Patents

Literature

48results about How to "Shorten pre-cooling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

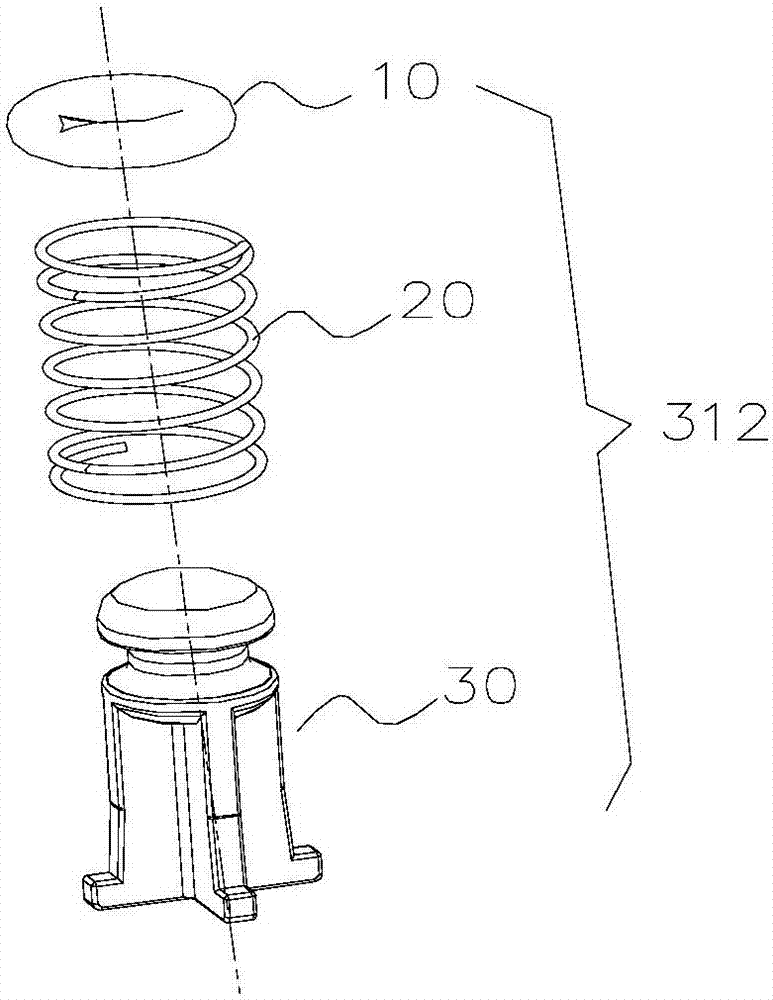

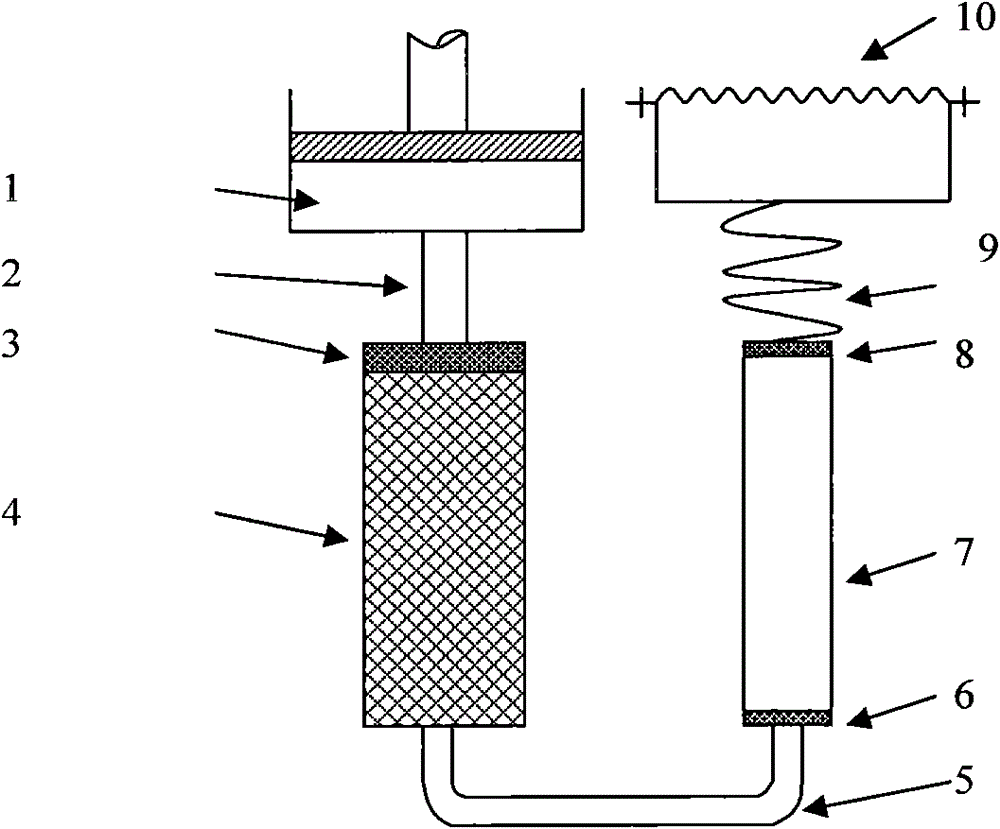

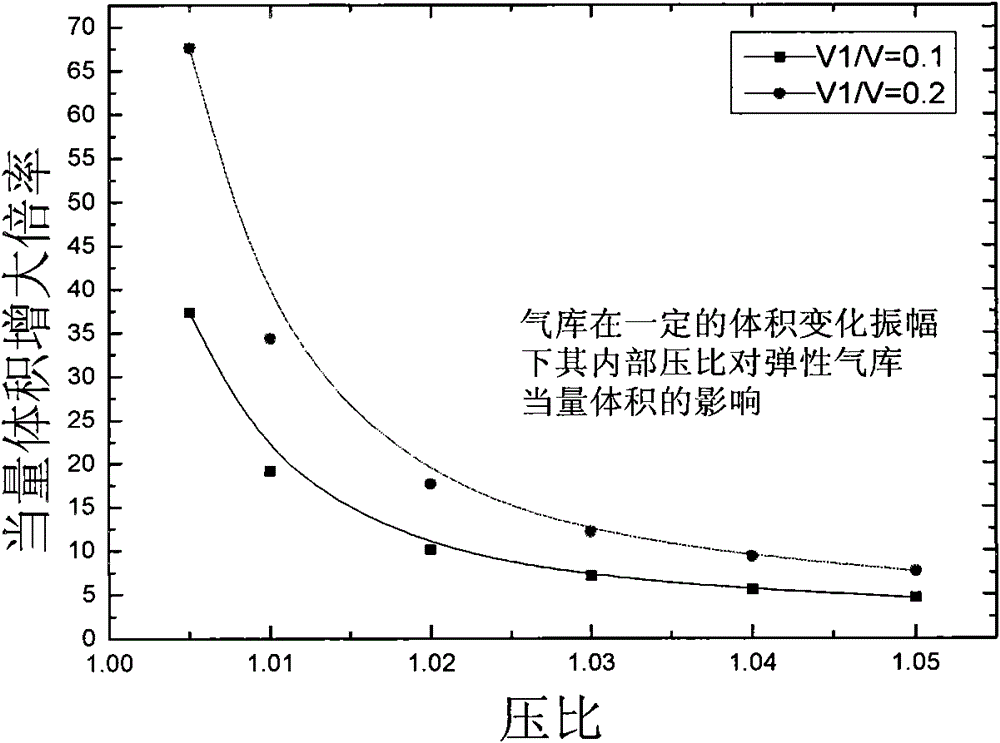

Pulse tube refrigerator with elastic air reservoir

InactiveCN101832675AShorten pre-cooling timeReduce chargeCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

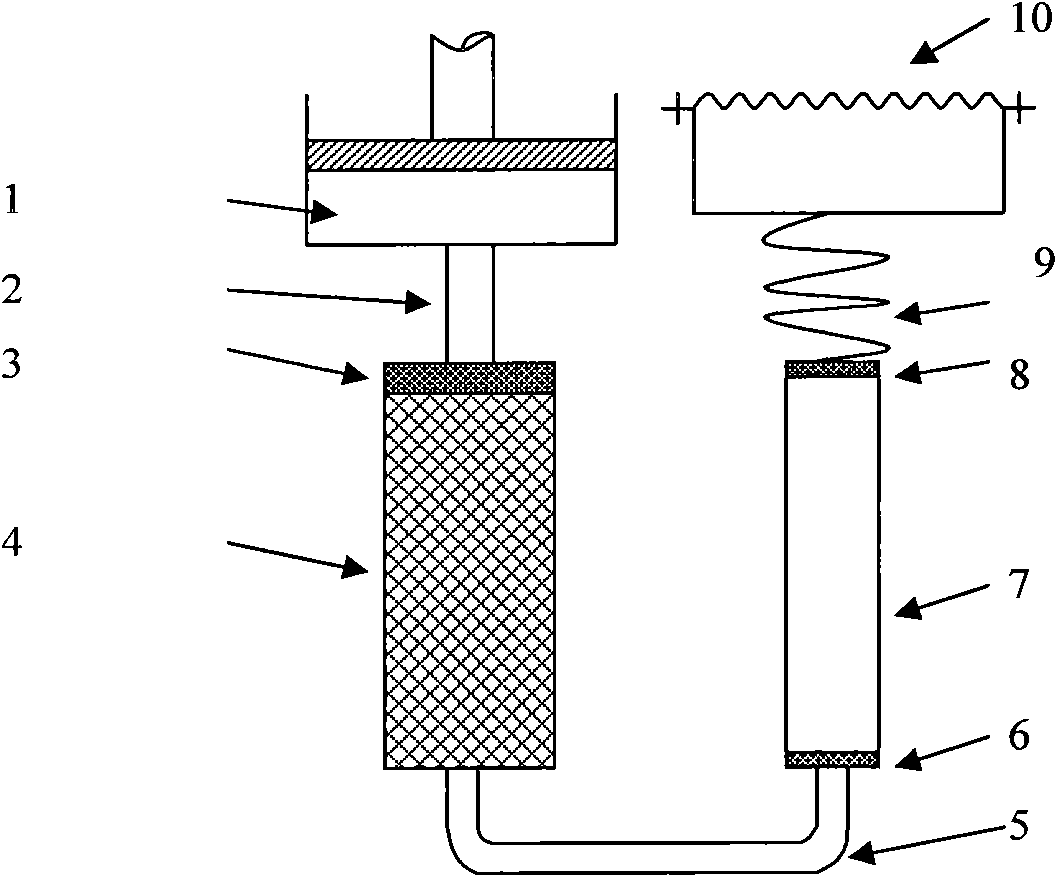

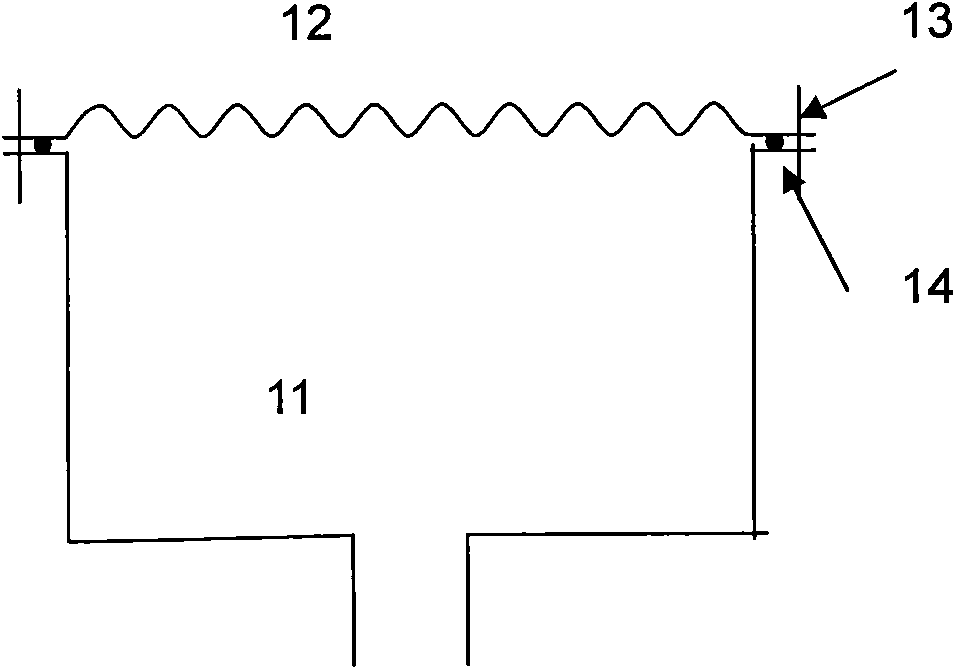

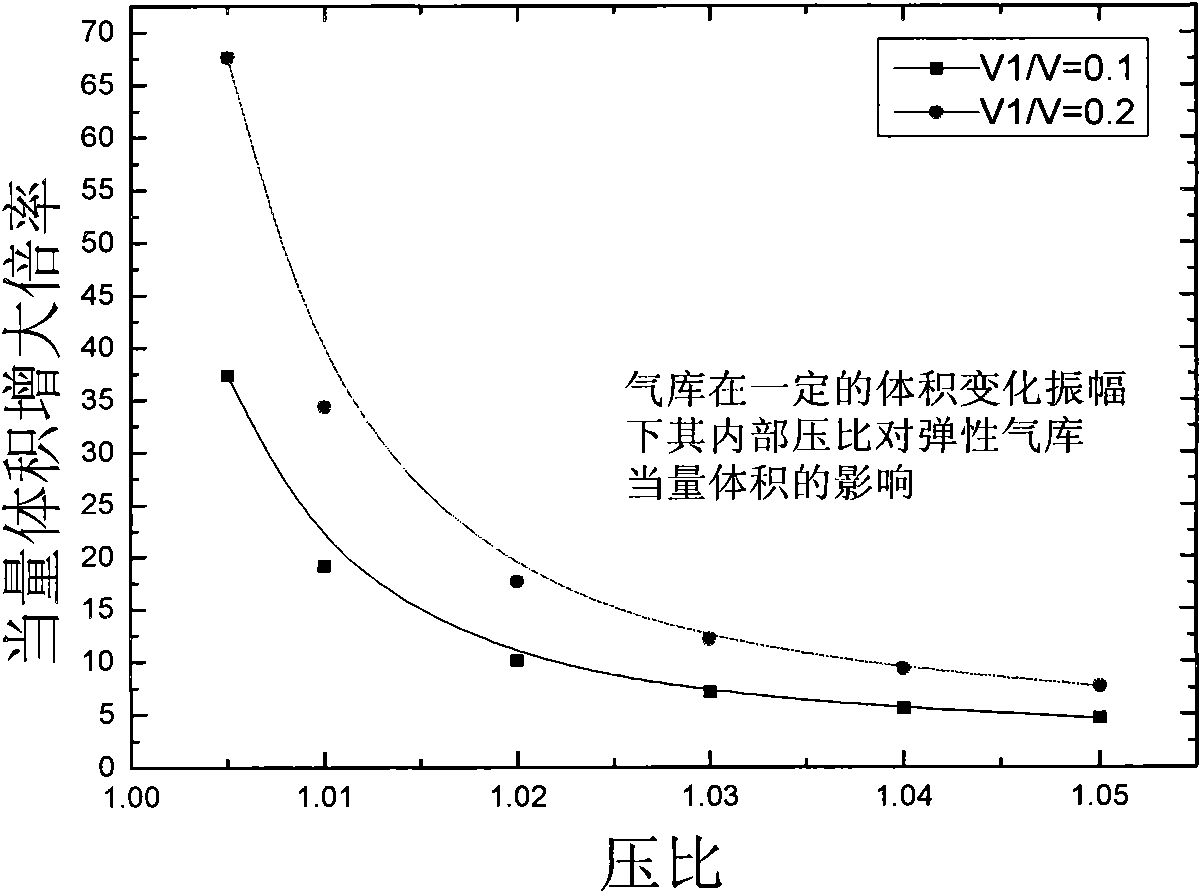

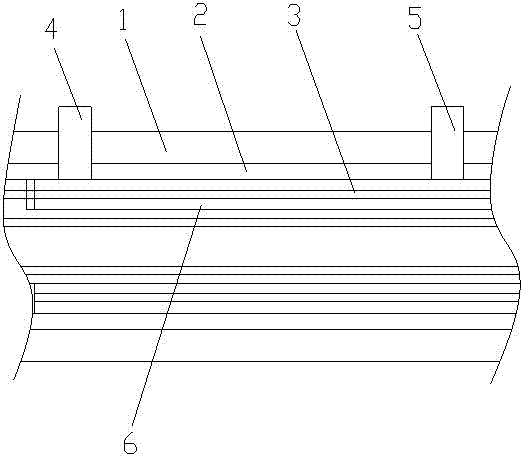

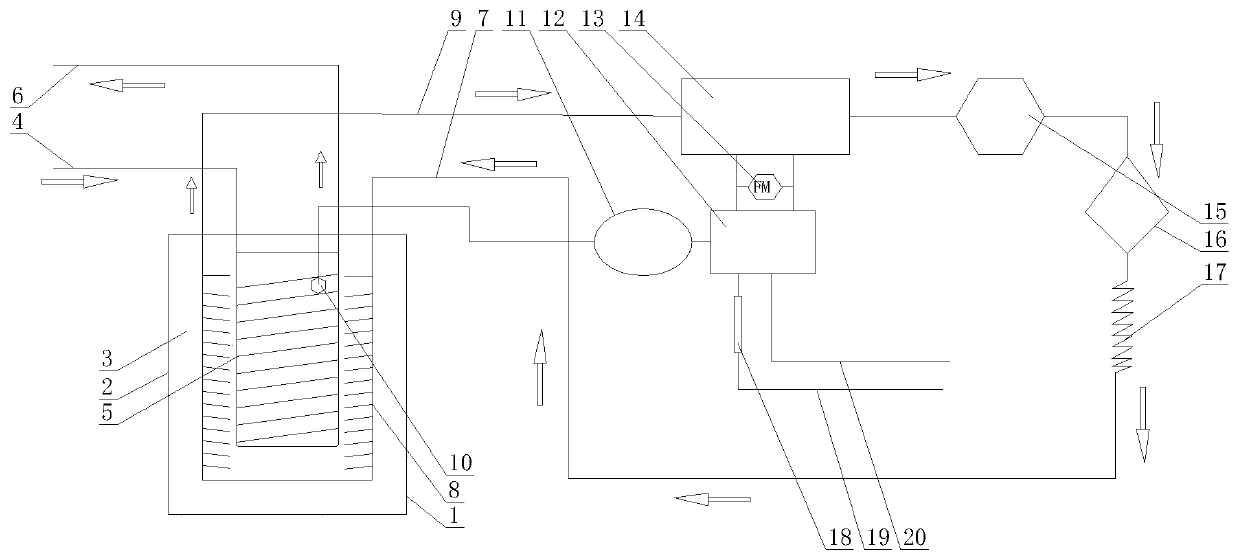

The invention discloses a pulse tube refrigerator with an elastic air reservoir. The pulse tube refrigerator comprises a compressor, a transport tube, a water cooler, a heat regenerator, a cold end connecting pipe, a cold end heat exchanger, a pulse tube, a hot end heat exchanger, an inertance tube and an elastic air reservoir. The compressor is sequentially connected with the transport tube, thewater cooler, the heat regenerator, the cold end connecting pipe, the cold end heat exchanger, the pulse tube, the hot end heat exchanger, the inertance tube and the elastic air reservoir. A pulse tube refrigerator is usually provided with a huge air reservoir to obtain a better performance. The pulse tube refrigerator with the elastic air reservoir can obtain the same phase modulation effect with just a few percent of a common air reservoir in volume after employing the elastic air reservoir, so that the whole system becomes compact, and the charging quantity of working medium is reduced, which is particularly important for rare helium-4 and helium-3. As for the air reservoir in low temperature, the elastic air reservoir can shorten the cooling time and accelerate the cooling speed of a system.

Owner:ZHEJIANG UNIV

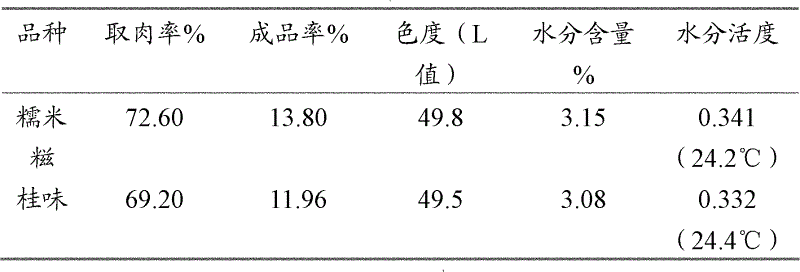

Fruit vacuum freeze drying method

ActiveCN102613283AInhibition of dissolutionSolution volumeFruit and vegetables preservationFreeze-dryingProcess engineering

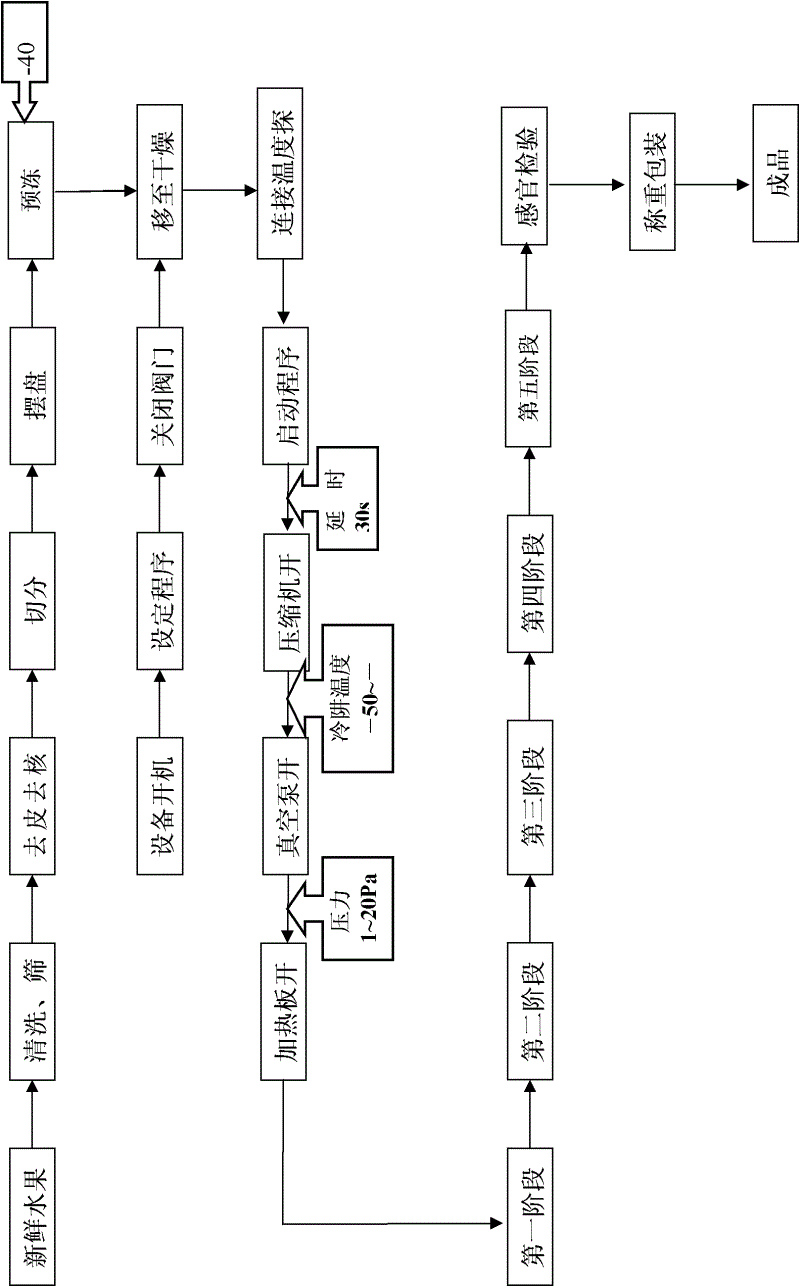

The invention which is suitable for the technical field of drying provides a fruit vacuum freeze drying method. The method comprises the following steps: prefreezing: refrigerating fruits to be dried; and carrying out five-stage drying under vacuum conditions. The fruit vacuum freeze drying method of the invention, which adopts a five-step gradient cooling mode of the heating temperature, allows heat required by water sublimation to be guaranteed, cooling to be timely, the basic balance of the heat supply and demand to maintained, the material dissolving caused by too fast heating to be prevented, and the water sublimation rate to be accelerated.

