Patents

Literature

61results about How to "Improve continuous operation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

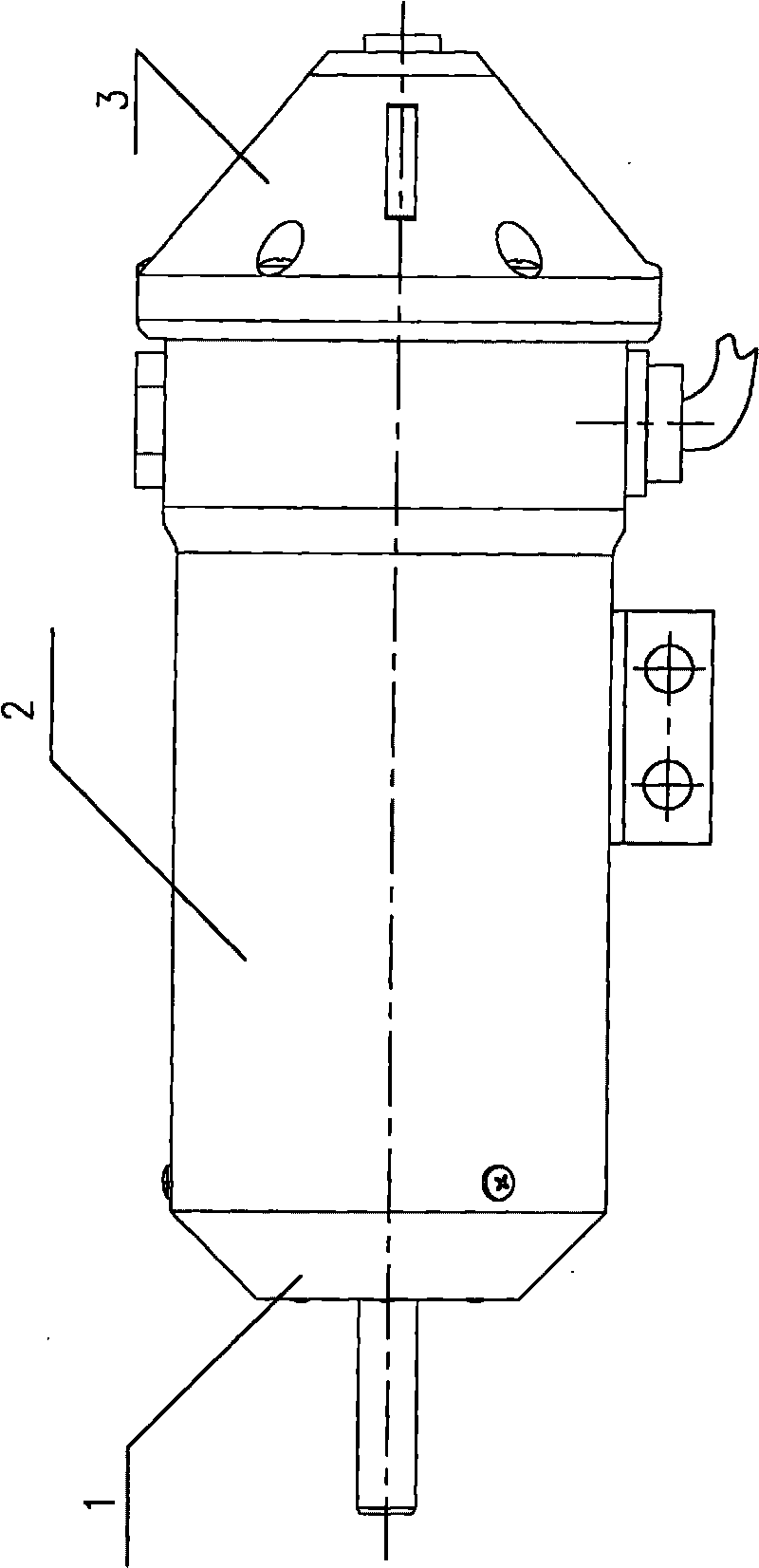

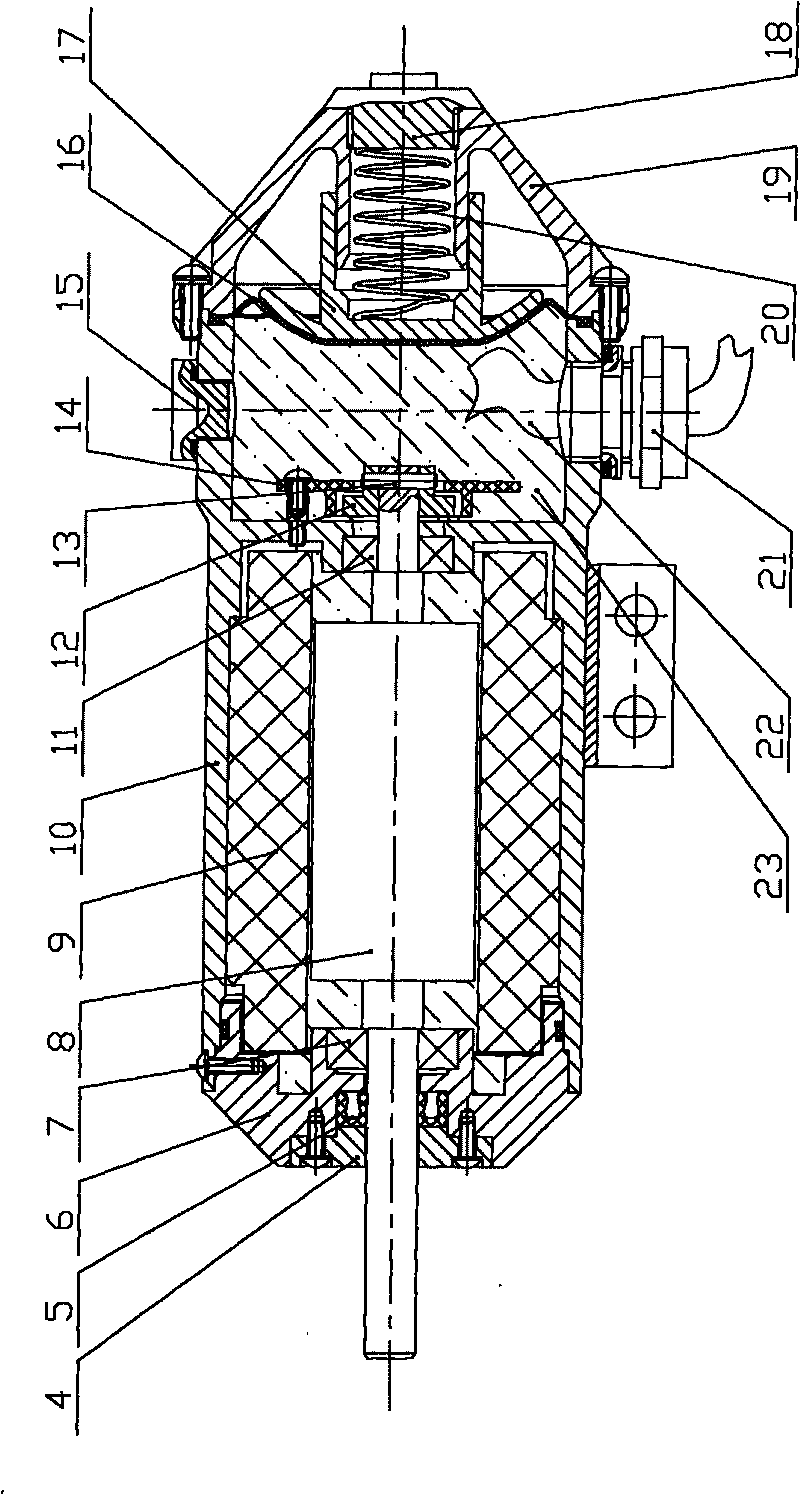

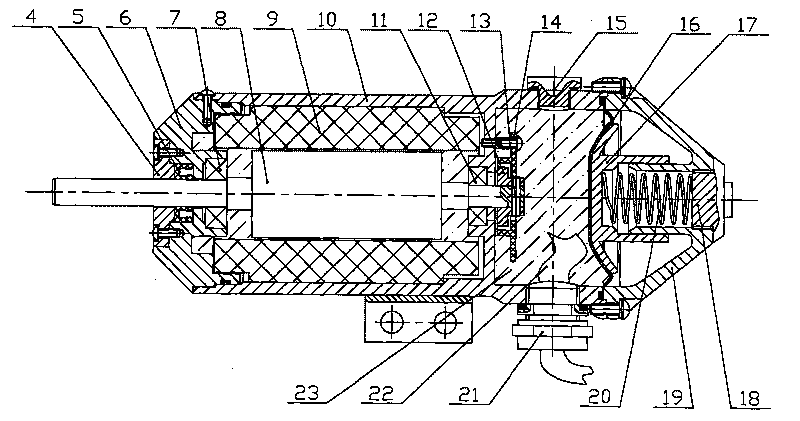

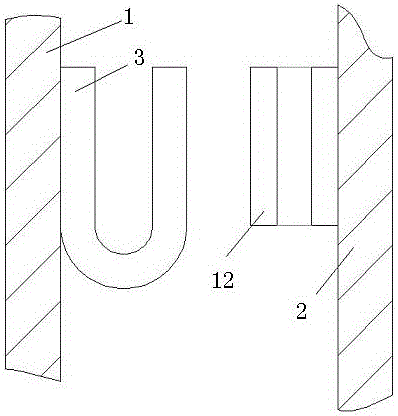

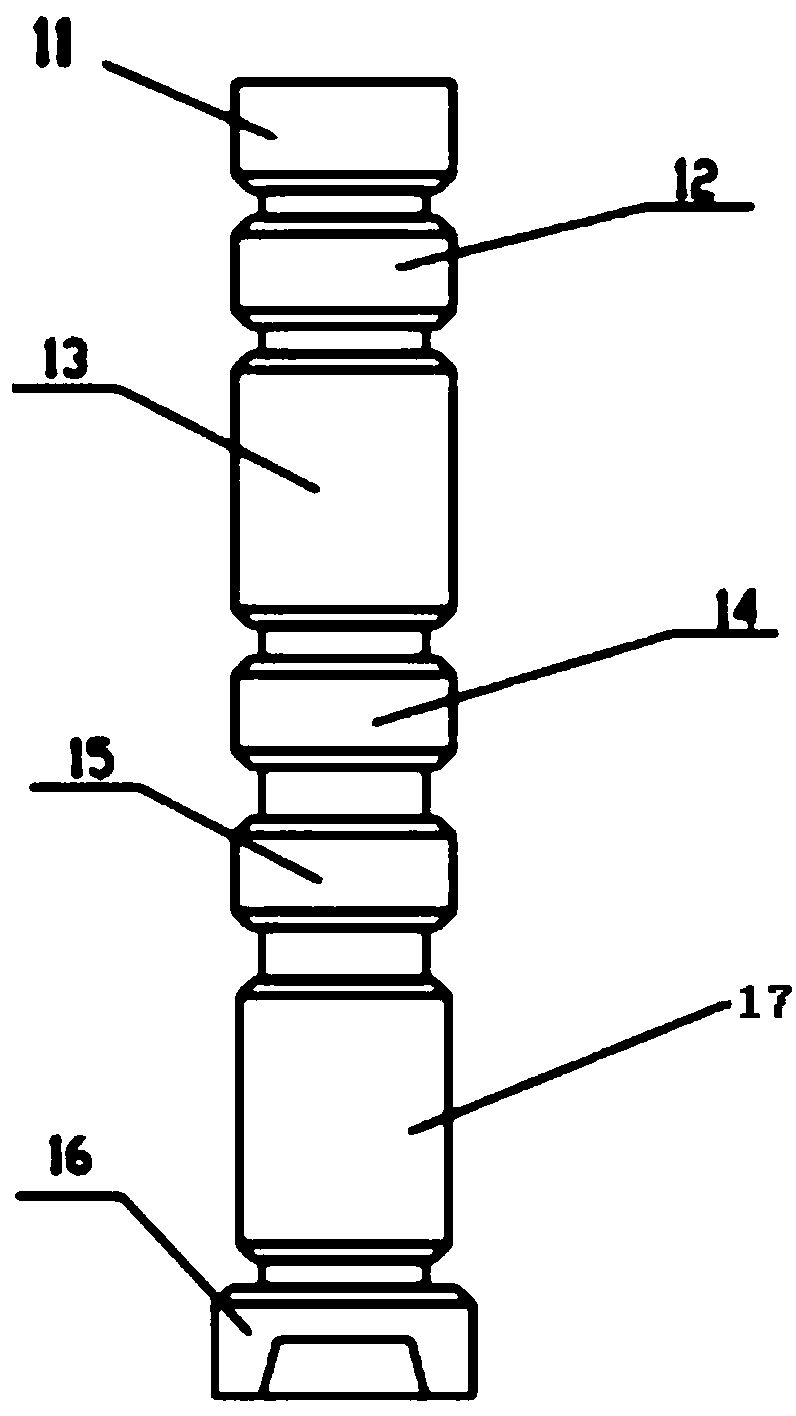

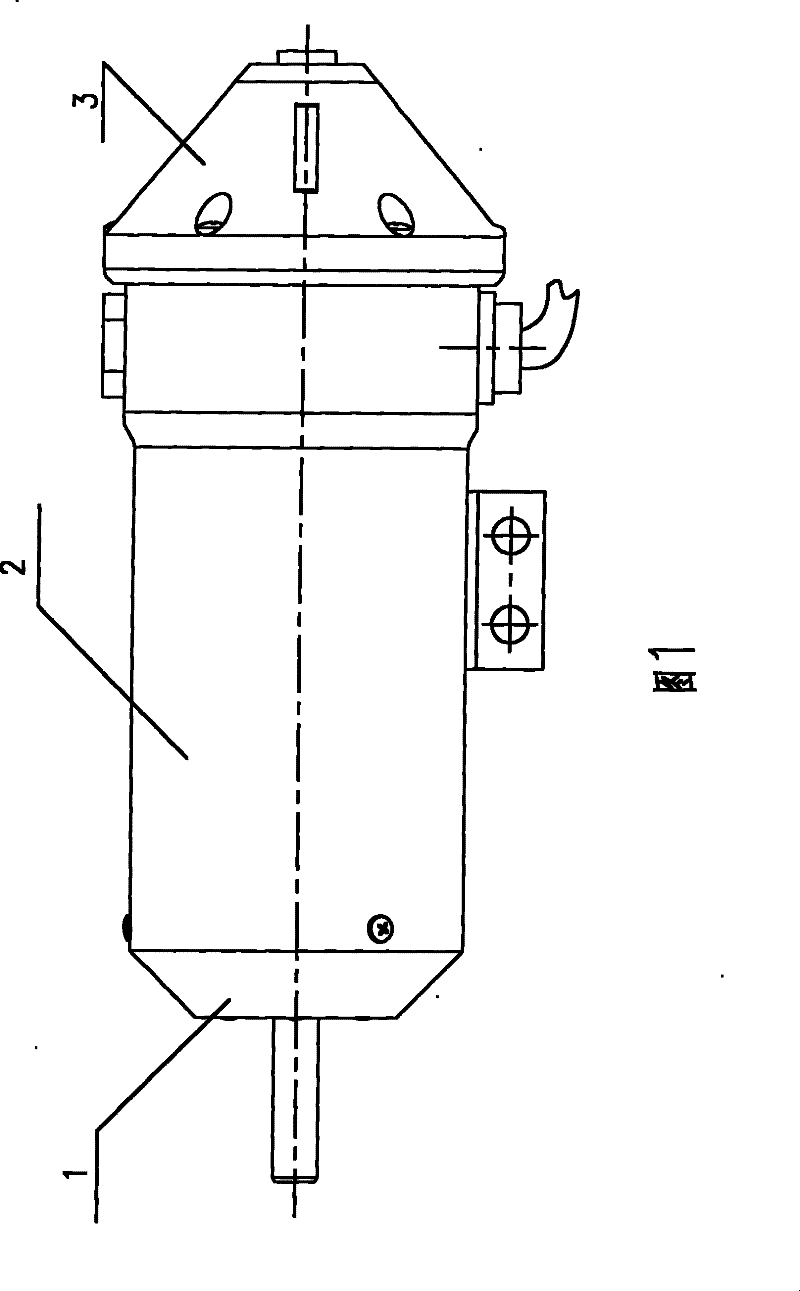

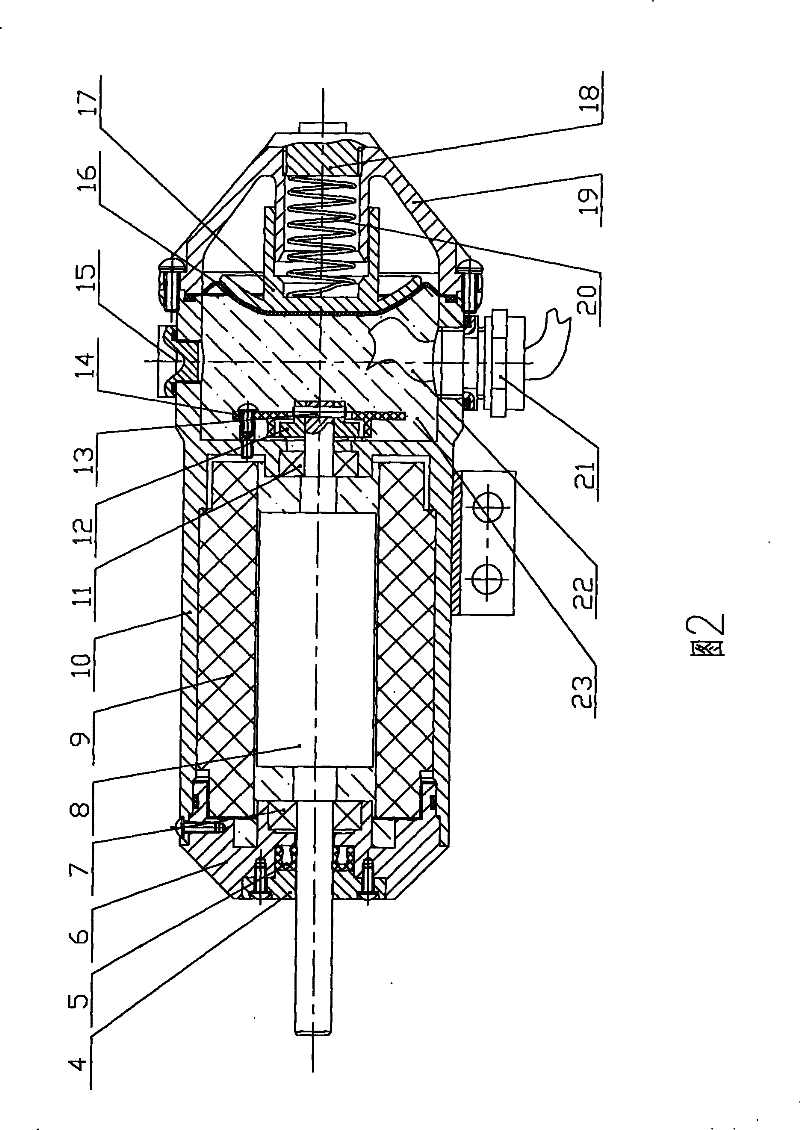

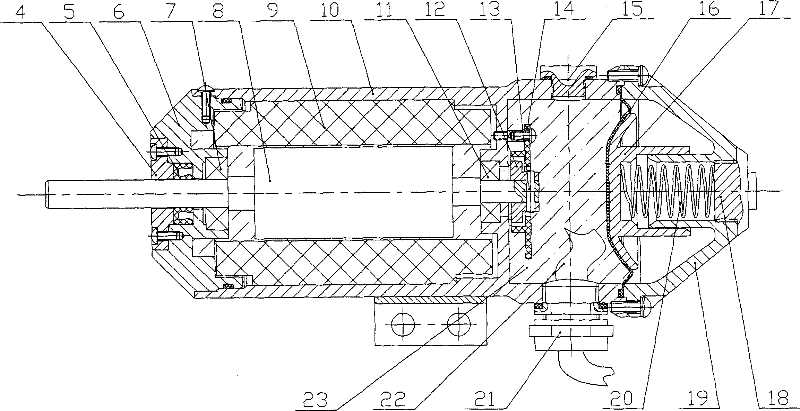

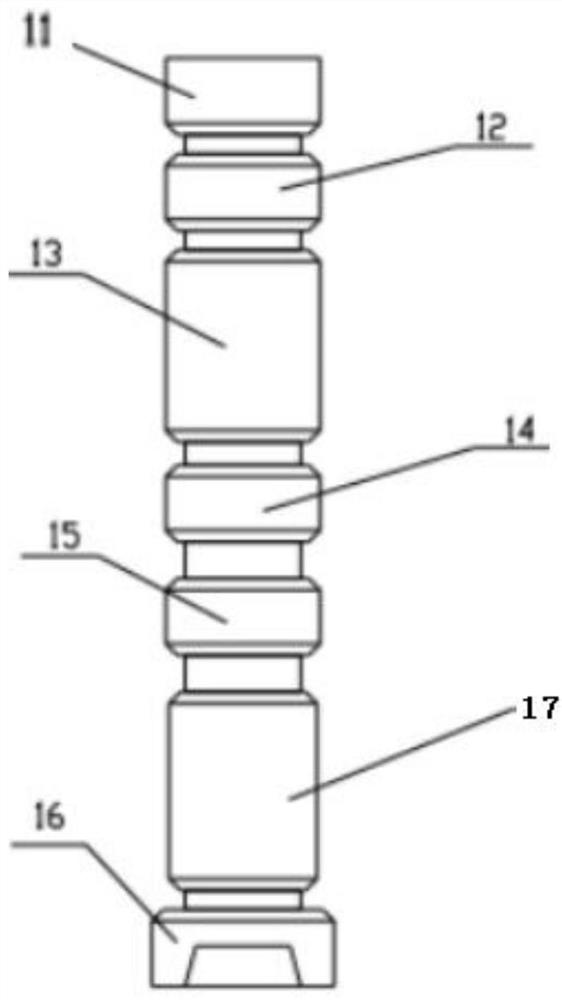

Compensated underwater brushless DC motor structure and assembly method thereof

InactiveCN101752937AImprove reconfigurabilityEasy maintenanceStructural associationSupports/enclosures/casingsUnderwaterEngineering

