Patents

Literature

82results about How to "Improve grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

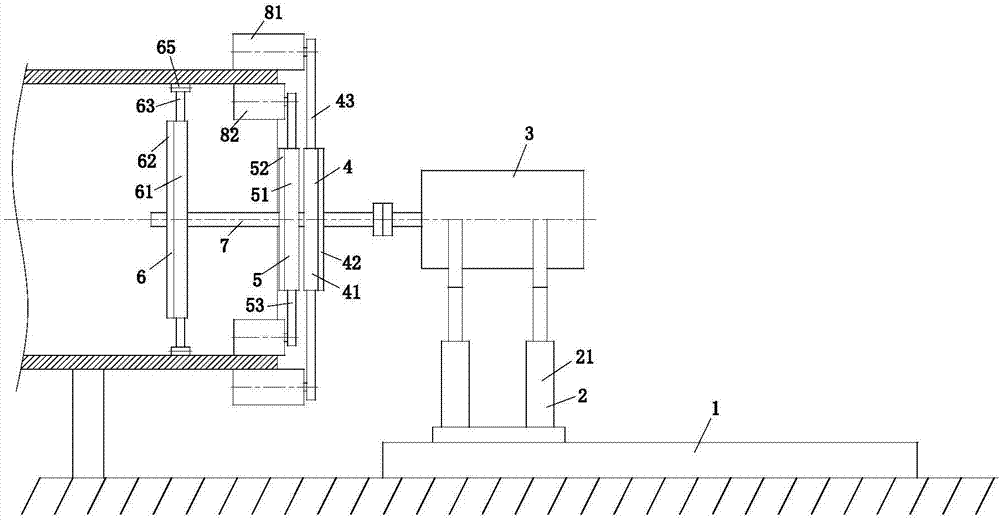

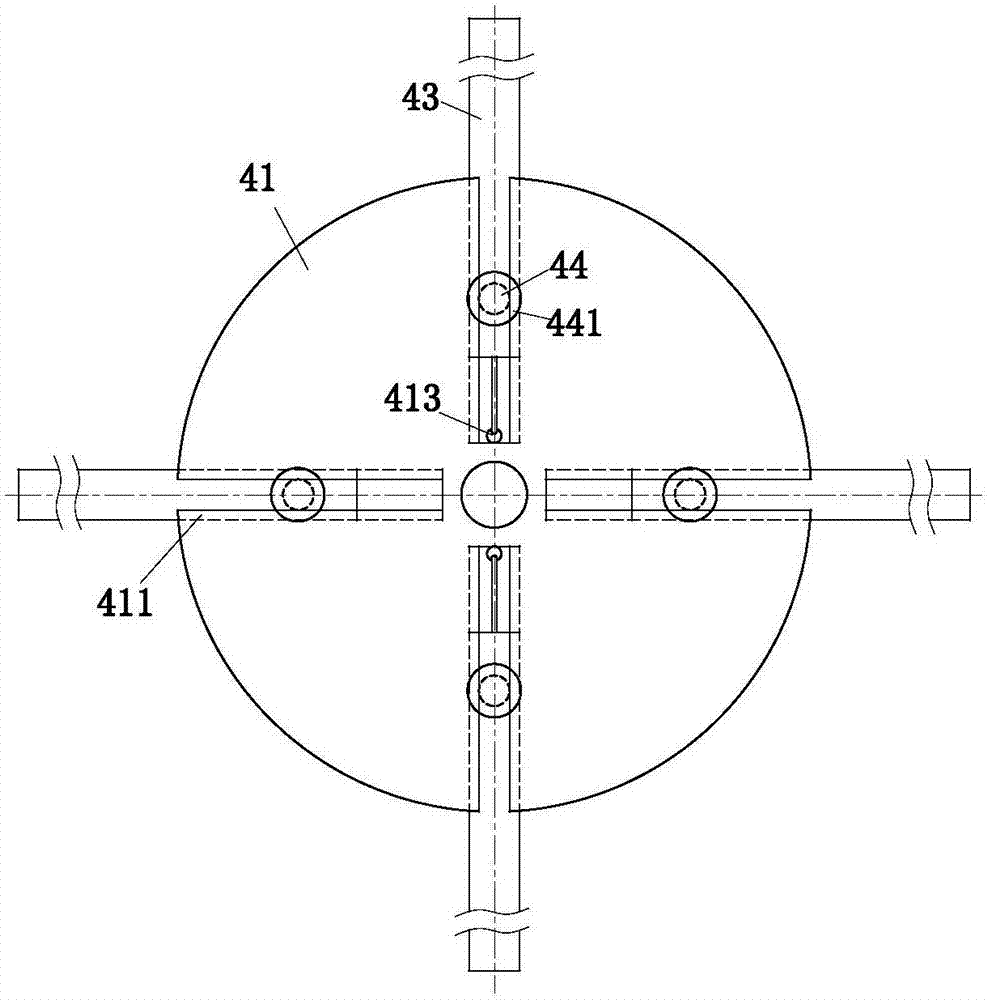

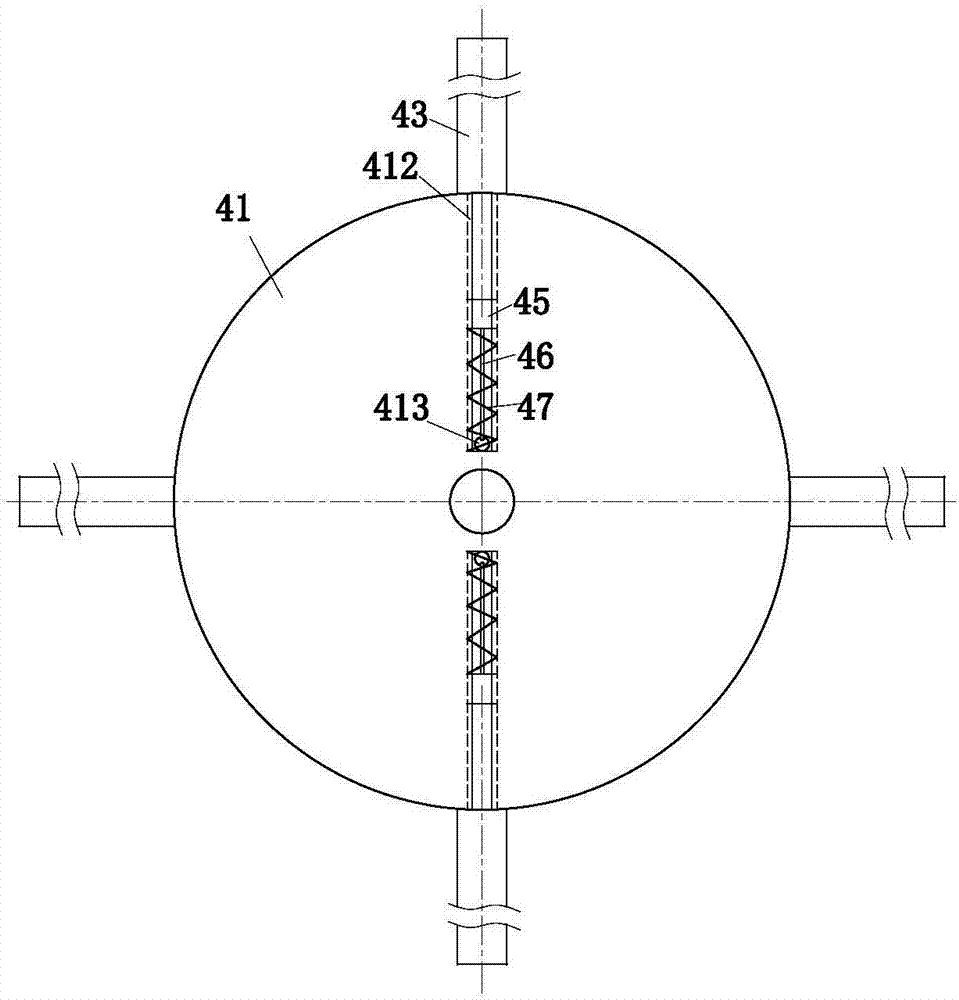

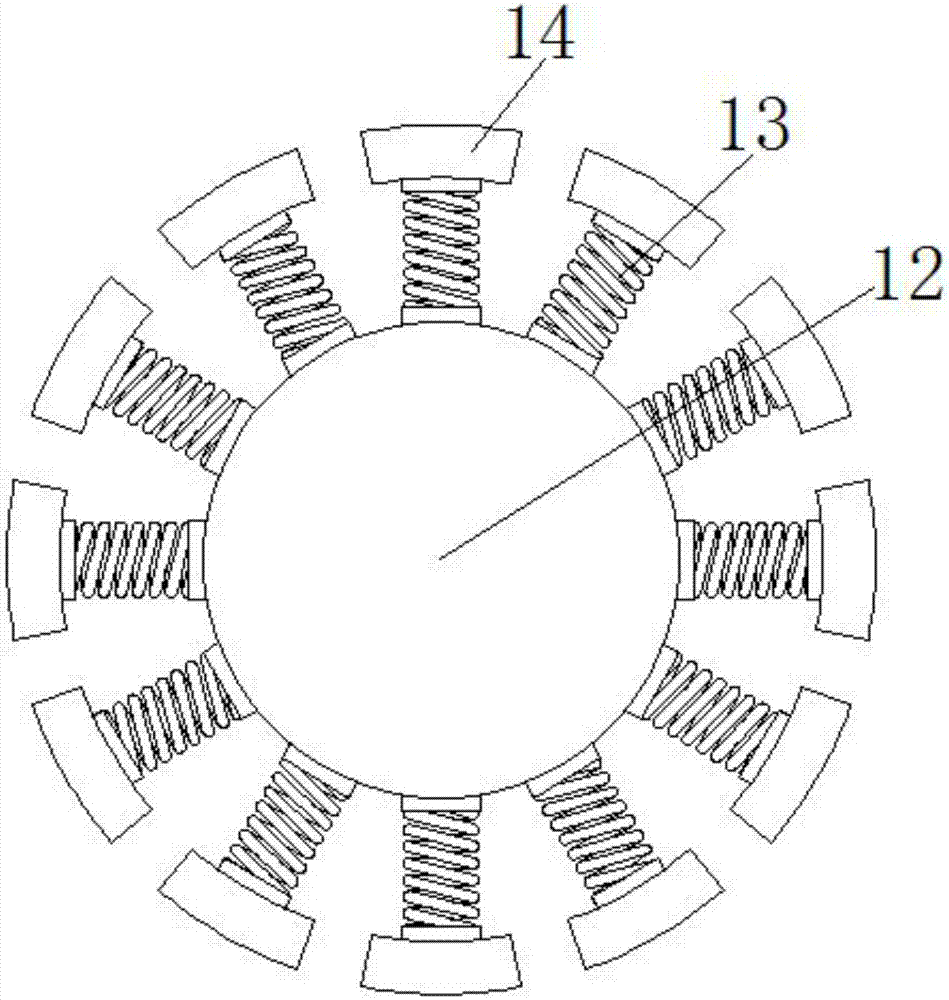

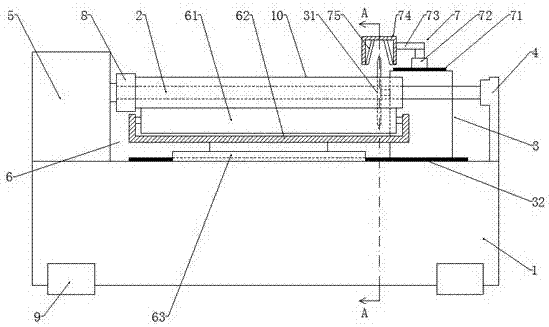

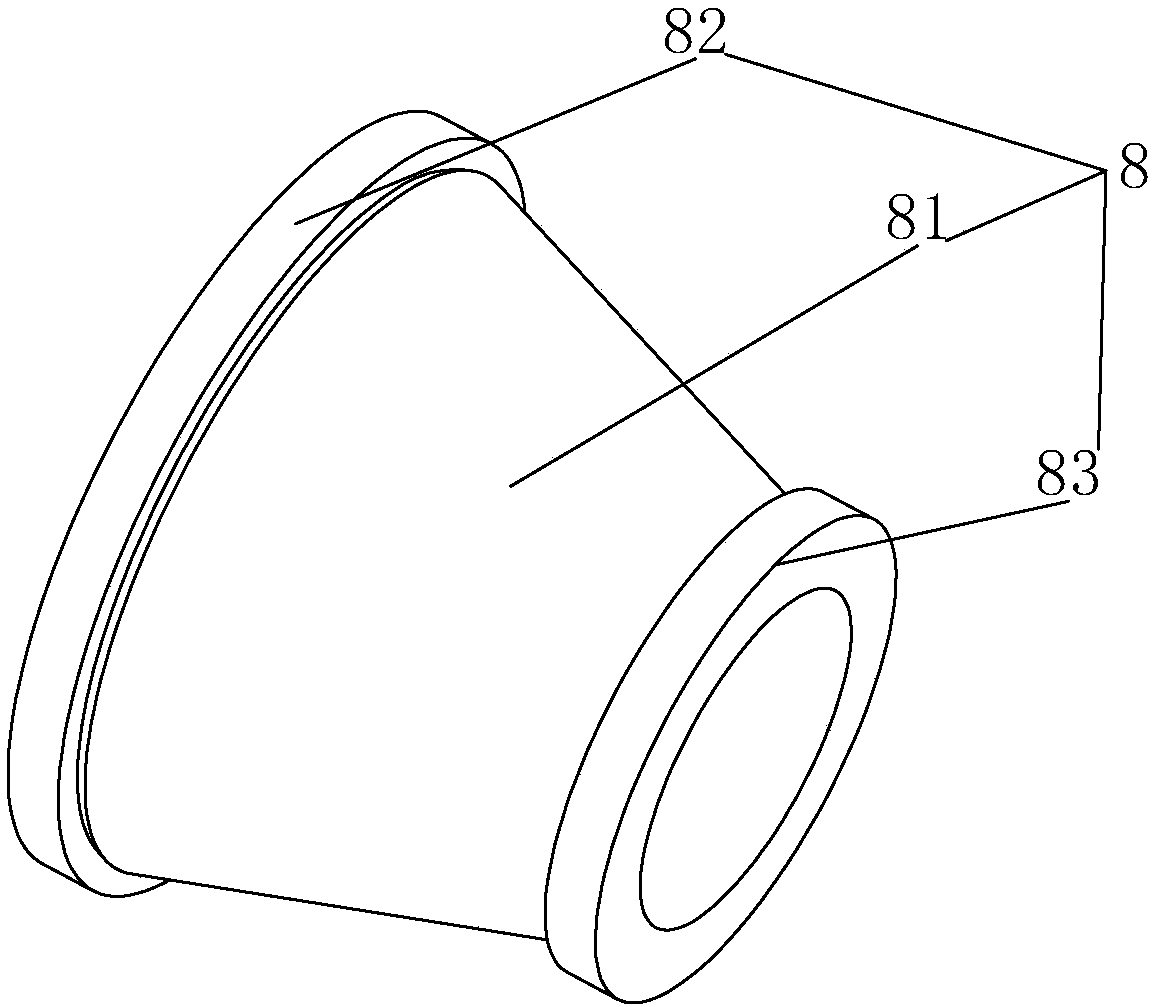

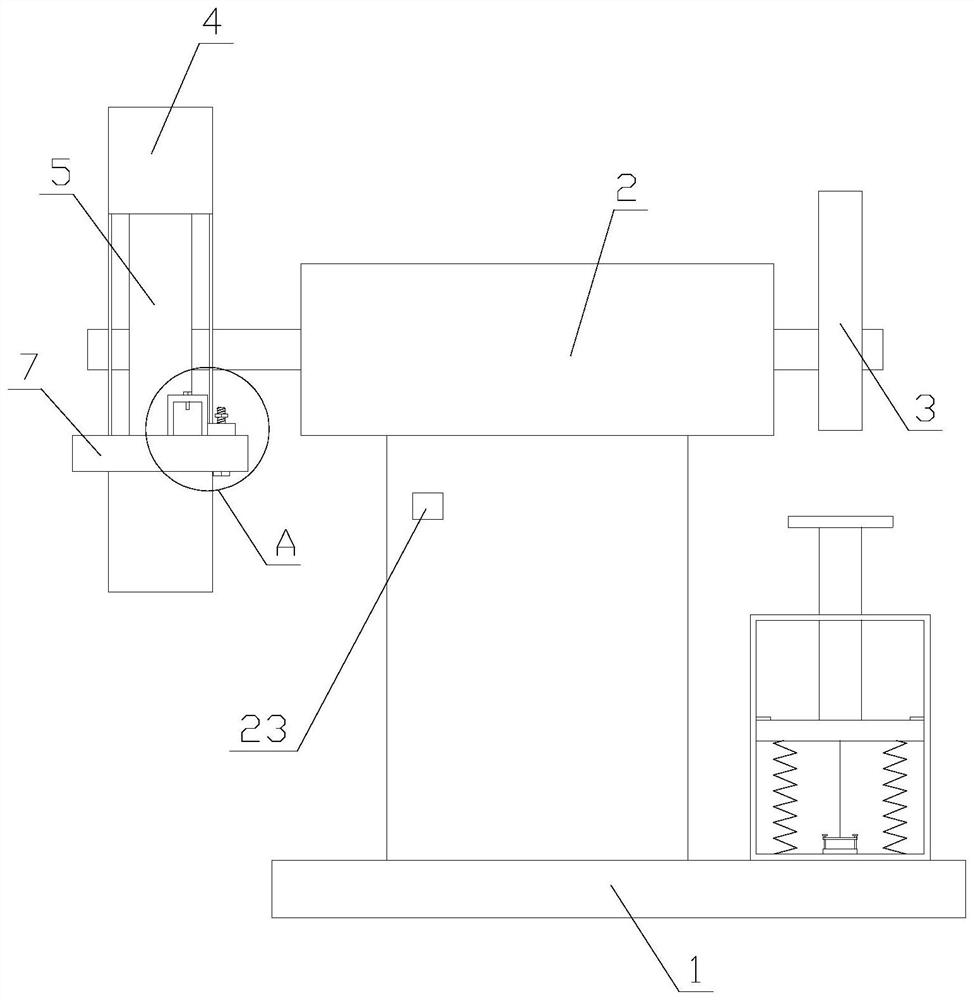

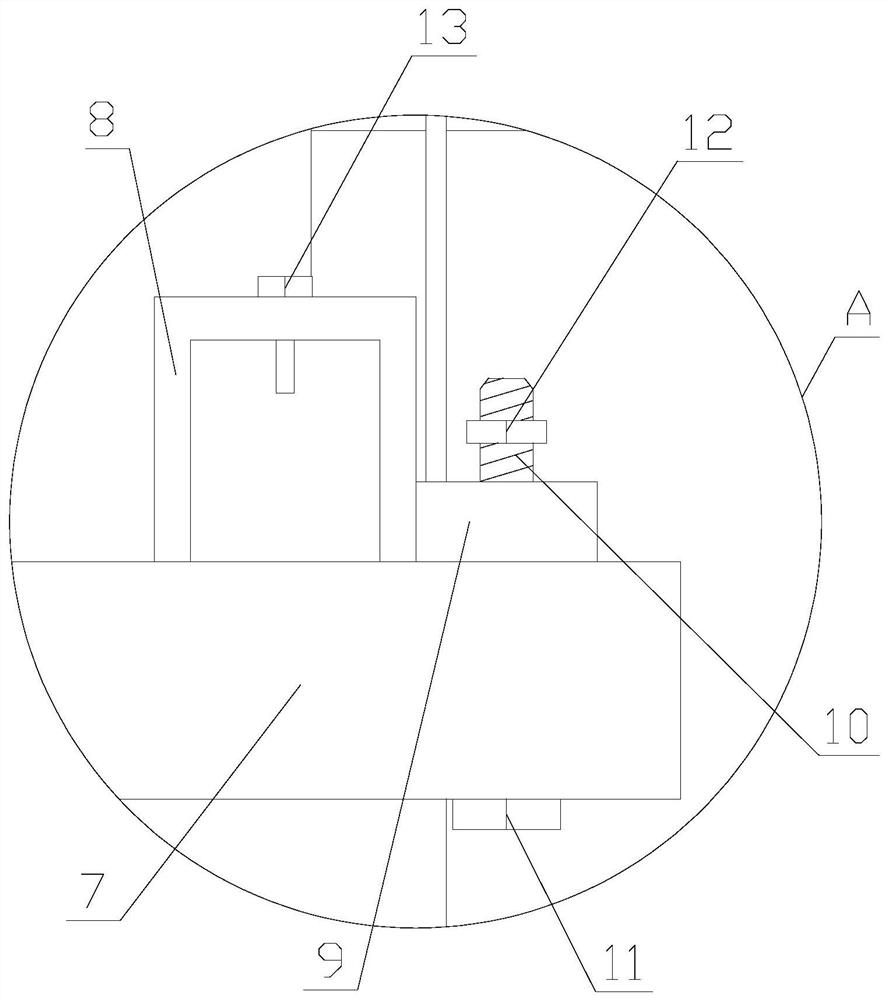

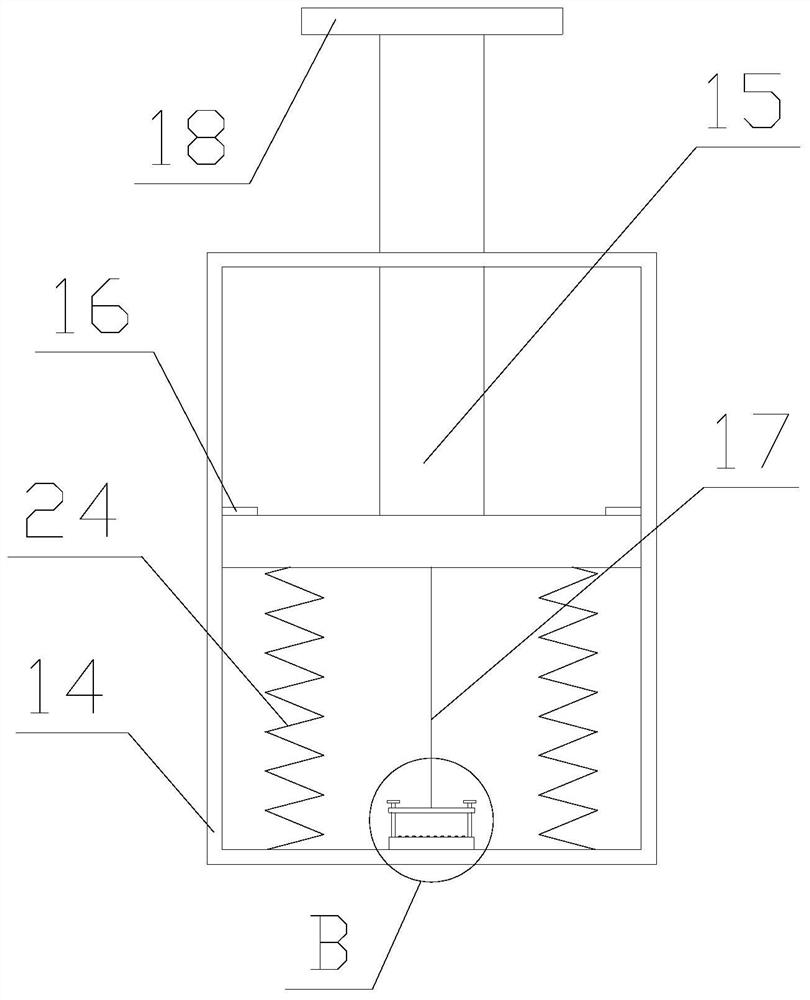

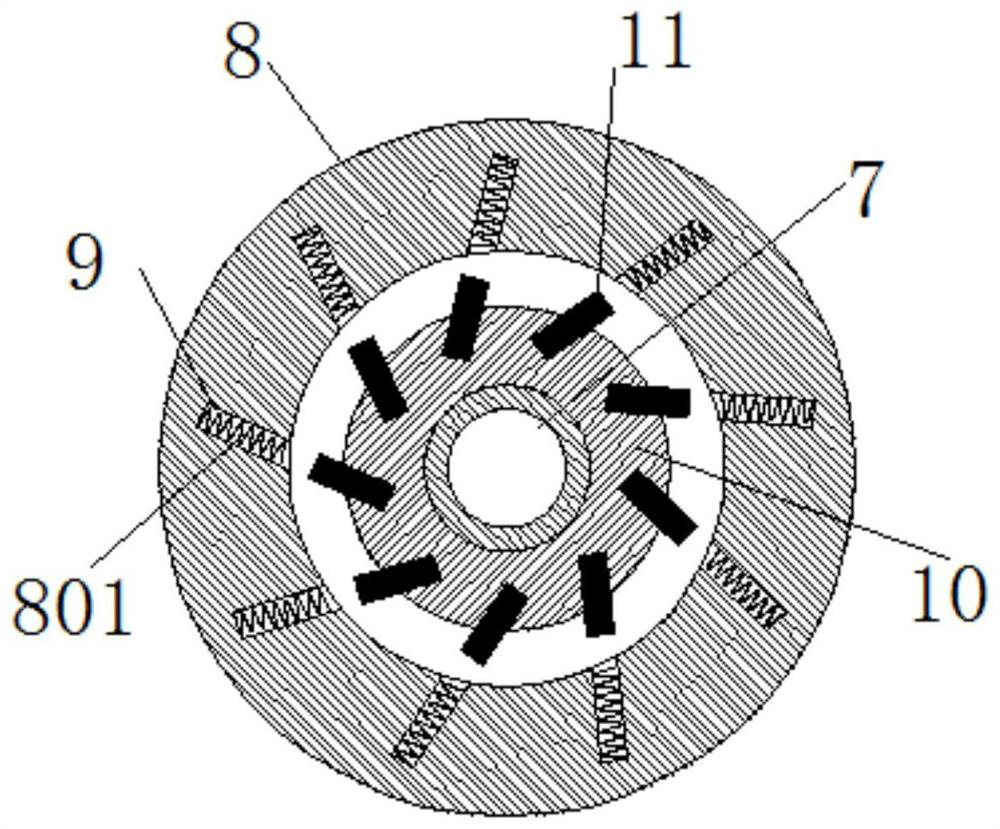

Stainless steel cylinder polishing wire-drawing treatment equipment

ActiveCN107363695ARealize automatic shrinkage adjustmentImprove production efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringDrive motor

The invention belongs to the field of mechanical processing equipment, and in particular discloses stainless steel cylinder polishing wire-drawing treatment equipment which comprises a bottom plate, an adjusting module, a driving motor, an outer cylinder grinding disc, an inner cylinder grinding disc, a centering support and a connecting rotating shaft, wherein the bottom plate is placed on the ground; an adjusting module is arranged on the upper surface of the bottom plate; the driving motor is mounted on the adjusting module; the inclination angle of an axis of the driving motor can be adjusted through the adjusting module; and the outer cylinder grinding disc, the inner cylinder grinding disc and the centering support are detachably mounted on the connecting rotating shaft coaxially. By adopting the equipment, automatic shrinkage adjustment on a polishing wire-drawing radius is achieved under the centrifugal action of the outer cylinder grinding disc and the inner cylinder grinding disc, then operation of polishing and wire-drawing is completed at one time, and the generation efficiency is improved.

