Patents

Literature

2494results about How to "Fast cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

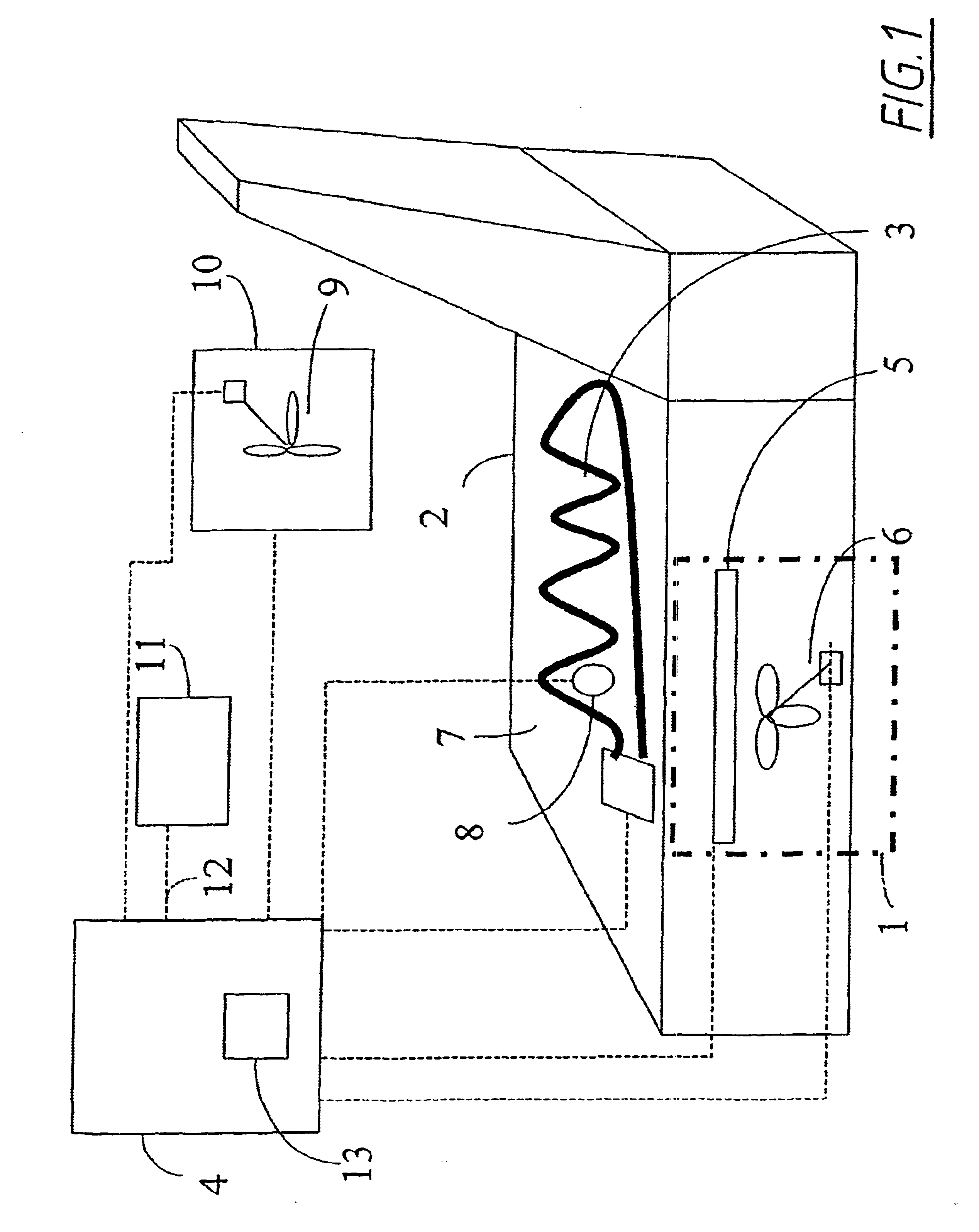

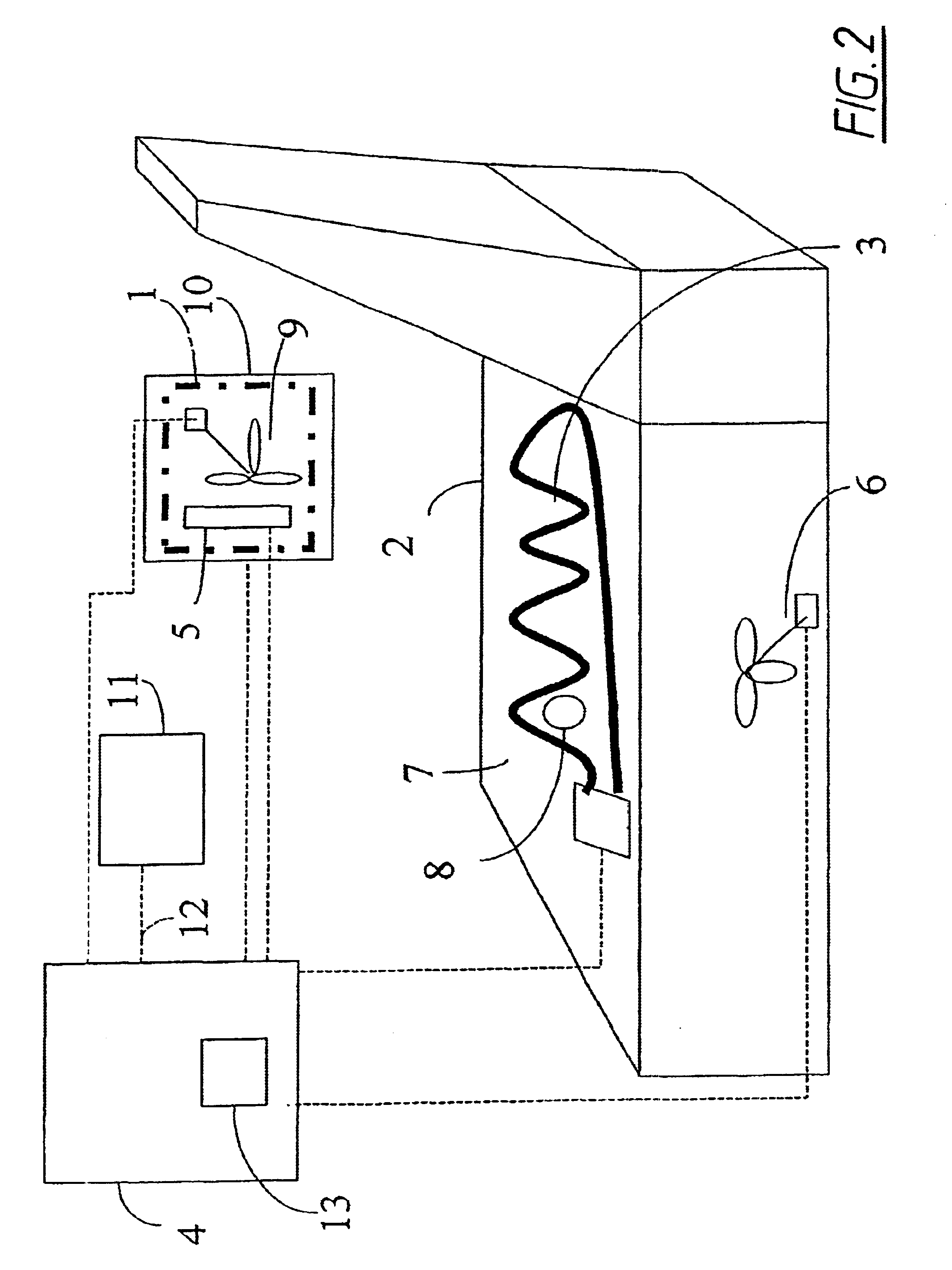

Seat with temperature control and ventilation and safety system for a vehicle

InactiveUS6892807B2Shorten drying timeReduce the negative local chillingDomestic cooling apparatusPower to electric heating circuitsTemperature controlEngineering

Methods and apparatus for controlling the temperature of a seat such as a vehicle seat are disclosed. The apparatus includes an electrical heater disposed in the seat, a cooling unit such as a cooling element and a fan, a detector for detecting the temperature associated with the electrical heater, and a controller for controlling the electrical heater and the cooler based upon the detected temperature and upon the humidity algorithm comprising a predetermined set of calculations of the humidity of air at different temperatures.

Owner:LEAR CORP

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Spherical attapulgite flower ceramsite

ActiveCN102503539AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses spherical attapulgite flower ceramsite. The key points of the technical scheme are that the spherical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The spherical attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The spherical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength and water absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the spherical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, the cylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Treatment of meat products

InactiveUS6113963AReduce microbial countPrevent browningBiocideDough treatmentCarboxylic acidNuclear chemistry

Described is a method of sanitizing meat product using aqueous streams having an antimicrobial composition added to the stream. Preferably, the antimicrobial composition includes a mixture of one or more carboxylic acids having up to 18 carbon atoms and one or more peroxycarboxylic acids having up to 12 carbon atoms, preferably a mixture of a C.sub.2-4 peroxycarboxylic acid and a C.sub.8-12 peroxycarboxylic acid.

Owner:ECOLAB USA INC

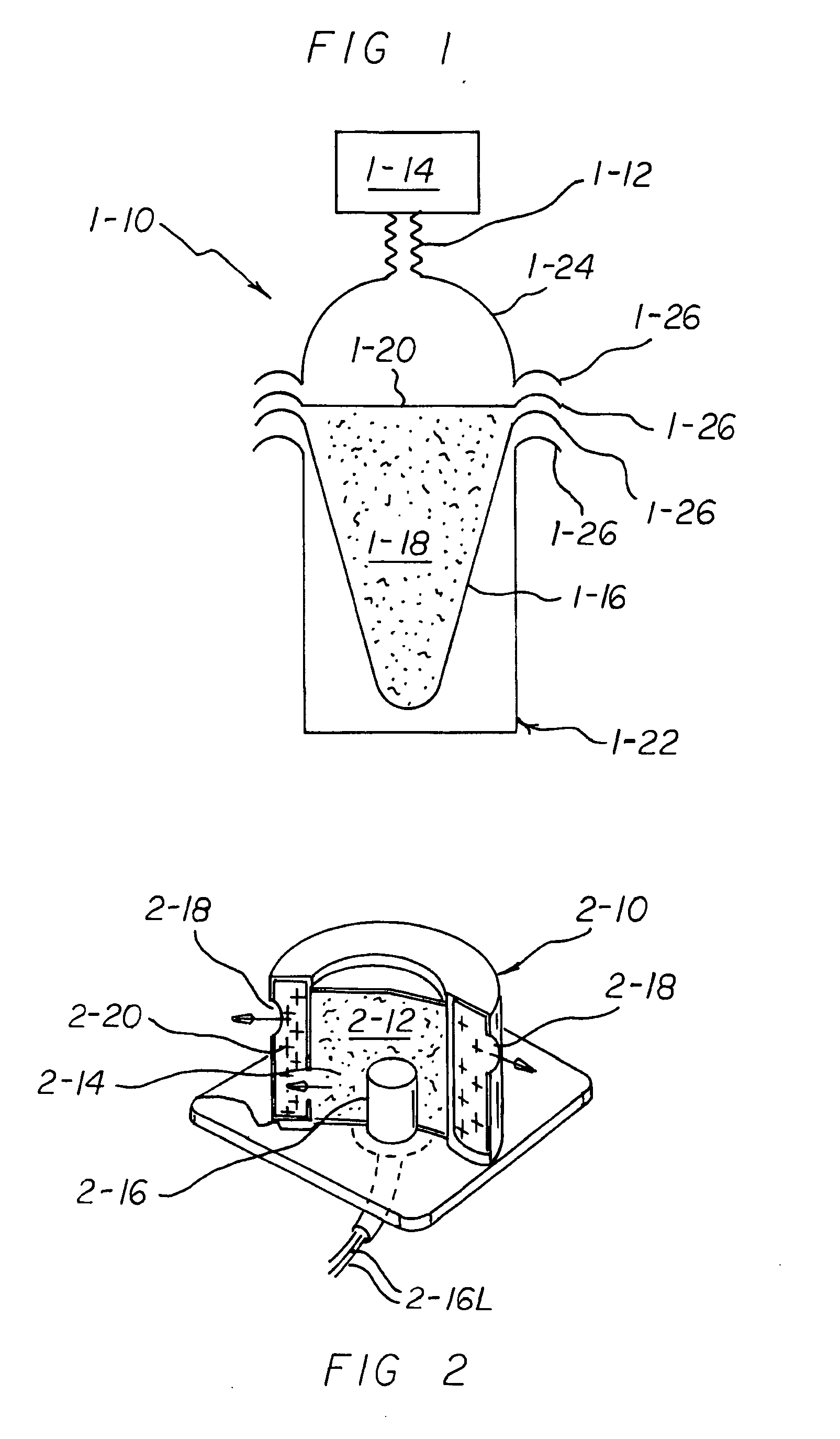

Apparatus and Method for Using Tetrazine-Based Energetic Material

InactiveUS20090301601A1Fast coolingInternal combustion piston enginesBlasting cartridgesEngineeringEnergetic material

The present invention comprises apparatus and methods employing a gas produced from a tetrazine-based energetic material such as that known as “BTATz” containing 3;6-BtS(1H-1,2,3,4-Tetrazol-5-ylamino)1-,2,4,5-tetrazine 3;6-BtS(1H-1,2,3,4-Tetrazol-5-ylamino)1-,2,4,5-tetrazine or salts thereof. The tetrazinebased energetic material is ignited through the use of a percussion cap, a piezoelectric crystal or a battery-supplied electric spark or by encapsulating it in a container that is then exposed to a burning flame. The gas produced upon ignition is employed a propellant such as to inflate life rafts, life vests, emergency evacuation slides, tires, air bags and other inflatable devices. The gas produced upon ignition is alternatively employed to power an engine and many other applications such as a fire suppressant.

