Patents

Literature

1407 results about "Settling chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Settling chamber. [′set·liŋ ‚chām·bər] (engineering) A vessel in which solids or heavy liquid droplets settle out of a liquid carrier by gravity during processing or storage.

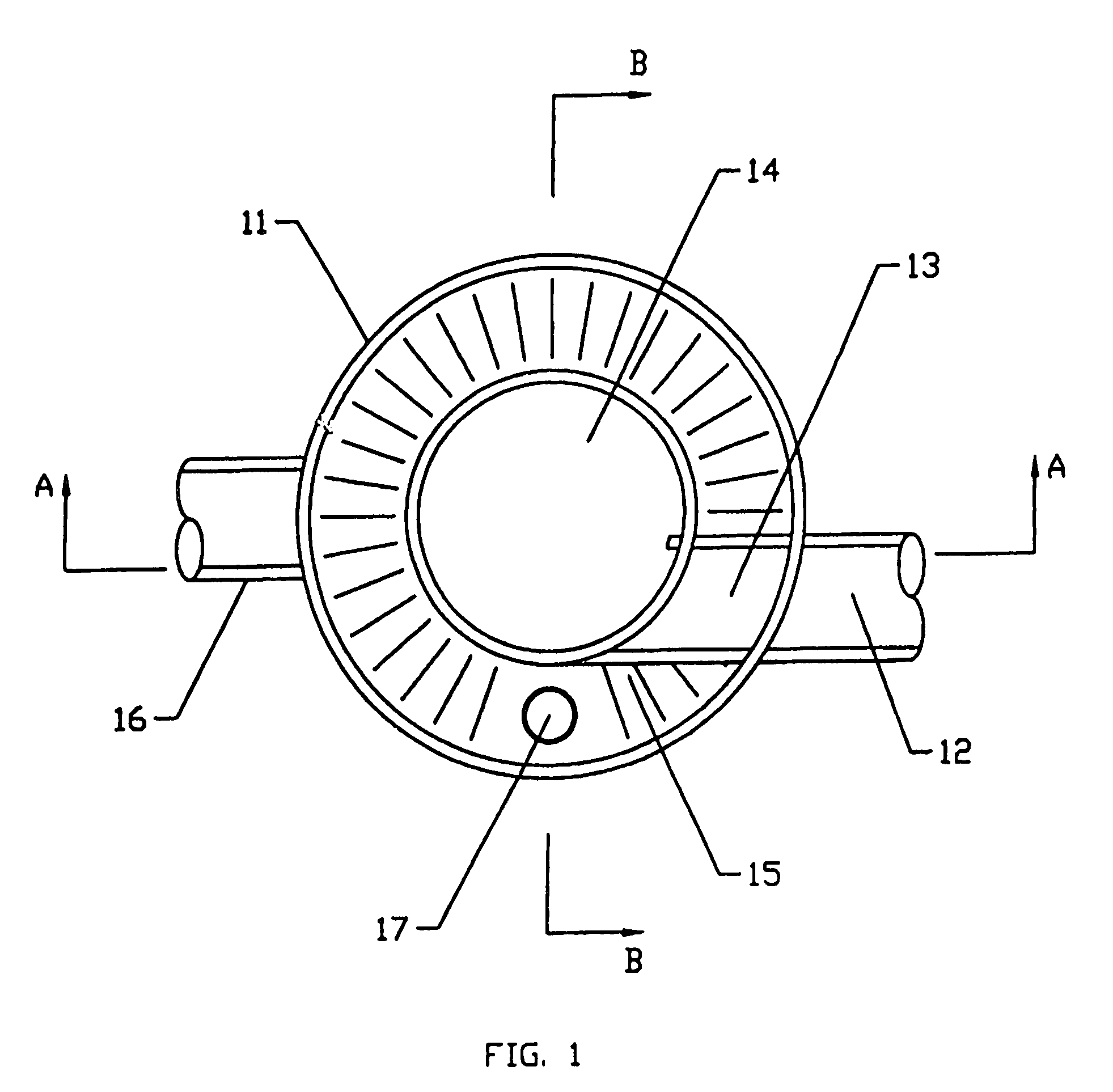

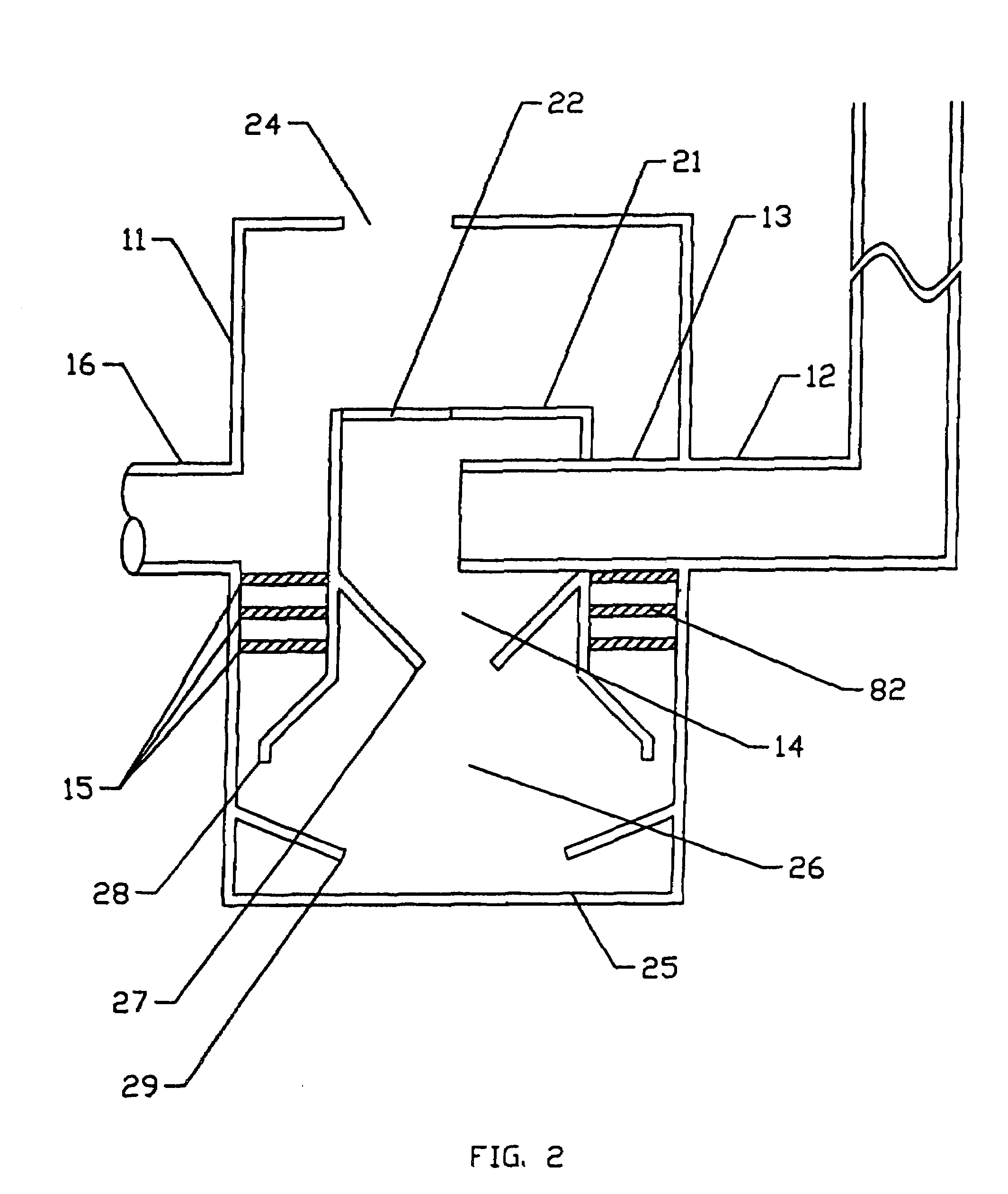

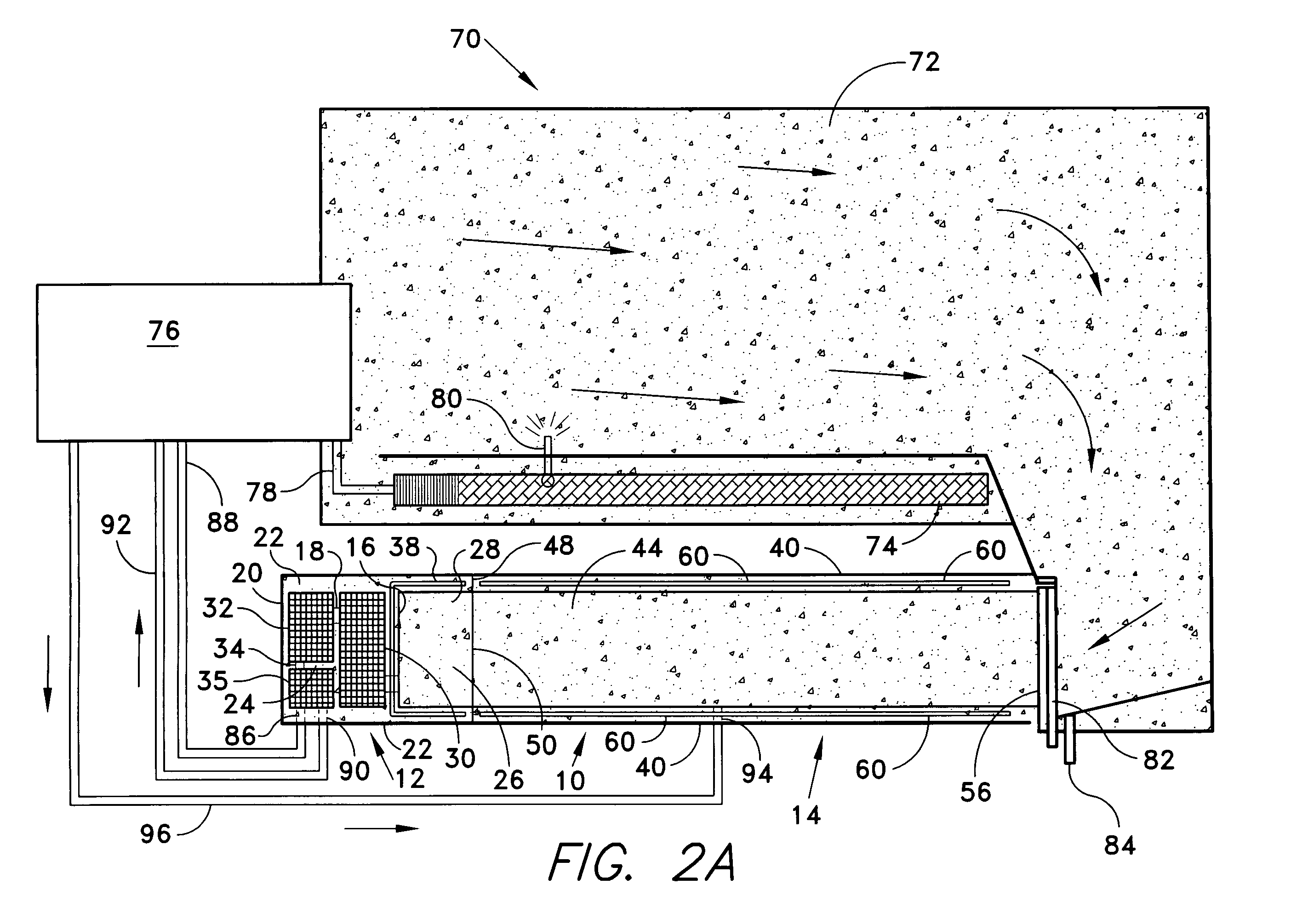

Acoustic device and methods thereof for separation and concentration

InactiveUS8889388B2Bioreactor/fermenter combinationsBiological substance pretreatmentsYeastCost effectiveness

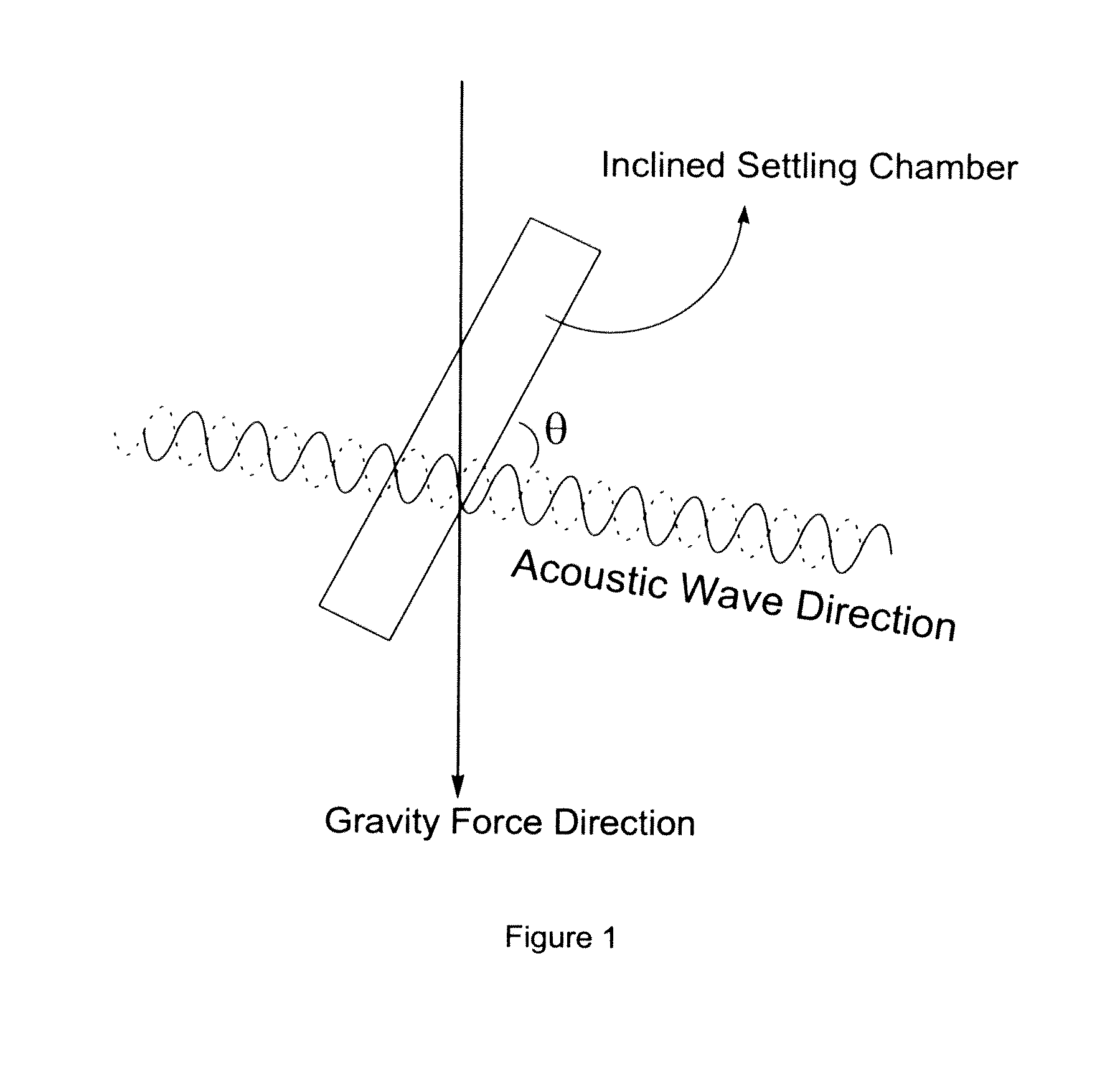

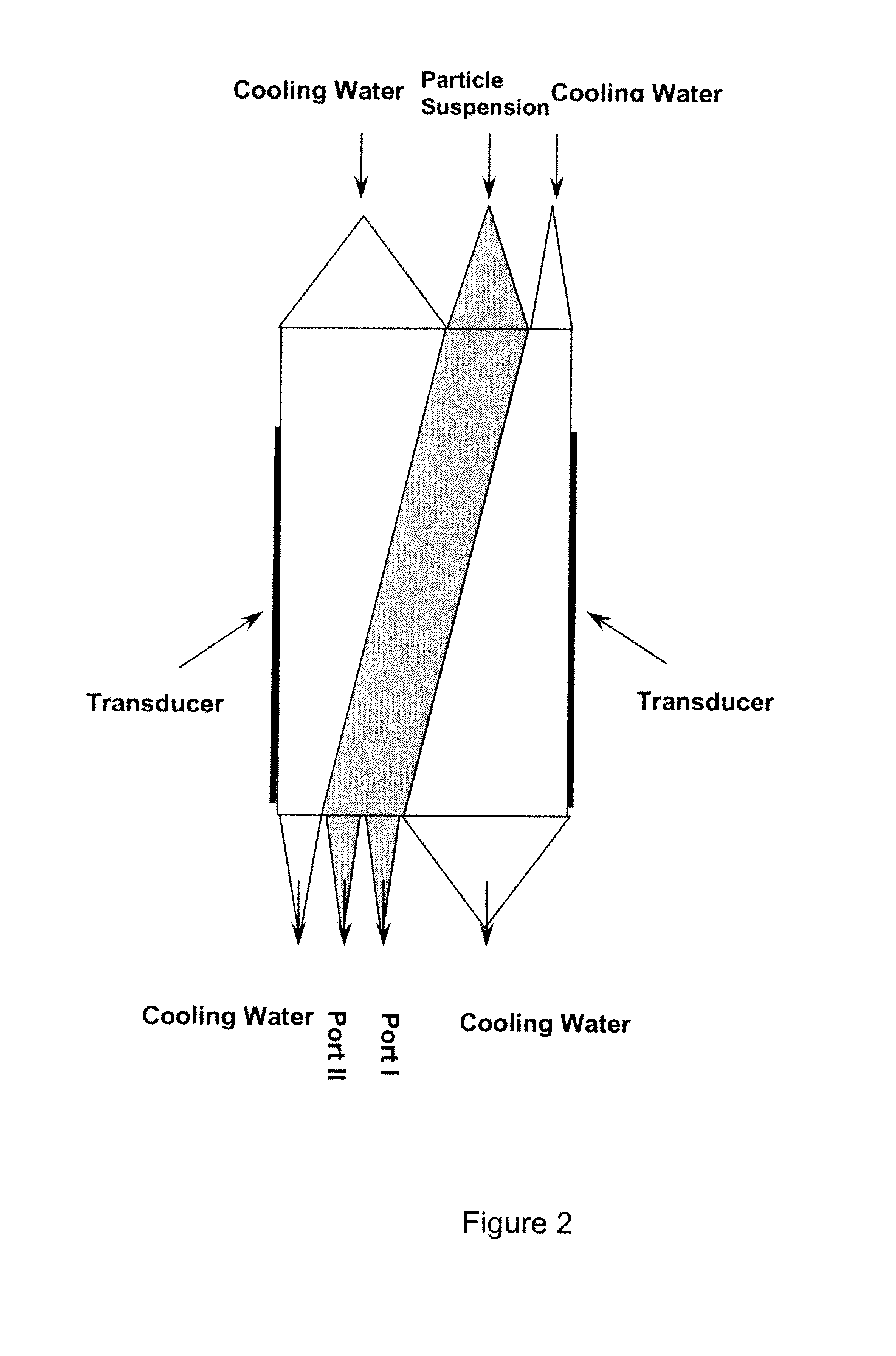

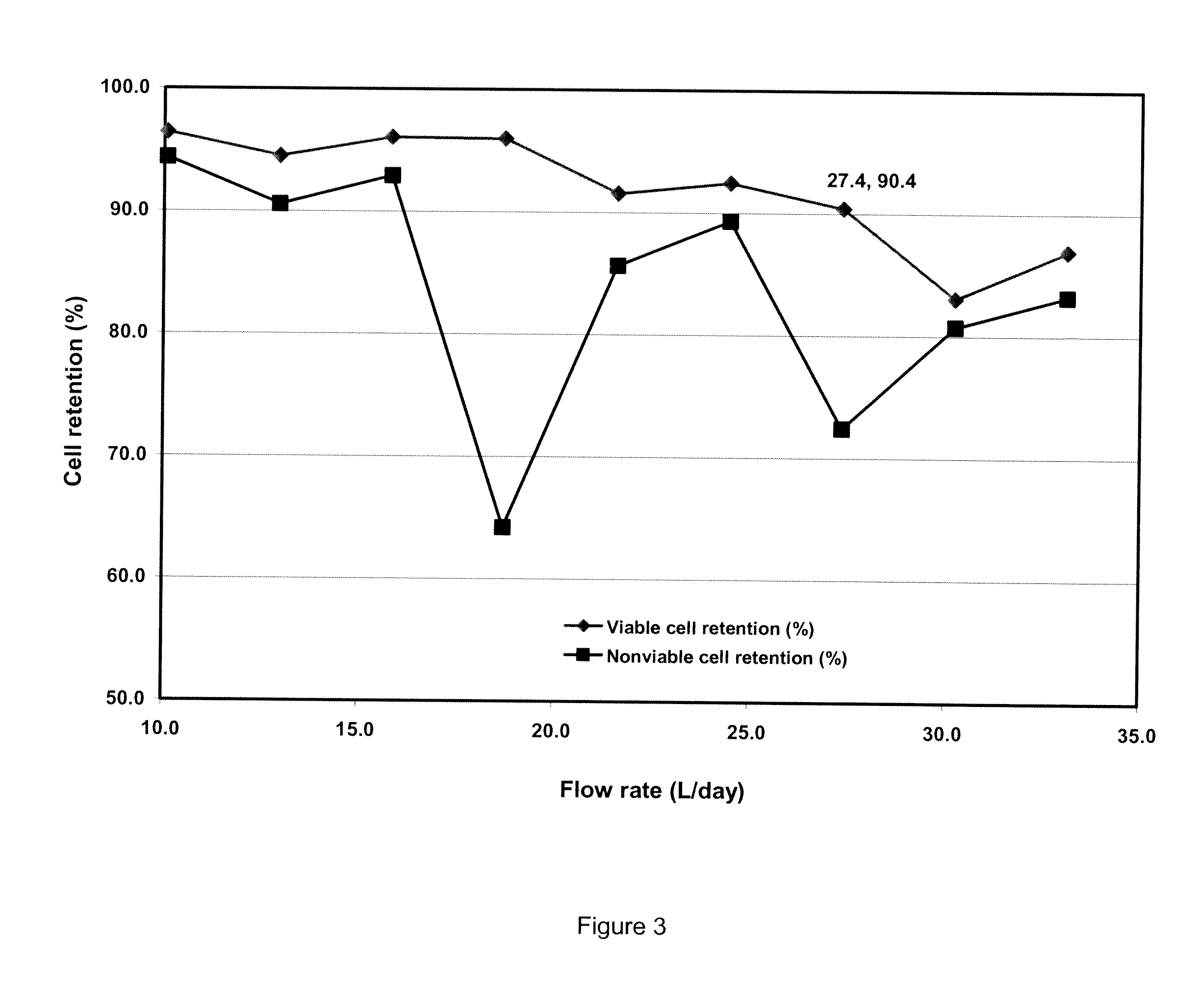

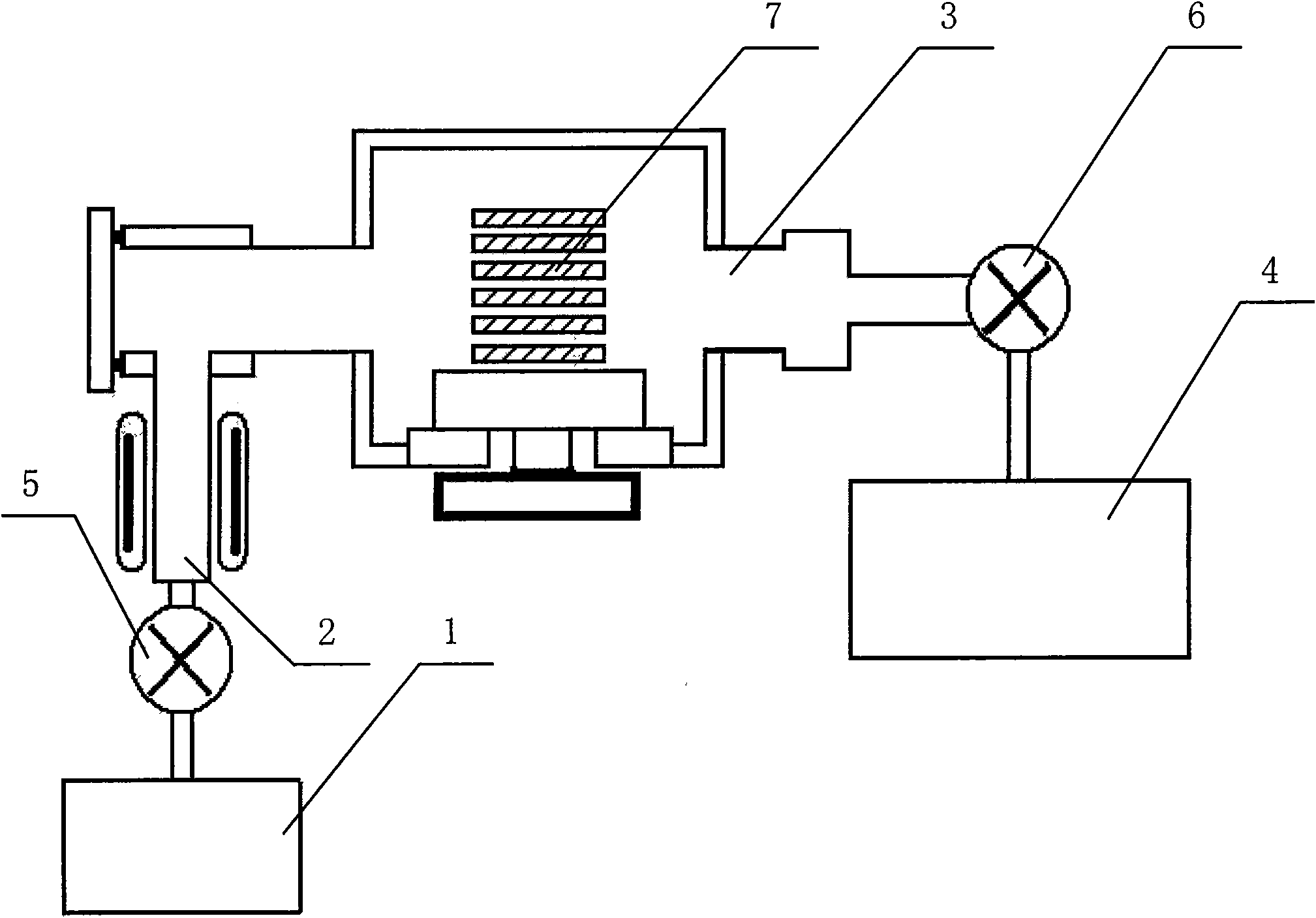

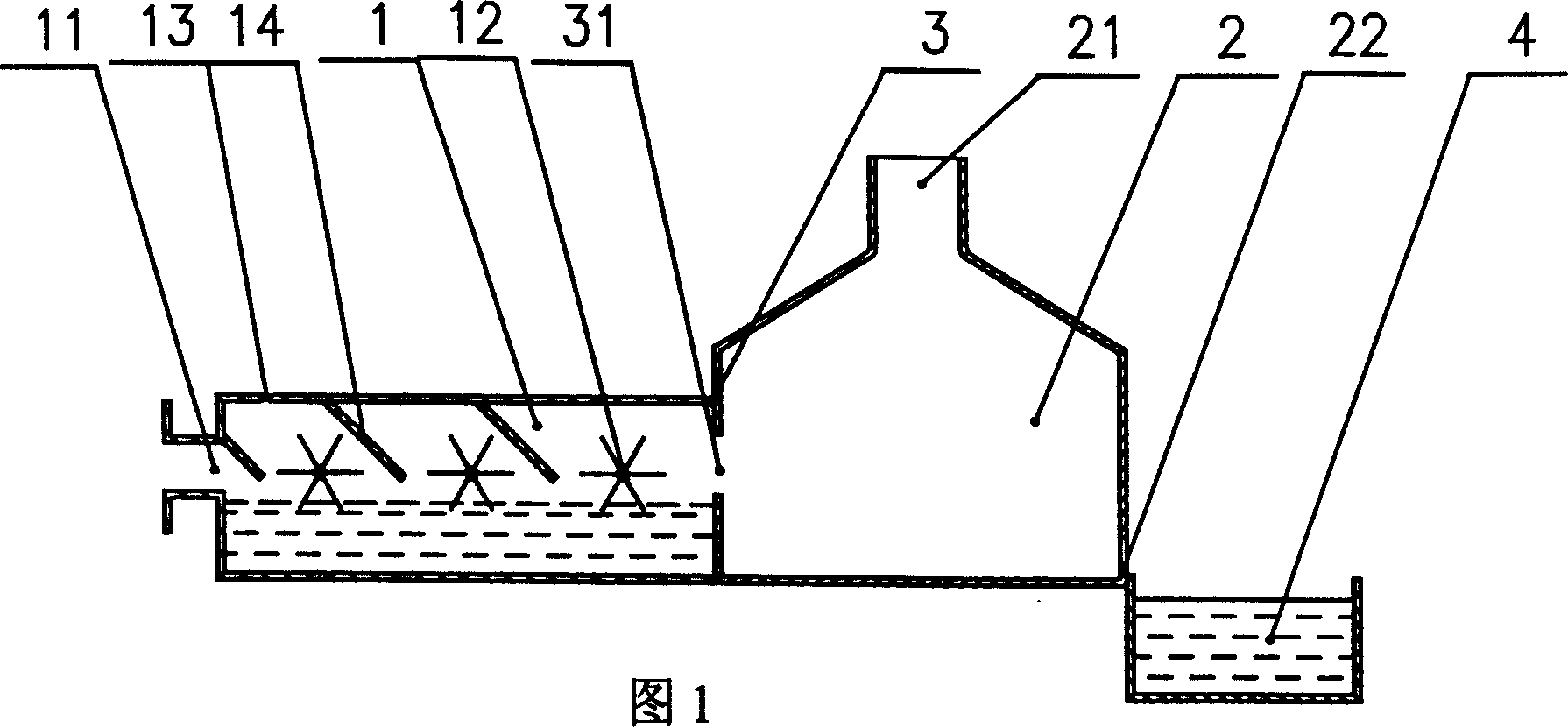

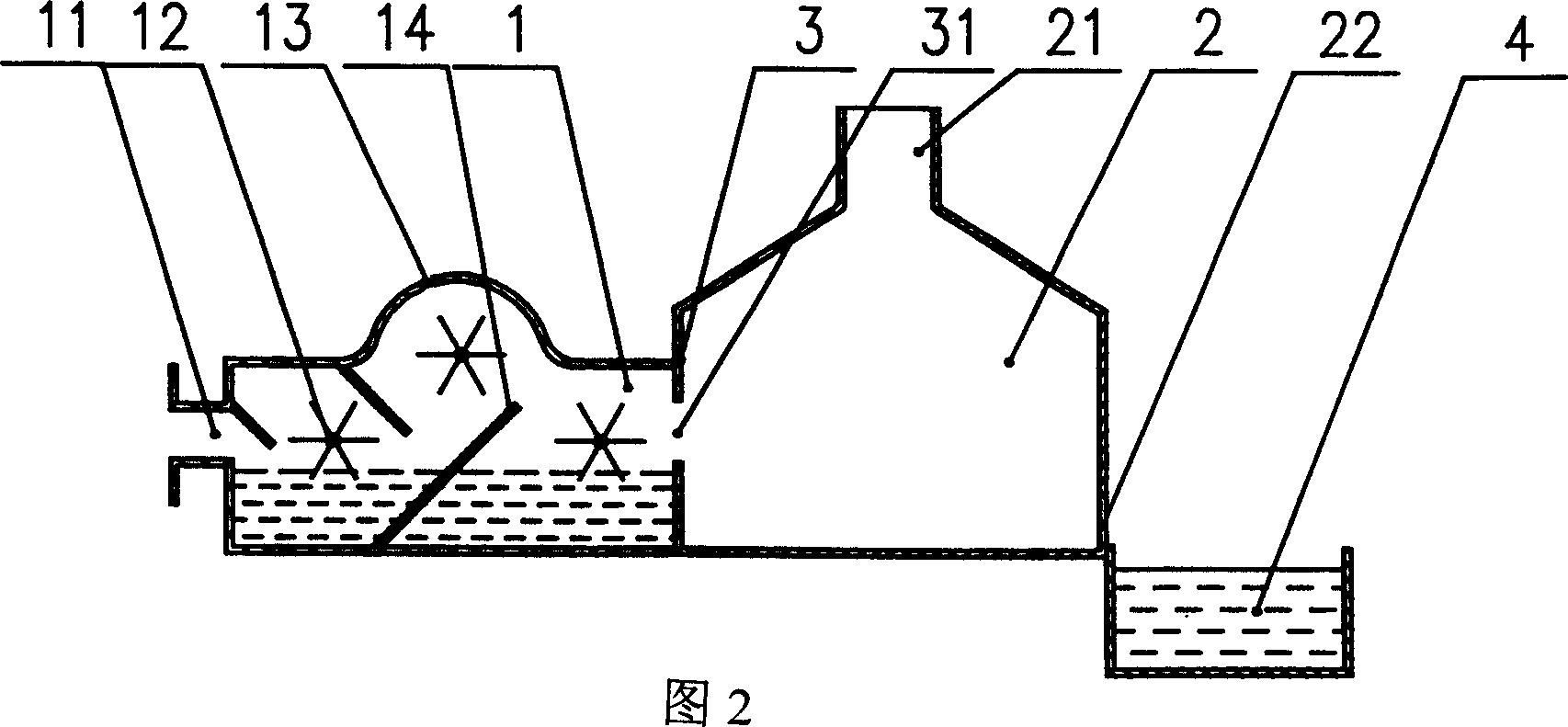

The invention provides a settling device comprising an acoustic wave generator and an inclined settling chamber. The angle θ between the acoustic wave direction and the inclined settling chamber is greater than 0 and less than 90°. The invention also provides a concentration method and a separation method using the device. The invention can be used to concentrate or separate particles such as inorganic particles, organic particles, and biological particles, for example, mammalian cells, bacteria, yeast, algae, and plant cells. The invention exhibits technical merits such as higher efficiency, cost-effectiveness, and large-scale production.

