Patents

Literature

89results about How to "Avoid dust pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

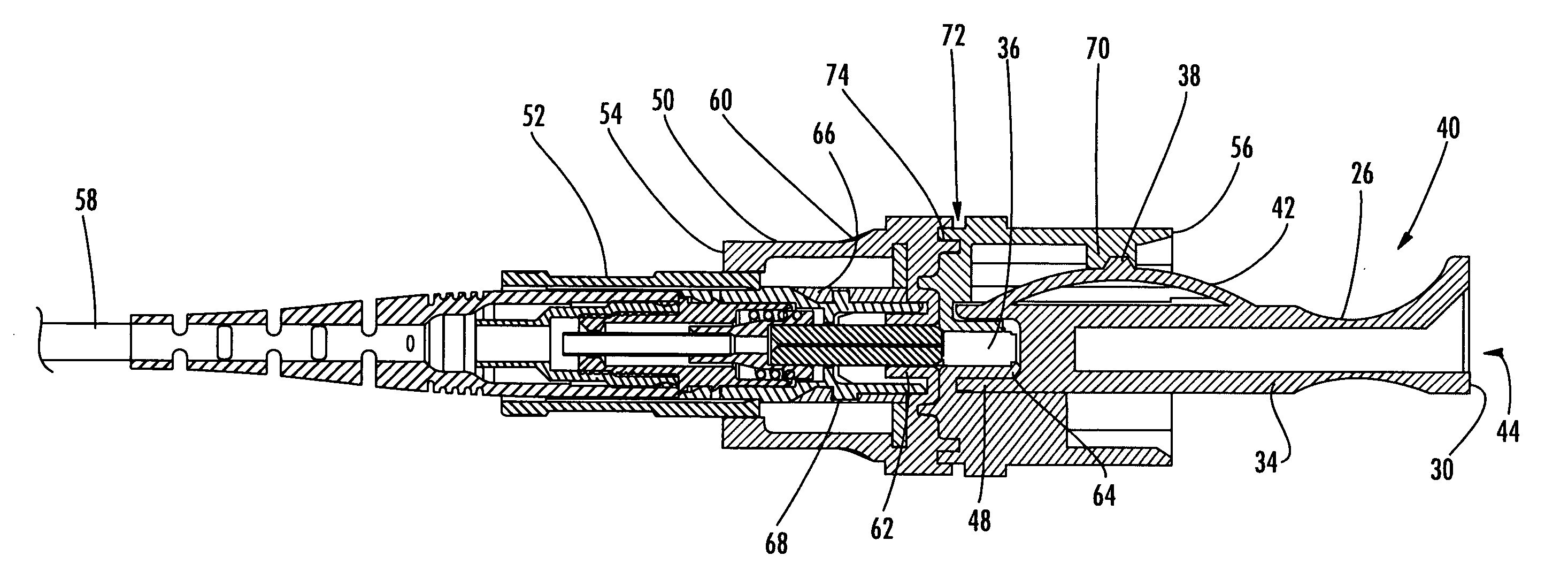

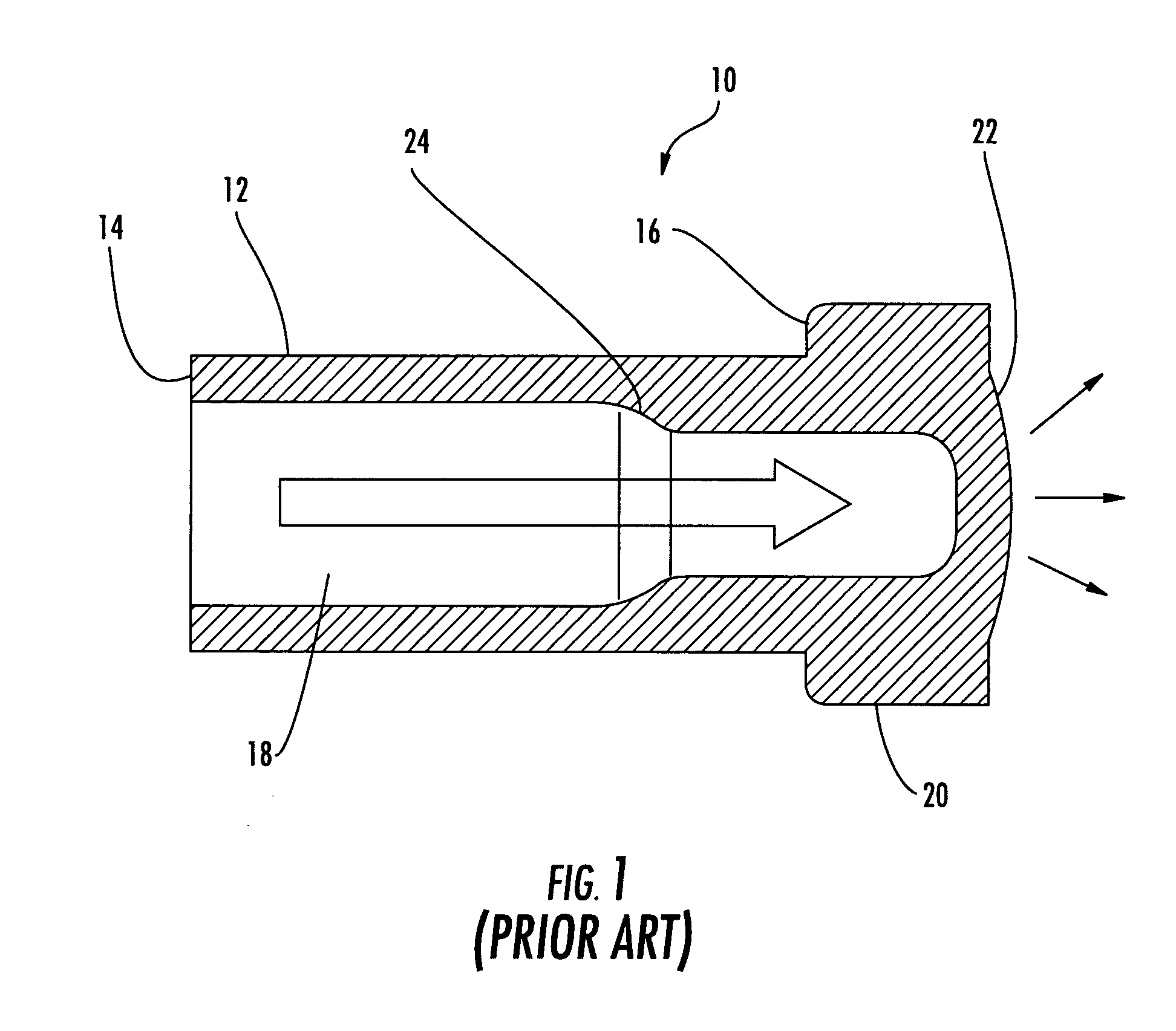

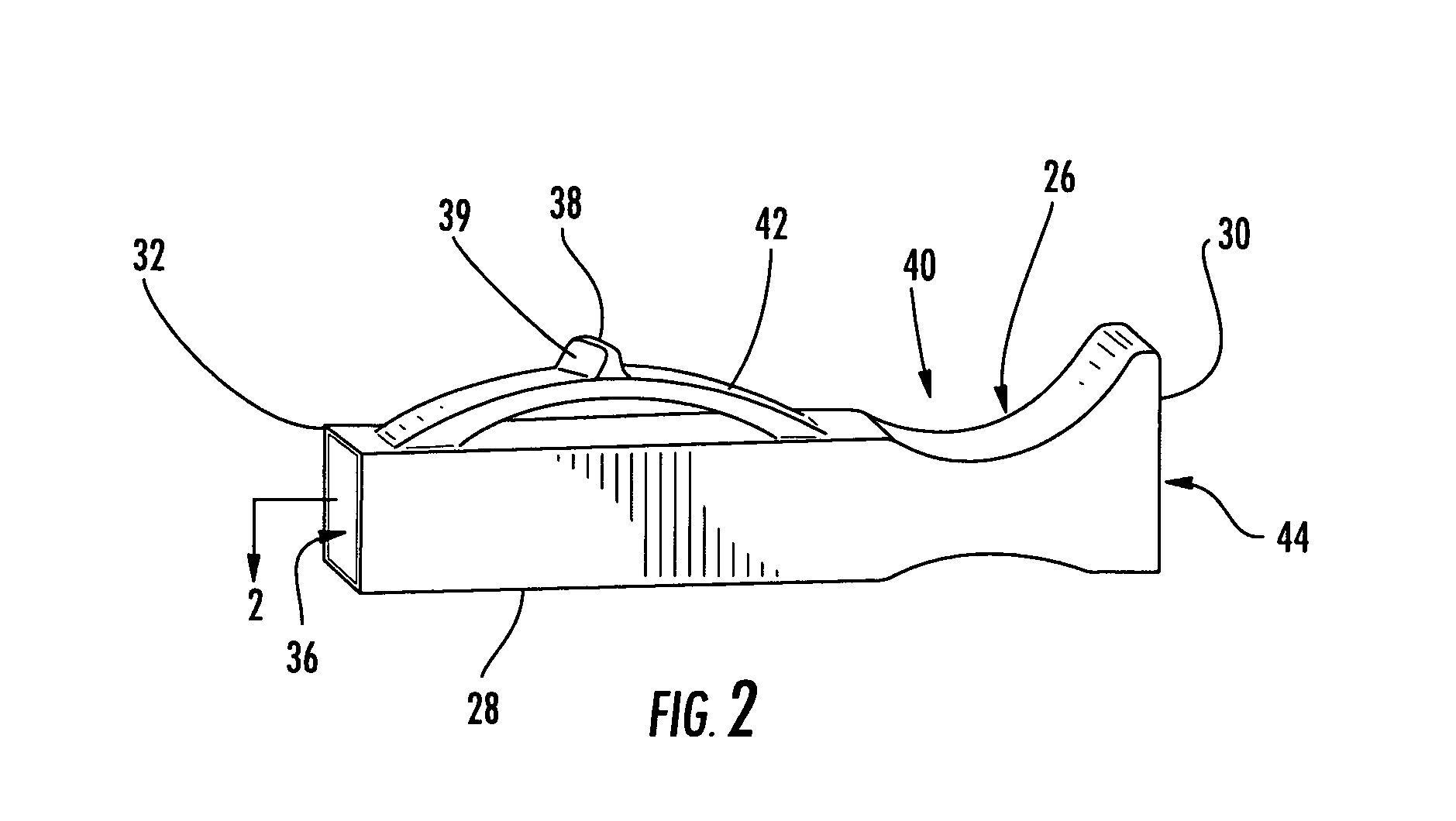

Dust cap for fiber optic adapter

An adapter dust cap comprising a dust cap body defining a clearance extending at least partially therethrough, a resilient member attached to the connector body, and a latching feature attached to the resilient member and configured to engage within internal geometry defined by a connector adapter. The adapter dust cap is translucent so that visible light from a connector may diffuse therethrough, and may include a material or coating thereon for converting light in the invisible spectrum to visible light so that the light can be detected through the dust cap without removing the dust cap from an adapter to which it is engaged.

Owner:CORNING OPTICAL COMM LLC

Optical device utilized in laser projector

ActiveUS20150029472A1Avoid problemsAvoid damageProjectorsColor television detailsLaser projectorMechanical engineering

An optical device utilized in a laser projector includes a circulatory air channel, a phosphor wheel disposed in the circulatory air channel, a thermal exchanger partially disposed in the circulatory air channel, and an air guiding component disposed in the circulatory air channel for guiding an air provided by the thermal exchanger toward the phosphor wheel. The temperature of the air passing through the phosphor wheel is lower than an environment temperature.

Owner:DELTA ELECTRONICS INC

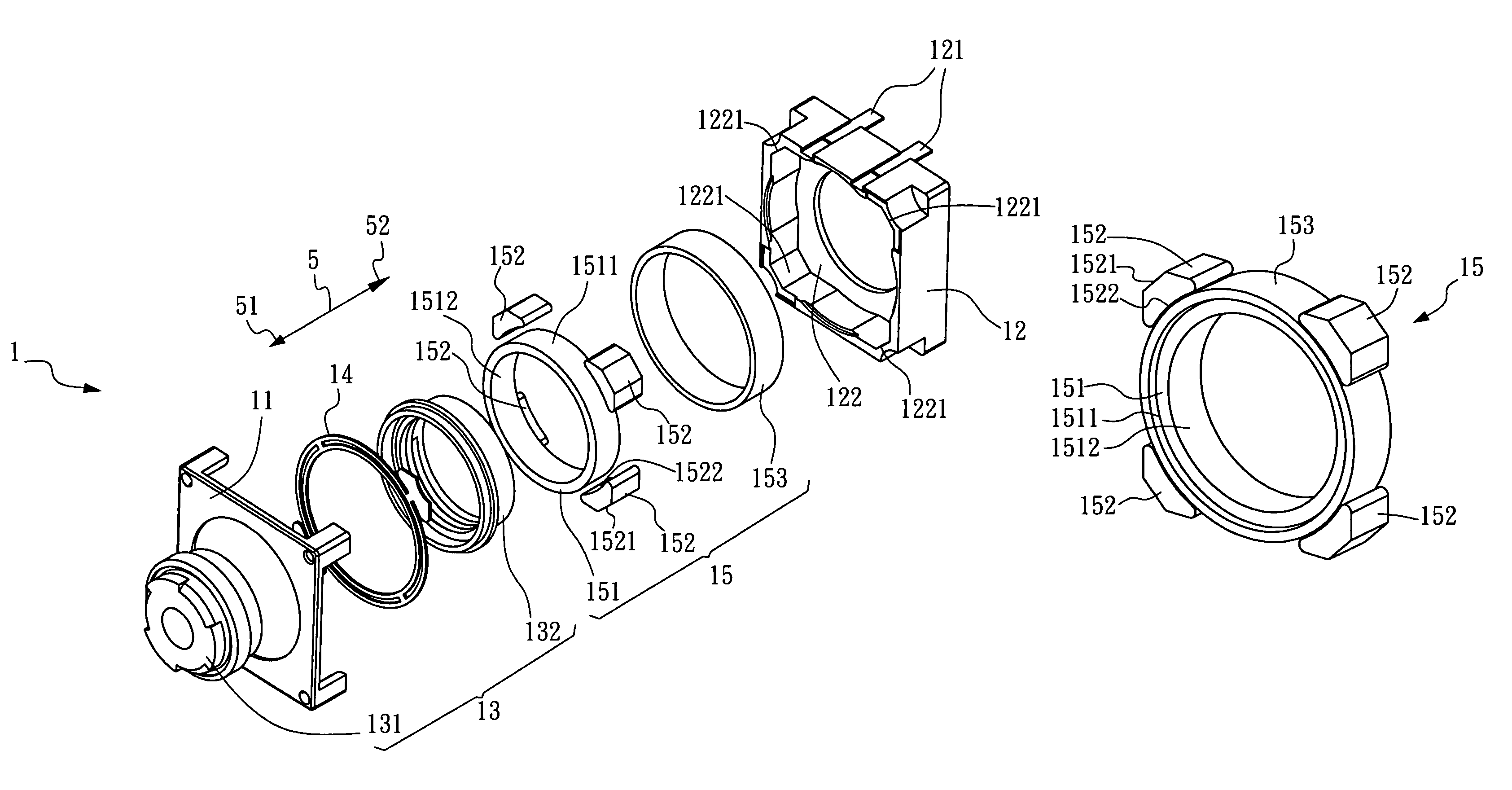

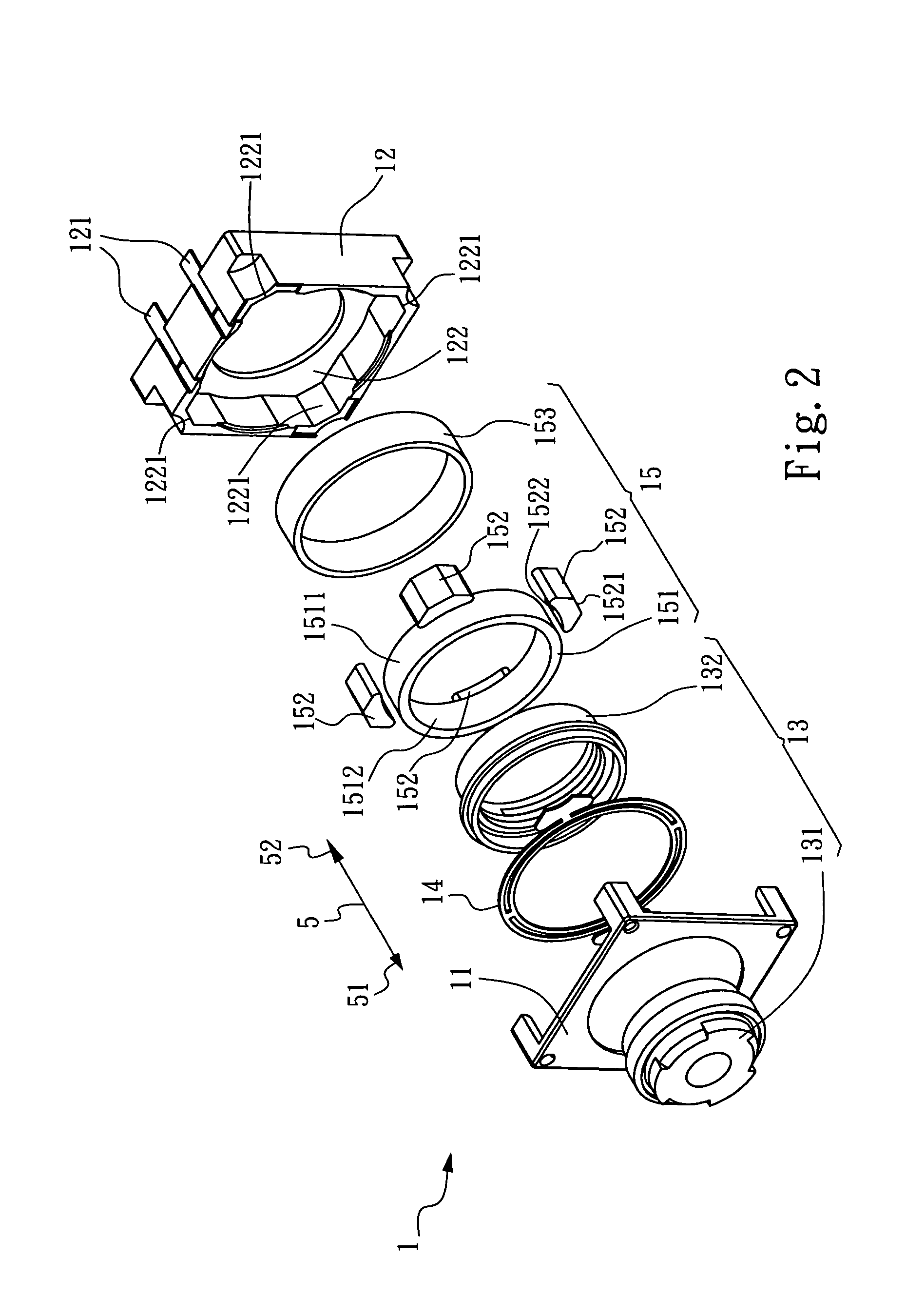

Miniature magnetic-levitated lens driving device

InactiveUS8040621B2Provide resistanceReduce frictionProjector focusing arrangementCamera focusing arrangementEngineeringMicroparticle

