Patents

Literature

58 results about "Francis turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

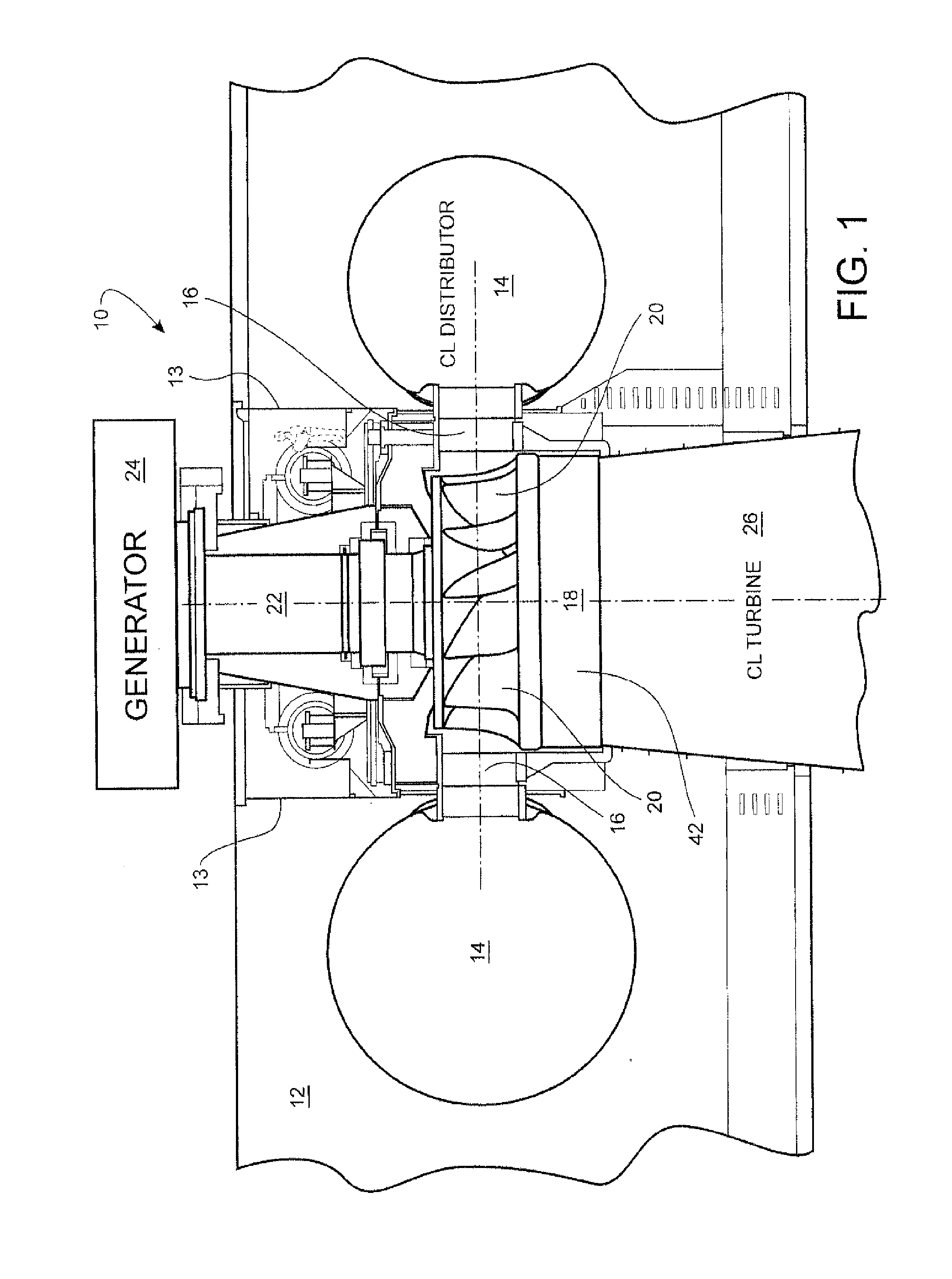

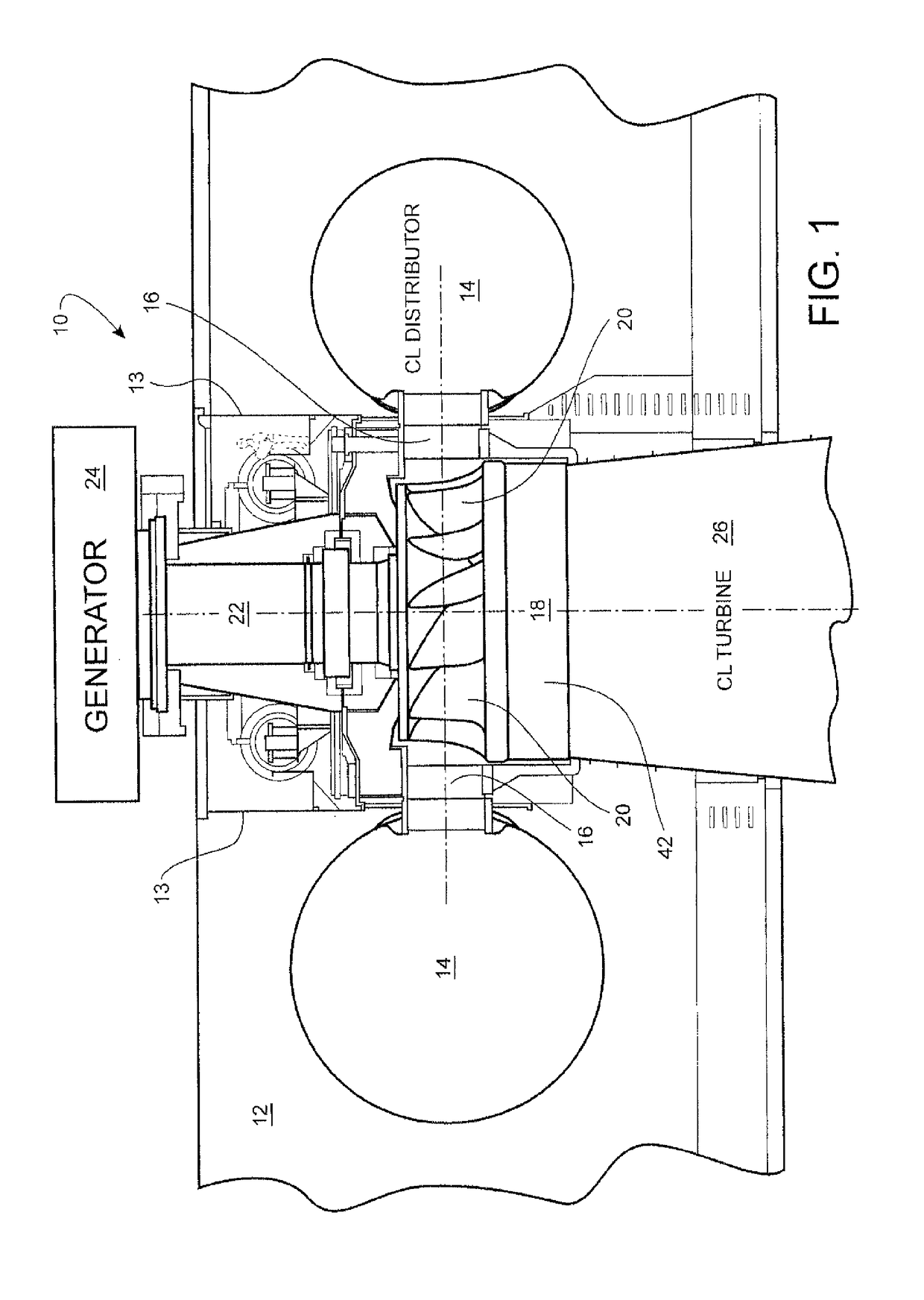

The Francis turbine is a type of water turbine that was developed by James B. Francis in Lowell, Massachusetts. It is an inward-flow reaction turbine that combines radial and axial flow concepts. Francis turbines are the most common water turbine in use today. They operate in a water head from 40 to 600 m (130 to 2,000 ft) and are primarily used for electrical power production. The electric generators that most often use this type of turbine have a power output that generally ranges from just a few kilowatts up to 800 MW, though mini-hydro installations may be lower. Penstock (input pipes) diameters are between 3 and 33 ft (0.91 and 10 m). The speed range of the turbine is from 75 to 1000 rpm. A wicket gate around the outside of the turbine's rotating runner controls the rate of water flow through the turbine for different power production rates. Francis turbines are almost always mounted with the shaft vertical so as to isolate water from the generator. This also facilitates installation and maintenance.

