Concrete foundation wall with a low density core and carbon fiber and steel reinforcement

a low density core, carbon fiber and steel reinforcement technology, applied in the direction of foundation engineering, building components, construction, etc., can solve the problems of high cost, inability to meet the requirements of construction, and many of the previously used building panels are prone to cracks and other damage, and achieve high insulating properties, high strength, and cost-effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

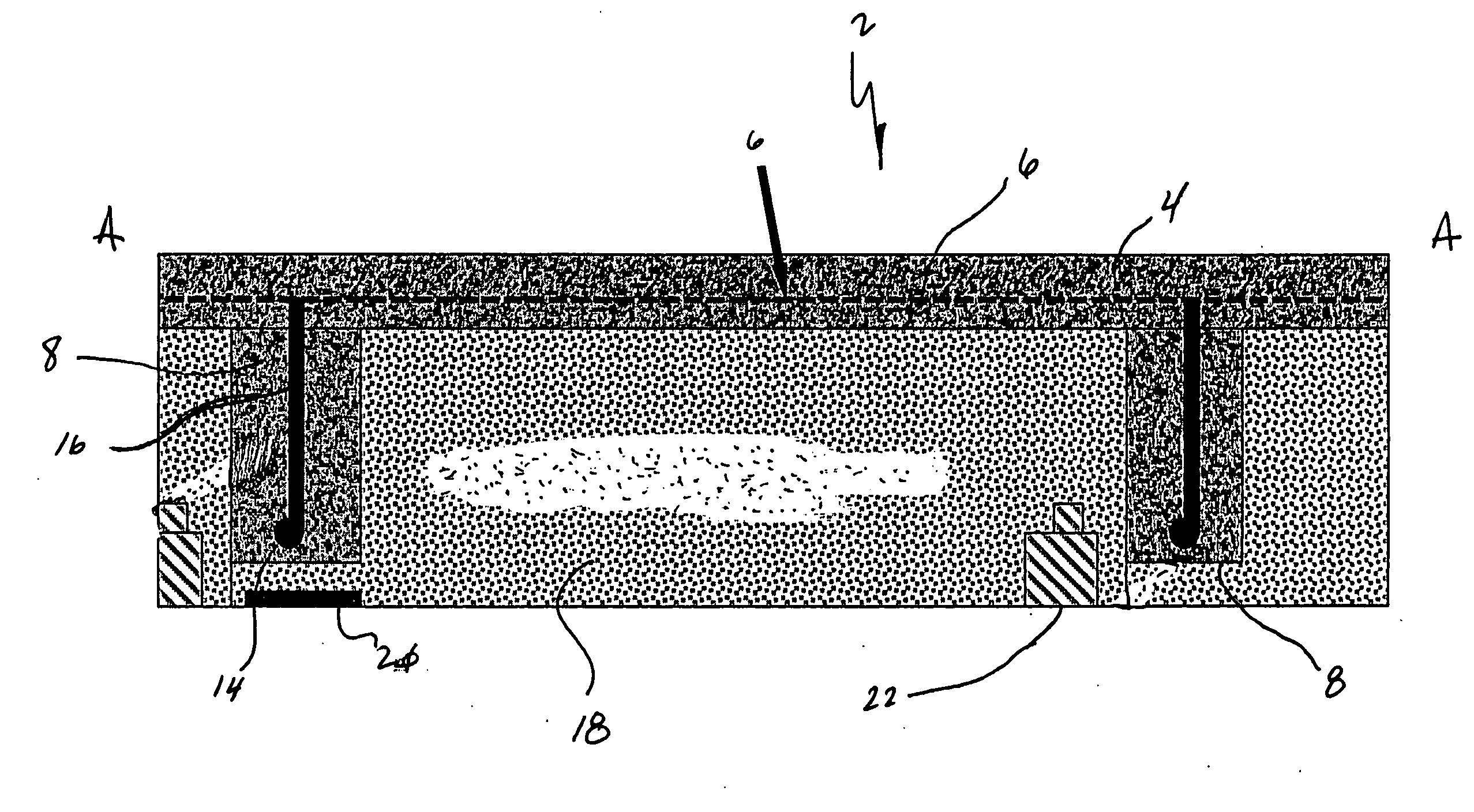

