Patents

Literature

47results about How to "Reduce secondary flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

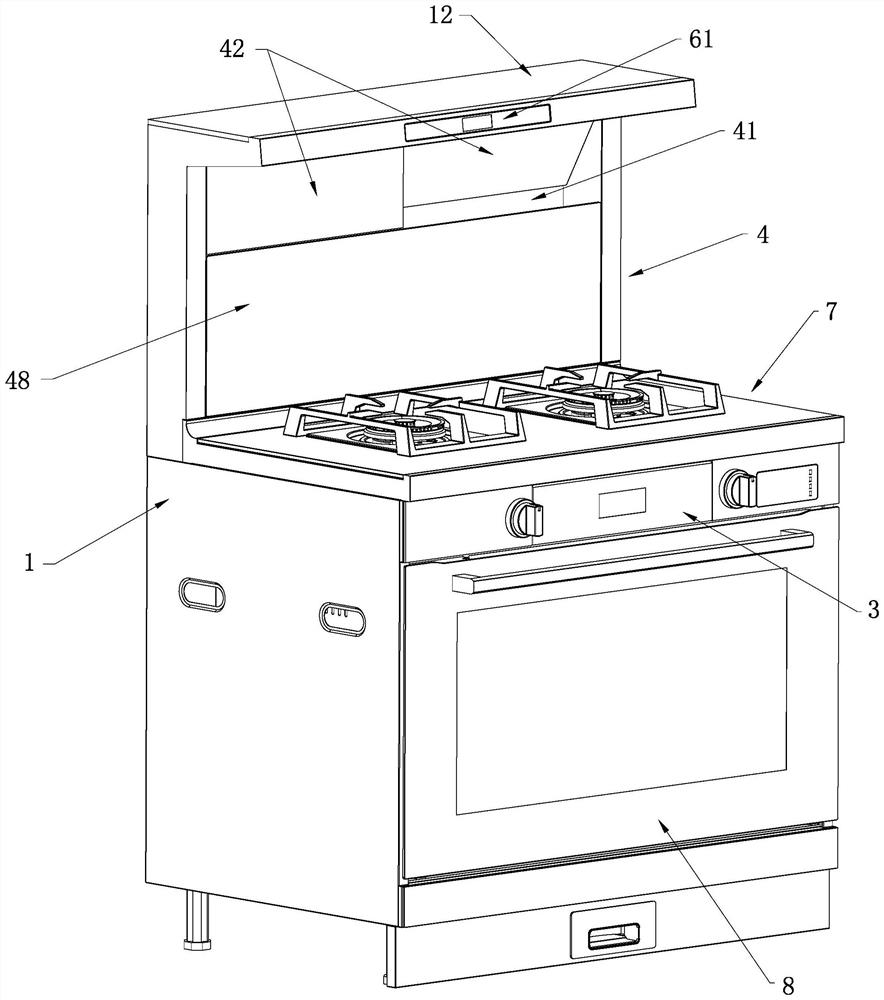

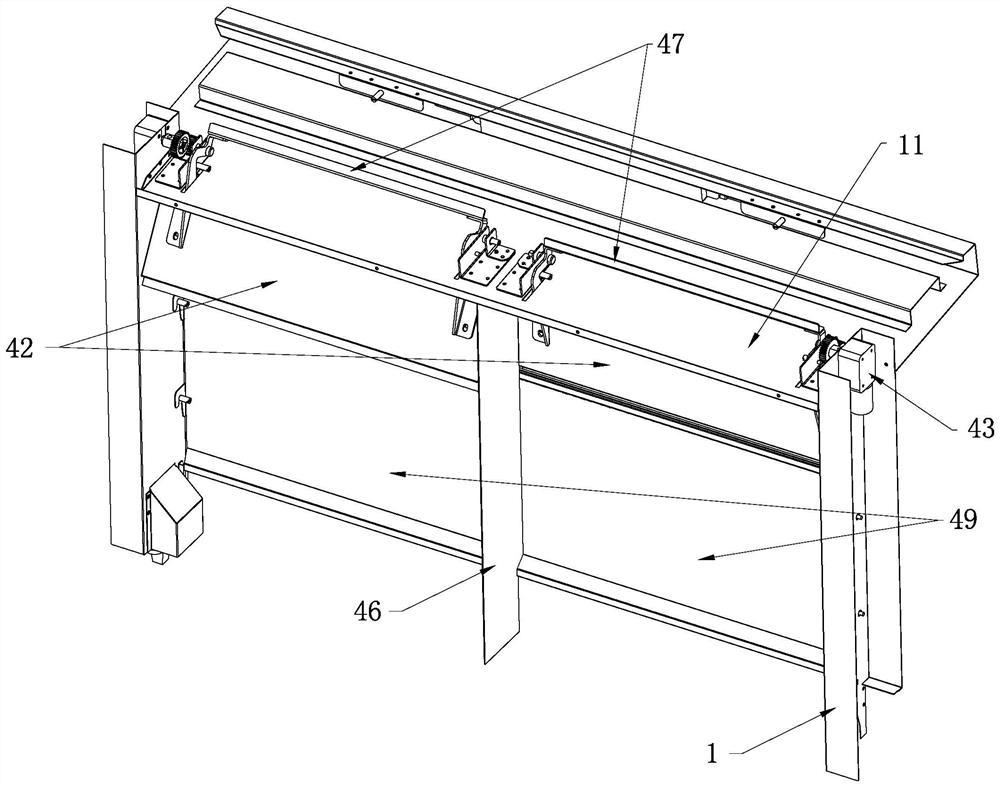

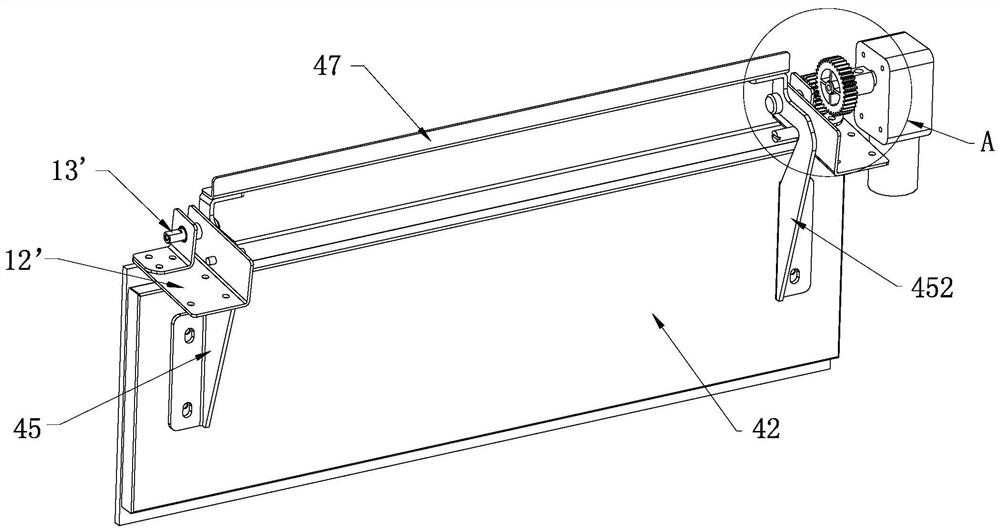

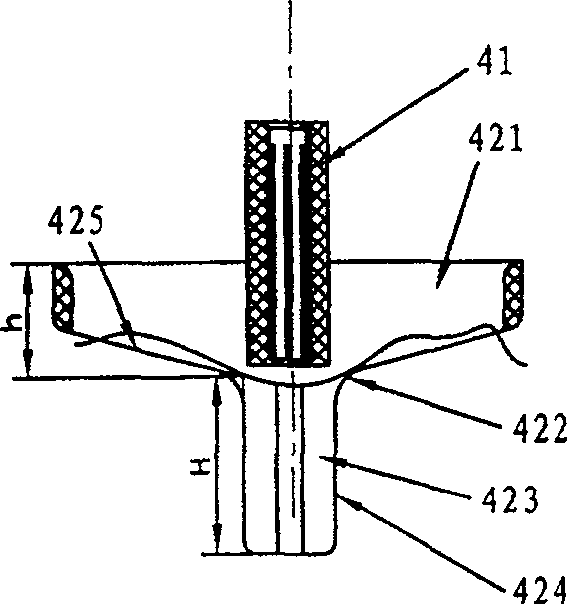

Integrated cooker

PendingCN112555906AOutstanding and Beneficial Technical EffectsGuaranteed tightnessDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention belongs to the technical field of kitchen appliances, and particularly relates to an integrated cooker. The integrated cooker comprises a machine body and a range hood body; the range hood body comprises an air inlet, an air collecting box and a fan assembly; the air collecting box communicates with the air inlet; the fan assembly is arranged in the air collecting box; a volute air duct of the fan assembly extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with an air outlet base; and an air outlet is formed in one side of the air outlet base. According to the integrated cooker, the volute air duct extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with the air outlet base; the air outlet base is directly located on the outer side of the air collecting box, and the situation that a channel is located inside and occupies too much space is avoided; a through hole does not need to be additionally formed in the side edge of the machine body, and leakproofnessof the side face of the machine body is guaranteed; and meanwhile, the air outlet base is rotatably arranged, so that a user can conveniently adjust the air outlet direction according to actual needs,and humanization is achieved.

Owner:浙江安德电器有限公司

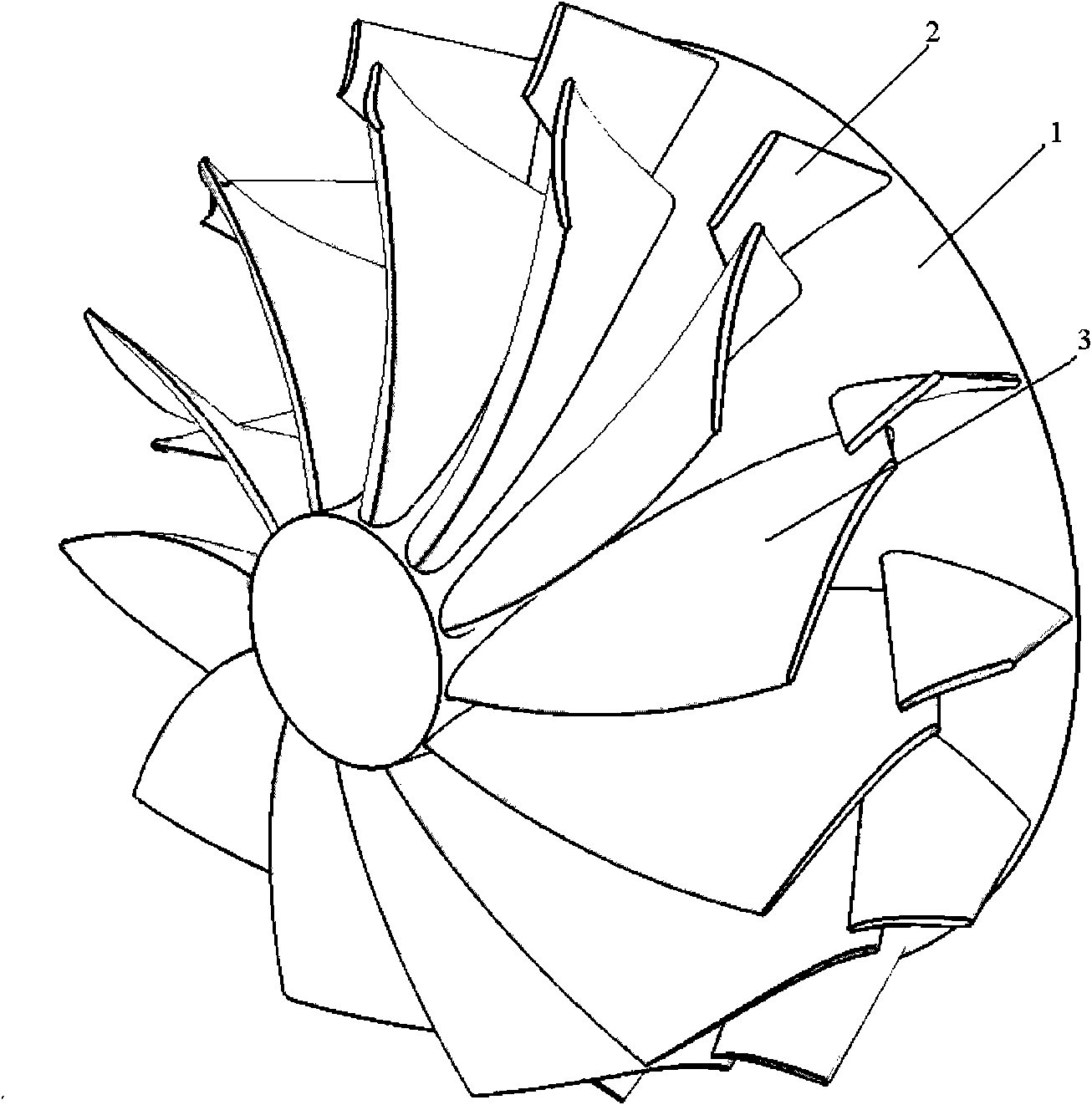

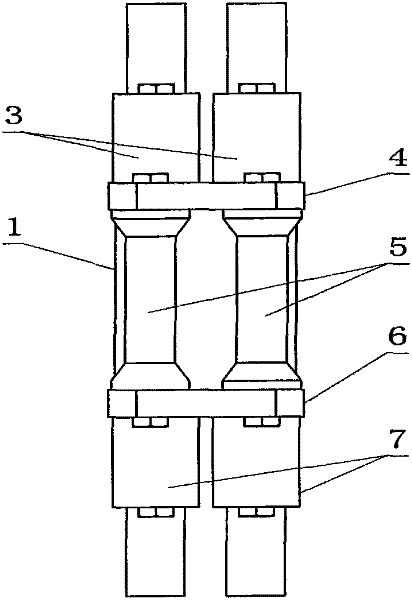

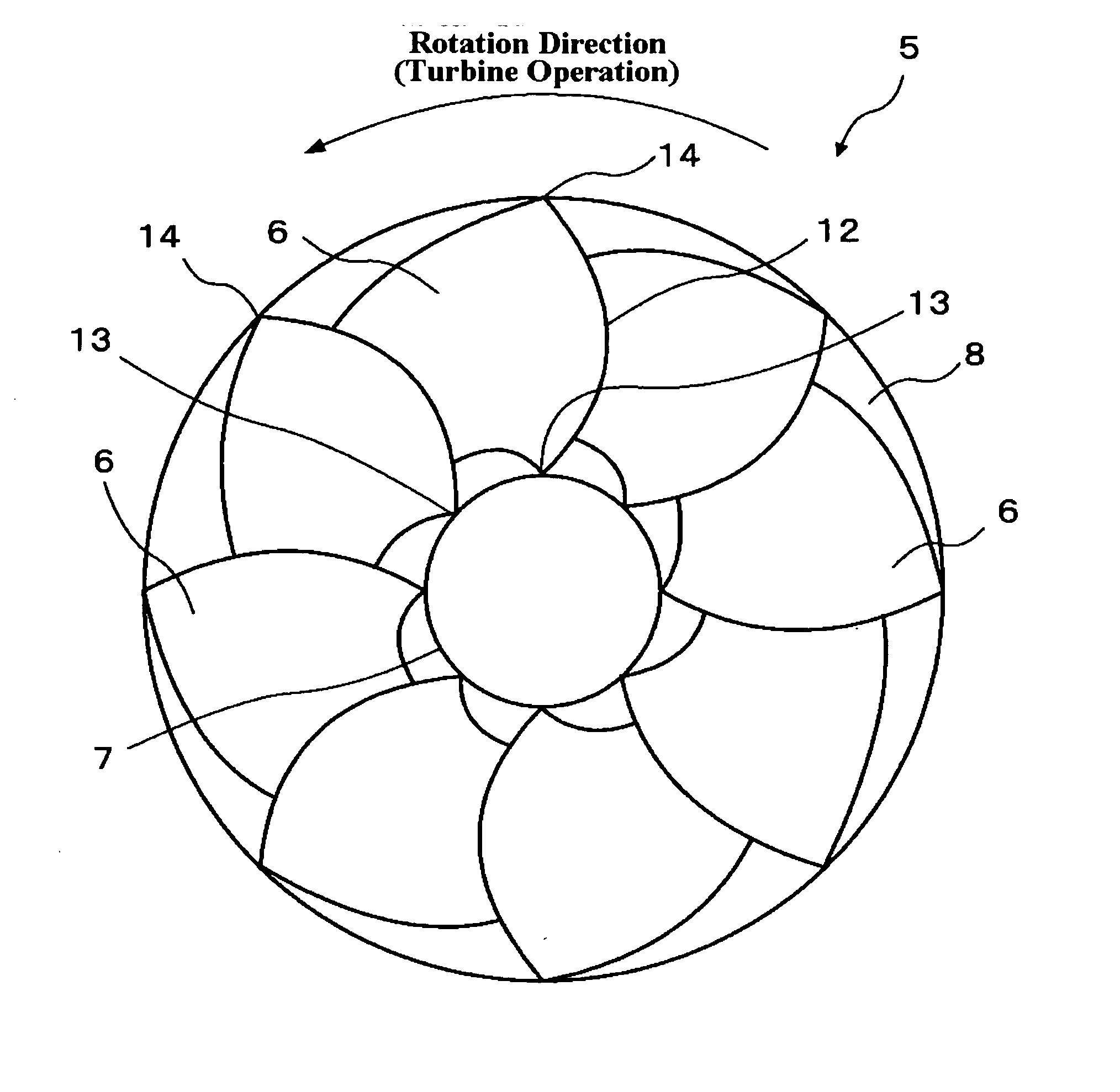

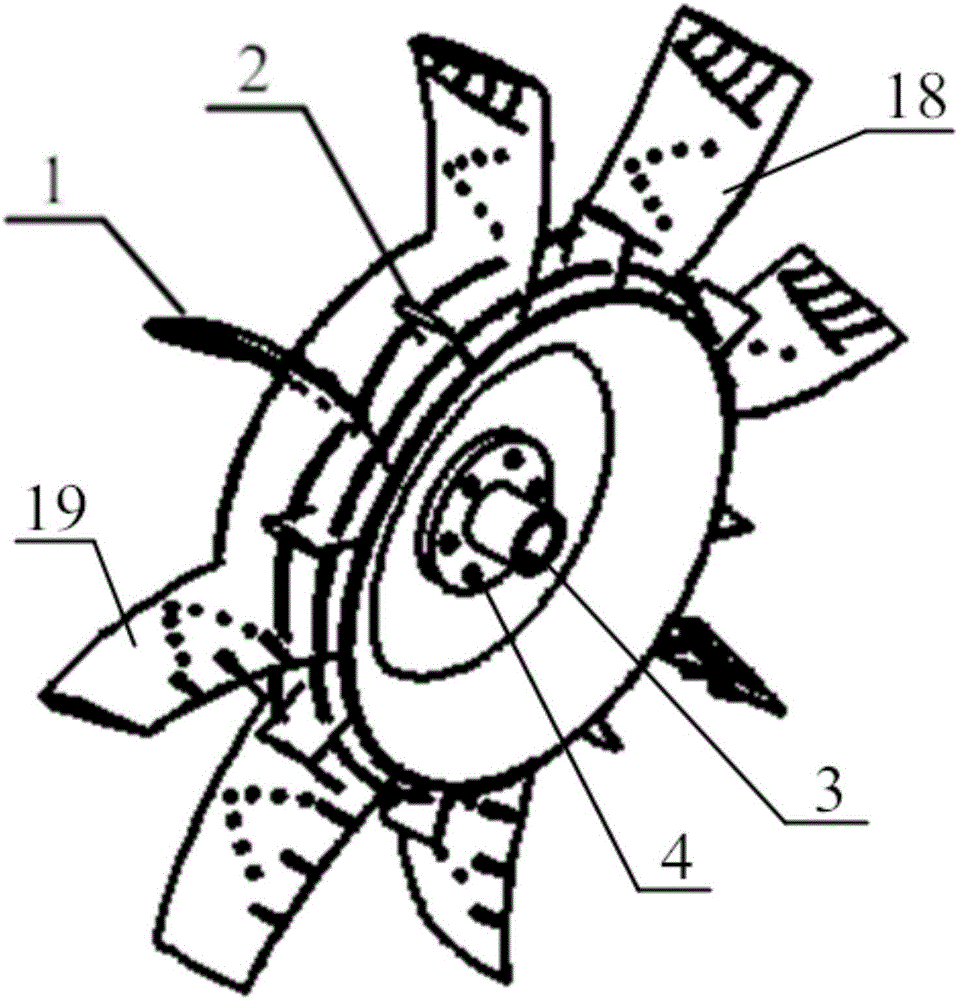

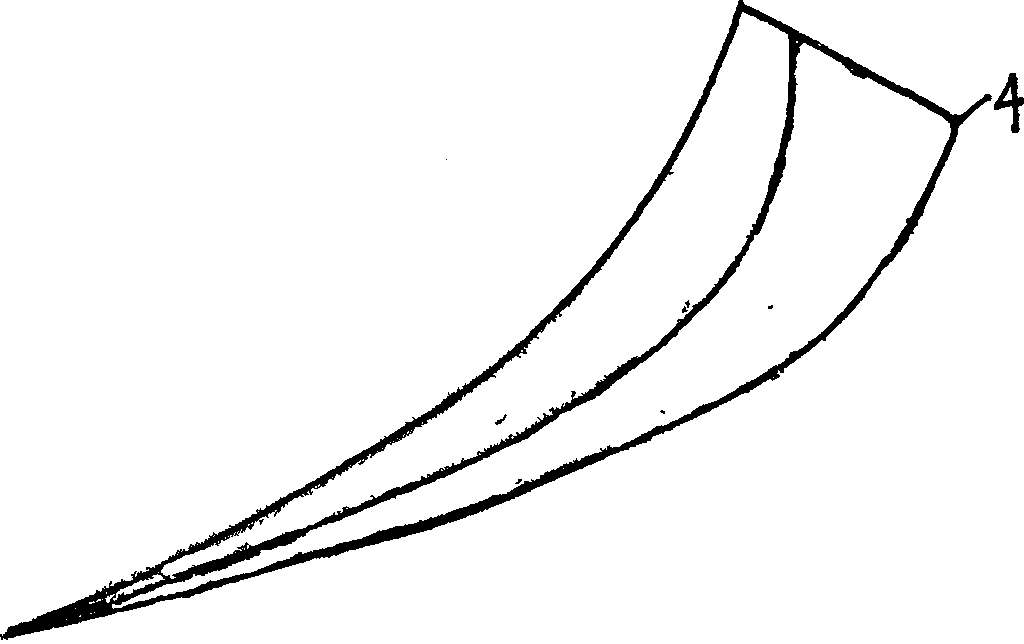

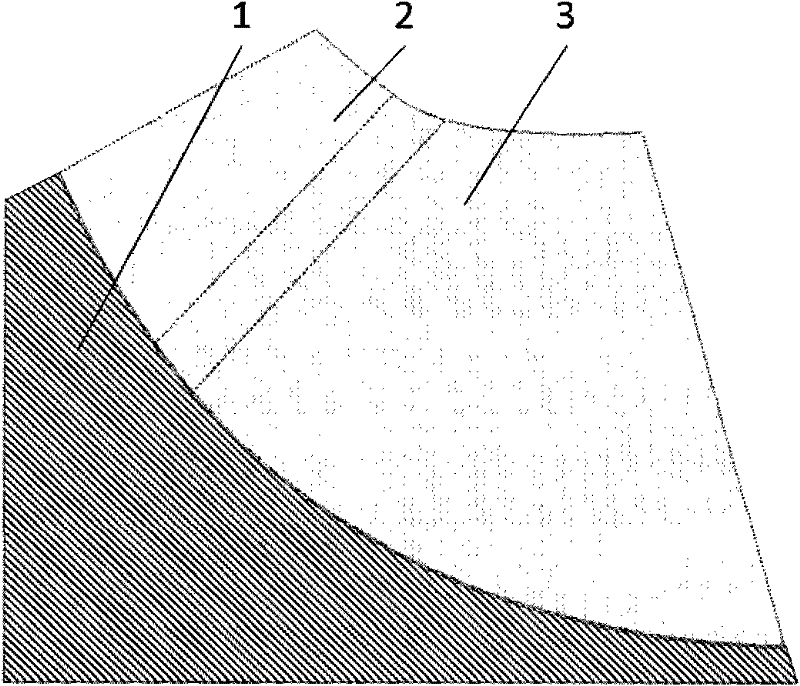

Tandem blade type mixed-flow or radial-flow turbine

InactiveCN101915126AImprove performanceInhibition of flow separationInternal combustion piston enginesBlade accessoriesMixed flowPulse charge

The invention relates to the technical field of blade type fluid machines, in particular to a tandem blade type mixed-flow or radial-flow turbine comprising a hub, front-row blades and back-row blades, wherein the ratio of the numbers of the tandem blade type front-row Z1 and the numbers of the back-row blades Z2 is 1:1 or 1:2, the ratio variation range of the lengths of the front-row and back-row blades is 0.1-0.5, the variation range of relative circumferential angles between the front edges of the back-row blades and the tail edges of the front-row blades is 0-2 pi / Z1, and the variation range of the distances between the tail edges of the front-row blades and the front edges of the back-row blades is -0.3 to 0.3 of the total blade chord length. By the airflow blowing-down function generated by a gap between the front-row blades and the back-row blades, the flow separation close to the front edges of the blades is restrained, the secondary flow is weakened, the efficient running range is enlarged, and the whole performance of the turbine under undersign conditions and pulse charging conditions is improved.