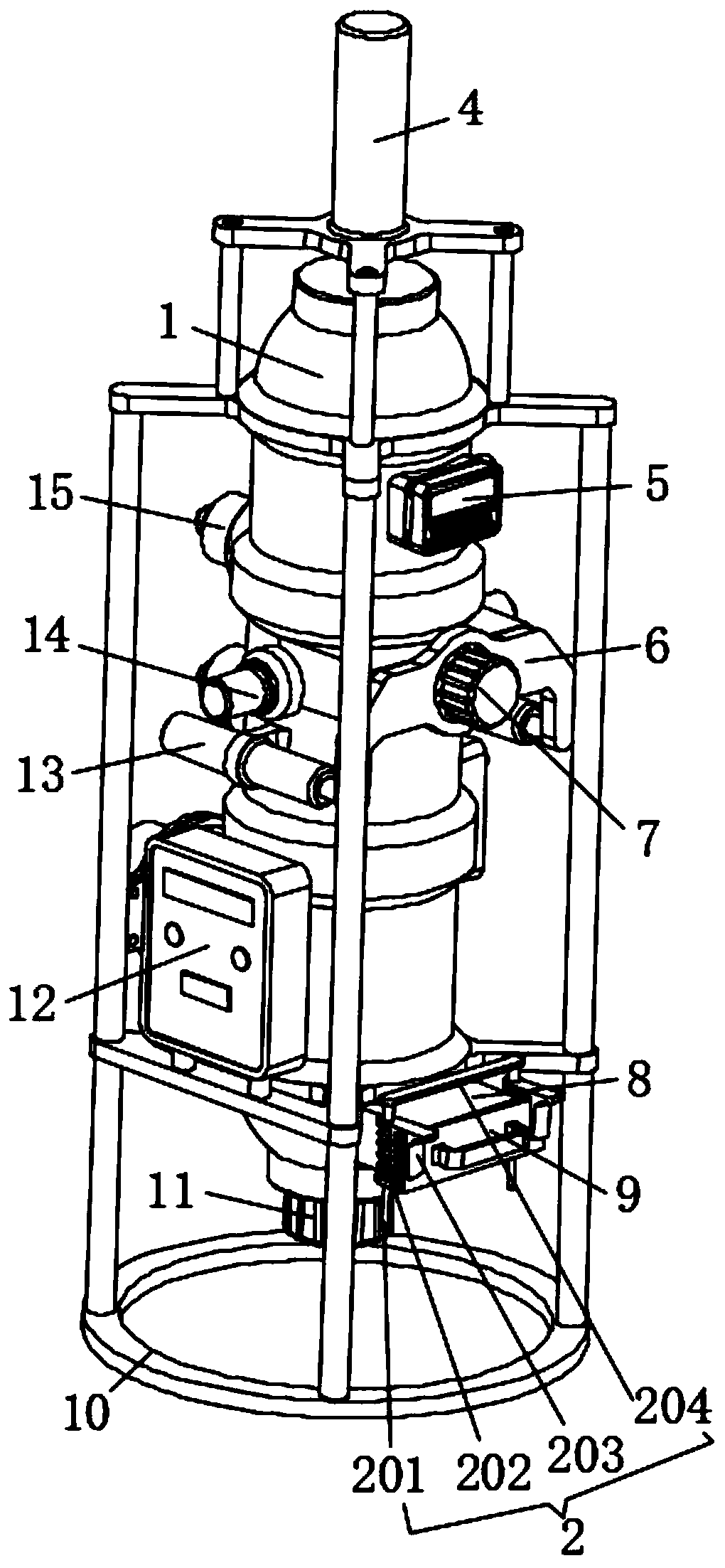

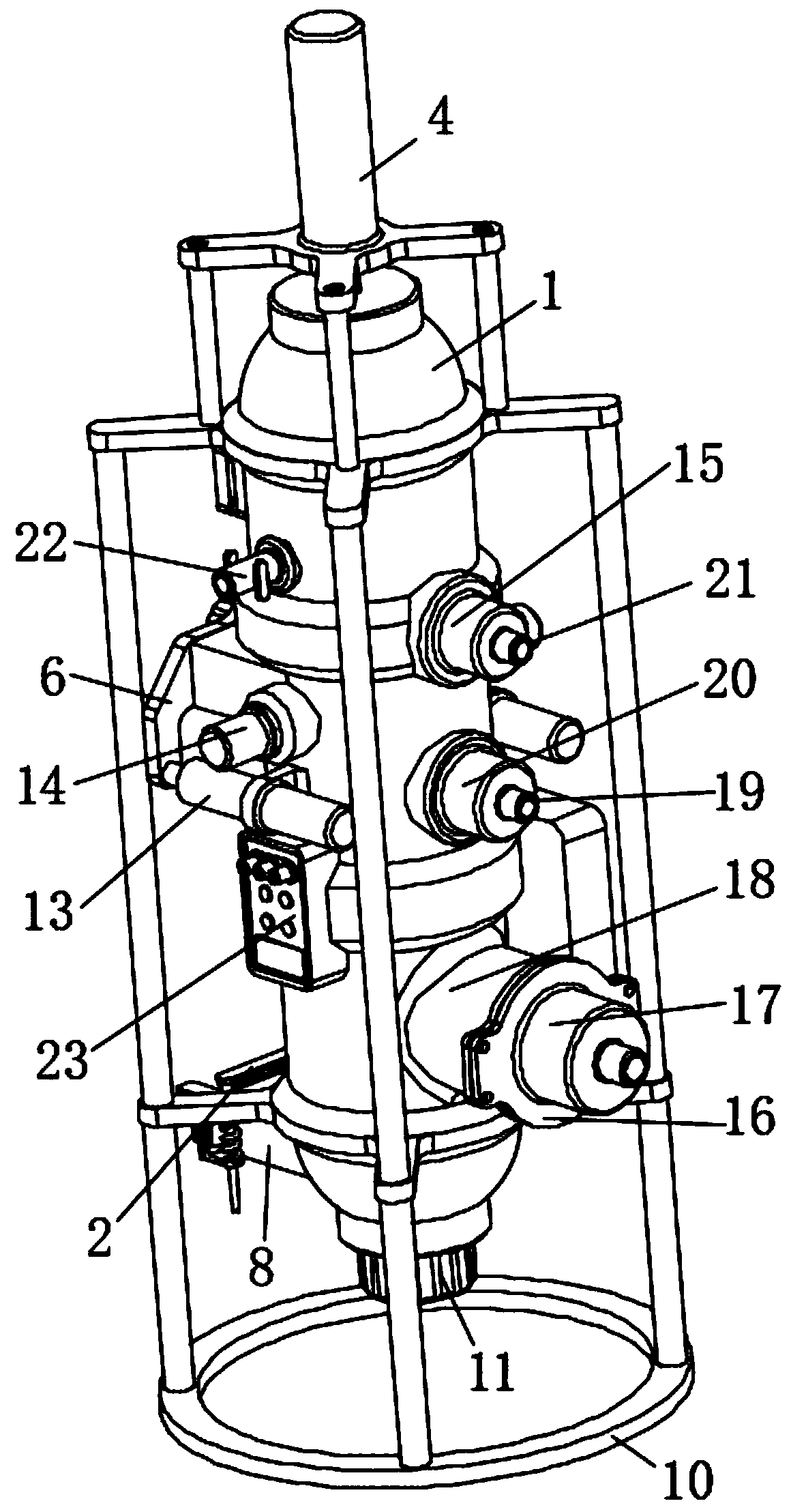

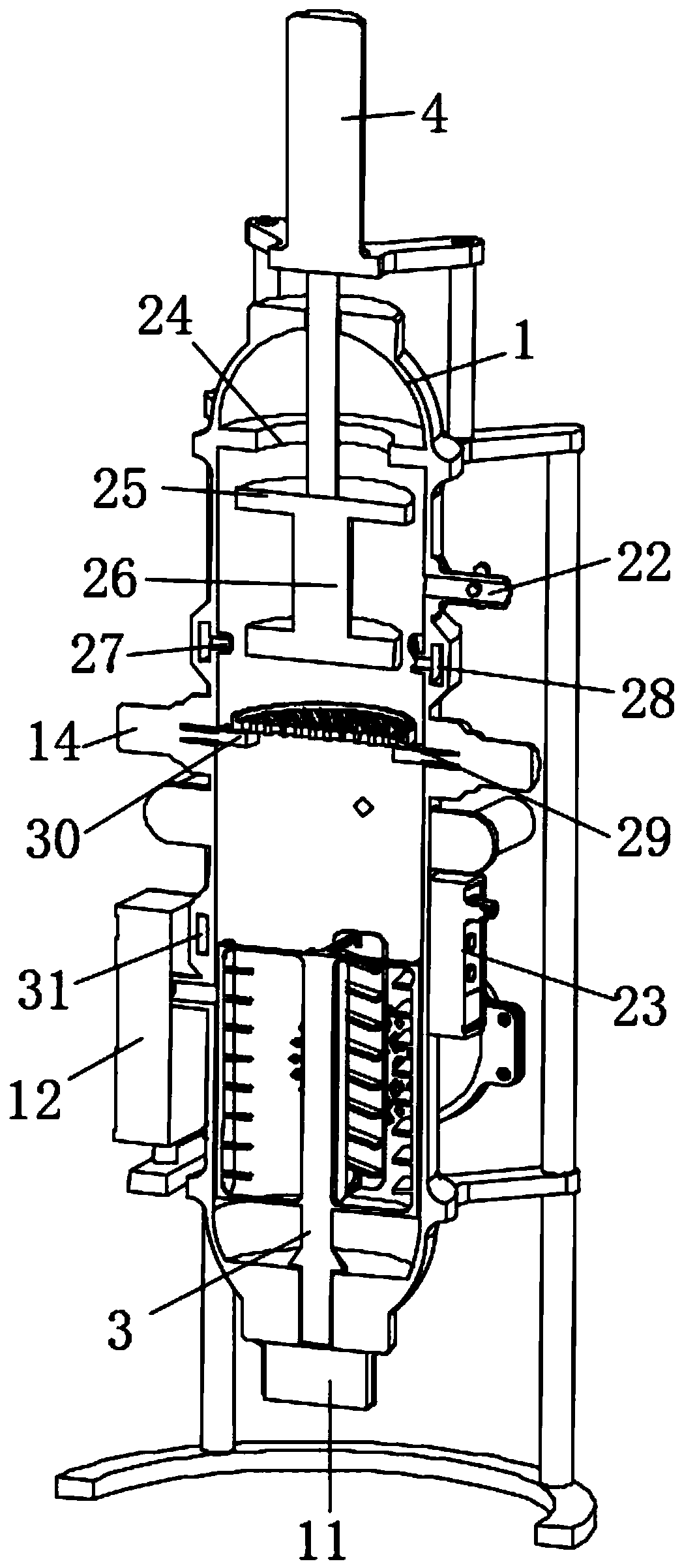

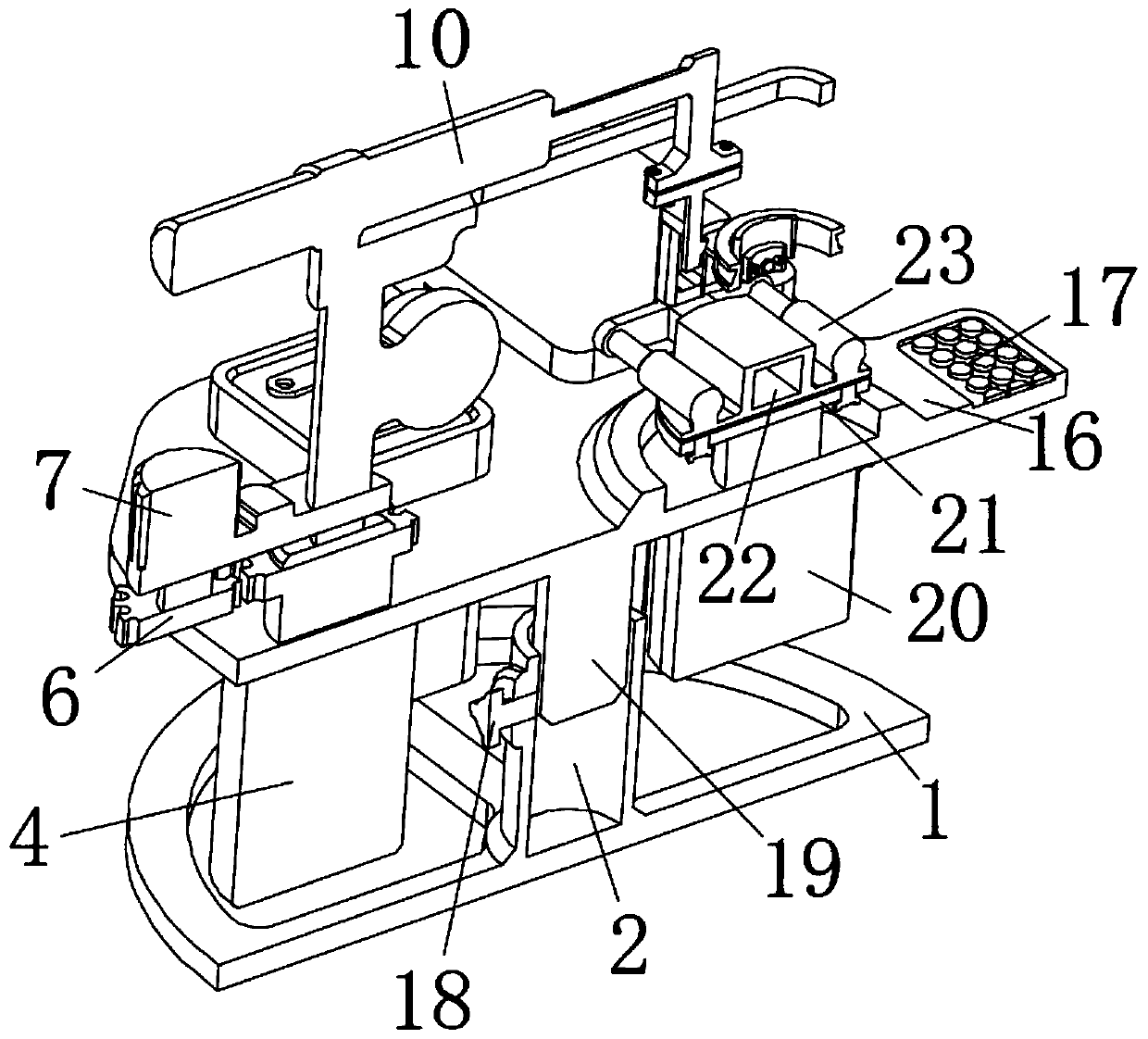

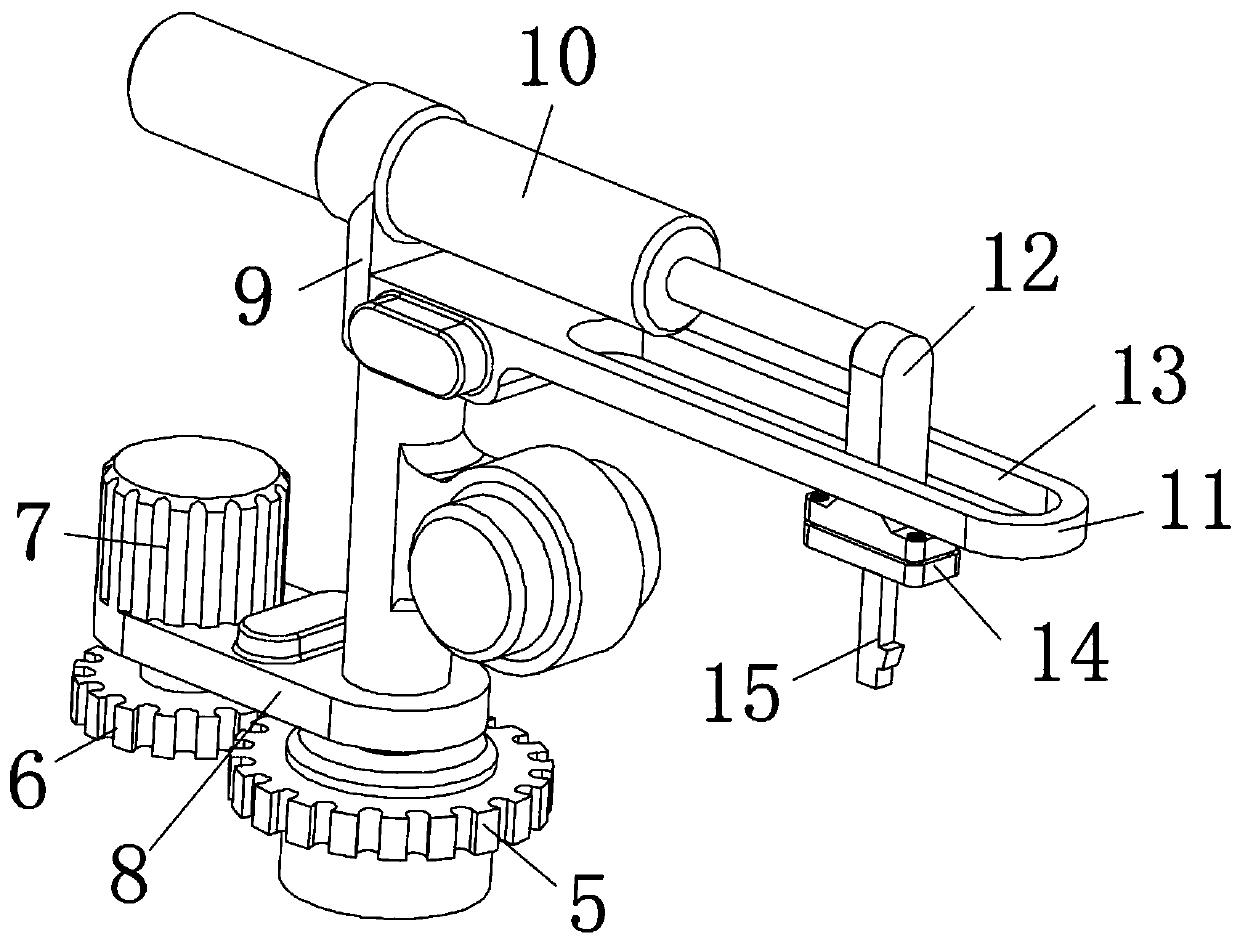

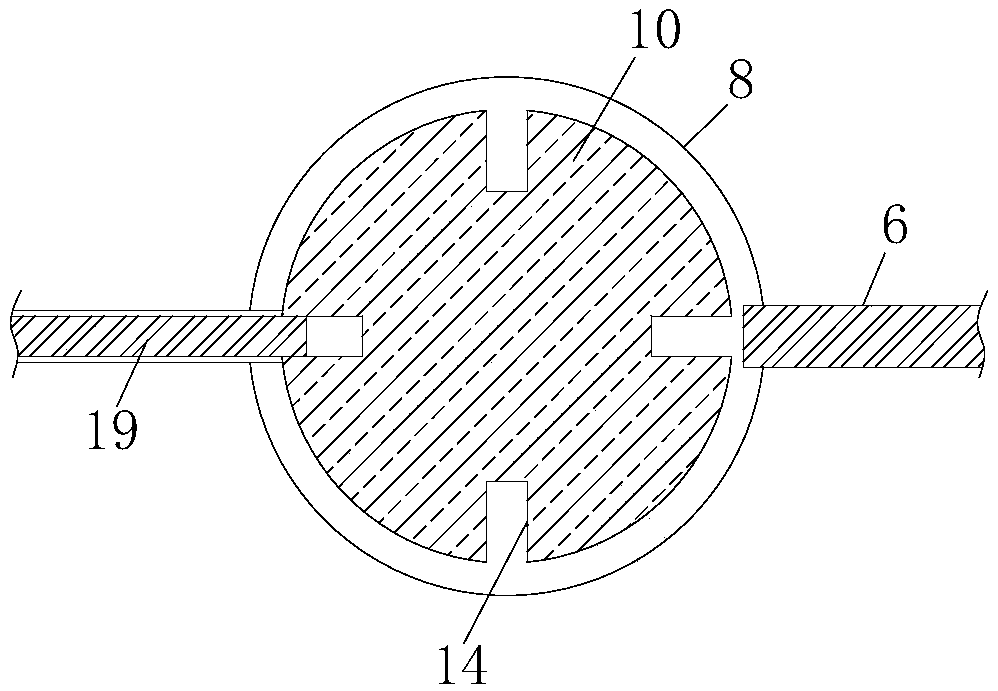

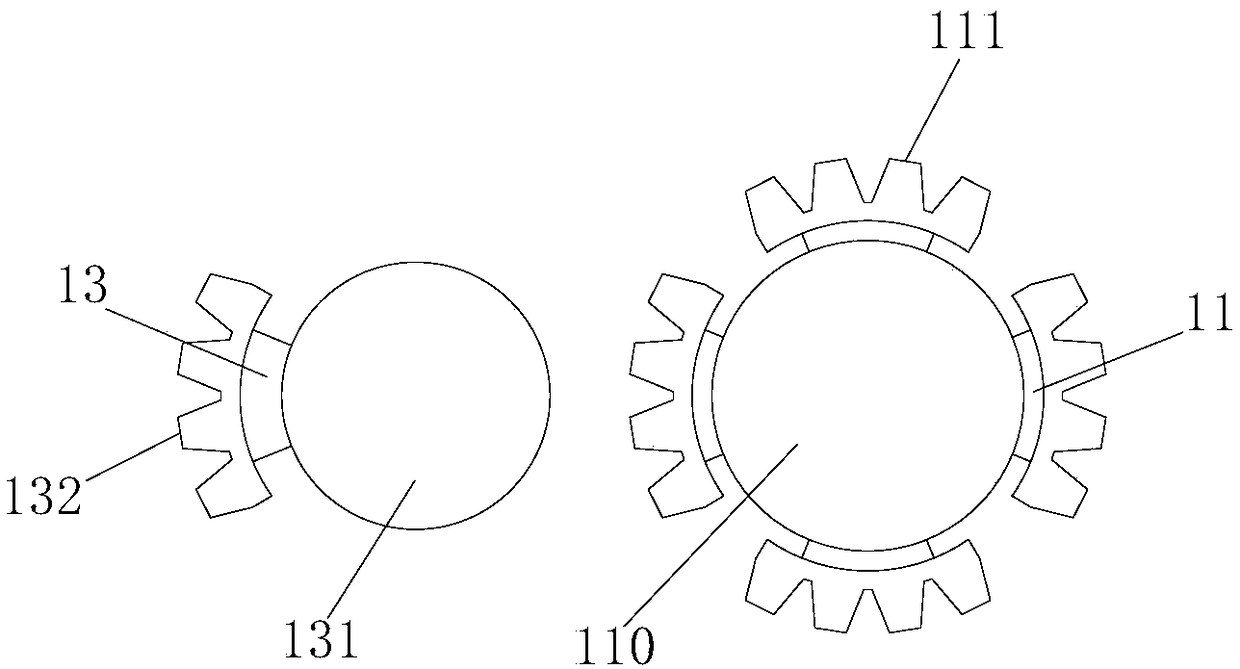

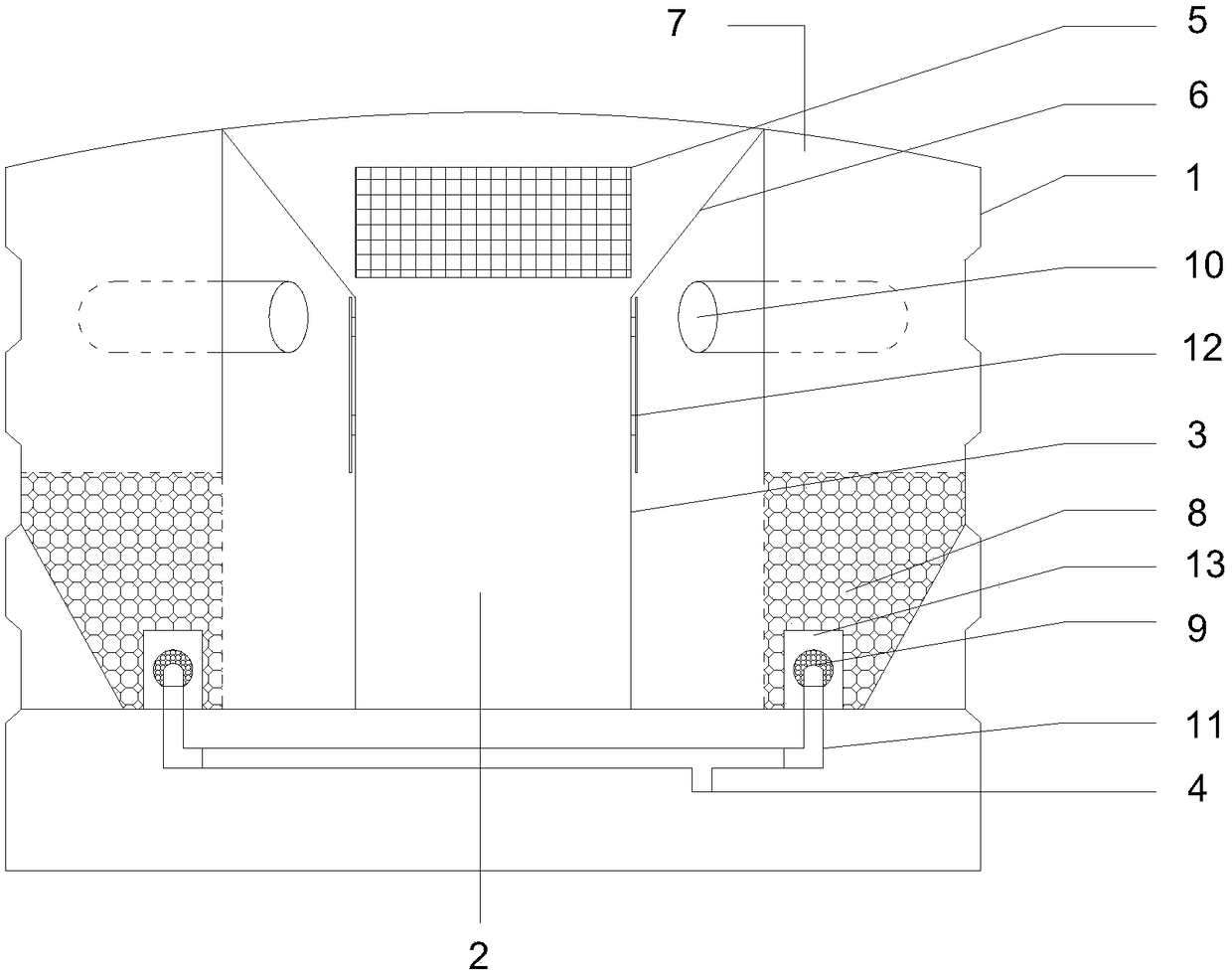

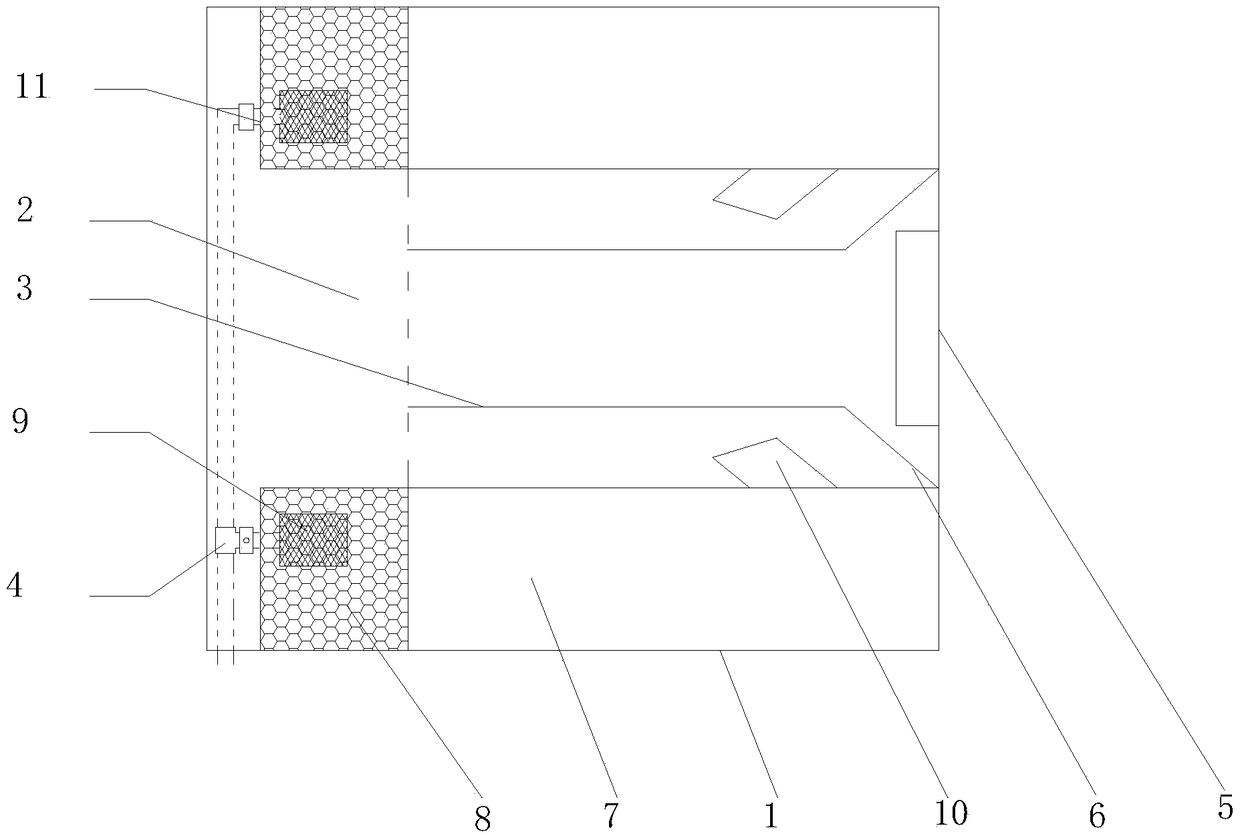

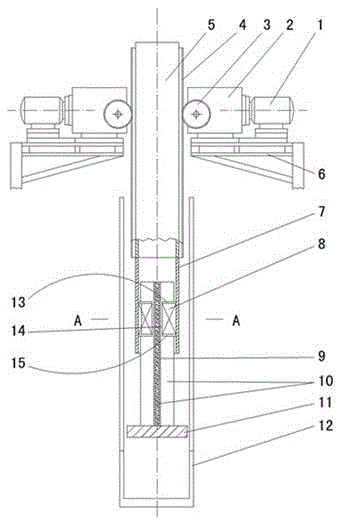

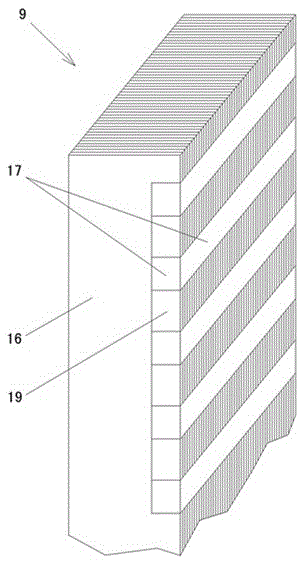

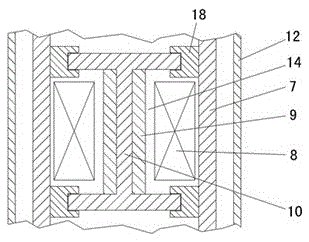

The invention relates to a compensated underwater brushless DC motor structure and an assembly method thereof. The motor structure comprises a motor end cover subassembly (1), a motor main body (2) and a compensator device (3), wherein the motor end cover subassembly (1) is positioned at the front end of the motor main body (2) and is fixedly connected with the motor main body (2) via bolts, the compensator device (3) is positioned at the tail of the motor main body (2) and connected with the motor main body (2) via bolts, and the compensator device (3) comprises a compensator skin (16), a compensator gland bush (17), a motor tail hood (19), a compensator spring (20) and a compensator screw cap (18). The motor structure has modularized design characteristic, the compensator device and the motor main body can be separated, and different compensator devices can be correspondingly adjusted or replaced for meeting different work environmental requirements so that the motor structure has the advantages of simple and compact structure, convenient assembly and debugging, and safe and reliable working and easy maintenance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

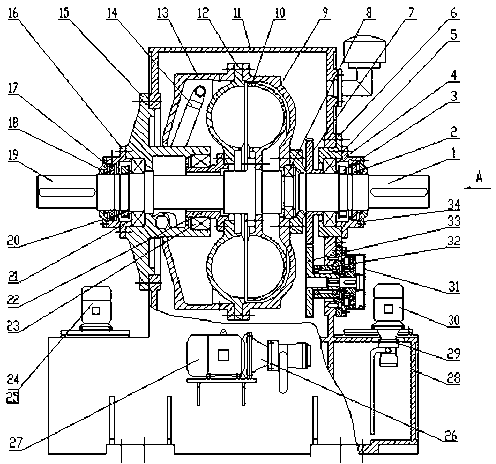

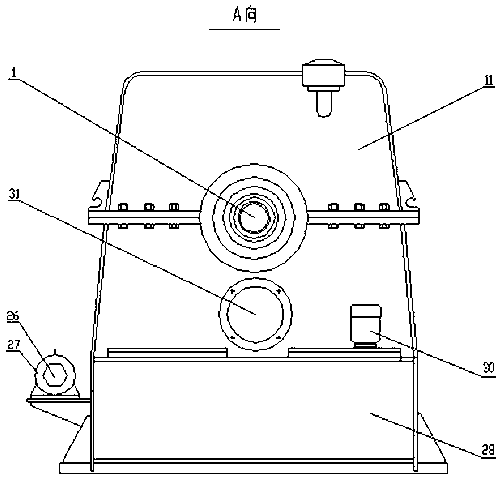

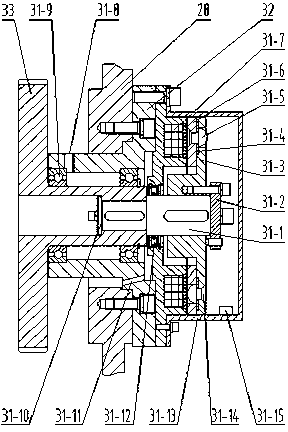

Flexible start speed adjusting device capable of realizing belt-type conveyor on-load power isolation

ActiveCN103343805AExpand the scope ofReduced braking torque requirementsConveyorsFluid gearingsContinuous operationElectromagnetic brake

A flexible start speed adjusting device capable of realizing belt-type conveyor on-load power isolation overcomes the defects that in an existing belt-type conveyor multi-motor driving system, the working condition of non-load operation or light-load operation often occurs, and energy is wasted. The flexible start speed adjusting device is characterized in that brake mounting holes are machined in one side, provided with a pump wheel axle, of a box body, an electro-magnetic brake is installed through a brake bearing seat, and a driven gear which is matched with a driving gear is installed on a brake shaft of the electro-magnetic brake. The flexible start speed adjusting device has the advantages that the multi-motor driven belt-type conveyor on-load power isolation function is realized, the purpose of saving energy is achieved, the type selection range of the electro-magnetic brake is small, the technology realizing difficulty is low, an electromagnetic brake body is low in manufacturing cost, the purposes that torque impact of equipment during the motor power isolation process or the motor power reapplication process is reduced, and when a certain motor in the driving system of the bet-type conveyor fails, the motor can be turned off under the condition that loads allow and the normal work and operation of the belt-type conveyor are not influenced are realized, and the continuous operation capacity of the conveyor is improved.

