Patents

Literature

215results about How to "Improve waste heat utilization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

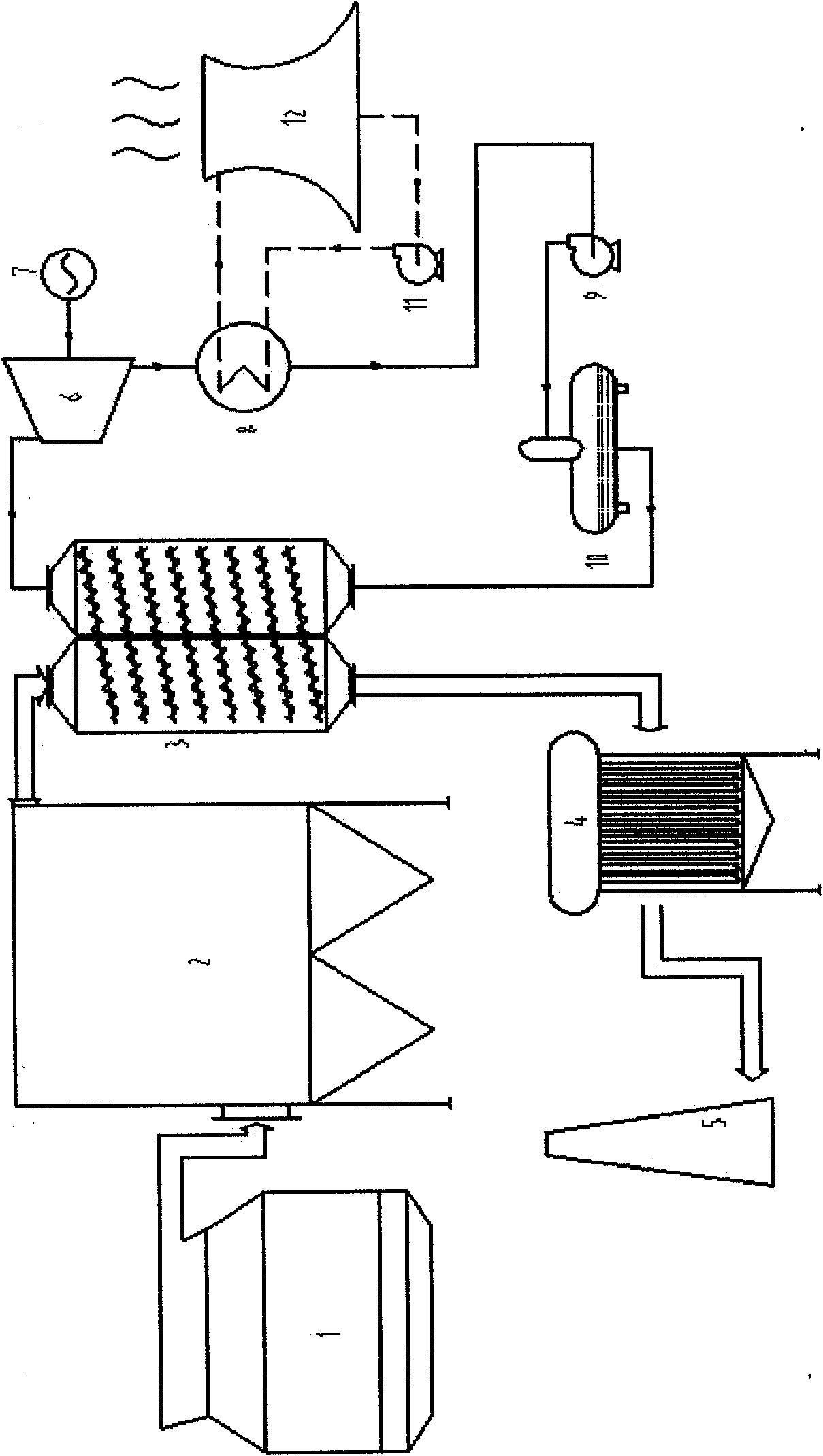

System for regulating and optimizing smoke by power generation and recycle of residual heat of sintering ring cold machine

ActiveCN101655319ATake advantage ofOptimize the operation modeEnergy industryIncreasing energy efficiencyIron plantEngineering

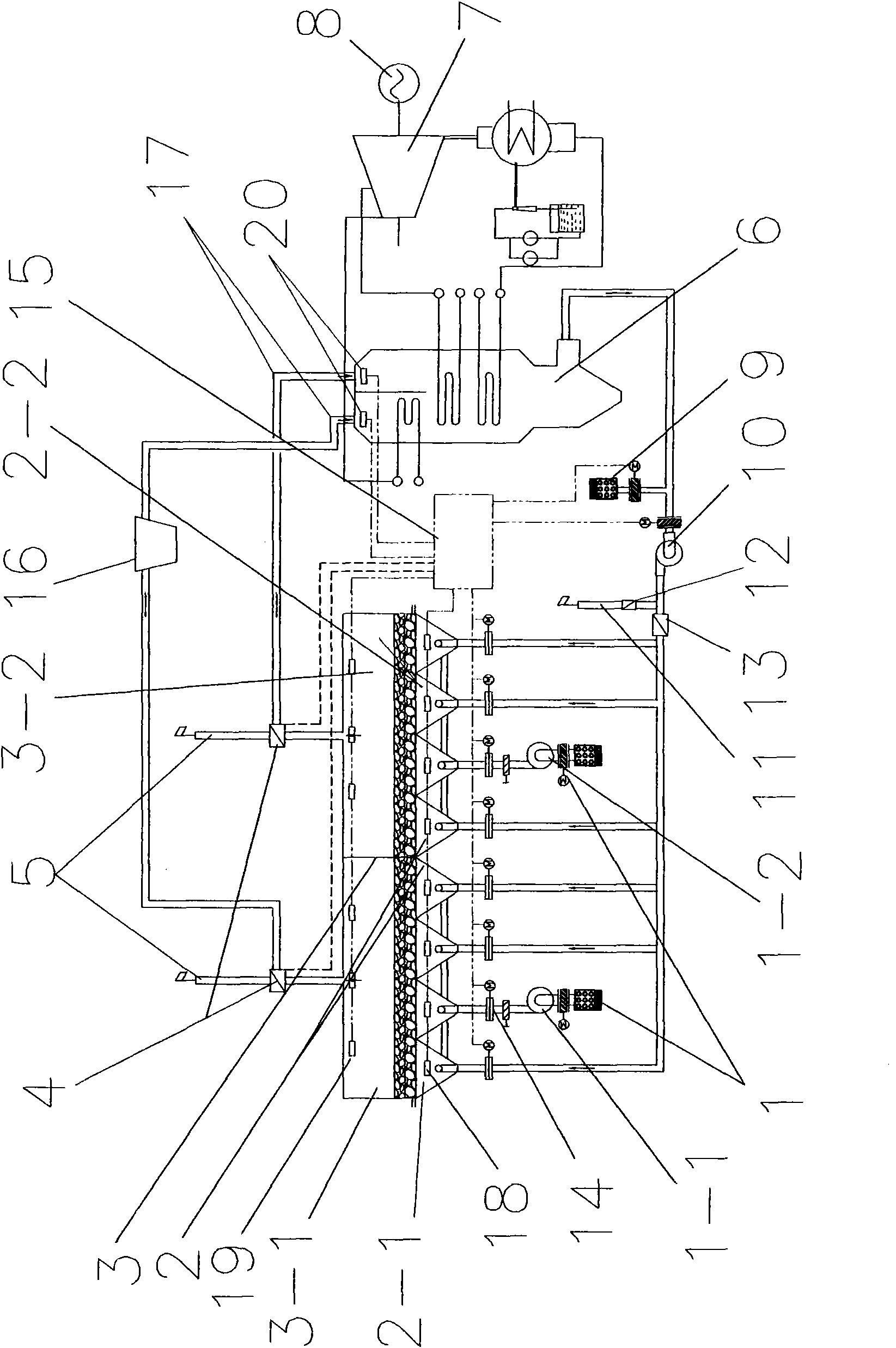

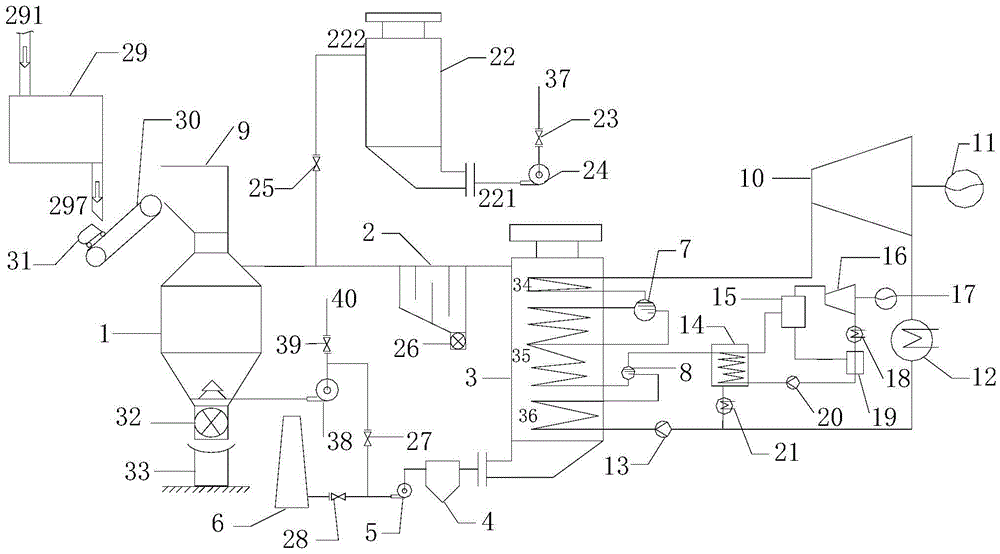

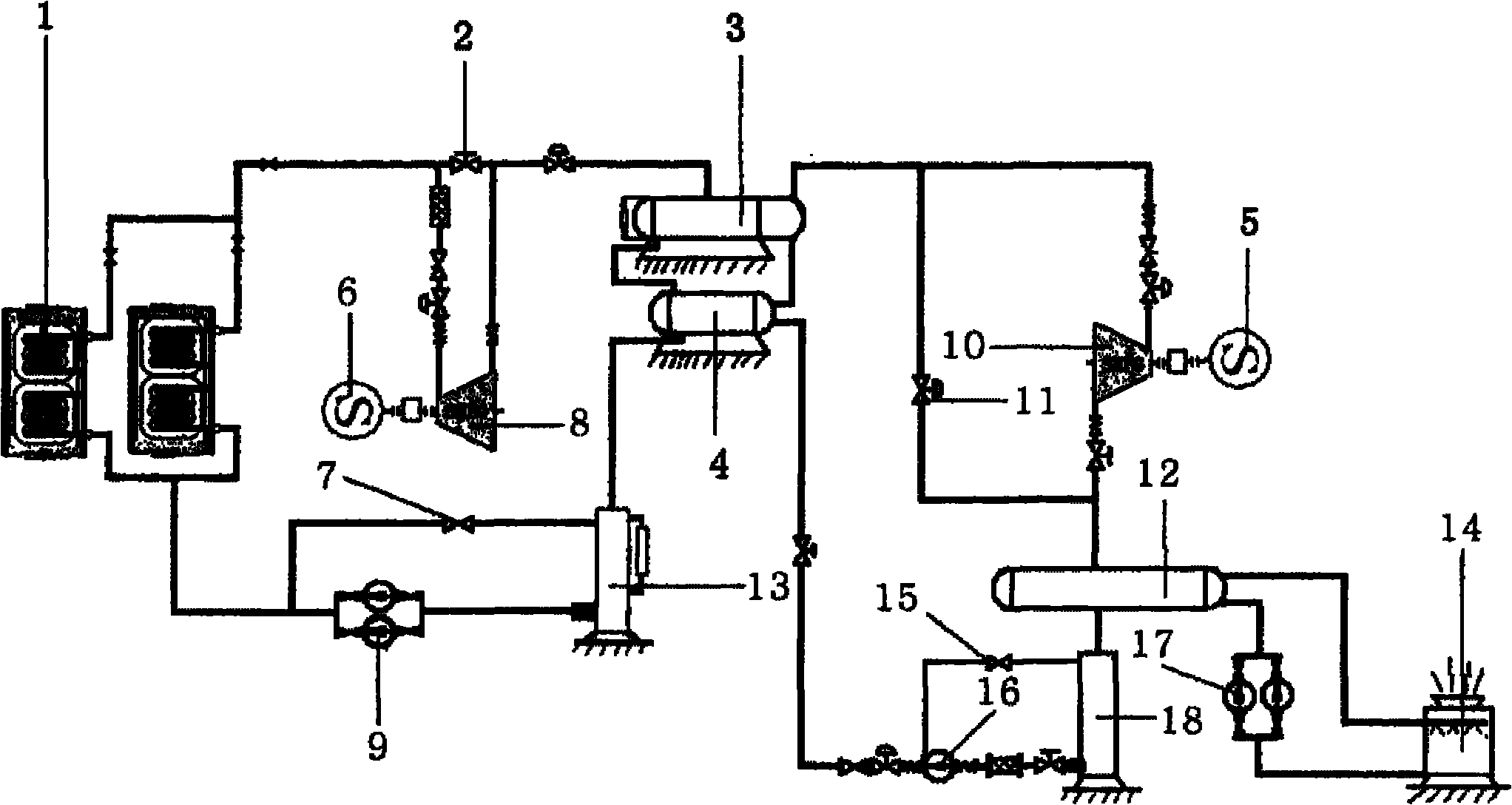

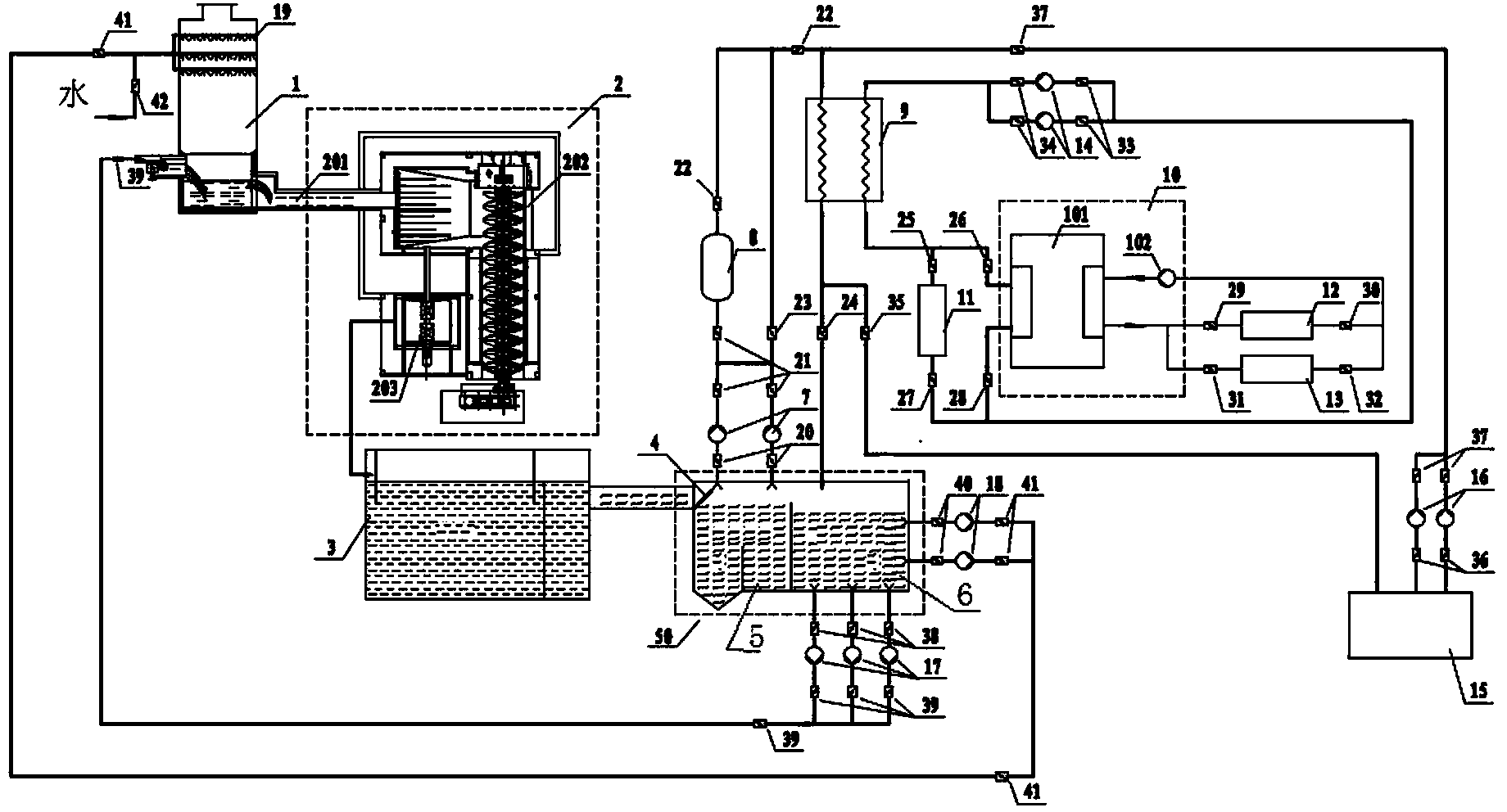

The invention discloses a system for regulating and optimizing smoke by power generation and recycle of residual heat of a sintering ring cold machine, which mainly comprises a ring cooling machine, a ring cooling machine wind box, a ring cooling machine wind chamber, a switching baffle door, a dual-pressure boiler without resisual heat and a steam filling and condensing type dual-pressure steam turbine, wherein the ring cooling machine wind chamber is divided into a high-temperature wind chamber and a low-temperature wind chamber which are respectively connected with the dual-pressure boilerwithout resisual heat through inlet flues, the steam outlet of the dual-pressure boiler without resisual heat is connected with the steam filling and condensing type dual-pressure steam turbine, and the outlet of a sediment chamber of the dual-pressure boiler without resisual heat is connected with a circulation fan through the flues and a wind complementing door. The invention has the highest efficiency in recovering residual heat, can use the resisual heat of sintering mineral materials at most, keeps stability, high efficiency and contineous operation for power generation by using the residual heat, and has important meaning for steal and iron plants.

Owner:ZHEJIANG XIZI UNITED ENG

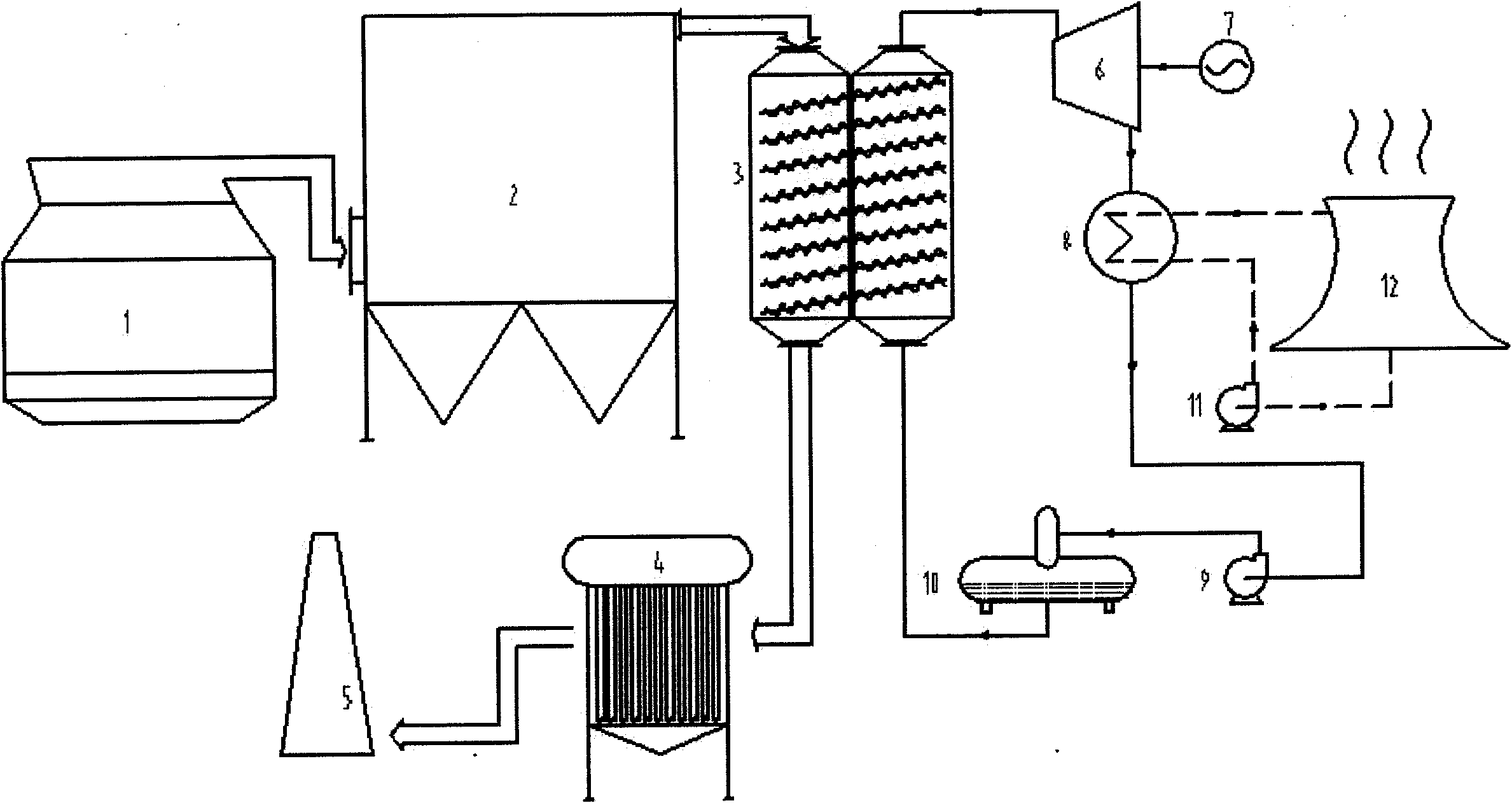

Energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system

InactiveCN104132550AReduce purification costsEmission reductionCombustion technology mitigationWaste heat treatmentSulfurDecomposition

