Patents

Literature

94 results about "Excessive weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

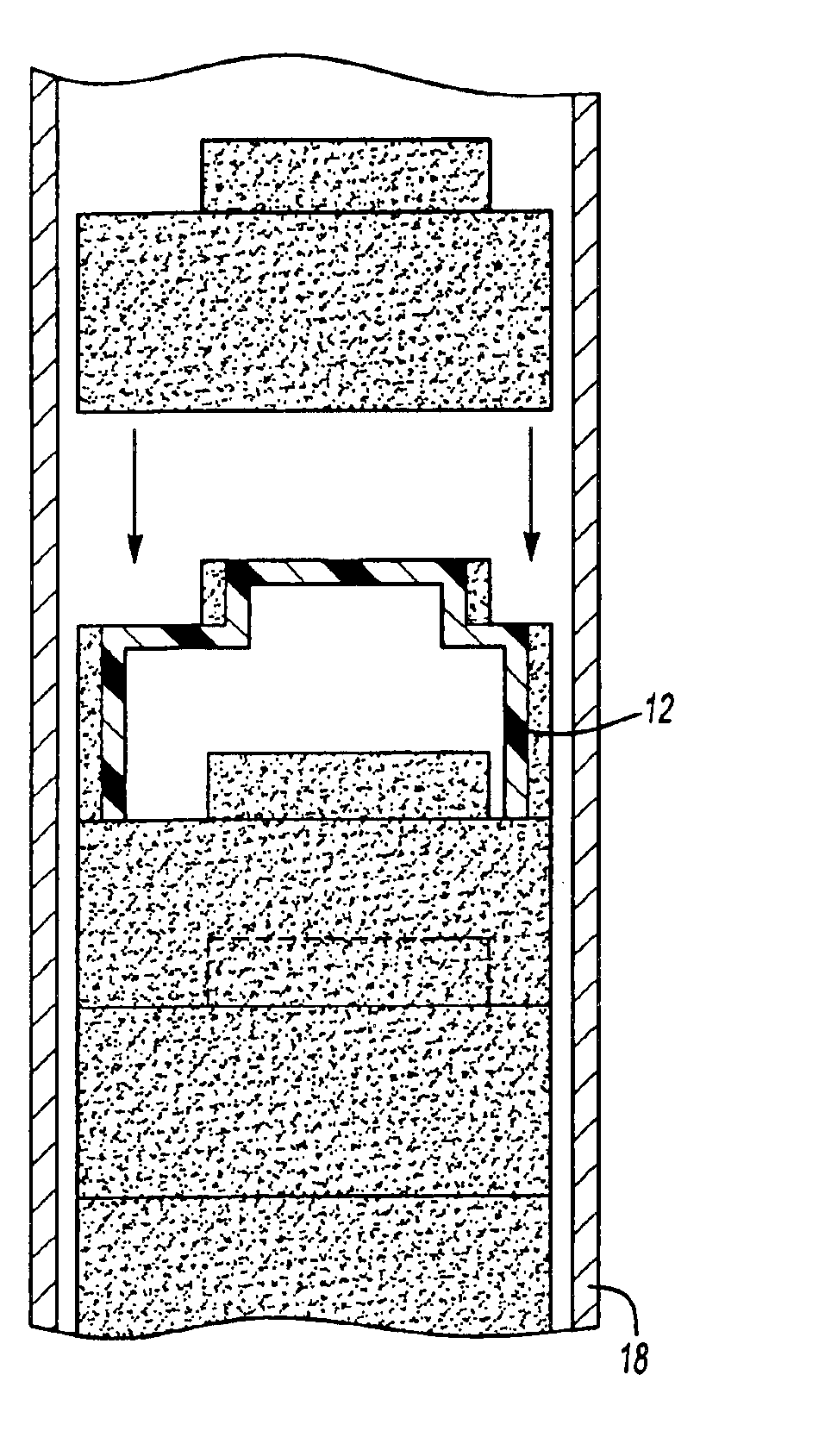

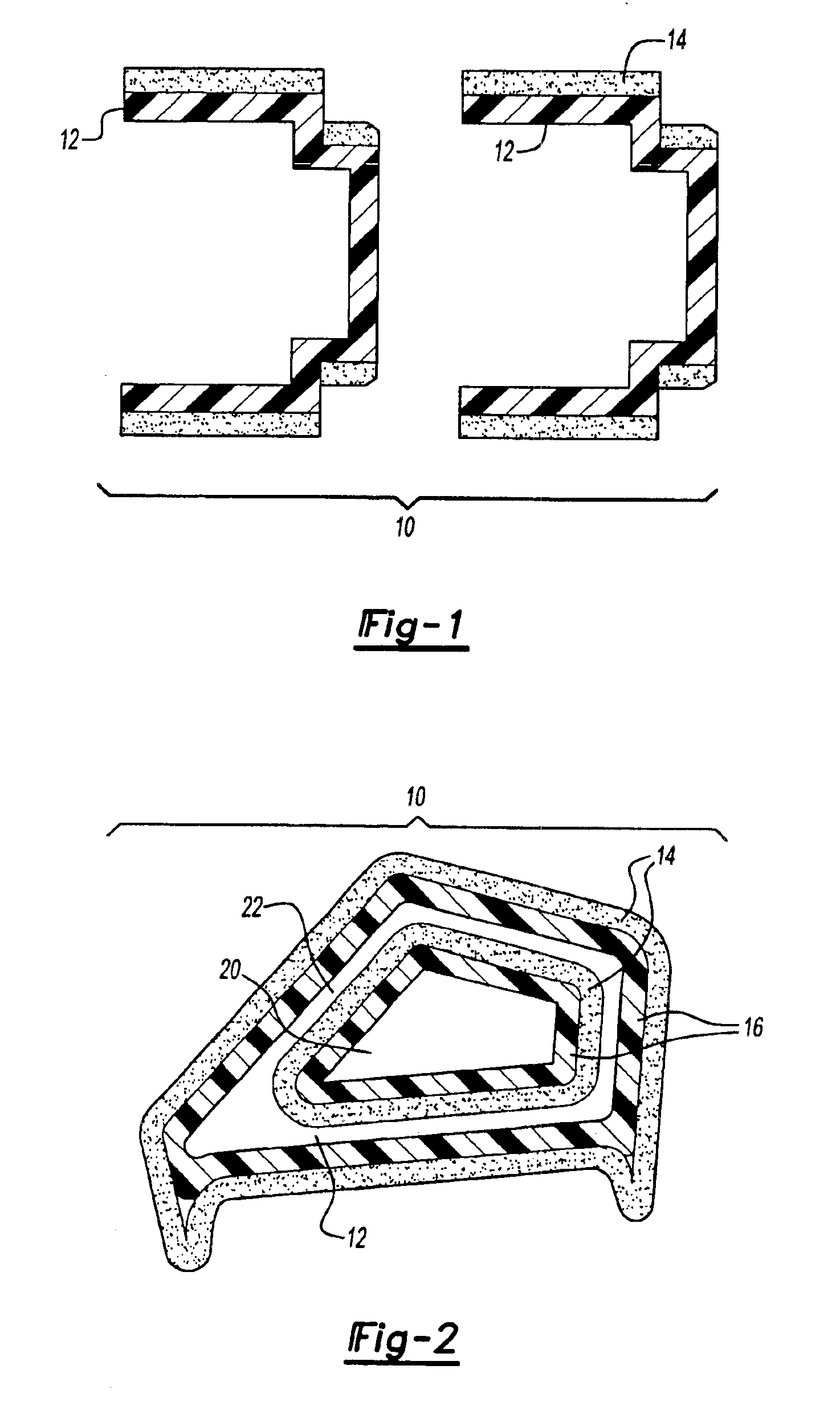

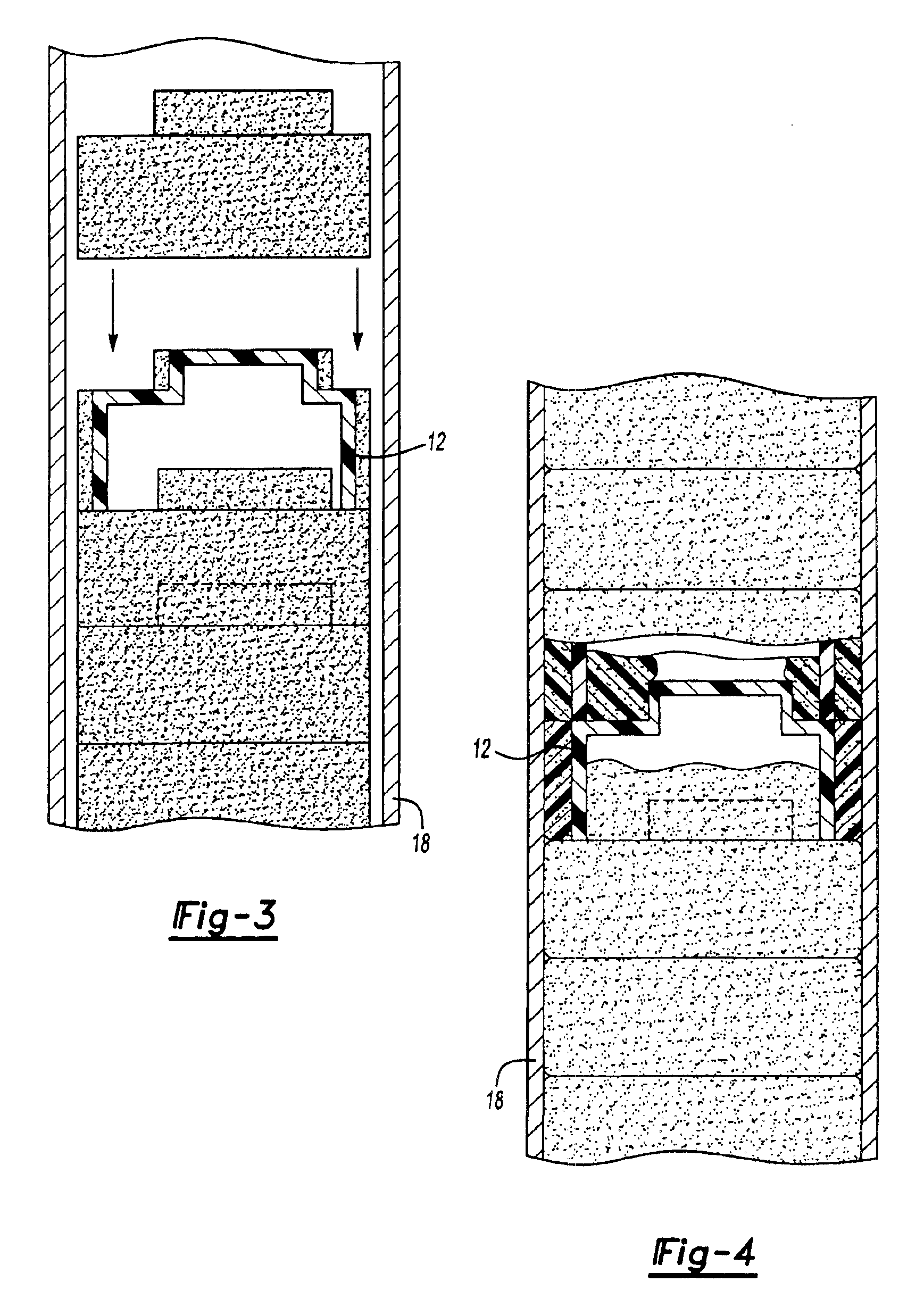

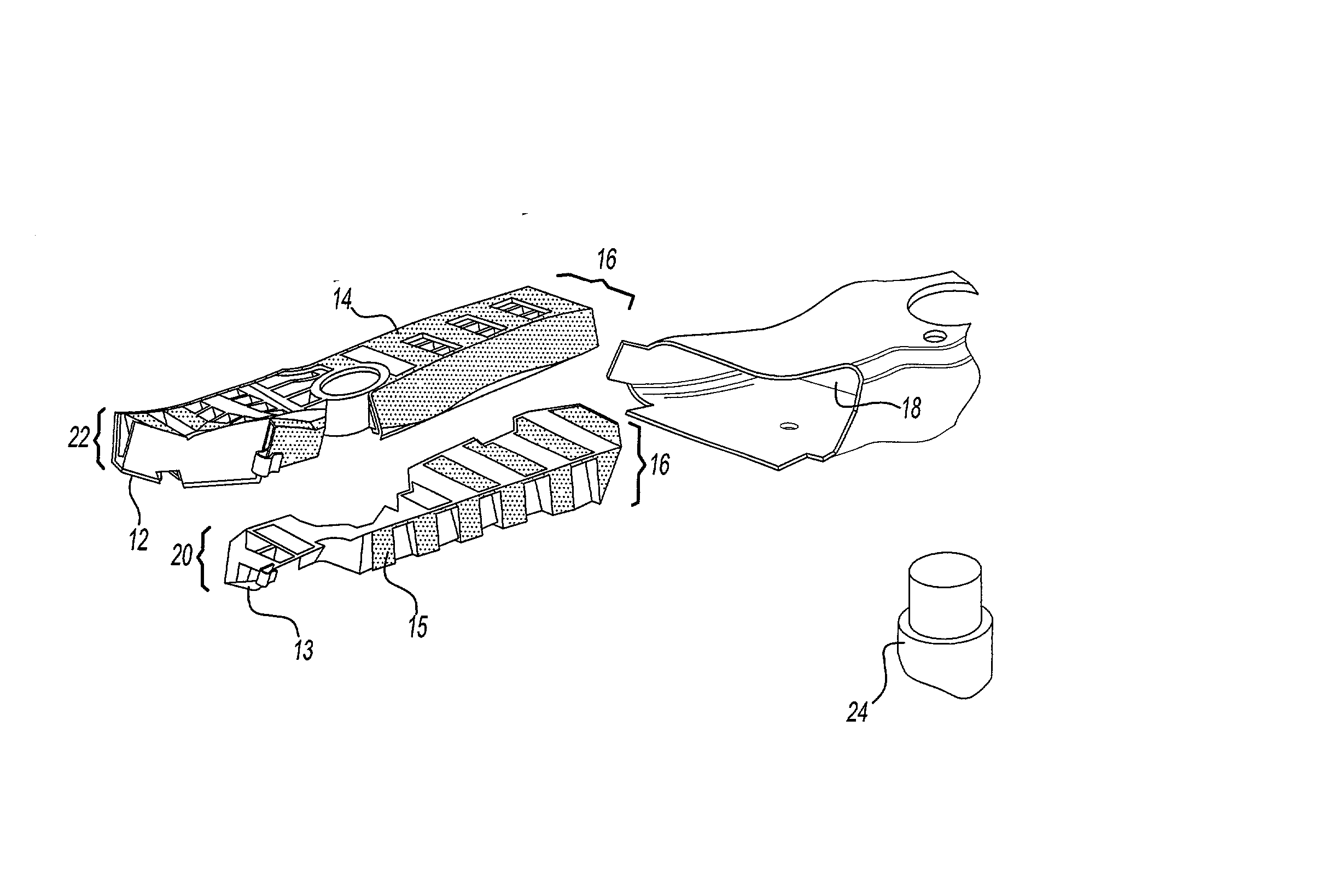

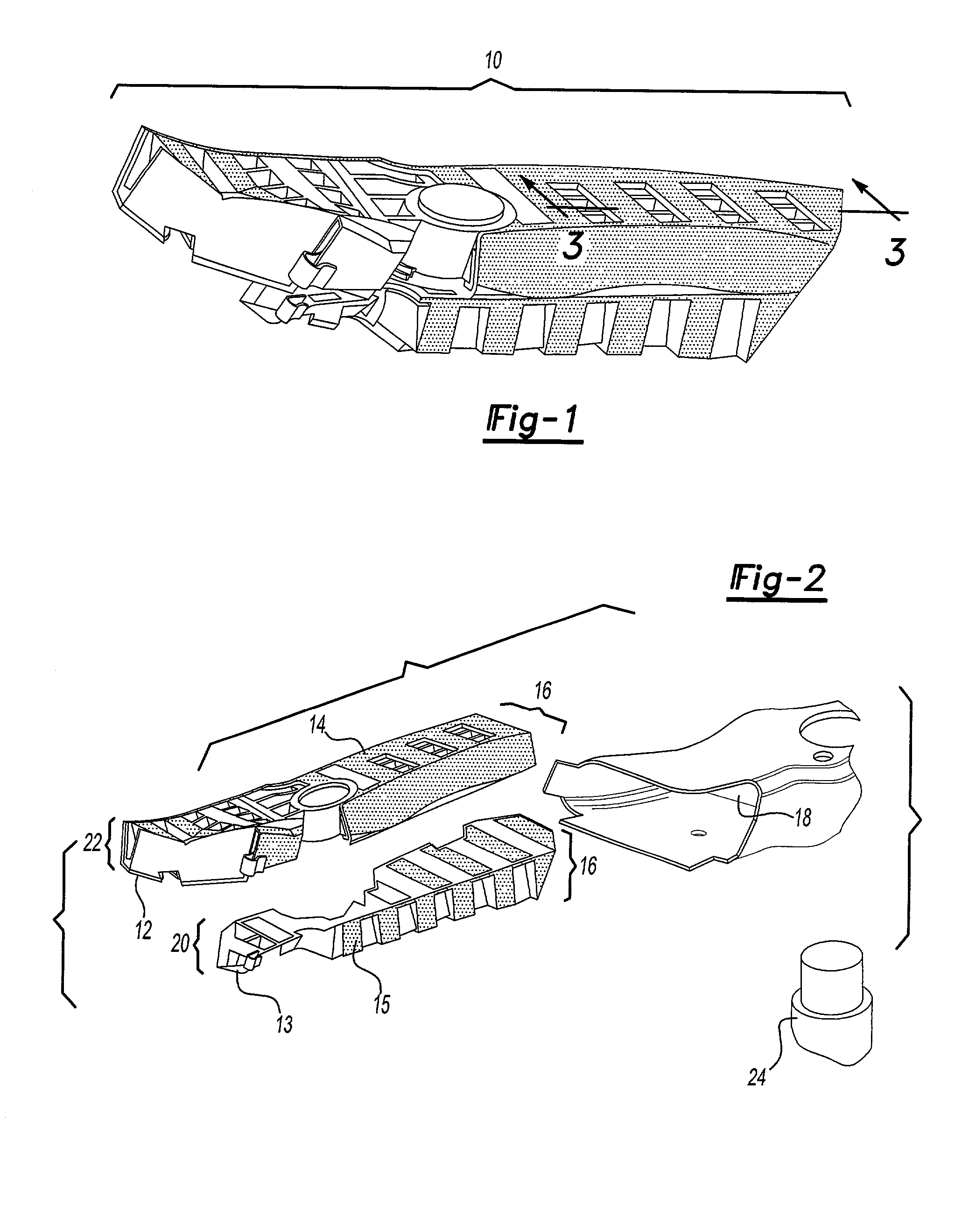

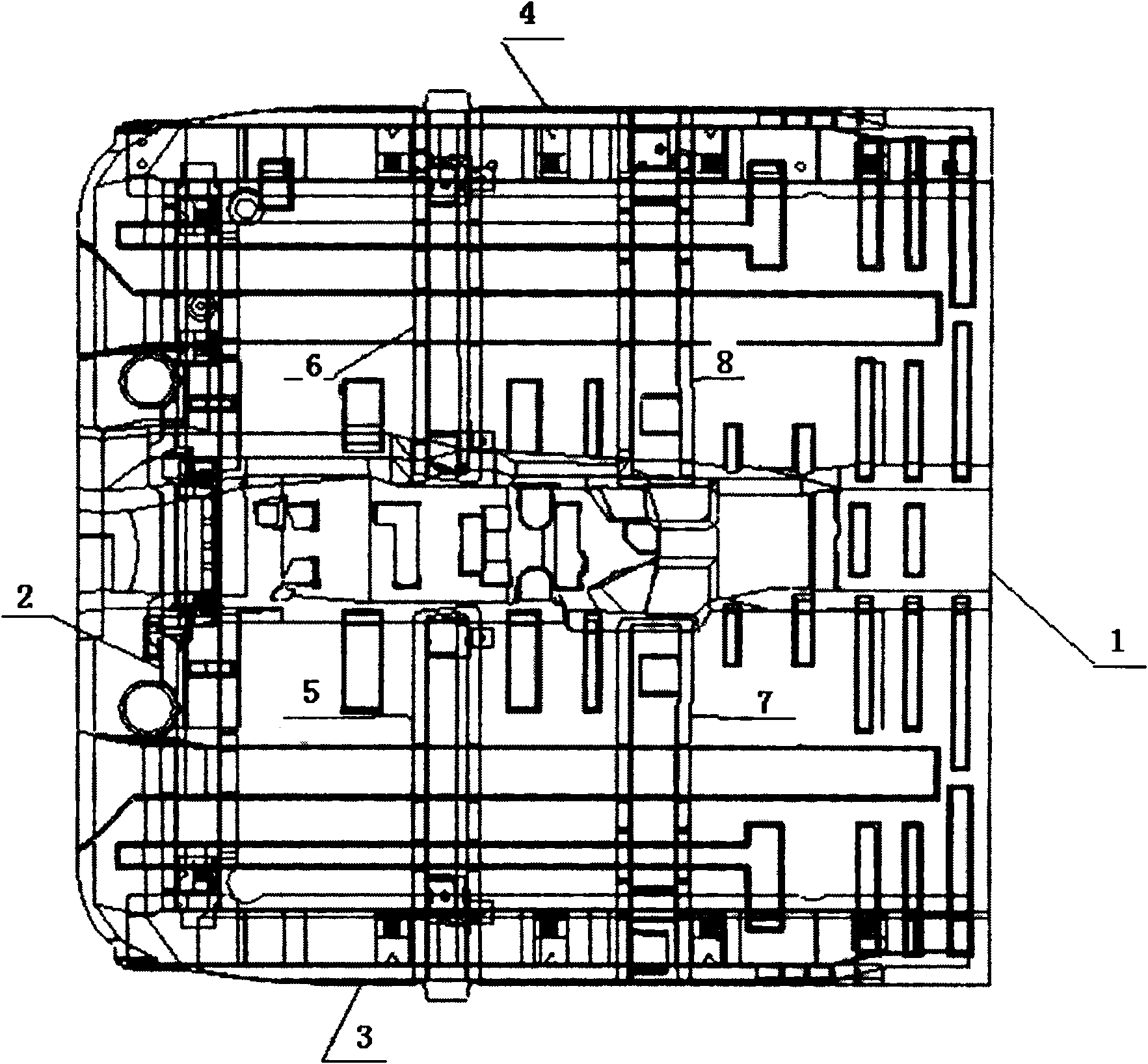

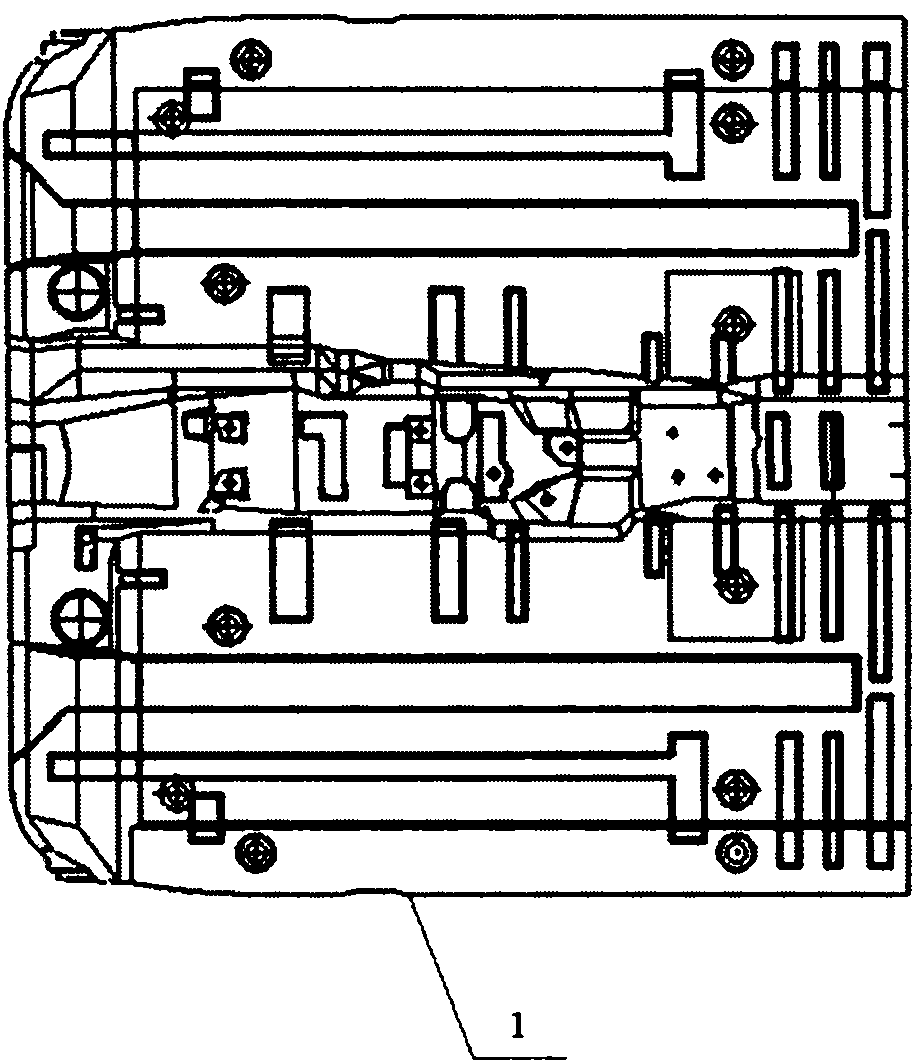

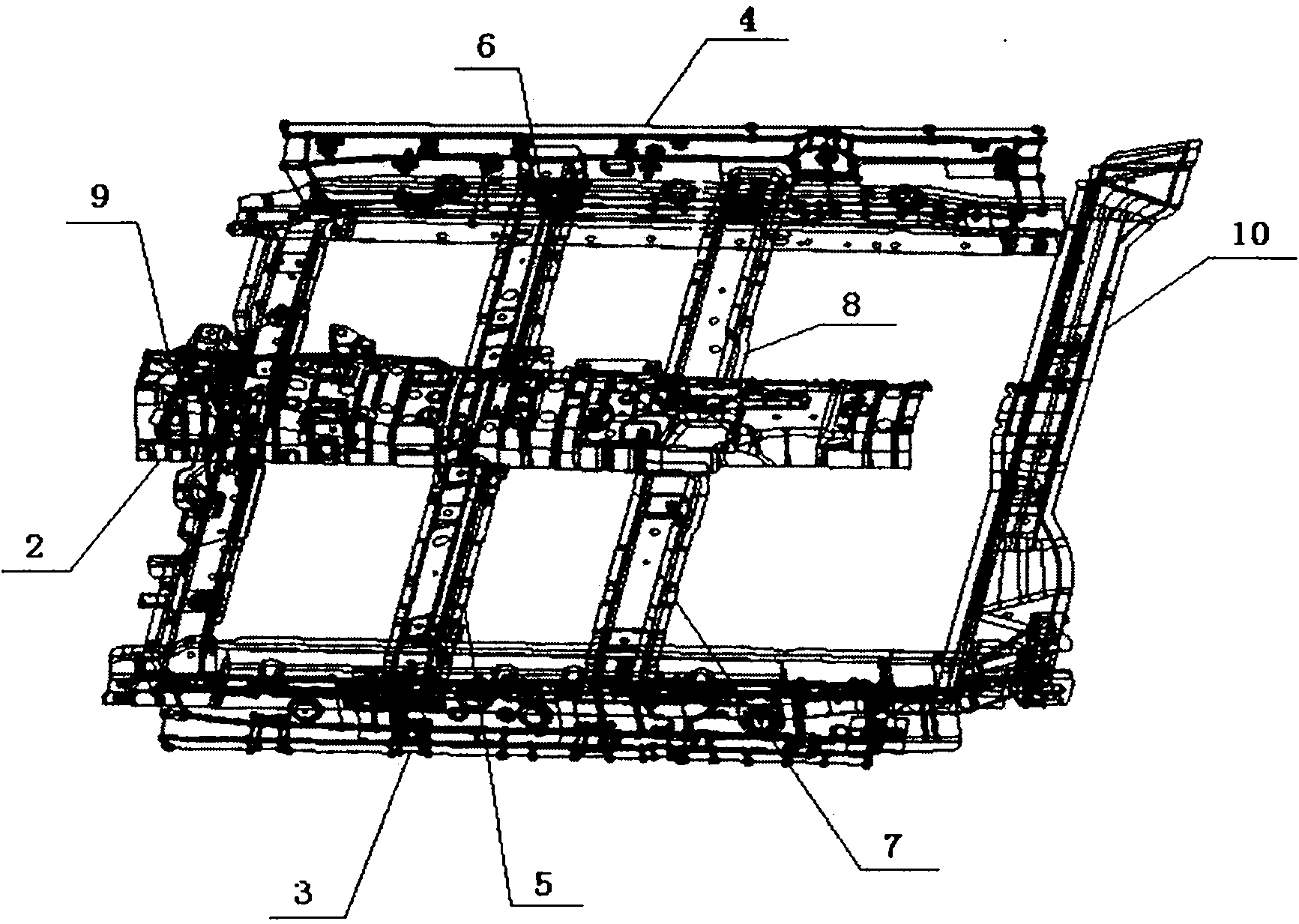

Structural reinforcement system having modular segmented characteristics

InactiveUS6890021B2Reduce vibrationReduce noiseVehicle seatsPedestrian/occupant safety arrangementMobile vehicleEpoxy

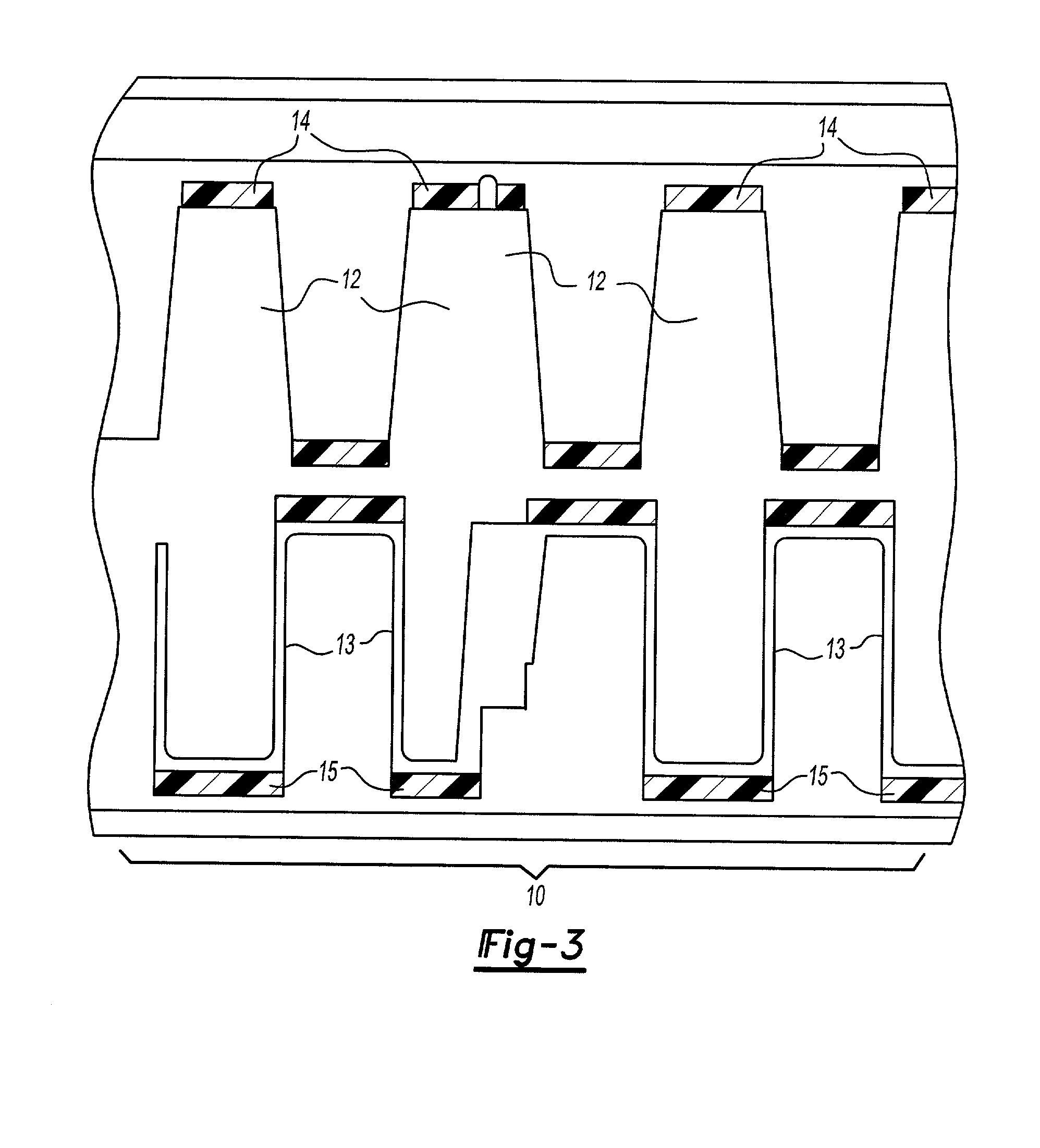

A modular segmented structural reinforcement system for use with closed forms or cavities defined with automotive vehicles having a plurality of modular segments designed to be secured within a defined portion of an automotive vehicle applications. An expandable or bonding material, such as an epoxy-based reinforcing foam or other sound absorption, damping, vibration reduction, or sealing material is disposed on at least a portion of the outer surface of each of the plurality of segments. Once the system is flexible fitted within the closed form or placed within a selected cavity of an automotive vehicle, the material expands and cures during an automobile assembly operation, bonding the reinforcement system to the segments. As a result, the reinforcement system provides enhanced load distribution over the vehicle frame without adding excessive weight and further serves to reduce noise and vibrational characteristics of the automotive vehicle.