Francis turbine

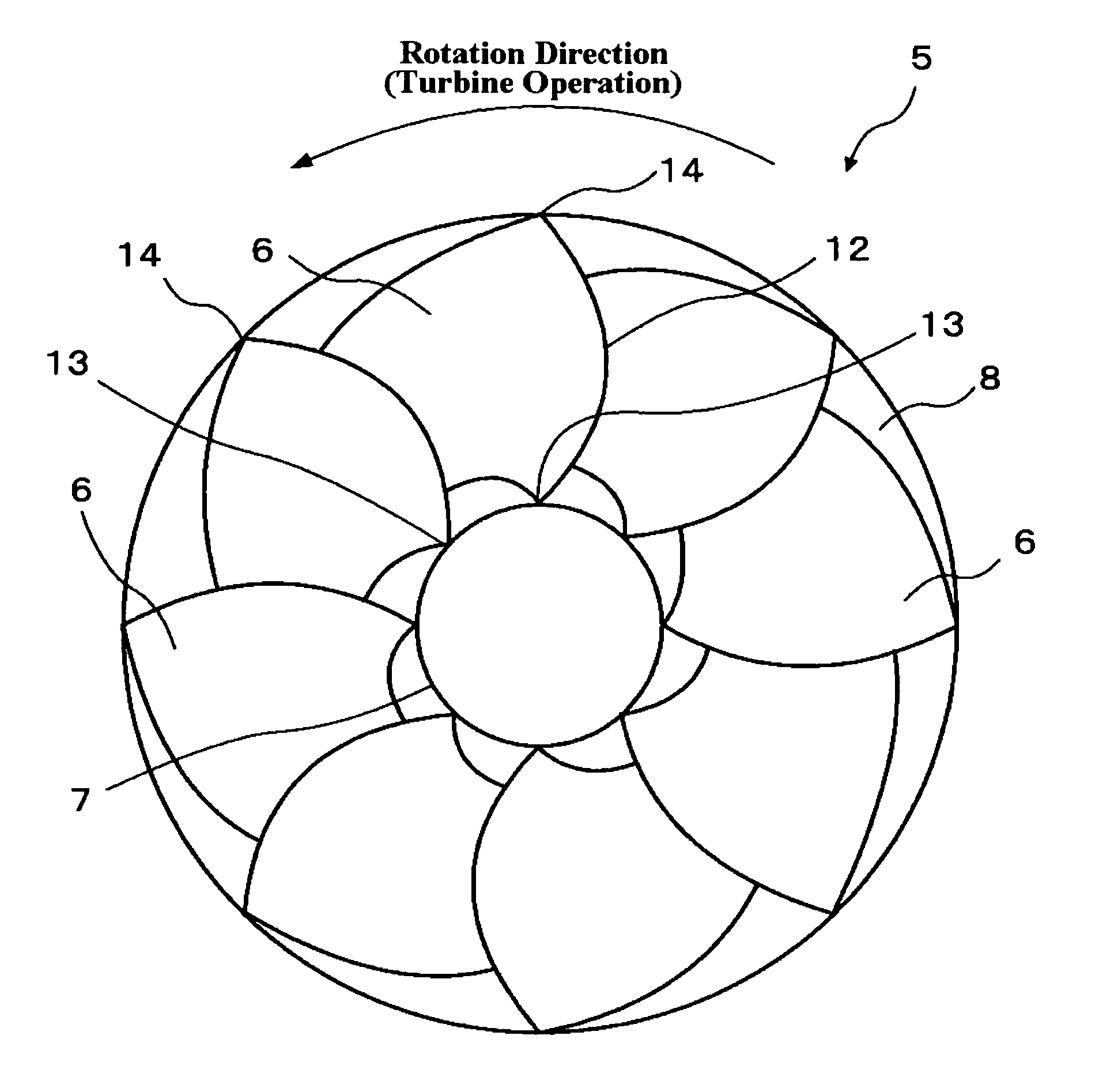

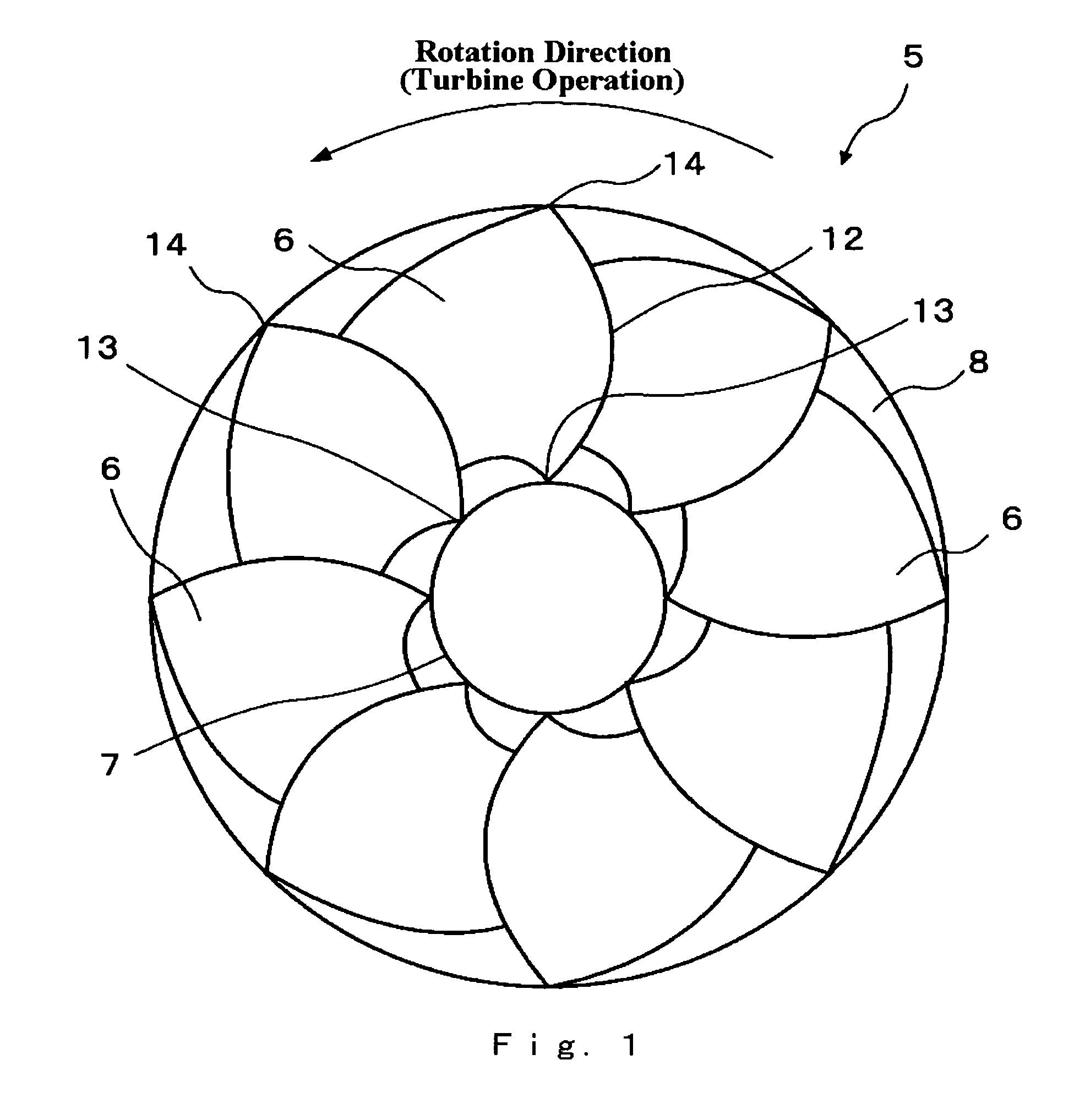

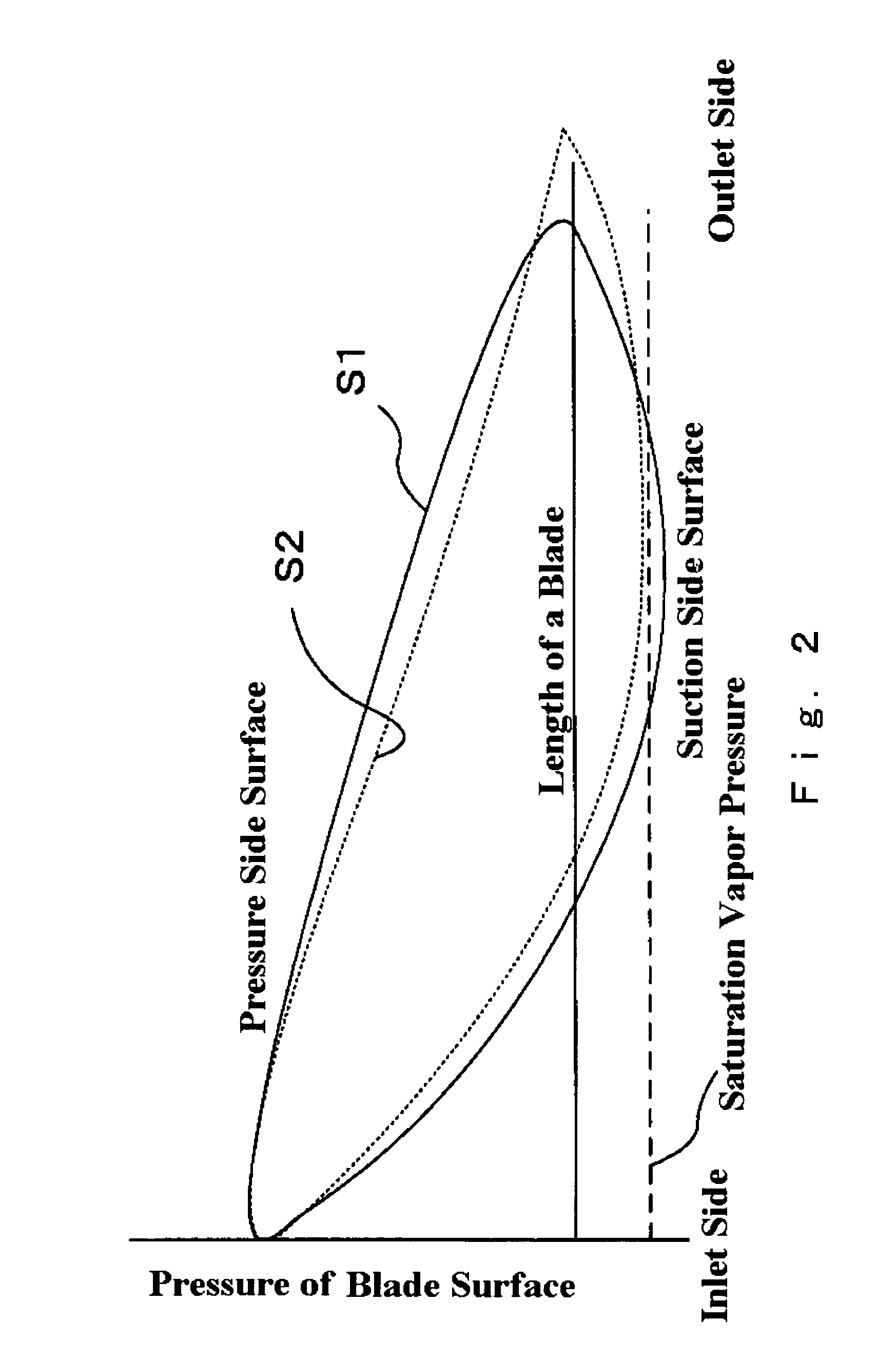

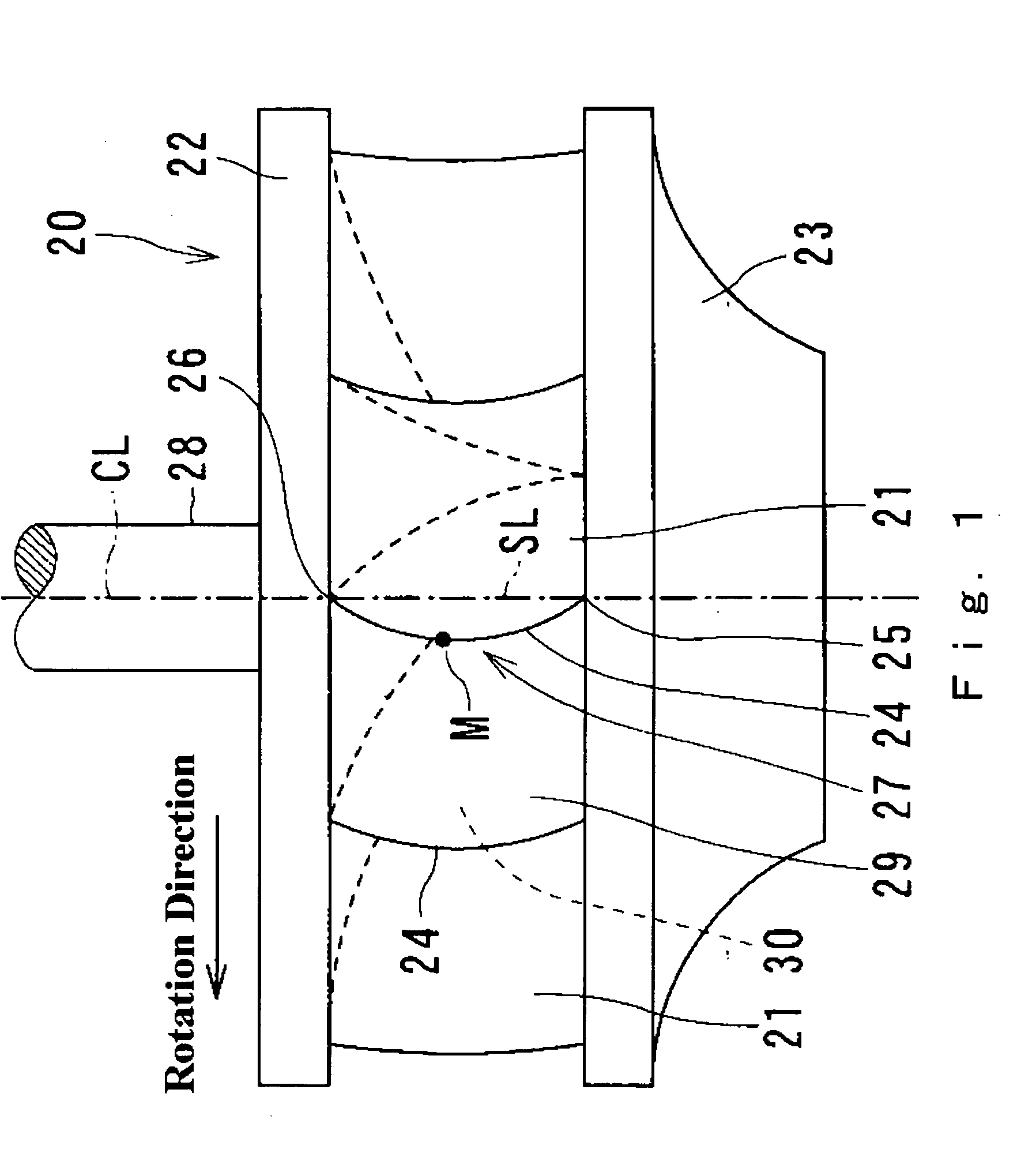

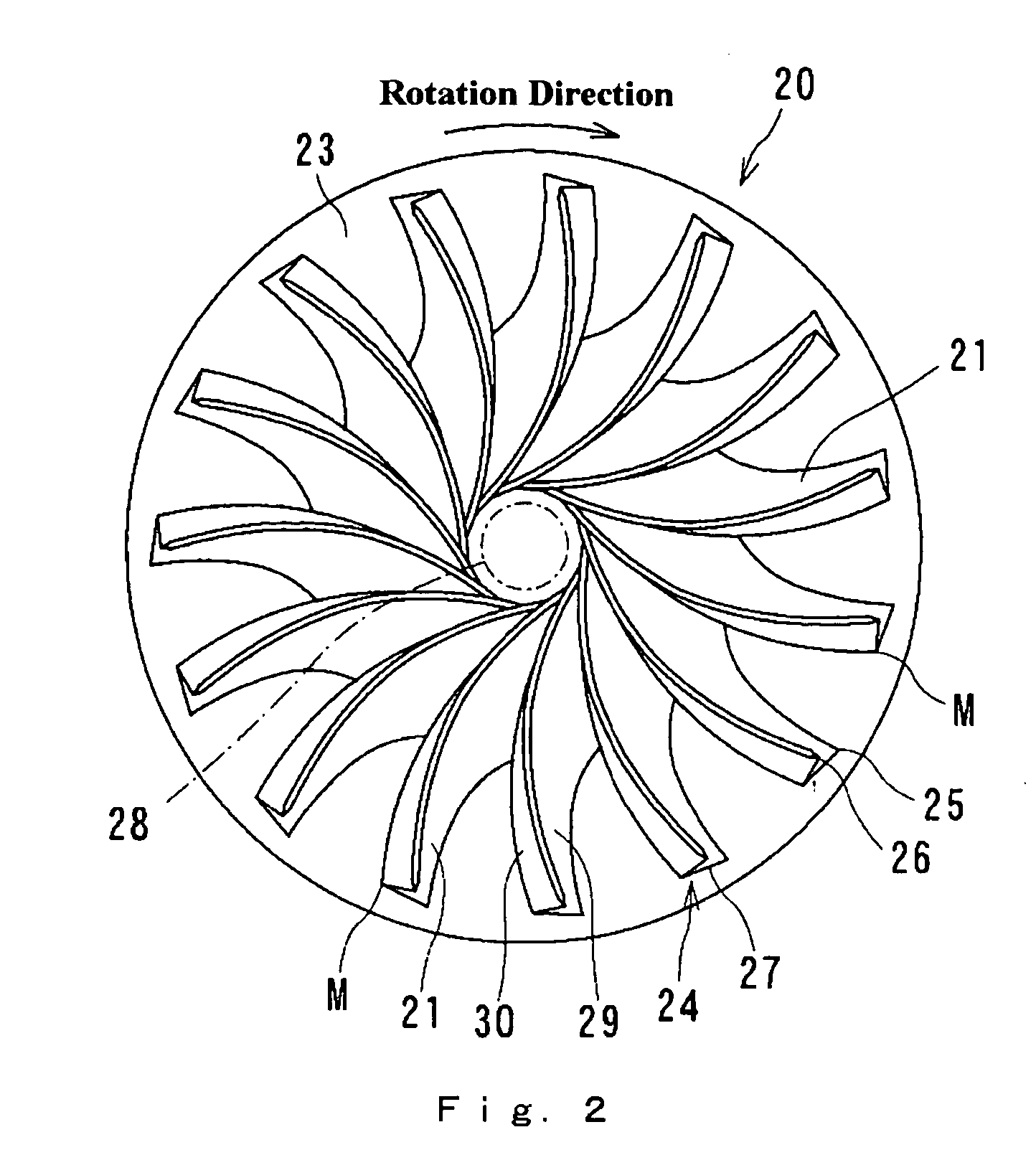

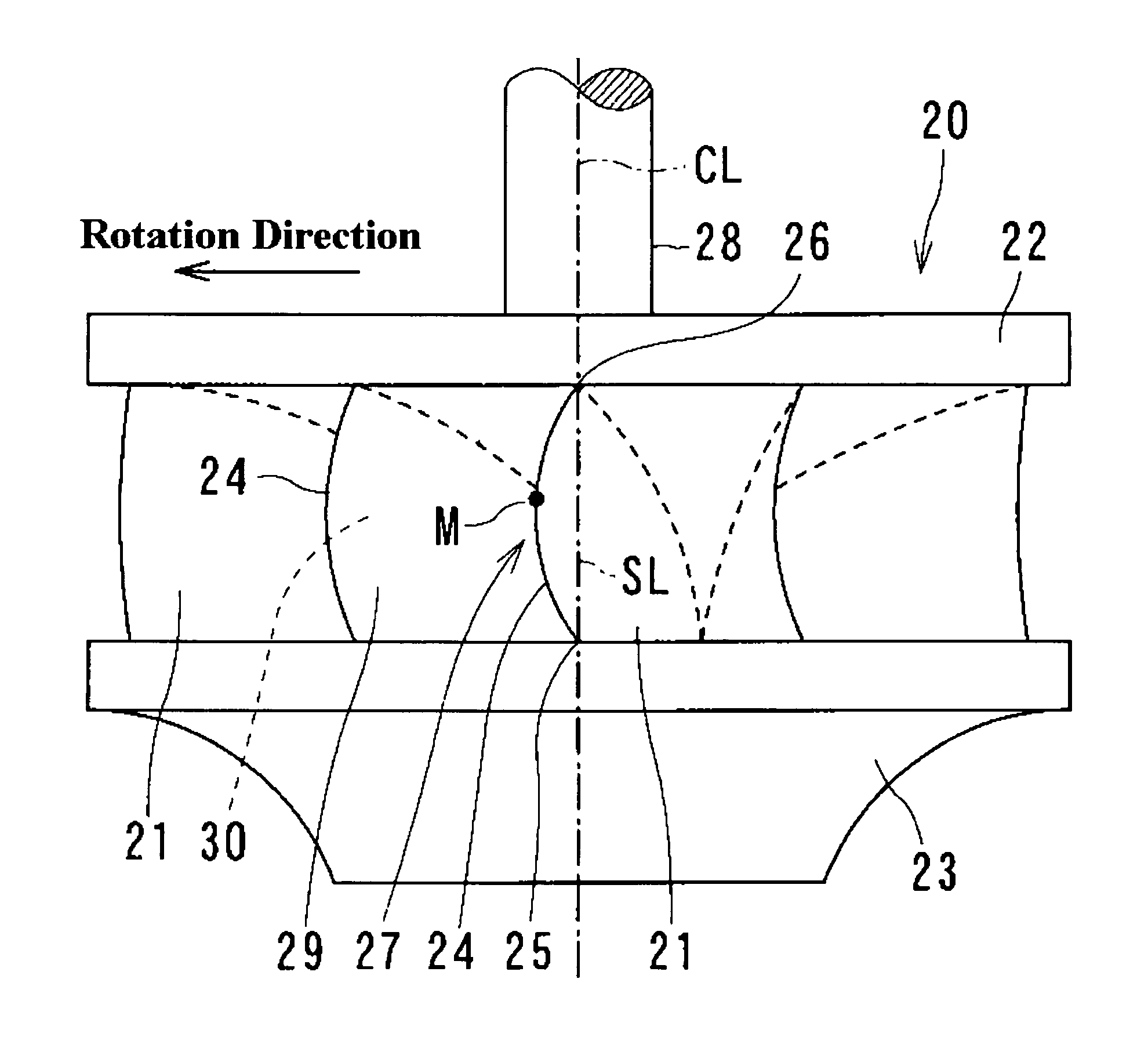

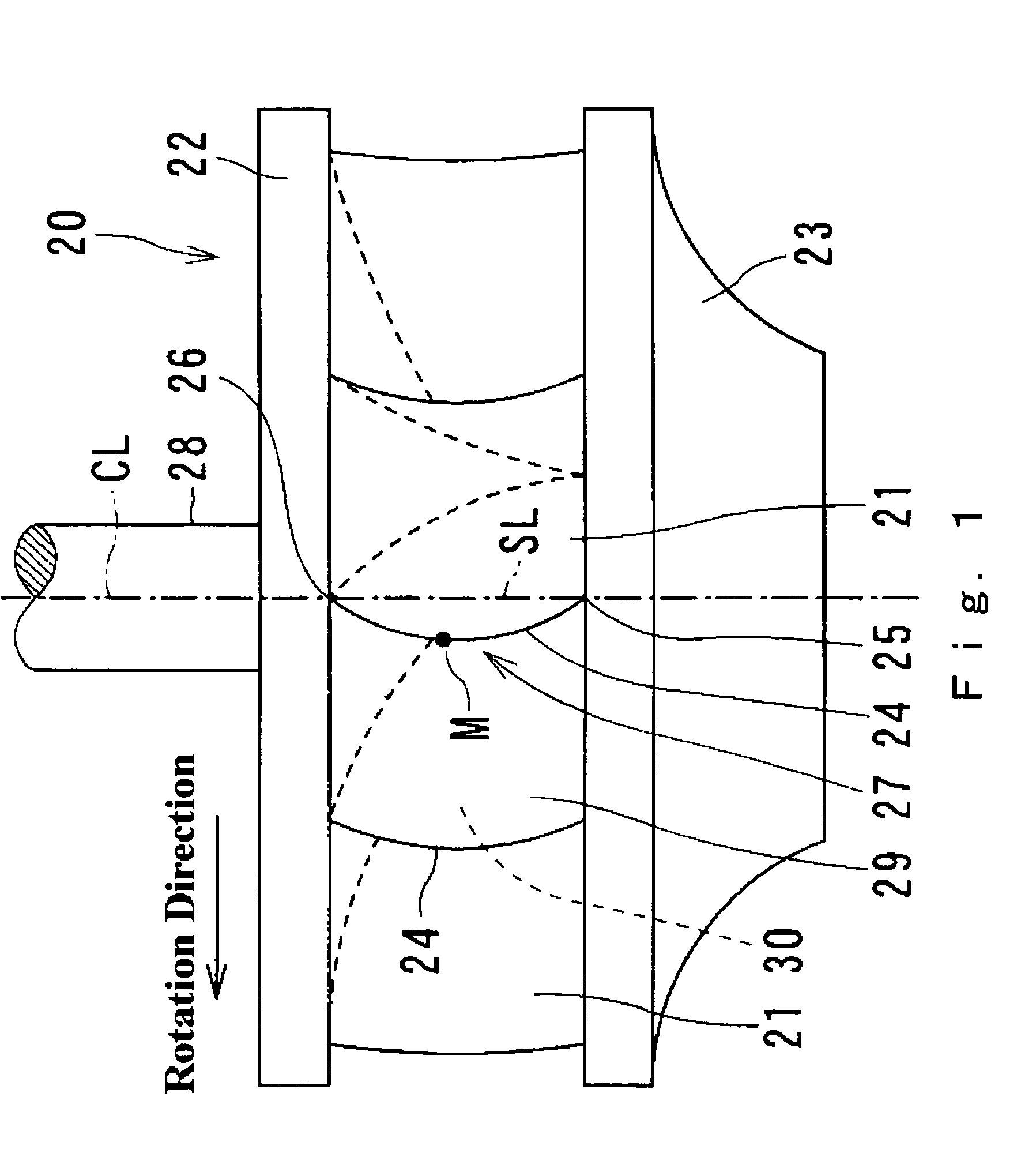

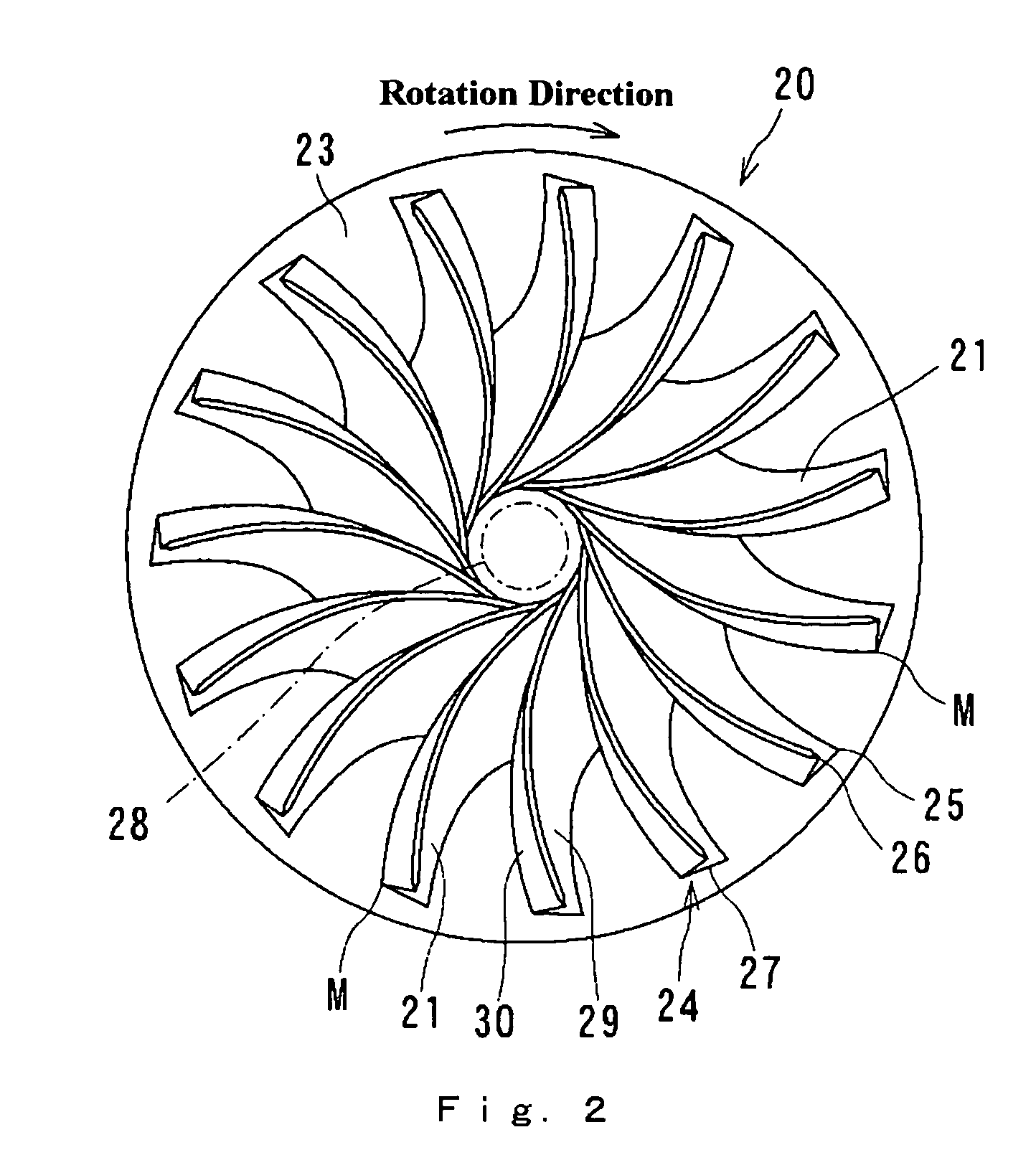

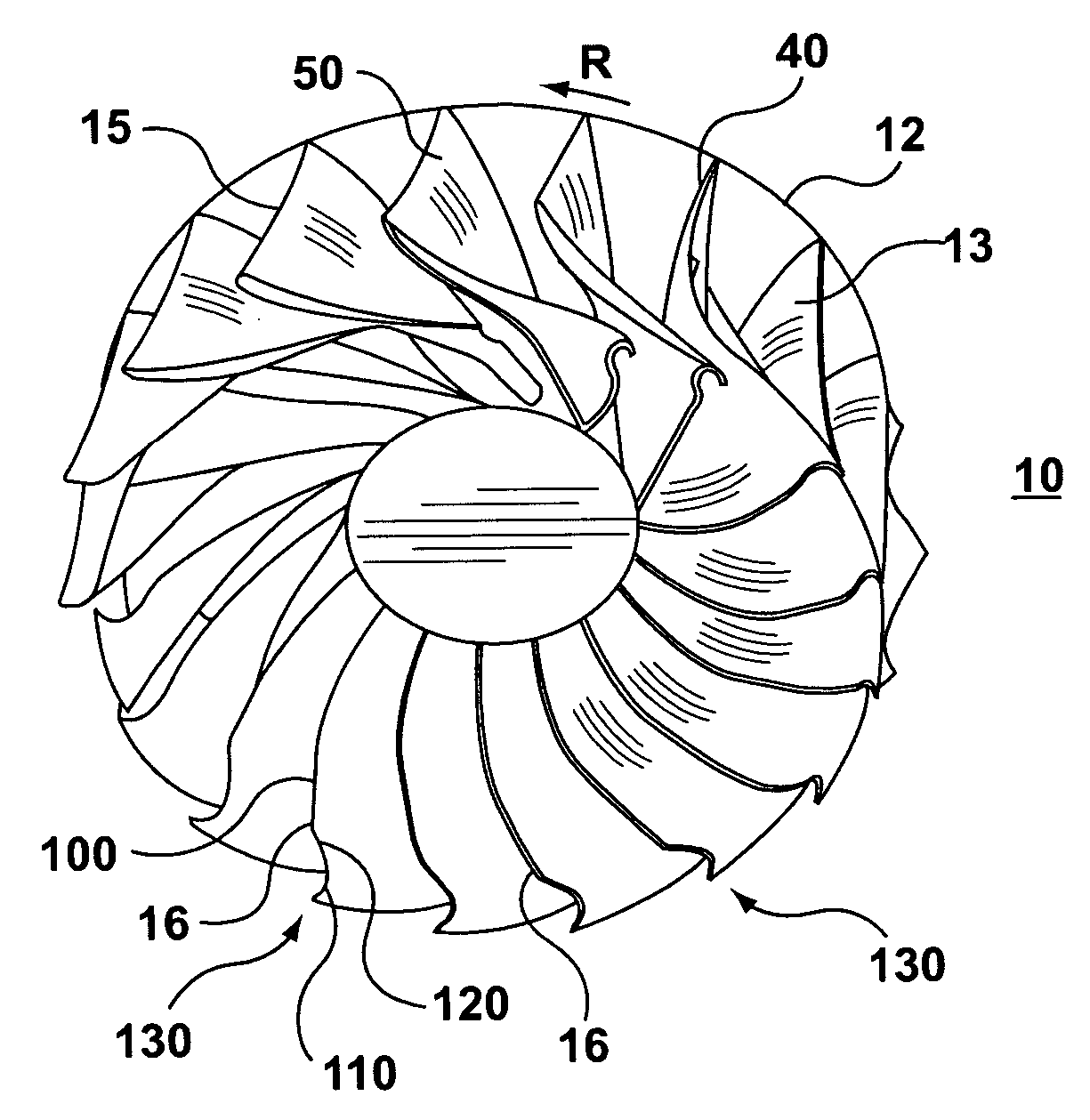

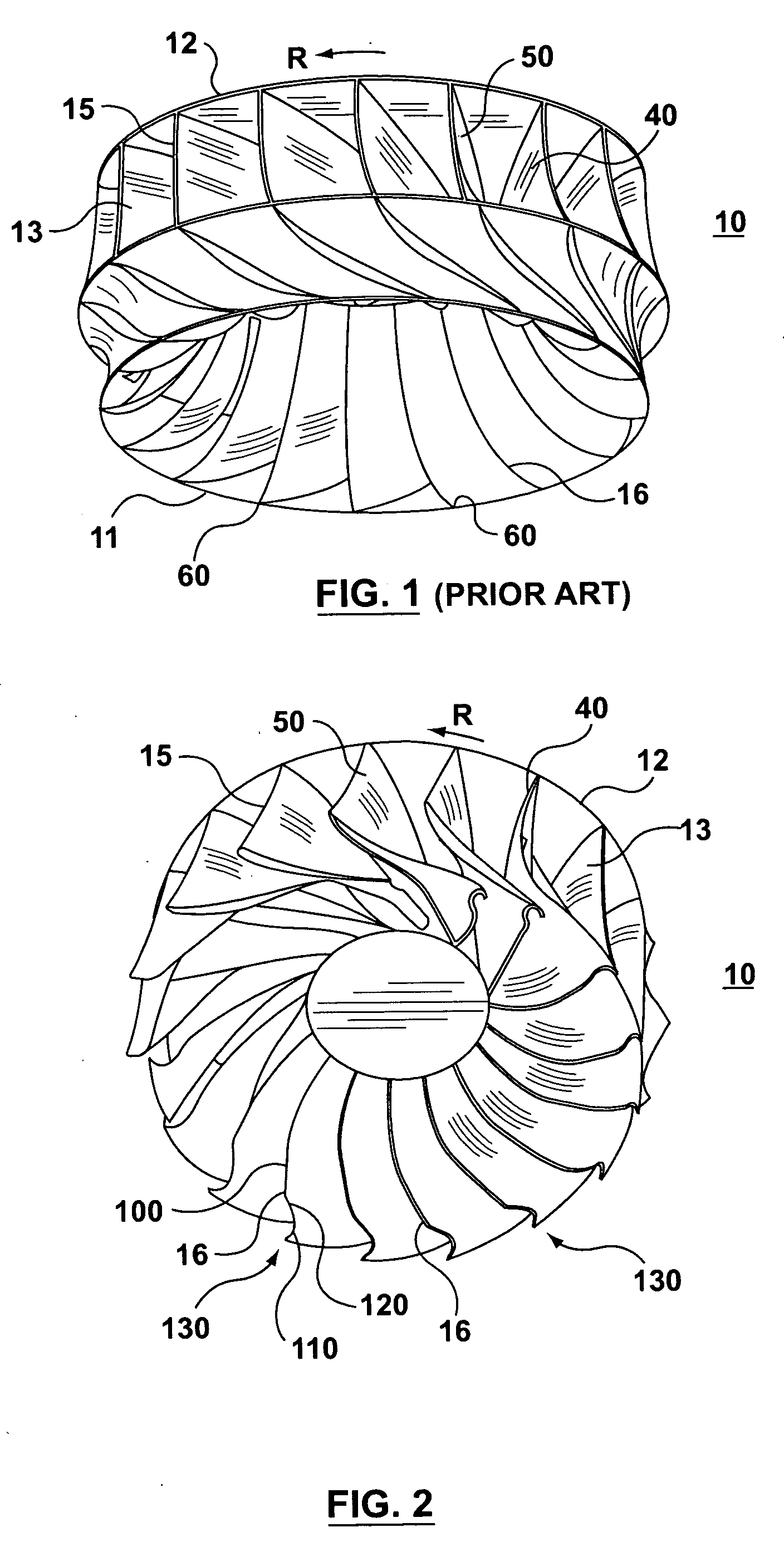

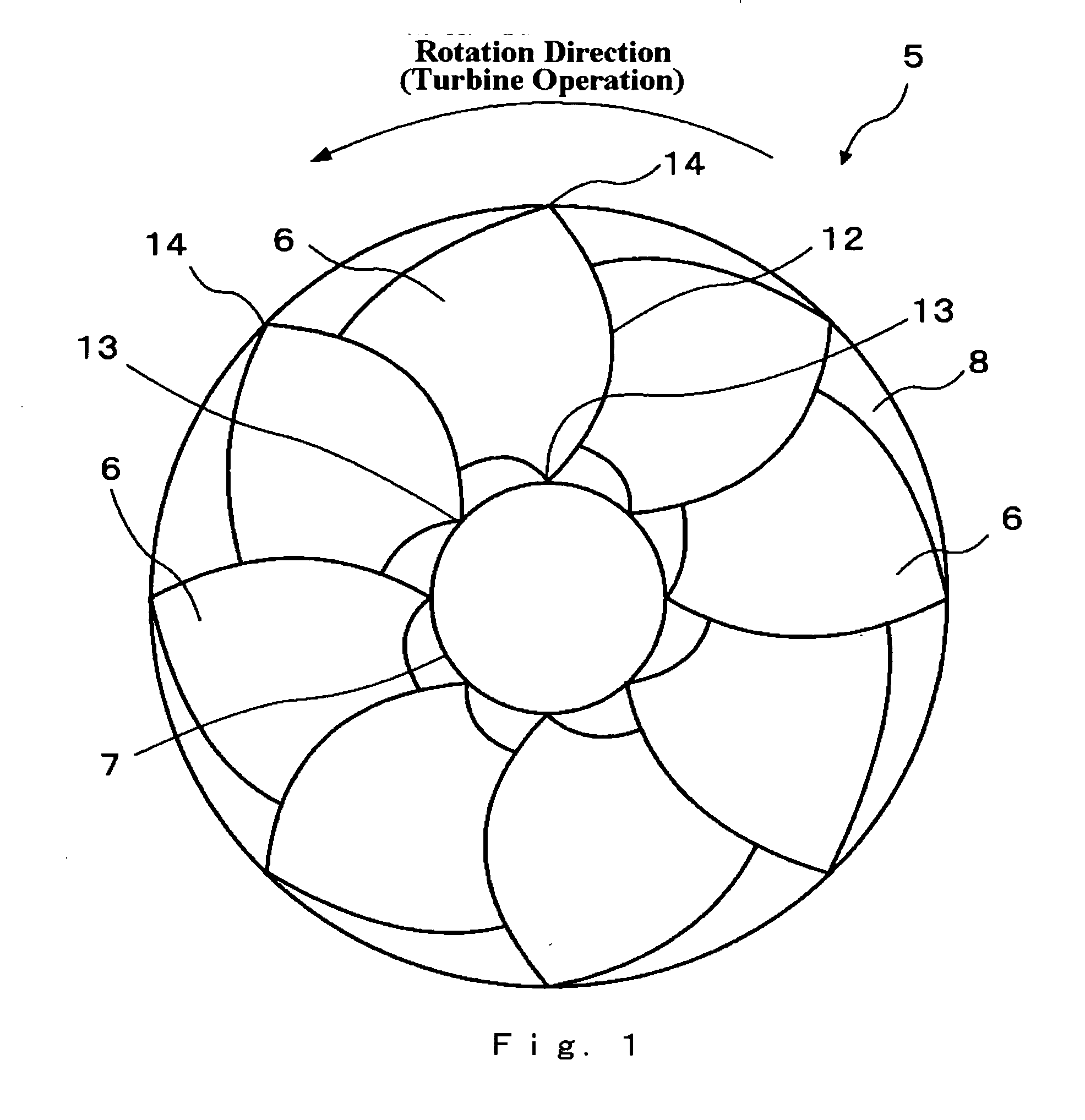

A Francis turbine with an improved shape of blades, which can reduce cavitations generated on the surface of the blades or reduce the secondary flow around the blades, is provided. A Francis turbine comprises a rotating shaft, a crown, a plurality of blades, and a band. The crown can rotate with the rotating shaft. The blades are circumferentially arranged on the crown, each of which including an inner end as a trailing edge. The band is coaxially coupled with the crown by the blades. The rotating shaft, the crown, the blades, and the band as a whole rotate toward a turbine direction during a turbine operation. A projected profile of the trailing edge on a perpendicular plane, which is perpendicular to a center axis of the rotating shaft, is curved toward a direction opposite to the turbine direction at least in the crown side.

Owner:KK TOSHIBA

Francis turbine

ActiveUS20050013691A1Easy to shapeReduce secondary flowPropellersRotary propellersLeading edgeFrancis turbine

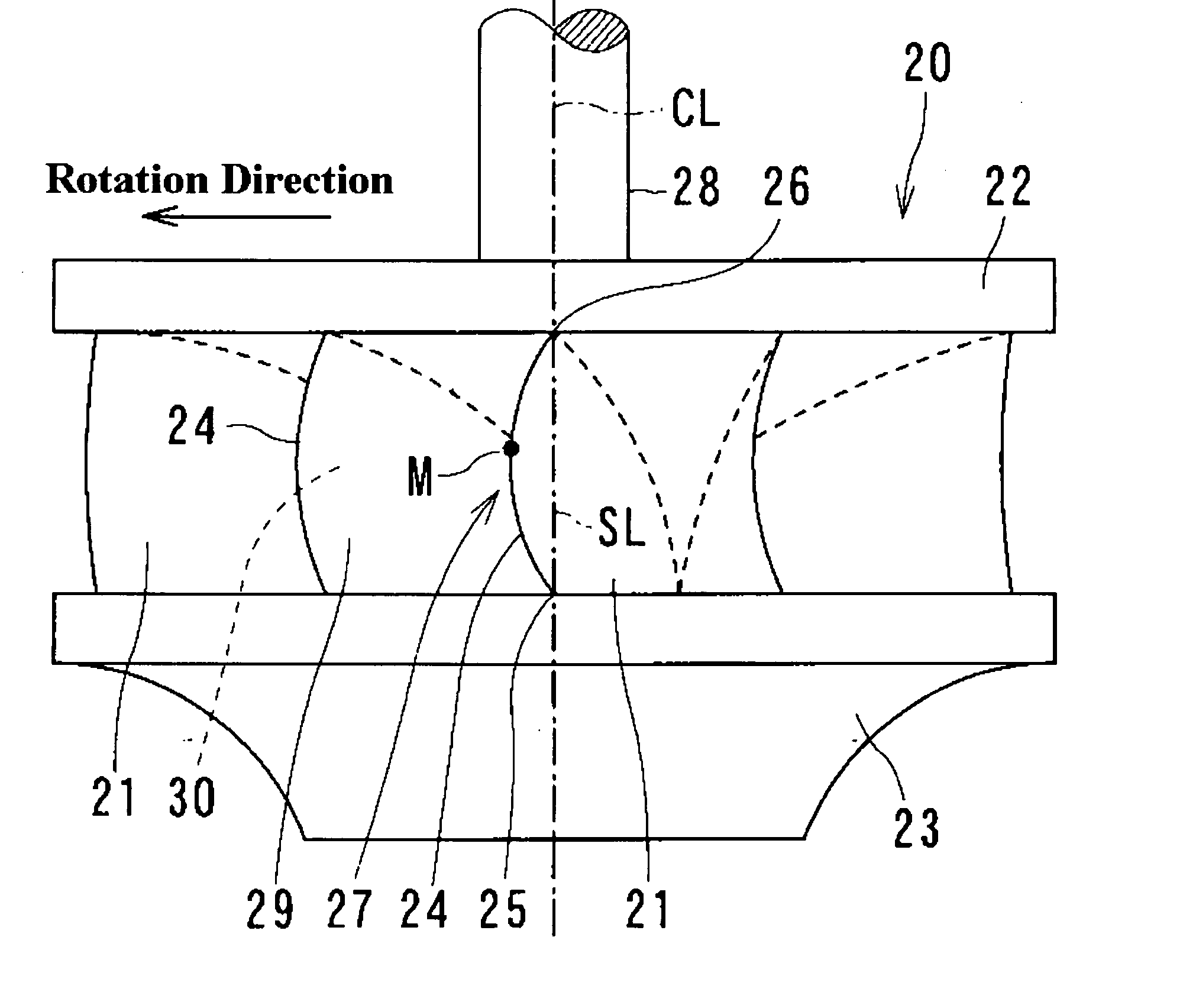

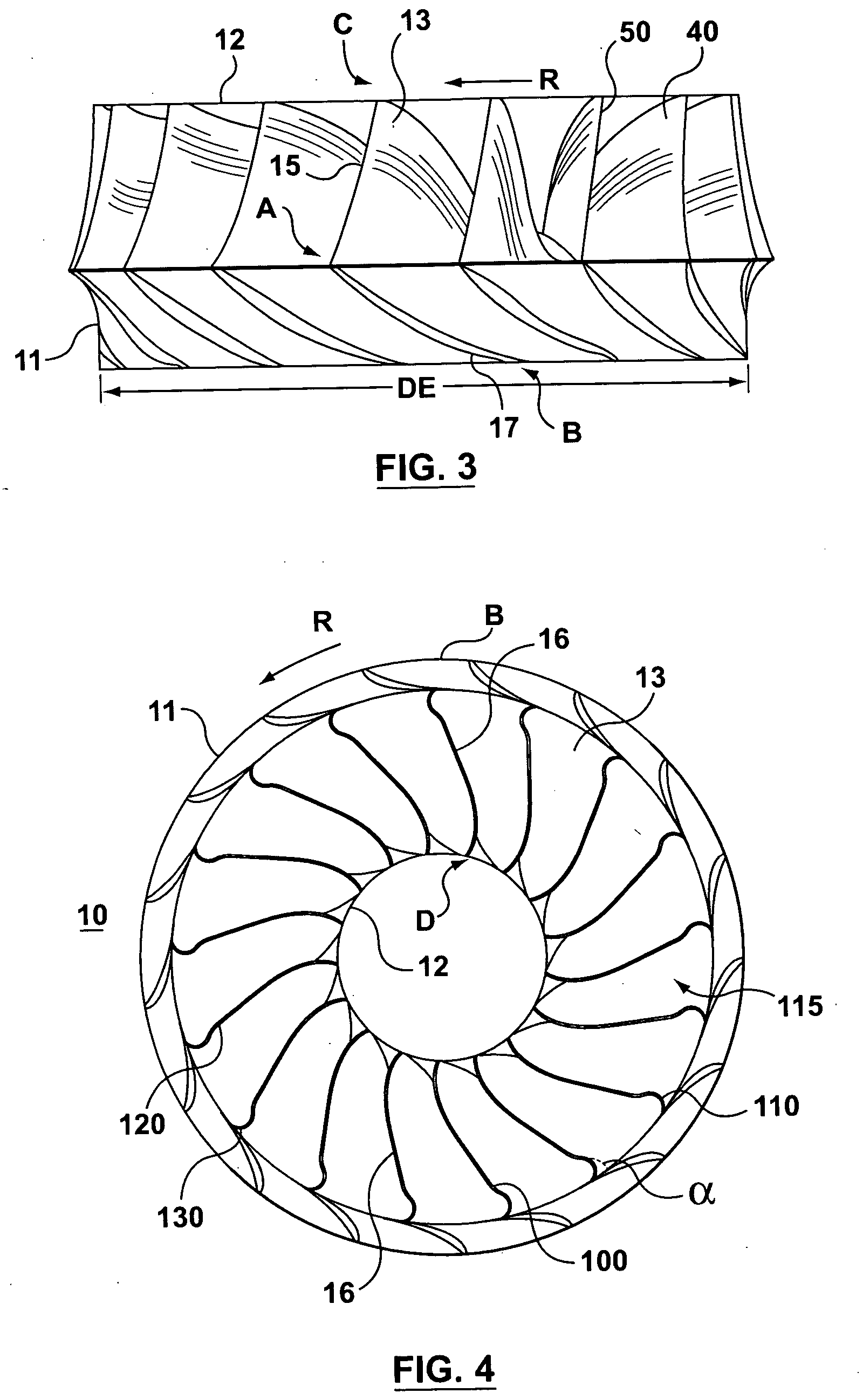

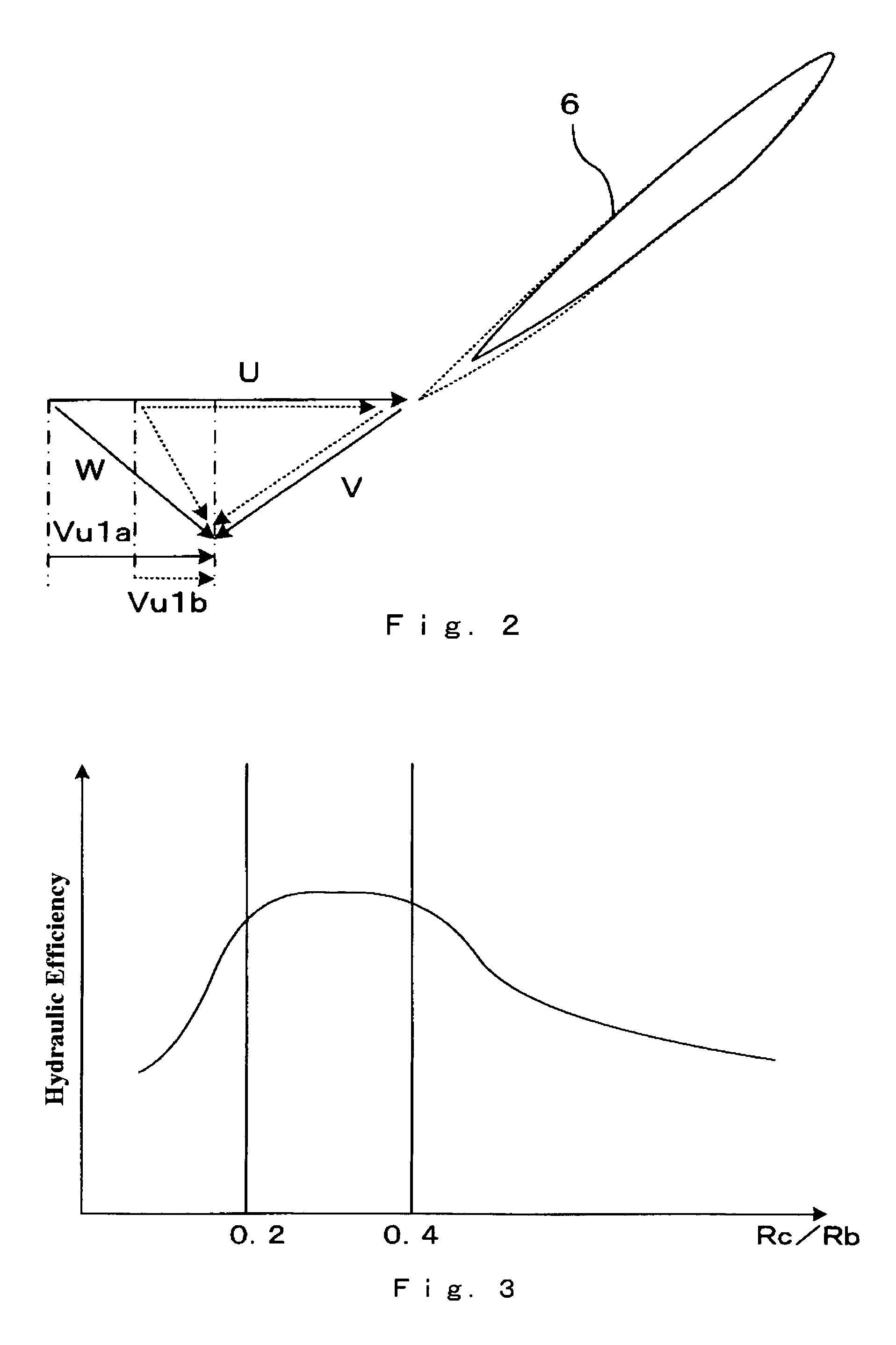

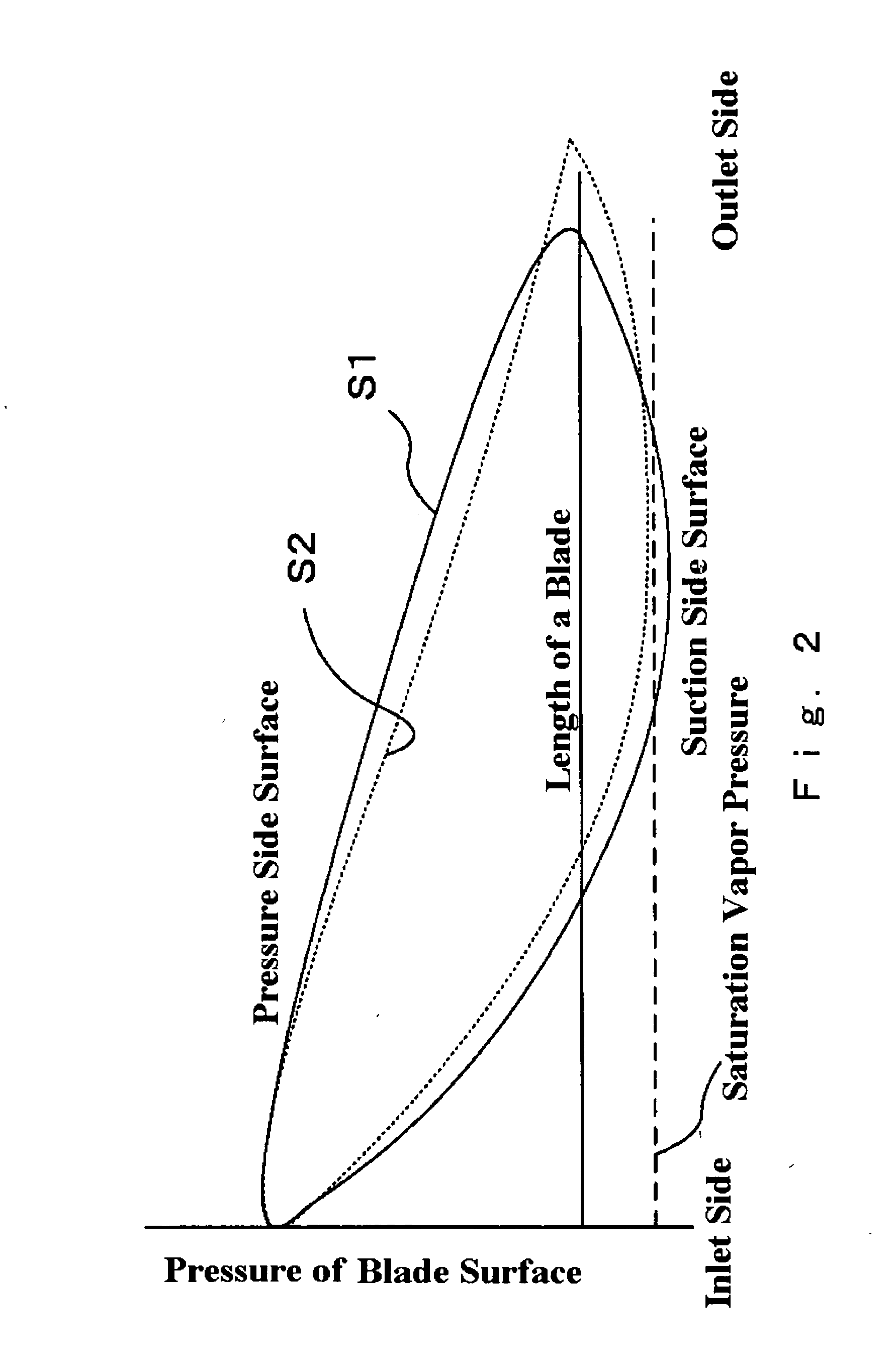

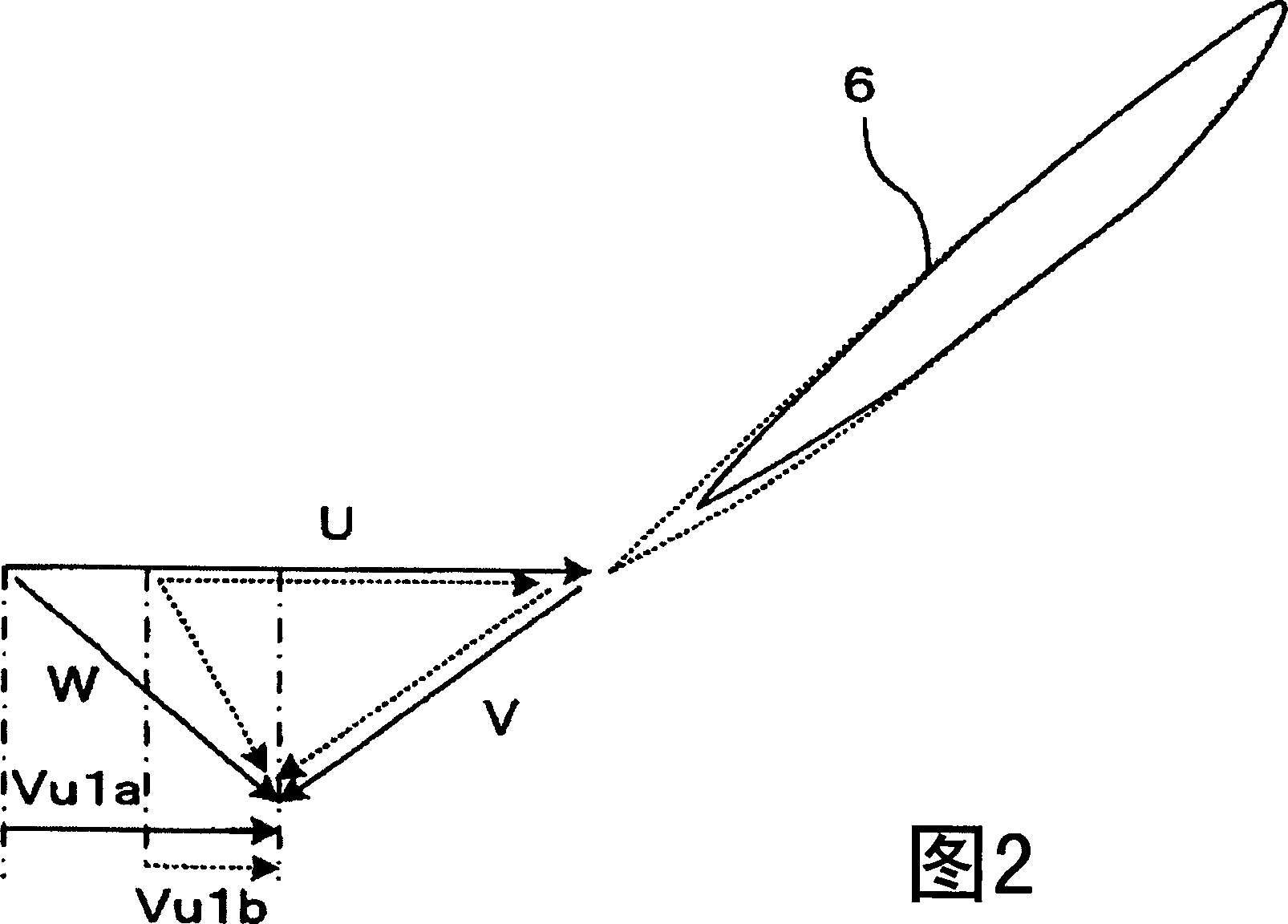

A Francis turbine with a improved shape of blades to reduce the secondary flow around the blades and improve the hydraulic efficiency is provided. A Francis turbine comprises a rotating shaft, a crown, a plurality of blades and a band. The band is coaxially coupled with the crown by the blades and the rotating shaft, the crown, the blades, and the band as a whole are driven by water and rotate toward a turbine direction during a turbine operation. On a leading edge of at least one of the blades, a local maximum point exists between the crown and the band. The leading edge leans toward the turbine direction from the band connecting point, where the band and the leading edge are connected. And, a circumferential distance in the rotating direction between the band connecting point and the leading edge is the largest at the local maximum point.

Owner:KK TOSHIBA

Francis turbine

A Francis turbine with a improved shape of blades to reduce the secondary flow around the blades and improve the hydraulic efficiency is provided. A Francis turbine comprises a rotating shaft, a crown, a plurality of blades and a band. The band is coaxially coupled with the crown by the blades and the rotating shaft, the crown, the blades, and the band as a whole are driven by water and rotate toward a turbine direction during a turbine operation. On a leading edge of at least one of the blades, a local maximum point exists between the crown and the band. The leading edge leans toward the turbine direction from the band connecting point, where the band and the leading edge are connected. And, a circumferential distance in the rotating direction between the band connecting point and the leading edge is the largest at the local maximum point.