The invention relates to an energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system. The energy-saving environment-friendly waste gas waste-heat utilization and pollutant purification process includes that sintering waste gas is divided into a low-temperature low-sulfur sintering waste gas, a middle-temperature high-sulfur sintering waste gas and a high-temperature middle-sulfur sintering waste gas according to waste gas temperature and pollutant discharge characteristics; content of sintering waste gas SO2 of the low-temperature low-sulfur is below the national discharge standard, and the SO2 can be directly discharged after dust removal; after the sintering waste gas in a middle-temperature high-sulfur section is subjected to dust removal and desulfurization processing, the SO2 meets the national discharge standard and can be discharged; the sintering waste gas in a high-temperature middle-sulfur section mixed with ring-cold waste gas is led into a sintering machine, and hot-wind igniting and hot-wind sintering are performed. The invention further provides a system for implementing the energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process. Waste heat of the sintering waste gas can be recycled in classification and gradiently utilized, so that energy can be saved; the low-sulfur waste gas can be discharged directly, so that desulfurization cost of the waste gas is lowered; part of the high-sulfur waste gas participate in circulation, so that total discharge amount of pollutants is decreased, splitting decomposition of dioxin happens due to high temperature, and the purification function of the sintering waste gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

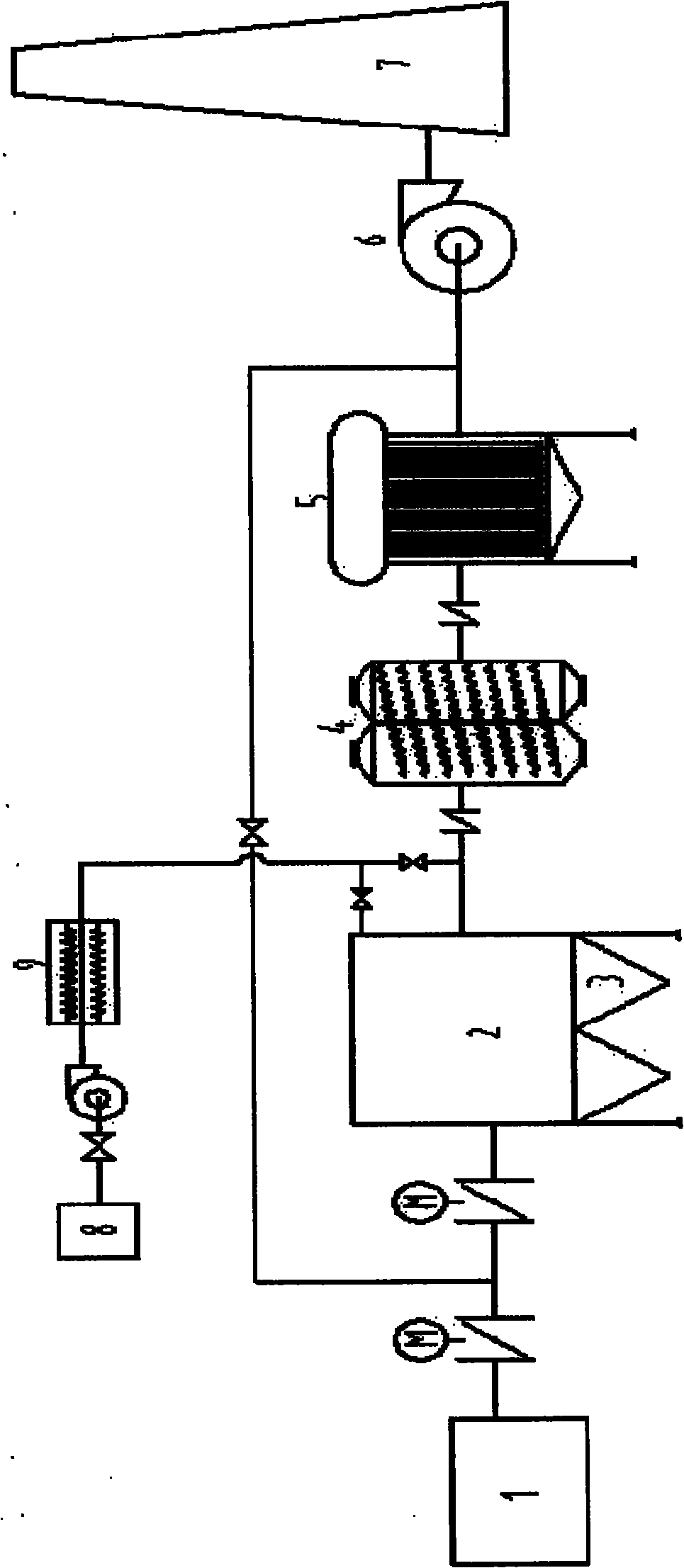

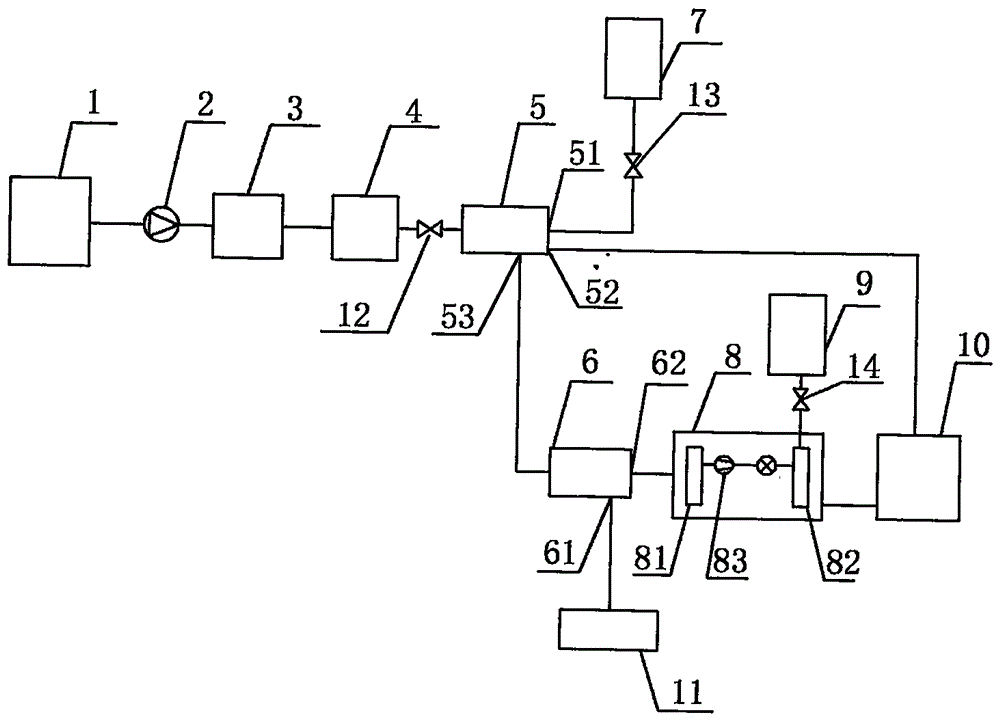

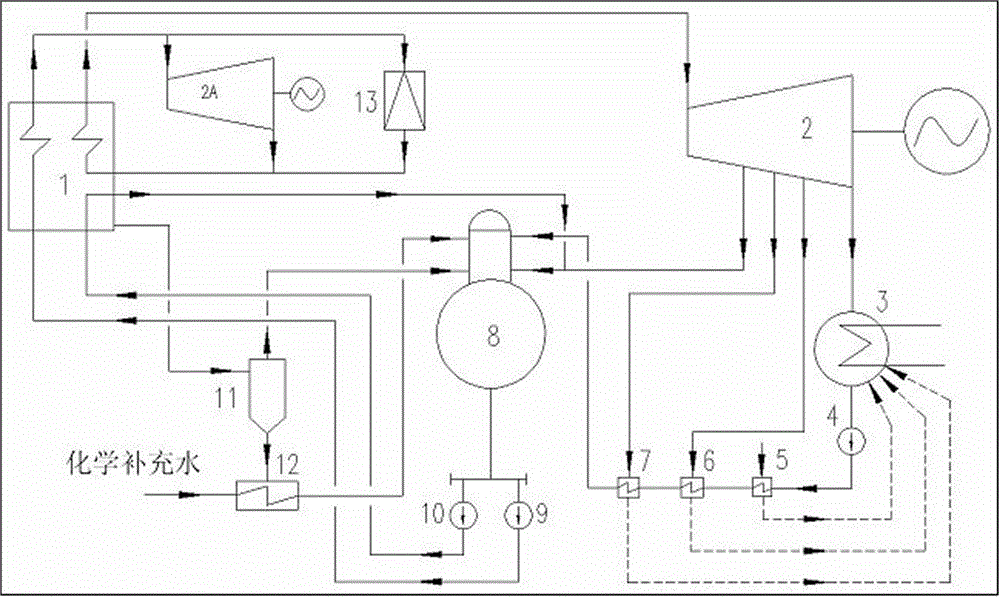

Integrated waste heat generating and heating system and process flow thereof

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

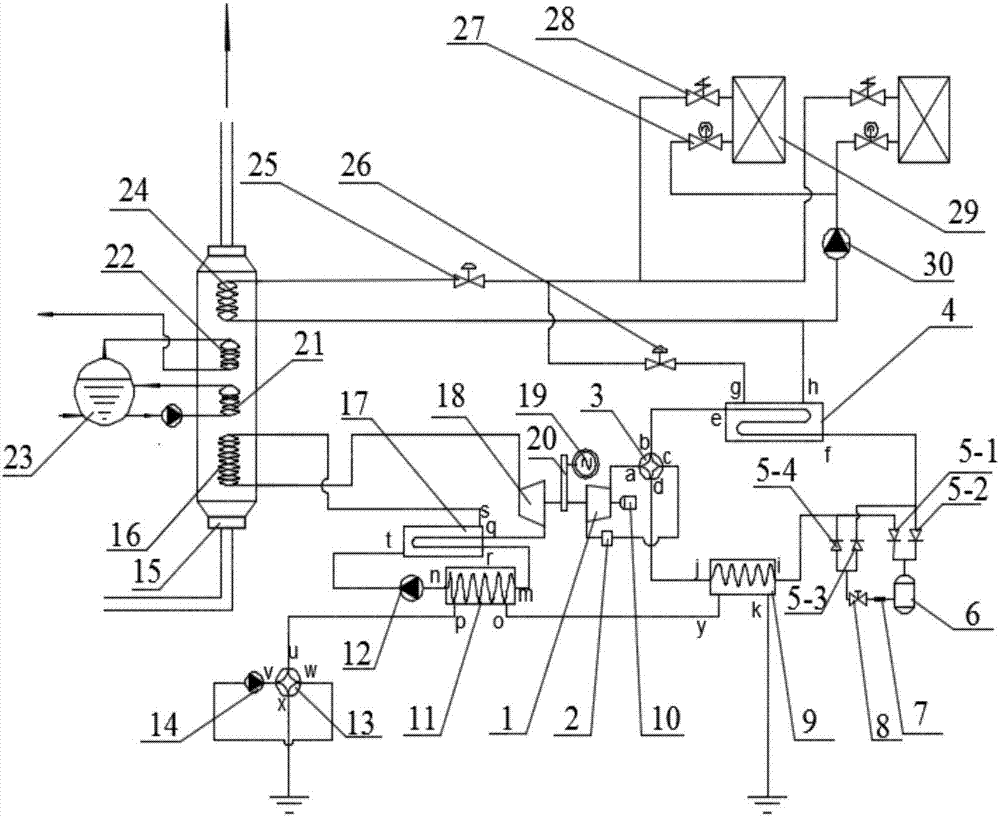

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

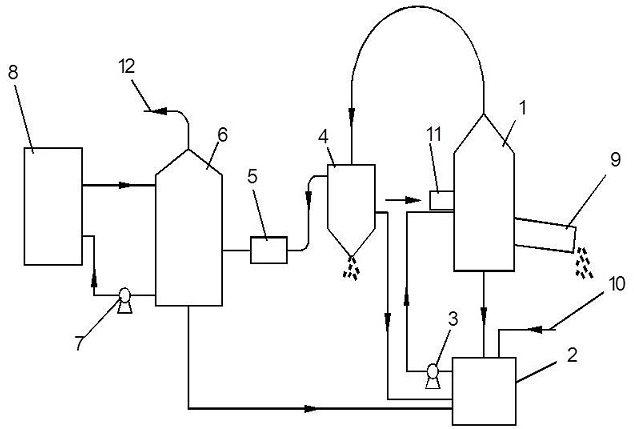

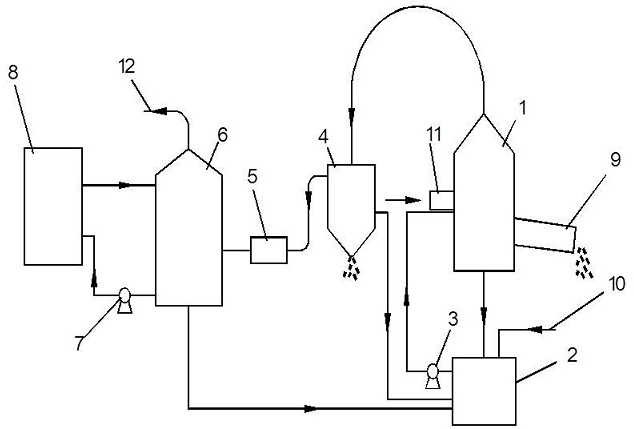

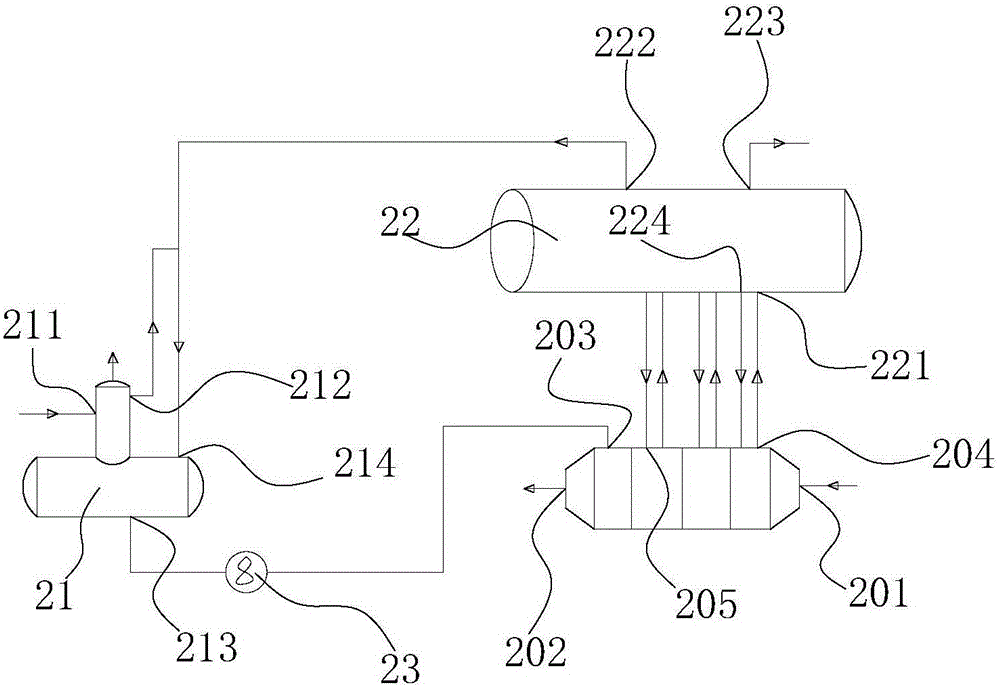

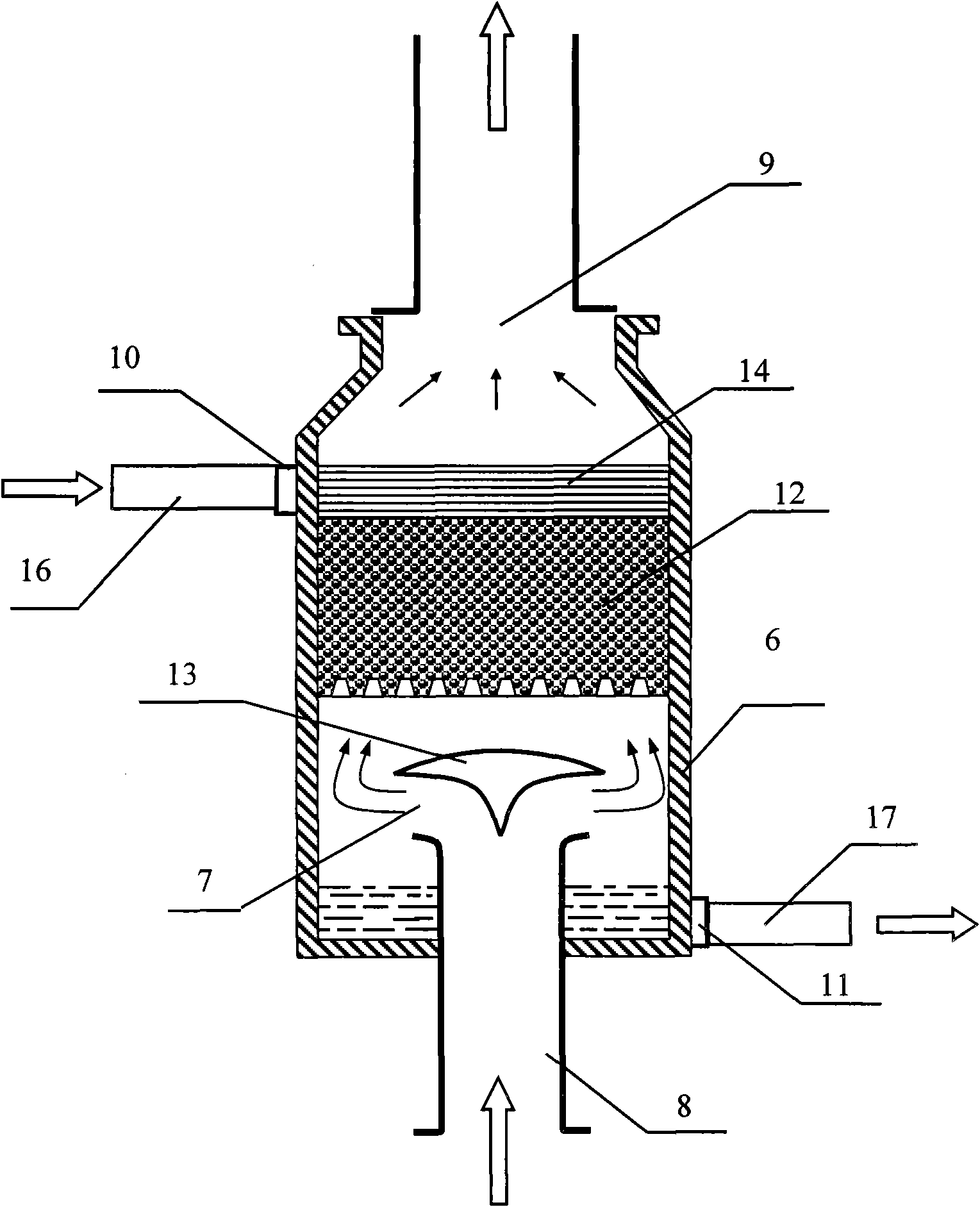

Blast furnace smelting slag water quenching waste steam waste heat recovery system

InactiveCN102424868AImprove waste heat utilization efficiencyIncrease waste heat recoveryLighting and heating apparatusProcess efficiency improvementBlast furnace smeltingWastewater