Owner:ZEPHYROS INC

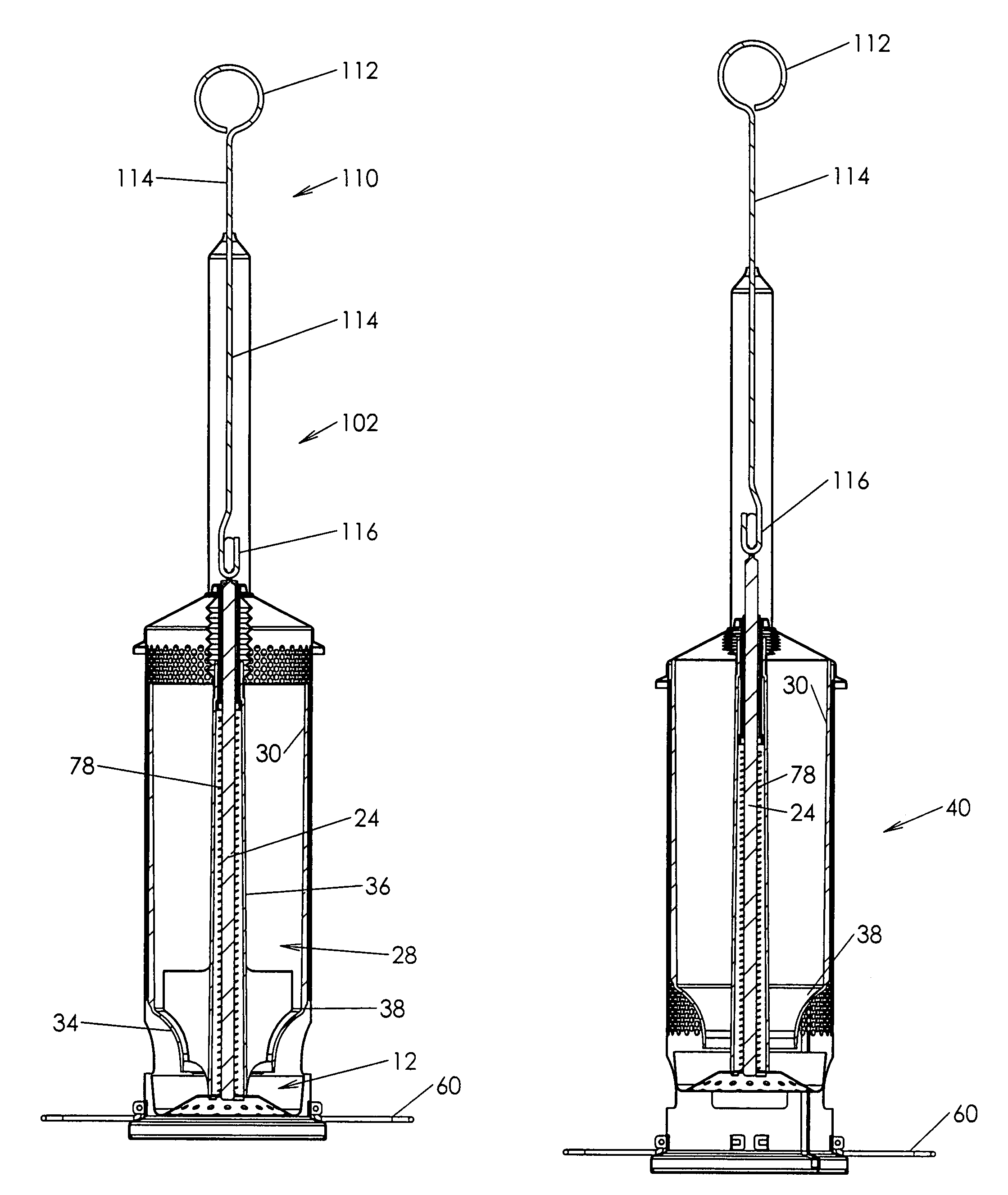

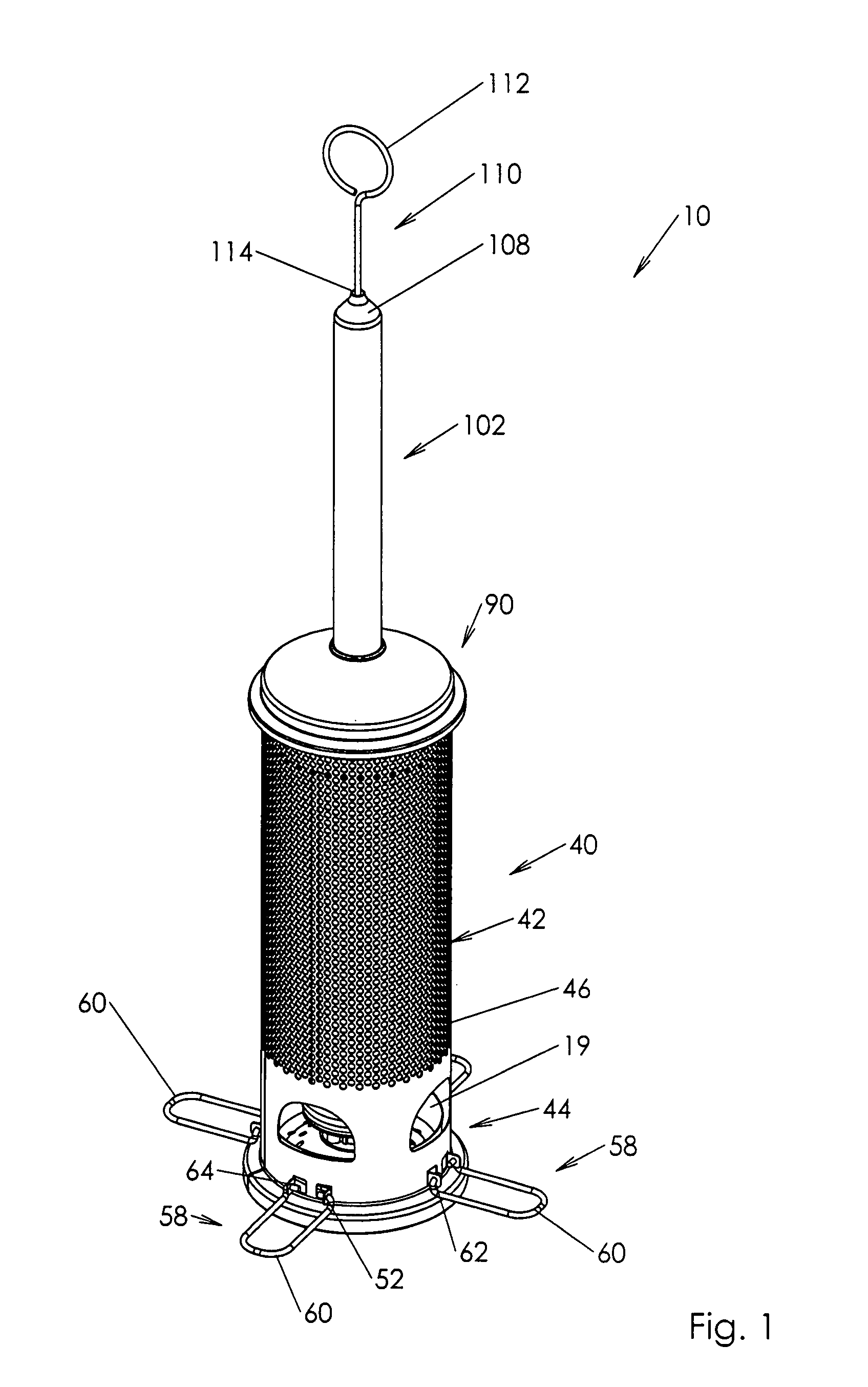

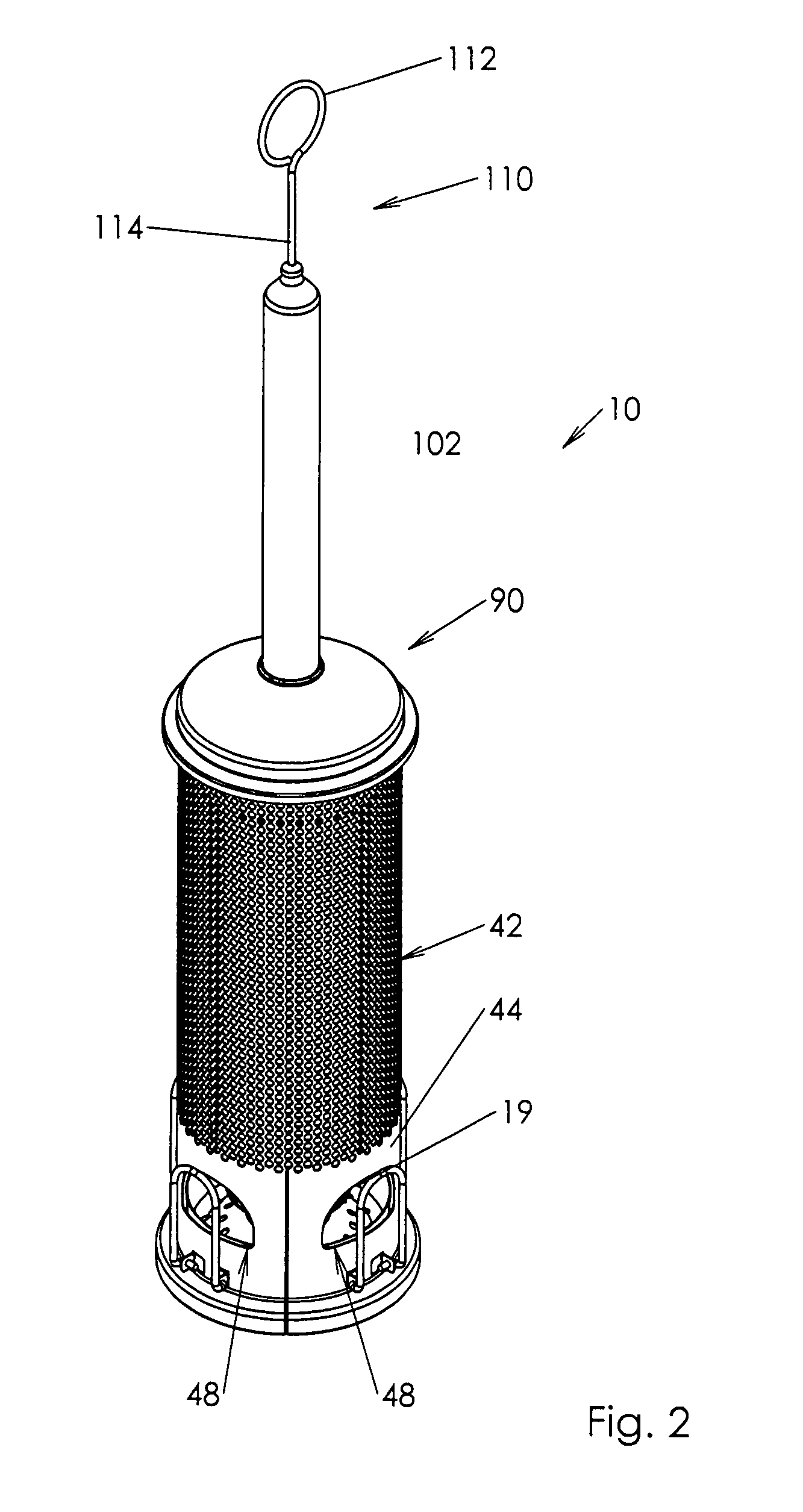

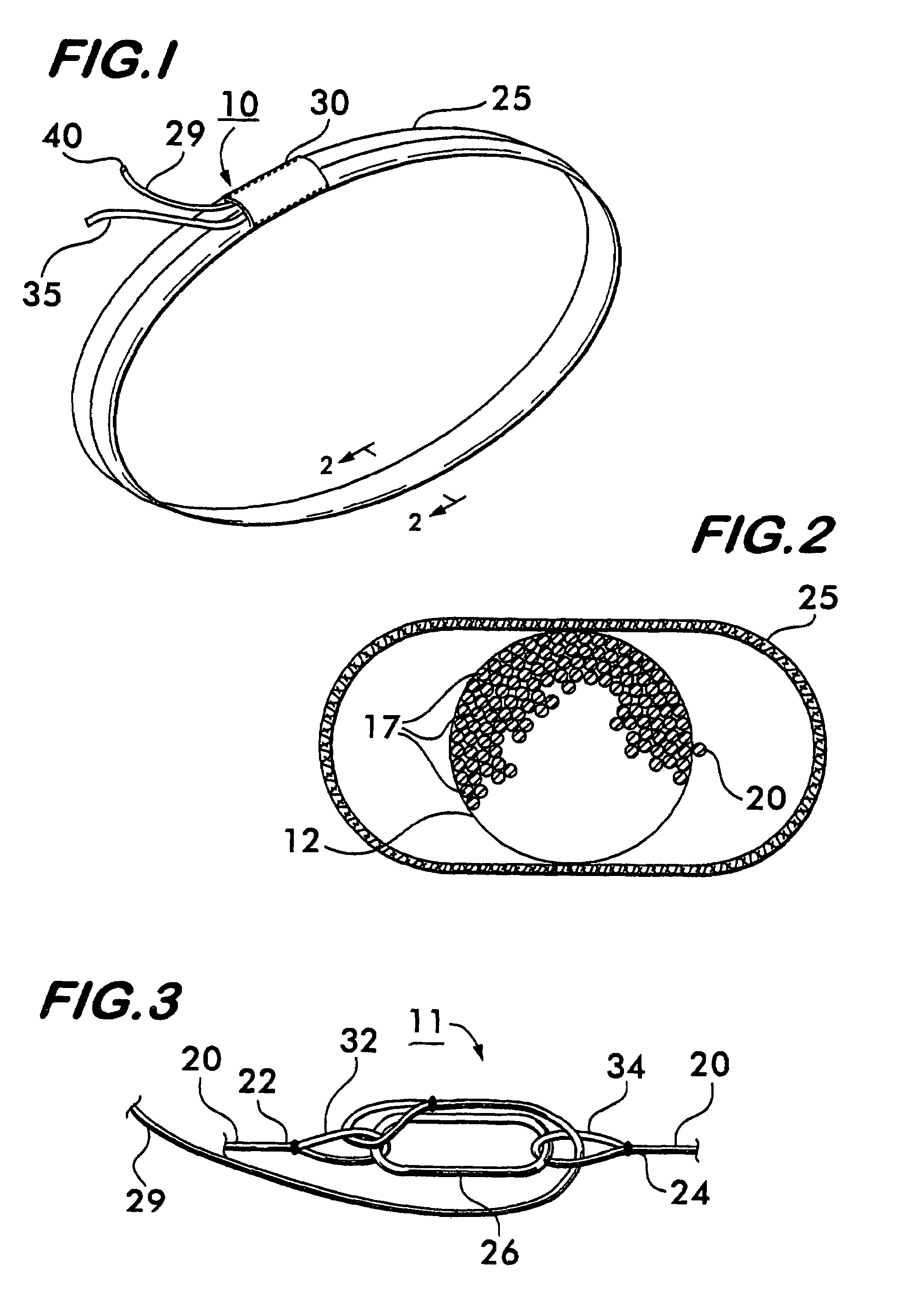

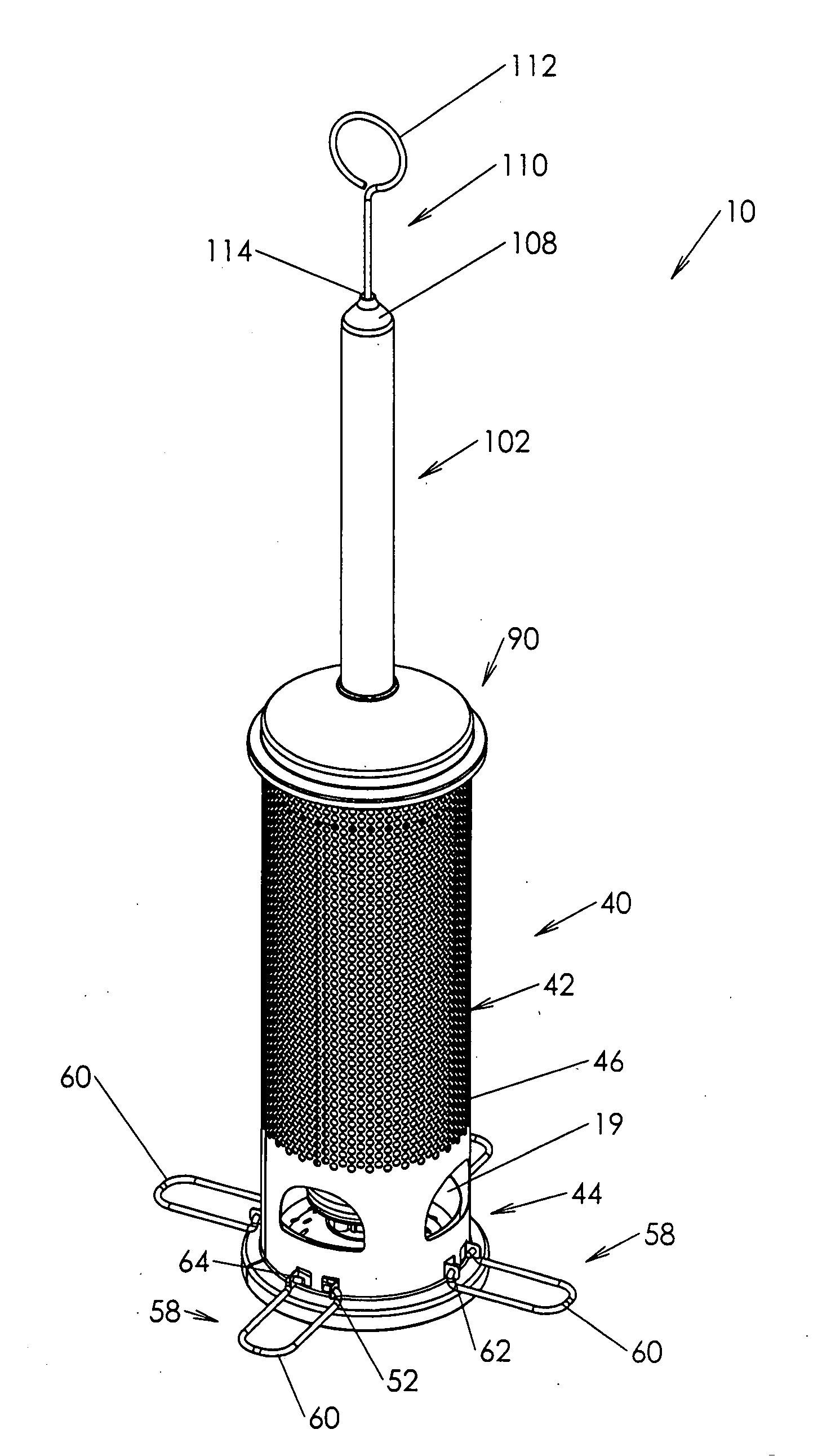

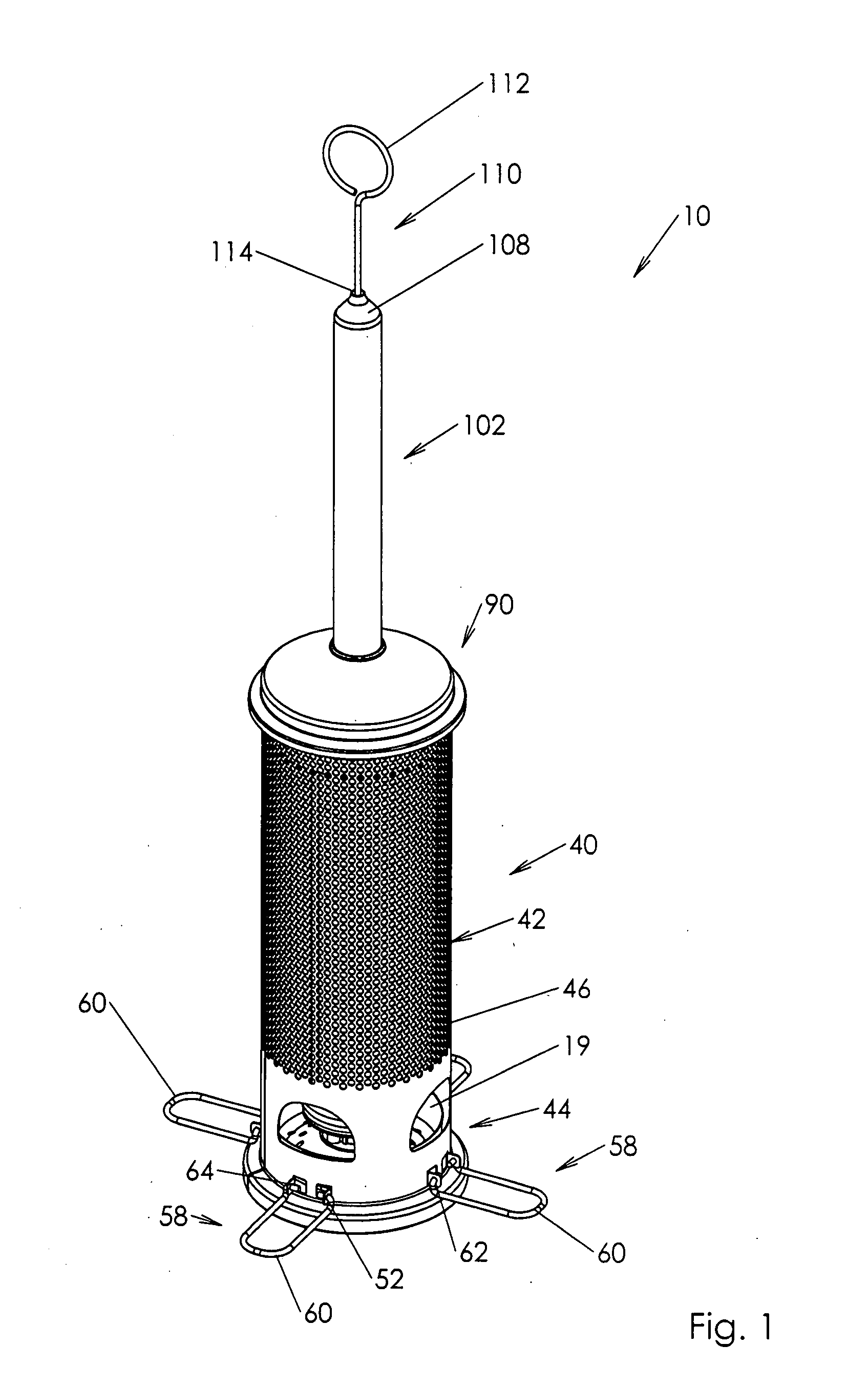

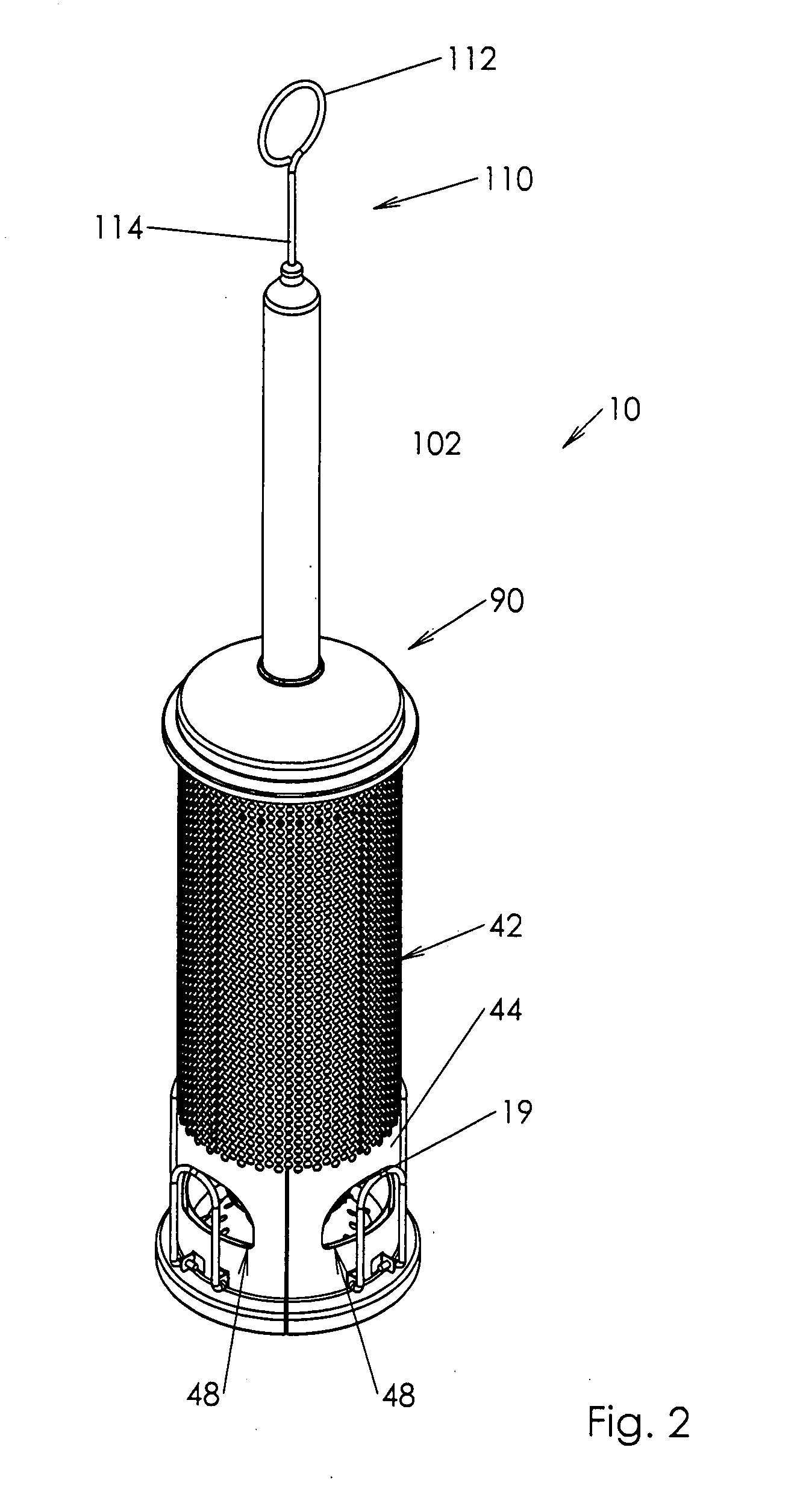

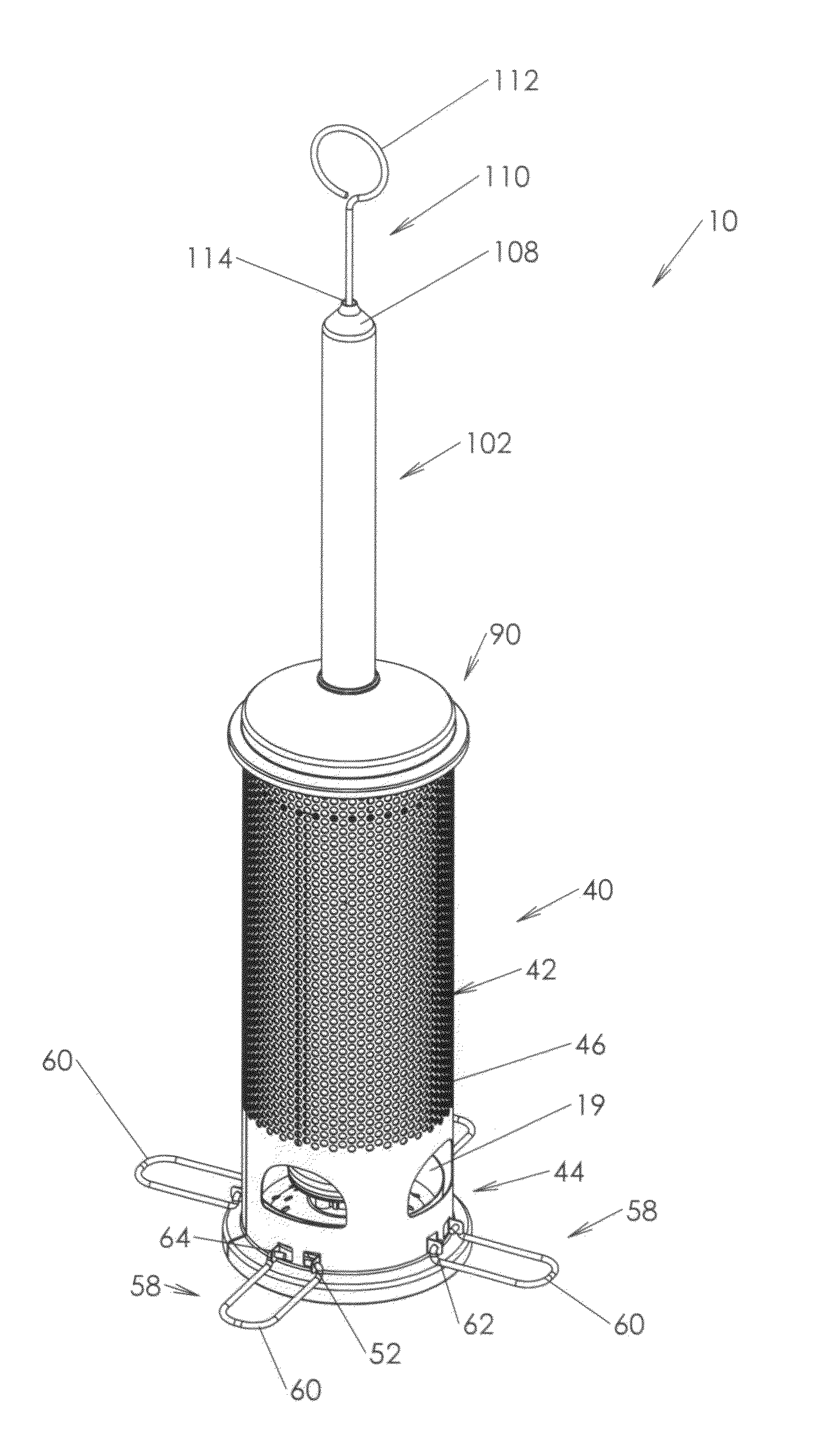

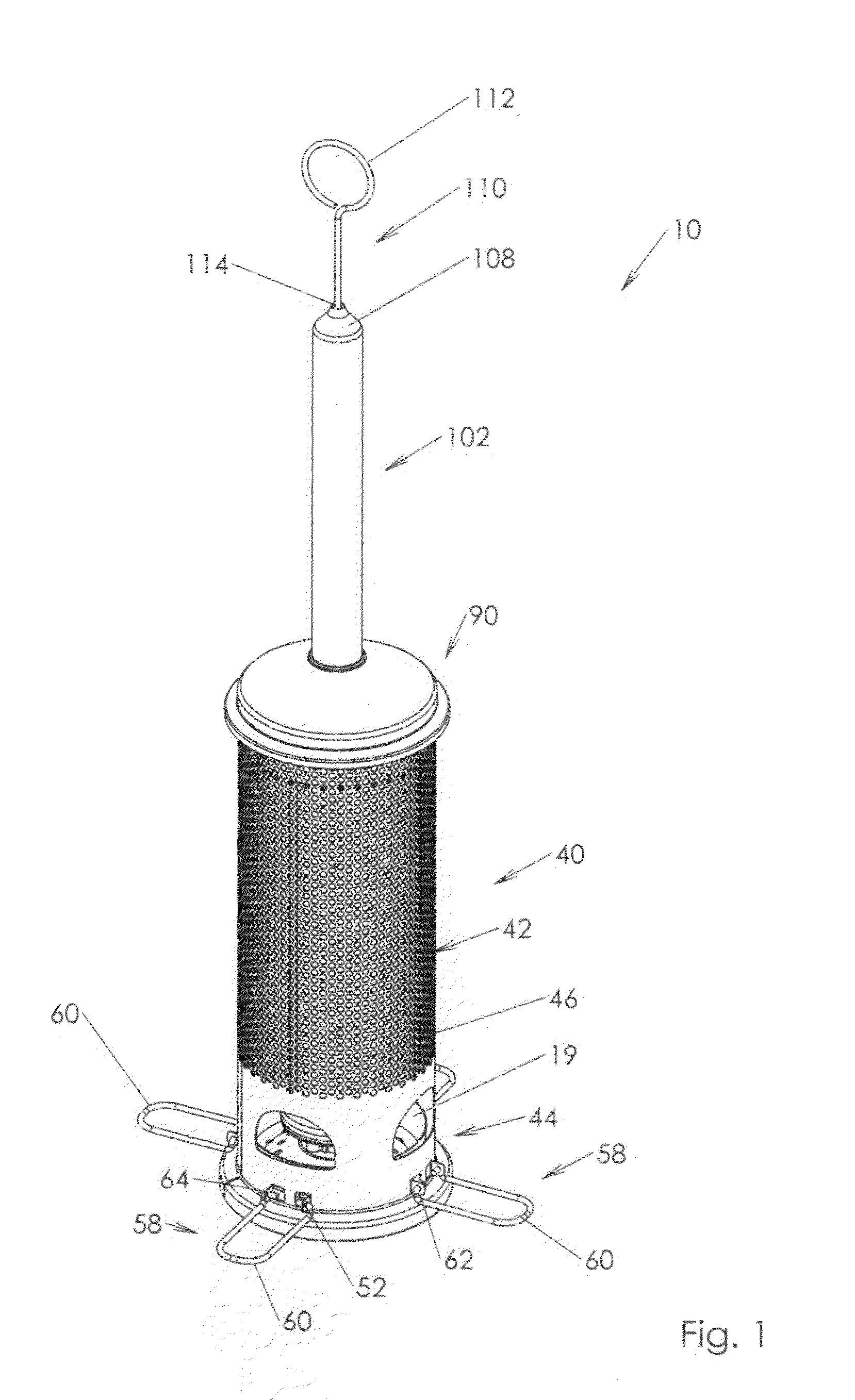

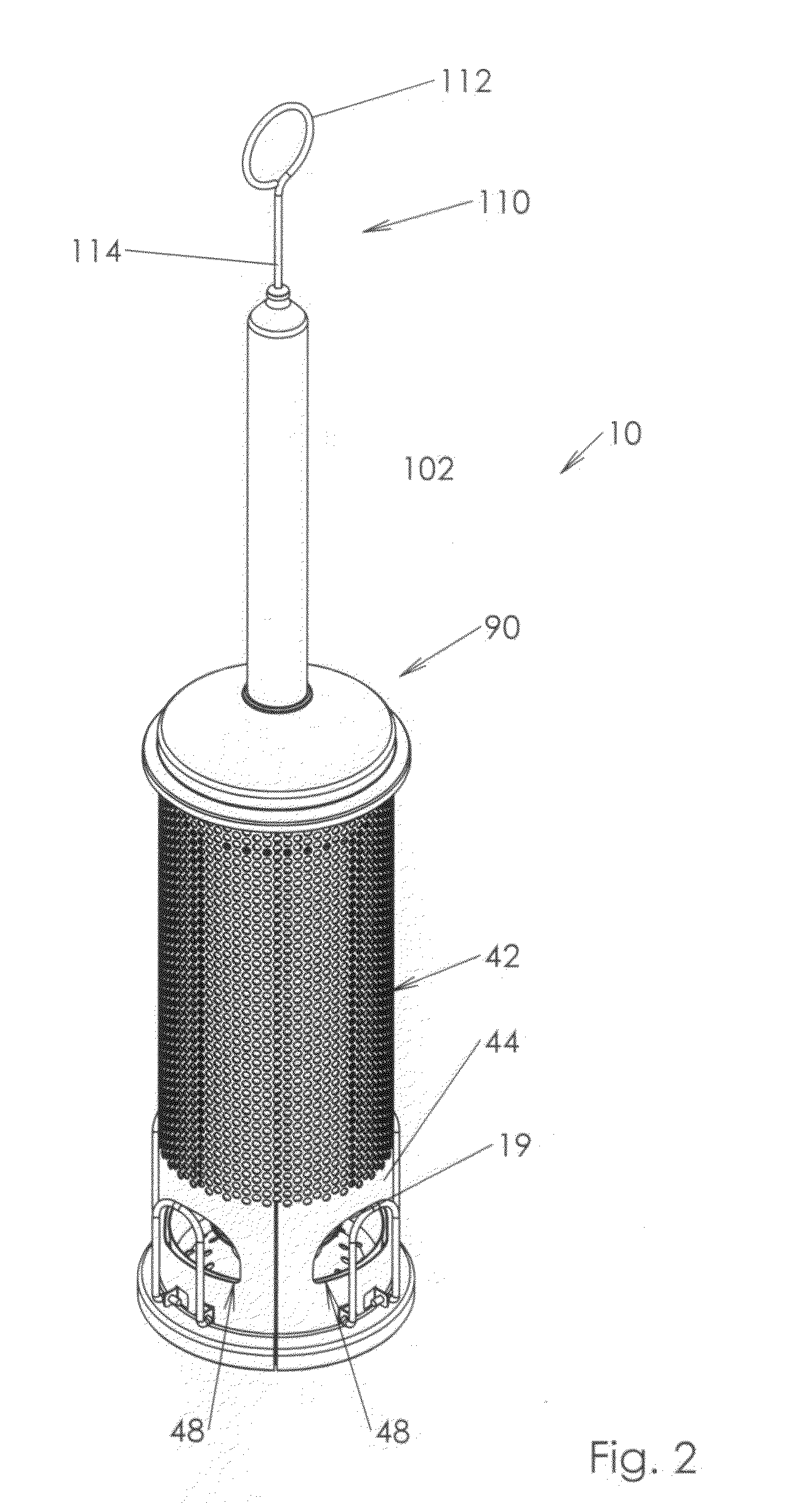

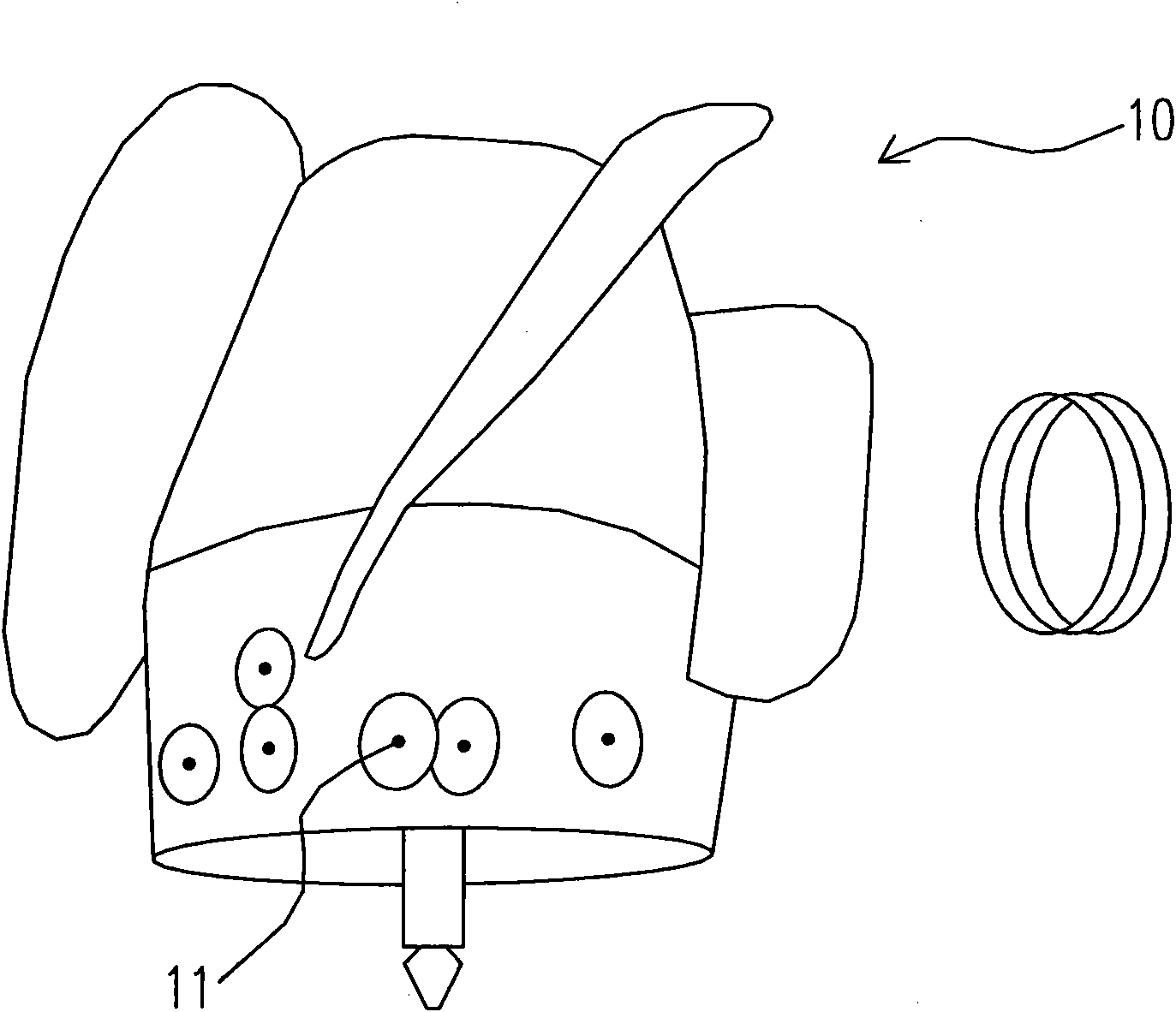

Bird feeder

ActiveUS7739982B2Eliminate useFunctional disturbancePisciculture and aquariaAvicultureBird feederEngineering

A squirrel resistant bird feeder having a seed container, a seed tray mounted below the seed container, a shroud extending about the seed member and seed tray, the shroud having openings in a lower portion thereof, with a spring member mounted internally of the seed container and being enclosed by a central tube, the spring member having a first end thereof abutting a portion of the seed tray and a second end acting on the cover and shroud. Any excessive weight placed on the shroud or cover will cause the shroud to move downwardly covering the seed tray.

Owner:BROME BIRD CARE

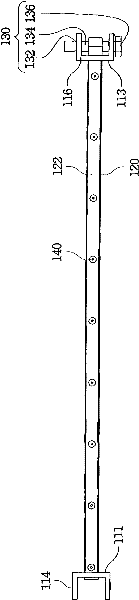

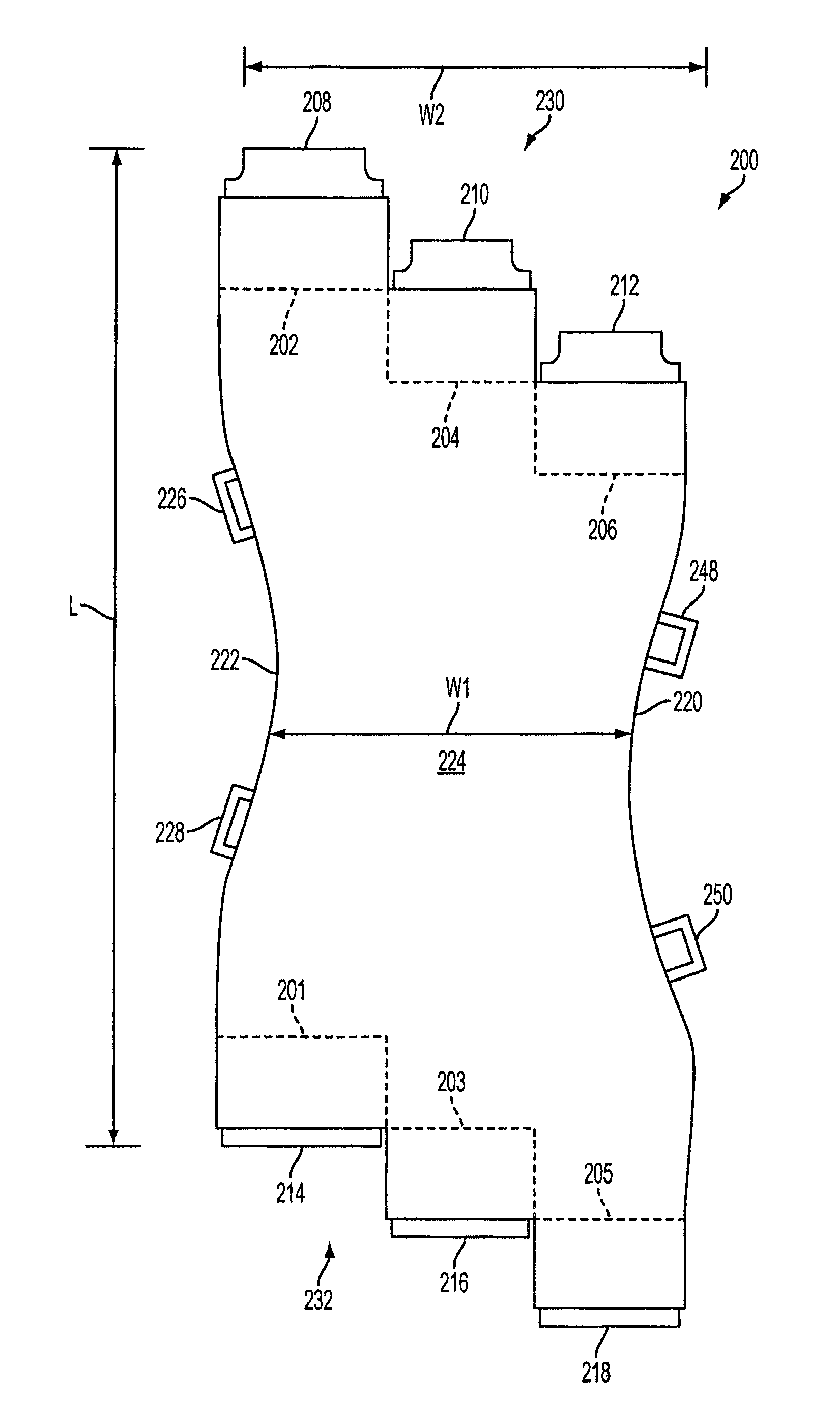

Hydroform structural reinforcement system

An structural reinforcement system for use with hydroforms and other closed forms having a plurality of members designed to be secured to a closed form, such as an hydroform tube used in automotive applications. A bonding material, such as an epoxy-based reinforcing foam, is disposed on at least a portion of the outer surface of each of the plurality of members. Once the system is attached to the closed form, the foam expands and cures during an automobile assembly operation, bonding the reinforcement system to the hydroform tube and the members. As a result, the reinforcement system provides enhanced load distribution over the vehicle frame without adding excessive weight and further serves to reduce noise and vibrational characteristics of the automotive vehicle.