Owner:KK TOSHIBA

Francis turbine

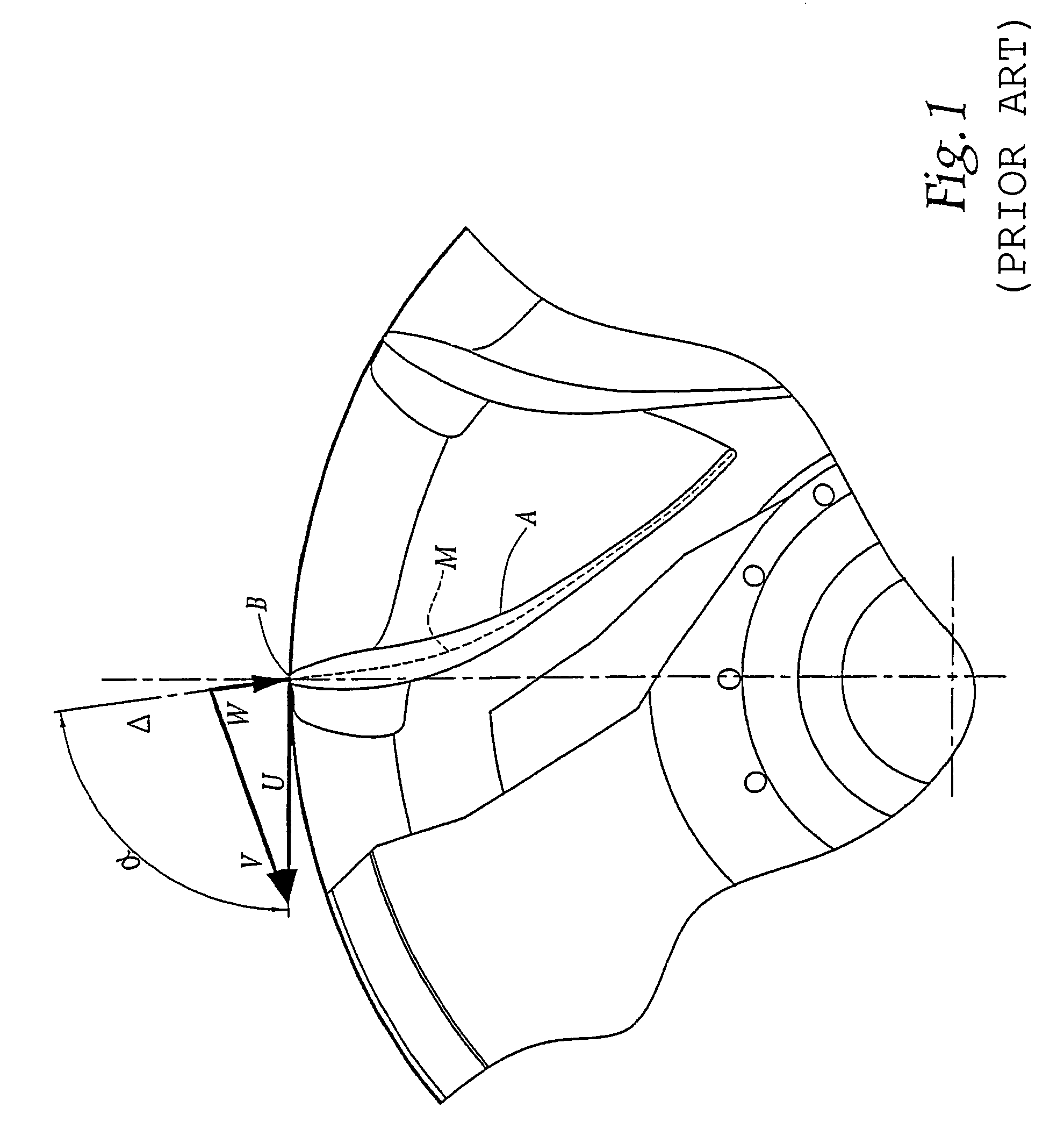

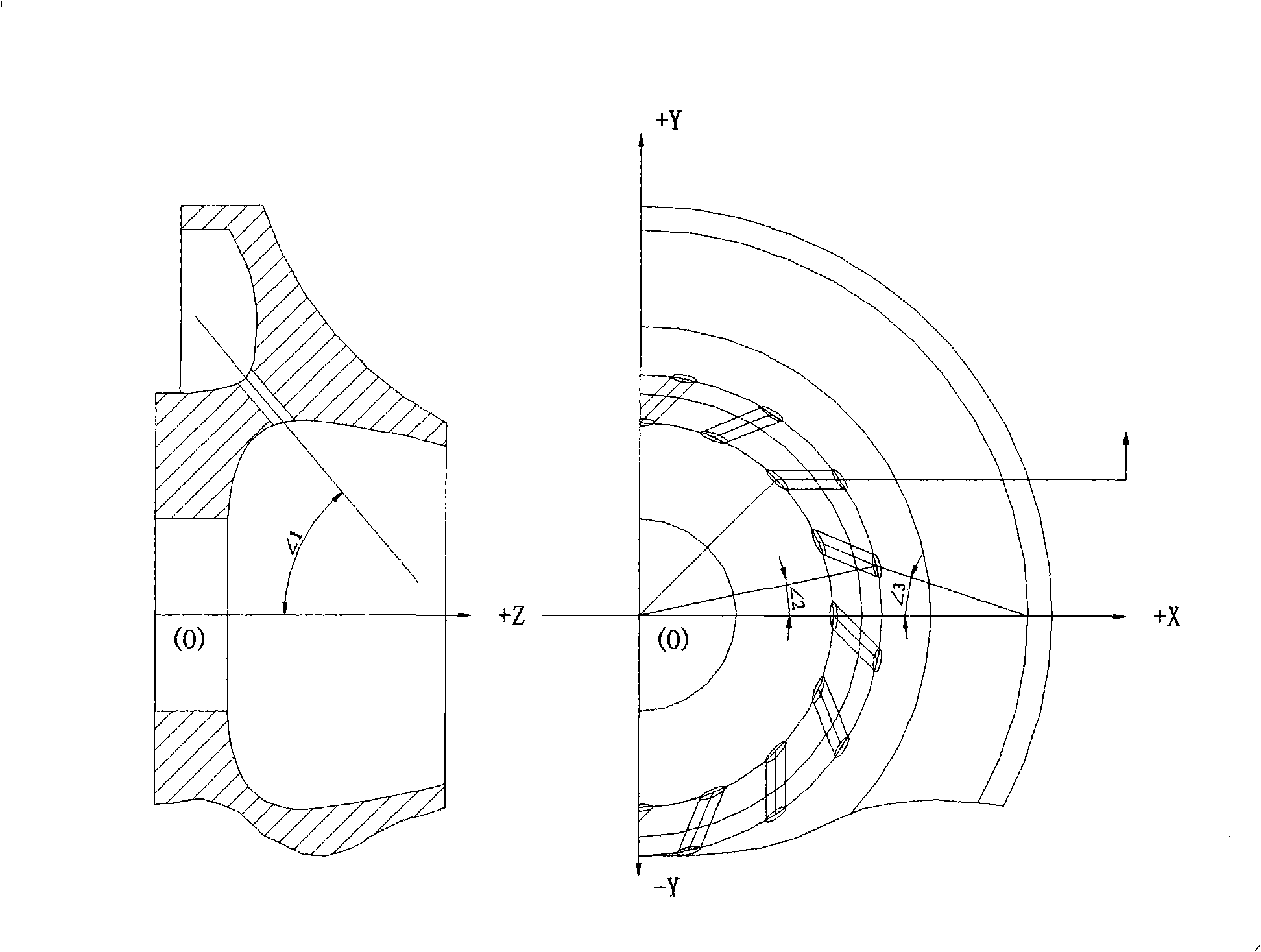

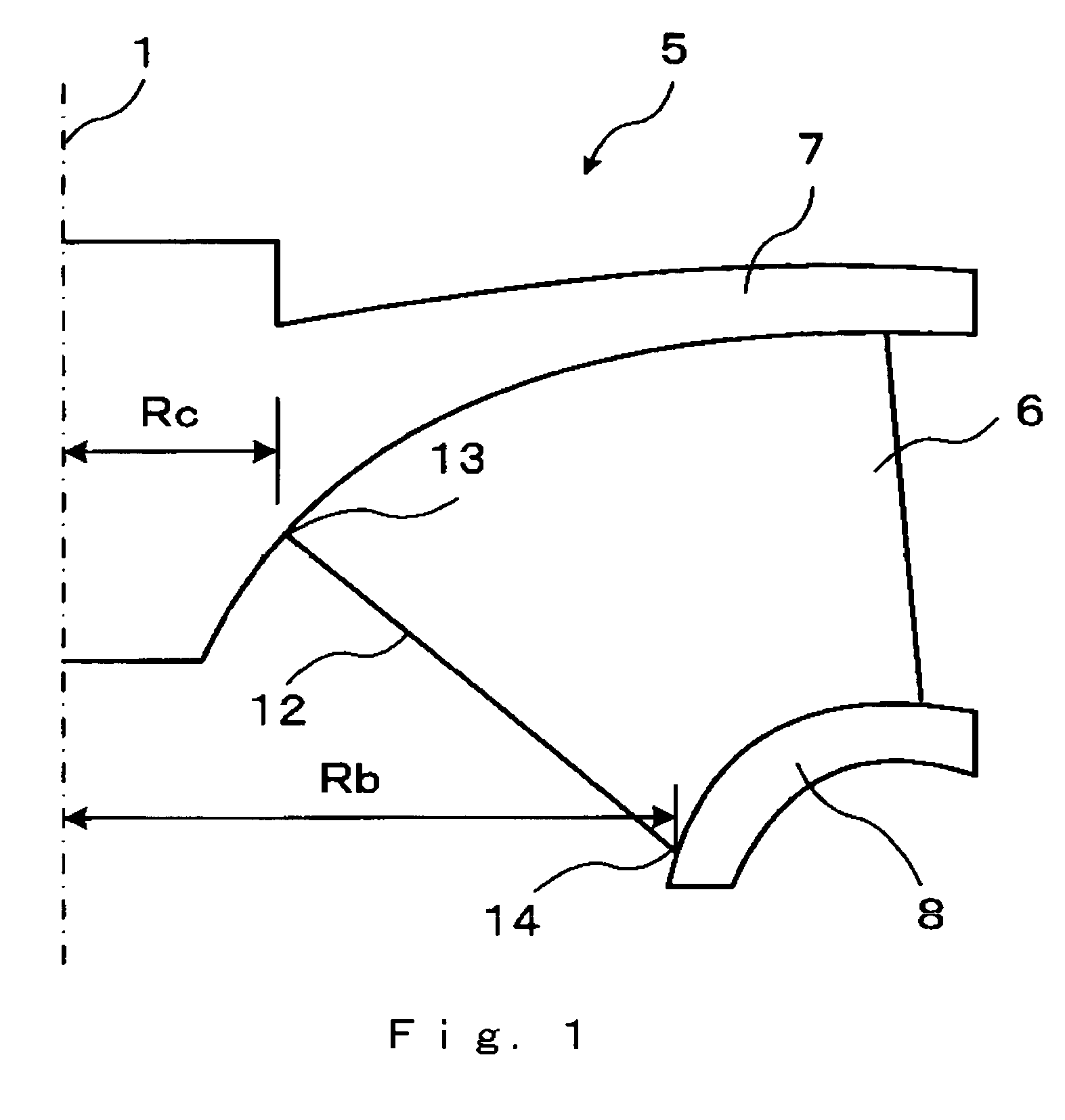

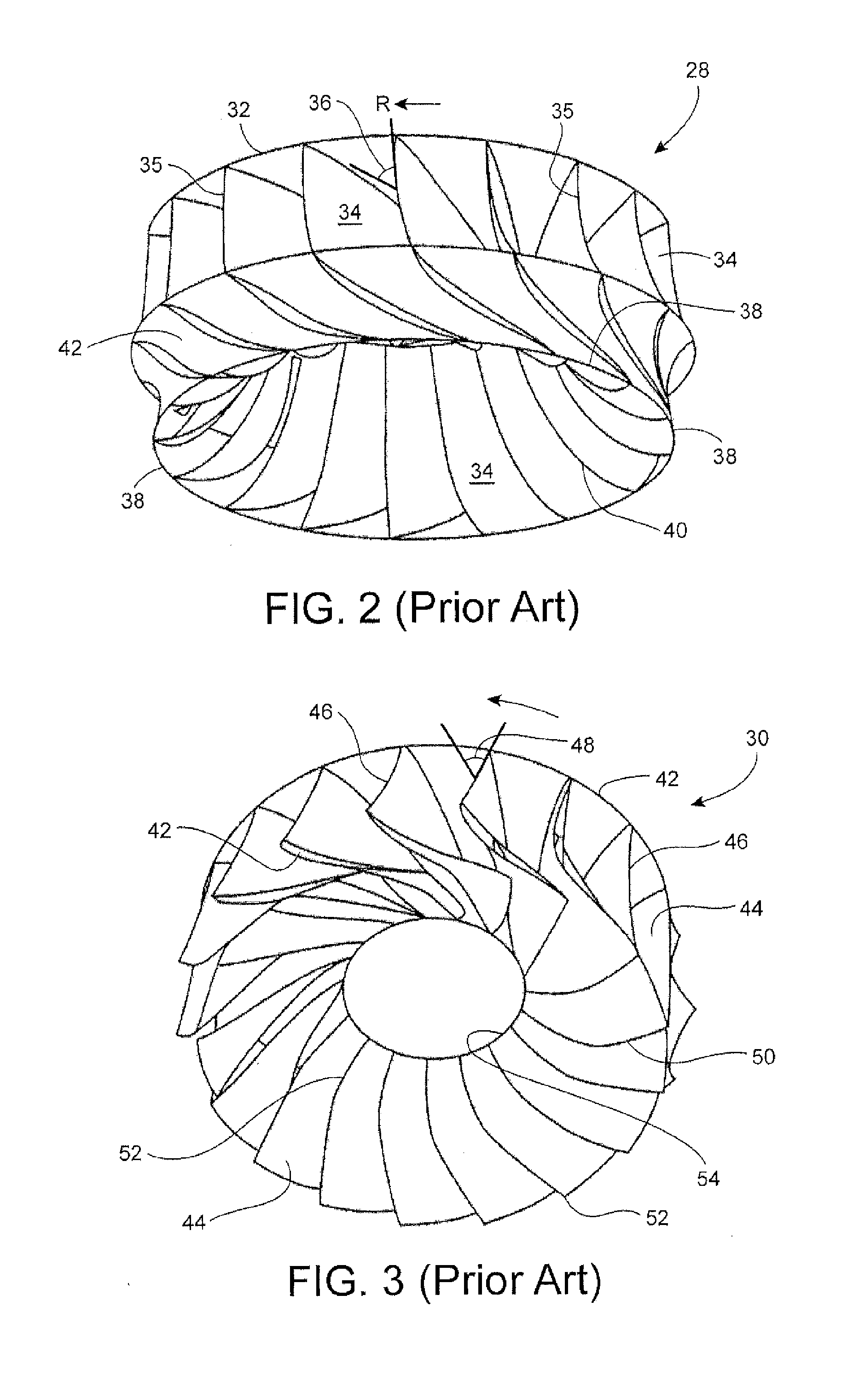

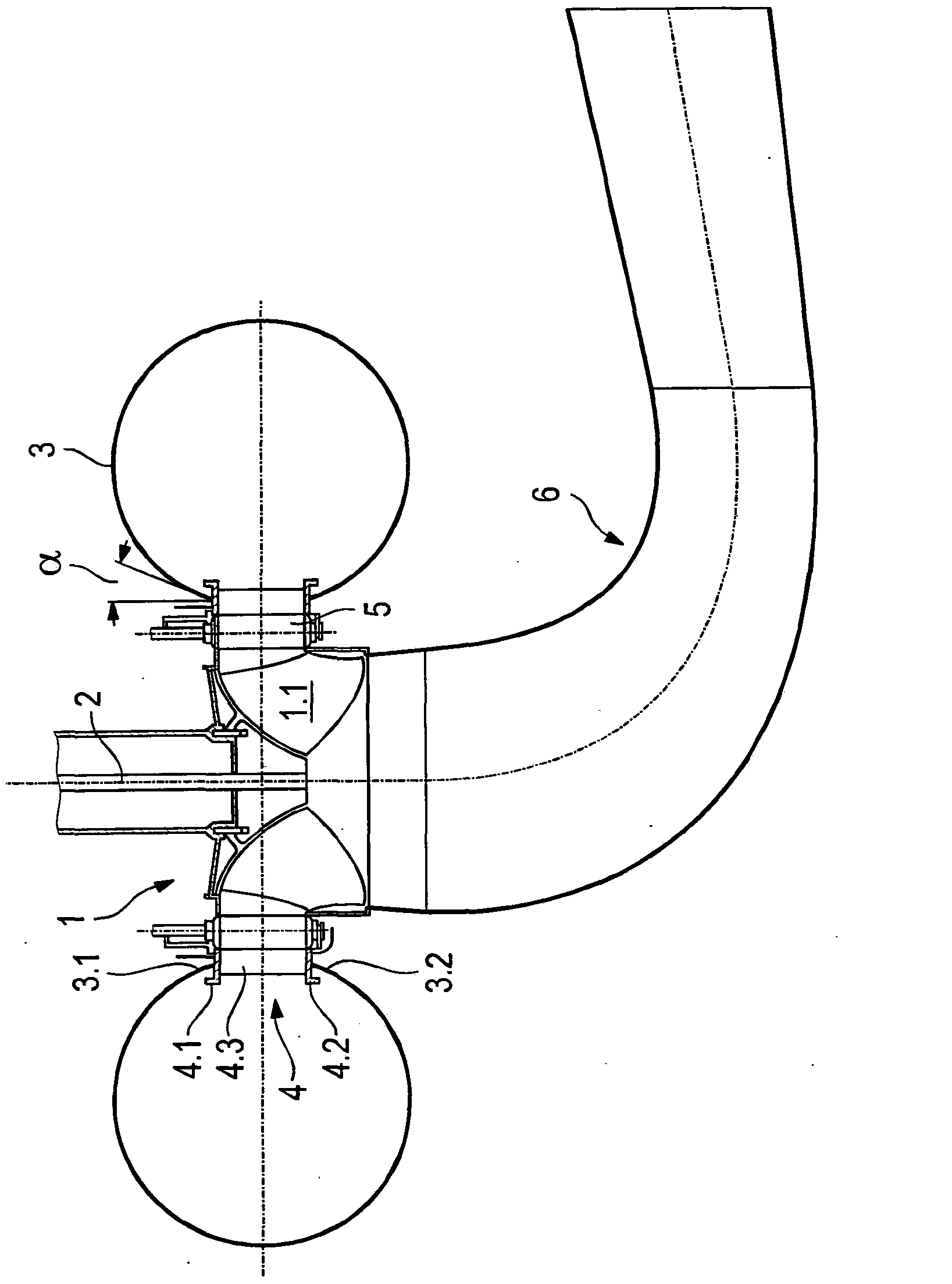

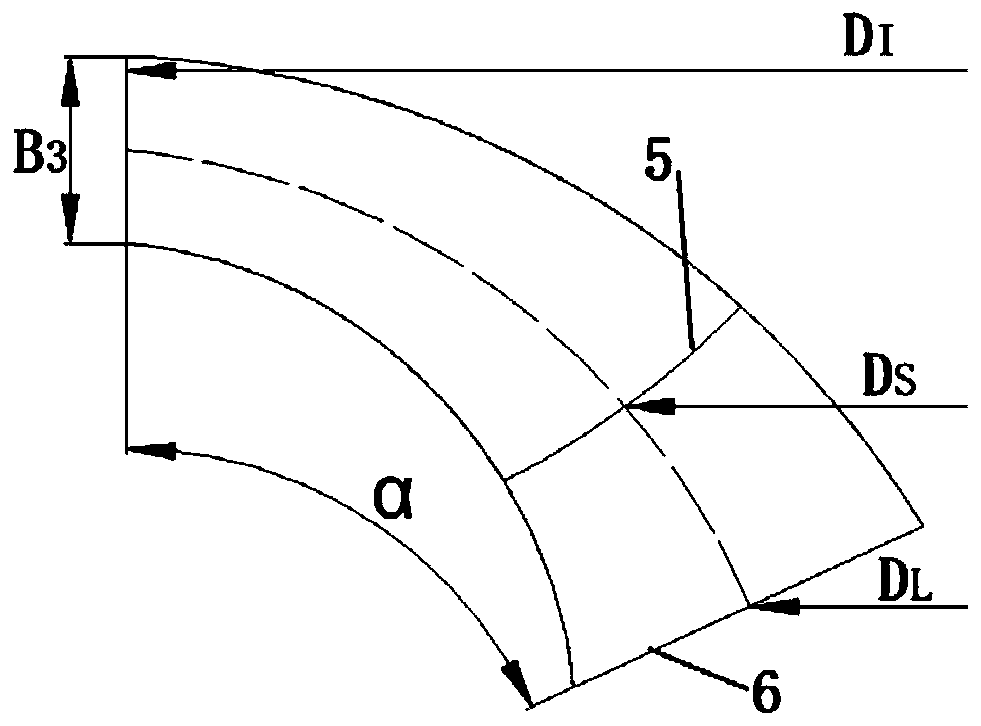

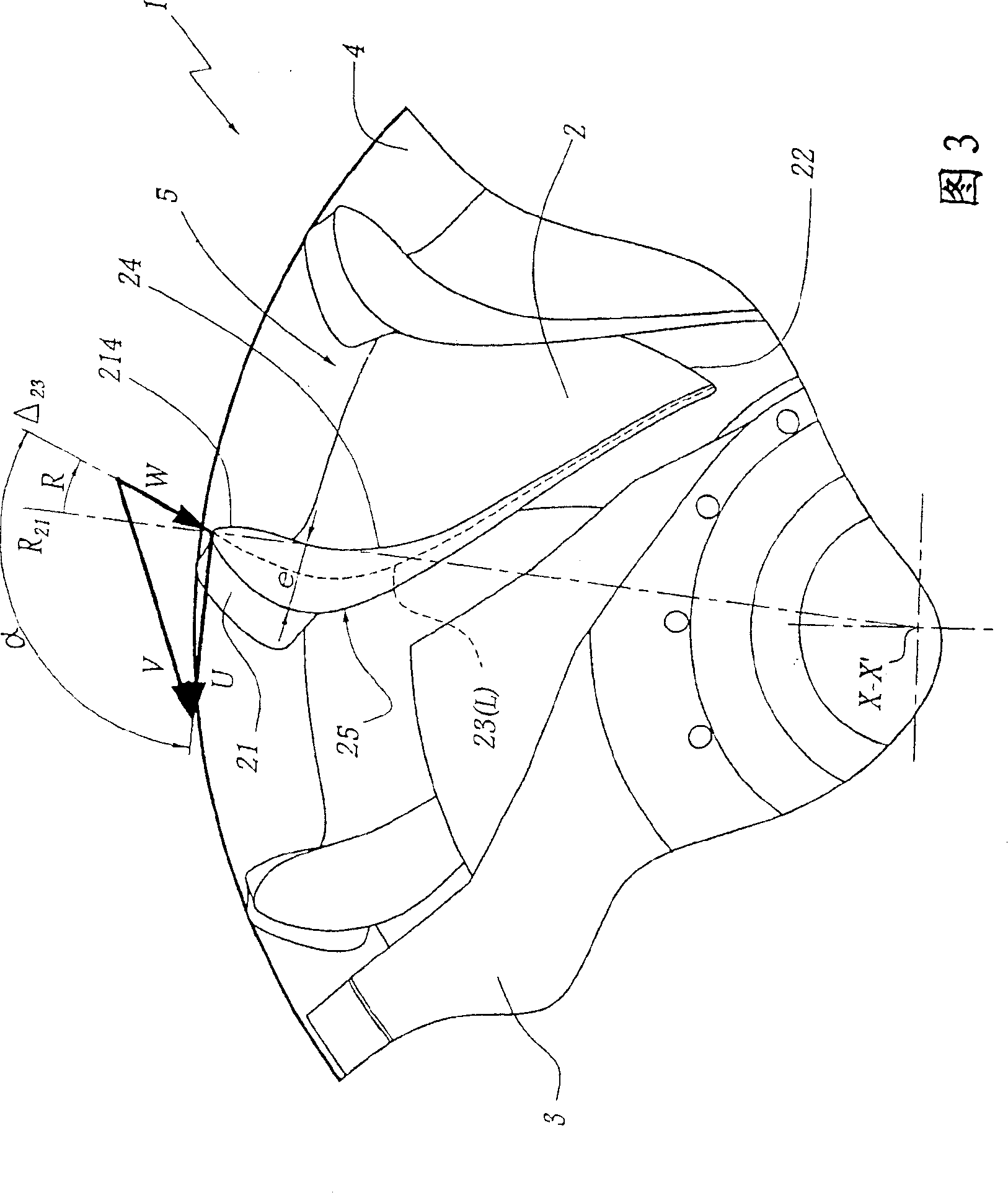

A Francis runner and a hydraulic turbine equipped with such a runner, wherein the runner includes a ceiling, a belt, and blades which extend between the ceiling and the belt and which define liquid flow channels therebetween. A ratio (e / L) of a maximum thickness Ce) of each blade to an average developed length (L) of an average fibre of each blade is between 0.1 and 0.2. At a leading edge of each blade, the average fibre is oriented, over essentially an entire height of the leading edge, along a straight line (Δ23), which forms an angle (α) greater than 90° relative to a line (U) defining a direction of rotation of the leading edge of the runner.

Owner:GE RENEWABLE TECH

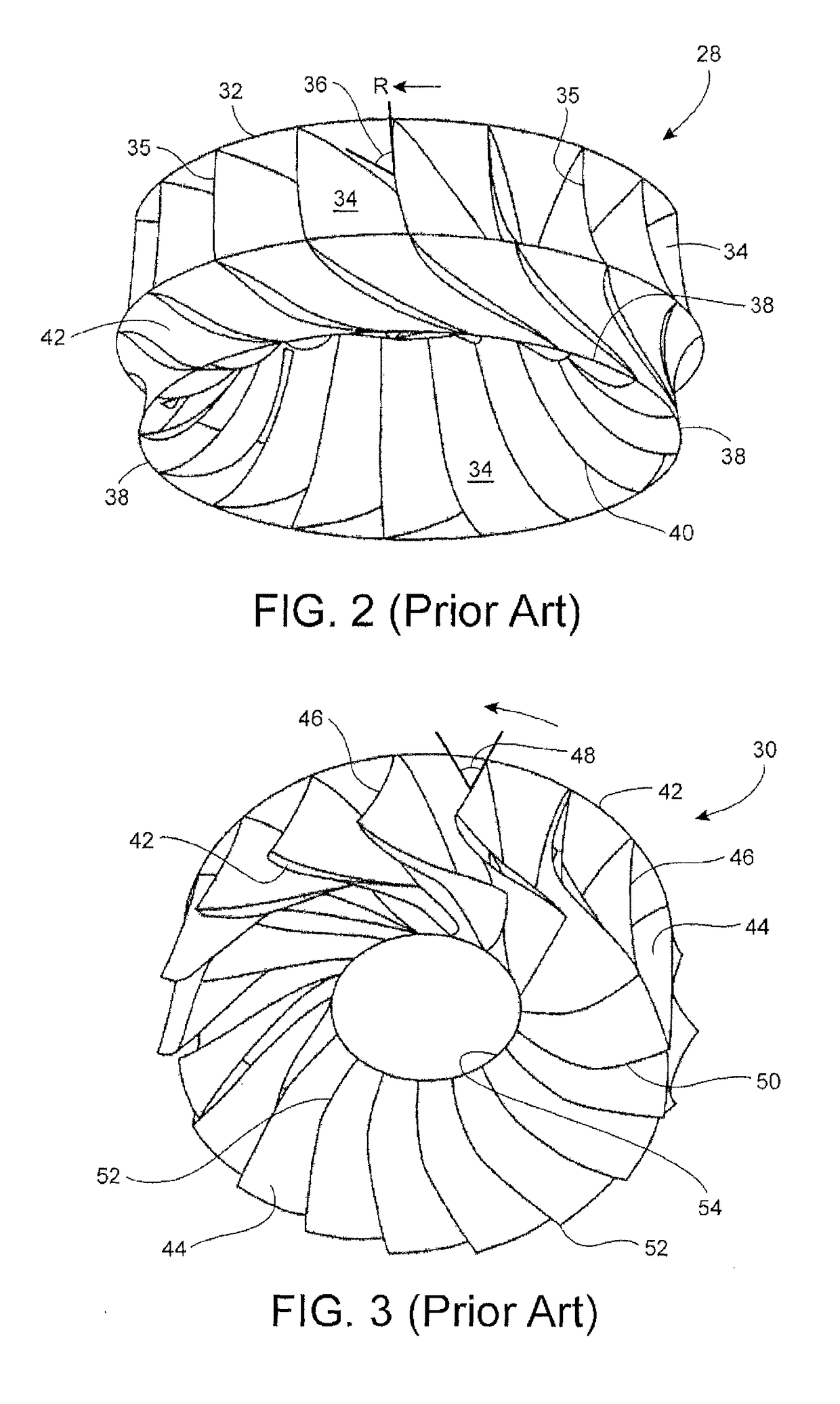

Runner for francis type hydraulic turbine

InactiveUS20060115357A1No negative impact on hydraulic performance or cavitation behaviorReduce stress concentrationPump componentsStatorsStress concentrationWater turbine

There is disclosed a runner for a Francis-type hydraulic turbine where each runner blade has a outlet edge comprising a deflected edge portion. The deflected edge portion is located adjacent to the junction or attachment point of the outlet edge to the band of the runner to define a stress reducing tip extension portion of the blade adjacent the band. This tip extension portion reduces stress concentration adjacent where the outlet edge joins the runner band.

Owner:GENERAL ELECTRIC CANADA MISSISSAUGA

Francis turbine runner with ultra-low specific rotating speed specially used for driving cooling tower fan

ActiveCN101555859AReduce manufacturing costSimple structureHydro energy generationReaction enginesSocial benefitsCooling tower

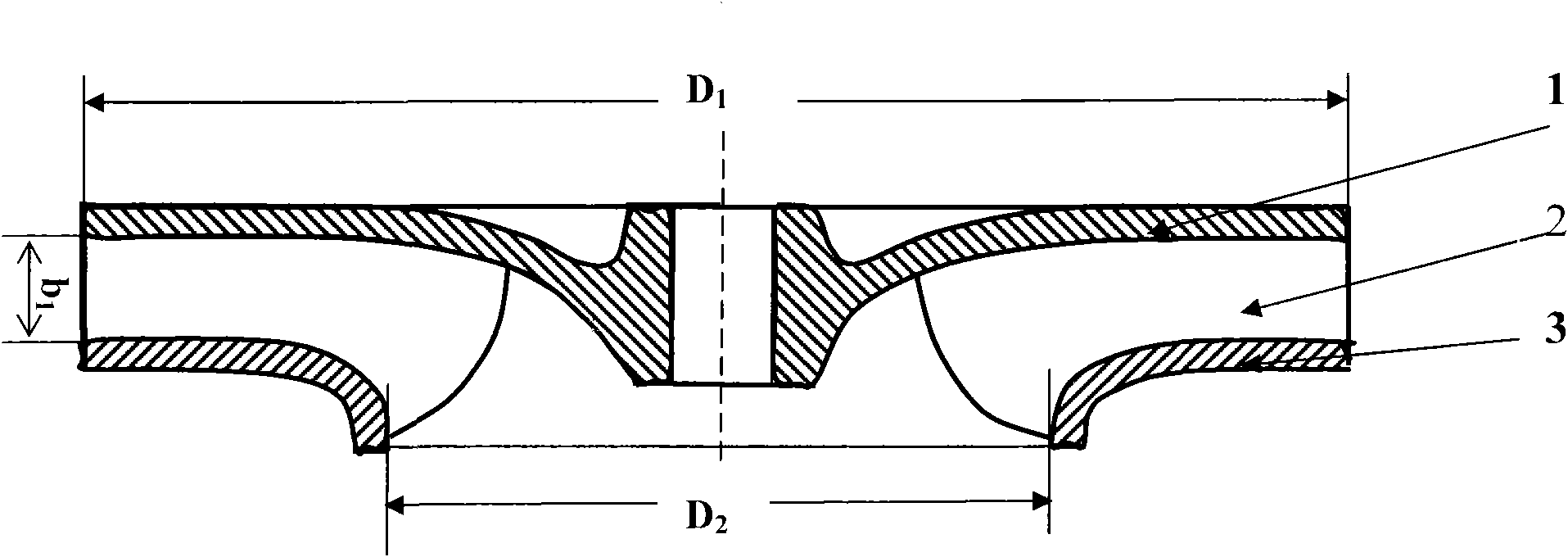

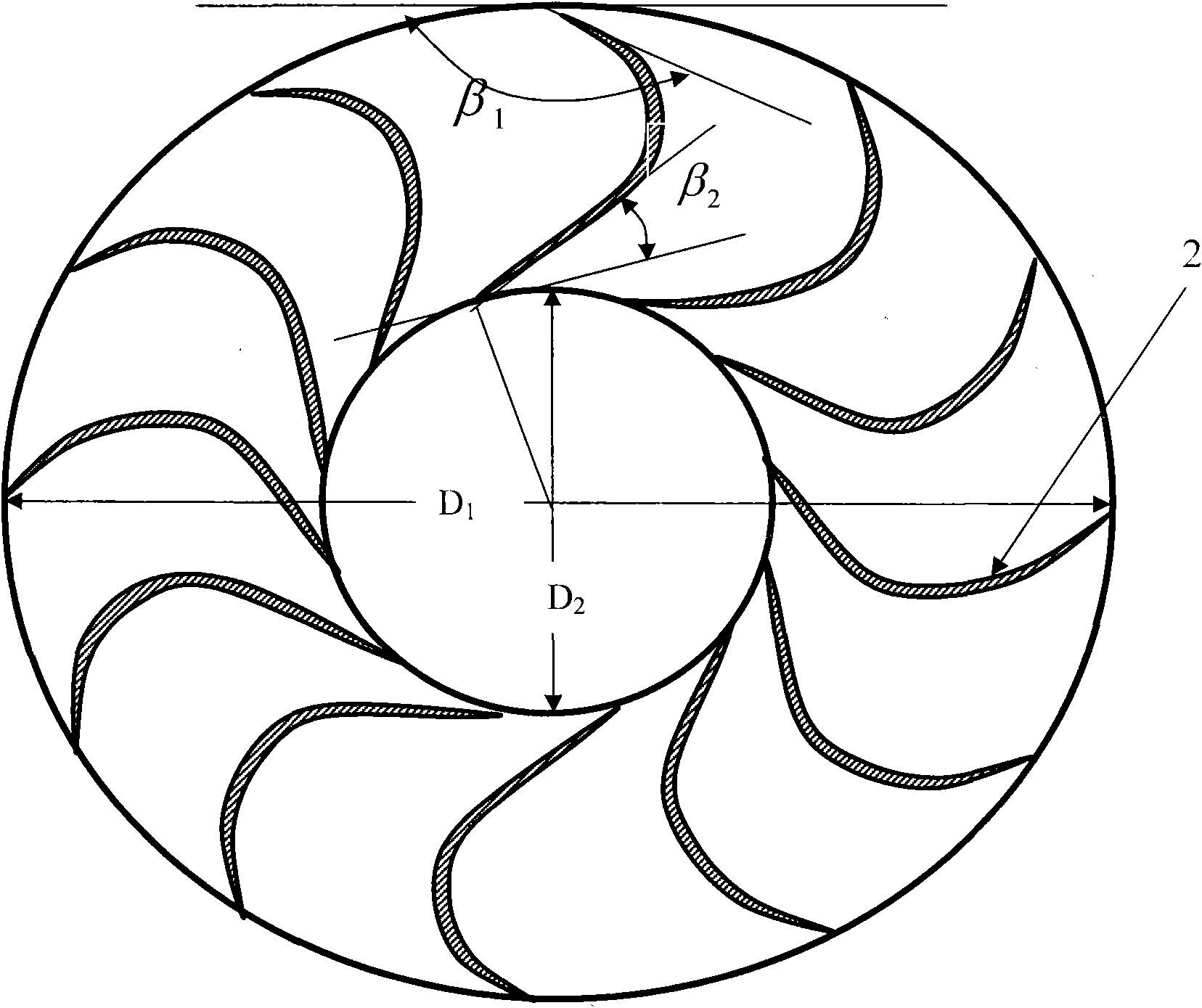

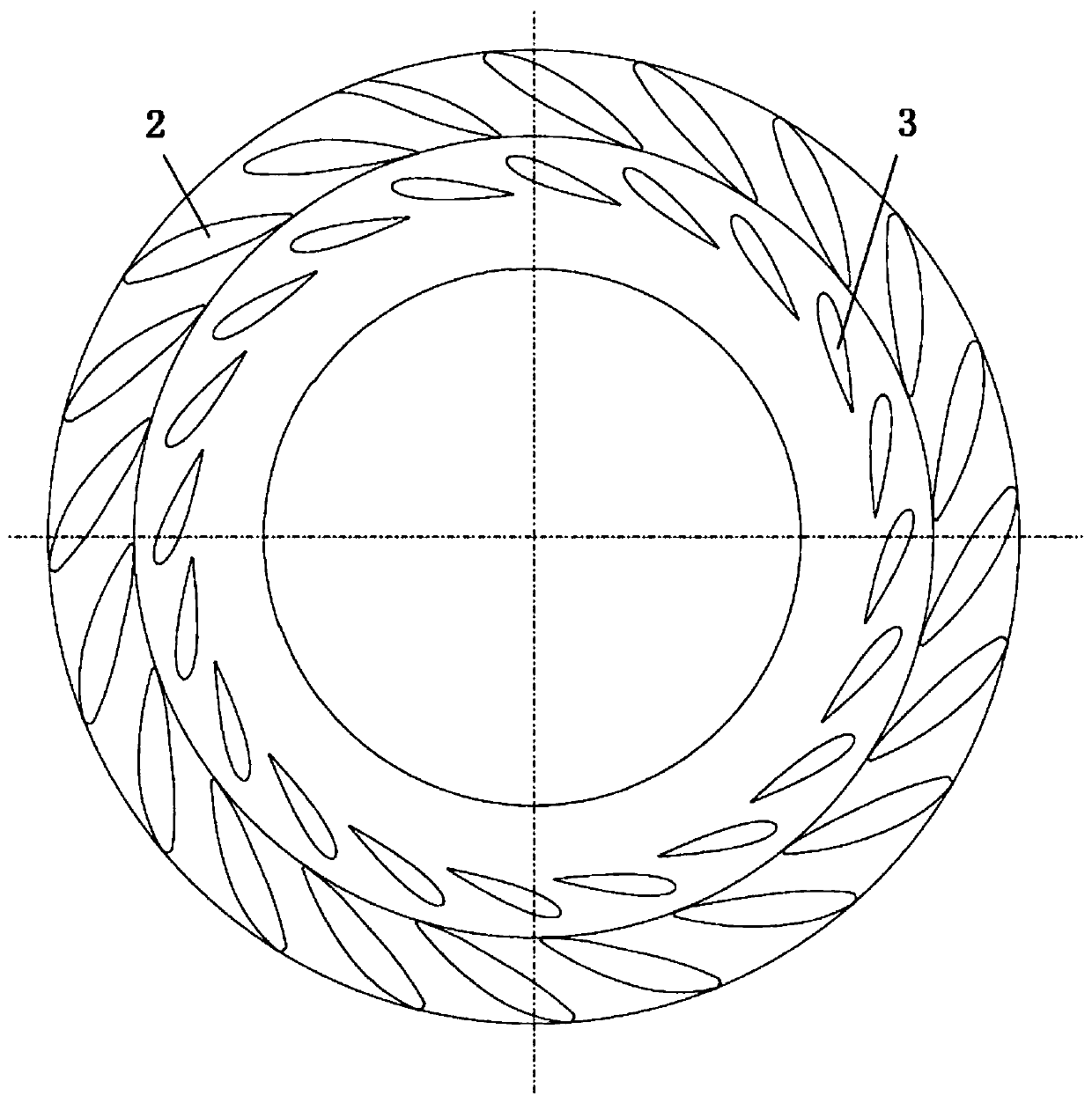

The invention relates to a Francis turbine runner with ultra-low specific rotating speed specially used for a driving cooling tower fan, which effectively solves the problems of the matching of the water turbine runner and the water flow system of the cooling tower and the fan parameters and the reduction of noise and vibration; the structure of the Francis turbine runner is characterized in that vanes are uniformly distributed between an upper coronal and a lower ring; the diameter ratio of a runner inlet and a runner outlet is 1.5-2.5; the ratio of the height of the runner inlet edge and the diameter of the runner outlet is 0.07-0.1; the specific rotating speed of the runner is 60-70m.kW; the unit rotating speed is 40-500r / min; therefore, characteristics of ultra-low rotating speed and ultra-low unit rotating speed are formed; and the space between the vane inlet and the vane outlet is a bent shape and the bending degree is decided by the difference of the vane inlet installation angle and the vane outlet installation angle and the amount of the vanes is 10-19. The Francis turbine runner has unique structure, ultra-low specific rotating speed and ultra-low unit rotating speed, sufficiently utilizes water flow energy, carries out conversion effectively and has excellent stability and huge economical and social benefits.