Owner:南京拓创精密金属材料有限公司

Preparation method for diamond cutting grinding piece

The invention relates to a preparation method for a diamond cutting grinding piece. The diamond cutting grinding piece comprises a diamond cutting grinding piece body arranged on a 65Mn steel substrate, and corrugated water channels are formed in the surface of the diamond cutting grinding piece body. The preparation method for the diamond cutting grinding piece comprises the steps of material mixture, substrate machining, compression forming, sintering and edge forming. The diamond cutting grinding piece produced through the preparation method for the diamond cutting grinding piece has the cutting effect and the grinding effect, and is safe and reliable in performance, simple and reasonable in structure, low in manufacturing cost, flexible in operation, good in sharpness of products and good in chip-removal performance.

Owner:JIANGSU FENGTAI TOOLS

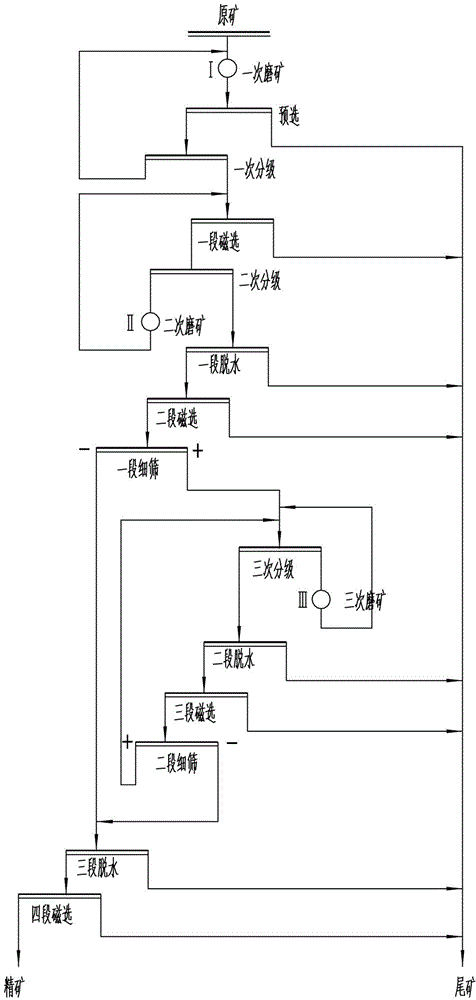

Simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore

ActiveCN104128259AEasy to handleImproved particle size compositionMagnetic separationPhysical chemistryMagnetic separator

The invention relates to a simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore. The process includes ore grinding, grading and magnetic separation and comprises the following concrete steps: ore grinding three times; presorting with a large-wrap angle medium-intensity magnet separator; grading with a cyclone three times; dehydration in three stages; fine sieving in two stages; and magnetic separation with a magnet separator in four stages. The invention provides the energy-saving, low-carbon, environment-friendly and reliable production process for treatment of iron carbonate-containing lean magnetite ore by using a simple magnetic separation method; the process can further improve treating capability, enhance technical and economic indexes, reduce production cost and greatly increase the utilization efficiency of inferior resources while improving ore grinding, grading and sorting efficiency.

Owner:ANSTEEL GRP MINING CO LTD

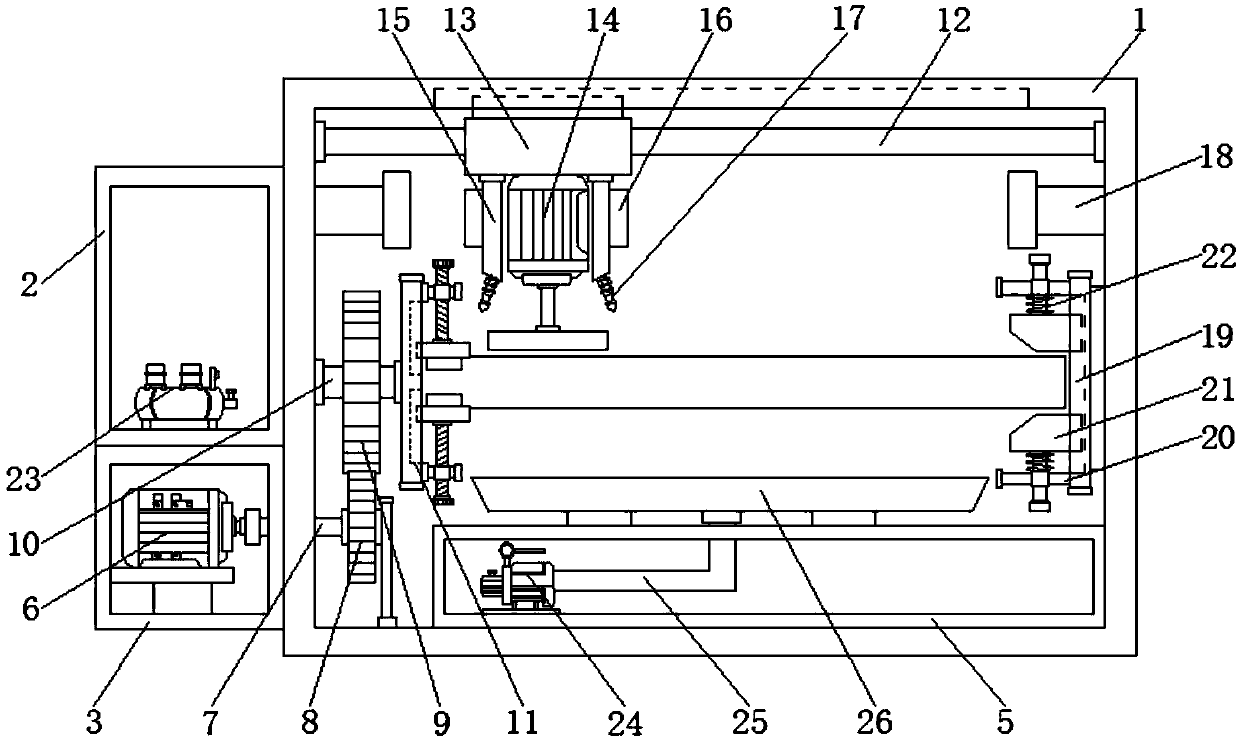

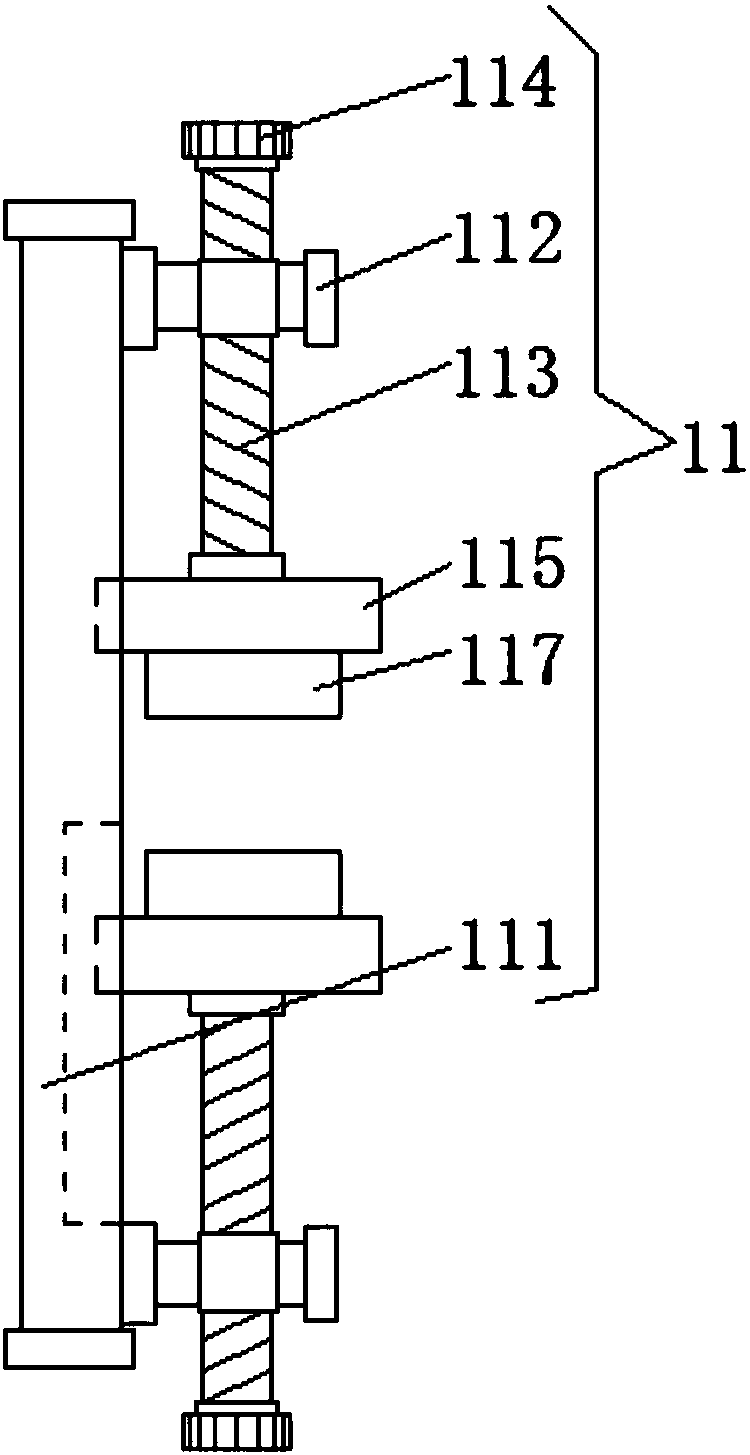

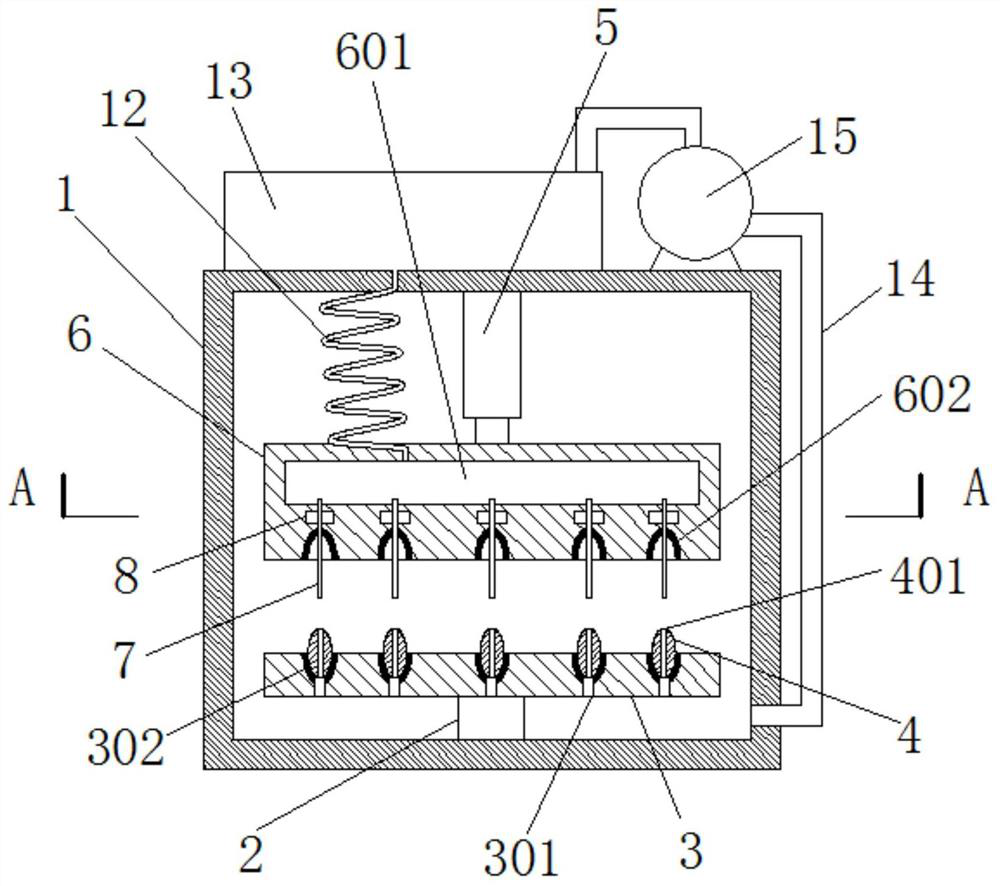

Polishing device for building engineering

InactiveCN107932209APrevent fallingEffective clampingGrinding carriagesRevolution surface grinding machinesArchitectural engineeringPinion

The invention discloses a polishing device for building engineering, and relates to the technical field of building engineering equipment. The polishing device comprises a box body; a top box is fixedly connected to the left side of the box body; a motor box is fixedly connected to the position, located at the bottom of the top box, of the bottom of the left side of the box body; a collecting boxis fixedly connected to the bottom of the inner wall of the box body; a first motor is fixedly connected to the bottom of the inner wall of the motor box through a motor seat; and the end, away from the first motor, of a middle shaft sequentially penetrates through the motor box and the box body and extends into the box body. According to the polishing device for the building engineering, effective clamping can be conducted, the situation that materials fall when polishing is conducted is prevented, the wasted time is shortened, follow-up uniform polishing can be conducted conveniently, and the materials can be driven to rotate at the constant speed during polishing; and meanwhile, a large gear and a pinion are designed, the rotating speed can be decreased, uniform polishing can be ensured, and the polishing efficiency is greatly improved.

Owner:魏熙圆

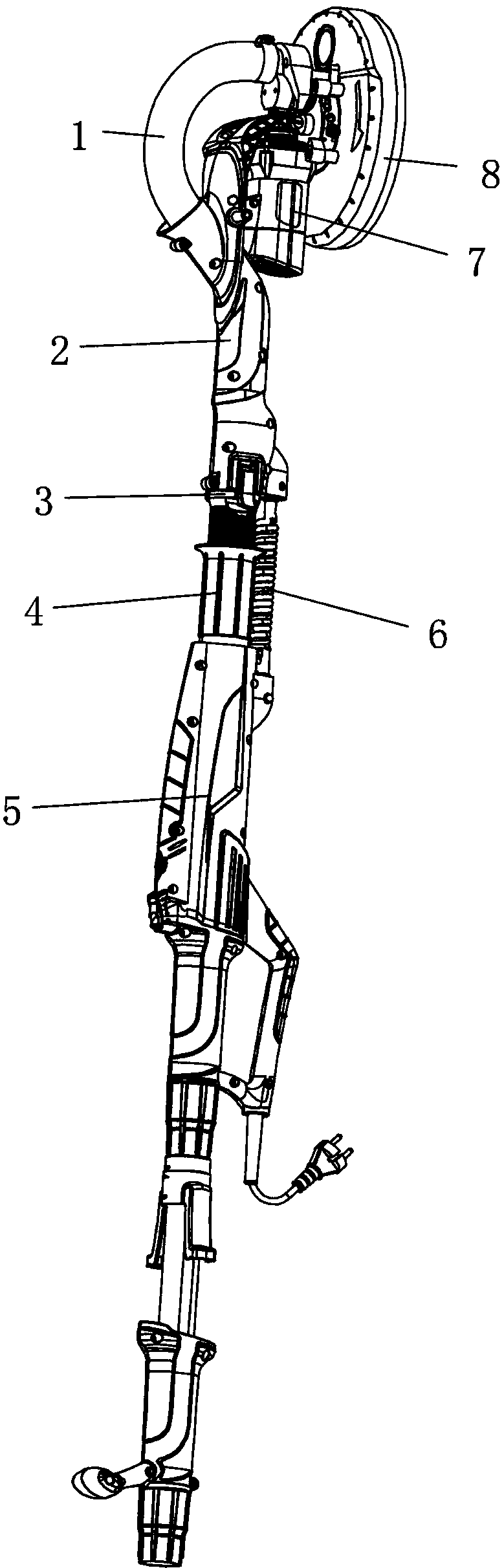

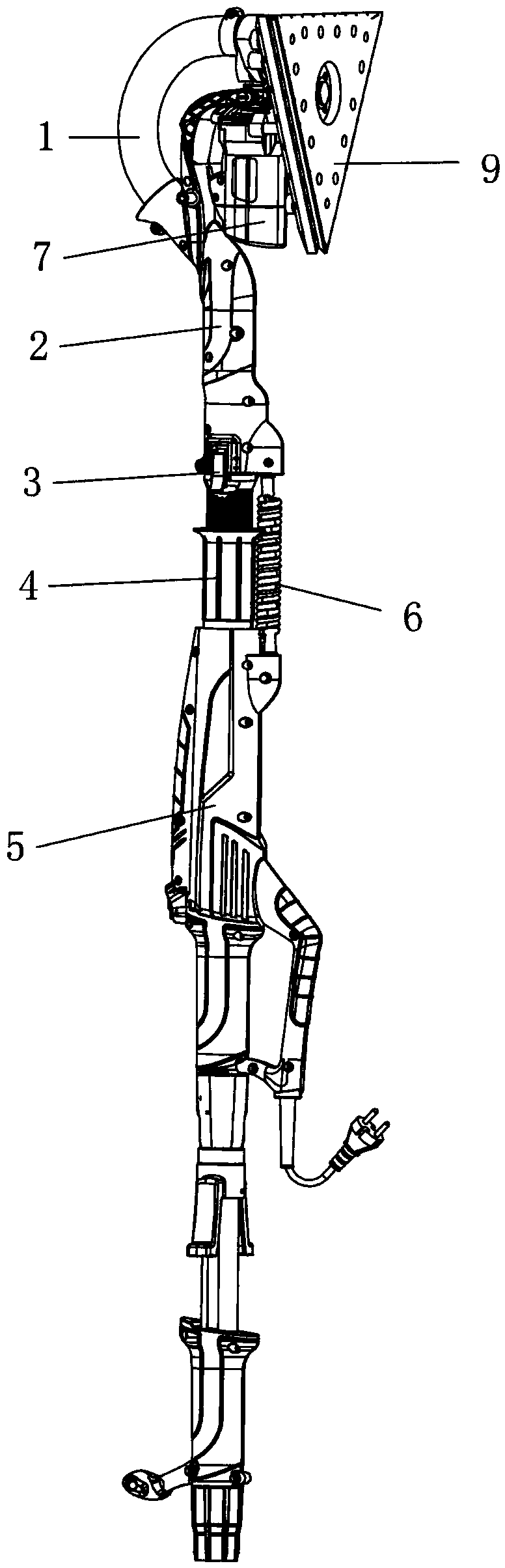

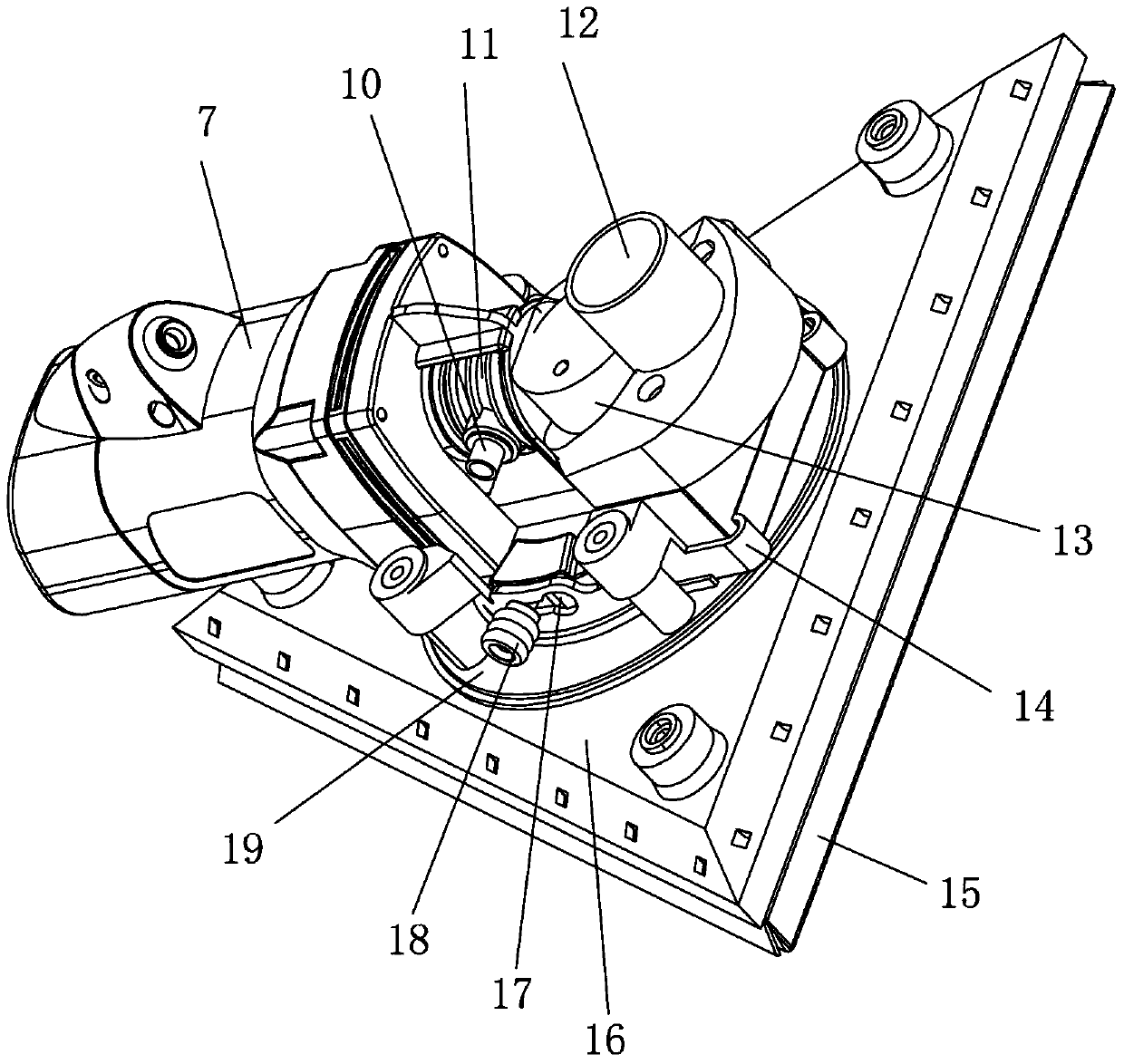

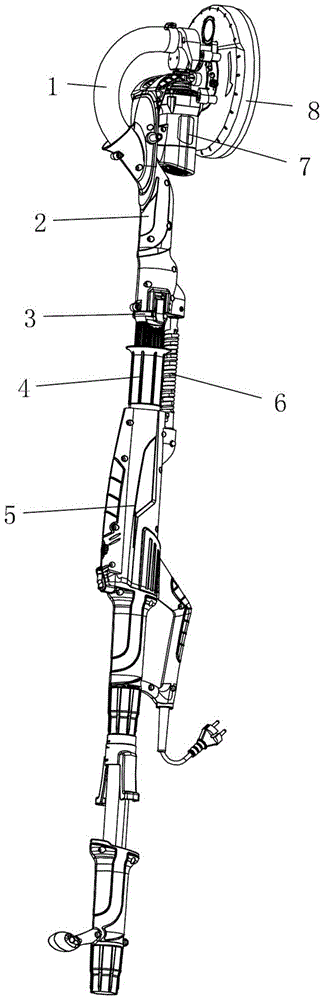

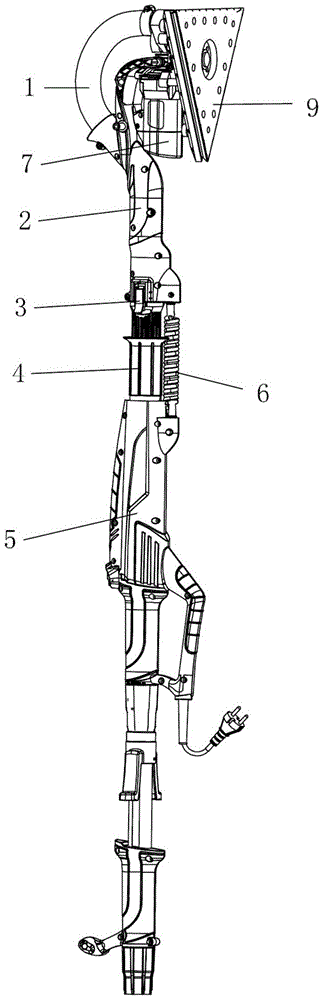

Wall polisher

ActiveCN103991015AOutstanding and Beneficial Technical EffectsQuick switchGrinding headsPlane surface grinding machinesEngineeringDISC assembly

