Handheld dust-free drilling device for plate processing

A technology of sheet metal processing and drilling device, applied in the field of sheet metal processing, can solve the problems of debris pollution, affecting drilling accuracy, no dust treatment measures, etc., to achieve the effects of preventing dust pollution, convenient disassembly, and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

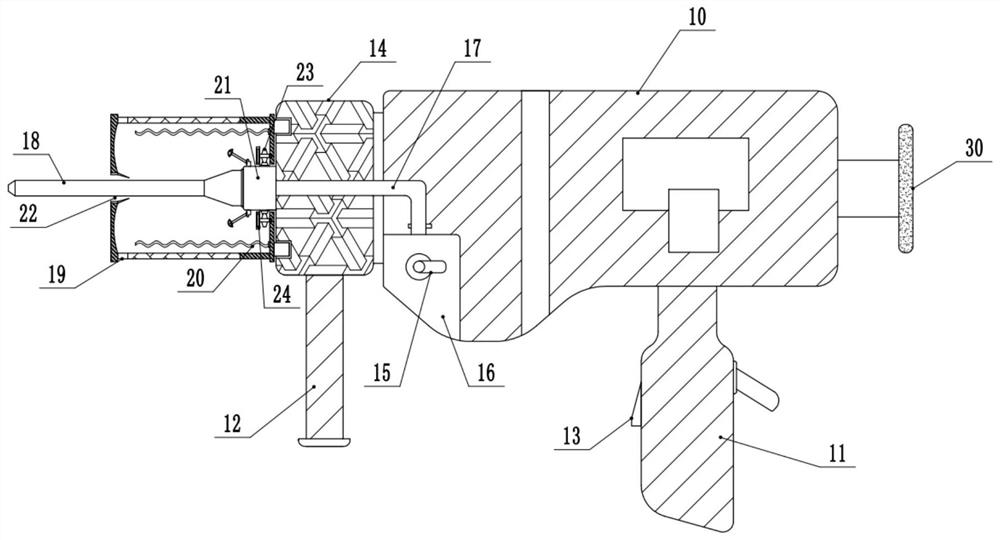

[0025] See Figure 1-3 , A hand-held dust-free drilling device for plate processing, including a body 10, a main handle 11, a switch 13, a metal head 14, and a drill rod 18. The main handle 11 is fixedly installed on the bottom right side of the body 10, and the main The left side wall of the handle 11 is provided with a switch 13 for controlling the operation of the entire device. A metal handpiece 14 is fixedly installed on the left middle of the fuselage 10, an auxiliary handle 12 is fixedly installed on the bottom of the metal handpiece 14 to facilitate the operator to control the fuselage 10, and the right side wall of the fuselage 10 is fixedly installed for holding the machine. The pallet 30 on which the body 10 is drilled. A rotating shaft 21 is connected to the left side of the left side wall of the metal head 14 to rotate to the left. The left end of the rotating shaft 21 is fixedly installed with a drill rod 18 for plate drilling. The left side wall of the metal hea...

Embodiment 2

[0027] On the basis of the first embodiment, a plurality of sets of slender sticky cloth belts 20 at equal intervals are fixedly installed in the inside of the dust collector 19, the sticky cloth belts 20 are arranged to absorb the dust inside the dust collector 19 , To prevent excessive dust from accumulating on the bottom of the dust collector 19, which requires a short time for cleaning, which is not conducive to a single long-term use.