Owner:河南新飞纪元节能科技股份有限公司

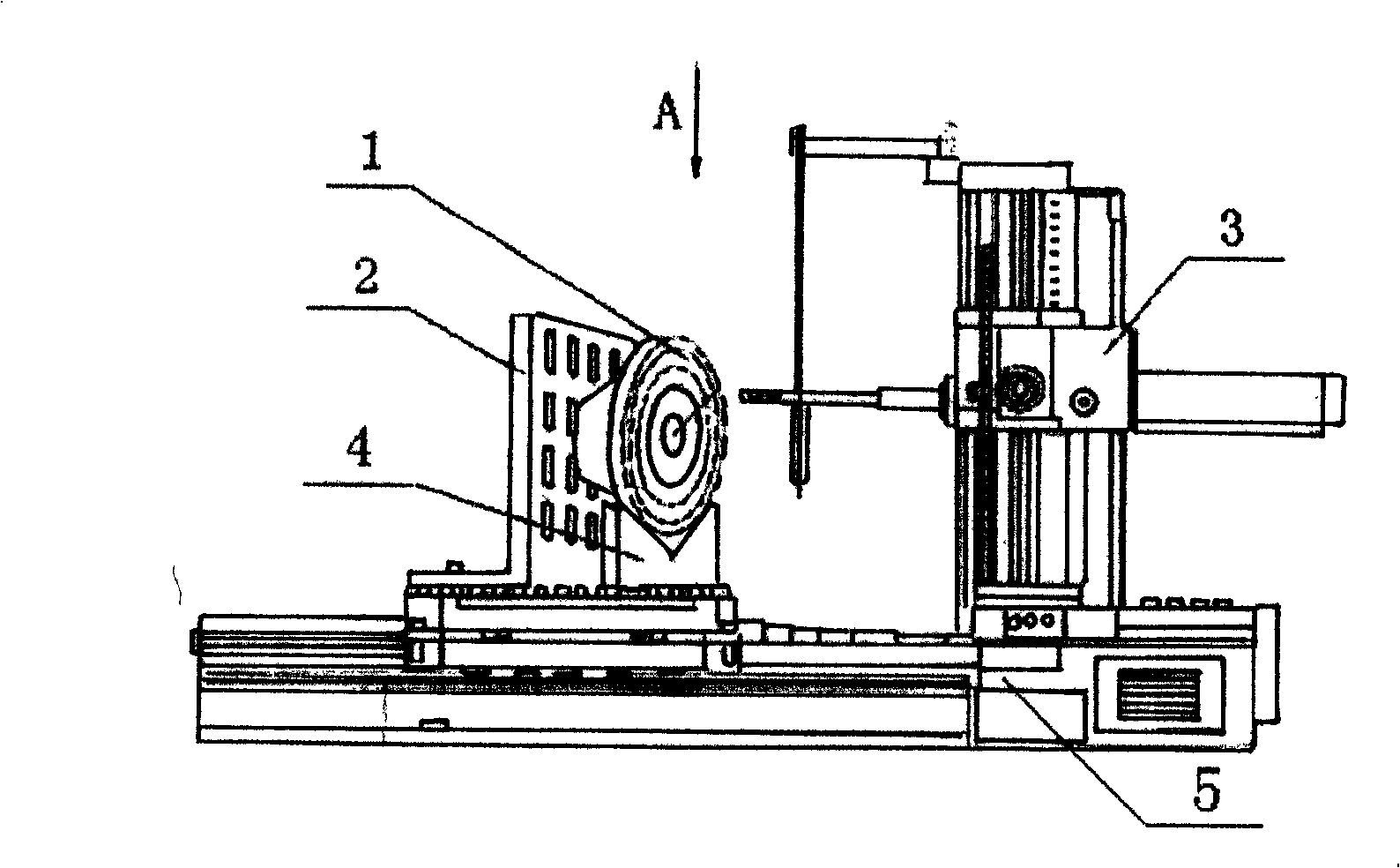

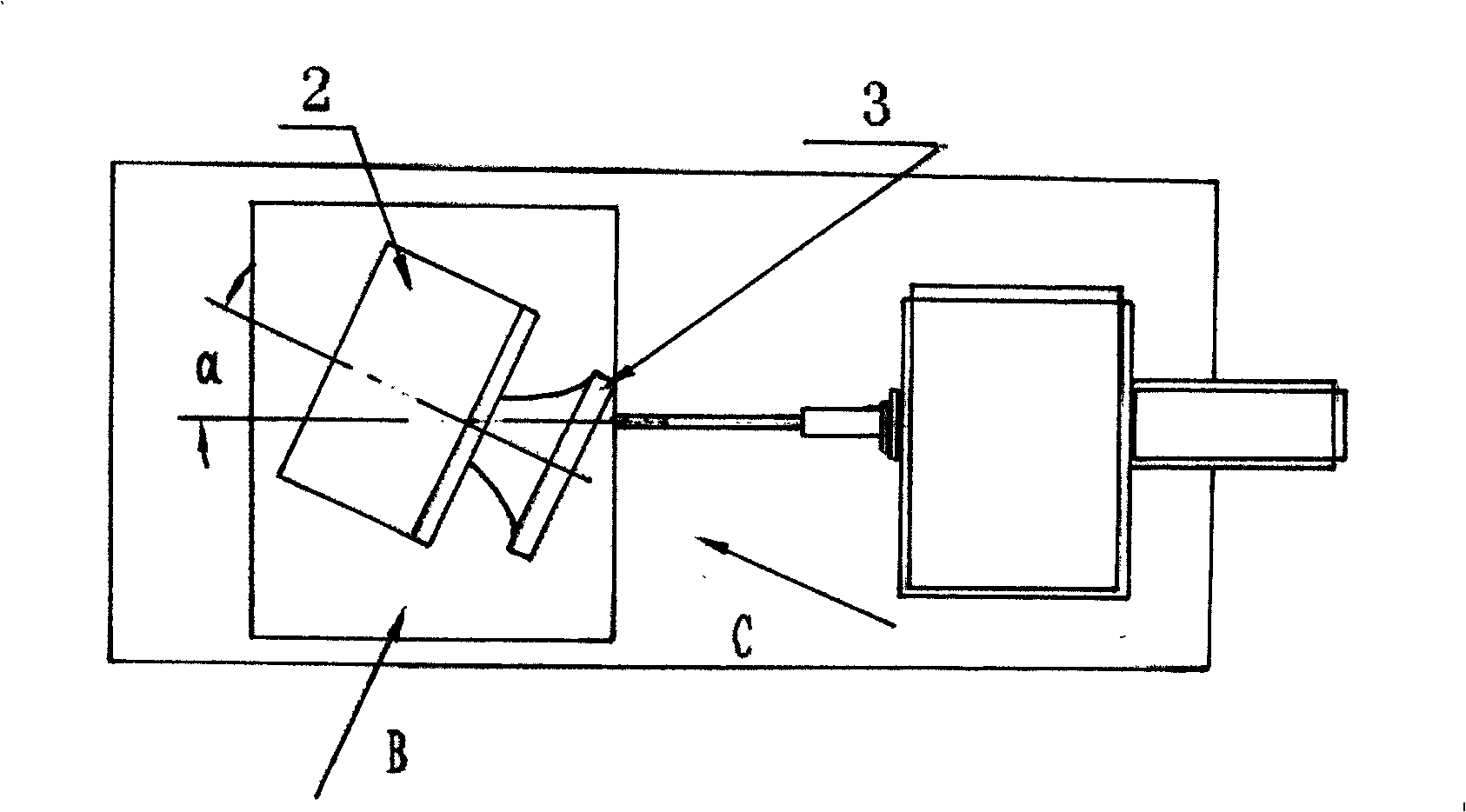

Mixed-flow turbine runner spilled water hole processing technique

InactiveCN101259542AImprove yieldImprove processing qualityHydro energy generationMachines/enginesMixed flowWater turbine

The invention discloses a processing technology of runner drain holes of a Francis turbine, a bored shaft is moved to point to a point to start the drilling according to a coordinate position Beta of the point to start the drilling on a cross central line and an rotation angle Alpha of a top crown that is relative to the bored shaft which are obtained by calculation, a first slant hole is drilled at the point to start the drilling, the bored shaft and the rotation center of the top crown are motionless, the top crown is rotated, thus allowing the point to start the drilling of the next drainage hole on the top crown to be pointed to the central line of the bored shaft and carrying out the processing of other holes sequentially. The processing method of the drain holes of the crown simplifies the processing steps, improves the processing precision and provides the powerful guarantee for the long-term stable operation of the Francis turbine unit.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

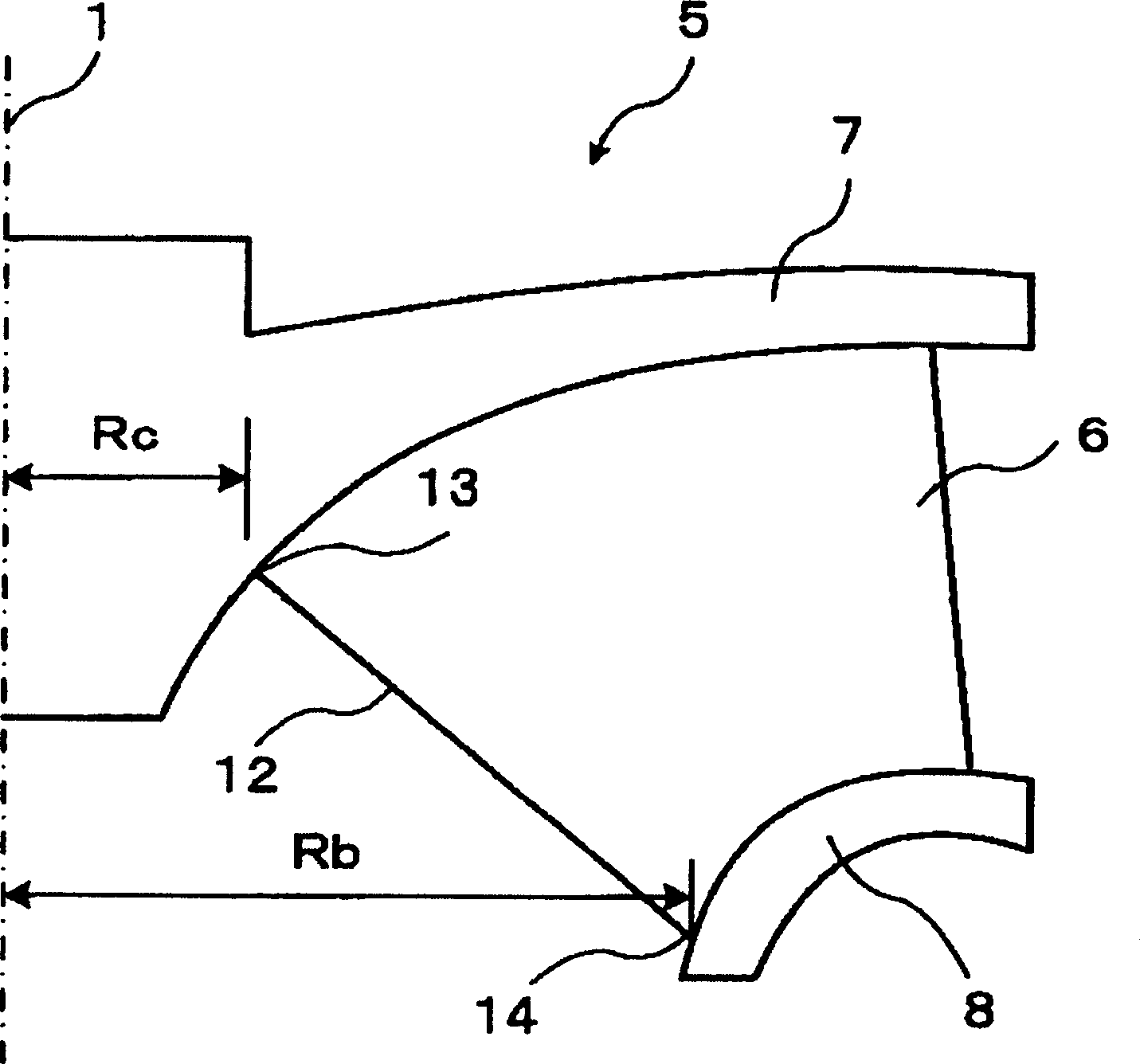

Francis turbine

InactiveUS20050089404A1Easy to shapeReduce componentsPropellersRotary propellersTrailing edgeFrancis turbine

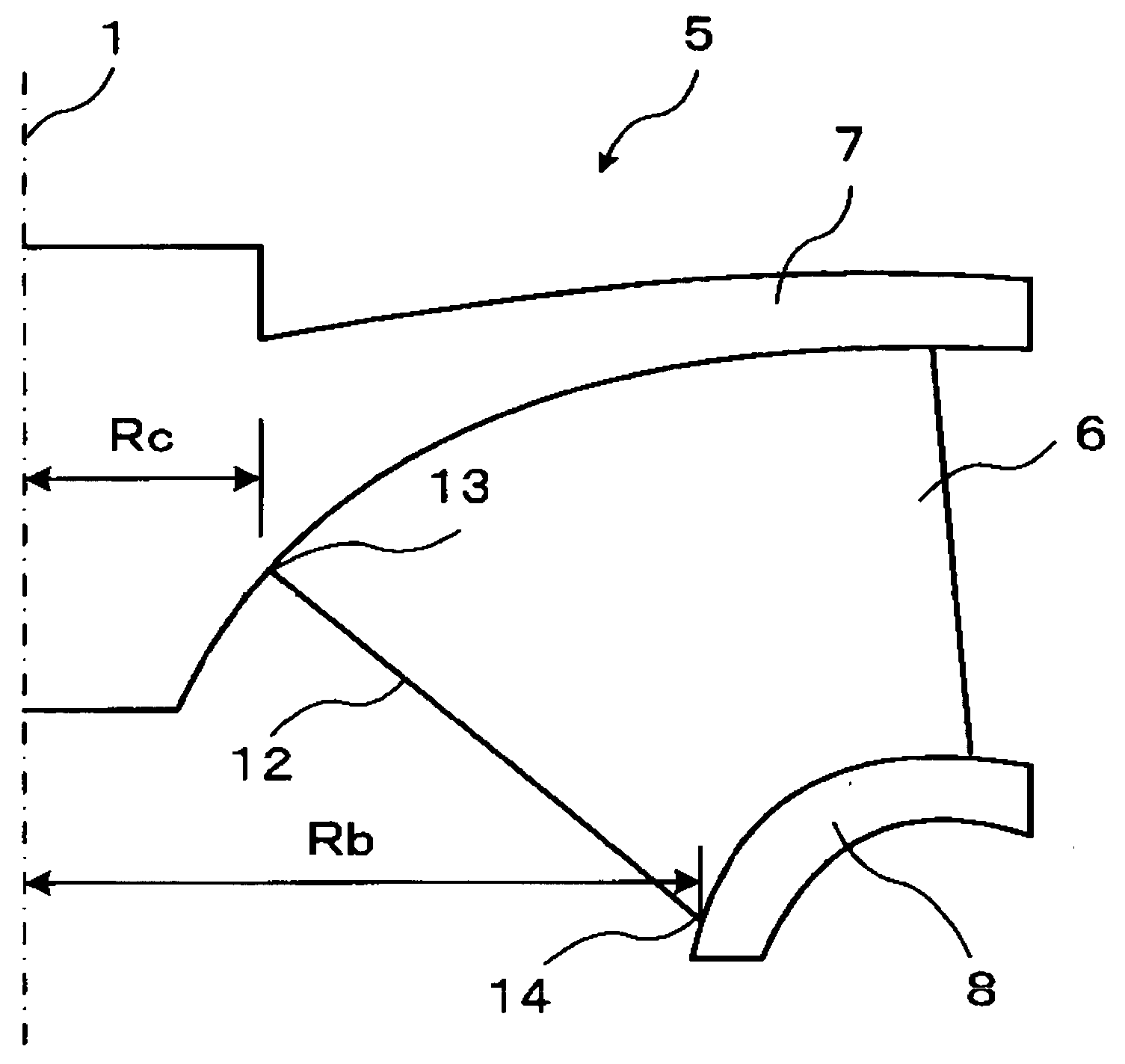

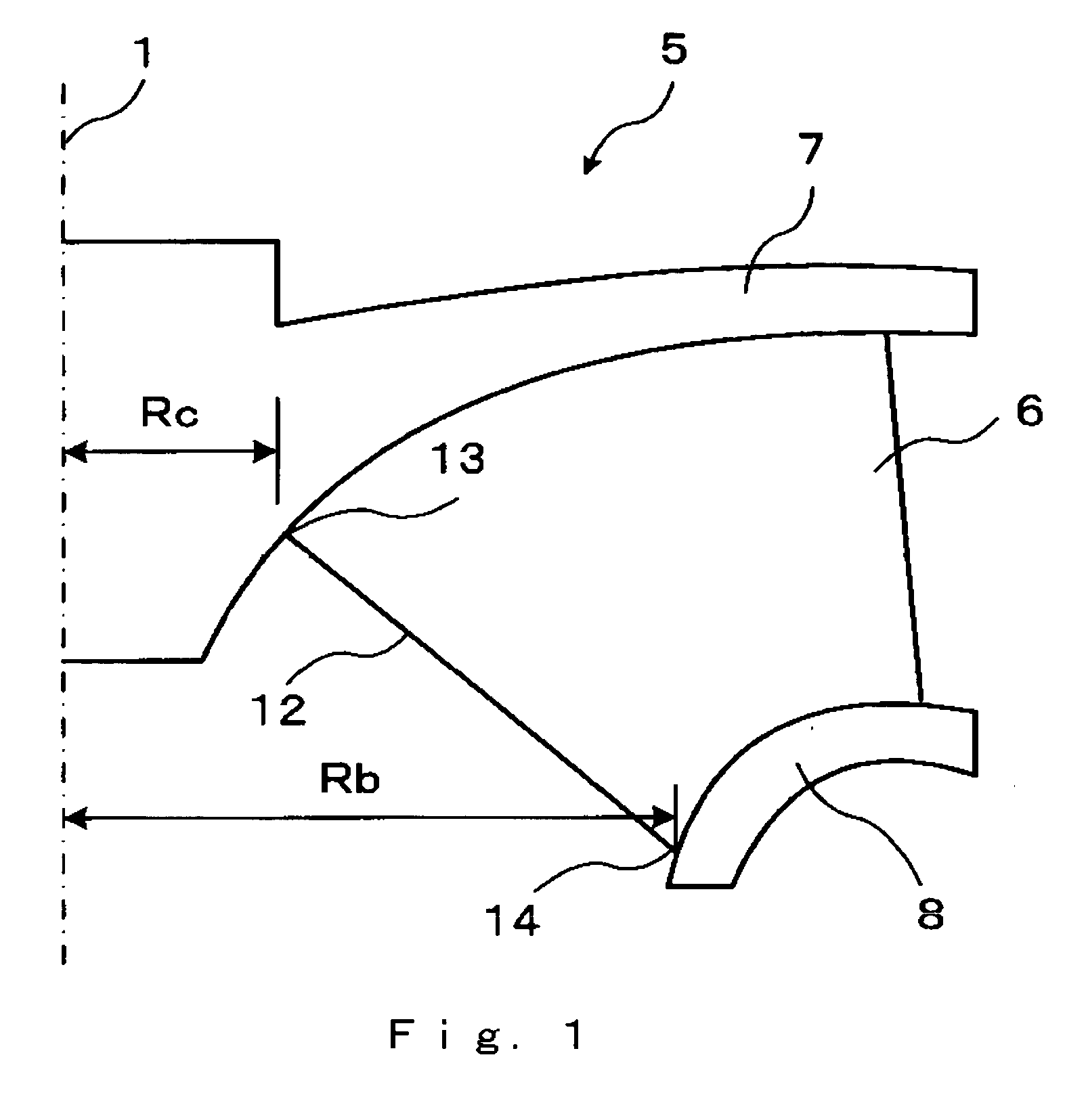

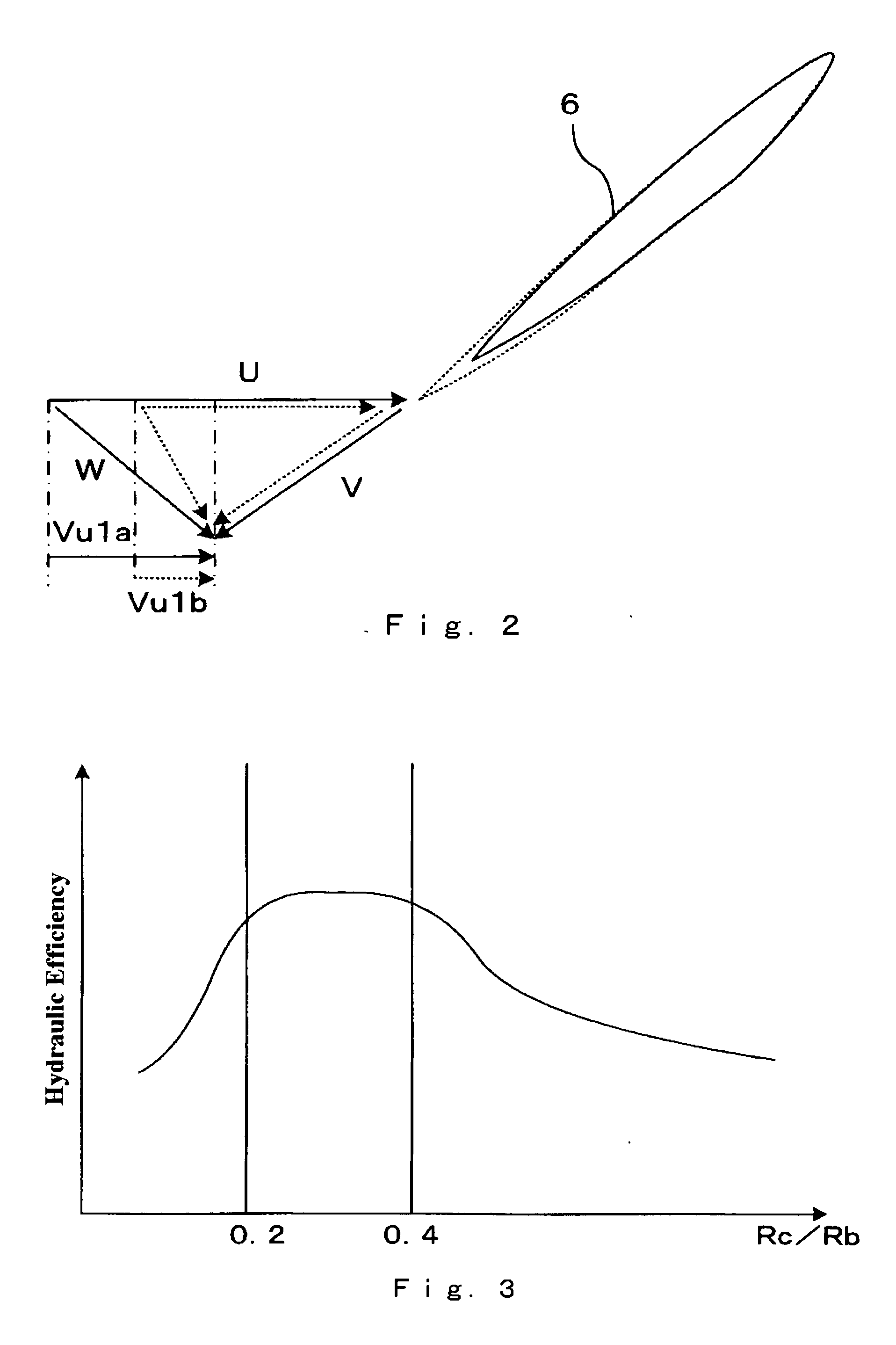

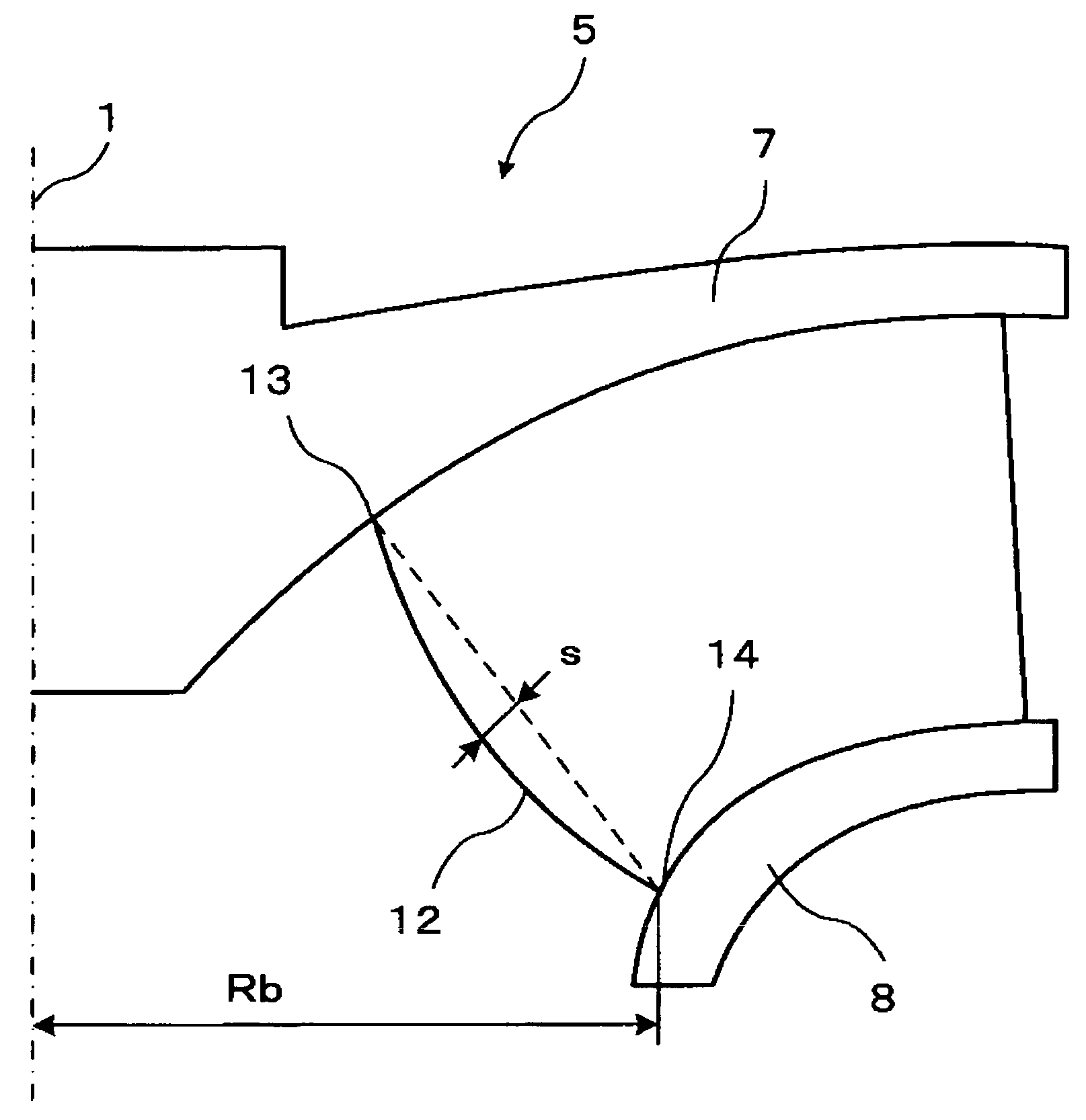

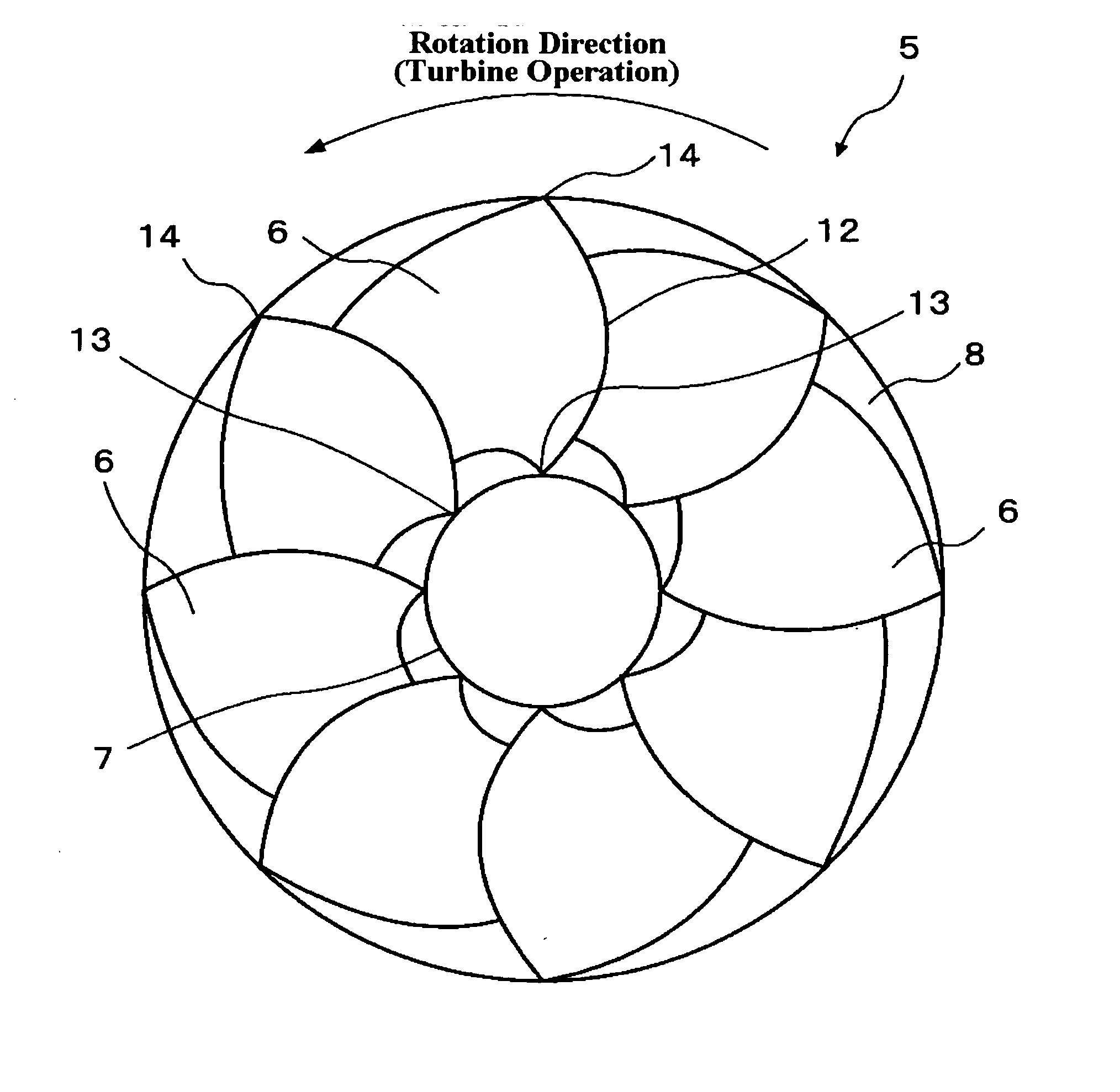

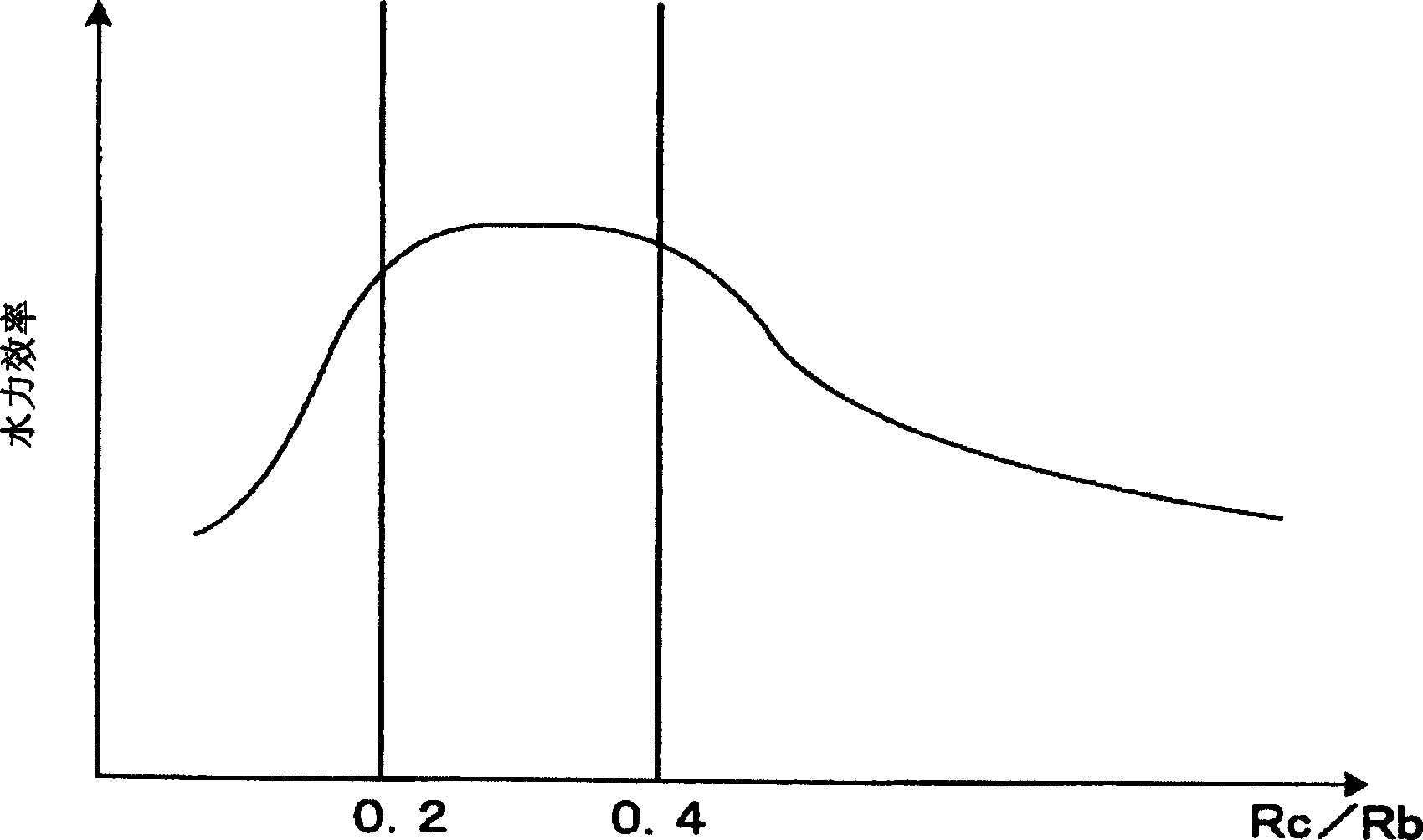

A Francis turbine with an improved shape of blades, which can reduce a circumferential velocity component generated in the flow downstream of the blades in a condition of a partial load operation, or reduce the secondary flow around the blades, is provided. A Francis turbine comprises a crown, a plurality of blades, and a band. The crown can rotate around a rotating axis. The blades are circumferentially arranged on the crown, each of which including an inner end as a trailing edge. The band is coaxially coupled with the crown by the blades. A distance Rc can be defined as a distance between the rotation axis and an end by the crown side of the trailing edge. A distance Rb can be defined as a distance between the rotation axis and an end by the band side of the trailing edge. The distance Rc and the distance Rb satisfy 0.2≤RcRb≤0.4.