Owner:沈阳中煤工程技术有限公司

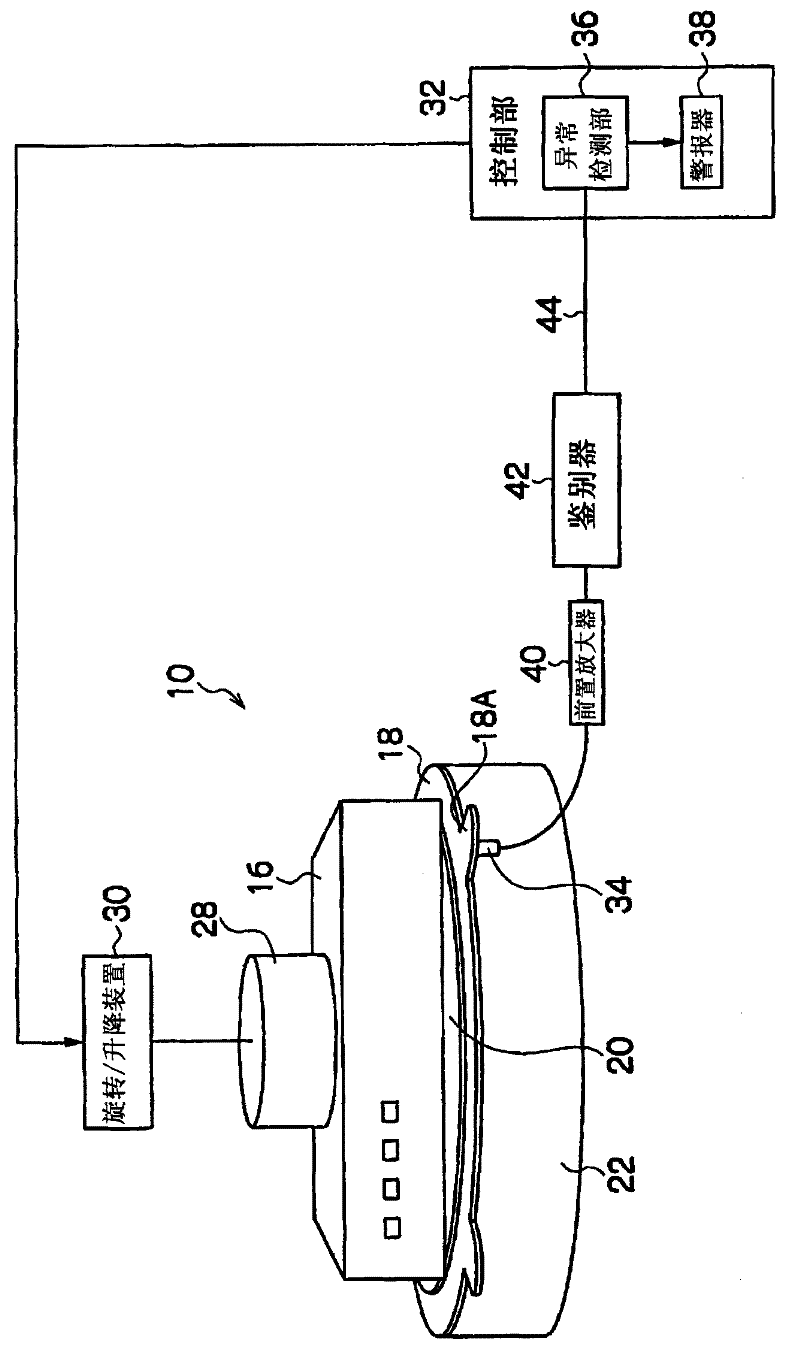

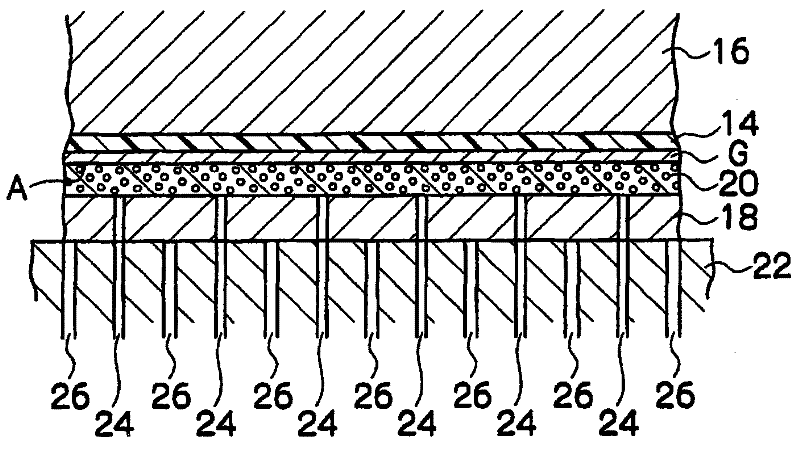

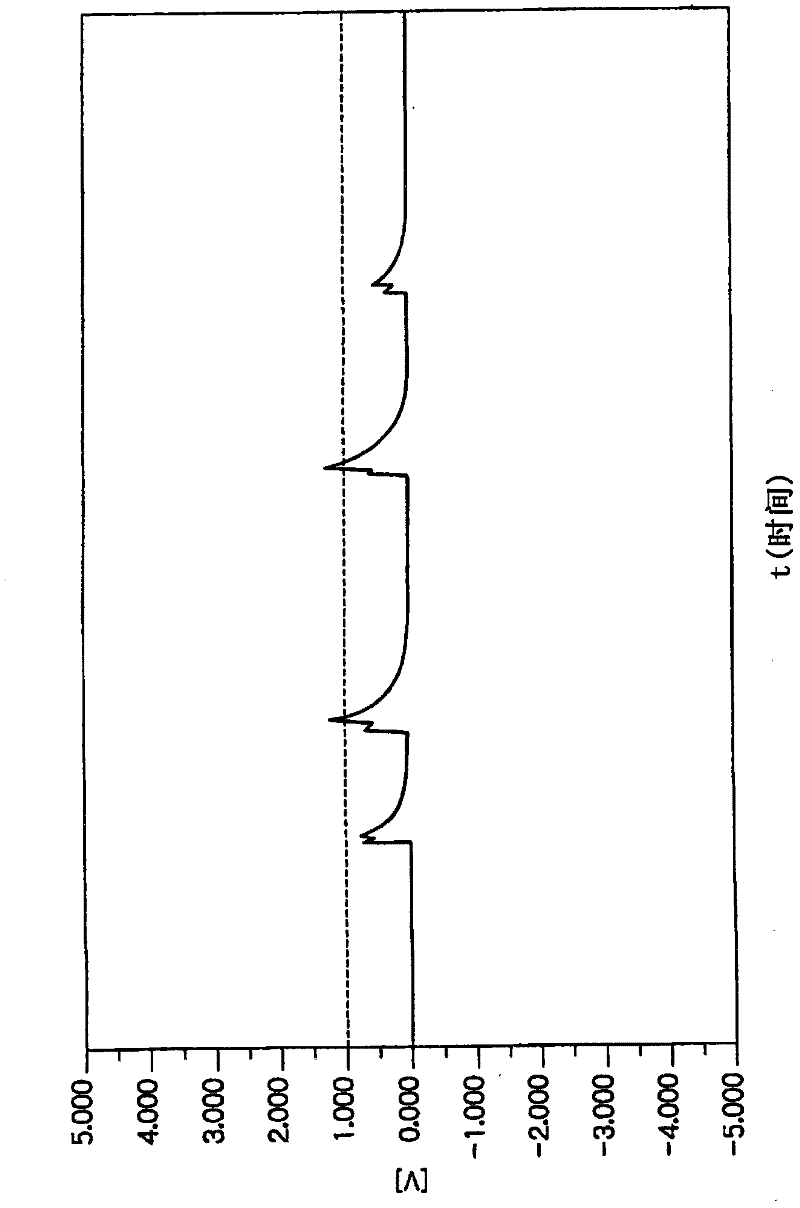

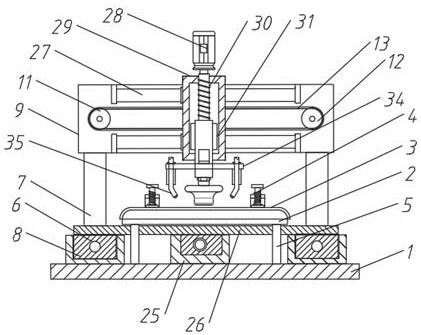

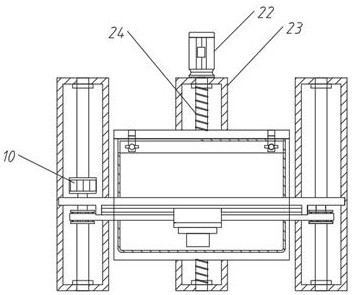

Grinding device, grinding method, and method of manufacturing glass sheet

ActiveCN102245350AInterrupt Time SuppressionImprove efficiencyLapping machinesGrinding feed controlAnomaly detectionEngineering

A grinding device for grinding an object to be ground in such a manner that a grinding tool and the object to be ground are moved while being pressed to each other and the object to be ground is ground by the grinding tool while a grinding liquid is supplied to between the grinding tool and the object to be ground. The grinding device is provided with: an AE sensor mounted to a plate supporting the grinding tool or the object to be ground; an abnormality detecting section for detecting an abnormality during grinding, the detection being performed on the basis of an output signal from the AE sensor outputted when an elastic wave from the object to be ground is detected by the AE sensor; and an alarm means for issuing an alarm when an abnormality of the object to be ground is detected by the abnormality detecting section.

Owner:ASAHI GLASS CO LTD

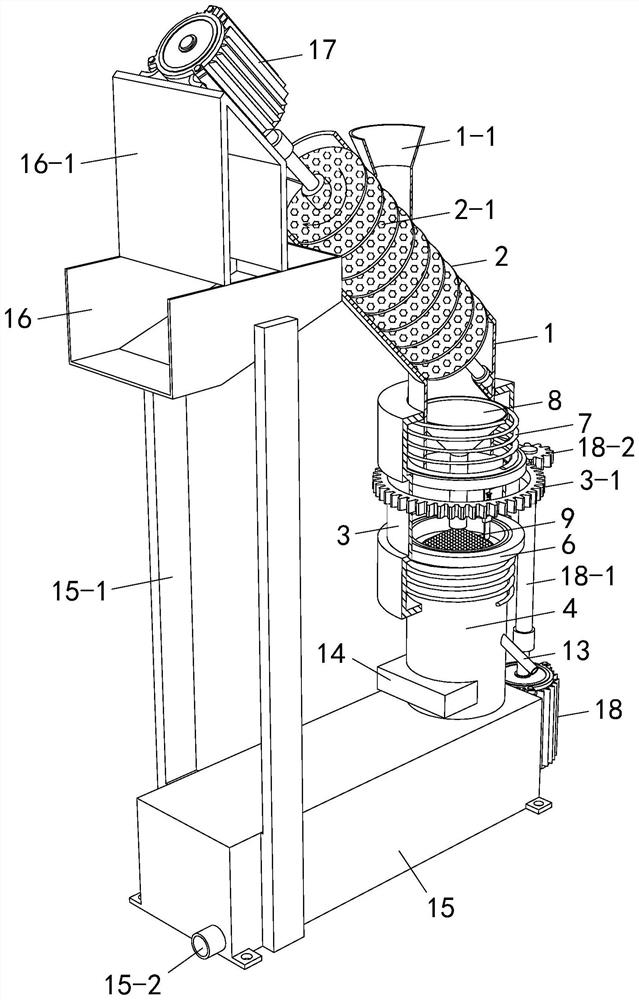

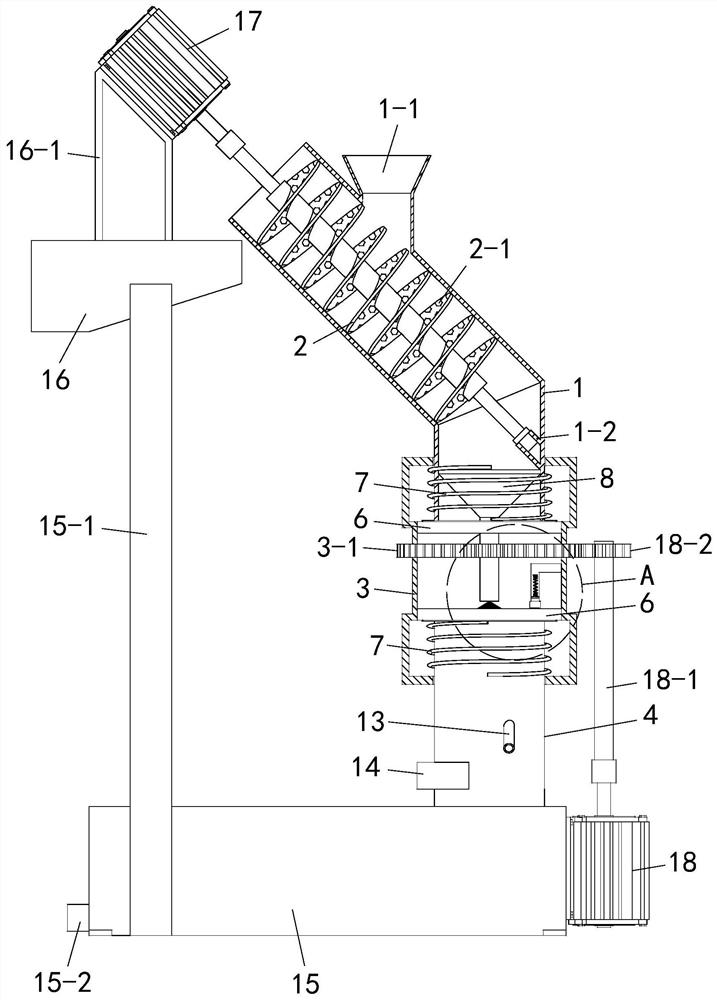

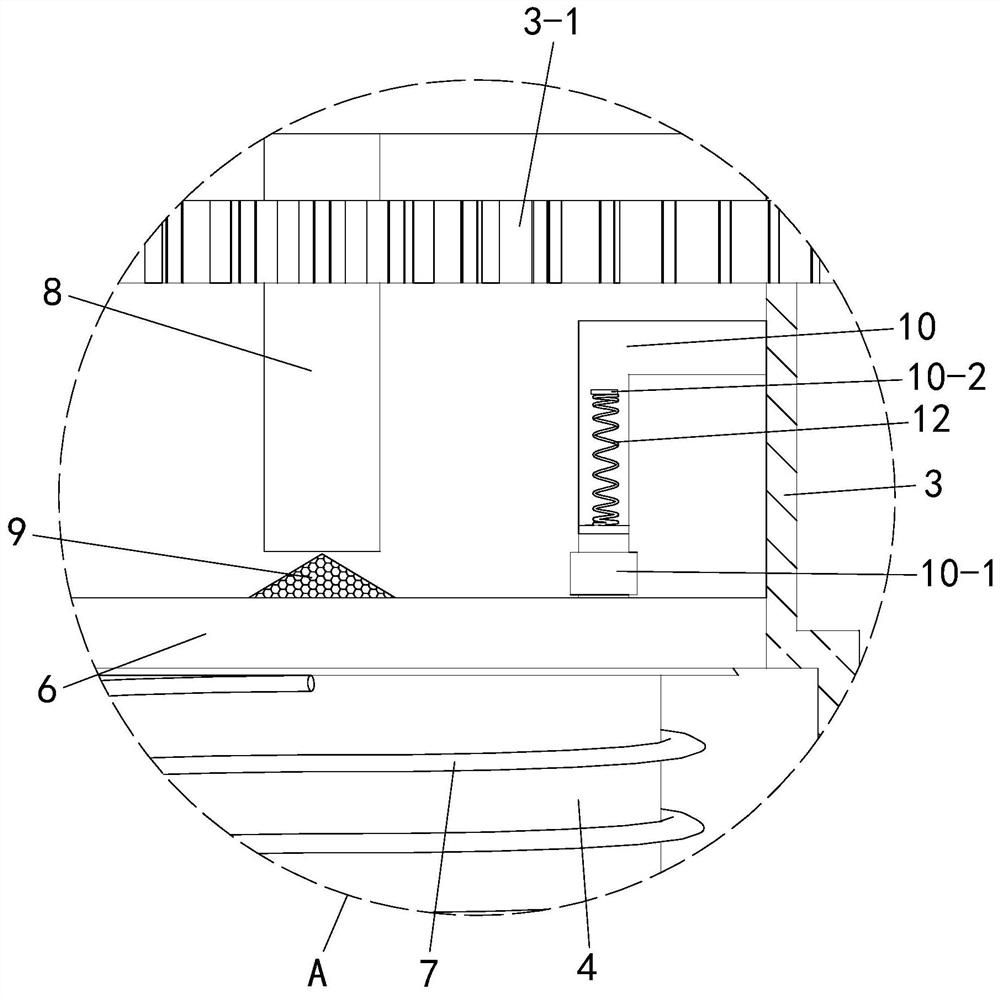

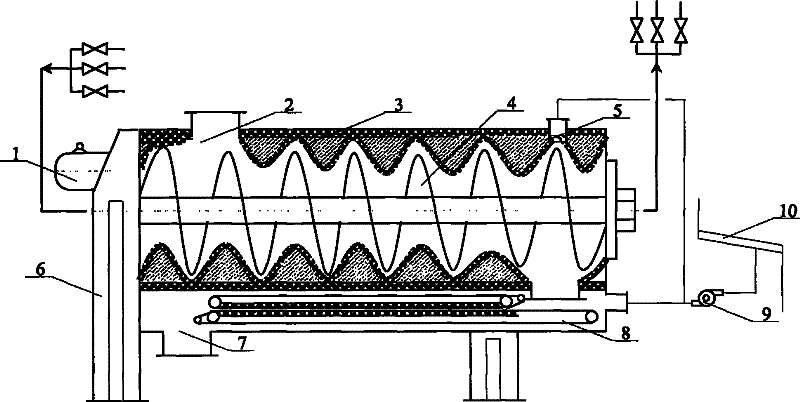

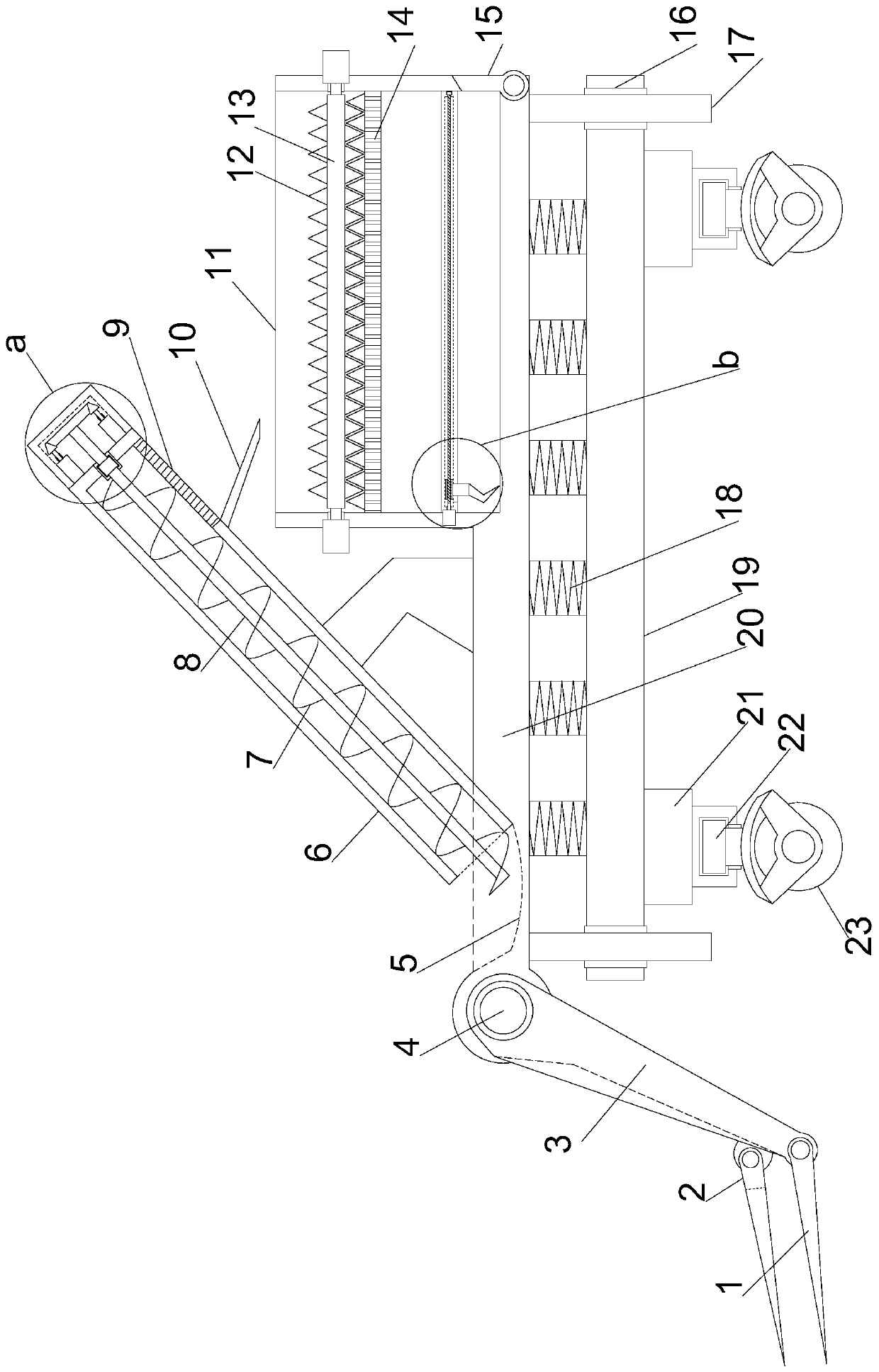

Sewage filtering treatment device and using method thereof

ActiveCN112023513AEasy to filterSimple structureTreatment involving filtrationMultistage water/sewage treatmentWater storage tankHelical blade

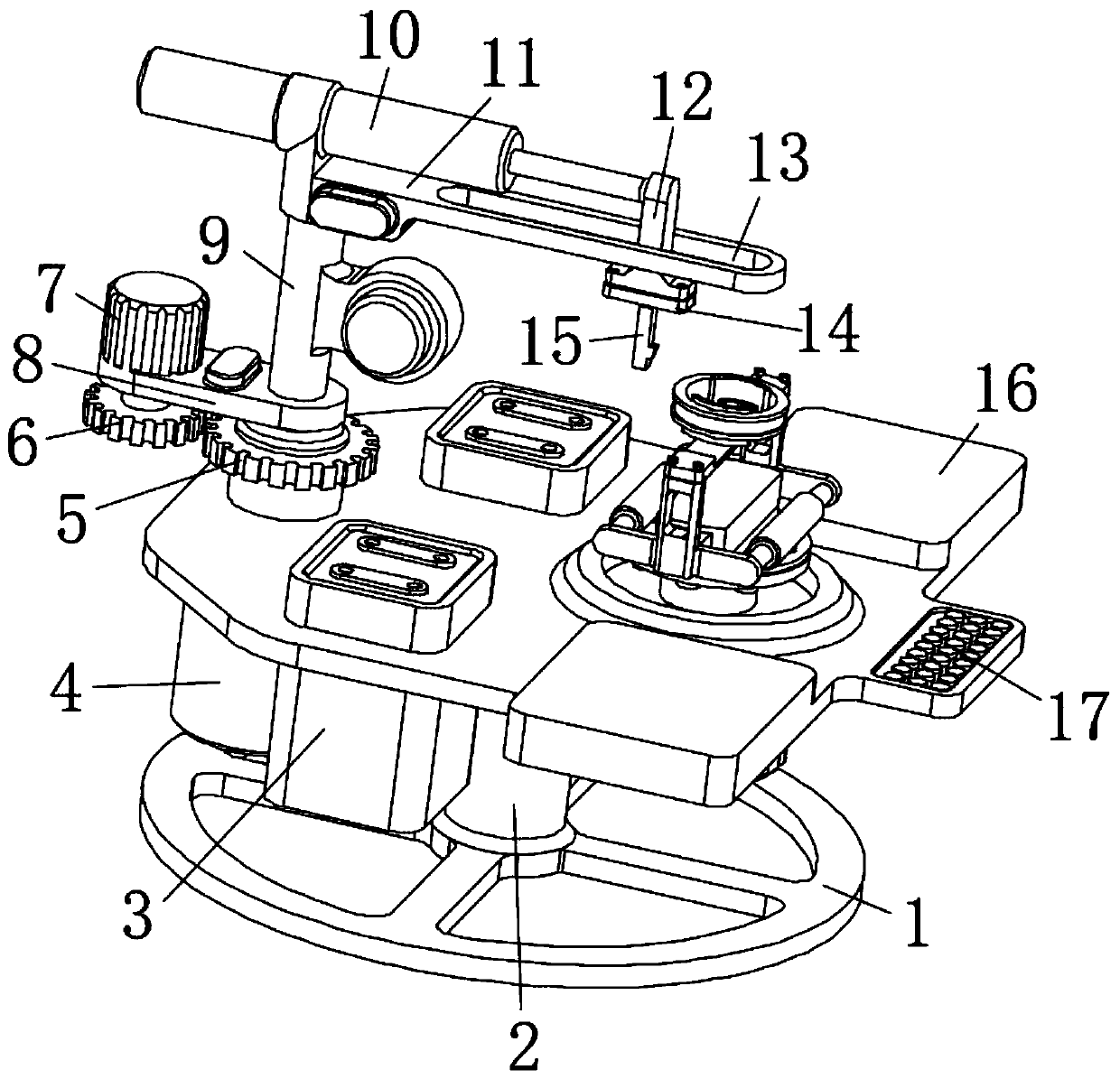

The invention discloses a sewage filtering treatment device and a using method thereof, and relates to a filtering device. An upper section of a first filter cartridge is arranged inclinedly, the lower section of the first filter cartridge is arranged vertically, and a part, close to the top of the first filter cartridge is provided with a water inlet; a spiral blade shaft is arranged in the uppersection of the first filter cartridge and is driven by a first driving motor, a blade is provided with a water passing hole, a second filter cartridge is arranged below the first filter cartridge, arotary drum is rotatably and hermetically arranged between the first filter cartridge and the second filter cartridge, and the rotary drum is driven by a second driving motor; an annular groove is formed in the bottom end of a conical filter screen and is fixedly connected with the inner wall of the second filter cartridge, a slope block is fixed on the annular groove, a leakage hole is formed inthe a part, adjacent to the slope top, of the slope block and is communicated with a sand discharging pipe, a mounting frame is fixed on the inner wall of the rotary drum, and the lower end of a telescopic scraper mounted by the mounting frame is elastically supported on the annular groove; a funnel is fixed in the lower section of the first filter cartridge and corresponds to the tip of the conical filter screen, and a water storage tank is fixedly communicated with the bottom end of the second filter cartridge. The device can continuously scrape and discharge impurities, and is simple in structure, not prone to blockage and high in continuous operation capacity.