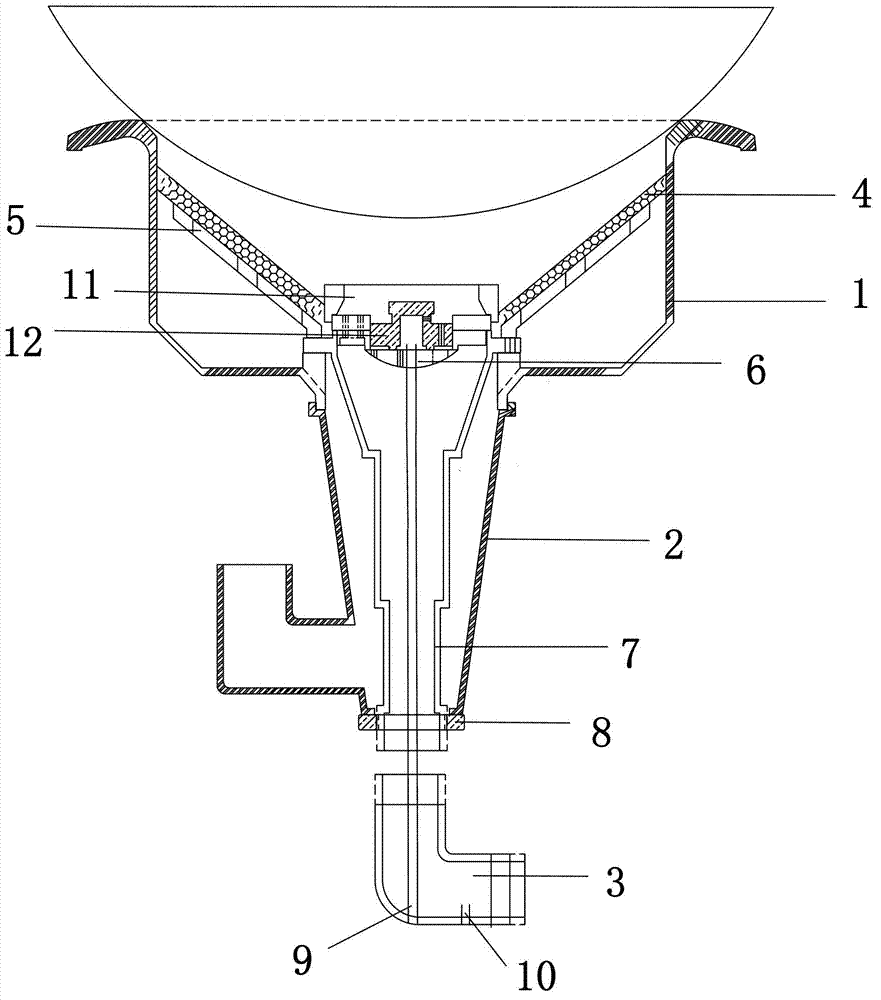

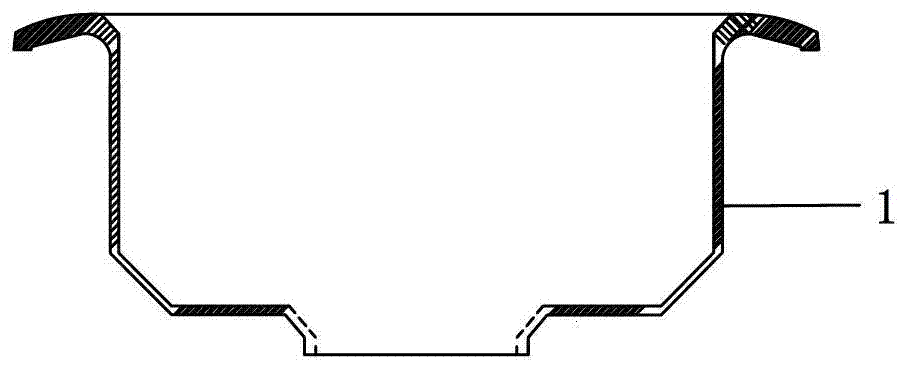

The present invention provides a blast furnace smelting slag water quenching waste steam waste heat recovery system. The system comprises a blast furnace slag water quenching apparatus, a slag quenching water circulation apparatus and a waste steam waste heat recovery apparatus. The blast furnace slag water quenching apparatus comprises a smelting slag groove, a water quenching apparatus and a slag discharging and conveying belt. The slag quenching water circulation apparatus comprises the water quenching apparatus, a water circulating tank, a water quenching pump and a water supplying pipe. The waste steam waste heat recovery apparatus comprises the water quenching apparatus, a three-phase separator, a fan, a heat exchanger, a hot water pump and a low-temperature user. The method of the present invention is different from the method in the prior art, wherein the recovery of the slag quenching waste water waste heat is adopted to recover the smelting slag waste heat by the method in the prior art, and the waste heat in the waste steam generated from the smelting slag quenching by the recovered water is adopted to recover the smelting slag waste heat by the method of the present invention, the water quality of the waste steam is better than the water quality of the waste water, such that the disadvantages of high hardness of the waste water, equipment scaling, equipment blocking and the like in the prior art are overcome. According to the present invention, the slag quenching waste steam waste heat is effectively recovered; the system has advantages of energy saving and emission reduction, and environmental protection; the collected waste heat can be used to meet the requirements of the low-temperature user.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

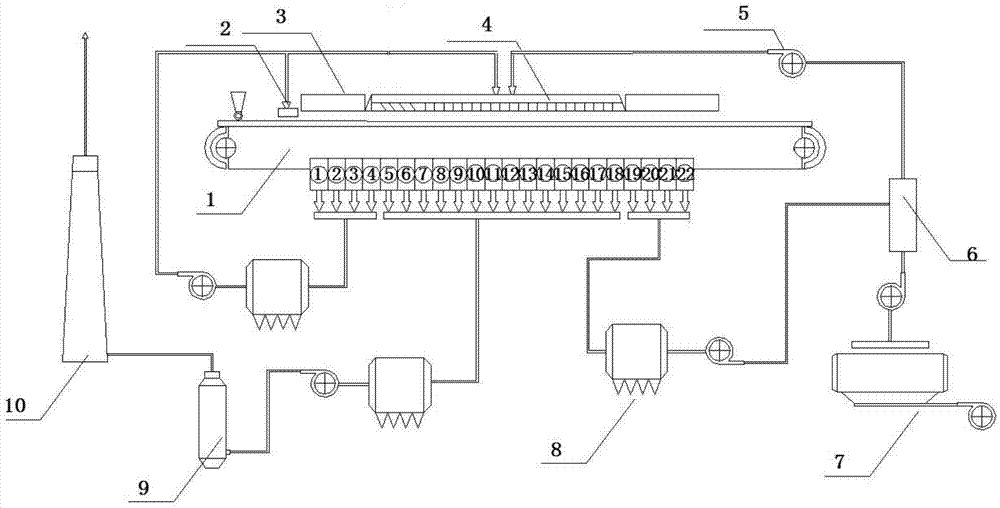

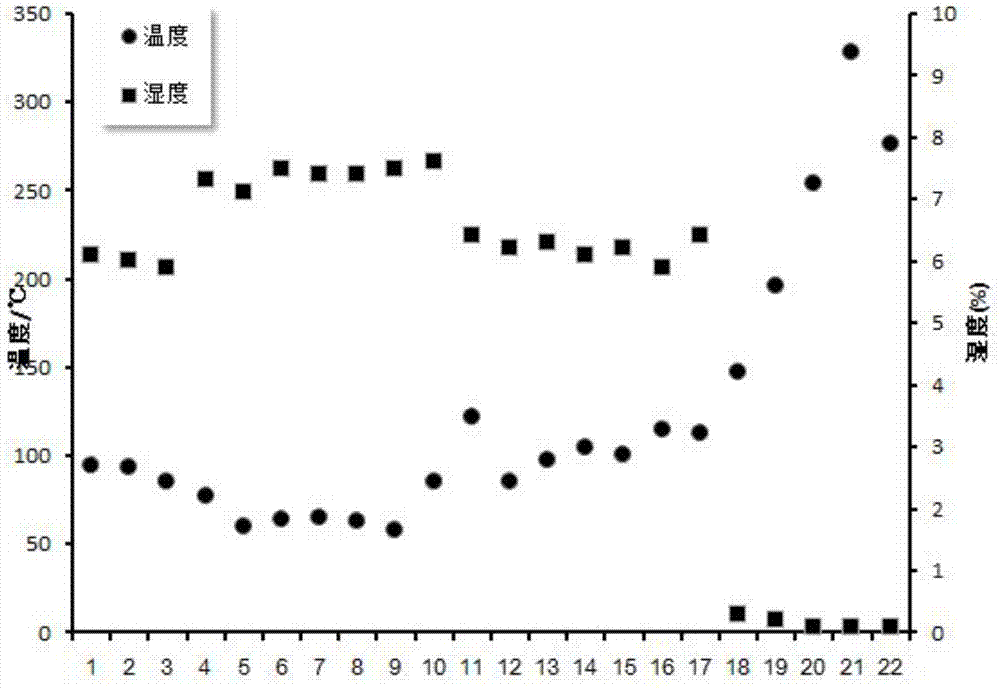

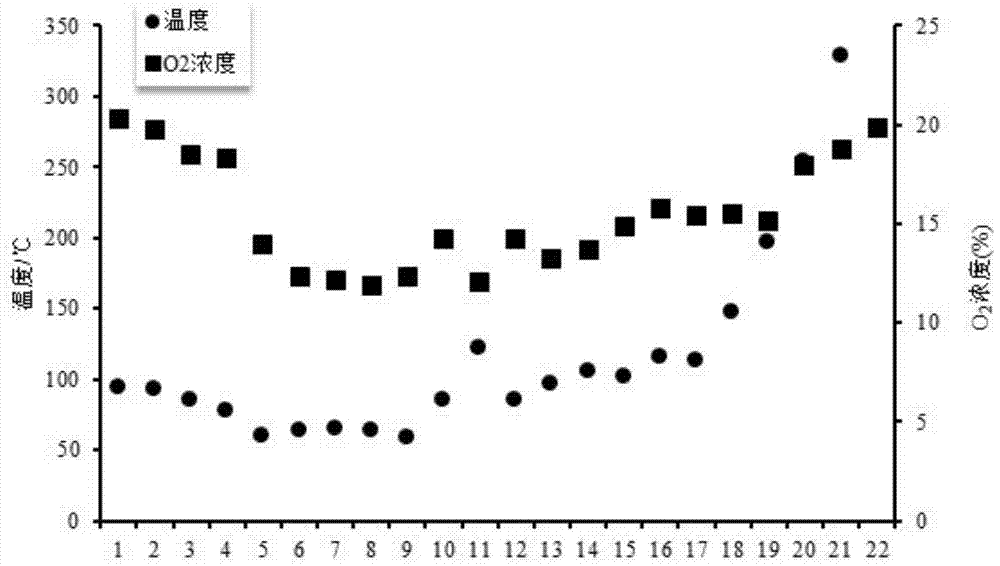

Sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system

ActiveCN104748567ARealize emission reduction controlEmission reductionGas treatmentDispersed particle separationHigh humidityHigh energy

The invention provides a sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system. According to the process, sintering flue gas is divided into low-temperature high-oxygen low-humidity section sintering flue gas, medium-temperature low-oxygen high-humidity section sintering flue gas and high-temperature high-oxygen low-humidity section sintering flue gas according to the emission characteristics of flue gas temperature and oxygen concentration and humidity. The low-temperature high-oxygen low-humidity section sintering flue gas is subjected to dust removal and then is led into a sintering machine for hot air sintering and hot air ignition. The medium-temperature low-oxygen high-humidity section sintering flue gas is subjected to dust removal and desulfurization treatment. The high-temperature high-oxygen low-humidity section sintering flue gas is mixed with cooling machine waste gas and then is led into the sintering machine for hot air sintering. The sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system can conduct staged utilization on flue gas waste heat, recover low-temperature sensible heat in flue gas, enable carbon monoxide left in the sintering flue gas to be secondarily combusted and reduce the energy consumption in the sintering process on the premise that the quality and yield of sintered ores are ensured. Cyclic flue gas utilization is achieved, the pollutant emission quantity of unit sintering ores and total emission quantity of the sintering flue gas are reduced, and the sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system have very high energy-saving emission-reduction value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

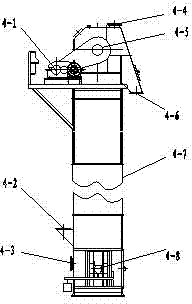

System used for sinter ore cooling and sensible heat efficient recycling

InactiveCN105627755AEfficient recyclingExtended sinter cooldownIncreasing energy efficiencyFurnace typesKilnMaterials science

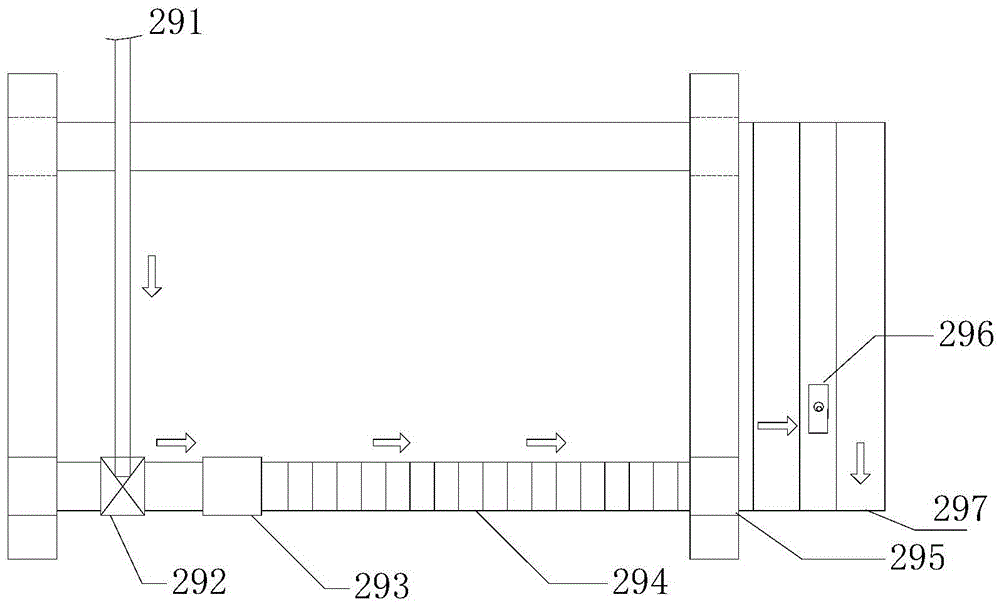

A system used for sinter ore cooling and sensible heat efficient recycling comprises a stepping sintering machine used for sintering mixed iron ore materials, a vertical cooling kiln used for cooling sinter ore which is sintered and crushed, a feeding mechanism arranged between a discharging opening of the stepping sintering machine and a feed inlet of a material receiving funnel of the vertical cooling kiln, a gravity dust remover, a high-temperature smoke unit, a discharging machine, a belt conveyer and a vertical double-pressure waste heat boiler used for heat exchange, wherein the gravity dust remover and the high-temperature smoke unit are connected with a gas outlet in the upper portion of the vertical cooling kiln, and the discharging machine and the belt conveyer are arranged on a discharging opening of the vertical cooling kiln. A gas outlet of the vertical double-pressure waste heat boiler is connected with a gas inlet of a low-temperature gas unit, a gas outlet of the low-temperature gas unit is connected with a gas inlet in the lower portion of the vertical cooling kiln, and a heat exchange pipe of the vertical double-pressure waste heat boiler is connected with a power generation system. By means of the system, the sinter ore and cooling air can flow reversely in a closed space, cooling time of the sinter ore is prolonged, heat exchange is sufficient, heat efficiency of the system is greatly improved, and efficient recycling of sensible heat of the sinter ore is achieved.

Owner:天津天丰钢铁股份有限公司 +2

Energy-saving stove preheating premixed combustible gas by using after heat

ActiveCN102829495ATo achieve the purpose of warming upSufficient heat exchangeDomestic stoves or rangesIndirect carbon-dioxide mitigationCombustorWhole body

The invention relates to an energy-saving stove preheating premixed combustible gas by using after heat. The stove comprise a stove plate, a burner and a mixing chamber, wherein the burner is arrange in the middle of the bottom of the stove plate, and the burner is communicated with the mixing chamber; the stove also comprises a fume guide hood for guiding fume after heat in the stove plate to the outer wall of the mixing chamber to preheat the premixed combustible gas in the mixing chamber; a flanged edge contacting with a cooker is arranged at the border of the stove plate; the fume guide hood is communicated with the bottom of the stove plate, and is sleeved outside the mixing chamber; the fume guide hood is in sealed connection with the outer wall of the mixing chamber at the bottom; the fume guide hood is provided with an after heat discharge outlet; and the stove plate is internally provided with cellular porous ceramic which is obliquely erected through an energy gathering plate bracket. According to the energy-saving stove provided by the invention, the traditional fume emission notch at the upper part of the stove plate is omitted, direct discharge of fume whose after heat is not utilized is reduced; and through arranging the mixing chamber in the fume guide hood, a preheating device and the stove form a whole body, and the purpose of preheating the premixed combustible gas delivered into the stove can be achieved without need of splitting for independent use.

Owner:珠海歌林能源科技有限公司

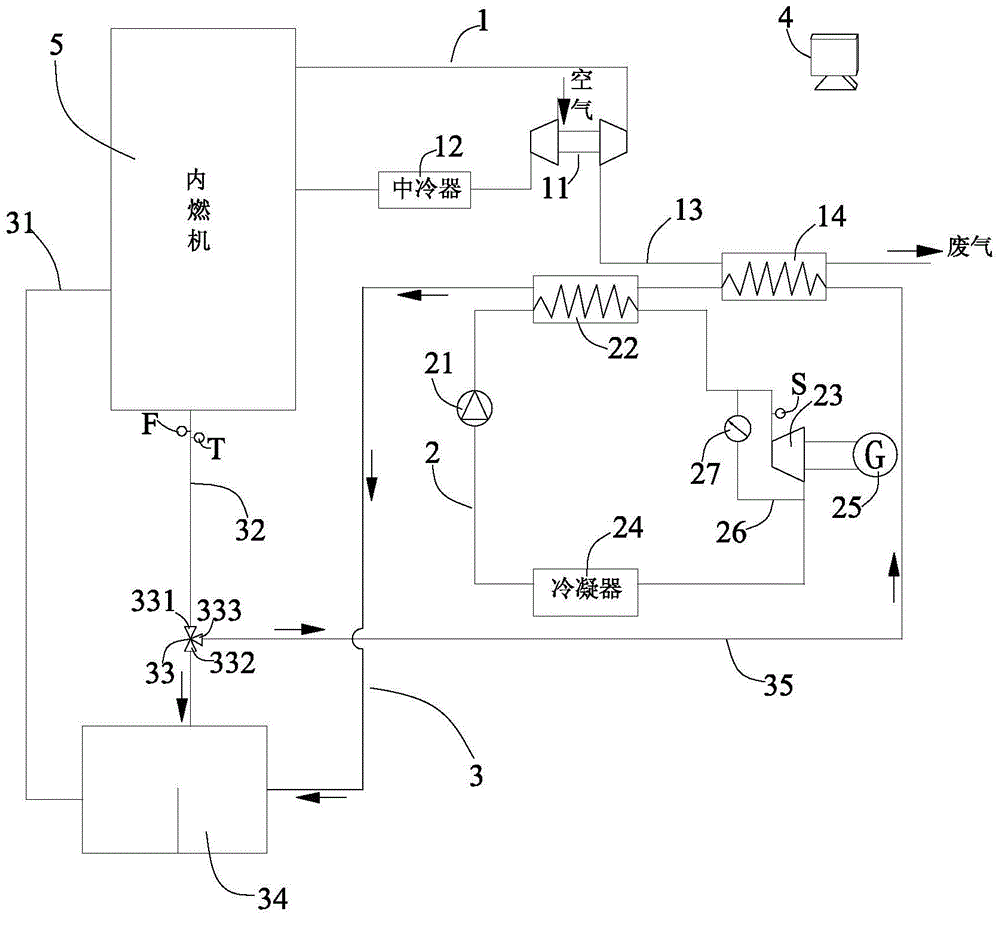

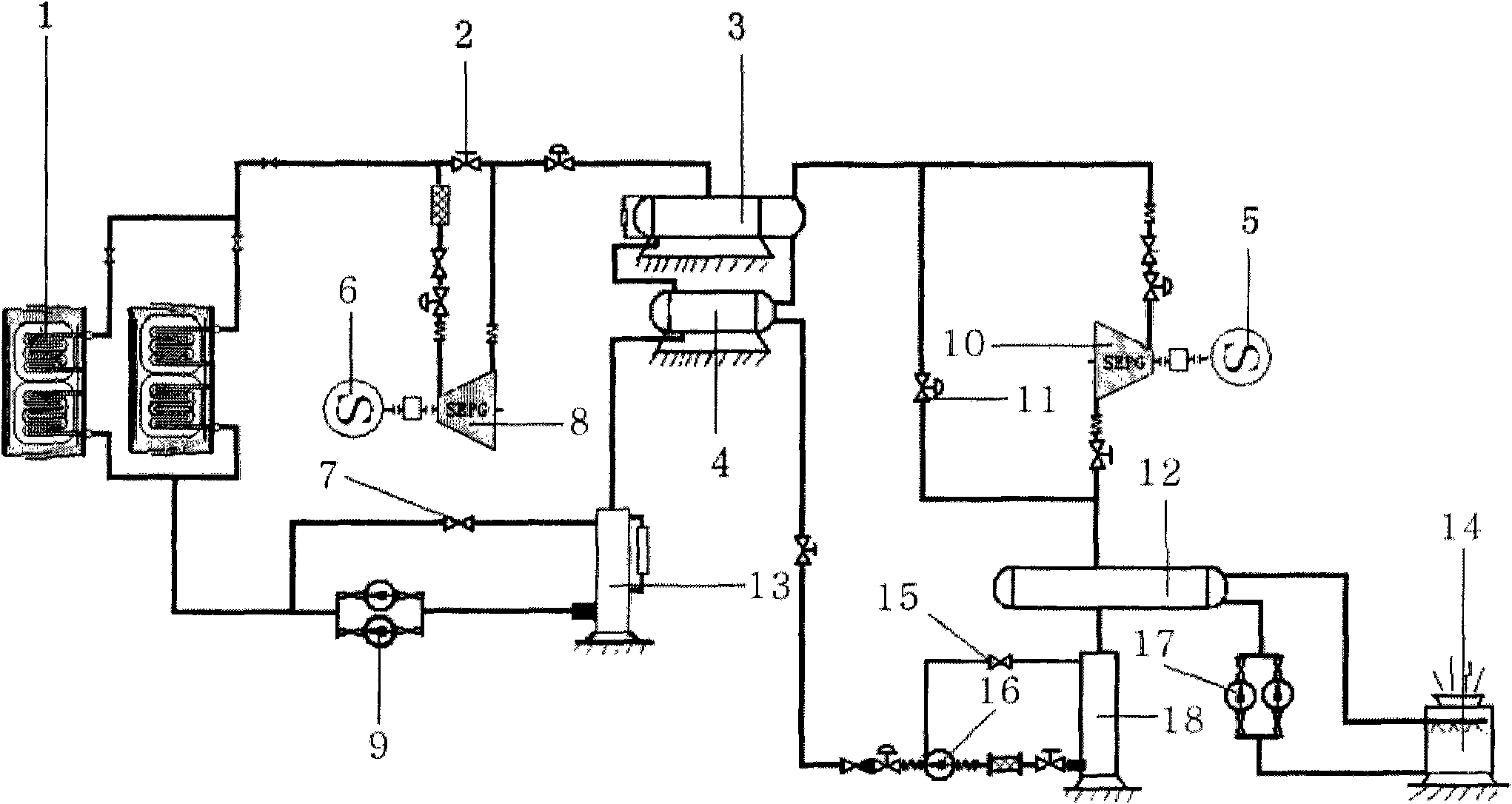

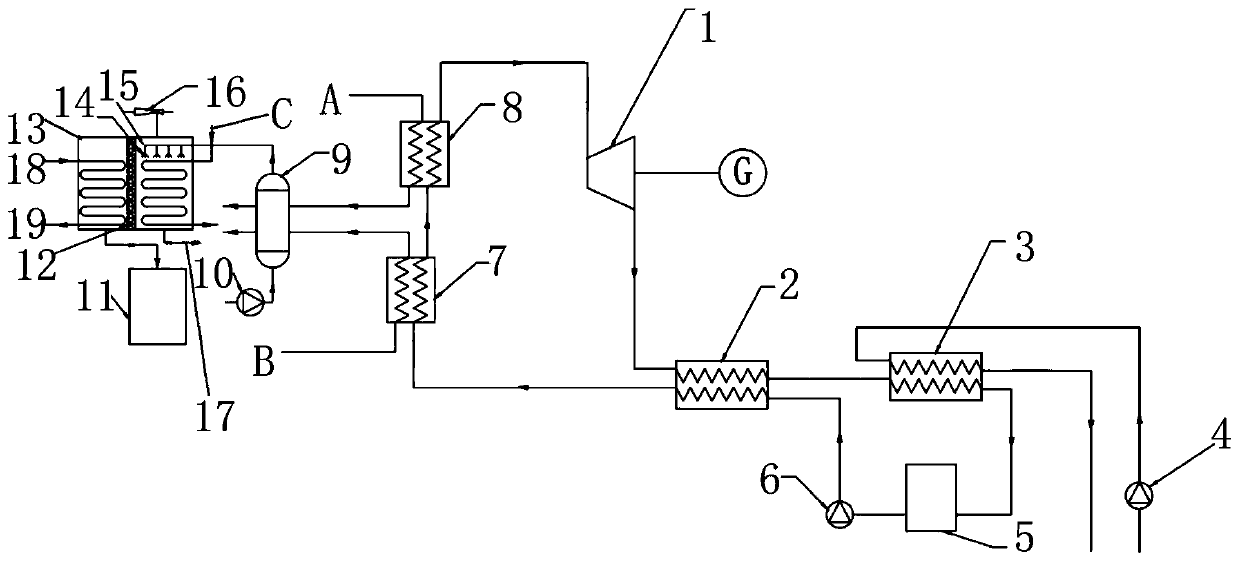

Comprehensive utilization system for waste heat of internal combustion engine

ActiveCN104564422AImprove waste heat utilization efficiencyImprove heat transfer efficiencyInternal combustion piston enginesEngine componentsWater dischargeTurbocharger