Owner:ZEPHYROS INC

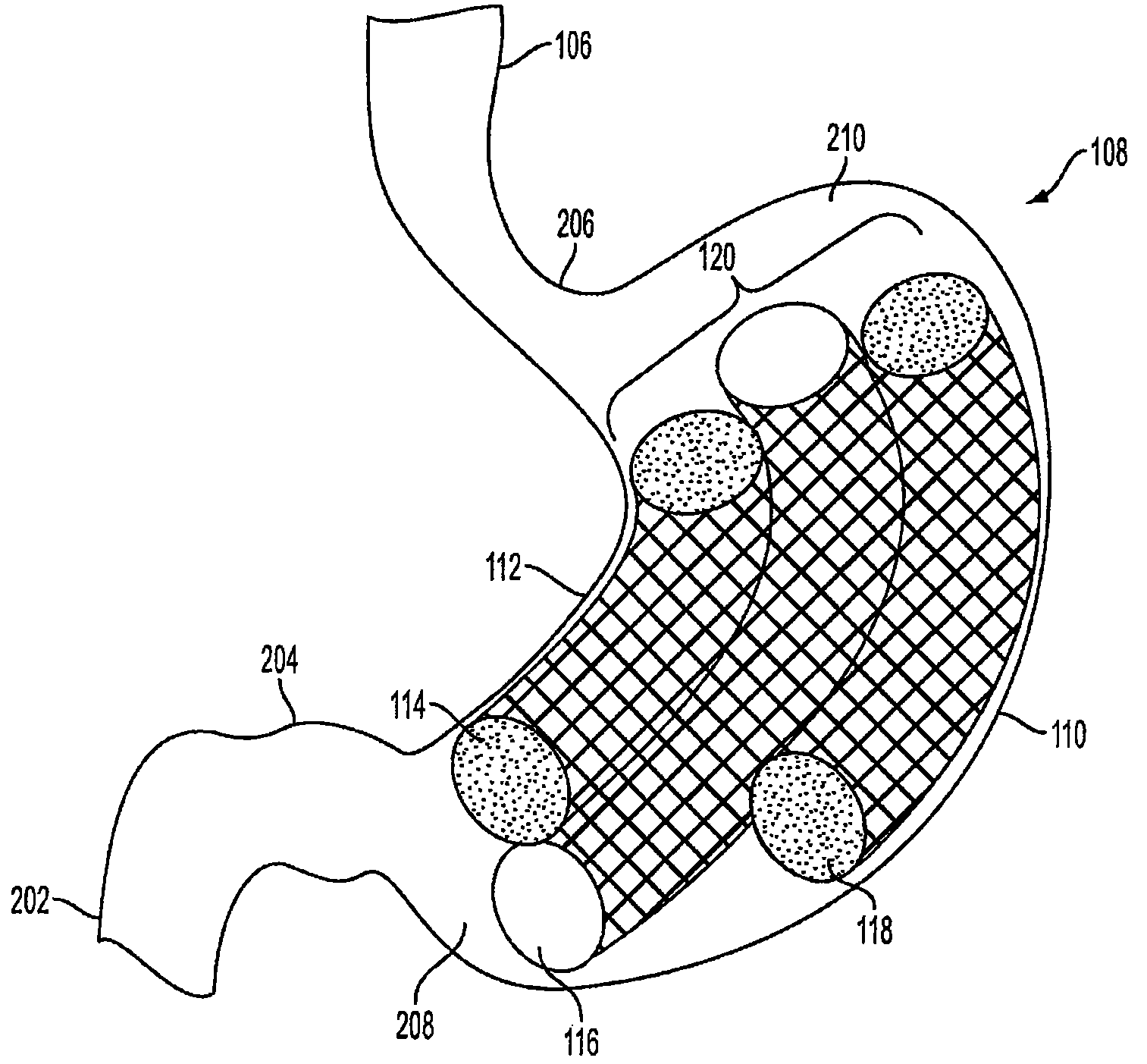

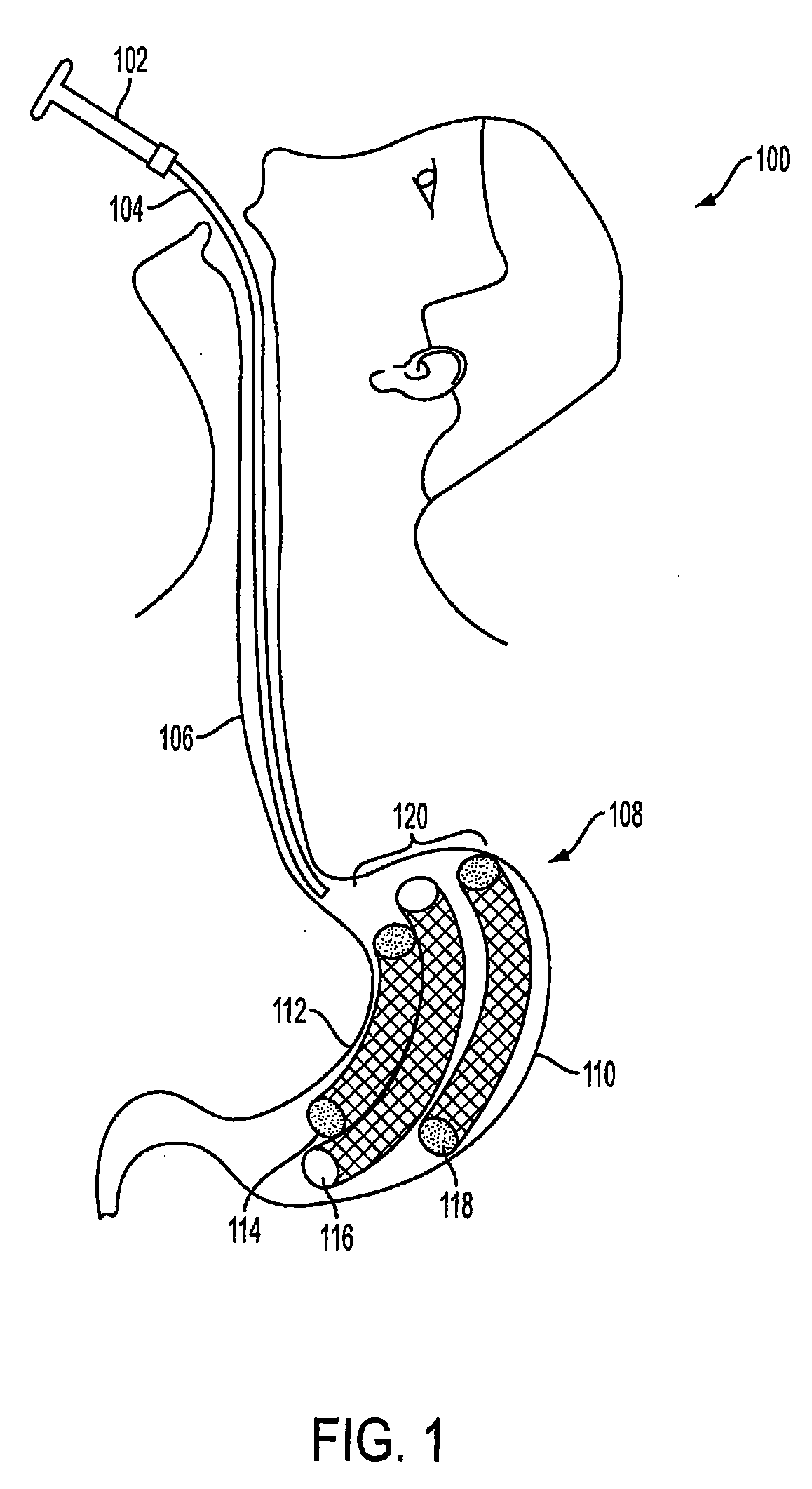

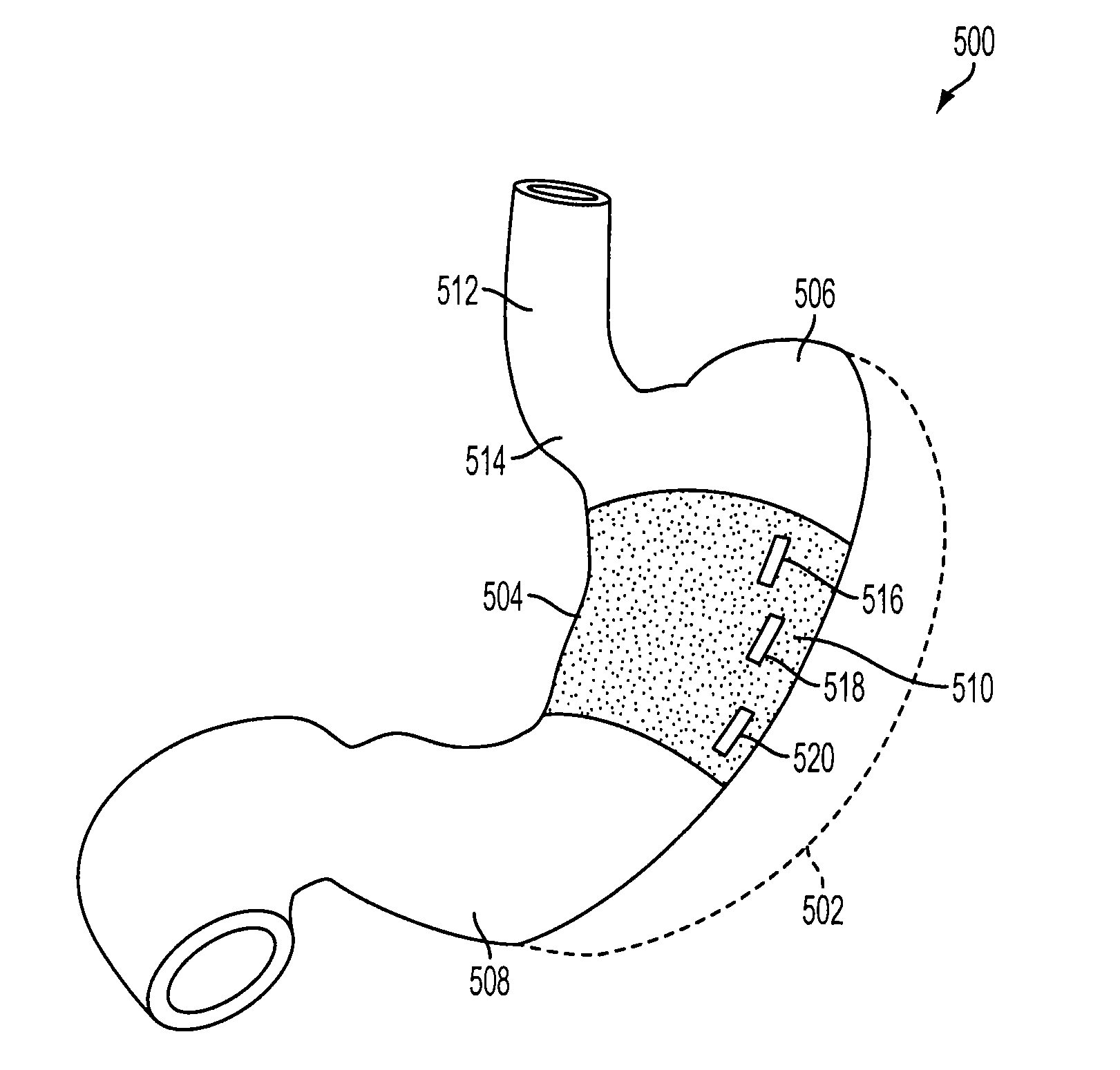

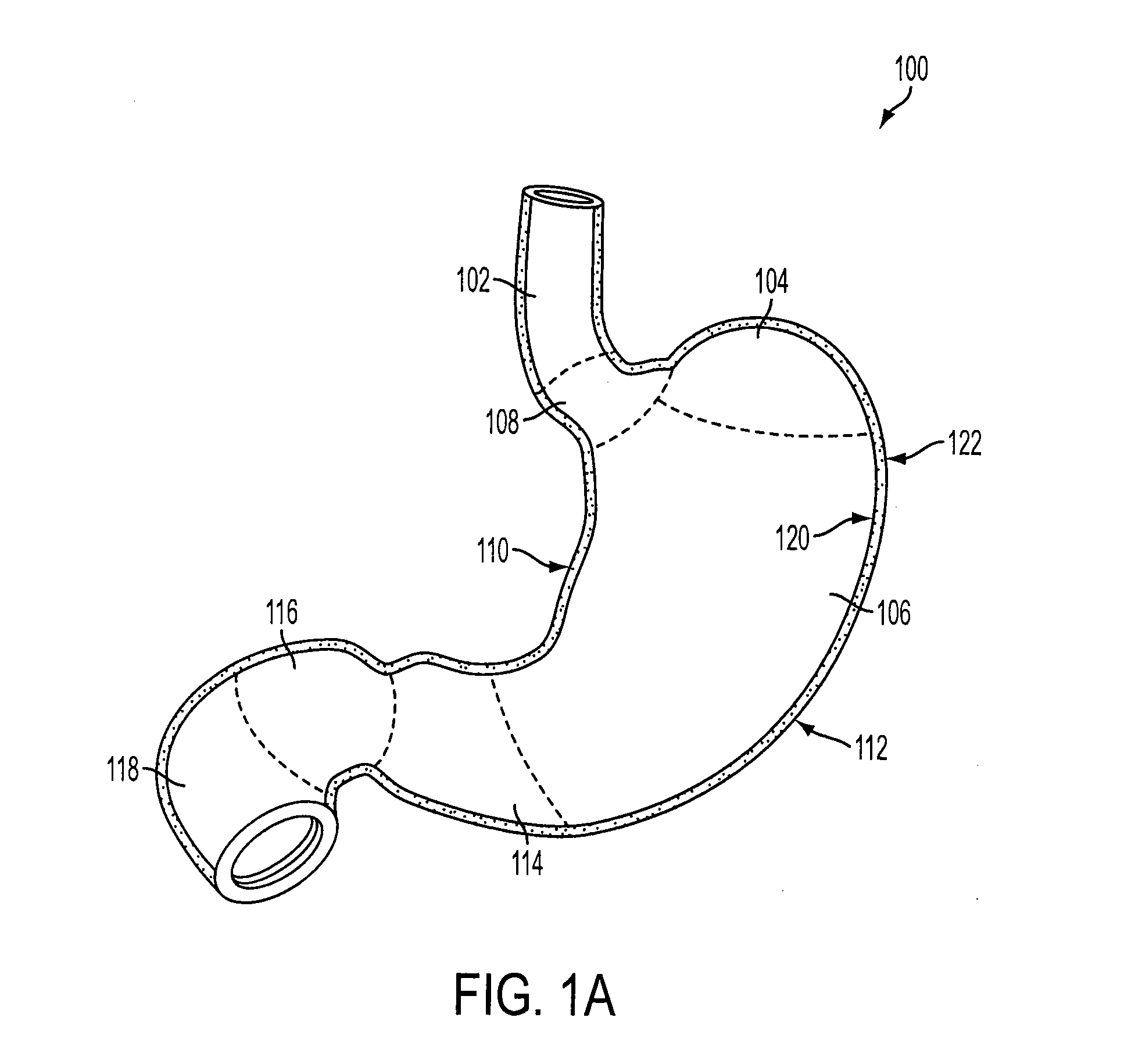

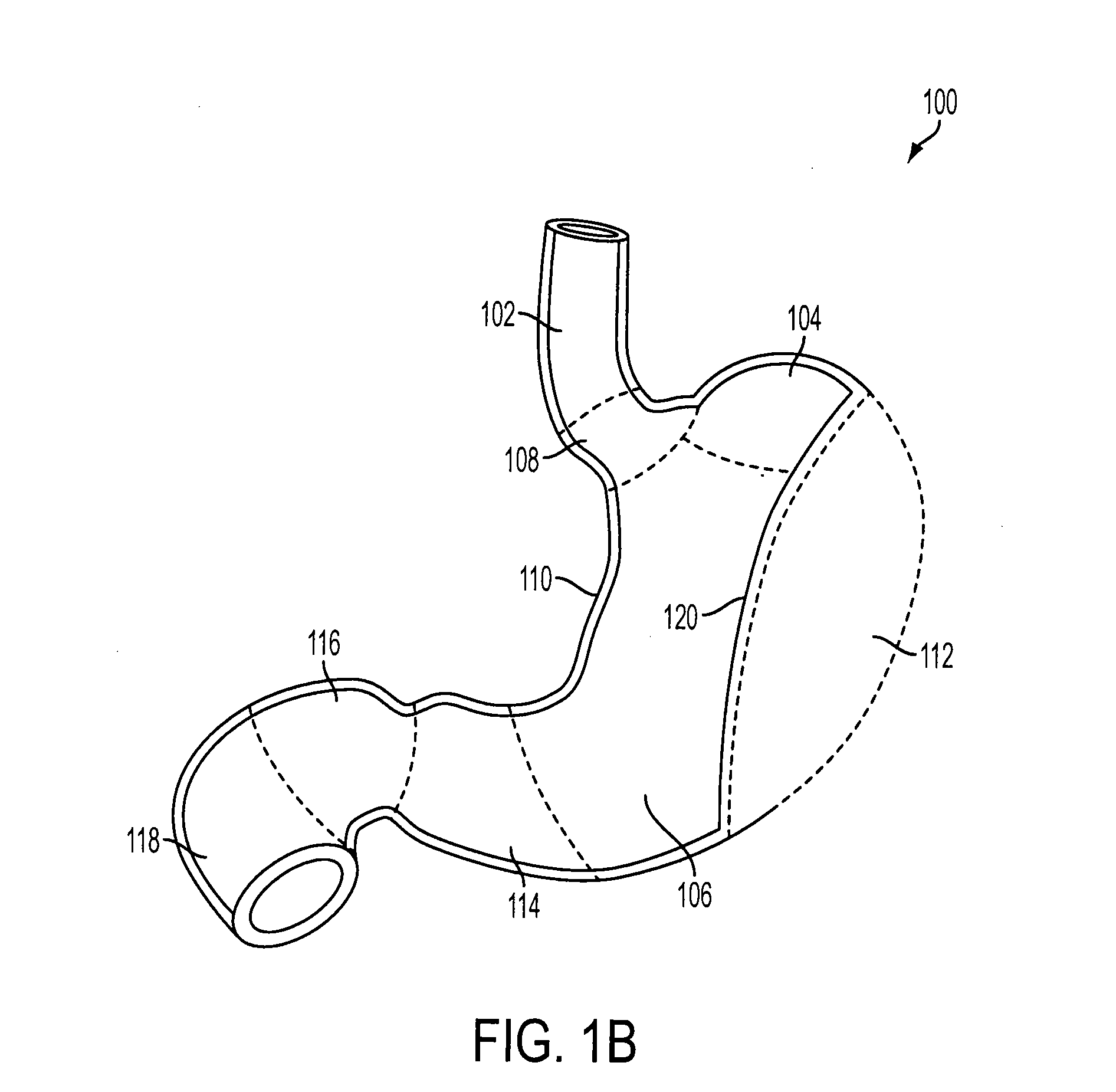

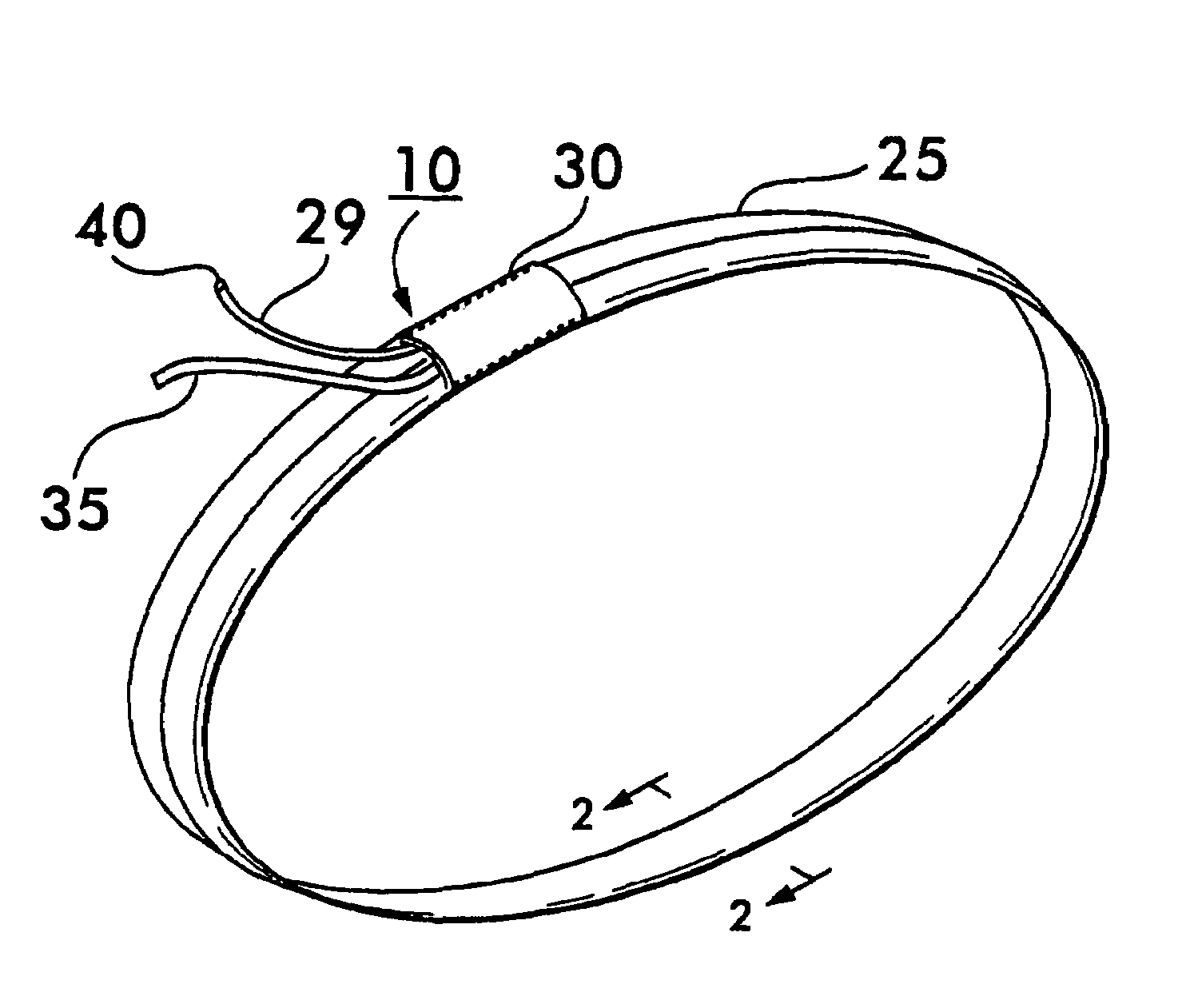

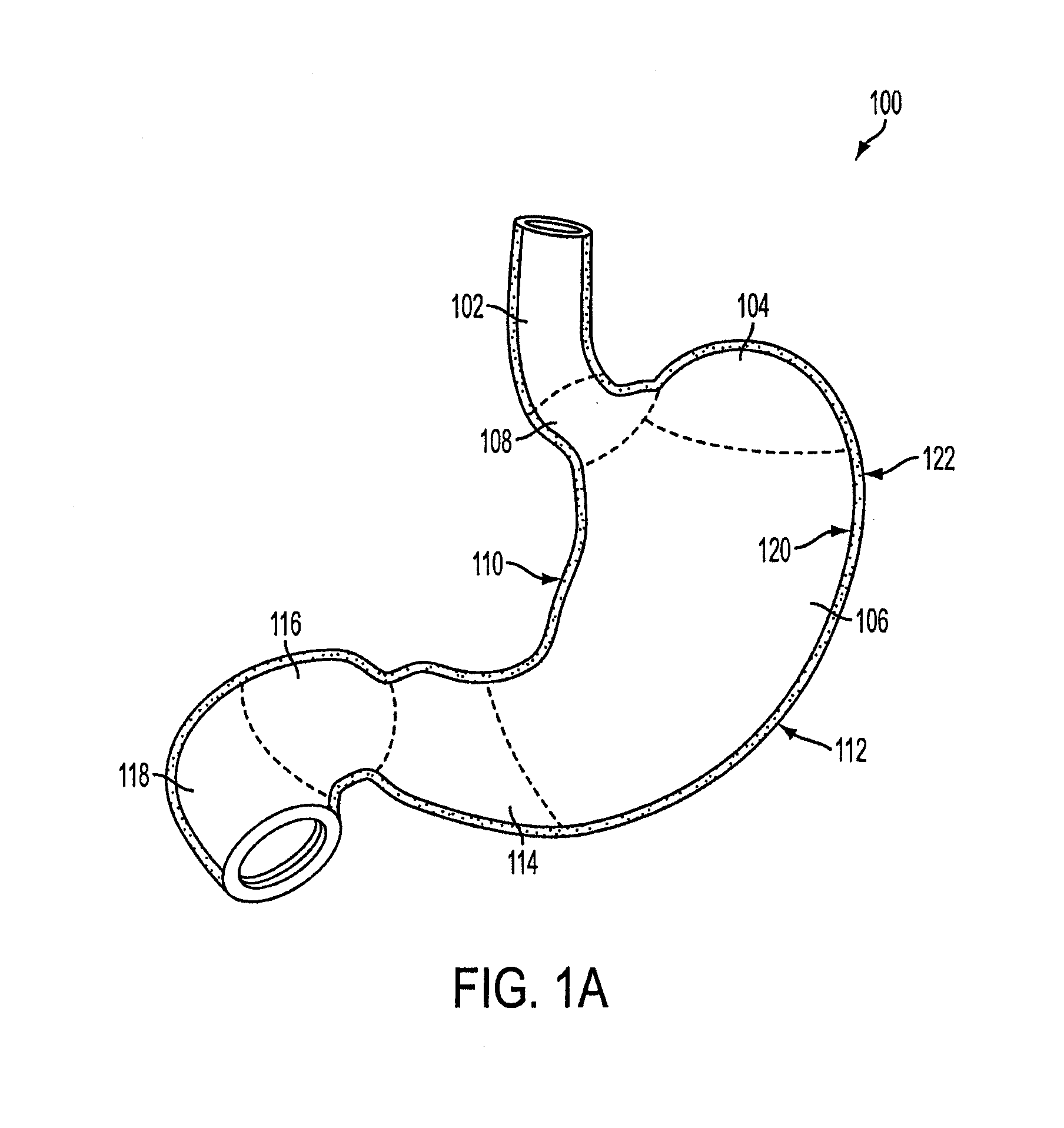

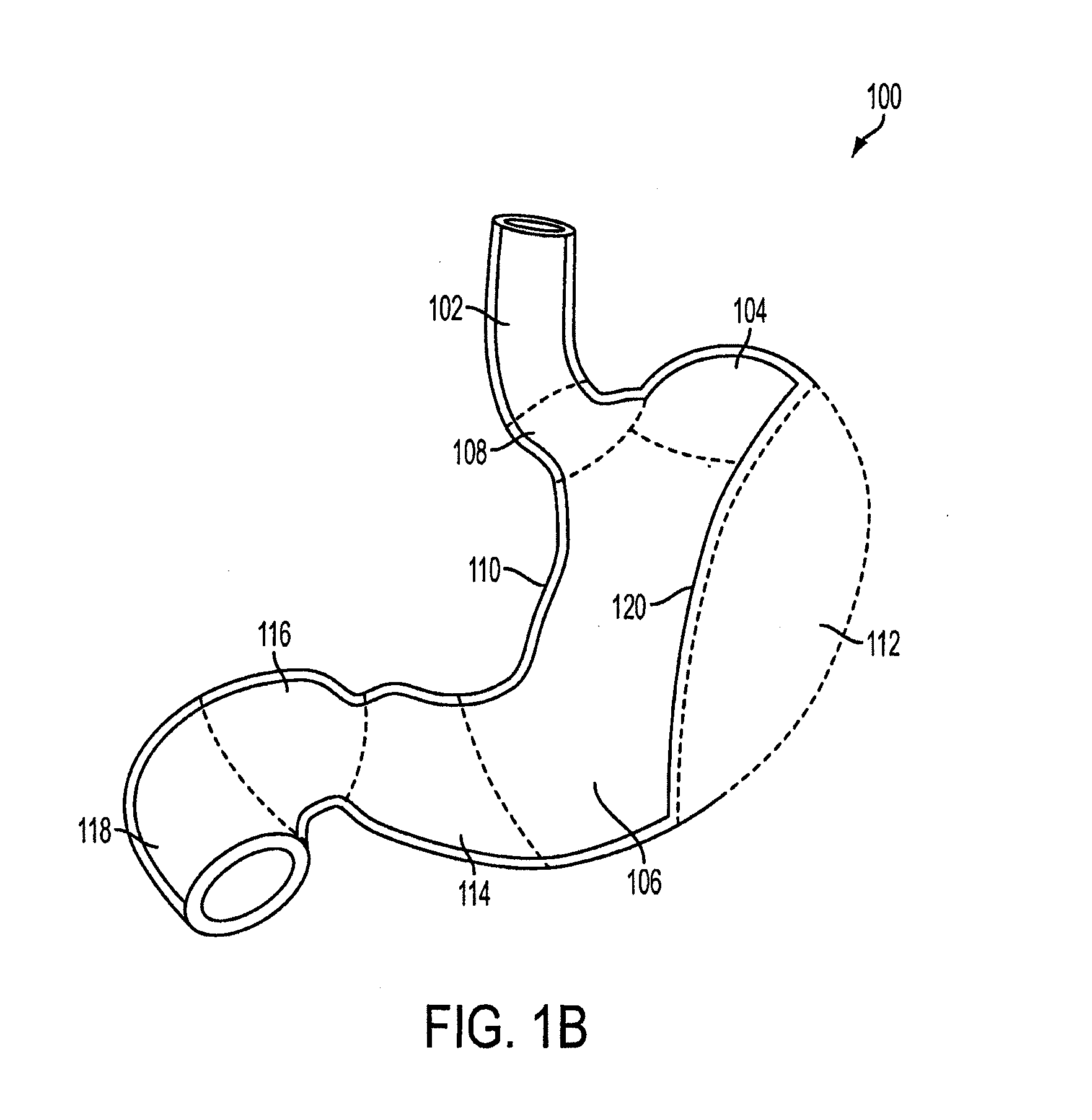

Method and apparatus for treating obesity and controlling weight gain using adjustable intragastric devices

The invention generally relates to an intragastric space-occupying device configured to be positioned within a stomach of a mammal for treating excessive weight or obesity. The intragastric space-occupying device may include an inner rod and an outer rod surrounding the inner rod, the outer rod moveable along the inner rod, the outer rod being movable between an outer first position and an inner second position. The intragastric space-occupying device may also include a plurality of support structures, each support structure having a first end connected to the inner rod and a second end connected to the outer rod, the plurality of support structures being in a collapsed position when the outer rod is in the outer first position and being in an extended position when the outer rod is in the inner second position and a covering positioned on the plurality of support structures.

Owner:ONCIOMED

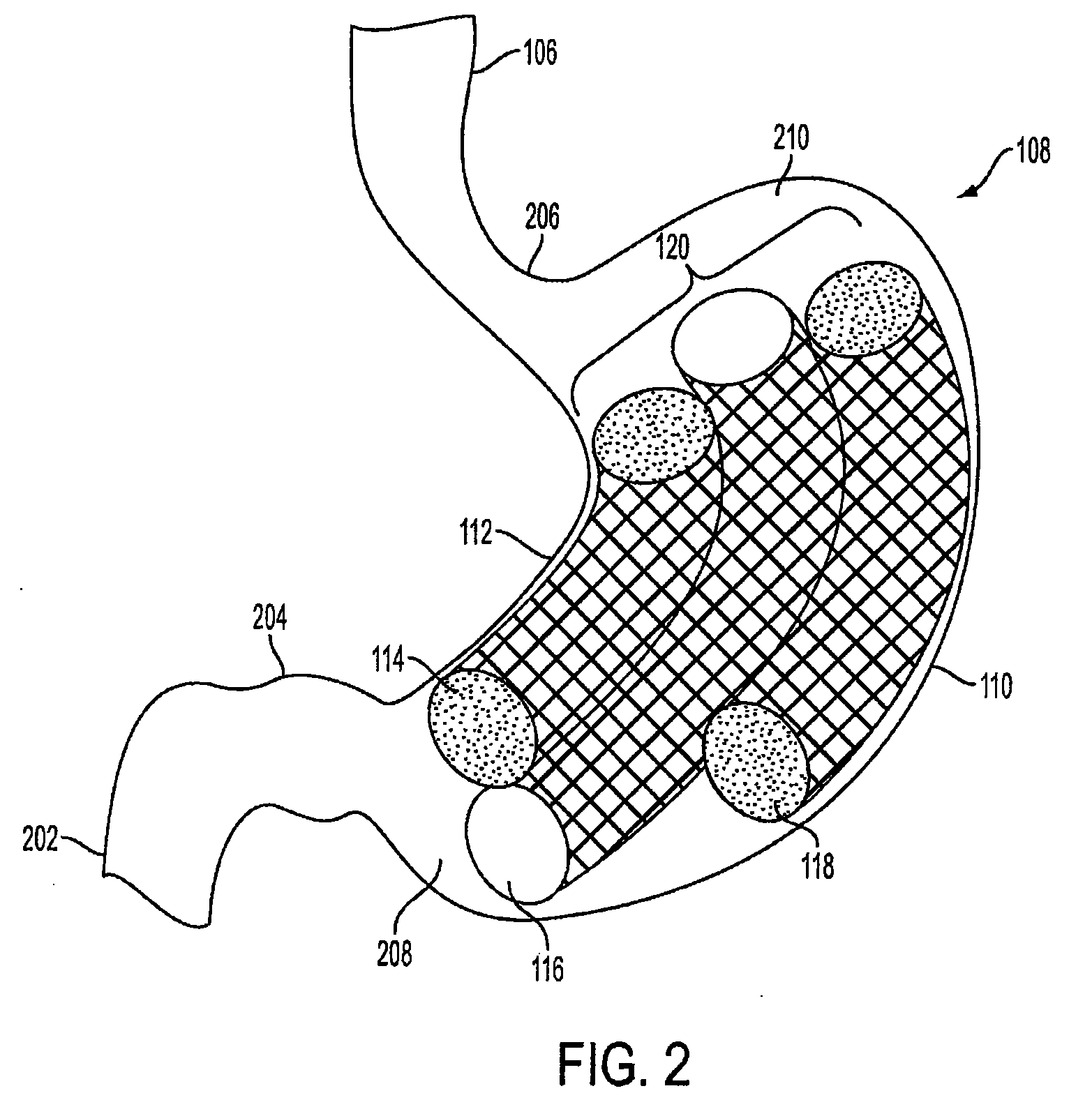

Gastric restriction devices with fillable chambers and ablation means for treating obesity

The invention relates to a gastric restraining device for treating excessive weight or obesity in mammals. The gastric restraining device includes an elastomeric sheet configured to be placed around a stomach of a mammal, an ablation device attached to the elastomeric sheet, the ablation device configured to emit energy toward an outer surface of the stomach when the elastomeric sheet is placed around the stomach, and an energy device coupled to the ablation device to generate the energy and to transfer the energy to the ablation device.

