Patents

Literature

188results about How to "Guaranteed Granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic-gravity separation technology for Anshan type lean magnetite

ActiveCN103272694AImprove mineral processing technical indicatorsGuaranteed GranularityMagnetic separationMagnetiteEngineering

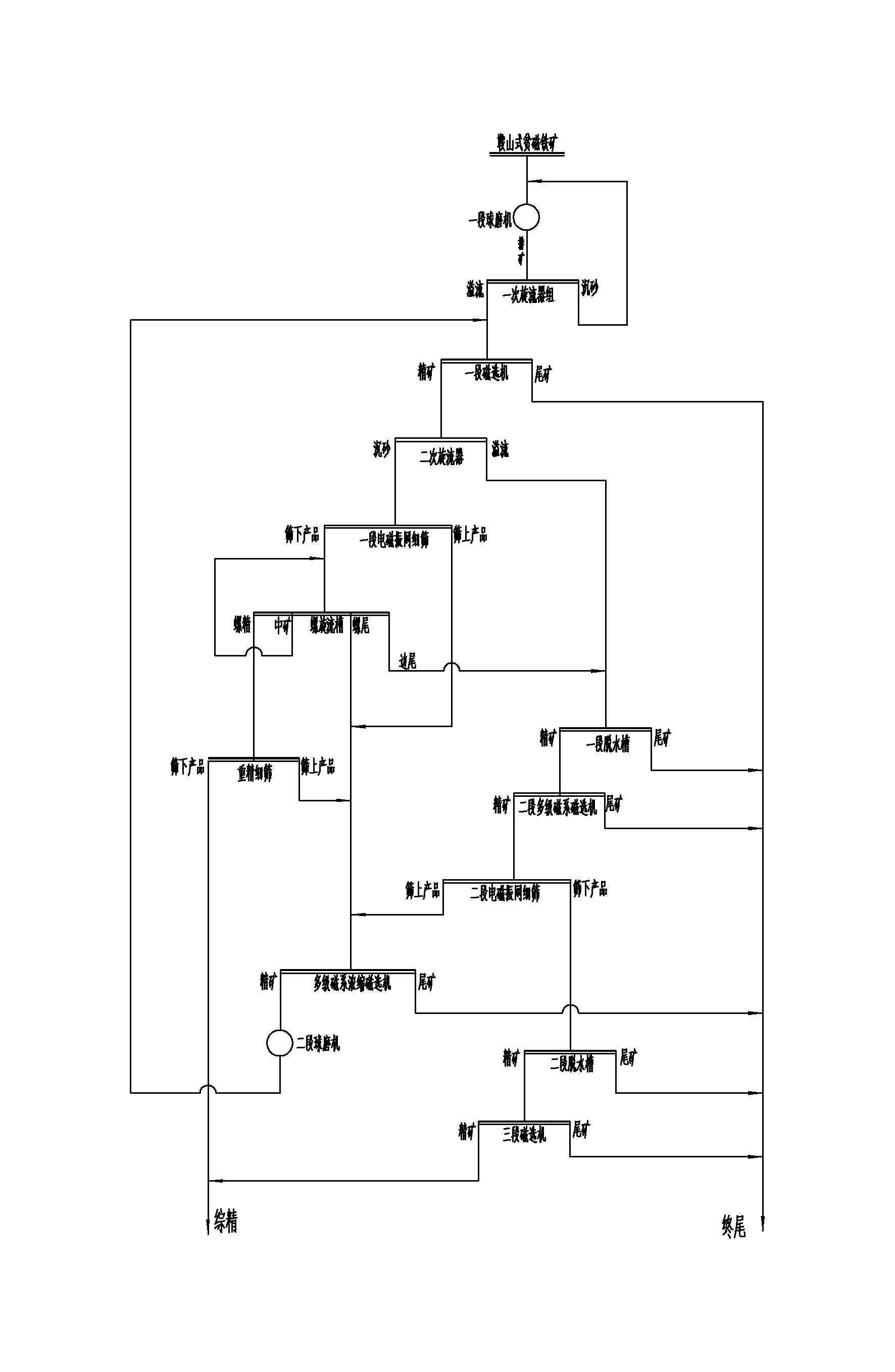

The invention relates to a magnetic-gravity separation technology for Anshan type lean magnetite, which comprises the following steps: after adoption of a first-stage ball mill for ore grinding, a primary cyclone, a first-stage magnetic separator and a secondary cyclone for classification, settled sand is subjected to first-stage sieve screening, an screened product is fed into a spiral chute, concentrate in the spiral chute is fed into a gravity fine sieve, and a screened product by the gravity fine sieve is qualified concentrate; after overflow of the secondary cyclone and the edge tail of the spiral chute are merged, the concentrate is fed into a second-stage sieve after separation by a first-stage dehydration tank and a second-stage magnetic separator; products on the first-stage sieve, the second-stage sieve and the gravity fine sieve as well as mineral tailings in the spiral chute are merged and fed into a concentration magnetic separator, the mixture is fed into a second-stage ball mill for ore grinding after concentration, then the products return to the first-stage magnetic separator, and after separation by a second-stage dehydration tank and a third-stage magnetic separator, the screened product of the second-stage sieve is merged with the screened product of the gravity fine sieve into the final concentrate. The magnetic-gravity separation technology has the advantages that mineral processing technical indexes for the Anshan type lean magnetite are improved, the mineral processing efficiency is improved, and the production cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Mobile phone curved glass panel and forming method thereof

ActiveCN104023099AFit tightlyComfortable fitGlass reforming apparatusTelephone set constructionsEngineeringGraphite

The invention discloses a mobile phone curved glass panel and a manufacturing method of the mobile phone curved glass panel. A curved glass panel body is formed by bending a mobile phone panel body toward the same side in an arc shape with the center line of the mobile phone panel body in the X-axis direction or the Y-axis direction as a center, or bending the periphery of the mobile phone panel body toward the same side in an arc shape with the center point of the mobile phone panel as the center, or the mobile phone curved glass panel comprises a main panel and curved panels. The curved panels are formed by bending one or more side edges of the main panel. The multiple curved panels are bent toward the same side relative to the main panel. The forming method includes the three steps of manufacturing a planar glass panel, manufacturing a graphite die and forming the curved glass panel. The good lubricating performance of graphite is used, through exerting certain pressure for deformation, heat deformation is achieved at the temperature below a glass softening point, the manufactured product is high in precision, the designing requirements of a 3D mobile phone glass panel are met, large-scale industrial production can be achieved, production cost can be reduced, and the requirement for personalized and fashionable mobile phones can be met for people.

Owner:LENS TECH

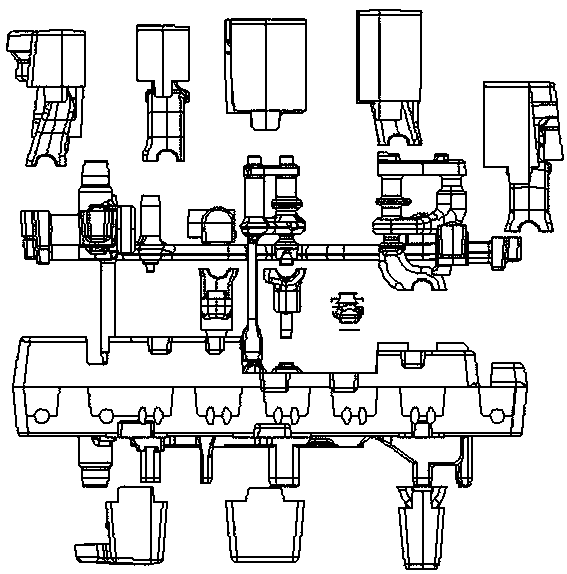

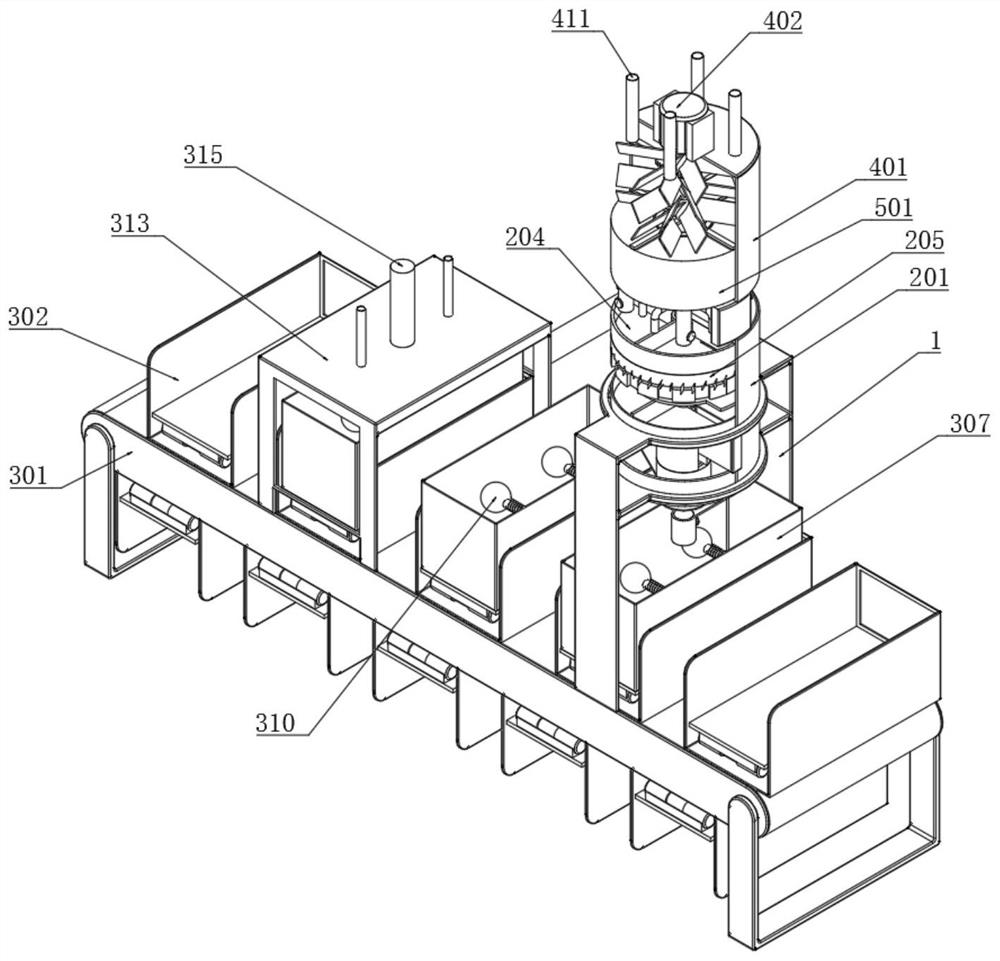

Continuous steeping method for grain carrier and equipment thereof

ActiveCN102019208AImprove impregnation efficiencyGuaranteed uptimeOther chemical processesCatalyst activation/preparationActive componentSorbent

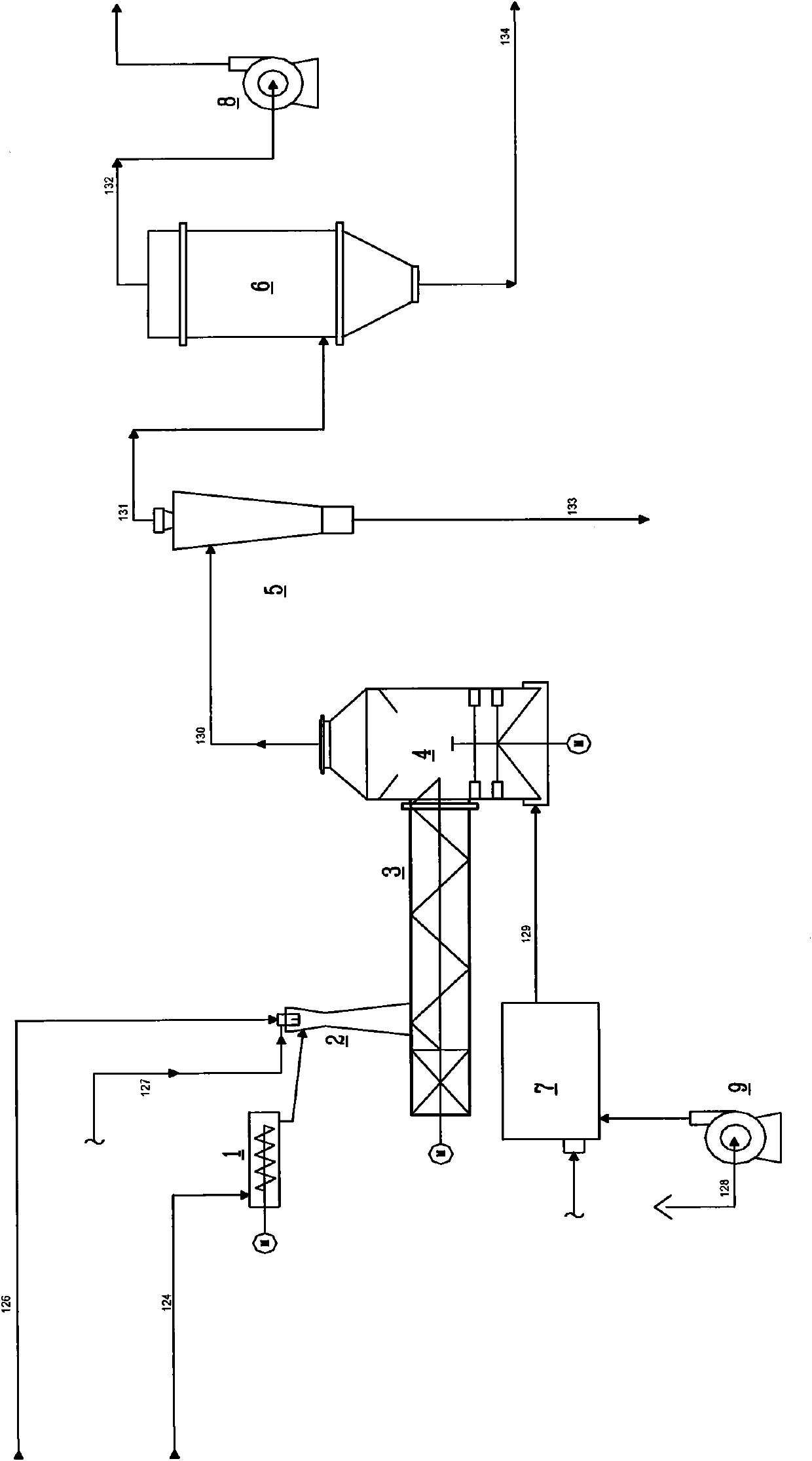

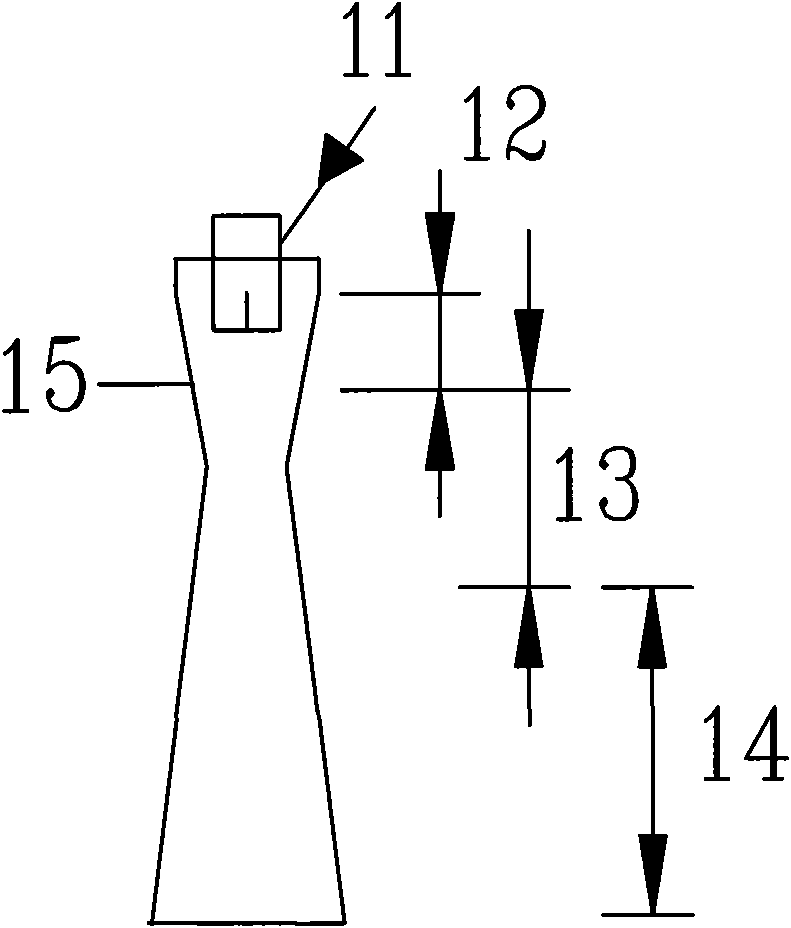

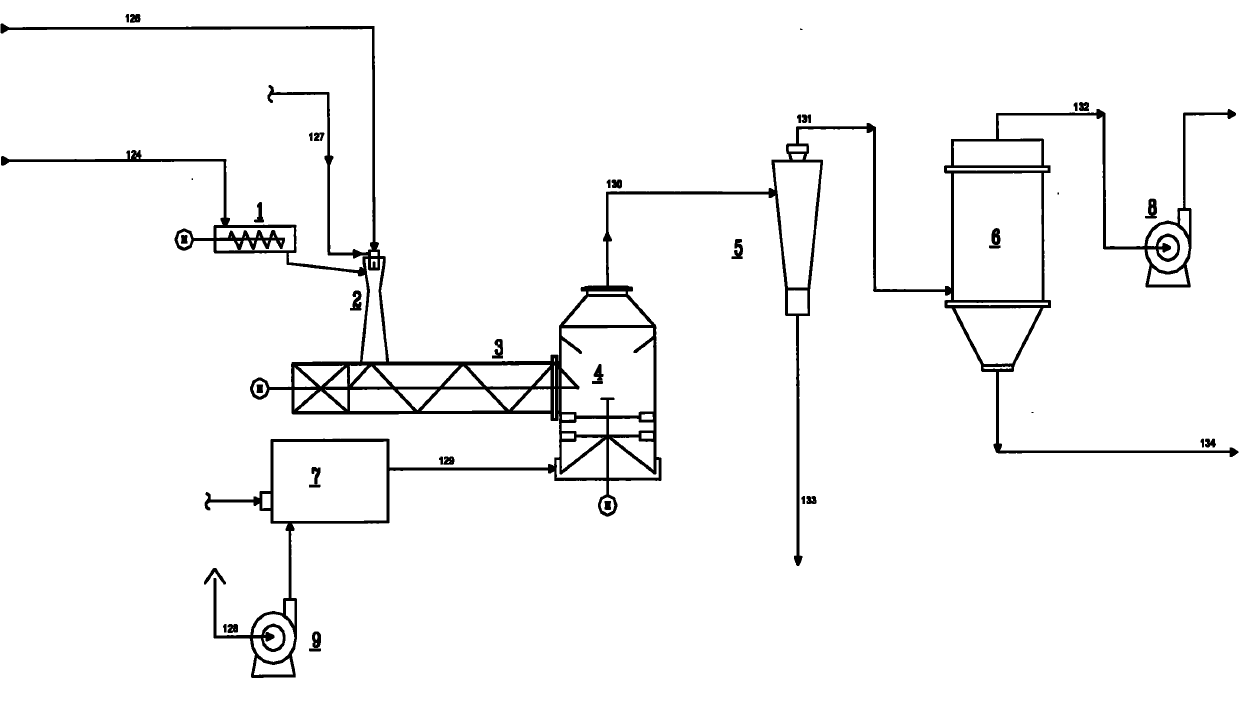

The invention relates to a continuous steeping method for a grain carrier and equipment thereof. The continuous steeping method comprises the following steps that steeping liquor is atomized into drops through a nozzle and is jetted into an atomizer; carrier grains are led into the atomizer; the steeping liquor drops and the carrier grains are mixed in the atomizer to form a mixture; the mixture enters into a steeping mixer to carry out sufficient contact; the average grain diameters of the carrier grains are 40-90 microns; the average grain diameters of the steeping liquor drops are 0.5-1.0 time the average grain diameters of the carrier grains; and the ratio of the volume flow of the steeping liquor to the mass flow of the carrier is 0.30-0.60L / kg. The continuous steeping equipment comprises the atomizer and the steeping mixer which is connected with the outlet of the atomizer. The method can implement the continuous steeping process of the grain carrier and can make active component evenly distributed in the carrier, thereby ensuring the strength of an adsorbent finished product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