The invention provides a comprehensive utilization system for waste heat of an internal combustion engine. The comprehensive utilization system comprises a tail gas energy recovery system, an organic Rankine circulating system and a cooling water circulating system, the tail gas energy recovery system comprises a turbocharger, an intercooler, a waste gas pipeline and a gas-water heat exchanger, the organic Rankine circulating system comprises an organic working medium pump, an evaporator, an expander, a condenser and a power generator, and a cooling water circulating loop comprises a water incoming pipe, a water outgoing pipe, a three-way valve with an inlet, a first outlet and a second outlet, a water tank and a double heat exchange pipeline. Cooling water discharged from a water outlet of the internal combustion engine flows through the water outgoing pipe, the inlet of the three-way valve, the second outlet of the three-way valve, the double heat exchange pipeline, the gas-water heat exchanger, the evaporator, the water tank, the water incoming pipe to enter a water inlet of the internal combustion engine so as to realize cooling water heat exchange circulating. Temperature of the cooling water is increased under heating action of waste-gas waste heat discharged by the internal combustion engine, so that heat exchange efficiency of an organic working medium and the cooling water is improved, more heat can be recovered by the organic working medium, and waste heat utilization efficiency of the internal combustion engine is improved.

Owner:TSINGHUA UNIV

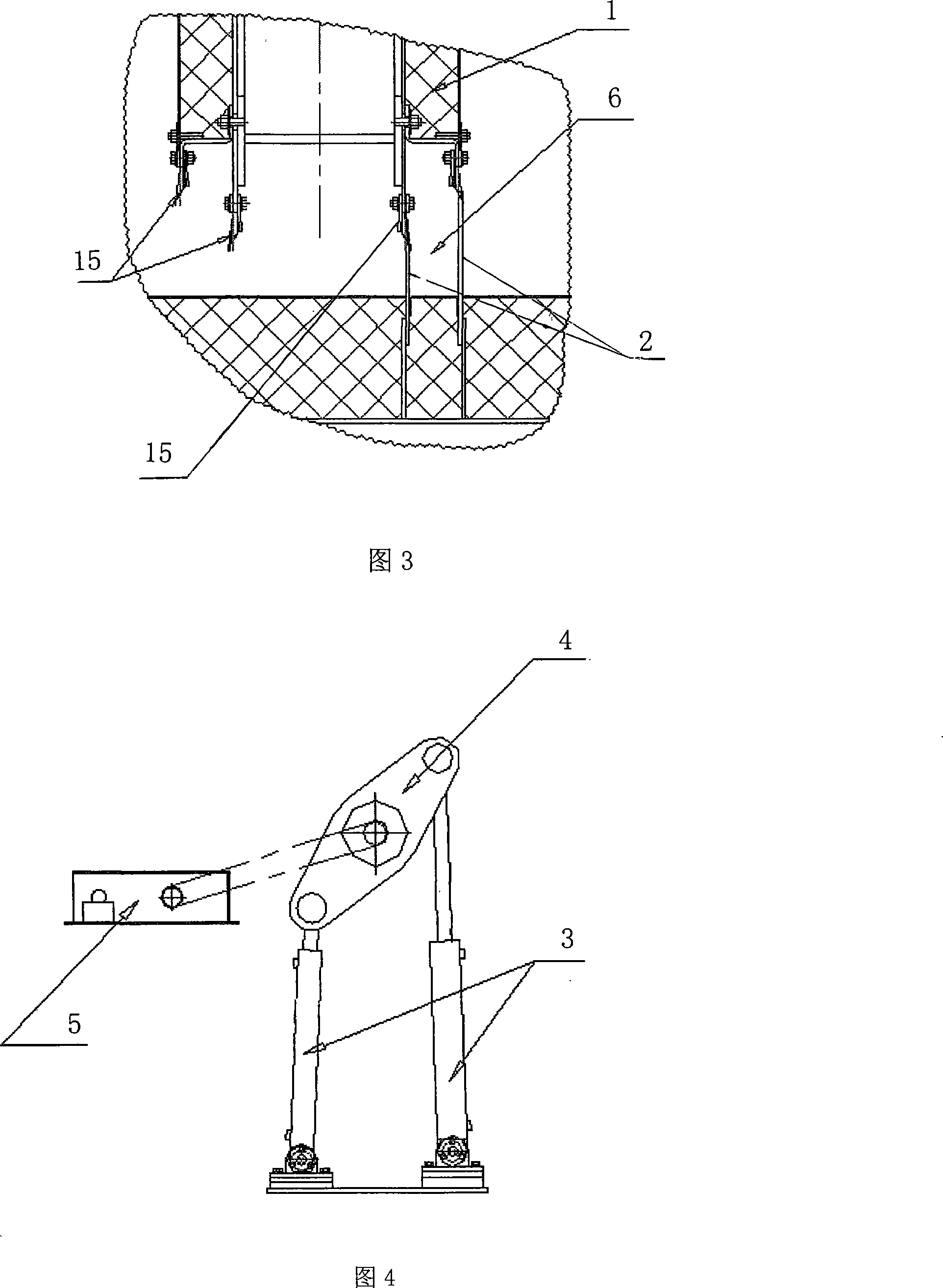

Smoke damper door

The invention relates to an off-gas baffle door which comprises three flues and baffle doors arranged in the flues. The invention is characterized in that the baffle door has a single-piece single-shaft structure; a door shaft is positioned at the top of the baffle door and is arranged horizontally, and the baffle door can turn around the shaft in an angle between 0 and 90 degrees; double-layer elastic metal sheets which preserve a gap between layers and interlaced positioning of layers are respectively adopted around the two side faces of the baffle door; double-layer sealing boards corresponding to the elastic metal sheet are respectively arranged around the flue of a matching face of the baffle door, and the elastic metal sheet is matched with the sealing board to form a sealing face; a sealed cavity is formed in the middle of the sealing face. The baffle door adopts a hydraulic driving system comprising a hydraulic oil cylinder which is arranged at the two ends of the door shaft in a mode of double-side arrangement; an emergence closing loop is arranged in the system and an energy storing device is arranged in the loop. The fume flow passage of the invention has no obstacle with low flow resistance, the sealing rate can reach 100 percent and the driving of the hydraulic oil cylinder is stable with reliable capability.

Owner:HANGZHOU BOILER GRP CO LTD

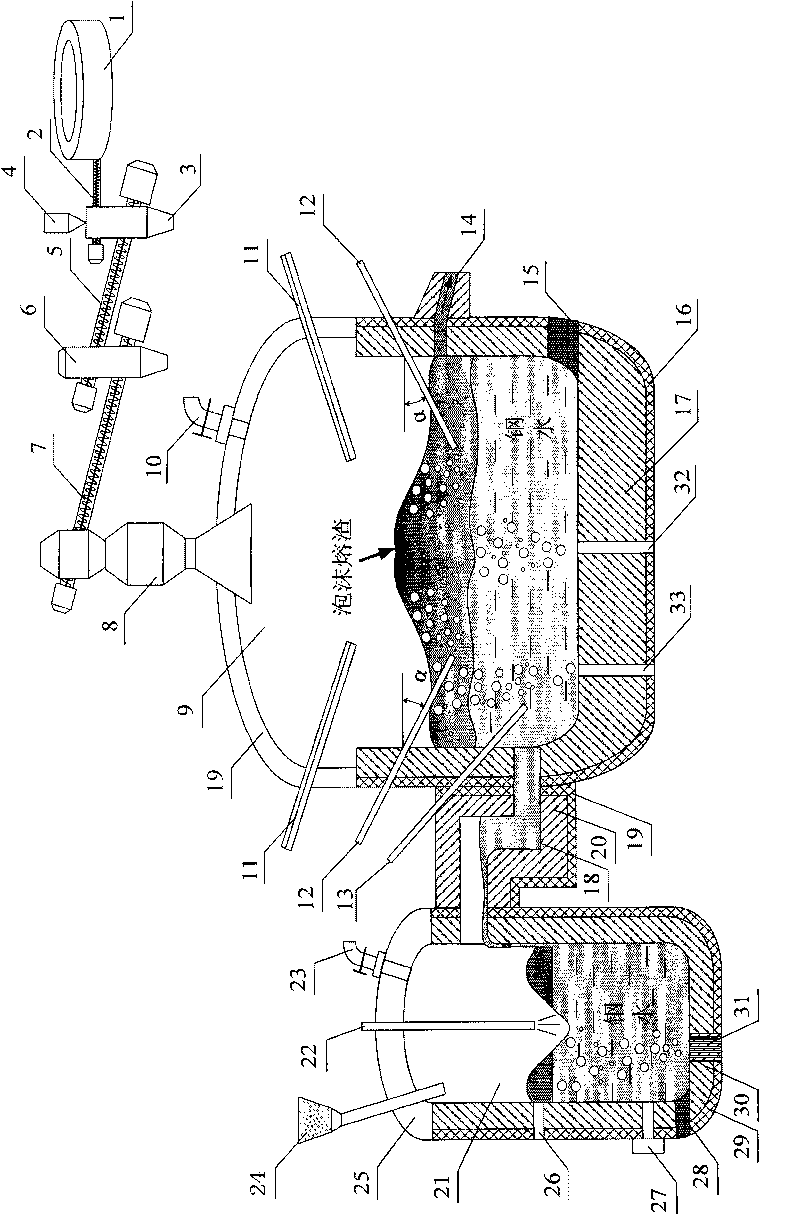

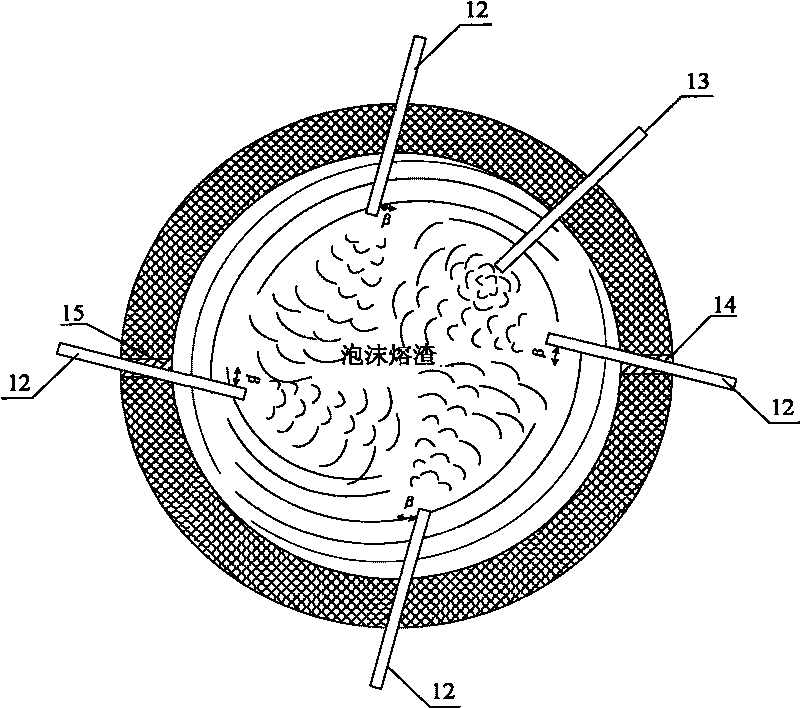

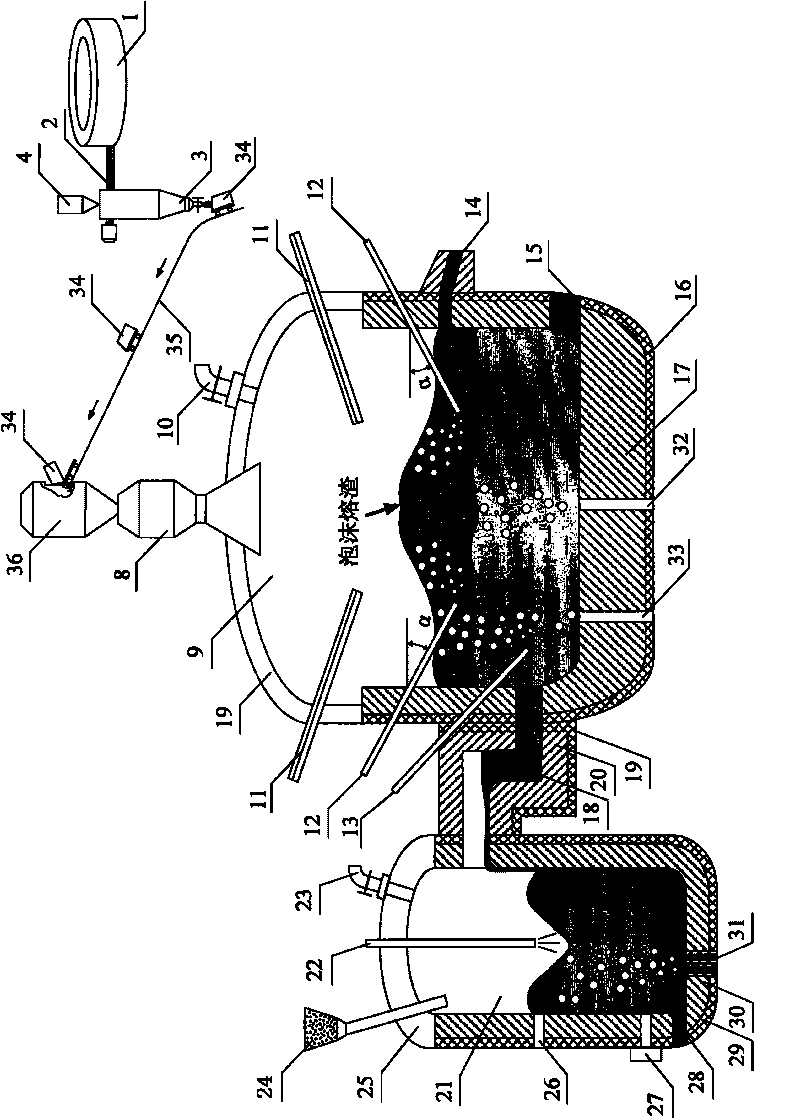

Process and device for dual continuous steel making with iron-containing material rotary hearth furnace

The invention relates to a process for dually continuously producing molten steel by using an iron-containing material rotary hearth furnace, which comprises the following steps: forming a molten pool in a smelting furnace in advance, and blowing a carbon-containing material and oxygen to form foam slag; reducing the iron-containing material to form an iron-containing material of which metallization rate is 90 to 97 percent and temperature is between 900 and 1,200 DEG C through the rotary hearth furnace, and feeding the iron-containing material into the smelting furnace through a high-temperature feeding system to be smelted and reduced; blowing high-temperature oxygen or oxygen-enriched air to combust with CO produced by the smelting furnace; continuously pouring the molten steel into an oxygen blowing furnace through a siphon port, adding a little amount of fusing agent into the oxygen blowing furnace to perform slagging, desulfuration and dephosphorization, and blowing oxygen by using a plug-in oxygen gun to further adjust the content of C in the molten steel and the temperature so as to obtain the molten steel directly supplied to an LF or RH refining furnace. The process has the advantages of high production rate, high thermal efficiency and long furnace service life, implements direct production of the molten steel from ores or iron-containing materials by using continuous steel making equipment consisting of the rotary hearth furnace, the smelting furnace and the oxygen blowing furnace, saves equipment and capital construction investment, saves the land, simplifies material flow, and is easy for serialization and automatic control of the production.

Owner:LAIWU IRON & STEEL GRP

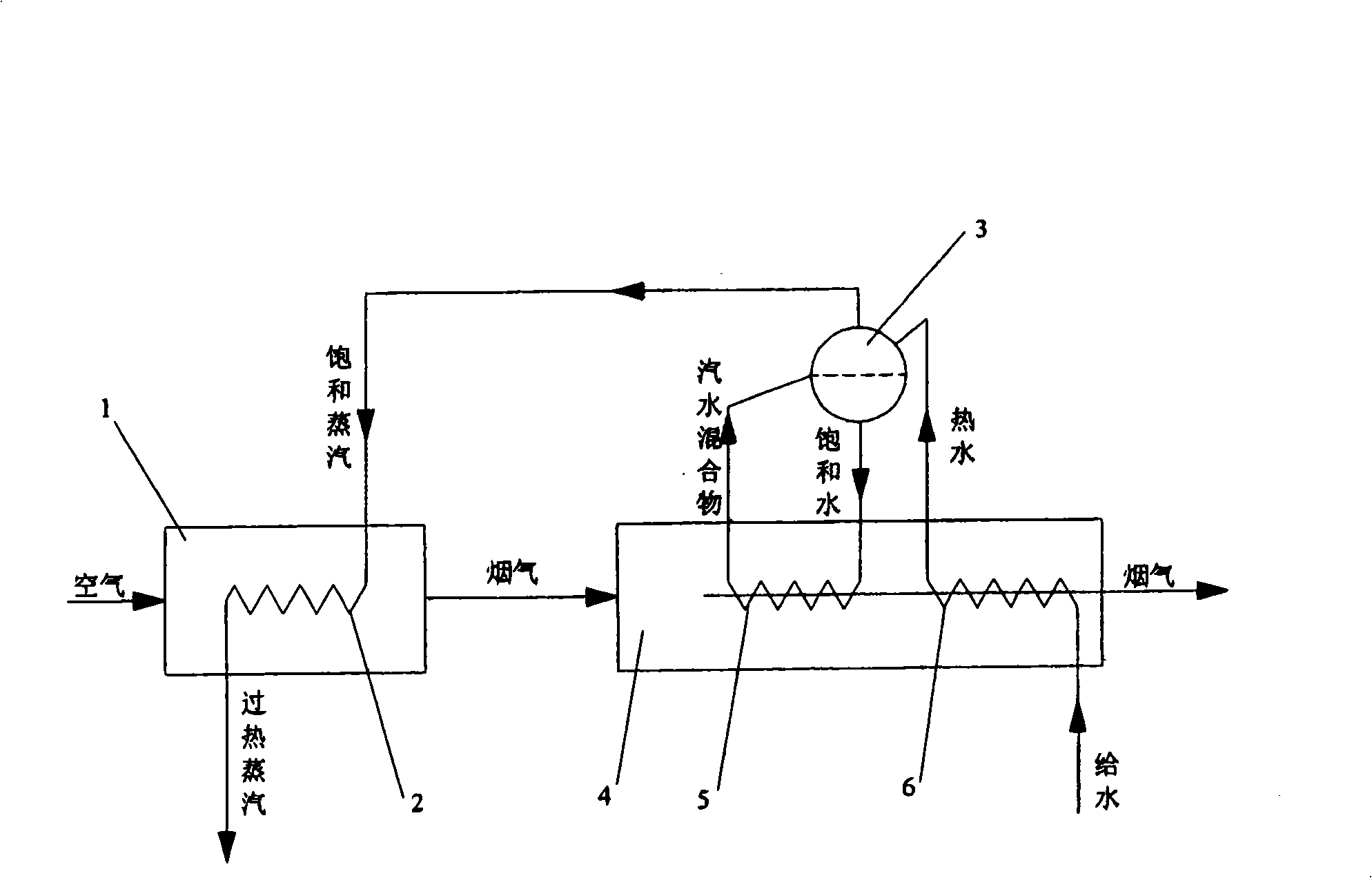

Flue gas waste heat recovery system of metallurgy electric furnace

InactiveCN101315183AImprove utilization efficiencyUse properlyWater circulationSteam generation using hot heat carriersCoalFlue gas

