Garlic combine harvester

A combine harvester and garlic technology, applied in the direction of digging harvesters, harvesters, topping machines, etc., can solve the problems of difficult control of digging depth, low production efficiency, easy operation congestion, etc., to improve harvesting efficiency and reliability performance, reduce the generation of large mud blocks, and improve the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

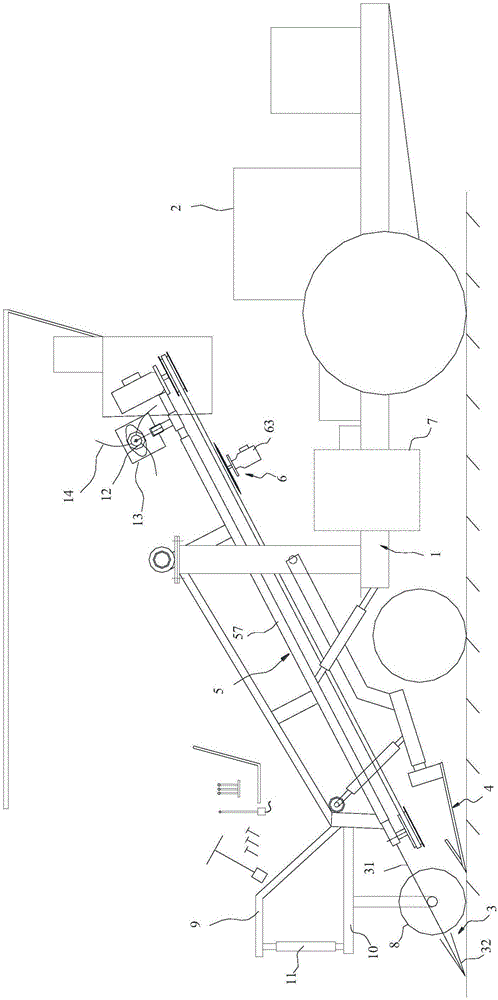

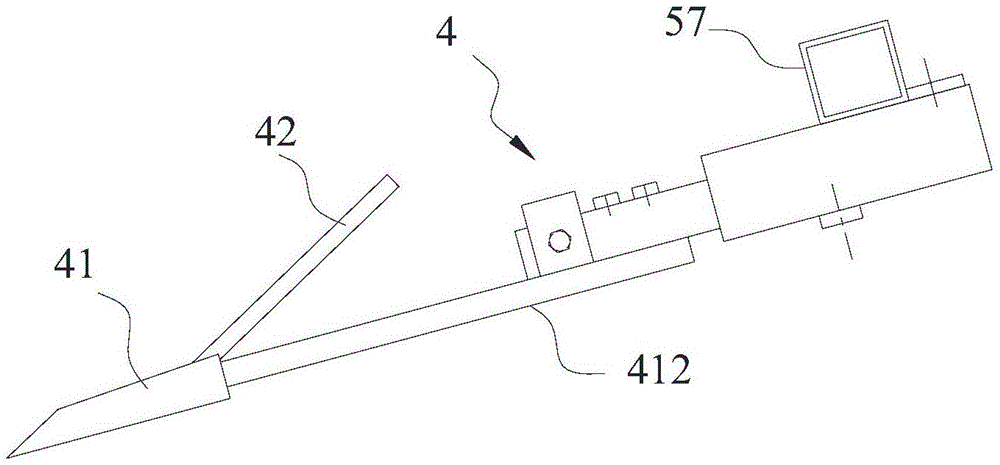

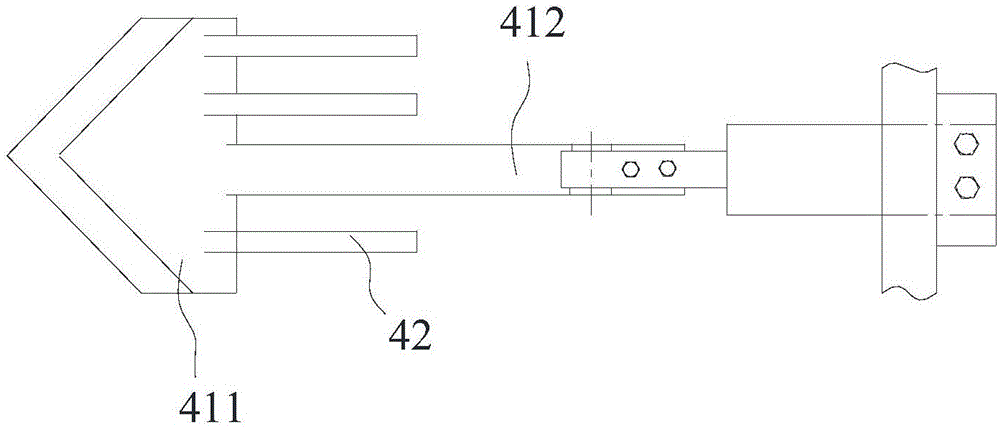

[0029] like figure 1 , Figure 4 The garlic combine harvester shown includes a body 1, a driving device 2 for driving the body 1 to move, a seedling separator 3 for separating garlic seedlings, a digging mechanism 4 for digging, and a mechanism for clamping and conveying The clamping and conveying mechanism 5 for garlic seedlings, the cutter mechanism 6 for cutting garlic and garlic seedlings, and the collecting device 7 for collecting and conveying garlic heads, the driving device 2 is connected to the body 1, and the clamping and conveying mechanism 5 is movable and suspended In the body 1, the clamping and conveying mechanism 5 has at least two clamping and conveying gaps 59, and the two ends of the clamping and conveying gaps 59 are respectively the entrance for sending garlic seedlings and the outlet for outputting garlic and garlic seedlings, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com