Owner:ENERSON JON R +4

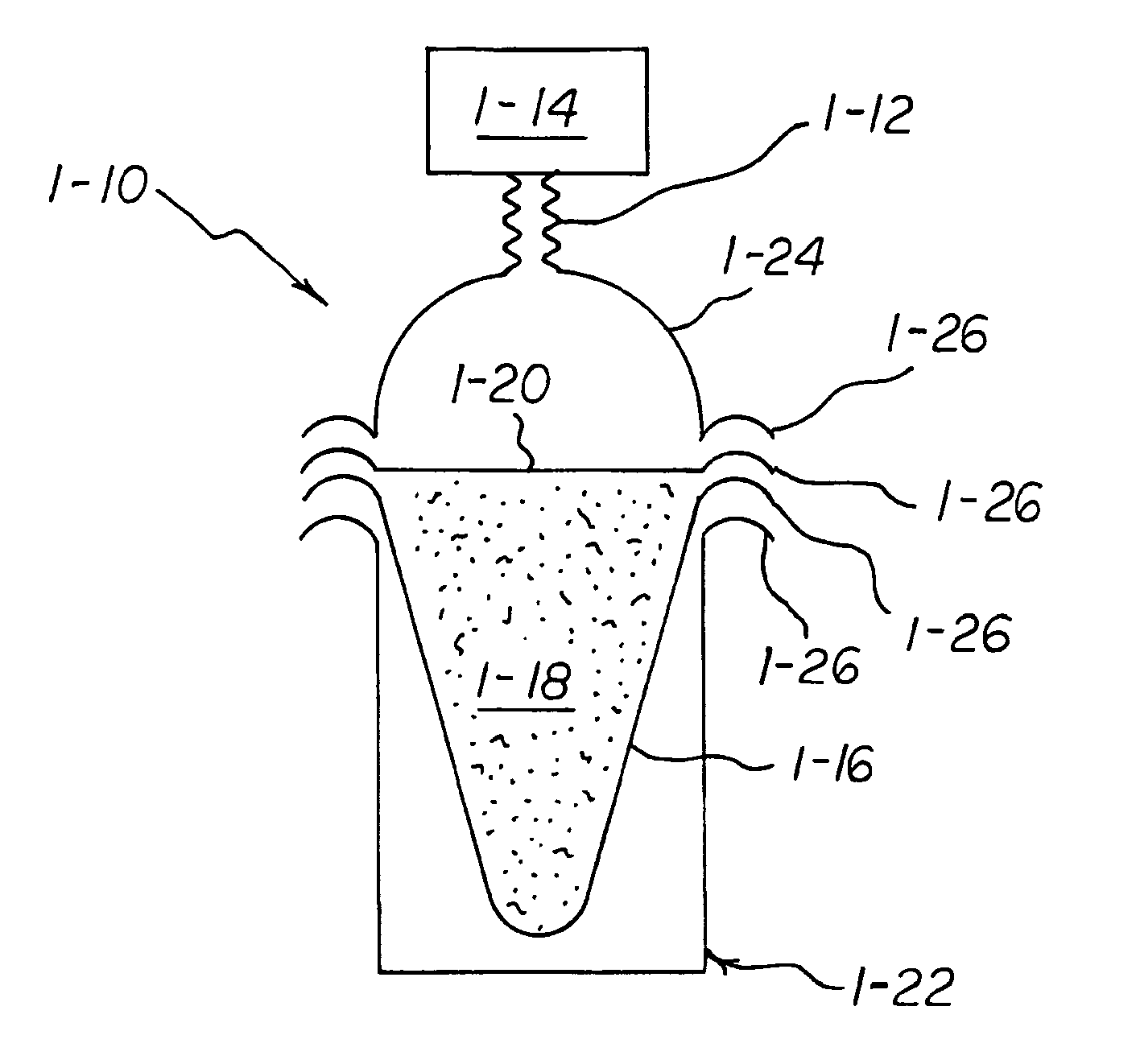

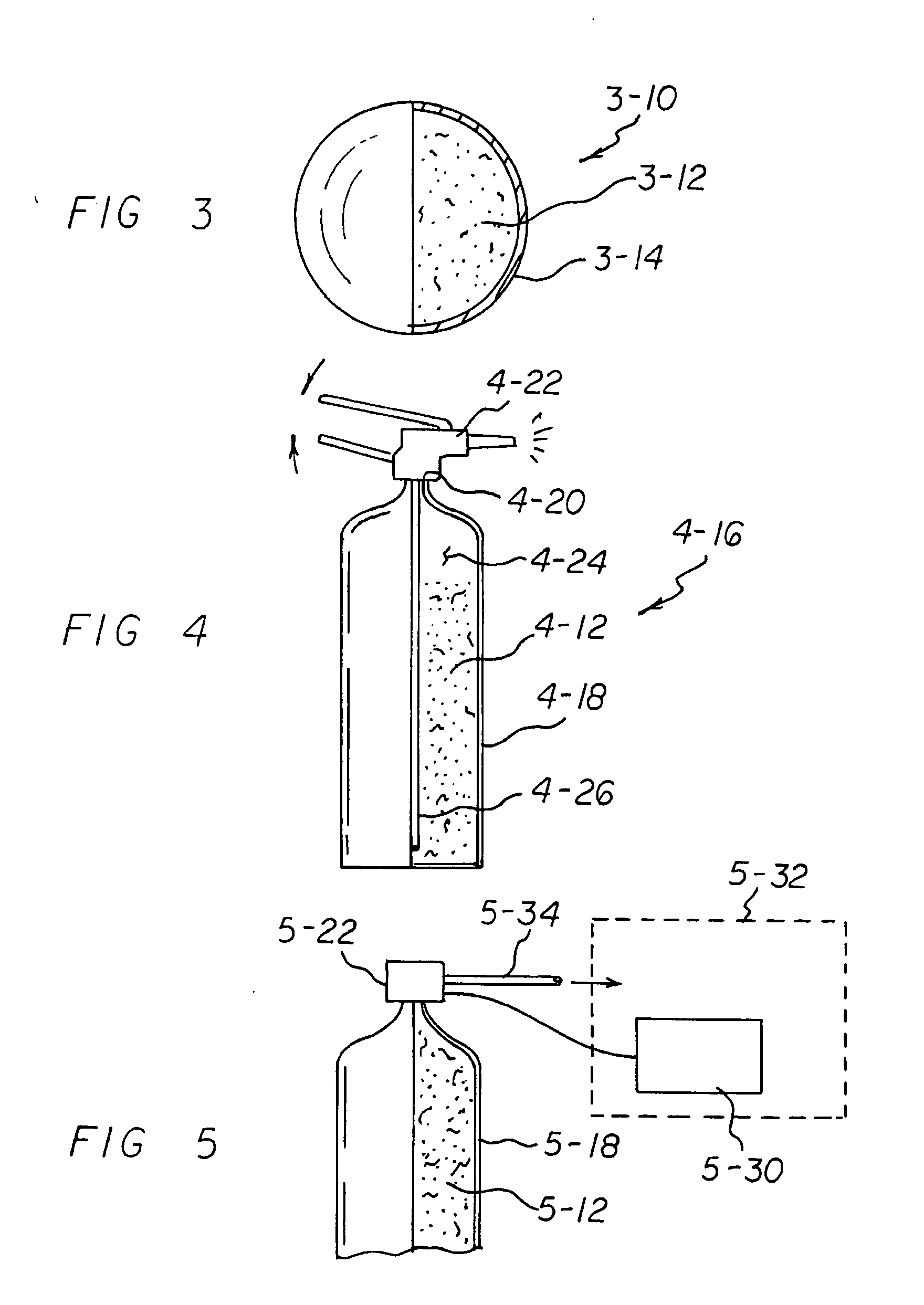

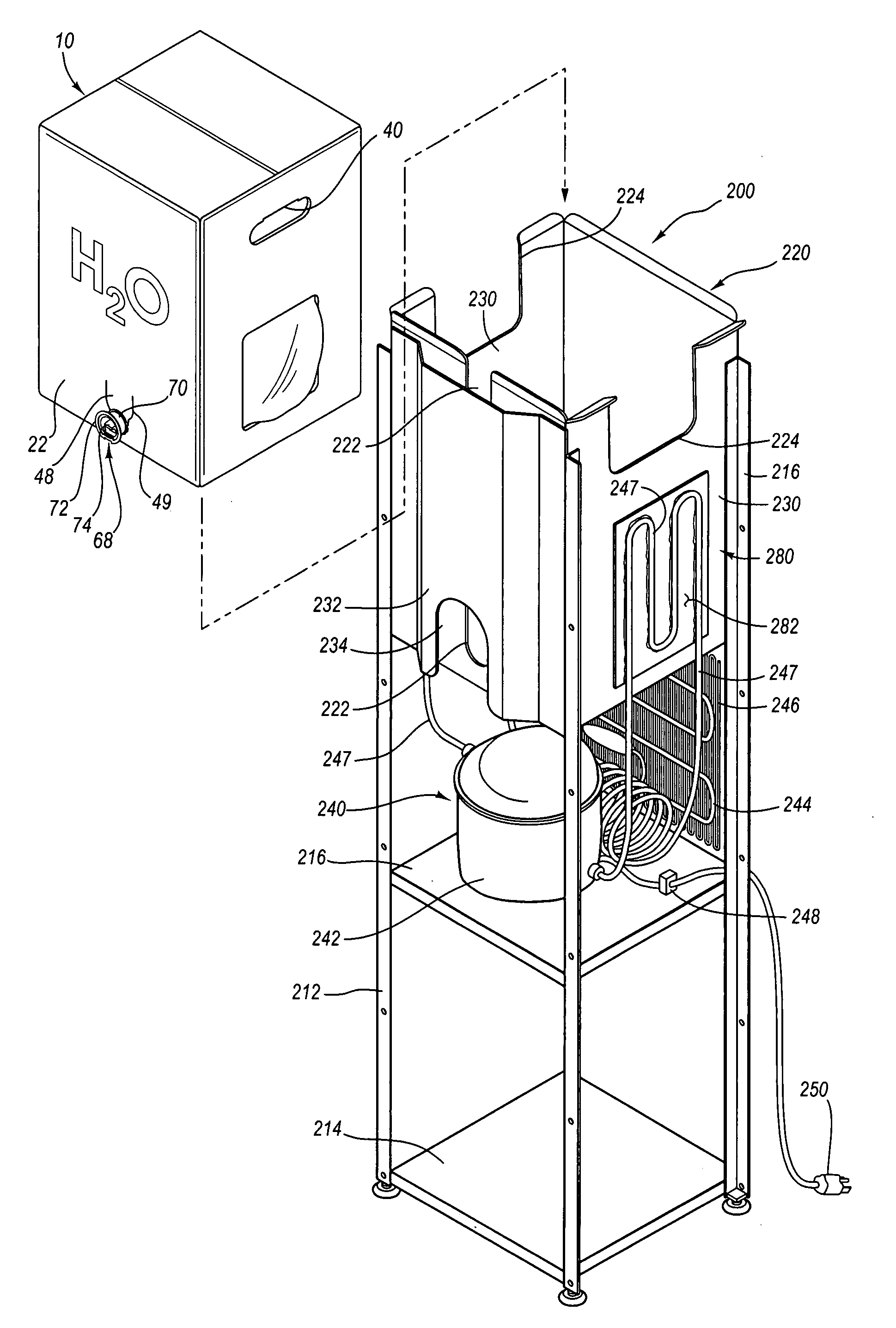

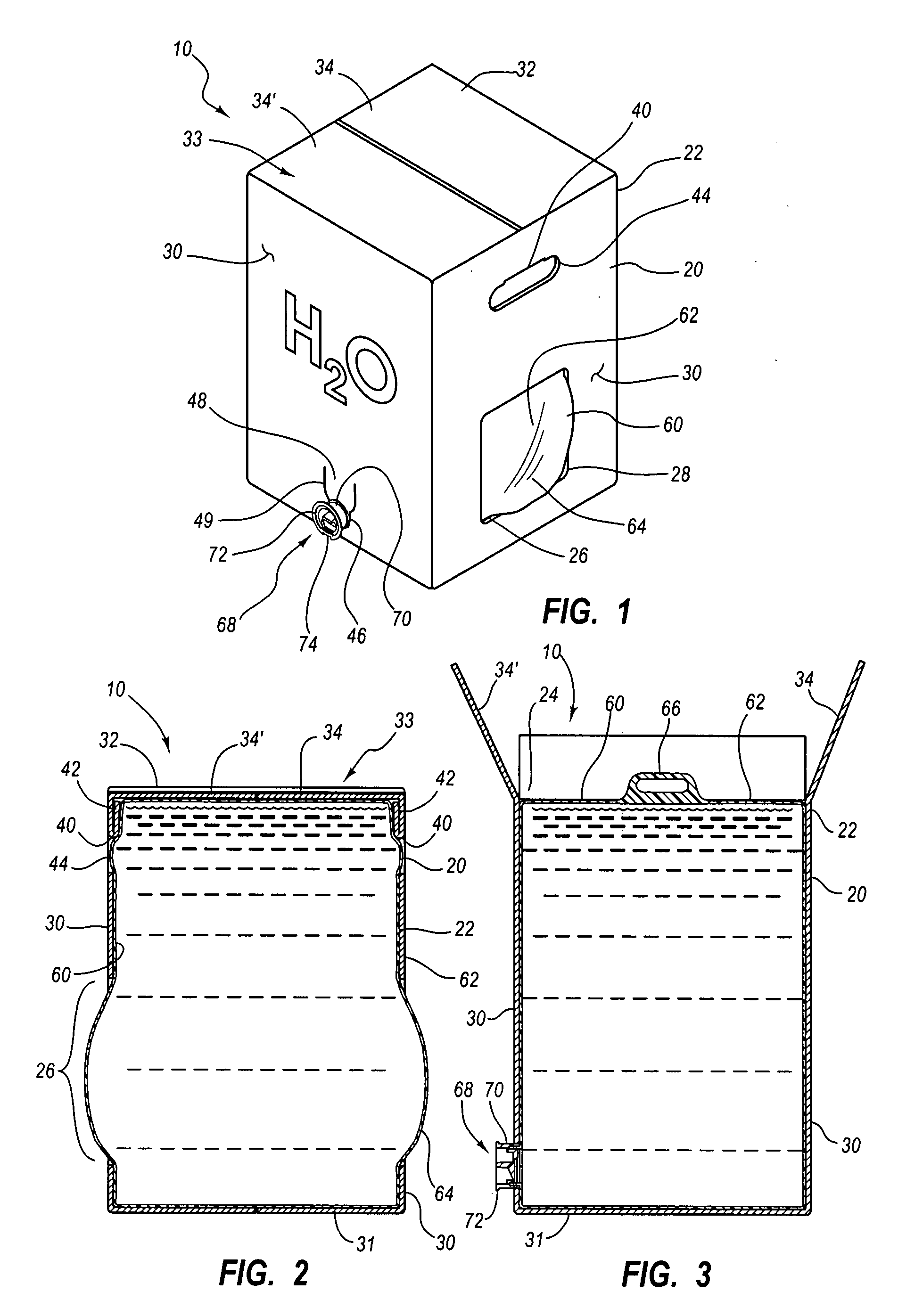

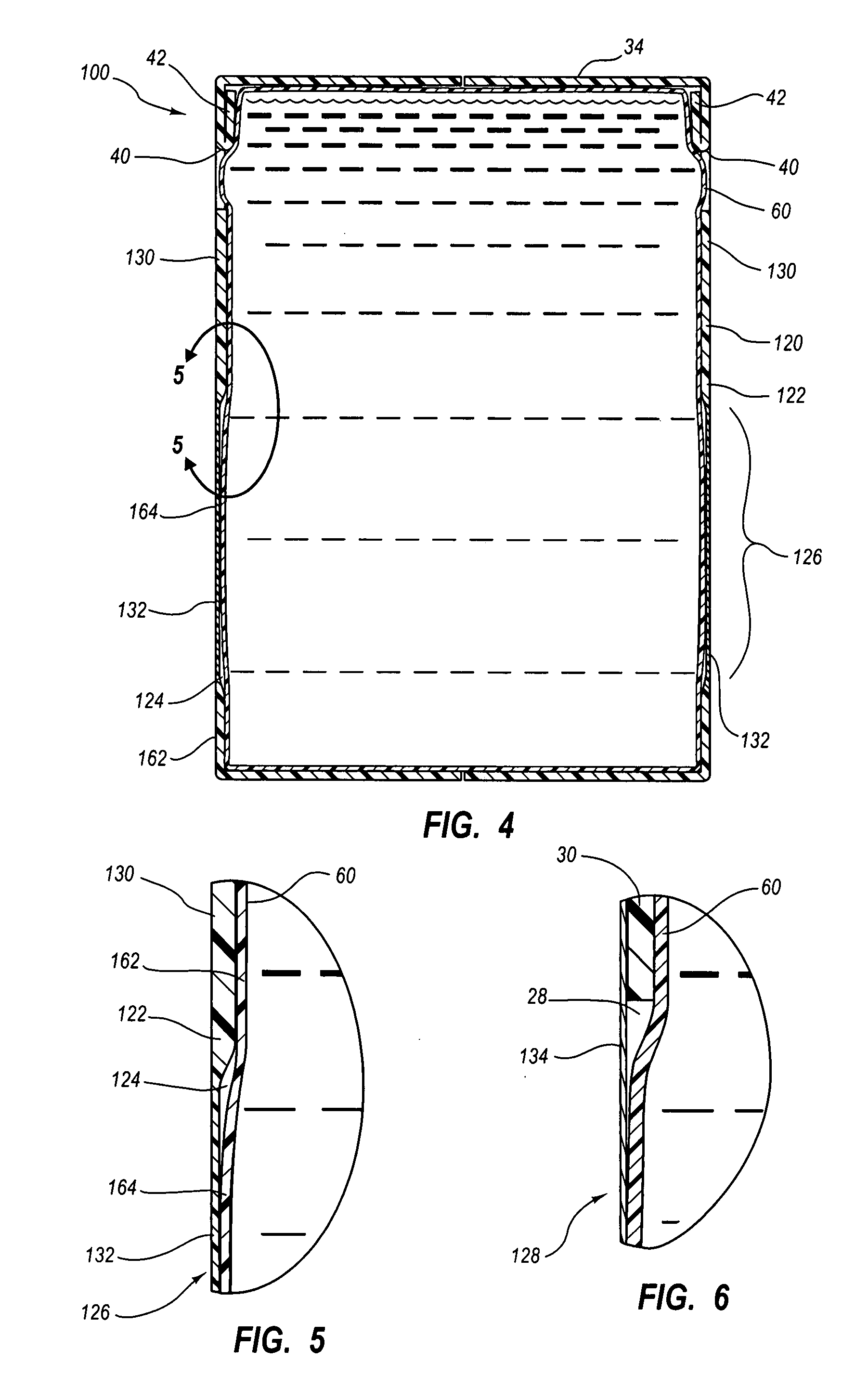

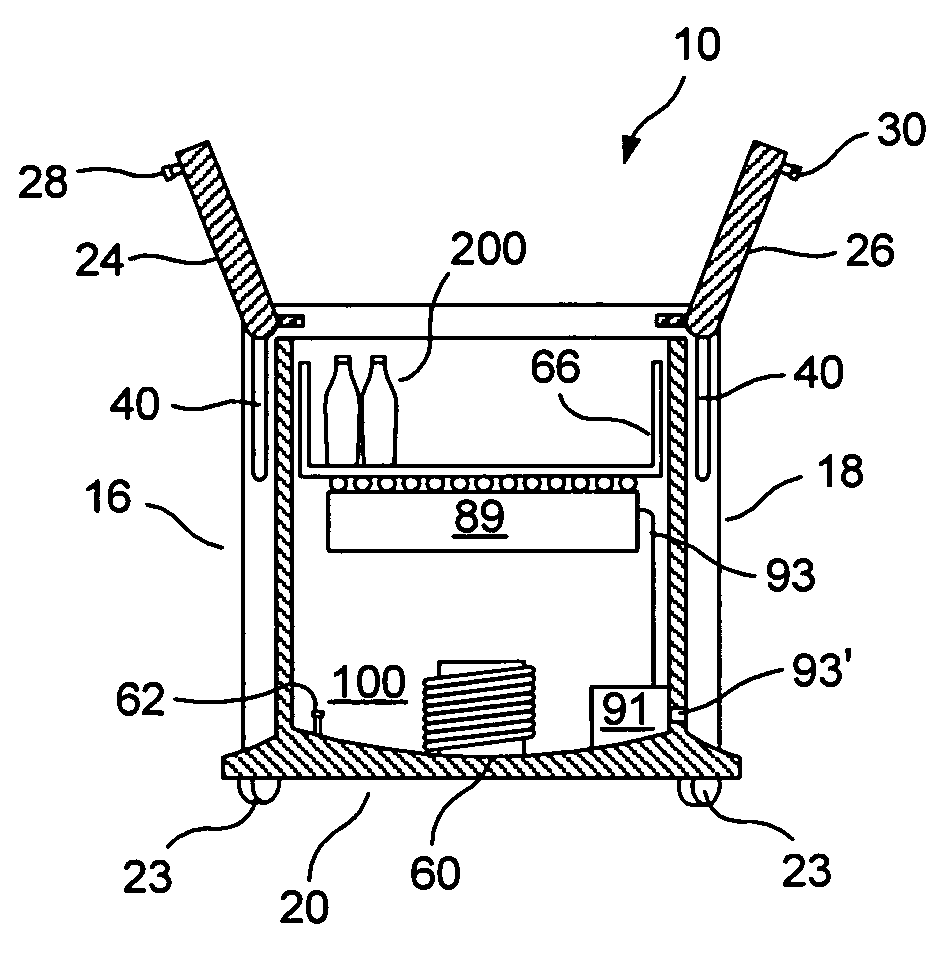

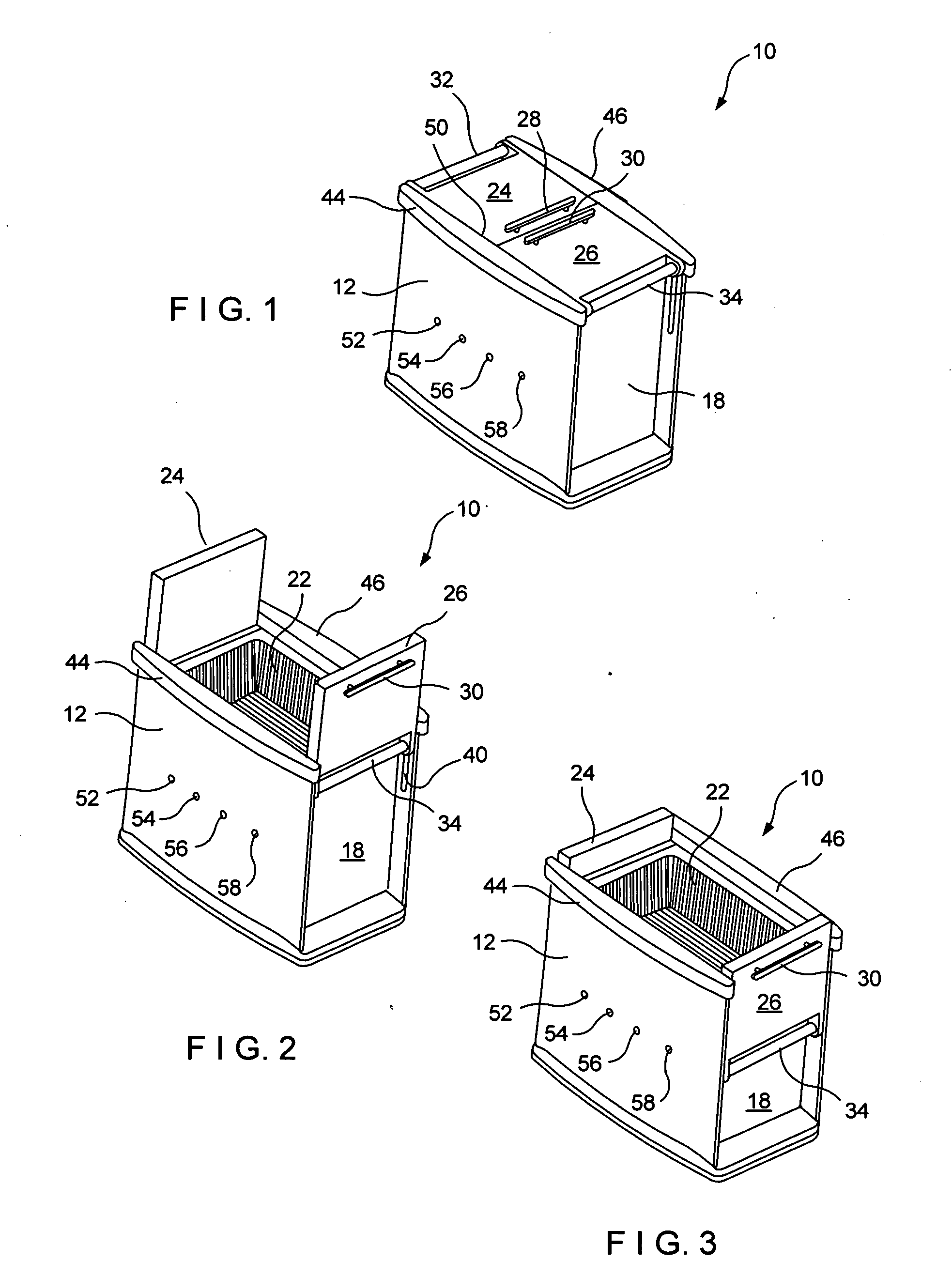

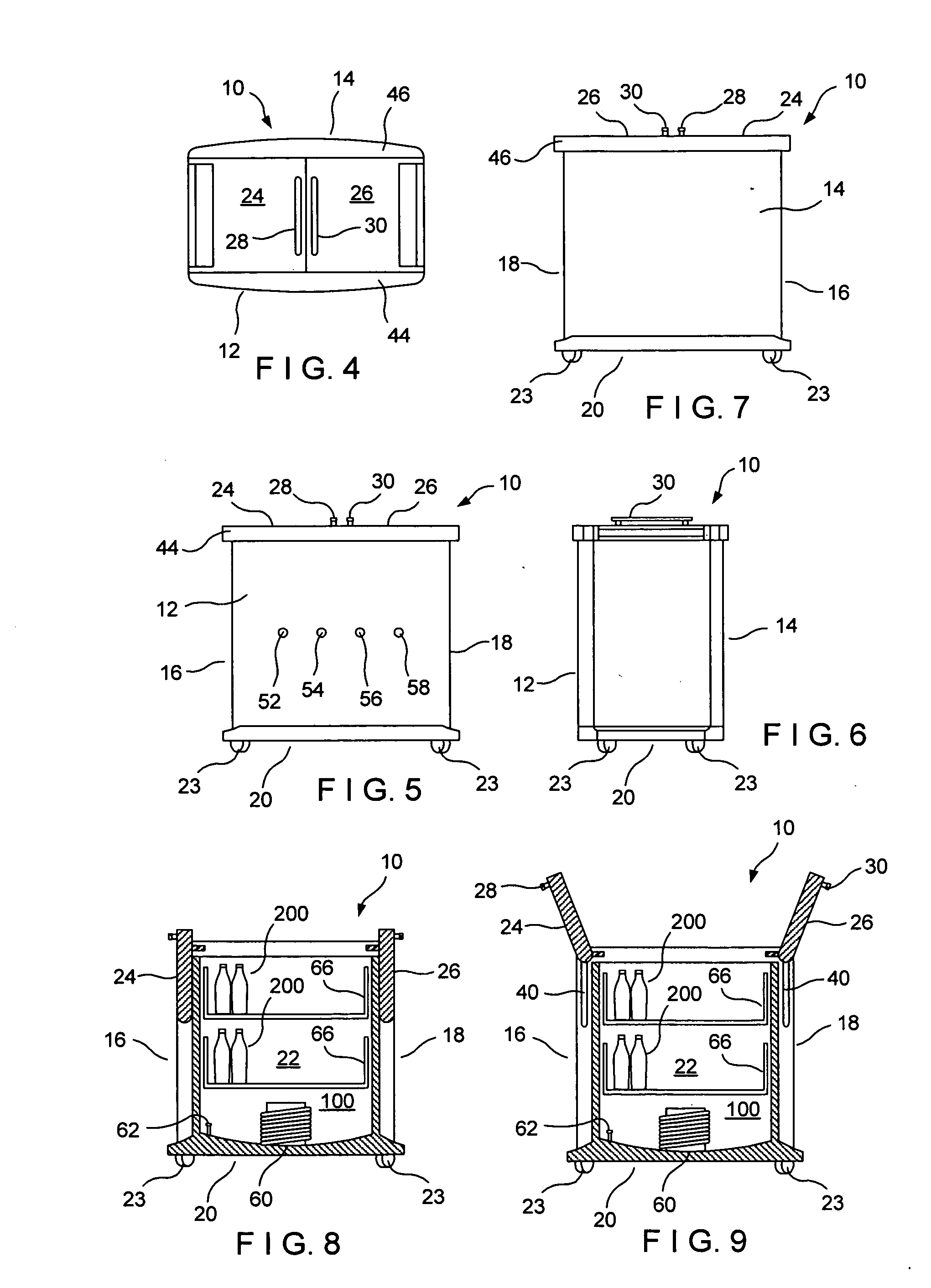

Temperature controlled liquid dispenser, containers therefore, and bag-in-box container construction

InactiveUS20080277417A1Improve thermal conductivityThermal energy is effectively and efficiently transferredDomestic cooling apparatusLiquid flow controllersTemperature controlThermal energy

A dispenser for relative rapid cooling or heating of the contents of a liquid storage container provides a receptacle for receiving the liquid storage container therein and positioning a thermal transfer portion of the liquid storage container in thermal conductive relationship with a thermal conduction pad associated with the receptacle. Thermal energy is effectively and efficiently transferred from the thermal conduction pad to the liquid in the liquid storage container. The thermal conduction pad is controlled to provide and maintain the desired temperature to the liquid. The liquid is dispensed directly from the container. Various types of containers can be used in the dispenser, with a special bag-in-box container having a inner container and outer box with thermal conduction windows in the box to provide good heat transfer between the thermal conduction pads and the inner container constituting an aspect of the invention. A special rigid container can also be used.

Owner:GROESBECK R CLAY

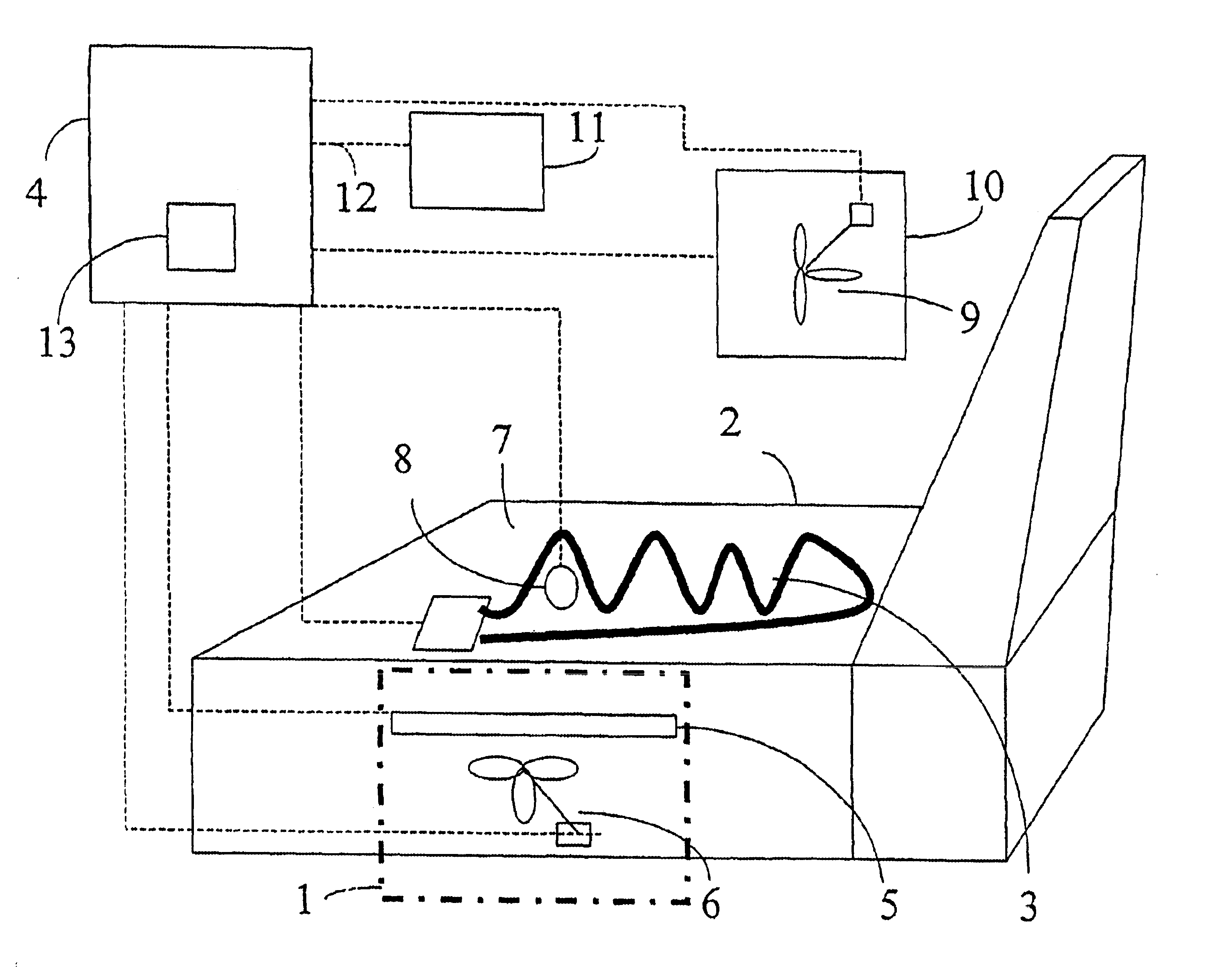

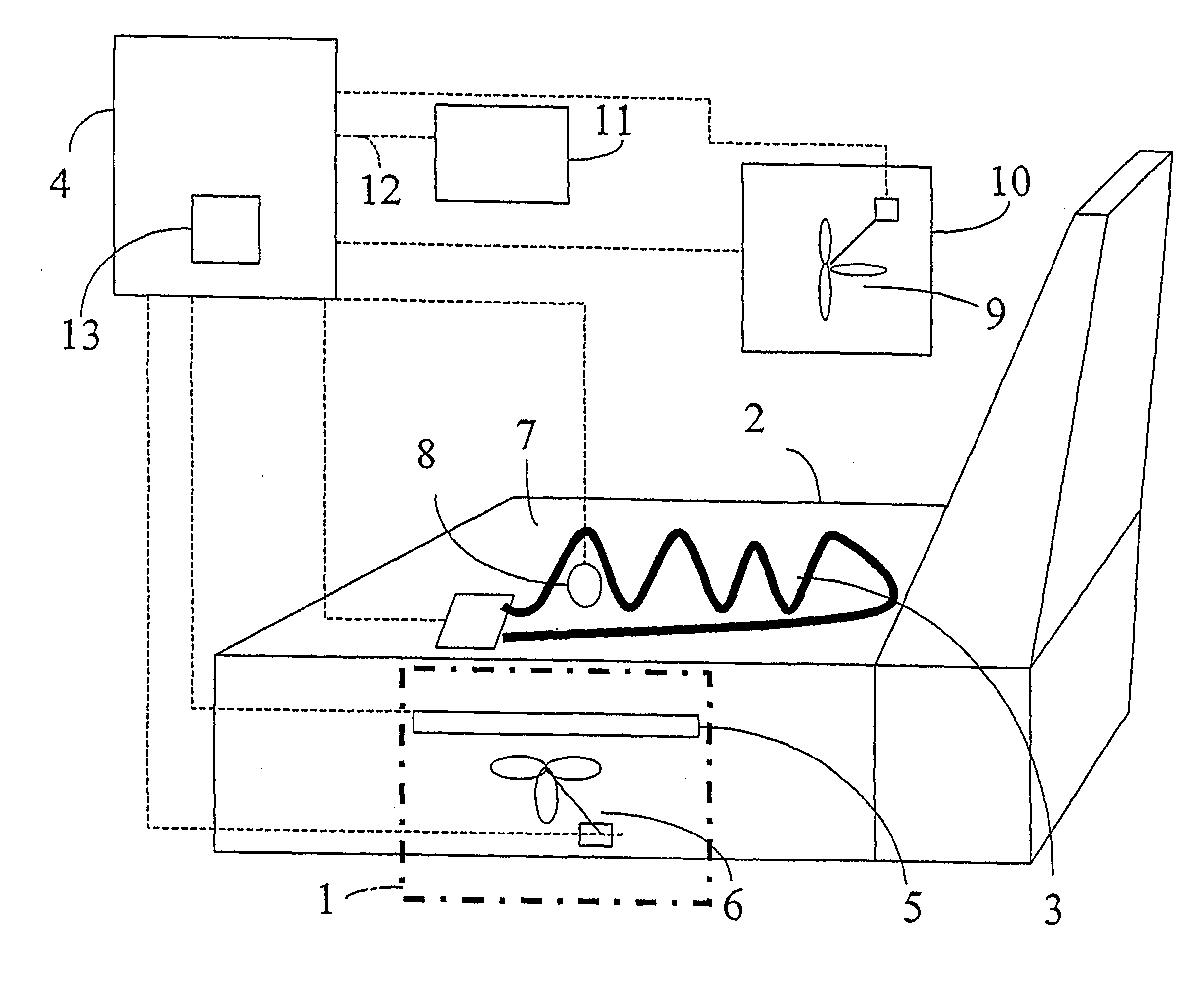

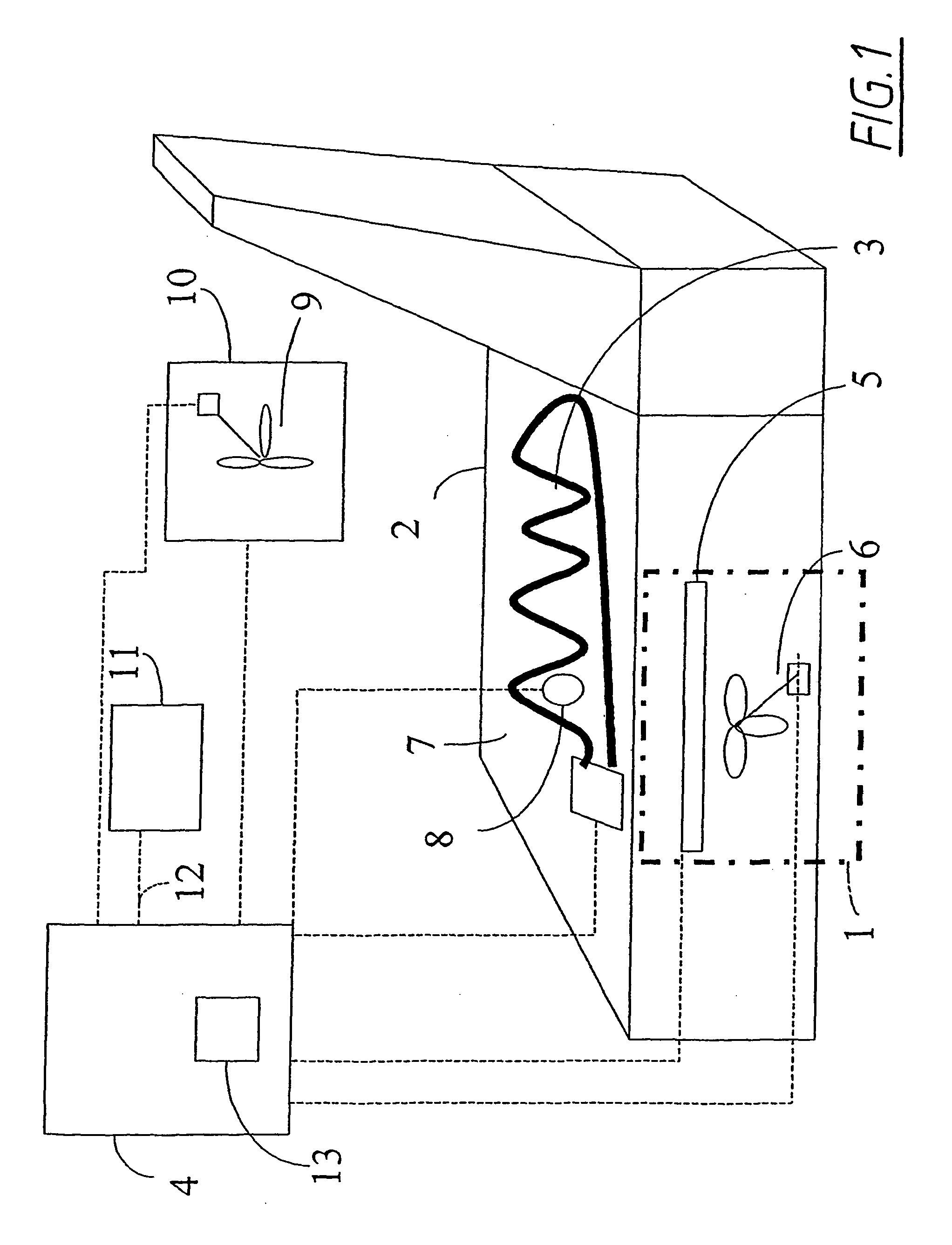

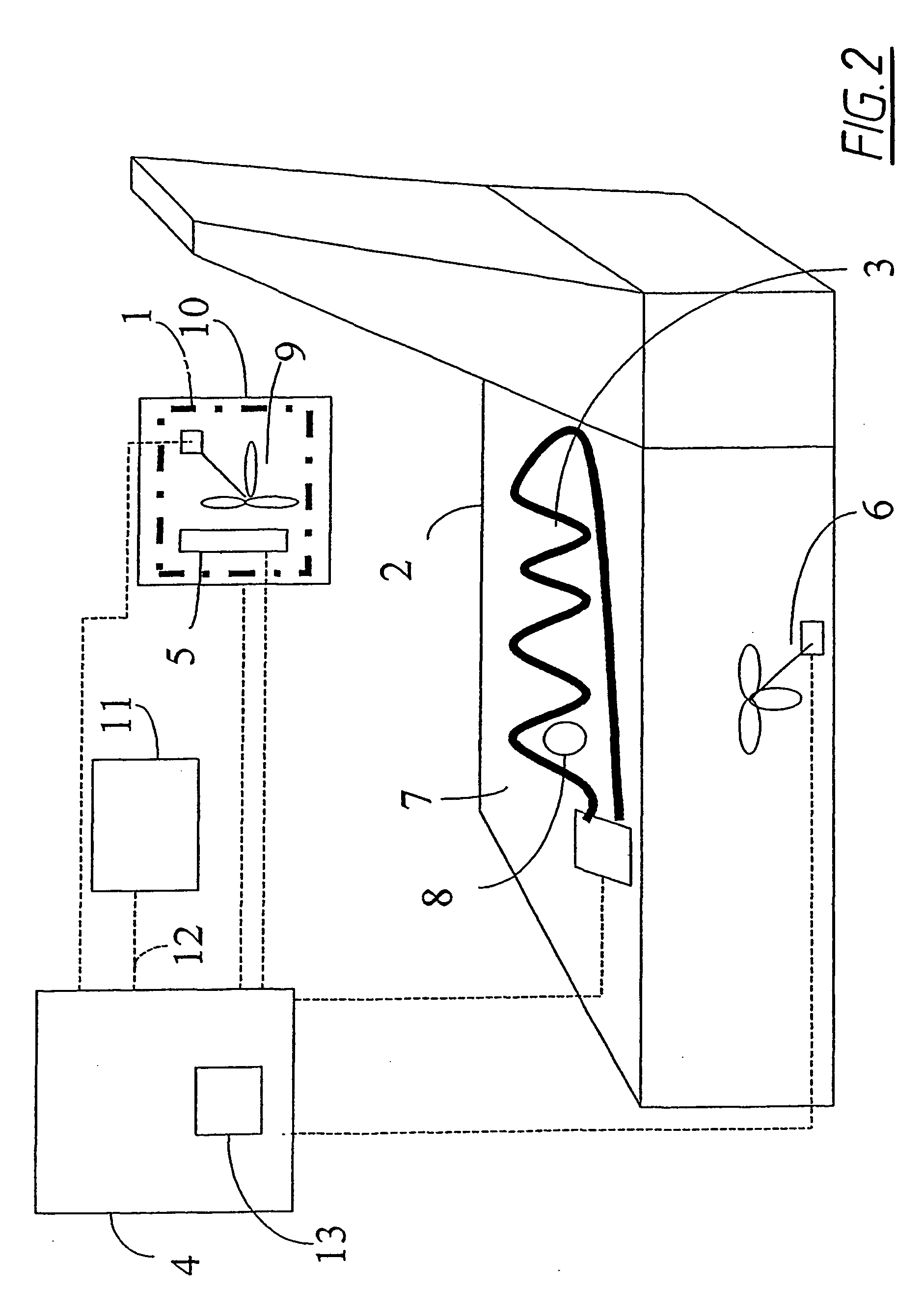

Seat with temparature control and ventilation and safety system for a vehicle

InactiveUS20040118555A1Improve cooling effectAccelerated dryingDomestic cooling apparatusPower to electric heating circuitsTemperature controlEngineering

Methods and apparatus for controlling the temperature of a seat such as a vehicle seat are disclosed. The apparatus includes an electrical heater disposed in the seat, a cooling unit such as a cooling element and a fan, a detector for detecting the temperature associated with the electrical heater, and a controller for controlling the electrical heater and the cooler based upon the detected temperature and upon the humidity algorithm comprising a predetermined set of calculations of the humidity of air at different temperatures.