Owner:TSINGHUA UNIV

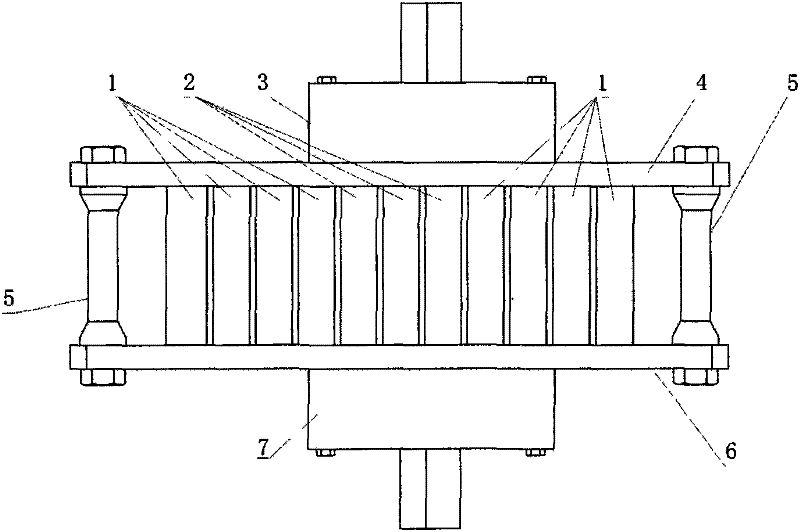

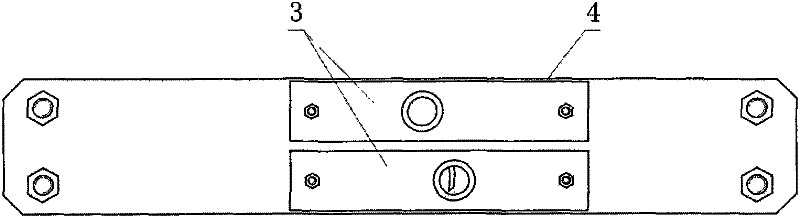

A compressor cascade experimental device

InactiveCN102287389AImprove performanceReduce lossesPump controlNon-positive displacement fluid enginesEngineeringCompressor cascade

A compressor cascade experimental device includes an even number of blades and an odd number of suction blades. An even number of blades and an odd number of suction blades are installed on the mounting surfaces of the first grid plate and the second grid plate, and the suction blades are located at the center of the first grid plate and the second grid plate. There is an end wall suction slot between each mounting slot. The installation groove of the suction vane and the suction groove of the end wall are provided with through gas suction slots. The first suction hood and the second suction hood are respectively installed at the centers of the outer surfaces of the first grid plate and the second grid plate, and the central air hole of the suction cover corresponds to the gas suction slit and the end wall suction groove respectively. In the present invention, through the combined suction of the blade surface of the compressor cascade and the end wall of the cascade, and connecting the second suction cover and the first suction cover to the suction equipment, the surface of the blade and the surface of the blade under different gas suction quantities can be simultaneously performed. The combined suction experiment of the end wall of the cascade obtains the optimal suction volume of the compressor cascade and improves the pressure ratio and efficiency of the compressor cascade.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

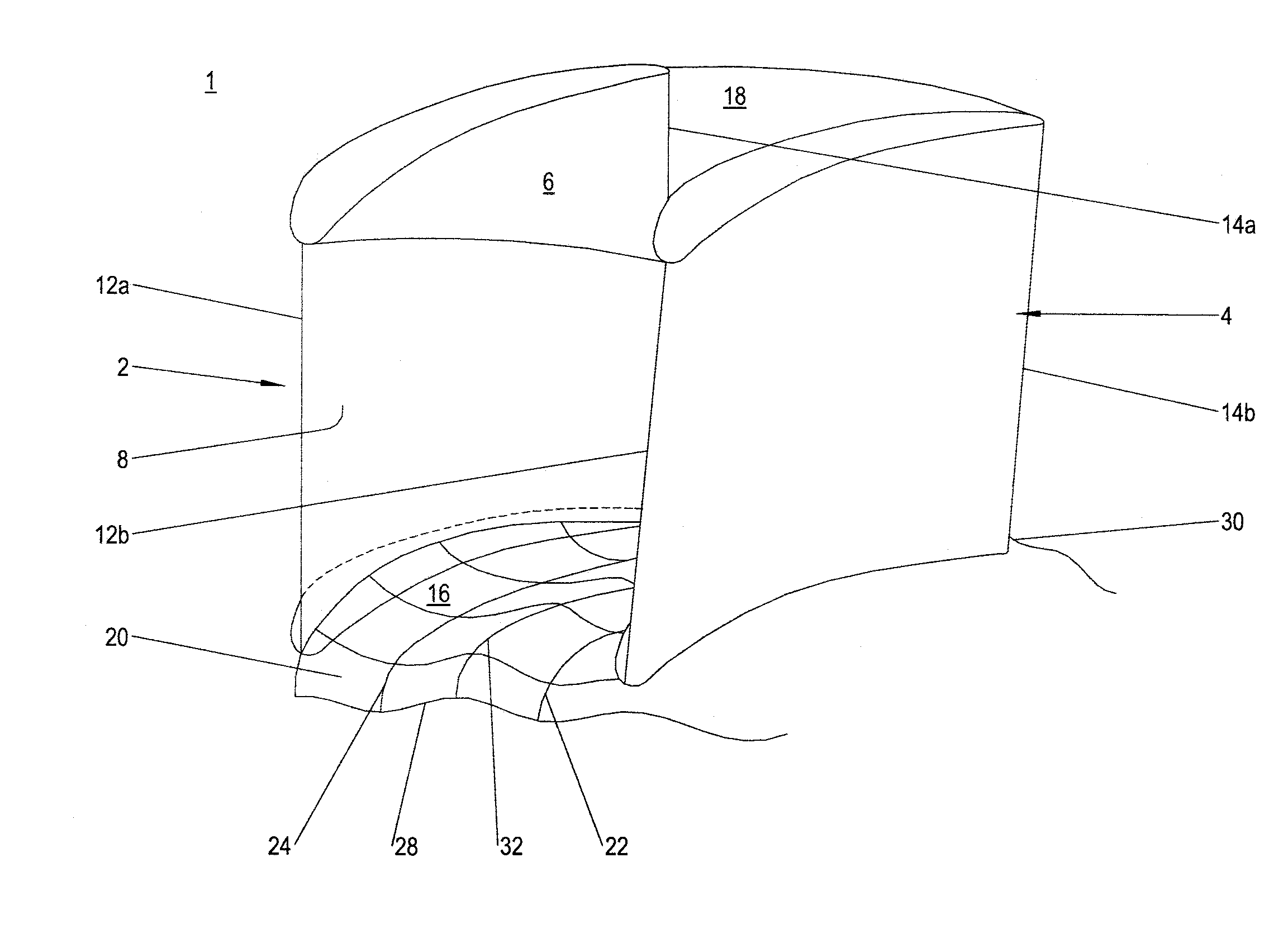

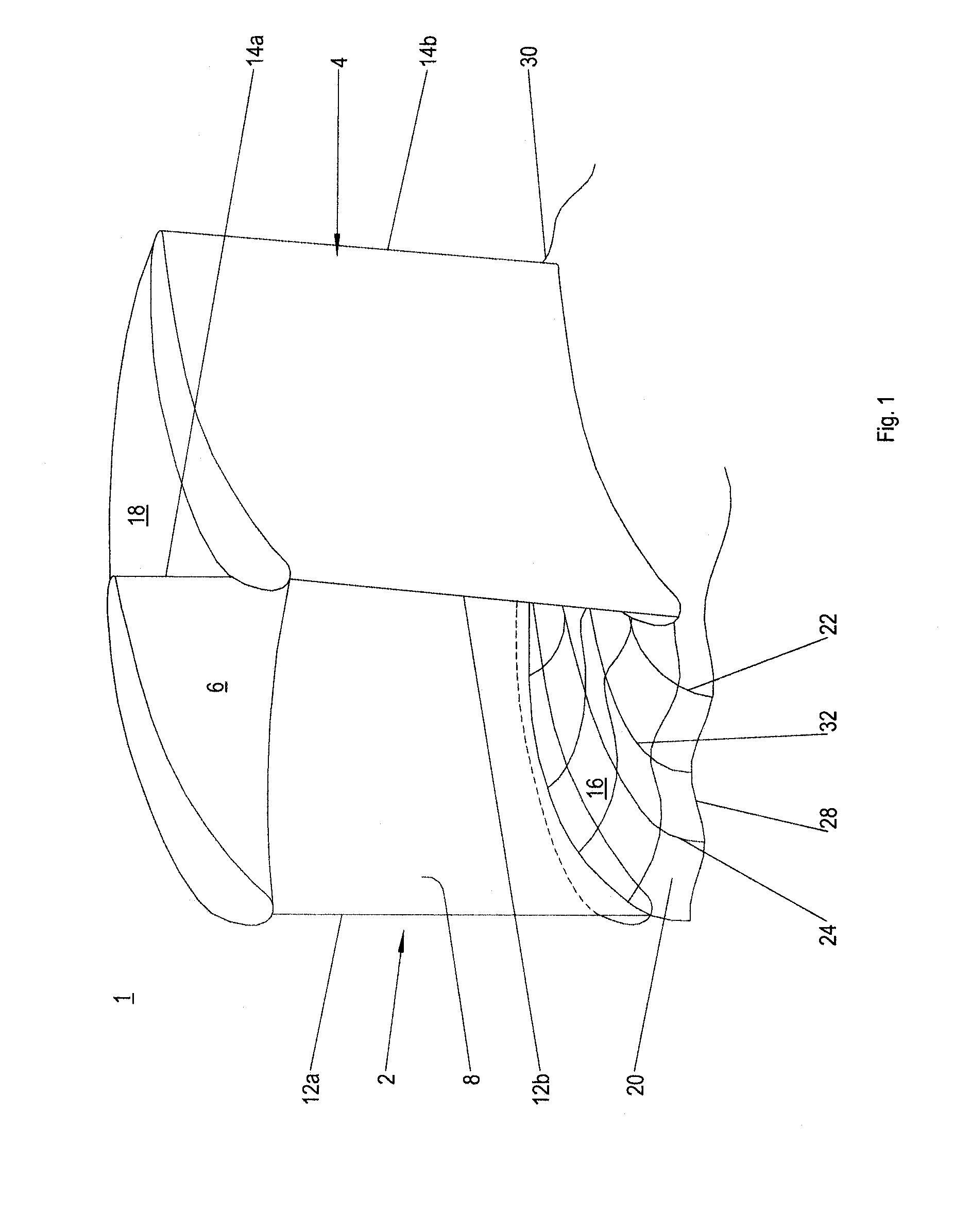

Blade cascade and turbomachine

ActiveUS20150044038A1Reduce secondary flowEnhanced efficiencyEngine manufacturePump componentsMechanical engineering

Owner:MTU AERO ENGINES GMBH

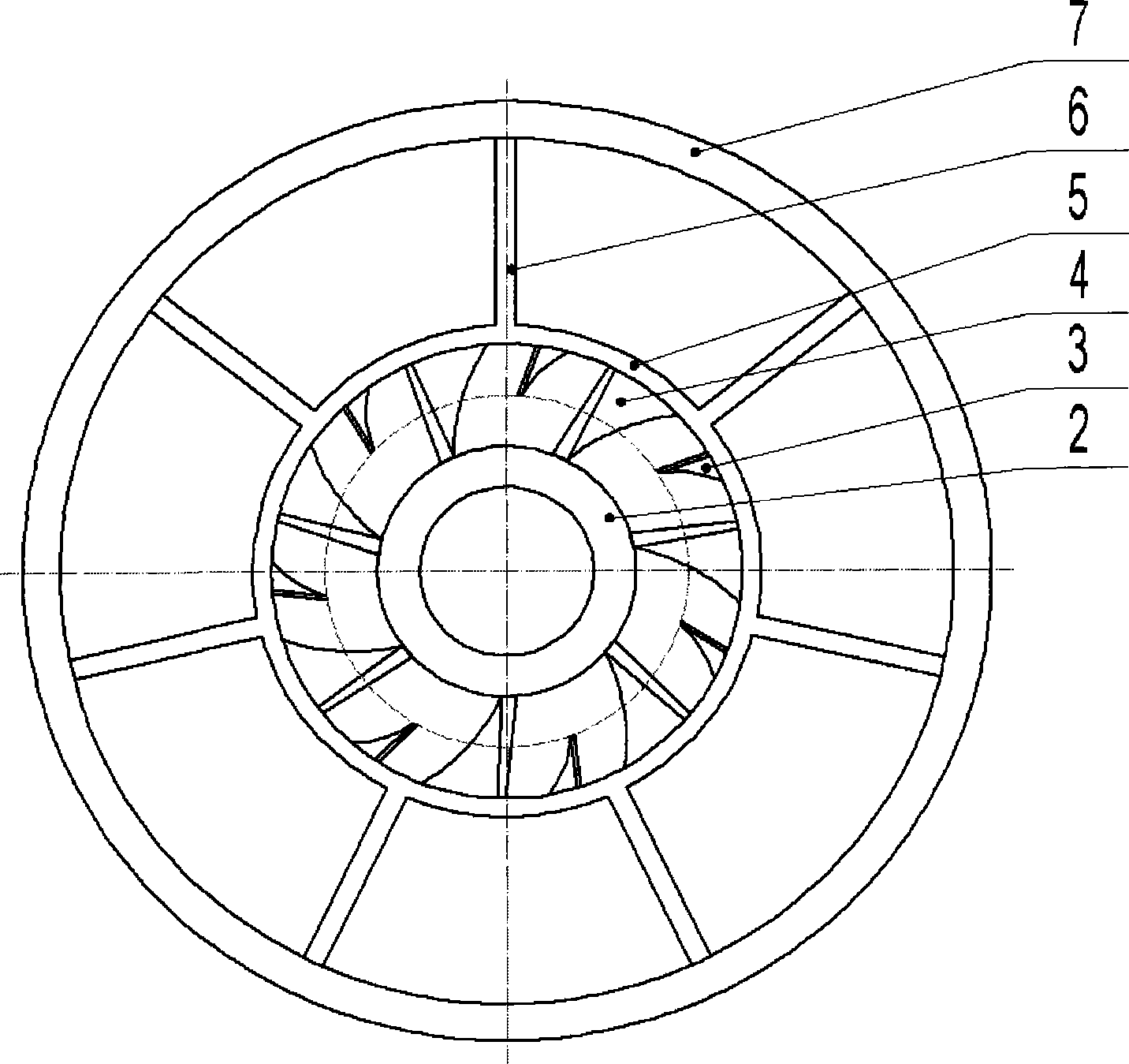

Space guide blade with auxiliary vanes

InactiveCN103591051AImprove overcurrent efficiencySimple structurePump componentsPumpsEngineeringMechanical engineering

The invention discloses a space guide blade which is used for a deep well centrifugal pump or other forms of multi-level centrifugal pumps and provided with auxiliary vanes. The auxiliary vanes are arranged in the middle of all runners of the space guide blade, the change rule of the auxiliary vanes in the axial direction conforms to the streamline shape of vanes of the space guide blade, the thickness of the auxiliary vanes is smaller than that of the vanes of the space guide blade, and the auxiliary vanes occupy small space. The space guide blade is simple in structure, the flowing form that the middle of the space guide blade is attached to a lower cover plate area of the space guide blade can be effectively improved, the probability of vortex and secondary flow is reduced, the hydraulic loss in the runners of the space guide blade can be reduced, and the overflowing efficiency of the space guide blade is improved.

Owner:JIANGSU UNIV

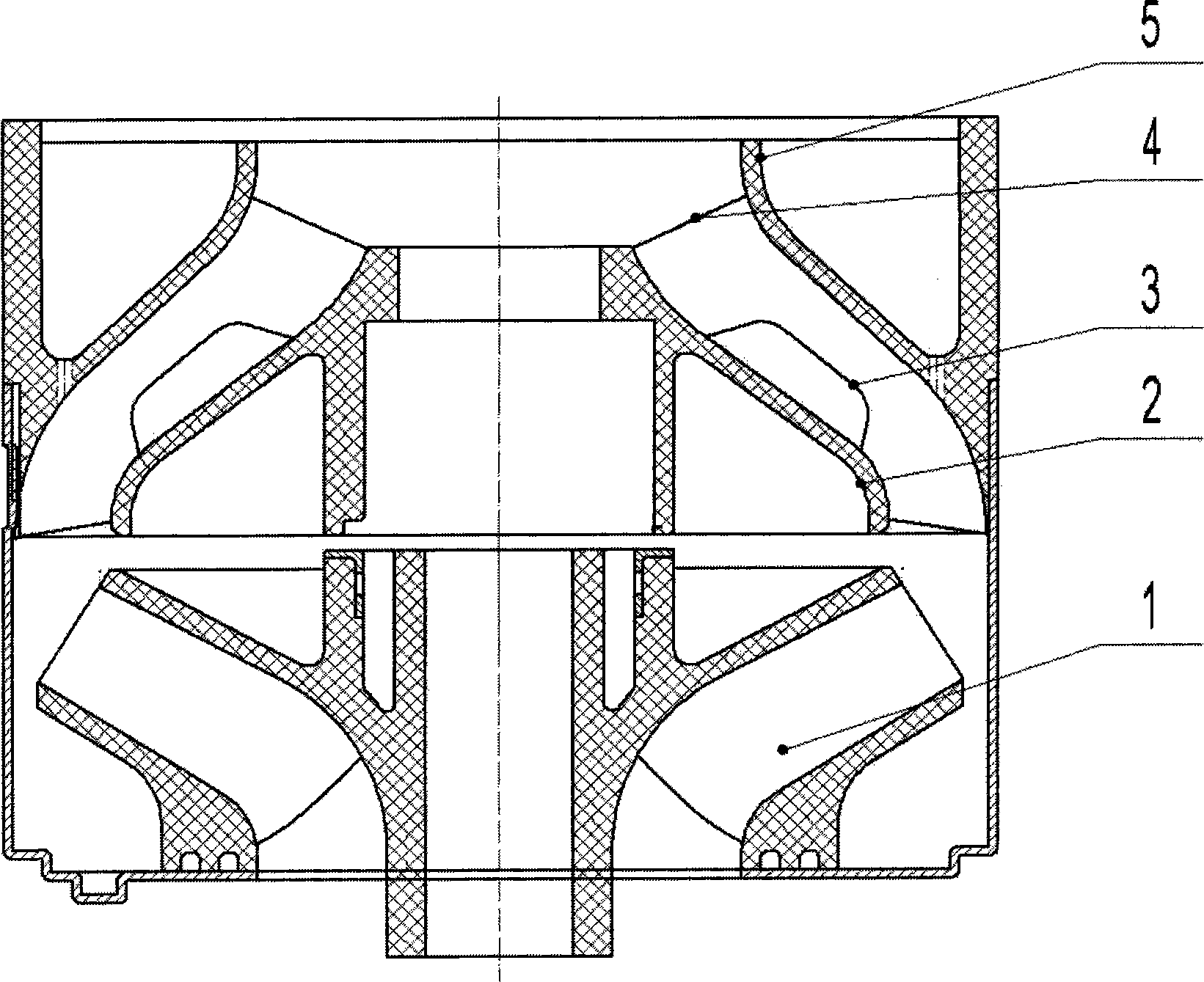

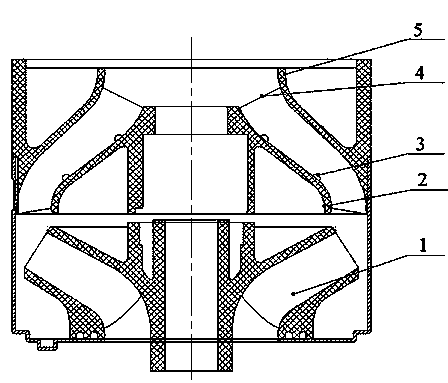

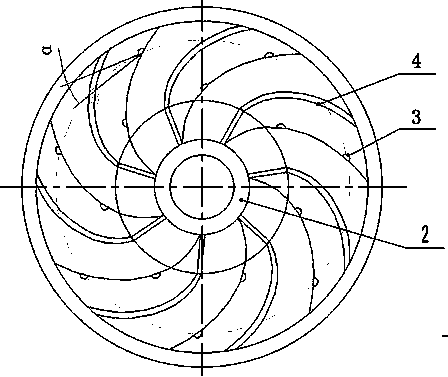

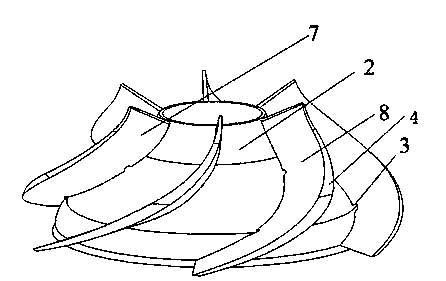

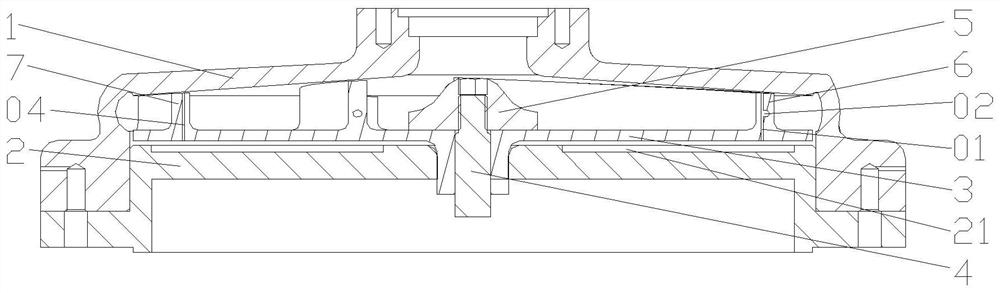

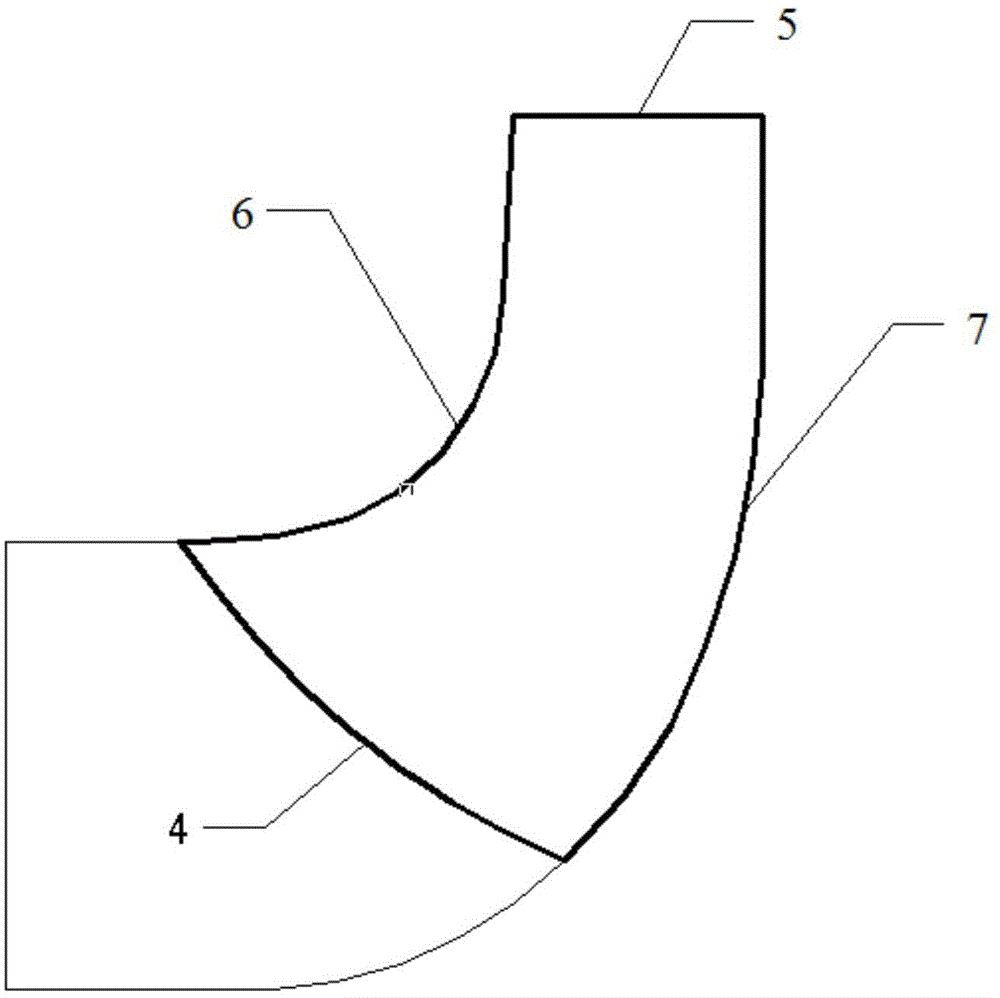

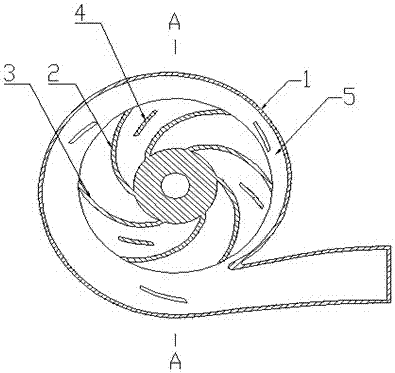

Impeller and volute chamber guide device in double-suction centrifugal pump

ActiveCN104776050AReduce wake flow phenomenonReduce secondary flowPump componentsPumpsCentrifugal pumpFront cover

The invention relates to an impeller and volute chamber guide device in a double-suction centrifugal pump. The impeller and volute chamber guide device comprises a centrifugal pump volute casing, blades, impeller guide plates, volute chamber guide plates, a front cover plate, a rear cover plate and an impeller rotary shaft. The impeller front cover plate and the rear cover plate are fixed with the impeller guide plates between the adjacent blade working surfaces and the blade back surfaces so as to guide liquid flow which just enters the impeller; the impeller guide plates are welded between the front cover plate and the rear cover plate; an included angle between each of the tail parts of the guide plates and the outer diameter of the impeller is equal to the blade outlet angle. The volute chamber guide plates are distributed on the inner wall of the centrifugal pump volute casting at different angles along an Archimedes spiral line. According to the impeller and volute chamber guide device disclosed by the invention, the pump operation efficiency can be greatly improved.