Owner:SHENZHEN POLYTECHNIC

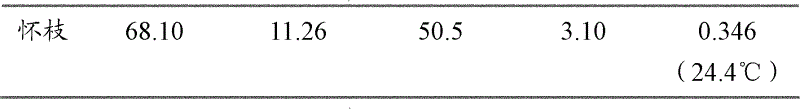

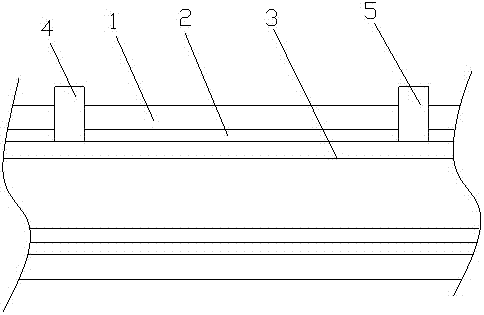

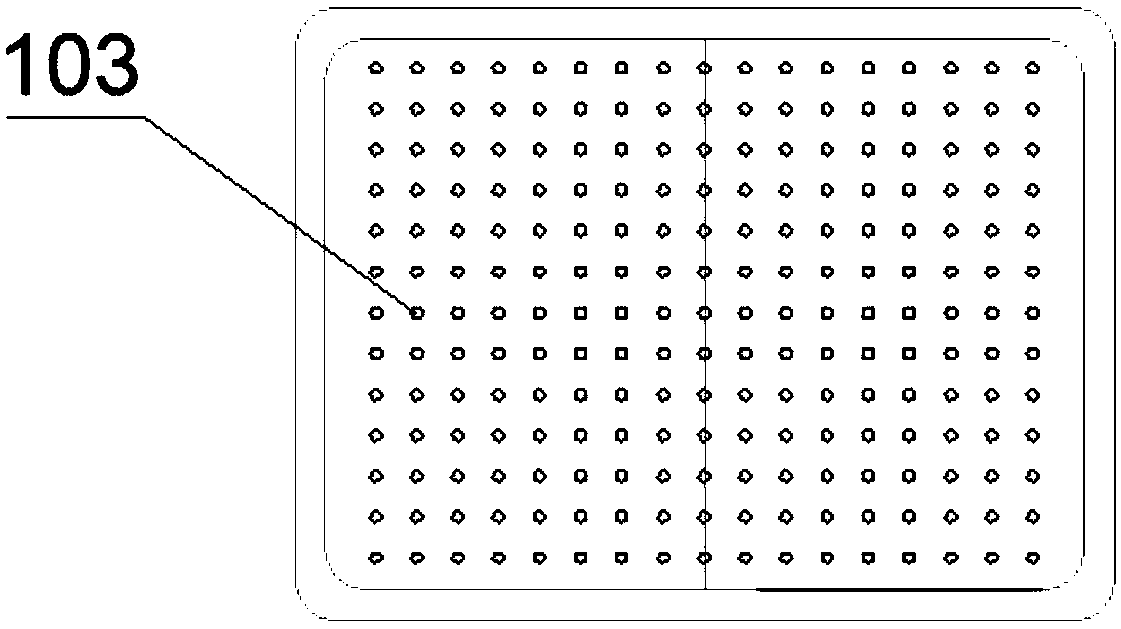

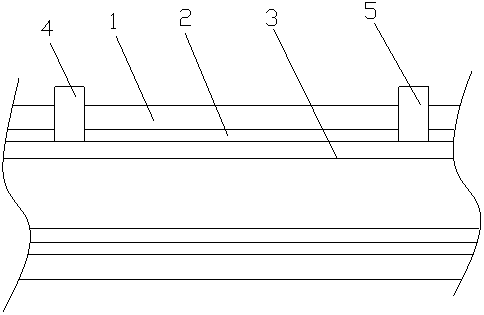

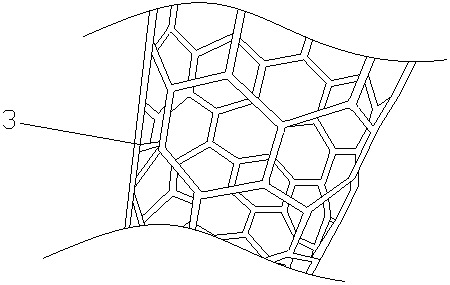

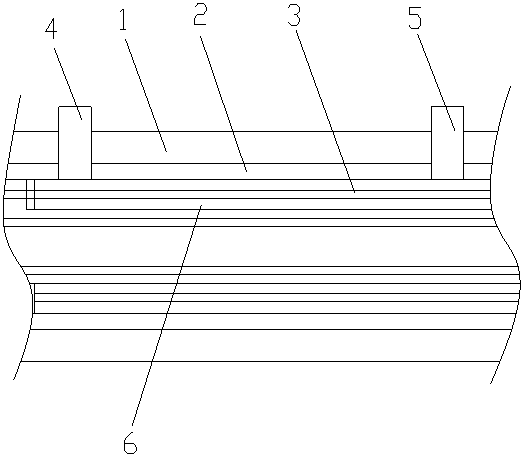

Superconducting cable

ActiveCN107103958AImprove heat exchange performanceShorten pre-cooling timeSuperconductors/hyperconductorsSuperconductor devicesEngineeringNitrogen

The invention discloses a superconducting cable. The cable comprises an external wrapping insulating protective layer, a conduit arranged in the external wrapping insulating protective layer and a superconductor arranged in the conduit, the conduit is provided with a nitrogen inlet tube and a nitrogen outlet tube, both the nitrogen inlet tube and the nitrogen outlet tube penetrate the external wrapping insulating protective layer, and the superconductor is of a hexagonal grid type and forms a tubular spatial topology structure. Precooling time, before use, of the superconducting cable is short.

Owner:广州市壹缆电缆实业有限公司

Hollow packaging box made of high-concentration ozone ice crystals

InactiveCN103318546AEffective control over decompositionEnhanced inhibitory effectLiving organism packagingFood preservationHigh concentrationPesticide residue

The invention discloses a hollow packaging box made of high-concentration ozone ice crystals, aiming to overcome defects that normal ice can only cool and suppress breeding of microorganisms and viruses and bacteria attached on surfaces of storages but cannot sterilize the same, and storages are short in preservation period, high in loss and poor in quality due to the fact that the ozone component in ozone ice is easy to decompose. The hollow packaging box made of the high-concentration ozone ice crystals comprises an ice-crystal made packaging box body, an ice-crystal made packaging box cover and an ozone and water solution pouring inlet. By utilizing double functions of bacterium inhibition and sterilization of the ozone component in the hollow ice crystals and an aseptic environment in a closed semi-vacuum state, the design purposes of prolonging the preservation period of the storages and improving green quality thereof are achieved. The hollow packaging box made of the high-concentration ozone ice crystals has the advantages of providing a proper environment capable of killing the microorganisms, viruses and moulds, decomposing harmful components, such as hormone, antibiotics, additives, pesticide residues, heavy metal, containing in the storages, and leading to the dormancy state of the storages within a short time, shortening the precooling time, prolonging the preservation period without any preservatives, improving green quality and being recycled.