Owner:LEAR CORP

Refrigerated chest for rapidly quenching beverages and visually identifying when such beverages reach target temperature

InactiveUS20100251755A1Fast coolingFast quenchingLighting and heating apparatusCooling fluid circulationSaline waterSalt water

The cooling chest for rapidly quenching beverages includes a quench tray for holding containers of beverage. The quench tray is lowered into salt-water or other cooling liquid which is cooled by a refrigeration unit. A processing device determines the temperature of the beverages within the containers within the quench tray and further activates a mechanism for removing the quench tray from the water or cooling liquid when the desired temperature is reached. The processing device can also activate the mechanism for removing the quench tray from the water or cooling liquid when the upper lid or access doors are opened.

Owner:LAUCHNOR JOHN C

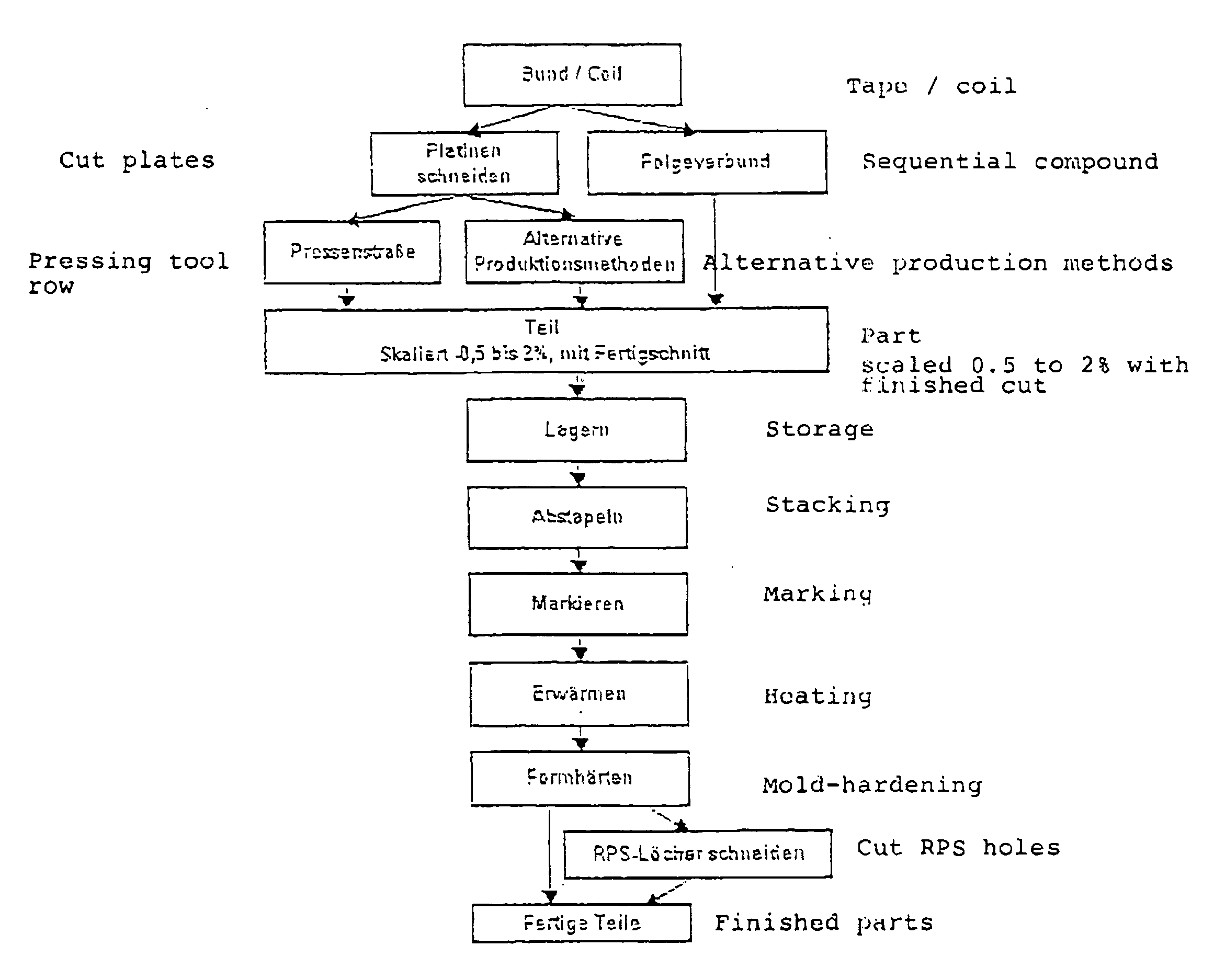

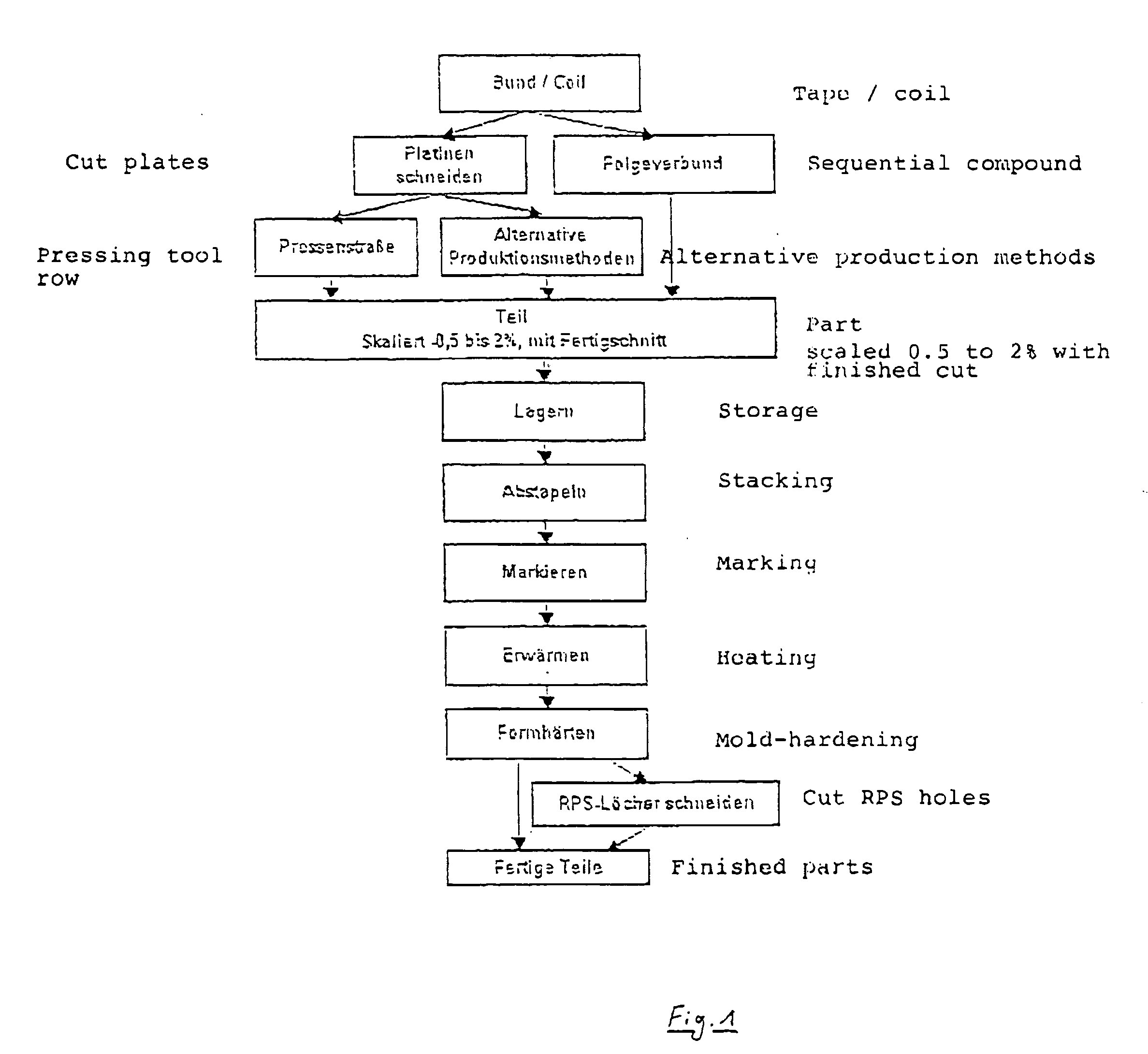

Method for producing hardened parts from sheet steel

ActiveUS20070000117A1Fast coolingEasy to integrateHot-dipping/immersion processesMetal rolling stand detailsPunchingSheet steel

The invention relates to a method for producing hardened structural parts from sheet steel. The method includes shaping at least one shaped part made of sheet steel provided with a cathodic corrosion protection coating, performing any required final trim of the shaped part and possibly any required punching, or the creation of a perforation pattern, subsequently heating the shaped part, at least over partial areas, under the admission of atmospheric oxygen to a temperature which permits austenizing of the steel material, and thereafter transferring the structural part to a mold-hardening tool and performing mold-hardening in the mold-hardening tool, wherein the structural part is cooled by the contact with and pressing by the mold-hardening tool and is hardened thereby.

Owner:VOESTALPINE STAHL GMBH

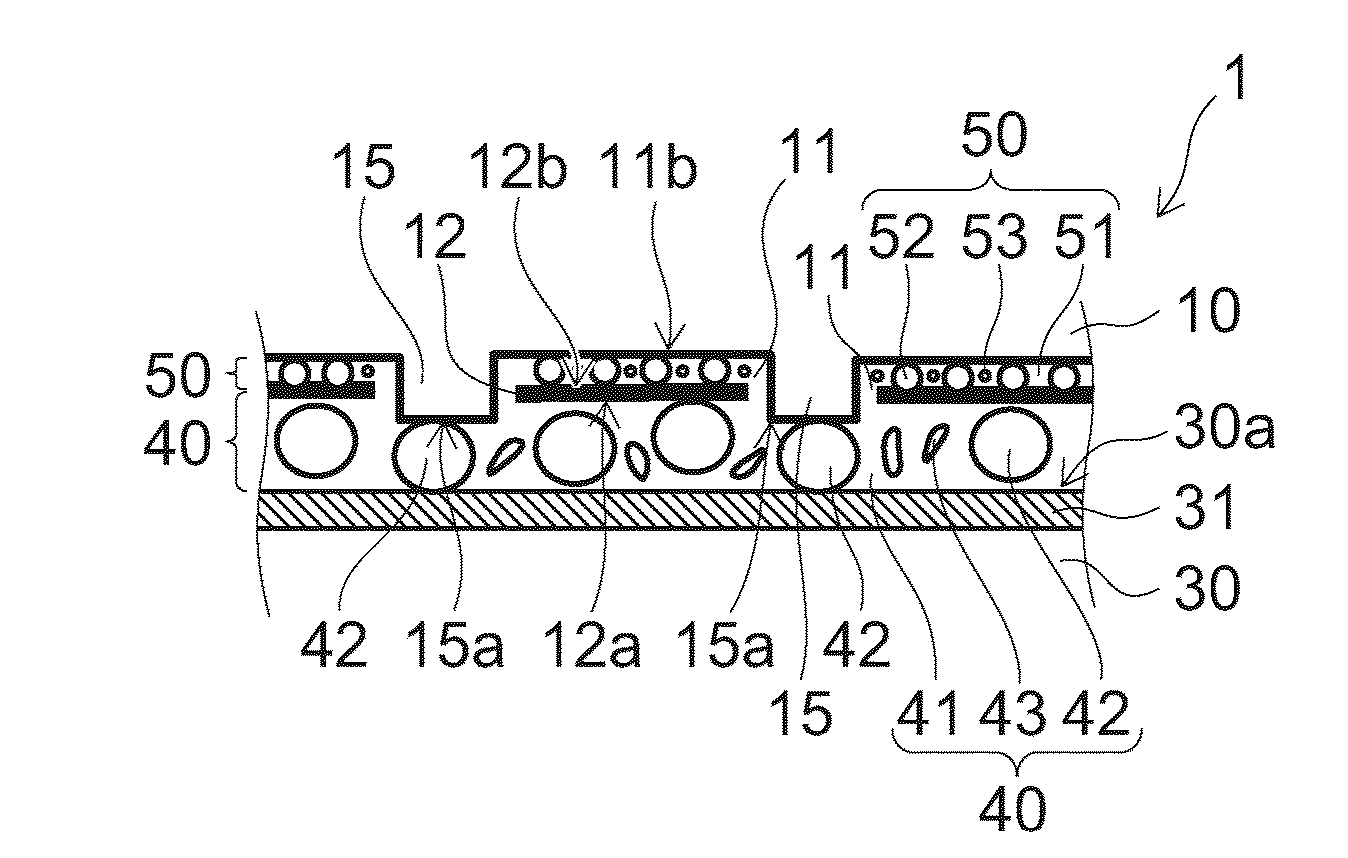

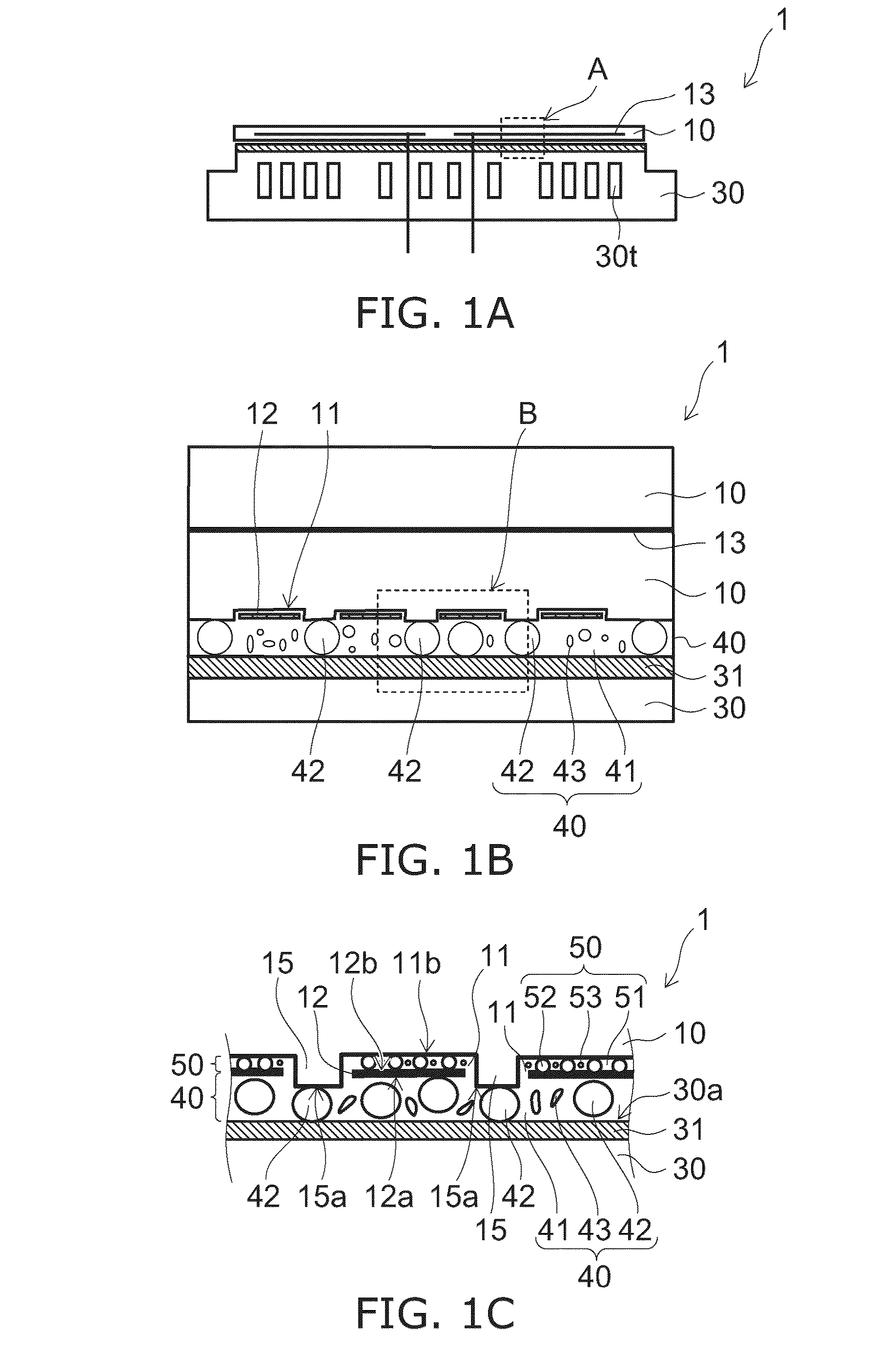

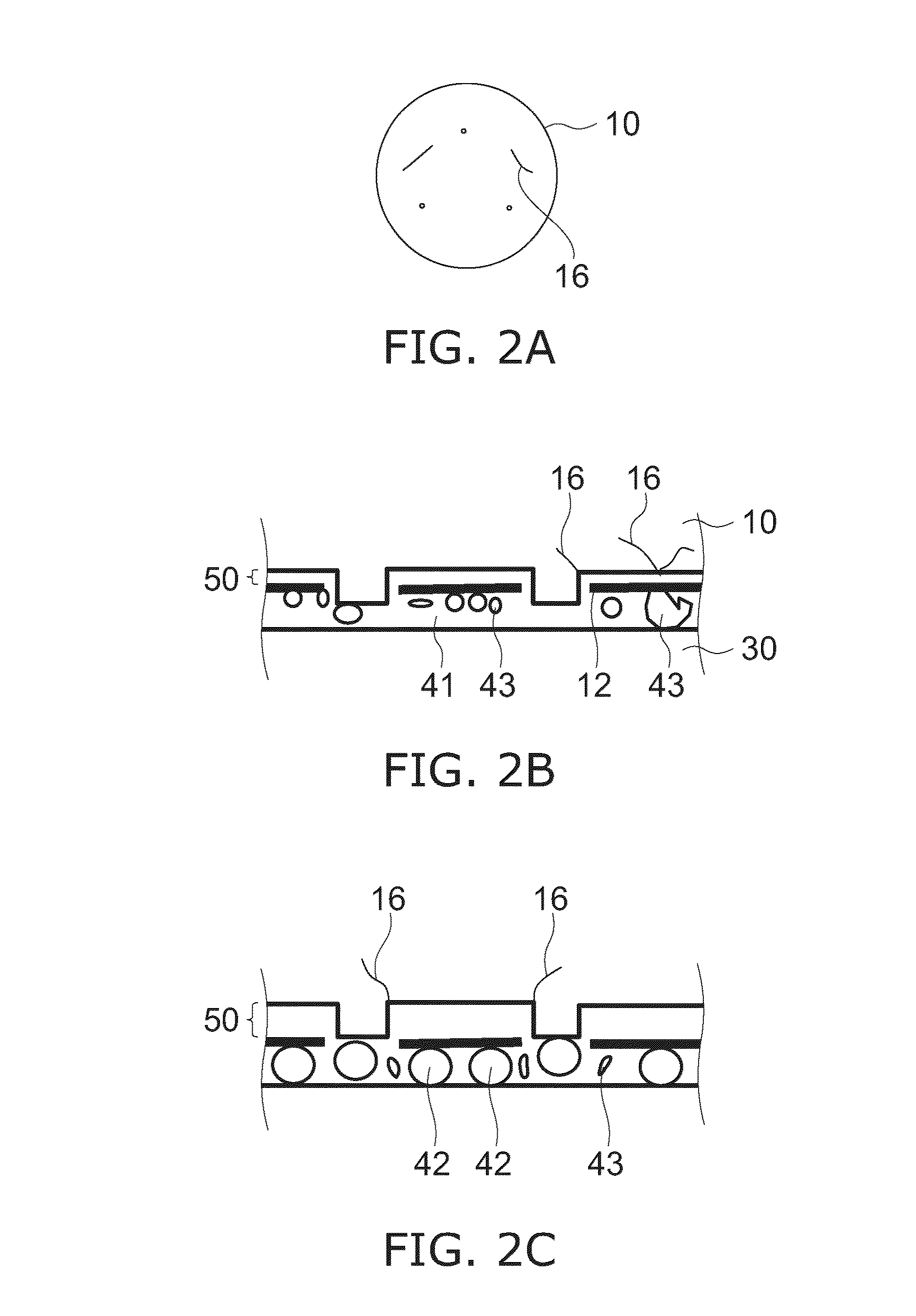

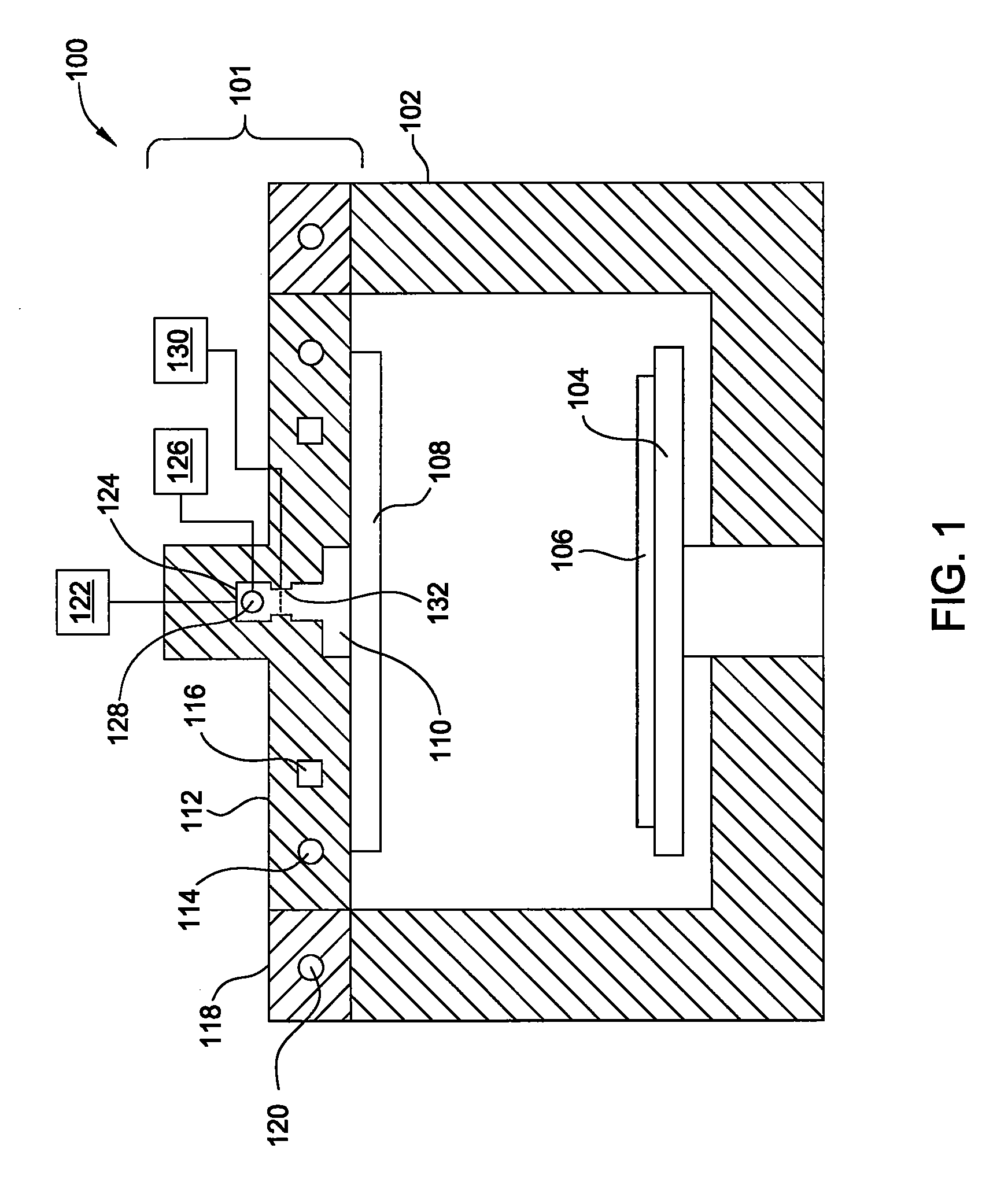

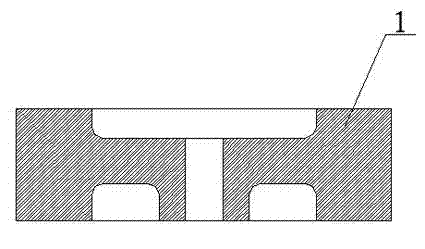

Electrostatic chuck

InactiveUS20130026720A1Inhibit the generation of cracksFast heatingSleeve/socket jointsSemiconductor/solid-state device manufacturingMetallurgyInorganic materials

An electrostatic chuck comprises: a ceramic plate provided with recesses on a major surface and provided with an electrode in an inner part of the ceramic plate; a temperature regulating plate bonded to the major surface of the ceramic plate; a first bonding agent provided between the ceramic plate and the temperature regulating plate; and a heater provided in the each of the recesses of the ceramic plate. The first bonding agent has a first major agent including an organic material, a first amorphous filler including an inorganic material, and a first spherical filler including an inorganic material. The first amorphous filler and the first spherical filler are dispersion-compounded into the first major agent. The first major agent, the first amorphous filler, and the first spherical filler are made of an electrically insulating material. An average diameter of the first spherical filler is greater than a maximum value of a minor axis of the first amorphous filler. A thickness of the first bonding agent is greater than or equal to the average diameter of the first spherical filler. A width of the each of the recesses is greater than a width of the heater, and a depth of the each of the recesses is greater than a thickness of the heater. The heater is adhered within the each of the recesses by a second bonding agent. A first distance between a major surface of the heater on the side of the temperature regulating plate and a major surface of the temperature regulating plate is greater than a second distance between the major surface between the recesses of the ceramic plate and the major surface of the temperature regulating plate.

