Patents

Literature

236 results about "Head cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

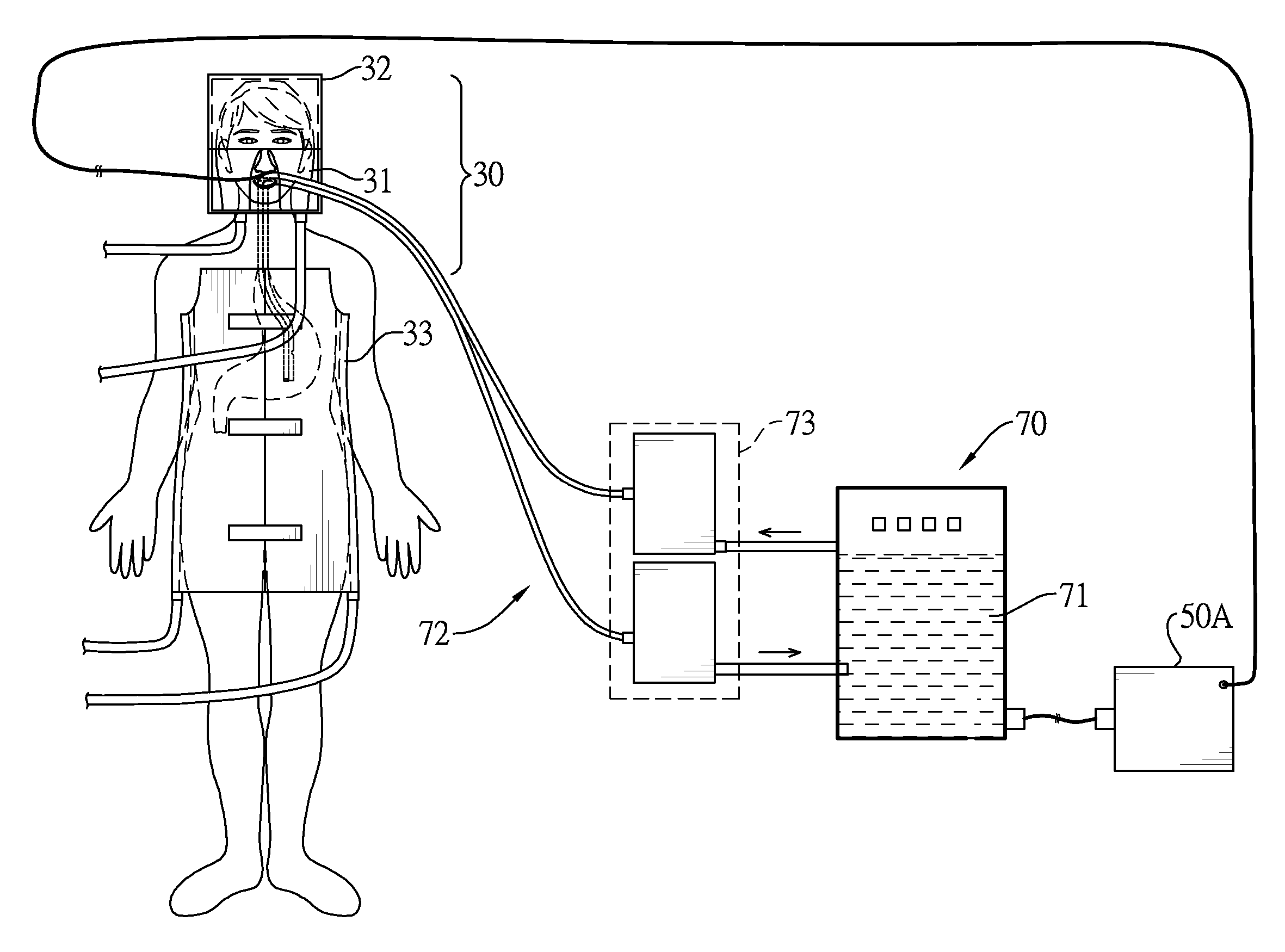

Uniform selective cerebral hypothermia

InactiveUS20030130651A1Surgical instrument detailsIntravenous devicesCooling chamberTemperature difference

