Method for preparing microfine mineral admixture by using waste heat of kiln

A technology of mineral admixture and waste heat, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of waste heat waste, low utilization efficiency and limited usage of kilns, and achieve the goal of improving the environment Pollution, strong crushing force, and the effect of reducing processing costs

Inactive Publication Date: 2010-02-24

陈海焱 +1

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, preheating air, preheating gas, heating, and other domestic heat only use kiln waste heat as a heat source, and the amount of use is limited. A large amount of kiln waste heat is wasted, and most of the kiln waste heat is used for power generation at this stage. The thermal energy utilization rate is about 22%, so the utilization efficiency is low and the investment is large; these methods of utilizing the waste heat of the kiln fail to fully and effectively utilize the energy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

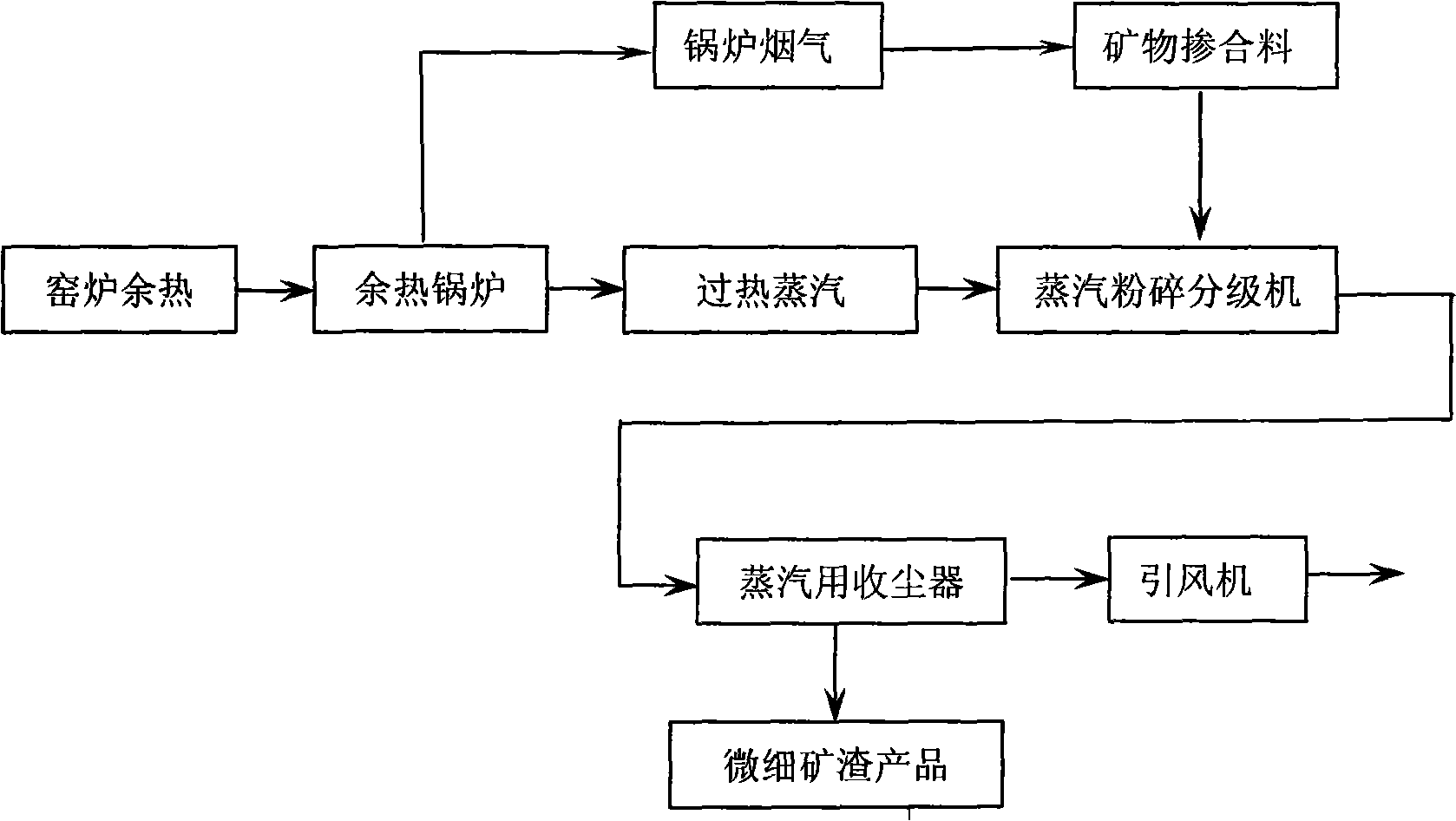

[0014] Below in conjunction with embodiment for further explanation. Specific embodiments of the present invention are as attached to the specification figure 1 shown. The waste heat of the kiln is used to heat the waste heat boiler, and the superheated steam produced by the waste heat boiler is used as the power of the steam pulverizer. Slag powder and waste steam are discharged by induced draft fan.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for preparing a microfine mineral admixture by using the waste heat of a kiln. The method comprises the following steps that: waste heat of waste gas generated by thekiln is used for preparing low-grade superheated vapor in a waste heat boiler; by taking the superheated vapor as power, a vapor stream grinding-grading machine is used for grinding the mineral admixture; and the slag is preheated by fume and delivered into the grinding-grading machine to realize the microfine processing of solid wastes such as the mineral admixture and the like. Compared with theprior technical scheme, the process can perform scale processing of the mineral admixture with low cost, can improve the utilization rate and the added value of the mineral admixture, realizes the resource recycling of wastes and improves environment.

Description

(1) Technical field: [0001] The invention relates to a production method of an ultrafine mineral admixture, in particular to the preparation of an ultrafine mineral admixture by utilizing waste heat of a kiln. (two) background technology: [0002] Slag powder is used as the main mineral admixture of cement and concrete. In order to improve the activity of the mineral admixture, it needs to be micro-processed. However, the processing cost of fine slag powder is expensive, and the amount of admixture in cement and concrete has not been large for a long time. , a large amount of slag is dumped as solid waste. According to the statistics of the National Environmental Bulletin, the national industrial solid waste production in 2006 was 1.52 billion tons. At present, in the cement concrete industry, the demand for slag powder as an admixture is increasingly tense, which cannot meet the strong engineering demand, and the comprehensive utilization of solid industrial waste is immine...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B18/12C04B20/02

CPCY02W30/91

Inventor 陈海焱胥海伦张明星林泷沅

Owner 陈海焱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com