Owner:TOTO LTD

Cylindrical attapulgite flower ceramsite

ActiveCN102503537AHigh strengthLower sintering temperatureCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses cylindrical attapulgite flower ceramsite. The key points of the technical scheme are that the cylindrical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The cylindrical attapulgite flower ceramsite is produced by the following stepsof mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The cylindrical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength andwater absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the cylindrical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, thecylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

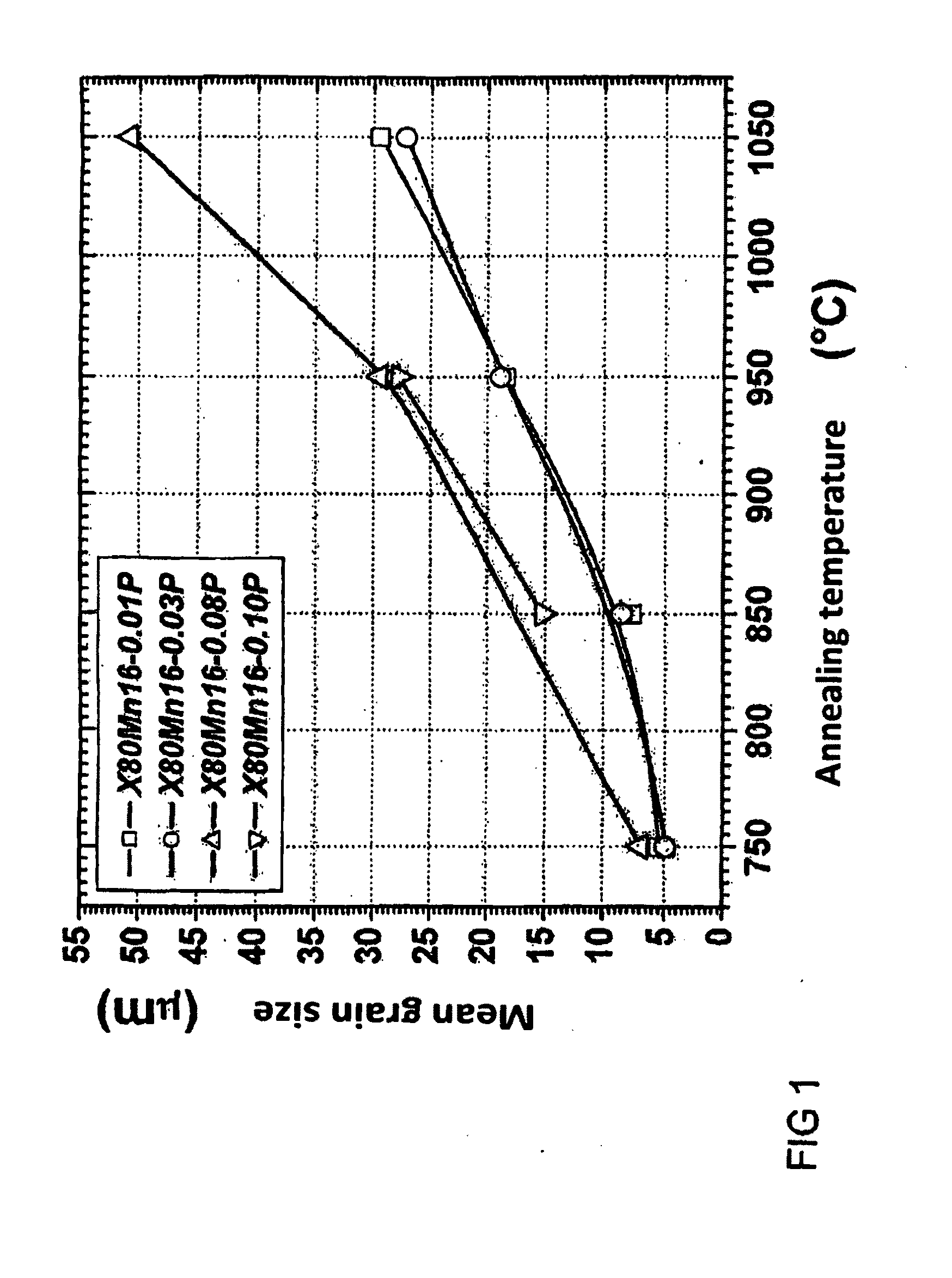

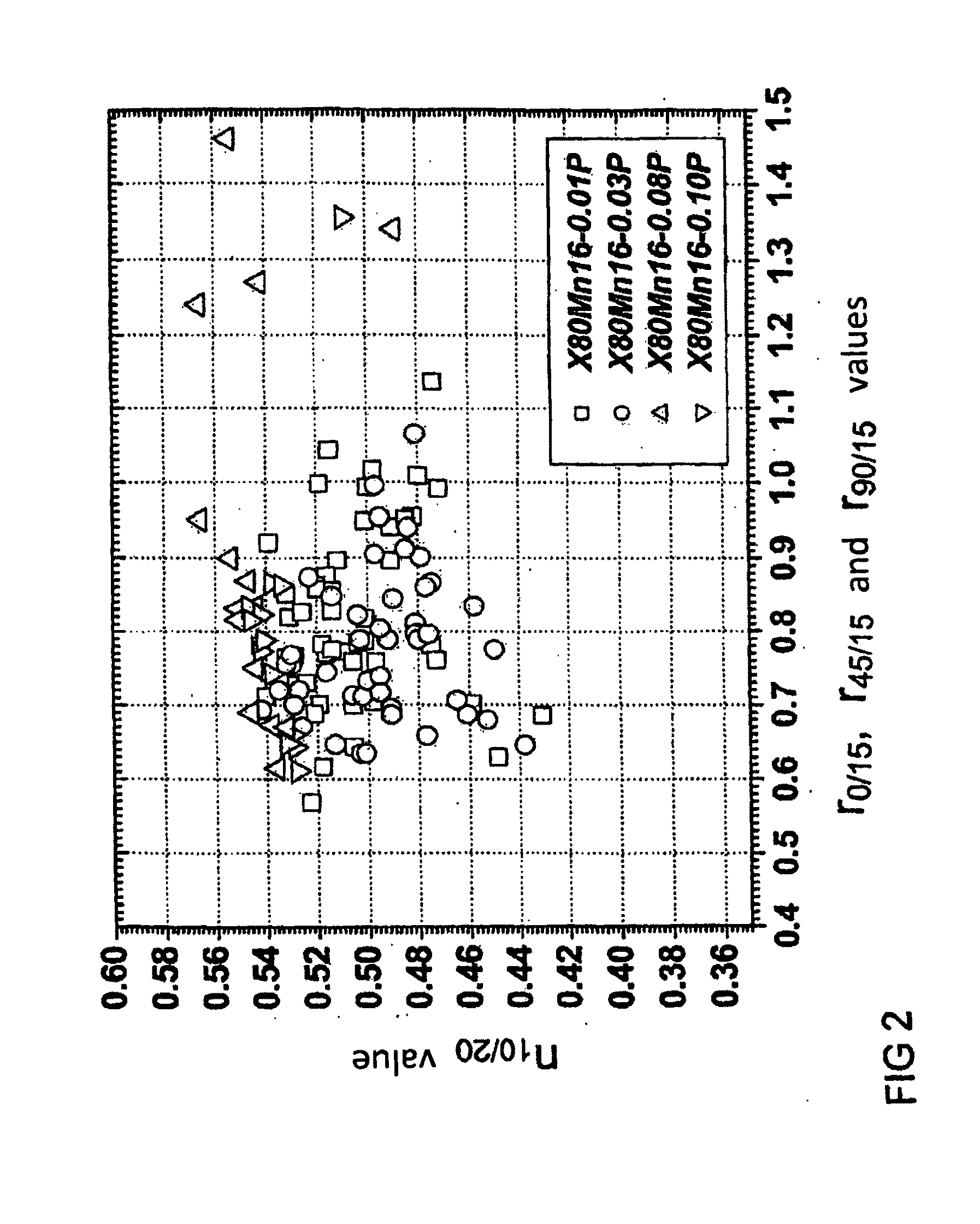

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

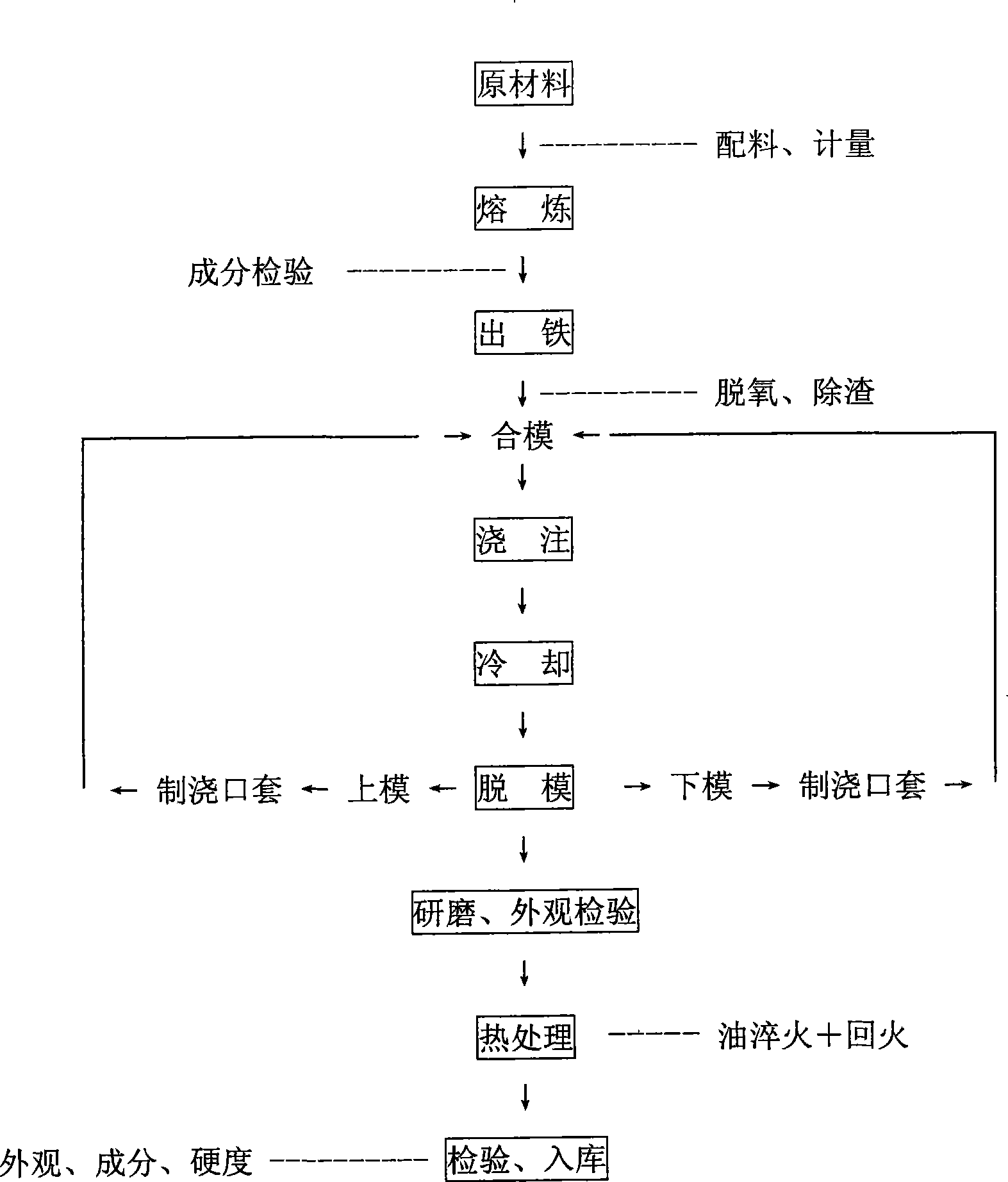

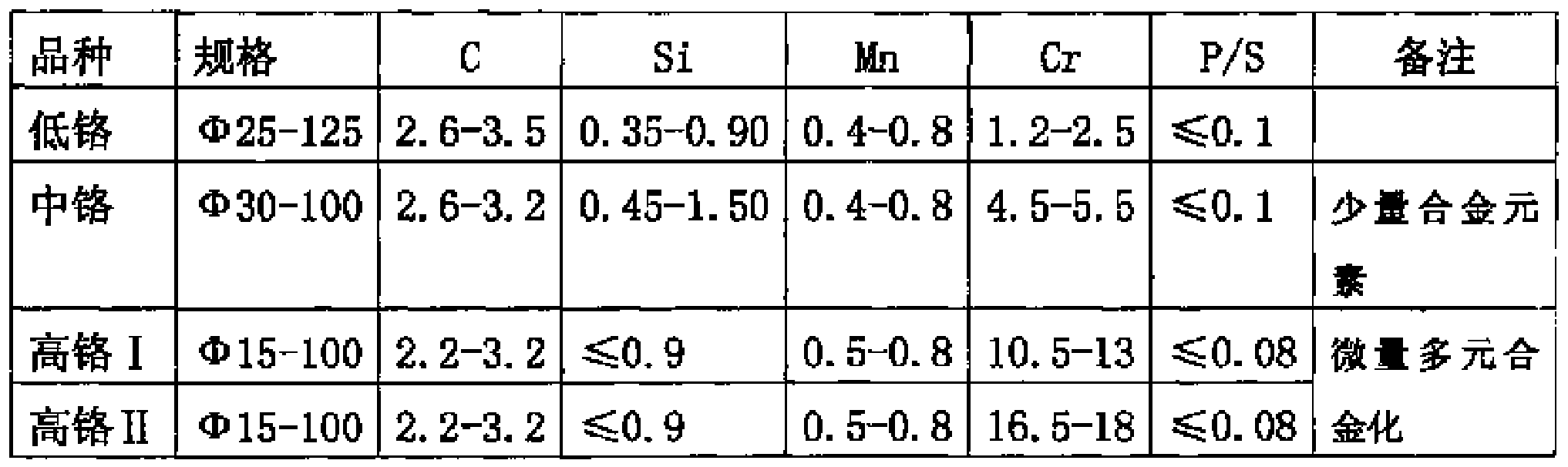

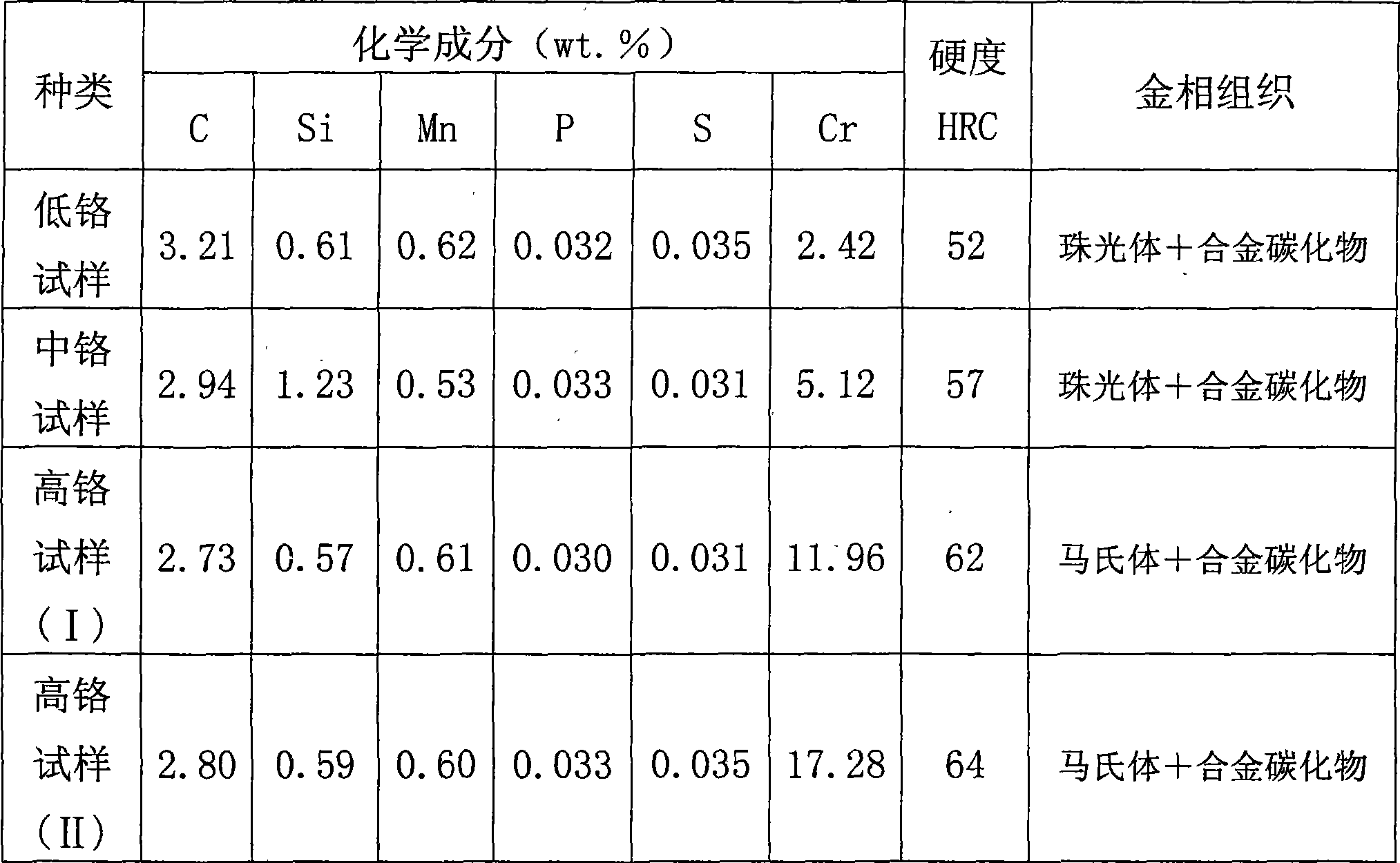

High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

InactiveCN101445889AHigh hardnessImprove toughnessEdge grinding machinesPolishing machinesIntermediate frequencyCarbide

The invention relates to a high abrasion proof resynthesizing cast iron grinding ball for a ball grinding mill and a preparation method thereof. The method reduces the content of carbon in material on the premise that carbide is formed in materials, thereby reducing the contents of chrome and molybdenum in the material and simultaneously controlling the content of other elements, so that the obtained material of the grinding ball has good overall mechanical property and service performance. Compared with a No. 45 steel forging ball, the abrasion proof property of the grinding ball is improved by 3 to 10 times, so that both the consumption of steel products and the recourses are saved. In the method, cast iron is melted and synthesized by using an intermediate frequency electric furnace and a large amount of scrap steel, steel scraps and other renewable resources are utilized, so that not only the quality of synthetic cast iron products is improved and the performance is stabler, but also the pollution to environment is reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

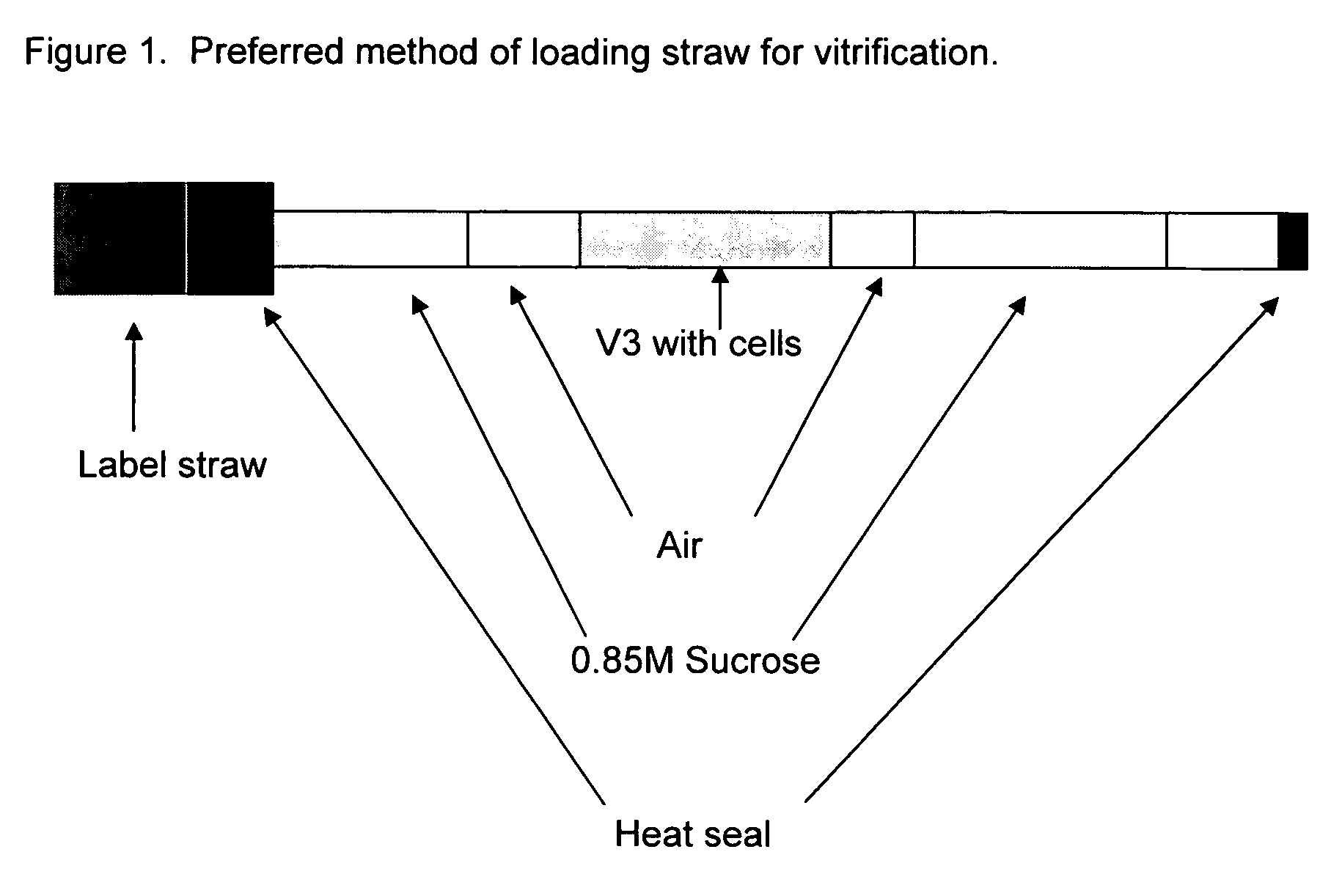

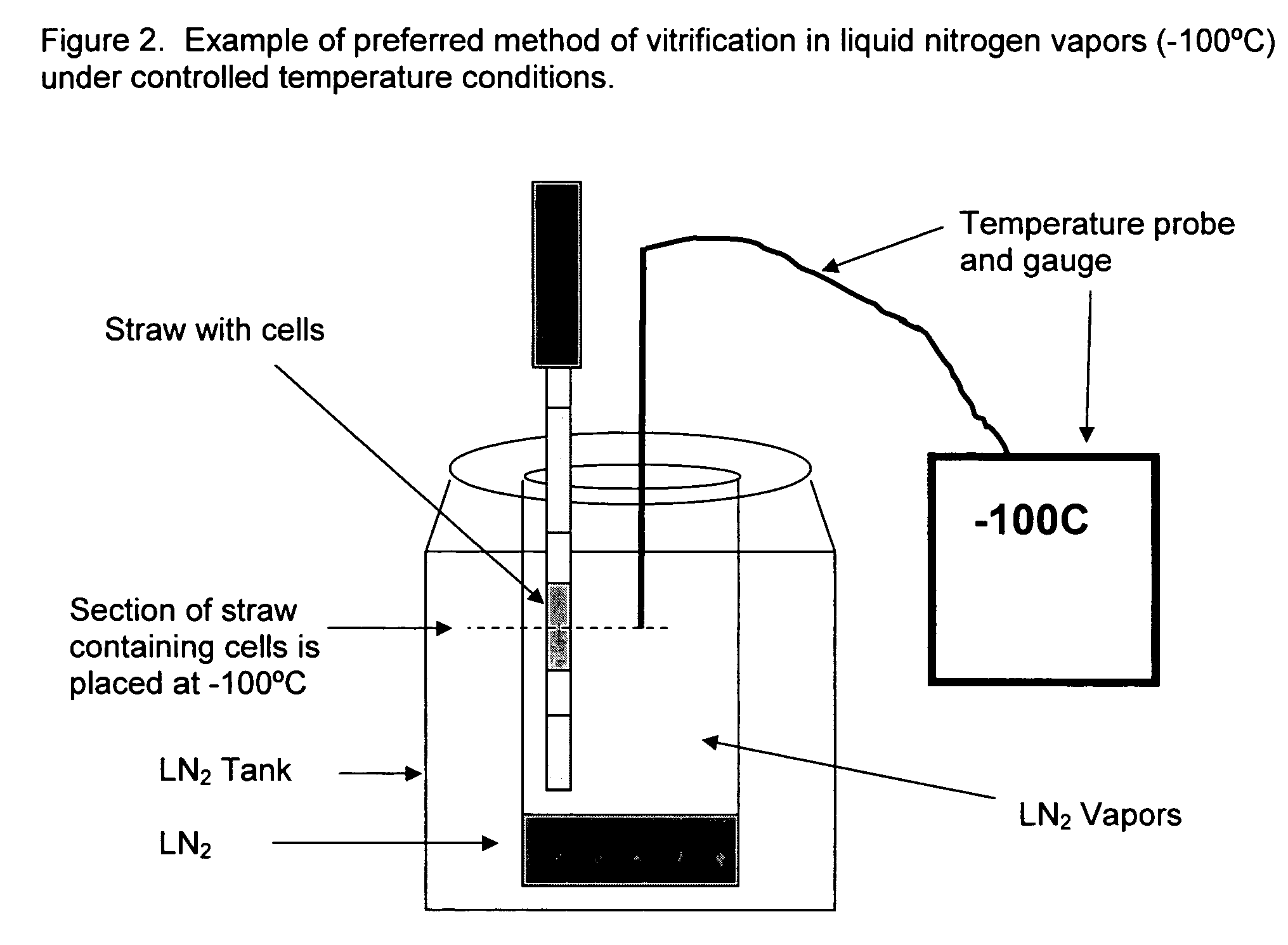

Method for vitrification of mammalian cells

InactiveUS20060046243A1Enough timeAffects successDead animal preservationVitrificationBiological cell

A method of vitrifying mammalian cells. According to the method of the present invention, biological cells of mammalian origin are frozen quickly by a vitrification method. Upon exposure to a coolant, the biological cells undergo vitrification. The biological cells which have undergone vitrification may be stored for a period of time and then devitrified at a later date. The devitrified biological cells remain viable. Preferred biological cells according to the present invention are developmental cells including blastocysts, embryos, and oocytes.