Owner:KK TOSHIBA

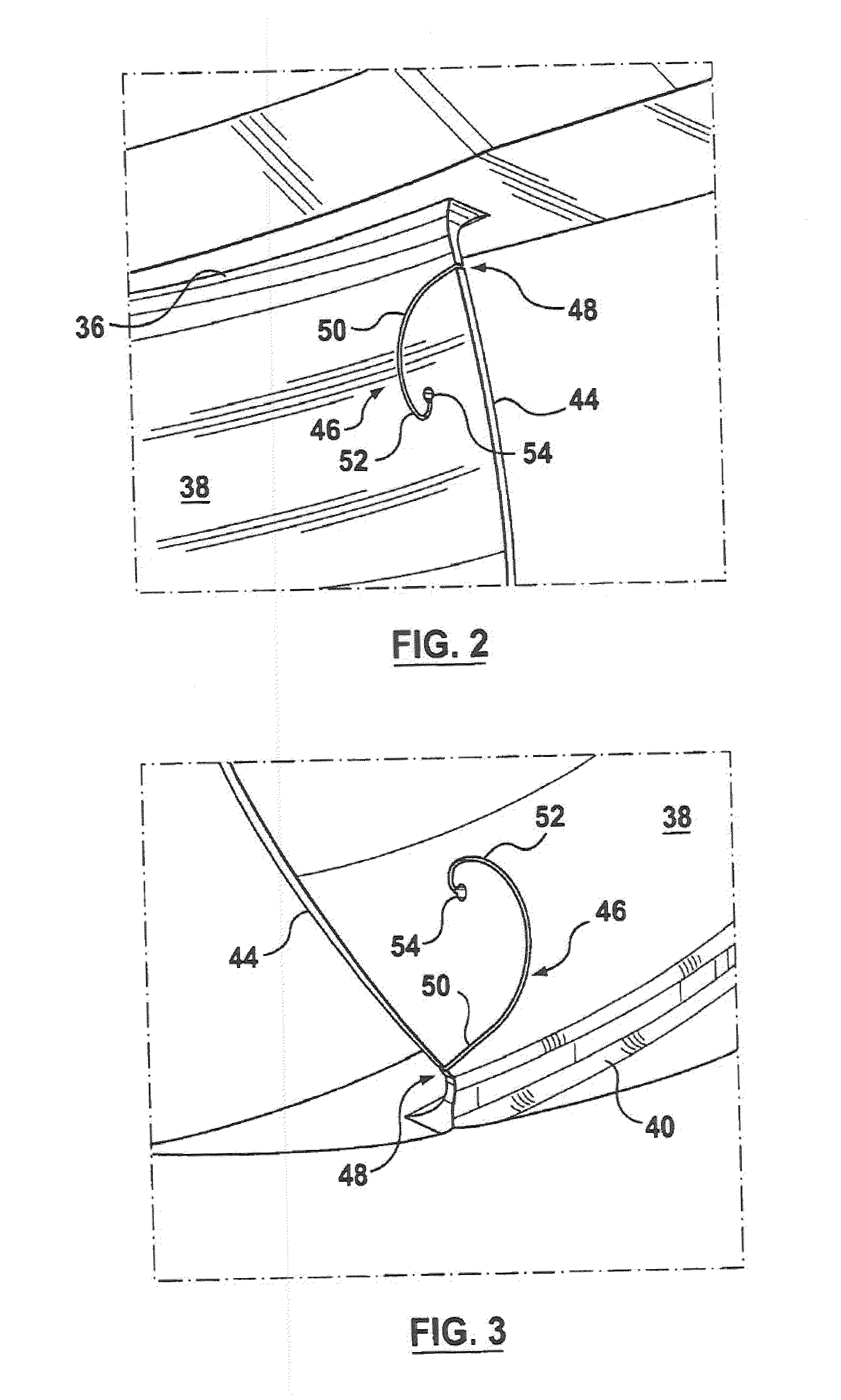

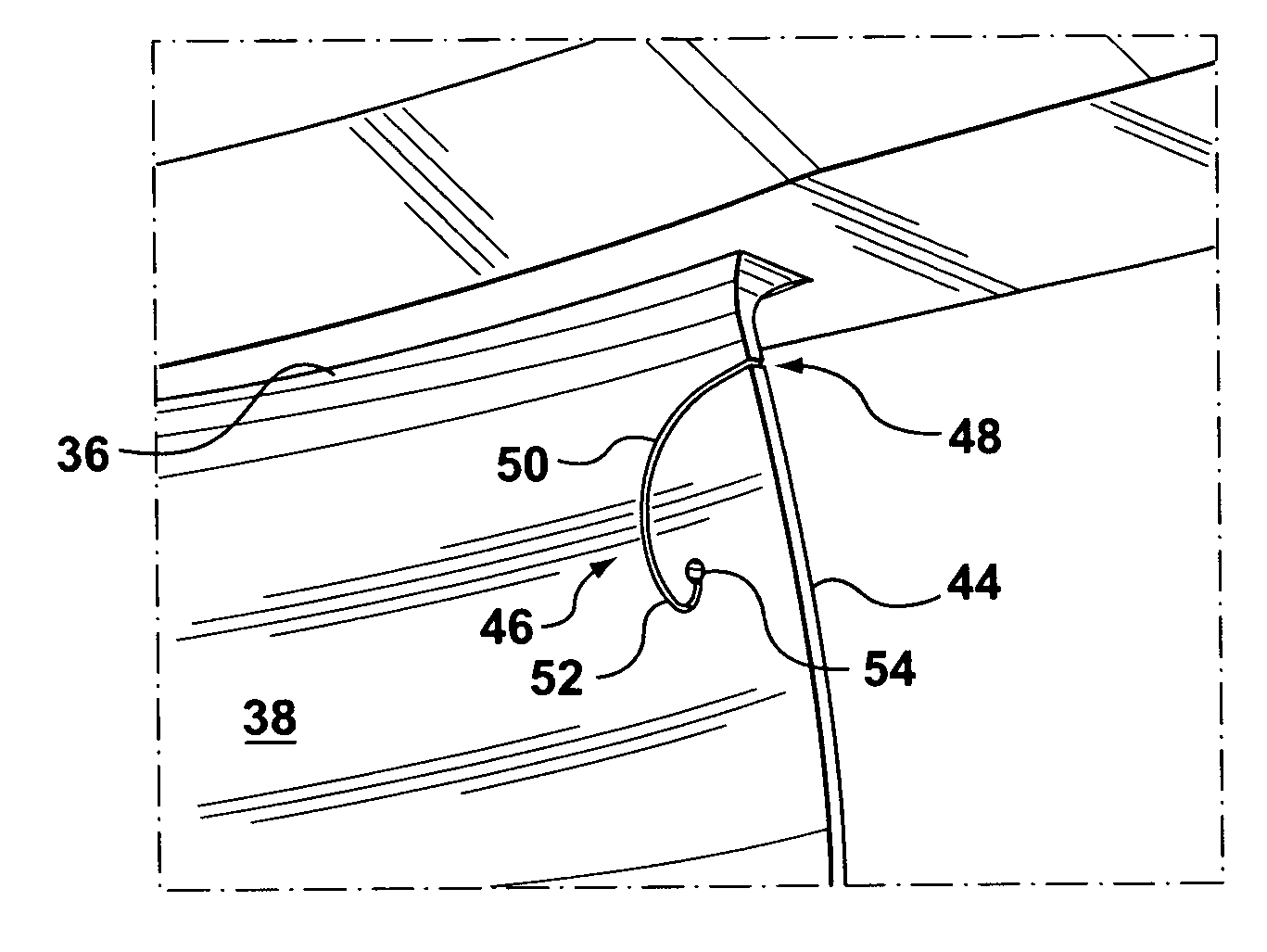

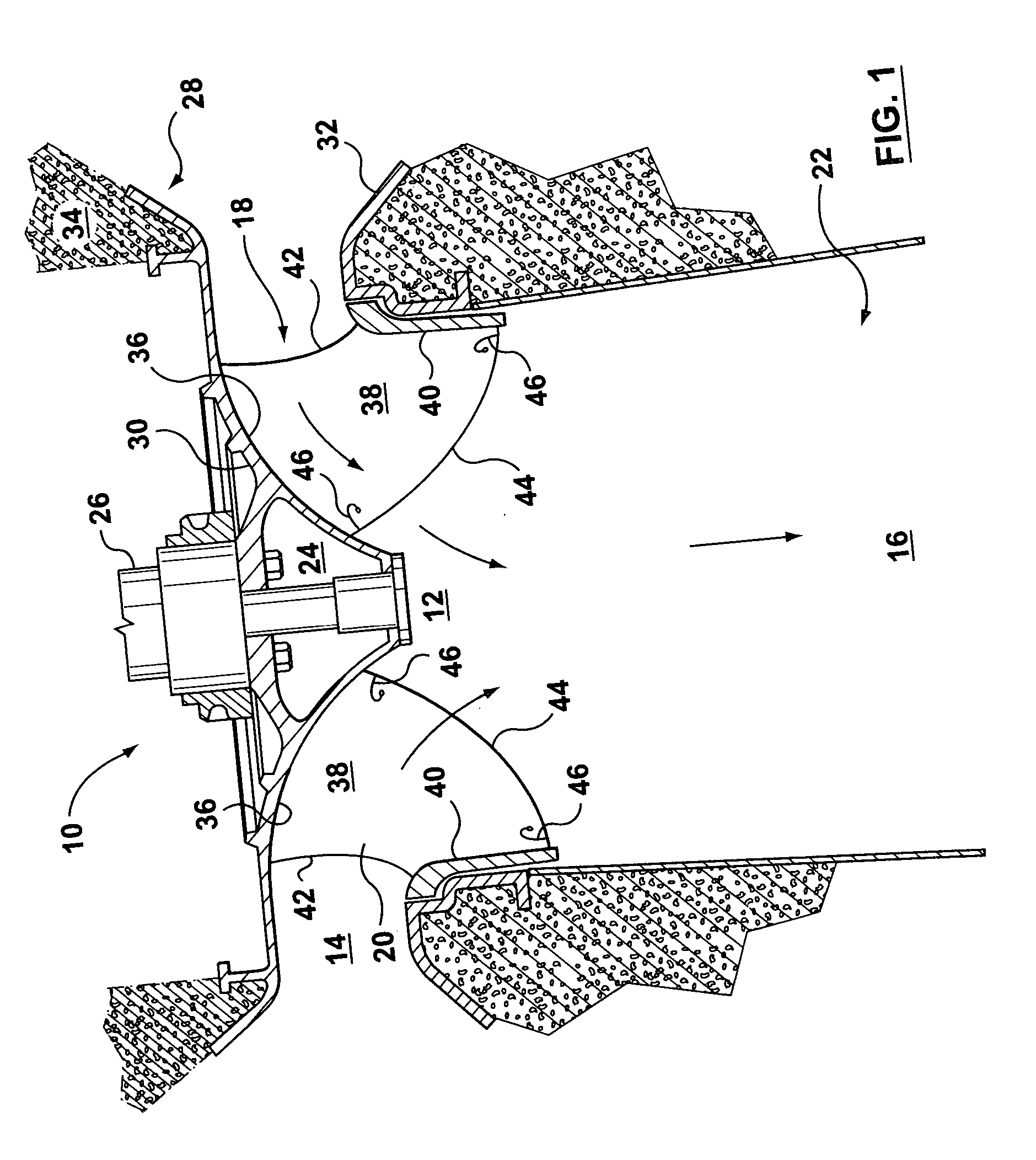

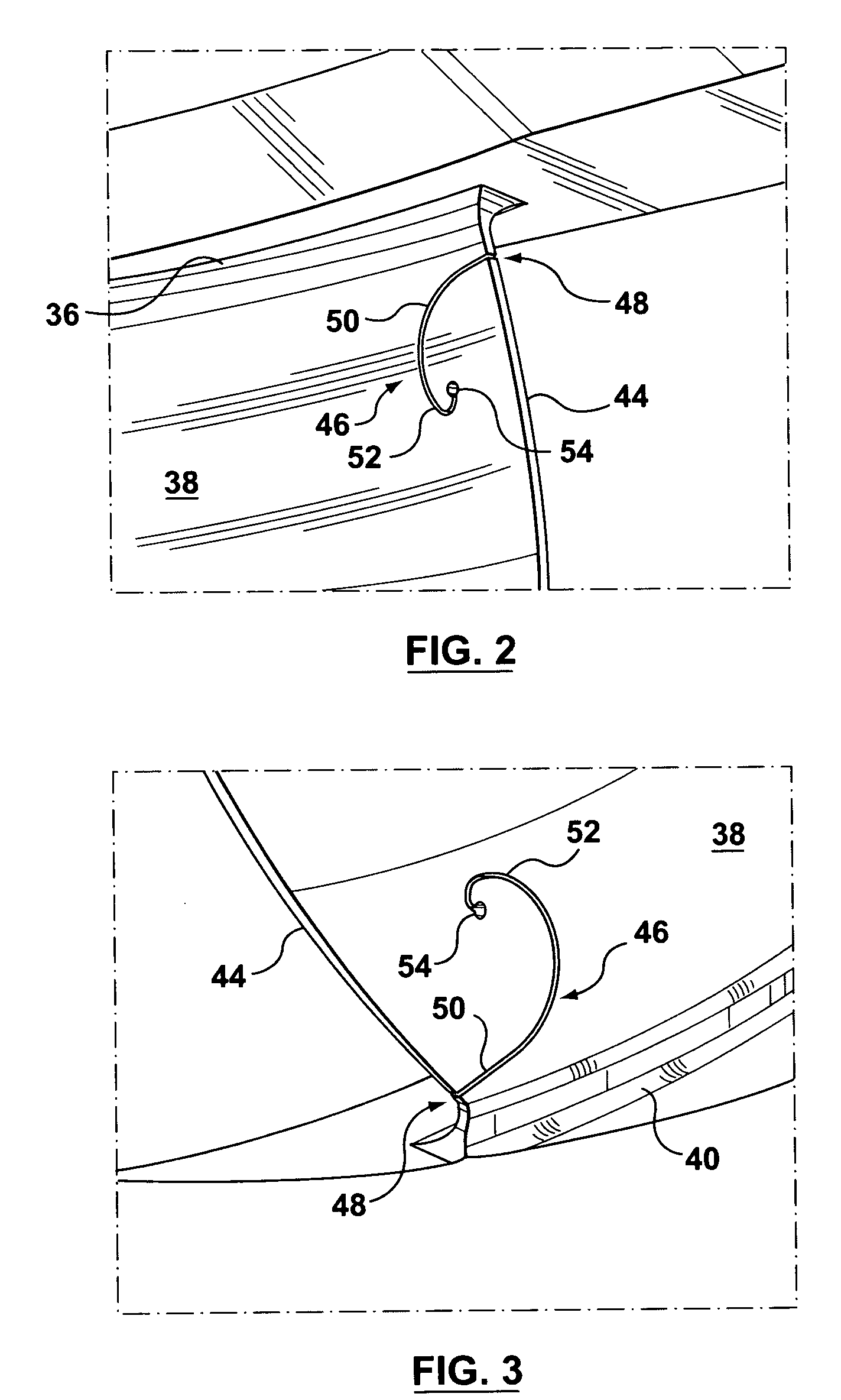

Stress relief grooves for Francis turbine runner blades

InactiveUS7736128B2Efficient loadingGood effectPropellersBlade accessoriesStress relievingStress relief

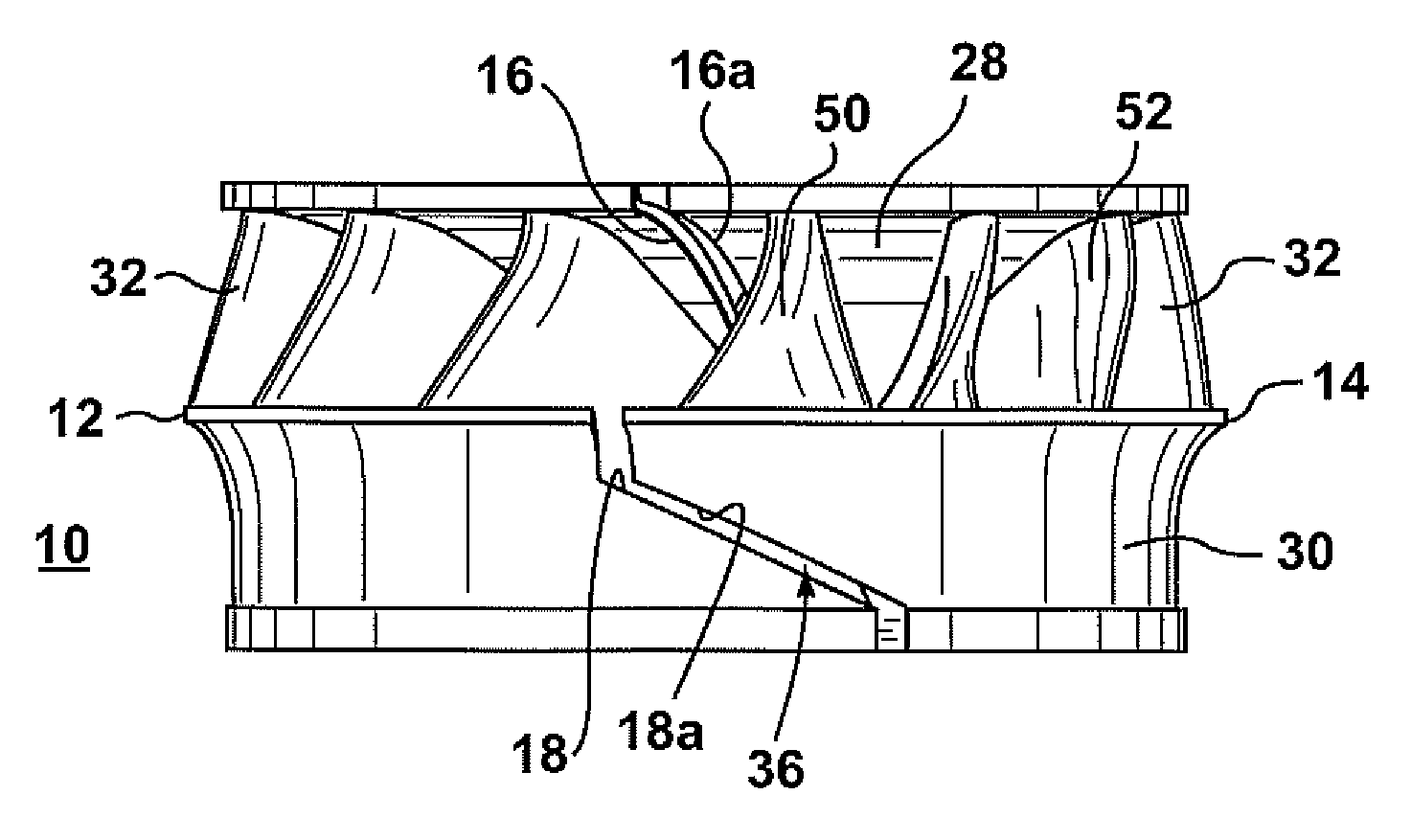

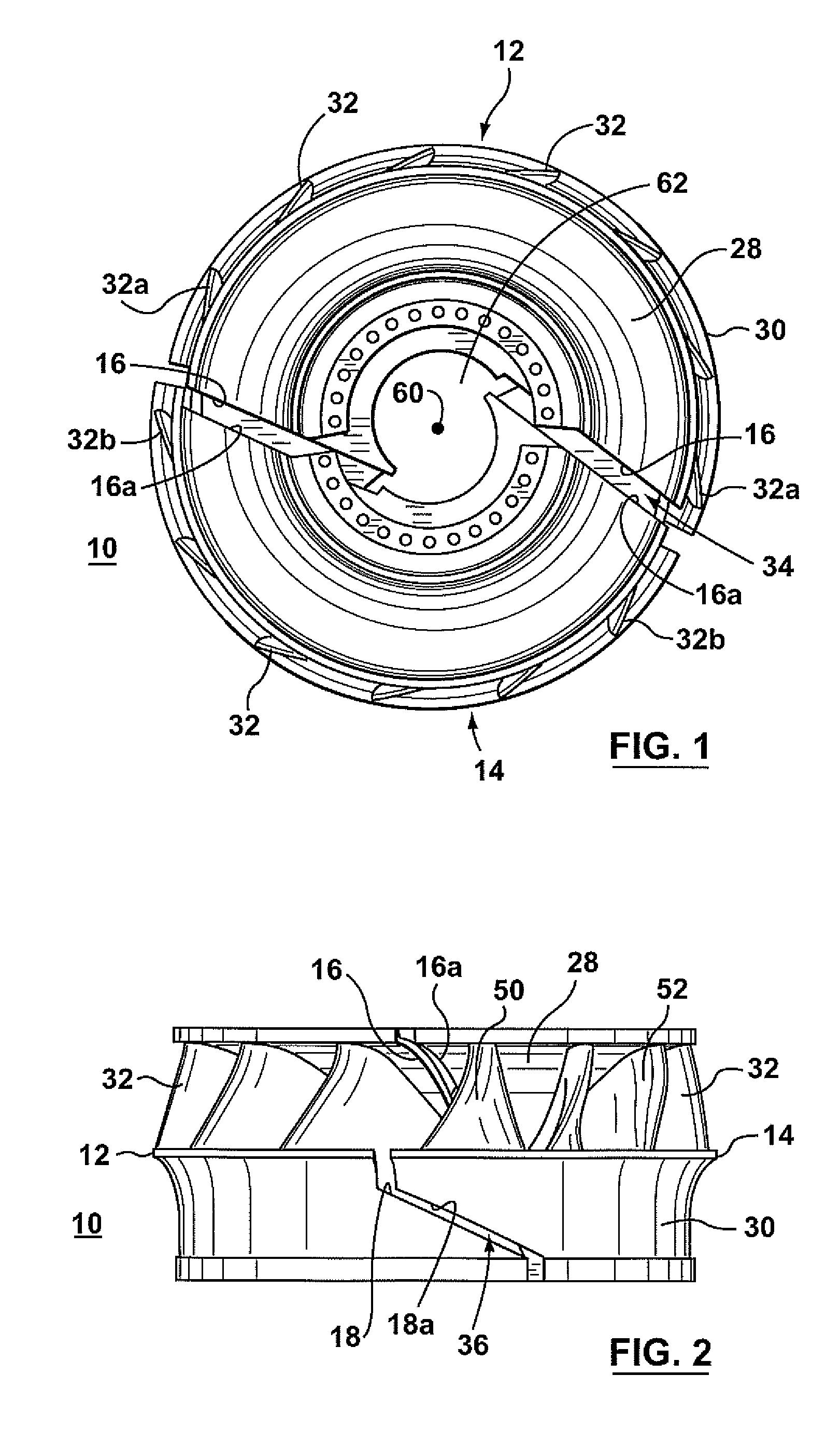

There is disclosed a runner for a Francis-type hydraulic turbine where each runner blade has an outlet edge with two stress relieving grooves cut through the blade from the outlet edge adjacent the crown and the band. The grooves each present an opening across the outlet edge and the grooves each extend a predetermined distance from the outlet edge into the blade.

Owner:GENERAL ELECTRIC CANADA MISSISSAUGA

Francis turbine

InactiveUS7195459B2Easy to shapeReduce componentsPropellersPump componentsTrailing edgeFrancis turbine

A Francis turbine with an improved shape of blades, which can reduce a circumferential velocity component generated in the flow downstream of the blades in a condition of a partial load operation, or reduce the secondary flow around the blades, is provided. A Francis turbine comprises a crown, a plurality of blades, and a band. The crown can rotate around a rotating axis. The blades are circumferentially arranged on the crown, each of which including an inner end as a trailing edge. The band is coaxially coupled with the crown by the blades. A distance Rc can be defined as a distance between the rotation axis and an end by the crown side of the trailing edge. A distance Rb can be defined as a distance between the rotation axis and an end by the band side of the trailing edge. The distance Rc and the distance Rb satisfy0.2≤RcRb≤0.4.

Owner:KK TOSHIBA

Francis turbine

A Francis turbine with an improved shape of blades, which can reduce cavitations generated on the surface of the blades or reduce the secondary flow around the blades, is provided. A Francis turbine comprises a rotating shaft, a crown, a plurality of blades, and a band. The crown can rotate with the rotating shaft. The blades are circumferentially arranged on the crown, each of which including an inner end as a trailing edge. The band is coaxially coupled with the crown by the blades. The rotating shaft, the crown, the blades, and the band as a whole rotate toward a turbine direction during a turbine operation. A projected profile of the trailing edge on a perpendicular plane, which is perpendicular to a center axis of the rotating shaft, is curved toward a direction opposite to the turbine direction at least in the crown side.

Owner:KK TOSHIBA

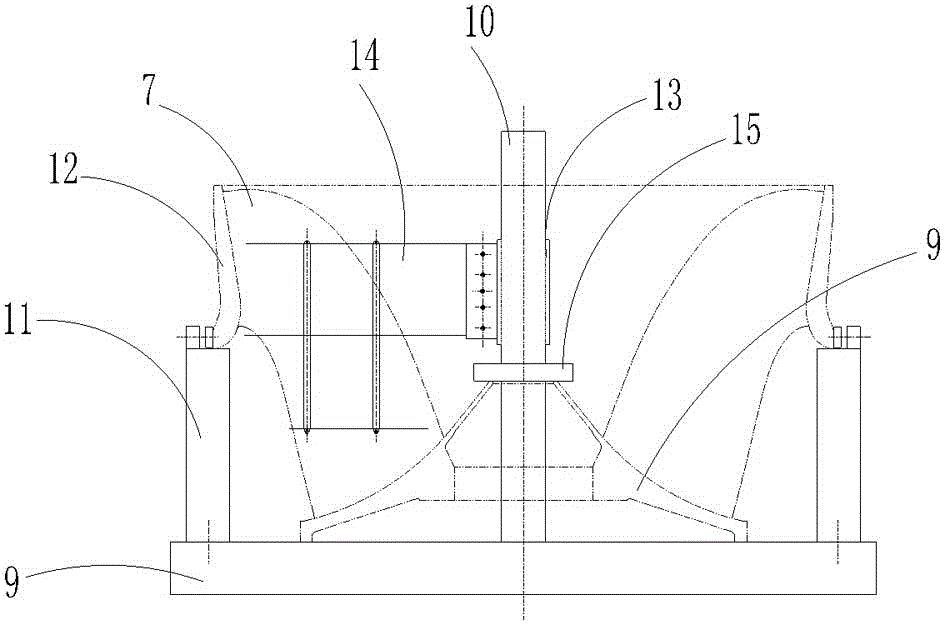

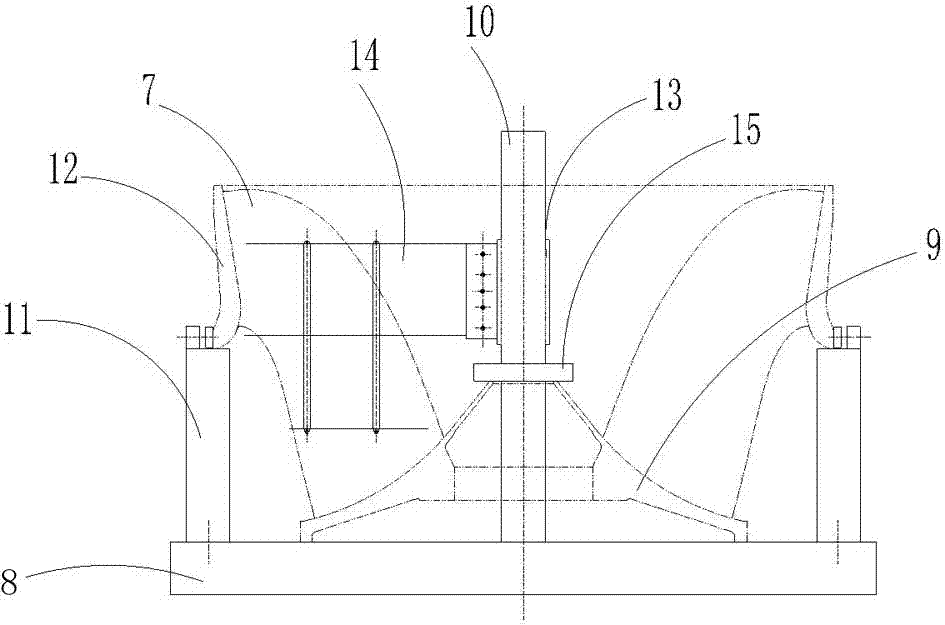

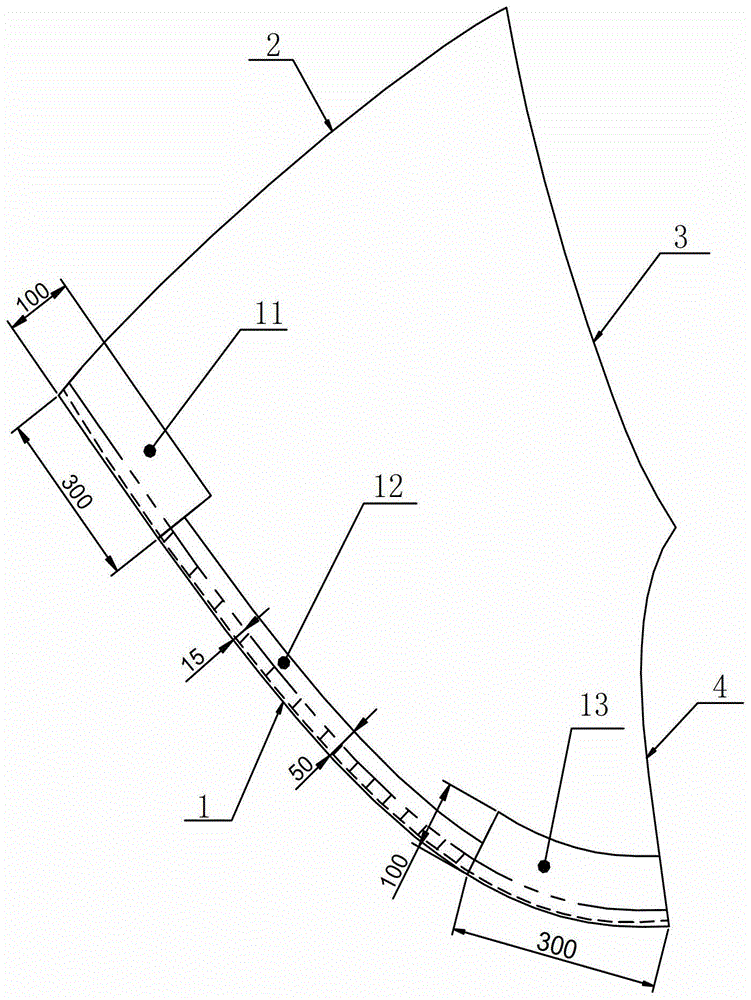

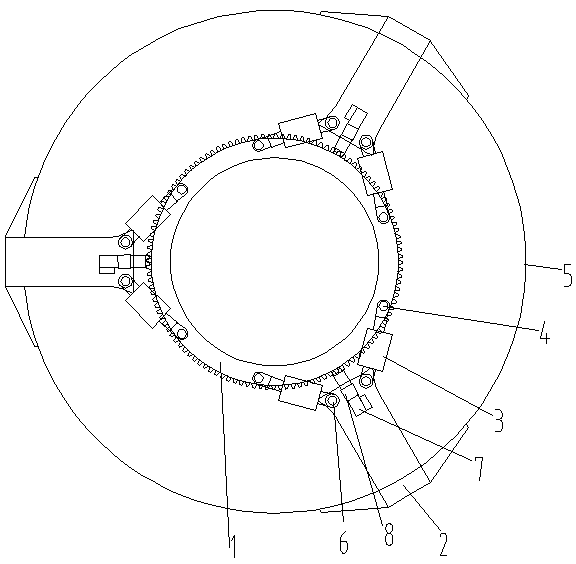

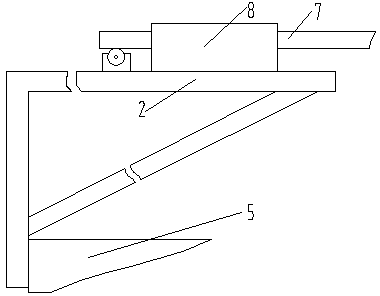

Welding positioning device for mixed francis turbine runner vanes and positioning measuring method thereof

ActiveCN105834649AJudgment accuracyCompact structureWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringFrancis turbine

The invention relates to a positioning device, in particular to a welding positioning device for francis turbine runner vanes and a positioning measuring method thereof. The device comprises a runner vane and further comprises a bottom plate, wherein a runner crown is arranged in the bottom plate, the runner crown is fixed with the bottom plate by a strut, adjustable lower ring supports are respectively arranged at two ends of the upper part of the bottom plate, a runner lower ring is arranged at the upper part of the adjustable lower ring support, the bottom end of the runner vane is fixed with the runner upper crown, and the upper end of the runner vane is in movable contact with the runner lower ring. The welding positioning device for francis turbine runner vanes and the positioning measuring method thereof are compact in structure, simple and convenient to operate and high in use performances.

Owner:HANGZHOU RESOURCE POWER EQUIP

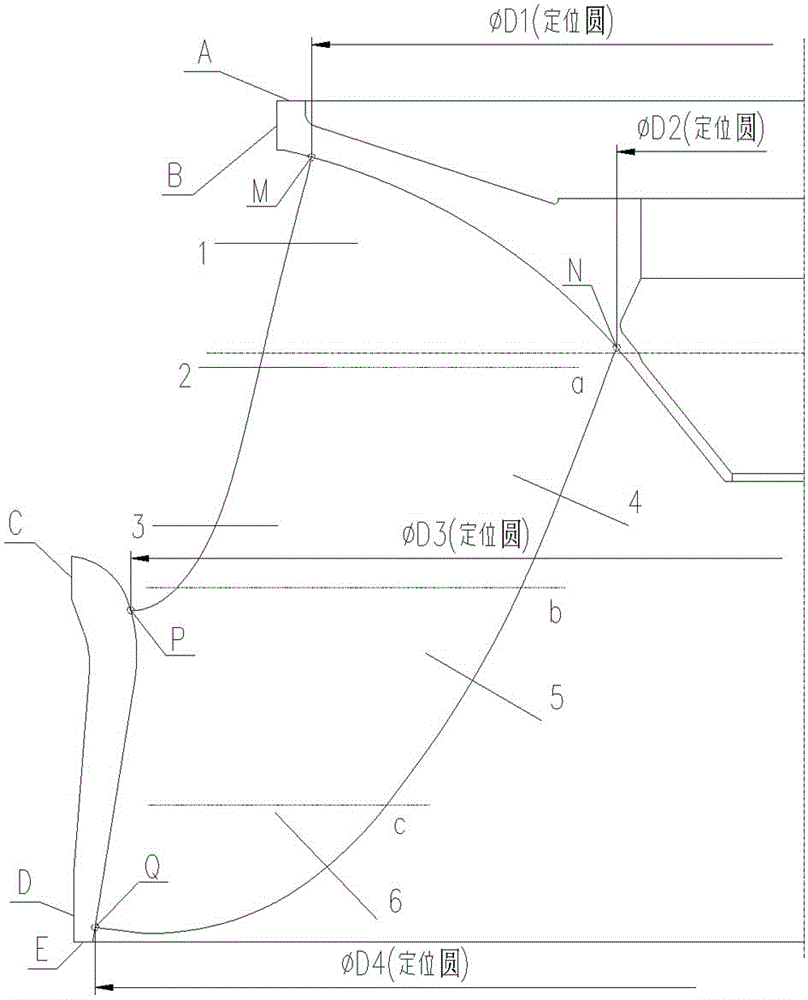

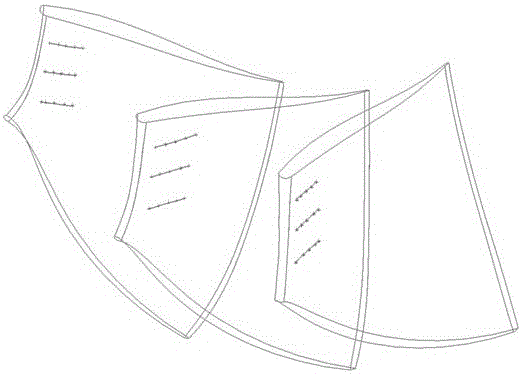

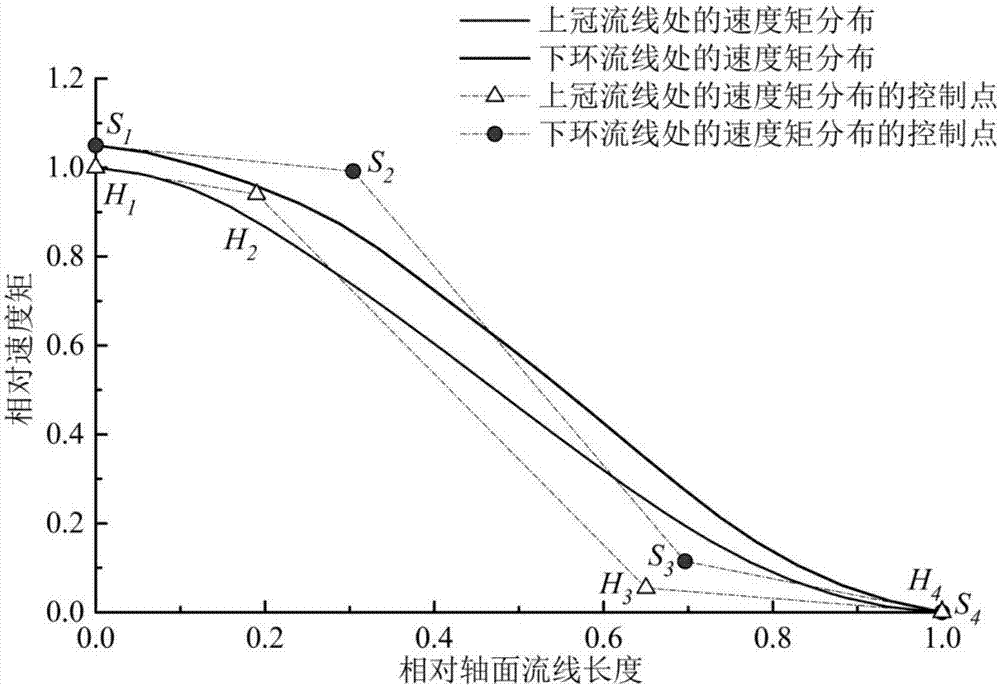

Francis turbine runner multi-condition optimization method capable of giving consideration to hydraulic and strength performances

