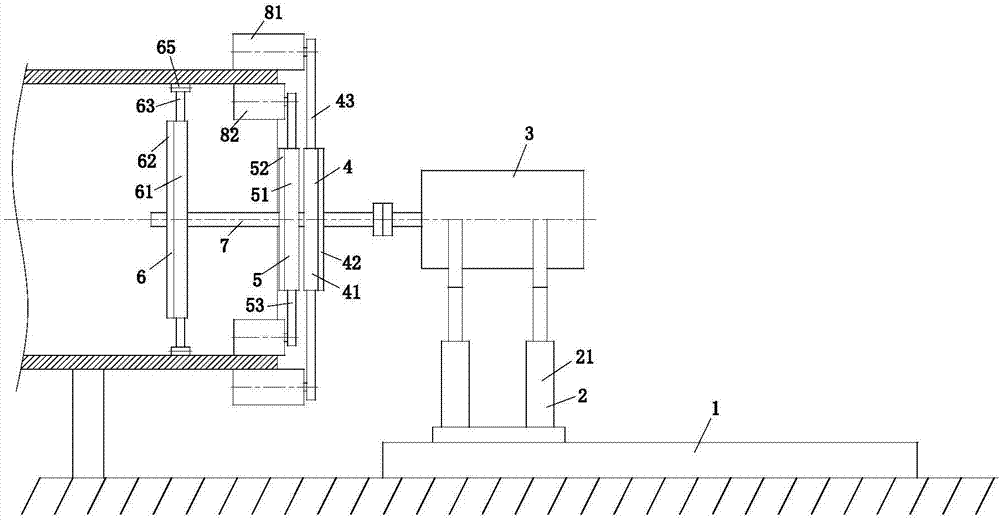

Stainless steel cylinder polishing wire-drawing treatment equipment

A technology for grinding wire drawing and processing equipment, used in grinding/polishing equipment, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of low work efficiency, inability to process, and low polishing gloss , to achieve the effect of improving generation efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