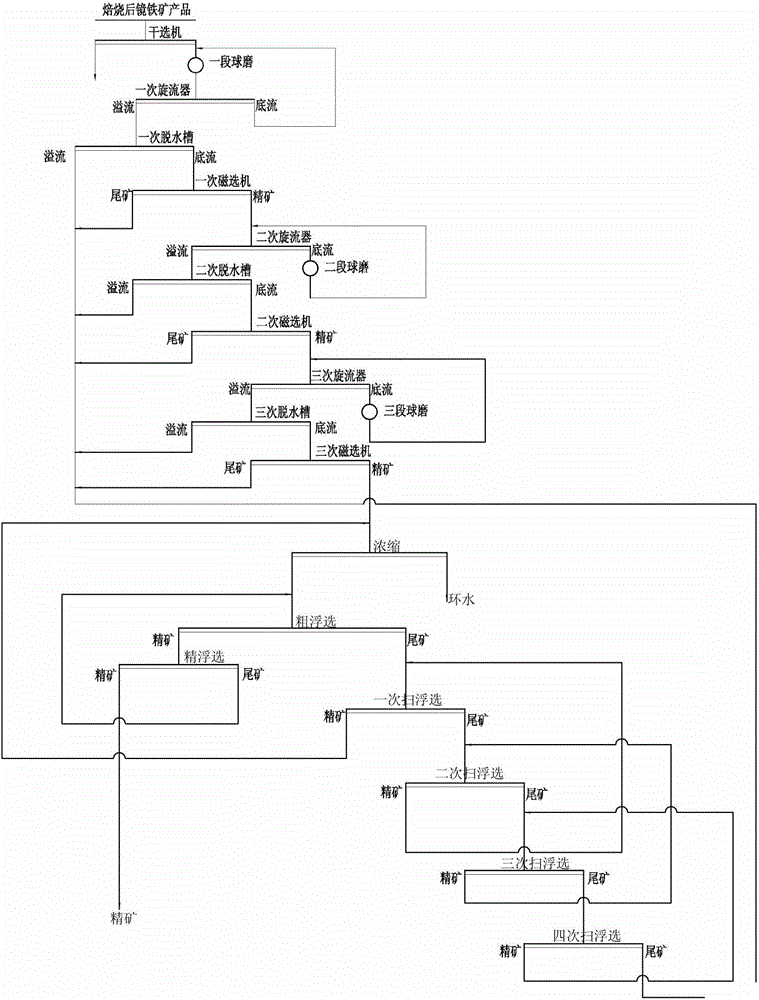

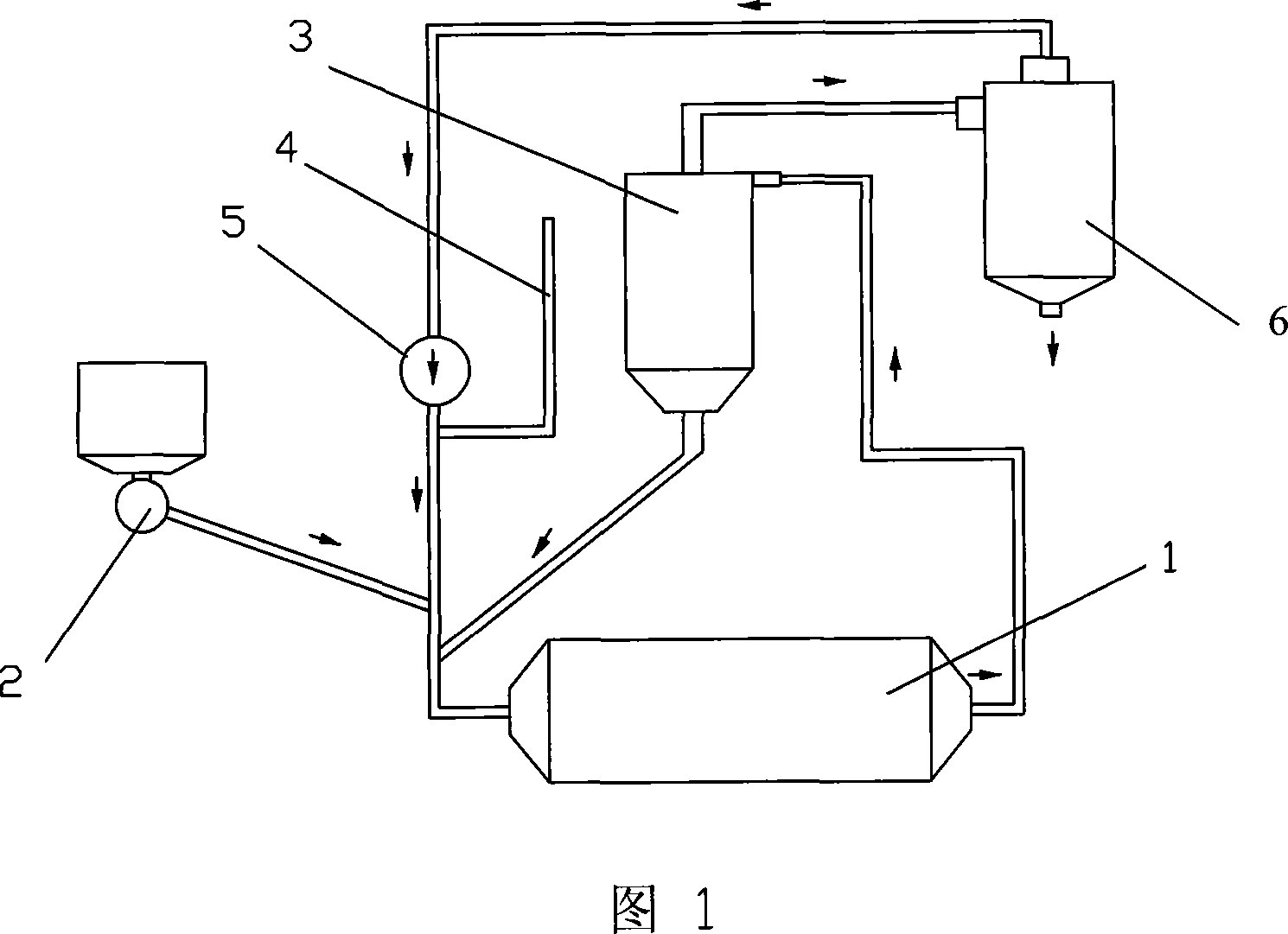

Separation technology of specularite after reduction roasting

InactiveCN104437826AImprove magnetismGuaranteed GranularityFlotationWet separationSeparation technologyEconomic benefits

The invention belongs to the field of mineral processing technologies and particularly discloses a separation technology of specularite after reduction roasting. The separation technology relates to a specularite reduction roasting system and is characterized in that the specularite after reduction roasting and water quenching is fed into a three-section stage grinding stage separation process of a magnetic separation system and is subjected to roughing flotation one time, fine flotation one time and scavenging operation four times, the final iron ore concentrate grade is 60%-62%, and the recovery rate is 80%-85%. Iron ore concentrate products meet the requirement of sintering process, in addition, the recovery rate is high, and therefore economic benefits of separation plants are greatly increased.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

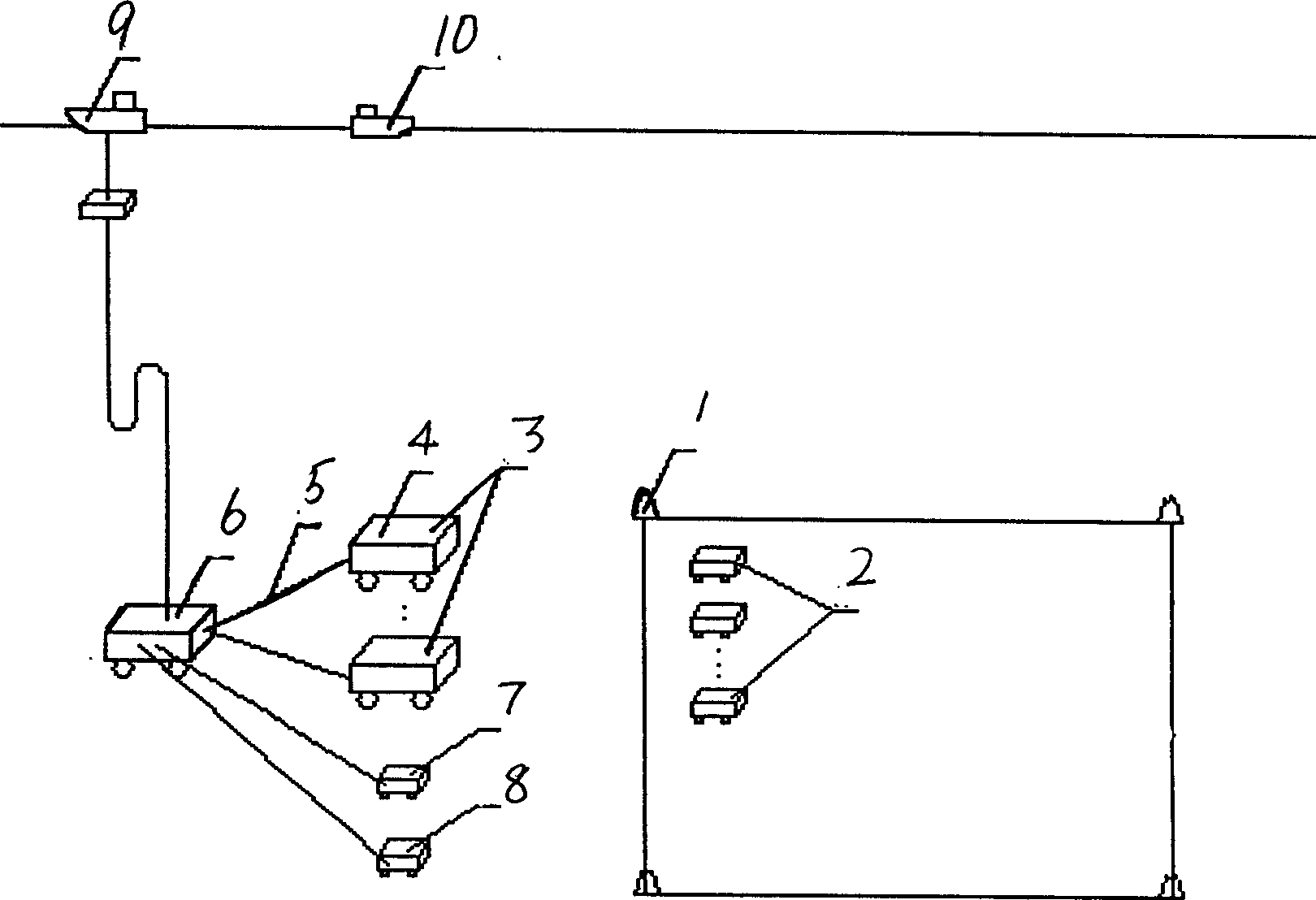

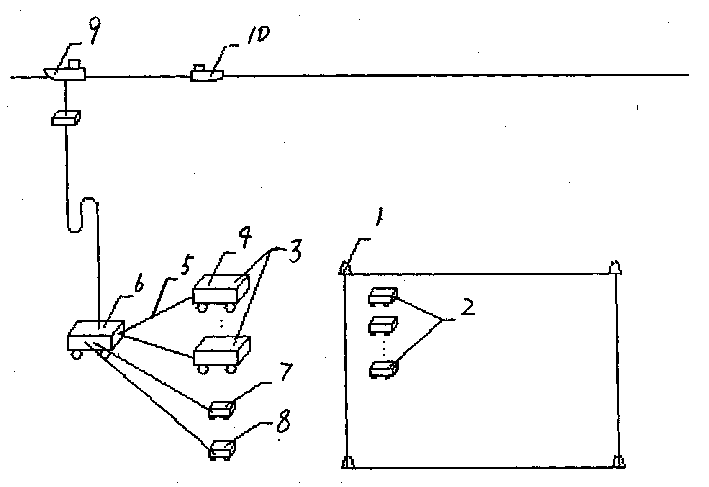

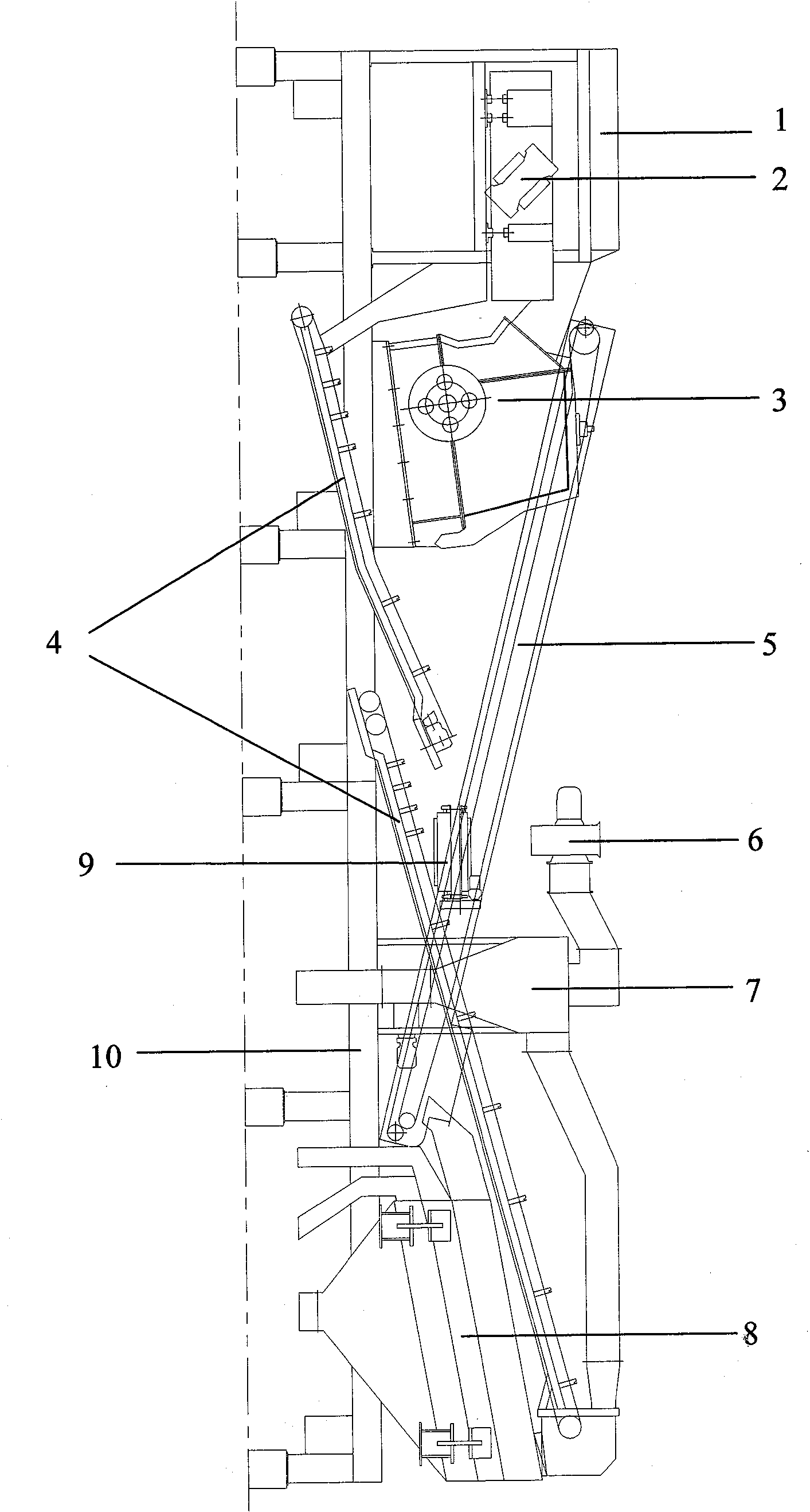

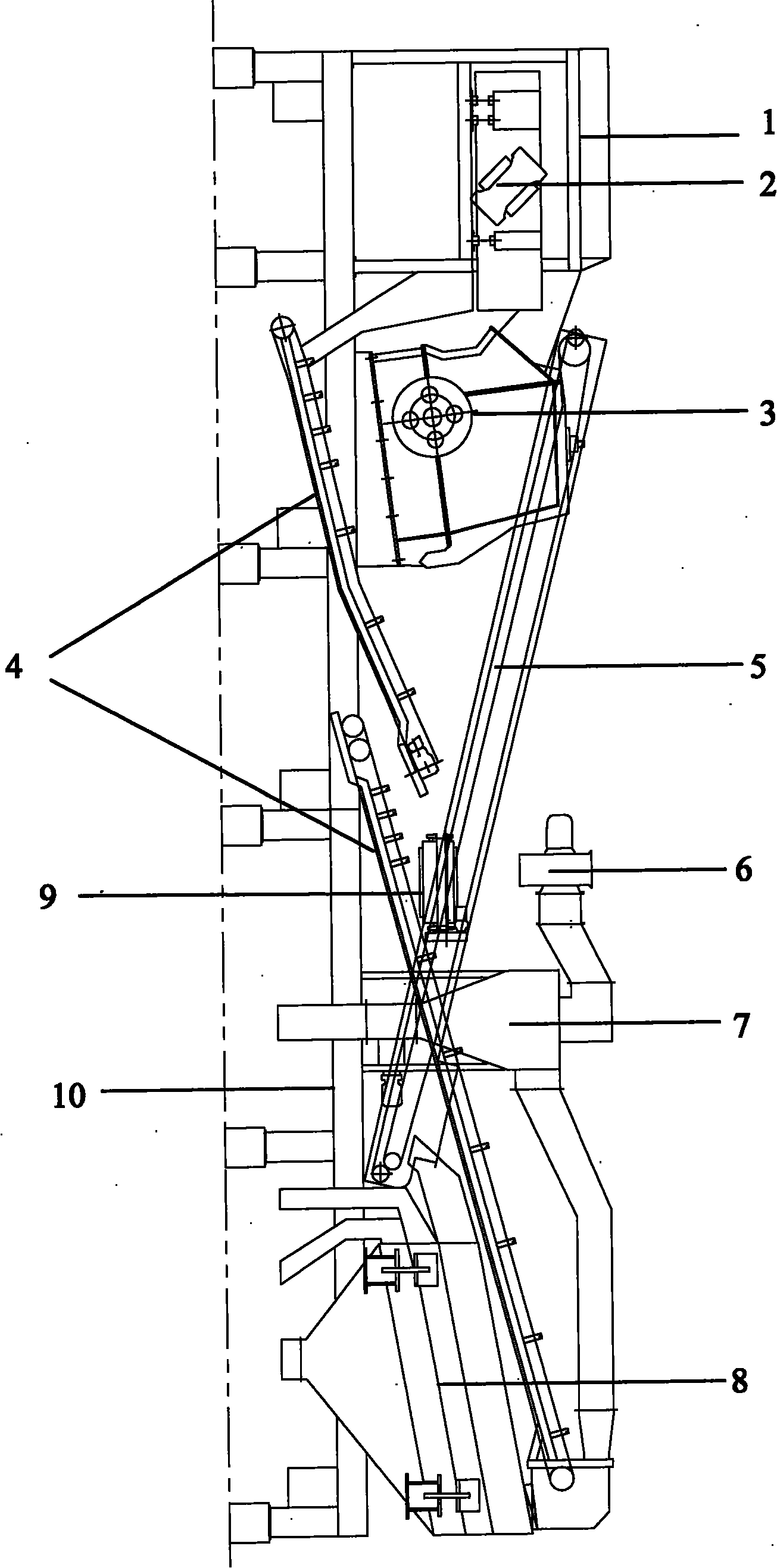

Movable distributive continuous exploitation method for deep sea mineral resources

