Liquid cooked food processing facility and method

A processing equipment and cooked food technology, applied in food freezing, food science, etc., can solve the problems of reducing food delivery efficiency and wasting energy, and achieve the effects of saving pre-cooling time, reducing energy consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

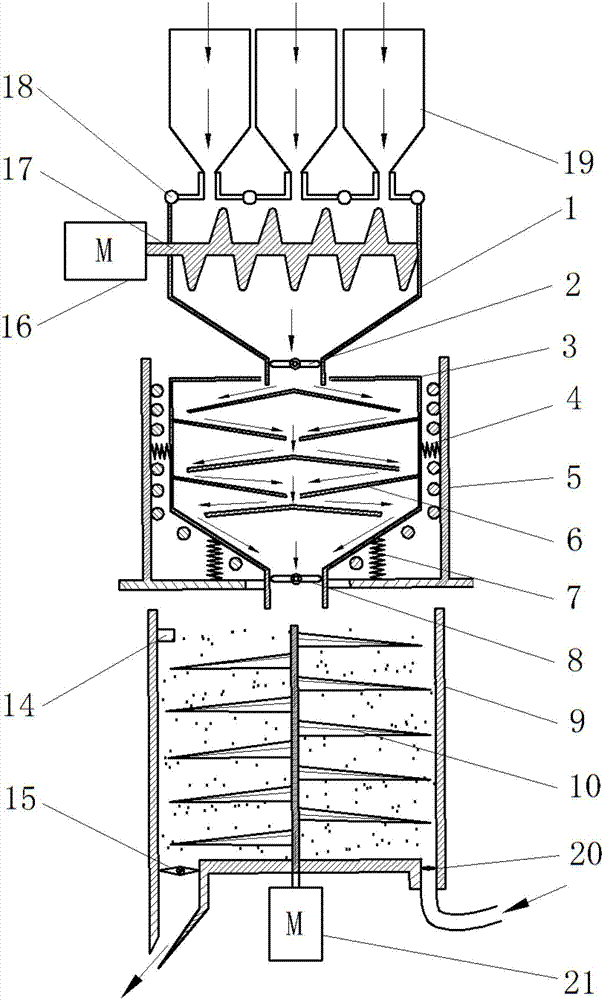

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

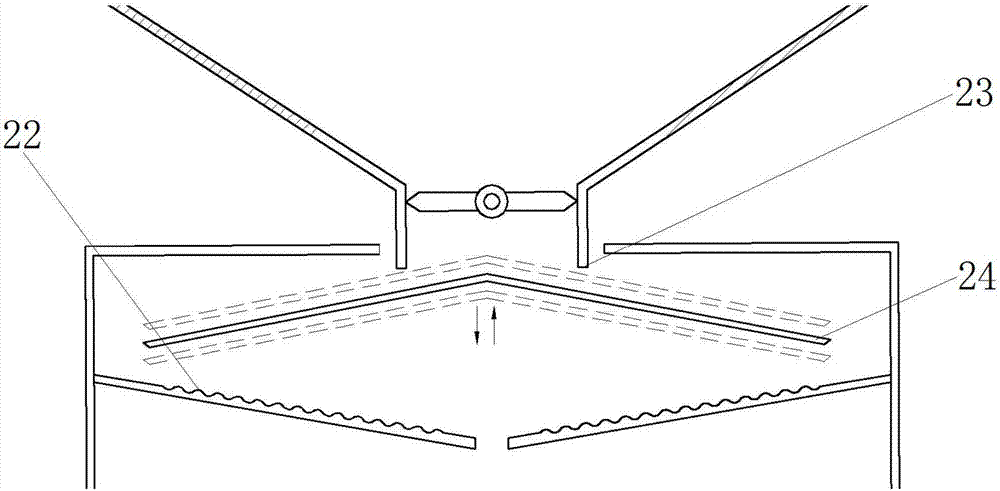

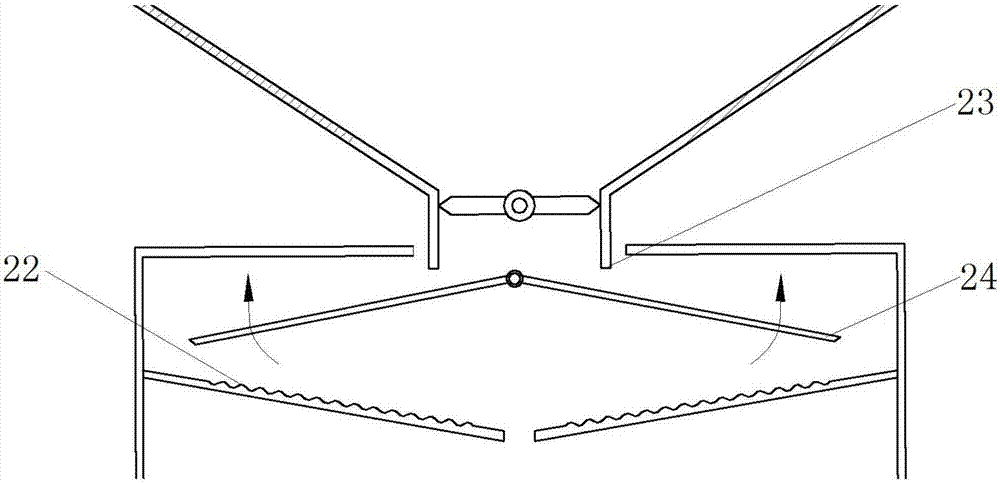

[0032] as attached figure 1 As shown, a liquid cooked food processing equipment includes a pre-mixing container water spray ball 18, a pre-mixing turbine 17, a pre-mixing turbine motor 16, a water level sensor 14, a pre-mixing container 1, a pre-mixing container flow control valve 2, and a microwave heating reaction container 3. Horizontal support spring 4, vibrating plate 5, longitudinal spring support 7, microwave heating reaction container flow control valve 8, crushing and stirring container 9, rotary blade 10, rotary blade motor 21, outlet guide plate 11, final food outlet valve 15 and water injection valve 20; several feeding devices are arranged at the top of the premixing container 1, and a premixing container outlet is arranged at the bottom of the premixing container 1; several premixing container water spray balls 18 are evenly arranged in the premixing cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com