Owner:CHINA JILIANG UNIV

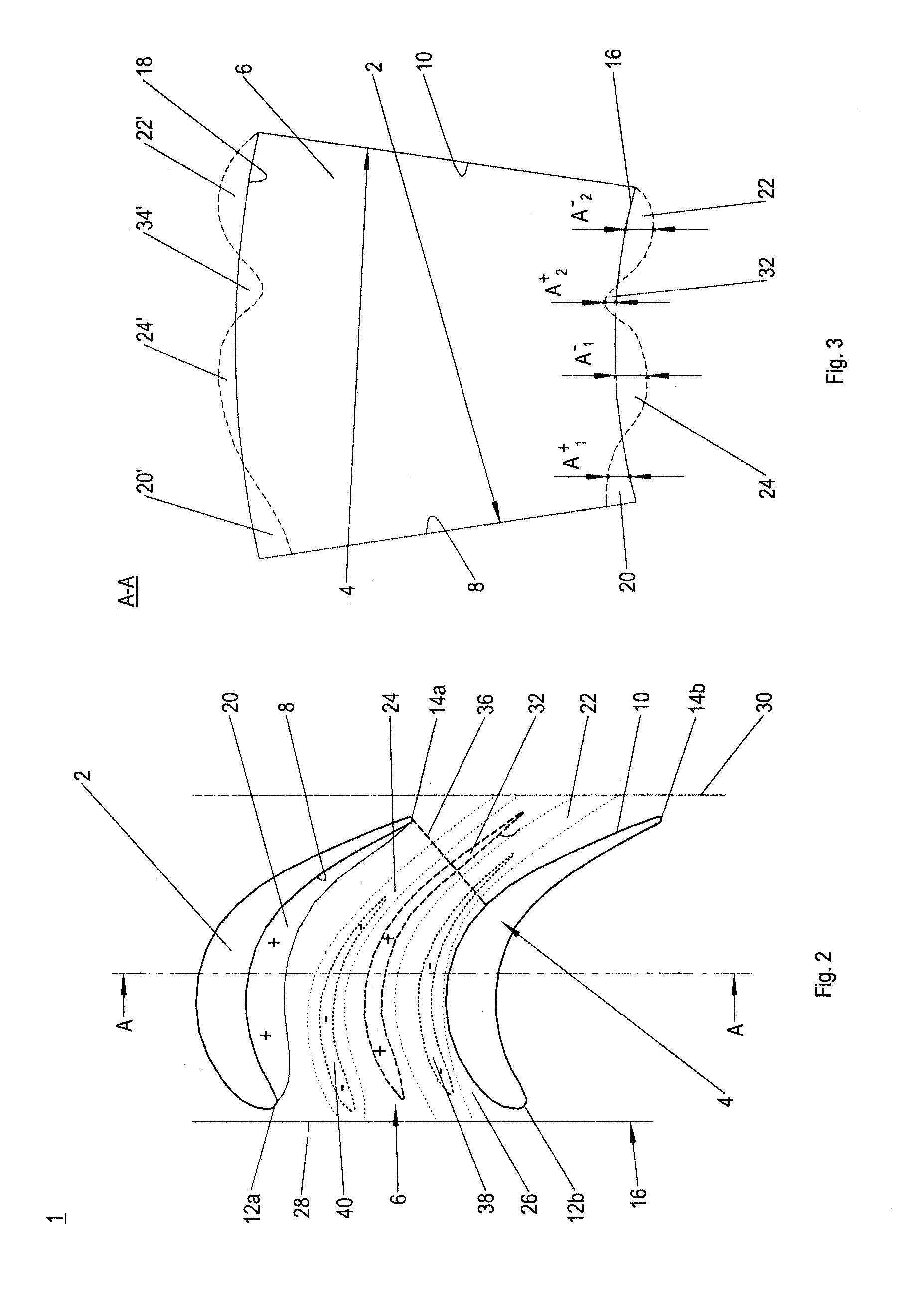

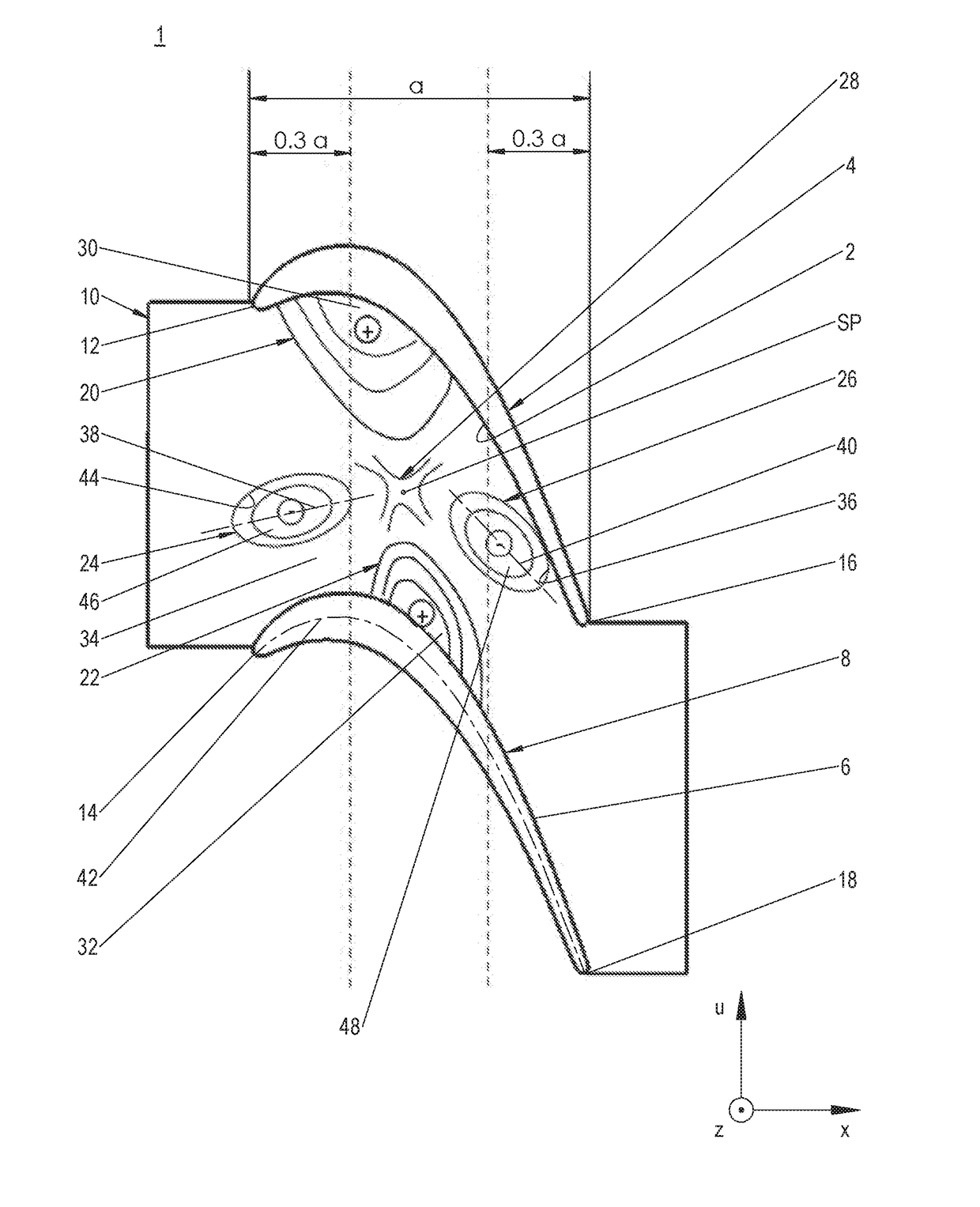

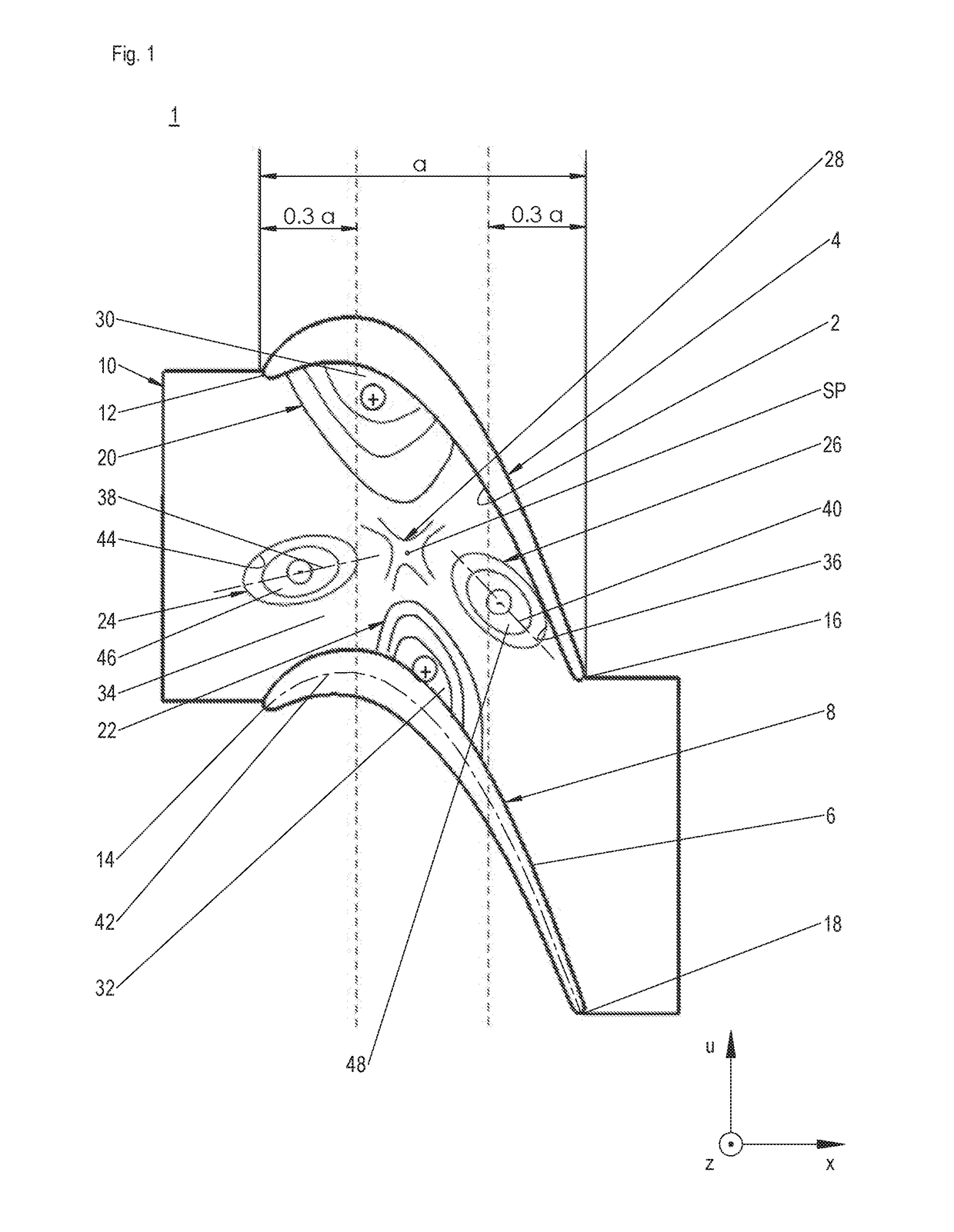

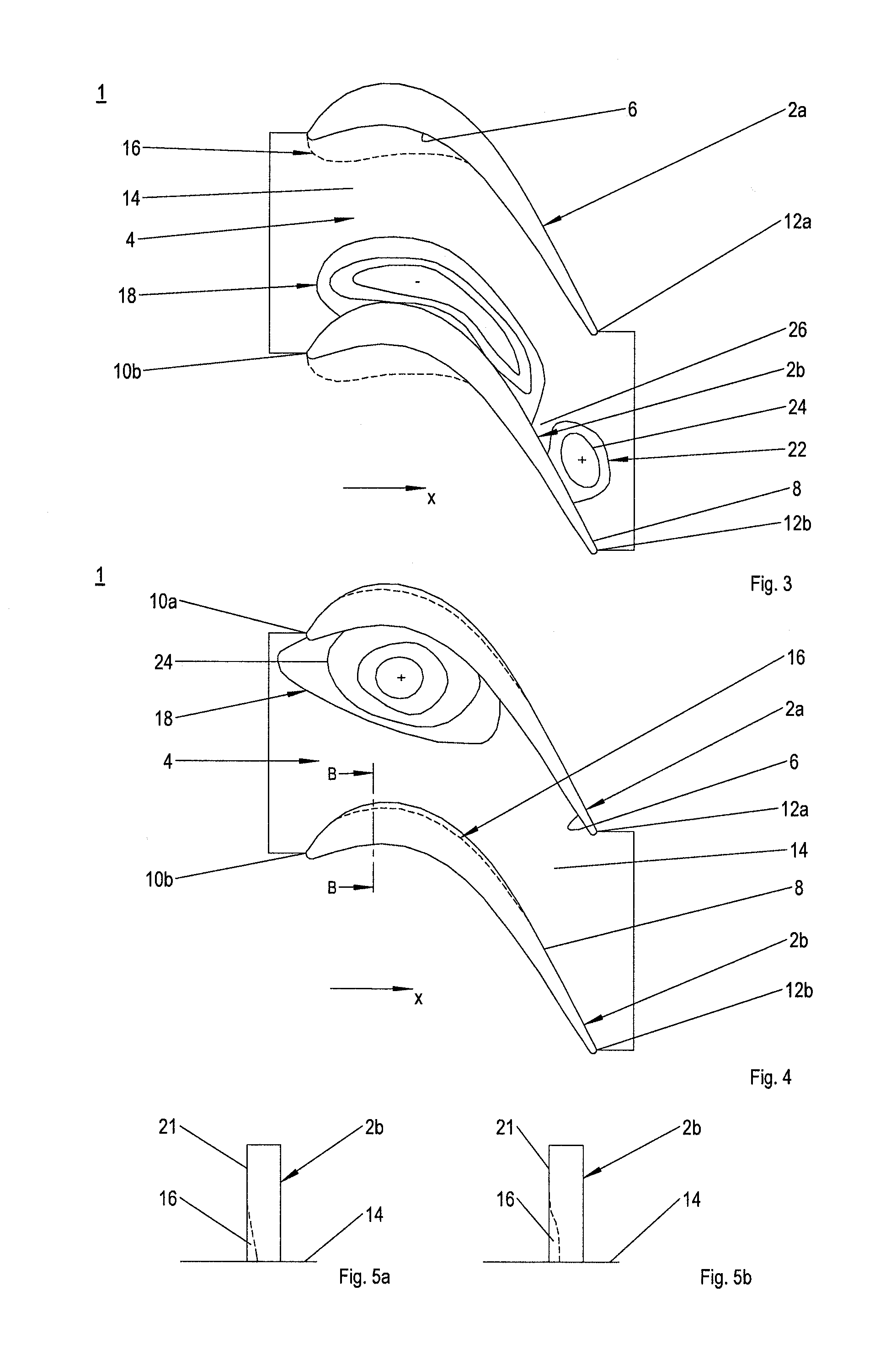

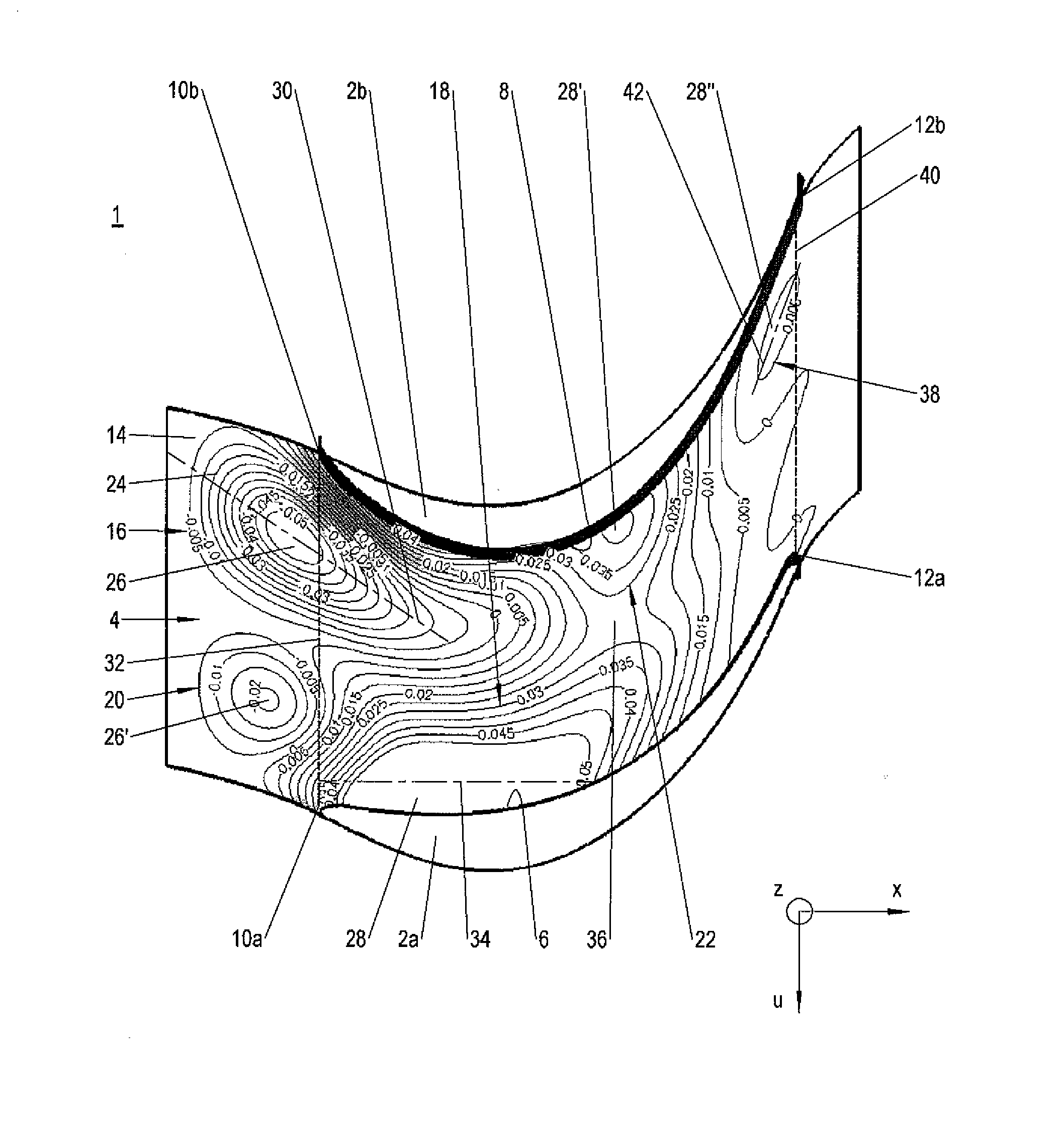

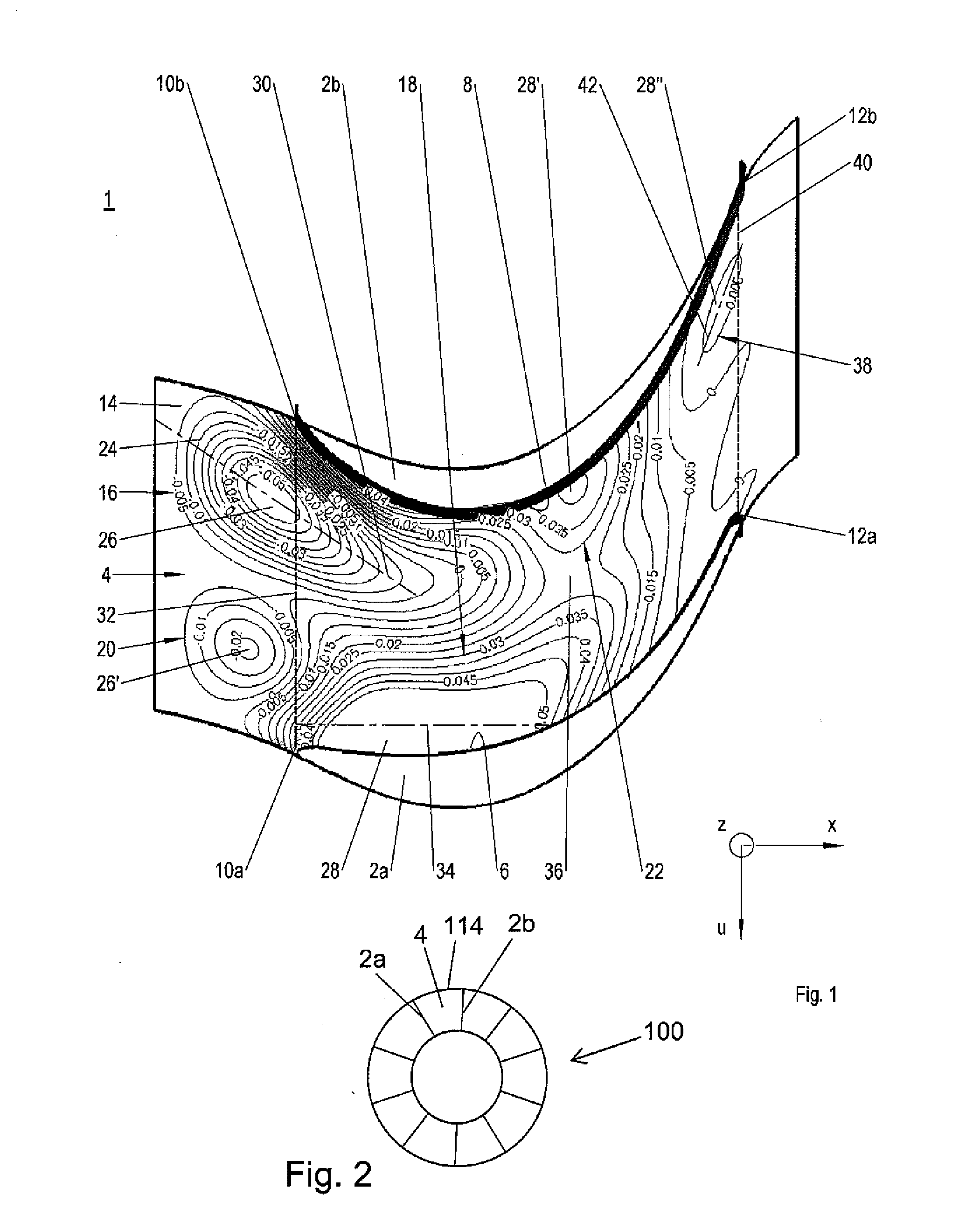

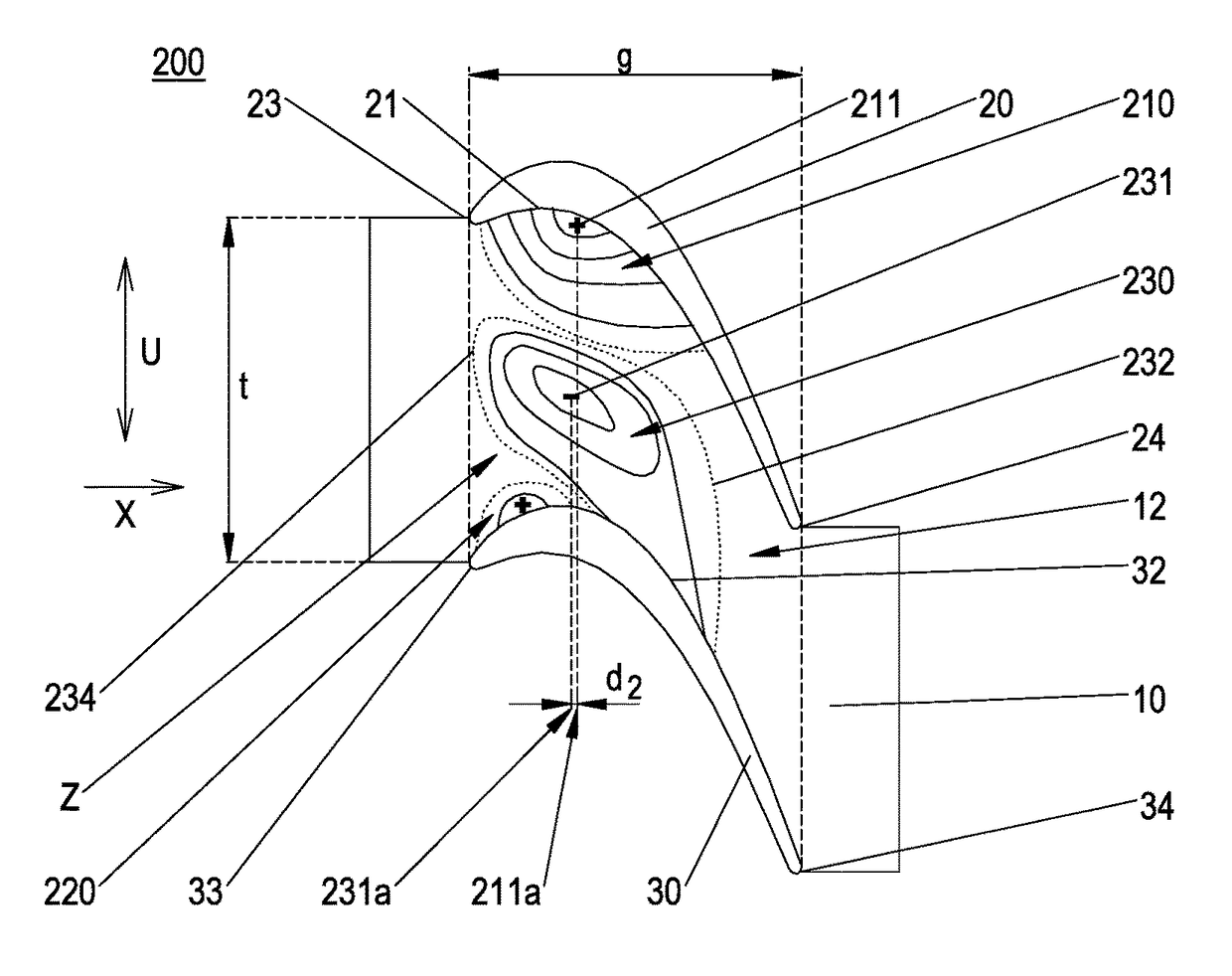

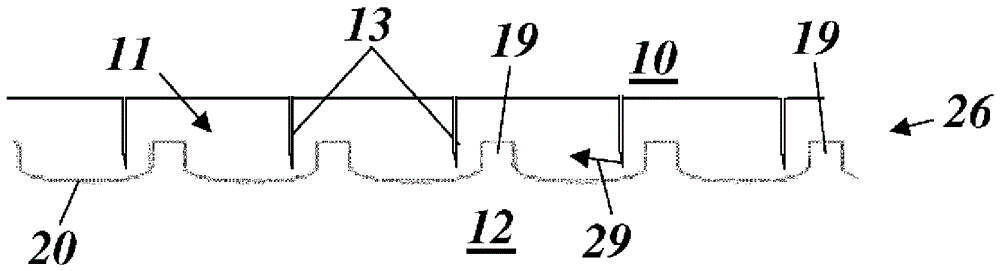

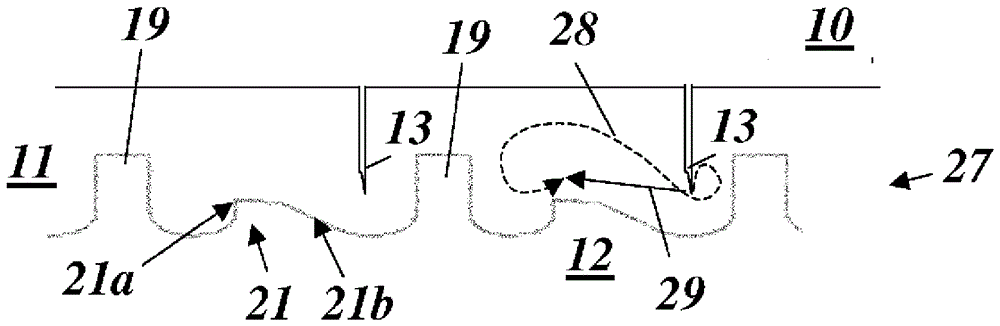

Blade channel, blade cascade and turbomachine

ActiveUS20170159444A1Reduce secondary flowReduce traffic lossRotary propellersPropulsion power plantsTrailing edgeMechanical engineering

A blade channel of a turbomachine that is delimited in the circumferential direction of the turbomachine by a pressure side of an airfoil and by an opposite suction side of an adjacent airfoil that, in the radial direction of the turbomachine, is delimited by two opposing side walls, and whose extent in the axial direction of the turbomachine is delimited by leading edges and by trailing edges of airfoils; at least one of the side walls being provided with localized contours, of which at least two are formed as elevations and at least two as depressions; a saddle surface being formed between the contours that, in one rotation, alternately merges into an elevation and a depression; a blade cascade having such blade channels, as well as a turbomachine having such a blade cascade.

Owner:MTU AERO ENGINES GMBH

Blade cascade and turbomachine

InactiveUS20140169977A1Improve efficiencyReduce secondary flowEngine manufactureEngine fuctionsEngineeringMechanical engineering

A blade cascade of a turbomachine having at least one shape variation of a blade situated on the blade side in the proximity of a side wall and extending downstream, and at least one side wall contouring of the side wall or at least one second shape variation of an adjacent blade near the side wall, as well as a turbomachine, are disclosed.

