Mushroom scrap spray-drying system

A drying system and fungal residue technology, which is applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of fungal residue being sent to the buffer, drying rate reduction, and fan efficiency reduction, achieving obvious environmental protection advantages and finished products The effect of increasing efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

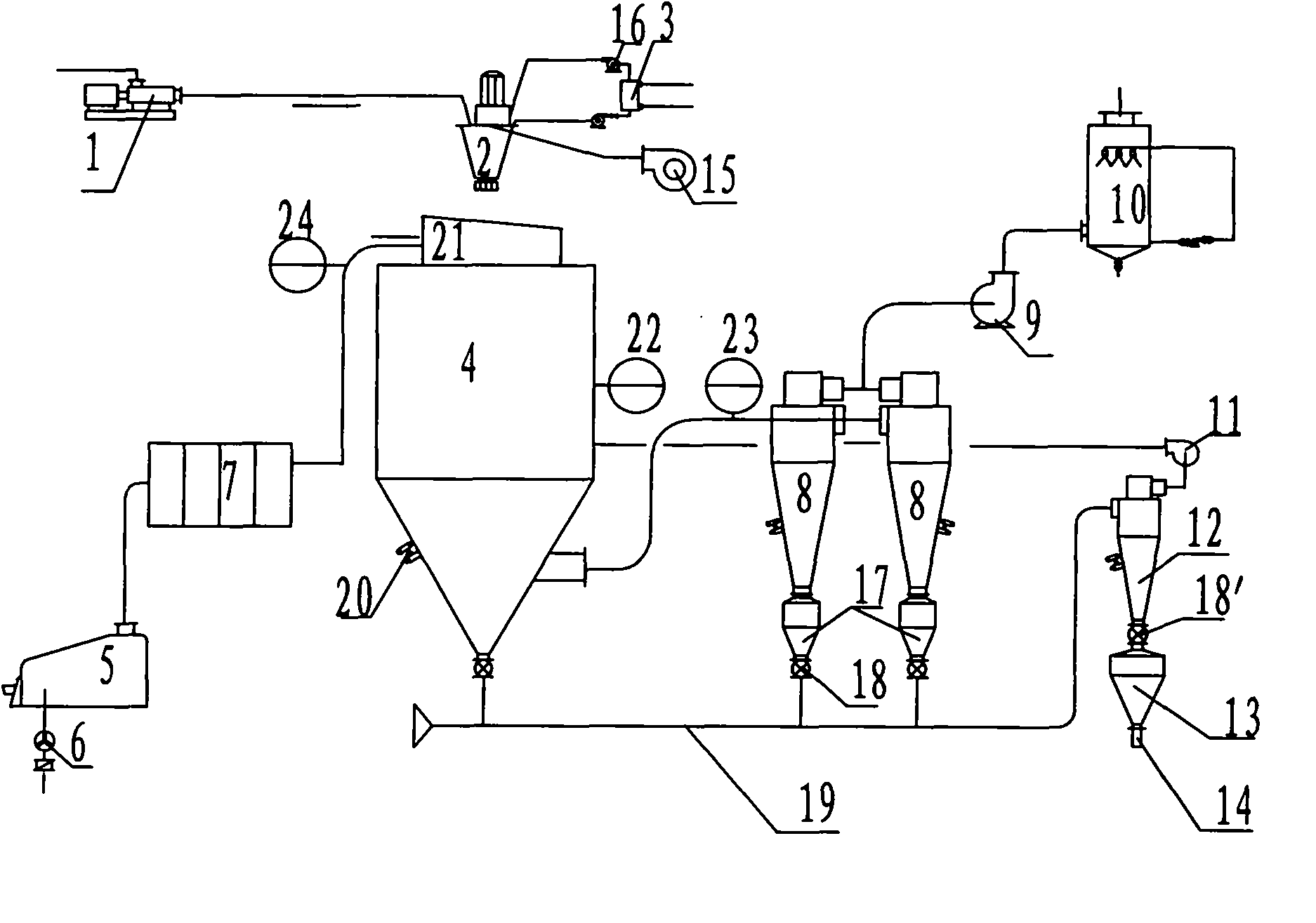

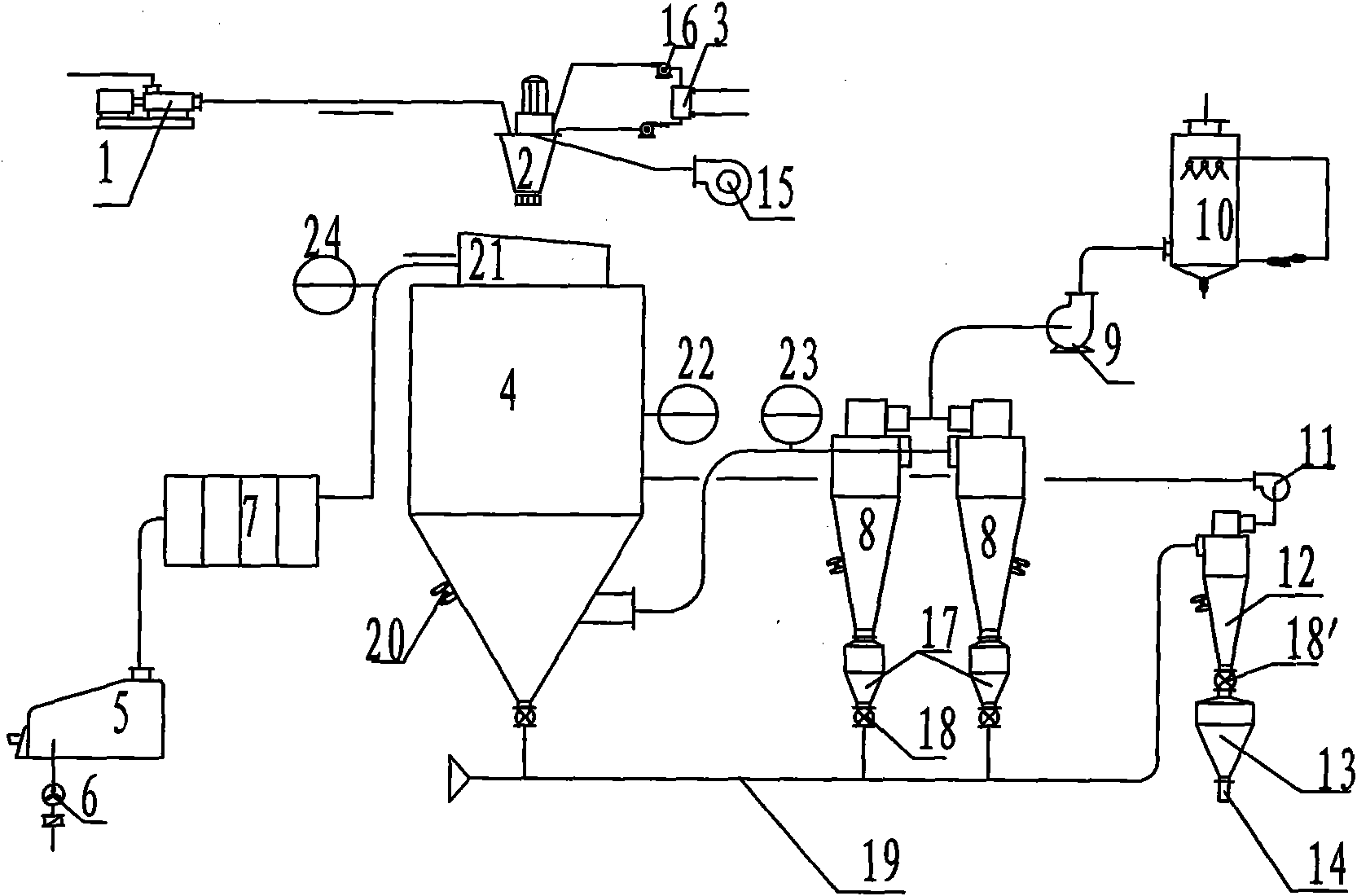

[0016] As shown in the figure, a spray drying system for bacteria residue includes atomization equipment, drying equipment, dust removal equipment and material recovery equipment. The atomization equipment includes a feeding pump 1, a high-speed centrifugal atomizer 2, and a nozzle cooling fan 15 And oil cooler 3; Drying equipment includes drying tower 4, combustion furnace 5, combustion furnace blower 6 and five-stage settling chamber 7; Dust removal equipment includes two parallel cyclone separators 8, induced draft fan 9 and water film dust collector 10; The material recovery equipment includes a small induced draft fan 11 , a small cyclone separator 12 , a finished product silo 13 and a receiving pants 14 .

[0017] An oil cooler 3 is arranged on the atomizer 2 of the high-speed centrifuge, and an oil pump 16 is arranged on the pipeline connecting the oil cooler 3 and the atomizer 2 of the high-speed centrifuge, and the feeding port of the feeding pump 1 and the atomizer 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com