Patents

Literature

113results about How to "High output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

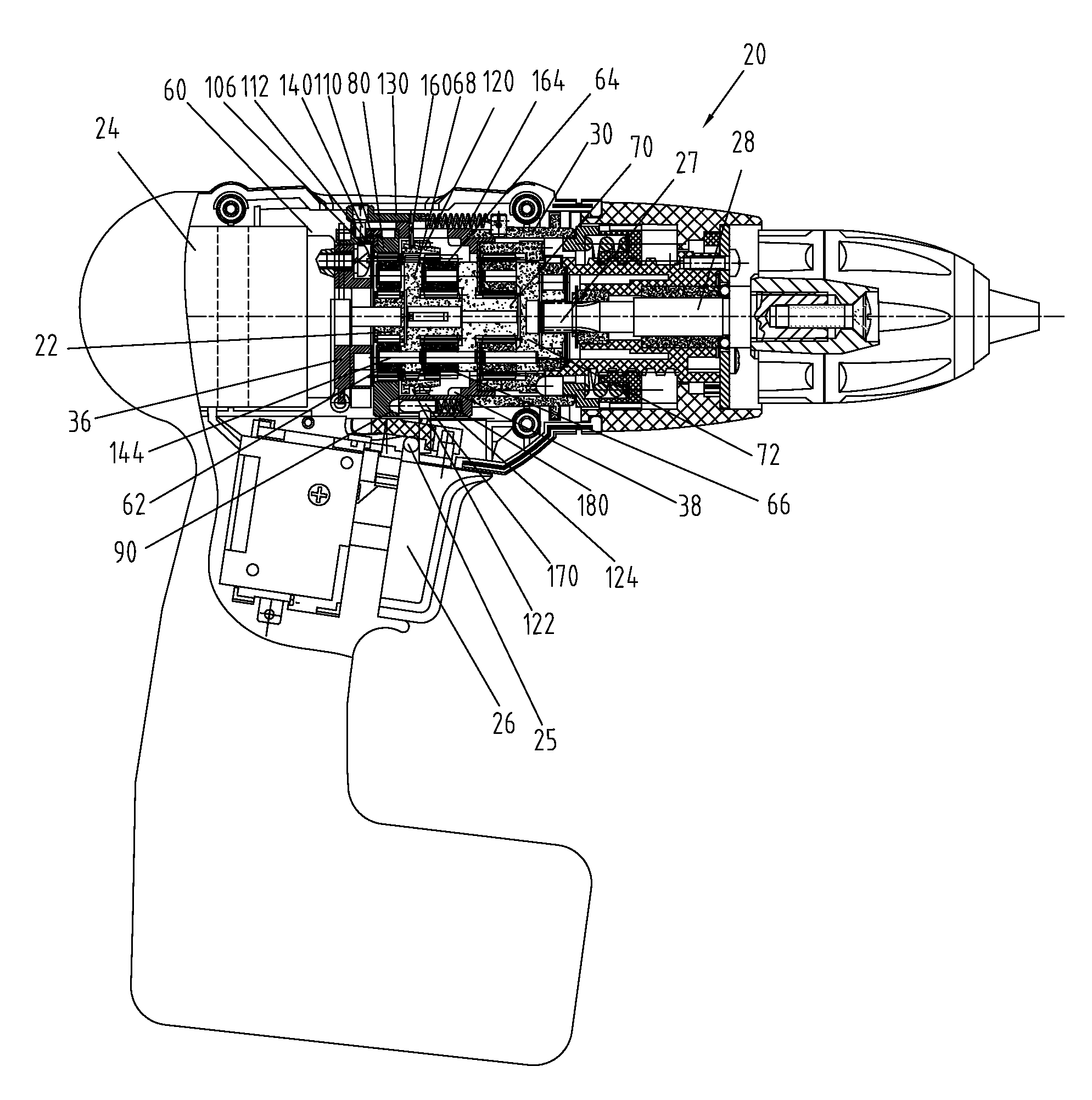

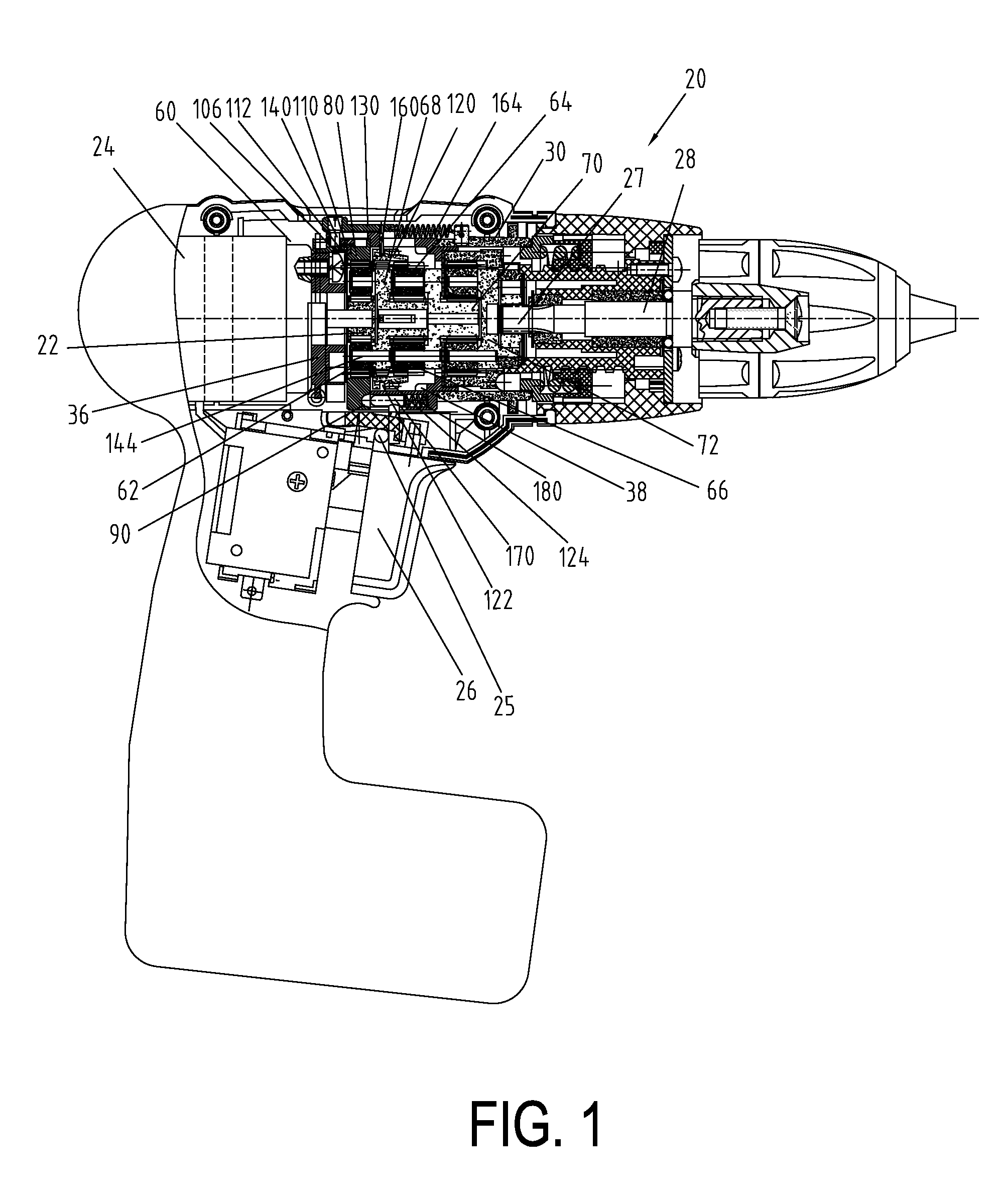

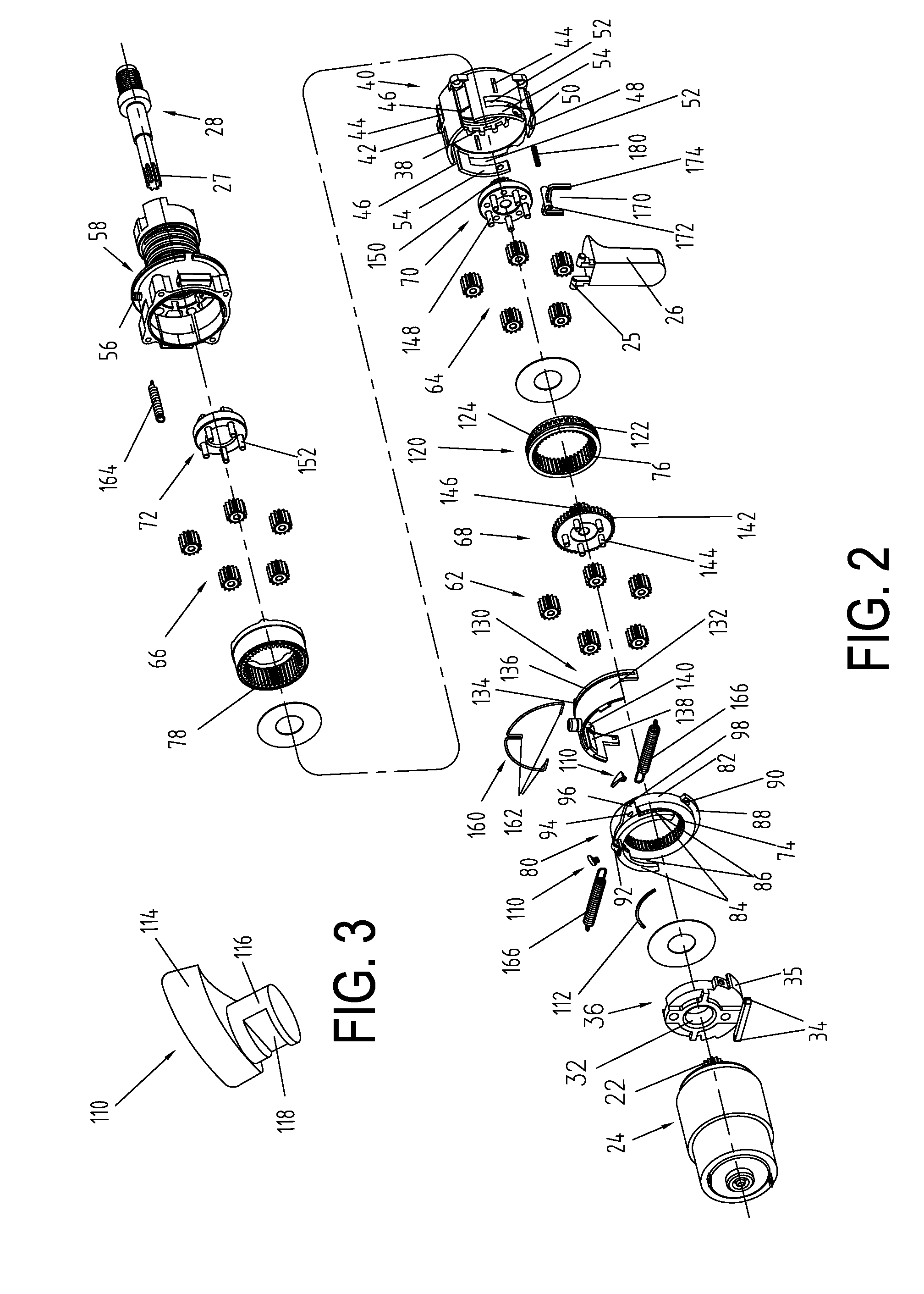

Variable speed tool and variable speed control method

ActiveUS20090277658A1Guaranteed uptimePrevent movementDrilling rodsConstructionsLoad torqueGear train

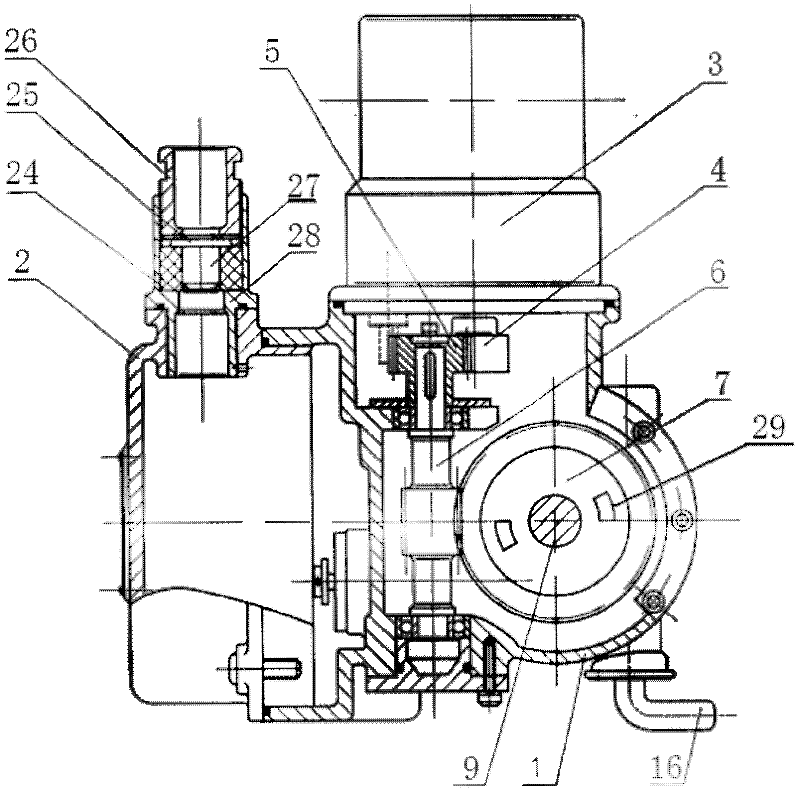

The present invention has disclosed a variable speed tool and a variable speed control method. The tool includes a switch; a gearbox housing; a motor; an outputting shaft; a multistage transmitting gear train and a gearshift ring which are mated with the motor and the outputting shaft, the gearshift ring having inner teeth; a gearshift fork mated with the gearshift ring; a tension spring arranged between the gearbox housing and the gearshift fork; and a torque sensing ring provided with a sliding groove in which the gearshift fork is movably disposed. When the load of the outputting shaft has reached to a predetermined value, the torque sensing ring makes the gearshift fork move axially in the sliding groove under the action of the tension spring, thus bringing the gearshift ring to move axially. The variable speed tool of the present invention may automatically adjust the rotating speed and the torque of the outputting shaft according to a variation of the load torque.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

