Patents

Literature

64results about How to "Low heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne energy-saving building coating and preparation method thereof

ActiveCN106700789AGet rid of the shortcomings of severely limited application fieldsIncreased hemispherical emissivityAntifouling/underwater paintsPaints with biocidesGreen environmentEmulsion

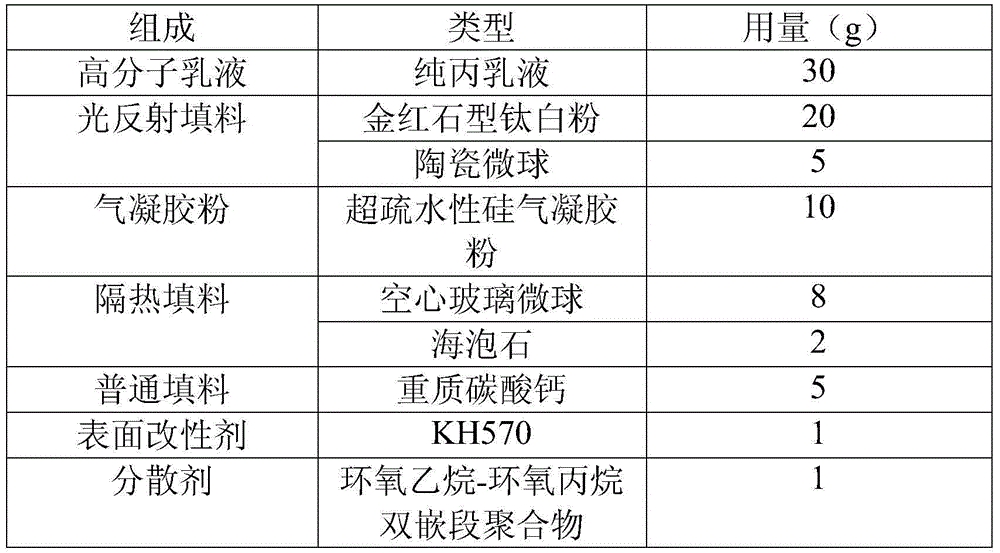

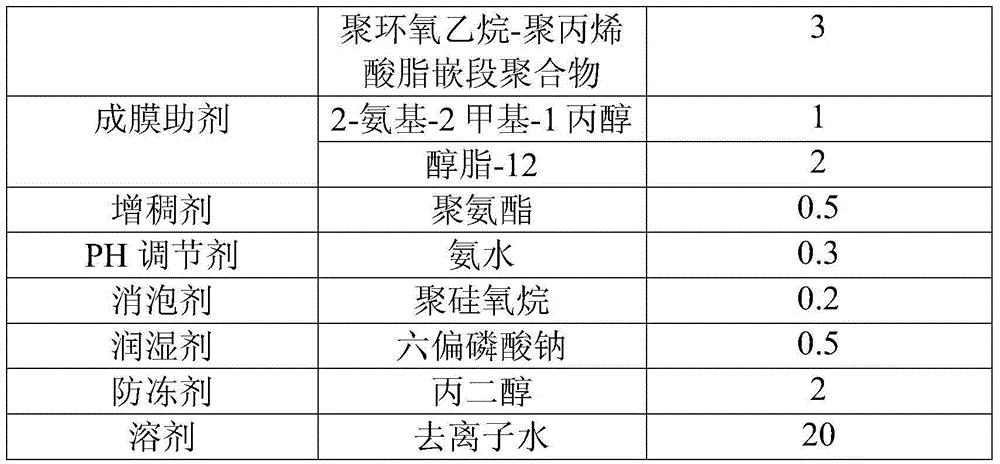

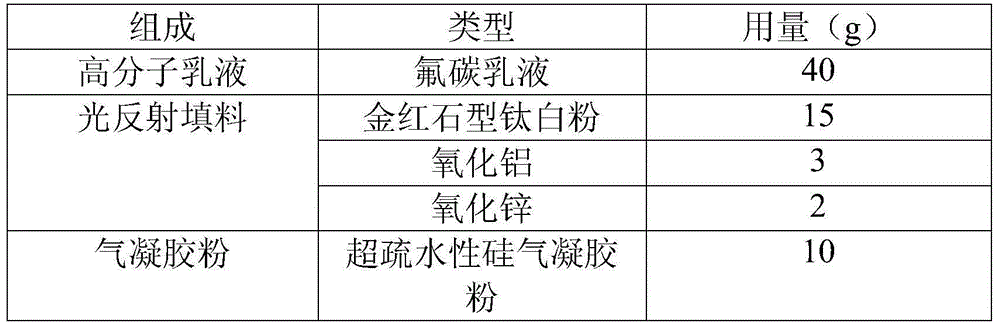

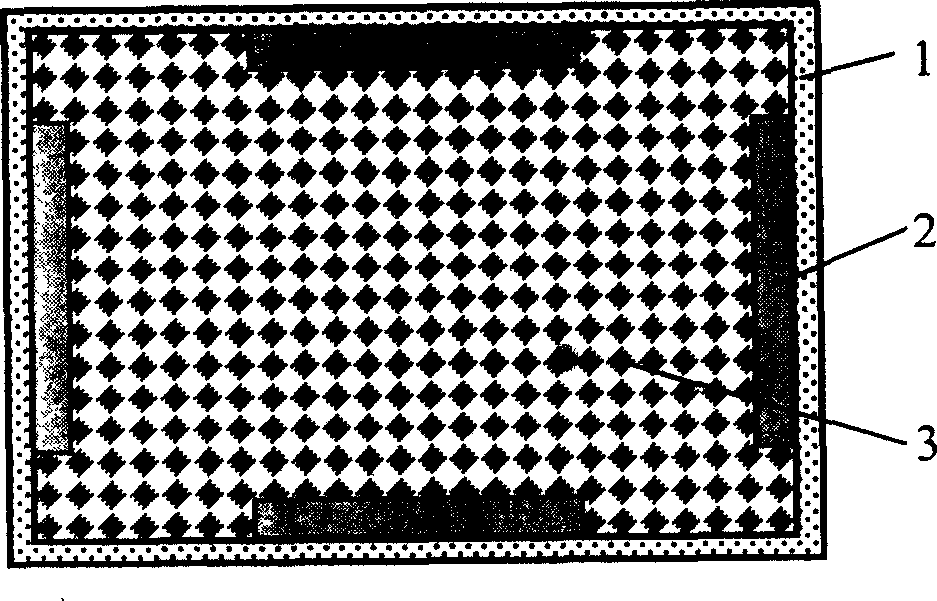

The invention specifically relates to a multifunctional green environment-friendly waterborne energy-saving building coating and a preparation method thereof, belonging to the technical field of energy-saving building coatings. The multifunctional high-efficiency energy-saving building coating comprises, by weight, 25 to 50% of a high polymer emulsion, 5 to 30% of a light-reflection filling material, 1 to 5% of aerogel powder, 5 to 10% of a heat-insulation filling material, 5 to 15% of a common filling material, 1 to 2% of a surface modifier, 1 to 5% of a dispersing agent, 0.1 to 4% of a film-forming aid, 0.1 to 2% of a thickening agent, 0 to 1% of an antifoaming agent, 0.01 to 0.5% of a pH regulating agent, 0.1 to 2% of a wetting agent and 0.5 to 2% of an antifreezing agent, with the balance being deionized water. The coating provided by the invention has heat-insulation and cooling effect in summer and heat preservation effect in winter, is applicable to energy-saving reconstruction of buildings in tropical zones and subtropical zones, and has the characteristics of safety, no toxicity, environment friendliness and no pollution; moreover, the coating has good weatherability, contamination resistance, flexibility and scrubbing resistance.

Owner:SHENYANG RES INST OF CHEM IND

Macromolecule material cold keeping agent making method

InactiveCN1570016ALow costUse low concentrationHeat-exchange elementsPolymer science(Hydroxyethyl)methacrylate

The invention discloses a macromolecule material cold keeping agent making method which consists of, preparing aqueous solution of polymers having strong hydrophilic radicals in the molecular structure, charging propenoic acid, hydroxyethyl methacrylate and maleic anhydride monomer, mixing homogeneously, charging bis-ethyl acrylate cross linking agent, agitating homogeneously, charging potassium peroxodisulfate initiating agent, mixing homogeneously, obtaining macromolecular material, dissolving into water of different mass.