Owner:TYHO GALILEO RES LAB

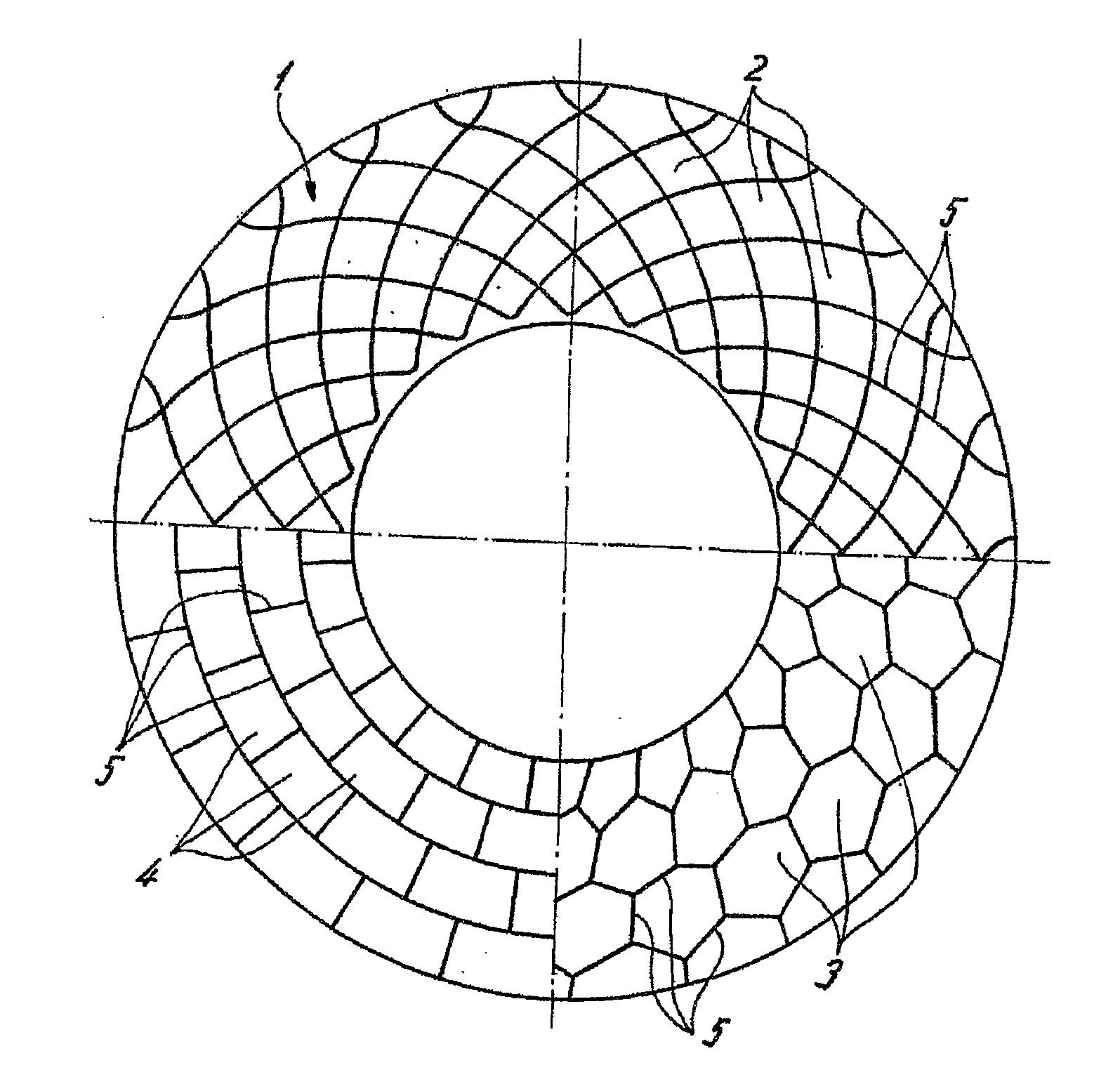

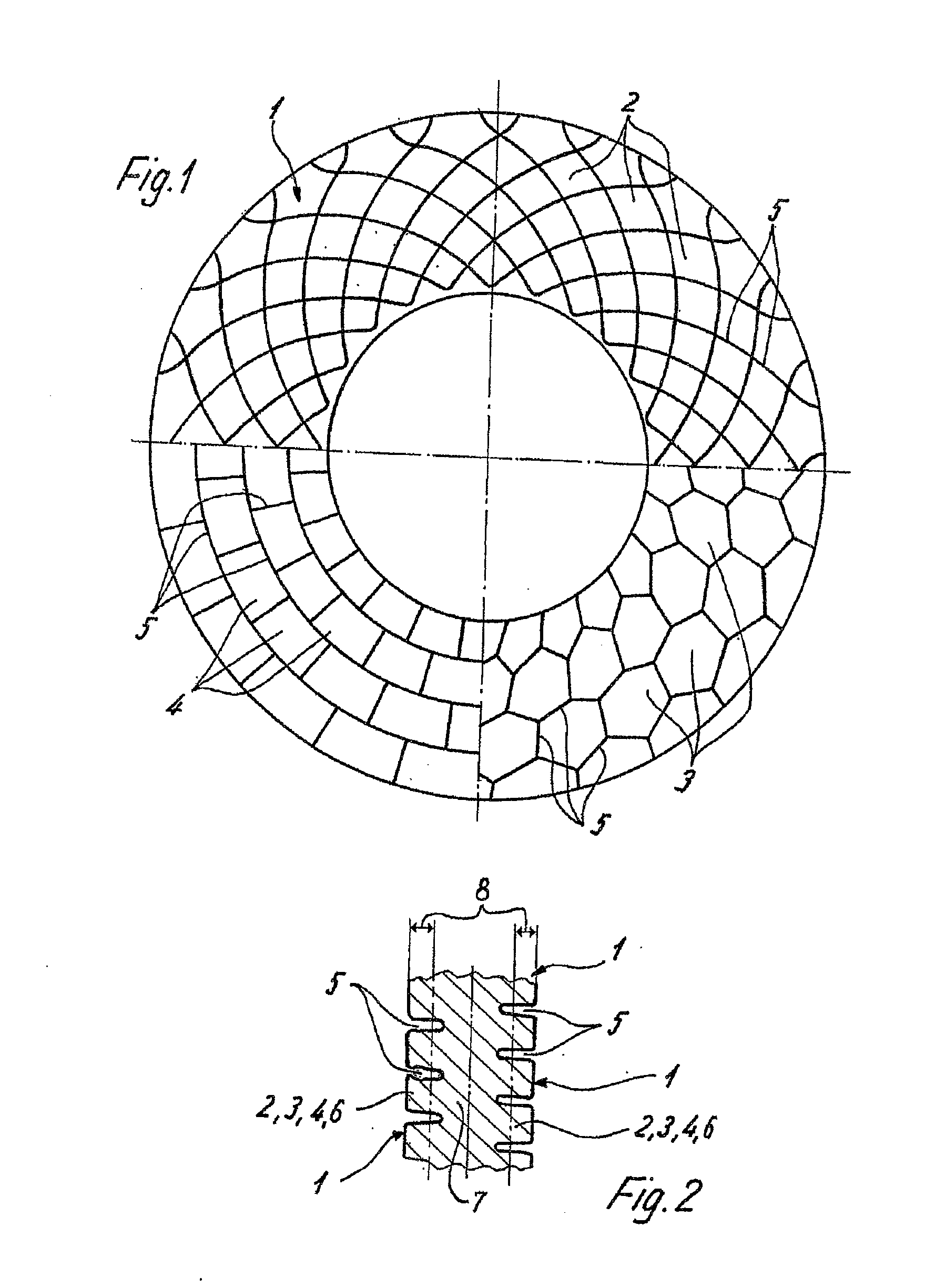

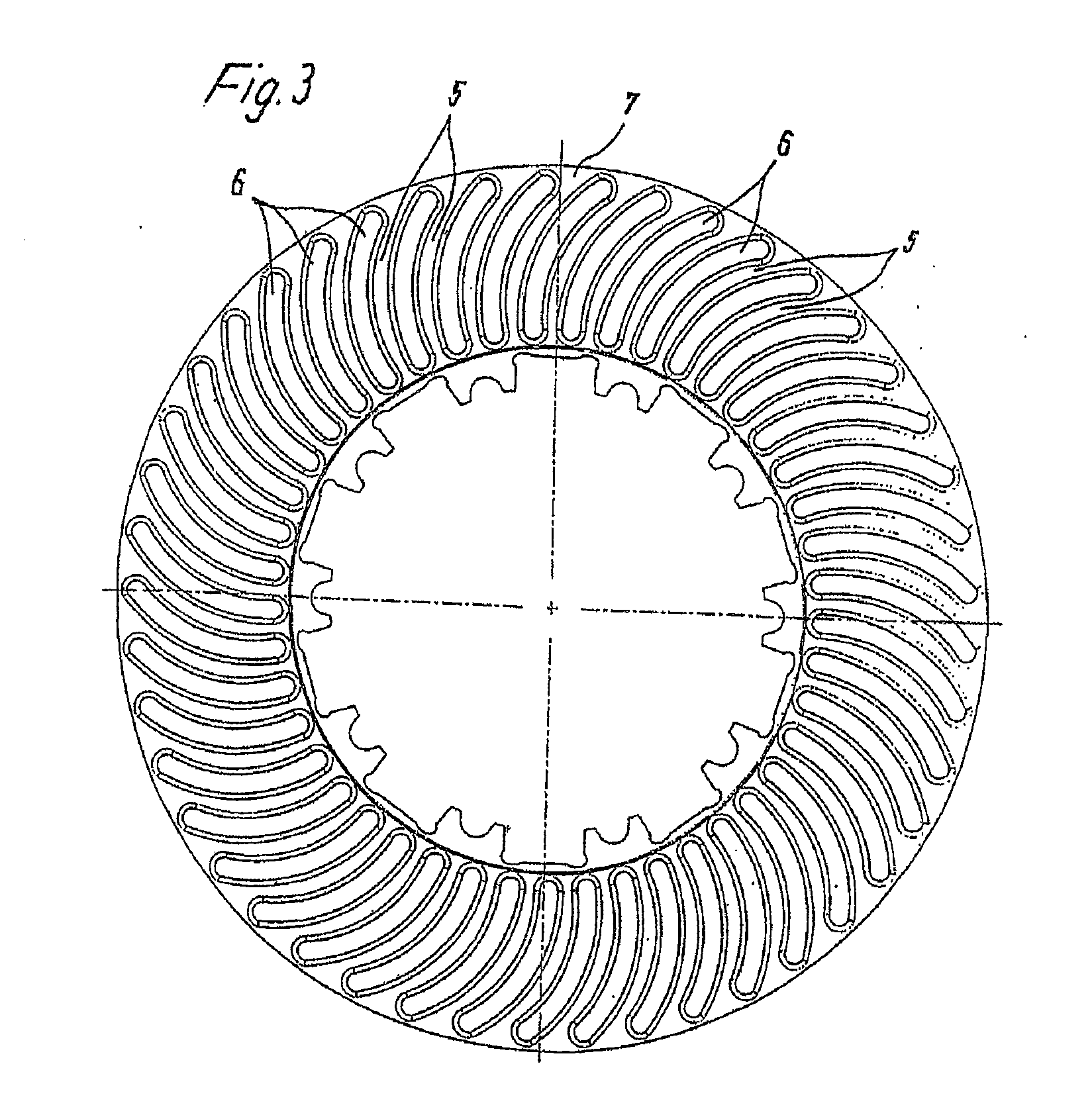

Brake Disk, In Particlular for a Vehicle

InactiveUS20080041675A1Reduce widthEasy to wearBraking discsFriction liningEngineeringExpansion joint

A brake disc for a vehicle has at least one annular friction surface provided on at least one outer face of the disc to which a brake pad can be applied for braking purposes. The friction surface has a large number of subsegments, at least some of which are physically separated from one another by expansion joints. The brake disc is configured in such a way that the depth of the expansion joints is greater than the permissible rate of wear of the friction surface.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

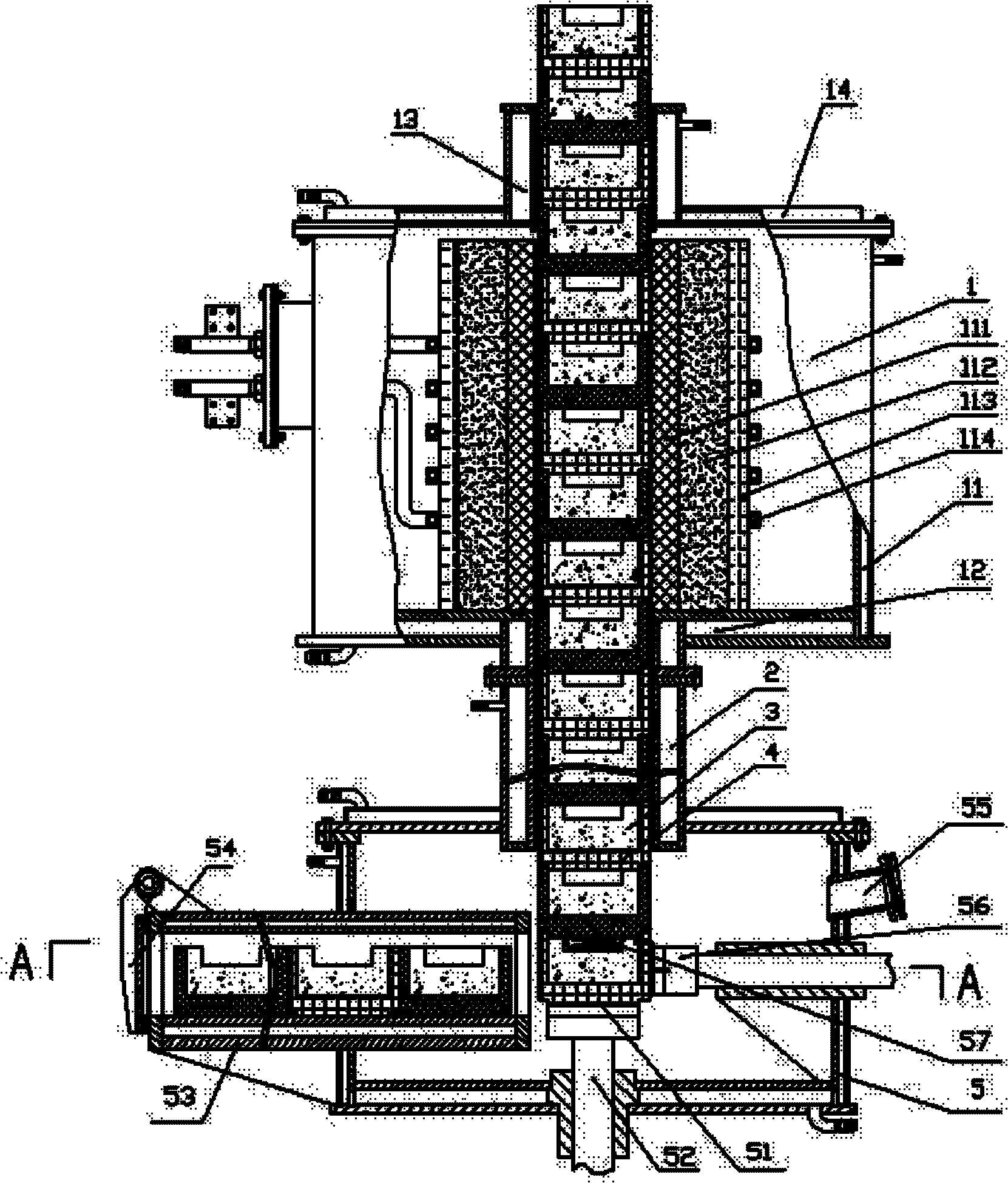

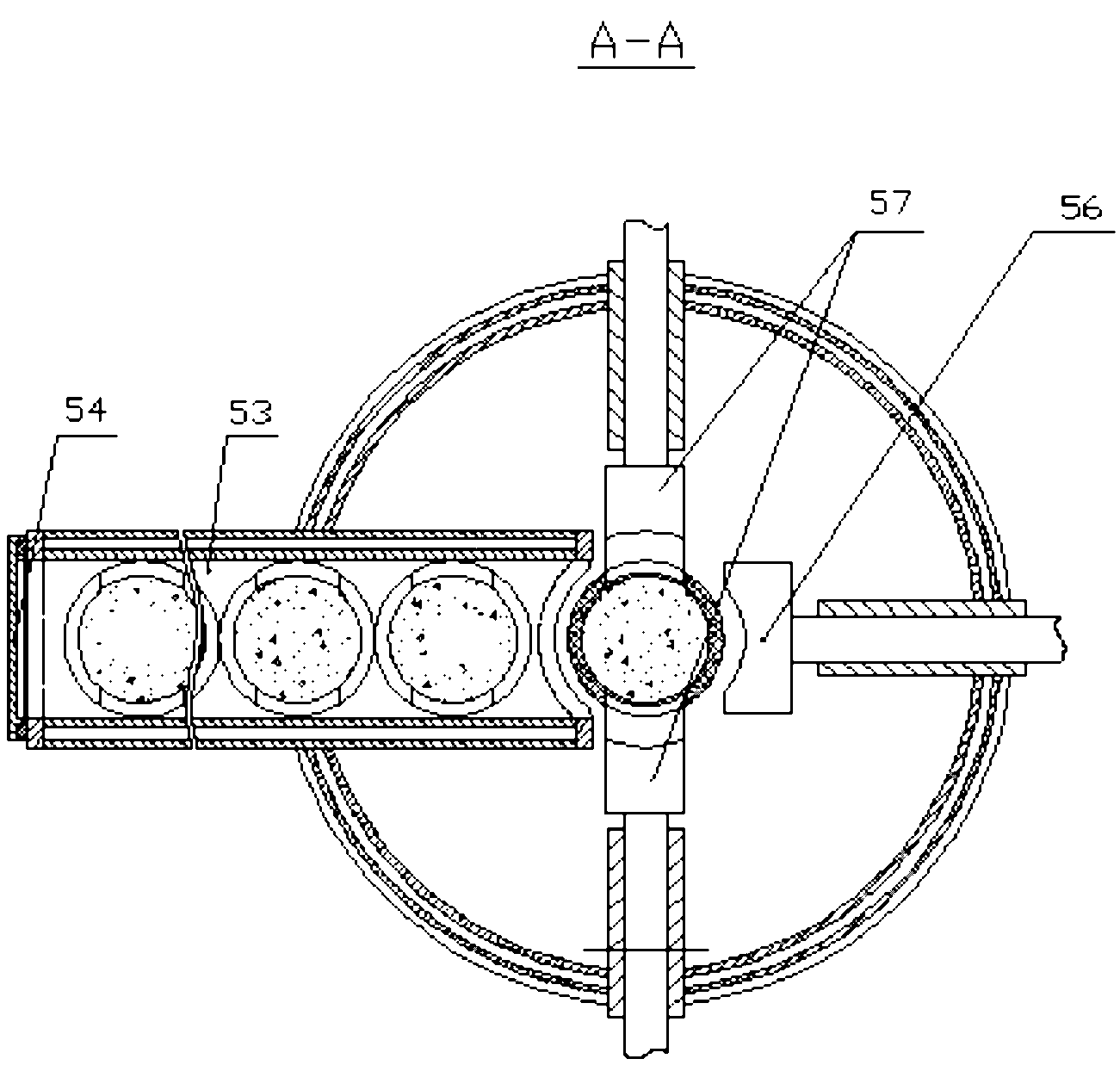

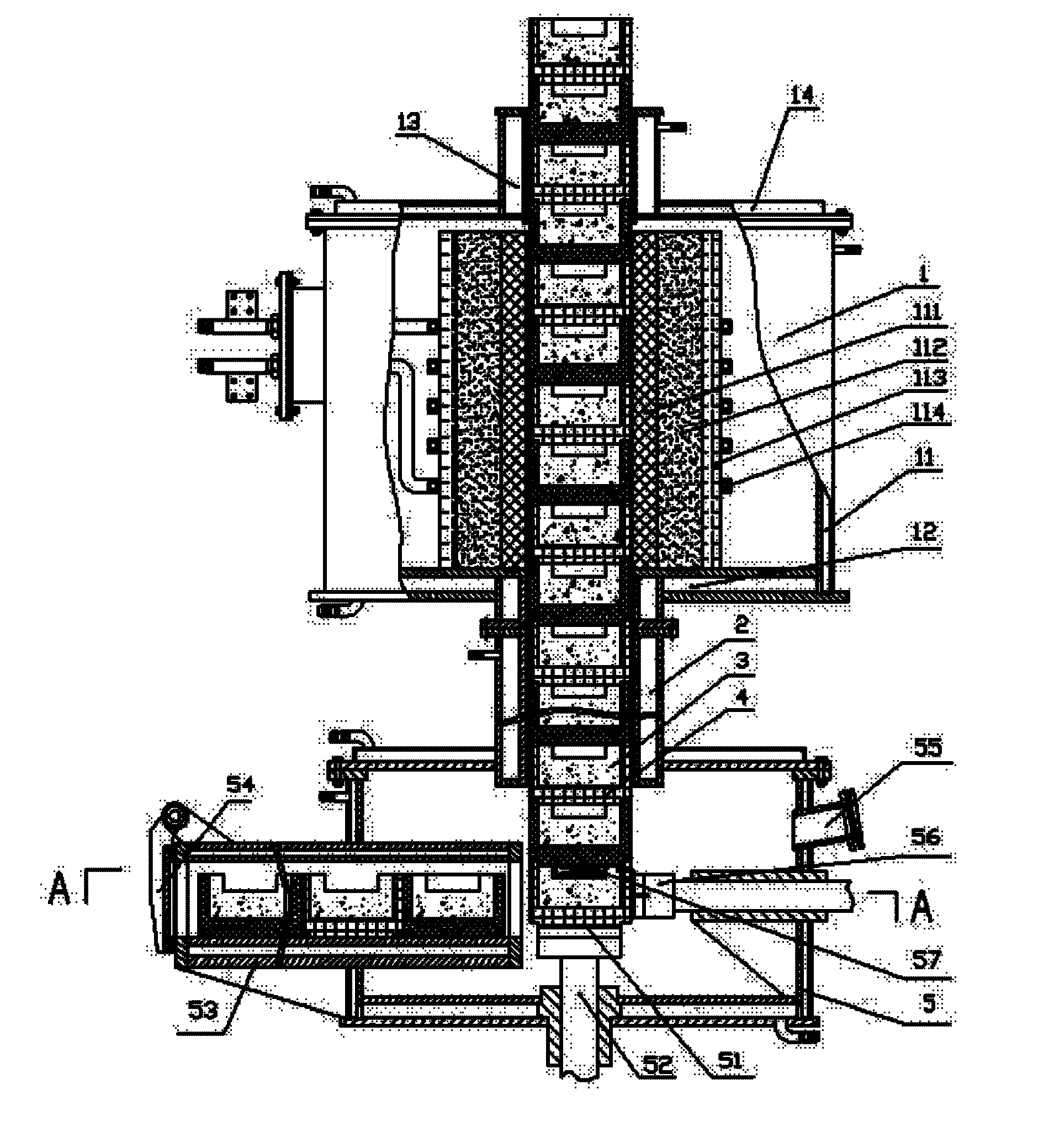

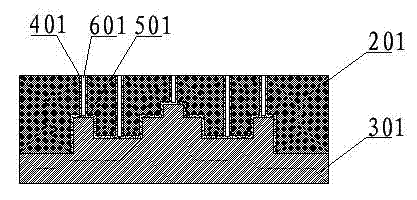

Induction heating ultra-temperature continuous carbonization furnace

ActiveCN101788227ASolve the above problemsInnovative designFurnace typesCarbonizationVertical channel

The invention relates to an induction heating ultra-temperature continuous carbonization furnace which comprises an upper furnace body, a middle water-cooling connecting sleeve and a lower furnace body to from a vertical channel and a horizontal channel, wherein the upper furnace body and the lower furnace body are communicated through the middle water-cooling connecting sleeve, the upper furnace body is mainly used for heating and the like, the middle water-cooling connecting sleeve is a cooling region part of the vertical channel; the lower furnace body is mainly used for cooling, discharging and the like; boats loaded with materials are sequentially overlapped and stepped to enter the vertical channel of the furnace body, and the boats loaded with carbonized materials are pushed into the horizontal channel through a manipulator and are stepped into and discharged out of the furnace body. Vertical heating, continuous carbonization, horizontal cooling and discharging are adopted, a high-temperature hearth needs not to support the weight of the boats and the materials; and the invention has high cooling speed, high yield and good product quality, and can better solve the problems of a horizontal continuous furnace and a vertical intermittent furnace.

Owner:湖南弗拉德连续高温科技有限公司

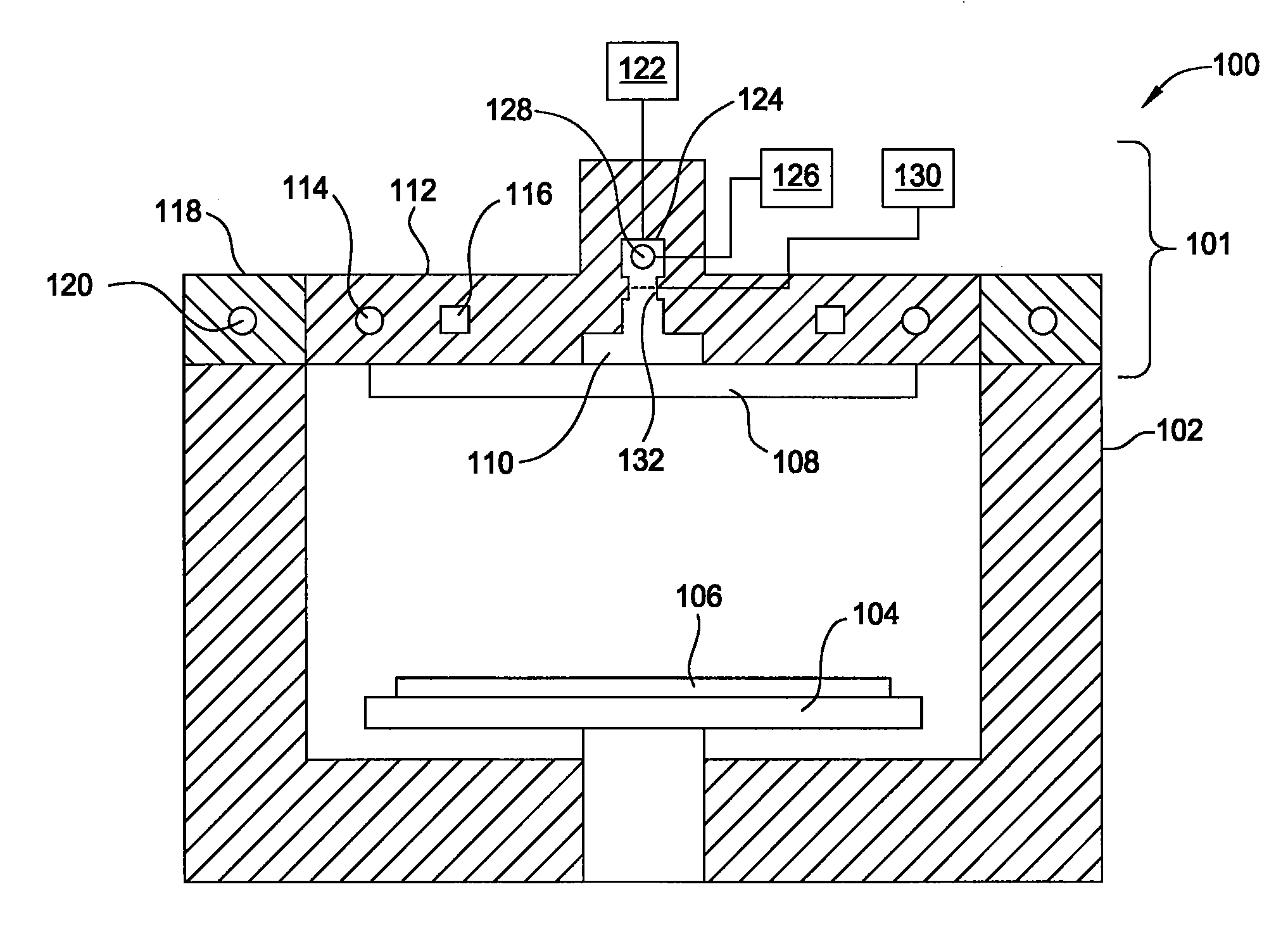

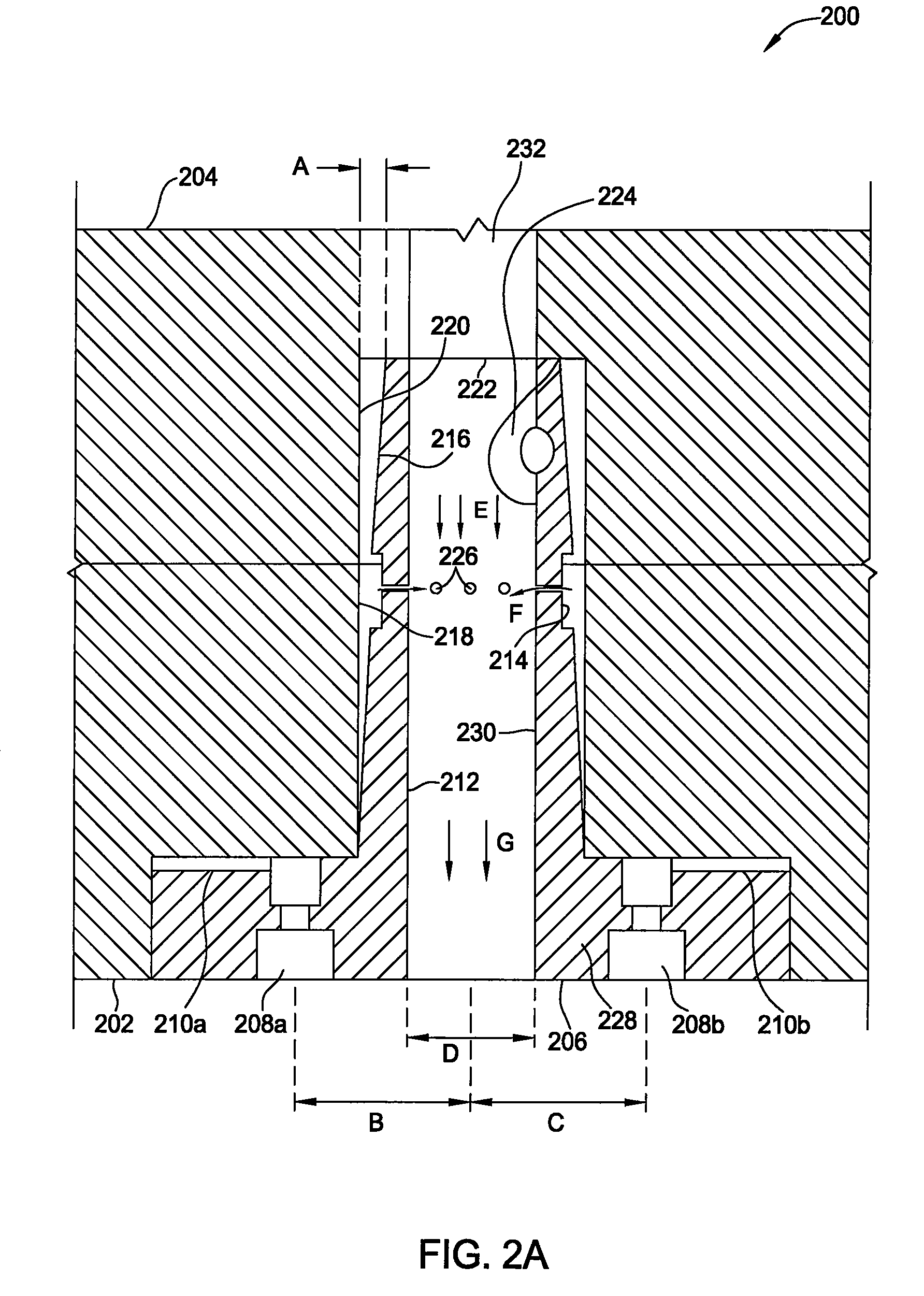

Temperature controlled lid assembly for tungsten nitride deposition

InactiveUS20080202425A1Fast heatingFast coolingChemical vapor deposition coatingTemperature controlElectrical resistance and conductance

Embodiments of the invention provide apparatuses for vapor depositing tungsten-containing materials, such as metallic tungsten and tungsten nitride. In one embodiment, a processing chamber is provided which includes a lid assembly containing a lid plate, a showerhead, a mixing cavity, a distribution cavity, and a resistive heating element contained within the lid plate. In one example, the resistive heating element is configured to provide the lid plate at a temperature within a range from about 120° C. to about 180° C., preferably, from about 140° C. to about 160° C., more preferably, from about 145° C. to about 155° C. The mixing cavity may be in fluid communication with a tungsten precursor source containing tungsten hexafluoride and a nitrogen precursor source containing ammonia. In some embodiments, a single processing chamber may be used to deposit metallic tungsten and tungsten nitride materials by CVD processes.