InactiveCN1458391AIncrease collection rateBroken particle sizeMineral miningProduction rateMineral Sources

The movable deep sea mineral resource exploiting system consists of under water positioning base point in the marine mining area, movable distributing mining vehicle, movable ore bin matching the exploitation amount, initial separating and crushing unit capable of inhibiting depletion rate and matching mineral granularity, conveyer to the ore raising unit, movable ore raising unit with driving plant and pipeline, movable underwater power distributing station, movable main control station, surface exploitation ship, transportation ship, etc. The present invention is adaptable to the exploitation of deep sea mineral resources, especially base rock mineral resources and deposit mineral resources, and has high production rate, high collecting rate, low exploitation cost, high reliability, and less marine environmental pollution.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

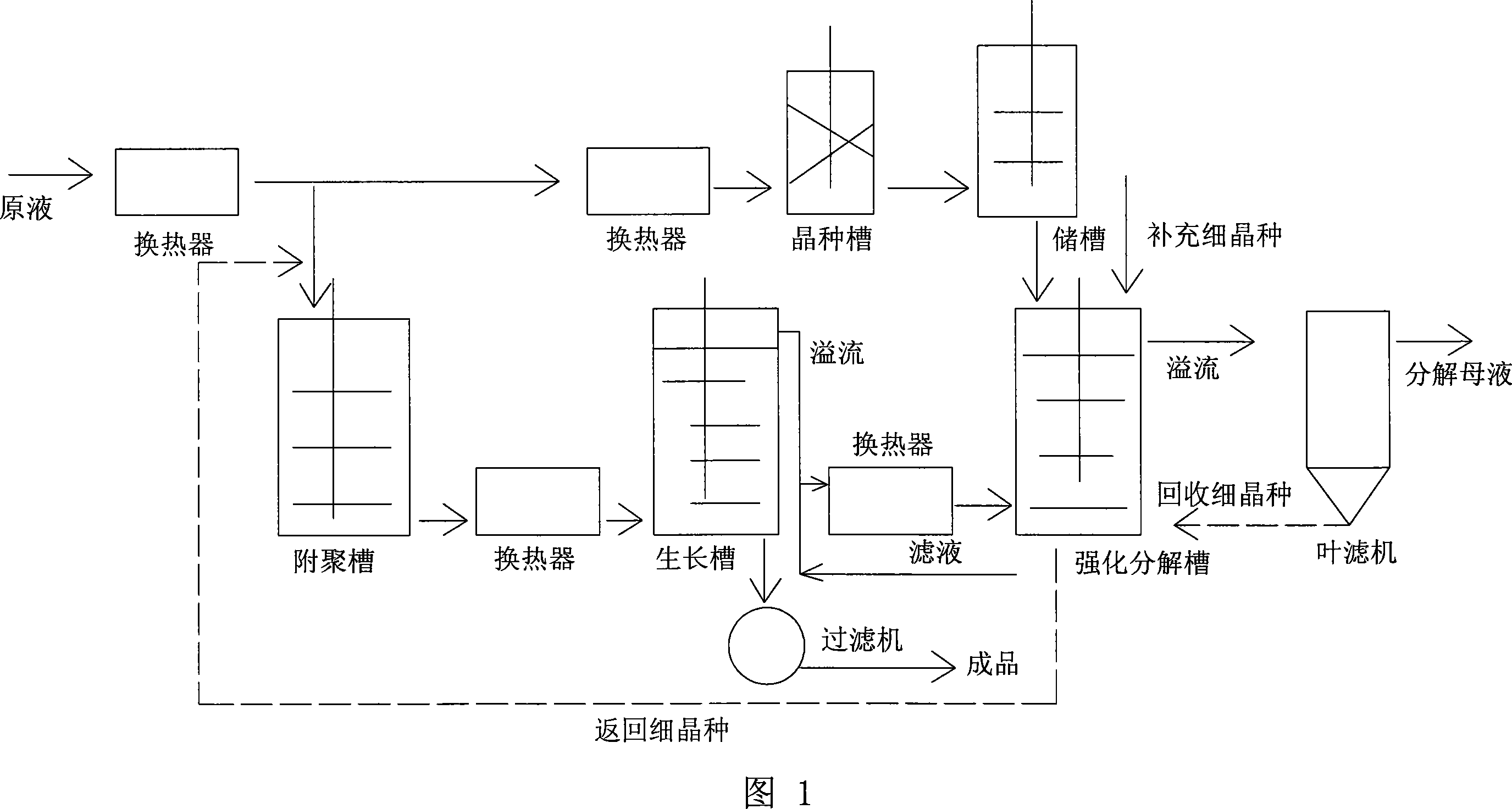

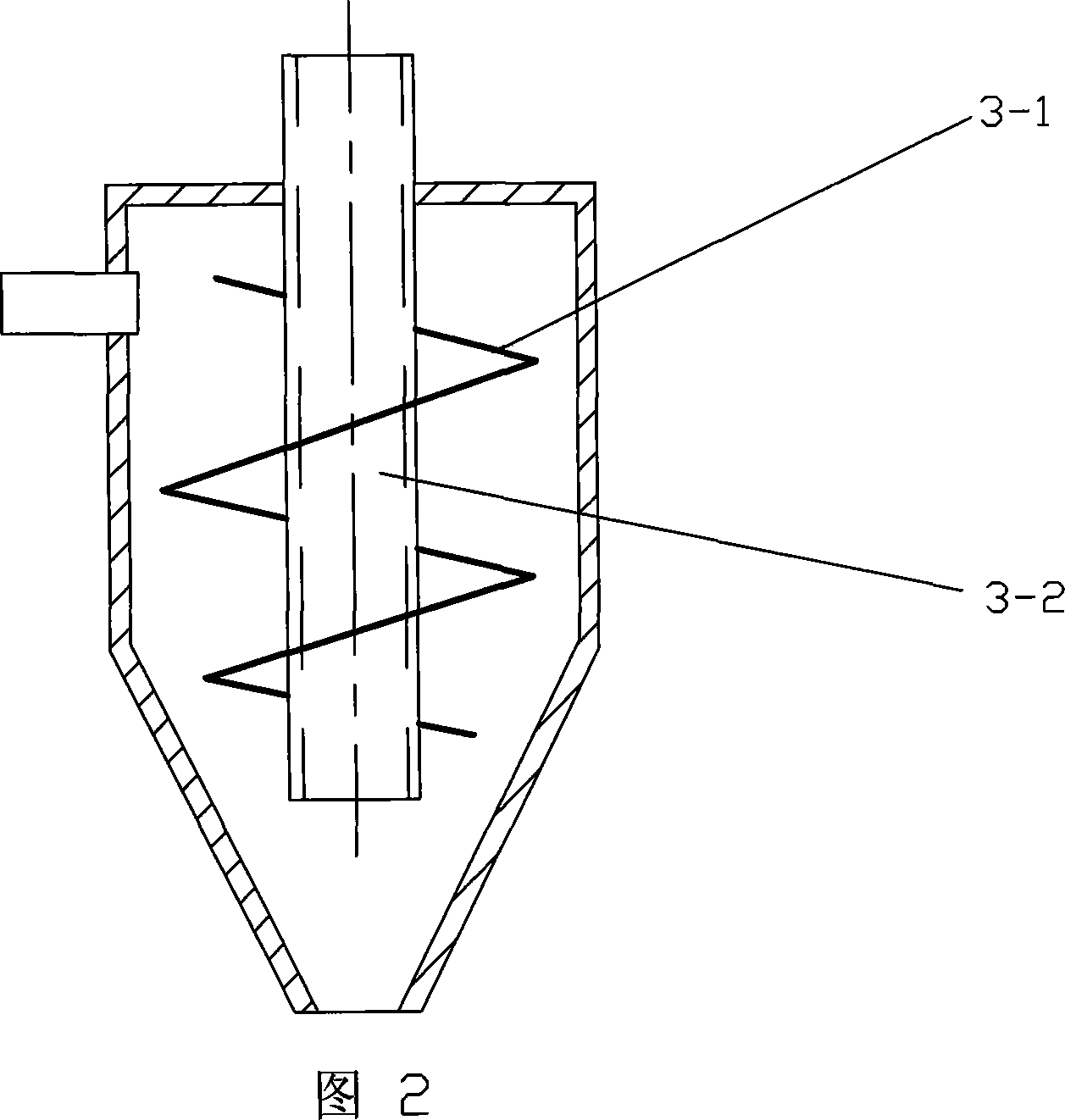

Three stages, two seeds technique of seed crystal decomposition

ActiveCN101092242AGood qualityControllable processSolution crystallizationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecomposerChemistry

This invention relates to a three-stage two-seed seed crystal decomposing process. The process comprises: passing the mother liquor through an agglomeration decomposer and a seed crystal growth decomposer in order, adding decomposing seed crystal into the seed crystal growth decomposer, then passing through a reinforced decomposer, adding fine seed crystal into the reinforced decomposer, sending the overflow liquid of the reinforced decomposer to a leaf filter to obtain decomposed mother liquor, recovering fine seed crystal from the leaf filter, returning to the reinforced decomposer, returning seed crystal from the reinforced decomposer to the agglomeration decomposer, and sending part of the mother liquor via the seed crystal growth decomposer to the reinforced decomposer for circulation. The process has such advantages as reasonable procedures, low energy consumption, low cost, easy control, high decomposition rate and high product quality.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

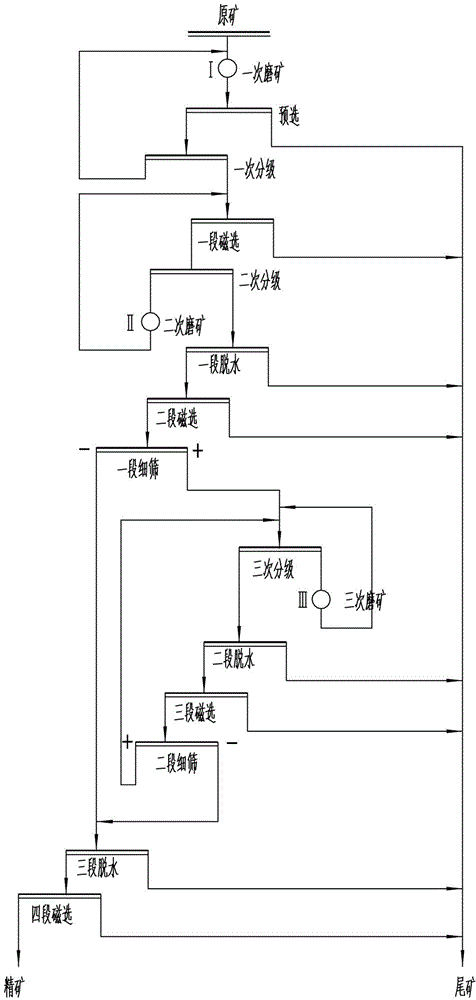

Simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore

ActiveCN104128259AEasy to handleImproved particle size compositionMagnetic separationPhysical chemistryMagnetic separator

The invention relates to a simple magnetic separation process for Anshan type iron carbonate-containing lean magnetite ore. The process includes ore grinding, grading and magnetic separation and comprises the following concrete steps: ore grinding three times; presorting with a large-wrap angle medium-intensity magnet separator; grading with a cyclone three times; dehydration in three stages; fine sieving in two stages; and magnetic separation with a magnet separator in four stages. The invention provides the energy-saving, low-carbon, environment-friendly and reliable production process for treatment of iron carbonate-containing lean magnetite ore by using a simple magnetic separation method; the process can further improve treating capability, enhance technical and economic indexes, reduce production cost and greatly increase the utilization efficiency of inferior resources while improving ore grinding, grading and sorting efficiency.

Owner:ANSTEEL GRP MINING CO LTD

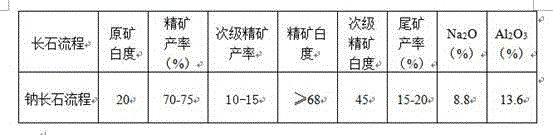

Method for efficiently preparing feldspar glazes for ceramics

The invention discloses a method for efficiently preparing feldspar glazes for ceramics. The method comprises the following specific steps: after raw feldspar ores are crushed, grinding the raw feldspar ores by a high-alumina ball grinding mill, classifying the raw feldspar ores in a spiral manner by a spiral classifier, and screening the raw feldspar ores by a high-frequency classifying screen, so that the sufficient dissociation of feldspar mines and the controlling the granularity can be ensured, the feeding granularity of the fed feldspar mines can be ensured, and conditions for the following magnetic separation and the classifying processes of a cyclone are created; separating and effectively removing magnetic impurities of the raw feldspar ores by the magnetic separation with various intensity in a classifying and multi-section manner of the granularity, increasing the kinds of products, and increasing the recovery of resources. Through the use of the technologies, such as the classification of the cyclone, the permanent magnet iron removal of a drum magnetic separator, the iron removal of a vertical ring pulsating high-gradient strong magnetic separator and the like, the adaptability and the reliability are greatly improved, the quality of the concentrates is effectively ensured and stabilized, the risk due to fluctuation of the impurity content is reduced, the separating efficiency and the comprehensive utilization of resources are improved, and the efficiently comprehensive utilization of the feldspar resources is realized.

Owner:赣州金环磁选科技装备股份有限公司

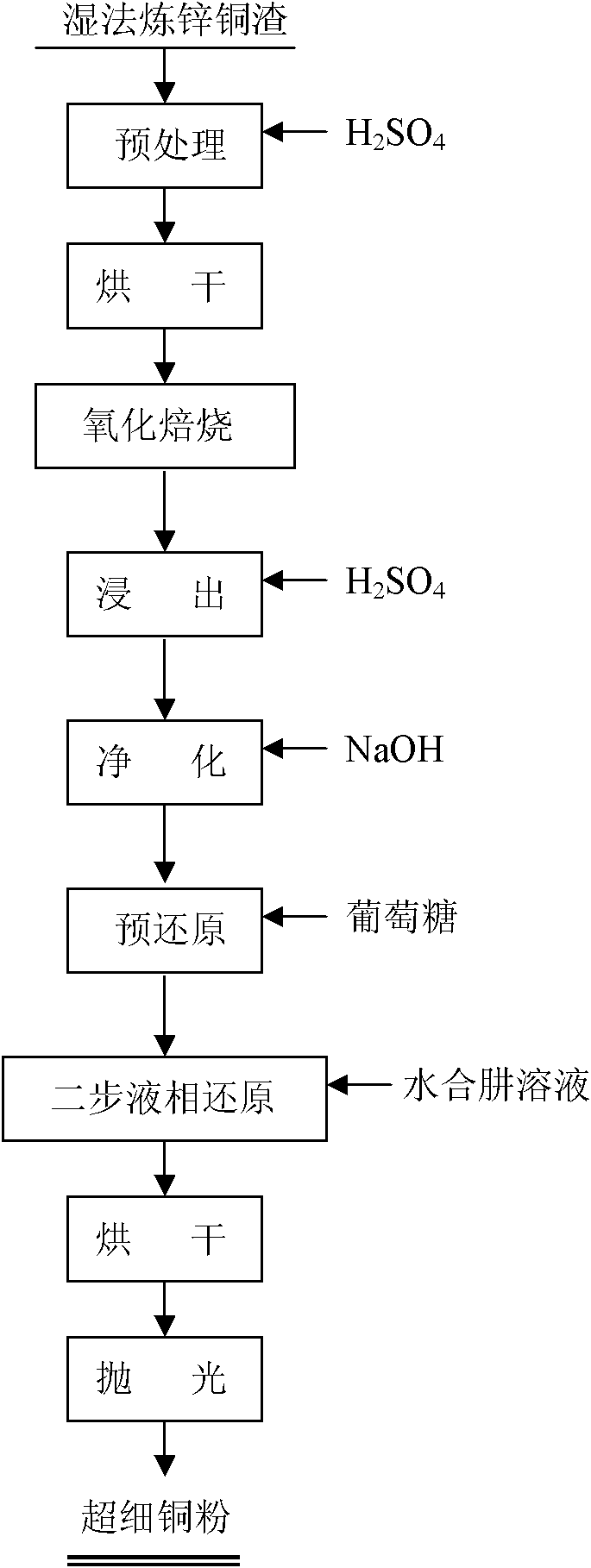

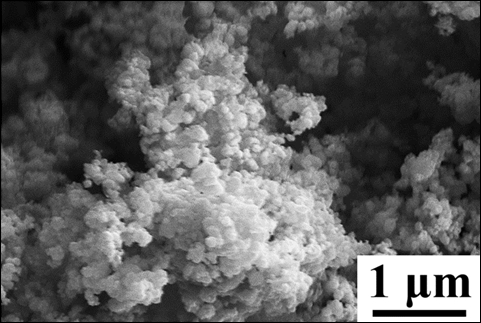

Superfine cupper powder and preparation method thereof

ActiveCN101890505AIncrease brightnessPrevent oxidationProcess efficiency improvementEconomic feasibilityOxide

The invention provides a preparation method of superfine cupper powder, which takes copper slag generated by hydrometallurgy of zinc as a raw material and is characterized by comprising the following steps: soaking the cupper slag in a sulfuric acid solution for pretreatment; filtering and drying; carrying out oxidization roasting to obtain roasted cupper slag; leaching the roasted cupper slag out by the sulfuric acid solution to obtain lixivium i.e. copper-bath; carrying out purification treatment on the copper-bath; and adjusting the pH value of the purified copper-bath; adding glucose in the copper-bath for pre-reduction to obtain the cuprous oxide sediment; adding a hydrazine hydrate solution in the cuprous oxide sediment to carry out reduction reaction to obtain solid reduced copper powder; and filtering the reduced copper powder, washing, drying and carrying out polished finish to obtain the superfine copper powder. The invention has the copper recovering rate as high as over 95% and simple process, produces the superfine cupper powder by hydrometallurgy of zinc with low cost and wide sources, and has the economic feasibility of industrialization production in a large scale.