Owner:TSINGHUA UNIV +2

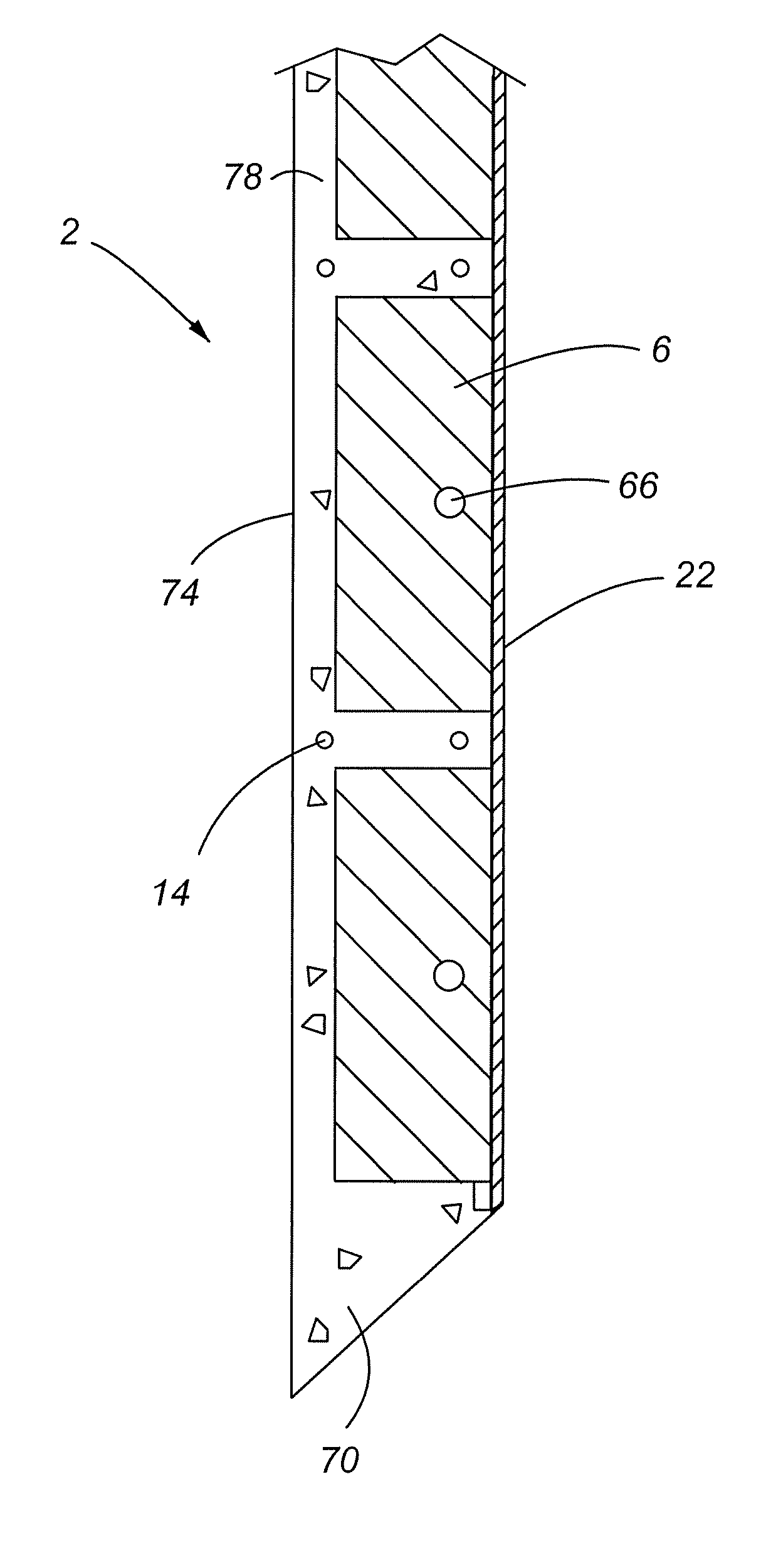

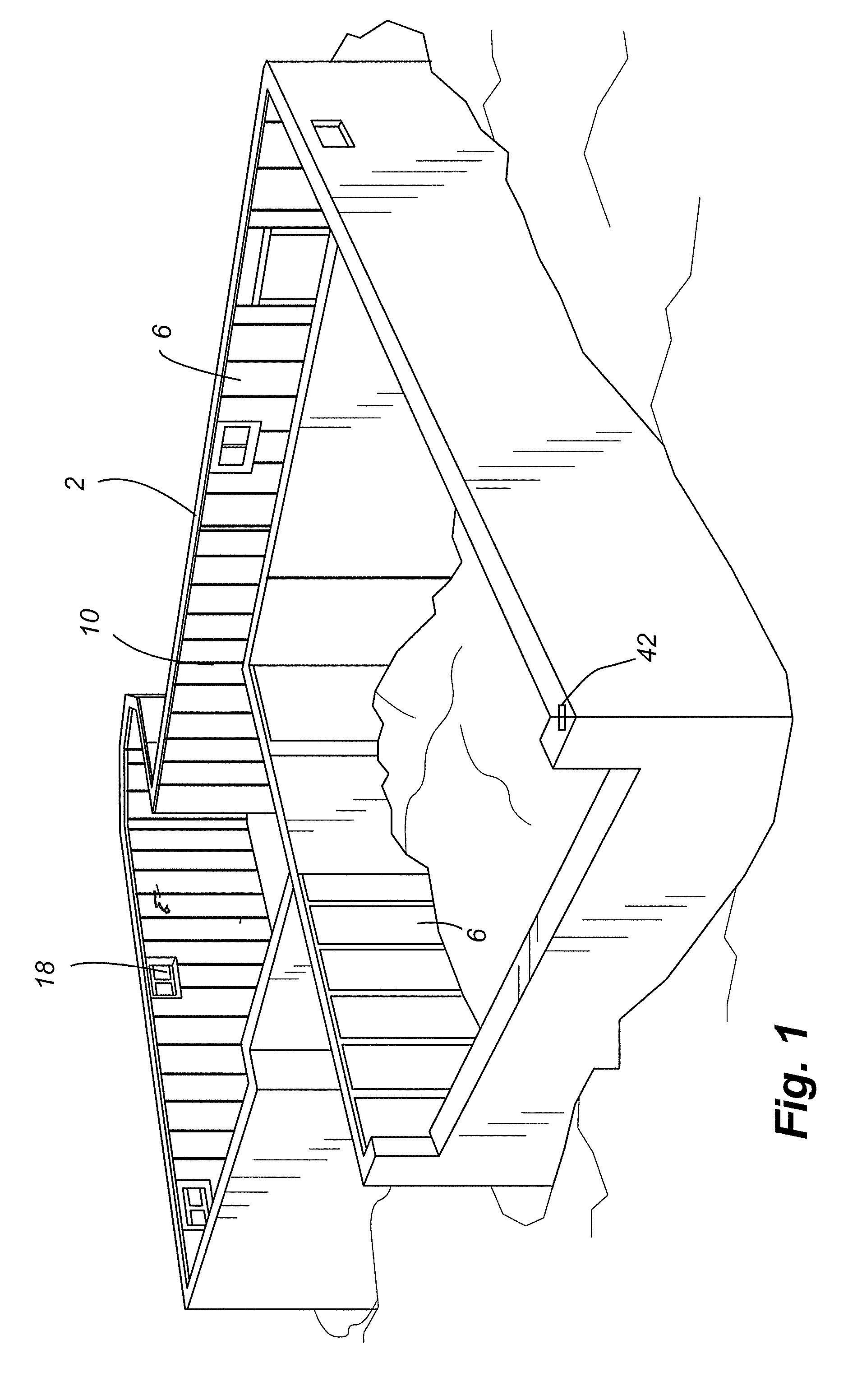

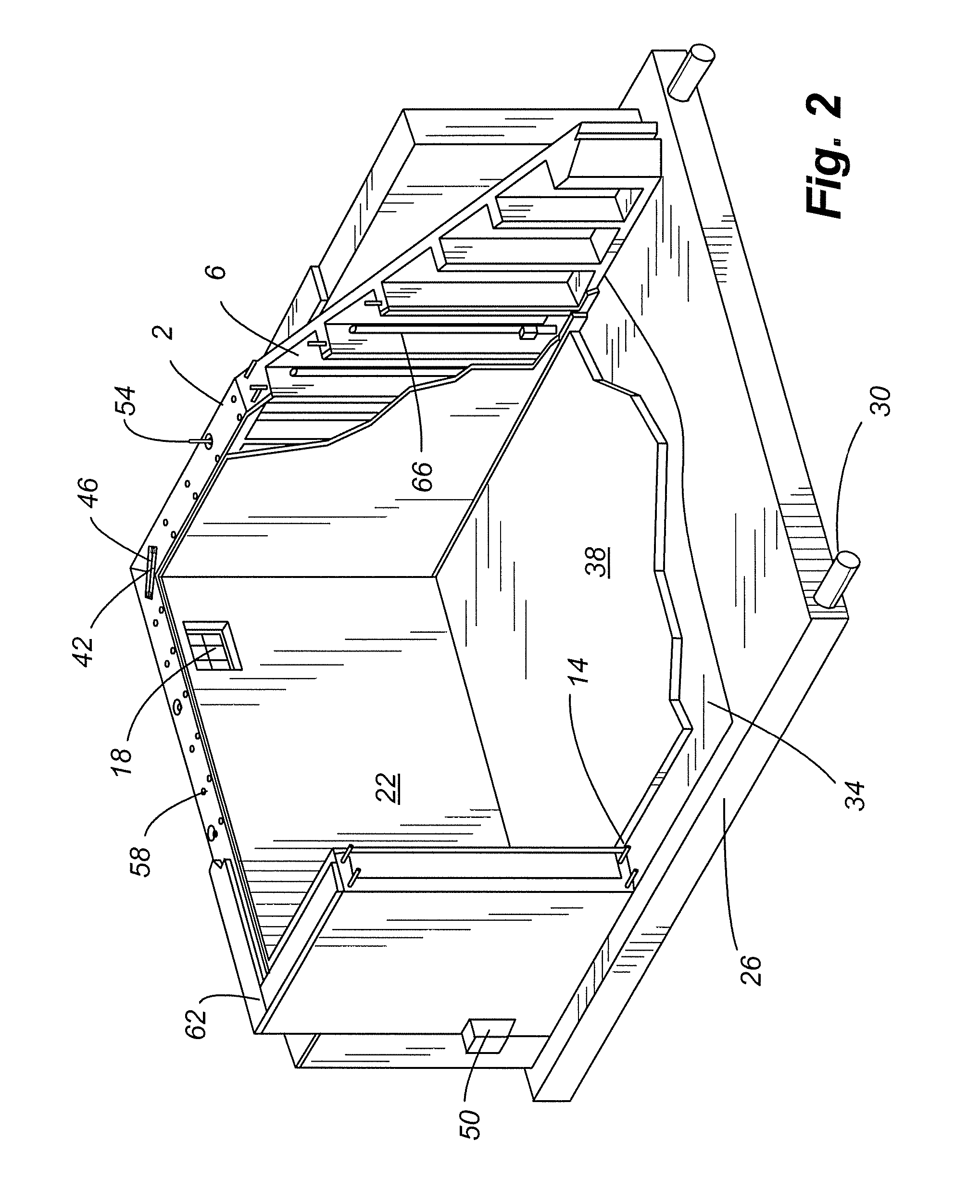

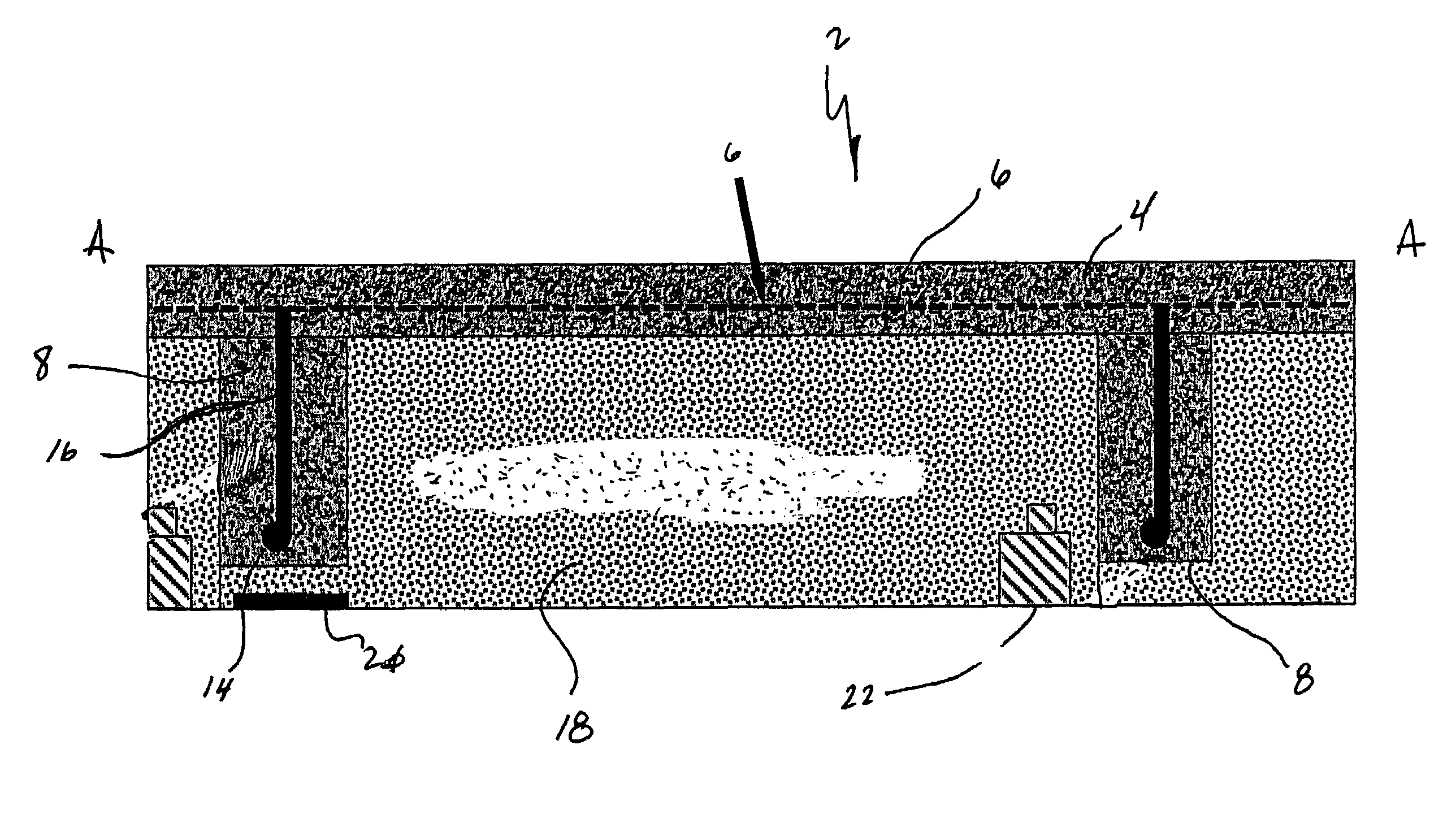

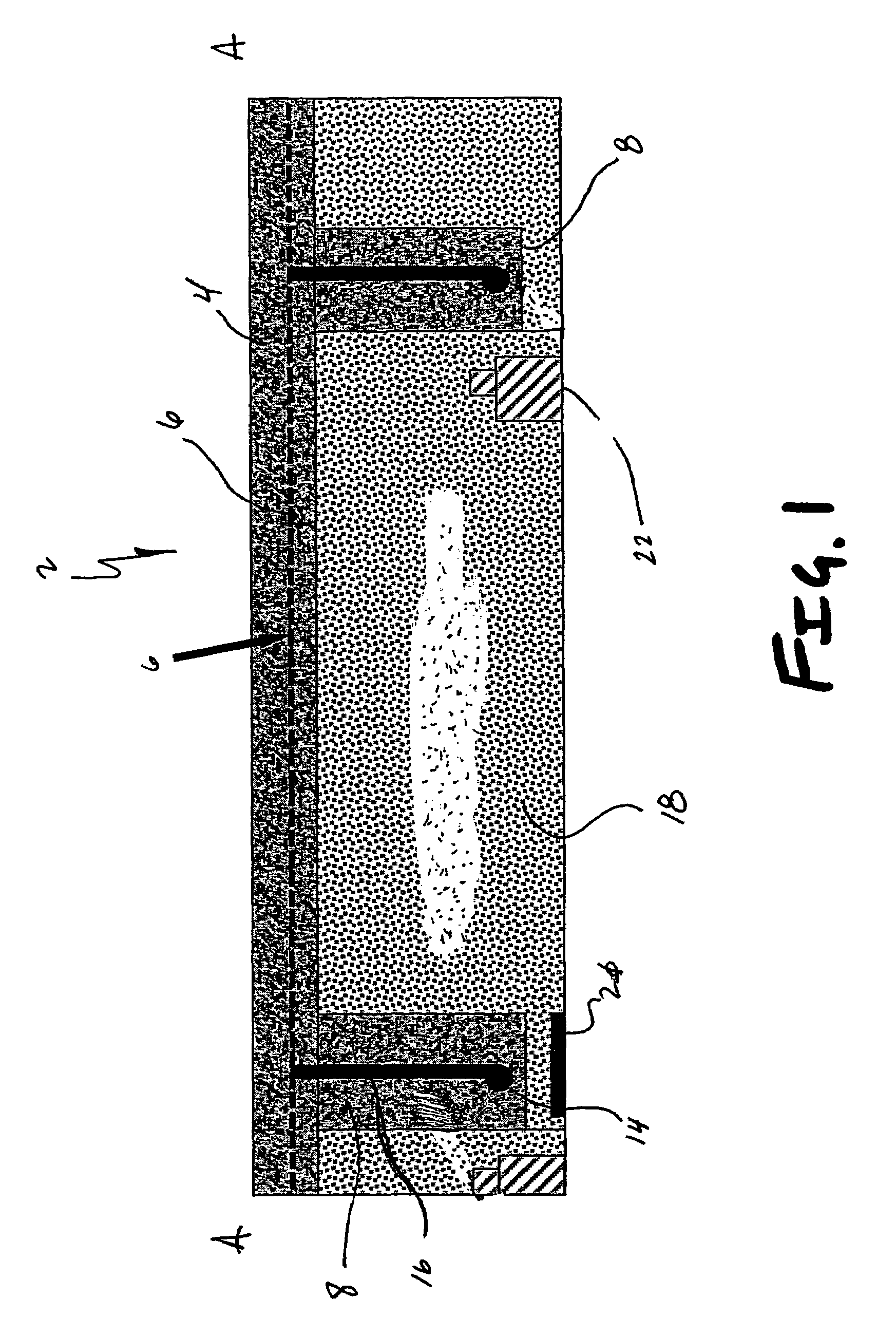

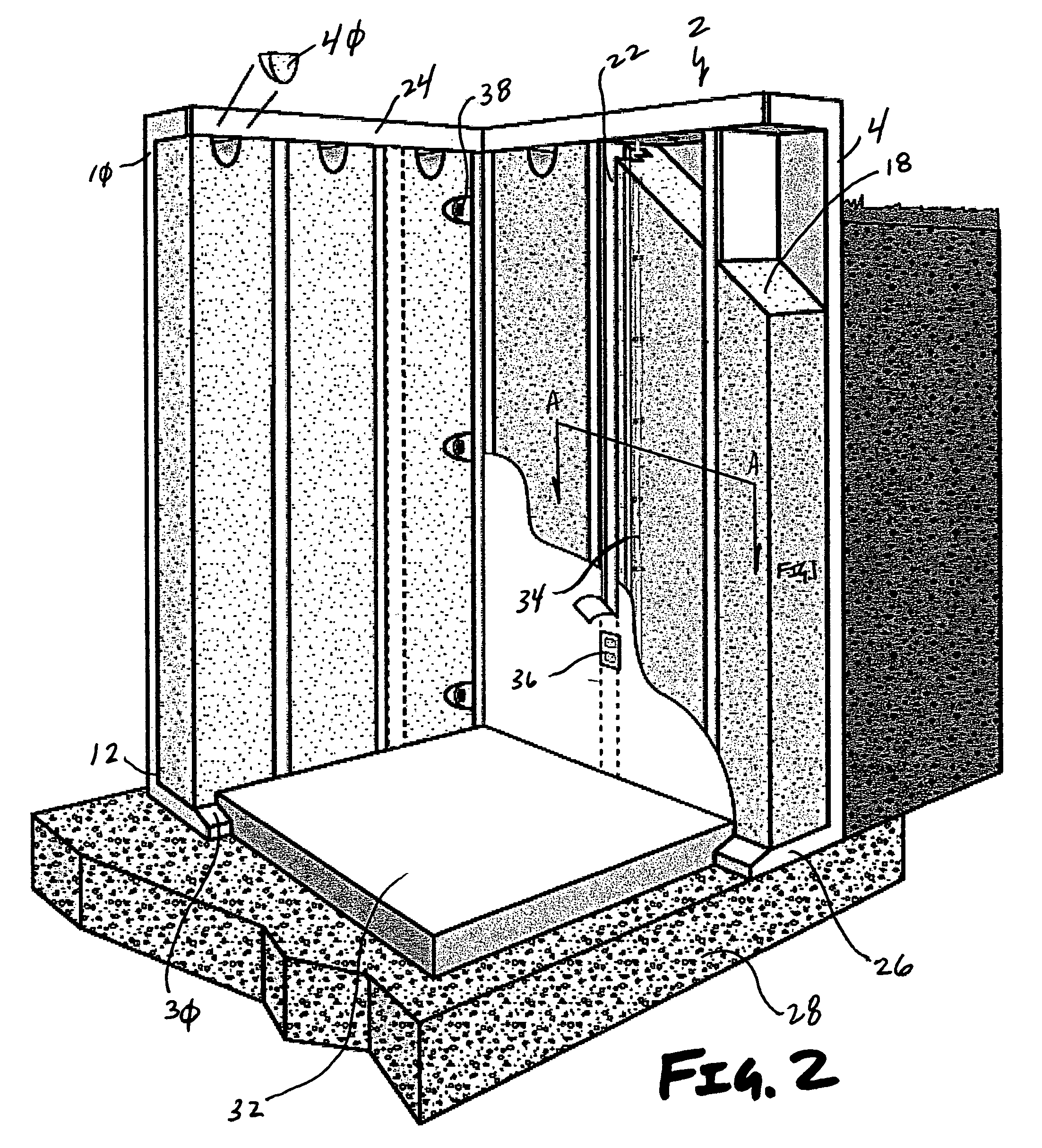

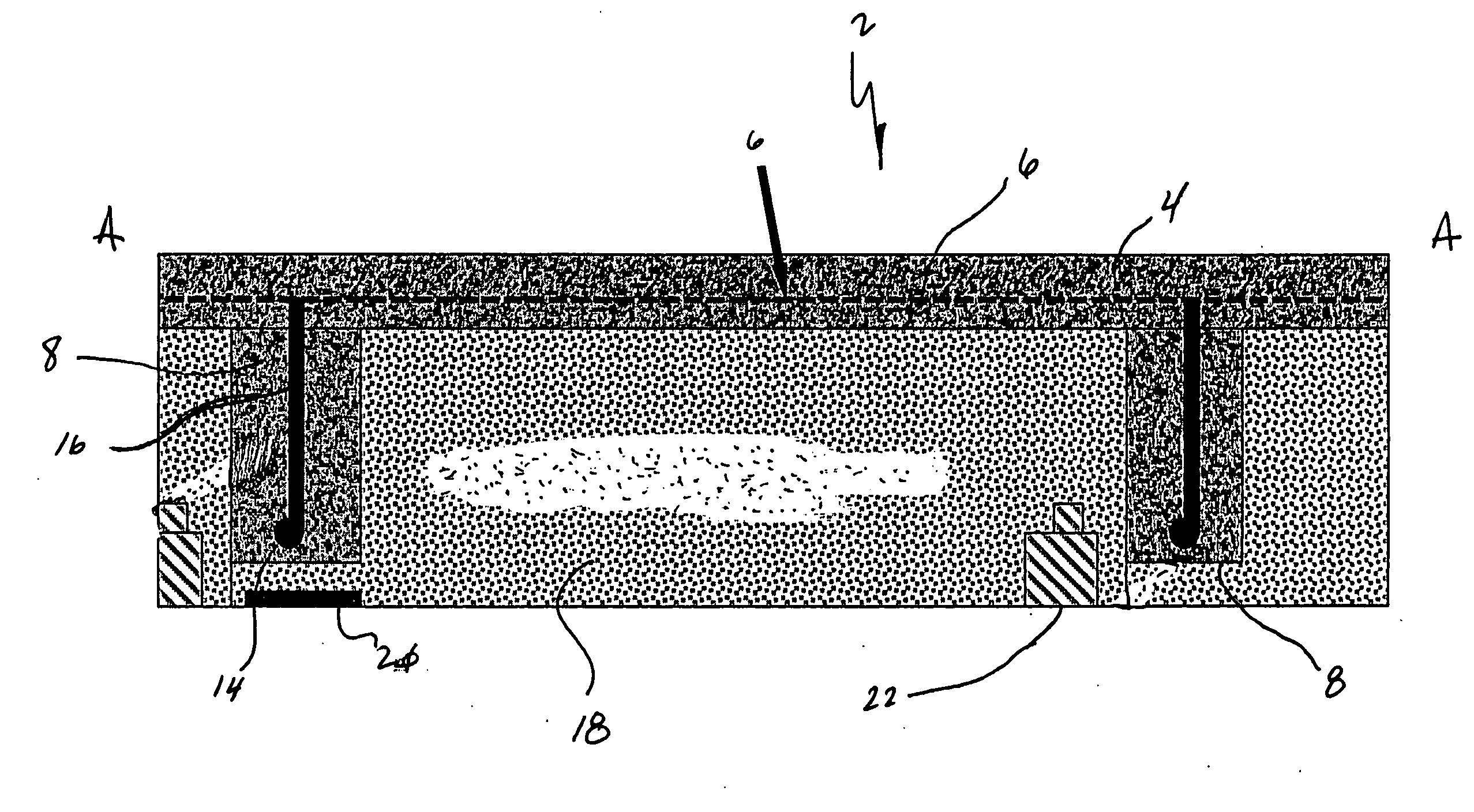

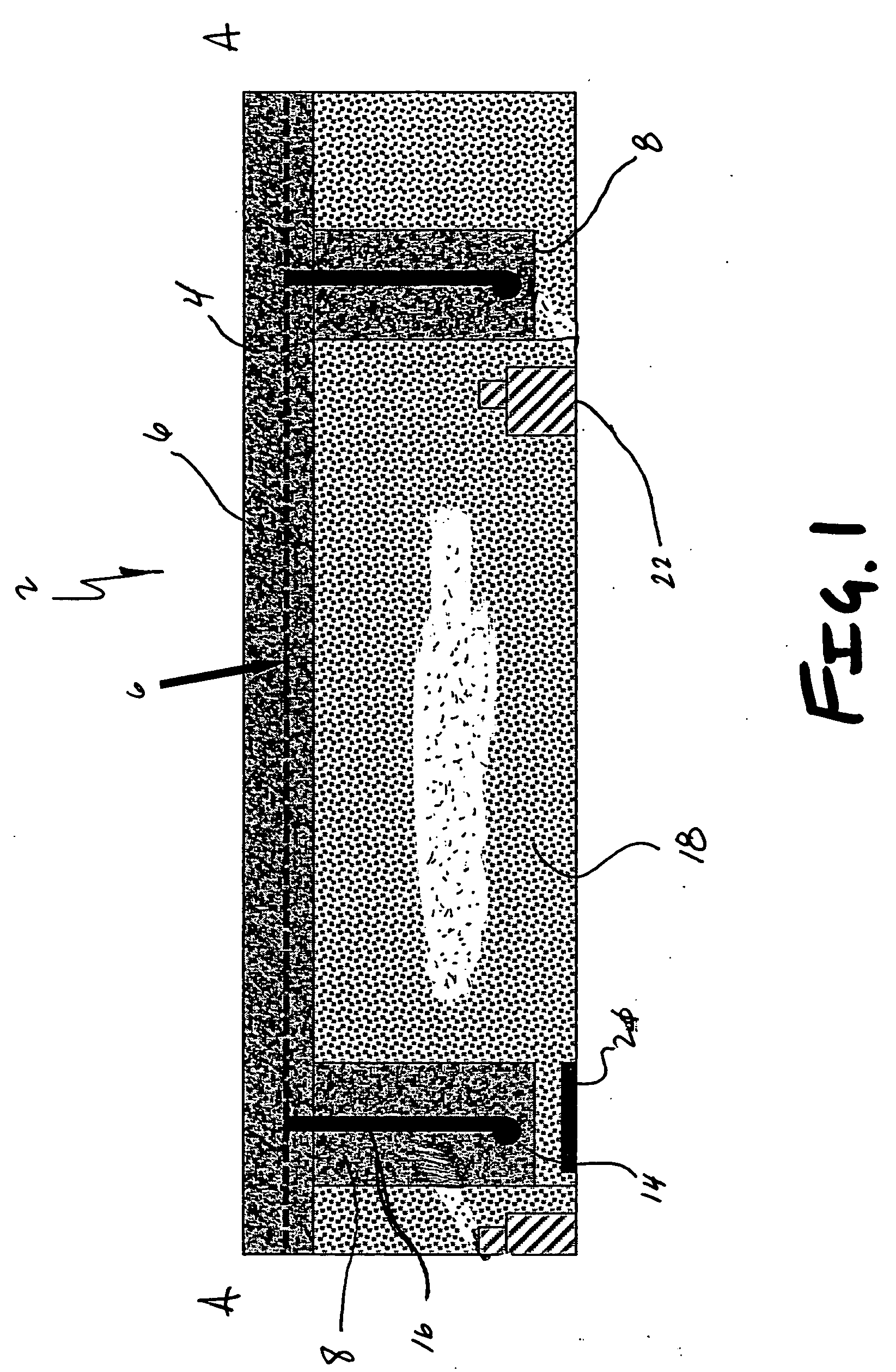

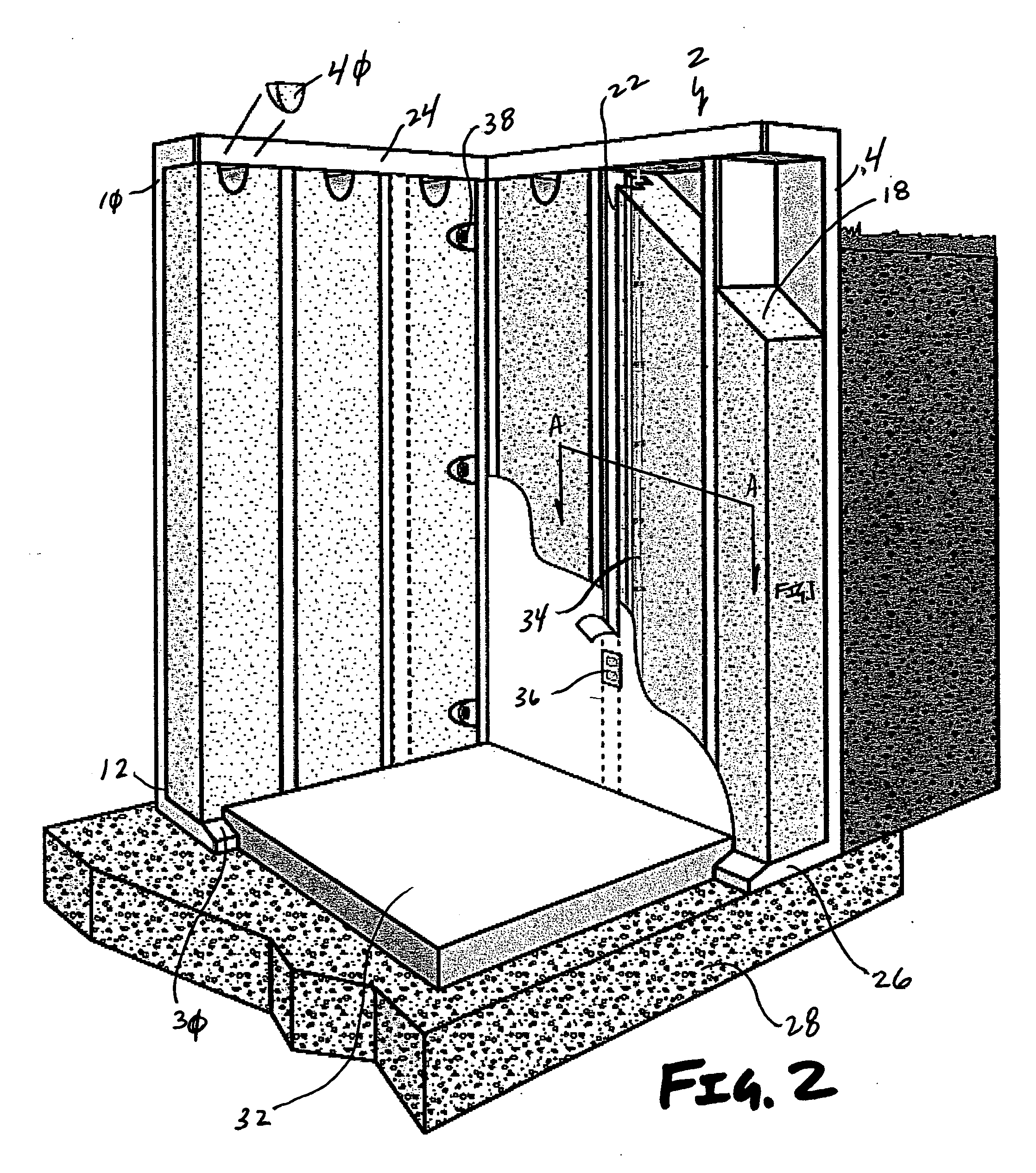

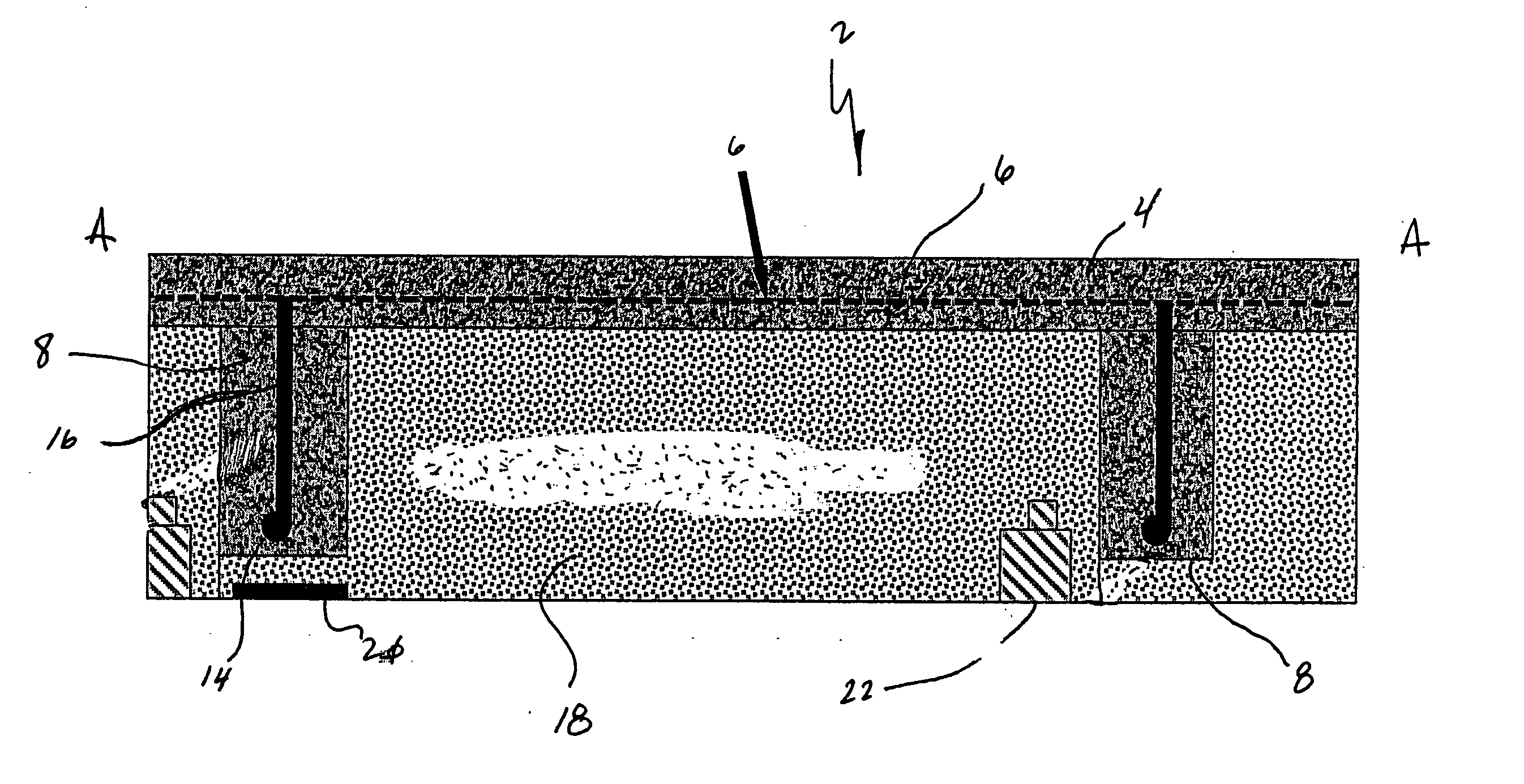

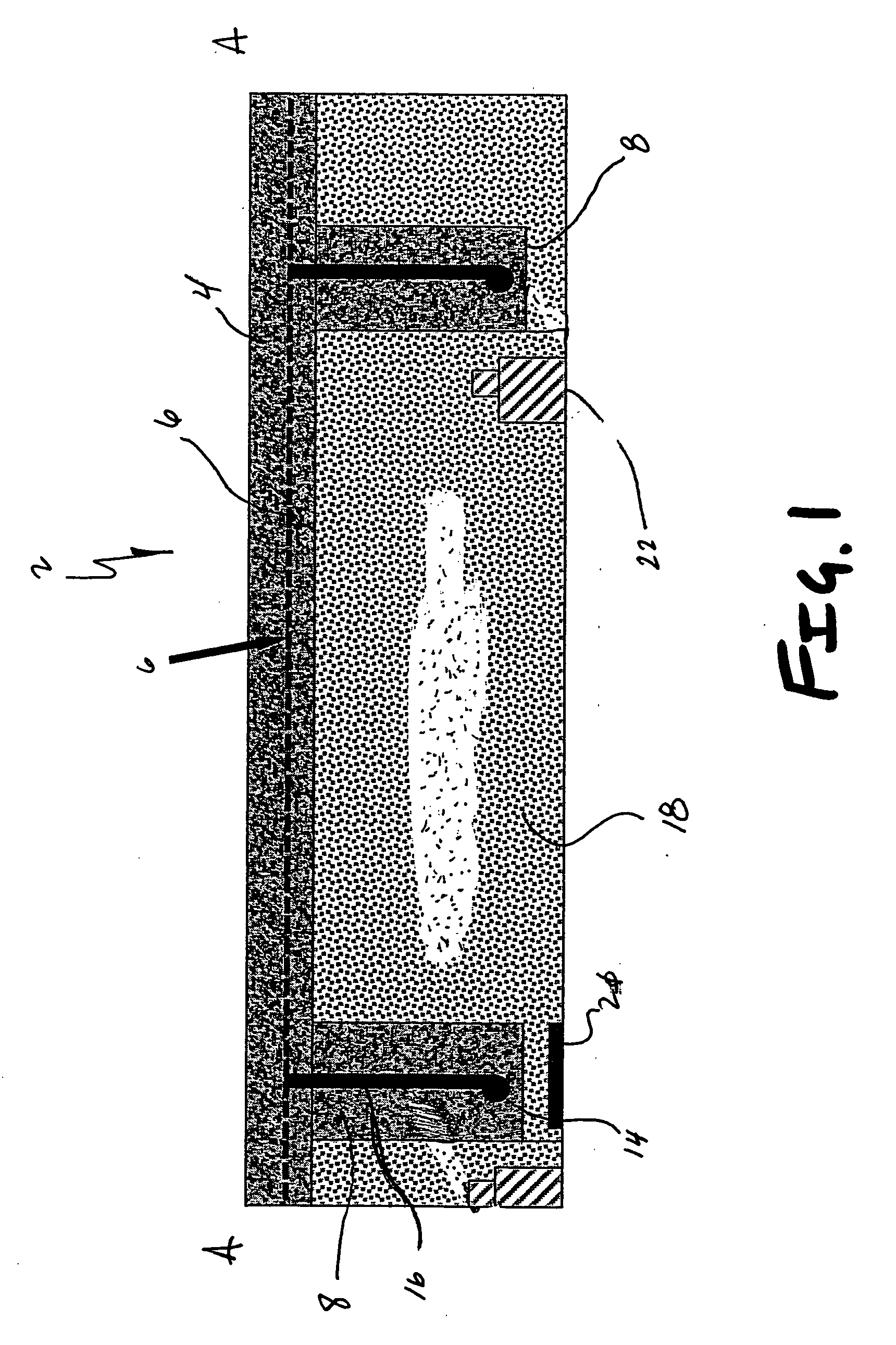

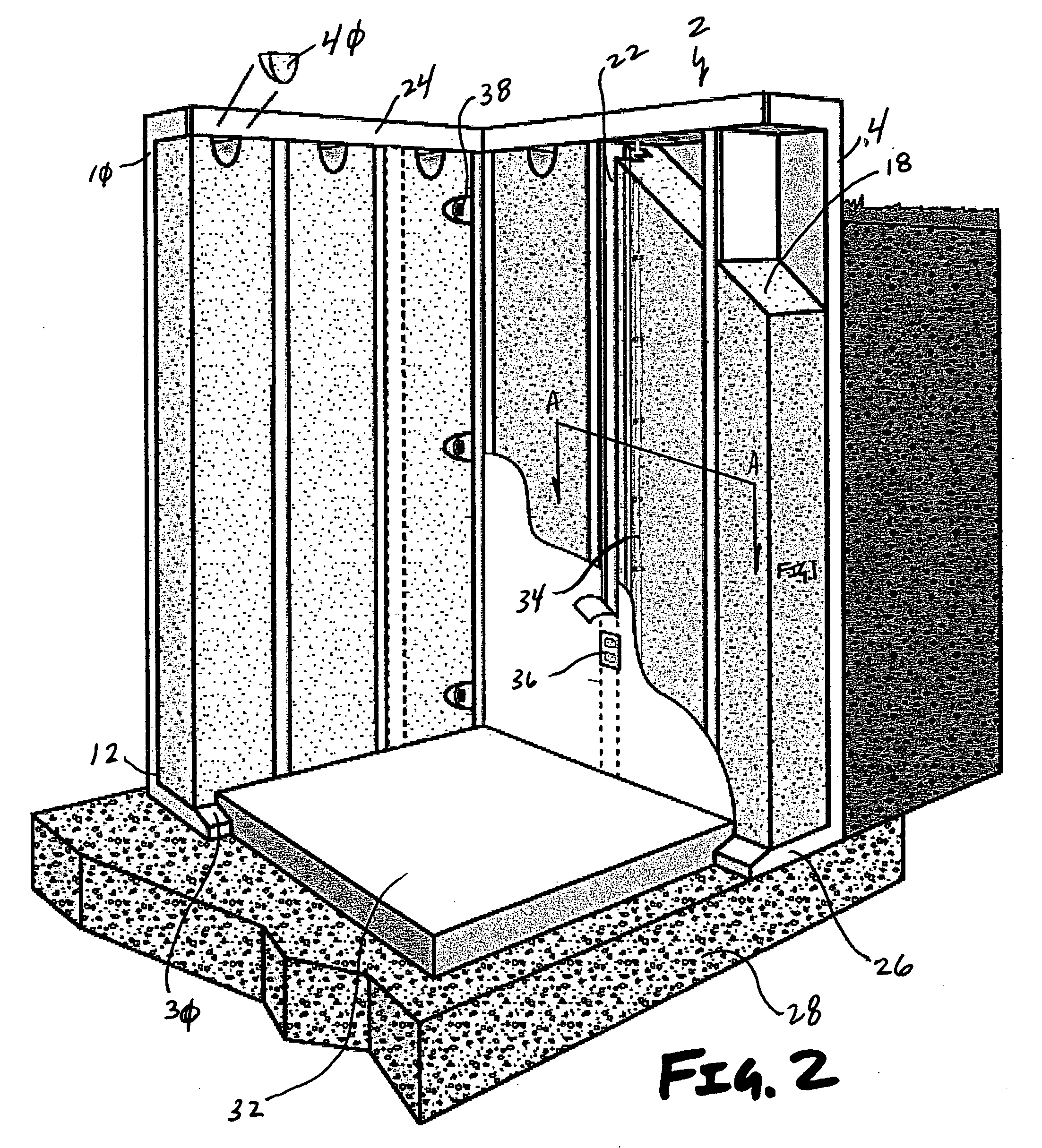

Method and apparatus for fabricating a low density wall panel with interior surface finished

InactiveUS20070144093A1High strengthImprove insulation performanceBuilding componentsFoundation engineeringSurface finishEngineering

A fabricated low density concrete foundation / wall panel is provided with a plurality of insulation panels and reinforcing ribs to improve strength and reduce the density of the wall panel. The wall panels are easily placed and interconnected together to quickly provide a foundation adapted to support the main walls of a home, for example. The fabricated wall panels in one embodiment generally includes an inner wall sheathing that is interconnected to the load-supporting segments of the wall panel during fabrication.

