Fume filer of range hood

A technology for oil fume filtration and fume hood, which is applied in the fields of oil fume removal, dispersed particle filtration, household heating, etc., can solve the problems of complicated cleaning process of the hood, and achieve the effects of increasing practicability, convenient installation, and stable and reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

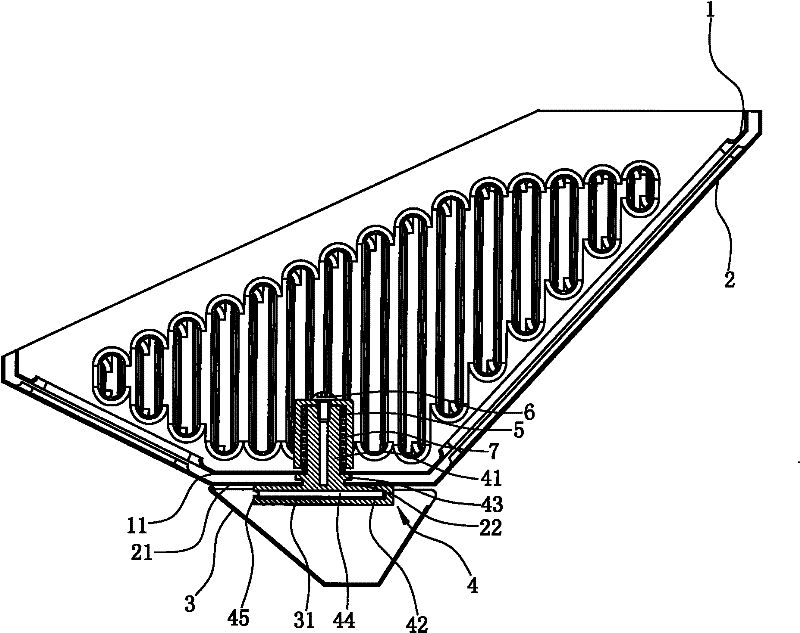

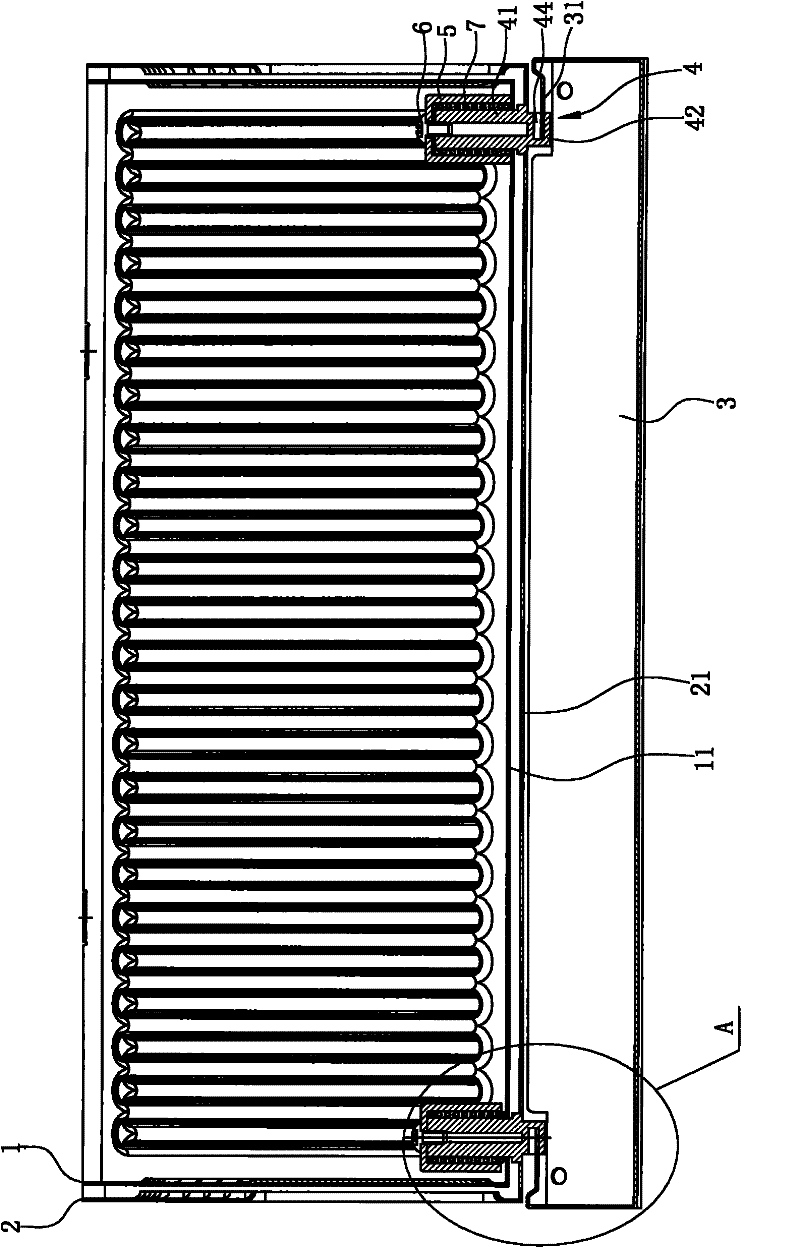

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] Such as Figure 1~6 Shown is a preferred embodiment of the present invention.