Owner:POWERGATE OPTICAL INC

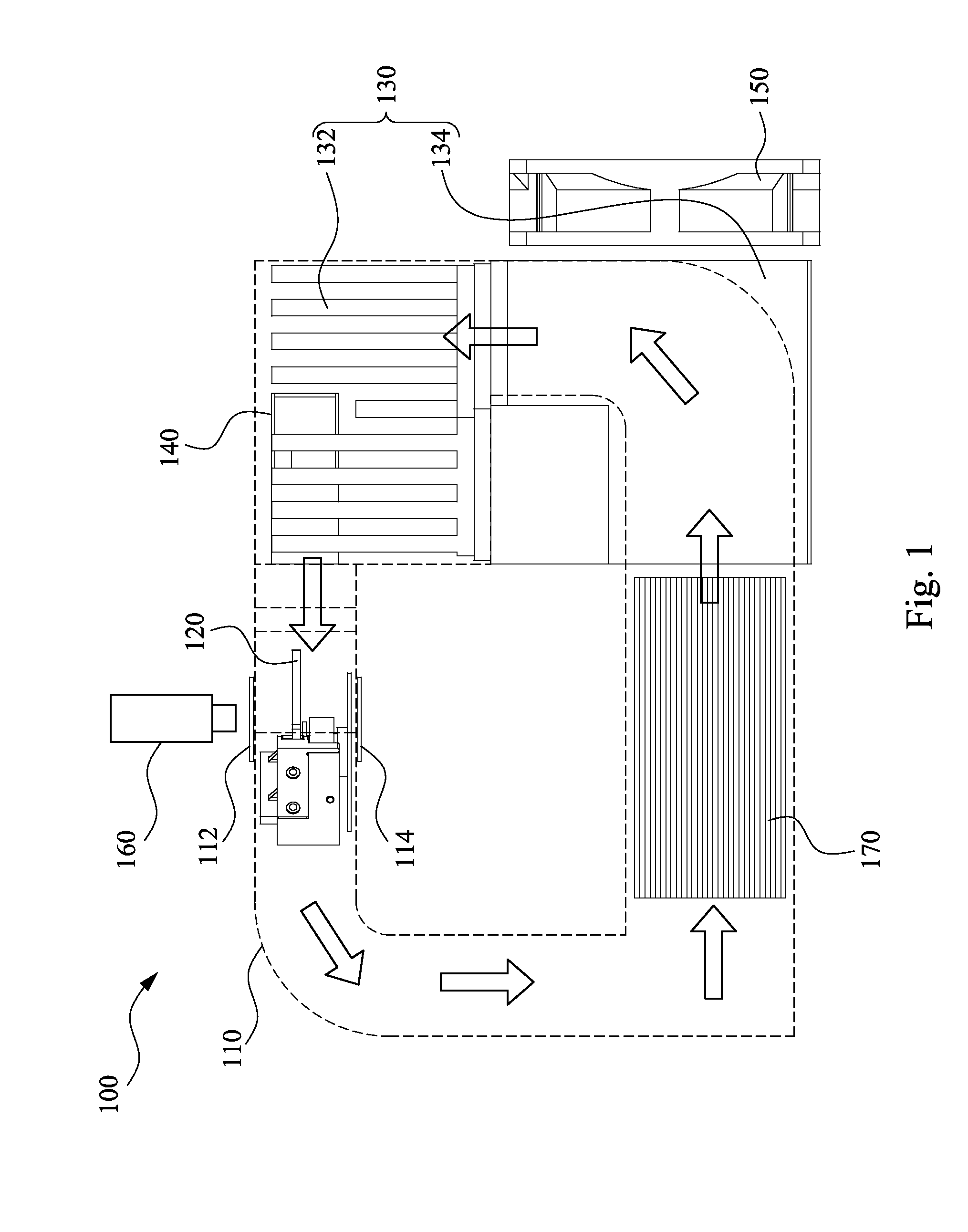

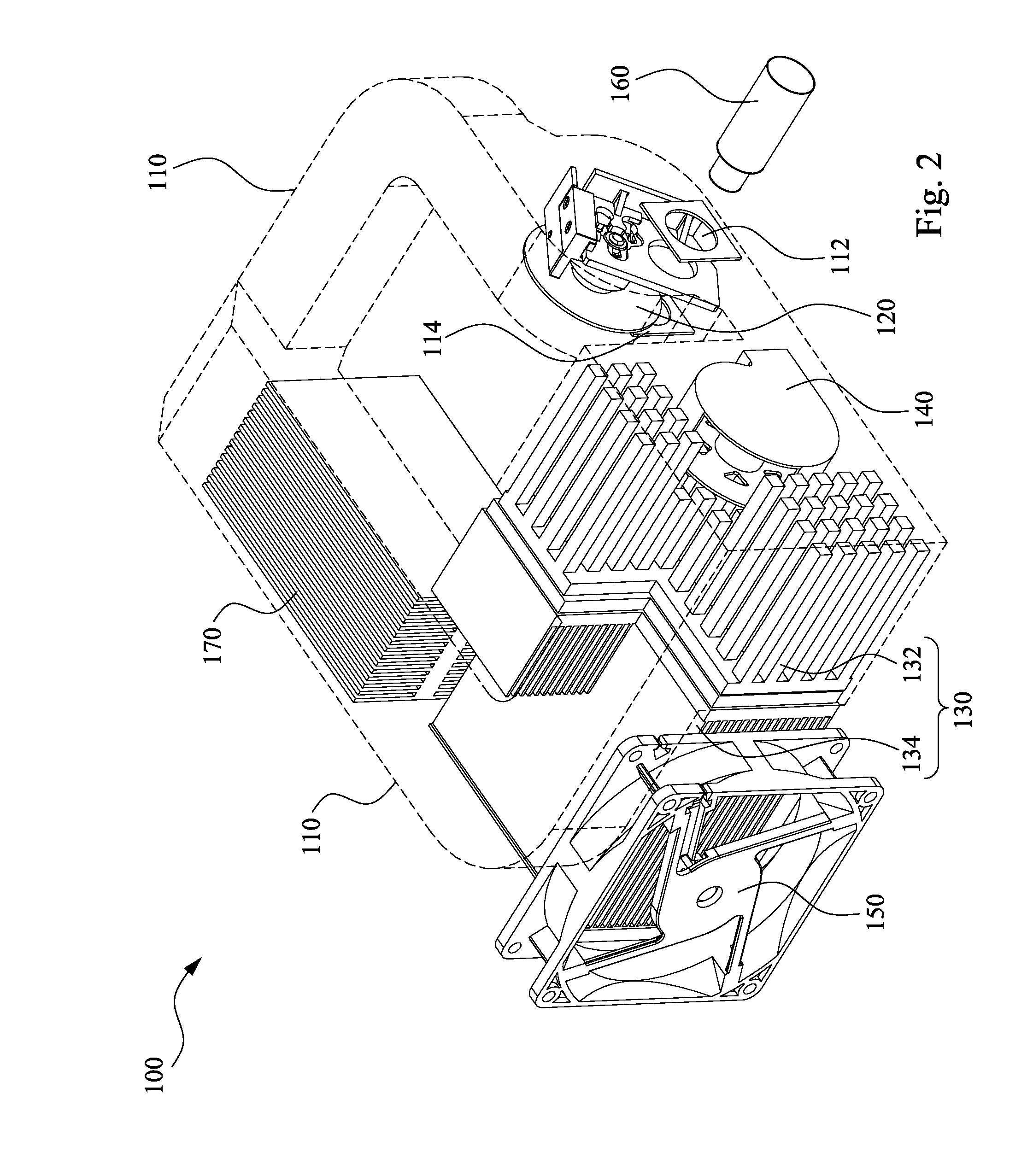

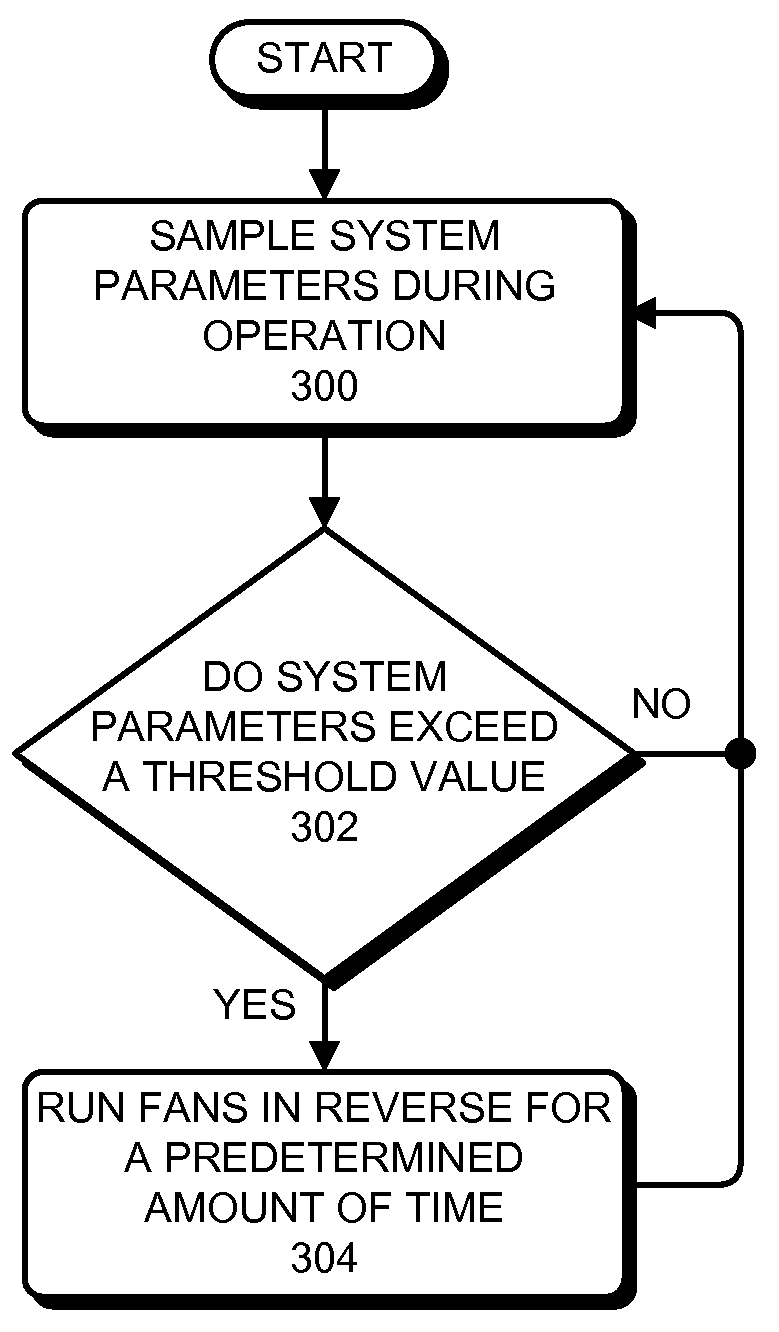

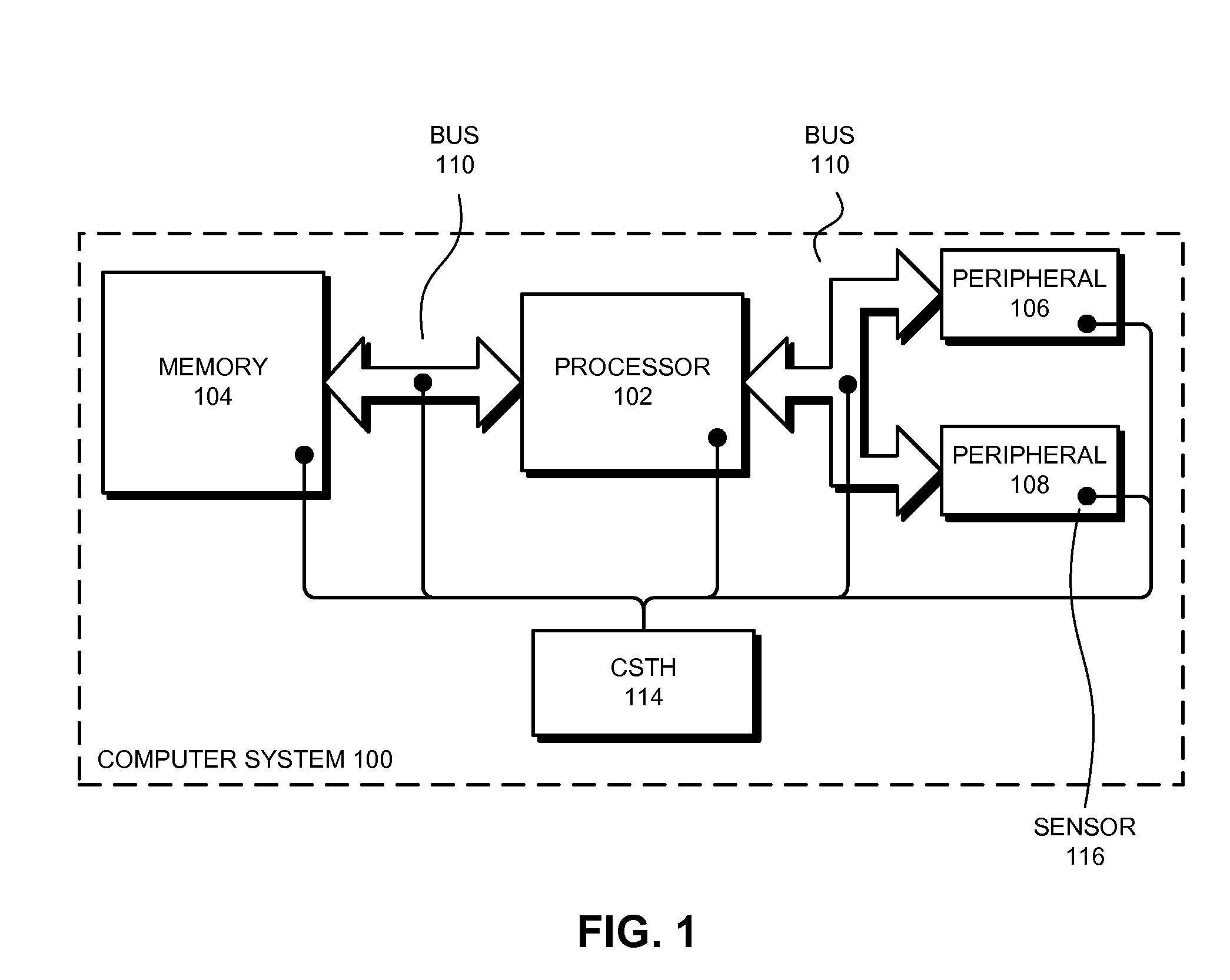

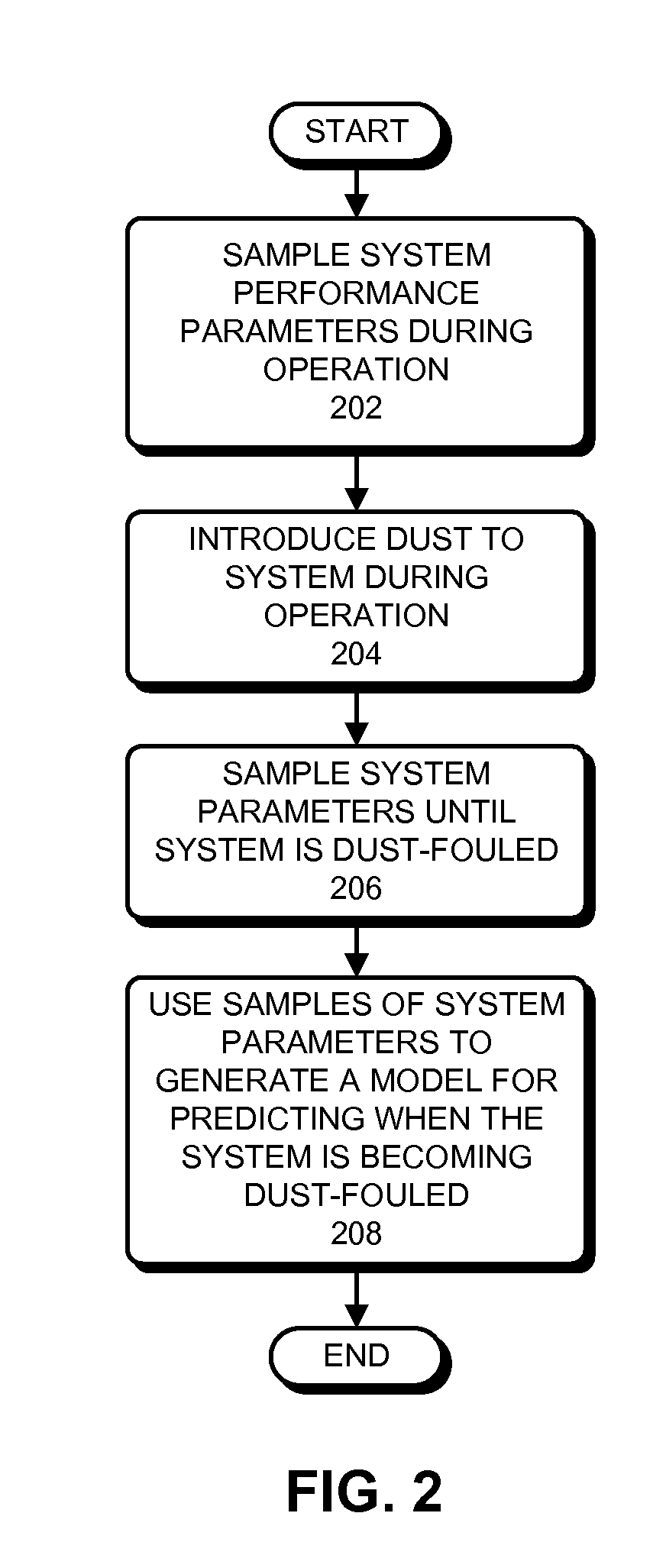

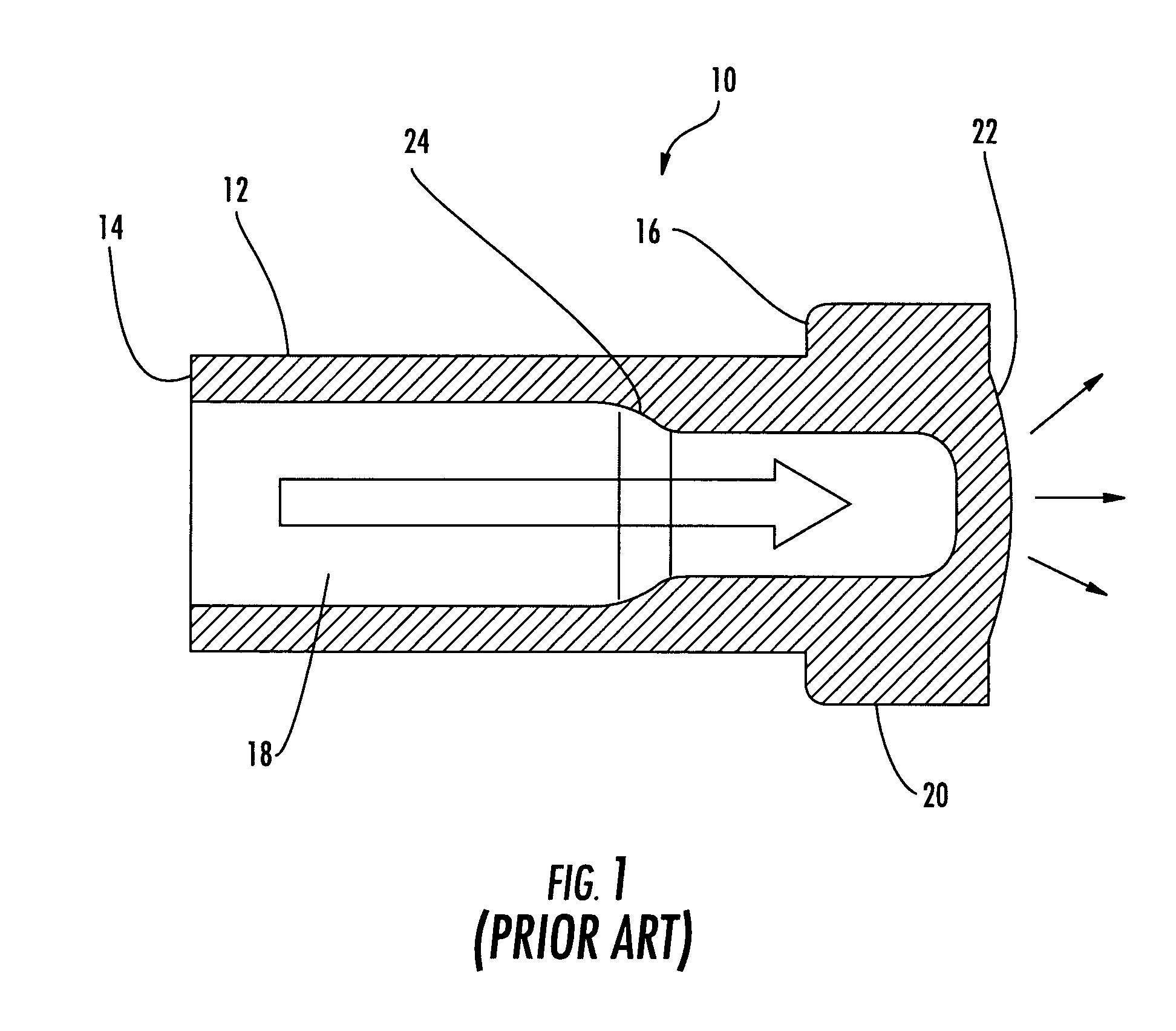

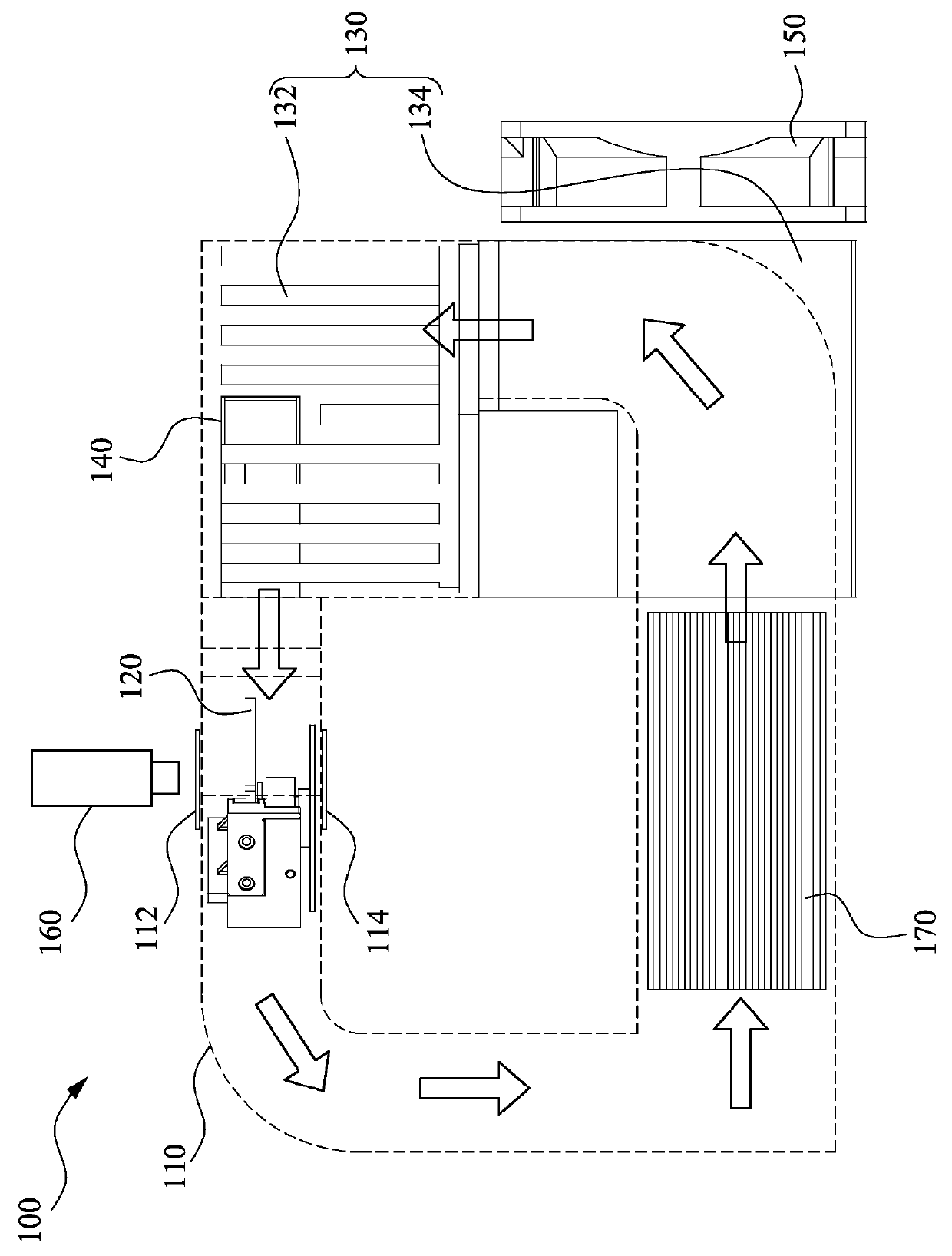

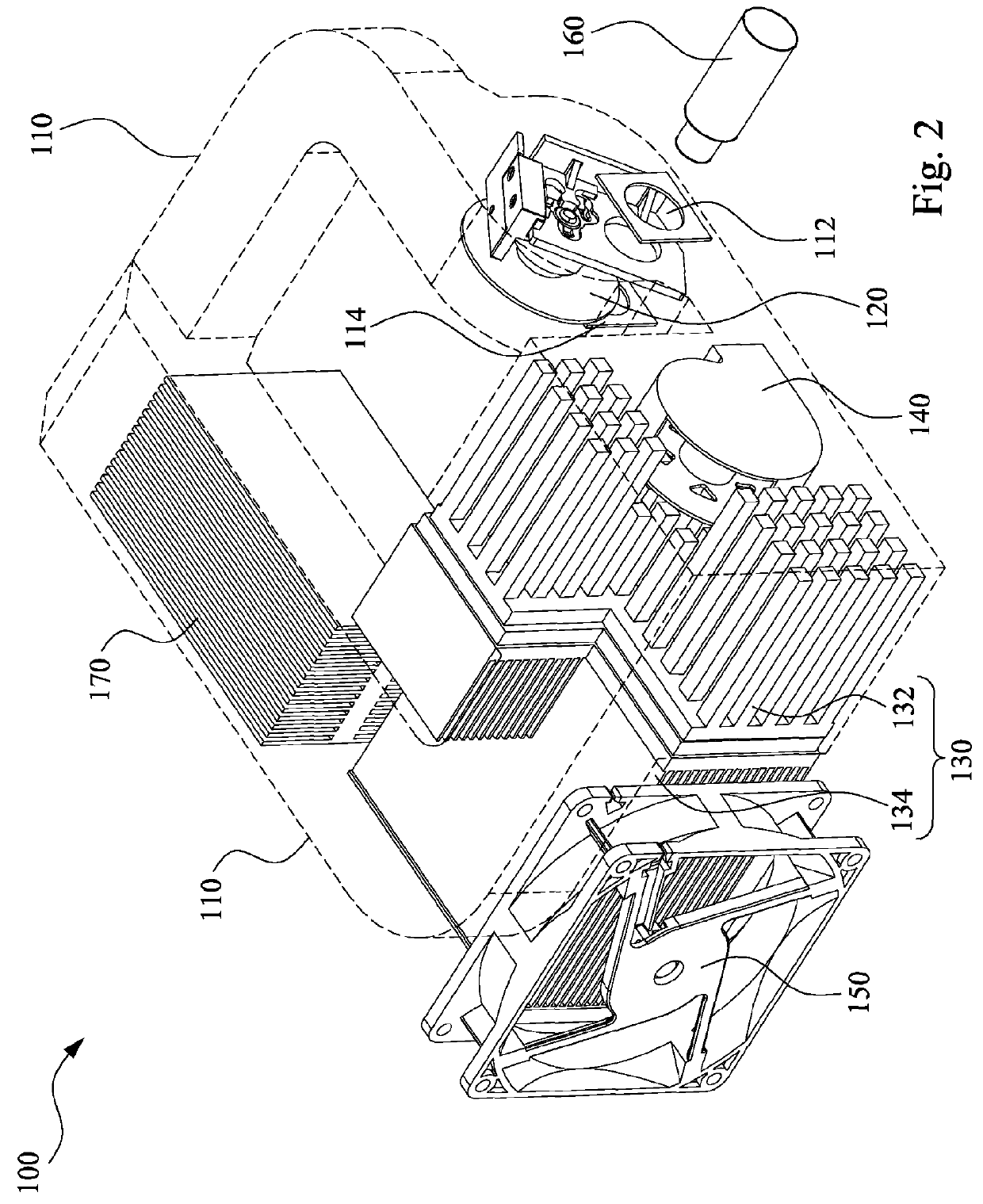

Method and apparatus for mitigating dust-fouling problems

InactiveUS20090009960A1Avoid dust pollutionComputation using non-denominational number representationModifications using gaseous coolantsComputerized systemEngineering

Embodiments of the present invention provide a system for preventing dust-fouling in a computer system. During operation of the computer system, the system monitors the computer system and determines if the computer system is becoming dust-fouled. If so, the system reverses fans in the computer system to circulate air through the computer system in the opposite direction to dislodge and disperse dust from the computer system.

