Sludge drying equipment using waste heat of landfill gas power generation

A technology of drying sludge and biogas power generation, which is applied in dehydration/drying/thickened sludge treatment, waste fuel, etc., can solve the problems of low waste heat utilization efficiency, slow progress of low-grade heat sources, and limited application fields, etc. The mud drying effect is good, the drying time is shortened, and the drying evaporation area is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

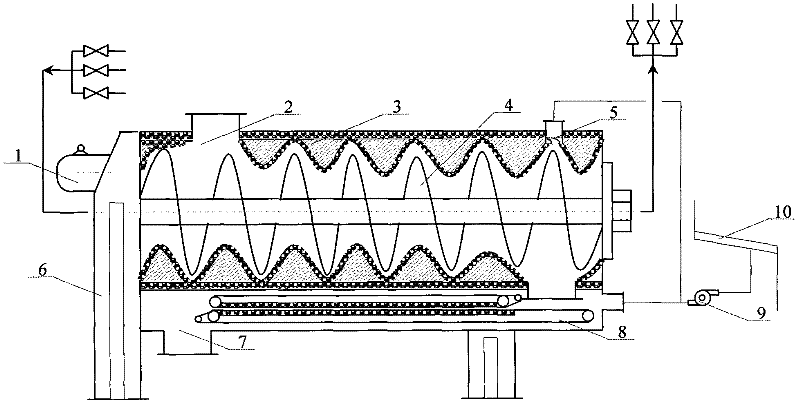

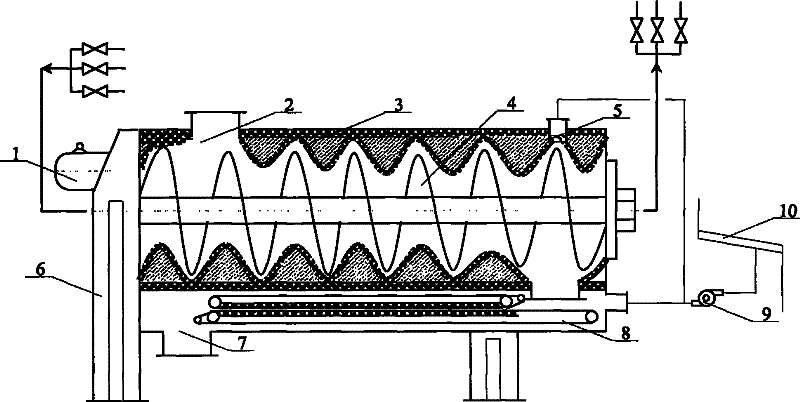

[0013] The utility model relates to waste heat drying sludge equipment for landfill biogas power generation, including a generator system. The drying sludge equipment is composed of a stirring and drying bin 2, a conveying and drying bin 7, a motor 1, a hollow agitator 4 and a conveying unit 8, and the conveying and drying bin 7 is closed and connected under the stirring and drying bin 2, In addition, the outlet of the stirring and drying bin 2 is located inside the conveying and drying bin 7, and the sludge conveying unit 8 is arranged inside the conveying and drying bin 7. The sludge conveying unit 8 is composed of an upper conveyor belt and a lower conveyor belt, and the upper conveyor belt is located in the stirring and drying bin. 2 and the outlet of the conveying and drying bin 7, the lower conveyor belt is located between the outlet of the stirring and drying bin 2 and the outlet of the conveying and drying bin 7, and discharges the dried sludge out of the equipment. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com