Patents

Literature

224results about How to "Inhibition of flow separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

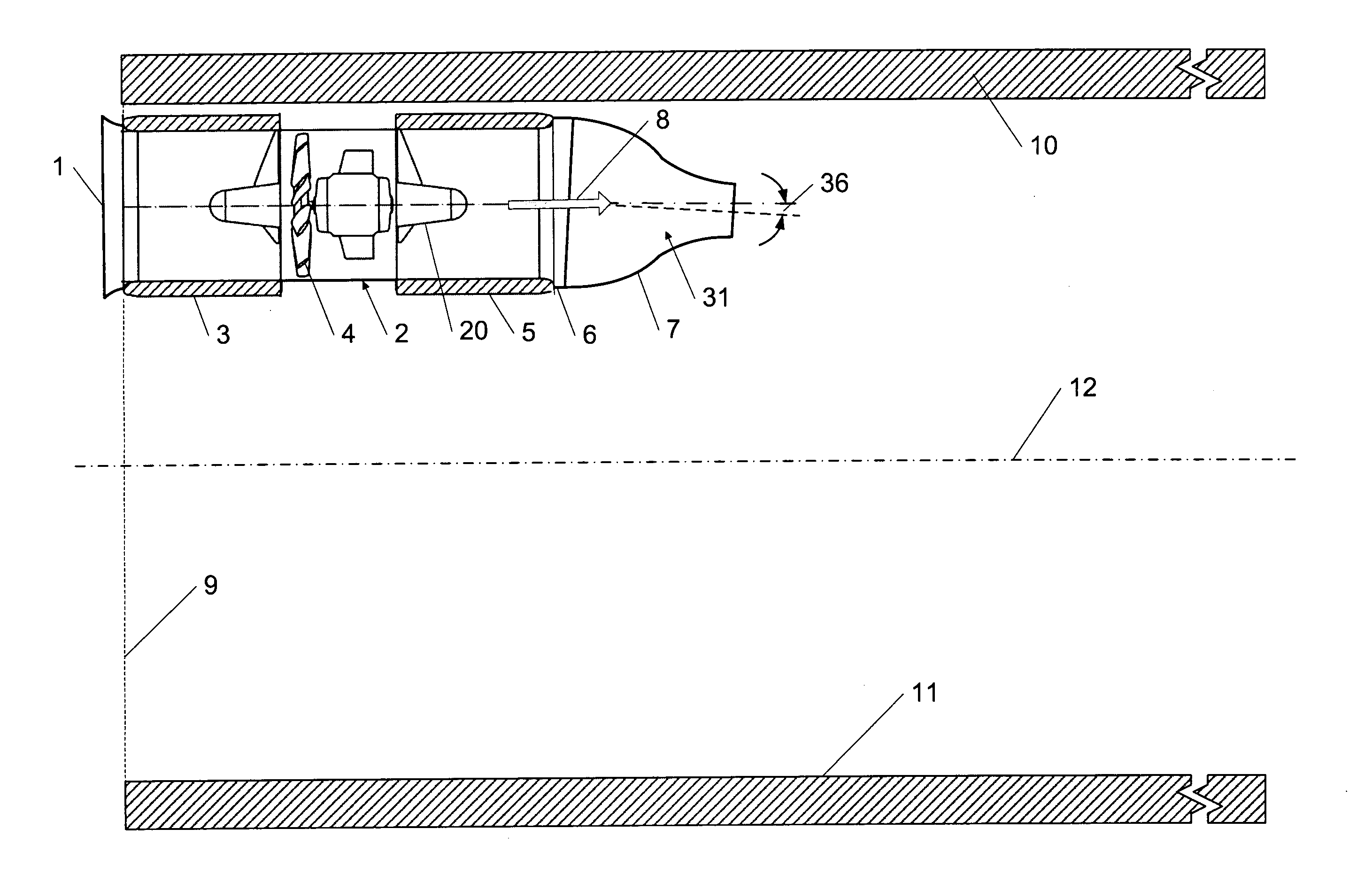

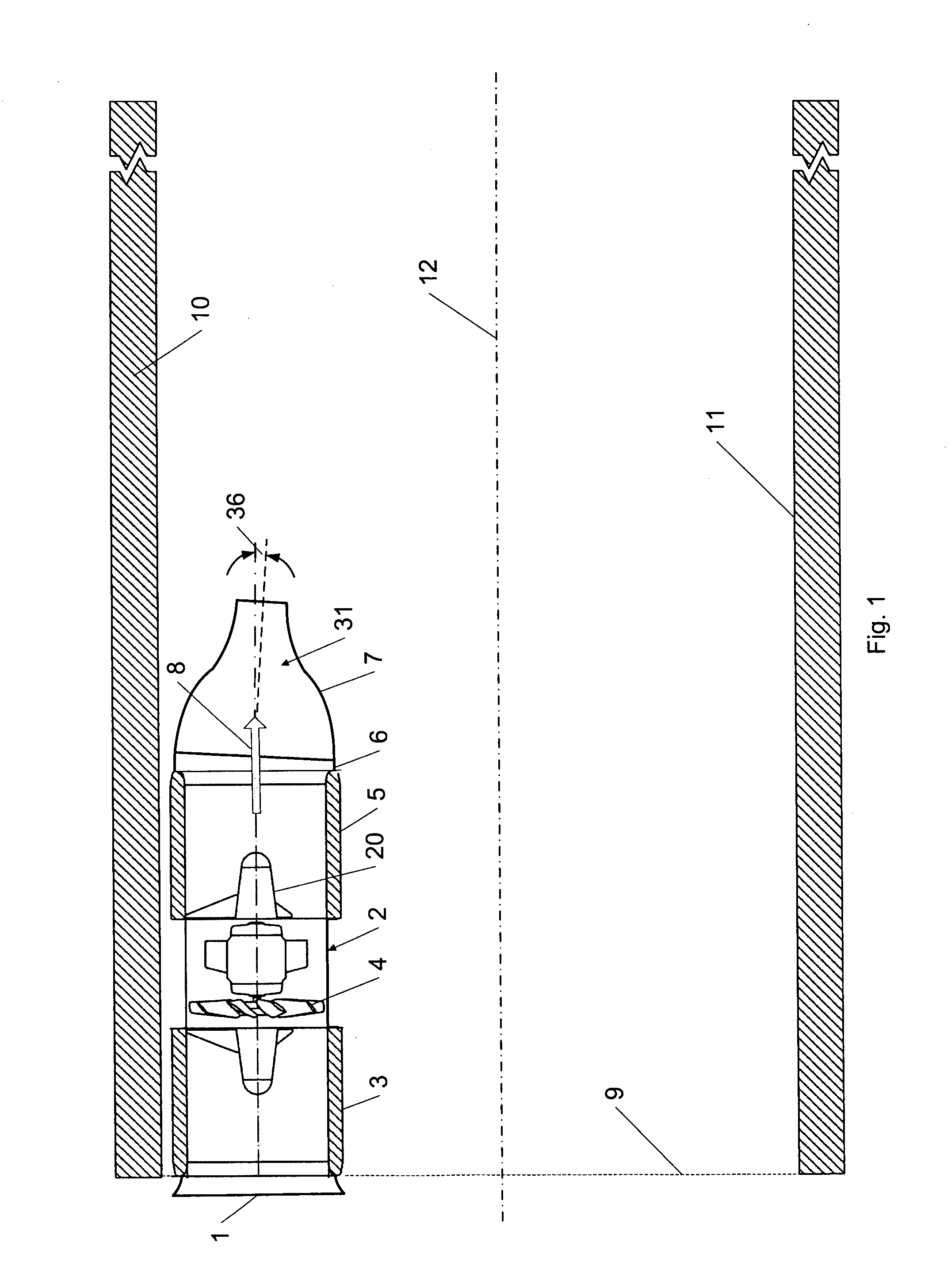

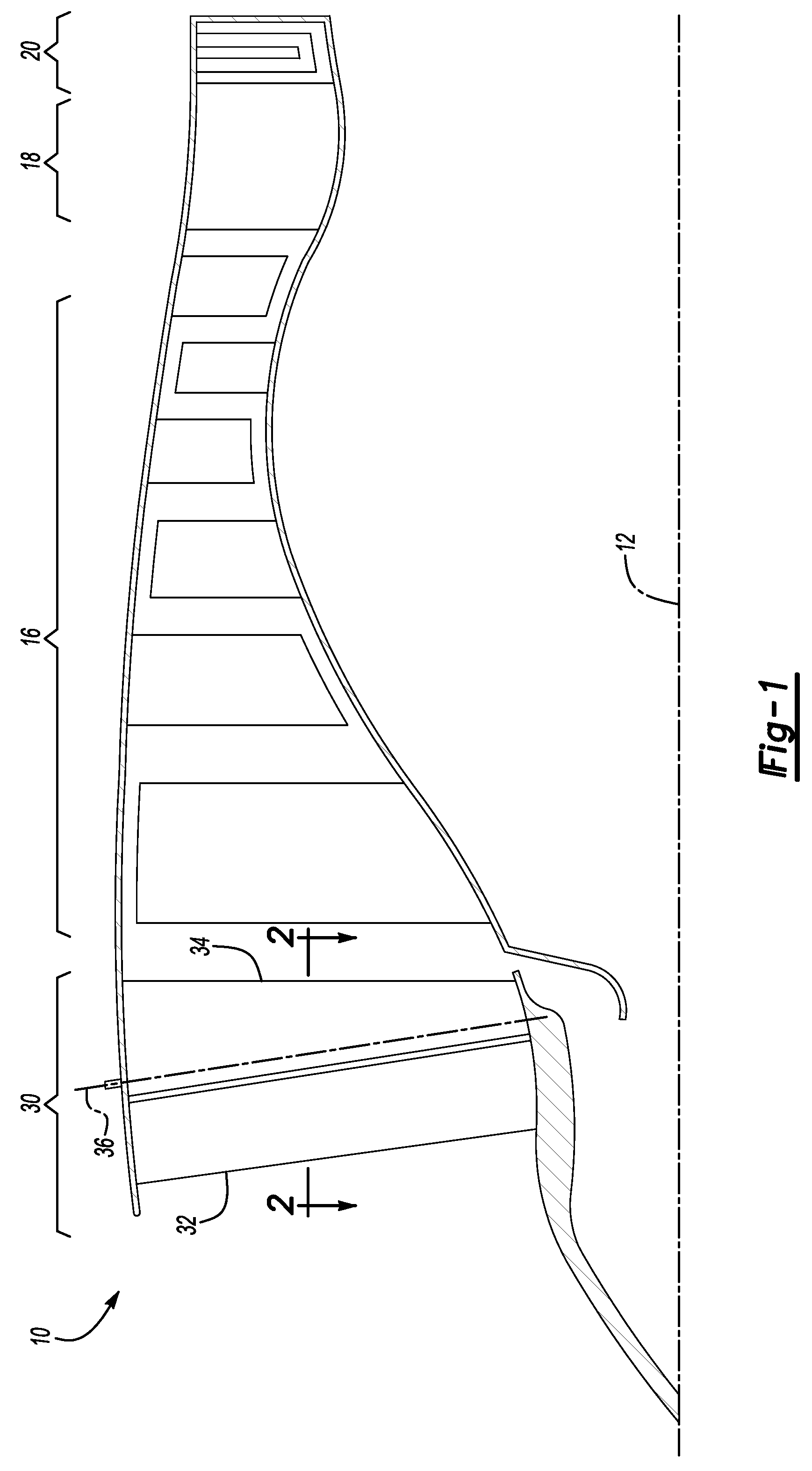