Owner:MTU AERO ENGINES GMBH

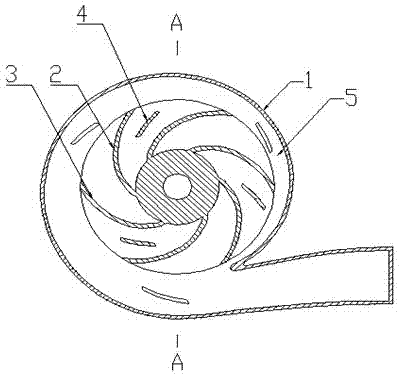

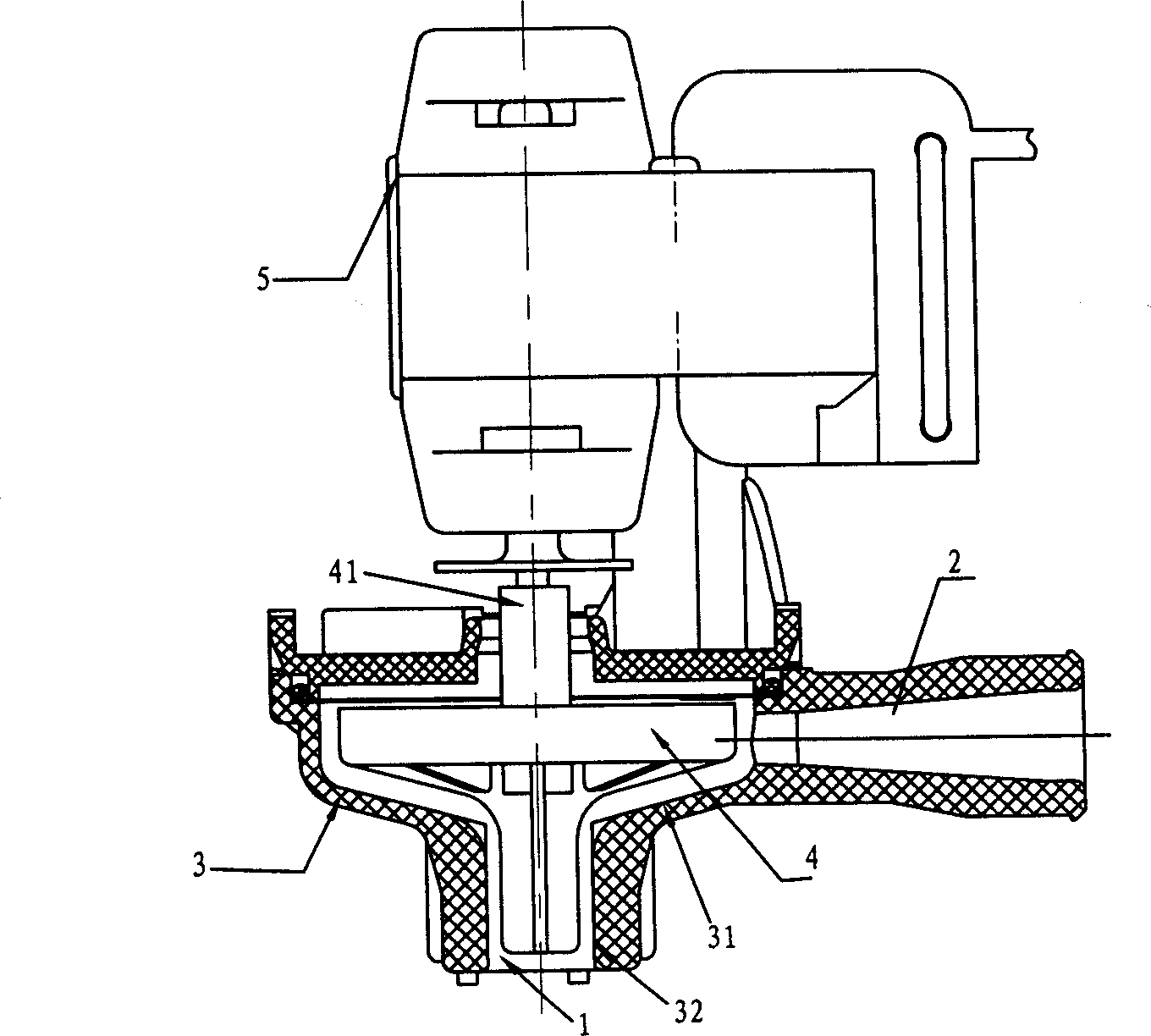

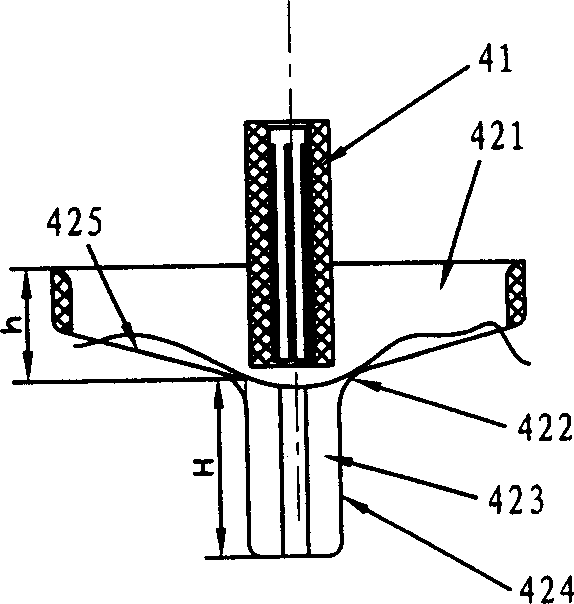

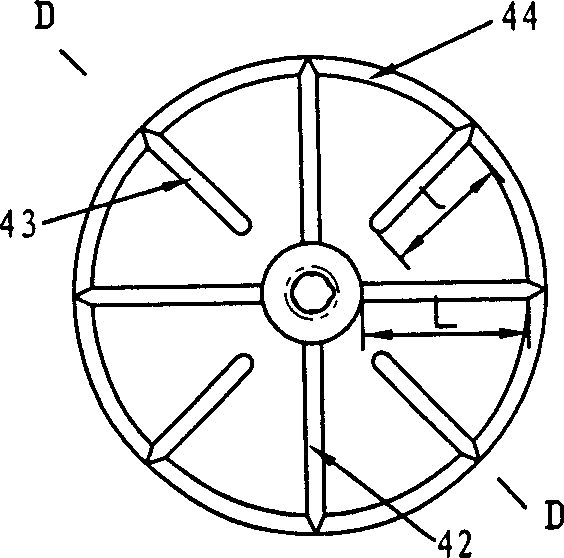

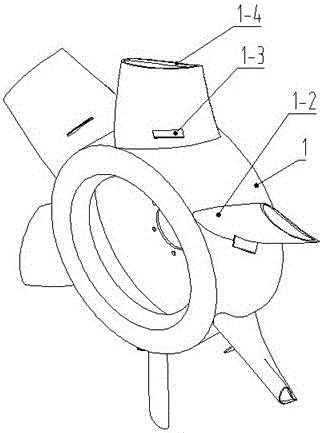

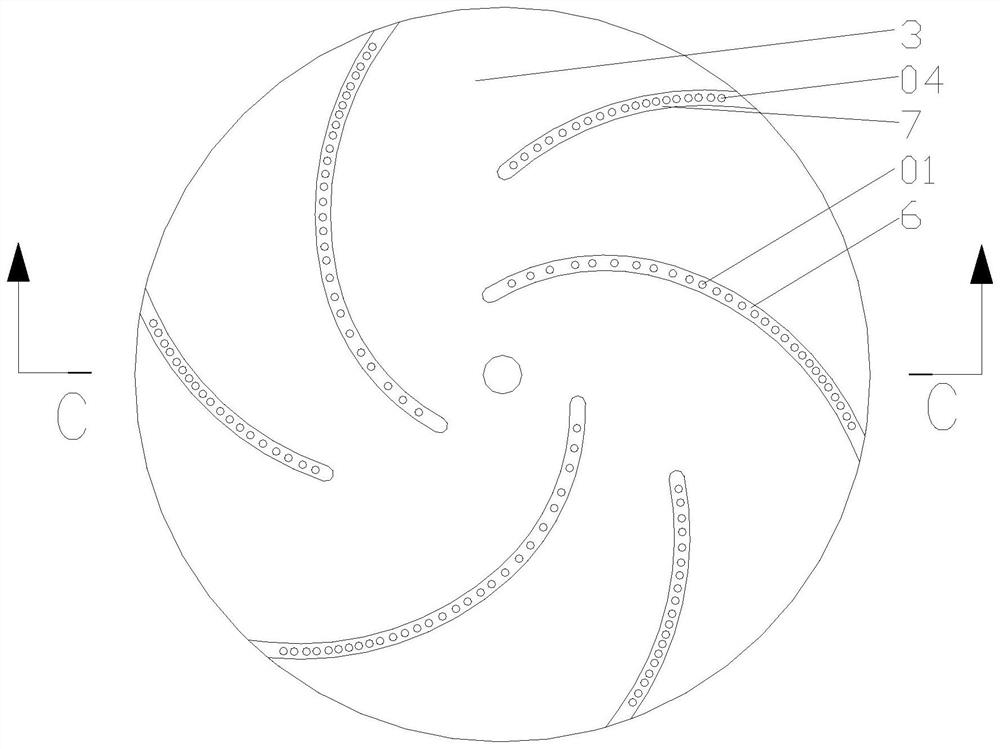

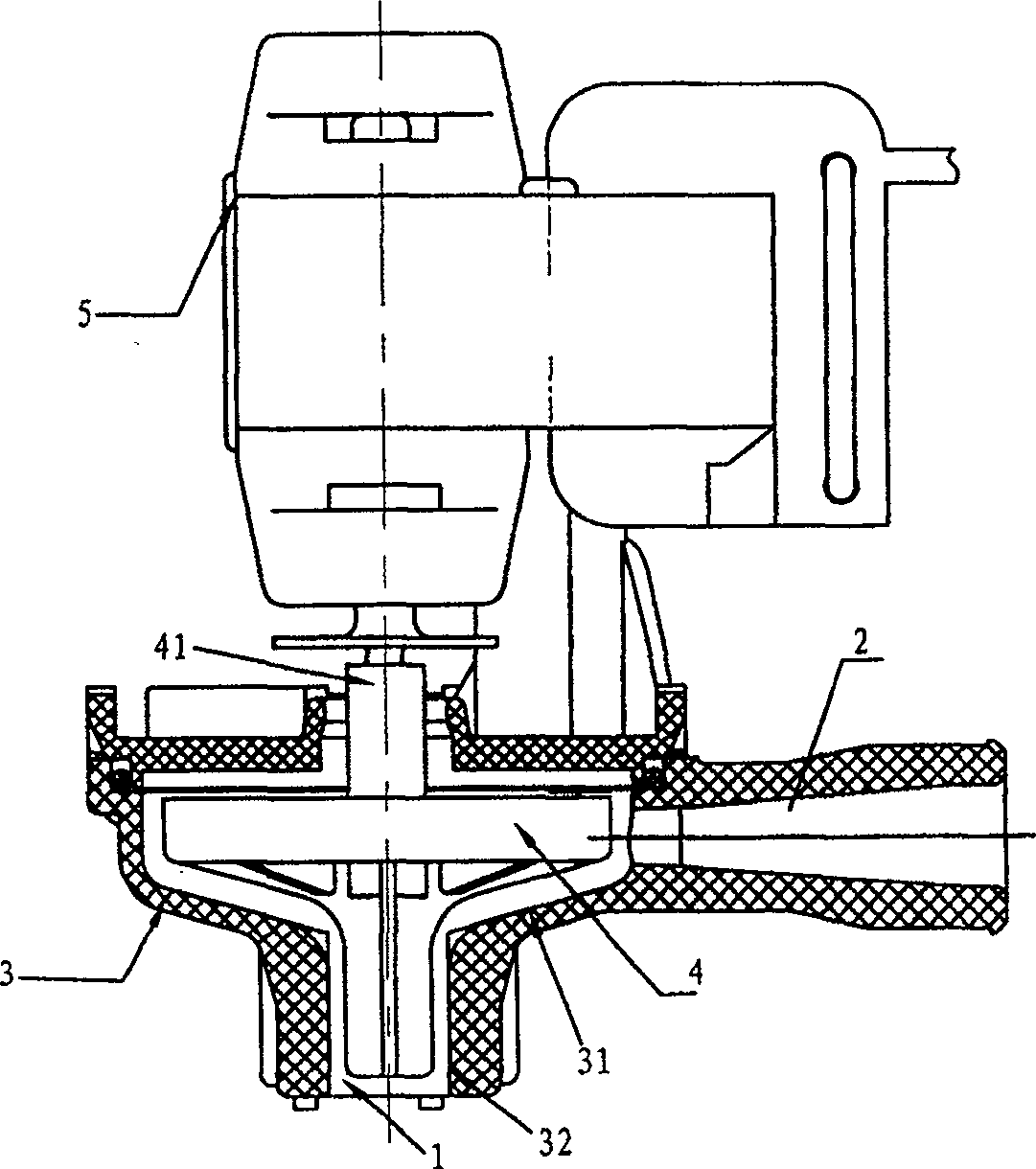

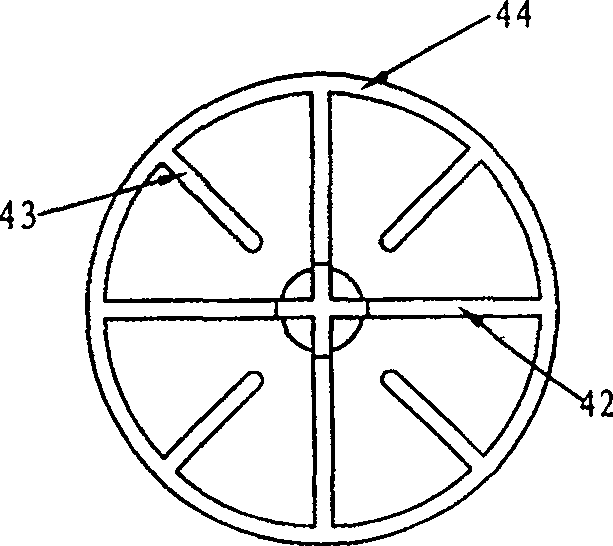

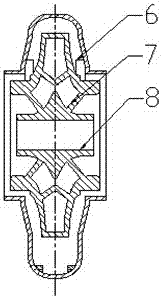

Draining pump

ActiveCN1804403AControl flowLower Edge Noise SuppressionCondensate preventionPump installationsImpellerEngineering

The invention relates to a discharge pump used in refrigeration system, which can overcome the defects of present discharge pumps which often depart from designed position, with lower efficiency and large noise. The invention comprises a pump which has an inlet at lower end and an outlet at upper part; a blade wheel inside the pump and a motor rotating the blade wheel. It is characterized in that: said blade wheels comprise main blades, short blades between nearby main blades, a stabilizing ring covering the upper edge of main blades and the outer edge of short blades, and an axial connection part connected with the output axle of motor. Wherein, the main and short blades are radial distributed with the center of the axes of axial connection part; the inner edge of main blade is connected to the axial connection part and the inner edge of short blade is distantly arranged from the axial connection part. The invention can improve the flux, the delivery lift, the flowing property and reduce the noise.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

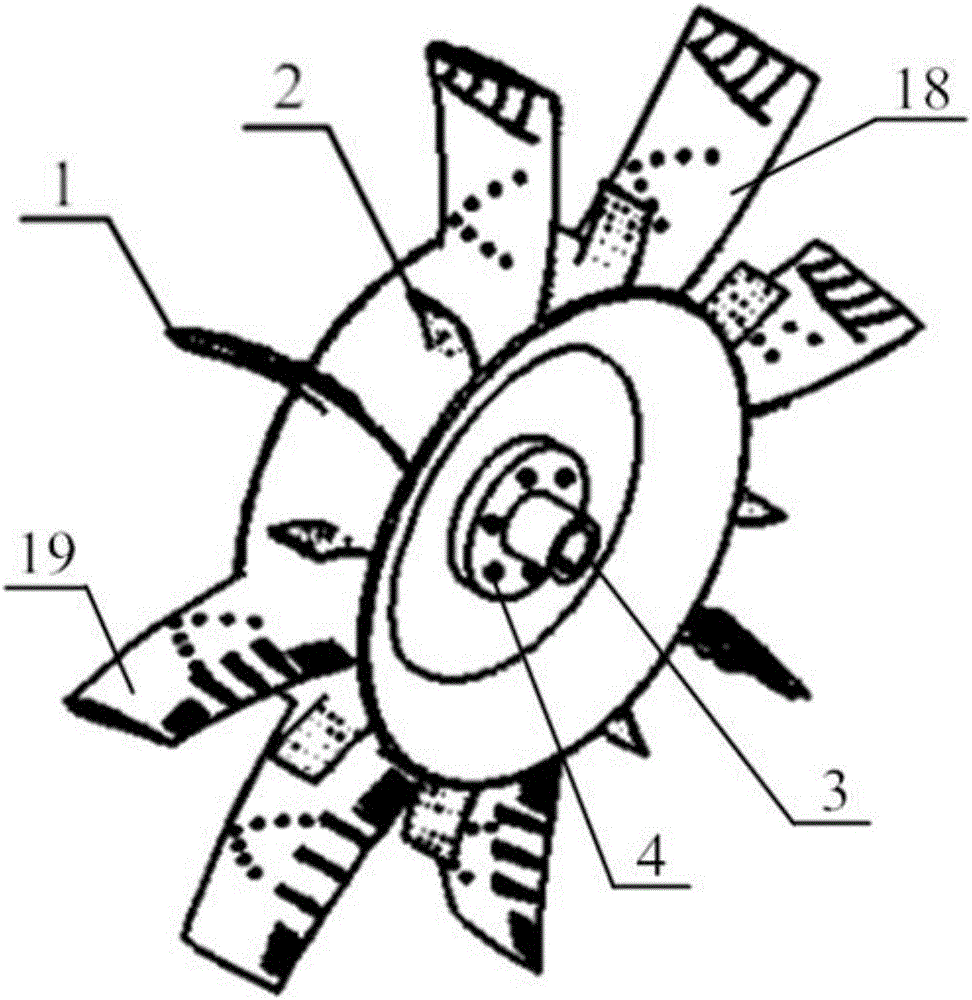

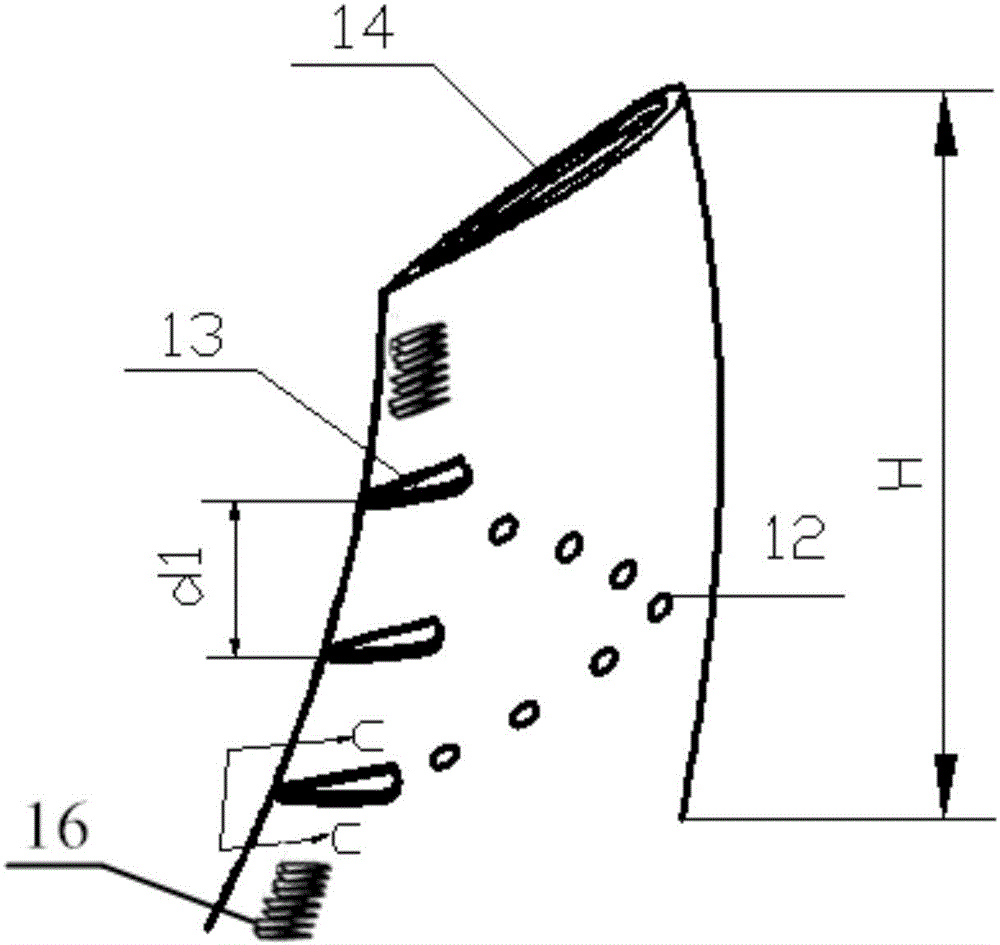

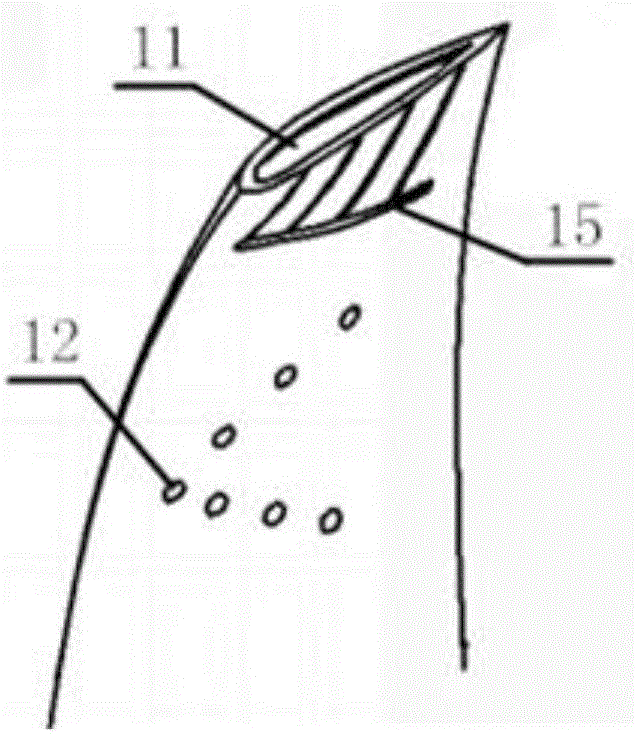

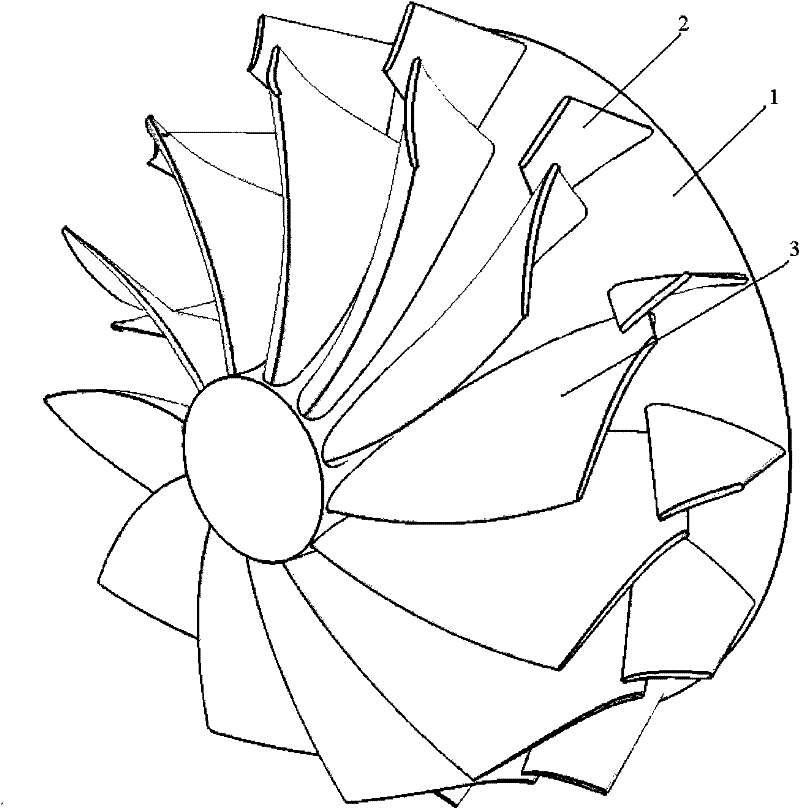

Axial flow fan ternary impeller with vein-shaped structure and nonuniform empennage

The invention discloses an axial flow fan ternary impeller with a vein-shaped structure and a nonuniform empennage. The axial flow fan ternary impeller comprises a hub, and a connecting piece for a shaft sleeve fixed on the hub. The axial flow fan ternary impeller further comprises twisted blades and splitter blades fixedly connected to the hub; the twisted blades include suction surfaces and pressure surfaces; wing-shaped grooves are formed in the tops of the twisted blades; vein-shaped grooves are formed in the upper half parts of the pressure surfaces of the twisted blades; the wing-shaped grooves are communicated with the vein-shaped grooves through exhaust ports; winglet projections and dense winglets are arranged at the tail parts of the suction furnaces of the twisted blades; the dense winglets are arranged on two sides of the winglet projections; parabola small holes are formed in the twisted blades; the splitter blades are arranged between two adjacent twisted blades; and the heights of the splitter blades are smaller than the heights of the twisted blades by one half.

Owner:杭州宏德智能装备科技有限公司

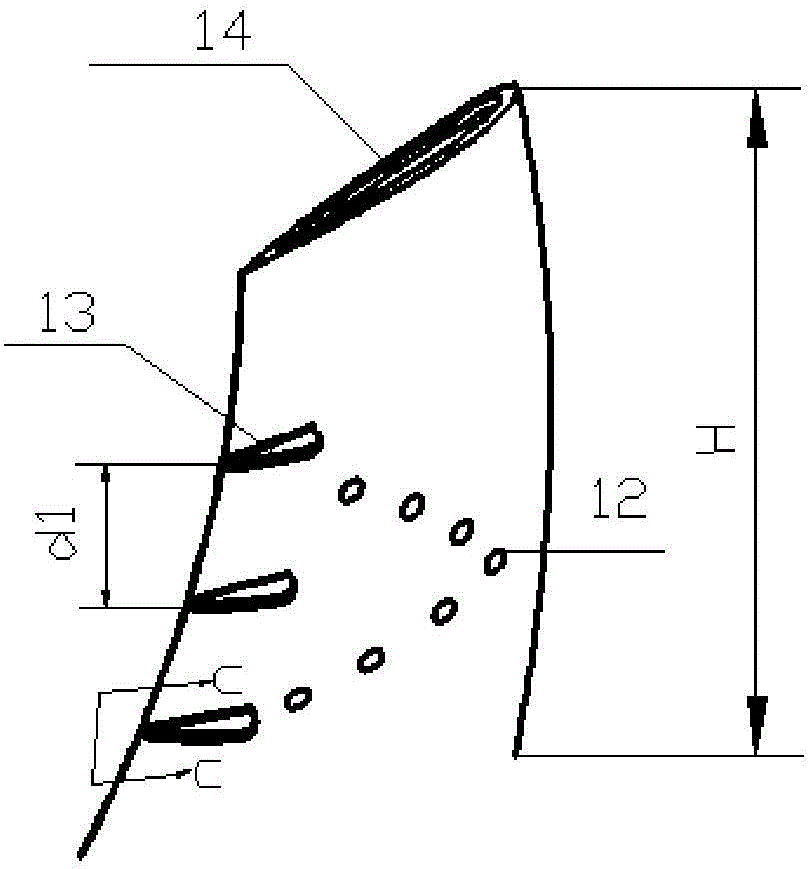

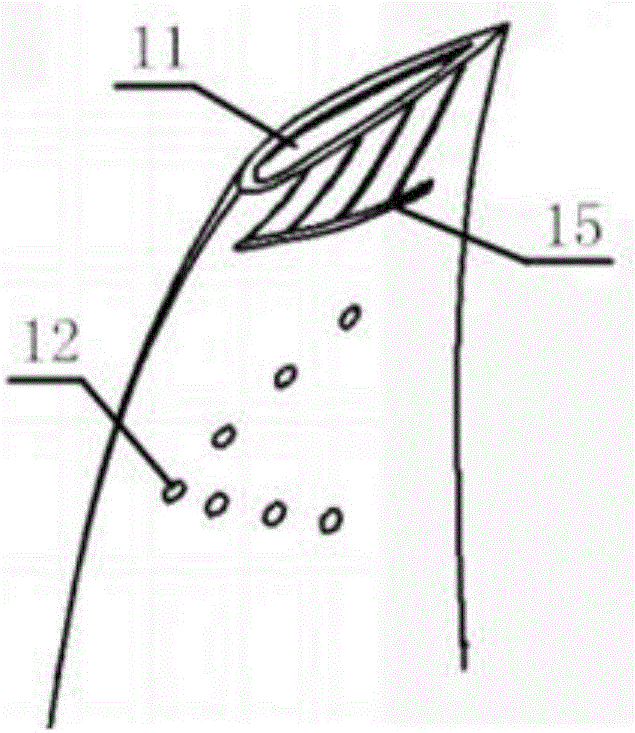

Guide vanes with vortex elimination and drag reduction holes

InactiveCN104047898AReduce lossesImprove overcurrent efficiencyPump componentsPumpsLow speedEngineering

The invention relates to spatial guide vanes with vortex elimination and drag reduction holes, wherein the spatial guide vanes are used for a deep-well centrifugal pump or multistage centrifugal pumps in other forms. One to three semicircular holes with the same size are arranged in the root portion of each of the spatial guide vanes and close to a lower cover plate, and the vortex elimination and drag reduction holes penetrate through the pressure faces and the suction faces of the guide vanes and are inclined. The guide vanes with the vortex elimination and drag reduction holes are simple in structure and convenient to machine, high-speed liquid flow flows to the suction faces from the pressure faces through the vortex elimination and drag reduction holes, low-speed liquid remaining near the suction faces can be dispersed, the form of flow of the suction faces of the guide vanes close to the lower cover plate area can be effectively improved, the probability of generating secondary flow and vortexes is reduced, hydraulic loss is reduced, and the overflow efficiency of the guide vanes is remarkably improved.