Owner:SUN MICROSYSTEMS INC

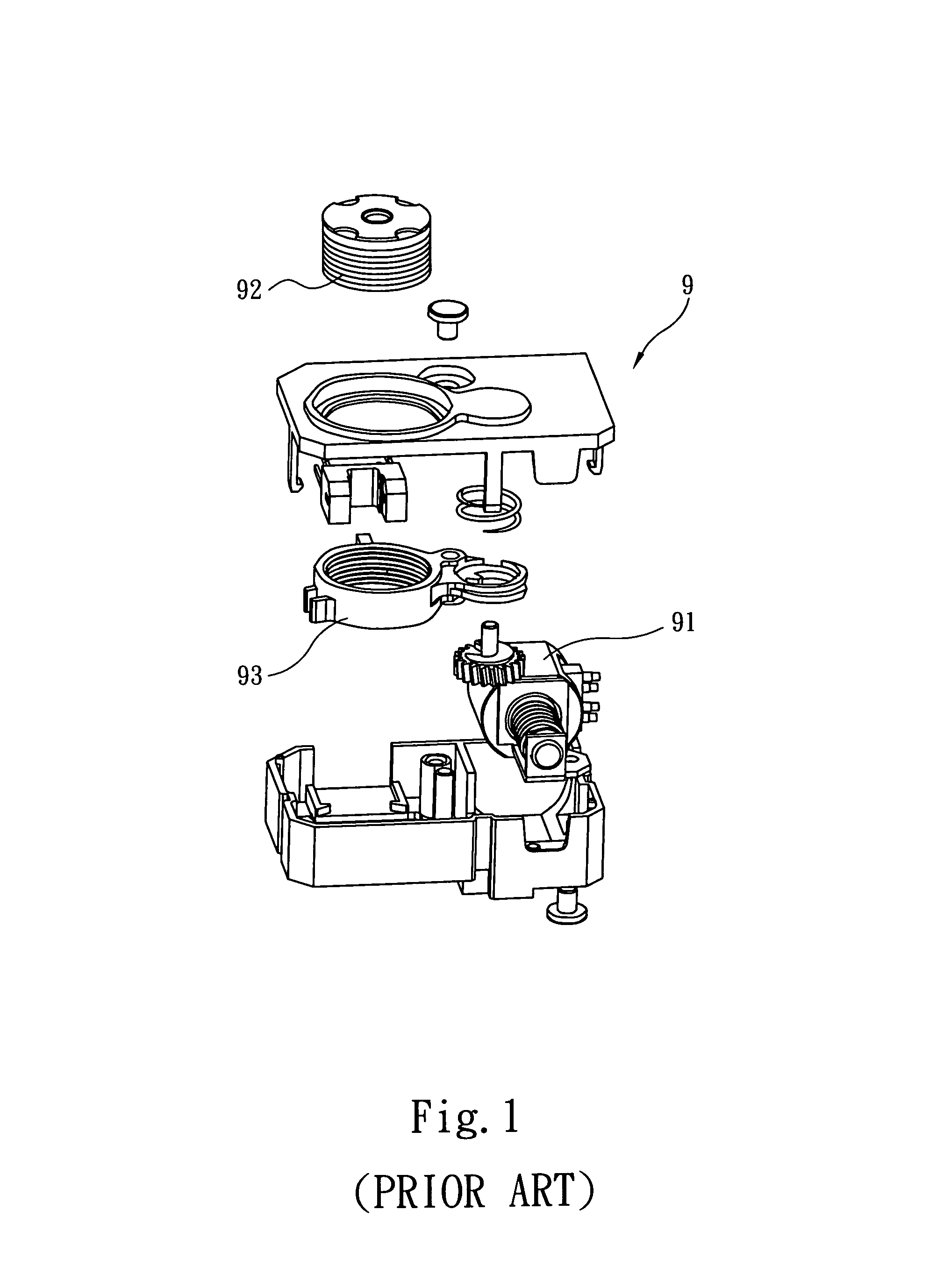

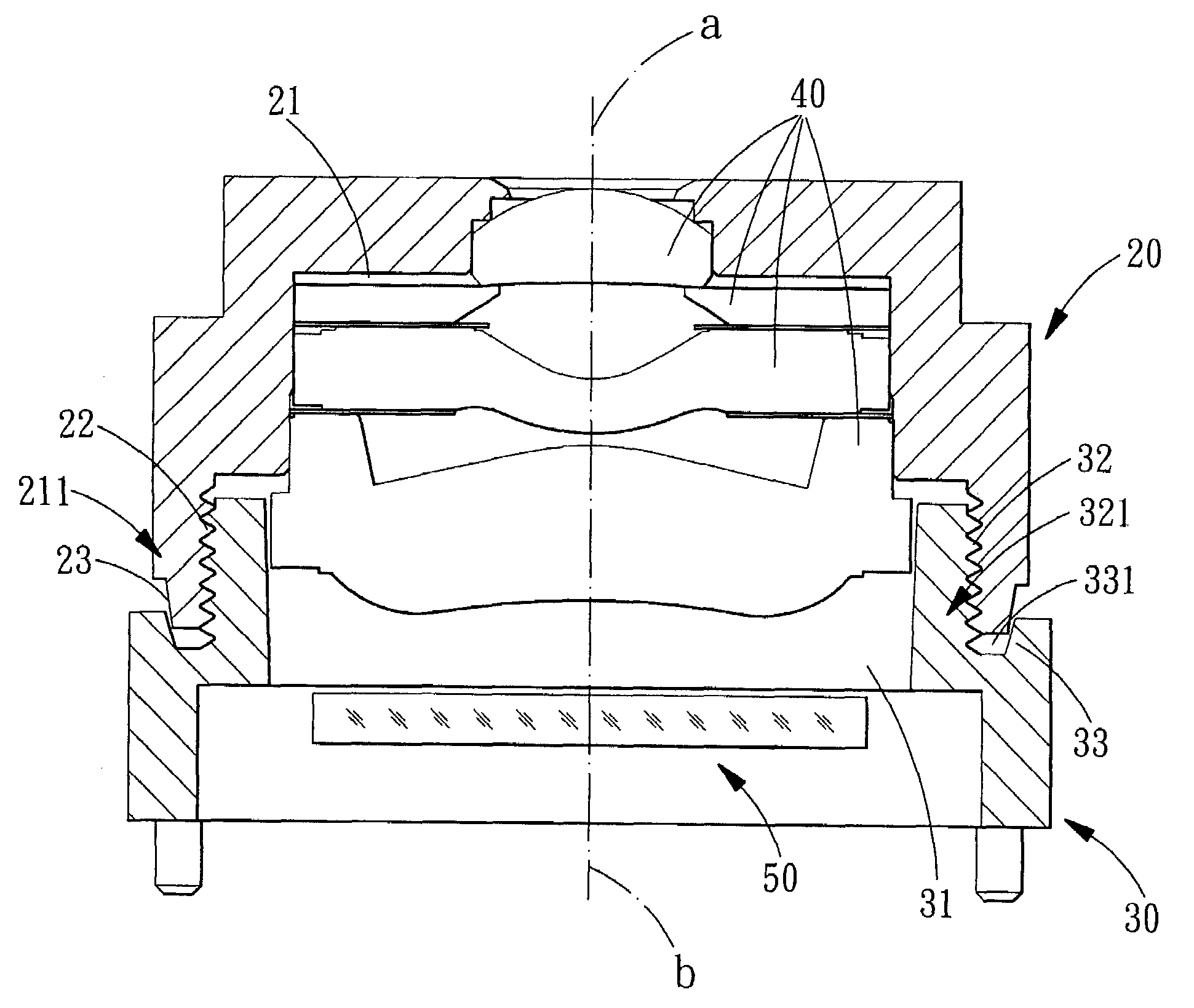

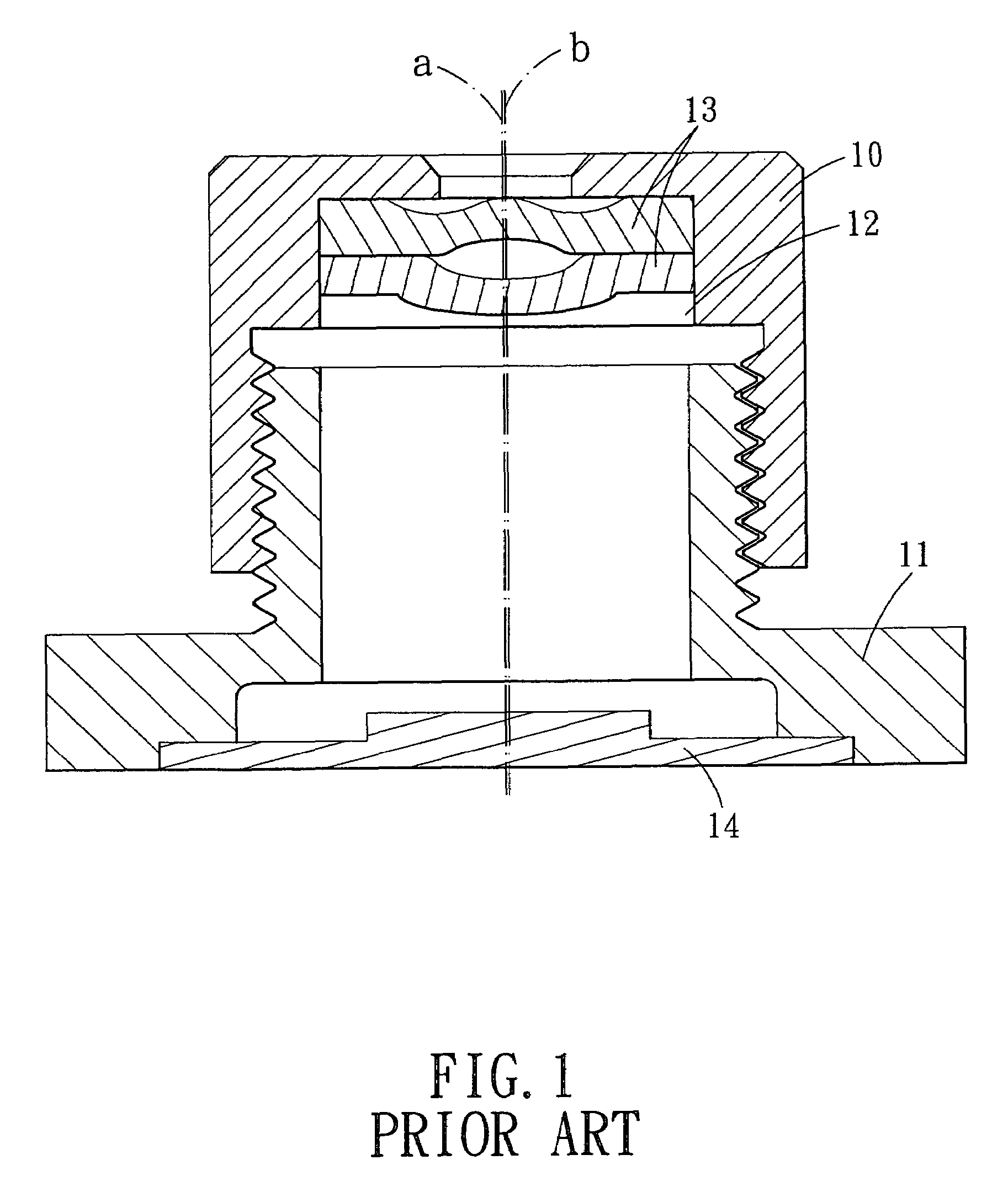

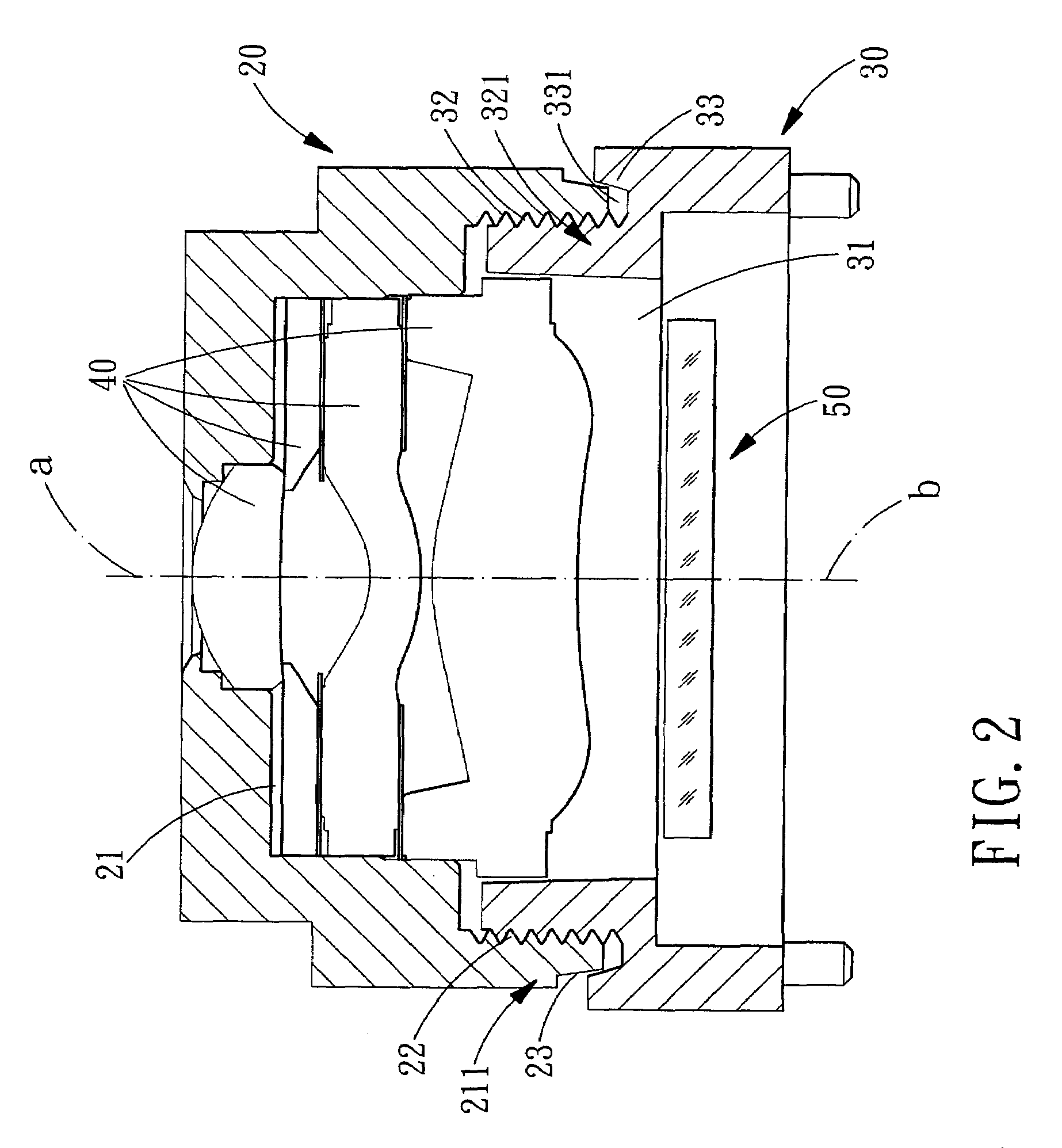

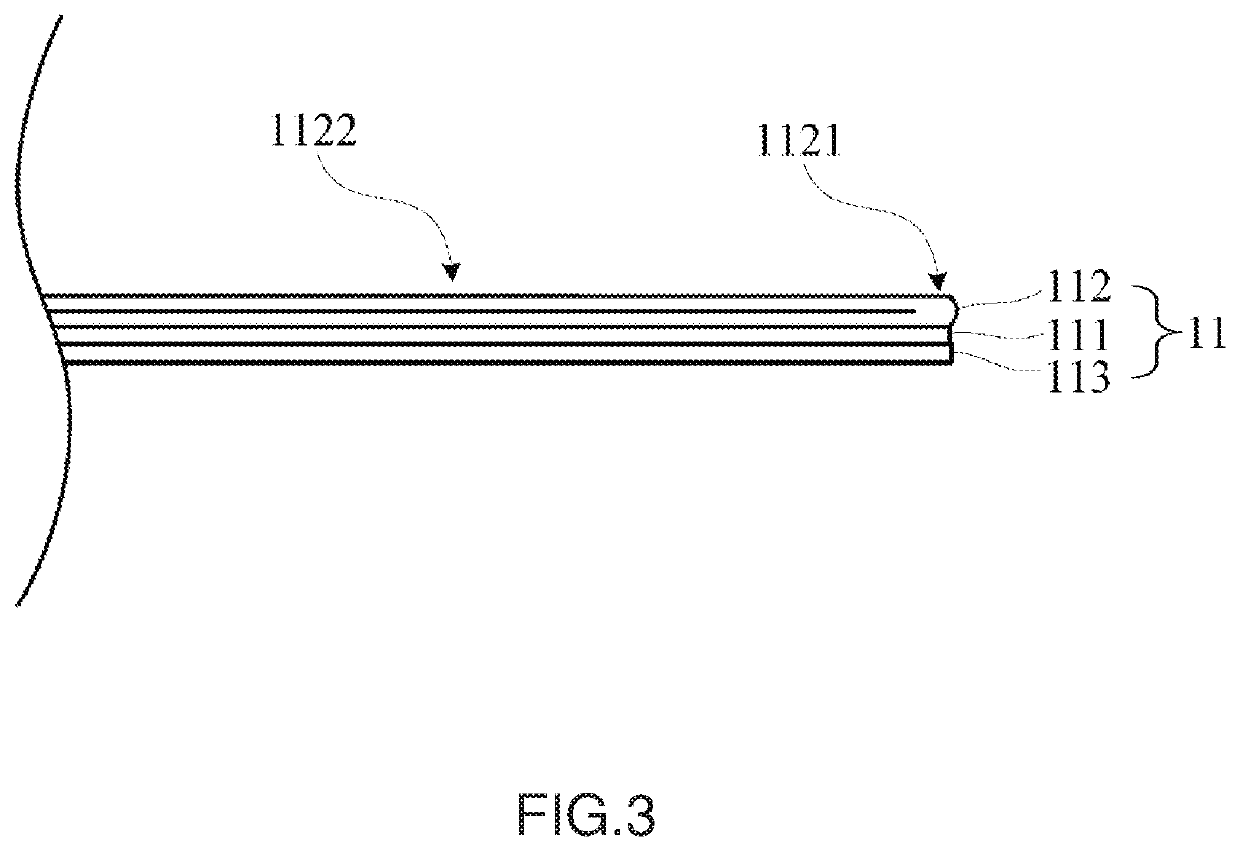

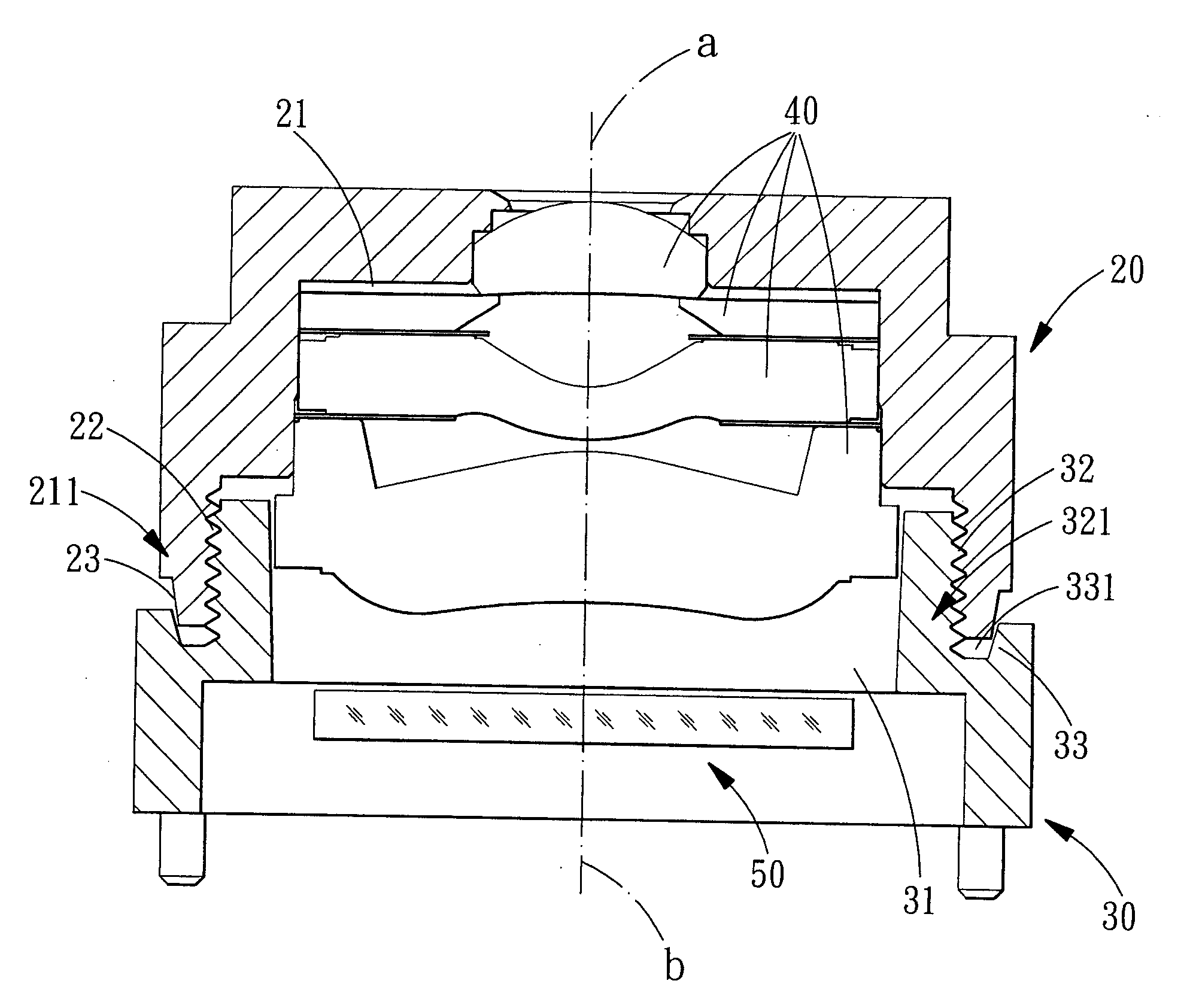

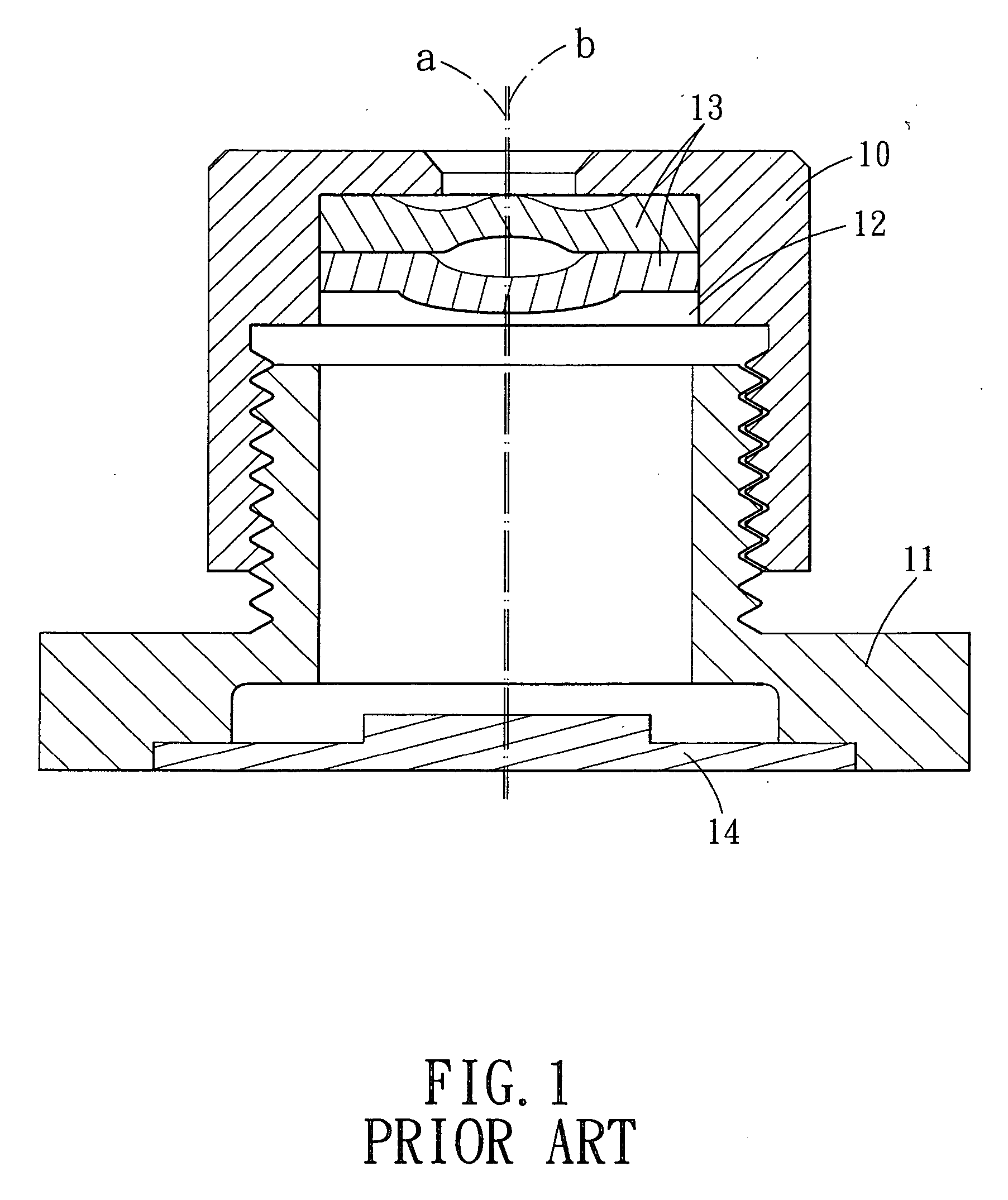

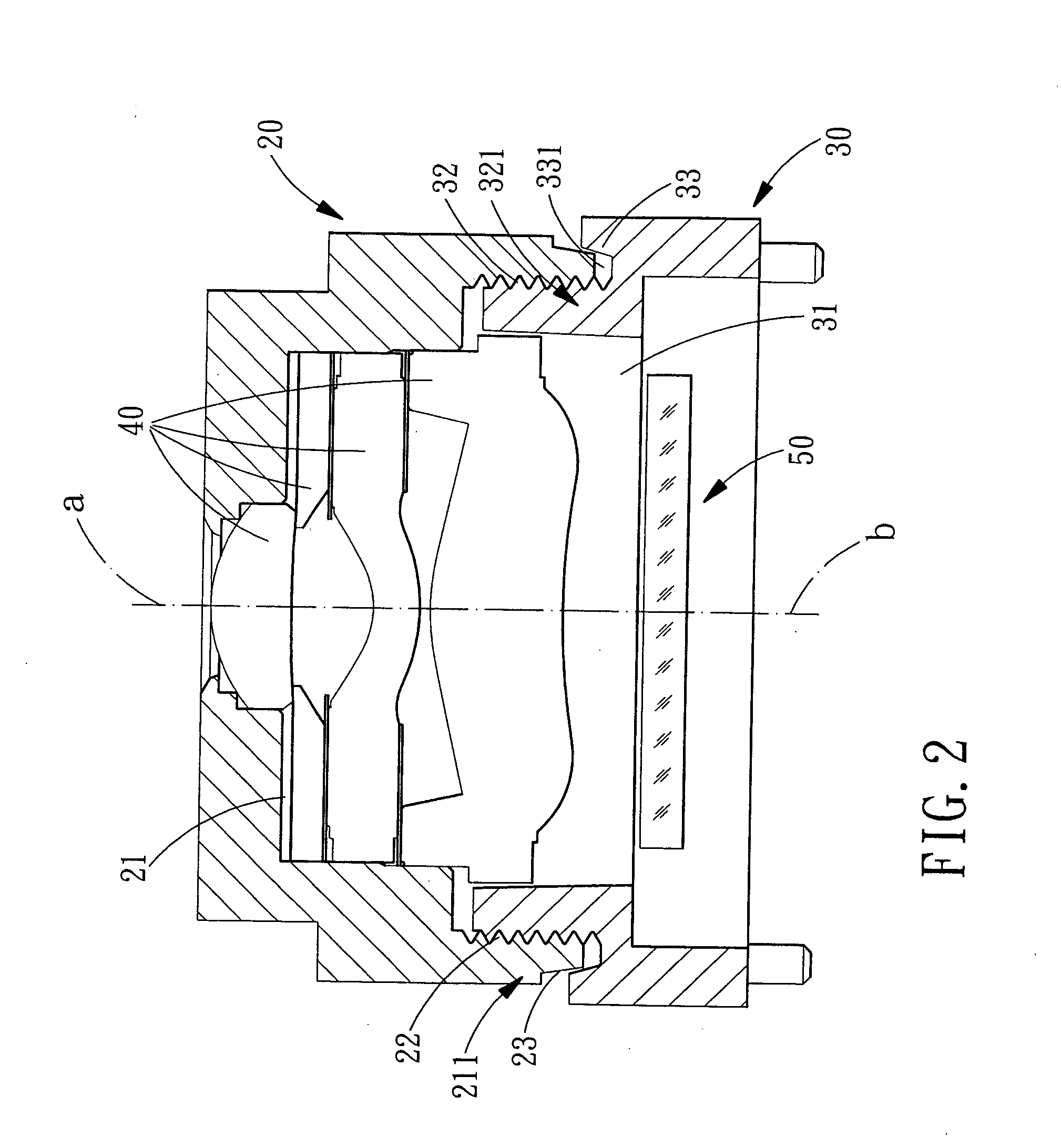

Lens tube and mounting base thereof

ActiveUS7311453B2Avoid dust pollutionReduce swingTelevision system detailsNon-electric lightingEngineeringOptical axis alignment

A lens tube and a mounting base thereof comprise a lens tube for reception of a lens array and a mounting base for accommodation of an image sensor. On an outer periphery of the lens tube is formed a first conical surface, and in the mounting base is formed a concave portion. A second conical surface is formed in the concave portion for mating with the first conical surface of the lens tube. The first conical surface of the lens tube and the second conical surface of the mounting base can cooperate with each other, so as to prevent dust contamination and to make the central axis aligned with the optical axis.