Owner:OLDCASTLE PRECAST

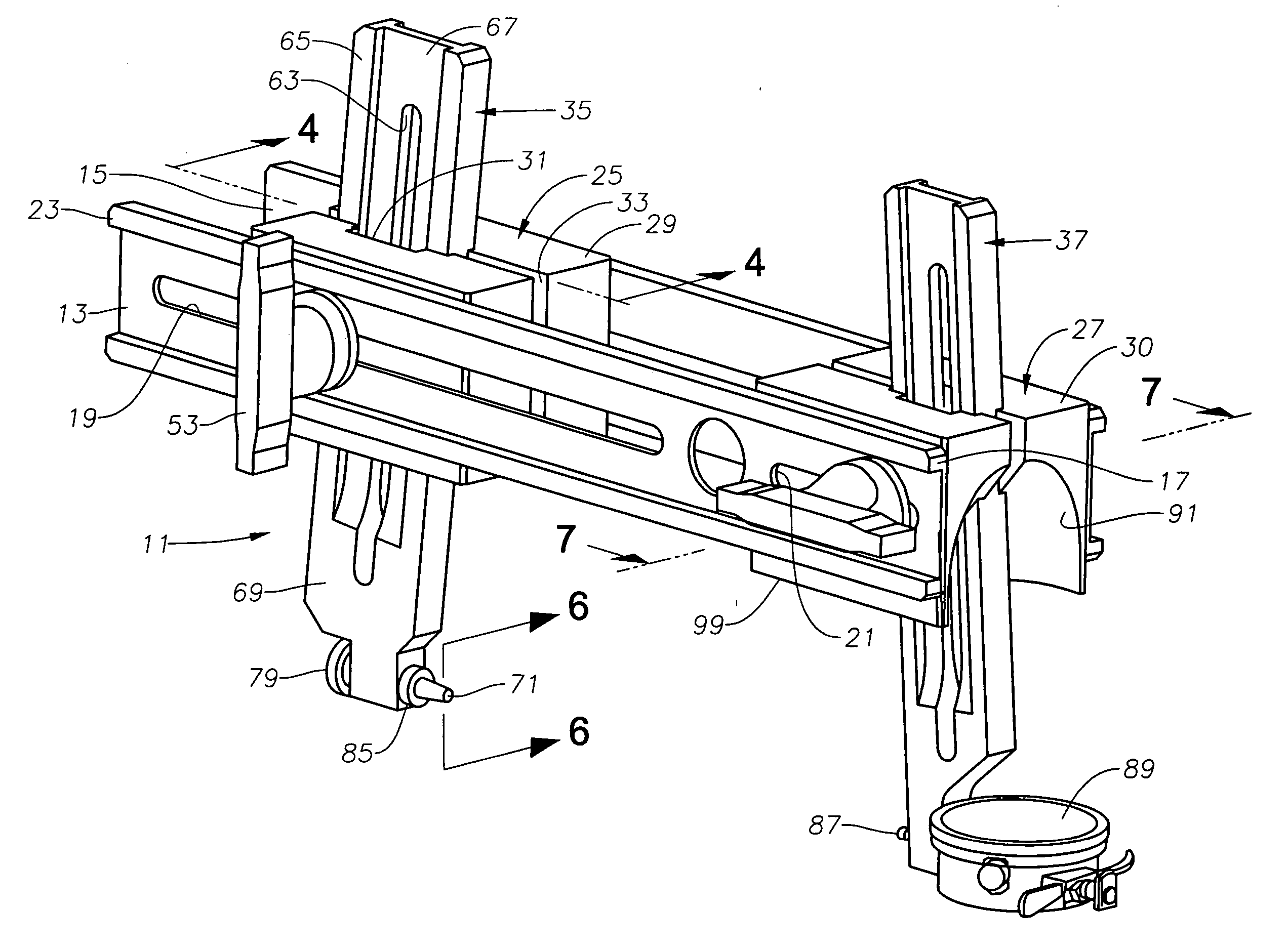

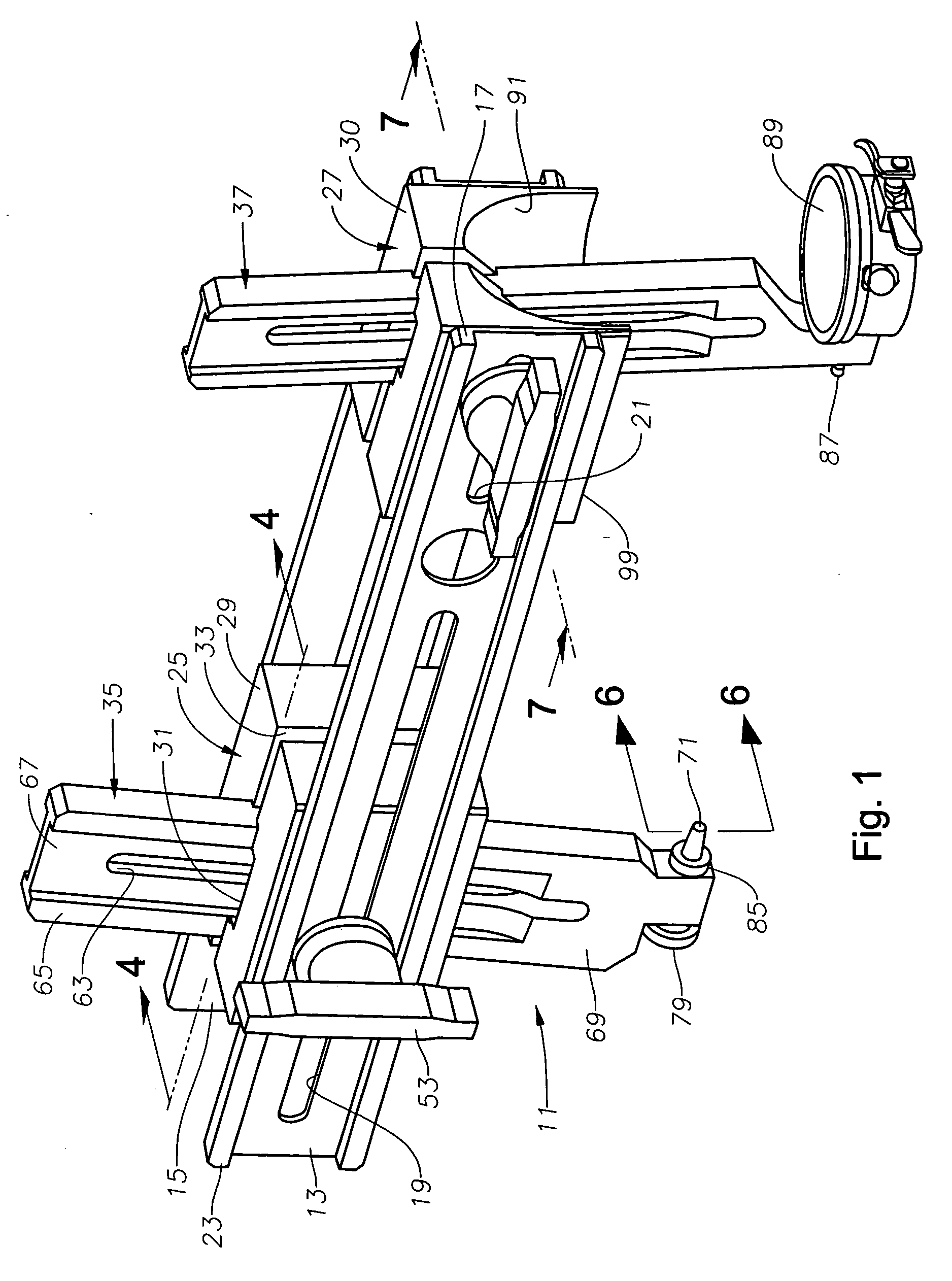

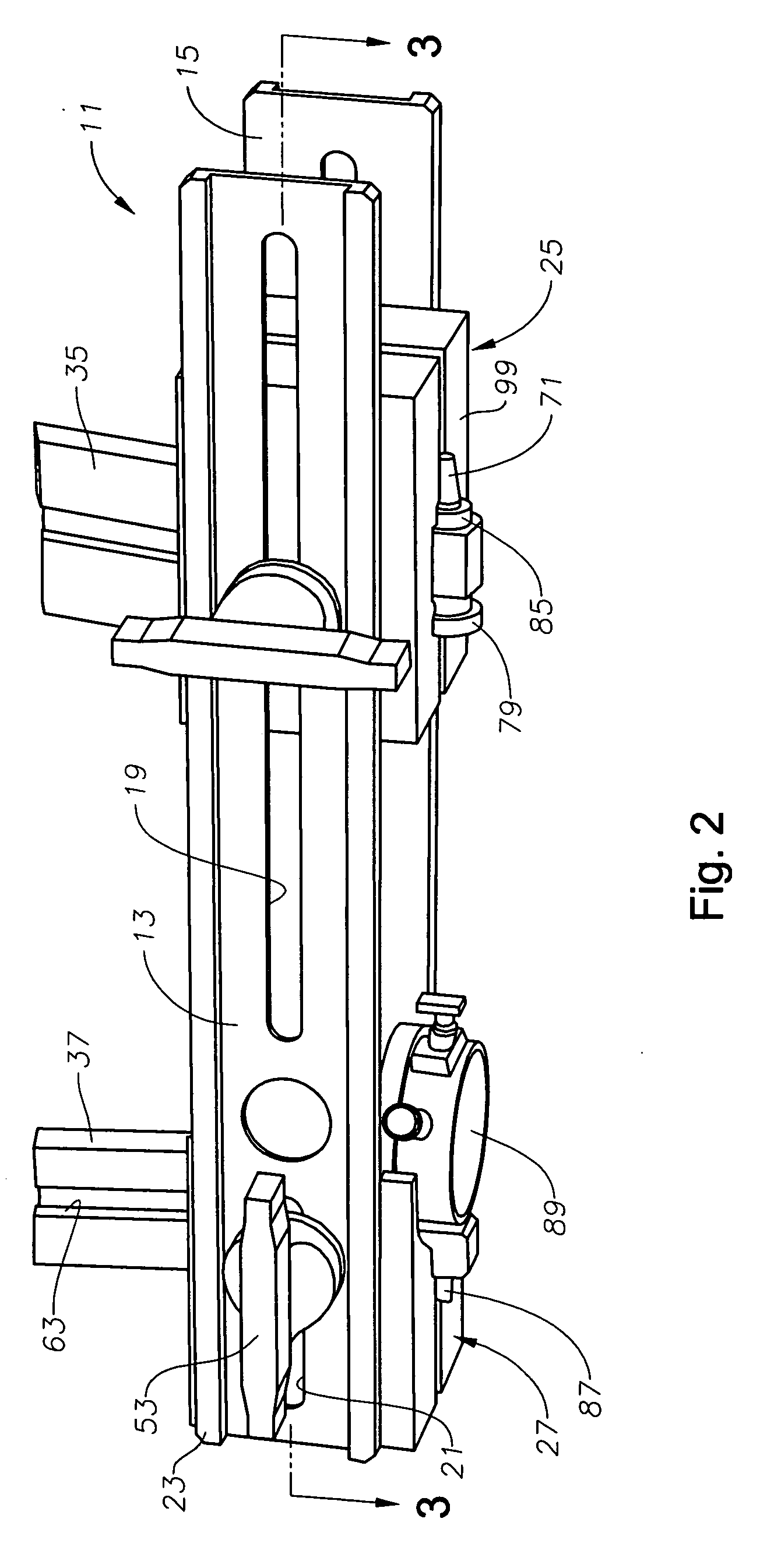

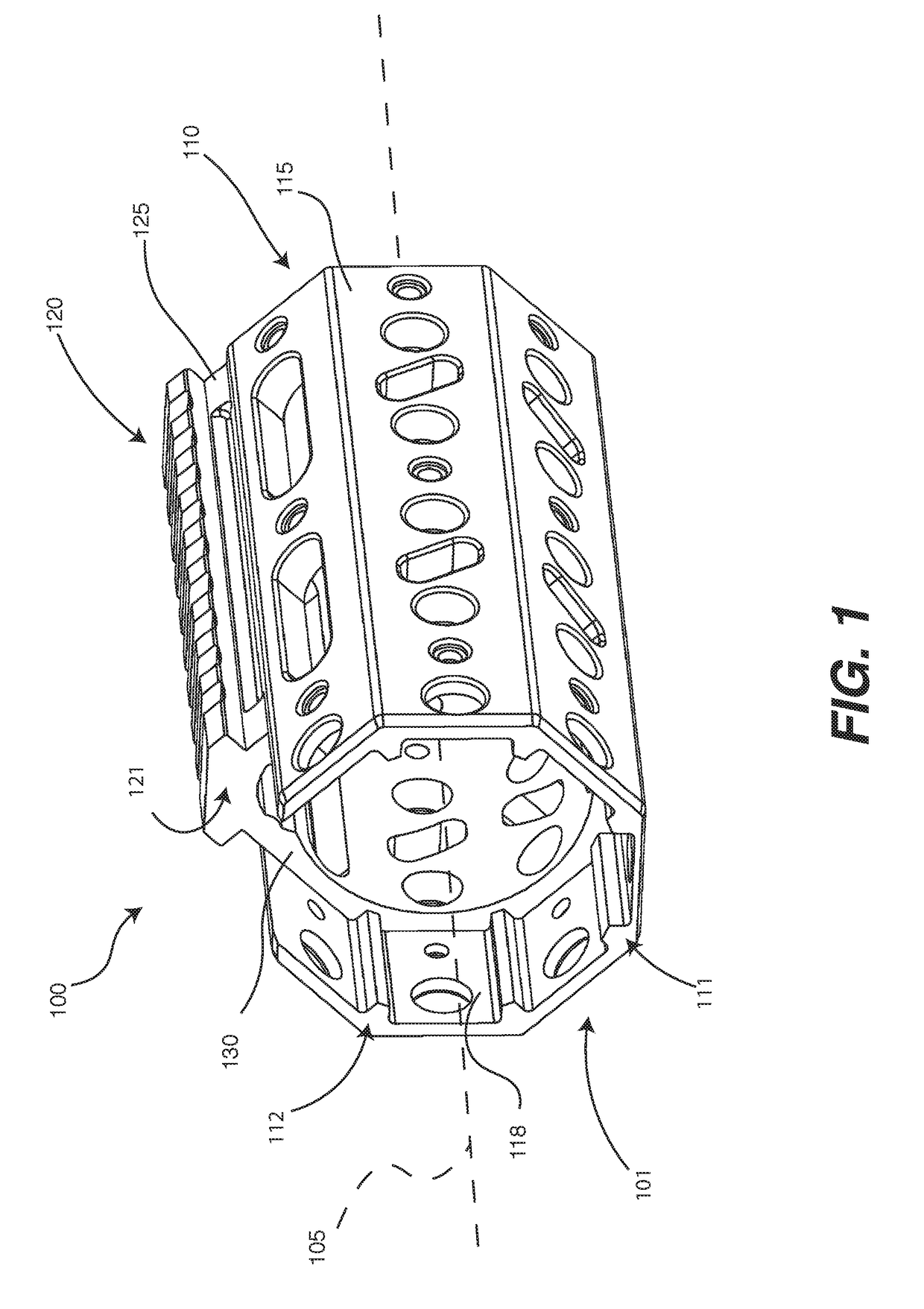

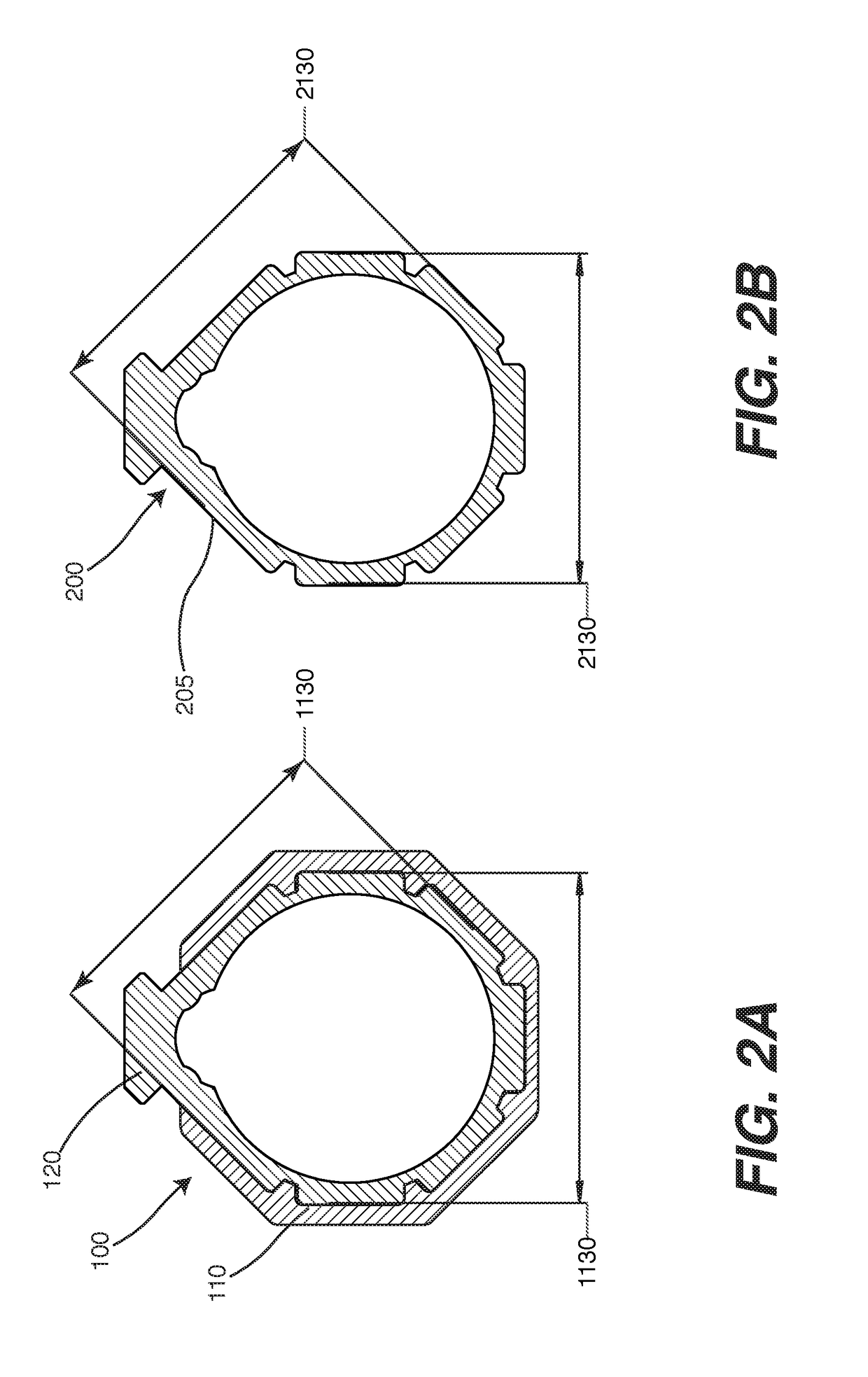

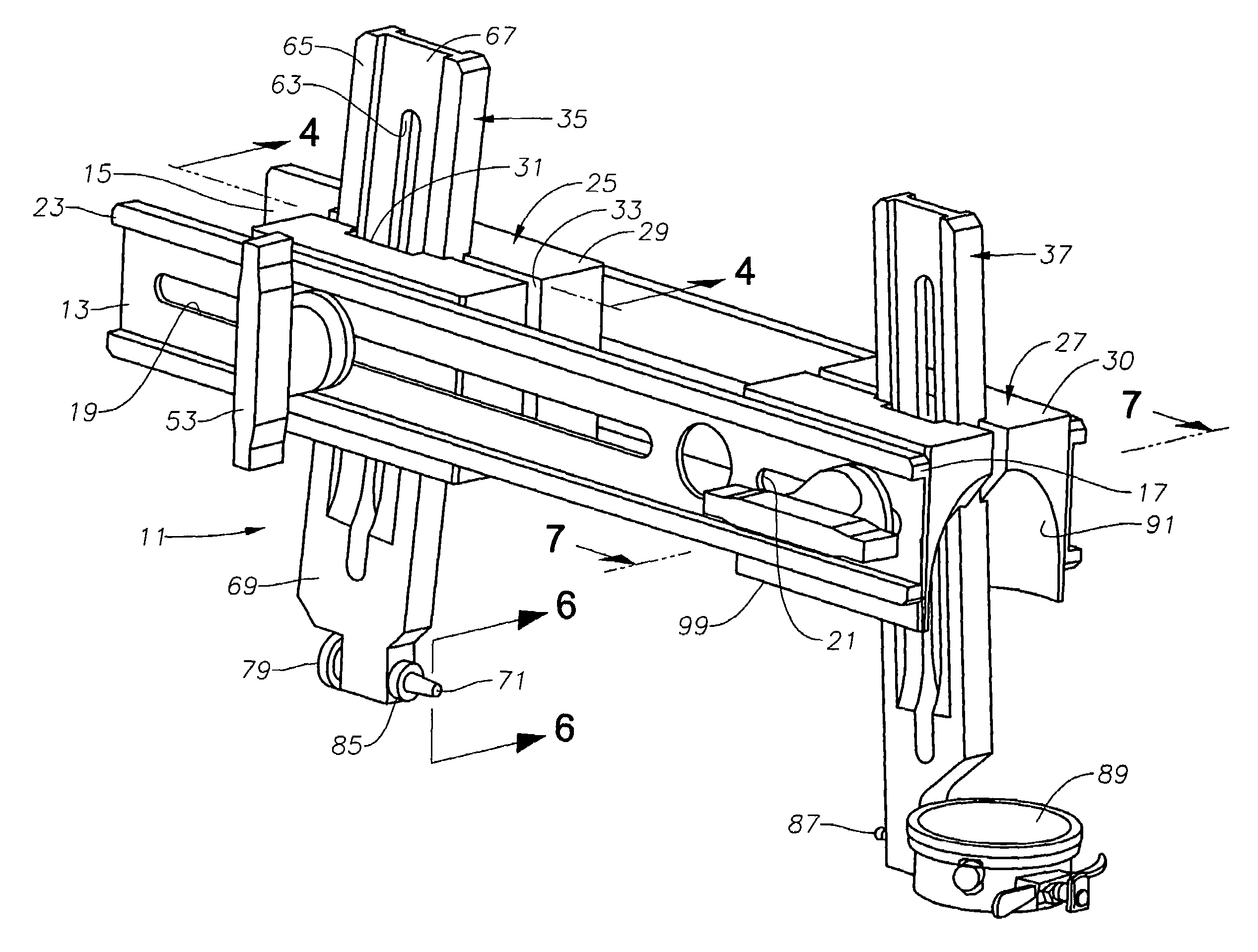

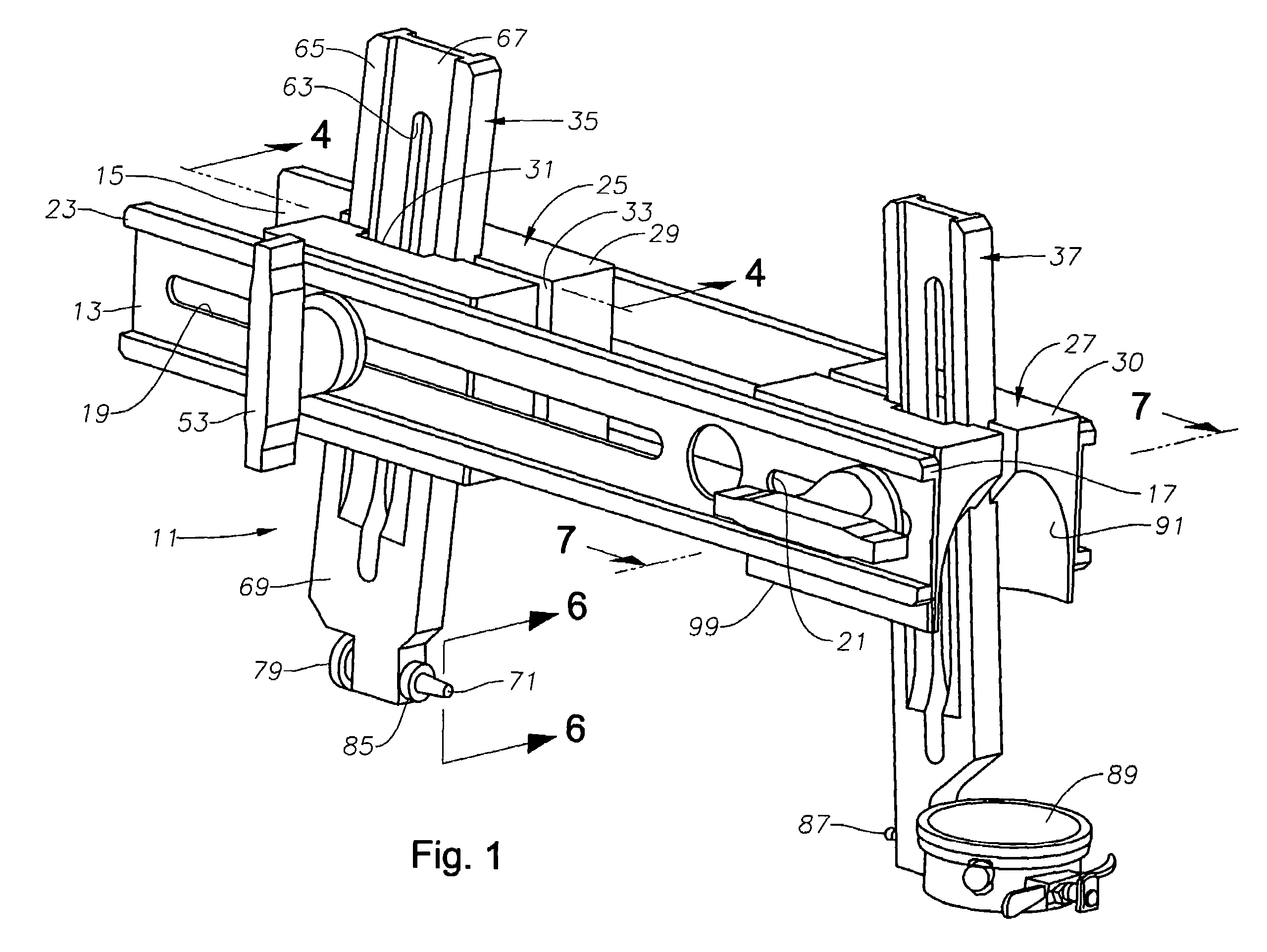

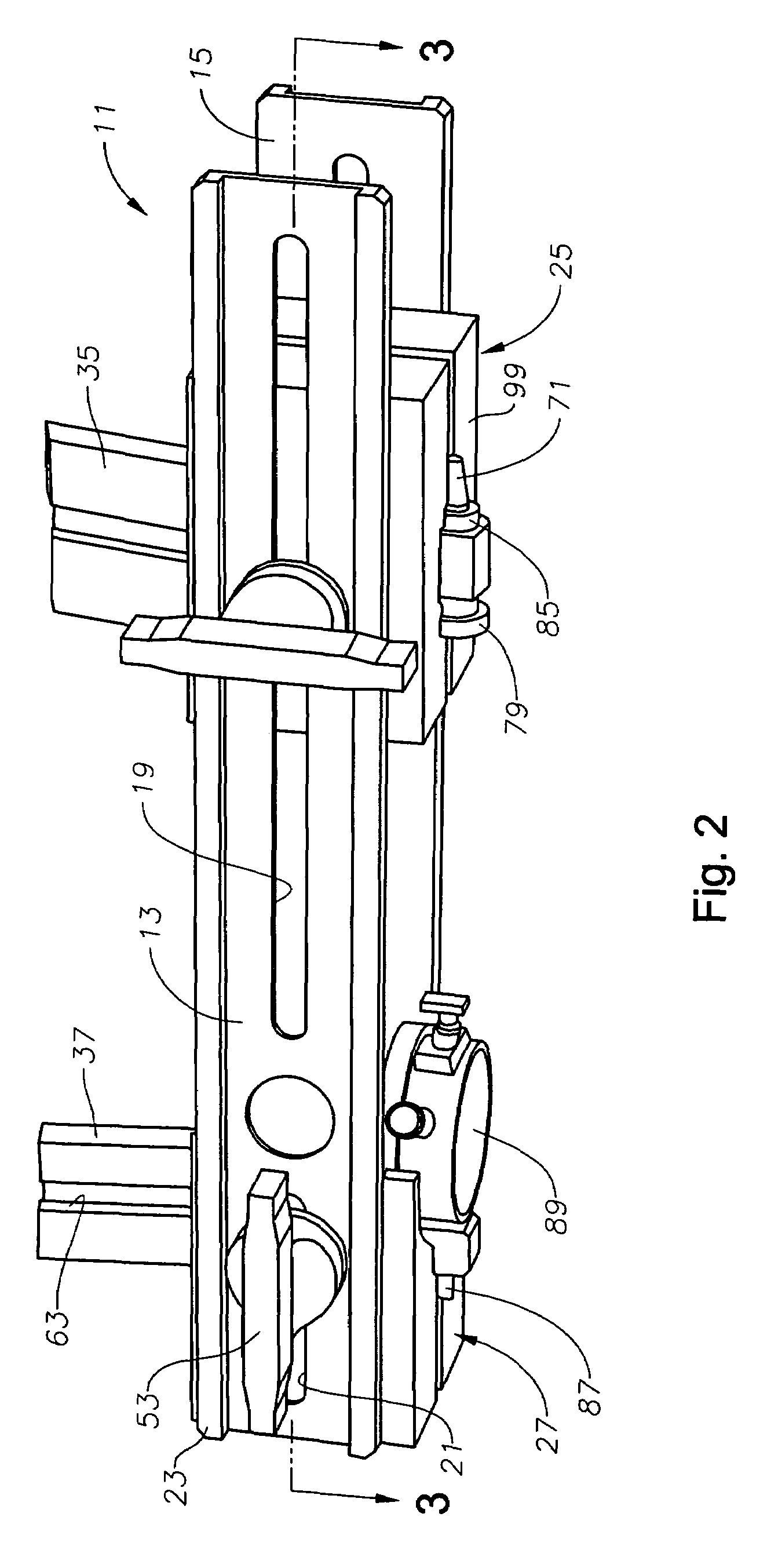

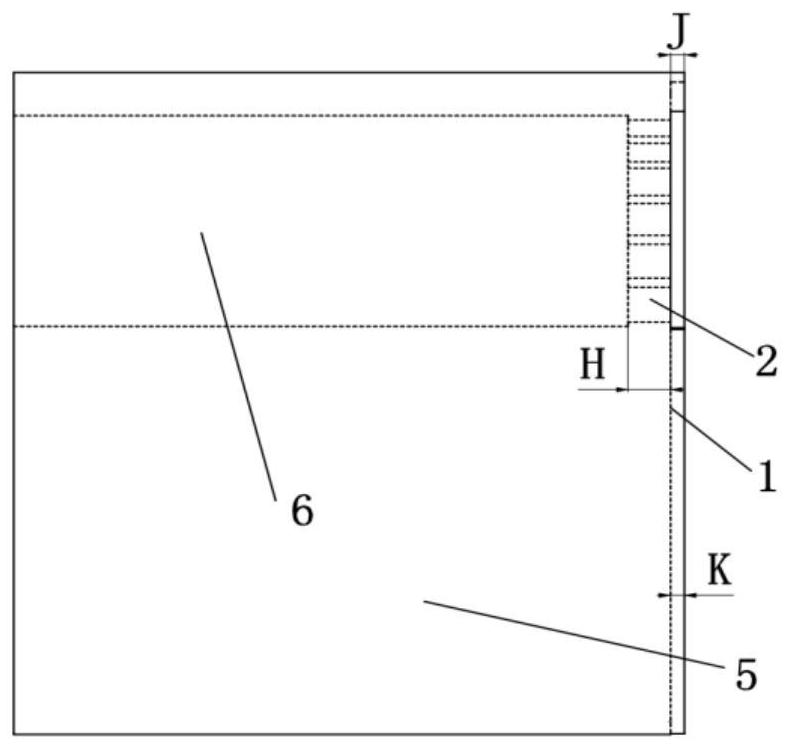

Gage for measuring diameters

ActiveUS20060283037A1Reduction factorEasy to adjustMechanical diameter measurementsMechanical clearance measurementsEngineeringFastener

A gage for measuring a diameter of a workpiece has a pair of parallel spaced apart side rails. A pair of block sets is mounted between the side rails and spaced apart from each other. A pair of arms extends transverse to the rails through mating profiles in the blocks of each block set. The arms are slidable in a transverse direction to the side rails. Each block set can slide along the side rails and has a single fastener that secures the blocks to the side rails and the arms to the blocks in a desired position. Drag brakes between the blocks and the side rails prevent the components from sliding of their own weight while the fasteners are loosened. The block sets and arms are rotatable 180 degrees about the fasteners when loosened to accommodate outside and inside measurements.