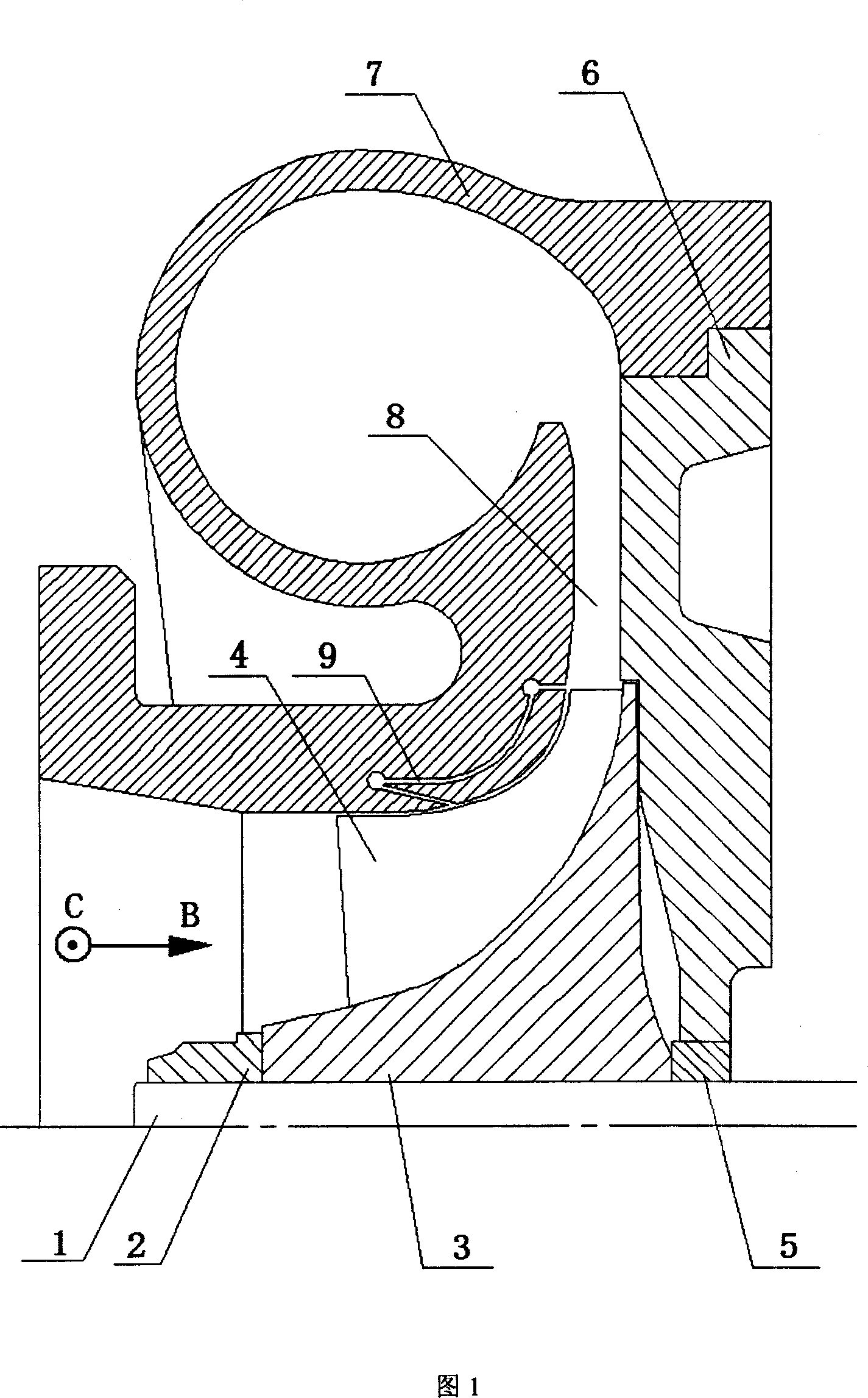

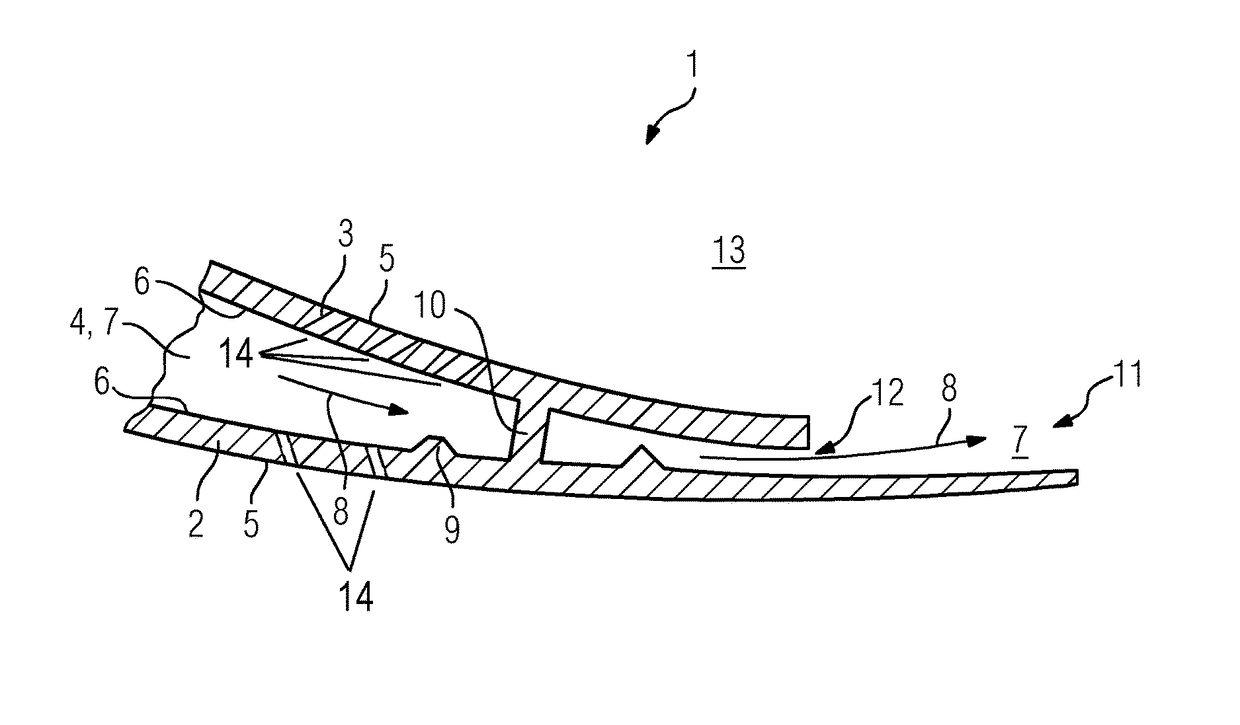

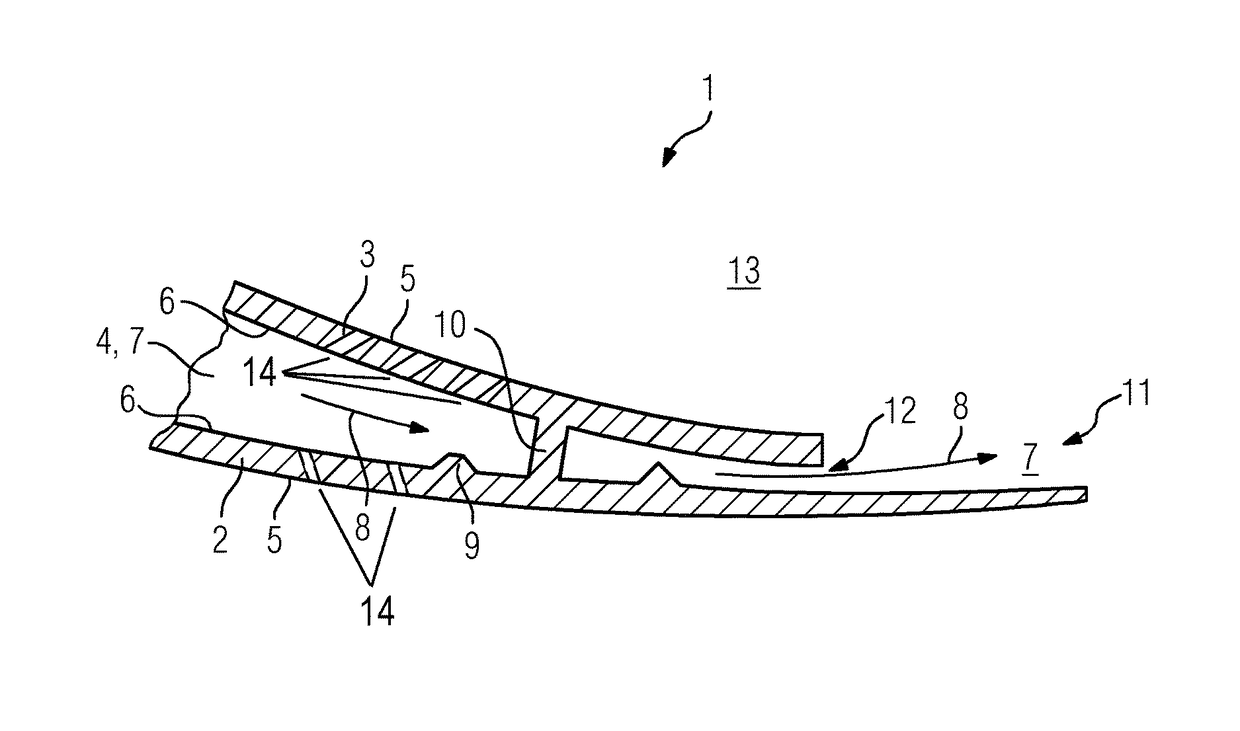

Improved tunnel ventilation device

InactiveUS20110275302A1Avoid flowInhibition of flow separationDucting arrangementsPump componentsAbsorbent materialTrailing edge