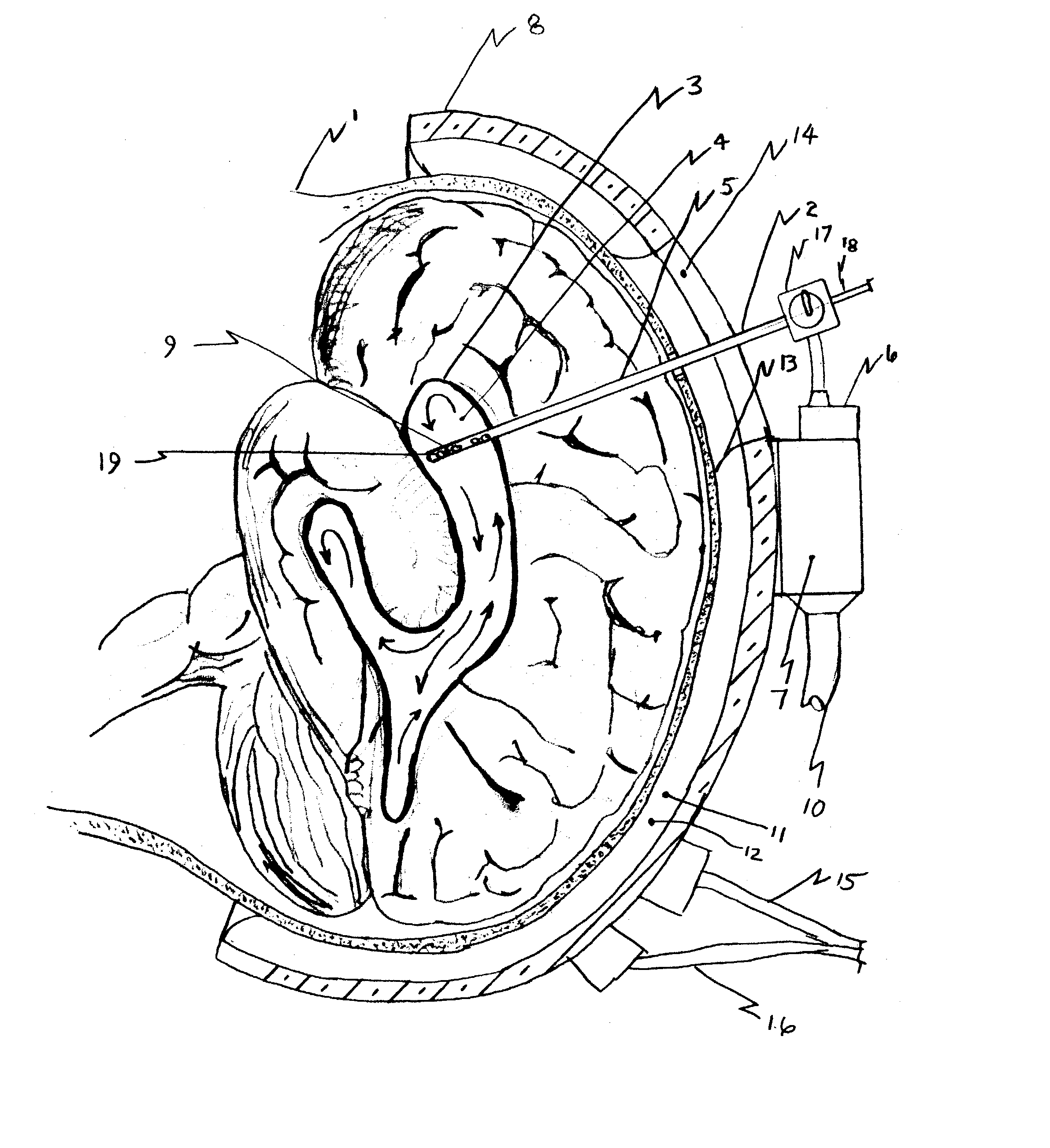

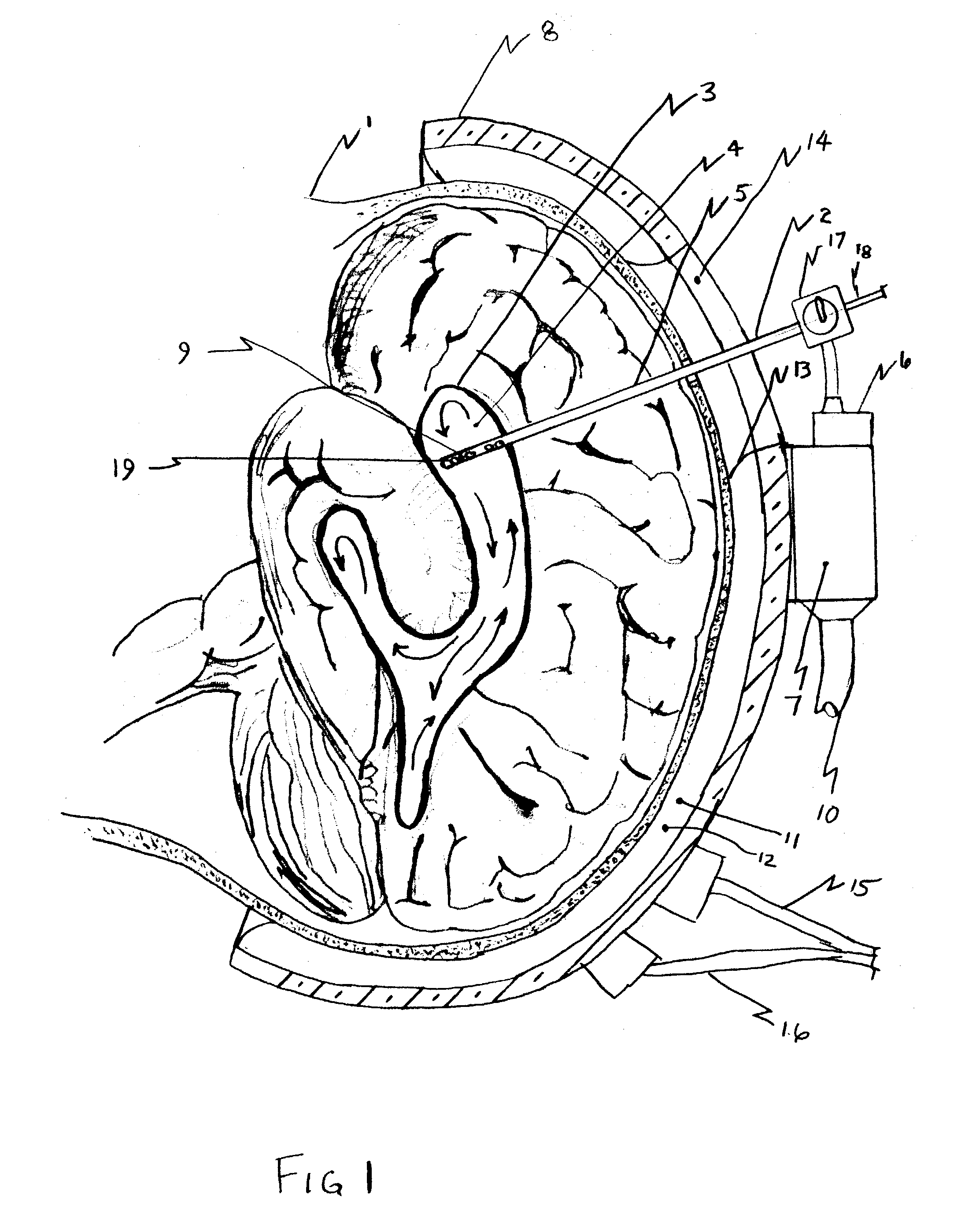

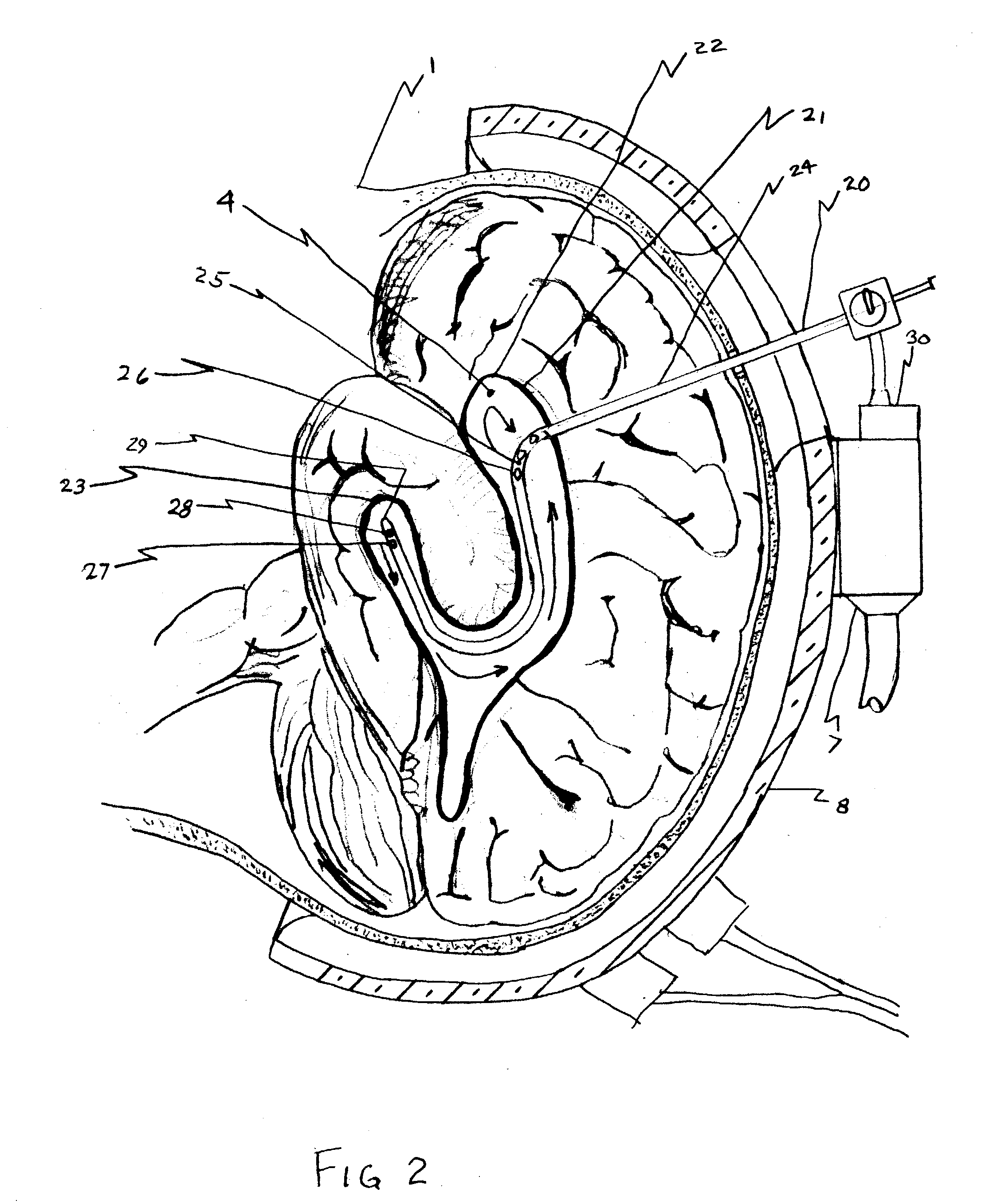

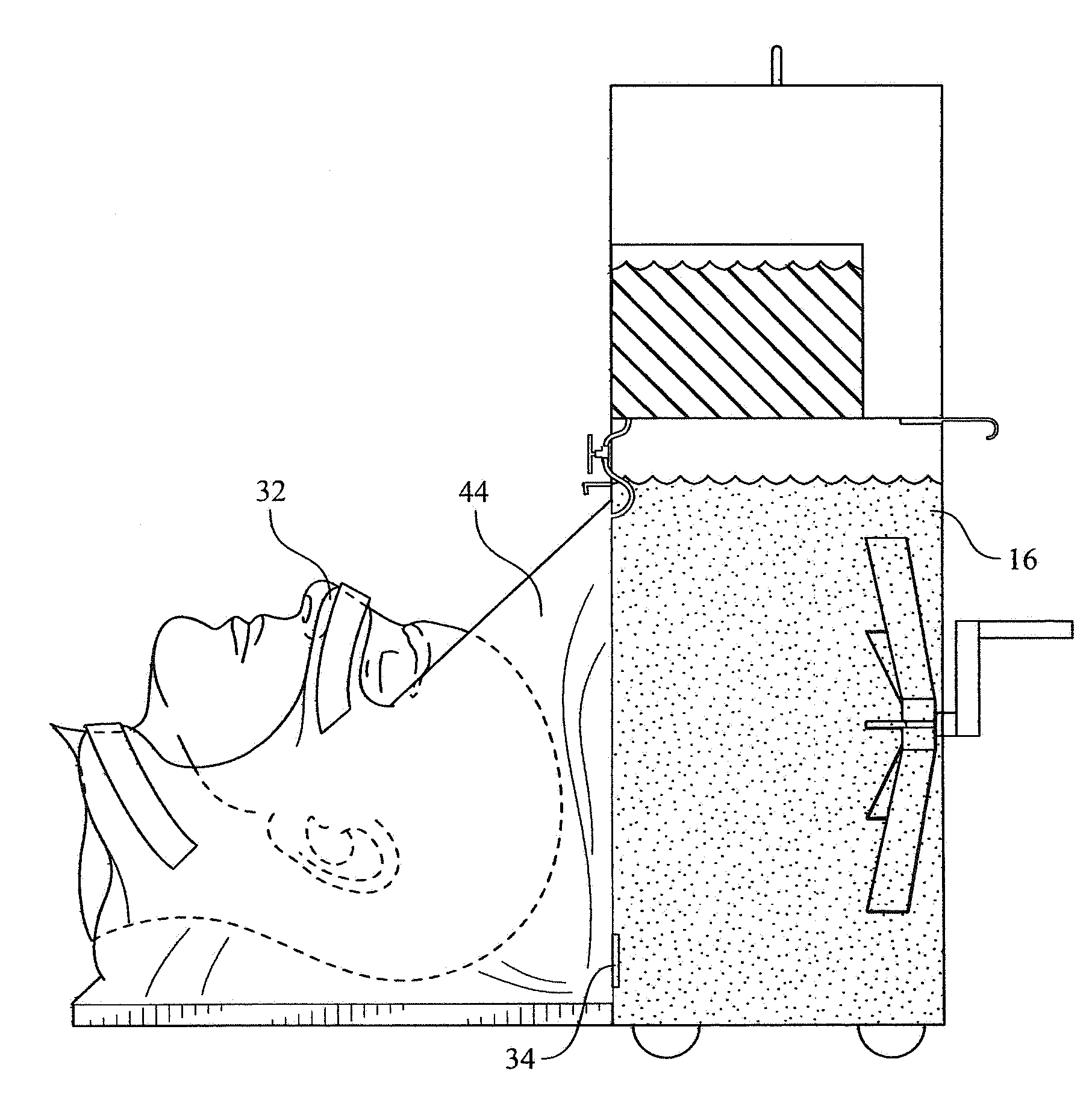

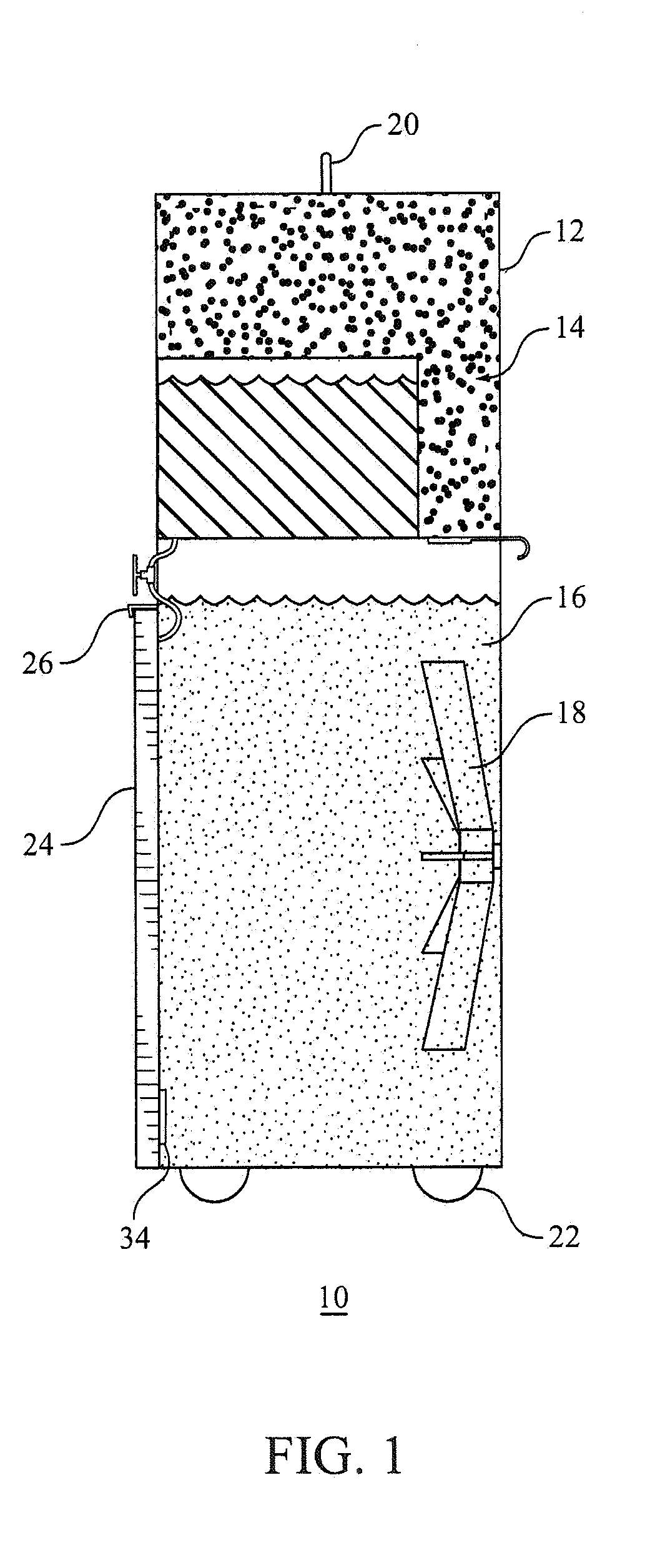

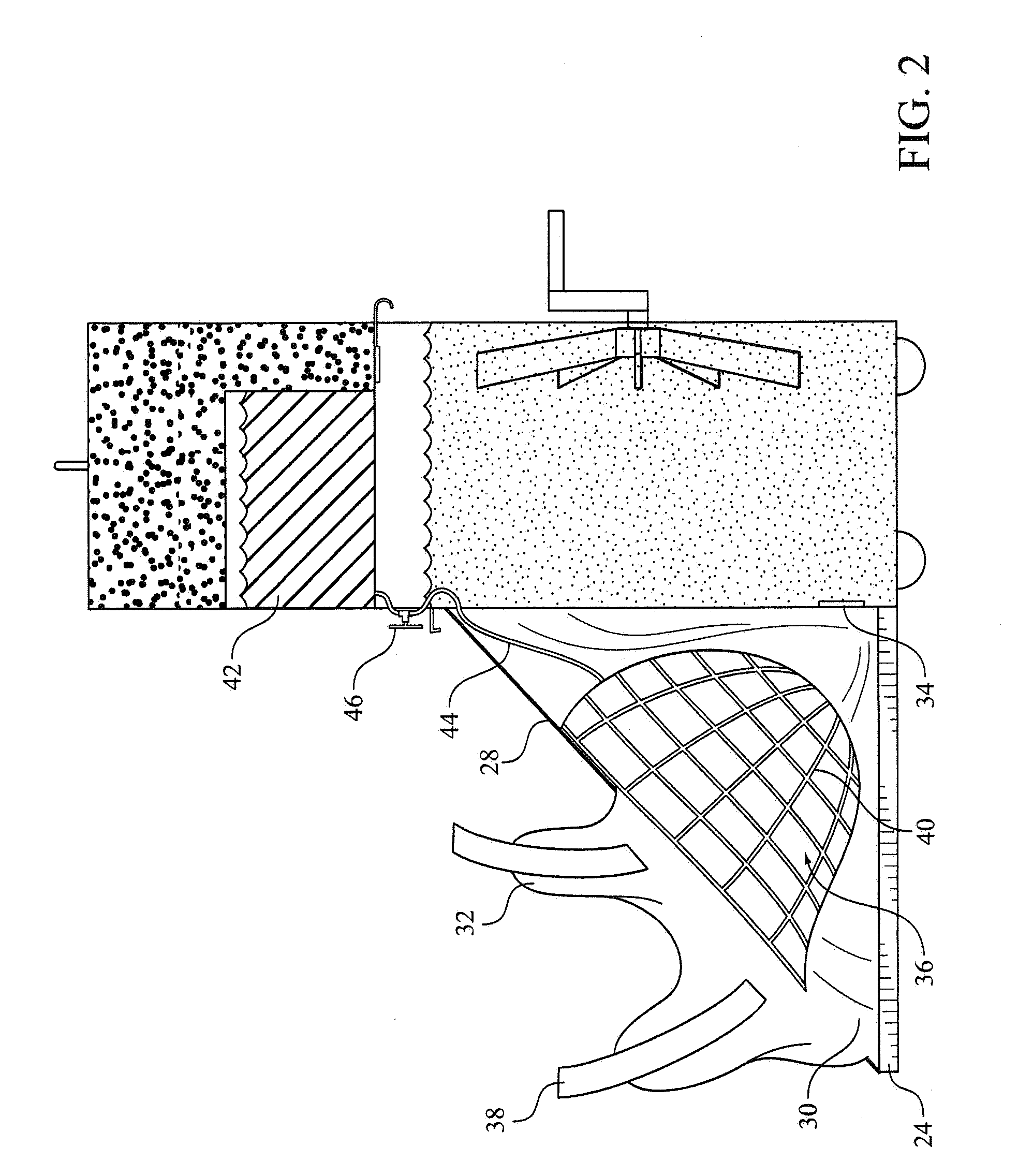

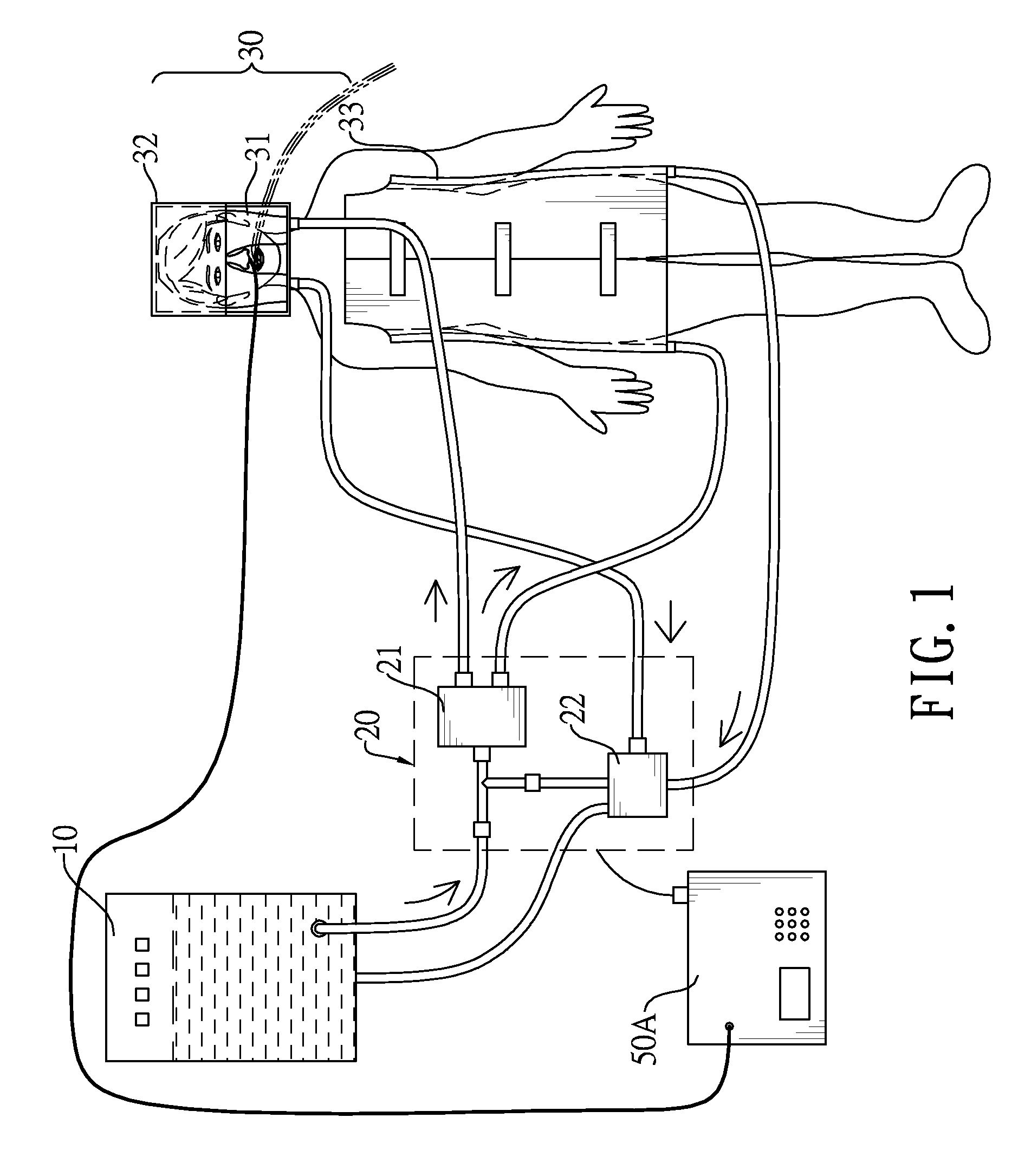

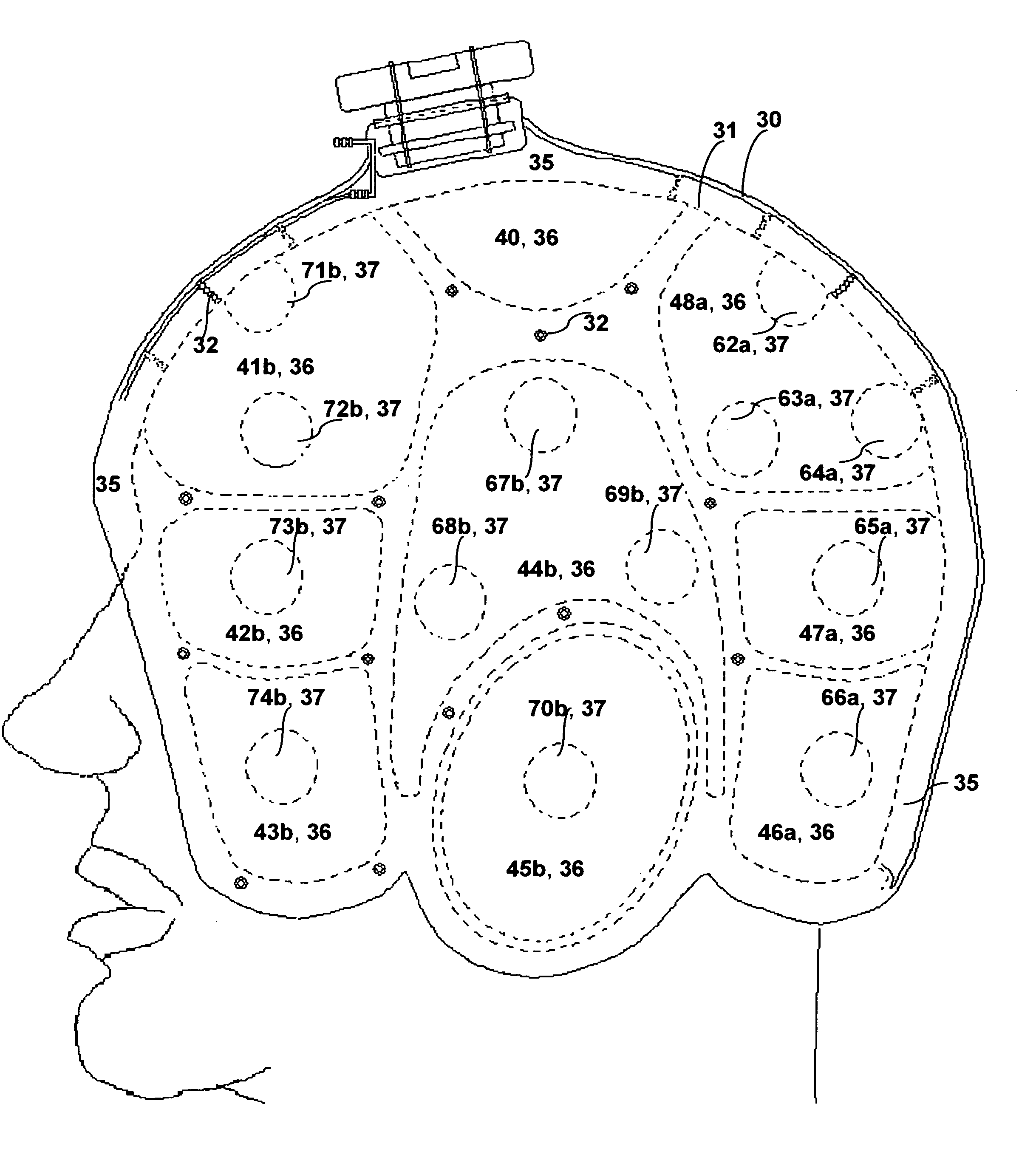

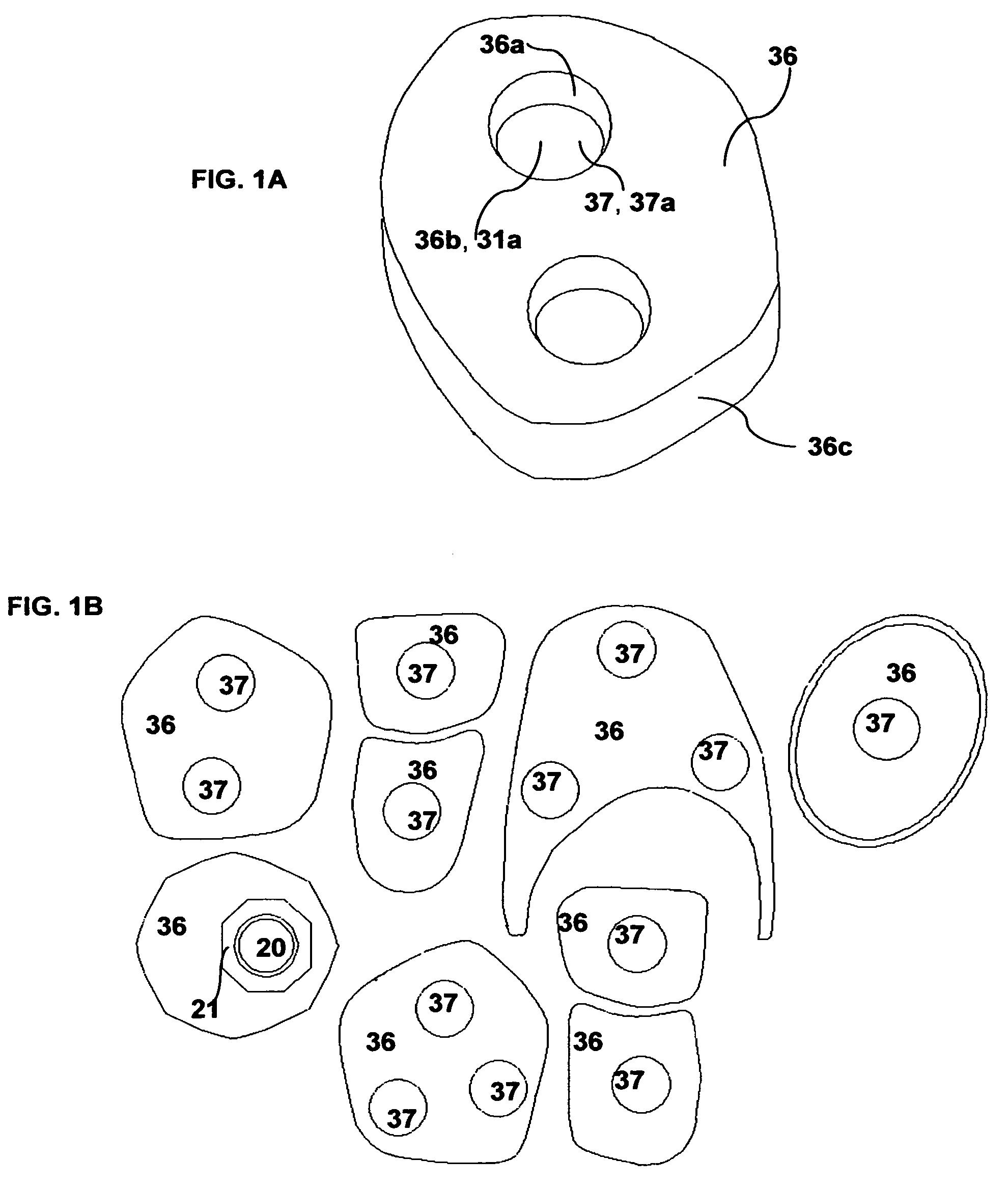

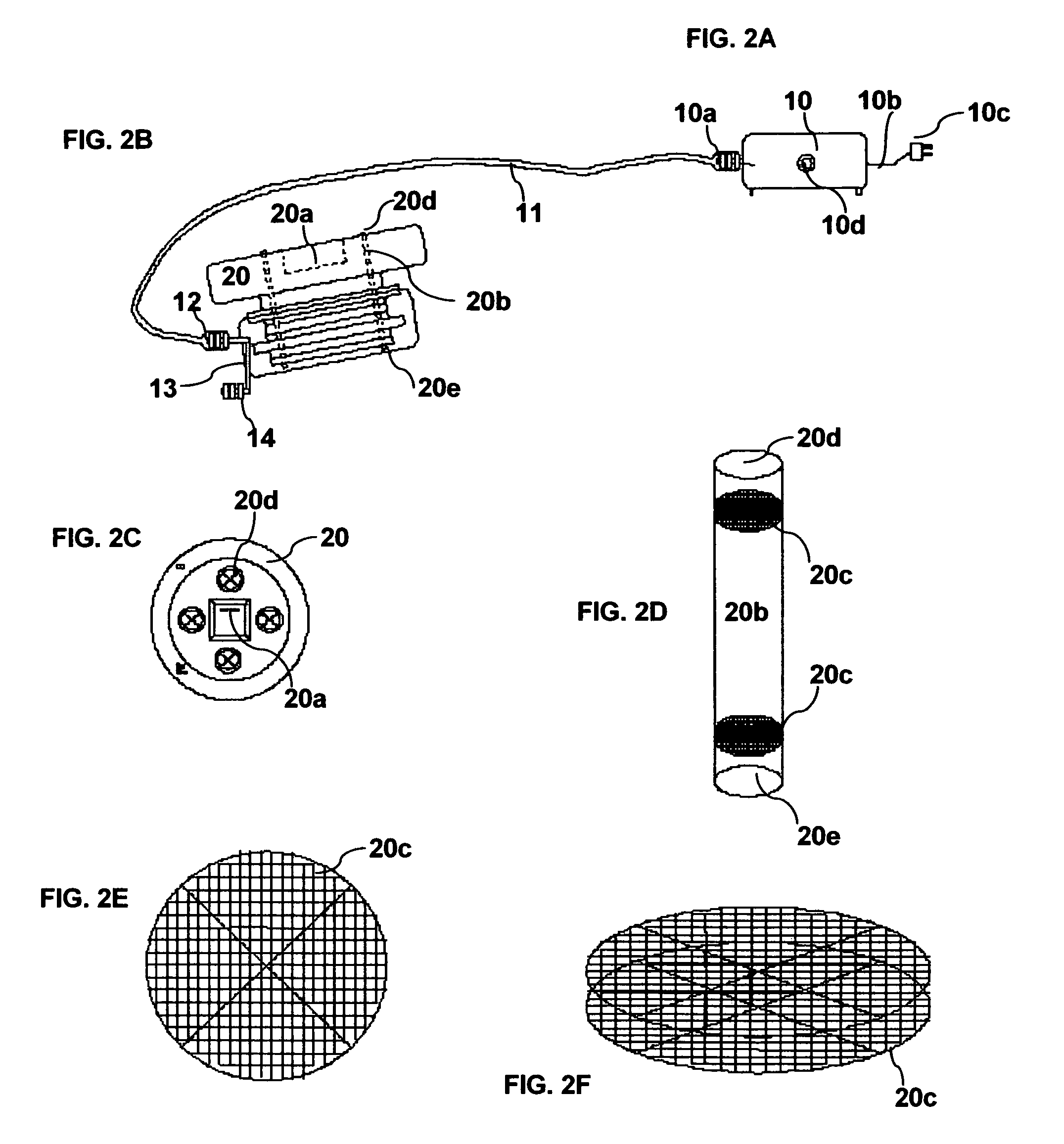

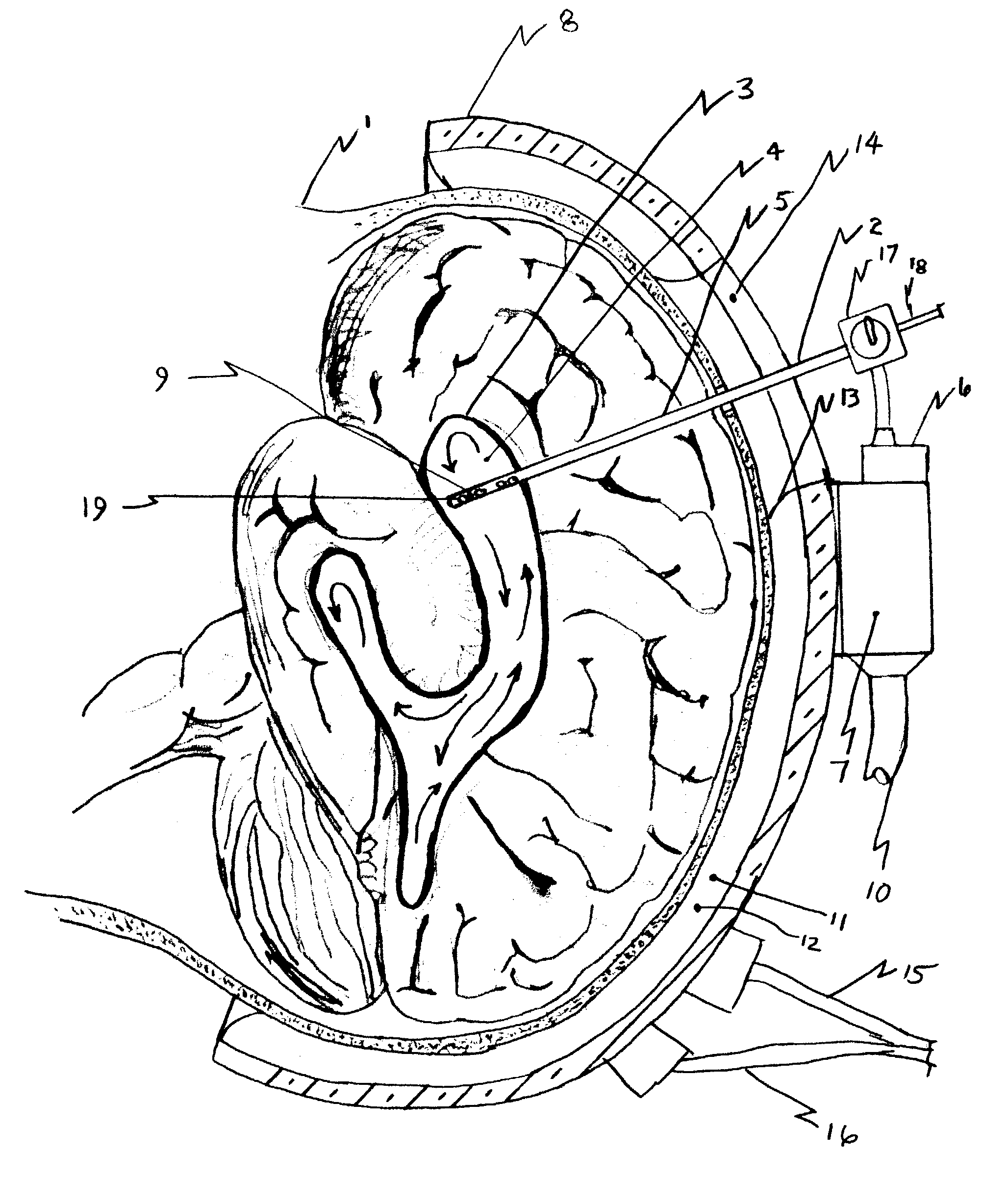

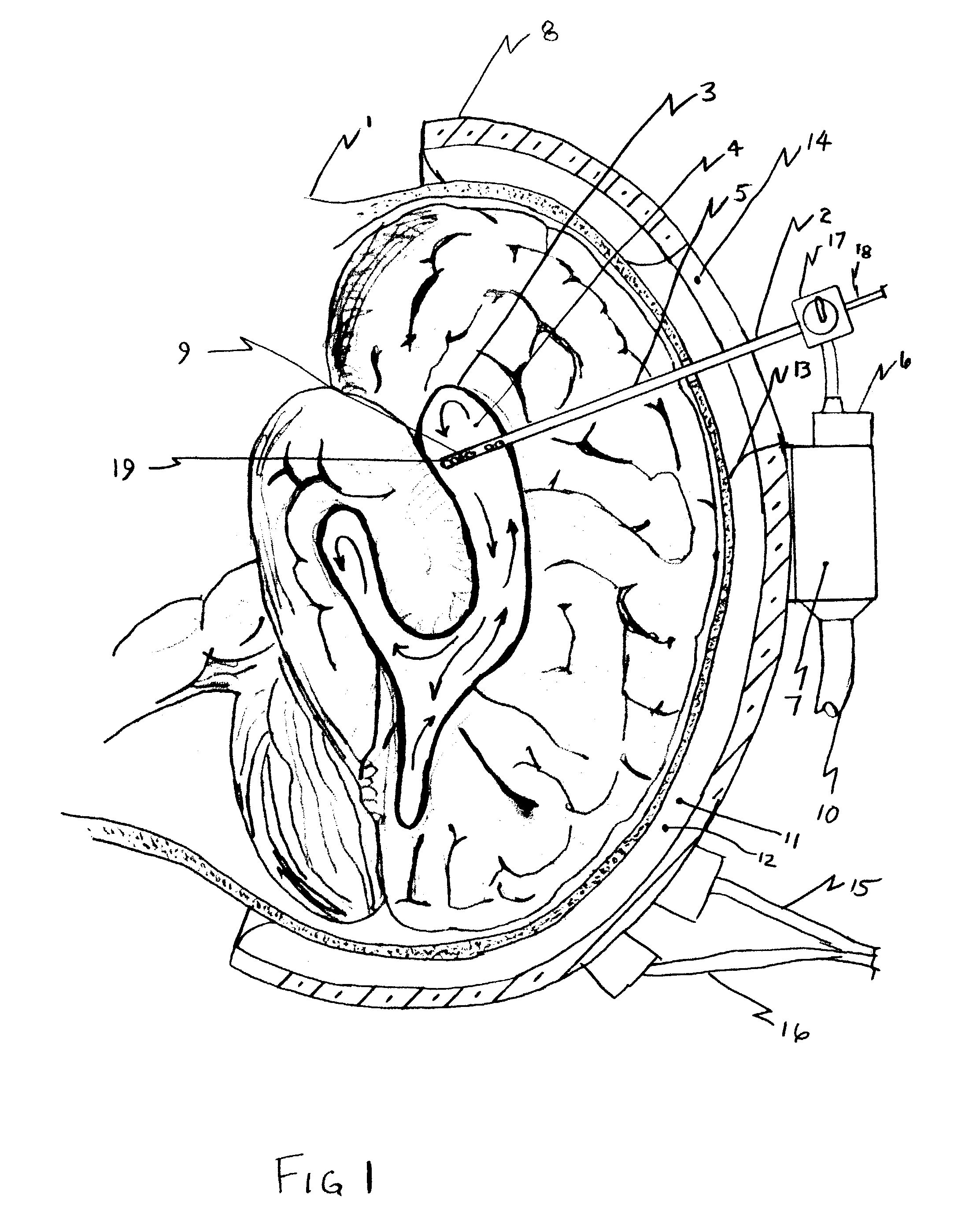

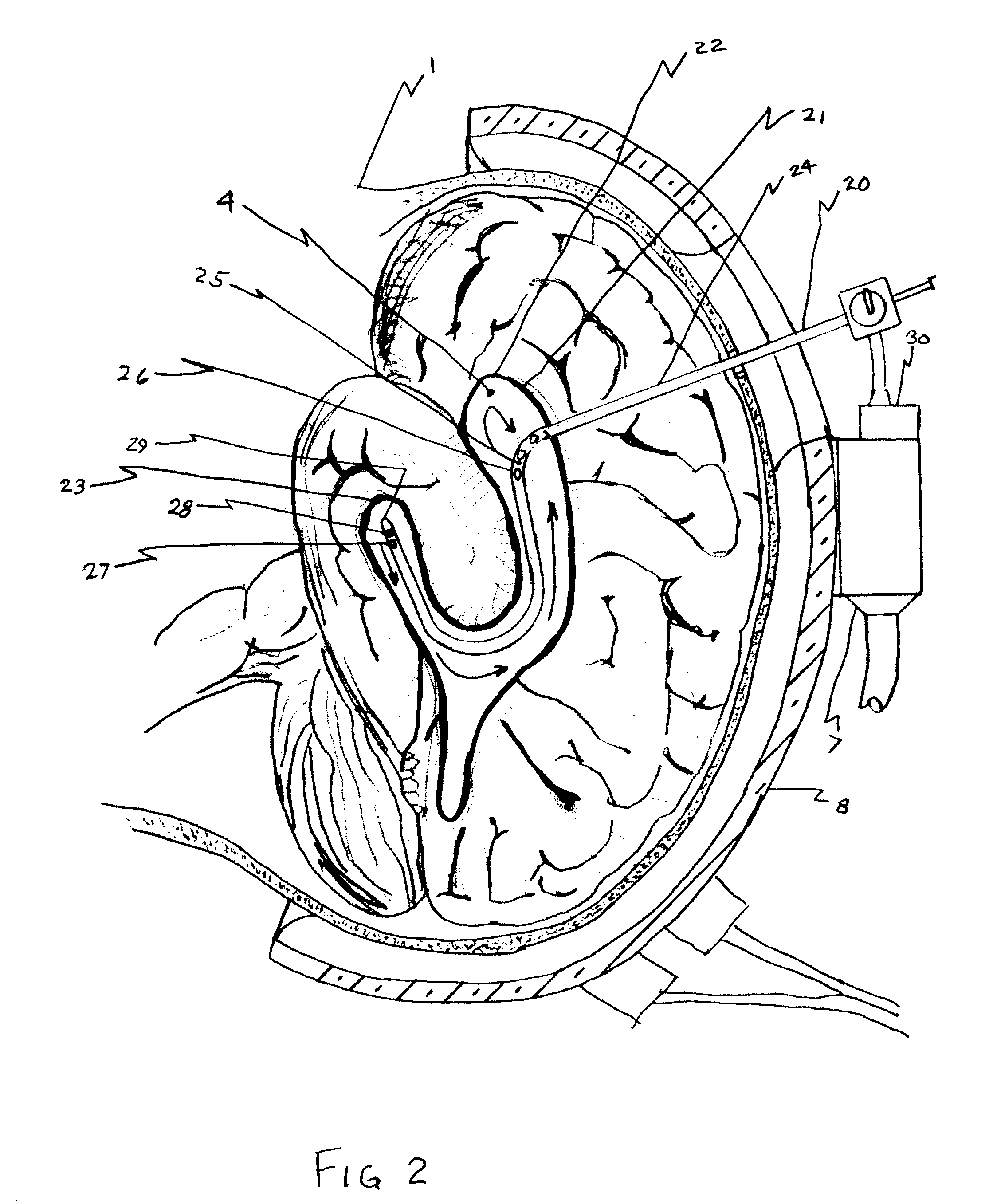

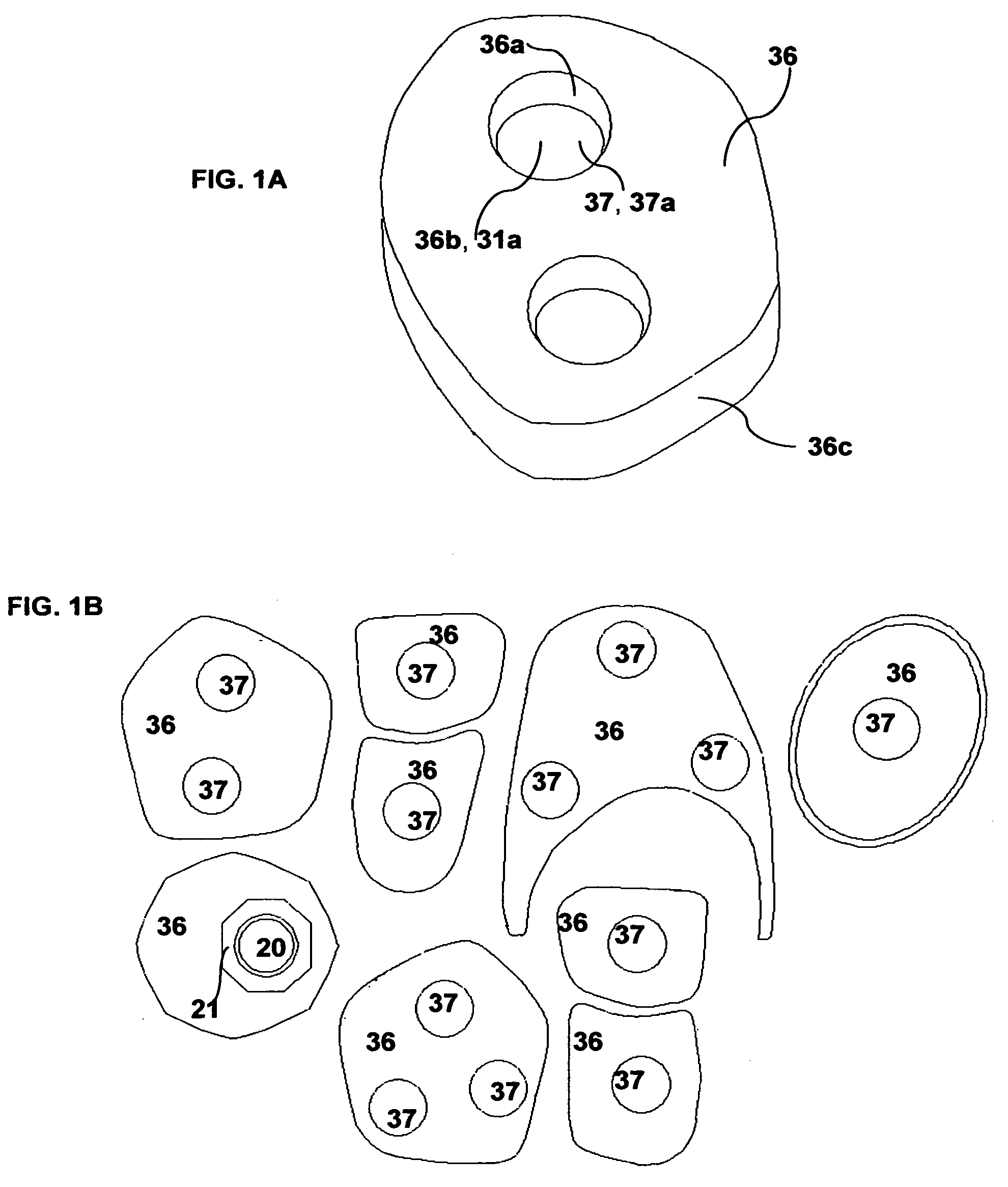

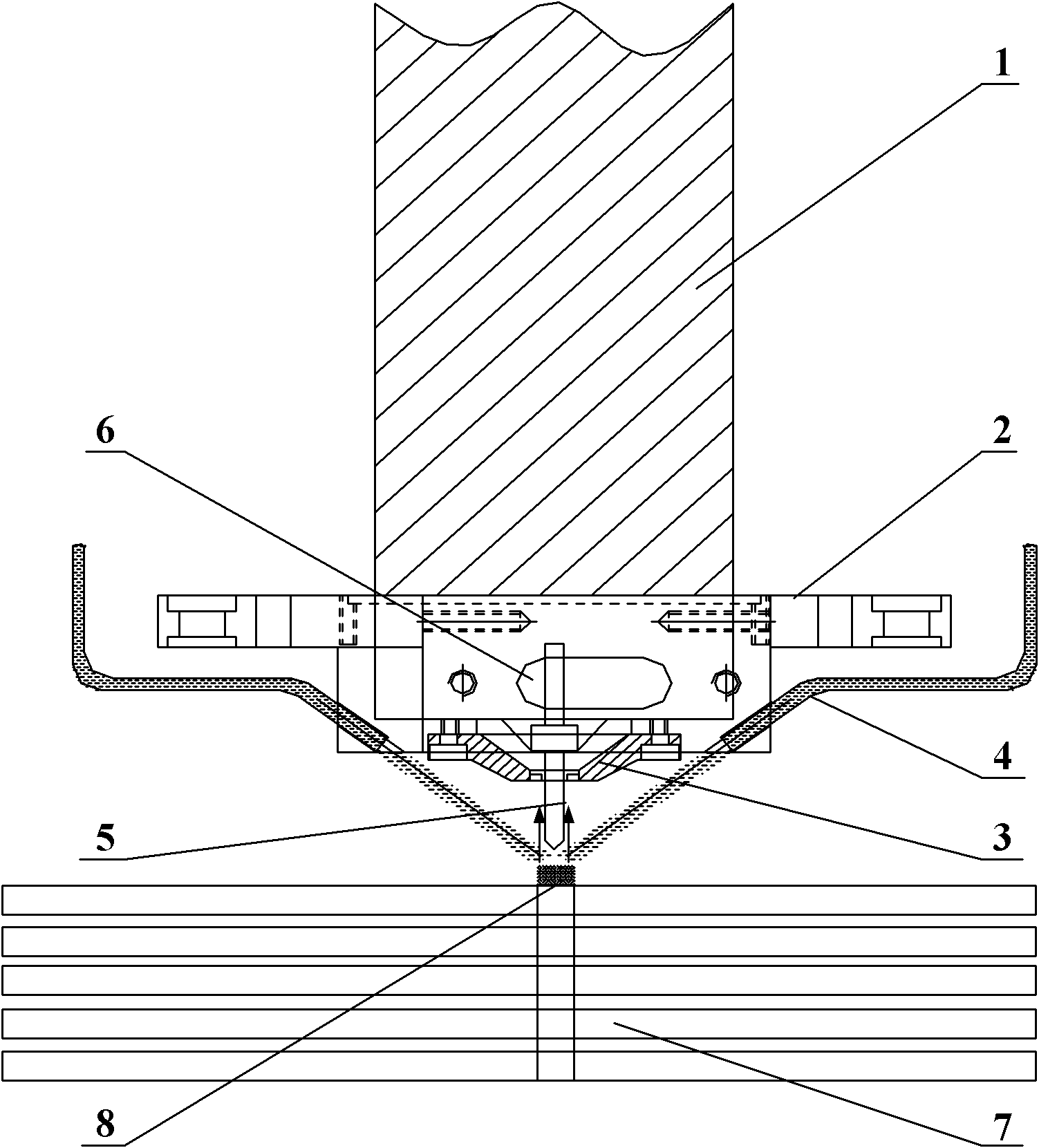

Disclosed is an apparatus and method for uniform selective cerebral hypothermia. The apparatus includes a brain-cooling probe, a head-cooling cap, a body-heating device and a control console. The brain-cooling probe cools the cerebrospinal fluid within one or more brain ventricles. The brain-cooling probe withdraws a small amount of cerebrospinal fluid from a ventricle into a cooling chamber located ex-vivo in close proximity to the head. After the cerebrospinal fluid is cooled it is then reintroduced back into the ventricle. This process is repeated in a cyclical or continuous manner. The head-cooling cap cools the cranium and therefore cools surface of the brain. The combination of ventricle cooling and cranium cooling provides for whole brain cooling while minimizing temperature gradients within the brain. The body-heating device replaces heat removed from the body by the brain-cooling probe and the head-cooling cap and provides for a temperature difference between the brain and the body where the brain is maintained a temperature lower than the temperature of the body.

Owner:MEDCOOL

Apparatus and method for preventing brain damage during cardiac arrest, cpr, or severe shock

InactiveUS20090276018A1Rapid coolingImprove hypothermiaTherapeutic coolingTherapeutic heatingInjury brainCardiorespiratory arrest

Apparatuses and methods for the cooling of the cranial and extracranial portions of a patient in need thereof. The apparatuses and methods of the present invention preferably employ a head cooling apparatus which includes a watertight shroud for the head and which needs no refrigeration. In certain preferred embodiments, the apparatuses of the present invention are collapsible and possess a reduced profile. In some presently preferred embodiments, the present invention includes a hammock that supports the head. In some embodiments, the present invention includes a shroud that lies behind the head with optional portions that may be drawn over the patient's neck and cranial area. The apparatuses and methods of the present invention also provide an improved mechanism for cooling the cranial and extracranial areas through the use of a novel distribution of endothermic solids (e.g. ammonium nitrate). The present invention provides a novel distribution of ammonium nitrate pellets that preferably includes multiple populations solid ammonium nitrate, preferably including small diameter (e.g., powdered) and larger diameter (e.g., 7 millimeter) ammonium nitrate to allow water initially to be cooled very quickly, thereby facilitating the rapid cooling of the cranial and extracranial areas, while at the same time producing extended hypothermia.

Owner:BRADER ERIC WILLIAM

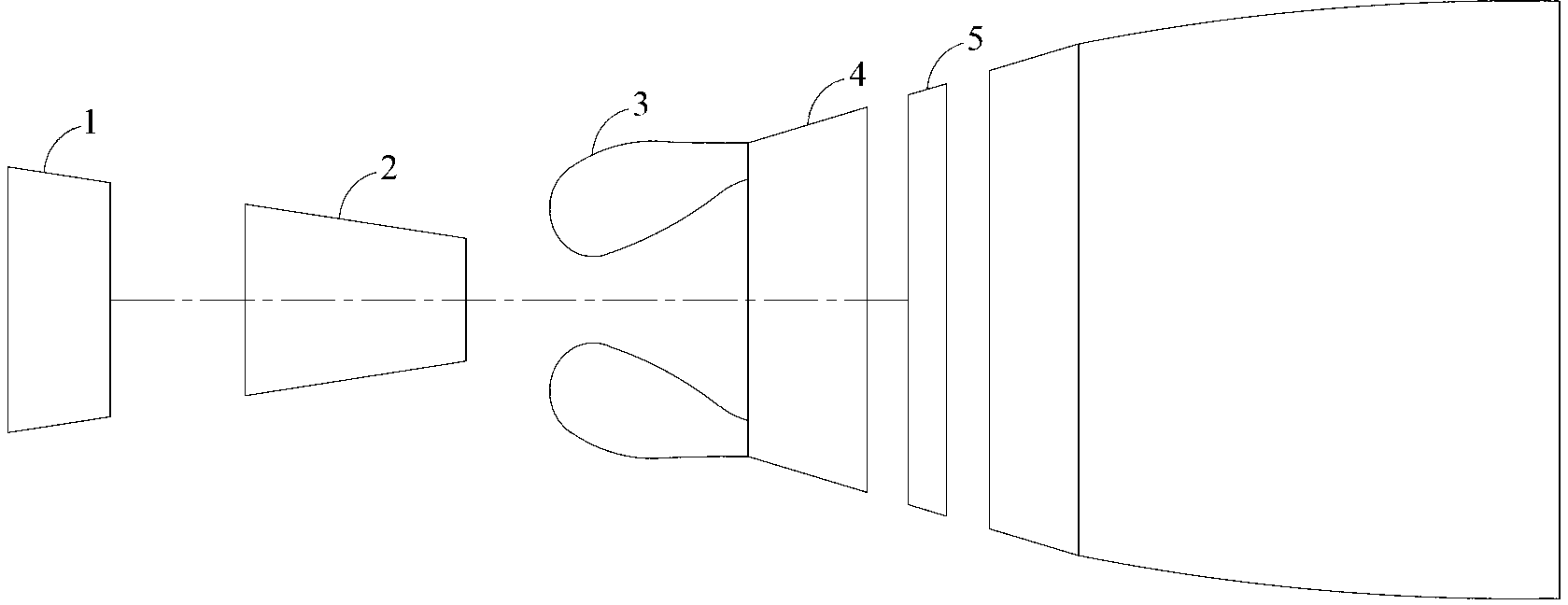

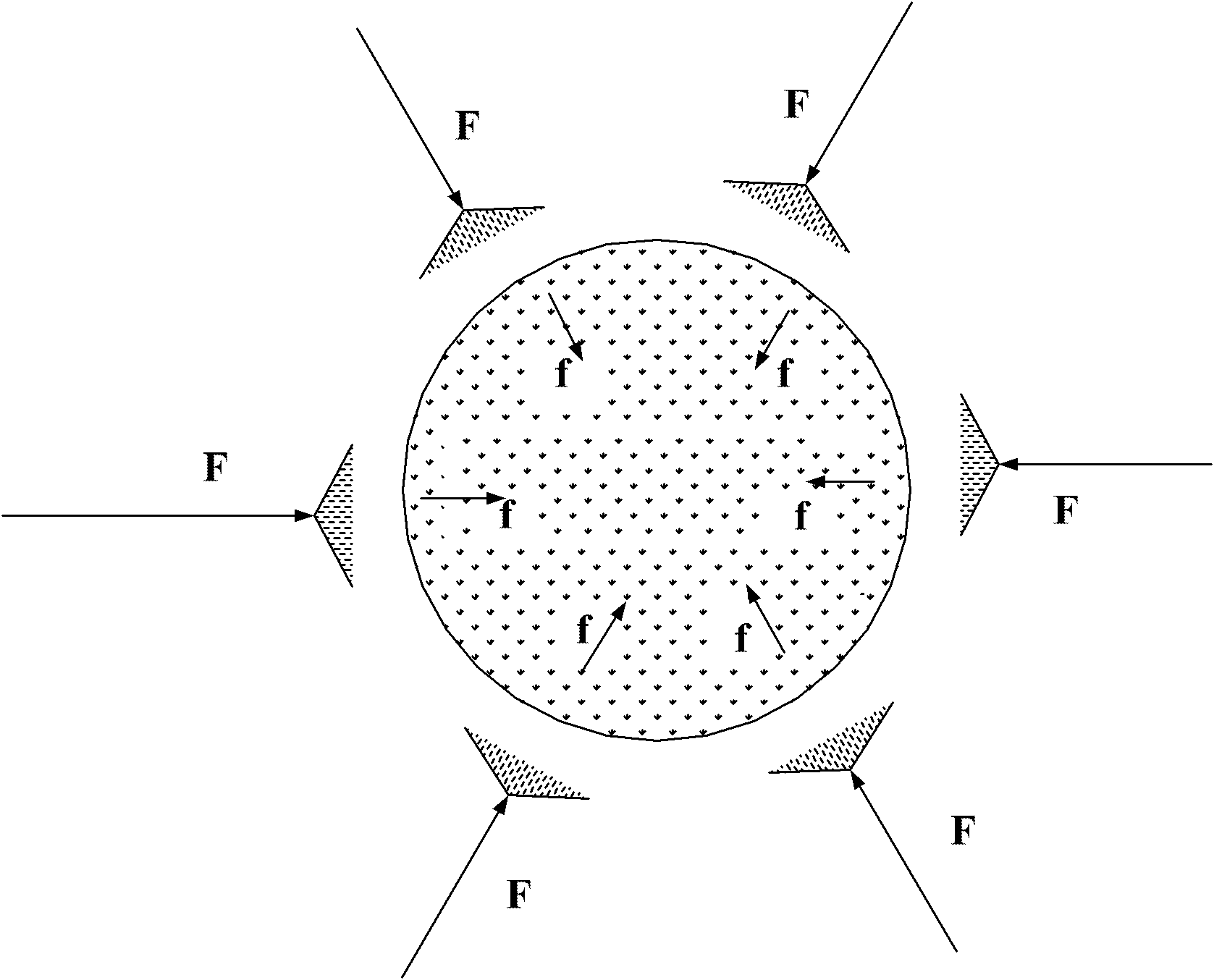

Beveling main combustion hole rotation aiding low-pollution backflow combustion chamber

ActiveCN103292356AIncrease swirl intensityBurn evenlyContinuous combustion chamberCombustion chamberPulp and paper industry