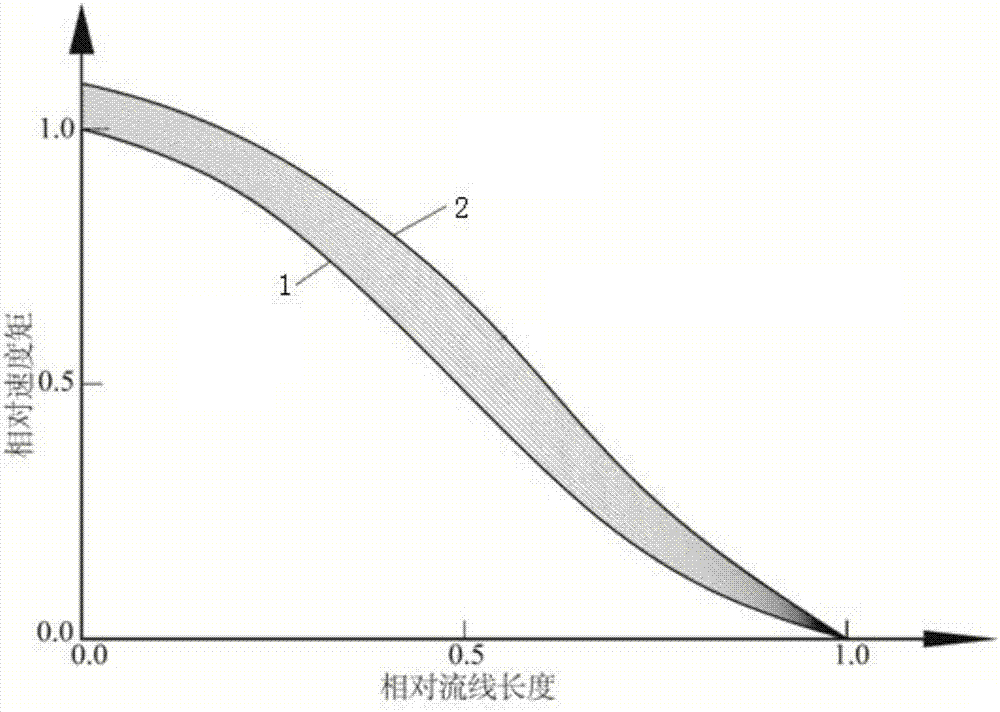

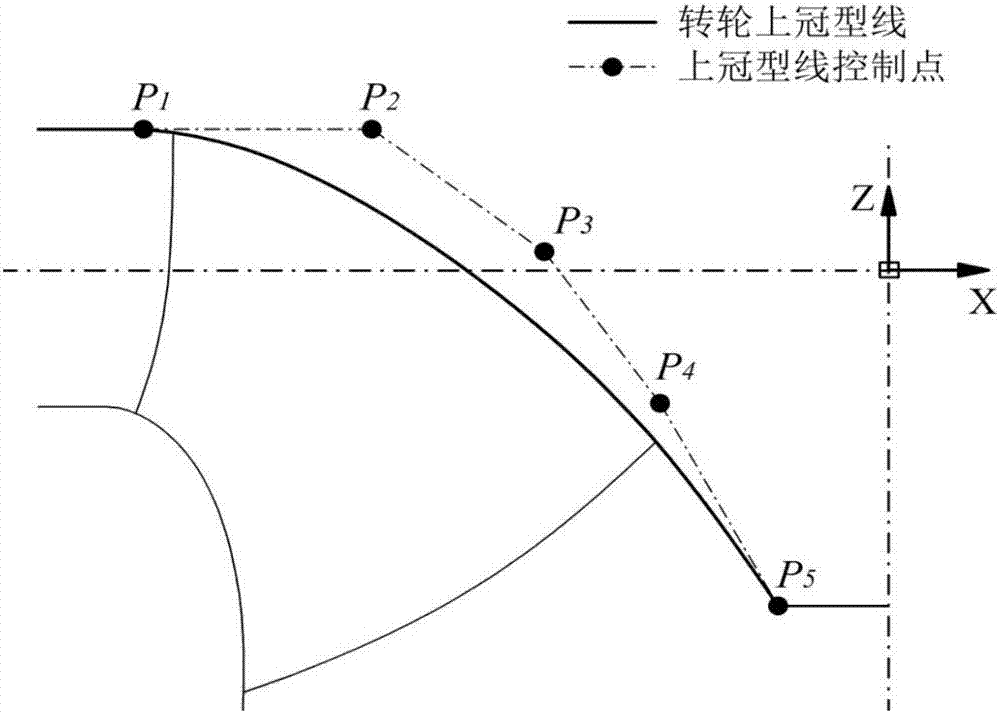

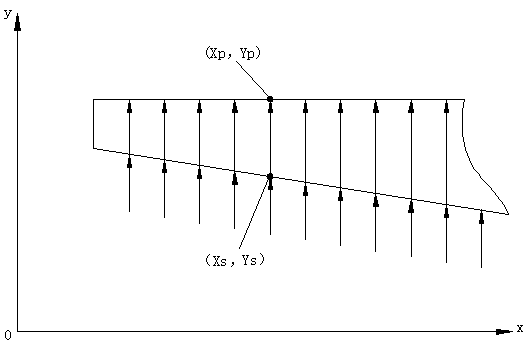

ActiveCN107529643AHigh strengthReduce in quantitySpecial data processing applicationsMathematical modelEngineering

The invention discloses a Francis turbine runner multi-condition optimization method capable of giving consideration to hydraulic and strength performances. The method specifically comprises the following steps: obtaining three-dimensional blade aerofoil data of runner blades according to an optimization design variable of the Francis turbine runner and an inflow vortex runner full three-dimensional inverse problem calculation method, thereby obtaining the runner blade aerofoil; obtaining hydraulic efficiency eta i of the runner blades under each condition, the lowest pressure coefficient Cpion the runner blades, and the maximum equivalent stress sigma i on the blades; and processing the obtained hydraulic efficiency eta i of the runner blades under each condition, the lowest pressure coefficient Cpi on the runner blades and the maximum equivalent stress sigma i on the blades, obtaining the final objective functions d eta (X), d Cp (X) and d sigma (X) of the optimized problem, and establishing a mathematical model to optimize the Francis turbine runner blades according to the obtained objective functions. According to the method disclosed by the invention, the problem that the hydraulic and strength performances under different conditions cannot be simultaneously taken into account in the existing Francis turbine runner design technology is solved.

Owner:XIAN UNIV OF TECH

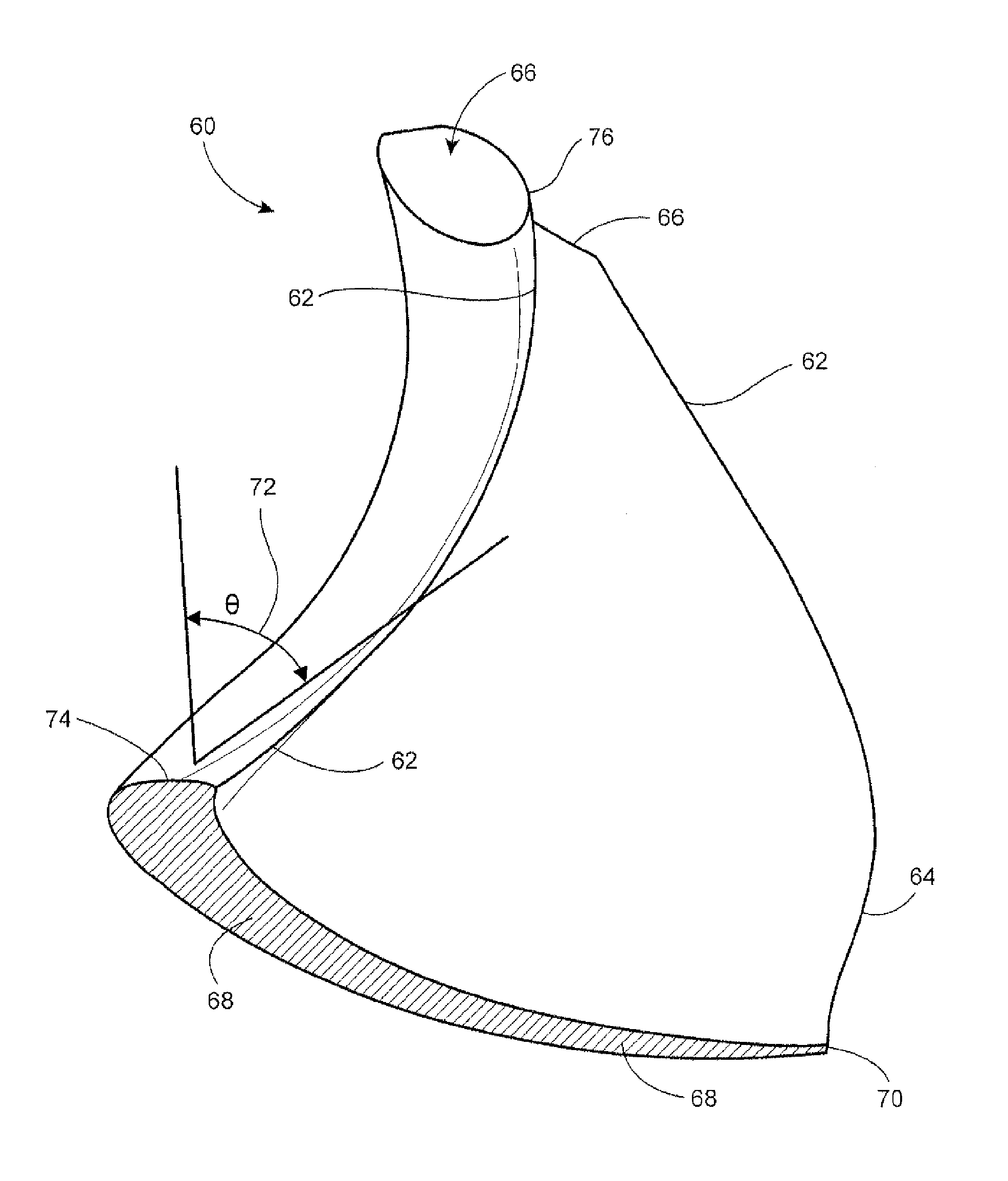

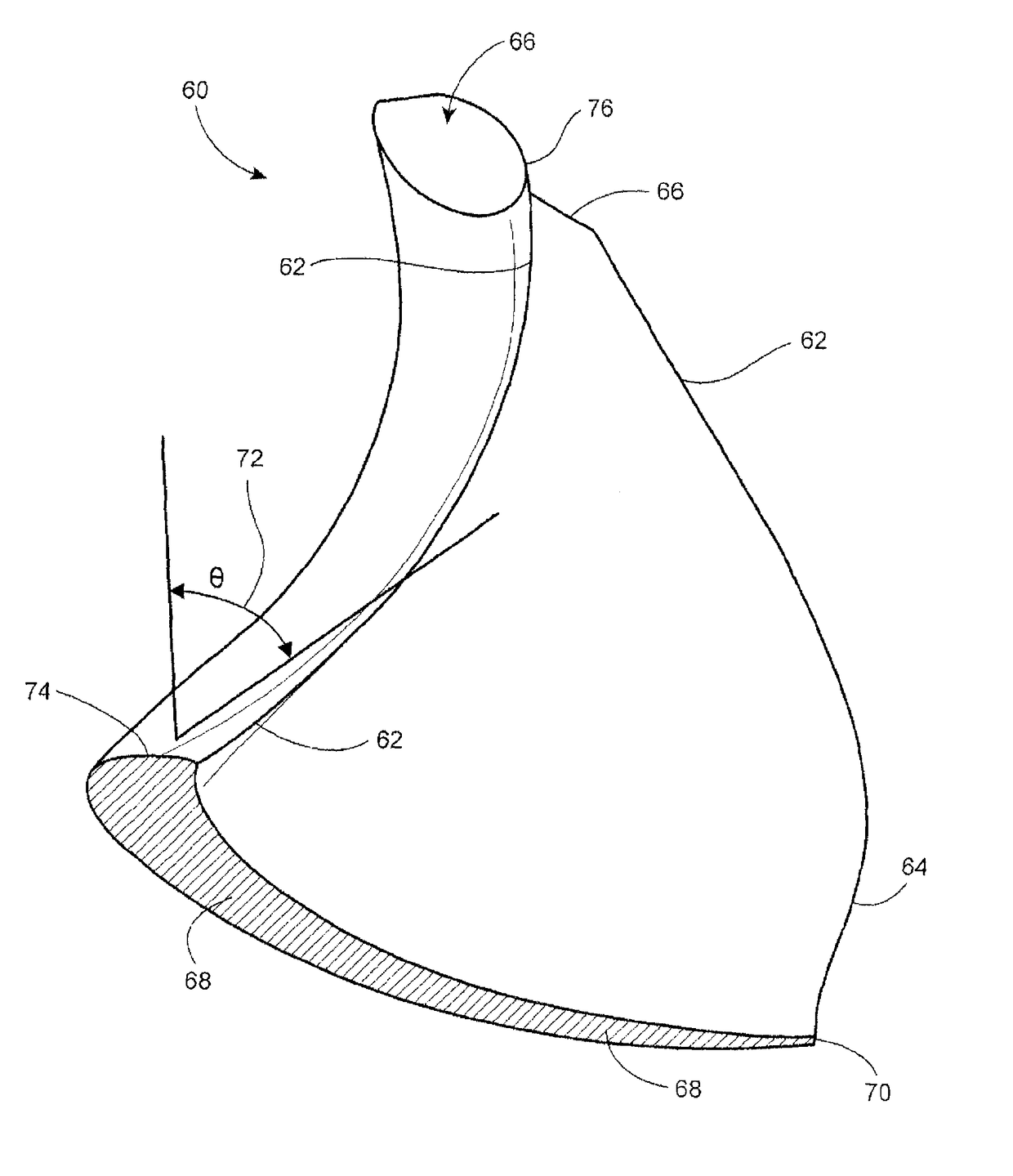

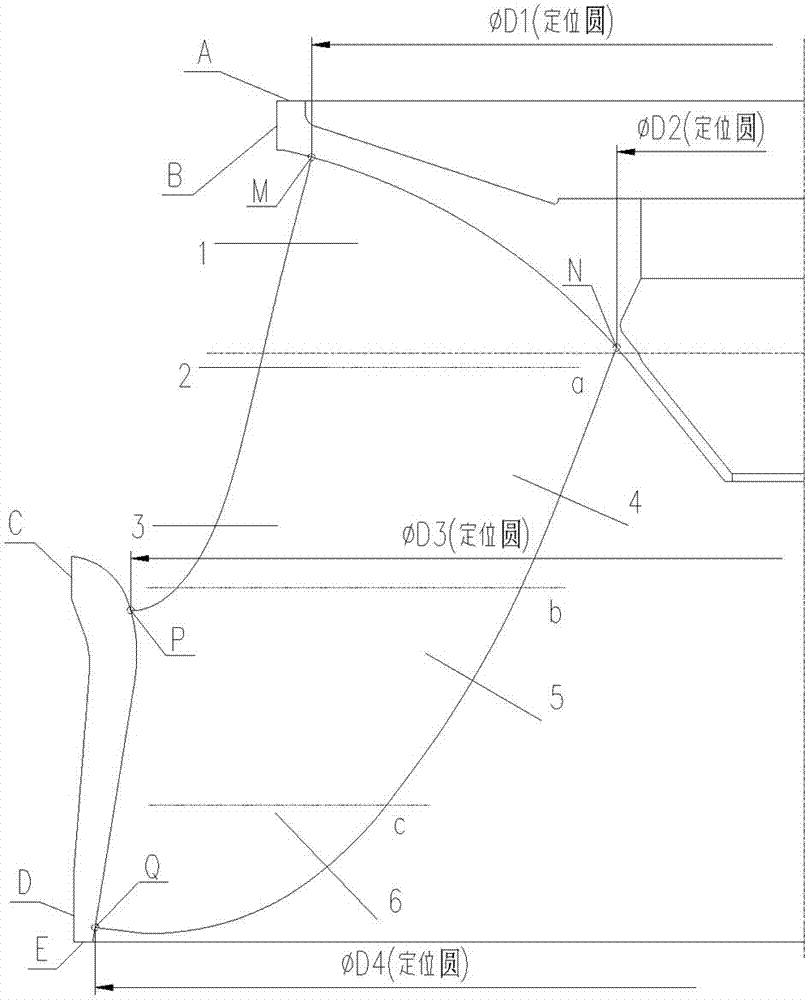

Compact blade for runner of francis turbine and method for configuring runner

ActiveUS20140294590A1Improve performanceEnergy efficiencyHydro energy generationReaction enginesLeading edgeFrancis turbine

A blade for a runner of a Francis turbine having a throat diameter (Dth), the blade including: a maximum thickness of no less than 0.03 Dth and a leading edge having a maximum lean angle of no less than 45 degrees, wherein the lean angle is defined by a vertical line and the leading edge.

Owner:ANDRITZ HYDRO LTD

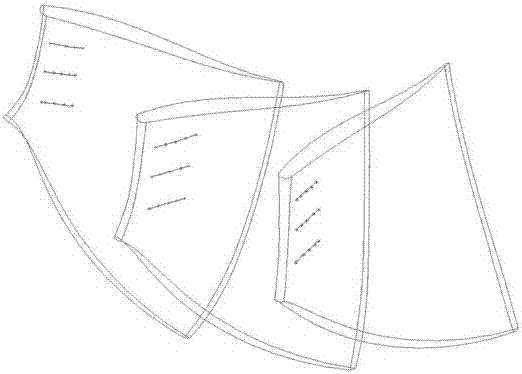

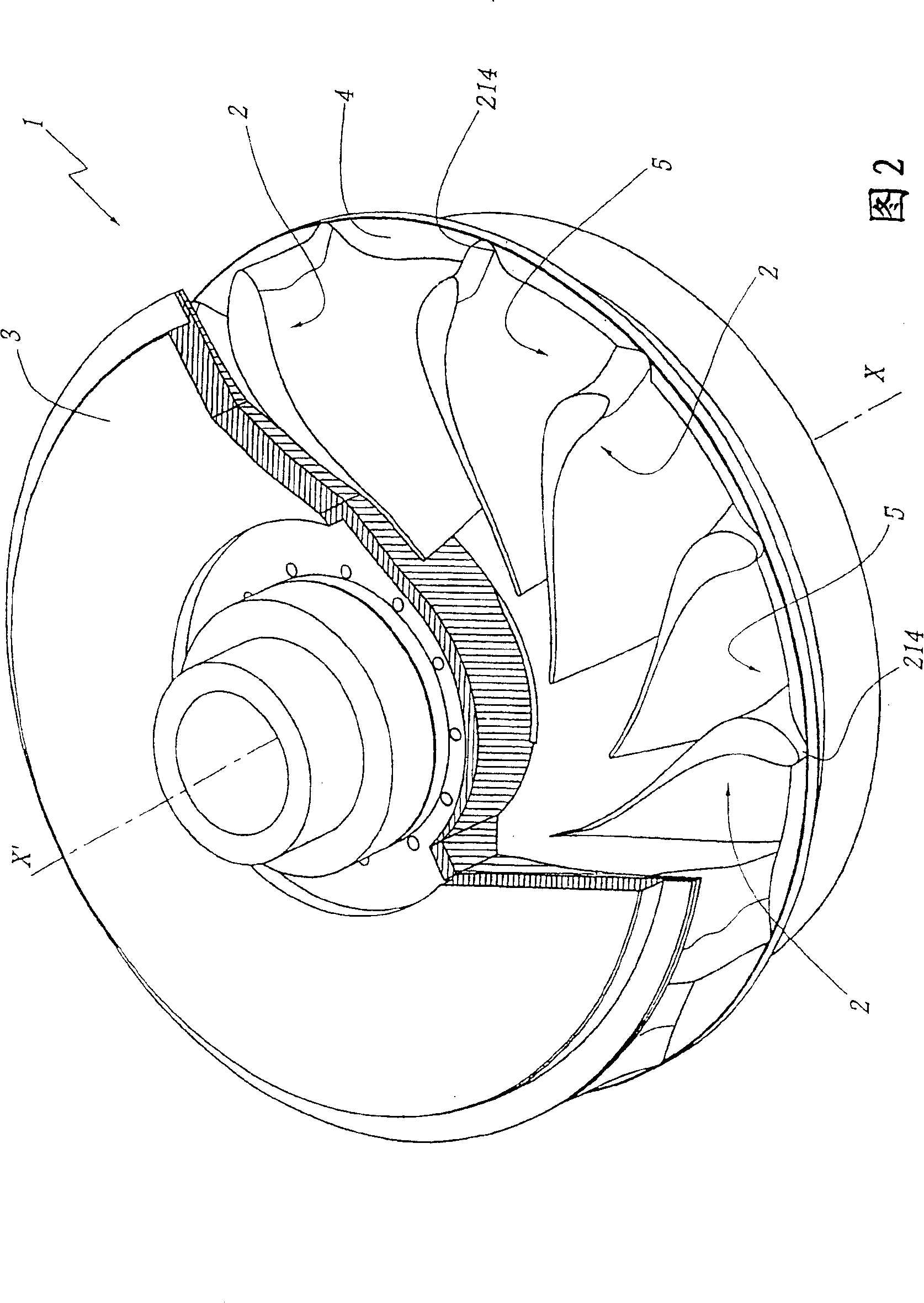

Split Francis Turbine Runner

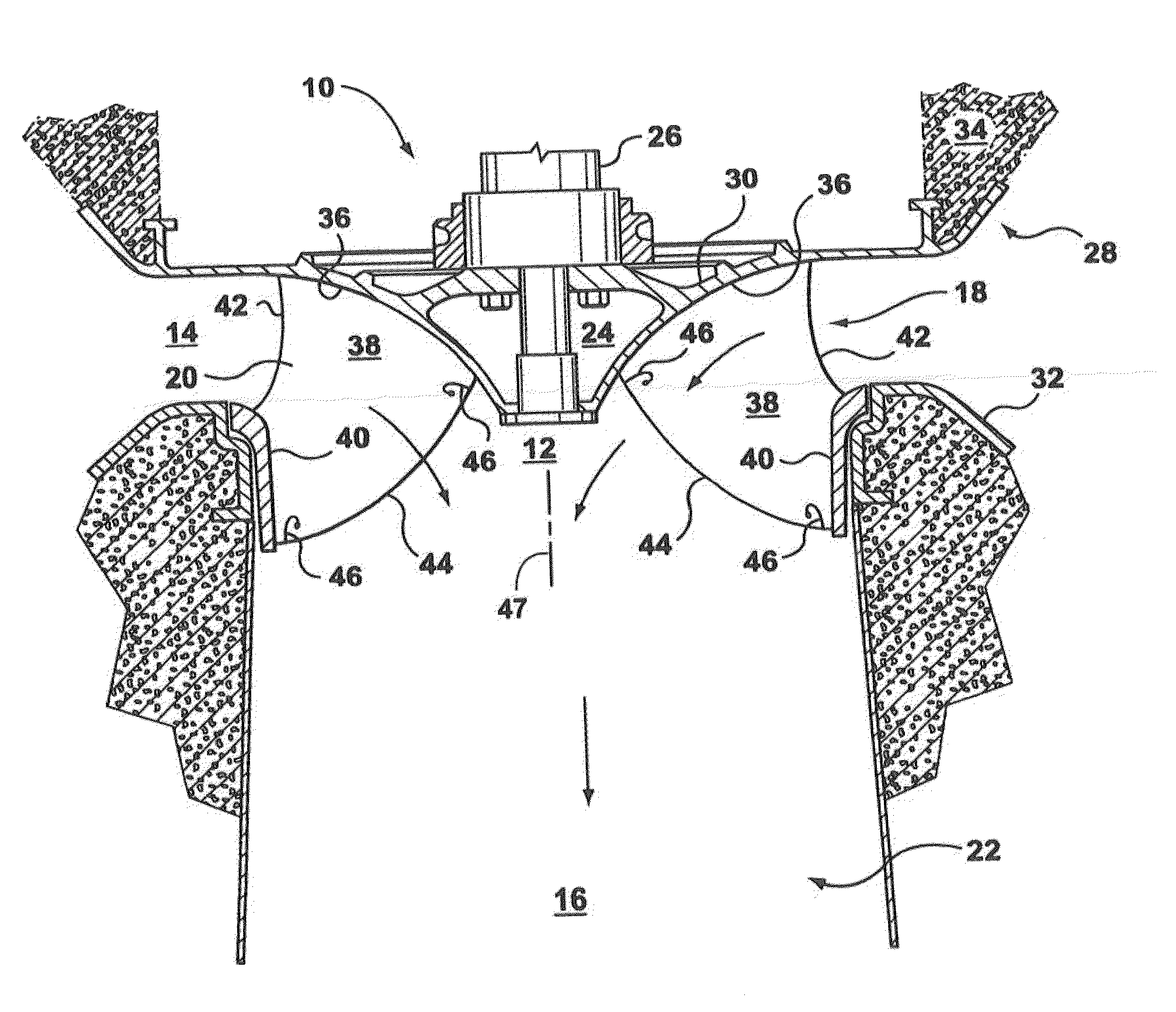

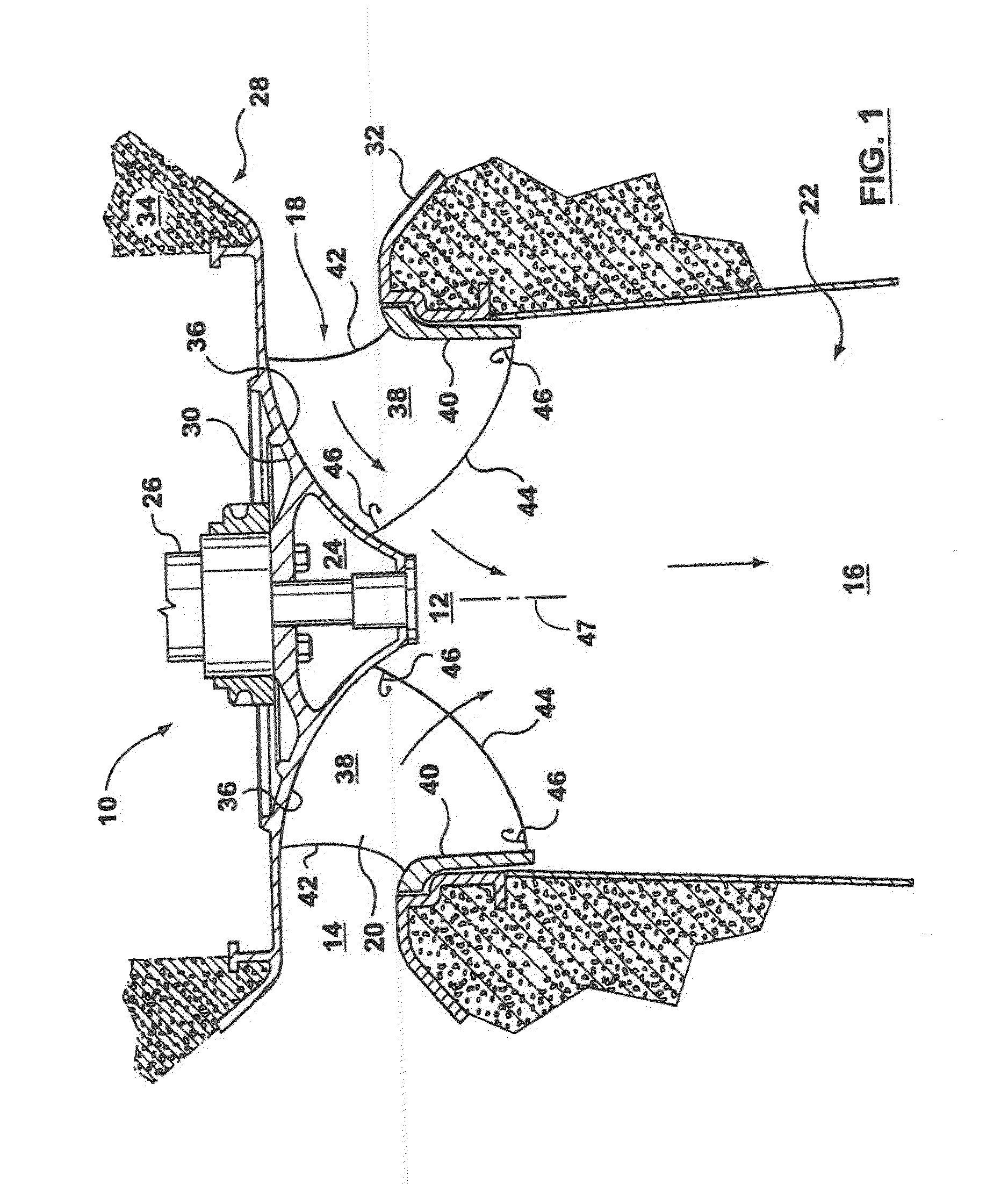

InactiveUS20070134098A1Not be eliminatePropellersEngine manufactureEngineeringMechanical engineering

A split runner for a Francis turbine has runner segments that are adapted to be joined together along confronting surface portions thereof to form a composite runner having a crown, a band and a plurality of blades extending between the crown and the band. The confronting surface portions of the runner segments are located only along portions of the crown and portions of the band, and the confronting surface portions of the runner segments are located in between and spaced from adjacent blades of the composite runner. Since the confronting surface portions are located only along portions of the crown and portions of the band, none of the blades are split eliminating the need to weld together blades during formation of the composite runner. Accordingly, the composite runner does not have weld joints formed in the blades which are highly stressed operating parts of the runner.

Owner:GENERAL ELECTRIC CANADA MISSISSAUGA

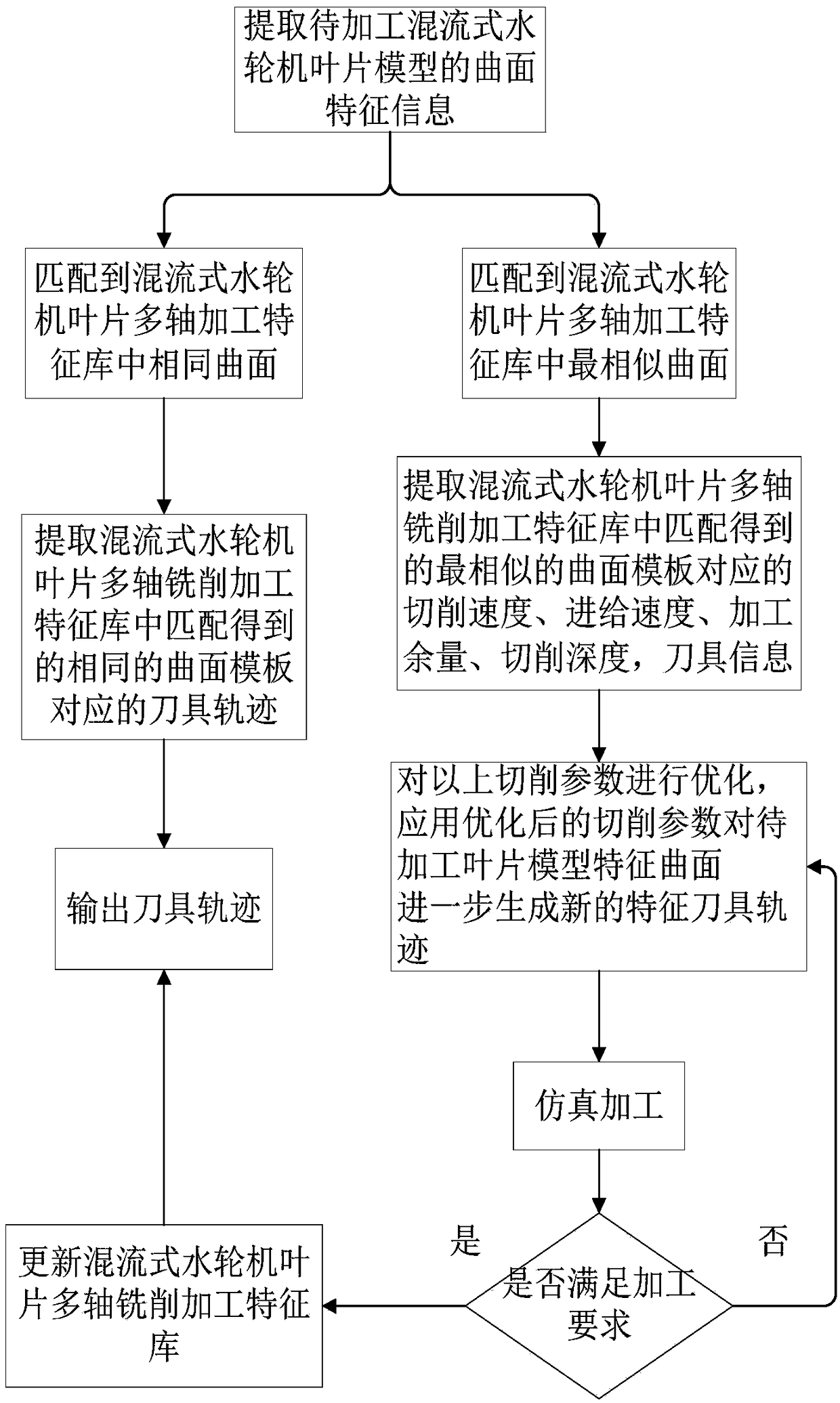

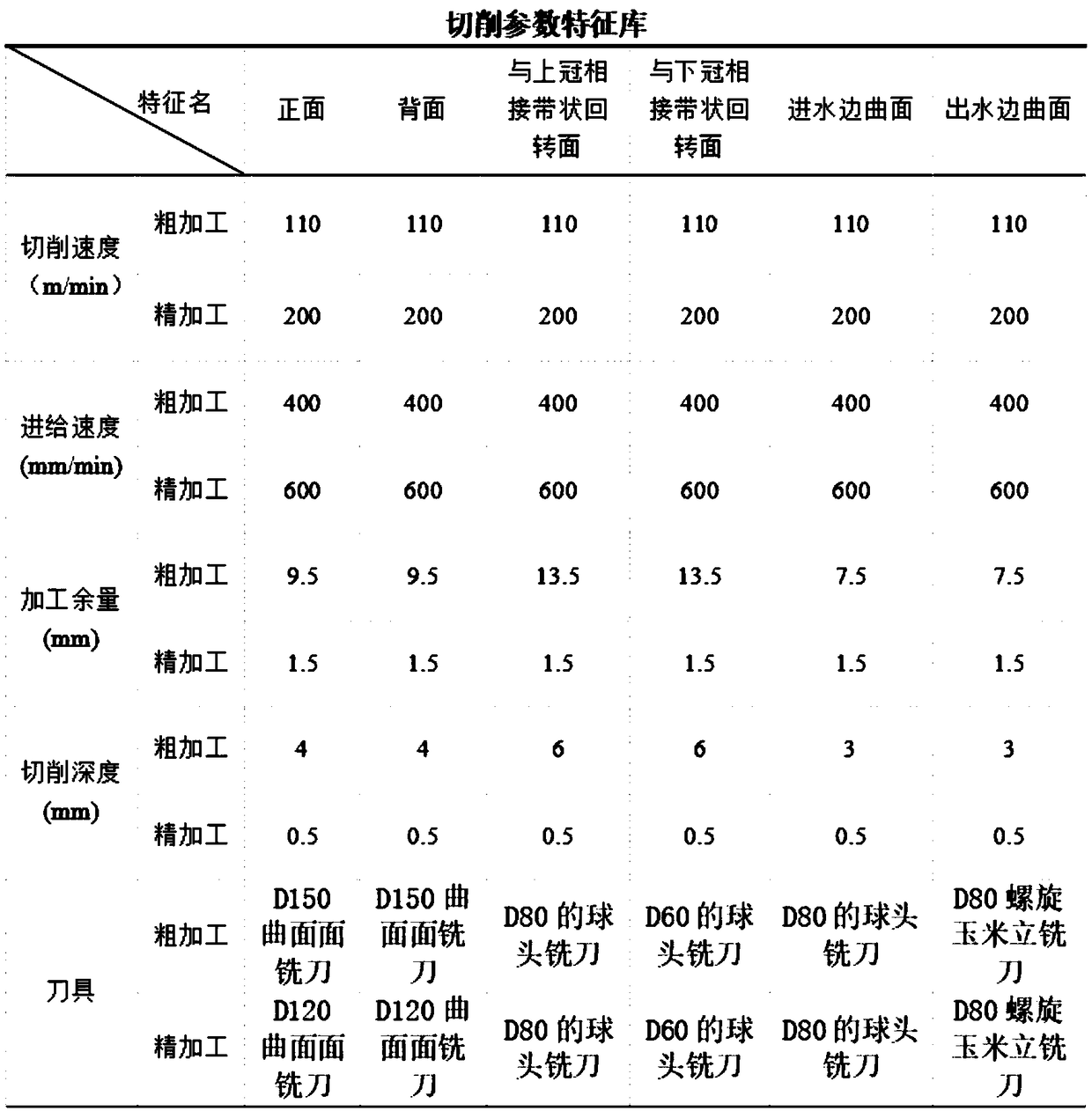

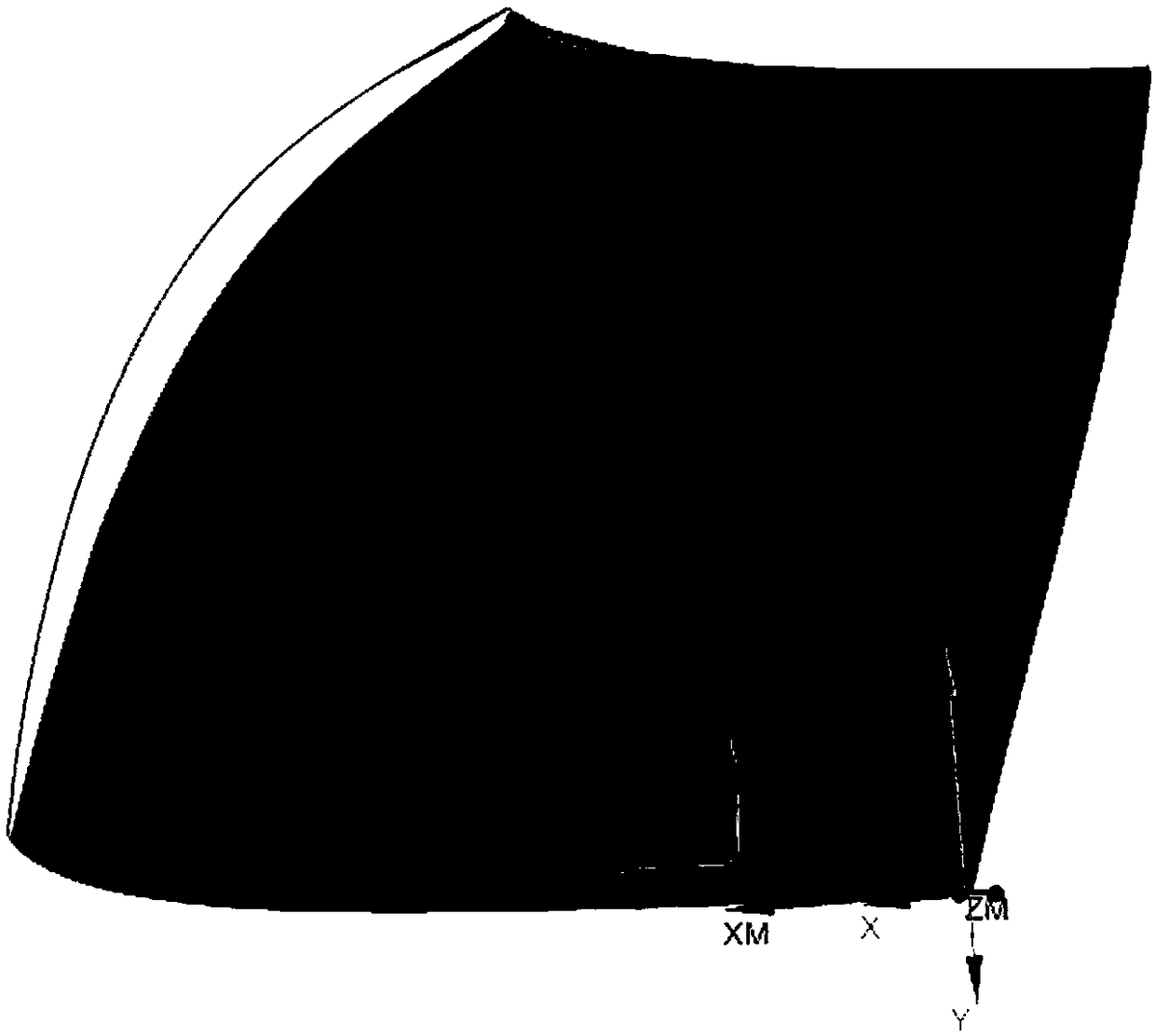

Generation method of blade cutter tracks of francis turbine

The invention relates to a generation method of blade cutter rail of francis turbine, which belongs to the field of multi-axis milling processing of complex curved surfaces. By constructing a multi-axis milling feature library of Francis turbine blade, matching the model of the blade to be processed with the feature library, and updating the feature library according to the matching results, the generation method of blade cutter tracks of francis turbine provides a new idea and basis for generating tool path based on surface features of the blade model to be machined.