Owner:WANG ZHAOWEI +2

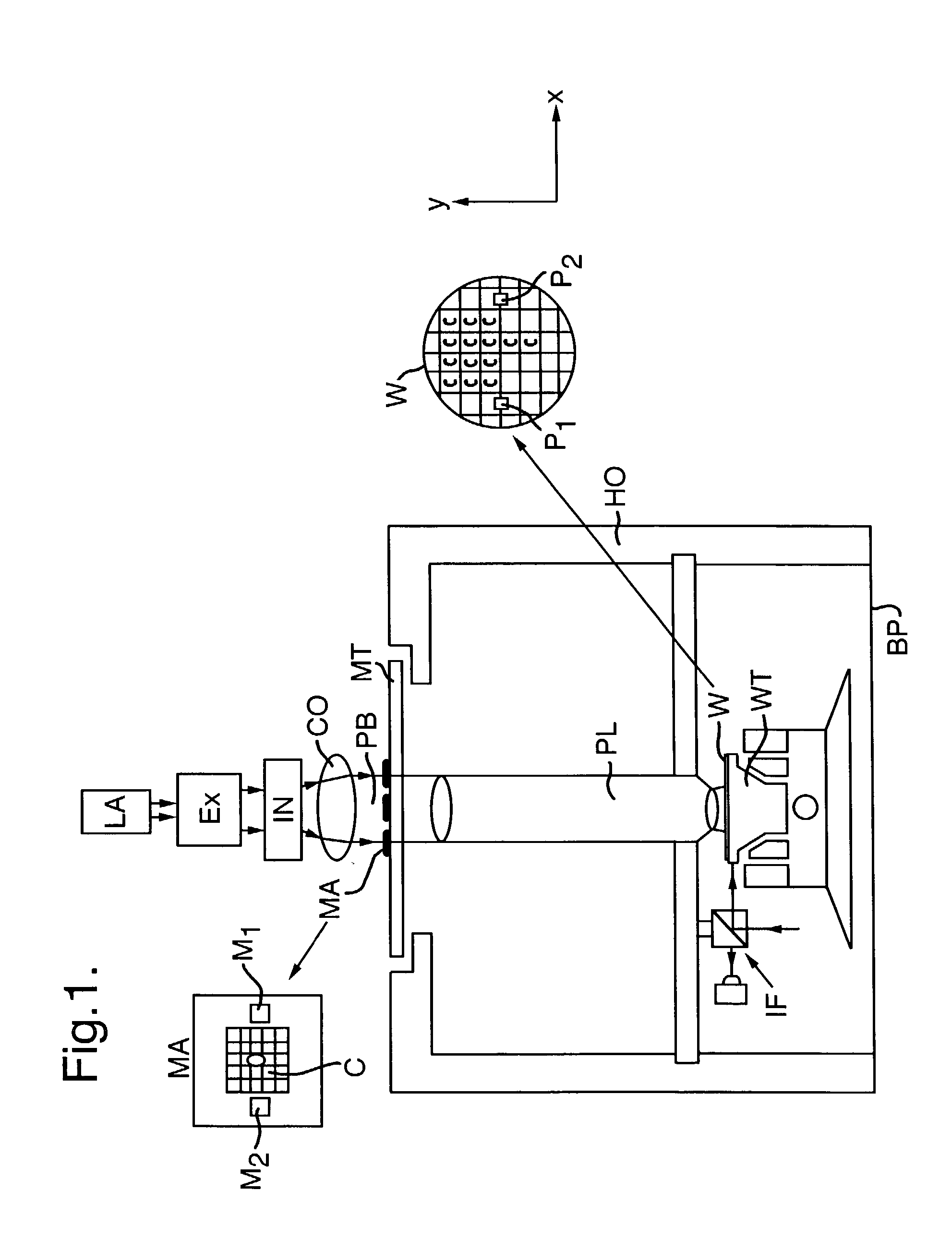

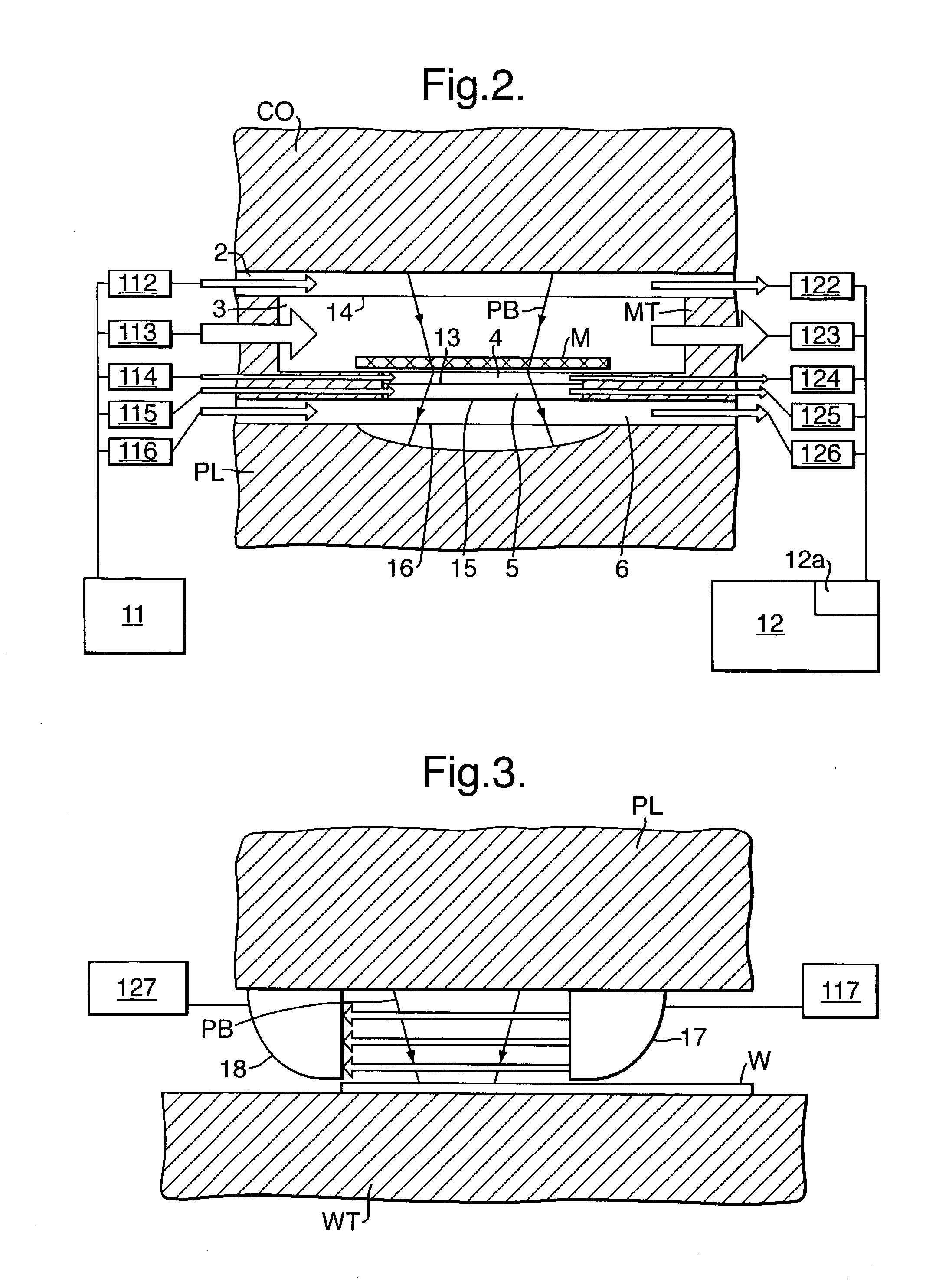

Gas flushing system for use in lithographic apparatus

InactiveUS20030006380A1Electric discharge tubesPhotomechanical exposure apparatusLight beamEngineering

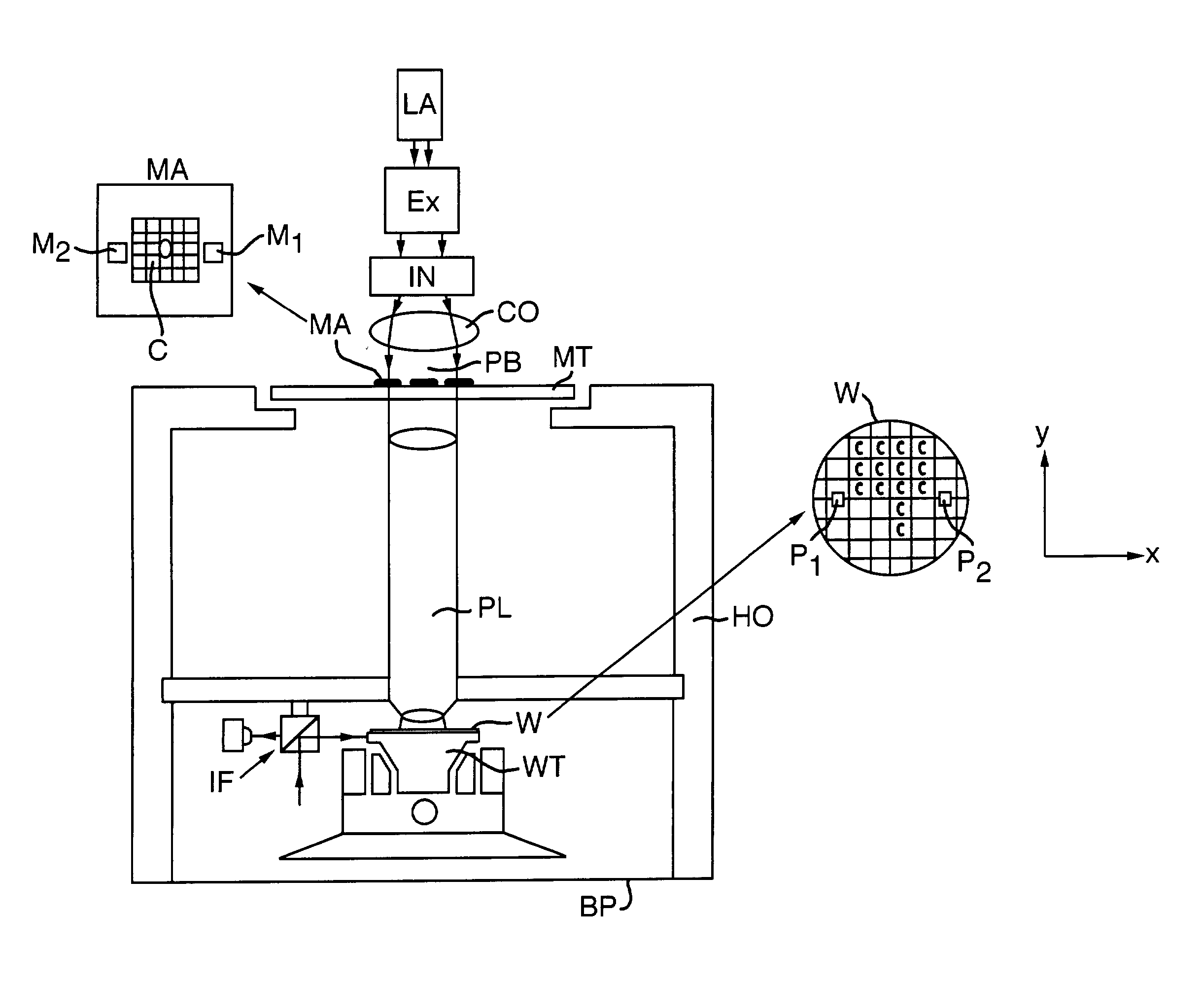

In a lithographic apparatus using exposure radiation of a relatively short wavelength, e.g. 157 or 126 nm, a laminar flow of N2 is provided across parts of the beam path in or adjacent to moving components of the apparatus. A variety of structures may be used to provide the laminar flow including a screen, a settling chamber, an angled inlet port and a flow path having increasing cross-sectional area.

Owner:ASML NETHERLANDS BV

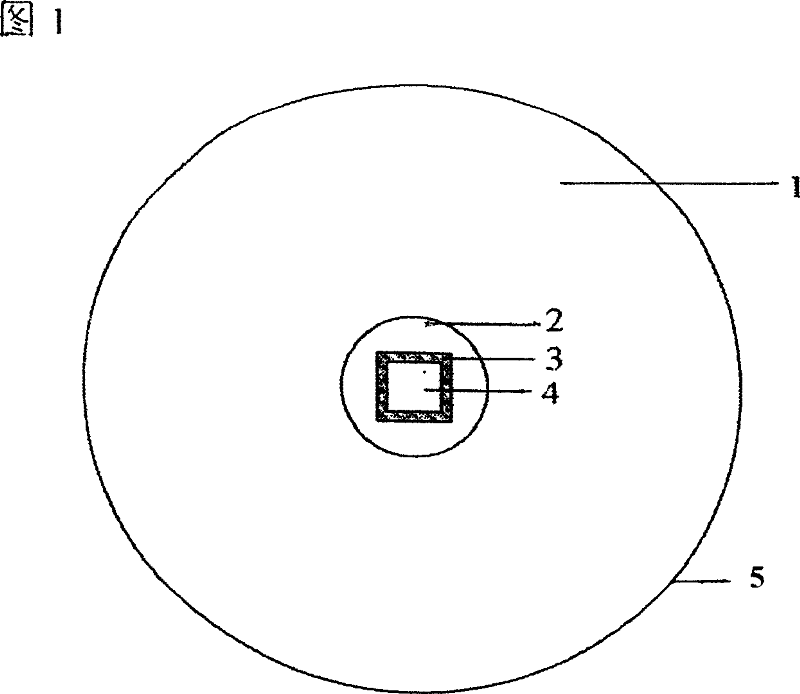

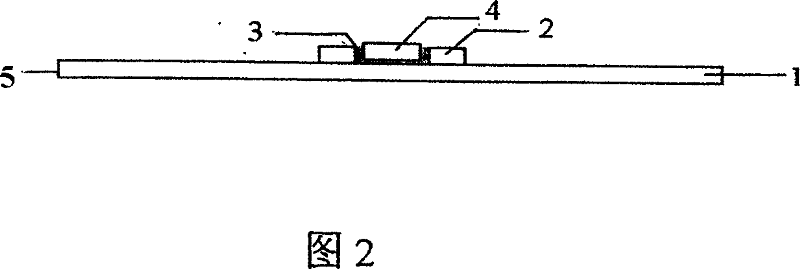

Device and method for high-speed rapid growth of diamond single-crystal

InactiveCN101037793AEasy to adjust temperatureSimple and applicable structurePolycrystalline material growthFrom chemically reactive gasesHydrogenGas phase

The inventive apparutus and method for growing diamond monocrystal at high-speed belongas to the technical field of diamond materials. The said apparatus is provided with sample tray 5 on the substrate holder in the settling chamber of chemical vaporous depositon system; sample tray 5 being provided with close annular frame 2 on the multi-crystal diamond film. It can also be provided with diamond powder 3 in the cavern in the close annular frame 2. The inventive method is that, monocrystal diamond crystallon 4 is placed into the settling chamber through the cavern in the close annular frame 2 and is etched in advance by plasma in situ; then diamond monocrystal is grown in the atmosphere of methane, hydrogen and nitrogen. The method includes that possible non-diamond phase and structural cavern are determined to be treated by observing brightness variation of growth face. The inventive apparatus is simple and easy to machine; and it does not bring any pollution for growing monocrystal diamond and has good thermal conduction. Transparent diamond monocrystal can be produced by the inventive method, and the growing speed can be more than 100 mm / hour.