Owner:BEIHANG UNIV

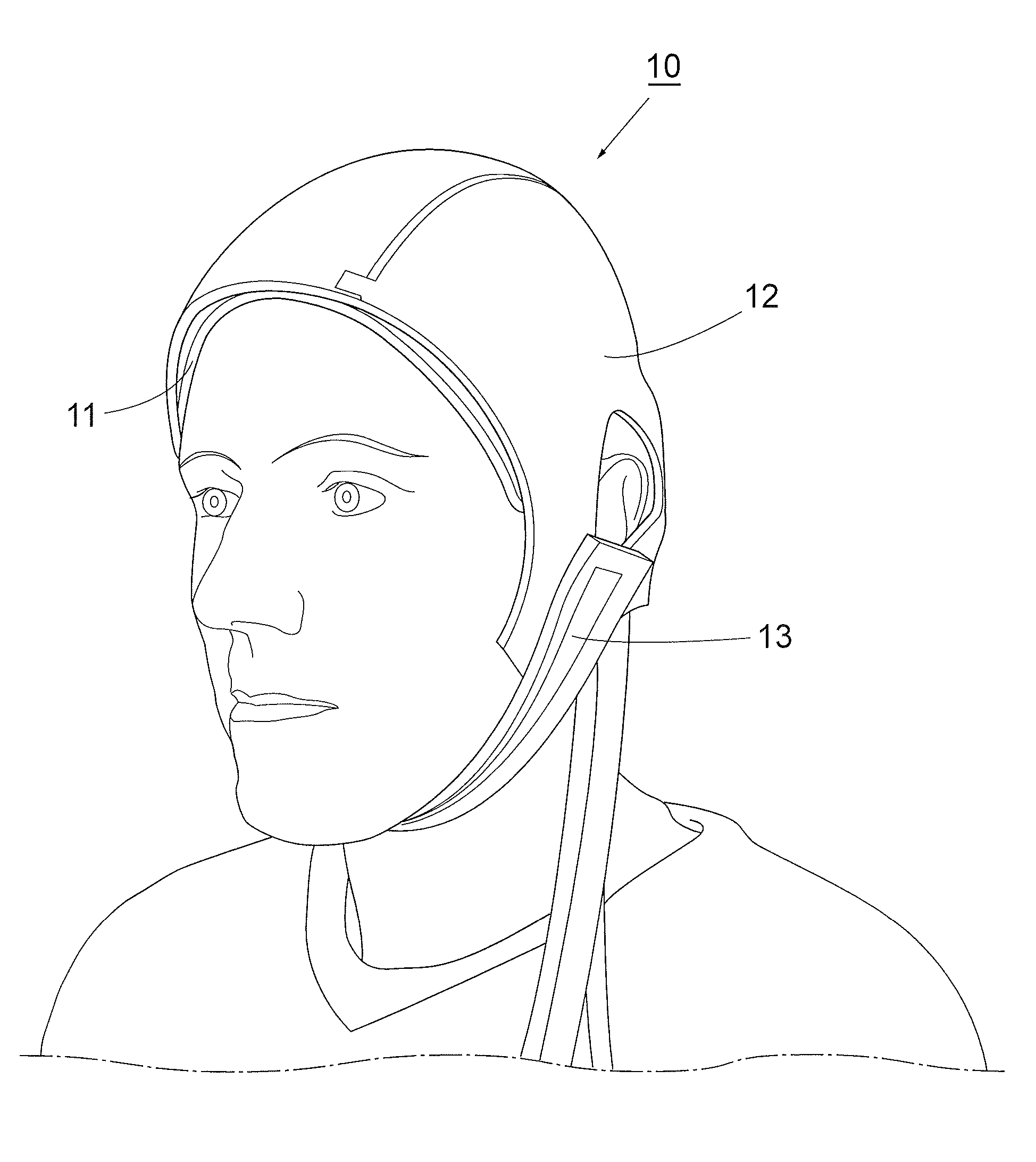

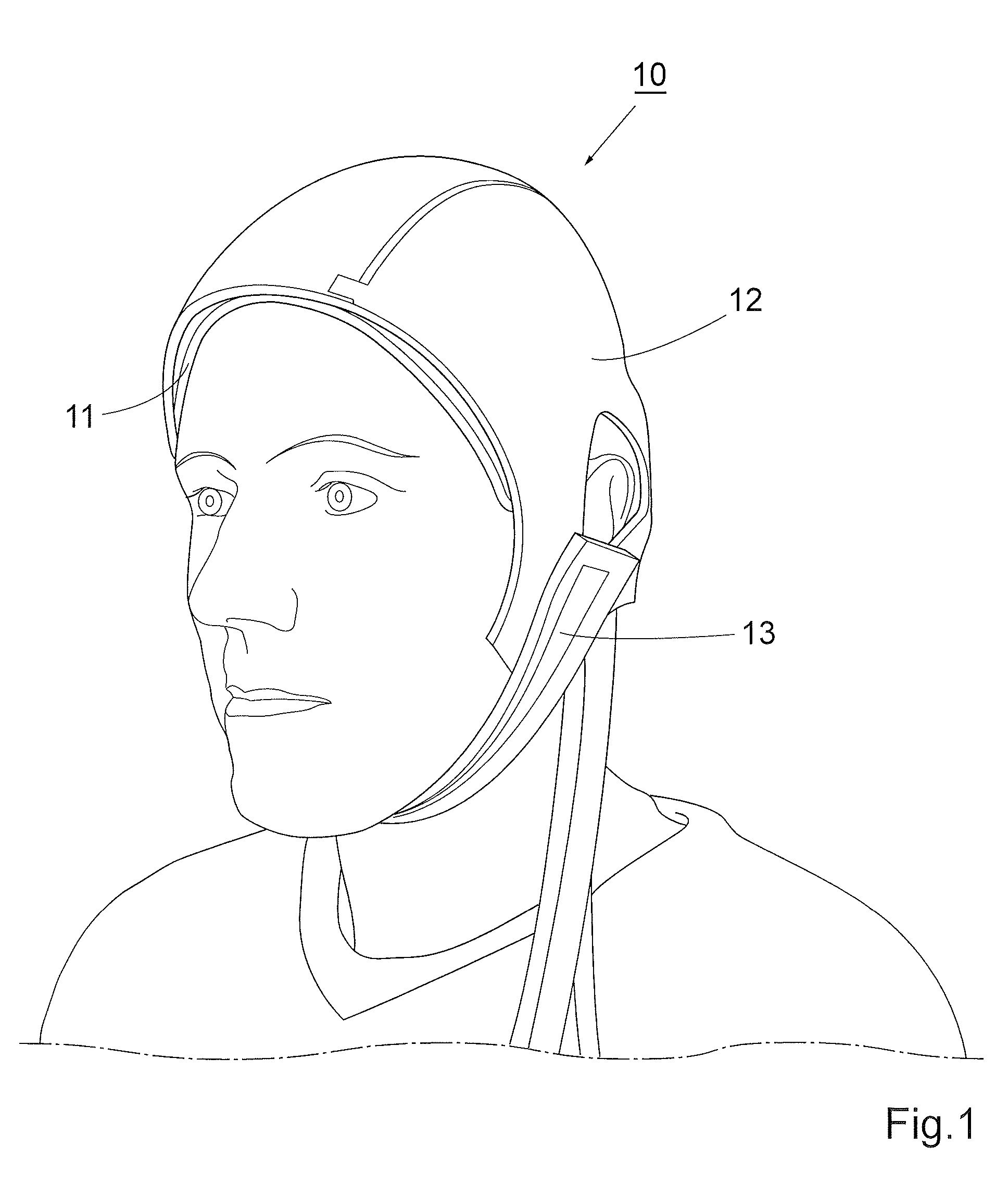

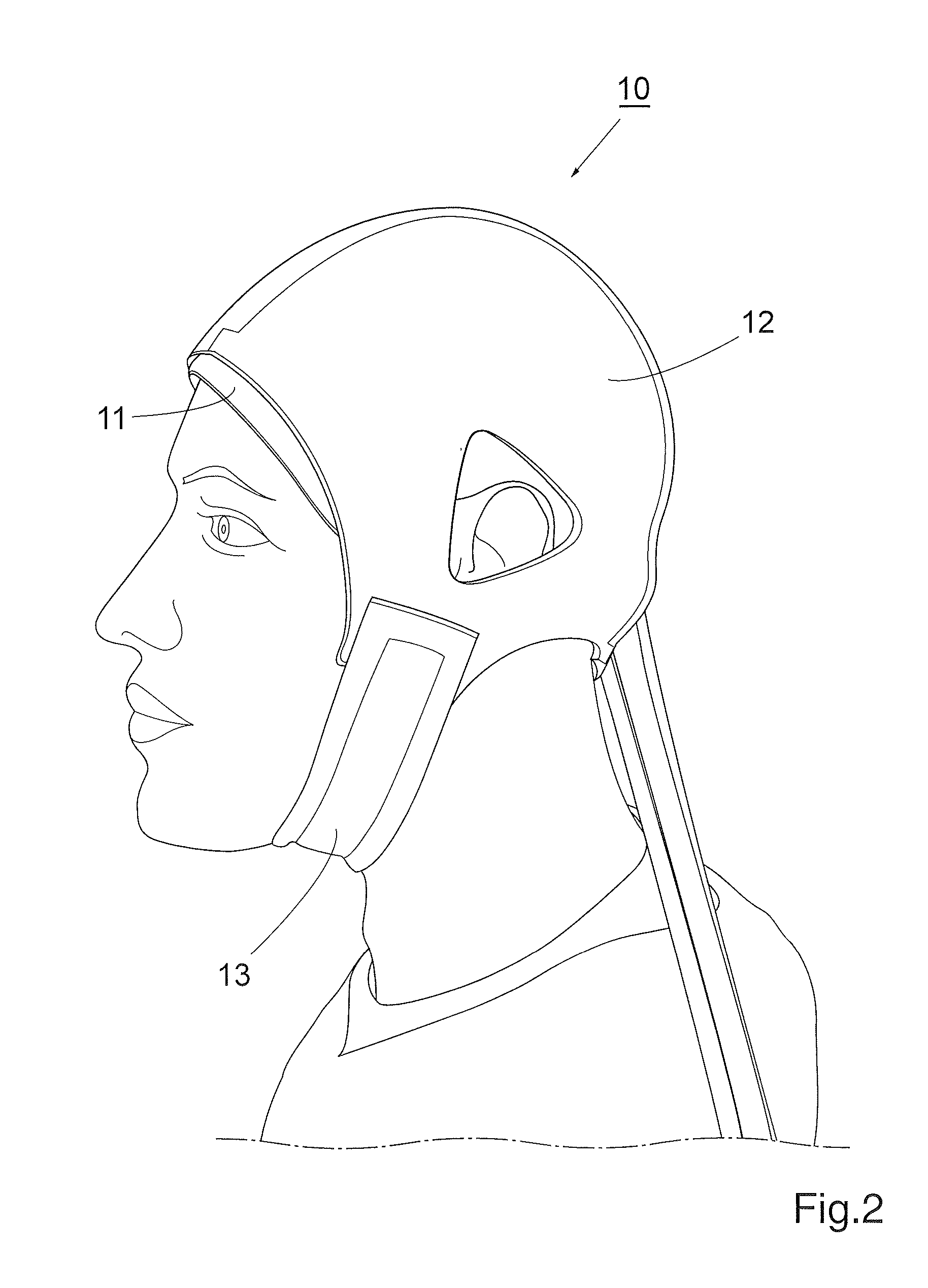

Head cooler

ActiveUS20100186436A1Preventing hair lossDomestic cooling apparatusLighting and heating apparatusCooling fluidChiller

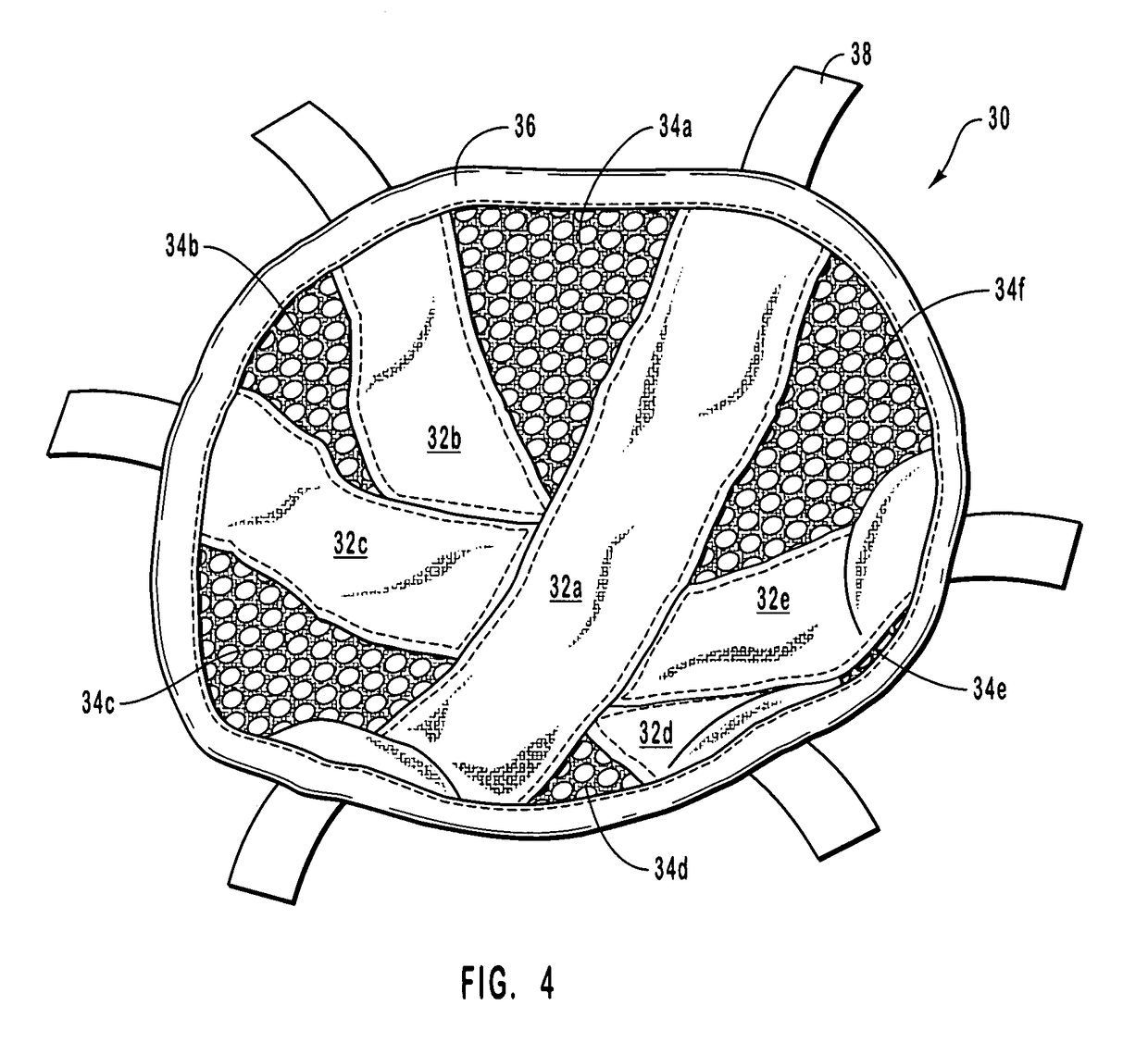

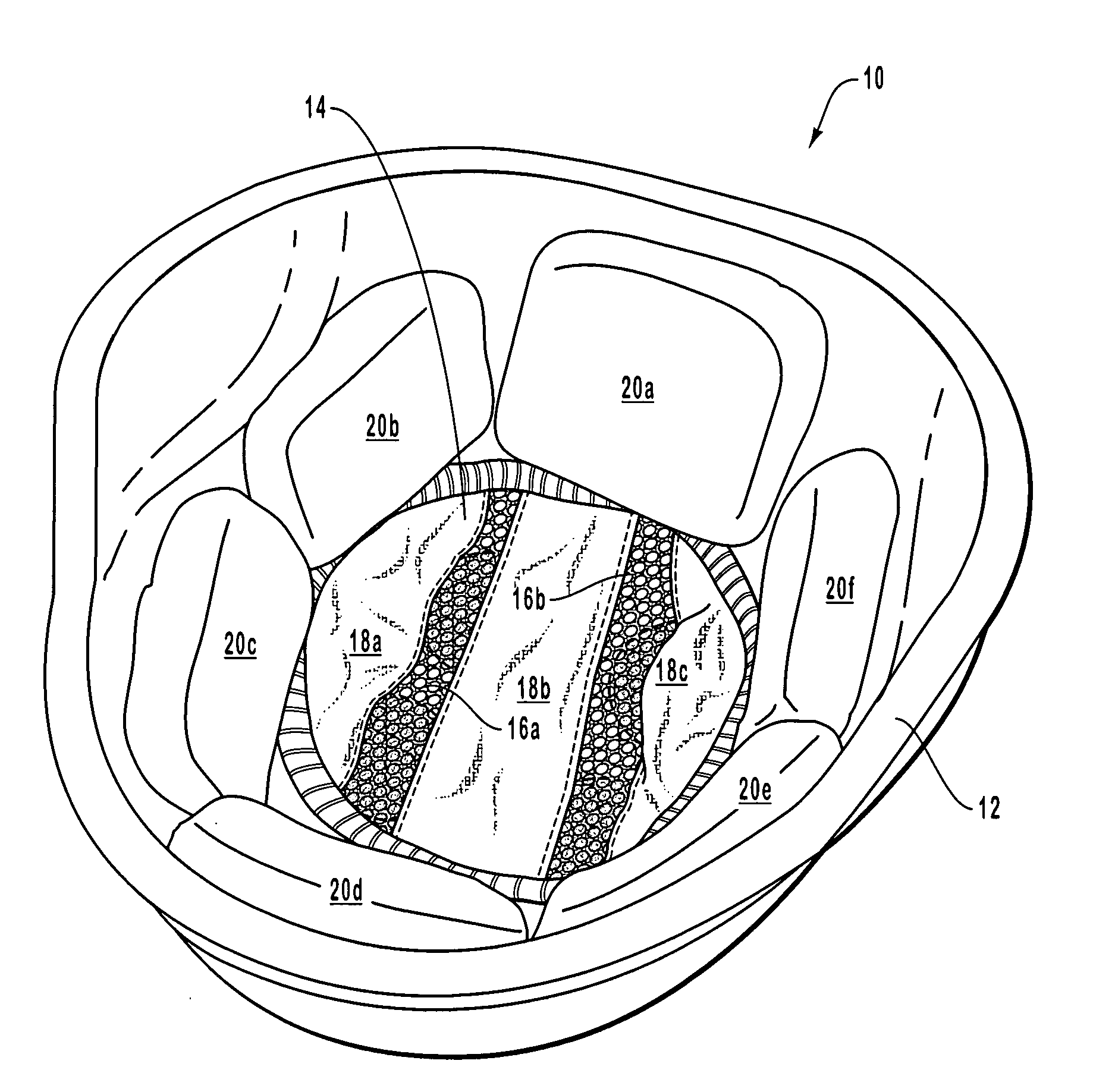

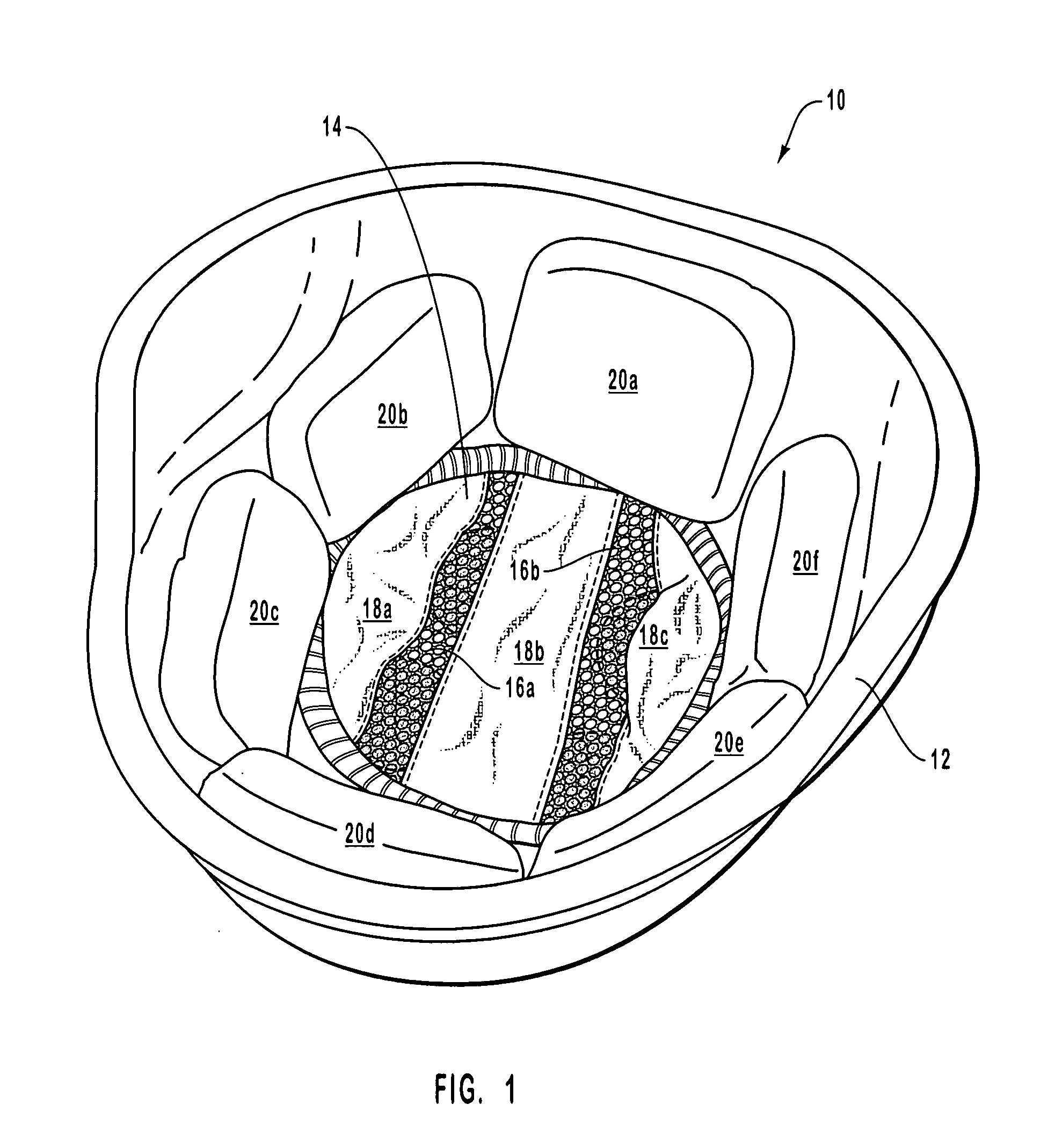

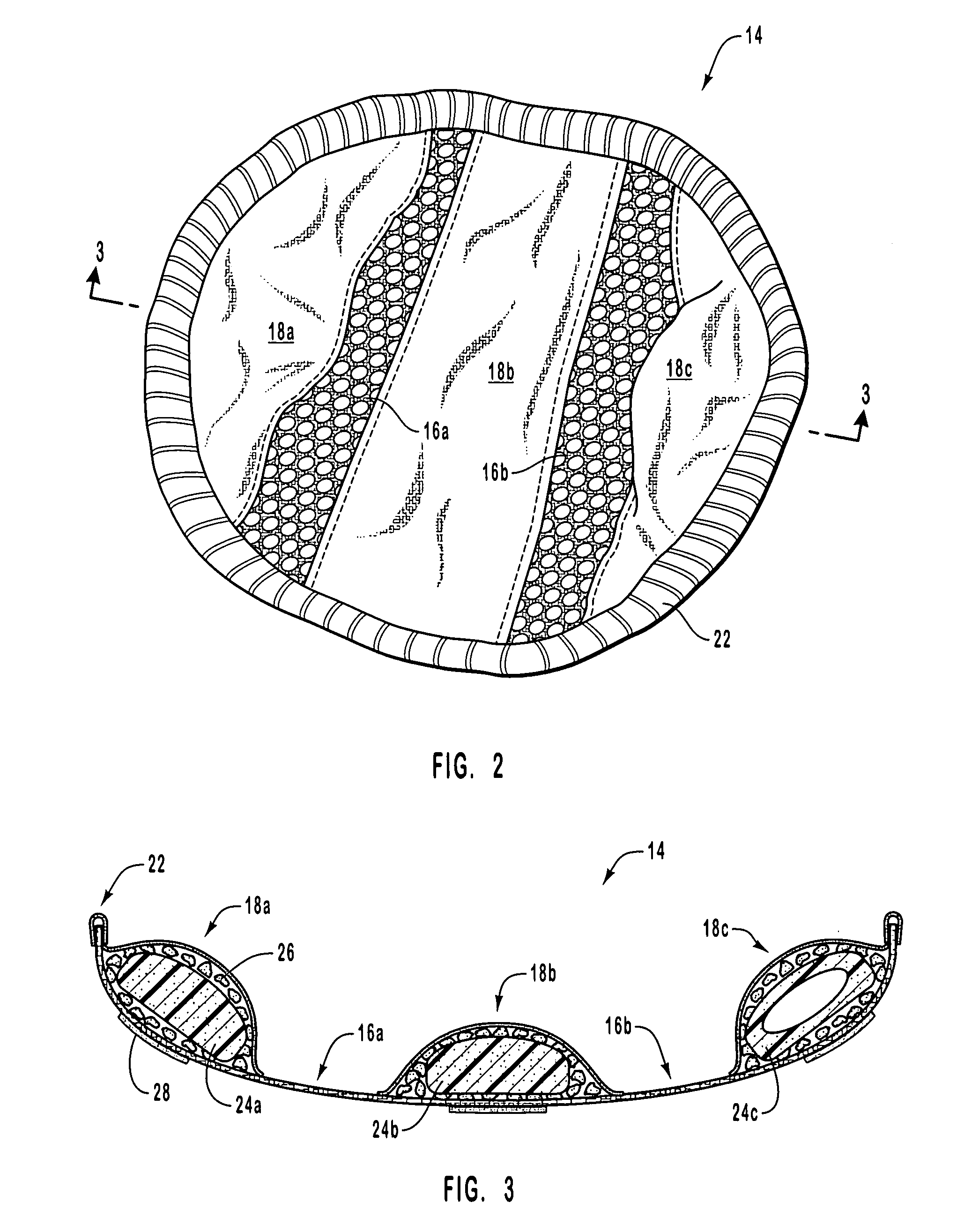

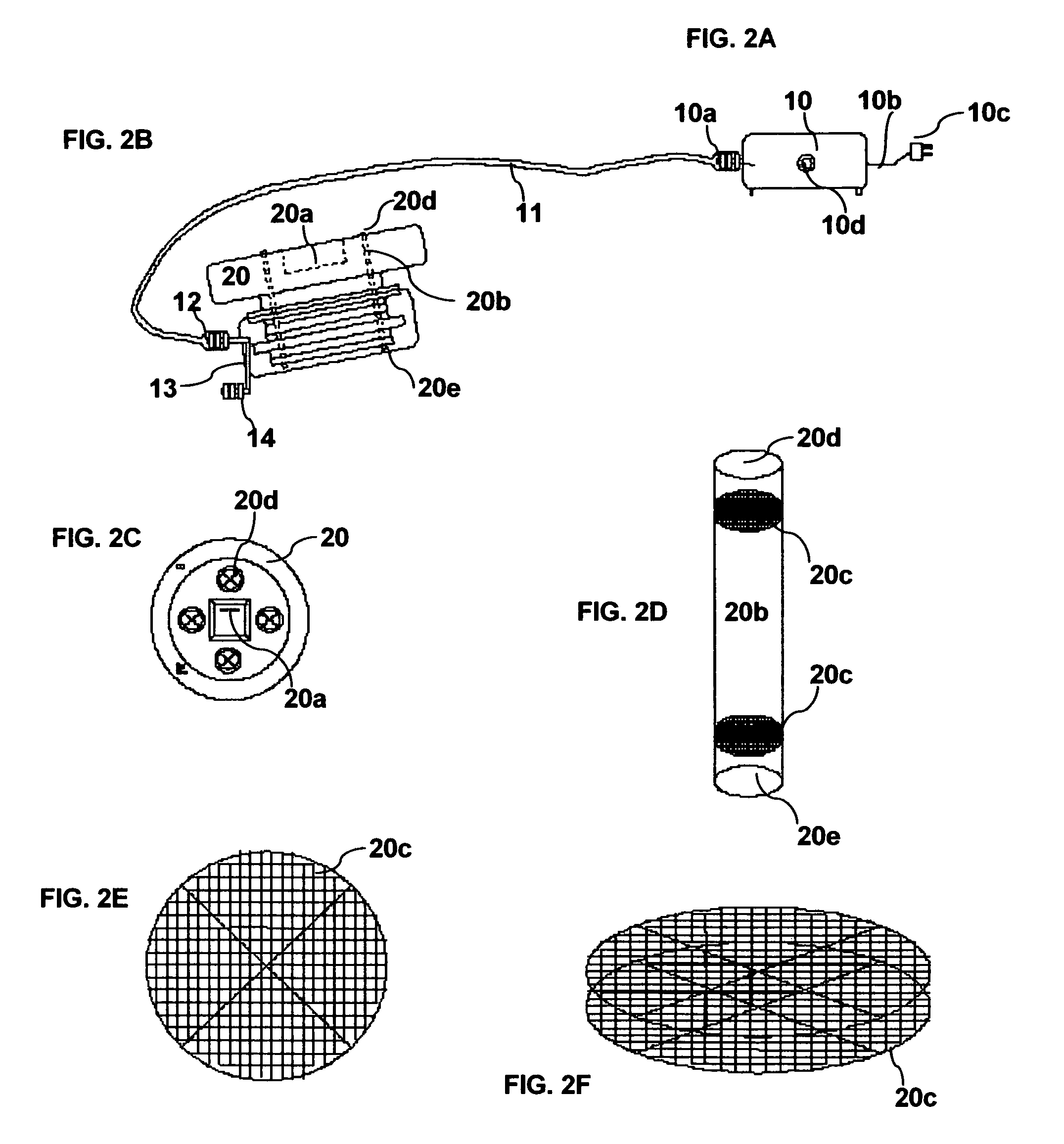

A head cooler (10) comprises a thermal exchange cap (11) and an outer insulating cover (12) to be arranged on a patient s head. The cap (11) has a channel system (31, 32) for a cooling fluid forming an inside heat exchange surface to be applied on said head for cooling the head. The thermal exchange cap (11, 60) is adjustable and / or adaptable to compensate for a discrepancy in shape and size between the inside surface of the head cooler (10) and the head. The head cooler (10) may further comprisean eyebrow cooler (140) for cooling the area of the eyebrows. The head cooler (140) is used in medicine. A method for preventing hair loss of a patient is provided by arranging the head cooler (10) on the head of said patient.

Owner:DIGNITANA

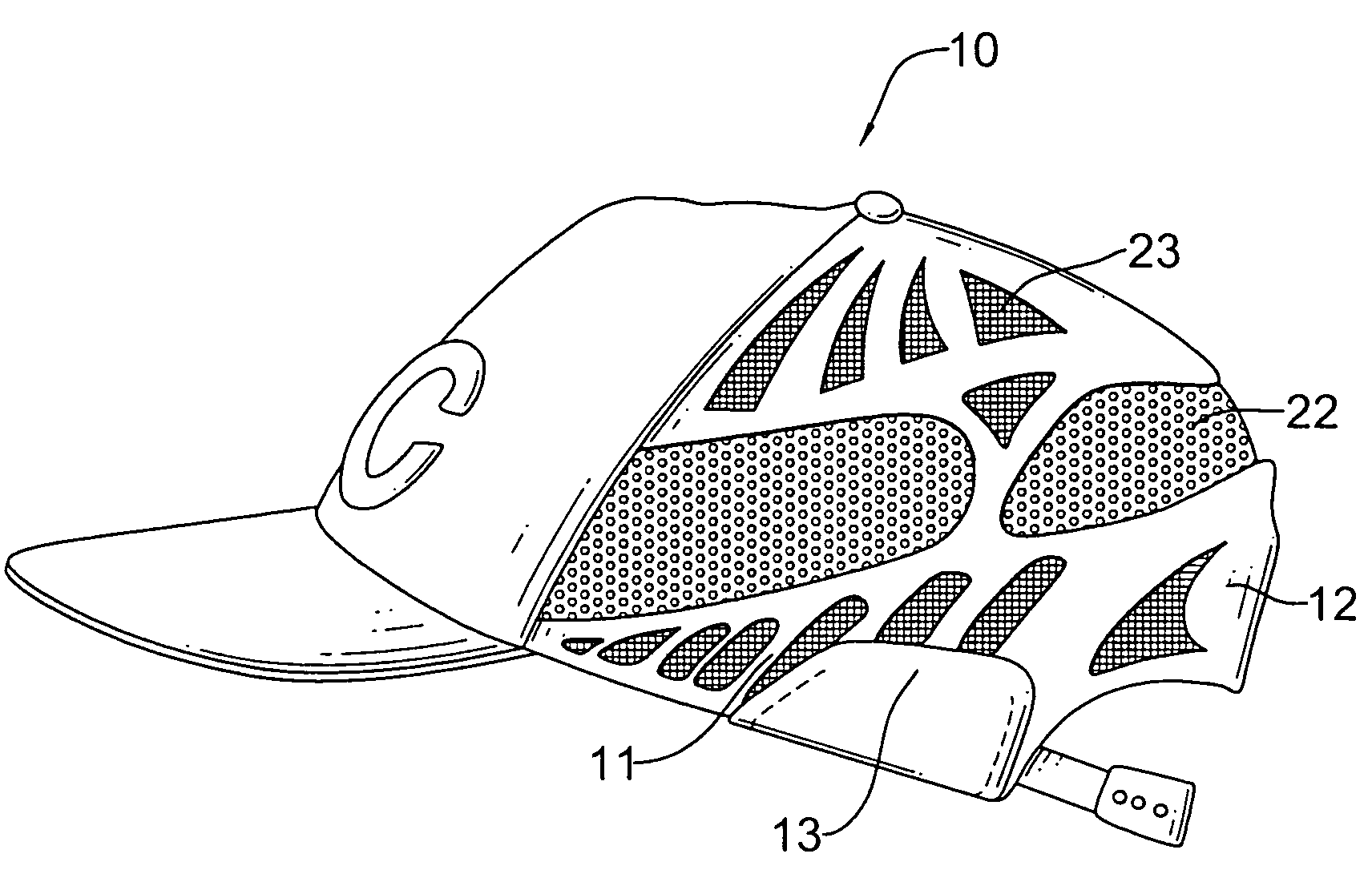

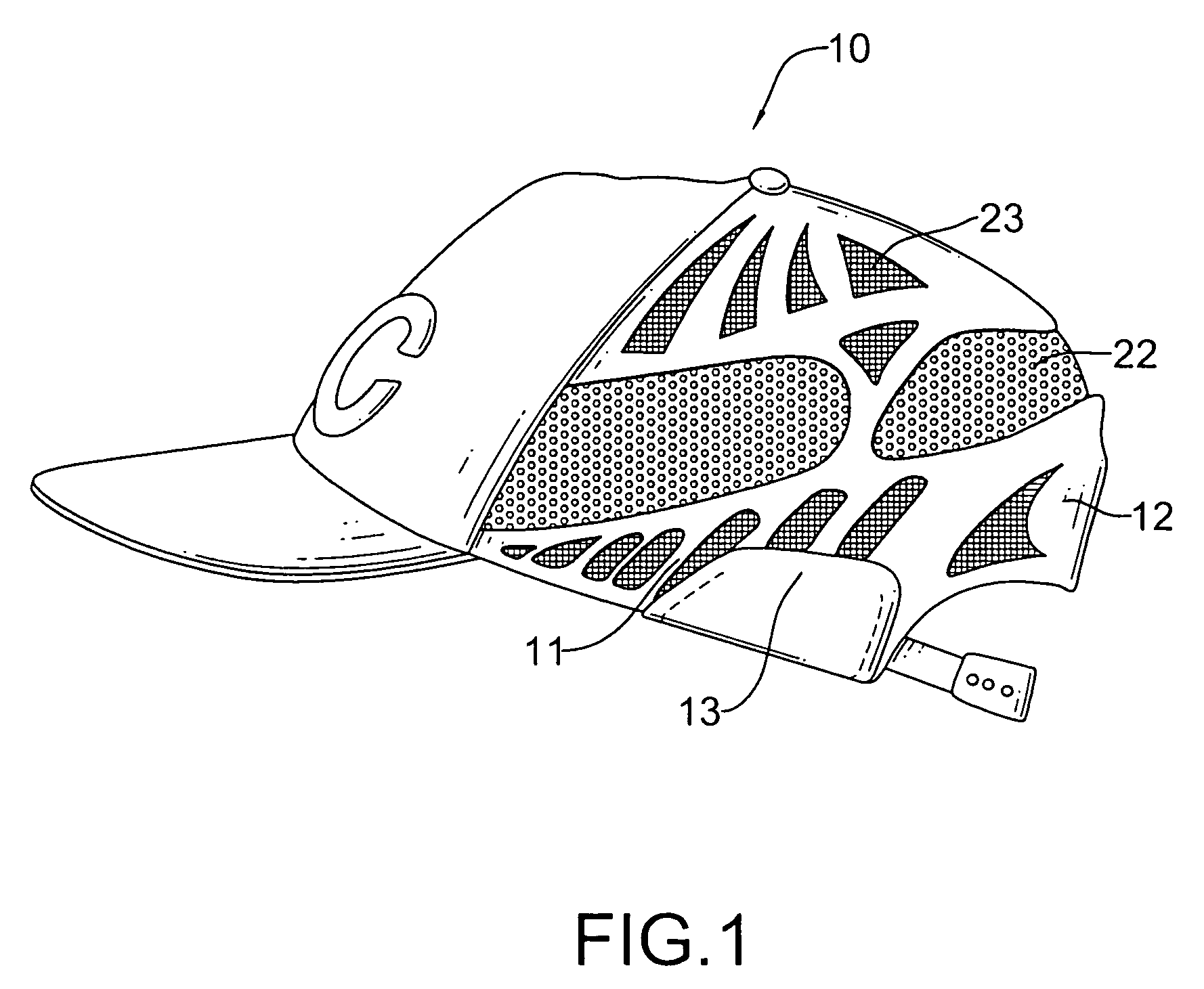

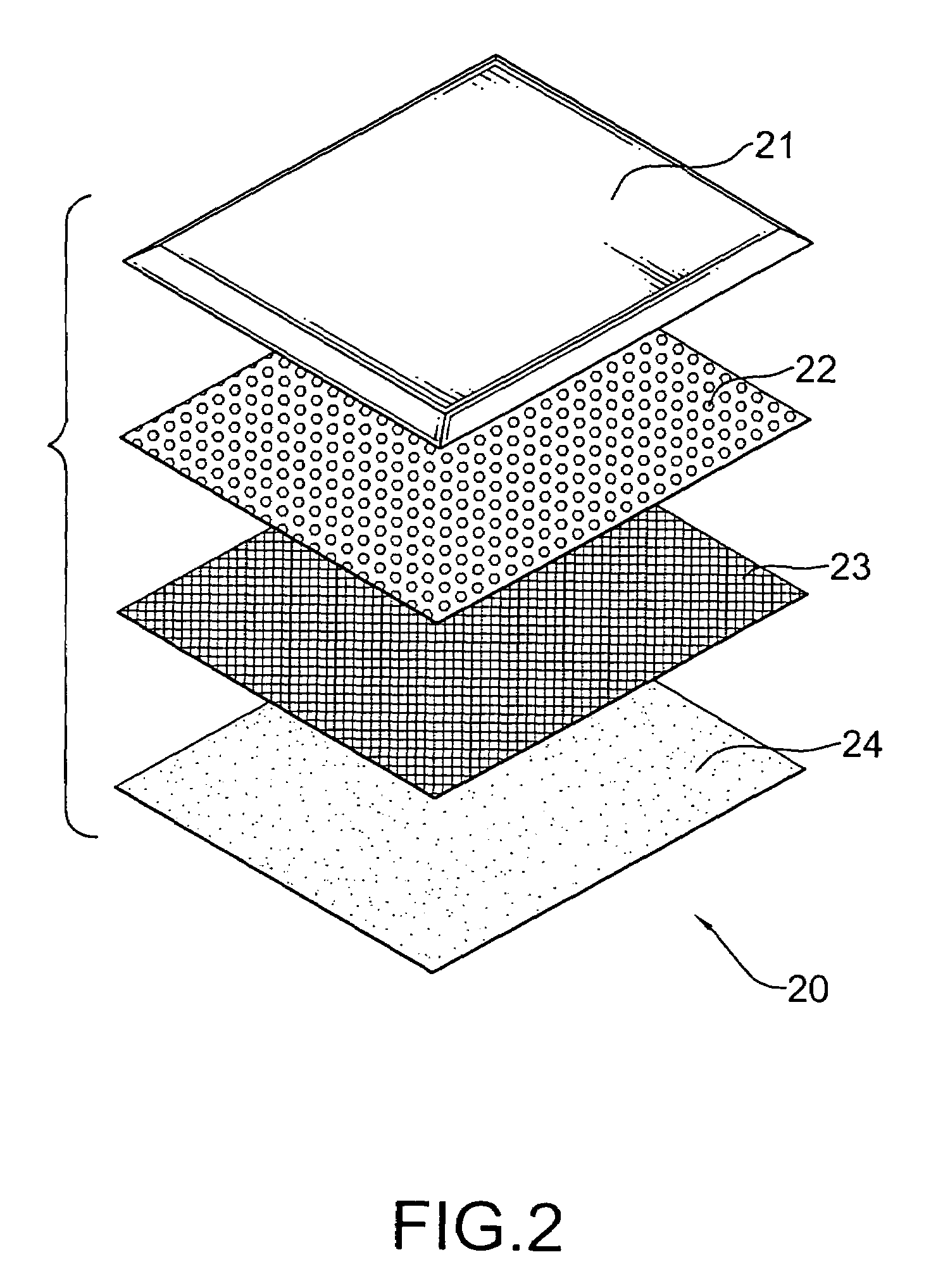

Decorative multiple layered hat

InactiveUS7174573B1Comfortable and light-weight to wearAppealing appearanceHatsHeadwear capsEngineeringMaterial Perforation

The decorative multiple layered hat has multiple layers. The multiple layers are made of different materials, have different structures and features, are joined together sequentially to form a shape with a surface by different layers being exposed so the hat has an appealing appearance and raises people's interests and include an outer layer, a ventilative layer, a mesh layer, a fabric layer and an outer surface. The outer area has cutout areas. The ventilative layer is bonded to the outer area and has multiple perforations through which air flows. The mesh layer is a mesh through which air flows to keep a person's head cool and is bonded to the ventilative layer. The inner layer is bonded to the mesh layer, touches a person's skin and is a soft fabric so the hat is comfortable. The outer surface has patterns formed by the cutouts in the outer layer.