The invention relates to the technical field of electric tools, in particular to a wall polisher. The wall polisher comprises an operating handle, a motor and a polishing head. The polishing head comprises a top cover, a base and abrasive disc assemblies. A transmission mechanism for transmitting the torque of the motor to the abrasive disc assemblies is arranged between the top cover and the base. An output shaft of the transmission mechanism is an eccentric shaft or a concentric shaft. An abrasive disc of each abrasive disc assembly is installed at the lower end of the eccentric shaft or the concentric shaft. The base is internally provided with a rotating disk, one side of the rotating disk is provided with a shifting handle, the rotating disk is provided with one or more limiting holes, the top cover is fixedly provided with a positioning rod stretching into the limiting holes, and the limiting holes can clamp or loosen the positioning rod through the rotation of the rotating disk. According to the wall polisher, the two different abrasive disk assemblies are usually prepared, the output shaft of the transmission mechanism of one abrasive disk is the eccentric shaft, the other output shaft of the transmission mechanism of the other abrasive disk is the concentric shaft, different abrasive disk assemblies can be rapidly switched, and therefore the wall corner can be polished very conveniently.

Owner:傅月华 +1

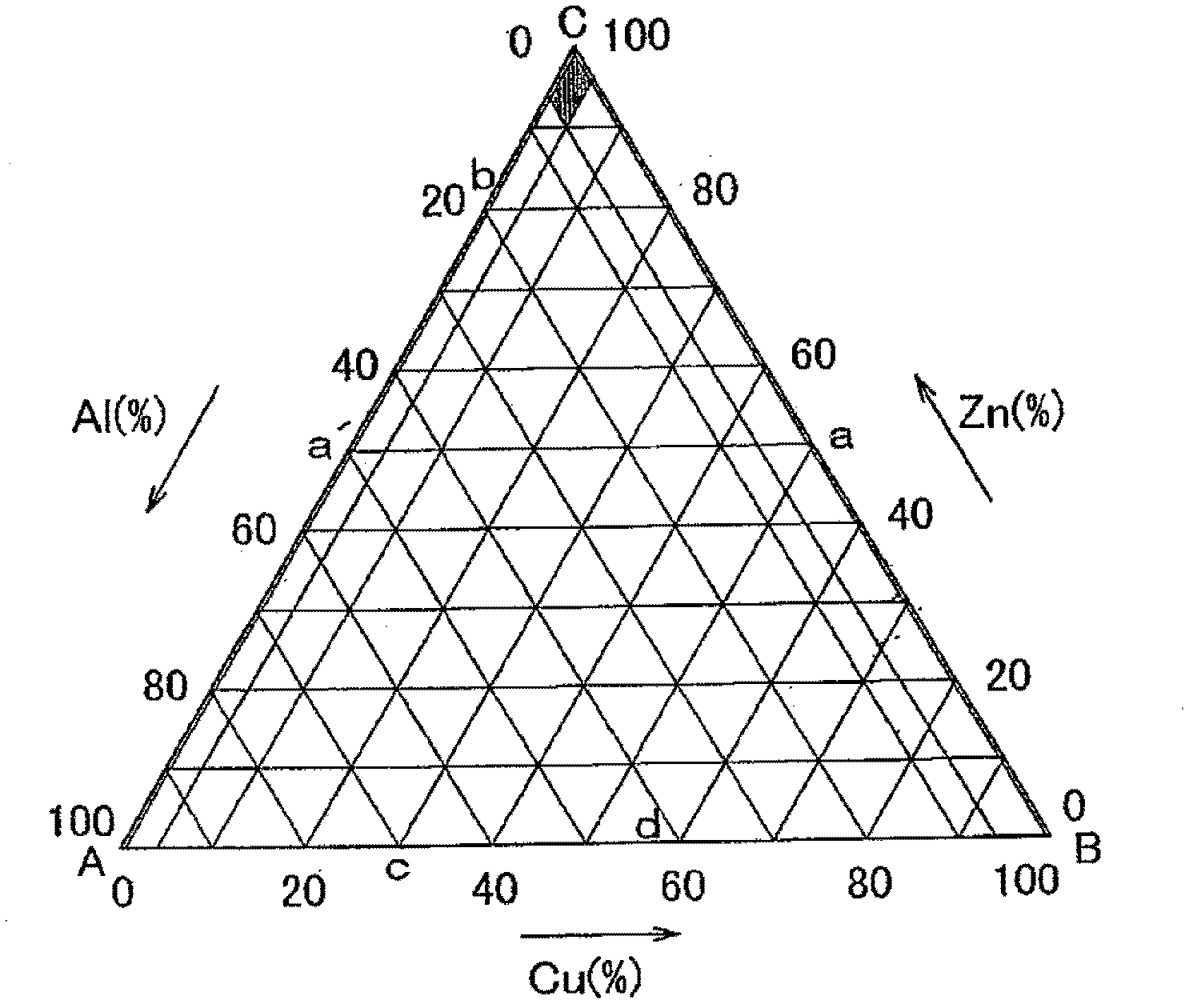

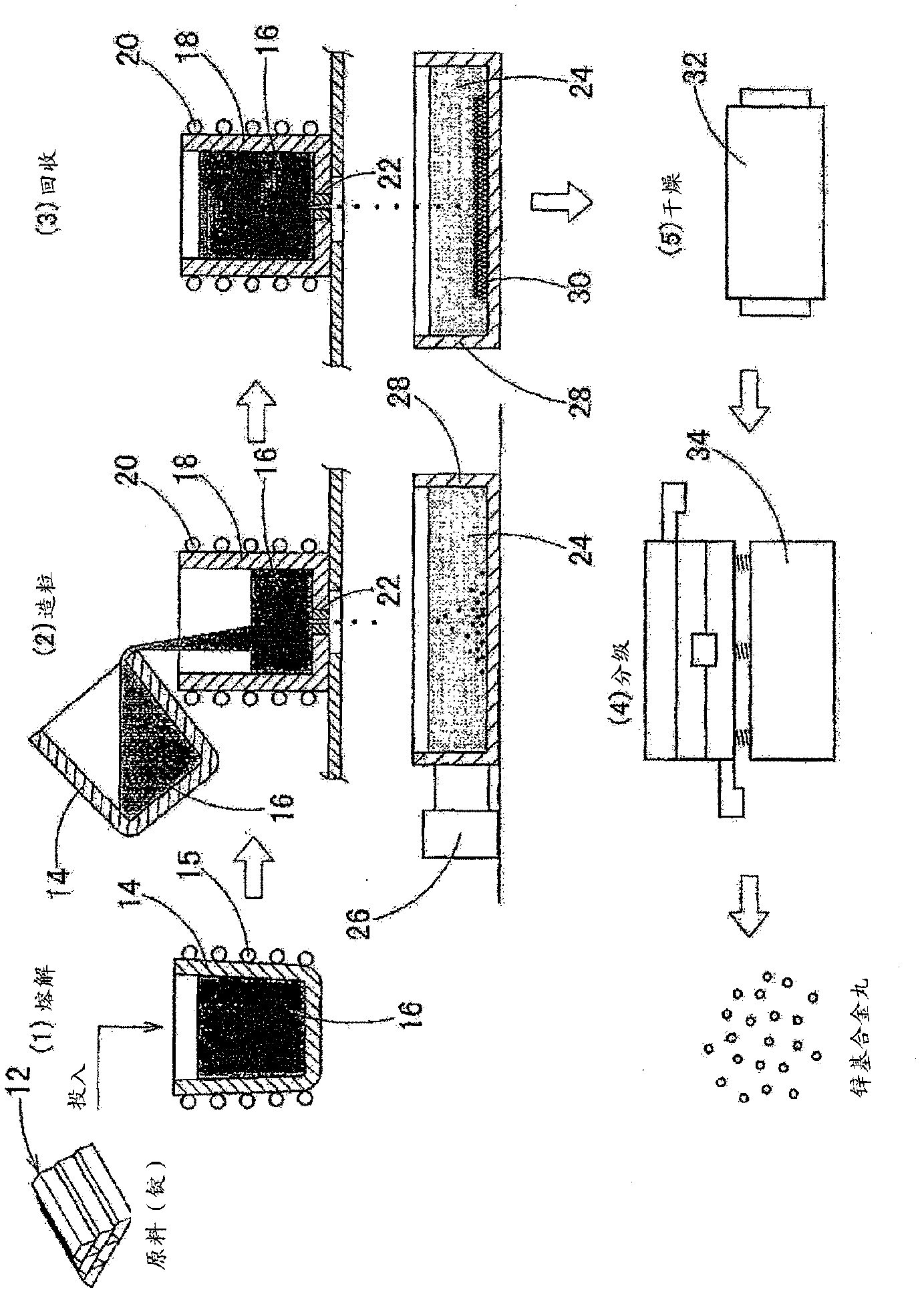

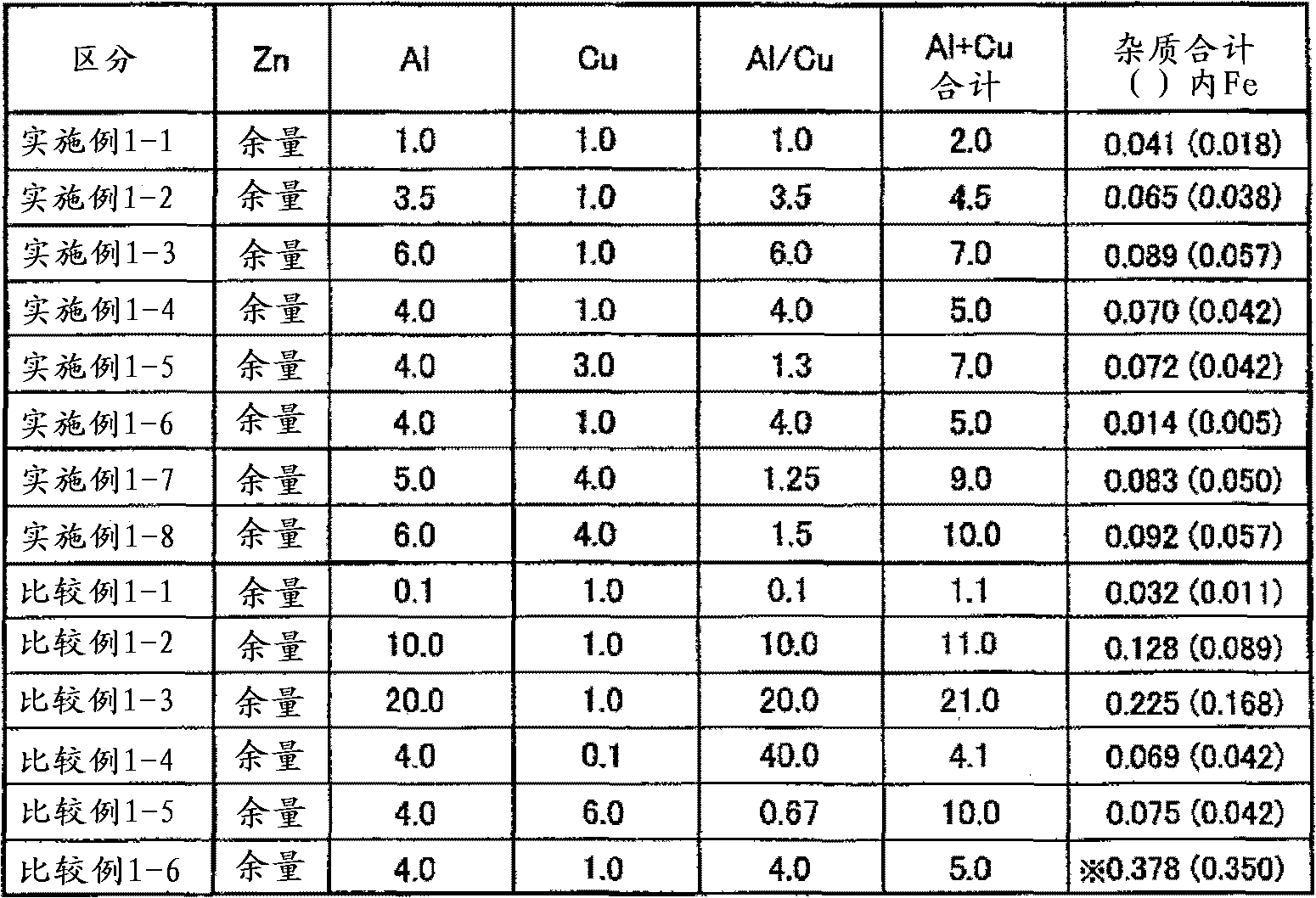

Zinc-based alloy shots

ActiveCN102574274AReduce consumptionReduce generationAbrasion apparatusMass compositionDust explosion

Provided are zinc-based alloy shots which, without risk of dust explosion, are capable of high performance deburring and abrasion cleaning through shot blasting and application of compressive residual stress through shot peening, with low quantities of shots consumed by shot projection. The zinc-based alloy shots include a three-component zinc-based alloy shot wherein 0.5 - 6.5 mass % Al, 0.5 - 4.5 mass % Cu are contained as additional elements, the mass composition ratio of Al to Cu (Al / Cu) is 1.0 - 13.0, the total amount (Al + Cu) is 1.5 - 10.5 mass %, and the Vickers hardness is 90 - 190 HV; and a four-component zinc-based alloy shot wherein 0.5 - 6.5 mass % Al, 0.5 - 4.5 mass % Cu, 0.01 - 0.2 mass % Mg are contained as additional elements, the mass composition ratio of Al to Cu (Al / Cu) is 1.0 - 13.0, the total additional amount (Al + Cu) is 1.5 - 8.0 mass %, and the Vickers hardness is 90 - 190 HV.

Owner:SINTOKOGIO LTD

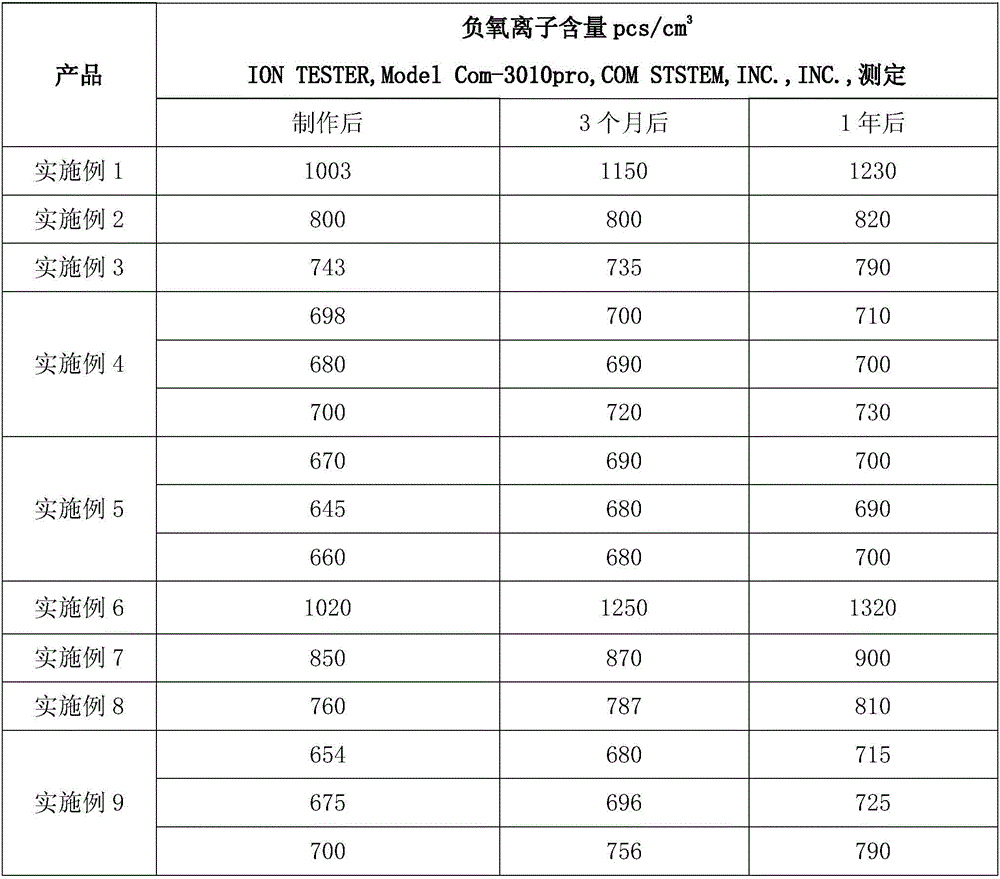

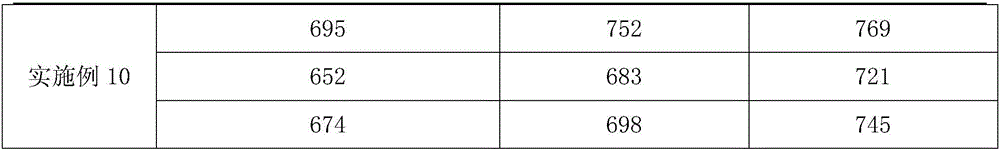

Natural terpene type nanocomposite material capable of releasing negative oxygen ions, and preparation method of natural terpene type nanocomposite material

InactiveCN106178878AImprove the production effectImprove immunityBiocideGas treatmentCinnamomum camphoraDistillation

The invention belongs to the technical field of air purification materials, and particularly relates to a natural terpene type nanocomposite material capable of releasing negative oxygen ions, and a preparation method of the natural terpene type nanocomposite material. The natural terpene type nanocomposite material capable of releasing the negative oxygen ions is prepared from 1-40 parts of cinnamomum camphora, 1-90 parts of pine pollen, 1-60 parts of beeswax, 1-70 parts of uncaria rhynchophylla, 1-30 parts of lotus leaves, 1-70 parts of pine needles, 1-40 parts of Chinese mugwort and 1-200 parts of substrates. The preparation method comprises the following steps of (1) weighing the cinnamomum camphora, the pine pollen, the beeswax, the uncaria rhynchophylla, the lotus leaves, the pine needles and the Chinese mugwort, performing mixing, performing grinding, adding deionized water, performing distillation, performing extraction, and performing separation so as to obtain terpene type substances; (2) weighing the substrates, grinding the weighed substrates, and activating the ground substrates; and (3) adding the terpene type substances obtained in the step (1) to the activated substrates obtained in the step (2), performing mixing, and performing grinding so as to obtain the natural terpene type nanocomposite material. The natural terpene type nanocomposite material capable of releasing the negative oxygen ions is scientific, natural and healthy in formula, can sufficiently release the negative oxygen ions, can promote metabolism of human bodies, can enhance immunity and has the functions of bacteriostasis, sterilization and deodorization.