Owner:JILIN UNIV

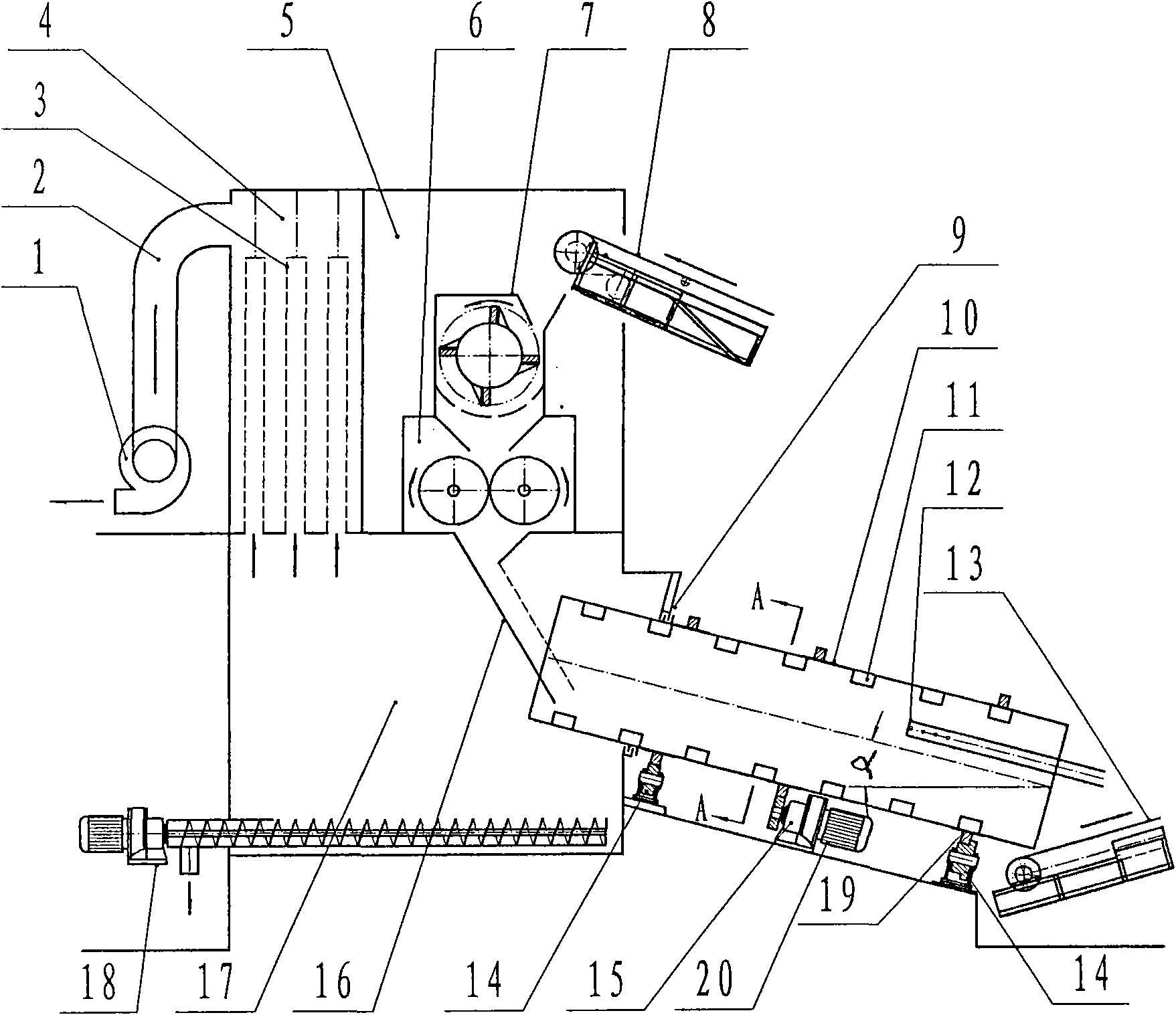

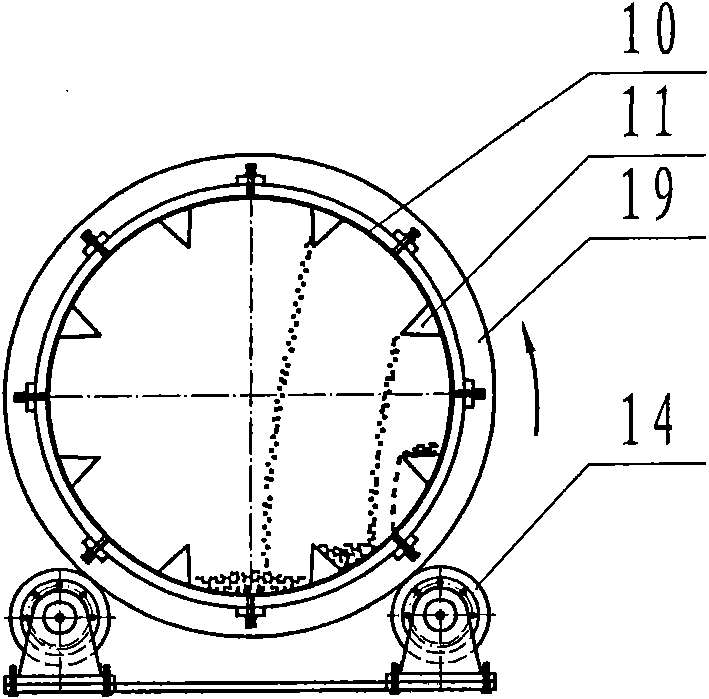

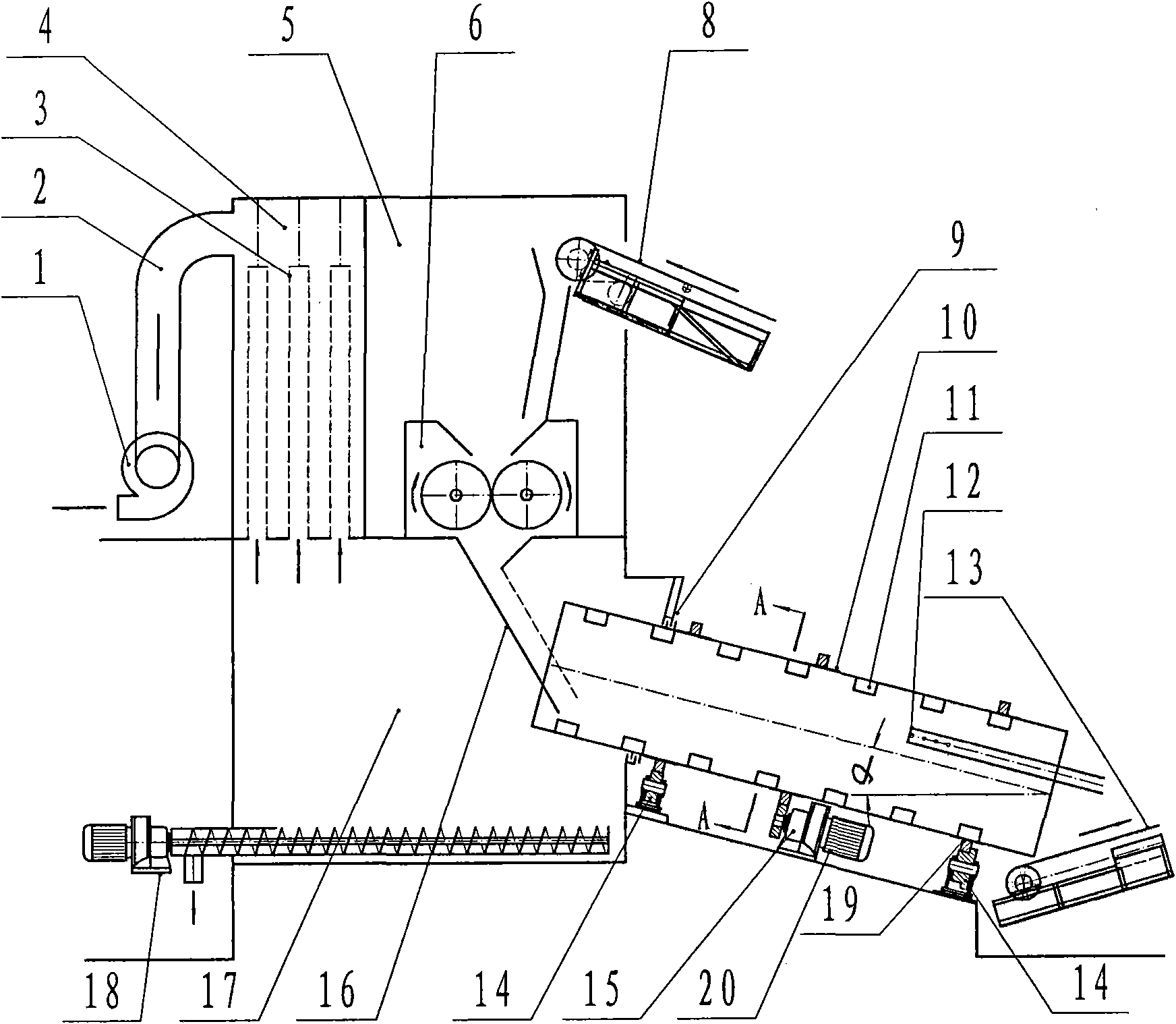

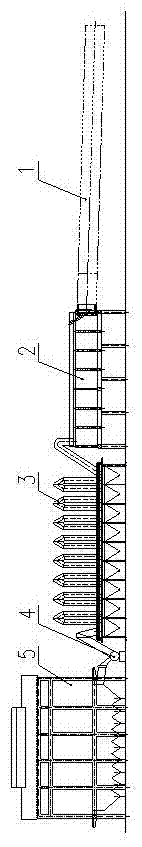

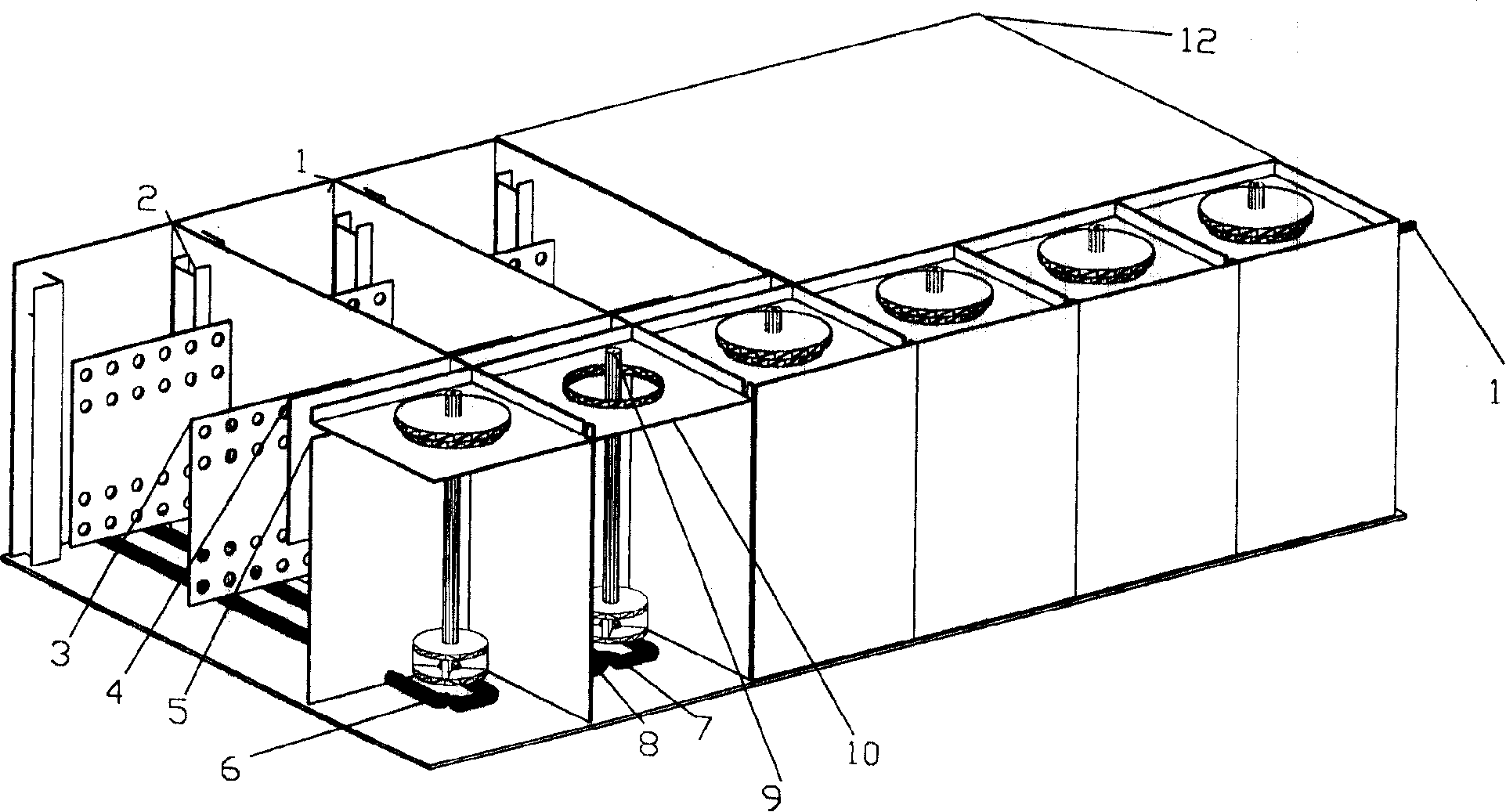

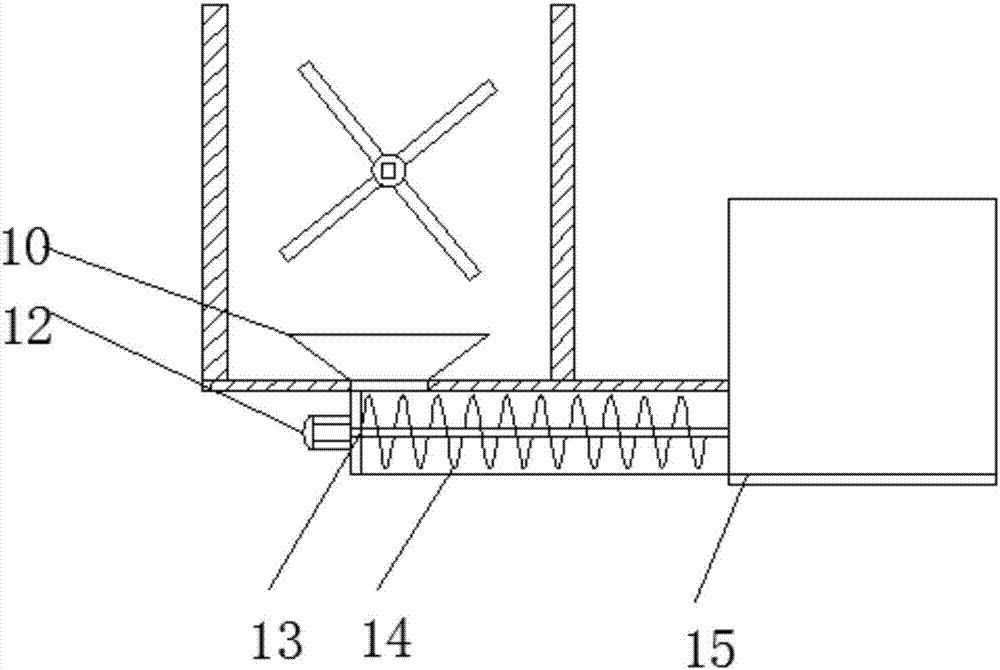

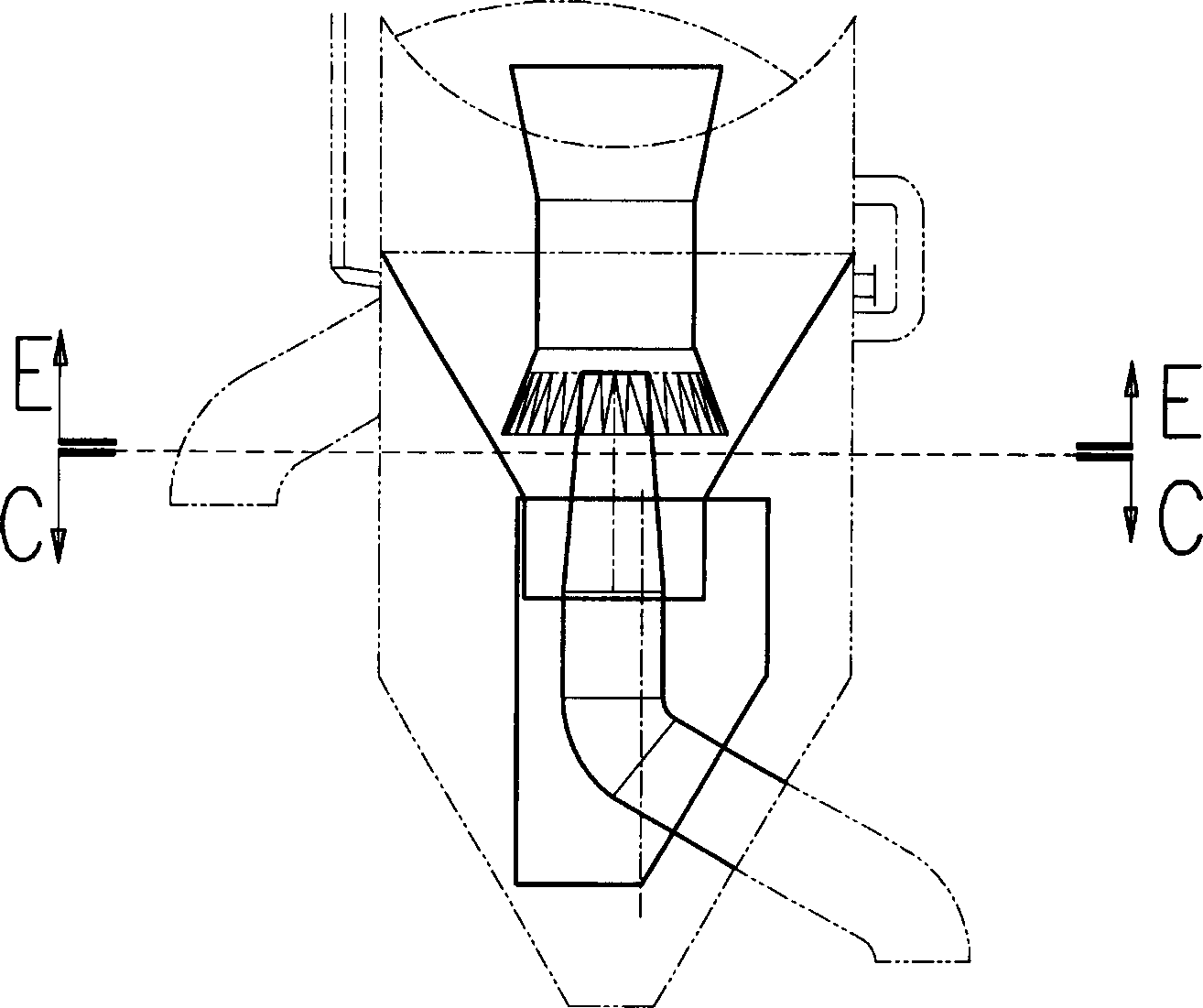

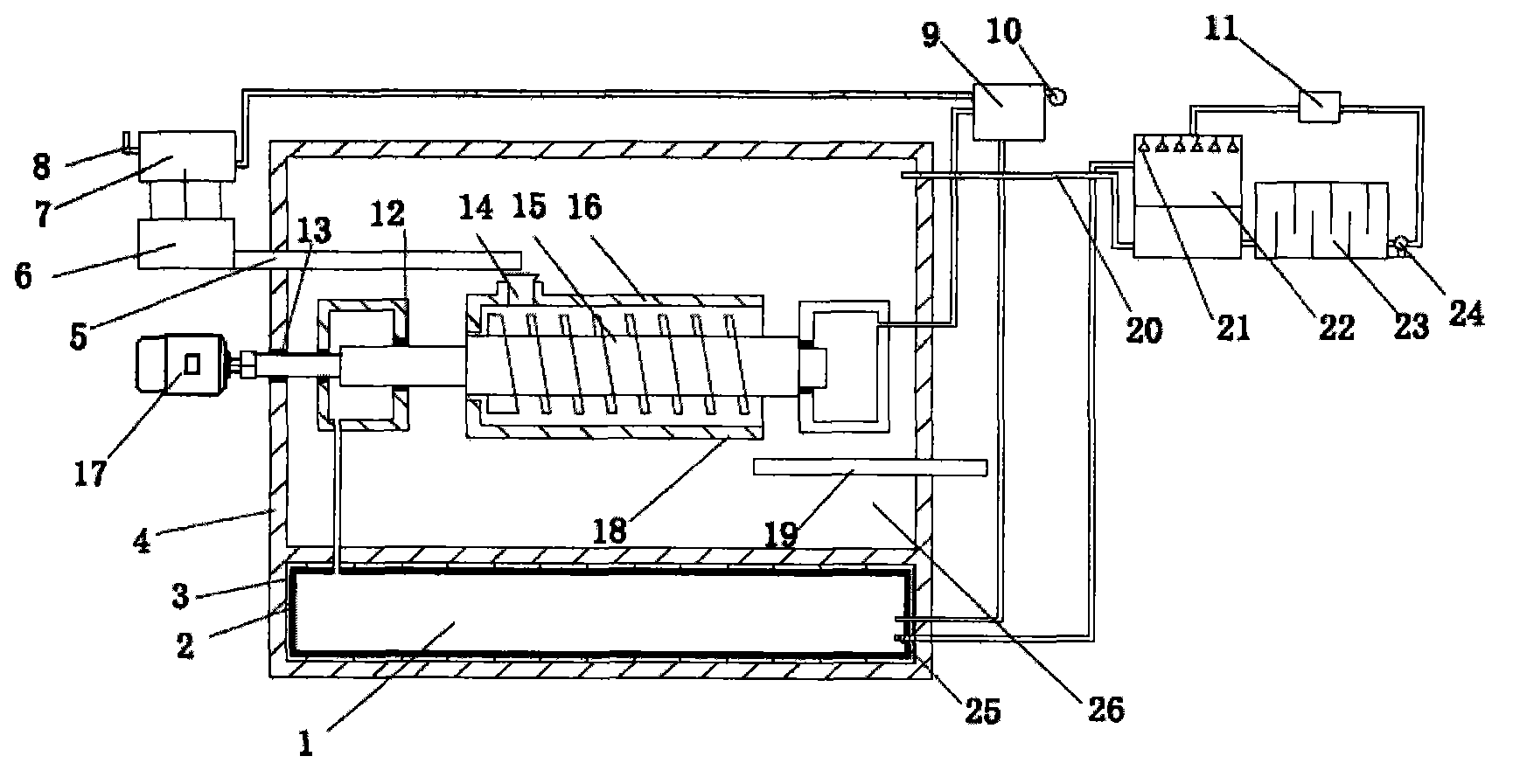

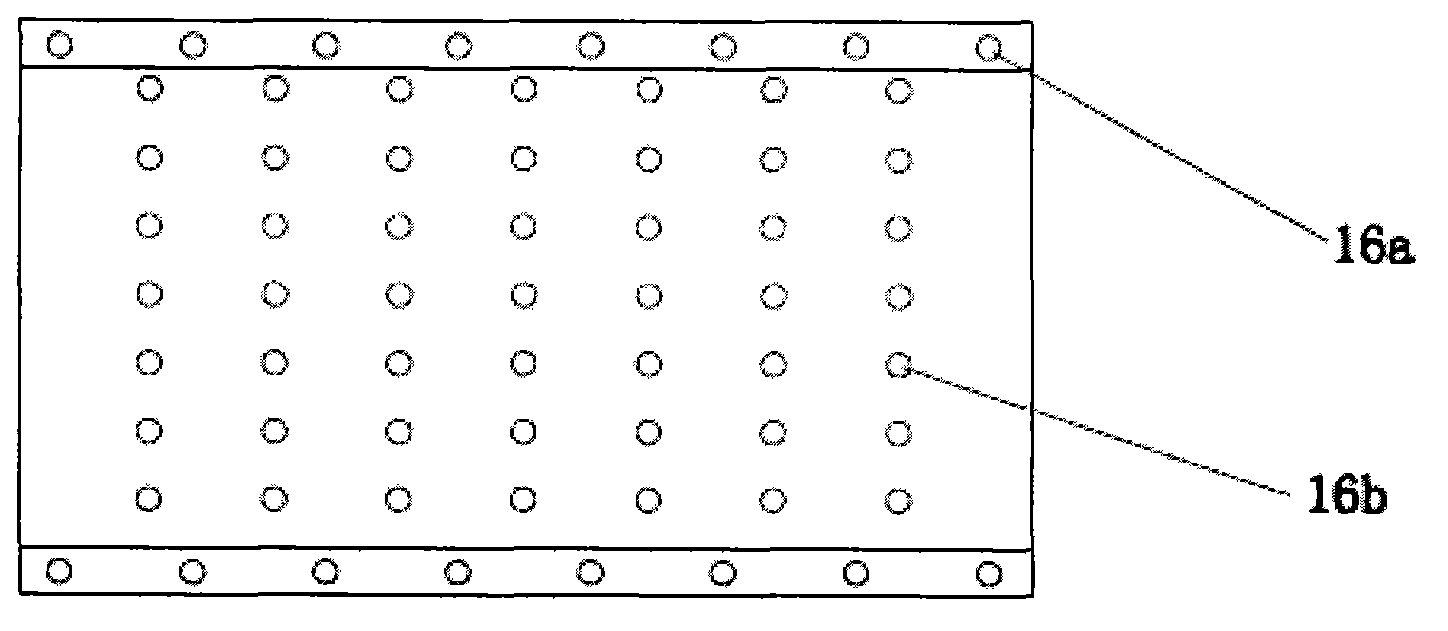

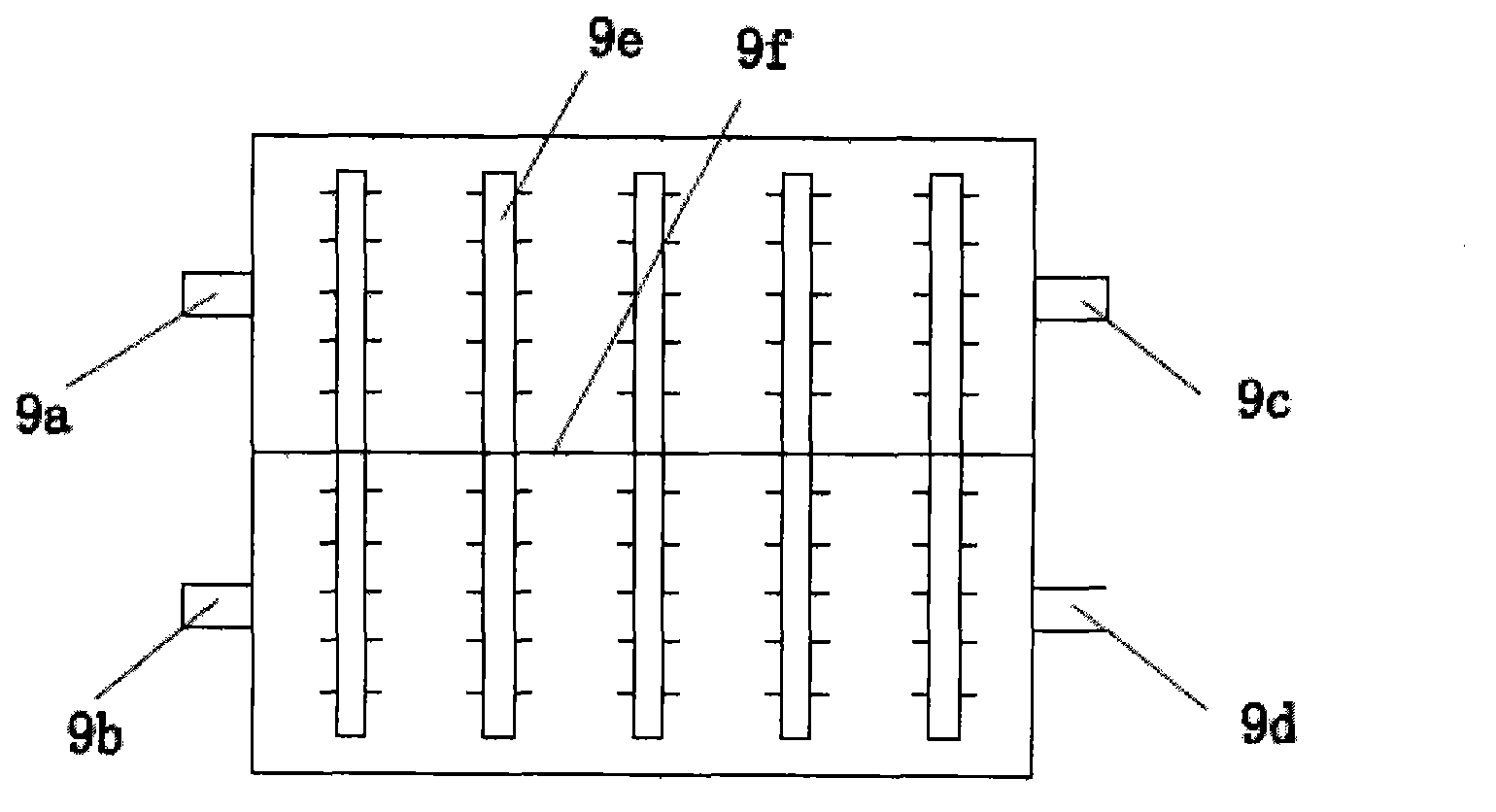

Integrated sand making complete equipment

InactiveCN101829625APowder content can be controlledNo leakage pollutionGas current separationDispersed particle filtrationEngineeringWaste management

The invention discloses integrated sand making complete equipment, comprising a crushing plant, a sand-powder separation device, a dust collection device, a crushing chamber, a dedusting chamber in a state of negative pressure and a dust settling chamber in a state of negative pressure, wherein the crushing chamber, the dedusting chamber and the dust settling chamber are integrally mounted; the crushing chamber and the dedusting chamber are arranged above the dust settling chamber; the sand-powder separation device comprises a drum the inner wall of which is provided with a material delivering plate, a riding wheel for supporting the drum and a transmission gear; the drum is mounted obliquely to the horizontal plane, the high end of the drum is inserted into the dust settling chamber, and a sealing element is arranged at the intersection of the drum and the wall of the dust settling chamber; the crushing device is mounted in the crushing chamber, the side wall of the crushing chamber is provided with a feed port, the bottom wall of the crushing chamber is provided with a discharge port, and the discharge port is provided with a chute for leading the mixture of sand and powder into the drum; a cloth bag for dedusting, which is provided with a sealed upper part and an open lower part, is mounted in the dedusting chamber, the opening of the cloth bag is communicated with the dust settling chamber, a fan is arranged outside the dedusting chamber, and the exhaust inlet of the fan is communicated with the dedusting chamber through air pipes.

Owner:杨干

Method for recovering zinc by using rotary kiln and device thereof

InactiveCN102899505AEfficient recyclingSolve processing problemsProcess efficiency improvementCombustionOxygen

The invention discloses a method for recovering zinc by using a rotary kiln. The method comprises the steps of (1) mixing electric furnace dust, anthracitic coal and gas mud into blast furnace dust; (2) sending the mixture into the rotary kiln for high temperature combustion, so that zinc gas in the mixture is changed into gasified zinc; (3) sucking the gasified zinc into a settling chamber, and removing dust in the gasified zinc while cooling; (4) enabling the gasified zinc to continue to advance and enter a surface cooler, cooling quickly, and combining the gasified zinc and oxygen in the air to produce zinc oxide; and (5) sucking the zinc oxide into a dust chamber by a centrifugal fan, and storing and recovering after filtering by a cloth bag. The invention also discloses a special rotary kiln zinc recovering device for the method. The device comprises the rotary kiln, wherein a gas outlet of the rotary kiln is communicated with an inlet of the settling chamber, a gas outlet of the settling chamber is communicated with an inlet of the surface cooler, and a gas outlet of the surface cooler is communicated with an inlet of the dust chamber through the centrifugal fan. By the aid of the method and the device, zinc in the blast furnace dust, the gas mud and the electric furnace dust can be effectively recycled.

Owner:SUZHOU YONGJI REGENERATION RESOURCE

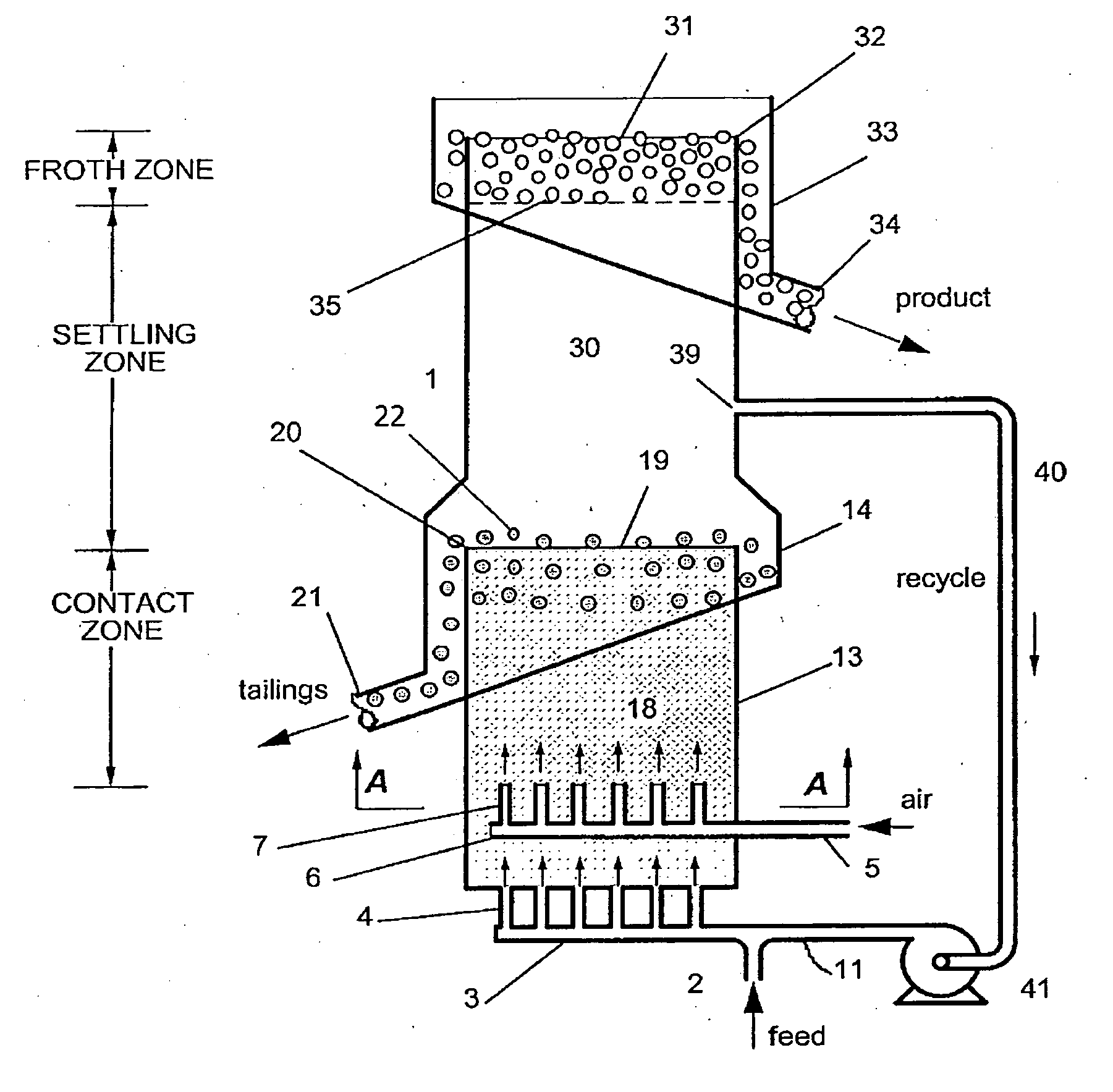

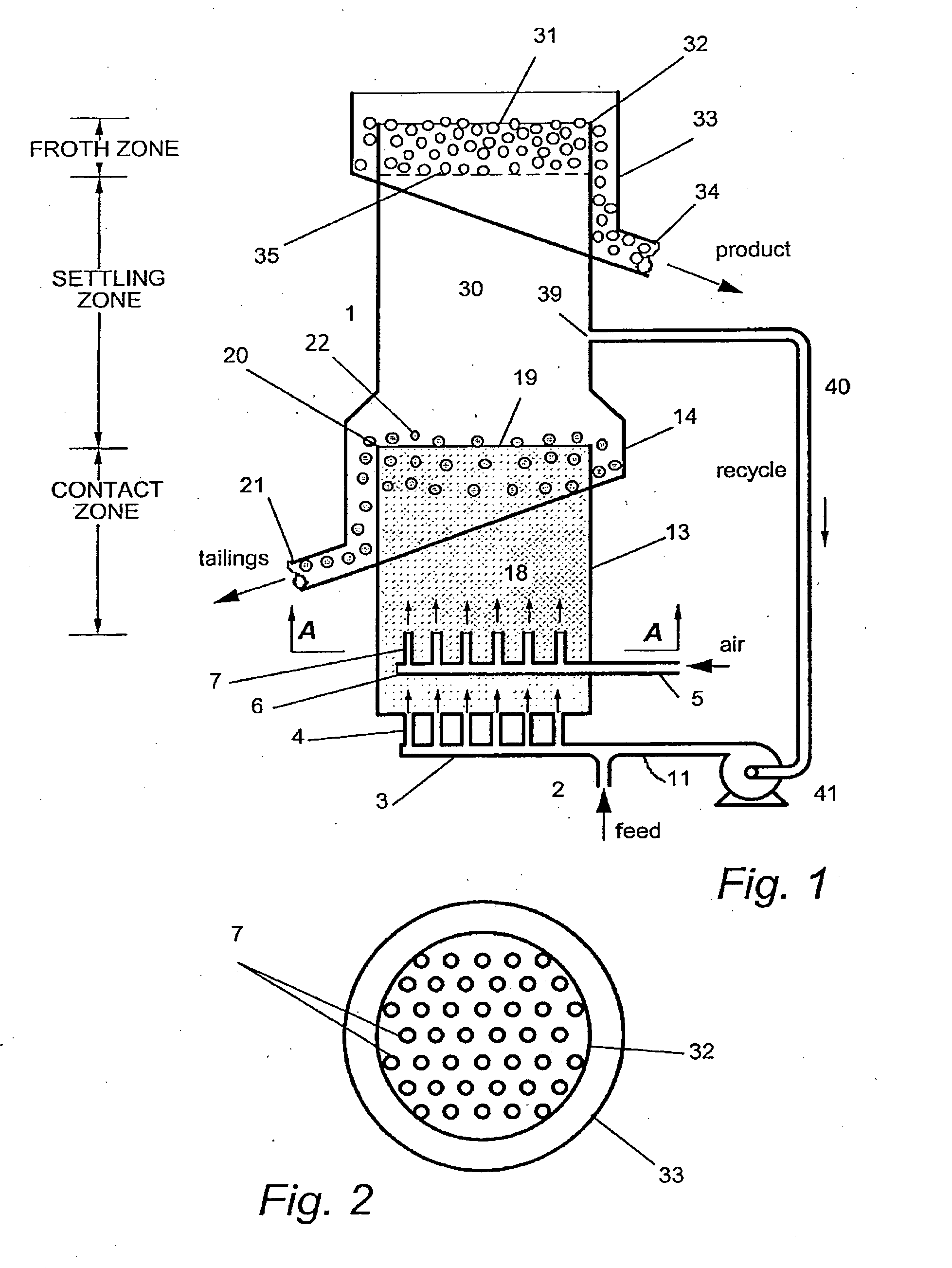

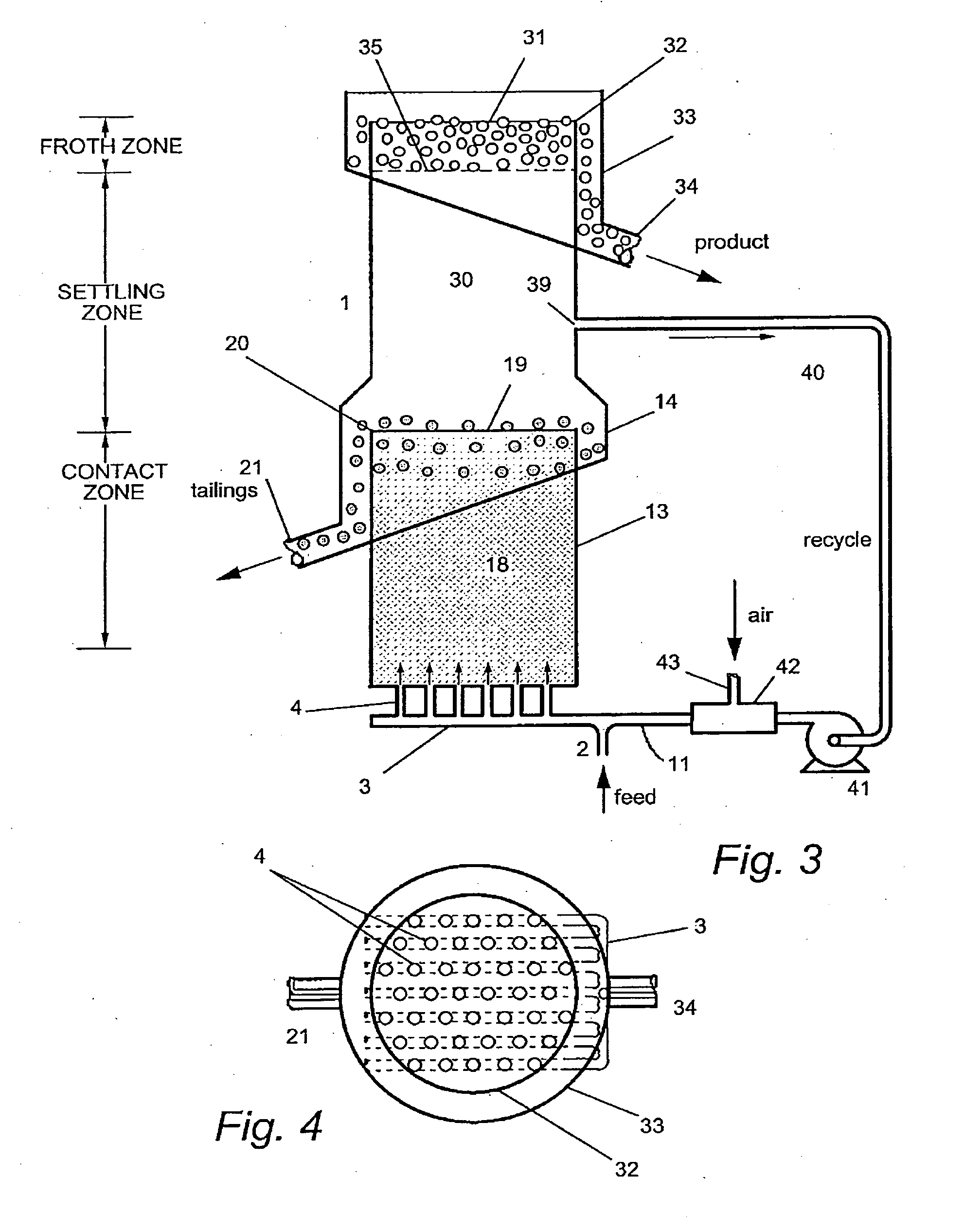

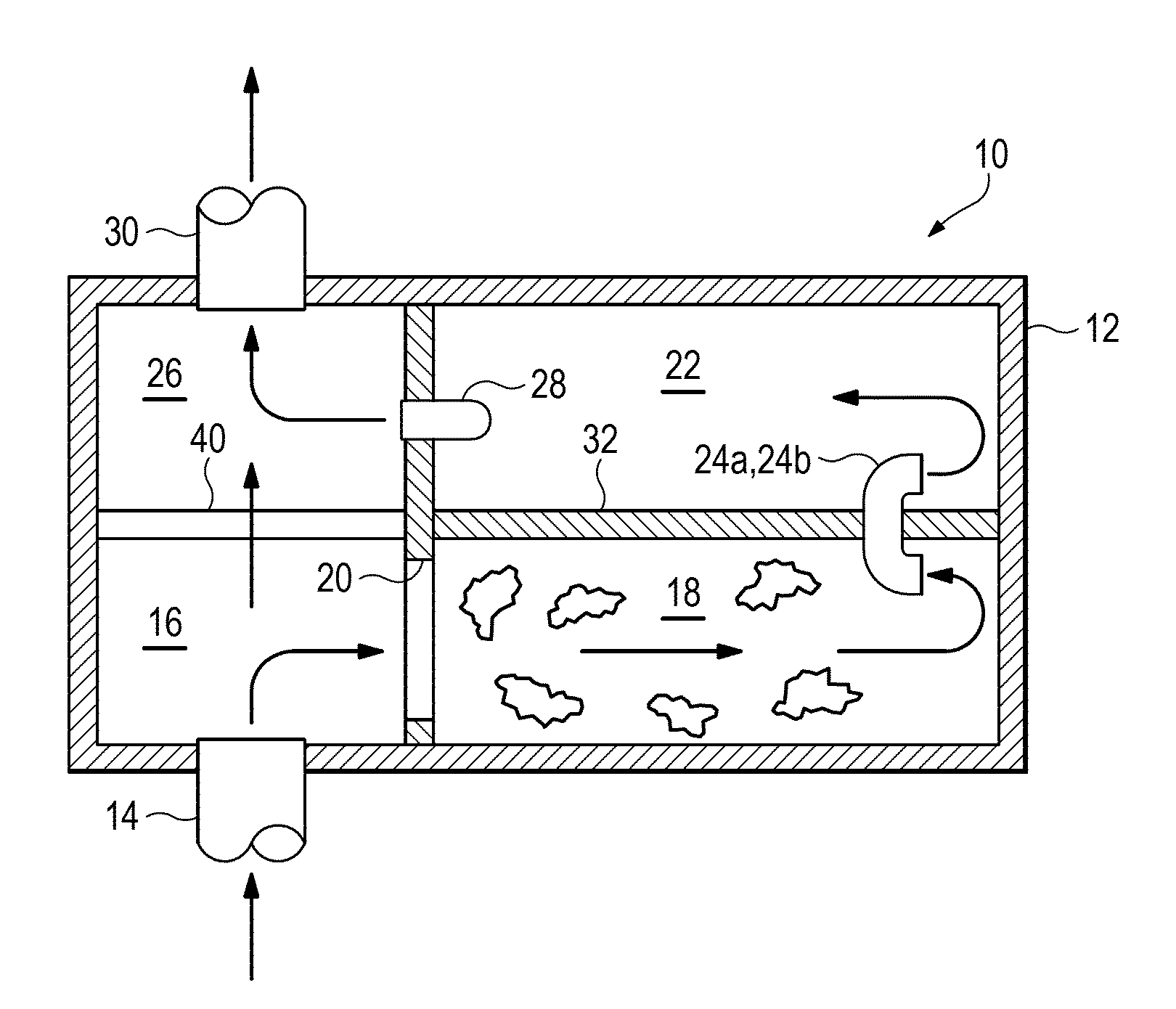

Method and apparatus for flotation in a fluidized bed

Separation of hydrophobic particles from a mixture of particles in a fluid is performed by providing a fluidized bed as a relatively non-turbulent contacting mechanism in a flotation cell incorporating a settling chamber located immediately above the fluidized bed. Hydrophobic particles attach to bubbles in the fluidized bed and rise to the interface with the settling chamber where non-hydrophobic particles flow over the lip of an internal launder and are removed as tailings at. The hydrophobic particles attached to bubbles float upwardly in the relatively placid settling chamber where unwanted gangue can fall back to interface. The bubbles form a froth layer at the upper surface of the settling chamber, and flow over the launder lip carrying the hydrophobic particles. An operation of the apparatus is kept stable by recirculating fluid from the settling chamber via pip and pump to mix with new feed entering at duct.

Owner:UNIV OF NEWCASTLE RES ASSOCS

Method for plating parylene film on surface of LED chip

InactiveCN101603170AStrong adhesionUniform thicknessVacuum evaporation coatingSputtering coatingParyleneEngineering

The invention discloses a method for plating a parylene film on a surface of a LED chip. The method is characterized by comprising the following steps that a plating part LED chip is placed into a settling chamber; a film plating material parylene is placed into an evaporation chamber; the film plating material enters the settling chamber as activated monomers after vaporizing and cracking; a uniform and transparent parylene film is settled on the surface of the LED chip, wherein, the film plating device comprises a vaporization chamber, a cracking chamber, the settling chamber and a cold trap chamber. The method has simple process, convenient operation, strong film adhesive force and uniform film thickness, greatly improves the reliability, safety and service life of the product, solves the problems of water resistance, humidity resistance, high temperature resistance and acid-base corrosion of LED lighting products, and contributes to further popularization and application of LED brightening and electricity saving engineering.

