Rotor static pressure bearing balance technique for large mixed-flow turbine

A process method and Francis technology, which is applied in the field of static pressure bearing balance technology of large Francis turbine runners, can solve problems affecting the static balance of large runners, deformation of balance balls and mirror plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

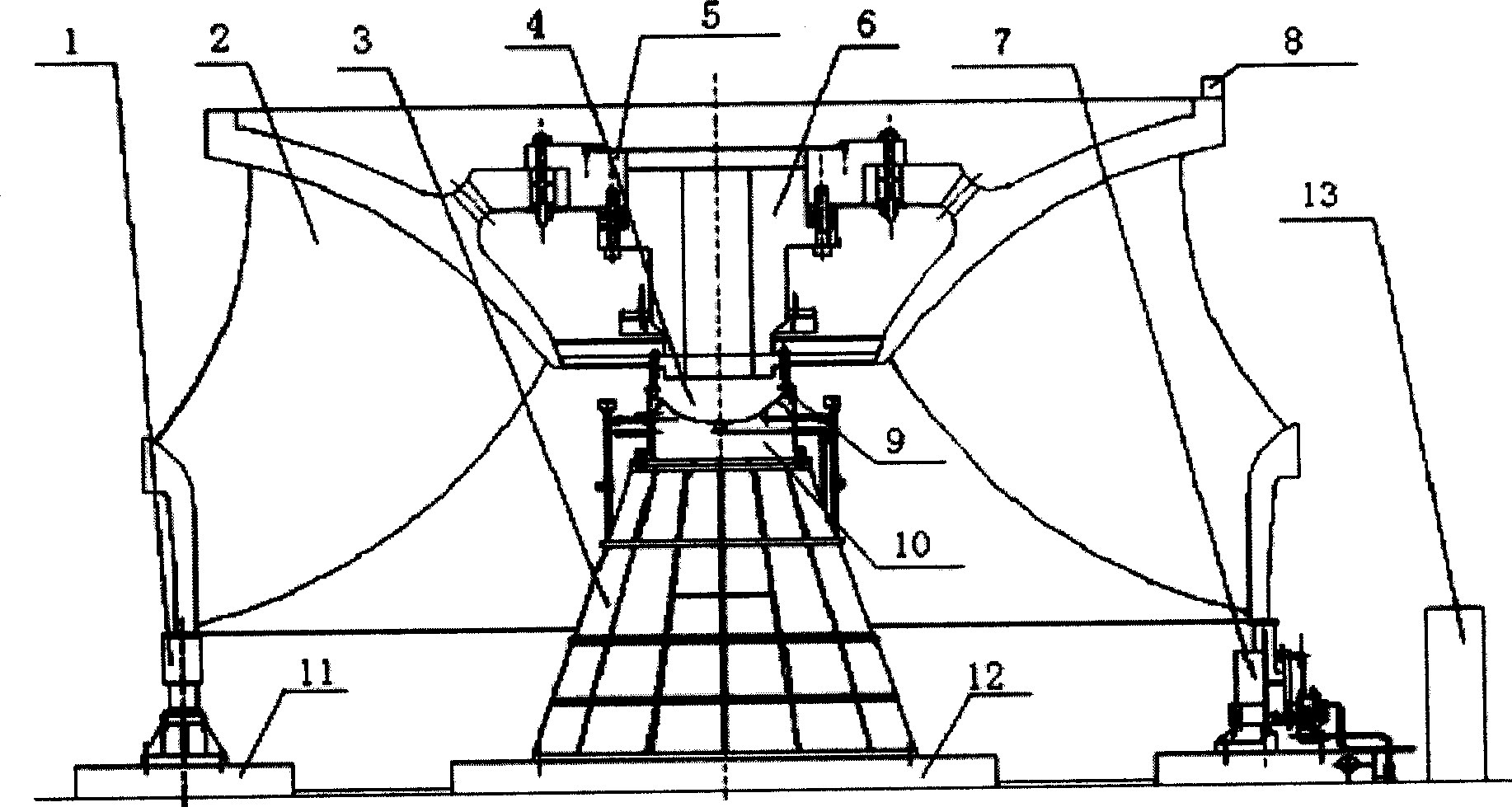

[0005] Such as figure 1 As shown, a large-scale Francis turbine runner hydrostatic bearing balancing process method, the specific process steps are: clean up the corresponding assembly platform, draw the position line of the support center of the lower ring of the runner 2, select the location of the hydraulic source, and install the balance device The transition base 12 of the main support part under the middle balance ball head 4 is fixed on the transition base 12 in the center of the balance field, and the four platforms 11 on which the jack 1 is placed are evenly placed on the lower ring support distribution of the runner 2 according to the quartering arrangement. At the round place, drop the assembled ball support 3 on the upper plane of the transition base 12 and fasten it, place the four hydraulic jacks 7 according to the determined positions, and connect the high-pressure oil pipelines of the four hydraulic jacks 7 and The pumping station is connected to the control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com