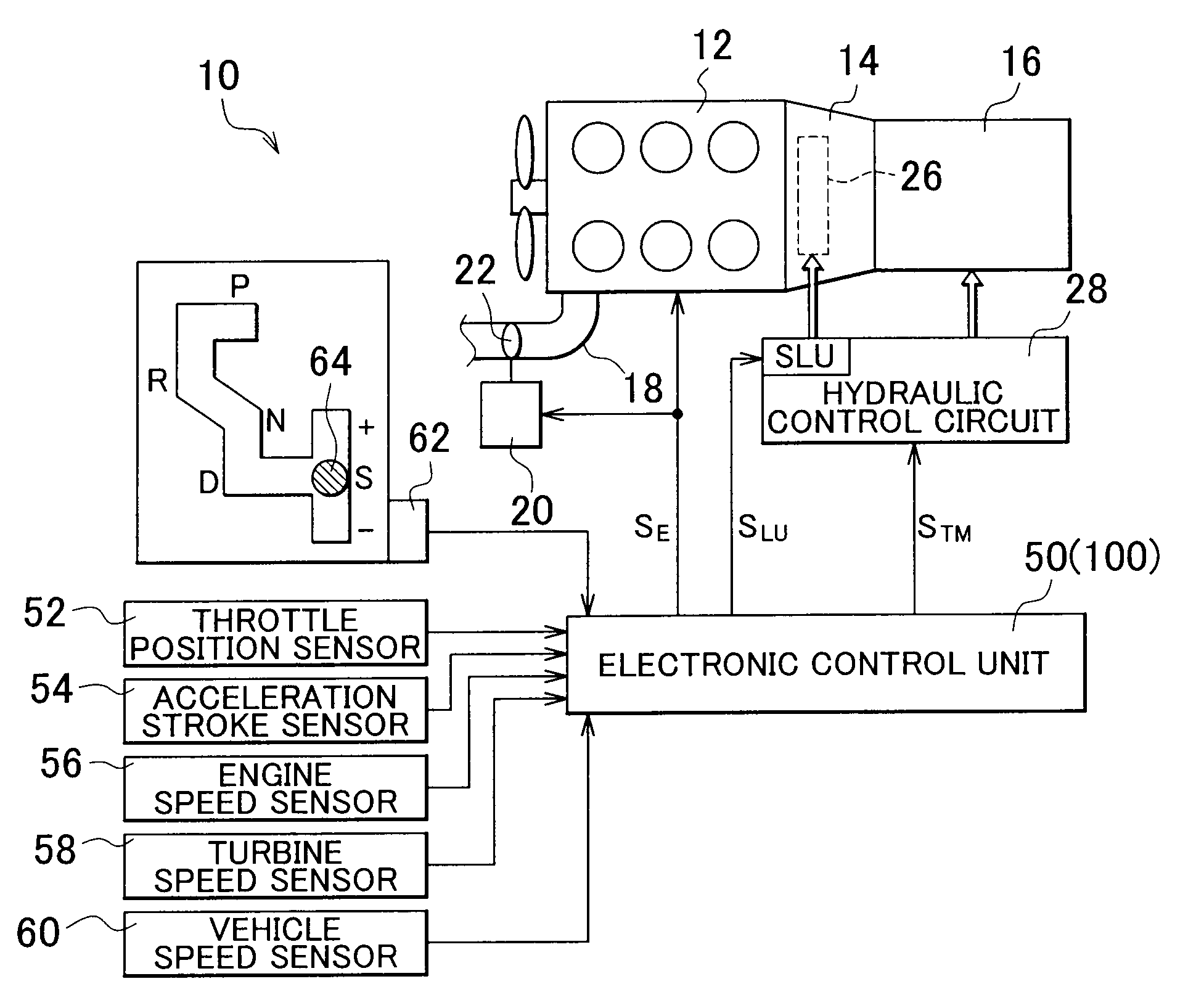

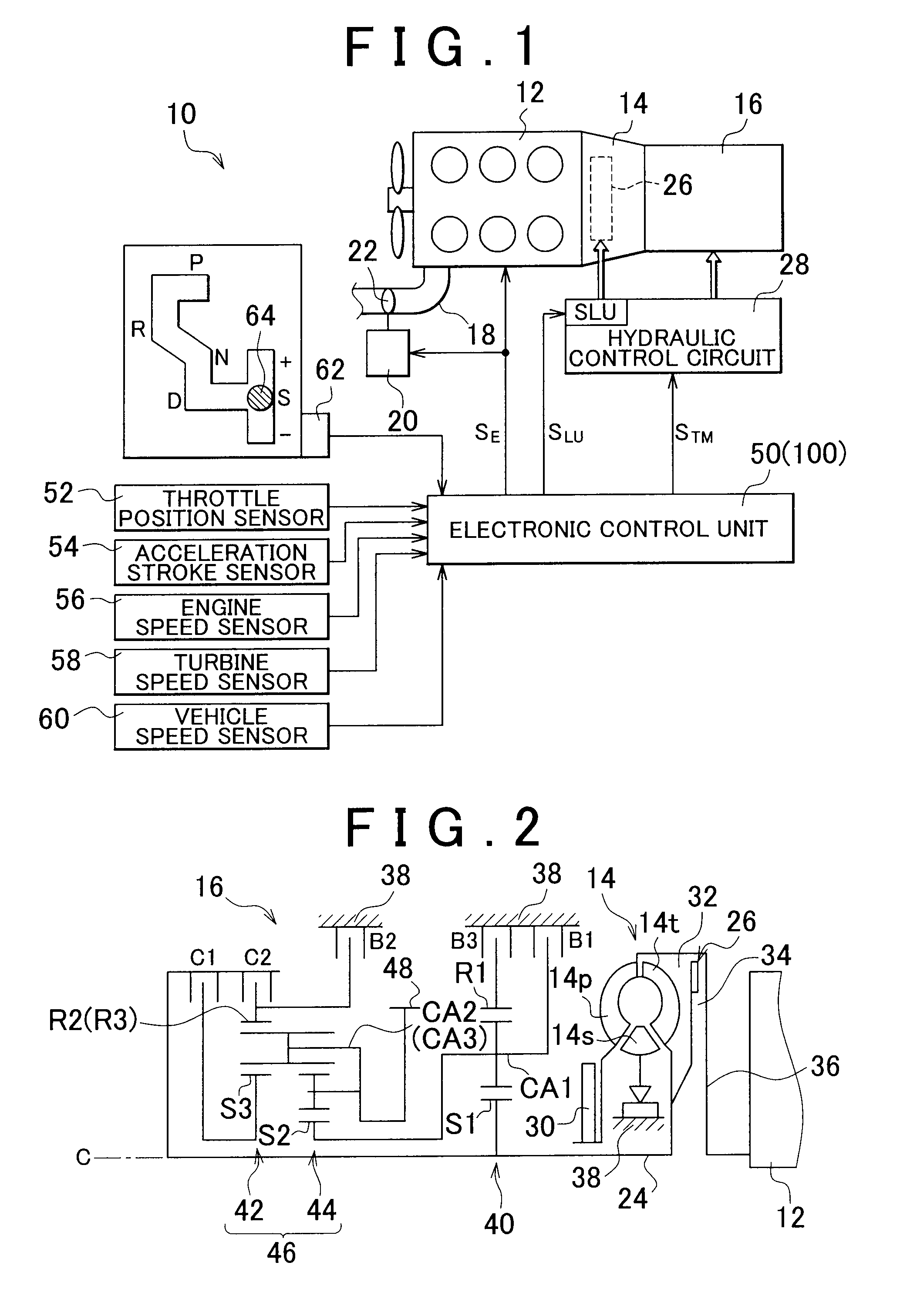

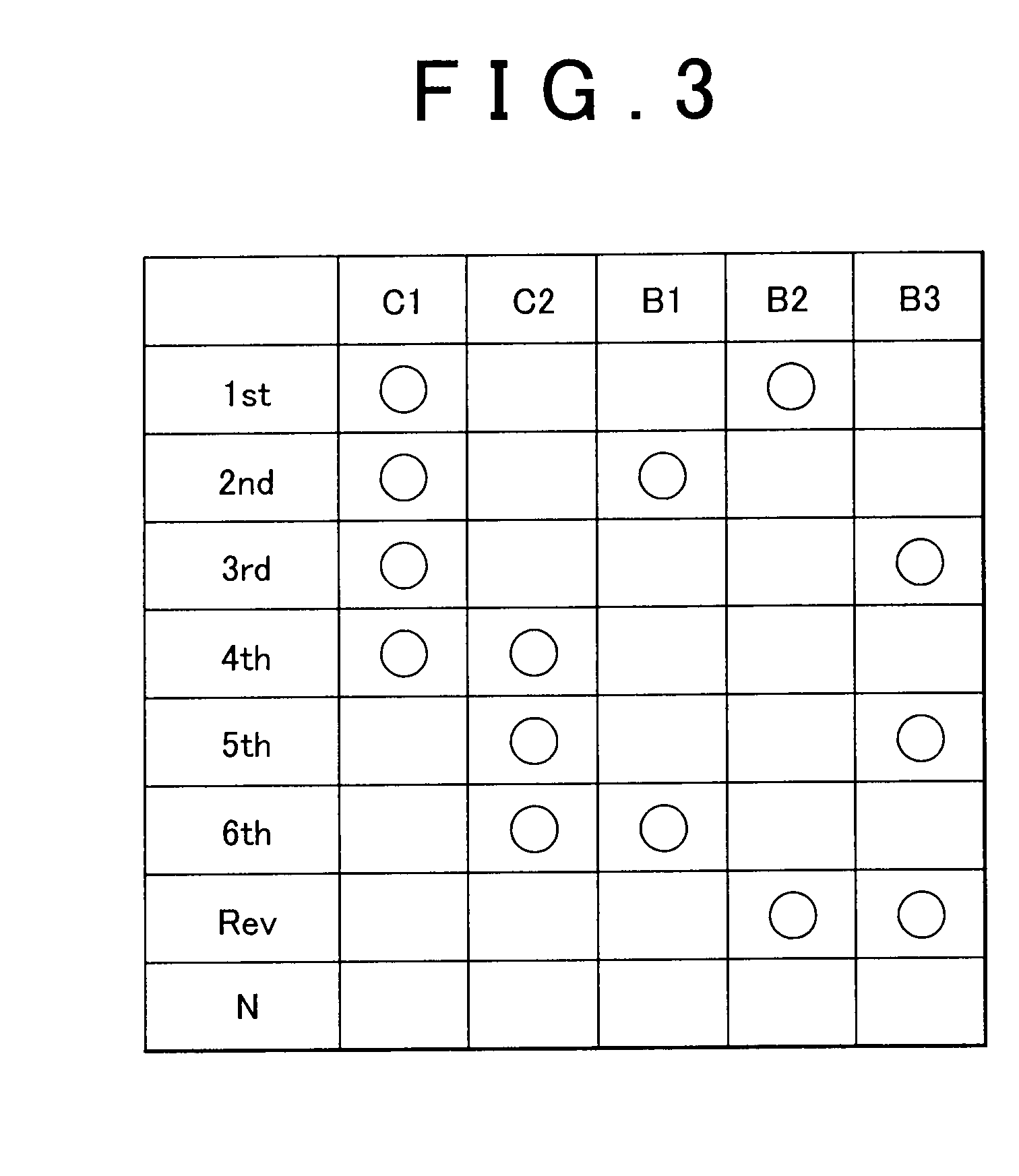

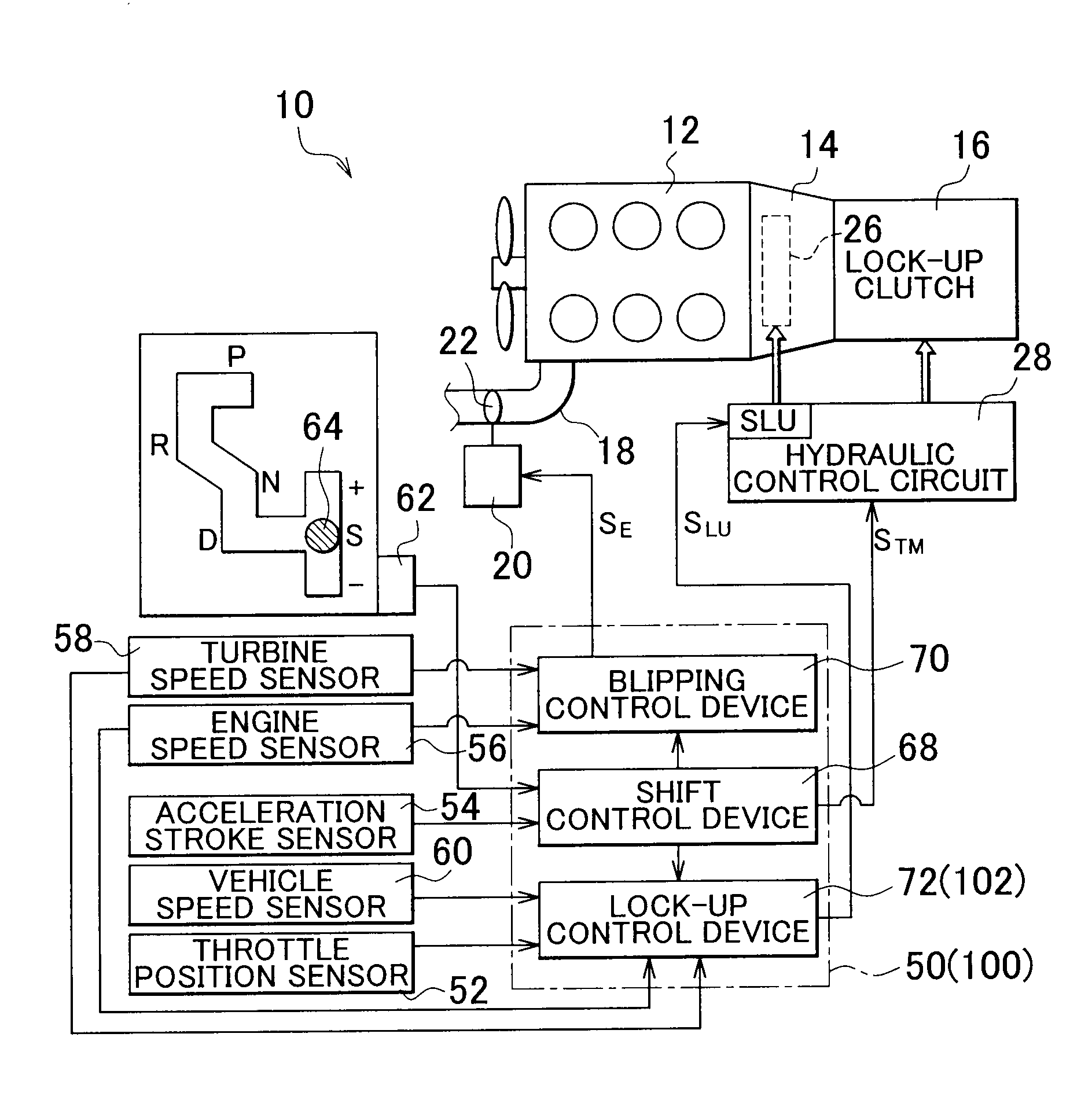

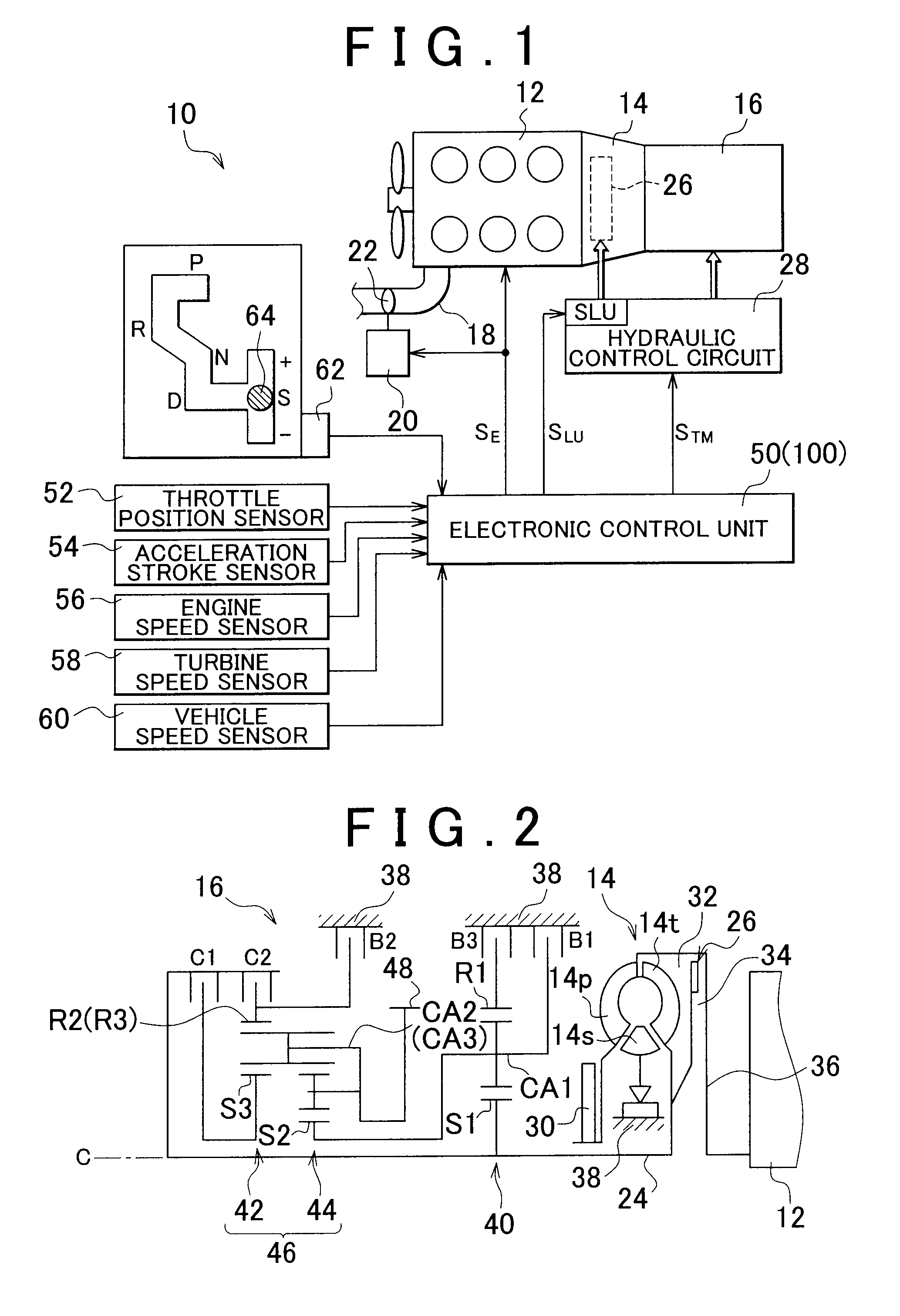

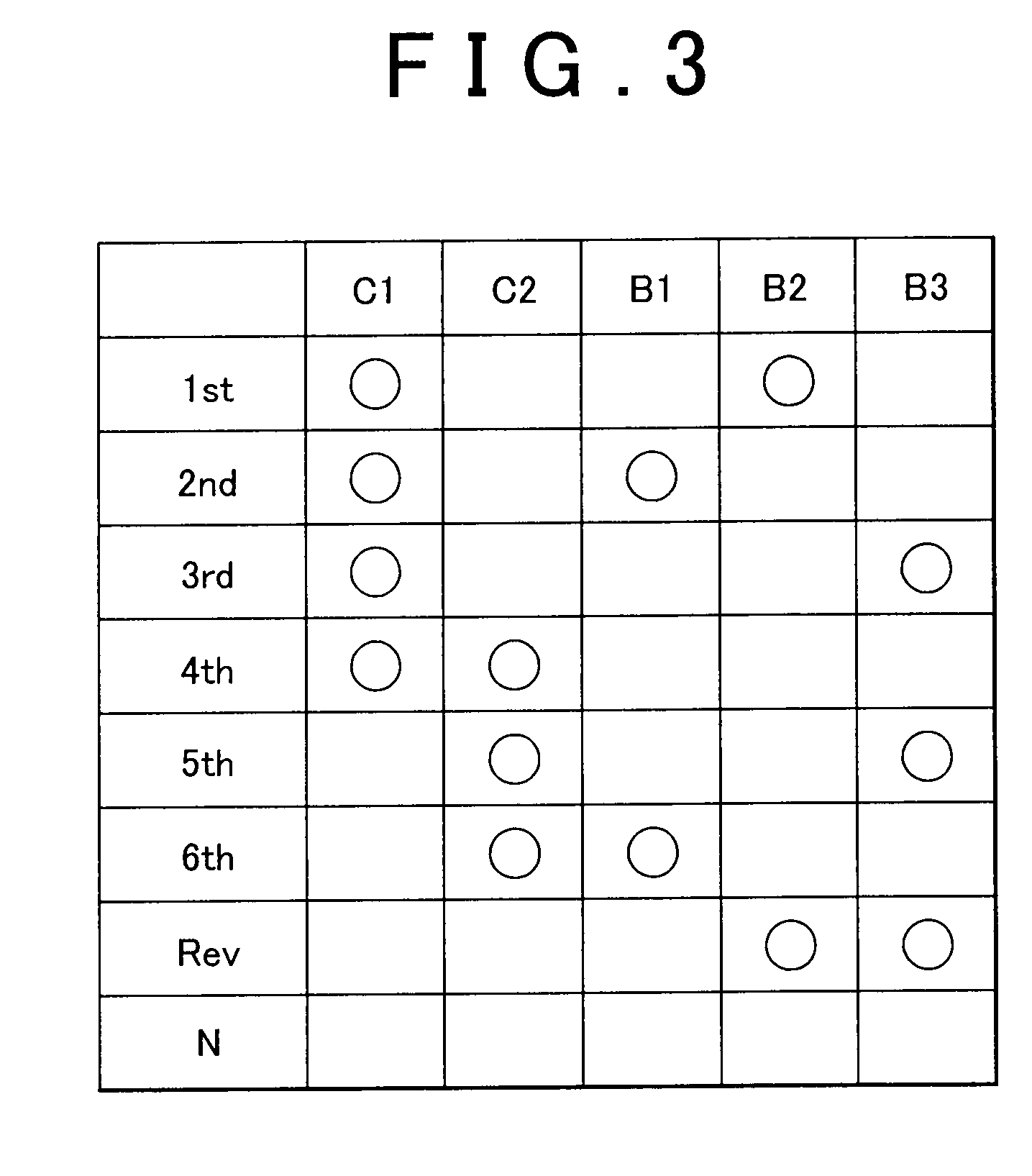

Control device of vehicle drive-train system

ActiveUS20110230308A1Promote absorptionEasy to eliminateElectrical controlGearing controlAutomatic transmissionElectronic throttle

A control device of a vehicle drive-train system including an engine, an electronic throttle valve, an automatic transmission having a manual shift mode, a torque converter provided between the automatic transmission and the engine, and a lock-up clutch operable to directly connect an input member and an output member of the torque converter with each other includes a blipping control device that performs blipping control for temporarily increasing the output rotational speed of the engine by means of the electronic throttle valve, when a power-off downshift is performed while the automatic transmission is in the manual shift mode; and a lock-up control device that engages or partially engages the lock-up clutch, based on a difference between a rotational speed of the output member of the torque converter and a rotational speed of the input member thereof, which the difference is reduced after the blipping control is started.