Owner:JIANGSU UNIV

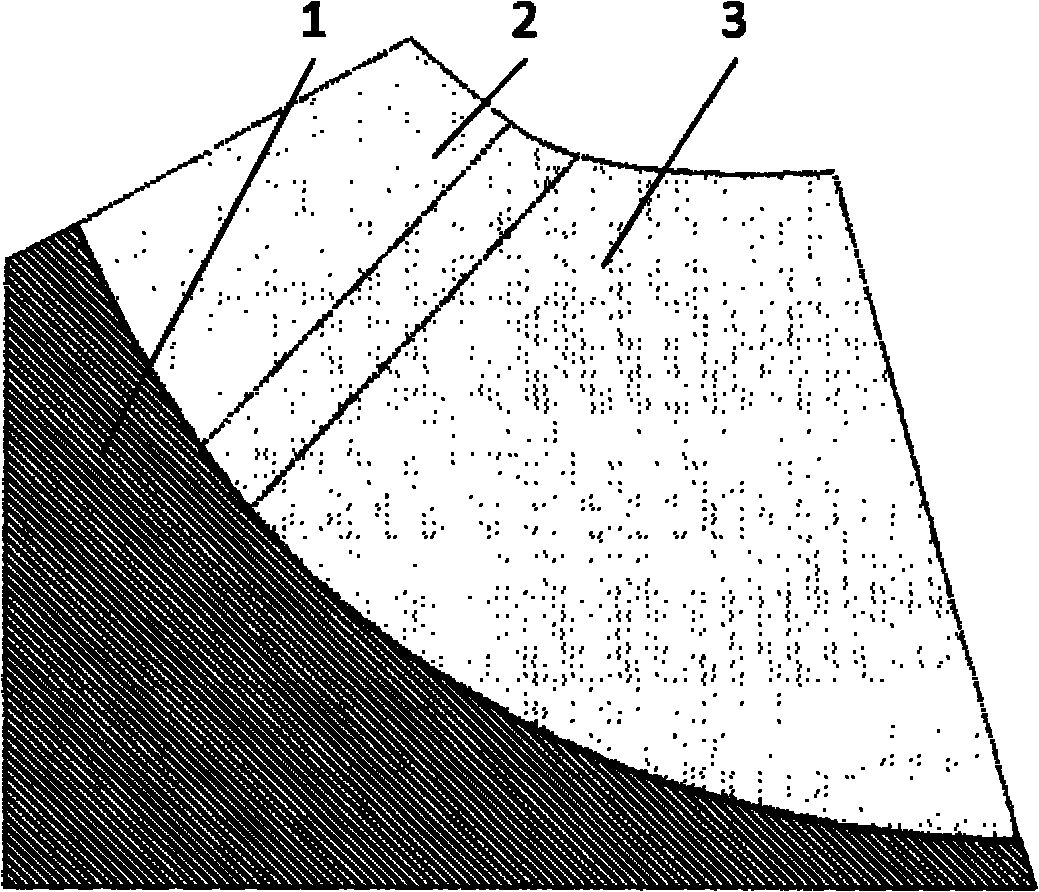

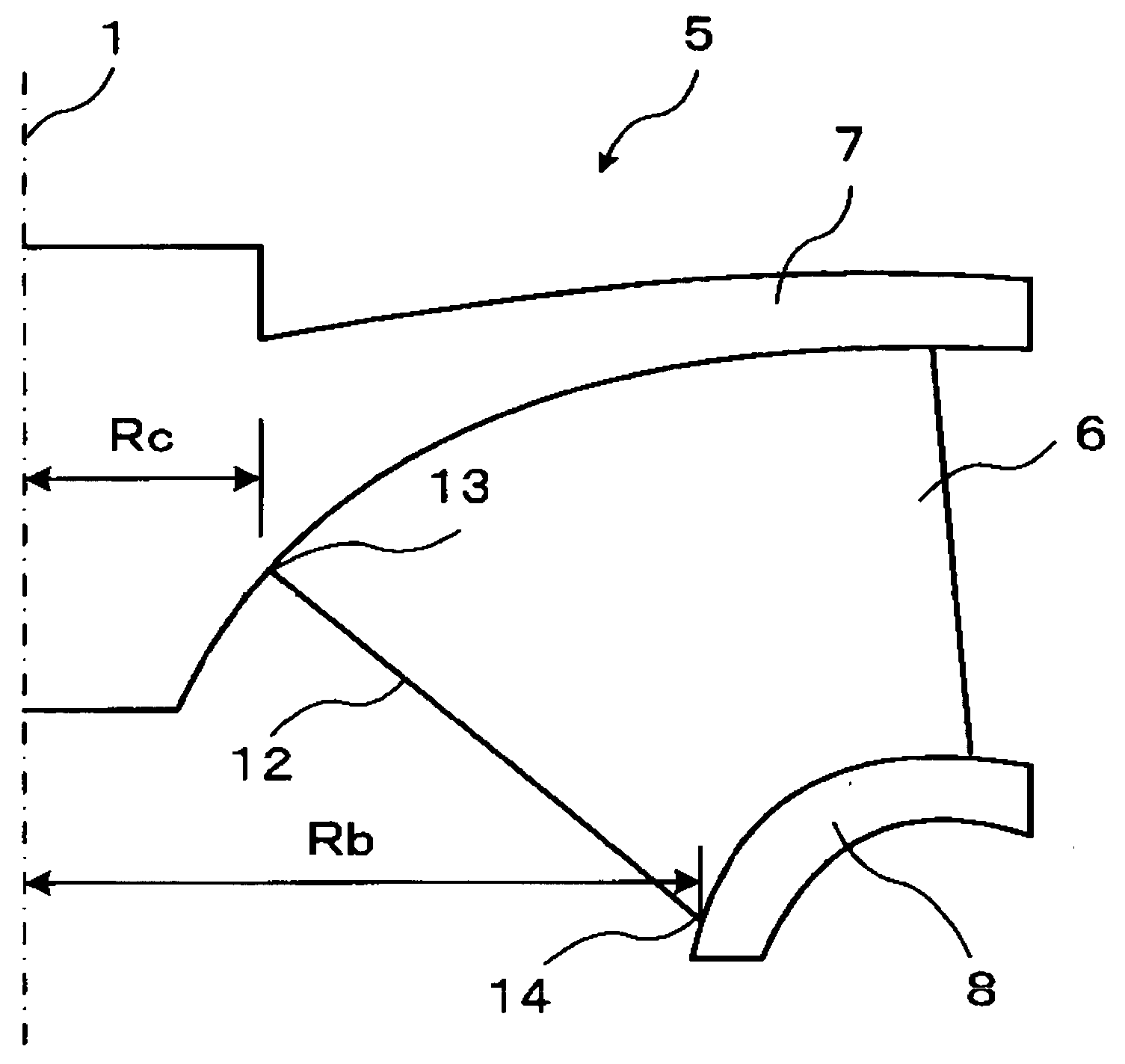

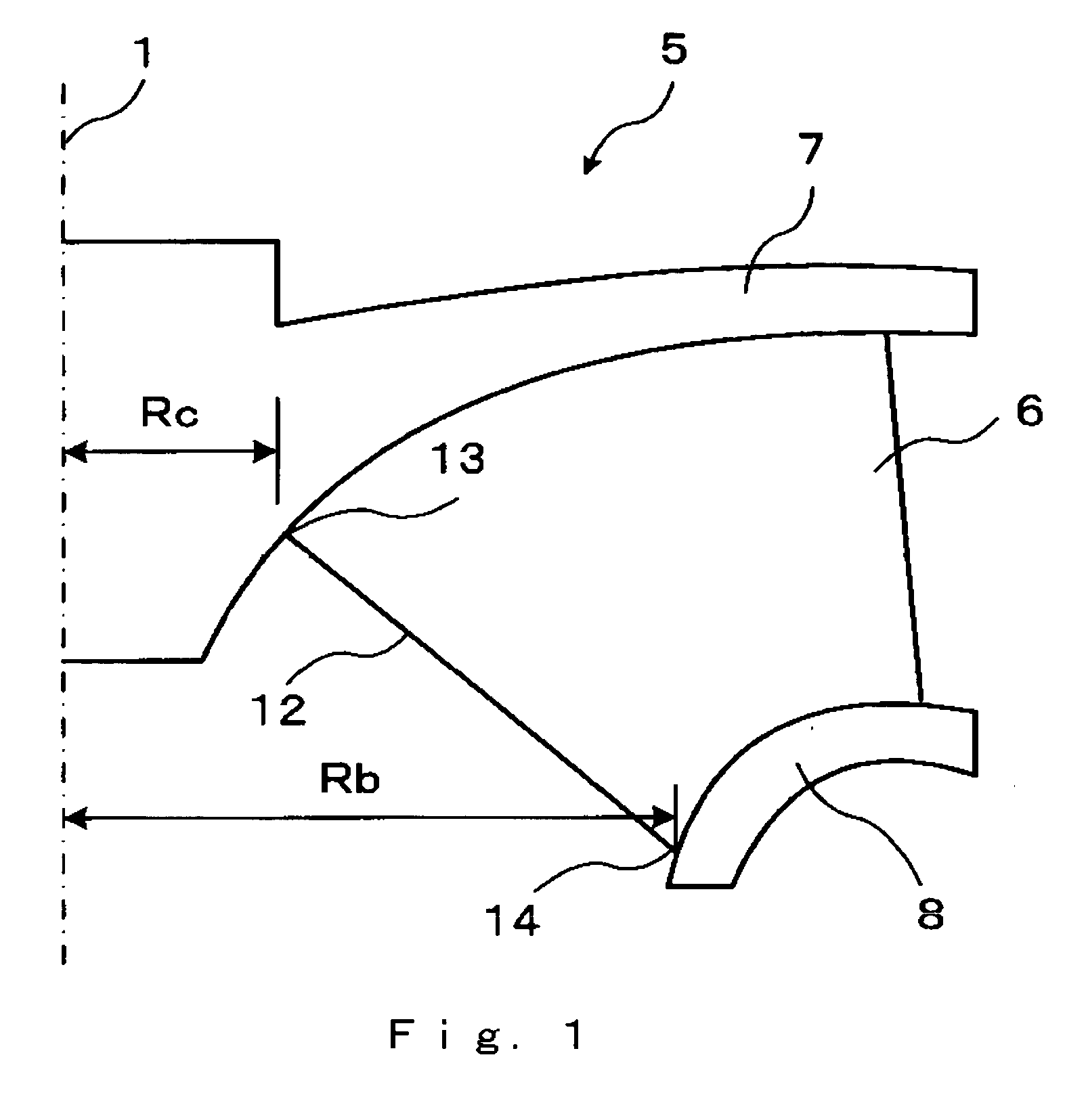

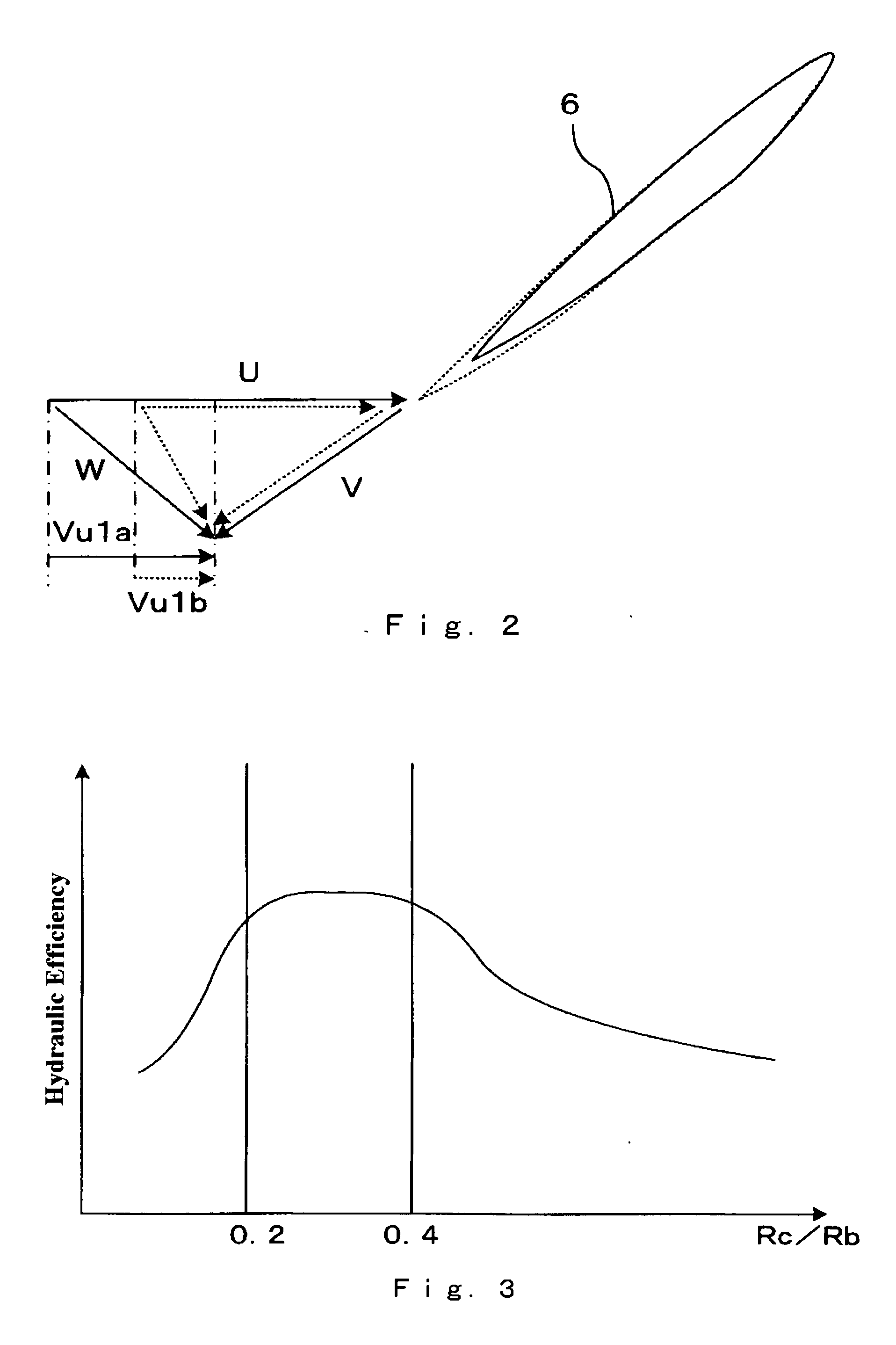

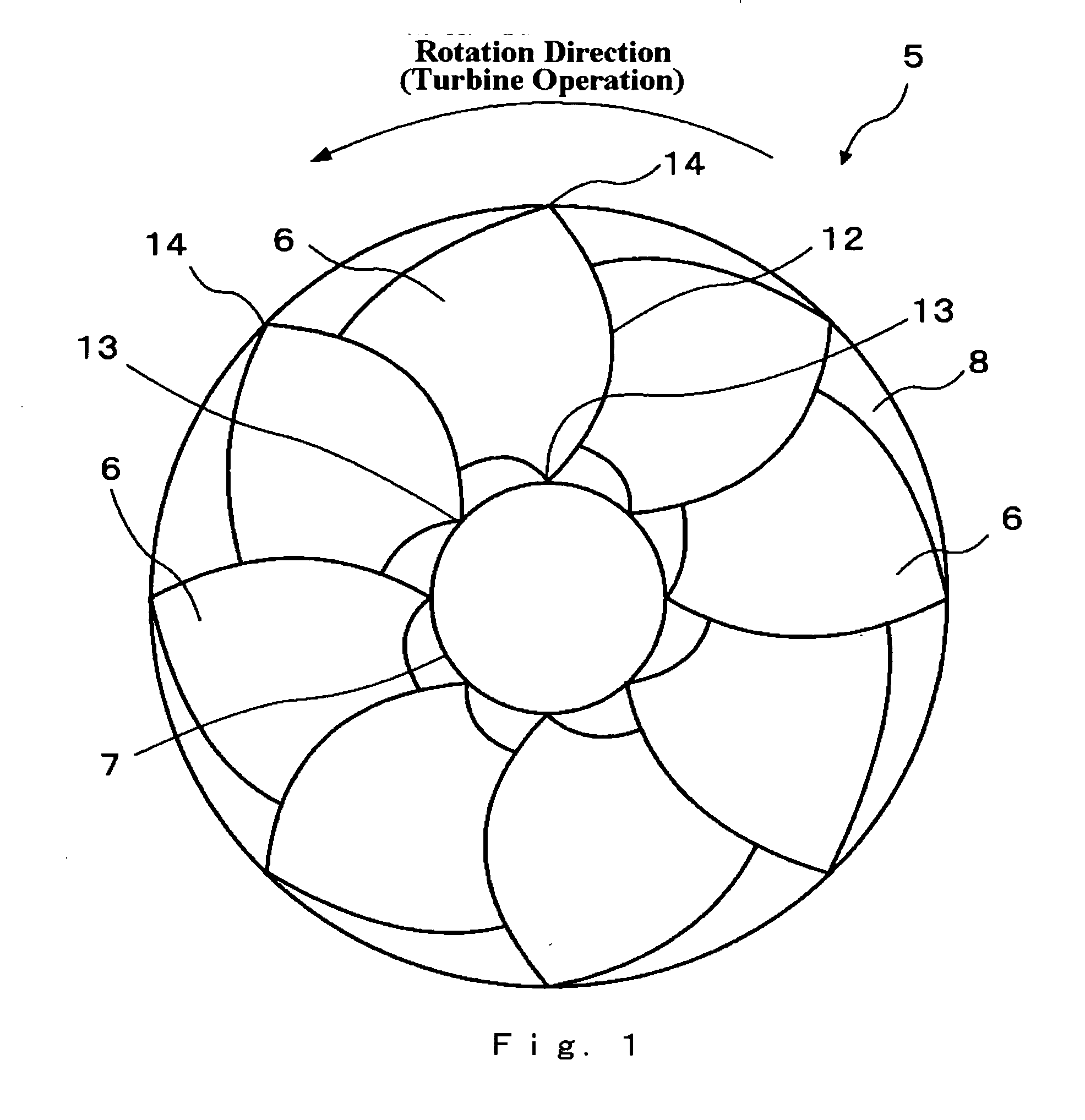

Francis turbine

InactiveUS20050089404A1Easy to shapeReduce componentsPropellersRotary propellersTrailing edgeFrancis turbine

A Francis turbine with an improved shape of blades, which can reduce a circumferential velocity component generated in the flow downstream of the blades in a condition of a partial load operation, or reduce the secondary flow around the blades, is provided. A Francis turbine comprises a crown, a plurality of blades, and a band. The crown can rotate around a rotating axis. The blades are circumferentially arranged on the crown, each of which including an inner end as a trailing edge. The band is coaxially coupled with the crown by the blades. A distance Rc can be defined as a distance between the rotation axis and an end by the crown side of the trailing edge. A distance Rb can be defined as a distance between the rotation axis and an end by the band side of the trailing edge. The distance Rc and the distance Rb satisfy 0.2≤RcRb≤0.4.

Owner:KK TOSHIBA

Axial flow fan with blade suction surfaces having vortex breaking structures and with grooves formed in blade tops

The invention discloses an axial flow fan with blade suction surfaces having vortex breaking structures and with grooves formed in blade tops. The vortex breaking structures are additionally arranged on the portions, close to roots, of the suction surfaces of blades of an impeller, the airfoil grooves are machined in the tops of the blades, a labyrinth seal structure is additionally arranged in the clearance between a hub and an inner barrel, rectangular grooves are machined in the tails of the suction surfaces of guide vanes, the size of channel vortexes in an impeller passenger can be restrained, and radial secondary flow is reduced. Development of leakage flow can be impeded, mixing of the leakage flow and main flow is weakened, and therefore leakage losses of the blade tops are reduced. A high throttling effect can be generated, the stability of airflow on an outlet of the impeller is improved, and the leakage amount of airflow at the roots of the blades is reduced. The thicknesses of boundary layers on the tails of the guide vanes can be well controlled, separation of the boundary layers is avoided, disengagement of the vortexes is restrained, and the disengaging frequency of the vortexes is reduced. By improving different positions of the axial flow fan, the axial flow fan is higher in efficiency, lower in noise and more environmentally friendly and saves more energy.

Owner:嘉兴笼列电子商务有限公司

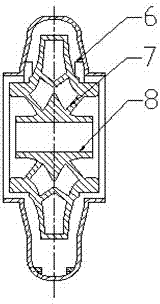

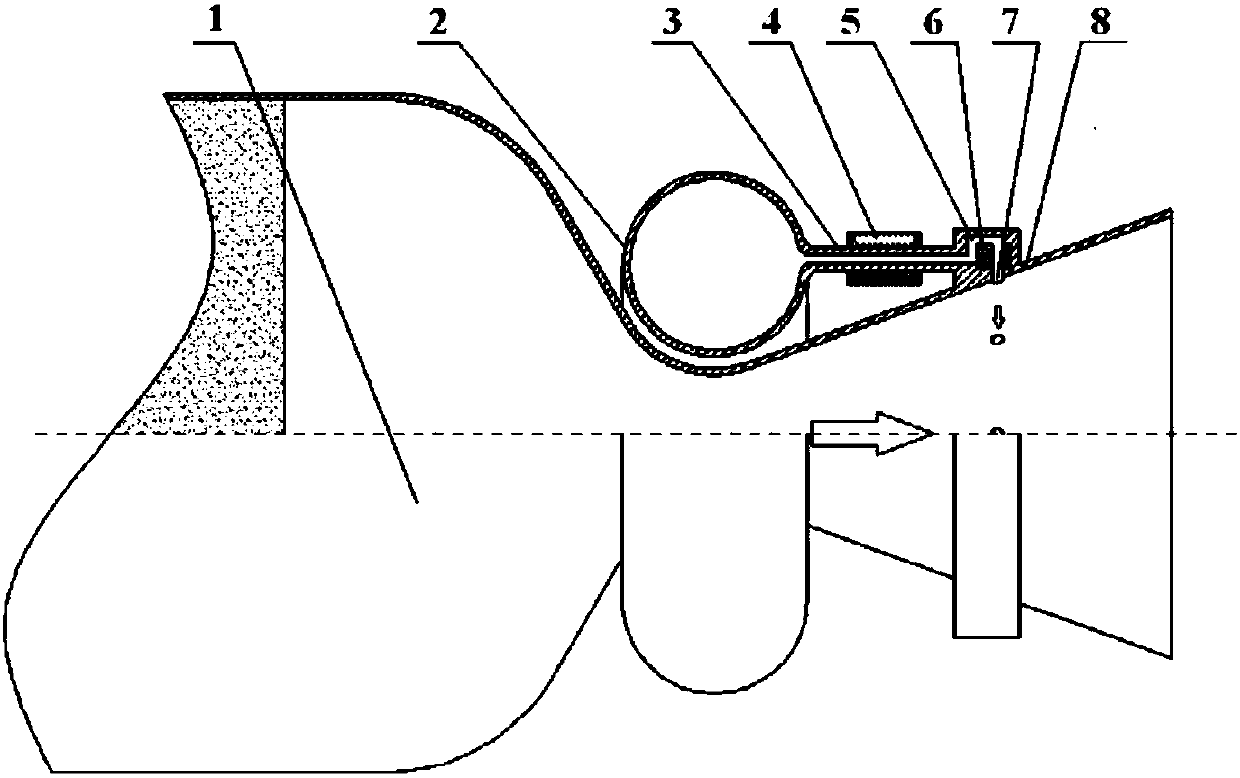

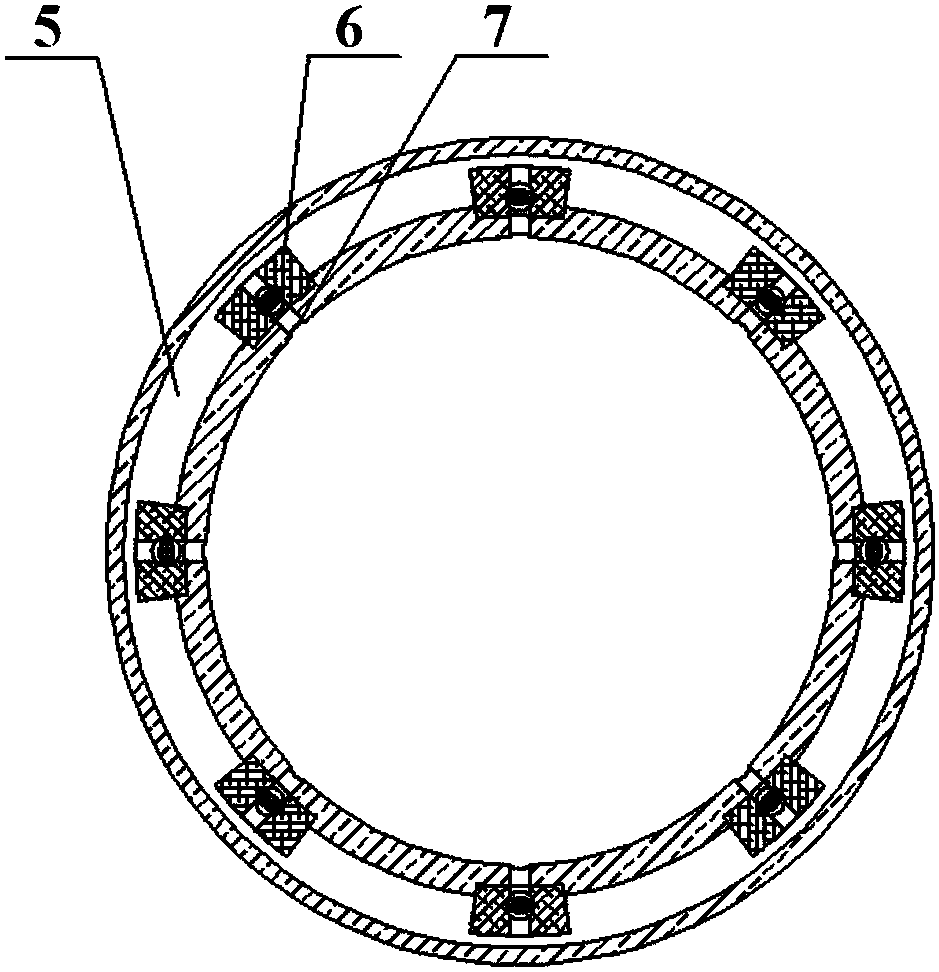

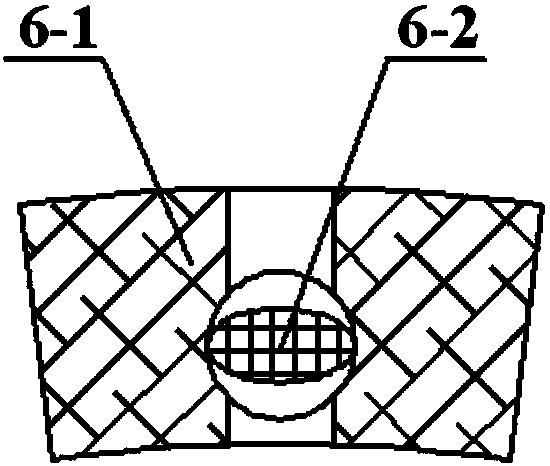

Impulse type secondary jet flow thrust vector control system

InactiveCN108035824AEffective Thrust Vector ControlEasy flight controlsRocket engine plantsControl vectorJet flow

The invention relates to an impulse type secondary jet flow thrust vector control system which comprises a rocket engine (1), an annular high pressure gas storage tank (2), a gas transporting pipeline(3), a pressure maintaining valve (4), a gas collecting cavity (5), an impulse jet flow control valve (6), a jet flow spout (7) and an engine jet pipe (8). The system facilitates flight control of anaircraft and adopts the secondary jet flow thrust vector control to reduce energy consumption, enhance the deflection capacity of secondary flow and effectively reduce the flow rate of the secondaryflow needed to be sprayed into.

Owner:JIANGXI HONGDU AVIATION IND GRP

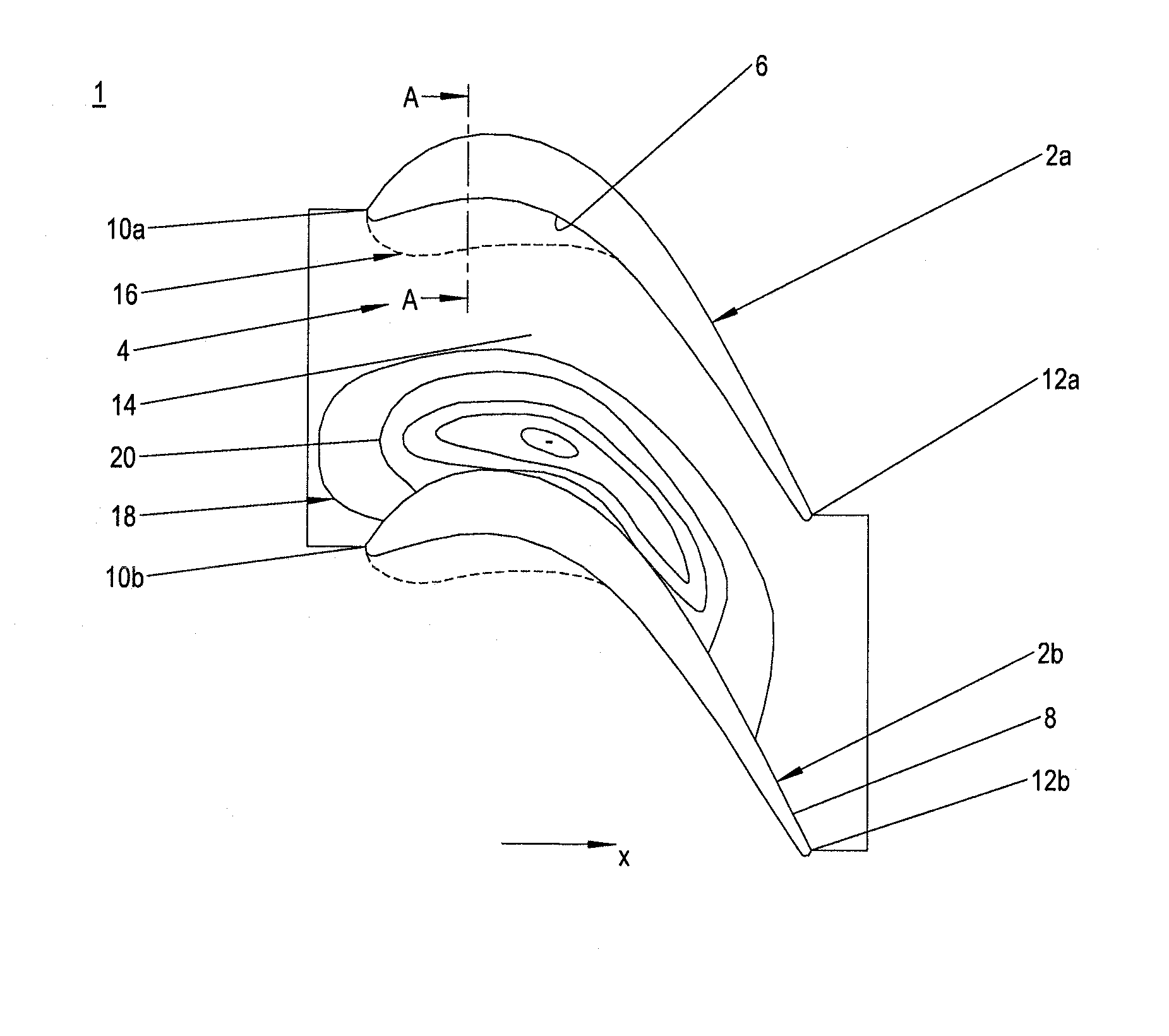

Blade cascade with side wall contours and continuous-flow machine

ActiveUS20140037453A1Reduce secondary flowImprove efficiencyPropellersRotary propellersLeading edgeContinuous flow

Owner:MTU AERO ENGINES GMBH

Francis turbine

A Francis turbine with an improved shape of blades, which can reduce cavitations generated on the surface of the blades or reduce the secondary flow around the blades, is provided. A Francis turbine comprises a rotating shaft, a crown, a plurality of blades, and a band. The crown can rotate with the rotating shaft. The blades are circumferentially arranged on the crown, each of which including an inner end as a trailing edge. The band is coaxially coupled with the crown by the blades. The rotating shaft, the crown, the blades, and the band as a whole rotate toward a turbine direction during a turbine operation. A projected profile of the trailing edge on a perpendicular plane, which is perpendicular to a center axis of the rotating shaft, is curved toward a direction opposite to the turbine direction at least in the crown side.

Owner:KK TOSHIBA

Contouring a blade/vane cascade stage

ActiveUS20180298761A1Reduce secondary flowReduce flowBlade accessoriesEfficient propulsion technologiesAerospace engineering

A blade / vane cascade segment of a blade / vane cascade for a turbomachine is disclosed, which comprises a stage with a stage surface as well as a first blade / vane element and a second blade / vane element. The stage surface comprises a first elevation reaching as far as the pressure side of the first blade / vane element and a second elevation reaching as far as the suction side of the second blade / vane element. A furthest downstream point of a boundary of the second elevation has an axial position which differs from the axial position of at least one highest point of the first elevation by a maximum of 10% of an axial cascade span. Furthermore, a blade / vane cascade, a blade / vane channel, a stage, a turbomachine and an aircraft engine are disclosed.