Owner:RESHAPE LIFESCIENCES INC

Glucagon analogues

InactiveUS20130316941A1Avoid weight gainGood for weight lossPeptide/protein ingredientsAntipyreticWeight gain preventionGlycemic

The invention provides glucagon analogue peptides and their use for promoting weight loss or preventing weight gain, and the treatment of obesity or excess body weight and associated conditions. The compounds may also be used to improve glycemic control and / or for the treatment of diabetes. The compounds may mediate their effect, inter alia, by having increased selectivity for the GLP-1 receptor as compared to human glucagon.

Owner:BOEHRINGER INGELHEIM INT GMBH +1

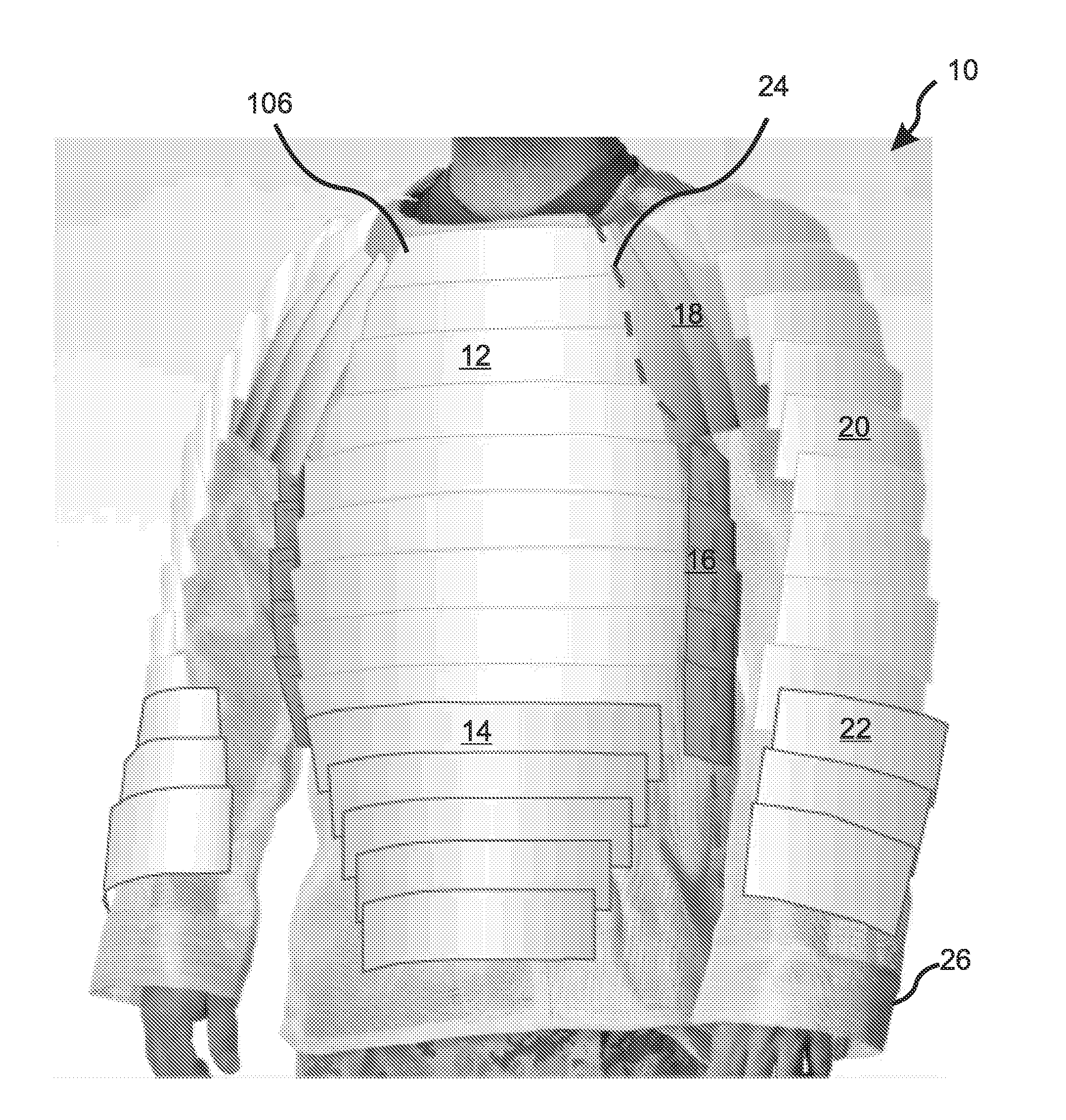

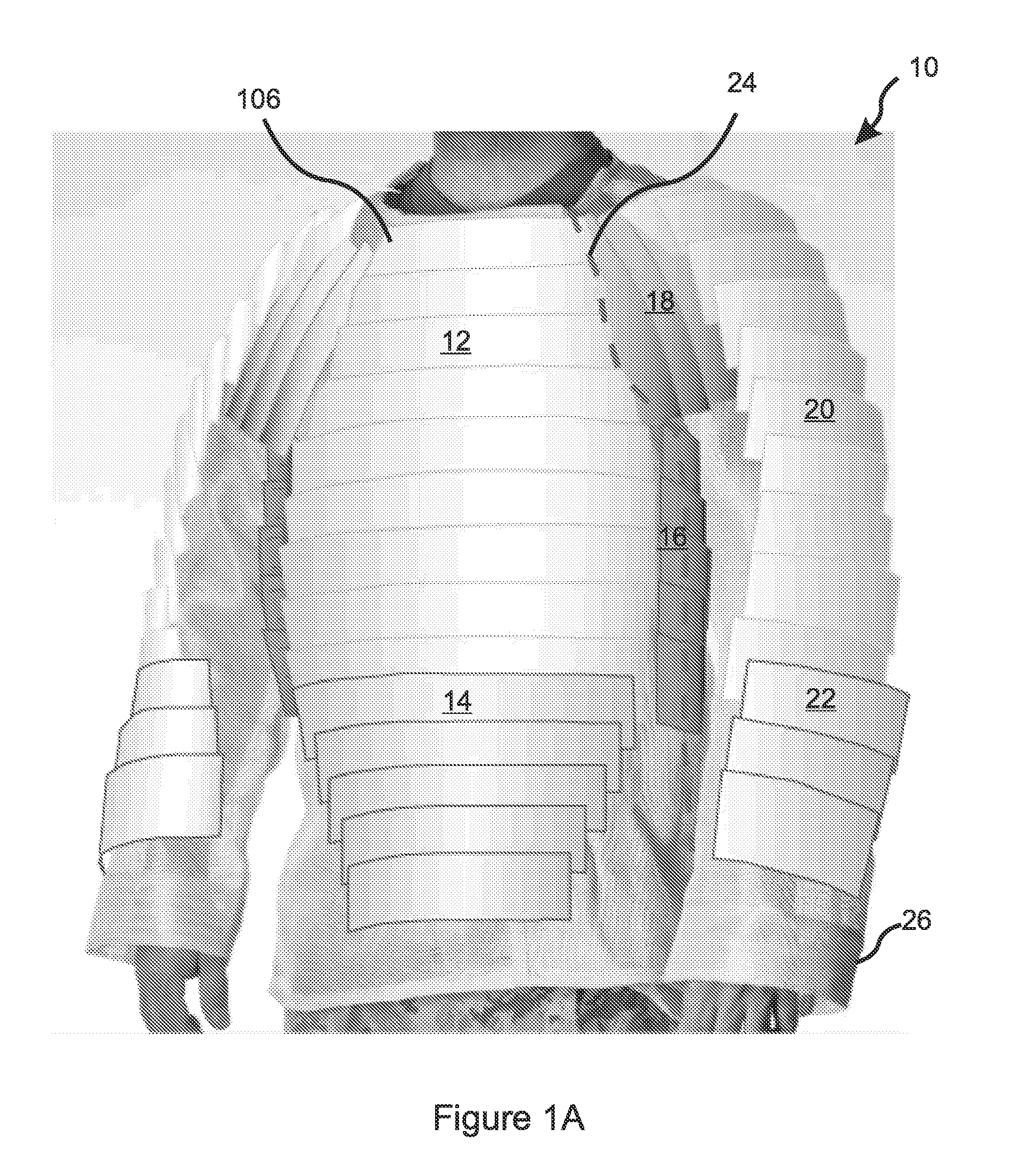

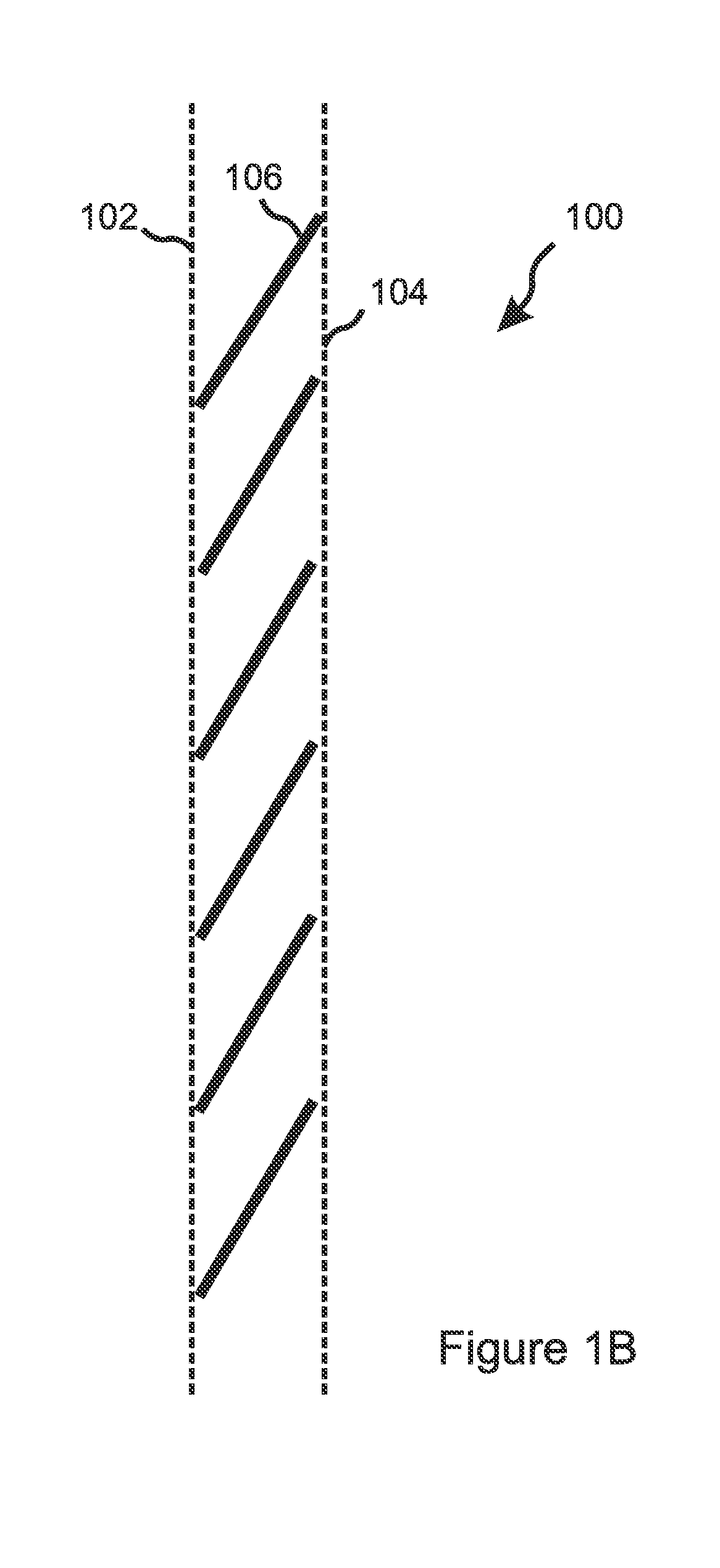

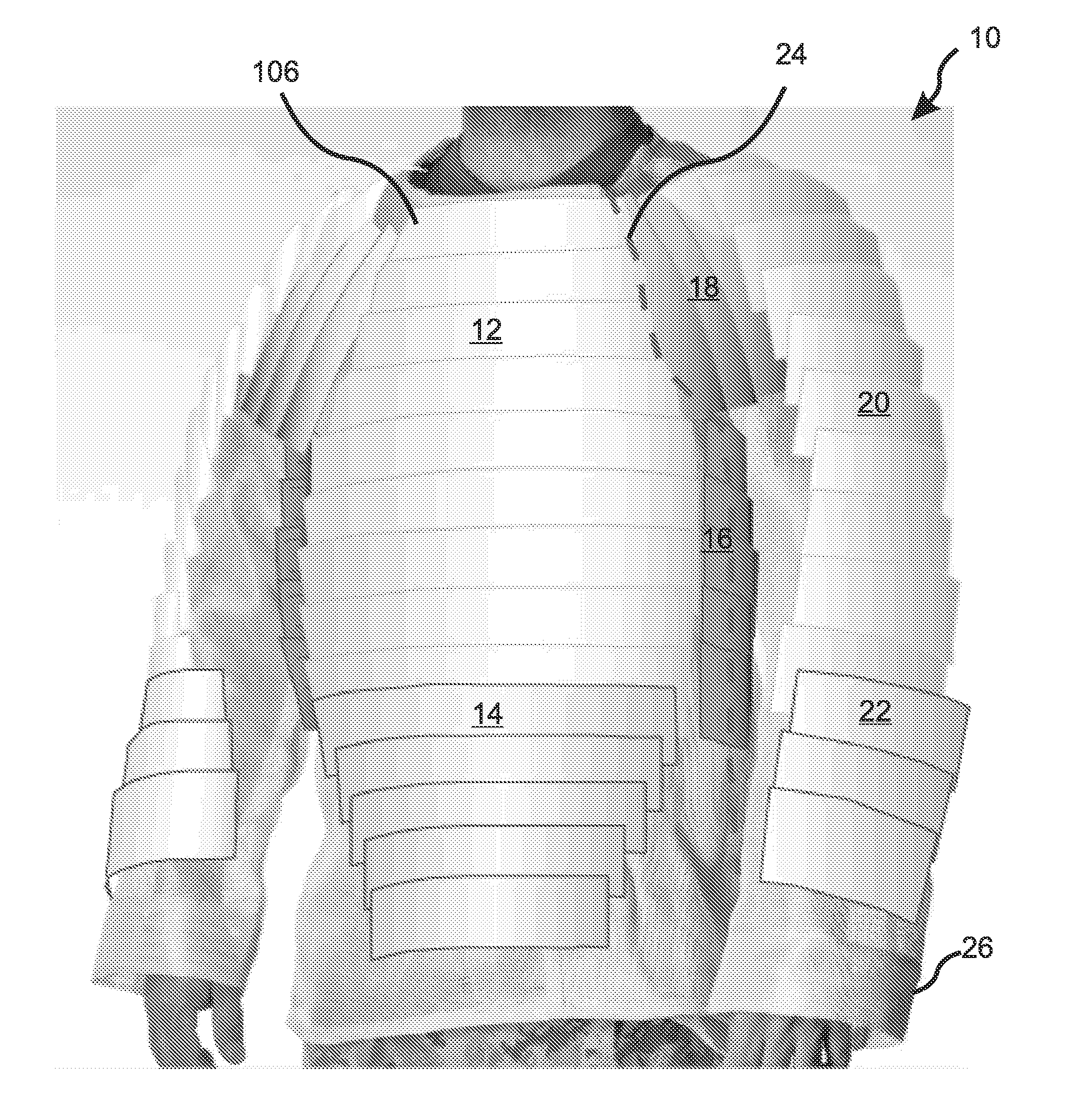

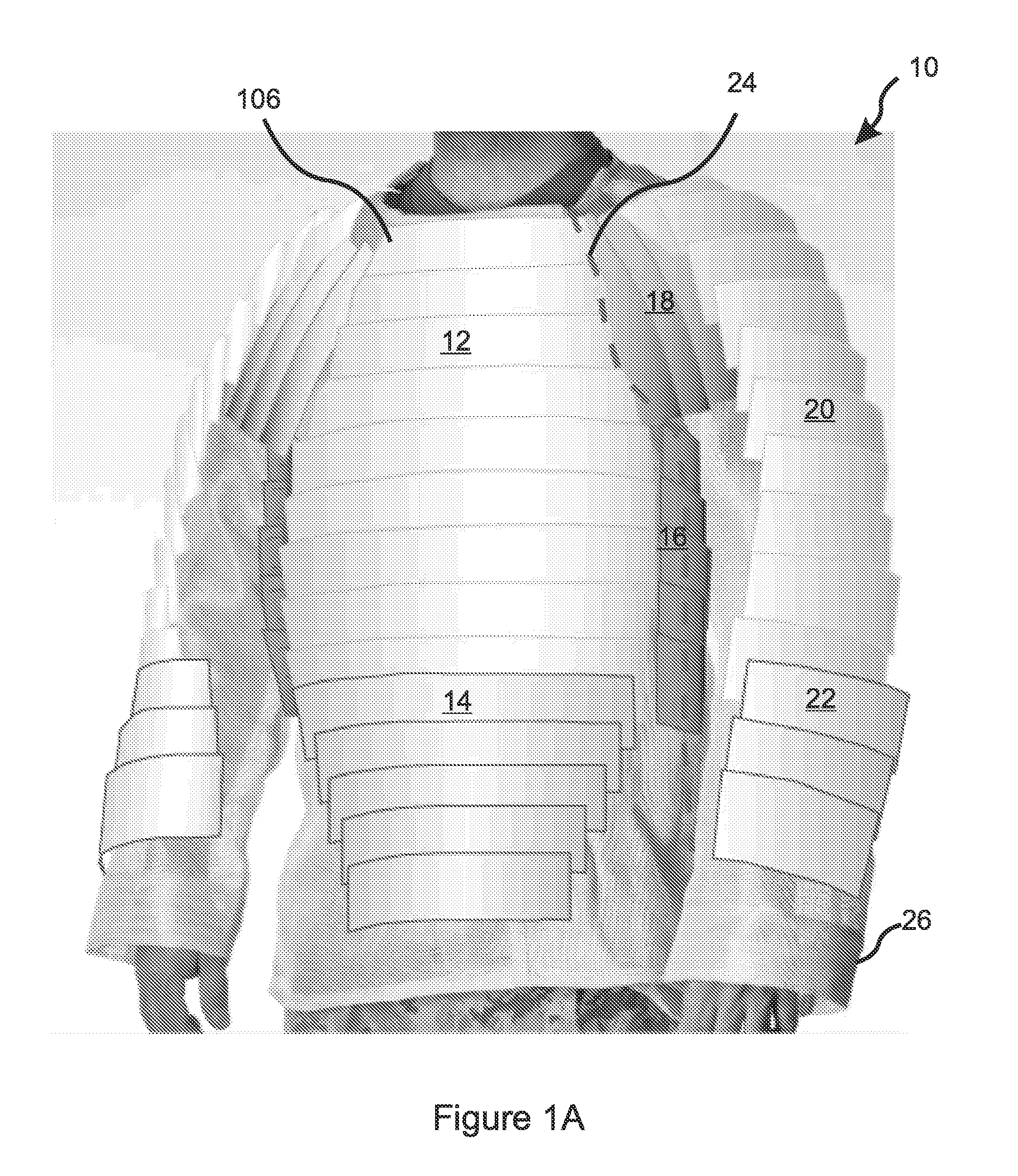

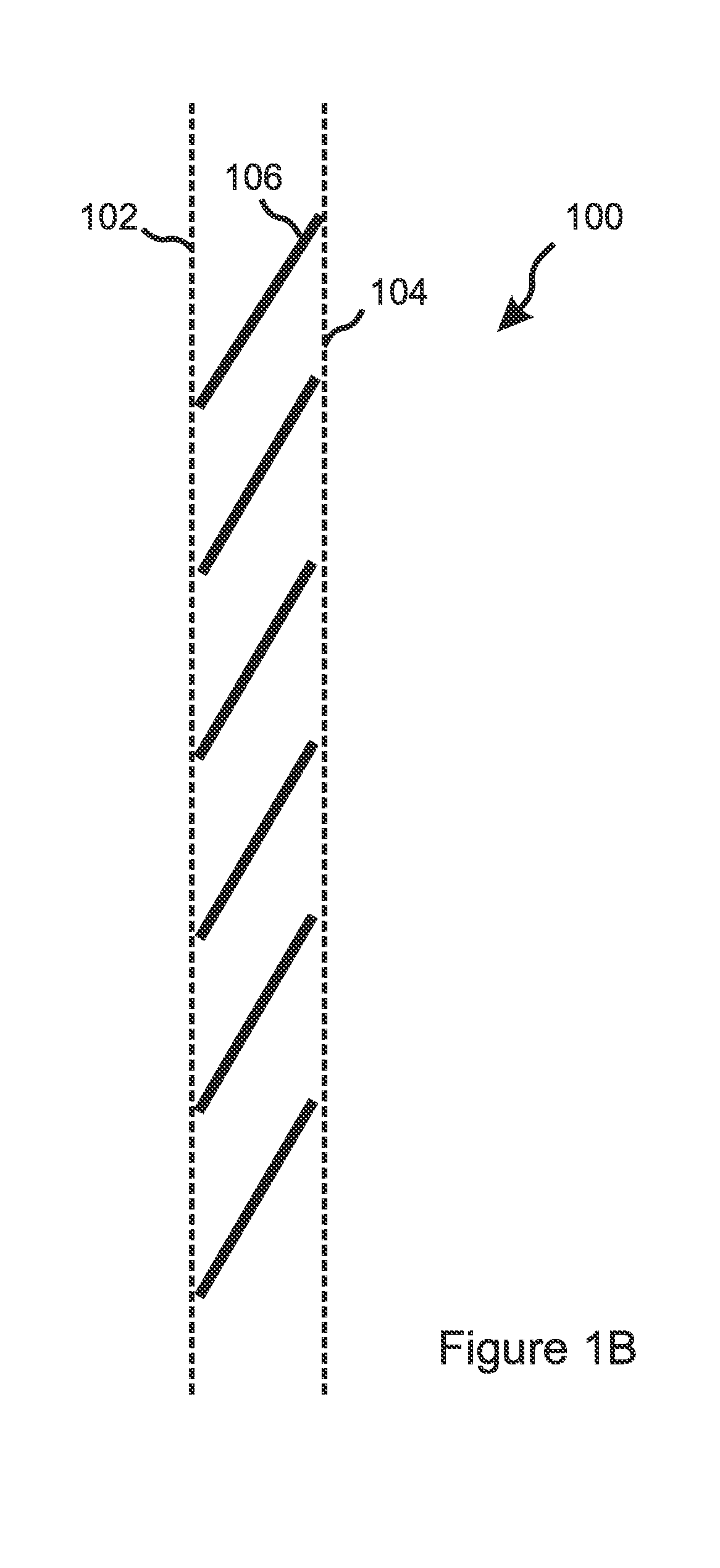

Thermally vented body armor

InactiveUS20120159680A1Stable positionMinimum wasted massArmourPersonal protection gearThermal compressionExcessive weight

A modular and field adaptable body armor system includes a plurality of flexible, air-permeable, thermally vented plates arranged in fixed relationships that pro-vide flexible, modular, field-adaptable protection for the torso and extremities without excessive weight or heat bur-den. The TVA plates include protective cards suspended in a parallel, louvered relationship between inner and outer mesh layers, thereby permitting air to flow therebetween while providing a flexible, compressible, modular barrier that protects the torso and extremities against projectiles. In embodiments, the outer mesh layer resists penetration and compresses cards together to intercept a projectile that would otherwise pass therebetween. Protective cards can include thermally pressed and flexed laminated UHMWPE. TVA panels can be removed and exchanged in the field according to the requirements of each mission. In embodiments, the TVA plates are laced together and / or attached to an underlying fabric carrier garment.