Owner:辽宁自然冰科技有限公司

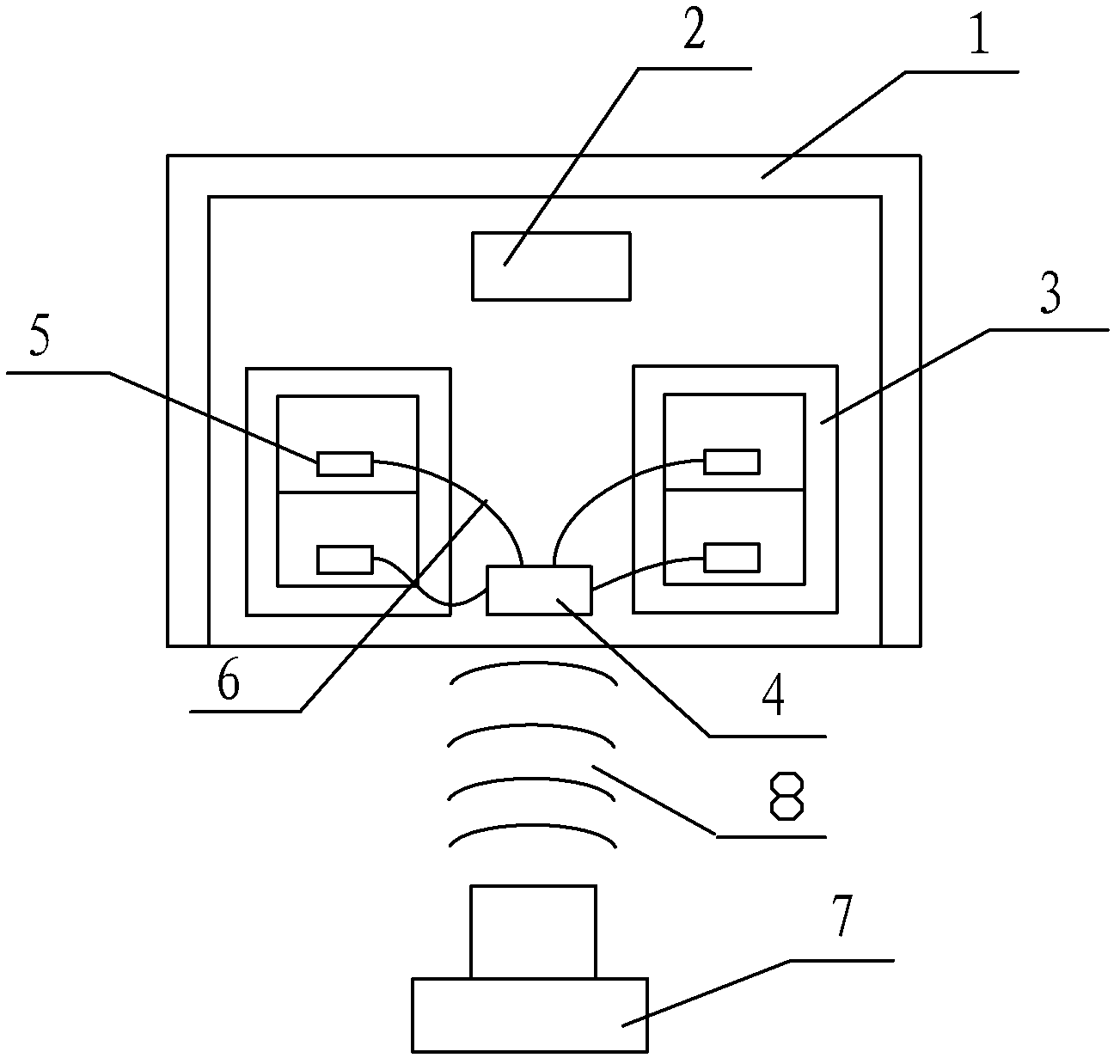

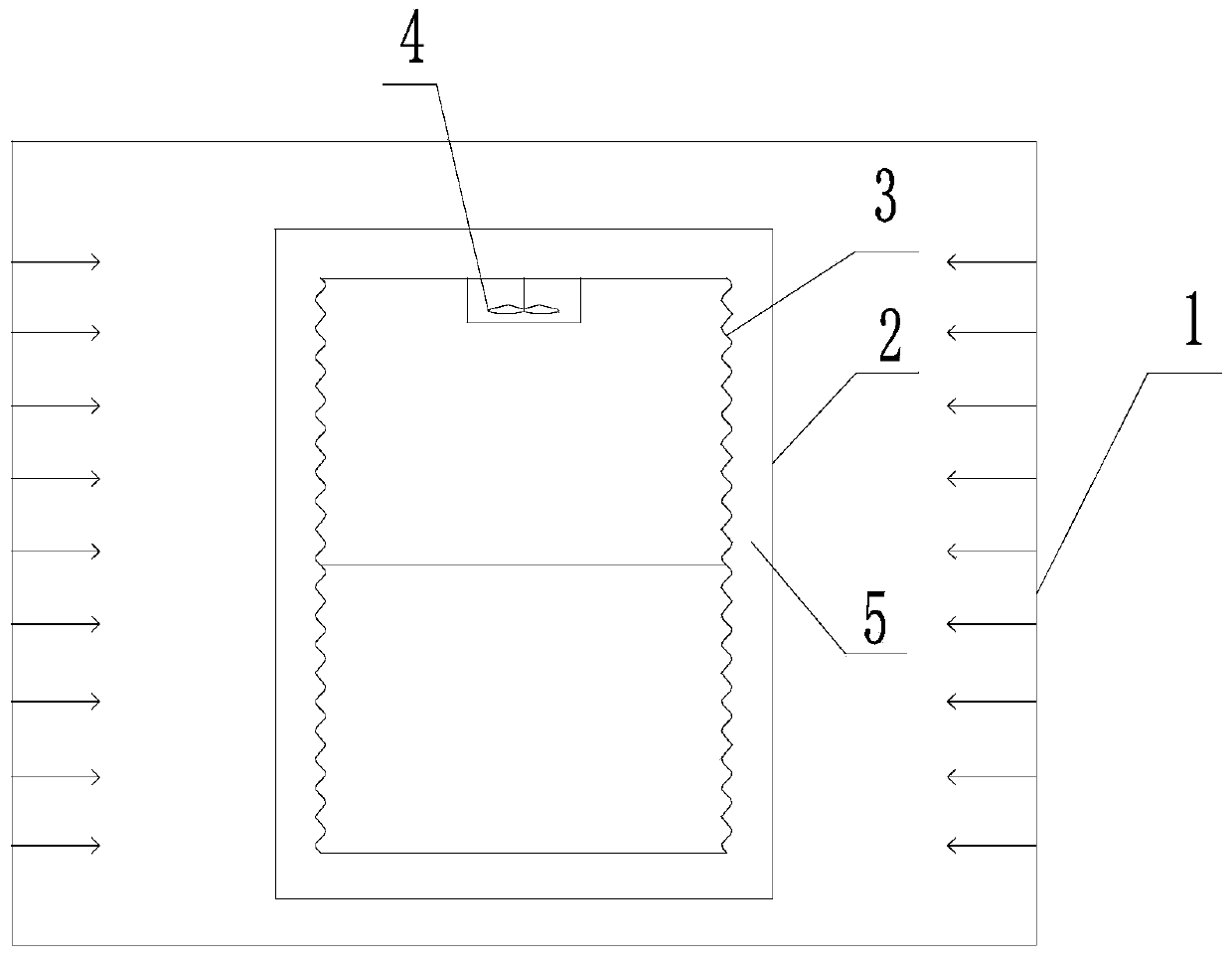

Cold-chain transportation box and cold-chain transportation method thereof

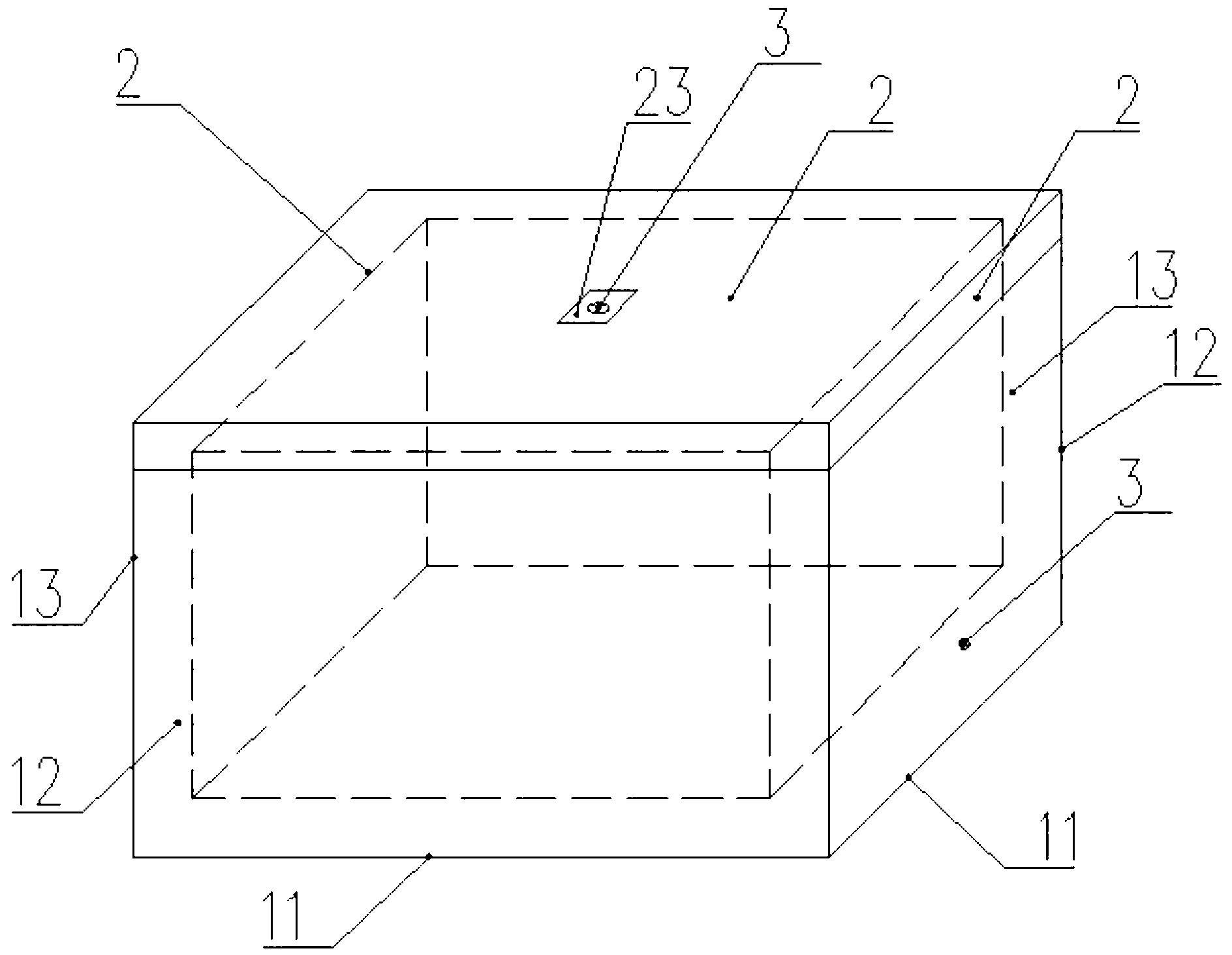

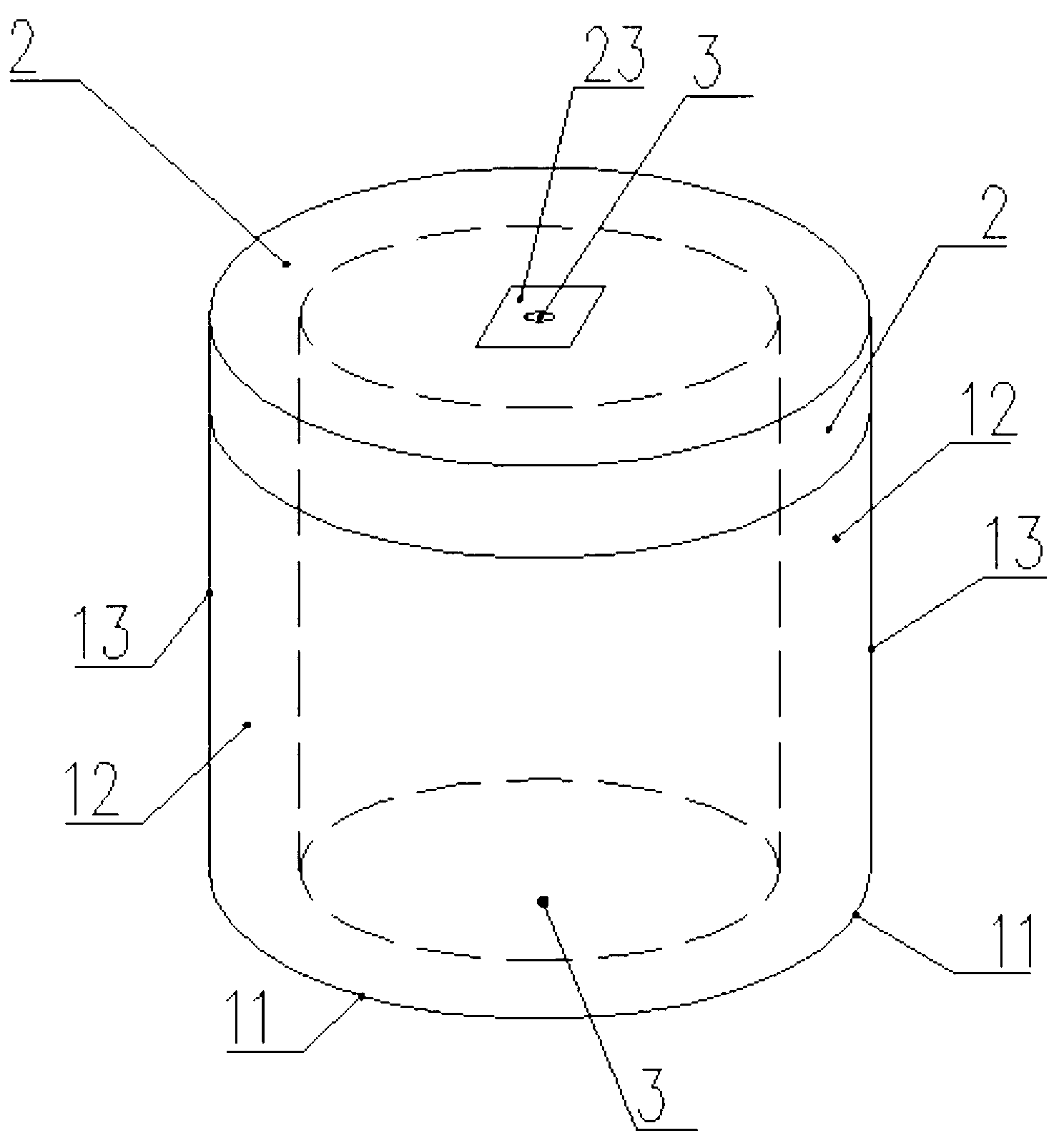

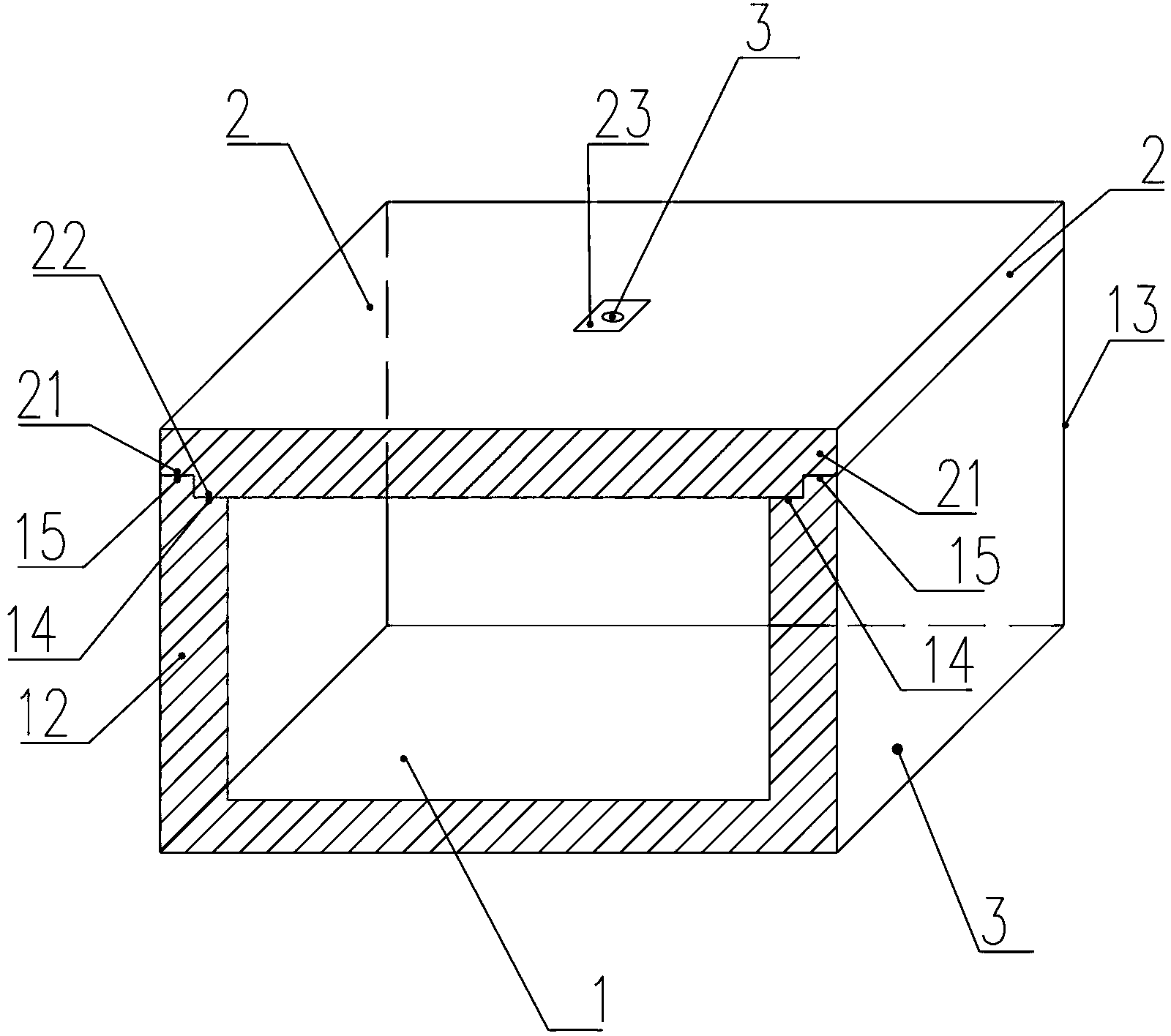

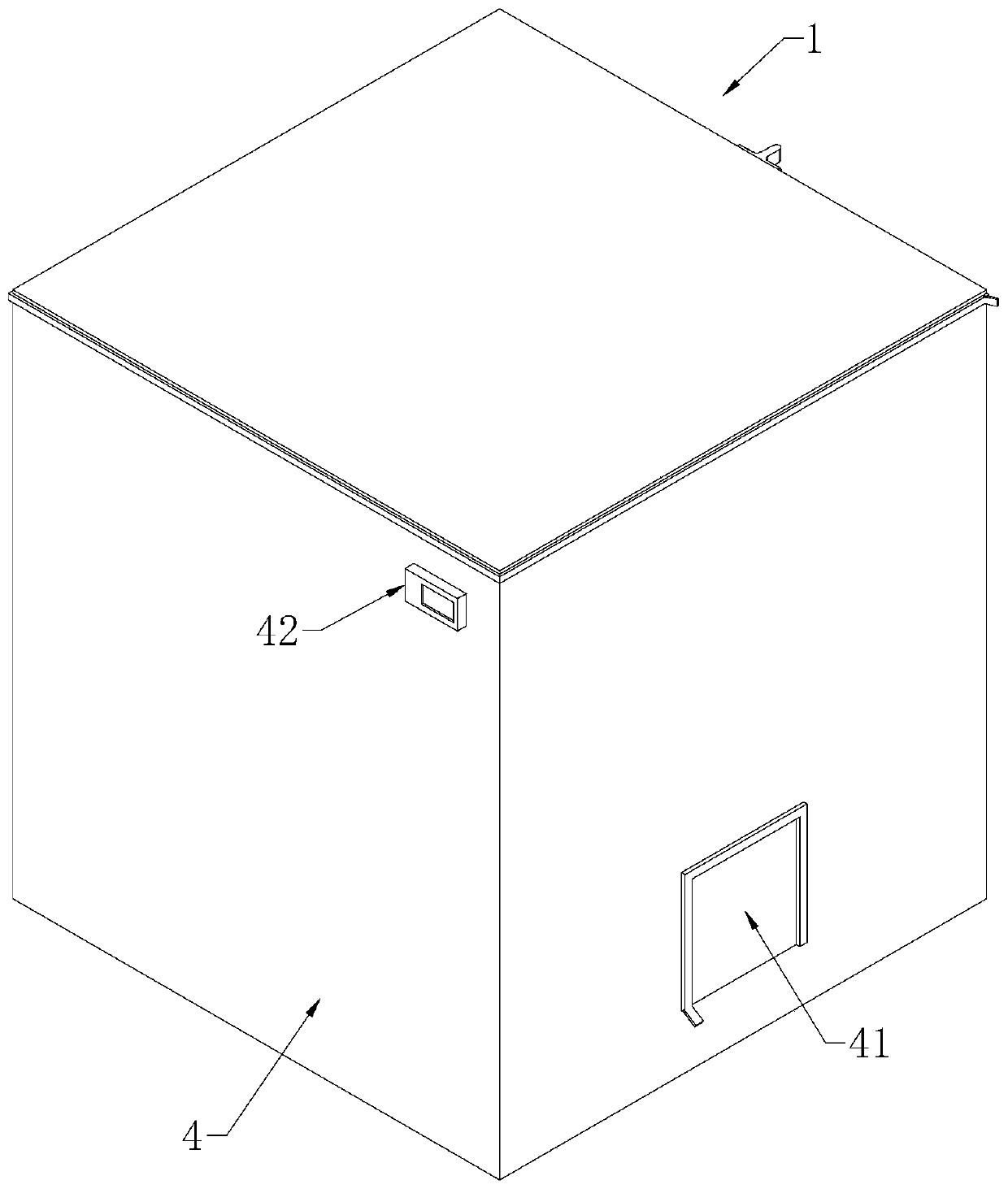

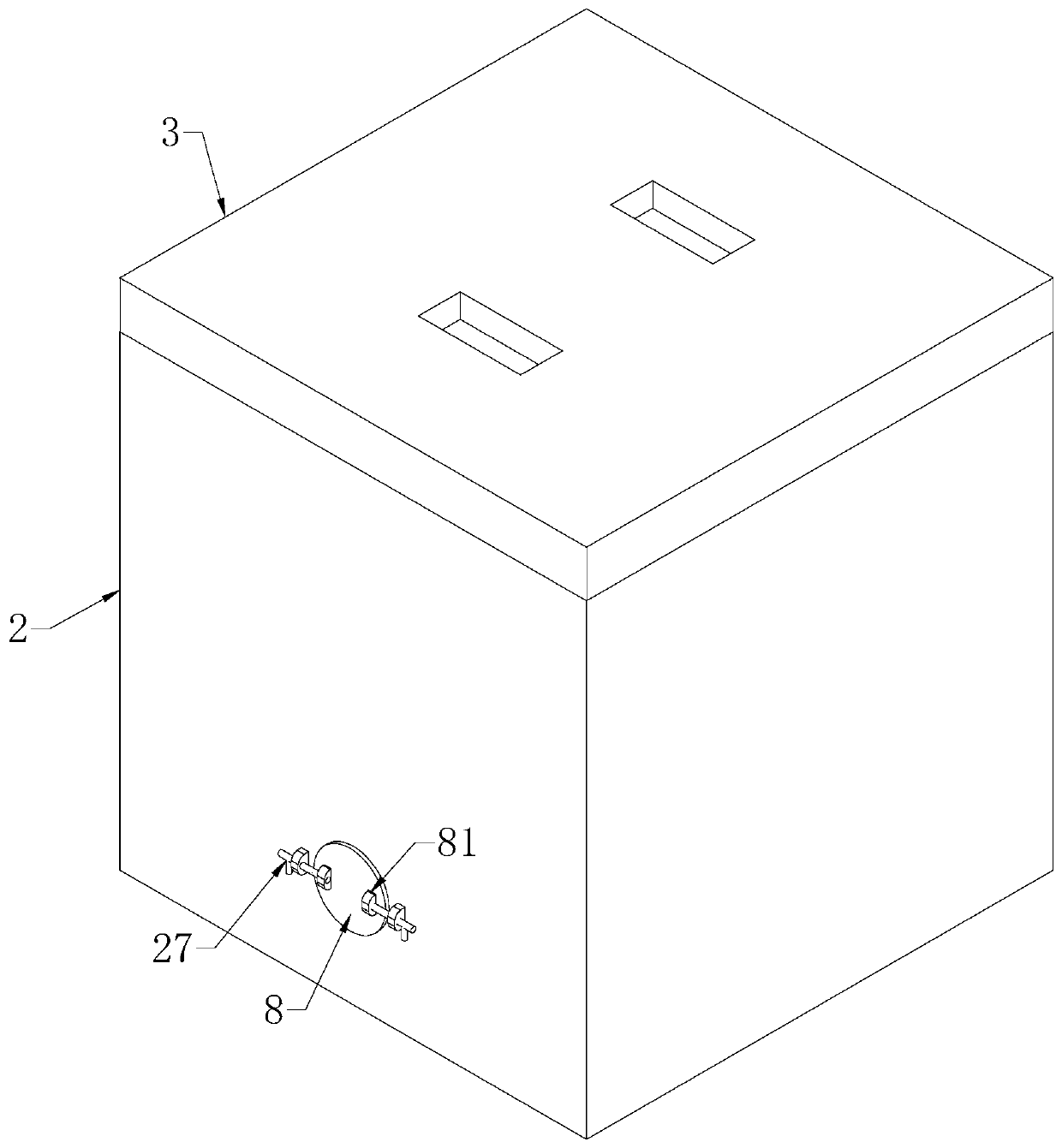

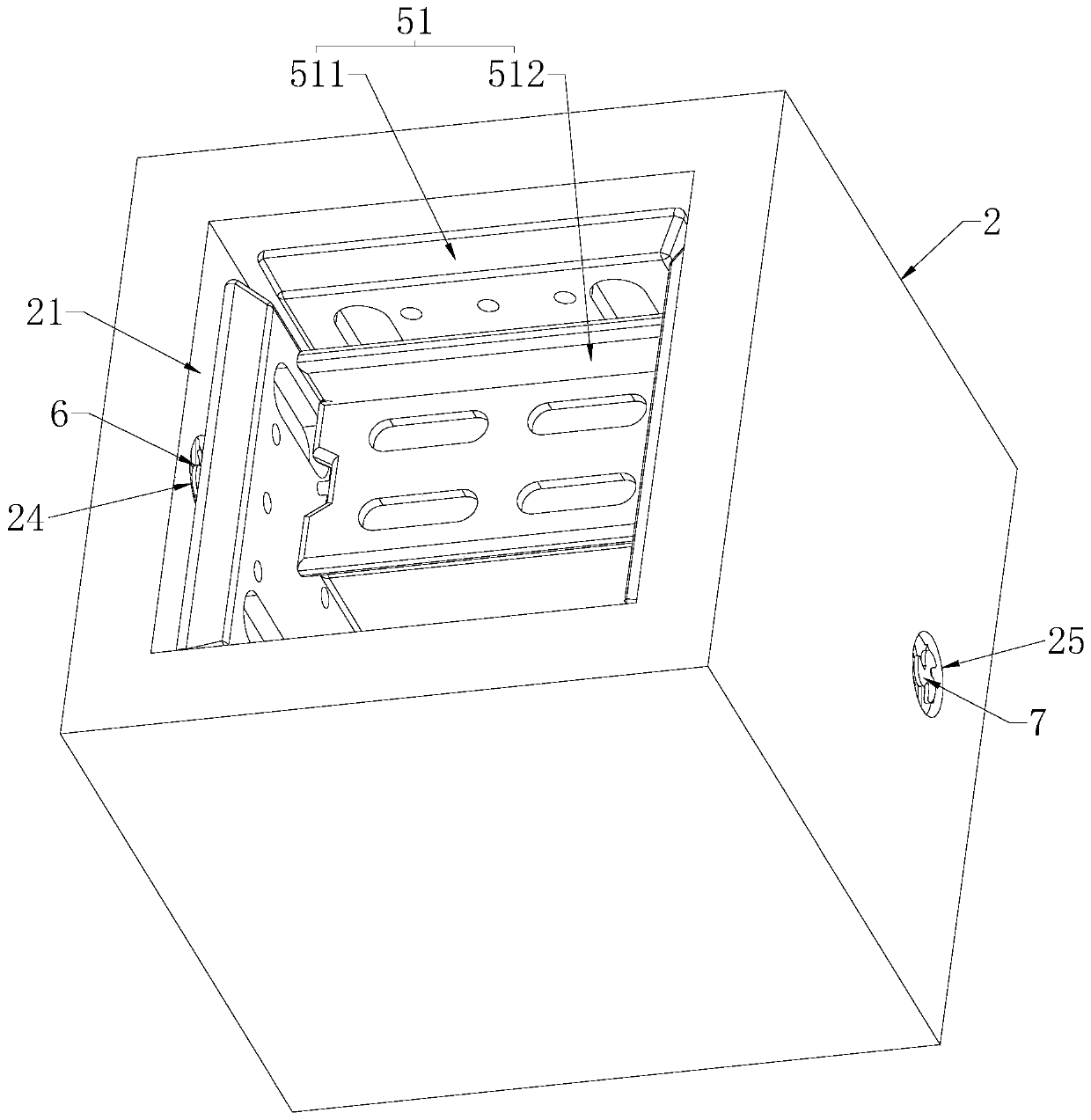

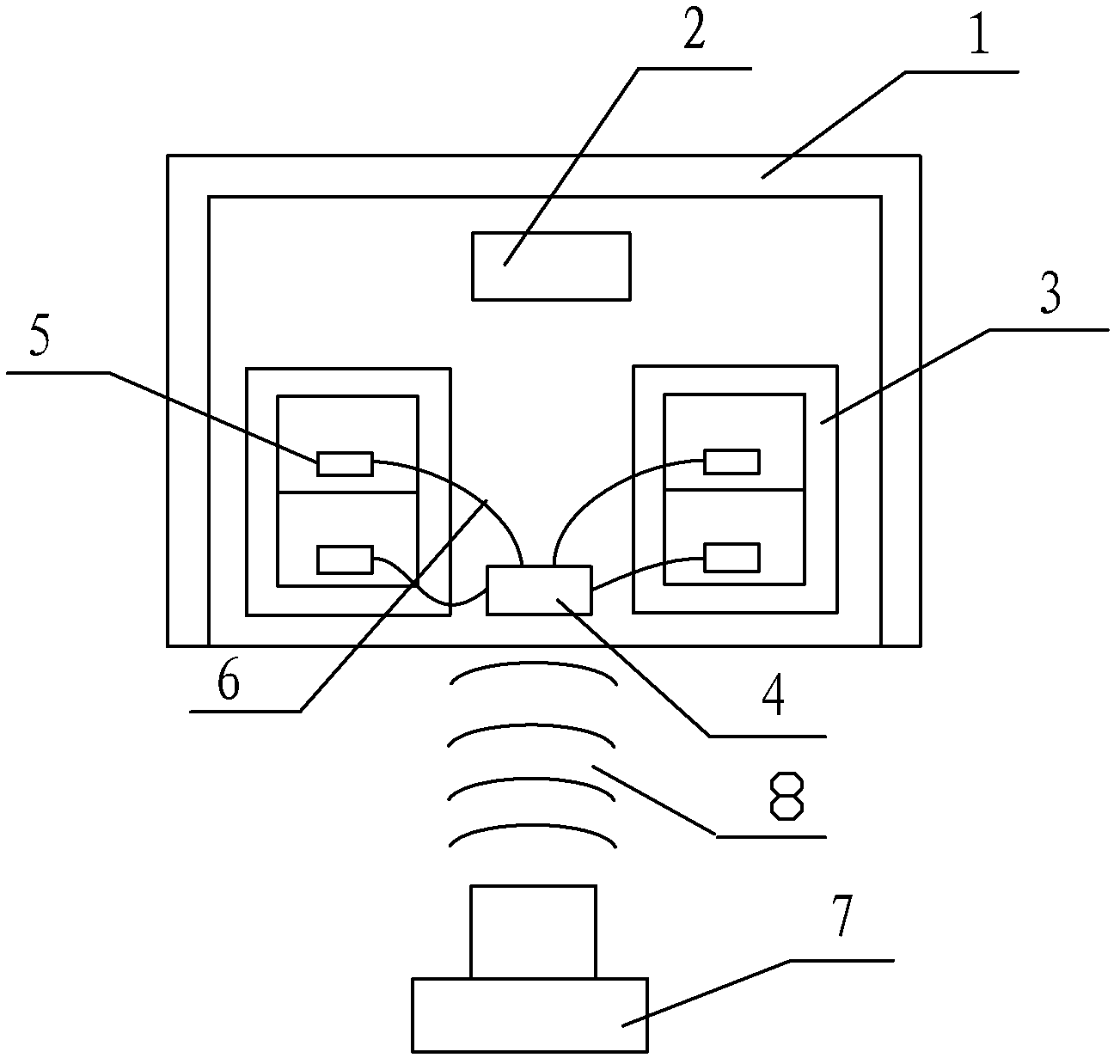

InactiveCN111099164AShorten pre-cooling timeAchieve consistencyDomestic cooling apparatusLighting and heating apparatusCold chainPharmacy medicine