Owner:APPLIED MATERIALS INC

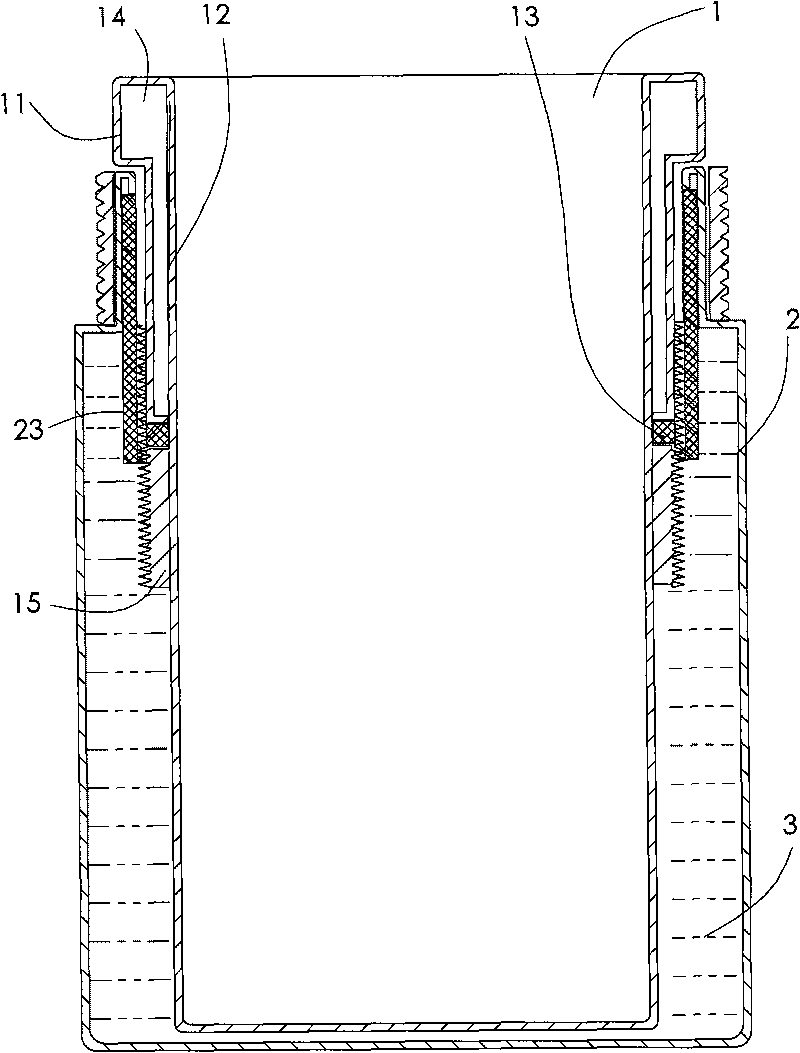

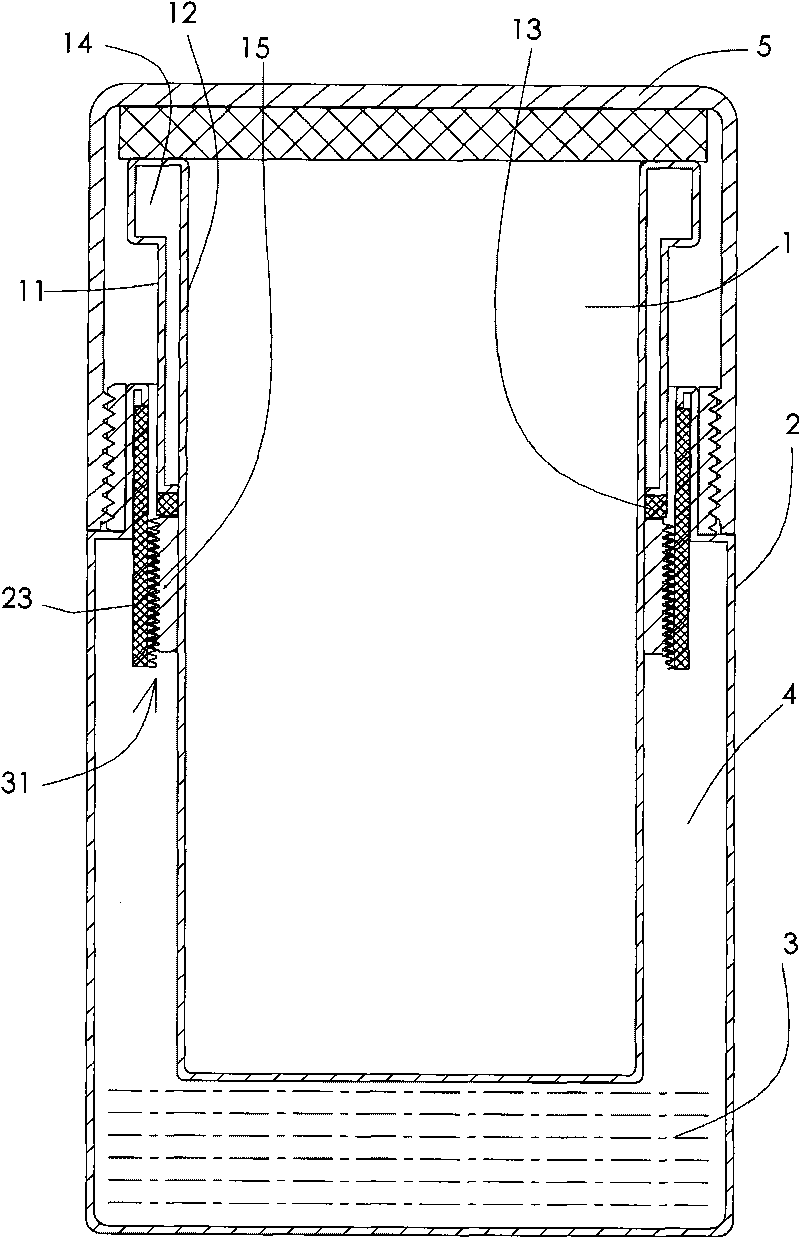

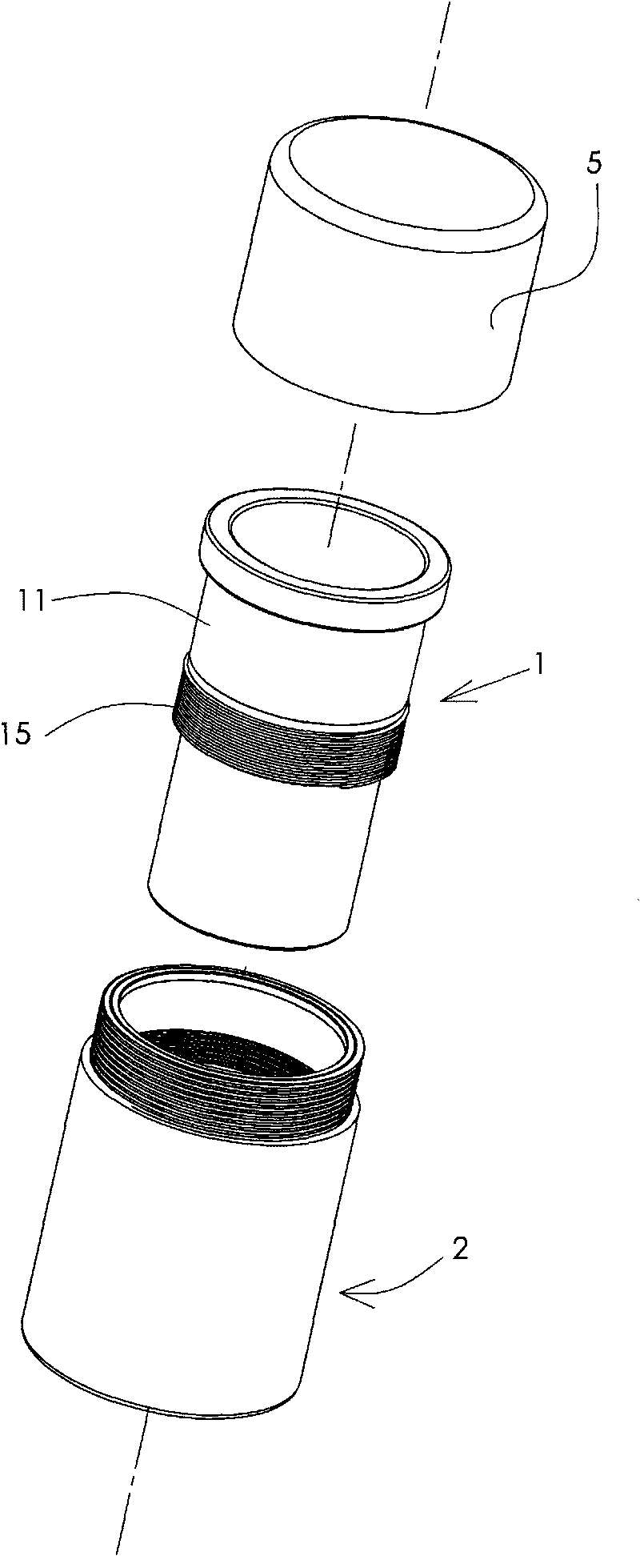

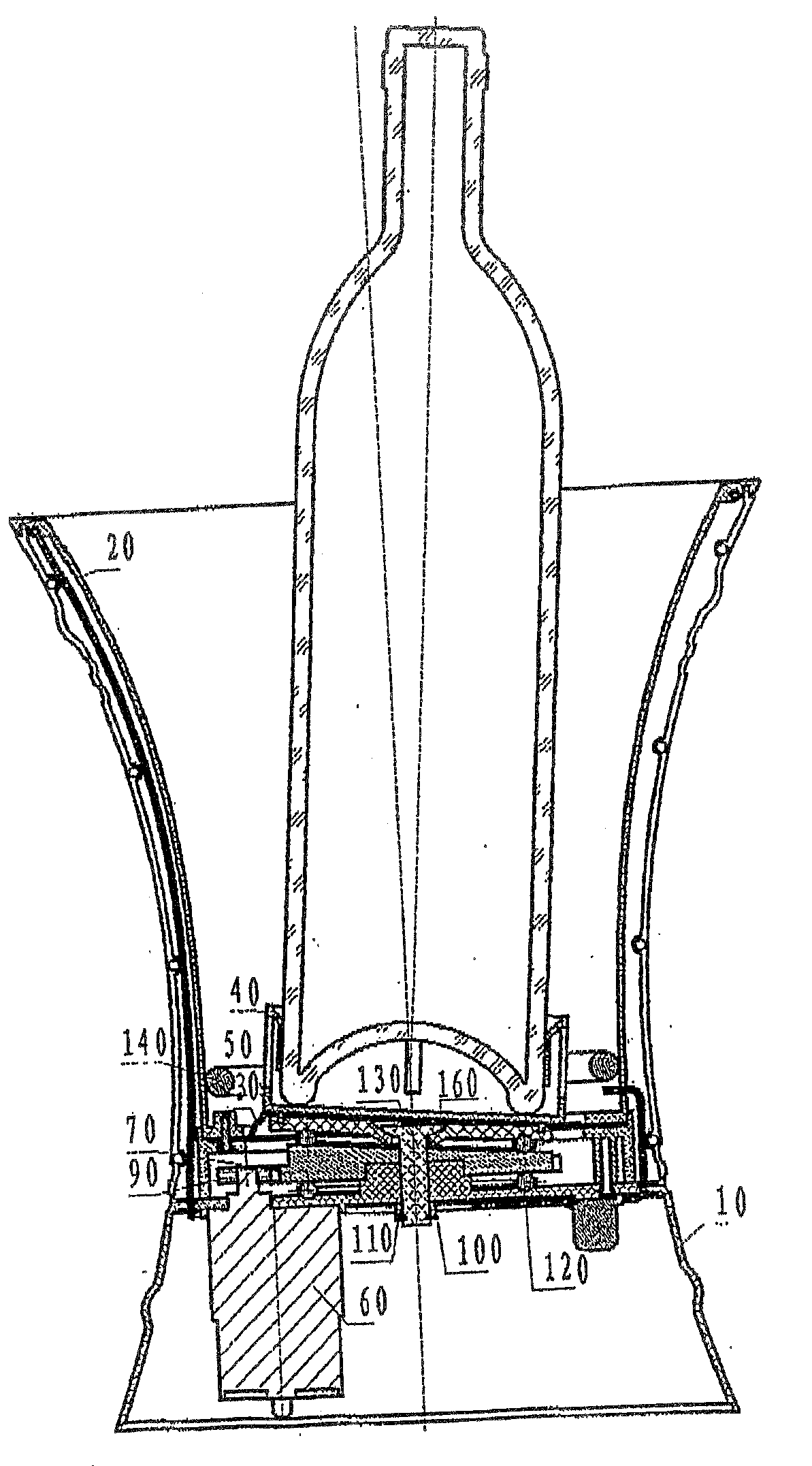

Rotation regulation fast-cooling thermal insulating cup and use method thereof

The invention relates to a rotation regulation fast-cooling thermal insulating cup and a use method thereof. The rotation regulation fast-cooling thermal insulating cup is characterized in that saline water for cooling is arranged between an inner cup and an outer cup, wherein the inner cup is made of stainless steel, a thermal insulating layer formed by enclosing an outer wall and an inner wall is arranged on the upper part of the inner cup, and a thread bushing is arranged in the middle; the outer cup is made from thermal conducting materials, and a thread bushing made from heat insulation materials is arranged on the upper part of the inner wall thereof and is meshed with the thread bushing in the inner cup. By downwards rotating the inner cup, the inner cup is led to be in contact with the saline water for cooling so that high-temperature water in the inner cup can be fast cooled; after proper degree is achieved by cooling, the inner cup is upwards rotated to be completely separated from the saline water for cooling, the space from which the saline water for cooling retreats between the inner cup and the outer cup becomes a thermal insulating layer, and the cup is covered by a cup cover so that the temperature of water in the inner cup can be thoroughly kept; and heat of the saline water for cooling is dissipated outside through the outer wall of the outer cup and is prepared for recooling. The rotation regulation fast-cooling thermal insulating cup has simple actions of selecting cooling and thermal insulating functions, and when being dissipated outside, the heat of the saline water for cooling just right warms hands of a user.

Owner:海门嘉濠建材贸易有限公司

Sand-line iron mould casting process for grey cast iron flywheel housing of diesel engine

ActiveCN102728790AGood size consistencyPut an end to the phenomenon of sand swellingFoundry mouldsFoundry coresDieselingSurface roughness

The invention discloses a sand-line iron mould casting process for grey cast iron flywheel housings of diesel engines. In the invention, upper and lower sand-line iron mould processes are used, so that produced grey cast iron flywheel housing blanks have favorable geometric size precision which can be up to CT8 grade, favorable surface roughness which can be up to 12.5 microns and favorable mechanical properties, the blank processing has small allowance which can be controlled in 3mm, small flashing distortion which can be controlled in 0.5mm and small cleaning workload, so that the labor environment is improved, the environmental protection is improved, the yield is high and can be up to 95%, and the national policies of energy conservation, environmental protection and sustainable development are met.

Owner:JIANGSU SONGLIN AUTOMOBILE PARTS

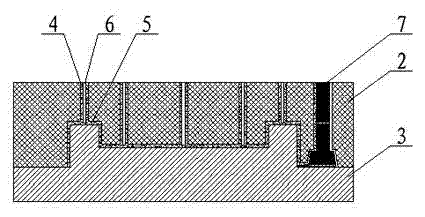

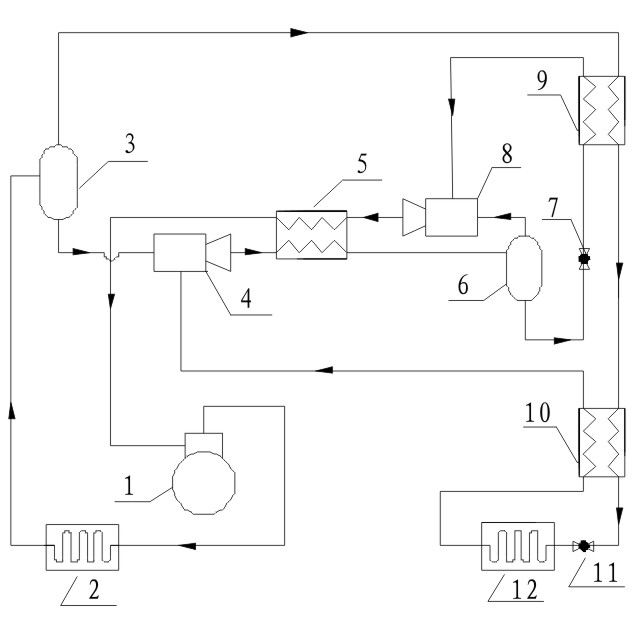

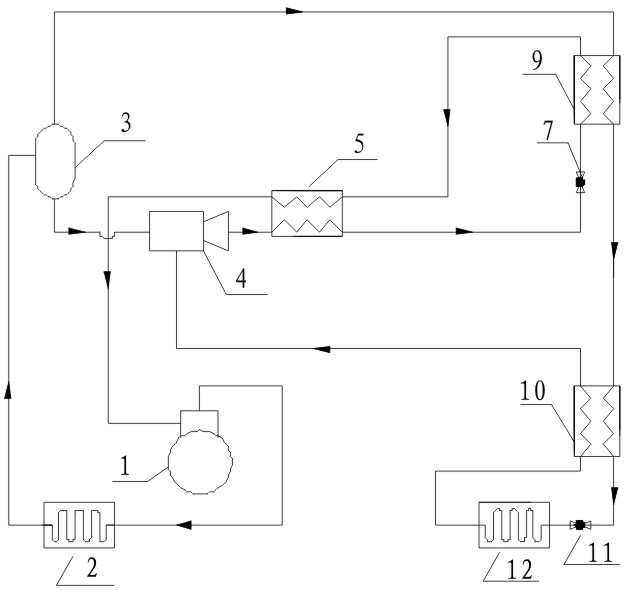

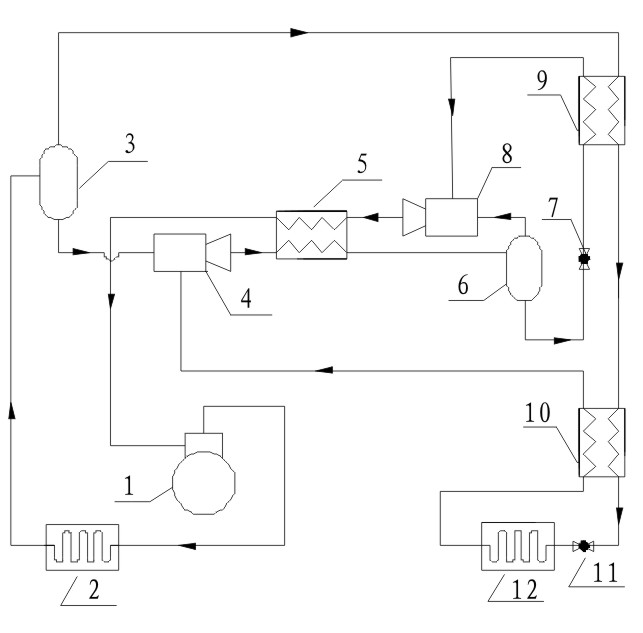

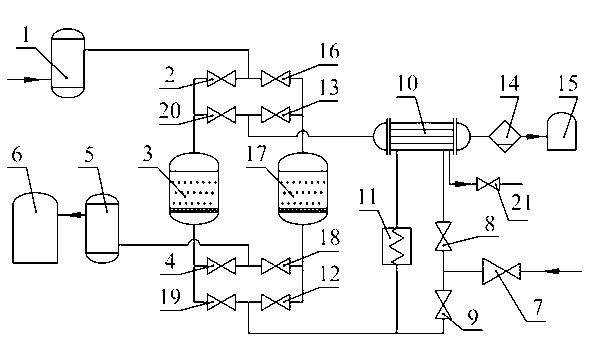

Ultra-low temperature circulation refrigeration method employing injectors

InactiveCN102003826AImprove cycle performanceIncrease inspiratory pressureCompression machinesFluid circulation arrangementVapor–liquid separatorWorking fluid

The invention relates to an ultra-low temperature circulation refrigeration method employing injectors. In the method, high-pressure mixed refrigerants compressed by a compressor (1) enter a condenser (2) and then enter a first gas-liquid separator (3) to realize gas and liquid phase separation, liquid refrigerants flowing out of the first gas-liquid separator (3) enter a first injector (4), gas and liquid two-phase mixed work media from an outlet of the first injector (4) are cooled by a first heat regenerator (5) and then enter a second gas-liquid separator (6) to be separated, work fluid of a second injector (8) is processed into low-pressure steam through a first throttling member (7) and a condensing evaporator (9), and the low-pressure steam is pressurized by the second injector (8), flows into the first heat regenerator (5) to be subjected to overheating and then flows back to the compressor (1); and gaseous refrigerants flowing out of the top of the first gas-liquid separator (3) flow into the condensing evaporator (9), are recooled through a second heat regenerator (10) and enter an evaporator (12) through a second throttling member (11) for refrigeration at low temperature, the ultra-low temperature can reach minus 40 DEG C to minus 170 DEG C, and the energy saving effect is good.

Owner:HENAN UNIV OF SCI & TECH

On-line quenching production technique for high toughness thick steel plate

InactiveCN101215624AShort production cycleLow costFurnace typesHeat treatment furnacesSteel platesQuenching

A press quenching manufacturing technique process of high strength and ductility thick steel plate belongs to low alloying steel manufacturing technique field, which comprises heating up steel billet to 1100 DEG C to 1250 DEG C, rolling steel plate through two stages of austenite recrystallization zone and non recrystallization zone with 860 DEG C to 950 DEG C of final rolling temperature, realizing steel plate press quenching through adopting two cooling ways of aerial fog and water-curtain with 25-45 DEG C / s of average cooling speed in cooling region, stopping the quenching when temperature reduced to 150 DEG C to 300 DEG C, and drawing the steel plate after quenched under high temperature. The invention overcomes the weaknesses of long productive cycle of current modified treatment method, high cost and unfavorable stability of high strength and ductility steel plate property which is manufactured by TMCP technique, and can manufacture 20mm-50mm high strength and high ductility steel plate with stable property. And the invention has the advantages of short production line and low energy consumption, which can be extensively applied to manufacture steel plate which is needed in the industries of metallurgy, petrifaction, hydroelectricity and marine and the like.

Owner:SHANDONG IRON & STEEL CO LTD

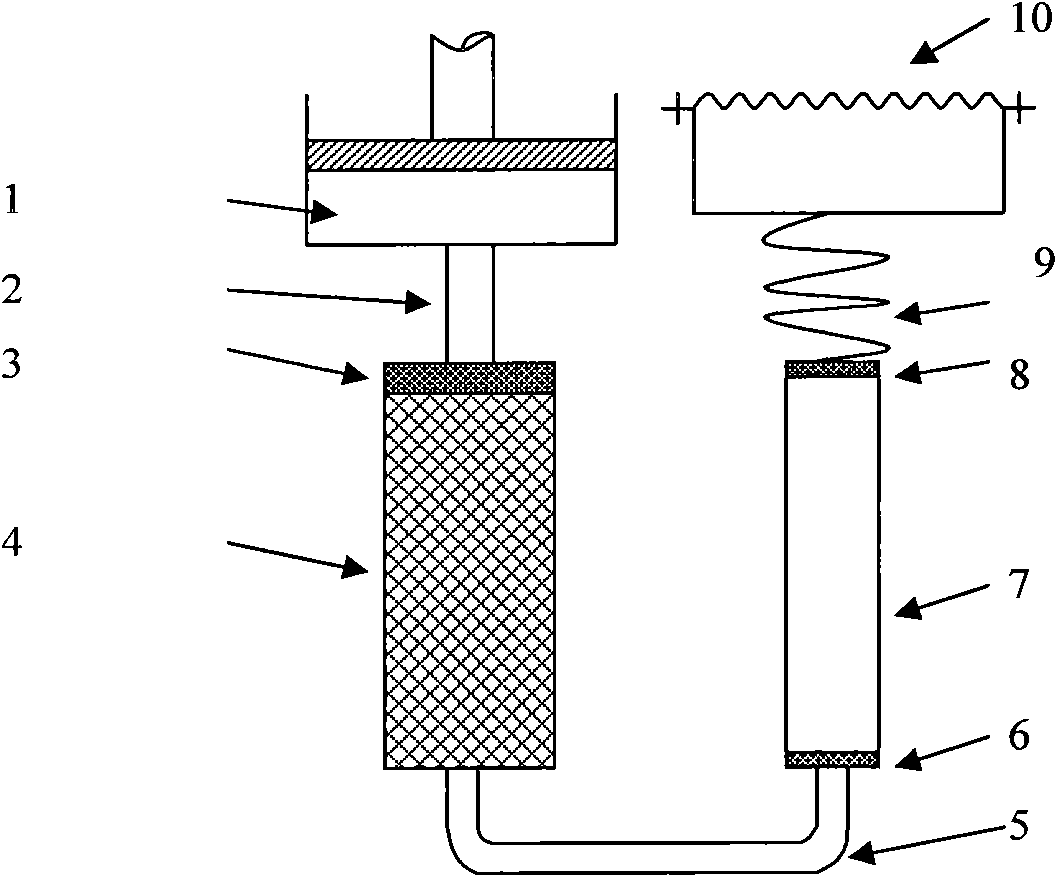

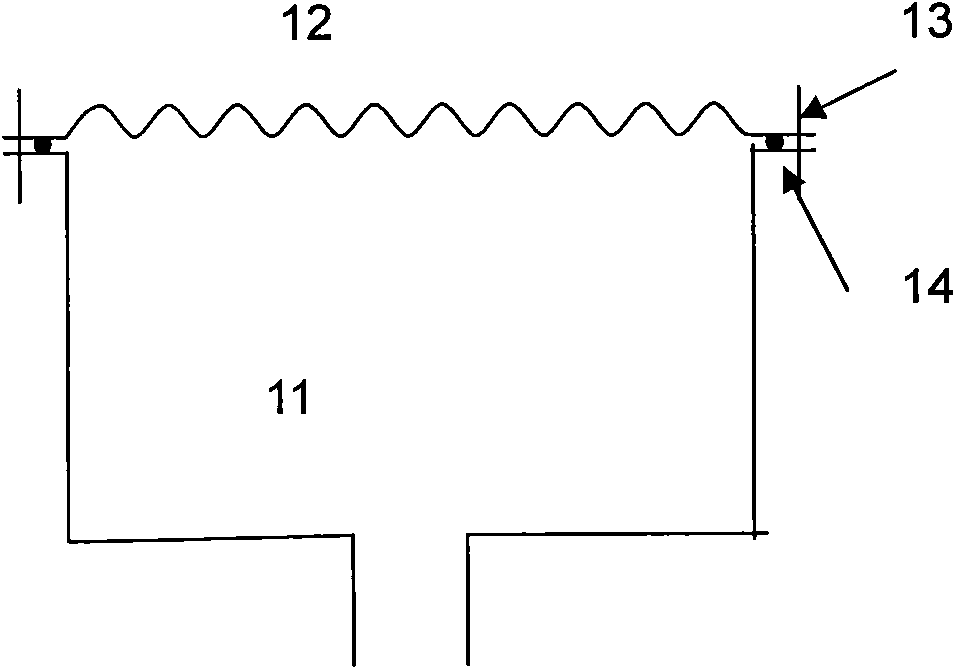

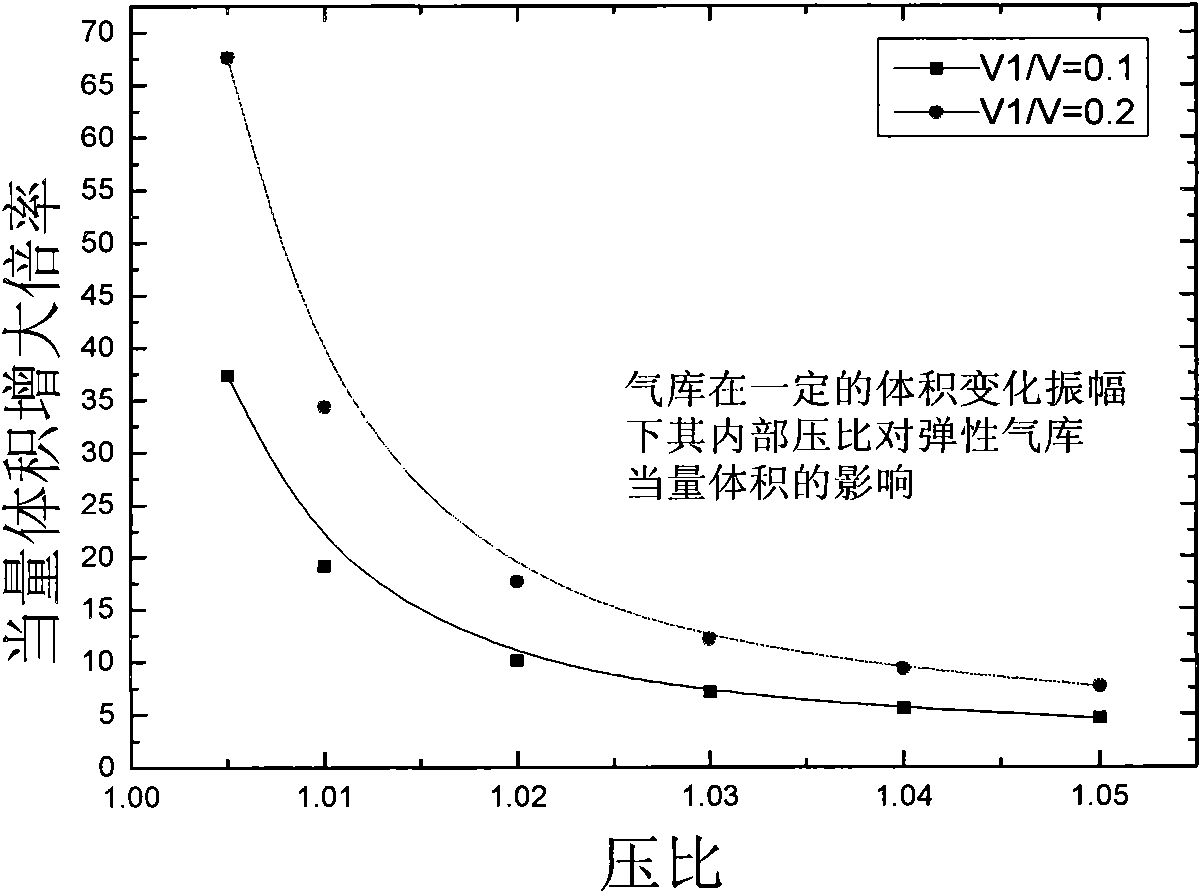

Pulse tube refrigerator with elastic air reservoir

InactiveCN101832675AShorten pre-cooling timeReduce chargeCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

The invention discloses a pulse tube refrigerator with an elastic air reservoir. The pulse tube refrigerator comprises a compressor, a transport tube, a water cooler, a heat regenerator, a cold end connecting pipe, a cold end heat exchanger, a pulse tube, a hot end heat exchanger, an inertance tube and an elastic air reservoir. The compressor is sequentially connected with the transport tube, thewater cooler, the heat regenerator, the cold end connecting pipe, the cold end heat exchanger, the pulse tube, the hot end heat exchanger, the inertance tube and the elastic air reservoir. A pulse tube refrigerator is usually provided with a huge air reservoir to obtain a better performance. The pulse tube refrigerator with the elastic air reservoir can obtain the same phase modulation effect with just a few percent of a common air reservoir in volume after employing the elastic air reservoir, so that the whole system becomes compact, and the charging quantity of working medium is reduced, which is particularly important for rare helium-4 and helium-3. As for the air reservoir in low temperature, the elastic air reservoir can shorten the cooling time and accelerate the cooling speed of a system.