Owner:WARWICK MILLS INC

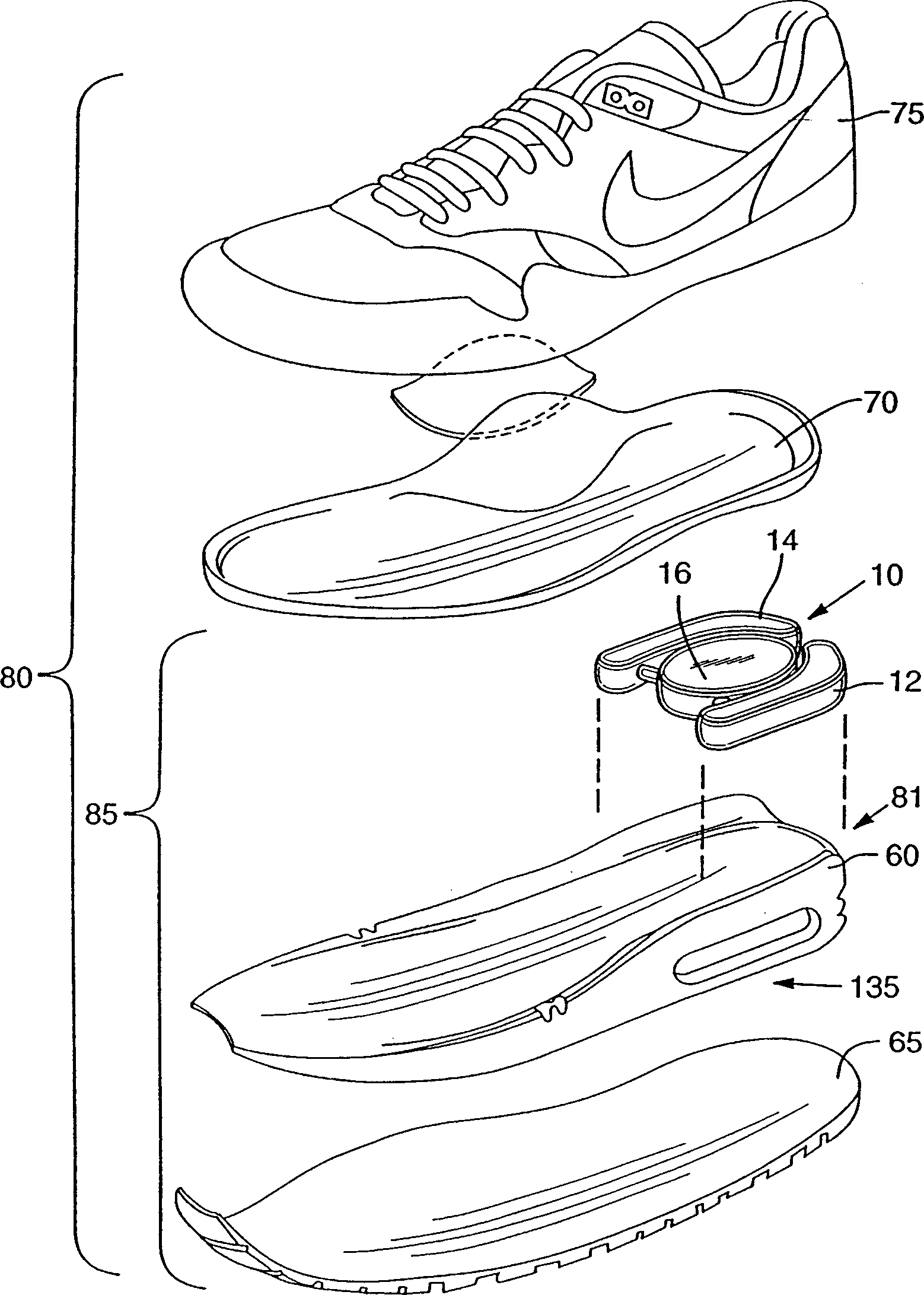

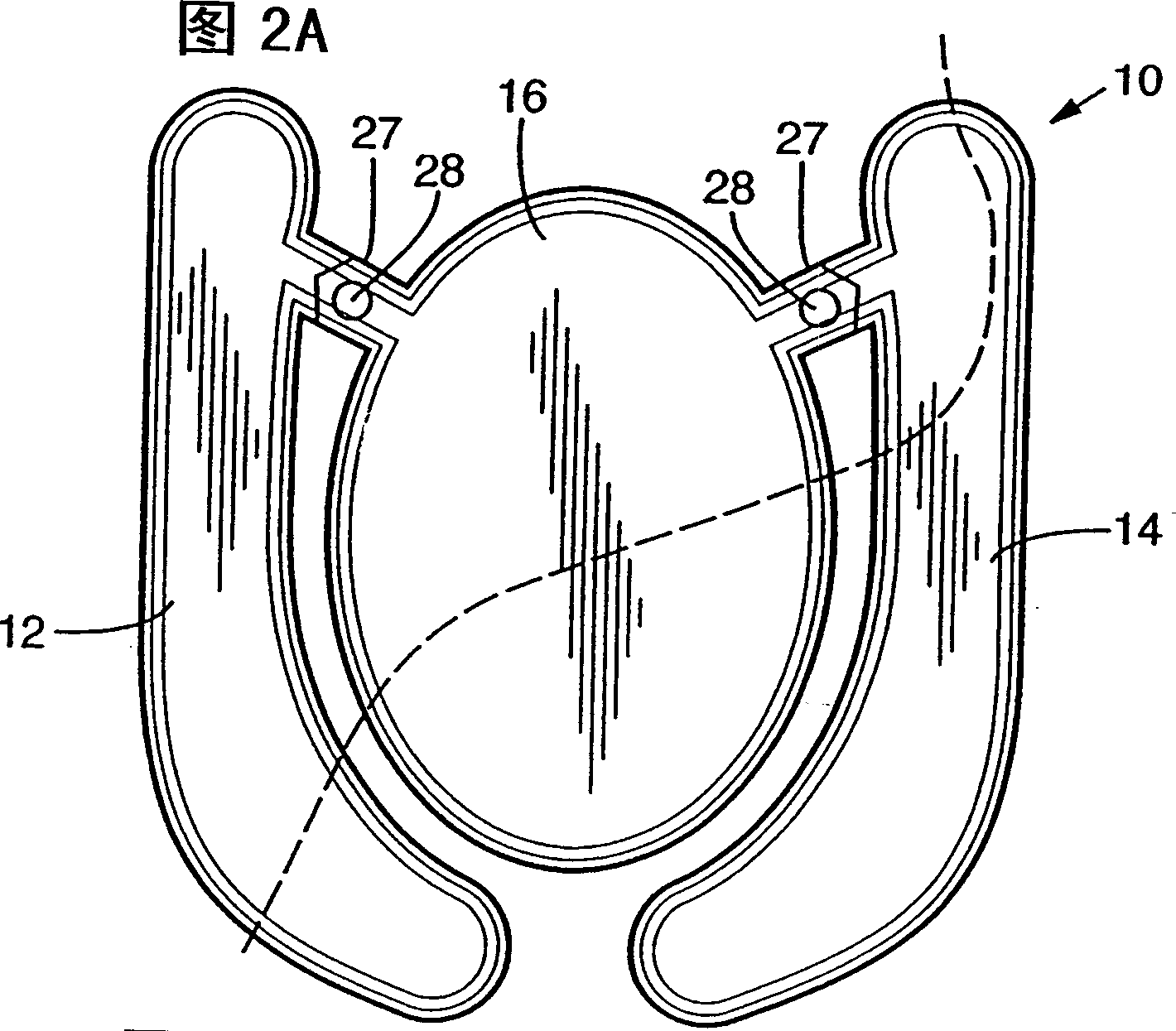

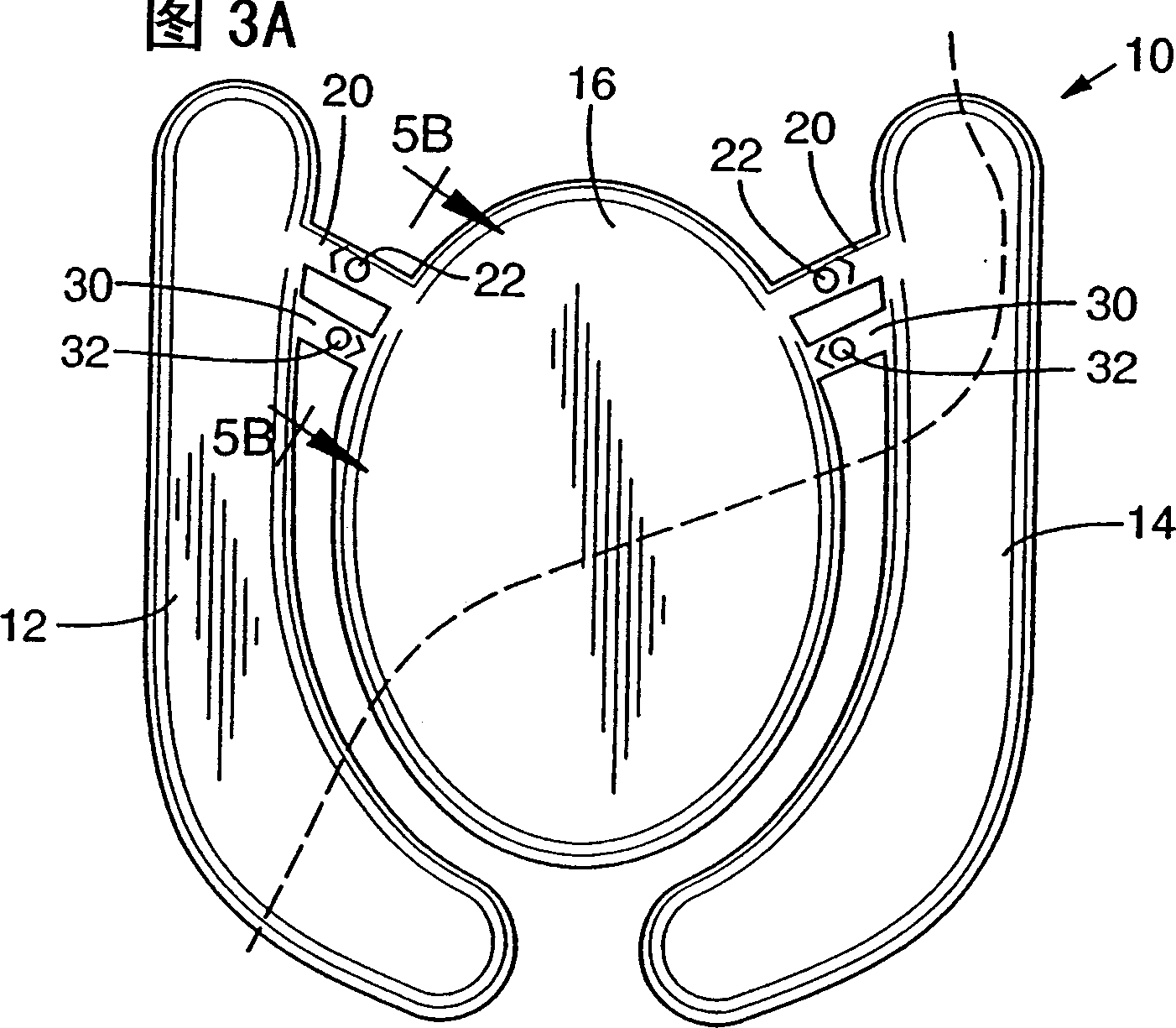

Article of footwear with motion control device

An article of footwear with a bladder system providing cushioning and dynamic motion control in a multi-bladder system. The bladder system gives the needed amount of motion control by stiffening a portion of the footwear in response to the individual user's side-to-side motion. When used in the heel, the bladder system takes into consideration a center-of-pressure pathway of the foot to increase medial stiffness in response to lateral-to-medial rotation of the foot, so the more a user pronates, the stiffer the medial portion of the footwear is made. The bladder system provides comfort and control without the extra weight and bulk of prior art support structures. The bladder system dynamically changes the stiffness of a portion of the footwear when pressure is applied thereto, and returns to equilibrium when the pressure is removed.

Owner:NIKE INNOVATE CV

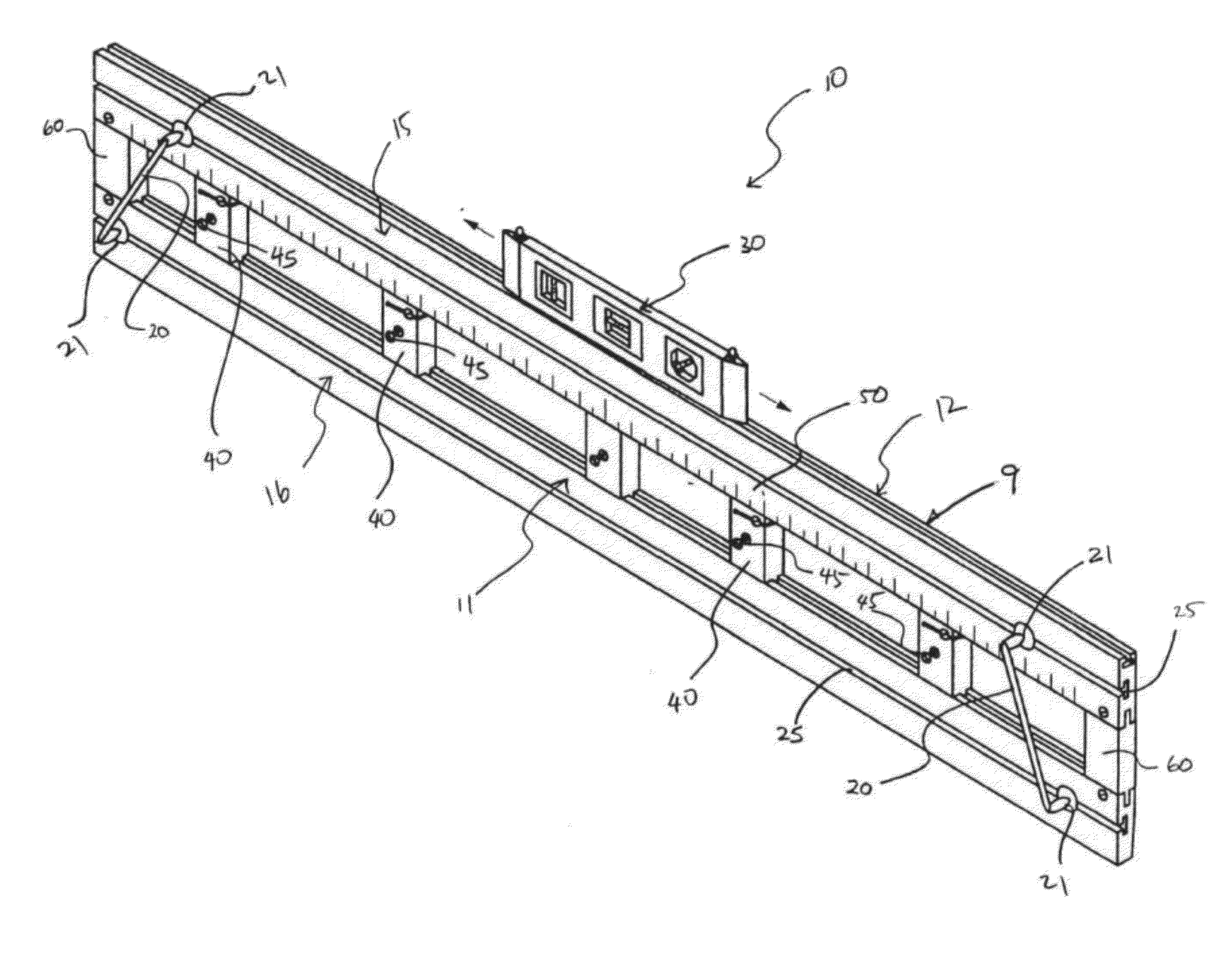

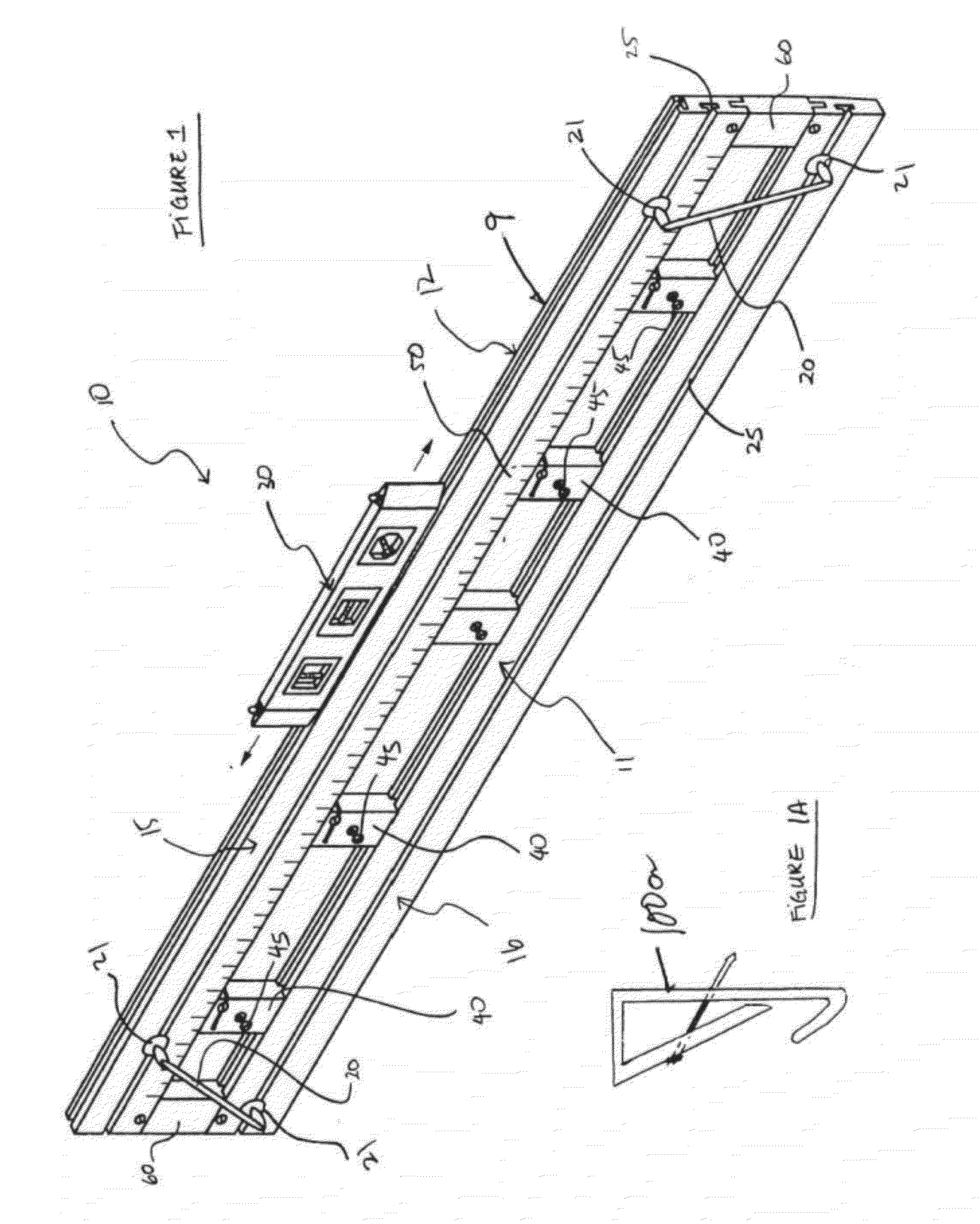

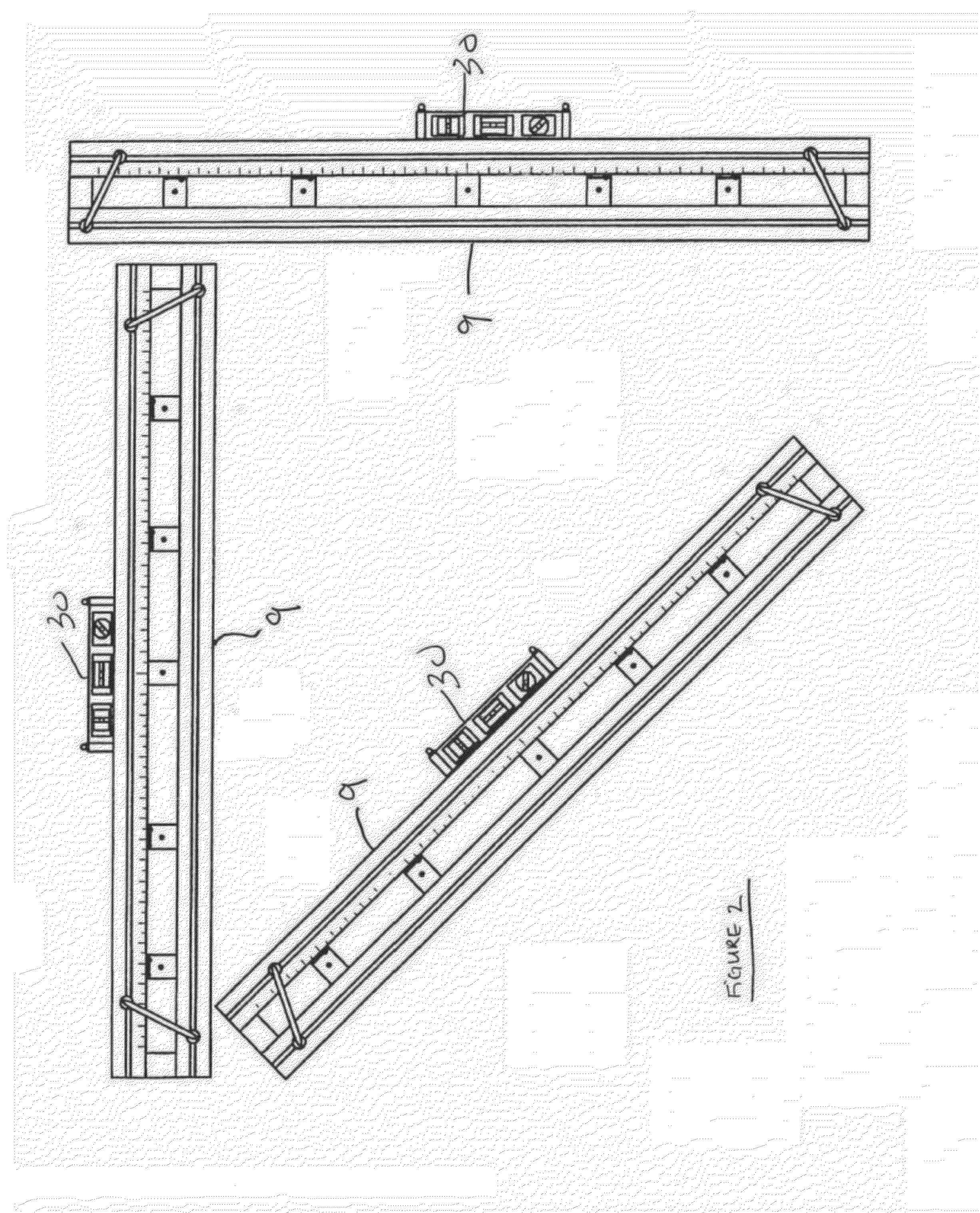

Hanging Device

An alignment device or jig that includes a level and a rule which is used for hanging wall supported items. The device includes locator blocks with locator pins for supporting the item and stud finder sensors for locating wall studs. The locator pins extend to protrude from the back side of the jig to allow a mark to be made into the hanging surface when the jig is pressed against the hanging surface. In the event that the item requires a stronger surface to hang onto due to excessive weight, a stud finder system can be utilized. In operation, one or more of picture frames to be mounted to a wall are hung on the device on one or more hangers. The hangers are slidingly spaced along the device scale for desired picture spacing. The device with the frames is placed against the wall and pressed to the wall, wherein the marking points mark the wall at the exact desired points where permanent hangers will be driven into the wall to support the one or more picture frames.

Owner:DANIEL ROBERTO R

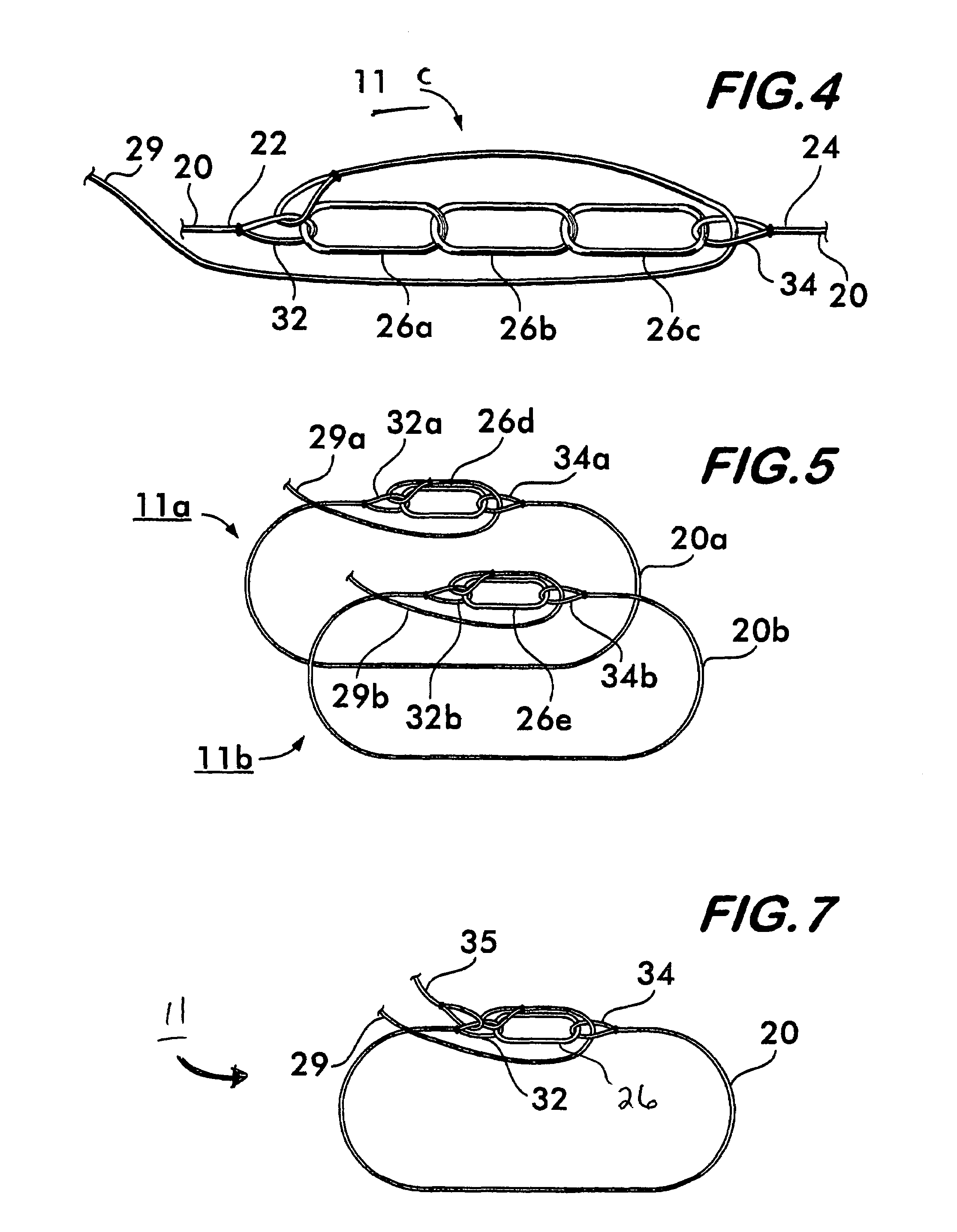

Sling with predictable pre-failure warning indicator

A pre-failure warning indicator is provided for use with a sling. The pre-failure warning indicator triggers at a point that is predictable within a relatively narrow range, thereby increasing the possibility that a damaged sling is removed from use. The pre-failure warning indicator includes a dedicated strand of material that is placed in close proximity to the load-bearing core yarns of the sling but remains separate and independent from the core yarns; the ends of the dedicated strand are connected via a sacrificial “ring.” A warning fiber having an end that is visible to operators / riggers works in conjunction with the sacrificial strand and the ring. The ring is designed to fail when the sling is subjected to a specifically chosen condition (e.g., excessive weight). The failure of the ring causes the warning fiber to withdraw from the rigger's view thereby warning the rigger that the sling was subjected to the specifically chosen condition and may be damaged.