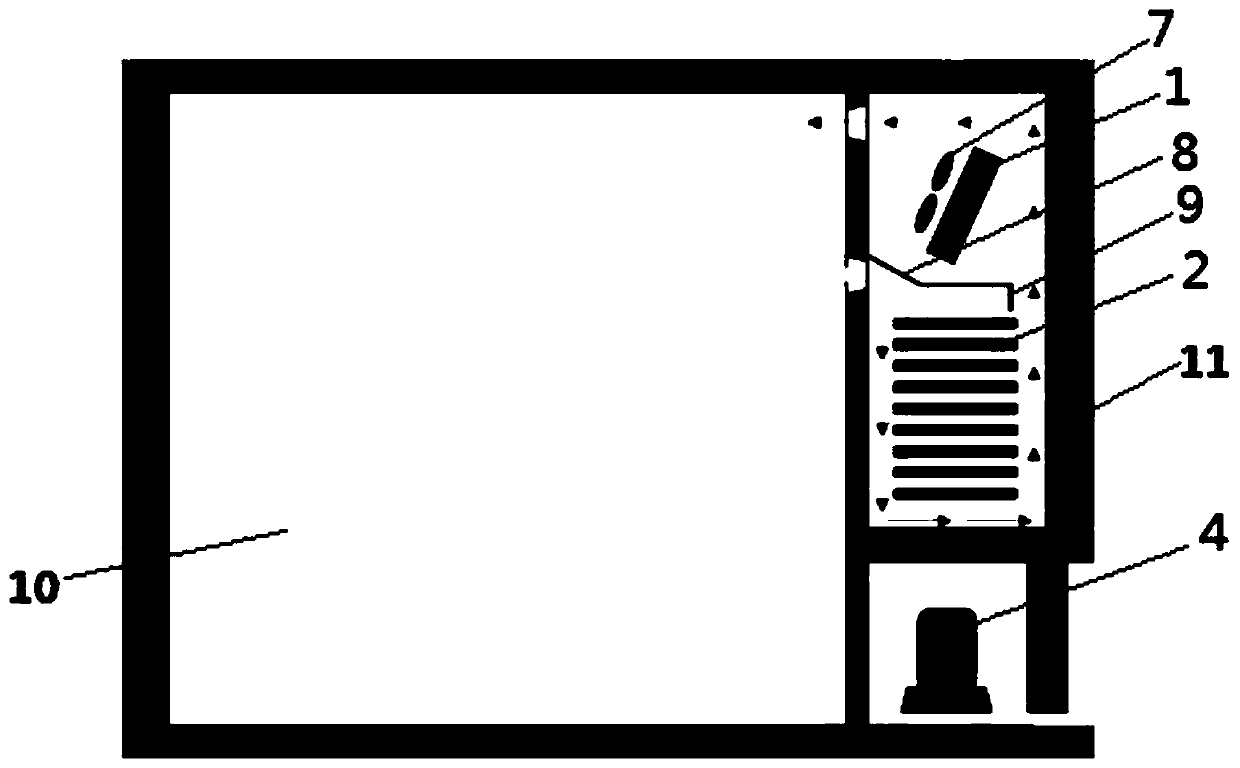

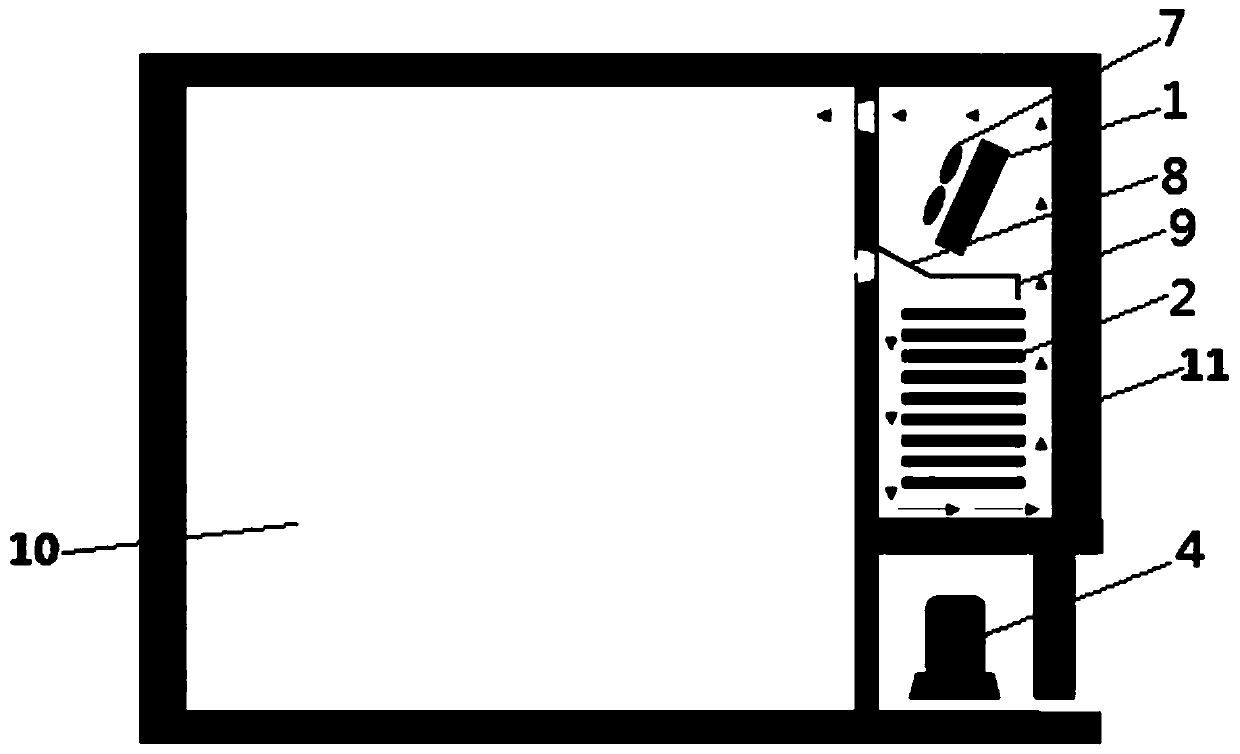

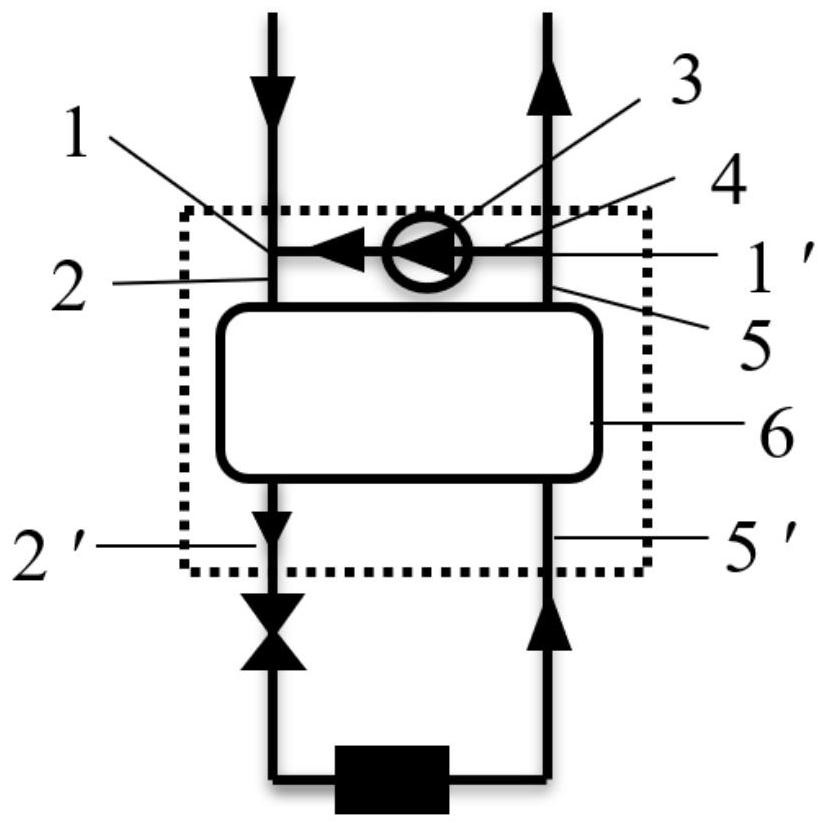

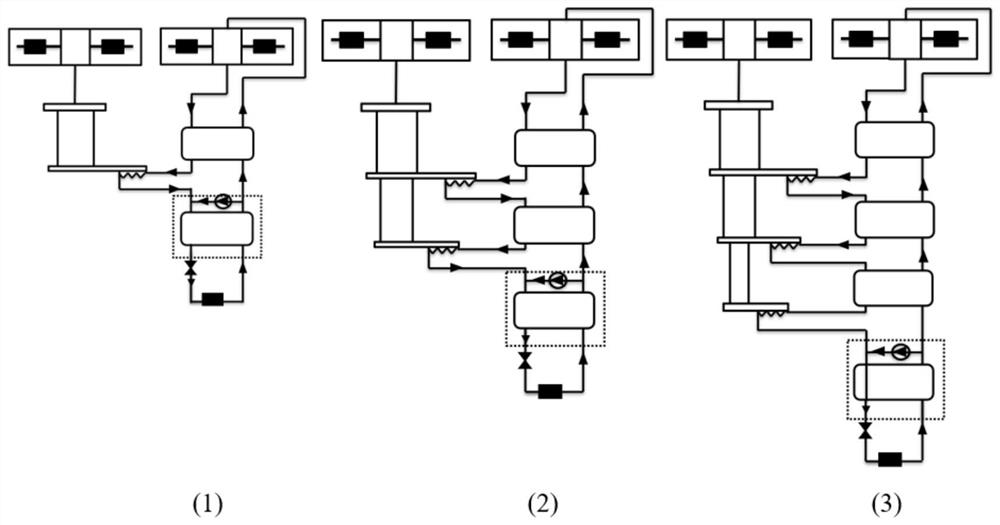

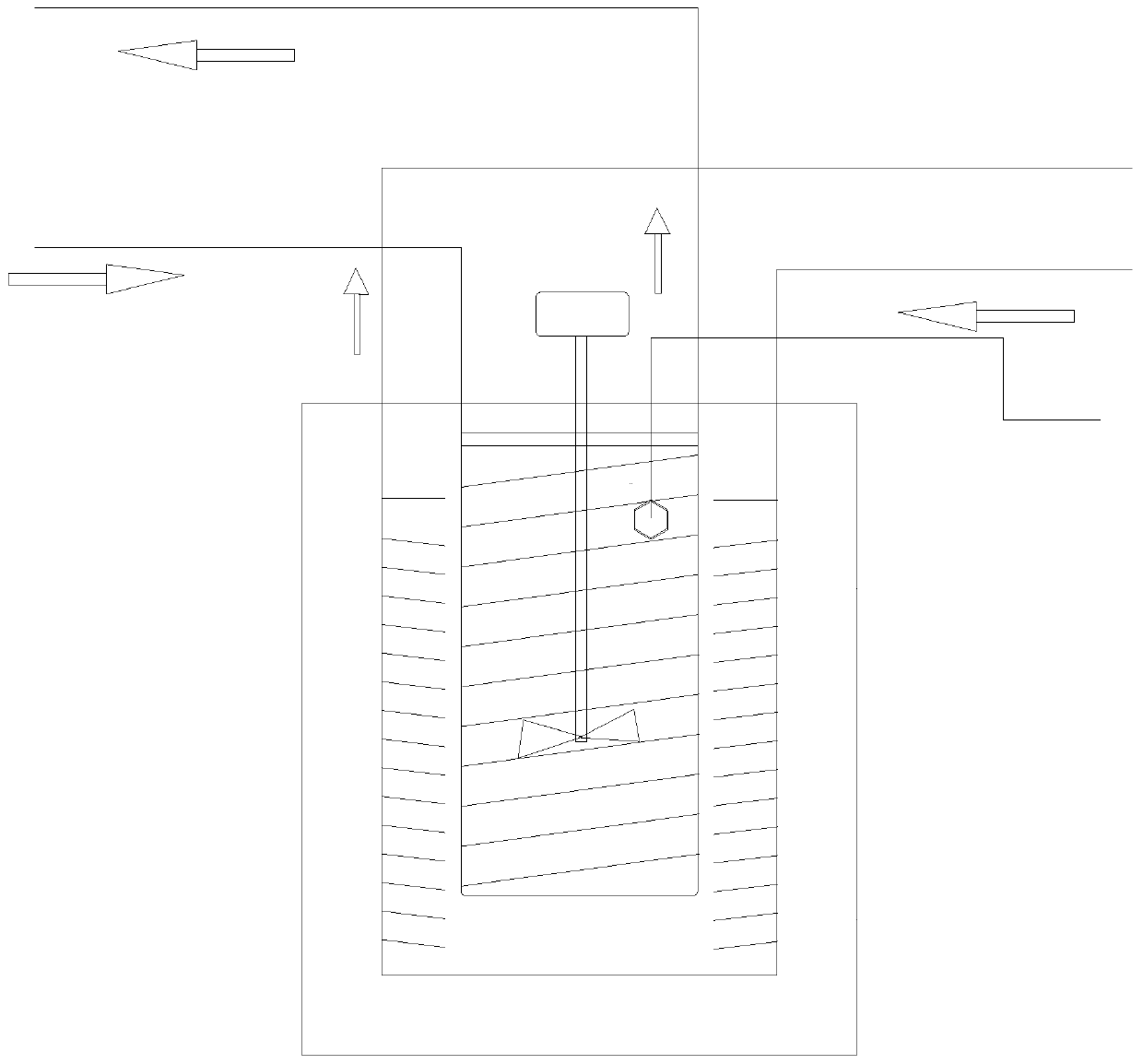

The invention discloses a cold-chain transportation box and a cold-chain transportation method thereof, and relates to the technical field of medical cold-chain transportation. The cold-chain transportation box comprises a heat preservation box, an ice raft is arranged in the heat preservation box, the heat preservation box comprises an inner box chamber and an interlayer box chamber, the ice raftcomprises an inner ice raft and an interlayer ice raft, the inner ice raft is arranged in the inner box chamber, and the interlayer ice raft is arranged in the interlayer box chamber; and the inner box chamber communicates with the interlayer box chamber, and a circulating device used for achieving air flow exchange between the inner box chamber and the interlayer box chamber and an internal temperature detection system used for detecting the temperature in the inner box chamber are arranged in the heat preservation box. The interlayer ice raft and the inner ice raft in the interlayer box chamber can be pre-cooled at the same time, so that the pre-cooling time of the cold-chain transportation box is shortened; and when the internal temperature detection system detects that the internal environment temperature of the heat preservation box is distributed unevenly, the circulating device can achieve air flow circulating communication between the interlayer box chamber and the inner box chamber, so that the temperature of the environment in the heat preservation box is distributed evenly, and then the purpose of consistency of the refrigeration environment of medicine supplies is achieved.

Owner:上海康展物流有限公司

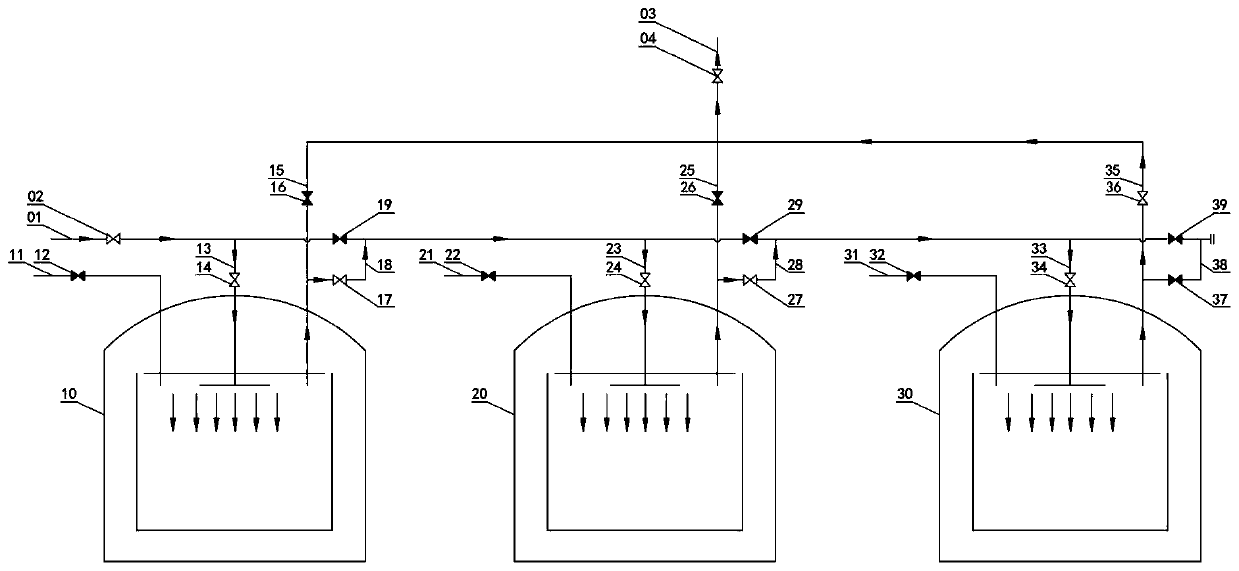

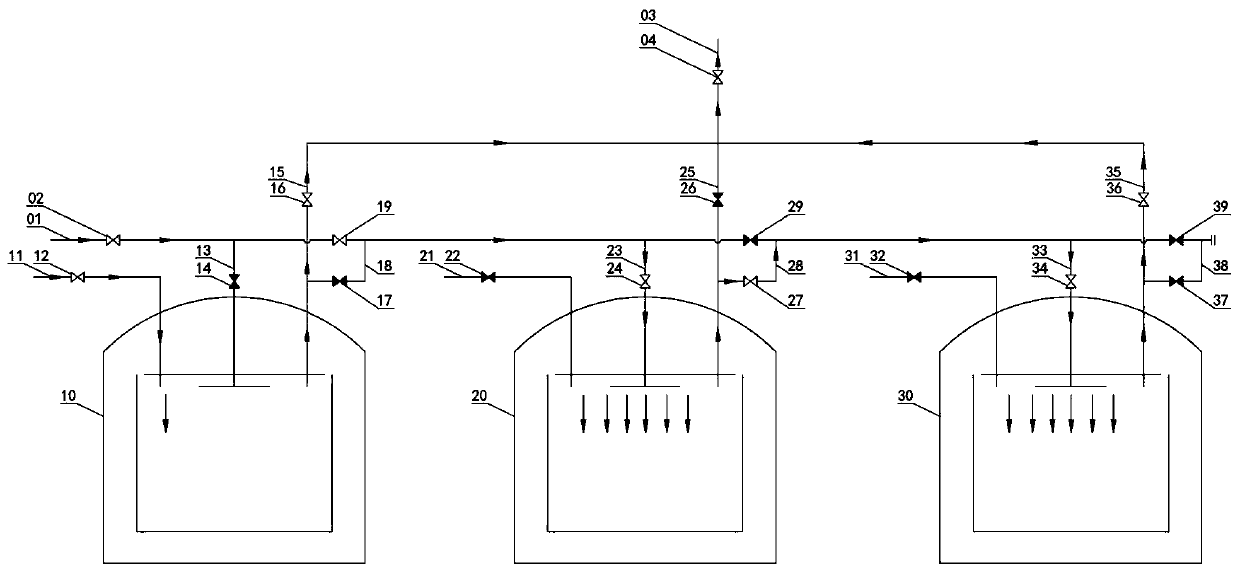

Low-temperature storage tank pre-cooling system and pre-cooling method

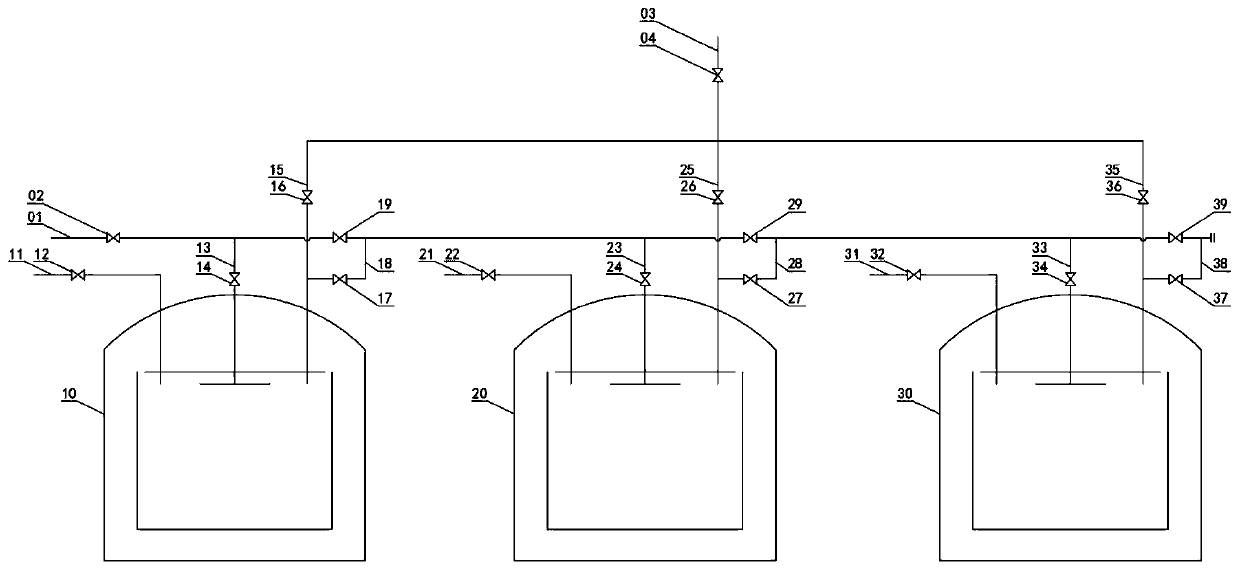

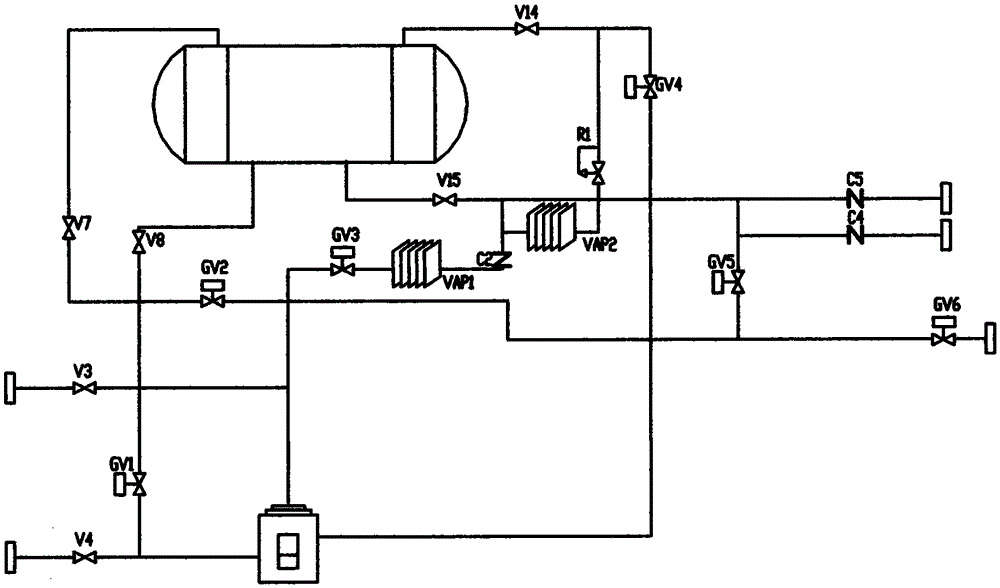

ActiveCN110145684AIncrease profitImprove pre-cooling efficiencyContainer filling methodsPipeline systemsGas phaseProcess engineering

The invention discloses a low temperature storage tank pre-cooling system. The low temperature storage tank pre-cooling system comprises a low temperature storage tank No. 1, a low temperature storagetank No. 2, a low temperature storage tank No. 3, a pre-cooling main pipe and a gas phase external transportation main pipe, wherein a pre-cooling main pipe valve is arranged on the pre-cooling mainpipe; and a gas phase external transportation main pipe valve is arranged on the gas phase external transportation main pipe. The low temperature storage tank pre-cooling system has the beneficial effects that the low temperature storage tank pre-cooling system is simple and convenient to operate; the utilization rate of the cold energy of a liquid phase low temperature medium is high; the pre-cooling efficiency is high; the problem that when a low temperature storage tank is pre-cooled, the cold energy is largely wasted, and the pre-cooling cost is high, is solved; meanwhile the efficiency ofsimultaneously pre-cooling multiple low temperature storage tanks in a tank field is improved; the pre-cooling time is saved; and the investment of owners in the pre-cooling of the storage tanks is greatly reduced.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

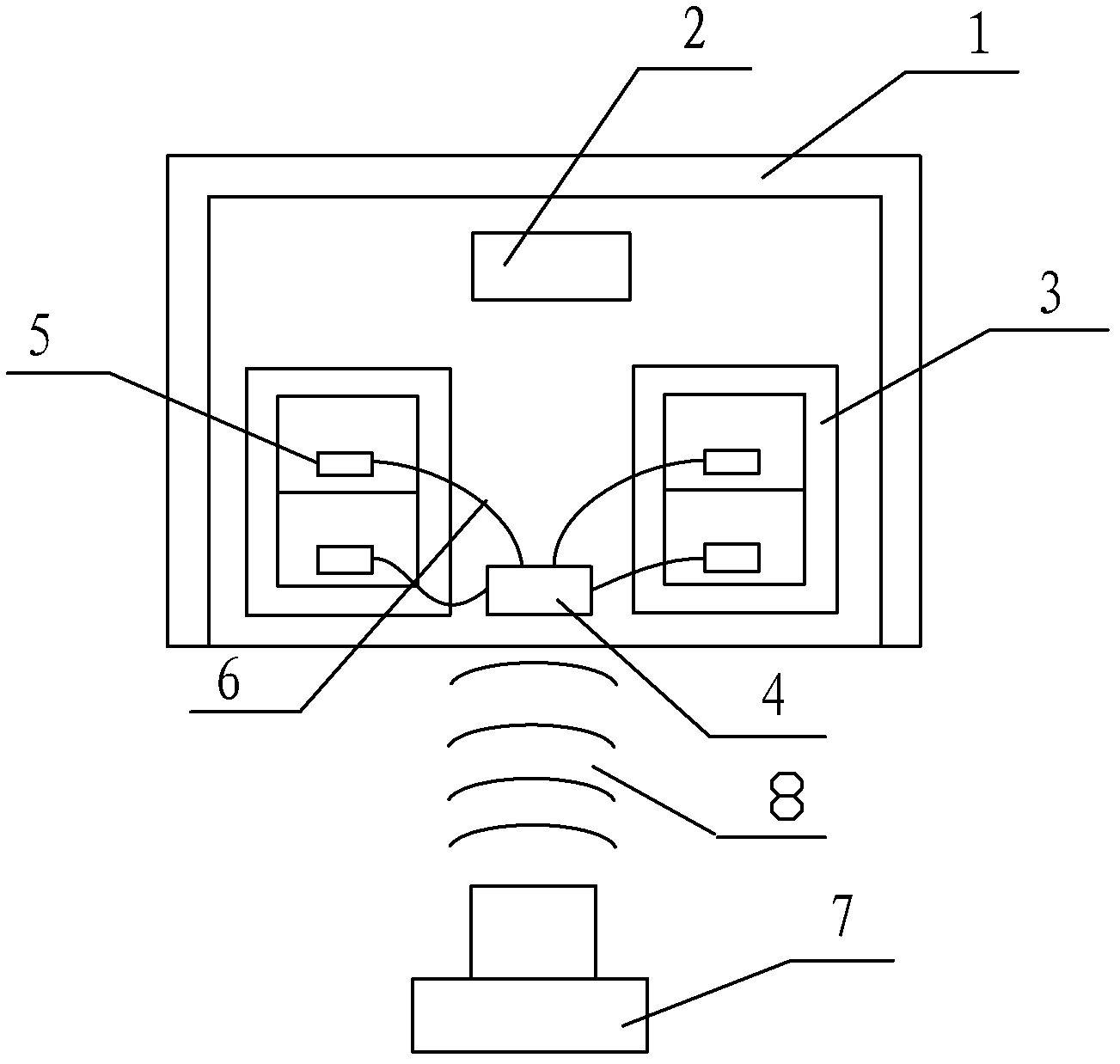

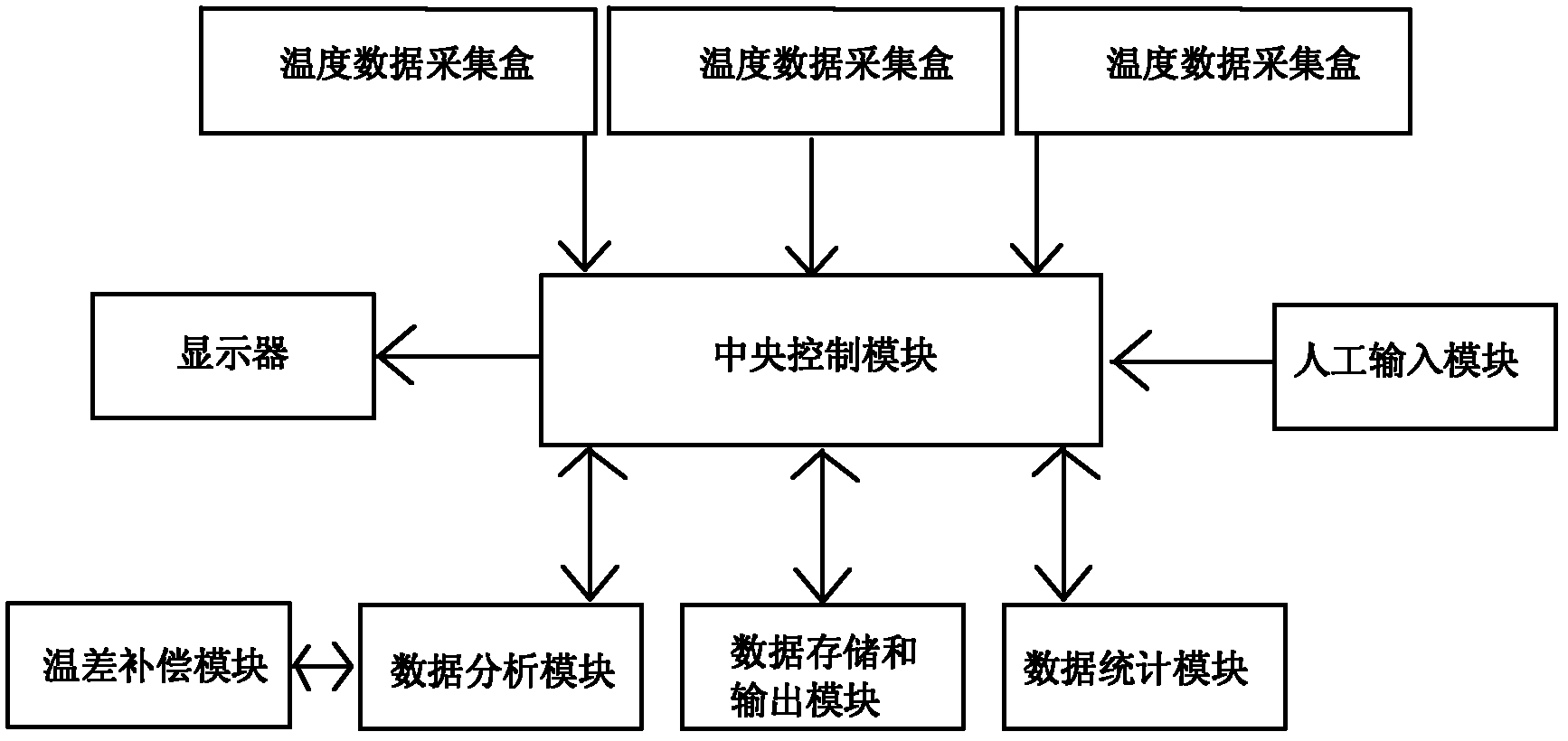

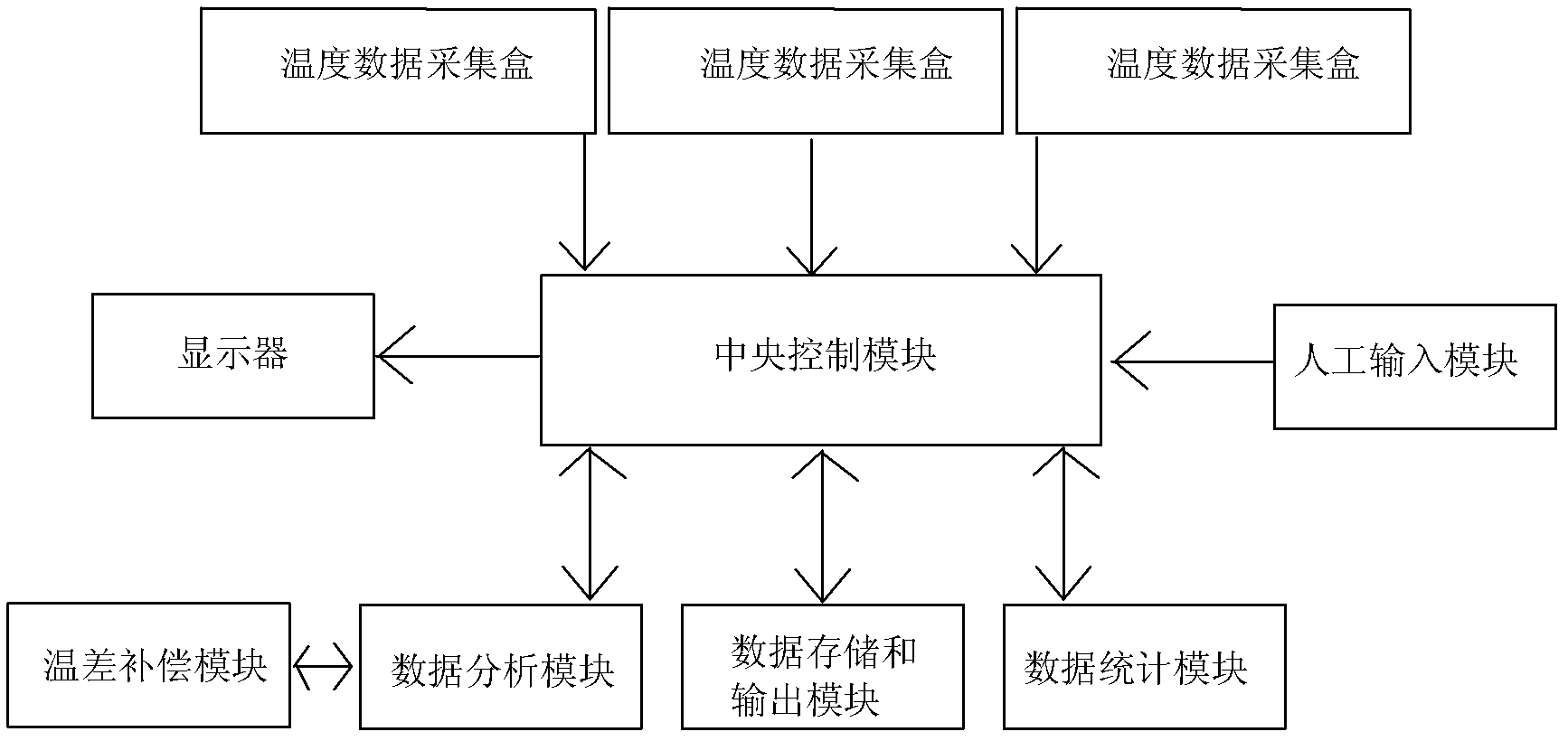

Temperature compensation method for detecting performances

ActiveCN102636362AShorten pre-cooling timeStructural/machines measurementData processing systemData acquisition

The invention discloses a temperature compensation method for detecting performances. The temperature compensation method includes acquiring and transmitting information to an industrial computer by a temperature data acquirer, storing and displaying the temperature information in a fixed format by a data processing system, setting an optimal ambient temperature value T1 and a temperature difference correspondence table including different differential intervals and corresponding compensation values, reading the ambient temperature Tx and actuating a temperature compensation subprogram when the Tx is unequal to T1; computing according to the equation of Tx-T1=A; comparing the A with the temperature difference correspondence table and obtaining a corresponding compensation value B; setting a qualified temperature value T in an input module, reading and storing temperature values Ta acquired by the temperature data acquirer at each interval t after a timer starts timing, and reading a current temperature value Tb when the timer stops timing; outputting a qualified result if Tb+B is smaller than or equal to the T; and outputting a disqualified result of Tb+B is larger than the T. by the aid of the temperature compensation method, the performances of a refrigerator at different ambient temperatures can be accurately evaluated, and refrigerator testing time is shortened.