Owner:ZHUZHOU SMELTER GRP

Preparation method of high-quality prebaked anode for 500KA electrolytic cell

The invention relates to a preparation method of a high-quality prebaked anode for a 500KA electrolytic cell. The method comprises the following steps of: (1) storing petroleum coke at different storage locations according to different producing areas; (2) crushing the petroleum coke blocks having the granularity greater than 200mm with a sledge hammer, sieving the petroleum coke blocks with the granularity less than 200mm, delivering the petroleum coke with the granularity less than 70mm into a petroleum coke conveyer belt, recrushing the petroleum coke with the granularity greater than 70mm so as to deliver the petroleum coke with the granularity less than 70mm into the petroleum coke conveyer belt; (3) feeding different petroleum cokes into a specified blending cabin, wherein the petroleum coke of one producing area is placed in each of the four blending cabins, and a belt weigher is arranged at the bottom of each blending cabin; (4) preparing calcined coke; (5) preparing rough coke, middle coke, fine coke and powdery coke; (6) preparing boiler-out thickeners; (7) preparing cooled thickeners; (8) preparing green bodies; (9) feeding the green bodies into a stacking storeroom for stacking; and (10) roasting the green bodies to obtain a prebaked anode. By using the preparation method, the electrolysis preparation requirement can be met, and safe and sable operation of the electrolytic cell is ensured.

Owner:嘉峪关索通预焙阳极有限公司

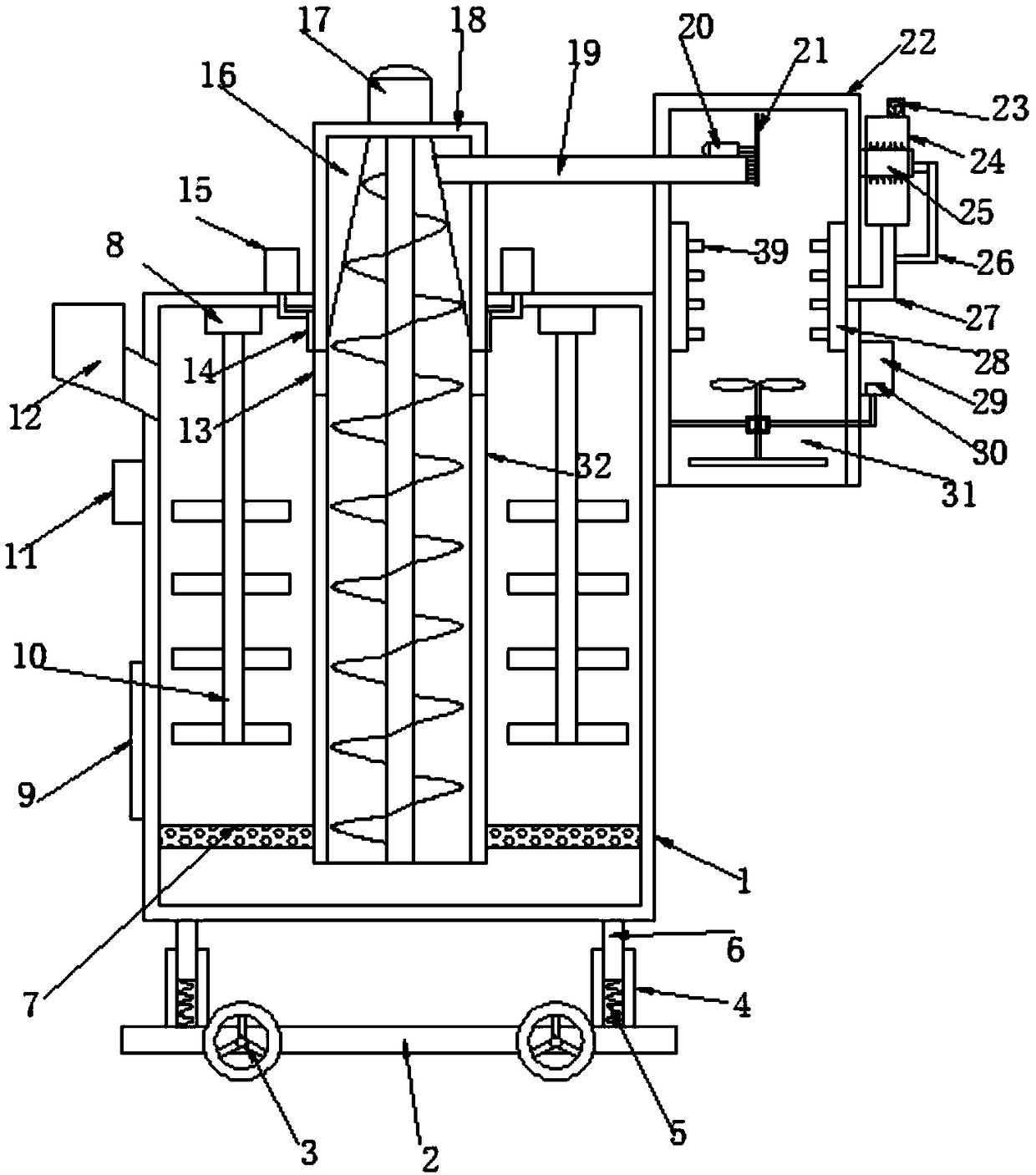

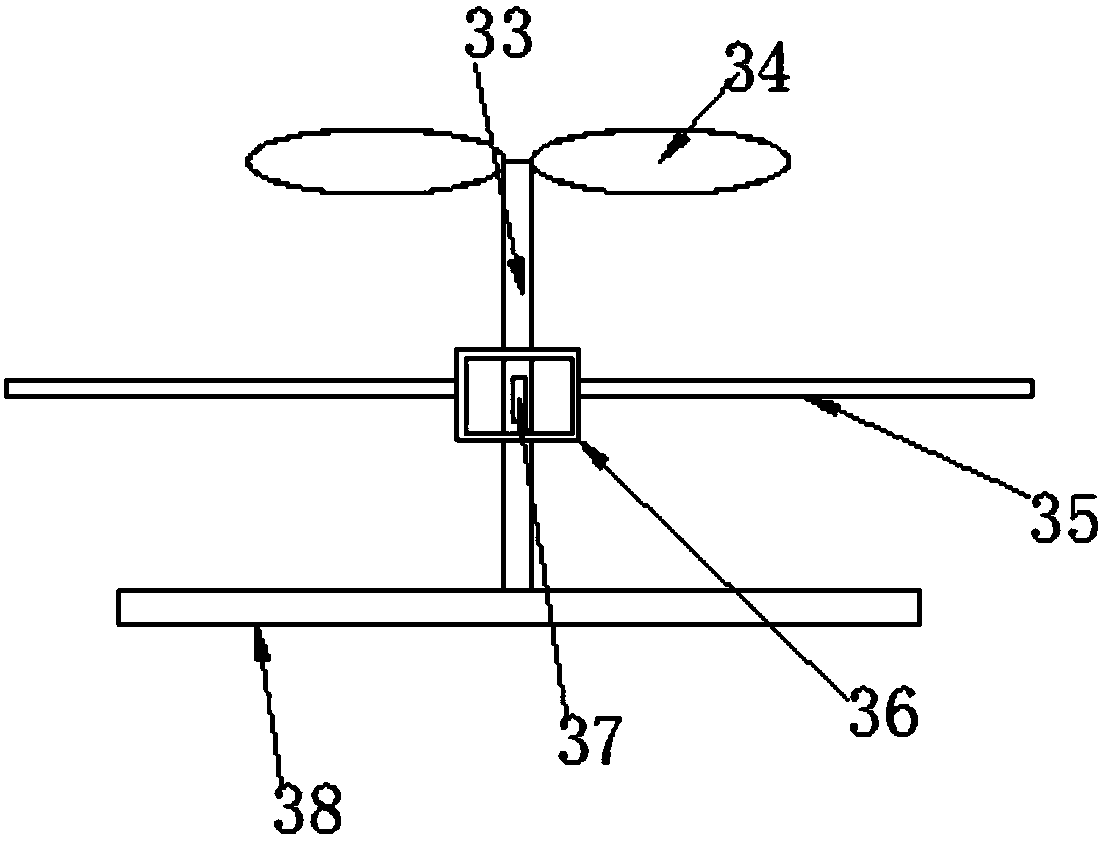

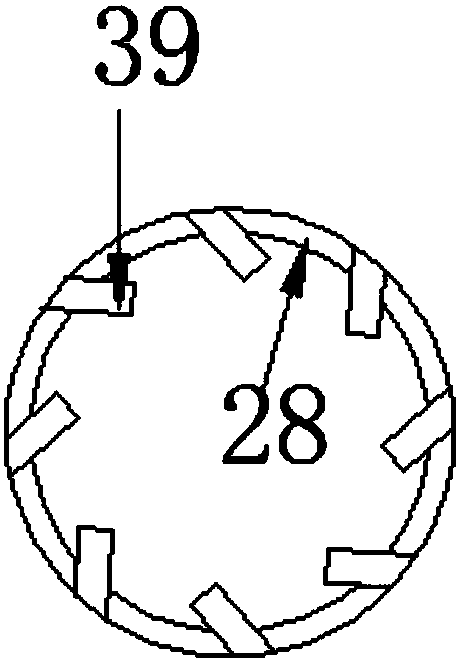

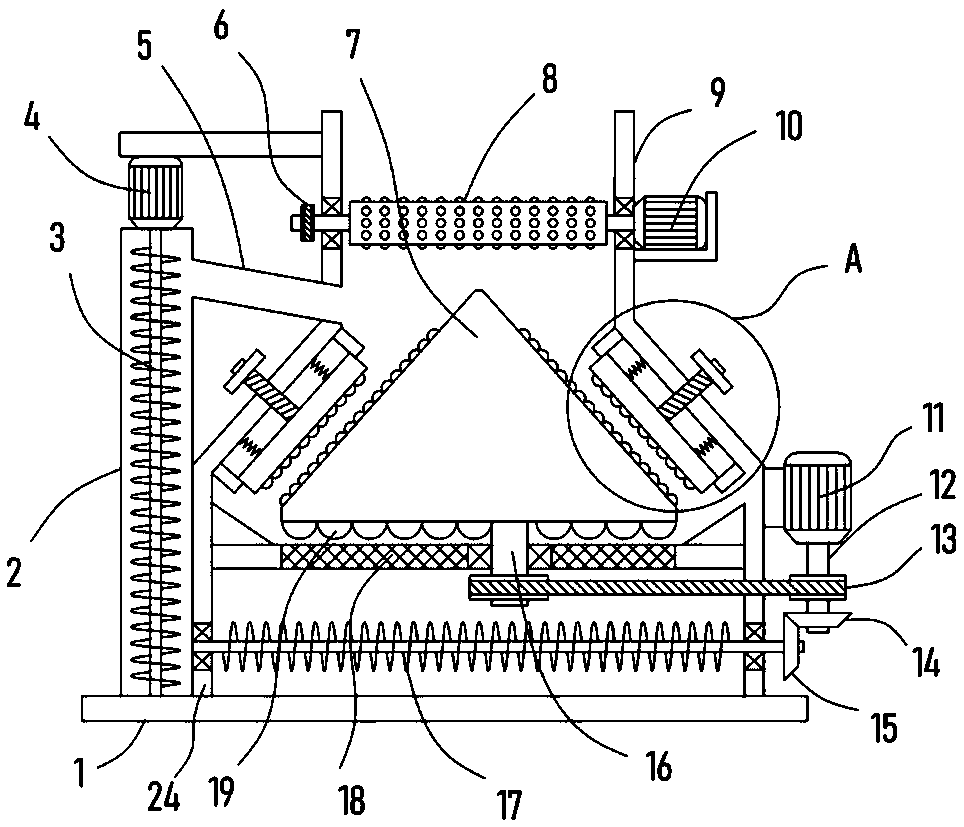

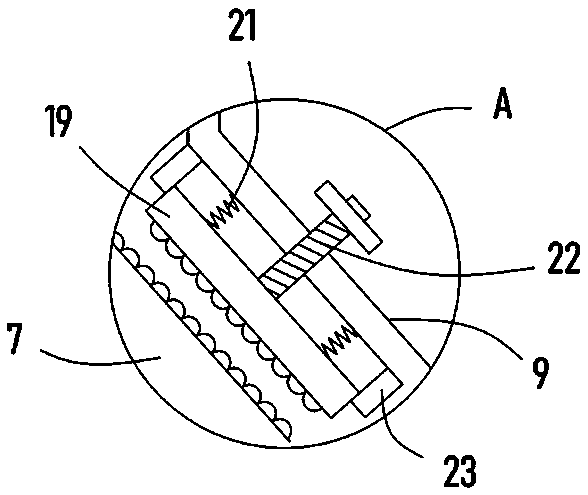

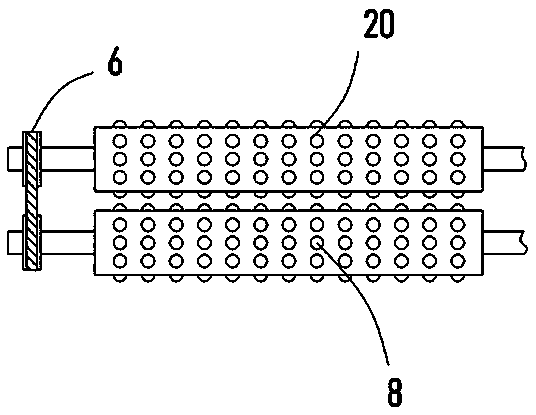

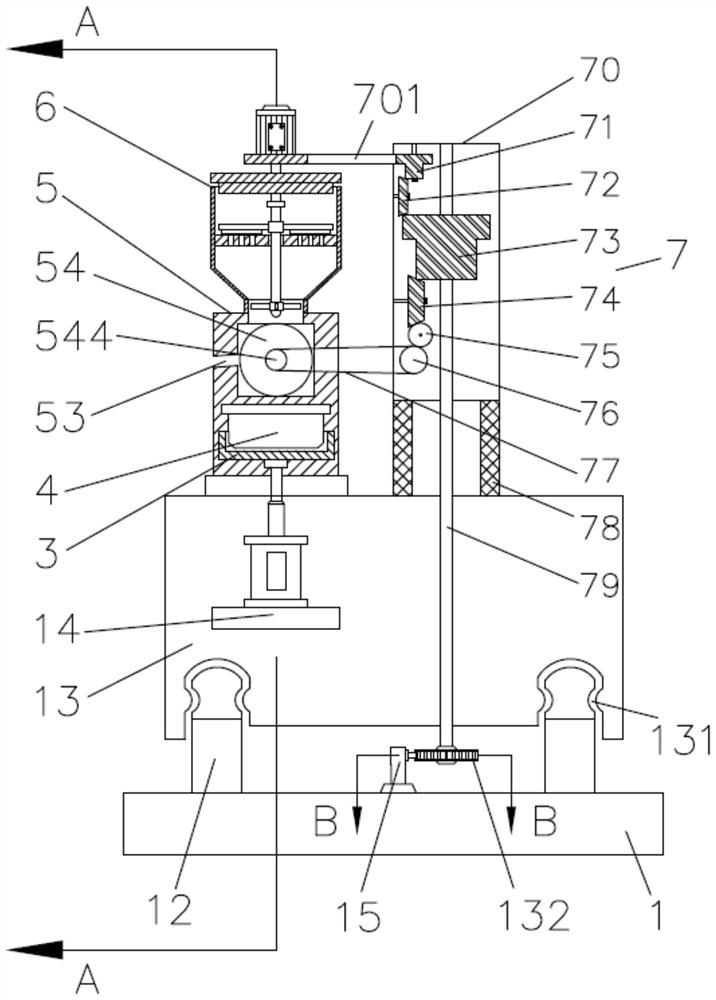

Argillization type soil remediation device

ActiveCN108393340AGuaranteed granularityImprove repair effectContaminated soil reclamationSoil remediationShock resistance

The invention discloses an argillization type soil remediation device. The argillization type soil remediation device comprises a machining box; a base is arranged below the machining box, and the left side and the right side of the base are provided with rolling wheels for allowing the device to be transferred conveniently; the two sides of the lower end of the machining box are symmetrically provided with supporting legs, and the lower ends of the supporting legs are slidably sleeved with supporting sleeves; buffer springs are arranged in the supporting sleeve, and the supporting sleeves andthe supporting legs are connected and fixed through the buffer springs; the lower ends of the supporting sleeves and the base are connected and fixed, and the shock resistance of the argillization type soil remediation device is improved by effectively arranging the buffer mechanism; and a lifting barrel penetrates through the middle of the upper end of the machining box. The argillization type soil remediation device is simple and reasonable in structure, convenient to transfer and good in shock resistance, soil is subjected to argillization at first, then, insoluble impurities are removed,the soil is refined and dried, accordingly, the refining degree of the soil is ensured, and final disinfection remediation is conducted. Through the remediation mode, the defect that existing devicesare not good in smashing is overcome, the soil remediation effect is greatly improved, and the practicality is high.