Owner:廖晓斌 +3

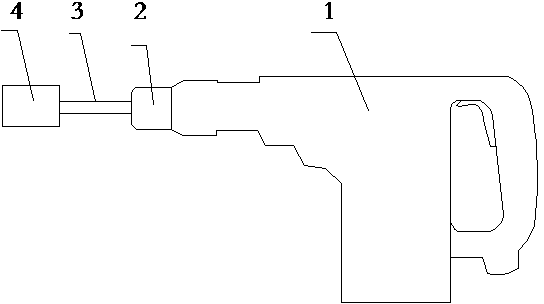

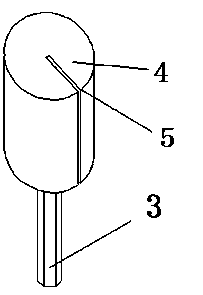

Polishing and cleaning tool for inner holes of tube plates of condensers

InactiveCN104044048AFast loadingEasy to cleanRevolution surface grinding machinesPortable grinding machinesEngineeringDrill

The invention provides a polishing and cleaning tool for inner holes of tube plates of condensers. The polishing and cleaning tool comprises an electric drill with a drill chuck, a polishing handle is clamped by the drill chuck, a cylindrical polishing head is arranged at the end of the polishing handle, the polishing head is provided with an axial clamping groove, openings of the clamping groove are formed in the top, the bottom and the outer circumferential surface of the polishing head, abrasive paper is wound around the outer circumferential surface of the polishing head, and the tail end of the abrasive paper is inserted into the clamping groove. The polishing and cleaning tool has the advantages that the filling speed of the abrasive paper is high, the pipe holes are cleaned up uniformly, polishing speed is multiple times that of a manual method, the inner walls of the pipe holes can be rapidly polished to be smooth, no oil dirt or oxidation layer or dust is formed, and labor efficiency and security coefficients are increased.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

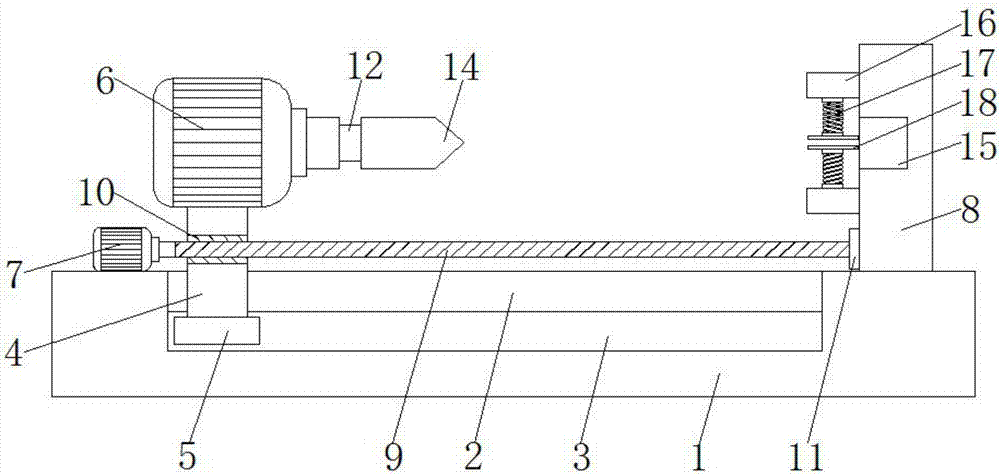

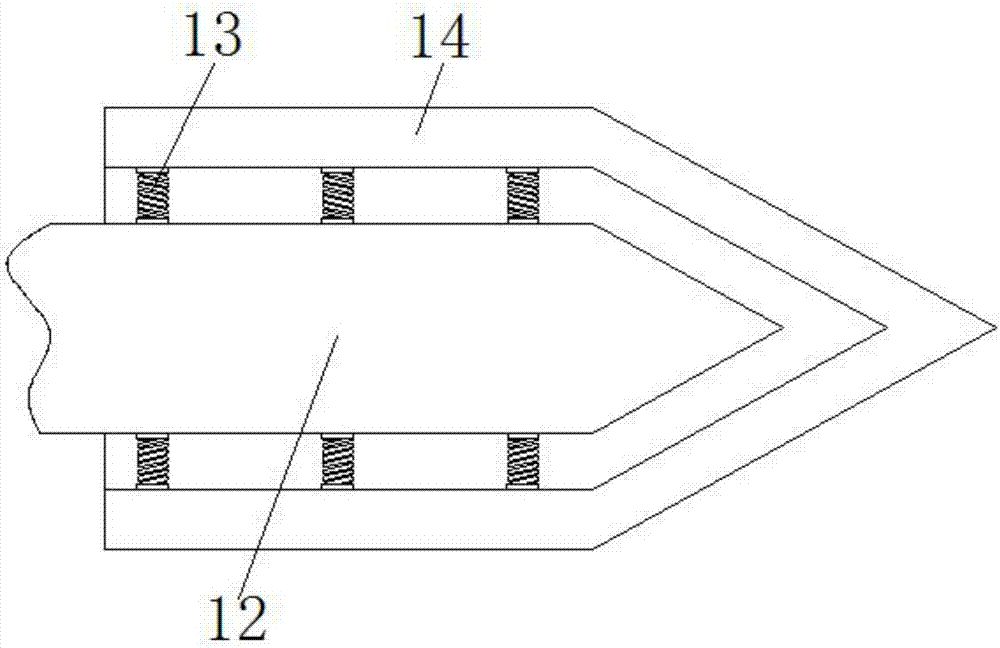

Steel pipe inner wall edge burr grinding device

InactiveCN107971861AEasy to installEasy to useEdge grinding machinesGrinding carriagesFurringDrive motor

The invention relates to the technical field of steel pipe machining equipment and discloses a steel pipe inner wall edge burr grinding device. The steel pipe inner wall edge burr grinding device comprises a pedestal; the upper surface of the pedestal is provided with a first sliding chute; the bottom of the first sliding chute is provided with a second sliding chute; a first sliding plate is inserted into the first sliding chute; and the bottom end of the first sliding plate penetrates through the first sliding chute and is fixedly connected with the upper surface of a second sliding plate which is positioned inside the second sliding chute. The steel pipe inner wall edge burr grinding device is provided with a driving motor, a positive and negative rotating motor, a threaded rod, a grinding bar and a second spring; the driving motor can move, so convenience is provided for installation of a steel pipe; meanwhile, the second spring and the grinding bar are matched with each other, sothe steel pipe inner wall edge burr grinding device is high in applicability and can be applicable to different specifications of steel pipes; burrs are ground in a rotation process of the driving motor, and manual operation is not needed, so the work intensity and the work difficulty are reduced; and meanwhile quicker grinding is realized, the grinding efficiency is improved, and the steel pipe inner wall edge burr grinding device is more convenient to use.

Owner:惠州市世育五金制品有限责任公司

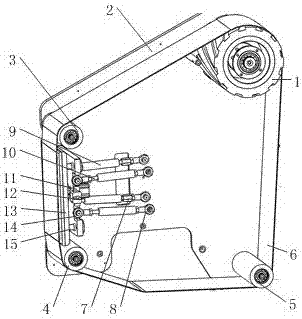

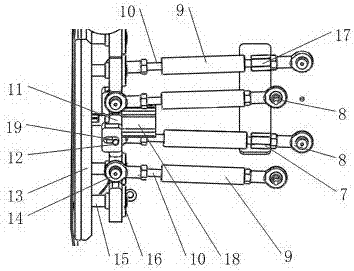

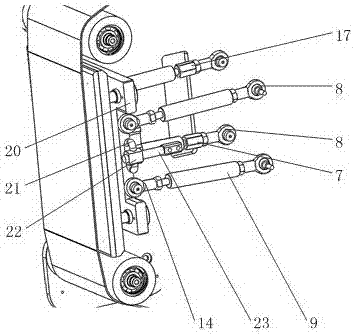

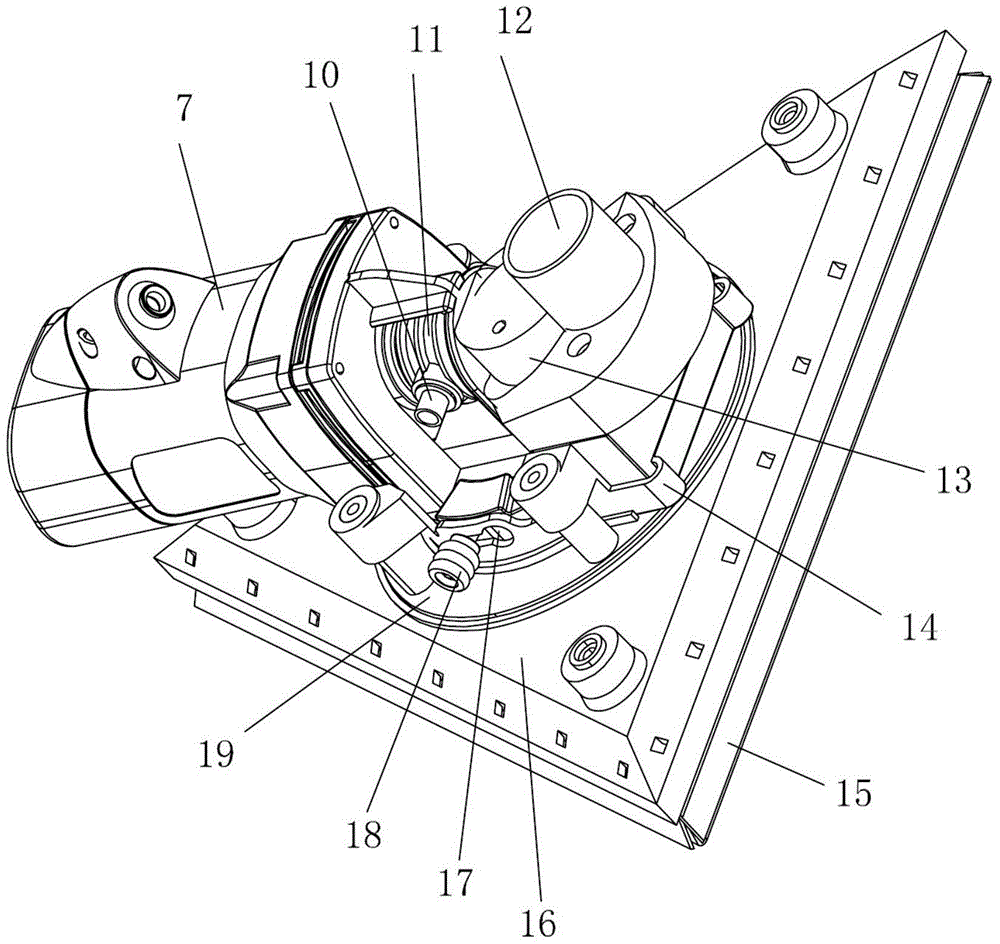

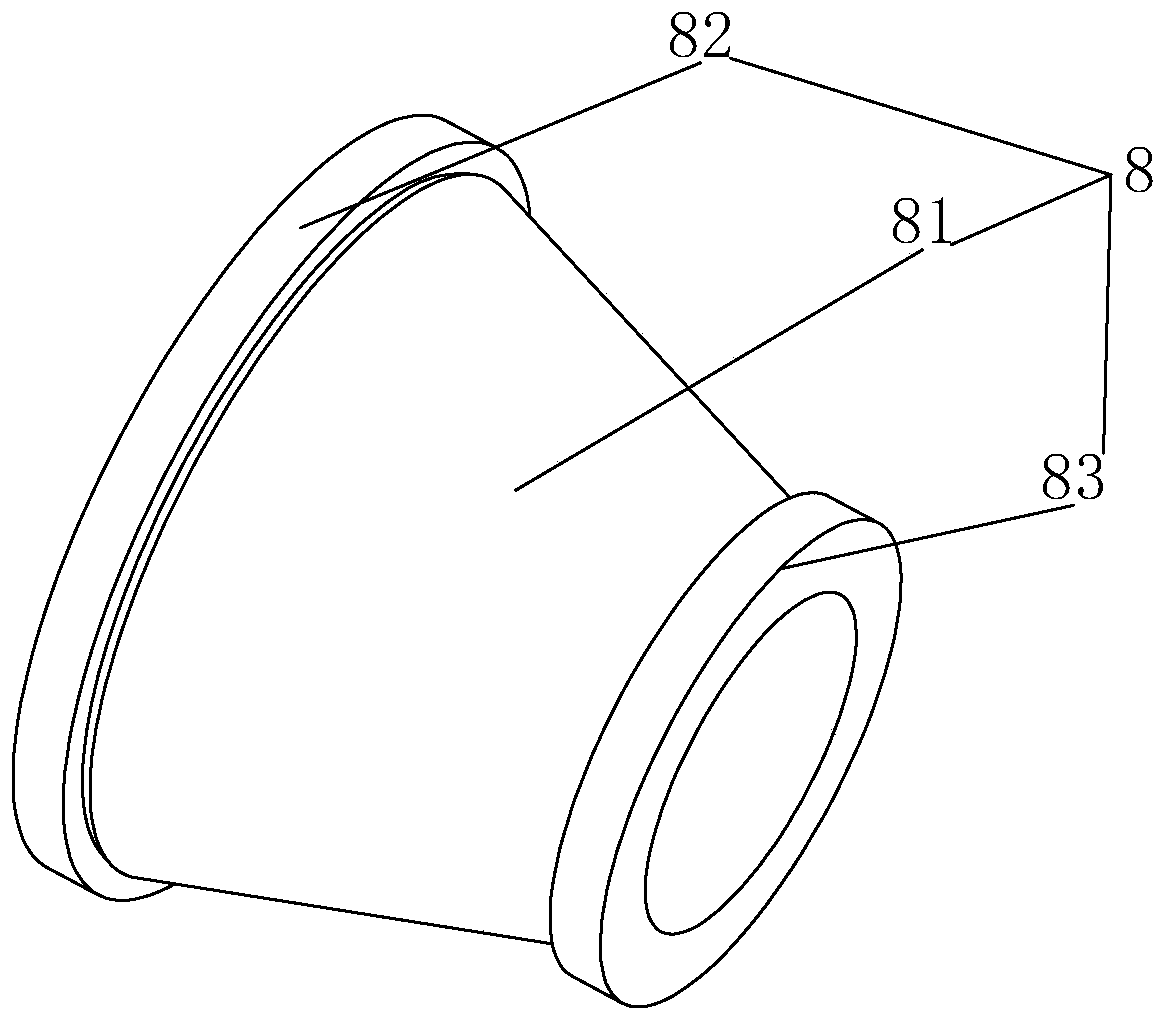

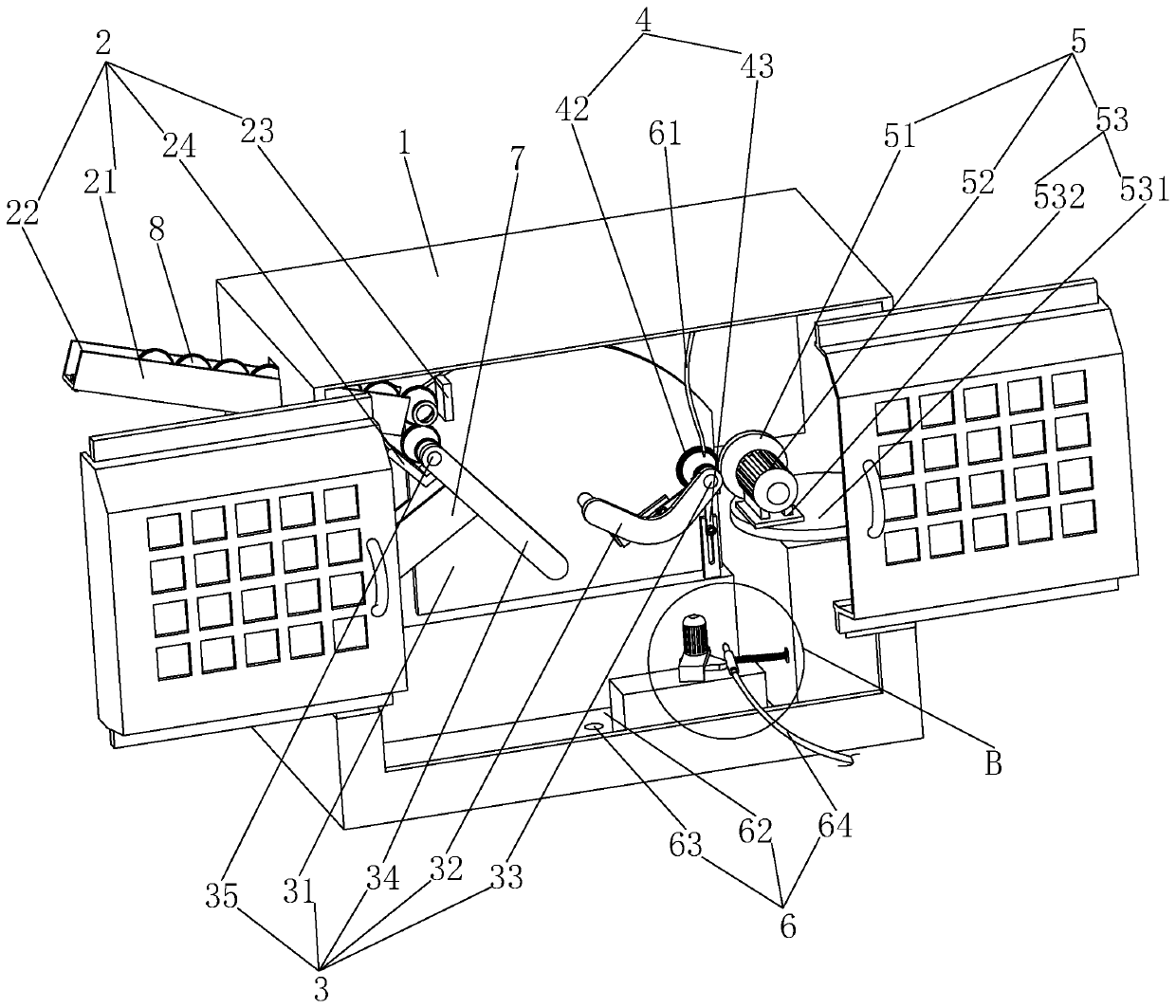

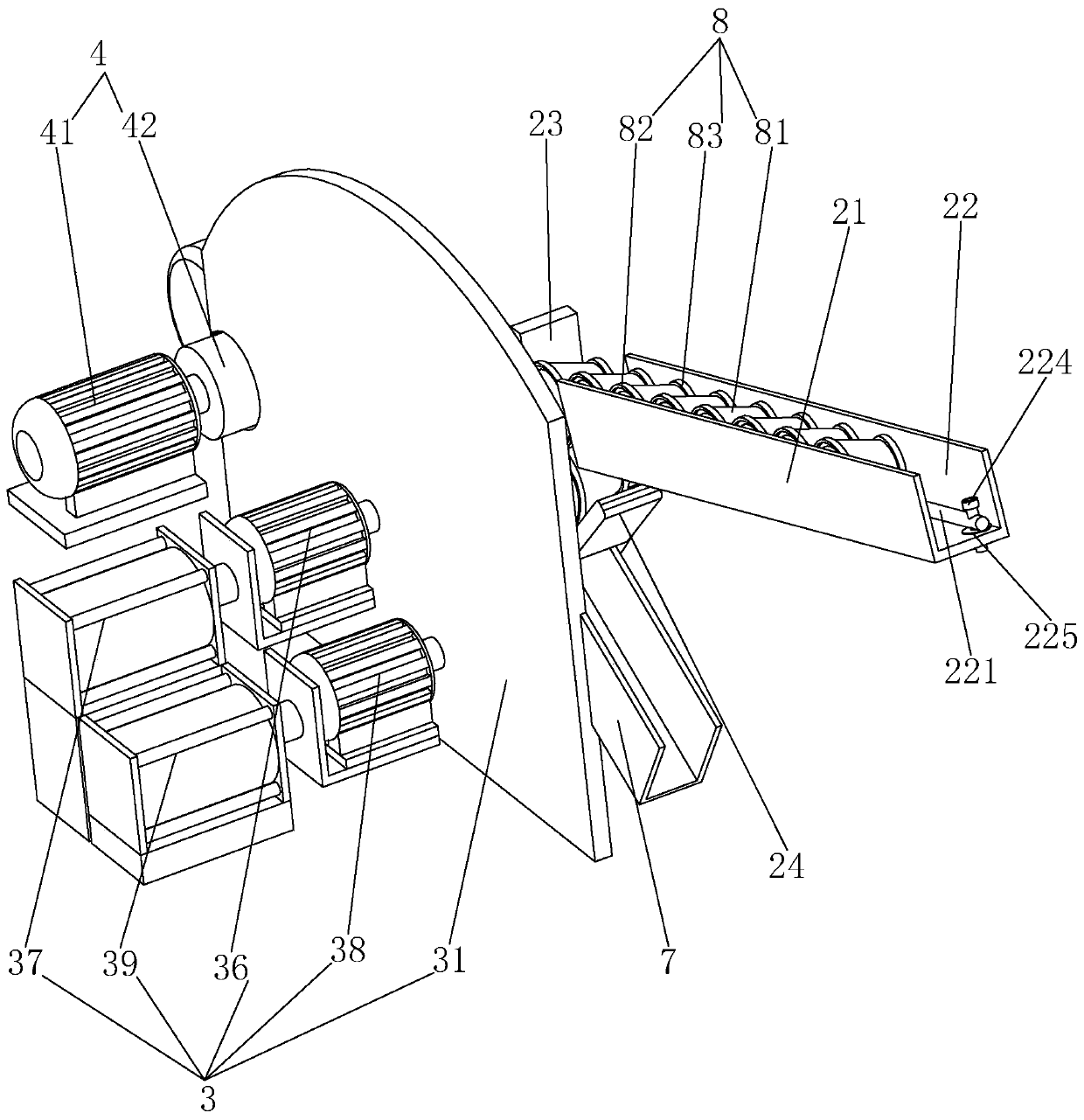

Two-DOF (degree of freedom) belt grinding unit attitude compensation device

ActiveCN107097129AReduce inter-calibration timeReduce labor intensityBelt grinding machinesAir springSpherical joint

The invention discloses a two-DOF (degree of freedom) belt grinding unit attitude compensation device; elastic support rods are composed of an air spring shell and a piston rod, each elastic support rod is hinged respectively to a first attitude compensation plate / second attitude compensation plate and a base plate through a second spherical joint bearing and a first spherical joint bearing; a first length adjusting rod and a second length adjusting rod are connected between each spring shell and the corresponding first spherical joint bearing such that the length of the elastic support rod between the first and second spherical joint bearings may be changed; an ejection cylinder is fixed to the first attitude compensation plate / second attitude compensation plate, a piston rod of the ejection cylinder is fixedly connected to an abrasive plate, and the ejection cylinder is positioned within a four-point line area of the hinging points of the four second spherical joint bearings; a guide shaft is fixed to each of four corners of the abrasive plate. The two-DOF belt grinding unit attitude compensation device has the advantages that correction time for mating with a robot in grinding can be saved, the positioning level for a robot and a grinding unit is lower, applicability of a grinding system is improved, and grinding quality can be guaranteed.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

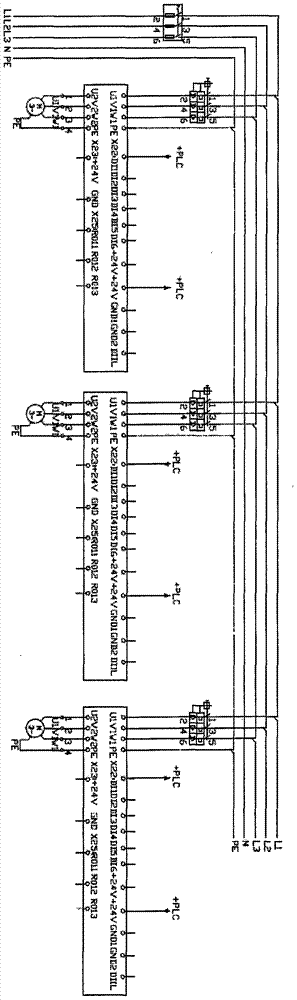

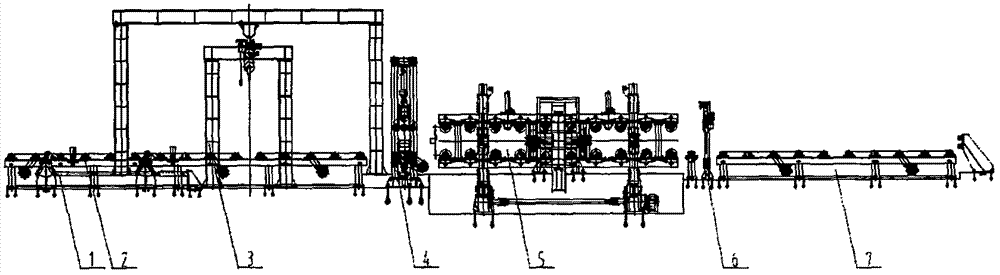

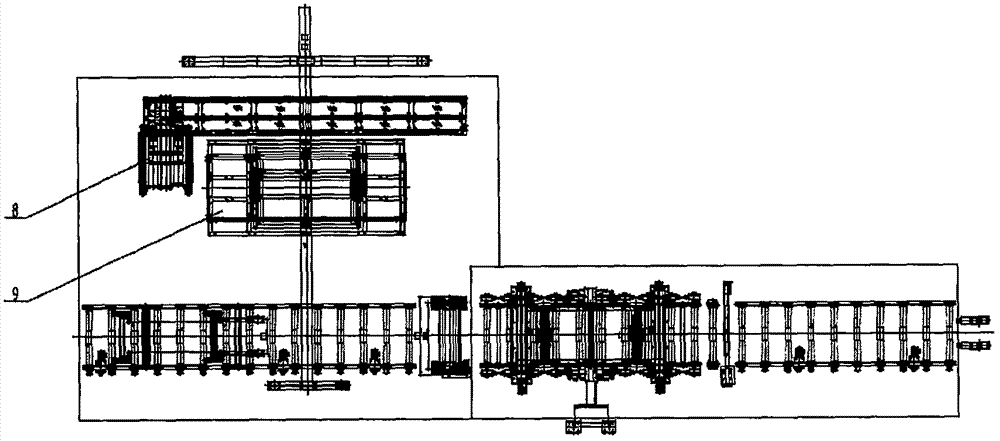

Novel aluminum alloy heat transmission material composite line

InactiveCN107443093AIncrease productivityReduce labor intensityOther manufacturing equipments/toolsOxideHeat transmission

The invention relates to a new aluminum alloy heat transmission material composite line: including a grinding device, a turning device, a vacuum suction crane, a feeding buffer device, a feeding roller table, a brazing pressurizing device, a turning device, a strapping machine, Outfeed roller table, hydraulic pneumatic system and electric control system. The milled aluminum ingots are transported to the feeding roller table, the grinding device grinds and removes the oxide layer on the alloy plate placed on the grinding platform, the turning device turns the polished composite surface downward, and the vacuum suction crane absorbs the composite sheet and places it on the On the aluminum ingot, the feed roller transports the aluminum ingot and the alloy plate to the brazing pressure device for brazing, and the welded composite aluminum ingot is sent to the turning device, which turns the composite aluminum ingot 180° to make the other compound aluminum ingot Facing up, it is transported to the upper alloy plate position towards the feed side, and after the alloy plate is placed again for brazing, the double-sided composite aluminum ingot is sent to the baler through the turning device, and sent to the discharge roller table, and the composite aluminum ingot is hoisted by the driving car. Walk. The invention has the beneficial effects of simple operation, high production efficiency, low labor intensity, safety and reliability.