Owner:CHEN HSEUHON +2

Precision-Controlled Cooling System for Inducing Diving Reflex and Achieving Safe Hypothermic Central Nervous System Protection

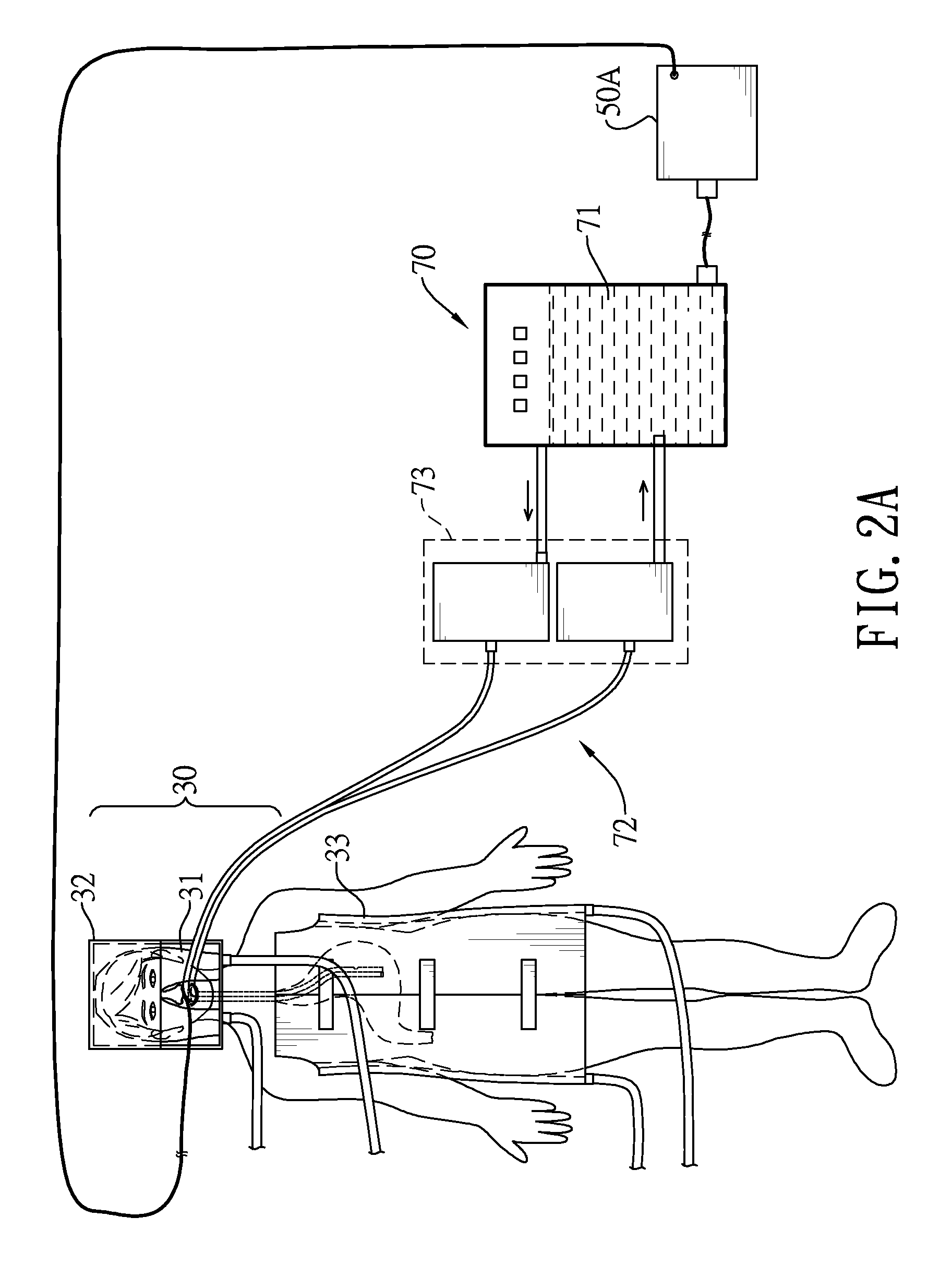

InactiveUS20120310312A1Efficient heat exchange rateEffective temperature reductionTherapeutic coolingTherapeutic heatingReflexRefrigerant distribution

Owner:YEE THOMAS CHIH HAN

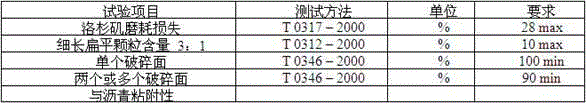

Thin layer overlaying surface construction method suitable for pavement overhaul and intermediate maintenance and preventive conservation

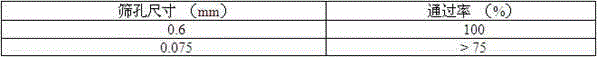

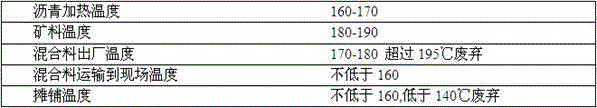

ActiveCN105350421AObvious technical advantagesThin R & D thicknessIn situ pavingsDisease damageThin layer

The present invention provides a thin layer overlaying surface construction method suitable for pavement overhaul and intermediate maintenance and preventive conservation, a synchronous construction process meeting the thin layer overlaying surface technology can be formulated by adjusting and upgrading on the basis of the traditional ultra-thin wearing layer construction process according to the characteristic of a thin layer overlaying surface, especially an extremely-thin wearing layer with the thickness of 0.8 to 1.5cm, the thin layer overlaying surface construction method mainly includes preparation before construction, original pavement disease damage treatment, fine milling napping processing, milling process knife head cooling water spray control, pavement cleaning, mixture mixing, mixture transportation, mixture paving, mixture rolling compaction, detection after forming and opening to traffic, the construction process conditions are clever and flexible to control, by the process using a fine milling machine for processing an old subgrade surface and emulsified asphalt and mixture synchronous paving, construction of the thin layer overlaying surface especially the extremely-thin wearing layer can be effectively realized, the major technical indicators of the constructed extremely-thin wearing layer are equivalent to that of an ultra-thin layer with the thickness of 20mm abroad, the cost is reduced by 25%, and a contribution is made for popularization and application.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP +1

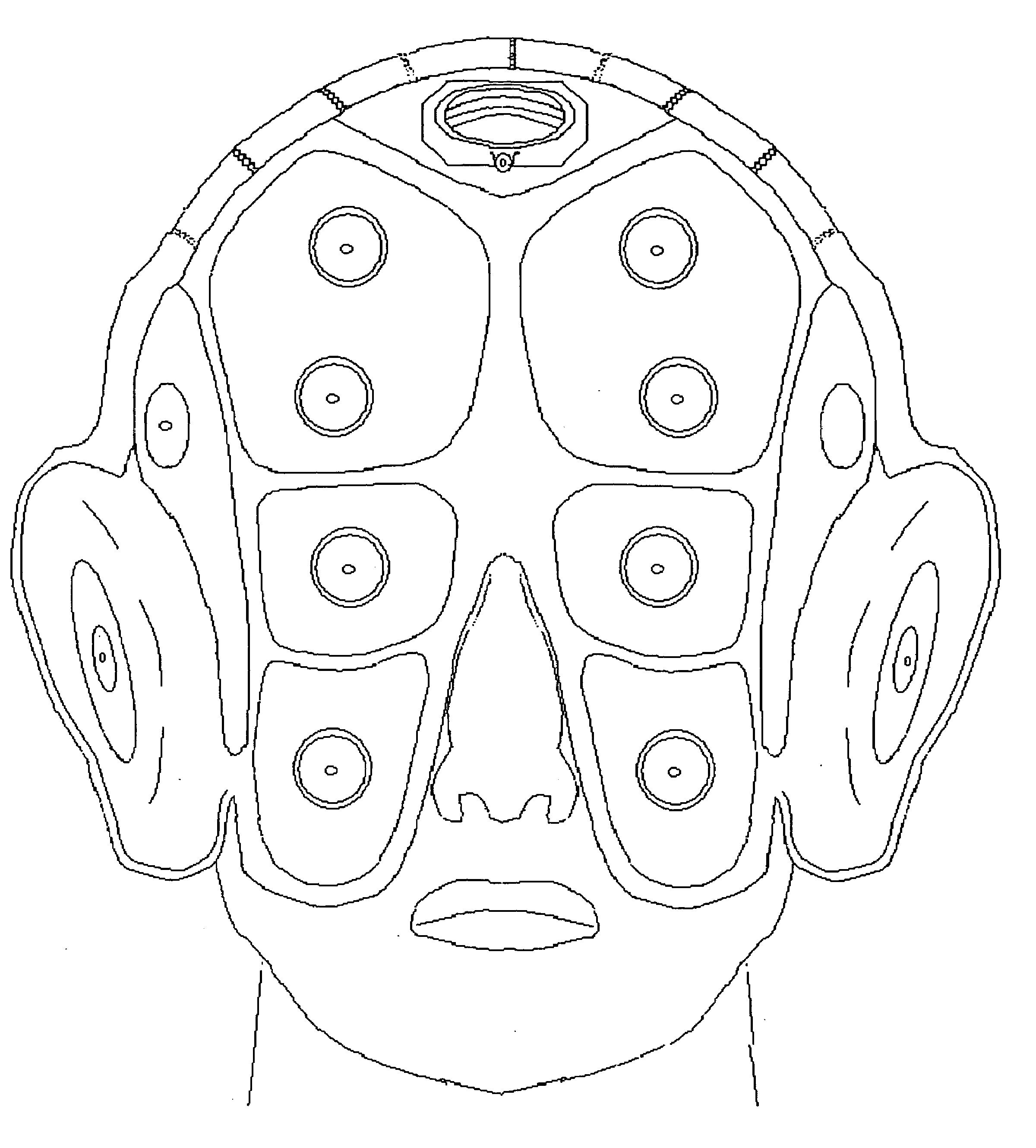

Blind head cooling helmet

Disclosed herein is a cooling device such as a blind head cooling helmet which will fully cover the head contour plus the area of the eyes, cheeks, and ears, having an lid arrangement with internal air ducts. An air pump generates and pushes small volumes of slow pace moving air, so that it be transferred to the blind head cooling helmet via an “C” shaped tube, to all the internal air duct, and finally escaping through the bottom of the lid arrangement, not without before the resulting air bubbles crashing against some areas of the internal layer creating a therapeutic effect or relaxing comfort to areas of the face.

Owner:FONTANEZ ACEVEDO PEDRO J

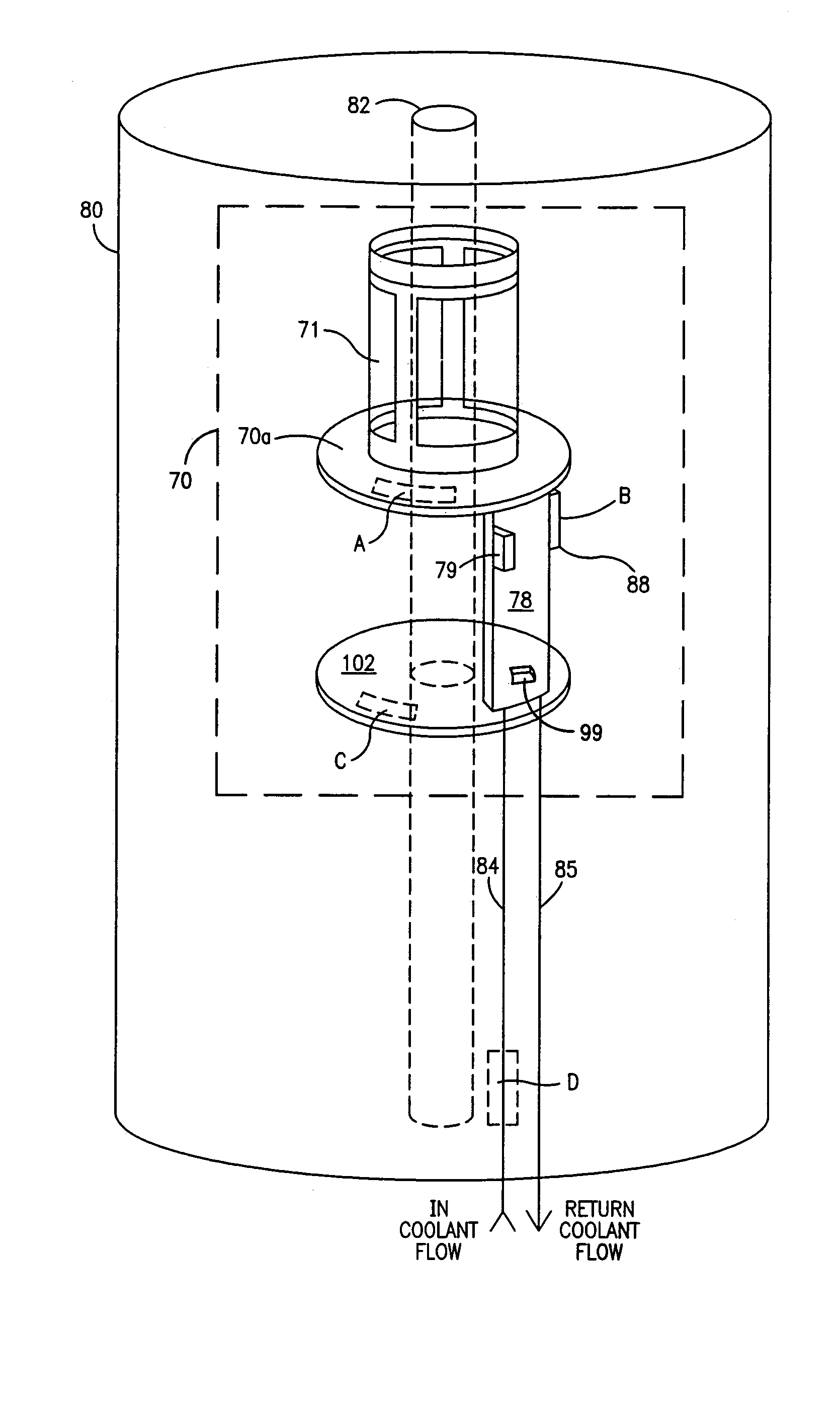

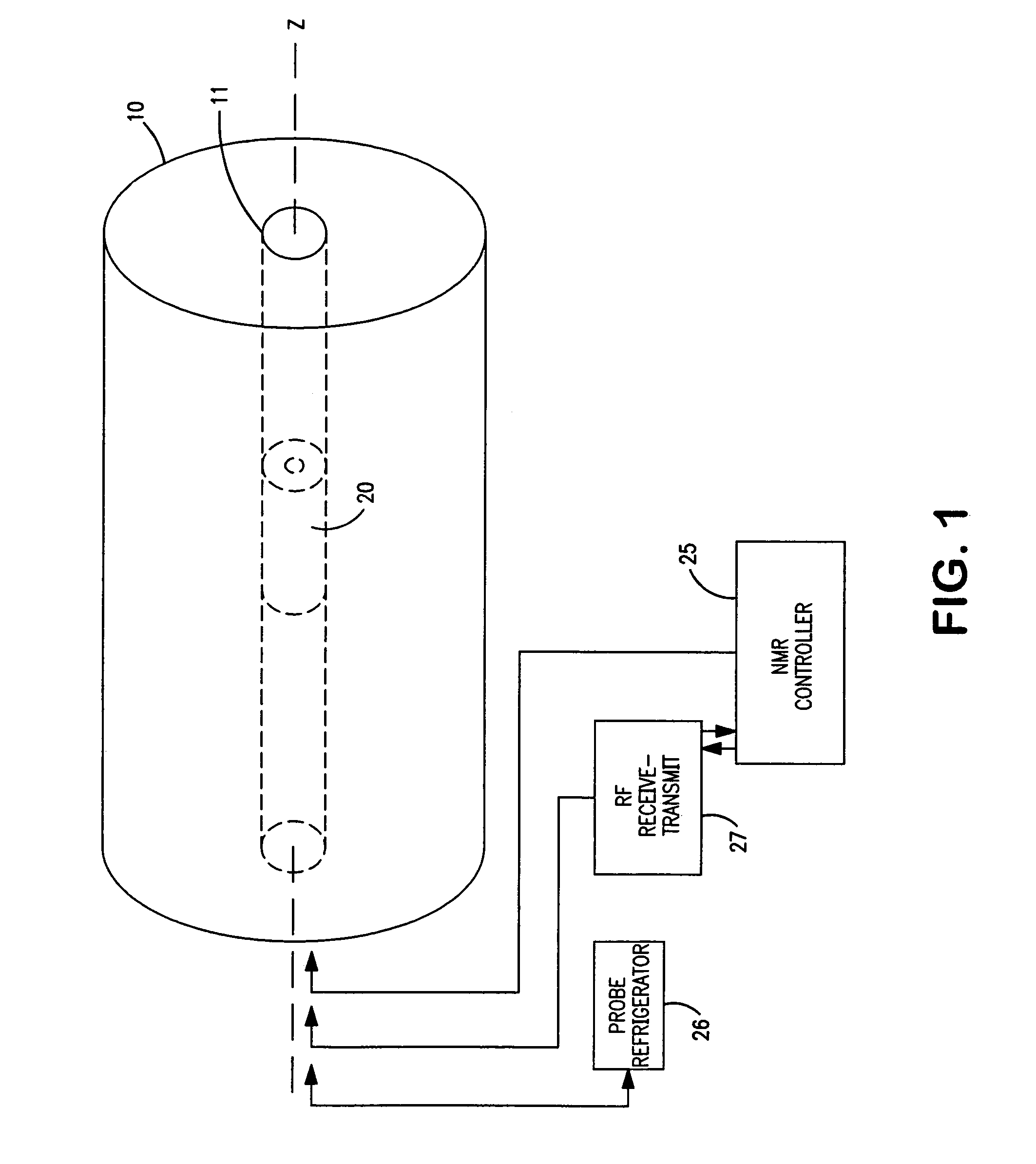

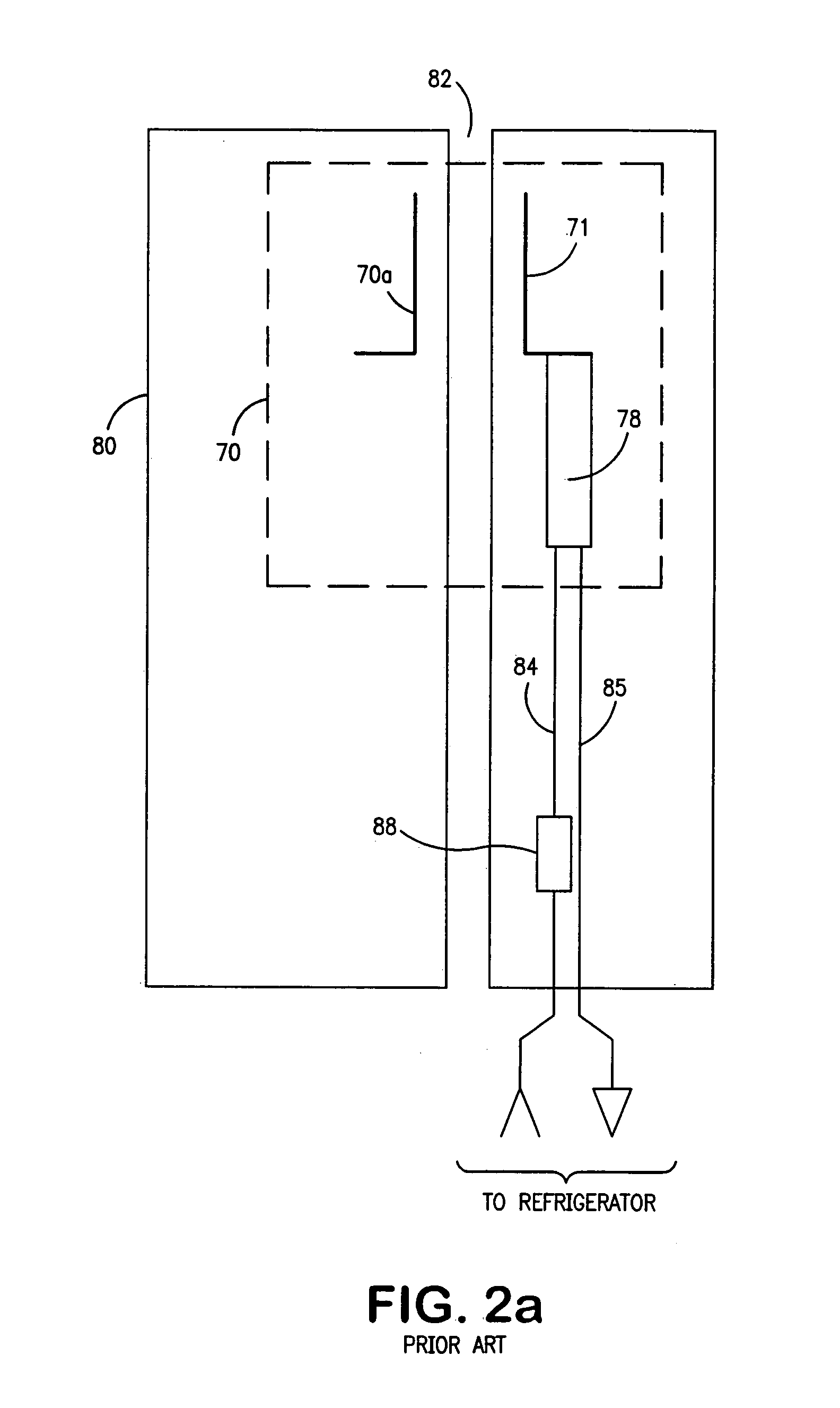

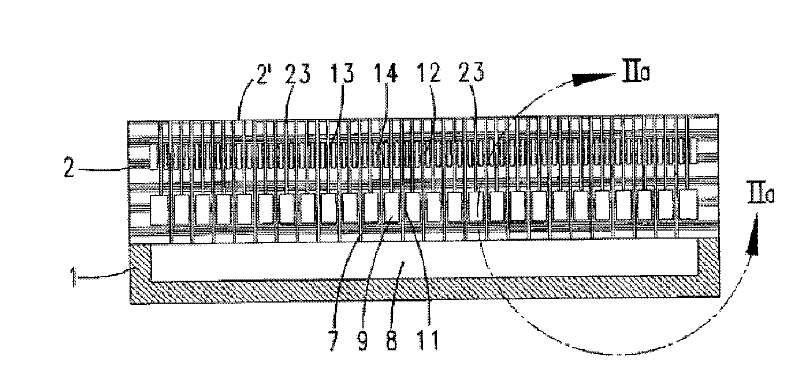

Cryogenic NMR probe

InactiveUS7288939B1Improve cold stabilityGreat isothermal surfaceElectric/magnetic detectionMeasurements using magnetic resonancePlate heat exchangerEngineering

The thermal performance and vacuum properties of a cryogenic NMR probe are improved when thermal control is implemented by conductive heat transfer to a cold head cooled by a heat exchanger to below the selected operating temperature. The heat load is manipulated by locating a heater to produce a more nearly constant heat load in conjunction with pulsed RF power and in one embodiment transferring such heater power through a common thermal path. In another embodiment, the heater power is conductively transferred directly to the heat exchanger.

