Melt deposition type 3D printer spray head cooling device

A 3D printer and fused deposition technology, applied in coating devices, 3D object support structures, additive manufacturing, etc., can solve problems such as nozzle clogging, achieve the effects of reducing vibration, improving heat exchange efficiency, and large thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below by accompanying drawing.

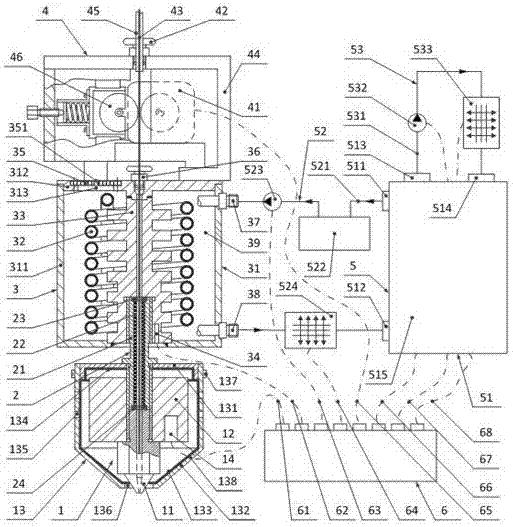

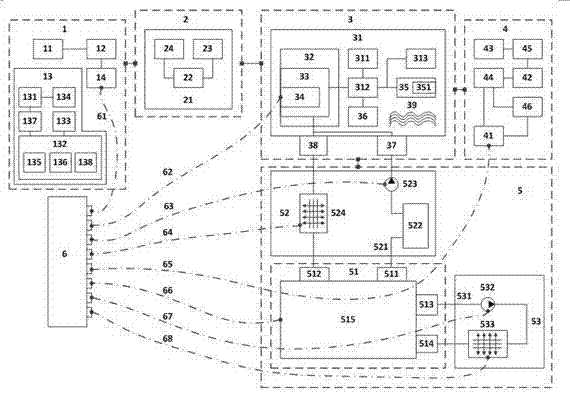

[0025] like figure 1 As shown, a fused deposition type 3D printer nozzle cooling device includes a nozzle hot end assembly 11, the hot end assembly 11 is connected to the throat assembly 2 through a threaded structure, and the throat assembly 2 is connected to the throat cooling assembly 3 through a threaded structure, The throat cooling assembly 3 is connected to the wire feeding mechanism 4 through the fixing frame 44, the throat cooling assembly 3 is connected to the refrigeration device 5 through the first cooling pipe joint 37 and the second cooling pipe joint 38, and the control device 6 is connected to the spray head through the power line 61. The hot end assembly 11 is connected.

[0026]The hot end assembly 11 of the nozzle is composed of a nozzle 11, a heat conducting block 12, a thermal radiation protection cover 13, a top cover 131, a cover body 132, a first heat insulating aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com