Owner:邹平齐星工业铝材有限公司

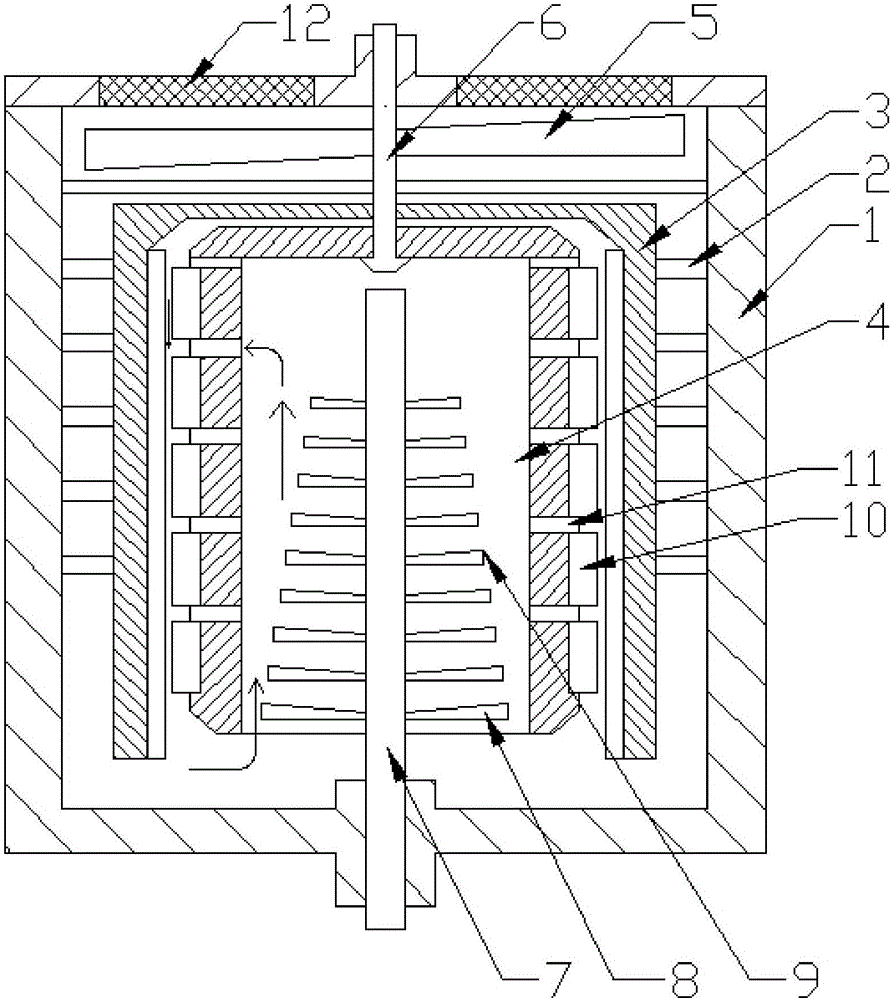

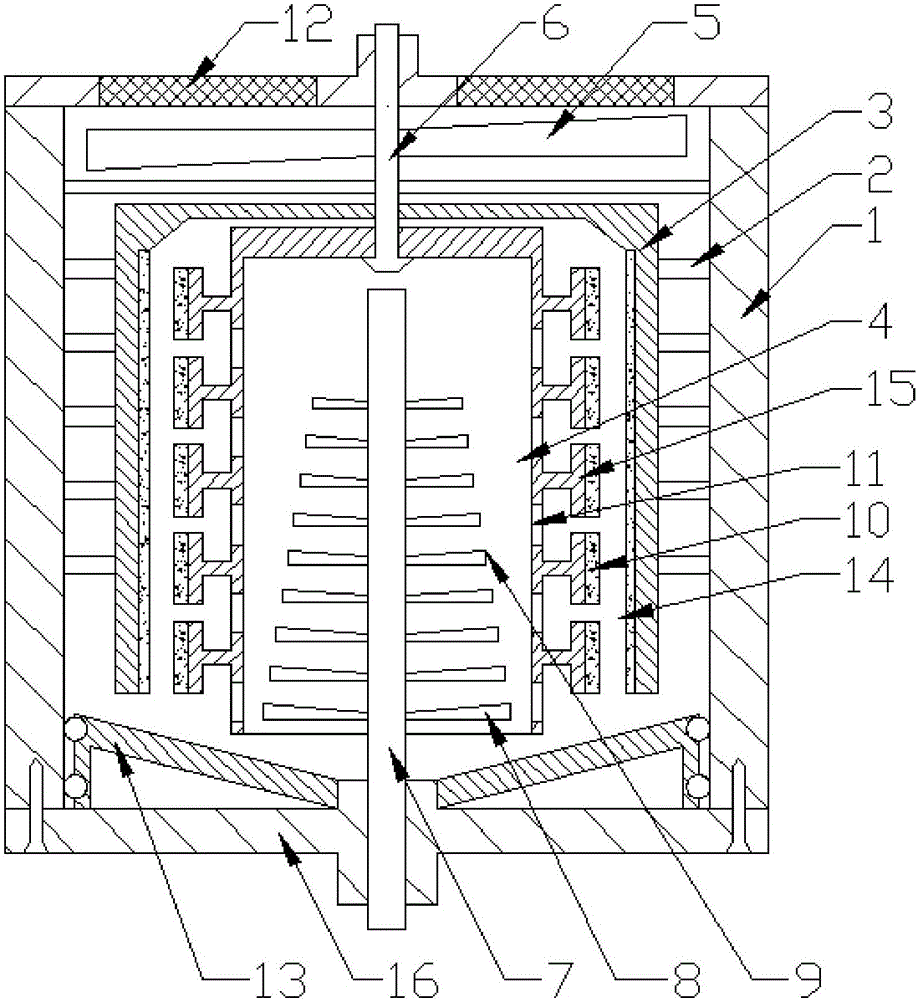

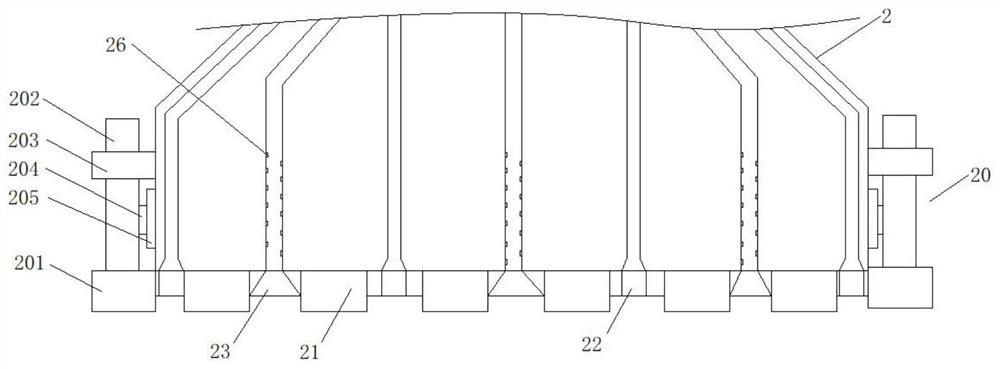

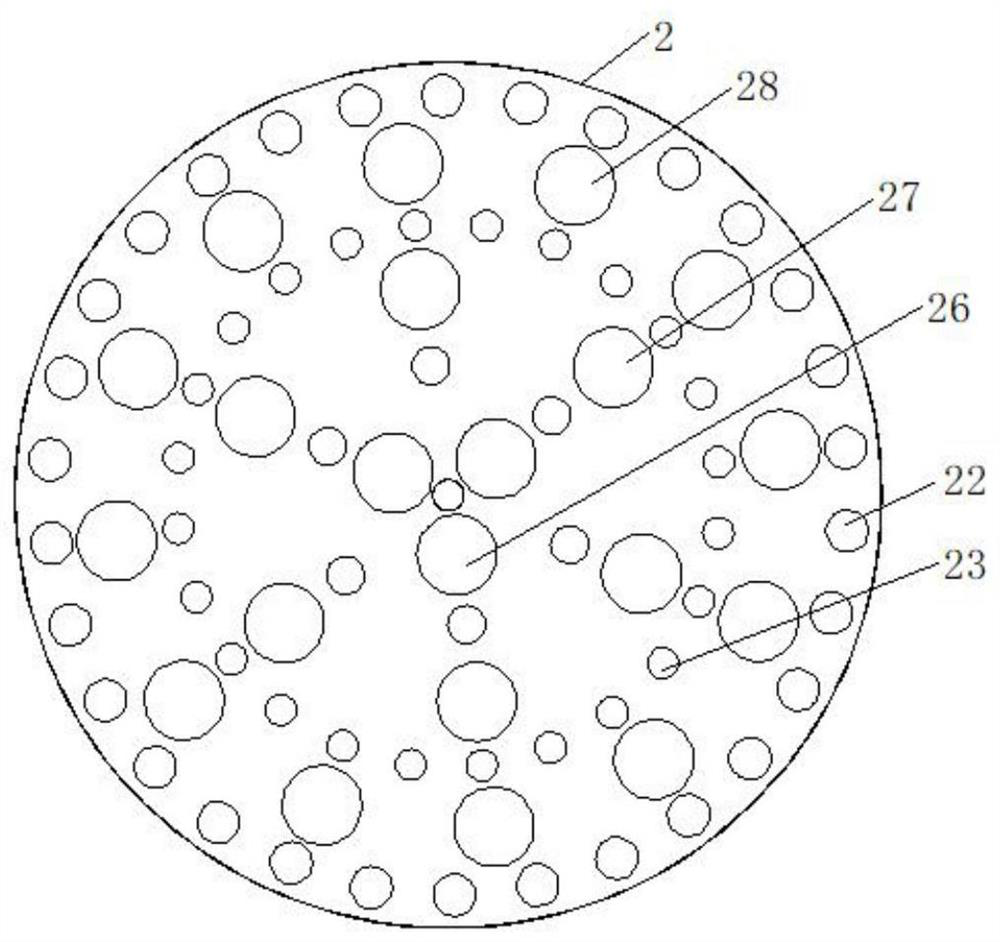

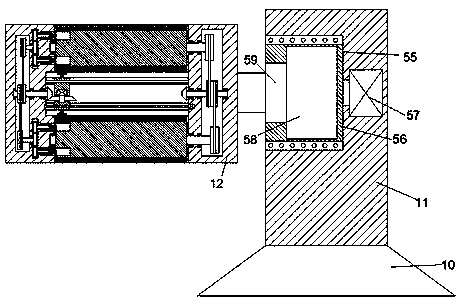

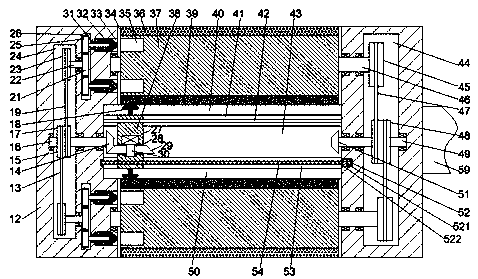

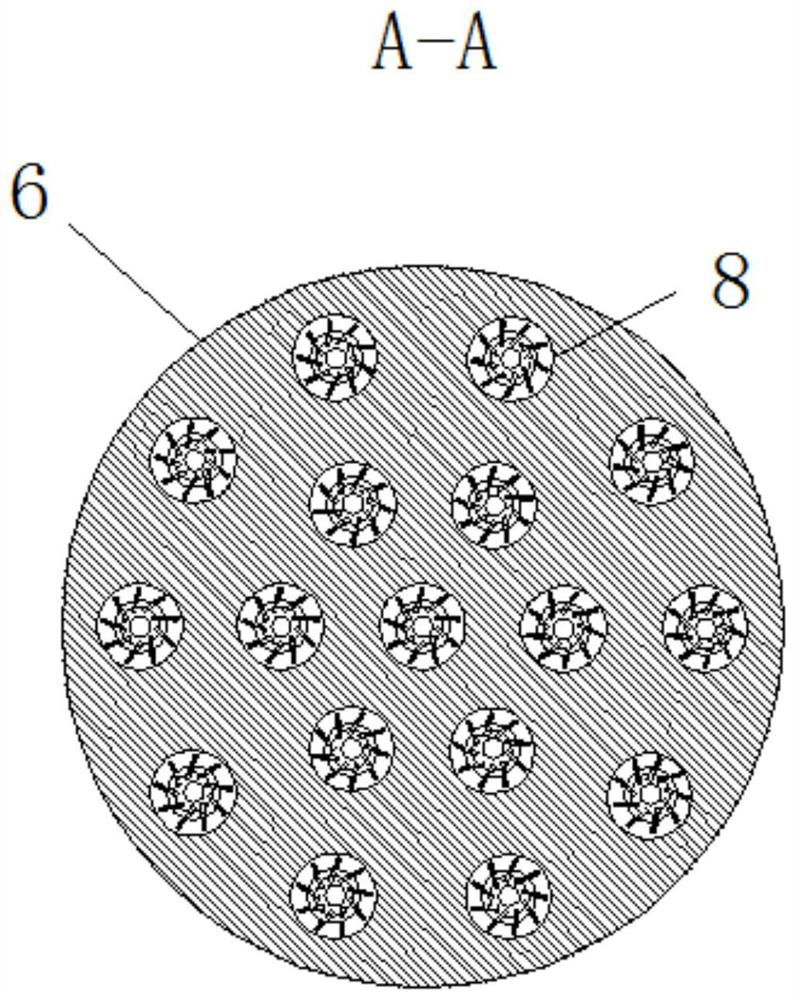

Micropowder manufacturing machine

InactiveCN106040391ARealize self-circulation crushingSimple processGrain treatmentsRefluxEngineering

The invention relates to a micropowder manufacturing machine. The micropowder manufacturing machine comprises a sealed outer cylinder, wherein a grinding inner cylinder is arranged in the sealed outer cylinder, and is of a cylindrical structure with a bottom opening, a reflux gap is formed between the outer wall of the grinding inner cylinder and the inner wall of the sealed outer cylinder, a crushing cylinder with a bottom opening is sheathed in the grinding inner cylinder, and a crushing gap is formed between the outer wall of the crushing cylinder and the inner wall of the grinding inner cylinder; a main driving shaft is arranged at the top part of the sealed outer cylinder, penetrates through the top part of the grinding inner cylinder and is fixedly connected with the top part of the crushing cylinder, a plurality of grinding rings are annularly arranged on the wall surface of the crushing cylinder in an array way, a plurality of material discharging holes are formed between the adjacent grinding rings on the wall surface of the crushing cylinder, the bottom part of the sealed outer cylinder is rotationally connected with a blast turbofan, and the blast turbofan extends into the crushing cylinder via the bottom opening of the crushing cylinder.

Owner:扬州锦盛微粉有限公司

Novel binding tape cutting machine

PendingCN107498613AQuality assuranceUniform sizeGrinding/polishing hand toolsMetal working apparatusEdge surfaceStructural engineering

The invention provides a novel binding tape cutting machine. The novel binding tape cutting machine comprises a working table, a rotating core shaft and a moving cutting mechanism. The working table is further provided with an abutting device and a cutter grinding device. The abutting device is arranged below the rotating core shaft and comprises an abutting rotating roller, a supporting base and a first lifting air cylinder. The cutter grinding device comprises a sliding guiding rail. The sliding guiding rail is arranged on the top of the moving cutting mechanism. The sliding guiding rail is provided with a second lifting air cylinder which can slide along the sliding guiding rail. A piston rod of the second lifting air cylinder is connected with a supporting plate. One end of the supporting plate is connected with the piston rod of the second lifting air cylinder. The other end of the supporting plate is connected with a cutter grinding shell. The novel binding tape cutting machine has the advantages that the abutting rotating roller can be tightly attached to the surface of the rotating core shaft, assisting and stabilizing functions are achieved, so that it is ensured that a cut binding tape is tidy is size, and the quality of the binding tape is improved; and by using the cutter grinding device, passivation of a round cutter is prevented, manually-held cutter grinding stone is not needed to grind the cutter, the potential safety hazard during cutter grinding is prevented, it is also ensured that the two edge surfaces of the round cutter are accurately ground, and damaging of the cutter is prevented.

Owner:JIANGSU YUEDA HOME TEXTILE

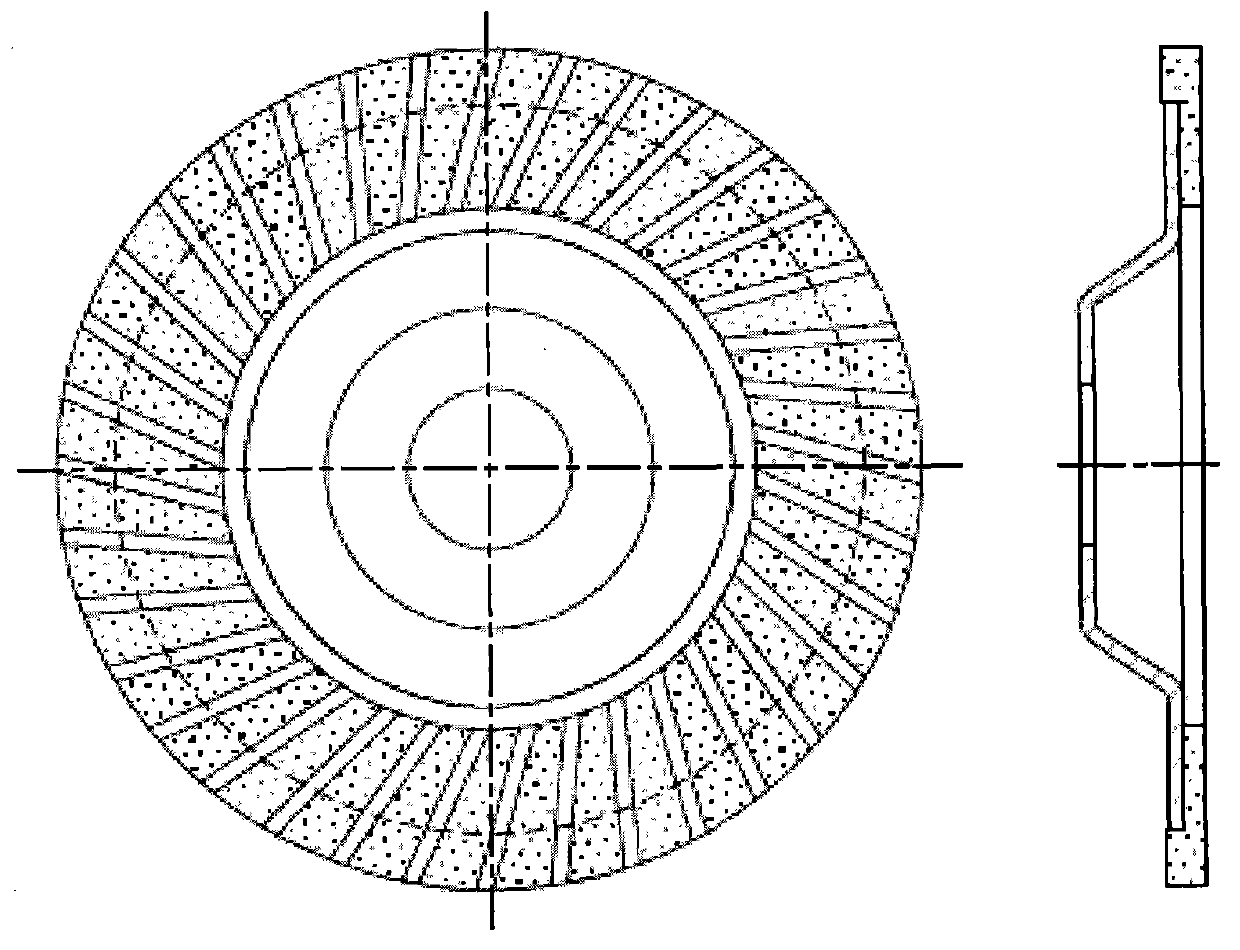

Multi-granularity stepped abrasive paper wheel

The invention discloses a multi-granularity stepped abrasive paper wheel. The multi-granularity stepped abrasive paper wheel comprises a first abrasive paper ring, a second abrasive paper ring, a third abrasive paper ring and a tubular mounting base material; the first abrasive paper ring, the second abrasive paper ring and the third abrasive paper ring respectively sleeve the tubular mounting base body; the second abrasive paper ring is arranged between the first abrasive paper ring and the third abrasive paper ring; the diameters of outer circles of the first abrasive paper ring, the second abrasive paper ring and the third abrasive paper are gradually reduced; the first abrasive paper ring, the second abrasive paper ring and the third abrasive paper ring are prepared by arranging pieces of different-granularity abrasive paper, and the pieces of abrasive paper for preparing the first abrasive paper ring, the second abrasive paper ring and the third abrasive paper ring are gradually decreased in quality. According to the mode above, the multi-granularity stepped abrasive paper wheel has the advantages that three types of abrasive paper rings are arranged by a stepped manner, so that the operation is convenient, the processes can be joined well, and as a result, the efficiency of abrading and polishing can be raised.

Owner:SUZHOU QUNLI NON SLIP MATERIAL

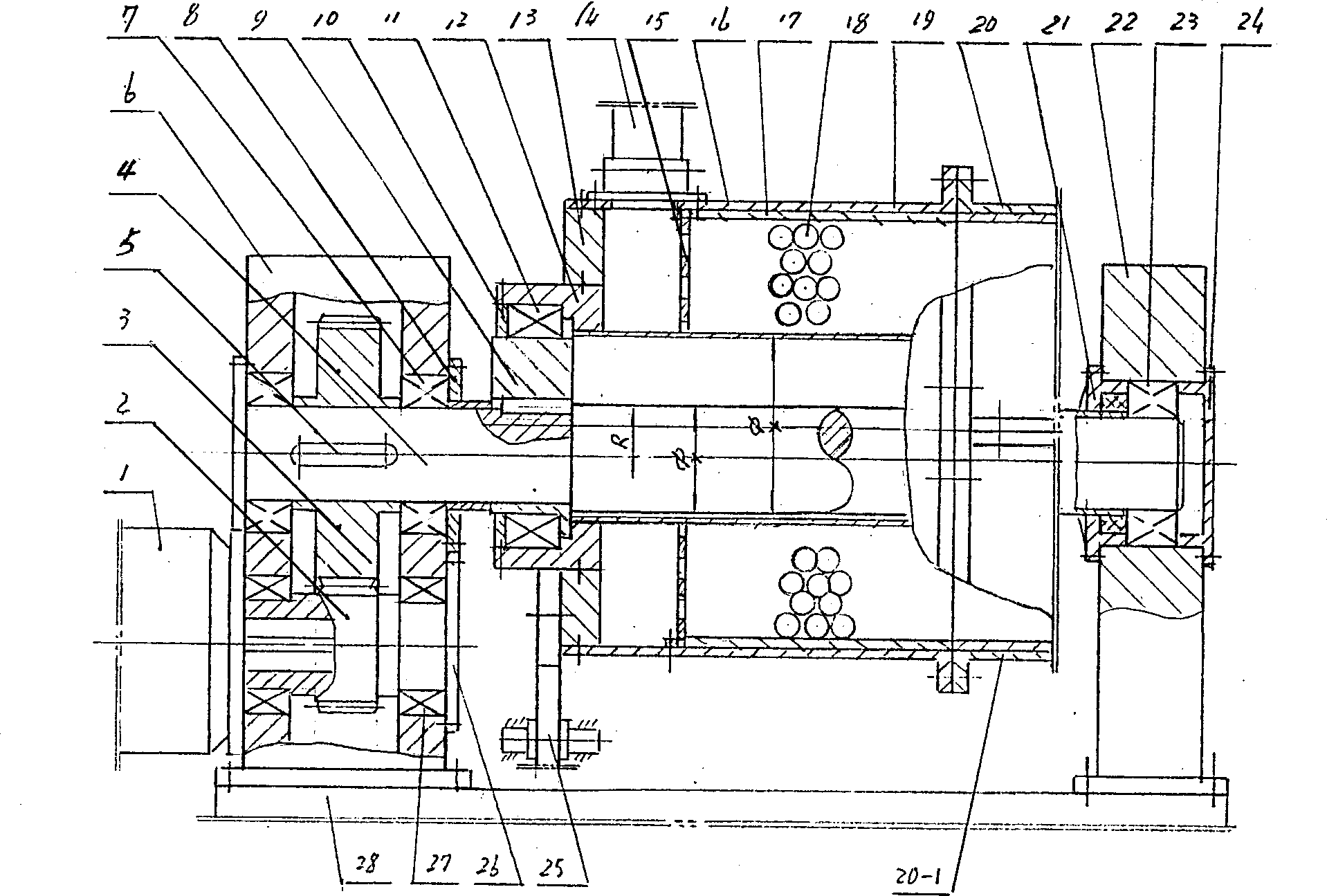

Large-amplitude centrifugal vibrating grinder

InactiveCN1335203AParticipating mass is smallReduce energy consumptionGrain treatmentsEngineeringFineness

The centrifugal vibrating grinder has medium balls to beat and crush material inside one material cylinder in centrifugal circular vibration. It has large amplitude of centrifugal circular vibration up to 50 mm, small vibrated mass, great beating force of the medium balls, and thus high grinding fineness, high production efficiency, long equipment service life and improved technological operationperformance. It has one bearing rod assembly penetrating the eccentric shaft of the material cylinder and limiting the rotation motion of the material cylinder as well as lining arc board, special partition board, material feeding and discharging device, balanced arrangement, etc. The present invention is suitable for both large scale production in mine, building industry, etc. and small scale production.