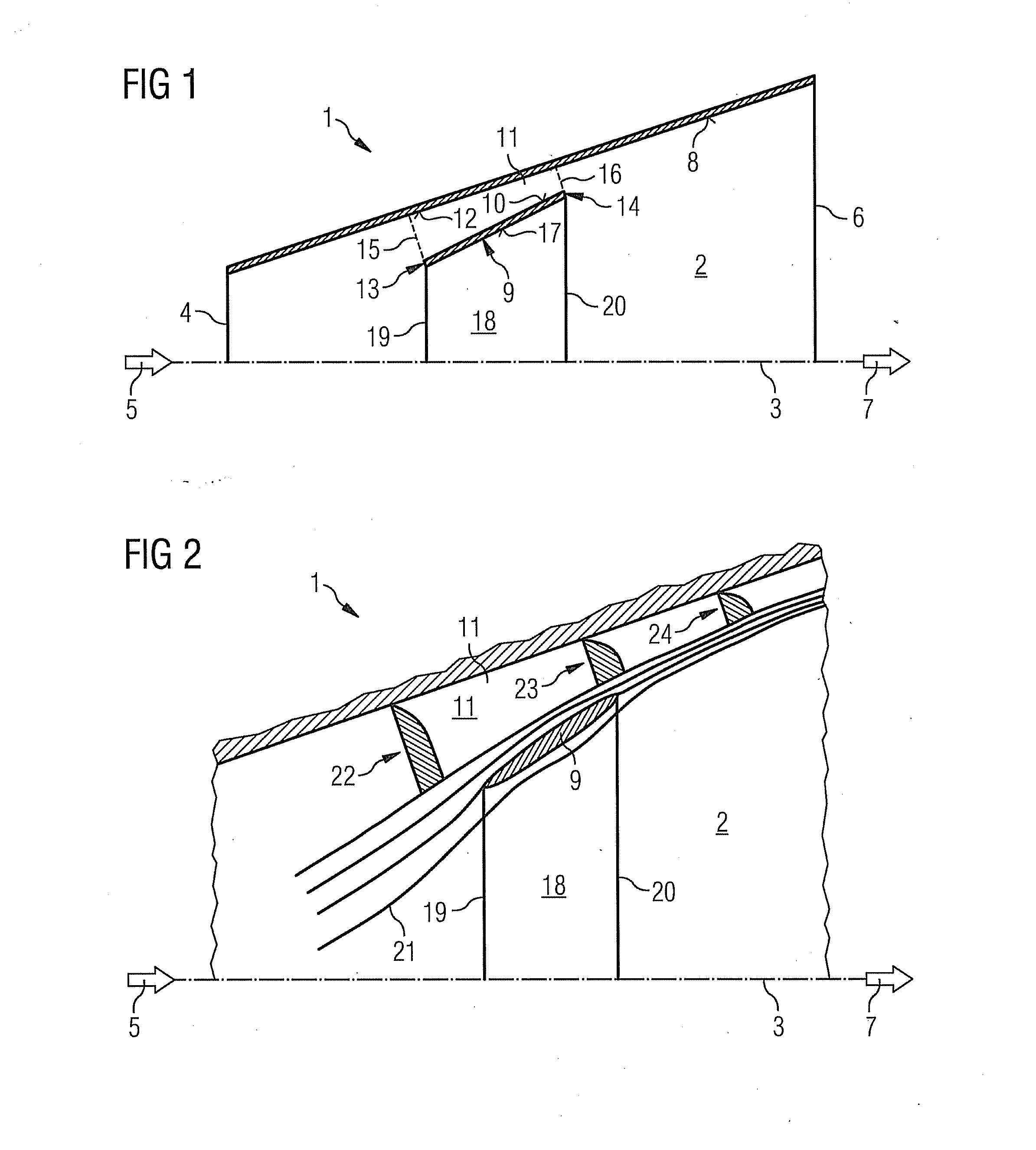

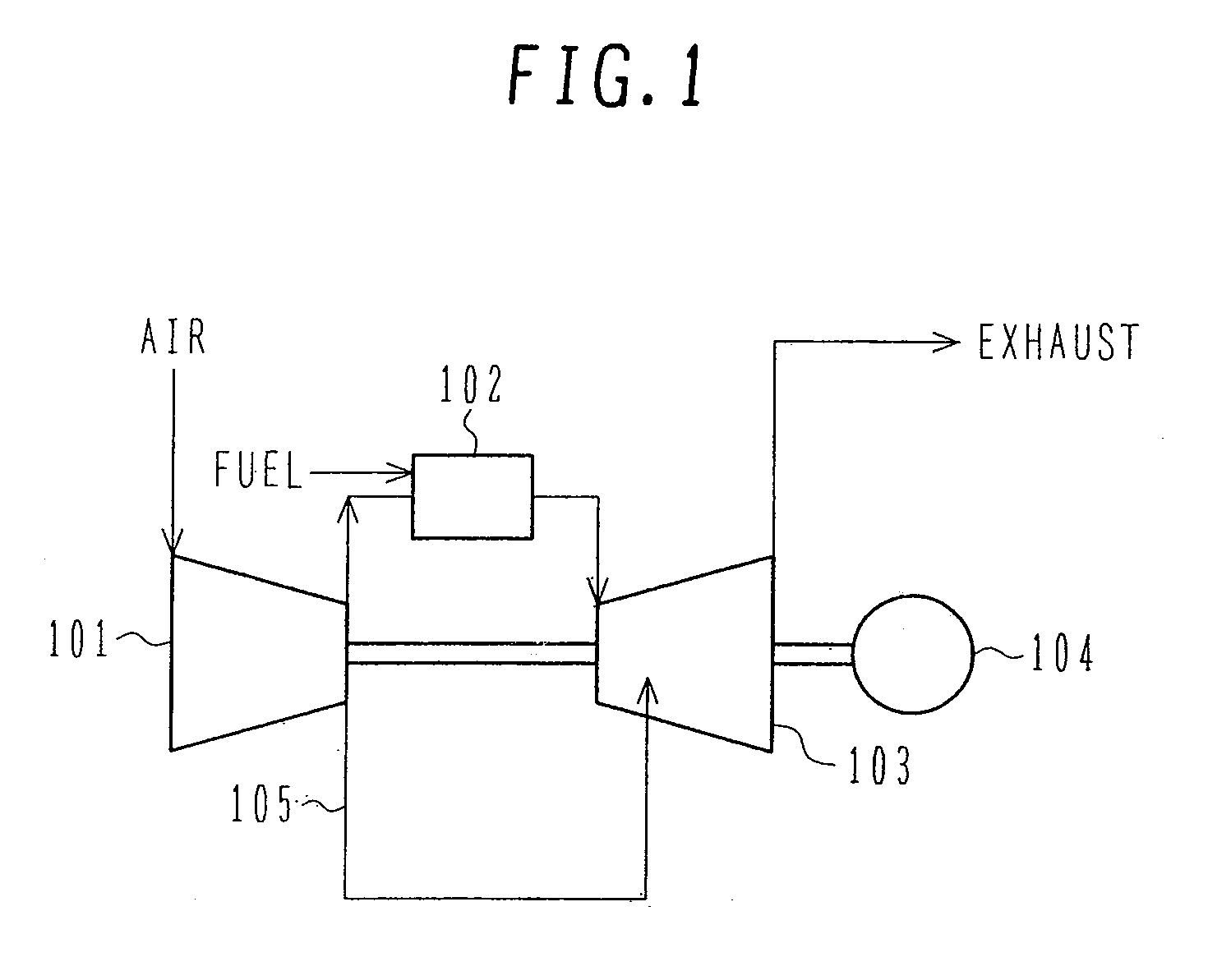

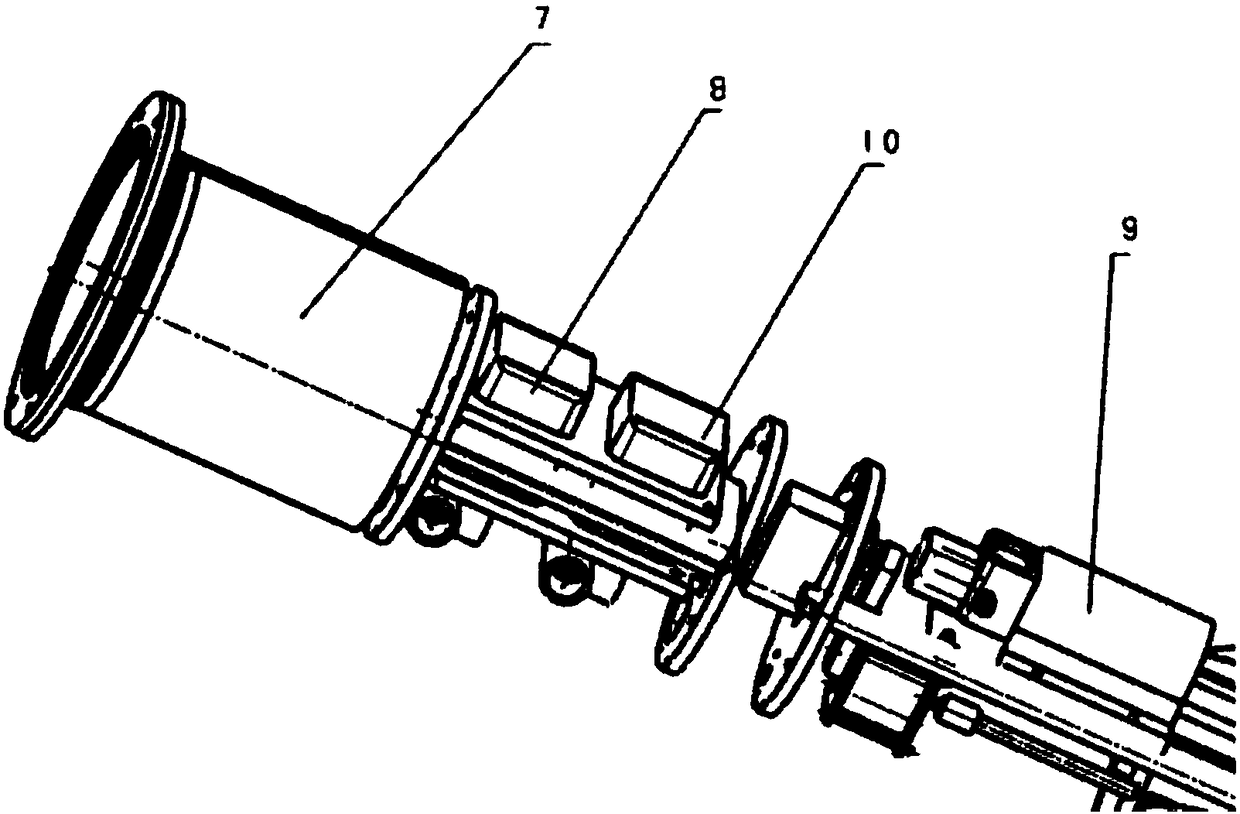

A ventilation device that enhances the longitudinal thrust of a fan (2) installed within a tunnel, by the introduction of a convergent nozzle (7) to accelerate the outlet flow (8). An angled transition piece (6) can turn the flow by a specific angle (36). Multiple fans can be connected to common inlet and outlet plenums, supplying one or more convergent nozzles. Bi-directional flow can be achieved by fitting convergent nozzles to both sides of a fan, with bypass dampers optionally installed between the fan and the two nozzles. The nozzle trailing edge can be shaped with multiple lobes, chevrons or tongues, and the fan centre-body can be shaped with multiple lobes. A fire suppression agent such as water mist can be supplied into the ductwork between the fan and the nozzle trailing edge. Acoustic silencing can be achieved using the absorbent material on the nozzle and fan centre-body.