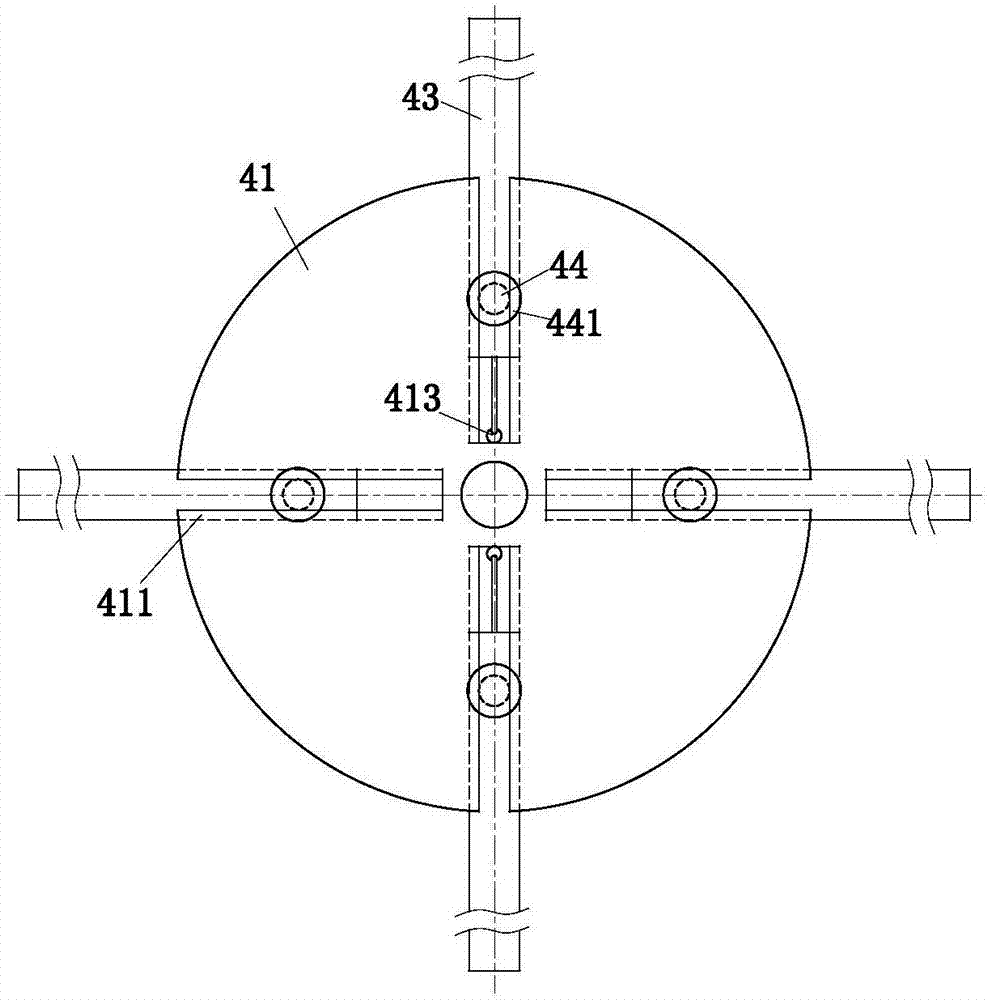

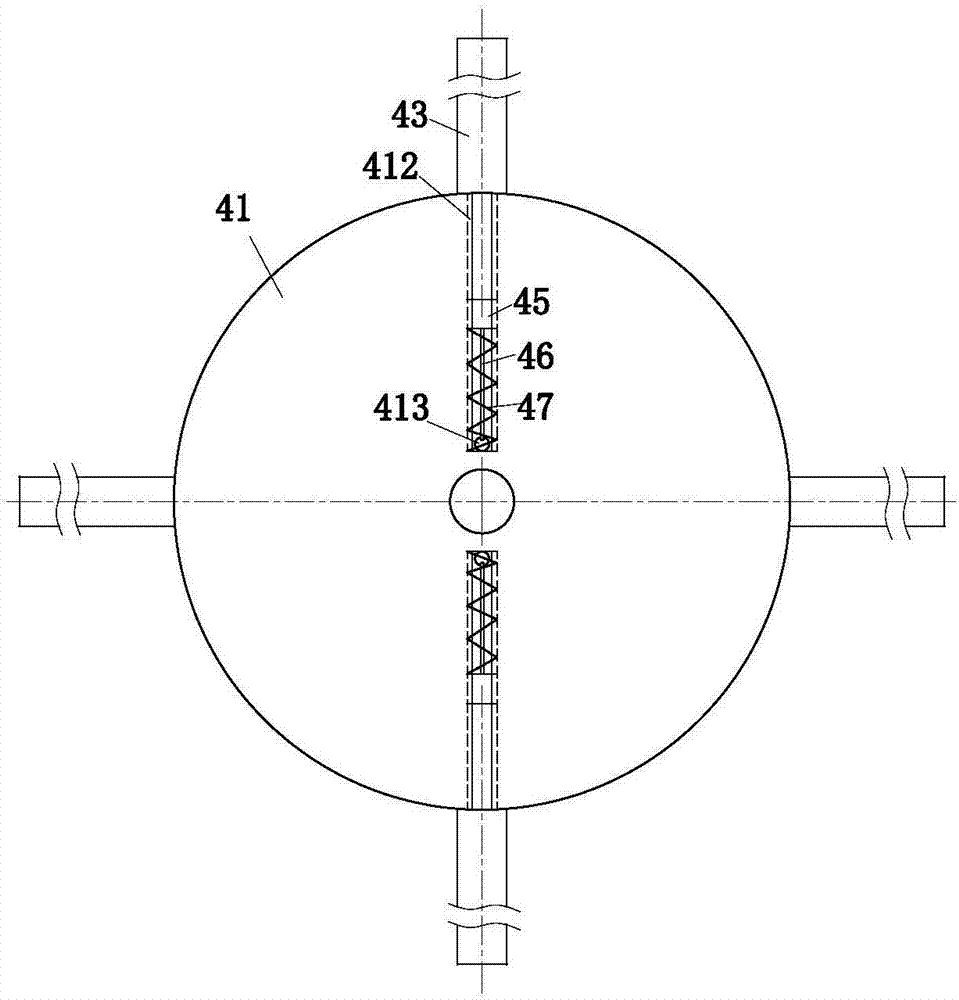

[0027]As an embodiment of the present invention, the inner barrel grinding disc 5 includes a second fixed disc 51, a second adjusting disc 52, a second adjusting rod 53, a tension spring 54, a second sliding pin 55, and a second baffle 56 and the second fastening screw 57, the second fixing disc 51 and the second adjusting disc 52 are disc-shaped structures, and the second fixing disc 51 and the second adjusting disc 52 are close to each other during use and the second adjusting disc 52 can be Relative to the rotation of the second fixed plate 51, the side wall of the second fixed plate 51 is uniformly provided with a second mounting hole 511 for installing the second adjusting rod 53, and the second mounting hole 511 preferably adopts a rectangular hole with a cross-sectional shape. The cross-sectional shape of the adjusting rod 53 is identical to the cross-sectional shape of the second mounting hole 511, which can prevent the second adjusting rod 53 from rotating in the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com