Owner:AGILENT TECH INC

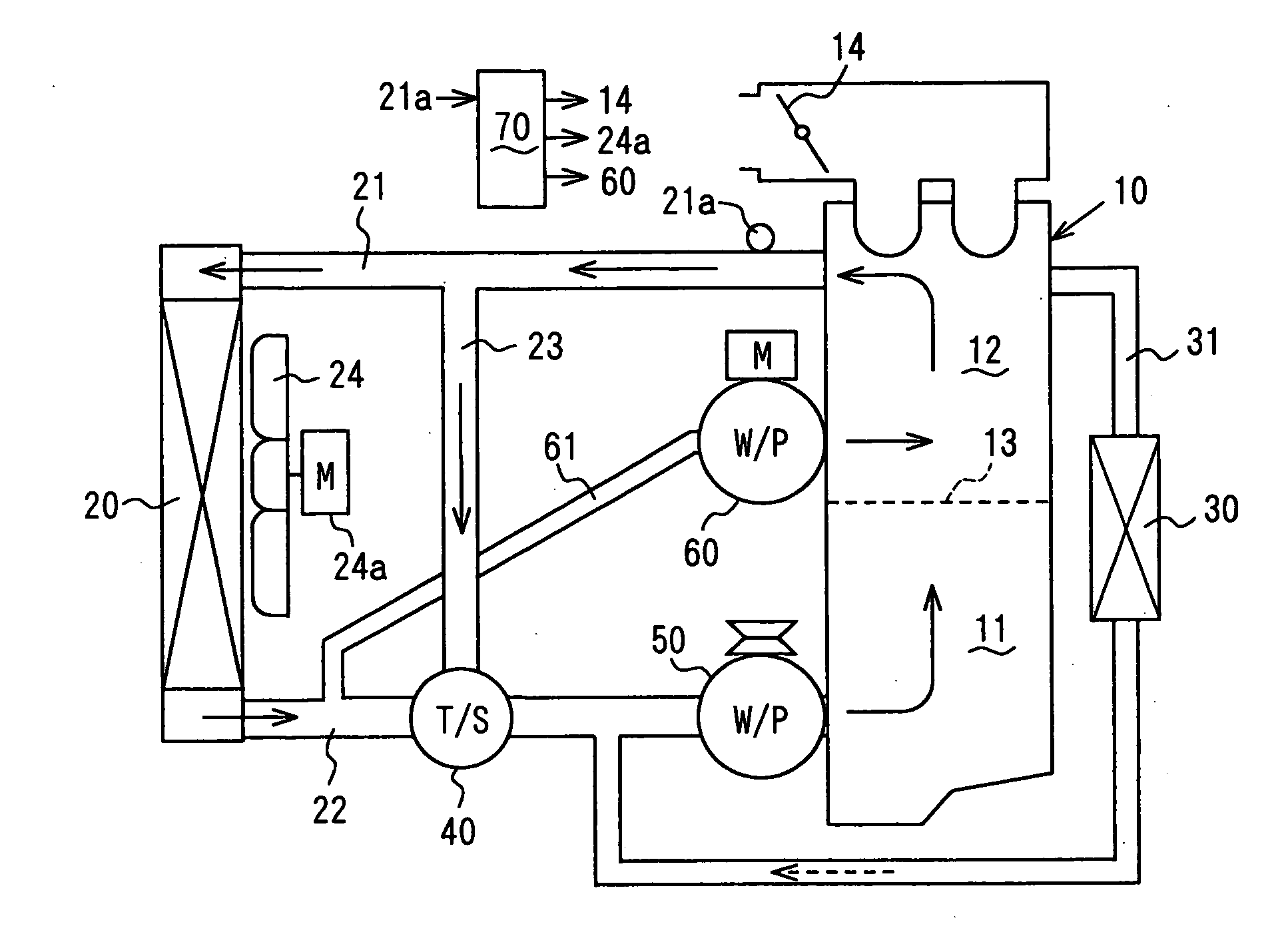

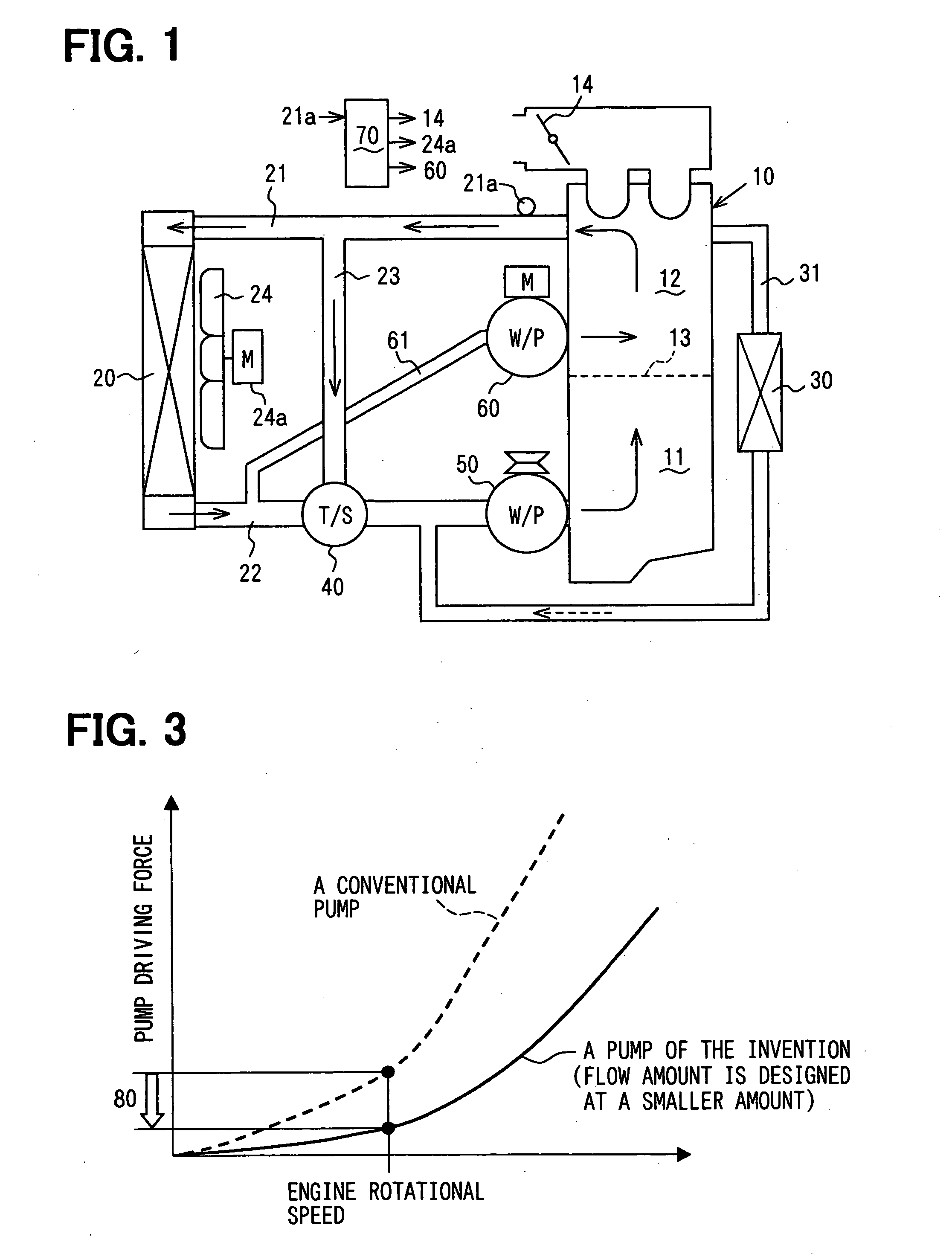

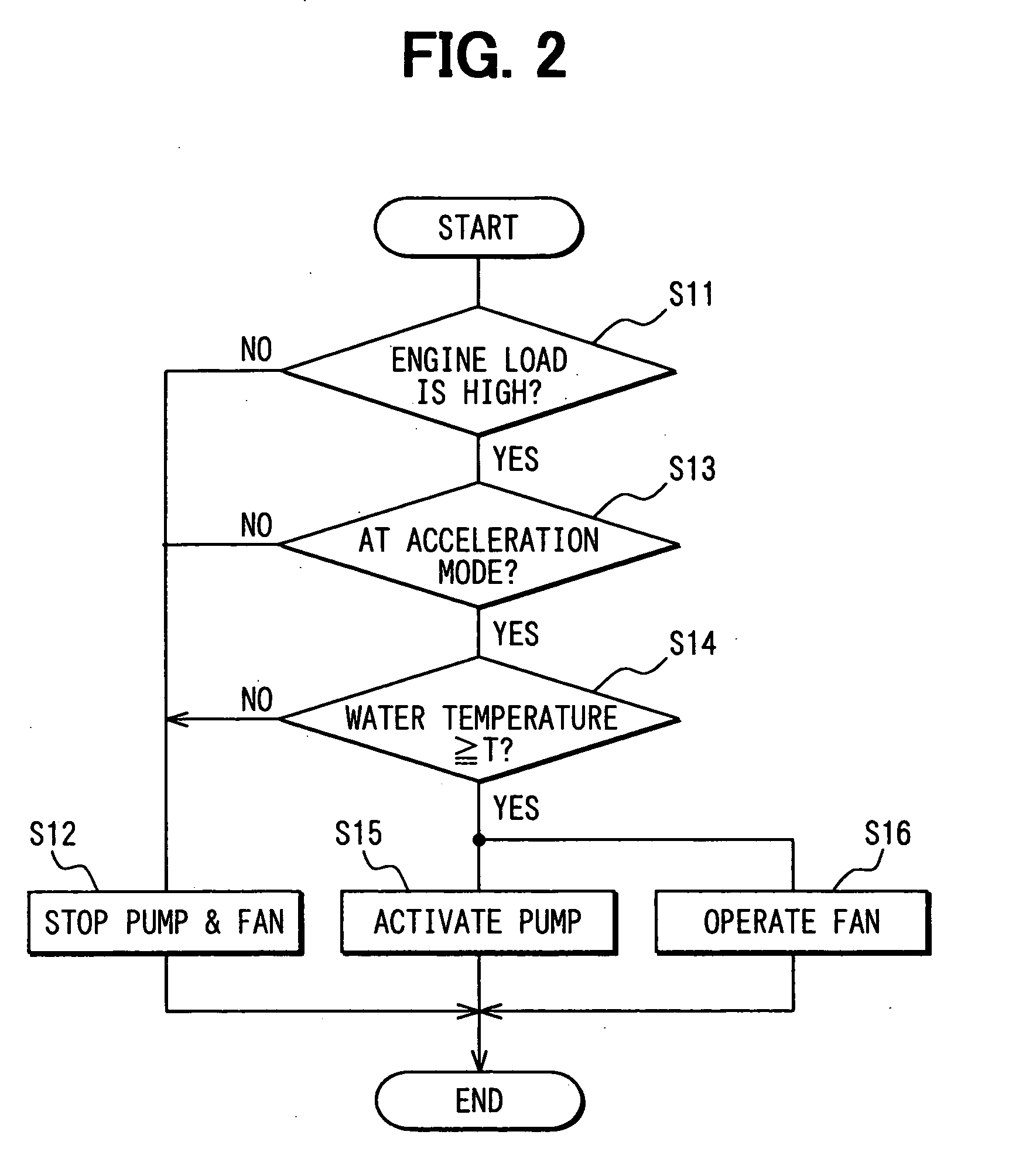

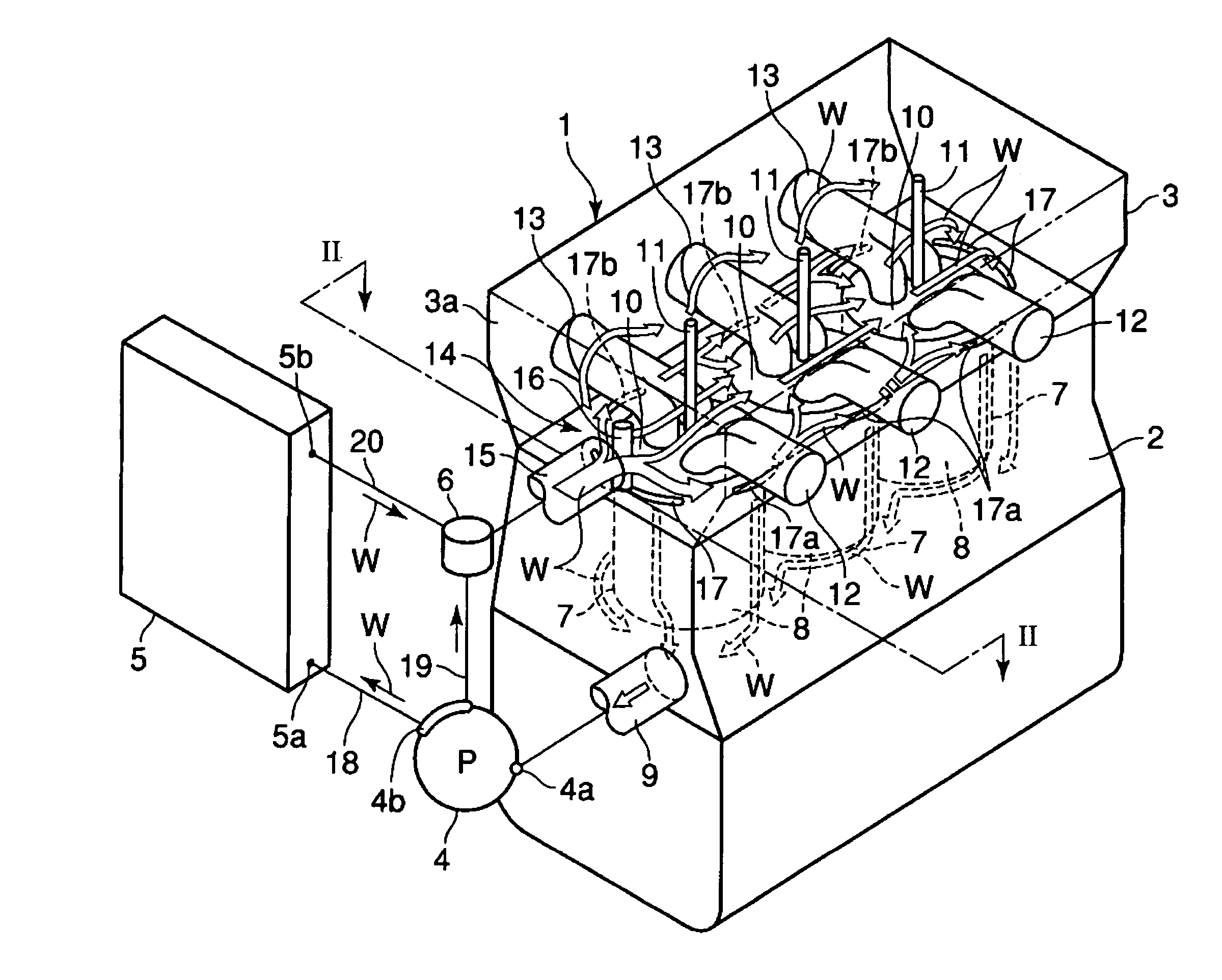

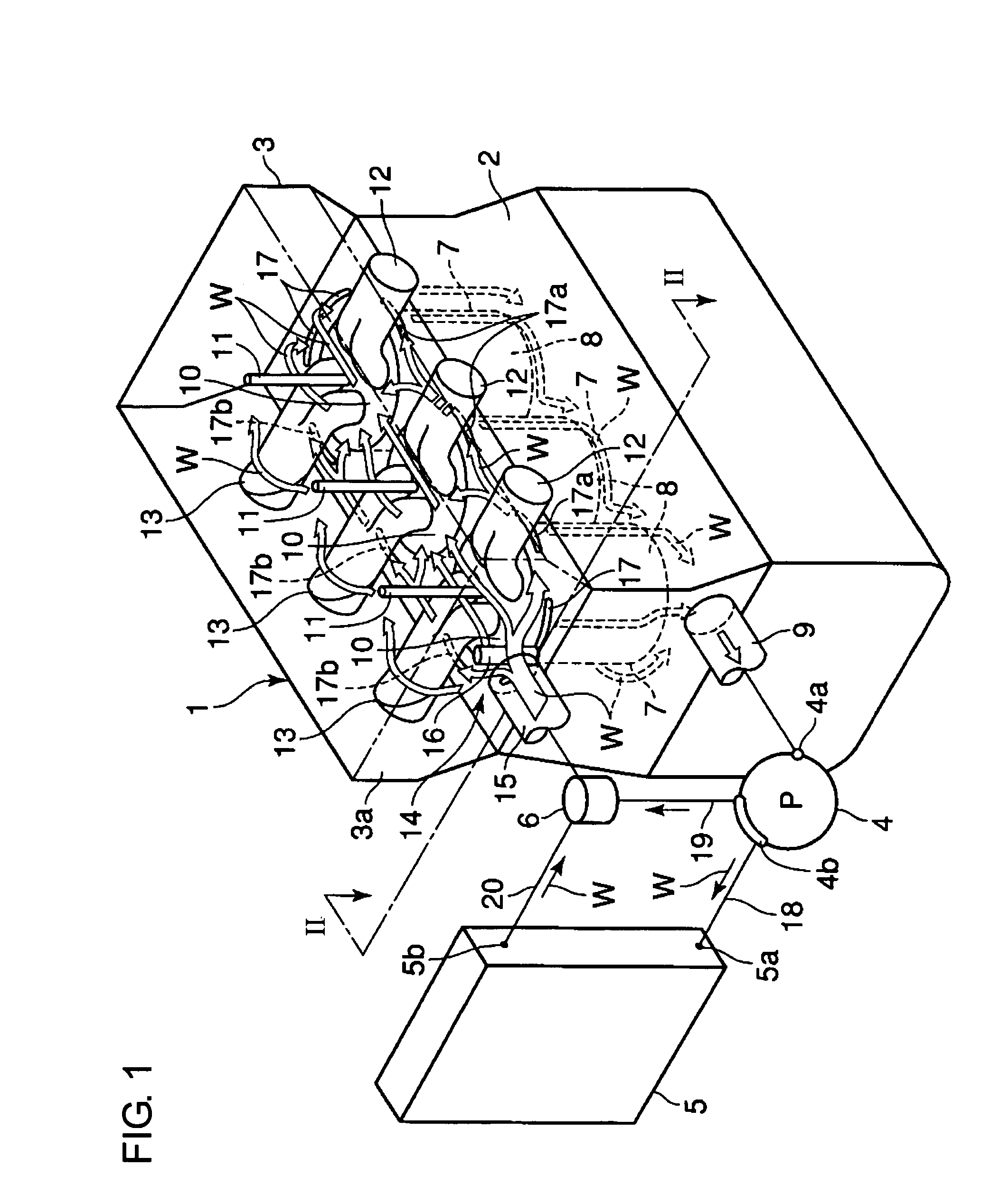

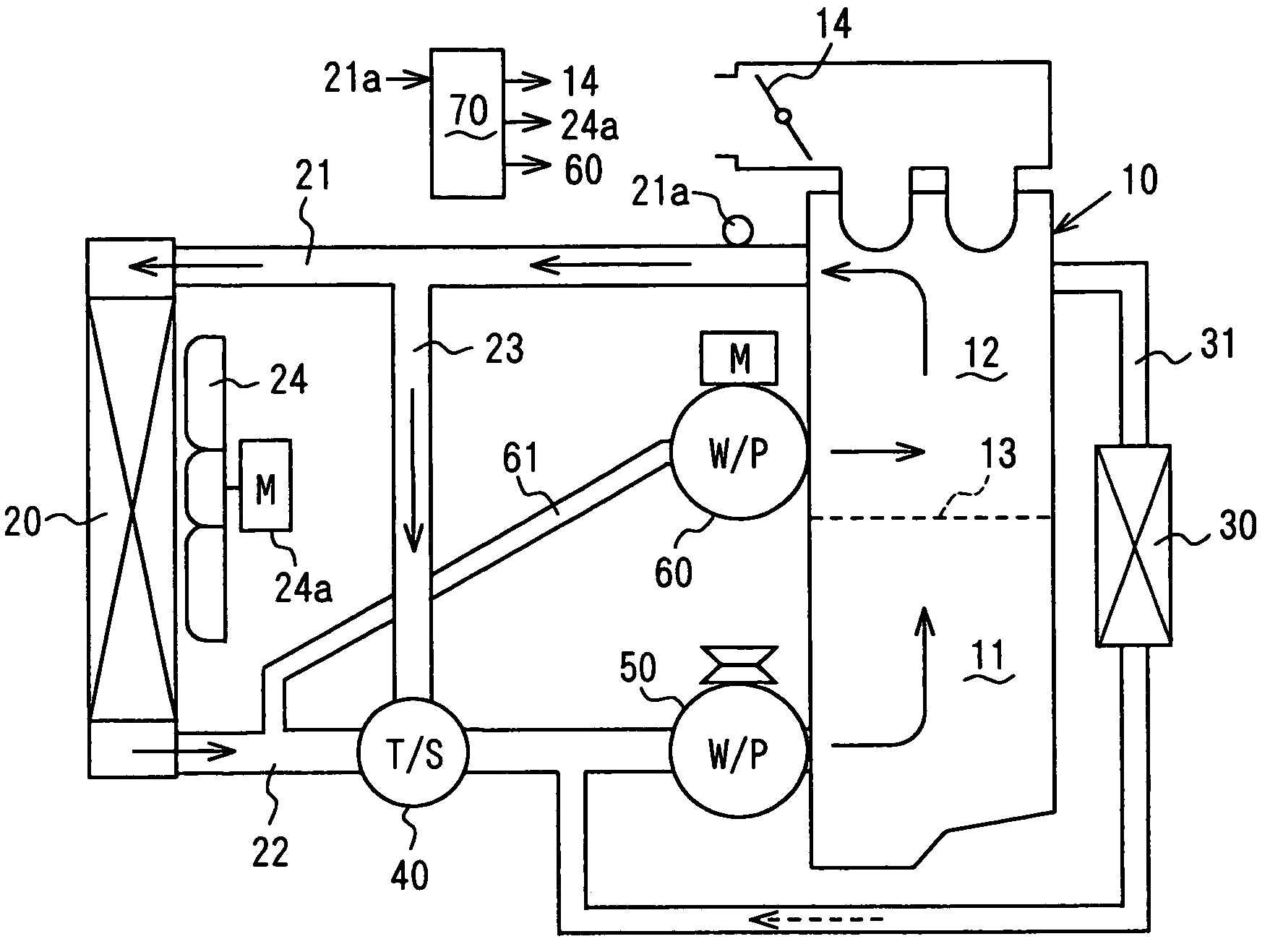

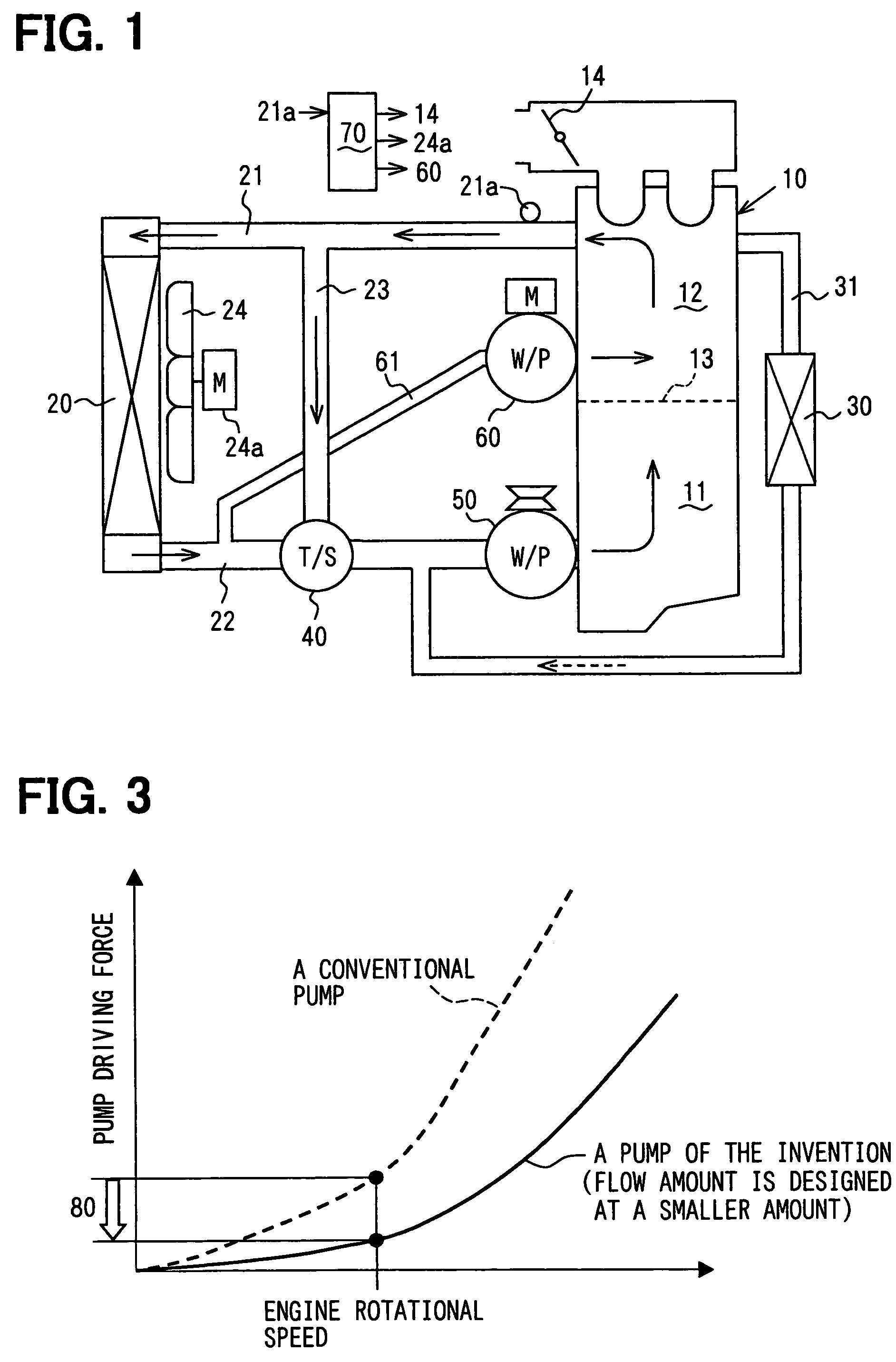

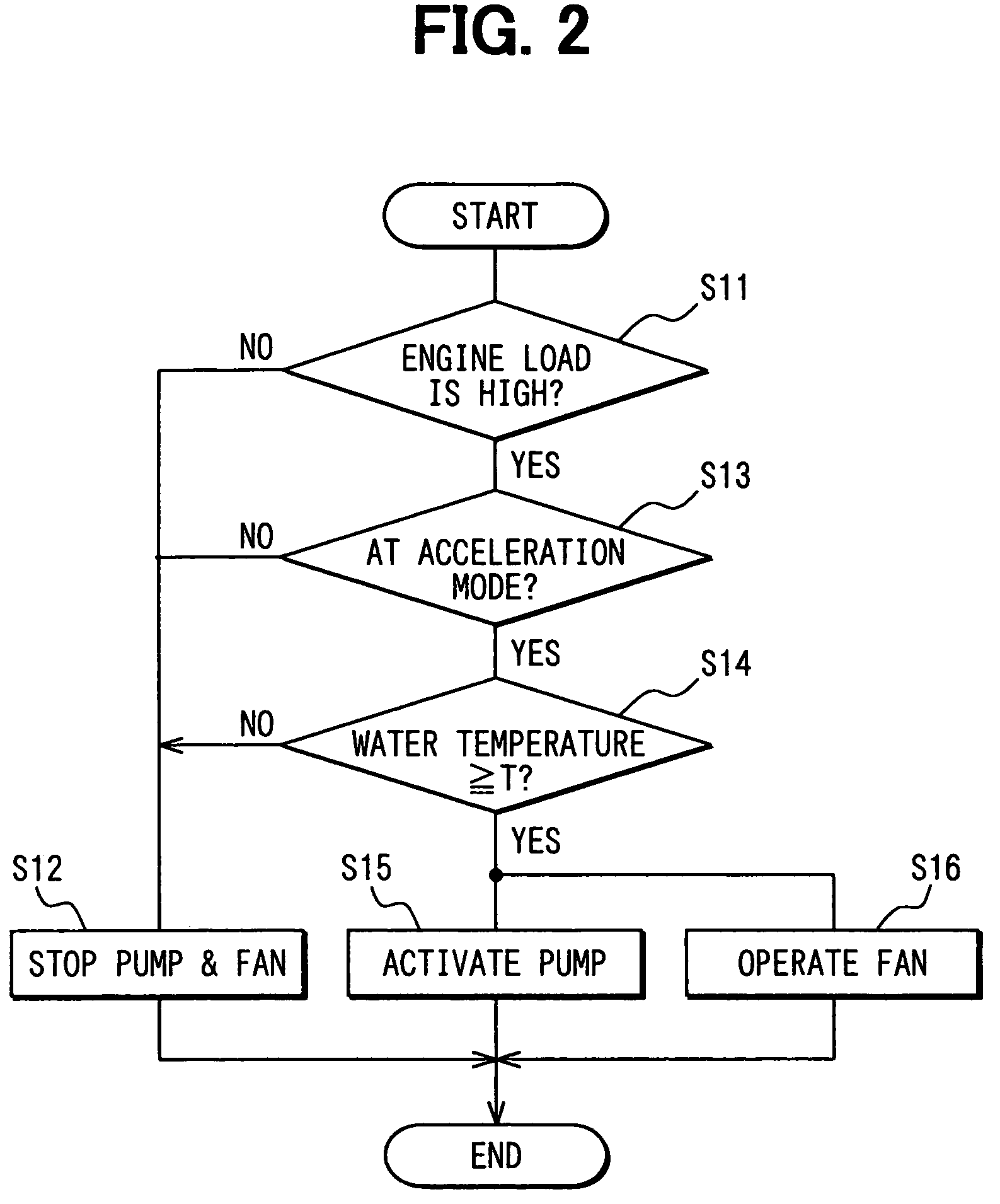

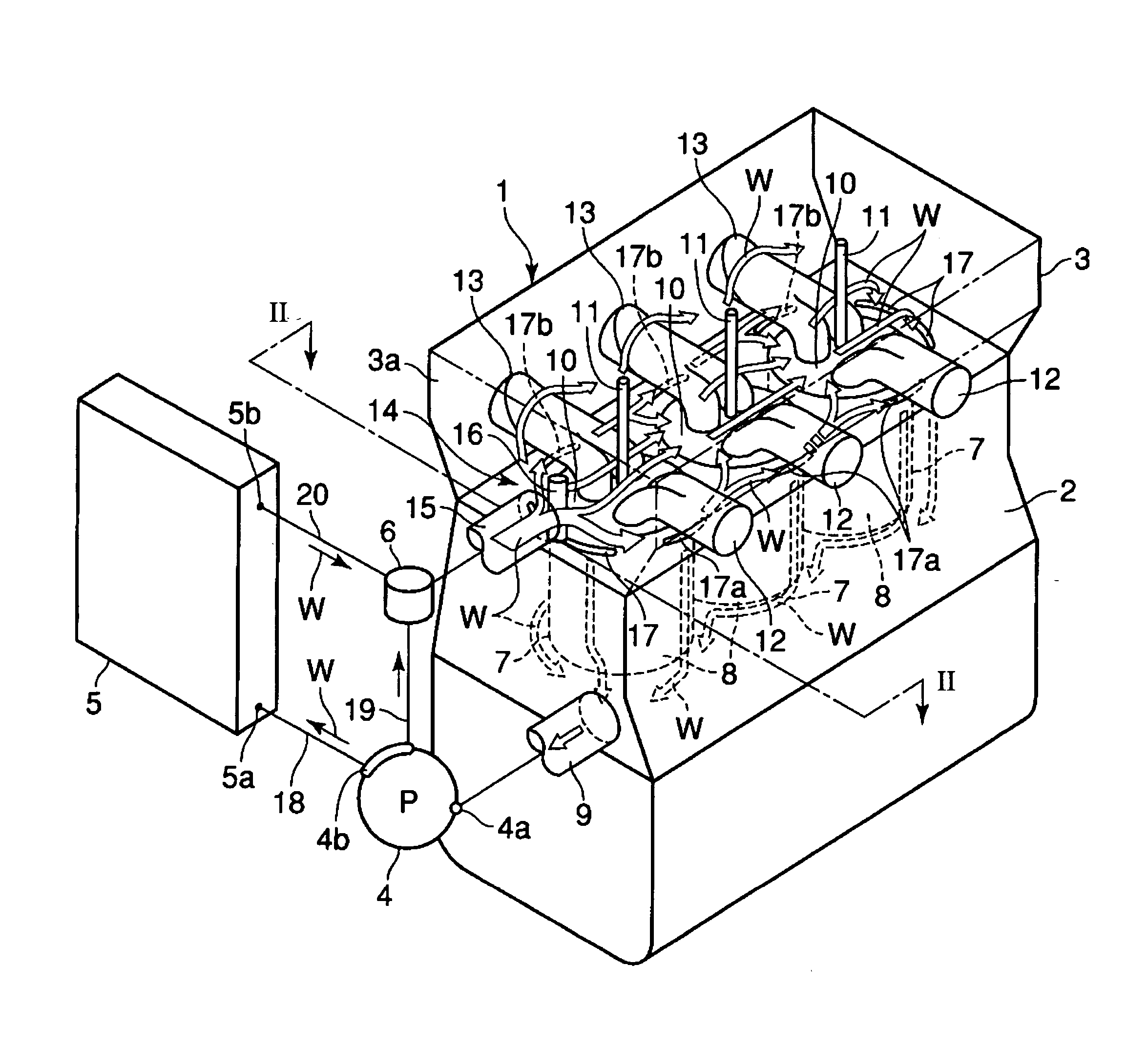

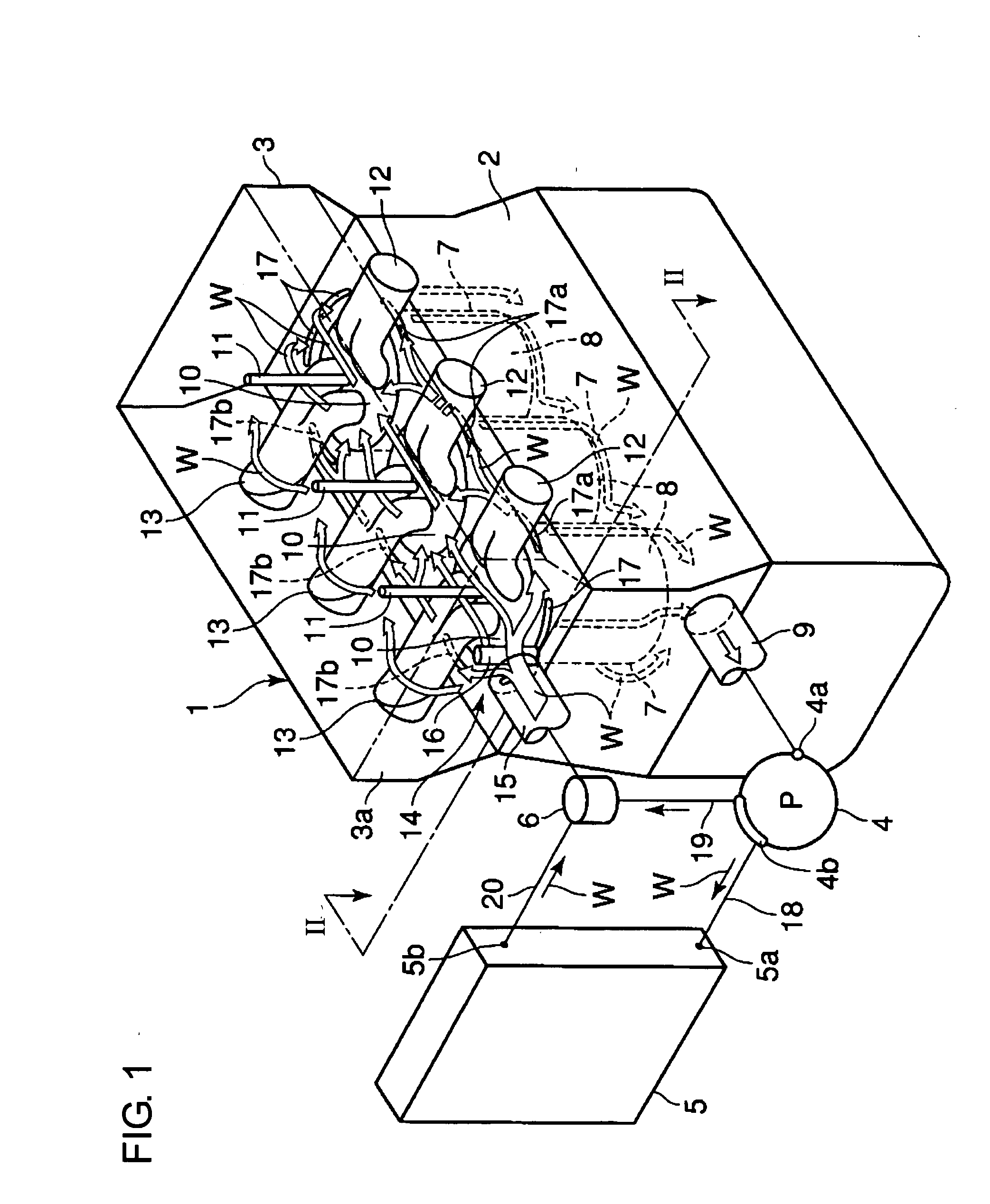

Liquid-cooling device for internal combustion engine

InactiveUS20060096553A1Effectively cooling down a cylinder headImprove cooling efficiencyLiquid coolingCoolant flow controlExternal combustion engineCylinder head

A head cooling path diverges from a backflow path at a position between a radiator and a thermostat and is connected with a cylinder head of an engine by bypassing a cylinder block of the engine. A pump circulates the cooling water through the head cooling path, to the cylinder head, when the engine is operated at a high load and / or a vehicle is in a rapid acceleration, so that sufficiently cooled cooling water is supplied directly to the cylinder head.

Owner:DENSO CORP

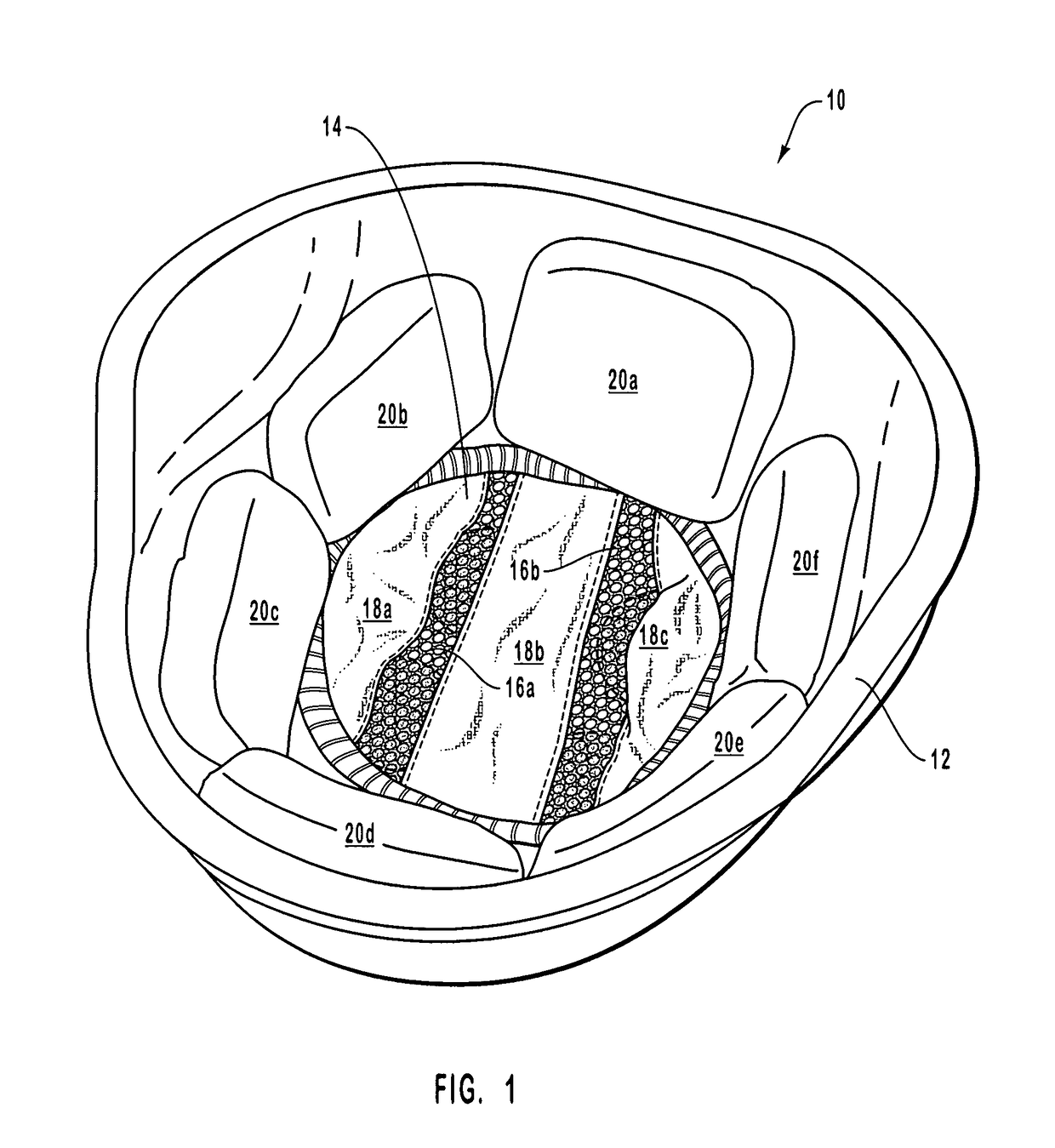

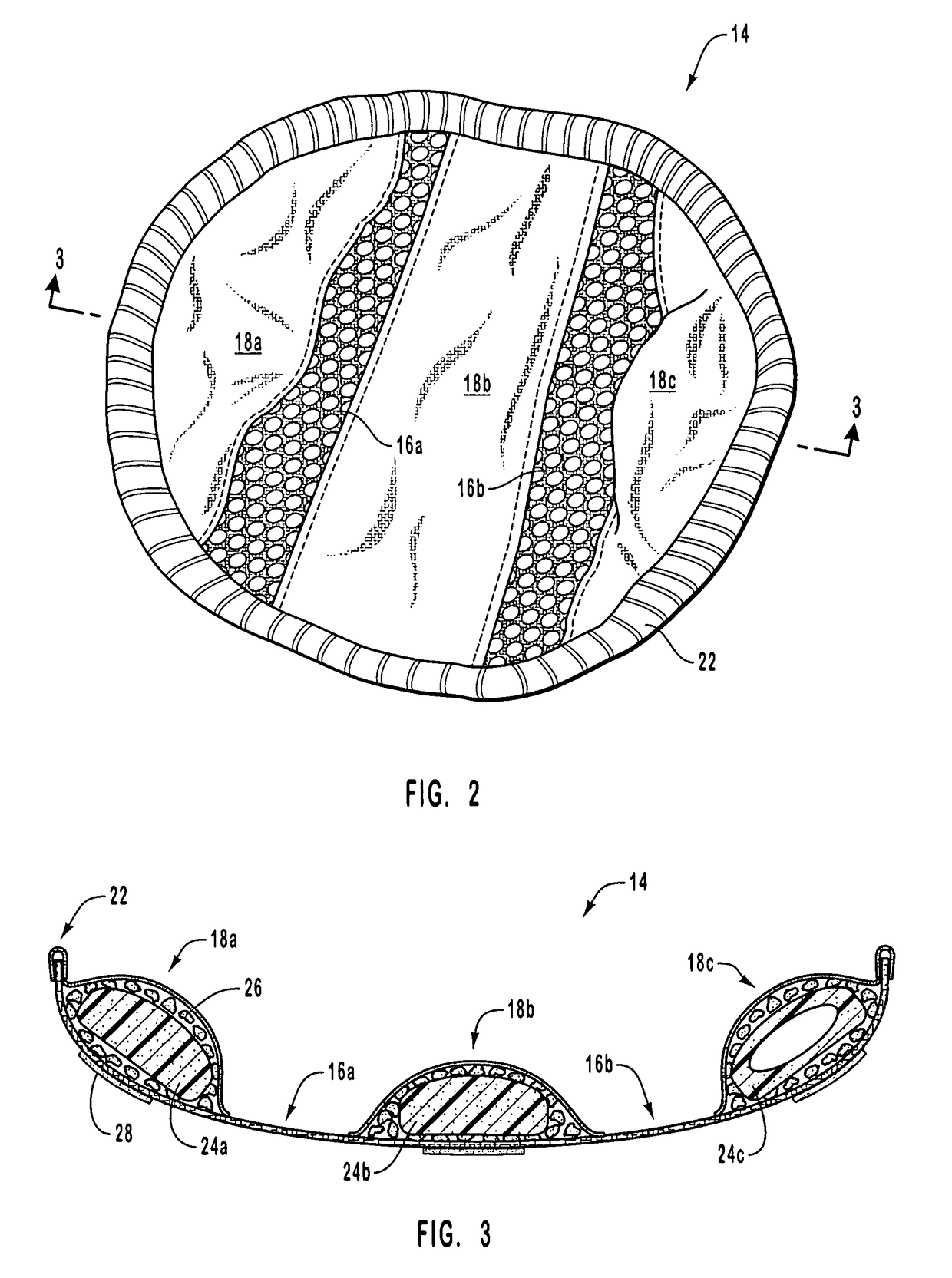

Systems and methods for providing a headgear cooling liner

InactiveUS8117677B2Facilitate natural evaporationDomestic cooling apparatusLighting and heating apparatusHead scalpMedicine

Systems and methods for providing an article associated with headgear that keeps the wearer's head cool and / or cushioned from the interior harness of the headgear. The article is a system, liner or pad that is inserted into the headgear or coupled to the headgear harness for cooling and / or comfort, and includes a liquid-absorbing material contained within non-impervious pocket partitions. One or more ventilation portions and / or devices may also be included to allow for the free flow of air, breathing of the wearer's scalp and to facilitate the natural evaporation of perspiration. In some implementations, the article may be used in a variety of different headgear. As the pocket partitions swell due to absorption of a liquid by the material, the pockets function as gel-like cushions or pads that protect the wearer's scalp. The article is held in place with small straps, Velcro® tabs, or other retention devices.

Owner:MISTY MOON CORP

Systems and methods for providing a headgear cooling liner

InactiveUS20110094012A1Provides a cooling effectDomestic cooling apparatusLighting and heating apparatusPerspirationEvaporation

Owner:MISTY MOON CORP

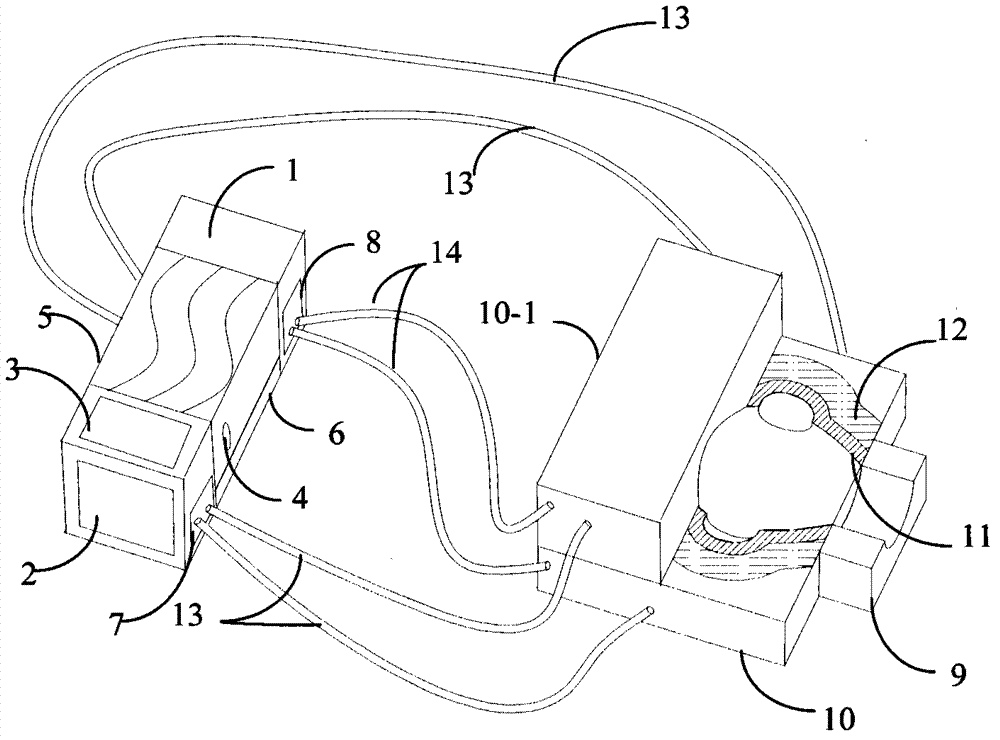

Uniform selective cerebral hypothermia

InactiveUS7156867B2Surgical instrument detailsIntravenous devicesCooling chamberTemperature difference

Disclosed is an apparatus and method for uniform selective cerebral hypothermia. The apparatus includes a brain-cooling probe, a head-cooling cap, a body-heating device and a control console. The brain-cooling probe cools the cerebrospinal fluid within one or more brain ventricles. The brain-cooling probe withdraws a small amount of cerebrospinal fluid from a ventricle into a cooling chamber located ex-vivo in close proximity to the head. After the cerebrospinal fluid is cooled it is then reintroduced back into the ventricle. This process is repeated in a cyclical or continuous manner. The head-cooling cap cools the cranium and therefore cools surface of the brain. The combination of ventricle cooling and cranium cooling provides for whole brain cooling while minimizing temperature gradients within the brain. The body-heating device replaces heat removed from the body by the brain-cooling probe and the head-cooling cap and provides for a temperature difference between the brain and the body where the brain is maintained a temperature lower than the temperature of the body.

