Method for titanium and iron separation and upgrading of titanium rough concentrate of beach placer

A technology for the separation of titanium and iron and coarse concentrate, which is applied in the field of mineral processing, can solve the problems of unutilized and separated, and achieve the effects of no chemical pollution, simple process and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Composition of seashore titanium sand rough concentrate: TiO 2 42.20%, Fe 38.76%, CaO 0.20%, MgO 0.62%, Al 2 o 3 0.82%, SiO 2 2.29%.

[0034] Above-mentioned raw ore is passed through following processing steps:

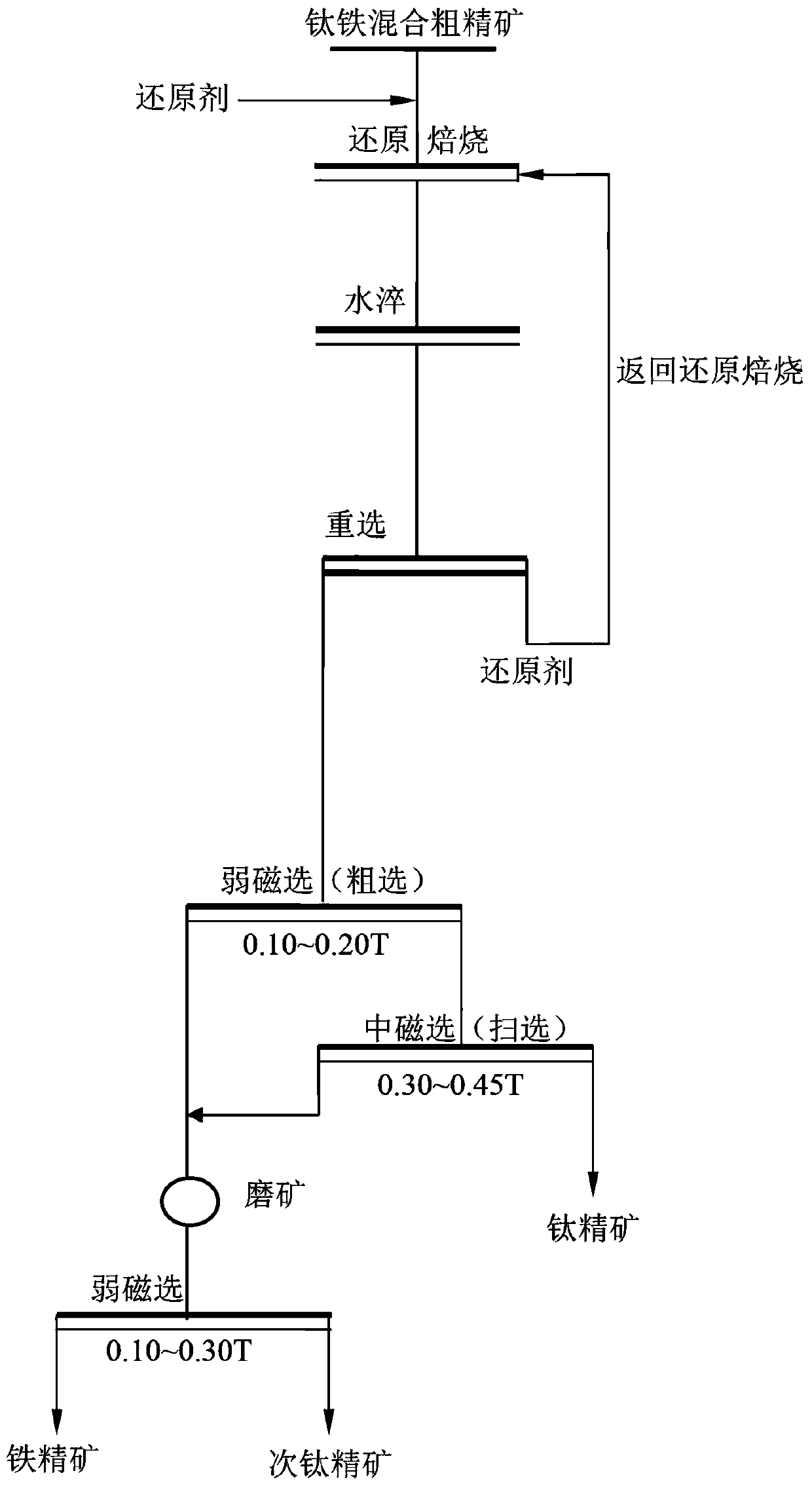

[0035] (1) Add 15% reduced carbon powder and mix evenly with titanium coarse concentrate, use rotary kiln equipment to carry out reduction roasting, the roasting temperature is 875 ° C, and the reduction roasting time is 55 minutes to obtain calcined sand;

[0036] (2) The calcined sand obtained by reduction roasting is cooled by water quenching, and then the excessive reducing agent in the calcined sand is recovered by a shaking table gravity separation process, and heavy sand is obtained;

[0037] (3) The heavy sand is separated by a two-stage weak magnetic separation process. The strength of the weak magnetic separation rough separation is 0.15T to obtain iron coarse concentrate 1. The rough separation tailings are subjected to weak magnetic separation ...

Embodiment 2

[0042] Composition of seashore titanium sand rough concentrate: TiO 2 : 43.07%, Fe: 41.47%, CaO: 0.18%, MgO: 0.51%, Al 2 o 3 : 0.83%, SiO 2: 1.85%.

[0043] Above-mentioned raw ore is passed through following processing steps:

[0044] (1) Add 25% reduced carbon powder and mix evenly with titanium coarse concentrate, and use rotary kiln equipment to carry out reduction roasting, the roasting temperature is 750 ° C, and the reduction roasting time is 85 minutes to obtain calcined sand;

[0045] (2) The calcined sand obtained by reduction roasting is cooled by water quenching, and then the excessive reducing agent in the calcined sand is recovered by a spiral chute gravity separation process, and heavy sand is obtained;

[0046] (3) The heavy sand is separated by two-stage weak magnetic separation process, the strength of weak magnetic rough separation is 0.10T, and iron coarse concentrate 1 is obtained. The strength is 0.30T, and the iron coarse concentrate 2 and titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com