Owner:ZHEJIANG UNIV

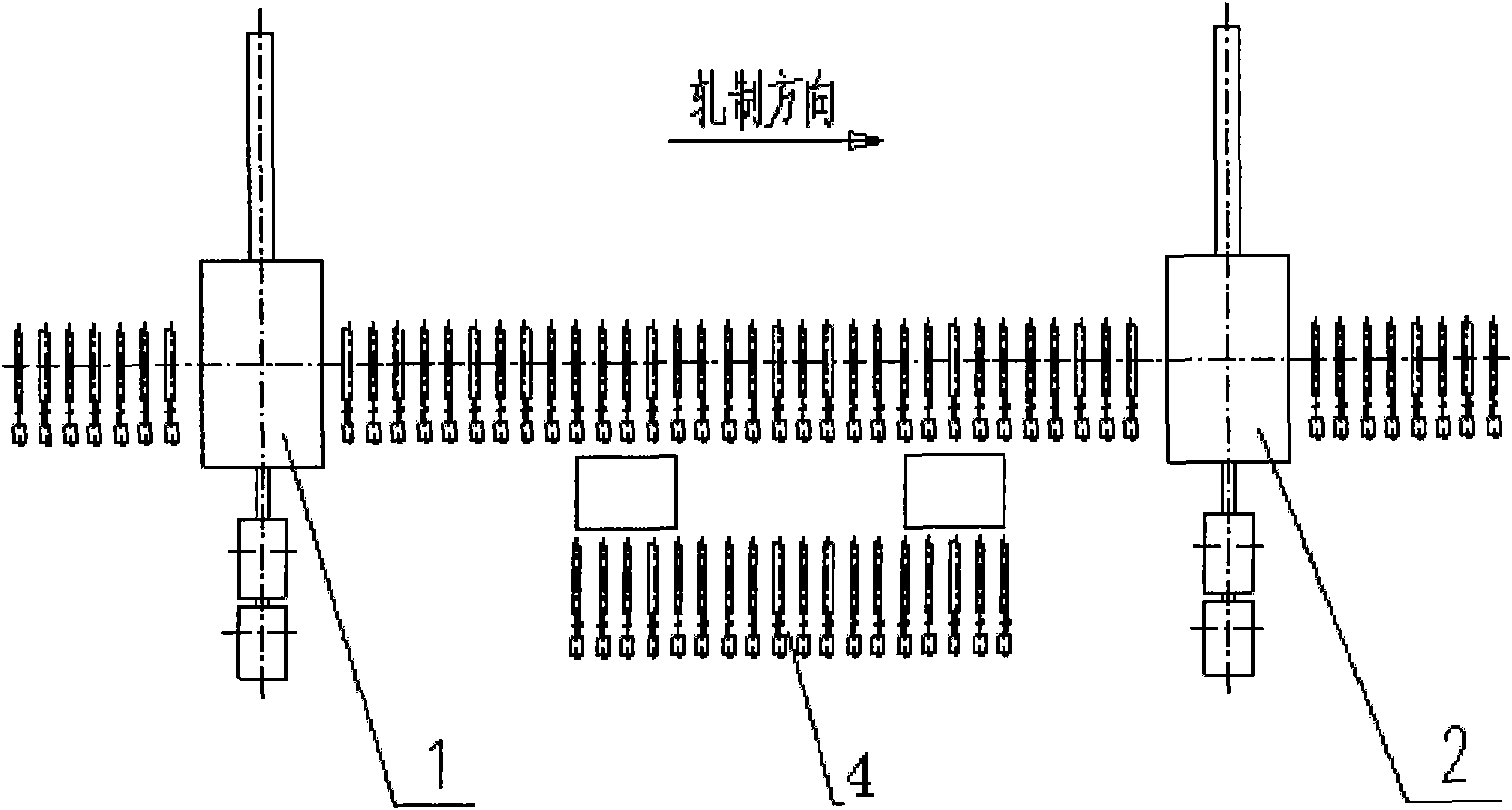

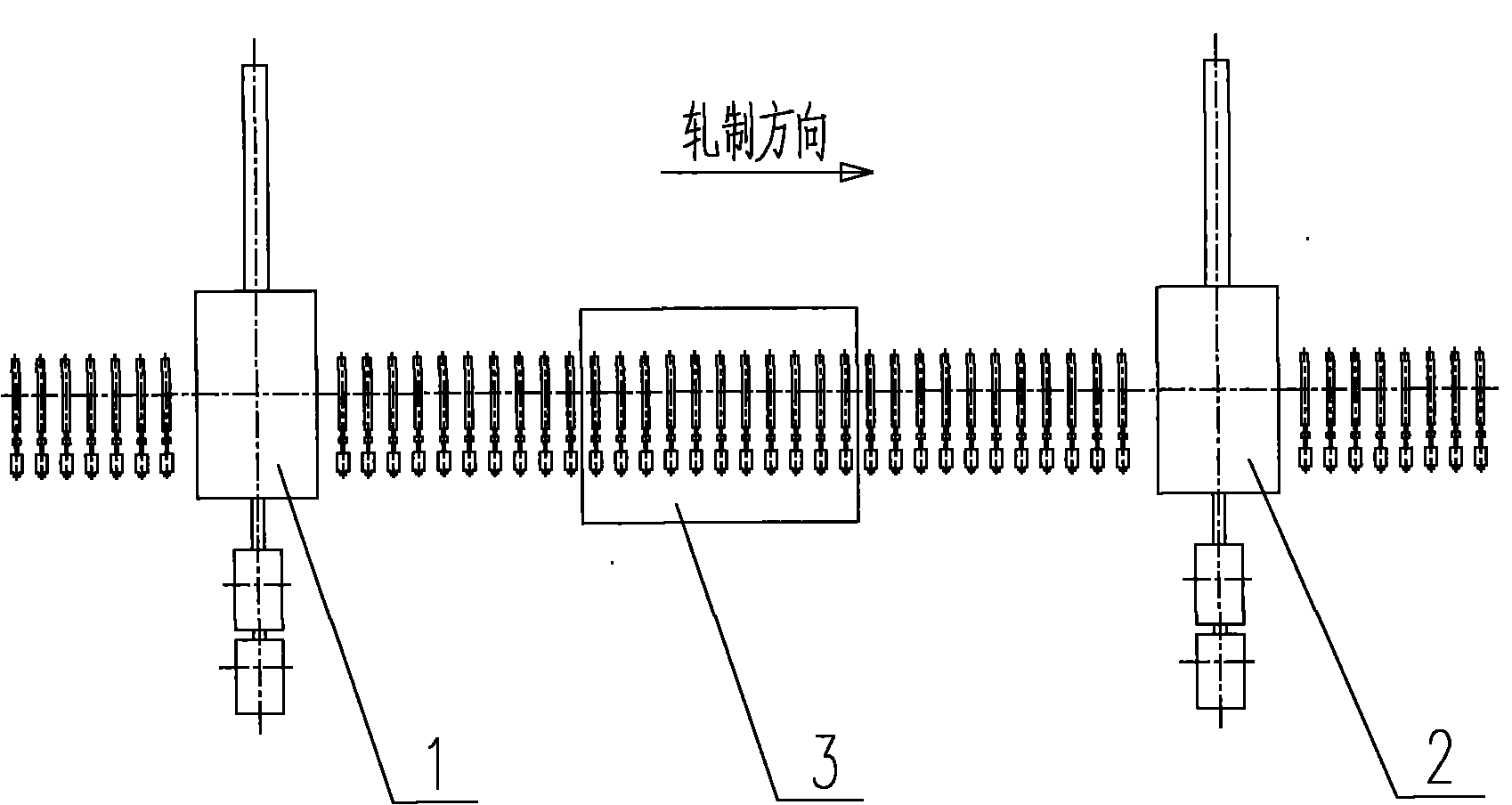

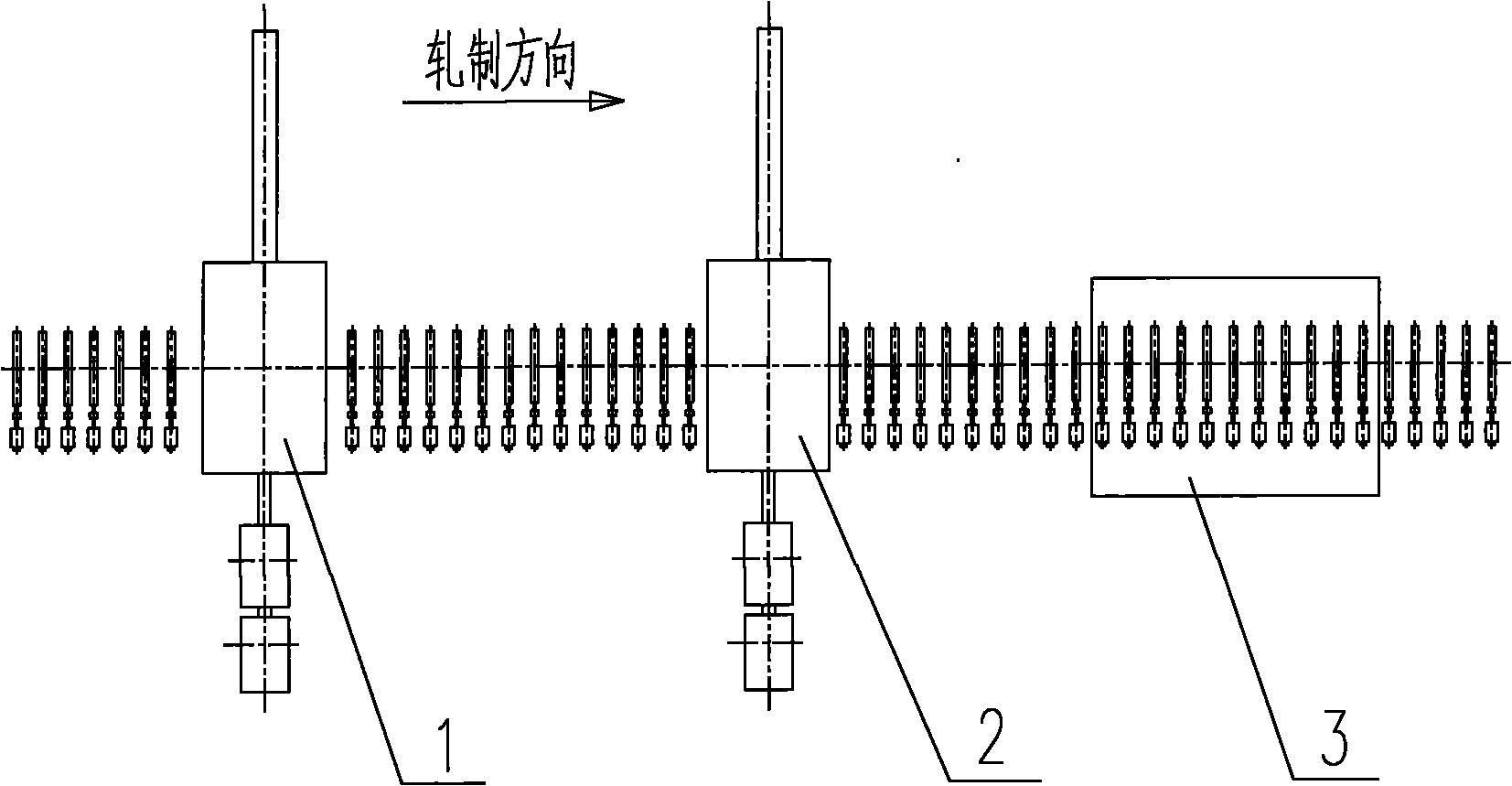

Cooling method of heavy and medium plate controlled rolling intermediate blank

InactiveCN101829688ALess investmentImprove applicabilityTemperature control deviceWater qualityWater cycling

The invention belongs to a producing and cooling technique of rolled steel, relating to a cooling method of a heavy and medium plate controlled rolling intermediate blank, which can be realized by both a single-stand heavy and medium plate roll and a double-stand heavy and medium plate roll. The cooling method comprises the following steps of: transmitting a roughly rolled intermediate blank with the thickness range of 30-110 mm in an austenite recrystallization zone into an intermediate controlled cooling zone from a transmission roller way for rapidly cooling to 800-950 DEG C, and then transmitting the intermediate blank into the roll for rolling in a non- recrystallization zone after short-time air cooling and temperature evening. In the intermediate cooling process, an upper collecting pipe and a lower collecting pipe with high density or ultra-high density are adopted to impact, jet and cool the intermediate blank, and specific technological parameters are accurately controlled by a computer. Water is cooling water for the roll with the pressure of 0.3-1.0 MPa in a common water circulating system for workshops. The intermediate cooling holding time is 30-70% shorter than that of the conventional process so that the production efficiency is improved, and due to austenite grain refinement after intermediate controlled cooling, the mechanical properties of a steel plate can be improved.

Owner:UNIV OF SCI & TECH BEIJING

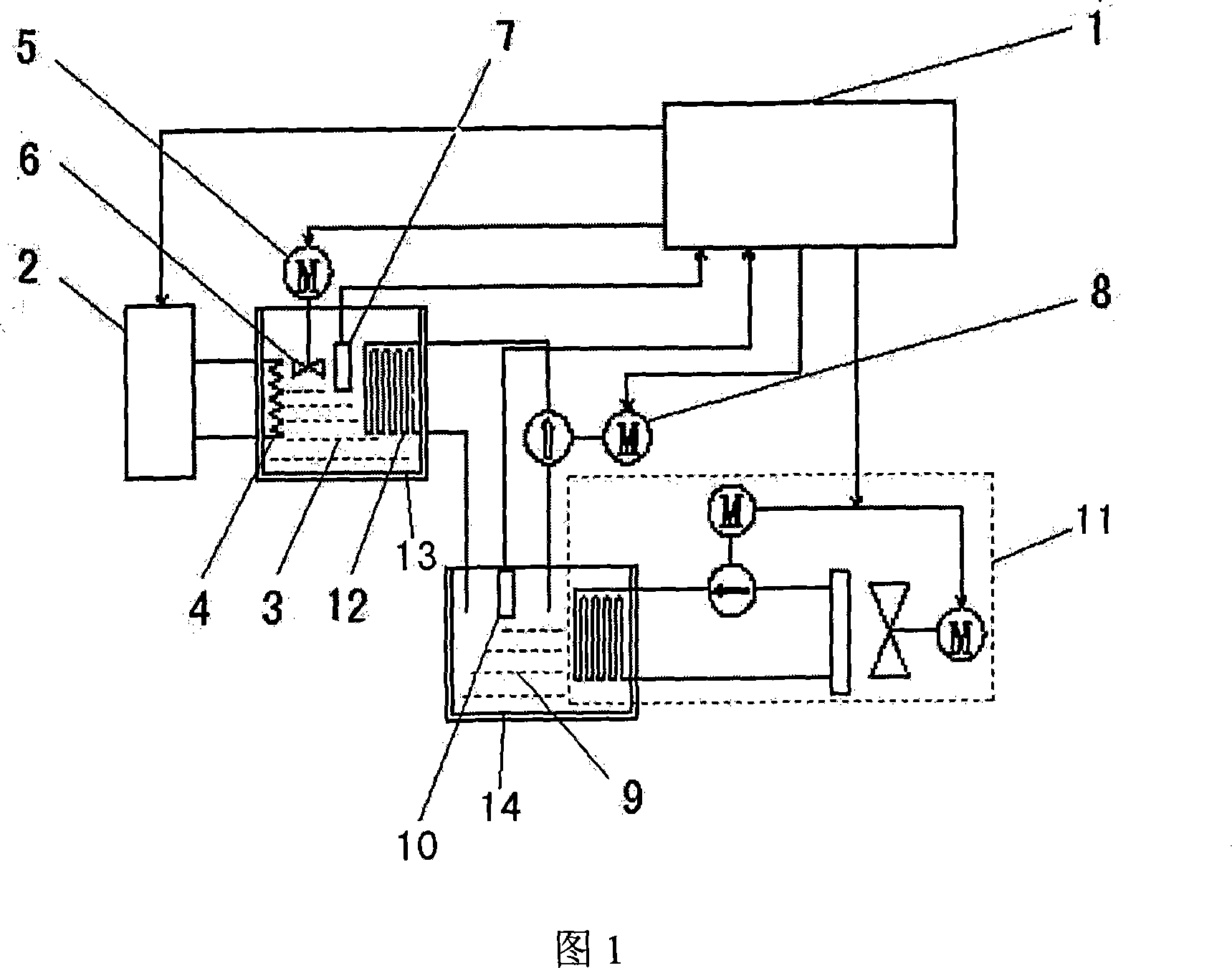

Liquid cooling cooling-down type thermostatic bath system and intelligent temperature control method

InactiveCN101219403AShorten the timeIncrease freedomWater/sand/air bathsTemperature controlEngineering

The invention relates to a liquid cooling temperature thermostatic bath system and an intelligent temperature control method thereof, comprising a cooling water tank and a cooling liquid, a liquid bath and a working liquid, and an intelligent temperature controller. The cooling water tank is provided with a water tank temperature sensor and a refrigerator, an electrical heater connected with an electrical heating executor, and a water cooler, a stirrer, a liquid bath temperature sensor, and a water inlet pipe and a water outlet pipe of the water cooler that are connected with the cooling water tank; the other end of the water inlet pipe is connected with a cooling water pump, a signal input end of the intelligent temperature controller is respectively connected with the temperature sensor of the cooling water tank and the temperature sensor of the liquid bath, while the output end is respectively connected with the electrical heating executor, a stirrer engine, the cooling water pump and the refrigerator. The system and the method can drop the temperature at a speed higher than the natural cooling by near 20 times through forced liquid cooling, and can effectively avoid the over regulating of temperature and reduce the negative impact of thermal inertia, thus greatly shortening the precision temperature controlling process and cutting down power consumption.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

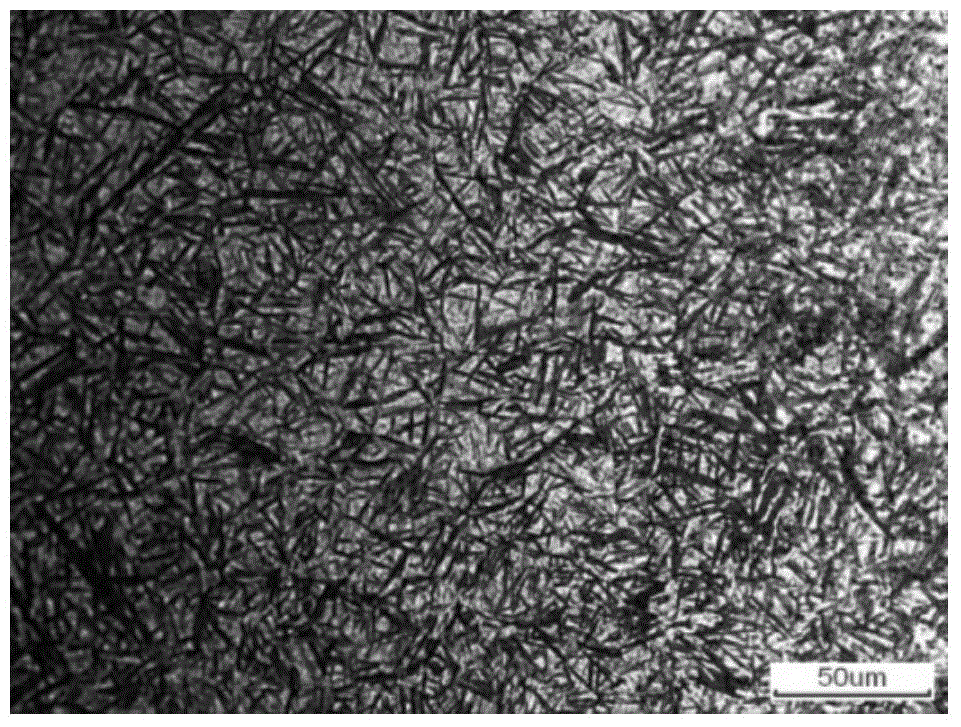

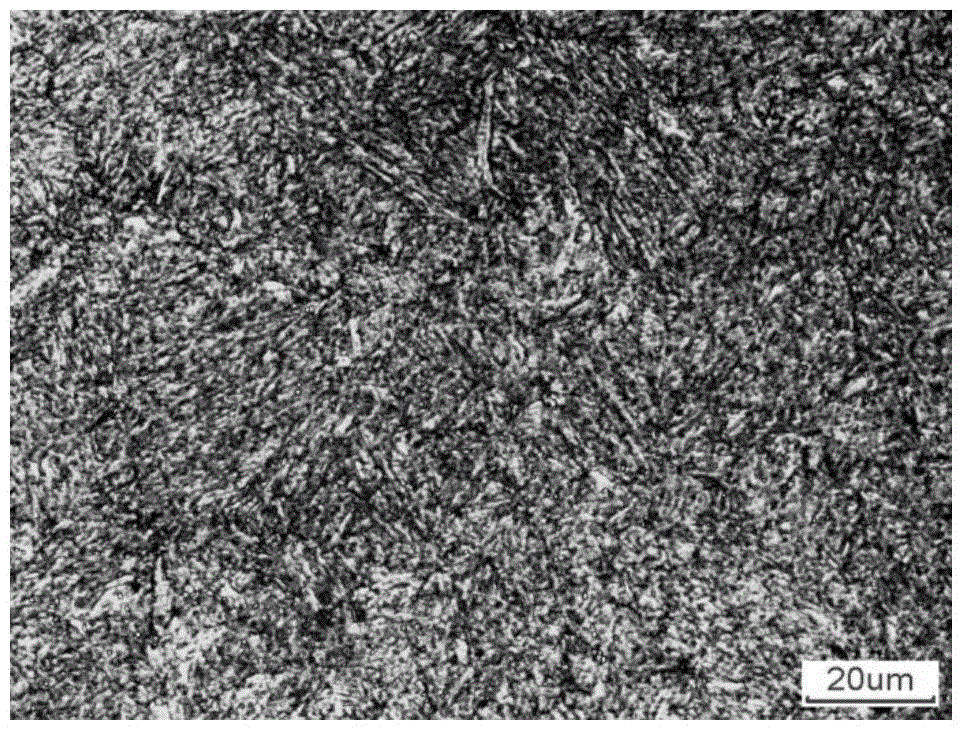

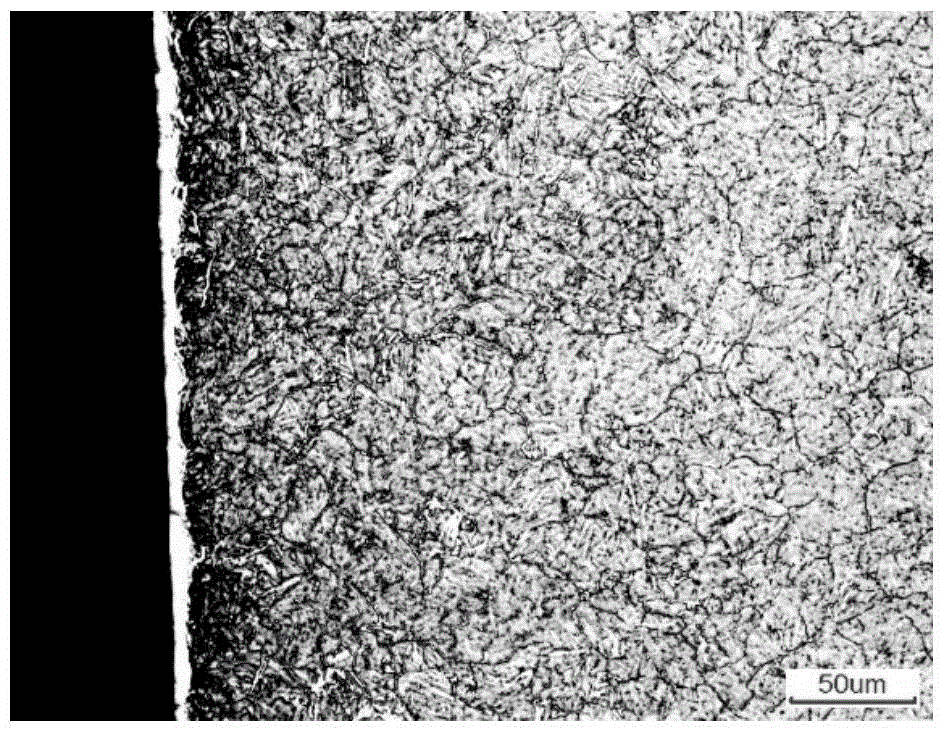

Hot stamping die steel and production method thereof

InactiveCN104928586AImprove the quality of heat treatmentImprove strength and toughnessSolid state diffusion coatingHot stampingHardness

The invention provides hot stamping die steel and a production method thereof. The hot stamping die steel is composed of, by weight, 0.45-0.50% of C, 0.1-0.3% of Si, 0.1-0.3% of Mn, 2.0-2.3% of Cr, 2.3-2.5% of Mo, 0.8-1.0% of V, smaller than or equal to 0.03% of P, smaller than or equal to 0.03% of S and the balance Fe and other inevitable impurities and meets the relational expressions that Mo / Cr=1-1.25 and V / Cr=0.35-0.43. By means of the electroslag remelting process, the ultrafine thermal treatment process, the vacuum thermal treatment process and the plasma nitriding surface treatment process, the produced and obtained hot stamping die steel is low in cost and high in comprehensive performance; the hot stamping die steel has a thermal conductivity coefficient of 34.3 W / m.k, quenching and tempering hardness of 50-53 HRC, ballistic work of 180-210 J, surface hardness of 850-1040 HV0.3 and diffusion thickness of 230-300 microns, and a white bright layer is ceaseless after nitriding.