Owner:MEDCOOL

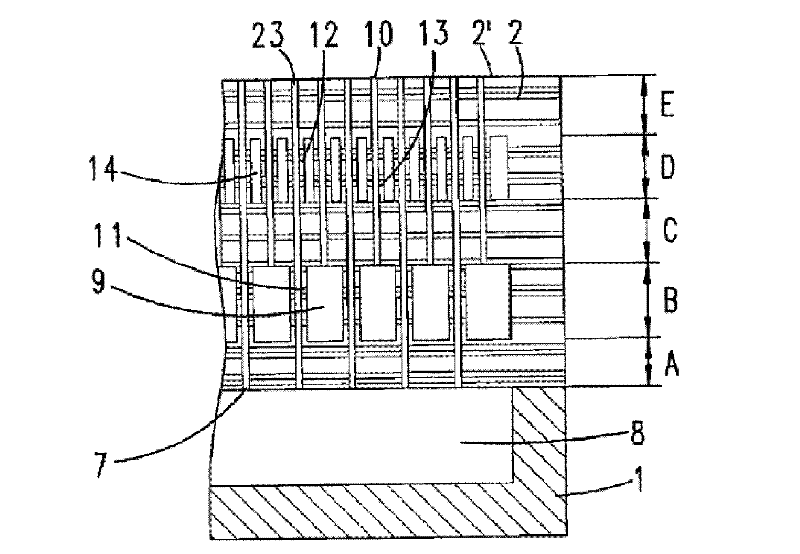

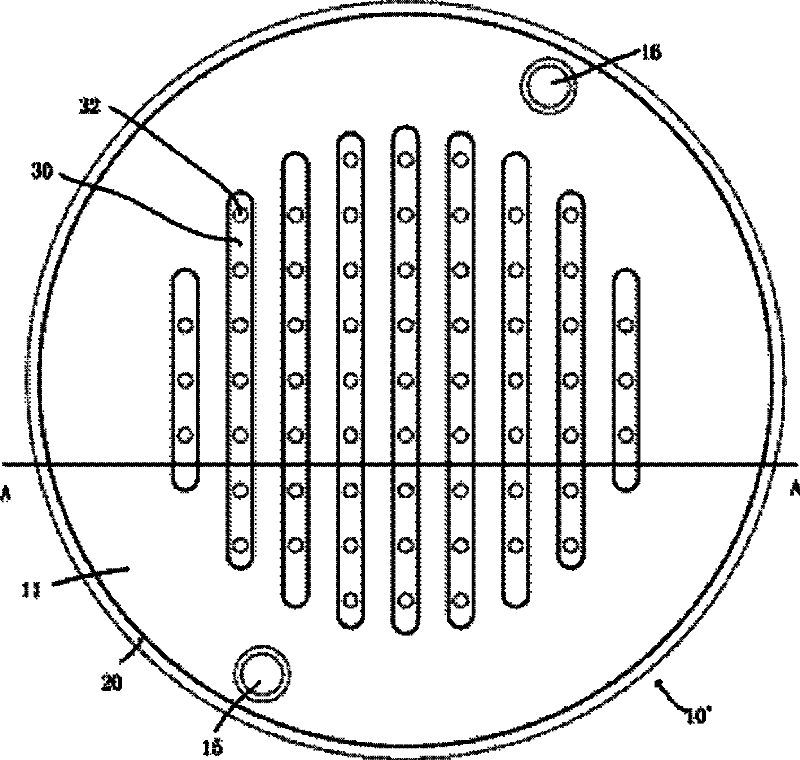

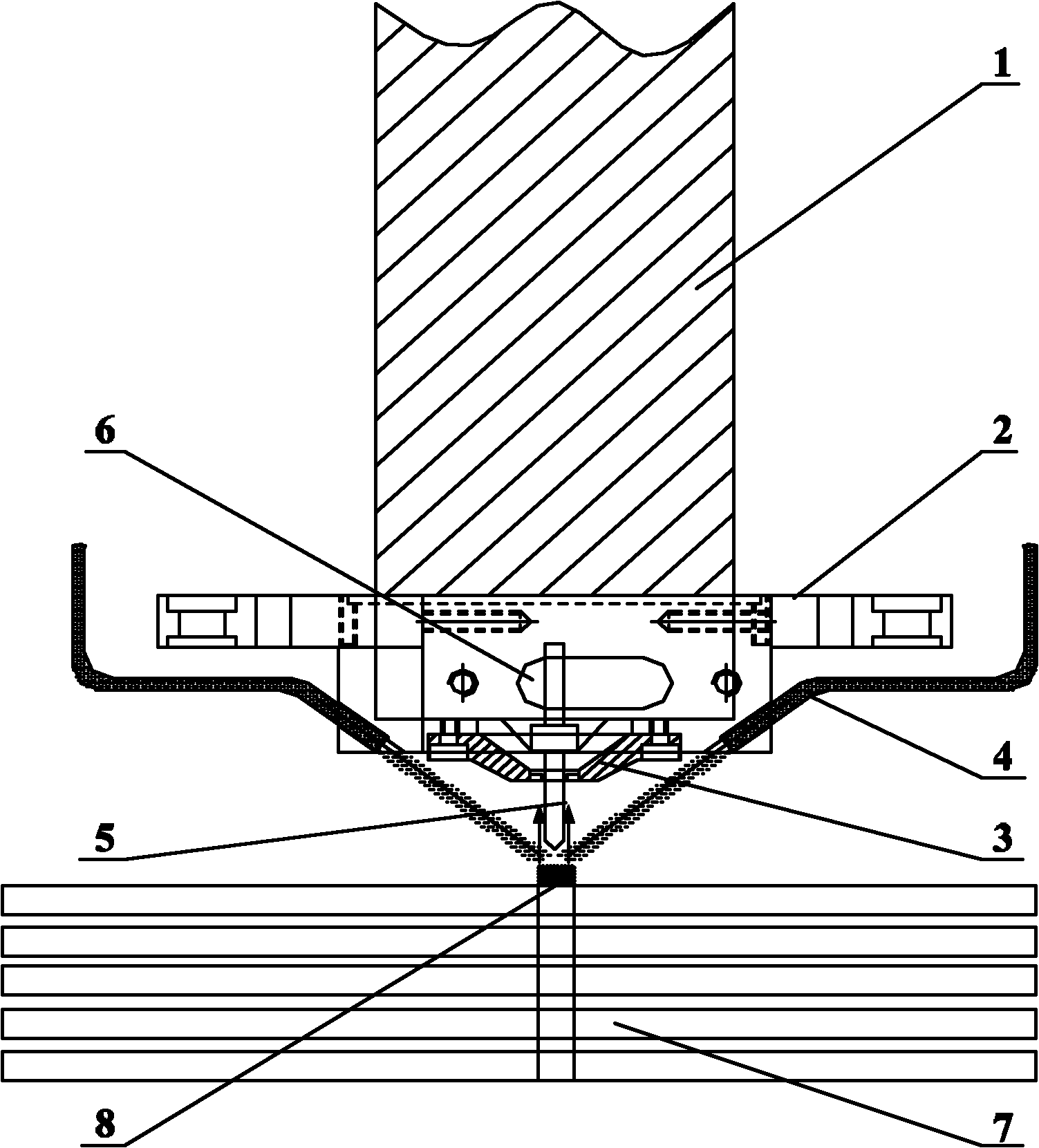

Semiconductor processing device and gas spray head cooling plate thereof

The invention discloses a gas spray head cooling plate comprising a cover plate and a base body, wherein the base body comprises a soleplate and a side wall; multiple cooling liquid separation devices are arranged on the soleplate at intervals; a cooling liquid channel used for passing cooling liquid is respectively formed between the adjacent cooling liquid separation devices; and a hole suitable for passing gas is respectively arranged on the cooling liquid separation devices so that the gas is evenly cooled by the gas spray head cooling plate. The invention also discloses a semiconductor processing device which comprises the gas spray head cooling plate.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Radiation coating, its preparing method and composition for making said coating

InactiveCN101070448AImprove surface heat dissipationSolve high temperatureSpecial surfacesEpoxy resin coatingsCooling effectBoron nitride

The invention provides a method for making paint coat which could strengthen the surface rejection of heat, and how to prepare the component of the coat elimination coat. The component of boron nitride and bonding agent formed a surface coating to enhance cooling effect. The paint coat could be used with head cooling metal, sheet, fins, metal backplane, metal or plastic material.

Owner:NAT NITRIDE TECH

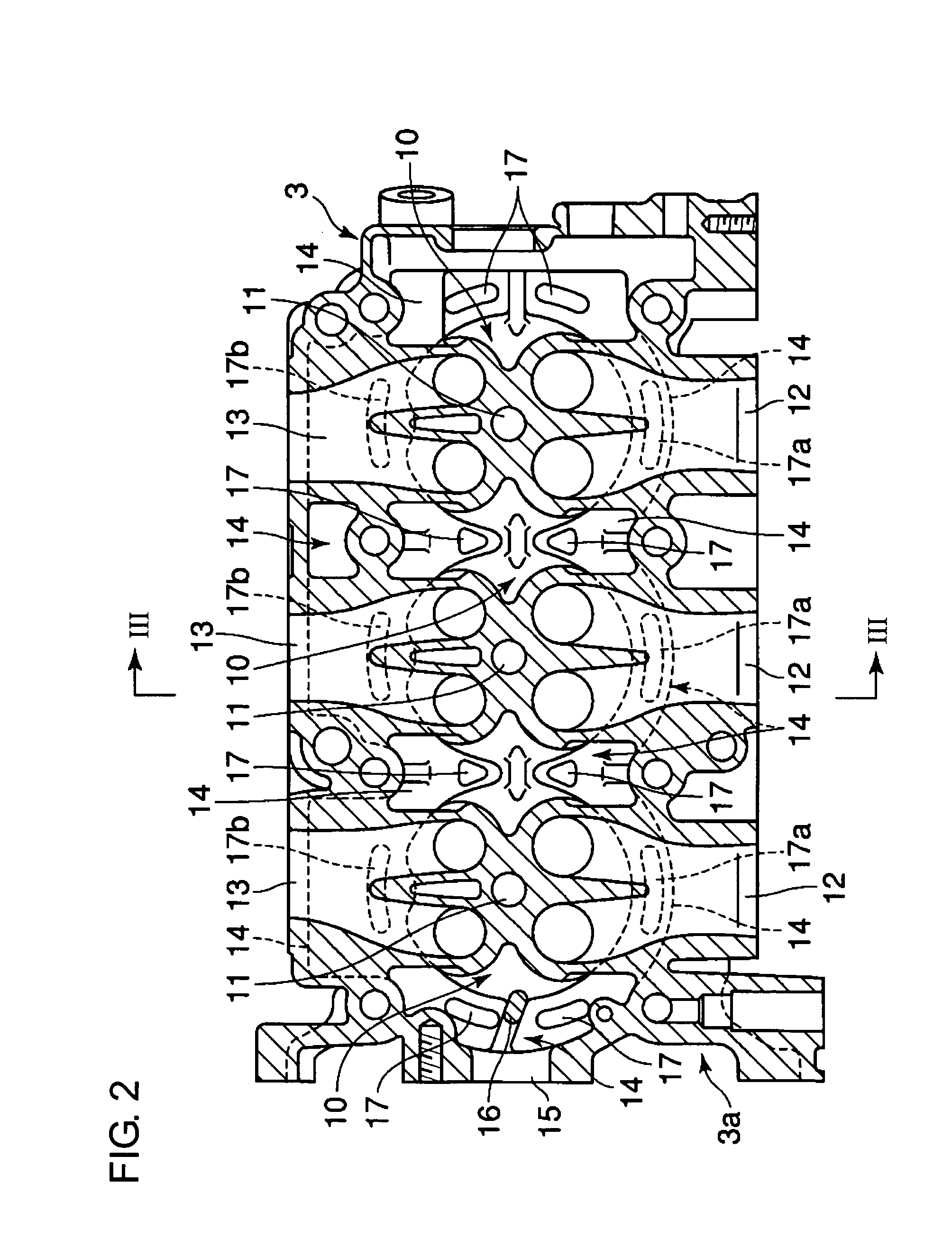

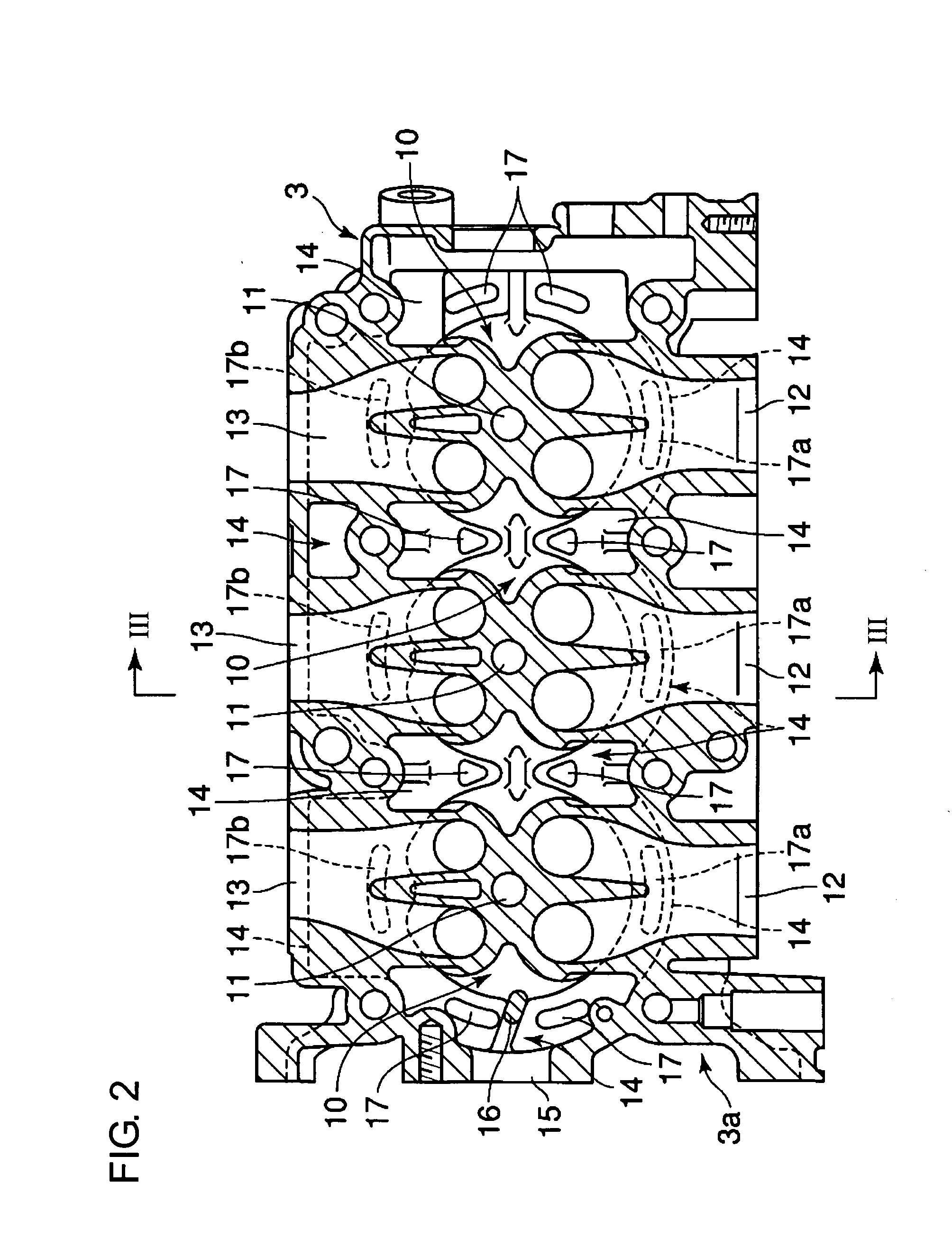

Cylinder head structure of engine

Head cooling passages are formed around intake ports and exhaust ports provided in a cylinder head, and a flow control member which controls the volume of cooling medium flowing toward the intake ports to be larger than the volume of cooling medium flowing toward the exhaust ports is provided in the vicinity of a supply port via which cooing medium is supplied.

Owner:MITSUBISHI MOTORS CORP

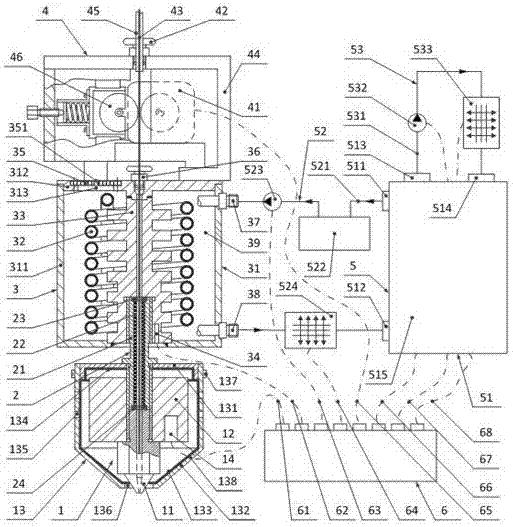

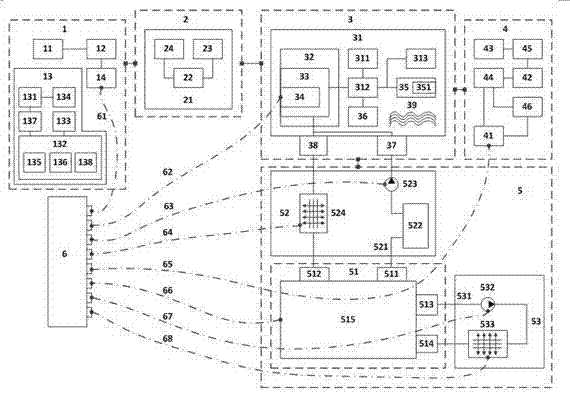

Melt deposition type 3D printer spray head cooling device

PendingCN106915075AAvoid passingSolidify as soon as possible3D object support structuresApplying layer meansTemperature controlFixed frame

The invention provides a melt deposition type 3D printer spray head cooling device which comprises a spray head hot end assembly, the hot end assembly is connected with a venturi assembly through a threaded structure, the venturi assembly is connected with a venturi cooling assembly through a threaded structure, the venturi cooling assembly is connected with a wire feeding mechanism through a fixing frame, the venturi cooling assembly is connected with a refrigerating device through a first cooling pipe connector and a second cooling pipe connector, and a control device is connected with the spray head hot end assembly through a power line. Work of the melt deposition type 3D printer spray head cooling device includes the steps of (1), selection of a PTC heater; (2), installation of the PTC heater; (3), injection of high-temperature conduction oil; (4), injection of heat-exchange liquid; (5), adjustment of a feeding wheel assembly; (6), start of a refrigeration device; (7), start of a venturi temperature sensor; (8), start of the PTC heater; (9), start of a 3D printer; (10), monitoring of material wire temperature; (11), temperature control over the venturi assembly; and by means of the melt deposition type 3D printer spray head cooling device, constant-temperature melting of the material wire in a spray nozzle and self-cooling of the material wire in a heat dissipation body can be achieved.