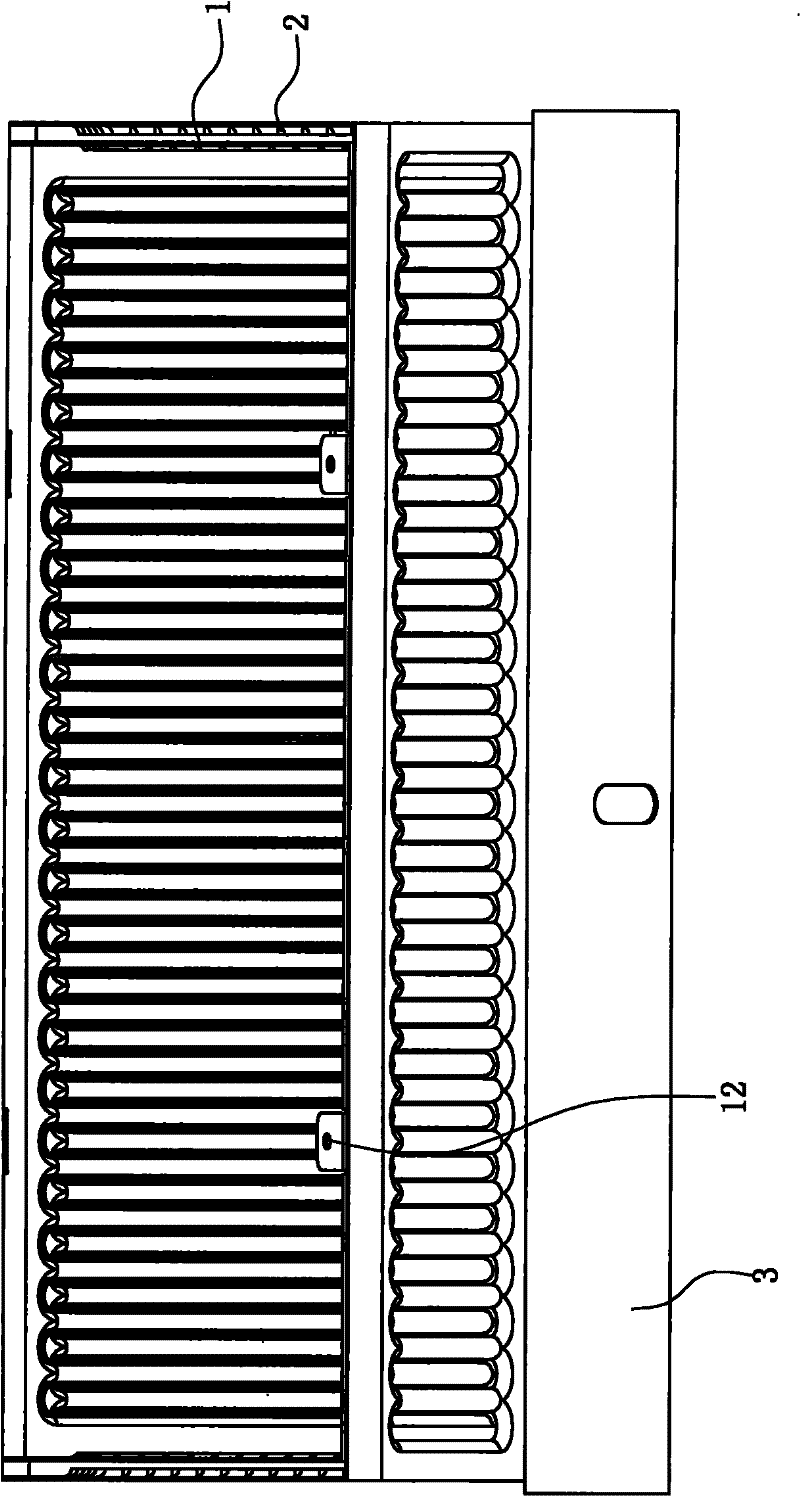

[0022] An oil fume filter device that is easy to disassemble and assemble, including an inner net cover 1 and an outer net cover 2 arranged at the air inlet of the range hood. The bottoms of the outer grilles 1, 2 all have rectangular installation planes 11, 21, and of course the general installation planes 11, 21 also have oil leakage holes.

[0023] The inner mesh cover 1 is fixedly connected with the range hood, that is, two mounting holes 12 are respectively provided on the two opposite edges of the inner mesh cover 1, and screws are passed through the mounting holes 12 to be threadedly connected with the range hood, and the outer mesh cover 2 Located below the inner grille 1, and the outer grille 2 and the inner grille 1 are independent of each other,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com