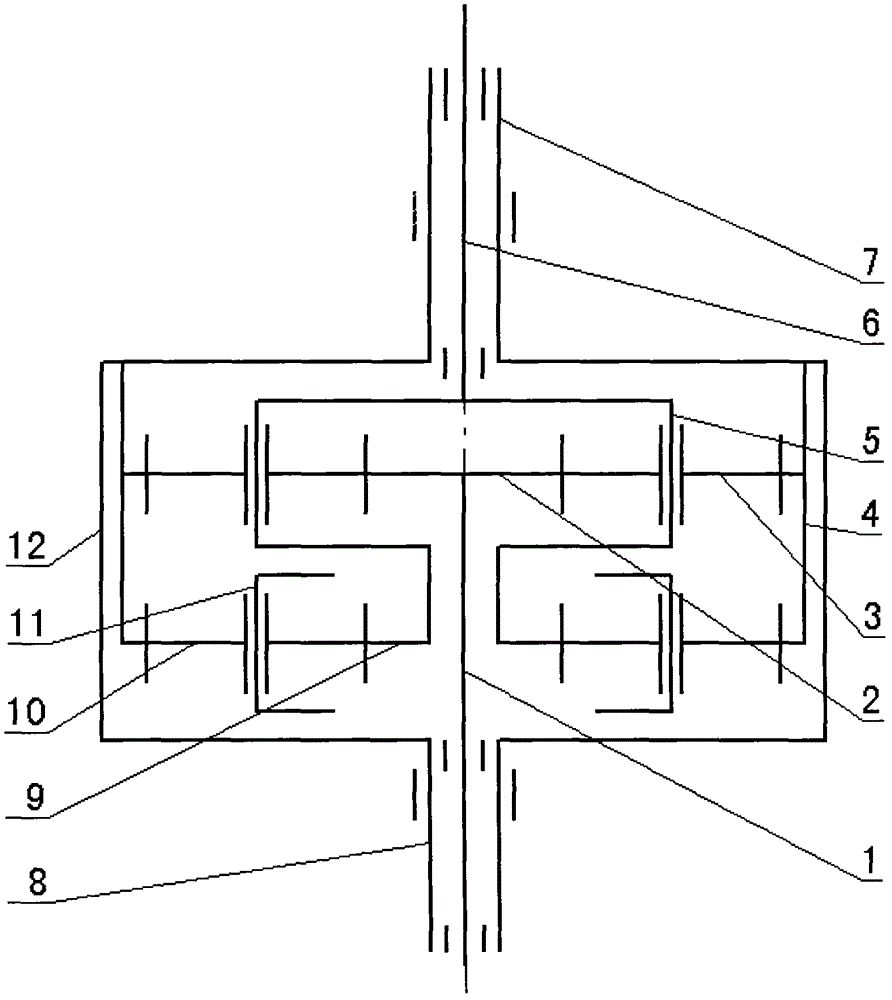

[0016] Combine figure 1 , Is a schematic diagram of the principle structure of an embodiment of a pulsator washing machine deceleration clutch of the present invention. The pulsator washing machine deceleration clutch is mainly composed of an input shaft 1, an output shaft 6, an output sleeve 7, an input sleeve 8 and a brake wheel 12. , The input shaft 1 is installed in the input shaft sleeve 8, the output shaft 6 is installed in the output shaft sleeve 7, the input shaft sleeve 8 is fixedly connected to the lower end of the brake wheel 12, and the lower end of the output shaft sleeve 7 is installed on the brake wheel 12 Inside, the brake wheel 12 is equipped with a double set of planets consisting of input shaft gear 2, upper planetary gear 3, internal gear 4, upper planet carrier 5, center wheel 9, lower planetary gear 10 and lower planet carrier 11. Gear mechanism, the input shaft 1 is connected with the input shaft gear 2, the upper planetary gear 3 is installed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com