Owner:黄益新

Flow channel type marine organism adhesion testing device

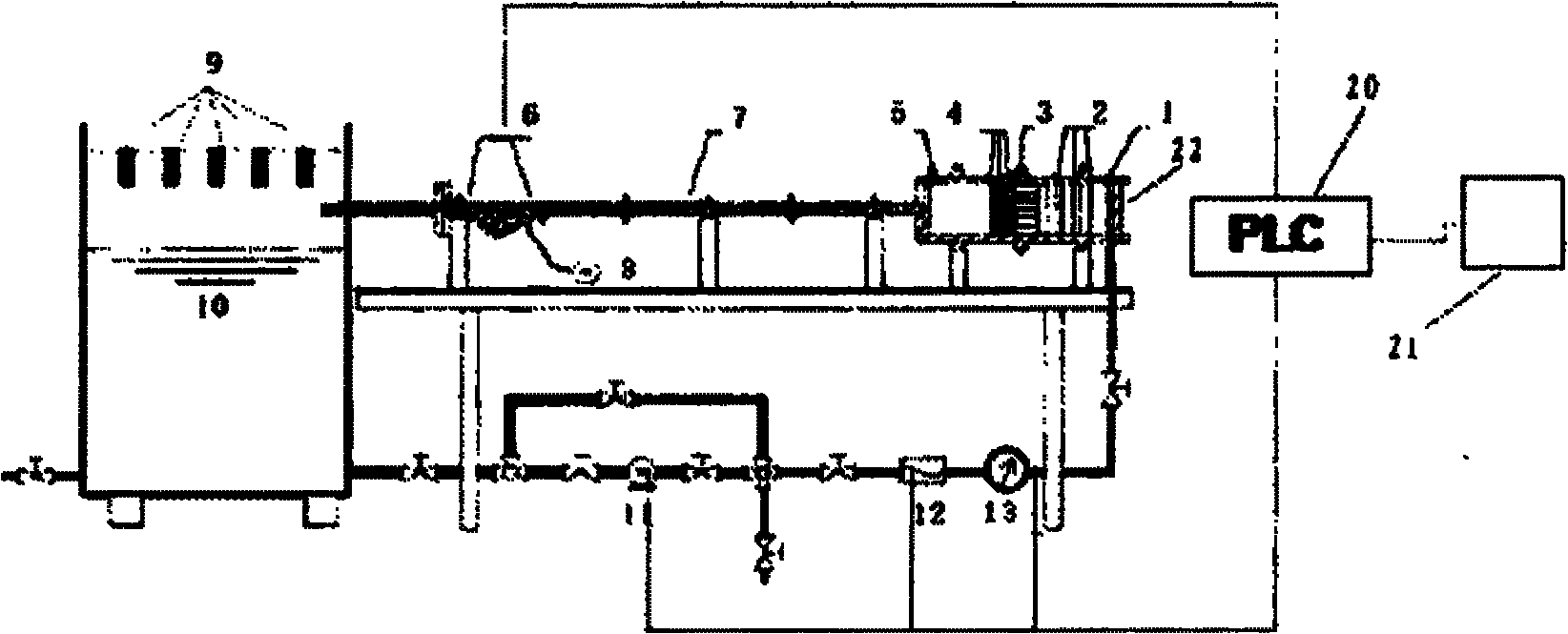

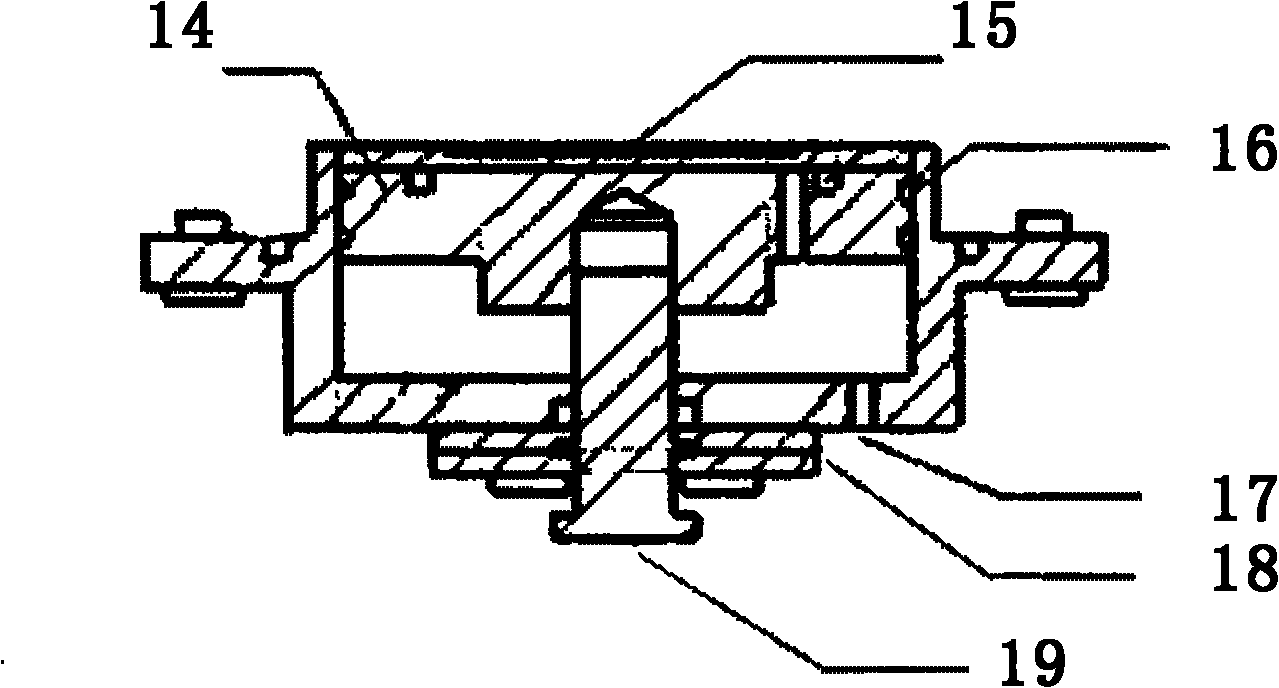

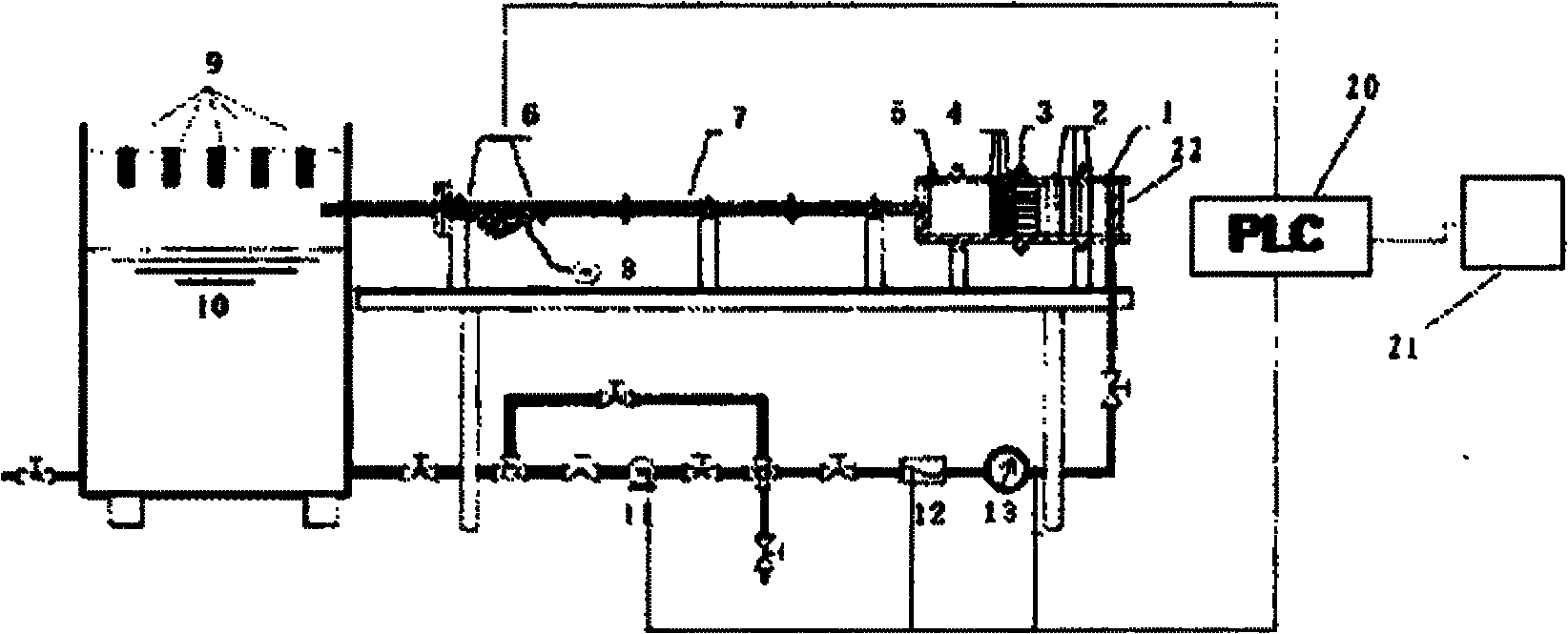

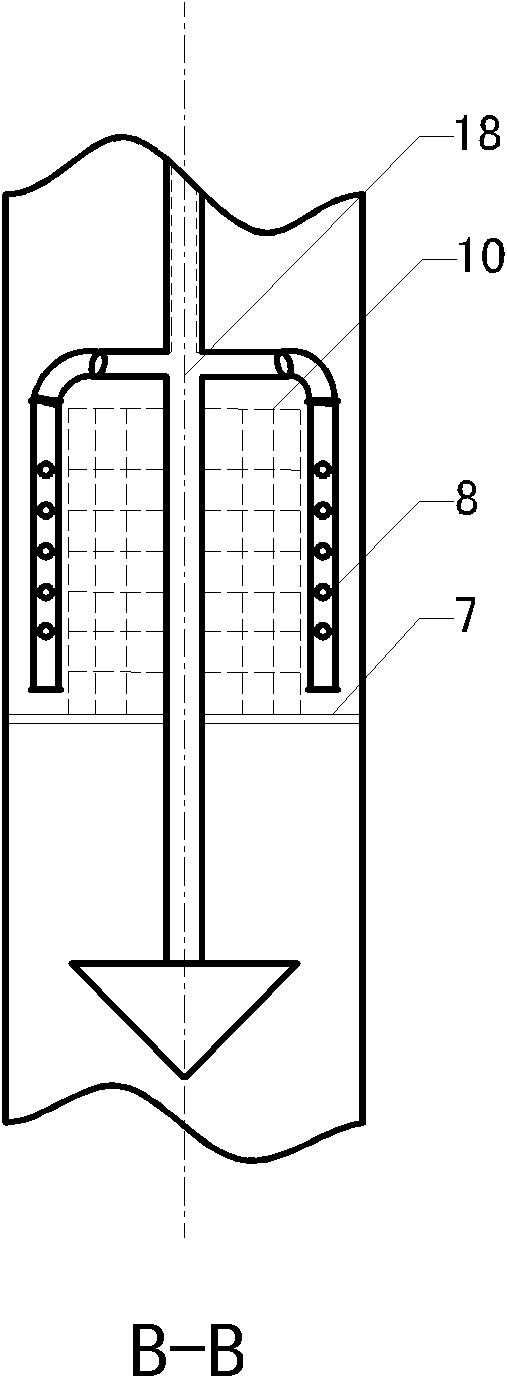

ActiveCN102023130AExpand the scope of testingReliable design principleUsing mechanical meansMaterial analysisExhaust valveDifferential pressure

The invention belongs to the technical field of marine organism tests and anti-fouling materials, and relates to a flow channel type marine organism adhesion testing device which is used for simulating the flowing state on the surface of a ship body, testing the adhesion of marine fouling organisms on the material surface and researching the effect of different flowing speed and environment conditions on the adhesion of marine fouling organisms. A water inlet, an stainless steel plate with openings, a honeycomb-shaped polycarbonate sheet, a stainless steel sieve plate and an exhaust valve are respectively manufactured on the upper side in a settling chamber of a box structure from right to left, a test cavity is manufactured at the left end of the settling chamber transversely, a differential pressure transformer is manufactured on the side edge at left end of the test cavity, a vacuum pump is arranged in the test cavity, a water tank is arranged at the left side end of the test cavity, a light source is manufactured at the top of the water tank, an outlet pipeline at the bottom part of the water tank is communicated with the water inlet under the control of a multi-end valve, and a frequency conversion pump, a flow meter and a pressure transmitter are respectively manufactured in the communicated pipeline sequentially; the structure is simple, the usage and operation are convenient and the data test is accurate, thereby being convenient for application and popularization.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Coal gas anhydrous dust collecting equipment of revolving furnace and technique thereof

ActiveCN101195766AReduce consumptionHigh calorific value utilizationEnergy inputGas dust removalThermal energyTemperature control

The invention relates to a converter coal gas non-water dust removing equipment, which comprises a converter, a radiant type waste-heat boiler, an adjusting valve, a cyclone dust remover, a bag-type dust remover, a coal gas temperature controlling device, a flow meter, a main induced draft fan, a three-way valve, an emission chimney, a rotary water seal, a U-shaped water seal, and a coal gas tank. The invention is characterized in that a convection type waste-heat boiler is connected between the outlet position of the radiant type waste-heat boiler and the adjusting valve, and the convection type waste-heat boiler is composed of a settling chamber, a heat exchange component, a baffle plate, a box body, and an ash discharging opening. A process method comprises the steps that converter coal gas comes into the convection type waste-heat boiler via radiant type waste-heat boiler after recovery waste heat, the gravitational settling is performed to come into the adjusting valve, and the bag-type dust remover, etc to perform dust fining removal after the recovery waste heat, the emission is performed through the three-way valve or the converter coal gas comes into the coal gas tank to perform coal gas recovery, and the invention has the advantage that the energy consumption is reduced through recovering heat energy.