Owner:北京埃克兰德生态环保技术有限公司

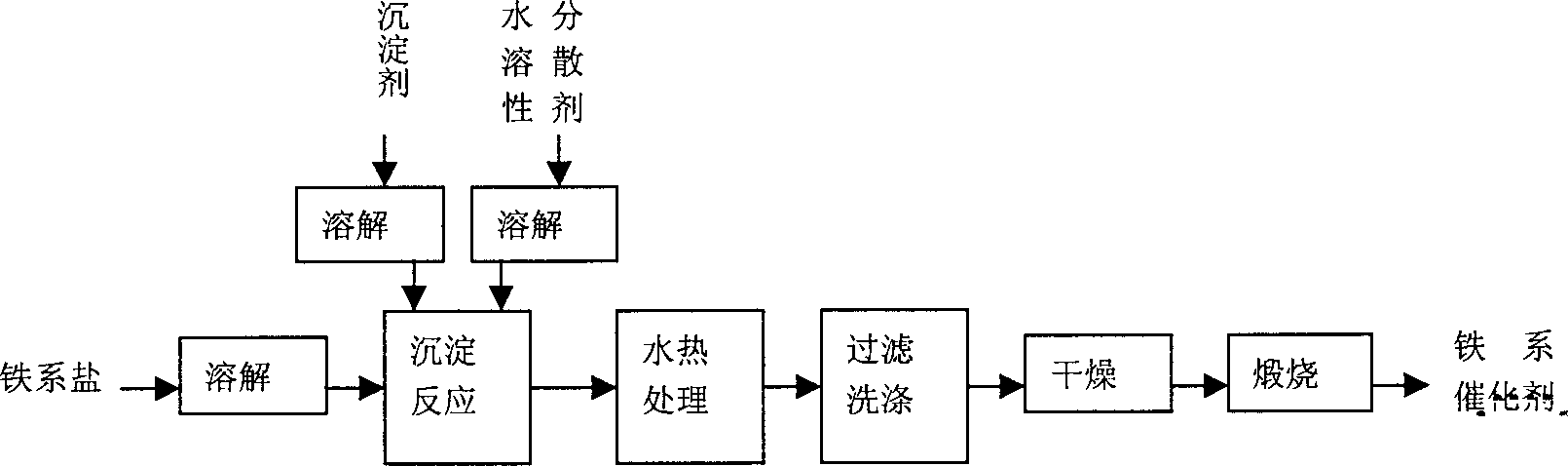

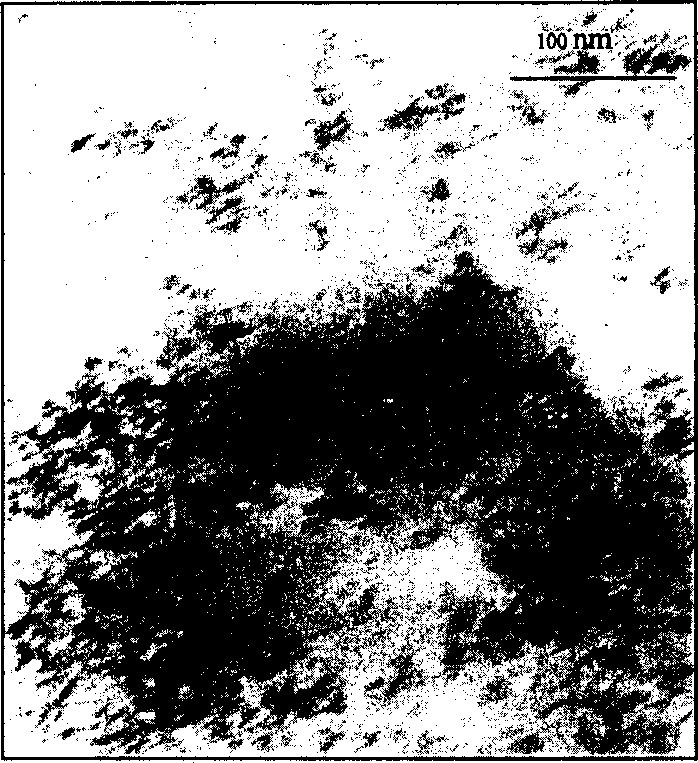

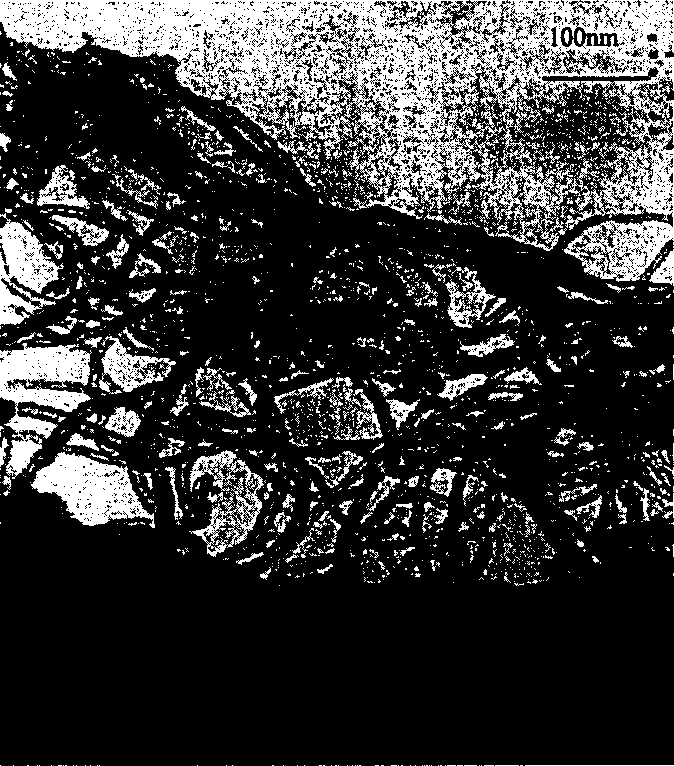

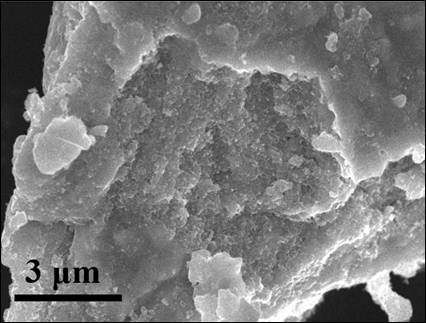

Process for preparing Fe-series catalyst used to synthesize nano carbon tubes

InactiveCN1376636ASimple processEasy to operateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsDispersityGas phase

A process for preparing Fe-series catalyst used to synthesize nano carbon tubes by gas-phase catalytic deposition method includes such steps as liquid-phase codeposition reaction of inorganic Fe saltand carbonate at 25-85 deg.C under existance of water-soluble disperser, hydrothermal modification of suspension at 105-150 deg.c, filtering and washing deposit, and calcining at 300-800 deg.C to obtain the high-dispersity catalyst. The nano carbon tubes prepared with said catalyst features thin wall, fine diameter (3-10 nm) and high uniformity.

Owner:TSINGHUA UNIV

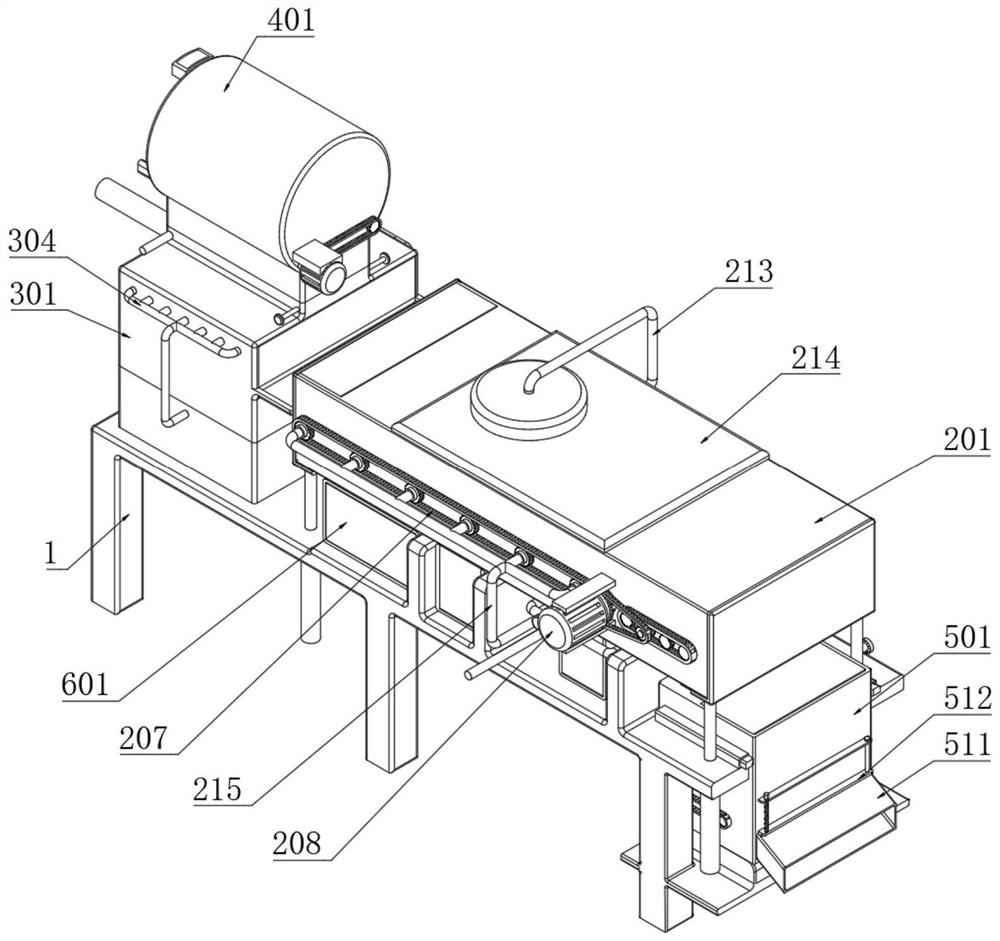

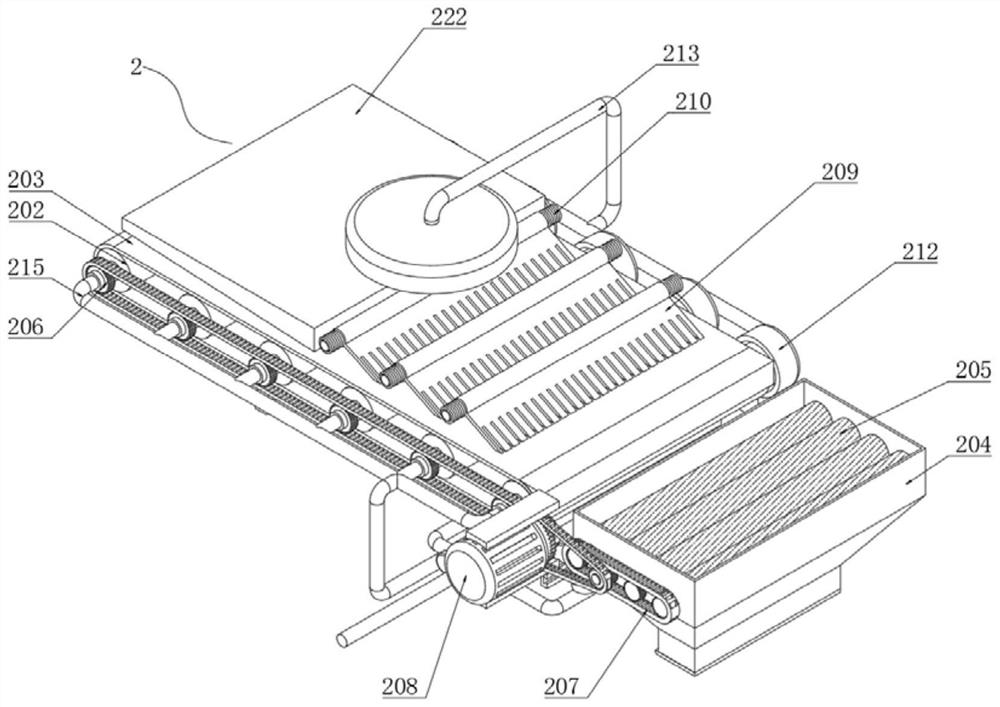

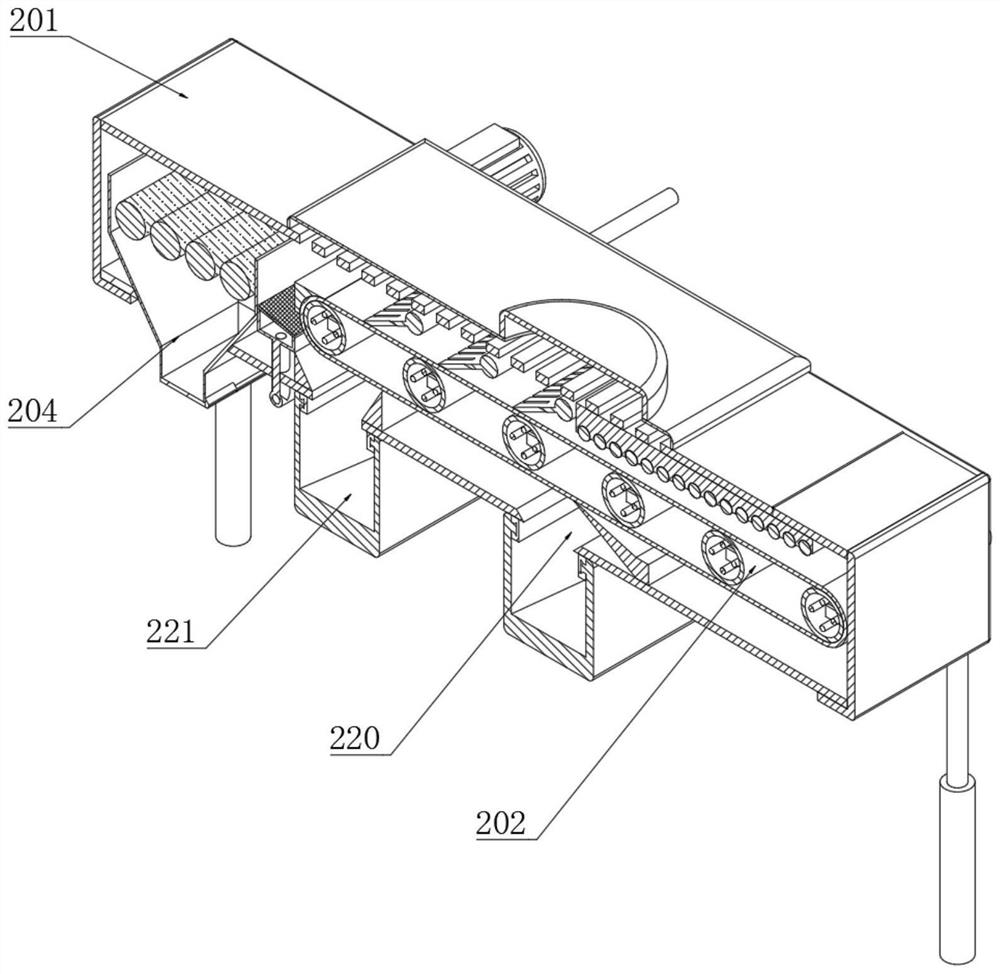

Mobile construction waste treatment device

InactiveCN101927258AImprove processing powerReduce energy consumptionSievingScreeningRebarReinforced concrete

The invention provides a mobile construction waste treatment device. The mobile construction waste treatment device can decompose and treat discarded construction waste such as reinforcing steel bar-containing reinforced concrete and the like and can separate the reinforcing steel bars. The mobile construction waste treatment device is provided with a non-construction waste light substance removing device which can separate impurities such as waste plastics, waste wood and the like from the construction waste, so that the quality of recycled aggregates (which are not only highway subgrade fillings, but also other construction material aggregates with high requirements, such as brickmaking aggregates, construction material aggregates with a certain strength requirement and the like) can be guaranteed. The mobile construction waste treatment device is provided with a multilayer vibrating sieve and a system is provided with a material-returning device for residues on the multilayer vibrating sieve, wherein the material-returning device can feed unqualified thick substances into a crusher again to crush, so that the required granularity of finished products can be guaranteed. Before the system crushes, the materials are sieved in the process of vibrating feeding and granules are sieved, so that the invalid crushing process is avoided, the processing capacity of the system is improved, and energy consumption is reduced.

Owner:CHANGSHU RIXIN MACHINERY

Spherical graphite production process

The invention discloses a spherical graphite production process.The spherical graphite production process comprises the steps of 1 raw material pretreatment, 2 smashing and balling, 3 grading, 4 primary purification, 5 second purification, 6 drying, 7 magnetic separation and 8 screening and package, wherein three smashing machines are arranged for the step 2.The spherical graphite production process is simple, spherical graphite is high in purity, smaller in surface area and higher in ramming density, and the rate of finished products is high.