The invention provides a metallurgic electric furnace flue gas waste heat recovery system for realizing high-efficiency recovery of waste heat of a metallurgic electric furnace. The system comprises a waste heat boiler (4). The waste heat boiler is arranged outside an electric furnace (1). The flue gas exhaust from the electric furnace is guided into the waste heat boiler. The waste heat boiler comprises an evaporation heating surface (5), a coal economizer (6) and a steam tank (3). The coal economizer supplies water to the waste heat boiler. The hot water flowing out of the exit of the coal economizer is supplied to the steam tank. The bottom of the steam tank is connected with the entrance of the evaporation heating surface. The steam tank supplies saturated water to the evaporation heating surface. The middle part of the steam tank is connected with the exit of the evaporation heating surface. The steam-water mixture enters the steam tank after heat absorption and undergoes steam-water separation in the steam tank. The system further comprises a radiation heating surface which is arranged inside the electric furnace. The entrance of the radiation heating surface is connected with the steam tank. The saturated steam inside the steam tank flows to the radiation heating surface, the radiation heating surface absorbs the high-temperature radiation heat inside the electric furnace and heats the saturated steam to form superheated steam, and the superheated steam is guided out of the exit of the radiation heating surface.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

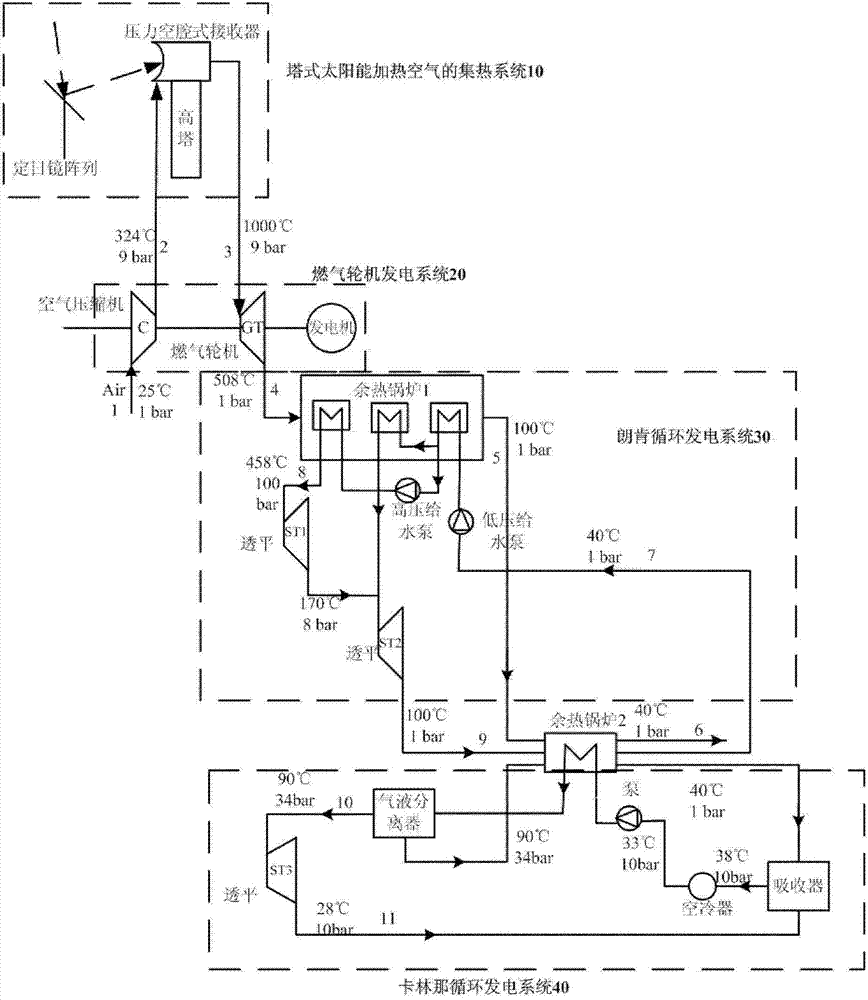

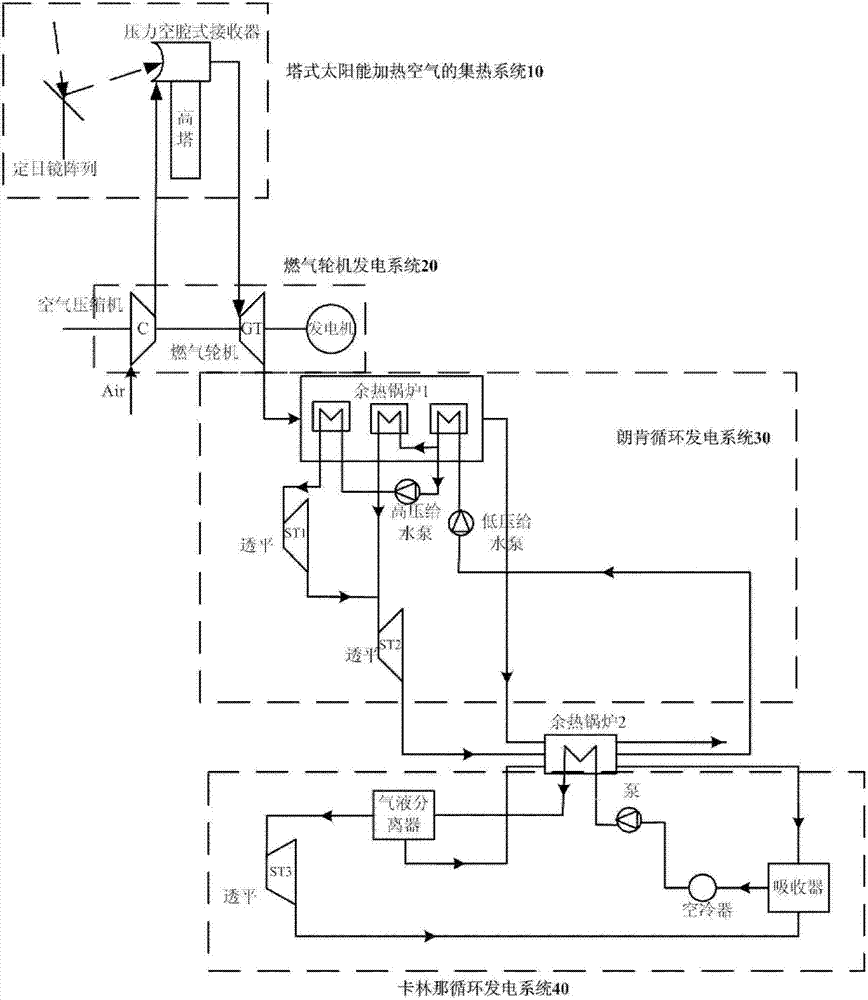

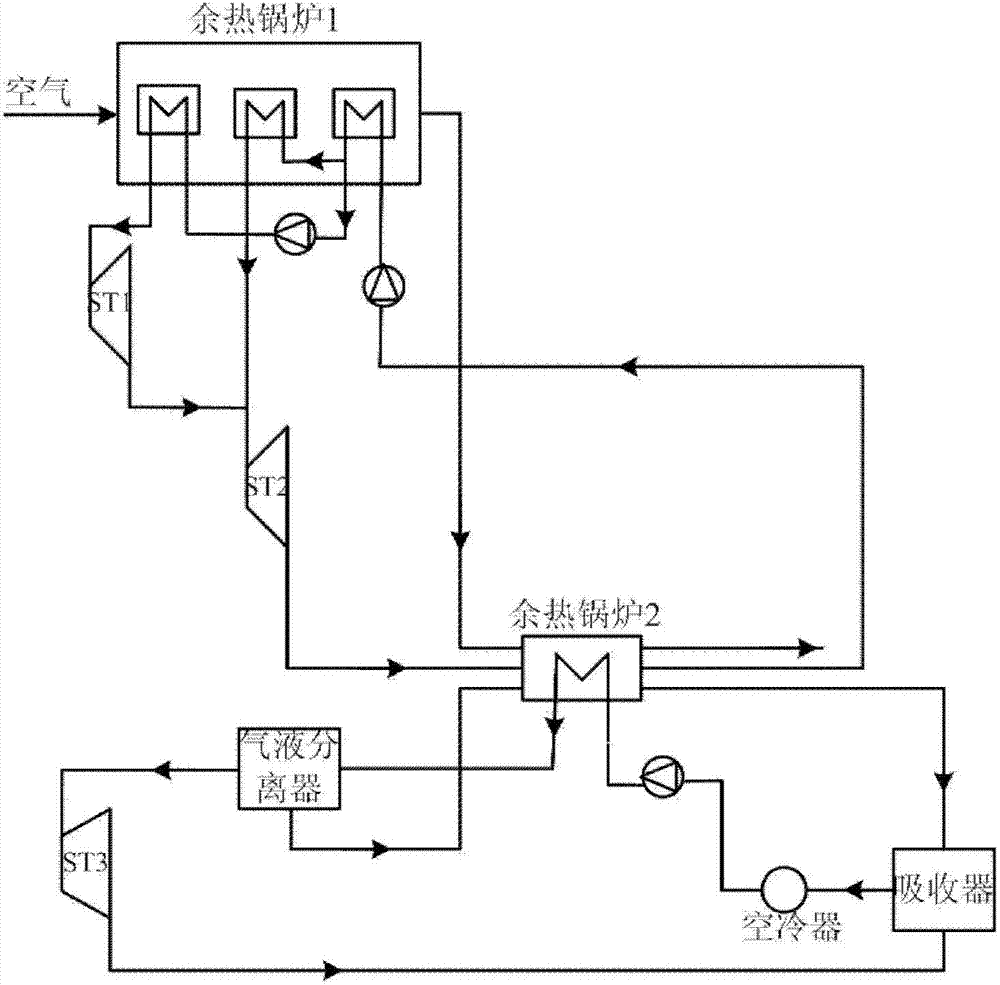

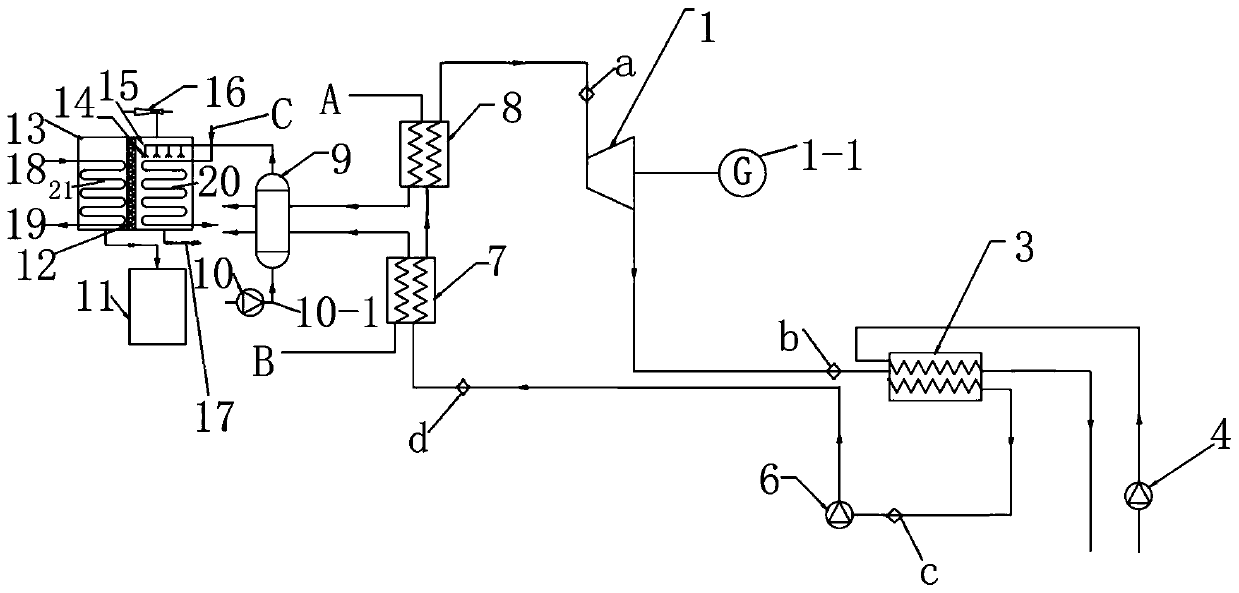

Solar energy combined cycle power generation system for variable irradiation regulation

ActiveCN103925178AAfterburn avoidanceTake advantage ofFrom solar energyGas turbine plantsFossil fuelAutomotive engineering

The invention discloses a solar energy combined cycle power generation system for variable irradiation regulation. The solar energy combined cycle power generation system comprises a tower-type solar heating air heat collecting system, a gas turbine power generation system, a Rankine cycle power generation system, and a Kalina cycle power generation system. According to the solar energy combined cycle power generation system for variable irradiation regulation, a fossil fuel is not required for afterburning during low irradiation, a solar energy storage device is not required, and when the intensity of solar irradiation is relatively low, by means of change of an operation mode, the system bypasses gas turbine cycle and directly supplies heat for Rankine cycle and Kalina cycle, or bypasses gas turbine cycle and Rankine cycle and directly supplies heat for Kalina cycle, so that afterburning of a number of fossil fuel during low irradiation is avoided, and low-irradiation solar energy can fully utilized for solar power generation.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