Owner:HEILONGJIANG COLLEGE OF CONSTR

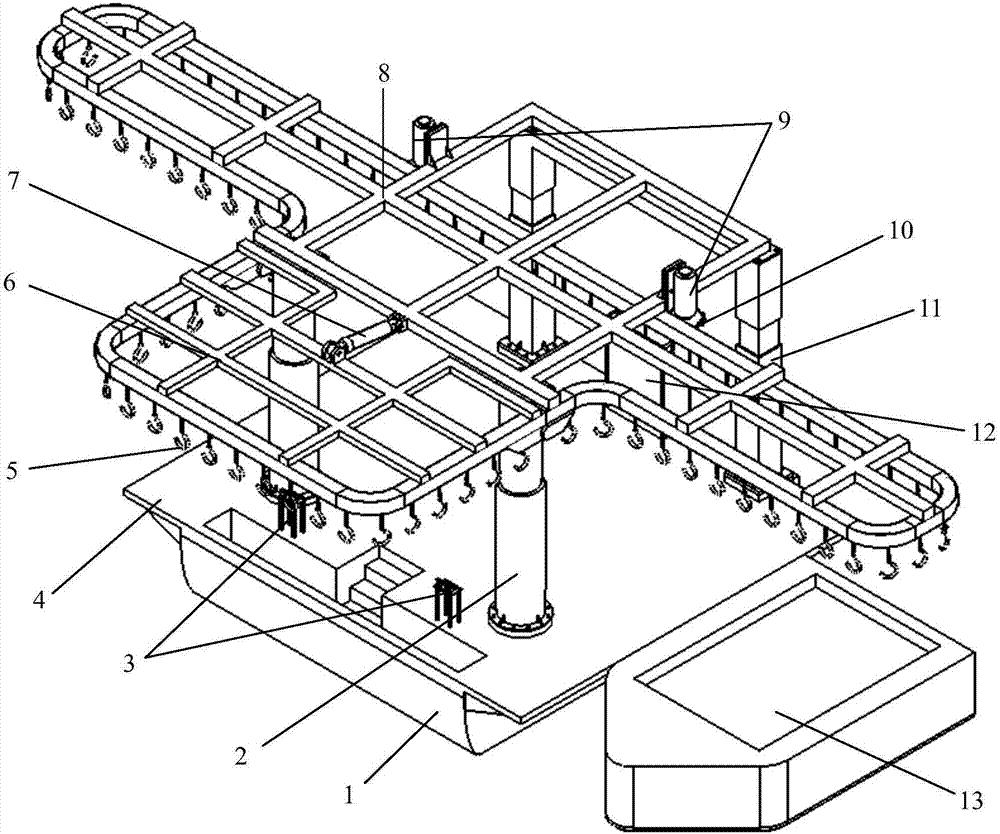

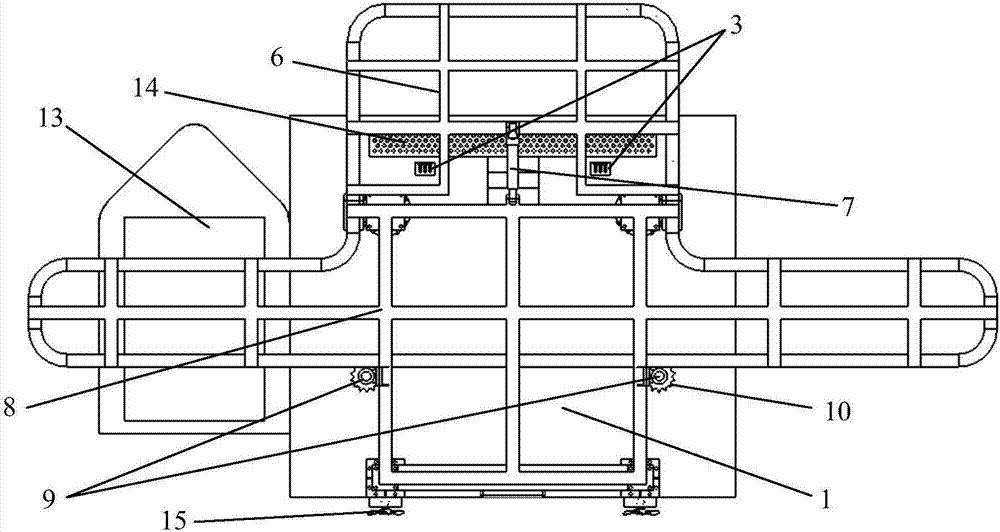

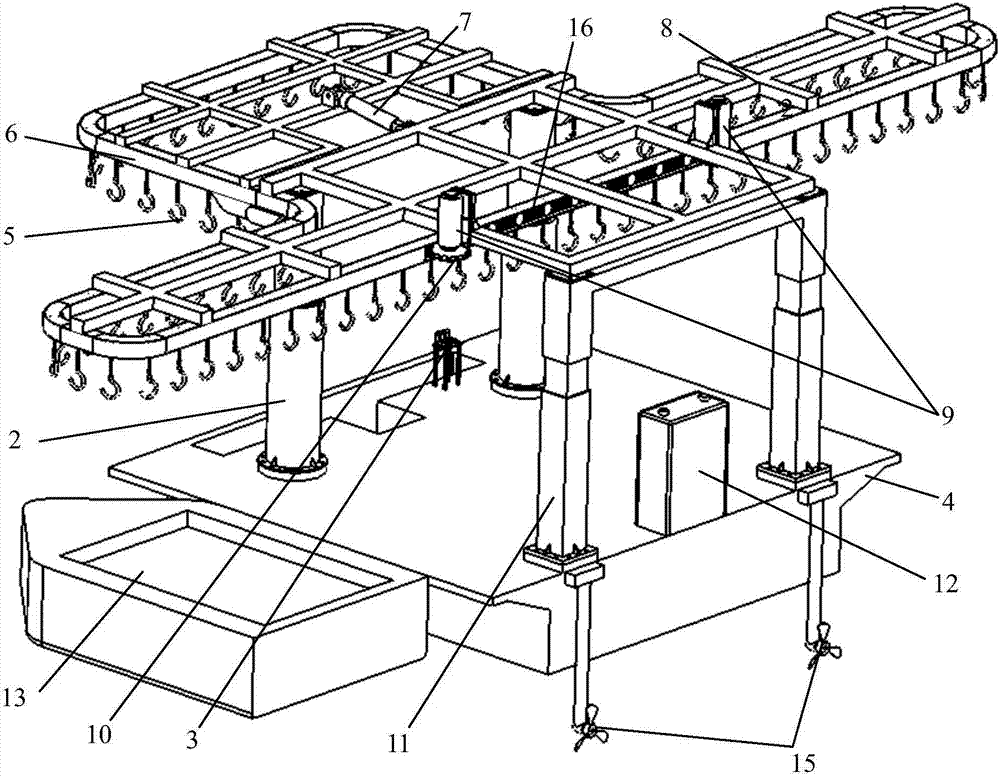

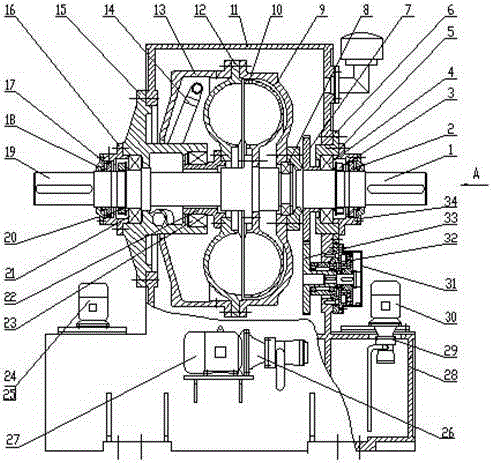

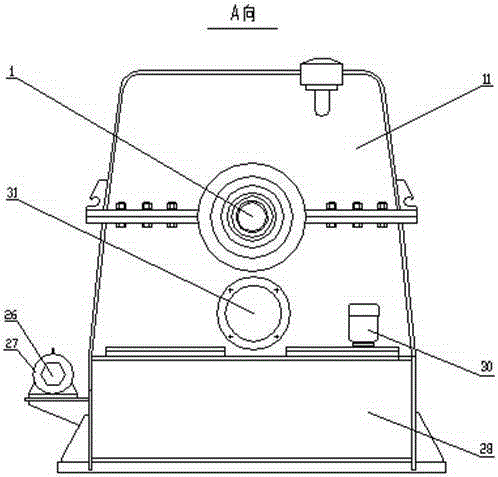

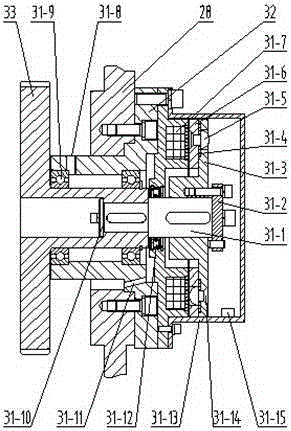

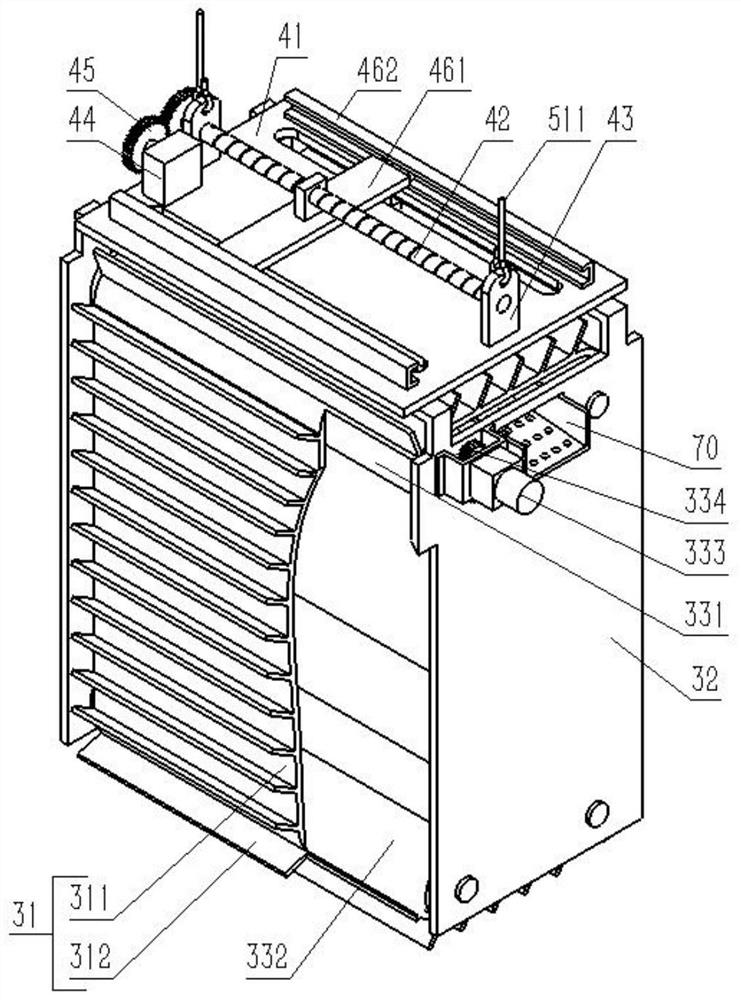

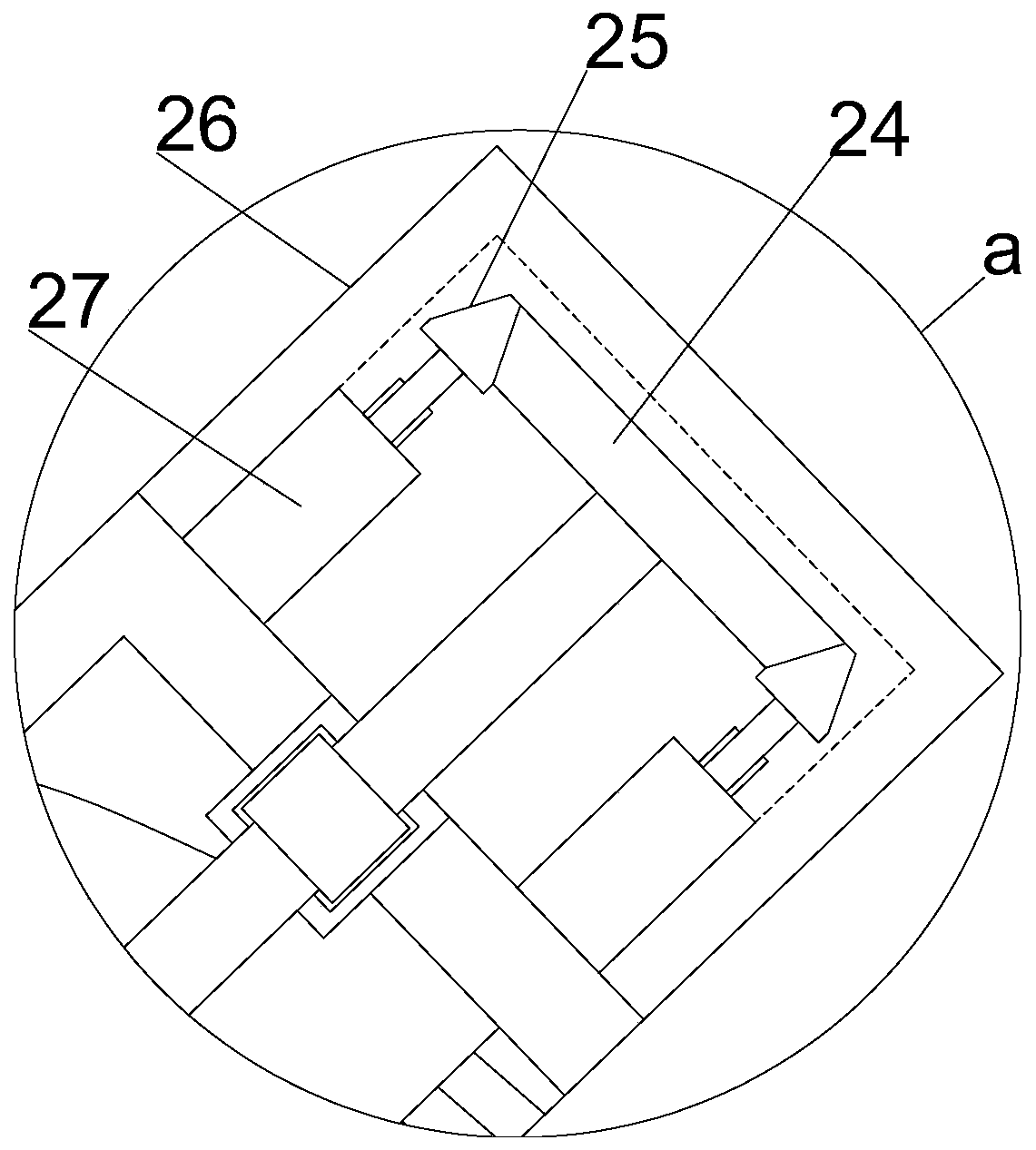

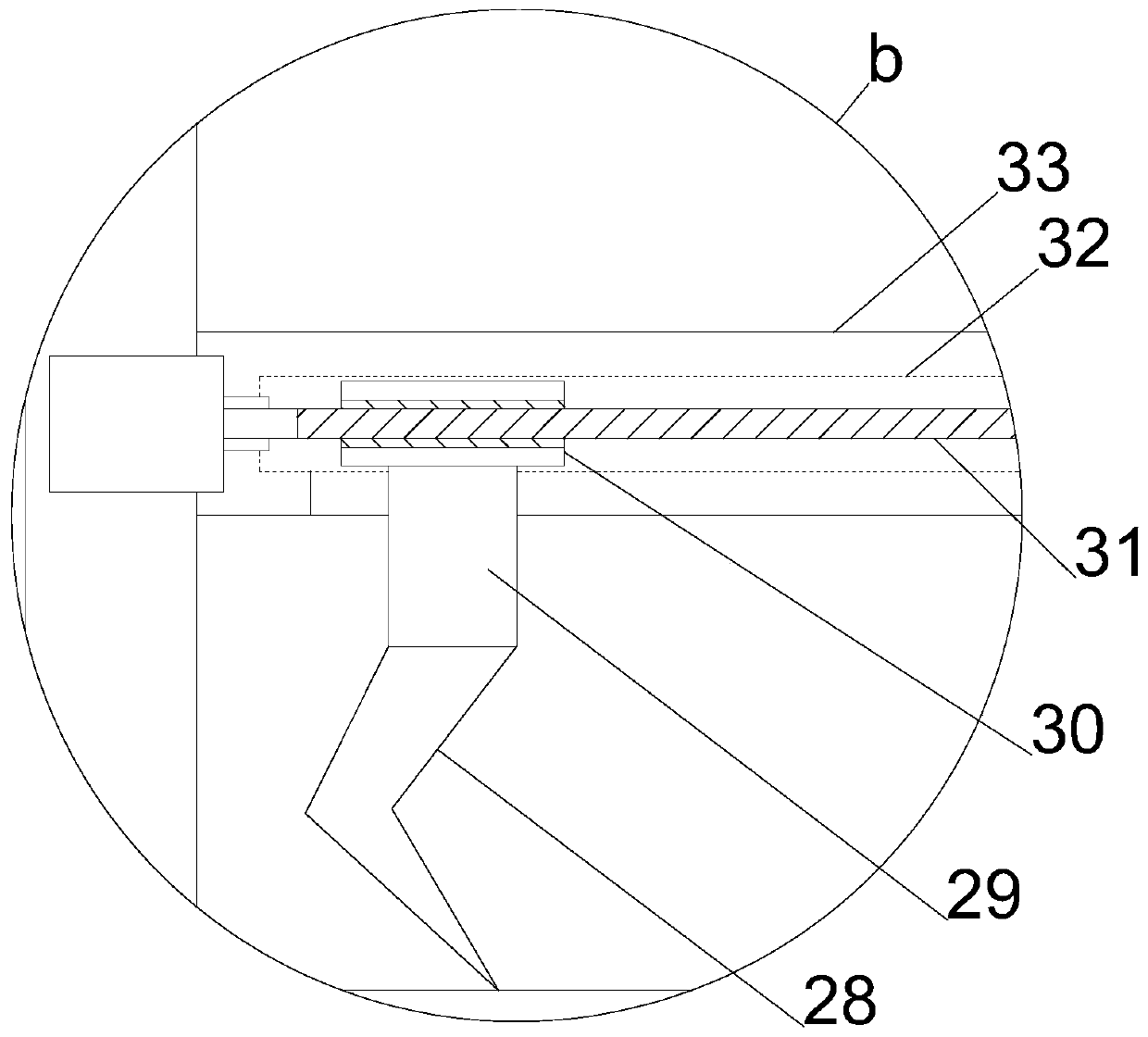

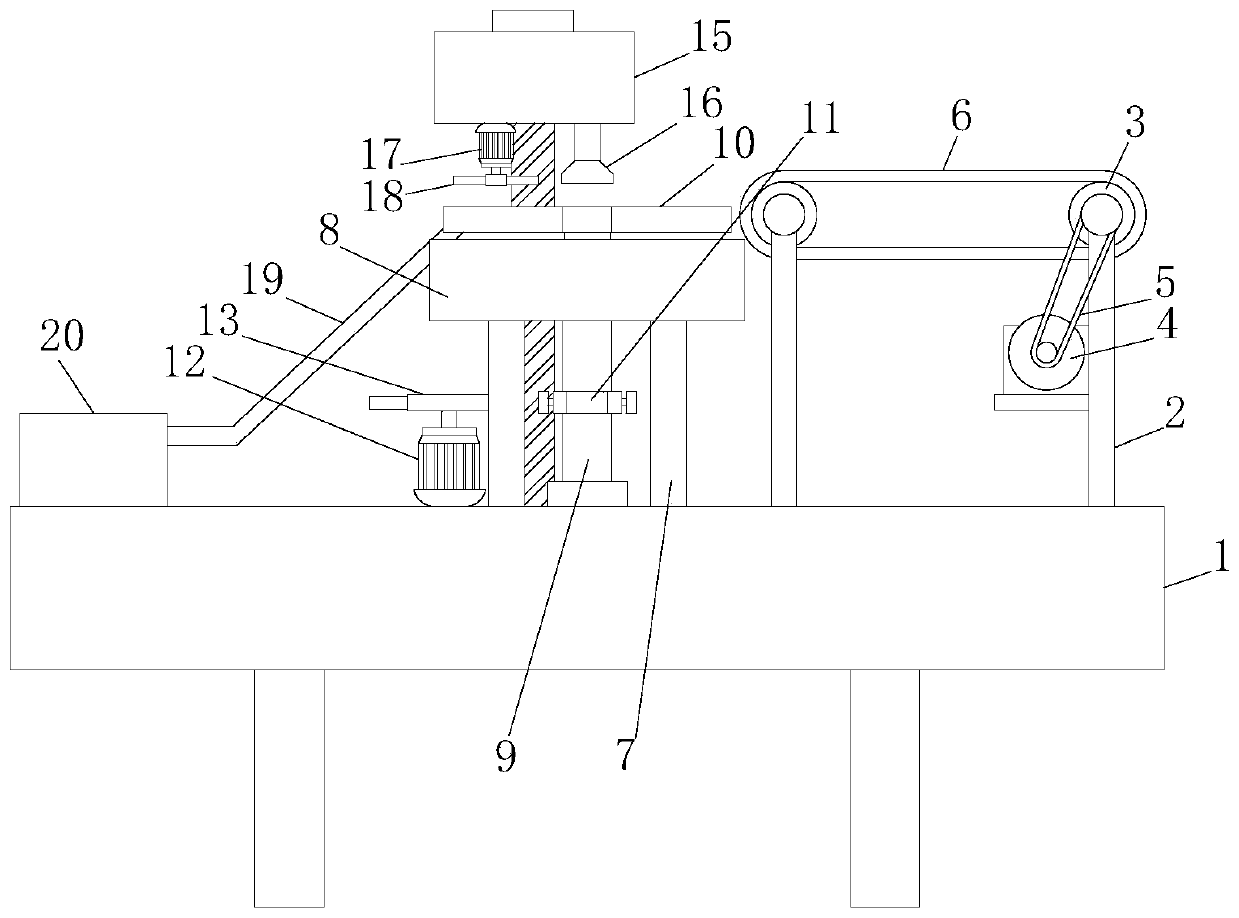

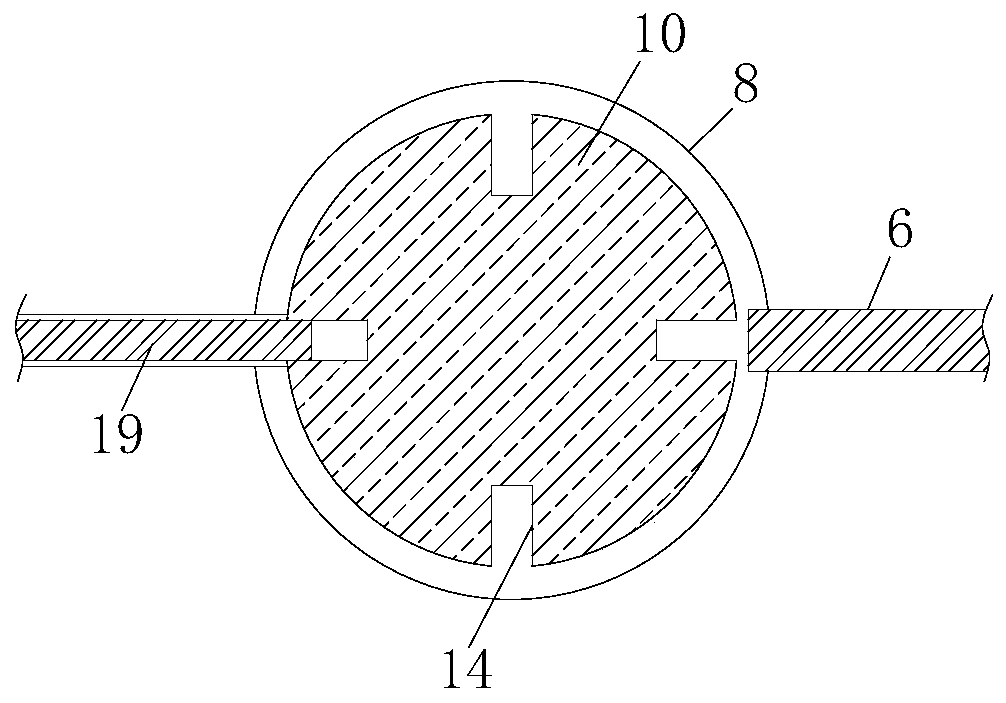

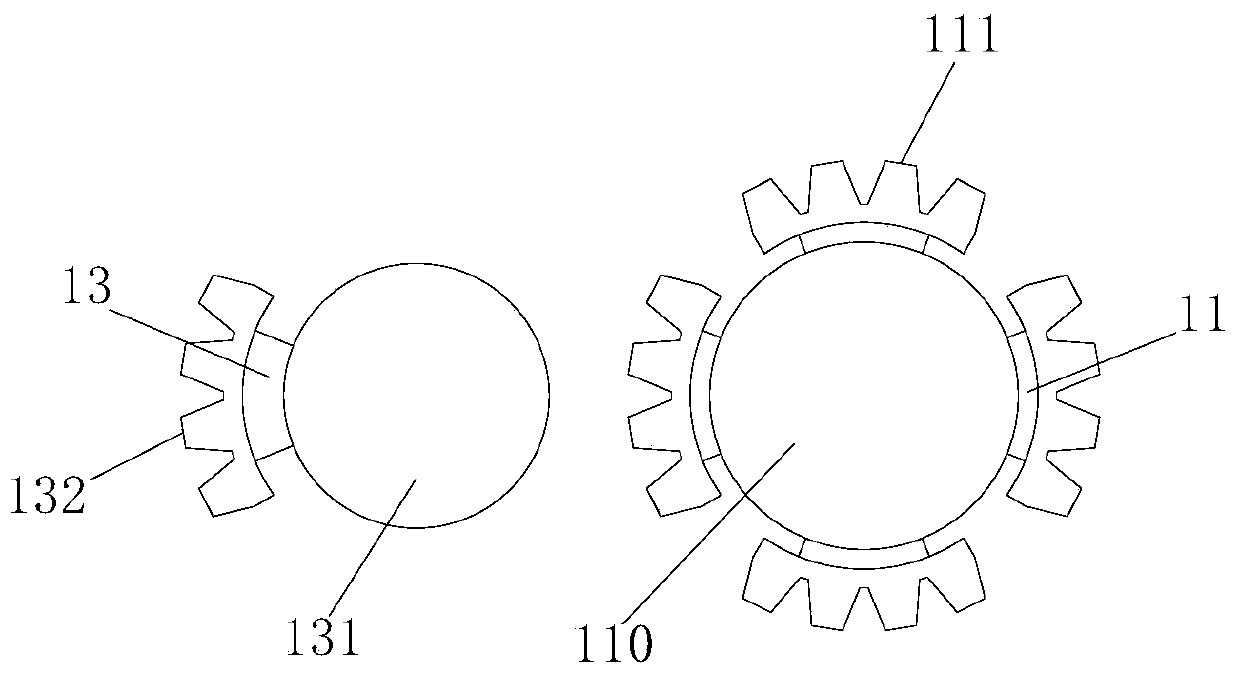

Kelp combine harvester

ActiveCN106941865AImprove harvesting efficiencyEasy to replaceClimate change adaptationHarvestersHydraulic motorMarine engineering

A kelp combine harvester is simple and convenient to operate and can continually harvest and quickly arrange kelp and is characterized in that a ship body is separated from a transport ship, and a fixed catenary support and a supporting plate on the ship body are symmetrically arranged, so that the transport ship can be conveniently connected as required; a circular support and a square support, used for supporting a movable catenary support and the fixed catenary support, on the ship body are adjustable in length, so that the kelp combine harvester can be conveniently used for kelp with different lengths in different kelp culture areas; the movable catenary support can lift kelp in water to be above the water level; a hanging chain brings convenience to convey kelp to be above the transport ship; and control rods can control movement of the ship body, a hydraulic support and a hydraulic motor. Therefore, the manual labor intensity is reduced, the continuous operation capability is enhanced, and the kelp harvesting efficiency is improved.

