Cable climbing robot

A robot and cable-climbing technology, applied in the field of special robots, can solve the problems of difficulty in returning to the ground automatically, difficulty in automatically adjusting the speed when energy is returned, and large consumption of robots, so as to prevent cable-pulling accidents, increase working frequency, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

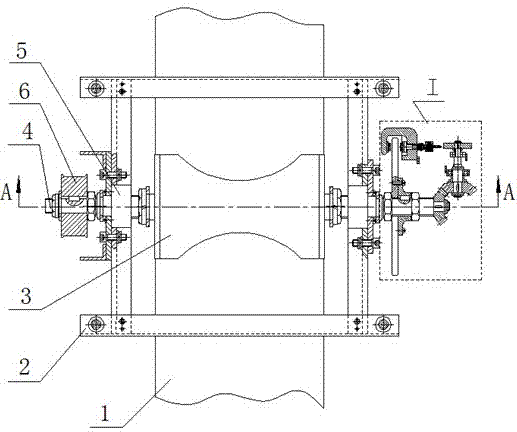

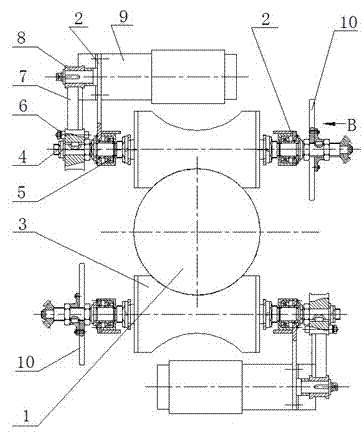

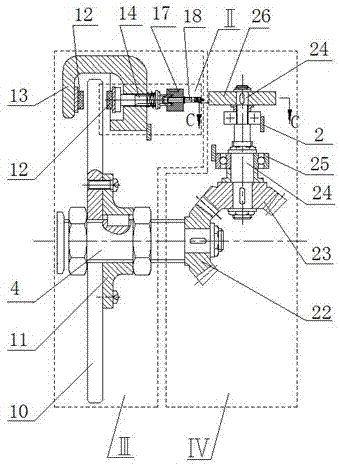

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, the cable climbing robot includes frame 2, roller 3, main shaft 4, rolling bearing A5, synchronous pulley A6, synchronous belt 7, synchronous pulley B8, synchronous motor 9, and frame 2 is provided with rolling bearing A5, synchronous motor 9 , the main shaft 4 is assembled in the rolling bearing A5, one end of the main shaft 4 is connected with the synchronous pulley A6, the roller 3 is assembled on the main shaft 4, the arc surface of the roller 3 is pressed on the surface of the cable 1, and the synchronous pulley B8 is assembled on the main shaft of the synchronous motor 9, The synchronous pulley A6 and the synchronous pulley B8 are both engaged with the synchronous belt 7, and also include a return mechanism I, and the return mechanism I is composed of a gap braking mechanism III and a speed-up transmission mechanism IV.

[0033] The gap braking mechanism III includes a brake ...

Embodiment 2

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the cable climbing robot includes frame 2, roller 3, main shaft 4, rolling bearing A5, synchronous pulley A6, synchronous belt 7, synchronous pulley B8, synchronous motor 9, and frame 2 is provided with rolling bearing A5, synchronous motor 9 , the main shaft 4 is assembled in the rolling bearing A5, one end of the main shaft 4 is connected with the synchronous pulley A6, the roller 3 is assembled on the main shaft 4, the arc surface of the roller 3 is pressed on the surface of the cable 1, and the synchronous pulley B8 is assembled on the main shaft of the synchronous motor 9, The synchronous pulley A6 and the synchronous pulley B8 are both engaged with the synchronous belt 7, and also include a return mechanism I, and the return mechanism I is composed of a gap braking mechanism III and a speed-up transmission mechanism IV.

[0038] The gap braking mechanism III includes a brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com