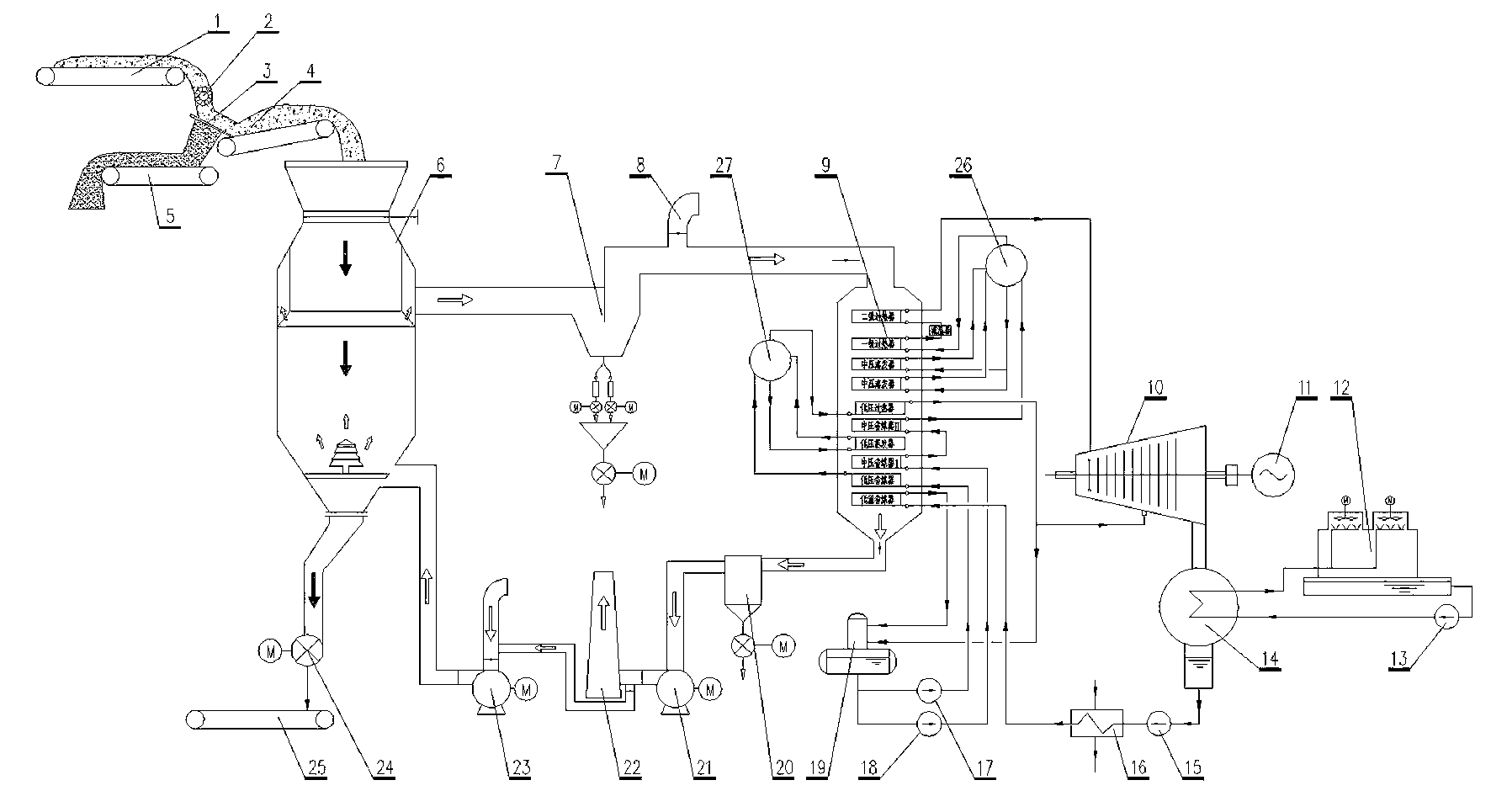

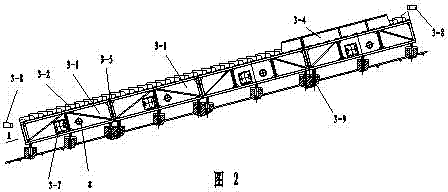

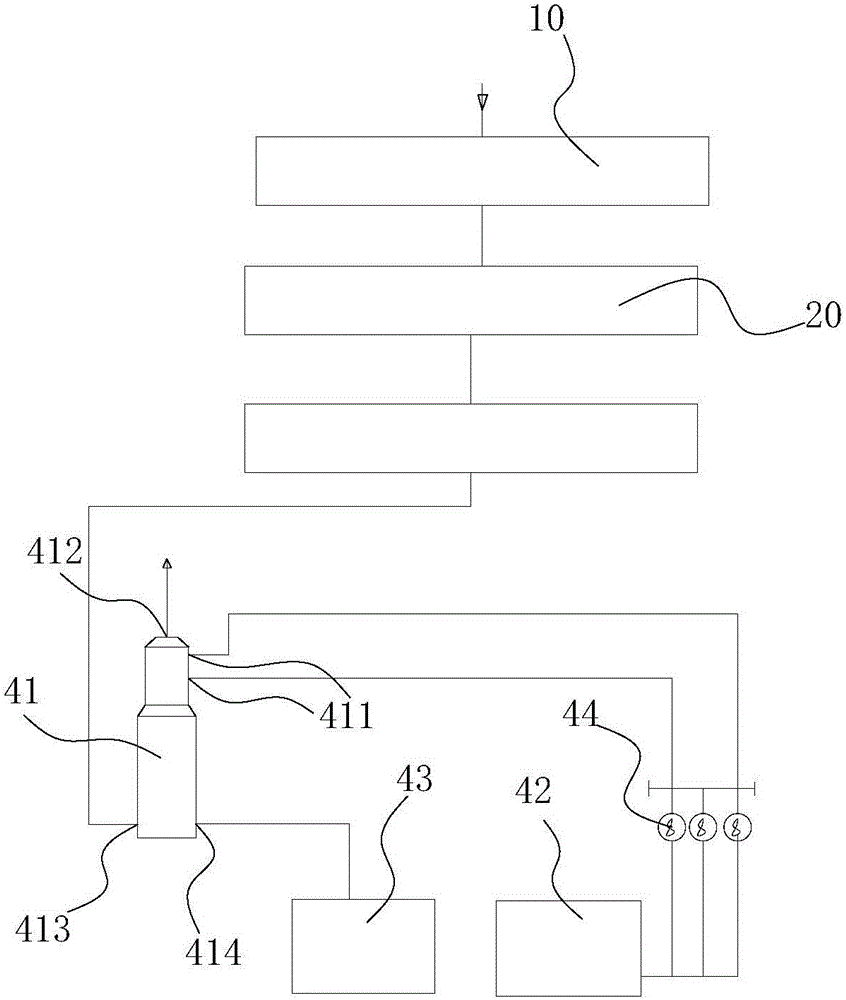

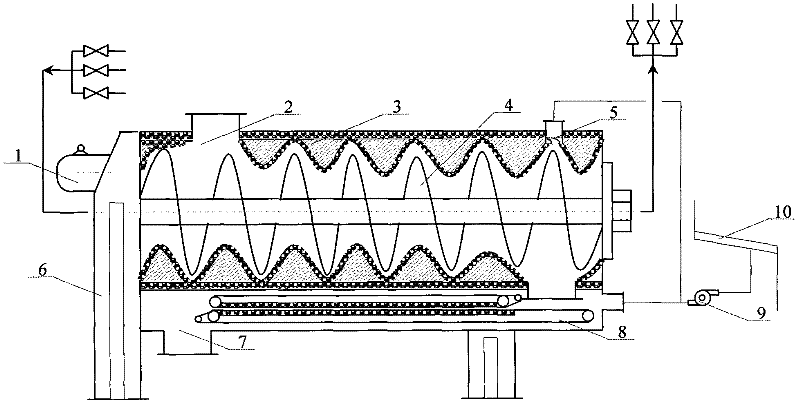

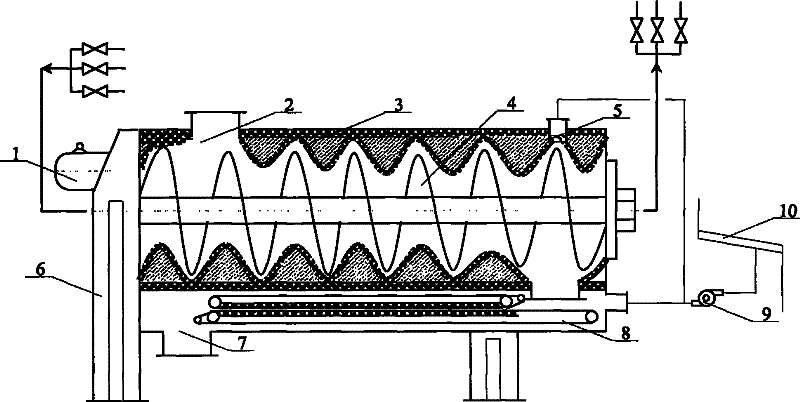

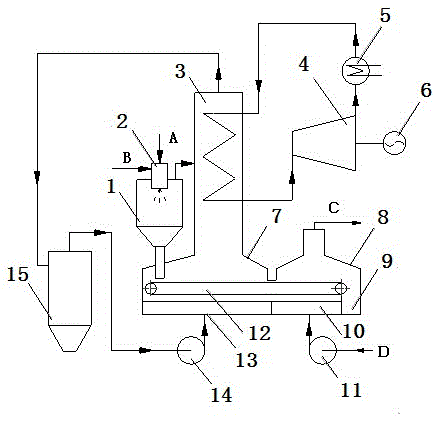

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

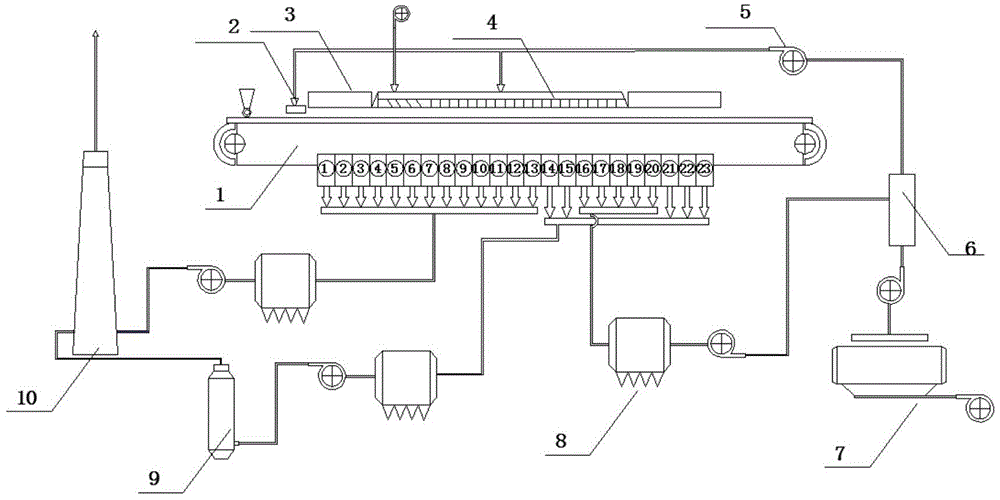

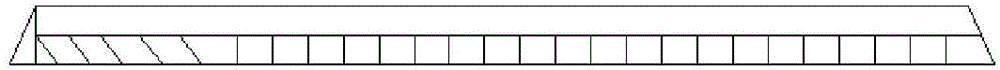

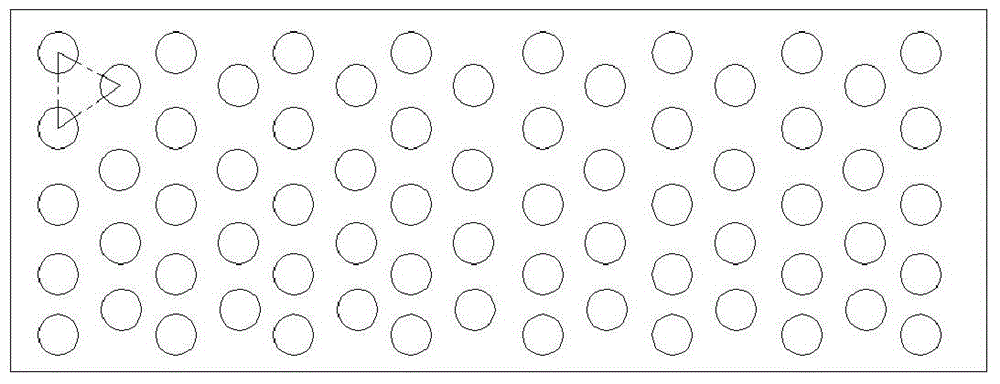

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

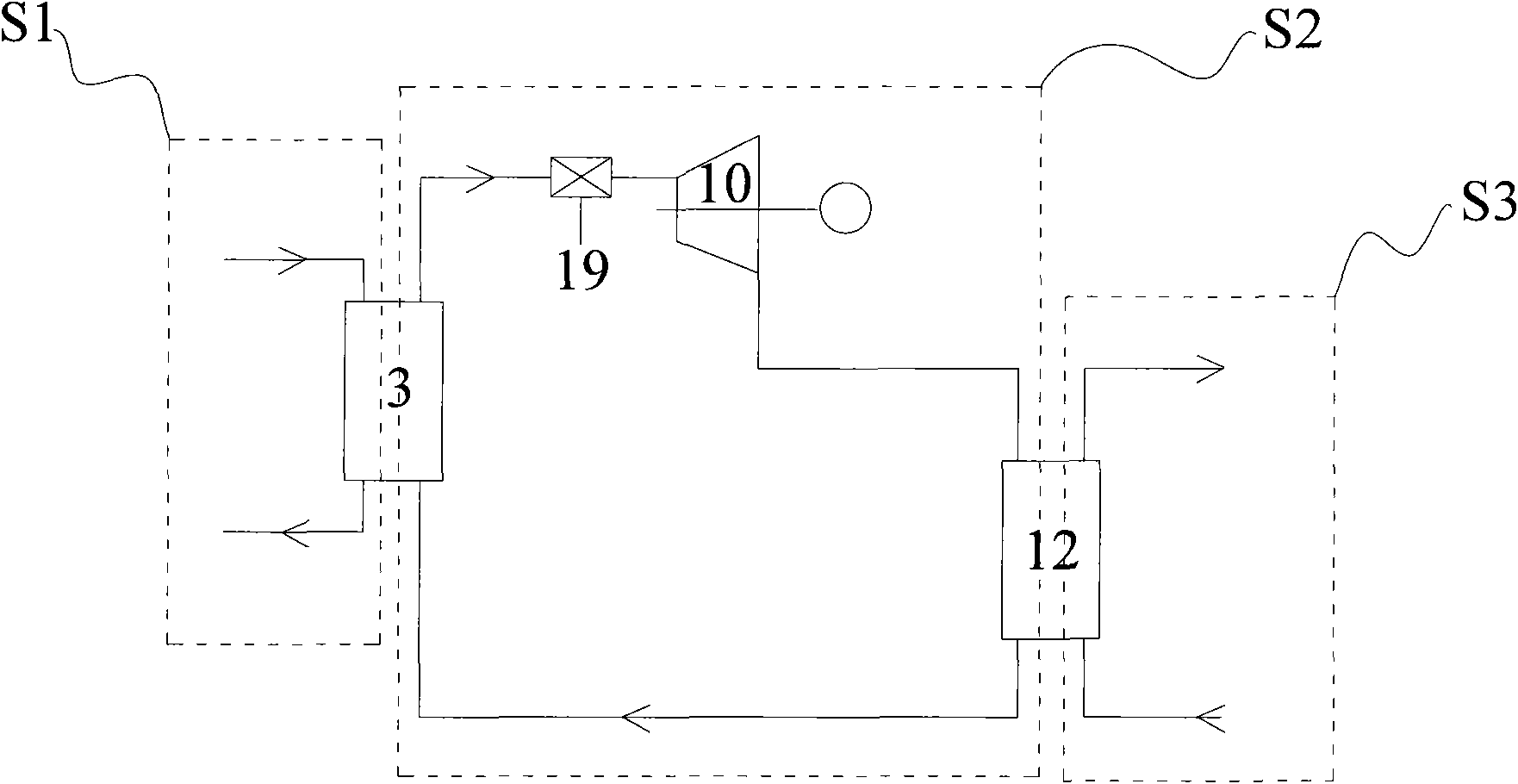

Triangular flash circulating system and method thereof

InactiveCN101871374ATake advantage ofImprove waste heat utilization efficiencyEngine of intermeshing engagement typeSteam engine plantsEngineeringCirculatory system

The invention discloses a triangular flash circulating system, wherein, an evaporator, a decompression mechanism, a first screw expansion power machine and a condenser are sequentially connected together through a pipeline to form a working medium circulating passage; the evaporator is equipped with a heating passage for heating the working medium in the working medium circulating passage; and the condenser is equipped with a cooling passage for cooling the working medium in the working medium circulating passage. In addition, the invention further provides a triangular flash circulating method, comprising the following steps: A. heating the working medium in the working medium circulating passage through the heating passage; B. decompressing the heated working medium so that the working medium reaches a flash critical state; C. allowing the working medium in the flash critical state to enter the screw expansion power machine for flash work; and D. cooling the working medium flowing out of the screw expansion power machine through the cooling passage, and then repeatedly operating the above steps. The triangular flash circulating system and the method thereof provided by the invention can fully utilize residual heat resources and improve residual heat utilization ratio.

Owner:江西华电电力有限责任公司

Air-conditioning device capable of realizing gradient utilization for waste heat of ship, and working method

ActiveCN107289670AImprove waste heat utilization efficiencyAchieving Cascade RecyclingMechanical apparatusAuxillariesSeawaterCogeneration

Owner:JIANGSU UNIV OF SCI & TECH

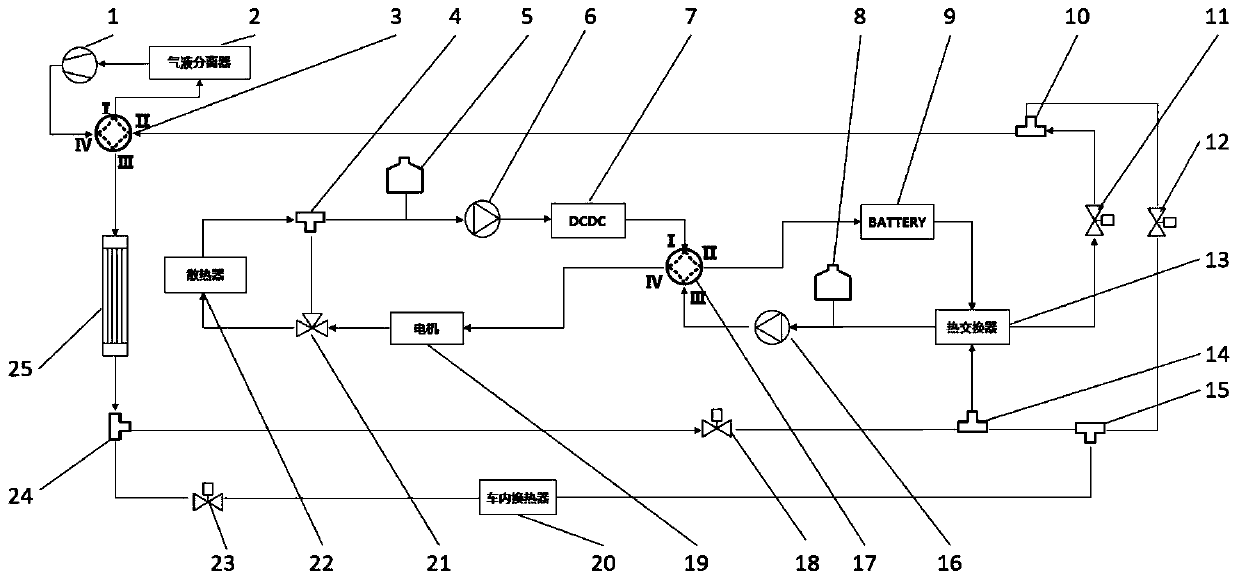

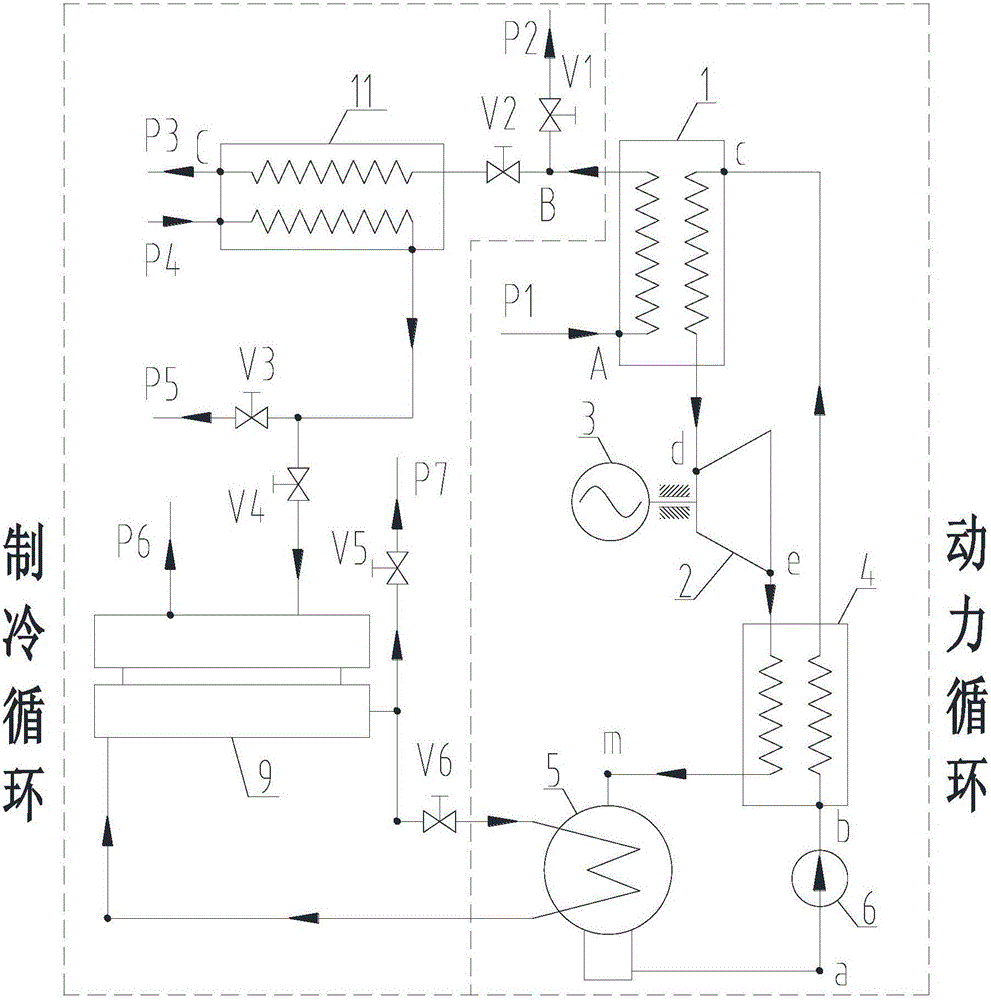

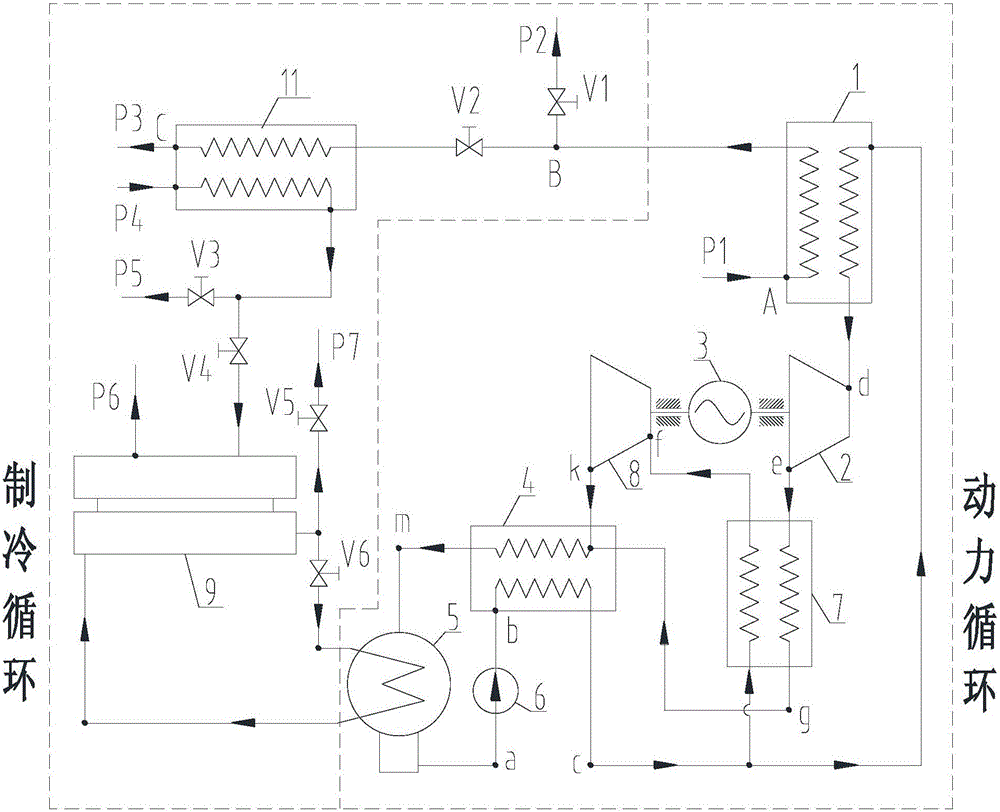

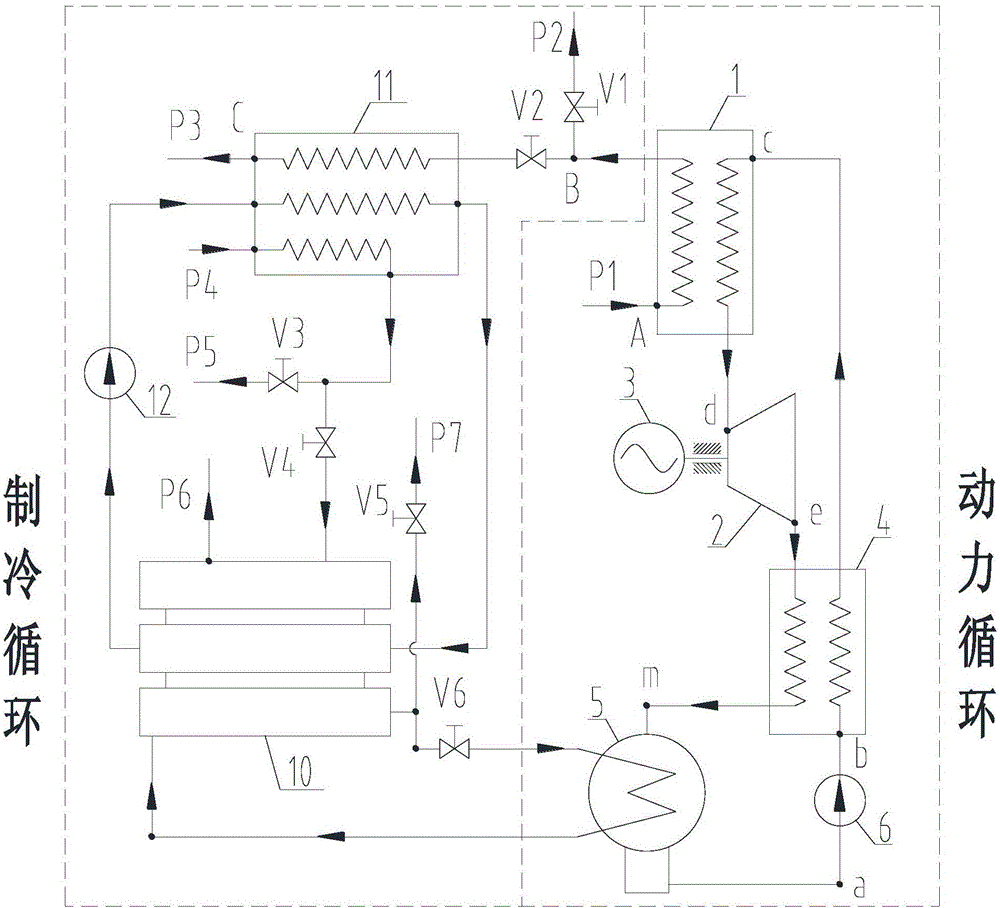

Electric vehicle motor waste heat utilization system and control method thereof

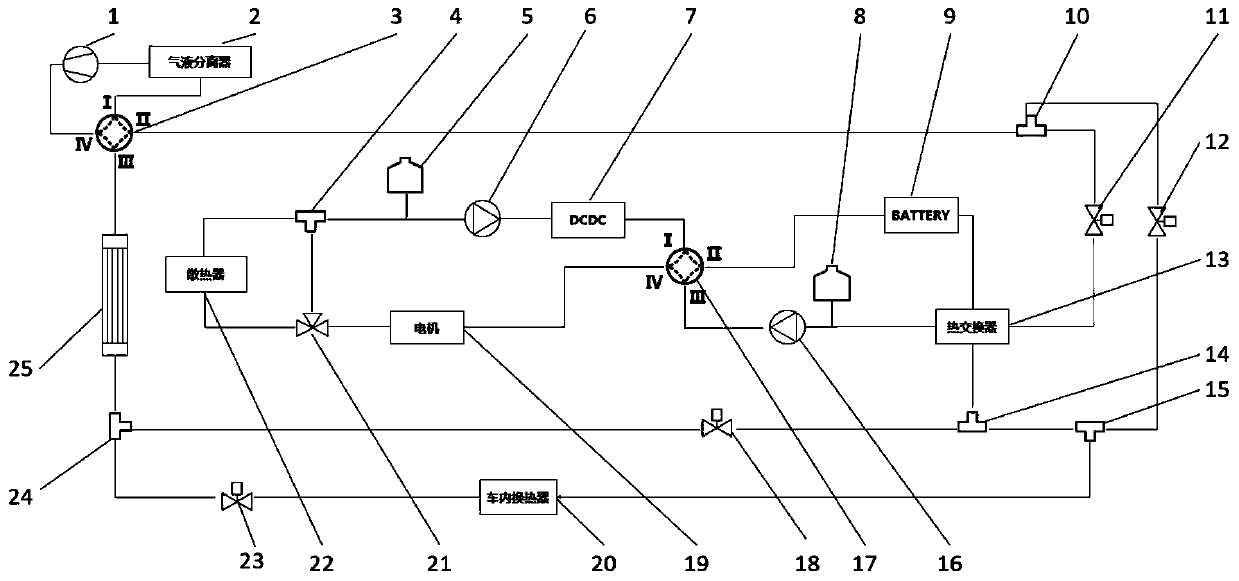

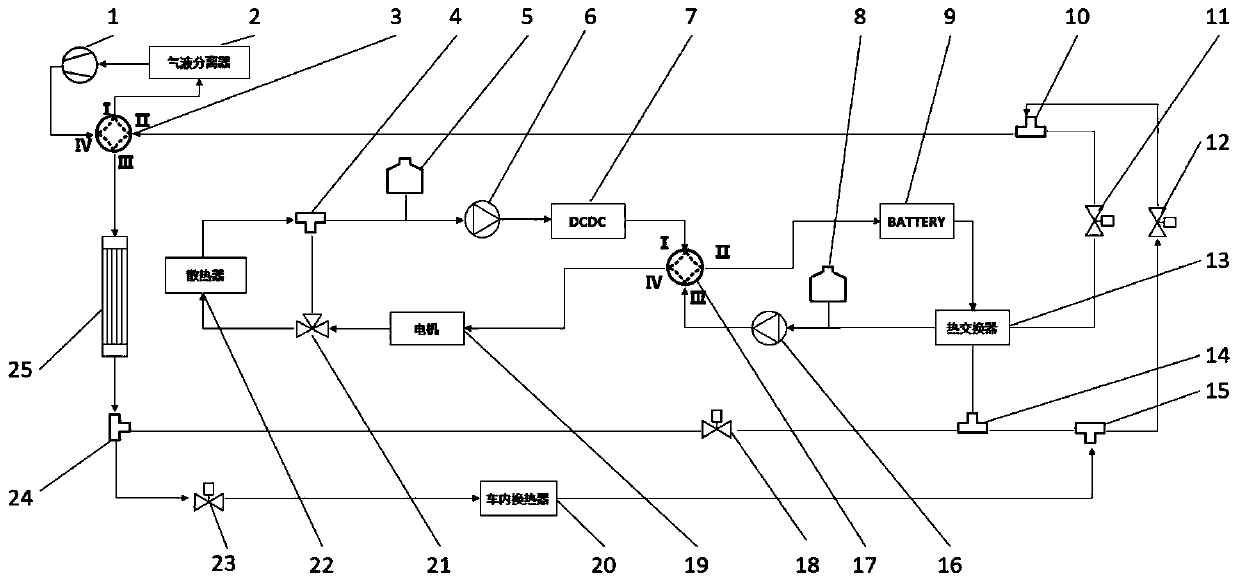

PendingCN111452592ASolve the problem of reduced energy efficiencyReduce consumptionAir-treating devicesElectric propulsion mountingPower batteryTemperature control