Owner:LARGAN PRECISION

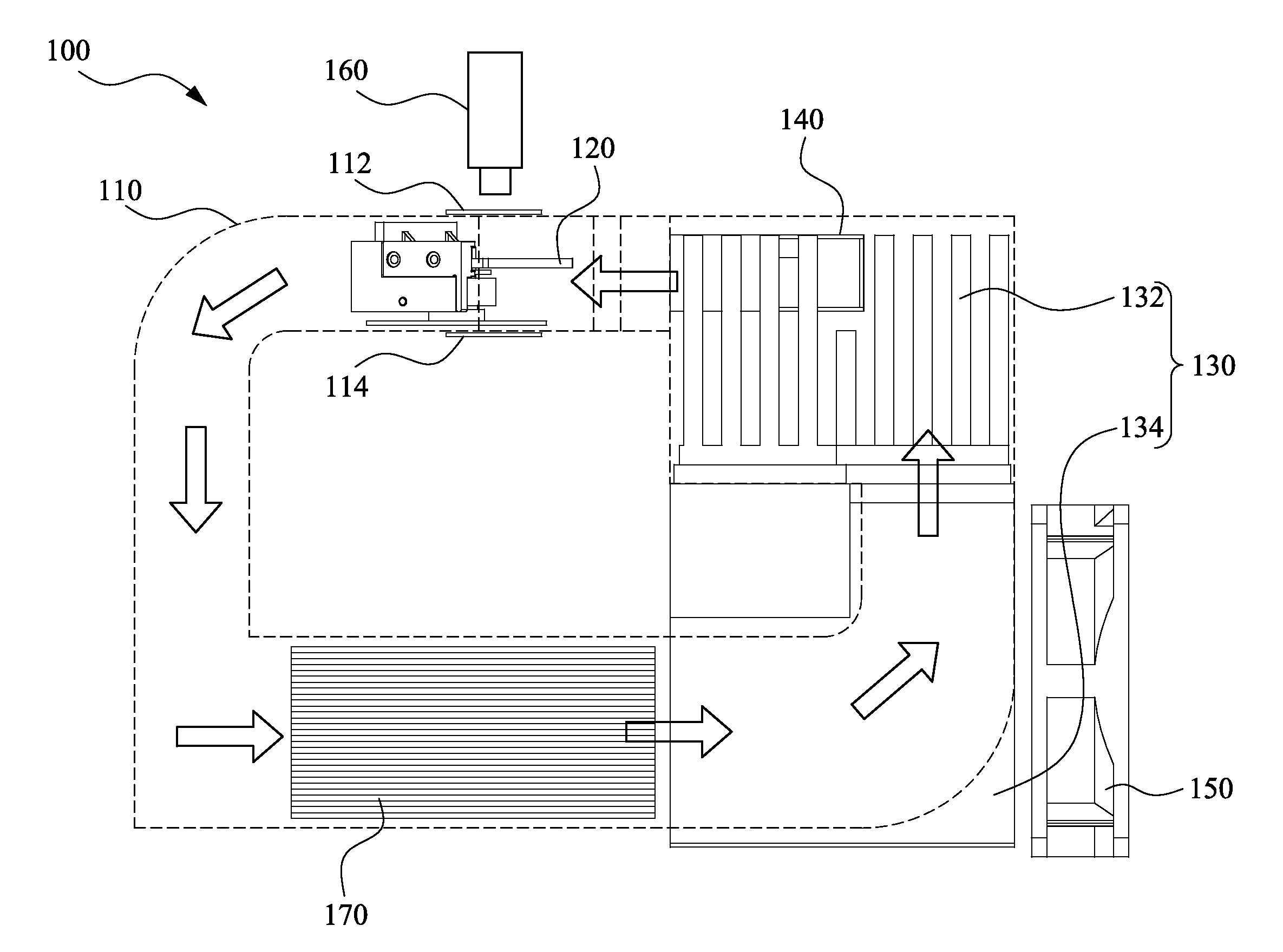

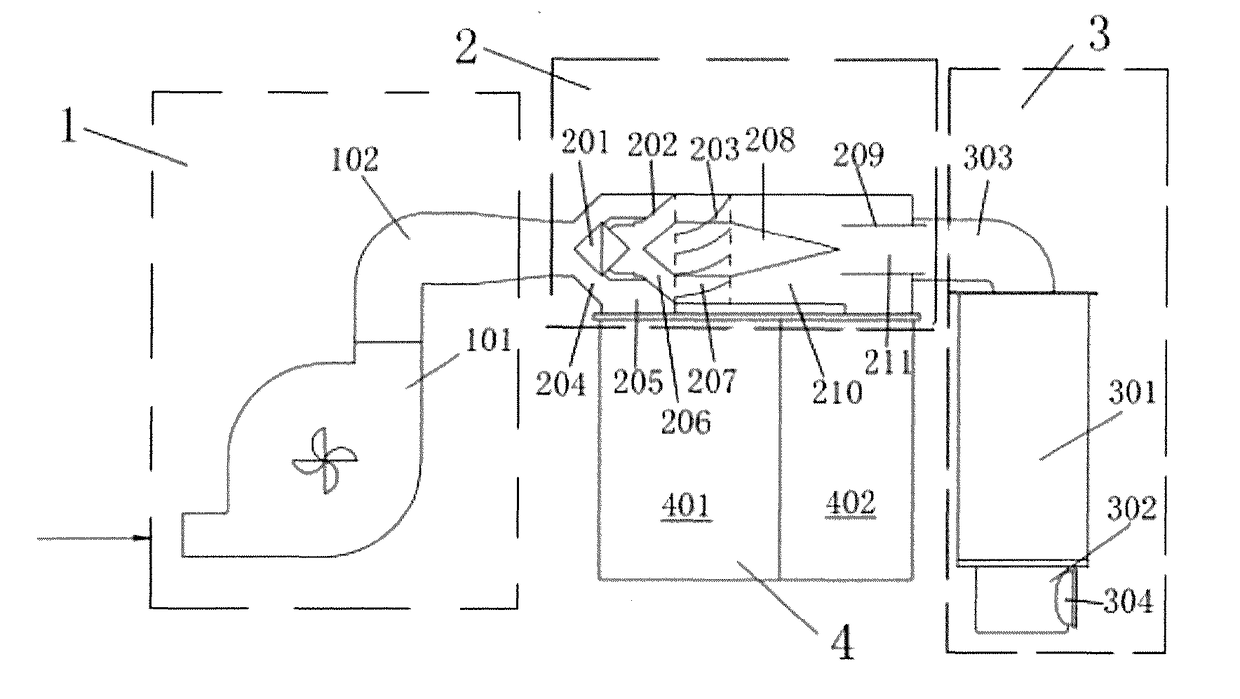

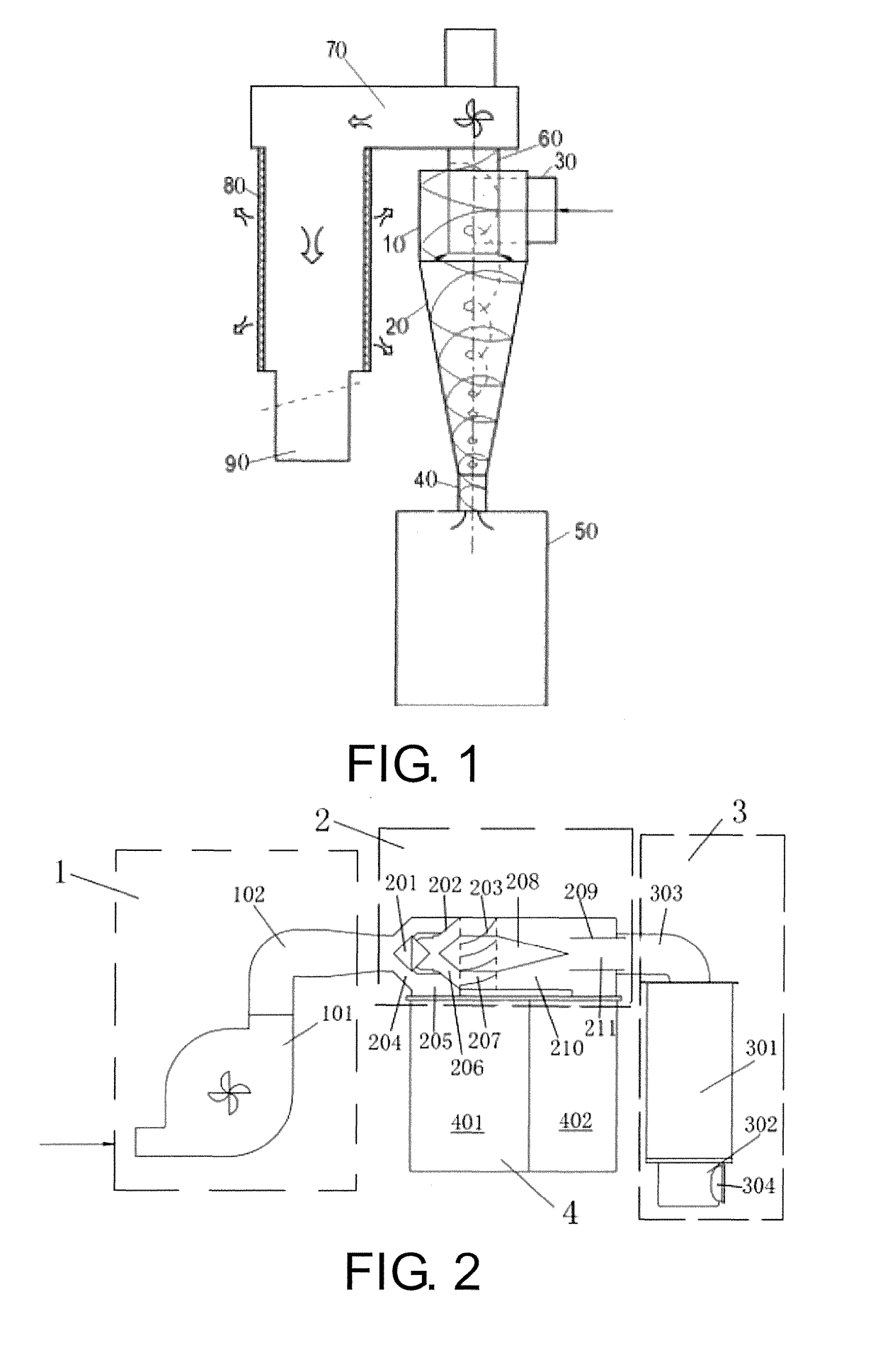

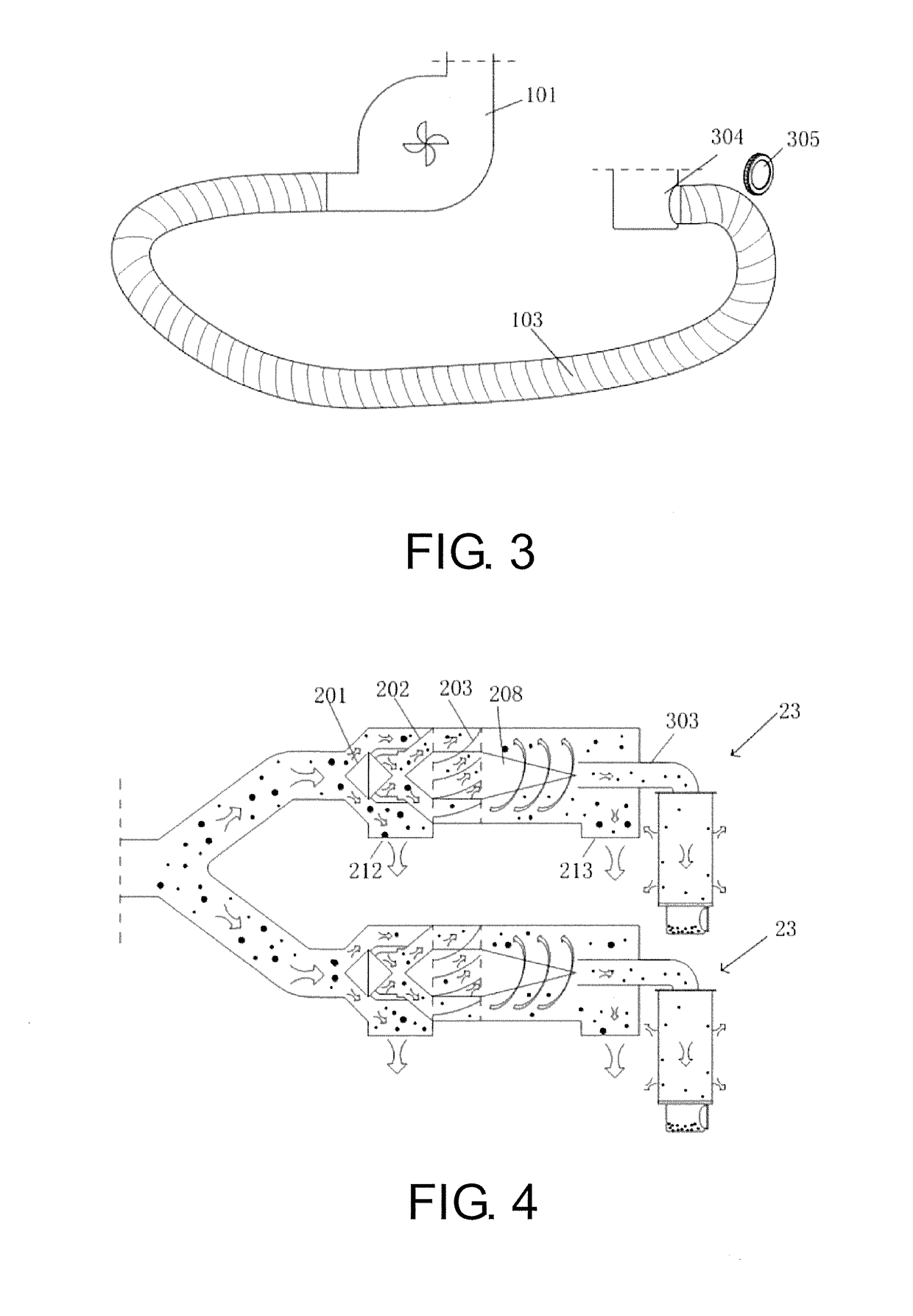

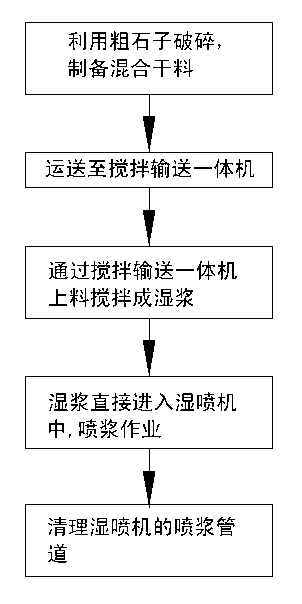

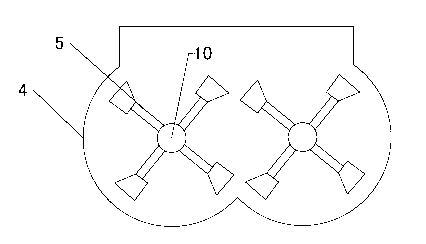

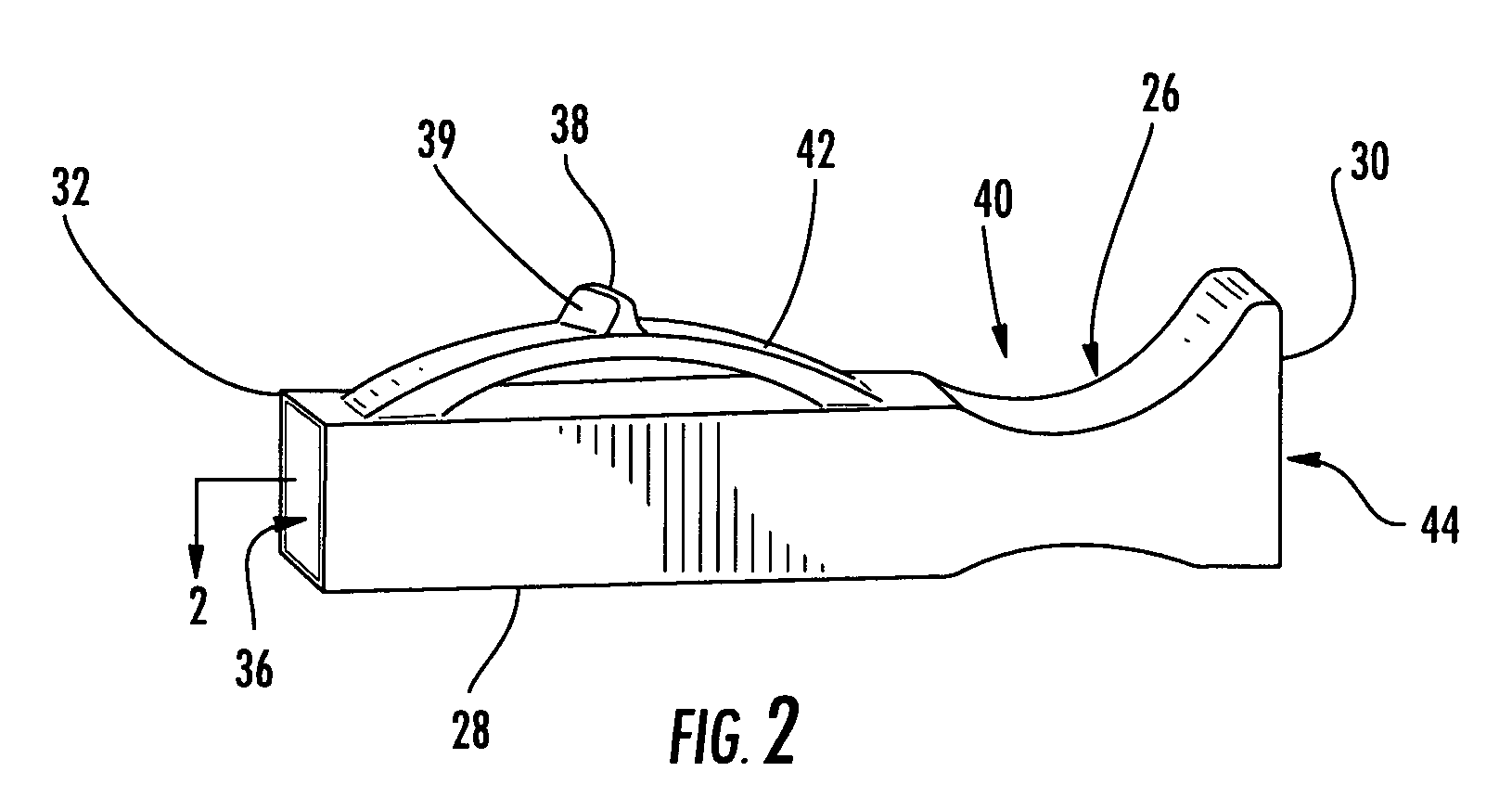

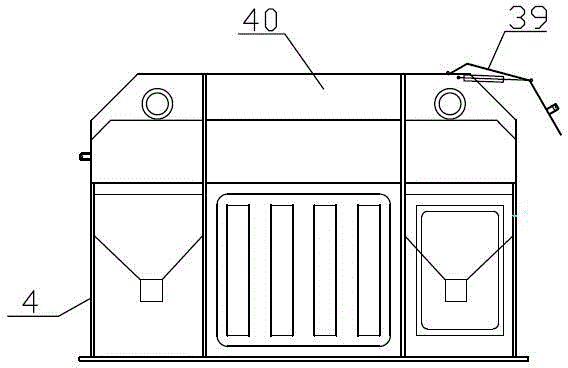

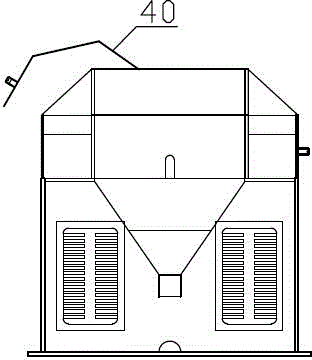

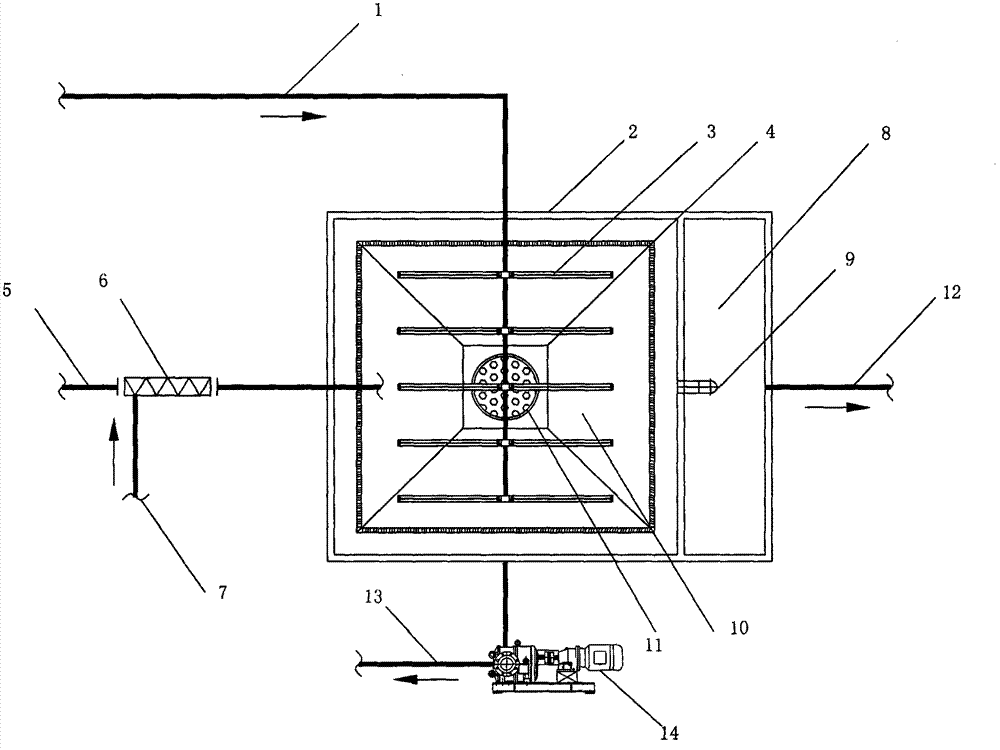

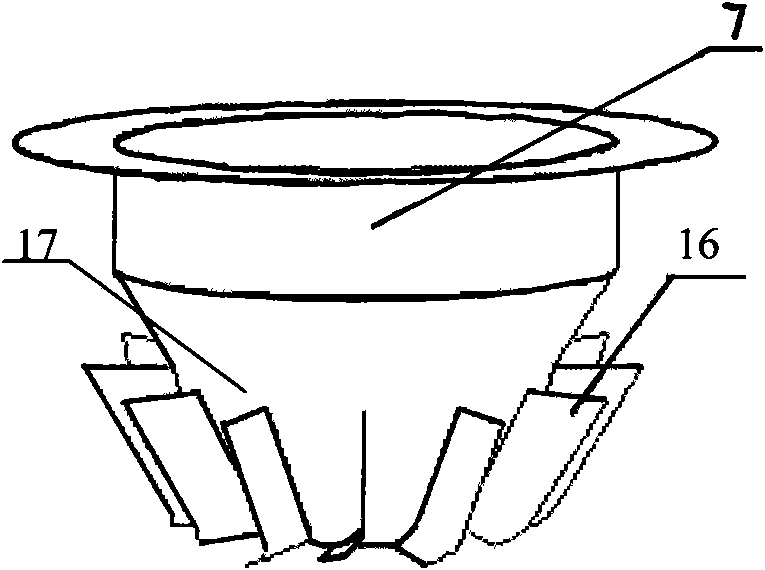

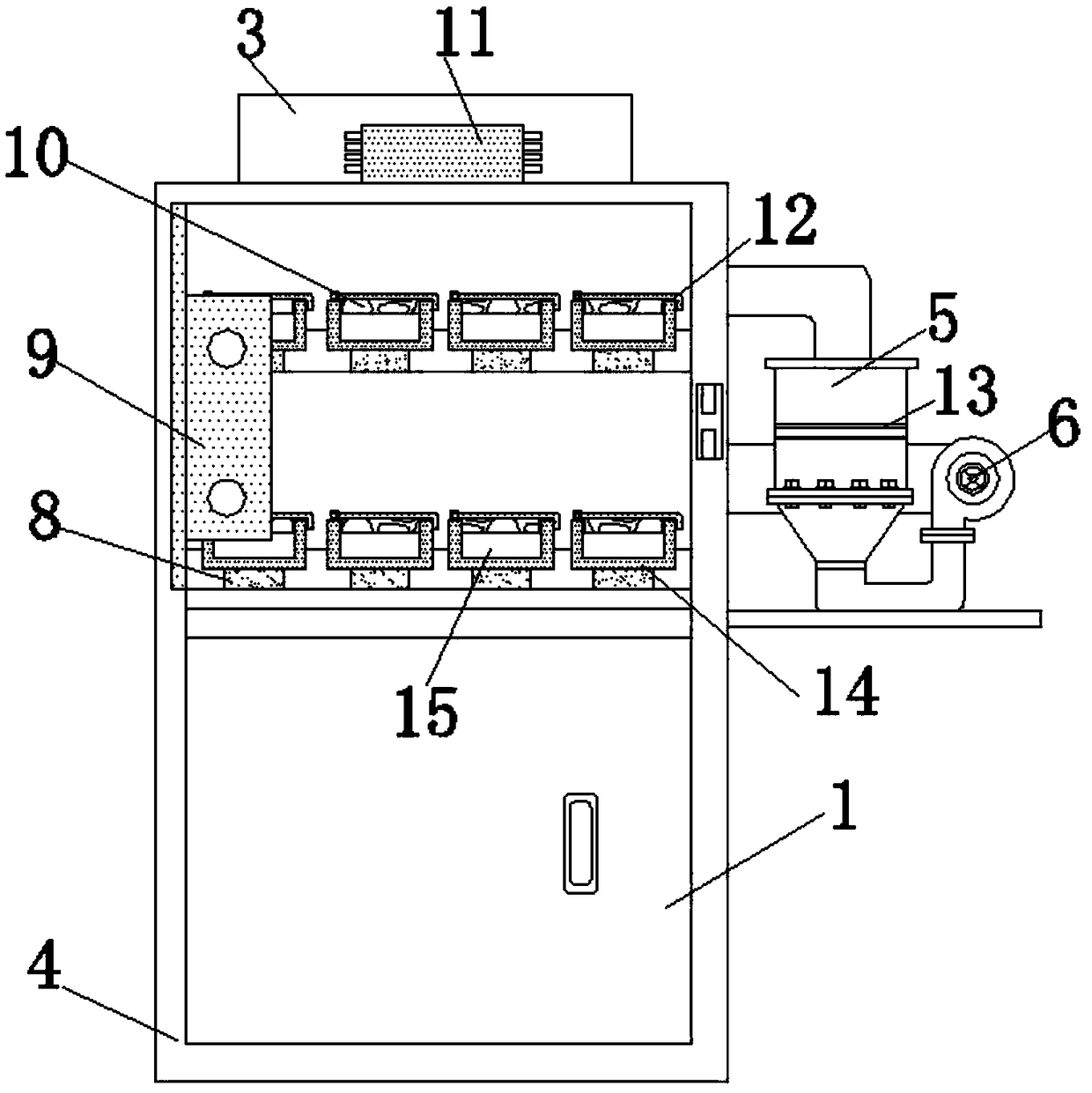

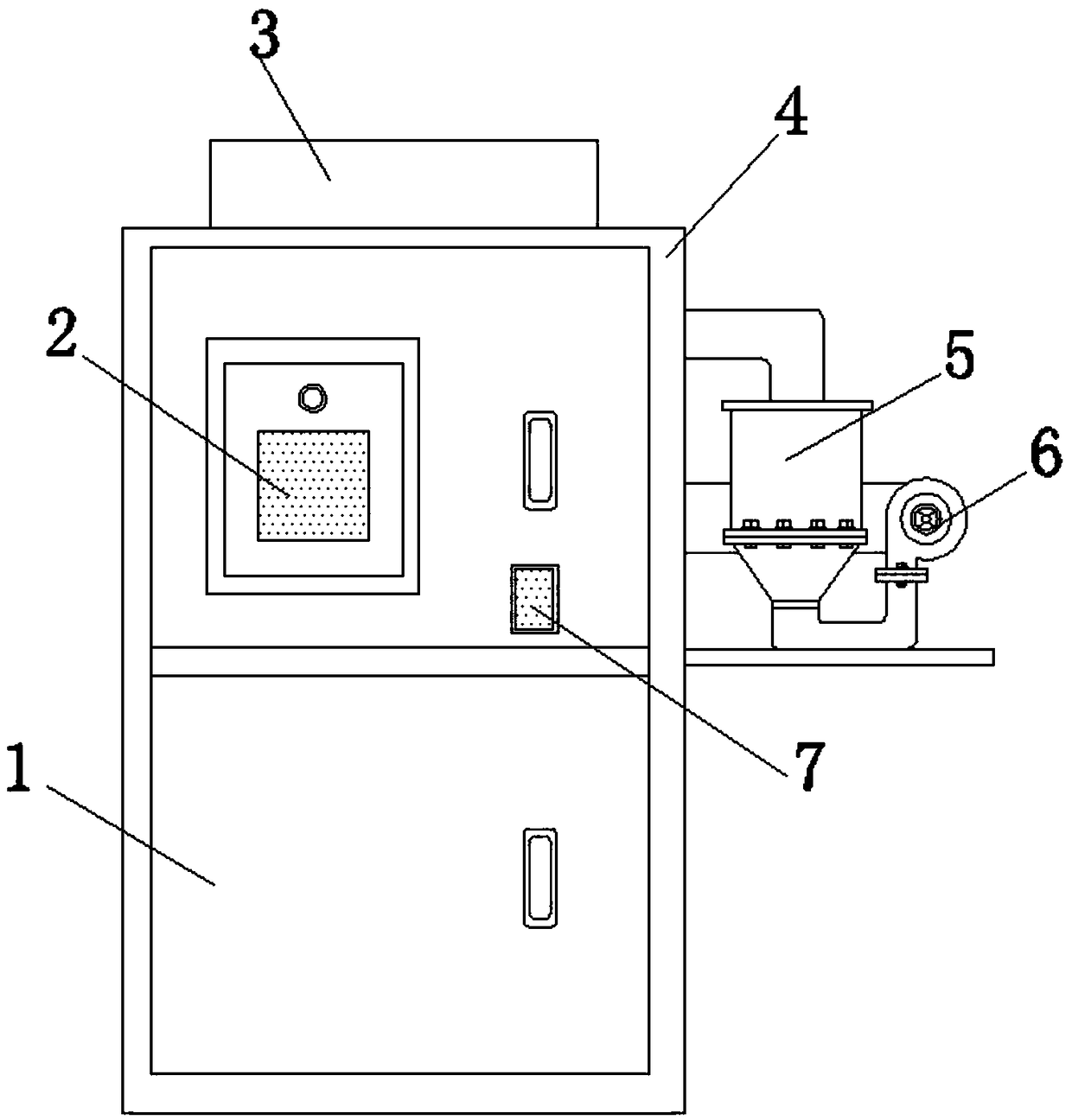

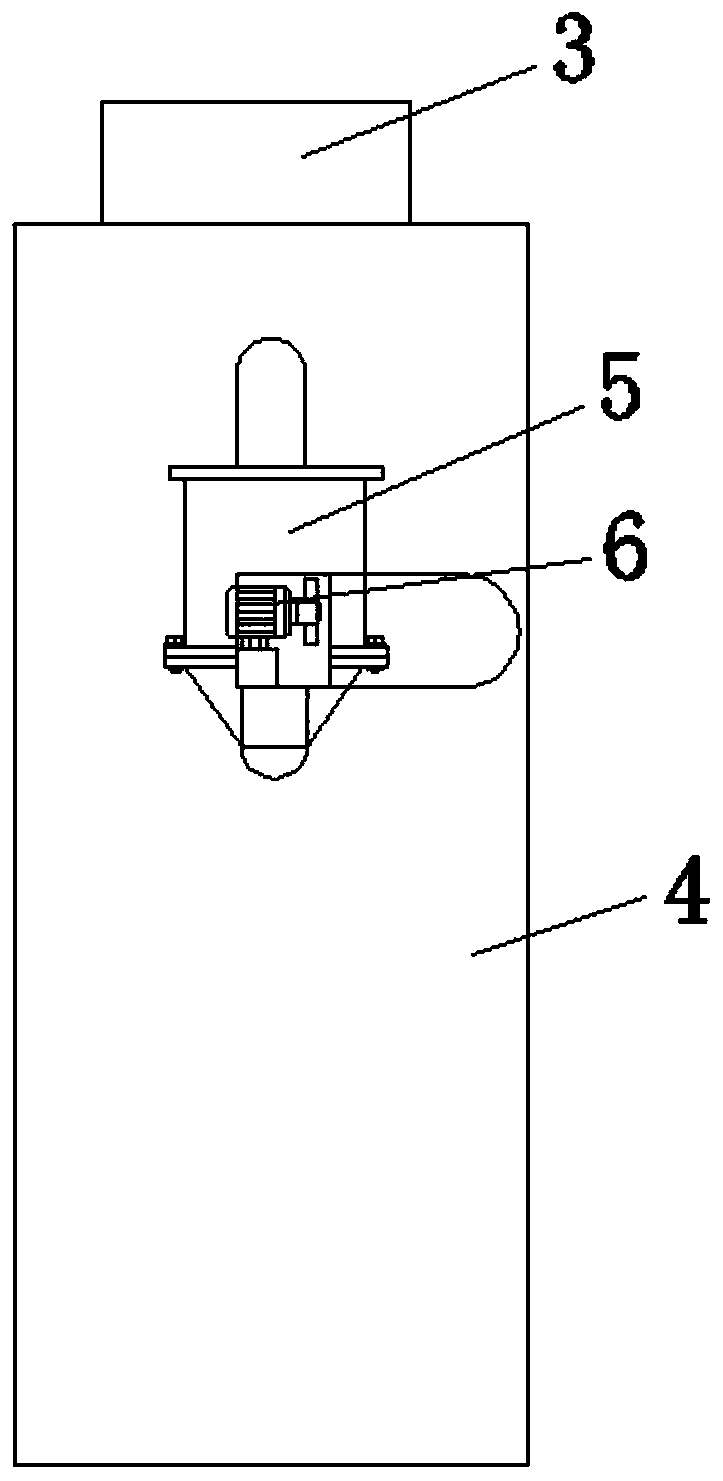

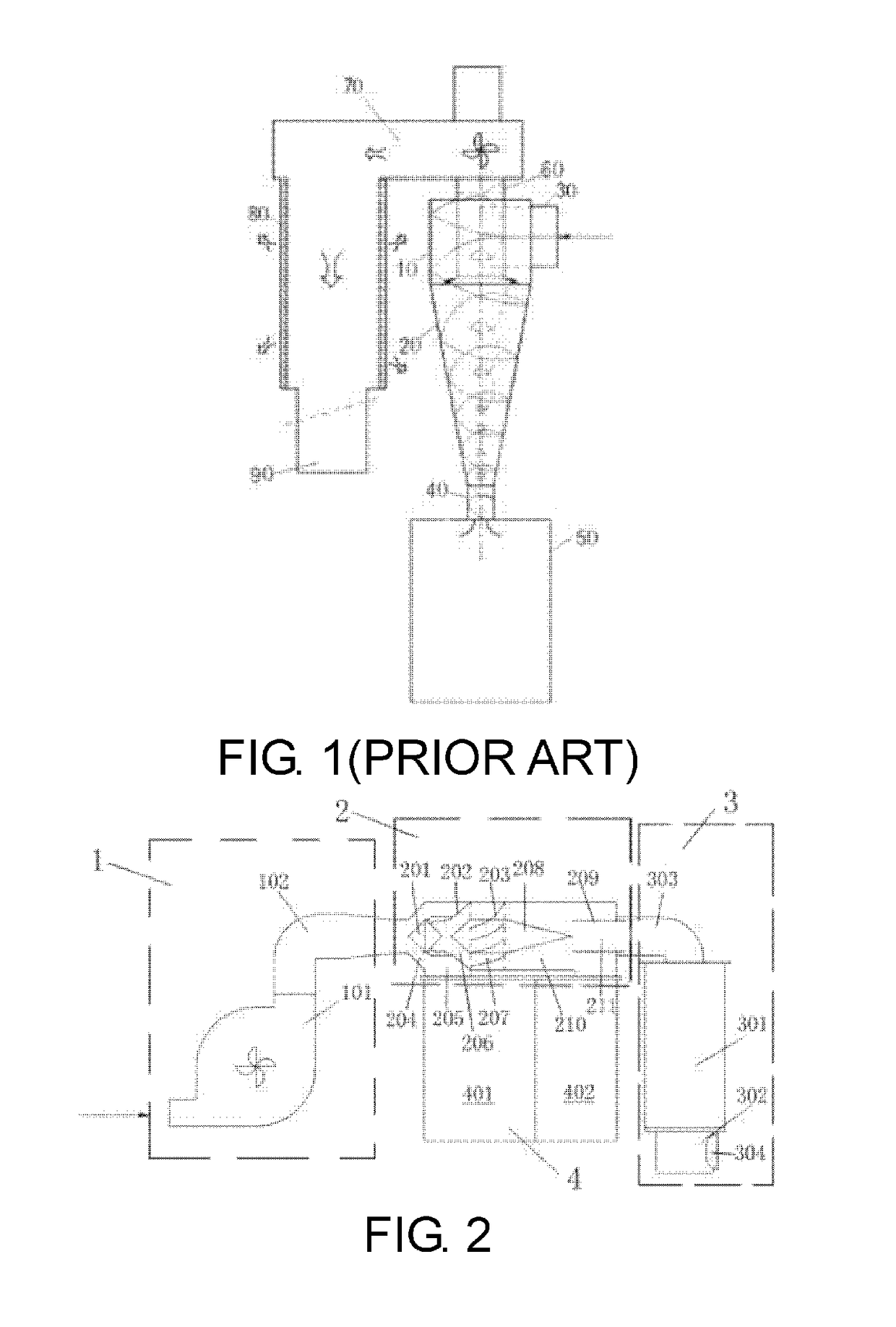

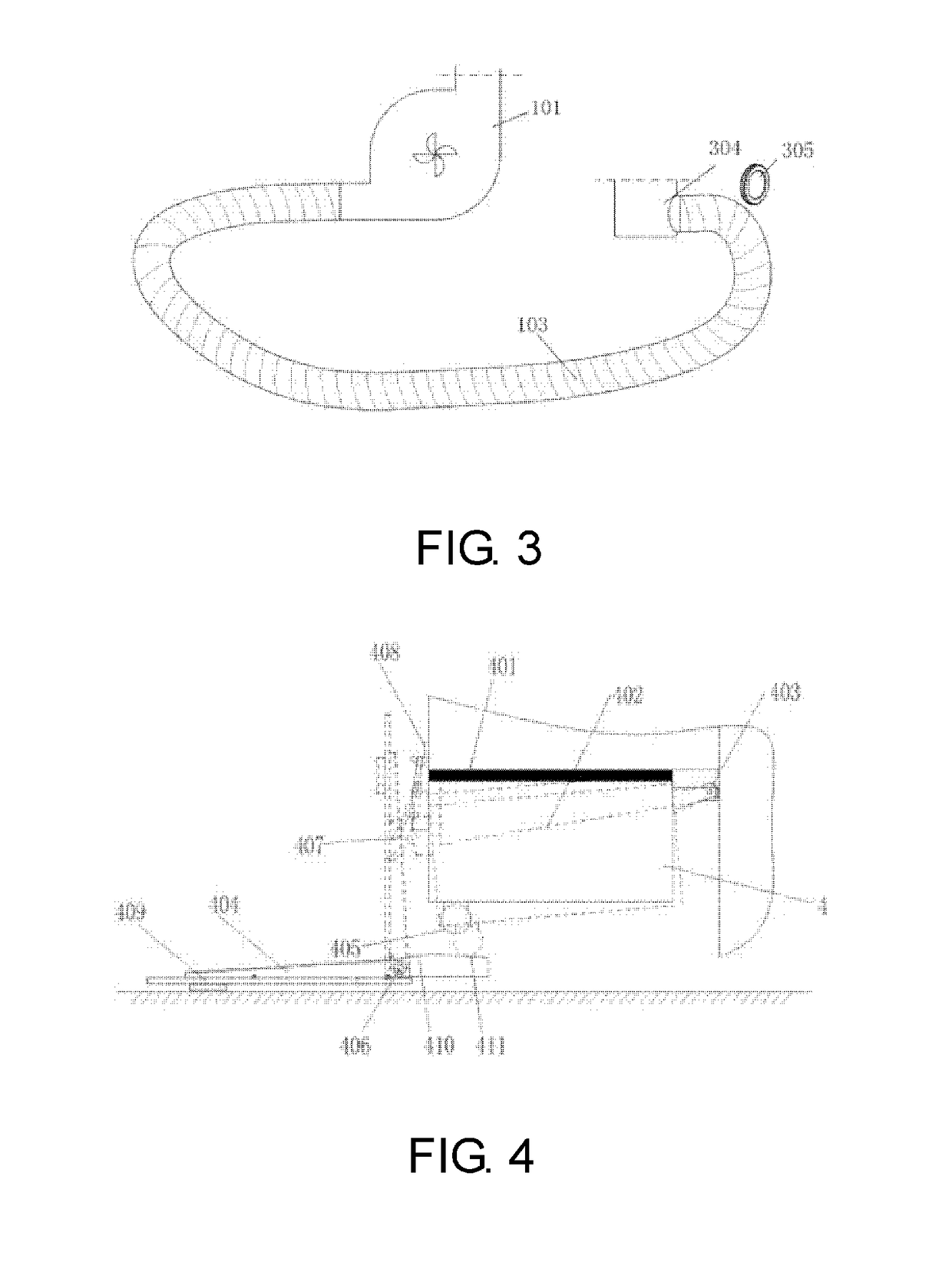

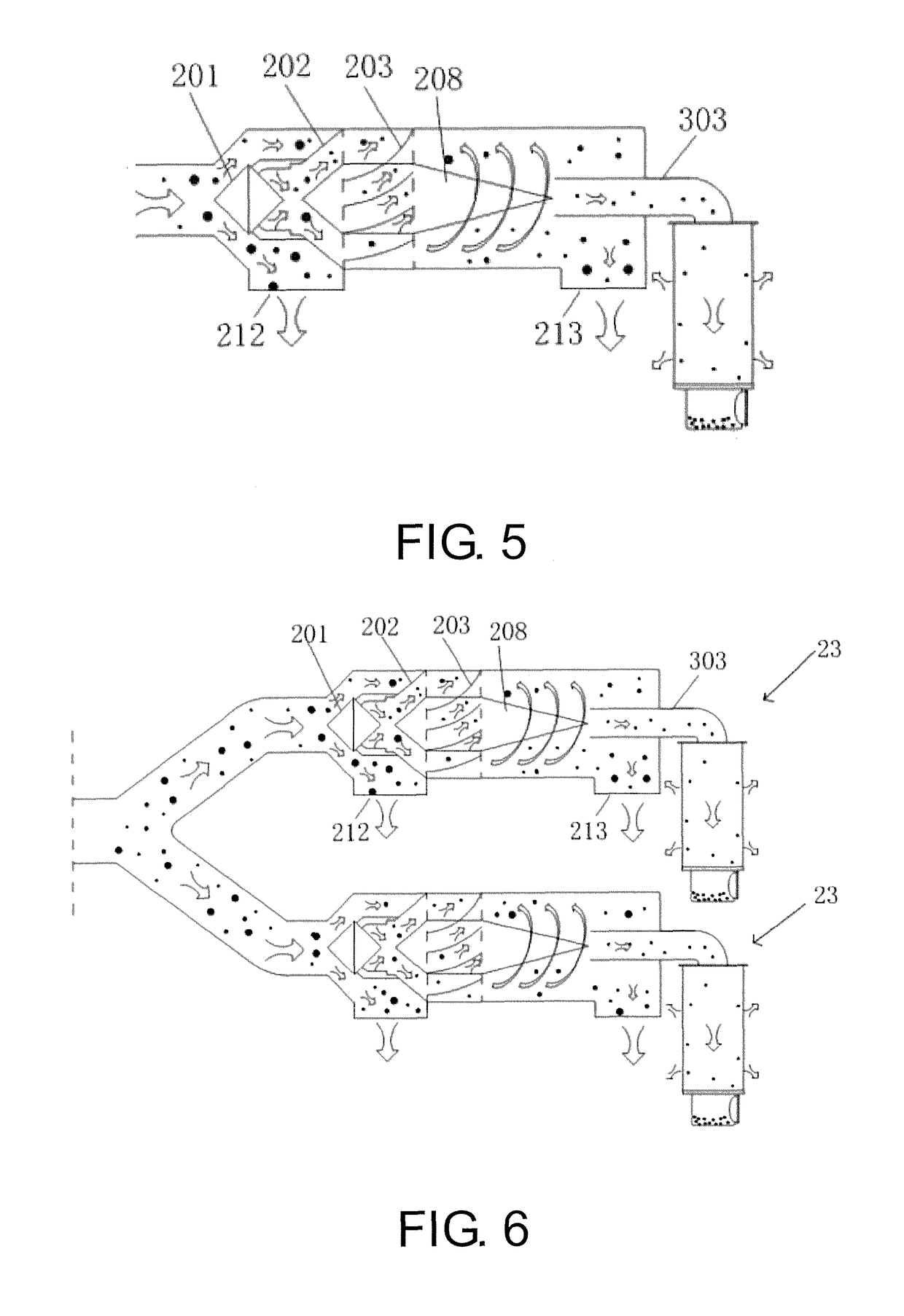

Dust separation apparatus and intelligent control system including the apparatus

ActiveUS20170333918A1Easy to cleanImprove dust removal efficiencyCombination devicesReversed direction vortexEngineeringIntelligent control

The dust separation apparatus includes a dust intake unit including a blower, an inertial separation unit, a centrifugal separation unit, and a filtering separation unit. The dust intake unit, the inertial separation unit, the centrifugal separation unit, and the filtering separation unit are sequentially connected in series and together form a horizontal structure. The inertial separation unit and the centrifugal separation unit are connected in a horizontal-axis direction to form an inertial and centrifugal separation unit. A dust collection box is provided below and connected to the inertial and centrifugal separation unit. The filtering separation unit includes a dust collection barrel. The intelligent control system includes the dust separation apparatus and an intelligent control unit.