Owner:TOYOTA JIDOSHA KK

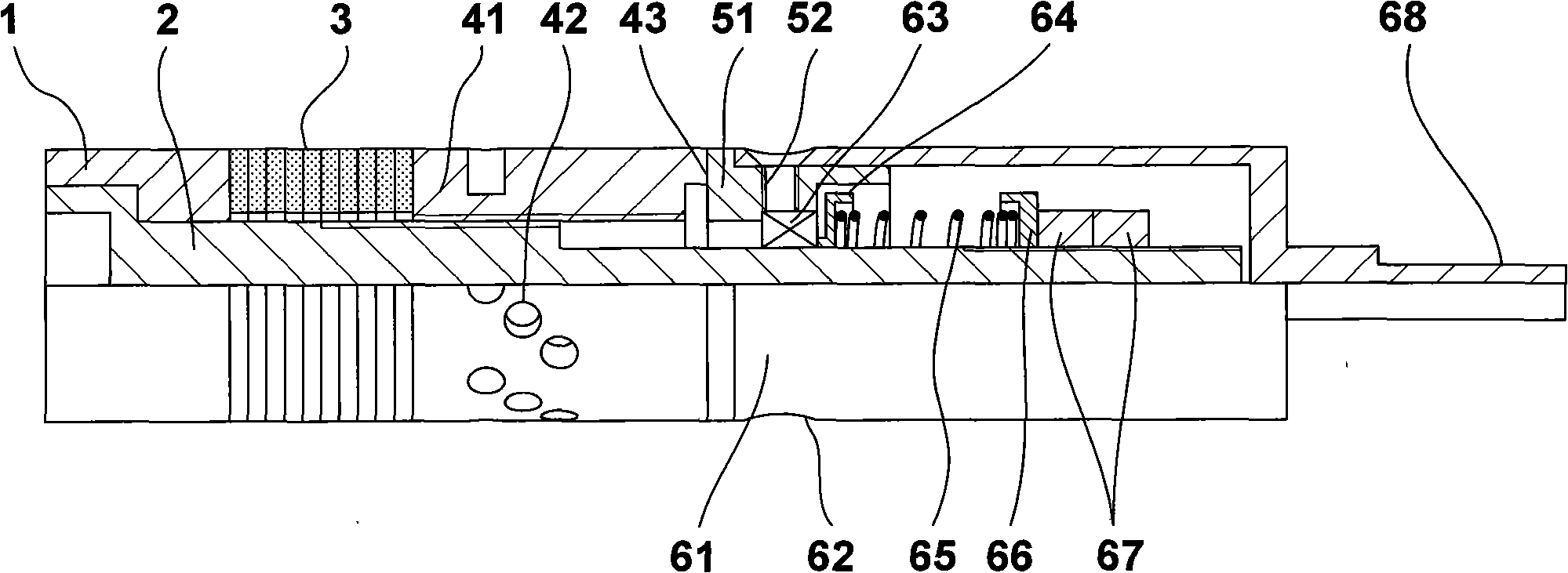

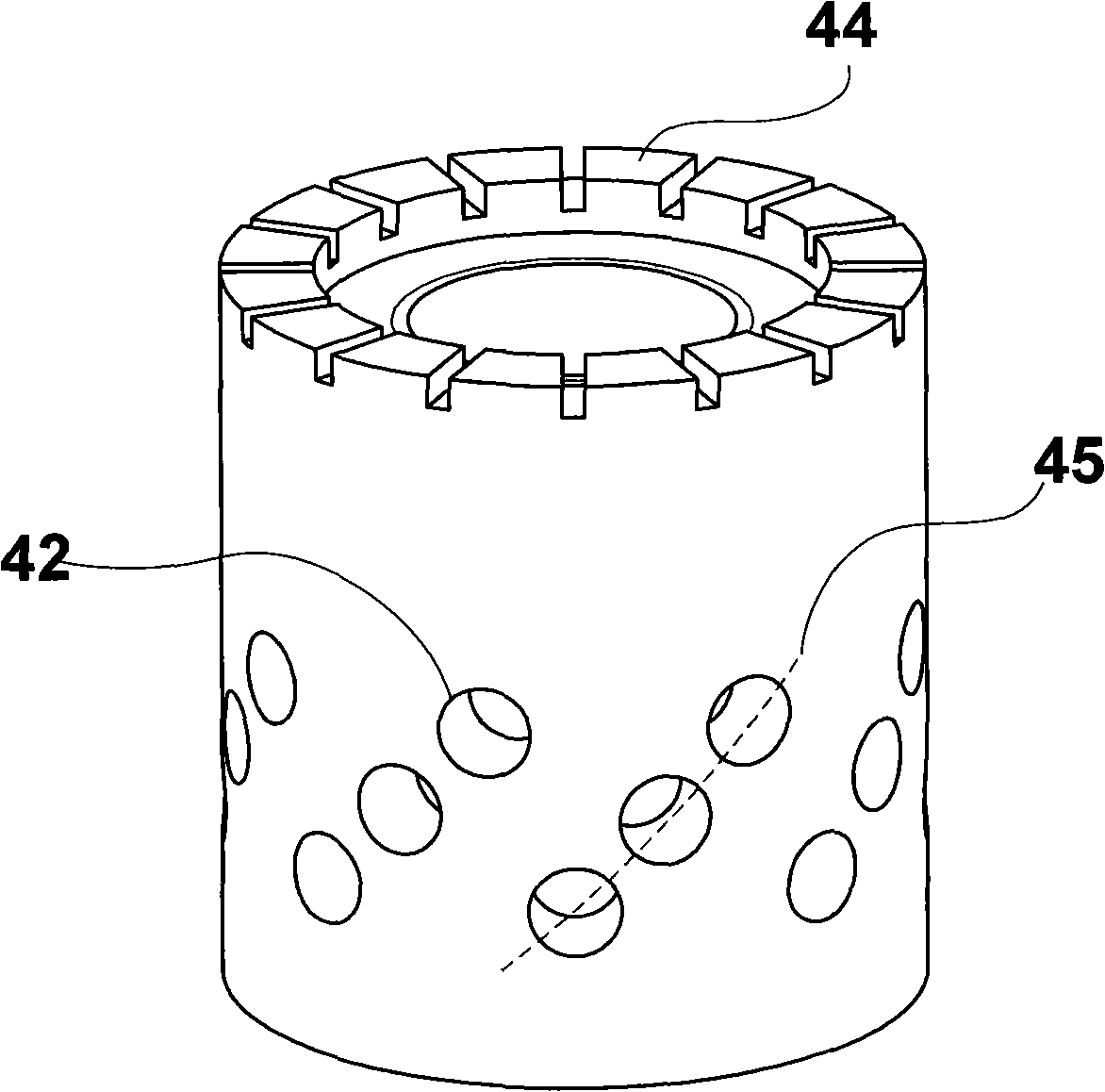

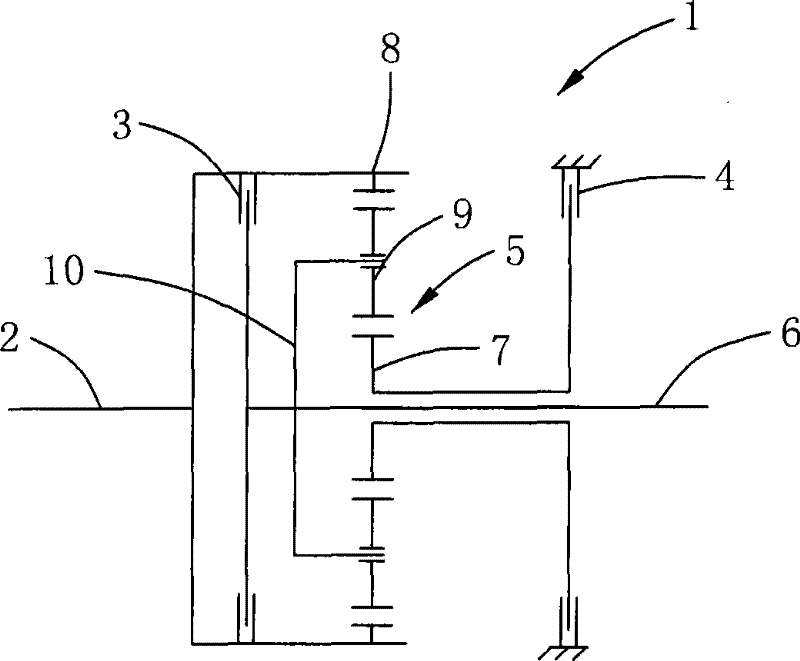

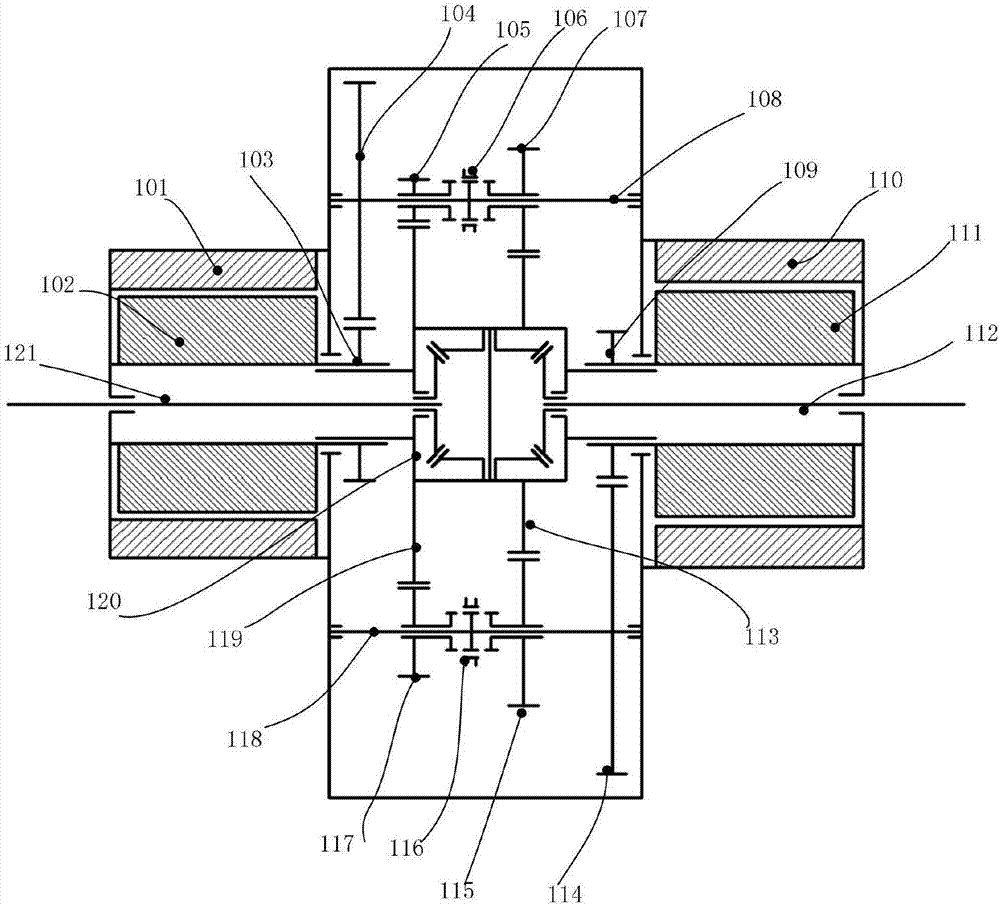

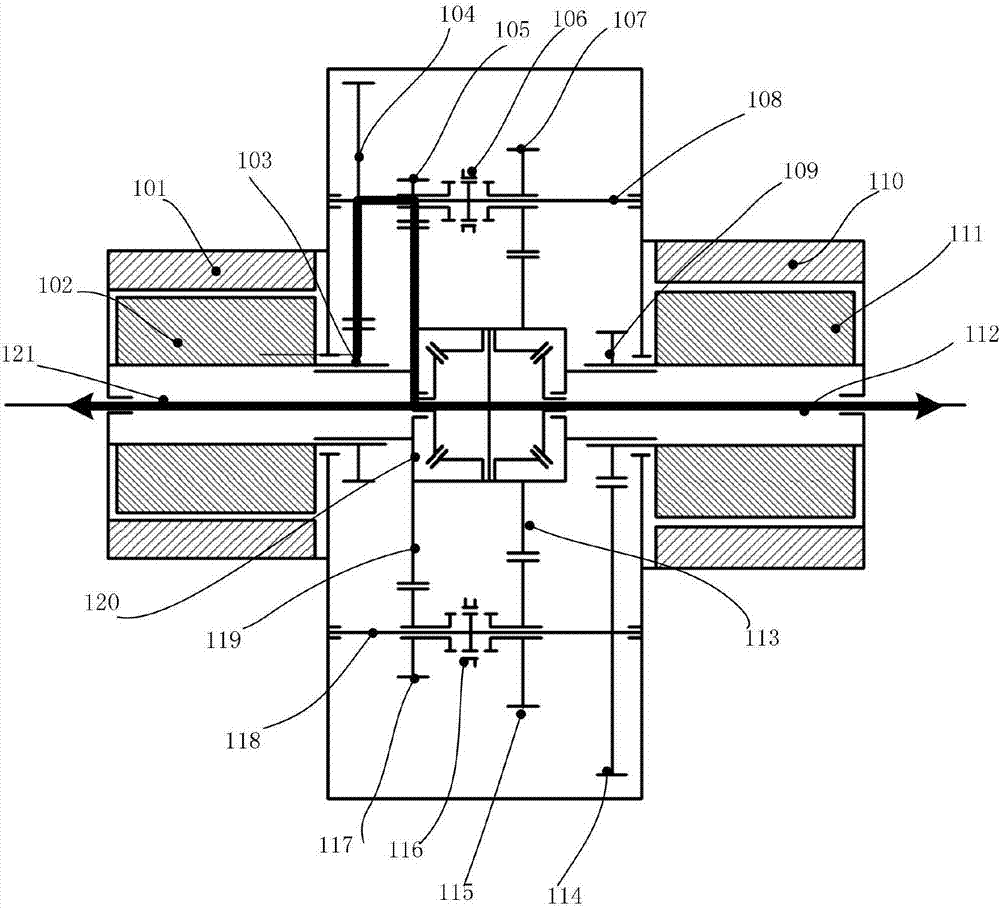

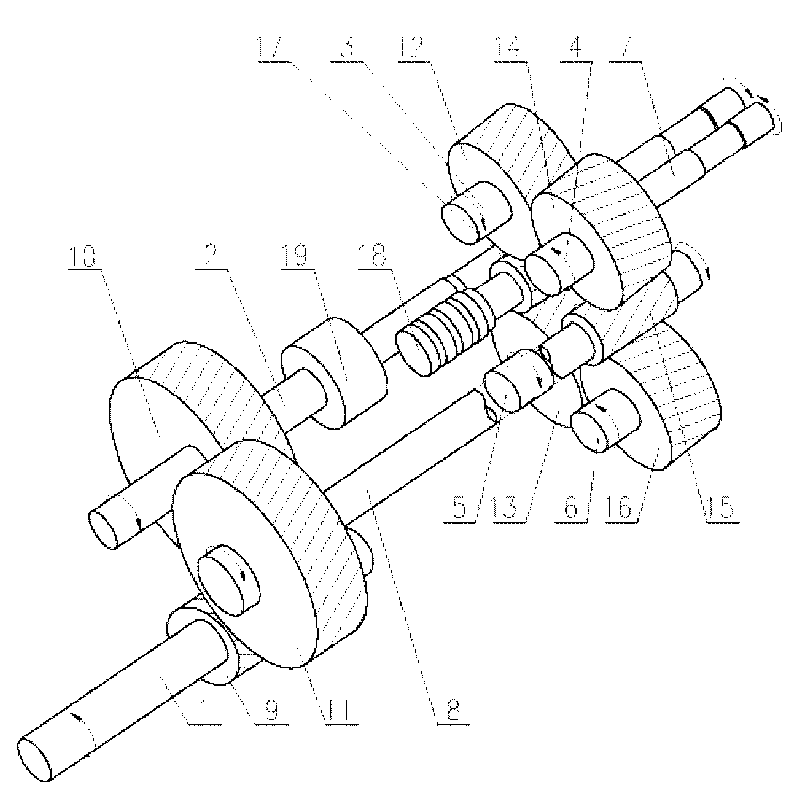

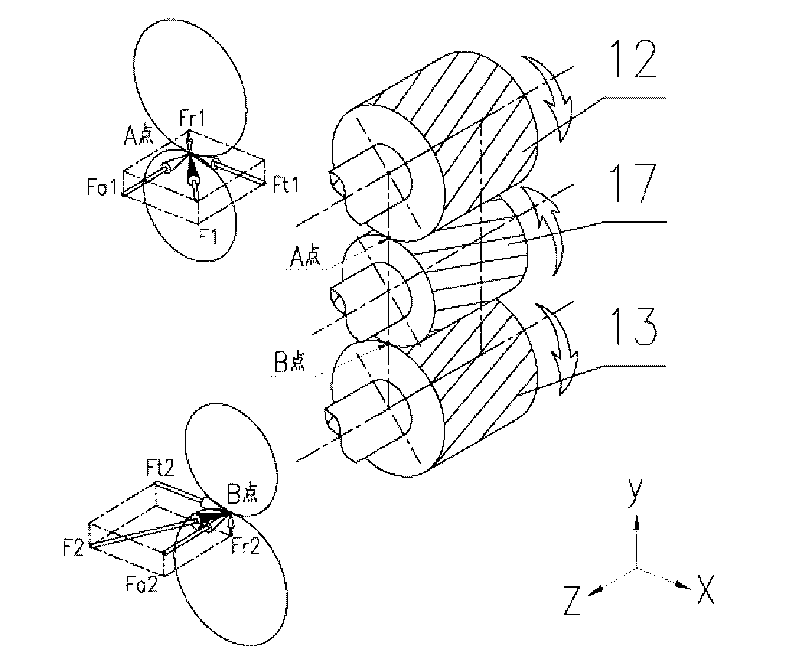

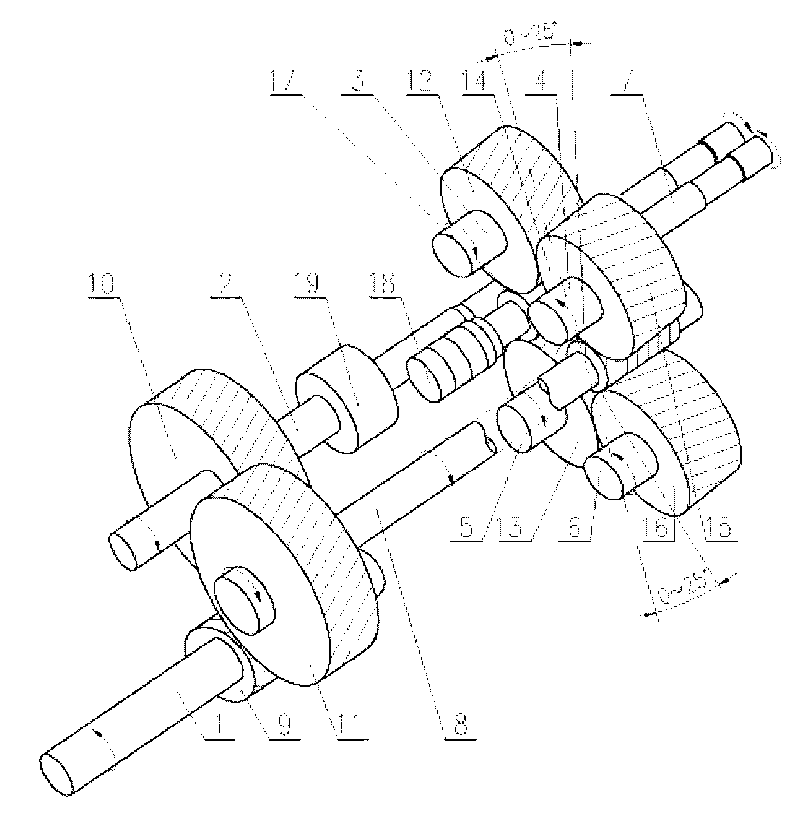

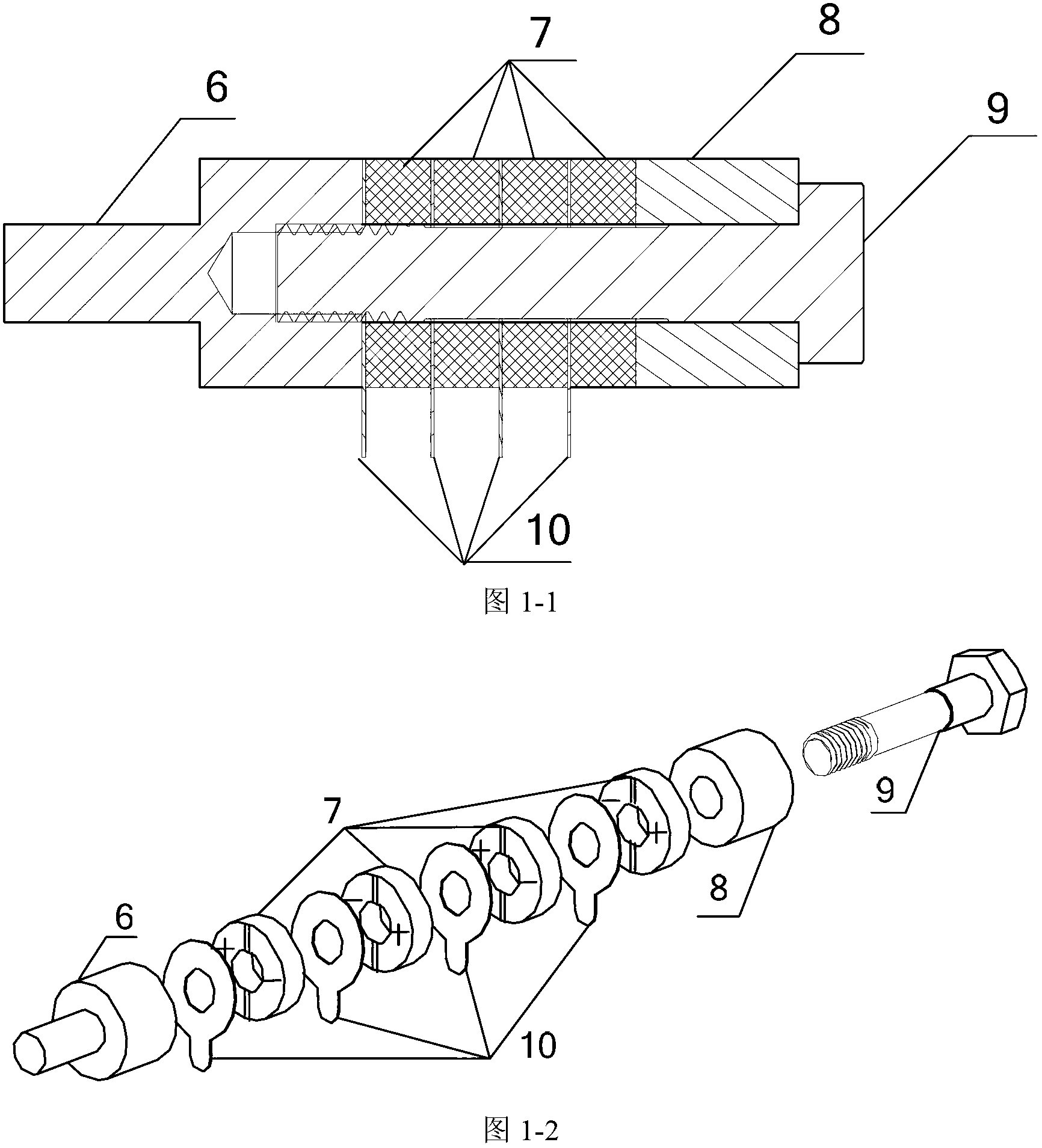

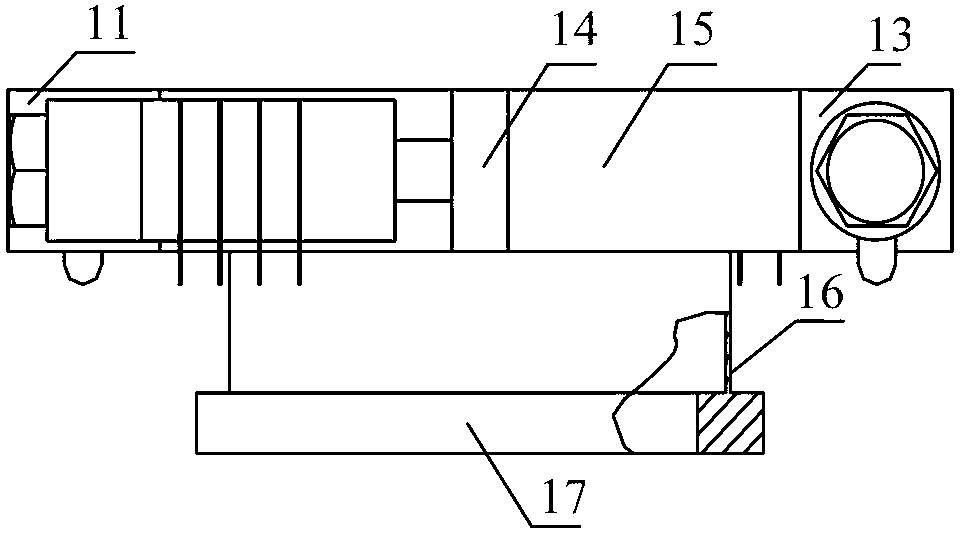

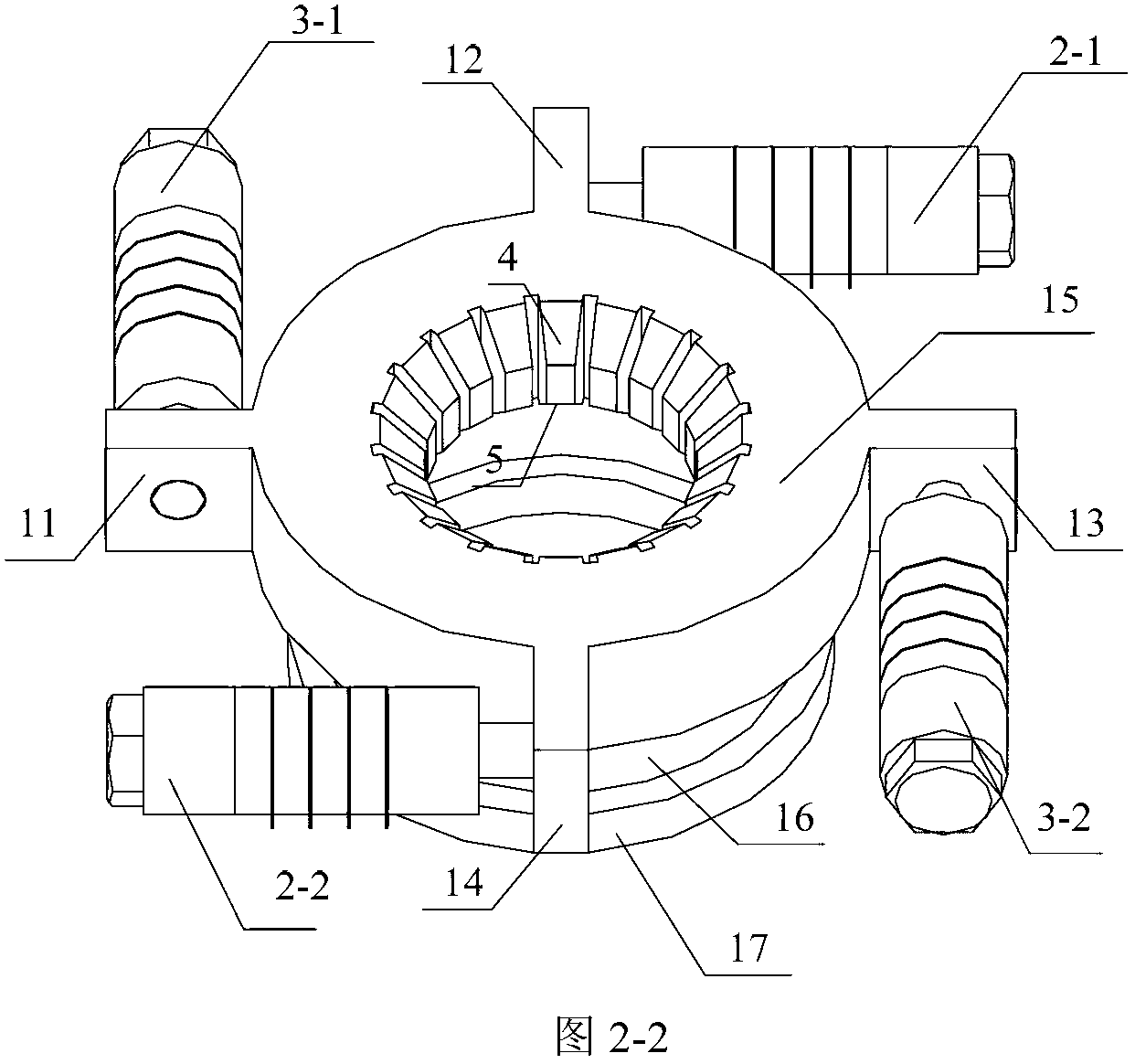

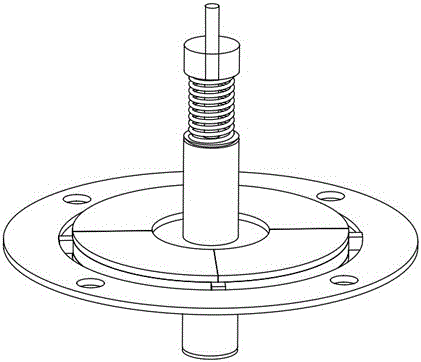

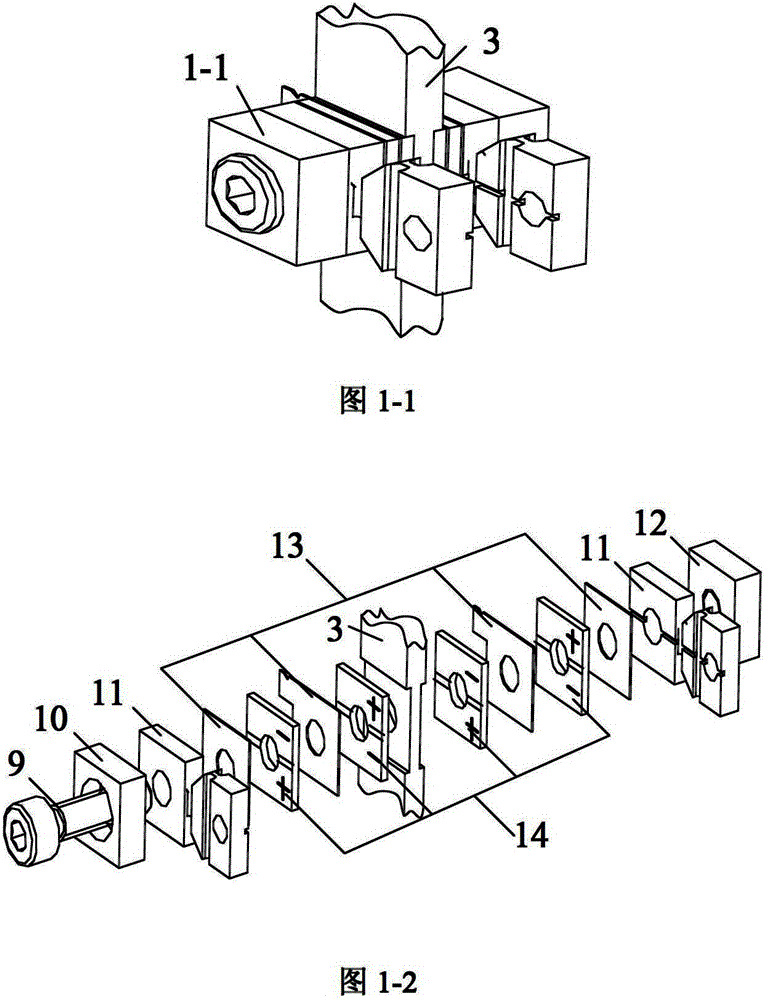

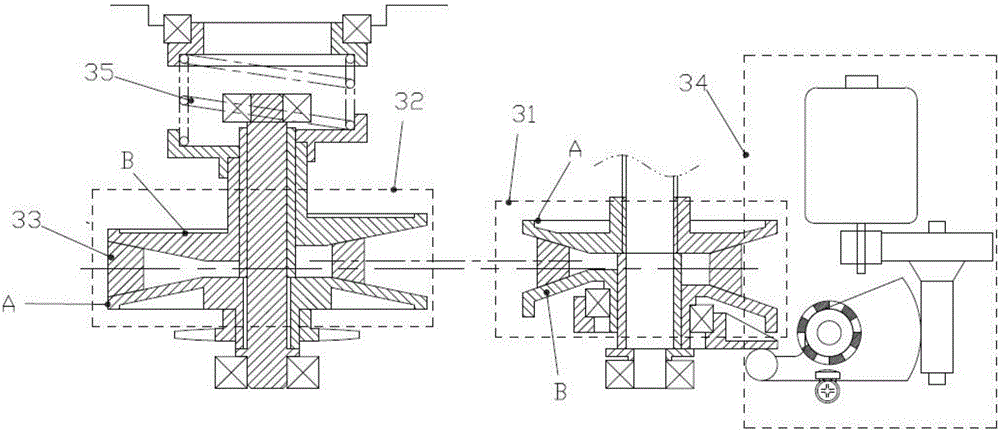

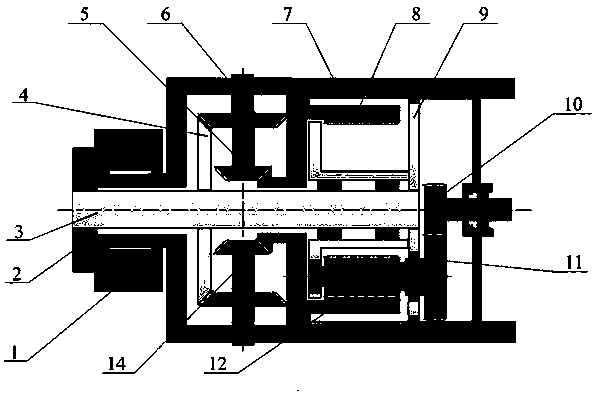

Ultrasonic rotary motor by using longitudinal-torsional vibration converter with holes

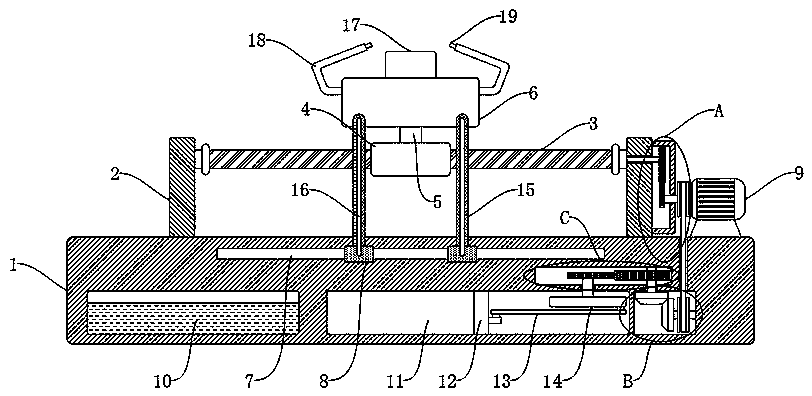

InactiveCN101789713ASimple structureEasy to industrializePiezoelectric/electrostriction/magnetostriction machinesTorsional vibrationControl theory

The invention discloses an ultrasonic rotary motor by using a longitudinal-torsional vibration converter with holes, which belongs to the ultrasonic motor. The motor comprises a stator component, a rotor component and a prestress device, wherein the stator component consists of a balance weight, a fastening bolt, a longitudinal vibrating piezoelectric ceramic element group and the longitudinal-torsional vibration converter with holes; the rotor component consists of a rotor, a torque output connector and a radial bearing; and the prestress device consists of a first spring cover, a spring, a second spring cover and a locking nut. The motor has the characteristics of simple structure, low cost and great output torque.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

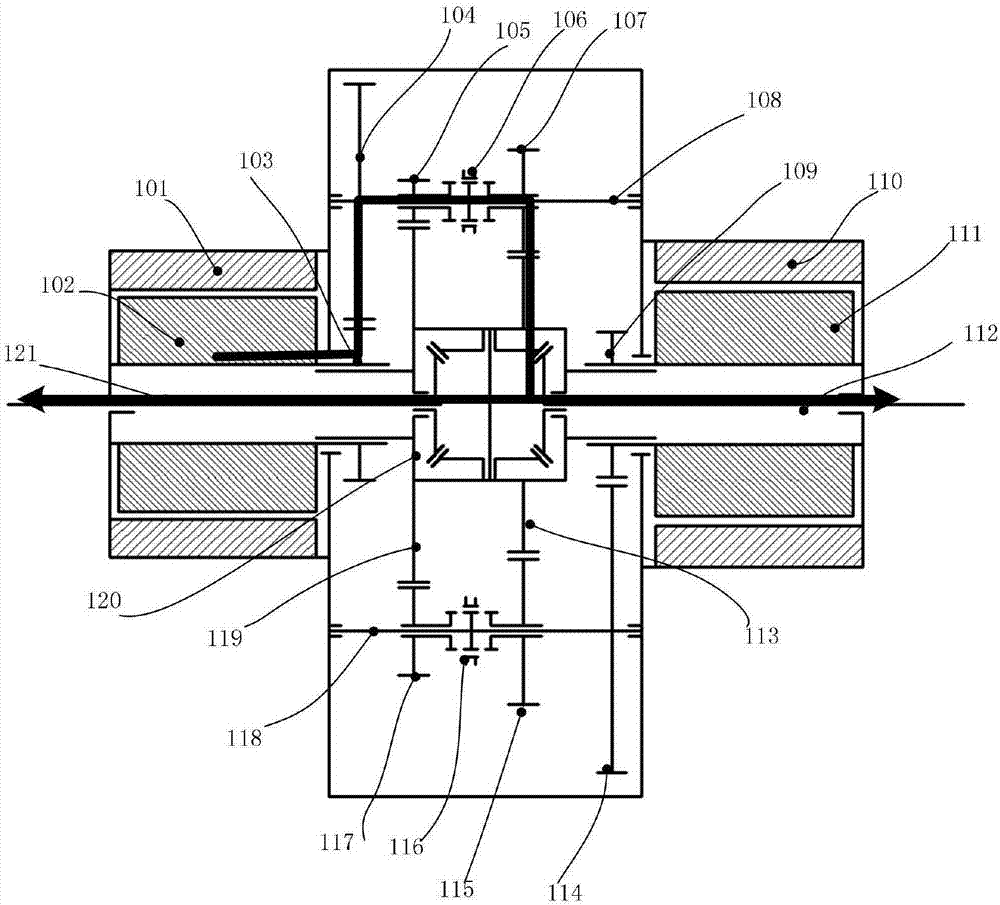

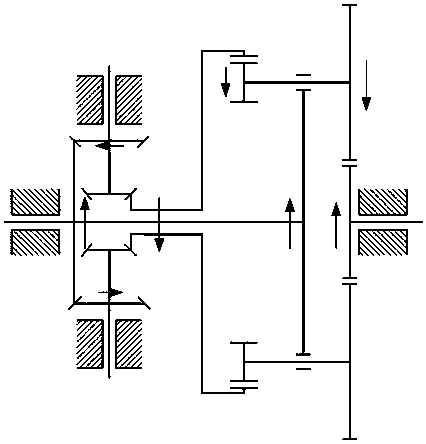

Transmission, driving system with transmission, and control method for driving system

ActiveCN102678846AWork quicklyEasy to controlHybrid vehiclesToothed gearingsSpur gearTransmission system

The invention provides a transmission, a driving system with the transmission, and a control method for the driving system. The transmission comprises a first shaft, a first clutch, a second clutch, a planetary gear mechanism and a second shaft which are coaxial, wherein the planetary gear mechanism comprises a sun gear, a gear ring, a planetary gear and a planetary carrier; the planetary gear can rotate on the planetary carrier and rotate around the sun gear and the gear ring; a driving disc of the first clutch, the first shaft and the gear ring are integrally arranged; the sun gear and a driven disc of the second clutch are integrally arranged; and the planetary carrier, a driven disc of the first clutch and the second shaft are integrally arranged. Through the arrangement, a multi-shaft design is avoided, the number of gears is reduced, the design, manufacturing and assembly of a transmission system are greatly simplified through a group of planetary gear mechanism and a few clutches, cost is reduced, the total weight of equipment is reduced, and the requirement on driving devices such as a motor and an engine is reduced.

Owner:SHANGHAI E PROPULSION AUTO TECH

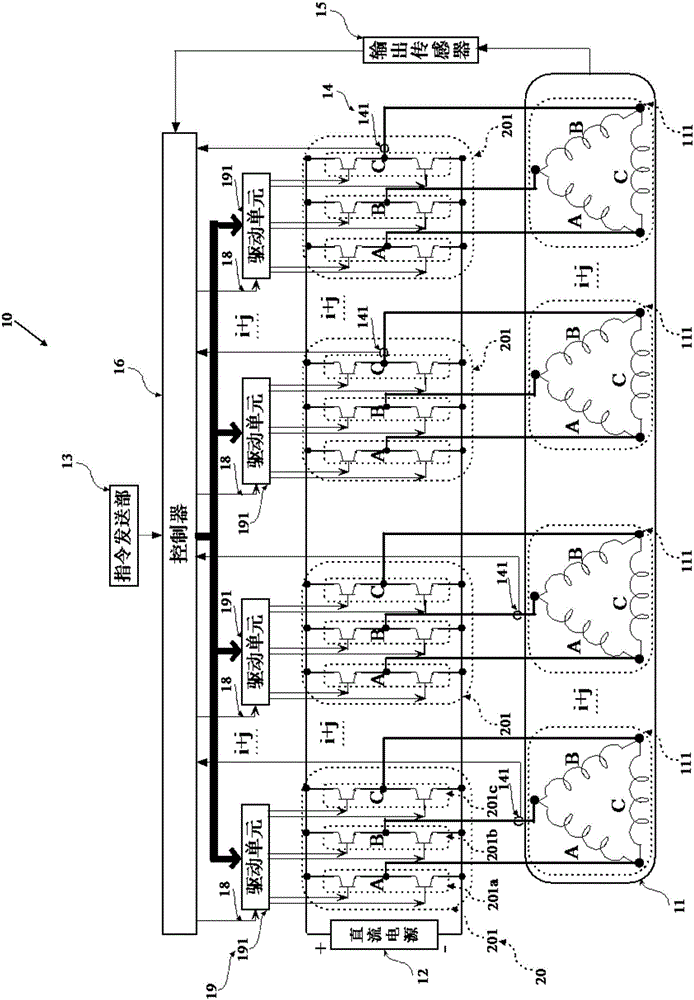

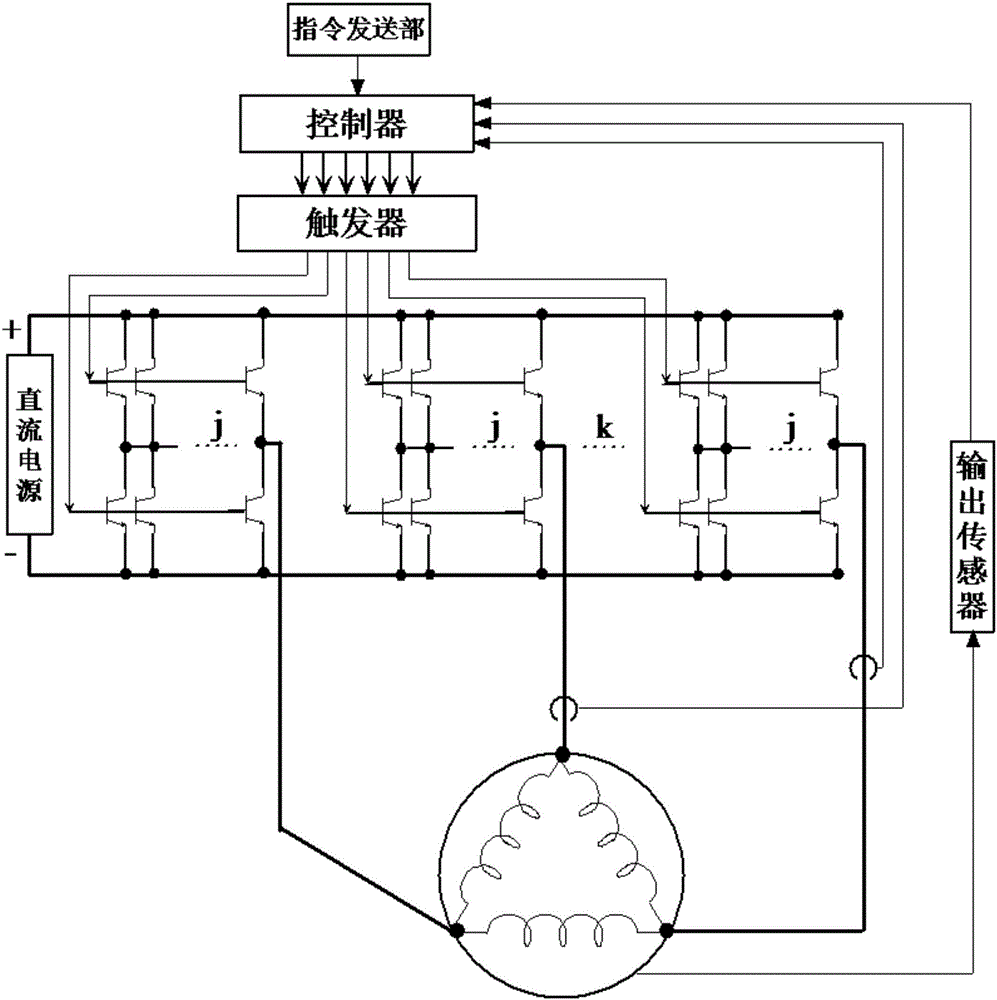

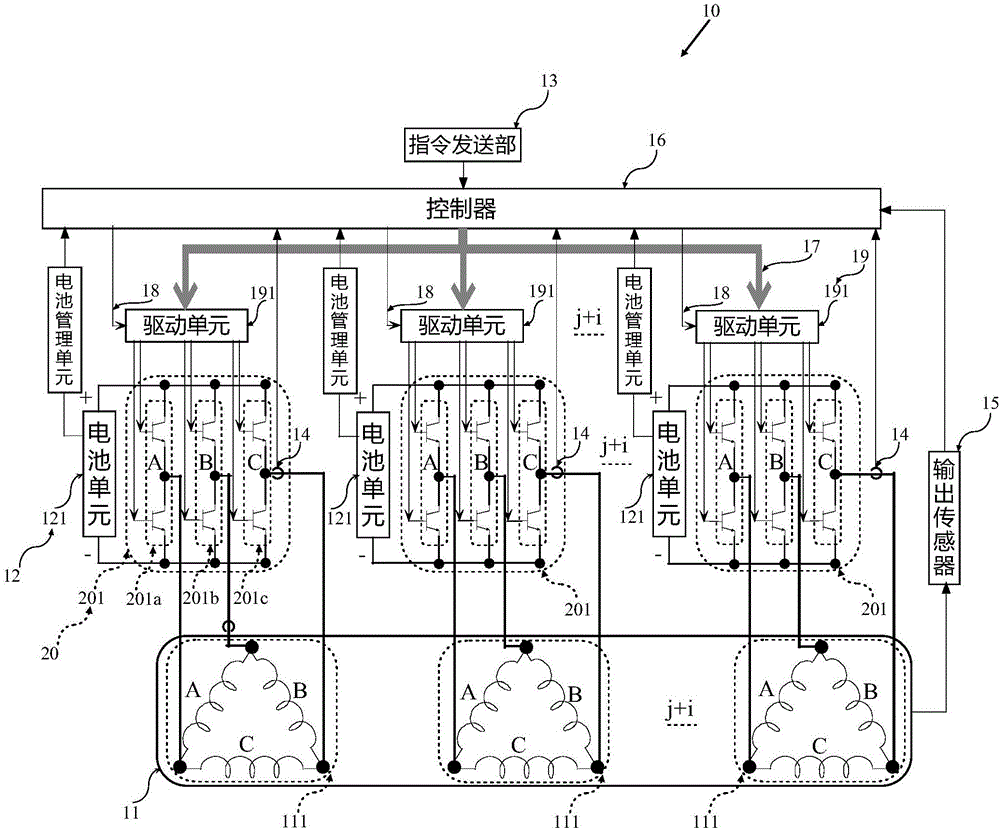

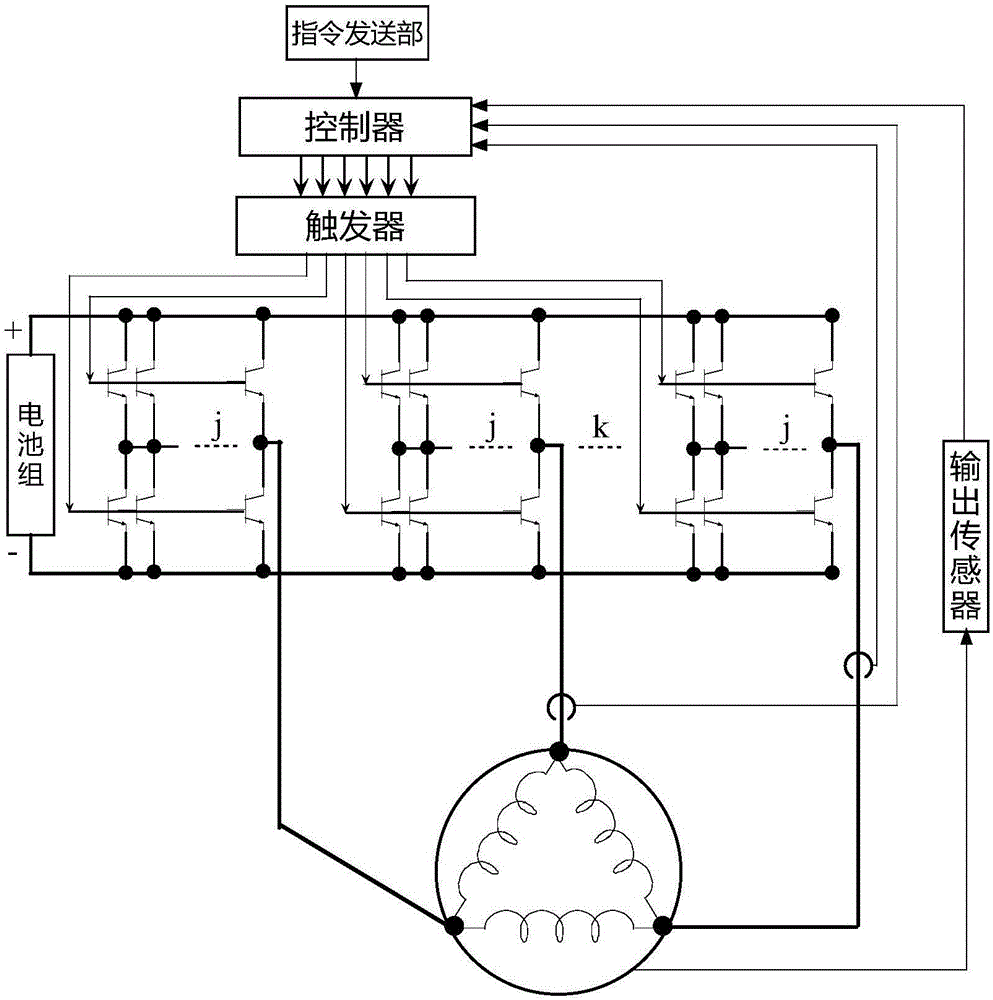

Motor drive fault-tolerant control device and electric device

PendingCN106712641AImprove safety and reliabilityAvoid sudden changes in performance indicatorsAC motor controlMotor driveElectrical and Electronics engineering