The invention discloses an electric vehicle motor waste heat utilization system and a control method thereof, and the system enables a motor temperature control loop to be connected with a cooling liquid loop in a battery through a four-way valve, so that the two loops realize independent circulation or are connected in series into a circulation loop, and the motor waste heat is guided into the battery, and heats the battery. In addition, the system further comprises a refrigerant loop, outside the battery, which is matched with the cooling liquid loop in the battery to achieve temperature control over the power battery, and further comprises a passenger compartment temperature control loop. The control method comprises the steps of independent heating or cooling control of the passenger compartment, independent heating or cooling control of the power battery, simultaneous heating or cooling control of the passenger compartment and the power battery, and utilization control of motor waste heat in the heating process of the power battery. The motor waste heat is introduced into the power battery heat management loop, the control strategy is simple and effective, the system efficiency is improved, the energy consumption is reduced, and the endurance mileage of the whole vehicle is increased.

Owner:FAW CAR CO LTD

CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization

InactiveCN105804818AImprove fuel efficiencyImprove thermal power conversion efficiencyInternal combustion piston enginesSteam engine plantsFuel oilHigh pressure

The invention discloses a CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization. The CO2 Rankine cycle system is a special CO2 Rankine cycle system with CO2 serving as a working medium, waste heat of diesel engine high-temperature flue gas serving as a heat source, and a waste heat driving absorption refrigeration product of diesel engine cooling system hot water serving as a cold source. The CO2 Rankine cycle system is mainly composed of a flue gas waste heat exchanger, CO2 turbines, power equipment, a regenerator, a condenser, a high-pressure pump, a flue gas water heater and an absorption refrigerator. The characteristic that the condensation enthalpy of the CO2 working medium near the critical point is reduced is skillfully utilized; and the efficiency of conversion of heat into power is higher than that of an ORC cycle or other cycles and is obtained through a special cascade stage combined cycle formed by high and low grade waste heat, so that the fuel oil use ratio of a diesel engine is increased by 18%-25% or above. The CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization is capable of achieving waste heat power generation / driving, heat supply and refrigeration poly-generation and has remarkable economic benefits, social benefits and application prospects.

Owner:XI AN JIAOTONG UNIV

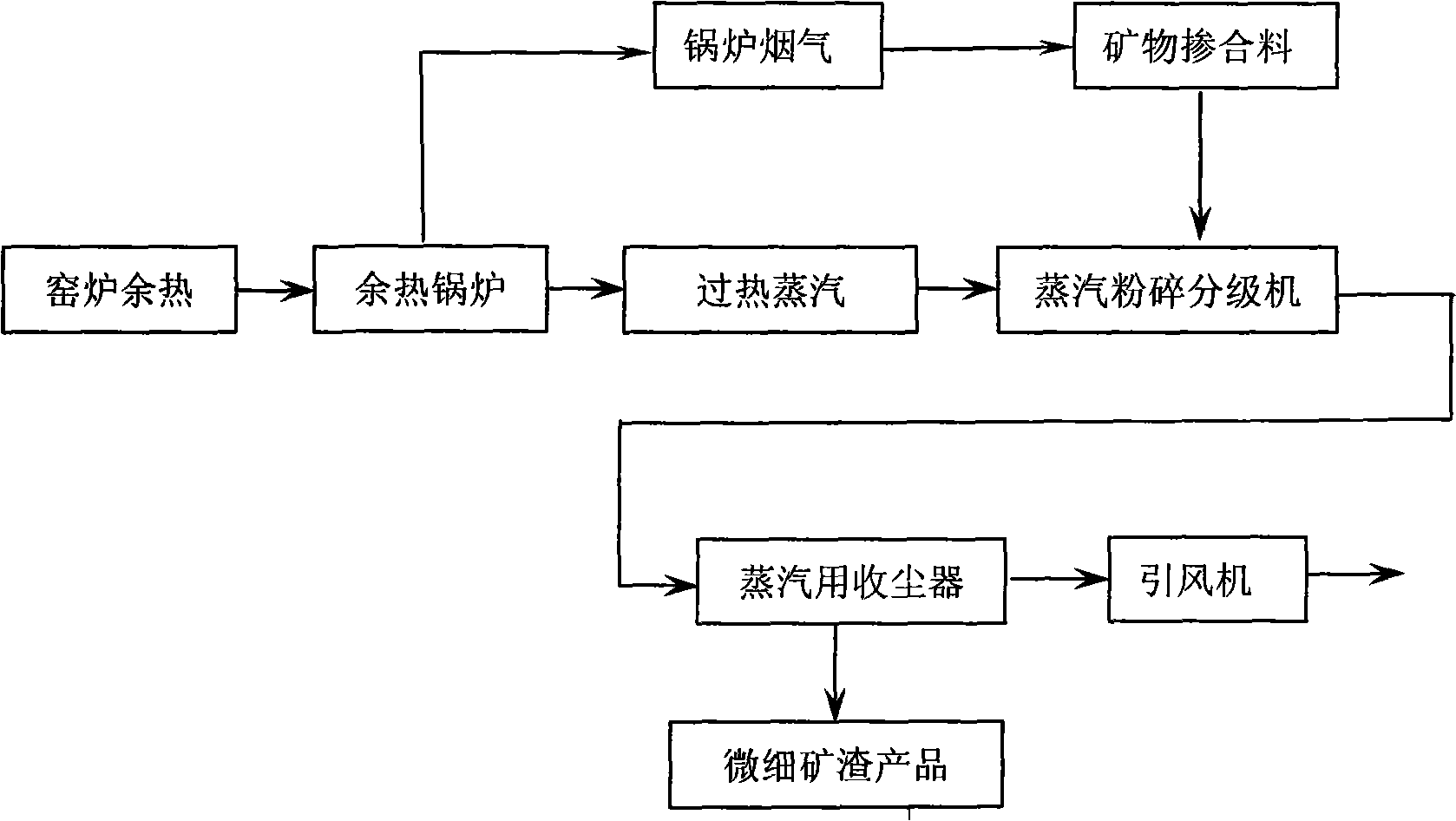

Method for preparing microfine mineral admixture by using waste heat of kiln

InactiveCN101654343AImprove waste heat utilization efficiencyImprove crushing effectSolid waste managementSlagLower grade

The invention discloses a method for preparing a microfine mineral admixture by using the waste heat of a kiln. The method comprises the following steps that: waste heat of waste gas generated by thekiln is used for preparing low-grade superheated vapor in a waste heat boiler; by taking the superheated vapor as power, a vapor stream grinding-grading machine is used for grinding the mineral admixture; and the slag is preheated by fume and delivered into the grinding-grading machine to realize the microfine processing of solid wastes such as the mineral admixture and the like. Compared with theprior technical scheme, the process can perform scale processing of the mineral admixture with low cost, can improve the utilization rate and the added value of the mineral admixture, realizes the resource recycling of wastes and improves environment.

Owner:陈海焱 +1

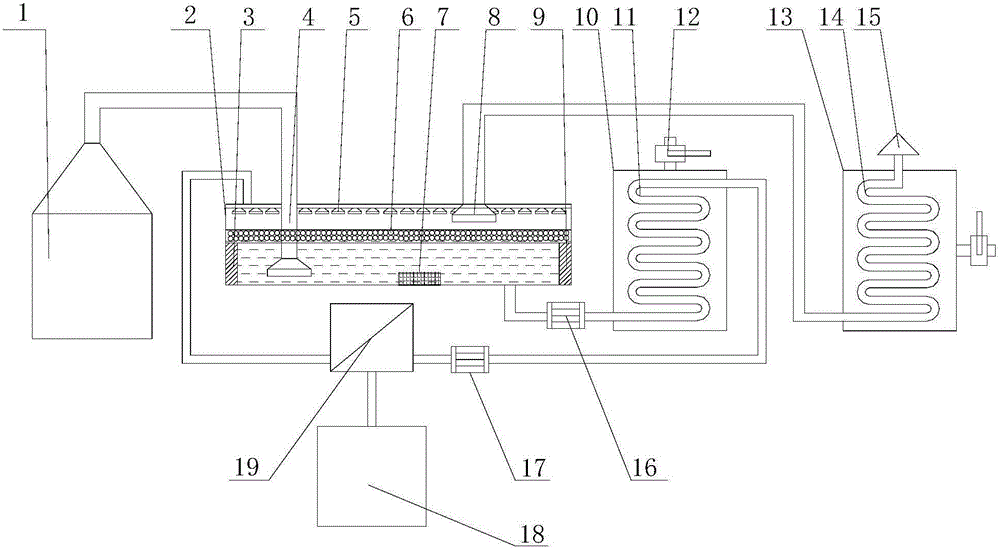

Recovery device for waste heat of waste water

InactiveCN105042933ADecrease productivityReduce stayClimate change adaptationEnergy industryPlate heat exchangerWastewater

The invention discloses a recovery device for waste heat of waste water. The recovery device is innovative in that the recovery device comprises a high-temperature wastewater pool, a sewage pump, a sewage pre-processor, a filter tank, a first-stage heat exchanger, a second-stage heat exchanger, a heat pump, a cold water tank A, a cold water tank B, a hot water tank and a low-temperature wastewater pool; the high-temperature wastewater pool is connected with the filter tank by means of the sewage pre-processor; the filter tank is connected with the first-stage heat exchanger by means of a pipeline; the first-stage heat exchanger is connected with the cold water tank A, the hot water tank and the second-stage heat exchanger; the second-stage heat exchanger is connected with the low-temperature wastewater pool and the heat pump; an evaporator and a condenser are arranged in the heat pump; a compressor and a throttle valve are arranged between the evaporator and the condenser; and one end of the condenser is connected with the cold tank B and the other end of the condenser is connected with the hot water tank. The recovery device for waste heat of waste water has following advantages: by means of two stages of heat exchangers, heat exchange of waste water is performed so that higher utilization efficiency of waste heat is obtained; and waste water is pre-processed before flowing into heat exchangers in order to reduce water dirt staying in the heat exchangers and therefore working efficiency of the heat exchangers is not reduced.

Owner:NANTONG HAOYOU FOOD ADDITIVES

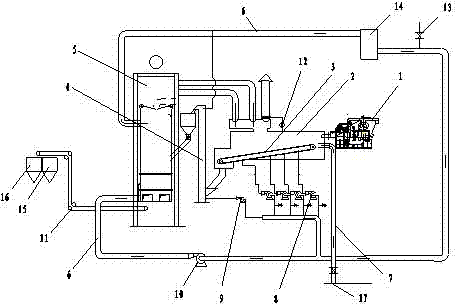

Boiler flue gas purifying and heat exchanging device and application method thereof

InactiveCN105749709AFully recycleReduce lossesCombination devicesGas treatmentActivated carbonFlue gas

The invention relates to a boiler flue gas purifying and heat exchanging device. The boiler flue gas purifying and heat exchanging device comprises a boiler, a flue gas purifying chamber, a first heat exchanger, a second heat exchanger and a reverse osmosis membrane set, wherein the boiler is communicated with a flue inlet in the flue gas purifying chamber through a flue gas pipeline, a flue gas outlet in the flue gas purifying chamber is communicated with the second heat exchanger, a liquid outlet in the flue gas purifying chamber is communicated with the first heat exchanger, the first heat exchanger is communicated with the reverse osmosis membrane set, and the reverse osmosis membrane set is communicated with a liquid inlet in the flue gas purifying chamber; the flue gas purifying chamber comprises a casing, a flue inlet pipe, a DC power supply, a negative electrode, a positive electrode, an activated carbon layer and a flue exhausting pipe; circulation liquid is stored in the casing; a coil pipe is arranged on the first heat exchanger, a heat exchanging flue pipe is arranged on the second heat exchanger, and an outlet in the heat exchanging flue pipe is communicated with a chimney. According to the boiler flue gas purifying and heat exchanging device disclosed by the invention, when flue gas is purified through the flue gas purifying chamber, the circulation liquid in the flue gas purifying chamber directly performs heat exchange with the flue gas; the circulation liquid is in direct contact with the flue gas, so that the heat exchanging efficiency is high, and the heat loss is low.

Owner:JIANGSU JINYUAN TENGFENG HEAT EXCHANGE EQUIP CO LTD

Method for online production of sponge iron by using steel residue waste heat

InactiveCN102851427AImprove waste heat utilization efficiencyLess investmentIncreasing energy efficiencyRetort furnacesSteelmakingMixed materials

The present invention discloses a method for online production of sponge iron by using steel residue waste heat. The method comprises the following steps: 1) uniformly mixing raw materials and a reducing agent according to a weight percentage ratio of 1:0.1-1, and filling the resulting mixed material into a high temperature resistance reaction tank; 2) pouring steel residue of a steelmaking furnace into a residue tank, then placing the reaction tank on the surface of the residue tank steel residue or sinking the reaction tank portion into the steel residue, such that the steel residue waste heat is transferred to the high temperature resistance reaction tank, and the raw materials and the reducing agent in the high temperature resistance reaction tank are heated, and subjected to an oxidation reduction reaction to produce the sponge iron. According to the present invention, the steel residue waste heat is completely utilized, and the waste material is adopted to produce the sponge iron during the normal treatment process of the steelmaking steel residue, such that steel residue waste heat utilization efficiency is effectively improved, recovery utilization rate and value of the waste material are substantially improved, steelmaking cost and sponge iron production cost are reduced, characteristics of extremely low investment, simple operation, convenient performing, energy saving, emission reduction, high finished iron grade, and the like are provided, and the method can be applicable for promotion and application in iron and steel enterprises with various types and various sizes.

Owner:杨龙

Equipment for steel slag air quenching and waste heat recycling

ActiveCN102952908AExpand the scope of processingImprove mobilityIncreasing energy efficiencyManufacturing convertersQuenchingSlag

Equipment for steel slag air quenching and waste heat recycling belongs to the technical field of the steel slag processing equipment and method. Steel slag air quenching and waste heat recycling processes are utilized to treat high-temperature steel slags and recovering heat; and the technical scheme is as follows: in the equipment, an air quenching slag pot is connected with a pelletization air tunnel which is connected with a grate cooling conveyor; the grate cooling conveyor is connected with a high-temperature-resistant bucket elevator; the high-temperature-resistant bucket elevator is connected with a circulating fluidized bed heat recovery boiler; an external nitrogen pipeline is connected with the pelletization air tunnel and the grate cooling conveyor, respectively; and a nitrogen circulating pipeline is connected with the high-temperature-resistant bucket elevator and the circulating fluidized bed heat recovery boiler, respectively. The process flow comprises hardening and cracking liquid-state steel slags into even particles by using low-temperature nitrogen, and then feeding the steel slag particles to the circulating fluidized bed heat recovery boiler through pneumatic transmission so as to collect waste heat and zero-valent iron. The integrated steel slag air quenching process provided by the invention is in a world leading level and is innovation of liquid-state steel slag treatment and heat recovery, thereby having wide prospect.

Owner:唐钢国际工程技术有限公司

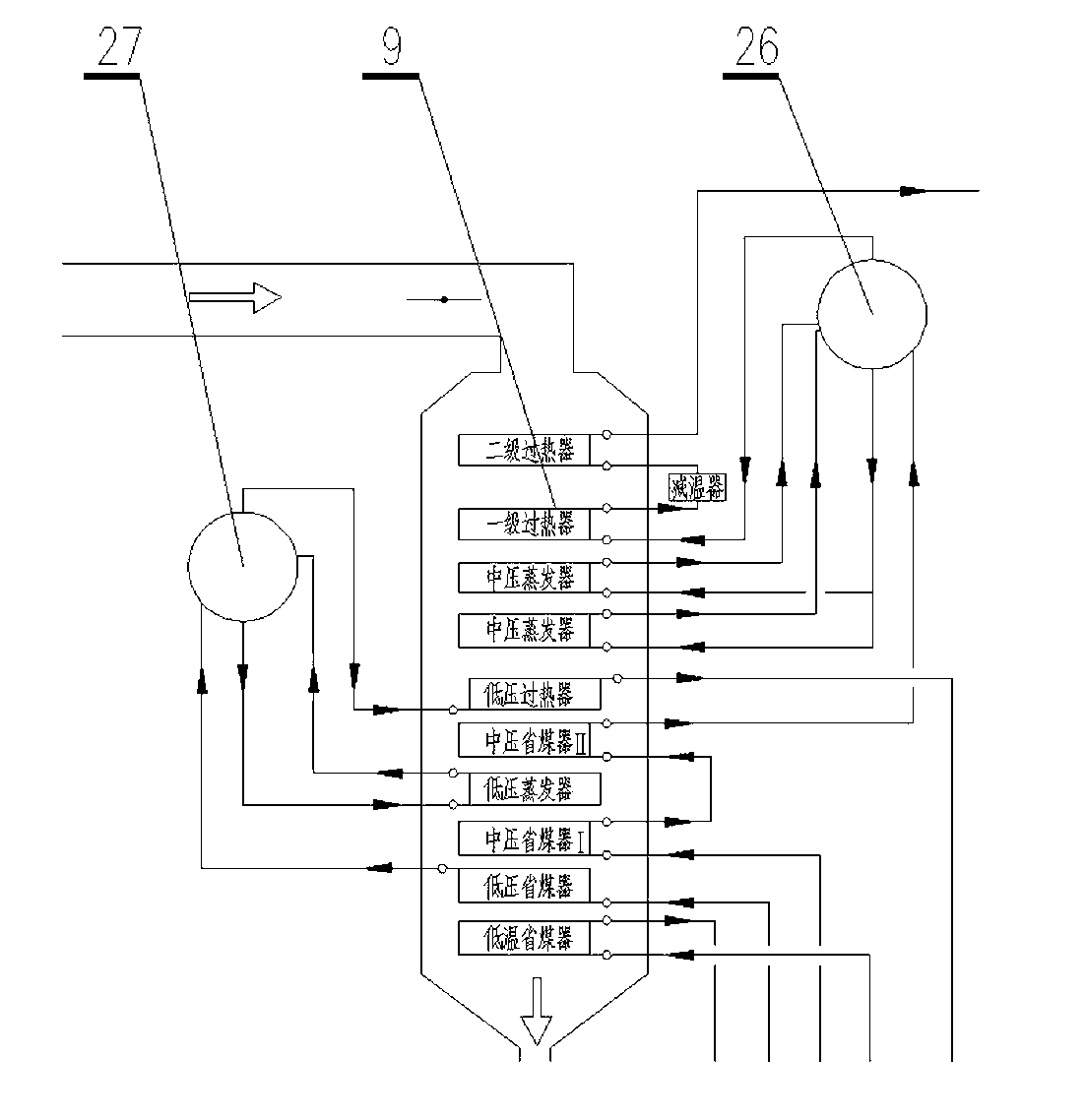

Power generation system utilizing waste heat of high-temperature flue gas

ActiveCN106321174AImprove qualityLower exhaust gas temperatureLiquid degasificationEnergy industryFlue gasEngineering

A power generation system utilizing waste heat of high-temperature flue gas comprises a dual-pressure waste heat boiler with a reheater arranged therein, wherein high-pressure steam of the dual-pressure waste heat boiler is pumped into a back-pressure turbo generator set to conduct power generation; steam obtained after power generation of the turbo generator set returns to the dual-pressure waste heat boiler to be heated by the reheater; and the reheated steam passes through a steam pipeline and enters the turbo generator set for power generation. The power generation system is provided with the dual-pressure waste heat boiler, which utilizes waste heat to produce high-temperature high-pressure or ultrahigh-pressure main steam and low-pressure steam and has the reheating function, and the main steam produced by the waste heat boiler is used for power generation through the high-temperature high-pressure or ultrahigh-pressure back-pressure turbo generator set.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Power generation and sea water desalination device based on marine diesel engine waste heat

ActiveCN110145407AHas a low boiling pointIncrease temperatureInternal combustion piston enginesGeneral water supply conservationWater desalinationEvaporation

The invention relates to the technical field of marine diesel engines, in particular to a power generation and sea water desalination device based on marine diesel engine waste heat. The device comprises a waste heat power generation unit and a sea water desalination unit, wherein the waste heat power generation unit comprises an expander, an electric generator, a condenser, a working medium pump,a gas temperature adjuster and an evaporator; the sea water desalination unit comprises a multi-heat-source heat exchanger and a distilled sea water desalination device, a pressurized air pipeline ofa marine diesel engine is in pipeline connection with the second input end of the gas temperature adjuster, a smoke pipeline of the marine diesel engine is in pipeline connection with the second input end of the evaporator, sleeve barrel cooling water of the marine diesel engine is in pipeline connection with an evaporation coil pipe of the distilled sea water desalination device, three recyclingwaste heat sources of the marine diesel engine are sufficiently used, smoke waste heat and pressurized air waste heat of the marine diesel engine can be used at twice in a gradability manner, and thewaste heat use efficiency of the marine diesel engine can be improved.

