Full closed superthin food container

A food container, fully-sealed technology, applied in the field of fully-sealed ultra-thin food containers, to achieve excellent sealing performance, excellent compressive strength, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

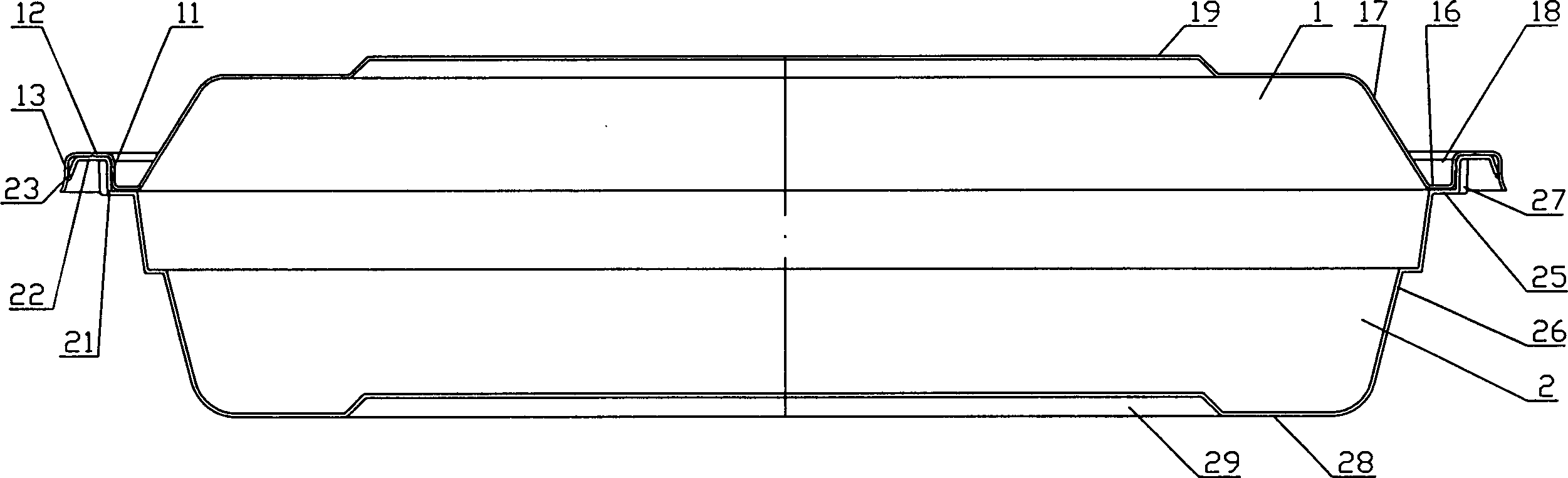

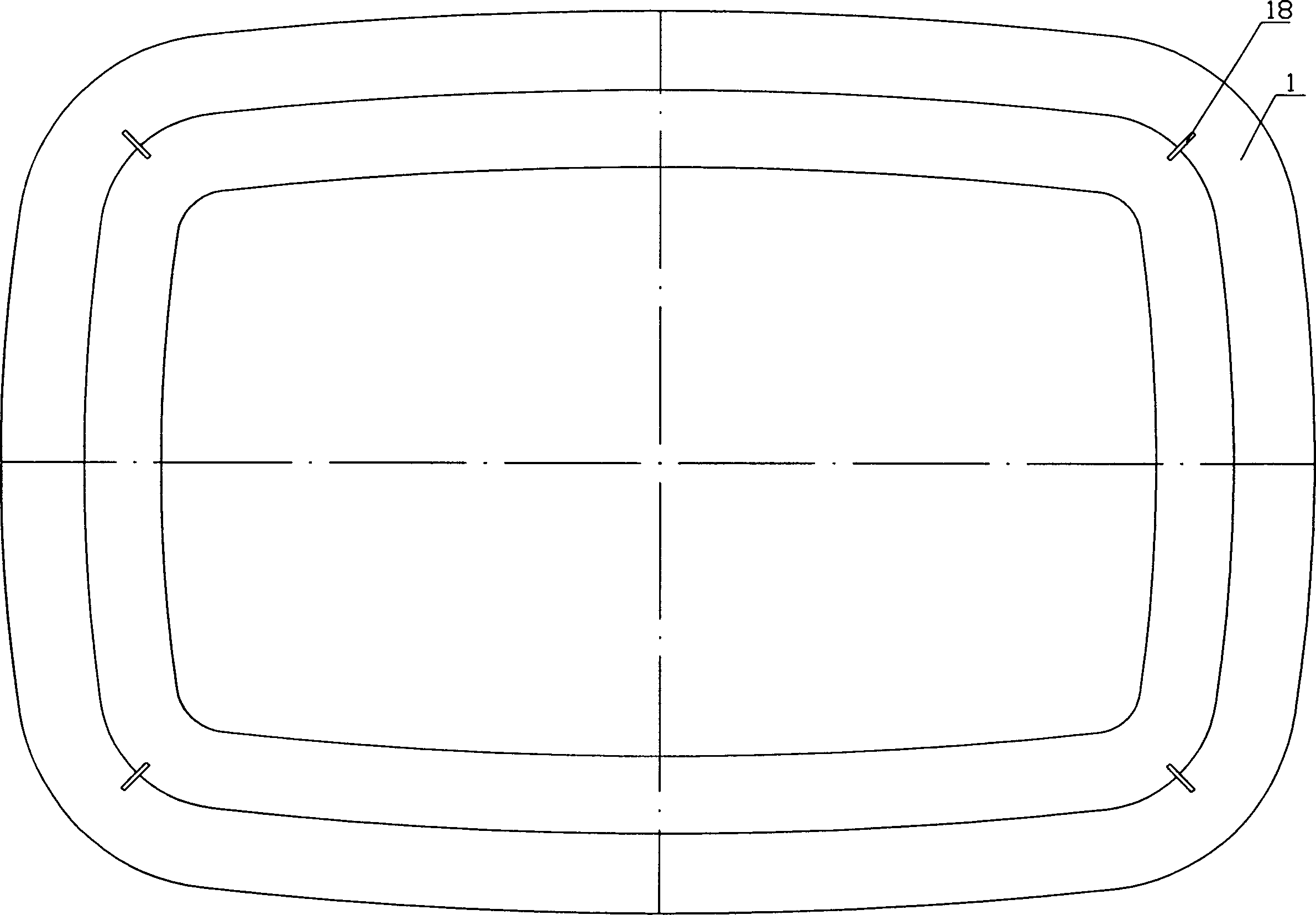

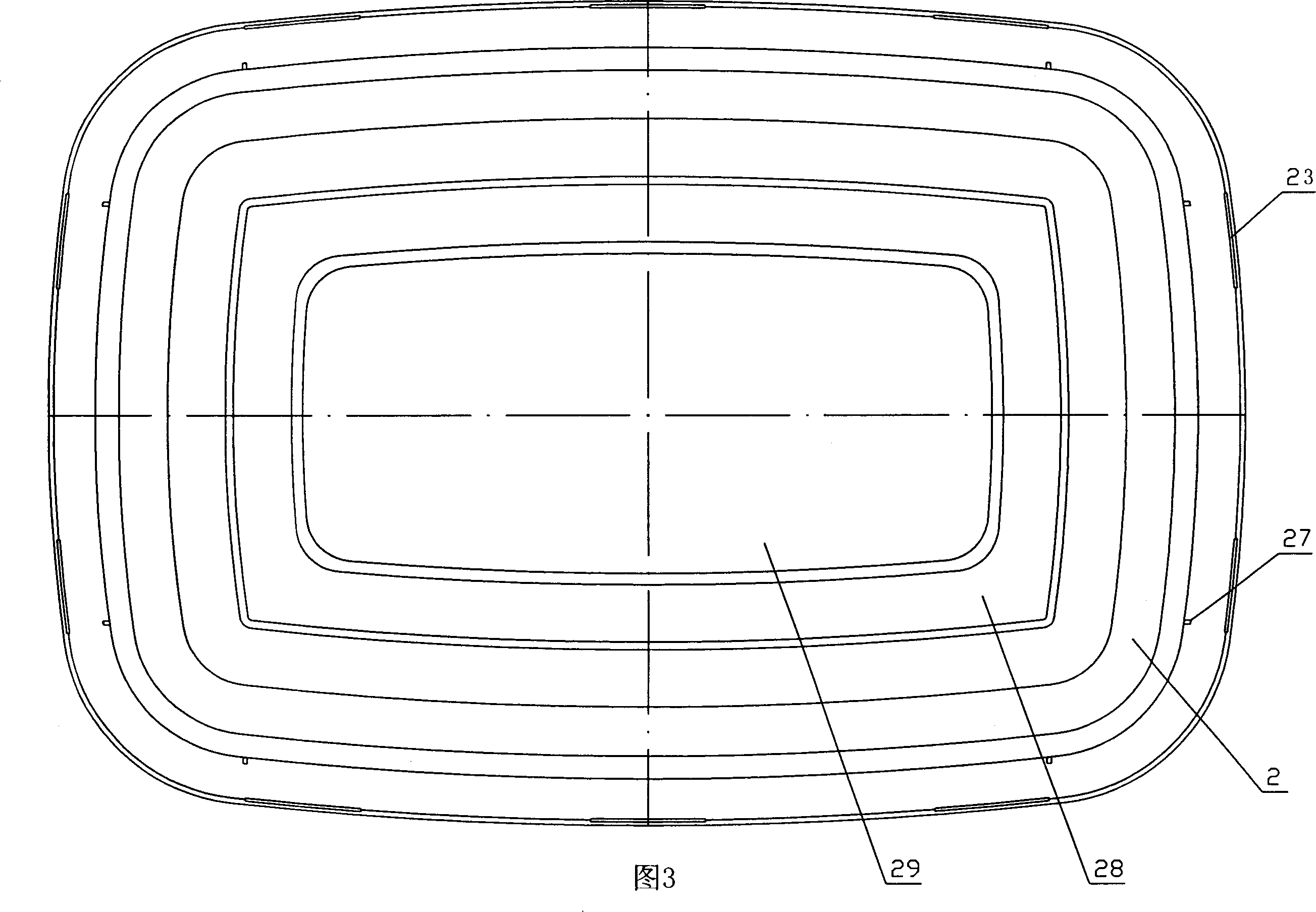

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0023] The fully sealed ultra-thin food container provided by the invention adopts renewable plastic materials (such as polypropylene resin) and precision mold technology, and through injection molding, is made into an ultra-thin box cover and box body with a wall thickness less than 0.5 mm. The fully sealed ultra-thin food container is formed by the cooperation of the box cover and the box body. The container is suitable for use as a snack box, food box, packaging box and the like.

[0024] Its structure refers to figure 1 As shown in Fig. 4 , including the box cover 1 and the open box body 2, the edge of the box cover 1 extends upwards to form an inner tank wall 11, and the upper end of the inner tank wall 11 is bent horizontally outwards to form a tank top 12, and the outside of the tank top 12 The end part is bent and extended downward t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com