Owner:OCEAN UNIV OF CHINA

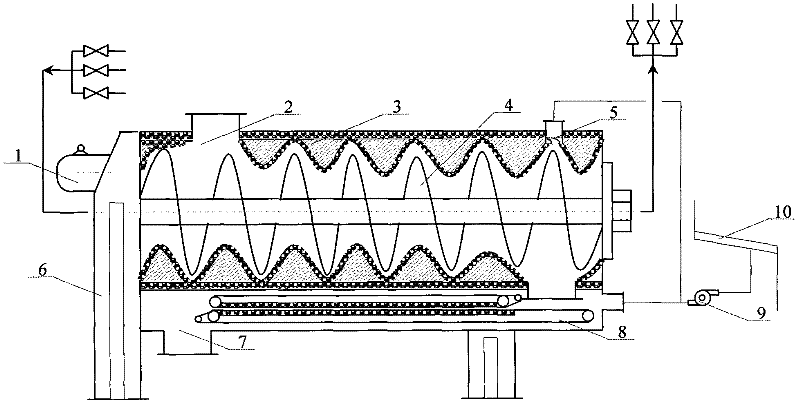

Sludge drying equipment using waste heat of landfill gas power generation

ActiveCN102351396ALower discharge temperatureReasonable structureSludge treatment by de-watering/drying/thickeningWaste based fuelSludgeFlue gas

The invention provides sludge drying equipment using waste heat of landfill gas power generation, which belongs to environmental protection equipment. The equipment employs waste heat of condensed water of a landfill gas power generator assembly, flue gas, waste water and the like to heat and dry sludge entering into the equipment with a hollow stirrer in the sludge drying equipment, and can recycle condensed water of the power generator assembly and reduce the temperature of flue gas and waste water to be discharged; the outer walls of a stirring drying cabin and a spindle are provided with vacuum heat pipes, and a conveying drying cabin is also provided with vacuum heat pipes, which enables a low grade heat source in the stirring drying cabin to be recycled again and to be used for redrying sludge in the conveying drying cabin, thereby realizing reutilization of the waste heat of landfill gas power generation. The sludge drying equipment provided in the invention has the advantages of a reasonable structure, a high waste heat utilization rate, a good sludge drying effect, strong capability of continuous working, etc.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Belt conveyor can be loaded with power isolation flexible start speed regulating device

ActiveCN103343805BTo achieve the purpose of energy savingSmall selectionConveyorsFluid gearingsEngineeringMotor power

A flexible start speed adjusting device capable of realizing belt-type conveyor on-load power isolation overcomes the defects that in an existing belt-type conveyor multi-motor driving system, the working condition of non-load operation or light-load operation often occurs, and energy is wasted. The flexible start speed adjusting device is characterized in that brake mounting holes are machined in one side, provided with a pump wheel axle, of a box body, an electro-magnetic brake is installed through a brake bearing seat, and a driven gear which is matched with a driving gear is installed on a brake shaft of the electro-magnetic brake. The flexible start speed adjusting device has the advantages that the multi-motor driven belt-type conveyor on-load power isolation function is realized, the purpose of saving energy is achieved, the type selection range of the electro-magnetic brake is small, the technology realizing difficulty is low, an electromagnetic brake body is low in manufacturing cost, the purposes that torque impact of equipment during the motor power isolation process or the motor power reapplication process is reduced, and when a certain motor in the driving system of the bet-type conveyor fails, the motor can be turned off under the condition that loads allow and the normal work and operation of the belt-type conveyor are not influenced are realized, and the continuous operation capacity of the conveyor is improved.

Owner:沈阳中煤工程技术有限公司

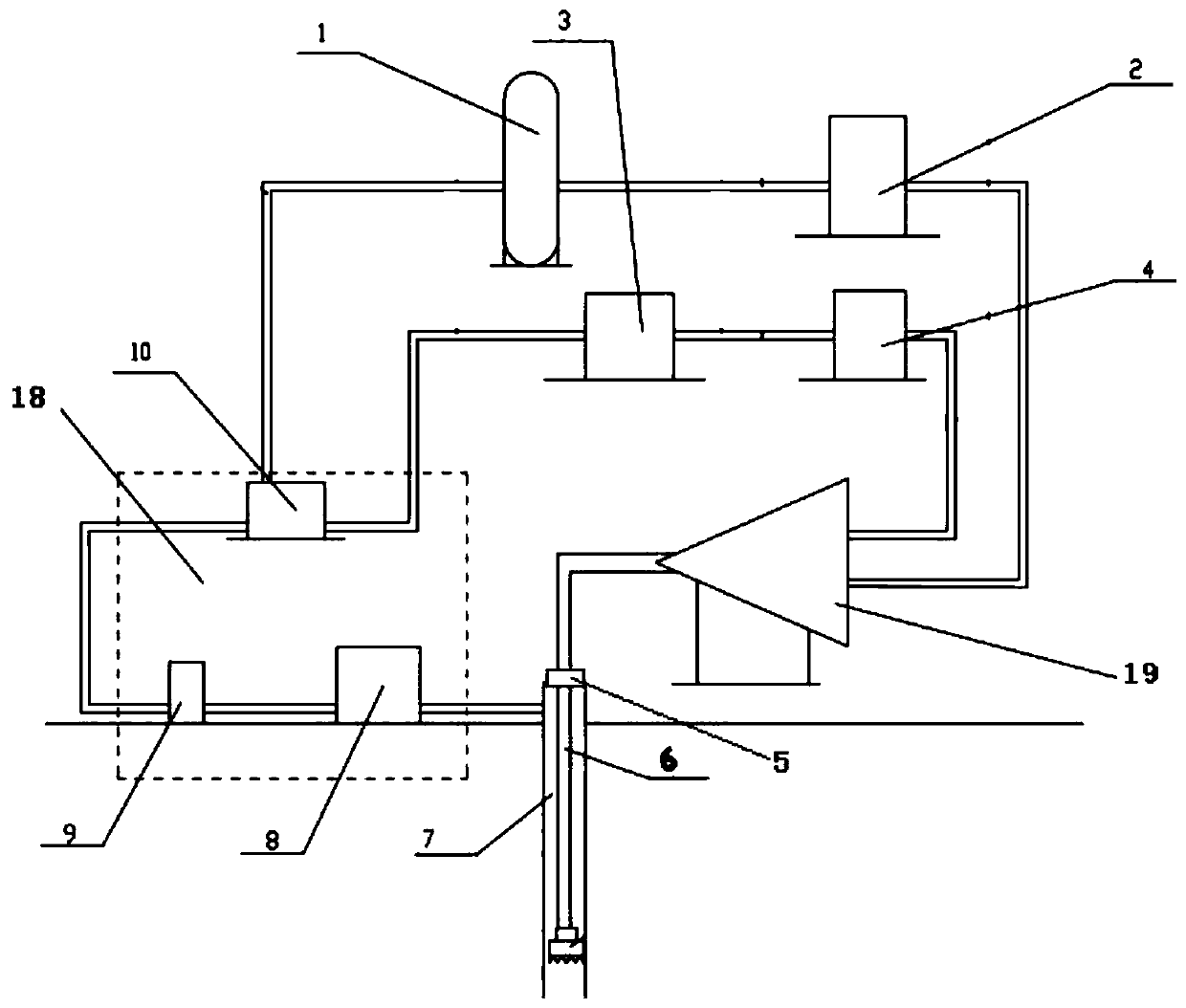

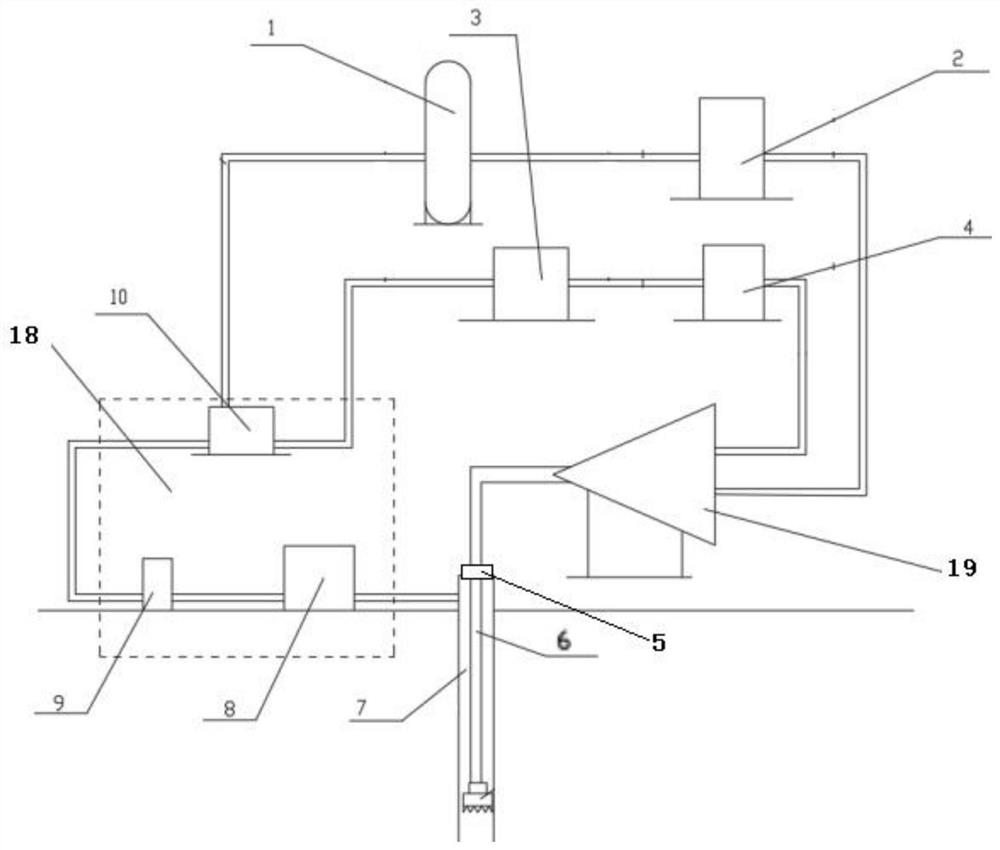

Method and system for charging by means of cooperation of unmanned aerial vehicle and unmanned surface vehicle

InactiveCN108363405AImprove continuous operation abilitySolve the real problemImage enhancementNear-field transmissionEngineeringUnmanned air vehicle

The invention relates to the technical field of unmanned aerial vehicle application, and particularly discloses a method and system for charging by means of cooperation of an unmanned aerial vehicle and an unmanned surface vehicle. The method comprises the steps that the unmanned aerial vehicle collects an unmanned surface vehicle image, and the relative position of a gripping device of the unmanned surface vehicle and the unmanned surface vehicle movement velocity are parsed, and the unmanned aerial vehicle hovers at a certain height in the gripping range; whether the unmanned aerial vehicleis within the gripping range or not is detected, and if yes, the unmanned surface vehicle grips the unmanned aerial vehicle; otherwise, the unmanned surface vehicle recollects the unmanned surface vehicle image; the unmanned aerial vehicle position is adjusted through the gripping device, and then wireless charging is conducted. Accordingly, by means of an unmanned aerial vehicle and unmanned surface vehicle cooperative control technology, a large capacity battery of the unmanned surface vehicle is used for charging the unmanned aerial vehicle, the continuous operation capacity and the actionrange of the unmanned aerial vehicle can be greatly improved, and meanwhile the problem that people need to participate in unmanned aerial vehicle charging is solved, and full autonomous control overthe unmanned aerial vehicle is achieved.

Owner:GUANGDONG HUST IND TECH RES INST +2

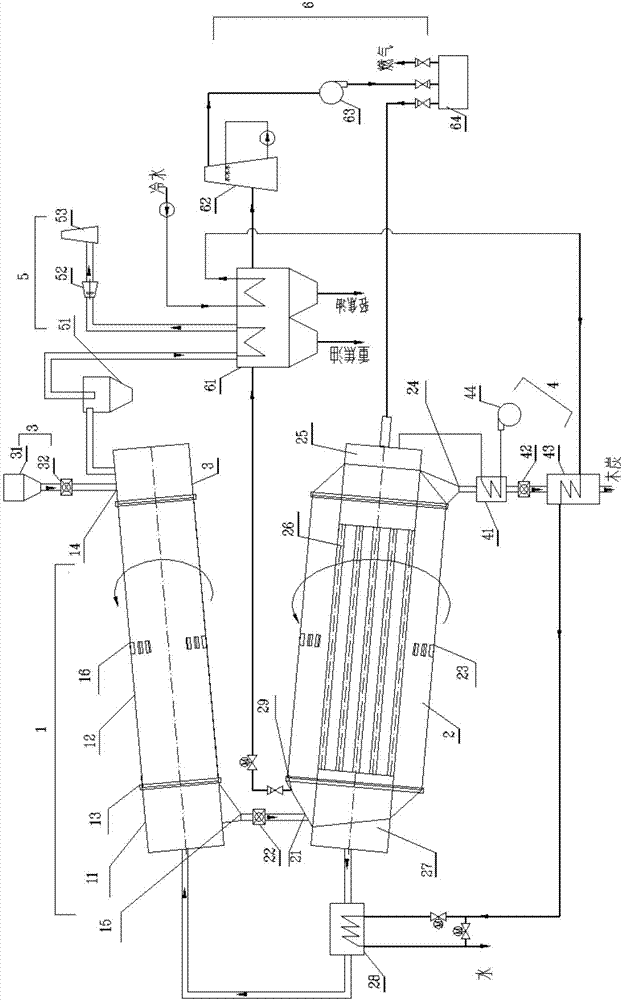

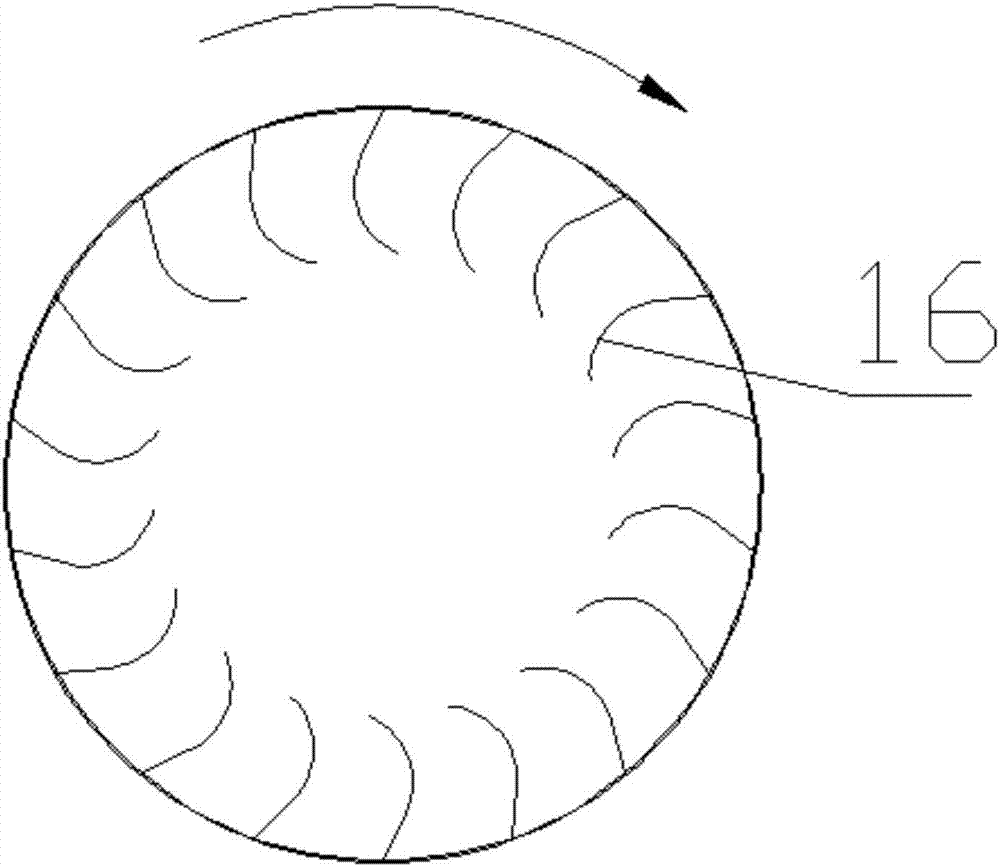

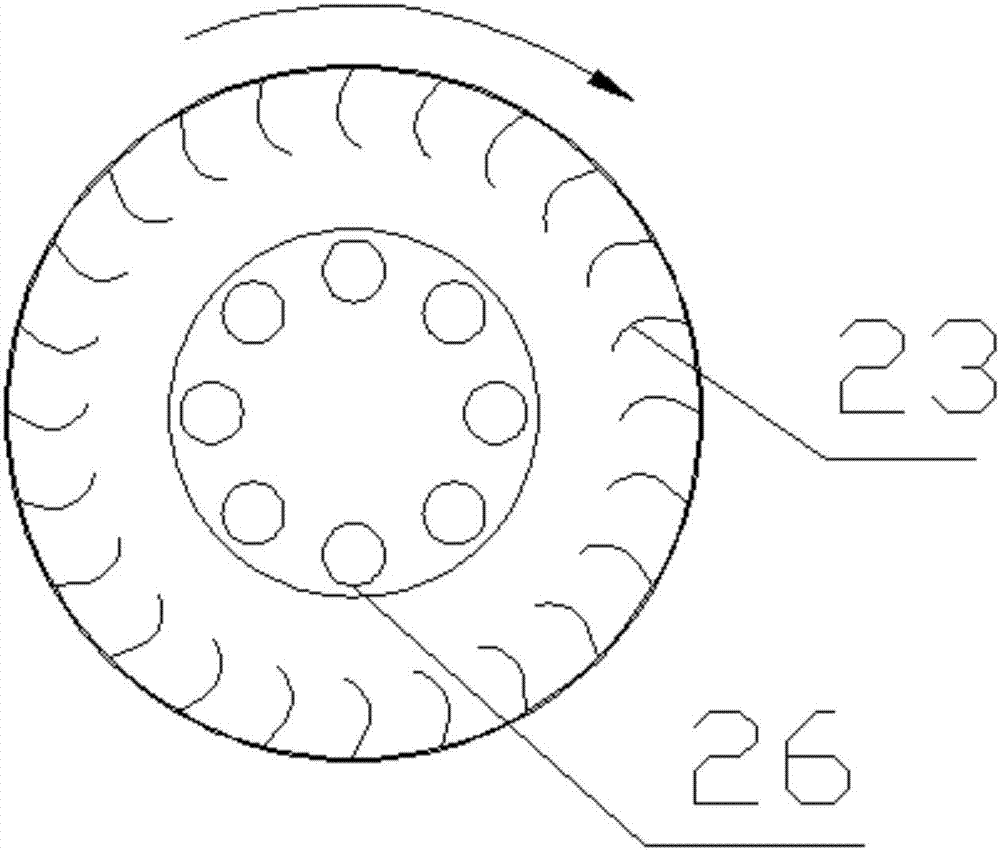

Biomass dry distillation pyrolysis device

The invention provides a biomass dry distillation pyrolysis device, which consists of a rotary baking chamber, a rotary dry distillation pyrolysis chamber, a biomass feeding system, a charcoal discharge cooling system, a biomass fuel gas purification system and a flue gas system. The rotary baking chamber is equipped with a first feed end and a first discharge end, and the first feed end is connected to the biomass feeding system. The rotary dry distillation pyrolysis chamber is equipped with a second feed end and a second discharge end, the second feed end is connected to the first discharge end, and the second discharge end is connected to the charcoal discharge cooling system. The first feed end of the rotary baking chamber is provided with a flue gas port, which is connected to the flue gas system. The second feed end of the rotary dry distillation pyrolysis chamber is equipped with an air suction port, which is connected to the biomass fuel gas purification system. The device has the advantages of simple structure, compact layout and strong continuous operation ability.

Owner:陈军武

Traditional Chinese medicinal material effective component soaking-extracting device

ActiveCN110917649ASave unnecessary transfer processReduce occupancySolid solvent extractionPharmaceutical drugProcess engineering

The invention relates to a technical field of traditional Chinese medicine processing, and specifically relates to a traditional Chinese medicinal material effective component soaking-extracting device, which comprises a base. A tank is fixedly mounted on the base through a bolt. The front end of the tank is fixedly provided with a controller, which is electrically connected to an external power supply, through a bolt. The upper end of the tank is fixedly provided with a main push rod through a bolt. The device has the advantages that the integration degree of the device is high; the unnecessary raw material transfer process is effectively eliminated, the occupied space is reduced, and moreover, the production efficiency is improved. The device can automatically carry out breaking, mixingand filtering, and automatically adjusts the temperature and pressure, the required labor force is reduced, the skill requirements on workers are lowered, at the same time, the device is convenient toclean, medicinal residues can be easily discharged, next operation can be carried out rapidly, the continuous operation performance is strong, and the maintenance difficulty is reduced.

Owner:临沂天源中药饮片有限公司

Conical bearing track physical-chemical quenching device

InactiveCN109811112AEasy to installEasy to replaceFurnace typesIncreasing energy efficiencyDrive wheelEngineering

The invention relates to the technical field of machining, and discloses a conical bearing track physical-chemical quenching device which comprises a base. A support seat is fixedly arranged above thebase; a lifting device is fixedly arranged on the support seat; a driven wheel is fixedly arranged at the drive end of the lifting device; and a connecting rod is arranged above the driven wheel through a bearing. According to the quenching device designed by the invention, a corresponding clamping arm and a corresponding quenching inductor can be selected according to the dimension and the shapeof a workpiece so as to quench the workpiece, and the surface of the quenching inductor can align at the surface of a bearing track on the workpiece, so that a quenching layer can be more uniform, the quenching accuracy can be better ensured, the workpiece can be conveniently installed and replaced, the continuous operation capability is high, and the conical bearing track physical-chemical quenching device is easy to use and has a high practical value.

Owner:南昌汇达知识产权有限公司

Sluice with garbage intercepting and sweeping functions

PendingCN112627126AImprove the efficiency of interception operationsImprove efficiencyBarrages/weirsCleaning using toolsWater flowHydraulic engineering

The invention relates to the technical field of water conservancy projects, and particularly relates to a sluice with garbage intercepting and sweeping functions. The sluice comprises a first fixing frame, a gate plate, a blocking net device and a sweeping device. The first fixing frame is arranged in a water channel; the two sides of the gate plate are in sliding connection with two first sliding grooves formed in the two sides of the first fixing frame correspondingly, and the water channel is opened or closed through a first hoisting assembly; the blocking net device is used for intercepting garbage in water flow; the sweeping device is arranged above the blocking net device and used for sweeping the garbage intercepted by the blocking net device; the blocking net device comprises a blocking belt, supporting plates and a drive assembly; the two supporting plates are symmetrically arranged on the two sides of the blocking belt; the drive assembly is connected with the blocking belt; and after the blocking belt intercepts the garbage in the water flow, the blocking belt is driven by the drive assembly to lift the garbage to the position below the sweeping device. The sluice solves the problems that in the prior art, manual work continuity is poor, the work efficiency is low, and the intercepted garbage cannot be cleared away in time.

Owner:大同市水旱灾害防御中心 +1

Electric welding machine used for machining of shell of high-voltage transformer

ActiveCN105855677AStable cooling effectImprove continuous operation abilityWelding/cutting auxillary devicesHeat-exchange elementsContinuous operationEngineering

The invention provides an electric welding machine used for machining of a shell of a high-voltage transformer. An automatic feeding device and an oil cooler are arranged on the electric welding machine. The automatic feeding device comprises a feeding channel, a first pushing air cylinder and a second pushing air cylinder. The first pushing air cylinder is used for pushing materials. The second pushing air cylinder is used for pushing the materials out of the automatic feeding device. Materials are rotated in the feeding channel. Elastic pieces are arranged on an inlet channel portion of the feeding channel. The materials are squeezed by the elastic pieces, so that the materials are made to adhere to a baffle till the materials reach an electric welding station, and thus the purpose of automatic feeding is achieved. In addition, the oil cooler hung on the electric welding machine is hung stably and communicates with the interior of the electric welding machine, the oil cooler is used for cooling the electric welding machine, the cooling effect is stable and rapid, the continuous operation capacity of the electric welding machine is improved, the machining efficiency of the shell of the high-voltage transformer is improved to a great extent, and accordingly the production efficiency of enterprises is improved. Meanwhile, the invention discloses novel cooling oil, the novel cooling oil is flexible in heat balance capacity and extremely high in heat conducting capacity, and thus the cooling effect of the interior of the electric welding machine is guaranteed.