Owner:青岛昕昊阳新能源材料有限公司

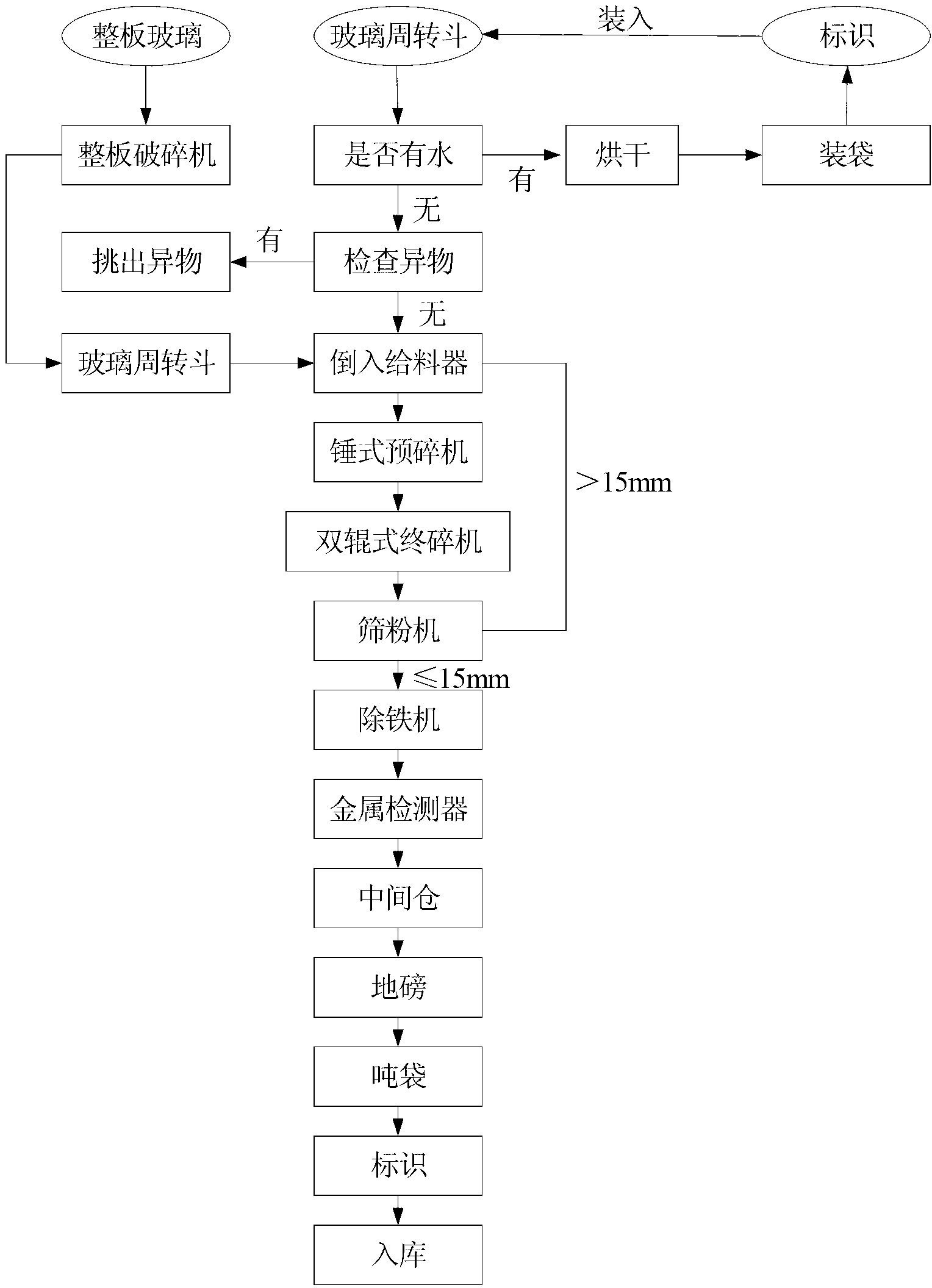

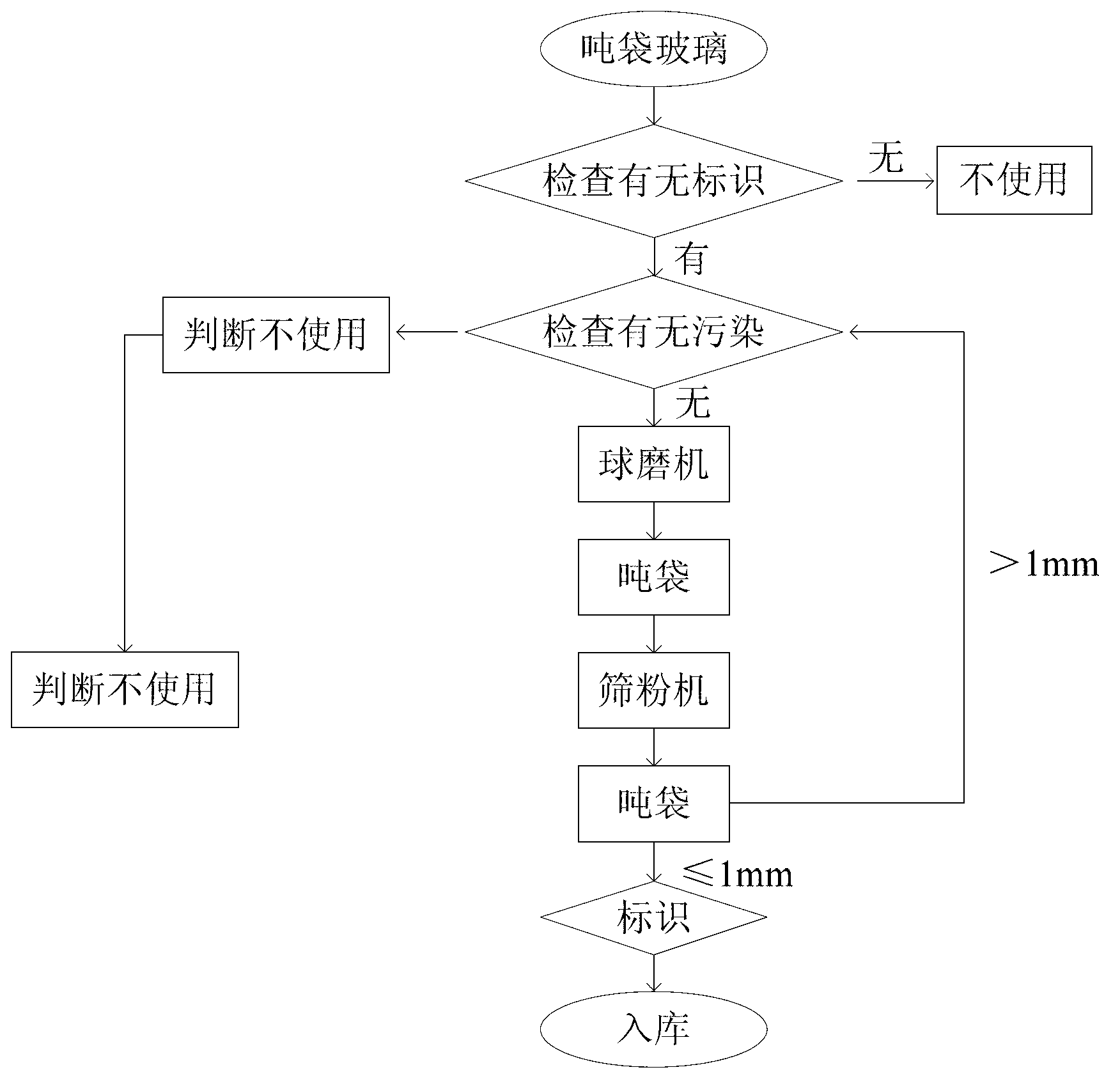

Glass cullet machining process

The invention discloses a glass cullet machining process, which comprises the following steps: a) feeding dry glass sheets into a crushing device through a feeding machine so as to carry out crushing on the dry glass sheets, thereby obtaining glass cullet subjected to coarse crushing; b) pouring the obtained glass cullet into a sieving machine to carry out sieving, if the diameter of the glass cullet subjected to sieving is less than or equal to 15 mm, removing metal impurities on the glass cullet; otherwise, feeding the glass cullet with a diameter of greater than 15 mm into the crushing device through the feeding machine to carry out crushing again; c) pouring the glass cullet subjected to metal impurity removal into a ball mill, and pouring a nonmetallic ball into the ball mill to carry out ball milling, thereby obtaining glass powder subjected to t ball milling; and d) pouring the glass powder subjected to ball milling into the sieving machine to carry out sieving, if the diameter of the glass powder subjected to sieving is less than or equal to 1 mm, bagging the glass powder, and putting the glass powder in storage; and if the diameter of the glass powder subjected to sieving is greater than 1 mm, repeating the steps c) and d). The glass cullet machining process disclosed by the invention meets the requirements on the particle size of glass cullet, and reduces metal harmful substances in glass; and the glass cullet machining process is high in degree of mechanization.

Owner:彩虹(张家港)平板显示有限公司

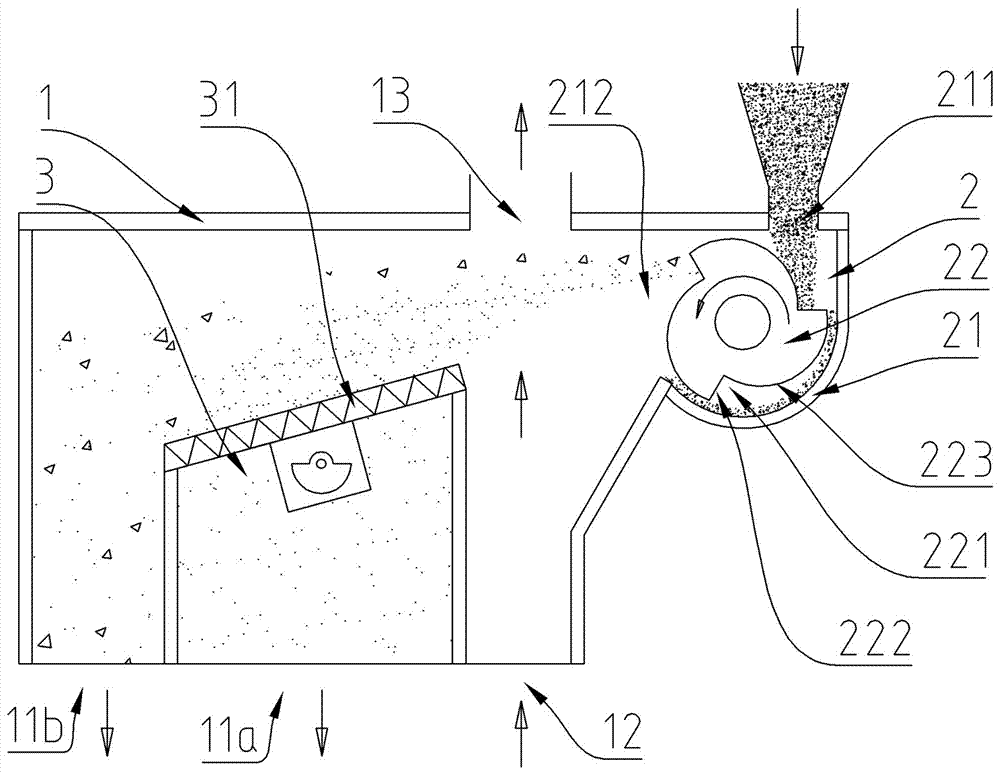

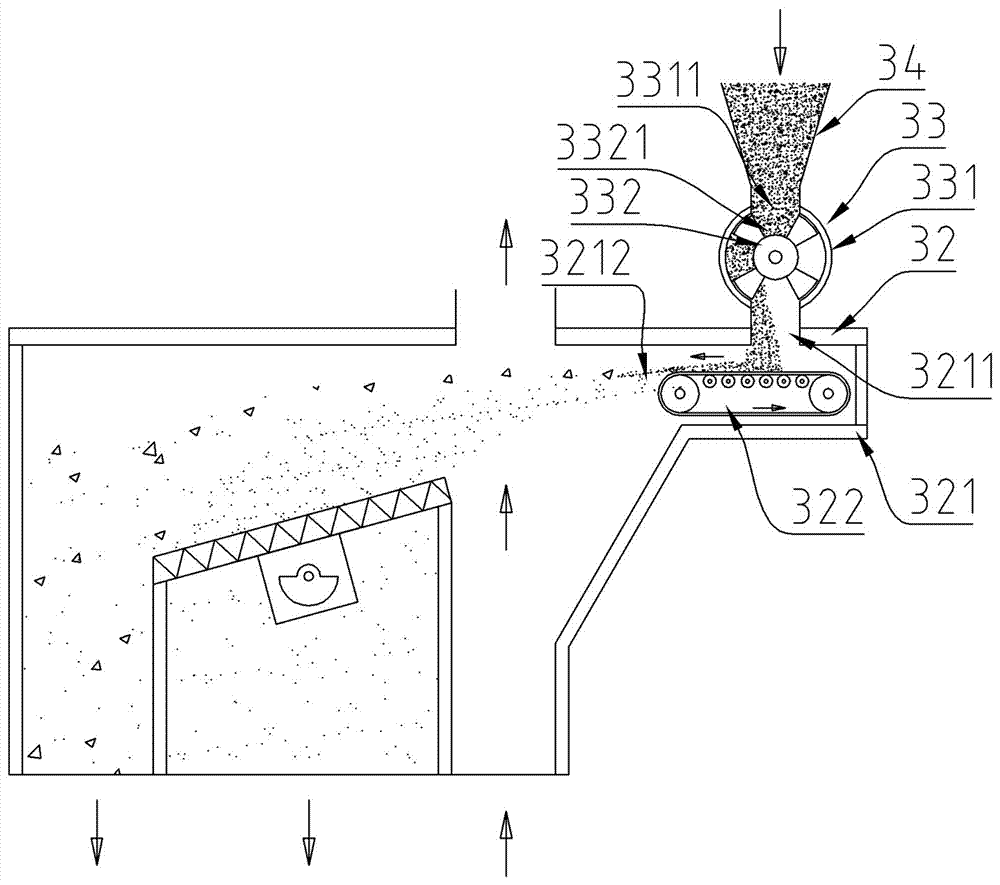

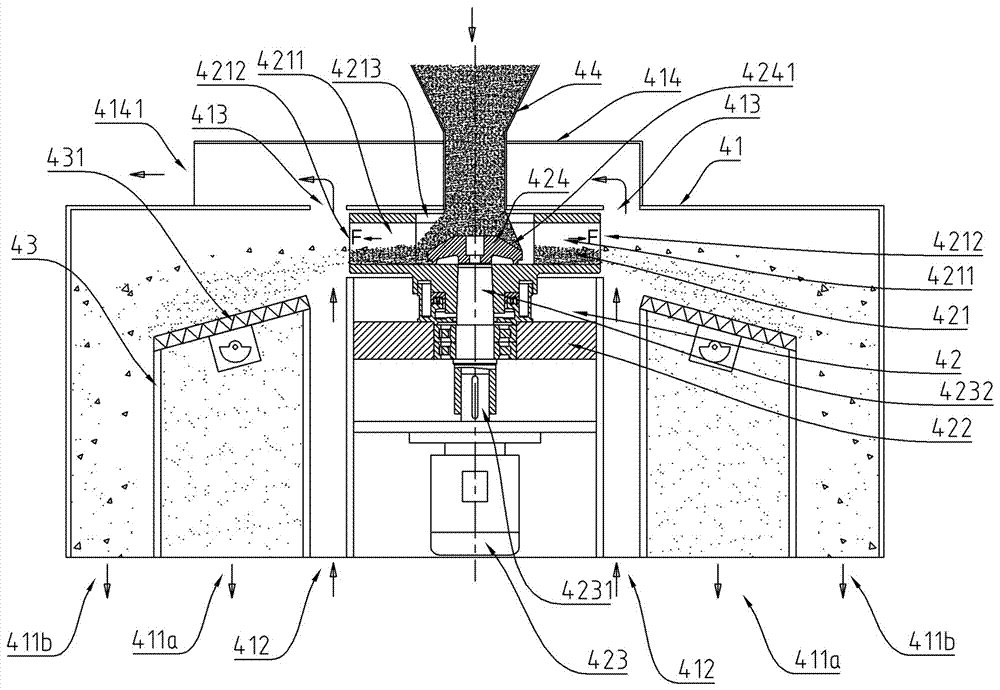

Cast type material separation method and device and separation bin

ActiveCN106984544AReduce work intensityReduced Power RequirementsSievingGas current separationCasting typesMixed materials

The invention relates to the field of material sorting equipment, in particular to a cast type material separation method and device and a separation bin. The cast type material separation method comprises the steps that at least one collecting area is provided with a screening device, a mixed material is cast through a cast device, the material falling into the collecting area where the screening device is located is screened through the screening device so that the material meeting the grain size requirement can be obtained. Compared with an existing material separation method, according to the cast type material separation method, the mixed material is preliminarily separated through the cast device, the screening device is arranged in the collecting area so as for further screen the material entering the collecting area, the effect that the grain size of the material obtained after screening is in the required range is guaranteed, and the problem that according to an existing cast type material separation method, due to the fact that further screening operation needs to be conducted, the production efficiency is low is solved.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY

Efficient pepper grinding device for seasoning processing

The invention discloses an efficient pepper grinding device for seasoning processing, and relates to the technical field of pepper processing. The efficient pepper grinding device comprises a supportplate, wherein a grinding chamber is fixedly installed on the support plate, a second motor is fixed to the grinding chamber, a grinding roller I and a grinding roller II are in driving connection tothe grinding chamber by virtue of belt pulley mechanisms I, the grinding roller II is driven by a second motor, an eccentric grinding frustum is eccentrically and rotatably arranged in the grinding chamber, and grinding heads which are abutted with a metal net plate are uniformly fixed to the lower end of the eccentric grinding frustum. According to the efficient pepper grinding device, the grinding roller I and the grinding roller II rotate, so that peppers are preliminarily pulverized; the eccentric grinding frustum eccentrically rotates, so that the peppers are further ground; the peppers on the metal net plate are ground again by the grinding heads, and three-time grinding is performed, so that the pepper refining degree is greatly increased; and a transverse auger and a longitudinal auger are arranged, so that the circulation of the peppers is realized, repeated grinding is realized, the pepper refining degree is fully guaranteed, and the grinding efficiency is high.

Owner:李影

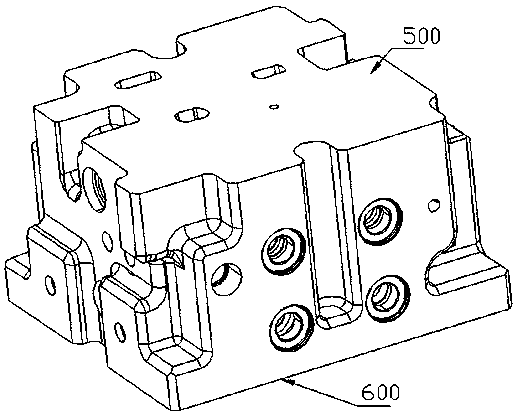

Casting method of hydraulic valve casting

InactiveCN109128010AHigh strengthGuaranteed StrengthFoundry mouldsFoundry coresIntegrated design3d printer

The invention relates to a casting method of a hydraulic valve casting. The casting method is characterized by comprising the following steps: designing a mold core including a hydraulic valve; selecting the bottom surface of the hydraulic valve and the top surface of the hydraulic valve as split surfaces of the mold core and dividing the mold core into a bottom core, an intermediate core and an upper cover core; printing the intermediate core by adopting a 3D printer; printing the bottom core and the upper cover core by adopting the 3D printer and / or preparing the bottom core and the upper cover core by adopting a wooden pattern; assembling the bottom core and the intermediate core; assembling the upper cover core on the intermediate core. The casting method of the hydraulic valve casting, provided by the invention, has the benefits that the intermediate core of the hydraulic valve and the external contour are combined together, so that the quantity of sand cores is reduced, and the process step is simplified; through the integrated design of the intermediate core, the sand core strength of the intermediate valve core is enhanced, so that the problems of sand core deformation andthe like are solved.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

Method of processing un-suspension powdered aluminium

The invention relates to a processing method for no-floating aluminum powder, conquering defects that aluminum powder paste generated by wet grinding technology possesses volatile organic component; the dispersion and the classification of product is difficult; the granularity and the uniformity of product can not be guaranteed. The invention can be realized by following steps. Rough aluminum powder is selected. The rough aluminum powder is set in ball mill to be grinded; nitrogen is used as air protection in the ball mill and oil block is added into the ball mill as additive, which is 0.8% to 1.0% by wt of the weight of rough aluminum powder. The fan is used to blow grinded rough aluminum powder in the ball mill into the input of cyclone separator; rough aluminum powder with relative smaller granularity is transported into the cyclone collector through the upper output of cyclone separator and rough aluminum powder with relative bigger granularity is sent into the ball mill to be grinded continuously. Rough aluminum powder is selected finely in cyclone collector; finished aluminum powder is discharged from the lower output and residual aluminum powder is sent into the ball mill to be grinded continuously.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Soil organic restoration device and soil restoration method for smart agriculture

The invention discloses a soil organic restoration device for smart agriculture. A thermal stripping box is clamped to one side of the top end of a supporting frame, a movable roller is placed on the inner side of the thermal stripping box, a discharging hopper is installed on the inner side of the thermal stripping box, a separation limiting plate is connected to the inner side of the thermal stripping box, a concentration sleeve is welded to one end of the thermal stripping box, and a gas conveying pipe penetrates through one end of the concentration sleeve. A gas inlet end of the gas conveying pipe is installed at the top end of a concentration box in a penetrating mode, a gas outlet pipe penetrates through one end of the movable roller, and a gas outlet end of the gas inlet pipe is installed at the bottom end of a separation box in a penetrating mode. Through a conveying belt, the movable roller and the gas conveying pipe, generated steam is exhausted while soil is subjected to thermal stripping, the moisture content in the thermal stripping box is reduced, and meanwhile, heat is recycled for the second time, so that the movable roller is heated, the temperature of the movable roller is guaranteed, soil is heated while the conveying belt is dried, the soil is prevented from being attached to the surface of the conveying belt, and the treatment effect of the soil is guaranteed.