Owner:SLINGMAX INC

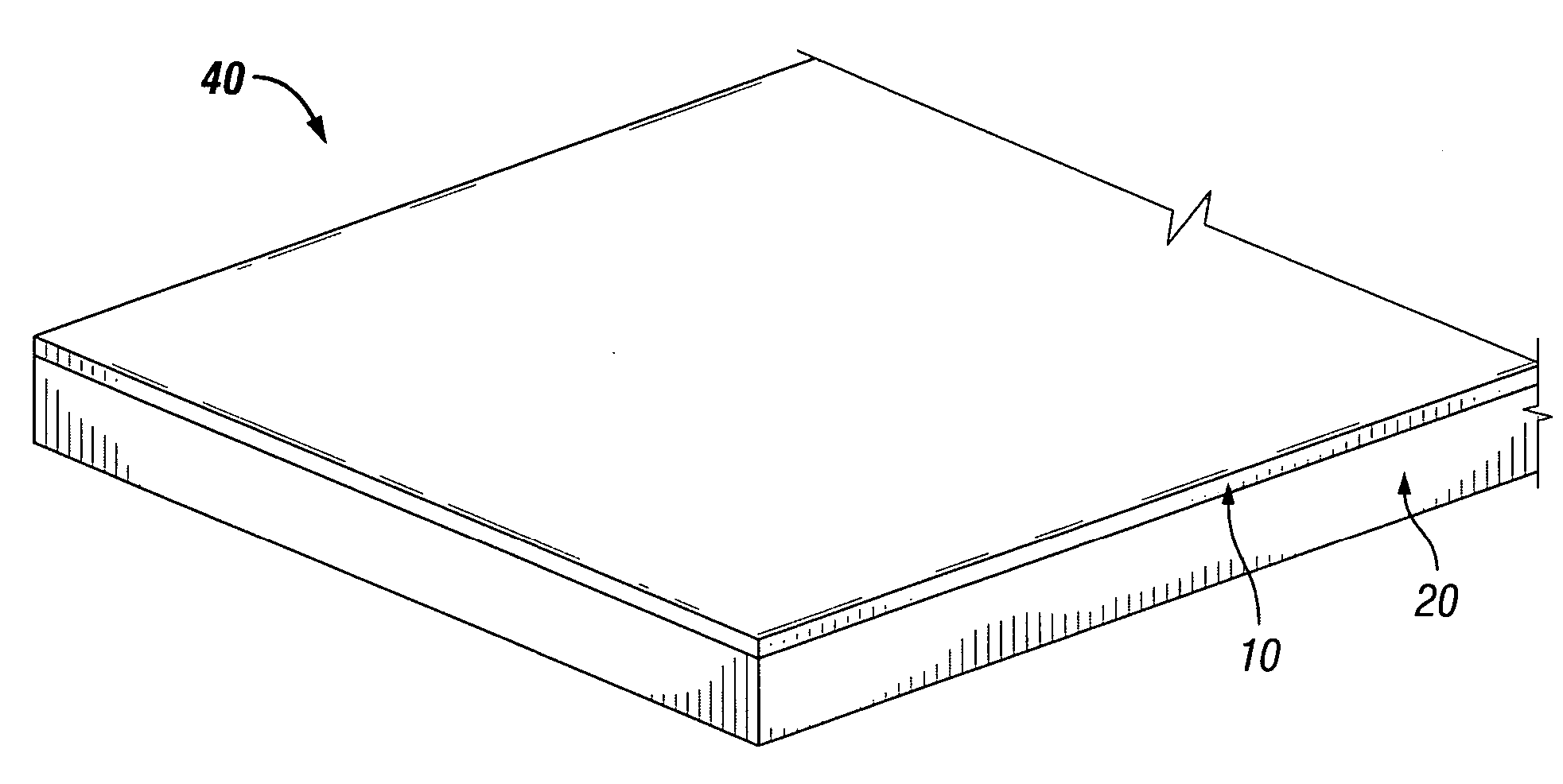

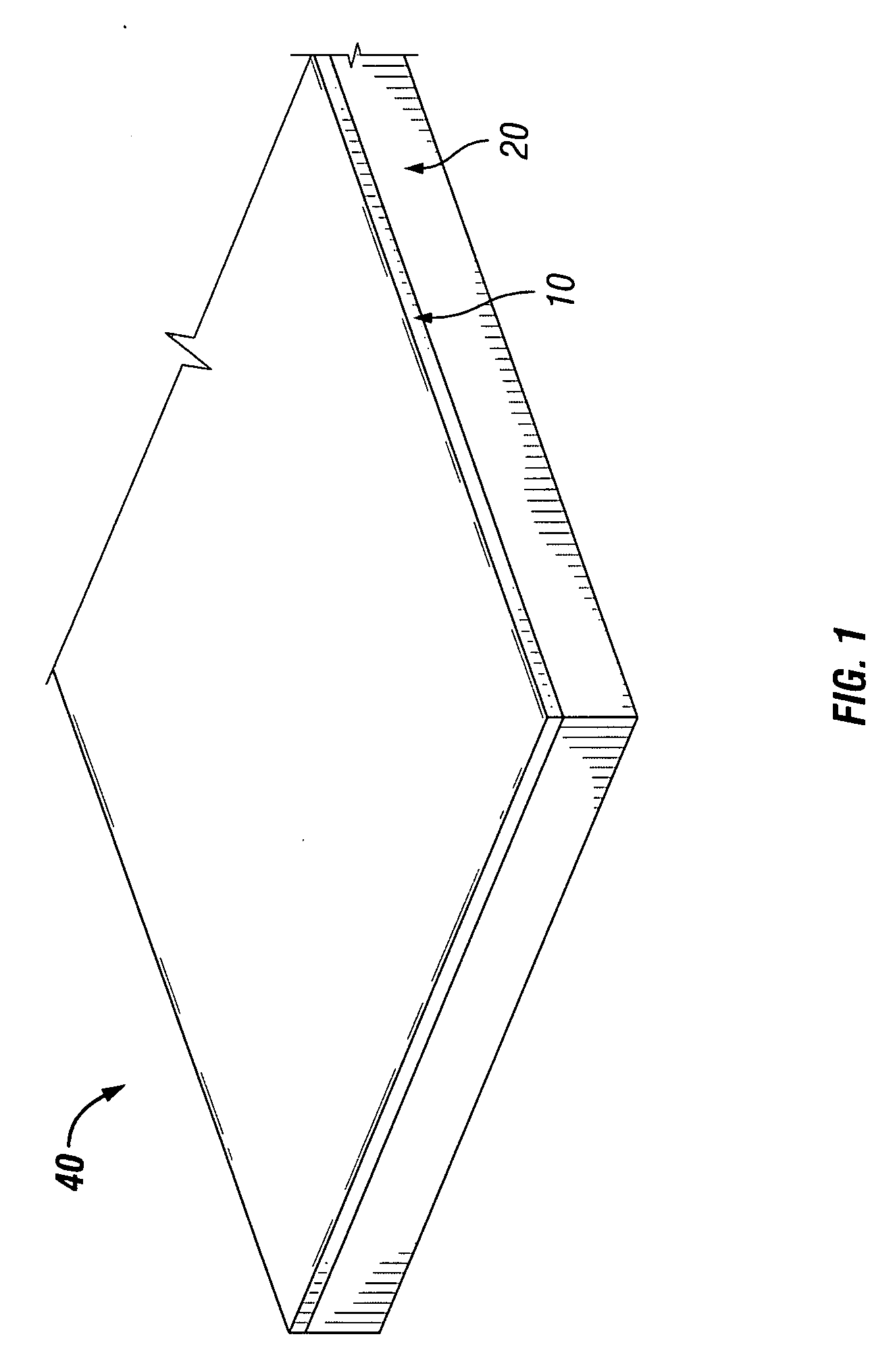

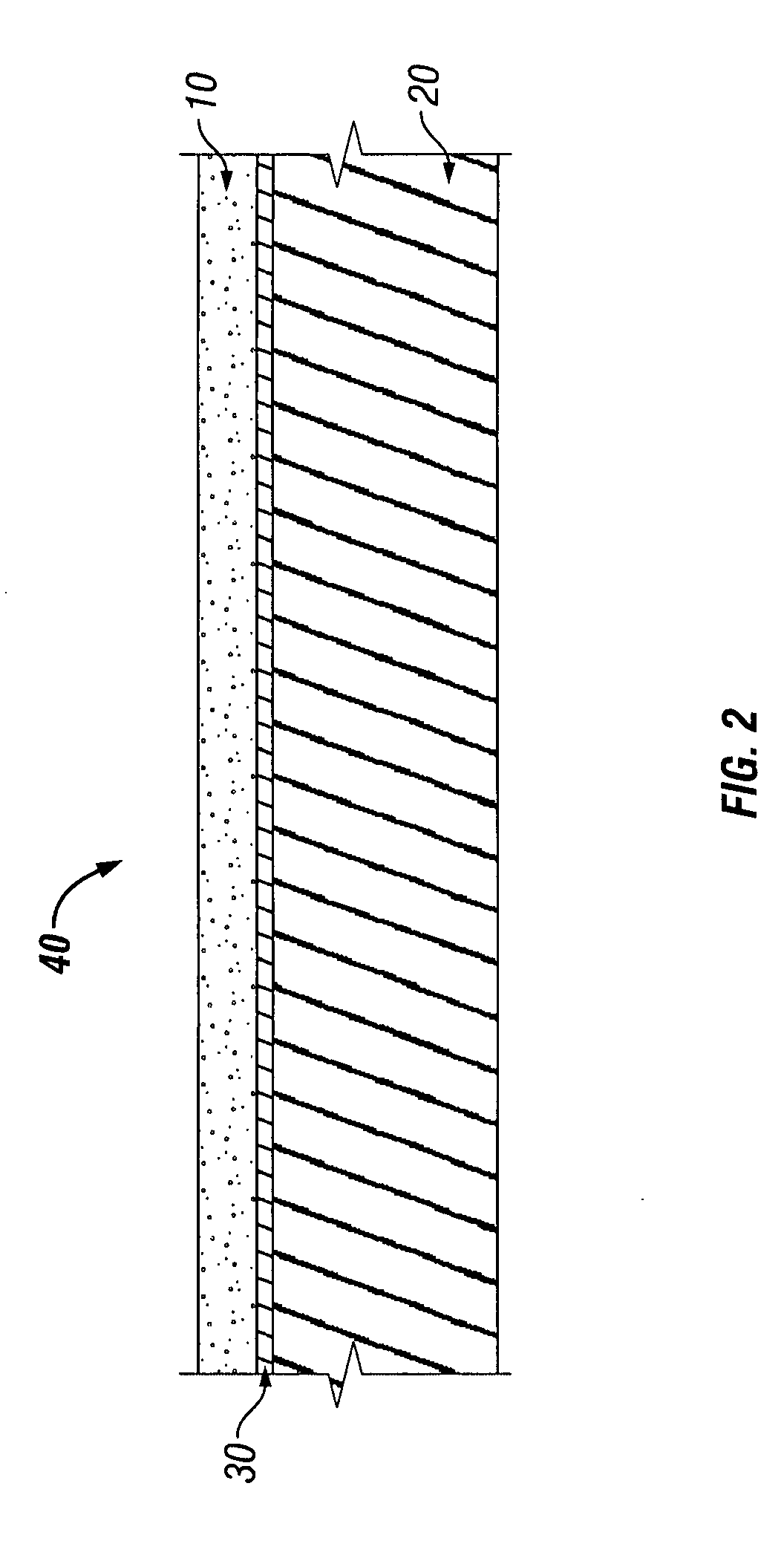

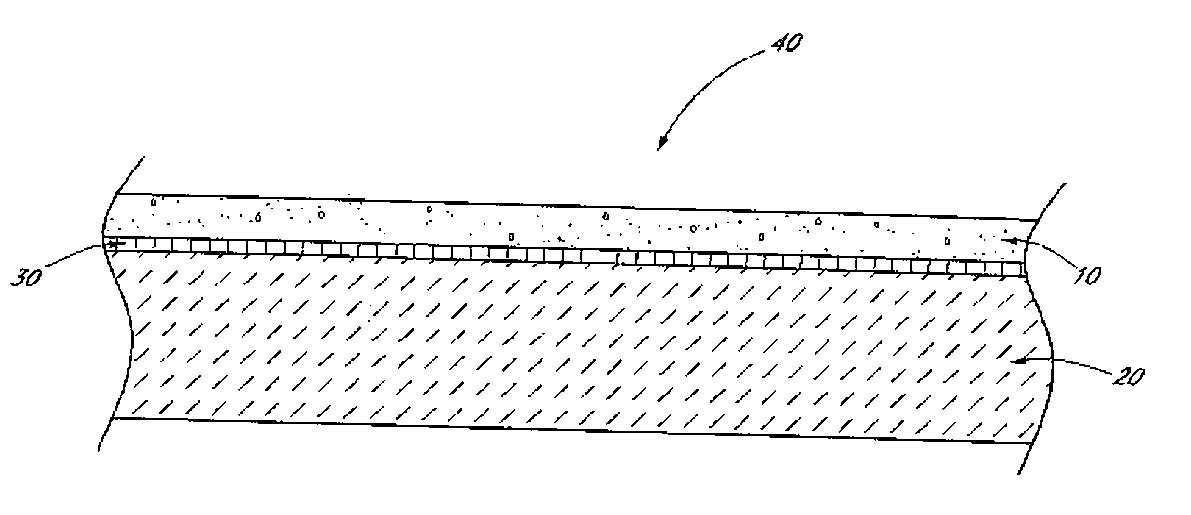

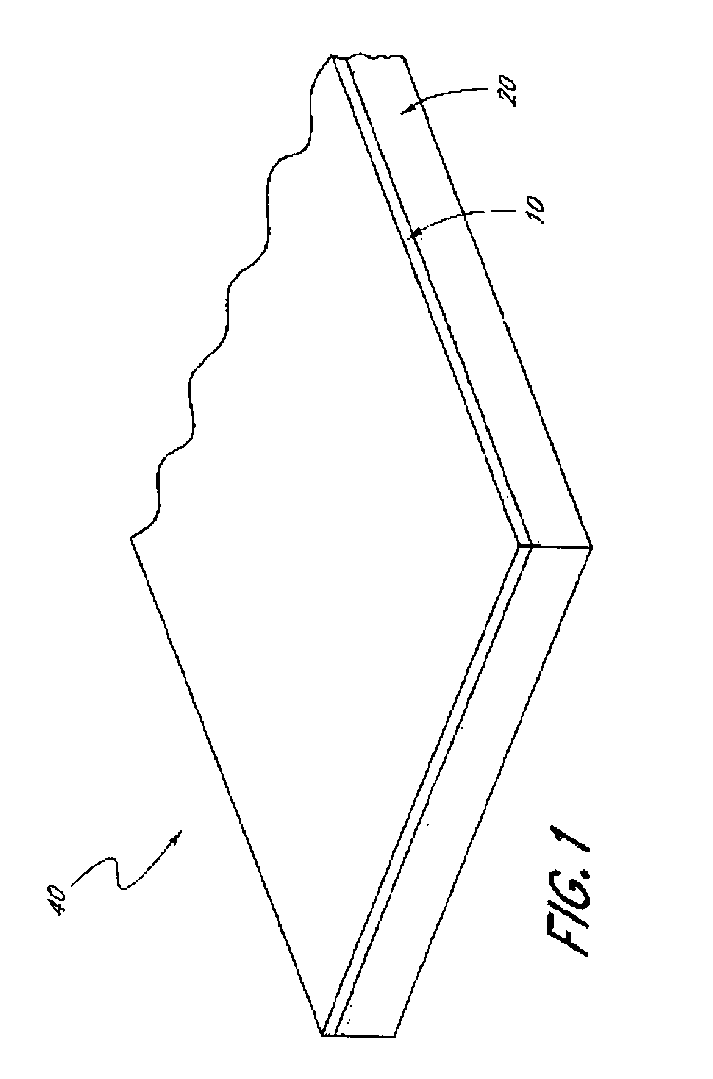

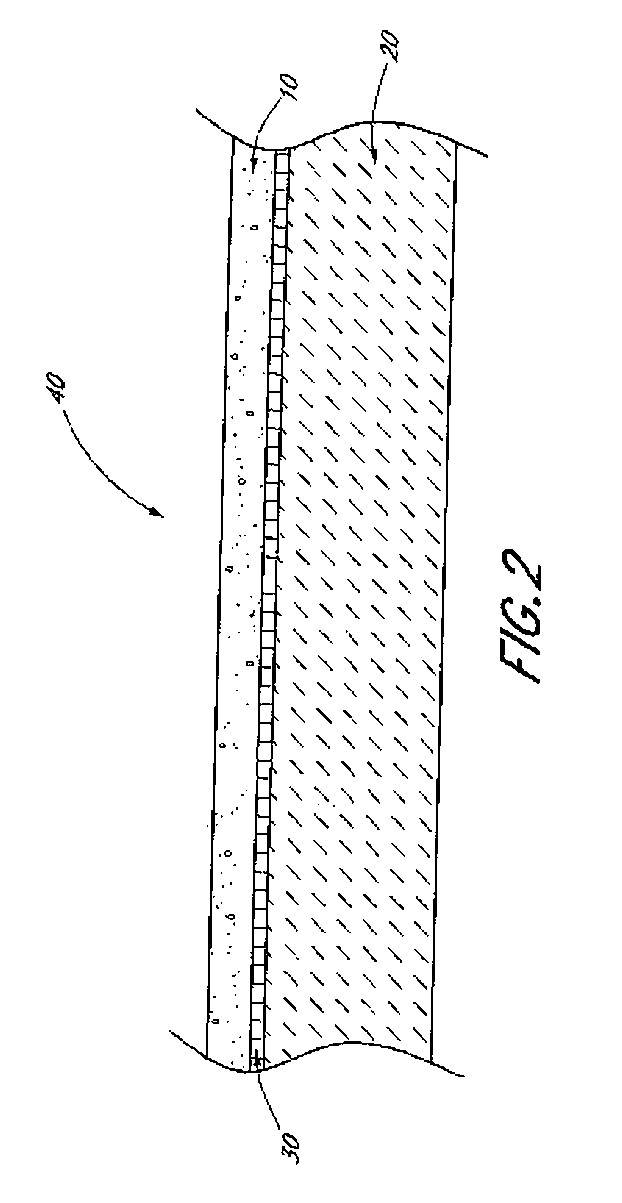

Fiber-cement/gypsum laminate

InactiveUS20080022627A1Increase resistanceEasy to manufactureConstruction materialCovering/liningsEngineeringExcessive weight

A building material (40) is provided comprising fiber-cement (10) laminated to gypsum (20) to form a single piece laminate composite. This single piece laminate composite exhibits improved fire resistance and surface abuse and impact resistance, but achieves these properties without the excessive weight and thickness of two piece systems. Additionally, because of the reduced thickness, the preferred laminate building material is easier to cut and is quicker and easier to install than two piece systems. Furthermore, forming the fiber-cement and gypsum into a single piece laminate eliminates the need to install two separate pieces of building material, thereby simplifying installation. In one embodiment, a ⅝″ thick laminate composite is provided comprising a ½″ thick gypsum panel laminated to a ⅛″ thick fiber-cement sheet, the laminate composite having a fire resistance rating of 1 hour when measured in accordance with ASTM E119.

Owner:JAMES HARDIE TECH LTD

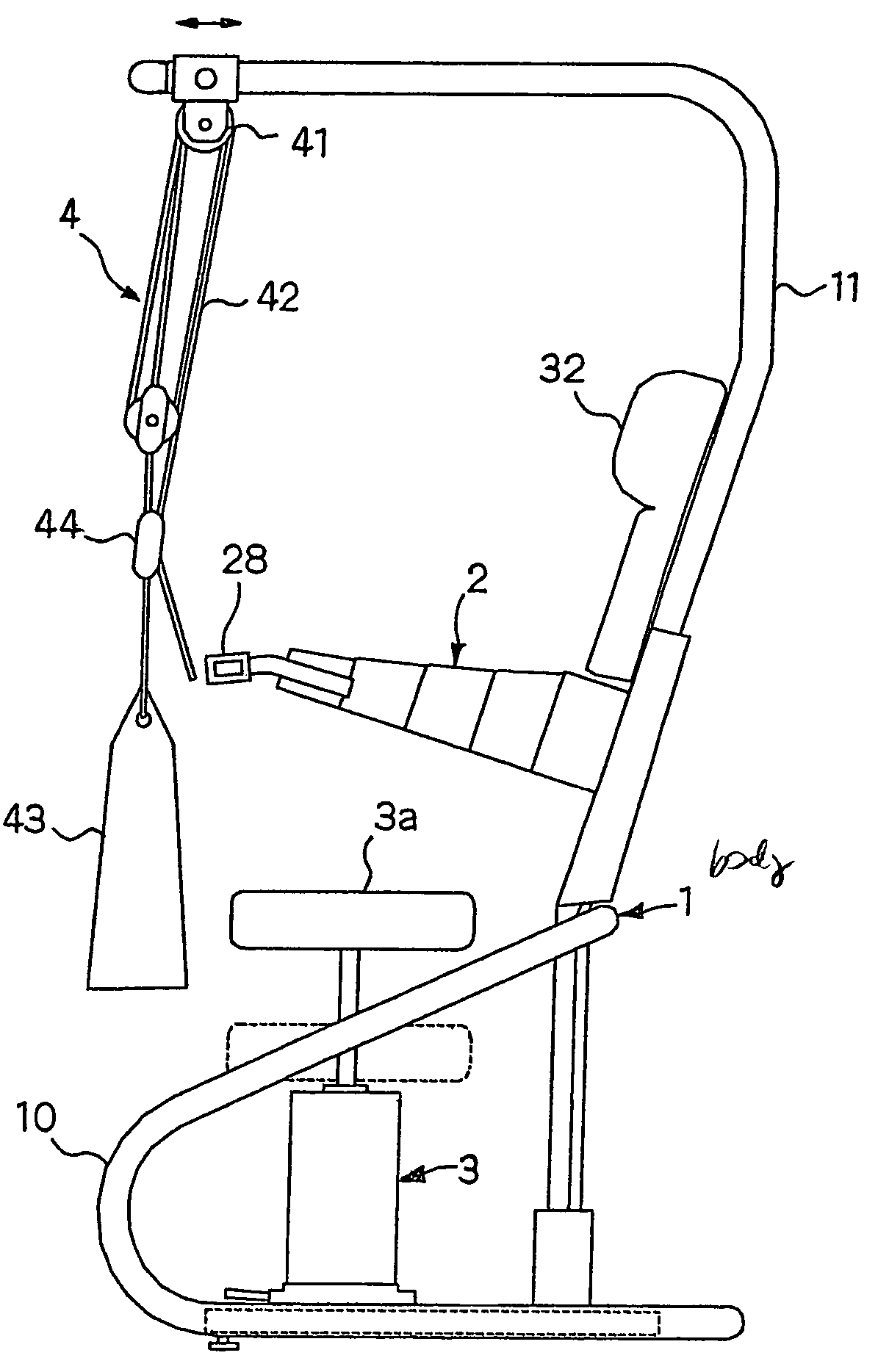

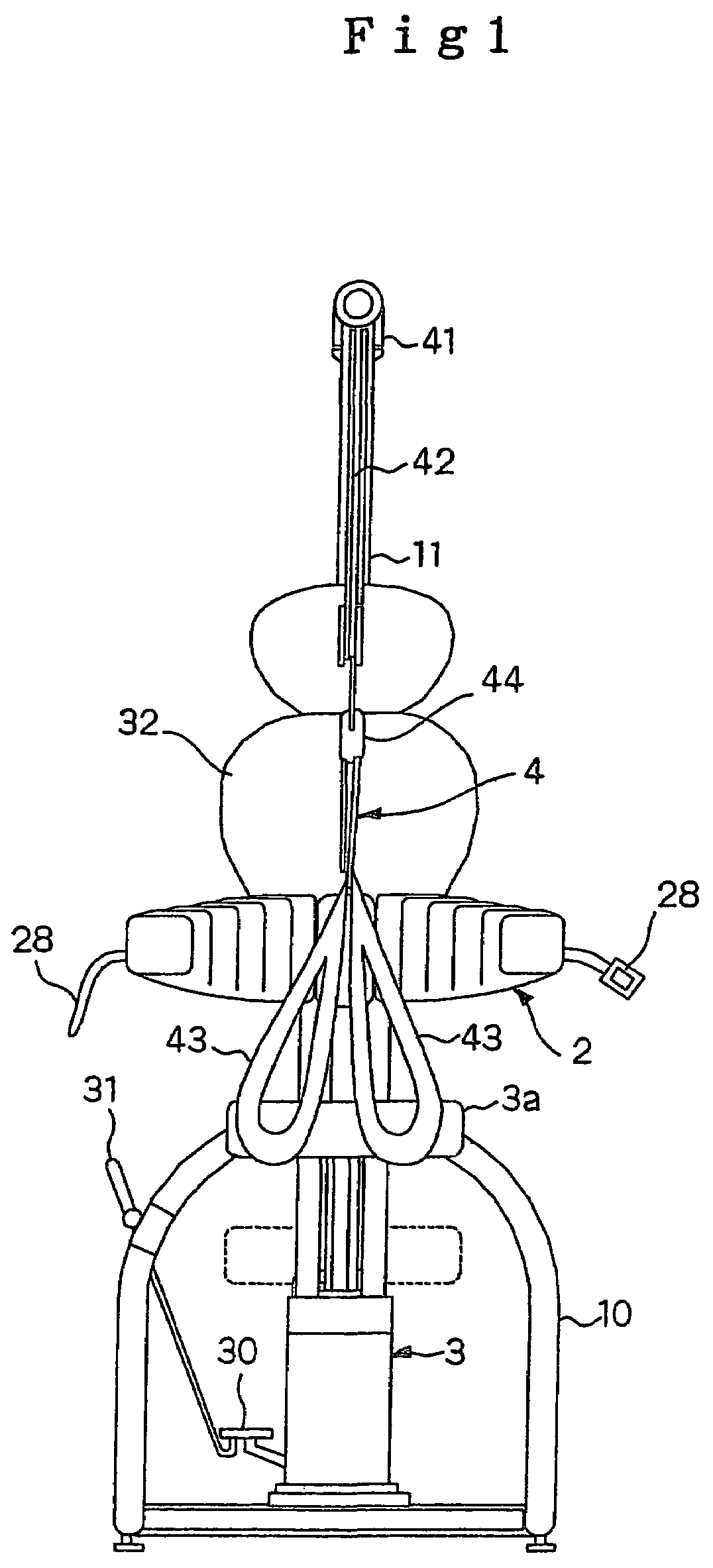

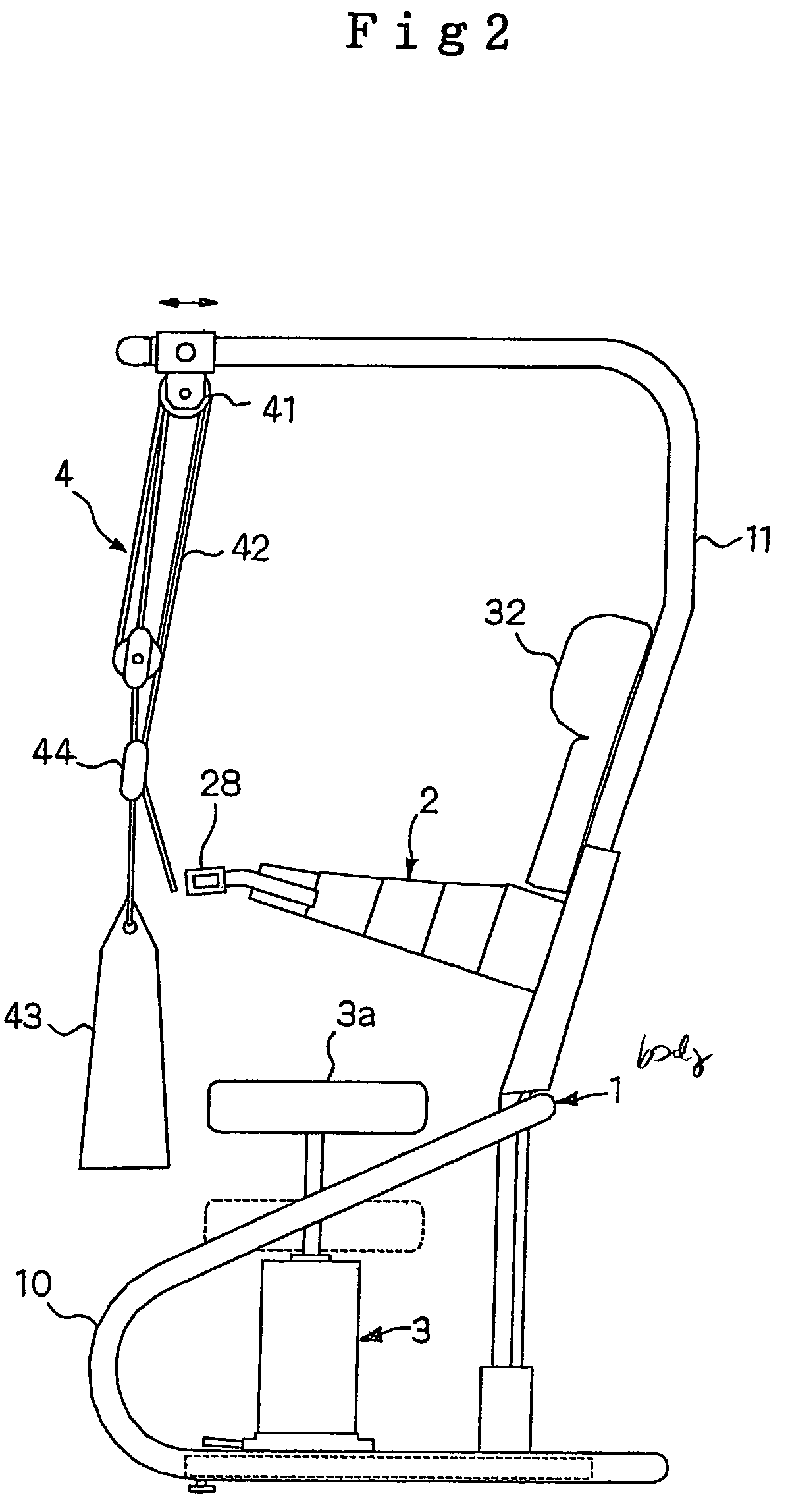

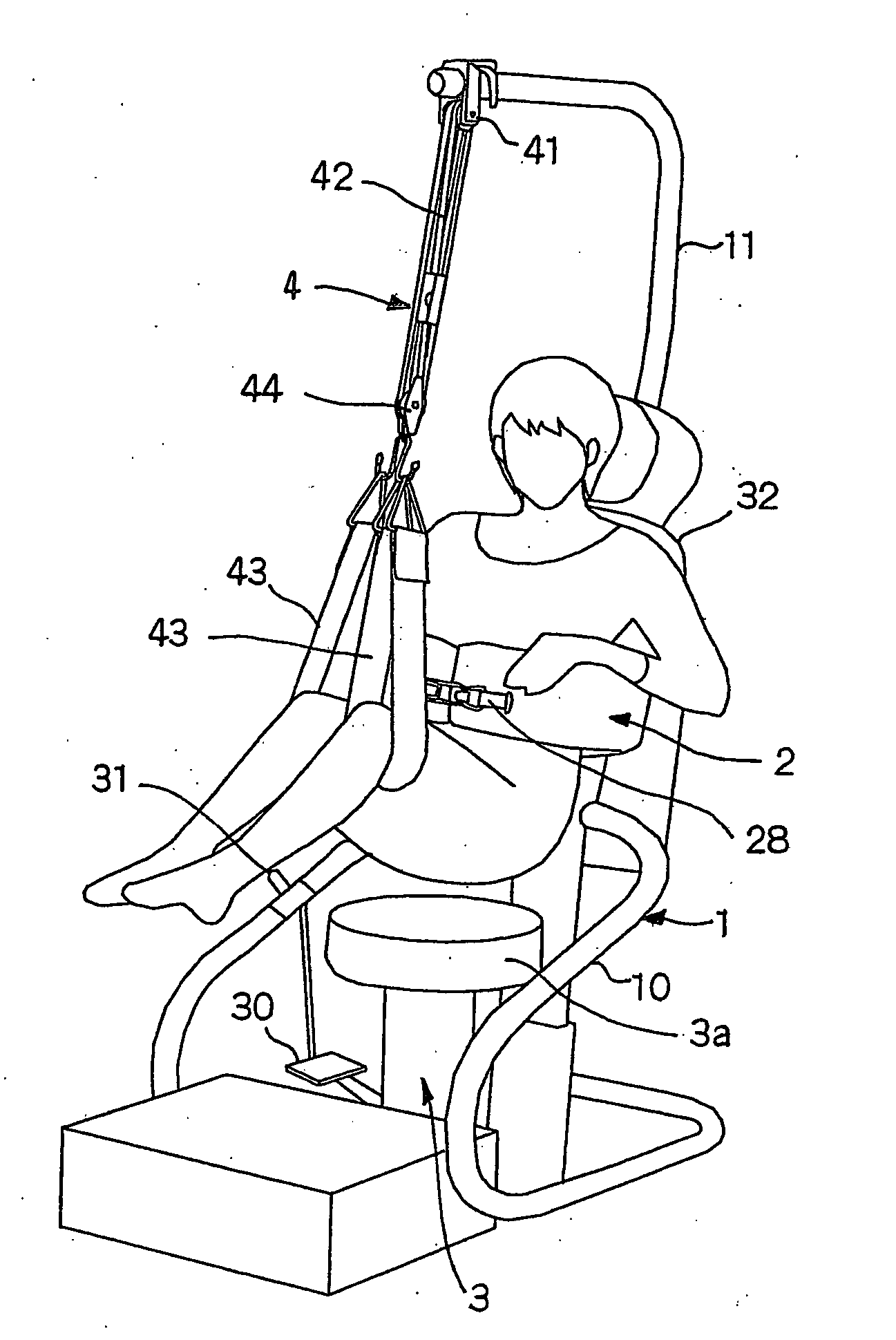

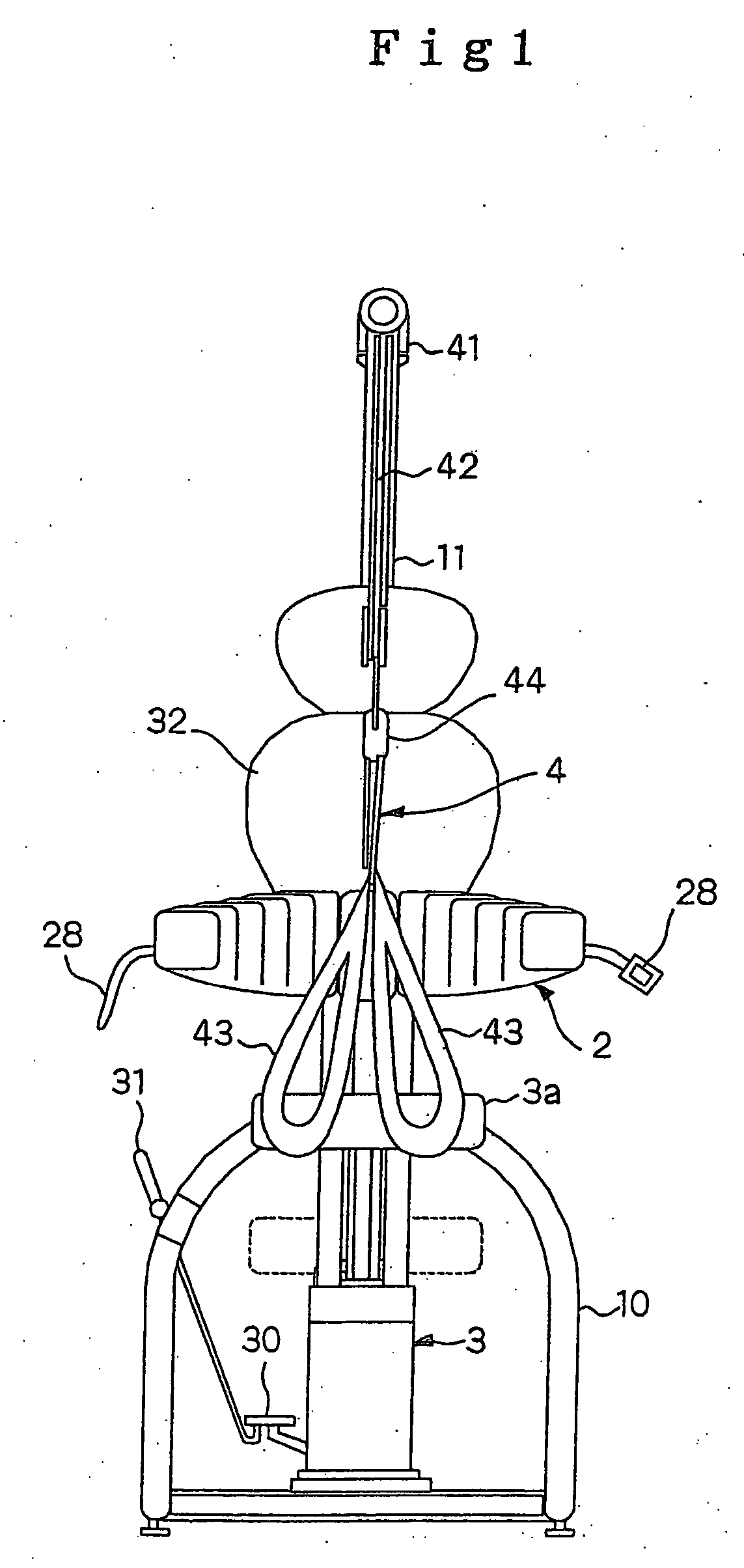

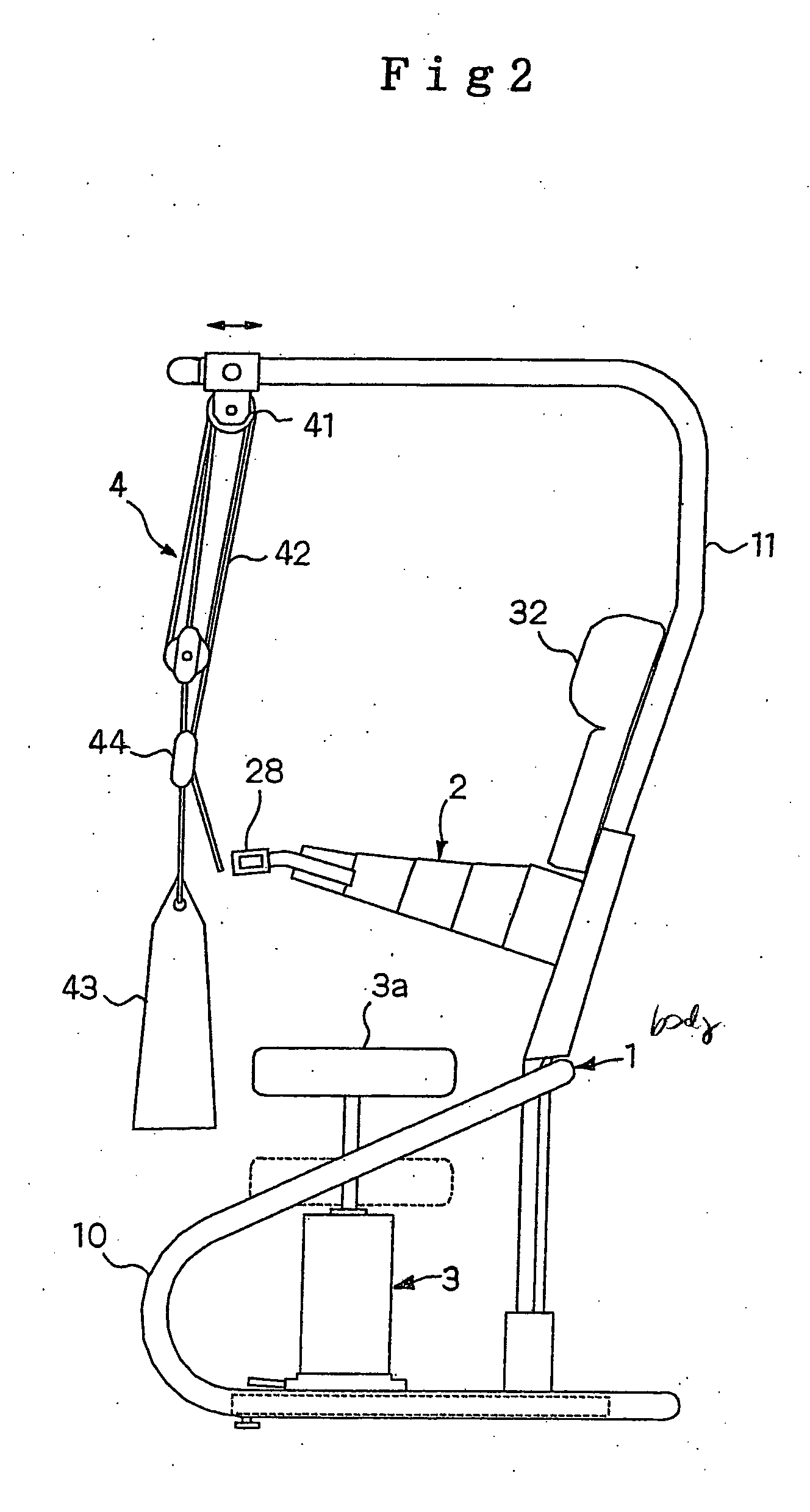

Health equipment

InactiveUS7510539B2Simple to executeFit tightlyChiropractic devicesNon-surgical orthopedic devicesHuman bodyPhysical medicine and rehabilitation

Health equipment for dragging the lumber with the trunk of the human body securely supported is provided. The trunk support 2 is bendable only inwardly, and holds and supports the trunk of the human body. Since the trunk support 2 is placed around the human body and enfolds from the area below the costae to above the pelvis, the human body is securely supported, whereby lumbago treatment can be carried out with the patient suspended in the air. Since the lumber is dragged with the weight of the lower part of the patient's body, there is no possibility that the lumber is dragged with the excessive weight. The leg hanging unit 4 is a device to hang the legs of the patient. By using this leg hanging unit 4, so called mobilization may be carried out with the lower back portion suspended in the air, thereby increasing effectiveness of lumbago treatment.