Owner:DA PAN ELECTRIC APPLIANCE IND CO LTD

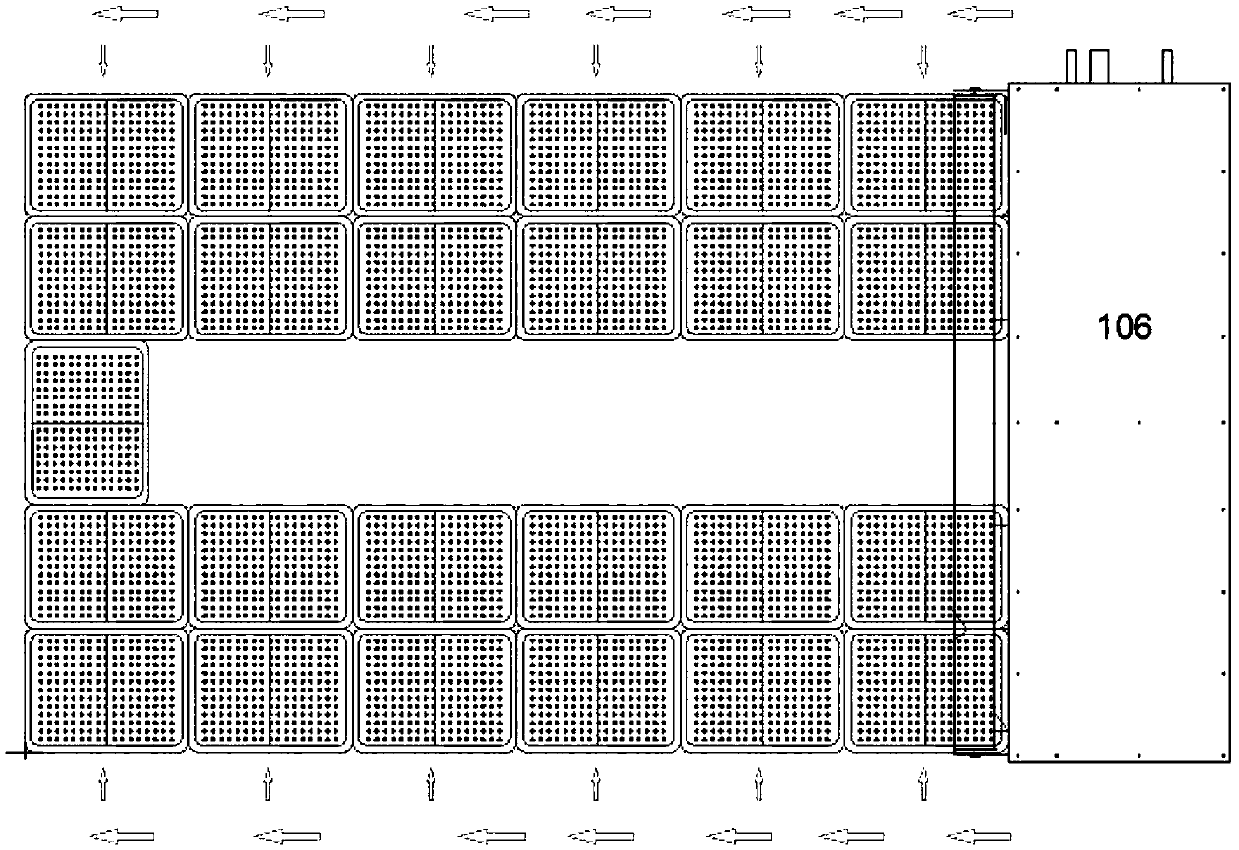

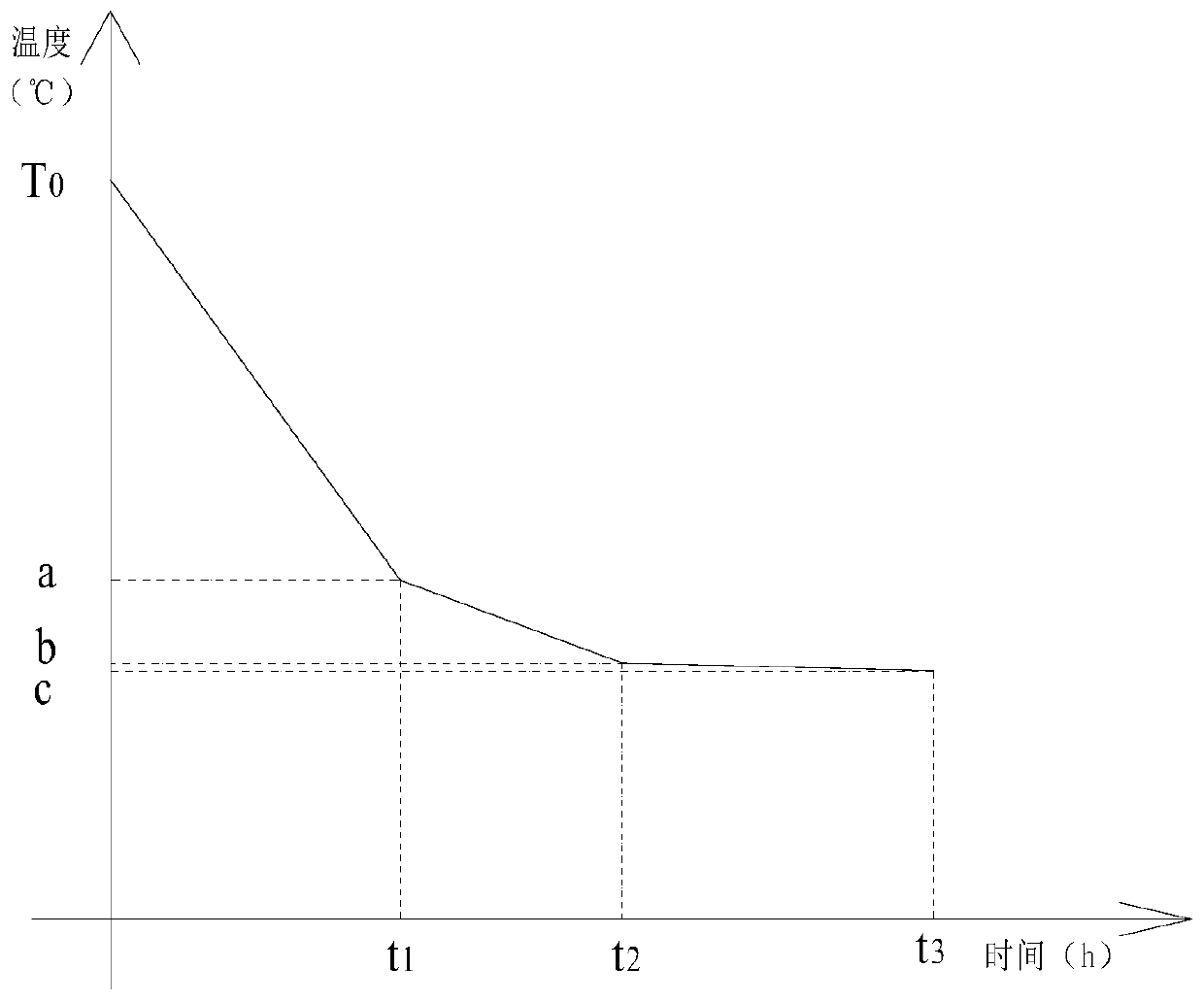

Picking, pre-cooling and storing integrated basket, application thereof, and method for pre-cooling small-fruit-diameter perishable fruits

ActiveCN109645105AAchieve standardizationRealize semi-automatic operationFood processingPackaging fruits/vegetablesCold chainProcess engineering

The invention provides a picking, pre-cooling and storing integrated basket, application thereof, and a method for pre-cooling small-fruit-diameter perishable fruits, and belongs to the technical field of fruit and vegetable picking after-treatment. Based on the design of the picking, pre-cooling and storing integrated basket, the modes of standard picking, pre-cooling, storing boxes and trays areadopted, the method for pre-cooling small-fruit-diameter perishable fruits is successfully provided, standardization of a cold chain process is easily realized, semi-automatic operation in the process is realized, and labor and time are saved. Meanwhile, a critical freeze injury temperature method is adopted for delivering air, in this way, pre-cooling time can be effectively shortened, pre-cooling energy consumption can be effectively lowered, meanwhile, a quench effect can be realized in fruit and vegetable pre-cooling treatment, and the storing circulating deadline of follow-up steps is delayed; an alternate-air-delivery variable-air direction method is adopted, in this way, the uniformity of the pre-cooling process is improved, and the phenomenon of dead zones during pre-cooling heattransfer is prevented; a time-period-division variable-air speed air delivery mode is adopted, so that while the pre-cooling time is guaranteed, the pre-cooling energy consumption is lowered.

Owner:SHANDONG UNIV

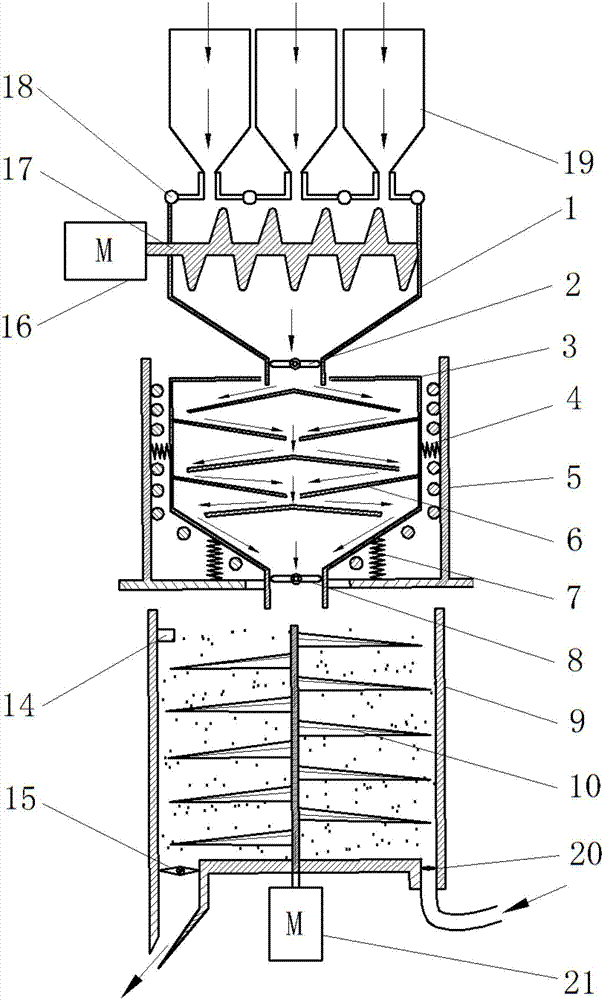

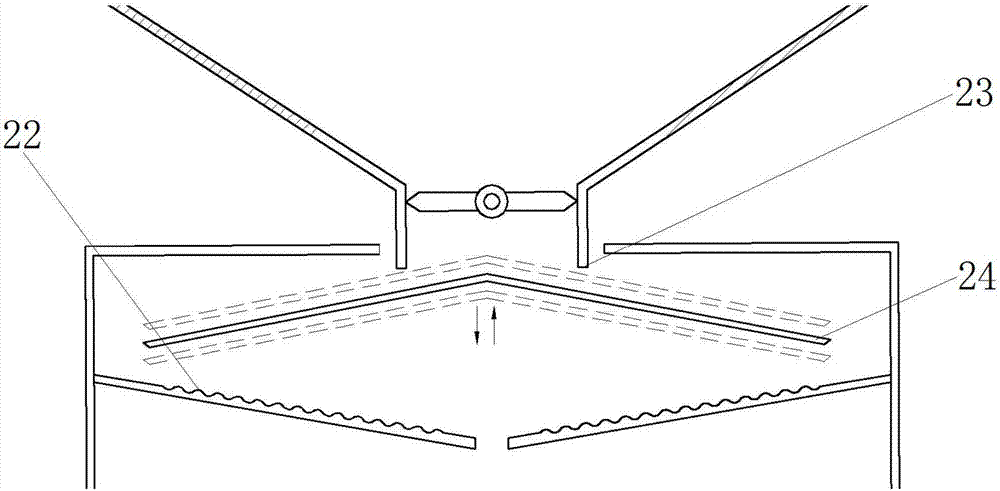

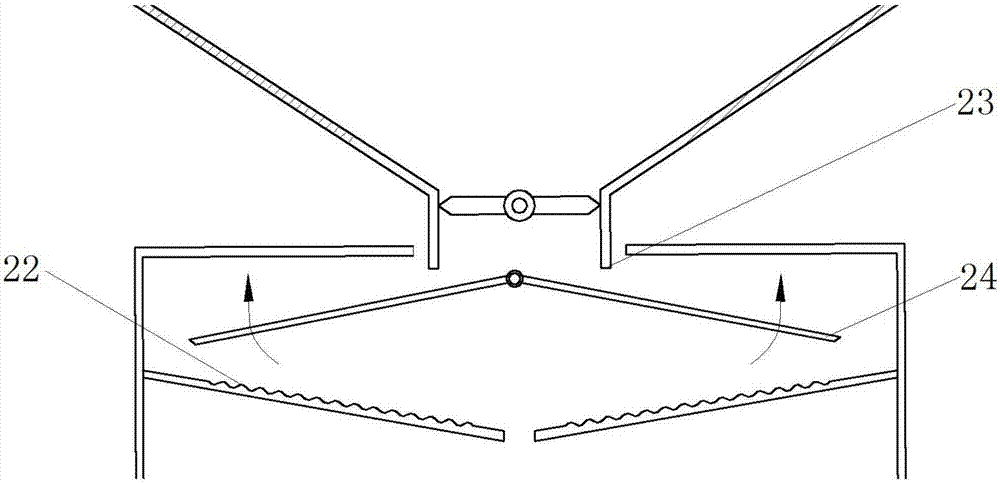

Liquid cooked food processing facility and method

The invention discloses a liquid cooked food processing facility and method. The liquid cooked food processing facility comprises a premixing container water injection ball, a pre-stirring turbine, a pre-stirring turbine motor, a water level sensor, a pre-mixing container, a pre-mixing container flow control valve, a microwave heating reaction vessel, a horizontal support spring, a vibration disc, a vertical spring support, a microwave heating reaction vessel flow control valve, a grinding and stirring container, a rotation blade, a rotation blade motor, an outlet guide plate, a final food outlet valve, and a water injection valve. During the food processing process, water does not participate into the food heating process, thus the energy consumption is largely reduced, at the same time, the processed food has a unique flavor, the finished food is cold, the pre-cooling time is saved, and the food processing efficiency is greatly improved.

Owner:贵州旺业农业科技有限公司

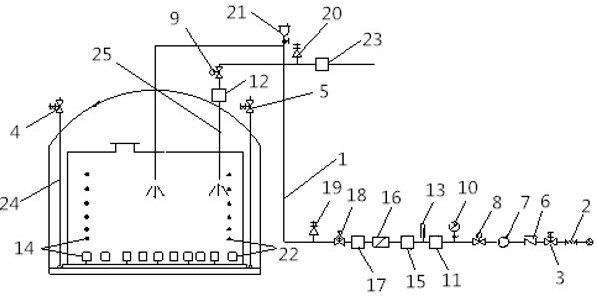

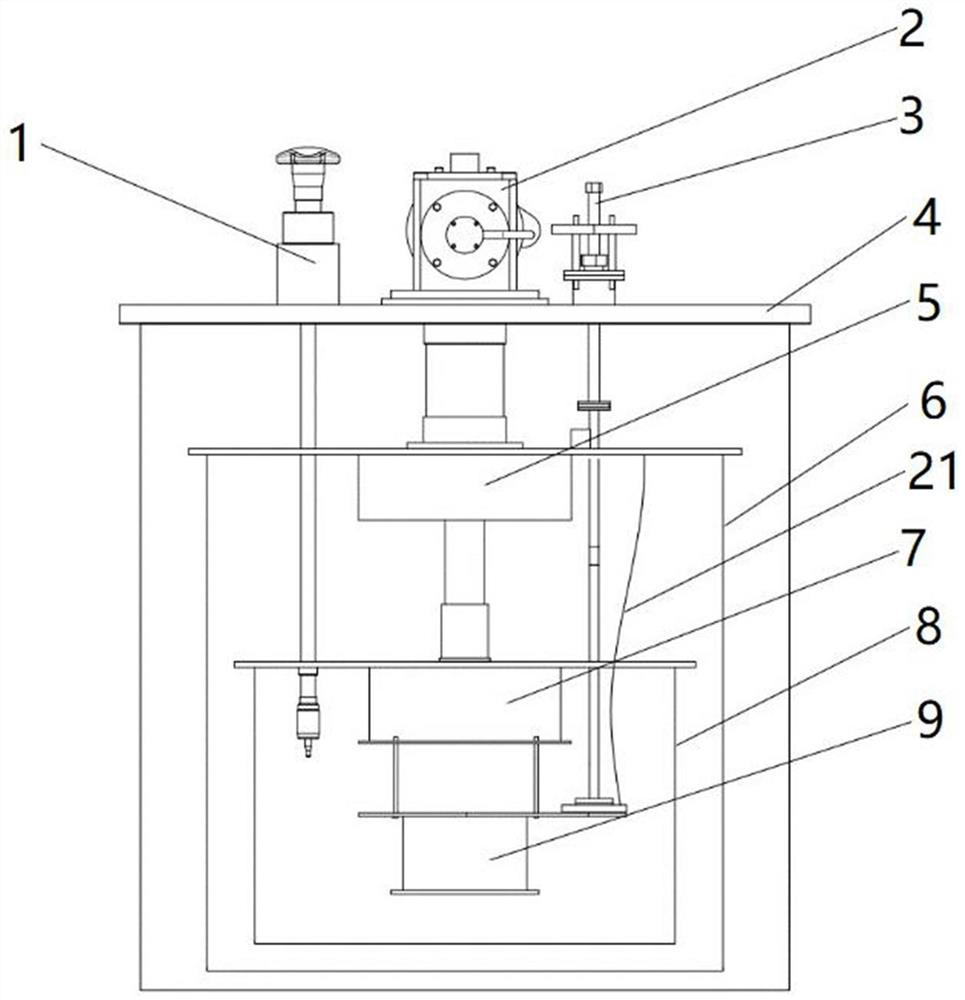

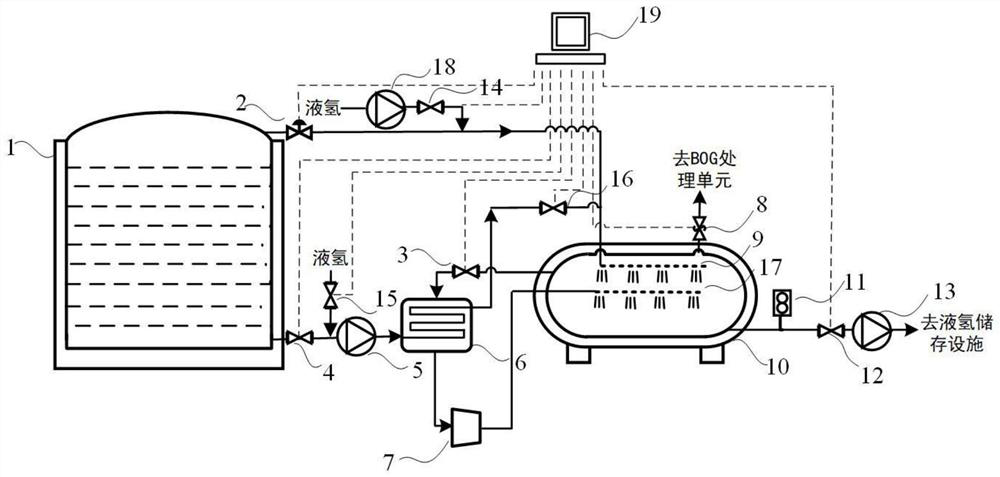

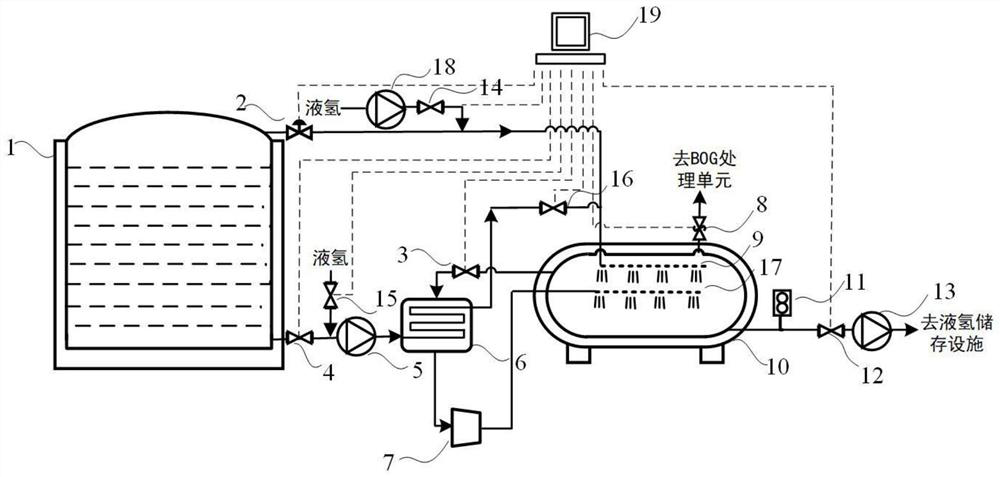

LNG storage tank automatic pre-cooling system based on efficient communication and pre-cooling method