Owner:XIJING UNIV

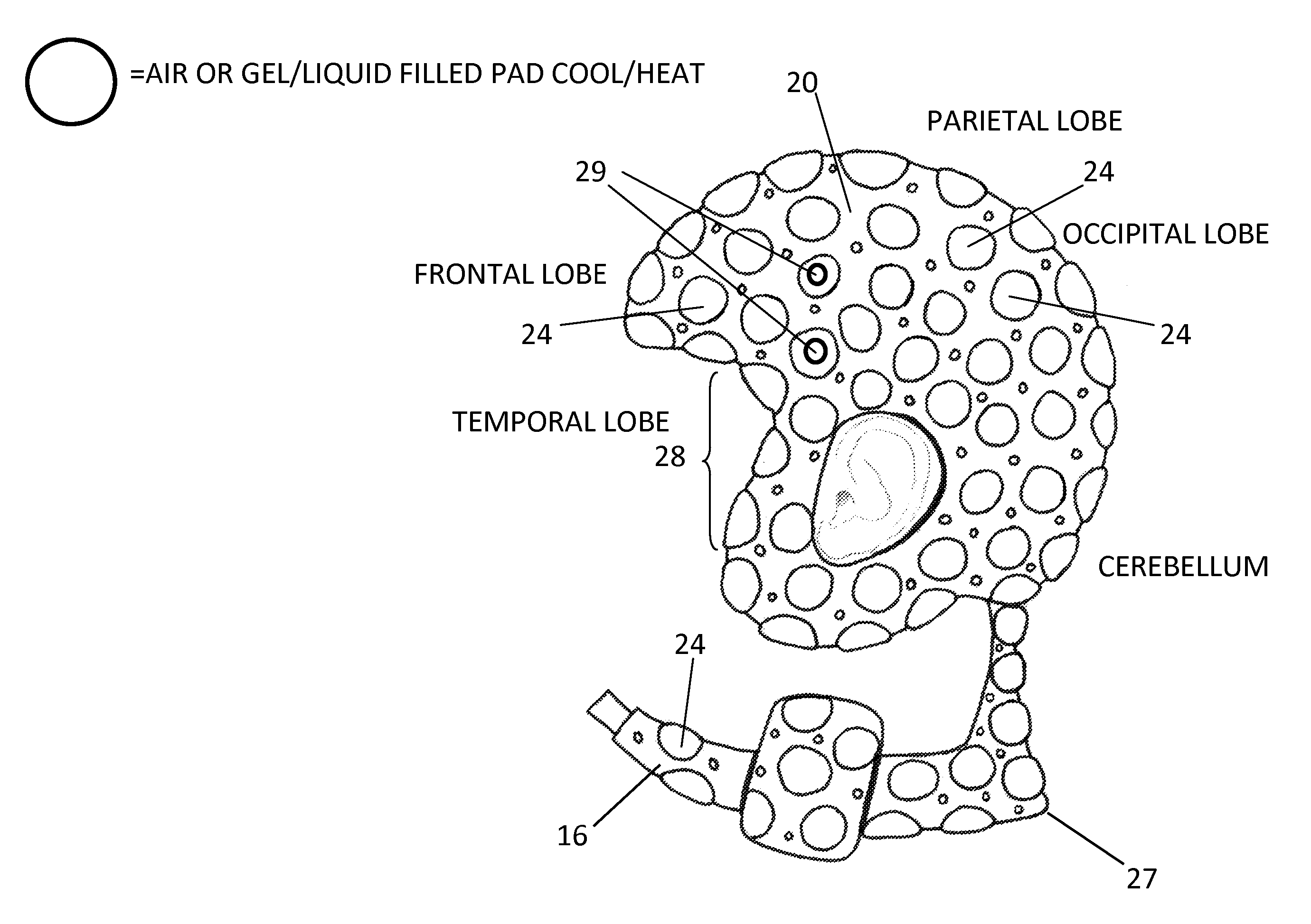

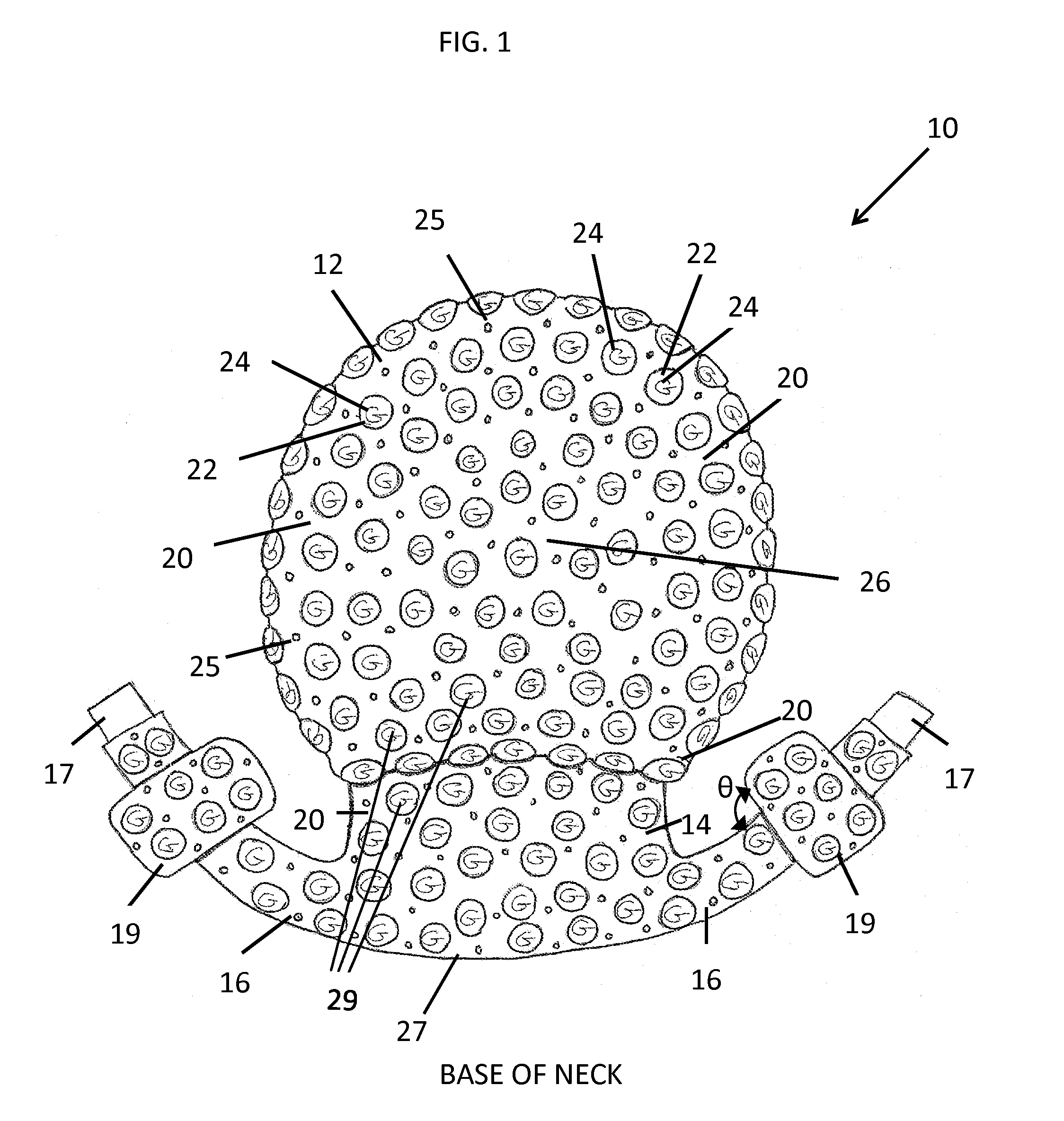

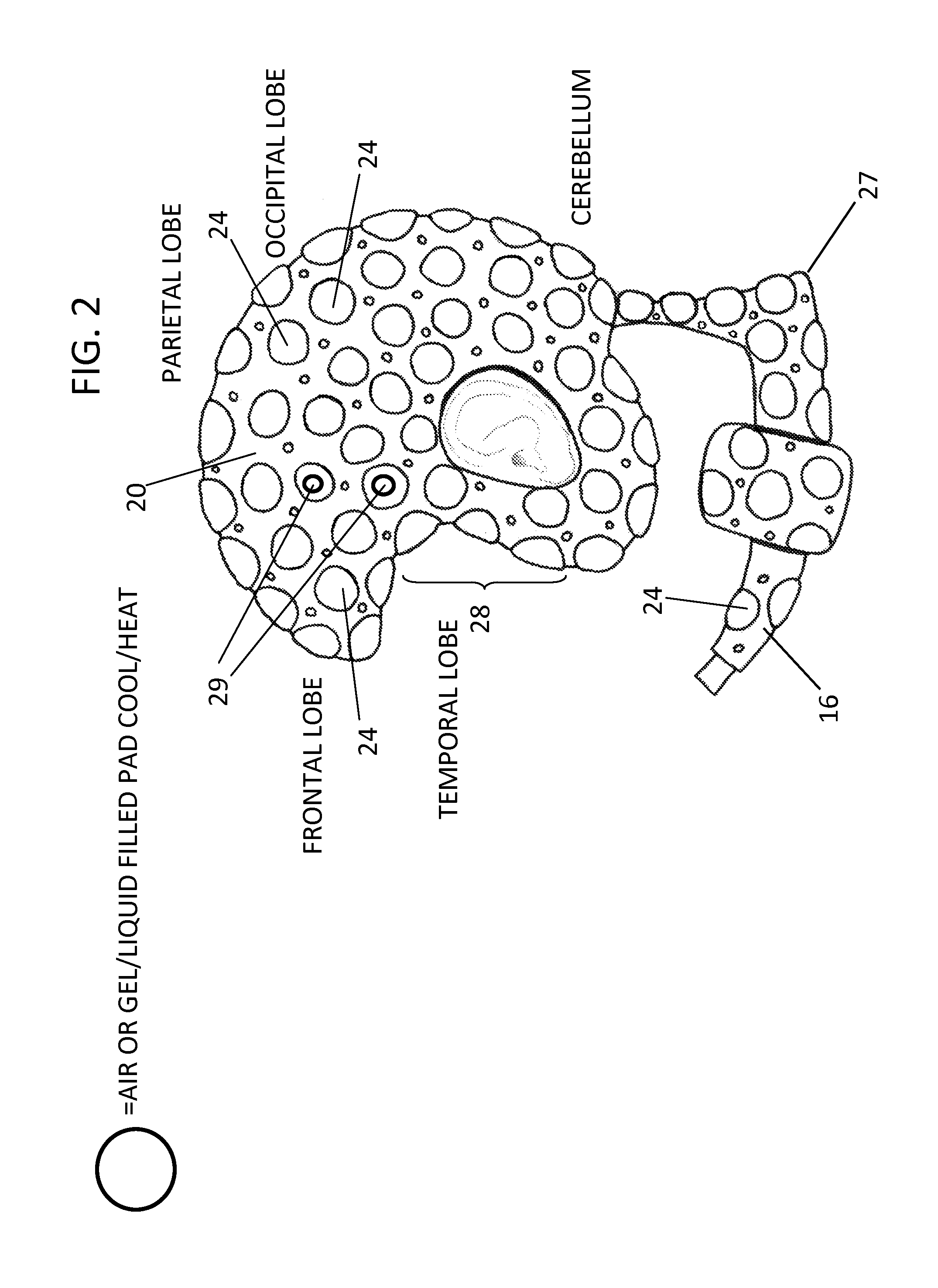

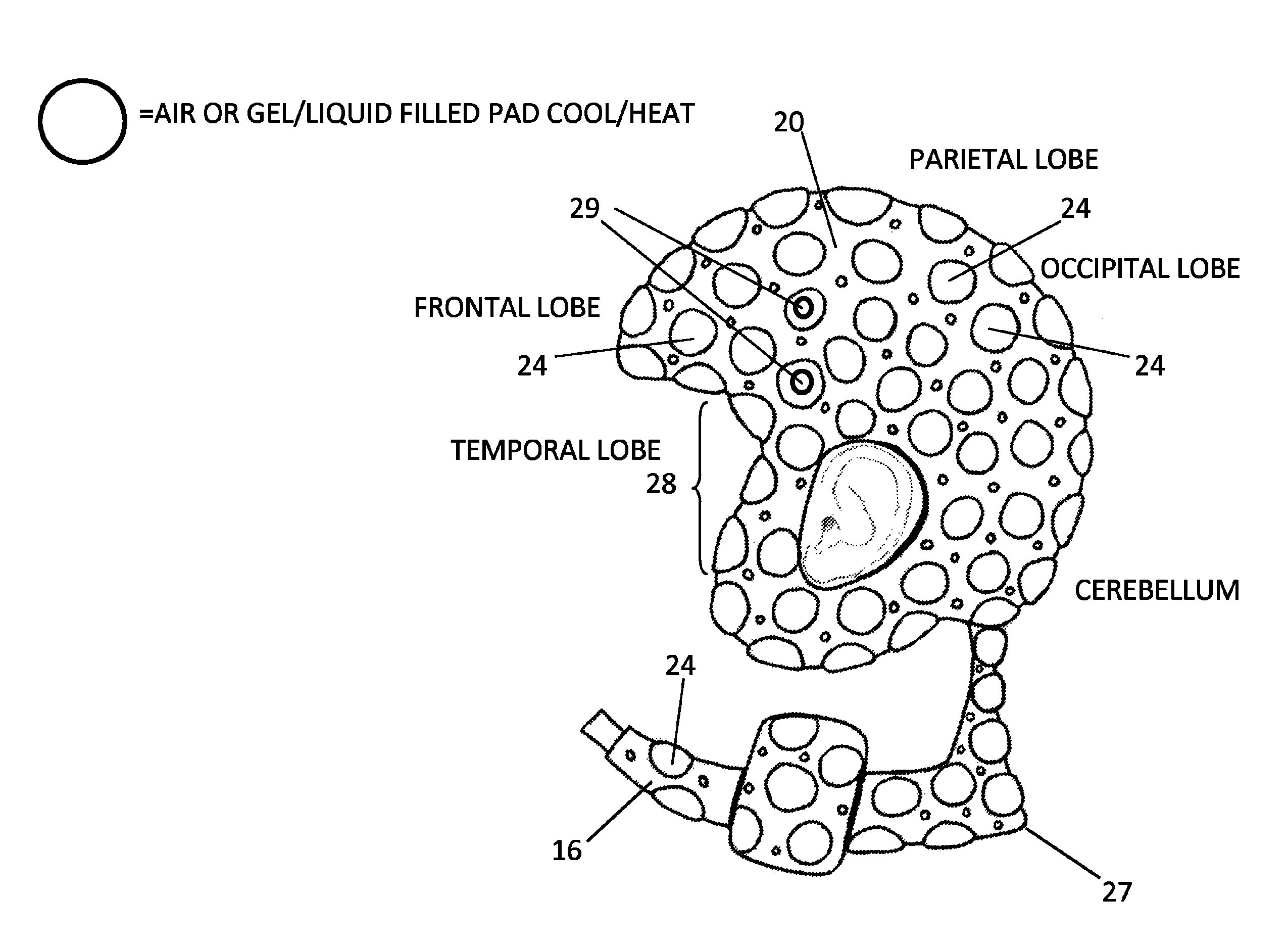

Protective temperature helmet, protective temperature helmet liner

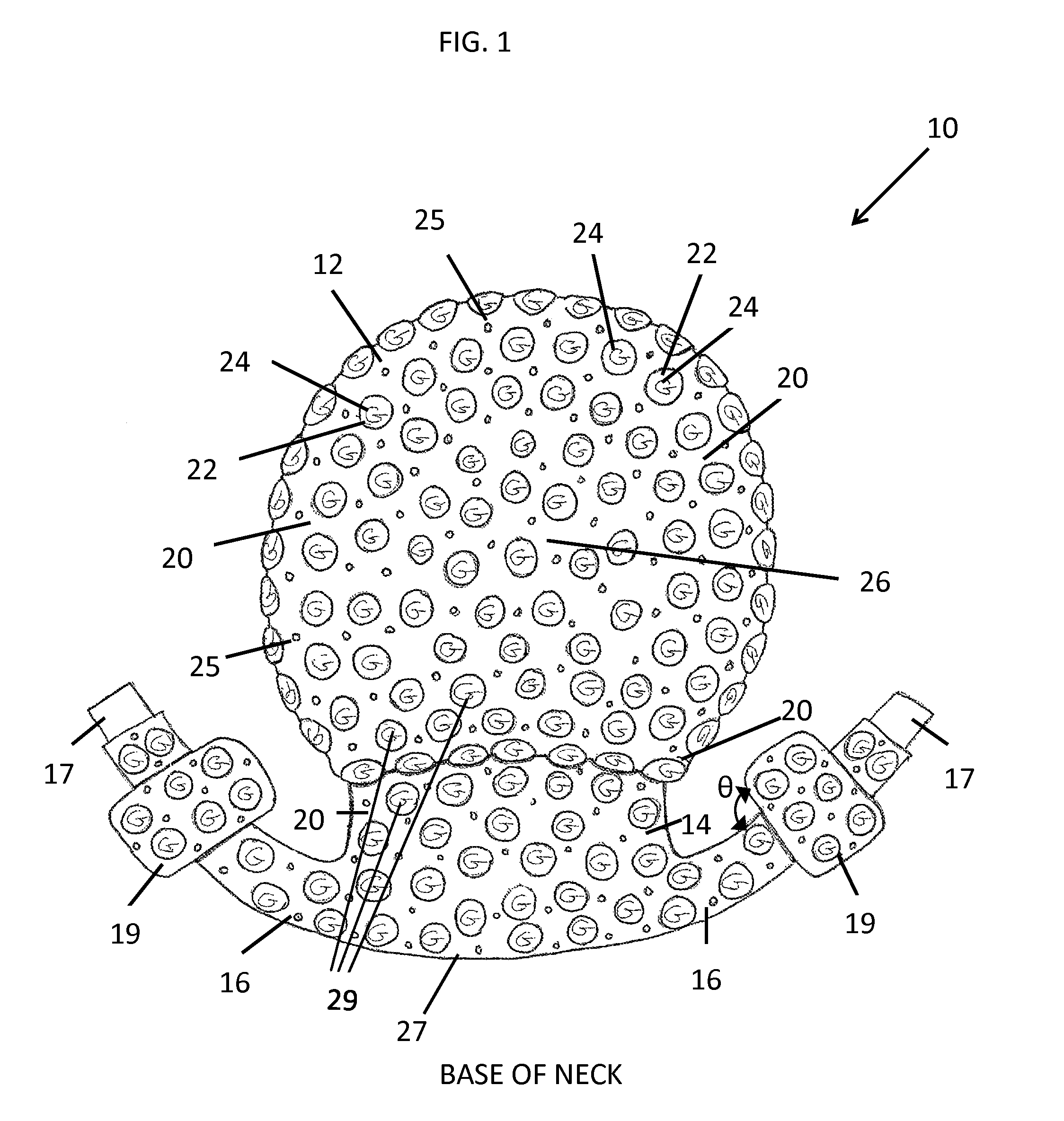

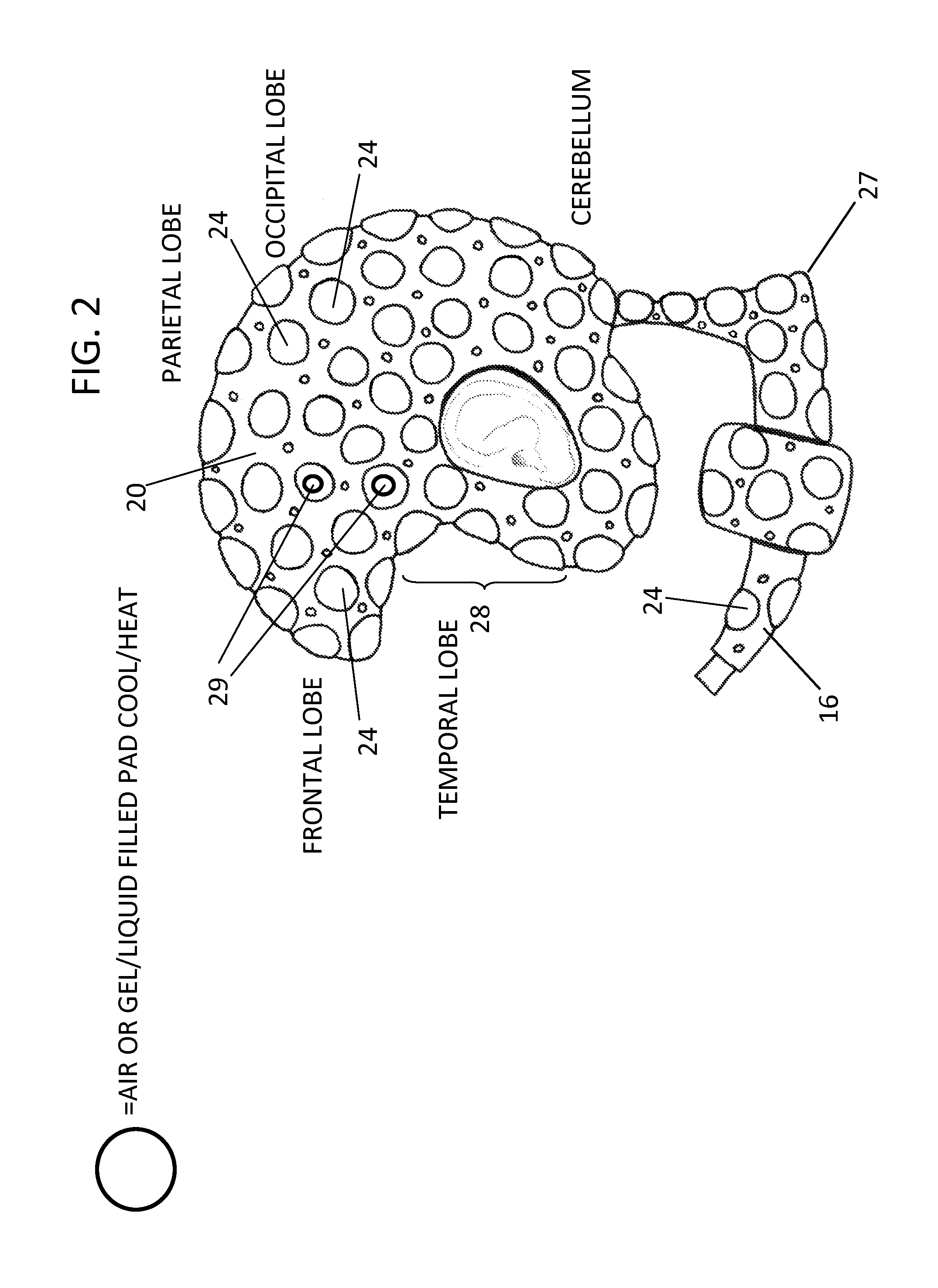

ActiveUS20120210490A1Prevent concussionPreventing brain swellingHatsHelmetsBiomedical engineeringWebbing

The invention provides a head cooling / heating device comprising a webbing adapted to encapsulate the human head; and a plurality of cavities defined by said webbing, said cavities adapted to reversibly receive a plurality of substrates, wherein the substrates are capable of being cooled or heated.

Owner:HARTY ROBERT D

Blind Head Cooling Helmet

InactiveUS20080184456A1Easy to wearEasy to removeHatsMagnetotherapy using permanent magnetsLiquid waterCooling effect

Disclosed herein is a cooling device such as a blind head cooling helmet which will fully cover the head contour plus the area of the eyes, cheeks, and ears, having an lid arrangement with internal air ducts or. An air pump generates and pushes small volumes of slow pace moving air, so that it be transferred to the blind head cooling helmet via an “C” shaped tube, to all the internal air duct, and finally escaping through the bottom of the lid arrangement, not without before the resulting air bubbles crashing against some areas of the internal layer creating a therapeutic effect or relaxing comfort to areas of the face. The present invention also comprises a small digital watch in the lid, a small flexible thermometer attached on the forehead of the blind head cooling helmet, plus sets of water pocket-magnet arrangements that will selectively adapt into empty cavity-gel pocket arrangements. Another embodiment of the present invention discloses a massage-like effect which can be obtained due to circular movements produced by the human head every time the weight of the enclosed water pushes against the external layer of the blind head cooling helmet which will cause the water to return back to the internal layer and vice versa thanks to the elasticity of both parallel layers and small flexible and elastic shock absorbers permanently holding both layers. The water pocket-magnet arrangement will configure into its respective gel pocket-empty cavity arrangement contributing as a pain relief therapy altogether with the cooling effect of the liquid water contained inside the main cavity. Also the flexible hollow intermediate skeleton or air ducts will proportionate armor to the blind head cooling helmet in the front, sides and back areas.

Owner:FONTANEZ ACEVEDO PEDRO J

Liquid-cooling device for internal combustion engine

InactiveUS7243620B2Effectively cooling down a cylinder headImprove cooling efficiencyLiquid coolingCoolant flow controlExternal combustion engineCylinder head

Owner:DENSO CORP

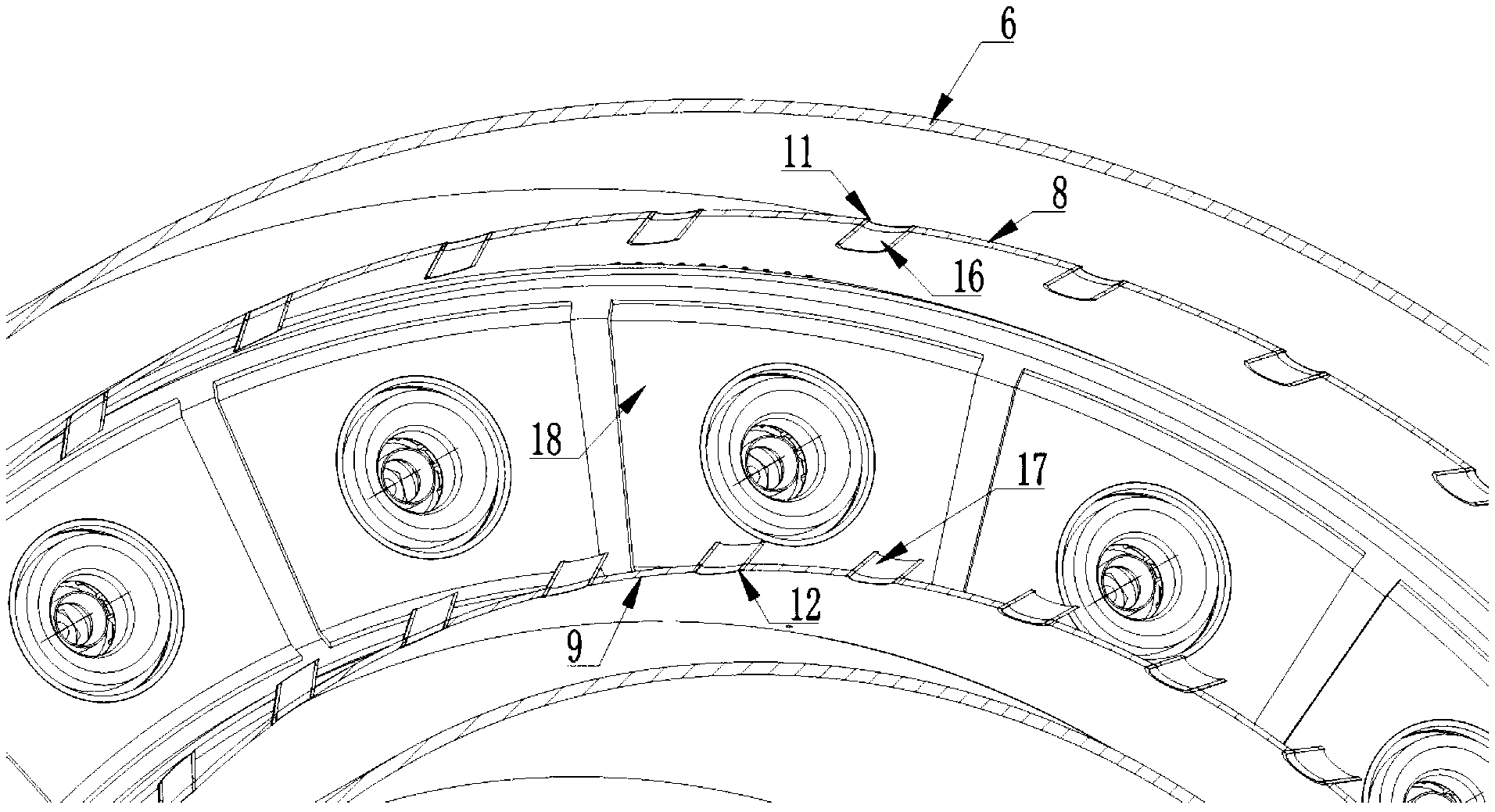

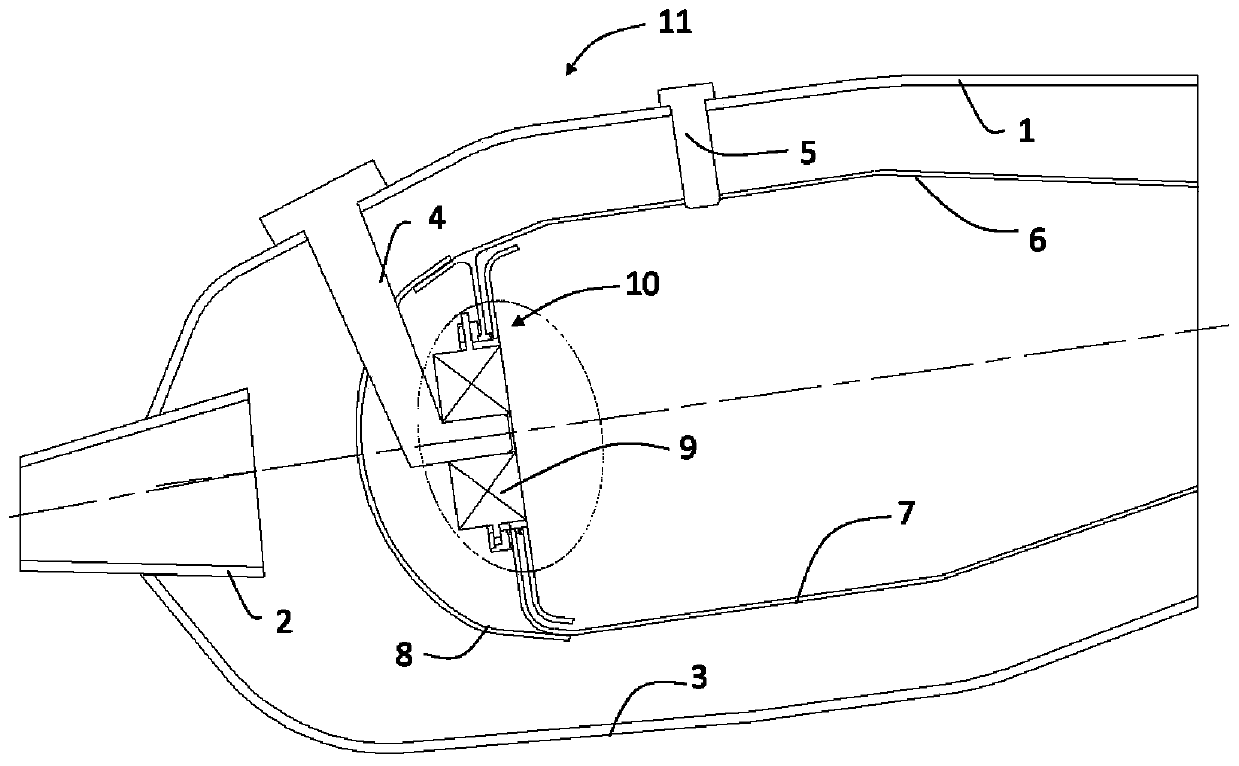

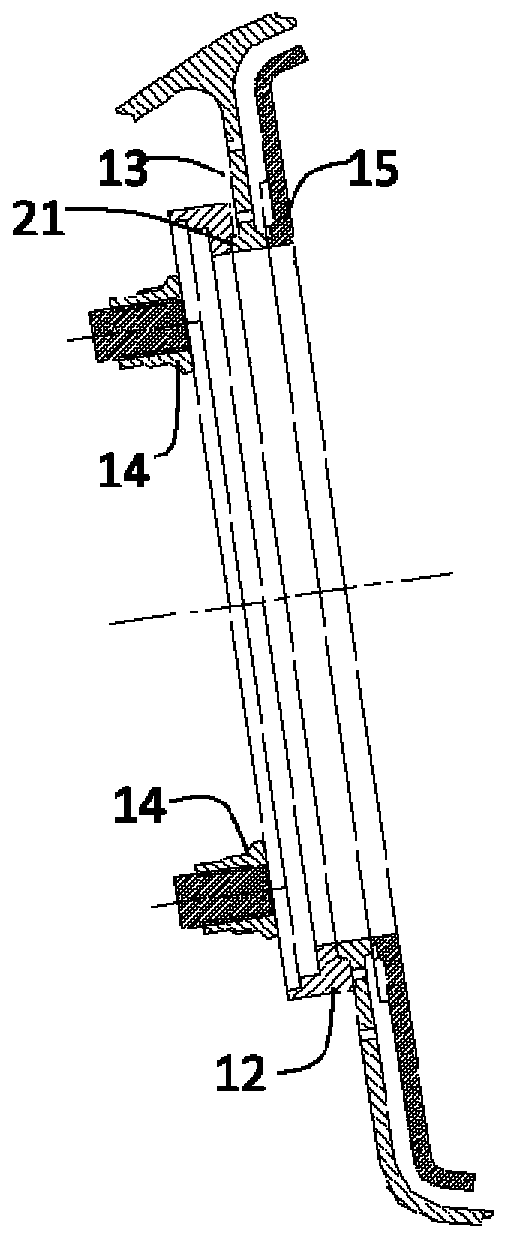

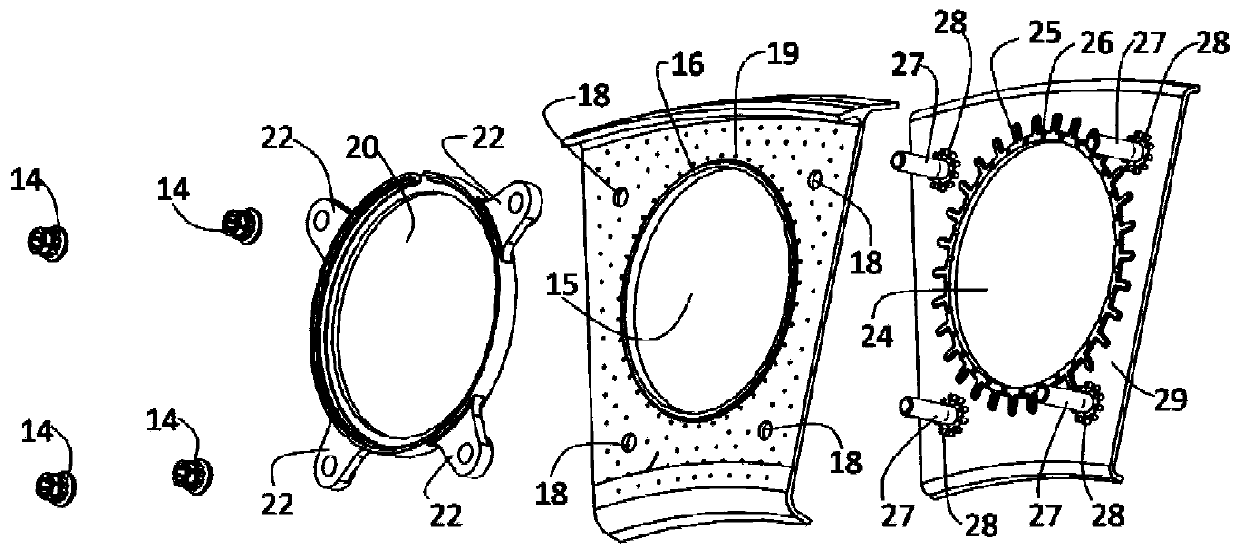

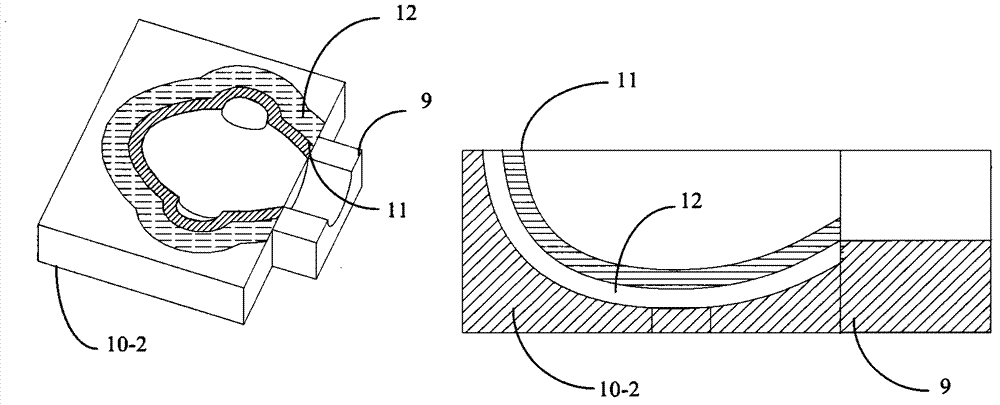

Angle-equipped cooling and positioning structure for flame tube head of aero-engine combustion chamber

InactiveCN110925797AExtend your lifeSimple structureContinuous combustion chamberCombustion chamberCooling effect

The invention discloses an angle-equipped cooling and positioning structure for a flame tube head of an aero-engine combustion chamber. The structure is suitable for various annular combustion chambers, and mainly comprises a cyclone mounting base (12), a head switching section (13), a splash disc (15), a self-locking nut (14) and the like. According to the structure, the flame tube head is simpleand feasible in structure, the temperature of each element of the head can be effectively reduced, and the cooling effect is good; compared with a conventional combustion chamber flame tube with a welded head, the flame tube only needs to be independently processed with the cyclone mounting base and the splash disc and then assembled, so that the production efficiency can be greatly improved; thesplash disc can expand towards the periphery when being heated, and heat stress is released, so that the service life of the splash disc is prolonged, and the service life of the flame tube is prolonged; and meanwhile, if the splash disc is damaged, parts can be replaced in time, so that maintenance is facilitated, and the structure has relatively good economic efficiency and very high practicalapplication value.

Owner:AECC SICHUAN GAS TURBINE RES INST

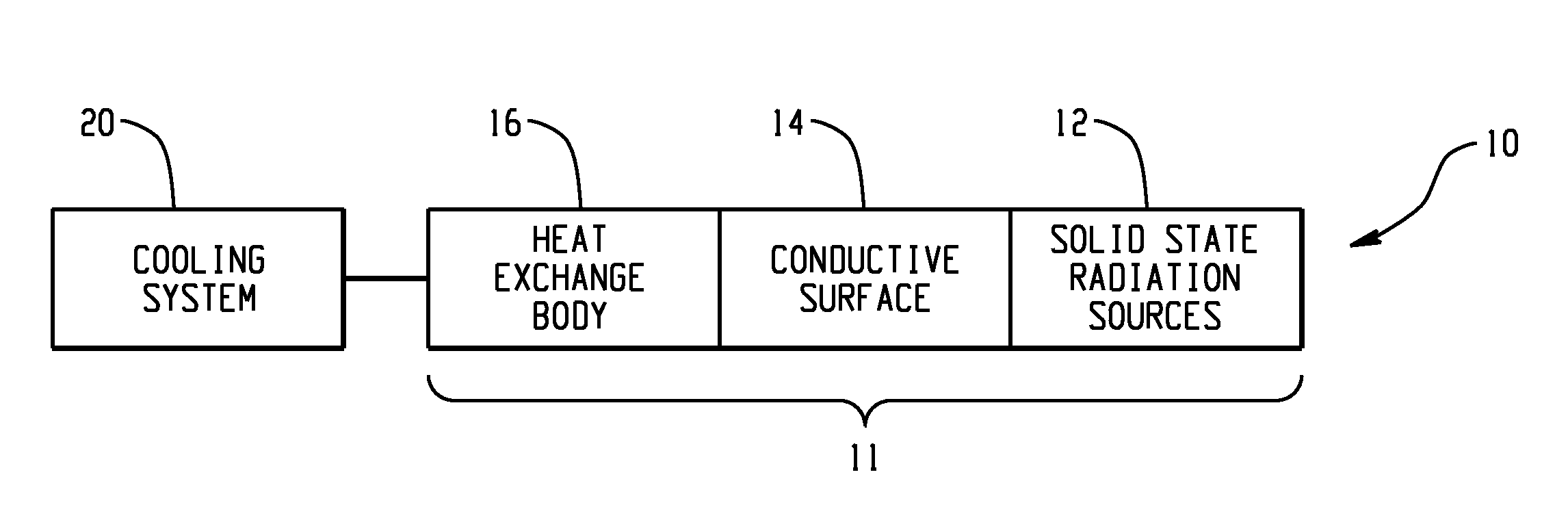

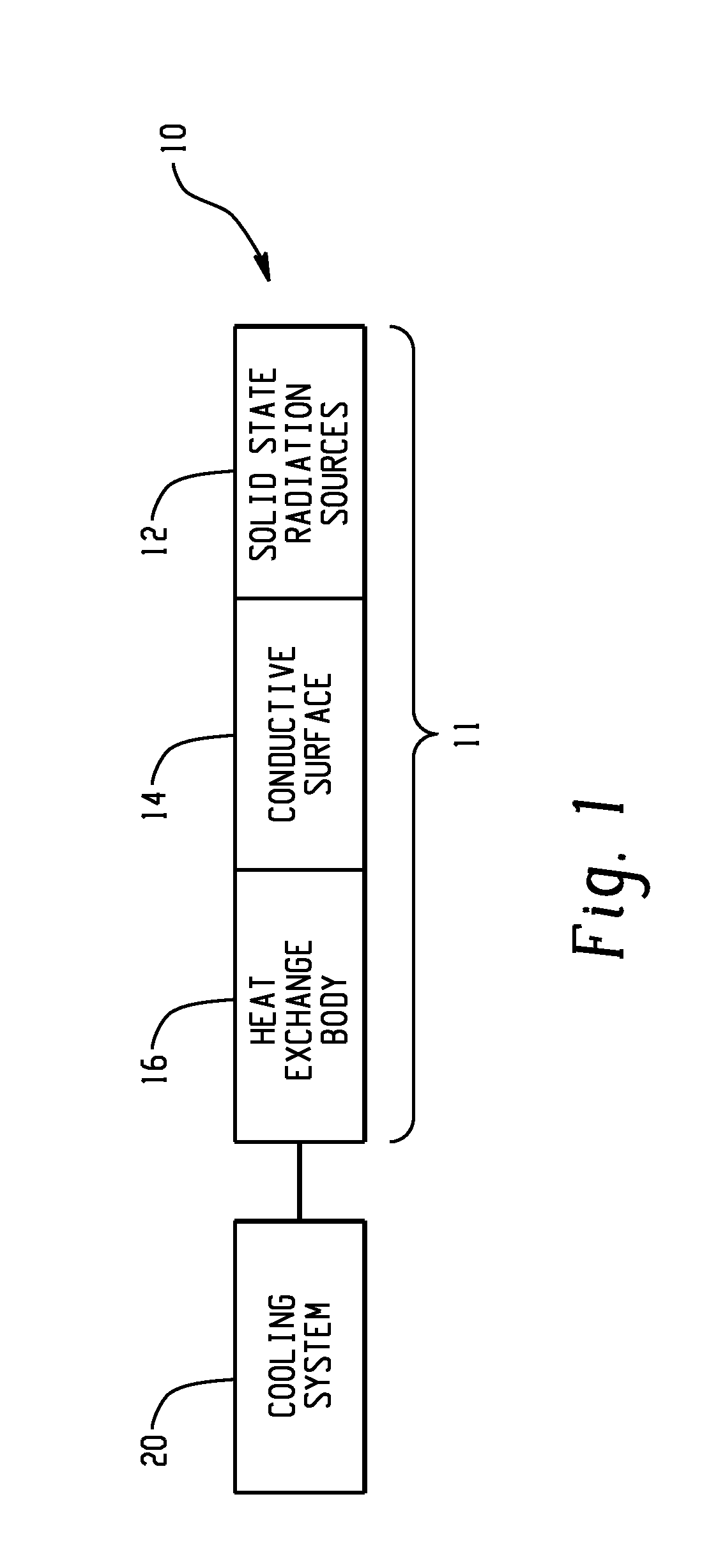

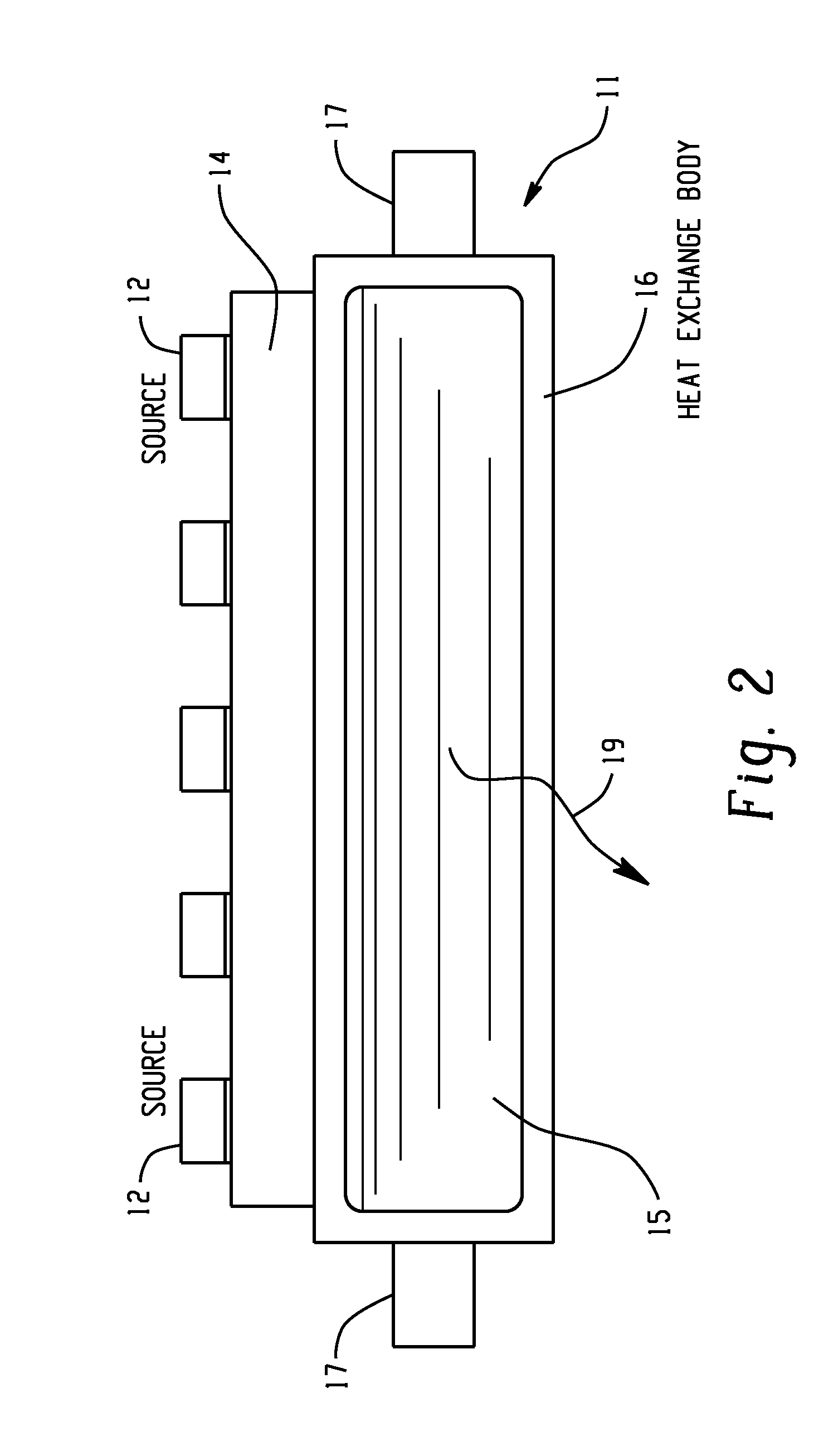

Distributed cooling of arrayed semi-conductor radiation emitting devices

InactiveUS20120061054A1Improve thermal conductivityPoint-like light sourceLighting heating/cooling arrangementsEngineeringSemiconductor

Techniques for the removal of waste heat from solid state, semiconductor devices (such as cooking or heating devices) are provided. In particular, techniques for conducting waste heat away from the device through a heat sink in contact with a cooling system are provided. In addition, a multi-head cooling system applicable to multiple solid state, semiconductor sources is provided.