Owner:SUQIAN GENERAL MACHINERY

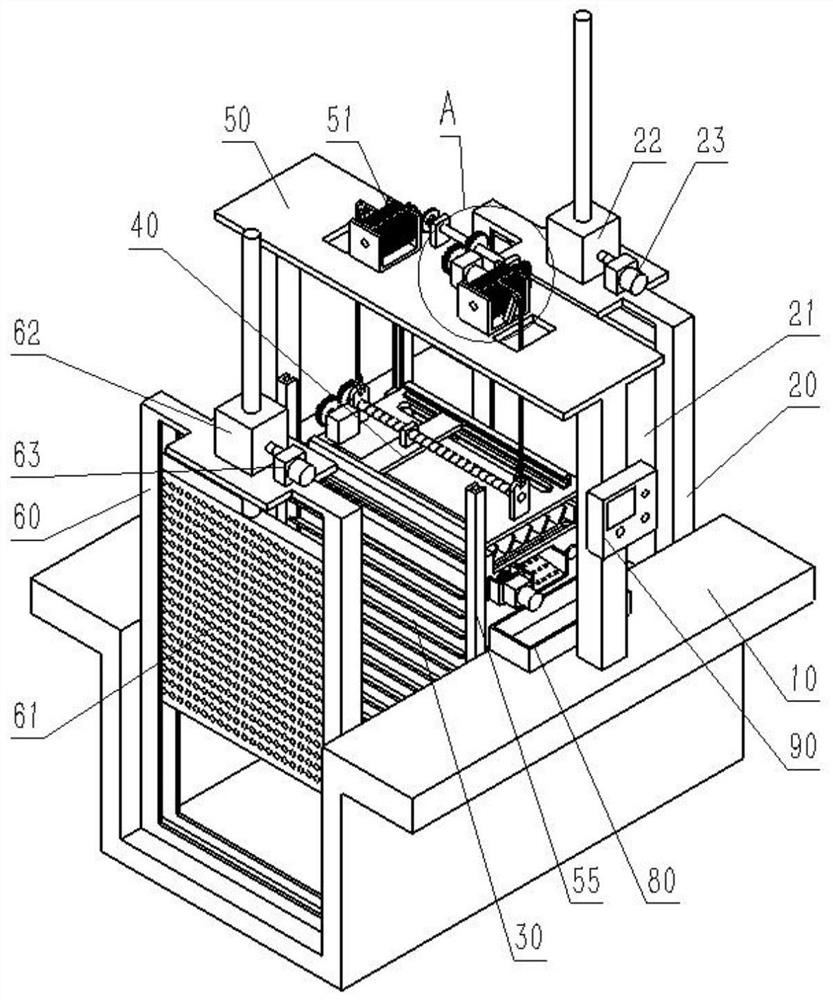

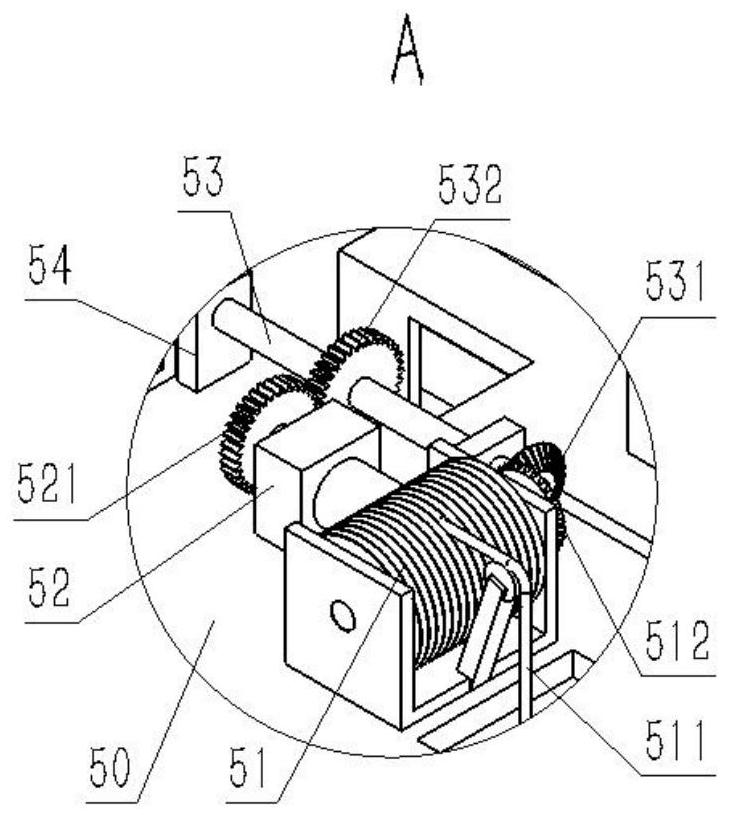

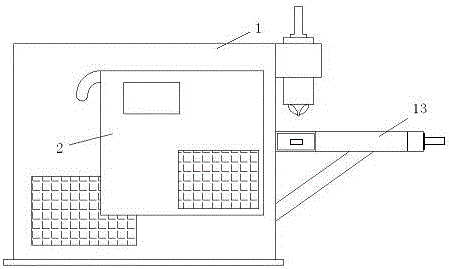

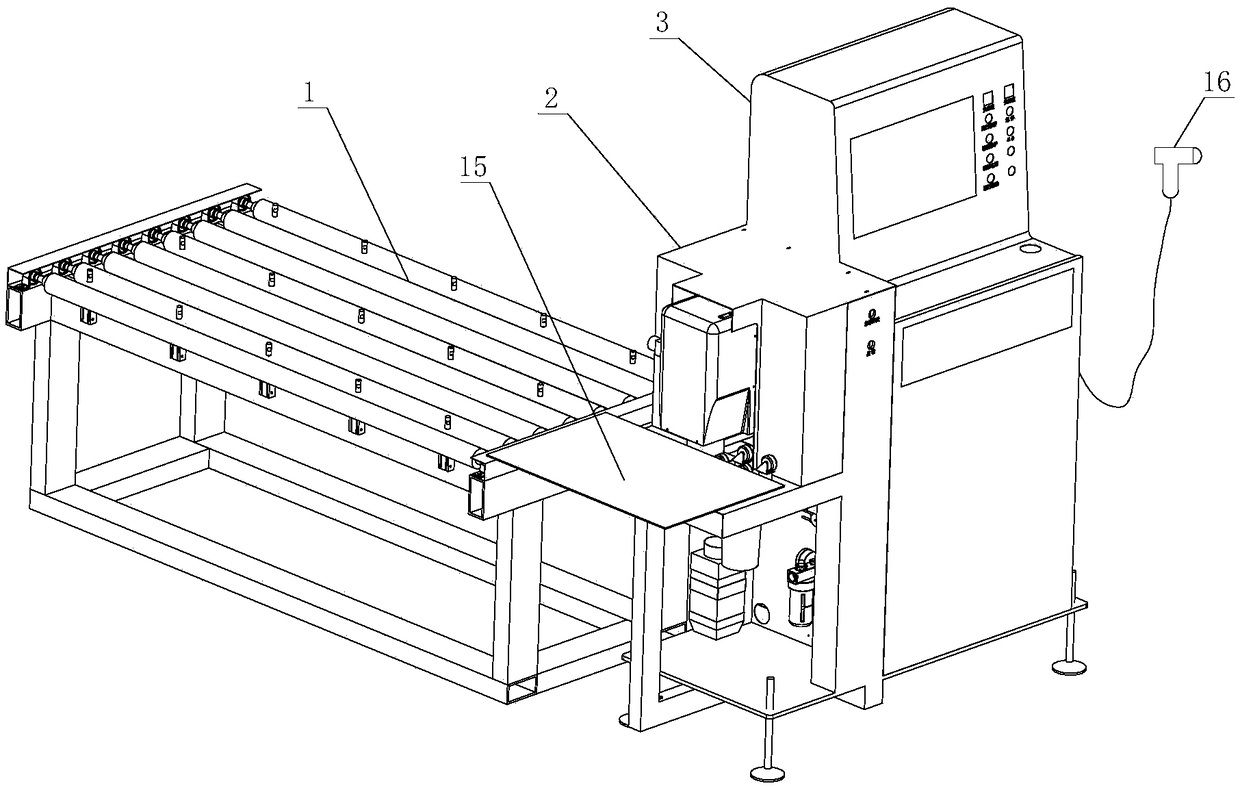

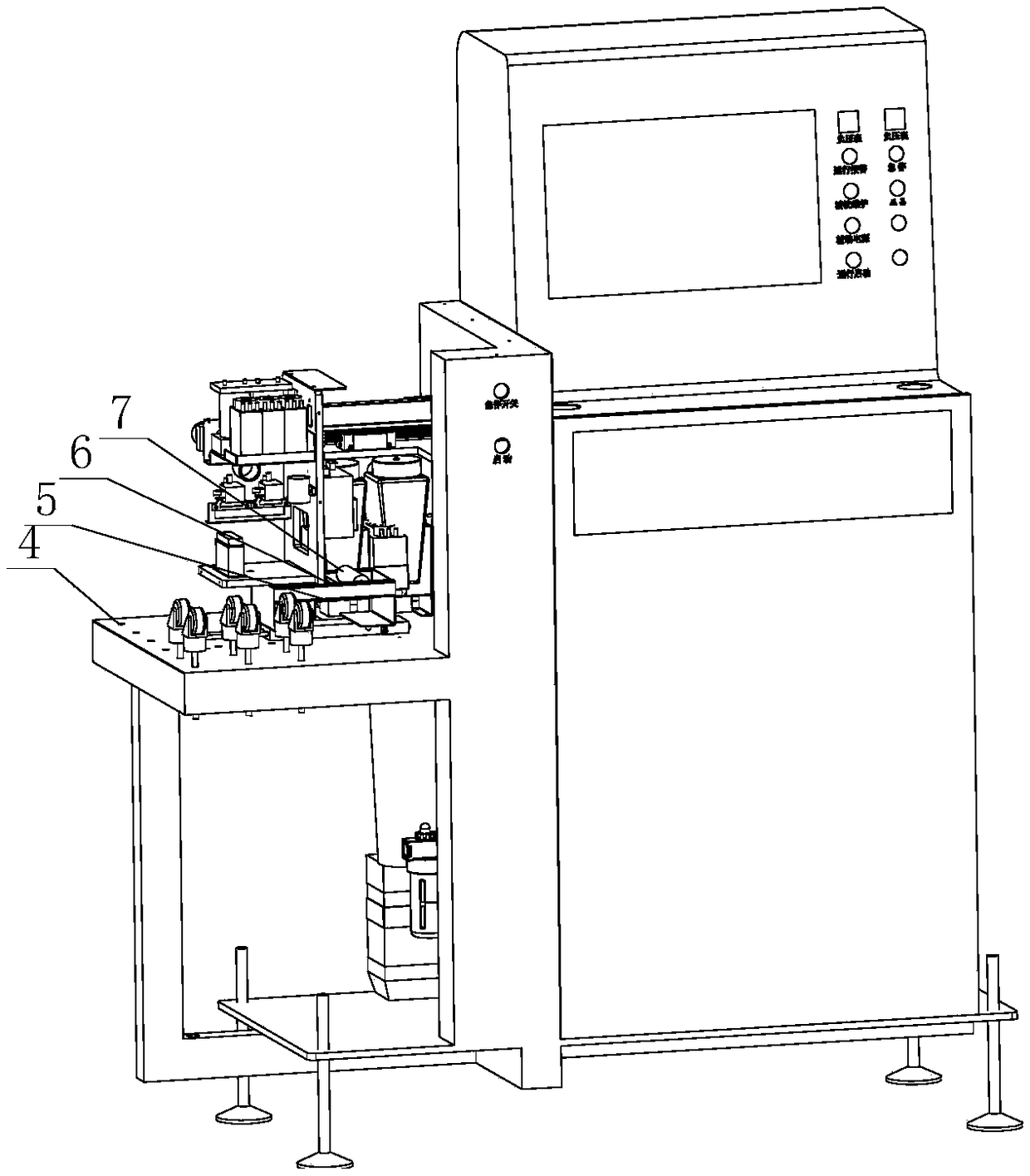

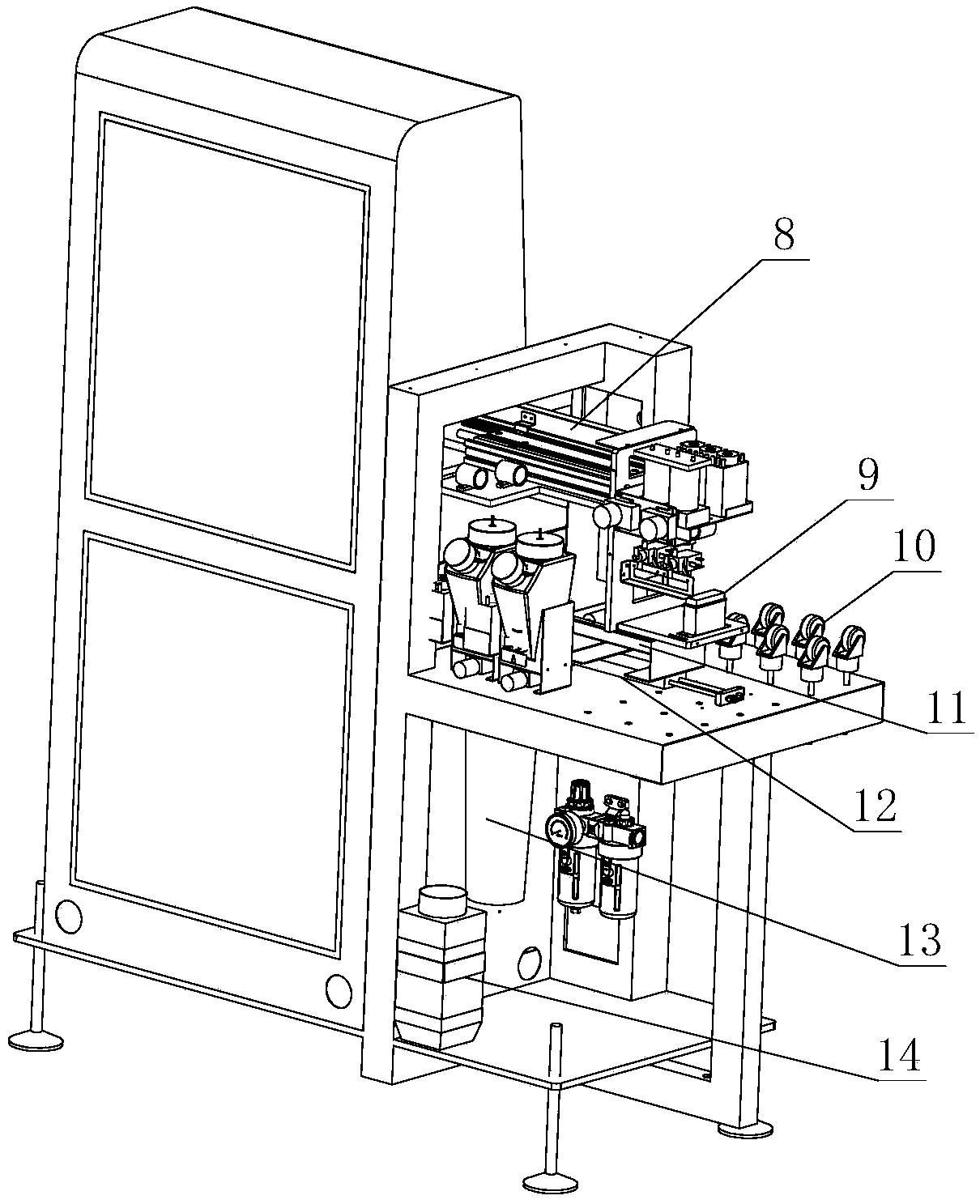

Automatic glass digital printing system and using method thereof

PendingCN108656760AImprove continuous operation abilityAvoid pollutionTypewritersPower drive mechanismsElectricityControl system

The invention discloses an automatic glass digital printing system which comprises a device body and a mechanical hand. The mechanical hand is located on one side of the device body, the device body is provided with a glass printing platform, and further provided with a control system, a first telescopic device and a digital printing device, the first telescopic device and the digital printing device are both electrically connected with the control system, the first telescopic device is installed on the device body, and the digital printing device is connected with the telescopic end of the first telescopic device. The automatic design concept is adopted, the production efficiency can be improved, and the labor cost can be reduced. For being matched with material grabbing of the mechanicalhand, the digital printing device has a telescopic function, the digital printing device stretches out for printing when printing is needed, the digital printing device retracts back after printing is finished, and no interference is produced to material grabbing of the mechanical hand. Meanwhile, a cleaning device is arranged for the digital printing device, and the continuous work capacity of the digital printing device can be improved.

Owner:付__灵 +2

Painting device for piano keyboard cover

The invention discloses a painting device for a piano keyboard cover. The painting device comprises a machine table, a support frame is welded on the right side of the top of the machine table, the top of the support frame is movably provided with pulleys, and one side of the support frame is provided with a first motor. The output end of the first motor and the pulleys are connected by a conveyorbelt in a transmission mode, and a conveyor belt is connected between the pulleys in the transmission mode. A support leg is welded to the center of the top of the machine table, and a fixed table iswelded at the top of the support leg. A rotating shaft is installed in the middle of the fixed table in the rotating mode, the bottom of the rotating shaft is movably connected with the top of the machine table, and the top of the rotating shaft extends through the fixed table and extends to the outside of the top of the fixed table. The painting device is provided with an intelligent painting mechanism and integrates the processes of feeding, painting and discharging, is high in continuous work capacity, reduces the working hours, can complete the whole painting work automatically basicallywithout manual participation, and can greatly improves the efficiency.

Owner:NANTONG TAIYING NEW MATERIAL SCI & TECH CO LTD

Cleaning sweeper trunk sewage filtering separation box

PendingCN108854258AImprove filtration efficiencyMake up for the limited volumeRoad cleaningFiltration circuitsFiltrationWater resources

The invention relates to a cleaning sweeper trunk sewage filtering separation box, and belongs to the technical field of environmental sanitation. The cleaning sweeper trunk sewage filtering separation box comprises a box body, wherein a sewage box and sewage suction pipes are arranged in the box body, the interior of the sewage box is divided into a left bin, a middle bin and a right bin by two lower baffles, the front ends of the three bins are separate, the rear ends of the three bins are communicated, an air suction hood is arranged at the top end of the middle bin, upper baffles are arranged at the upper ends of the left bin and the right bin respectively, clearing water boxes are arranged in the left bin and the right bin respectively, primary filtering screen boxes are arranged at front ends of the lower portions of the clear water boxes, secondary filtering cylinders are arranged in the primary filtering screen boxes, and the lower ends of the secondary filtering cylinders areconnected with water outlets; the sewage suction pipes penetrate through the side walls of the box body and the clear water boxes and extend to the lower baffles in sequence. The cleaning sweeper trunk sewage filtering separation box is simple in structure and easy to produce, primary two-time filtering of sewage in a cleaning sweeper trunk can be easily achieved, and a foundation is laid for subsequent refined filtration and recycle, so that water resources are saved, continuous operation time is prolonged, and the cleaning efficiency is improved.