Owner:MTU AERO ENGINES GMBH

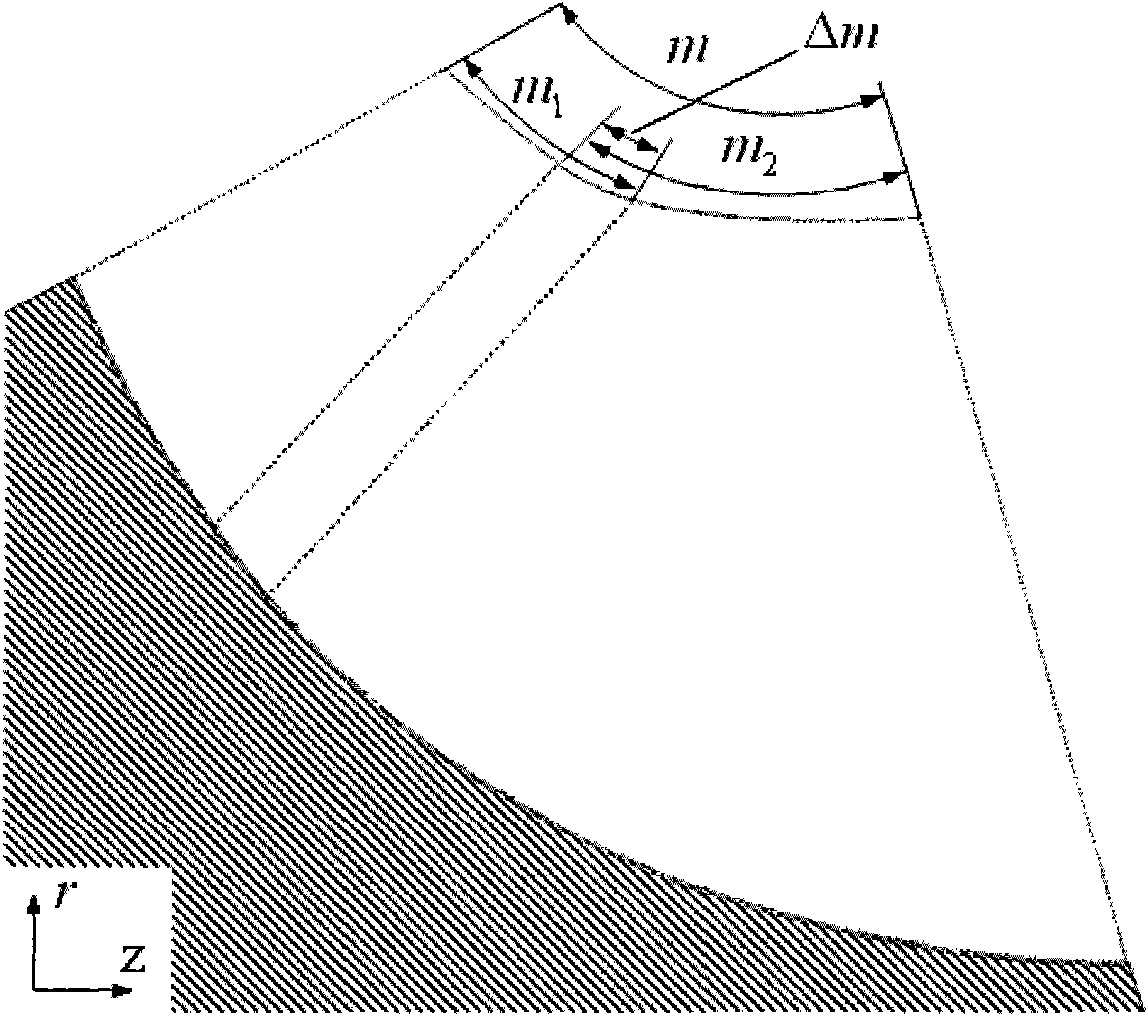

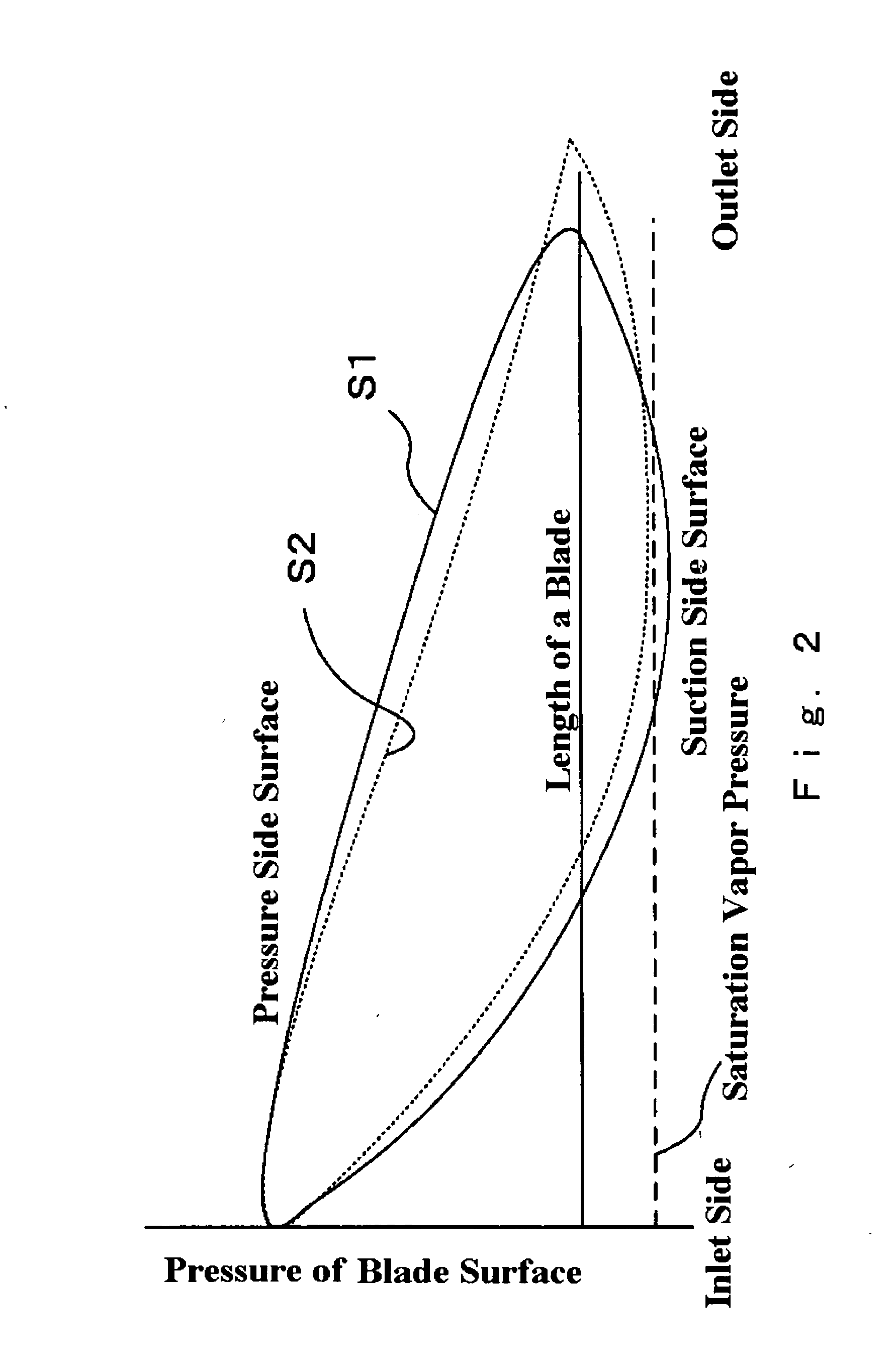

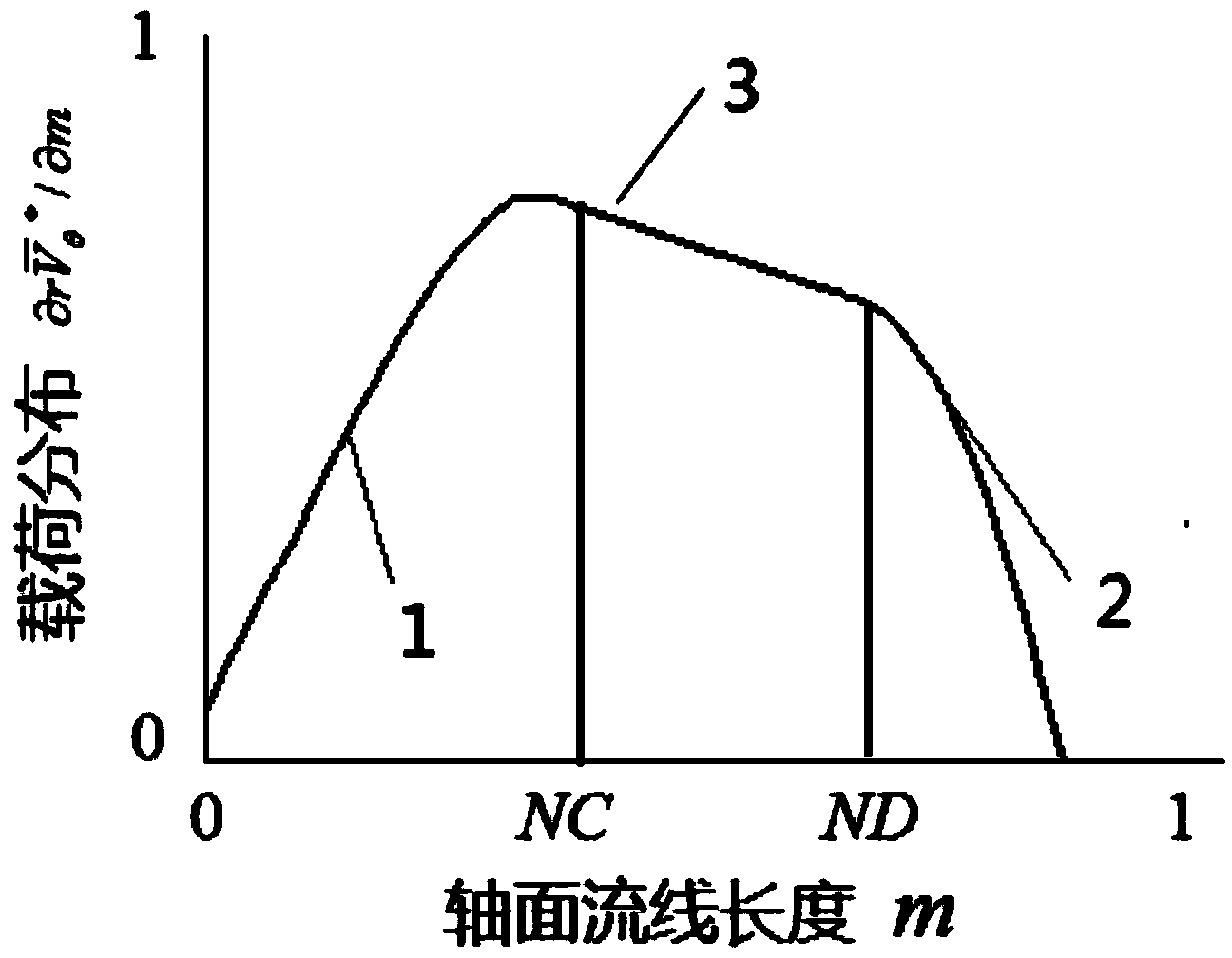

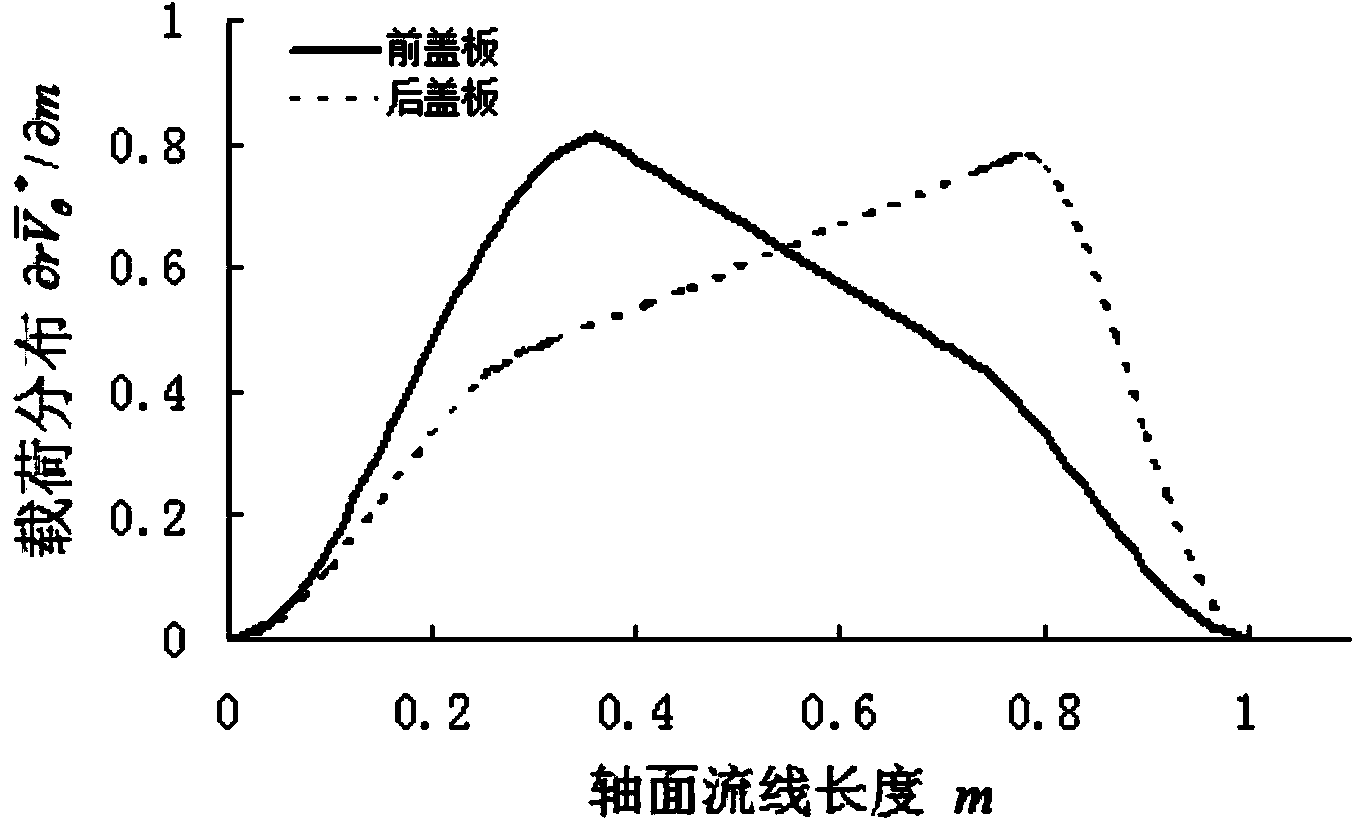

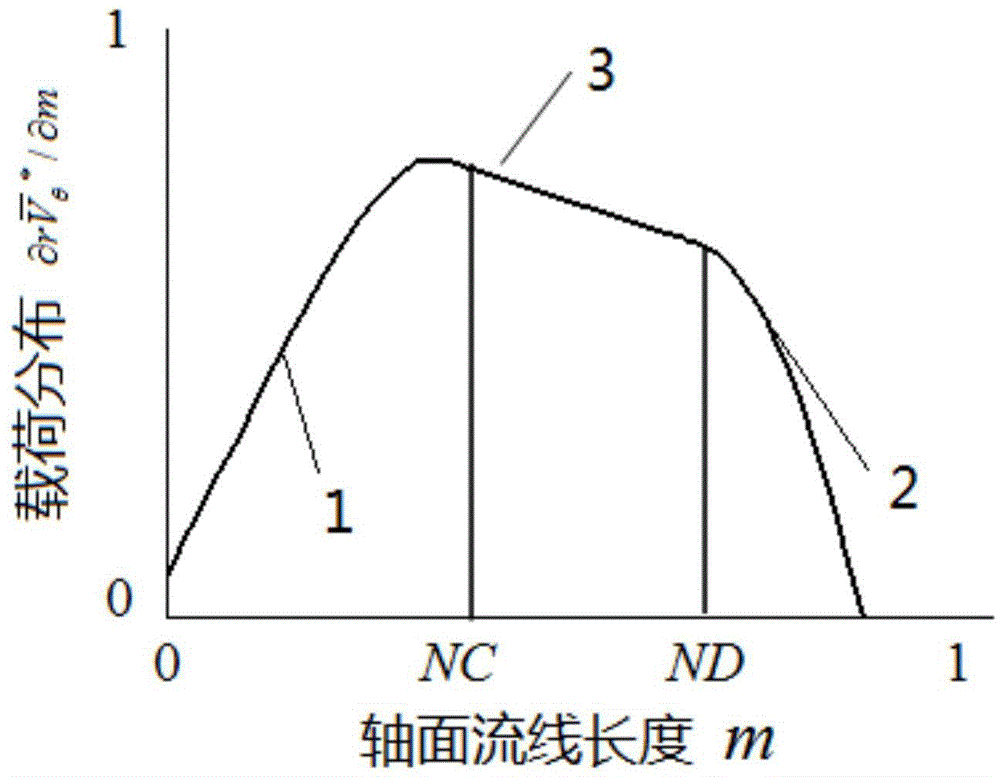

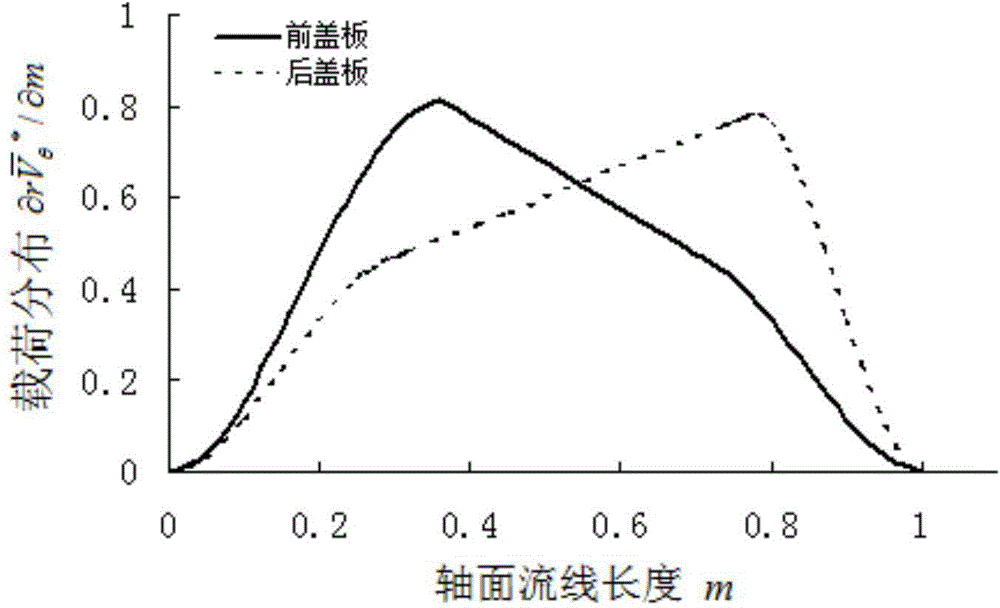

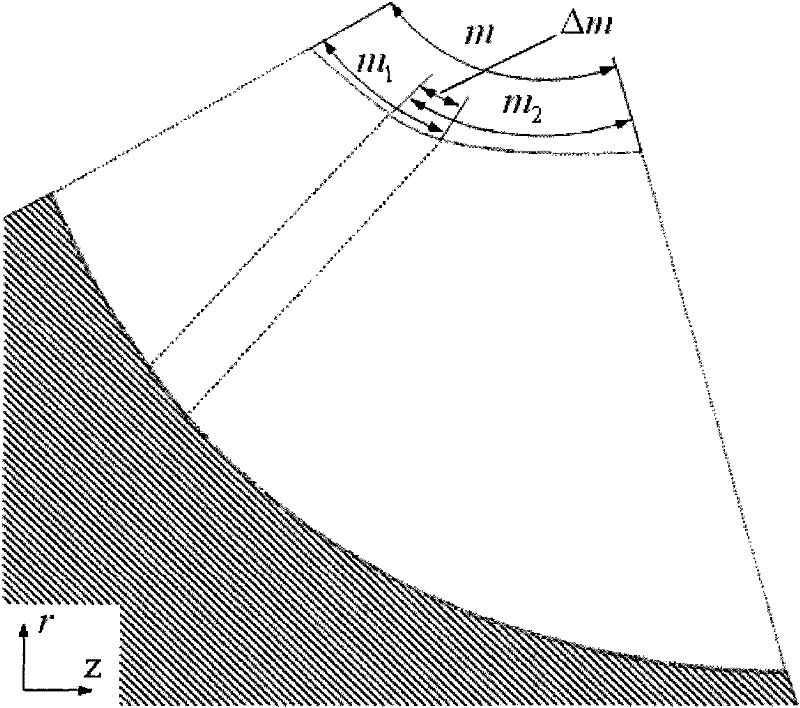

Method for acquiring load distribution curve of blade of double-suction centrifugal pump

ActiveCN103644141AUniform pressure changeReduce secondary flowPump componentsPumpsSurface pressureEngineering

The invention relates to a method for acquiring the load distribution curve of a blade of a double-suction centrifugal pump. The method comprises the following steps: working out the specific speed and drawing the axial projection drawing of the blade according to performance parameters of the double-suction centrifugal pump, working out the key parameters of load distribution curves of a front cover plate flow line and a rear cover plate flow line of the double-suction centrifugal pump, drawing the load distribution curves of the front cover plate flow line and the rear cover plate flow line, thickening the blade of the double-suction centrifugal pump according to the size, the working capacity and the casting level of the blade, working out the flow lines of a front cover plate and a rear cover plate according to the load distribution curves of the front cover plate flow line and the rear cover plate flow line and the thickening value, and performing numerical prediction to the efficiency and the inside fluid field of a conventional double-suction centrifugal pump model and a double-suction centrifugal pump model acquired through the method provided by the invention by adopting an analogue simulation method. The blade of the double-suction centrifugal pump, acquired through the invention, has the advantages that the surface pressure variation is uniform, a secondary flow in the outlet area of the blade is reduced remarkably, and the range of a high-efficiency area is broadened.