Owner:北京中冶设备研究设计总院有限公司

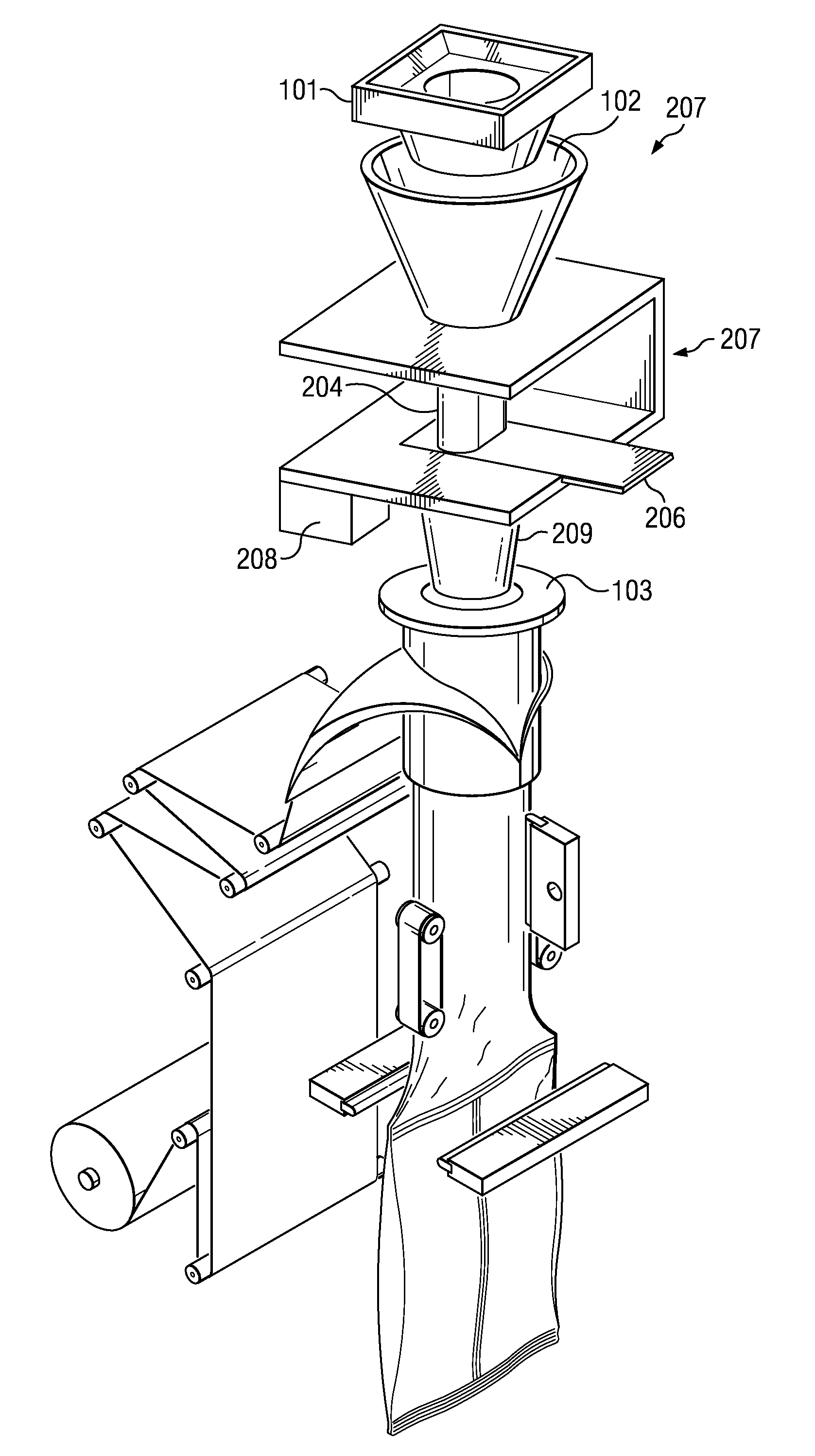

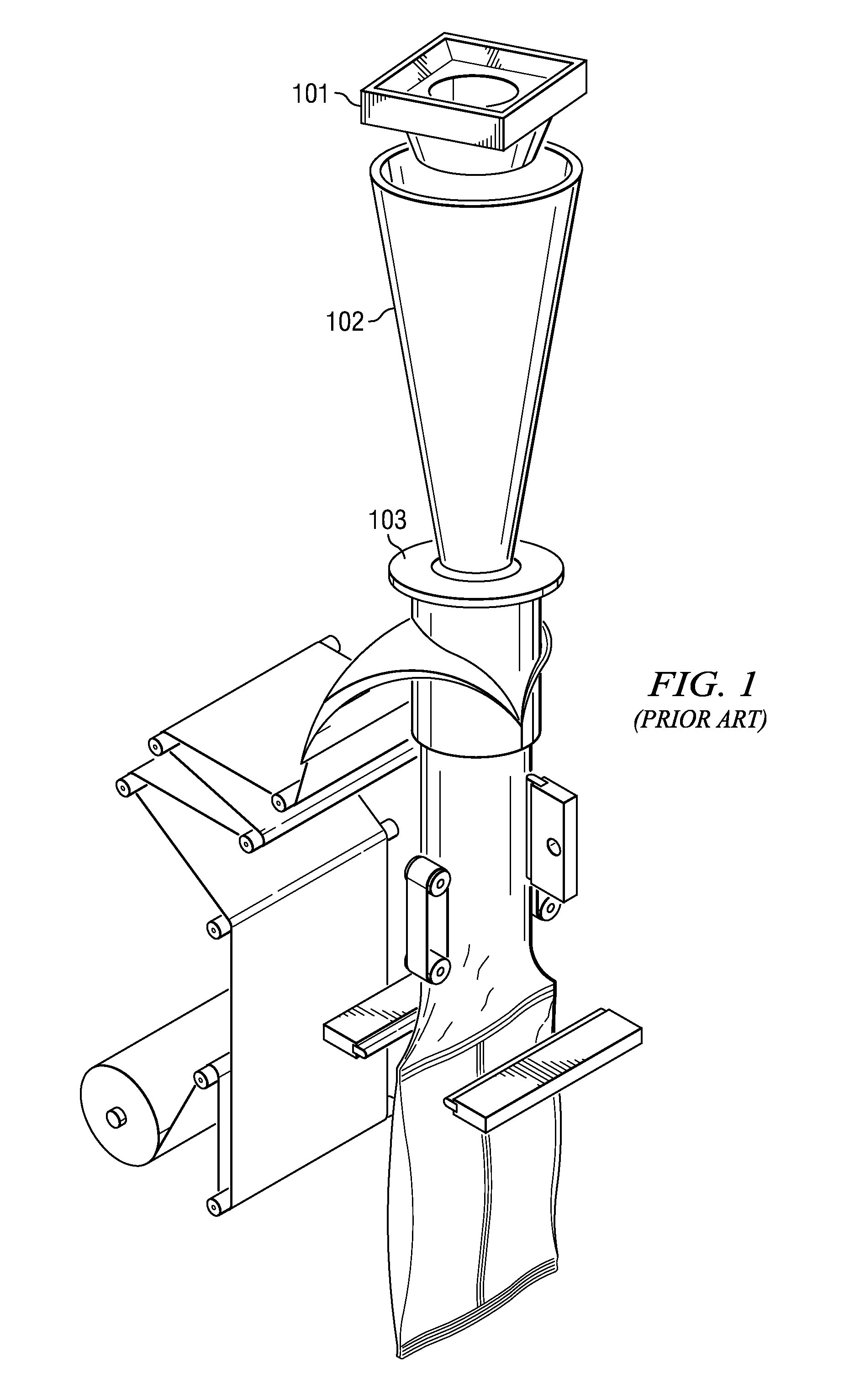

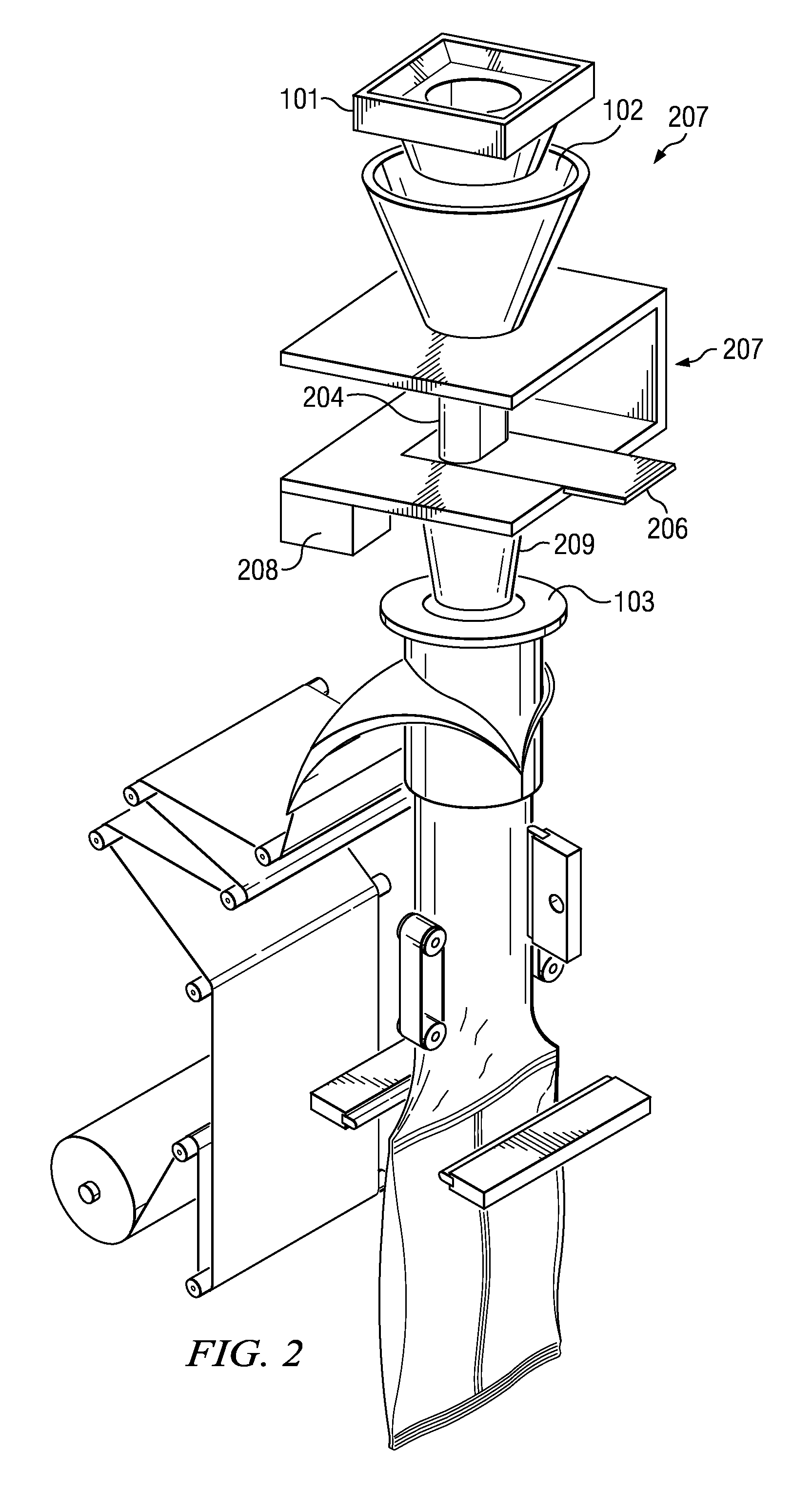

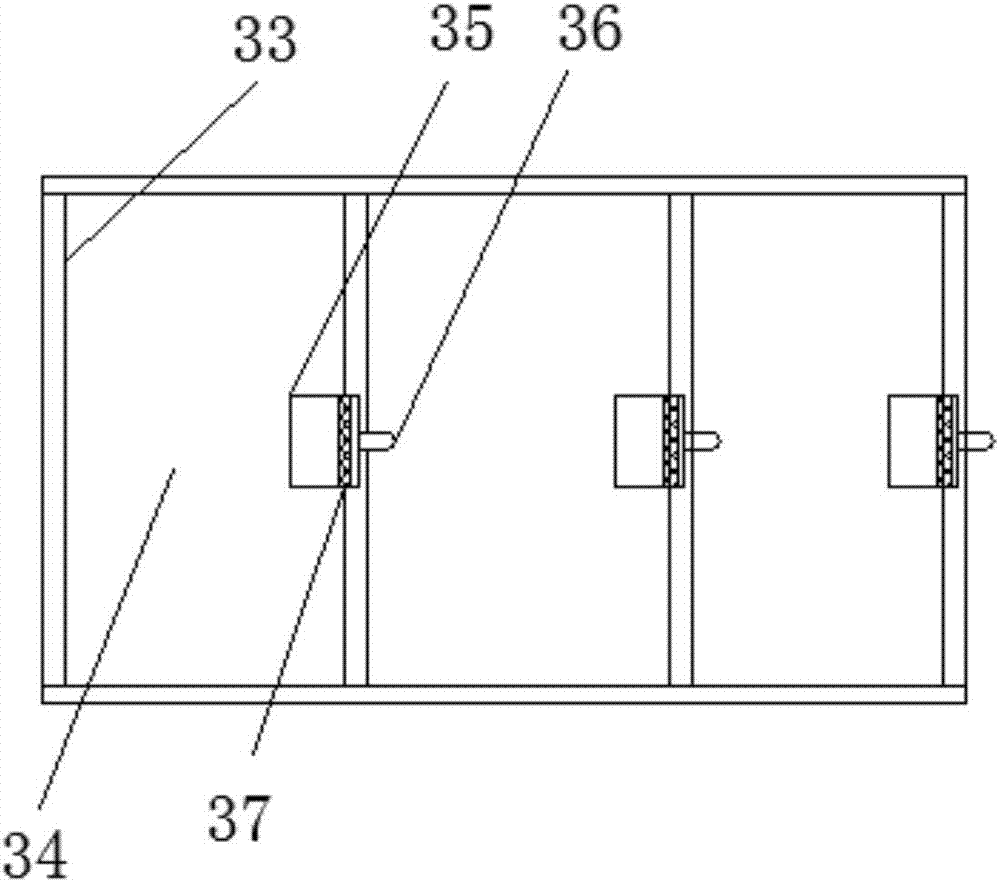

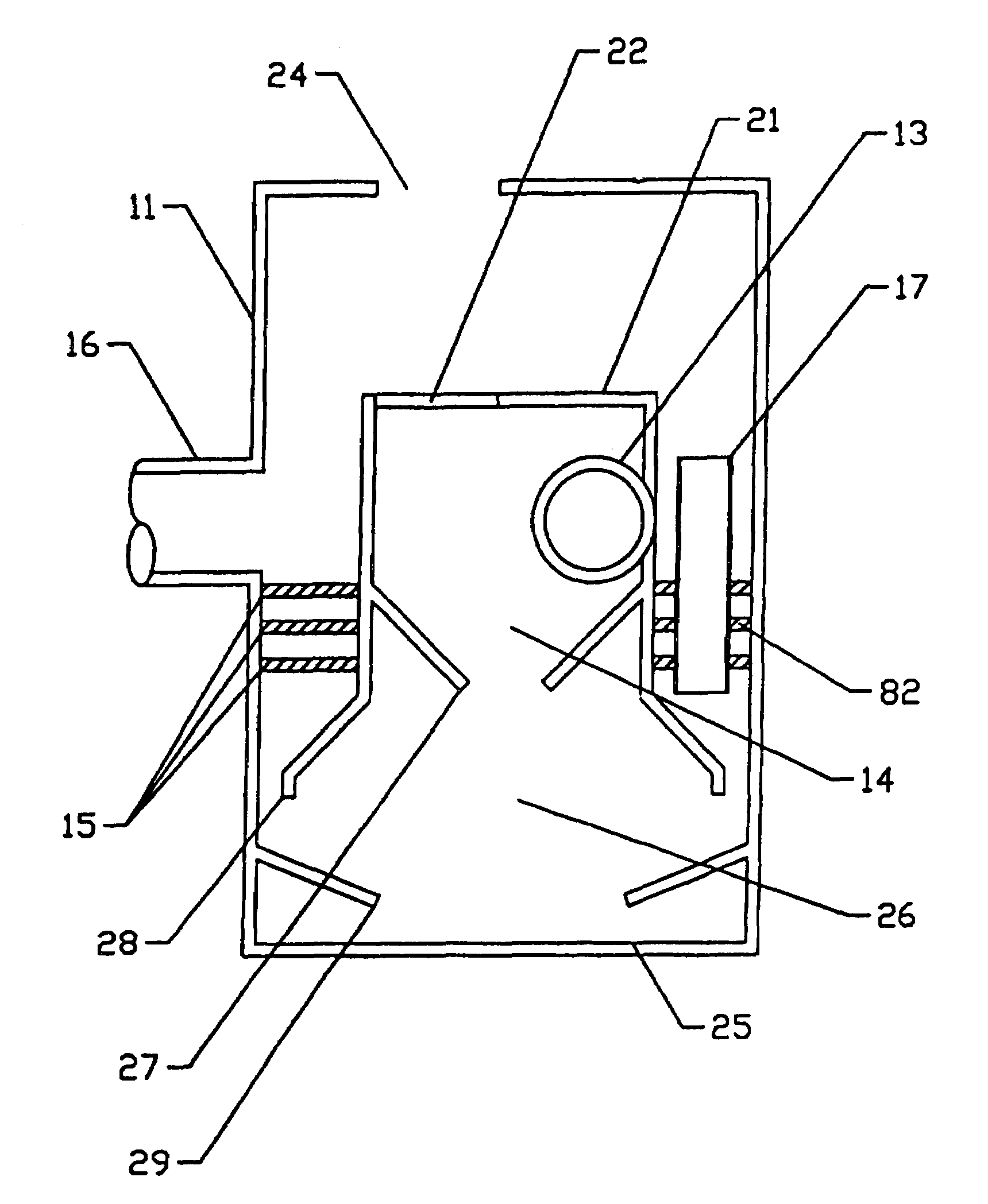

Method and apparatus for compacting product

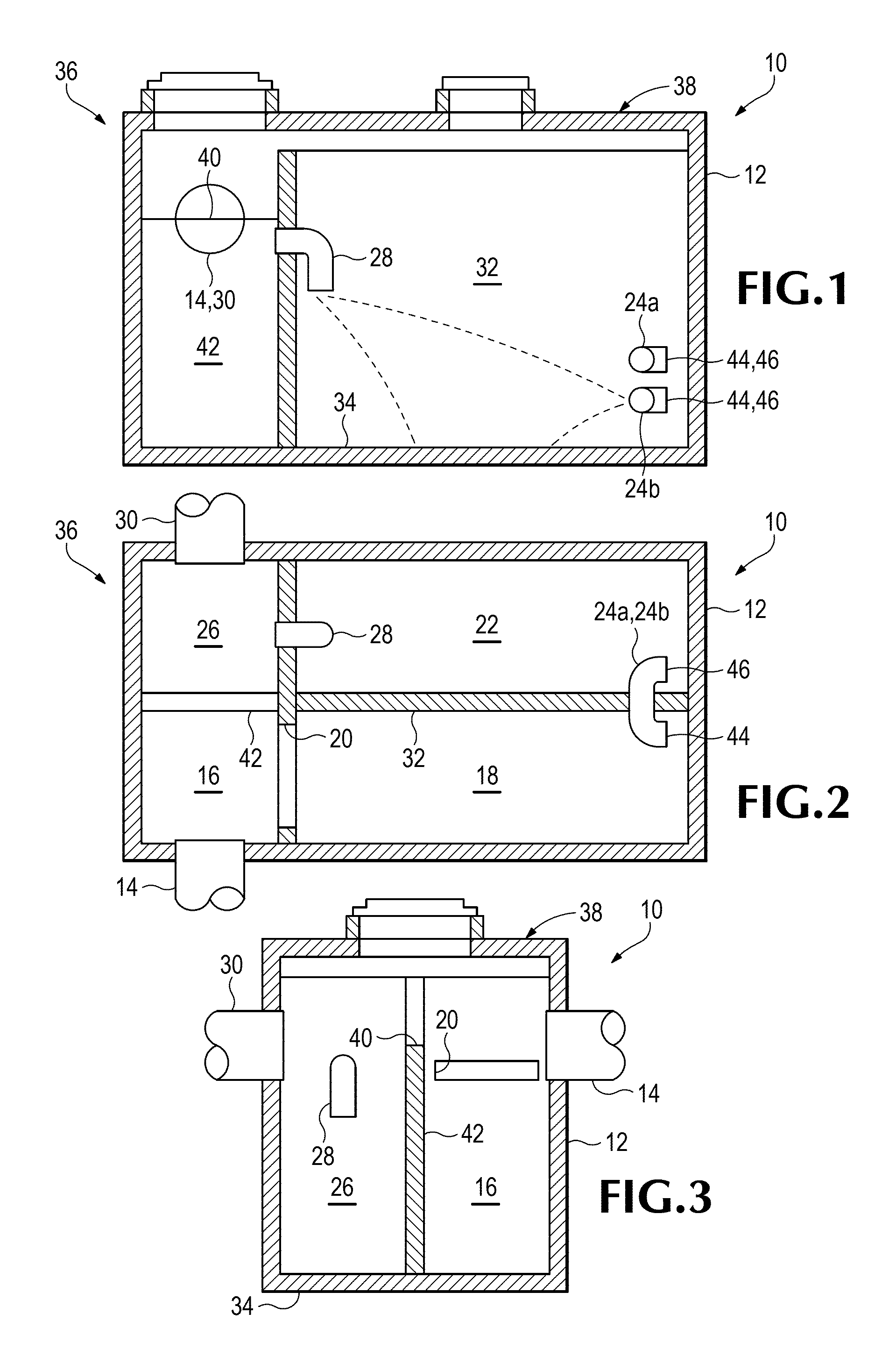

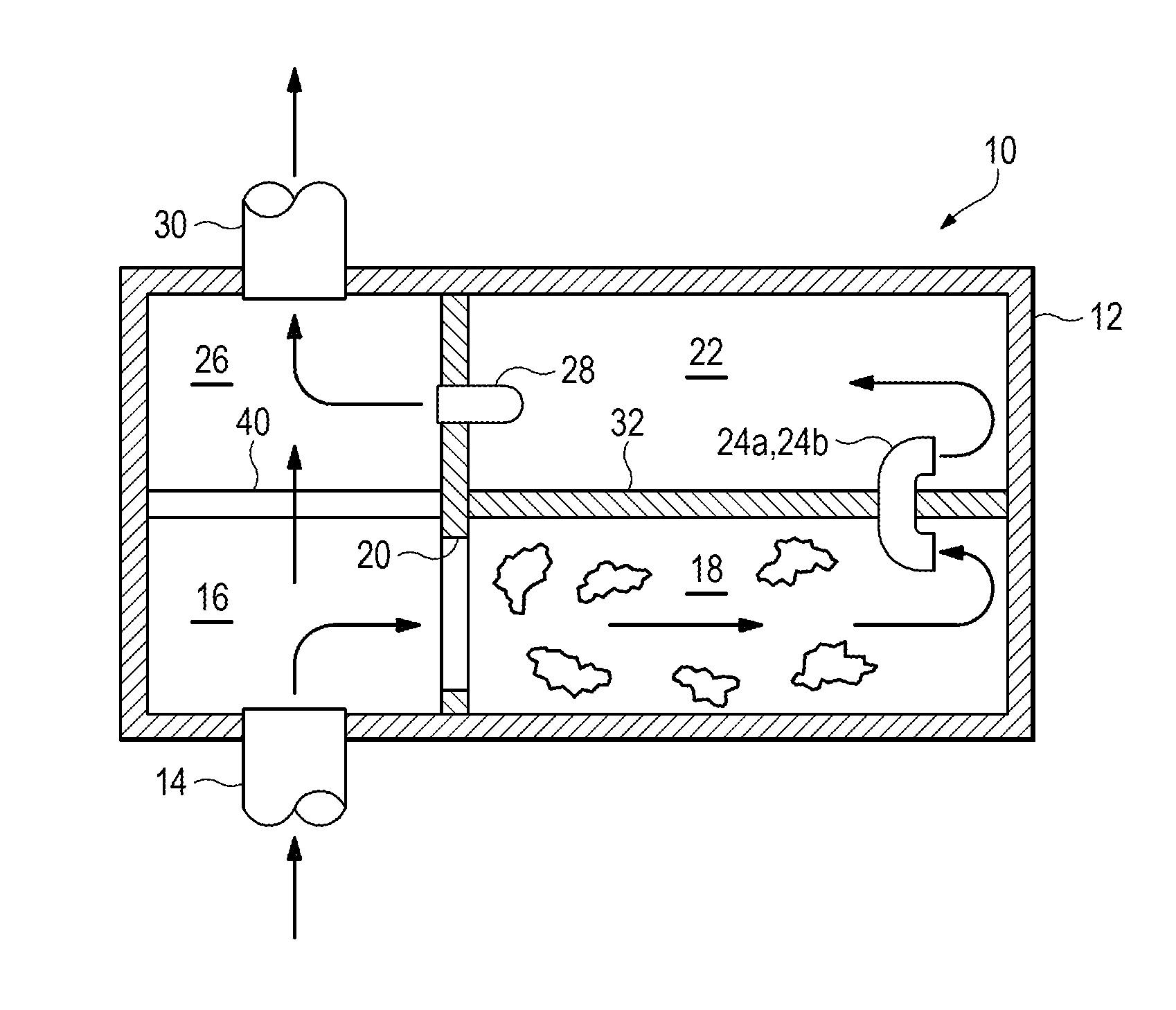

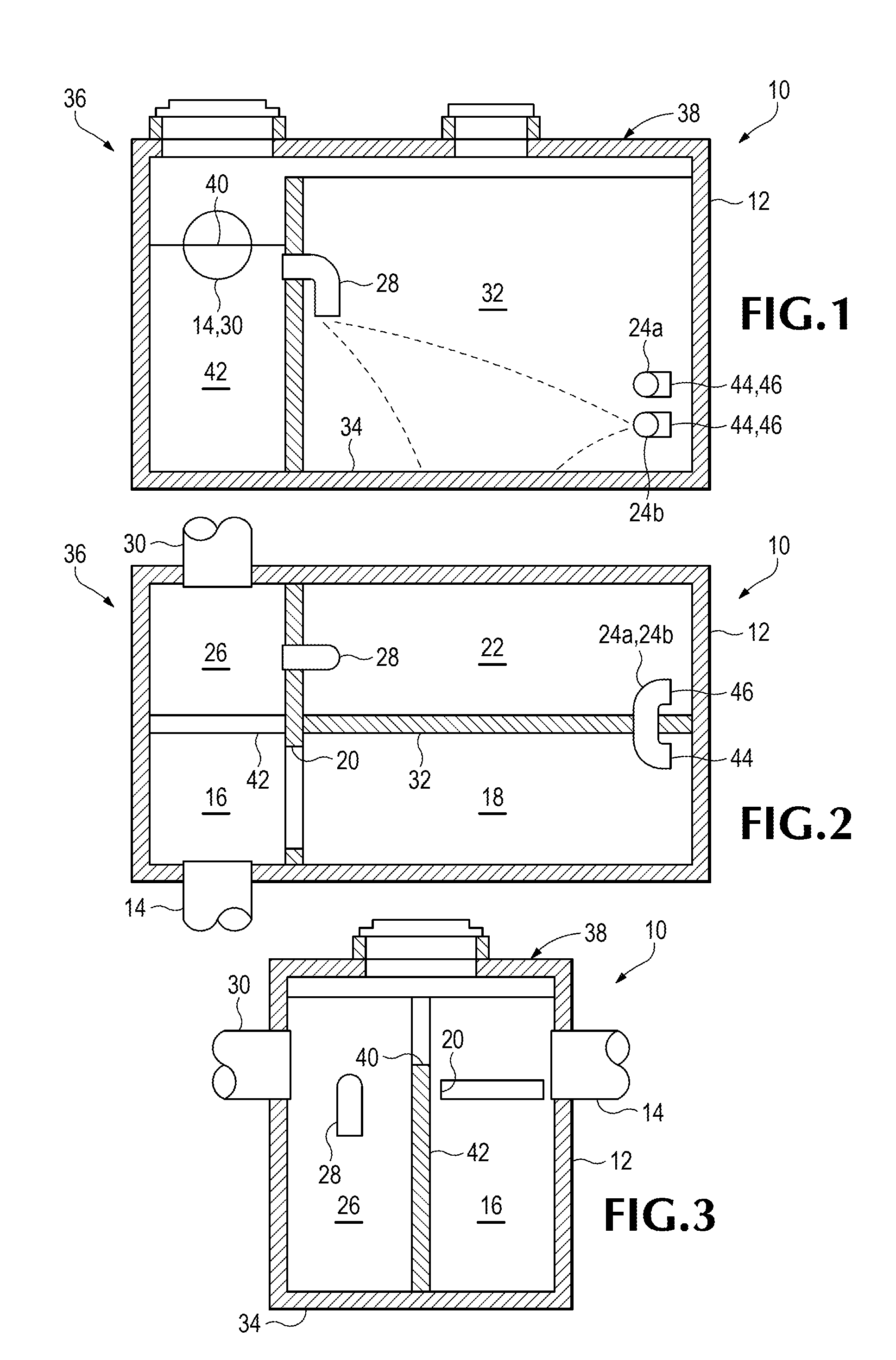

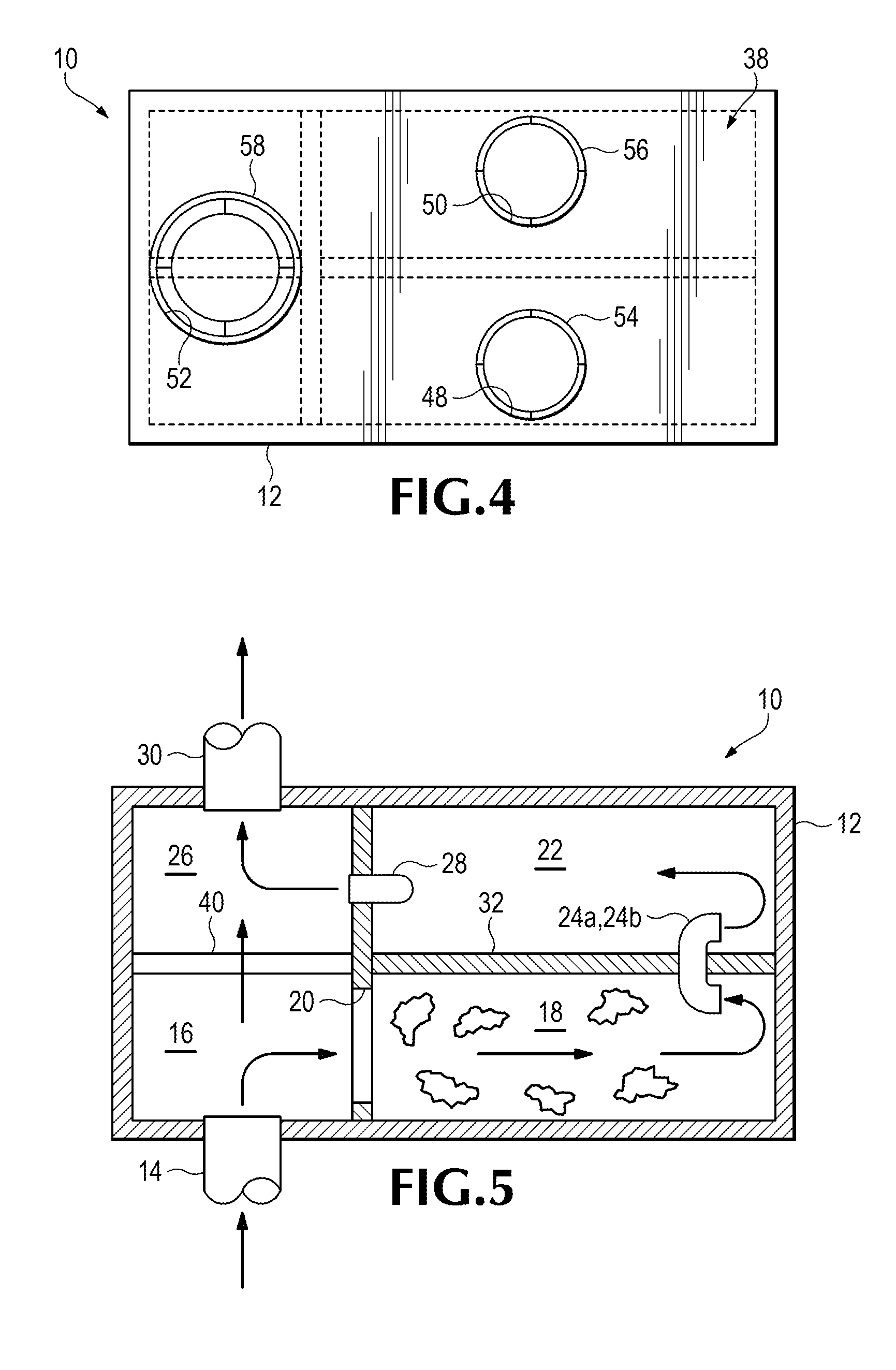

ActiveUS8656690B2Solid materialPackaging under special atmospheric conditionsEngineeringSettling chamber

A method for compacting a slug of product and apparatus for accomplishing the same. The invention describes collecting weighed product in an intermediate settling device to form a compact slug of product. The device can comprise a single settling chamber or can comprise multiple settling chambers which are axially rotatable. The slug can be compacted by jostling and / or vibrating the settling device. Thereafter, the product is discharged to a packaging apparatus. Because the product in the final package is denser, a smaller package can be utilized reducing manufacturing and shipping costs.

Owner:FRITO LAY NORTH AMERICA INC

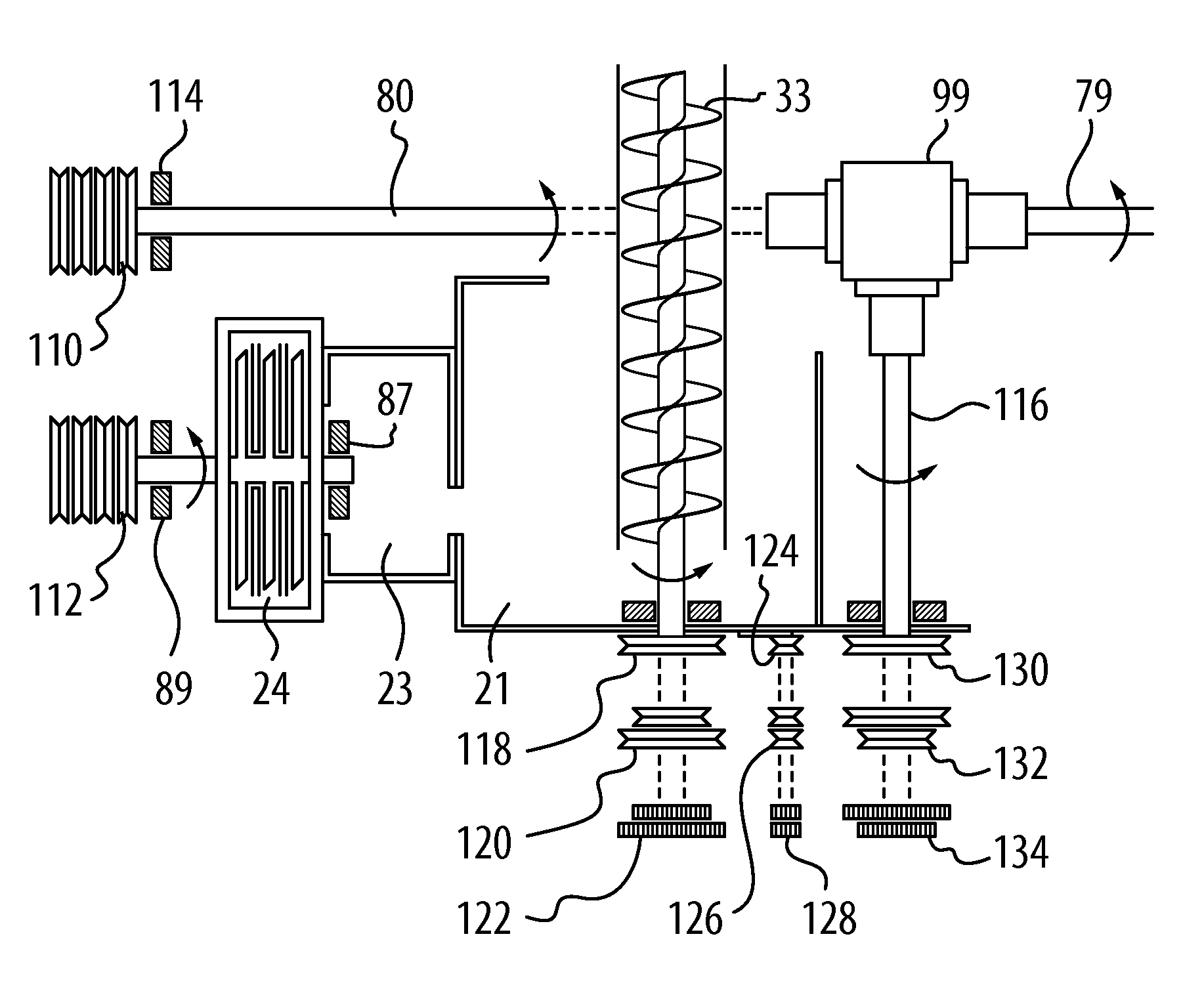

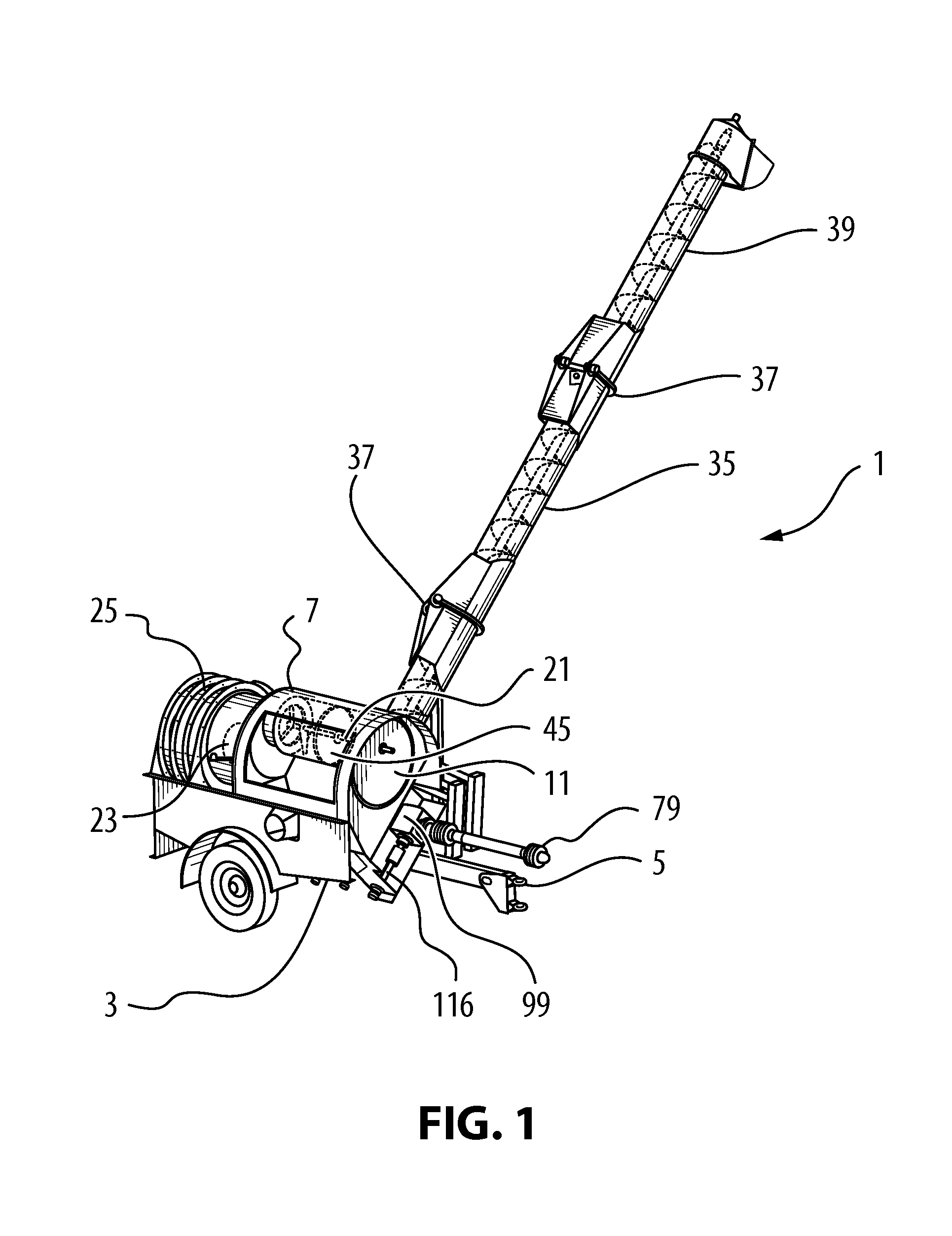

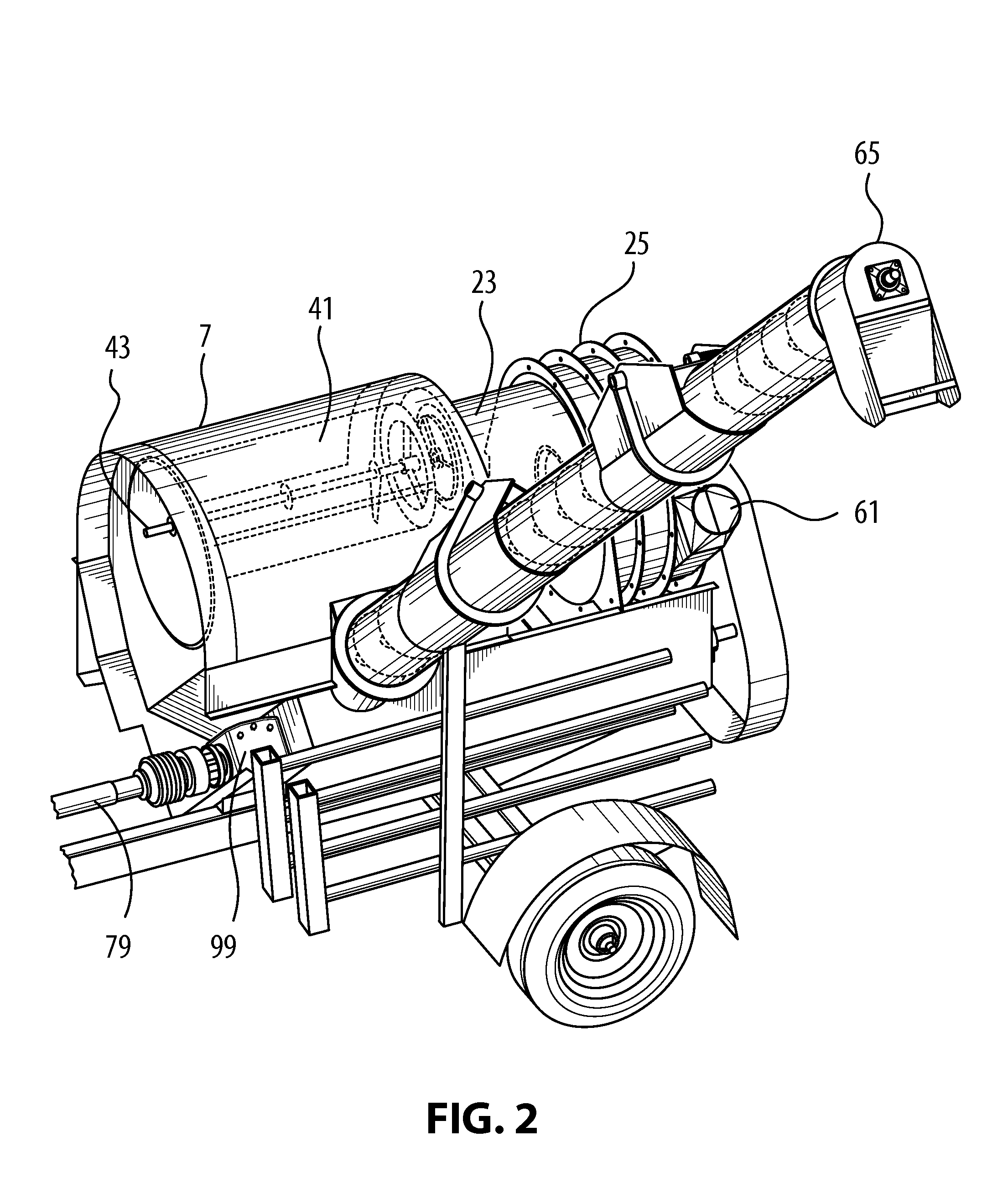

High capacity particulate loader and transfer apparatus

InactiveUS7431537B2Large capacityImprove efficiencyLoadersLoading/unloading vehicle arrangmentParticulatesSuction stress

A high capacity particulate loader having an intake hose on one sidewall thereof which communicates with a source of negative pressure formed by a multi-stage suction mechanism, to create a high suction, high volume and high speed air stream that draws particulate materials through the hose and propels them into a separation chamber where they separate from the air stream and are directed into a discharge auger assembly on the opposite sidewall of the loader. The multi-stage suction mechanism communicates with a separation chamber and / or a settling chamber, the settling chamber providing an area where dust or fine chaff from the suctioned particulate materials, which may be present in the air stream, can settle, through gravity, on a bottom surface of the settling chamber, thus avoiding contact with the blowers so as to prevent clogging of the blowers and rotor wear thereof.

Owner:AG GROWTH IND PARTNERSHIP

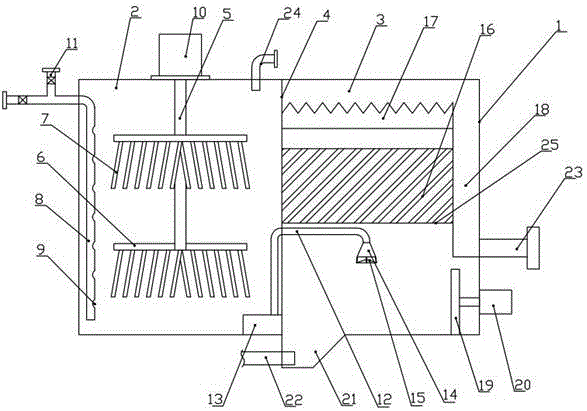

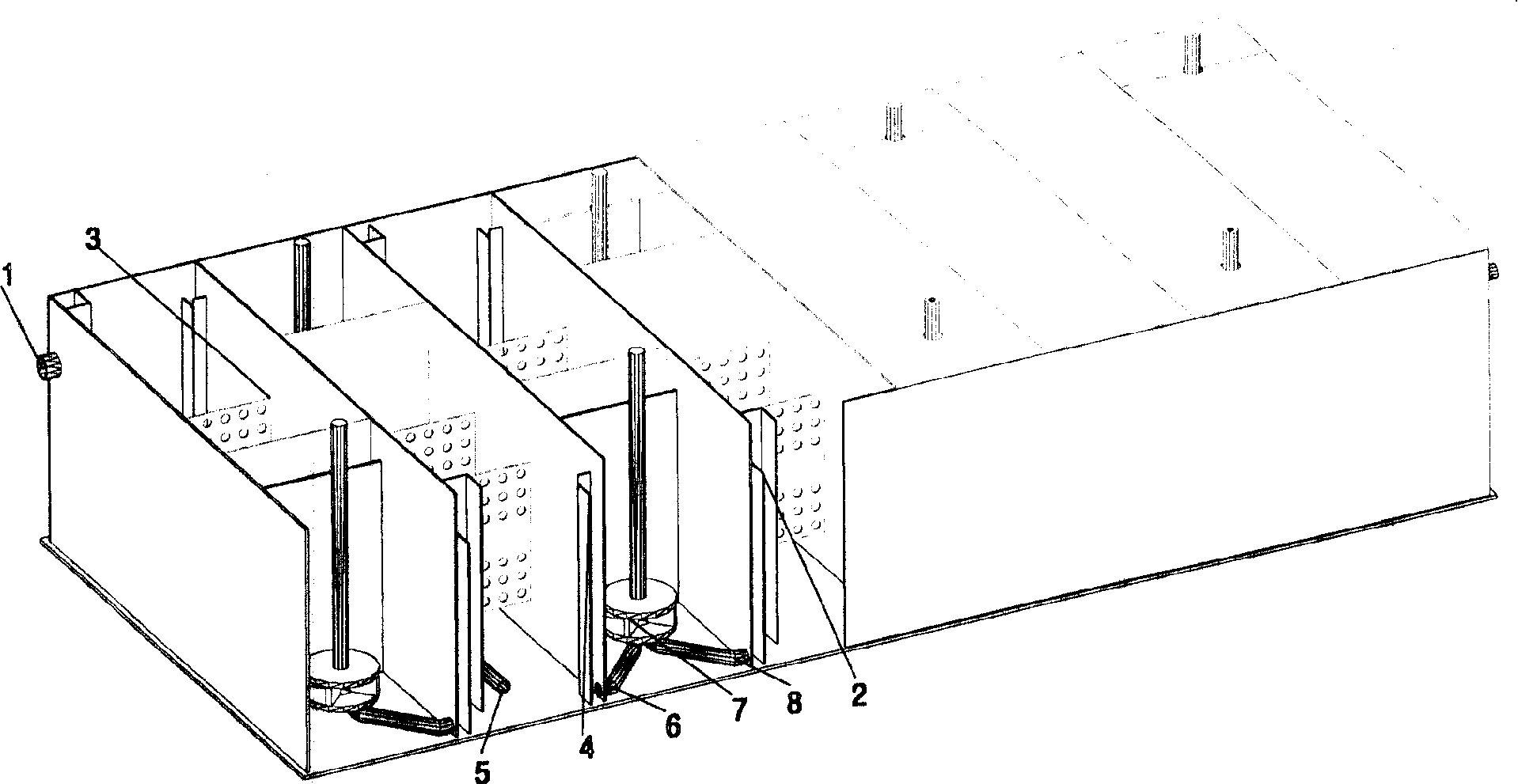

Integrated waste water treatment equipment

InactiveCN106310736ASmall footprintEasy to useSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationHoneycombSewage

The invention discloses integrated waste water treatment equipment, and relates to the technical field of waste water treatment. The integrated waste water treatment equipment comprises a box body and a partition board for dividing the box body into a stirring chamber and a settling chamber; a stirring shaft is arranged in the stirring chamber; a fixed mount is arranged on the stirring shaft, and stirring blades are arranged onto the fixed mount in an articulated manner; a vertical dosing pipeline is further arranged in the box body, and a plurality of medicament feeding holes are formed in the dosing pipeline; the box body is further internally provided with a conveying pipeline for communicating the stirring chamber with the settling chamber; the settling chamber is further internally provided with a net plate, the net plate is positioned above a water outlet, and honeycomb inclined tubes are arranged on the net plate; an overflow plate is further arranged above the inclined tubes; a clean water storage tank is further arranged in the settling chamber; a vertical push plate is further arranged at the bottom of the settling chamber, a pushing device is further arranged on the box body, and the pushing device is fixed with the push plate. According to the integrated waste water treatment equipment, stirring and settling of waste water can be completed at one time, and the equipment is more convenient to use.

Owner:四川乐根水处理设备有限公司

Mixed settler extractor

InactiveCN101219289AEliminate pollutionQuick layeringLiquid solutions solvent extractionSingle stagePhase ratio

The invention relates to a mixer settle extraction tank that is applicable to the extraction of high flow rate solvent, in particular to an extraction case combined by single-stage mixer settle extraction tanks. A two-phase mixer is stirred and driven by a turbine and the stirring has a pumping effect for two-phase fluid. Two phases are induced to a place below a stirring axial center by a diversion tube in a mixing chamber. The mixed phases are layered in a settling chamber, wherein, a light phase flows into a light phase box and enters a next stage mixing chamber through the diversion tube and a heavy phase gets across an overflow plate of a heavy phase box and enters a former stage mixing chamber and the two phases form an adverse current mode in a cascade stage device. The settling chamber is provided with a return line to be communicated with the mixing chamber to guarantee that the mixing phase ratio of the two phases in the mixing chamber is less than 4 when the flow rate of the two phases is high. A heat protection layer is coated around the extraction case, a cover board is arranged at the upper part and temperature in the tank body is constant. Water sealing is used at the top part of the mixing chamber of the extraction tank, thus organic gas evaporated from the extraction tank can be recovered.

Owner:GRIREM ADVANCED MATERIALS CO LTD

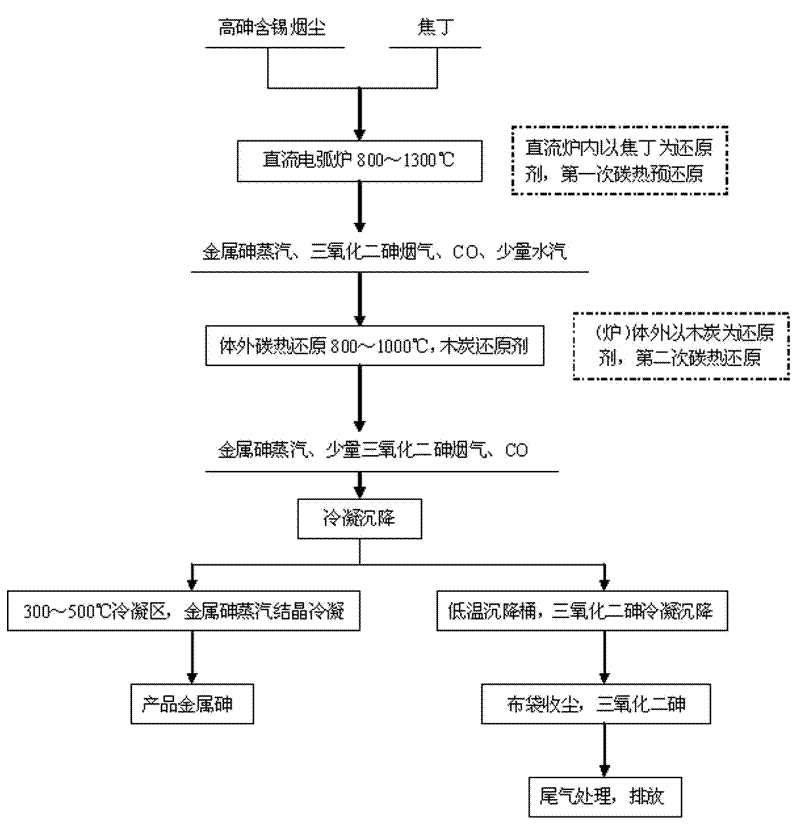

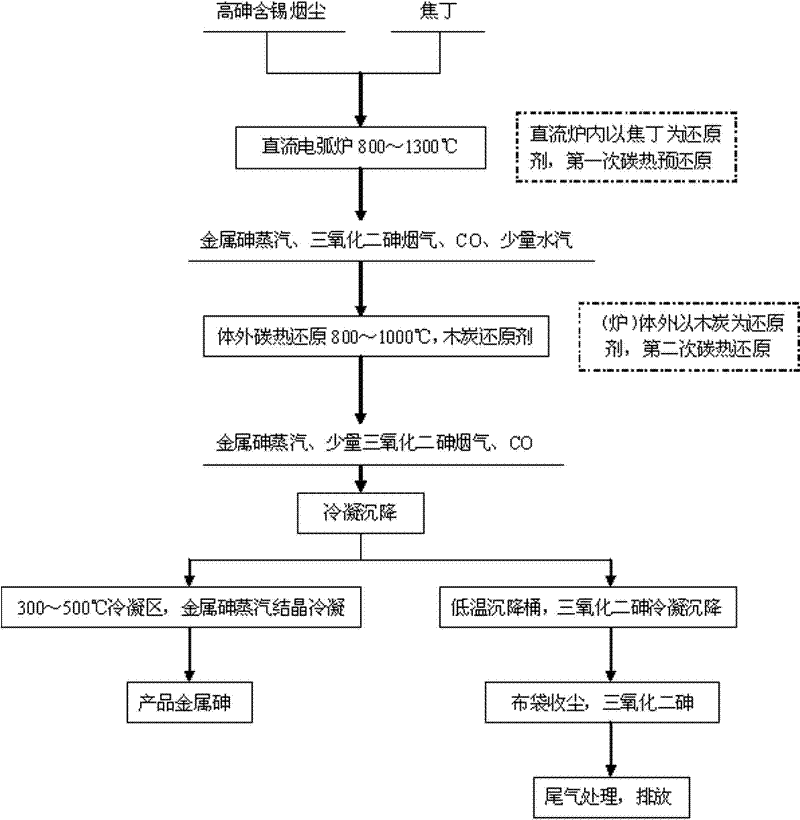

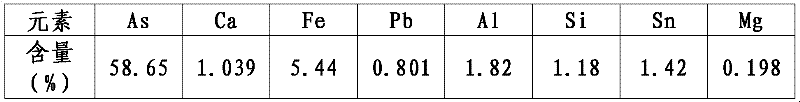

Method for extracting arsenic metal from arsenic trioxide material by two-stage carbon reduction

The invention relates to a method for extracting arsenic metal from arsenic ash by carbon thermal reduction outside a direct current furnace, belonging to the technical field of metallurgy. In the method, arsenic ash or arsenic trioxide is used as a raw material, and nut coke is used as a reducer, wherein the mol ratio of the raw material to the reducer is 1.0:(3.0-5.0). The method comprises the following steps: carrying out first-stage carbon thermal reduction in a closed direct current furnace at 800-1300 DEG C under a pressure of 0-20Pa, thus generating arsenic metal vapor and other flue gas through reduction; introducing the generated arsenic metal vapor and other flue gas into a reduction device which is filled with charcoal and arranged outside the furnace, and carrying out second-stage carbon thermal reduction at 800-1000 DEG C under a pressure of 0-20Pa; and introducing the arsenic metal vapor generated through two-stage reduction into a arsenic metal condensing and settling chamber to obtain arsenic metal blocks, and condensing and settling the arsenic trioxide which is not fully reduced in a settling vat. The method provided by the invention causes less environment pollution, does little harm to the health of operating personnel, and can realize the continuous production in the technical process; and the total reduction rate and purity of the arsenic metal are high.