The present invention provides a motor drive fault-tolerant control device and an electric device. The device comprises a polyphase machine, a direct current source, an instruction sending part, a current sensor, an output sensor, a controller, a driver and a power converter. The polyphase machine winding has (k-1)(i+j) mutually independent polyphase winding units with the same parameters, the power converter has power conversion units correspondingly connected with the polyphase winding units, each polyphase winding unit has k power conversion circuits configured to provide k-way line current to the corresponding polyphase winding units, the driver has (k-1)(i+j) driving units which are respectively connected with power conversion units, the current sensor has current detection units correspondingly connected with the power conversion units, the number of the current detection units configured to detect each phase outputted line current is equal to (i+j), k is a positive integer of larger than 2, j is a positive integer of larger than 1, and i is a redundant number and a natural number.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

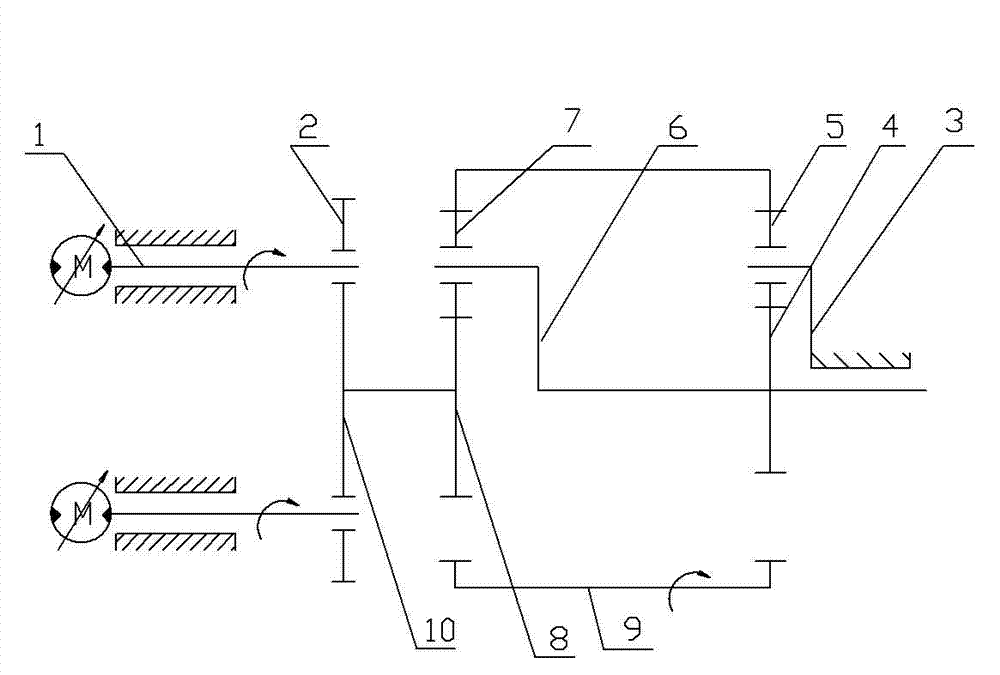

Dual-motor power assembly for pure electric automobile and operating mode thereof

InactiveCN107985068AIncrease output torqueHigh output speedElectric propulsion mountingControl devicesElectricityFault tolerance

The invention relates to a dual-motor power assembly for a pure electric automobile and an operating mode thereof. The dual-motor power assembly comprises a first driving motor, a second driving motor, a first input gear, a second input gear, a first gear shaft, a second gear shaft, a dual-row gear differential mechanism, a left-side transmission half shaft, a right-side transmission half shaft, afirst shift combination sleeve and a second shift combination sleeve, wherein the first driving motor is connected to the first input gear, dual-row gears of the first gear shaft are meshed with dual-row gears of the differential mechanism to form two gear positions, the second driving motor is connected to the second input gear, dual-row gears of the second gear shaft are meshed with the dual-row gears of the differential mechanism to form two gear positions, and the torque of the first gear shaft and the torque of the second gear shaft are coupled in a differential mechanism housing to forma dual-motor multi-gear coupled driving system. The dual-motor power assembly can improve the power performance and economical efficiency of the whole vehicle, eliminate the power interruption problem of shifting and improve the fault tolerance and reliability.

Owner:HEFEI UNIV OF TECH

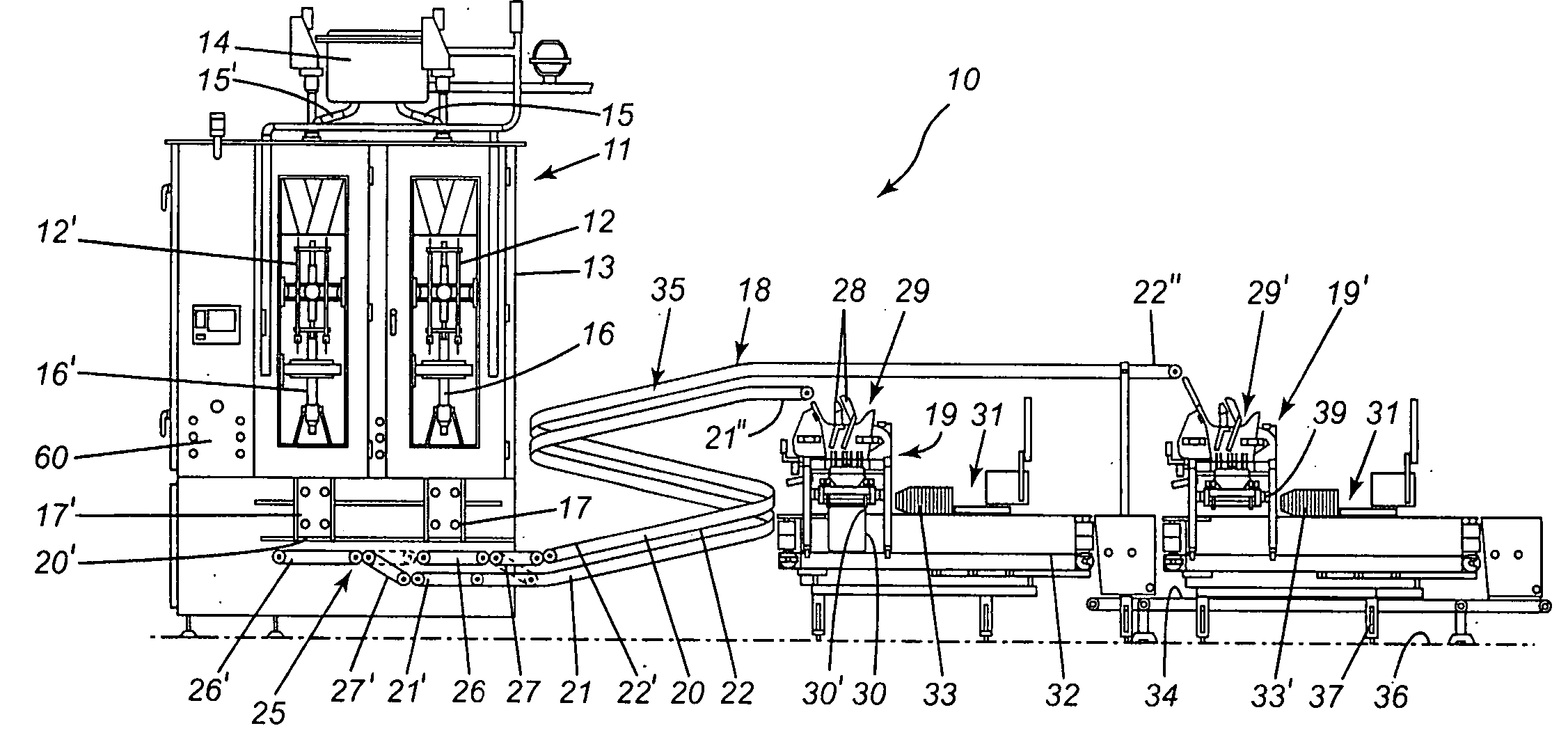

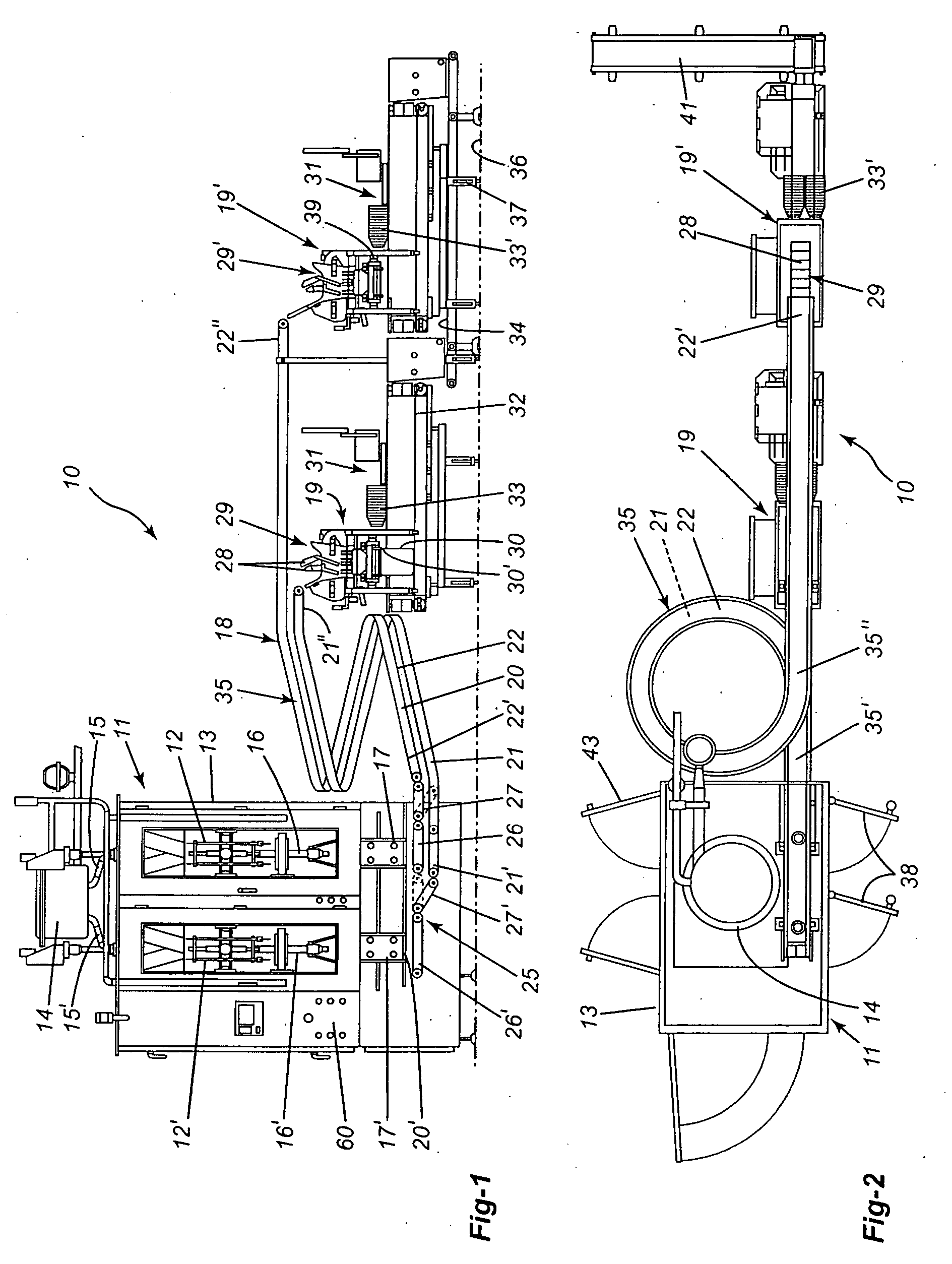

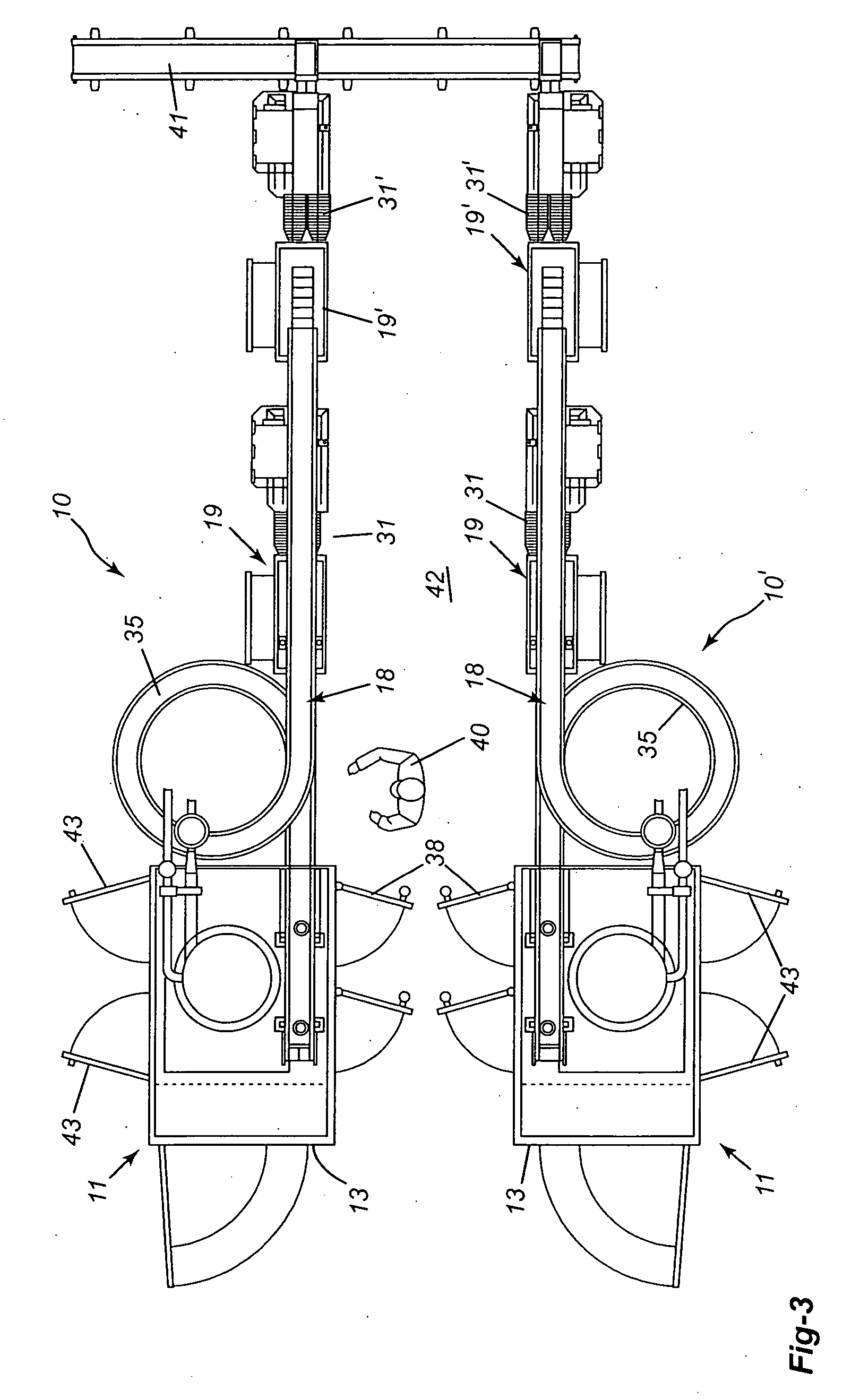

High speed bagging system and method

InactiveUS20040237473A1Increase the output speedHigh speed outputWrapping material feeding apparatusMultiple wrapper applicationLiquid productWork cycle

A high speed bagging system and a method for placing a liquid product into a bag and placing at least two of these bags into a pouch is described. The system comprises at least two bag fillers housed in a common filler housing and operating simultaneously to place the liquid product in respective bags on a continuous basis during a working cycle. Filled bags are simultaneously conveyed on a two lane conveyor system. The two-lane conveyor is configured to optimize floor space area. Each conveyor belt has an outlet end associated with a respective bagging machine at a bagging station. The bagging machines are adapted to place at least two of the bags into a pouch on a continuous basis during the working cycle. The bagging machines feed a respective pouch closure device to close a mouth opening of the pouches which are then discharged on a discharge conveyor.

Owner:GLOPAK INC

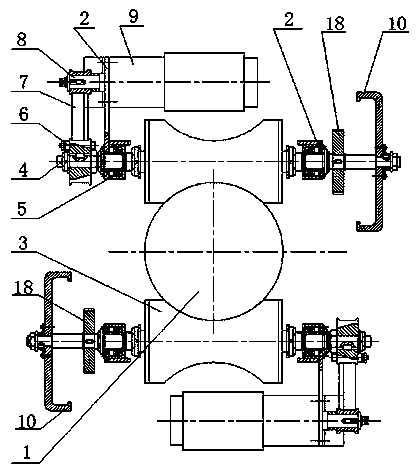

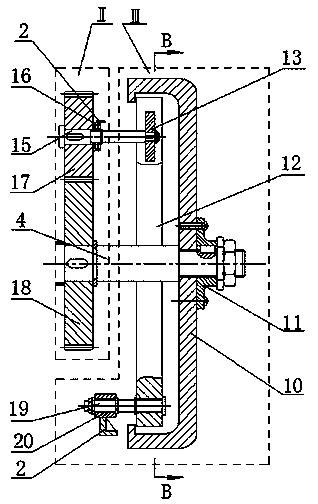

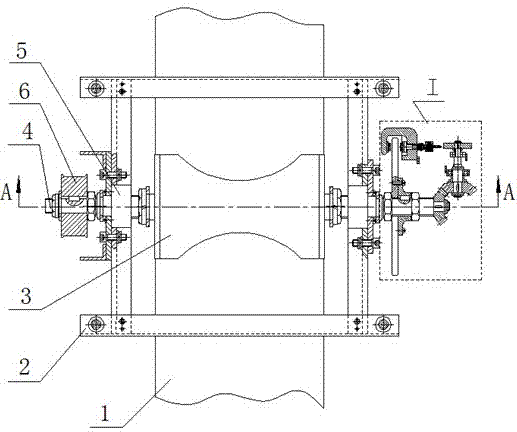

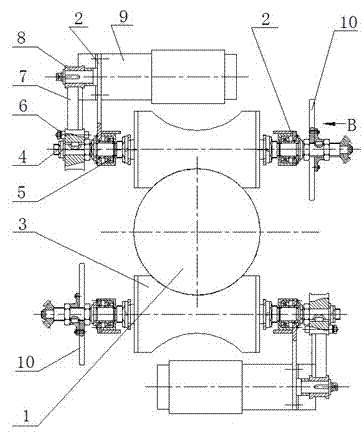

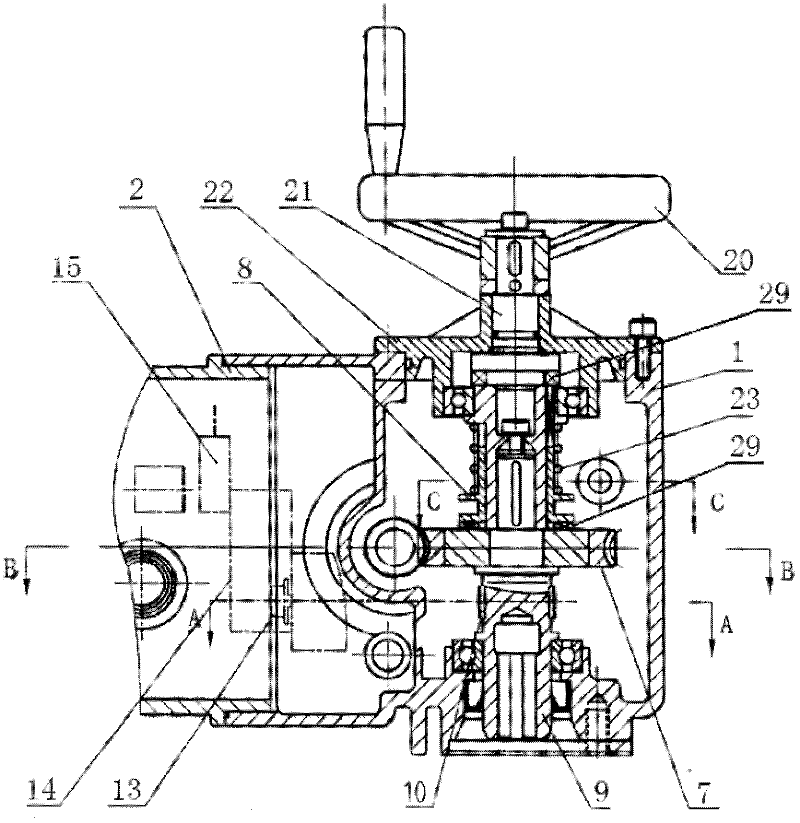

High rotation speed gear box for anisotropic parallel twin-screw extruding machine

InactiveCN101694236AImprove carrying capacitySolve bottlenecksToothed gearingsDrive shaftThrust bearing

A high rotation speed gear box for an anisotropic parallel twin-screw extruding machine comprises an input shaft, an output shaft I, an upper drive shaft I, an upper drive shaft II, a lower drive shaft I, a lower drive shaft II, a middle drive shaft and an output shaft II, wherein an input gear of the input shaft is meshed with a gear of the output shaft I and is meshed with a gear of the middle drive shaft simultaneously, the middle drive shaft is meshed with a gear of the upper drive shaft II and a gear of the lower drive shaft II through a gear II simultaneously, the gear of the upper drive shaft II and the gear of the lower drive shaft II are respectively meshed with the gear of the upper drive shaft I and the gear of the lower drive shaft I, the gear of the upper drive shaft I and the gear of the lower drive shaft I are meshed with the gear of the output shaft II simultaneously, a thrust bearing is arranged on the output shaft I, and a series thrust bearing is arranged on the output shaft II. The gear box is characterized in that the output rotation speed is high, and the output torque is big, and drives upward and downward to counteract the radial force of the output shaft, thereby enabling the bearing of the output shaft to be located in the best forced state and prolonging the service life of the output shaft and the bearing to the maximum.

Owner:成都中孚高分子工程有限公司

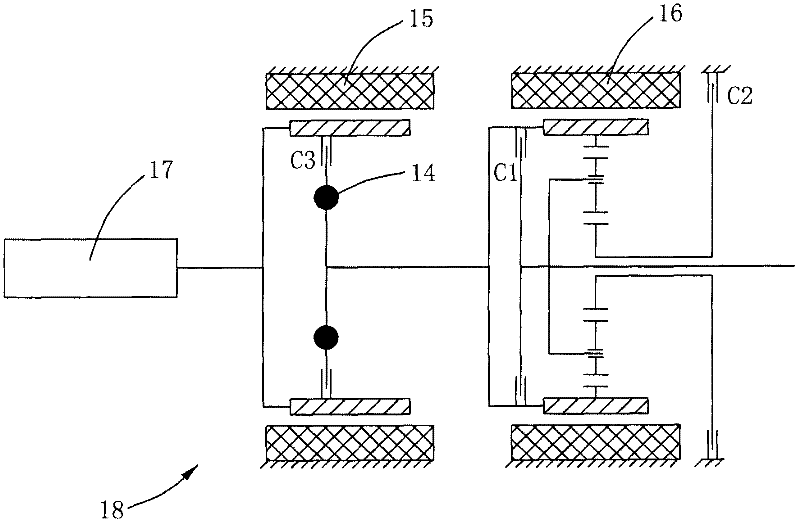

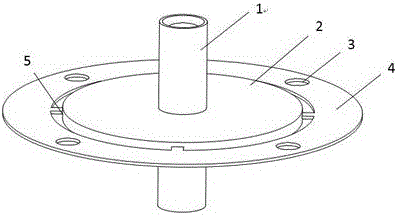

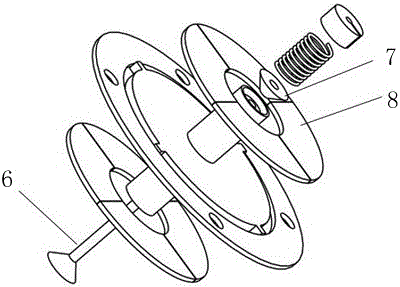

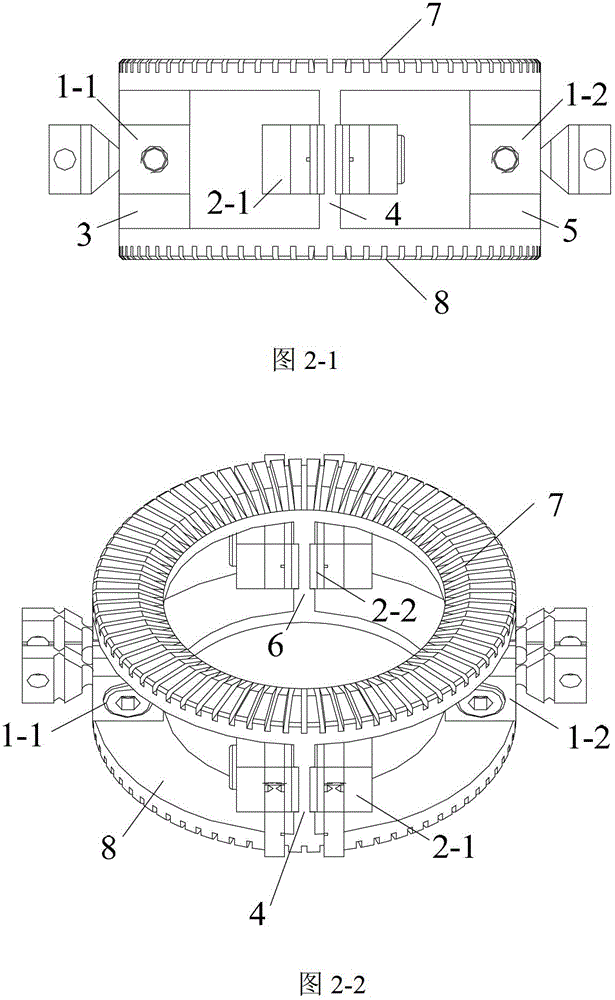

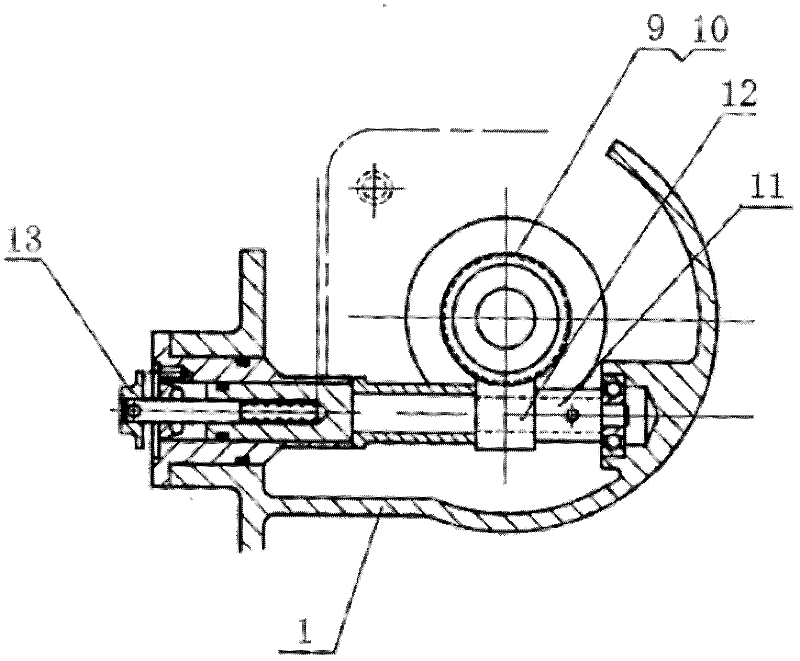

Bent oscillator stimulated rotary ultrasonic motor and electric excitation mode thereof

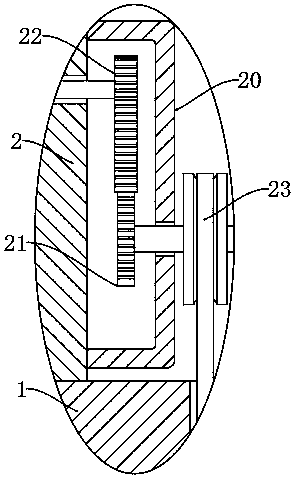

InactiveCN102710167ACompact layoutIncrease output powerPiezoelectric/electrostriction/magnetostriction machinesElectric machineEngineering

