Numerical control drill head cooling device and method

A technology of cooling device and cooling method, applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

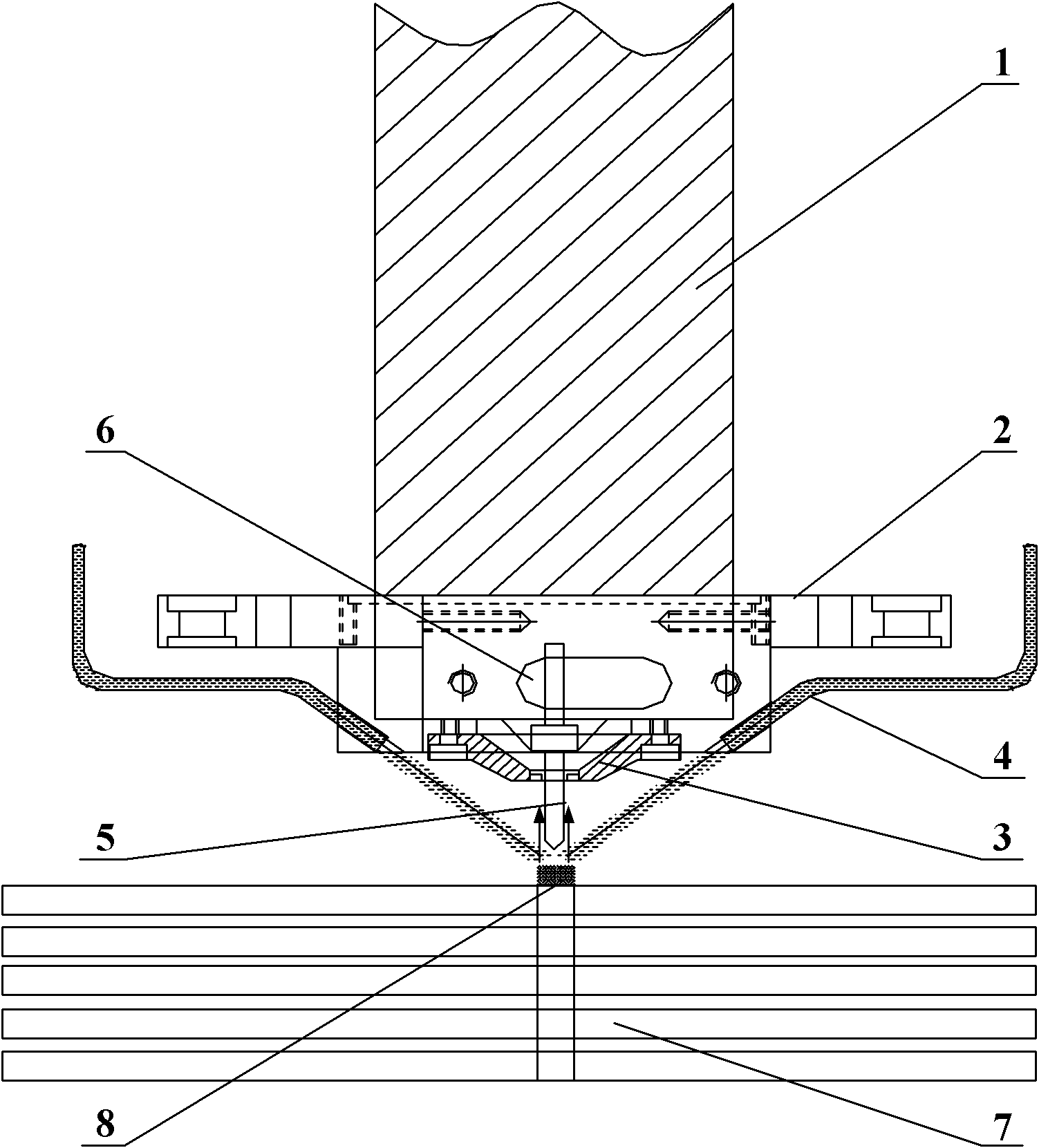

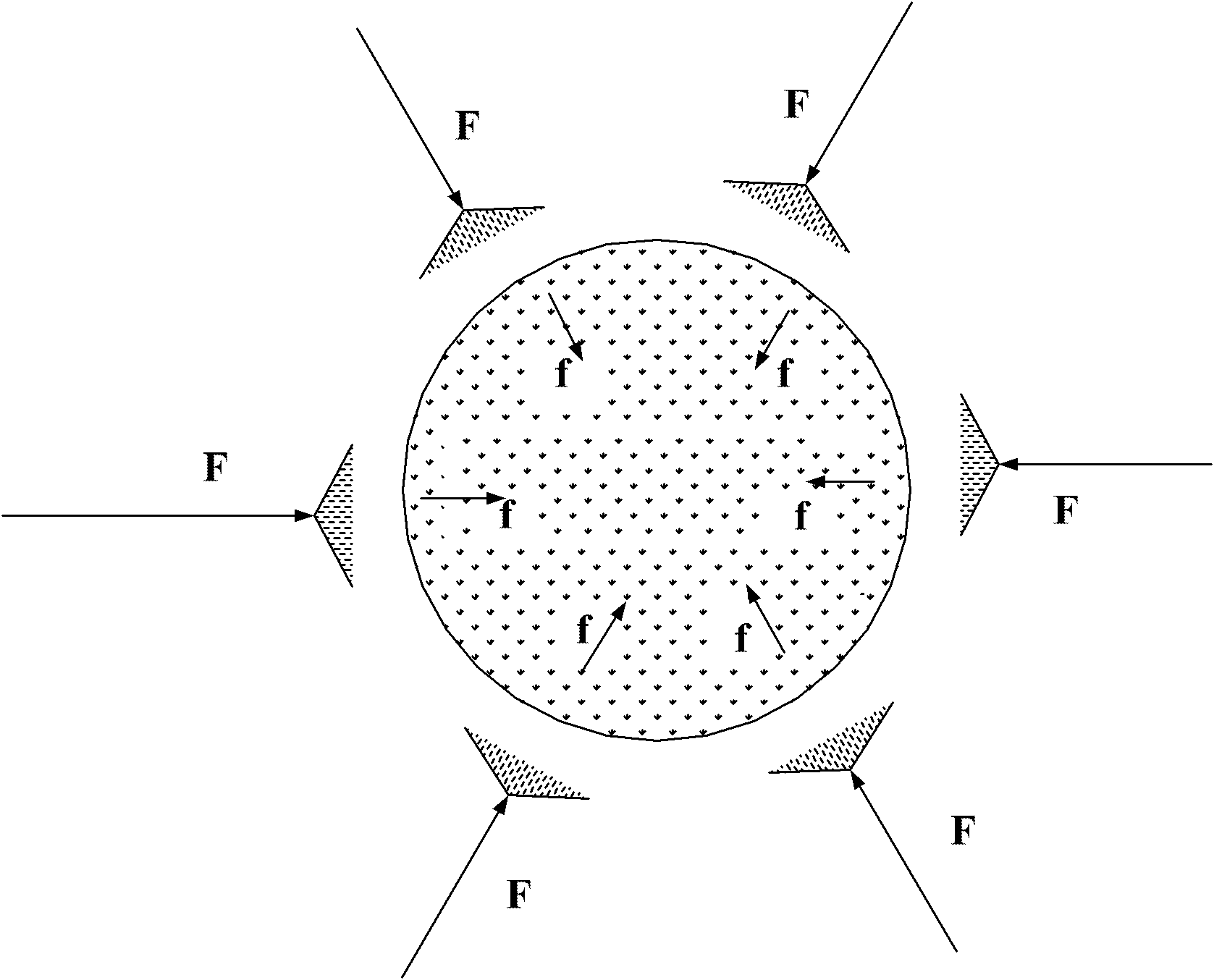

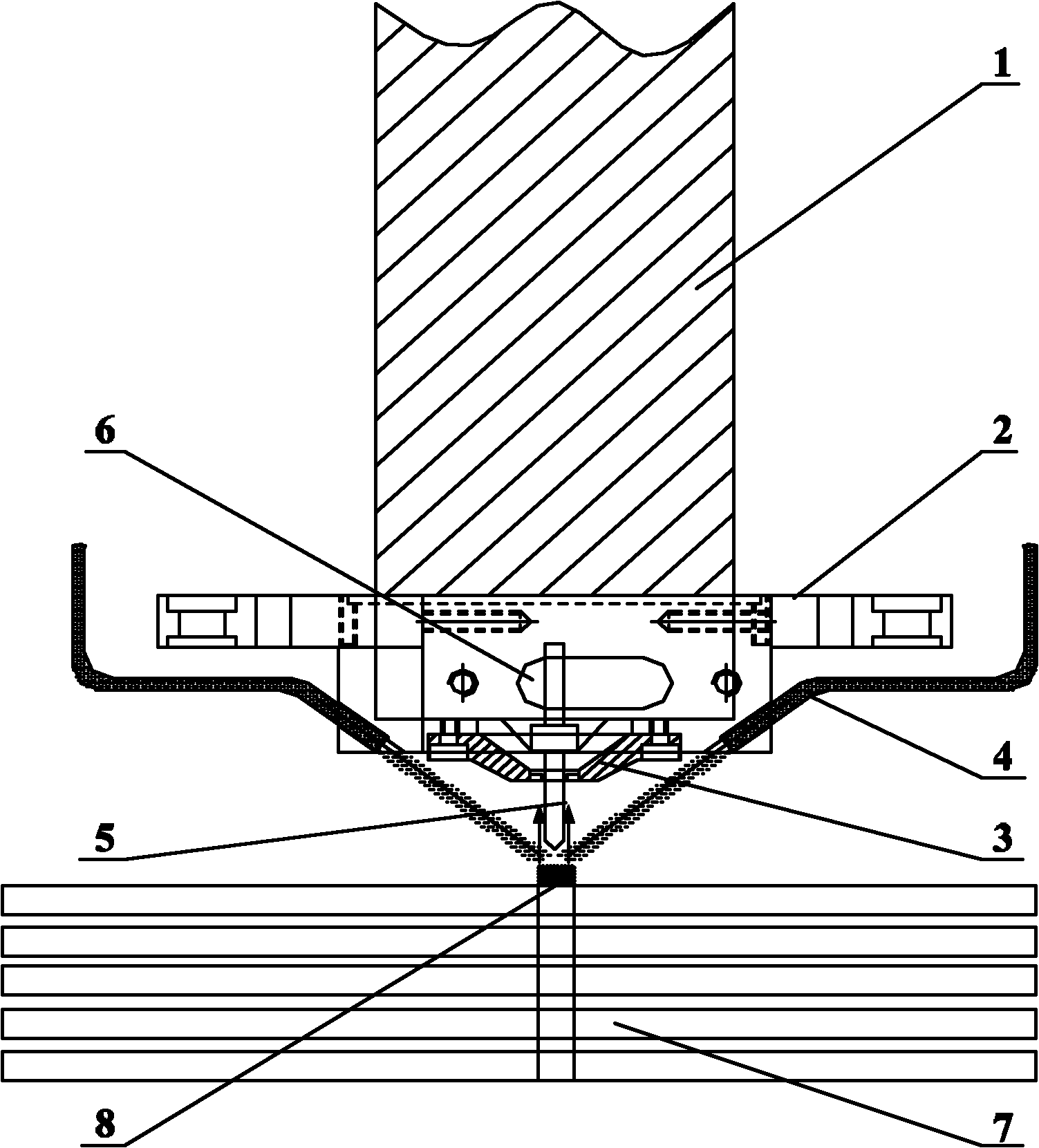

[0019] When the PCB is drilled, a CNC drilling machine is used. When the CNC drilling machine is drilling, the drill bit rotates at high speed and rubs against the circuit board. The drill bit and the circuit board will heat up instantly, and the temperature is very high. Some special circuit boards cannot withstand such a high temperature. , so the drill bit and the circuit board must be cooled with liquid nitrogen, but the more deadly point is that the underside of the presser foot is the protruding part of the drill bit, which is the dust suction area, forming a high negative pressure. When the board is removed, it will be sucked away by strong negative pressure, and the cooling effect cannot be achieved.

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com