Owner:湖北宏宇专用汽车有限公司

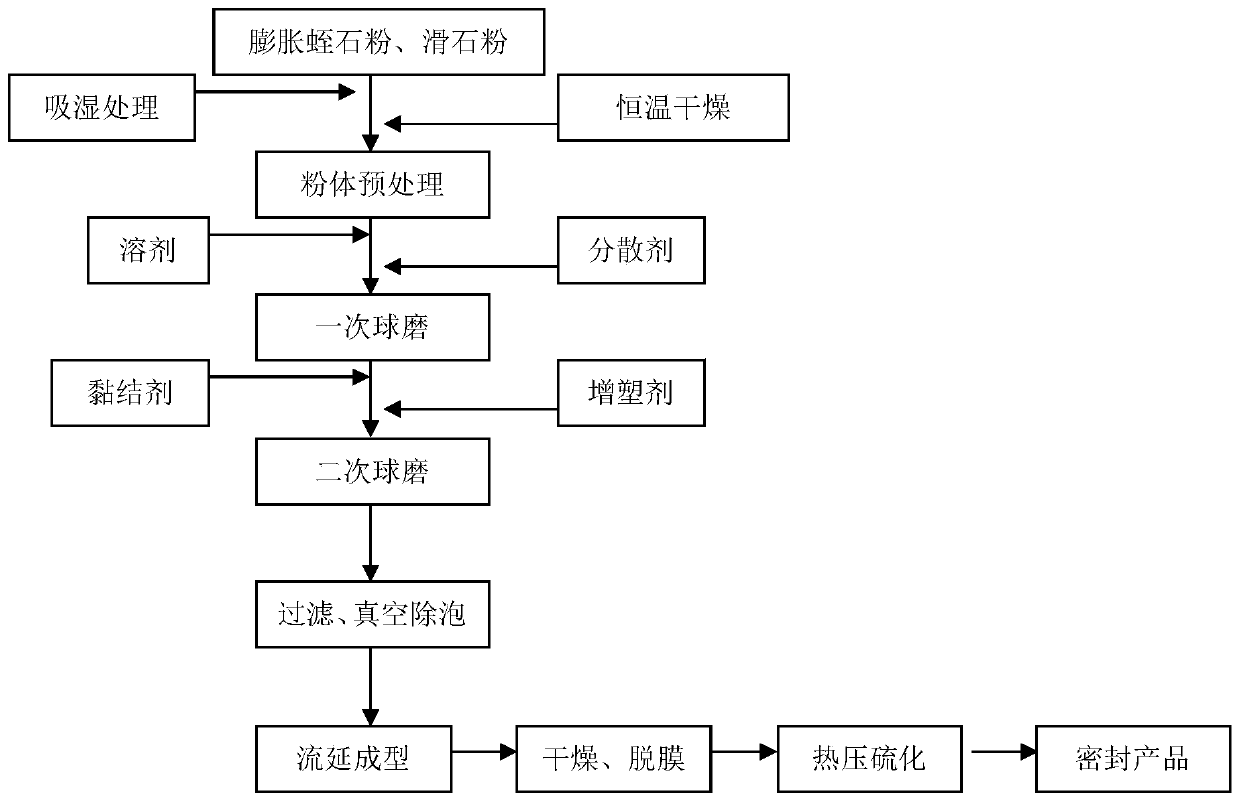

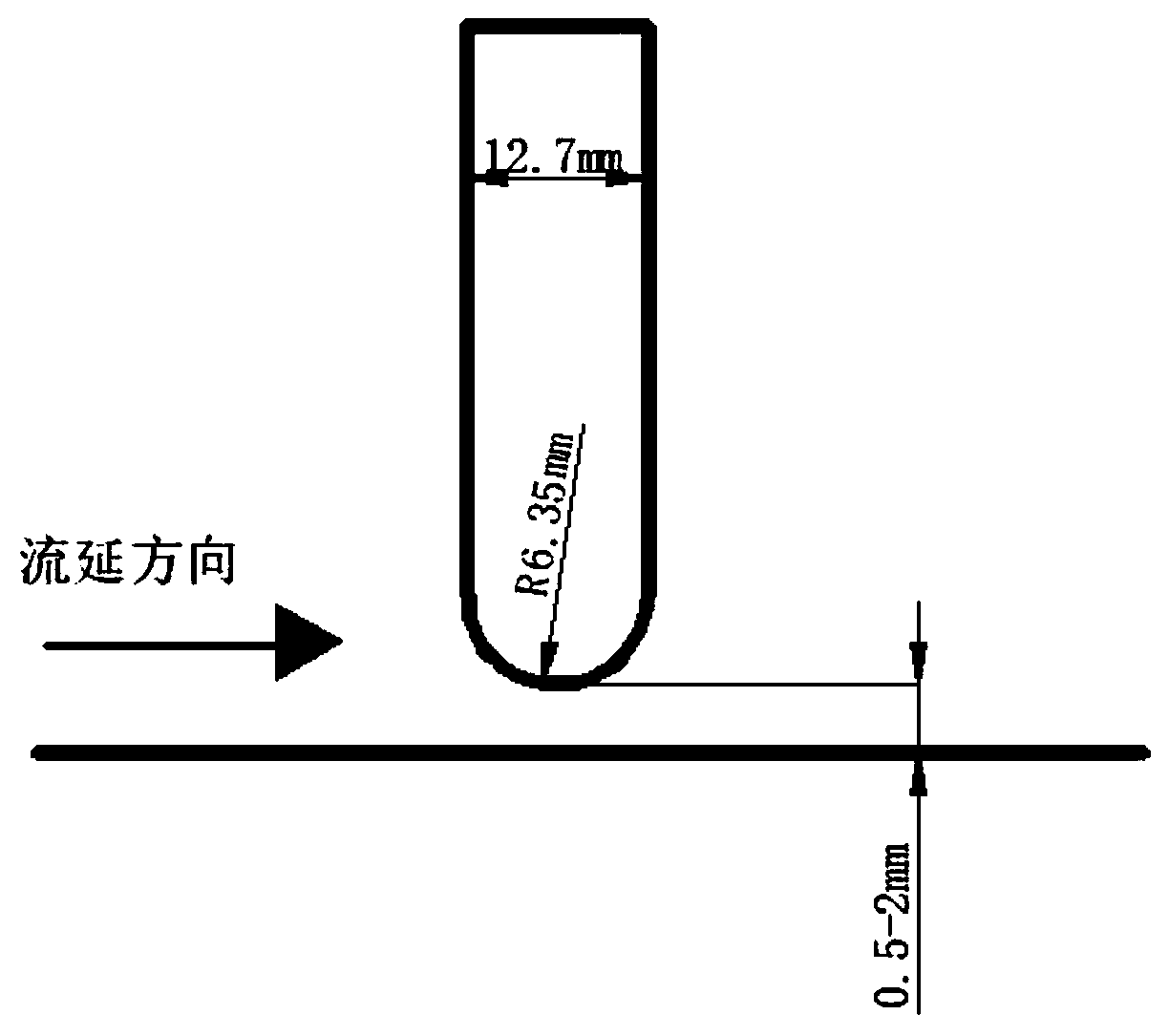

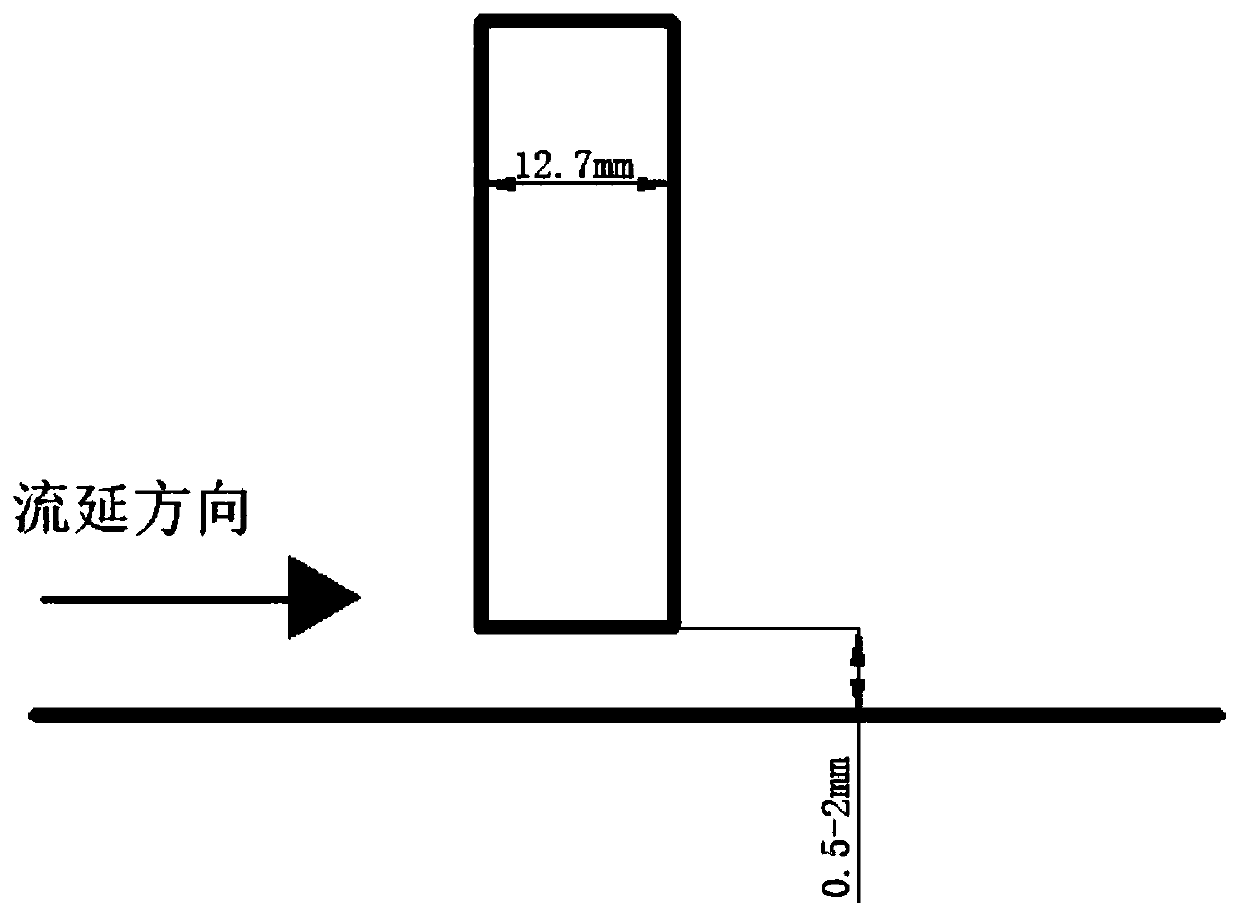

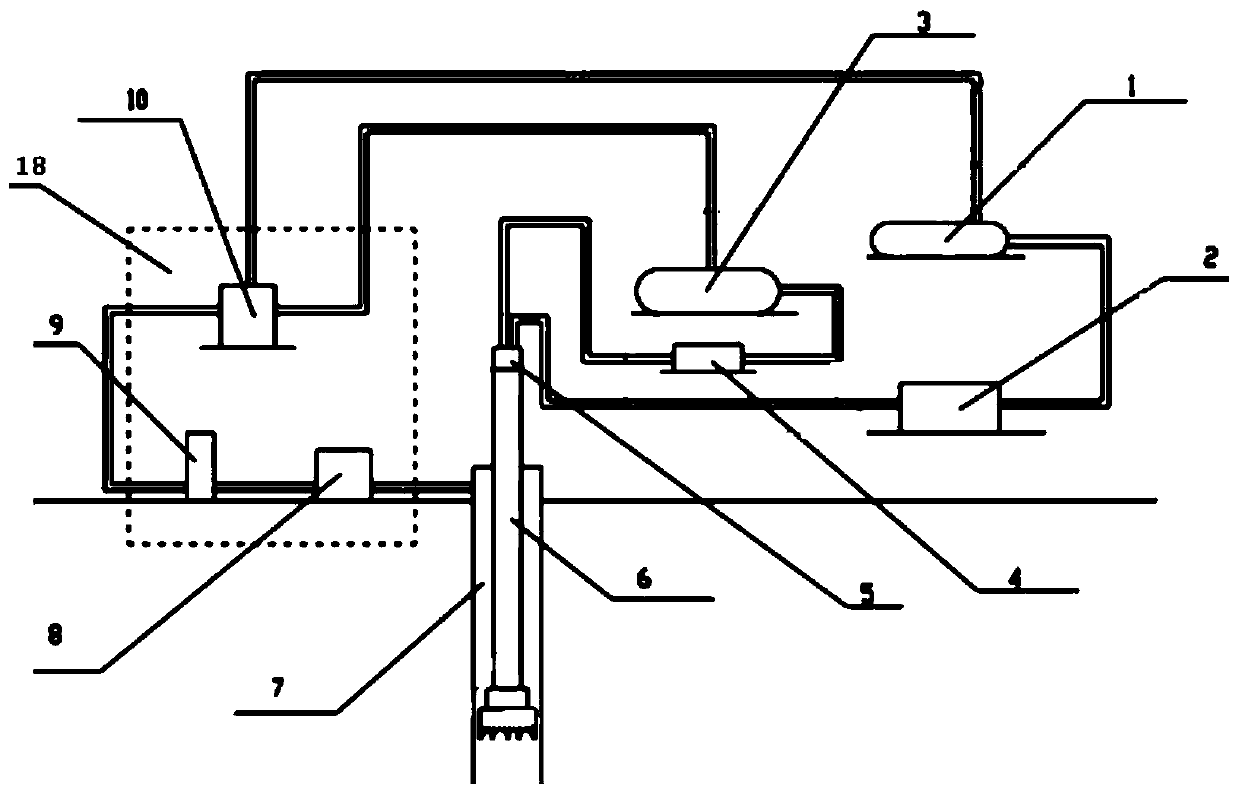

Preparation method of vermiculite-based flexible sealing material

ActiveCN110723923AImprove processing stabilityFlat surfaceCoatingsGrain treatmentsVulcanizationAdhesive

The invention provides a preparation method of a vermiculite-based flexible sealing material. The preparation method is characterized by comprising the following steps of step 1) putting dried vermiculite-based powder into a ball milling tank, adding a solvent and a dispersant, and performing primary ball-milling dispersion; step 2) after primary ball milling is finished, adding an adhesive and aplasticizer for performing secondary ball milling to obtain a mixed slurry; step 3) carrying out filtration treatment on the mixed slurry, and then carrying out defoaming treatment to obtain a shapedslurry; step 4) carrying out casting forming on the obtained shaped slurry, controlling the height from a scraper to a base belt to be 0.5-2 mm, controlling the speed of the base belt to be 0.2-2m / min, and controlling the drying temperature to be 25-60 DEG C to obtain a sealing material blank; and step 5) enabling the sealing material blank to be subjected to hot-pressing vulcanization molding, and then obtaining the vermiculite-based flexible sealing material through cutting and molding. The vermiculite-based flexible sealing material with excellent performance is obtained through casting molding and powder pretreatment.

Owner:WUHAN UNIV OF TECH +1

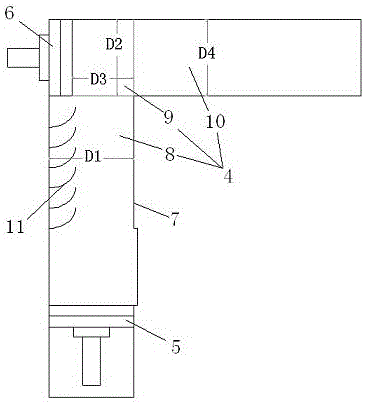

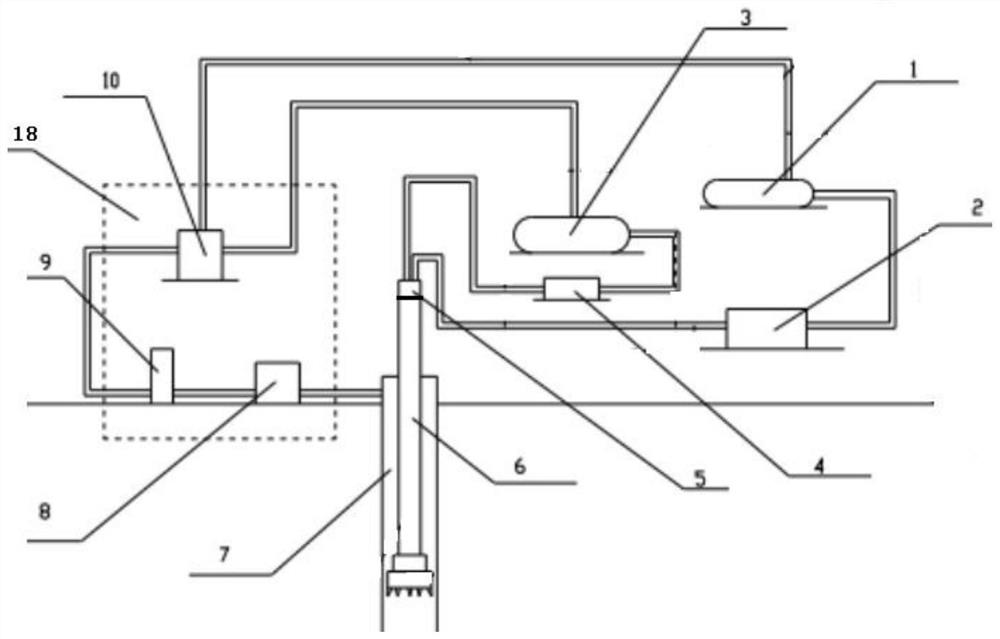

Dual-wall screw well drilling system based on gas-liquid two-phase drive

InactiveCN110344752AReduce thermal wearImprove continuous operation abilityConstructionsLiquid/gas jet drillingDirectional wellUniversal joint

A dual-wall screw well drilling system based on gas-liquid two-phase drive comprises a ground system, a well opening device and a downhole drilling tool assembly. The ground system comprises a gas storage and collection tank and a liquid storage and collection tank, wherein the gas storage and collection tank and the liquid storage and collection tank communicate with the well opening device through an air compressor and a liquid high-pressure pump correspondingly and then are connected with a gas-liquid two-phase flow recovery device. The gas-liquid two-phase flow recovery device comprises asand recover, a back-pressure valve and a ground gas-liquid separation device. The downhole drilling tool assembly comprises a dual arm drilling rod I connected with the well opening device. The lowerportion of the dual arm drilling rod I is sequentially connected with a short joint, a dual-wall screw motor, a universal joint, a downhole gas-liquid separation device I, a dual arm drill rod II anda drill bit. According to the dual-wall screw well drilling system, the problem that an air screw is prone to being damaged under a well can be reduced, the rock breaking efficiency can be improved,and therefore safe, rapid and economical well drilling can be achieved on a horizontal well and a directional well.

Owner:SOUTHWEST PETROLEUM UNIV

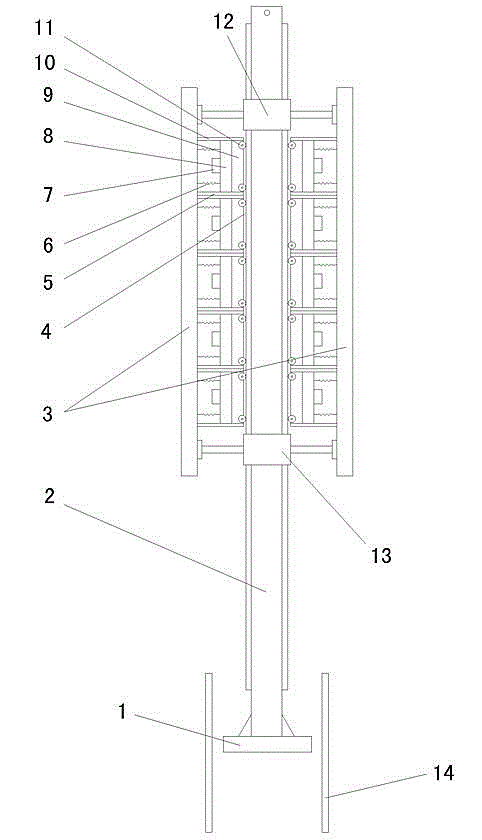

Electromagnetic tamping machine of tamping coke oven

The invention discloses an electromagnetic tamping machine of a tamping coke oven. The electromagnetic tamping machine comprises a steel structure, wherein a vertical hammer lever is matched with the steel structure, a hammer head is installed below the hammer lever, the hammer lever is connected with driving mechanisms, and the driving mechanisms are linear motors; the linear motors are symmetrically distributed at the two sides of the hammer lever, and at least one group of linear motors are arranged on each side; the stators of each group of linear motors are installed between an upper slide way and a lower slide way, the upper slide way and the lower slide way are fixedly connected with the steel structure, a roller is installed on the stator shell of the linear motor close to one side of the hammer lever, the roller is matched with the side face of the hammer lever, a tension spring is arranged between the other side of the stator shell of the of the linear motor and the steel structure, and the rotors of the liner motors are of plate-shaped structures and are fixedly connected on the side face of the hammer lever; and the air gap between the stator and the rotor of the linear motor at the working state is 1.5-2.5mm. The structure is simple, the action is flexible and reliable, the maintenance rate is low and the working efficiency is improved.

Owner:孙杰 +1

Movable building waste breaking and collecting device

InactiveCN111036382AStable and efficient picking processEfficient material guideMechanical machines/dredgersGrain treatmentsSteering wheelArchitectural engineering

The invention relates to the field of building related equipment, in particular to a movable building waste breaking and collecting device. The movable building waste breaking and collecting device comprises a movable installation plate which is horizontally arranged. Electric control lifting pillars are vertically arranged at the four corners of the lower end of the movable installation plate, and limiting steering wheel frames are arranged at the lower ends of the electric lifting pillars. Drive guide wheels are arranged at the lower ends of the limiting steering wheel frames. A supporting installation plate is horizontally arranged over the movable installation plate. A material collecting groove is formed in the left upper end of the supporting installation plate, and a rotating material guide plate is arranged at the left end of the supporting installation plate through an electric control rotating shaft. Due to movable material shoveling and rotating material guiding, the pickingprocess of materials is stable and efficient; due to a spiral material lifting structure, the device can conduct one-time breaking work and material lifting work at the same time; and due to the factthat a dislocation breaking structure is rotated, the breaking quality of the device is good, after collection is completed, due to cooperation of a threaded screw chamber, broken materials can be efficiently guided out, and the continuous work capability of the device is obviously improved.

Owner:时守贺

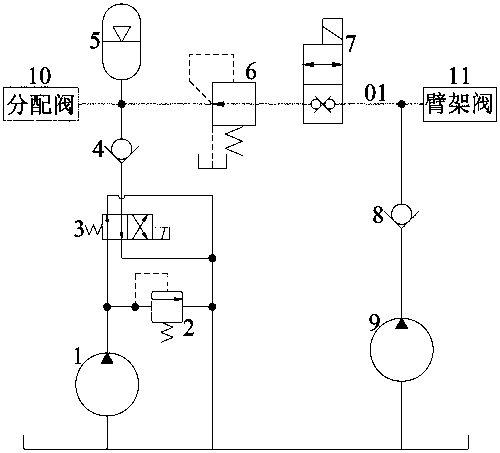

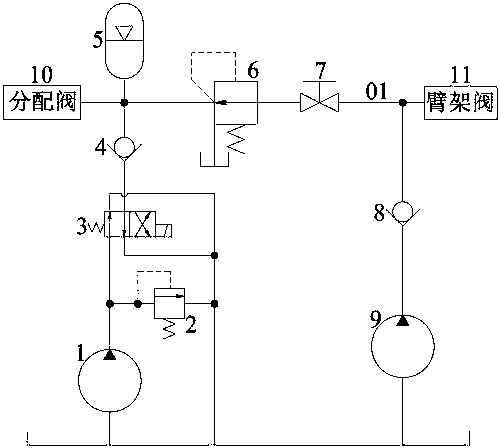

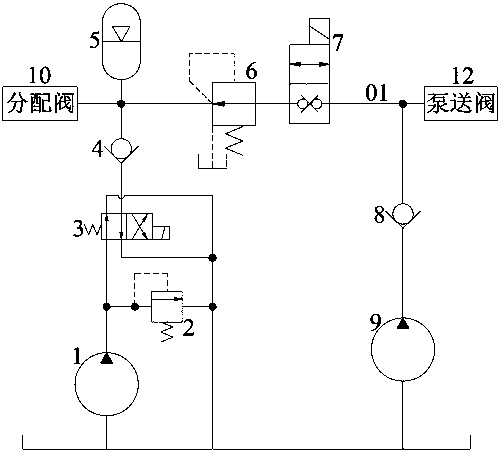

Fluid transportation emergency device

InactiveCN109555736AImprove continuous operation abilityImprove resource utilizationMechanical apparatusBuilding material handlingEmergency SupplyResource utilization

The invention provides a fluid transportation emergency device. The fluid transportation emergency device comprises a proportioning hydraulic system, a transportation hydraulic system and an executinghydraulic system; and an emergency oil circuit is arranged among the transportation hydraulic system, the executing hydraulic system and the proportioning hydraulic system, and the an emergency oil circuit is used for supplying oil for the proportioning hydraulic system in emergency. According to the fluid transportation emergency device, the transportation hydraulic system and the executing hydraulic system of fluid machinery own are fully used for being as emergency oil sources, emergency supply is carried out on the proportioning hydraulic system through the emergency oil circuit to realize normal work of a distribution valve, it is ensured that the fluid machinery continuously transports fluid, the resource utilization rate is improved, and continuous operation performance of the fluid machinery is further improved.

Owner:常州华睿新能源汽车发展有限公司

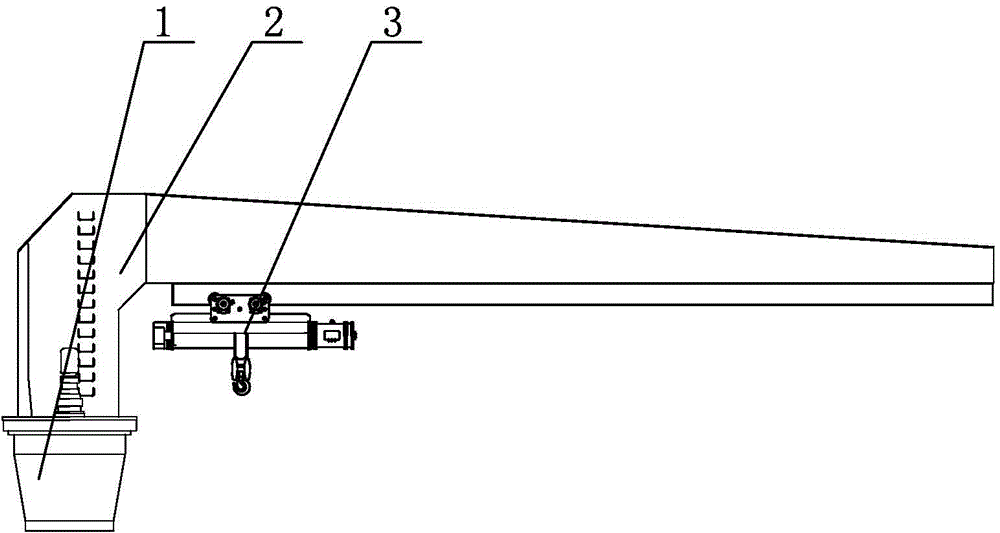

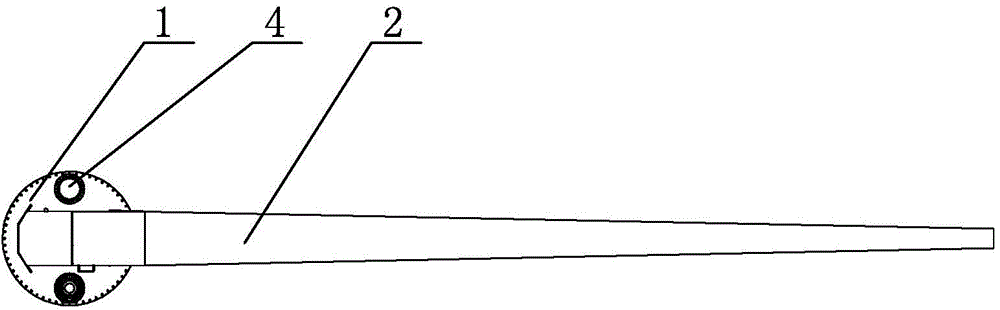

Marine electric cantilever crane

InactiveCN104671115AImprove work efficiencyImprove continuous operation abilityCranesMarine engineeringReducer

The invention relates to a marine electric cantilever crane. The marine electric cantilever crane comprises a base connected with a ship deck, wherein a cantilever is welded on the base; the cantilever is in a right-angle structure; an electric lifting hoist which slides along the cantilever is mounted at the bottom of the horizontal part of the cantilever; and an electric rotary speed reducer for controlling the crane to rotate to work is further mounted on the base. The marine electric cantilever crane has a compact and reasonable structure, is convenient to operate and can be widely applied to engineering ships; and the crane has high working efficiency, wide application range and long continuous working capability. The cantilever is a horizontal cantilever; when small-radius work needs to be carried out, only the electric hoist needs to be operated to walk to a corresponding position, and the troublesome operation that a marine crane in the prior art can be operated by lifting the cantilever is avoided; and the marine electric cantilever crane has a compact structure and small occupying area and is also suitable for fields with compacted spaces on the engineering ships.

Owner:邓耀林

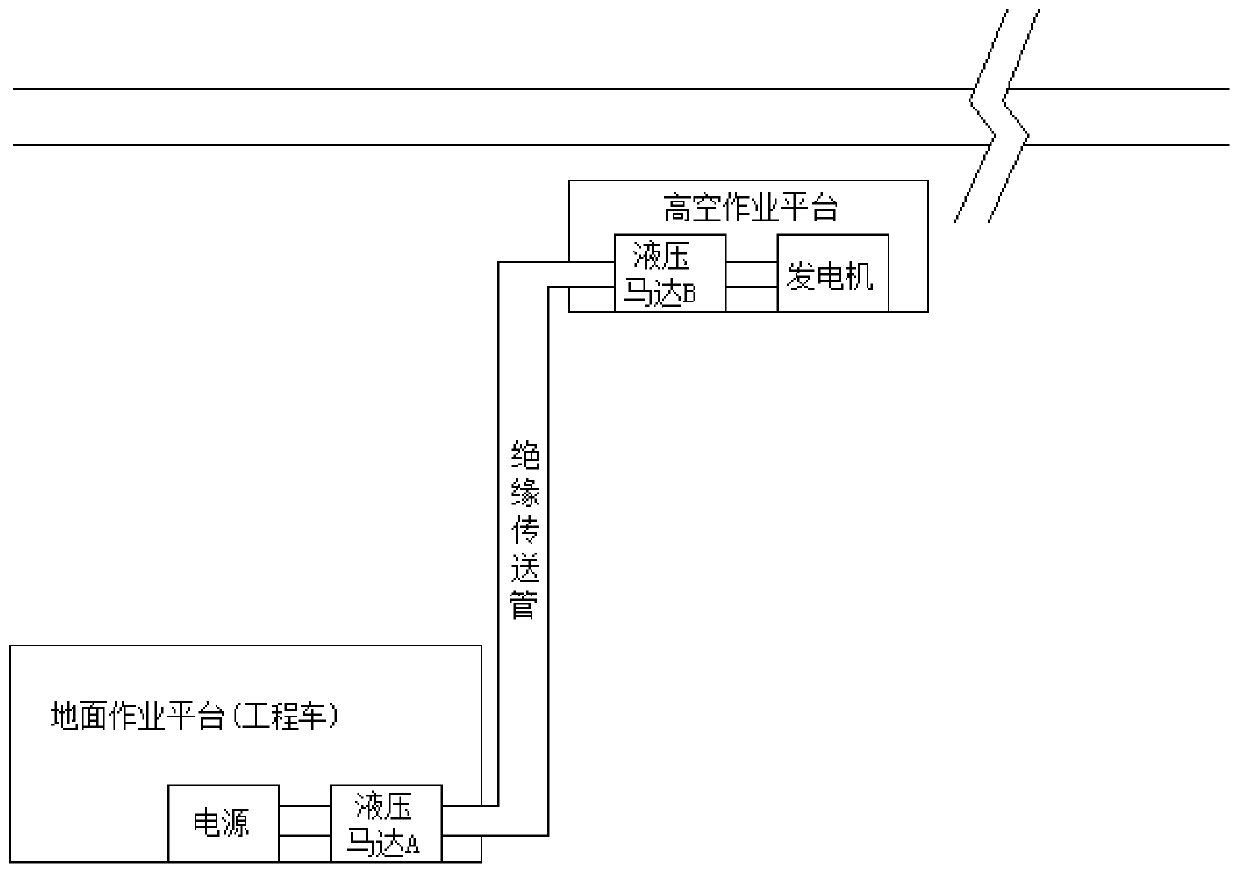

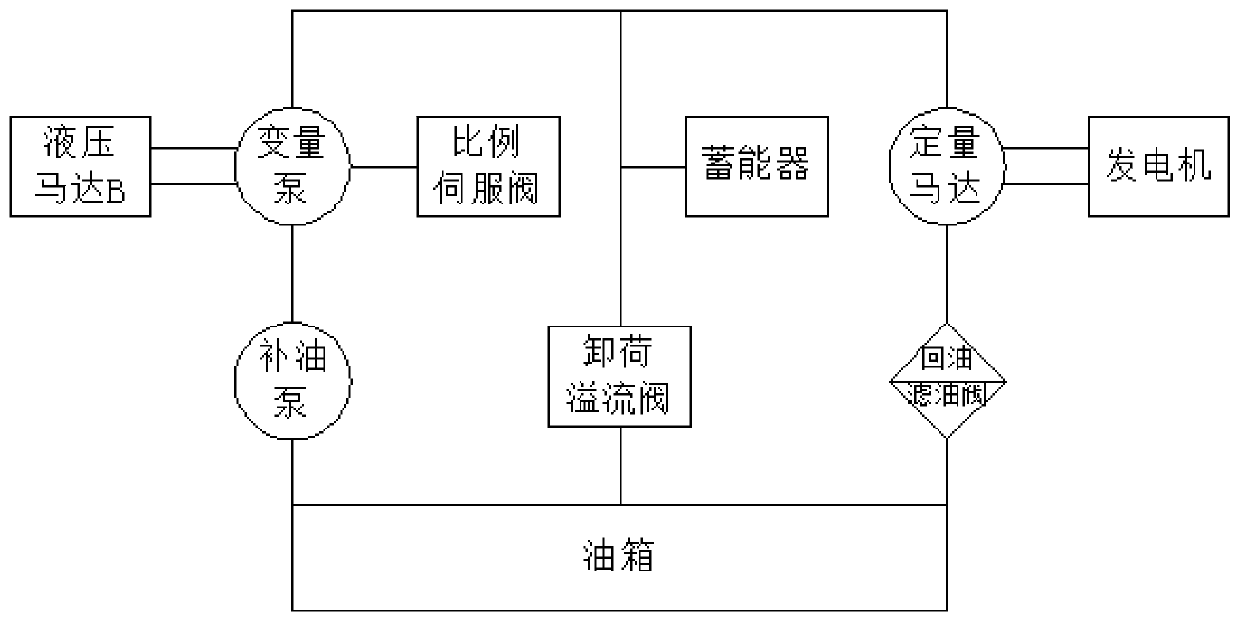

Hydraulic power generation system and refrigerating system used for constructing under high-voltage power transmission environment

InactiveCN111022247ARaise security concernsPrevent breakdownReciprocating piston enginesHydraulic motorPotential difference

The invention provides a hydraulic power generation system and a refrigerating system used for constructing under high-voltage power transmission environment. The power generation system is used for solving the problem that under the high-voltage power transmission environment, power is supplied to the position nearby a high-voltage circuit from the ground, and due to the potential difference, a ground power source is broken down, and therefore safety power utilization of an aerial work platform can be achieved. According to the technical scheme, the power generation system comprises a groundoperation platform and the aerial work platform, a hydraulic motor A is mounted on the ground operation platform, a hydraulic motor B, a hydraulic variable pump, a constant displacement motor, an oiltank and an electric generator are mounted on the aerial work platform, the hydraulic motor A and the hydraulic motor B convey hydraulic oil through an insulation conveying pipe, the hydraulic variable pump is connected with the hydraulic motor B and the constant displacement motor, and a constant displacement motor electric generator, the variable pump and the constant displacement motor are connected with the oil tank.

Owner:GUANGDONG POWER GRID CO LTD +1

A varnishing device for a piano keyboard cover

ActiveCN108816569BImprove continuous operation abilitySave man hoursSpraying apparatusPianoElectric machinery

The invention discloses a painting device for a piano keyboard cover. The painting device comprises a machine table, a support frame is welded on the right side of the top of the machine table, the top of the support frame is movably provided with pulleys, and one side of the support frame is provided with a first motor. The output end of the first motor and the pulleys are connected by a conveyorbelt in a transmission mode, and a conveyor belt is connected between the pulleys in the transmission mode. A support leg is welded to the center of the top of the machine table, and a fixed table iswelded at the top of the support leg. A rotating shaft is installed in the middle of the fixed table in the rotating mode, the bottom of the rotating shaft is movably connected with the top of the machine table, and the top of the rotating shaft extends through the fixed table and extends to the outside of the top of the fixed table. The painting device is provided with an intelligent painting mechanism and integrates the processes of feeding, painting and discharging, is high in continuous work capacity, reduces the working hours, can complete the whole painting work automatically basicallywithout manual participation, and can greatly improves the efficiency.