Owner:MOSEN

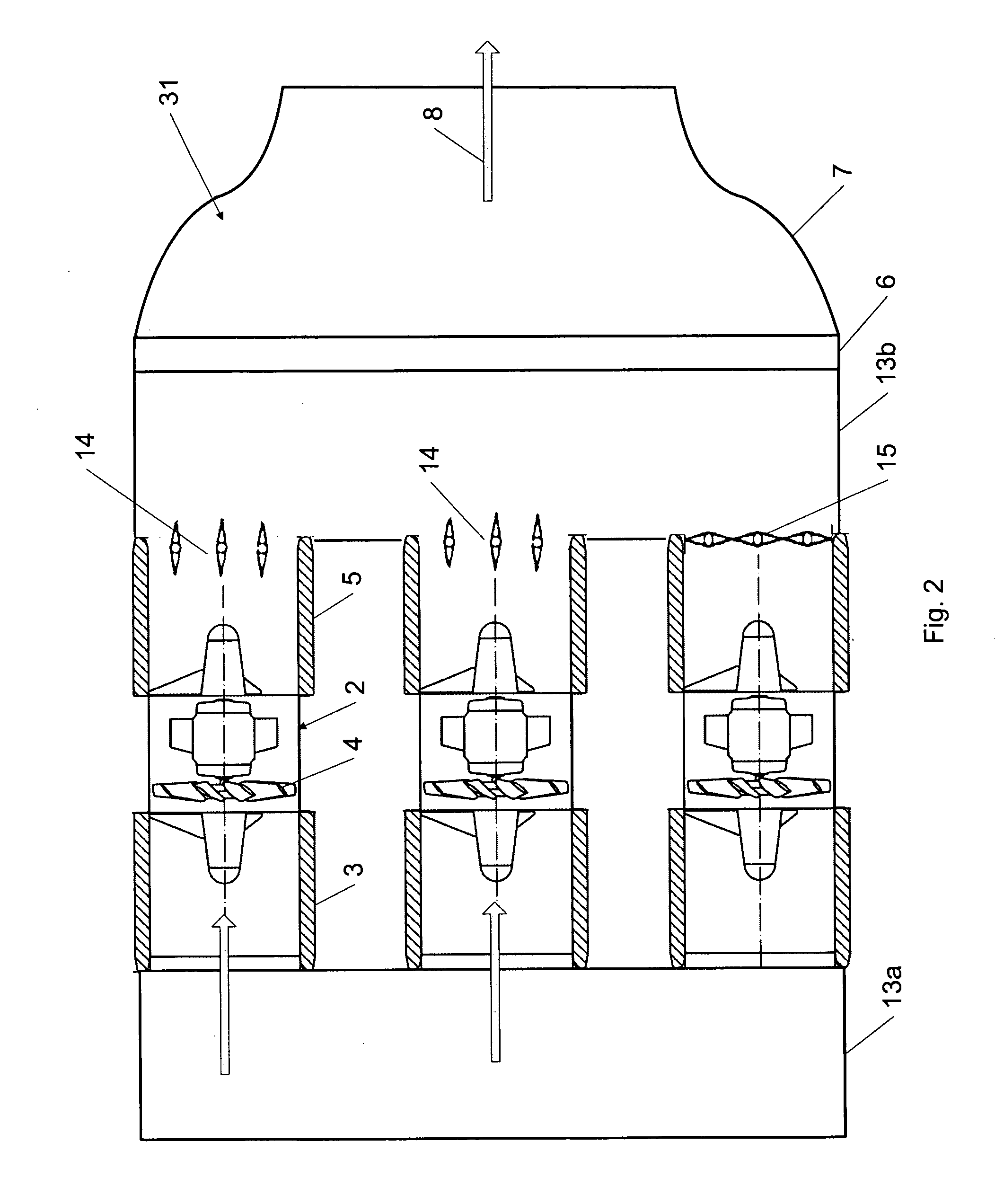

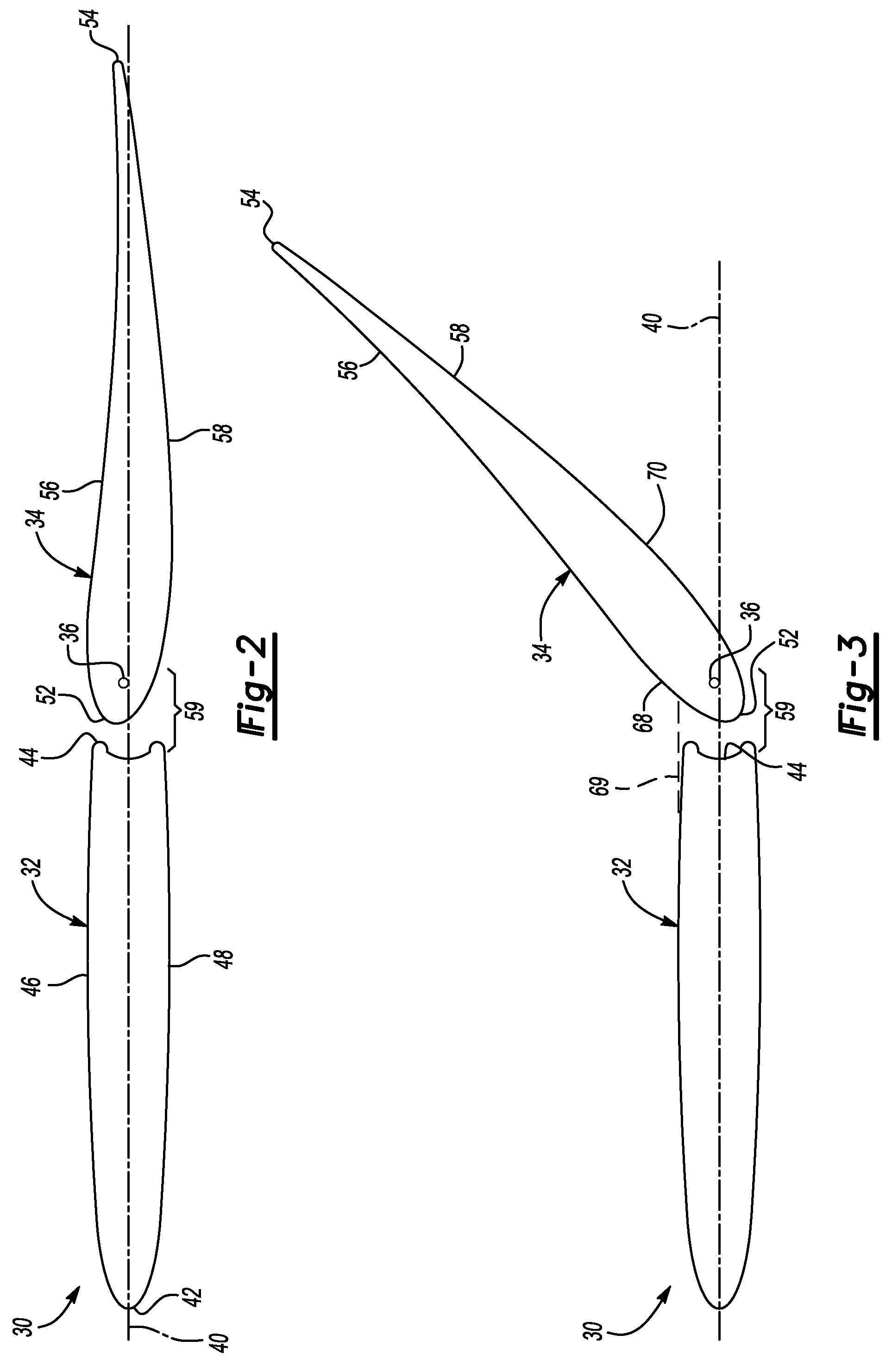

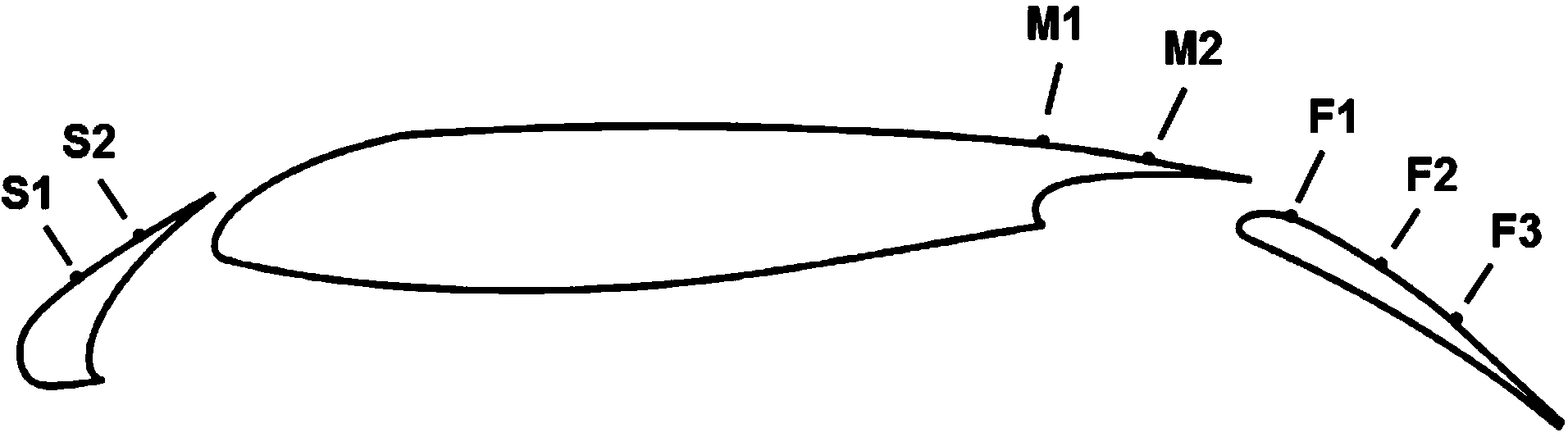

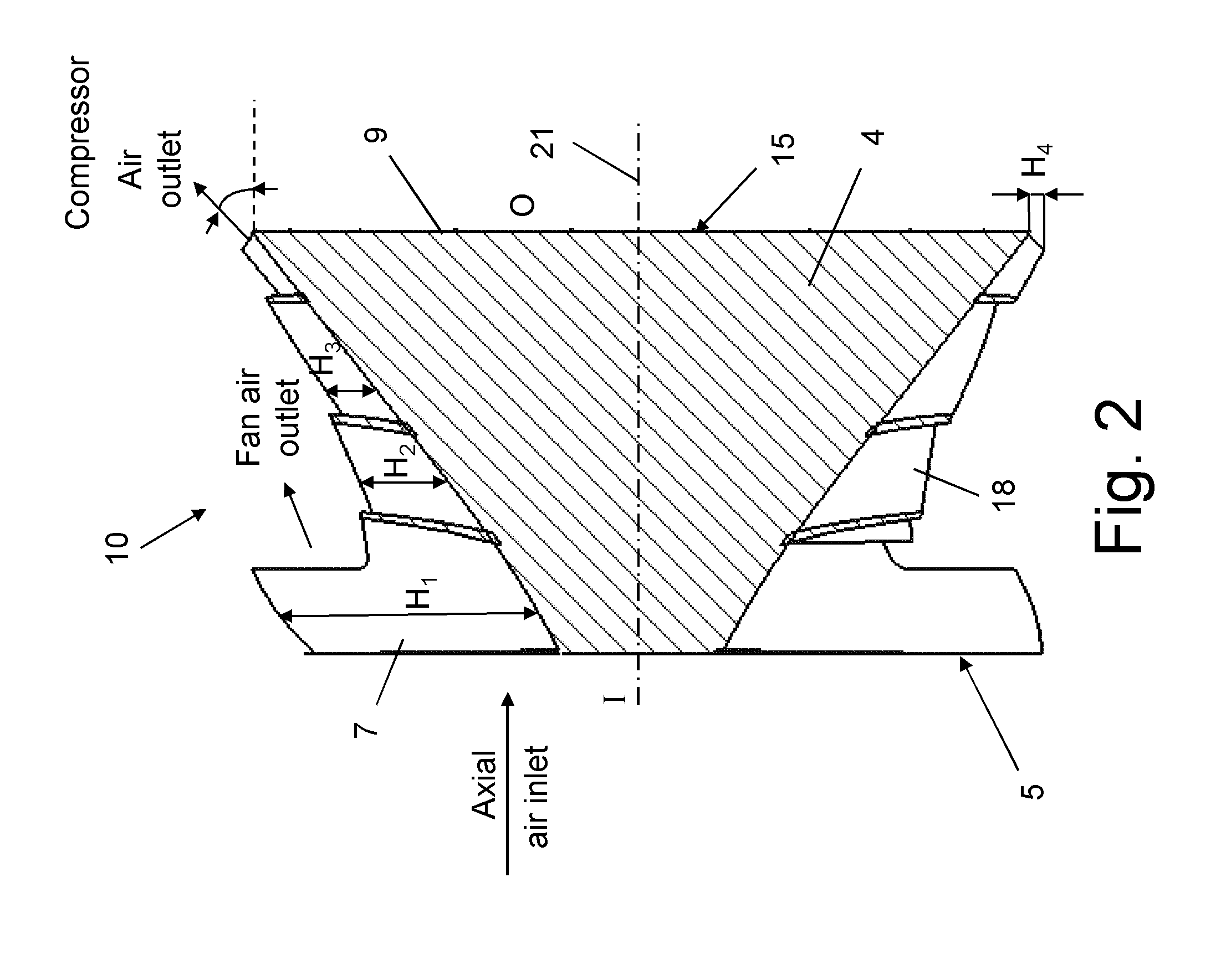

Variable geometry inlet guide vane

ActiveUS7549839B2Inhibition of flow separationHigh trafficPump componentsWind motor controlLeading edgeMomentum

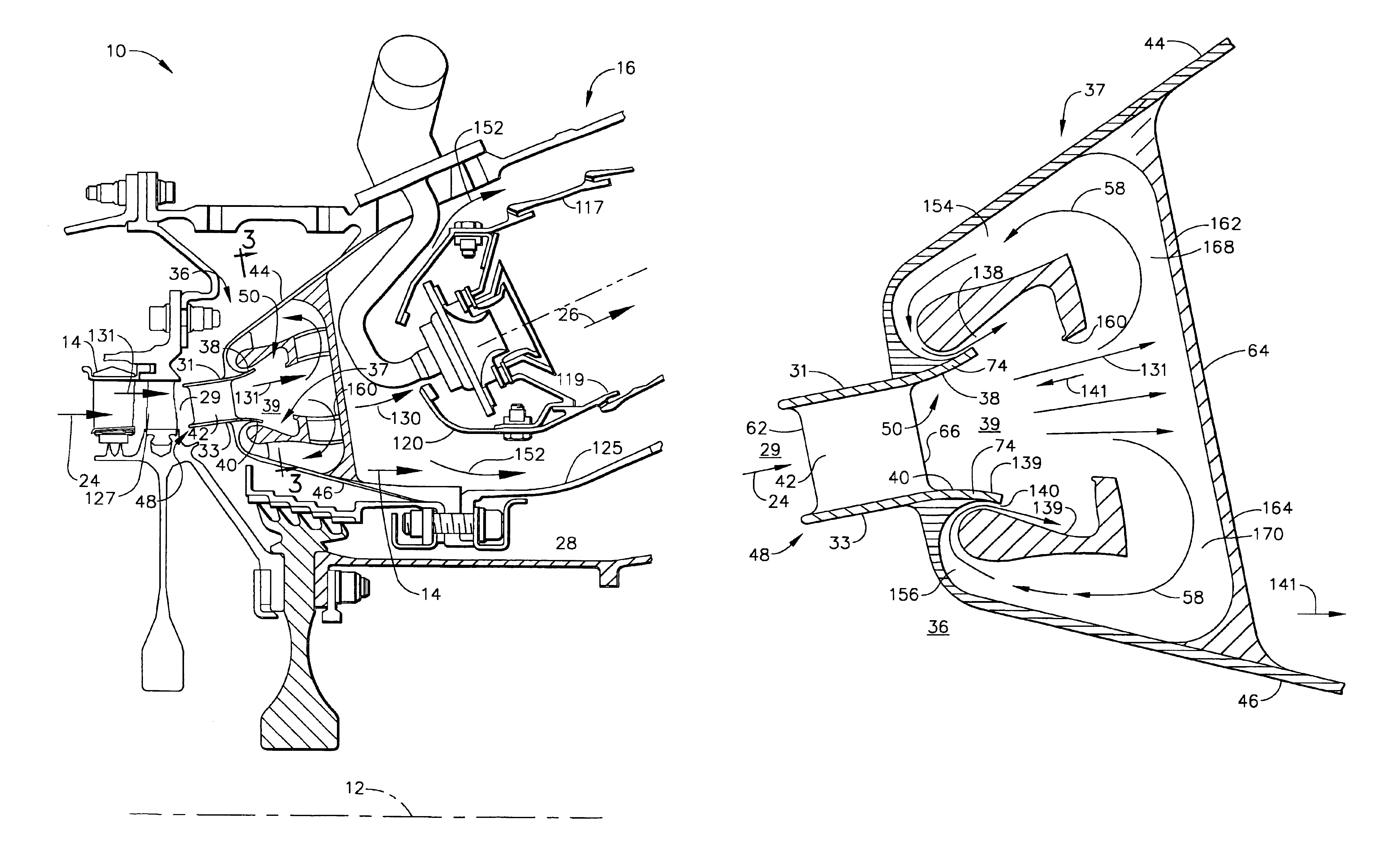

An inlet guide vane provides improved, smooth airflow and avoids separation of flow even at high incidence angles. The inlet guide vane includes a strut having opposite side surfaces that are continuously curved to provide a controlled velocity distribution at the trailing edge of the strut. The inlet guide vane further includes a flap having a leading edge aligned behind the trailing edge of the strut. Generally, the strut and the flap are designed together so that low momentum air in the gap between the strut and the flap will be energized and entrained in the boundary layer of the flap. The airflow from the gap will remain attached to the flap to improve the flow from the flap.