Owner:NANJING HAIFENG ENVIRONMENTAL PROTECTION TECH CO LTD

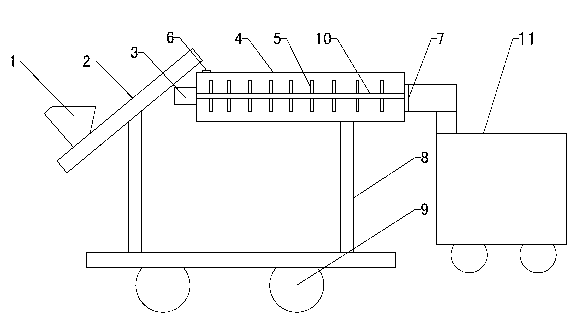

Coal mine wet method guniting process

InactiveCN103244148AContinuously adjustable particle size distributionRegular shapeUnderground chambersTunnel liningFiberDry mixing

The invention provides a coal mine wet method guniting process and belongs to the technical field of coal mine wet method guniting. The coal mine wet method guniting process comprises the following steps of 1.1 manufacturing mixed dry materials, namely performing dry mixing of a sand and stone mixed material, cement, coal ash, a water reducing agent, fiber and an accelerator to form the mixed dry materials; 1.2 performing dry material transportation, namely transporting the mixed dry materials to a guniting working face under a coal mine; 1.3 manufacturing wet slurry, namely pouring the mixed dry materials into a stirring, conveying and guniting integrated machine and simultaneously adding water to perform stirring to form evenly-mixed wet slurry; 1.4 performing guniting operation, namely utilizing a plunger type wet spraying machine (11) to perform continuous and quick guniting operation to the working face needing guniting; and 1.5 cleaning a pipeline, namely cleaning the guniting pipeline of the plunger type wet spraying machine (11), keeping the pipeline to be clean and preventing blockage. By means of the coal mine wet method guniting process, dry mixing, conveying, stirring, guniting and other processes are tightly combined integrally, the processes are compact, manpower is saved, the efficiency is improved, guniting materials are even and consistent in proportion, and the guniting effect is remarkable.

Owner:ZIBO MINING GRP

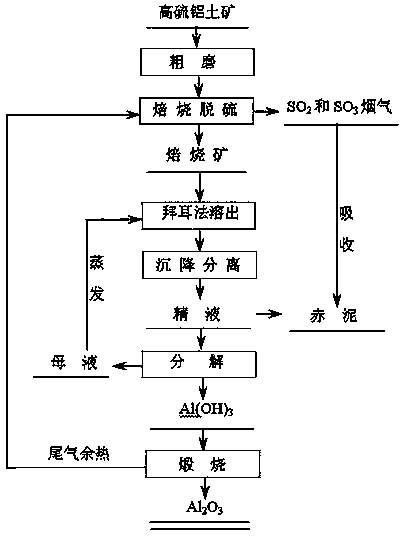

Method for producing alumina by use of high sulfur bauxite

InactiveCN103833056APromote dissolutionReduce energy consumptionAluminium oxides/hydroxidesEnergy consumptionMaterials science

The invention discloses a method for producing alumina by use of high sulfur bauxite, and the method comprises the following steps: carrying out coarse grinding on crushed high sulfur bauxite, roasting the crushed high sulfur bauxite to enable the sulfur content of the ore to be smaller than 0.7%, and then, directly entering an alumina production flow by use of a Bayer process. After the pre-roasting treatment, the leaching performance of the ore is perfected, a better leaching effect can be obtained without fine grinding, and the energy consumption in a fine grinding process of the ore is reduced, so that the method is beneficial to equipment selection in the roasting process and suitable for treating the high sulfur bauxite. The ore in the invention is roasted at a rough particle size, thus helping the overflow of the generated SO2 (or SO3) gas and ensuring a good roasting desulfurization effect; in addition, by adopting the method disclosed by the invention, the energy consumption in the fine grinding process of the ore is reduced, the over burning and dust pollution problems caused by superfine particle size are avoided, the cyclic utilization of energy source is achieved and the desulfurization cost is reduced.

Owner:GUIZHOU UNIV

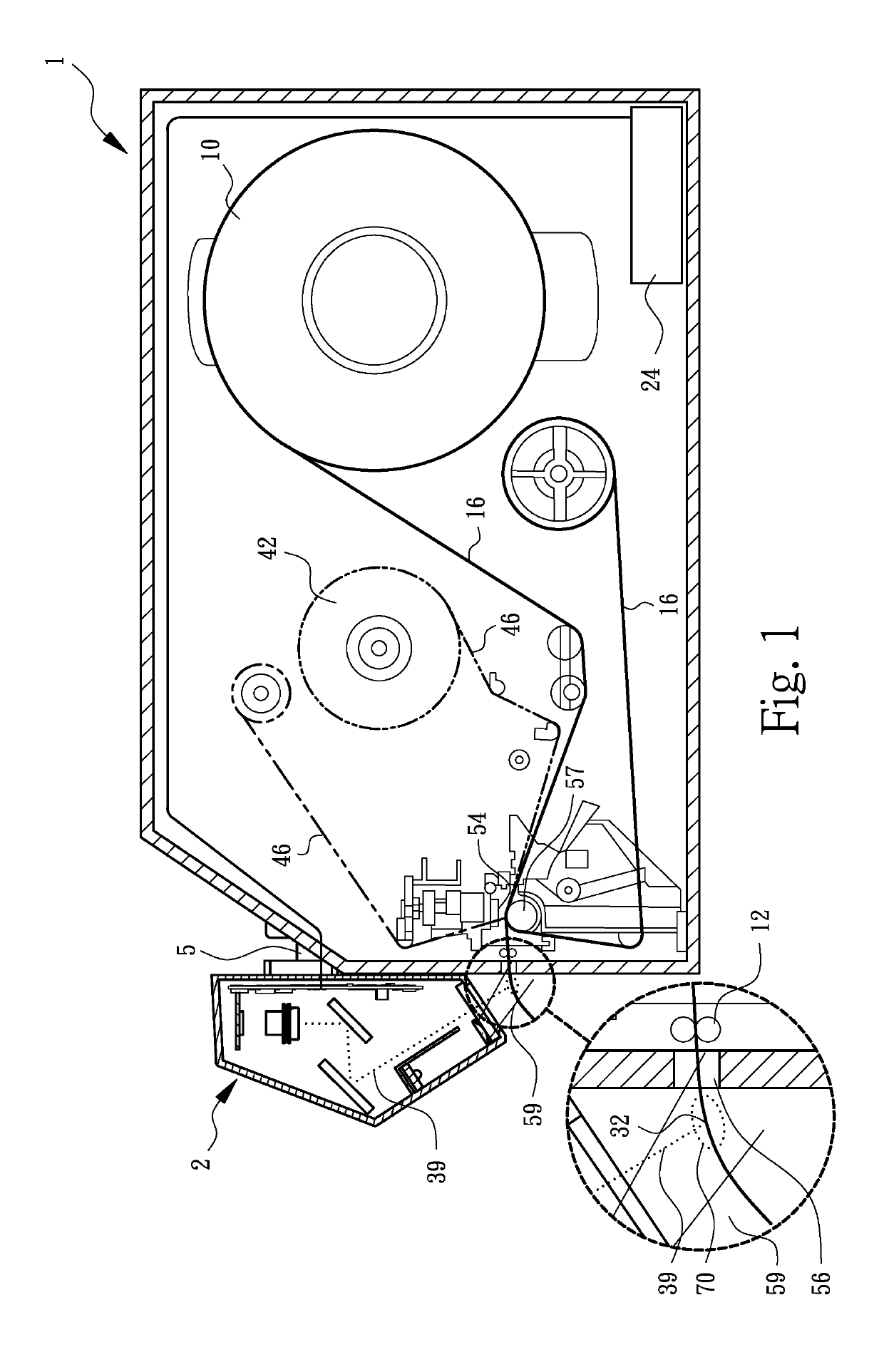

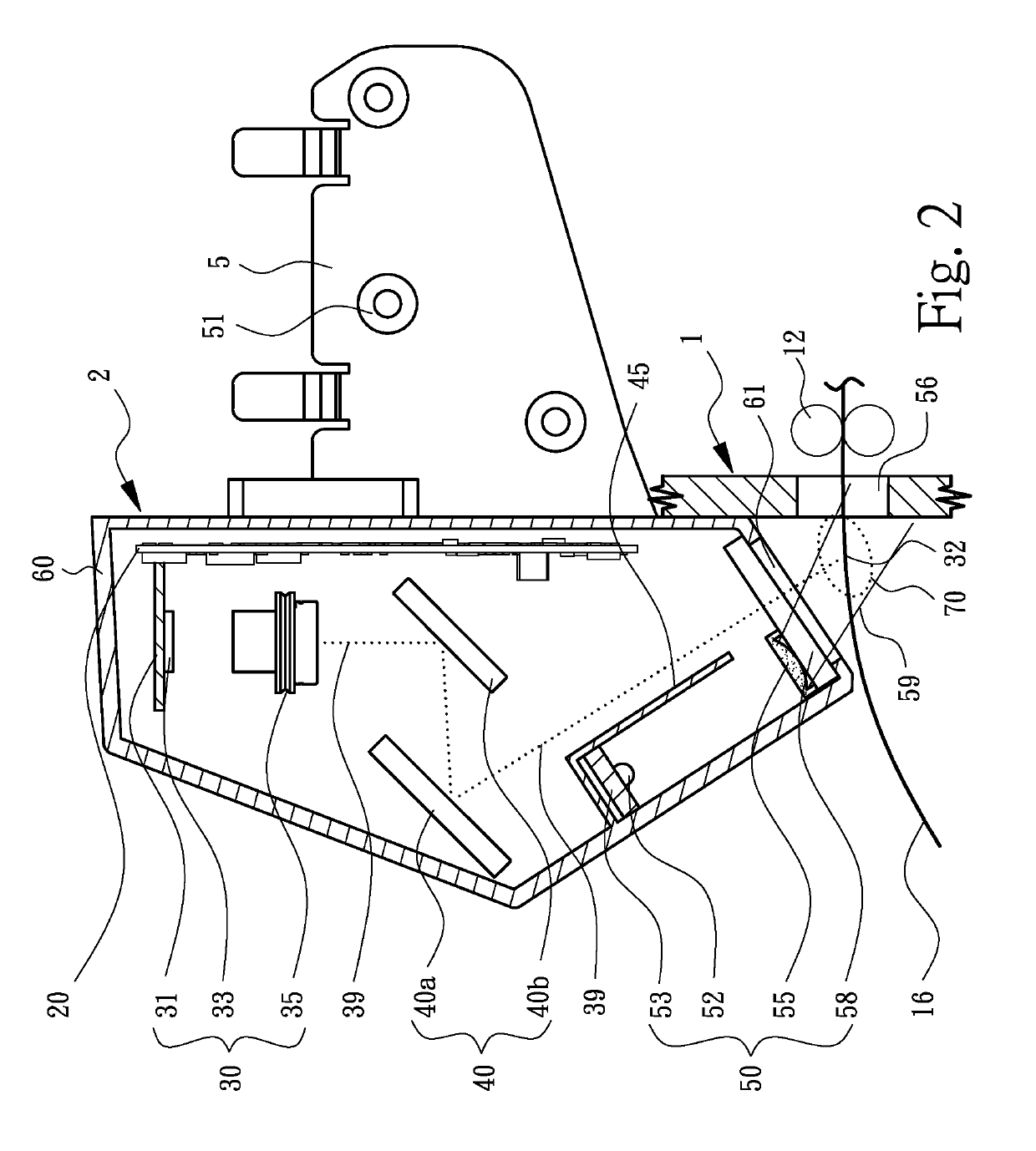

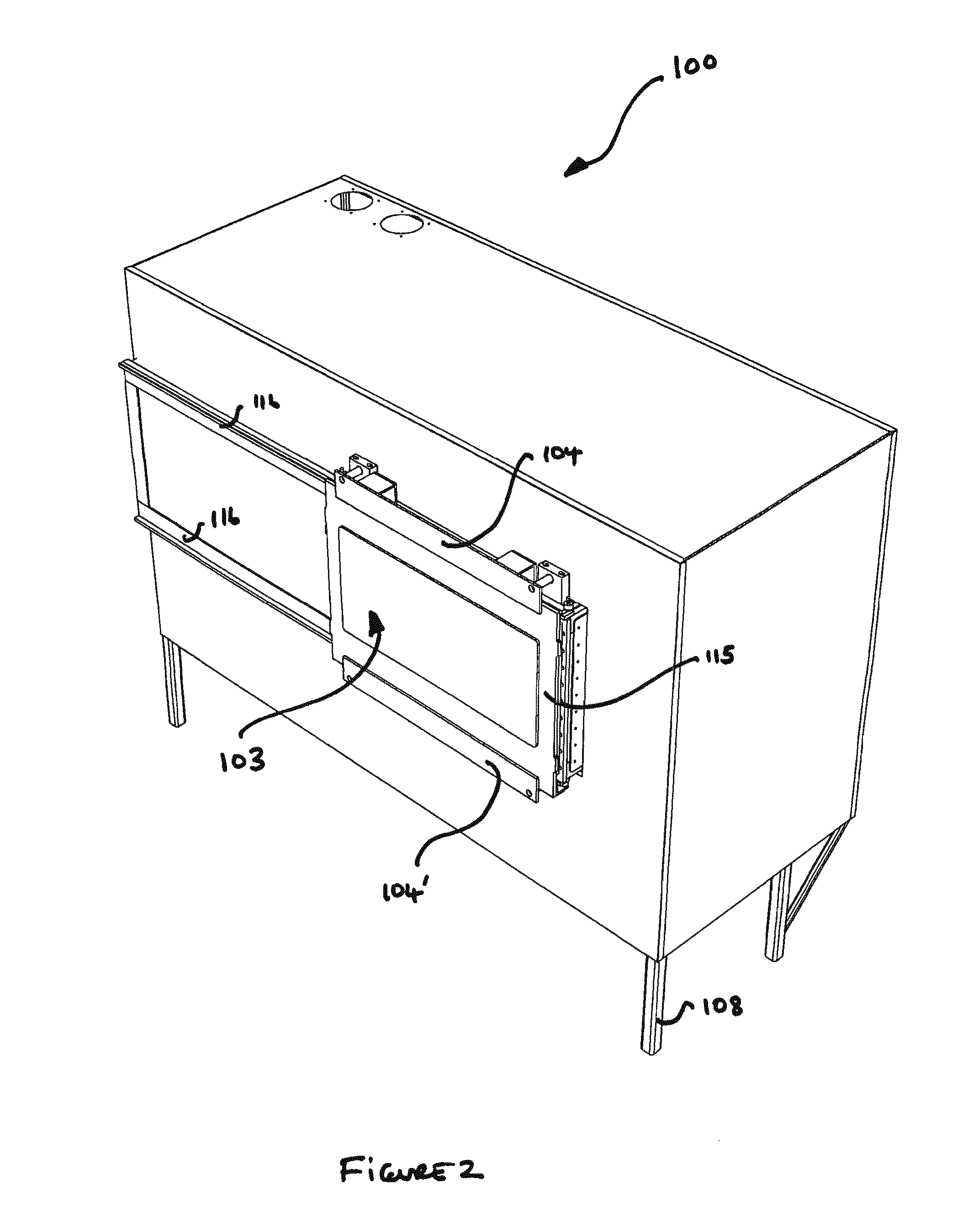

Online data validator of the printing unit

ActiveUS20190116275A1Reduced footprintAvoid dust pollutionOther printing apparatusVerifying markings correctnessData validationFresnel lens

An online data validator is a digital imaging system integrated onto the front side of a printing unit wherein an exit of the printing unit is set on the same side close to the online data validator for a media exiting therefrom. The online data validator comprises a controller facilitating communication with a printing unit controller and controlling overall operation of the online data validator functions; a camera module including a sensor PCB and an optical lens, wherein the sensor PCB contains a camera sensor for capturing 2D digital images of moving labels; and a light source module including a lightbar, a lightbar PCB, a Fresnel lens and a window for providing uniform and flattened illumination on the media.

Owner:TSC AUTO TECH

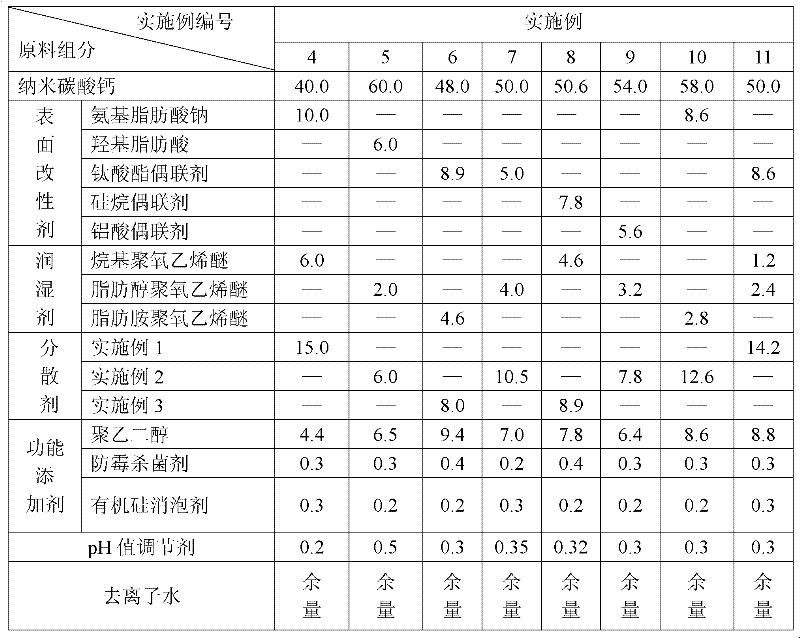

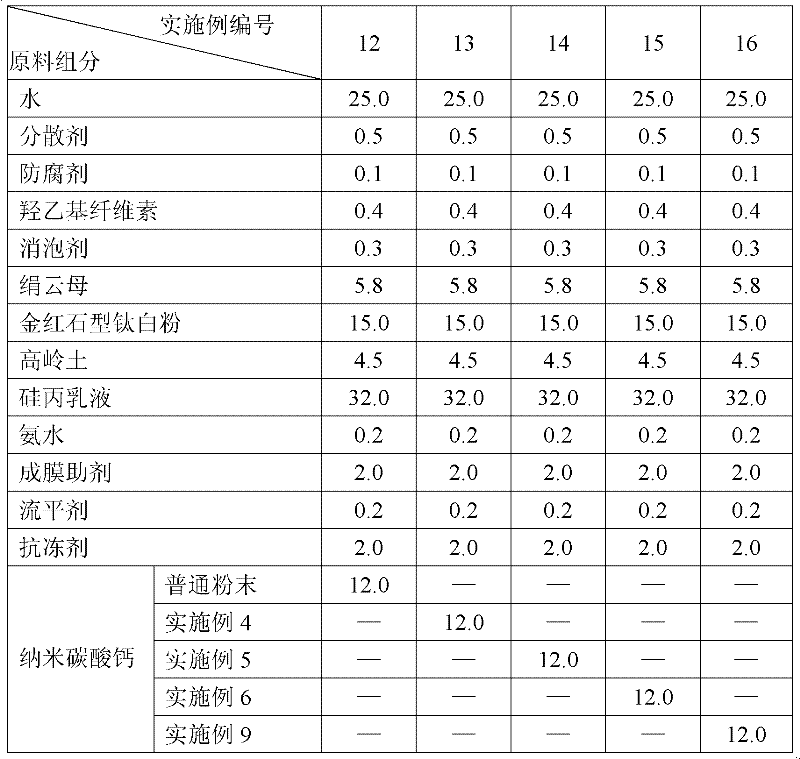

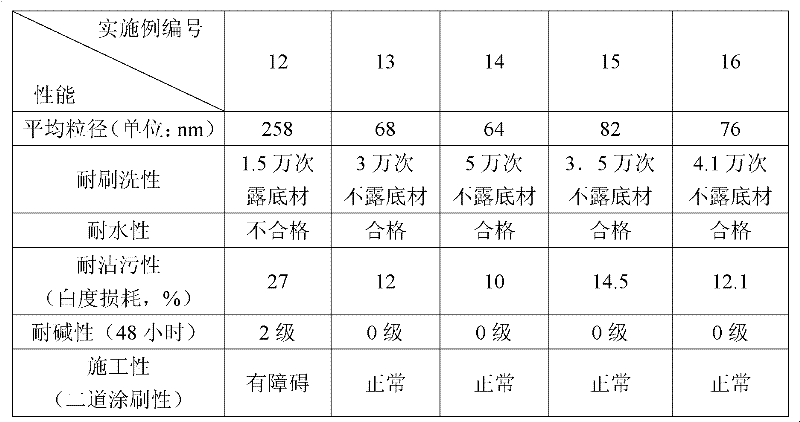

Aqueous high-content nanometer calcium carbonate dispersoid and preparation method thereof

InactiveCN102532976AImprove wettability and dispersibilityAvoid dust pollutionAntifouling/underwater paintsPaints with biocidesNanometreCalcium carbonate

The invention discloses an aqueous high-content nanometer calcium carbonate dispersoid and a preparation method of the aqueous high-content nanometer calcium carbonate dispersoid. The aqueous high-content nanometer calcium carbonate dispersoid comprises the following ingredients through being metered by the total mass percentage: 40.0 to 60.0 weight percent of nanometer calcium carbonate, 5.0 to 10.0 weight percent of surface modifying agents, 2.0 to 6.0 weight percent of wetting agents, 6.0 to 15.0 weight percent of dispersing agents, 5.0 to 10.0 weight percent of functional additives, 0.2 to 0.5 weight percent of pH value conditioning agents and the balance de-ionized water, wherein the dispersing agents are formed by the self preparation of three polymerizable monomers through reaction. The aqueous high-content nanometer calcium carbonate dispersoid can replace nanometer calcium carbonate powder of the same quantity in the paint preparation process, in addition, the calcium carbonate dispersoid is easily dispersed, and the performance of the paint in multiple aspects of water resistance, washing resistance, stain resistance, construction performance and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

Dust cap for fiber optic adapter

An adapter dust cap comprising a dust cap body defining a clearance extending at least partially therethrough, a resilient member attached to the connector body, and a latching feature attached to the resilient member and configured to engage within internal geometry defined by a connector adapter. The adapter dust cap is translucent so that visible light from a connector may diffuse therethrough, and may include a material or coating thereon for converting light in the invisible spectrum to visible light so that the light can be detected through the dust cap without removing the dust cap from an adapter to which it is engaged.

Owner:CORNING OPTICAL COMM LLC

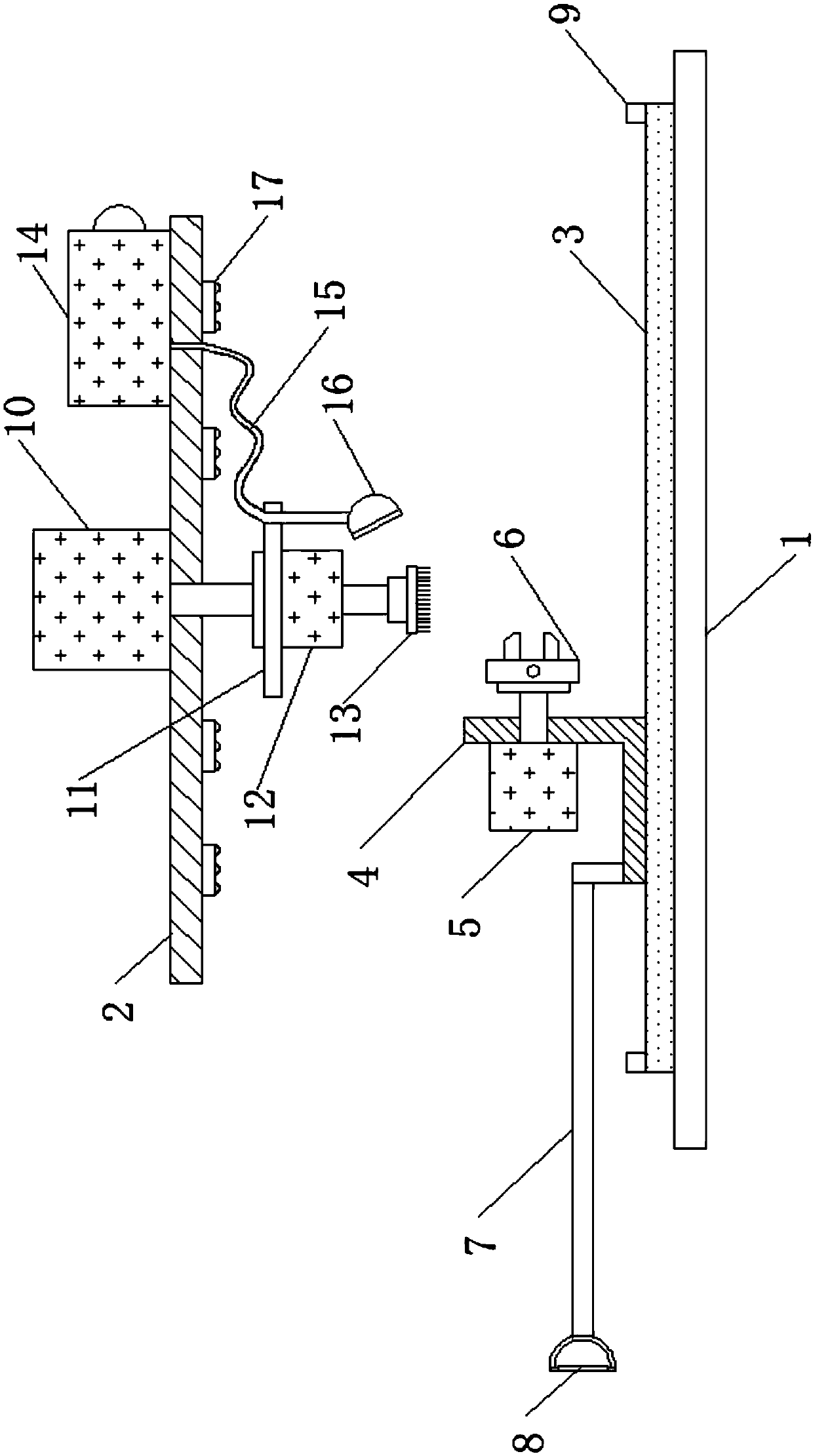

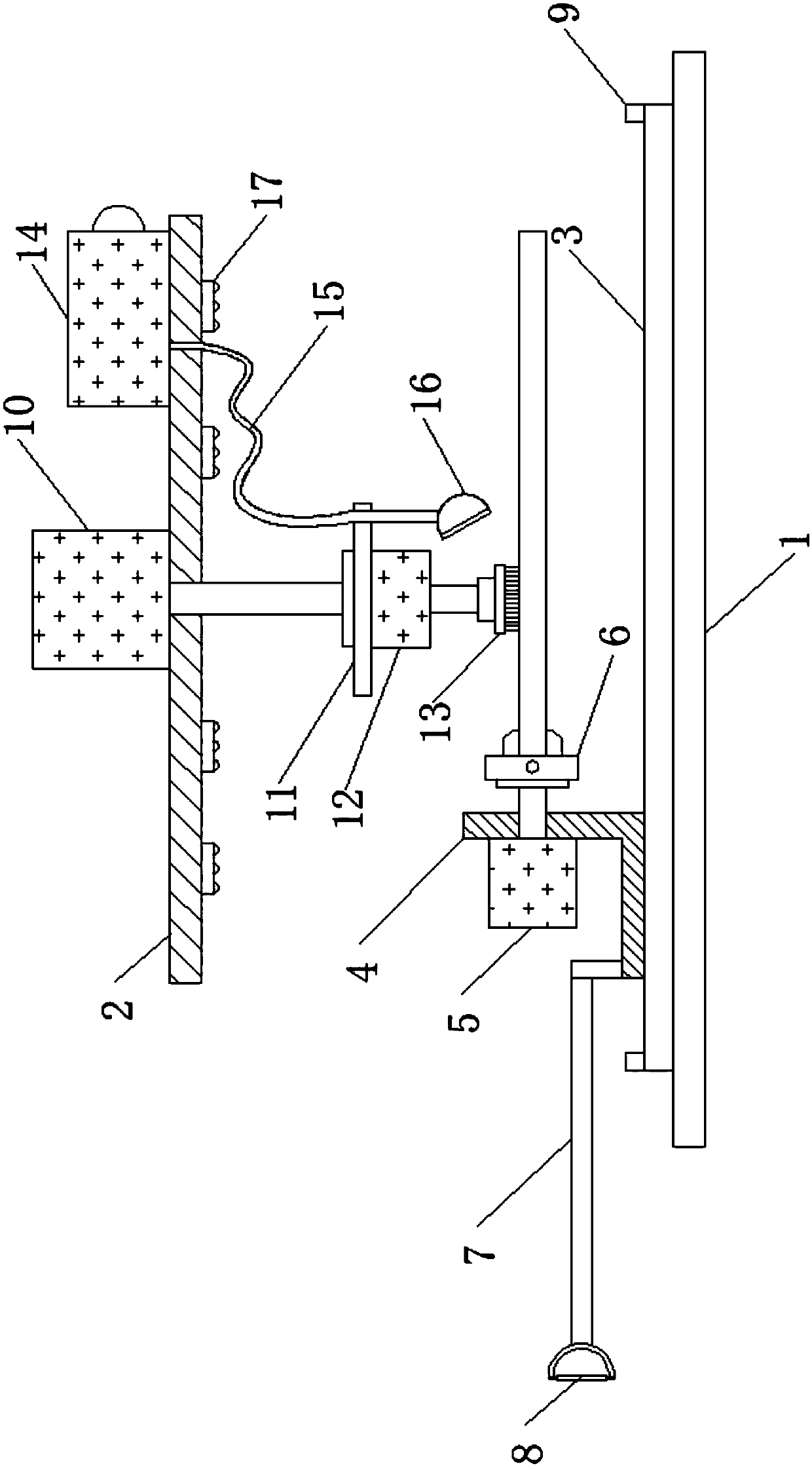

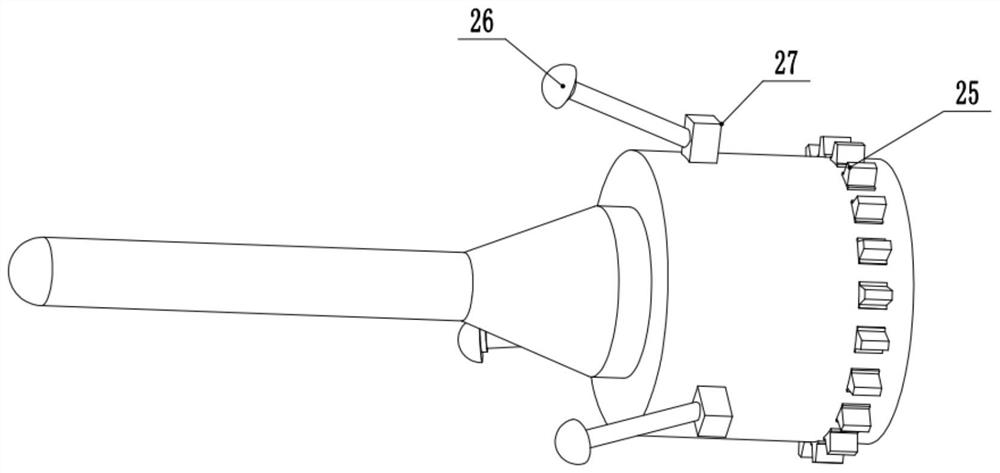

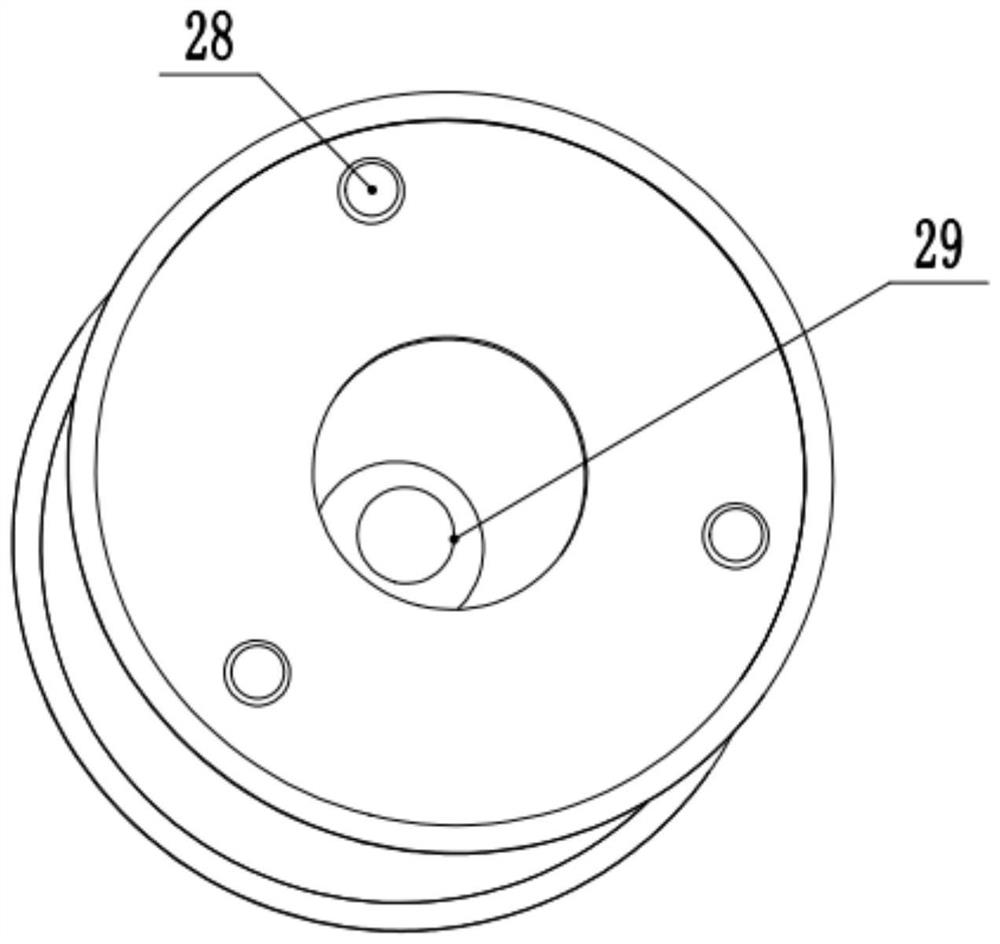

Wire surface rust removal polisher

ActiveCN104907907AAvoid dust pollutionReduce manufacturing costGrinding drivesBelt grinding machinesBelt grindingEngineering