Owner:胡传东

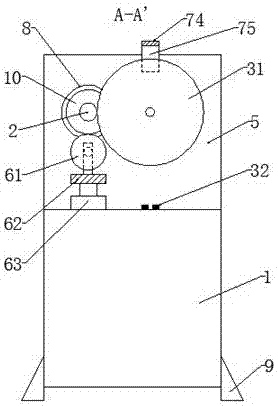

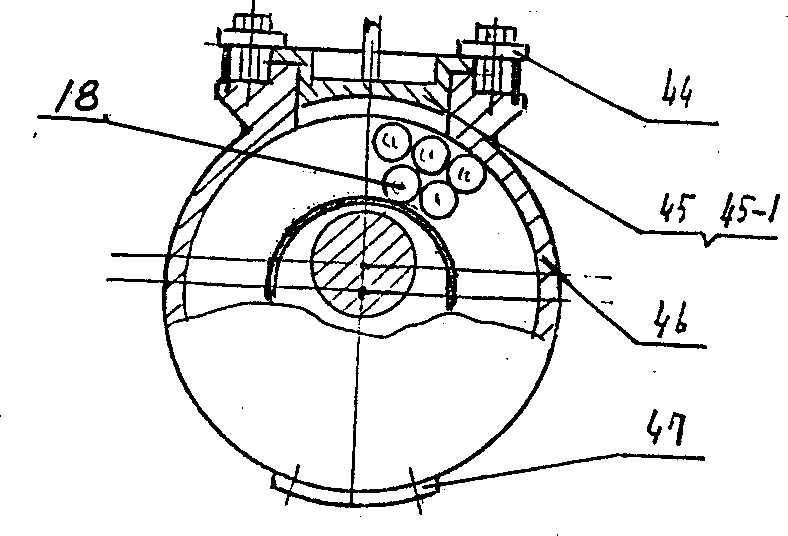

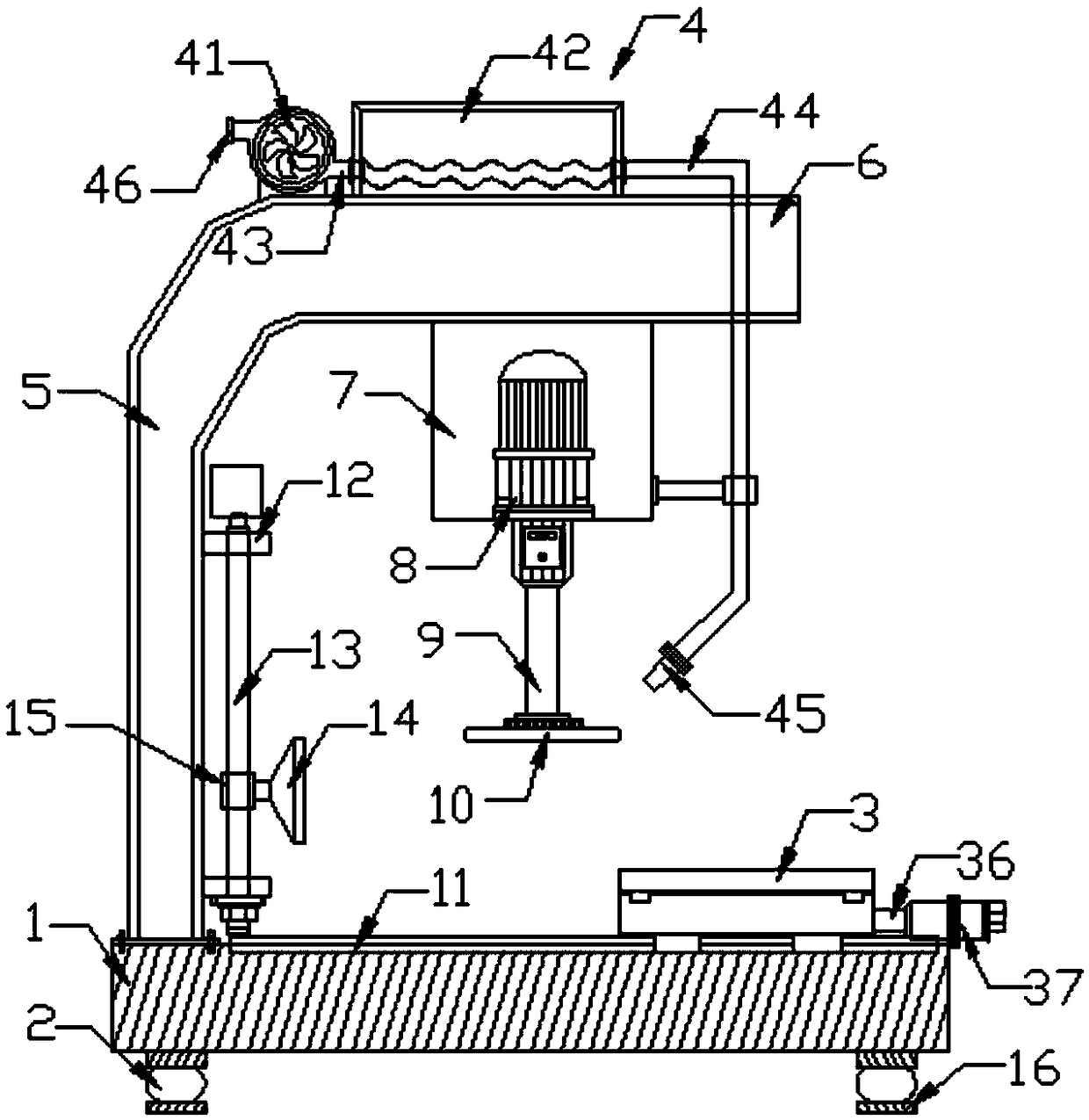

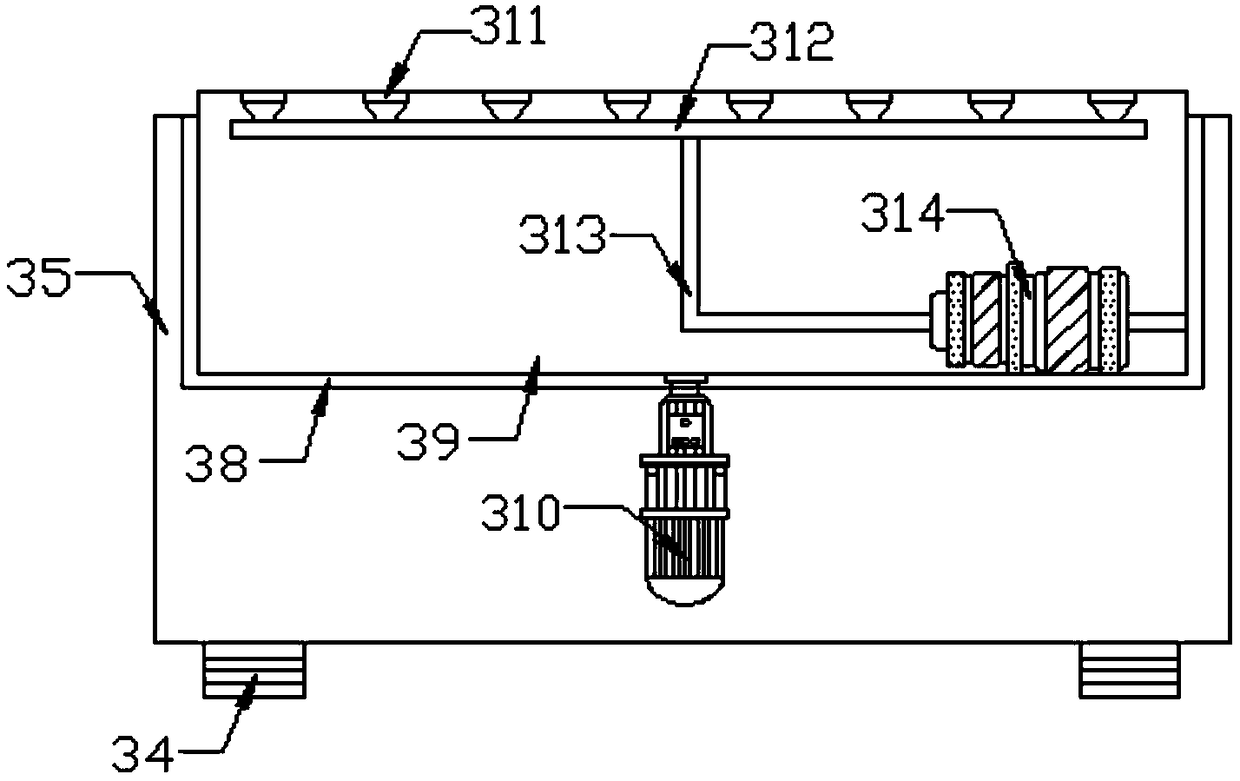

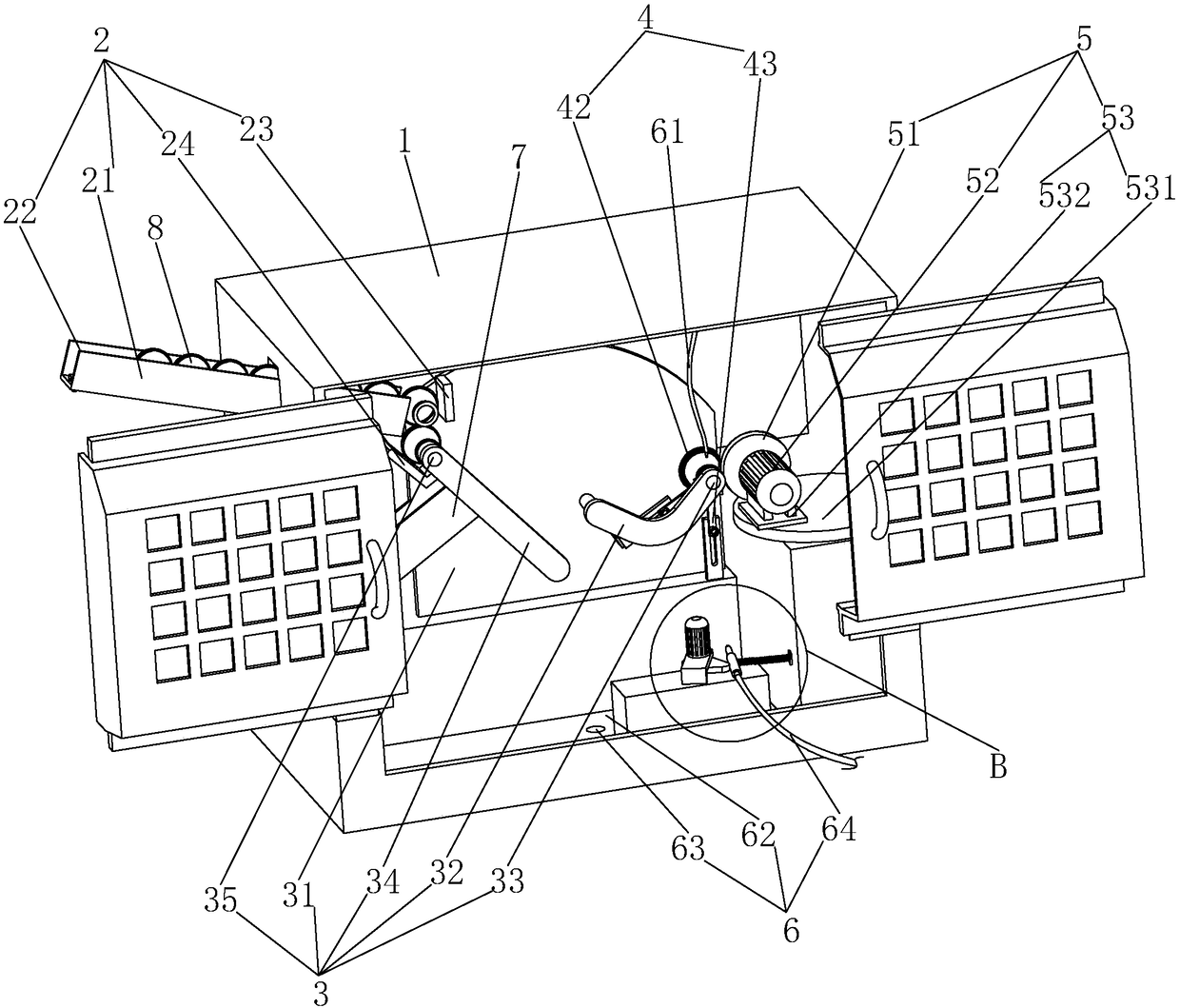

Centerless grinder used for magnetic elements

InactiveCN109048562AImprove cooling effectSimple structureGrinding carriagesGrinding drivesRelative motionEngineering

The invention discloses a centerless grinder used for magnetic elements. The centerless grinder comprises a bearing base, four supporting seats, a movable table, a cooling device, a support, a cross beam, a mounting base, a grinding motor, a rotary bar, a grinding wheel, two guide rails, a mounting plate, an adjusting lead screw, a deduster and a movable component. The four supporting seats are fixedly mounted at the bottom of the bearing base. The two guide rails are arranged at the top of the bearing base. The movable table is mounted at the top of the bearing base. The support is fixedly mounted at one end of the top of the bearing base. The cross beam is fixedly mounted at the top of the support. The cooling device is mounted on the cross beam. The centerless grinder is reasonable andsimple in structure, convenient to use and capable of saving energy and protecting the environment, vacuum adsorption fixation guarantees stable grinding, the magnetic elements rotate and move relative to the grinding wheel so as to improve the grinding efficiency, the magnetic elements are cooled during grinding, atomization humidified air can be used for effectively improving the cooling effectof the grinder, in addition, the water consuming amount for atomization is small, energy is saved, environment friendliness is achieved, and the practicability is higher.

Owner:FOSHAN CHENG XIAN TECH CO LTD +2

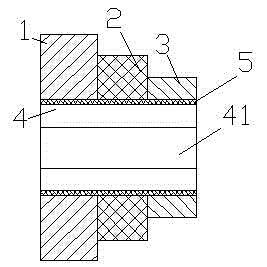

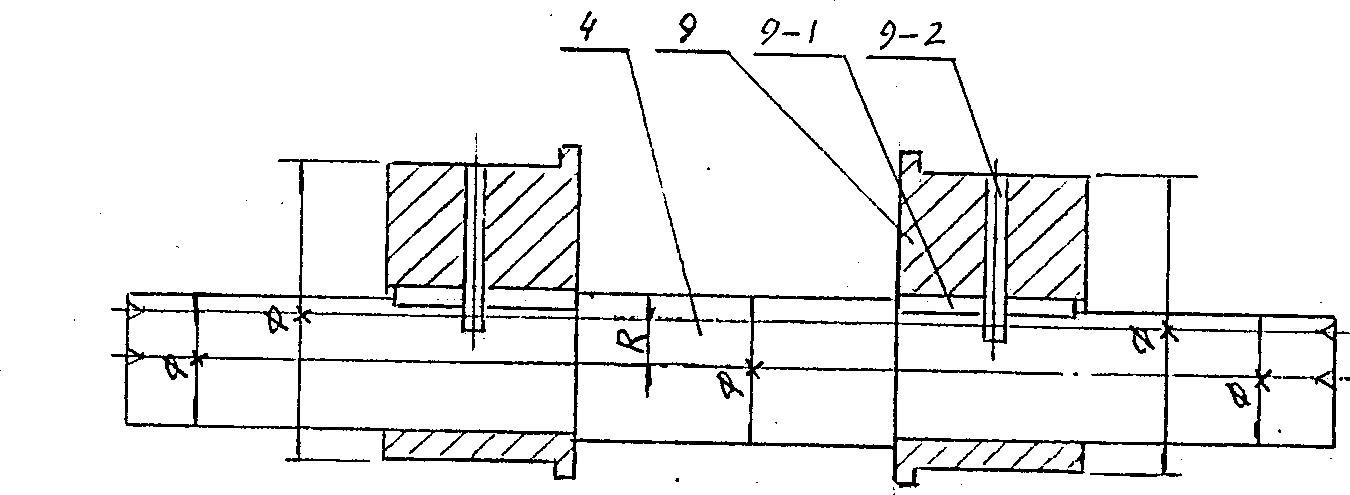

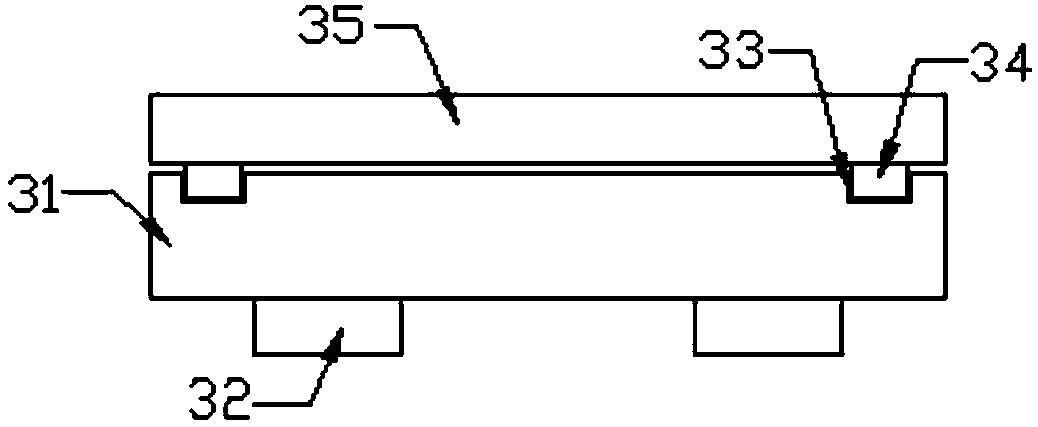

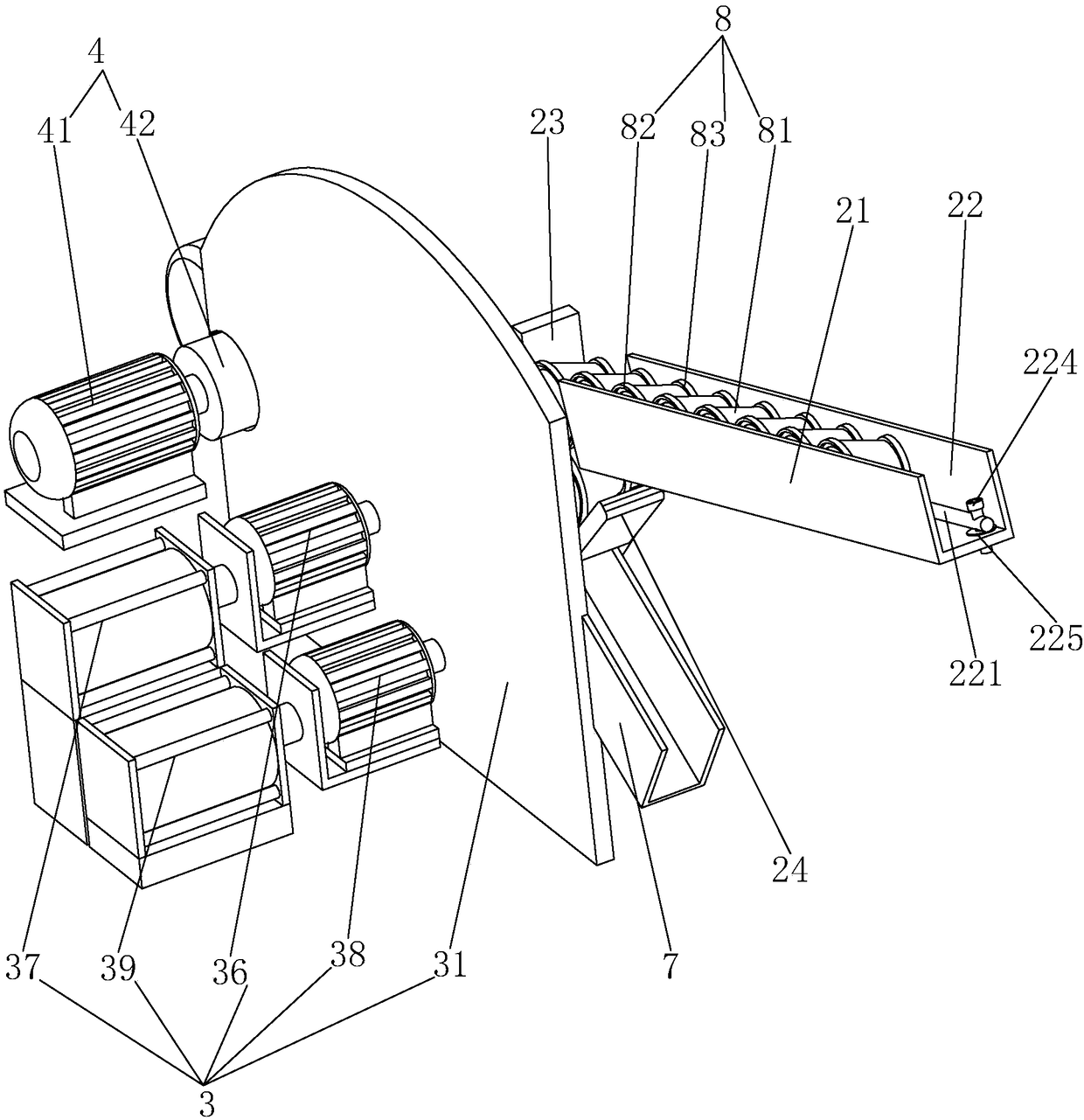

Grinding machine for inner ring of bearing

ActiveCN108326695AReduce adhesionReduce the possibilityGrinding machinesGrinding feedersEngineeringGrinding wheel

The invention relates to the technical field of bearing processing equipment, and discloses a grinding machine for an inner ring of a bearing. The machine comprises a machine body, a feeding mechanism, a charging and discharging mechanism, a workpiece mounting mechanism, a grinding mechanism, and a cleaning mechanism which is arranged on the machine body and used for cleaning waste dust of a grinding wheel, wherein the cleaning mechanism comprises a spraying pipe which is arranged on the machine body and is positioned above the workpiece mounting mechanism, a collecting platform which is arranged at the lower side of the machine body, an unloading port which is formed in the collecting platform, a flushing water pipe which is arranged on the collecting platform, and a driving part which isarranged on the collecting platform and used for driving a nozzle of the flushing water pipe to swing in a reciprocating manner. According to the machine, a workpiece is cooled through the spraying pipe, and meanwhile, the machine body is sprayed by the spraying pipe, so that the possibility that the waste dust of the grinding wheel is attached to the machine body is reduced; the collecting platform is flushed through the flushing water pipe, thus the waste dust, accumulated on the collecting platform, of the grinding wheel is flushed into the unloading port, and finally, the waste dust of the grinding wheel is discharged from one side of the unloading port, and as a result, the fallen waste dust of the grinding wheel can be effectively cleaned.