The invention discloses a bent oscillator stimulated rotary ultrasonic motor and an electric excitation mode thereof. The rotary ultrasonic motor comprises a stator assembly, a rotor assembly and a rotation shaft arranged along the axial direction of the stator assembly, wherein the stator assembly and the rotor assembly are coaxially arranged; the stator assembly comprises a metal ring body and four piezoelectric bent oscillators; the metal ring body comprises an upper circular ring; four connecting feet are evenly distributed on the circumferential direction of an upper circular ring and are correspondingly connected with the four piezoelectric bent oscillators one by one; the four piezoelectric bent oscillators are evenly distributed at 90 degrees in a rotating mode around the center shaft of the metal ring body; and meanwhile, the length direction of each piezoelectric bent oscillator is tangent with the circumferential direction of the upper circular ring. Therefore, according to the invention, the rotary ultrasonic motor can realize forward and reverse rotation motion, and has high-power output characteristic and an electric excitation mode. The bent oscillator stimulated rotary ultrasonic motor has the characteristics of stable performance, high output power, compact structure, single requirement on a ceramic chip and low processing and assembling requirement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

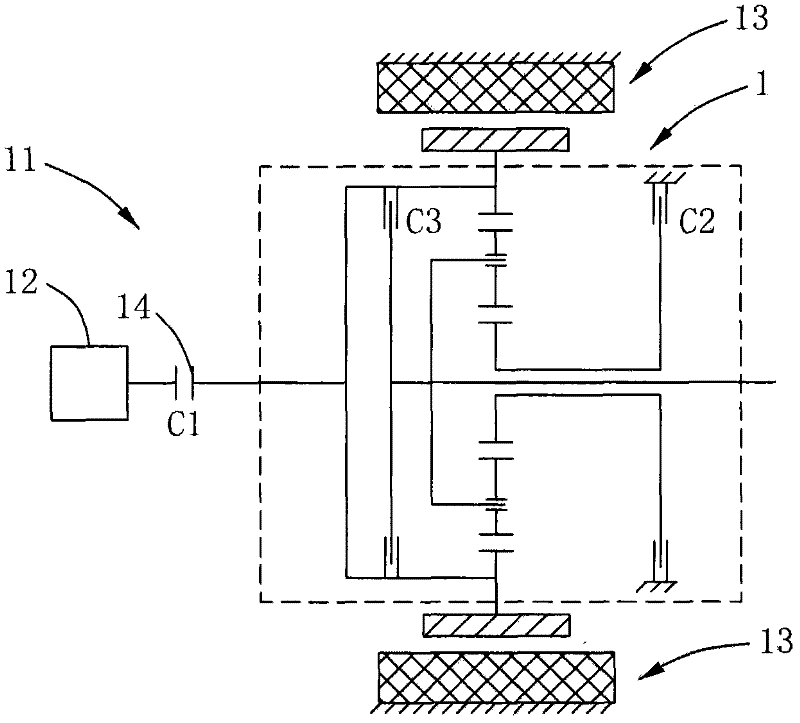

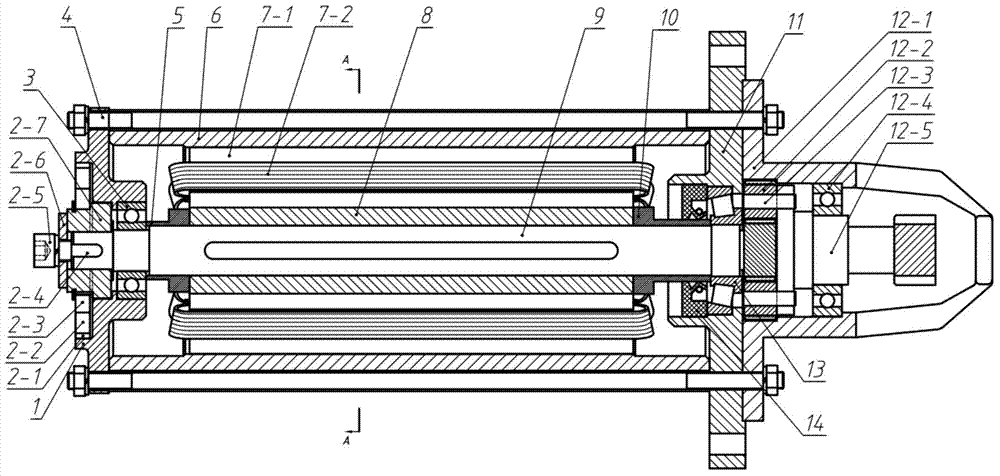

High-speed rotating ultrasonic motor and electric excitation method of stator of high-speed rotating ultrasonic motor

ActiveCN106208804ASimple structureGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesFiberElectricity

The invention provides a high-speed rotating ultrasonic motor and an electric excitation method of a stator of the high-speed rotating ultrasonic motor. A stator main body of the motor comprises a metal disk and a carbon fiber tube; the stator comprises the metal disk, the carbon fiber tube and piezoelectric ceramics; four ceramic wafers are used for exciting two out-of-plane bending working modes, of which the space phase difference is pi / 2, of the lower end surface of the stator; and two paths of sine signals of which the time phase difference is pi / 2 are utilized for simultaneously exciting two orthogonal working modes, so that elliptic motion is generated on inner bevels of two ends of the carbon fiber tube; and the rotor is pushed to move through a friction effect. The ultrasonic motor has the characteristics of being simple in structure, high in rotating speed, light in quality and the like, and a bearing is not needed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

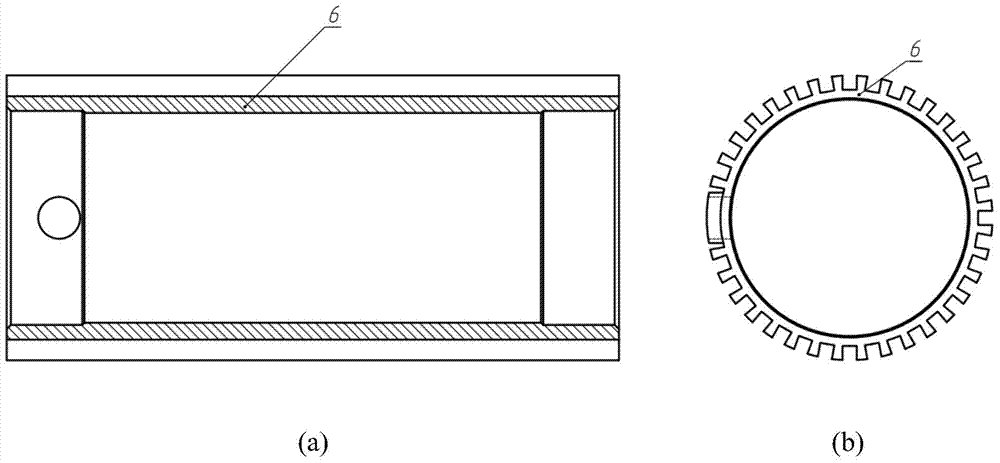

Starting and generating integrated switch magnetic flux motor for automobile

InactiveCN103715794AImprove cooling effectReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsAdhesiveElectric machine

A starting and generating integrated switch magnetic flux motor for an automobile comprises a stator assembly. The stator assembly is fixed on an outer shell through anaerobic adhesive. A rotor is fixed on a gear shaft of the motor through front and rear sleeves and a flat key. An air gap is reserved between the stator assembly and the rotor. The two ends of the gear shaft of the motor are supported on end caps through bearings. The side, close to the stator and rotor, of the front end cap is provided with an oil seat for preventing lubricating oil of gears and bearings from polluting the stator and rotor. The front and rear end caps and a planetary reducer assembly are fixed on the outer shell through tensioning bolts. A rotary transformer assembly is fixed in the rear end of the gear shaft of the motor. An output gear shaft is engaged with an engine flywheel tooth ring and outputs power to an engine crankshaft when an engine needs to start, and the inputted power is converted into electric energy to charge a storage battery when the engine runs normally. The starting and generating integrated switch magnetic flux motor is simple and compact in structure and low in production cost, and satisfies starting and generating function requirements of the automobile.

Owner:XI AN JIAOTONG UNIV

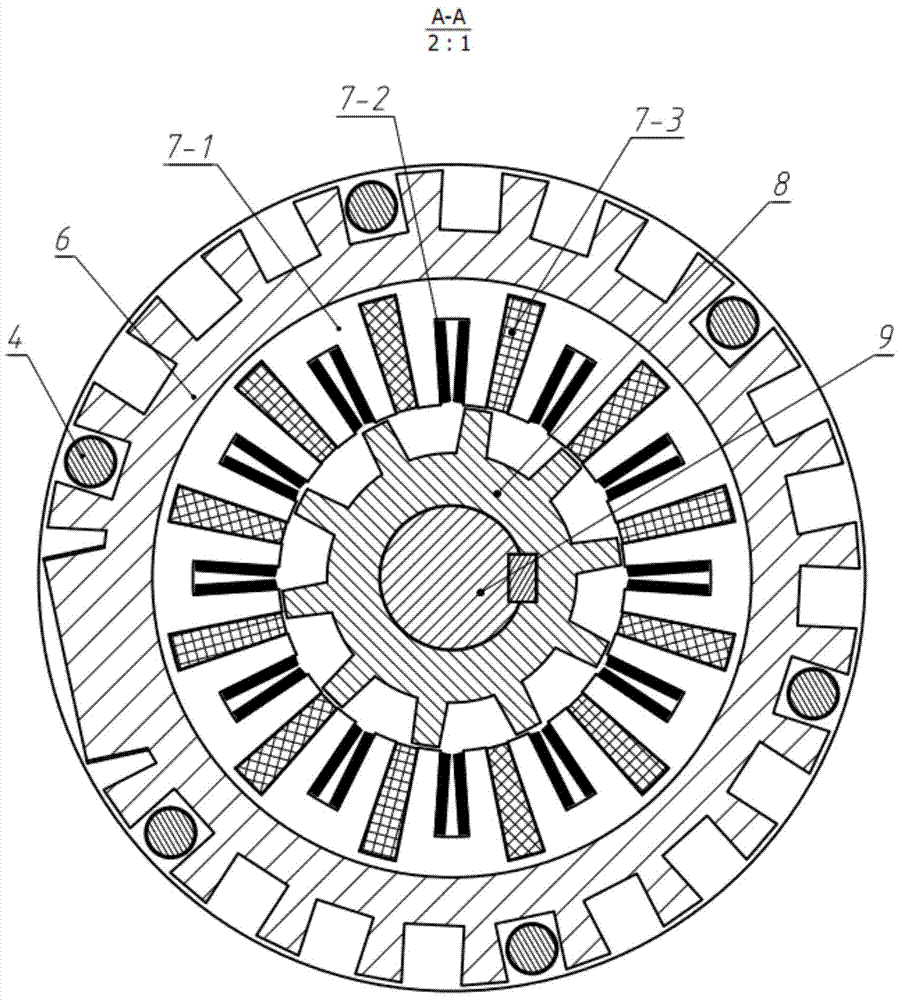

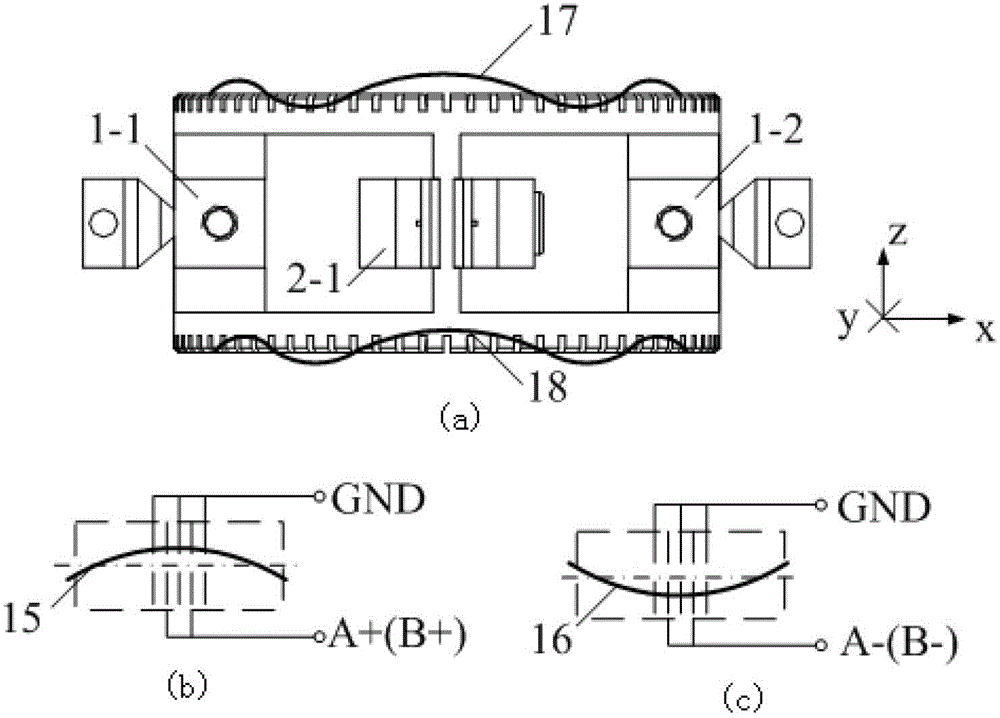

Novel double-tooth-surface rotary ultrasonic motor stator and excitation way thereof

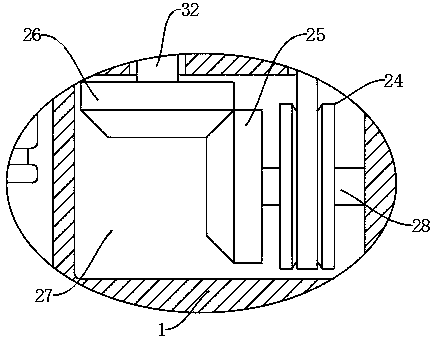

InactiveCN102751905ASolve the problem that the machining accuracy is difficult to controlCompact layoutPiezoelectric/electrostriction/magnetostriction machinesElectric machineDouble teeth

The invention discloses a novel double-tooth-surface rotary ultrasonic motor stator and an excitation way thereof. The novel double-tooth-surface rotary ultrasonic motor stator comprises a double-tooth-surface stator ring and a curved vibrator; the double-tooth-surface stator ring comprises a first stator ring and a second stator ring, which are opposite to each other, adjacent annular surfaces of the first stator ring and the second stator ring are connected with each other through four groups of drive columns, and the outer side annular surfaces of the first stator ring and the second stator ring are respectively provided with a serrate drive surface for driving a motor rotor; and each drive column is provided with one curved vibrator, the vibrators are uniformly distributed relative to a center joint line of the first stator ring and the second stator ring, and every two adjacent curved vibrators are vertical to each other in the length direction. A rotary ultrasonic motor adopting the stator structure can realize the forward-backward rotation movement and has large power output property. A motor main body has characteristics that the performance is stable, the output power is large, the structure is compact, requirement for a ceramic plate is single, the machining and assembling requirement is low, and adaptability to the running in a high-temperature environment is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

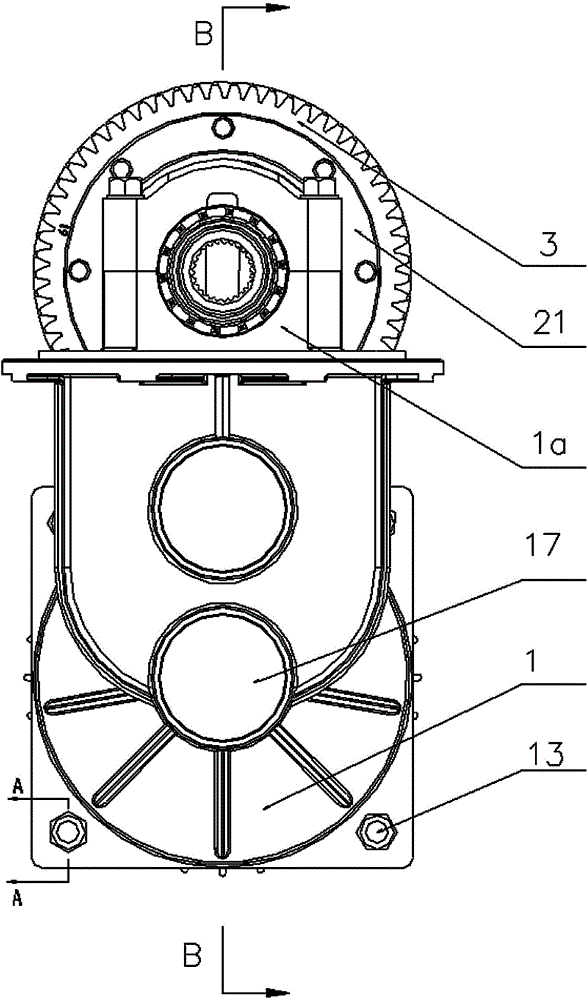

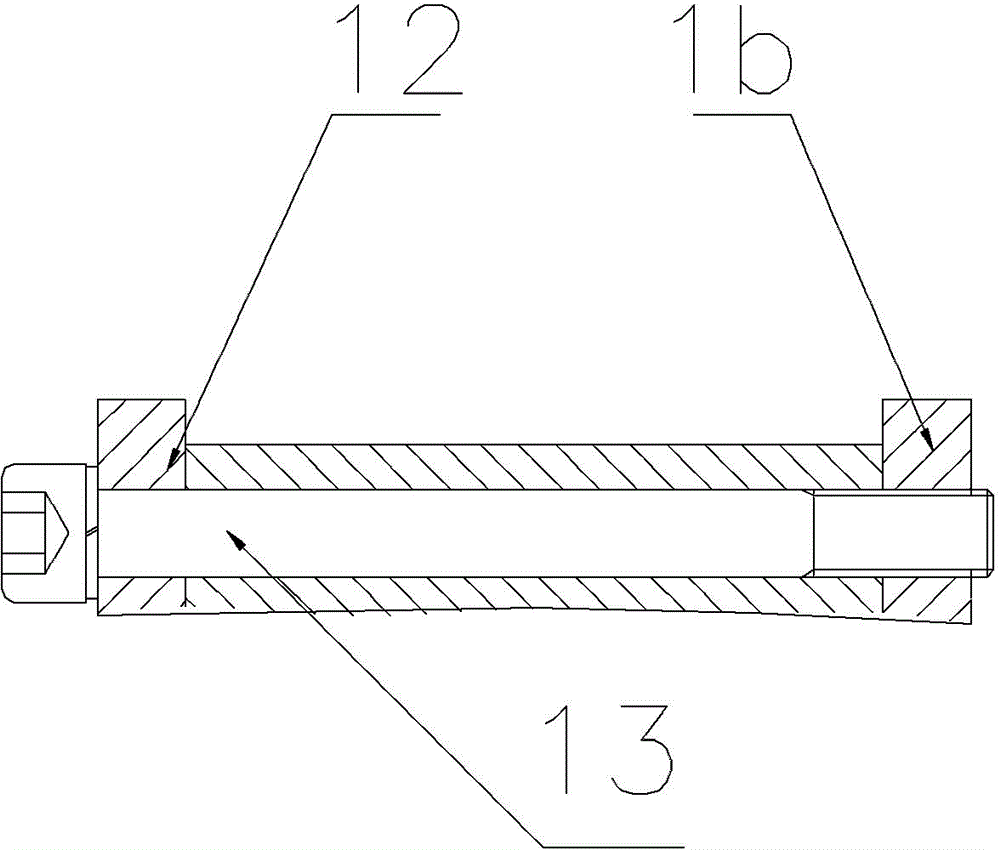

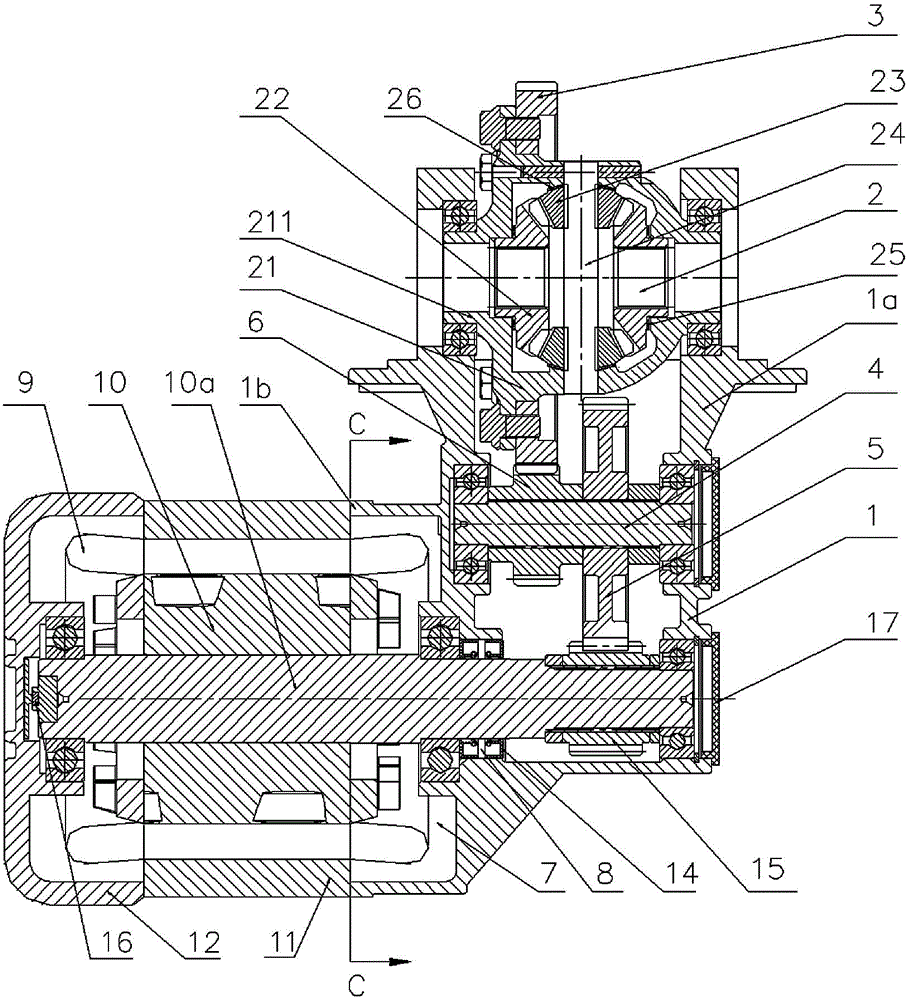

Gear transmission case

ActiveCN102897682AIncrease output torqueHigh output speedToothed gearingsWinding mechanismsEngineeringControl theory

The invention discloses a gear transmission case. The gear transmission case comprises input shafts, gears, a planetary gear set, sun gears, an inner gear ring, an output shaft and the like. The gear transmission case comprises two input shafts, a small gear is mounted on each input shaft, each small gear is meshed with a same large gear, the large gear is connected with the sun gear of a first-stage planetary gear mechanism, the sun gear is meshed with a planetary gear of the first-stage planetary gear mechanism, the planetary gear set is meshed with the inner gear ring, a planet carrier of the first-stage planetary gear mechanism is connected with the sun gear of a second-stage planetary gear mechanism, the plant carrier of the second-stage planetary gear mechanism is fixed on a base, the sun gear of the second-stage planetary gear mechanism is meshed with the planetary gear set of the second-stage planetary gear mechanism, second-link inner teeth of the inner gear ring are meshed with the planetary gear set of the second-stage planetary gear mechanism, and torque is output through the inner gear ring. Compared with the prior art, the gear transmission case disclosed by the invention can solve the problems of small output torque and low output rotational speed of the traditional ordinary gear transmission case.

