Lamp and liquid-cooling radiator thereof

A technology of liquid cooling and heat dissipation, lamps and lanterns, applied in the direction of cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of slow heat dissipation, many parts, difficult installation and disassembly, etc., to improve heat dissipation The effect of high performance, fast flow speed and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

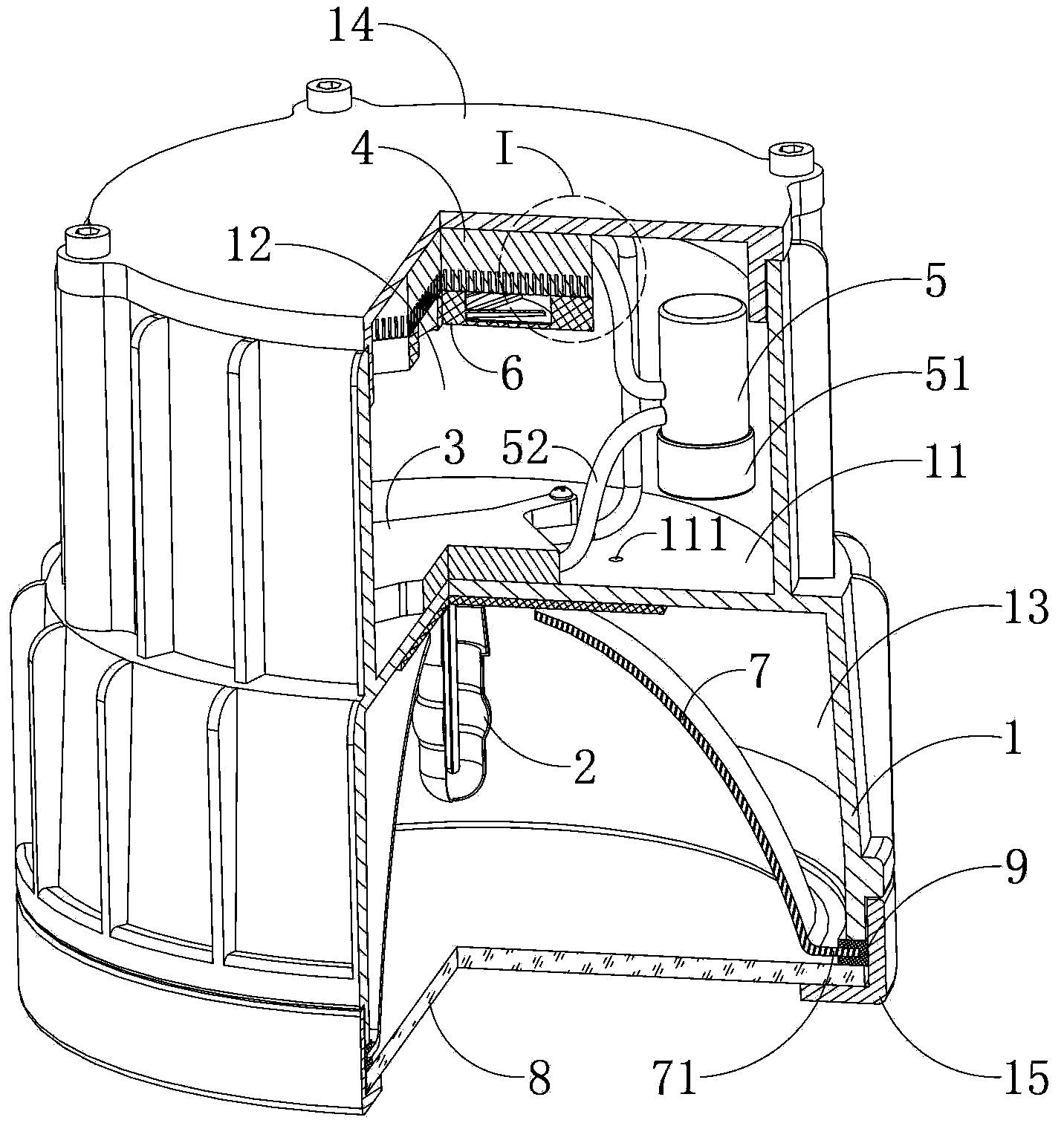

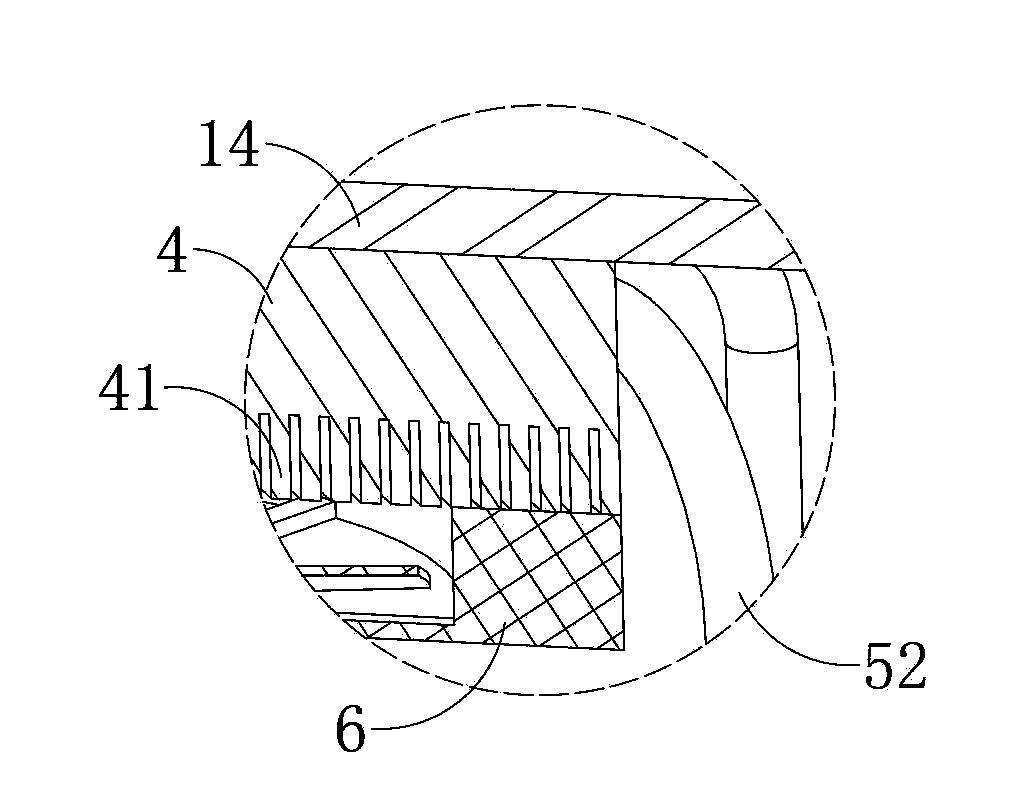

[0027] Embodiment one: see figure 1 , in this embodiment, the partition 11 is integrally formed with the lamp housing 1, the first chamber 12 forms a closed cavity by setting a rear cover 14, and the heat exchanger 4 is installed on the rear Cover 14 on. This method is suitable for the situation that the parts of the cooling device can be replaced and installed at the back of the lamp, and the parts of the cooling device can be replaced by opening the rear cover 14 . The partition 11 is formed integrally with the lamp housing 1 , and the heat on the partition 11 is more easily transferred to the lamp housing 1 , which is beneficial to the rapid dissipation of heat.

Embodiment 2

[0028] Embodiment two: see figure 1 , in this embodiment, the partition 11 is installed in the lamp housing 1 through fasteners, the tail end of the lamp housing in this embodiment is sealed without a rear cover, and the parts of the heat sink are replaced by opening the partition 11 Parts, this type of luminaire is suitable for situations where parts cannot be replaced at the rear end, for example, a luminaire embedded in a wall or placed in water at the end.

Embodiment 3

[0029] Embodiment three: see figure 1 , in this embodiment, the partition 11 is installed in the lamp housing 1 through fasteners, the first chamber 12 forms a closed cavity by setting a rear cover 14, and the heat exchanger 4 is installed on the back cover 14. This embodiment can not only replace parts of the heat sink at the tail end of the lamp housing, but also open the partition 11 to replace parts of the heat sink, which is suitable for lamps with different needs.

[0030] In the above three embodiments of the structure of the lamp housing 1 and the partition 11 , the partition 11 can also be provided with an exhaust hole 111 . The air in the first chamber 12 will absorb heat and expand, causing the pressure in the chamber to increase. If the pressure is too high, it may cause the lamp housing to be swollen and cracked. If it is not properly discharged, it will easily cause the temperature of the water pump 51 to be too high and burn out. The vent hole 111 penetrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com