Generation method of blade cutter tracks of francis turbine

A water turbine and mixed-flow technology, which is applied to computer components, character and pattern recognition, instruments, etc., can solve the problems of large volume, high cost, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

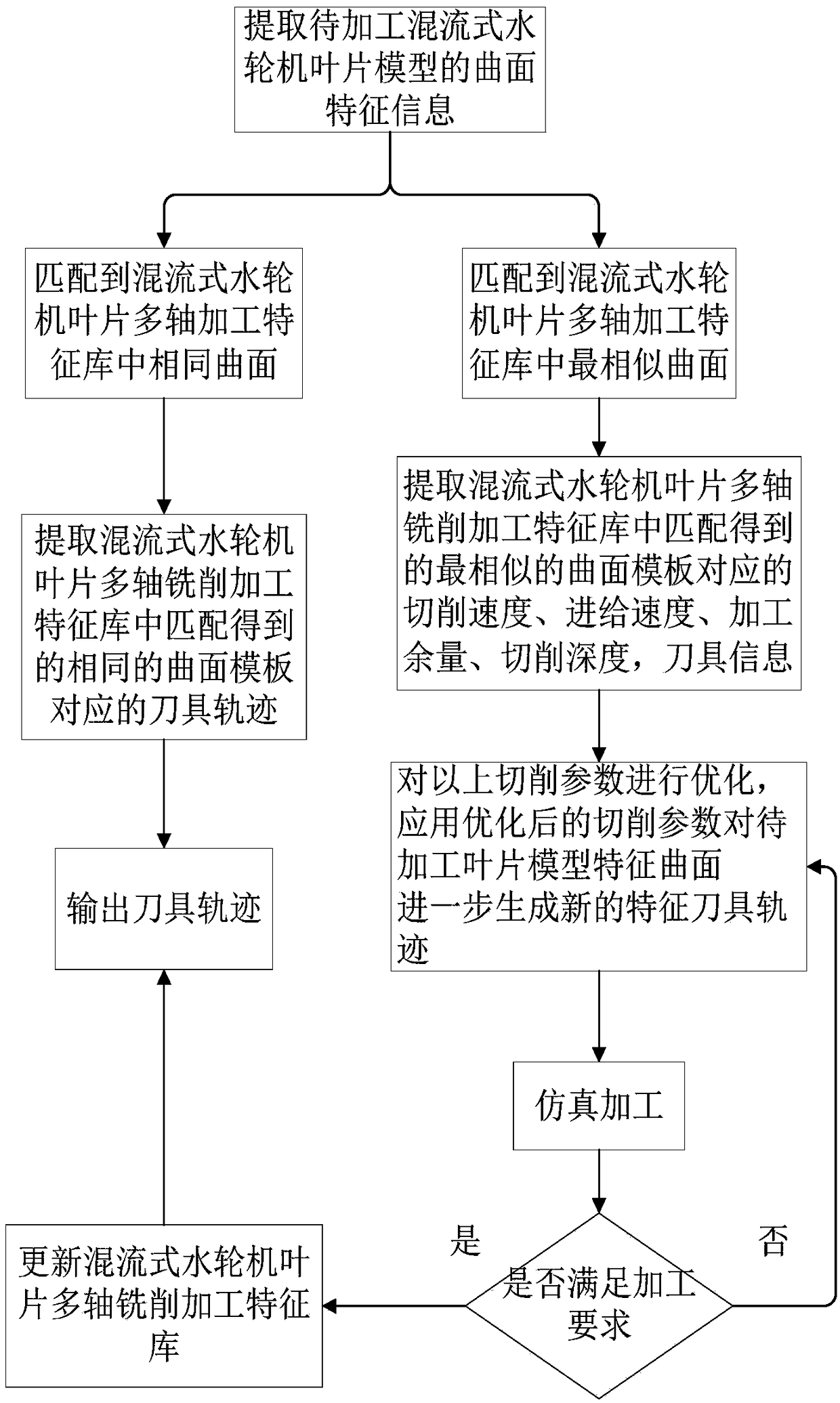

[0036] Embodiment 1: as Figure 1-Figure 20 As shown, a Francis turbine blade tool track generation method, the specific steps of the method are as follows:

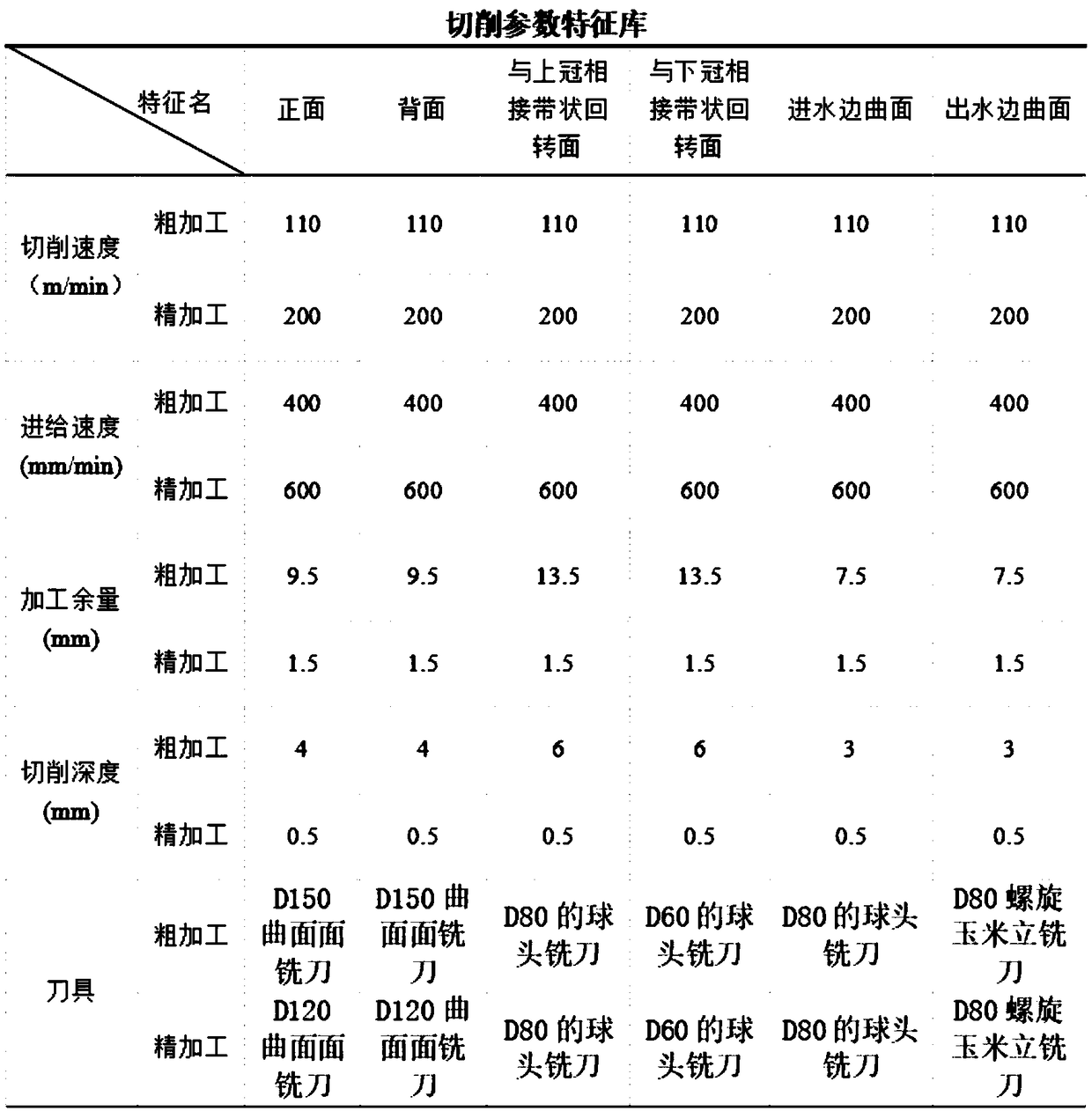

[0037] Step S1: Extract the surface feature information of the Francis turbine blade model to be processed, and perform step S2-1; the surface feature information specifically includes the front, back, belt-shaped turning surface connected to the upper crown, and belt-shaped turning surface connected to the lower crown 1. A characteristic surface composed of point features, line features, and boundary feature information of the six characteristic surfaces of the water inlet surface and the water outlet surface, the curvature radii of the six characteristic surfaces and the corresponding curvature radius contours;

[0038] Step S2-1: Use image recognition technology to combine the characteristic surface formed by the point features, line features, and surface feature information of the characteristic surface of the Franci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com