Owner:SOUTH CHINA MARINE MACHINERY

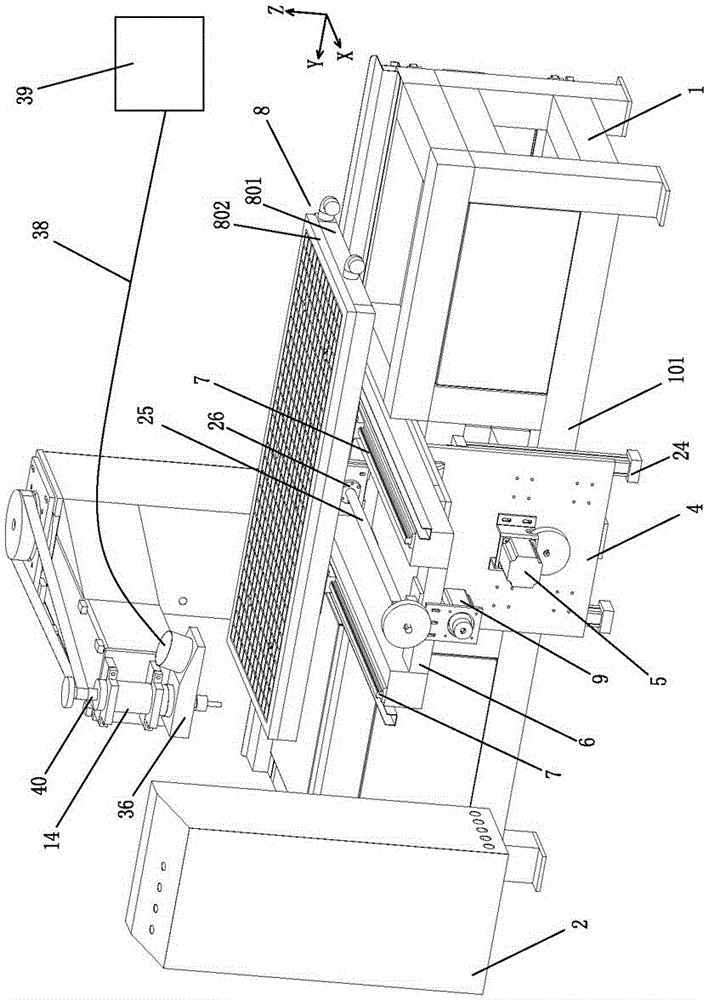

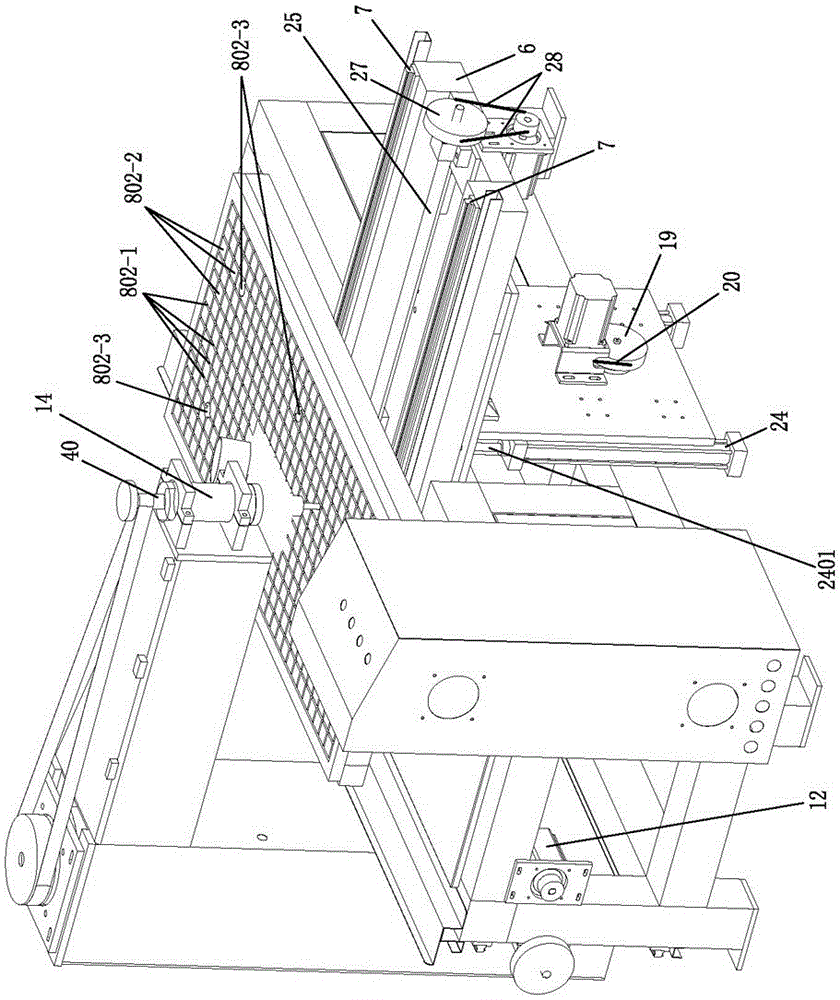

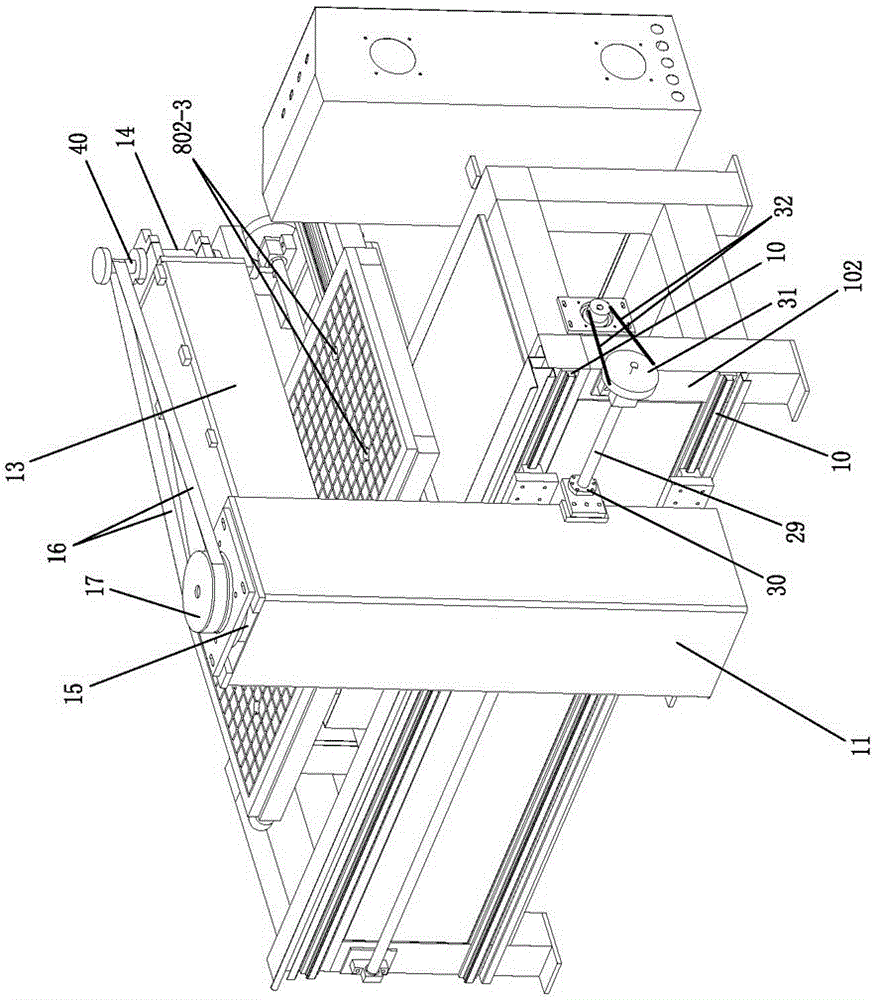

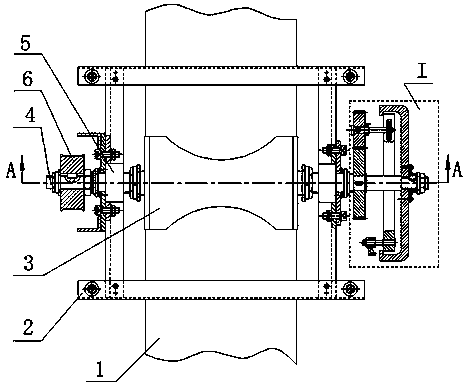

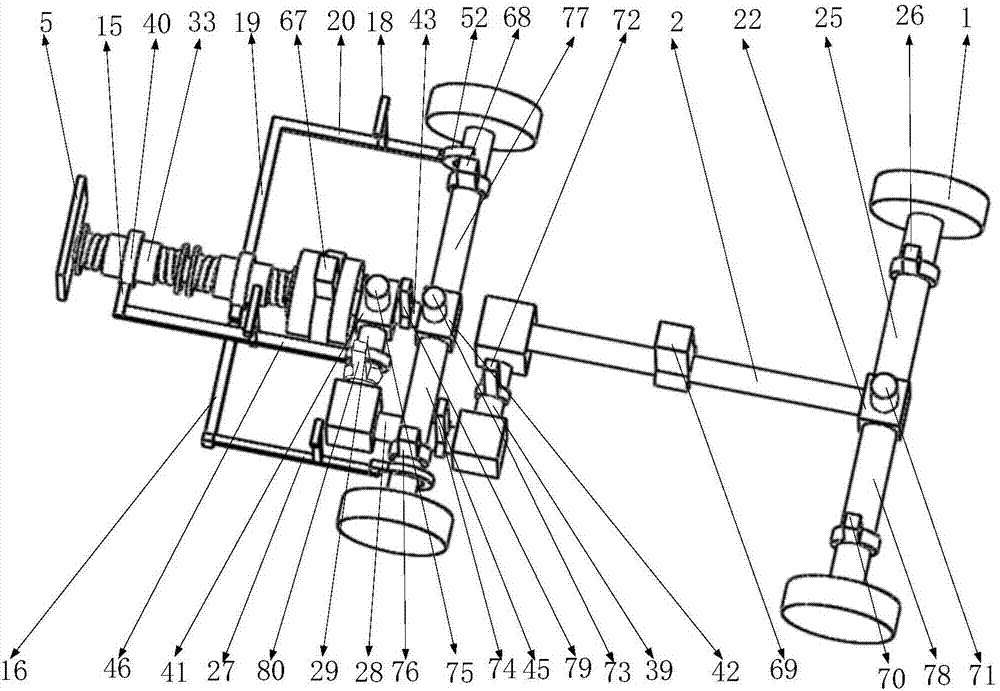

Full-automatic woodworking numerical control engraving and milling machine

InactiveCN105058513ASimple structureReasonable structureProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlSlide plate

The invention relates to a full-automatic woodworking numerical control engraving and milling machine. Z-axis guiding rails extending in the altitude directions are fixed on the front end surface of a base, a Z-axis sliding plate frame is connected to the Z-axis guiding rails in a sliding manner, and a Z-axis motor for driving the Z-axis sliding plate frame to lift up and down along the Z-axis guiding rails is mounted on the Z-axis sliding plate frame; an X-axis bracket is fixed on the Z-axis sliding plate frame, X-axis guiding rails extending in the X-axis direction are fixed on the X-axis bracket, and an X-axis motor for driving a bench to slide front and back along the X-axis guiding rails is mounted at the bottom of the X-axis bracket; Y-axis guiding rails extending in the Y-axis direction are arranged on the rear end surface of the base, and a Y-axis motor for driving a stand column to slide left and right along the Y-axis guiding rails is mounted on one side of the base; a support arm extending to a position above the bench is arranged at the top end of the stand column, a main shaft vertically rotating is connected to one end of the support arm, and a main shaft motor is connected with a main shaft through a main shaft belt in a driving manner. The full-automatic woodworking numerical control engraving and milling machine is simple and reasonable in structure and free from manual operation, so that the operating efficiency is high, and the processing accuracy is high.

Owner:刘忠文 +1

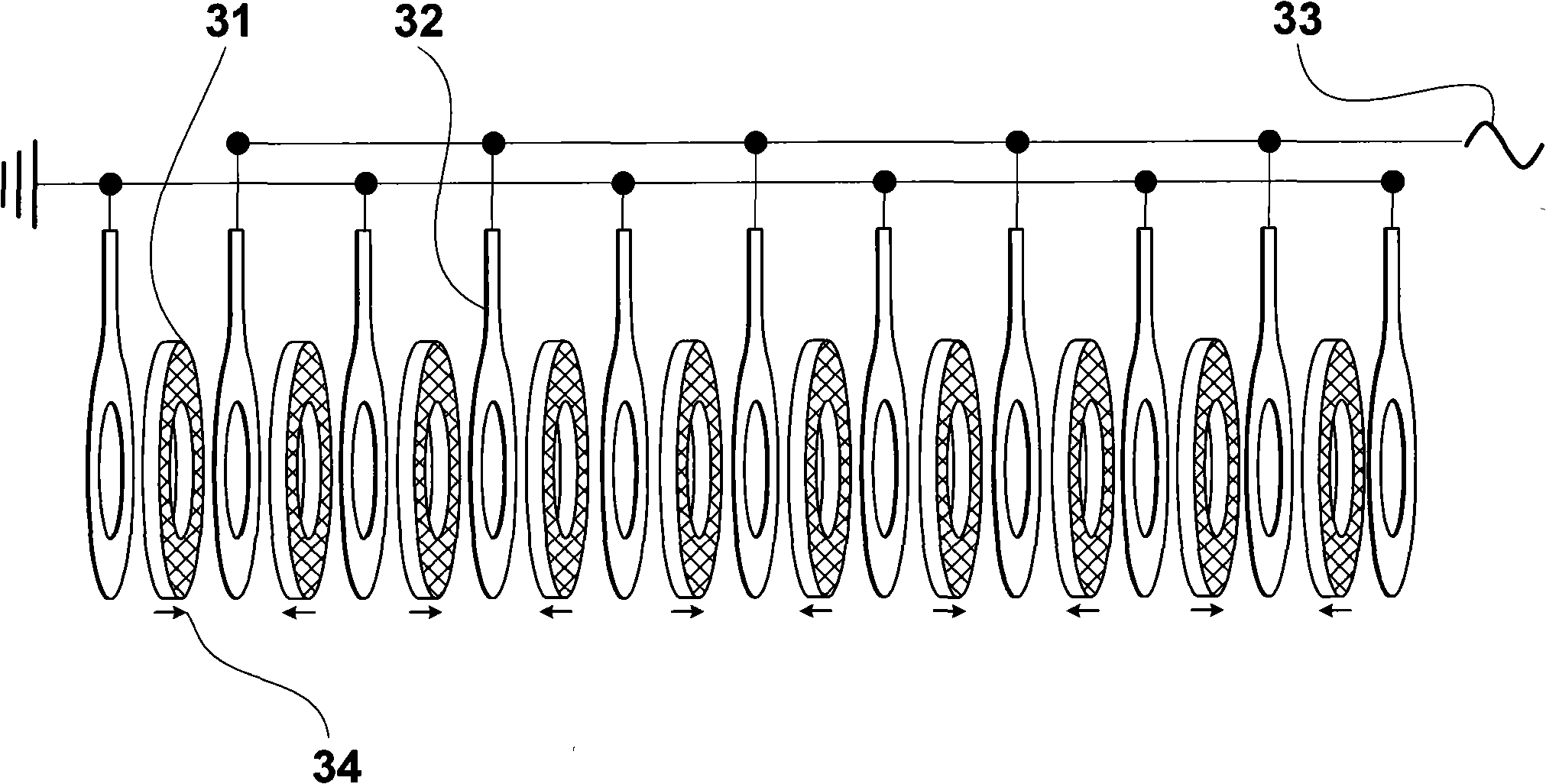

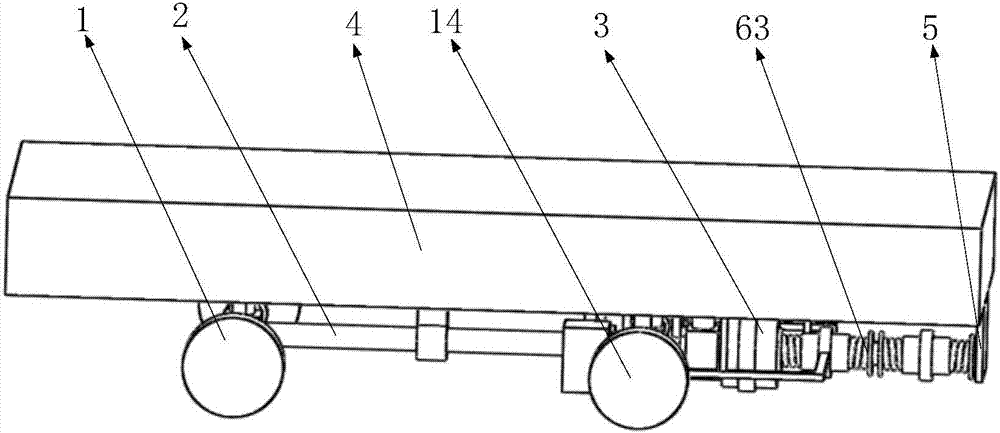

Automatic speed adjustment type cable robot

The invention discloses an automatic speed adjustment type cable robot and belongs to the field of special robots. The cable robot comprises a frame, a roller wheel, a main shaft, a rolling bearing A, a synchronous belt wheel A, a synchronous belt, a synchronous belt wheel B, a synchronous motor and a return stroke mechanism, wherein the return stroke mechanism comprises a speed increment mechanism and an internal expansion block type brake mechanism; the speed increment mechanism comprises a transmission shaft, a rolling bearing B, a gear B and a gear A; the internal expansion block type brake mechanism comprises a brake wheel, a flange plate, a brake shoe, a cam, a tension spring, a rotary shaft and a shaft sleeve. The cable robot solves the problems that an existing cable robot hardly and automatically returns to the ground in case of unexpected power outage and a large amount of energy is consumed and the speed is not easy to adjust automatically when the robot normally returns to the ground, and has the advantages of reasonable design and simplicity for manufacturing.

Owner:平湖市中劢磁业股份有限公司

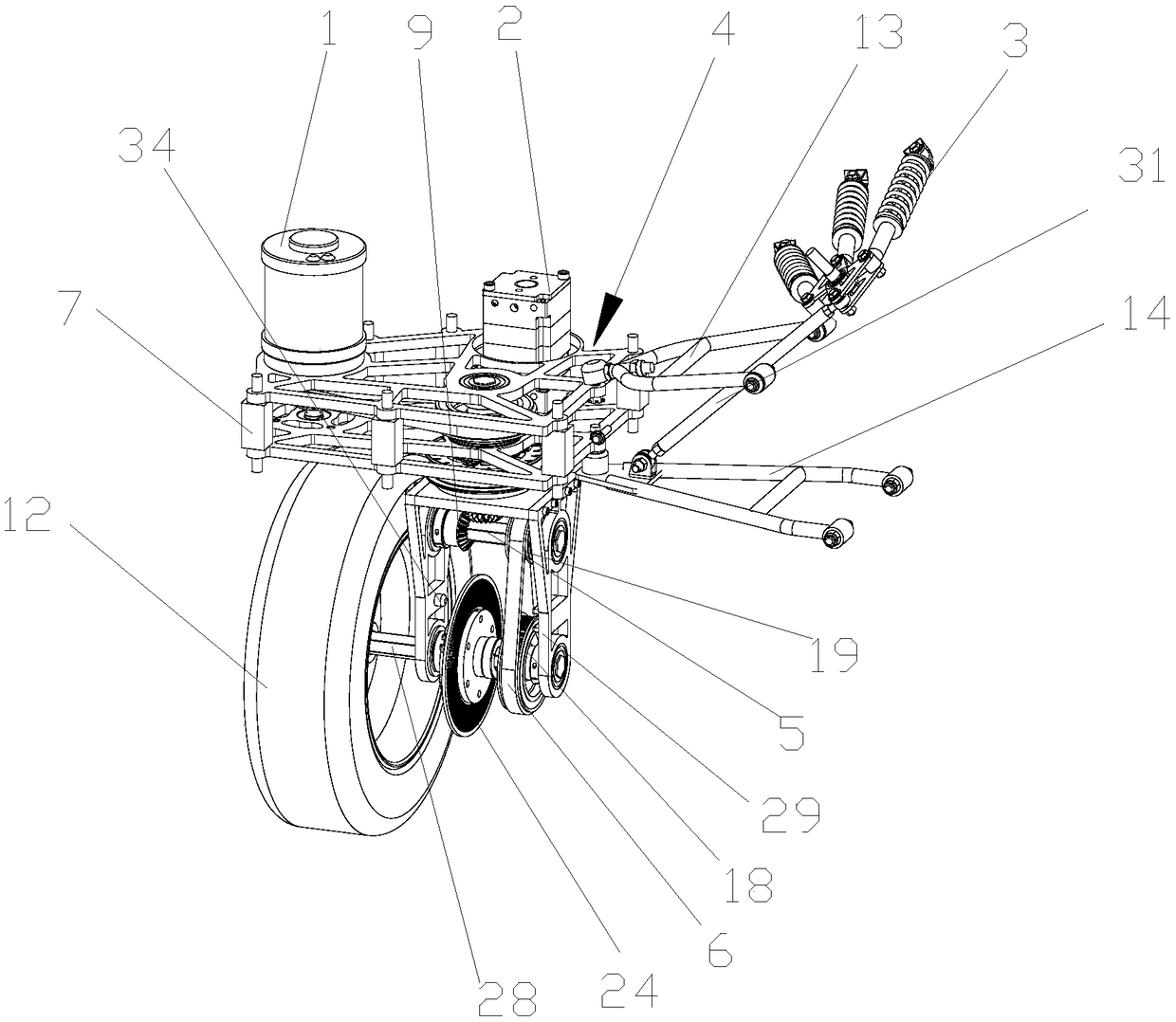

Cable climbing robot

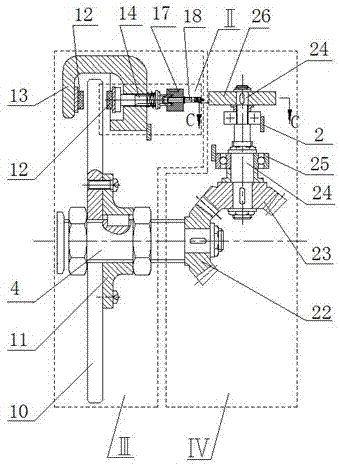

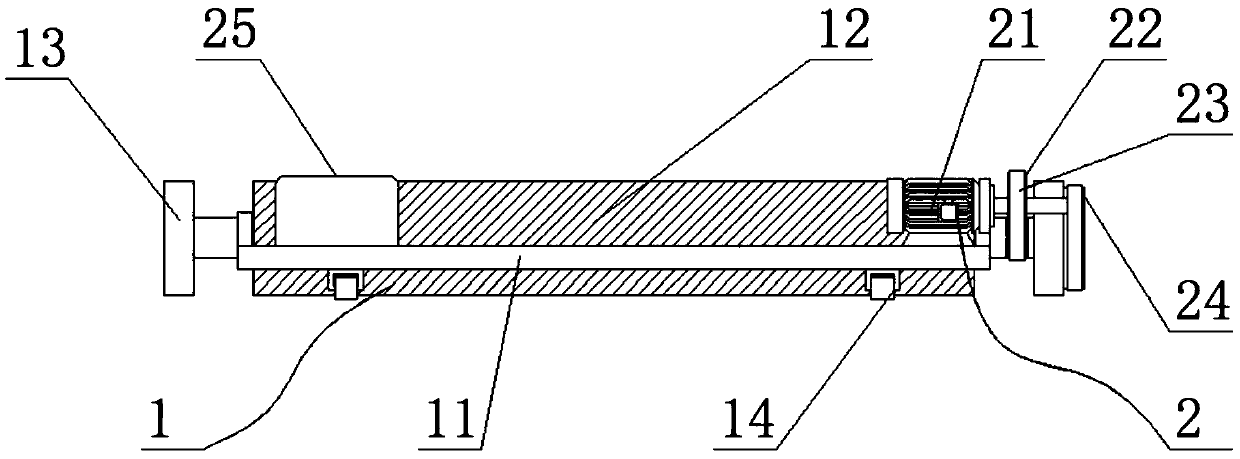

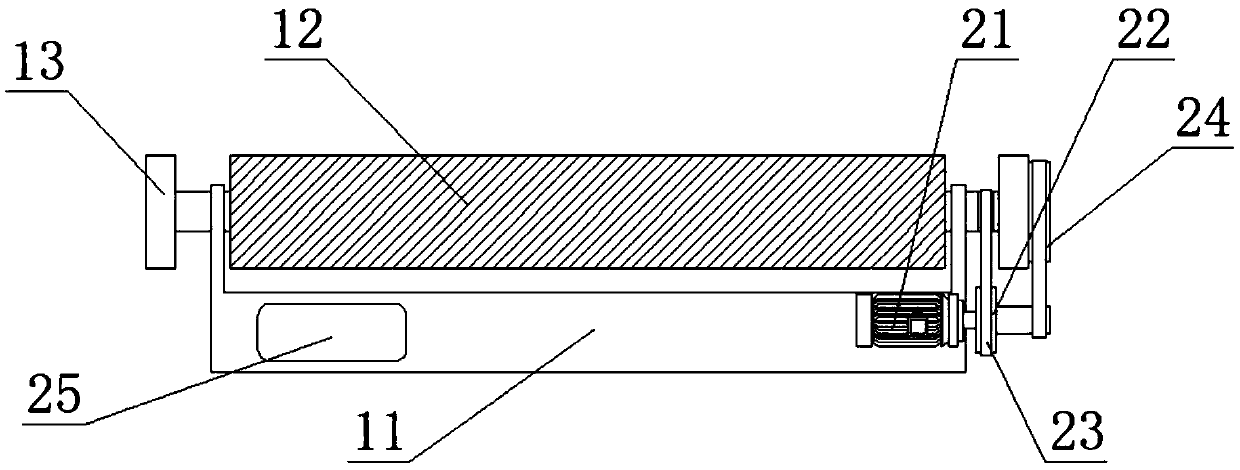

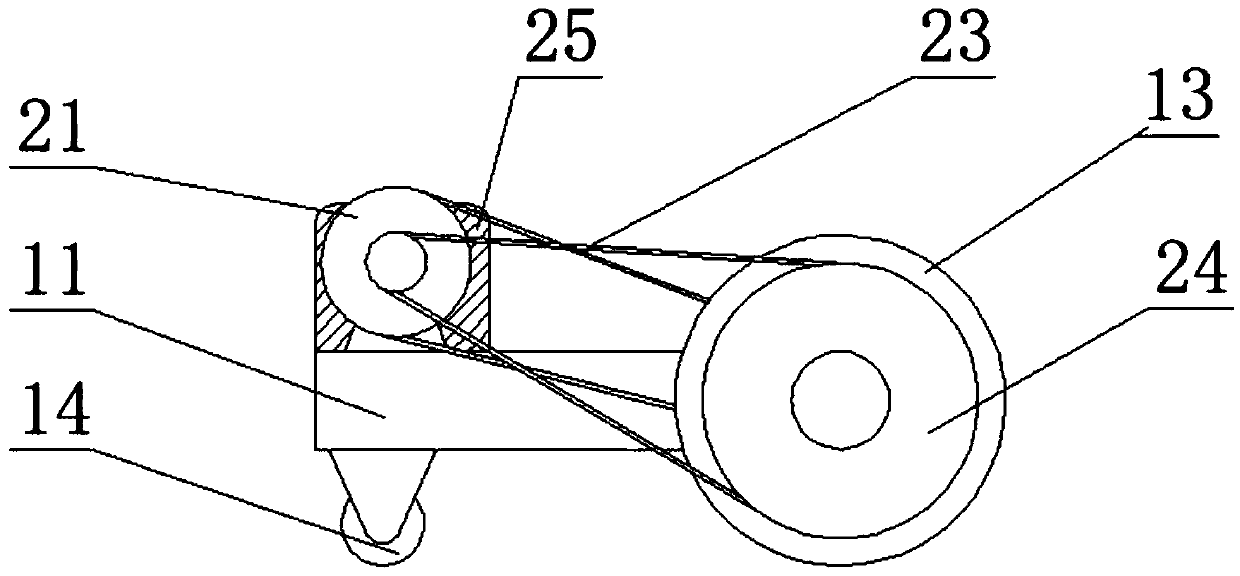

ActiveCN103692436AHigh output speedIncrease working frequencyProgramme-controlled manipulatorBridge erection/assemblyAuto regulationSynchronous motor

The invention discloses a cable climbing robot and belongs to the field of specialized robots. The cable climbing robot comprises racks, rollers, spindles, rolling bearings A, synchronous wheels A, synchronous belts, synchronous wheels B, synchronous motors and a return stroke mechanism. The return stroke mechanism is formed by a clearance brake mechanism and an acceleration transmission mechanism. The clearance brake mechanism is composed of a brake disc, a flange disc, a friction block, a brake caliper, a brake shaft, an adjusting spring, an adjusting nut A, an adjusting block, an adjusting shaft, an adjusting nut B, a roller and a roller shaft. The acceleration transmission mechanism is composed of a conical gear A, a conical gear B, a transmission shaft, a rolling bearing B and a cam. By means of the cable climbing robot, the problems that returning of prior cable climbing robots to the ground is difficult during accidental outage and when the cable climbing robots return to the ground normally, a large amount of energy is consumed, and the speed is difficult to adjust automatically are solved, the design is reasonable, and manufacturing is facilitated.

Owner:长沙猎空智能科技有限公司

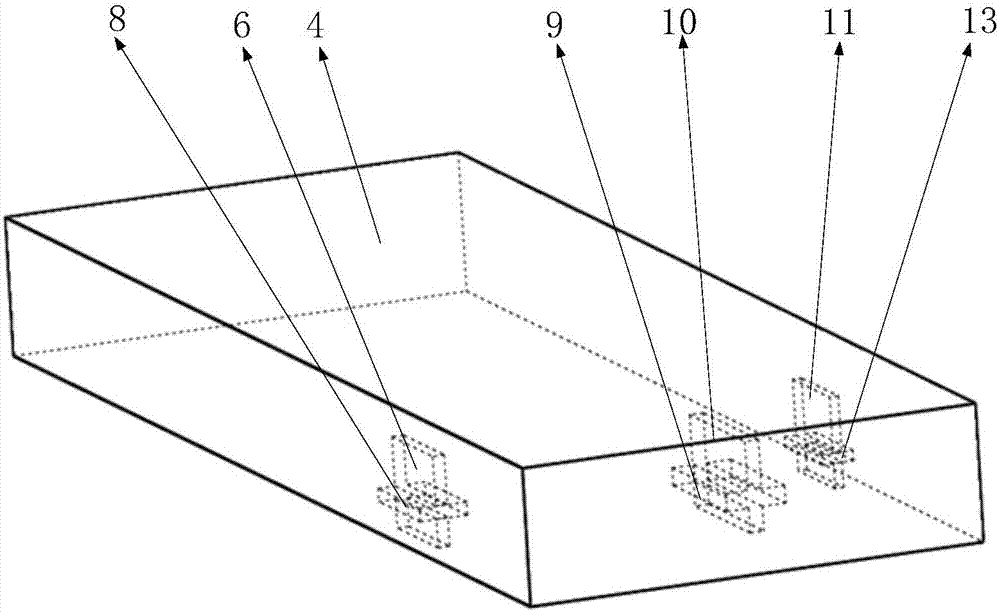

Automatic solar panel cleaning device

InactiveCN109092741AHigh output speedReduce output speedPhotovoltaicsCleaning using toolsMotor driveTransmission belt

The invention is suitable for the field of environmentally-friendly cleaning, and provides an automatic solar panel cleaning device. The automatic solar panel cleaning device comprises a supporting component and a transmission component, wherein the supporting component comprise a supporting seat, a roller, an idler wheel and driven wheels; the roller is rotatably connected to the supporting seatand is positioned on one side of the supporting seat; the motor is arranged to drive the roller to rotate through a driving shaft; the diameter of the driving shaft is greater than the diameter of oneend of the roller, and therefore, the output revolving speed of the motor for the roller is improved; the output shaft of the motor drives the driven shaft to rotate through a transmission belt, andthe output revolving speed of the motor for the idler wheel is lowered; therefore, the revolving speed of the roller is far higher than the revolving speed of the idler wheel, the roller rotates at ahigh speed to clean the solar panel while the device slowly rotates and goes forward along with the idler wheel, the device automatically go forward to clean the solar panel so as to be convenient inoperation, and the labor intensity of people is lowered.

Owner:芜湖品源装饰工程有限责任公司

Rear axle electric power drive for electric vehicles

The invention discloses a rear axle electrodynamic force drive device of an electric vehicle. The drive device comprises a reducer shell, wherein the reducer shell is provided with two supports, the two supports support a differential shell, a second driven gear is fixed on the differential shell, a transmission shaft is arranged in the differential shell, a first driven gear and a second drive gear are fixed on the periphery of the transmission shaft, the second drive gear is meshed with the second driven gear, the reducer shell is provided with an end face, a cavity is formed on the end face, a shaft hole is formed in the bottom of the cavity, one end of an alternating current motor stator core is connected with the end face, the other end of the alternating current motor stator core is connected with a rear end cover, the rear end cover, the alternating current motor stator core and the reducer shell are fixed through bolts, one end of a rotor shaft of an alternating current motor supports on the rear end cover, the other end of the rotor shaft of the alternating current motor penetrates through the shaft hole to support on the reducer shell, the first drive gear is fixed on the rotor shaft of the alternating current motor, and the first drive gear is meshed with the first driven gear. The electrodynamic force drive device realizes stepless speed regulation, shifting impact is eliminated, and the heat dissipation of a drive motor is ensured.

Owner:CHONGQING DONGBA TECH

Automobile all-directional parking auxiliary device

The invention discloses an automobile all-directional parking auxiliary device which comprises a rack and a rotating mechanism, an advancing mechanism and a damping mechanism which are installed on the rack; the rack comprises a transverse fixing frame connected with an automobile chassis and a longitudinal support which is arranged below the fixing frame and is of a hollow structure, the longitudinal support is located at the inner side of a tire, a spindle is installed in the center of the tire, the advancing mechanism comprises a driving motor installed on the transverse fixing frame, a first advancing belt pulley installed inside the transverse fixing frame and a transmission shaft installed inside the longitudinal support and located above the main shaft, and the rotating mechanism comprises a rotating belt pulley fixedly installed on a roof of the longitudinal support and a rotating motor driving the rotating belt pulley to rotate. By arranging the rotating mechanism and the advancing mechanism, an automobile achieves running in different directions and moving in all 360-degree directions, meanwhile, steering and advancing of tires can be completed within the limited space, the device can adapt to complex the terrain environment, and the parking process becomes more efficient, safe and simple.