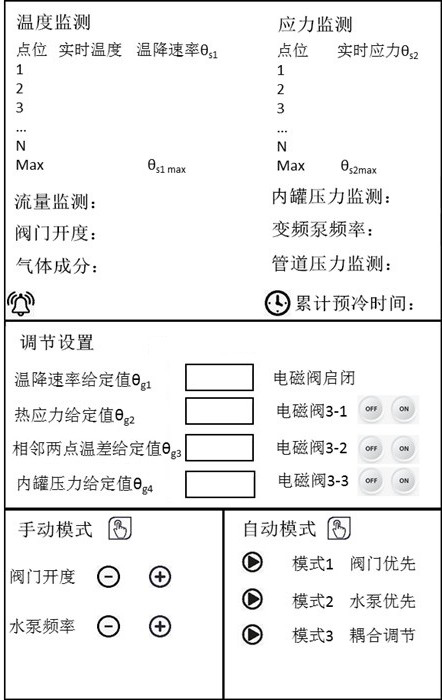

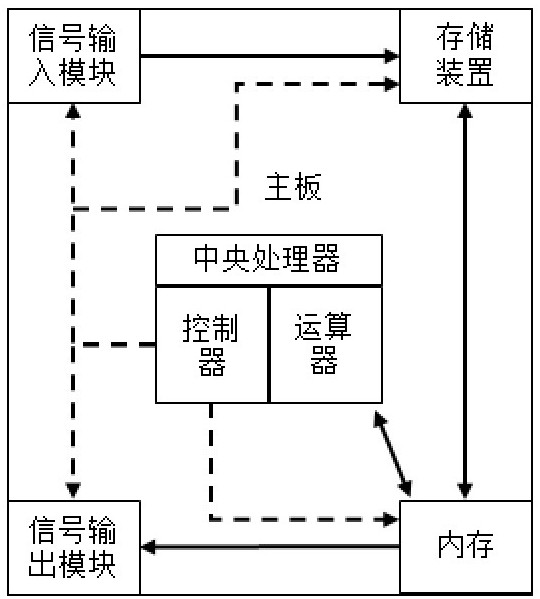

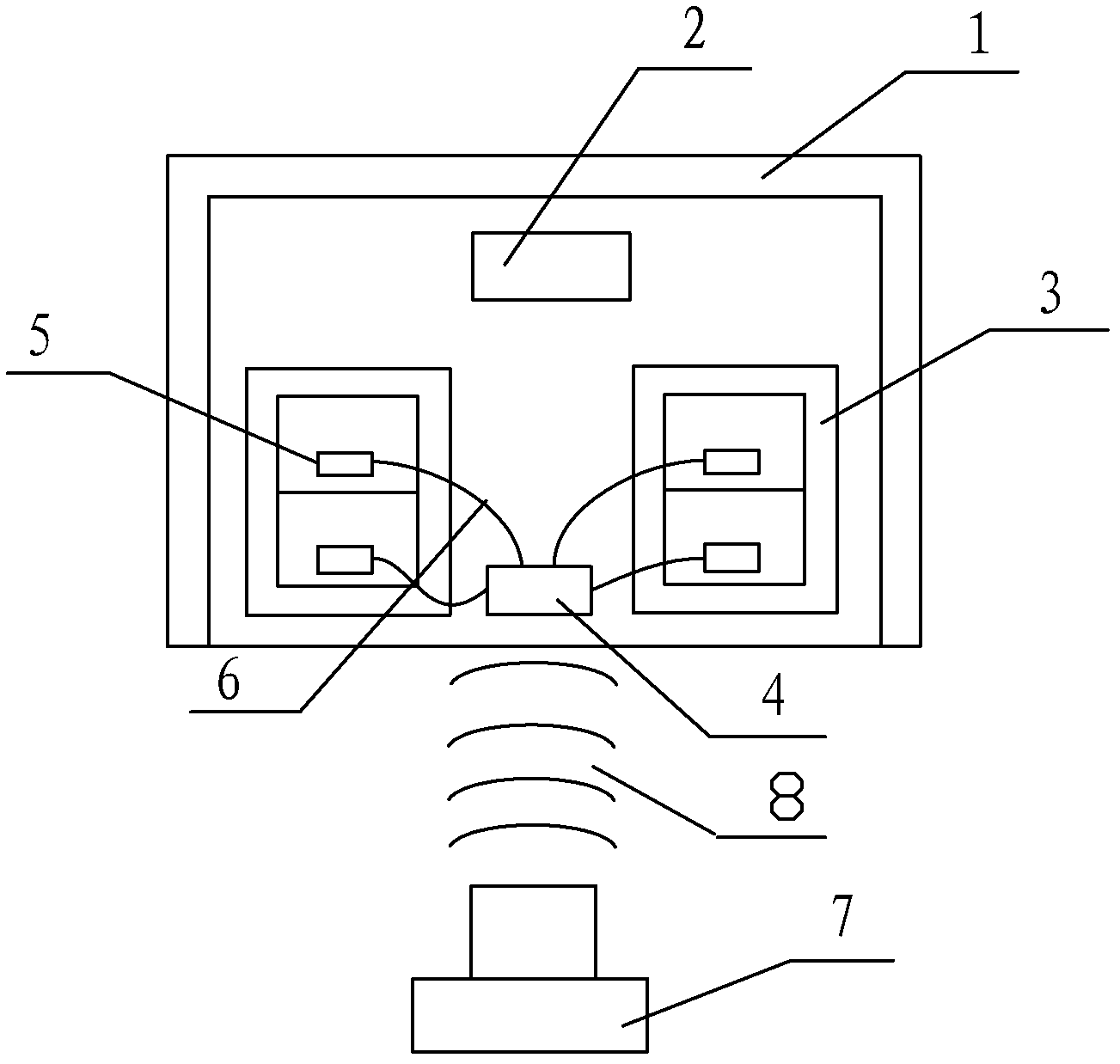

ActiveCN113339695ASolve blindnessImprove pre-cooling effectFluid handling accessoriesContainer discharging methodsMaterial resourcesElectric control

The invention provides an LNG storage tank automatic pre-cooling system based on efficient communication and a pre-cooling method. A CFD numerical simulation module is used for conducting pre-cooling process simulation, and initial flow parameters are provided for the pre-cooling process; and the point positions are installed on a storage tank in a modularized manner, and signal transmission between all sensors in the pre-cooling system and an integrated operation platform is achieved through 5G technology. According to the LNG storage tank automatic pre-cooling system and the pre-cooling method, limit values of parameters such as temperature drop rate, thermal stress, temperature difference between two adjacent points, inner tank pressure and the like are set on the basis of the integrated operation platform, monitoring results and the limit values are compared and analyzed, and then an electric control valve module and a variable frequency pump module are automatically adjusted, so that the conveying flow of a pre-cooling medium is adjusted, and it is guaranteed that the pre-cooling process is stably and safely carried out. According to the LNG storage tank automatic pre-cooling system and method, automatic, integrated and integrated control over the pre-cooling process can be achieved, monitoring personnel do not need to be arranged at monitoring points for a long time, potential safety hazards are avoided, manpower and material resources are saved, pre-cooling control is more accurate, and the pre-cooling efficiency is high.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Refrigerator performance detecting method and temperature compensating method

ActiveCN102636361AShorten pre-cooling timeReduce false positive rateStructural/machines measurementData processing systemWireless transmission

The invention discloses a refrigerator performance detecting method. A temperature data collector collects temperature information in a refrigerator and transmits the information to an industrial personal computer; a data processing system is arranged on the industrial personal computer and used for storing and displaying the temperature information; a signal transmitting and receiving device for wireless transmission, an input module capable of writing in parameter instructions, a comparator and a timer are arranged in the industrial personal computer and the data collector. The refrigerator performance detecting method comprises the following steps of: 1) setting an acceptable temperature value T in the input module; 2) reading and storing temperature Ta collected by the temperature data collector every t when the timer begins timing; and 3) reading the current temperature value Tb when the timer stops timing, and comparing Tb with T, if Tb is smaller than or identical to T, outputting a result that the performance is acceptable, and if Tb is greater than T, outputting a result that the performance is unacceptable. The method disclosed by the invention can be used for detecting a plurality of refrigerators at the same time, and a temperature compensating module can be used for exactly evaluating the performance of the refrigerators at different temperatures, so that the testing time of the refrigerators is reduced.

Owner:DA PAN ELECTRIC APPLIANCE IND CO LTD

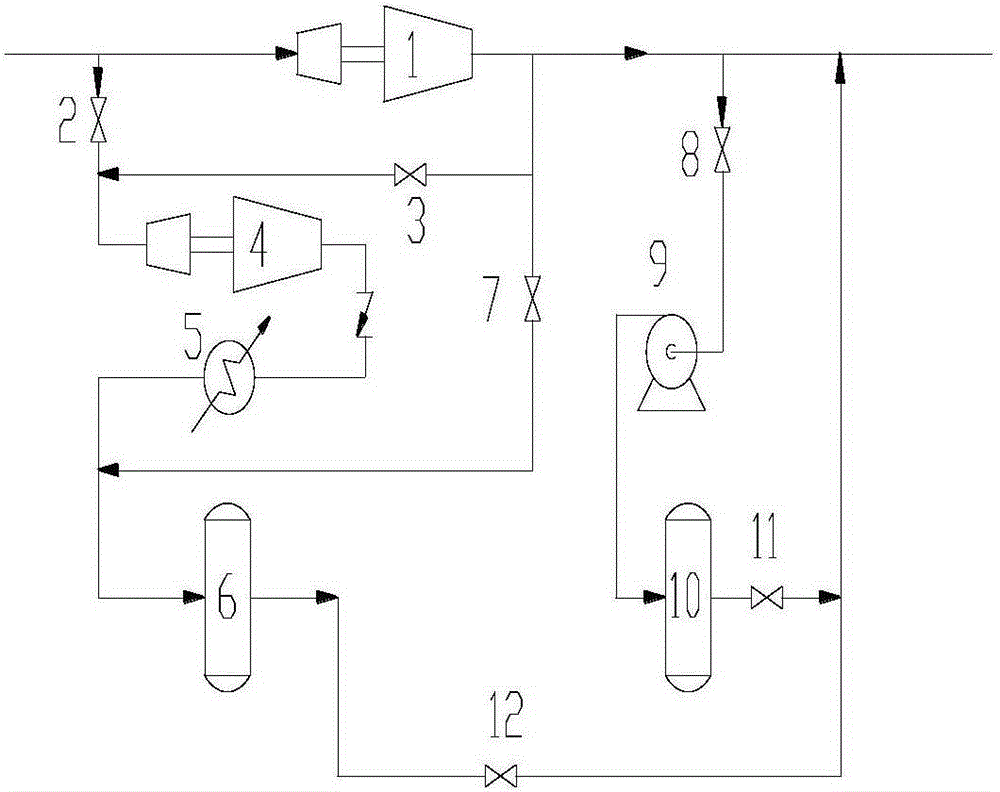

Technical method for totally recycling mixed cryogens

ActiveCN105180534AReduce emissions and wasteReduce economic lossRefrigeration componentsGas phaseEngineering

The invention relates to the technical field of cryogen recycling of the oil-gas industry, in particular to a technical method for totally recycling mixed cryogens. Cold cryogens and hot cryogens are isolated into two systems and recycled respectively. The hot low pressure cryogens are pressurized to be at a high pressure through a small compressor and stored in the high pressure state. The hot high pressure cryogens are recycled to a cryogen recycling tank through a cryogen pump, and after being depressurized, other gas phases are pressurized through a compressor to be recycled. The pressure of the low temperature cryogens is supplemented through a system, the low temperature cryogens are recycled to a low-temperature-cryogen recycling tank and stabilized by controlling the temperature, and when starting is carried out again, the low temperature side of a cold box is directly supplemented with the low temperature cryogens. The pre-cooling time is shortened, and meanwhile the cryogens can be totally recycled.

Owner:SICHUAN HENGRI GAS ENG CO LTD

Cold chain unit distribution box with independent cold storage space

PendingCN110758924APrevent frostbiteGuaranteed temperature managementLarge containersTank wagonsCold chainTemperature control

The invention discloses a cold chain unit distribution box with independent cold storage space. The cold chain unit distribution box comprises a machine box body, and cold storage space arranged in the machine box body; a cold storage device is arranged in the cold storage space; and an evaporator with a fan is arranged in the machine box body. The cold chain unit distribution box further comprises a compressor connected to the cold storage device and an outlet end of the evaporator with the fan, and a condenser connected to an outlet end of the compressor; and a refrigerant outlet end of thecondenser is connected to an expansion valve. The cold chain unit distribution box can preferably guarantee the temperature management of goods space, prevents the risk of no temperature control of cold chain goods by failures of an air cooler system, preferably retains a cooling plate to achieve more exquisite capacity of temperature difference control and temperature maintenance, prevents the problem of higher temperature difference in the temperature control process due to refrigeration and temperature maintenance always by the air cooler, and can meet the distribution demands with more exquisite temperature requirements.

Owner:ZHEJIANG XUEBOLAN TECH CO LTD

Bypass type low-temperature negative-pressure heat exchanger for pre-cooling type JT refrigerator and design method

ActiveCN112212719AIncrease the cooling capacity of the final stageImprove efficiencyCompression machinesStationary tubular conduit assembliesRefrigeration temperatureMechanical engineering

The invention discloses a bypass type low-temperature negative-pressure heat exchanger for a pre-cooling type JT refrigerating machine and a design method. The heat exchanger is composed of a high-pressure side pipeline, a low-pressure side pipeline, a bypass pipeline, a bypass element, a three-way element and a low-temperature negative-pressure dividing wall type heat exchanger. According to theinvention, the temperature and flow distribution of a fluid in the low-temperature negative-pressure heat exchanger are changed through the bypass pipeline, the irreversible loss of the pipeline and the pressure drop loss of the low-pressure pipeline side are reduced, the low-pressure pressure of the pre-cooling type JT refrigerating machine after throttling is reduced, and the final-stage refrigerating temperature of the pre-cooling type JT refrigerating machine is reduced; the flow velocity of a high-low pressure pipeline fluid in the low-temperature negative-pressure dividing wall type heatexchanger is increased, so that the heat exchange efficiency of the low-temperature negative-pressure heat exchanger is improved; the fluid temperature before throttling is reduced, and the refrigerating capacity of the pre-cooling type JT refrigerating machine is increased; and the overall efficiency of the pre-cooling type JT refrigerating machine is improved. The bypass type low-temperature negative-pressure heat exchanger for the pre-cooling type JT refrigerator and the design method have very positive significance for application of the pre-cooling type JT refrigerator in special fieldssuch as extremely low temperature areas, aerospace and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

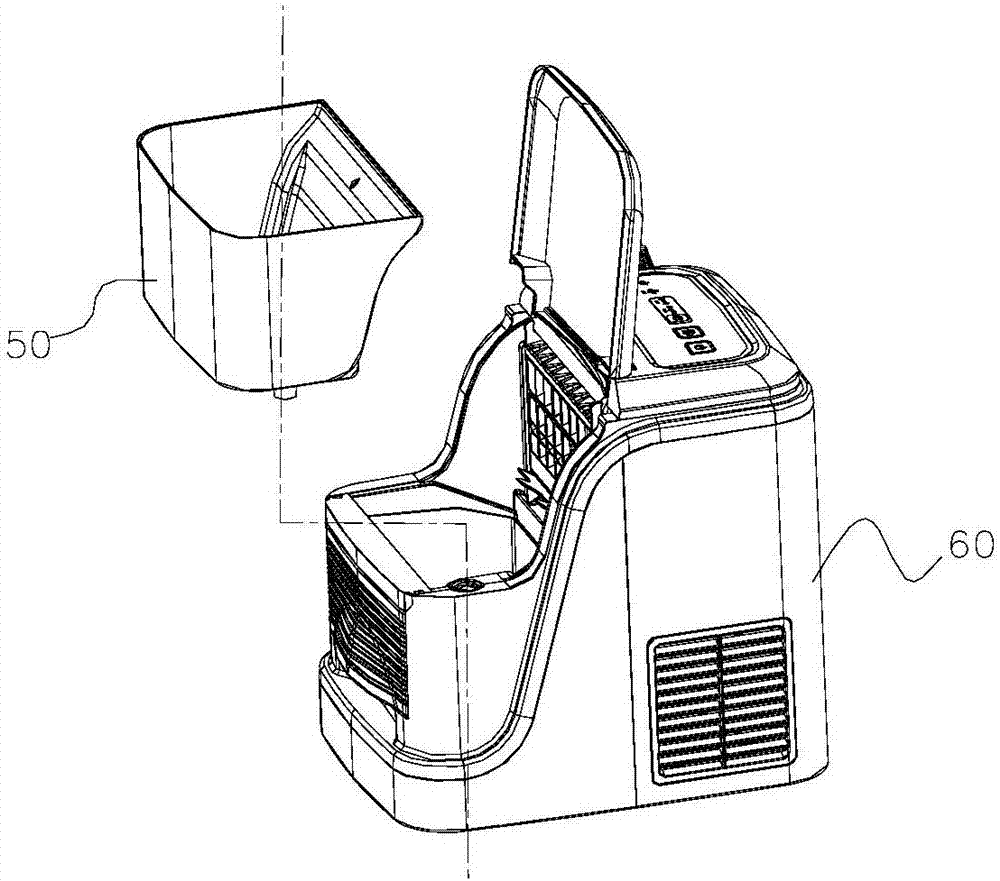

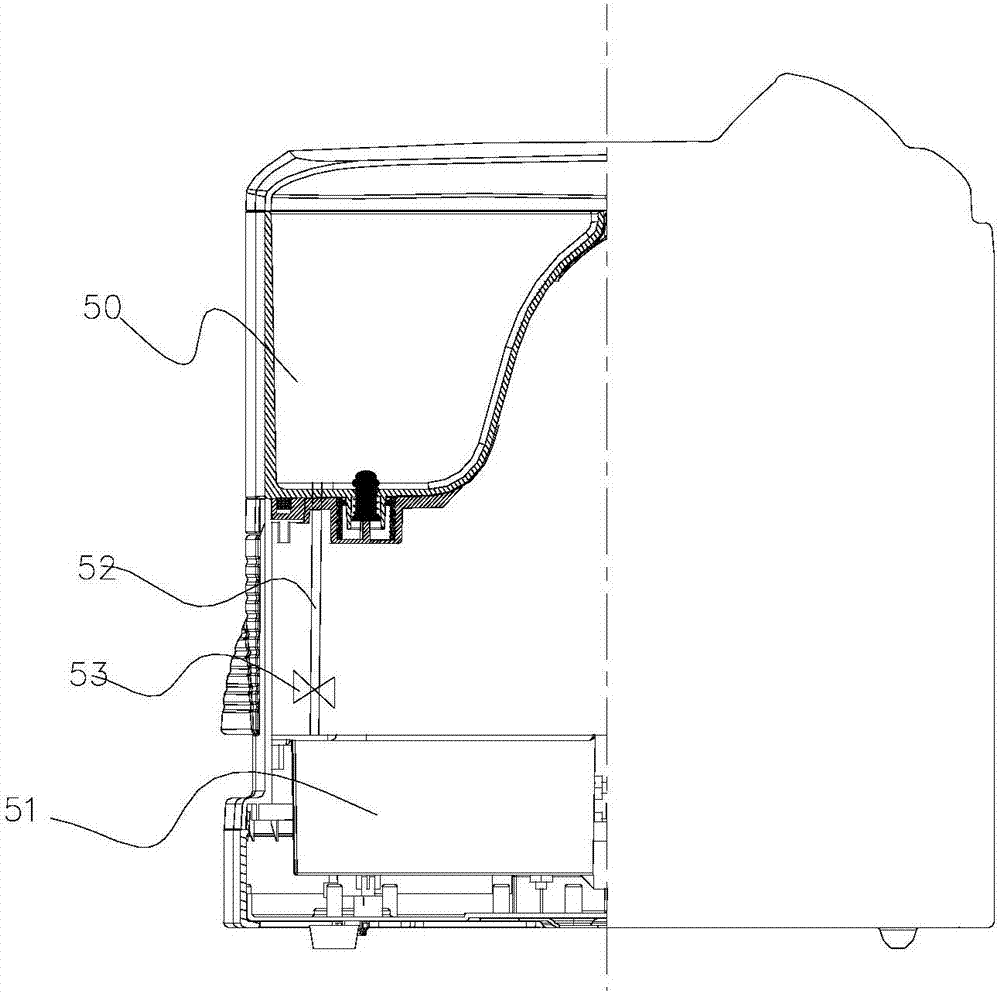

External water tank and ice maker

PendingCN106918174AShorten pre-cooling timeImprove ice production efficiencyLighting and heating apparatusIce productionPre coolingWater tanks

The invention discloses an external water tank and an ice maker. The external water tank is of an inverted cone structure. The ice maker comprises an ice maker body and the external water tank arranged outside the ice maker body. The external water tank communicates with an internal water tank located in the ice maker body. A flow controller is arranged in a communicating channel between the external water tank and the internal water tank. The external water tank is used for supplement so that the size of the internal water tank can be designed to be smaller; on the one hand, the external water tank can supply water into the internal water tank continuously according to requirements, and thus the defect of frequently adding water into the internal water tank can be overcome; and on the other hand, the volume of the internal water tank is reduced, the amount of water contained in the internal water tank is reduced accordingly, the amount of water, needing to be pre-cooled before ice making, in the internal water tank is reduced, the pre-cooling time is shortened, and thus the effect of improving the ice making efficiency can be achieved.

Owner:ZHONGSHAN DONLIM WEILI ELECTRICAL APPLIANCES CO LTD

Postharvest pre-cooling method for leaf vegetables

PendingCN111374172AReach the storage conditionReduce pre-cooling cycle timeFruits/vegetable preservation by freezing/coolingEngineeringHorticulture

The invention discloses a postharvest pre-cooling method for leaf vegetables. The postharvest pre-cooling method comprises the following steps: (1) picking water-free leaf vegetables, and placing theleaf vegetables in a grading manner according to plant sizes and grades of maturity; (2) putting the leaf vegetables into a low-temperature refrigerator, carrying out frosting at (-2)-0 DEG C for 1-3hours until moisture in the leaf vegetables is adequately frozen; (3) carrying out staged vacuum temperature-varying pre-cooling; (4) putting the pre-cooled leaf vegetables into packaging bags, and filling the packaging bags with fresh gas; (5) stacking the bagged leaf vegetables, putting the bagged leaf vegetables into a pass box, and arranging a wood pulp paper layer between every two layers ofthe packaging bags; and (6) storing the full pass box under a refrigeration condition of 0-4 DEG C. According to the postharvest pre-cooling method, a vacuum pre-cooling link is added into a preliminary working production process chain of a postharvest production place of the leaf vegetables, so that a pre-cooling link is shortened, a storage condition of the processed leaf vegetables can be faster realized, and the problems that the pre-cooling time is too long, field heat cannot be timely removed, and the quality of the leaf vegetables is degraded are avoided.