Owner:TECH ALLIANCE INC THE

Concrete foundation wall with a low density core and carbon fiber and steel reinforcement

InactiveUS7627997B2High strengthImprove insulation performanceConstruction materialLayered productsFiberCarbon fibers

A fabricated concrete foundation wall is provided with a plurality of insulation panels and reinforcing ribs to improve strength and reduce the density of the wall panel. The foundation wall panels are easily placed and interconnected together to quickly provide a foundation adapted to support the main walls of a home, for example. The foundation panels in one embodiment generally include a facewall that may have at least one carbon fiber band positioned horizontally therethrough to provide additional stiffness.

Owner:OLDCASTLE PRECAST

Concrete foundation wall with a low density core and carbon fiber and steel reinforcement

InactiveUS20050262786A1High strengthImprove insulation performanceConstruction materialFoundation engineeringFiberCarbon fibers

A fabricated concrete foundation wall is provided with a plurality of insulation panels and reinforcing ribs to improve strength and reduce the density of the wall panel. The foundation wall panels are easily placed and interconnected together to quickly provide a foundation adapted to support the main walls of a home, for example. The foundation panels in one embodiment generally include a facewall that may have at least one carbon fiber band positioned horizontally therethrough to provide additional stiffness.

Owner:OLDCASTLE PRECAST

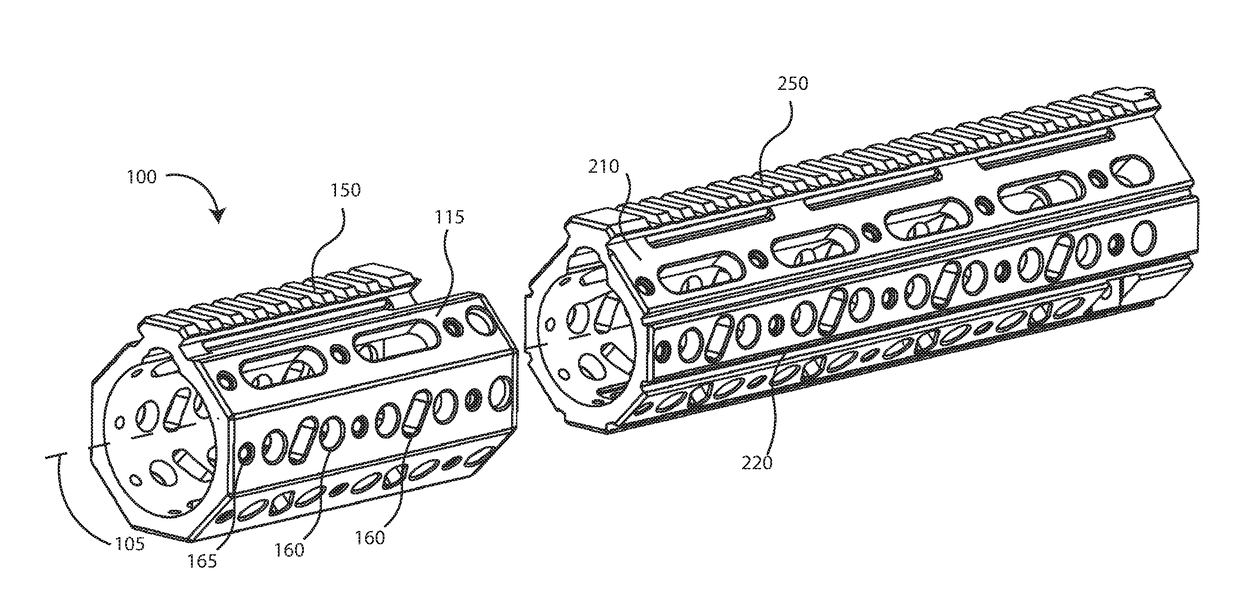

Modular handguard device for a firearm

InactiveUS20180010881A1Protect from harmReduce heat transferWeapon assembly/disassemblyButtsModularityEngineering

A modular handguard device configured to be slidably mated to an outer surface of an existing or affixed handguard. The handguard of the present invention may be configured to mate with any handguard to provide an extension of the handguard for purposes including mitigation of detectable heat signature, operator safety and increased reconfigurability of firearms for mission specific needs.

Owner:ASCENDANCE INT LLC

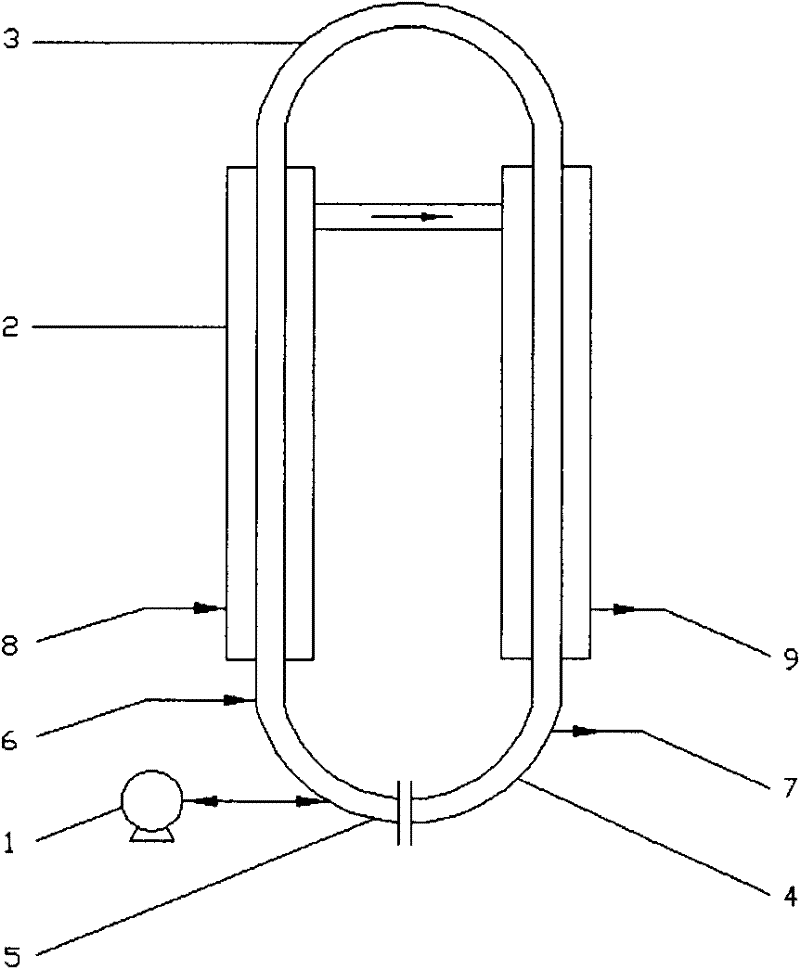

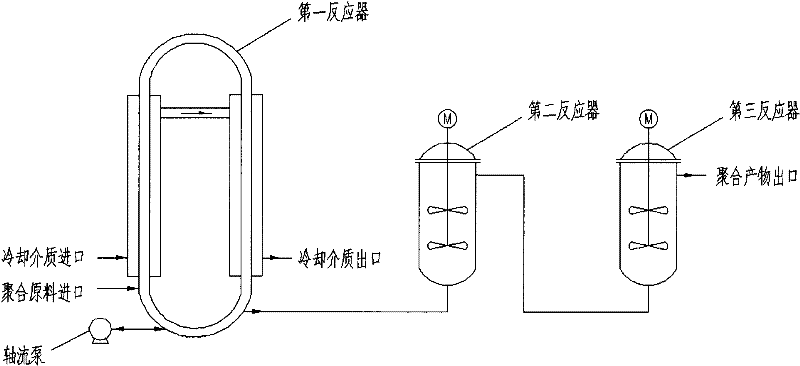

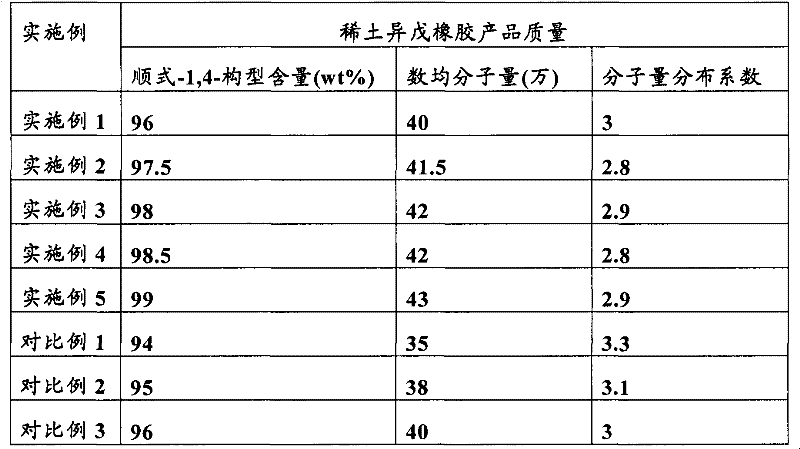

Polymerization method for preparing rare earth isoprene rubber

ActiveCN102532379AIncrease the heat exchange areaAvoid "hanging on the wall" phenomenonRare earthContinuous stirred-tank reactor

The invention relates to a polymerization method for preparing rare earth isoprene rubber, which adopts at least three reactors which are in series connection to conduct a solution polymerization reaction of an isoprene monomer, wherein a first reactor is an annular tube reactor which adopts isothermal operation, a following reactor is a continuous stirrer tank reactor which adopts heat insulation operation. By means of the method, the cis-form-1,4-configuration content of obtained gathering rare earth isoprene rubber can be high as 98wt%, the number-average molar mass can reach over 0.4 million, and molecular weight distribution coefficient is smaller than 3.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gage for measuring diameters

ActiveUS7328520B2Easy to moveLow heat transfer coefficientMechanical diameter measurementsMechanical clearance measurementsEngineeringFastener

A gage for measuring a diameter of a workpiece has a pair of parallel spaced apart side rails. A pair of block sets is mounted between the side rails and spaced apart from each other. A pair of arms extends transverse to the rails through mating profiles in the blocks of each block set. The arms are slidable in a transverse direction to the side rails. Each block set can slide along the side rails and has a single fastener that secures the blocks to the side rails and the arms to the blocks in a desired position. Drag brakes between the blocks and the side rails prevent the components from sliding of their own weight while the fasteners are loosened. The block sets and arms are rotatable 180 degrees about the fasteners when loosened to accommodate outside and inside measurements.

Owner:TECH ALLIANCE INC THE

Concrete foundation wall with a low density core and carbon fiber and steel reinforcement

InactiveUS20060000171A1High strengthImprove insulation performanceConstruction materialLayered productsFiberCarbon fibers

A fabricated concrete foundation wall is provided with a plurality of insulation panels and reinforcing ribs to improve strength and reduce the density of the wall panel. The foundation wall panels are easily placed and interconnected together to quickly provide a foundation adapted to support the main walls of a home, for example. The foundation panels in one embodiment generally include a facewall that may have at least one carbon fiber band positioned horizontally therethrough to provide additional stiffness.

Owner:OLDCASTLE PRECAST

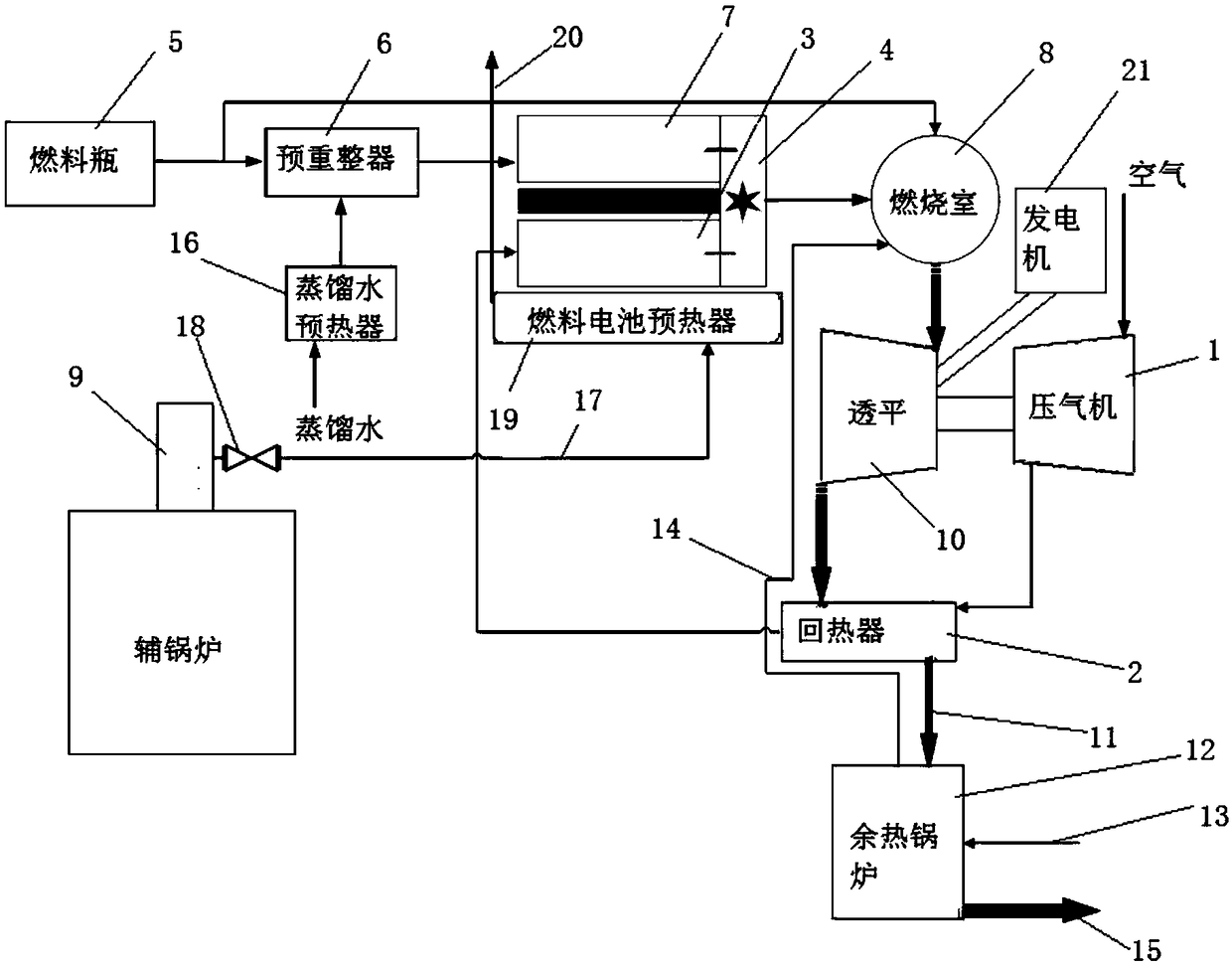

Marine solid oxide fuel cell and steam-injected gas turbine combined generating system and marine solid oxide fuel cell and steam-injected gas turbine combined generating method

ActiveCN109252959AExtend your lifeIncrease output powerFuel cell heat exchangeBiofuelsCombustion chamberEngineering

The invention discloses a marine solid oxide fuel cell and steam-injected gas turbine combined generating system and a marine solid oxide fuel cell and steam-injected gas turbine combined generating method. The air input port of the air compressor of the system is used for introducing air, the air output port of the air compressor is connected with a heat regenerator, the gas output end of the heat regenerator is connected with a cell stack cathode, the fuel output end of a fuel bottle is connected with the fuel input end of a pre-reformer, the output end of a distilled water heater is connected with the pre-reformer, the output end of the pre-reformer is connected with a cell stack anode, the anode discharge gas output pipeline and the cathode discharge gas output pipeline of a solid oxide fuel cell are used for a combustion chamber, the exhaust gas output end of the combustion chamber is connected with the gas inlet of a turbine, the gas outlet of the turbine is connected with the gas inlet of the heat regenerator, the exhaust gas outlet of the heat regenerator is connected with a waste heat boiler through an exhaust gas transmission pipeline, and the superheated steam output endof the waste heat boiler is connected with the superheated steam input end of the combustion chamber. The system realizes waste heat utilization of a marine auxiliary boiler.

Owner:WUHAN UNIV OF TECH

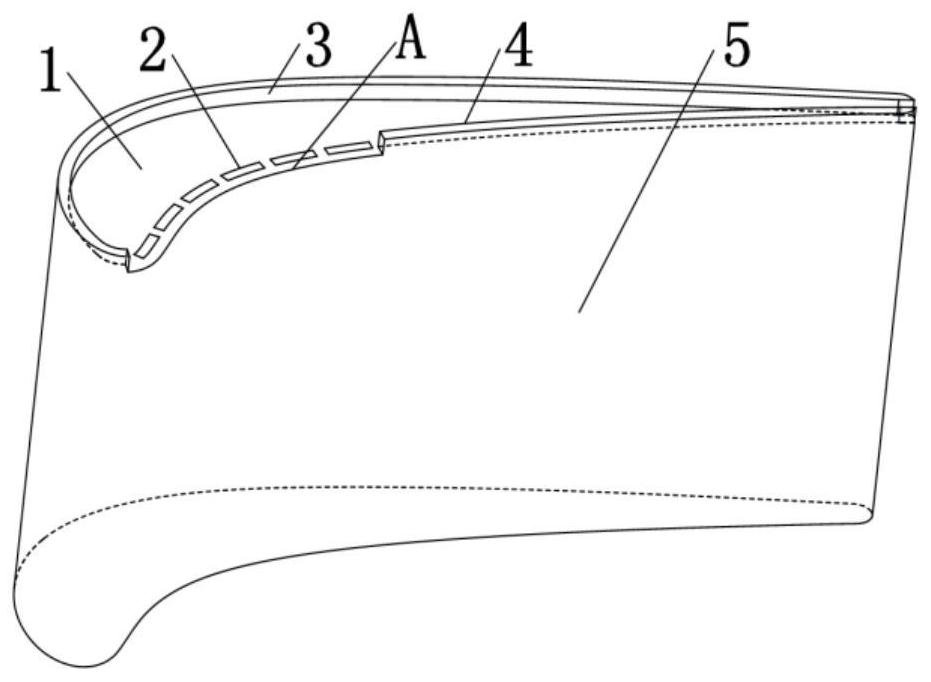

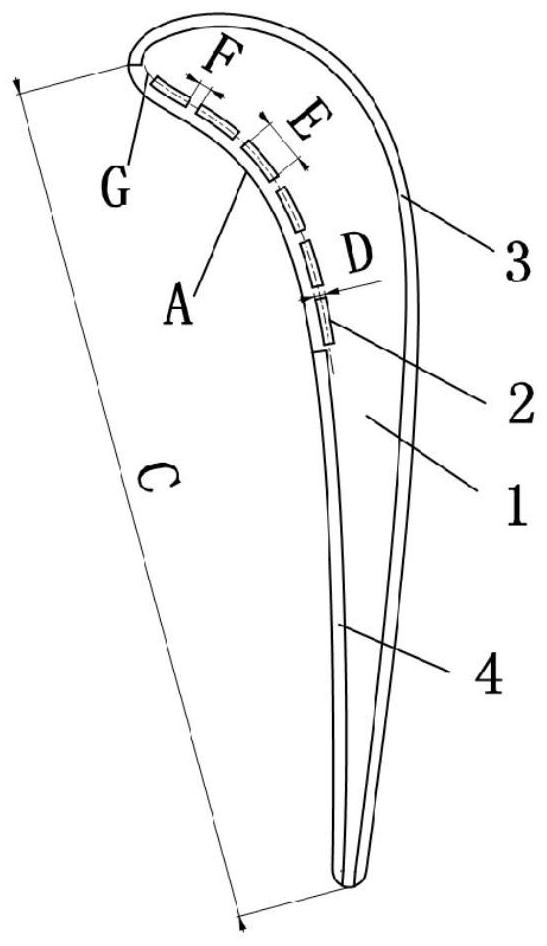

Interrupted groove blade top structure with transverse seam holes for turbine blade

PendingCN112240228AImproved cooling characteristicsExtended service lifeEngine fuctionsBlade accessoriesSuction forceJet flow

The invention discloses an interrupted groove blade top structure with transverse seam holes for a turbine blade. The structure is characterized in that a suction surface side groove wall and a pressure surface side groove wall are arranged on a blade top, the transverse seam holes are formed in the broken groove wall, the interrupted part of an interrupted groove is positioned on the pressure surface side, and the interrupted starting position is positioned at a front edge stationary point. By eliminating a gas reattachment area formed in the groove blade top in the interrupted area, the heatexchange coefficient of the front edge area of the blade top is effectively reduced, the local heat exchange strength is weakened, and the cooling characteristic of the blade top is improved. The transverse width of the groove can be controlled through the reasonable length of the pressure surface side groove wall, so that only one backflow vortex is formed in the groove after fuel gas enters thegroove, and the gas reattachment area in the groove is eliminated; and the transverse seam holes can effectively improve the transverse coverage area after jet flow outflow, the local air film cooling efficiency of the blade top is improved, the working efficiency of the turbine power blade is effectively improved, and the overall performance of an aero-engine is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