Owner:YUNNAN TIN GROUP HLDG

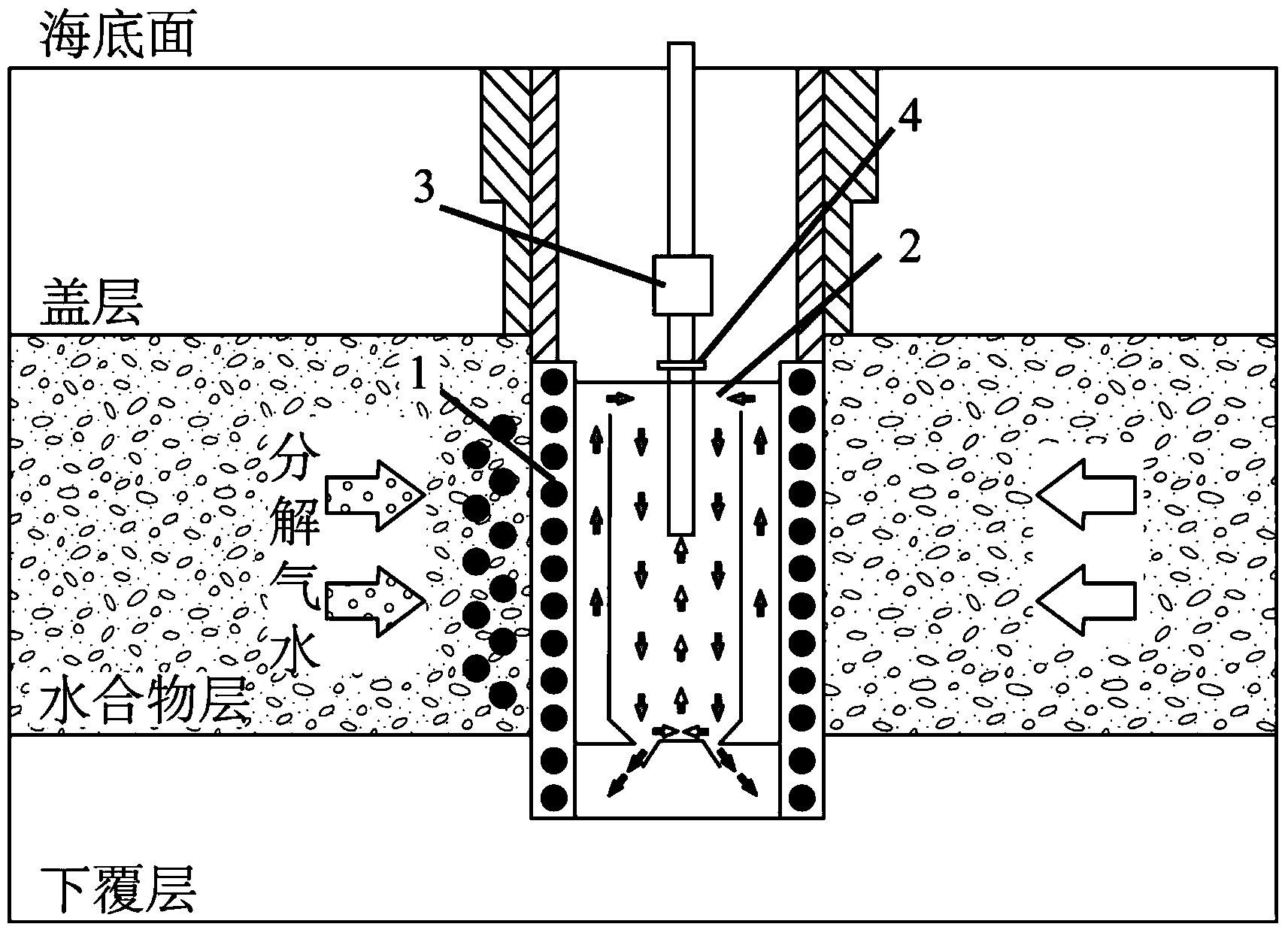

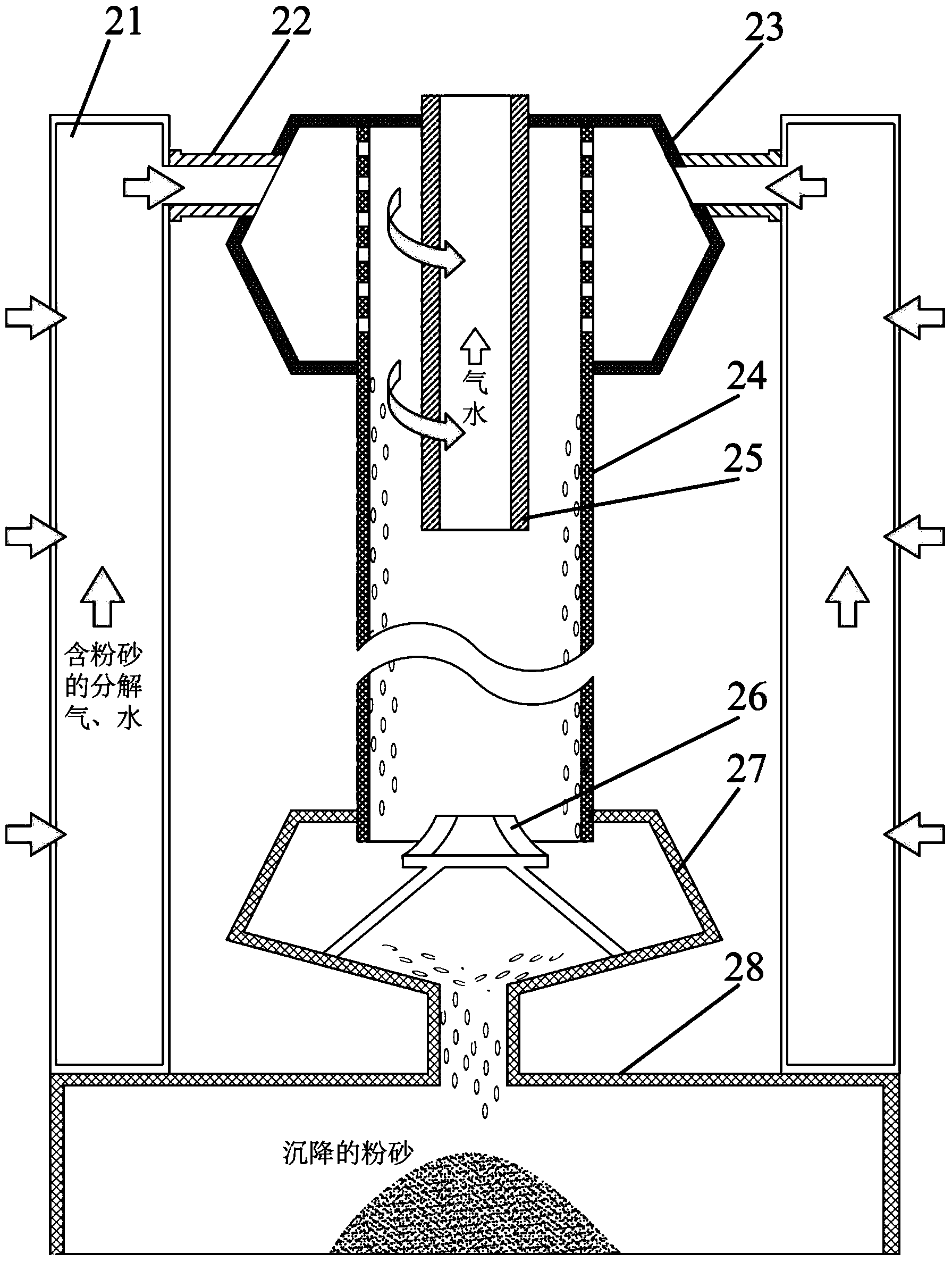

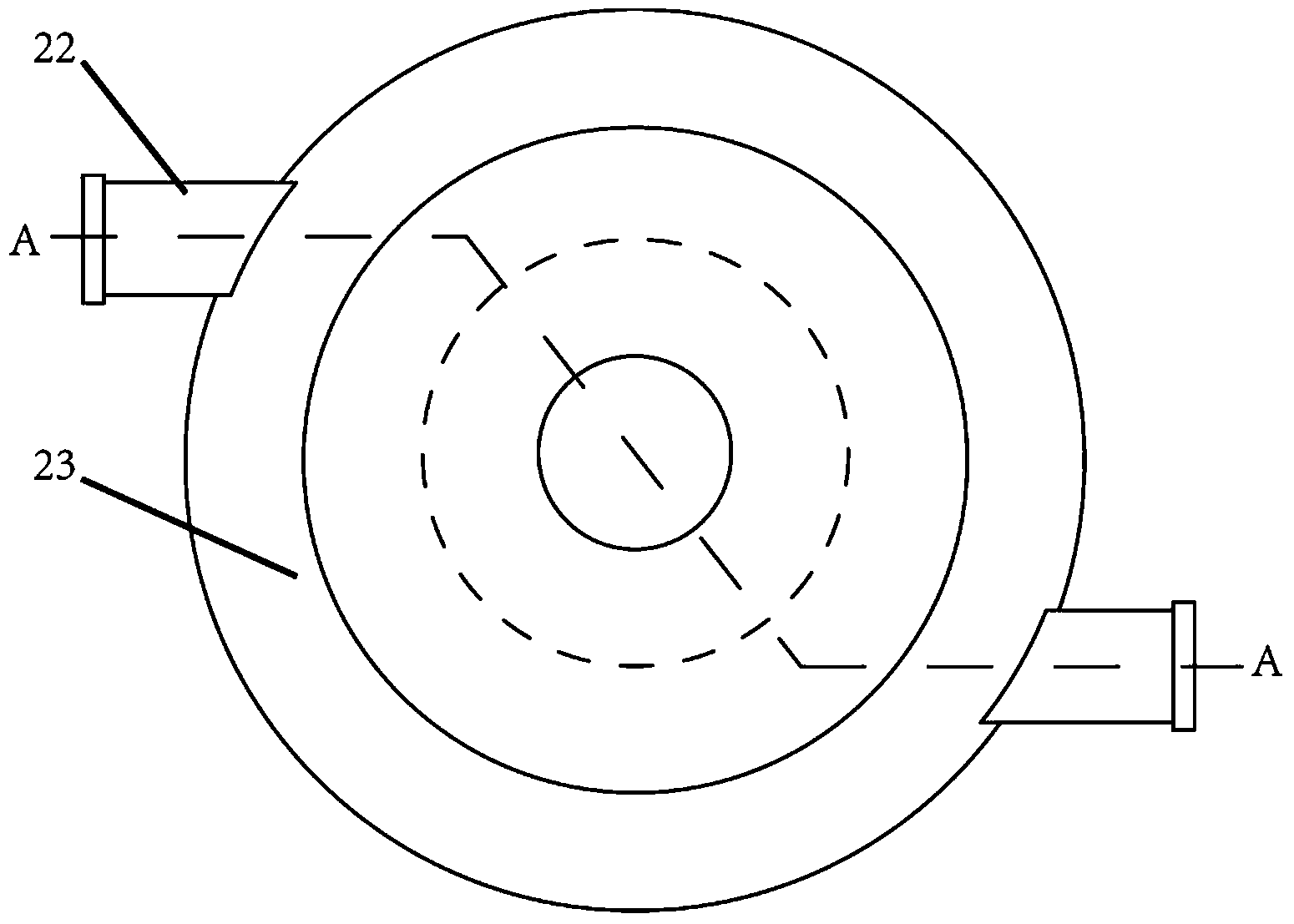

Device and method for desanding of submarine natural gas hydrate exploitation well

ActiveCN103967473ADoes not significantly affect permeabilityAvoid enteringFluid removalDesanderCentrifugal force

The invention provides a device and method for desanding of a submarine natural gas hydrate exploitation well. The device comprises a gravel filling set, a centrifugal desander, a submerged pump and a connecting flange. The gravel filling set is arranged at the bottom of the exploitation well, the centrifugal desander and the submerged pump are connected through the connecting flange and wholly descend to the bottom of the exploitation well, and the outer wall of a flow guide chamber is attached to the inner wall of the gravel filling set. By the adoption of the device, in the centrifugal desanding process, gas-water sand is firstly decomposed and flows to a shaft, large settled layer sand is blocked by the gravel filling set, and gas and water containing fine sand enters the shaft; gas and water containing the fine sand enter an upper collection box through the flow guide chamber and an inflow port, and cyclones are generated; under the effect of centrifugal force, the fine sand is gathered on the inner wall of a settling chamber and descends into a sand collection box. By the adoption of a secondary desanding method, desanding efficiency is improved, and permeability of a hydrate settled layer cannot be remarkably affected; by the adoption of a cyclone centrifugal mode, the fine sand and decomposed gas and water can be effectively separated, the fine sand is prevented from entering the submerged pump, and equipment wear is reduced.

Owner:DALIAN UNIV OF TECH

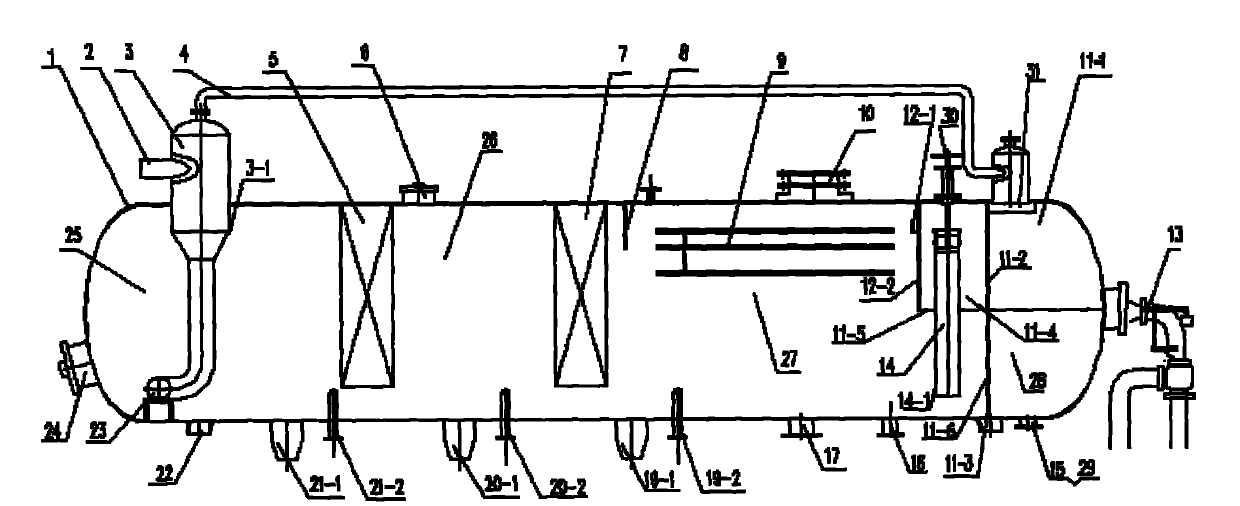

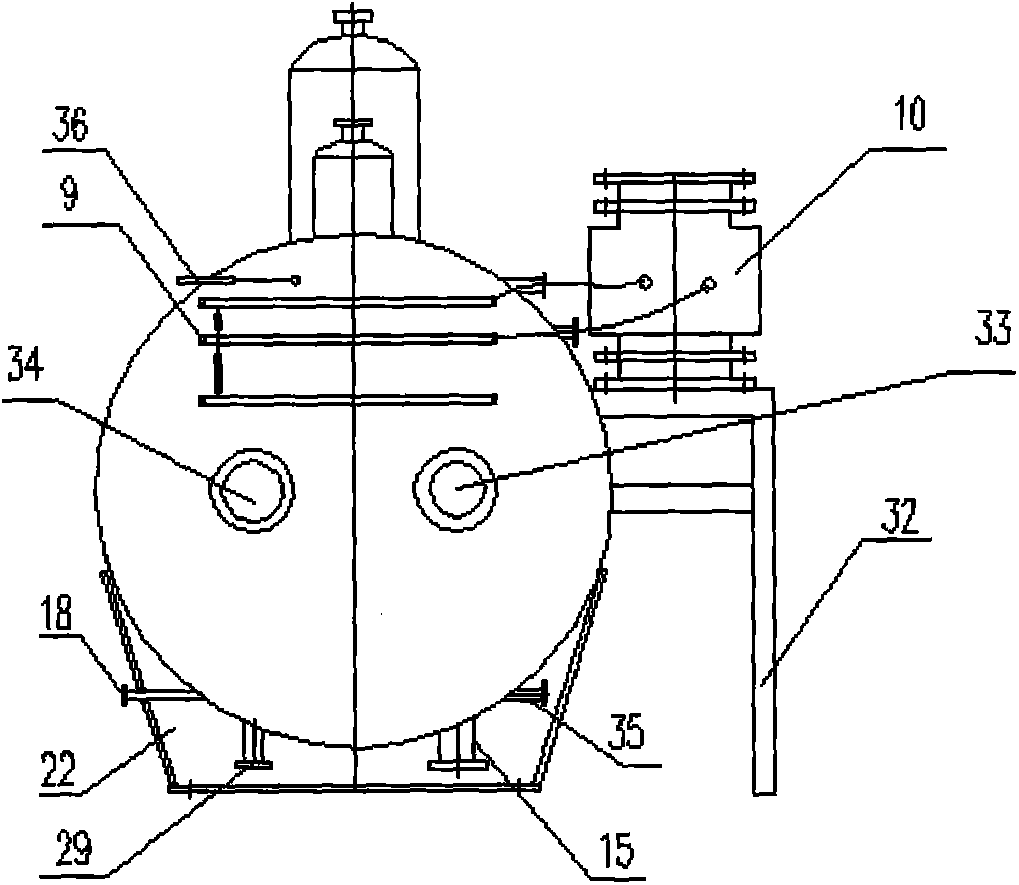

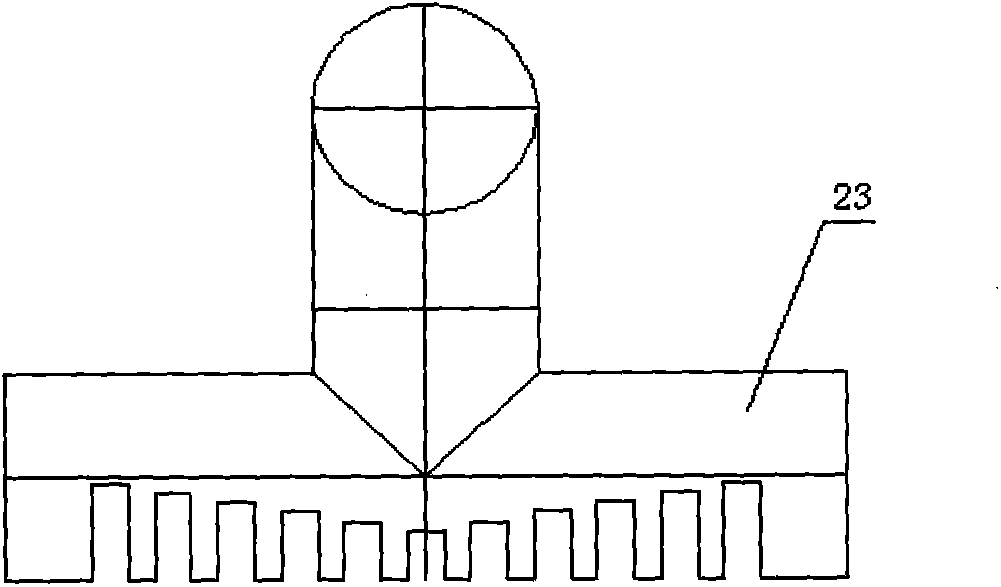

High-frequency electric collective oil-gas-water three-phase flow separator

InactiveCN103695029AEasy to handleOvercome the "inverted electric field" phenomenon that is easy to appearTreatment with plural serial refining stagesWater storageDemulsifier

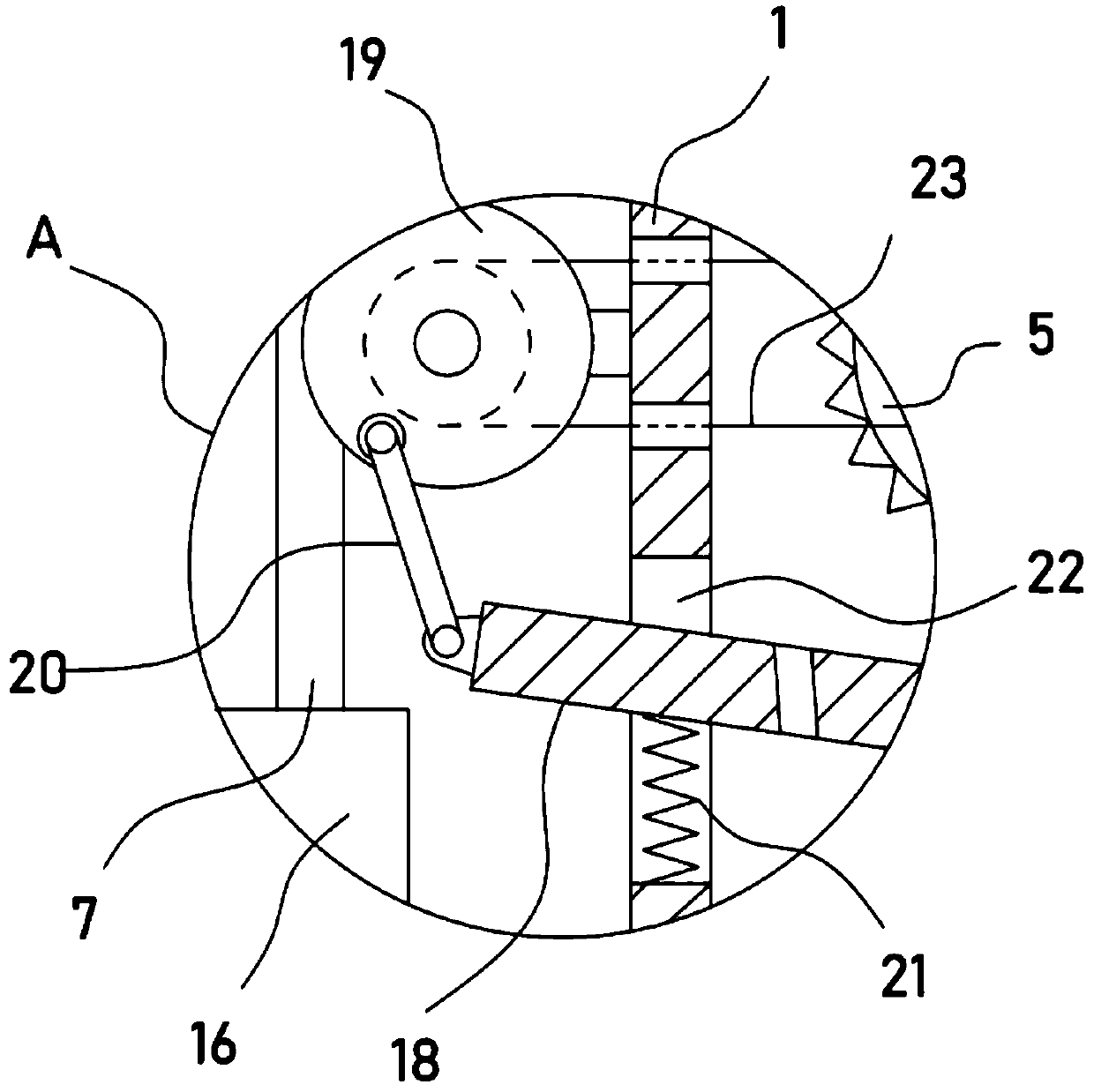

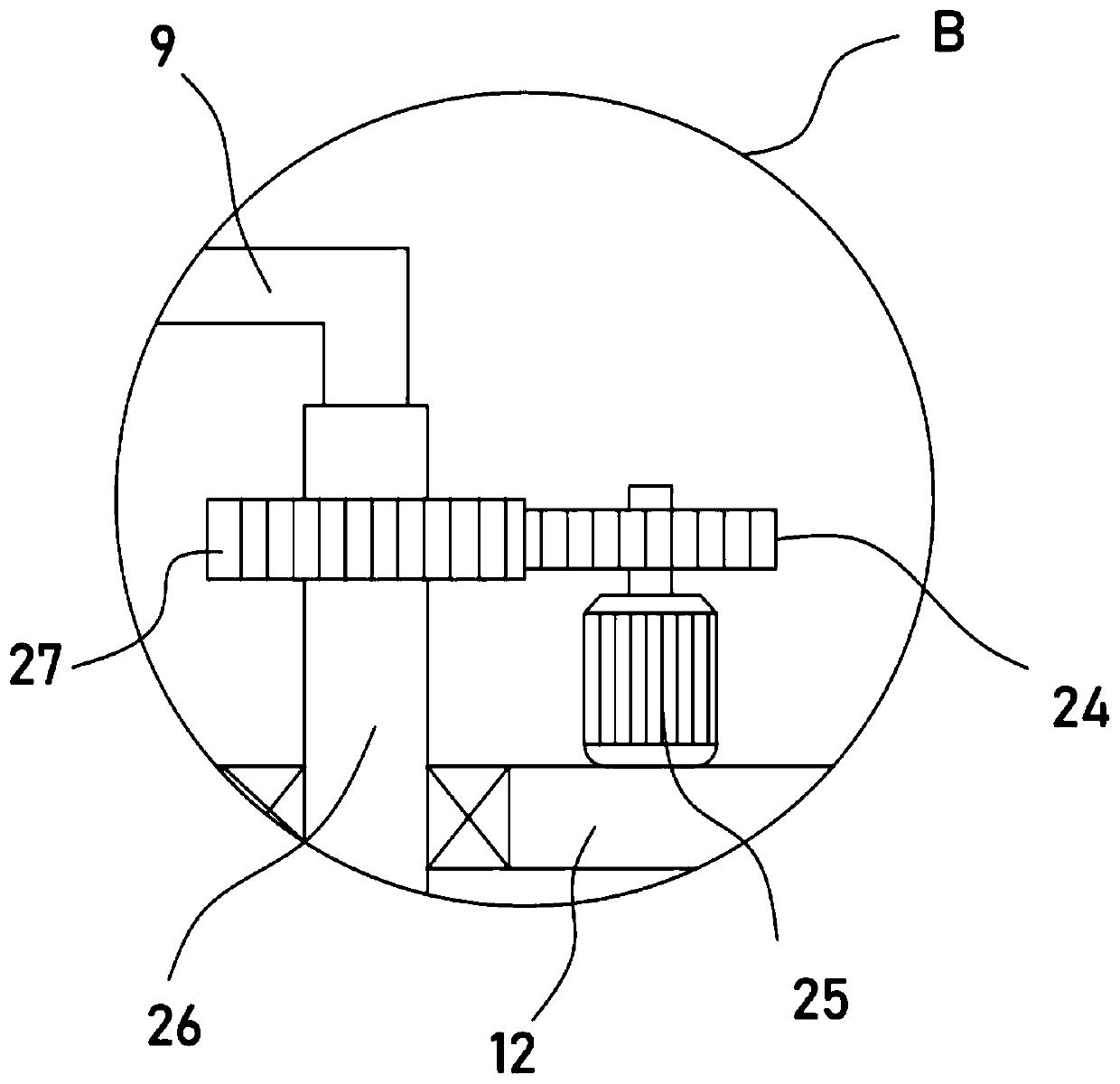

The invention provides a high-frequency electric collective oil-gas-water three-phase flow separator. The separator is composed of a horizontal tank body 1 and a high-frequency rectangular wave crude oil dehydration power supply 10, wherein the horizontal tank body 1 is divided into a primary separation chamber 25, a horizontal settling chamber 26, an electric dehydration chamber 27 and an oil and water storage chamber 28; sand cleaning devices 19, 20 and 21 are arranged at the bottom of the separator; a drain outlet 17 and a water outlet 16 are formed at the bottom of the electric dehydration chamber; and an oil outlet 15 and a water outlet 29 are respectively formed at the bottom of the oil and water storage chamber. The separator disclosed by the invention avoids the 'reserved electric field' phenomenon in the operation of a conventional electric dehydrator, and overcomes the shortcoming of a conventional oil-gas-water three-phase flow separator which is poor in effect; and the separator solves the problem on dehydrating high-water crude oil, ageing oil and crude oil high in the contents of polymer and demulsifier.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Impurity removal filtering device for sewage treatment

InactiveCN107321051AQuality assuranceFacilitate subsequent processingTreatment involving filtrationMultistage water/sewage treatmentFiltrationSewage

The invention discloses a miscellaneous filtering device for sewage treatment, which includes a miscellaneous discharge chamber, a primary sedimentation chamber and a secondary sedimentation chamber, a water inlet pipe is installed above the left end of the miscellaneous discharge chamber, and the waste discharge chamber The middle position of the left side wall of the miscellaneous room is provided with a first motor, and the right end of the first motor is equipped with a first rotating shaft. filter screen, the bottom plane of the miscellaneous room is provided with a miscellaneous bucket, the bottom end of the described miscellaneous bucket is provided with a miscellaneous chamber, and the described primary sedimentation chamber is located on the right side of the miscellaneous room. The miscellaneous room and the primary sedimentation chamber are communicated through the infusion tube, and the top of the primary sedimentation chamber is provided with an auxiliary material box; the beneficial effect of the present invention is: the principle of multi-stage sedimentation is adopted, and the sewage in the upper layer is repeatedly pumped out before being treated. Filtration treatment can fully ensure the quality of sewage after filtration.