Owner:CHINA AGRI UNIV

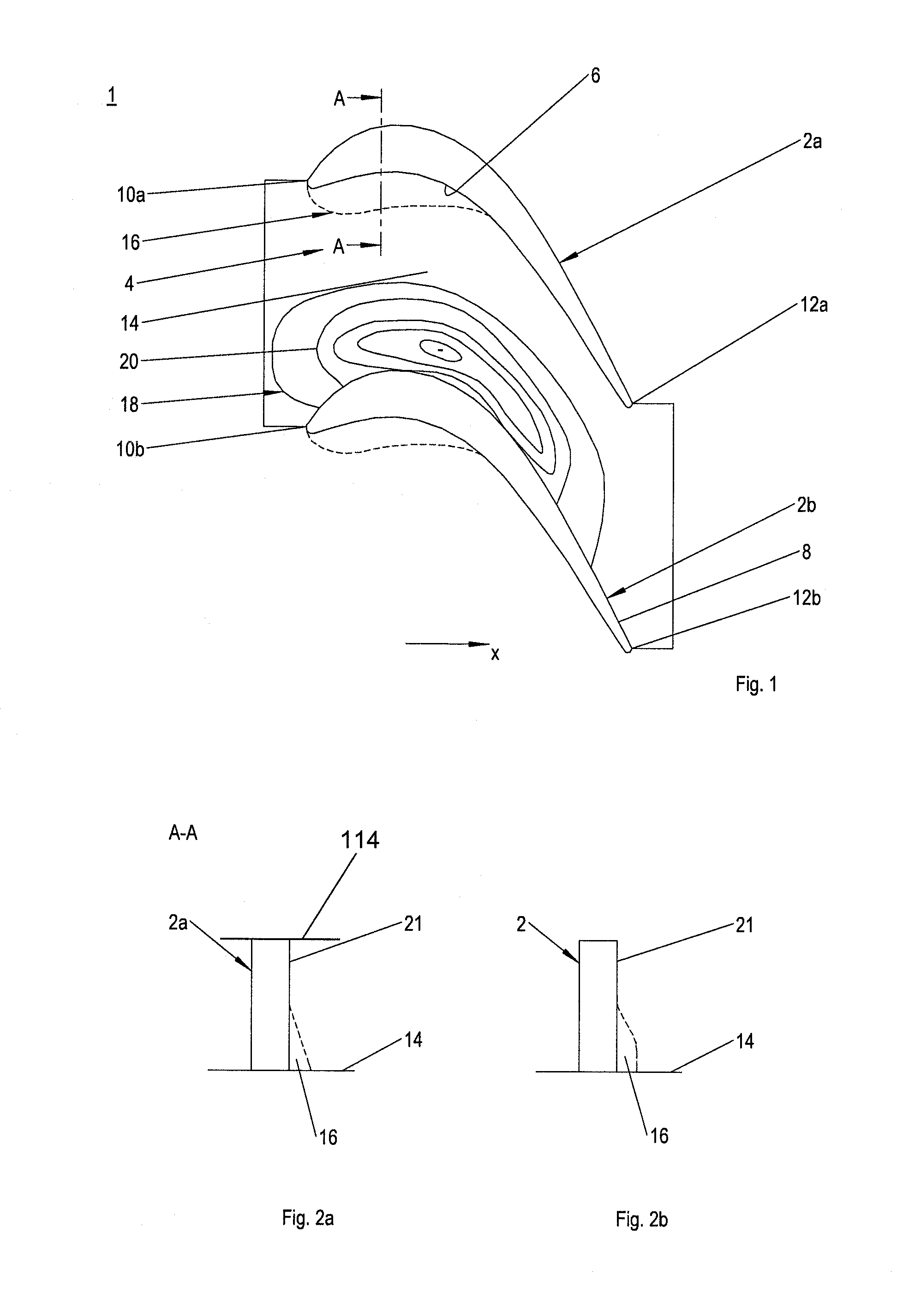

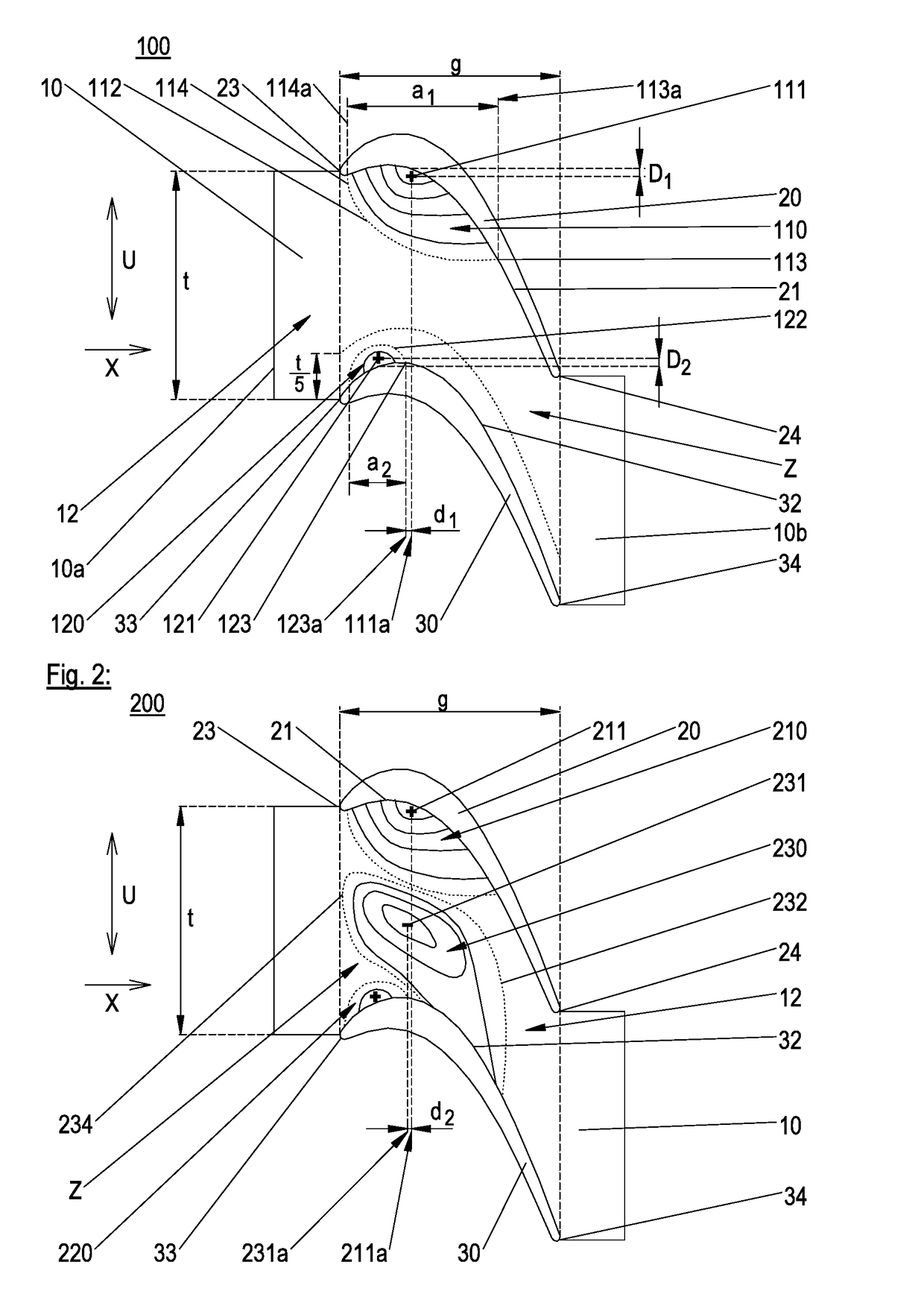

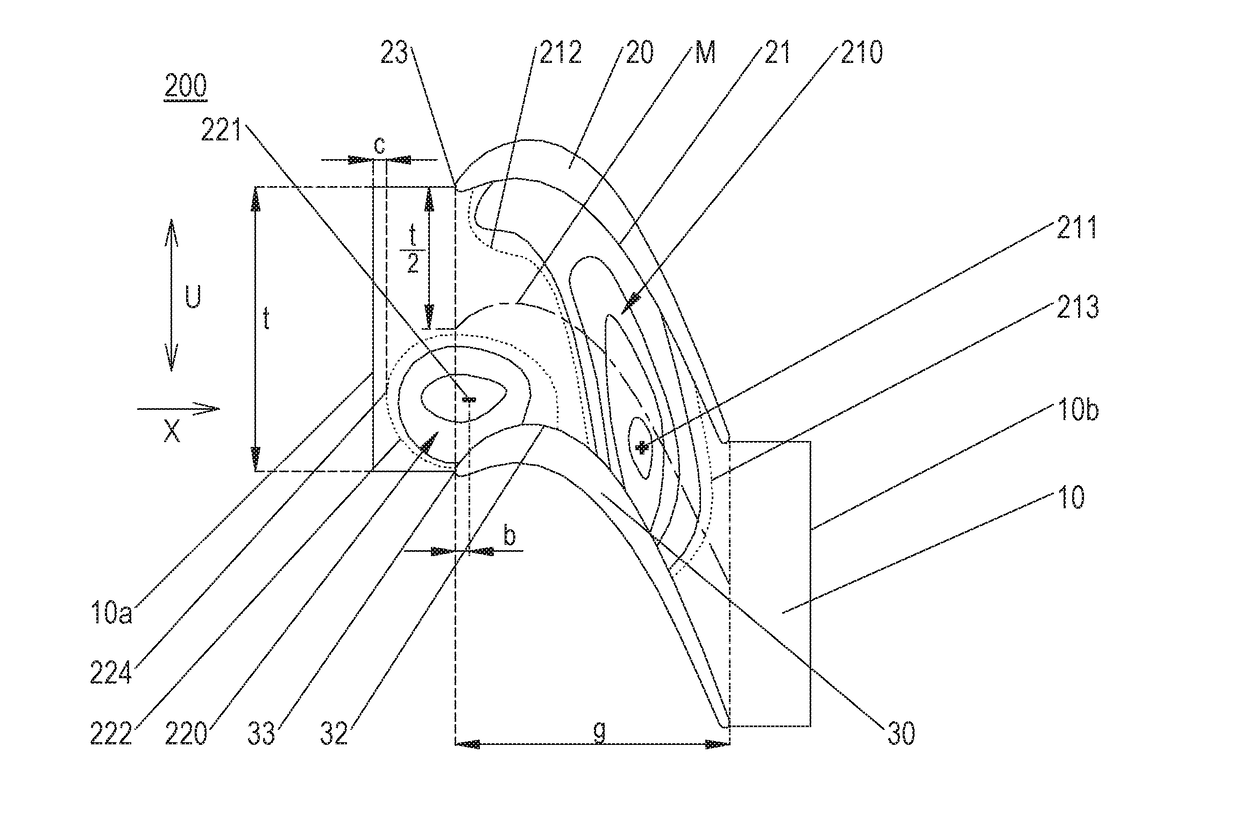

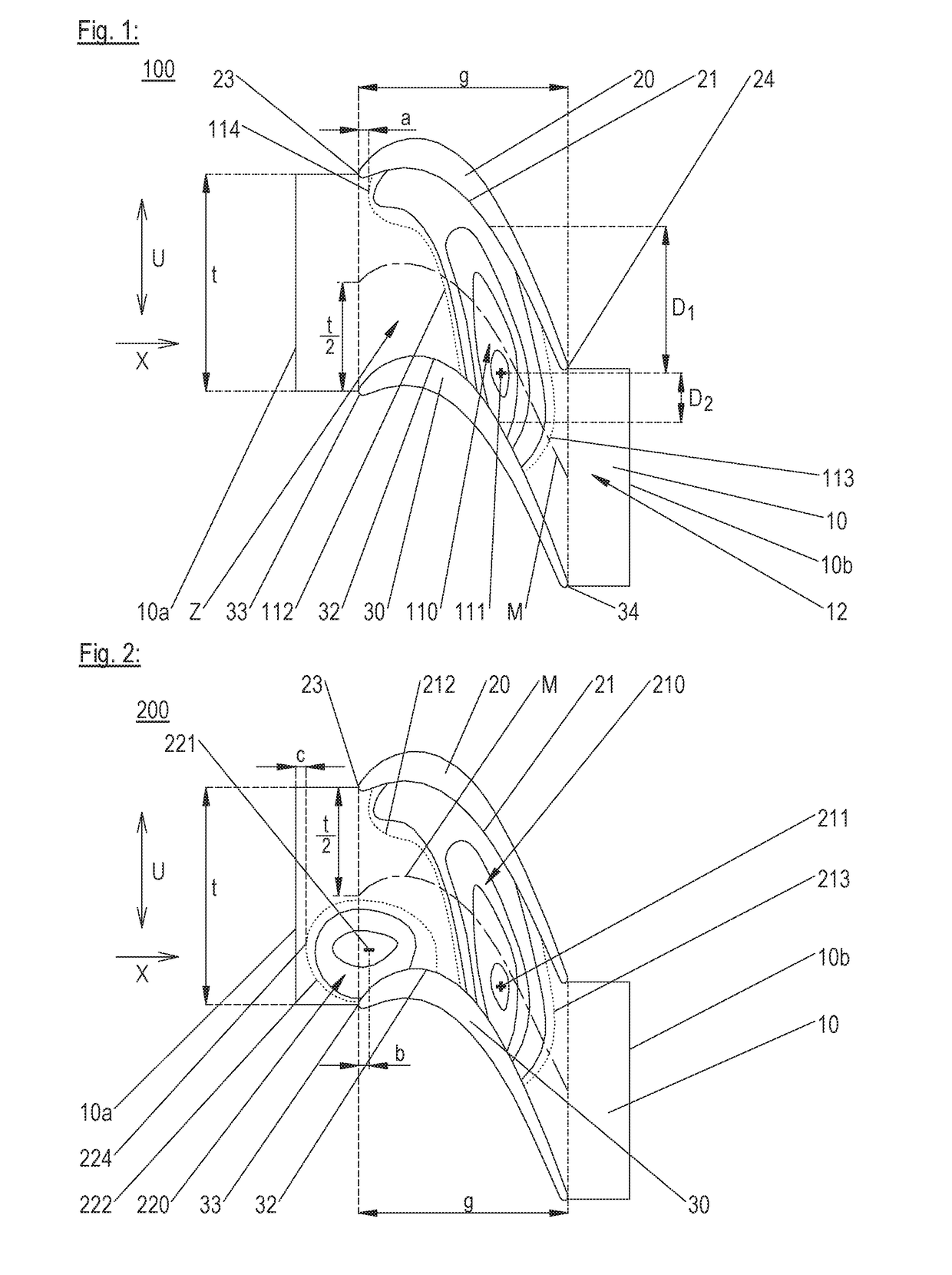

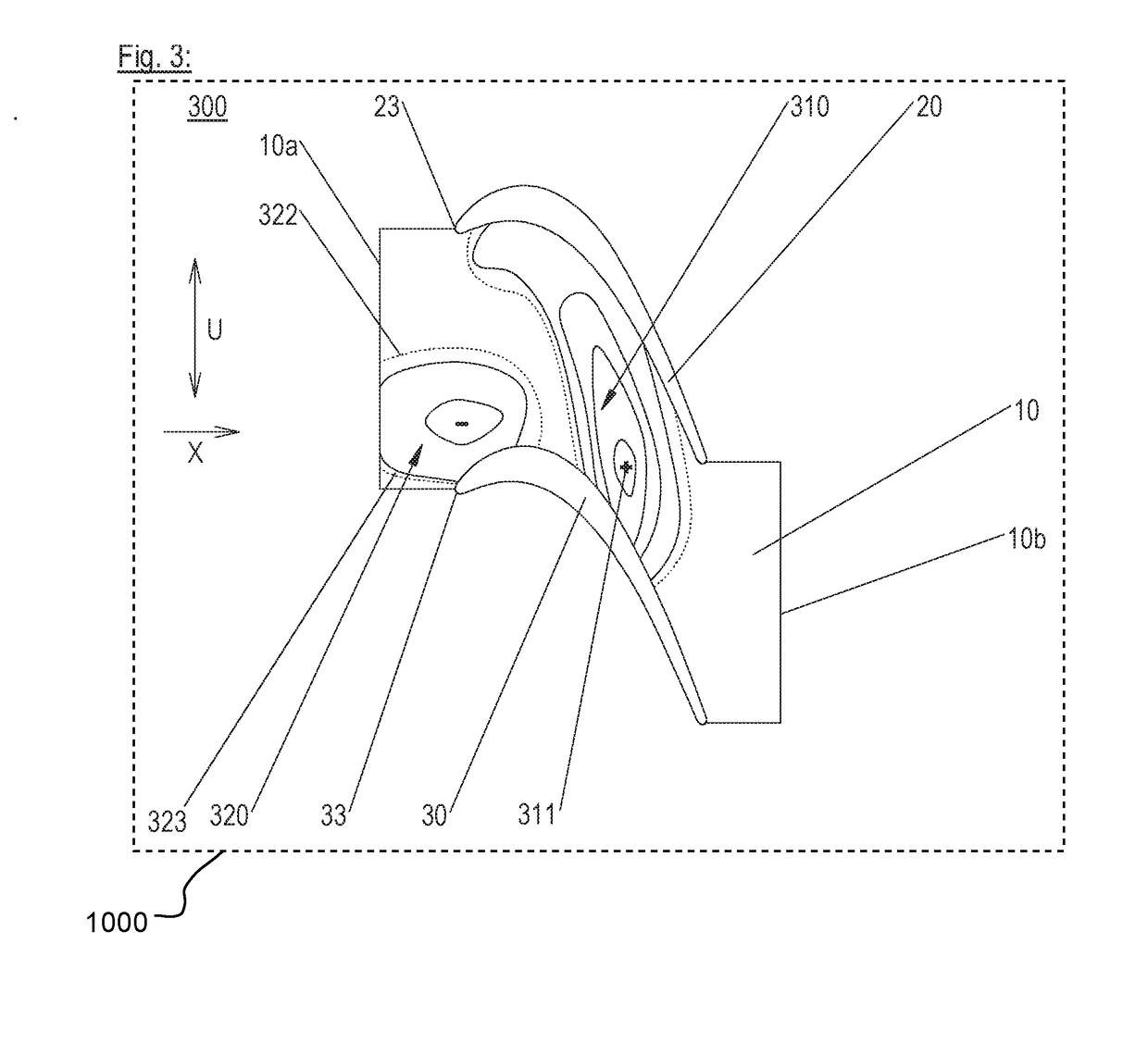

Endwall contouring for a turbomachine

ActiveUS20180328184A1Reduce secondary flowReduce flowBlade accessoriesEfficient propulsion technologiesEngineering

Described are an airfoil array segment (100, 200, 300) having at least two airfoils (20, 30) and a platform (10) that features an axis asymmetrical platform surface (12). This platform surface features an elevation (110, 210, 310) that extends from the pressure side (21) of the first to the suction side (32) of the second airfoil (30). A highest point (111, 211, 311) of the elevation is more proximate to the suction side 32 of the second airfoil (30) than to the pressure side (21) of the first airfoil (20). Also described are an airfoil, a platform, an airfoil passage and a turbomachine.

Owner:MTU AERO ENGINES GMBH

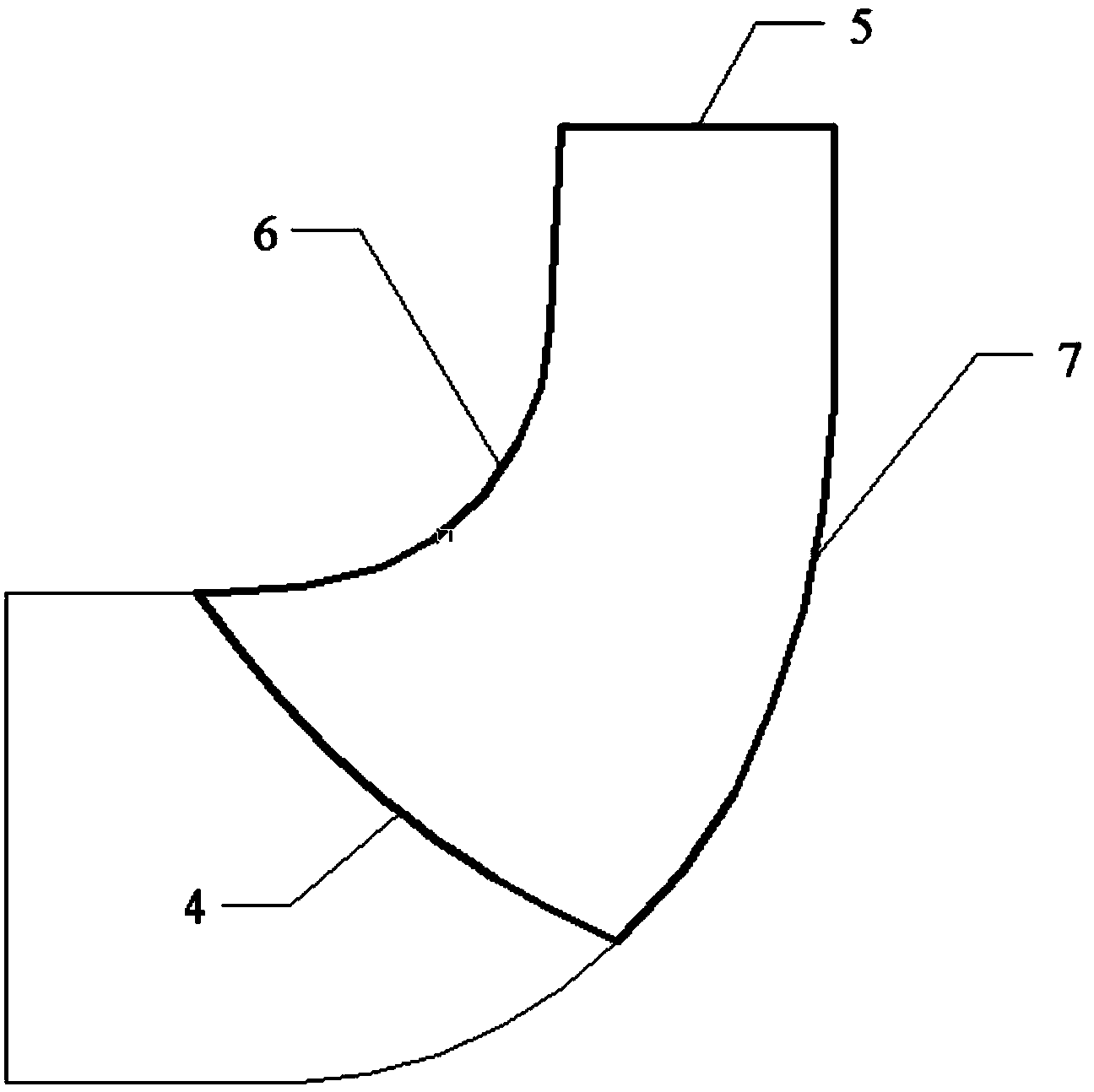

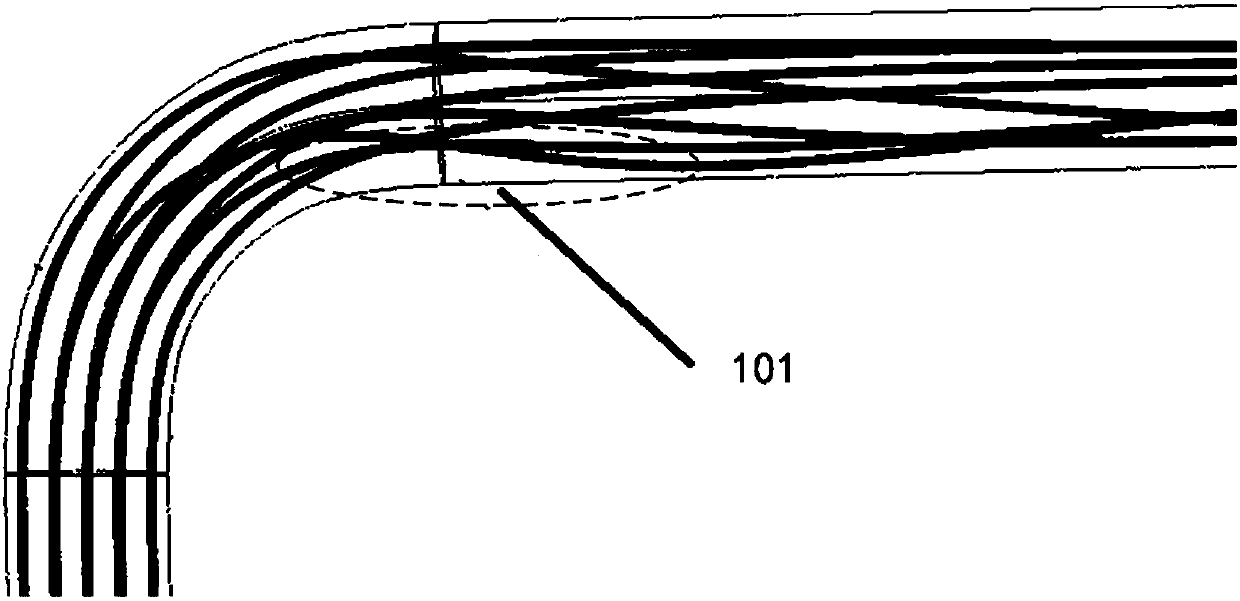

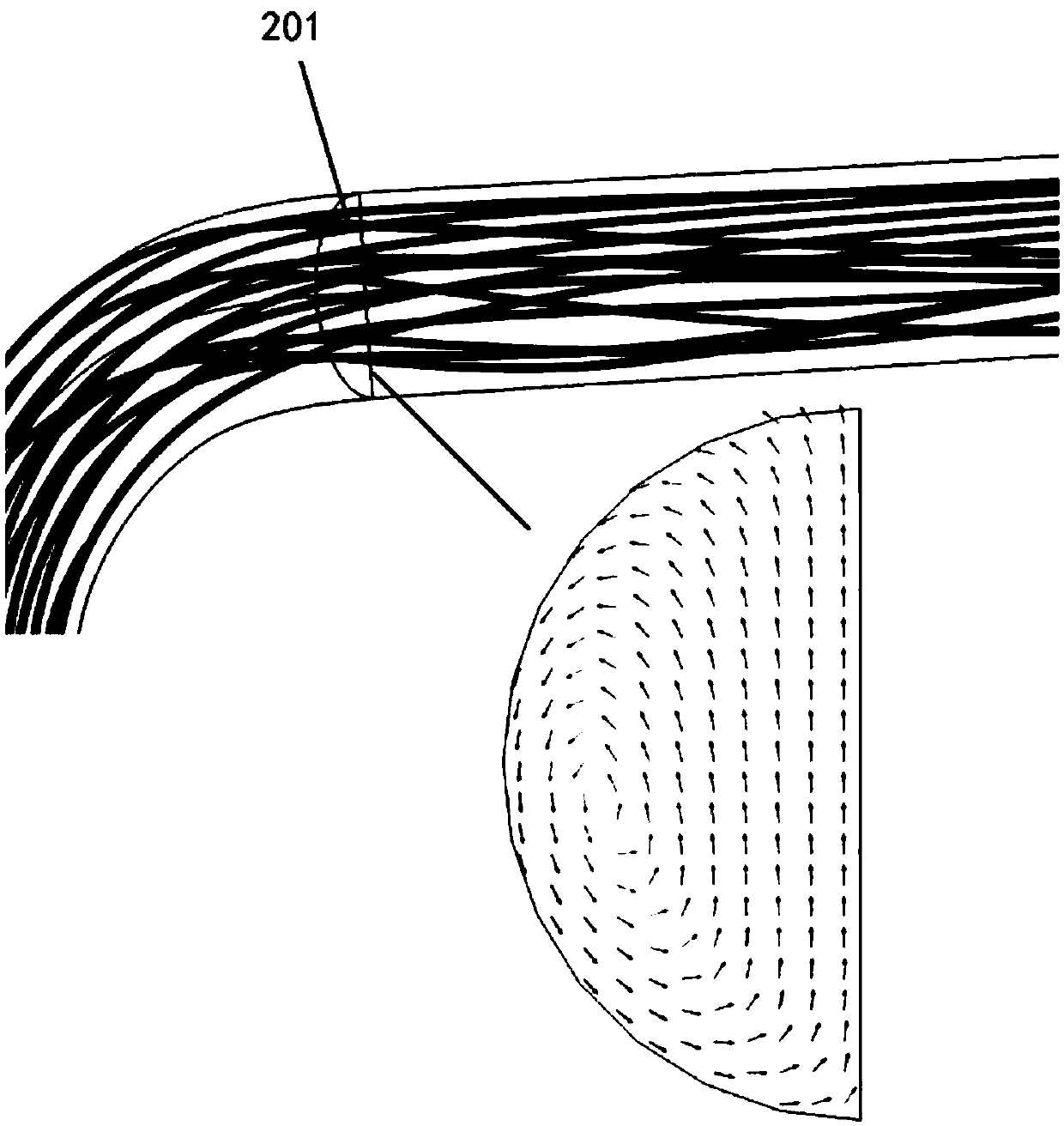

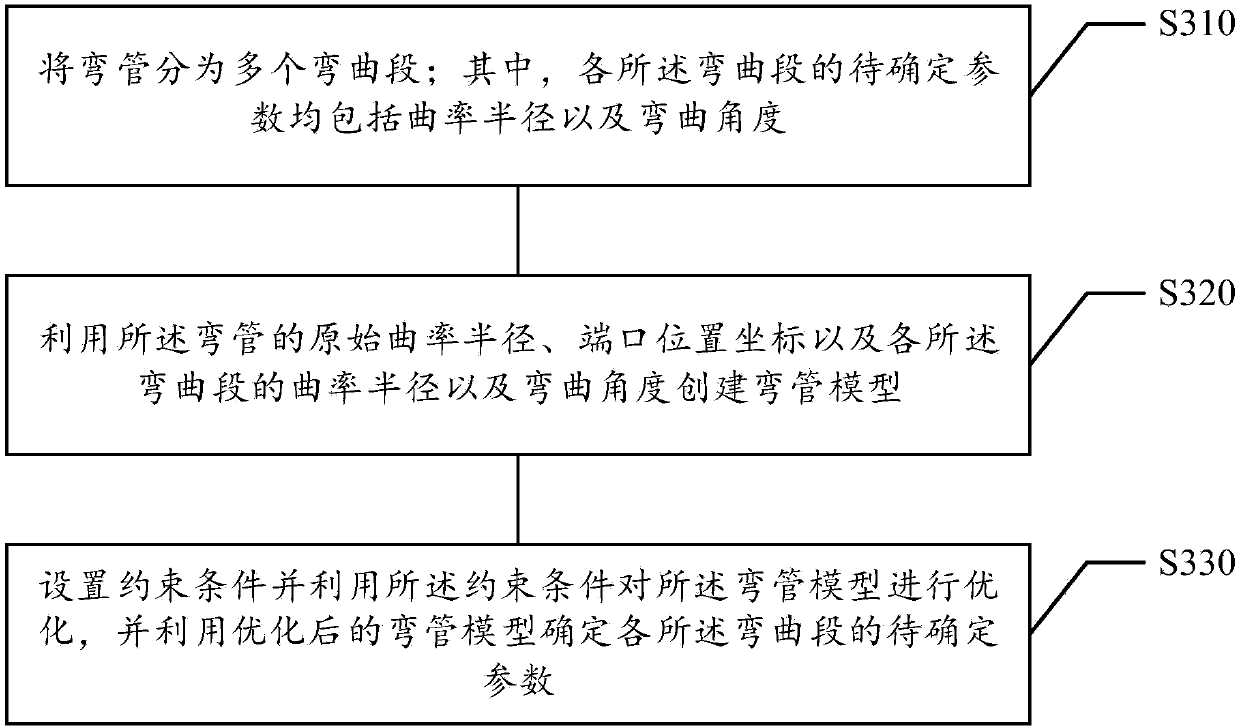

Bent pipe parameter determination method

ActiveCN108062444ASmall pressure lossImprove reliabilityGeometric CADSpecial data processing applicationsEngineeringHigh pressure

The invention relates to a bent pipe parameter determination method and belongs to the technical field of fluid dynamics and mechanical vibration. The method comprises the steps of dividing a bent pipe into a plurality of bending sections, wherein a to-be-determined parameter of each bending section includes a curvature radius and a bending angle; creating a bent pipe model by use of an original curvature radius of the bent pipe, a port position coordinate, and the curvature radius and the bending angle of each bending section; setting a constraint condition and optimizing the bent pipe modelby use of the constraint condition; and determining the to-be-determined parameter of each bending section by use of the optimized bent pipe model. According to the method, the bent pipe is divided into the plurality of bending sections, the purposes of reduction of vortexes inside a high-pressure and high-speed pipeline and secondary flow can be achieved only through the detailed tubular design of the bending part on the premise of not modifying the structure size of the bent pipe, and the working efficiency of a hydraulic system is improved while reducing the pressure loss of the bent pipe.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