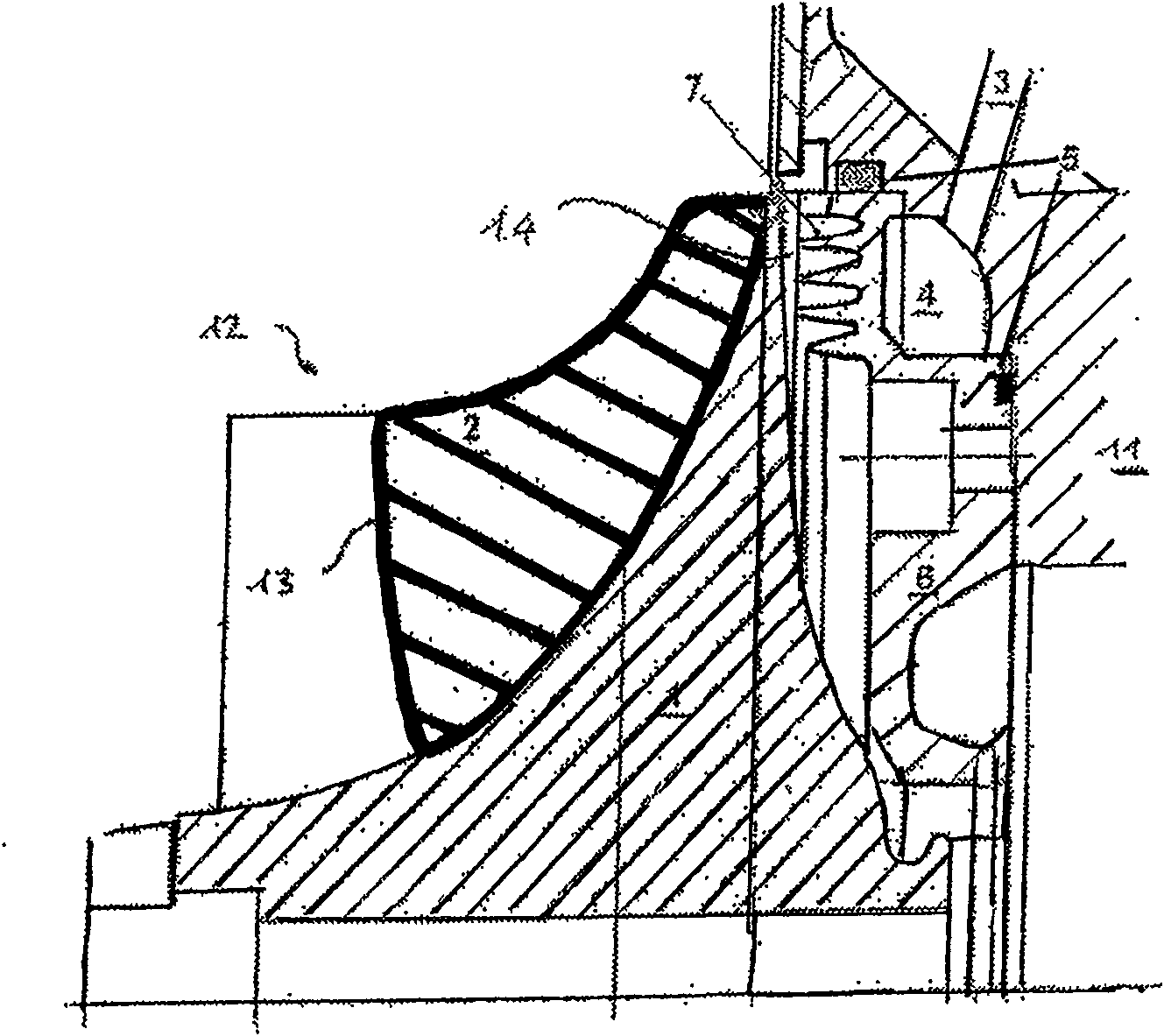

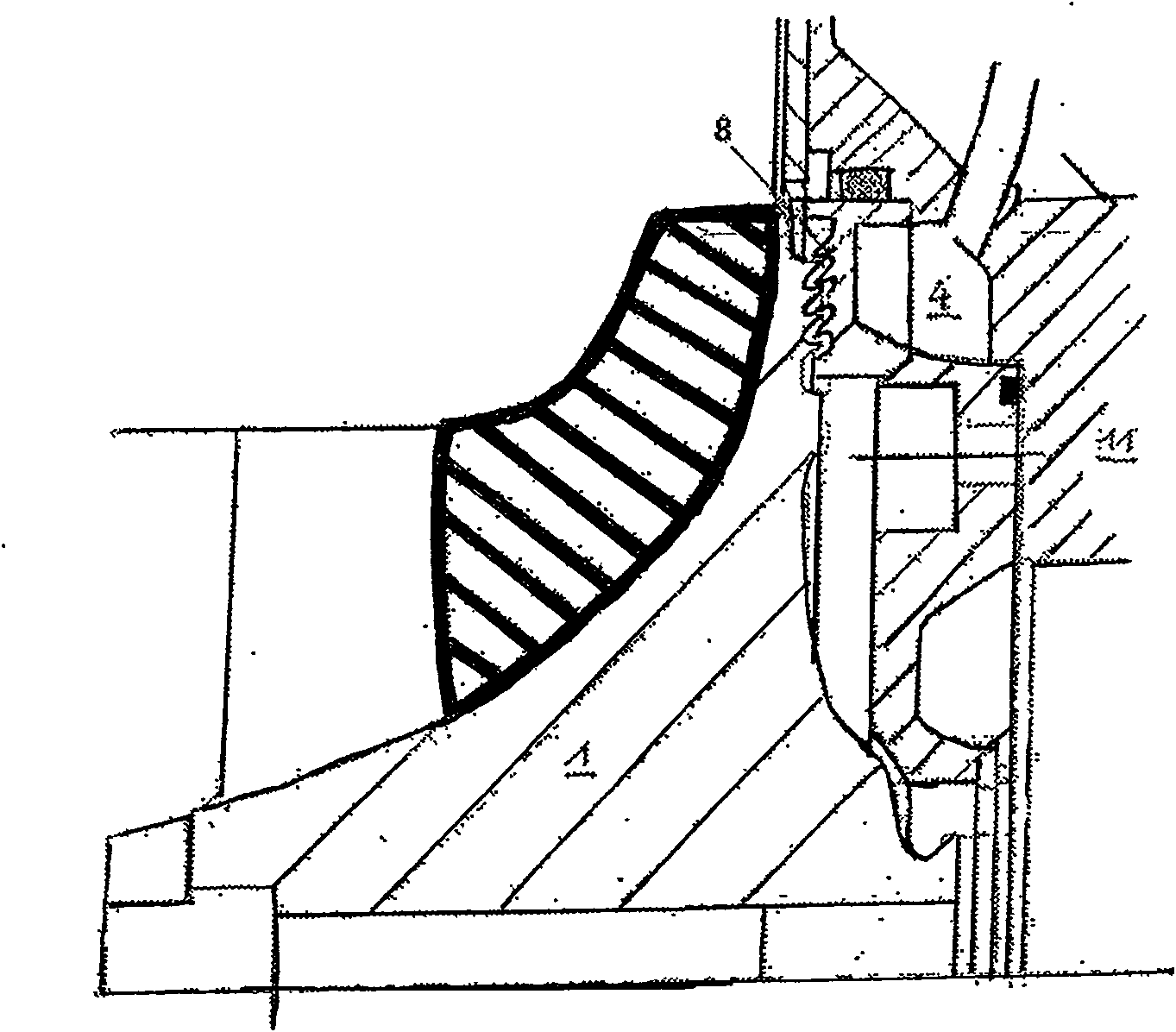

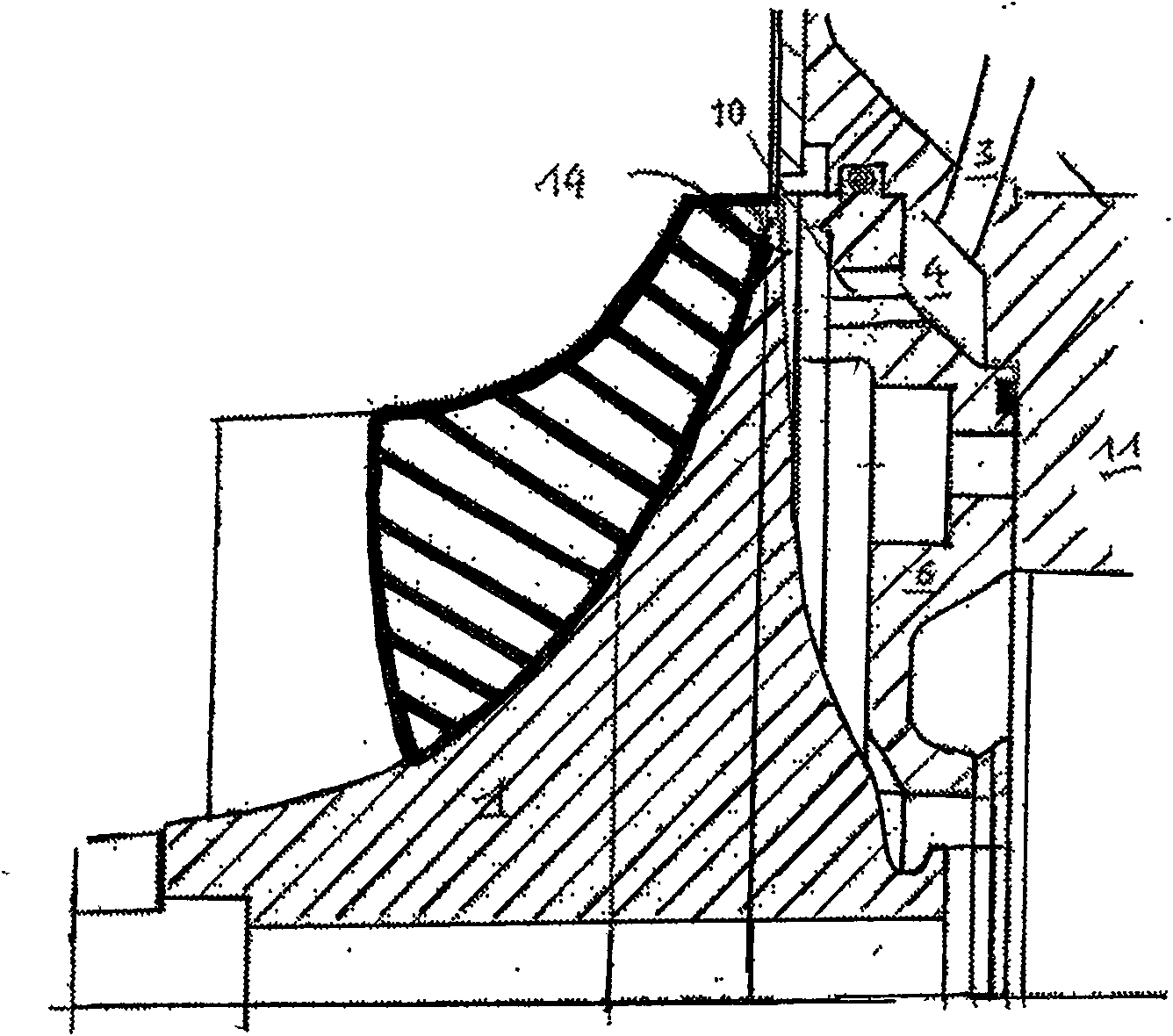

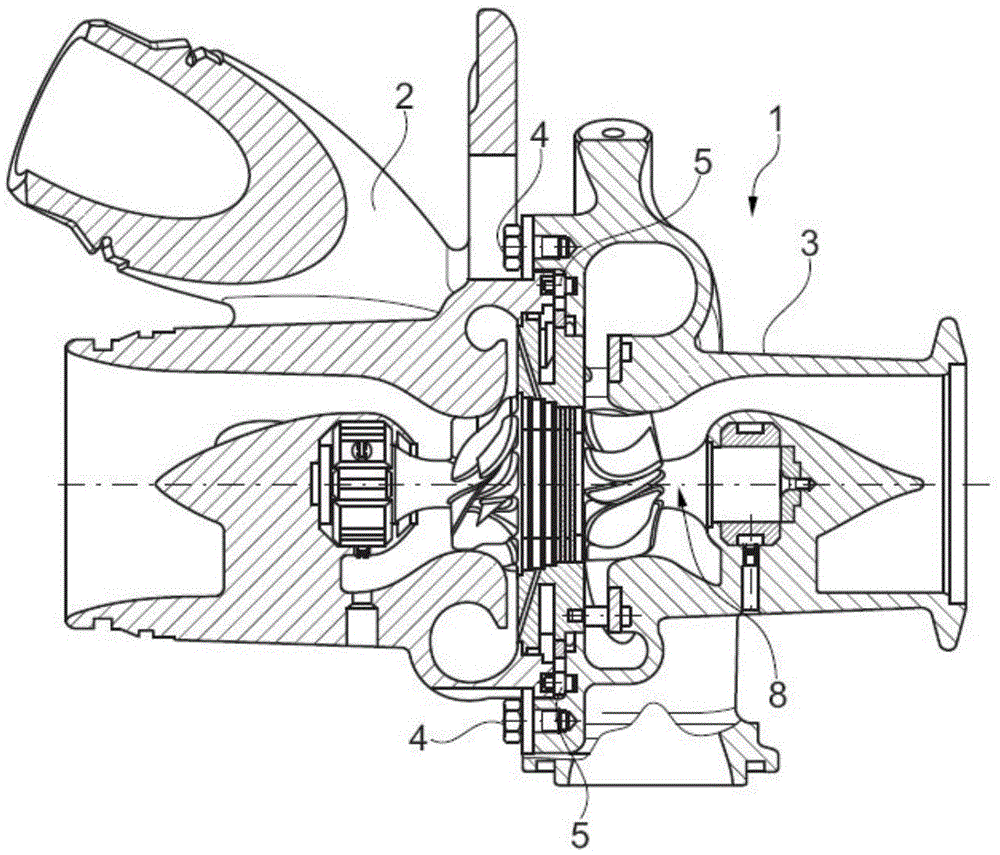

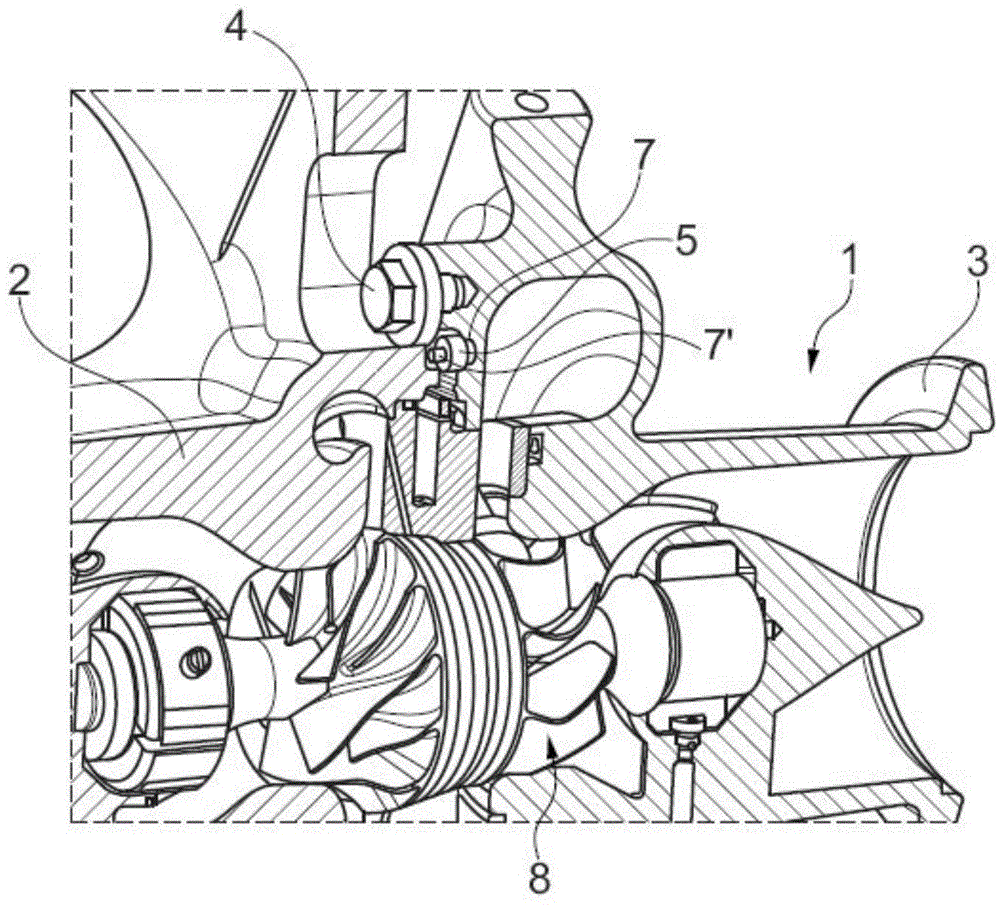

Compressor for a turbocharger and method for cooling thereof

InactiveCN101631940AReduce the amount requiredReduce sizePump componentsEngine fuctionsImpellerTurbocharger

A compressor, particularly a radial compressor, for a turbocharger comprises a compressor impeller (1), which is rotatably received in a compressor housing, wherein cooling fluid flows through a part (6) of the compressor housing adjacent to the compressor impeller. The compressor impeller comprises at least partially a heat input reducing coating (2).

Owner:MAN B & W DIESEL AS

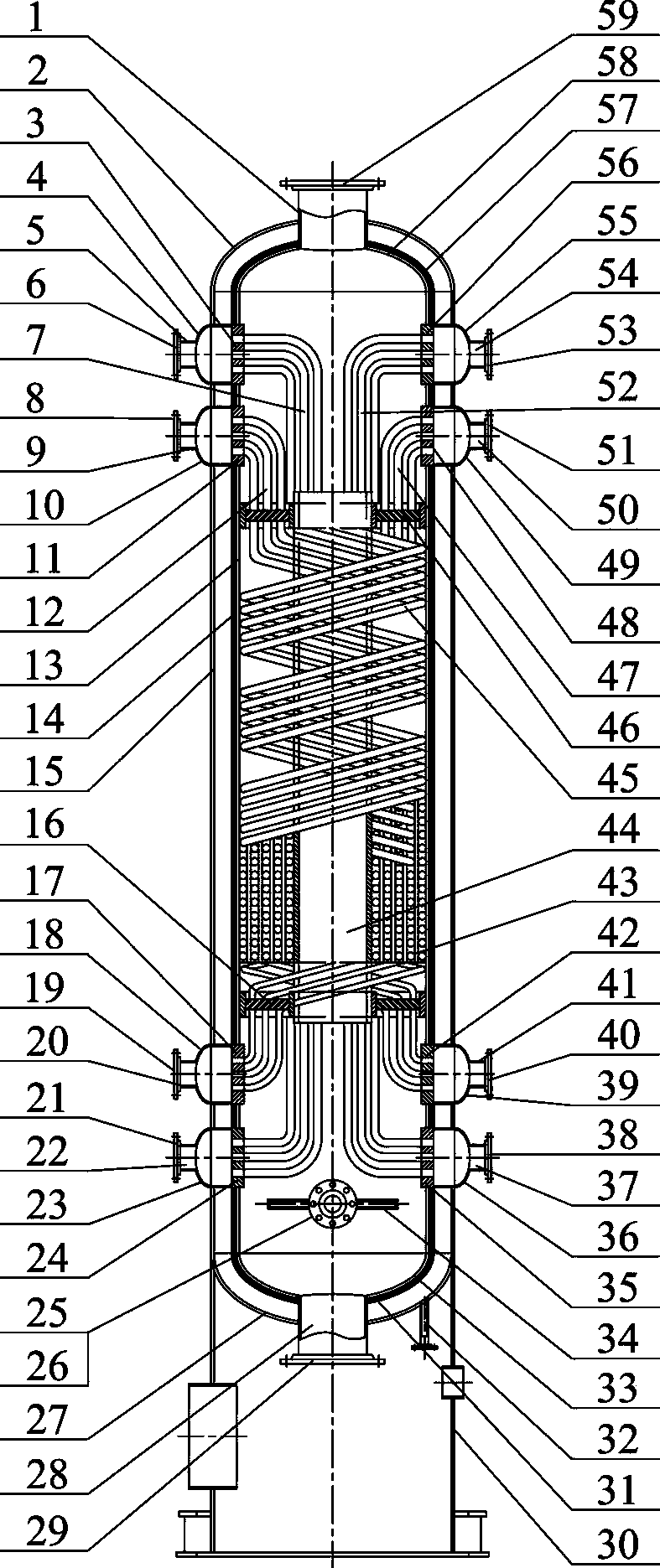

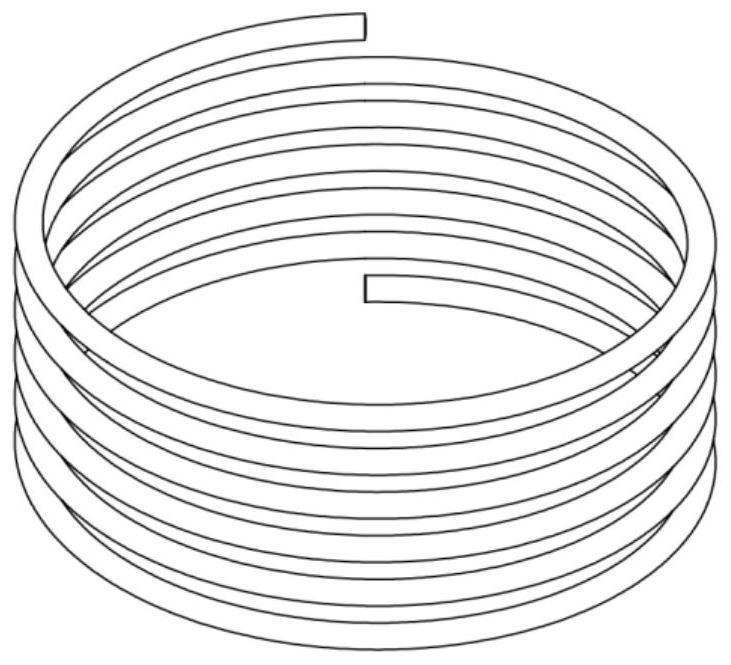

Three-stage back heating multi-strand winding pipe type heat exchange device for low-temperature liquid nitrogen

InactiveCN103438667AWith self-tightening adjustment functionReduce volumeLiquefactionStationary tubular conduit assembliesProcess systemsSyngas

The invention mainly relates to the technical field of synthesis ammonia and low-temperature liquid nitrogen, and relates to the technology of a three-stage back heating multi-strand winding pipe type heat exchange device for the low-temperature liquid nitrogen. Through N2-H2 synthesis gas synthesized by H2 at the temperature of 191.5 DEG C below zero and the pressure of 1.8MPa and N2 at the temperature of 193.4 DEG C below zero and the pressure of 5.19MPa, through waste nitrogen N2-Ar-CO-CH4 at the temperature of 191.5 DEG C below zero and the pressure of 0.18MPa and through compensated high pressure LN2, N2 at the temperature of 127.2 DEG C below zero and the pressure of 5.7MPa is cooled to be N2 at the temperature of 188 DEG C below zero and the pressure of 5.6MPa, and purified gas H2-N2-CO-Ar-CH4 washed by low-temperature methanol is cooled to be purified gas at the temperature of 188.2 DEG C below zero and the pressure of 5.21MPa, namely, the incoming high-pressure N2 and the purified gas washed by the low-temperature methanol are cooled through cooling capacity back heating of the washed N2-H2 synthesis gas, high-pressure H2 and the waste nitrogen, and the temperature condition for washing the purified gas through the low-temperature liquid nitrogen is provided for a washing tower. The three-stage back heating multi-strand winding pipe type heat exchange device for the low-temperature liquid nitrogen is compact in structure and high in heat exchange efficiency and can be used for solving the technical problems of the three-stage six-strand four-bundle winding pipe type heat exchange for the low-temperature liquid nitrogen with the temperature ranging from 127.2 DEG C below zero to 193.4 DEG C below zero, and the low-temperature heat exchange efficiency of a low-temperature liquid nitrogen process system is improved.

Owner:张周卫

Manufacturing process of high-quality wide and thick plate blank

The invention relates to the field of wide and thick plate blanks for a wide and thick plate mill, in particular to a manufacturing process of a high-quality wide and thick plate blank, which is used for manufacturing a wide and thick plate blank for a wide and thick plate mill and solving the problems of higher manufacturing cost, lower efficiency and the like in the prior art, wherein the thickness of the wide and thick plate blank is 350 to 1,200mm. A water-cooling moving die is separately arranged on the front, back, left and right four faces of a tool water-cooling chassis; and the water-cooling moving dies arranged on the front, back, left and right four faces and the water-cooling chassis arranged on the lower part form a combined water-cooling die. The wide and thick plate blank is manufactured by using a high-efficiency water-cooling blank casting machine; and the high-efficiency blank casting machine adopts a hydraulic power system to extrude a casting blank, so that the wide and thick plate blank is solidified and crystallized under the action of a pressure, and internal shrinkage cavities and looseness of the wide and thick plate blank are eliminated. At the same time,a clearance between the die and the casting blank is controlled, the interface heat exchange coefficient between the casting blank and the die is adjusted, and surface cracks of the wide and thick plate blank are eliminated, by using the hydraulic power system, so the wide and thick plate blank with high quality is obtained finally.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

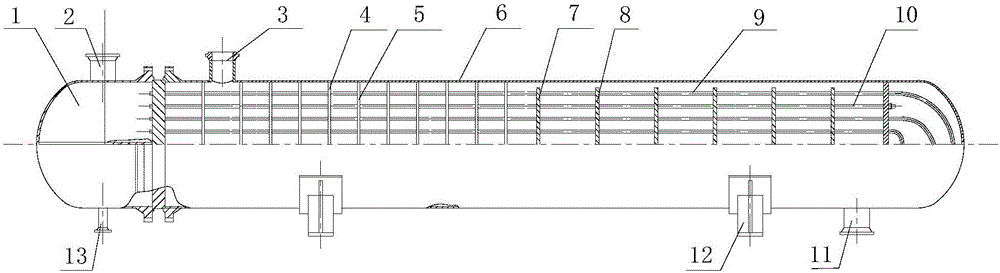

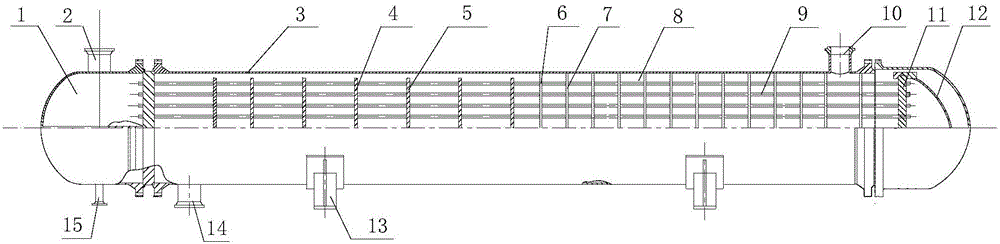

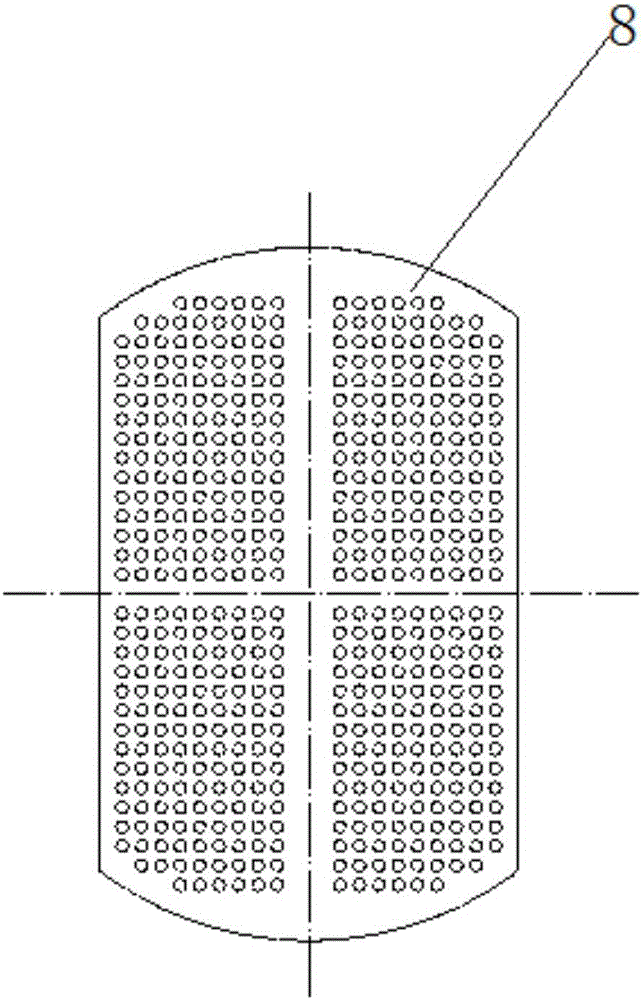

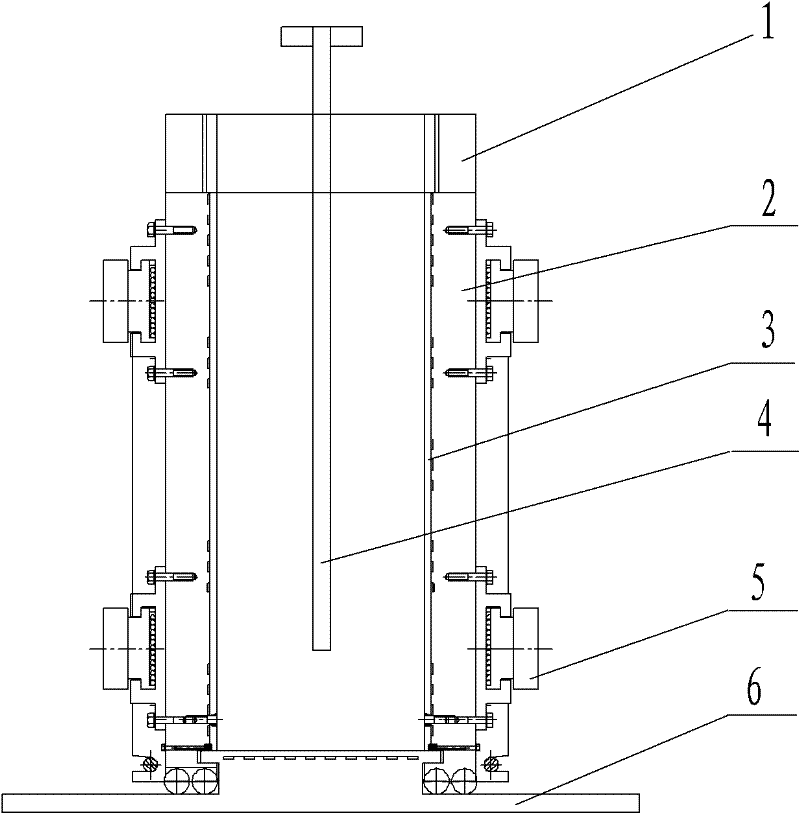

Mixed baffling stream type reboiler

ActiveCN106643227AImprove heat transfer efficiencyLow flow resistanceHeat exchanger casingsStationary tubular conduit assembliesReboilerEngineering

The invention discloses a mixed baffling stream type reboiler. The mixed baffling stream reboiler comprises a shell body and a support which is arranged at the lower part of the shell body and is used for supporting the shell body, shell side in-out ports are correspondingly arranged at two ends of the shell body, multiple groups of tube bundles are arranged at intervals in the axial direction of the shell body in the shell body, baffling stream plates and baffling stream fences are arranged in the radial direction of the tube bundles in the shell body, and the baffling stream plates and the baffling stream fences are used for supporting the tube bundles and conducting stream guidance on shell side fluid. The mixed baffling stream type reboiler is reasonable in structure and safe and efficient in work, and combines an optimal heat transfer property and a minimum flow-induced vibration property.

Owner:XI AN JIAOTONG UNIV

Manufacturing process of high-quality wide and thick plate blank

The invention relates to the field of wide and thick plate blanks for a wide and thick plate mill, in particular to a manufacturing process of a high-quality wide and thick plate blank, which is used for manufacturing a wide and thick plate blank for a wide and thick plate mill and solving the problems of higher manufacturing cost, lower efficiency and the like in the prior art, wherein the thickness of the wide and thick plate blank is 350 to 1,200mm. A water-cooling moving die is separately arranged on the front, back, left and right four faces of a tool water-cooling chassis; and the water-cooling moving dies arranged on the front, back, left and right four faces and the water-cooling chassis arranged on the lower part form a combined water-cooling die. The wide and thick plate blank is manufactured by using a high-efficiency water-cooling blank casting machine; and the high-efficiency blank casting machine adopts a hydraulic power system to extrude a casting blank, so that the wide and thick plate blank is solidified and crystallized under the action of a pressure, and internal shrinkage cavities and looseness of the wide and thick plate blank are eliminated. At the same time, a clearance between the die and the casting blank is controlled, the interface heat exchange coefficient between the casting blank and the die is adjusted, and surface cracks of the wide and thick plate blank are eliminated, by using the hydraulic power system, so the wide and thick plate blank with high quality is obtained finally.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Transparent glass paint and preparation method thereof

InactiveCN107090219AExtended service lifeHigh light transmittanceBiocideAntifouling/underwater paintsWeather resistanceAcrylic resin

The invention discloses transparent glass paint and a preparation method thereof, and relates to the technical field of glass paint. The transparent glass paint is prepared from the following raw materials in parts: 100 to 120 parts of acrylic resin, 70 to 80 parts of epoxy polyurethane synthetic resin, 55 to 65 parts of ATO (Antimony Tin Oxide) powder, 35 to 45 parts of modified colloidal rheological thickener, 25 to 30 parts of ultraviolet absorbent, 15 to 20 parts of insect repellent, 10 to 15 parts of auxiliary and 200 to 220 parts of water. The transparent glass paint is high in light transmittance, low in heat transfer coefficient, good in heat insulation performance, is long in service life of a coating, is good in weathering resistance, and has the long-acting advantages of energy saving, self cleaning and attractiveness when being used on the glass of buildings.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