Owner:PROTEK KO

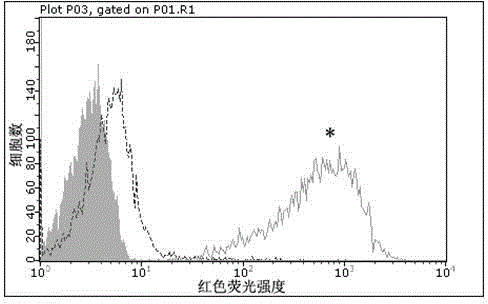

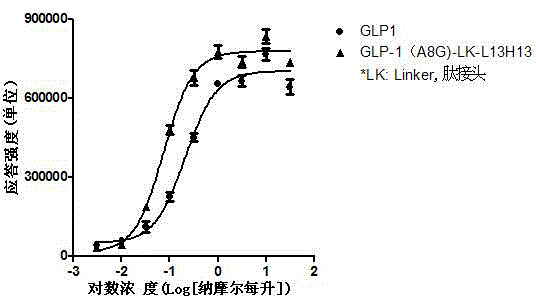

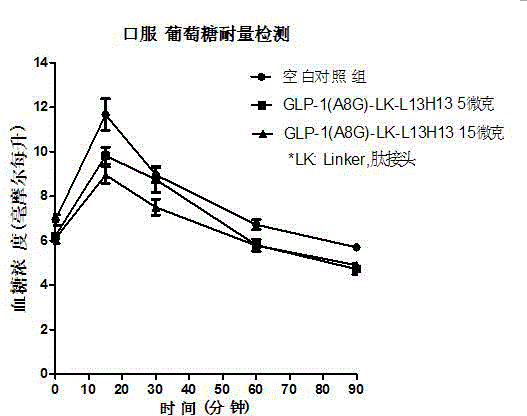

Antibody capable of being specifically combined with GLP-1R and fusion protein of antibody and GLP-1

ActiveCN104371019AProlong half-life in vivoRetain molecular biological activityPeptide/protein ingredientsAntibody mimetics/scaffoldsDiabetes mellitusAntiendomysial antibodies

Disclosed in the present invention is an antibody specifically binding to GLP-1R and a fusion protein thereof with GLP-1. The fusion proteins can effectively bind to a human GLP-1R receptor and activate a receptor signalling channel, thus are useful for treating diabetes, excessive weight, obesity and related disorders thereof.

Owner:GMAX BIOPHARM

Bird feeder

ActiveUS20080295777A1Eliminate useFunctional disturbancePisciculture and aquariaAvicultureBird feederEngineering

A squirrel resistant bird feeder having a seed container, a seed tray mounted below the seed container, a shroud extending about the seed member and seed tray, the shroud having openings in a lower portion thereof, with a spring member mounted internally of the seed container and being enclosed by a central tube, the spring member having a first end thereof abutting a portion of the seed tray and a second end acting on the cover and shroud. Any excessive weight placed on the shroud or cover will cause the shroud to move downwardly covering the seed tray.

Owner:BROME BIRD CARE

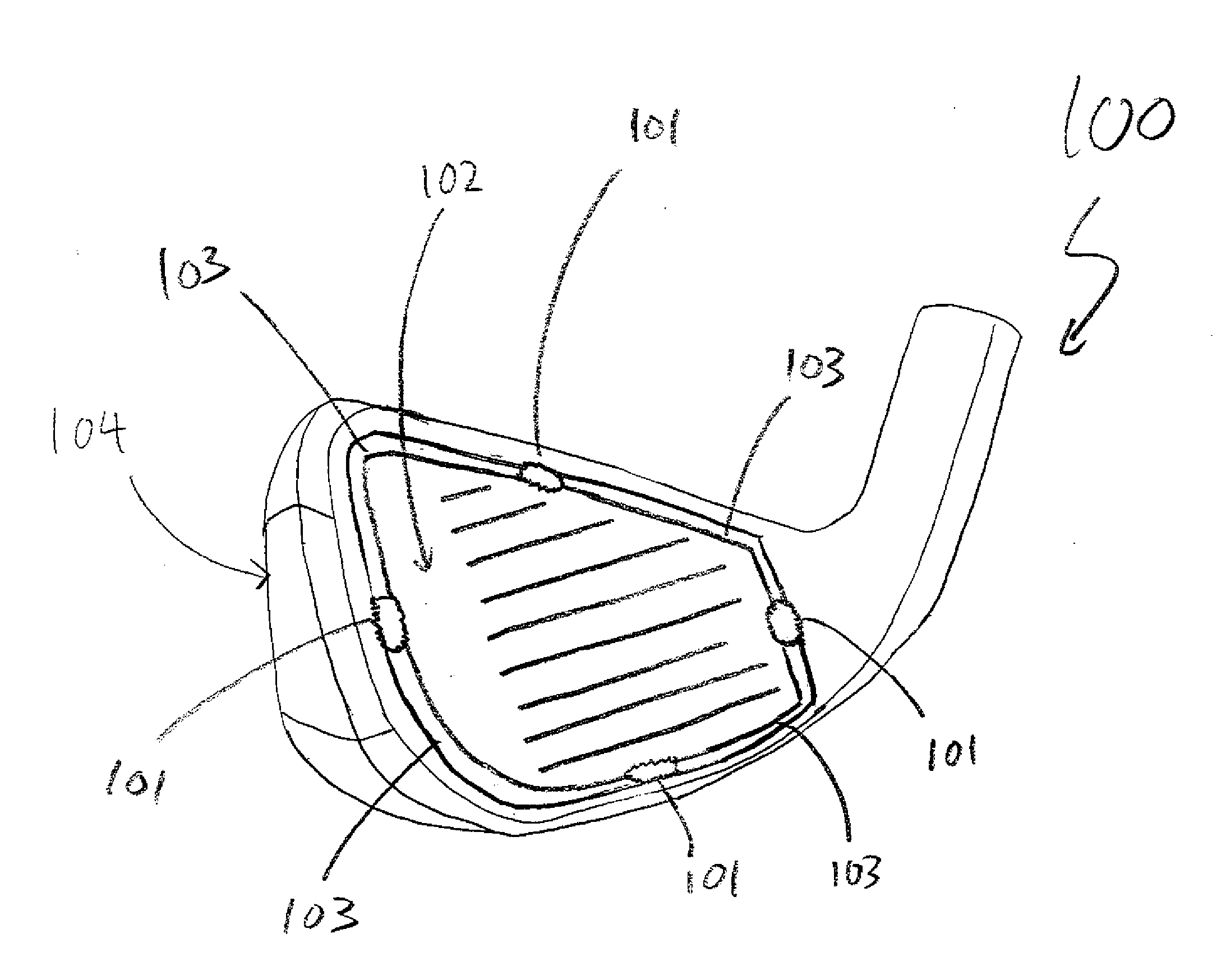

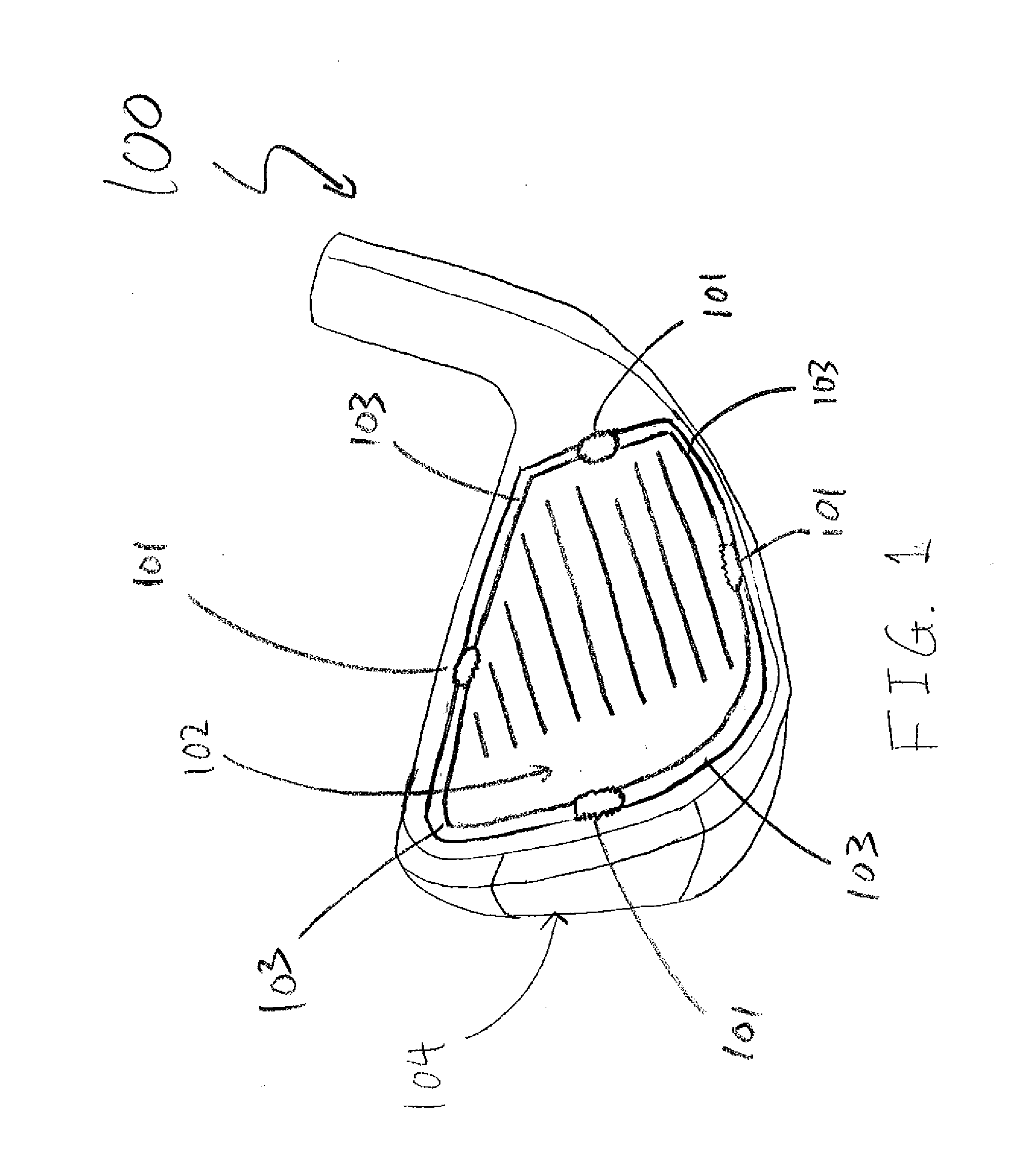

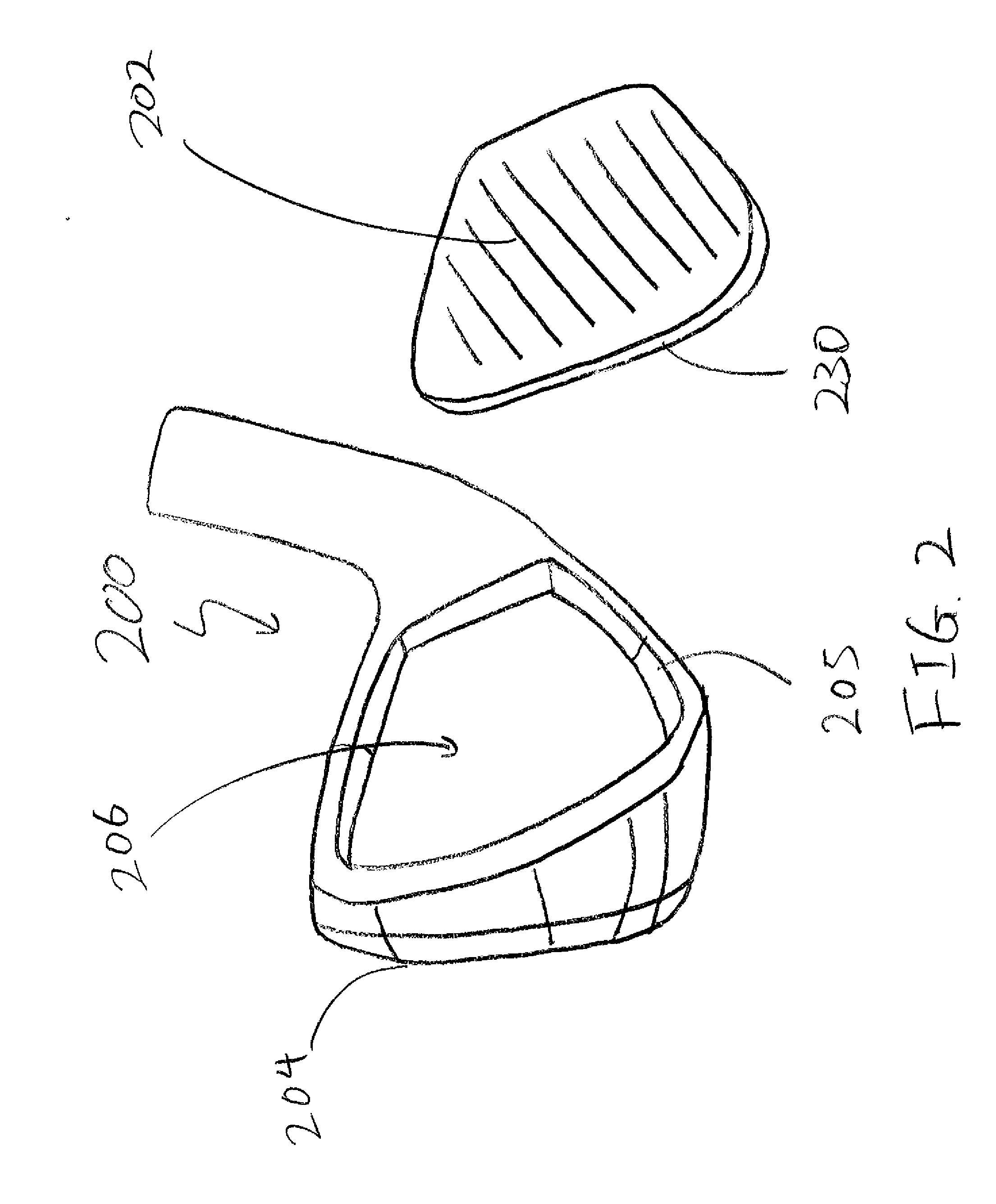

Golf club head with face insert

A golf club head with a face insert that is only partially connected to the body of the golf club head is disclosed herein. More specifically, the present invention discloses a golf club head with a face insert wherein the face insert is only connected to the body of the golf club head at specific engagement portions around the perimeter of the face insert while keeping the remainder of the perimeter unengaged. The golf club head disclosed in accordance with the present invention will allow for removal of excessive weight traditionally needed to connect the face insert to the body of the golf club head, therefore improving the performance of the golf club head.

Owner:COBRA GOLF

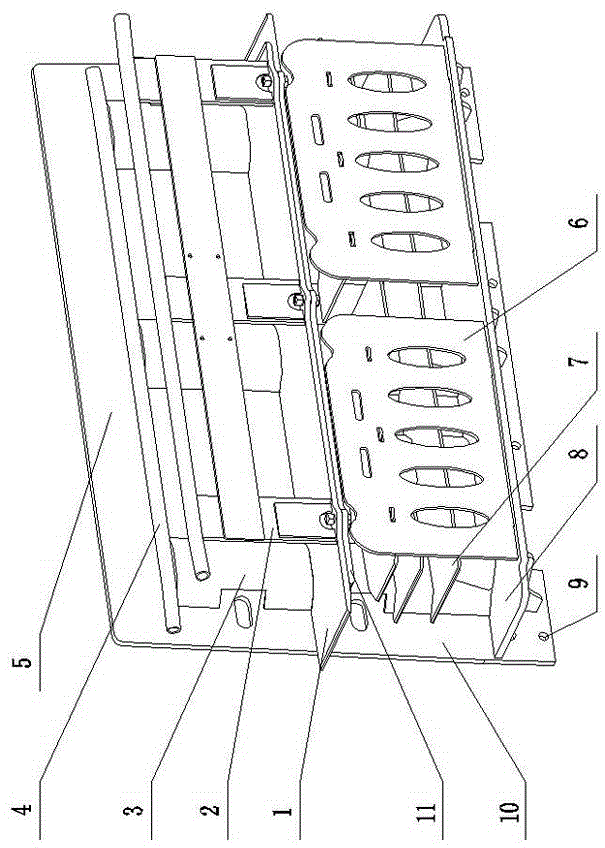

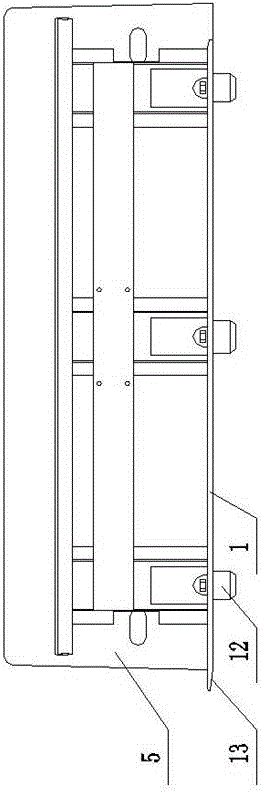

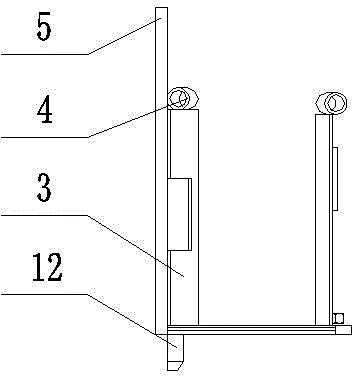

Split cable trough of scraper conveyer

InactiveCN104617531AOvercome maintenance inconvenience and other related problemsEasy maintenanceElectrical apparatusStructural engineeringExcessive weight

A split cable trough of a scraper conveyer comprises a cable trough upper trough body and a cable trough lower trough body, wherein the cable trough upper trough body is a U-shaped trough body consisting of an upper outer side vertical plate, an upper inner side baffle and an upper supporting plate. The cable trough lower trough body comprises a lower top plate and a lower supporting plate, wherein a lower vertical plate is arranged between the lower top plate and the lower supporting plate right under the upper outer side vertical plate, and a rear cover plate is arranged between the lower top plate and a lower supporting plate under the upper inner side baffle. The problems including too large size of the single cable trough, excessive weight, inconvenient transportation and installation, inconvenient overhaul of a coal mining machine and other relevant problems of the heavy-duty extra-heavy-type scraper conveyer are solved by utilizing the cable trough upper trough body and the cable trough lower trough body forming a vertical split structure, the cable trough lower trough body is assembled on a mine well, the cable trough upper trough body is assembled underground, the problems of transportation size and excessive weight of a single are solved, and assembling efficiency and safety are further improved. In addition, overhaul of any position of the coal mining machine is also greatly facilitated.

Owner:LIANYUNGANG TIANMING EQUIP

Hanging device

An alignment device or jig that includes a level and a rule which is used for hanging wall supported items. The device includes locator blocks with locator pins for supporting the item and stud finder sensors for locating wall studs. The locator pins extend to protrude from the back side of the jig to allow a mark to be made into the hanging surface when the jig is pressed against the hanging surface. In the event that the item requires a stronger surface to hang onto due to excessive weight, a stud finder system can be utilized. In operation, one or more of picture frames to be mounted to a wall are hung on the device on one or more hangers. The hangers are slidingly spaced along the device scale for desired picture spacing. The device with the frames is placed against the wall and pressed to the wall, wherein the marking points mark the wall at the exact desired points where permanent hangers will be driven into the wall to support the one or more picture frames.

Owner:DANIEL ROBERTO R

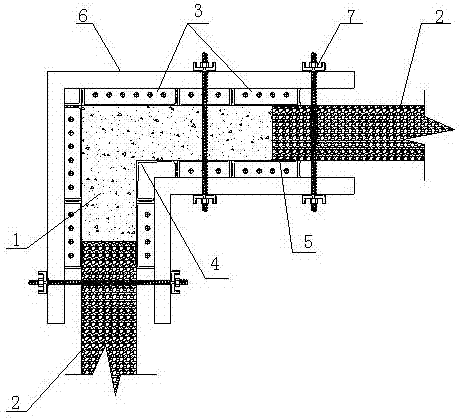

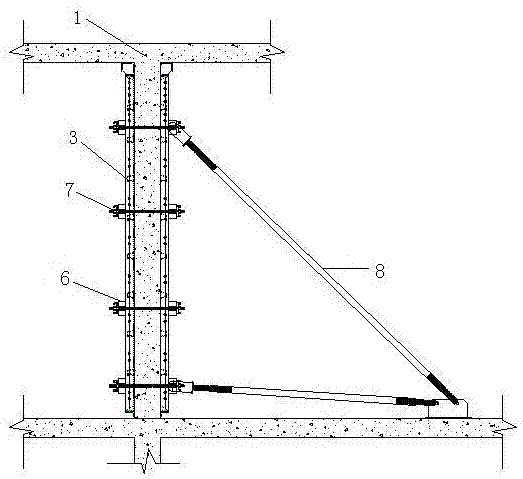

Construction method for combined aluminum alloy template applied to assembly type precast concrete structure

InactiveCN107130791ASolve the installationSolve the difficulty of dismantlingForming/stuttering elementsDecompositionExcessive weight

The invention relates to a construction method for a combined aluminum alloy template applied to an assembly type precast concrete structure. The method comprises the following steps of precasting an aluminum alloy template component, manufacturing a precast concrete component, measuring and despooling, hoisting and installing, pouring overall, and disassembling a mold; when precasting the precast concrete component, ensuring the cross-pulling threaded rod hole site of the precast concrete component and the cross-pulling threaded rod hole site of the aluminum alloy template are identical; during installation, using cross-pulling threaded rods to penetrate directly, utilizing strict command reinforcement to ensure an existing poured wall body is closely connected with a precast wall body; after completing installation of all precast concrete components and the aluminum alloy template, starting concrete pouring, and realizing one-time pouring and molding of a wall column, a beam and a plate by using the aluminum alloy template. By the construction method, the problems that in the construction of a precast concrete structure, the template at an on-site pouring position is difficult to assemble and disassemble, grout runs away or is leaked, safe and civilized construction is poor, the construction efficiency is influenced due to excessive weight and the construction quality is influenced due to deformation and decomposition are solved; the repeated use rate is high; the universality is strong; and the quality and effect are relatively good.

Owner:22MCC GRP PRECISION FORGING

Health equipment

InactiveUS20050020954A1Recovery of muscular strengthSimple to executeChiropractic devicesTherapy exerciseHuman bodyPhysical therapy

Health equipment for dragging the lumber with the trunk of the human body securely supported is provided. The trunk support 2 is bendable only inwardly, and holds and supports the trunk of the human body. Since the trunk support 2 is placed around the human body and enfolds from the area below the costae to above the pelvis, the human body is securely supported, whereby lumbago treatment can be carried out with the patient suspended in the air. Since the lumber is dragged with the weight of the lower part of the patient's body, there is no possibility that the lumber is dragged with the excessive weight. The leg hanging unit 4 is a device to hang the legs of the patient. By using this leg hanging unit 4, so called mobilization may be carried out with the lower back portion suspended in the air, thereby increasing effectiveness of lumbago treatment.

Owner:PROTEK KO

Fiber-cement/gypsum laminate composite building material

InactiveUS20050262799A1Good abuse resistanceImprove fire resistanceConstruction materialSolid waste managementCement boardExcessive weight

Abstract of the DisclosureA building material (40) is provided comprising fiber-cement (10) laminated to gypsum (20) to form a single piece laminate composite. This single piece laminate composite exhibits improved fire resistance and surface abuse and impact resistance, but achieves these properties without the excessive weight and thickness of two piece systems. Additionally, because of the reduced thickness, the preferred laminate building material is easier to cut and is quicker and easier to install than two piece systems. Furthermore, forming the fiber-cement and gypsum into a single piece laminate eliminates the need to install two separate pieces of building material, thereby simplifying installation. In one embodiment, a 5 / 8” thick laminate composite is provided comprising a ½” thick gypsum panel laminated to a 1 / 8” thick fiber-cement sheet, the laminate composite having a fire resistance rating of 1 hour when measured in accordance with ASTM E119.

Owner:JAMES HARDIE FINANCE

Bird feeder

InactiveUS20100258055A1Eliminate useFunctional disturbancePisciculture and aquariaAvicultureBird feederEngineering

A squirrel resistant bird feeder having a seed container, a seed tray mounted below the seed container, a shroud extending about the seed member and seed tray, the shroud having openings in a lower portion thereof, with a spring member mounted internally of the seed container and being enclosed by a central tube, the spring member having a first end thereof abutting a portion of the seed tray and a second end acting on the cover and shroud. Any excessive weight placed on the shroud or cover will cause the shroud to move downwardly covering the seed tray.