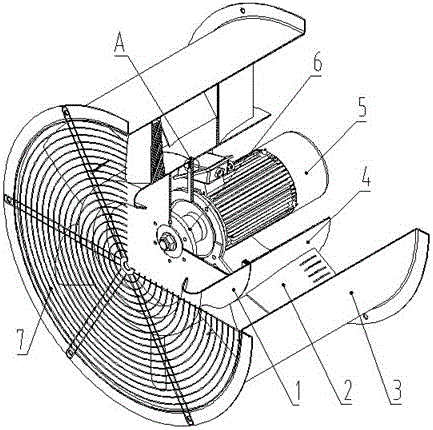

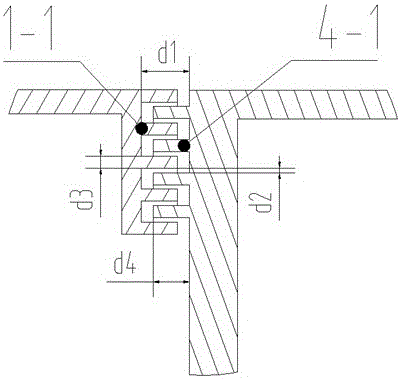

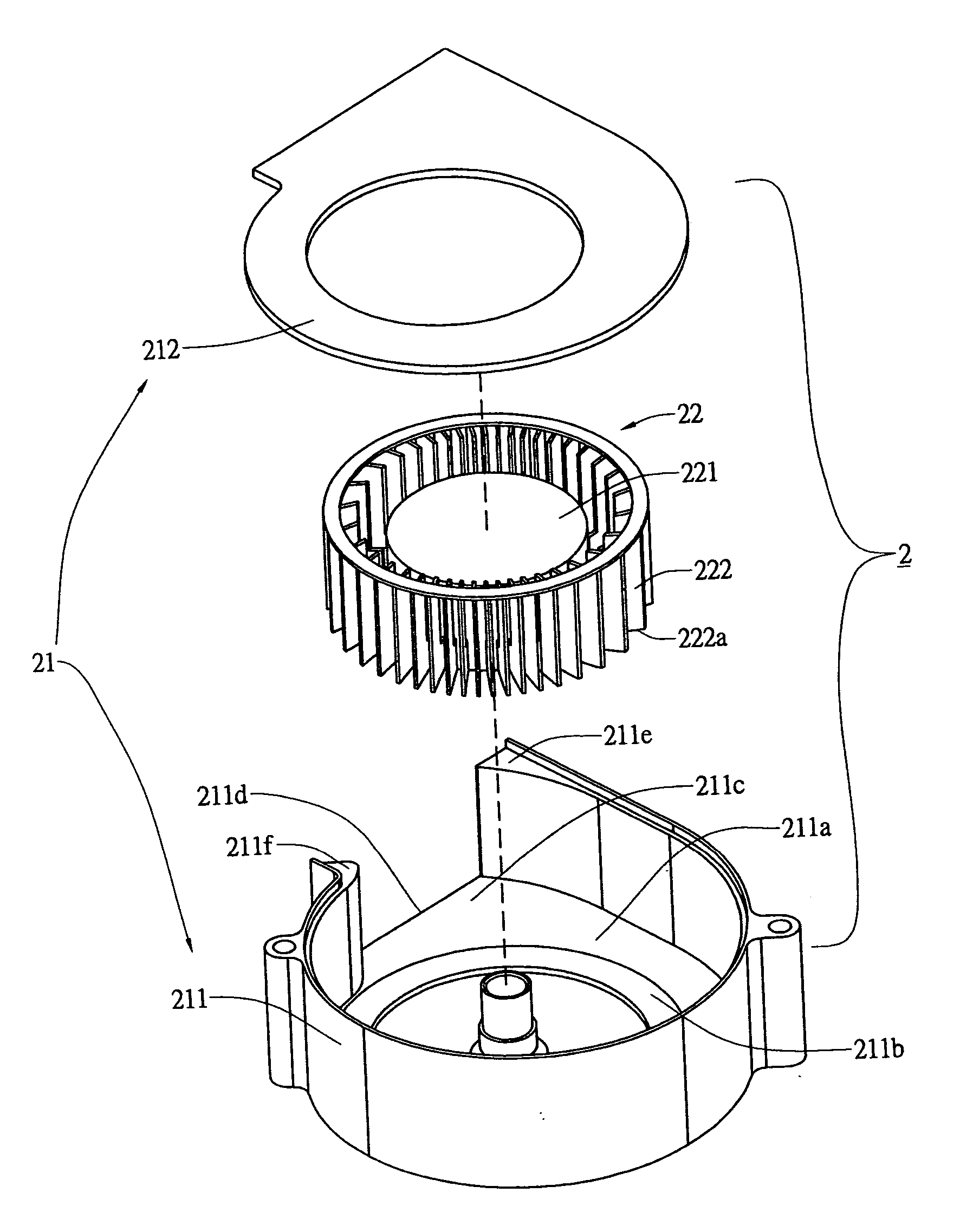

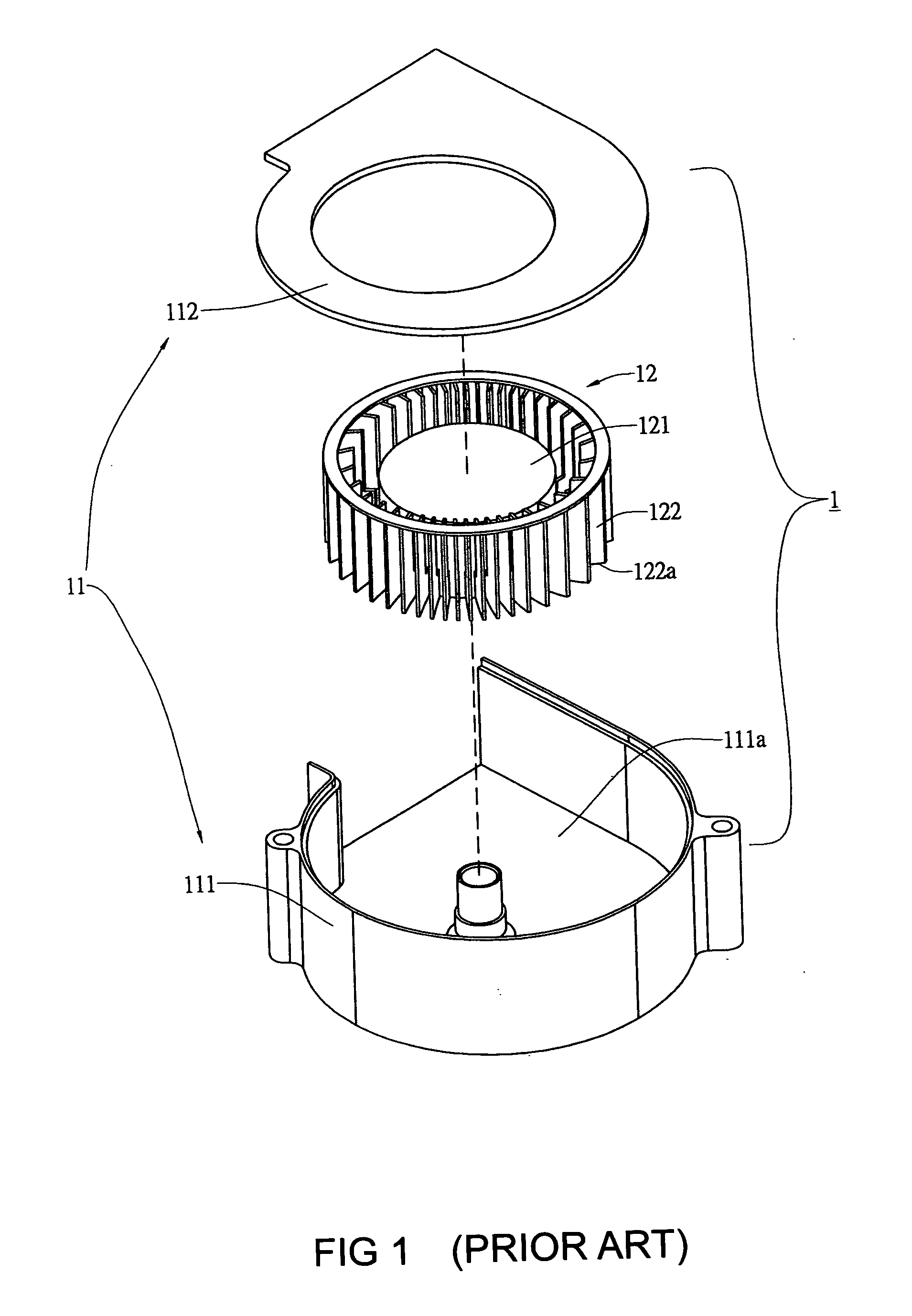

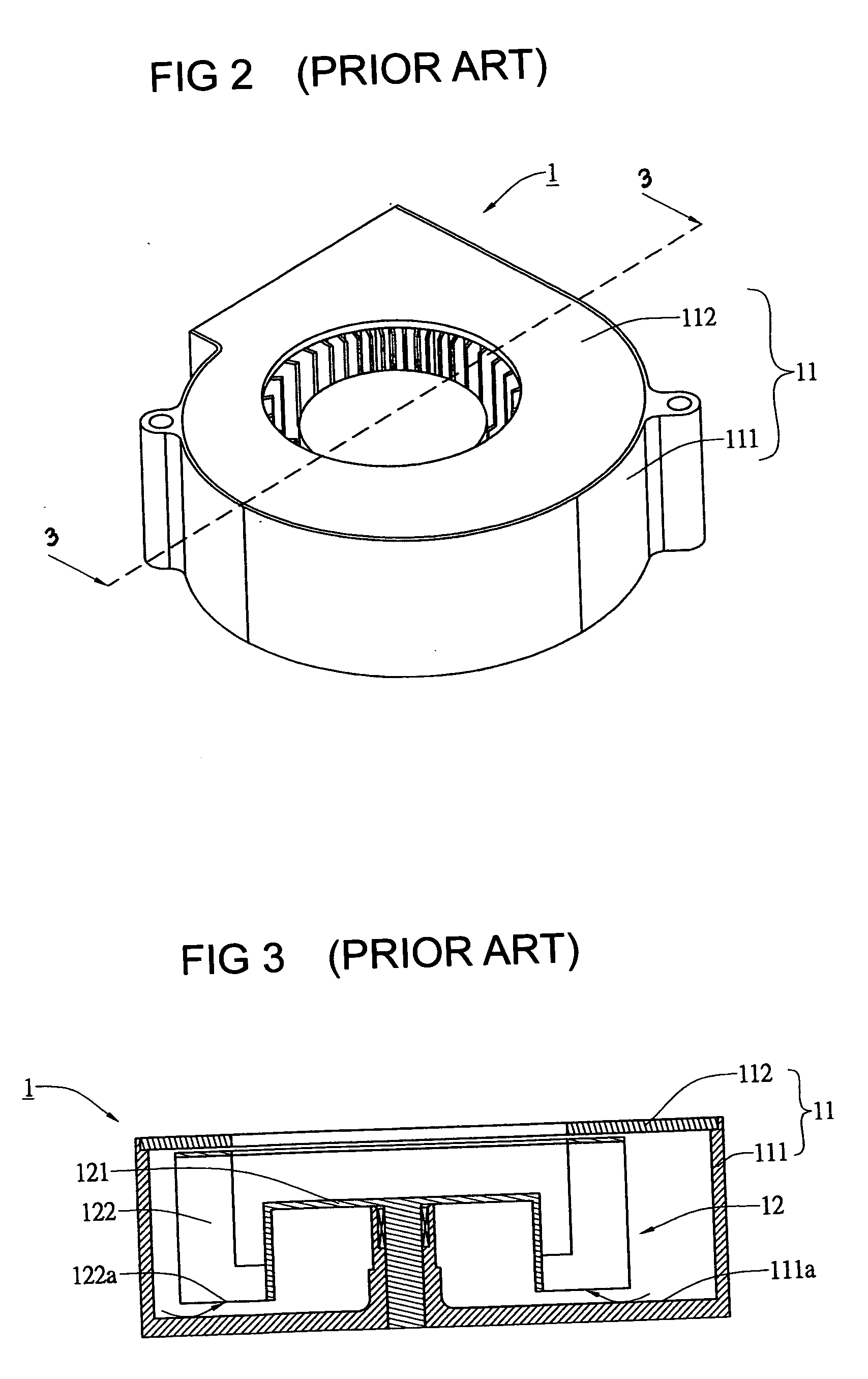

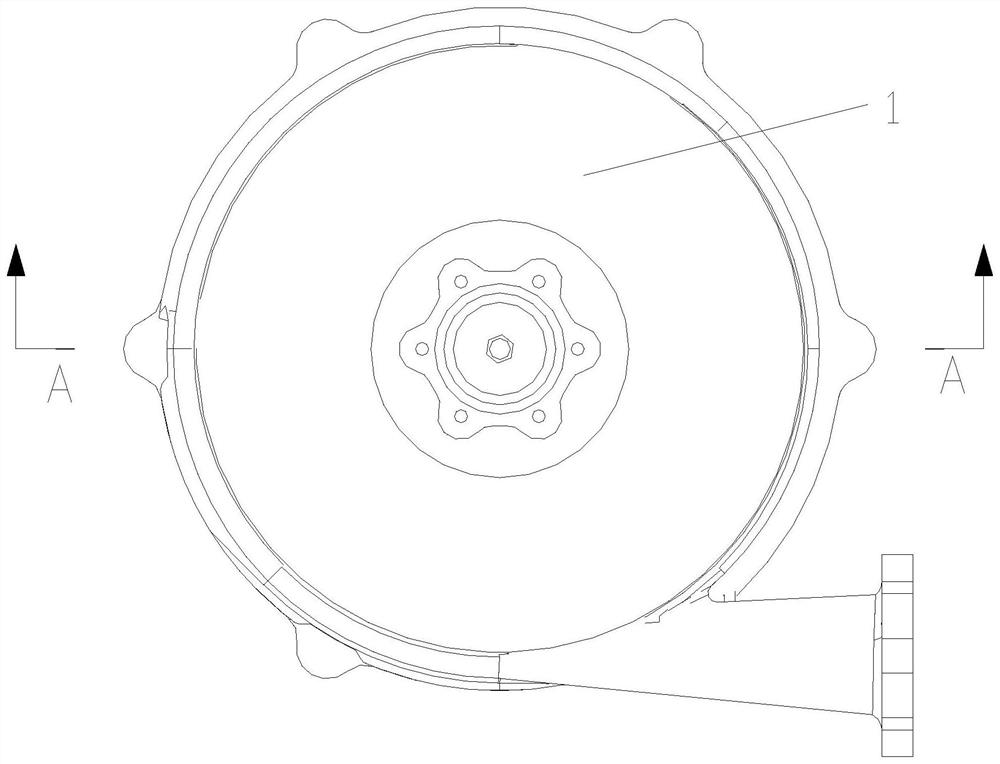

Blower capable of reducing secondary flow

InactiveUS20060078426A1Reduce secondary flowReduce flowCircumferential flow pumpsPump componentsEngineeringMechanical engineering

Owner:ASIA TAL COMPONENT

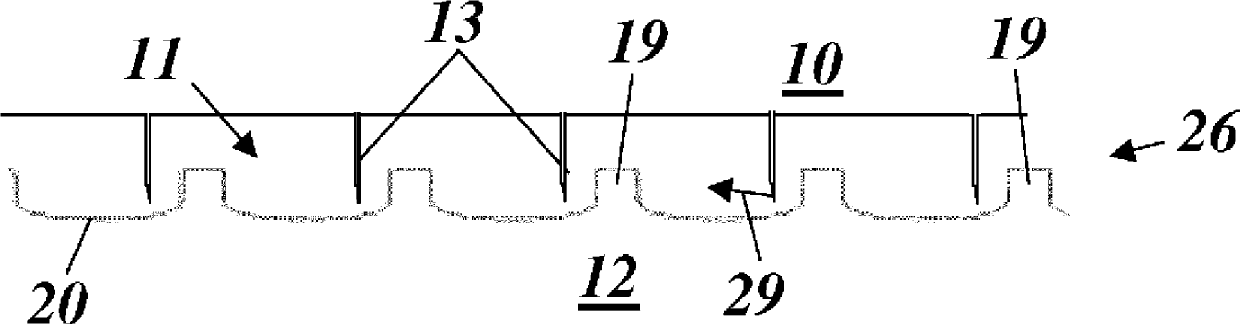

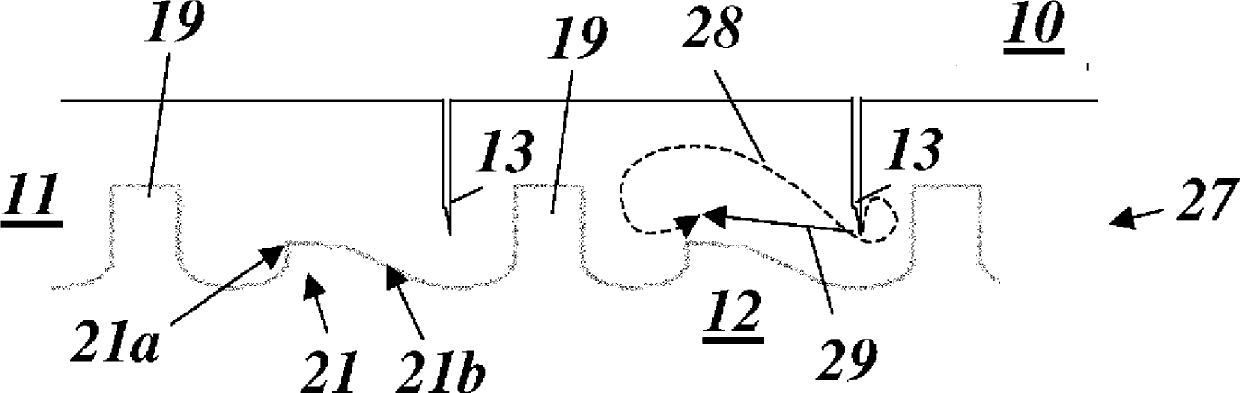

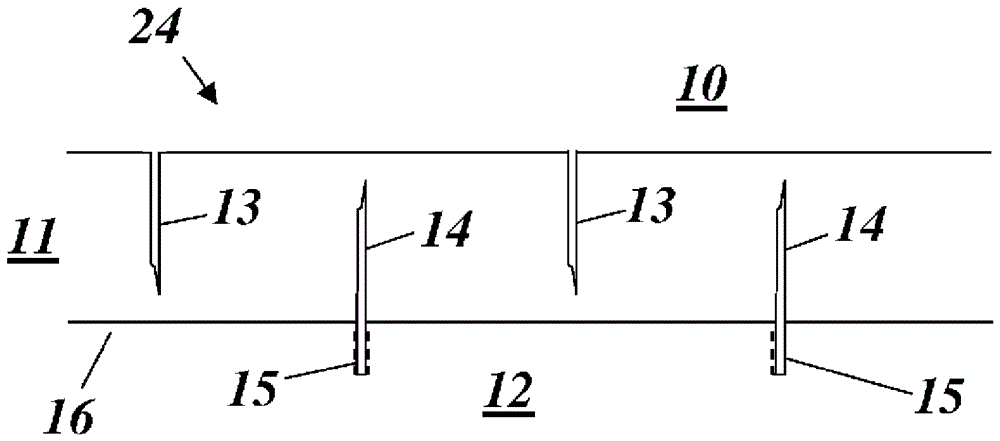

Labyrinth seal

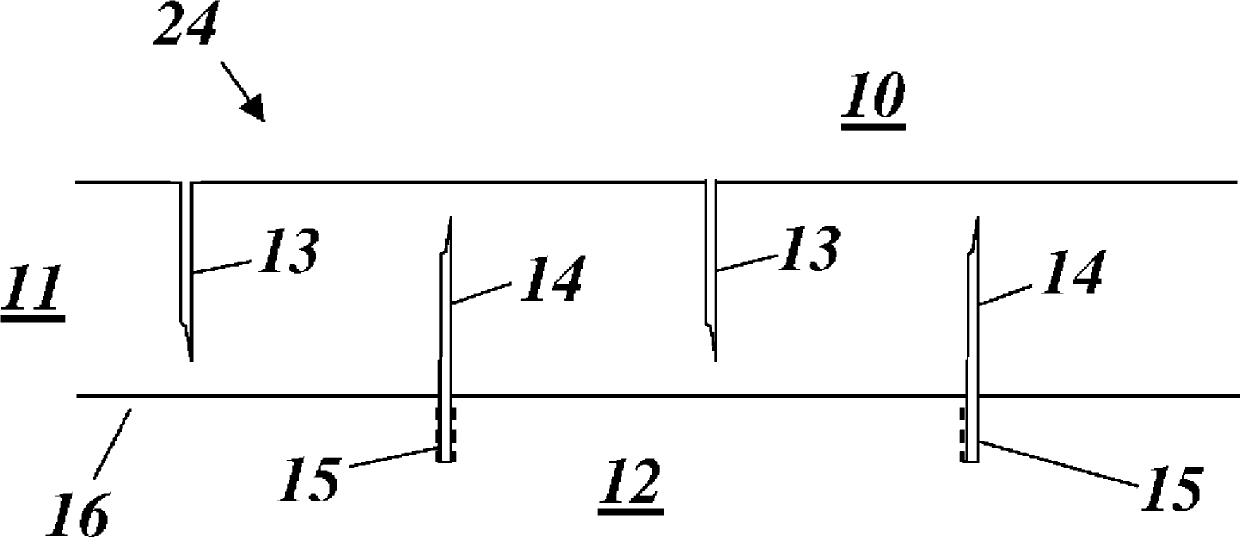

ActiveCN103827558ARealize passive controlReduce secondary flowEngine sealsLeakage preventionGas turbinesStator

A labyrinth seal (25,...,27), for sealing the annular interspace (11) between the rotor (12) and the stator (10) of a steam turbine or gas turbine, comprises a multiplicity of sealing strips (13) which are arranged in series in the axial direction, are fastened on the stator (10) and project into the interspace (11), which sealing strips interact, with sealing effect, with rotor-side sealing elements (14, 19) which are arranged in a staggered manner. With such a labyrinth seal (25,...,27), an improved sealing effect is achieved by the sealing strips (13) in the cold installed state being offset in relation to a symmetrical position, wherein the offset has the reverse direction and the same amount as the distance (29) by which the sealing strip (13) is displaced relative to adjacent rotor-side sealing elements (14, 19) as a result of thermal expansions of the stationary and rotating components and support structure when being heated from the cold installed state to a hot steady-state operating condition.

Owner:ANSALDO ENERGIA IP UK LTD

Axial flow fan three-dimensional impeller with leaf vein structures and arc cylindrical splitter blades

ActiveCN106762825AIncrease reaction rateImprove flow capacityPump componentsPumpsImpellerSuction surface

The invention discloses an axial flow fan three-dimensional impeller with leaf vein structures and arc cylindrical splitter blades. The axial flow fan three-dimensional impeller comprises a hub and further comprises curved-twisted blades and splitter blades, wherein a shaft sleeve is fixed on the hub by a connecting piece; the curved-twisted blades and splitter blades are fixedly connected onto the hub; the curved-twisted blades comprise suction surfaces and pressure surfaces; wing grooves are formed in the tops of the curved-twisted blades; leaf vein shaped grooves are formed in upper half parts of the pressure surfaces of the curved-twisted blades; the wing grooves are communicated with the leaf vein shaped grooves through air outlets; small wing protrusions are arranged at the tails of the suction surfaces of the curved-twisted blades; parabolic pinholes are formed in the curved-twisted blades; a splitter blade is arranged between every two adjacent curved-twisted blades; and the height of each splitter blade is smaller than one half of that of the curved-twisted blade.

Owner:ZHEJIANG SCI-TECH UNIV

Centrifugal pump

PendingCN113294342AReduce cavitationGuaranteed structural strengthPump componentsRadial flow pumpsAxial forceBalance shaft

The invention discloses a centrifugal pump which comprises a volute, a rear cover plate and an impeller. The impeller is rotationally arranged between the volute and the rear cover plate, and blades are connected to the impeller; axial holes are formed in each blade, and the axial holes penetrate through the blades and the impeller; and the multiple axial holes are formed in the blades in the extending directions of the blades at intervals, and at least one of the following effects including reduction of liquid backflow in blade top gaps and reduction of cavitation and axial force can be achieved, so that the efficiency of the centrifugal pump is improved.

Owner:XIAN AERONAUTICAL UNIV

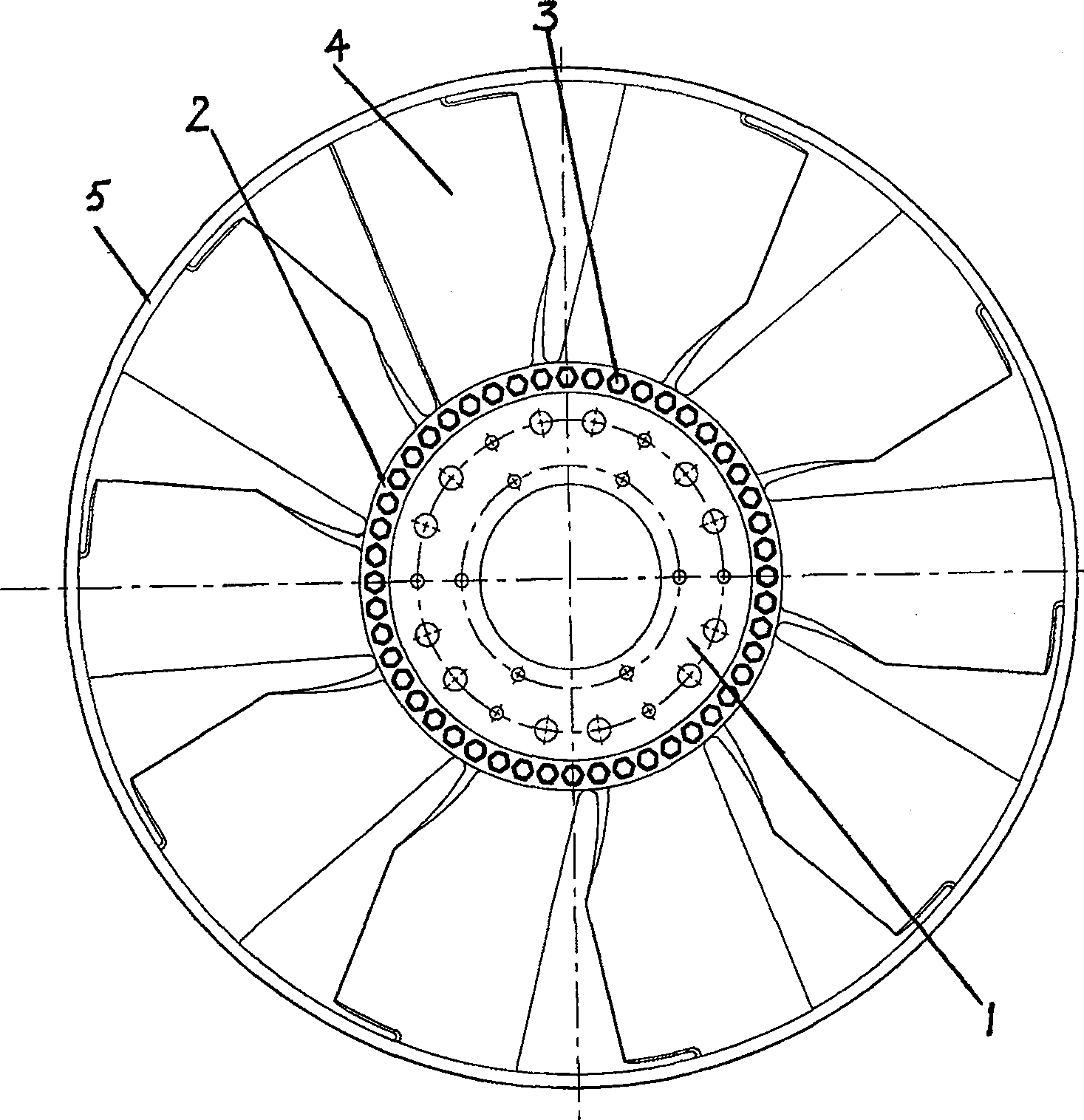

Automobile engine cooling fan

A vehicle engine cooling fan is disclosed. The invention comprises a tray, a wheel hub and a reinforced rib, and blades. The impeller comprises a tray, a wheel hub, and blades. the blades are airfoil shaped cross section blades, the blades and the wheel hub are formed an integral body, the chord length ratio of the inner and the outer diameters of each blade is between 1:1.1 to 1:1.5, the included angle of each cross section gravity line and the radial straight line of the blades is between 5 degrees to 25 degrees, the projection distance on the rotating axle of each cross section gravity line of the blades is controlled between 2% to 8% of the impeller diameter, the projection distance presents a space twisted shape, and the arc transition is adopted at the connection of the blade and the wheel hub. The reinforced rib is a honeycomb-shaped reinforced rib, and the honeycomb-shaped reinforced rib is of a regular hexagon hexagonal shape. The blades and the diversion ring are connected together. The efficiency is high, the noise is small, the slip flow can not easily occur at the tail part, and the service life is long.

Owner:WENZHOU YILONG AUTO PARTS CO LTD

A Method for Obtaining the Distribution Curve of Blade Load of Double Suction Centrifugal Pump

ActiveCN103644141BUniform pressure changeReduce secondary flowPump componentsPumpsEngineeringSurface pressure

Owner:CHINA AGRI UNIV

Labyrinth seal

ActiveCN103827558BRealize passive controlReduce secondary flowEngine sealsLeakage preventionThermal expansionGas turbines

A labyrinth seal is provided for sealing the annular interspace between the rotor and the stator of a steam turbine or gas turbine. The labyrinth seal includes a multiplicity of sealing strips which are arranged in series in the axial direction and fastened on the stator and project into the interspace. The sealing strips interact, with sealing effect, with rotor-side sealing elements which are arranged in a staggered manner. An improved sealing effect is achieved by the sealing strips in the cold installed state being offset in relation to a symmetrical position, wherein the offset has the reverse direction and the same amount as the distance by which the sealing strip is displaced relative to adjacent rotor-side sealing elements as a result of thermal expansions of the stationary and rotating components and support structure when being heated from the cold installed state to a hot steady-state operating condition.

Owner:ANSALDO ENERGIA IP UK LTD

Draining pump

ActiveCN100497948CControl flowLower Edge Noise SuppressionCondensate preventionPump installationsImpellerRefrigeration

The invention relates to a discharge pump used in refrigeration system, which can overcome the defects of present discharge pumps which often depart from designed position, with lower efficiency and large noise. The invention comprises a pump which has an inlet at lower end and an outlet at upper part; a blade wheel inside the pump and a motor rotating the blade wheel. It is characterized in that: said blade wheels comprise main blades, short blades between nearby main blades, a stabilizing ring covering the upper edge of main blades and the outer edge of short blades, and an axial connection part connected with the output axle of motor. Wherein, the main and short blades are radial distributed with the center of the axes of axial connection part; the inner edge of main blade is connected to the axial connection part and the inner edge of short blade is distantly arranged from the axial connection part. The invention can improve the flux, the delivery lift, the flowing property and reduce the noise.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

Tandem blade type mixed-flow or radial-flow turbine

InactiveCN101915126BImprove performanceInhibition of flow separationInternal combustion piston enginesBlade accessoriesMixed flowPulse charge

The invention relates to the technical field of blade type fluid machines, in particular to a tandem blade type mixed-flow or radial-flow turbine comprising a hub, front-row blades and back-row blades, wherein the ratio of the numbers of the tandem blade type front-row Z1 and the numbers of the back-row blades Z2 is 1:1 or 1:2, the ratio variation range of the lengths of the front-row and back-row blades is 0.1-0.5, the variation range of relative circumferential angles between the front edges of the back-row blades and the tail edges of the front-row blades is 0-2 pi / Z1, and the variation range of the distances between the tail edges of the front-row blades and the front edges of the back-row blades is -0.3 to 0.3 of the total blade chord length. By the airflow blowing-down function generated by a gap between the front-row blades and the back-row blades, the flow separation close to the front edges of the blades is restrained, the secondary flow is weakened, the efficient running range is enlarged, and the whole performance of the turbine under undersign conditions and pulse charging conditions is improved.

Owner:TSINGHUA UNIV

A double-suction centrifugal pump impeller and vortex chamber guide device

The invention relates to a double-suction centrifugal pump impeller and a vortex chamber guide device. The invention comprises centrifugal pump volute, blade, impeller guide plate, vortex chamber guide plate, front cover plate, rear cover plate and impeller rotating shaft. The front cover and the rear cover of the impeller are fixed with an impeller deflector between the working surface of the adjacent blade and the back of the blade to guide the liquid flow just entering the impeller. The impeller deflector is welded on the front cover and the rear cover Between, the angle between the tail of the deflector and the outer diameter of the impeller is equal to the blade outlet angle. On the inner wall of the volute of the centrifugal pump, there are vortex deflectors distributed at unequal angles along the Archimedes spiral. The combination guide device of the impeller and the volute proposed by the invention can greatly improve the operating efficiency of the pump.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com