Bypass type low-temperature negative-pressure heat exchanger for pre-cooling type JT refrigerator and design method

A low-temperature negative pressure and heat exchanger technology, applied in refrigerators, heat exchanger types, indirect heat exchangers, etc., can solve the problem that high-efficiency low-temperature negative pressure partition wall heat exchangers are rare, and the high-pressure side gas cannot be fully obtained. Cooling, affecting the performance of refrigerators, etc., to achieve the effect of improving temperature field distribution, improving mass flow distribution, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

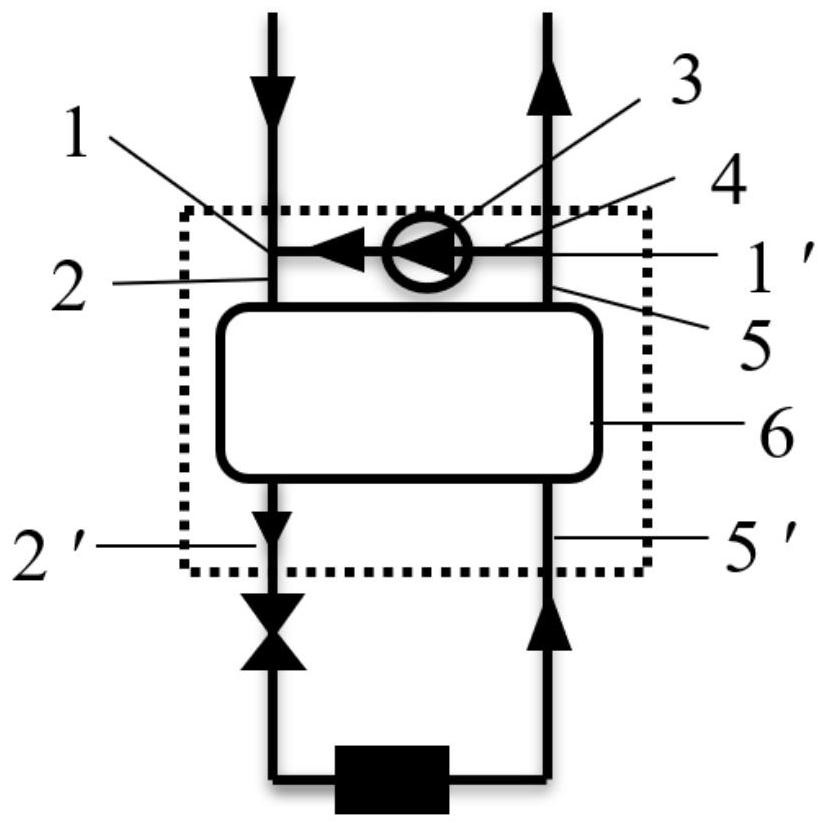

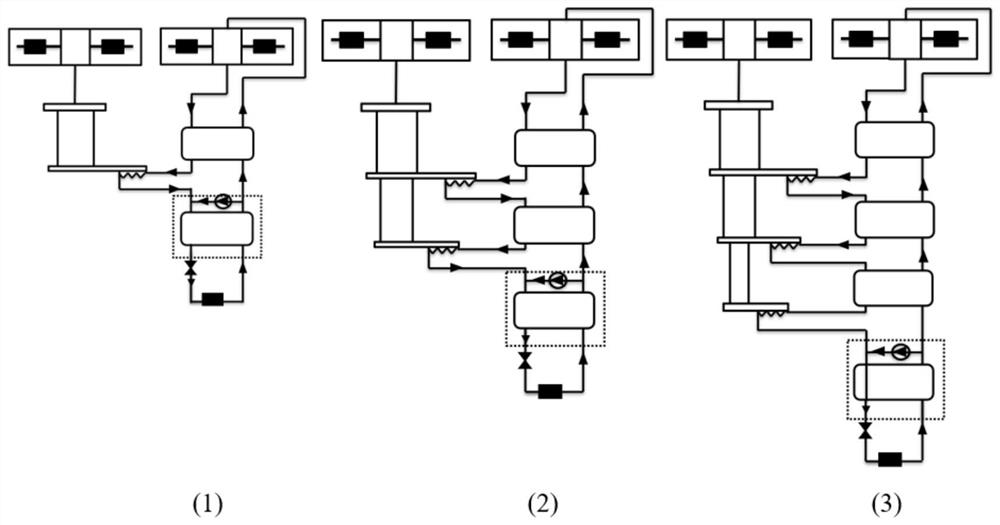

[0030] figure 1 The bypass type low-temperature negative pressure heat exchanger invented for the invention, it includes the high-pressure side pipeline-2, the low-pressure side pipeline-5, the bypass pipeline 4, the bypass element 3, the three-way element-1, the three-way element Two 1', high pressure side pipeline two 2', low pressure side pipeline two 5' and low temperature negative pressure partition wall heat exchanger 6.

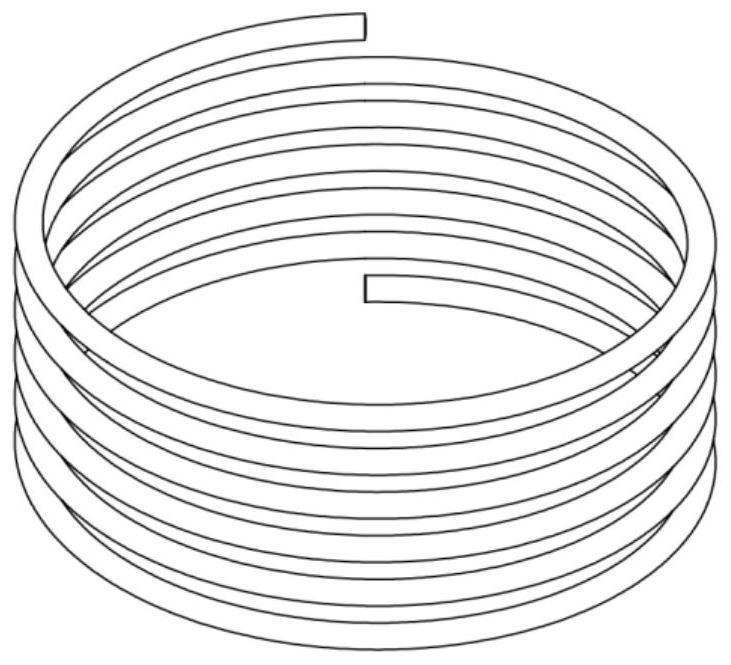

[0031] Such as figure 1 As shown, the low-temperature negative pressure partition wall heat exchanger 6 is a tube-in-tube heat exchanger, which is composed of an inner tube 7 and an outer tube 8, all of which are thin-walled stainless steel tubes, and the diameter of the tube is generally 1-6mm. 7. The outer wall is fixed in the center of the outer tube by welding thin copper wire or silver solder bum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com