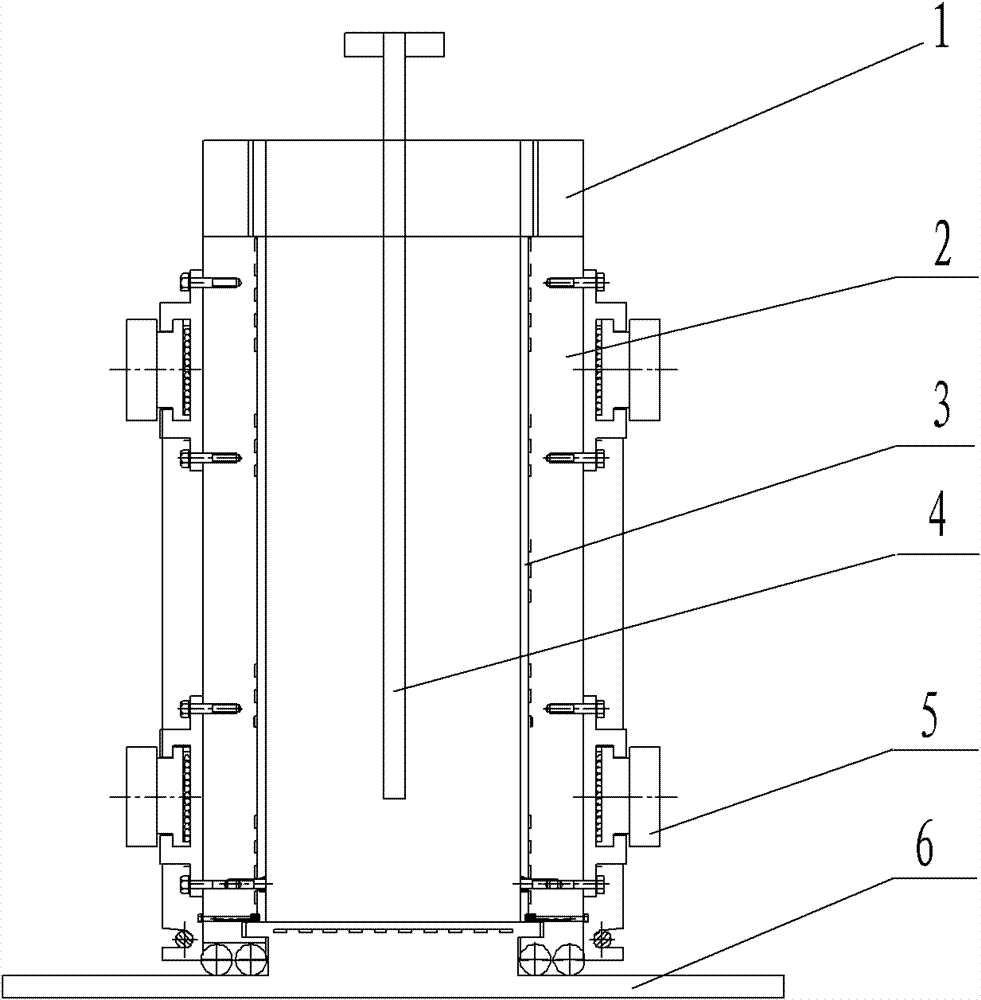

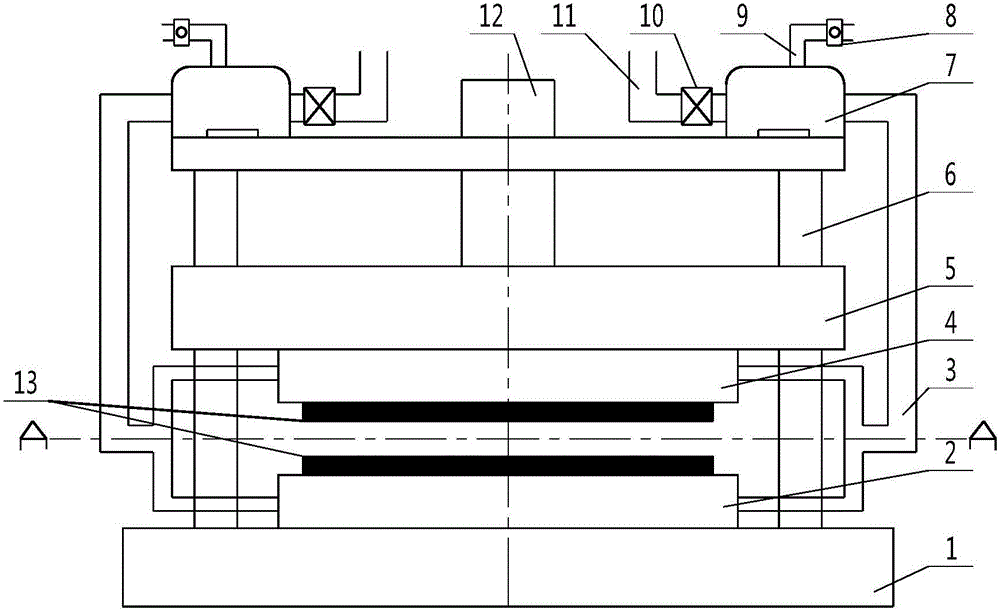

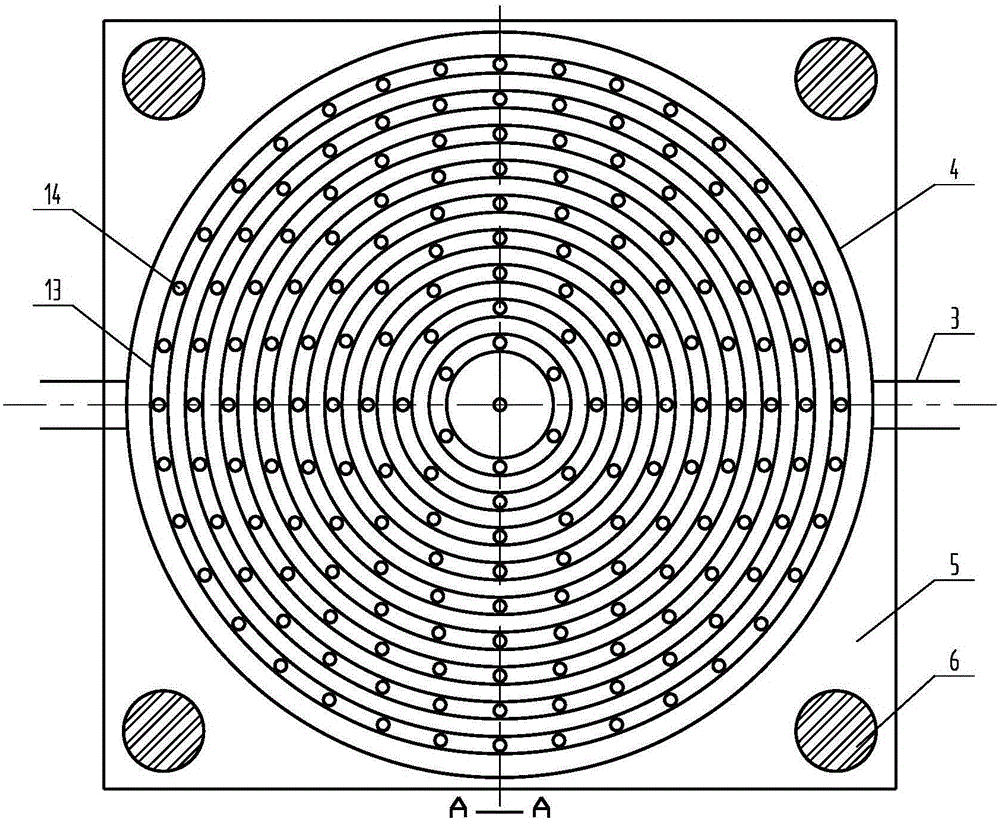

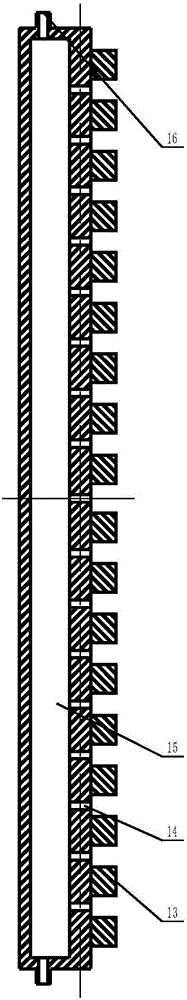

Air quenching method of circular saw web

ActiveCN106435147ASimple structureEasy to manufactureFurnace typesHeat treatment furnacesReciprocating motionCircular saw

The invention relates to an air quenching method and device of a circular saw web. A rack, an upper press plate and a lower press plate are included. The upper press plate and the lower press plate capable of doing up-and-down reciprocating motion are symmetrically arranged on the rack. The upper press plate and the lower press plate are each provided with an air cavity. Nozzle openings are evenly distributed in the upper press plate and the lower press plate and communicate with the corresponding air cavities. The air cavities are connected with an air inlet pipeline. In the whole quenching process, the manner of gas and gas-liquid atomization gas alternative cooling is adopted, by means of the characteristic of the low and adjustable cooling speed of air media and atomization gas, deformation cracks of the saw web in the quenching process are greatly reduced, and the performance quality of the saw web is improved; and meanwhile, the whole quenching process is clean, no waste gas is generated, the surface does not need to be cleaned after the saw web is quenched, and the requirement of green production is met.

Owner:RIZHAO HEIN SAW

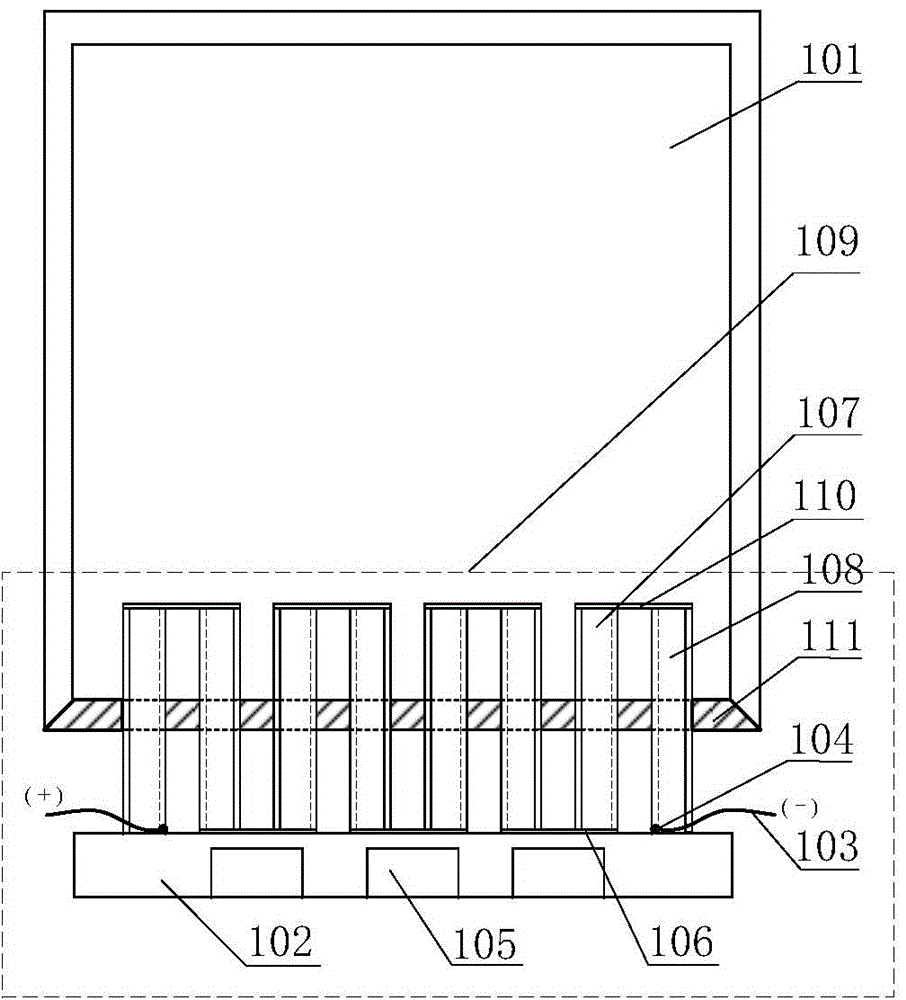

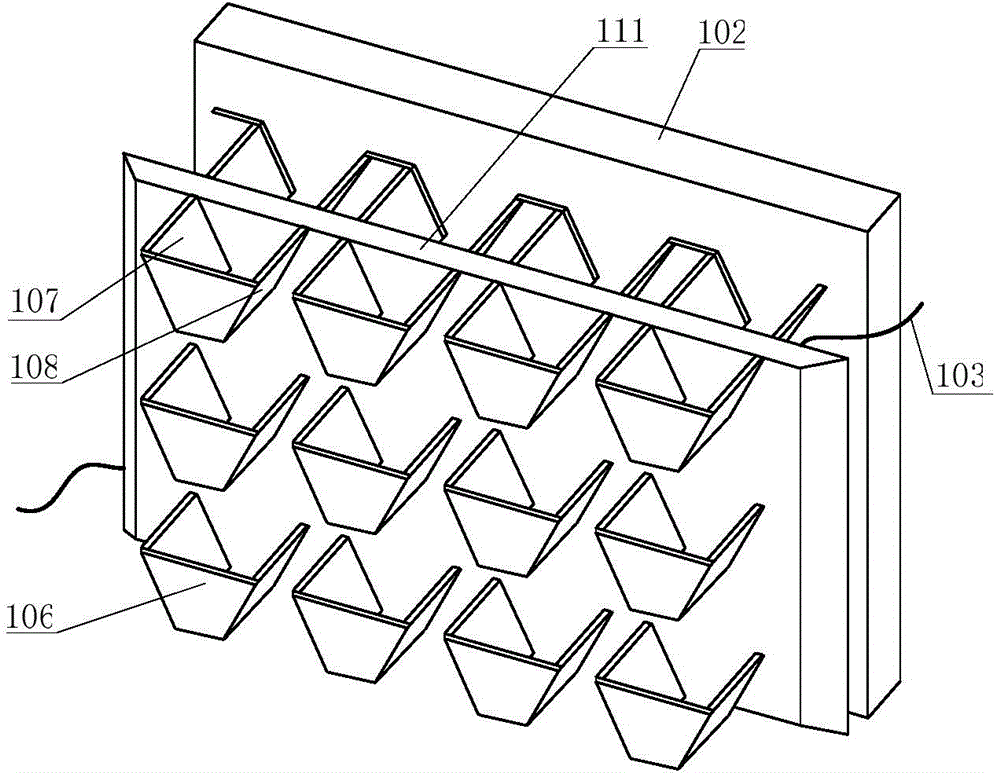

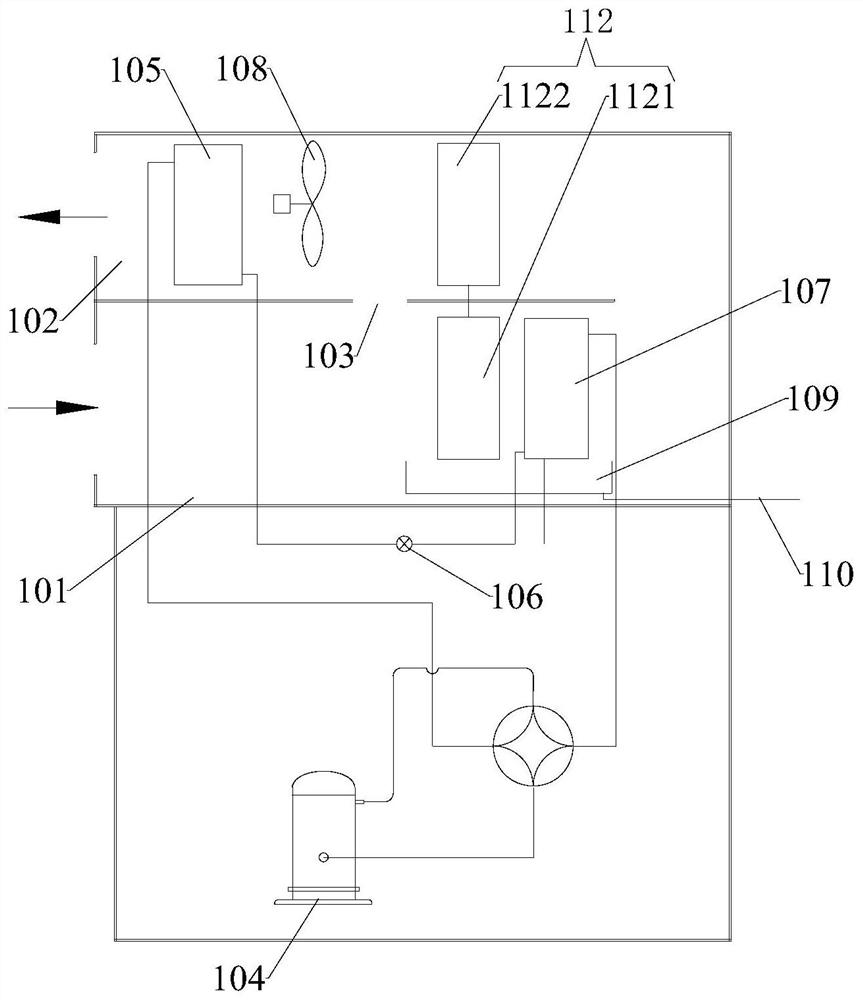

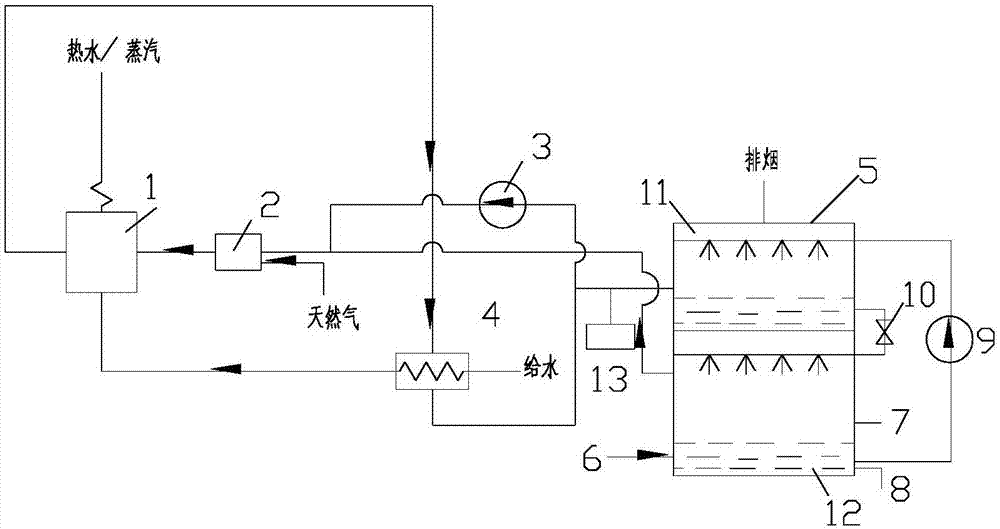

Thermoelectric power generation device using flue gas waste heat of rear smoke channel of boiler and semiconductor power generation device

ActiveCN104901585ALow heat transfer coefficientReduce the temperatureIncreasing energy efficiencyGenerators/motorsThermal insulationAtmospheric temperature

The invention relates to a semiconductor power generation device using flue gas waste heat of a rear smoke channel of a boiler. The semiconductor power generation device comprises a boiler rear smoke channel (101) and a thermoelectric power generation device (109). The thermoelectric power generation device consists of a hot end surface (110), a cold end surface (102), a leading-out wire (103), welding points (104), guide plates (106), P type semiconductors (107), N type semiconductors (108), and a thermal insulation material layer (111). Cooling holes (105) are formed in the cold end surface. The thermoelectric power generation device is connected with the boiler rear smoke channel by the thermal insulation material layer. According to the thermoelectric power generation device, a temperature difference is generated between the hot end surface (110) formed by flue gas waste heat and the cold end surface (102) under an atmospheric temperature, so that the P type semiconductors and the N type semiconductors generate electromotive forces respectively. The P type semiconductors and the N type semiconductors are connected in series by the guide plates; and the generated electrical energy is outputted to the user based on the welding points and the leading-out wire. According to the invention, with the heat sensitivity of the semiconductors, the flue gas waste heat is utilized and the low-temperature waste heat is converted into the electric energy directly, so that no pollution is caused and installation is convenient; and the effect of energy conservation and emission reduction is realized well.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

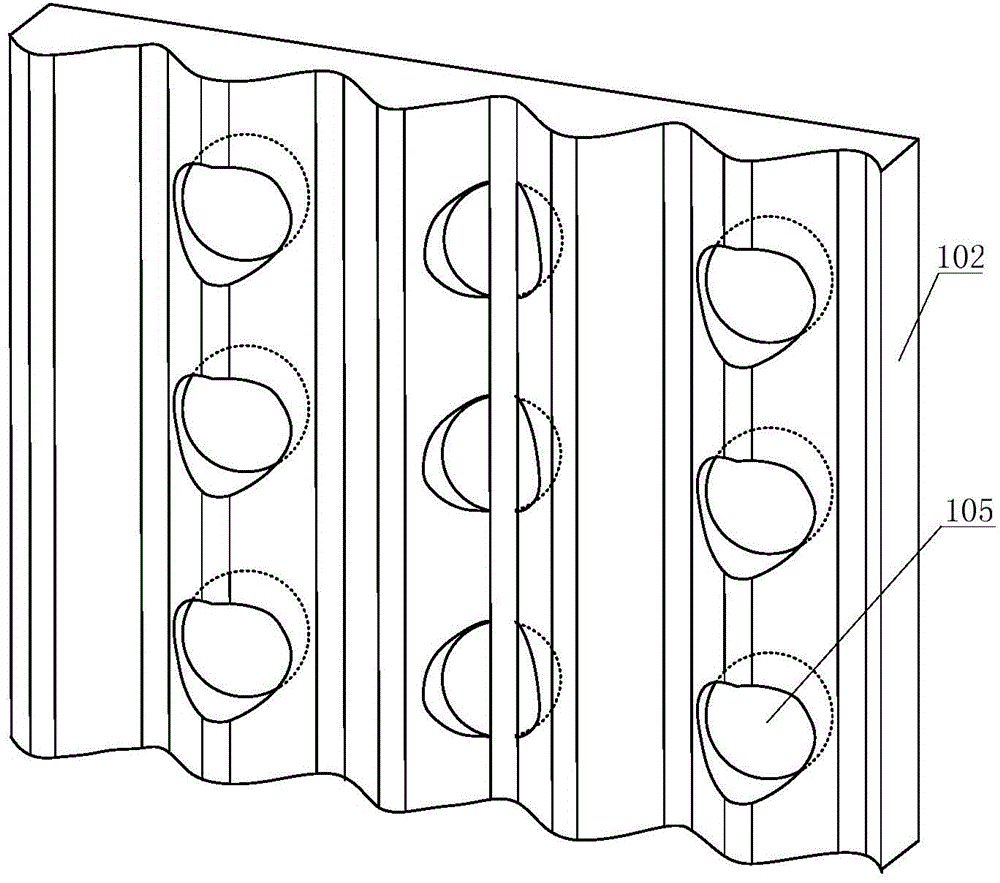

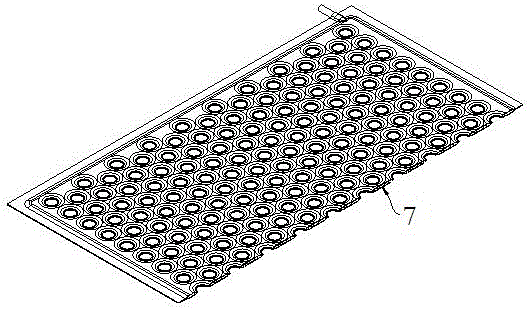

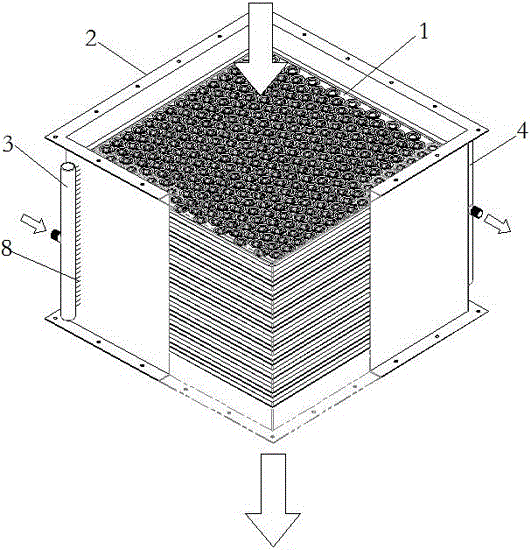

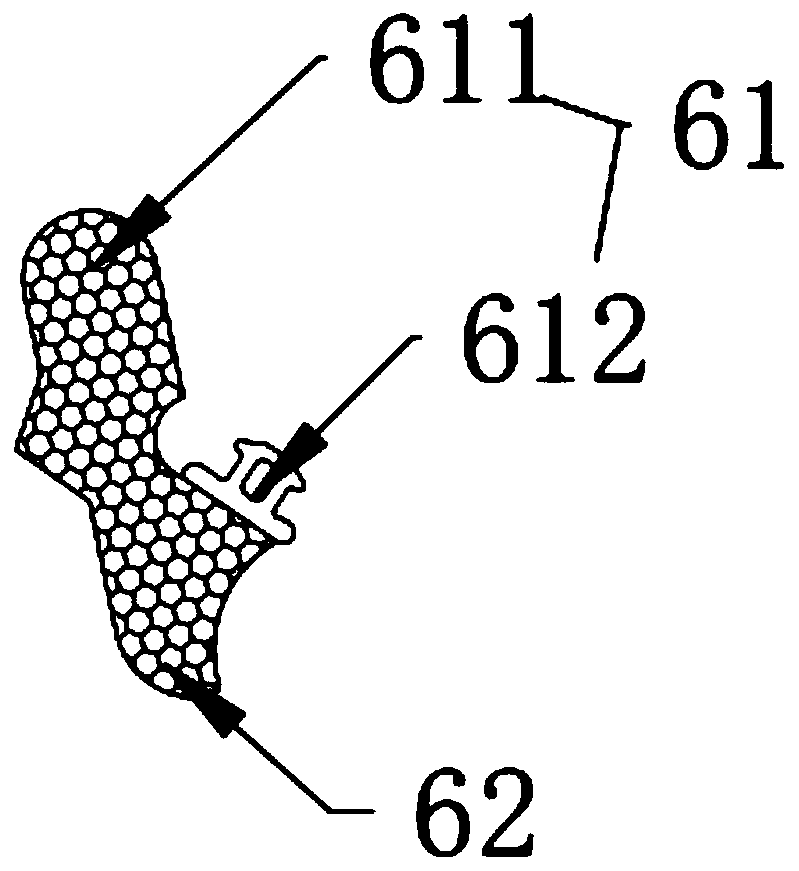

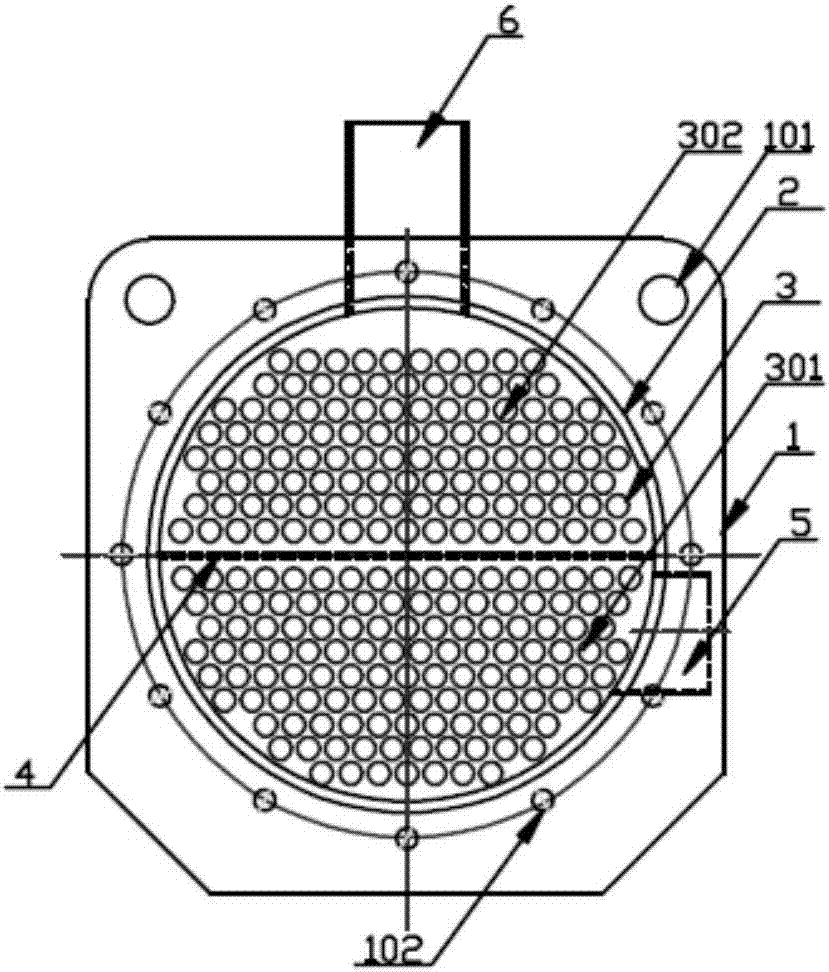

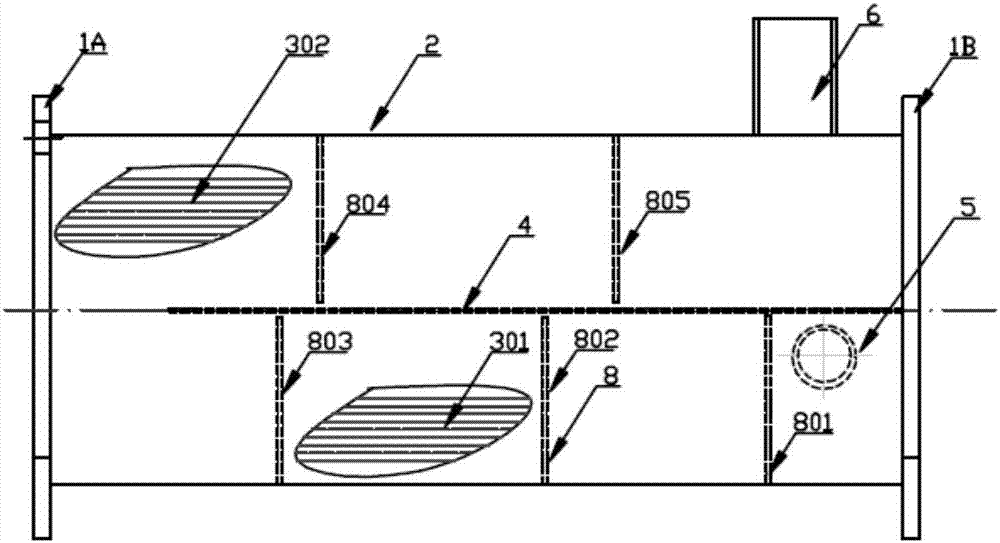

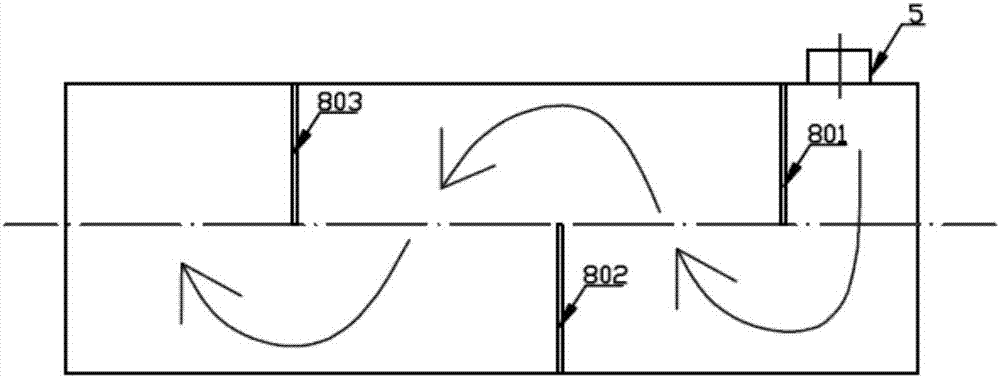

Heat exchanger with net type lung-shaped heat exchange plates

ActiveCN106152838ACompact structureLow flow resistanceLaminated elementsStationary plate conduit assembliesEngineeringExchange coefficient

The invention discloses a heat exchanger with net type lung-shaped heat exchange plates. The heat exchanger with the net type lung-shaped heat exchange plates comprises net type heat exchanger plates, a heat exchanger shell, a liquid inlet tube and a liquid outlet tube, wherein the net type heat exchanger plates are distributed in the heat exchanger shell from top to bottom at equal intervals to form a lung-shaped hollow structure; the liquid inlet tube and the liquid outlet tube are respectively arranged on the heat exchanger shell in the longitudinal direction; and according to each net type heat exchanger plate, two plate bodies with through holes are superposed vertically, the peripheries of the plate bodies and side seams of the through holes are welded together in an argon arc welding or laser welding mode, and a fluid channel in each plate is formed. By the heat exchanger with the net type lung-shaped heat exchange plates, fluid flowing resistance of the outside of each plate is reduced, meanwhile, large Reynolds number can be obtained at low speed, turbulent flow is formed, heat exchange coefficient is increased effectively, therefore, the heat exchanger is simple, efficient and energy-saving, and is compact in structure, occupied space and initial investment are saved, the resistance of the product is lower than that of a traditional plate type heat exchanger, and the heat exchange coefficient can be high.