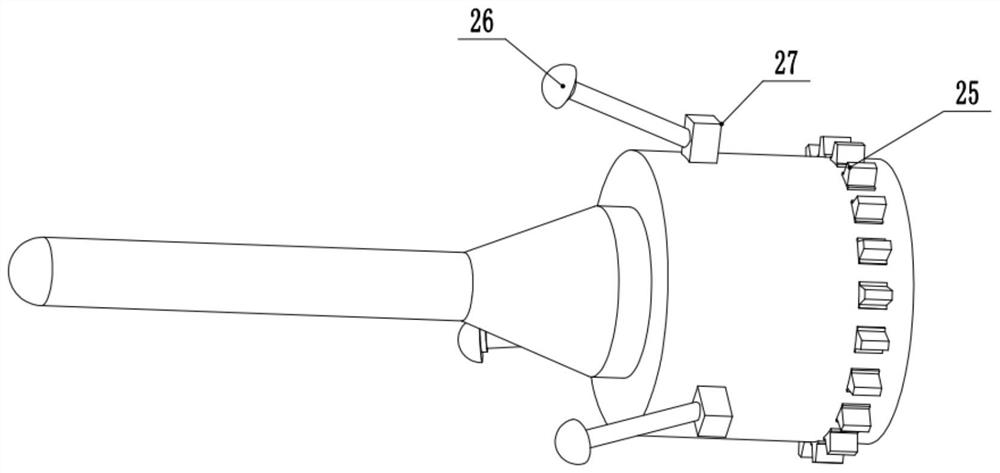

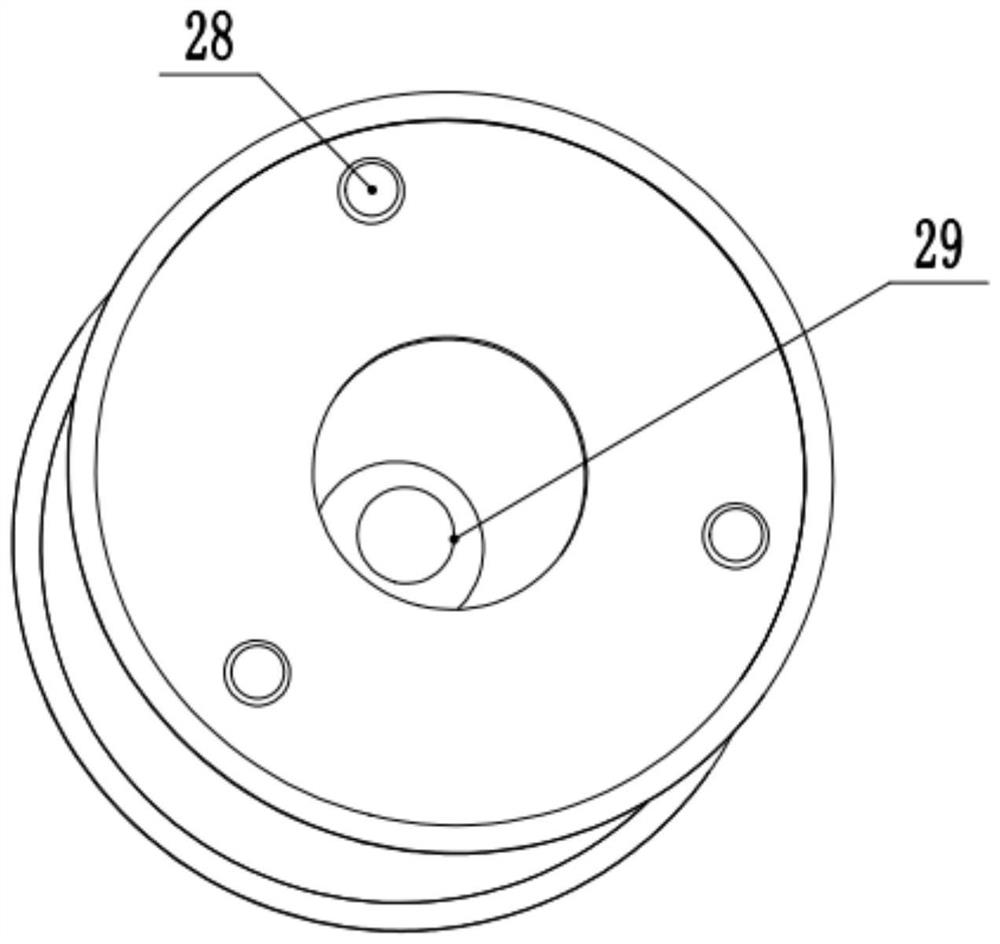

[0028] The working principle of the present invention is: by embedding the dust collection sleeve 19 on the left side of the metal handpiece 14 with the connecting post 28, then inserting the drill rod 18 through the through hole 22, and starting the drill rod 18 through the switch 13 to drill the plate , And then the driving teeth 25 and the driven teeth 23 mesh with each other to drive the fan 24 to rotate, thereby sucking the dust generated by the drilling of the drill rod 18 into the dust collection sleeve 19, so as to achieve a dust-free ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com