Owner:CHENGDU ACAD OF AGRI & FORESTRY SCI

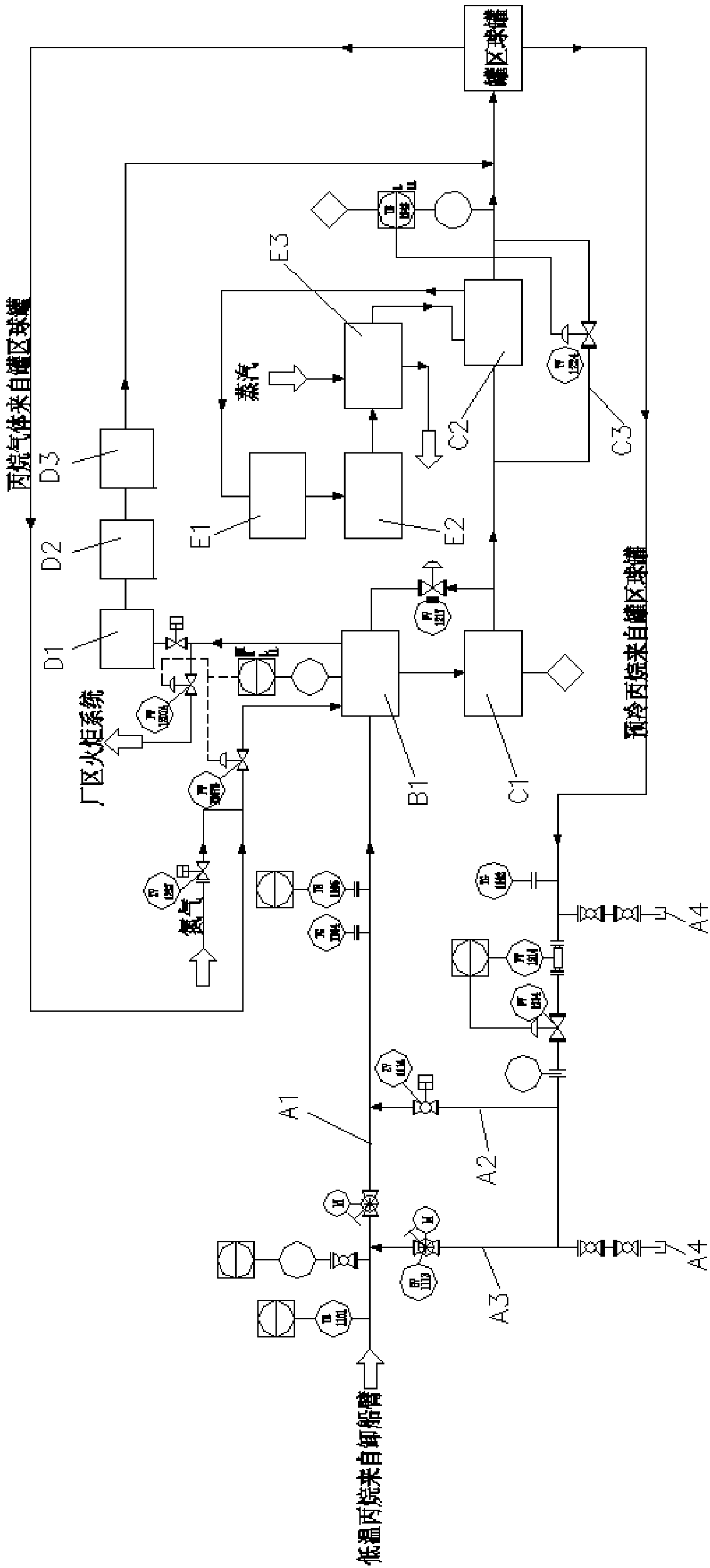

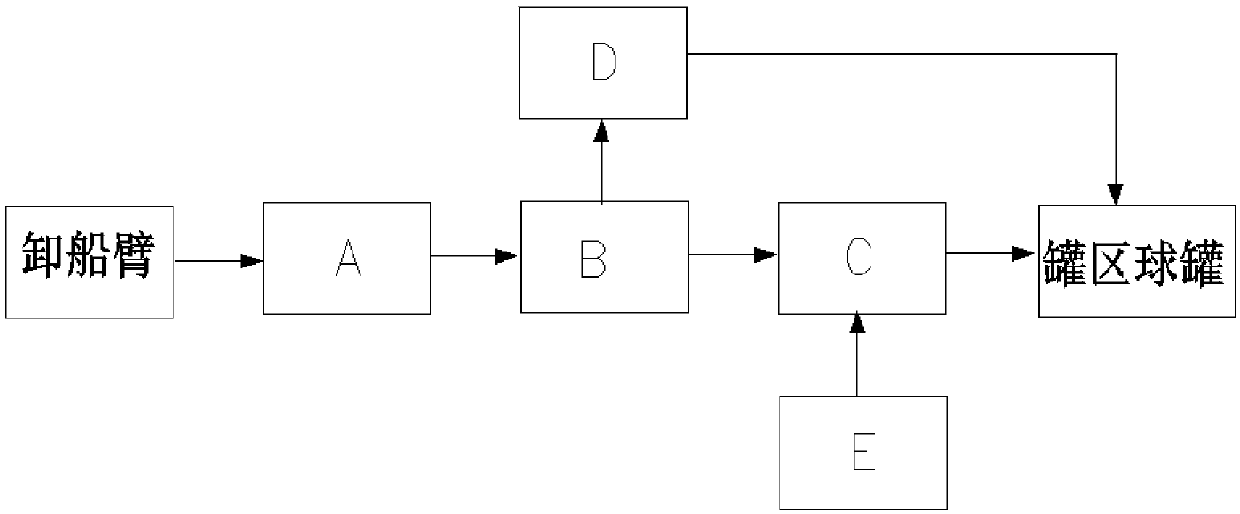

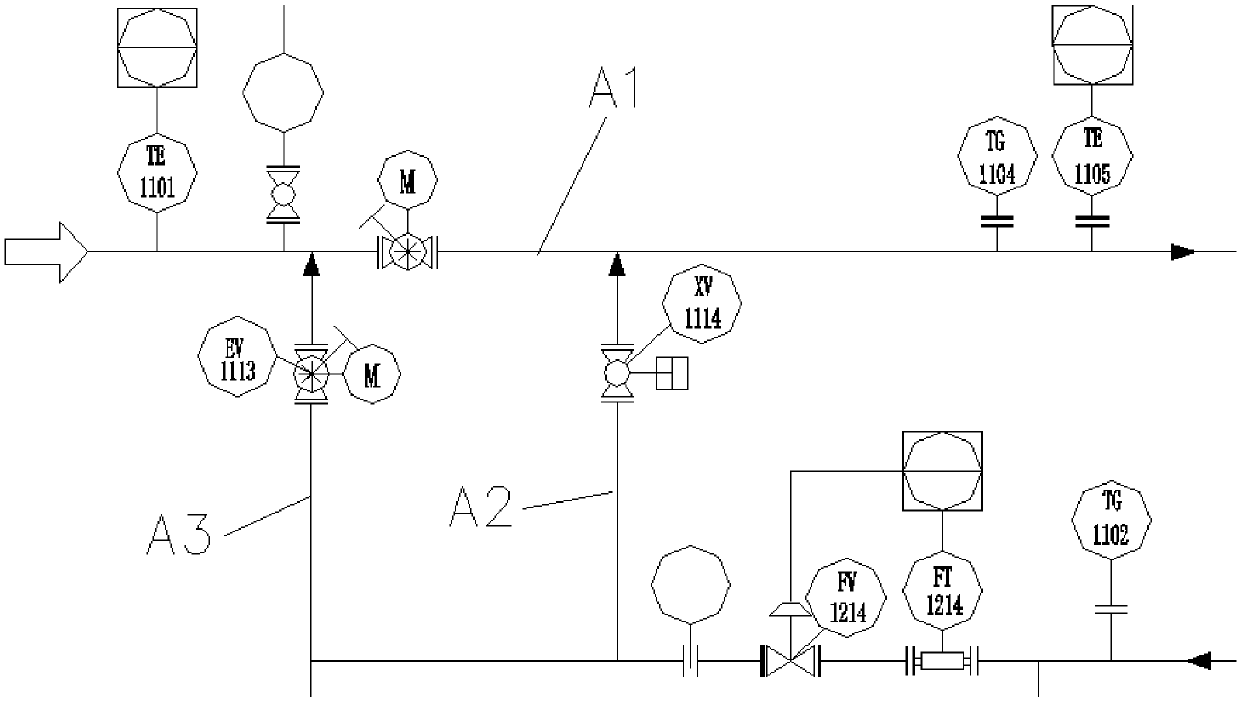

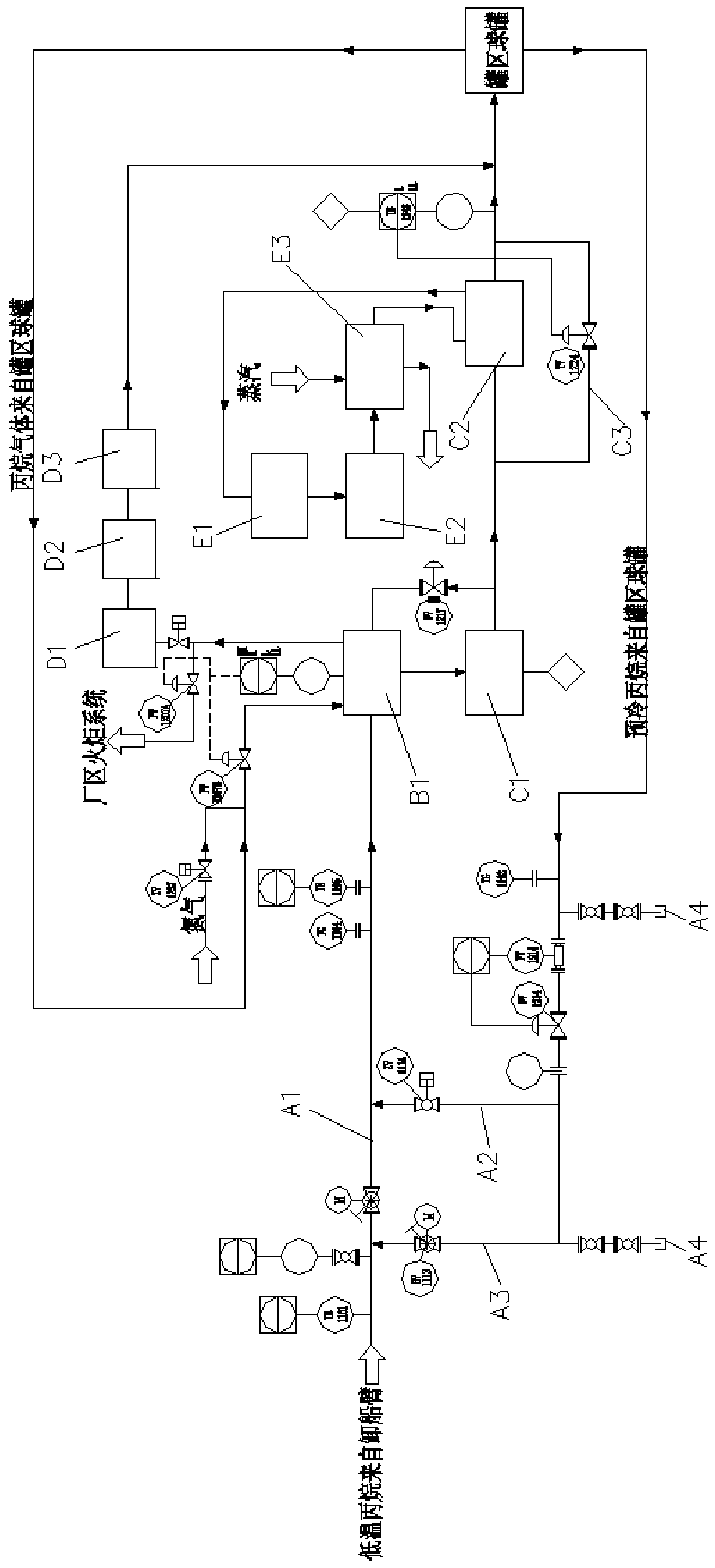

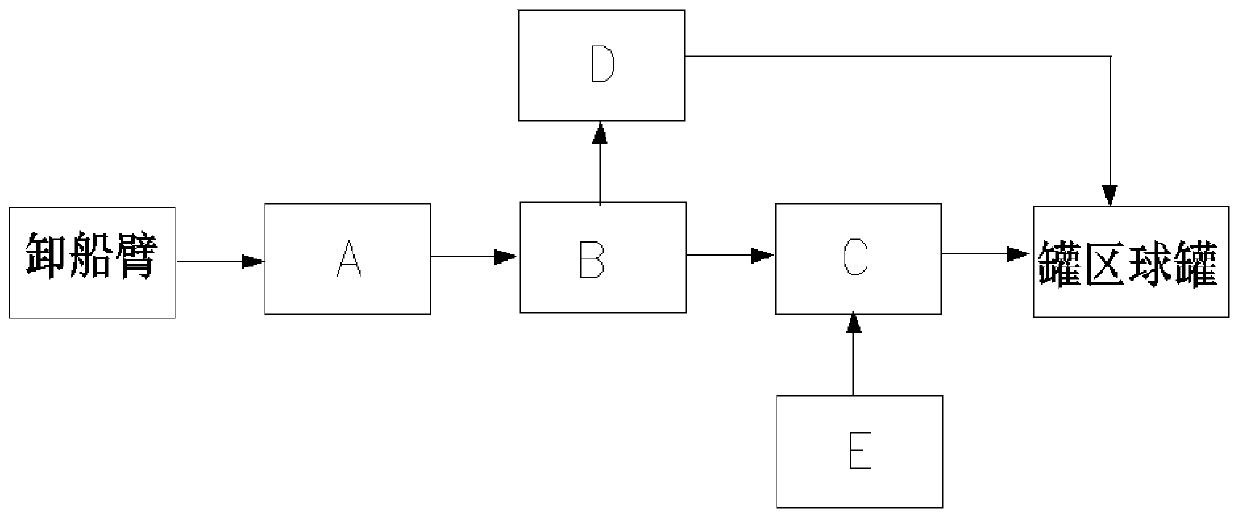

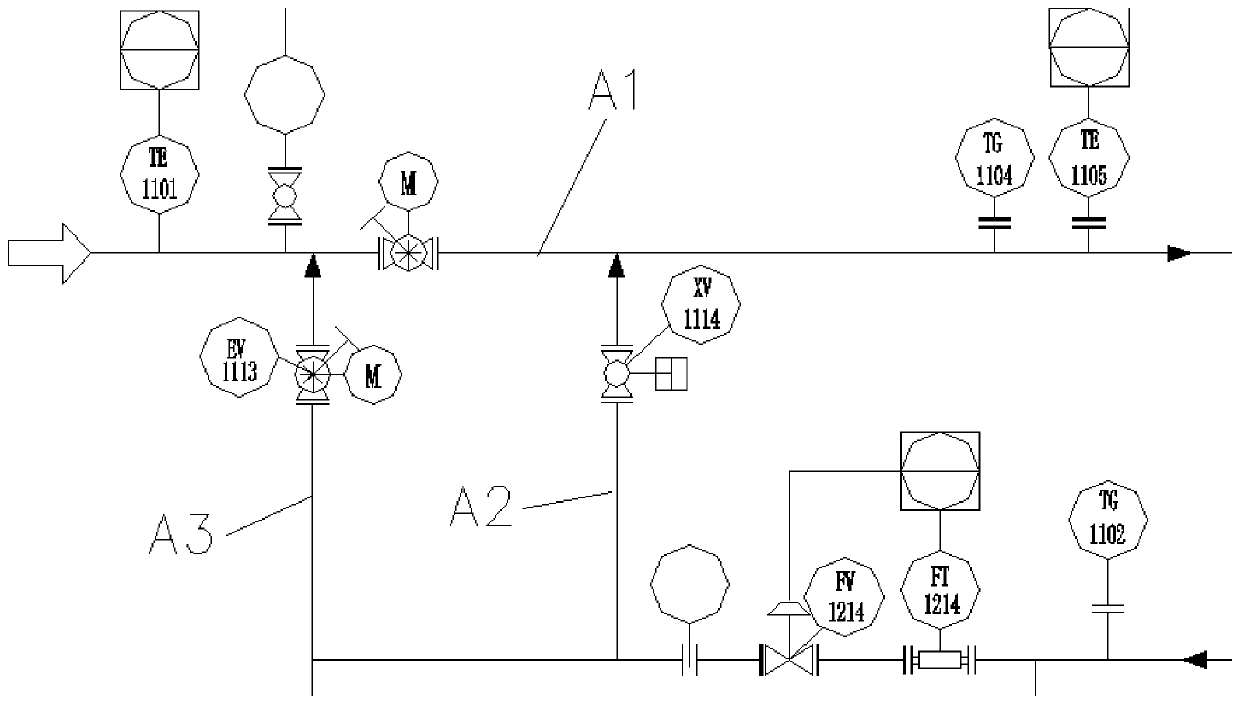

Low-temperature propane ship unloading and heating process

ActiveCN109553058AShorten pre-cooling timeLess investmentLiquid transferring devicesEngineeringCarbon steel

The invention provides a low-temperature propane ship unloading and heating device and process. The device comprises a ship unloading arm, a pre-cooling unit, a pre-cooling buffering unit, a heating and boosting unit and a tank area spherical tank, wherein the ship unloading arm, the pre-cooling unit, the pre-cooling buffering unit, the heating and boosting unit and the tank area spherical tank are sequentially connected with one another, the pre-cooling buffering unit is connected with a condensate recovery unit, and the heating and boosting unit is connected with a heat exchange unit. The device has the beneficial effects that the whole set of ship unloading and heating device and process comprising a pre-cooling pipeline are designed, the pre-cooling time of a ship unloading pipeline iseffectively shortened through a segmented pre-cooling mode, and the stability and the safety of the pre-cooling process are high; and the heating and boosting unit of low-temperature propane is arranged, the received low-temperature propane can be heated to 10 DEG C-0 DEG C, and low-temperature steel can be replaced conveniently by a common carbon steel material for a spherical tank of a subsequent storage device, so that the investment of the spherical tank equipment is saved.

Owner:天津辰力工程设计有限公司

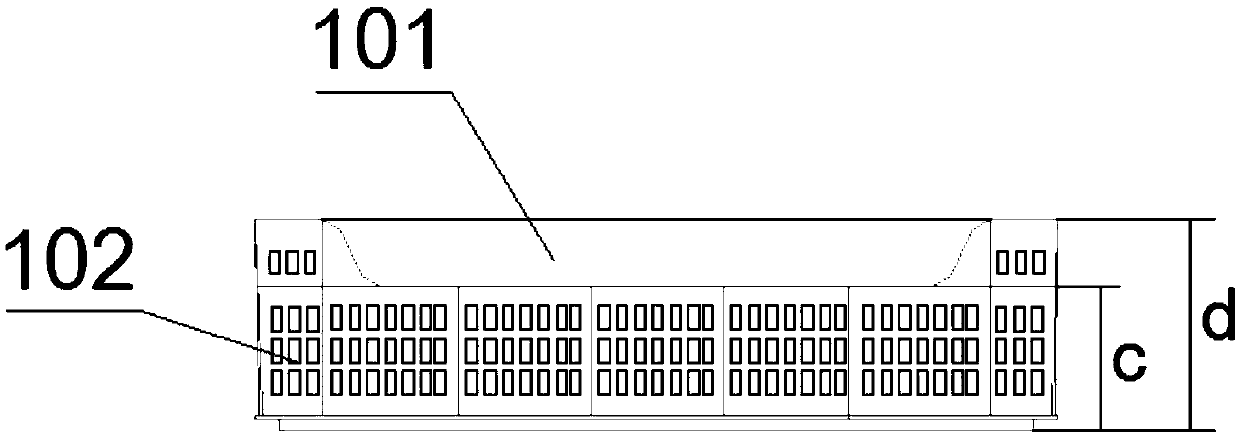

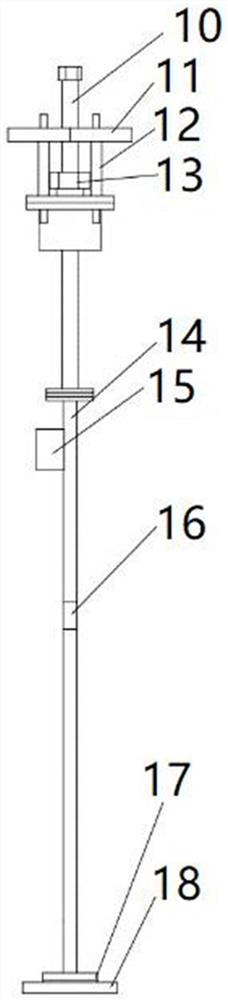

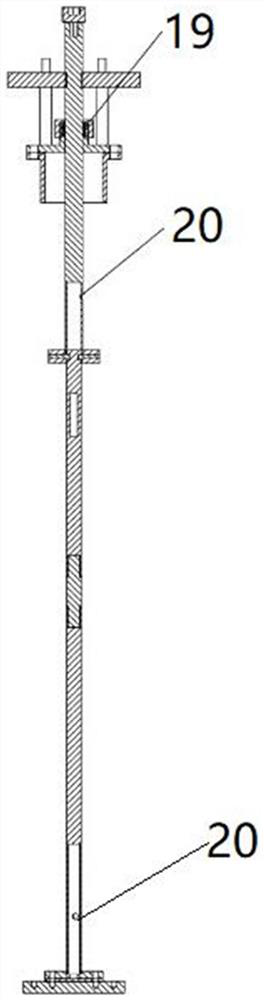

Pre-cooling device of superfluid helium system

ActiveCN114279167AShorten pre-cooling timeRapid coolingSolidificationLiquefactionEngineeringCooling capacity

The embodiment of the invention provides a precooling device of a superfluid helium system. The precooling device comprises a vacuum cover, a refrigerating machine, a heat exchanger, a condenser, a superfluid helium cavity, a low-temperature throttling valve and a mechanical thermal switch. The refrigerating machine is provided with a first-stage cold head and a second-stage cold head, and the first-stage cold head and the second-stage cold head are both located in the vacuum cavity of the vacuum cover. The first-stage cold head is connected with the heat exchanger, the second-stage cold head is connected with the condenser, and the low-temperature throttling valve is connected with the condenser and the superfluid helium cavity, so that liquid helium is converted into superfluid helium. The mechanical thermal switch is inserted in the vacuum cover in a lifting mode, one end of the mechanical thermal switch penetrates into an inner cavity of the vacuum cover and extends to the superfluid helium cavity, a heat conduction flange is arranged at the lower end of the mechanical thermal switch, and the heat conduction flange can make contact with or be separated from the superfluid helium cavity. The heat conduction flange is connected with the first-stage cold head through a heat conduction piece so as to transmit the cooling capacity of the first-stage cold head to the heat conduction flange. The precooling device can greatly shorten the precooling time of the superfluid helium system.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

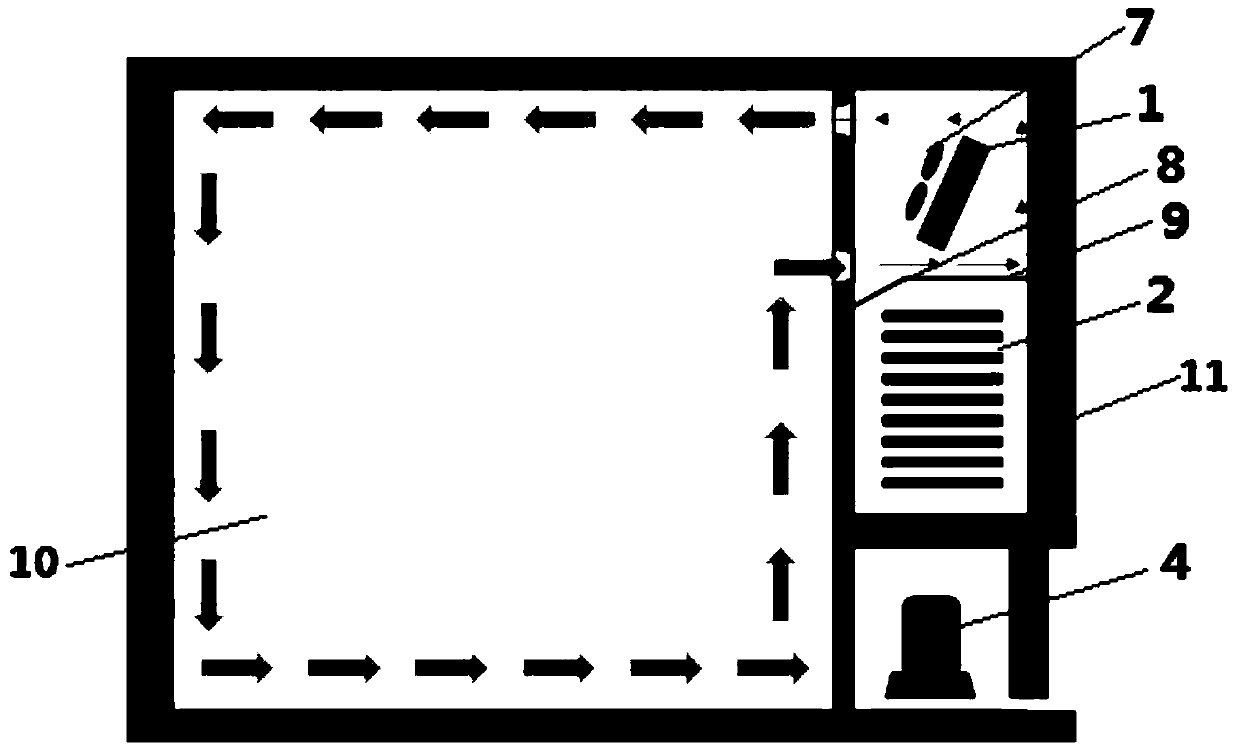

Fresh-keeping device with good fresh-keeping effect and control method for fresh-keeping device

PendingCN111426116APrevent spoilageReduced activityLighting and heating apparatusDomestic refrigeratorsThermodynamicsEngineering

The invention provides a fresh-keeping device with a good fresh-keeping effect and a control method for the fresh-keeping device. The fresh-keeping device comprises a refrigerating device, a fresh-keeping box, and a heat exchange accelerating mechanism which is arranged in an inner container and used for accelerating the gas flow rate in the inner container. According to the fresh-keeping device with the good fresh-keeping effect and the control method for the fresh-keeping device, a secondary refrigerant is arranged between a shell and the inner container, the influence caused by environmenttemperature fluctuation is avoided through the buffering effect of the secondary refrigerant, then the temperature fluctuation in the inner container is controlled within the range of + / -0.2 DEG C, sothat food spoilage is avoided, the eating quality of food is guaranteed, the storage period of food is prolonged, meanwhile, the gas flow rate in the inner container is increased through the heat exchange accelerating mechanism, thus the heat transfer rate in the inner container is increased, in addition, the heat transfer rate and the heat transfer area are increased through corrugated plates made of metal, the heat transfer rate is further increased, so that the pre-cooling time is greatly shortened, and the fresh-keeping effect of the fresh-keeping device is improved.