Owner:XIAN UNIV OF SCI & TECH

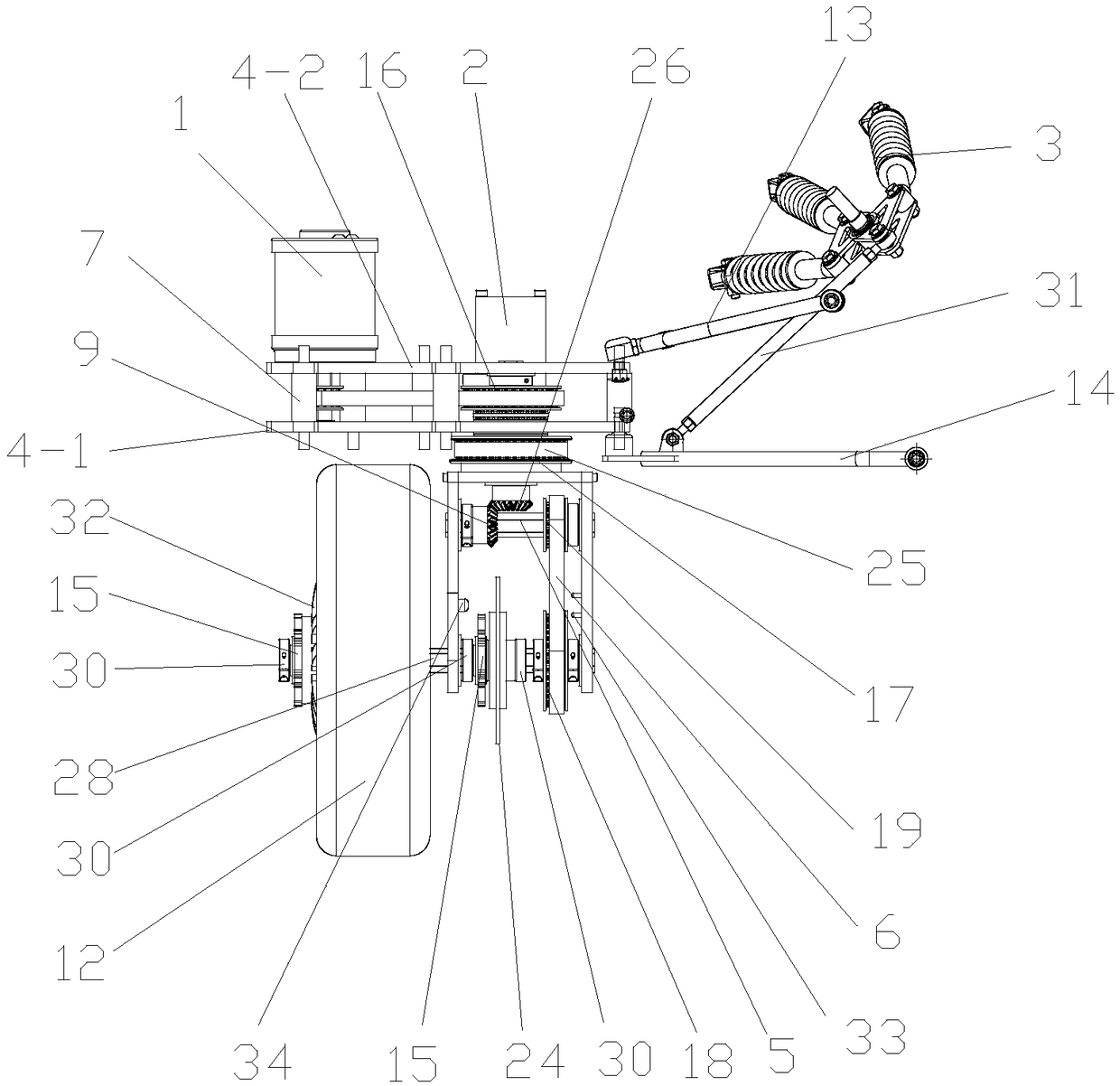

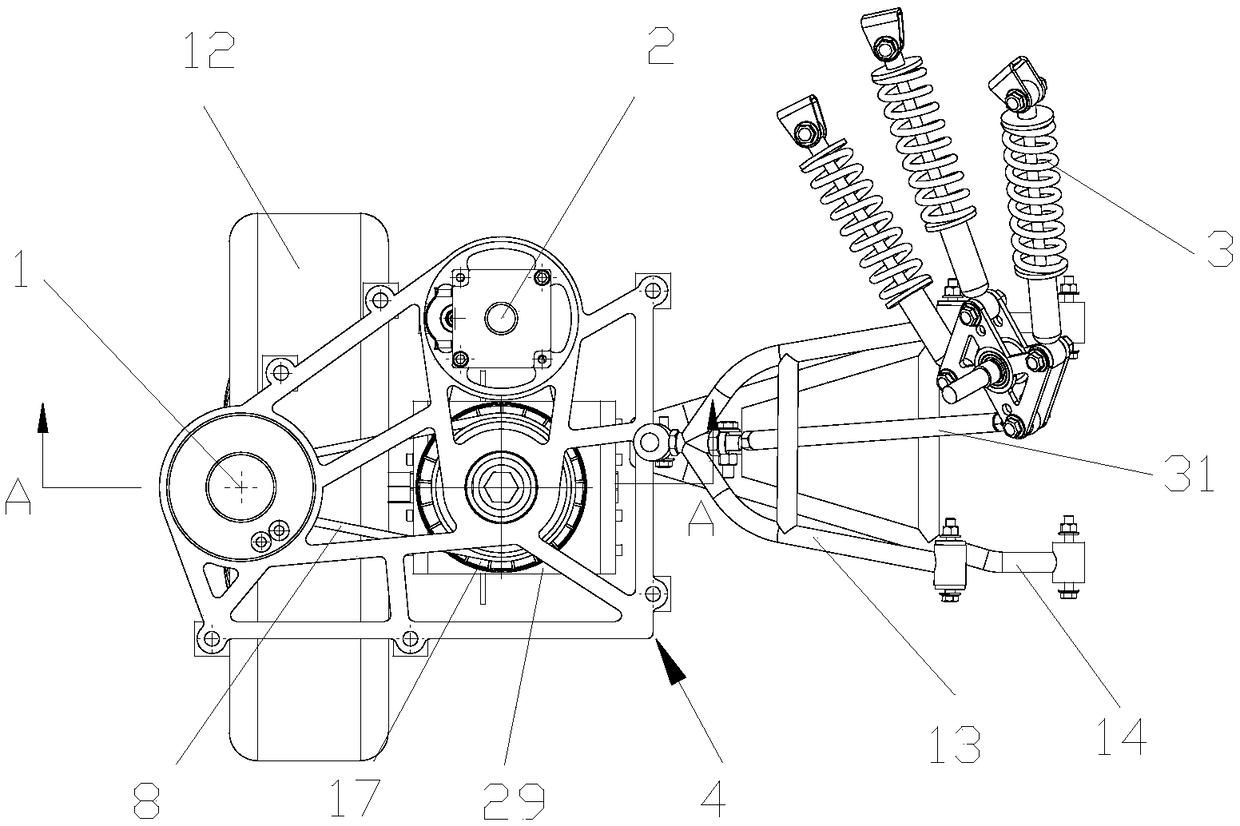

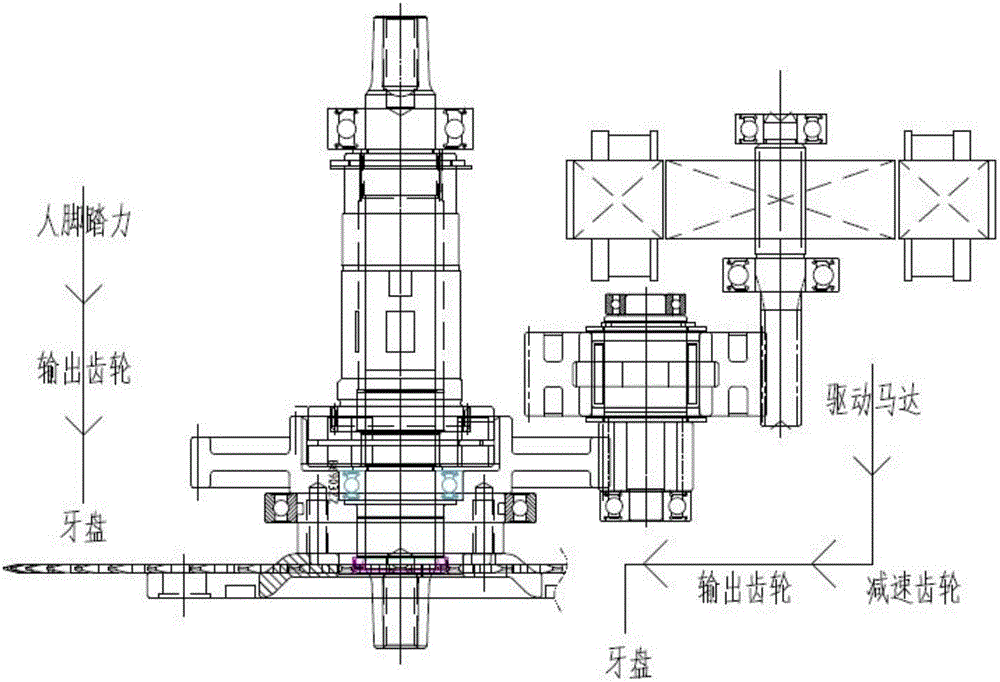

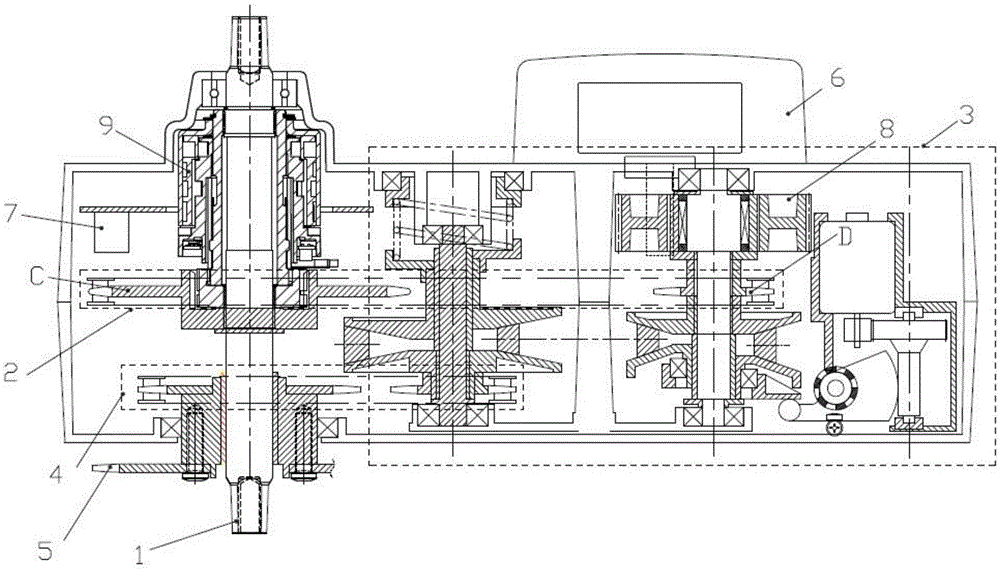

Bicycle speed change system and speed change method for power-assisted bicycle comprising same

InactiveCN106627971AGuaranteed uptimeExpand the scope ofChain/belt transmissionRider propulsionOperation point

The invention discloses a bicycle speed change system. By integrating a stepless speed change mechanism into a central system of a power-assisted bicycle, the current riding state is judged by a controller according to sensor information, the speed reducing ratio of manpower and a motor to a rear wheel of the bicycle is automatically adjusted, and thus, the driving motor can operate nearby a rated operation point; an efficient operation area and a torque output range of the central system are broadened, the endurance mileage is prolonged, and the cost of a power-assisted bicycle system is reduced; the central system can automatically judge the whole bicycle operation state according to the bicycle speed, the human foot treading frequency, the foot treading force and the treading direction, and the current power assist rate is automatically adjusted; and operation is easier, more convenient and more humanized, and speed change gears do not need to be adjusted manually.

Owner:SUZHOU WANJIA ELECTRIC

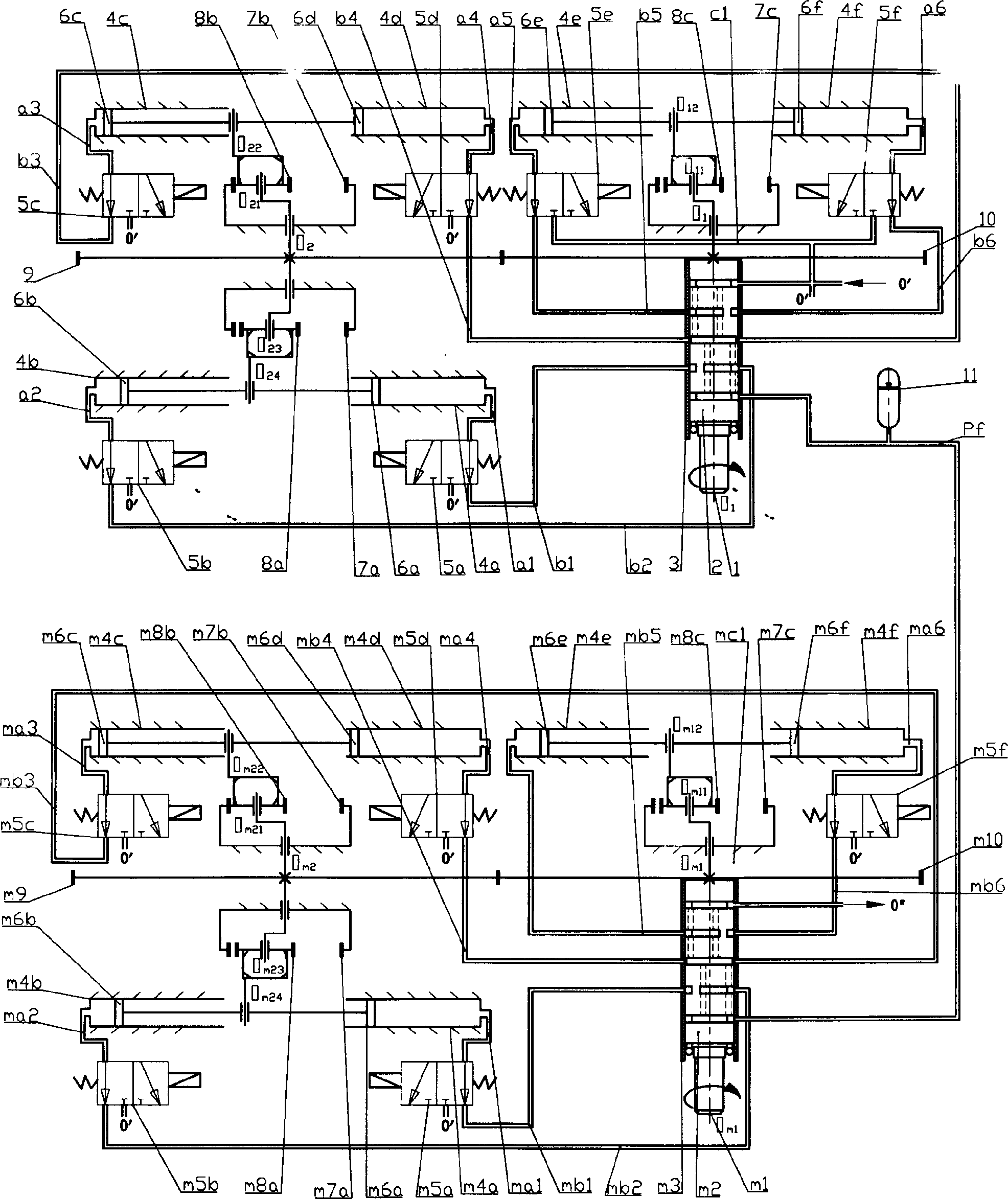

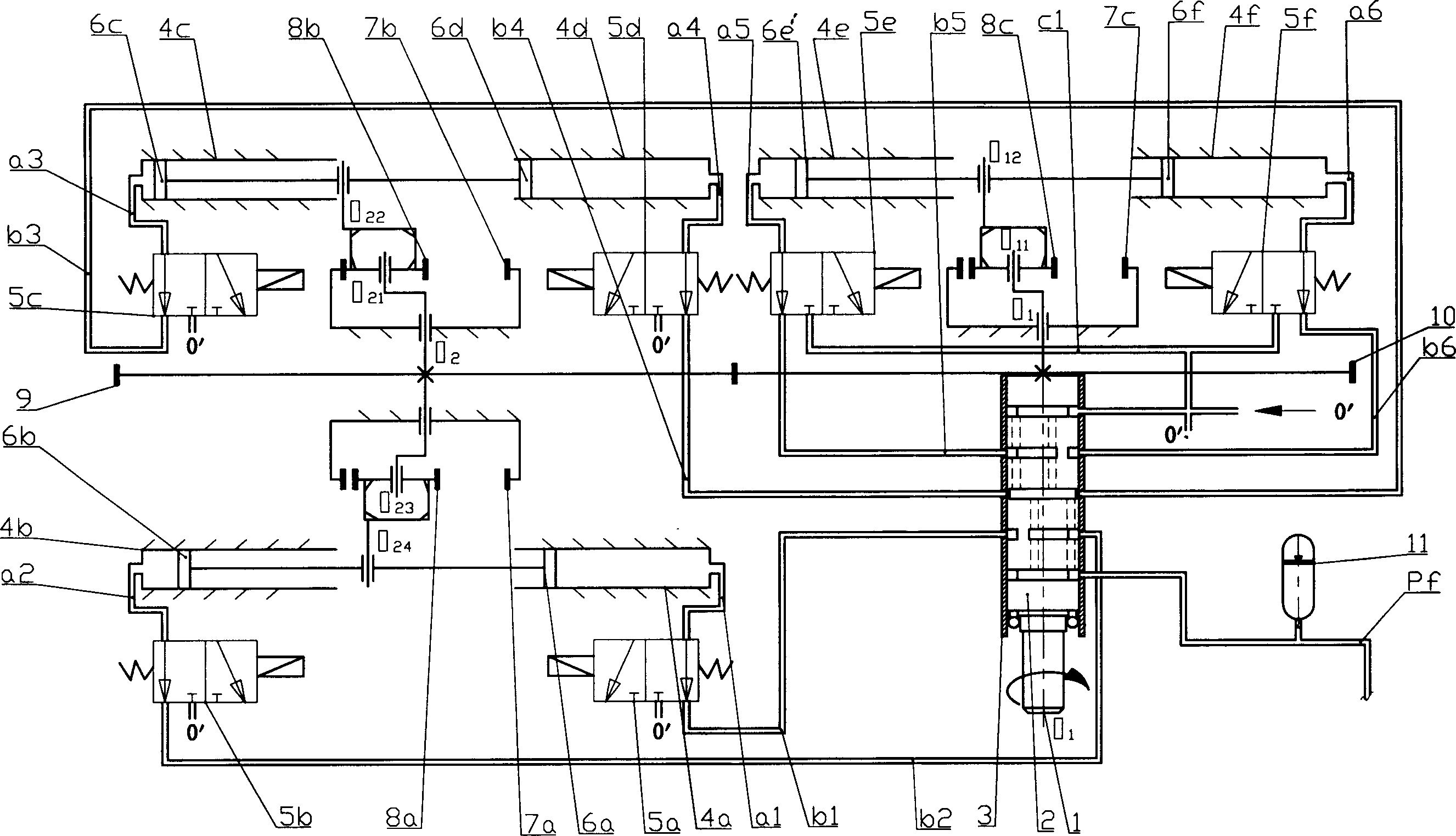

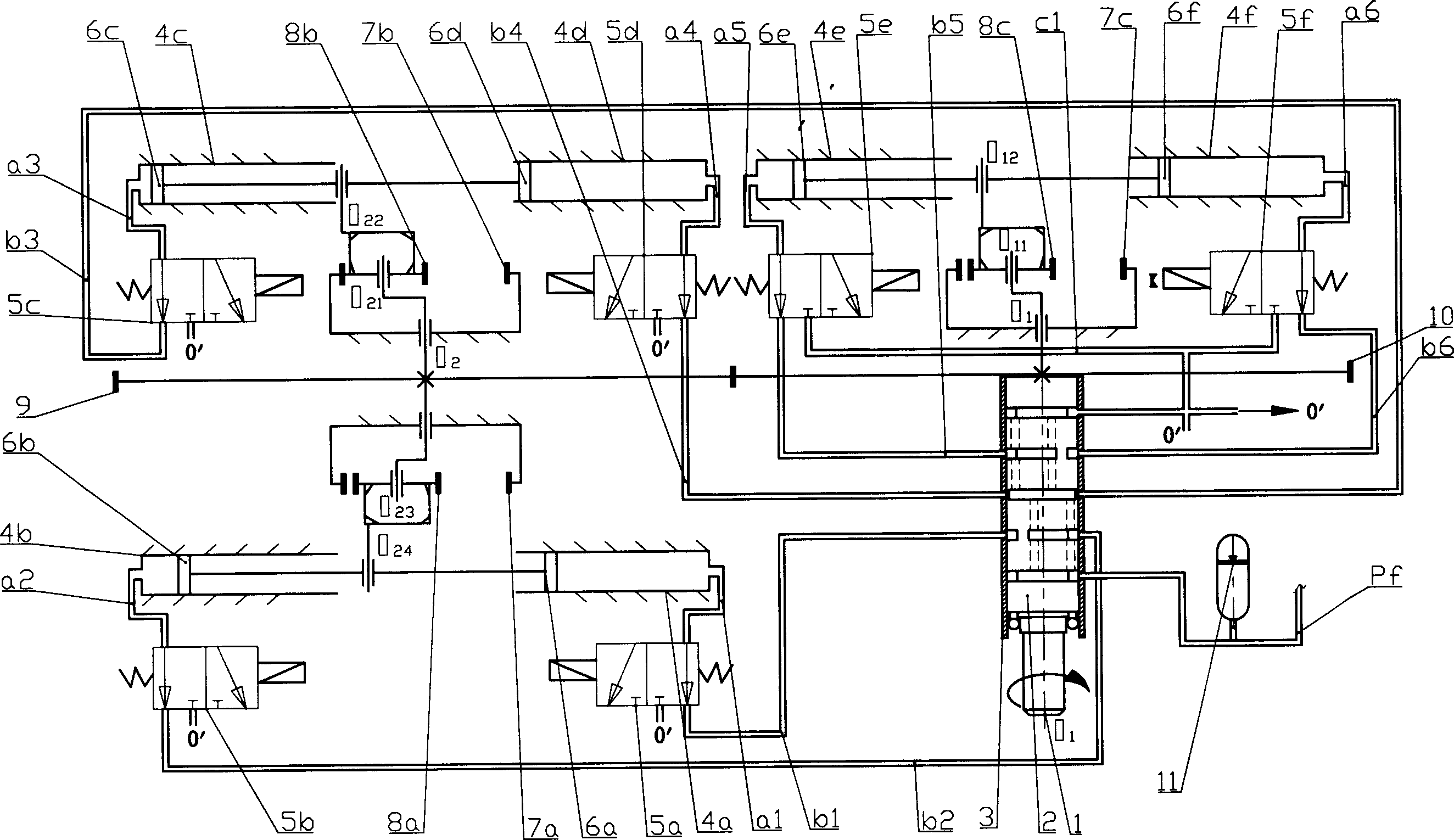

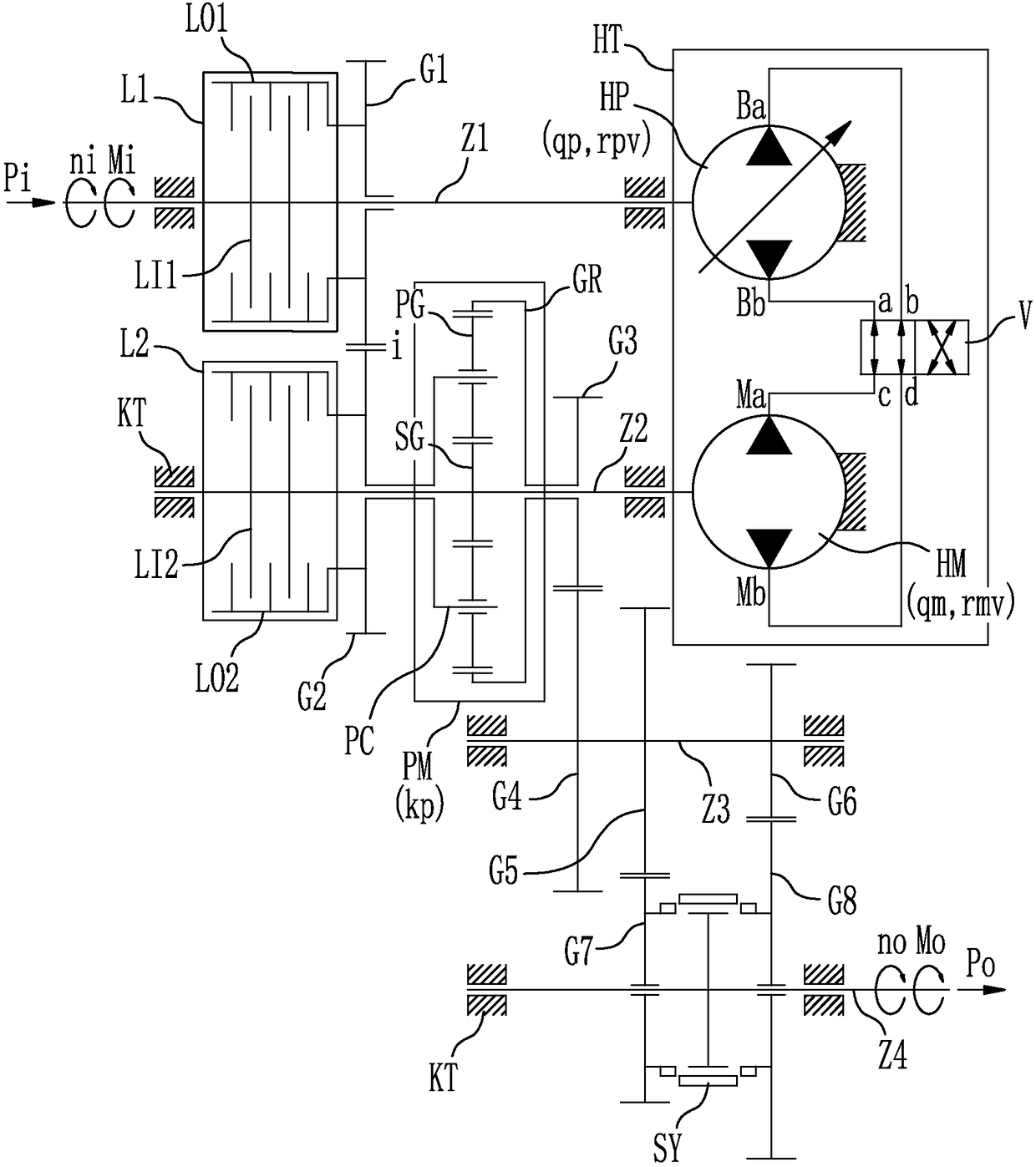

Planetary gear hydraulic speed changing system

InactiveCN1619187AInput displacement reducedHigh output speedFluid gearingsHydraulic motorGear wheel

The present invention relates to a planetary gear type hydraulic speed change system. It includes a six-plunger planetary gear type hydraulic pump and a six-plunger planetary gear type hydraulic motor, in which the hydraulic pump includes epicyclic train, plunger and plunger cylinder, and the hydraulic motor includes epicyclic train, plunger and plunger cylinder. The above-mentioned hydraulic pump and hydraulic motor are respectively series-connected with a two-position three-way electromagnetic valve.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Control device of vehicle drive-train system

ActiveUS8366587B2Rapid decelerationHigh output speedElectrical controlGearing controlAutomatic transmissionElectronic throttle

A control device of a vehicle drive-train system including an engine, an electronic throttle valve, an automatic transmission having a manual shift mode, a torque converter provided between the automatic transmission and the engine, and a lock-up clutch operable to directly connect an input member and an output member of the torque converter with each other includes a blipping control device that performs blipping control for temporarily increasing the output rotational speed of the engine by of the electronic throttle valve, when a power-off downshift is performed while the automatic transmission is in the manual shift mode; and a lock-up control device that engages or partially engages the lock-up clutch, based on a difference between a rotational speed of the output member of the torque converter and a rotational speed of the input member thereof, which the difference is reduced after the blipping control is started.

Owner:TOYOTA JIDOSHA KK

Electric drive fault tolerant device, multiphase motor, power converter and electric device

ActiveCN106788104AKeep running lightGuaranteed to workAC motor controlElectric motor controlManagement unitElectrical battery

The invention provides an electric drive fault tolerant device with fault tolerating function, a multiphase motor, a power converter and an electric device. The electric drive fault tolerant device provided herein is used for driving the electric device and comprises a multiphase motor, a direct-current power source, a command transmitting portion, a current sensor, an output sensor, a battery management unit, a controller, a driver, and a power converter, and is characterized in that a winding of the multiphase motor includes j+i multiphase winding units, the direct-current power source has j+i battery units, the power converter has power conversion units in corresponding connection with the j+i multiphase winding units and the j+i battery units, each power conversion unit has k power conversion circuits which supply k linear currents to the corresponding multiphase winding units, the driver has j+i drive units in respective connection with the j+i power conversion units, k is a positive integer greater than 2, j is a positive integer greater than 1, and i is a natural redundant number.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Transmission system capable of achieving three variable transmission processes

ActiveCN108591411AAdapt to variable speed transmission needsMeet variable speed transmission needsFluid gearingsHydraulic pumpMechanical equipment

A transmission system capable of achieving three variable transmission processes comprises an input shaft, a sun gear shaft, an input gear, a linkage gear, an intermediate driving gear, a first clutch, a second clutch, a planetary mechanism, a hydraulic pump and a hydraulic motor. The input shaft and the sun gear shaft are arranged in parallel. The input gear is meshed with the linkage gear. The input end of the first clutch is in transmission connection with the input shaft. The driven end of the first clutch is fixedly connected with the input gear. The input end of the second clutch is in transmission connection with the sun gear shaft, and the driven end of the second clutch is fixedly connected with the linkage gear. A sun gear in the planetary mechanism is fixedly connected with thesun gear shaft. A tooth ring is fixedly connected with the intermediate driving gear. A planet carrier is fixedly connected with the linkage gear. A rotor of the hydraulic pump is fixedly connected with the input shaft. A rotor of the hydraulic motor is fixedly connected with the sun gear shaft. The hydraulic pump and the hydraulic motor are connected into an oil supply loop in series. The transmission system capable of achieving the three variable transmission processes enables the variable-speed transmission process to both have the features of mechanical transmission and hydraulic transmission, and therefore the transmission system capable of achieving the three variable-speed transmission processes can meet the variable transmission needs of different types of mechanical equipment.