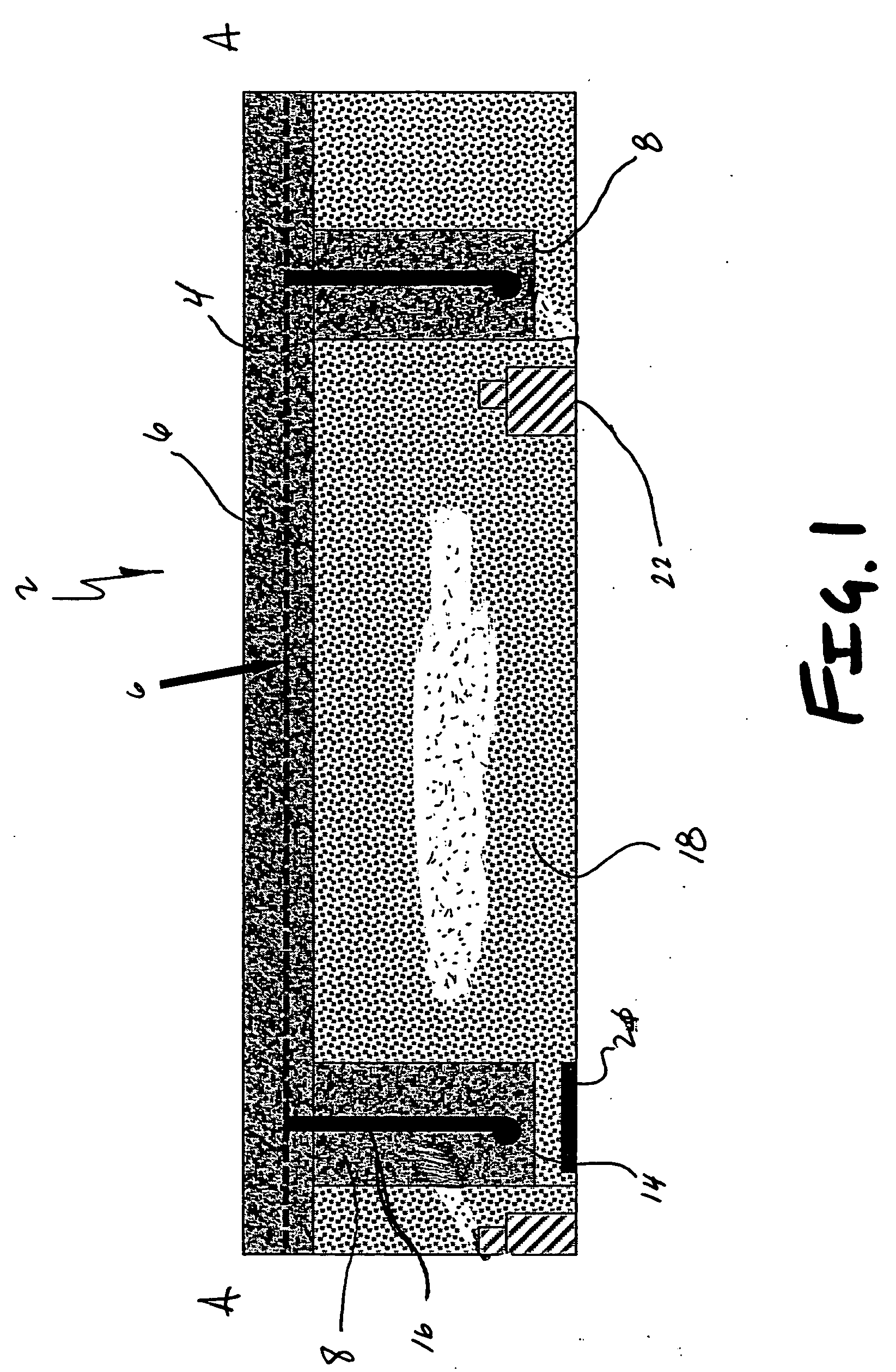

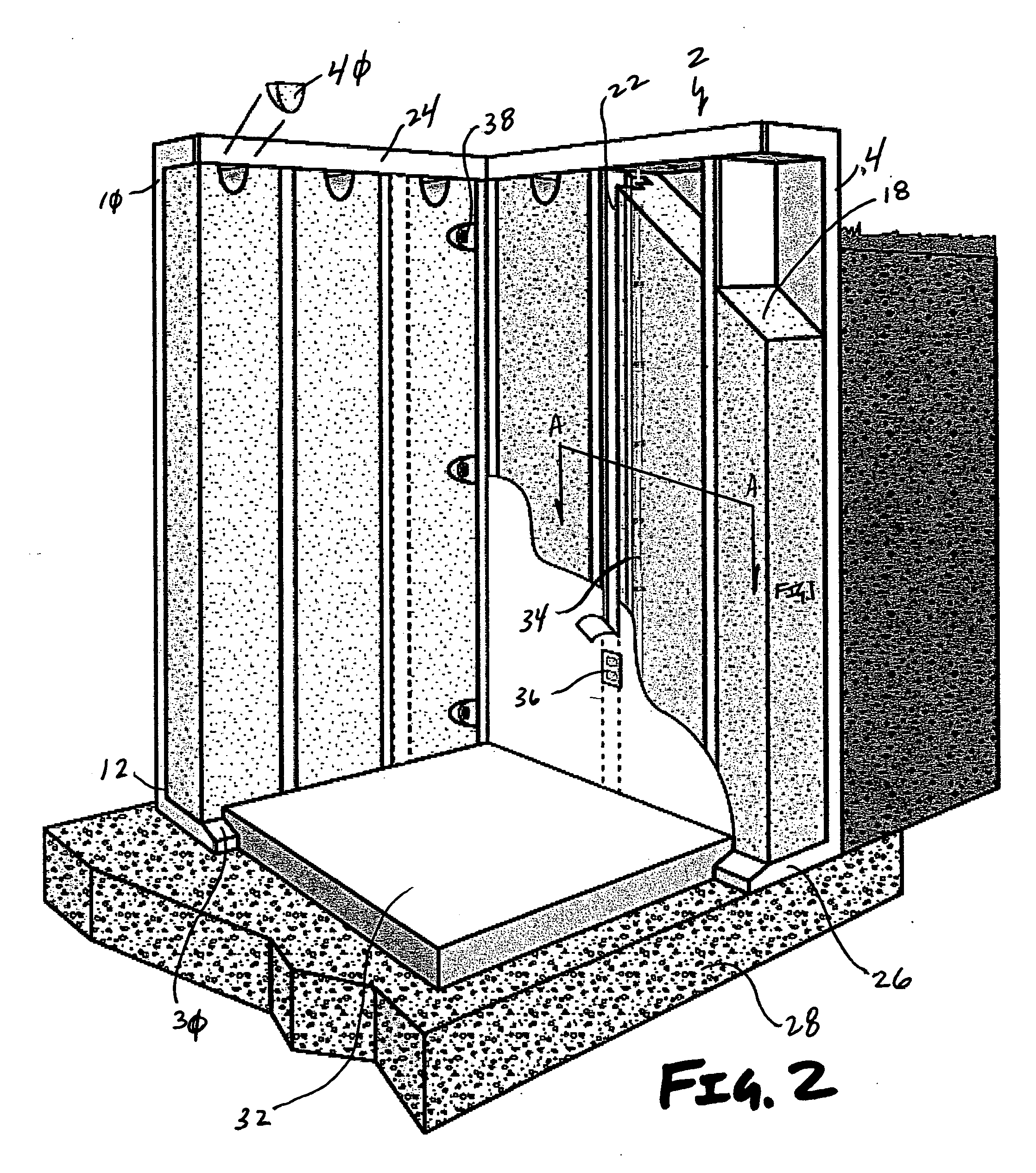

[0038] Referring now to FIGS. 1-9, one embodiment of an insulated foundation wall panel 2 is shown. More specifically, an insulated foundation panel 2 is provided that includes an exterior face wall 4 with one or more embedded carbon fiber strips 6. Interconnected to the exterior face wall 4 are a plurality of reinforcing ribs 8 running generally from an upper edge 10 to a lower edge 12 of the foundation panel 2. Tying the ribs 8 to the foundation wall 2 are reinforcing bars 14 and carbon fiber or metallic stirrups 16. Preferably, the space between each rib 8 is filled with foam insulation 18, thus providing a foundation panel 2 that is strong, light, and that has superior insulative properties. Optionally, some embodiments of the present invention employ wood, foam or metal strips 20 running substantially the length of the ribs 8 to provide a location for nails, screws, etc. such that sheet rock or other wall finishings may be applied to the foundation panel 2.

[0039] Referring aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com