The invention relates to a wire surface rust removal polisher. Rust removal polishing is performed on the surface of a wire in the mode that an abrasive belt moves to grind the wire and rotates around the circumference of the wire, the abrasive belt conducts helical motion on the surface of the wire due to linear movement of the wire, and therefore grinding dust removal can be performed on the whole surface of the wire. In addition, removed iron rust can be recycled, and therefore the production cost is lowered; a physical abrasive belt grinding method replaces a traditional chemical electrolysis pickling method, and therefore air pollution is reduced.

Owner:HANGZHOU XINGGUAN MACHINERY

Premixed colored pervious concrete

Disclosed premixed colored pervious concrete is prepared from the following components in parts by weight: 289 to 306 parts of cement, 51 to 54 parts of fly ash, 15 to 25 parts of a reinforcing agent, 1450 to 1550 parts of coarse aggregate, 3.4 to 3.6 parts of a water reducing agent, 90 to 120 parts of mixing water, 0.51 to 0.54 part of a tackifier and 10 to 15 parts of a coloring agent. The cement is adopted as a main cementing material, the coal ash improves the workability and durability, the reinforcing agent improves the strength of the premixed colored pervious concrete and inhibits surface efflorescence, the tackifier improves the bonding force between slurry and an aggregate interface, and the inorganic coloring agent ensures that the color of a surface layer of the premixed colored pervious concrete is durable and does not fade. In the premixed colored pervious concrete, the slurry can uniformly wrap the aggregate and is clustered by hand holding, the cementing force of the slurry and the aggregate is strong, stones do not fall off for a long time, the permeable rate after hardening is high, the strength is not lower than C20, the color is lasting and does not fade, saltpetering is avoided, and the durability is good.

Owner:陕西建工集团混凝土有限公司

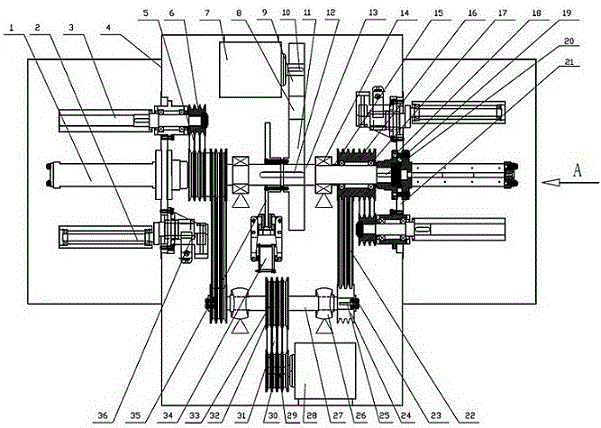

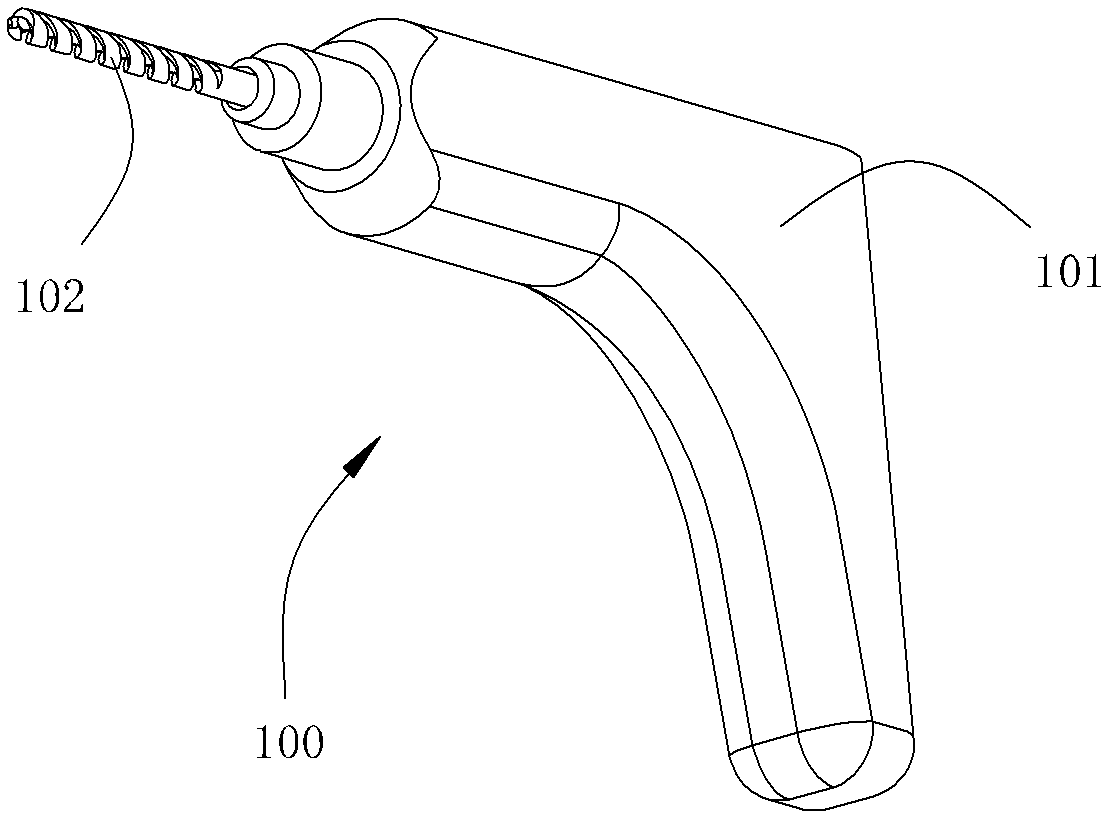

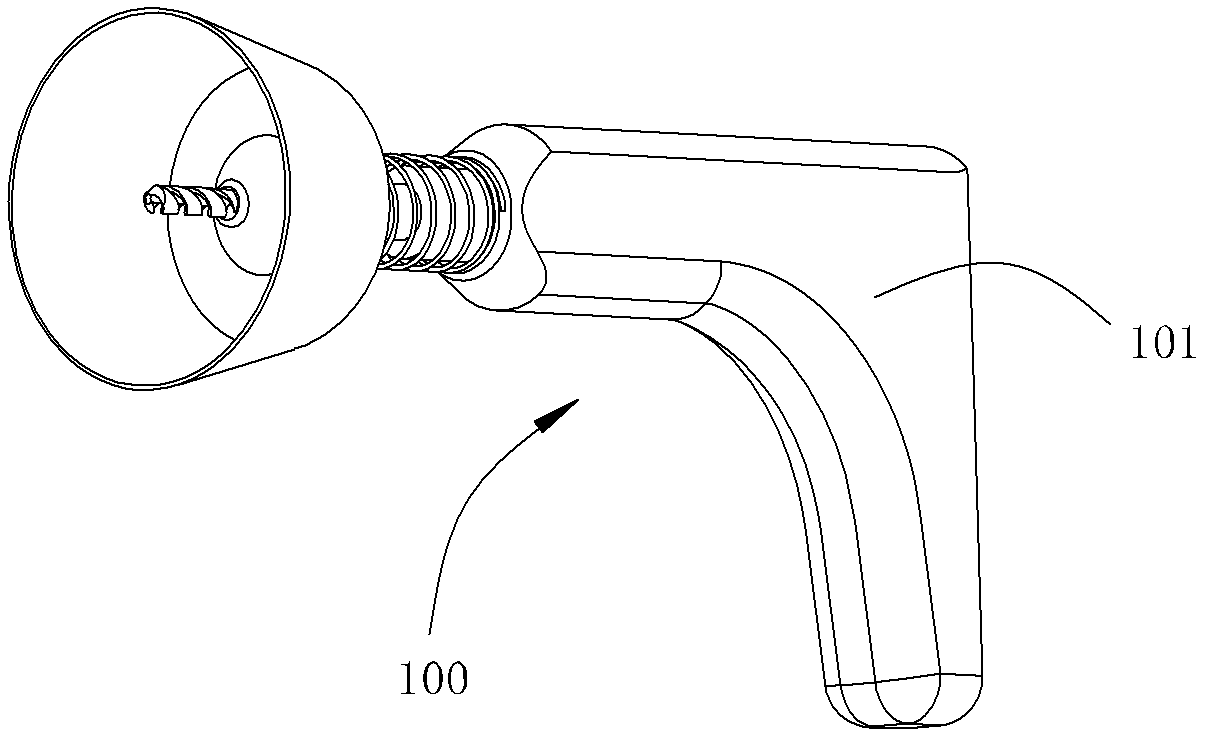

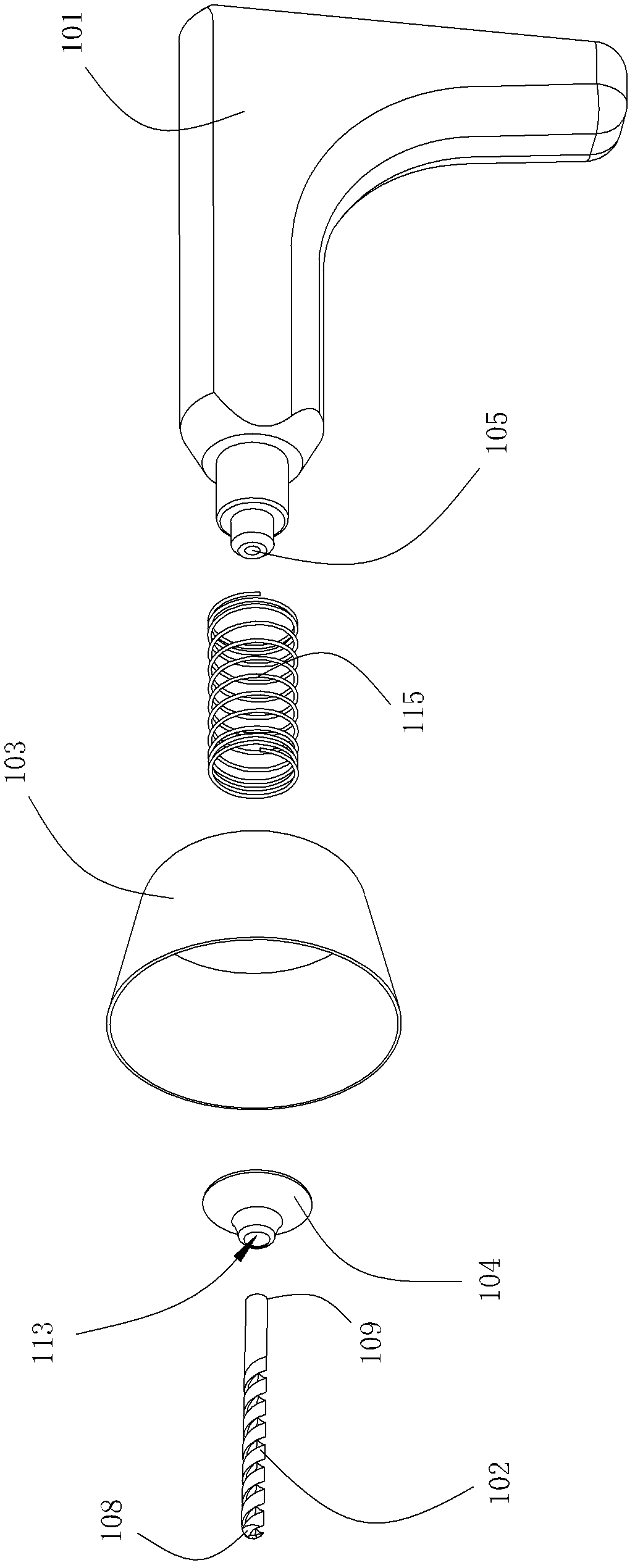

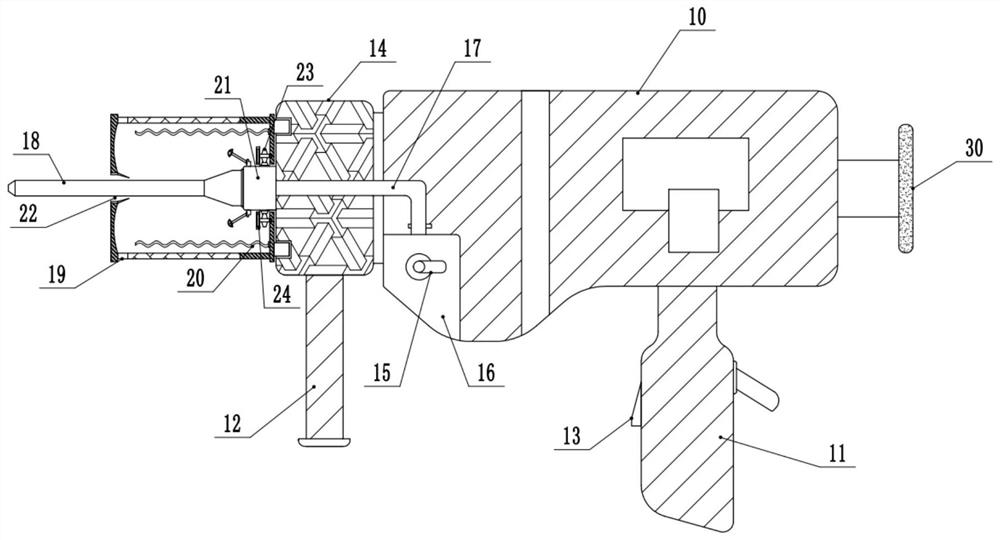

Dustproof device and electric hand drill

The invention relates to a dustproof device special for an electric hand drill and the electric hand drill applying the dustproof device. The dustproof device comprises a dustproof cover and a dust discharging plate, wherein the dustproof cover is a bowl-shaped casing formed by a bottom, a peripheral wall and an open end. The center of the bottom protrudes towards the open end to form an annular dust collection chamber between the protruded top end and the peripheral wall, and a through hole penetrating through the bottom and used for being in clearance fit with a drill bit is arranged at the protruded top end. The dust discharging plate is an umbrella-shaped round plate, and the center of the round plate is provided with a locking hole fixed relative to the drill bit. By means of the electric hand drill applying the dustproof device, dust explosion in the hole drilling process is eliminated, and environment pollution and physical and psychological harm caused by the dust produced by hole drilling can be effectively avoided.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

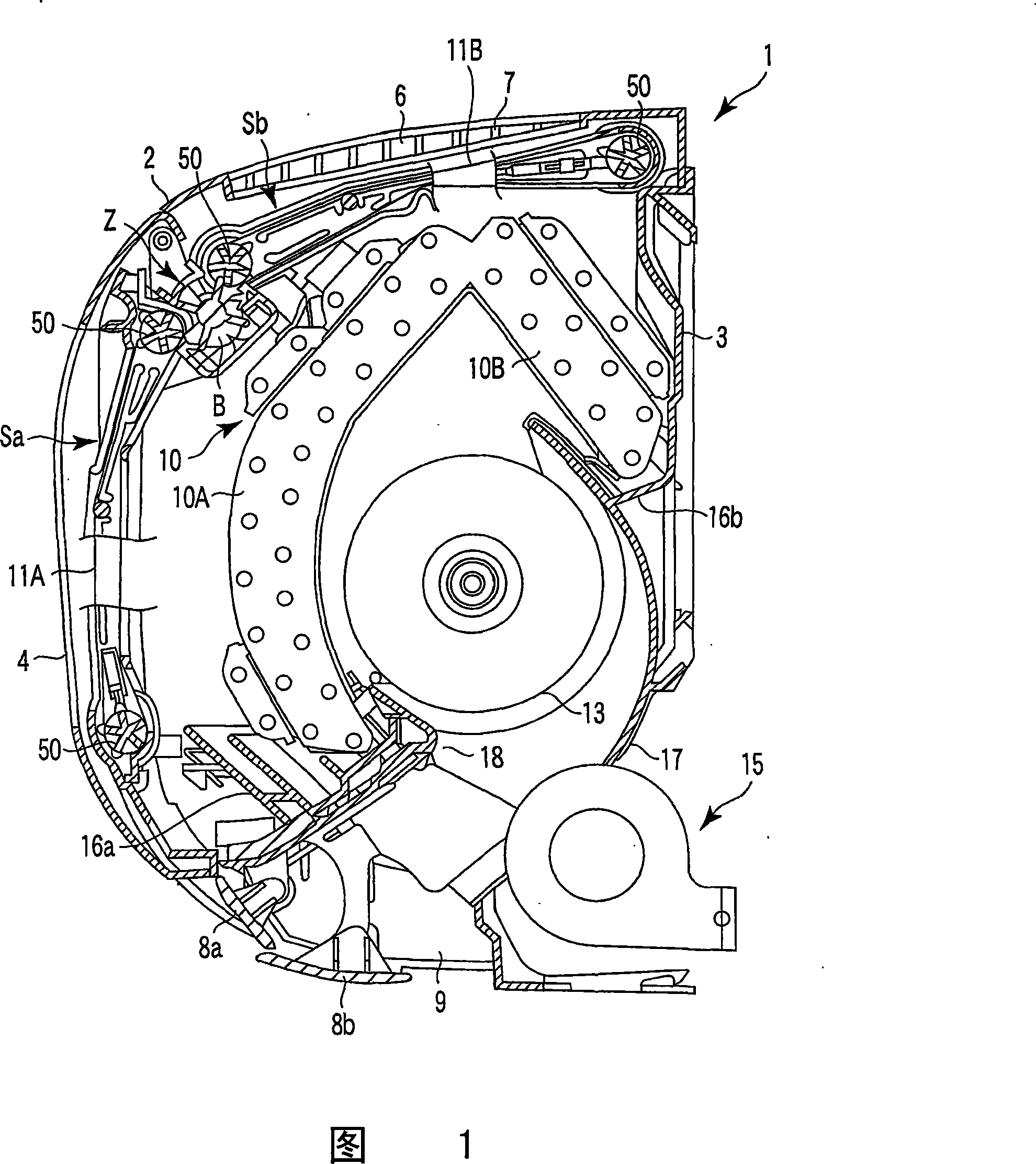

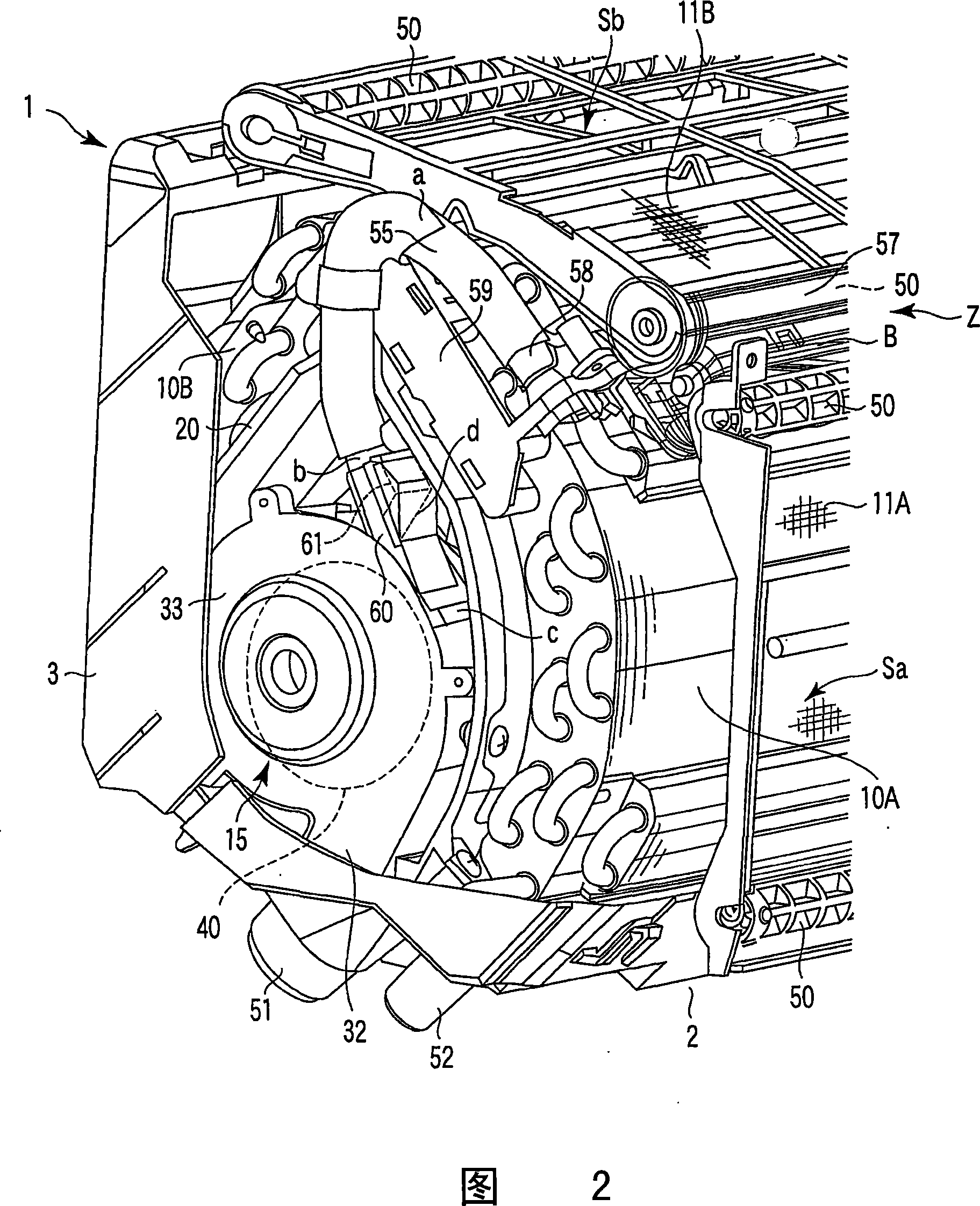

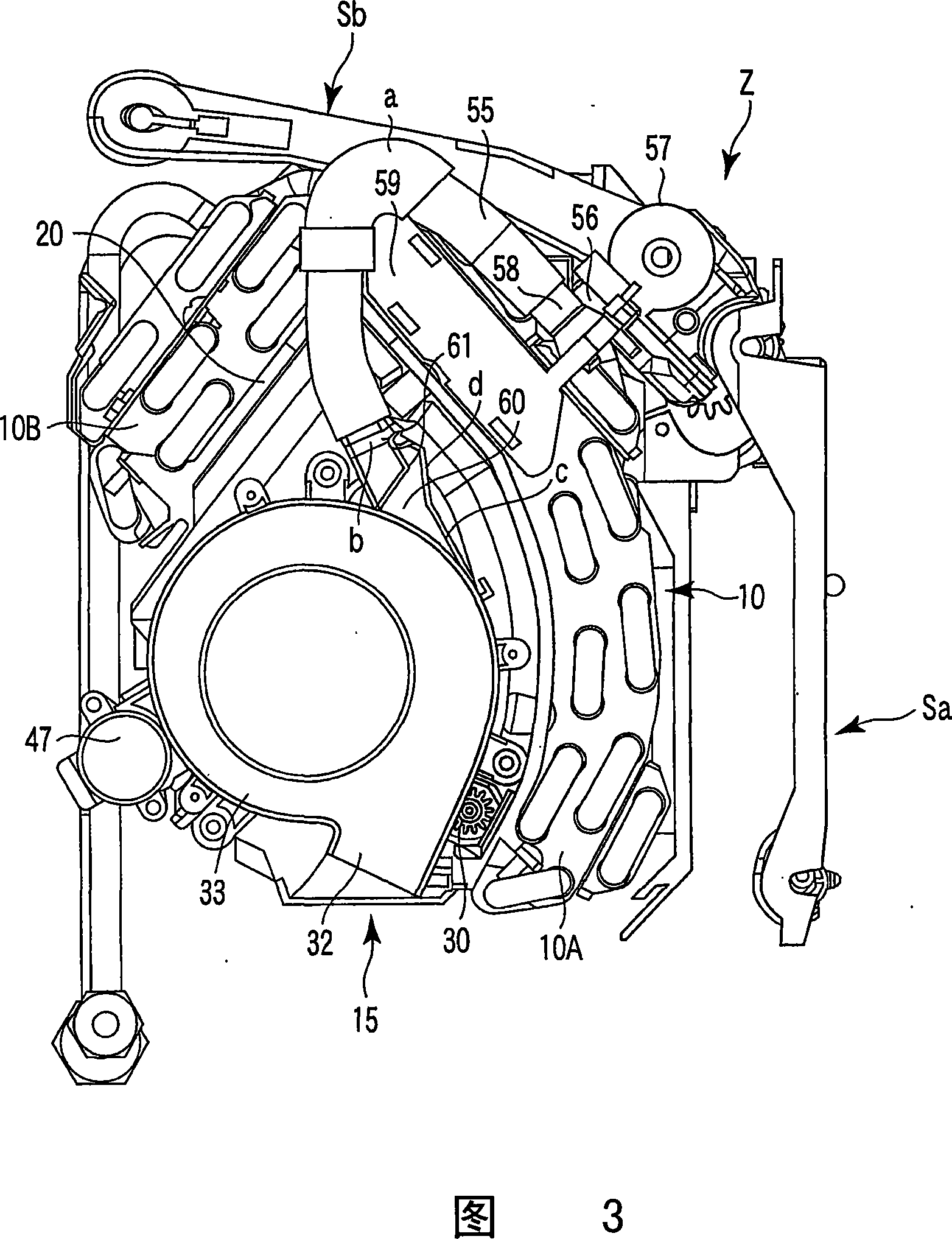

Indoor unit of air-conditioner

InactiveCN101243291AAvoid dust pollutionAchieve removalMechanical apparatusLighting and heating apparatusIndoor airEngineering

Suction ports 4 and 6 and a blowoff port 9 are equipped on a ventilation passage between the suction ports 4 and 6 and blowoff port 9, a heat exchanger 10 and a blower 13 are arranged to an indoor unit proper 1, and air filters 11A and 11B are mounted between the suction port and the heat exchanger. In addition, a ventilation unit 15 which discharges indoor air to the outside is equipped, and air filters have a sweeping unit Z which removes dust adhering to the air filter surfaces and collects it in a dust box. The ventilation unit has a fan casing on which an intake port 31 and an exhaust port 32 are provided, an exhaust fan 35, and a connection hose 55 which communicates with a dust box of the sweeping unit and the ventilation unit, wherein the head end portion of the connection hose is connected to the outer circumferential portion upstream of the exhaust port of the fan casing.