Owner:HEFEI UNIV OF TECH +1

Robot travelling platform traveling at constant speed in single-drive mode and based on centrifugation

The invention belongs to the technical field of robot travelling platforms and particularly relates to a robot travelling platform traveling at a constant speed in a single-drive mode and based on centrifugation. The robot travelling platform comprises a bearing plate, a travelling mechanism and a transmission mechanism. By adoption of design of the robot travelling platform, the effect of a third brake piece is that when a robot turns, the rotary speed of a sixth transmission shaft gets lower through friction effect of the third brake piece on the sixth transmission shaft, the rotary speed of an eighth transmission shaft gets higher through a third differential mechanism, and therefore the rotary speeds of tenth transmission shafts on the two sides of a second differential mechanism get higher so as to enable steering to be more smooth. The effect of the second differential mechanism is that according to the sizes of the resistance of the tenth transmission shafts and thirteenth transmission shafts on the two sides of the second differential mechanism, the rotary speeds of the tenth transmission shafts and the thirteenth transmission shafts on the two sides of the second differential mechanism are changed; and the effect of a first differential mechanism is that according to the sizes of the resistance of fourth transmission shafts and fourteenth transmission shafts on the two sides of the first differential mechanism, the rotary speeds of the fourth transmission shafts and the fourteenth transmission shafts on the two sides of the first differential mechanism are changed.

Owner:新昌县城关宾立机械厂

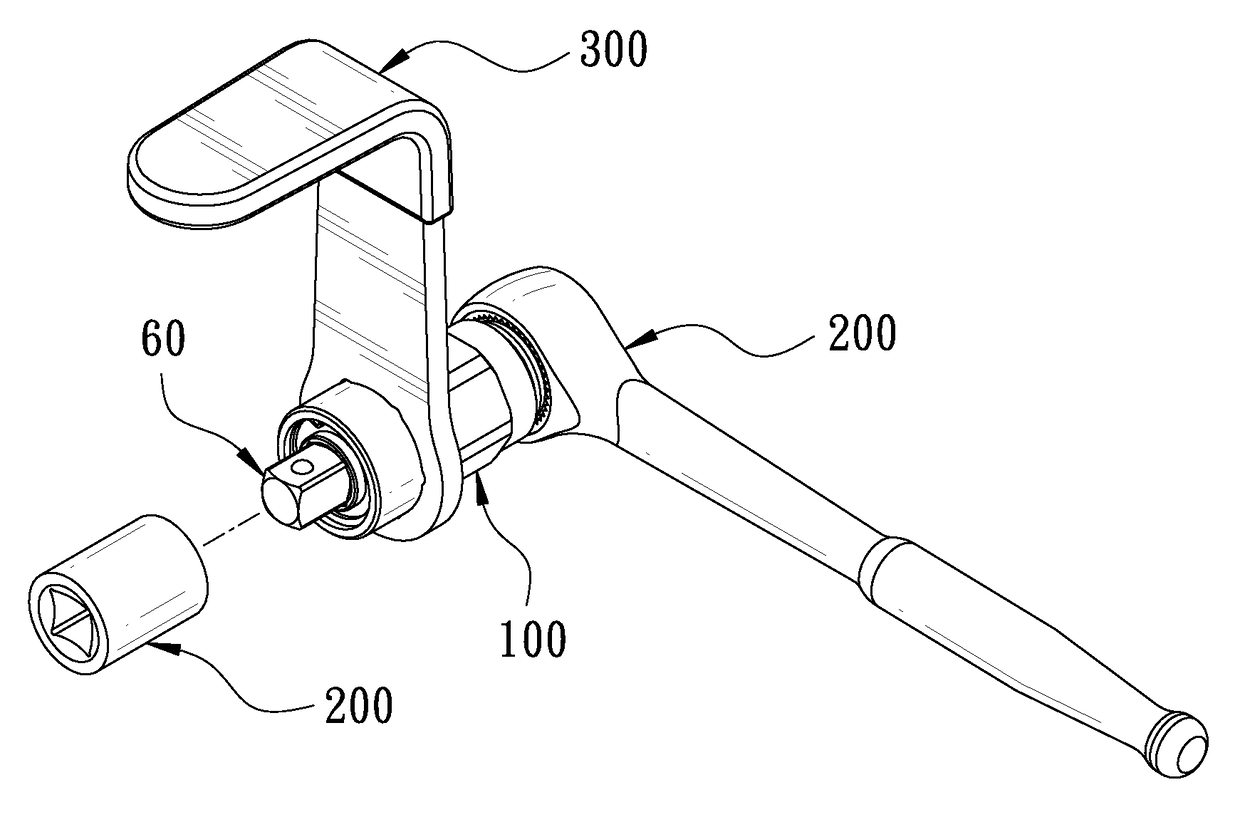

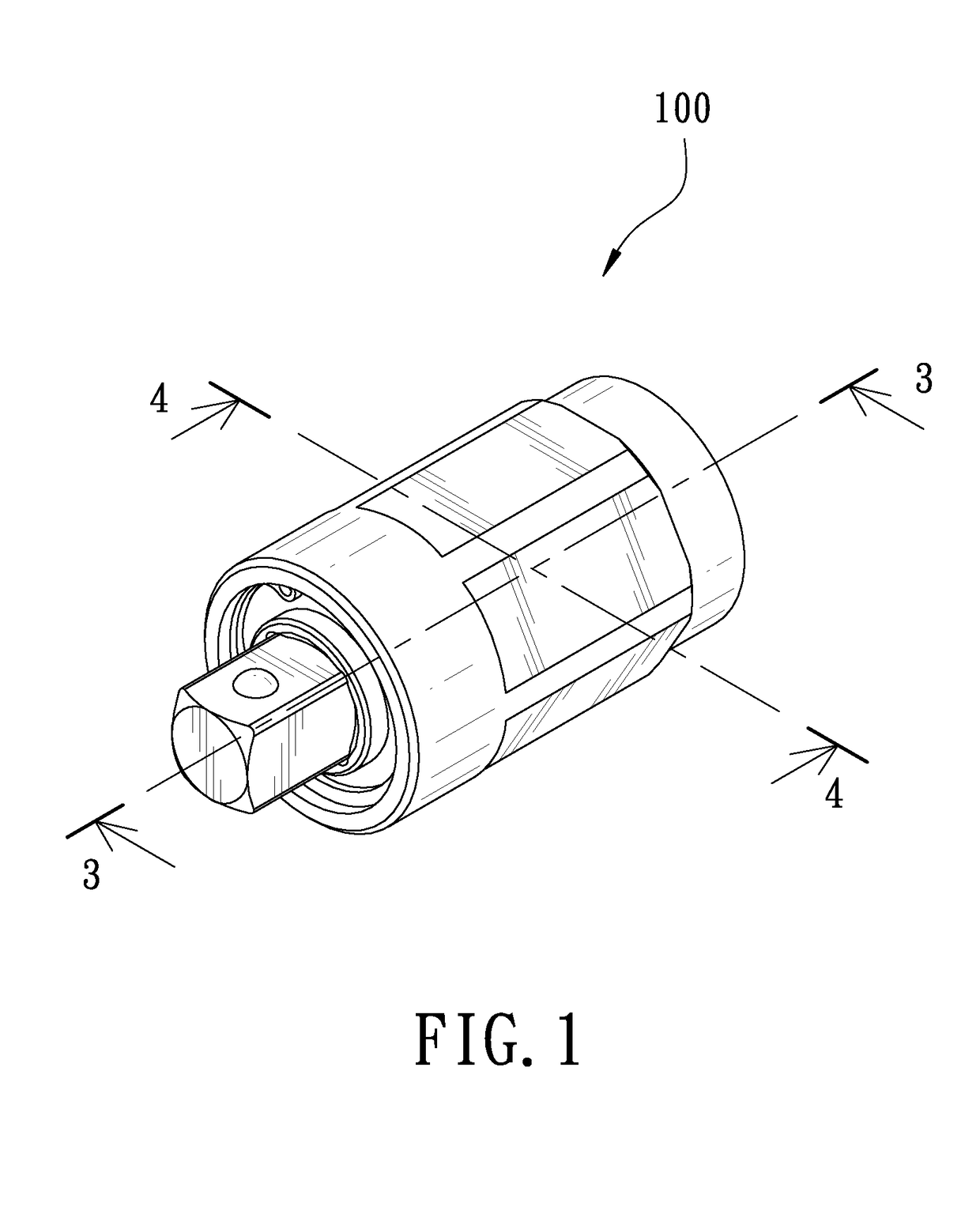

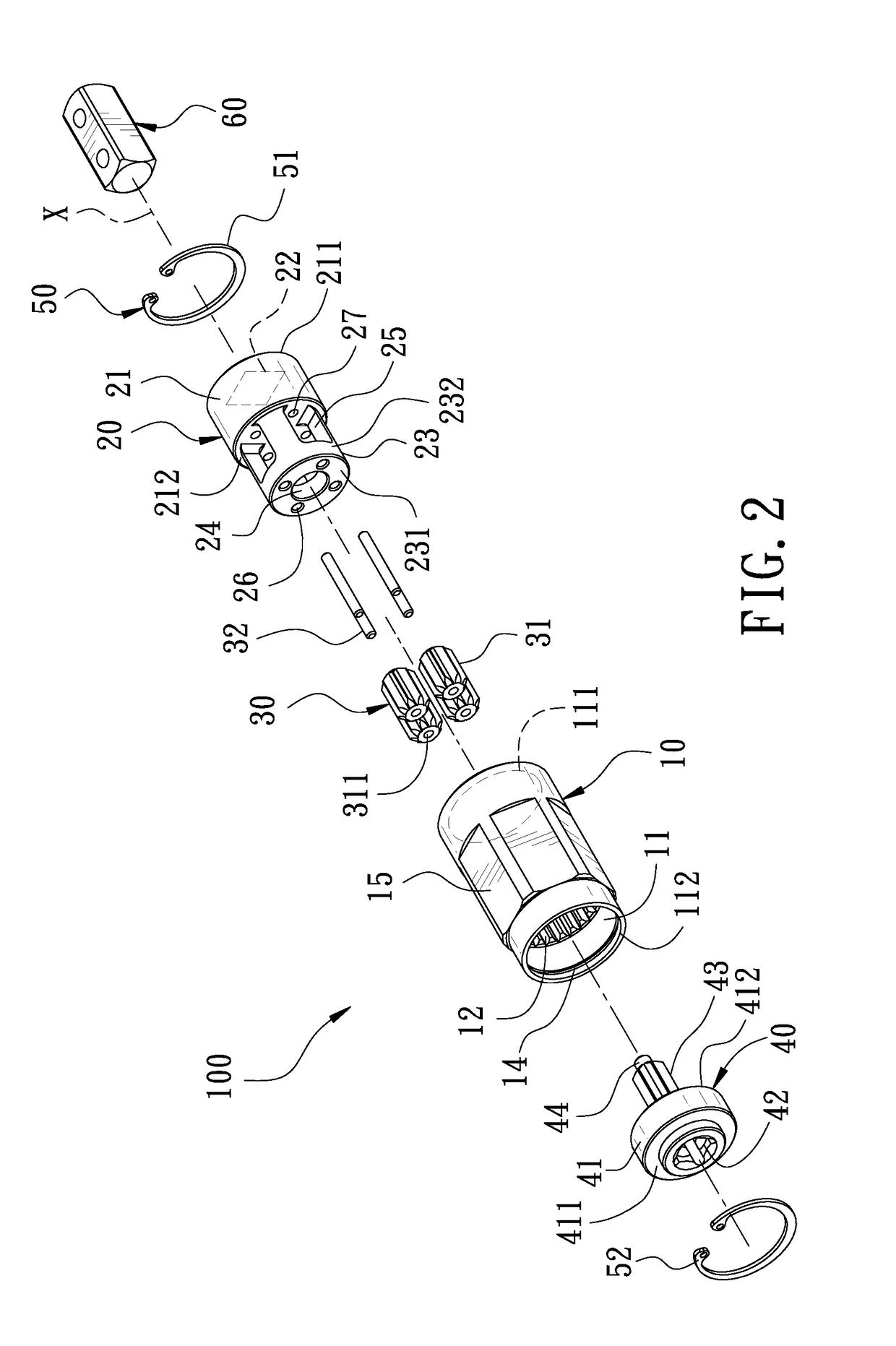

Hand tool adapter capable of increasing output torque or rotational speed

ActiveUS20170197300A1Increase output torqueTightening and loosen quicklySpannersWrenchesEngineeringMechanical engineering

A hand tool adapter capable of increasing output torque or rotational speed has a main body. The main body has a through hole. The through hole is provided with a first rotary seat and a second rotary seat. The through hole of the main body is provided with an annular toothed portion. The first rotary seat is provided with a plurality of gears to mesh with the annular toothed portion. The second rotary seat is provided with a gear axle to mesh with the gears. By the speed-changing principle of the planetary gear, the first rotary seat is selected as the input axle to increase the output rotational speed of the second rotary seat, or the second rotary seat is selected as the input axle to increase the output torque of the first rotary seat.

Owner:TORQUE TECH PRECISION

Wind power gear box transmission structure

InactiveCN108468756AGuaranteed uptimeIncrease power generationToothed gearingsWind motor combinationsImpellerLine shaft

The invention discloses a wind power gear box transmission structure which comprises an impeller and a box body. The impeller is arranged on a convex neck outer ring of the box body through a bearing;the side edge of the impeller is connected with a main shaft through a hub coupler; the main shaft penetrates through a convex neck of the box body so as to stretch into the box body; a planet carrier is connected to the tail end of the main shaft and is supported on an inner wall of the box body through a bearing; a drive bevel gear is arranged on the main shaft close to a front side wall of thebox body and is in transmission connection with a driven bevel gear through a duplex bevel gear; the duplex bevel gear is arranged on an inner wall of the tank through a bearing; the driven bevel gear is fixed onto an inner gear ring; a planet wheel in the planet carrier meshes with the inner gear ring, stretches out of a roller outside the planet carrier through the bearing so as to mesh with asun wheel; and a sun wheel axle stretches out of a rear side wall of the box body so as to externally output the torque. The wind power gear box transmission structure provided by the invention has the technical effects that the transmission ratio is improved, so that an operation performance, the generating capacity and the generating efficiency of a fan are improved.

Owner:CHONGQING UNIV

Electric device of fire monitor barbette

The invention provides an electric device of a fire monitor barbette, which comprises a main box, a motor, a deceleration mechanism, a stroke control mechanism, a manual / electric switching mechanism, a manual operation mechanism and a direct introduction type cable inlet seal mechanism. The deceleration mechanism comprises a worm arranged in the main box, an output shaft connected with the main box by a bearing, a worm wheel and a multichannel worm which are arranged on the output shaft, the worm is vertically engaged with the worm wheel, a worm gear with one end engaged with a motor gear of a motor shaft head is sleeved on the worm. The invention has the beneficial effects that the main box and a control box cover use an aluminum alloy material and a direct introduction type explosion-proof structure, so that the volume of barbette is decreased and the weight of the barbette is mitigated. The electric device of the fire monitor barbette is capable of greatly facilitating the installation and carrying, reducing the design difficulty and manufacture cost of the fire monitor, and raising the explosion-proof performance of the electric device. The deceleration mechanism is composed of a primary gear pair and a primary multichannel worm gear pair and increases the output speed.

Owner:TIANJIN AIKETE MEASUREMENT CONTROL TECH

High-speed feeding transmission mechanism for ram type milling head for numerical control machine tool

InactiveCN110576210ARealize horizontal reciprocating motionReduce output speedFeeding apparatusMilling equipment detailsNumerical controlReciprocating motion

The invention discloses a high-speed feeding transmission mechanism for a ram type milling head for a numerical control machine tool. A base is included. The two sides of the side wall of the base arefixedly connected with stand columns. The opposite side walls of the stand columns are rotationally connected with a reciprocating lead screw, and the reciprocating lead screw is in threaded connection with a screw nut. The side wall of the screw nut is fixedly connected with a ram through a connecting rod, and the side wall of the ram is fixedly connected with the milling head. Through the arrangement of a first drive mechanism, a liquid pumping mechanism, a pushing mechanism, a first transmission mechanism, a second transmission mechanism and a second drive mechanism, a motor can be used for driving the reciprocating lead screw to rotate so that the ram feeding motion can be finished, and compared with a traditional feeding mechanism, more stability is achieved; meanwhile, the motor further synchronously drives a sliding plug to reciprocate, accordingly, cooling liquid is sprayed to the surfaces of the milling head and a milling tool, the milling head cooling and temperature reduction function is achieved, the producing and machining cost is saved, meanwhile, synchronous actions with the ram can be conducted, and deformation caused by the tool high milling head temperature due to untimely cooling is avoided.

Owner:杨伟朕

Method for continuously outputting high power on basis of few-gear speed change mechanism for vehicle

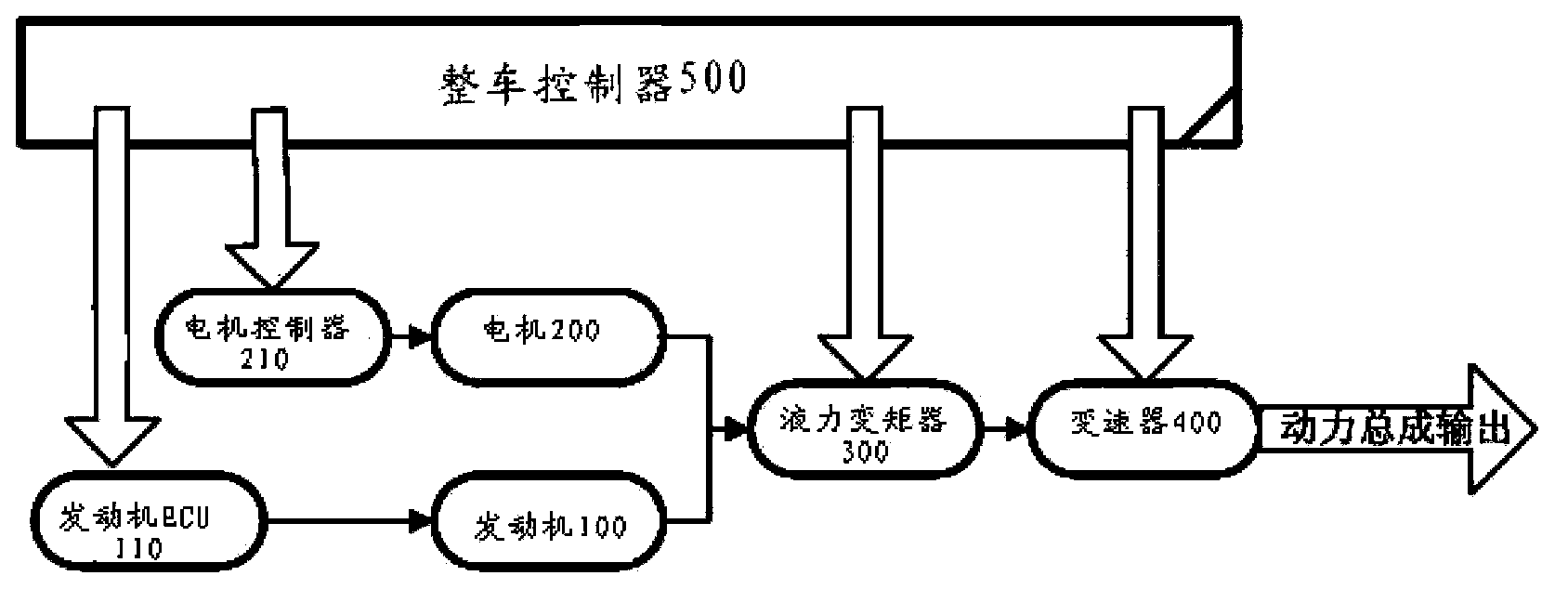

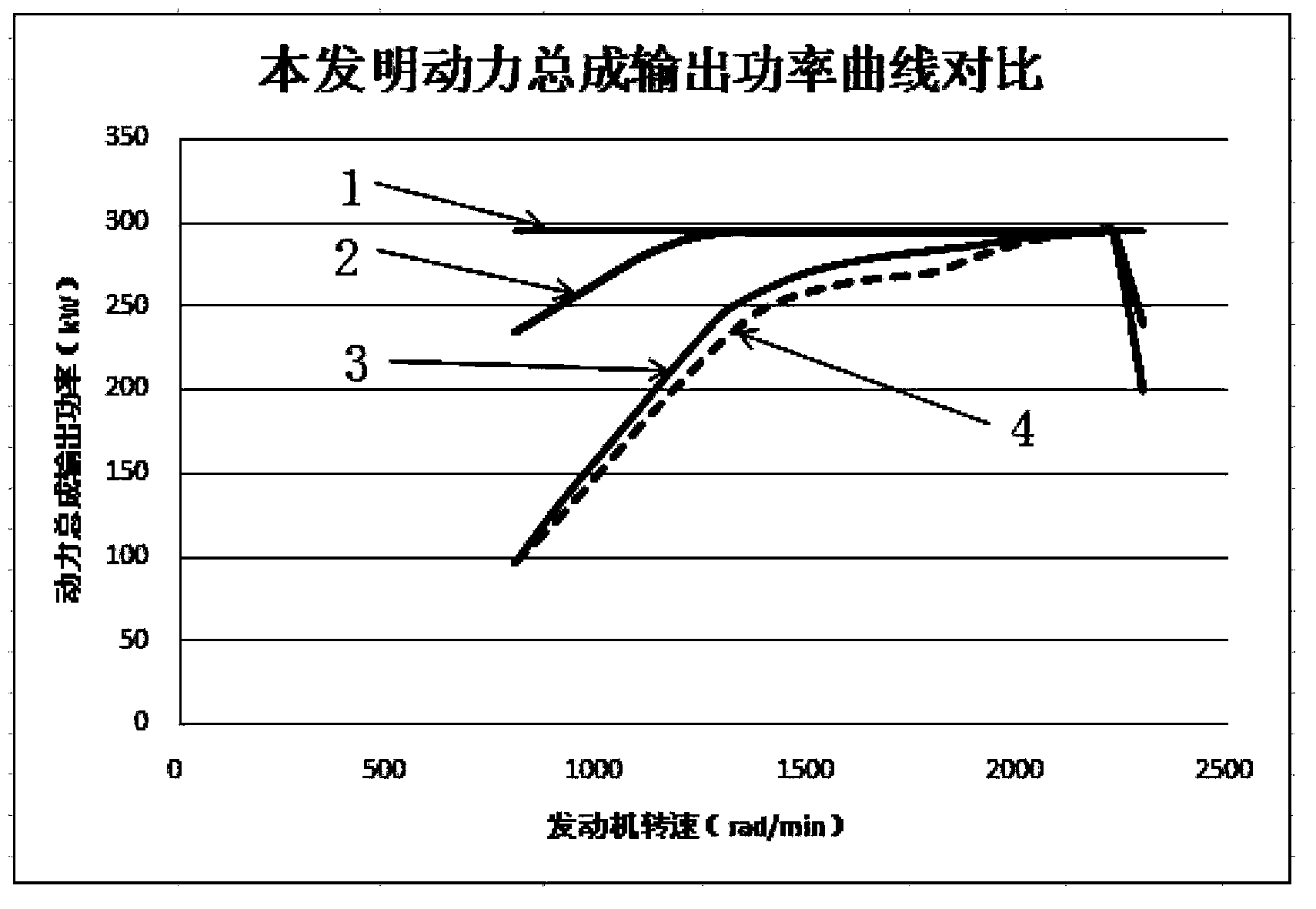

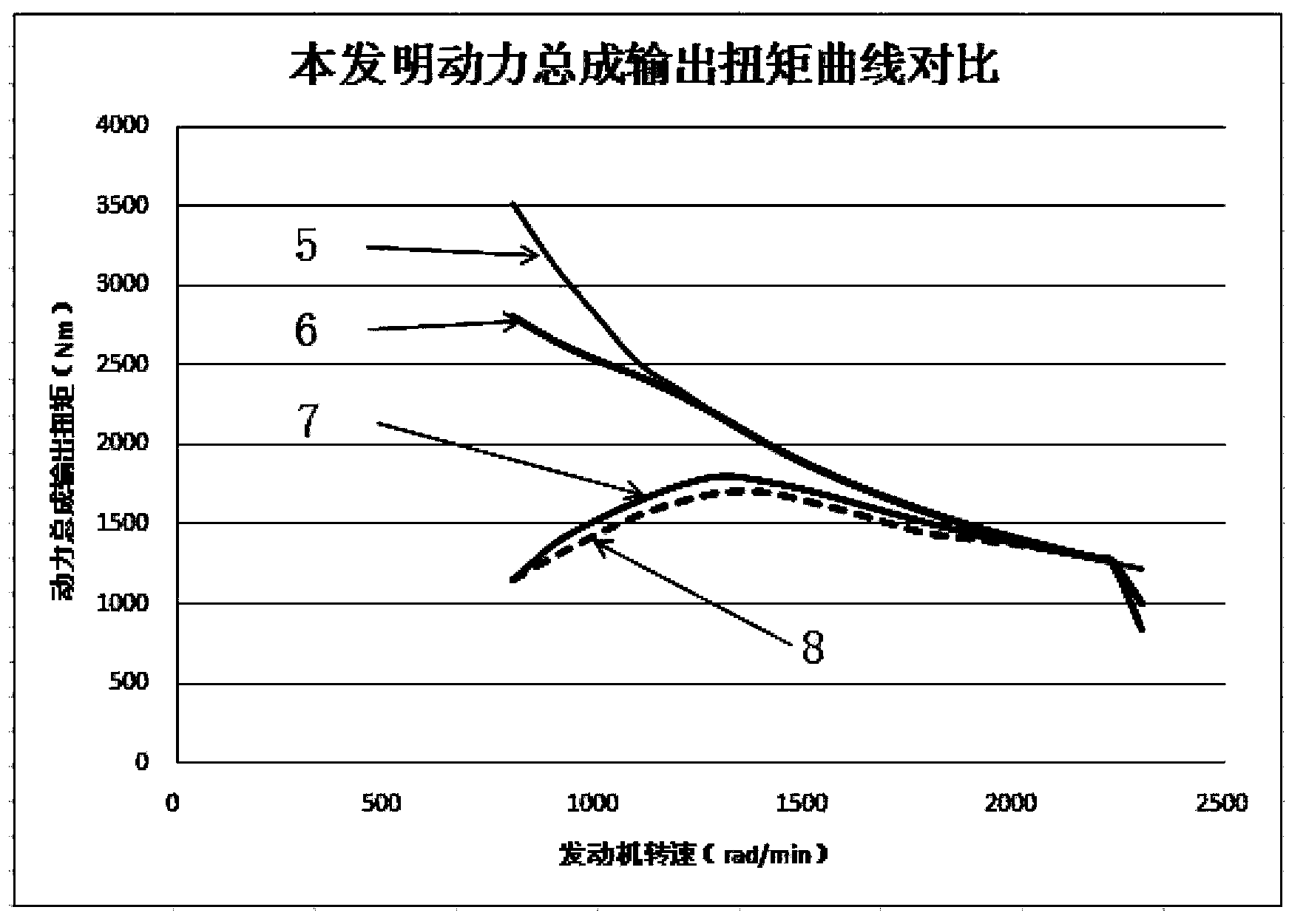

ActiveCN103786571AIncreased torque outputChange speedControl devicesInternal combustion enginePowertrain

The invention discloses a method for continuously outputting high power on the basis of a few-gear speed change mechanism for a vehicle. The method is characterized in that power and transmission matching output of a power assembly includes two stages, a rotational speed of an output end of the speed change mechanism at the first stage is changed from zero to a set rotational speed, an internal combustion engine and a second power unit simultaneously output power to a hydraulic torque converter, and a transmission ratio of the hydraulic torque converter is changed; after the rotational speed of the output end of the speed change mechanism at the second stage exceeds the set rotational speed, the internal combustion engine and / or the second power unit output power to the hydraulic torque converter, the transmission ratio of the hydraulic torque converter is unchanged, an input rotational speed of the speed change mechanism is equal to an output rotational speed of a hydraulic torque converter end, and an output rotational speed of the speed change mechanism is equal to a quotient obtained after an input rotational speed of a speed changer is divided by a transmission ratio of the speed change mechanism. The method has the advantages that power and torque curves of a matched power system of the vehicle are close to characteristic curves of an equivalent-power engine with engine characteristics of a perfect power system of the vehicle under the condition that the vehicle has few gears or even only a single gear, accordingly, the dynamic property of the vehicle can be improved, and the economical efficiency of the vehicle can be enhanced.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com