Owner:芷兰生态环境建设有限公司

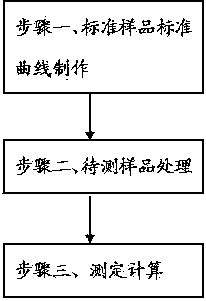

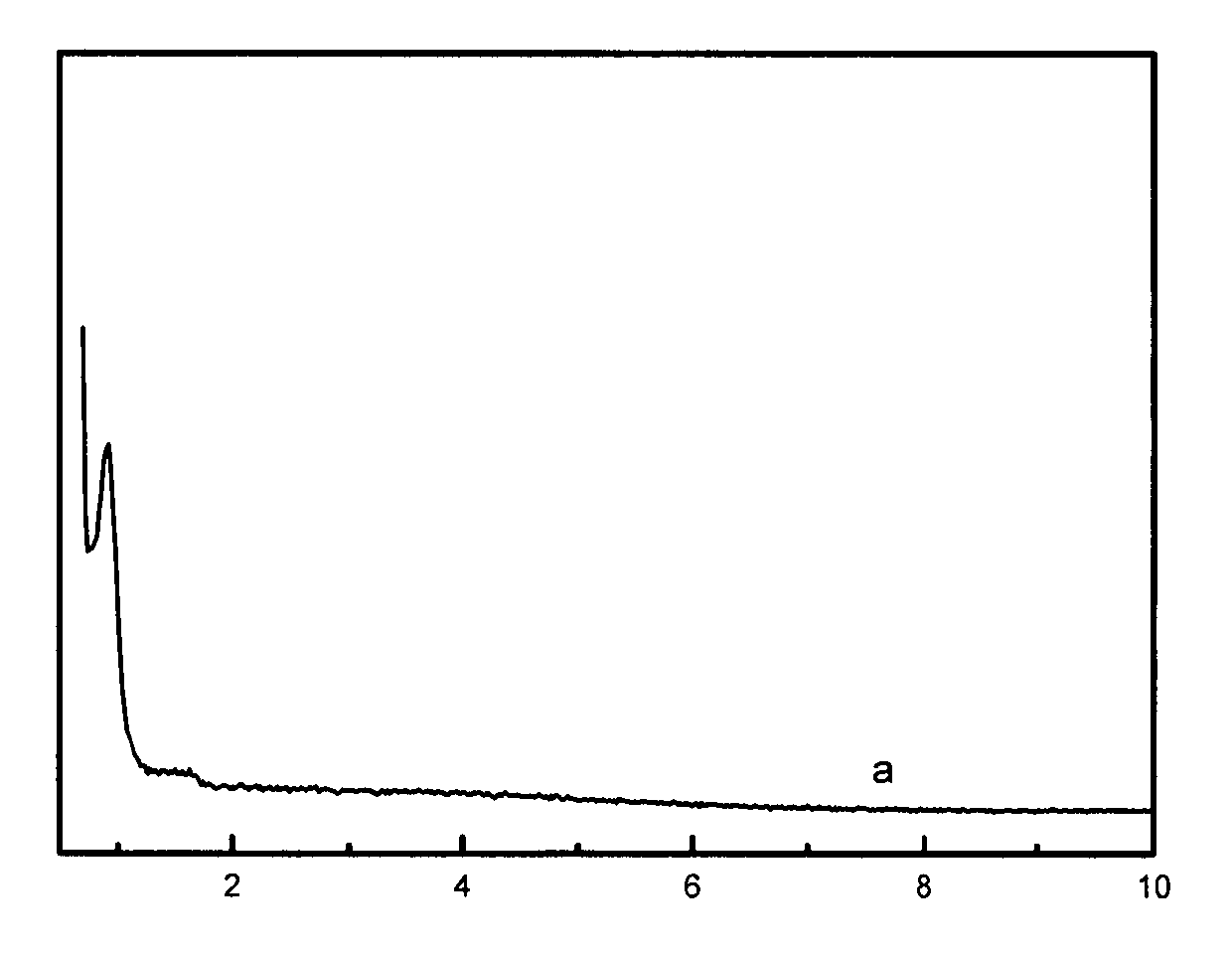

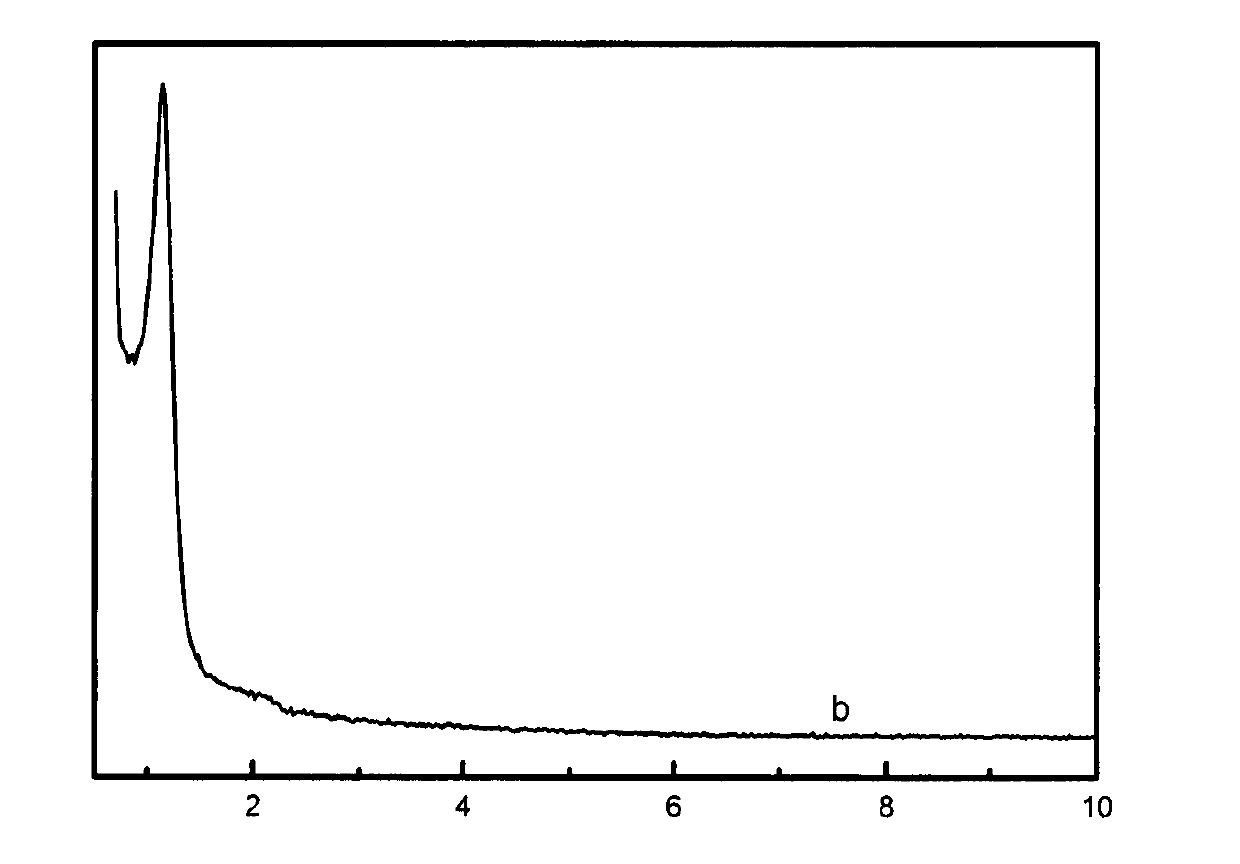

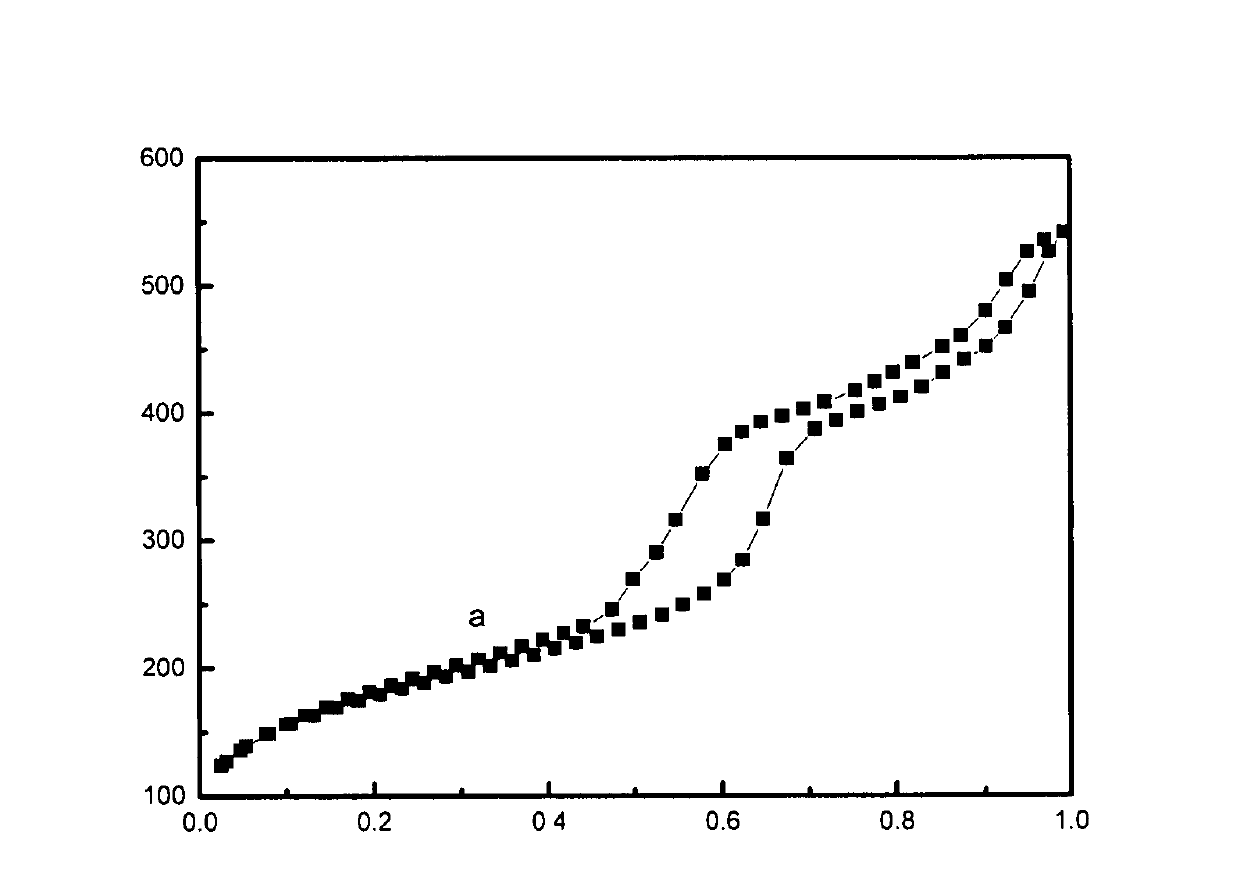

Method for rapidly measuring arsenic element in grain by X fluorescent spectrometry

InactiveCN104181182AIncrease randomnessAccurateMaterial analysis using wave/particle radiationCyclonePhysical chemistry

The invention discloses a method for rapidly measuring arsenic element in grain by an X fluorescent spectrometry. The method comprises the steps of step one, manufacturing a standard curve of a standard sample, namely sieving a series of arsenic grain powder with standard content gradient, putting the sieved powder into a sample cup and compacting; scanning a series of standard sample on a machine to obtain the X fluorescence intensity of the standard sample with known content, and calibrating the standard curve; and step two, treating a sample to be measured, namely removing peels of a certain amount of taken grain, grinding and sieving; packaging the taken powder into the sample cup and compacting to form the sample to be measured, wherein the amount of the powder is equal to that of the powder in the step one; testing by a machine, and calculating the content. Due to adoption of the method, the current detection accuracy and the repeatability are optimized, so that the high accuracy of the test results, good regularity and good evenness are guaranteed; meanwhile, the treatment method is simple, and only a hammer type cyclone grinder is used for grinding and sieving the sample, so that the time is short, and the pretreatment of the sample only needs 2 seconds; the instrument can test simply and can be operated by a key, no instrument exists, environmental protection is realized, and waste consumable is not produced.

Owner:JIANGSU SKYRAY INSTR

Loaded metallocene catalyst and preparation method thereof

The invention provides a loaded metallocene catalyst and a preparation method thereof. The catalyst comprises a carrier and a metallocene compound and alkyl aluminoxane which are loaded on the carrier, wherein the carrier is rodlike macroporous silica, the average particle diameter of the carrier is 20-80 micrometers, the specific surface area is 400-700 m<2> / g, the pore volume is 0.3-1.5 ml / g, the most probable aperture is 3-20 nanometers; the metallocene compound has the structure shown in formula 1, wherein M is one of titanium, zirconium and hafnium, and X is halogen. When the loaded metallocene catalyst is used for catalyzing olefin to polymerize, the catalytic efficiency can reach 2409 g PE / gcat-h.

Owner:CHINA PETROLEUM & CHEM CORP +1

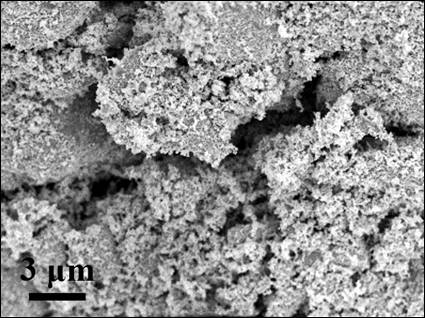

Preparation method and application of nano tungsten trioxide and nano tungsten powder

ActiveCN112222421AEasy to controlIncrease nucleation rateTungsten oxides/hydroxidesNanotechnologyAmmonium metatungstateMaterials science

The invention discloses a preparation method of nano tungsten trioxide and nano tungsten powder. The preparation method comprises the steps of firstly, dispersing carbon nanoparticles, then adding ammonium metatungstate, and uniformly stirring the materials to obtain a mixed solution; secondly, drying the mixed solution to obtain combined powder; thirdly, heating and decomposing the combined powder to obtain the nano tungsten trioxide; and fourthly, carrying out segmented hydrogen reduction on the nano tungsten trioxide to obtain the nano tungsten powder. In addition, the invention discloses application of the nano tungsten powder to preparation of superfine nano tungsten carbide and fine-grain tungsten alloy. According to the preparation method, the carbon nanoparticles are used as a nucleating agent and a pore-forming agent for decomposition of the ammonium metatungstate, and therefore the nucleation and growth processes of the tungsten trioxide are effectively controlled, the nucleation rate of the tungsten trioxide is increased, the granularity of the tungsten trioxide is reduced, the nano tungsten powder is obtained through hydrogen reduction, and the problems of regulation and control over the nucleation, the granularity and the dispersity in the ammonium metatungstate decomposition process are solved; and an application method of the nano tungsten powder is simple, crystal grains of a tungsten material are prevented from being coarse, and the high-performance tungsten material can be obtained advantageously.

Owner:西安稀有金属材料研究院有限公司

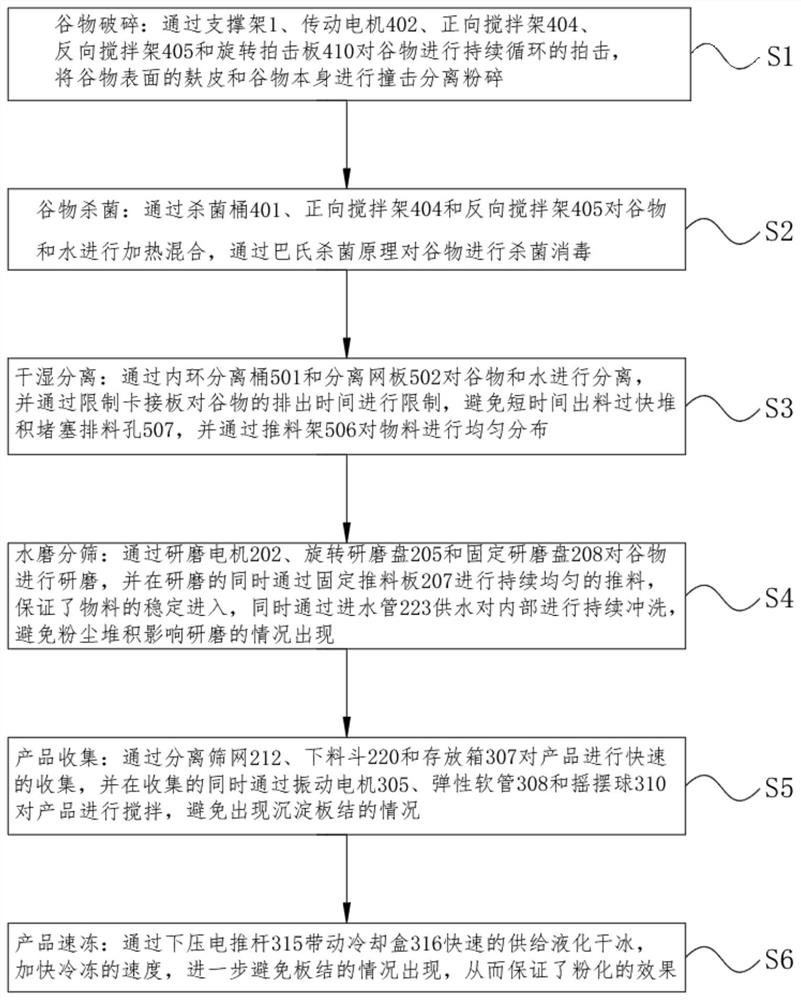

Preparation method of meal replacement powder

ActiveCN113198564AScientific and reasonable structureEasy to useGrain huskingGrain polishingMeal replacementProcess engineering

The invention discloses a preparation method of meal replacement powder. The preparation method comprises the steps of S1, cereal crushing; S2, cereal sterilization; S3, dry-wet separation; S4, water milling and screening; S5, product collection; S6, quick freezing of the product. The cereals are beaten and crushed, bran remaining on the surfaces of the cereals is removed, and large cereals are rapidly crushed, so that the surfaces of the cereals are clean. Meanwhile, the situation that a discharging port is blocked due to accumulation of large particles is avoided, the bacteria-free condition of subsequent production of the product is guaranteed through continuous sterilization, dry-wet separation is conducted on the sterilized product, a large amount of water is prevented from rapidly entering the grinding position, and therefore the concentration of a powder solution is guaranteed, and the situation that the drying efficiency is affected due to too low concentration is avoided. Dust raising and wet powder accumulation caused by too dry powder are avoided through water milling, normal production of the product is guaranteed, and in addition the production quality of the product is guaranteed.