Owner:TOSHIBA CARRIER CORP

Rust conversion and rust-proof coating agent for construction steel structure and its usage method

The invention discloses a steel structural rust conversion anti-rust paint used in building. The formulation is that rust conversion agent of polyatomic acid is 300-700 parts, gelling agent is 20-40 parts, atmospheric inhibitor is 1-2 parts, penetrating agent is 0.5-1 parts, organic silicon defoaming agent is 0.1-0.5 parts, and water is 256-678 parts. The steps of usage of the invention include that the components are sequentially added in a reaction tank, mixed and stirred for about 50 minutes under the temperature of 40-60 DEG C, and cooled and filtered to prepare the steel structural rust conversion anti-rust paint. The steel structural rust conversion anti-rust paint is directly brushed on the surface of steel products to remove greasy dirt, mud and sand, and dust which are on the surface of constructional steel structure. The steel products which are coated with the rust conversion anti-rust paint are placed in the air for 1-2 hours, and then are processed via oil paint construction. The rust conversion anti-rust paint has the advantages of thorough rust conversion, simple construction, economy and efficiency, energy-saving, environmental protection and the like, and is capable of strengthening the anti-rust and anti-fire property of the oil paint and increasing the inherent quality of the oil paint.

Owner:叶云川

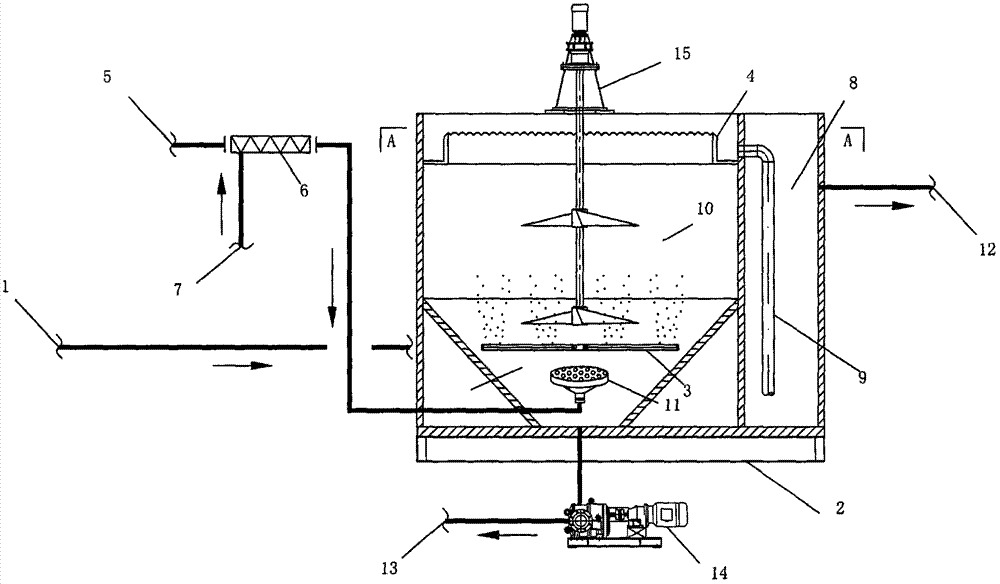

Softening device for treating high-hardness, low-alkalinity salt-containing wastewater

InactiveCN104496041AImprove utilization efficiencyAvoid dust pollutionWater softeningWater pipeCarbon dioxide

The invention relates to a softening device for treating high-hardness, low-alkalinity salt-containing wastewater and belongs to the field of water treatment in environmental protection. A settling tank and a water-production tank are arranged on a tank body pedestal of the softening device, an inverted stirrer is arranged in the settling tank, a water outlet weir is arranged above the settling tank, a mixing reaction zone and a settling zone are sequentially arranged at the upper part and a lower part of the settling tank, microporous aeration pipes are arranged at the upper part of the settling zone and are communicated by virtue of gas inlet pipes; and water distributors are arranged in the middle of the settling zone and are communicated with water inlet pipes, pipeline mixers are arranged on the water inlet pipes, and chemical agent adding pipes are arranged on the pipeline mixers. According to the softening device, by adding carbon dioxide and caustic soda into the wastewater, chemical agent addition, gas distribution, stirring and reaction are performed in the softening device so that carbon dioxide and caustic soda and calcium and magnesium ions in water are reacted to achieve the removal of water hardness, the utilization efficiency is increased, the dust pollution is avoided, the energy consumption is decreased, the chemical agent cost is saved, the removal rate of the hardness is very high and the reaction is completely performed.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Quick polishing and polishing device for machinery manufacturing

InactiveCN107627159ANovel structureEasy to operateRevolution surface grinding machinesGrinding/polishing safety devicesSteel tubePush pull

The invention discloses a quick polishing and polishing device for machinery manufacturing. The quick polishing and polishing device comprises a base and a rack, wherein a sliding rail is installed onthe top of the base, a movable plate is arranged on the top of the sliding rail, a first motor is installed on the movable plate, a three-jaw chuck is connected to the output end of the first motor,a push-pull rod is connected to the left side of the movable plate, a handle is connected to one end of the push-pull rod, a hydraulic cylinder is installed on the top of the rack, a lifting plate isconnected to the output end of the hydraulic cylinder, a second motor is installed at the bottom of the lifting plate, a polishing ball is connected to the output end of the second motor, a dust collector is installed on the top of the rack, and a dust collection bucket is connected to the dust collector through a flexible tube. The three-jaw chuck is arranged, so that a steel tube is accurately positioned; the dust collector is installed on the top of the rack, and the dust collection bucket is arranged near the polishing ball, so that dust generated during polishing and grinding is convenient to absorb, the effect of environmental friendliness is achieved, and dust pollution is prevented.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Optical device utilized in laser projector

ActiveUS9335616B2Avoid problemsAvoid damageProjectorsPicture reproducers using projection devicesPhosphorEngineering

An optical device utilized in a laser projector includes a circulatory air channel, a phosphor wheel disposed in the circulatory air channel, a thermal exchanger partially disposed in the circulatory air channel, and an air guiding component disposed in the circulatory air channel for guiding an air provided by the thermal exchanger toward the phosphor wheel. The temperature of the air passing through the phosphor wheel is lower than an environment temperature.

Owner:DELTA ELECTRONICS INC

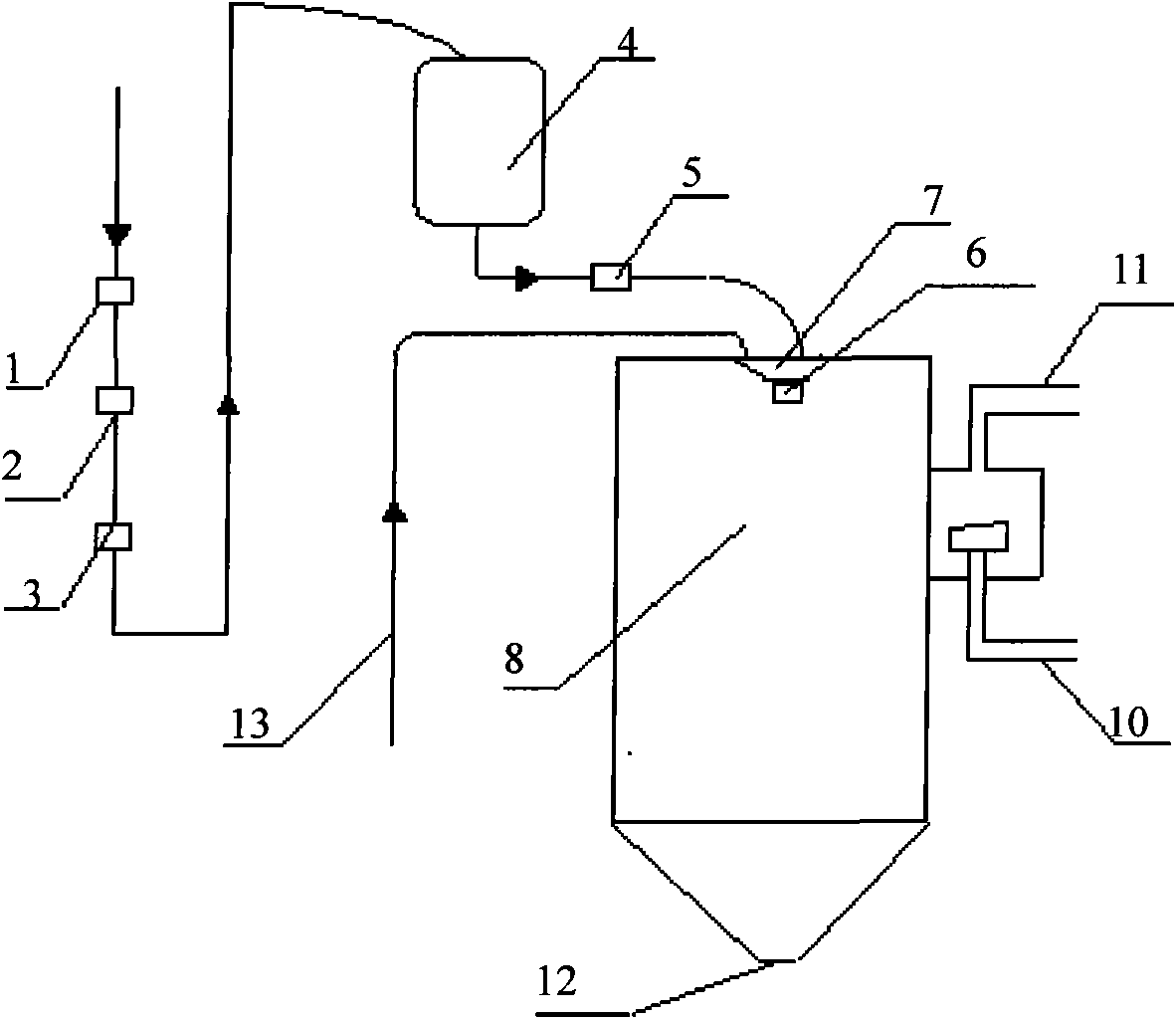

Method for drying hydrocortisone sodium succinate asepsis powder

ActiveCN101559287ASolve the problem of heat deteriorationSolve for uniform dryingSteroidsEvaporation by sprayingTemperature controlTower

The invention discloses a method for drying hydrocortisone sodium succinate asepsis powder, which comprises the following steps: delivering filtered hydrocortisone sodium succinate water solution into a temperature control tank, delivering the water solution after passing through a second precision filter into a spray drying tower, atomizing the water solution through an atomizer, and contacting the water solution with hot aseptic air to be dried. The top inside the spray drying tower is provided with a hot air distributor which comprises an inner pipe and an air deflector, the lower part of the air deflector is bent to one side, the outer surface of the tower wall of the spray drying tower is provided with a tower wall shaking device, one end of a dust discharge pipe is connected with an air hammer chamber, the other end of the dust discharge pipe is arranged outside a sterile room, the air hammer chamber is hermetically connected with the tower wall of the spray drying tower, and the dried hydrocortisone sodium succinate asepsis powder is discharged from a discharge hole at the bottom of the spray drying tower and collected by a cyclone separator. The method strictly ensures asepsis of liquid medicine, ensures even drying of materials, avoids dust pollution, and strictly ensures the cleanliness of the sterile room.

Owner:TIANJIN BIOCHEM PHARMA

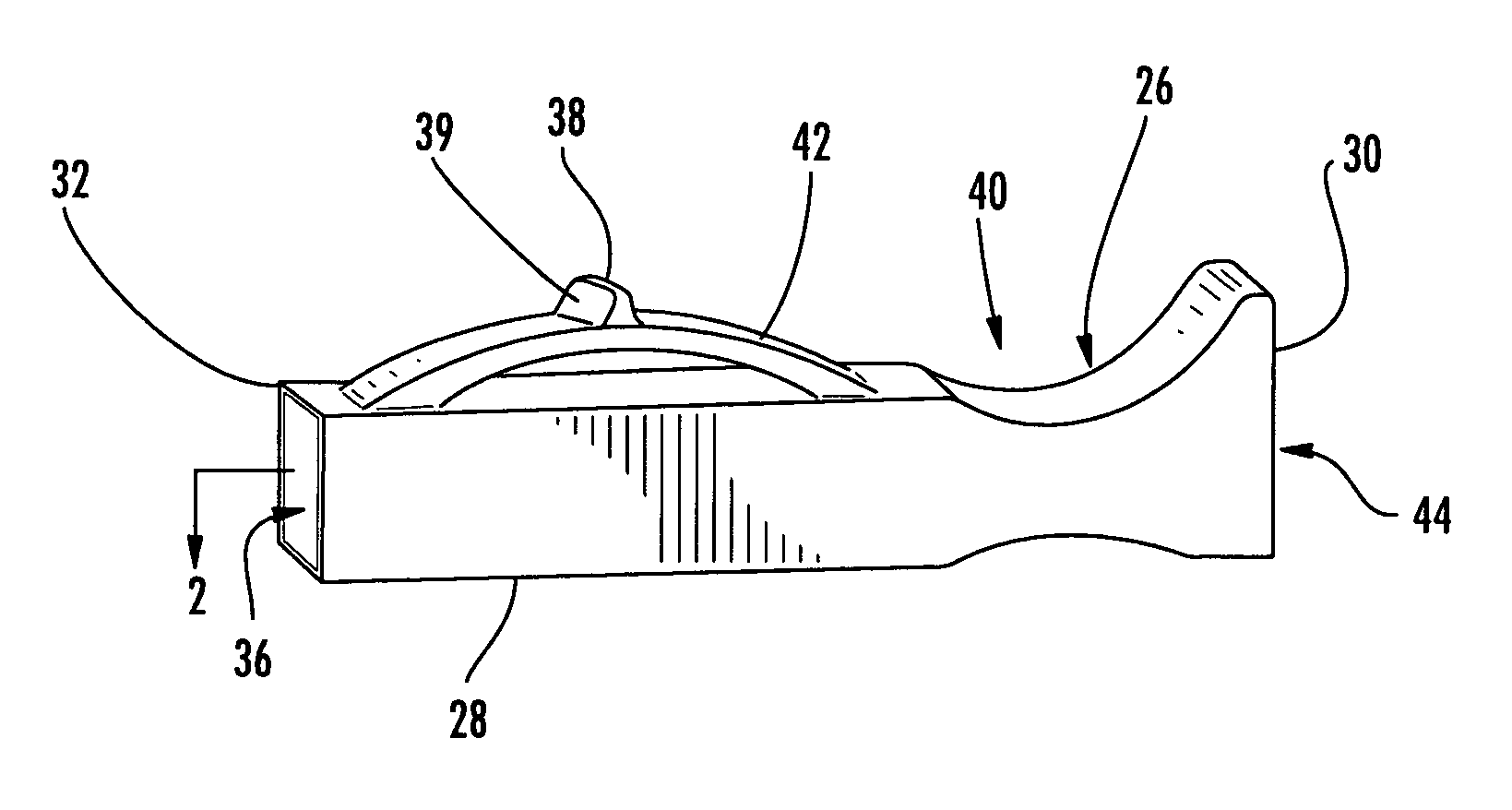

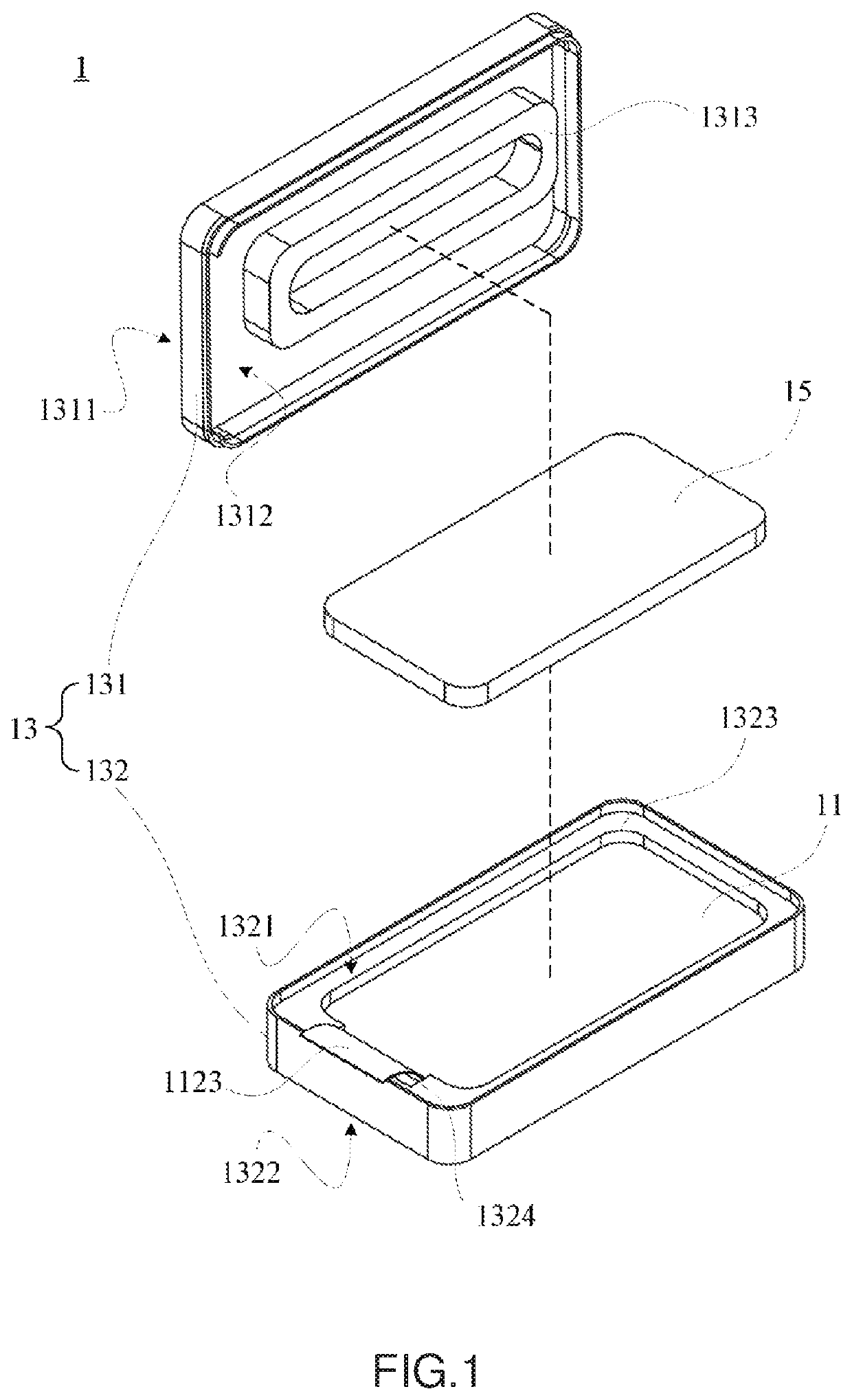

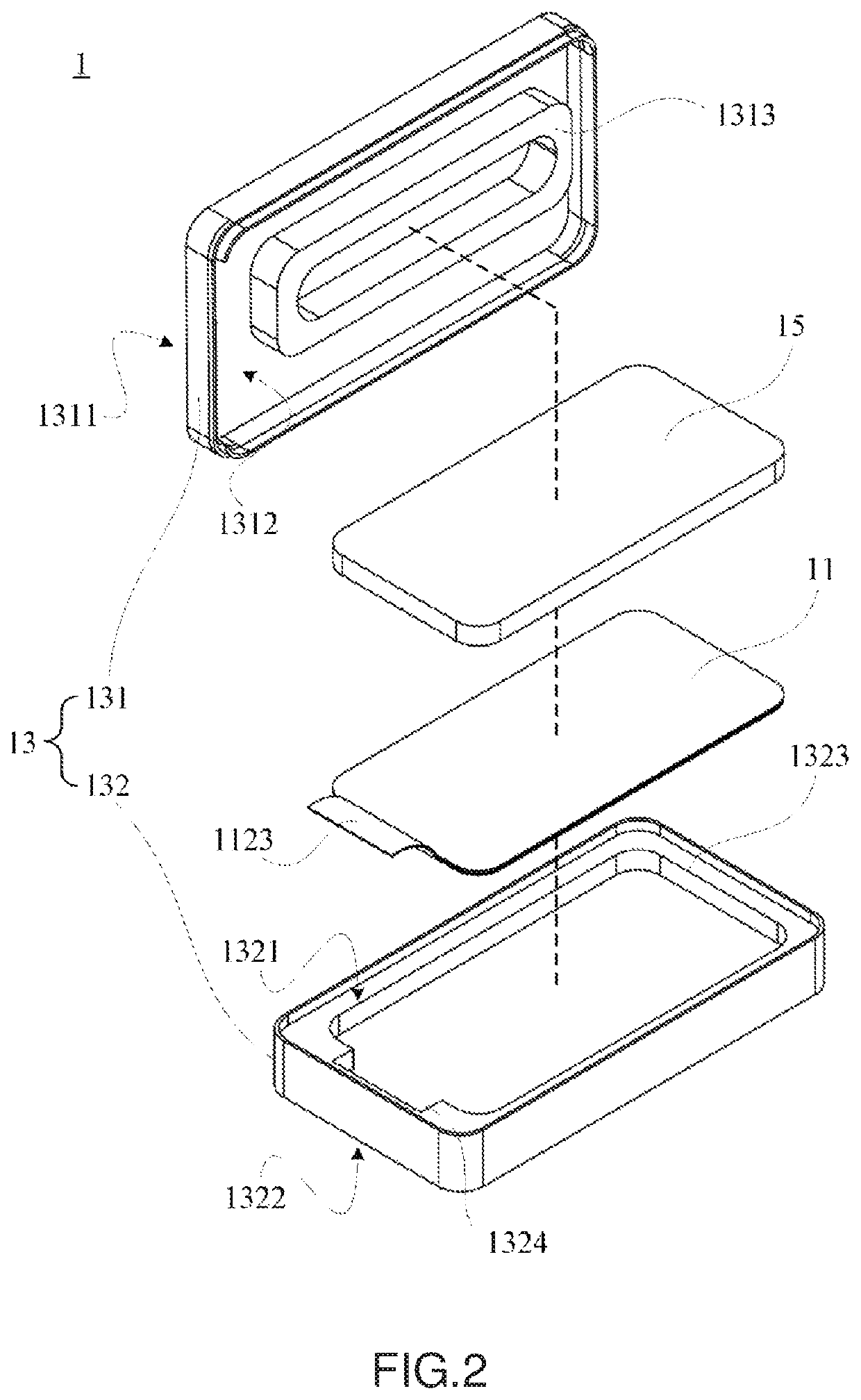

Packaging box of covering film and film applicator

ActiveUS10751931B1The process is simple and convenientImprove coating efficiencyPackaging vehiclesContainers for machinesThin membraneEngineering

The present invention discloses a packaging box of a covering film and a film applicator. By structural designs of the packaging box and the covering film, the packaging box is provided with an internal cavity matching an outer shape of an electronic device and the covering film includes a release film having an extension portion, enabling the packaging box to provide the covering film with storage, dustproof and shock-absorbing functions and to further serve as a film application auxiliary tool when a film application process is performed. Thus, a user is allowed to accurately, quickly and efficiently form a layer providing protection on a surface of the electronic device directly by using the packaging box.

Owner:HSU HSIANG PIN

Intelligent, green and environmental-friendly integrated building structure

The invention discloses an intelligent, green and environmental-friendly integrated building structure. The intelligent, green and environmental-friendly integrated building structure comprises two partition wall plates, wherein a same first clamping plate is arranged on the two partition wall plates through clamping, a plurality of mobile grooves are formed in one side of the first clamping plateat an equal distance, a mobile plate is connected with inner walls of the mobile grooves in a sliding way, one side of the mobile plate extends to an outer side of the first clamping plate and is arranged between the two partition wall plates, a screw rod is in threaded connection with one side of the mobile plate, a same second clamping plate is arranged at the other sides of the two partition wall plates in a clamping way, and a plurality of installation holes are formed in the second clamping plate at an equal distance. The intelligent, green and environmental-friendly integrated buildingstructure is simple to operate, the screw rod and a nut are connected, thus, the two partition wall plates can be spliced by the first clamping plate and the second clamping plate, a traditional brickwall body can be substituted, and the problem of dust pollution is prevented; and meanwhile, building waste can be effectively reduced, the intelligent, green and environmental-friendly integrated building structure is convenient to disassemble and recycle, and the manufacturing cost is effectively reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +2

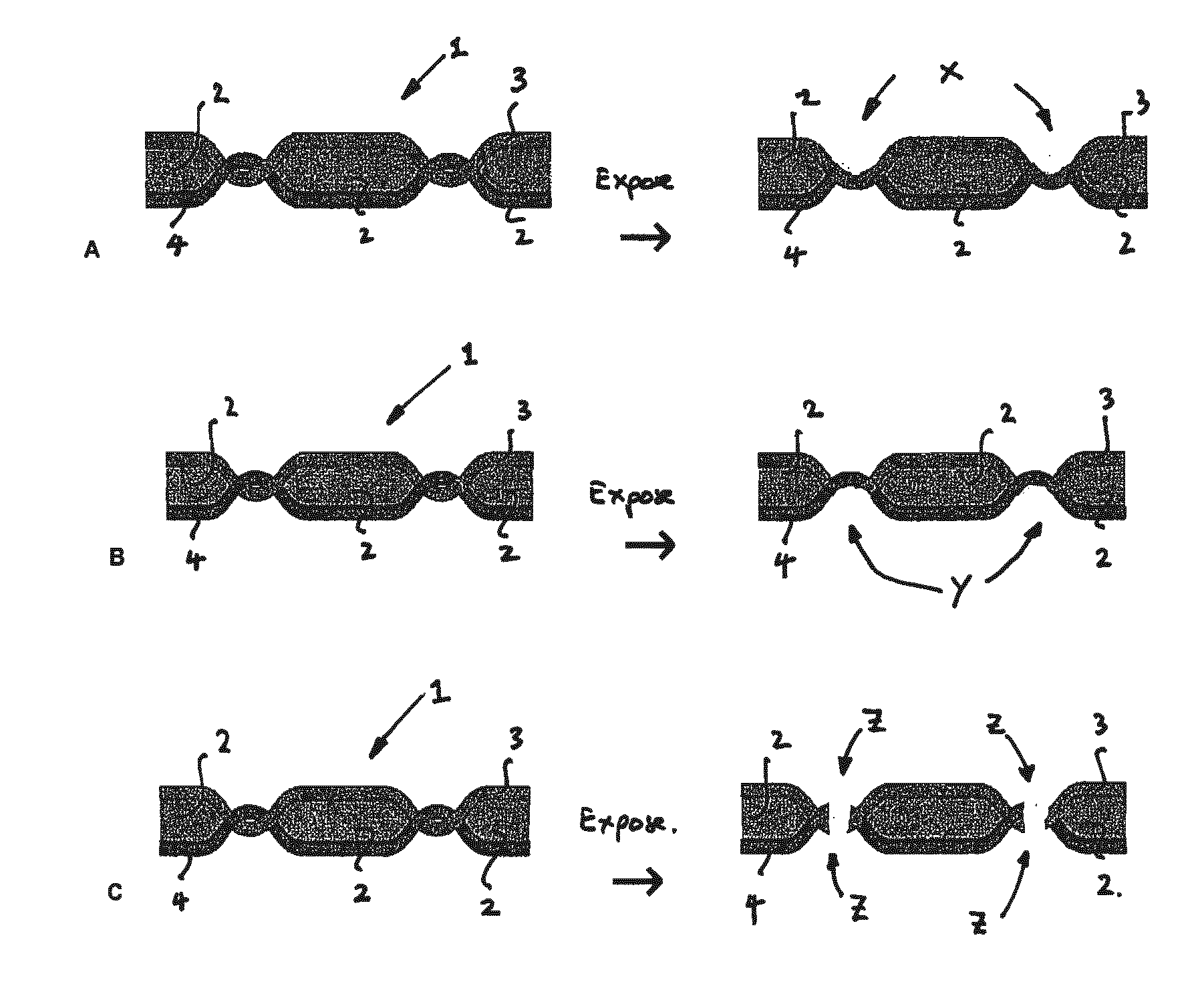

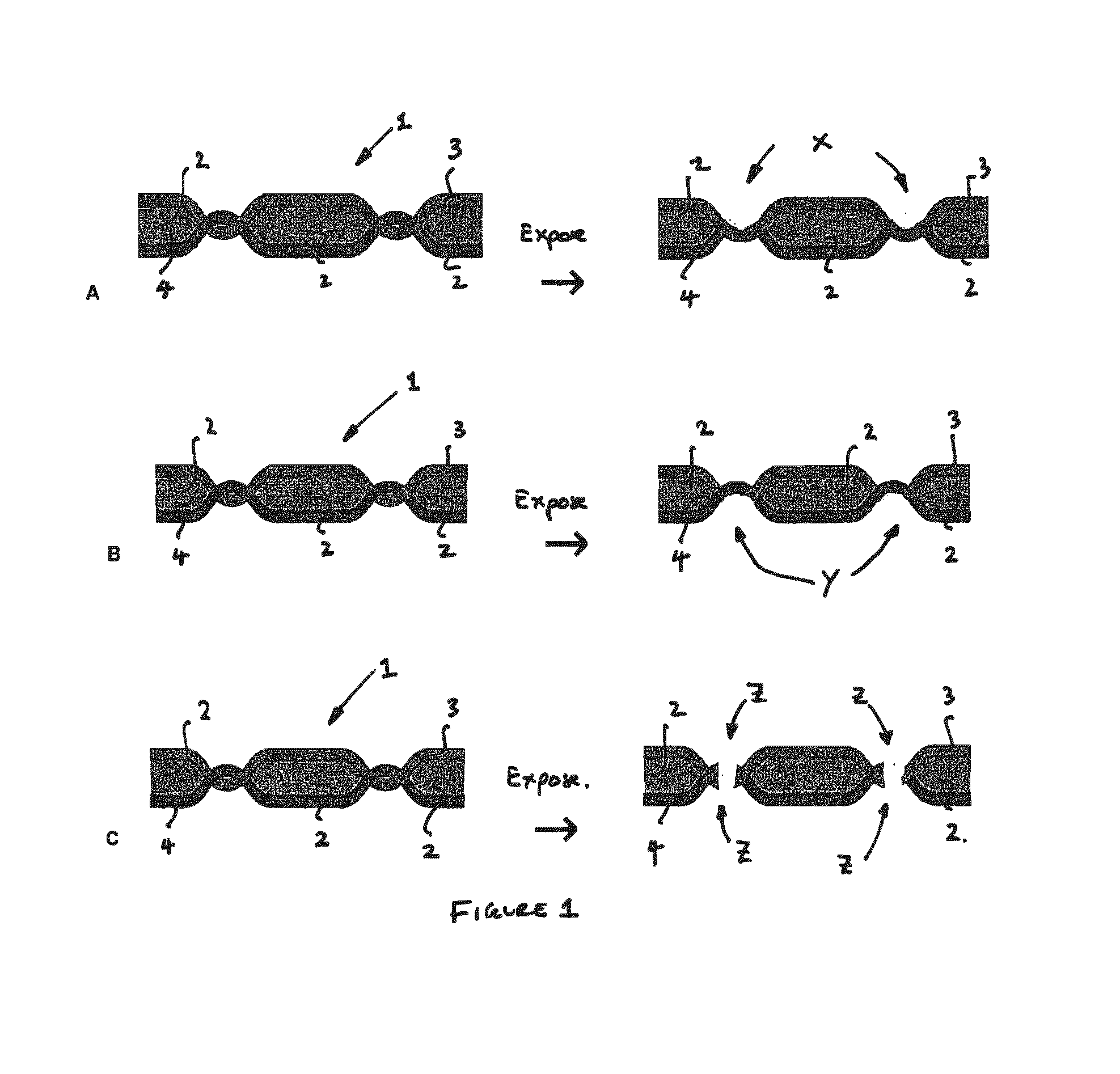

Article assembly disassembly system

ActiveUS20150167230A1Easy to produceModifying colour and appearanceGarmentsPlastic recyclingYarnMicrowave

There is described a system, article, method, connectors and apparatus for article reuse or recycling, which system including the assembling of an article from at least two components at least one of which has a textile material brought into communication with each other through one or more connectors and the subsequent disassembling of the article and use of one or more of the components in the assembling stage. The assembled article is susceptible to automatic or semi-automatic disassembly through one or more of its connectors being susceptible to a reduction in one or more mechanical properties under exposure of the article to electromagnetic energy especially microwave. The article may be a garment that has joins stitched with a microwave susceptible yarn. The yarn is ideally manufactured from pseudo-conductive materials and is metal free.