Owner:SEHENSTAR ENERGY TECH SUZHOU

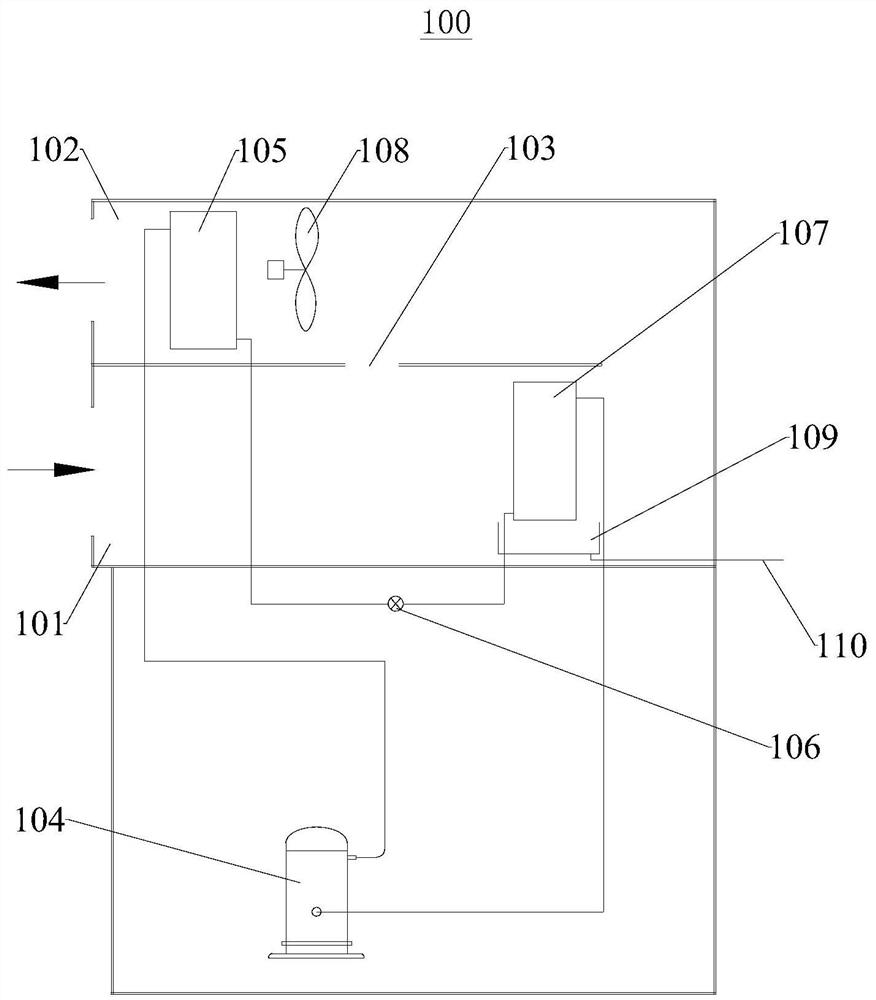

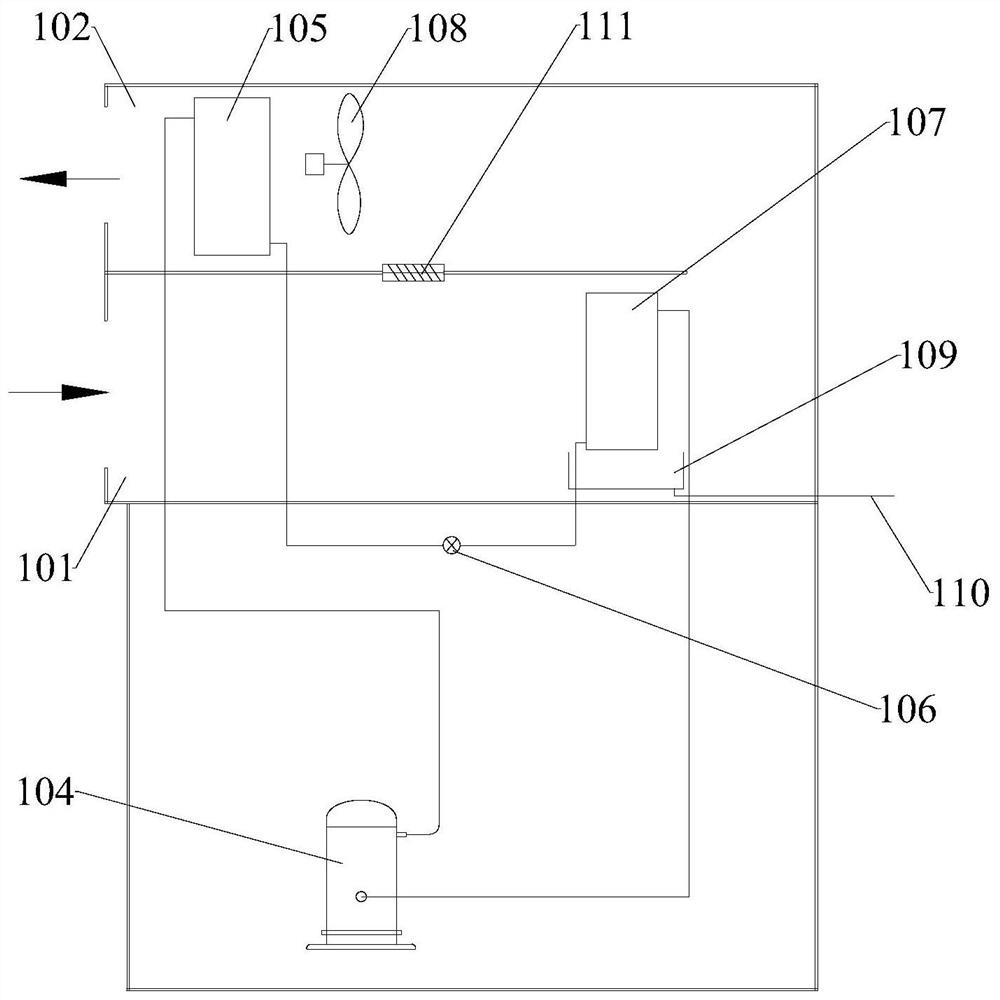

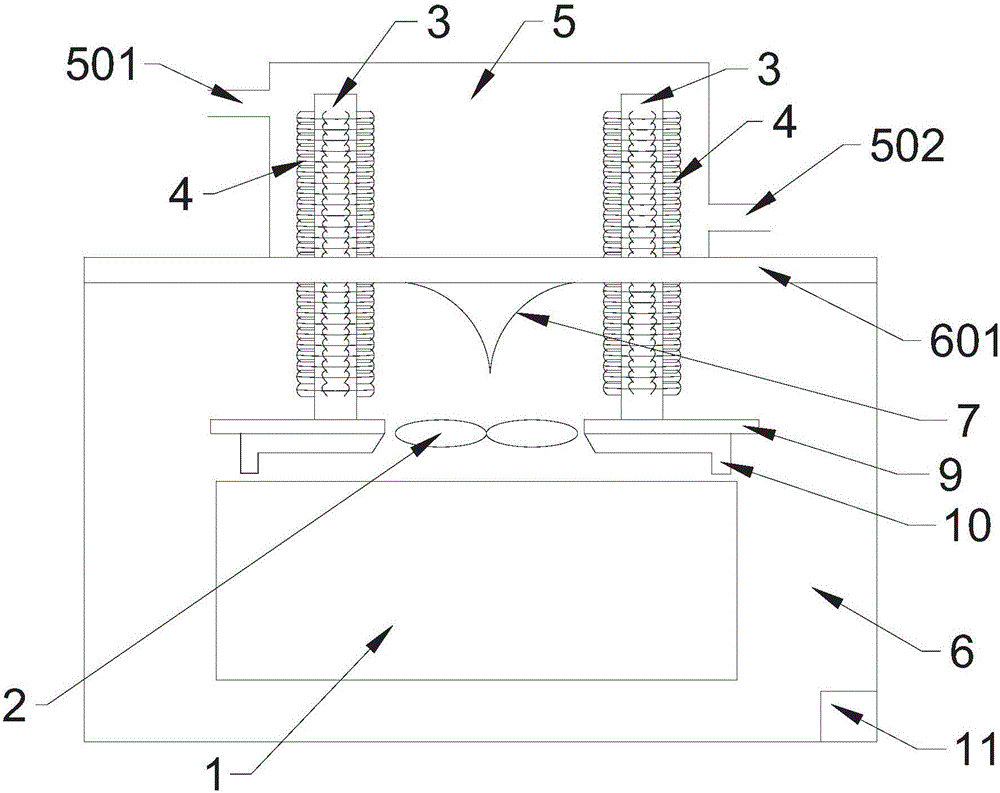

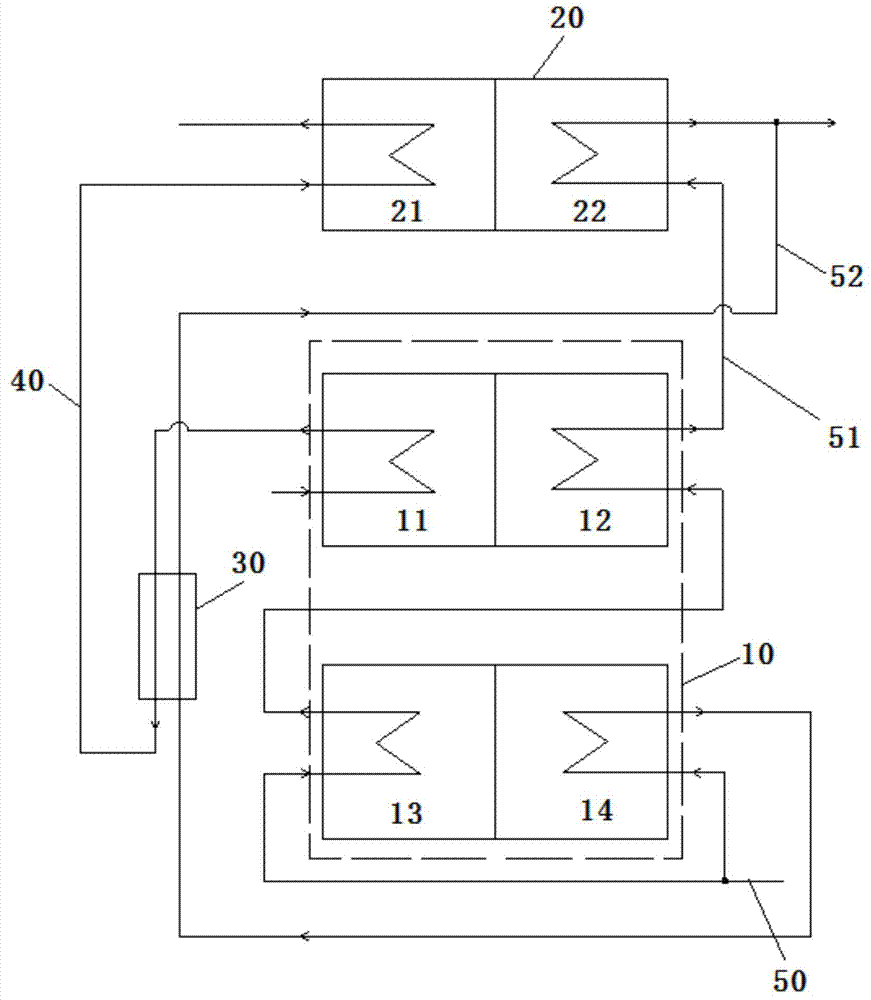

Heat pump drying system

PendingCN111895773AGuaranteed uptimeImprove heat transfer coefficientHeat pumpsDrying gas arrangementsEngineeringMechanical engineering

The embodiment of the invention provides a heat pump drying system and relates to the field of heat pump drying. The heat pump drying system comprises a wind return wind channel, a wind supply wind channel, a bypass wind channel, a first compressor, a first heat exchanger, a first throttling device, a second heat exchanger and a first fan. An exhausting opening of the first compressor is connectedwith an inlet of the first heat exchanger. An outlet of the first exchanger is connected with one end of the first throttling device. The other end of the first throttling device is connected with aninlet of the second heat exchanger. An outlet of the second heat exchanger is connected with an air sucking opening of the first compressor. The first fan is used for enabling first part air in the wind return wind channel to enter the wind supply wind channel after exchanging heat with the second heat exchanger, and then exchange heat with the first heat exchanger. The first fan is also used forenabling second part air in the wind return wind channel to enter the wind supply wind channel through the bypass wind channel, and exchange heat with the first heat exchanger. According to the heatpump drying system, the higher wind output temperature can be achieved under the circumstance of the lower condensing temperature.

Owner:张勇

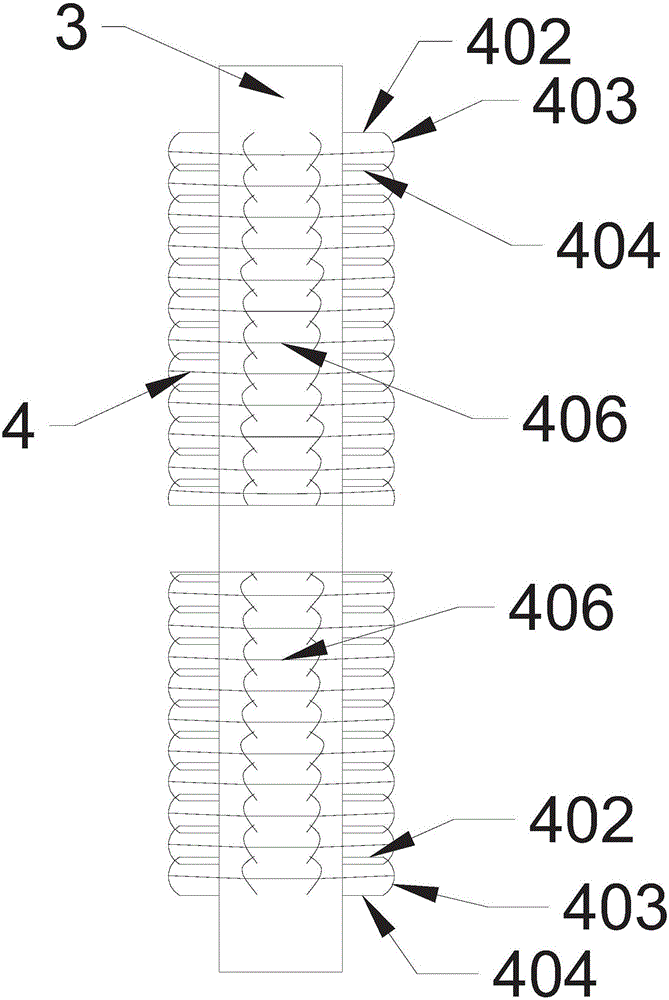

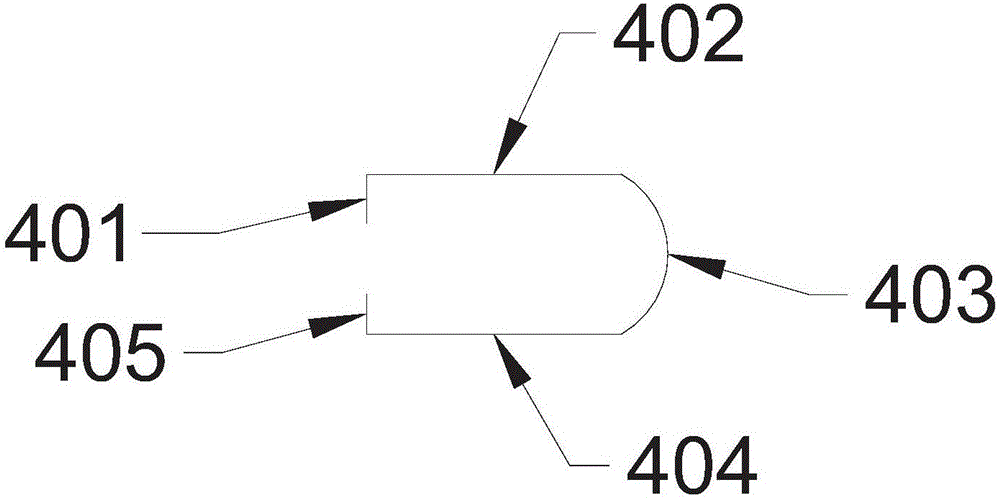

Generator cooling device with vertical low-resistance heat pipes

InactiveCN106059199AImprove heat transfer efficiencyImprove heat transfer performanceCooling/ventillation arrangementCold sideHigh density

The invention discloses a generator cooling device with vertical low-resistance heat pipes, comprising multiple heat pipes, a hot-side circulation fan, and a cold-side water tank. The condensation ends of the heat pipes are in the cold-side water tank, and the evaporation ends of the heat pipes are in a generator cabin. The outer wall of each heat pipe is configured with a high-density multi-layer and multi-column linear bent heat exchange member, and the linear bent heat exchange member is composed of a first bent part, a second bent part, a third bent part, a fourth bent part and a fifth bent part which are formed by bending a metal wire four times. A bracket is arranged at the bottom of the evaporation ends of the heat pipes, and the bracket is fixed on a liquid collecting tray. The heat pipes are used as heat exchange elements, and a generator can be cooled quickly. The condensation ends of the heat pipes are in the cold-side water tank, so the heat generated by generators is fully utilized, and energy saving is achieved. The bracket is fixed on the liquid collecting tray, so the working liquid in the heat pipes does not flow to generators after the heat pipes leak accidentally, and a generator short circuit accident is avoided.

Owner:SUZHOU BSE AIR CONDITIONER

Bypass type low-temperature negative-pressure heat exchanger for pre-cooling type JT refrigerator and design method

ActiveCN112212719AIncrease the cooling capacity of the final stageImprove efficiencyCompression machinesStationary tubular conduit assembliesRefrigeration temperatureMechanical engineering

The invention discloses a bypass type low-temperature negative-pressure heat exchanger for a pre-cooling type JT refrigerating machine and a design method. The heat exchanger is composed of a high-pressure side pipeline, a low-pressure side pipeline, a bypass pipeline, a bypass element, a three-way element and a low-temperature negative-pressure dividing wall type heat exchanger. According to theinvention, the temperature and flow distribution of a fluid in the low-temperature negative-pressure heat exchanger are changed through the bypass pipeline, the irreversible loss of the pipeline and the pressure drop loss of the low-pressure pipeline side are reduced, the low-pressure pressure of the pre-cooling type JT refrigerating machine after throttling is reduced, and the final-stage refrigerating temperature of the pre-cooling type JT refrigerating machine is reduced; the flow velocity of a high-low pressure pipeline fluid in the low-temperature negative-pressure dividing wall type heatexchanger is increased, so that the heat exchange efficiency of the low-temperature negative-pressure heat exchanger is improved; the fluid temperature before throttling is reduced, and the refrigerating capacity of the pre-cooling type JT refrigerating machine is increased; and the overall efficiency of the pre-cooling type JT refrigerating machine is improved. The bypass type low-temperature negative-pressure heat exchanger for the pre-cooling type JT refrigerator and the design method have very positive significance for application of the pre-cooling type JT refrigerator in special fieldssuch as extremely low temperature areas, aerospace and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

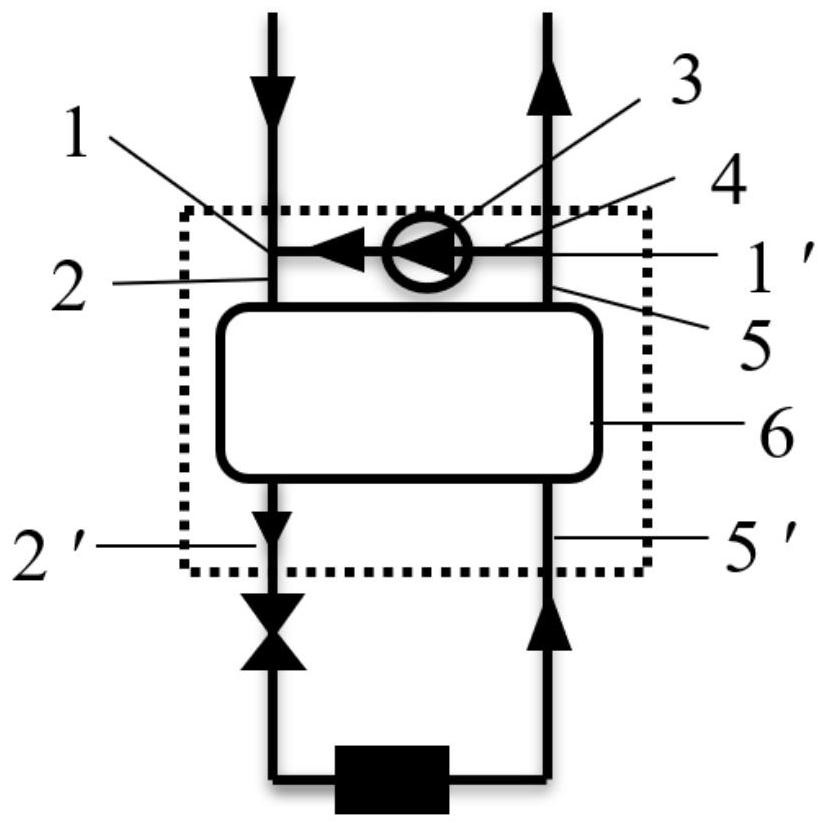

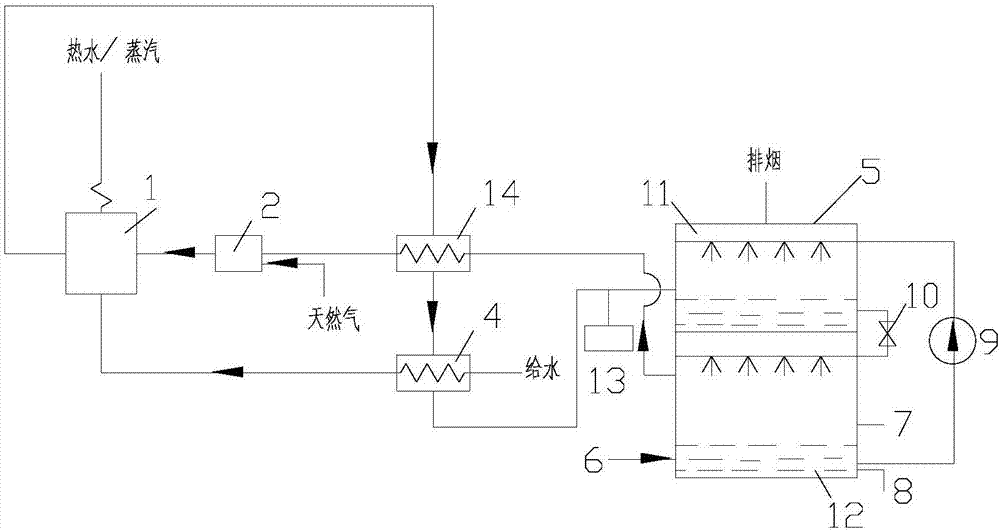

Contact heat exchange desulfurization and denitrification integrated natural gas condensation boiler

PendingCN107490191AAvoid pollutionImprove heat transfer efficiencyEmission preventionAir heatersWater vaporAir heater

The invention discloses a contact heat exchange desulfurization and denitrification integrated natural gas condensation boiler. A smoke outlet of a combustor communicates with a smoke inlet of a boiler body; a water outlet of a smoke water feeding heat exchanger communicates with a water inlet of the boiler body; a smoke inlet of the smoke water feeding heat exchanger communicates with a smoke outlet of the boiler body; a smoke inlet of a contact condensation smoke cooler communicates with the smoke outlet of the smoke water feeding heat exchanger through a first pipeline; an ozone adding port is formed in the first pipeline, and communicates with an ozone adding device; a wet air outlet of a contact air heater communicates with a combustion assistance gas inlet of the combustor; and a condensation absorbing liquid inlet of the contact air heater communicates with a condensation absorbing liquid outlet of the contact condensation smoke cooler. The desulfurization and denitrification natural gas condensation boiler is simple in structure, environment-friendly, high in efficiency, lower in investment cost and higher in utilization rate of latent heat of water vapor in discharged smoke.

