Mixed-flow turbine runner spilled water hole processing technique

A processing technology and scupper hole technology, applied in the directions of hydroelectric power generation, mechanical equipment, engine components, etc., can solve the problems affecting the pressure at the upper crown, unstable operation of the unit, complicated processing operations, etc., to achieve the accuracy of processing positioning and processing. Good rigidity, improved workpiece yield and processing quality, and less processing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

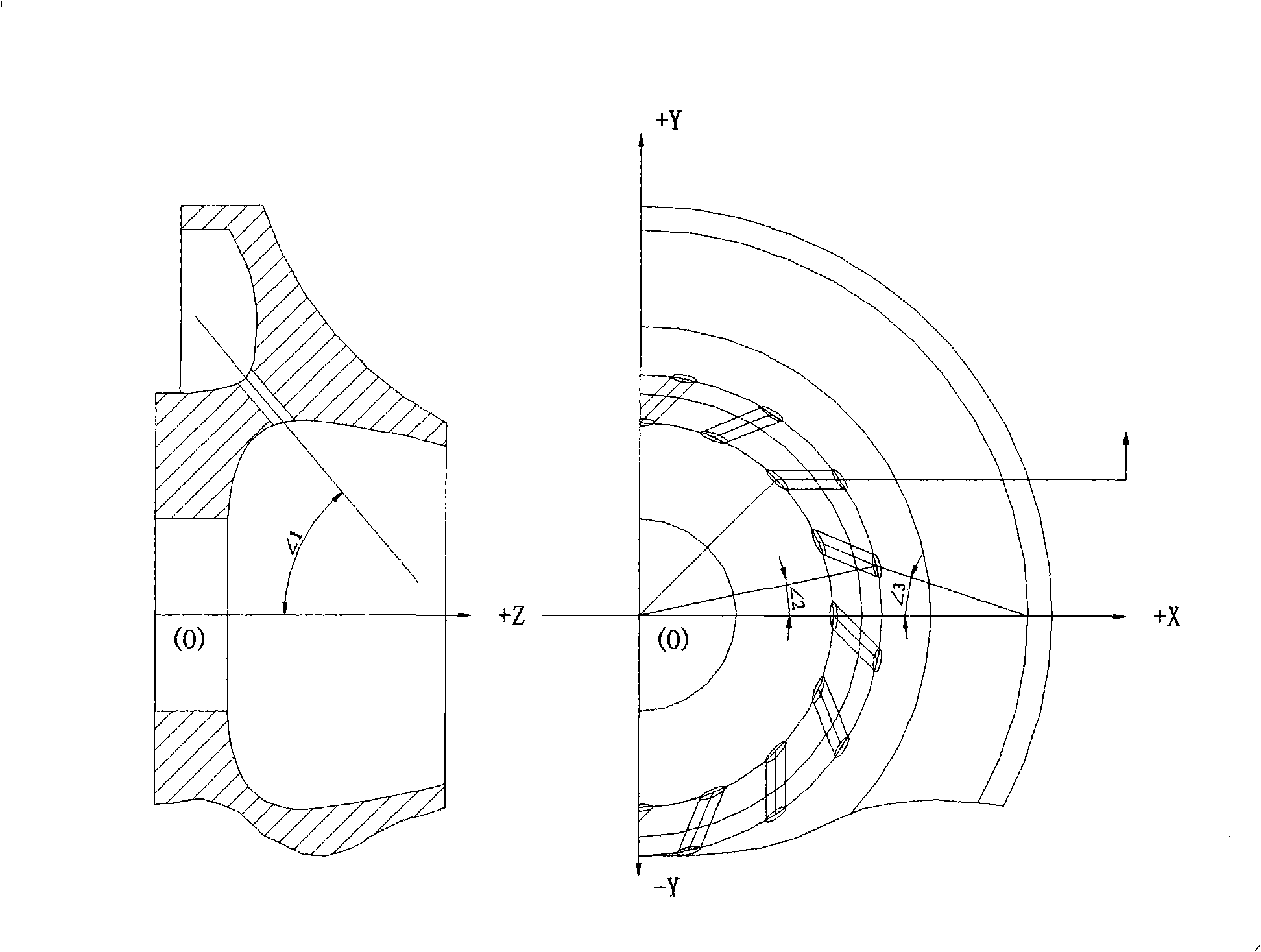

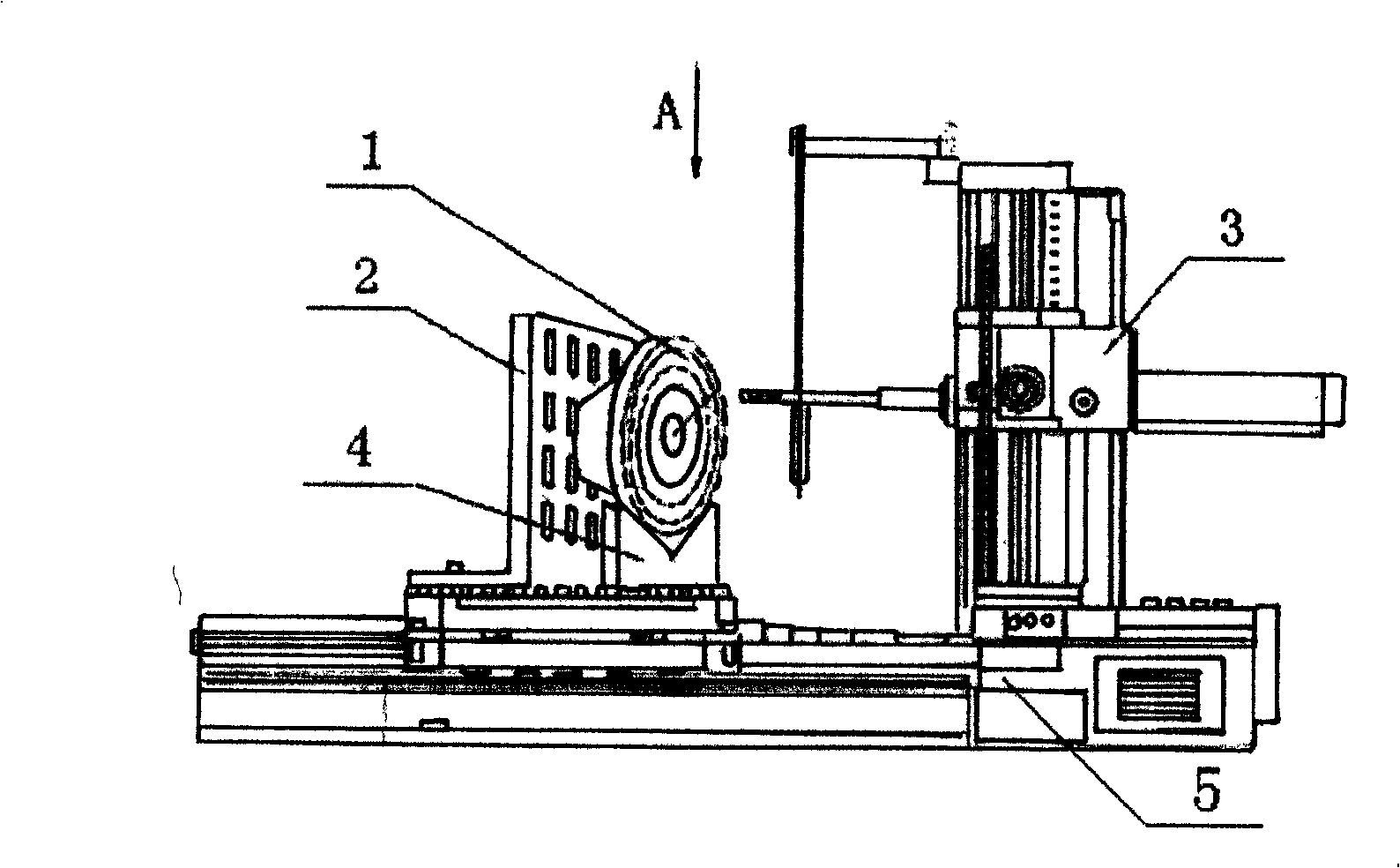

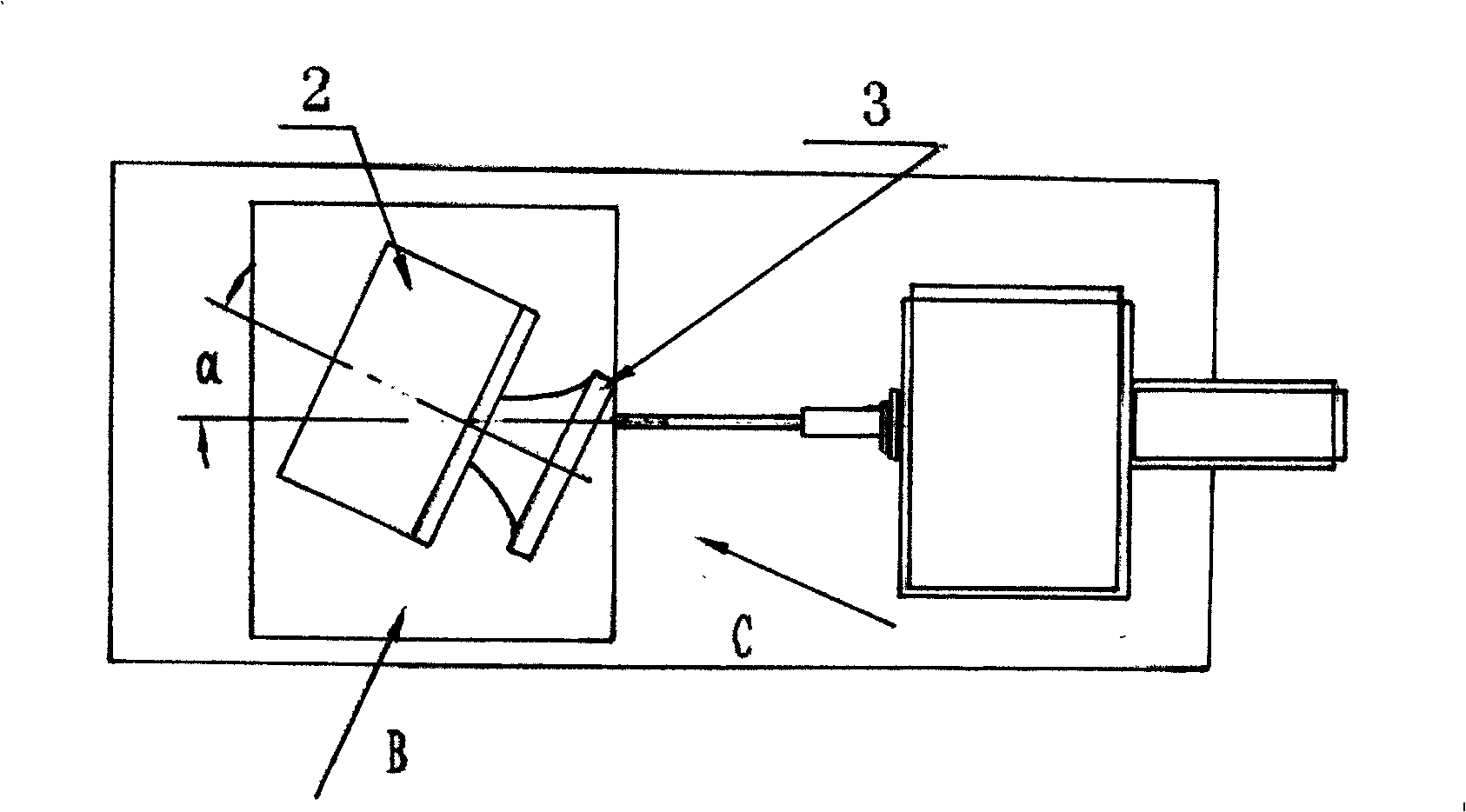

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. figure 1 It is the processing diagram of the weep hole. In the figure, ∠1 is the angle between the orthographic projection of the center line of the weep hole in the sectional plane of the rotation axis of the upper crown and the center axis of the rotation, and ∠2 is the starting point of the weep hole at the center of the cross. The distribution angle within the line, ∠3 is the angle between the orthographic projection of the centerline of the weep hole in the sectional plane of the rotation axis of the upper crown and the horizontal line of the centerline of the cross.

[0021] The processing technology of the runner drain hole of the mixed-flow unit includes the following steps;

[0022] (1) Based on the inner and outer circles of the upper crown, draw the cross centerlines of -X-+X, -Y-+Y processing technology, and measure the orthographic projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com