Owner:WEAR2GO BV

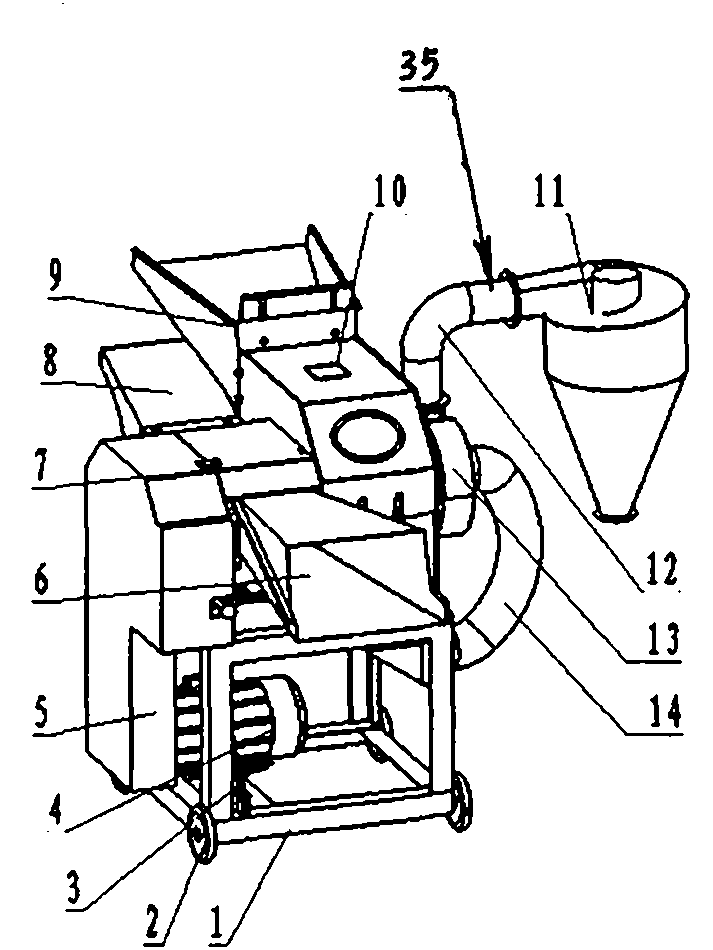

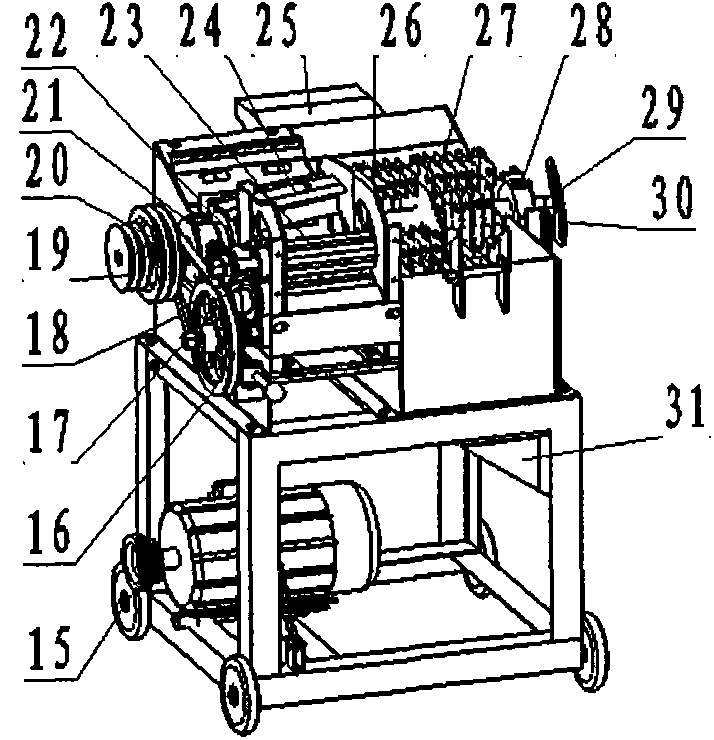

Multifunctional rubbing machine

Disclosed is a multifunctional rubbing machine. The multifunctional rubbing machine comprises a motor, a fan, a base, a spindle, a straw cutting case, a crushing case, a cutter disc assembly, a straw roller assembly and a powder collector assembly. The base is fixedly provided with a motor support, the motor is fixed onto the motor support, and the power output shaft of the motor is provided with a motor belt pulley; the four corners at the bottom of the base are respectively provided with a ground wheel; the spindle penetrates the straw cutting case and the crushing case; the front side and the rear side of the straw cutting case are provided with a feeding hopper and a discharging hopper respectively; the cutter disc assembly is mounted on the spindle; the straw roller assembly is mounted on a left straw roller support and a right straw roller support; the outer side of the straw cutting case is fixedly provided with a belt pulley protecting cover; the crushing case is provided with a crushing discharging hopper, the inside of the crushing case is provided with a hammer piece assembly, the hammer piece assembly comprises a hammer piece rack which is mounted on the spindle and provided with a plurality of hammer piece shafts, and every hammer piece shaft is provided with a plurality of hammer pieces. The multifunctional rubbing machine has the advantages of being simple in structure, attractive and elegant in appearance, high in working efficiency, free from environmental pollution and the like.

Owner:范嘉丽

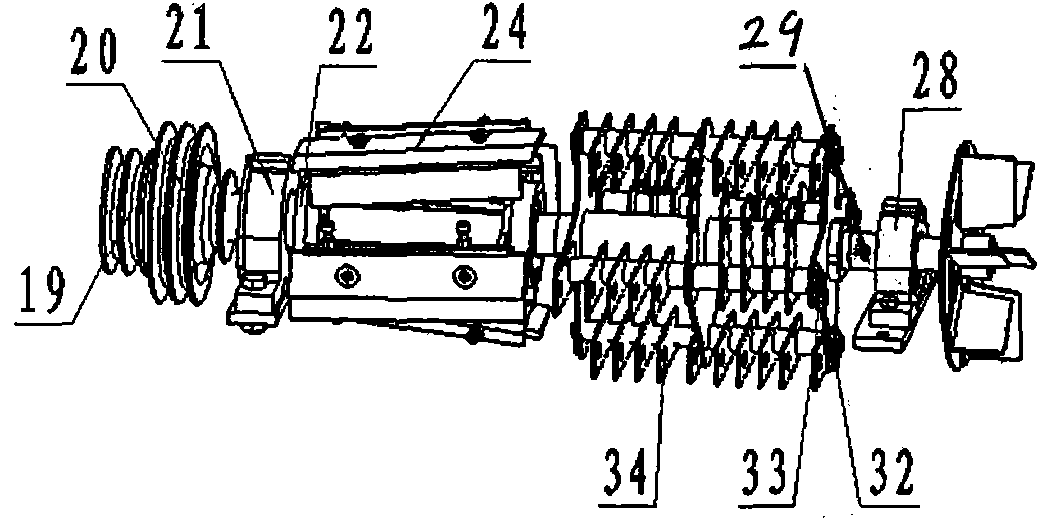

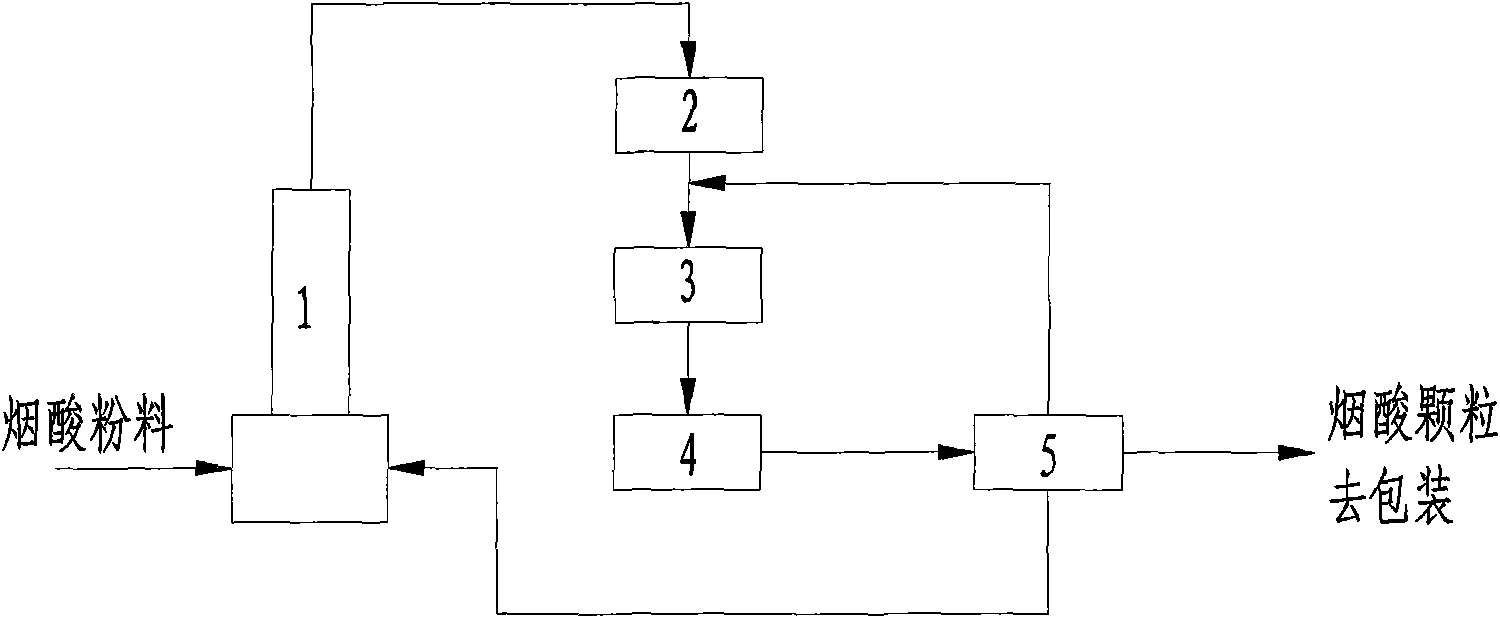

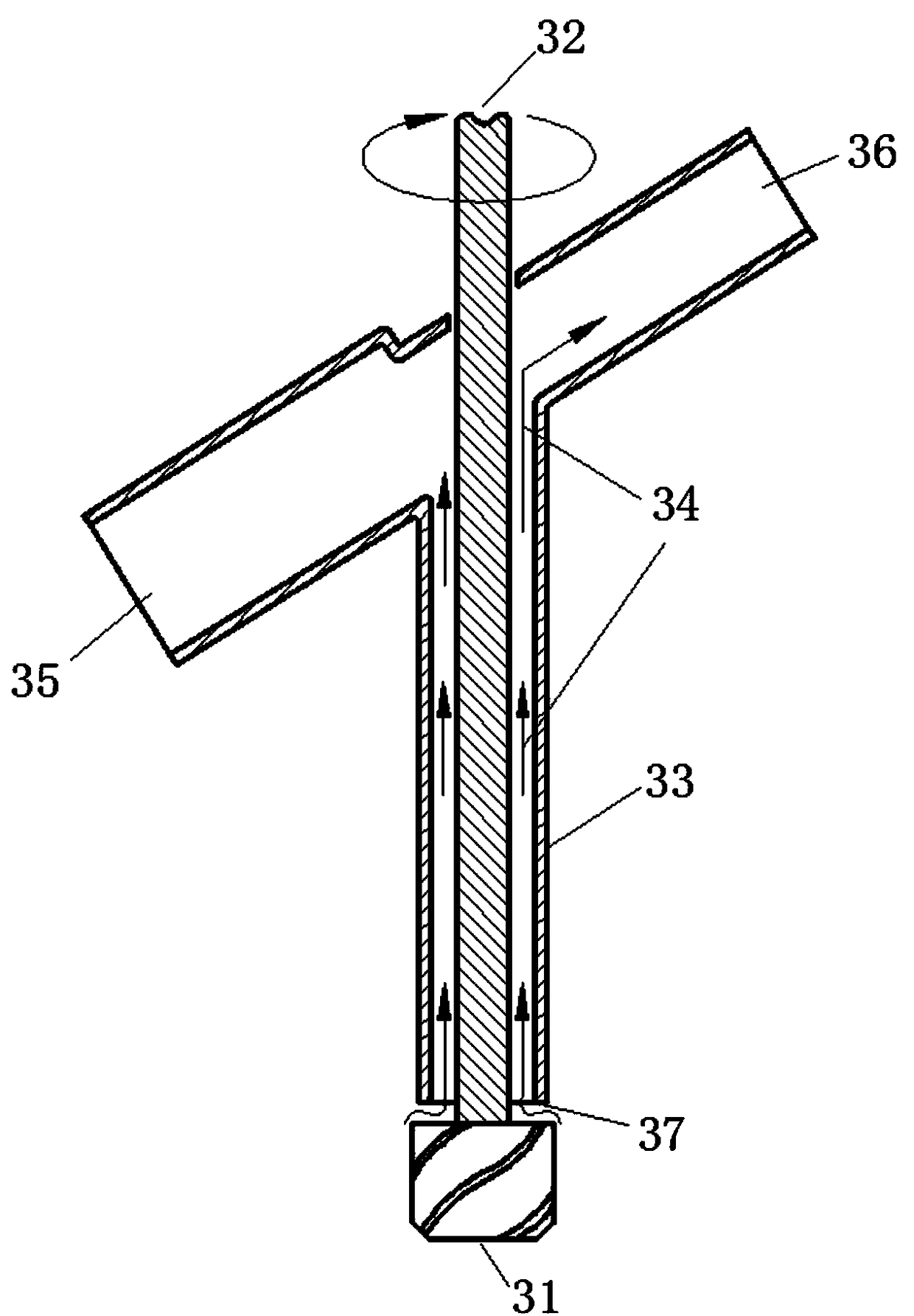

Granular niacin production method by extrusion and granulation

InactiveCN101565401AReduce granulation energy consumptionAvoid agglomeration and dust pollution problemsOrganic chemistryGranulation by material expressionNiacinPelletizing

The invention provides a production method of niacin / isonicotinic acid granules by extrusion and granulation, comprising the following steps: lifting a hopper to a measuring tank and measuring the materials in the hopper and tabletting the materials in a tablet machine, crushing, screening the tablets to obtain the granular niacin / isonicotinic acid product with grain size of 0.2-0.8mm, respectively returning the over-large or over-small granules into the crushing and measuring step. The niacin / isonicotinic acid granules prevents the defects of the niacin / isonicotinic acid powder produced by the prior production method such as severe dust pollution of package, application place due to over-small grain size and grains cluster phenomena in storage and transportation and provides the convenience for the use of the niacin / isonicotinic acid granules as additives.

Owner:HANGZHOU SHENGDA PHARMA

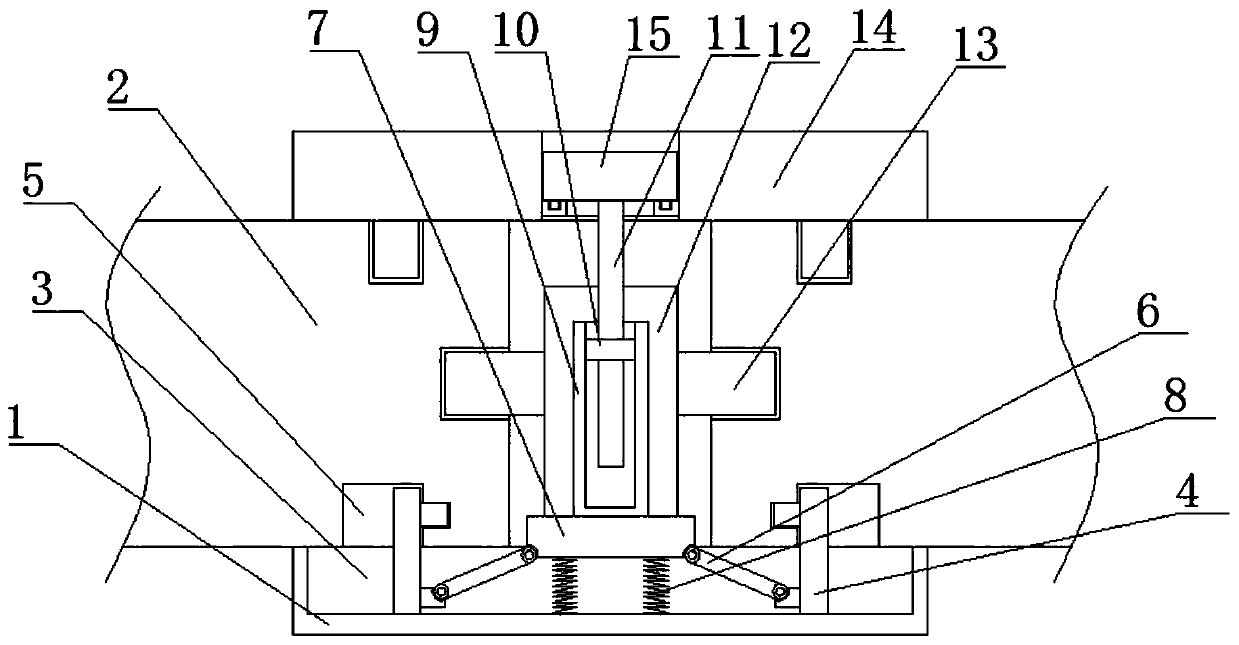

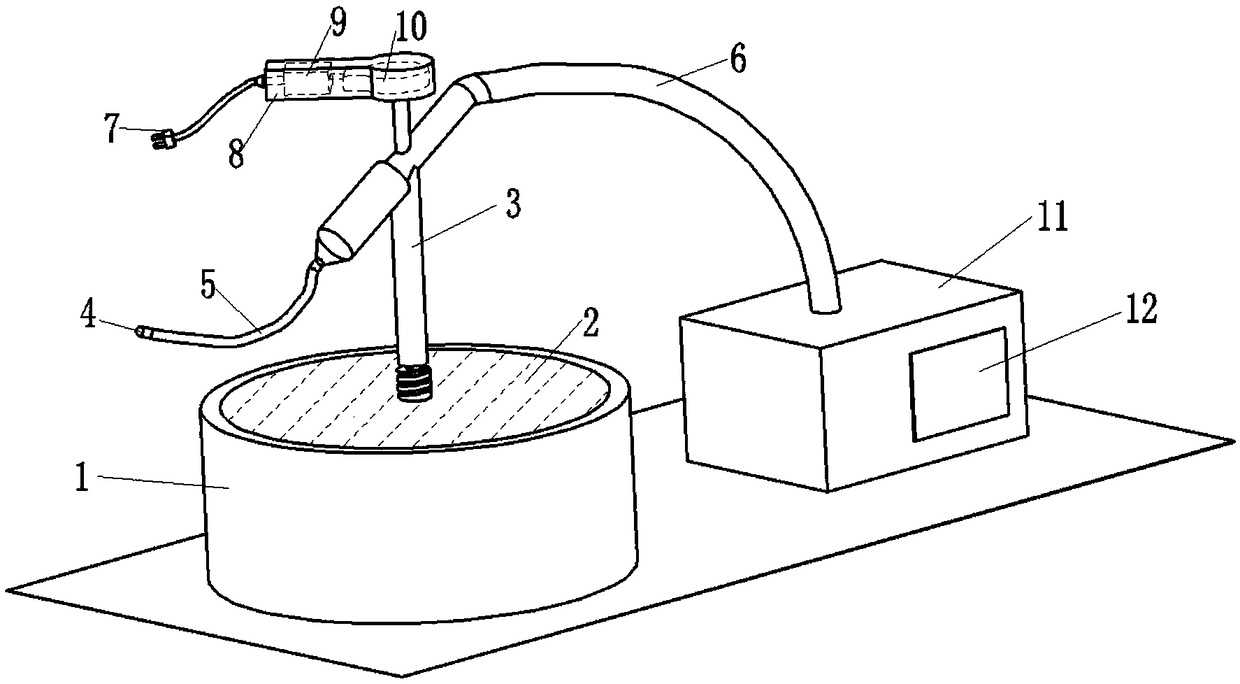

Drilling device for sand cleaning and sand cleaning method

The invention provides a novel sand removing method and device. The device comprises a drilling device for sand cleaning and a dust collecting system based on the rotating cutting and crushing principle and the Bernoulli principle. The drilling device mainly comprises a drill bit, a rotating rod and a three-way communicating pipe, wherein the drill bit is connected with the rotating rod, and the rotating rod is used for exerting rotating cutting force on the drill bit to which the drill bit belongs; and the rotating rod connected with the drill bit sleeves the dust suction end of the three-waycommunicating pipe, and the rotating rod is provided with a gap in the dust collecting end of the three-way communicating pipe, so that dust can be prevented from passing through the dust collectingend; the rotating rod is connected with a power source, and the rotating power is provided; and the end a in the other two ends of the three-way communicating pipe is an air inlet end, and the end b is an air outlet end; and a negative pressure is formed at the dust suction end of the three-way communicating pipe when the gas flows from the air inlet end to the air outlet end at a high speed, andthe dust generated by rotary cutting of the dust suction end drill bit is sucked into and enters the dust collecting system from the air outlet end in the flowing direction of the gas. The method aimsto solve the problem of difficulty in sand cleaning in the existing casting production post-treatment process, dust pollution, high noise pollution and the like are solved; and a new method is provided for solving the problems of large dust pollution, large noise pollution and the like.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

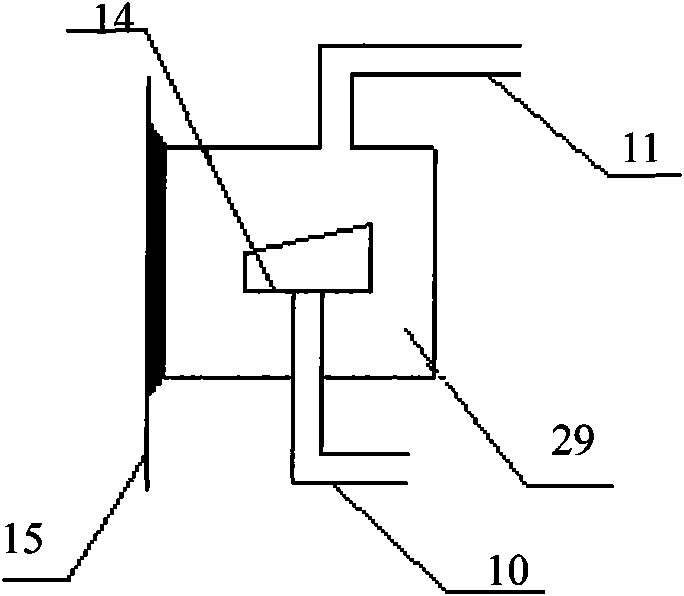

Lens tube and mounting base thereof

ActiveUS20070139939A1Avoid dust pollutionReduce swingTelevision system detailsNon-electric lightingOptical axisEngineering

A lens tube and a mounting base thereof comprise a lens tube for reception of a lens array and a mounting base for accommodation of an image sensor. On an outer periphery of the lens tube is formed a first conical surface, and in the mounting base is formed a concave portion. A second conical surface is formed in the concave portion for mating with the first conical surface of the lens tube. The first conical surface of the lens tube and the second conical surface of the mounting base can cooperate with each other, so as to prevent dust contamination and to make the central axis aligned with the optical axis.

Owner:LARGAN PRECISION

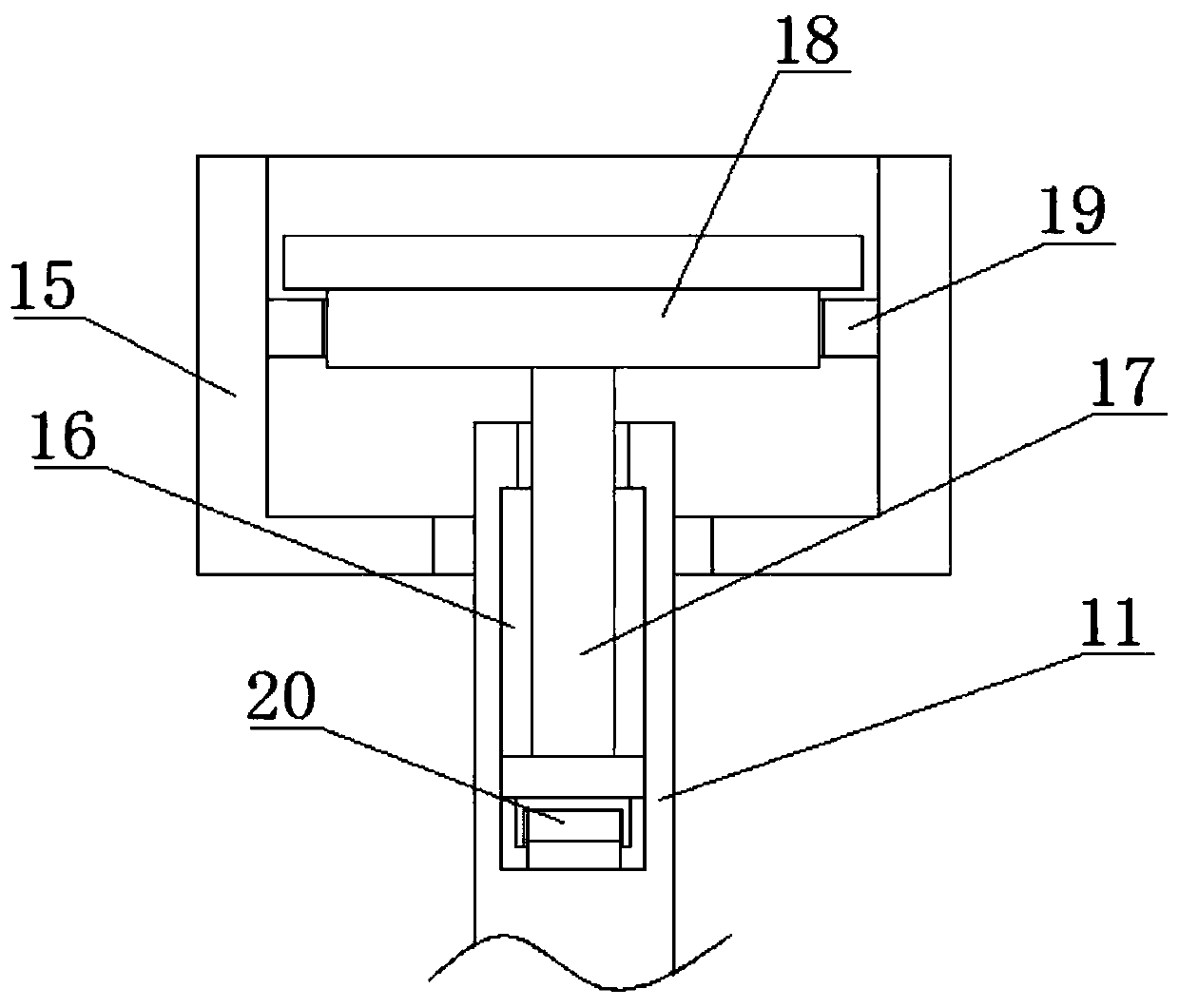

Handheld dust-free drilling device for plate processing

InactiveCN111633842AEasy to install and disassembleAvoid dust pollutionWorking accessoriesStone-like material working toolsDrill holeStructural engineering

The invention relates to the technical field of plate processing, and discloses a handheld dust-free drilling device for plate processing. The device comprises a device body, a main handle, a switch,a metal nose, and a drilling rod. Three groups of connecting grooves are equidistantly and inwardly formed in the edge of the left side wall of the metal nose; a group of dust absorption sleeves whcihare of a columnar structure are installed jointly on the left sides of connecting columns; through holes are formed in the left side central positions of the dust absorption sleeves and are used forthe drilling rod to penetrate; a circle of driving teeth is fixedly installed on the right part of the outer side surface of the curved surface of a transmission shaft; two groups of horizontal movingrods are rotatably connected with the upper parts and the lower parts of the right side walls inside the dust absorption sleeves; driven teeth which are engaged with the driving teeth are fixedly arranged on a transmission rod positioned at the same vertical positions as the driving teeth; fans are fixedly installed at the left end of the transmission rods; three groups of pump bodies are equidistantly and fixedly installed on the outer side surface of a rotating shaft positioned on the left sides of the driving teeth; and inclined atomization nozzles communicate with the tail ends of the pump bodies. The device has the advantages of dust-free drilling, safety and reliability, and convenient disassembly.

Owner:陈二凤

Maintenance equipment management cabinet

InactiveCN108972477AAvoid dust pollutionReduce humidityWork tools storageDrying AgentsMaintaining equipment

The invention discloses a maintenance equipment management cabinet, which comprises a cabinet body, a protective cover is arranged at the top of the cabinet body, a cabinet door is arranged on one side of the cabinet body, a face recognition device accommodating box is arranged on the back surface of the cabinet door, a display screen is arranged on one side of the face recognition device, one side of the cabinet body is provided with a dryer, drying agent is arranged inside the dryer, a placing plate is arranged inside the cabinet body, a cover plate is arranged above the placing plate, according to the invention, the dryer is arranged, when the dryer is in use, themoisture in the management cabinet is drawn out, after being dried by the internal drying agent, the moisture is discharged to the inside of the management cabinet, the humidity inside the management cabinet is reduced, the problem that the accuracy of the maintenance equipment is affected by the large amount of moisture inthe management cabinet, the cover plate, a sponge and the placing plate are arranged, the cover plate covers on the placing plate, the dust does not fall on the equipment shielded by the cover plate,and the problem that the equipment are polluted by dust is avoided.

Owner:QIANNAN NORMAL UNIV FOR NATTIES +1

Dust separation apparatus and intelligent control system including the apparatus

ActiveUS10159990B2Easy to cleanImprove dust removal efficiencyCombination devicesSuction filtersEngineeringIntelligent control

The dust separation apparatus includes a dust intake unit including a blower, an inertial separation unit, a centrifugal separation unit, and a filtering separation unit. The dust intake unit, the inertial separation unit, the centrifugal separation unit, and the filtering separation unit are sequentially connected in series and together form a horizontal structure. The inertial separation unit and the centrifugal separation unit are connected in a horizontal-axis direction to form an inertial and centrifugal separation unit. A dust collection box is provided below and connected to the inertial and centrifugal separation unit. The filtering separation unit includes a dust collection barrel. The intelligent control system includes the dust separation apparatus and an intelligent control unit.

Owner:NANJING HAIFENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com