Owner:RTX CORP

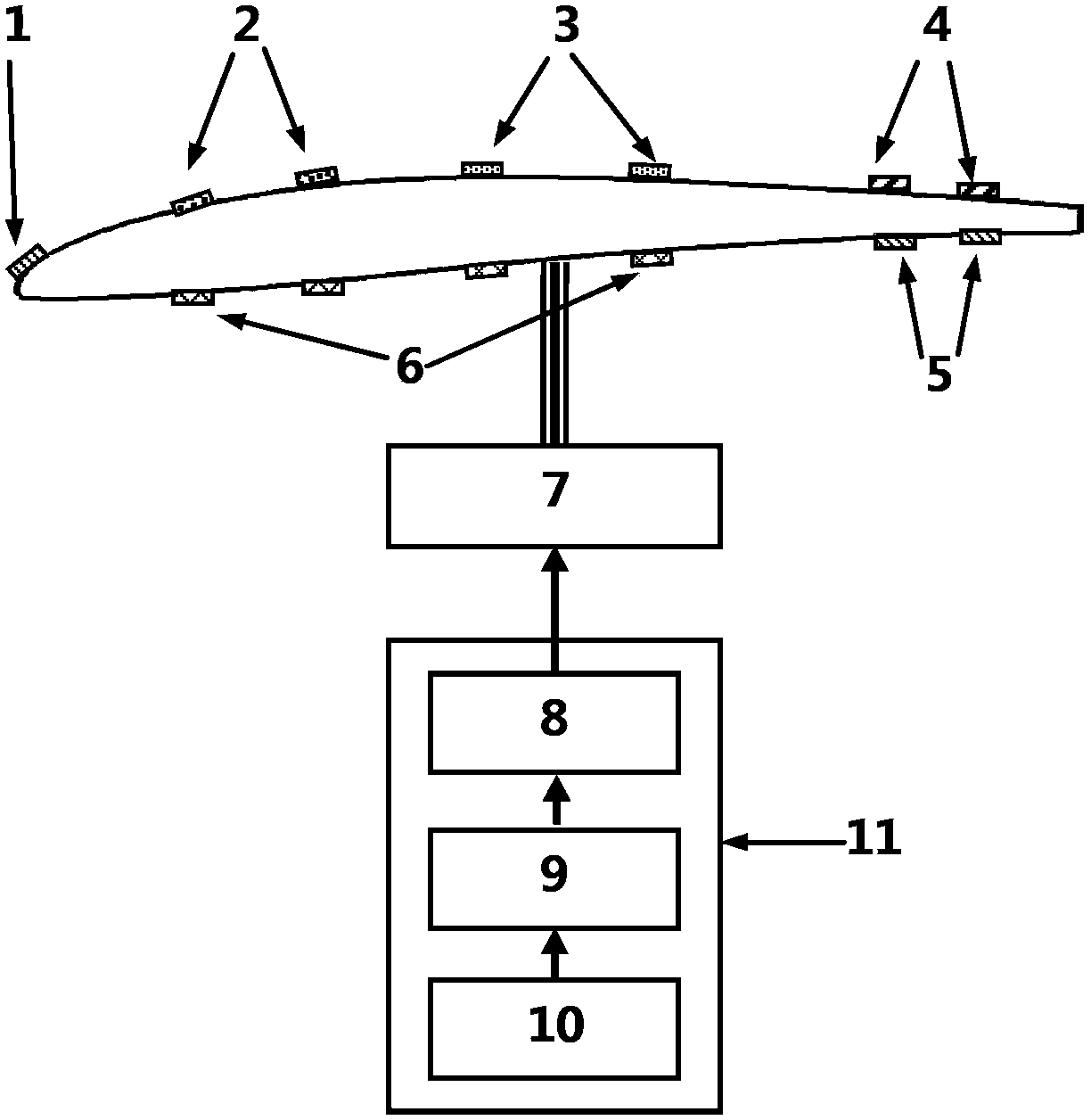

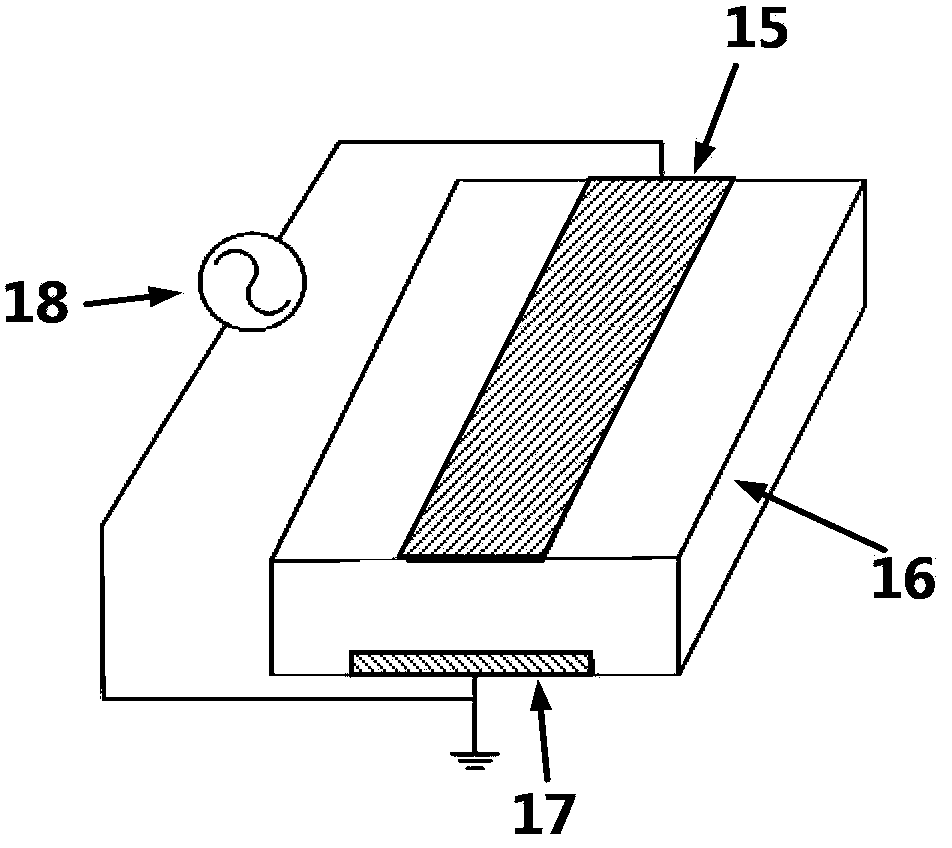

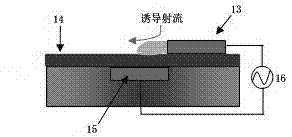

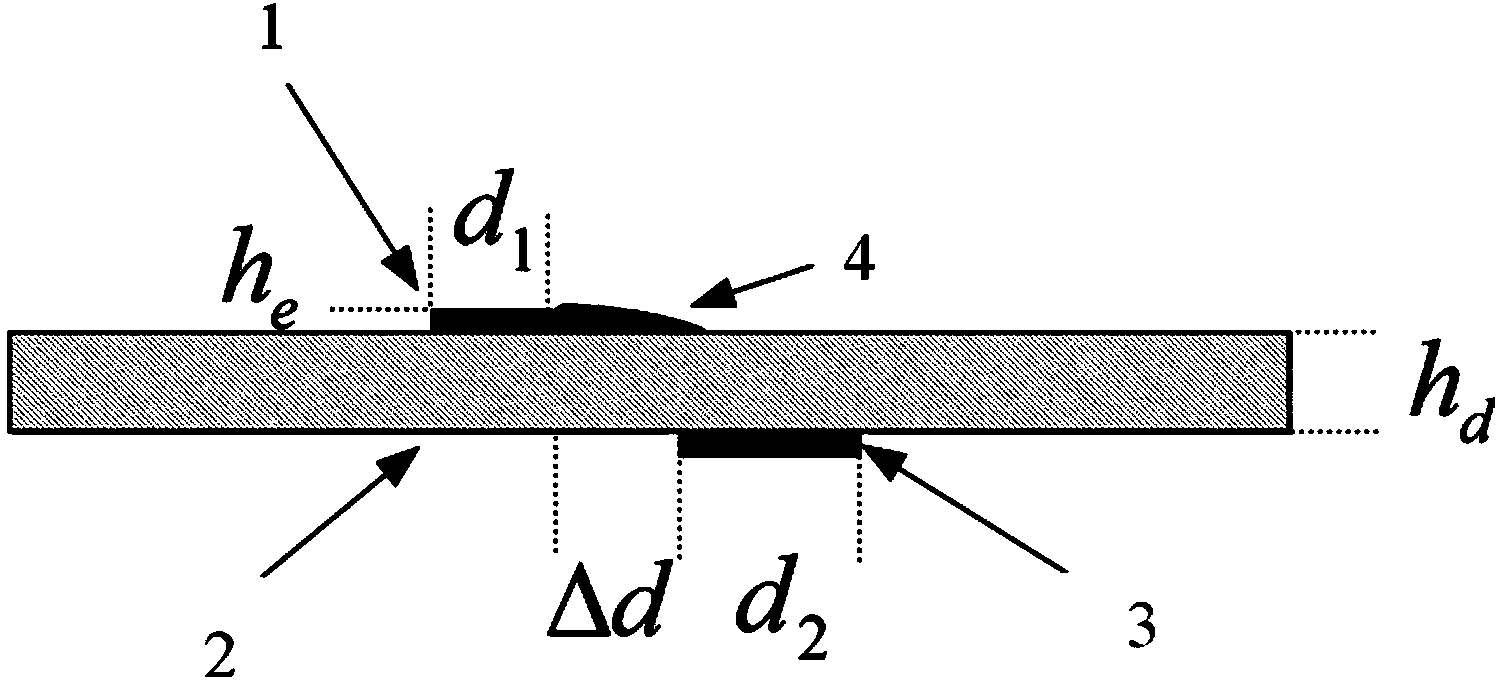

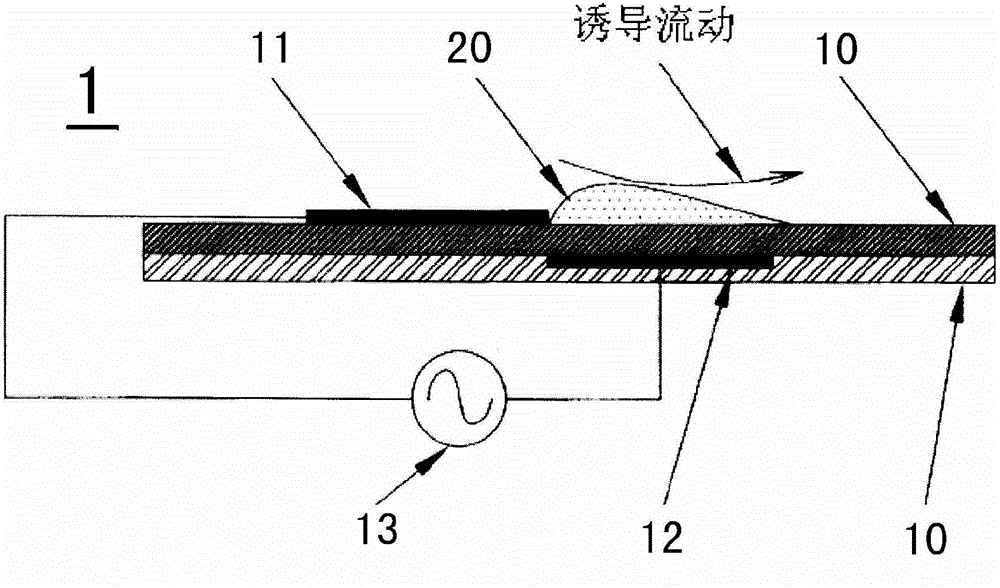

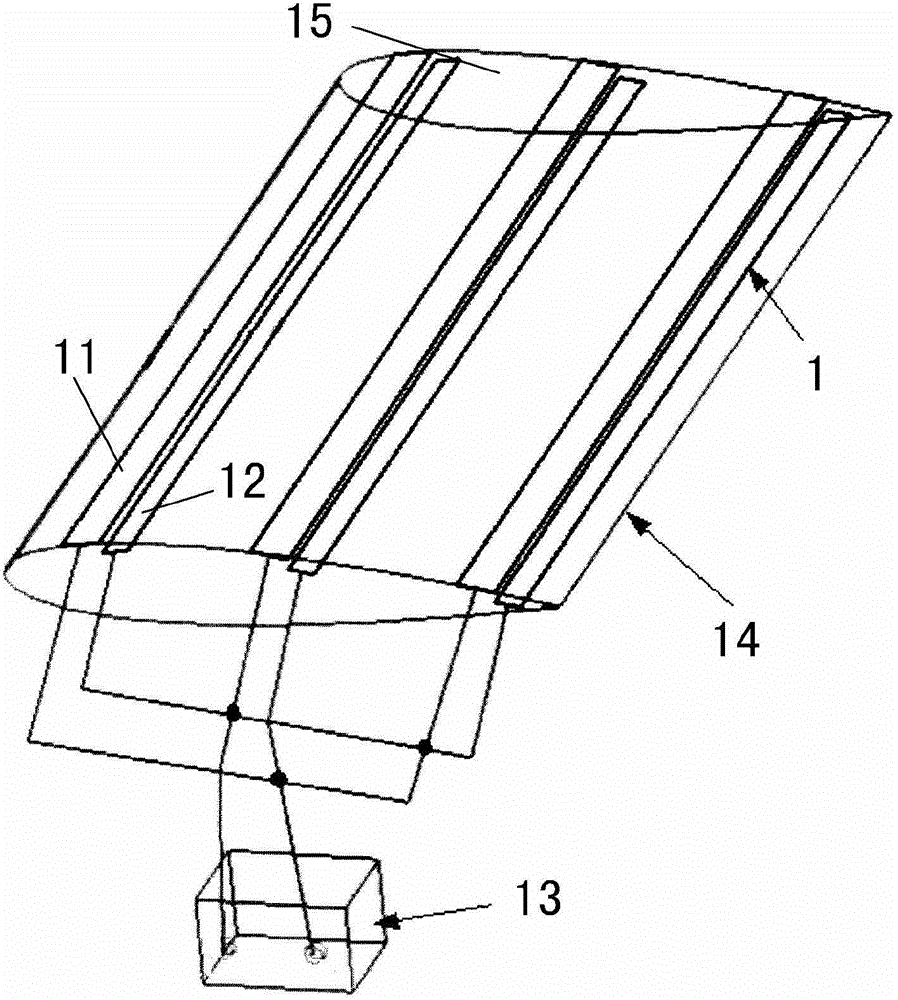

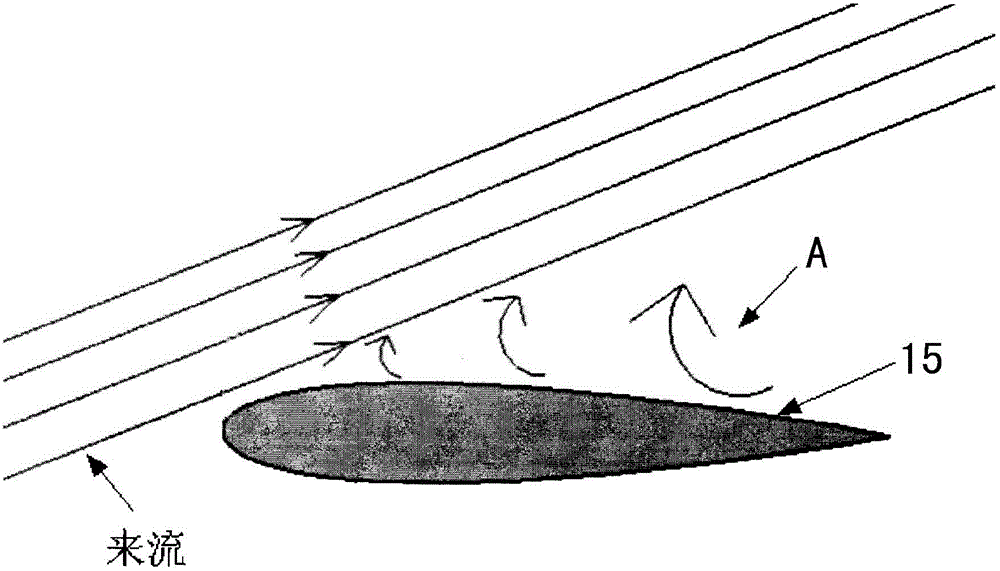

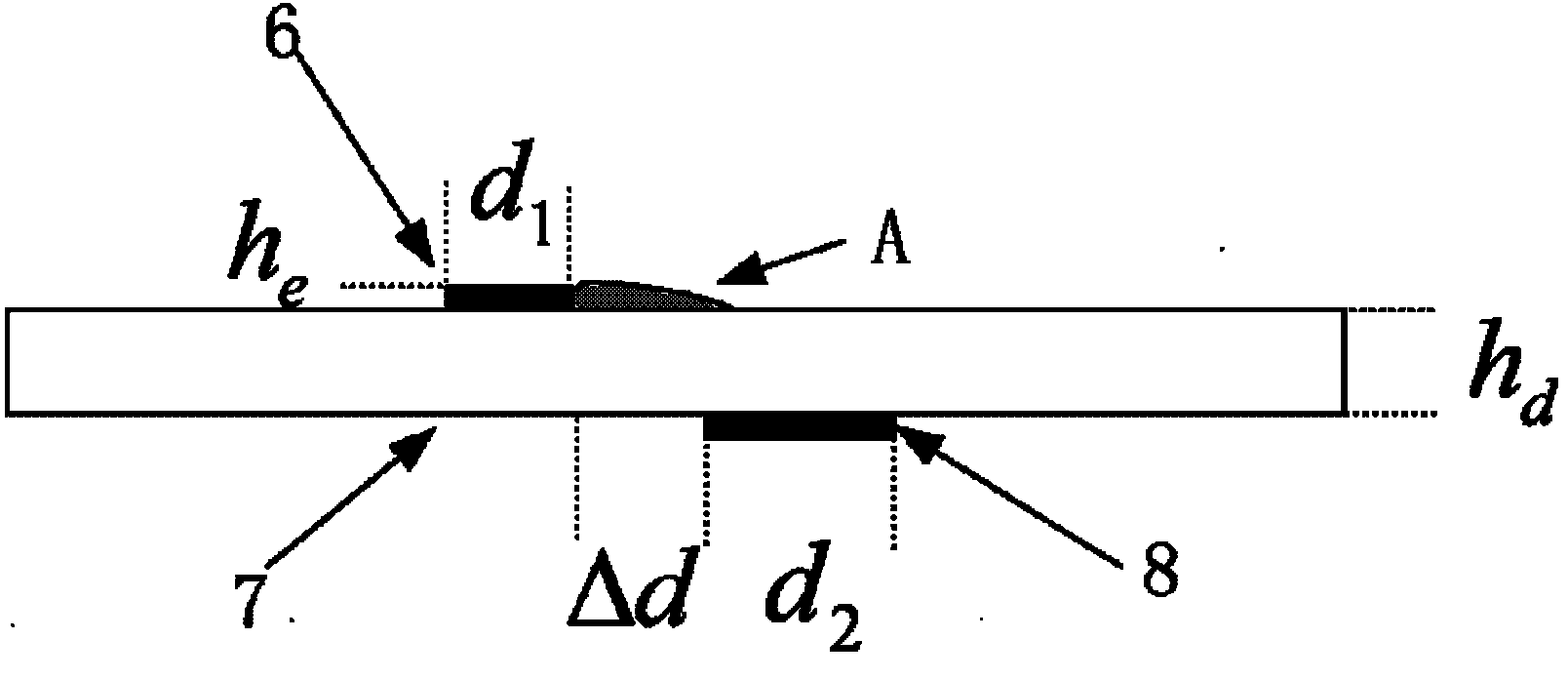

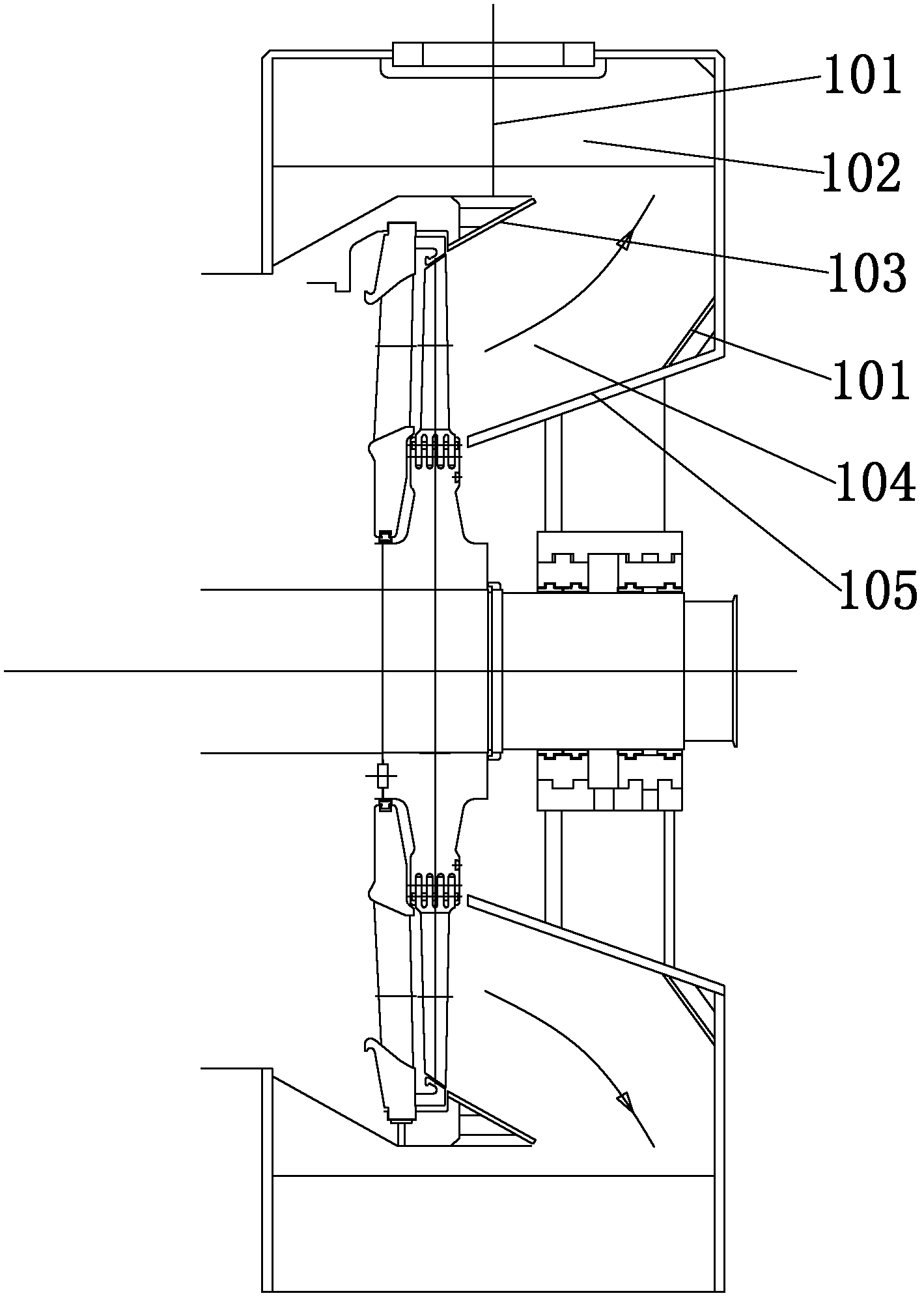

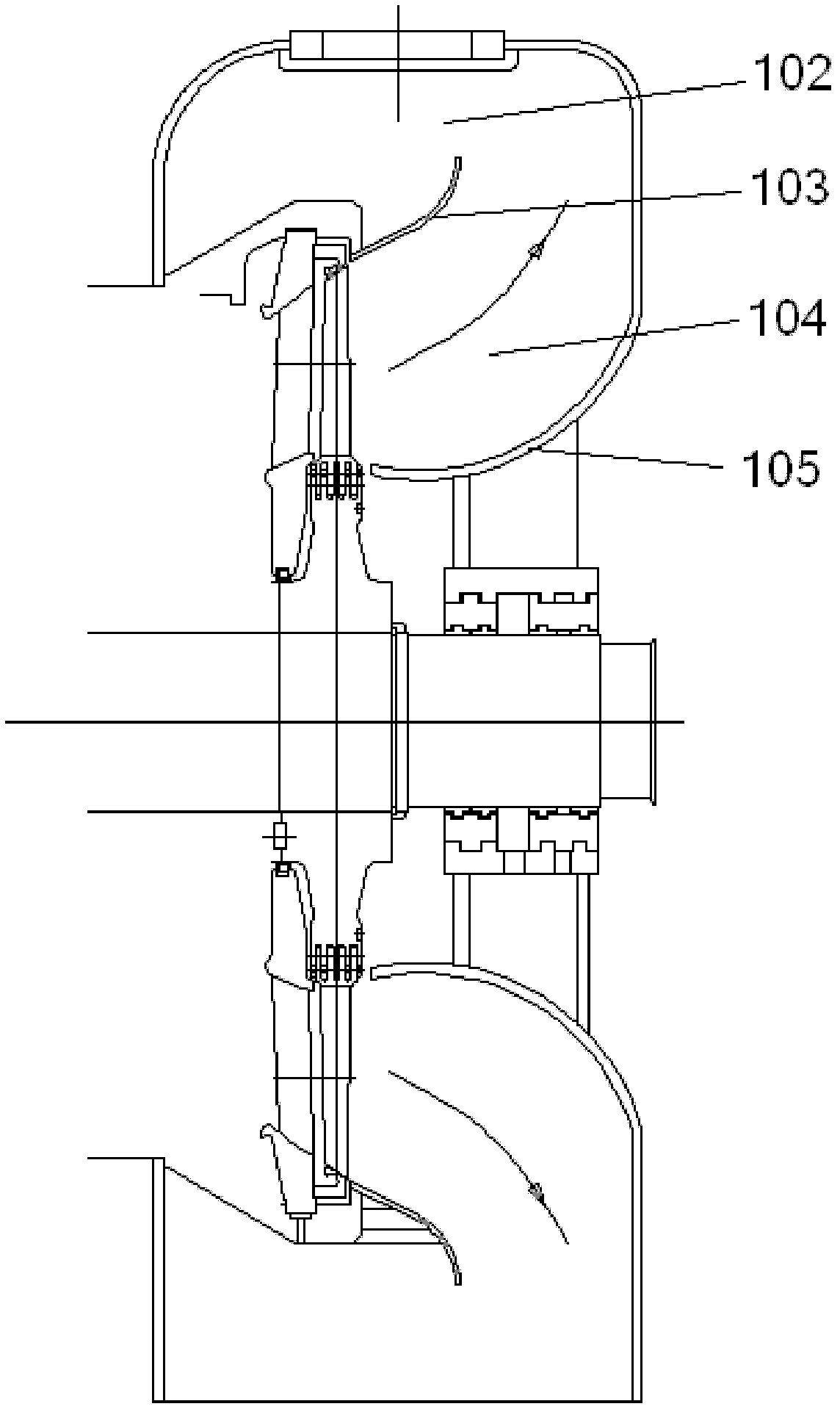

Plasma control device and method for blades of wind driven generator

ActiveCN103410680AHigh energyInhibition of flow separationWind motor controlMachines/enginesWind drivenPlasma control

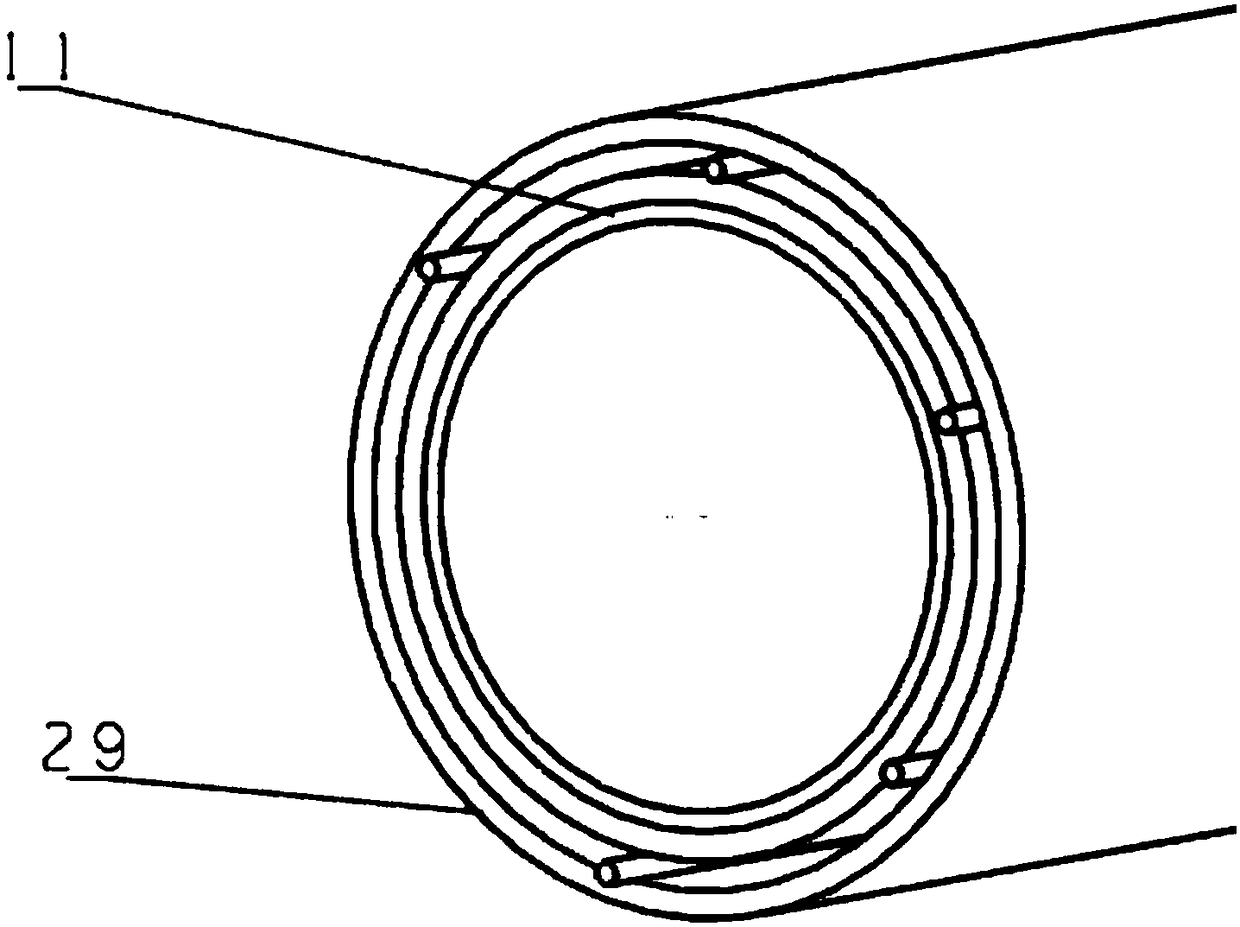

Disclosed are a plasma control device and method for blades of a wind driven generator. A plasma exciter is composed of an exposed electrode, an implantation electrode and a medium blocking layer, wherein the exposed electrode and the implantation electrode are pasted to the upper surface and the lower surface of the medium blocking layer respectively; the exposed electrode is exposed in air and connected with the high pressure end of an excitation power supply (7); the surface of the implantation electrode is wrapped by insulation materials, and the implantation electrode is connected with a ground electrode. The plasma exciter is installed on the surfaces of the blades of the wind driven generator smoothly. According to the environment where the wind driven generator is located and freezing parameters of the surfaces of the blades, a control system (11) adjusts the output waveform, potential, frequency and duty ratio of the excitation power supply (7), and controls the excitation power supply to be opened and closed. The plasma exciter produces air discharge under the action of the high voltage of the excitation power supply (7), produced plasma has the impact function, the acceleration function and the heating function on ambient air, flow separation on the surfaces of the blades of the wind driven generator is restrained, and icing is prevented and removed.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