Owner:GOLDEN HORSE BEARING ZHEJIANG

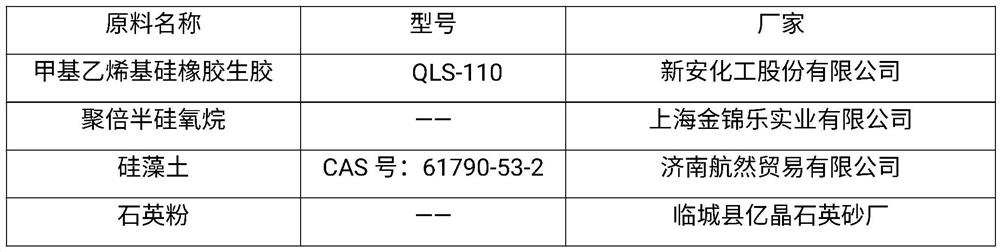

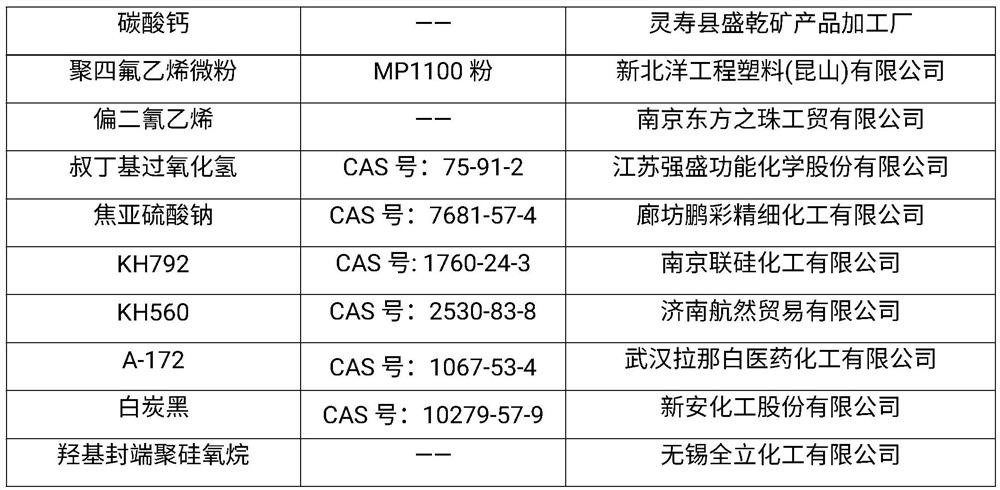

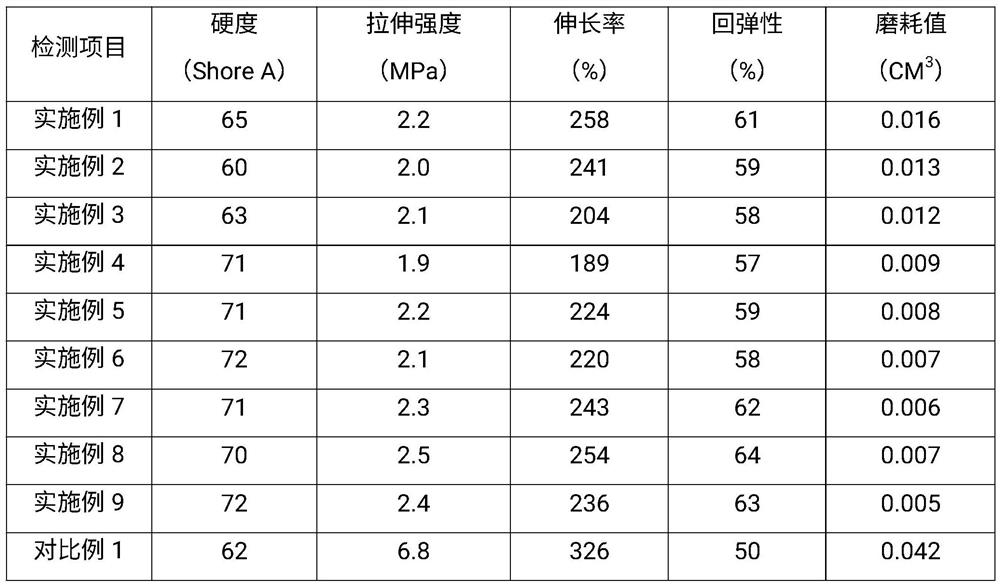

White-carbon-black-free solid silicone rubber for high-hardness rubber roller, and preparation method of white-carbon-black-free solid silicone rubber

The invention discloses white-carbon-black-free solid silicone rubber for a high-hardness rubber roller, and a preparation method of the solid silicone rubber, and relates to the technical field of rubber roller silicone rubbers. The silicone rubber comprises methyl vinyl silicone rubber raw rubber, polysilsesquioxane, diatomite, a silane coupling agent and a non-white-carbon-black auxiliary agent. The preparation method comprises the following steps: mixing methyl vinyl silicone rubber raw rubber, polysilsesquioxane and a silane coupling agent into a ball; then carrying out heating vulcanization treatment; and cooling to below 90 DEG C, and adding diatomite and non-white-carbon-black auxiliary agent to obtain the silicon rubber. The rubber roller silicone rubber produced by the inventionhas the advantages of low abrasion value, standard hardness and rebound resilience, low surface viscosity and good stripping performance between the rubber roller silicone rubber and a plastic film.

Owner:福建固泰有机硅材料有限公司

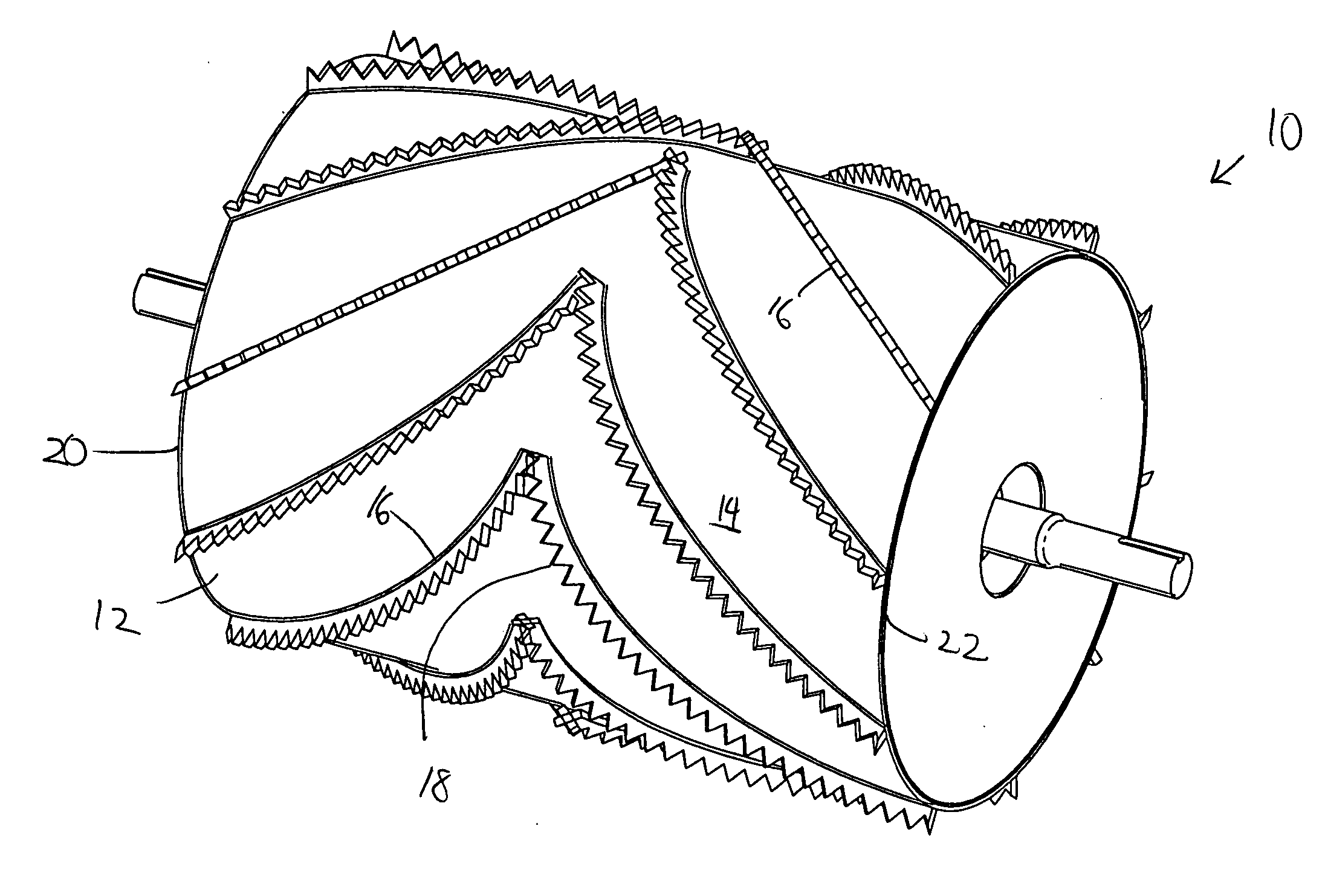

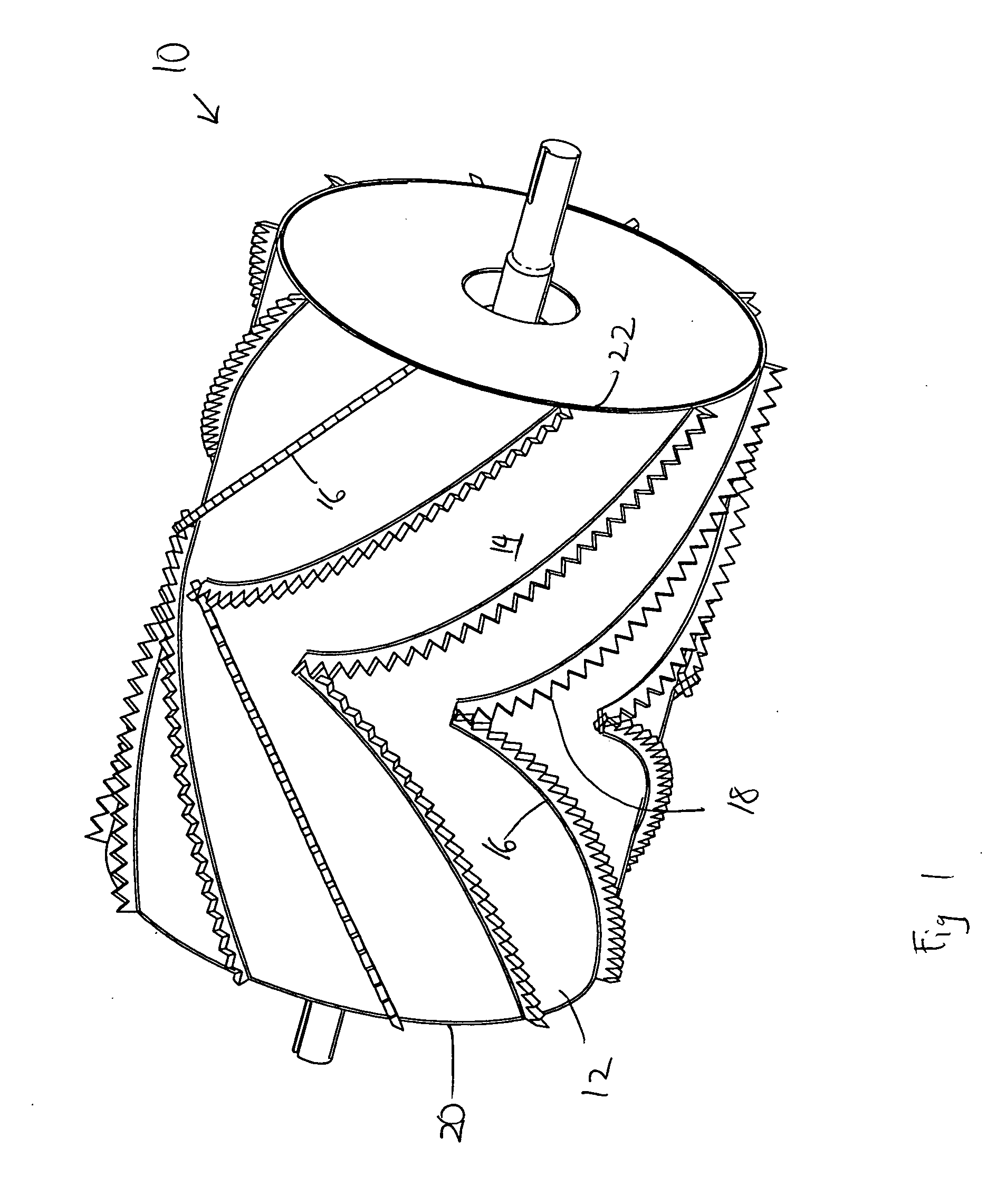

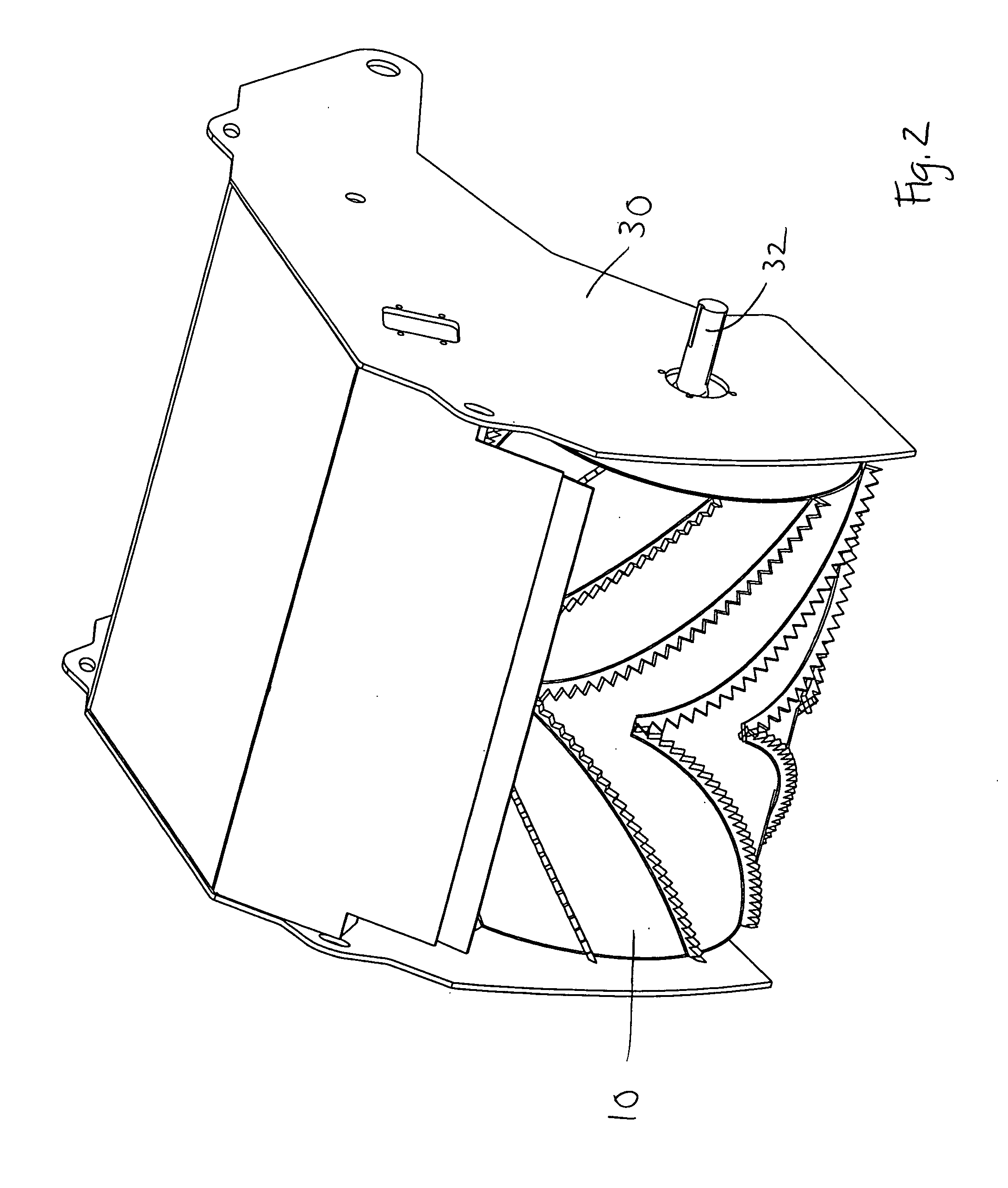

Angled toothed feed drum for hammermill

The present invention includes a feed roller for hammermills that includes teeth arranged in rows at an angle with alternating larger and smaller teeth. This arrangement of rows of teeth and larger / smaller teeth on the feed roller of a hammermill increases the grip of the feed roller on the material and intends to move material from the lateral edges towards the center of the hammermill. This is advantageous for grinding, as some lateral motion upon feeding material into the hammermill is desirable.

Owner:DIAMOND Z MFG

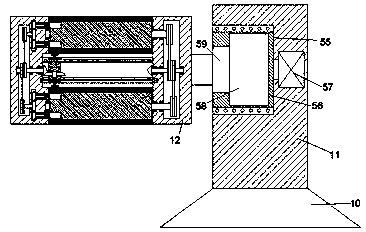

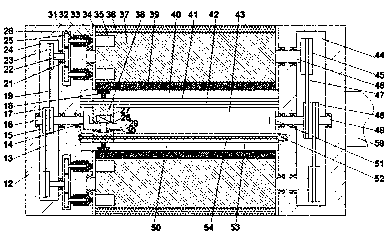

Micro powder manufacturing equipment

InactiveCN106140427ARealize self-circulation crushingSimple processGrain treatmentsEngineeringAnnular array

The invention relates to a micropowder manufacturing equipment, comprising a closed outer cylinder, a grinding inner cylinder is arranged in the closed outer cylinder, a backflow gap is arranged between the outer wall of the grinding inner cylinder and the inner wall of the closed outer cylinder, and a grinding inner cylinder is sleeved with The crushing cylinder with an open bottom, a crushing gap is set between the outer wall of the crushing cylinder and the inner wall of the grinding inner cylinder; the main drive shaft is arranged on the top of the closed outer cylinder, and the main driving shaft passes through the top of the grinding inner cylinder and the grinding cylinder. The top is fixedly connected, and a number of support rings with a T-shaped cross section are arranged in an annular array on the wall of the crushing cylinder. The T-shaped bottom of the support ring is fixedly connected with the outer wall of the crushing cylinder, and a grinding ring is attached to the T-shaped top of the support ring. ; An annular friction ring is provided on the inner wall of the grinding inner cylinder; a number of discharge holes are arranged in an array at the position between the adjacent support rings on the wall surface of the grinding cylinder, and a blowing turbofan is also rotatably connected to the bottom of the closed outer cylinder. The blast turbofan extends into the inside of the crushing cylinder.

Owner:扬州锦盛微粉有限公司

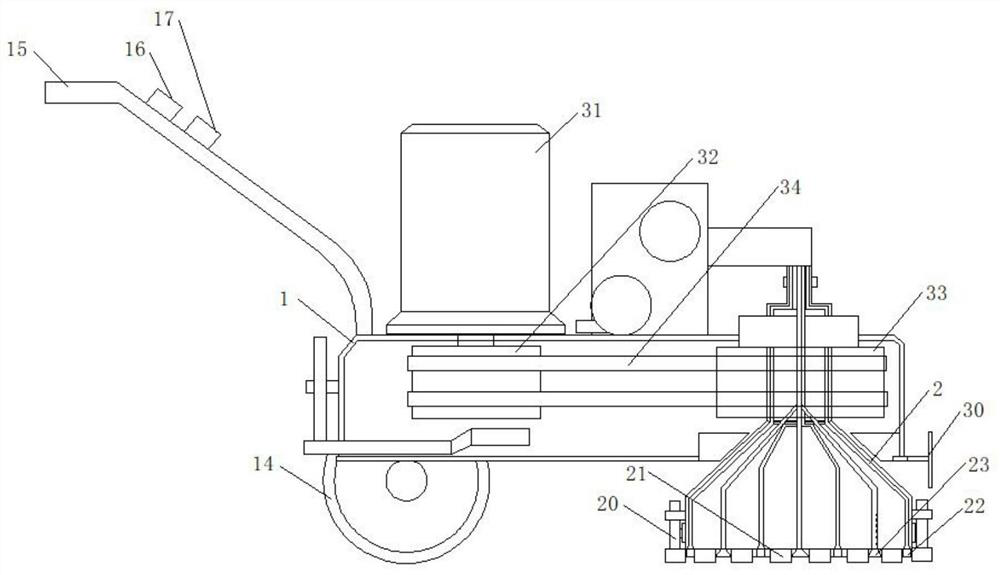

Grinding disc for grinding ground below wall corners and stone grinding machine adopting same

ActiveCN111673556ANot hitImprove grindingBonded abrasive wheelsPlane surface grinding machinesEngineeringMaterials science

The invention discloses a grinding disc for grinding the ground below wall corners and a stone grinding machine, and belongs to the field of machinery. The grinding disc comprises a grinding disc bodyin an inverted cone shape and grinding blocks uniformly distributed on the lower surface of the grinding disc body; and more than three reinforced grinding block components for grinding the ground with the range of the outer circumference of the grinding disc body are uniformly installed on the grinding disc body in the circumferential direction. The grinding disc and the stone grinding machine have the beneficial effect that by installing the reinforced grinding block components outside the grinding disc body to specially grind the ground below the wall corners, the application range of grinding the ground by the grinding disc is effectively extended.

Owner:泉州市宏铭机械开发有限公司

wall grinder

ActiveCN103991015BQuick switchAdjustable suctionGrinding headsPlane surface grinding machinesDISC assembly

The invention relates to the technical field of electric tools, in particular to a wall polisher. The wall polisher comprises an operating handle, a motor and a polishing head. The polishing head comprises a top cover, a base and abrasive disc assemblies. A transmission mechanism for transmitting the torque of the motor to the abrasive disc assemblies is arranged between the top cover and the base. An output shaft of the transmission mechanism is an eccentric shaft or a concentric shaft. An abrasive disc of each abrasive disc assembly is installed at the lower end of the eccentric shaft or the concentric shaft. The base is internally provided with a rotating disk, one side of the rotating disk is provided with a shifting handle, the rotating disk is provided with one or more limiting holes, the top cover is fixedly provided with a positioning rod stretching into the limiting holes, and the limiting holes can clamp or loosen the positioning rod through the rotation of the rotating disk. According to the wall polisher, the two different abrasive disk assemblies are usually prepared, the output shaft of the transmission mechanism of one abrasive disk is the eccentric shaft, the other output shaft of the transmission mechanism of the other abrasive disk is the concentric shaft, different abrasive disk assemblies can be rapidly switched, and therefore the wall corner can be polished very conveniently.

Owner:傅月华 +1

A bearing inner ring grinding machine

ActiveCN108326695BReduce adhesionReduce the possibilityGrinding machinesGrinding feedersEngineeringGrinding wheel

The invention relates to the technical field of bearing processing equipment, and discloses a grinding machine for an inner ring of a bearing. The machine comprises a machine body, a feeding mechanism, a charging and discharging mechanism, a workpiece mounting mechanism, a grinding mechanism, and a cleaning mechanism which is arranged on the machine body and used for cleaning waste dust of a grinding wheel, wherein the cleaning mechanism comprises a spraying pipe which is arranged on the machine body and is positioned above the workpiece mounting mechanism, a collecting platform which is arranged at the lower side of the machine body, an unloading port which is formed in the collecting platform, a flushing water pipe which is arranged on the collecting platform, and a driving part which isarranged on the collecting platform and used for driving a nozzle of the flushing water pipe to swing in a reciprocating manner. According to the machine, a workpiece is cooled through the spraying pipe, and meanwhile, the machine body is sprayed by the spraying pipe, so that the possibility that the waste dust of the grinding wheel is attached to the machine body is reduced; the collecting platform is flushed through the flushing water pipe, thus the waste dust, accumulated on the collecting platform, of the grinding wheel is flushed into the unloading port, and finally, the waste dust of the grinding wheel is discharged from one side of the unloading port, and as a result, the fallen waste dust of the grinding wheel can be effectively cleaned.

Owner:GOLDEN HORSE BEARING ZHEJIANG

Robot control system

InactiveCN109048520AAvoid affecting the grinding effectReduce labor intensityGrinding carriagesRevolution surface grinding machinesControl systemRobot control system

The invention discloses a robot control system which comprises a machine base, a supporting column fixedly arranged above the machine base and a pipe sleeve arranged on the end face of the left side of the supporting column. The pipe sleeve is internally provided with up-down symmetrical first rotating grooves with outward slots, a rotating frame is rotationally arranged in the first rotating groove through a first rotating pin shaft, a polishing strip is fixedly arranged on the end face of the outer side of the rotating frame, a cleaning sponge is fixedly arranged on the end face of the innerside of the rotating frame, the end face of the left side of the rotating frame is provided with up-down symmetrical lock holes with leftward slots, the inner walls of the left sides of the first rotating grooves are provided with up-down symmetrical first sliding connection grooves opposite to the lock holes, lock blocks are installed in the first sliding connection grooves in a sliding mode, and a first screw hole with a leftward slot is formed in each lock block.