Owner:GREE ELECTRIC APPLIANCES INC

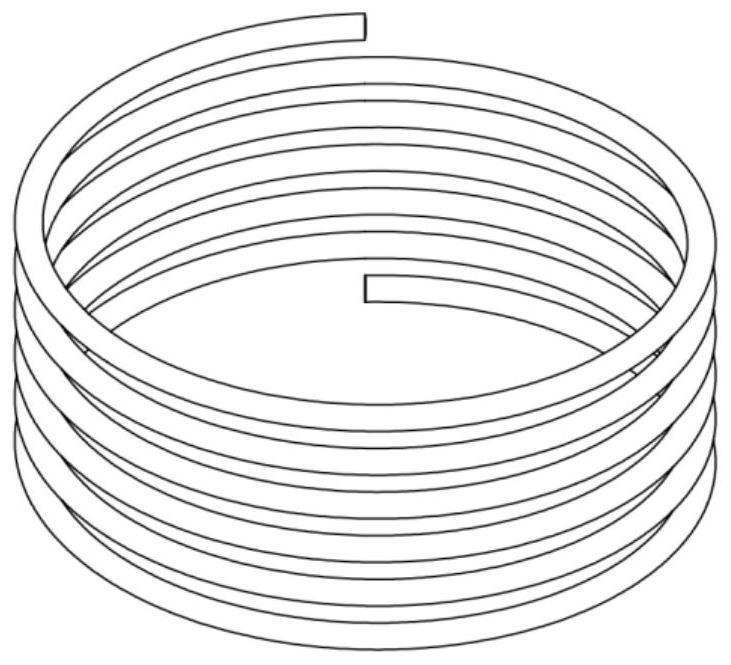

Real-time cooling draught beer machine adopting graphite solid heat exchange

PendingCN110470101AAvoid replacementShorten pre-cooling timeLighting and heating apparatusRefrigeration devicesTemperature controlControl system

The invention discloses a real-time cooling draught beer machine adopting graphite solid heat exchange. The real-time cooling draught beer machine comprises a heat exchange module, a temperature detector, a temperature controller, a fan, a compressor, a heat radiator, a filter and a capillary tube. The heat exchange module comprises a sealing shell, a beer drainage coil pipe, a condensation pipe coil pipe and a temperature inductor. The beer drink coil pipe is fixedly mounted in the sealing shell. The real-time cooling draught beer machine adopting graphite solid heat exchange carries out cooling through a solid efficient heat conducting medium and has the following advantages that 1) a water cooling system is replaced, a water medium does not need to be replaced, and the cost is reduced;2) the cooling efficiency is high, and the cooling amount of beer is increased; 3) the heat exchange rate is increased without stirring cold water, electric energy is saved, and the cost is reduced; 4) a circuit control system of an ice making system is omitted, the problem that ice is not made in time is solved, and the related part cost is reduced; and 5) the solid efficient heat conducting medium is used, so that the product is small in size and low in weight and can be used in the family.

Owner:上海陆蒙贸易有限公司

A filling process of LNG skid-mounted filling station

InactiveCN104390127BGuaranteed gas supplyReduce lossContainer discharging methodsContainer filling under pressureEconomic benefitsEngineering

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

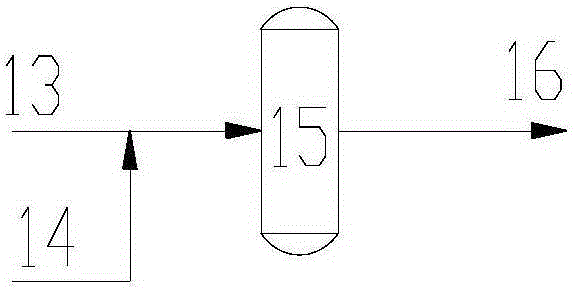

A rapid precooling method for low temperature medium pipeline system

ActiveCN113124320BReduce consumptionImprove utilization efficiencyPipeline systemsFluid handling accessoriesProcess engineeringCooling capacity

The invention relates to a pre-cooling process for a low-temperature medium pipeline, in particular to a rapid pre-cooling method for a low-temperature medium pipeline system, which is used to solve the problems of long pre-cooling time and low utilization efficiency of low-temperature medium cooling capacity existing in the prior art. However, a rapid pre-cooling method for a low temperature medium pipeline system is provided. The rapid pre-cooling method of the low-temperature medium pipeline system includes the following steps: 1) injecting low-temperature medium into the low-temperature container; 2) using high pressure and small flow mode to perform pre-cooling in the early stage; 3) switching the mode for the first time; The flow mode is pre-cooled in the middle; 5) The second mode is switched; 6) The low-pressure small flow is used for the post-cooling.

Owner:XIAN AEROSPACE PROPULSION INST

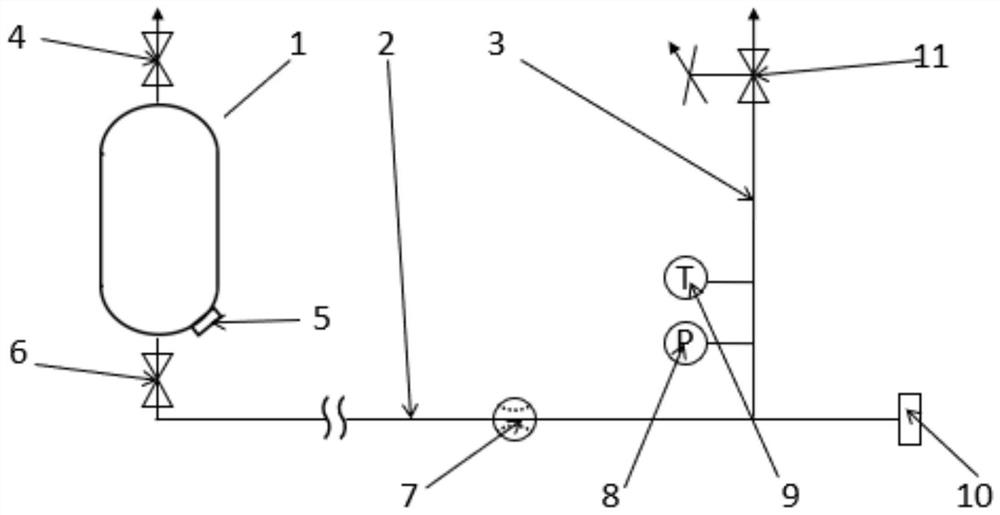

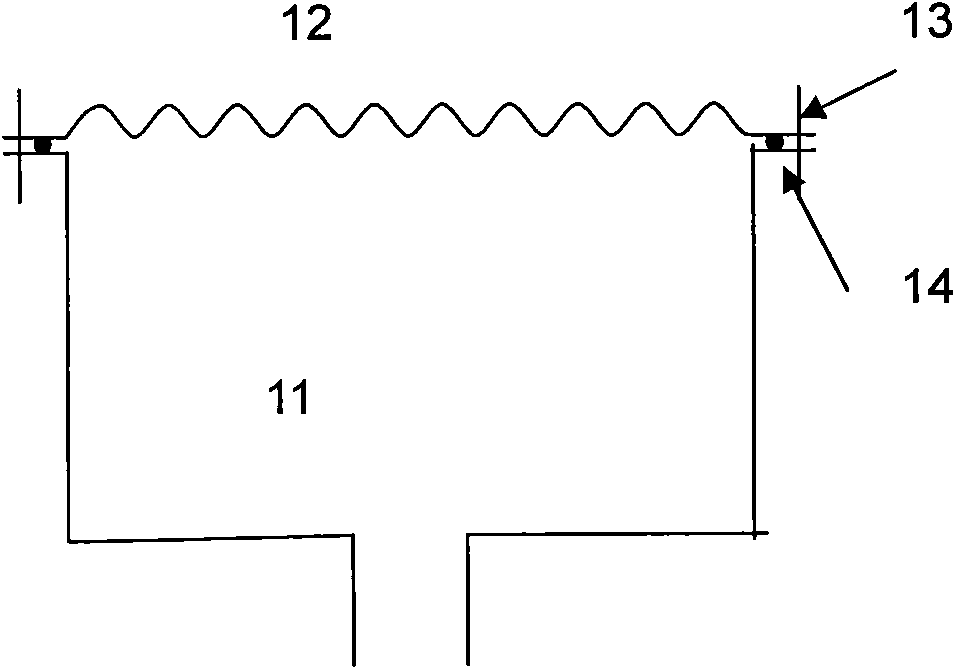

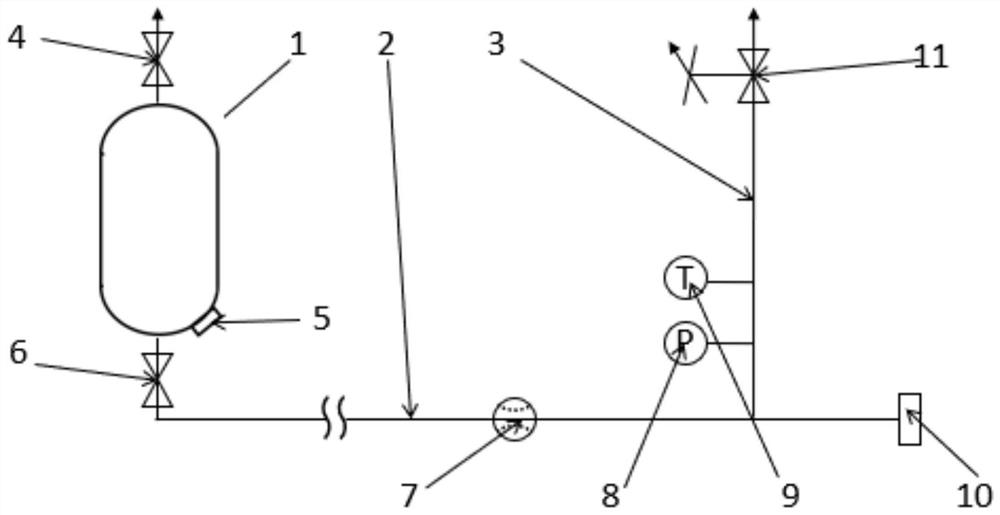

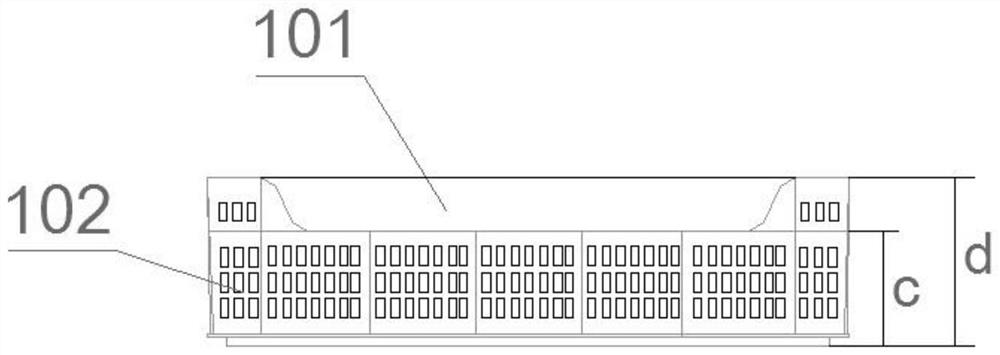

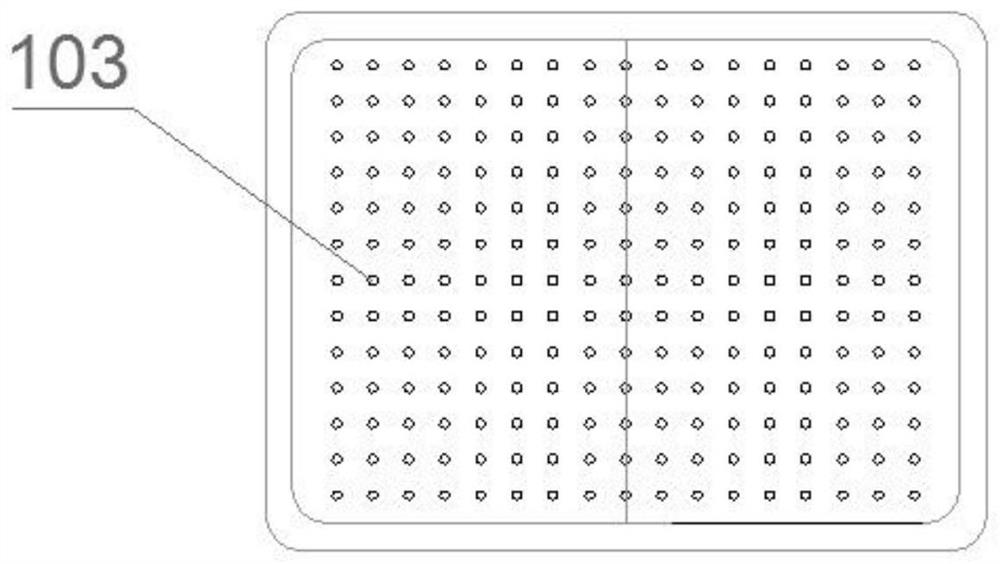

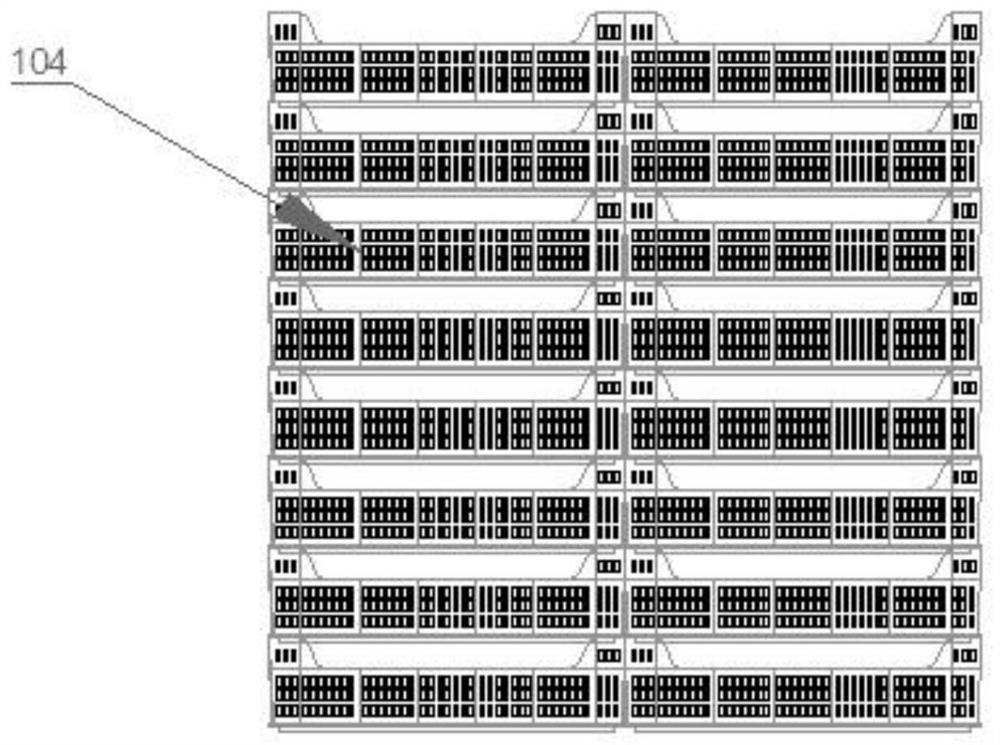

A pre-cooling device before filling liquid helium storage tank

ActiveCN112944802BReduce consumptionGuaranteed puritySolidificationLiquefactionLiquid hydrogenProcess engineering

The patent of the present invention discloses a precooling device before filling a liquid helium storage tank, which relates to the technical field of liquid helium storage tank precooling, including a liquid helium storage tank, a throttle valve, a cryogenic pump, a heat exchanger, a compressor, and a safety valve , injection device, liquid helium storage tank, density meter, one-way valve, second injection device, control unit and various stop valves, etc. The present invention adopts the method of "preliminary liquid hydrogen precooling + helium immersion precooling + liquid helium evaporation precooling". Reduced, process economic benefits improved. The invention adopts the method of helium soaking and precooling to further cool the liquid helium storage tank, liquefy the residual hydrogen and discharge it, and ensure the purity of the product quality is qualified. Heat rate, reduce pre-cooling time.

Owner:SOUTHWEST PETROLEUM UNIV

Pulse tube refrigerator with elastic air reservoir

InactiveCN101832675BShorten pre-cooling timeReduce chargeCompression machinesGas cycle refrigeration machinesPlate heat exchangerPulse tube refrigerator

The invention discloses a pulse tube refrigerator with an elastic air reservoir. The pulse tube refrigerator comprises a compressor, a transport tube, a water cooler, a heat regenerator, a cold end connecting pipe, a cold end heat exchanger, a pulse tube, a hot end heat exchanger, an inertance tube and an elastic air reservoir. The compressor is sequentially connected with the transport tube, thewater cooler, the heat regenerator, the cold end connecting pipe, the cold end heat exchanger, the pulse tube, the hot end heat exchanger, the inertance tube and the elastic air reservoir. A pulse tube refrigerator is usually provided with a huge air reservoir to obtain a better performance. The pulse tube refrigerator with the elastic air reservoir can obtain the same phase modulation effect with just a few percent of a common air reservoir in volume after employing the elastic air reservoir, so that the whole system becomes compact, and the charging quantity of working medium is reduced, which is particularly important for rare helium-4 and helium-3. As for the air reservoir in low temperature, the elastic air reservoir can shorten the cooling time and accelerate the cooling speed of a system.

Owner:ZHEJIANG UNIV

a superconducting cable

ActiveCN107103958BShorten pre-cooling timeSpeed up coolingSuperconductors/hyperconductorsSuperconductor devicesNitrogenGuide tube

The invention discloses a superconducting cable. The cable comprises an external wrapping insulating protective layer, a conduit arranged in the external wrapping insulating protective layer and a superconductor arranged in the conduit, the conduit is provided with a nitrogen inlet tube and a nitrogen outlet tube, both the nitrogen inlet tube and the nitrogen outlet tube penetrate the external wrapping insulating protective layer, and the superconductor is of a hexagonal grid type and forms a tubular spatial topology structure. Precooling time, before use, of the superconducting cable is short.

Owner:广州市壹缆电缆实业有限公司

A kind of low temperature propane unloading and heating technology

ActiveCN109553058BShorten pre-cooling timeLess investmentLiquid transferring devicesEngineeringMechanical engineering

The invention provides a low-temperature propane ship unloading and heating device and process. The device comprises a ship unloading arm, a pre-cooling unit, a pre-cooling buffering unit, a heating and boosting unit and a tank area spherical tank, wherein the ship unloading arm, the pre-cooling unit, the pre-cooling buffering unit, the heating and boosting unit and the tank area spherical tank are sequentially connected with one another, the pre-cooling buffering unit is connected with a condensate recovery unit, and the heating and boosting unit is connected with a heat exchange unit. The device has the beneficial effects that the whole set of ship unloading and heating device and process comprising a pre-cooling pipeline are designed, the pre-cooling time of a ship unloading pipeline iseffectively shortened through a segmented pre-cooling mode, and the stability and the safety of the pre-cooling process are high; and the heating and boosting unit of low-temperature propane is arranged, the received low-temperature propane can be heated to 10 DEG C-0 DEG C, and low-temperature steel can be replaced conveniently by a common carbon steel material for a spherical tank of a subsequent storage device, so that the investment of the spherical tank equipment is saved.

Owner:天津辰力工程设计有限公司

Precooling method for infiltrative type low-temperature liquid pump

InactiveCN103075334AAvoid wastingShorten pre-cooling timePositive displacement pump componentsLiquid fuel engine componentsLiquefied natural gasSafety coefficient

The invention discloses a precooling method for an infiltrative type low-temperature liquid pump. The method comprises the following steps of: (1) preparing two storage tanks between which a pressure difference exists, wherein the storage tanks are connected in series with the infiltrative type low-temperature liquid pump through a pipeline and a valve body arranged on the pipeline respectively; (2) opening the valve, feeding a low-temperature liquid into a low-pressure storage tank from a high-pressure storage tank by the infiltrative type low-temperature liquid pump while precooling the infiltrative type low-temperature liquid pump; and (3) when the temperature of the infiltrative type low-temperature liquid pump falls below a usage temperature according to display of a computer, which indicates that the infiltrative type low-temperature liquid pump is pre-cooled fully and can be put into use, starting the infiltrative type low-temperature liquid pump. Compared with the conventional precooling technology for an infiltrative type low-temperature liquid pump, the precooling method has the advantages that waste caused by precooling of the infiltrative type low-temperature liquid pump through low temperature dissipating liquids (such as substance which are gaseous at the normal temperature including liquefied natural gas and liquefied coal gas) is avoided, the precooling time is shortened, energy and precooling time are saved, the safety coefficient is increased, and the production cost is lowered.

Owner:SHANDONG TAISHAN STEEL GROUP

Quick precooling method of low-temperature medium pipeline system

ActiveCN113124320AReduce consumptionImprove utilization efficiencyPipeline systemsFluid handling accessoriesProcess engineeringIndustrial engineering

The invention relates to a precooling process of a low-temperature medium pipeline, in particular to a quick precooling method of a low-temperature medium pipeline system. The quick precooling method of the low-temperature medium pipeline system is used for overcoming the defects of long precooling time and lower utilization efficiency of cold energy of a low-temperature medium in the prior art. The quick precooling method of the low-temperature medium pipeline system comprises the following steps of: 1) injecting a low-temperature medium into a low-temperature container; 2) performing early-stage precooling by adopting a high-pressure small-flow mode; 3) performing first-time mode switching; 4) performing middle-stage precooling by adopting a low-pressure large-flow mode; 5) performing second-time mode switching; and 6) performing later-stage precooling by adopting a low-pressure small flow.

Owner:XIAN AEROSPACE PROPULSION INST

Pre-cooling device before filling of liquid helium storage tank

ActiveCN112944802AReduce consumptionGuaranteed puritySolidificationLiquefactionEngineeringLiquid hydrogen

The invention discloses a pre-cooling device before filling of a liquid helium storage tank, and relates to the technical field of pre-cooling of liquid helium storage tanks. The pre-cooling device comprises the liquid helium storage container, a throttle valve, a low-temperature pump, a heat exchanger, a compressor, a safety valve, an injection device, a liquid helium storage tank, a densitometer, a one-way valve, a second injection device, a control unit, various stop valves and the like. A method of liquid hydrogen preliminary pre-cooling, helium soaking pre-cooling and liquid helium evaporation pre-cooling is adopted, compared with other pre-cooling devices, cold energy of helium in the liquid helium storage container is fully utilized, the liquid helium consumption is reduced, and the process economic benefits are improved. A helium soaking pre-cooling method is adopted, the liquid helium storage tank is further cooled, residual hydrogen is liquefied and discharged, it is guaranteed that the purity of a product is qualified, meanwhile, a liquid helium evaporation pre-cooling method is adopted, the heat exchange rate of helium and the liquid helium storage tank is increased, and the pre-cooling time is shortened.

Owner:SOUTHWEST PETROLEUM UNIV

An integrated basket for picking, precooling and storage, application thereof, and precooling method for perishable fruits with small diameters

ActiveCN109645105BAchieve standardizationRealize semi-automatic operationFood processingPackaging fruits/vegetablesCold chainProcess engineering

The invention provides an integrated basket for picking, pre-cooling and storage, an application thereof, and a pre-cooling method for small-diameter perishable fruits, belonging to the technical field of post-harvest processing of fruits and vegetables. Based on the design of an integrated basket for picking, pre-cooling and storage, the present invention adopts standard picking, pre-cooling, storage boxes, trays and other methods to successfully propose a pre-cooling method for perishable fruits with small diameters, which is conducive to realizing the cold chain process. standardization, realizing semi-automatic operation in its process, saving manpower and time. At the same time, the invention adopts the method of critical freezing injury temperature to supply air, which can effectively reduce the pre-cooling time and energy consumption of pre-cooling. The pre-cooling method of supplying air with variable wind direction improves the uniformity of the pre-cooling process and stops the dead zone phenomenon of pre-cooling and heat transfer. energy consumption.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com