Owner:东莞市霖鑫牛食品科技有限公司

Process for producing sand alumina by Bayer precipitation process

InactiveCN1594094AGuaranteed GranularityGuaranteed StrengthAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionFoxtail

The invention discloses a pocess for producing sand alumina by Bayer precipitation process which consists of, charging seed crystal into refined aluminum oxide solution in one or two times for decomposition, separating the obtained decomposition product by grades, returning the seed crystal back to decomposition process, subjecting the aluminum hydroxide product to filtering, scouring, drying, and sintering to obtain the sand form aluminum oxide product.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

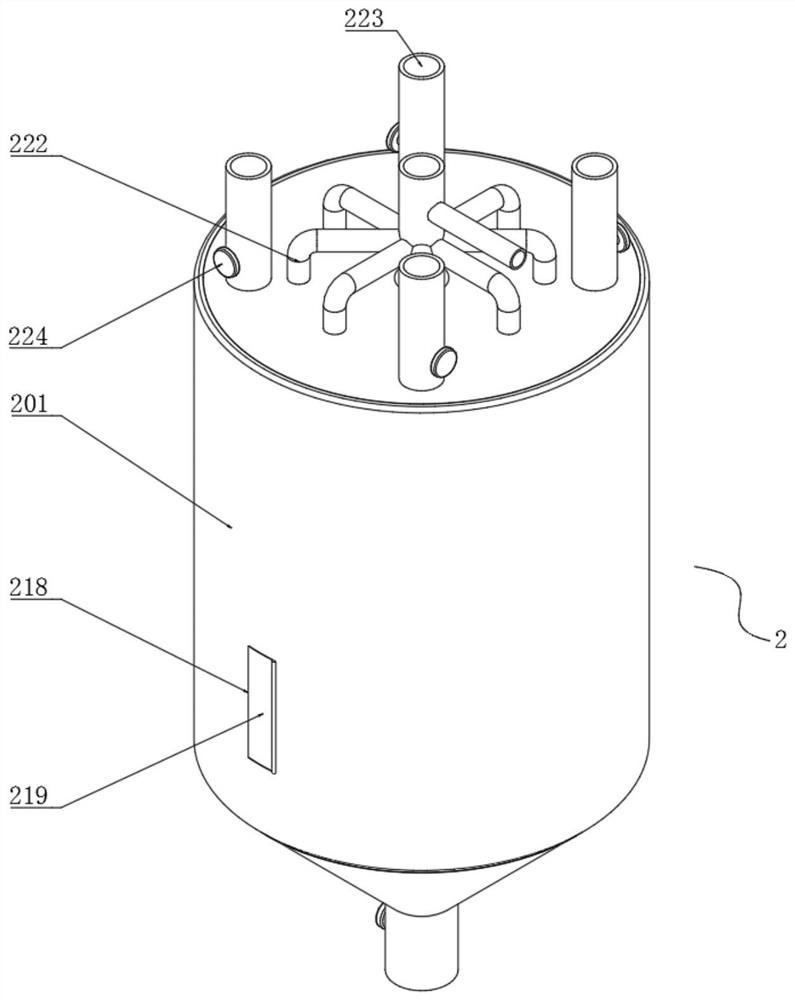

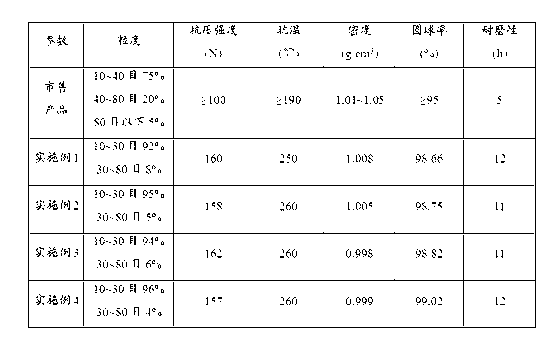

Plastic ball solid lubricating agent for drilling fluid and method for preparing plastic ball solid lubricating agent

ActiveCN103013462AAvoid stickingGuaranteed shapeDrilling compositionBenzoyl peroxidePolyvinyl alcohol

The invention discloses a plastic ball solid lubricating agent for drilling fluid and a method for preparing the plastic ball solid lubricating agent. The plastic ball solid lubricating agent for the drilling fluid is prepared from the raw materials in parts by weight: 35-56 parts of styrene, 6-10 parts of divinylbenzene, 5-10 parts of acrylic acid, 5-10 parts of polytetrafluoroethylene, 10-20 parts of paraffin, 10-15 parts of silicon dioxide, 0.5-1 part of benzoyl peroxide, 0.5-1 part of polyvinyl alcohol and 0.5-1.5 parts of dodecylbenzene sulfonic acid. The method for preparing the plastic ball solid lubricating agent comprises the following five steps of resistance removing, soaking, crosslinking, sepherical boiling and grading. The high temperature resistance and extrusion resistance of the plastic ball solid lubricating agent for the drilling fluid are improved, the density is close to water density, and the plastic ball solid lubricating agent can realize the purposes of effectively lubricating and preventing blockaged.

Owner:河北华运鸿业化工有限公司

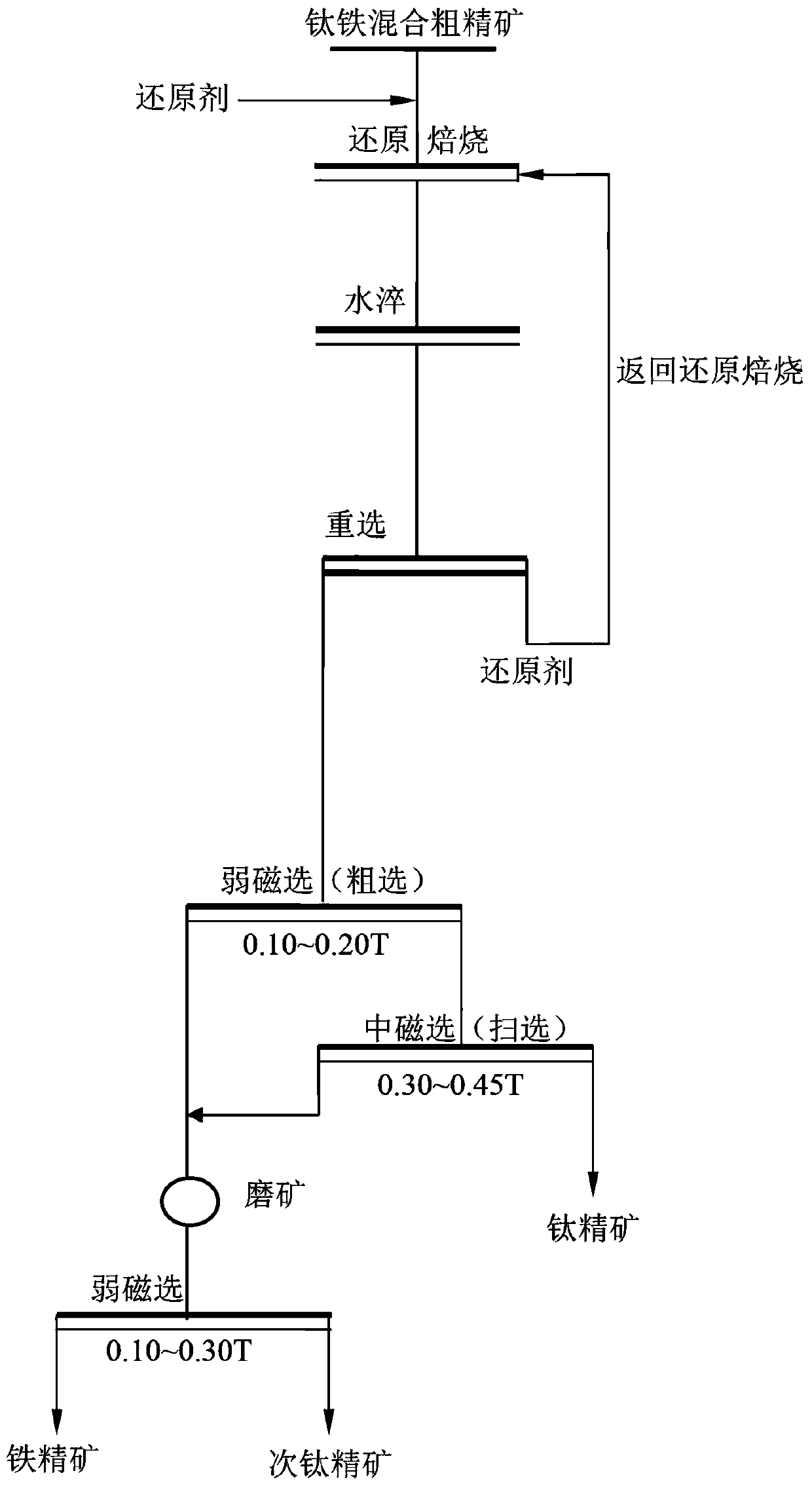

Method for titanium and iron separation and upgrading of titanium rough concentrate of beach placer

ActiveCN110292989AImprove qualitySimple processMagnetic separationWet separationGravity separationTitanium

The invention discloses a method for titanium and iron separation and upgrading of titanium rough concentrate of beach placer. The method comprises the following steps of adding a solid reducing agentinto the titanium rough concentrate, and carrying out reduction roasting by using a rotary kiln to obtain calcine; carrying out water quenching on the calcine, then carrying out gravity separation onthe calcine through a shaking table to recover excessive solid reducing agent to obtain a reducing agent and heavy concentrate; performing two-stage low-intensity magnetic separation on the heavy concentrate to obtain iron rough concentrate and titanium concentrate; and carrying out fine grinding on the iron rough concentrate, and carrying out separation by adopting low-intensity magnetic separation to obtain magnetite concentrate and secondary titanium concentrate. According to the method for titanium and iron separation and upgrading of the titanium rough concentrate containing hematite alteration, titanium and iron are efficiently separated, the quality of the titanium concentrate is improved, meanwhile, the iron concentrate is recovered, the process is simple, no medicament pollutionexists, the process is easy to operate, and the method is convenient to popularize.

Owner:广东省科学院资源利用与稀土开发研究所

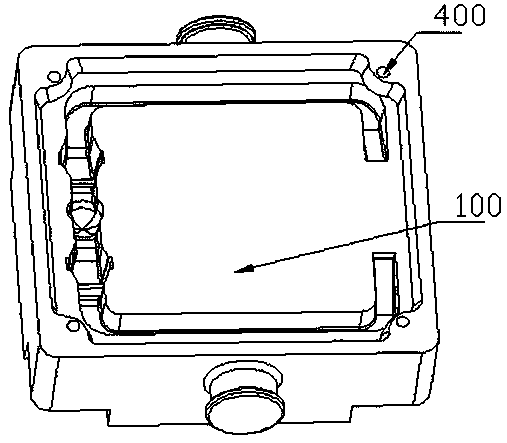

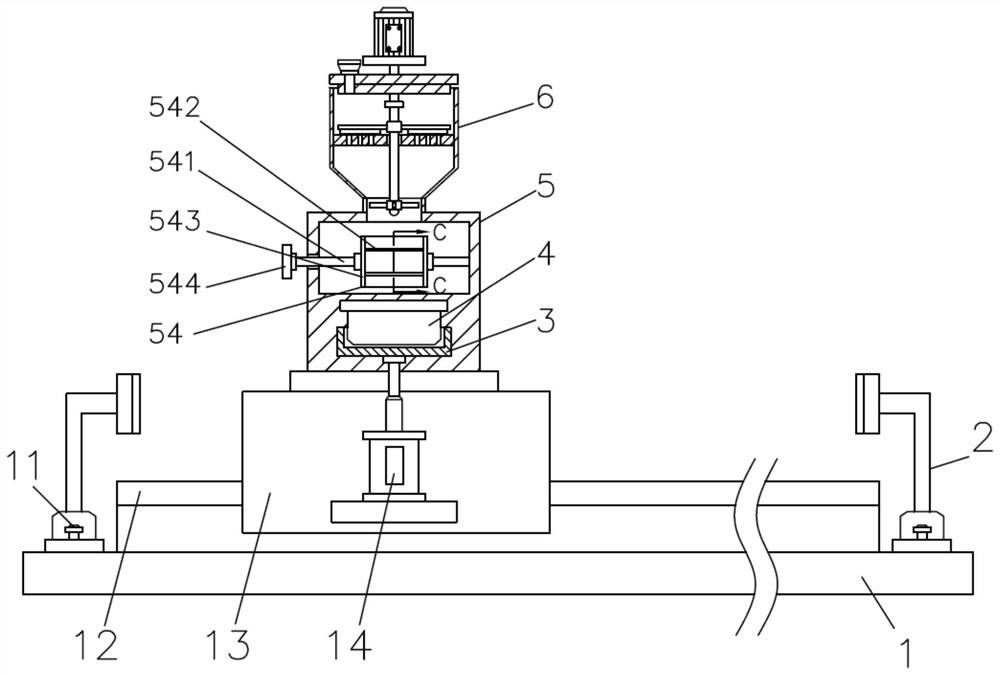

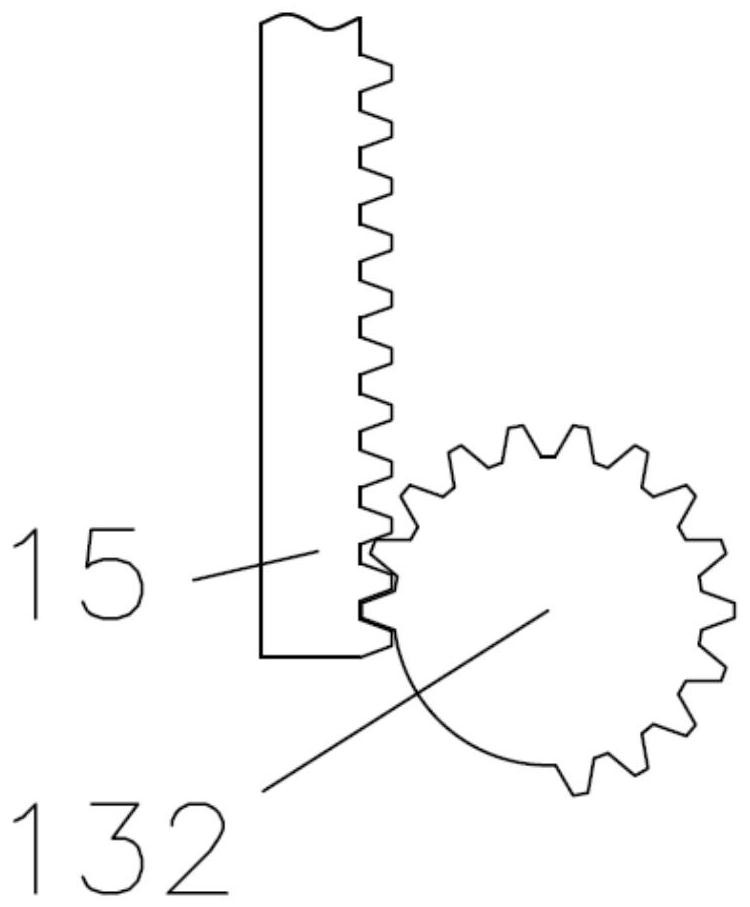

Feed throwing device for aquatic animal breeding

ActiveCN112044758AAvoid repeated additionImprove feeding efficiencySievingTransportation and packagingAnimal scienceAquatic animal

The invention provides a feed throwing device for aquatic animal breeding. The feed throwing device comprises a base (1), two sliding rails (12) are symmetrically and fixedly installed on the upper surface of the base (1), a sliding table (13) is jointly and slidably connected to the two sliding rails (12), a material putting box (5) and a gearbox (7) are fixedly installed at the top end of the sliding table (13), and a material storage mechanism (6) is fixedly installed at the top end of the material putting box (5). An air cylinder (14) is fixedly installed in the sliding table (13), a supporting plate (3) is fixedly installed at the output end of the air cylinder (14), a leakage receiving box (4) is installed at the top end of the supporting plate (3) in a clamped mode, and the supporting plate (3) and the leakage receiving box (4) are both located at the bottom of the material putting box (5). According to the feed throwing device, putting of feed particles can be achieved in the operation process, meanwhile, the uniformity of feed feeding is guaranteed through screening and processing of the feed particles, and therefore the uniformity degree of feeding is guaranteed; and thedevice is high in mechanization degree, and manpower and material resources are saved.

Owner:CHONGQING UNIV OF ARTS & SCI

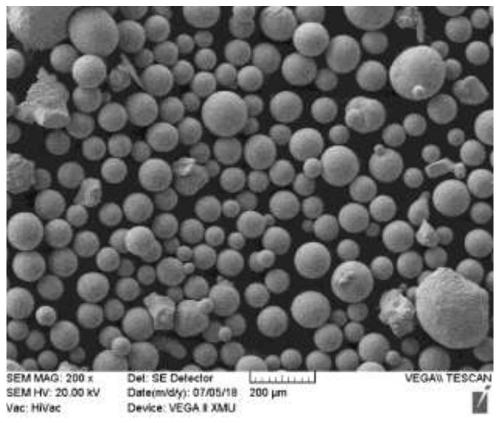

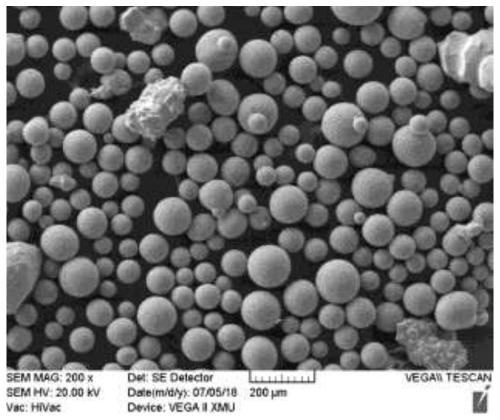

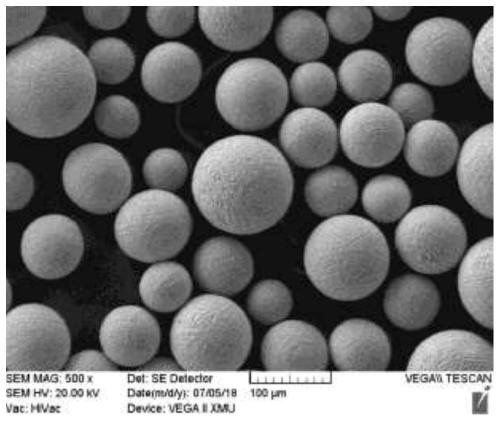

Preparation method of low-cost medium carbon steel spherical powder for 3D printing

PendingCN111570814AHigh sphericityGood surface morphologyTransportation and packagingMetal-working apparatusCarbon steelVacuum induction melting

The invention discloses a preparation method of low-cost medium carbon steel spherical powder for 3D printing. The preparation method comprises the following steps: proportioning medium carbon steel from the following components: 0.43% of C, 0.58% of Mn, 0.18% of Si, 0.25% of Cr, 0.24% of Ni and the balance of Fe, adopting vacuum induction melting to prepare a carbon steel bar, removing the oxidescale on the surface of the alloy bar through machining to process an electrode bar size meeting the requirement of a plasma rotating electrode atomization powder manufacturing apparatus, placing theelectrode bar in a flour mill, adopting a plasma gun to melt the end part of the electrode bar to obtain spherical powder under the action of the centrifugal force, and later, adopting supersonic vibration to screen the collected powder according to different particle sizes. According to the preparation method, plasma rotating electrode atomization is adopted to prepare medium carbon steel spherical metal powder, and the prepared powder has the characteristics of being high in degree of sphericity, less in satellite powder, high in powder density and low in impurity content, can meet the demand of metal powder for 3D printing and is suitable for wide popularization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com