Owner:GUANGDONG OCEAN UNIVERSITY

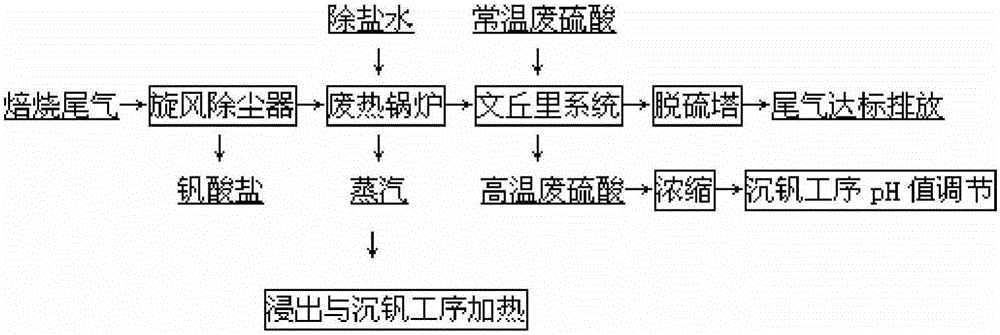

Treating method for vanadium slag roasting tail gas

InactiveCN105727727AReduce coal consumptionImprove waste heat utilization efficiencyGas treatmentDispersed particle separationSlagSulfide

The invention belongs to the field of production of vanadium pentoxide, and particularly relates to a treating method for tail gas produced after vanadium slat is roasted through a rotary kiln. The method comprises the following steps that a, vanadium slag roasting tail gas enters a dust removal system and is separated to obtain vanadate and tail gas I, wherein the vanadate is transferred into a pulping groove; b, the tail gas I enters a waste heat boiler system and exchanges heat with process water supplied externally to be cooled, tail gas II is obtained, and the process water is changed into saturated vapor to be supplied externally; c, the tail gas II enters a Venturi system to be cooled further, and tail gas III is obtained; d, the tail gas III enters a desulfurizing tower from the bottom and makes countercurrent contact with alkali liquor sprayed on the top, defogging is carried out, up-to-standard emission is carried out, and the alkali liquor enters a sewage treating system. By means of the method, the vanadium pentoxide rotary kiln roasting tail gas waste heat utilization rate can be improved, sulfide in the roasting gas can be discharged on standard completely, and therefore a new technological process of clean production of a vanadium pentoxide roasting tail gas system is achieved.

Owner:PANZHIHUA UNIV

Waste-heat utilization triple generation system for blast furnace slag water employing minter process

ActiveCN103834754AIncrease savingsImprove heat transfer efficiencyHeat recovery systemsIncreasing energy efficiencySlagWater quality

The invention relates to a waste-heat utilization triple generation system for blast furnace slag water employing a minter process. The waste-heat utilization triple generation system comprises a granulating device, wherein the granulating device is orderly communicated with a slag-water separating device, a settling pond and a sediment heat storage pool, wherein the sediment heat storage pool is connected with a first inlet of a heat exchange device by virtue of a waste heat water supply pump group; a first outlet of the heat exchange device is communicated with a granulating reservoir; a second inlet of the heat exchange device is respectively connected with the outlet of a heating user and the first outlet of a refrigeration mechanism through heating water supply pump groups; the inlet of the heating user and the first inlet of the refrigeration mechanism are communicated with the second outlet of the heat exchange device; the second inlet of the refrigeration mechanism is communicated with the second outlet of the refrigeration mechanism by virtue of an indoor refrigeration user and a dehumidified blast user; the outlet of the granulating reservoir is communicated with the granulating device by virtue of the granulating water supply pump group. The system is applied to triple generation of heating, refrigerating or blast furnace dehumidified blasting, and is high in heat efficiency and stable in water quality.

Owner:WISDRI ENG & RES INC LTD

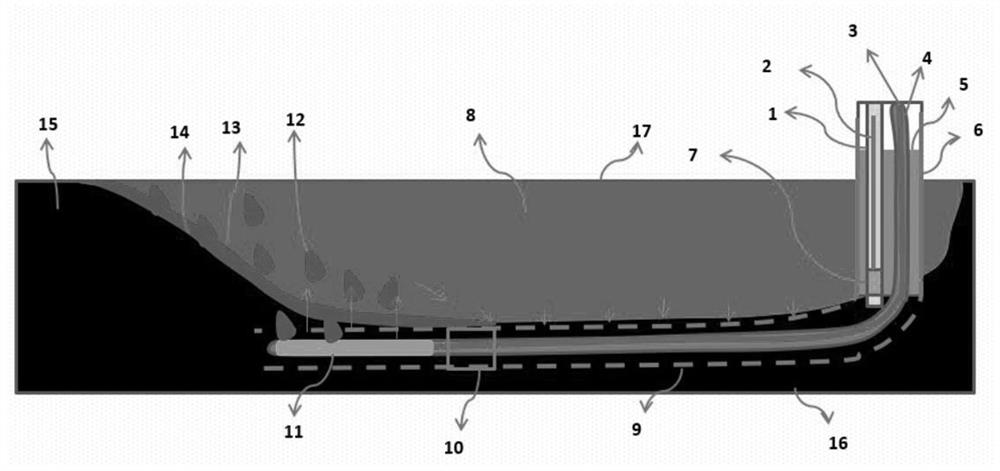

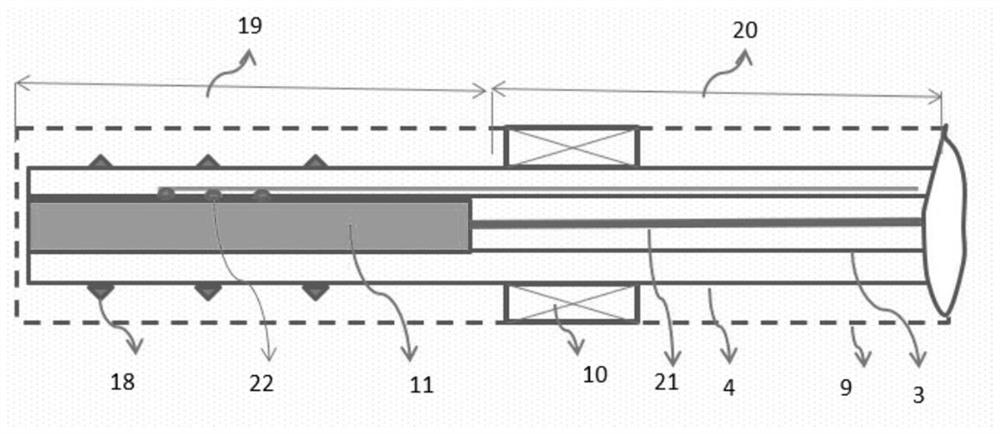

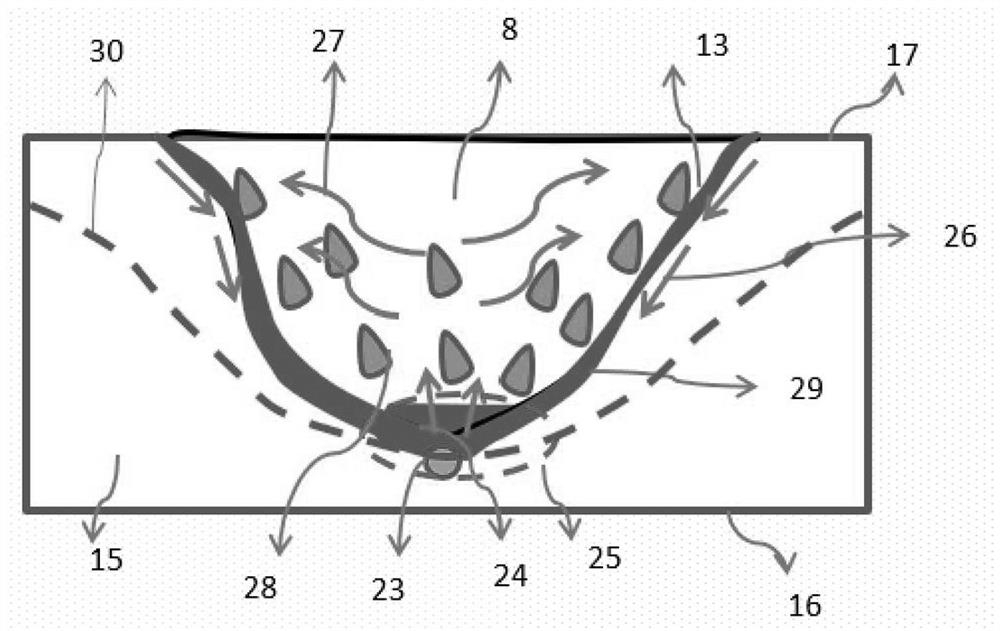

Method for in-situ production of solvent in oil layer to exploit thickened oil

The invention relates to a method for the in-situ production of solvent in an oil layer to exploit thickened oil. The method includes the steps that crude oil in the oil layer near a shaft is heated to a target temperature by using an electric heating device, a chemical reaction assistant is injected into a heating section to achieve the reaction condition of high-temperature hydrothermal crackingof the crude oil, light oil components and gas generated move upwards to a vapor cavity under the action of heating power and gravity, and the light oil and part of gas transferred to a vapor-liquidinterface are dissolved into the crude oil to reduce the viscosity of the crude oil and increase the yield of the crude oil; non-condensed gas left in the vapor cavity is used for expanding and supplementing energy for the vapor cavity, so that the heat loss of the vapor cavity to a top cover layer is reduced; and the crude oil discharged to a cracking reaction section is heated and then continuesto be cracked, and the crude oil discharged to a production section enters into a screen pipe and then is lifted to the ground through an underground pump. According to the method for the in-situ production of the solvent in the oil layer to exploit the thickened oil, the solvent is generated in the oil layer in situ to achieve solvent-assisted thickened oil recovery, so that the heat utilizationrate is increased, the CO2 emission is reduced, the final recovery ratio is increased, and the method has wide market application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

Sludge drying equipment using waste heat of landfill gas power generation

ActiveCN102351396ALower discharge temperatureReasonable structureSludge treatment by de-watering/drying/thickeningWaste based fuelSludgeFlue gas

The invention provides sludge drying equipment using waste heat of landfill gas power generation, which belongs to environmental protection equipment. The equipment employs waste heat of condensed water of a landfill gas power generator assembly, flue gas, waste water and the like to heat and dry sludge entering into the equipment with a hollow stirrer in the sludge drying equipment, and can recycle condensed water of the power generator assembly and reduce the temperature of flue gas and waste water to be discharged; the outer walls of a stirring drying cabin and a spindle are provided with vacuum heat pipes, and a conveying drying cabin is also provided with vacuum heat pipes, which enables a low grade heat source in the stirring drying cabin to be recycled again and to be used for redrying sludge in the conveying drying cabin, thereby realizing reutilization of the waste heat of landfill gas power generation. The sludge drying equipment provided in the invention has the advantages of a reasonable structure, a high waste heat utilization rate, a good sludge drying effect, strong capability of continuous working, etc.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Cascade utilization system for blast furnace slag waste heat

InactiveCN105567889AReduce wind speedLow flow resistanceRecycling and recovery technologiesSteam generation using hot heat carriersTurbo generatorSlag

The invention relates to a cascade utilization system for blast furnace slag waste heat. A molten blast furnace slag granulating device is connected with a separator. A slag particle discharging pipe of the separator is connected with a first gas collecting cover. An outlet of the first gas collecting cover is connected with a first inlet of a waste heat boiler. A gas discharging pipe of the separator is connected with a second inlet of the waste heat boiler. A tail gas outlet of the waste heat boiler is connected with an inlet of a dust remover. An outlet of the dust remover is connected with an inlet of a circulating fan. An outlet of the circulating fan is connected with an inlet of a first wind chamber. An outlet of an air feeder is connected with an inlet of a second wind chamber. An outlet of the first wind chamber and an outlet of the second wind chamber are connected with a gas inlet in the bottom of a cooling machine. A gas outlet in the top of the cooling machine is connected with an inlet of the first gas collecting cover and an inlet of a second gas collecting cover. The tail end of the cooling machine is connected to a slag pit. Through the cascade utilization system, the functions that molten blast furnace slag is granulated, the blast furnace slag high-grade heat is recycled to generate steam used for generating electricity through a turbo generator set, the blast furnace slag low-grade heat is recycled to preheat air fed to a hot air furnace, tail gas is purified can be achieved. The utilization efficiency of the blast furnace slag waste heat is high, and the good energy-saving and environment-friendly effects are achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

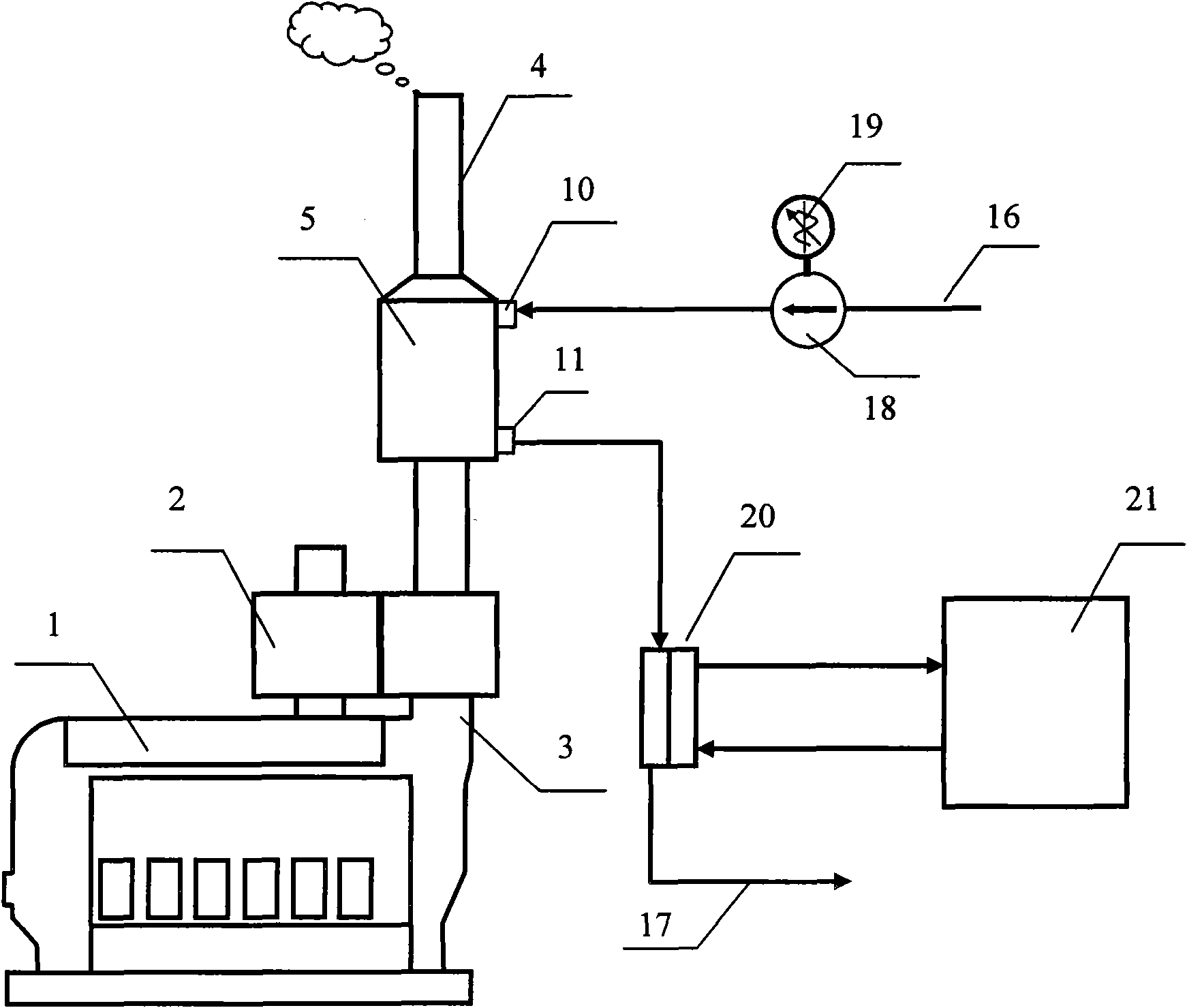

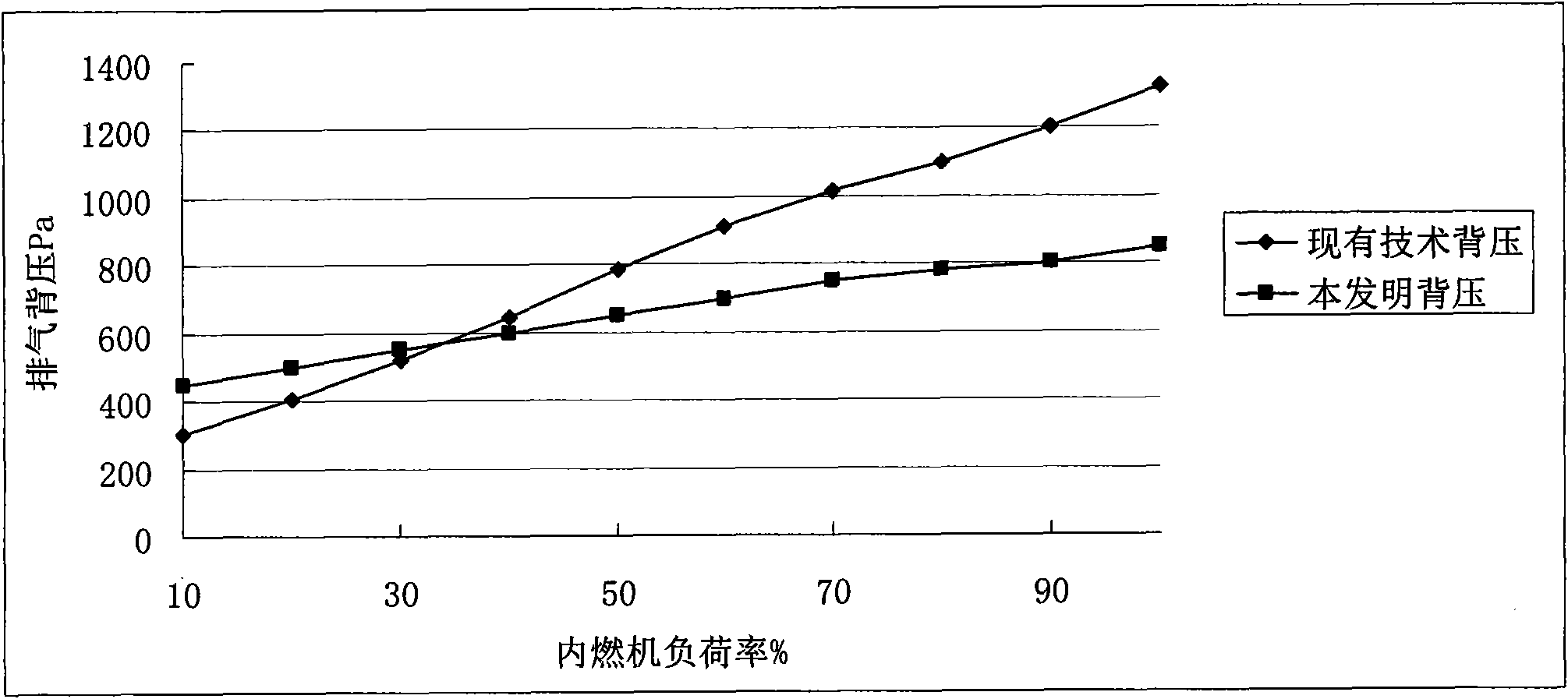

Method, device and system for optimizing exhaust back pressure of internal combustion engine

InactiveCN102852596AHigh expansion ratioIncrease resistanceGas treatmentInternal combustion piston enginesExternal combustion engineInternal combustion engine

The invention provides a method for optimizing exhaust back pressure of an internal combustion engine. The method comprises arranging a damping component in an exhaust passage of the internal combustion engine, and enabling tail gas exhausted out of the internal combustion engine to pass the damping component; and enabling the tail gas to be cooled before passing the damping component, or enabling the tail gas to be cooled while passing the damping component. Through the method, the internal combustion engine has the high exhaust back pressure when in a low load, and the exhaust back pressure does not rise too quickly when the internal combustion engine is in a high load. The invention further provides a device and system for optimizing the exhaust back pressure of the internal combustion engine.

Owner:彭斯干

Popular searches

Great effort Guaranteed uptime Increase waste heat power generation Achieve the goal of energy saving and emission reduction Realize collaborative control Improve recycling efficiency Process energy saving and environmental protection Flexible adjustment Great operating flexibility Reduce manufacturing cost

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com