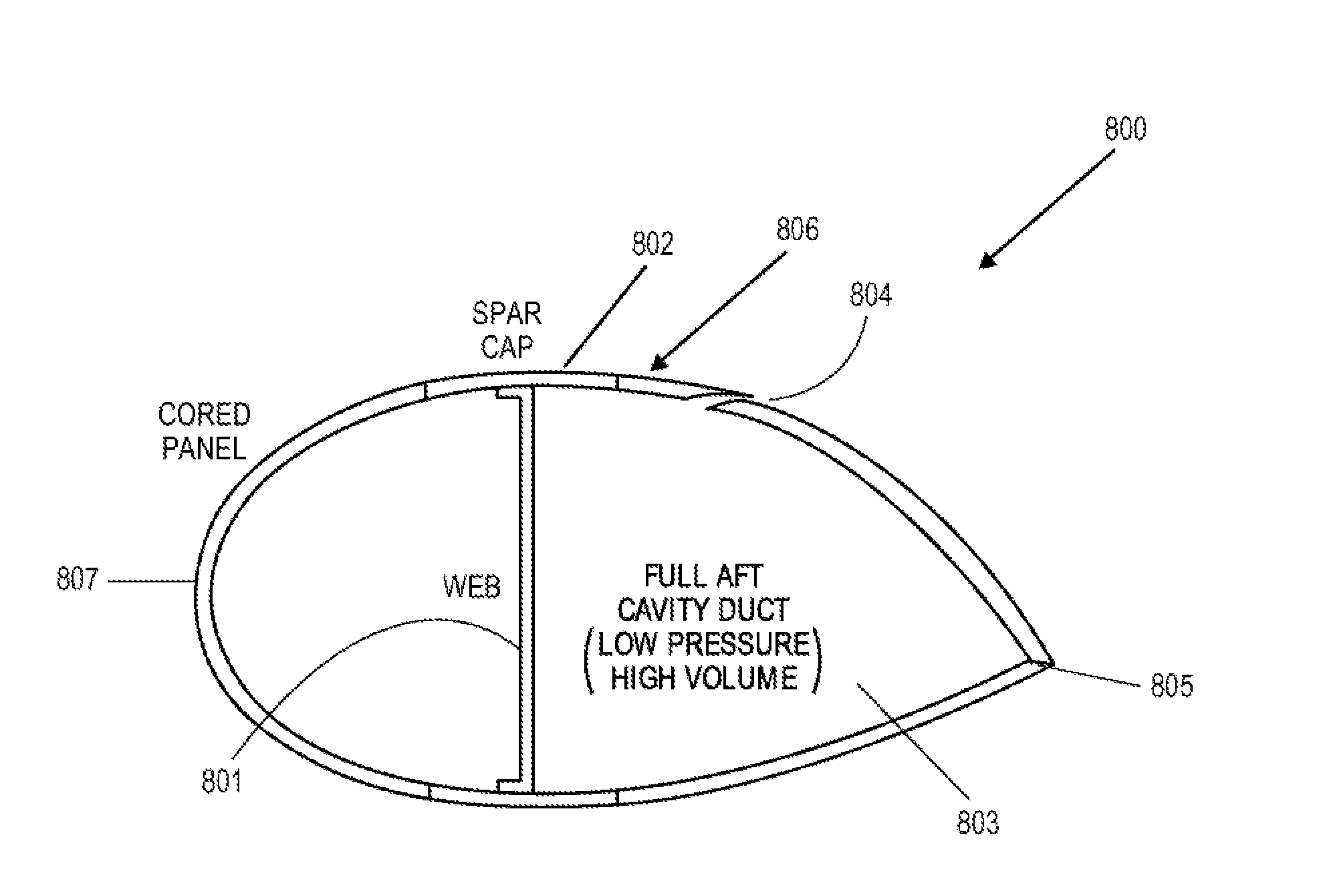

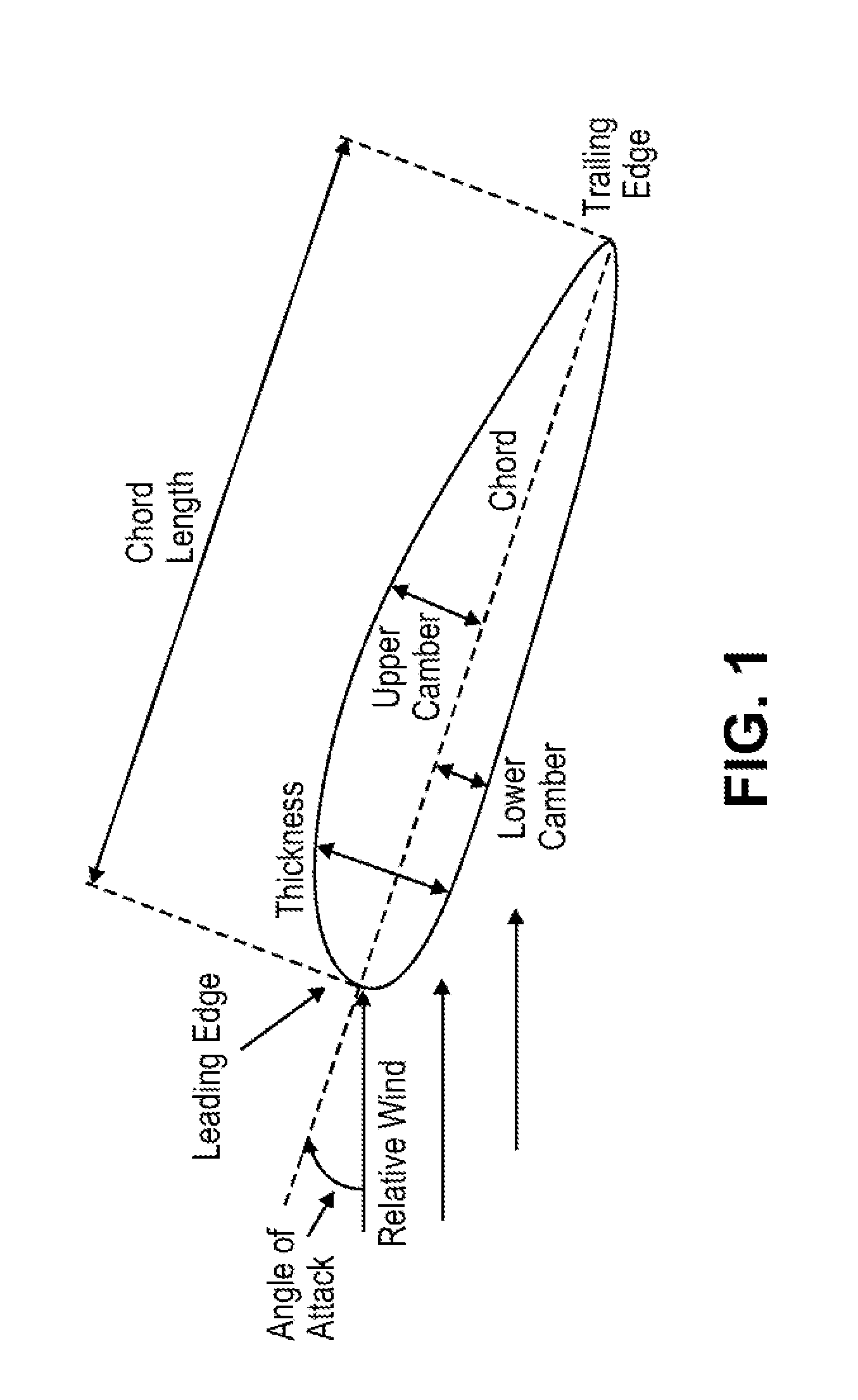

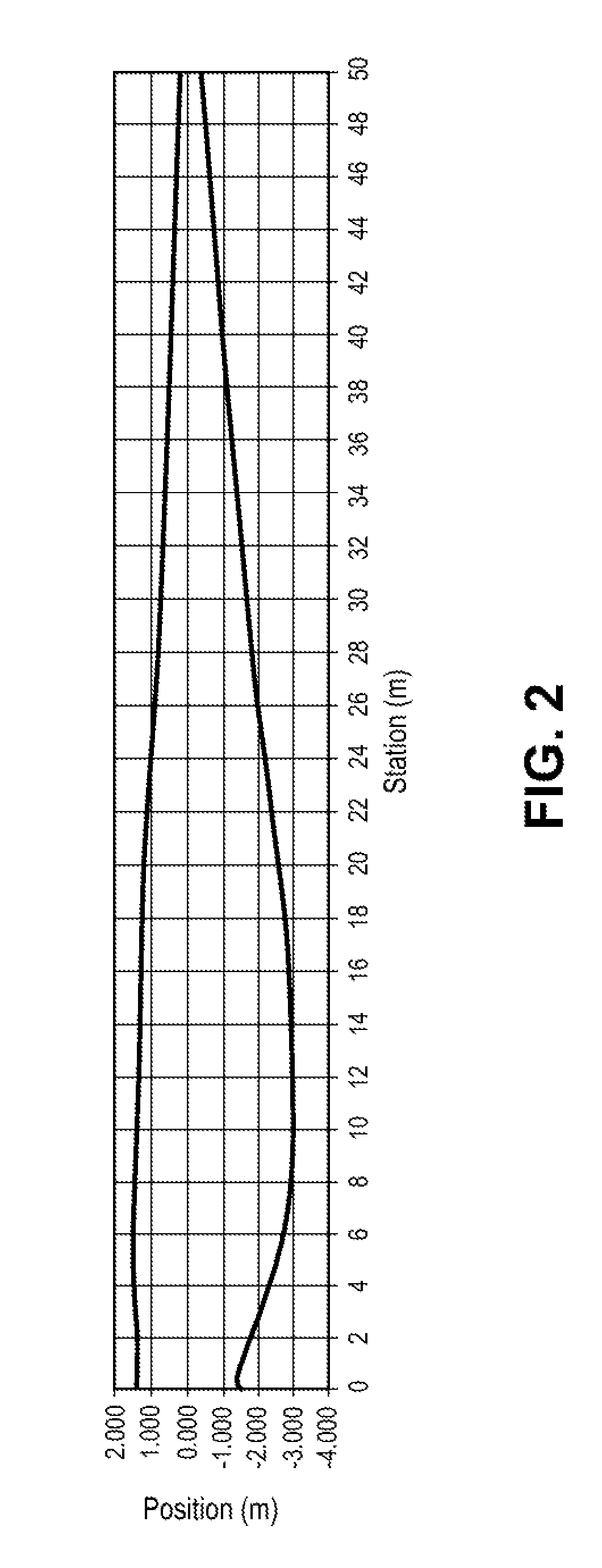

Turbine blades, systems and methods

InactiveUS20120020803A1Energy efficiencyImprove efficiencyPropellersWind motor controlLeading edgeTurbine blade

A blade for use in a wind turbine comprises a pressure side and suction side meeting at a trailing edge and leading edge, the pressure side having a pressure side surface and the suction side having a suction side surface, the pressure side surface and suction side surface for providing lift to the turbine blade upon the flow of air from the leading edge to the trailing edge and over the pressure side and suction side surfaces, the pressure side and suction side extending from a root portion to a tip portion of the turbine blade. In some situations, the root portion is non-aerodynamic. The aerodynamics of such a blade is improved with the aid of pneumatic blowing through one or more blown passages for providing pressurized air (or other fluid) to a suction side and / or pressure side of the blade.