Owner:XI AN JIAOTONG UNIV

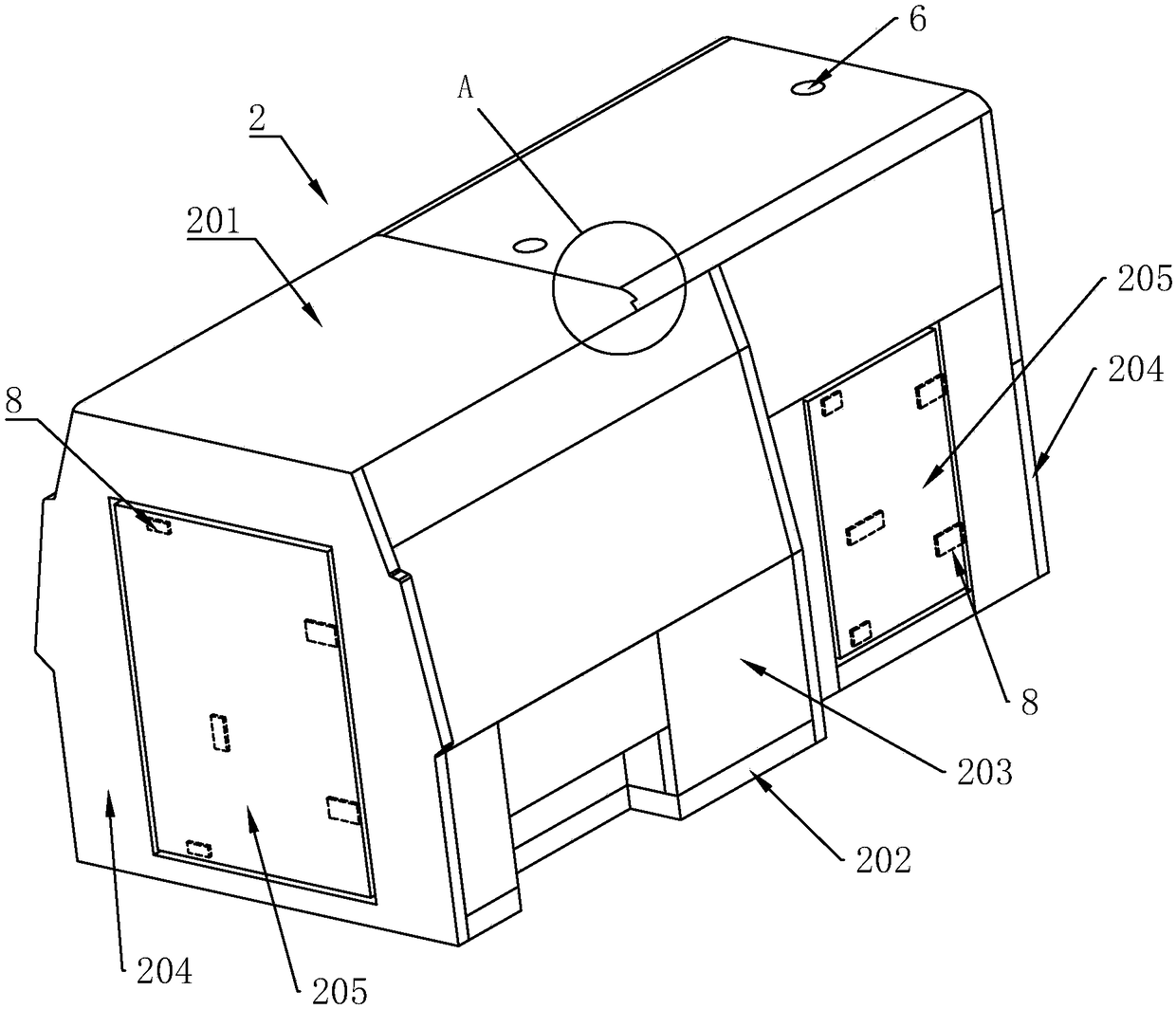

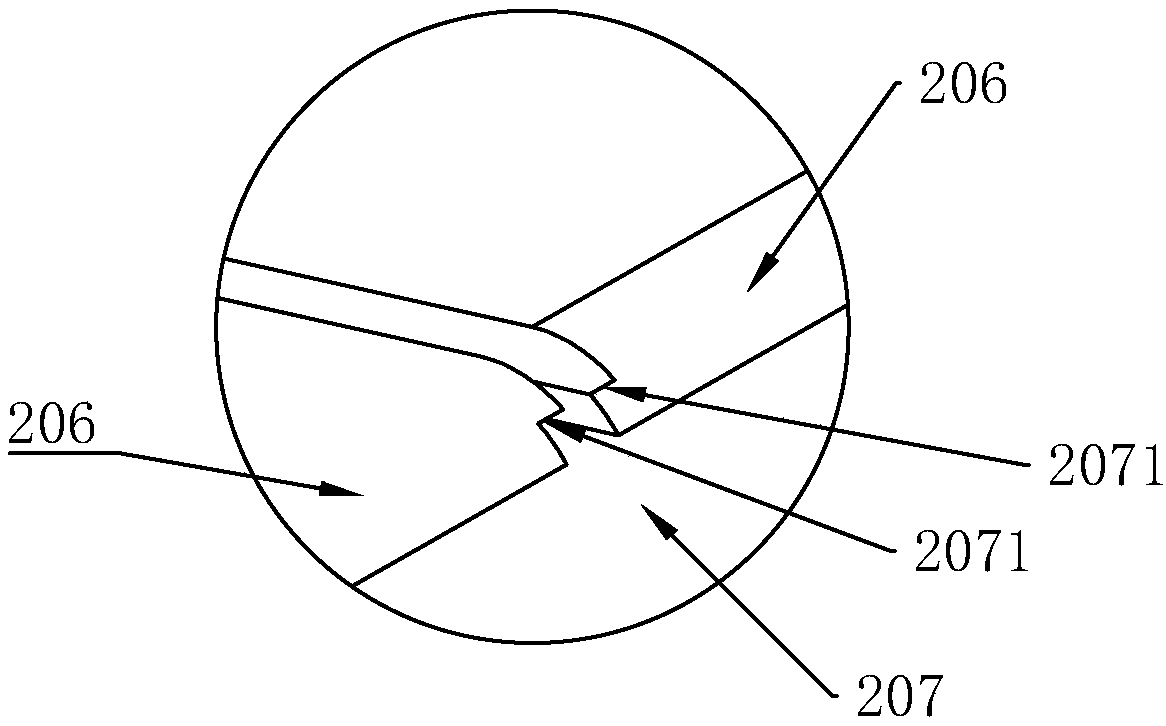

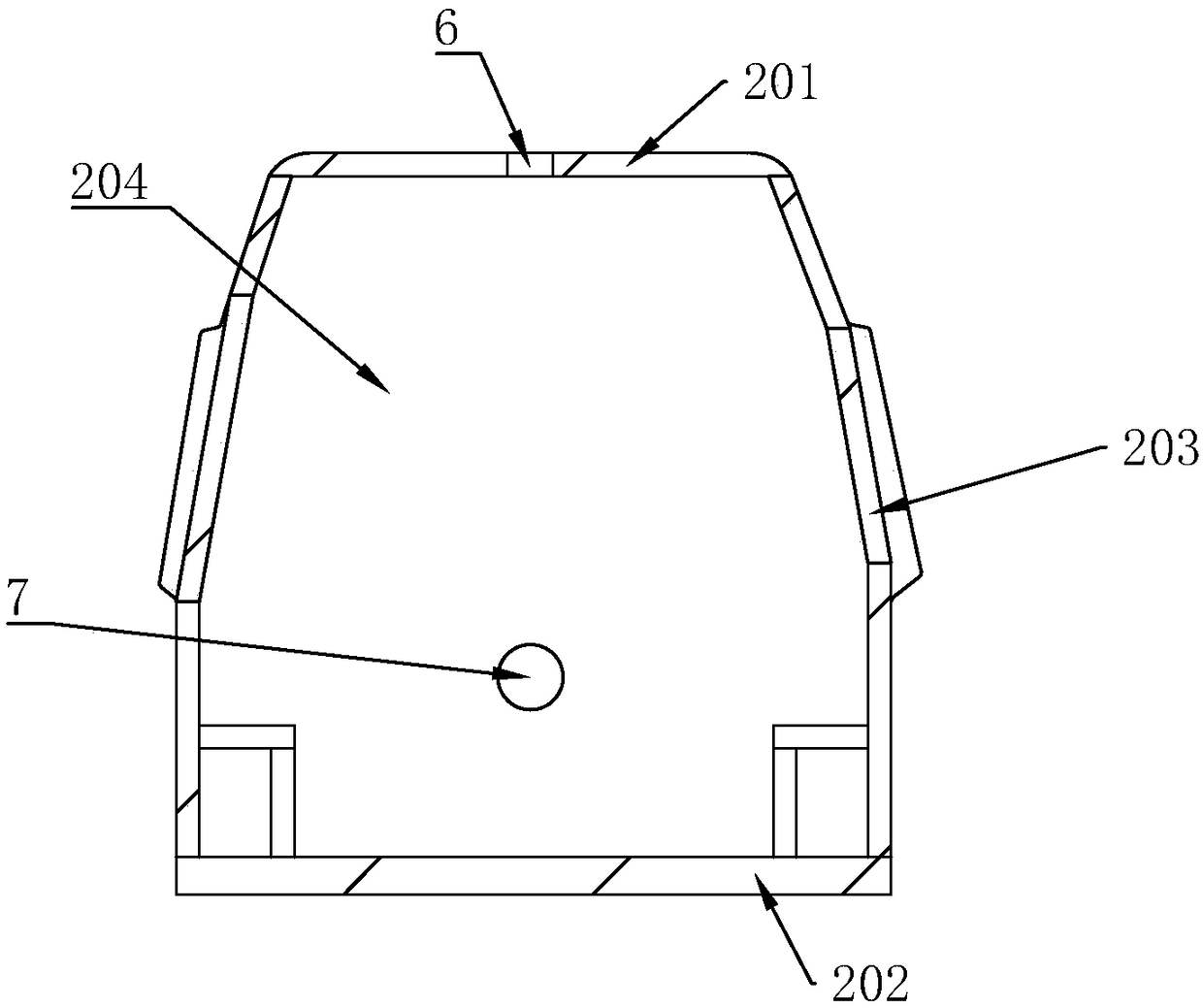

Heat preservation box for refrigerated lorry

InactiveCN108128554AHigh strengthImprove aestheticsDomestic cooling apparatusLighting and heating apparatusEnvironmental resistanceCross ventilation

The invention discloses a heat preservation box for a refrigerated lorry. The heat preservation box comprises a heat preservation box body arranged in the refrigerated lorry, wherein the heat preservation box body comprises a top plate and a bottom plate, two side plates and two end plates are arranged between the top plate and the bottom plate, one of the two side plates is hinged to a door platethrough hinge pieces, and the end plate which is far away from a head end is provided with a door plate through hinge pieces; the door plates, the top plate, the bottom plate, the side plates and theend plates all comprise polyurethane protection layers, a vacuum heat insulation structure is arranged in each of the polyurethane protection layers, and panels are arranged on the sides, far away from the refrigerated lorry, of the polyurethane protection layers; and a vent hole is formed in the top plate, and a wire hole is formed in the end plate close to the head end. According to the heat preservation box, thermal transmission caused by cross-ventilation is effectively avoided through the vacuum heat insulation structures in the polyurethane protection layers, and therefore the heat conduction coefficient is greatly reduced, the long-time heat preservation effect is good, and the heat insulation capability is high; the wall thickness of the heat preservation box body is thin, and therefore the use volume and the space utilization rate of the heat preservation box body are greatly increased; and meanwhile, the heat preservation box has the advantages of being efficient, energy-saving and environment-friendly.

Owner:WEIFANG FUXIN AUTO PARTS

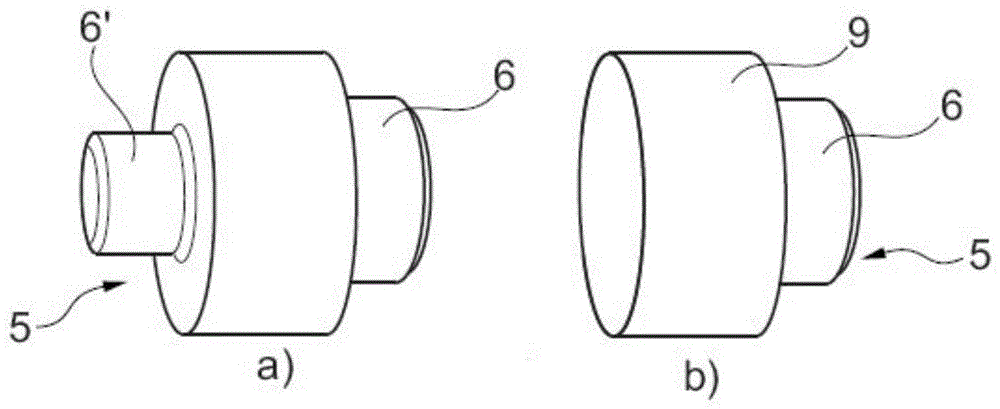

Exhaust gas turbocharger

InactiveCN104975949AReduce heat transferGood chemical resistanceEngine fuctionsGas turbine plantsTurbochargerExhaust fumes

An exhaust gas turbocharger may include a compressor housing and a turbine housing. The turbine housing may be connected to the compressor housing via a plurality of spacer pins composed of a heat-insulating material. The plurality of spacer pins may respectively include a head and at least one axial pin.

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

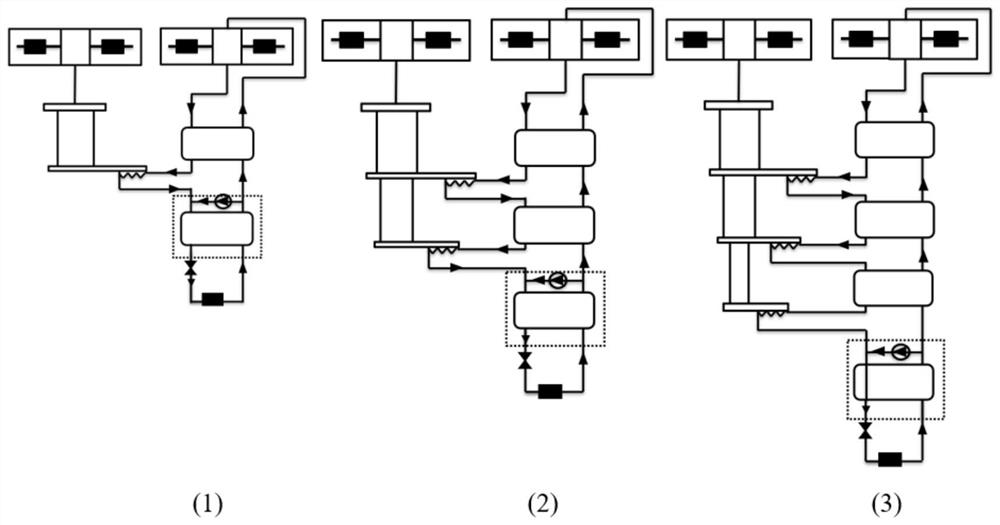

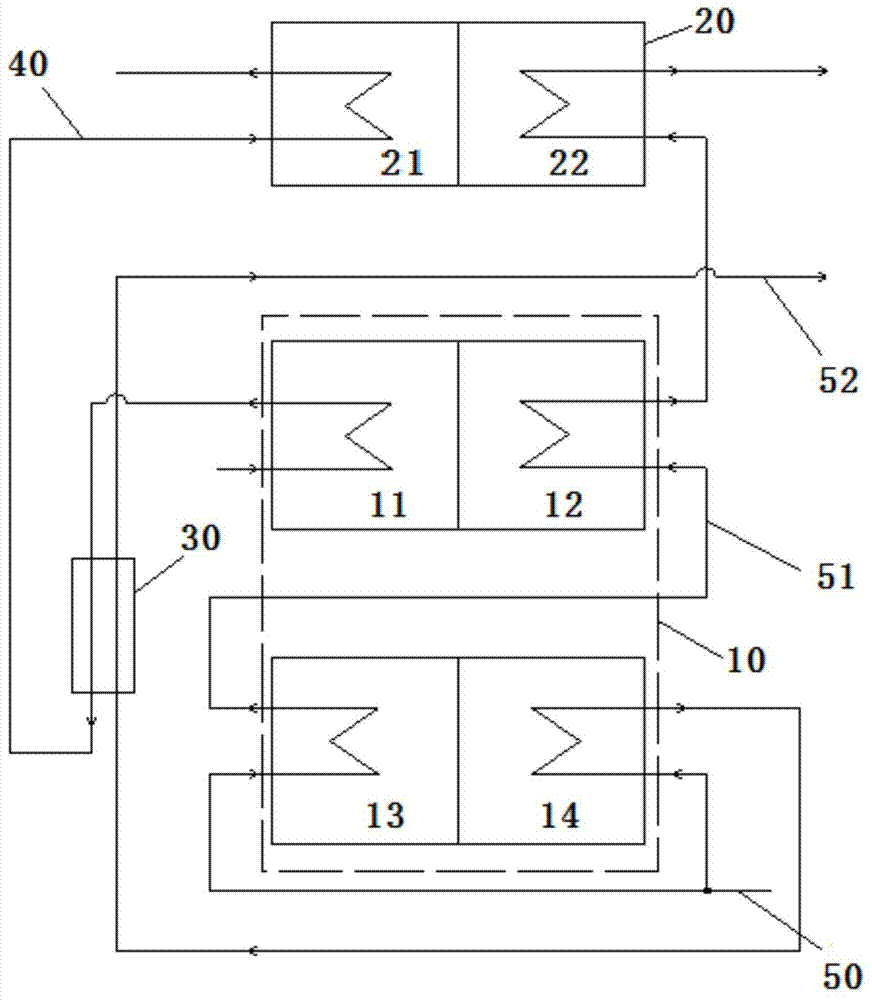

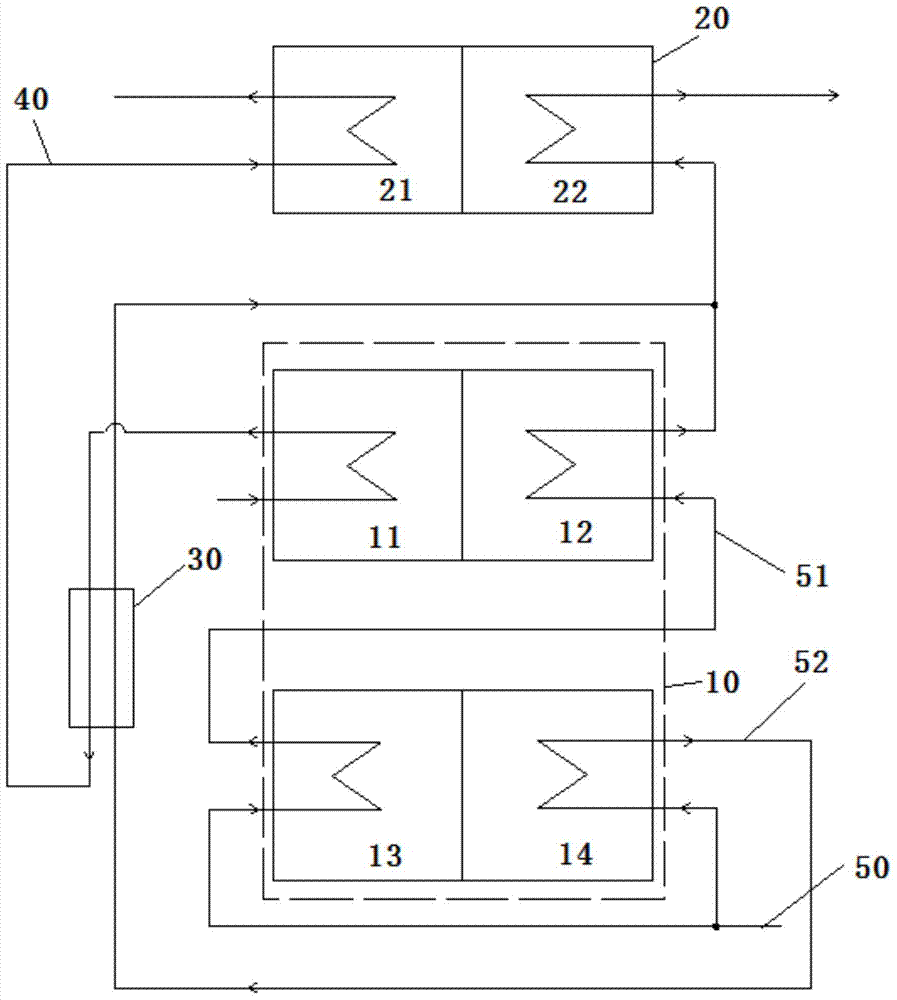

Compound type heat pump unit and concentrated heating system

ActiveCN104764069ANo need to overcome resistanceIncrease the flow rate in the pipeHot-water central heatingRefrigeration machinesWater flowAbsorption heat pump

The invention discloses a compound type heat pump unit and a concentrated heating system. The compound type heat pump unit comprises an absorption type heat pump, a compression type refrigerator, a heat exchanger, a primary side pipeline and a secondary side pipeline. The absorption type heat pump comprises a generator, an absorption type heat pump condenser, an absorber and an absorption type heat pump evaporator. The compression type refrigerator comprises a compression type refrigerator evaporator and a compression type refrigerator condenser, the primary side pipeline is sequentially connected with the generator, the heat exchanger and the compression type refrigerator evaporator in series in the water flowing direction, and the primary side pipeline is only connected with the generator and a generator in the absorption heat pump evaporator. According to the compound type heat pump unit, primary water pressure drop is reduced, and meanwhile the low primary water return temperature can be ensured.

Owner:GREE ELECTRIC APPLIANCES INC

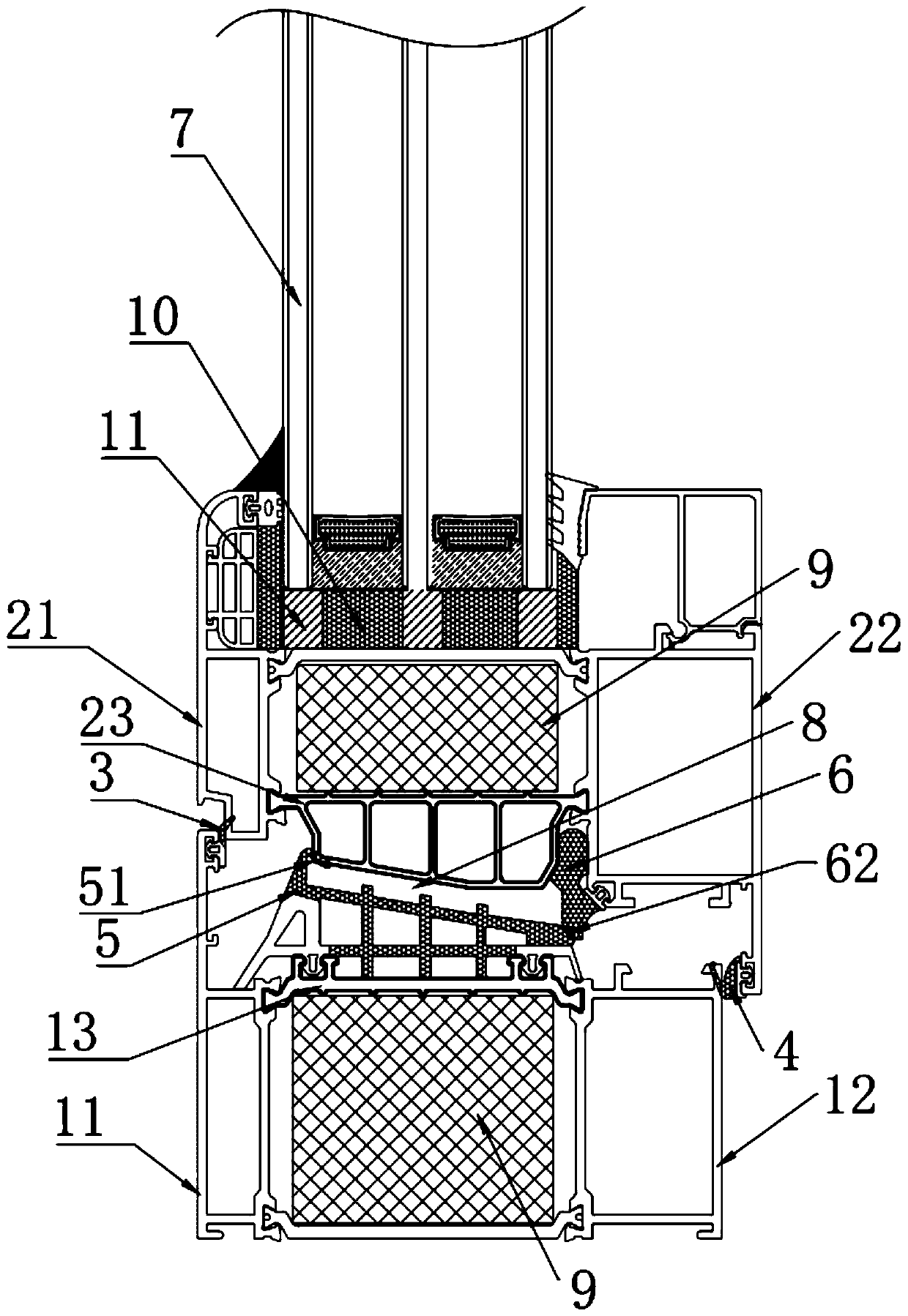

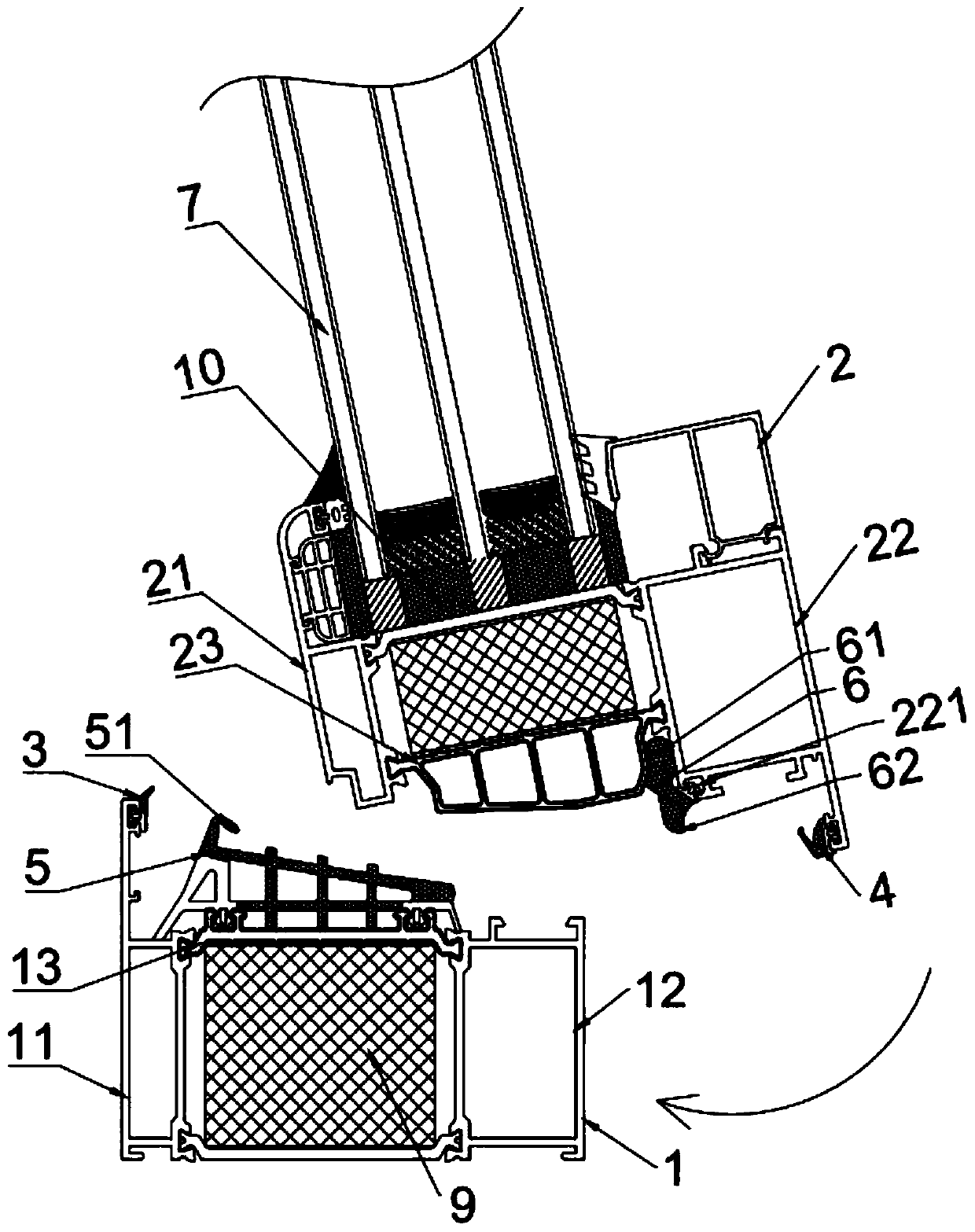

Energy-saving window

InactiveCN109798051AImprove sealingImprove insulation effectSealing arrangementsGlass pane fixingConservation energyEnergy consumption

The invention discloses an energy-saving window. The energy-saving window comprises a window frame fixed on a wall body, a movable window body hinged to the window frame and a fixed window body hermetically connected with the movable window body. The outer layer and the inner layer of the movable window body are connected by a first heat insulation plate, and the outer layer and the inner layer ofthe fixed window body are connected by a second heat insulation plate; the inner layer of the movable window body is provided with a first sealing strip which is hermetically abutted to the fixed window body; the outer layer of the fixed window body is provided with a second sealing strip which is hermetically abutted to the movable window body; the side surfaces of the fixed window body are provided with third foaming sealing rubber strips which are hermetically abutted to the side surfaces of the movable window body; the movable window body is also provided with fourth foaming sealing rubber strips which are hermetically abutted to the fixed window body; the fourth foaming sealing rubber strips are connected with the inner surface of the inner layer of the movable window body; and the surfaces, which are hermetically abutted to the fixed window body, of the fourth foaming sealing rubber strips are positioned on the plane where the inner surface of the inner layer of the movable window body is located. According to the energy-saving window, through arrangement of the multi-sealing structure, the temperature transmission efficiency of the two sides of the window is reduced, and the indoor temperature is effectively kept, so that the energy is saved and the energy consumption is reduced.

Owner:青岛万和装饰门窗工程有限公司

Marine flowing type evaporator and application method thereof

PendingCN106969549AReduce chargeLow densityEvaporators/condensersHeat exchanger casingsEngineeringRefrigerant

The invention relates to a marine flowing type evaporator. The marine flowing type evaporator comprises a cylinder, a heat exchange tube bundle, an exhaust pipe and a liquid inlet; the inner wall of the cylinder is fixedly provided with a set of baffle plates perpendicular to the inner wall of the cylinder; the baffle plates are provided with small holes for enabling the heat exchange tube bundle to penetrate through; the baffle plates divide the internal of the cylinder into refrigerant channels for enabling a refrigerant to scour the heat exchange tube bundle in a reciprocating manner; the exhaust pipe is vertically upward; a liquid inlet pipe can be arranged in any corresponding position on the cylinder according to arrangement of the refrigerant channels; and the flowing direction of non-refrigerant liquid in the heat exchange tube bundle is opposite to the flowing direction of the refrigerant in the cylinder. The marine flowing type evaporator has the advantages of a dry evaporator, a full-liquid evaporator and a falling film evaporator, meanwhile, overcomes the defects of the three evaporators, and has such characteristics as compact structure, convenience in oil return, low injecting quantity of the refrigerant, high heat exchange coefficient and high degree of freedom in liquid inlet setting.

Owner:英得艾斯(上海)冷冻空调有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com