Owner:KUNMING UNIV OF SCI & TECH

Compact blade for runner of Francis turbine and method for configuring runner

ActiveUS9605647B2Improve performanceSuppress cavitationRotary propellersHydro energy generationLeading edgeFrancis turbine

A blade for a runner of a Francis turbine having a throat diameter (Dth), the blade including: a maximum thickness of no less than 0.03 Dth and a leading edge having a maximum lean angle of no less than 45 degrees, wherein the lean angle is defined by a vertical line and the leading edge.

Owner:ANDRITZ HYDRO LTD

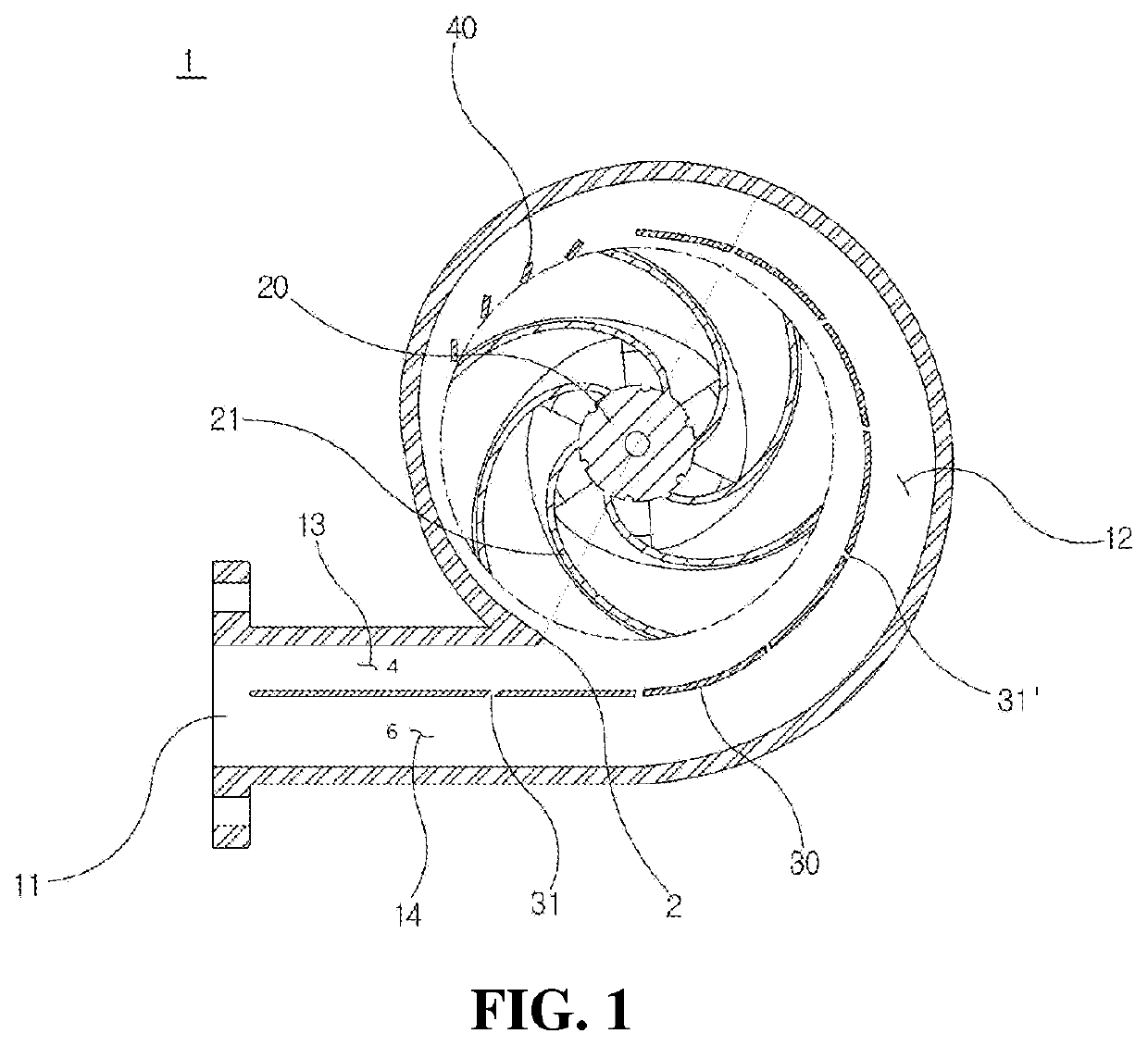

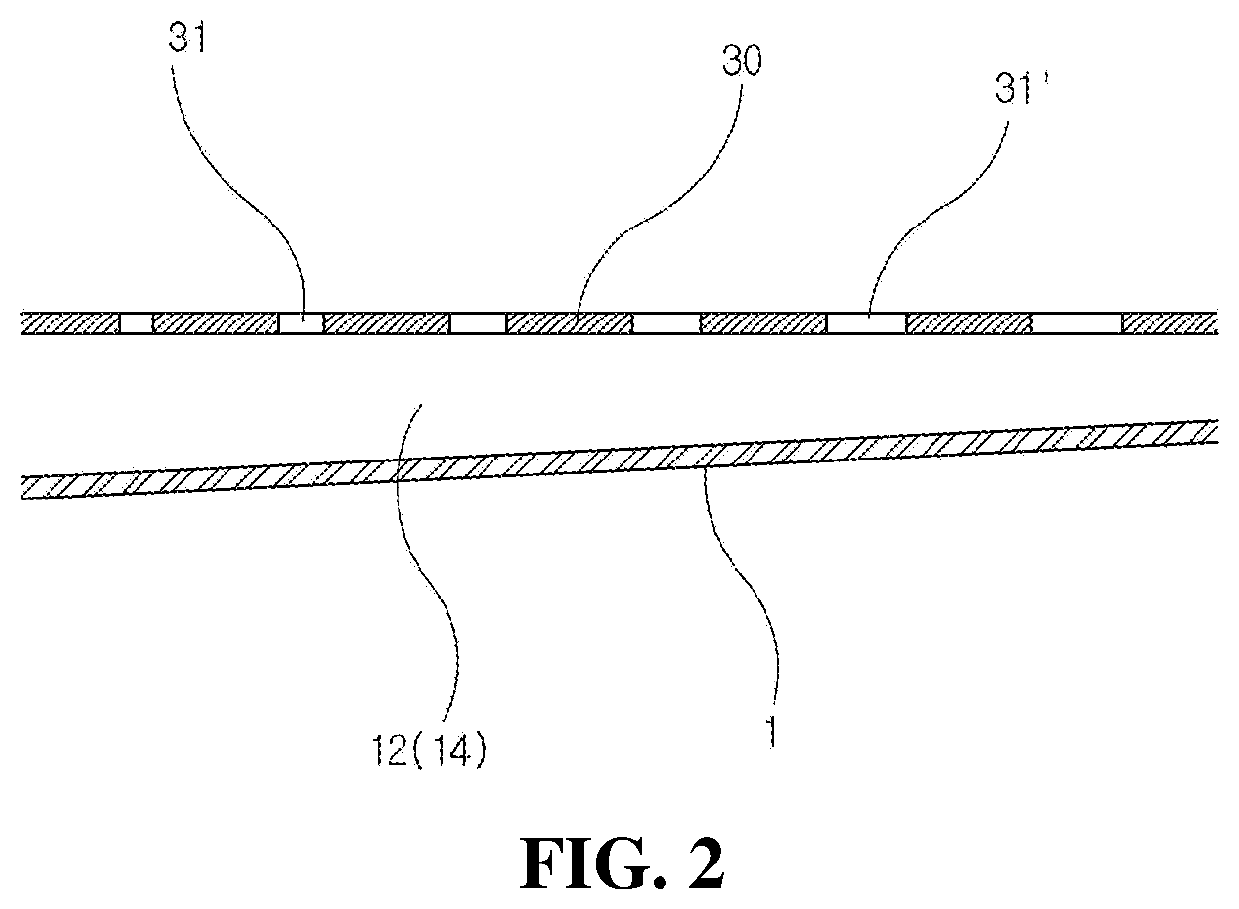

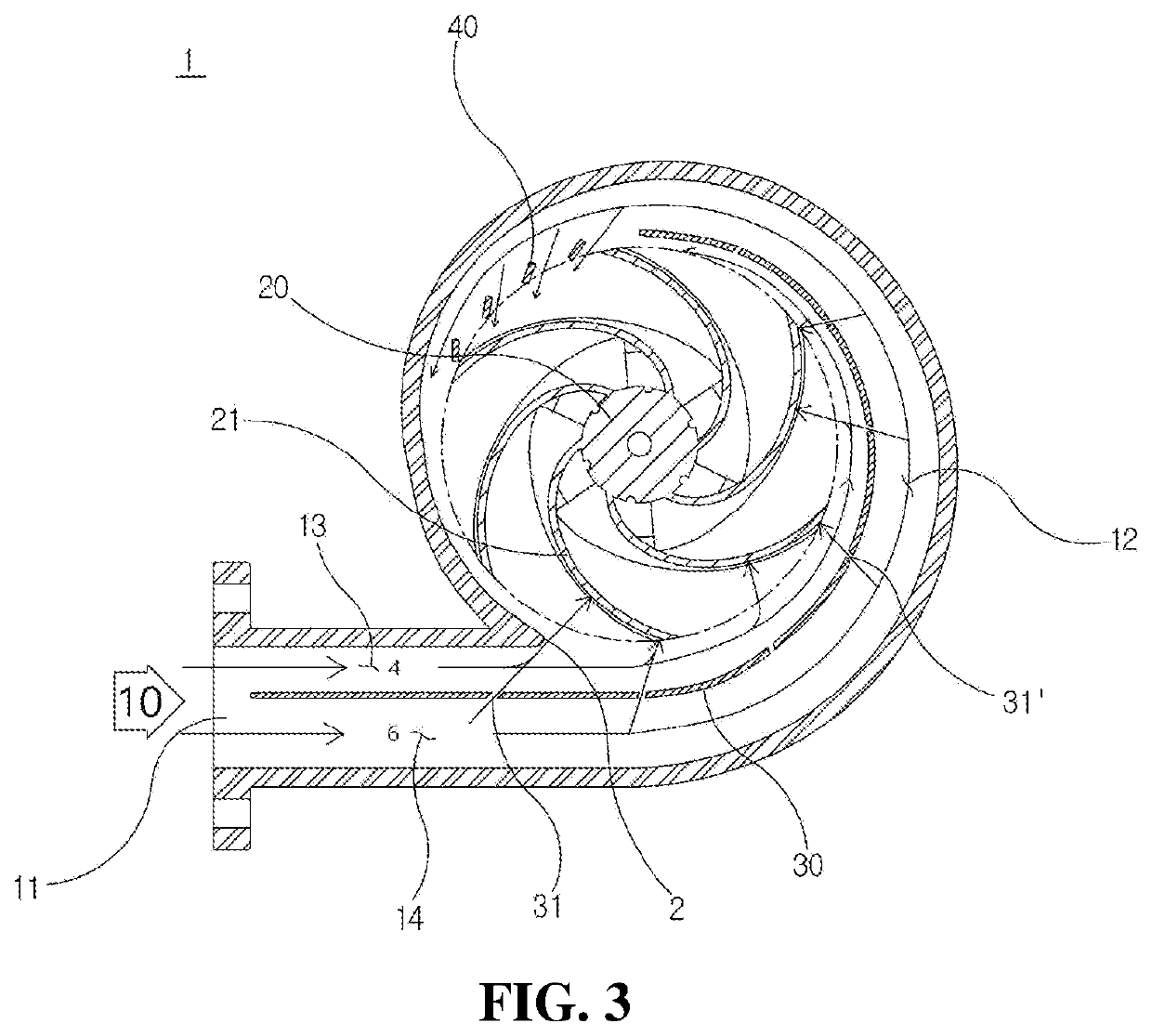

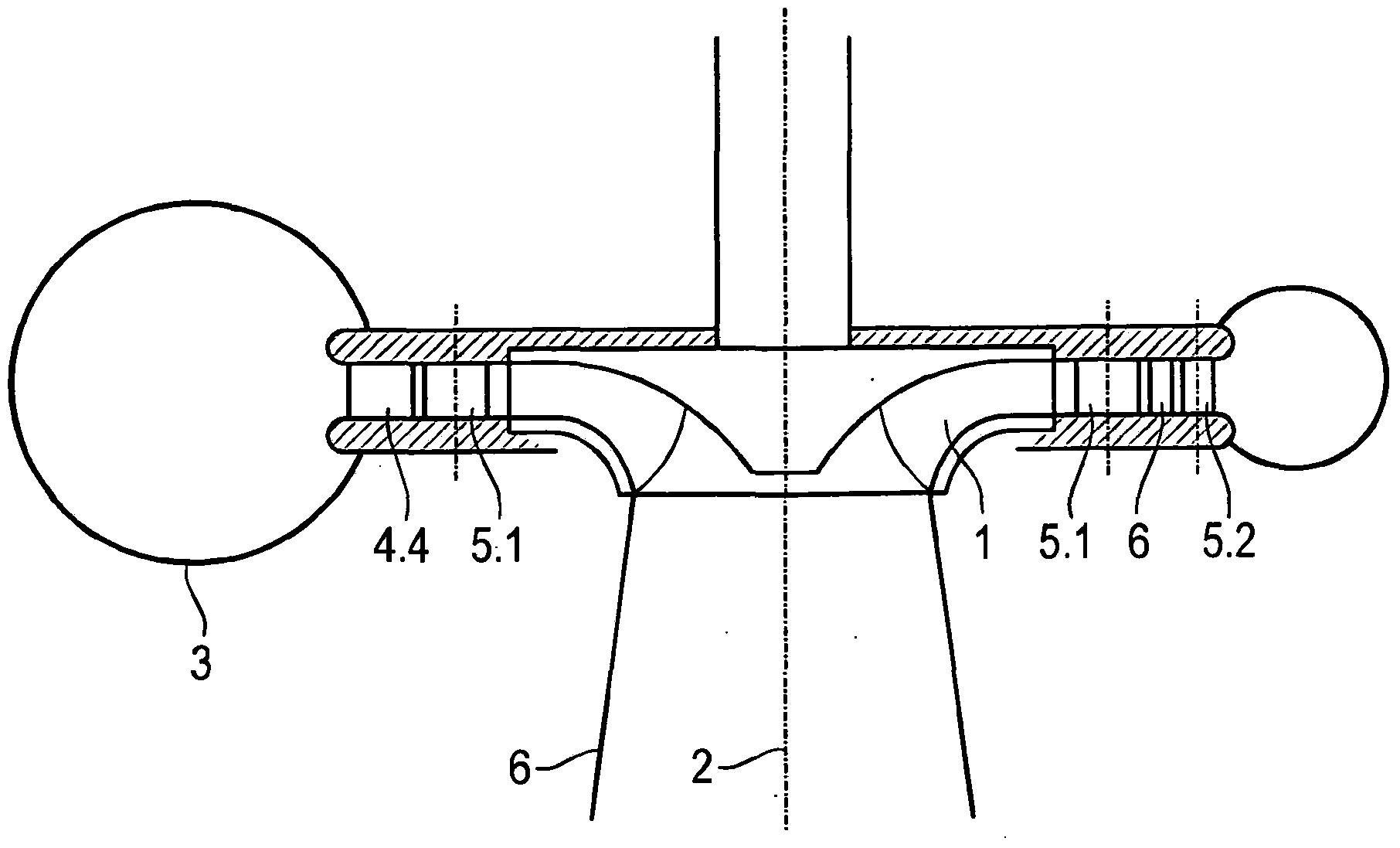

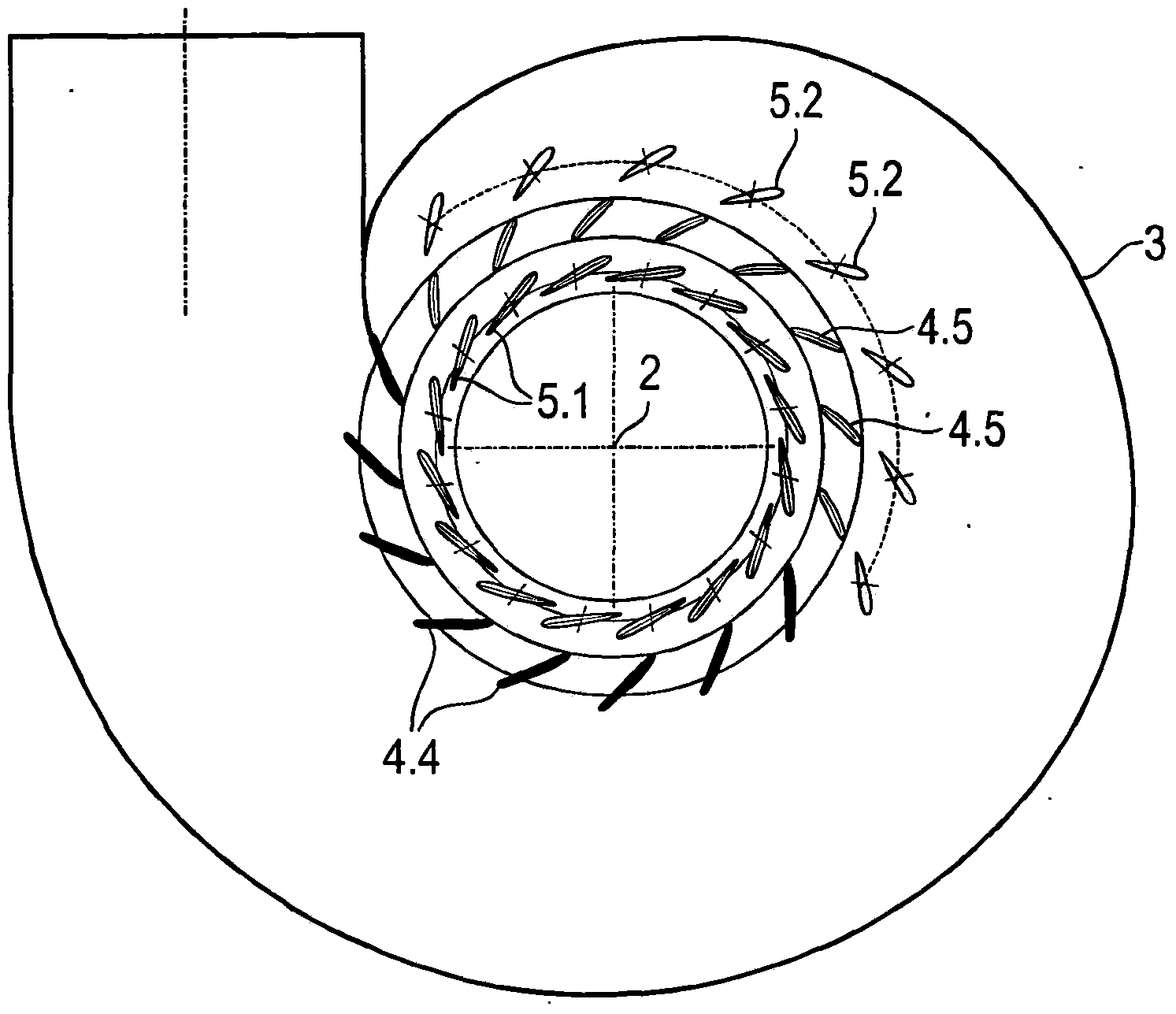

Double-flow type volute casing having structure for changing direction of flow in turbine inlet

ActiveUS20200040758A1Quantity minimizationAvoid it happening againStatorsHydro energy generationTurbine bladeWater turbine

Disclosed is a Francis turbine, and more particularly a double-flow type volute casing having a structure for changing the direction of flow in a turbine inlet, wherein a partition plate for partitioning a volute defined in the casing into an inner flow channel and an outer flow channel is provided so as to surround a turbine, the ratio in sectional area of the inner flow channel to the outer flow channel in a volute inlet, into which a fluid is introduced, is 4:6, a plurality of flow-rate adjustment holes is formed in the partition plate so as to be arranged at a gradually decreasing interval such that a high-pressure fluid flowing in the outer flow channel is introduced into the inner flow channel and the fluid flowing in the inner flow channel is directed perpendicularly to the turbine blades, in order to minimize the amount of energy that is lost and to reduce imbalanced variation of torque applied to the turbine blades, whereby it is possible to prevent the generation of vibration and to obtain high rotational force based on the guarantee of stable output, and therefore it is possible to improve the performance of a hydraulic turbine and to increase the lifespan of the hydraulic turbine through the stable driving thereof.

Owner:DONG HAE ENG

Stress relief grooves for Francis turbine runner blades

InactiveUS20060228215A1Efficient loadingGood effectPropellersRotary propellersStress relievingStress relief

There is disclosed a runner for a Francis-type hydraulic turbine where each runner blade has an outlet edge with two stress relieving grooves cut through the blade from the outlet edge adjacent the crown and the band. The grooves each present an opening across the outlet edge and the grooves each extend a predetermined distance from the outlet edge into the blade.

Owner:GENERAL ELECTRIC CANADA MISSISSAUGA

Francis turbine or francis pump or francis pump turbine

The invention relates to a Francis turbine or other machine built according to the Francis principle; with an impeller having rotor blades; with a volute housing that surrounds the impeller; with a traverse ring comprising a number of traverses; with an inner rotor blade ring having larger traverses, which is arranged downstream of the traverse ring. The invention is characterised by the following features: suggested is an outer rotor blade ring that is arranged upstream of the traverse ring; a part of the traverse ring extends with larger traverses over a part of the circumference of the impeller, beginning at the start of the volute, and a part of the traverse ring extends with smaller traverses over the broader circumference of the impeller as far as the end of the volute.

Owner:VOITH PATENT GMBH

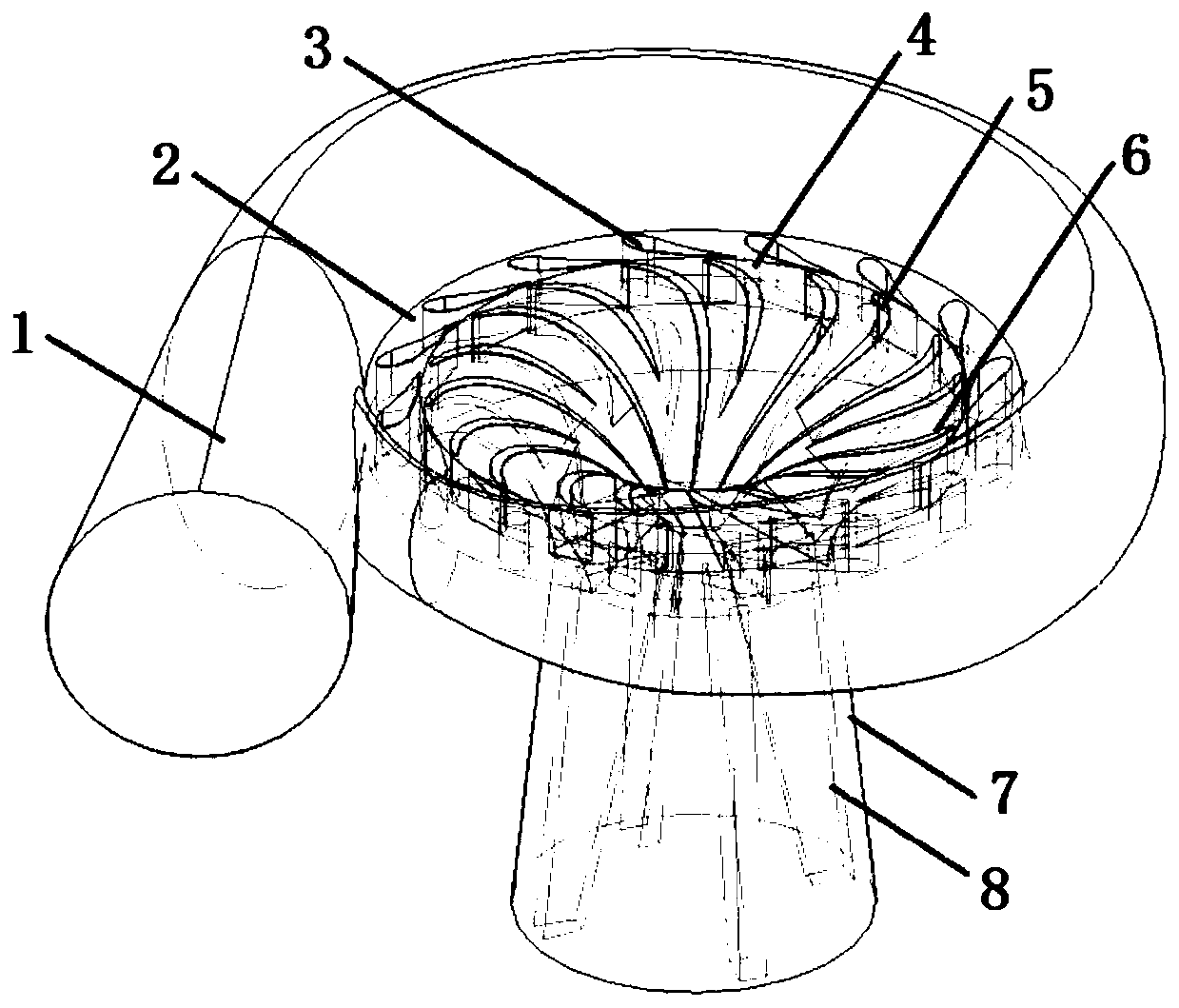

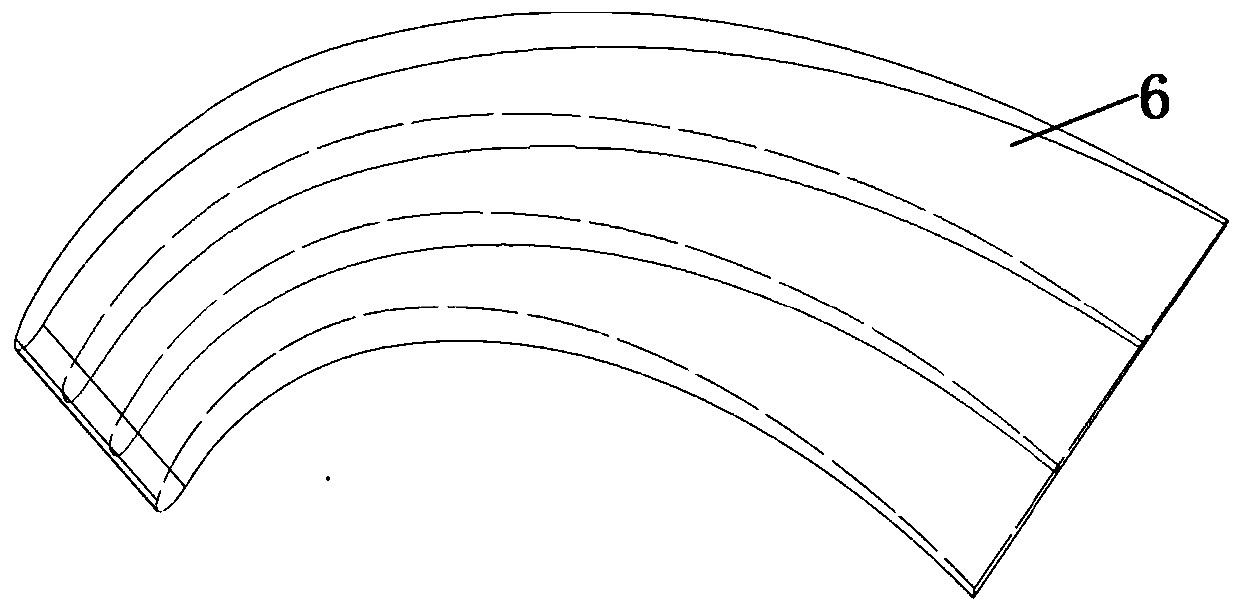

A Francis turbine with draft tube and rectification plate

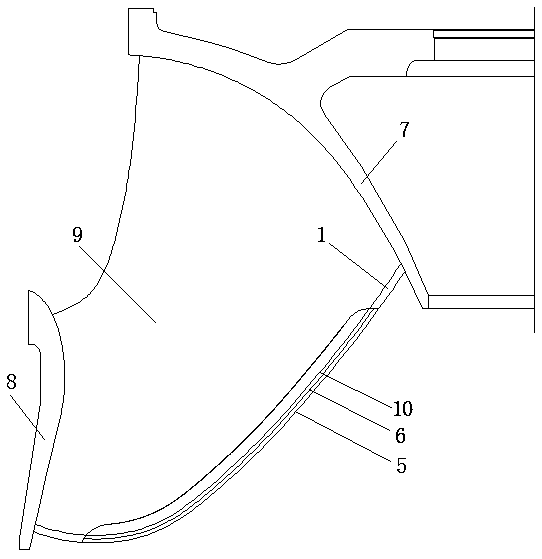

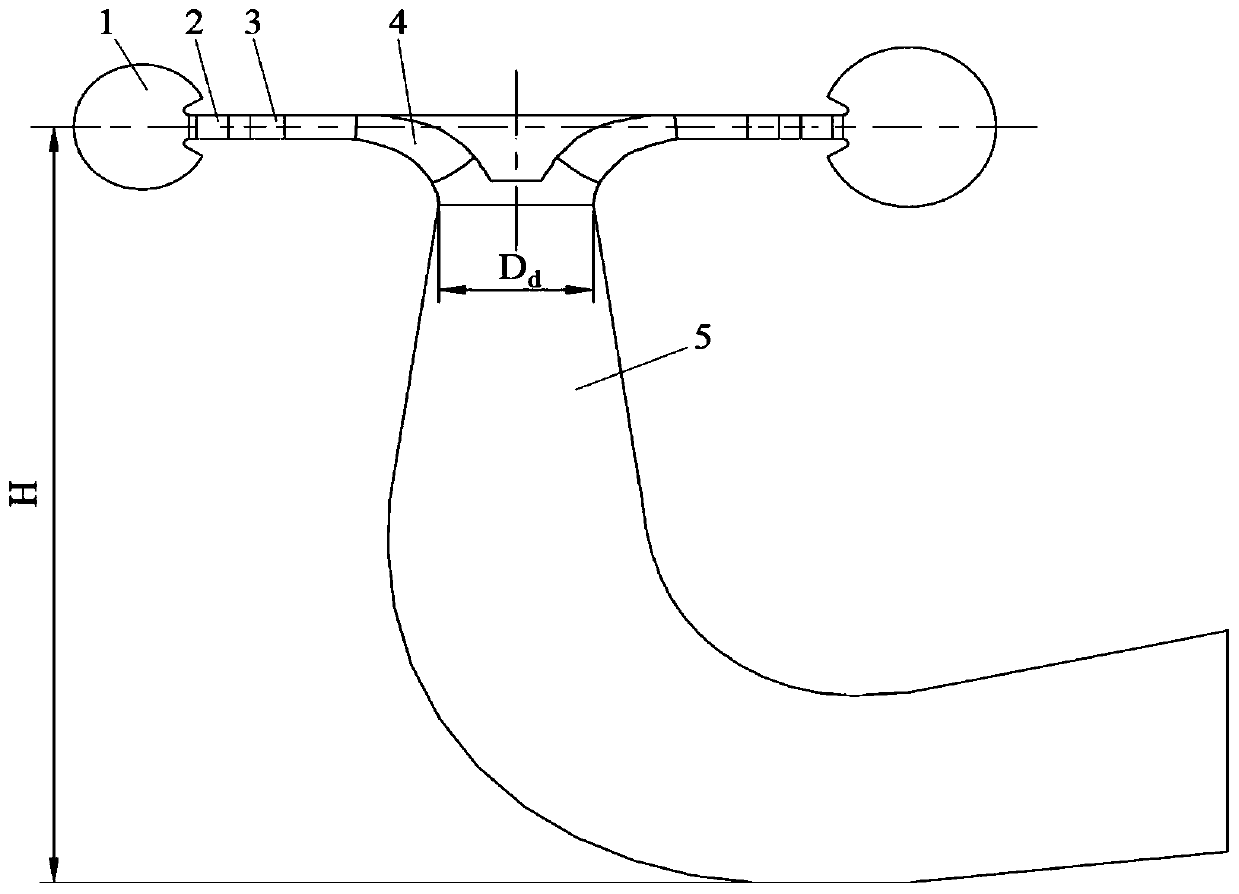

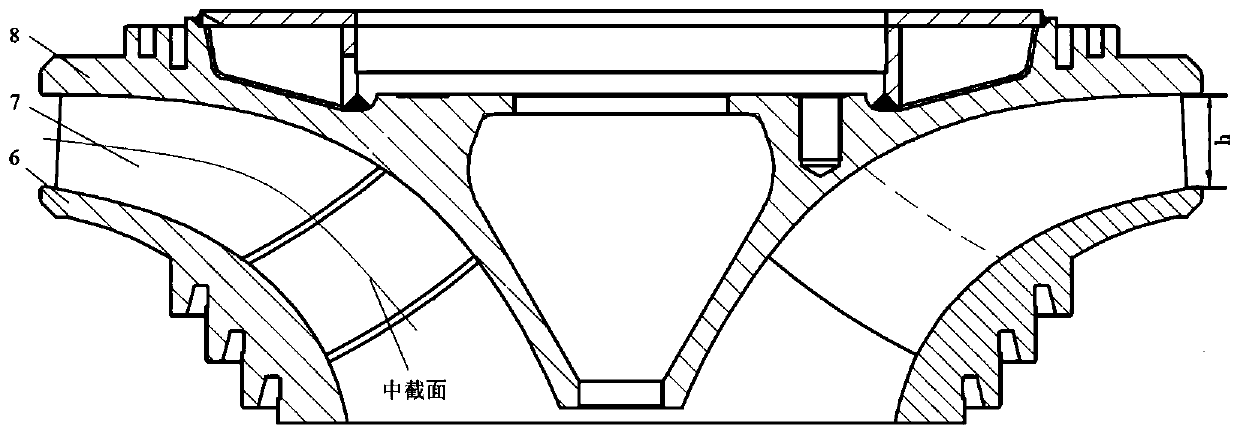

ActiveCN109441691BGuaranteed uptimeSmall sizeHydro energy generationReaction enginesWater turbineEnergy recovery

The invention discloses a mixed-flow water turbine with an exhaust water pipe provided with current plates. An overflowing area of the mixed-flow water turbine comprises a worm shell (1), a guide blade area (2), a rotary wheel (4) and the exhaust water pipe (7) with the four to six current plates (8), wherein the worm shell (1), the guide blade area (2), the rotary wheel (4) and the exhaust waterpipe (7) are sequentially connected; the diffusion angle beta 1 of the straight cone section of the exhaust water pipe (7) is 6 degrees; the current plates (8) with circular arc sides and the trapezoidal sections are arranged in the exhaust water pipe, and all the current plates (8) are circumferentially arranged around the axis of the water turbine in the mode of being internally attached to theinner wall of the exhaust water pipe (7); the conical angle beta 2, close to the shaft end, of the current plates (8) is 9 degrees; and the angle beta 3 in the thickness control direction of the current plates (8) is 10 degrees. The mixed-flow water turbine aims to increase the energy recovery coefficient of the exhaust water pipe and improve or eliminate the eddy current phenomenon in the exhaustwater pipe under the non-design working condition while improving an unsteady flow field of the rotary wheel to improve the operating performance of the water turbine, and the thought is universal, especially for various forms of water pumps, water turbines and reversible water pump and water turbine units with the exhaust water pipes.