Owner:广州正昇软件技术开发有限公司

High-end grinding technology equipment

InactiveCN109015178AEnable mobilityEasy to operateEdge grinding machinesRevolution surface grinding machinesEngineeringMechanical engineering

The invention discloses high-end grinding technology equipment. The high-end grinding technology equipment comprises a base, a bearing column fixedly arranged above the base and rotating sleeves arranged on the left end face of the bearing column. The rotating sleeves are provided with first rotating cavities with ports facing outwards are vertically symmetrically arranged. Rotating plates are rotatably arranged in the first rotating cavities by first rotating shafts. Grinding strips are fixedly arranged on the outer end faces of the rotating plates. Cleaning cotton is fixedly arranged on theinner end faces of the rotating plates. Locking holes with ports facing leftwards are vertically symmetrically formed in the left end faces of the rotating plates. First sliding grooves opposite to the locking holes are vertically symmetrically formed in the left inner walls of the first rotating cavities. Locking blocks are slidably mounted in the first sliding grooves. First screw holes with ports facing leftwards are formed in the locking blocks.

Owner:广州一德智能科技有限公司

Grinding device with protection function

InactiveCN112059746ARealize againstImprove securityPlaning/slotting toolsTurning toolsElectric machineryMetal sheet

The invention relates to a grinding device with a protection function. The grinding device comprises a base, a motor, a cam, a protection cover, a grinding wheel, a connecting column, a protection mechanism and a grinding mechanism, wherein the grinding mechanism comprises a fixing block and a grinding assembly, and the protection mechanism comprises a piston cylinder, a piston rod, spring strips,a pull rope, an abutting plate and a protection assembly. According to the grinding device with the protection function, the motor is protected through the protection mechanism, the pull rope is broken through the restoring force of springs, a control switch abuts against a metal sheet through the dead weight of the metal sheet, the motor is controlled to be turned off through a PLC to reduce loss, a cutter is ground through the grinding mechanism, and through an extended tool shank, heat generated by friction of the grinding wheel and the cutter is reduced, so that an operator can grind thecutter for longer; and meanwhile, the cutter is fixed through a bolt, so that when the operator loosens suddenly due to the fact that a connecting block is too hot, the cutter and the grinding wheel cannot be stuck, and the use practicability is improved.

Owner:深圳市俊达通办公智能科技有限公司

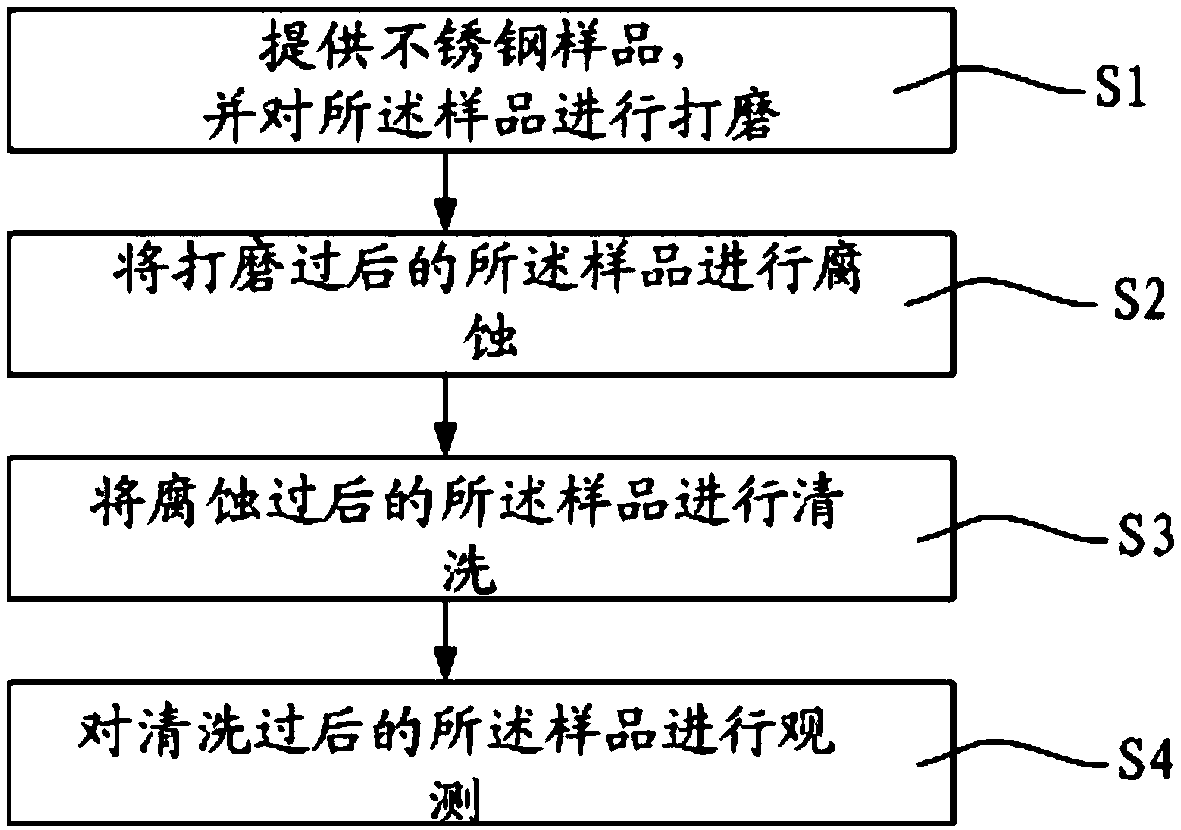

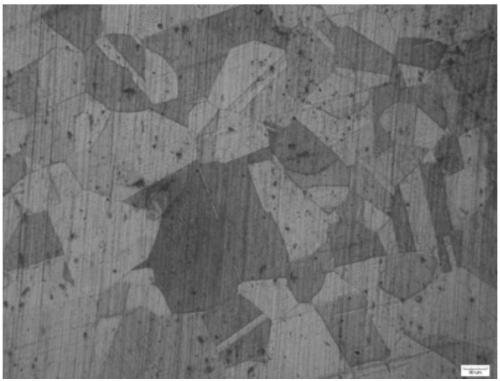

Target material corrosive agent and application method thereof

InactiveCN111074279AStrong corrosion performanceHighly corrosivePreparing sample for investigationFluorhydric AcidGrain boundary energy

Disclosed are a target material corrosive agent and an application method thereof. The target material corrosive agent comprises sulfuric acid, nitric acid, hydrofluoric acid and hydrochloric acid, wherein the mass percentage of the sulfuric acid is 20-23%, the mass percentage of the nitric acid is 15-18%, the mass percentage of the hydrofluoric acid is 21-24%, and the mass percentage of the hydrochloric acid is 33-40%. A stainless steel sample is also provided, and the target material corrosive agent is used for corroding the sample, and the corroded sample is cleaned and dried in a blowing mode. Metallographic observation is carried out on the stainless steel sample by using the target material corrosive agent, the target material corrosive agent is used for corroding the stainless steelsample, the grain boundary of the sample can be completely displayed, and the grain size error caused by incomplete displaying of the grain boundary of the sample is avoided. The completely corrodedsample is cleaned and dried in a blowing mode, impurities on the surface of the sample are reduced, and the observation of the grain boundary of the interior of the sample is more accurate.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

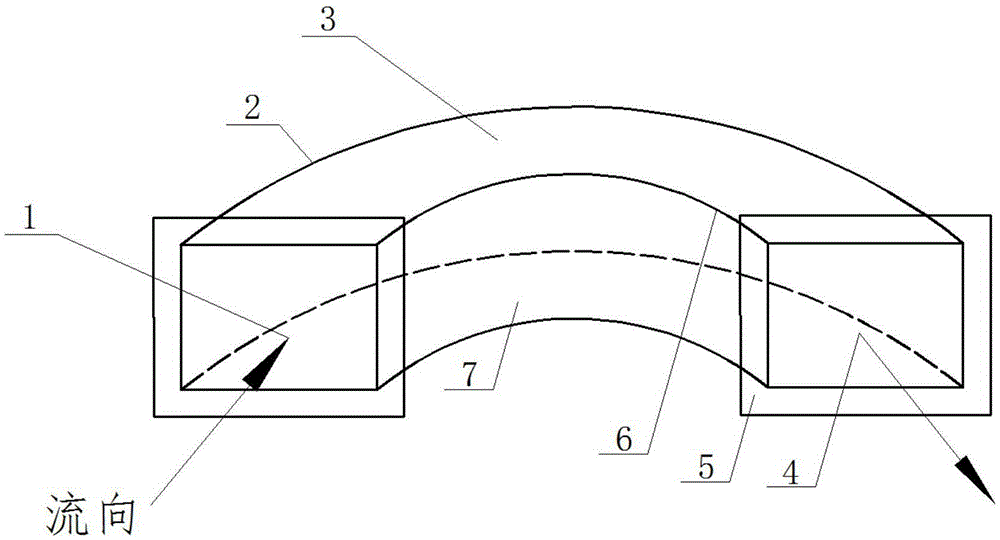

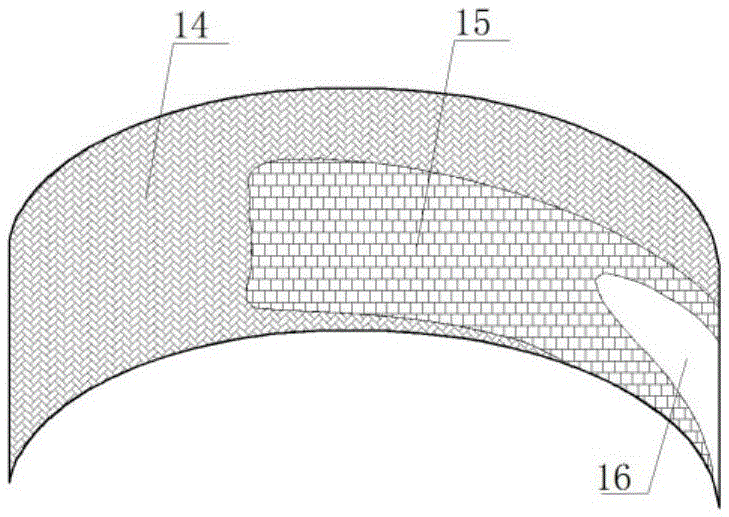

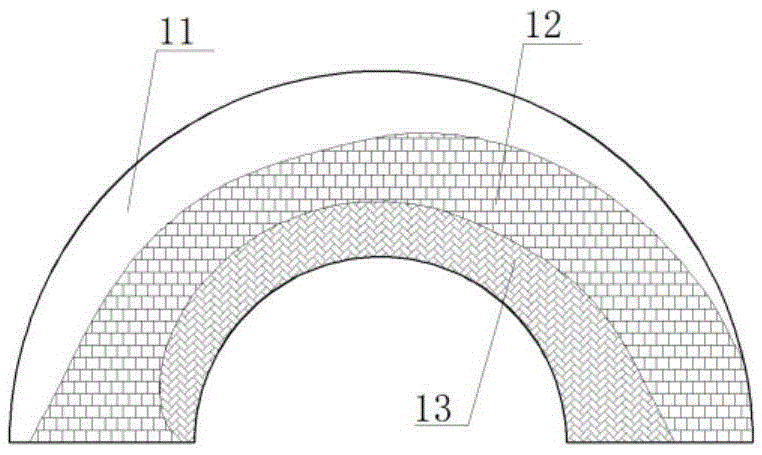

Wear-resistant processing method of U-shaped pipeline elbow

ActiveCN105653780AAccurately locate the distribution of friction forceImprove grindingGeometric CADSpecial data processing applicationsWear resistantEngineering

The invention discloses a wear-resistant processing method of a U-shaped pipeline elbow. The method comprises the following steps: determining a steady-state turbulent velocity field and a velocity gradient of the U-shape pipeline elbow; solving to obtain a volume concentration of second-phase dust particles; calculating to obtain a friction force range of board surface of the U-shaped pipeline elbow; obtaining a high-medium friction force area enveloping curve and a medium-low friction force area enveloping curve of the board surface; obtaining fitted curve equations corresponding to the high-medium friction force area enveloping curve and the medium-low friction force area enveloping curve so as to a high friction force area, a medium friction force area and a low friction force area of the board surface; and adopting a high-polymer aluminum oxide ceramic plate in the high friction force area of the board surface and adopting a high-chromium wear-resistant alloy in the medium friction force area. According to the method disclosed in the invention, the grinding caused by the materials to the pipeline in the pneumatic transmission process can be effectively resisted, so that the wear resistance strengthening is carried out on different parts of the pipeline according to the grinding degree, the expensive materials are saved and the construction cost of the elbow is reduced.

Owner:陕西华净环保科技有限责任公司

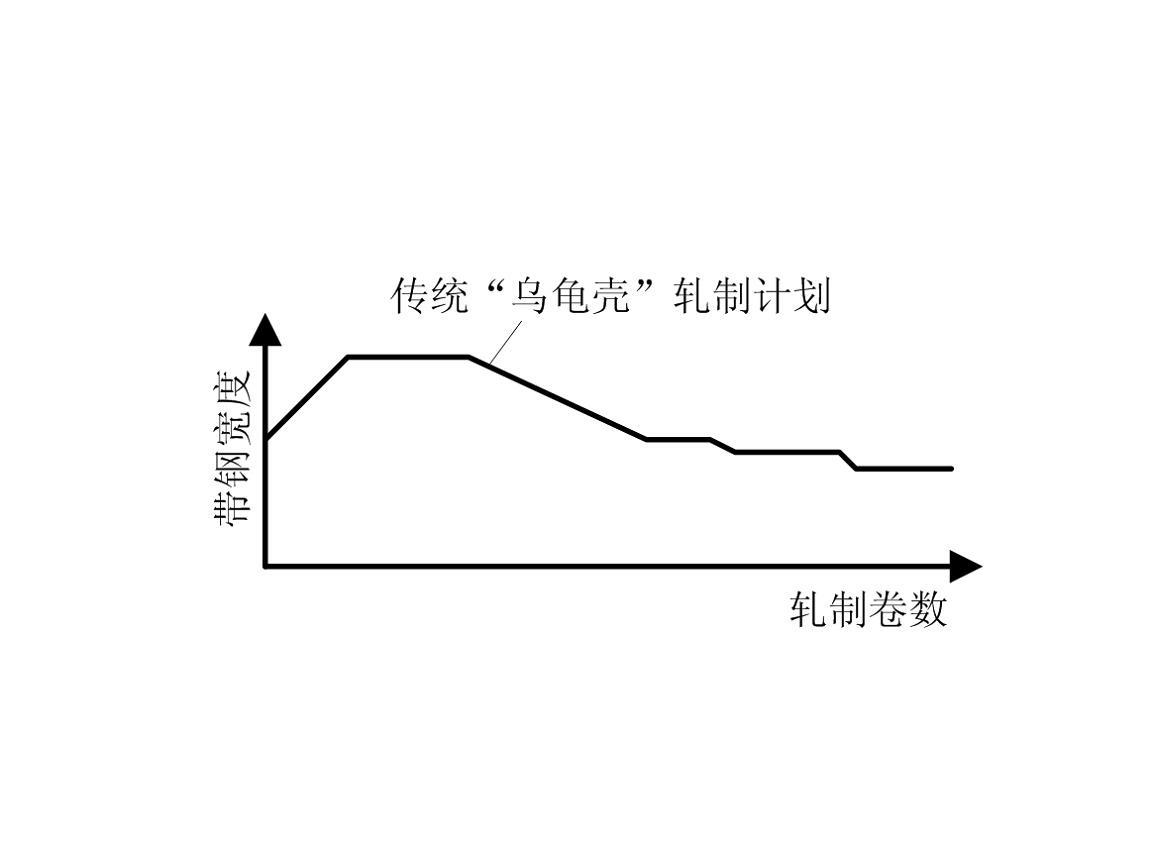

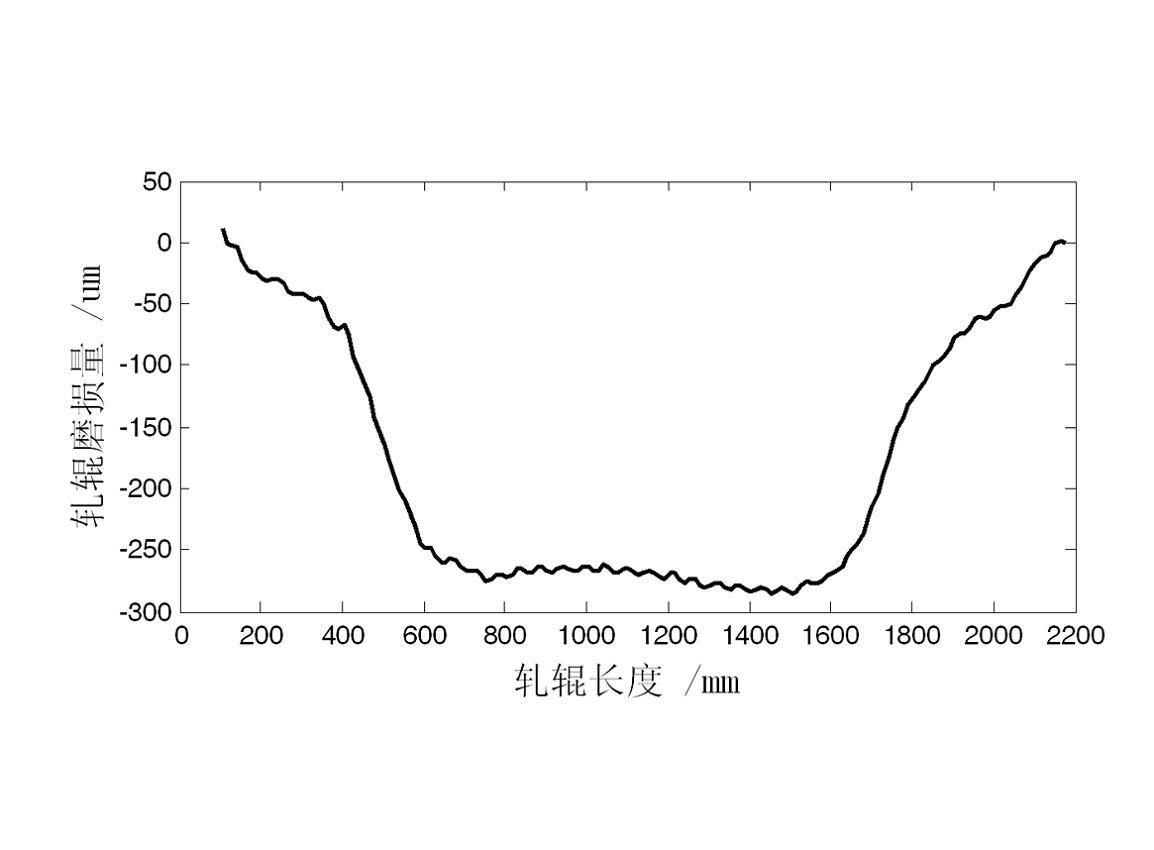

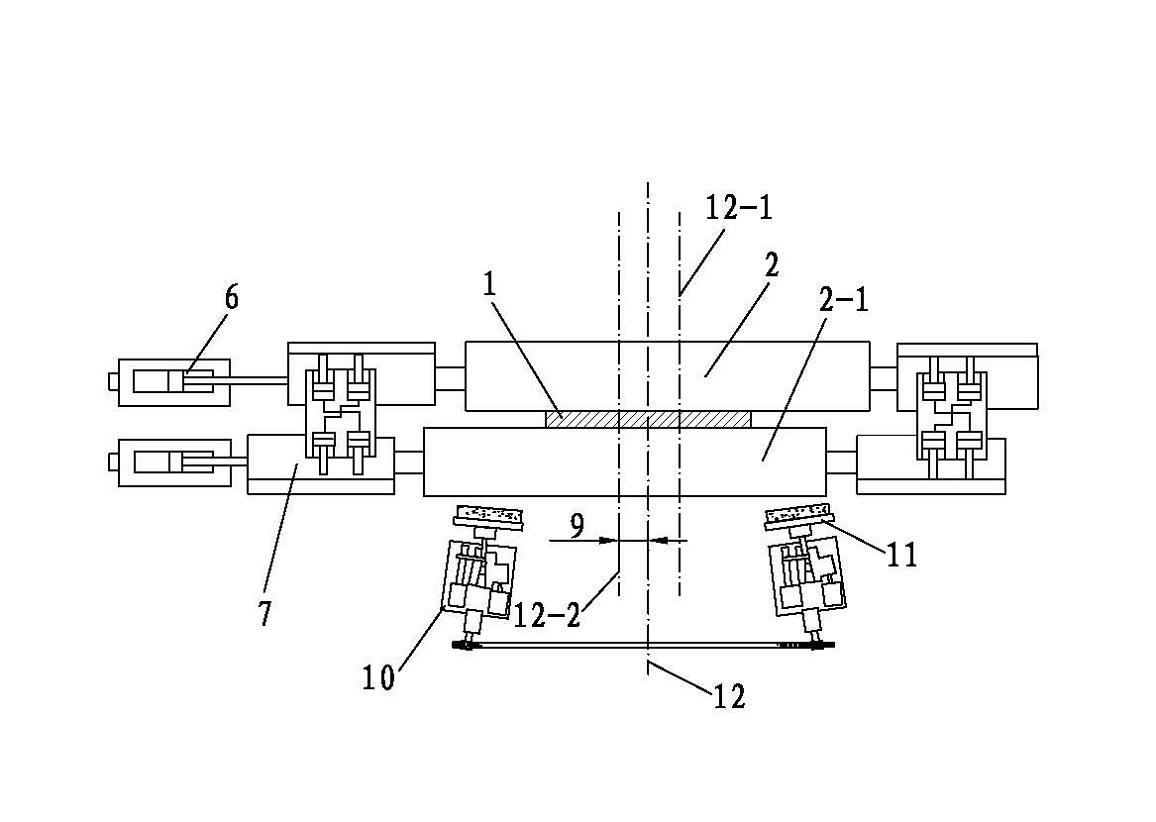

Online roller grinding method capable of realizing reverse width rolling

InactiveCN102615560AAvoid ineffective grindingImprove grindingRevolution surface grinding machinesGrinding feed controlEngineeringMachine

The invention discloses an online roller grinding method capable of realizing reverse width rolling. According to the maximum plate width of band steel and the roller altering amount of working rollers in an actual rolling plane, an effective working area range of a roller is determined, an online roller grinding machine is controlled to grind an effective working area in the center of the roller within limited rolling time, and an invalid area which is not contacted with the band steel is not ground, so that a through plate area of the roller is ground to the maximum extent; and therefore, a flat roller in the through plate area of the roller is generated, and the reverse width rolling is realized finally.

Owner:XIAMEN UNIV OF TECH

A jewelry inner hole grinding device using centrifugal principle

InactiveCN110666704BSolve wear and tearNot to be wornBlast gunsAbrasive machine appurtenancesEngineeringField coil

The invention relates to the technical field of jewelry processing equipment, and discloses a device for polishing inner holes of jewelry by utilizing a centrifugation principle. The device for polishing the inner holes of the jewelry by utilizing the centrifugation principle comprises a box body, wherein rotary pipes are connected in a polishing device, an inclined hole is formed in the outer side of the lower end of each rotary pipe in a surrounding mode, a drive device is connected with the outer side of each rotary pipe, a coil is arranged in each drive device, a fixing disk is connected with the outer side of the upper end of each rotary pipe, and a permanent magnet is connected with the outer side of each fixing disk in a surrounding mode. According to the device for polishing the inner holes of the jewelry by utilizing the centrifugation principle, a magnetic field opposite to the permanent magnet is generated by the coil, the magnetic field generated by the coil pushes the permanent magnet to rotate, the permanent magnet drives the rotary pipes to rotate through the fixing disk, the inclined holes in the lower ends of the rotary pipes spray water or water-sand mixed liquidfor polishing the inner holes of the jewelry, and the structure achieves the effect of evenly polishing the inner holes of the jewelry, and avoids the problems that due to vibration of a motor and a polishing rod of an existing polishing device, the diameter of the inner holes of the jewelry is different from the top down, and abrasion is easily caused to the jewelry.

Owner:浦江狸步机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com