Owner:NANTONG TAIYING NEW MATERIAL SCI & TECH CO LTD

Tamping Coke Coke Oven Electromagnetic Compound Tamping Machine

The invention discloses a tamping coke coke oven electromagnetic compound type tamping machine, which comprises a fixed steel structure and a hammer rod, a hammer head is connected to the lower end of the hammer rod, and a lower steel structure, between which There is a symmetrical linear motor in between, and the linear motor is controlled by the electric control device to run in both forward and reverse directions; the upper end of the lower steel structure is connected with a vertical steel structure, between the vertical steel structure and the fixed steel structure Equipped with a vertical steel structure lifting device. The overall structure of the tamping machine is simple, few parts, light weight, not easy to damage, low maintenance rate, strong continuous operation ability, significantly increased tamping force, and reduced operating costs.

Owner:大连钢机重工设备工程有限公司

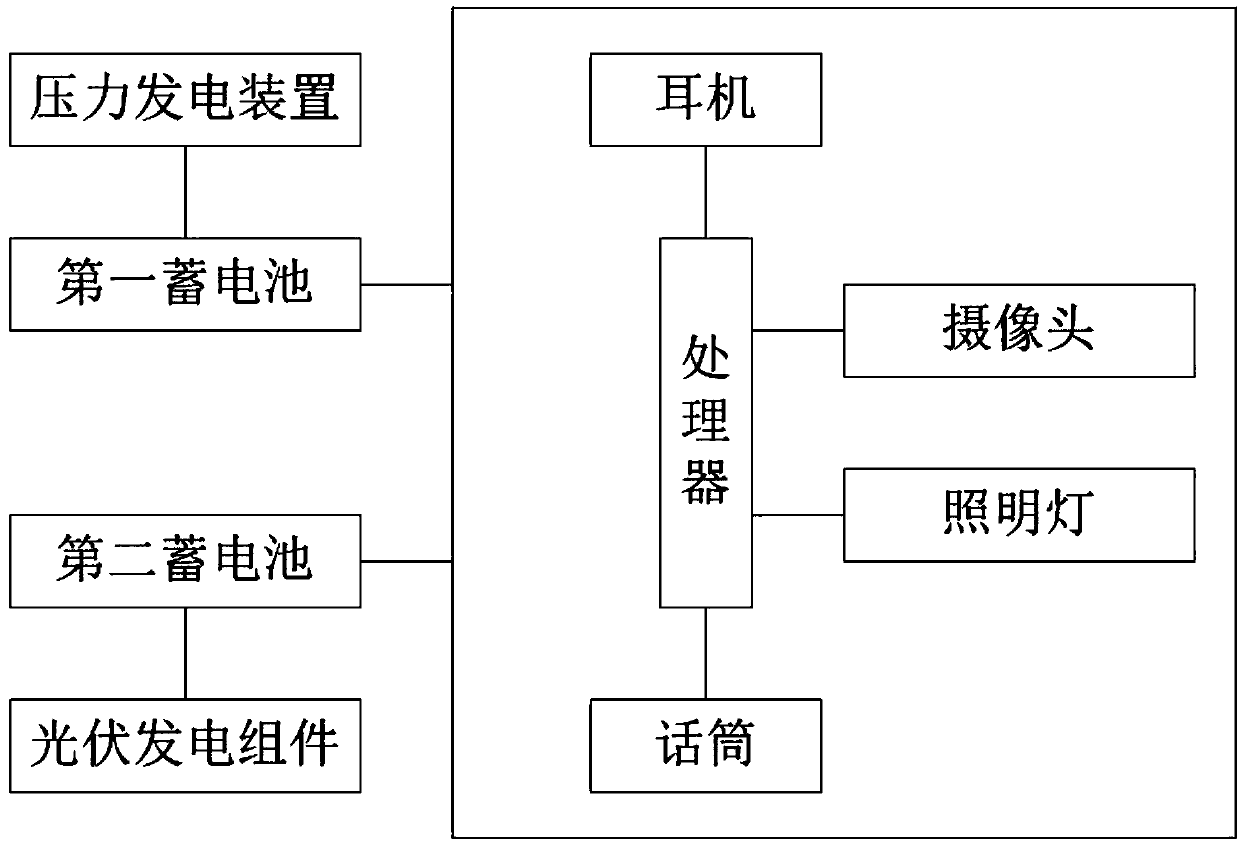

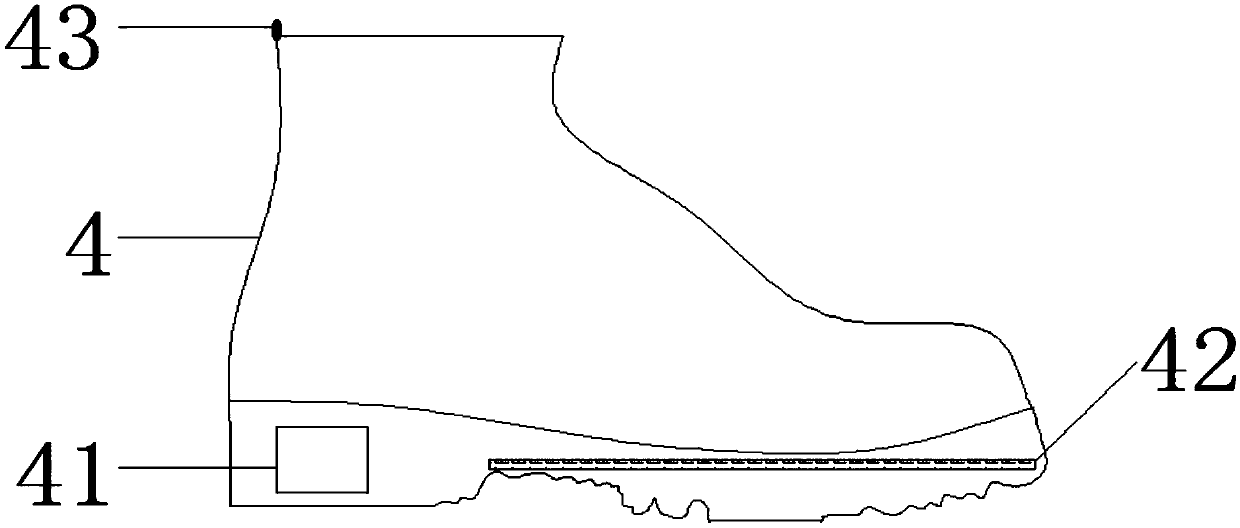

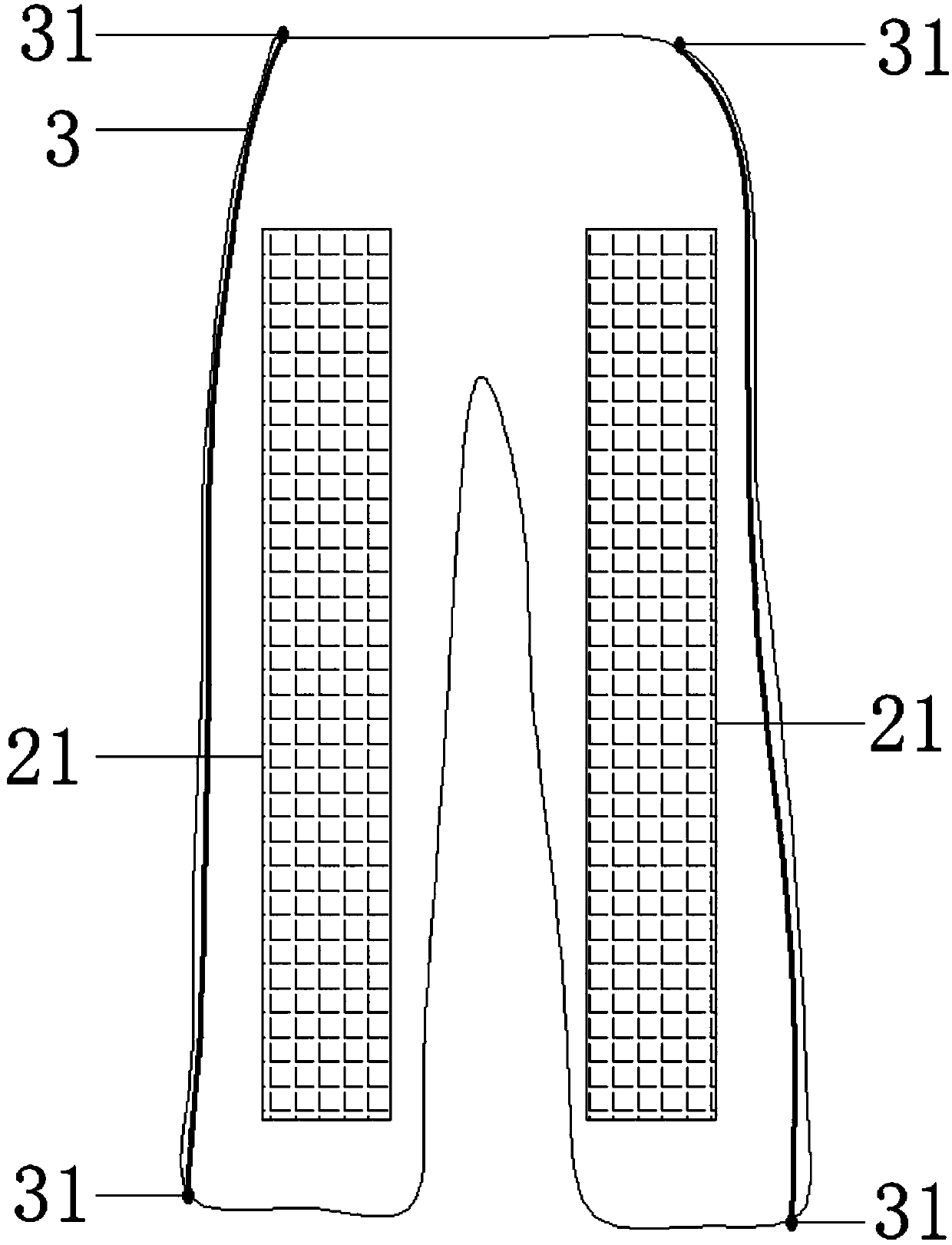

Power system field operation suit

PendingCN107647515AImprove work efficiencyInterconnectedBatteries circuit arrangementsElectric powerContinuous operationMicrophone

The invention is applicable to the technical field of power working equipment, and provides a power system field operation suit. The power system field operation suit comprises insulated shoes, trousers, a jacket and a helmet. Each of the insulated shoes is provided with a first battery, a pressure generating device and a first power jack. The surfaces of the trousers are photovoltaic power generation components. Each leg of the trousers is provided with a conducting wire penetrating the trouser legs to the trouser waist. Both ends of the conducting wire are each provided with a first plug. The jack is provided with the photovoltaic power generation components, a second battery and a second power jack. The helmet is provided with a processor, a microphone, headphones, a camera, a light andwires. In this way, the entire system can generate electricity by itself without the need of external power supply so as to meet the long-term field work requirements of workers and enhance the continuous operation capability of the whole device.

Owner:INST OF ECONOMIC & TECH STATE GRID HEBEI ELECTRIC POWER +1

Highlight treatment device for notebook computer cover plate

ActiveCN112846320AImprove continuous operation abilityFeeding apparatusMilling equipment detailsMilling cutterEngineering

The invention relates to the field of highlight treatment, in particular to a highlight treatment device for a notebook computer cover plate. The highlight treatment device comprises a workbench, a mold plate is installed above the workbench through a supporting rod, and a clamping piece used for clamping and fixing is arranged on the rear side of the mold plate; a first lead screw transmission mechanism is fixedly arranged between the mold plate and the workbench, sliding rods are arranged on the two sides of the first lead screw transmission mechanism, sliding seats moving along the sliding rods are arranged on the sliding rods correspondingly, and a supporting column is fixedly arranged on each sliding seat; a second lead screw sliding assembly is arranged in the middle of the front side of a supporting plate, and the front side of the second lead screw sliding assembly is connected with a milling mechanism used for milling and polishing the notebook computer cover plate; and a belt is fixedly connected with the second lead screw sliding assembly. According to the highlight treatment device, multi-station movement of the surface of the notebook computer cover plate is achieved, the machining procedures of the notebook computer cover plate are effectively reduced by using a multi-face milling cutter, and the efficiency is remarkably improved.

Owner:JIANGSU YOUFU AUTO PARTS TECH CO LTD

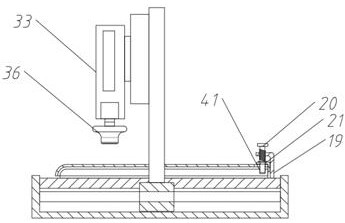

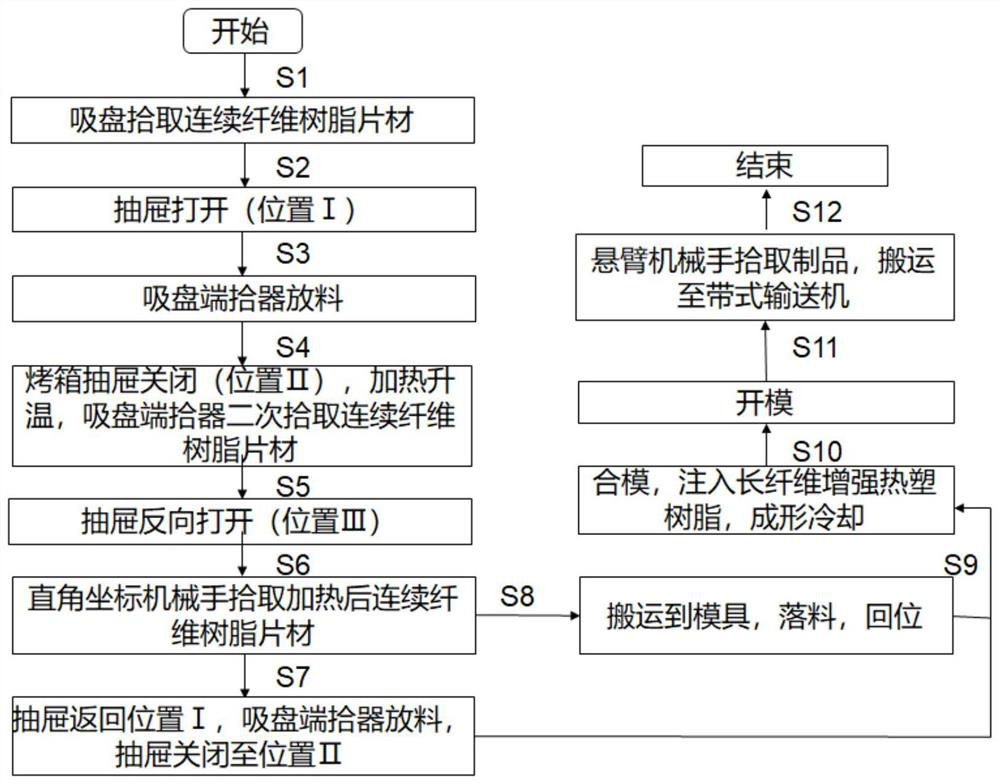

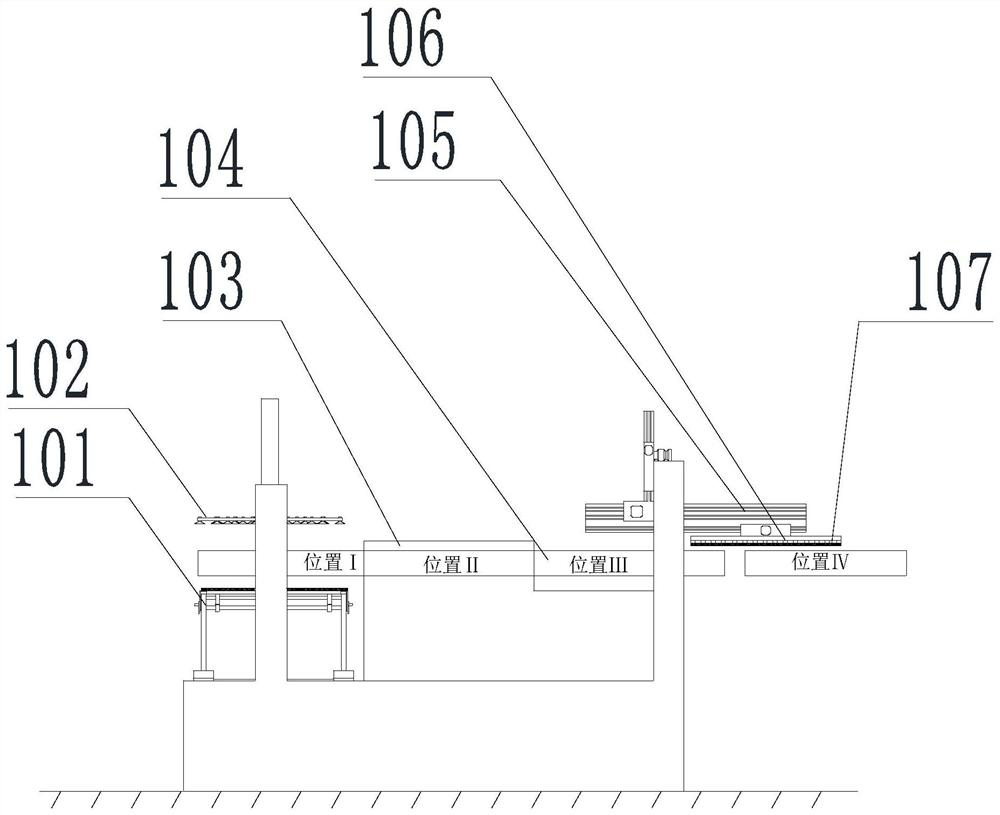

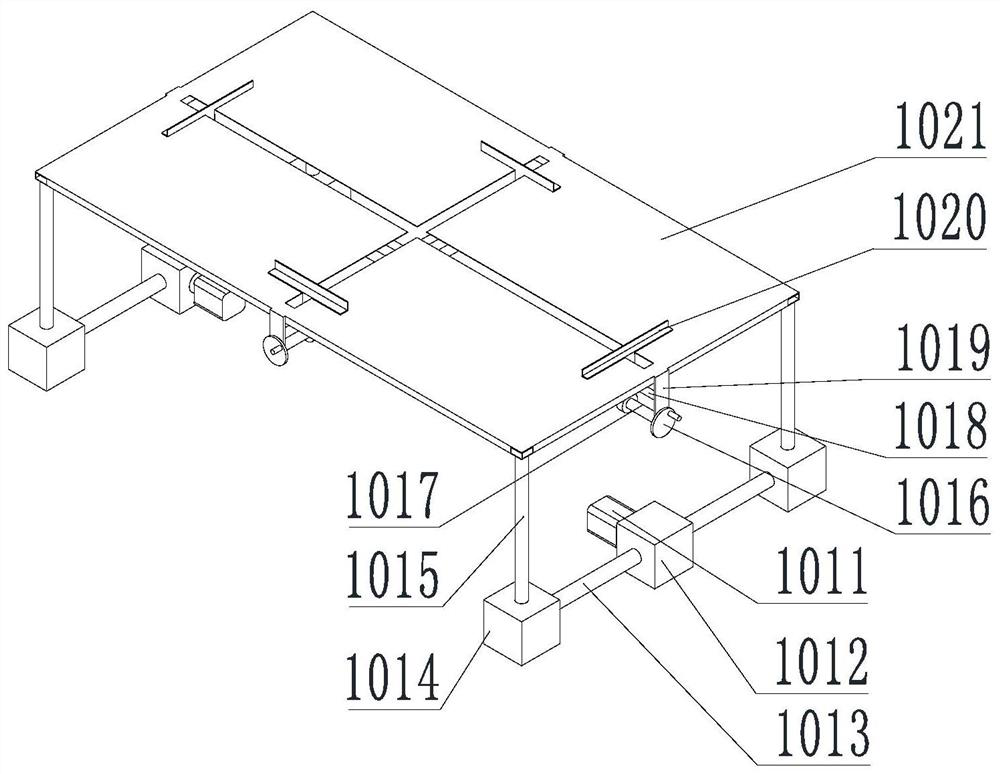

Composite material hot-press forming device

The invention relates to a composite material hot-press forming device. The composite material hot-press forming device comprises a suction cup end picker arranged on one side of the device, a feeding device, a manipulator mechanism, a hearth, a moving mechanism, a forming device and a discharging device, wherein the feeding device comprises a panel and a first driving mechanism, the panel is arranged below the suction cup end picker and used for providing resin fiber sheets, and the first driving mechanism is used for driving the panel to move upwards; the manipulator mechanism is arranged on the other side of the device and is used for grabbing the resin fiber sheets; the hearth is arranged in the middle of the device; one side of the moving mechanism is located on the lower side of the suction cup end picker, the other side of the moving mechanism is located on the lower side of the manipulator mechanism, and the moving mechanism is used for conveying away the resin fiber sheets placed in by the suction cup end picker through the manipulator mechanism after the resin fiber sheets are heated by the hearth; the forming device is arranged on one side of the manipulator mechanism and used for performing injection molding of the resin fiber sheets; and the discharging device is arranged on one side of the forming device, and is used for transporting formed products, and the carrying time is shortened. The composite material hot-press forming device has the advantages that the forming time can be shortened, the die assembly pressure can be reduced, the compatibility with injected resin can be improved, the product performance can be enhanced, and continuous operations can be achieved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

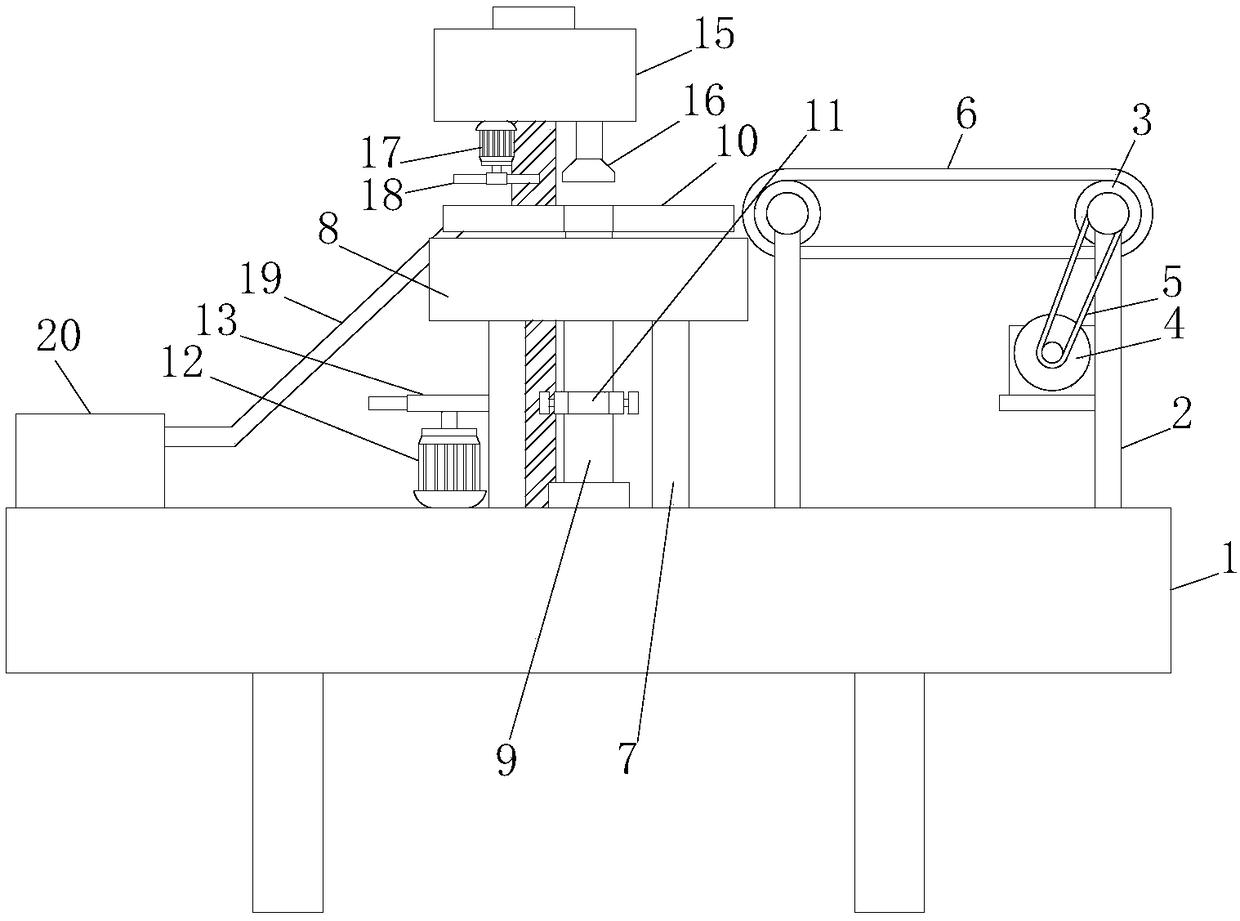

Compensated underwater brushless DC motor structure and assembly method thereof

InactiveCN101752937BImprove reconfigurabilityEasy maintenanceStructural associationSupports/enclosures/casingsUnderwaterEngineering

The invention relates to a compensated underwater brushless DC motor structure and an assembly method thereof. The motor structure comprises a motor end cover subassembly (1), a motor main body (2) and a compensator device (3), wherein the motor end cover subassembly (1) is positioned at the front end of the motor main body (2) and is fixedly connected with the motor main body (2) via bolts, the compensator device (3) is positioned at the tail of the motor main body (2) and connected with the motor main body (2) via bolts, and the compensator device (3) comprises a compensator skin (16), a compensator gland bush (17), a motor tail hood (19), a compensator spring (20) and a compensator screw cap (18). The motor structure has modularized design characteristic, the compensator device and themotor main body can be separated, and different compensator devices can be correspondingly adjusted or replaced for meeting different work environmental requirements so that the motor structure has the advantages of simple and compact structure, convenient assembly and debugging, and safe and reliable working and easy maintenance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Double-wall screw drilling system based on gas-liquid two-phase drive

InactiveCN110344752BReduce thermal wearImprove continuous operation abilityConstructionsLiquid/gas jet drillingHorizontal wellsDirectional well

A dual-wall screw well drilling system based on gas-liquid two-phase drive comprises a ground system, a well opening device and a downhole drilling tool assembly. The ground system comprises a gas storage and collection tank and a liquid storage and collection tank, wherein the gas storage and collection tank and the liquid storage and collection tank communicate with the well opening device through an air compressor and a liquid high-pressure pump correspondingly and then are connected with a gas-liquid two-phase flow recovery device. The gas-liquid two-phase flow recovery device comprises asand recover, a back-pressure valve and a ground gas-liquid separation device. The downhole drilling tool assembly comprises a dual arm drilling rod I connected with the well opening device. The lowerportion of the dual arm drilling rod I is sequentially connected with a short joint, a dual-wall screw motor, a universal joint, a downhole gas-liquid separation device I, a dual arm drill rod II anda drill bit. According to the dual-wall screw well drilling system, the problem that an air screw is prone to being damaged under a well can be reduced, the rock breaking efficiency can be improved,and therefore safe, rapid and economical well drilling can be achieved on a horizontal well and a directional well.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com