Simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore

A technology of magnetite ore and iron carbonate, applied in the field of single magnetic separation process of Anshan-type iron carbonate-containing lean magnetite ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be described in detail below in conjunction with the examples.

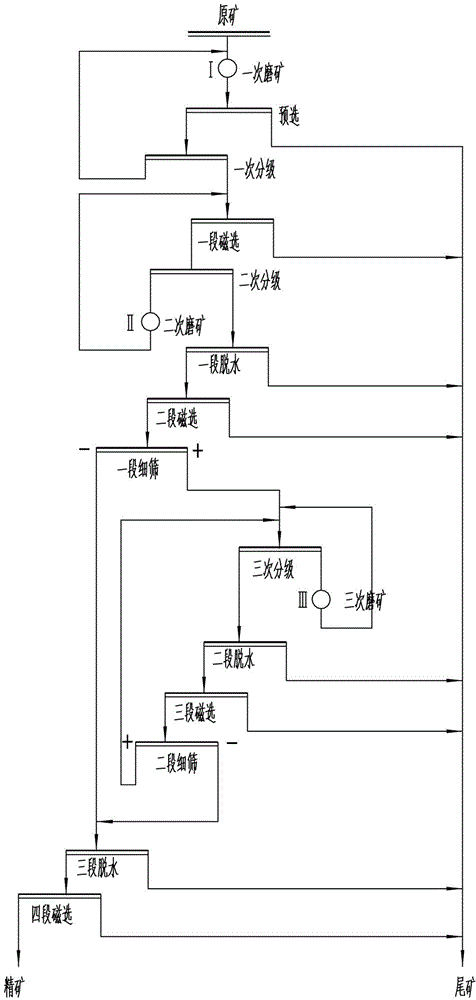

[0032] Such as figure 1 Shown, according to a kind of Anshan formula of the present invention contains iron carbonate poor magnetite ore single magnetic separation process, comprises grinding-grading-magnetic separation, comprises the following steps:

[0033]1) Feed iron carbonate-poor magnetite ore with particle size -12mm accounting for more than 93%, total iron grade of 17-28%, and iron grade of more than 7% in iron carbonate into the long barrel overflow ball mill I for a grinding operation. The discharged ore products are fed into the magnetic field pre-selector with large wrap angle, and the pre-selected concentrate is fed into the dynamic pressure feed cyclone for a classification operation, and the sand settling of the dynamic pressure feed cyclone returns to the primary mill. The primary dynamic pressure feeds the ore cyclone with a part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com