Owner:PRESSCO IP LLC

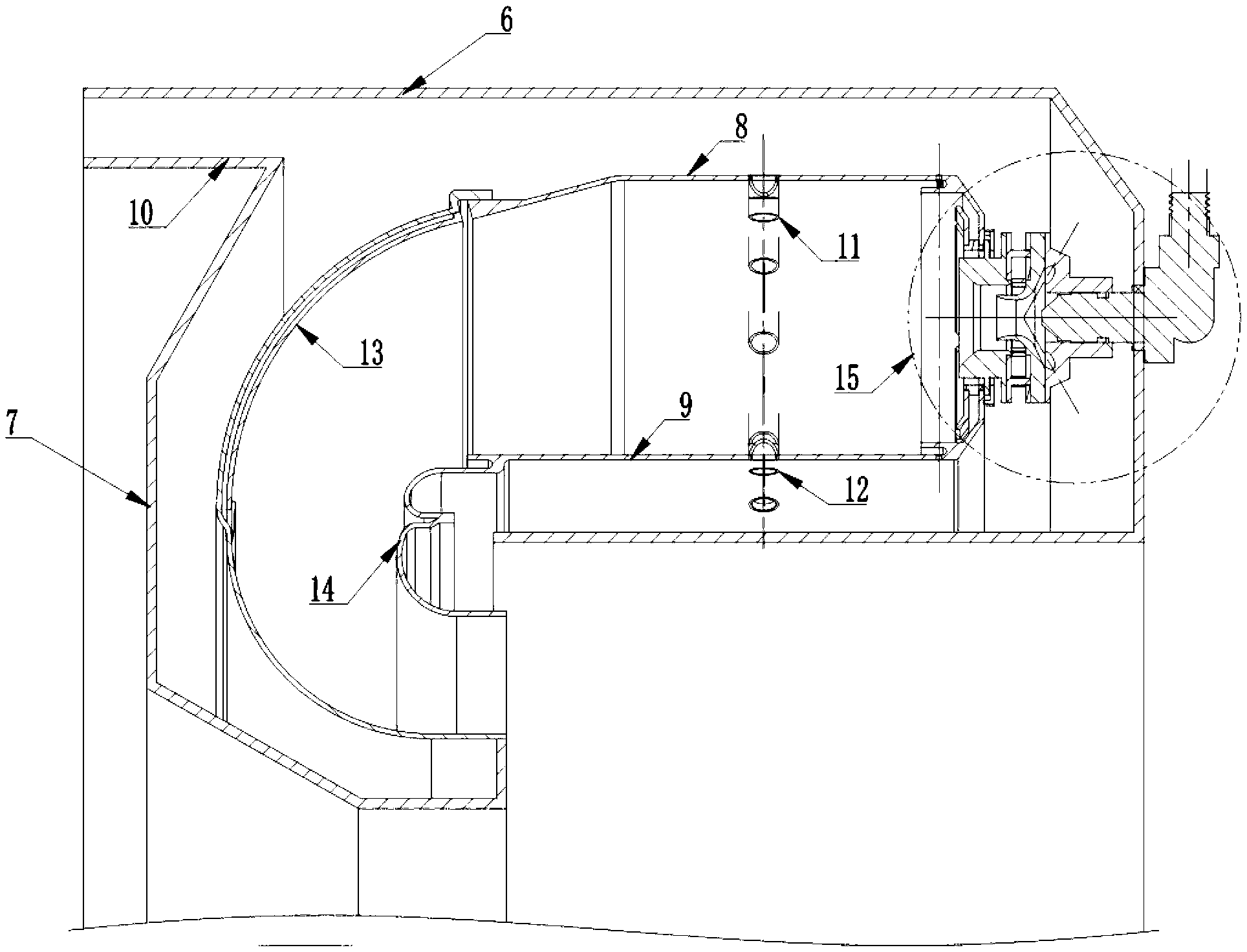

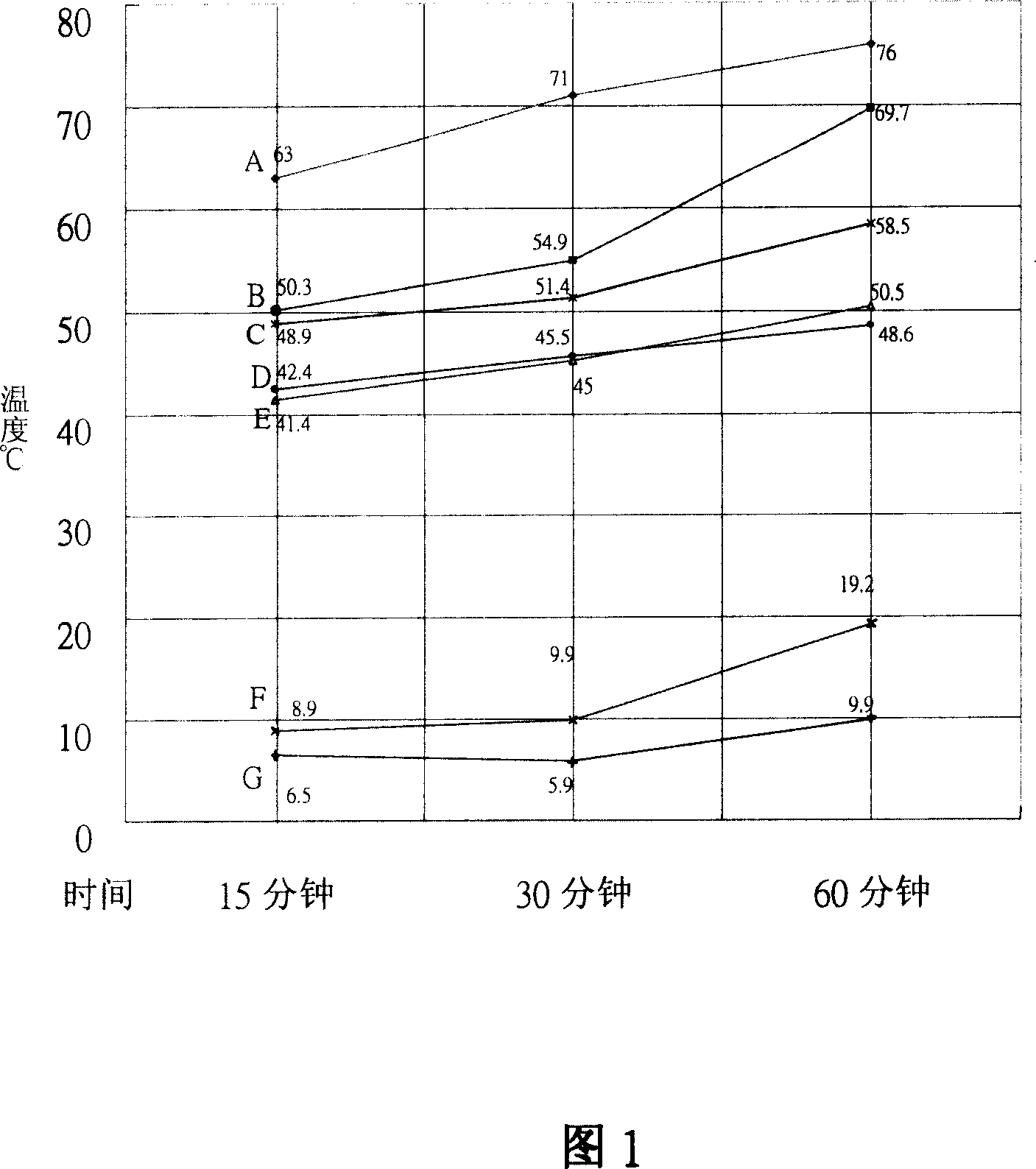

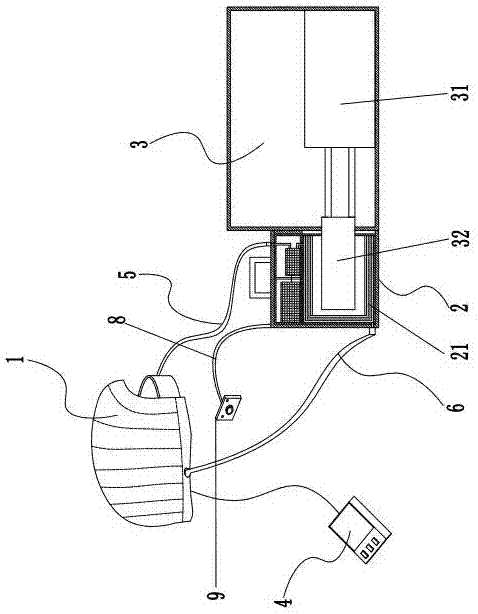

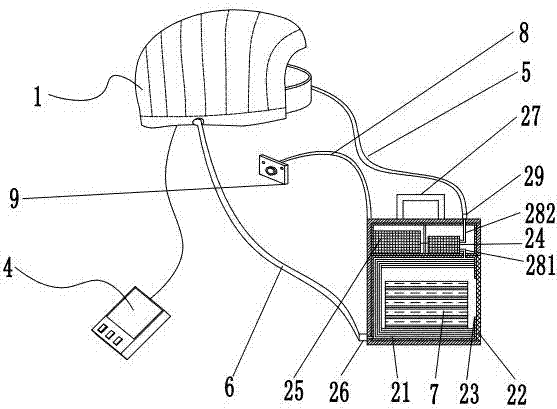

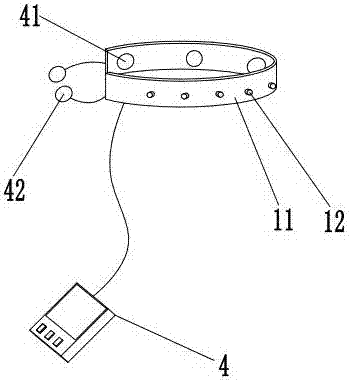

Medical use head cooling device

InactiveCN104758117APrecise temperature controlImprove cooling effectTherapeutic coolingTherapeutic heatingCooling effectEngineering

The invention discloses a medical use head cooling device, wherein a display screen is installed in the front of a device body, a controller is installed inside the device body, a temperature detecting device is installed on a water tank, the water tank is installed inside the device body, a refrigerating device is installed on one side of the water tank, a circulation water pump is installed on the lower portion of the device body, an air pump is installed on the lower portion of the device body, a neck bracket is connected with a head bracket, an air inflation layer is arranged inside the head bracket, and a cooling water layer is arranged on the air inflation layer. One end of a water pipe is connected with the circulation water pump, the other end is connected with the cooling water layer. One end of an air inflation pipe is connected with the air pump, and the other end is connected with the air inflation layer. The medical use head cooling device is provided with the air inflation layer and the cooling water layer for achieving the cooling effect. Additionally, the circulation water pump and the refrigerating device are used for continuously conveying cold water to the cooling water layer, so as to precisely control the temperature of the cooling water layer, accordingly solving the problems that a larger gap exists between the inner wall of the existing cooling hat, the cooling time is long, the low temperature is uneven, and the temperature cannot be controlled.

Owner:孔丽丽

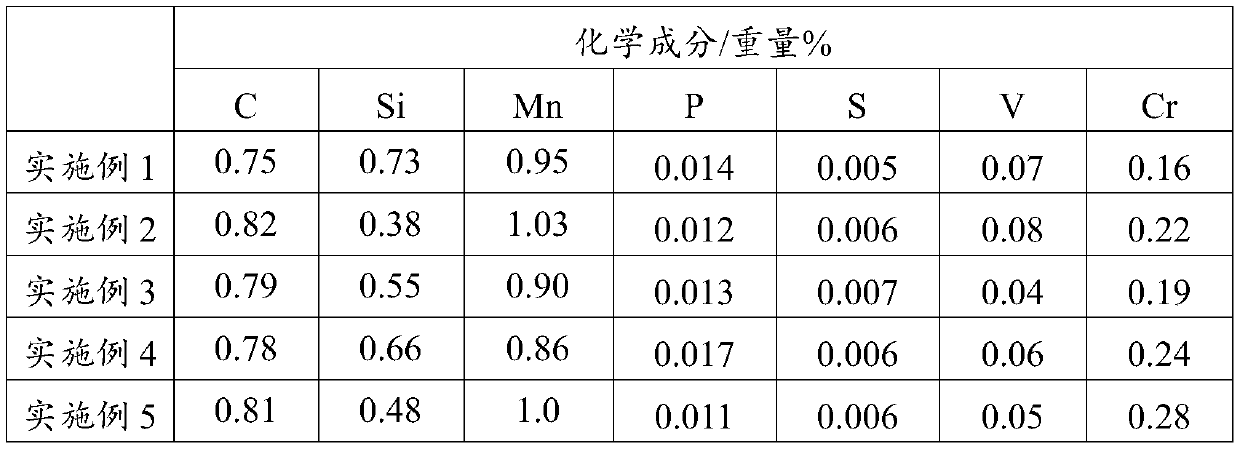

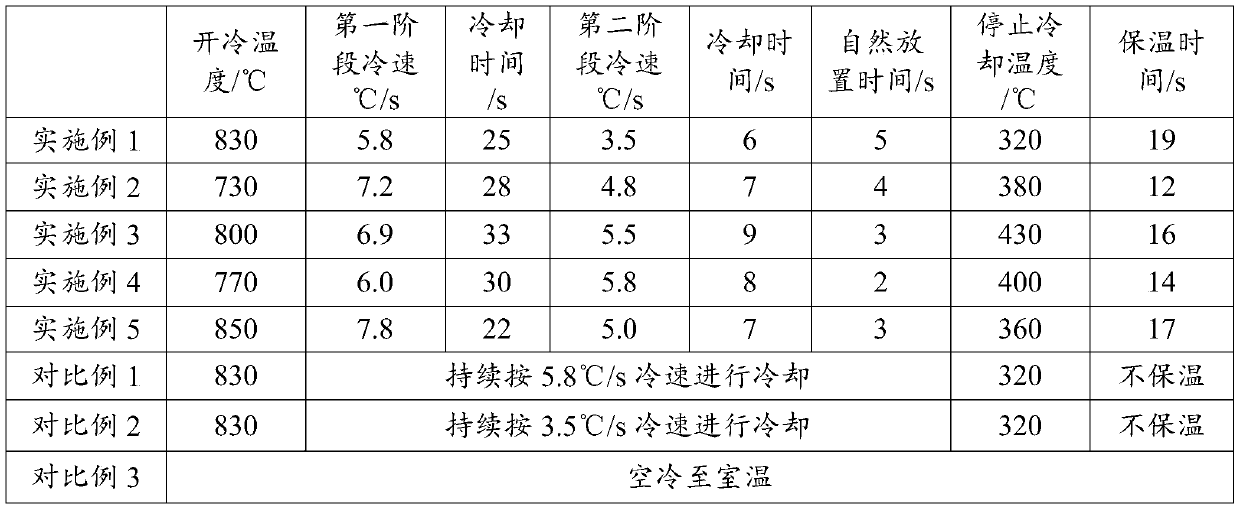

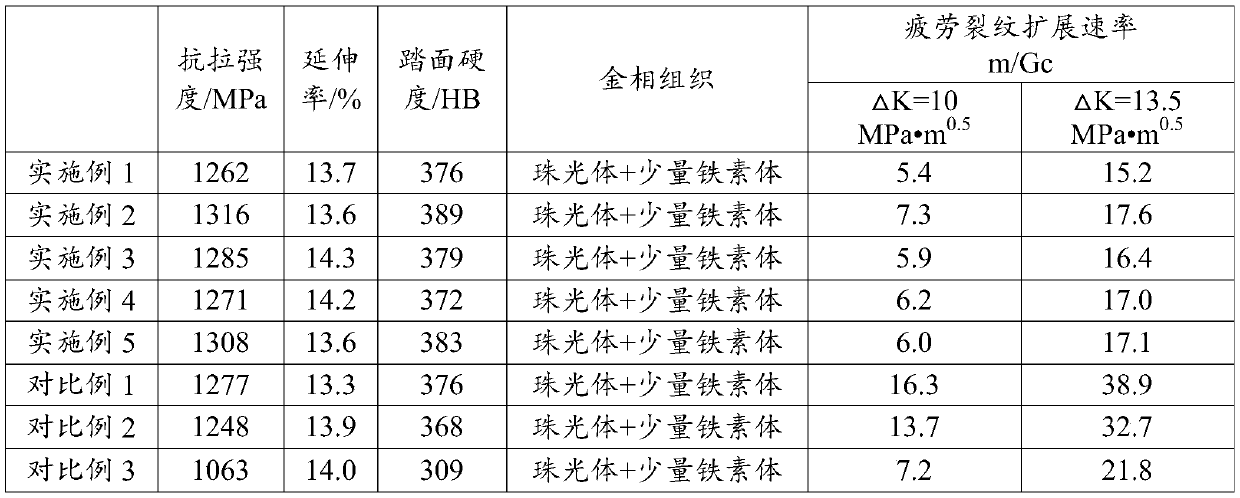

Heat treatment method for reducing steel rail fatigue crack propagation rate

ActiveCN110527816AExtended service lifeImprove driving safetyFurnace typesHeat treatment furnacesFree coolingRoom temperature

The invention discloses a heat treatment method for reducing the steel rail fatigue crack propagation rate. The heat treatment method comprises the following steps: a hot-rolled steel rail head is subjected to segmented accelerated cooling heat treatment: specifically, the initial cooling temperature is controlled to be 720-860 DEG C, the first-stage rail head cooling speed is 5-8 DEG C / s, and thecooling time is 20-35 s; subsequent second-stage cooling: in this stage, circulating periodic cooling is adopted, firstly, the rail head is cooled in an accelerated manner, wherein the cooling speedis 3-6 DEG C / s, the cooling time is 6-10 s, then accelerated cooling is stopped, the steel rail is naturally placed for 2-5 s, a cooling period is formed, through continuous circulation of said cooling period, when the temperature of the rail head is reduced to 300-450 DEG C, accelerated cooling is stopped, then the rail head is subjected to heat preservation for 10-20 min, and finally the rail head is naturally cooled to the room temperature. In the steel rail obtained through the method, the room-temperature metallographic structure of the whole section is composed of lamellar pearlite and asmall amount of ferrite; the fatigue crack propagation rate can be controlled to be 5-8 m / Gc (delta K = 10 MPa.m < 0.5 >) and 14-18 m / Gc (delta K = 13.5 MPa.m < 0.5 >); the method can be applied to various lines of passenger transportation, passenger and cargo mixed transportation and the like, the service life of the steel rail is prolonged, and the driving safety of the steel rail is improved.

Owner:武汉钢铁有限公司

Head cooling and monitoring device for emergency treatment

InactiveCN107961111AReal-time temperature monitoringAdjustable temperatureDiagnostic recording/measuringSensorsVideo monitoringContinuous use

The invention discloses a head cooling and monitoring device for emergency treatment. The head cooling and monitoring device for emergency treatment comprises a cooling head sleeve, a temperature monitoring mechanism, a heat exchange mechanism, a video monitoring mechanism and a refrigerating mechanism, wherein a liquid flow path is arranged in the cooling head sleeve; assisted cooling is carriedout by feeding of a cooling medium, so that cooling treatment can be carried out by wearing the cooling head sleeve on the head of a patient by a medical worker only; and moreover, the temperature monitoring mechanism is adhered to the head of the patient, thus, the temperature monitoring mechanism monitors the temperature of the head of the patient in real time, and thus, the medical worker can take necessary emergency nursing measures in time; and the head exchange mechanism is connected with the cooling head sleeve, through a miniature water pump of the heat exchange mechanism, the coolingmedium in the cooling head sleeve is driven to circulate, the cooling medium in the cooling head sleeve flows through a heat exchange tube of the heat exchange mechanism to carry out heat exchange, the cooling medium in the cooling head sleeve can be cooled in time, the temperature of the cooling medium can be controlled, and continuous use reliability of the cooling head sleeve is improved.

Owner:王娟

Protective temperature helmet, protective temperature helmet liner

ActiveUS8943617B2Prevent concussionPreventing brain swellingEye treatmentHatsEngineeringBiomedical engineering

The invention provides a head cooling / heating device comprising a webbing adapted to encapsulate the human head; and a plurality of cavities defined by said webbing, said cavities adapted to reversibly receive a plurality of substrates, wherein the substrates are capable of being cooled or heated.

Owner:HARTY ROBERT D

Numerical control drill head cooling device and method

ActiveCN102059581ANo flying dust phenomenonMaintainance and safety accessoriesNumerical controlNitrogen

The embodiment of the invention provides a numerical control drill head cooling device. A numerical control drill head is provided with a dust absorbing pipe, the dust absorbing pipe is formed with a negative pressure region during working, the dust absorbing pipe comprises a plurality of liquid nitrogen pipes which are evenly distributed on the same periphery, the distances between a plurality of spray heads of the liquid nitrogen pipes and the numerical control drill head are all equal, and the spraying pressure of each liquid nitrogen pipe is larger than the suction of the negative pressure region. In the embodiment of the invention, a ring form is formed by setting the negative pressure region which can absorb the dust around the drill head, the liquid nitrogen spraying pipes are arranged around the circle, the liquid nitrogen is sprayed to the negative pressure region in which the drill head is arranged at the same time, and a part of the liquid nitrogen can be remained on the surface of a plate and the upper surface of the drill head as long as the liquid nitrogen spraying force is larger than the dust absorbing force to be capable of cooling the drill head instantaneously. Due to the structure, the dust generated by working can not be flied caused by uneven force application. The embodiment of the invention further discloses a numerical control drill head cooling method.

Owner:SHENNAN CIRCUITS

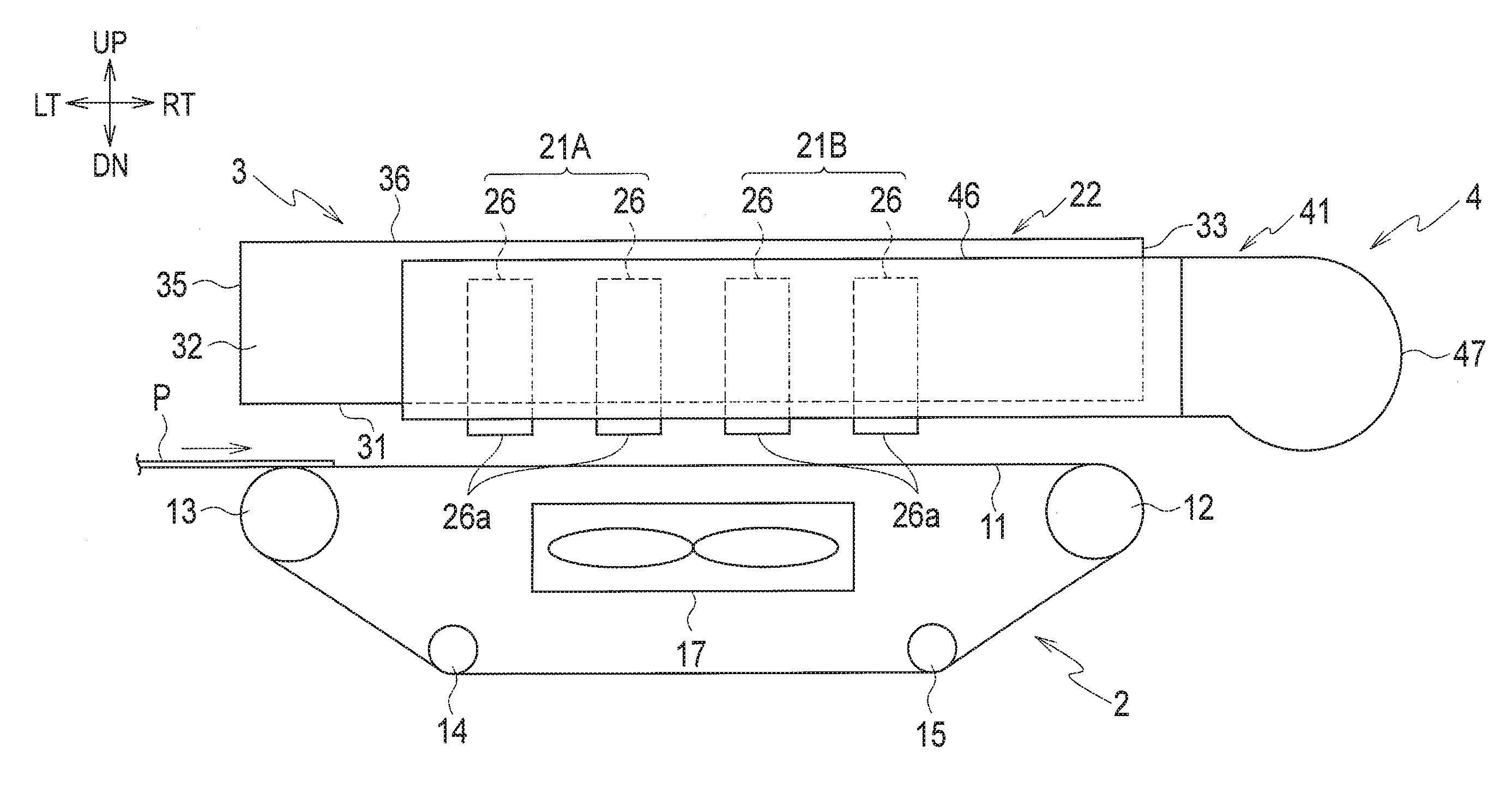

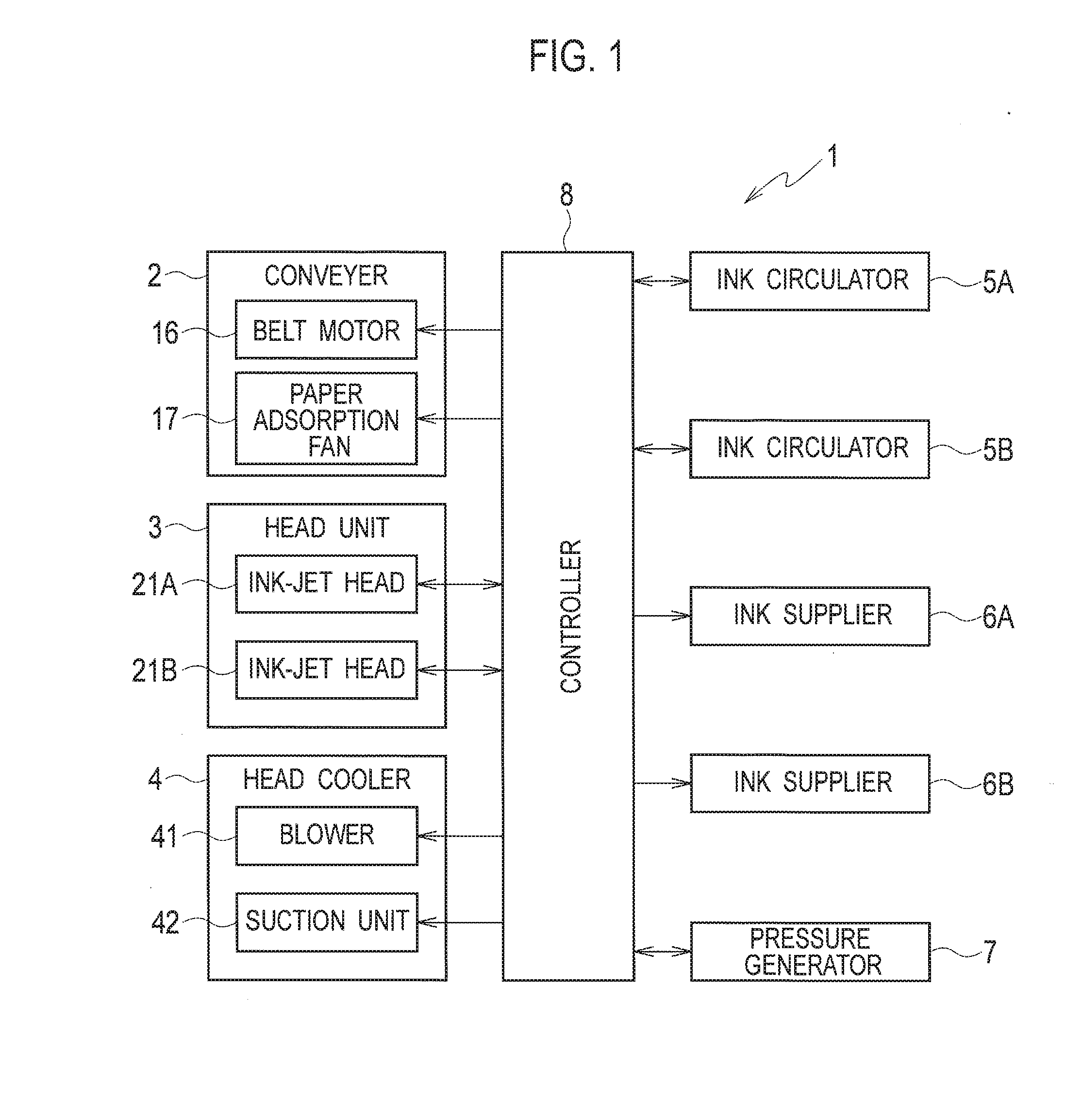

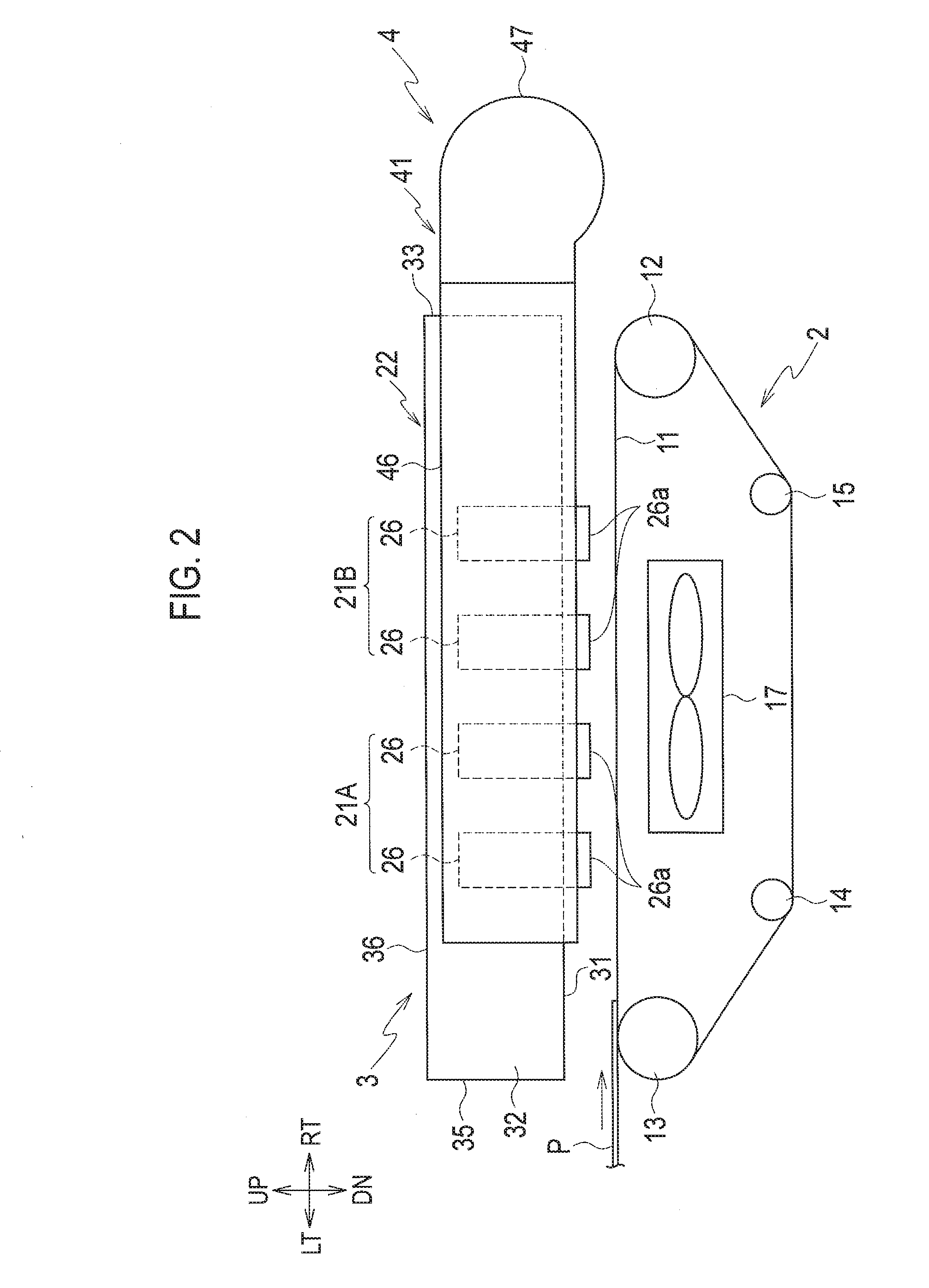

Ink-jet printer

ActiveUS20160243857A1Drop in print productivityIncrease temperatureInking apparatusOther printing apparatusInk printerEngineering

A head holder has an opening through which a space between the head holder and a conveyer communicates with an inside of the head holder. A head cooler includes a blower configured to blow air into the head holder from an outside of the head holder with a flow rate of blow air and a suction unit configured to suction air from the head holder with a flow rate of suction air. The head cooler generates cooling air for cooling an ink-jet head inside the head holder by the blower and the suction unit. A controller controls the flow rate of blow air and the flow rate of suction air such that air containing ink mist is suctioned into the head holder through the opening.

Owner:RISO KAGAKU CORP

Cylinder head structure of engine

Head cooling passages are formed around intake ports and exhaust ports provided in a cylinder head, and a flow control member which controls the volume of cooling medium flowing toward the intake ports to be larger than the volume of cooling medium flowing toward the exhaust ports is provided in the vicinity of a supply port via which cooing medium is supplied.

Owner:MITSUBISHI MOTORS CORP

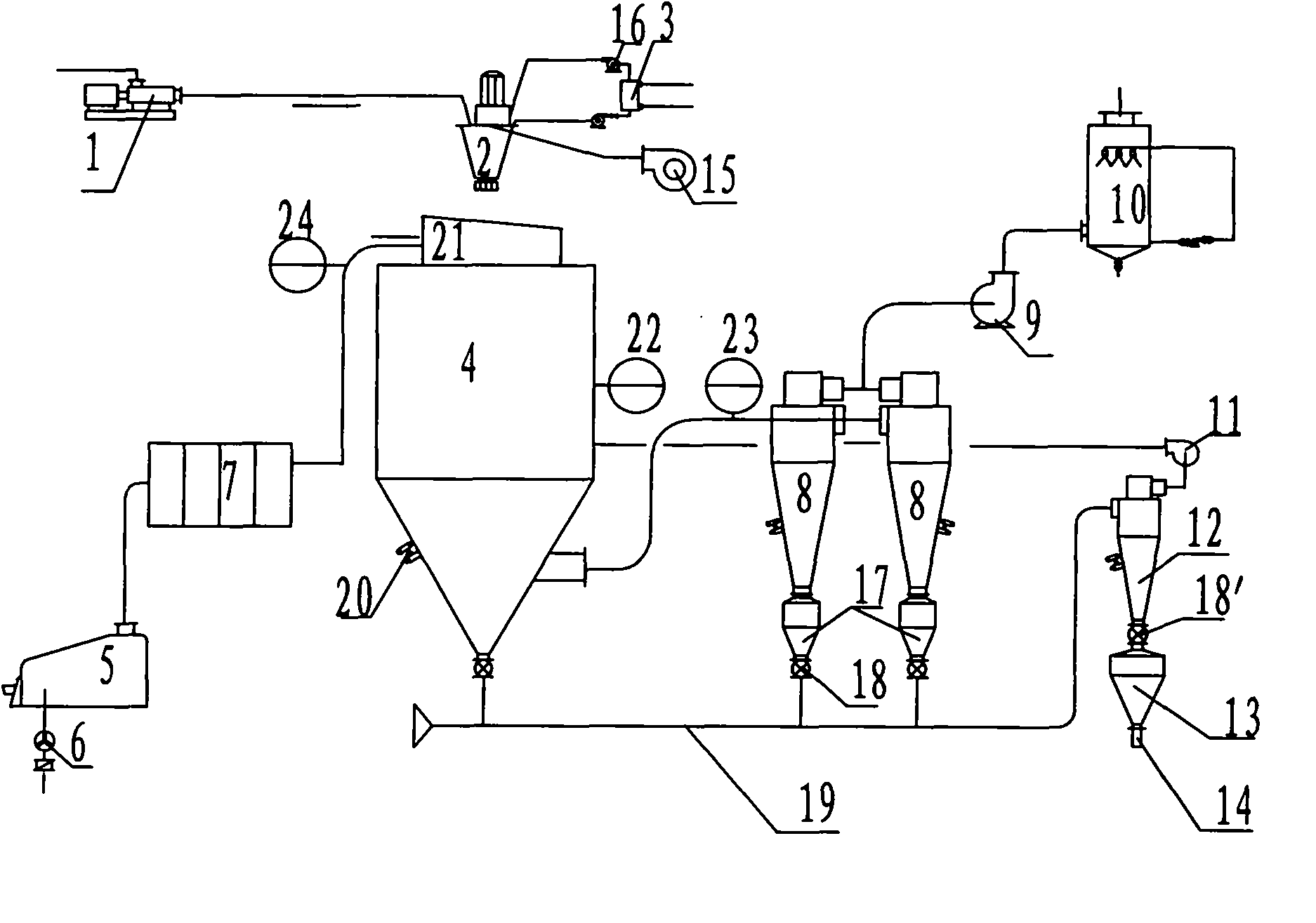

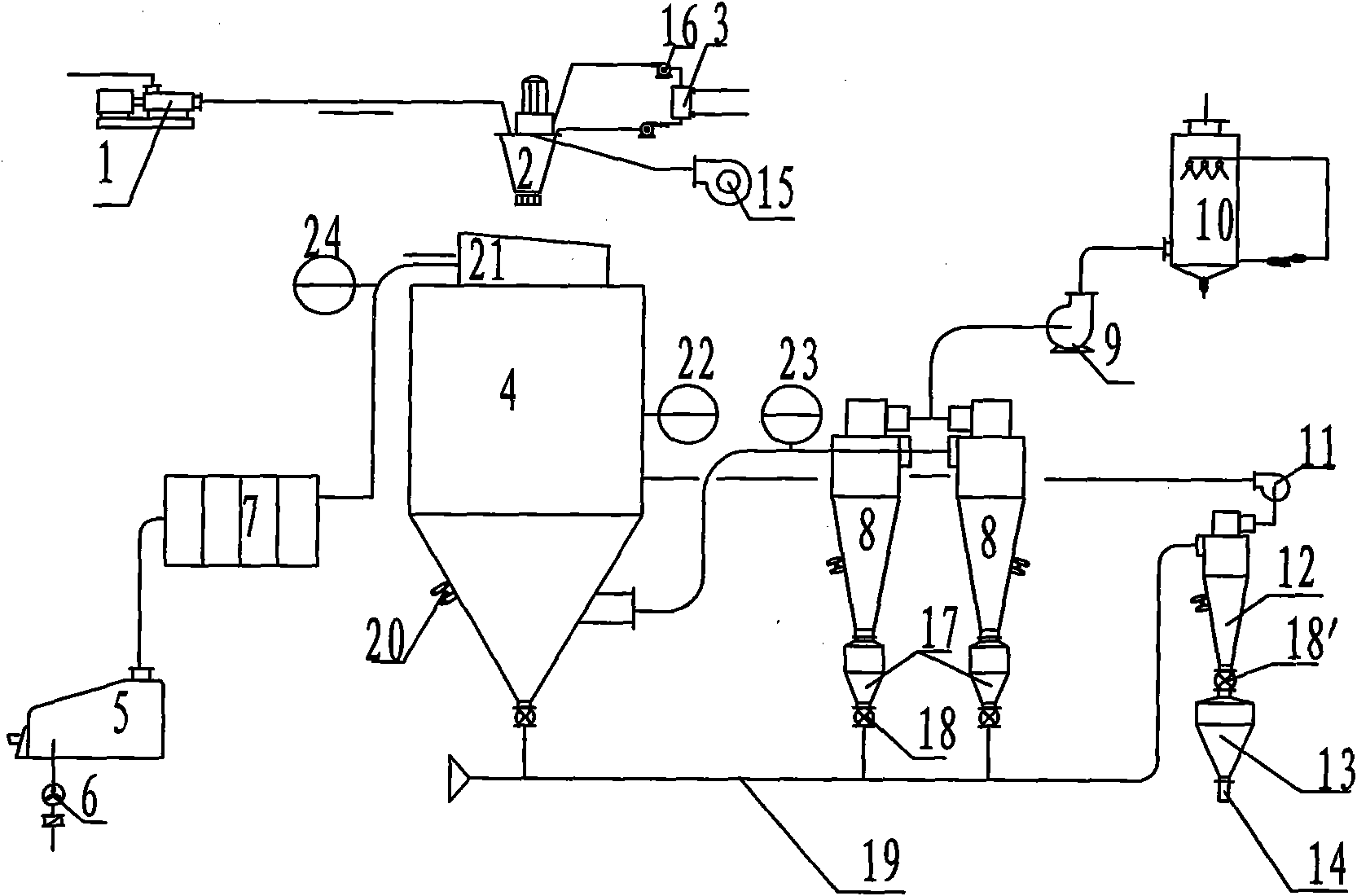

Mushroom scrap spray-drying system

ActiveCN102374759AEmission reductionDry thoroughlyDrying solid materialsDrying machinesDistributorMushroom

The invention dicloses a mushroom scrap spray-drying system, which comprises atomizing equipment, drying equipment and material recovery equipment, wherein a charging pump is communicated with the feeding port of a supercentrifuge atomizer, the discharge port of the supercentrifuge atomizer is communicated with the upper end of a drying tower, and an injection head cooling fan is arranged at the discharge port of the supercentrifuge atomizer; a hot air distributor on the upper part of the drying tower is communicated with a combustion furnace through a settling chamber, and the outlet of the drying tower is communicated with the uppper part of a cyclone separator. By adopting the technical scheme of the invention, spray, drying, dedusting and material recovery are organically integrated, therefore, during mushroom scrap drying process, drying is more thorough, ratio of finished products is improved, and cost is lowered, exhaust emission is nearly zero, environment-friendly advantage is obvious.

Owner:焦作健康元生物制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com