Owner:NORTHWEST A & F UNIV

Welding positioning device for mixed-flow runner blade and its positioning measurement method

ActiveCN105834649BCompact structureSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesFrancis turbineAerospace engineering

The invention relates to a positioning device, in particular to a welding positioning device for francis turbine runner vanes and a positioning measuring method thereof. The device comprises a runner vane and further comprises a bottom plate, wherein a runner crown is arranged in the bottom plate, the runner crown is fixed with the bottom plate by a strut, adjustable lower ring supports are respectively arranged at two ends of the upper part of the bottom plate, a runner lower ring is arranged at the upper part of the adjustable lower ring support, the bottom end of the runner vane is fixed with the runner upper crown, and the upper end of the runner vane is in movable contact with the runner lower ring. The welding positioning device for francis turbine runner vanes and the positioning measuring method thereof are compact in structure, simple and convenient to operate and high in use performances.

Owner:HANGZHOU RESOURCE POWER EQUIP

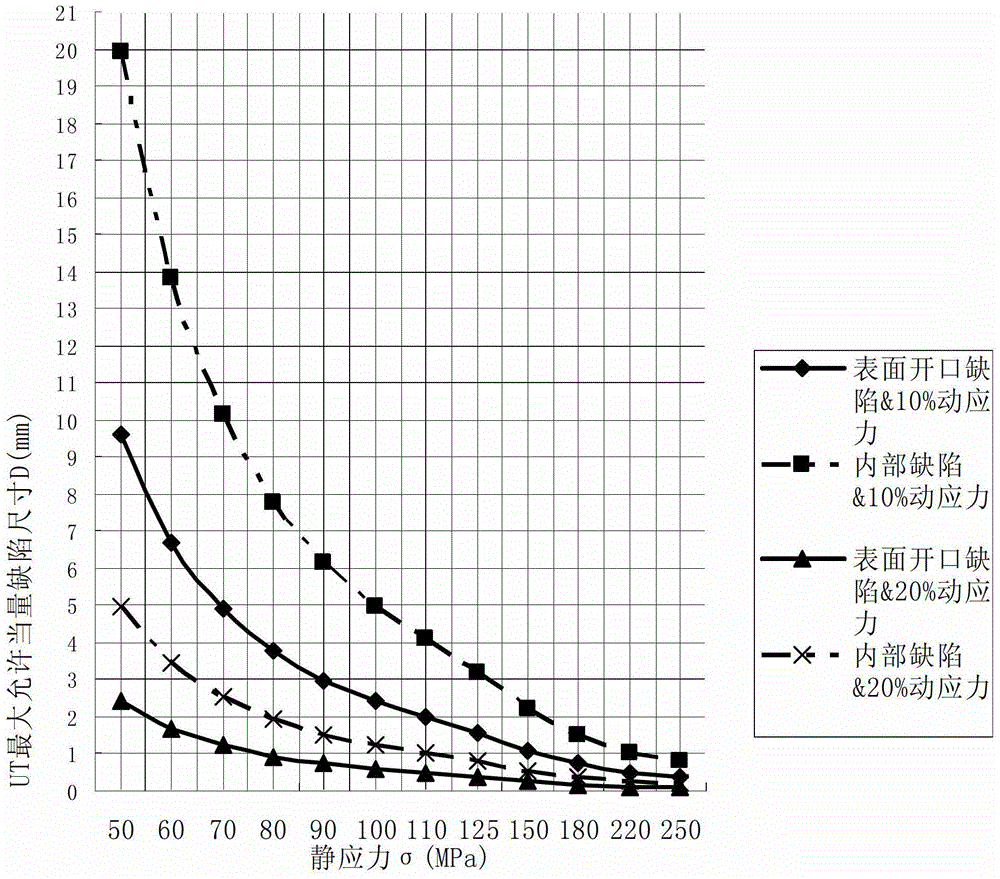

The Method of Avoiding Cracks in the Runner Blades of Francis Turbine

ActiveCN103706996BEasy to operateEquivalent defect size is reasonableAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationDefect sizeMixed flow

Owner:上海福伊特水电设备有限公司

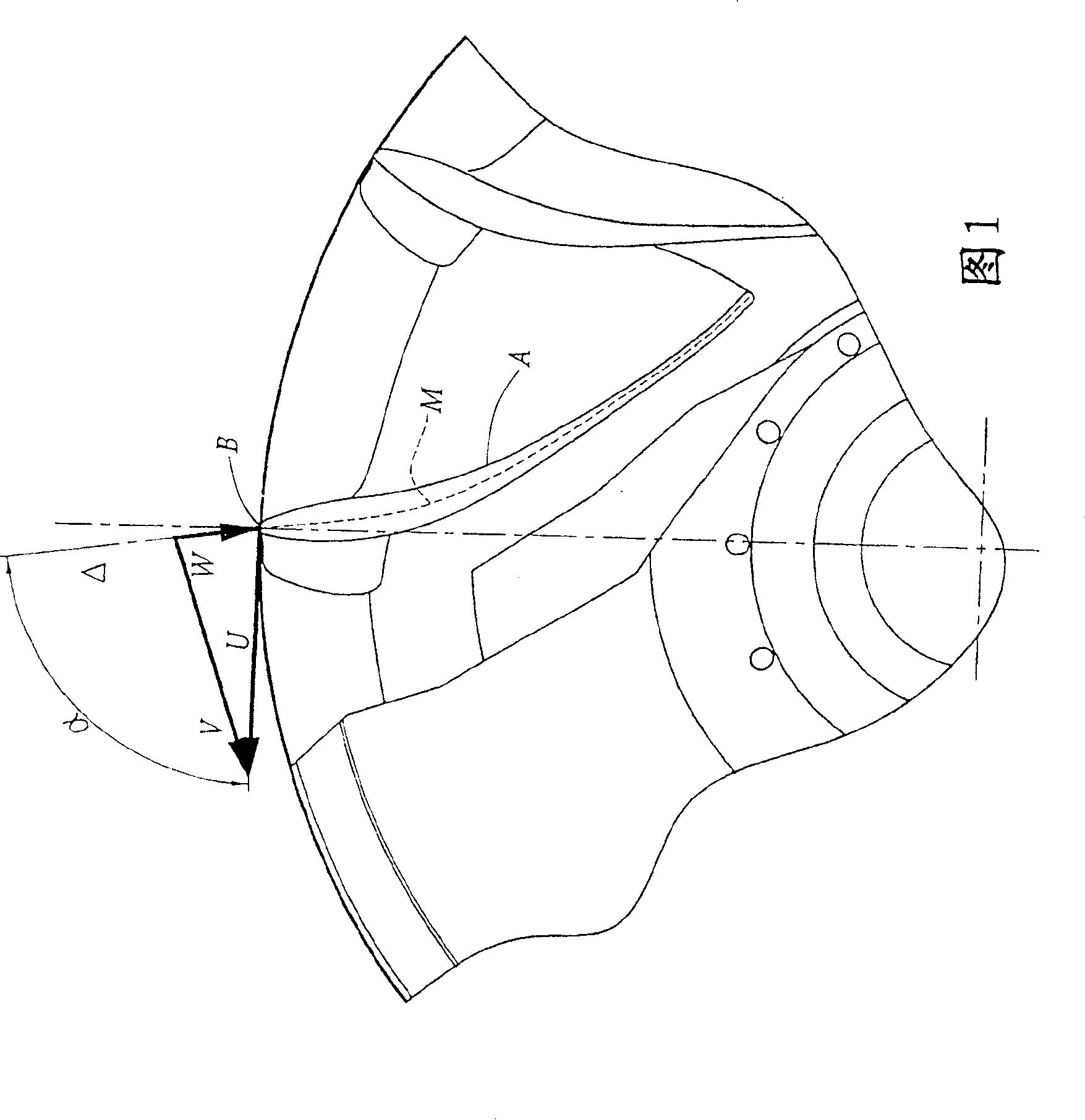

Francis turbine

The invention relates to a Francis turbine and a hydraulic turbine comprising one such Francis turbine. The inventive Francis turbine comprises a ceiling, a belt and blades ( 2 ) which extend between the ceiling and the belt and which define liquid flow channels therebetween. The ratio (e / L) of the maximum thickness (e) of each blade ( 2 ) to the average developed length (L) of the average fibre ( 23 ) thereof is between 0.1 and 0.2. According to the invention, over essentially the entire height of the leading edge ( 21 ), said average fibre ( 23 ) is oriented along a straight line (Delta23) which forms an angle (alpha) greater than 90 DEG in relation to the linear feed speed (U) of the leading edge ( 21 ) of the blade ( 2 ).

Owner:GE RENEWABLE TECH

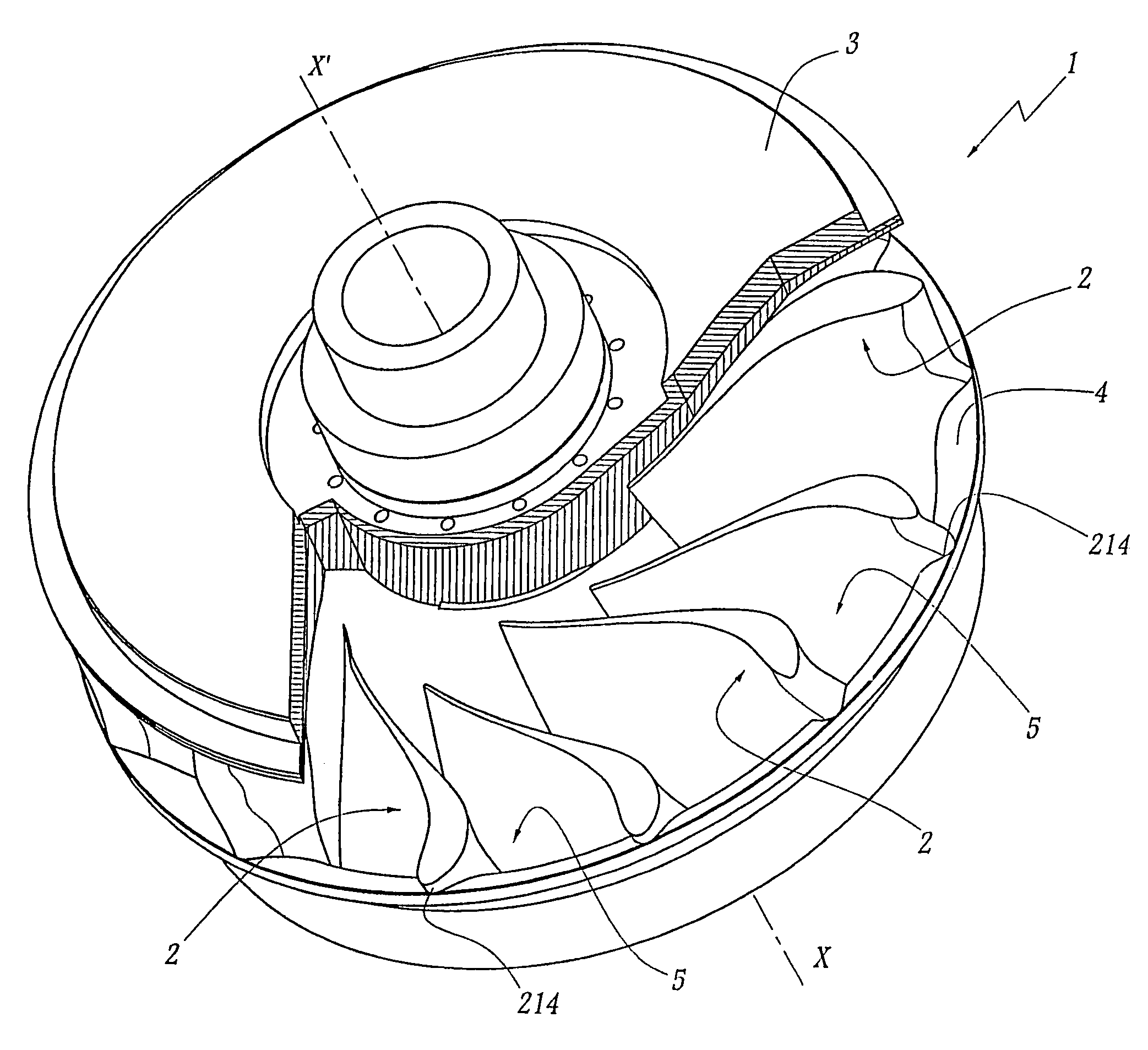

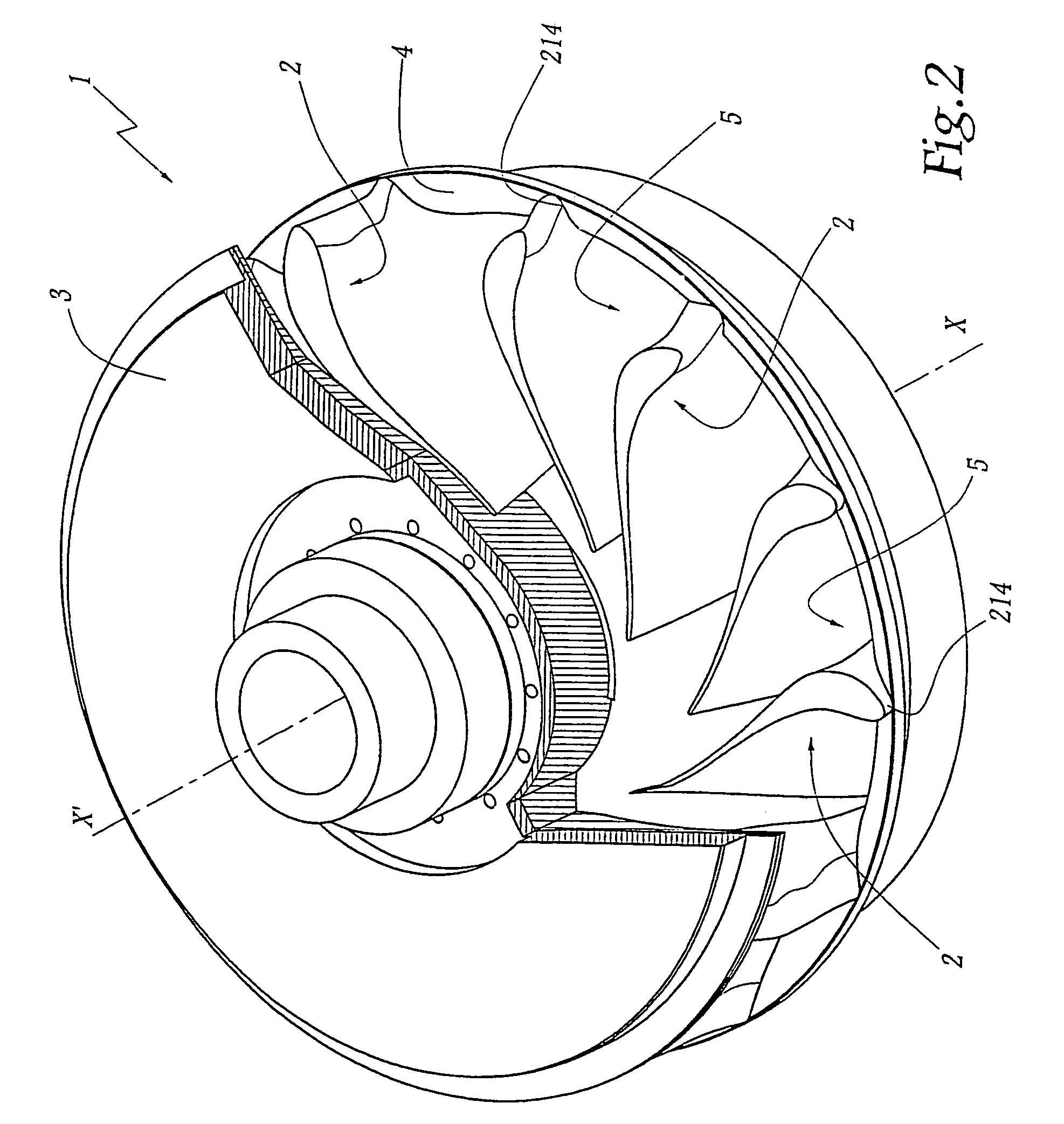

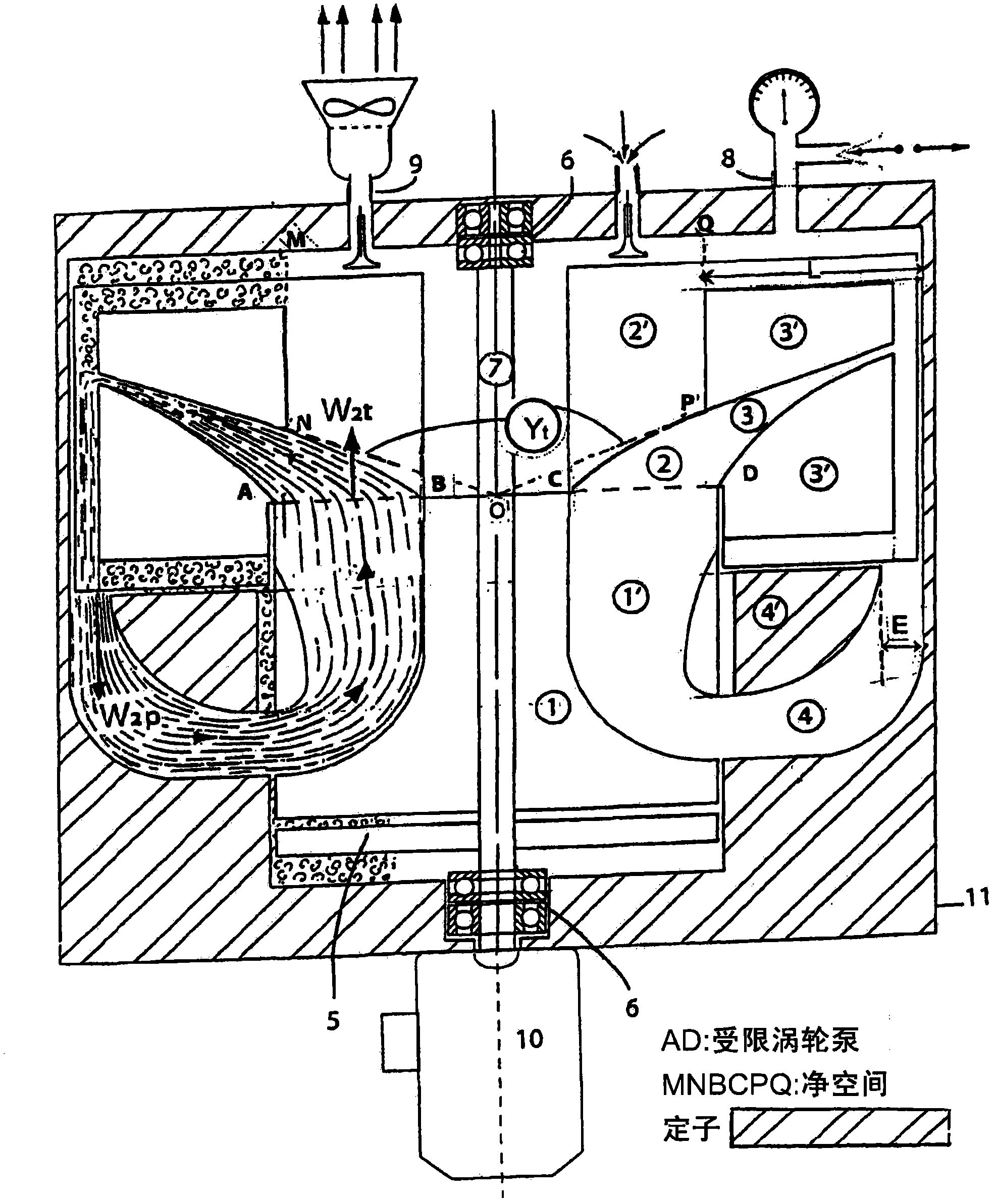

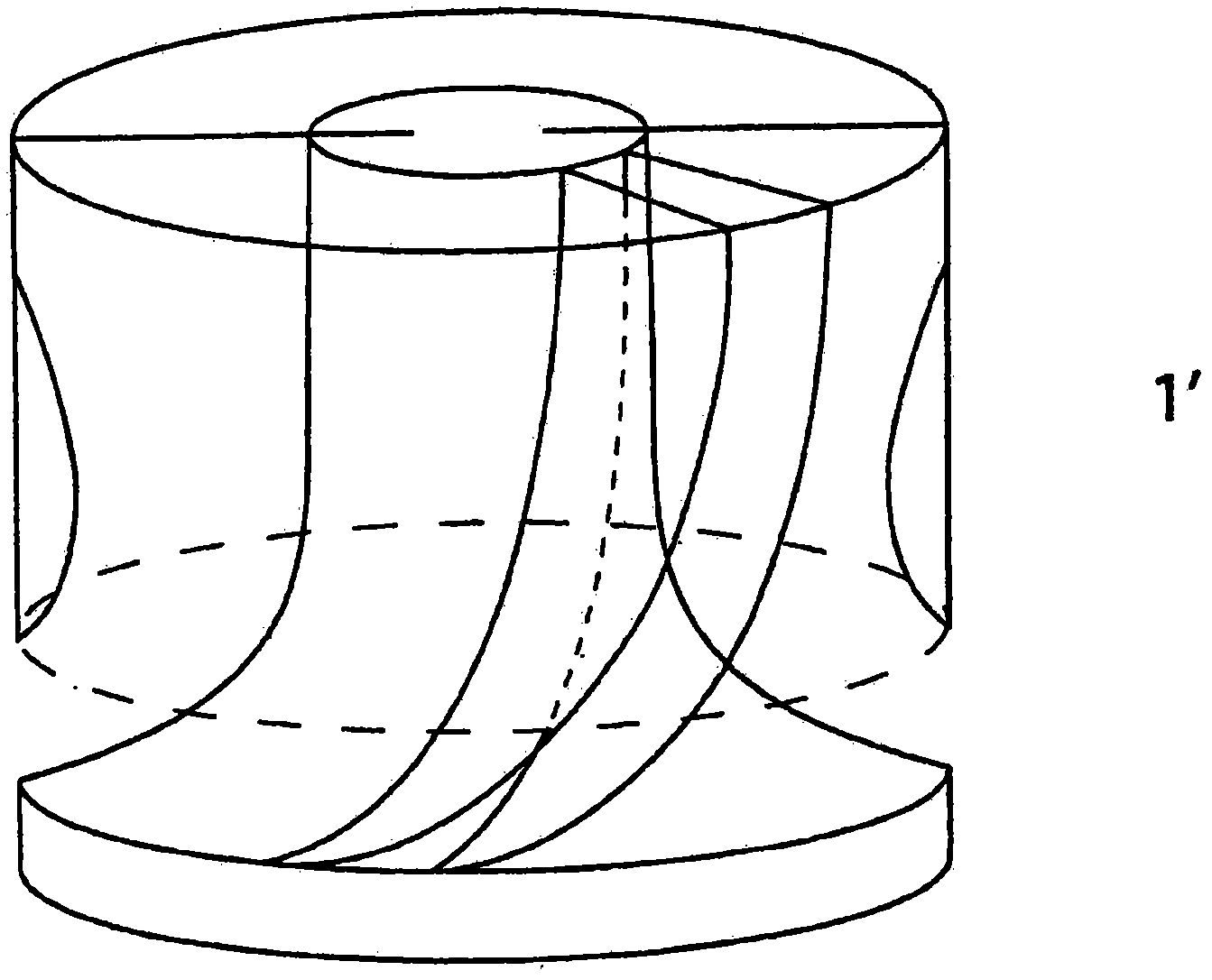

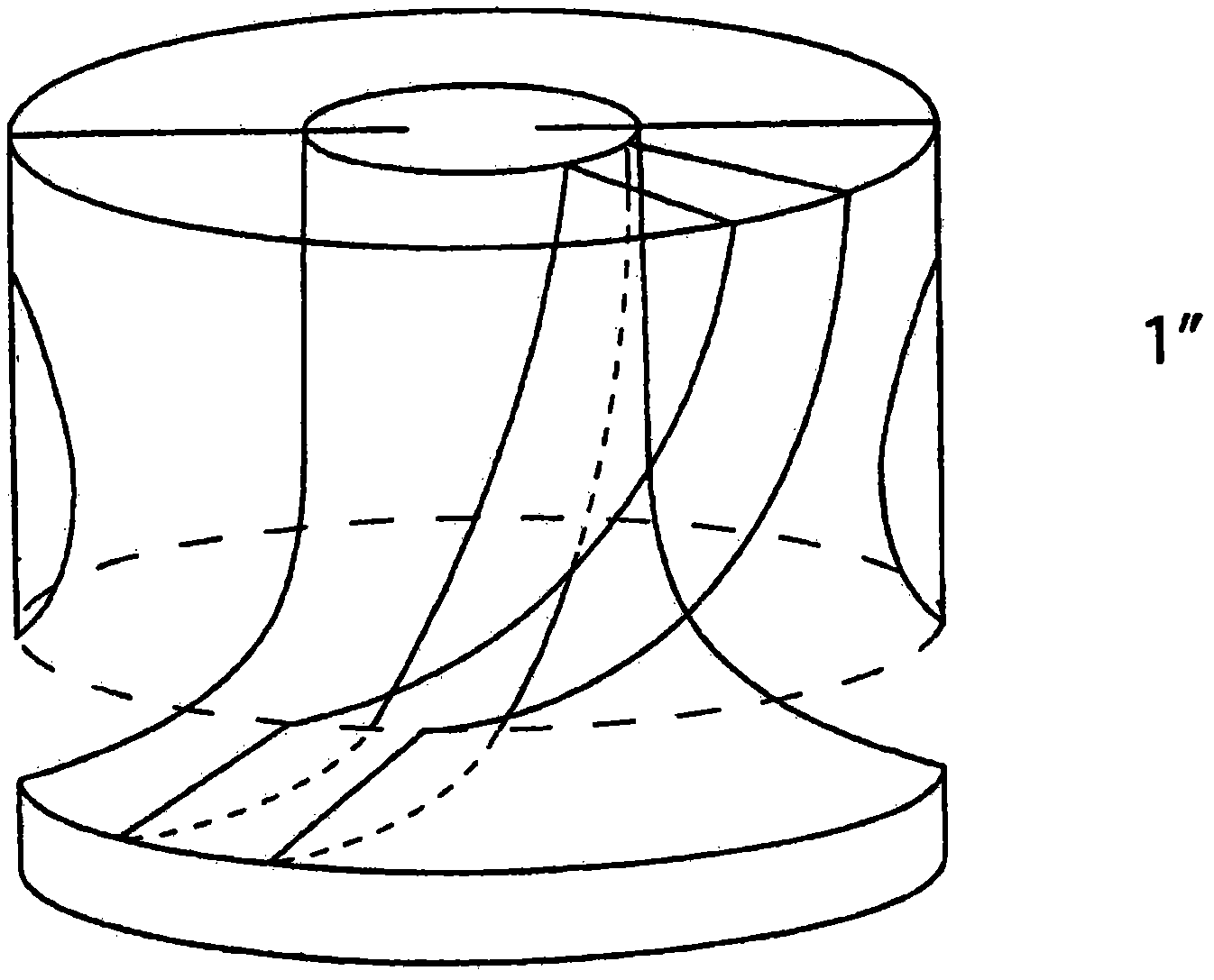

Ecological power unit

ActiveCN102844526BHigh densityReduce frictionEfficient propulsion technologiesHydro energy generationMechanical energyVolumetric Mass Density

The invention relates to an ecological thrusting device enabling optimum thrust independent from the outside environment. It consists of a special Francis turbine (1) from which the fluid is axially ejected at the outlet of the vane (1'), at a relative speed W2t, and is collected in a defined free space of a straight radial pump (2). Under the action of the centrifugal force, the limit of the current lines forms a fixed virtual barrier Yt, thus preventing the centrifuged fluid from reaching the bottom of the pump in the free space area MNBCPQ, thereby eliminating the antagonistic force exerted on said zone. As a result, the thrusting force exerted on the turbine by the fluid remains intact. As the fluid leaves the pump, it is axially reinjected at a relative speed W2p into a tank (4) for resupplying the turbine. There is therefore an energy exchange between the pumps and the turbine that form a closed circuit, the entire system being driven by a motor (10). It is shown that the thrust force P=(½) ppiomega2 r4; p being the density of the centrifuged fluid in en Kg / m3; omega being the angular speed of the turbine in rad / s; and r its radius in metres and P in Newtons. The calculation shows that the amount of thrust generated is very high; said thruster can be used to generate mechanical energy anywhere in space, and especially to drive the most highly efficient flying machines.

Owner:吉尔伯特·里

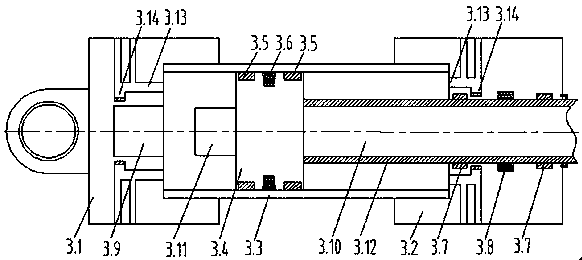

Adjusting device for a Francis turbine

ActiveCN105927453BReliable adjustmentSmall footprintEngine sealsFluid-pressure actuator testingMixed flowWater turbine

Owner:浙江国正安全技术有限公司

Axial radial-flow type turbine

InactiveCN1580545ADecrease the peripheral velocity componentReduce secondary flowOther chemical processesHydro energy generationLeading edgeTurbine blade

A Francis turbine has a rotating array of turbine blades rotating on a hub and enclosed within a rotating shroud. Each blade has a root, a tip, a leading edge and a trailing edge. The distance Rc between the axis of rotation (1) and the shroud (7), divided by the distance Rb between the axis of rotation (1) and the root end (14), is a ratio between 0.2 and 04.

Owner:KK TOSHIBA

Method of Repairing the Outlet Edge of the Runner Blade of Francis Turbine

ActiveCN108661840BGuaranteed mechanical strengthAvoid crackingHydro energy generationGrinding machinesWater turbineMechanics

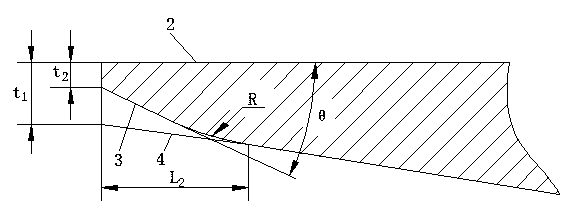

Disclosed is a trimming method for a blade outlet edge (1) of a mixed-flow water turbine runner. The method comprises the steps of: cutting out a blade wing profile, and determining a blade outlet edge (1) trimming area; enabling an after-trimming blade back molded line (3) and a pre-trimming blade back molded line (4) to be in circular arc transition, wherein the radius R of the circular arc is 4-7 times of the thickness t1 of the blade outlet edge before trimming; determining the final geometric dimension of trimming of the blade outlet edge (1); determining the sizes of a child-mother sample plate (11, 12) and a circular arc sample plate (13) of the back of the blade, and integrally machining the child-mother sample plate and the circular arc sample plate of the back of the blade; marking off on the blade outlet edge (1), and determining the final position of a back pressure edge (6) of the outlet of the blade after trimming; adjusting the angle of the blade outlet edge (1) until the angle meets the size of the child-mother sample plate (11, 12); and grinding the circular arc of the back of the blade until the circular arc meets the size of the circular arc sample plate (13) of the back of the blade. The method can prevent or eliminate water turbine hissing and blade cracks generated by blade hydraulic power elastic resonance induced by Karman Vortex of a runner outlet, and improves the structural integrity of the mixed-flow water turbine runner and the operation safety of the water turbine.

Owner:DONGFANG ELECTRIC MACHINERY

A wear-resistant Francis turbine suitable for high water head, high speed and high sediment concentration

ActiveCN110439722BMatching structural strengthReduce wearHydro energy generationReaction enginesMixed flowWater turbine

The invention relates to an anti-wear mixed flow water turbine capable of adapting to high head, high rotation speed and high sand content. The anti-wear mixed flow water turbine comprises a volute, afixed guide vane, a movable guide vane, a rotating wheel and a draft pipe. The movable guide vane molded lines are symmetrical two cubic curve assembly, which makes the velocity in the guide vane area and the resistance loss in the flow passage smaller and the flow more smoothly, and effectively reduces the wear of sediment to the guide vane outlet area; and the newly designed long and short vanerotating wheel can better match the flow field and the structural strength of the rotating wheel, and significantly reduce the wear of sediment to the outlet side of the rotating wheel. The thickness change rule of rotating wheel diameter, vane wrap setting angle, vane inlet angle and the vane from inlet to the outlet can be designed newly through the long and short vane rotating wheel, so thatthe flow field can be matched better, the structural strength of the rotating wheel is better, and the wear of the sediment to the outlet side of the rotating wheel.

Owner:TSINGHUA UNIV +1

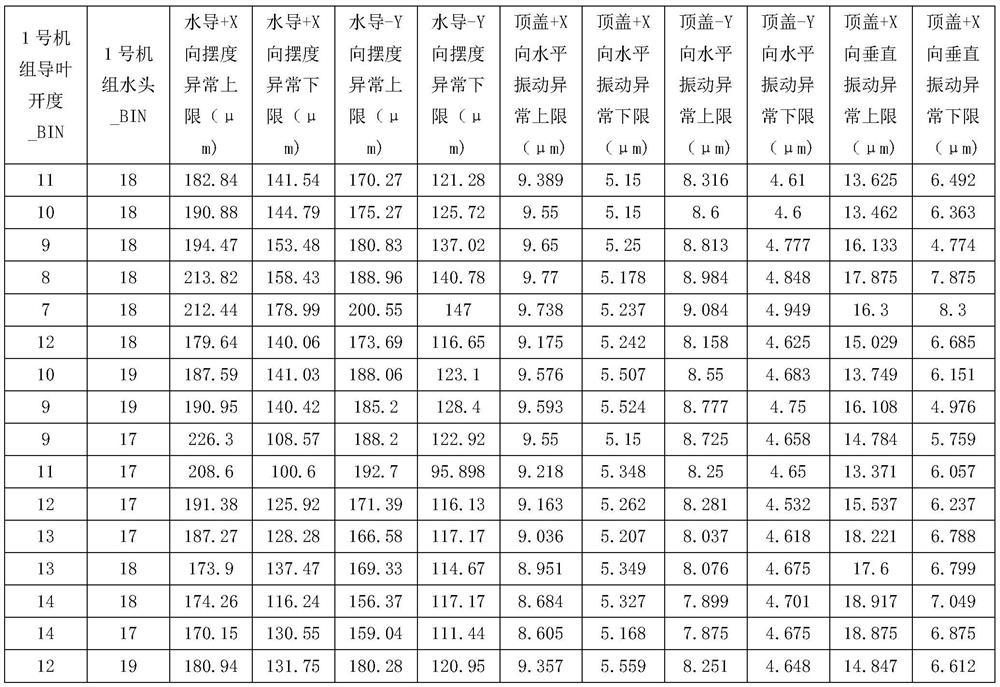

Early warning method for penetrating cracks in vertical Francis hydro-generator runners

ActiveCN112796920BAvoid false alarmsKeep valid samplesHydro energy generationMachines/enginesData setNormal range

The invention relates to a method for early warning of penetrating cracks in a runner of a vertical Francis turbine generator, belonging to the technical field of coatings. The method includes: installation of monitoring sensors; data collection; data screening; working condition segmentation; data is divided into sample data sets and monitoring data sets; data cleaning; Limit ratio; runner crack judgment logic calculation and alarm output. The method of the invention utilizes the state monitoring time series data such as the active power, water head, and vibration swing of the hydro-generator to quickly calculate the water-conducting swing of the hydro-generator under different operating conditions, the upper limit of the normal range of the roof vibration, and the current When a penetrating crack occurs in the runner, the water guide swing and the over-limit ratio of the top cover vibration are in line with the judgment logic, and an alarm is output in time to avoid the further expansion of the crack and cause a major accident. The method of the invention has the characteristics of simple operation and strong versatility, and is easy to popularize and apply.

Owner:HUANENG LANCANG RIVER HYDROPOWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com