Owner:COTE PAUL

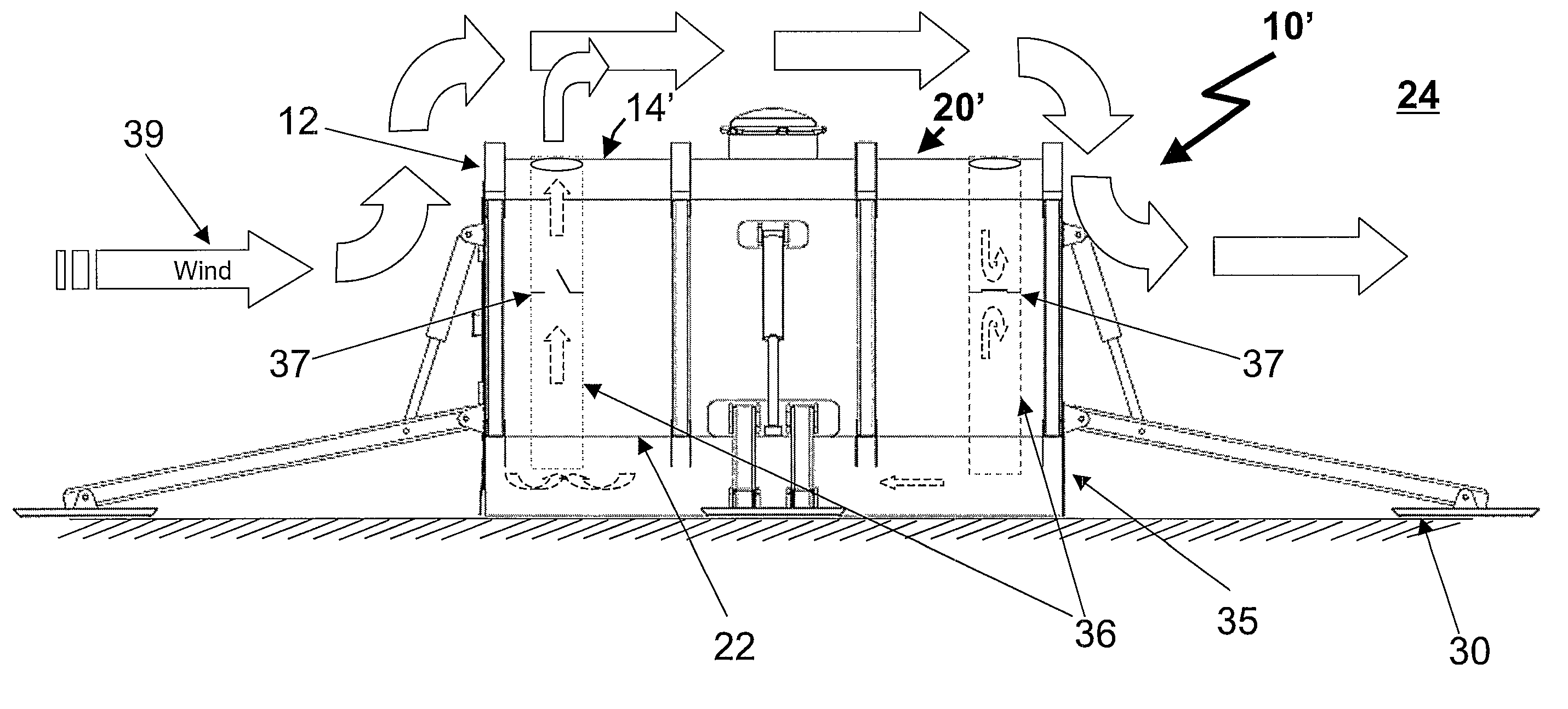

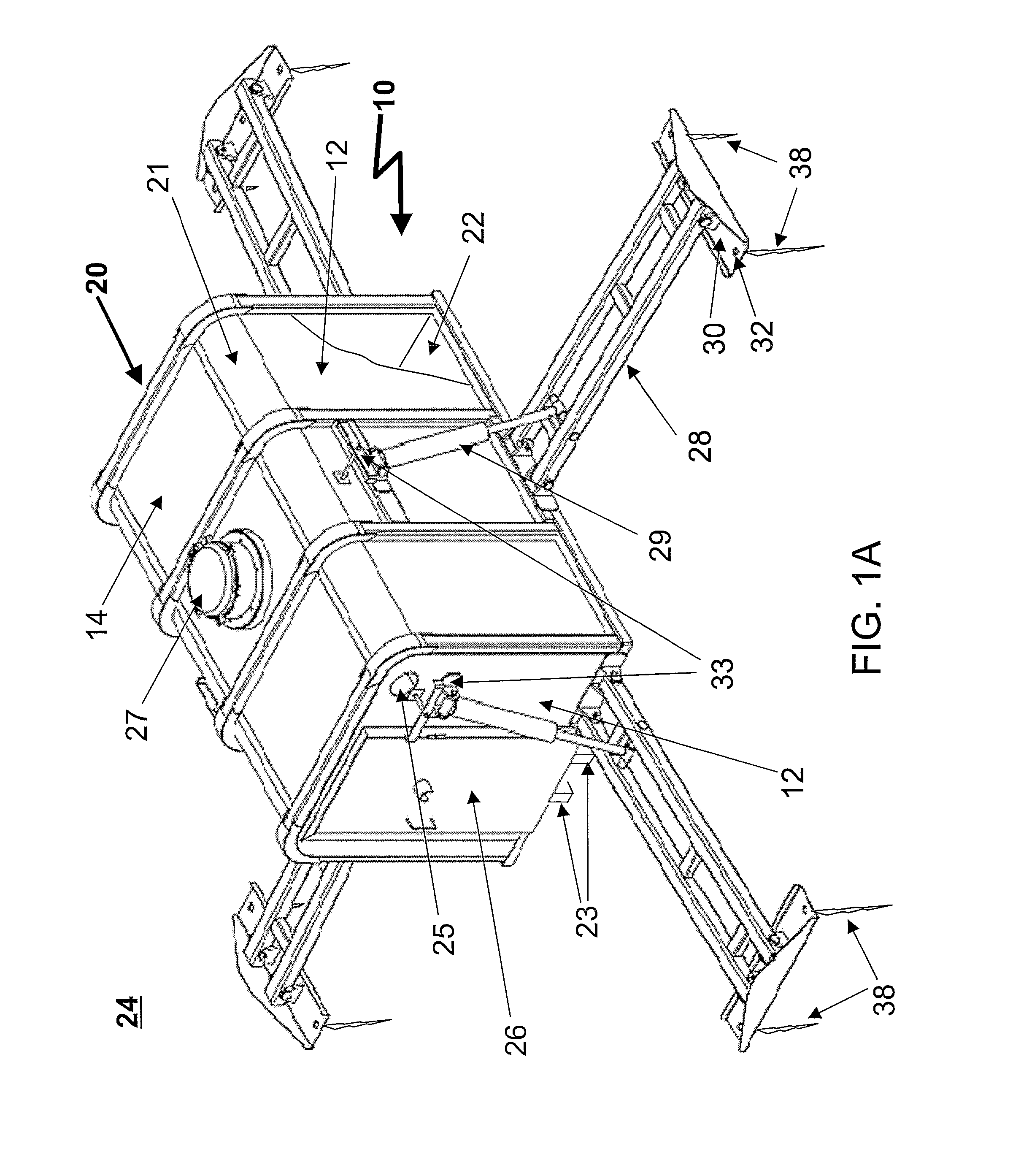

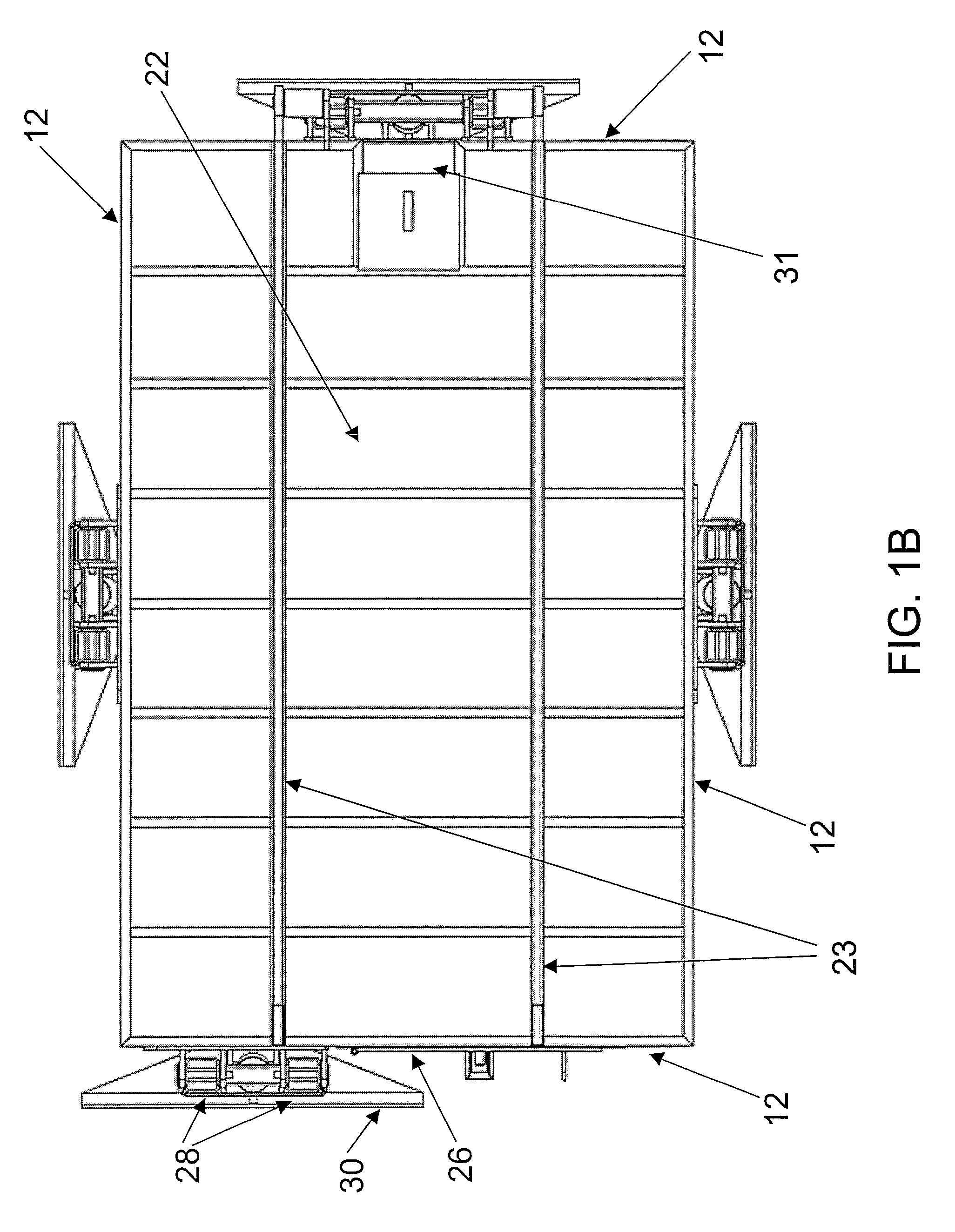

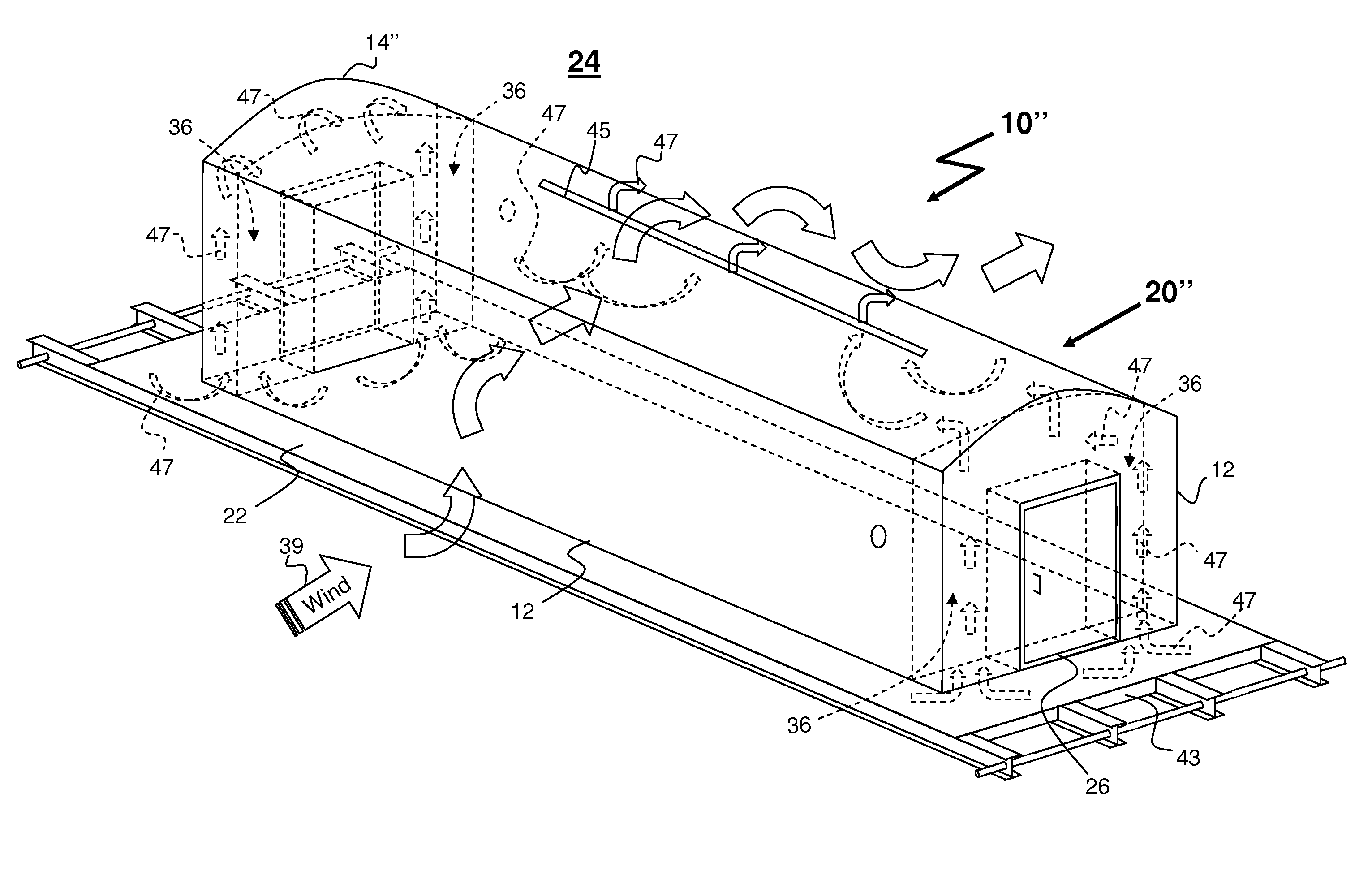

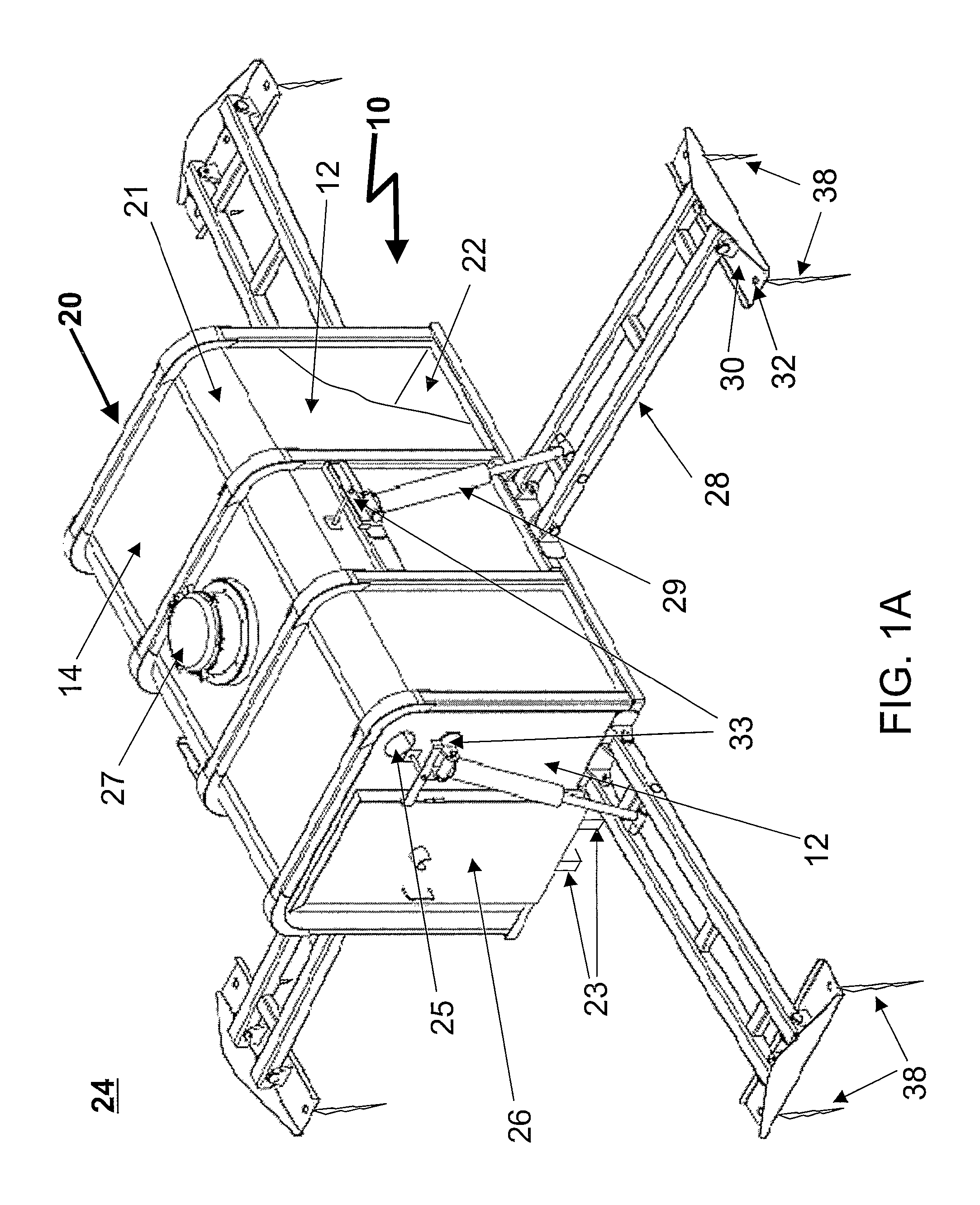

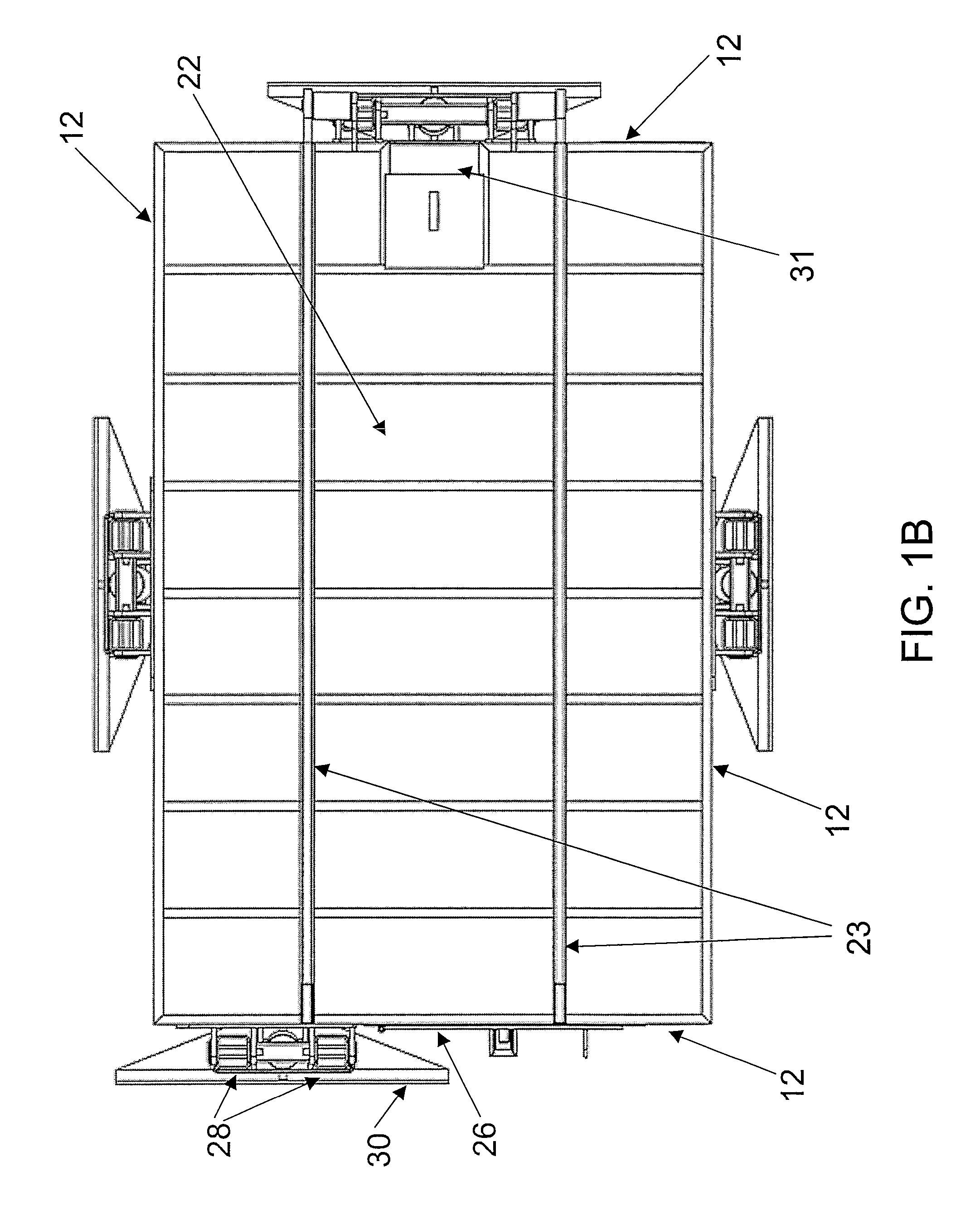

Re-deployable above ground shelter

ActiveUS8136303B2Quickly and easily and inexpensivelyHuman health protectionProtective buildings/sheltersAbove groundEngineering

Work crews temporarily operating in remote areas can be subject to dangers such as tornadoes, hurricanes and explosive blast waves. A re-deployable aboveground protective shelter suitable for use in such environments utilizes retractable stabilizing arms and / or passive valved ductwork to resist uplift, overturning and sliding. Because the protective shelter does not rely upon excessive weight to counter wind forces, the protective shelter can be quickly, easily and inexpensively redeployed to new sites.

Owner:RED DOG MOBILE SHELTERS LLC DELAWARE

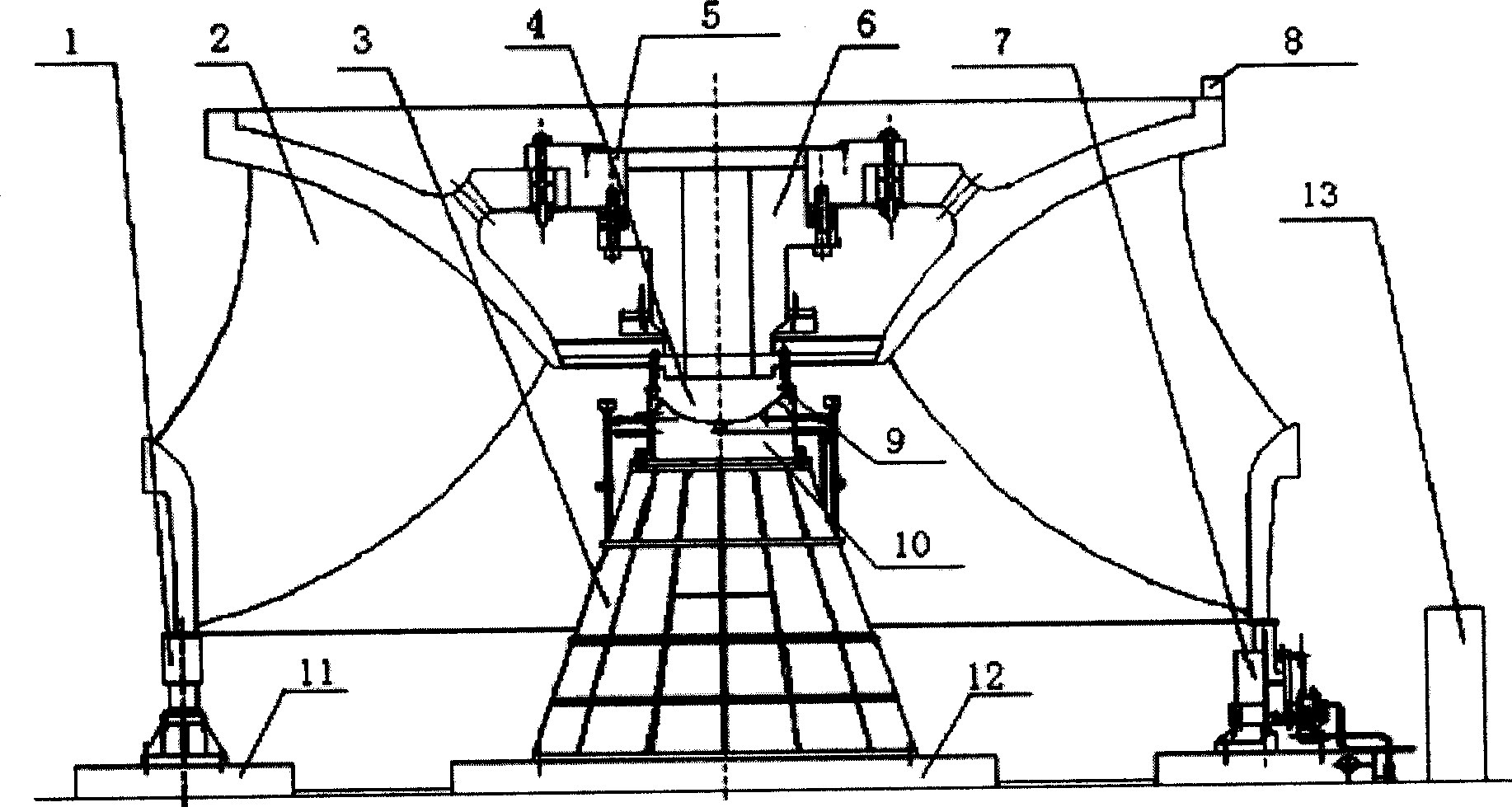

Rotor static pressure bearing balance technique for large mixed-flow turbine

InactiveCN101482443AHigh quality and precisionIncreased load-bearing capacityStatic/dynamic balance measurementMixed flowWater turbine

The invention relates to a rotating wheel static pressure bearing balance process used in large-scale mixed-flow water turbine. By injecting high pressure oil membrane between the sliding surface of ball and ball cup in the static pressure bearing balance tool all the time for jacking the rotating wheel weight, the invention achieves the friction coefficient between oil membranes far less than that between the steel ball and the rotating plate; solves the problem that the certain deformations of the balance ball and the rotating plate caused by excessive weight of the rotating wheel influence the static balance precision of the large-scale rotating wheel, and achieves the advantages of high mass precision and strong bearing capability, is suitable for the static balance of large scale rotating wheel.

Owner:HARBIN ELECTRIC MASCH CO LTD

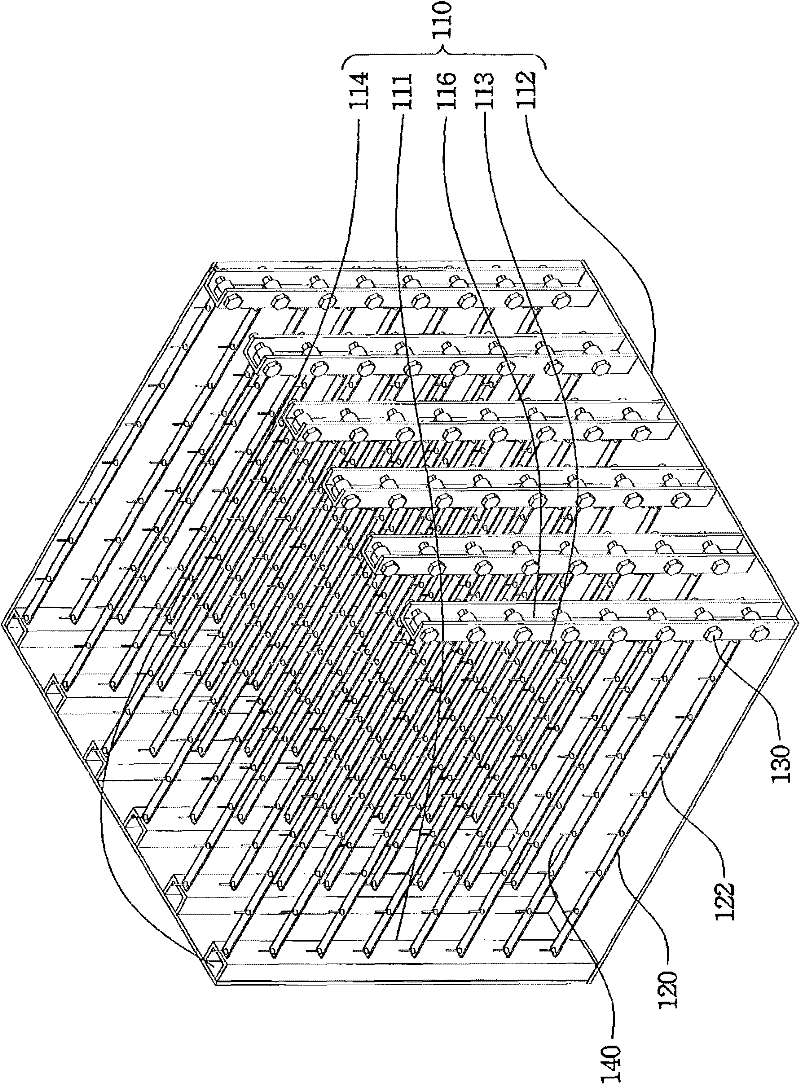

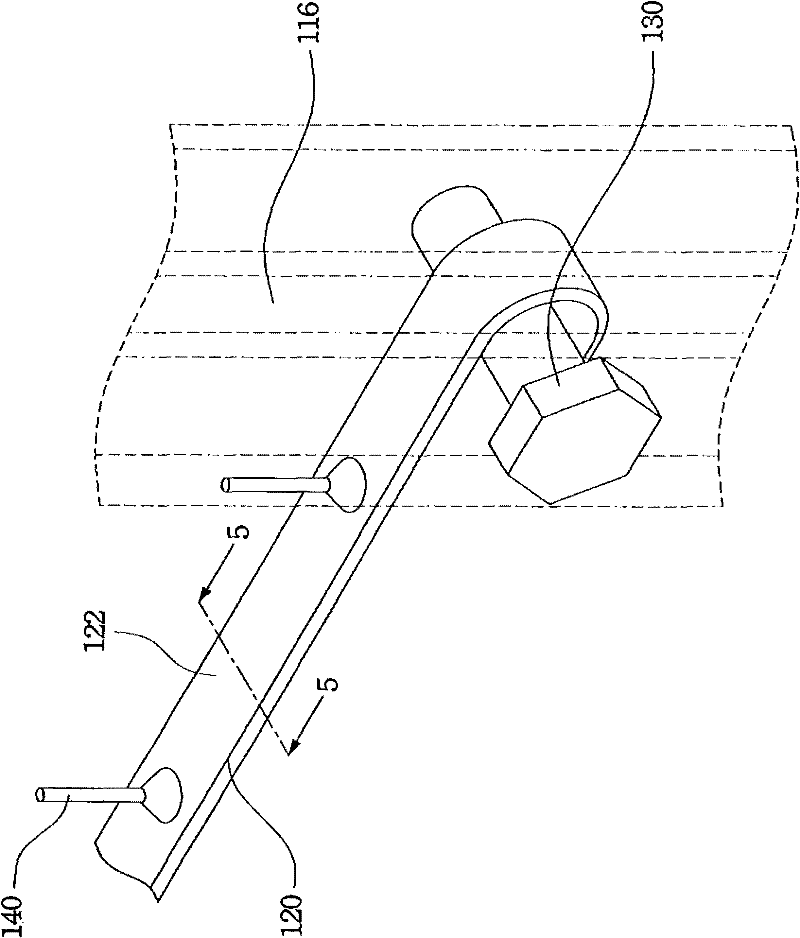

Cartridge

The invention provides a cartridge, comprising a frame, a stretching tape, a tension mechanism, and a plurality of supporting columns. The frame comprises a first side and a second side opposite to each other. The stretching tape transverses the first side and the second side of the frame. The tension mechanism is disposed at the second side of the frame, and provides a pull force to the stretching tape, making the stretching tape be straight. The supporting columns are arranged at the upper surface of the stretching tape. The cartridge, via use of a mechanical arm to place or take out a glass substrate, prevents deformation of the stretching tape caused by excessive weight of the glass substrate.

Owner:AU OPTRONICS CORP

Re-deployable mobile above ground shelter

ActiveUS8245450B2Quickly and easily and inexpensivelyHuman health protectionProtective buildings/sheltersAbove groundAtlantic hurricane

Work crews temporarily operating in remote areas can be subject to dangers such as tornados, hurricanes and explosive blast waves. A re-deployable mobile aboveground protective shelter suitable for use in such environments utilizes retractable stabilizing arms and / or structures that leverage air pressure differential to resist uplift, overturning and sliding. Because the protective shelter does not rely exclusively upon excessive weight to counter wind forces, the protective shelter can be quickly, easily and inexpensively redeployed to new sites.

Owner:RED DOG MOBILE SHELTERS LLC DELAWARE

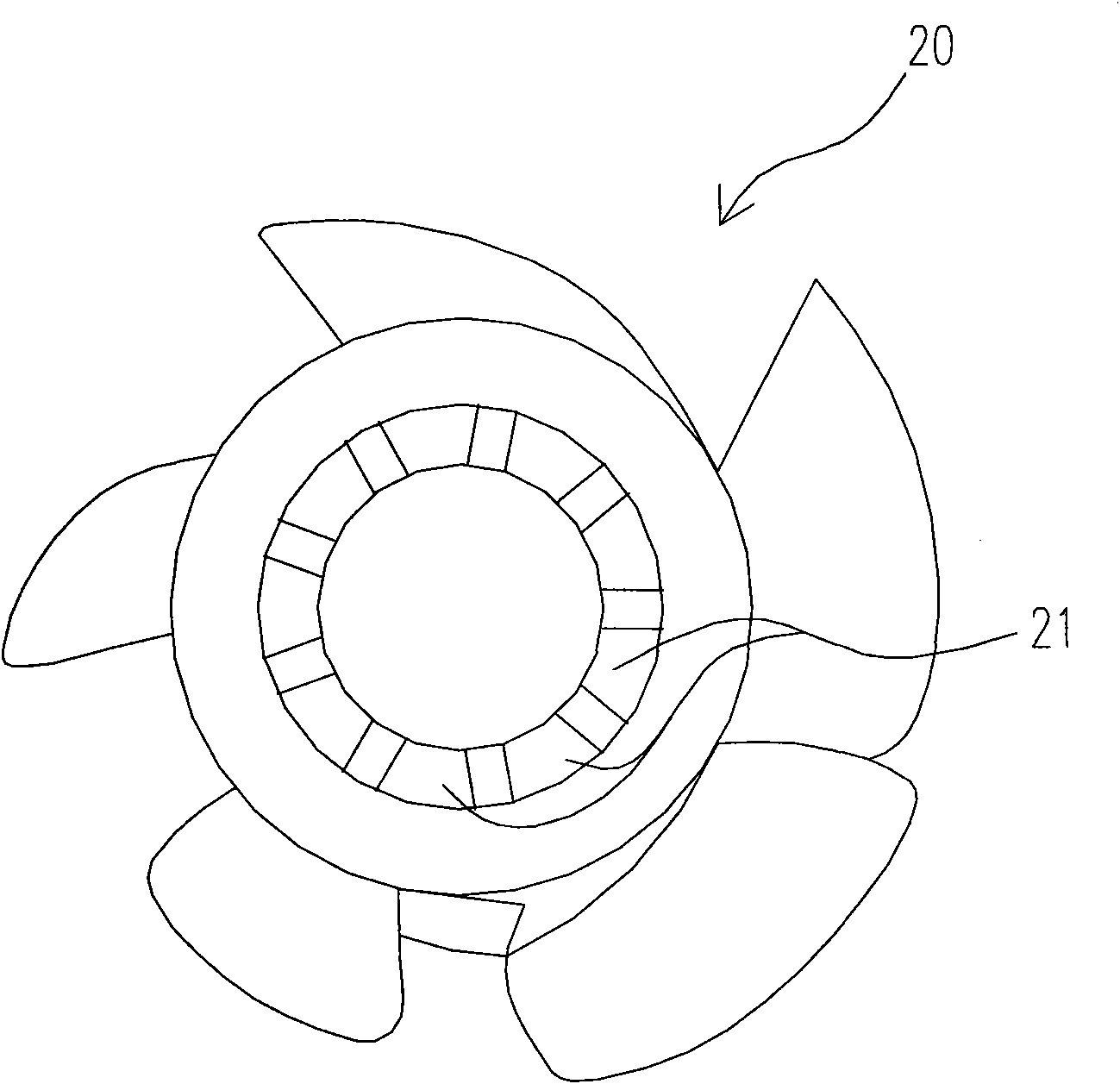

Balancing method and processing method of fan

InactiveCN101782452AImprove the problem that it is difficult to apply the right amountSolve the shortcomings of manual processing being too slowPump componentsStatic/dynamic balance measurementExcessive weightLaser beams

The invention discloses a balancing method and a processing method of a fan. The balancing method comprises the following steps of: detecting an excessive weight part of a rotor of the fan; removing the excessive weight part by utilizing a laser beam, and executing an excessive weight removal operation in one period. The method achieves the effect of balancing the rotor.

Owner:DELTA ELECTRONICS INC

Thermally vented body armor

InactiveUS8904915B2Minimizing required overlapImprove mechanical stabilityPersonal protection gearArmour platesThermal compressionModularity

A modular and field adaptable body armor system includes a plurality of flexible, air-permeable, thermally vented plates arranged in fixed relationships that provide flexible, modular, field-adaptable protection for the torso and extremities without excessive weight or heat burden. The TVA plates include protective cards suspended in a parallel, louvered relationship between inner and outer mesh layers, thereby permitting air to flow therebetween while providing a flexible, compressible, modular barrier that protects the torso and extremities against projectiles. In embodiments, the outer mesh layer resists penetration and compresses cards together to intercept a projectile that would otherwise pass therebetween. Protective cards can include thermally pressed and flexed laminated UHMWPE. TVA panels can be removed and exchanged in the field according to the requirements of each mission. In embodiments, the TVA plates are laced together and / or attached to an underlying fabric carrier garment.

Owner:WARWICK MILLS INC

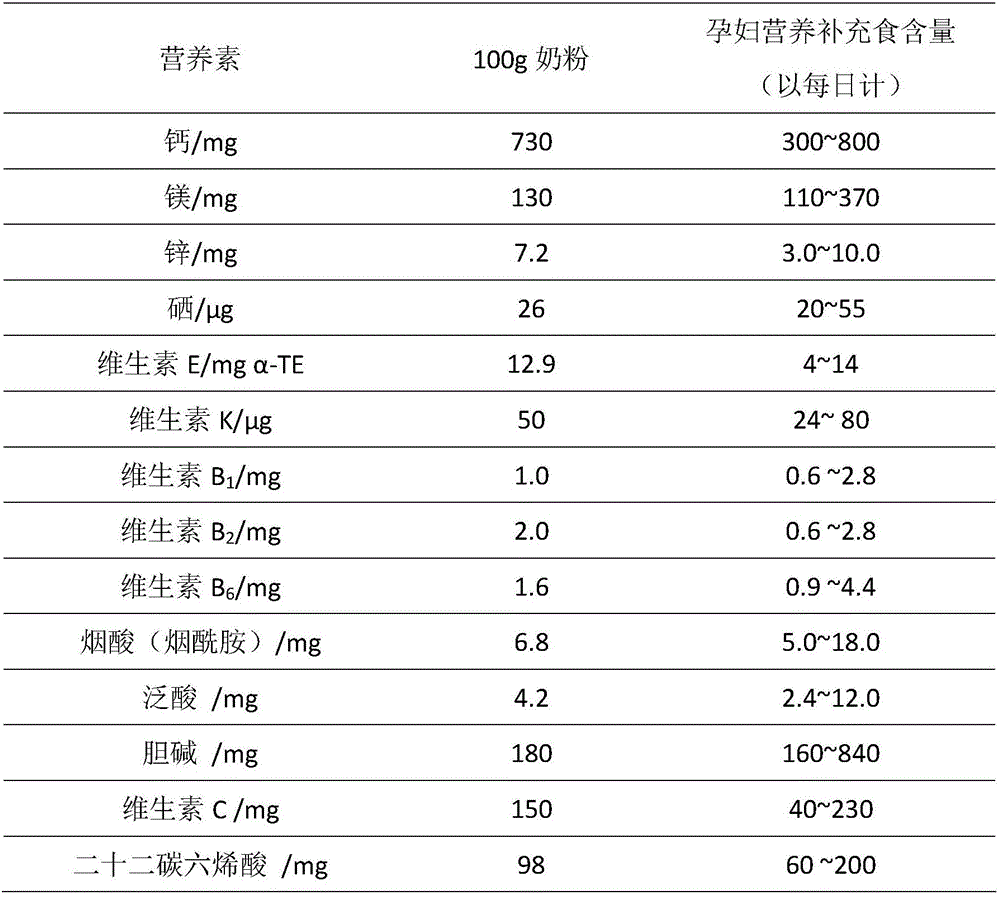

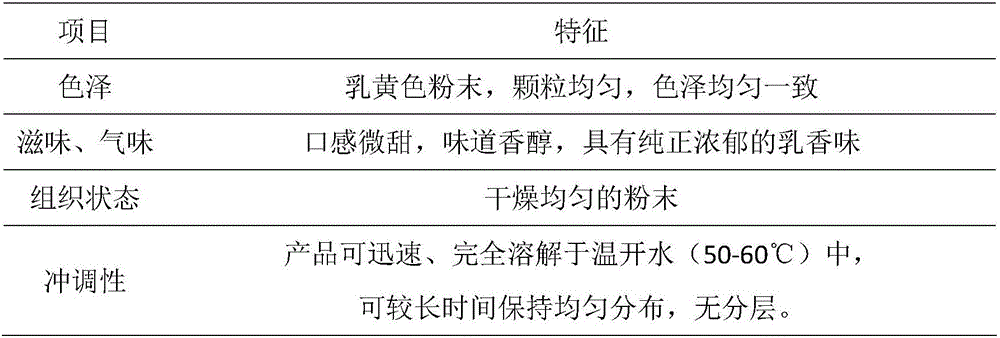

Constipation prevention and treatment formula milk powder suitable for women in pregnancy preparation period and gestation period

InactiveCN106804730APromote absorptionEnhance body nutrition levelsMilk preparationAdditive ingredientWarm water

The invention provides constipation prevention and treatment formula milk powder suitable for women in a pregnancy preparation period and a gestation period. The formula milk powder is prepared by blending of skim milk powder, demineralised whey powder, vegetable fatty powder, whole milk powder, concentrated whey protein powder, fructo-oligosaccharide, phospholipids, DHA algae oil powder, choline bitartrate, lactoferrin powder, potassium chloride, calcium carbonate, magnesium oxide, zinc gluconate, ferric pyrophosphate, sodium selenite and various vitamins. The formula milk powder has advantages that nutritional requirements of fetal development and women in the pregnancy preparation period and the gestation period can be comprehensively met while excessive weight increase caused by food intake increase for nutrition supplementing can be avoided. In addition, the formula milk powder is great in taste and can be mixed with warm water, thereby being an optimum nutritional product for supplementing essential nutrients to fetuses and women in the pregnancy preparation period and the gestation period to promote fetal normal development and health of pregnant women.

Owner:王程

Novel front floor system of electric automobile

InactiveCN102050152AMeet the installationImprove battery lifeSuperstructure subunitsEngineeringExcessive weight

The invention relates to a front floor system of an electric automobile, which comprises a front floor, a front floor lower crossbeam assembly, a front floor left longitudinal beam assembly, and a front floor right longitudinal beam assembly, wherein the front floor, the front floor lower crossbeam assembly, the front floor left longitudinal beam assembly, and the front floor right longitudinal beam assembly are welded together to form a box structure on which a battery tray can be installed; a crossing type reinforcing structure formed by a front floor left front crossbeam assembly, a front floor right front crossbeam assembly, a front floor left rear crossbeam assembly, a front floor right rear crossbeam assembly, a floor lower reinforcing part and a front and rear floor connecting piece is arranged in the box structure. The front floor system greatly enhances the strength for installing the frame of a battery assembly, solves the problems in the prior art, such as fatigue of a metal plate and battery falling caused by the instable structure of a floor system and the excessive weight of a battery, and meanwhile meets the requirements for installation of a heavier storage battery assembly, and promotes the cruising capability of the electric automobile.

Owner:HAFEI MOTOR

Gastric restriction devices for treating obesity

ActiveUS20160166417A1Non-surgical orthopedic devicesObesity treatmentGastric restrictionExcessive weight

A gastric restraining device for treating excessive weight or obesity in mammals. The gastric restraining device includes an elastomeric sheet configured to be placed around a stomach of a mammal, an ablation device attached to the elastomeric sheet, the ablation device configured to emit energy toward an outer surface of the stomach when the elastomeric sheet is placed around the stomach, and an energy device coupled to the ablation device to generate the energy and to transfer the energy to the ablation device.

Owner:RESHAPE LIFESCIENCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com