Owner:深圳市花蘑菇网络科技有限公司

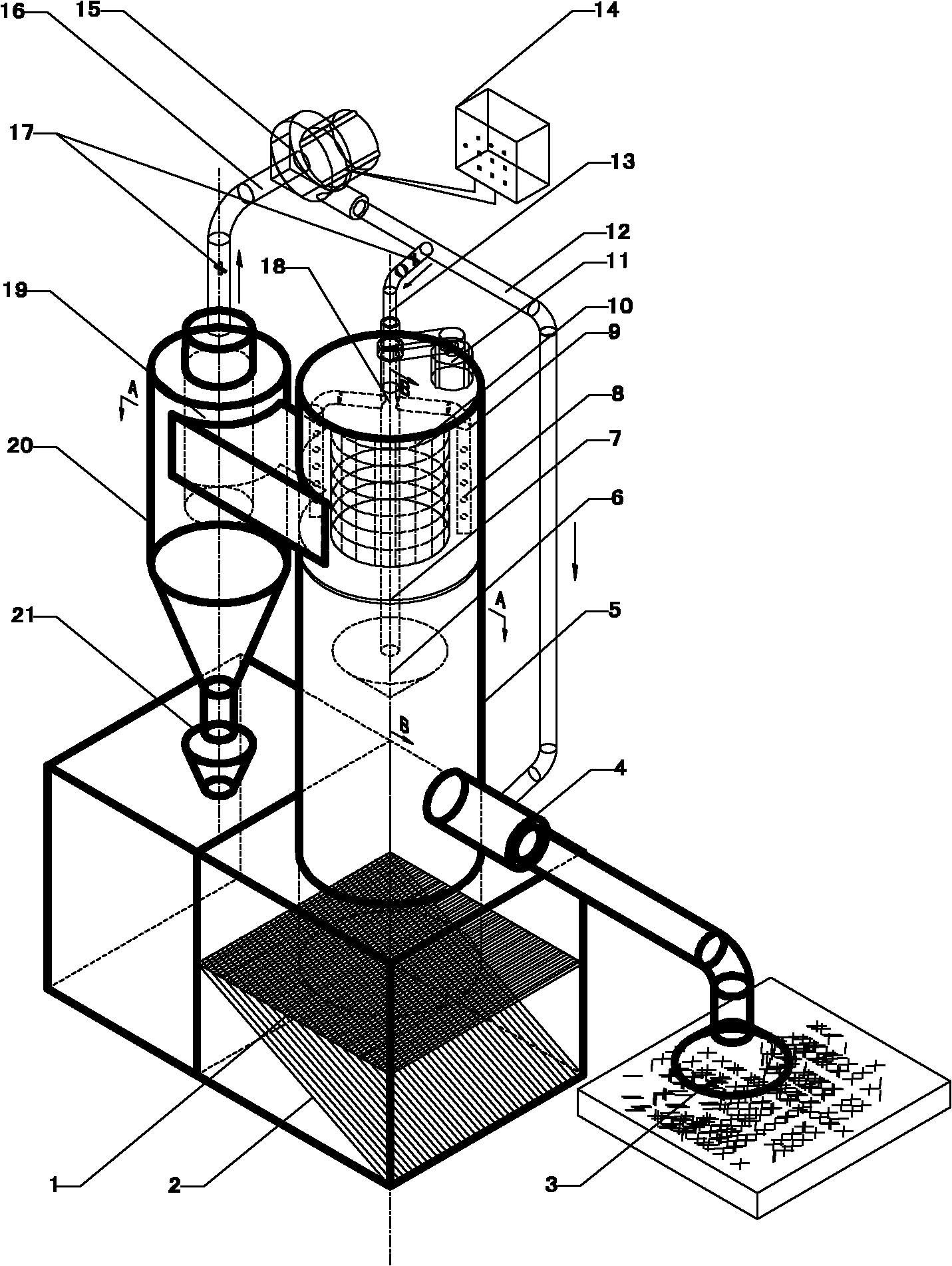

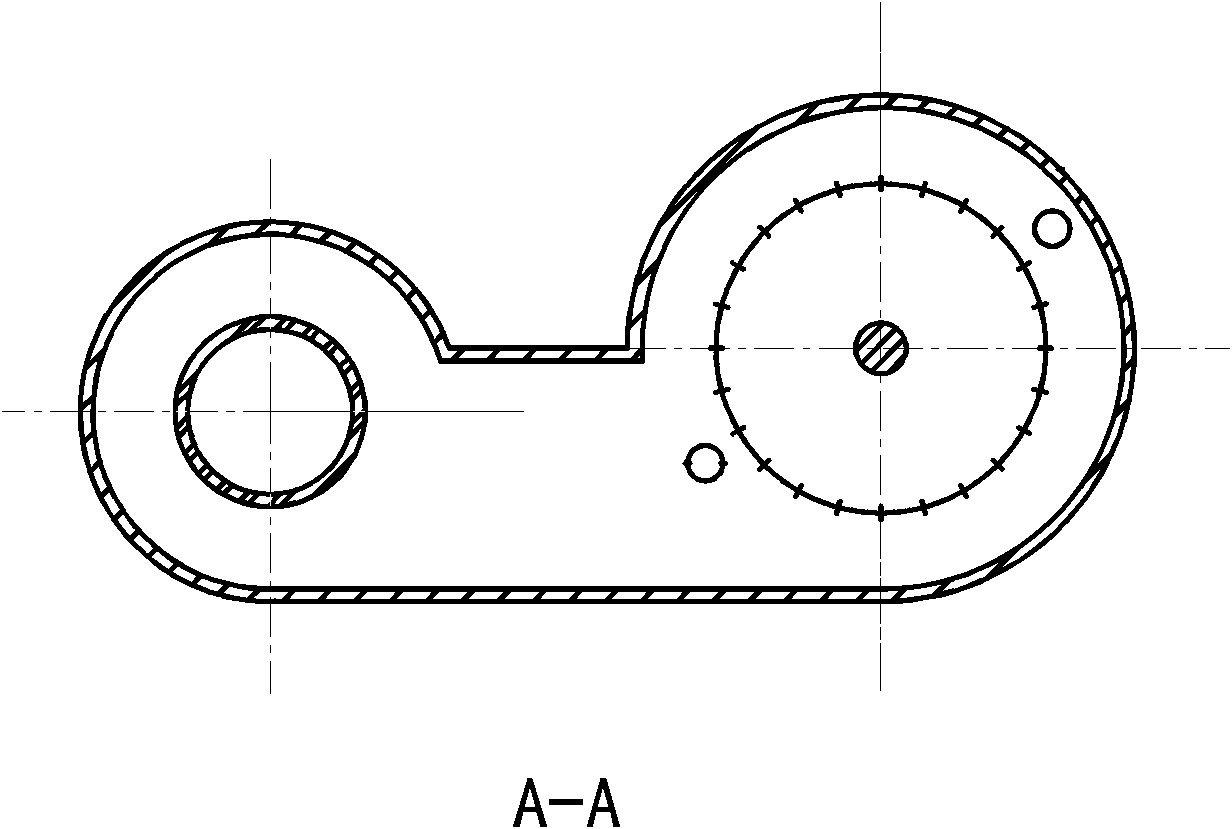

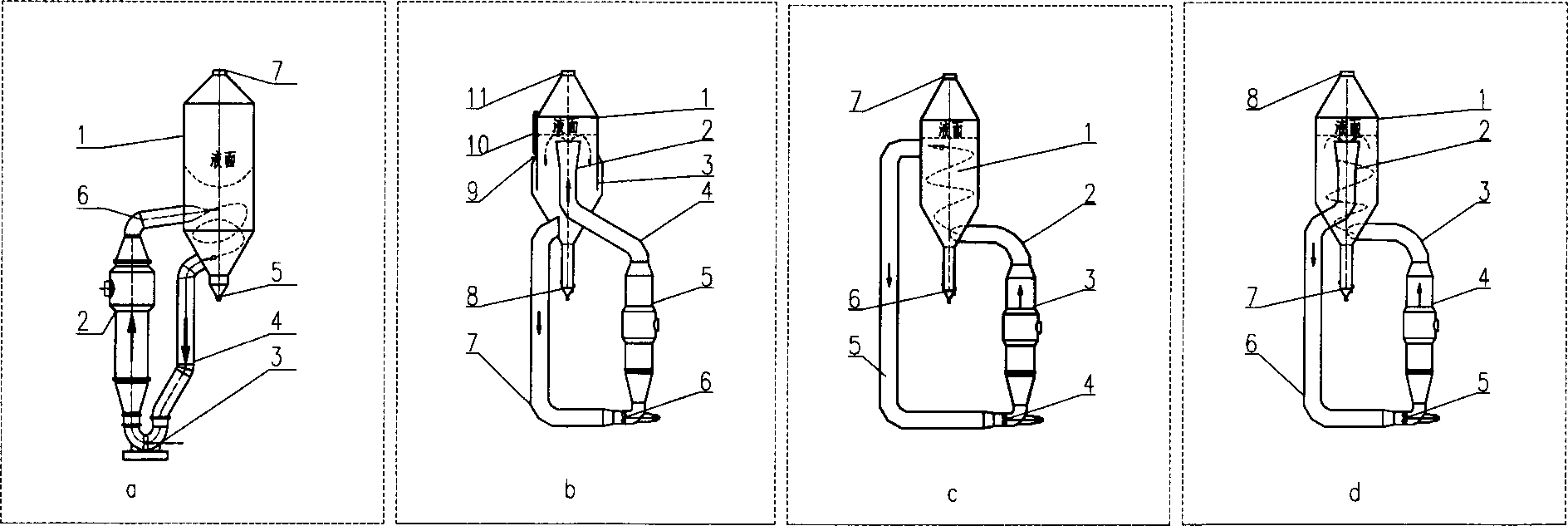

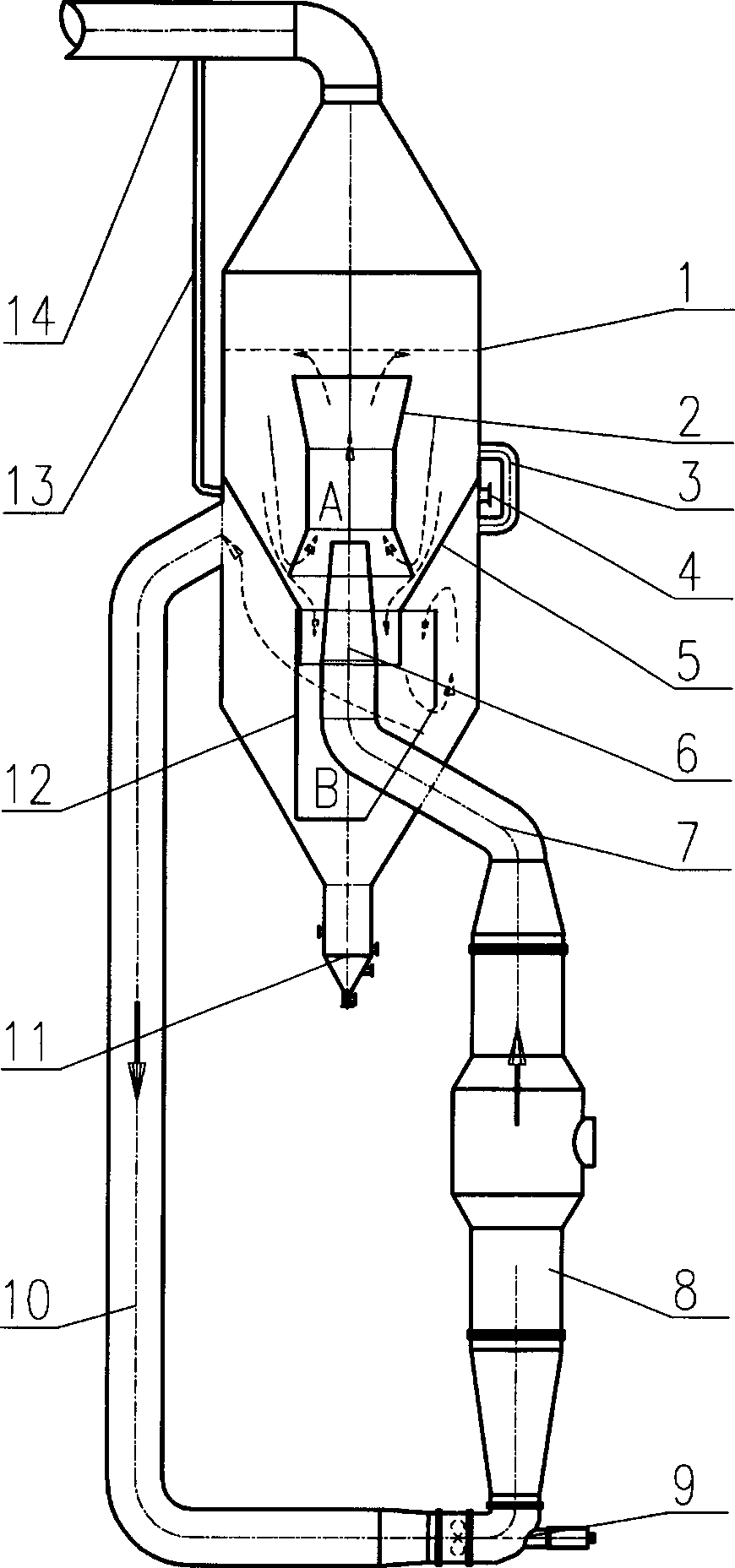

Combined cyclone separation/collection device and method for separating and collecting pollen

The invention discloses a combined cyclone separation / collection device and a method for separating and collecting pollen based on the device. The device comprises a cylindrical settling chamber and a double-cylinder cyclone. The cylindrical settling chamber is down communicated with an umbrella-type taker. The sidewalls of the top of the cylindrical settling chamber are communicated with the outer cylinder of the cyclone. An air duct is arranged outside the cylindrical settling chamber, and is communicated with the cylindrical settling chamber and the inner cylinder of the cyclone, respectively. Besides, the air duct is connected to an external variable frequency fan. A cylinder screen, a reflecting cone and a three-way air blowback pipe are arranged in the inner space of the cylindrical settling chamber. The rotating central shaft of the reflecting cone rotates through connection with an external variable speed motor. A stripper plate and a discharge chute are arranged on the bottom of the cylindrical settling chamber. Furthermore, a pollen collecting chamber is arranged on the bottom of the double-cylinder cyclone. The method comprises the following steps of: suctioning dust-containing pollen by means of an airflow, and filtering the dust-containing pollen; performing separation in the cylindrical settling chamber; and collecting the pollen in the cyclone, and purifying the dust-containing airflow for recycling. The device and the method of the invention are capable of effectively improving the pollen separation / extraction efficiency and preventing dispersion of pollen, and suitable for being popularized and used.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

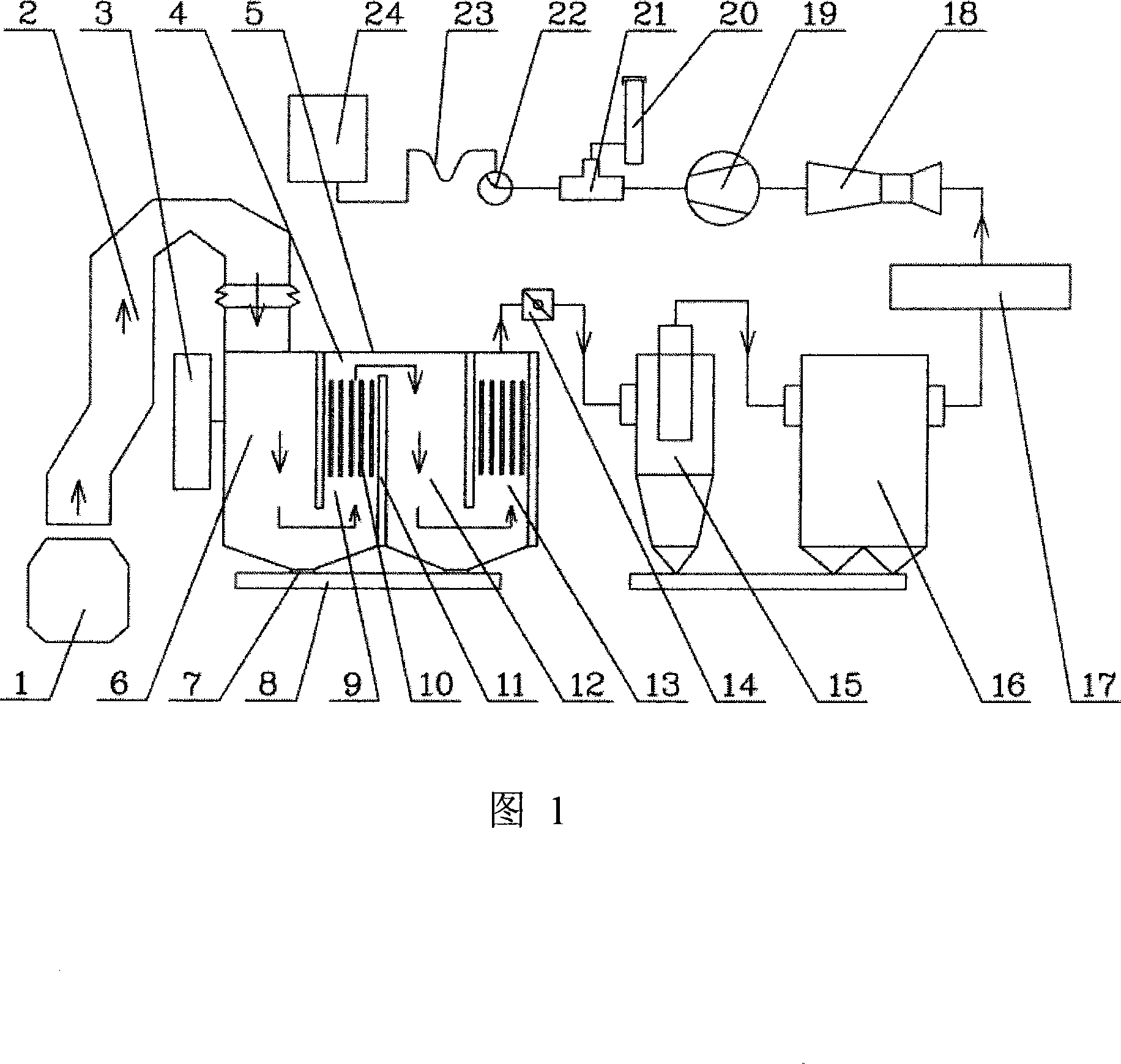

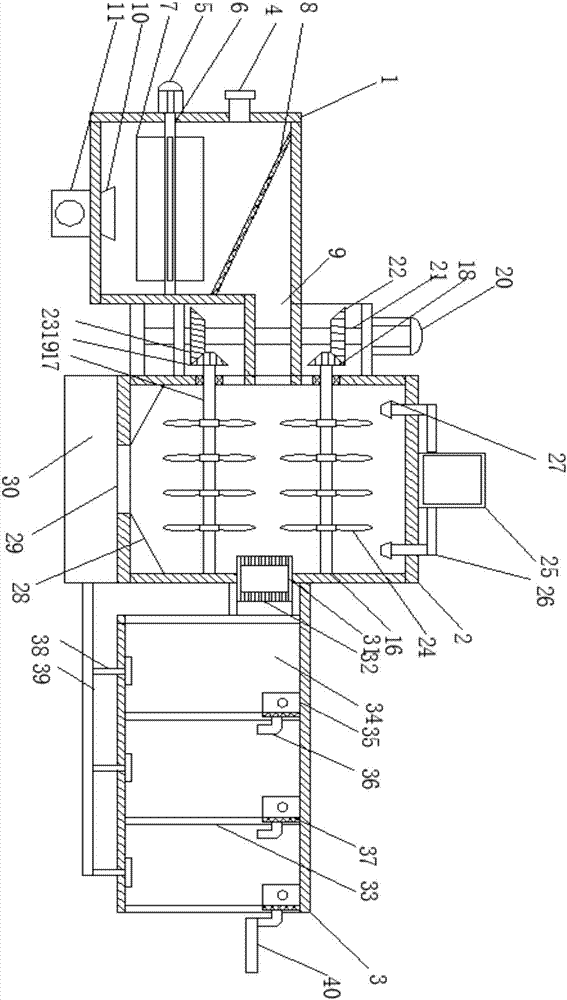

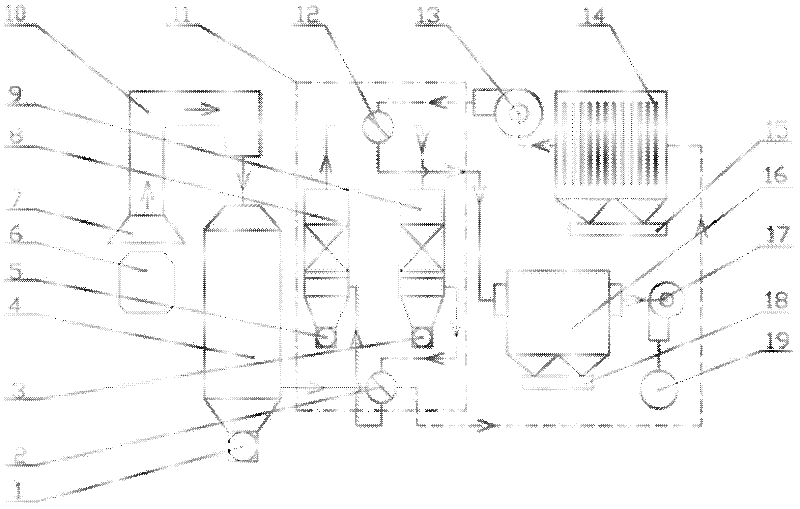

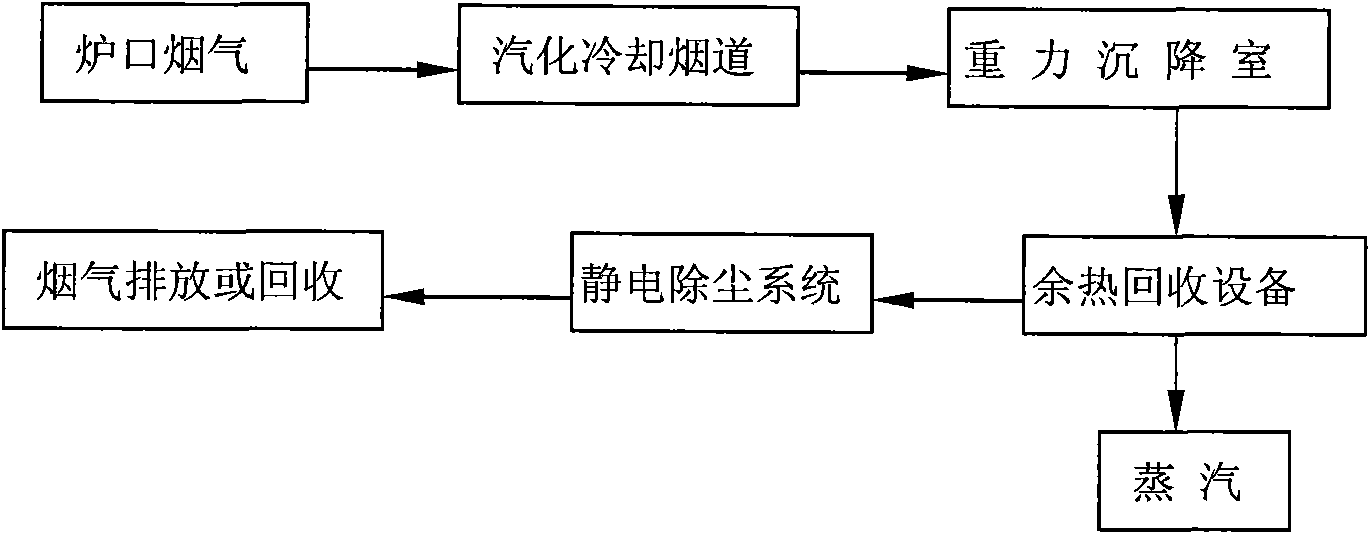

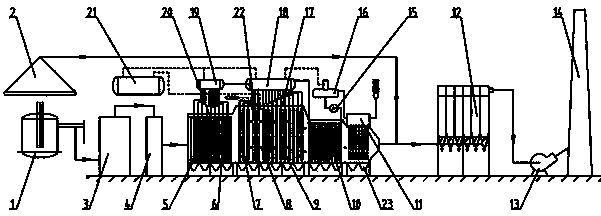

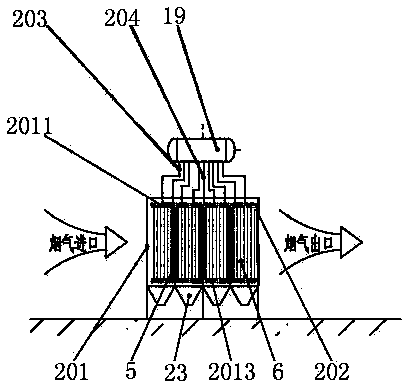

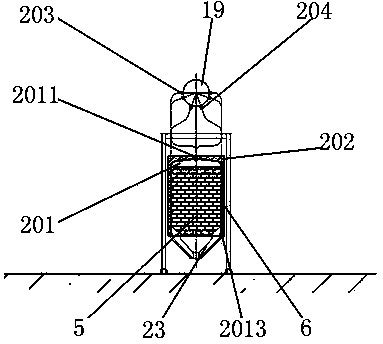

Process and device for recycling flue gas afterheat of electric furnace

ActiveCN102243025AHuge heat exchange area per unit volumeIncrease heat exchange intensityIncreasing energy efficiencyWaste heat treatmentElectric arc furnaceFull recovery

The invention provides a process for recycling flue gas afterheat of an electric furnace. The process comprises the following steps: firstly passing high-temperature flue gas generated by the electric furnace through a flue gas hood and an evaporative cooling flue so as to enter into a burning settling chamber, introducing the discharged flue gas into a heat accumulating type rapid cooling device, changing the working conditions of two heat accumulating units (A and B) of the heat accumulating type rapid cooling device periodically, introducing the flue gas into a bag-type dust collector for dedusting, and then discharging the processed flue gas into the atmosphere through a draft fan and a chimney. The invention provides a device for recycling flue gas afterheat of the electric furnace. The device mainly comprises the hood, a flue, the burning settling chamber, a flue gas inlet, a flue gas outlet, a circulating inlet, a circulating air outlet, a circulating fan, a convection type afterheat boiler, the bag-type dust collector, the draft fan and the chimney, and is characterized in that the heat accumulating type rapid cooling device is installed on the back of the burning settling chamber, mainly consists of a heat transfer unit A and a heat transfer unit B which are provided with honeycomb ceramic heat accumulators, and has two operating modes. The process and device for recycling the flue gas afterheat of the electric furnace have the advantages of realizing full recovery of low-temperature flue gas afterheat, simultaneously avoiding the new synthesis of dioxin, and realizing the standard flue gas emission.

Owner:北京中冶设备研究设计总院有限公司

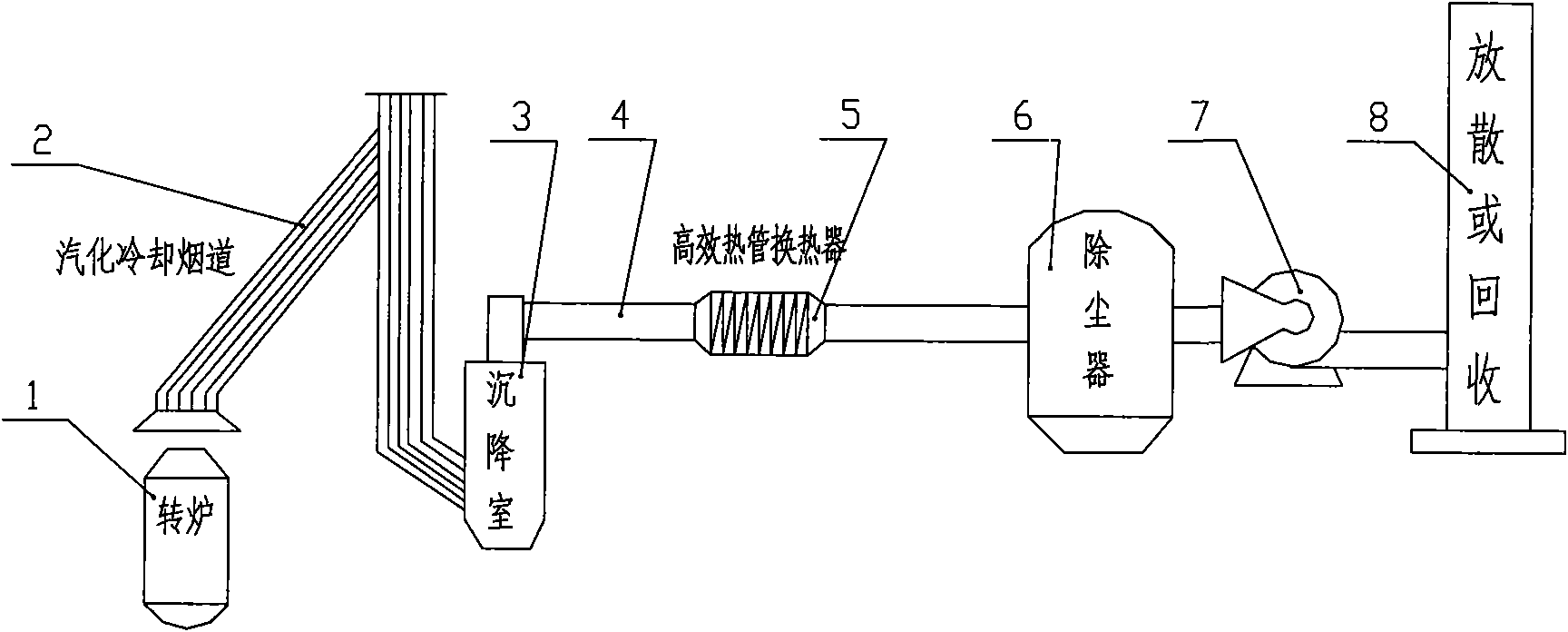

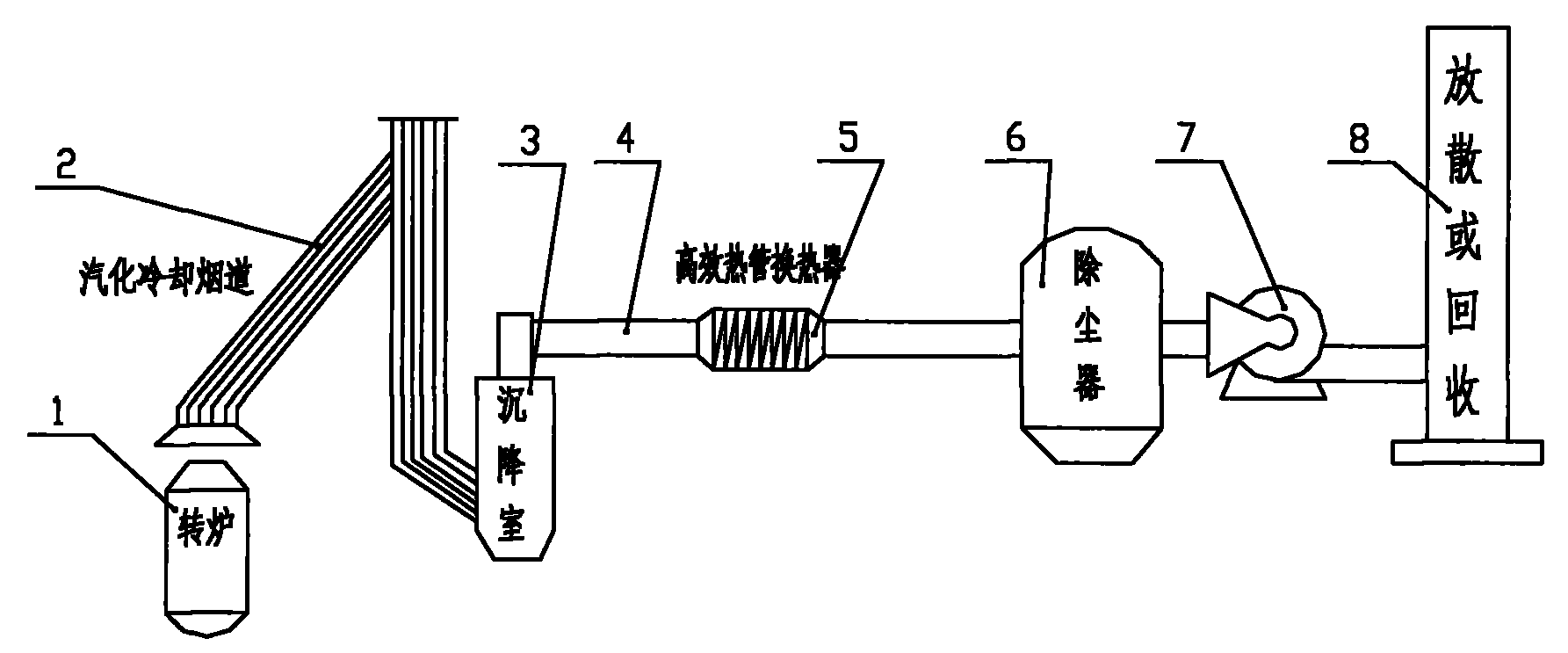

Device and method for removing dust from converter smoke by dry method and recycling waste heat

InactiveCN101875992AImprove heat transfer efficiencyReduce resistanceManufacturing convertersWaste heat treatmentTowerGas chamber

The invention discloses a device and a method for removing dust from converter smoke by a dry method and recycling waste heat and belongs to the technical field of comprehensive utilization of the converter smoke. The device comprises a converter, a vaporizing and cooling flue, a gravity settling chamber, a flue, a heat exchanger, an electrostatic dust remover, an axial flow fan and a smoke diffusing tower or a gas chamber, wherein the gravity settling chamber is connected with the converter through the vaporizing and cooling flue and is connected with an efficient heat pipe exchanger through the flue; the heat exchanger is connected with the electrostatic dust remover through the flue; the electrostatic dust remover is connected with the axial flow fan through the flue; the axial flow fan is connected with the smoke diffusing tower or the gas chamber through the flue; and the lower ends of the gravity settling chamber, the efficient heat pipe exchanger and the static dust remover are all provided with an ash discharge port. The device and the method are suitable for all converters and have the advantages of improving the dust removing effect compared with the OG method, making the emission index of smoke concentration lower than 20 mg / m<3>, greatly saving the cooling water and recycling a large amount of physical heat of the smoke.

Owner:CENT IRON & STEEL RES INST

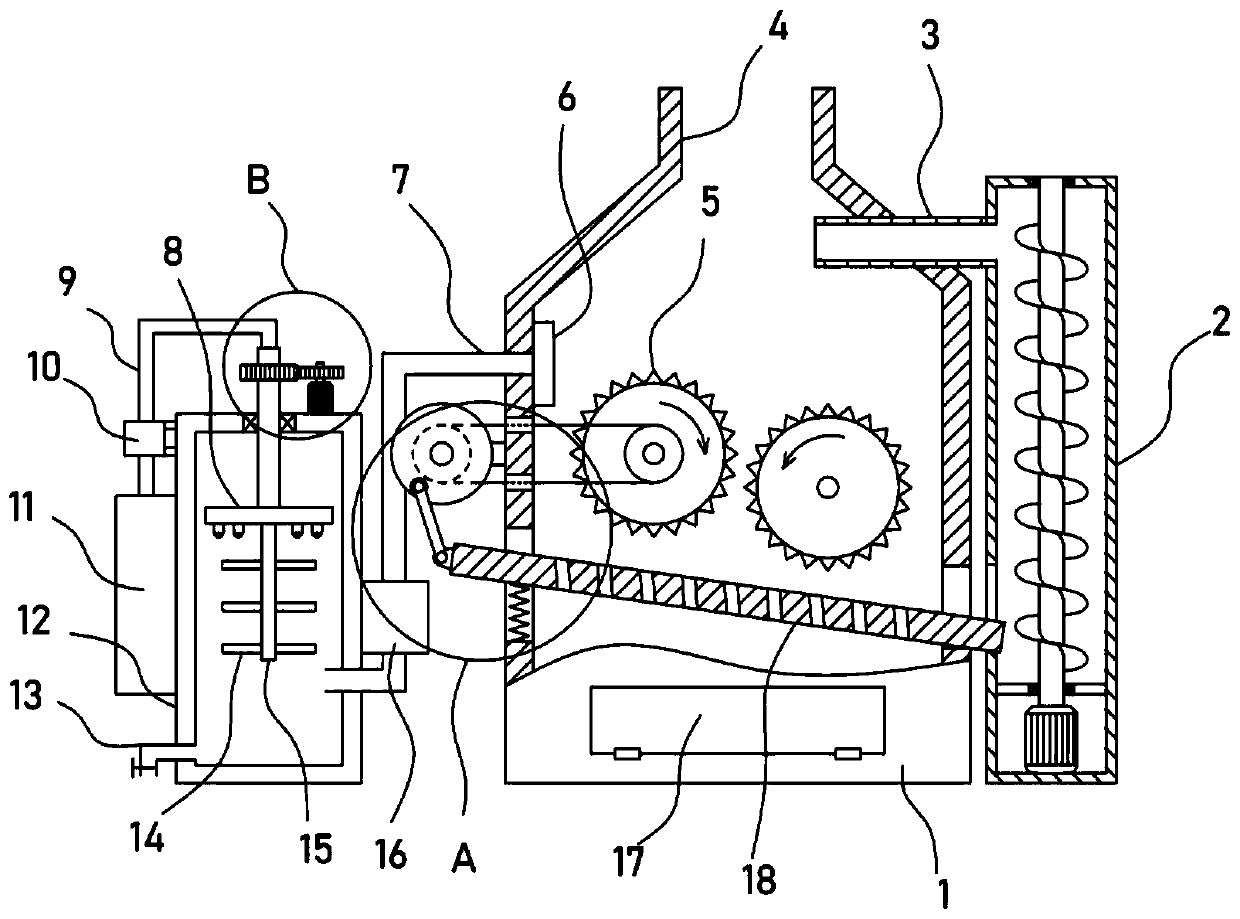

Environment-friendly dust falling type building garbage breaking device

InactiveCN110215956AAchieve repeated crushing effectReduce pollutionUsing liquid separation agentGrain treatmentsArchitectural engineeringEngineering

The invention discloses an environment-friendly dust falling type building garbage breaking device and relates to the technical field of environment-friendly buildings. The environment-friendly dust falling type building garbage breaking device comprises a breaking chamber with a feeding pipe arranged on the top. Two breaking rollers are rotationally arranged in the breaking chamber. A settling chamber communicating with the breaking chamber is arranged on the side of the breaking chamber. A lifting auger vertically arranged communicates with the breaking chamber. A circulation pipe is arranged between the upper side wall of the lifting auger and the breaking chamber in a communication manner. By means of the environment-friendly dust falling type building garbage breaking device, the arranged breaking rollers rotate so that building garbage can be sufficiently broken, the building garbage can be cycled through the lifting auger, a repeated breaking effect of the breaking rollers is achieved, the breaking process is more efficient and more thorough, dust generated in the breaking process can enter the settling chamber in time and can be combined with sprinkling water after being stirred through a dispersing rod, a fast and efficient dust falling effect is achieved, dust pollution generated in the building garbage breaking process is greatly reduced, and the environment-friendlydust falling type building garbage breaking device is very environment-friendly.

