Kelp combine harvester

A combine harvester and kelp technology, which is applied in the fields of harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of unfavorable rapid development of the kelp industry, large hull shaking, damage to seabed legs, etc., to enhance continuous operation ability, reduce The effect of labor intensity and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

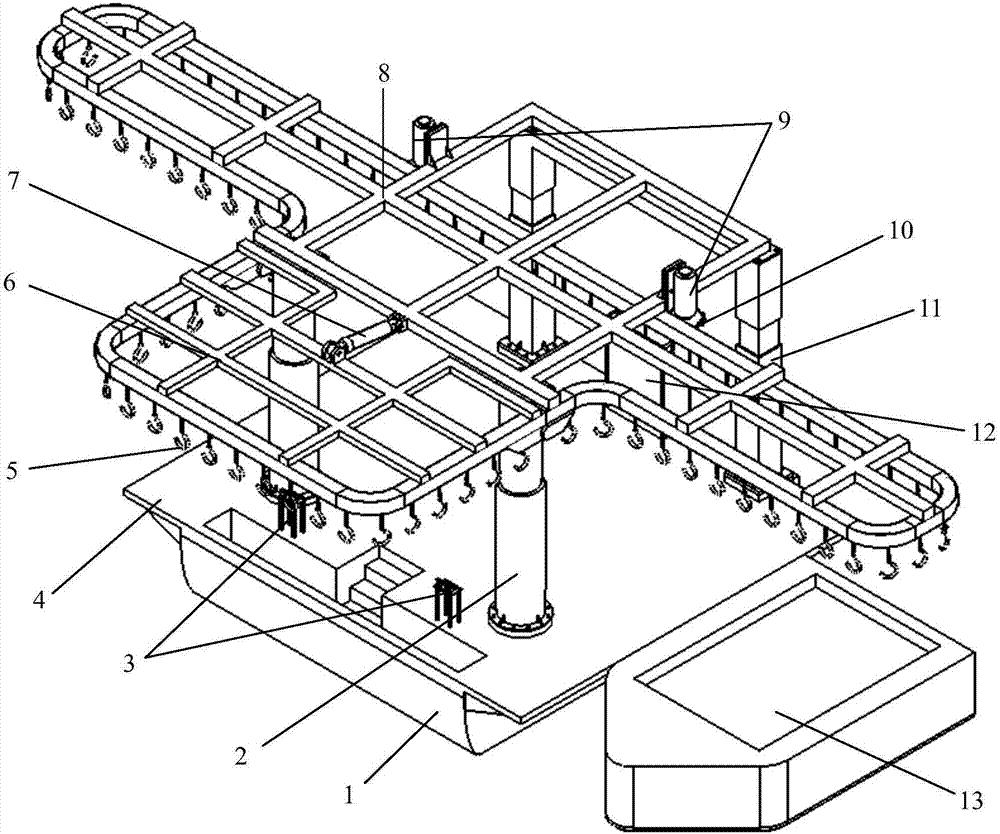

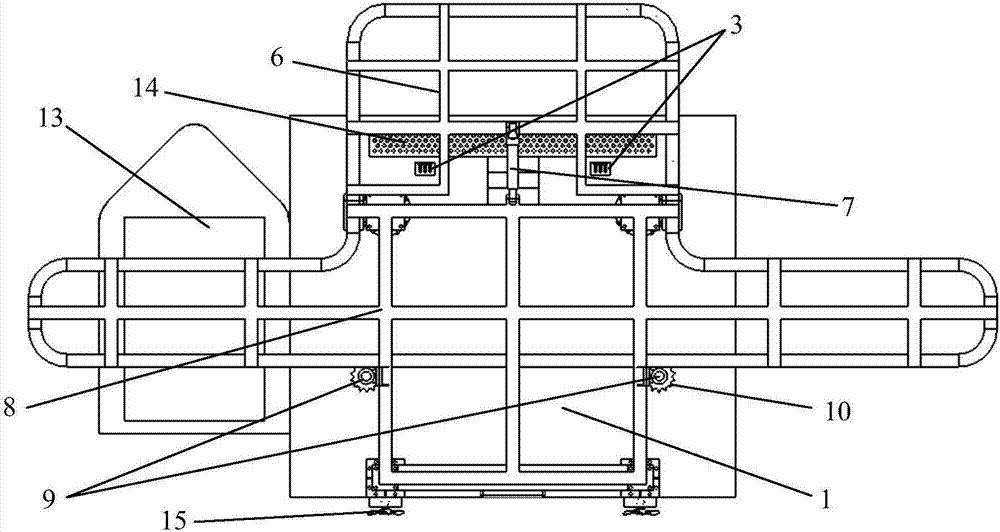

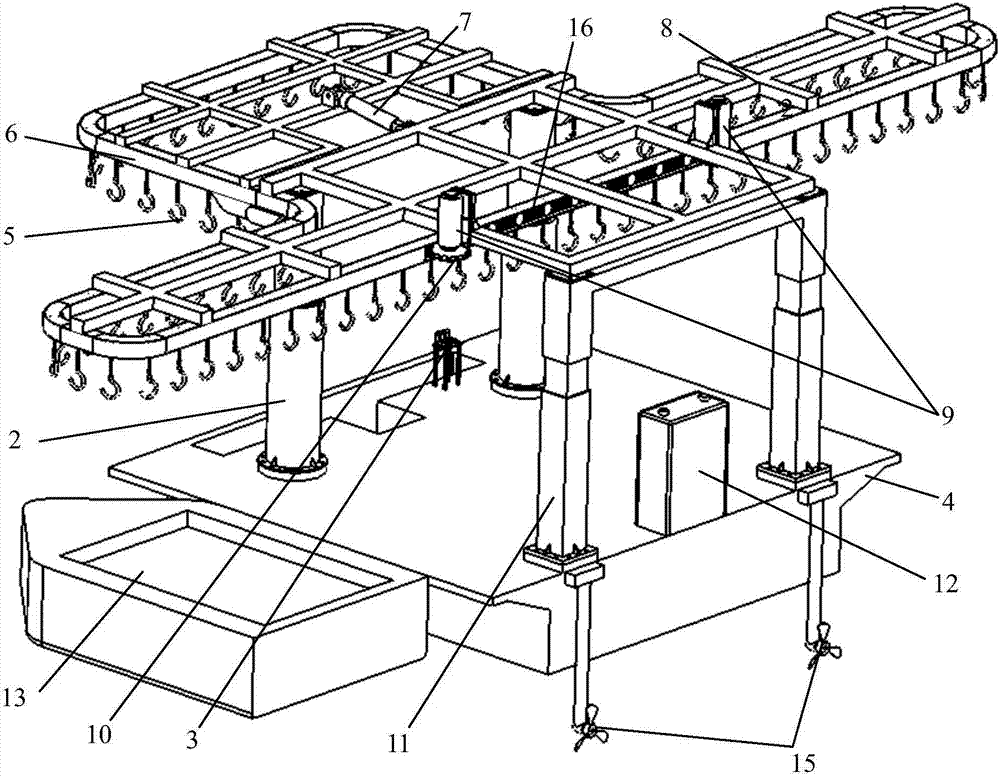

[0011] exist figure 1 Among them, the hull (1) of the kelp combine harvester is separated from the harvesting cabin, and a general transport ship (13) is used as the kelp harvesting cabin, and the transport ship (13) is connected to the support plate (4) on the hull (1) by cables. A control lever (3) is installed in front of the kelp combine harvester hull (1), and the control lever (3) can not only control the forward and backward movement of the hull (1), but also control the movement of the hydraulic support (7) and the hydraulic motor (9). Motion, when hydraulic support (7) stretches, the kelp hook (5) of movable catenary support (6) front end descends, and the kelp seedling rope in water is manually hung on the kelp hook (5) this moment, by control lever ( 3) Control the contraction of the hydraulic support (7), the front end of the movable catenary support (6) is lifted together with the kelp hook (5) and the kelp, and then the hydraulic motor (9) is controlled by the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com