Owner:BAOSHAN IRON & STEEL CO LTD

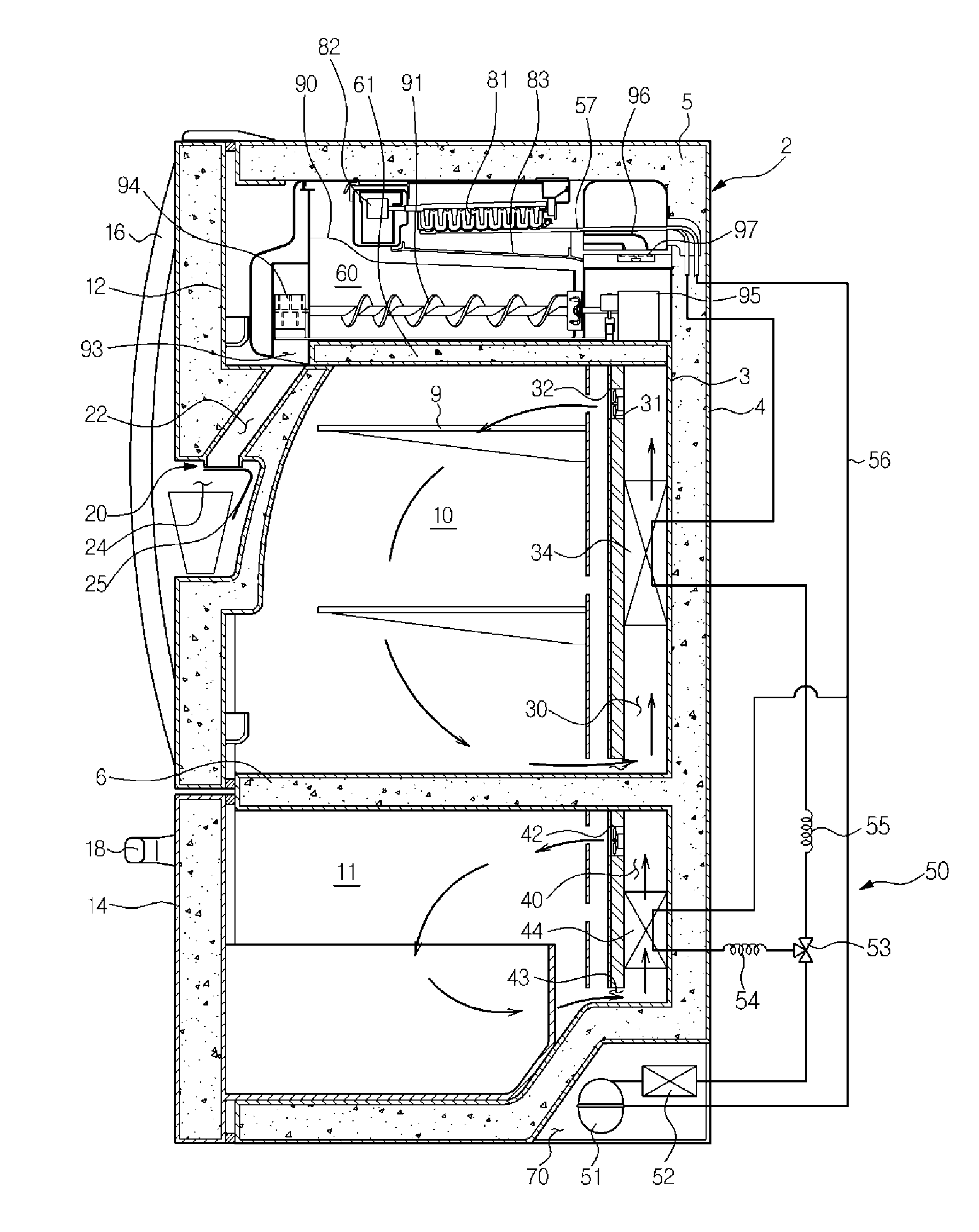

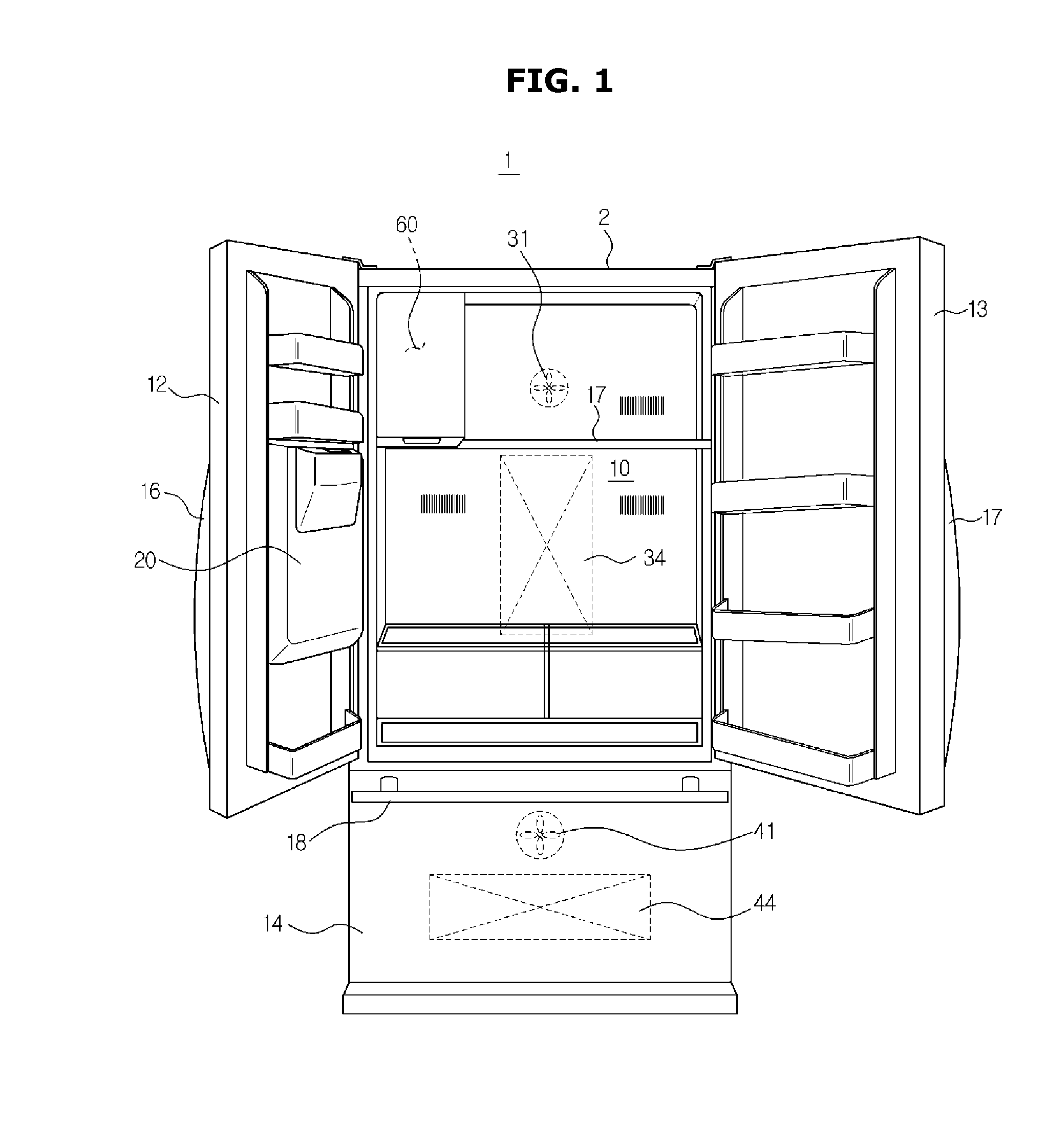

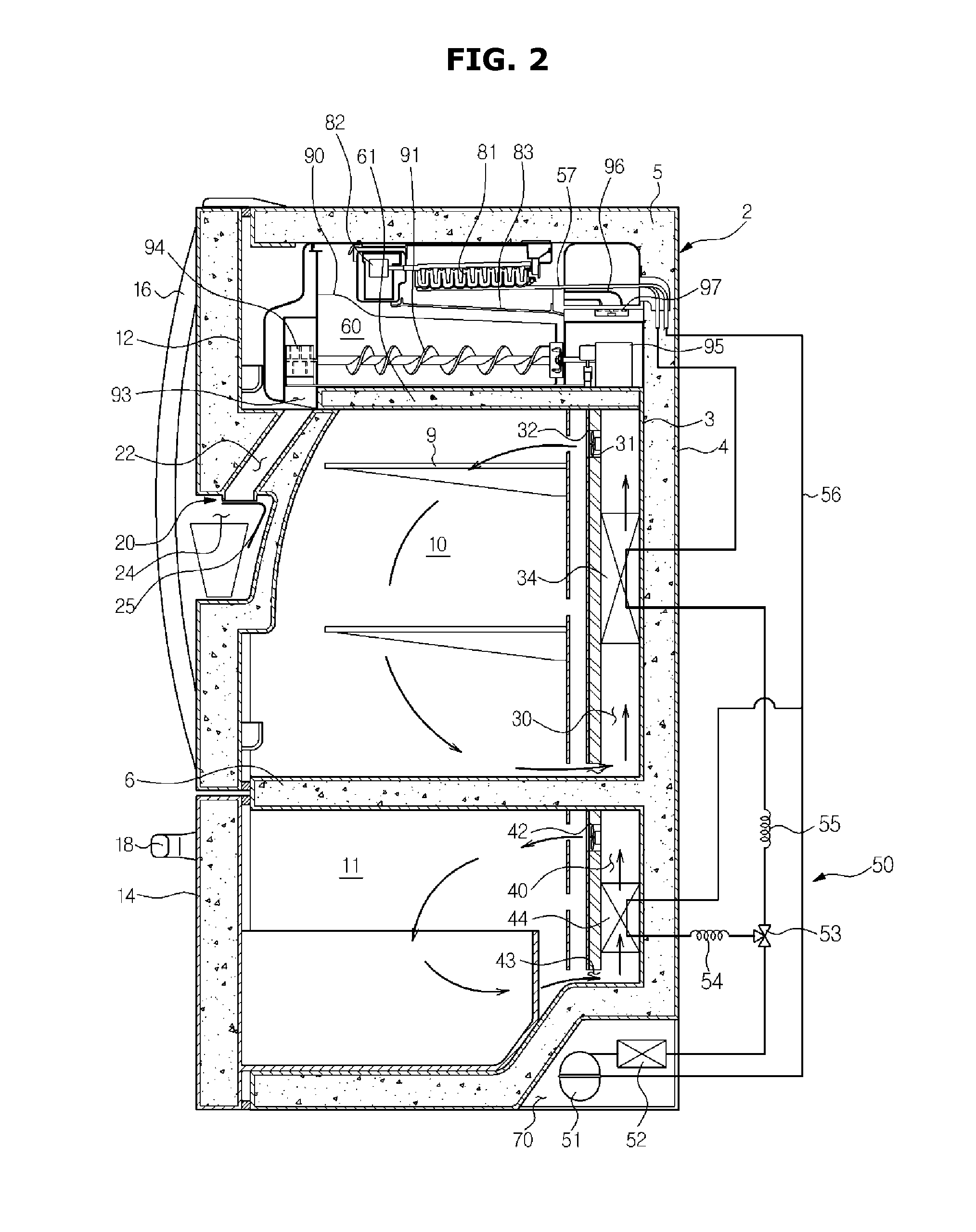

Ice-making tray and refrigerator comprising same

ActiveUS20160245574A1High transparencyShorten speedLighting and heating apparatusIce productionIce waterPlastic materials

An ice-making tray according to the concept of the present invention is capable of making ice at high speed and improving the transparency of ice by providing a second tray having ice cells for storing ice-making water to be coupled, in an overlapping manner, to the upper surface of a first tray which is in contact with a refrigerant pipe. The first tray may be formed of an aluminum material, the second tray may be formed of a plastic material, and the first tray formed of an aluminum material can efficiently function as a heat exchanger of an ice-making space due to having high thermal-conductivity. In the second tray, a fixing part for fixing the ice-making tray inside the ice-making space, a shaft accommodating part for accommodating the rotation shaft of an ejector, a temperature sensor accommodating part for accommodating a temperature sensor, and an air insulating part for insulating the ice-making tray and an ice separating motor may be formed integrally.

Owner:SAMSUNG ELECTRONICS CO LTD

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

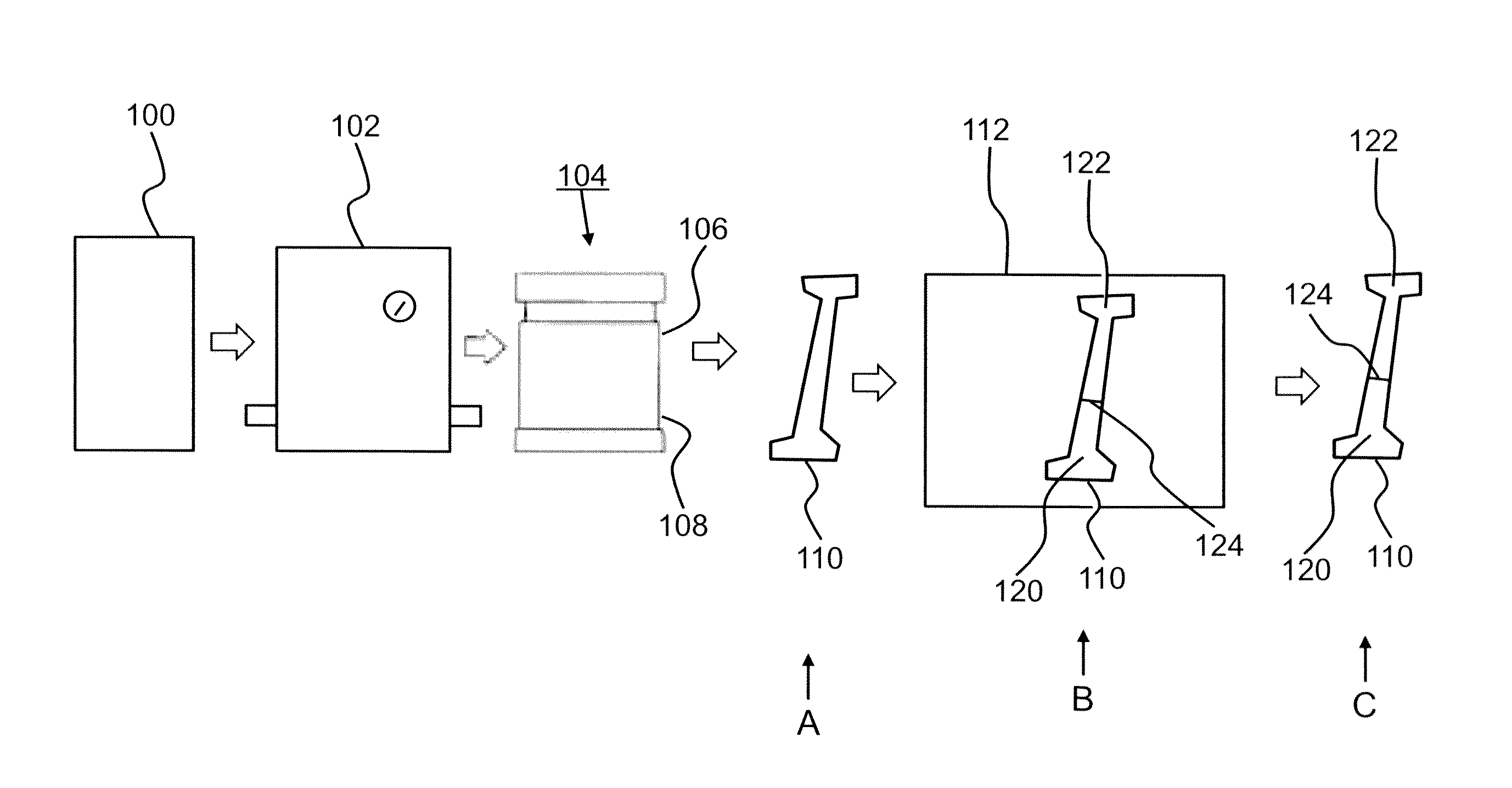

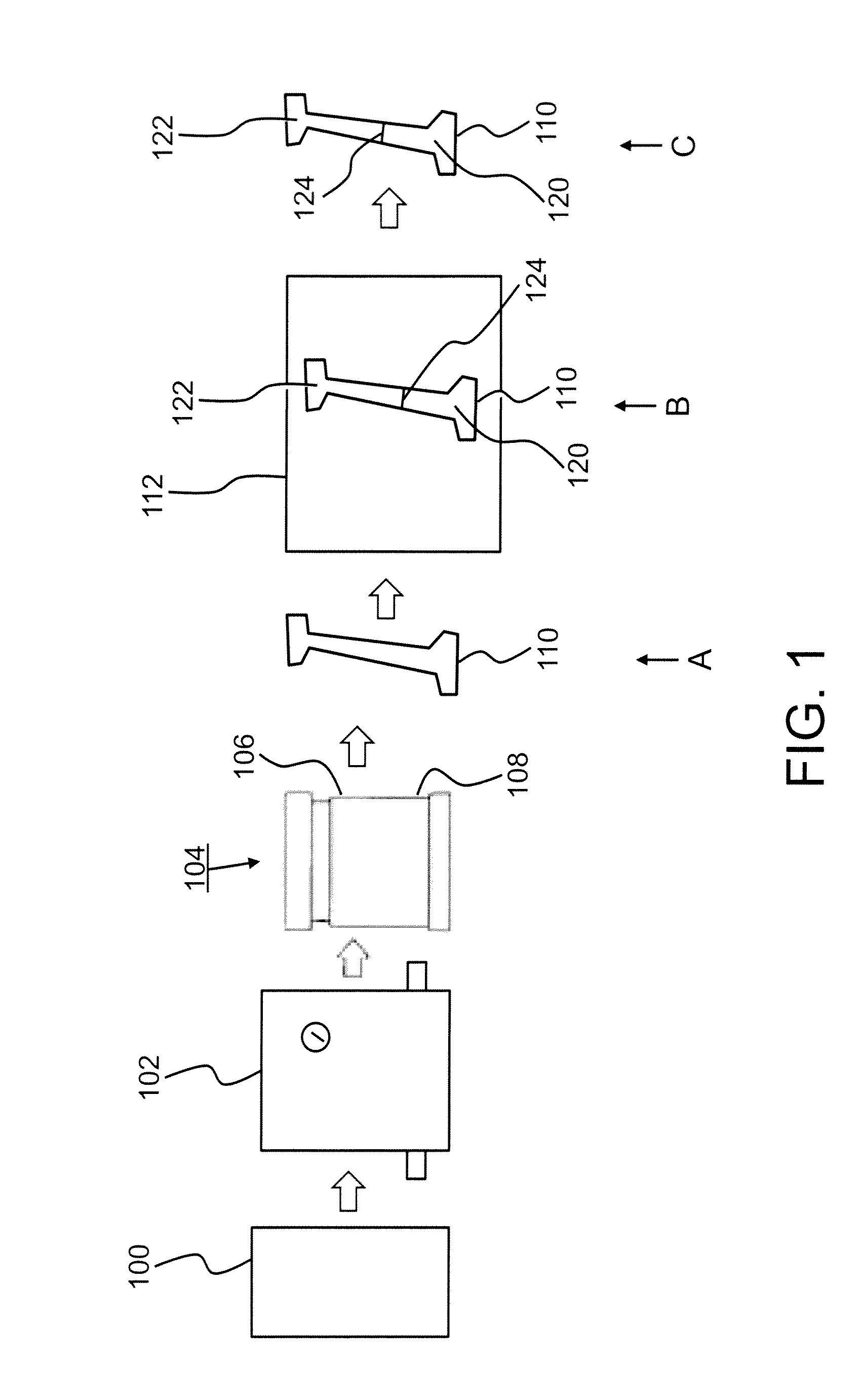

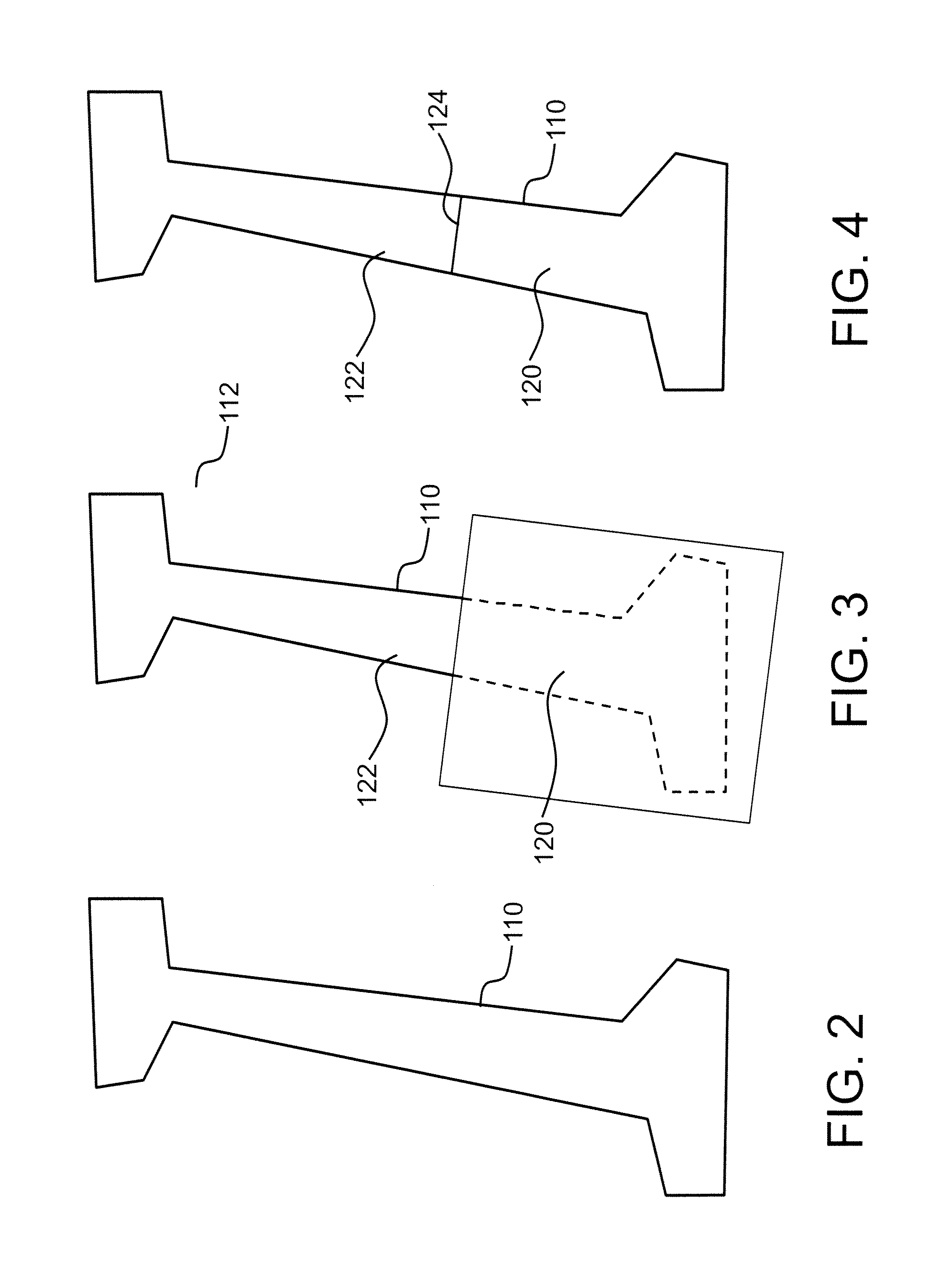

Tailored Properties By Post Hot Forming Processing

InactiveUS20110315281A1Uniform first tensile strengthFast coolingSuperstructure subunitsSteering controlsRegioselectivityForm processing

A method of forming a product from an initial blank comprises subjecting the initial blank to a hot forming and press hardening operation to form the product with substantially a uniform first tensile strength. Subsequently, the product is subjected to post hot-forming processing in which a first region of the product is heated selectively to above a known temperature, using one of conduction heating, resistance heating, and induction heating. The first region is then cooled, such that the first region attains a second tensile strength that is substantially less than the first tensile strength.

Owner:MAGNA INTERNATIONAL INC

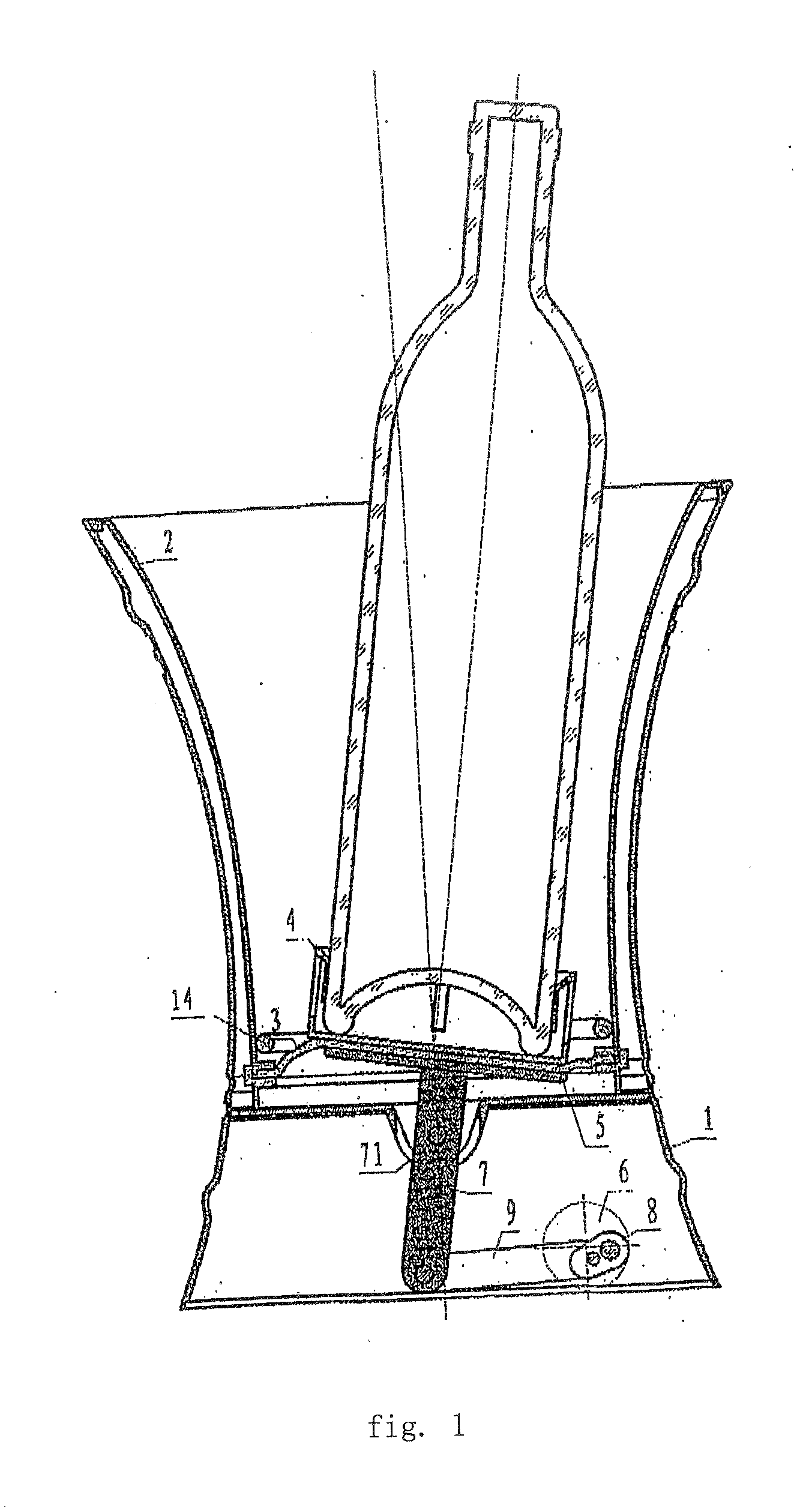

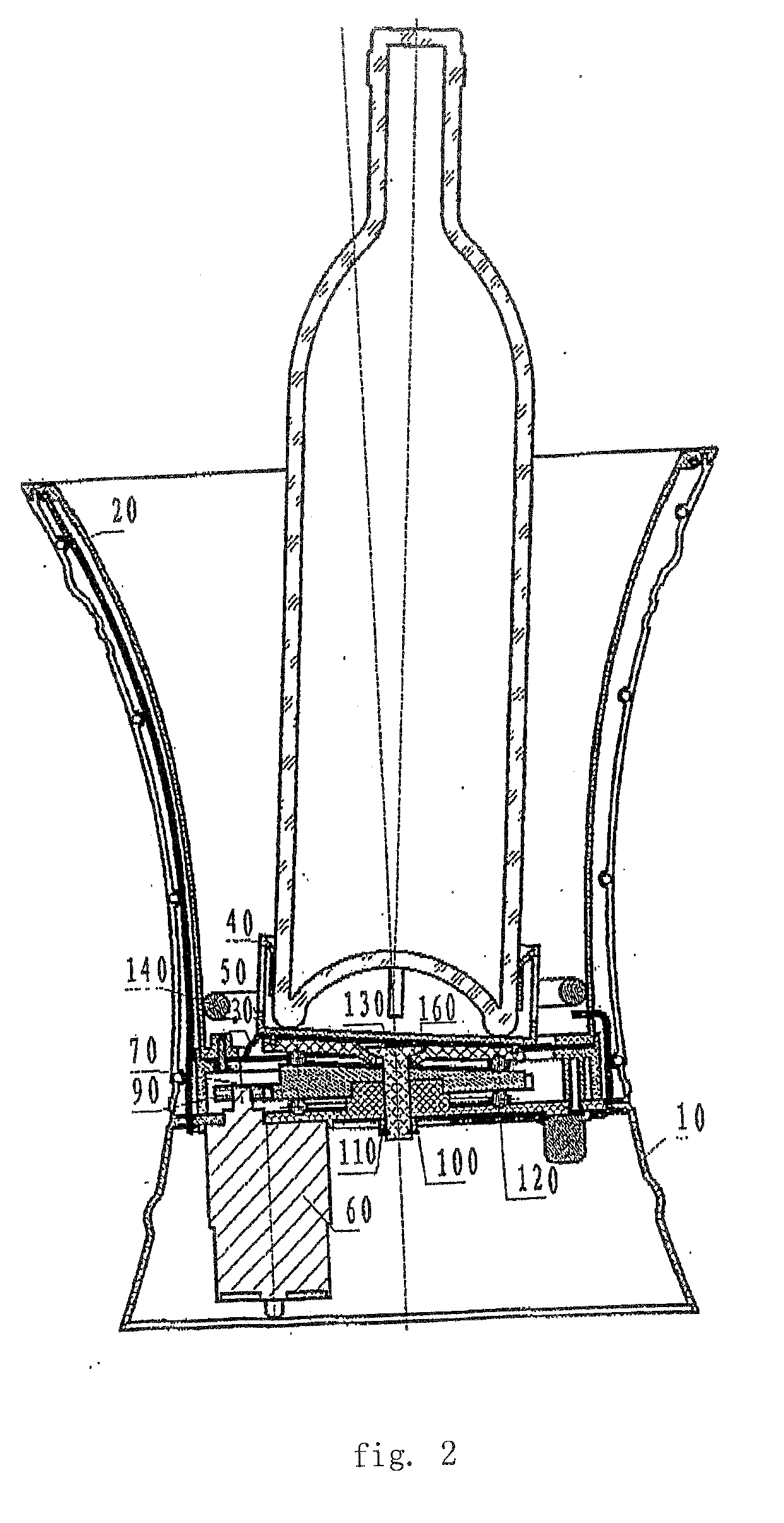

Drink Swinging Apparatus

InactiveUS20080304356A1Improve visual senseAdds interest and joynessRotating receptacle mixersShaking/oscillating/vibrating mixersElectric machineryBreathing

Owner:ZHUANG MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com