Owner:陈莹

Evaporating crystallizer

ActiveCN103071310AExtended routeExtended stayEvaporationSolution crystallizationEconomic benefitsEngineering

The invention relates to an evaporating crystallizer which comprises an evaporating chamber, a center drainage cylinder, an evaporating chamber inner cone, a clear liquid transfer pipe, a crystal cultivation settling chamber baffling cylinder, an upper circulation pipe, an outer circulation feed nozzle, a heating chamber, a lower circulation pipe, a forced circulation pump, a salt foot, a secondary steam pipe and a steam discharge pipe. Outer circulation of the evaporating crystallizer are formed by the evaporating chamber, the upper circulation pipe, the heating chamber, the forced circulation pump and the lower circulation pipe; and inner circulation of the evaporating crystallizer is formed by the center drainage cylinder, the evaporating chamber inner cone and the crystal cultivation settling chamber baffling cylinder. With the adoption of the evaporating crystallizer, salt crystals with large particle sizes and high purity can be produced, energy consumption per unit product is further reduced, the normal production cycle is prolonged, and the comprehensive economic benefit is increased.

Owner:江苏苏盐井神股份有限公司

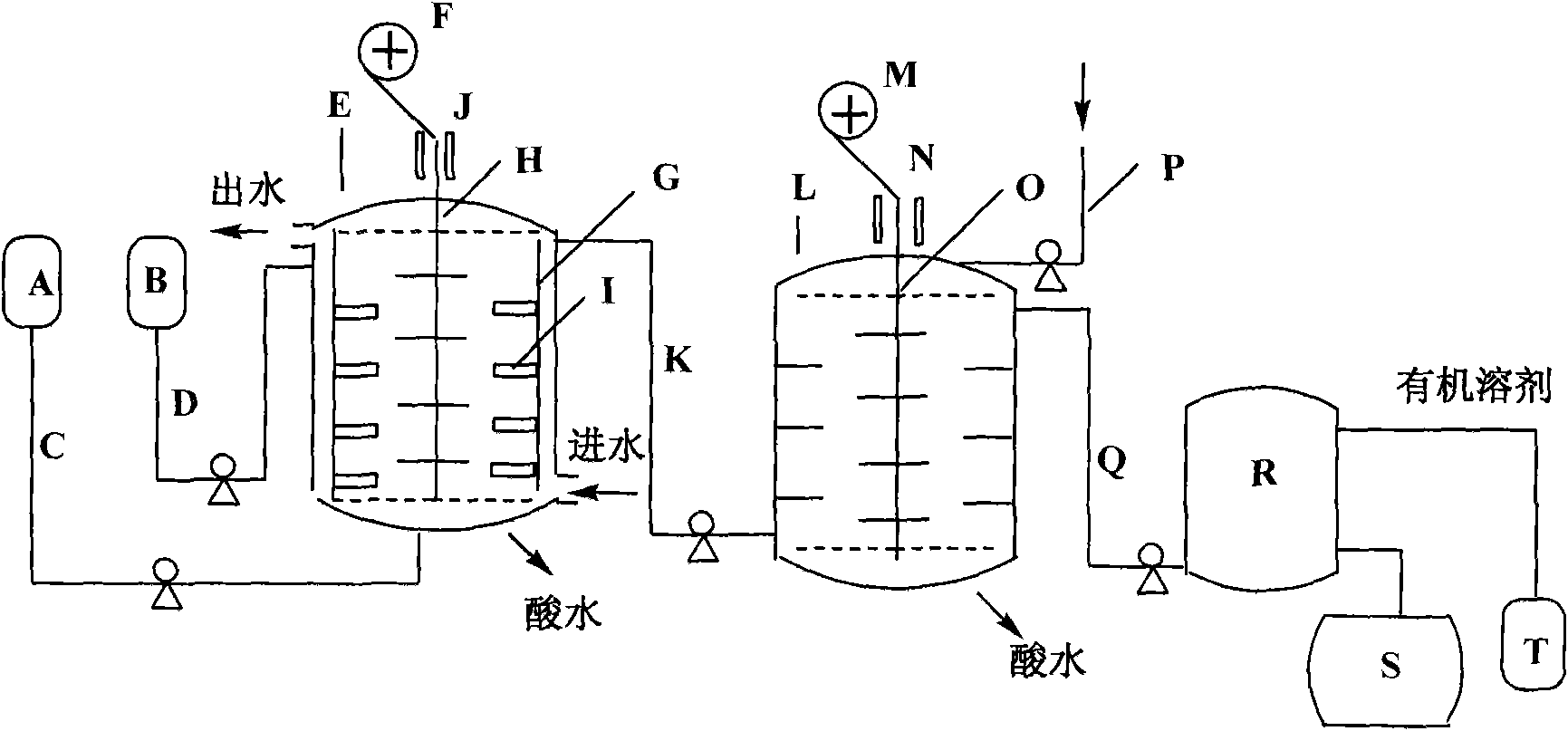

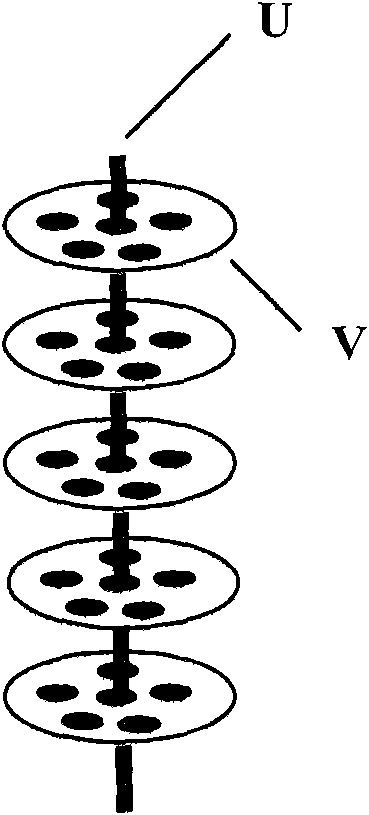

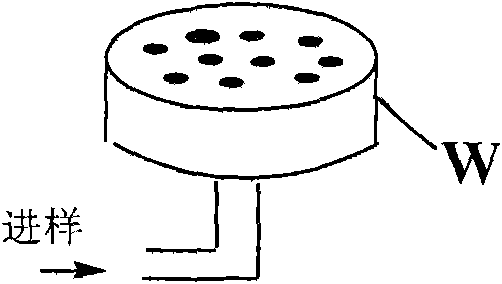

Alkyl silicone continuous production system and production method

The invention relates to an alkyl silicone continuous production system and a production method thereof. The production system comprises a reaction still and a washer; a first reciprocating sieve plate and a second reciprocating sieve plate are respectively arranged in the reaction still and the washer and driven to reciprocate by a motor and an eccenter; a conduit is connected between the reaction still and the washer, a tap water input conduit is arranged on the top of the washer and a water outlet is arranged at the bottom of the washer; alkylsilanol solution flows into the bottom of the washer through a conduit, and a conduit is arranged between the washer and a vacuum distillation tower; the vacuum distillation tower is communicated with a product storage pot through a conduit. The production method includes that alkylchlorosilane reactant solution and hydrolysate are prepared; alkylchlorosilane is hydrolyzed under 1-25 DEG C, the hydrolyzed silanol solution is separated from a settling chamber on the top of the washer, washed in the washer and conducted to the washer bottom through a flowmeter by 0.1-1.0 cubic meters per hour; water is sent in from the washer top through the flowmeter by 0.2-5.0 cubic meters per hour; the silanol solution is washed in countercurrent until the pH value is 6.5-7 and then condensed in vacuum to become alkyl silicone.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Biomass carbonization device

InactiveCN103254917AQuality improvementAvoid Hygroscopic ReactionBiofuelsEnergy inputAir preheaterAutomatic control

The invention relates to a biomass carbonization device, which mainly includes: a combustion chamber, a feed transmission belt, a biomass stock bin, a flash dryer, a flue gas outlet, a heat pipe air preheater, a hollow screw shaft with a heat accumulator, an upper sleeve, a lower sleeve, a biomass charcoal transmission belt, a pipeline, a spraying settling chamber, an oil separation pool, a carbonization chamber and auxiliary equipment. The device can realize comprehensive utilization of biomass carbonization products, and can realize co-production of biomass charcoal and bio-oil. At the same time, by adopting a circulating heat exchanger repeatedly, the emptied gas can have a low temperature, and the energy loss can be substantially reduced. The design of the hollow screw shaft with the heat accumulator realizes staged carbonization and combustion, thus improving the carbonization efficiency. The biomass carbonization device provided in the invention has the advantages of little pollution, high carbonization efficiency, good production environment, etc., and can achieve automated control. The biomass carbonization device is applicable to carbonization of straws, rice husks, sawdust, peanut shells and other biomass, and is suitable for rural families.

Owner:HEFEI UNIV OF TECH

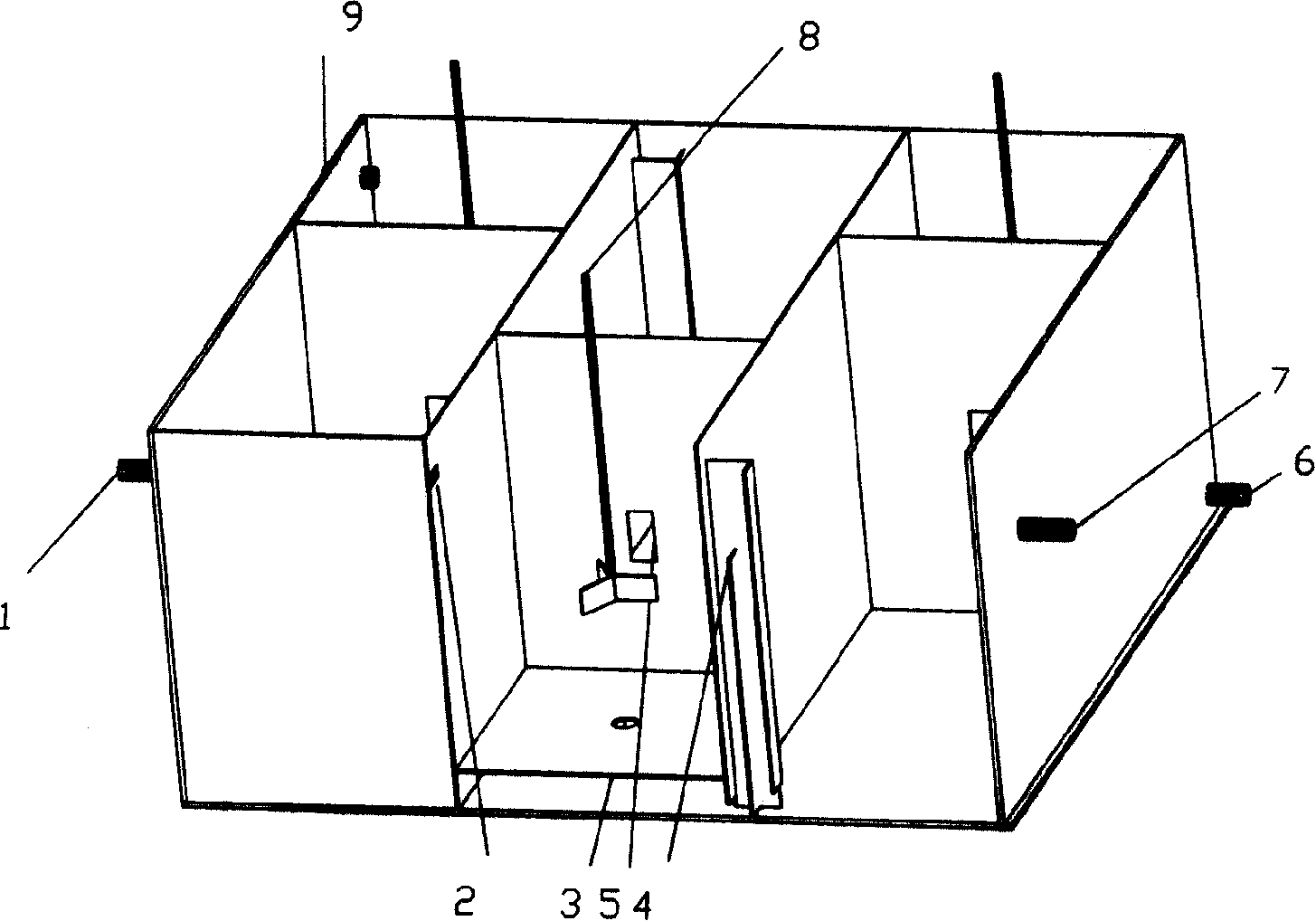

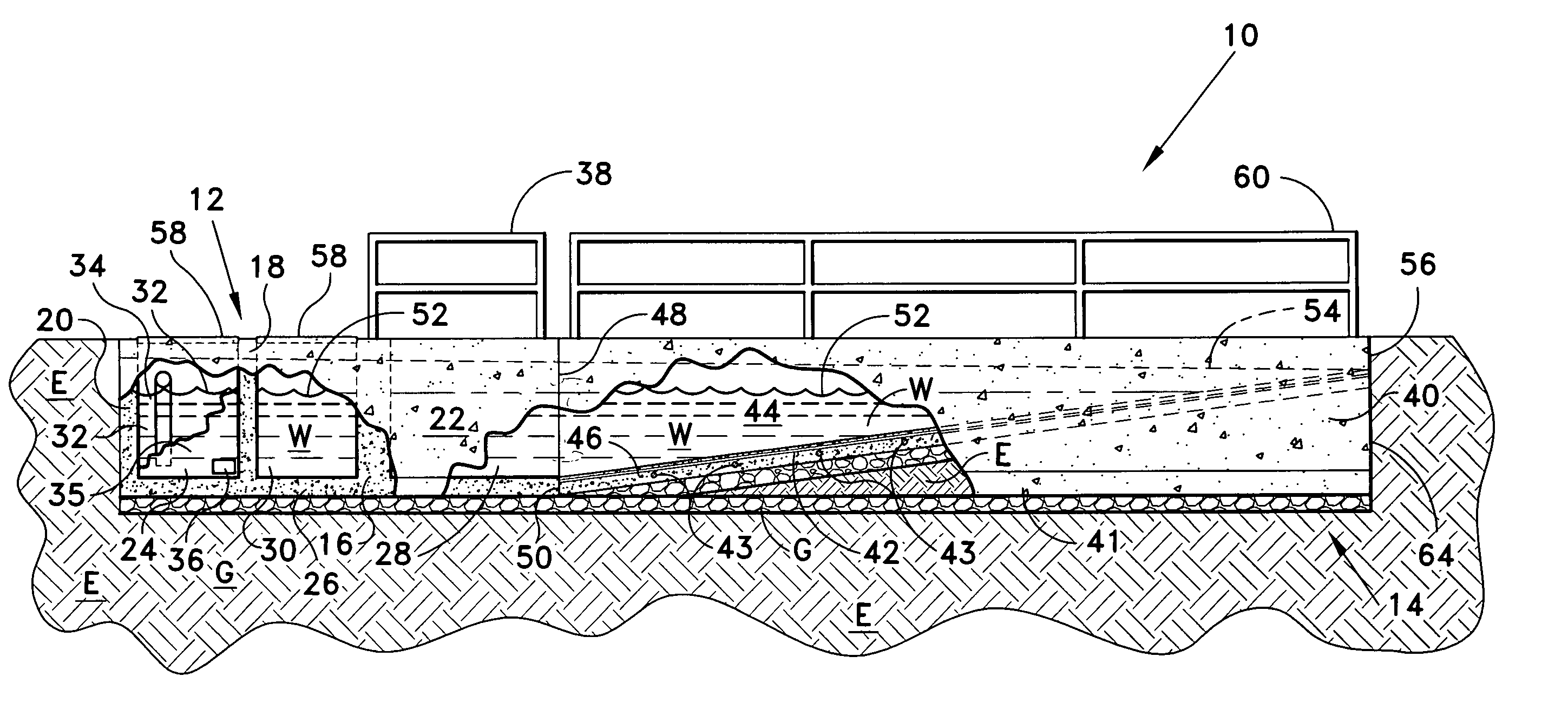

Stormwater plug flow separation system

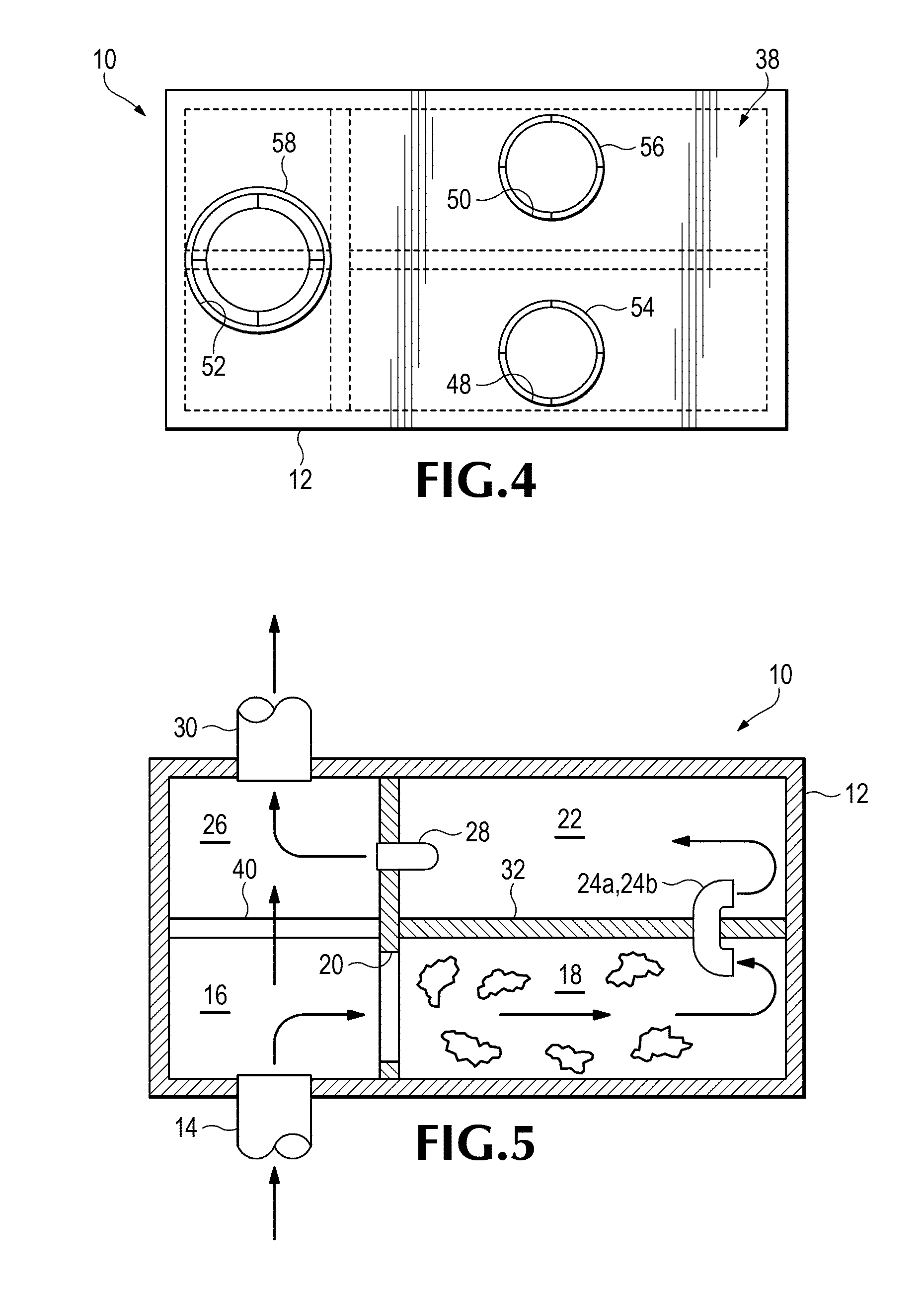

ActiveUS7892425B2Water cleaningFatty/oily/floating substances removal devicesStormwaterSeparation system

A water separation system includes a flow container includes a water inlet pipe; an inlet chamber in fluid communication with the water inlet pipe; a first settling chamber configured to settle grit and to float oil; an elevated, horizontally-oriented, elongate-rectangular water treatment flow inlet leading from the inlet chamber to the first settling chamber; a second settling chamber configured to settle solids; one or more plug flow conduits leading from the first settling chamber to the second settling chamber; an outlet chamber; an elevated treatment flow outlet disposed between the second settling chamber and the outlet chamber; a water outlet pipe in fluid communication with the outlet chamber; and an overflow mechanism disposed between the inlet chamber and the outlet chamber.

Owner:NEWTERRA CORP INC

Decontamination equipment for exhaust gas

A waste gas cleaning apparatus for removing water-soluble toxic substances and dust is composed of an atomizing chamber containing water, atomizing unit on it wall, blade wheels and airflow guiders, a settling chamber with water outlet and gas outlet, and perforated partition between said two chambers.

Owner:沈福昌

Method of and apparatus for cleaning runoff water

Runoff water from parking lots and filling stations is cleaned by first passing via an inlet pipe tangentially into a vortex chamber where the swirling action separates the contaminants from the water. Floating contaminants are stored in the vortex chamber, trapped at the top of the chamber by the roof of that chamber and at the lower part of the chamber by a skirt. That roof has an access opening to permit removal of the floating contaminants. The body of the fluid thereafter moves downward into a settling chamber where heavier-than-water contaminants settle. As the fluid in the settling chamber builds up, it passes through cleaning screens to a clean water outlet. A by-pass overflow pipe to process very large volumes of water extends upward from the settling chamber. Each screen may have louvers for preventing contaminants from blocking the screen.

Owner:PANK THOMAS E

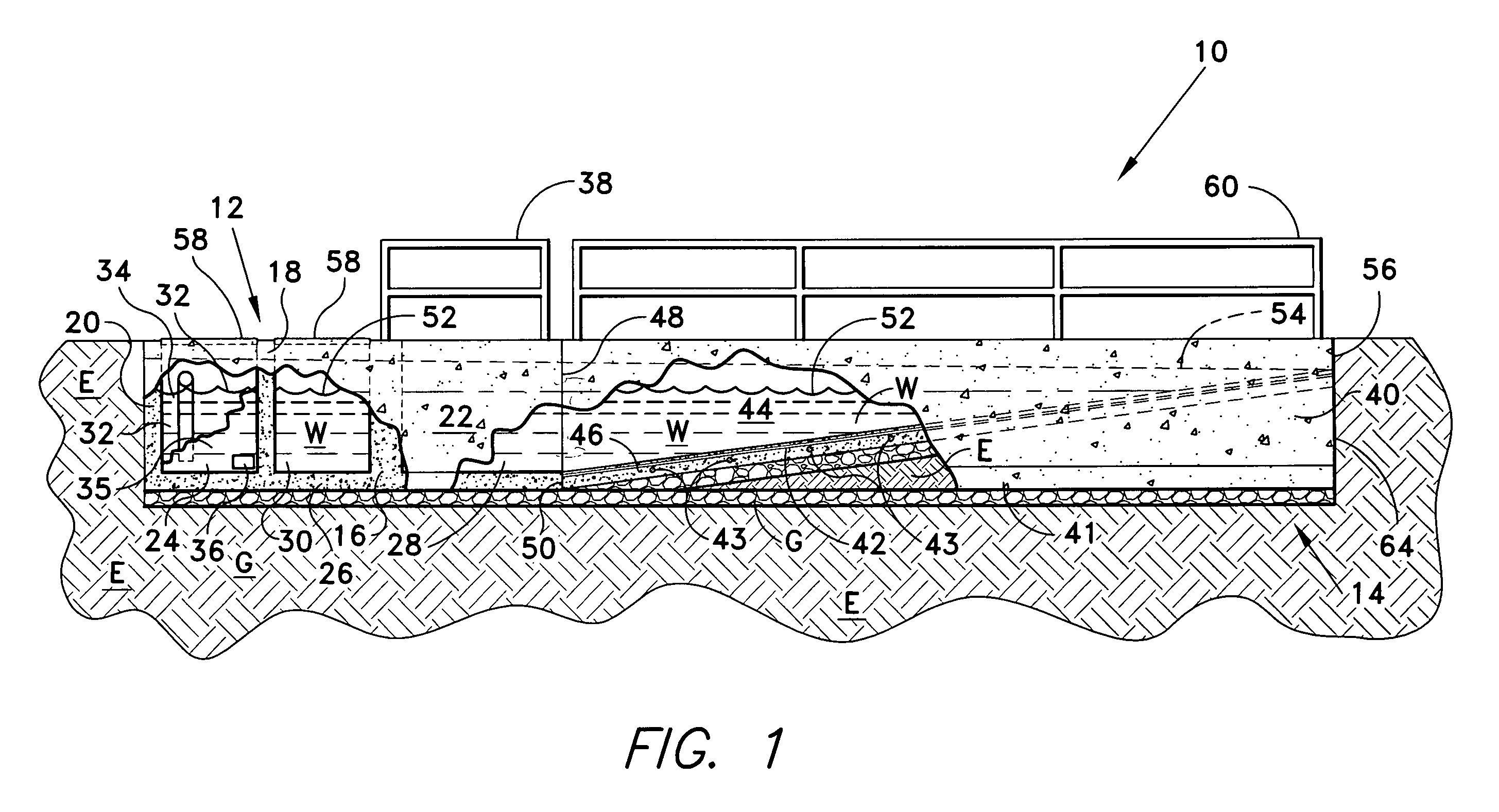

Stormwater plug flow separation system

ActiveUS20100213119A1Fatty/oily/floating substances removal devicesSedimentation tanksStormwaterSeparation system

A water separation system includes a flow container includes a water inlet pipe; an inlet chamber in fluid communication with the water inlet pipe; a first settling chamber configured to settle grit and to float oil; an elevated, horizontally-oriented, elongate-rectangular water treatment flow inlet leading from the inlet chamber to the first settling chamber; a second settling chamber configured to settle solids; one or more plug flow conduits leading from the first settling chamber to the second settling chamber; an outlet chamber; an elevated treatment flow outlet disposed between the second settling chamber and the outlet chamber; a water outlet pipe in fluid communication with the outlet chamber; and an overflow mechanism disposed between the inlet chamber and the outlet chamber.

Owner:NEWTERRA CORP INC

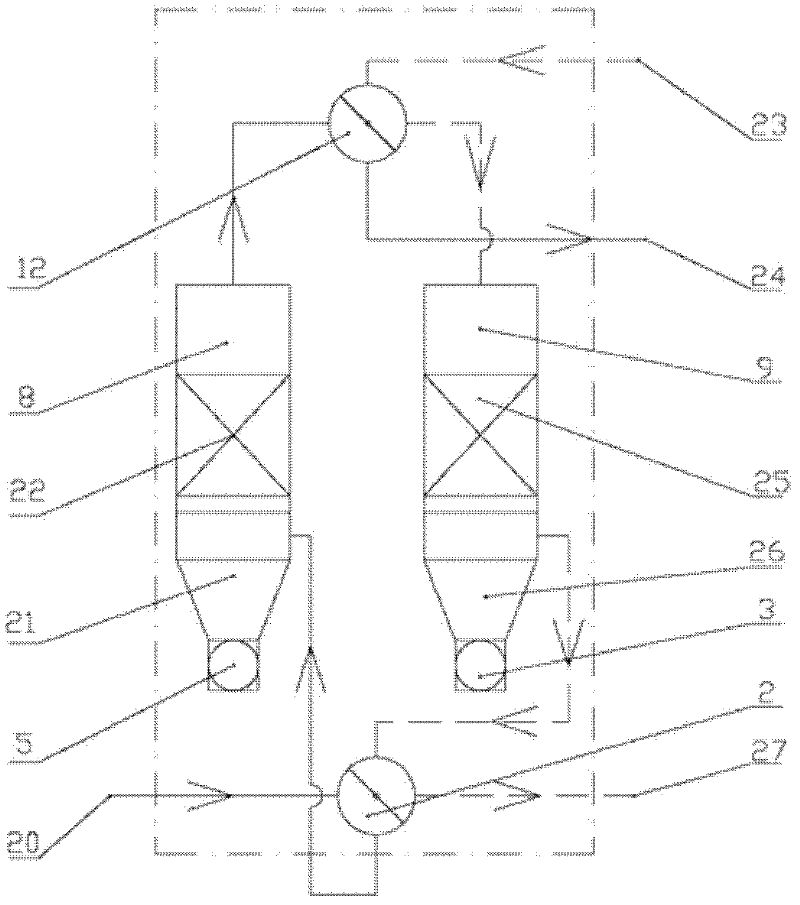

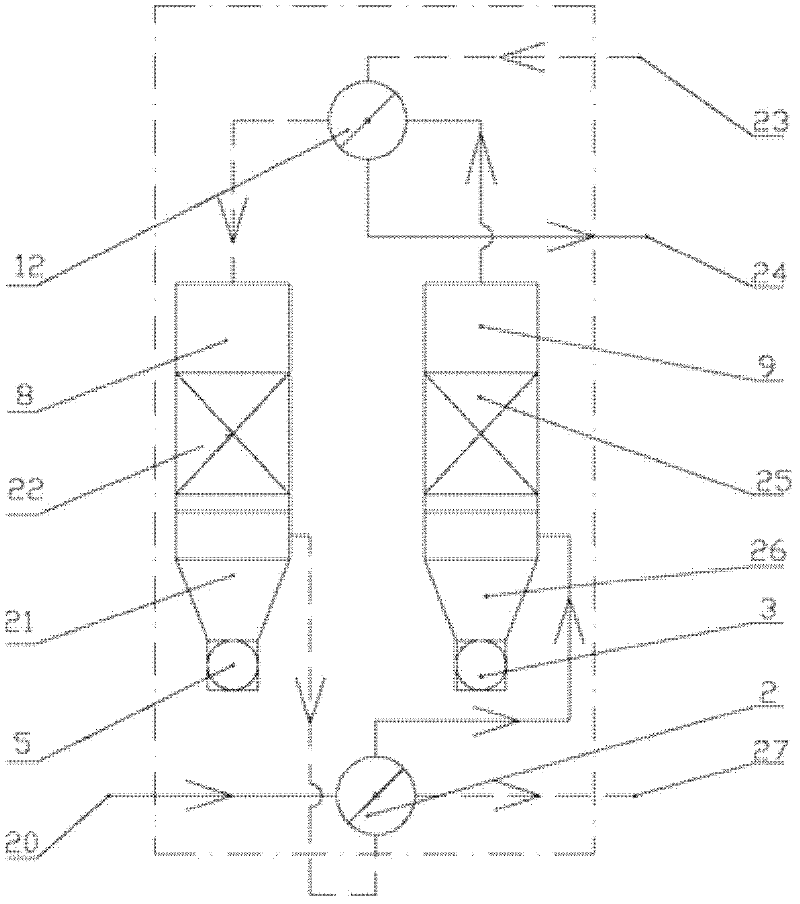

Heat accumulation type electric furnace flue gas waste heat recovery system

ActiveCN103940248AImprove waste heat utilization efficiencyReduce the impact of volatilityEnergy industryIncreasing energy efficiencyAtmospheric airDeaerator

The invention provides a heat accumulation type electric furnace flue gas waste heat recovery system which comprises a perpendicular type connecting flue, a heat accumulation type water-cooling settling chamber, a heat convection waste heat boiler, a feed water heater, a steam heat accumulator and the like. After flue gas inside a combustion settling chamber passes through the perpendicular type connecting flue, the temperature and the flow rate of the flue gas are preliminarily integrated through the heat accumulation type water-cooling settling chamber, and then the flue gas sequentially enters the heat convection waste heat boiler and is exhausted to the atmosphere after the flue gas is cooled through the feed water heater and dust of the flue gas is removed through a dust remover. Raw water is heated through the feed water heater and then enters a deaerator for removing oxygen in the raw water. Then, the raw water flows through the heat convection waste heat boiler and the heat accumulation type water-cooling settling chamber and generates saturated steam to be fed into the steam heat accumulator. The steam enters a superheater after being buffered by the steam heat accumulator, and the superheated steam is output stably in a superheated mode. According to the heat accumulation type electric furnace flue gas waste heat recovery system, due to the fact that the two peak clipping trough levelling measures of the heat accumulation type water-cooling settling chamber and the steam heat accumulator are set, flue gas waste heat, generated by an electric furnace, with unstable fluctuations passes through the heat accumulation type electric furnace flue gas waste heat recovery system so as to stably and efficiently output the superheated steam.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

Pre-cast drive-down water separation pit system

ActiveUS6966984B1Easy to assemblePositive sealLiquid displacementLoose filtering material filtersWater holdingTongue and groove

A unitary or modular, pre-cast, drive-down pit system suitable for use in a heavy equipment wash installation. The completed pit collects runoff generated by the washing of heavy equipment such as construction, industrial, farming, or road-building equipment. The pre-cast concrete separation unit and separate wall sections have tongue and groove mating ends that facilitate assembling the pit and provide for sealing against leakage of water. The wall sections have built-in rebar attachment and water block elements at an angle so as to provide for a strong and waterproof bond with the ramp floor. The ramp floor is concrete, poured after installation of the separation unit and the wall sections to complete the finished drive-down pit. The separation unit has up to four chambers: a primary solids collection section; a secondary solids settling chamber; a free oil separating section; and a pump water holding section.

Owner:SOLOMON MICHAEL L +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com