Owner:PAUL LEES DBA MACH 2 WIND +2

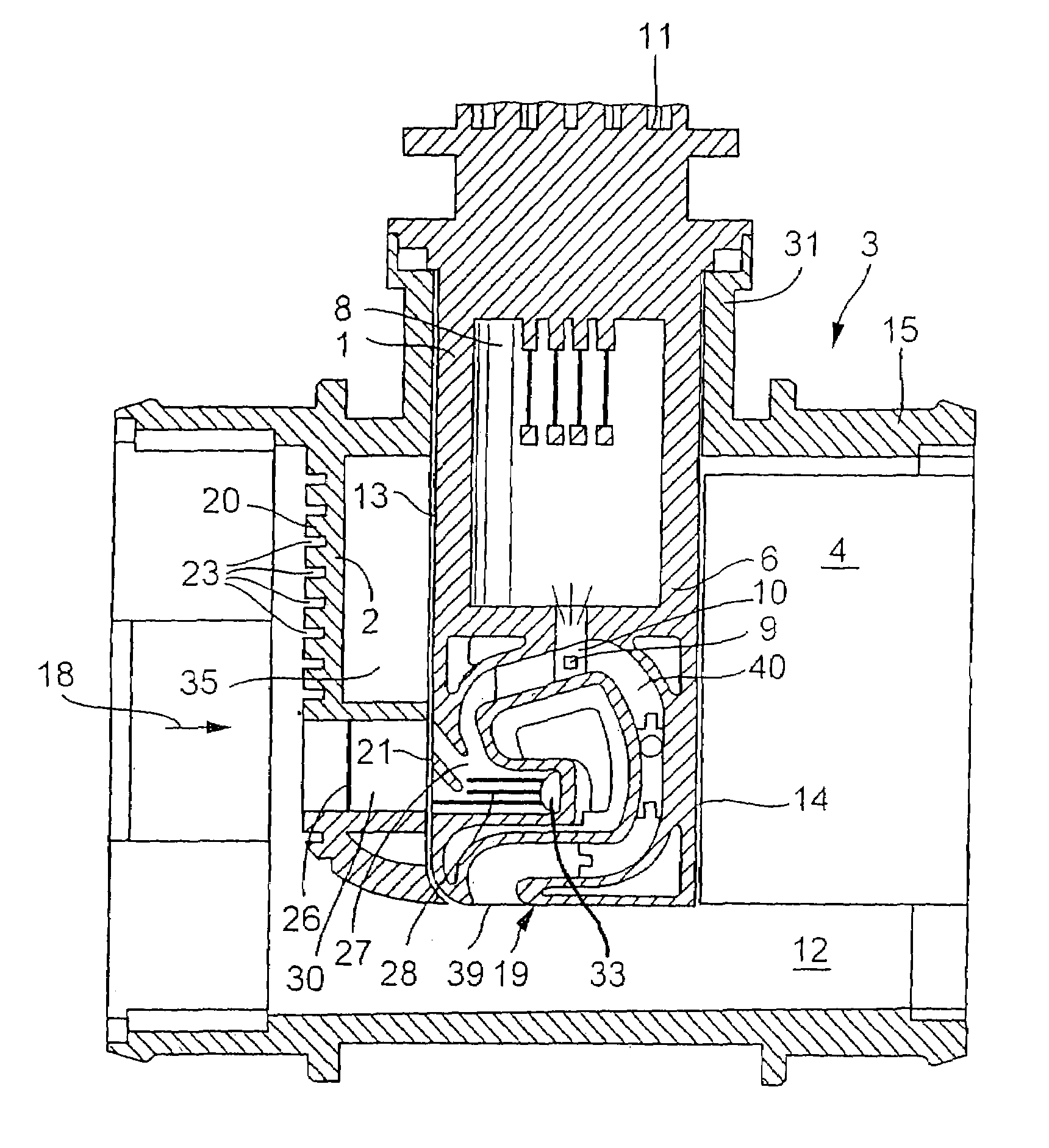

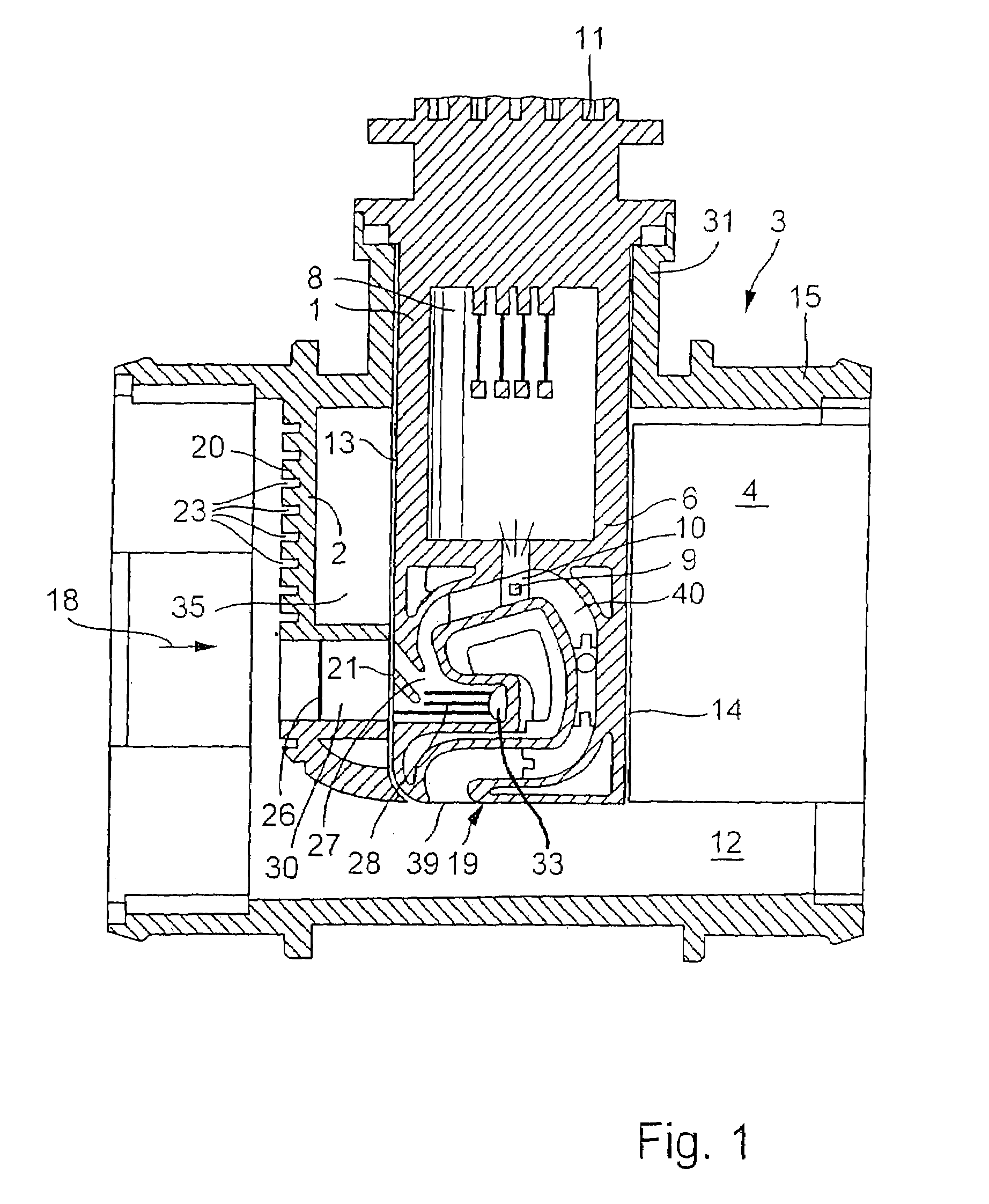

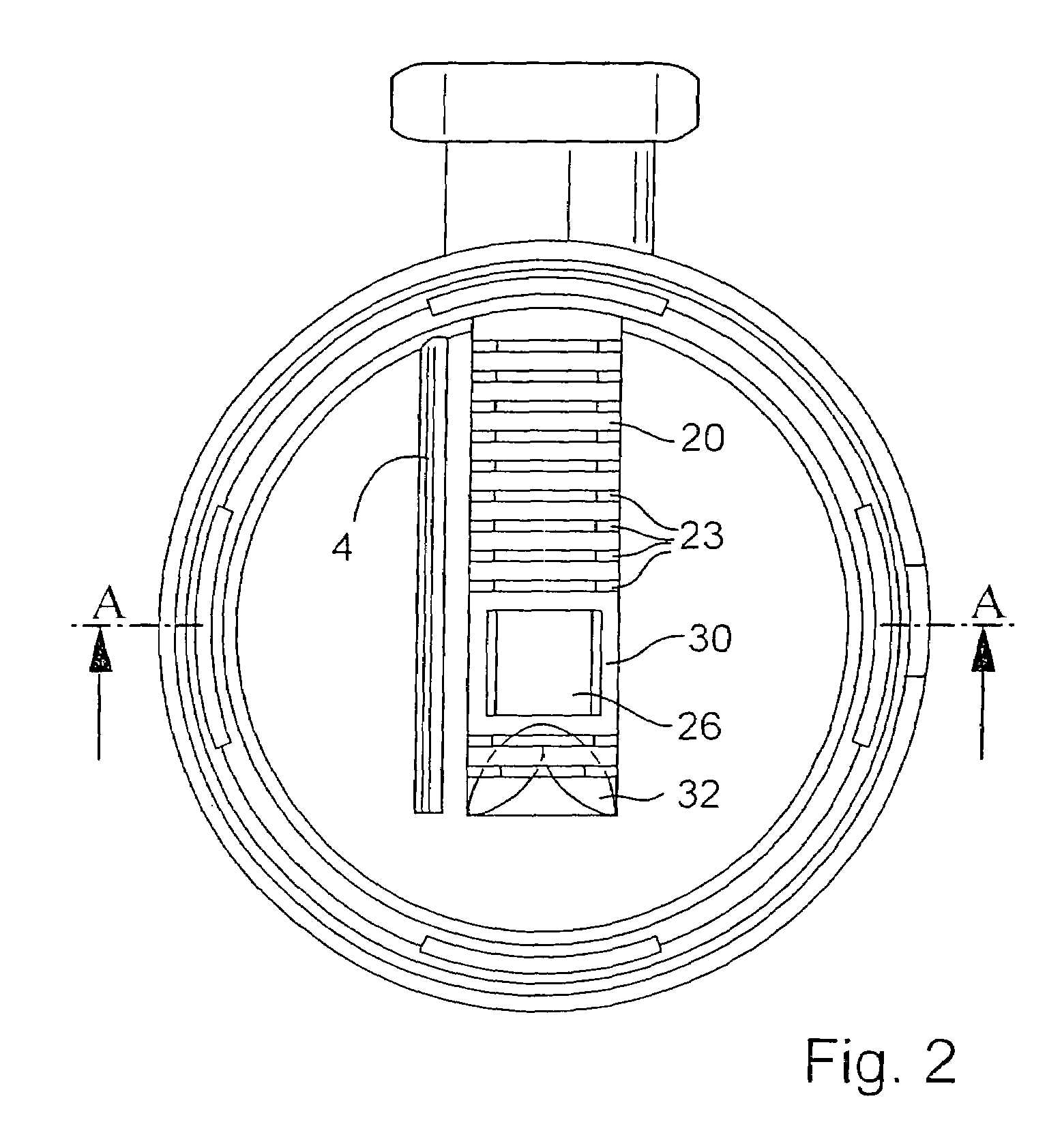

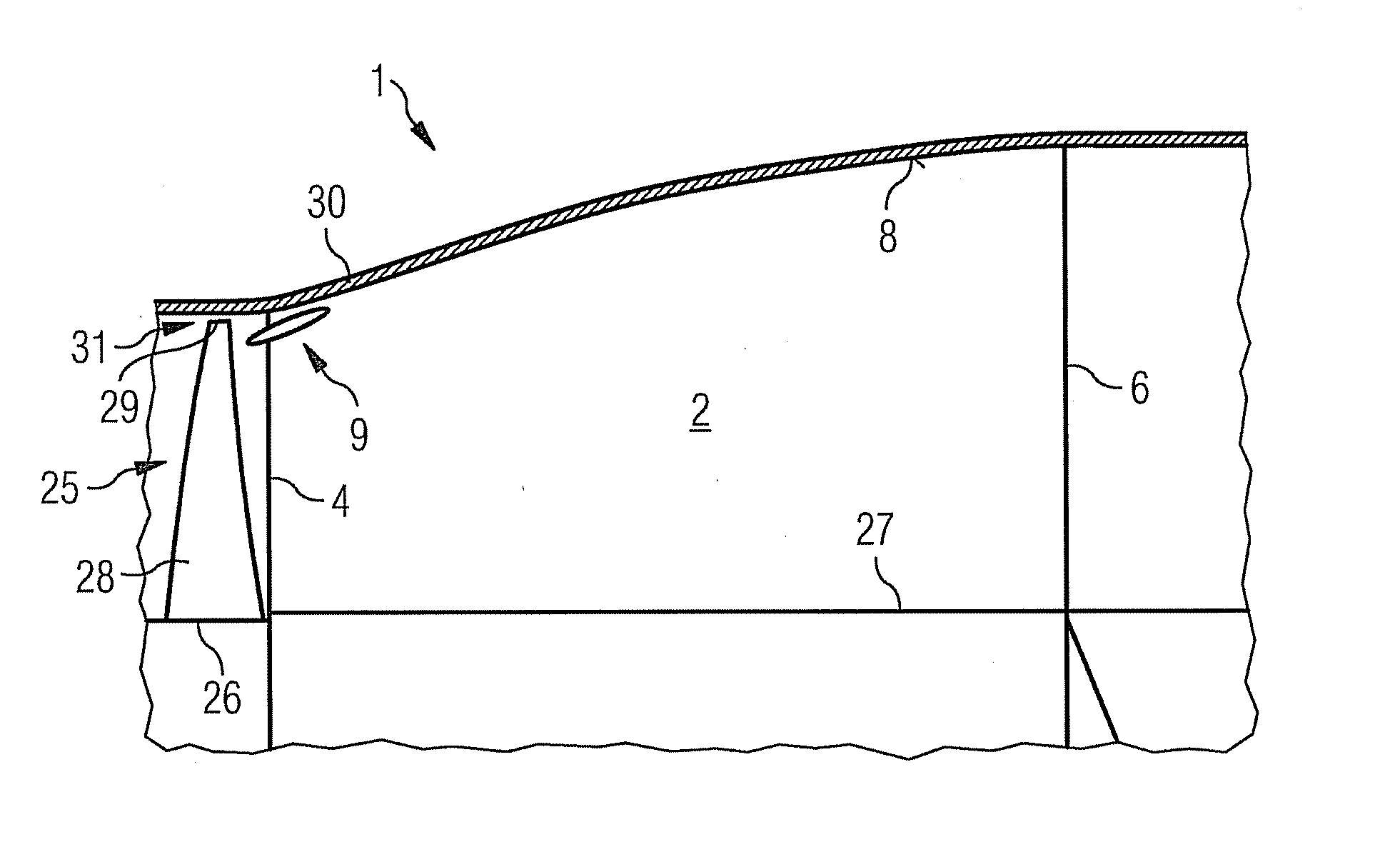

Device for determining at least one parameter of a medium flowing in a line having diversion surface

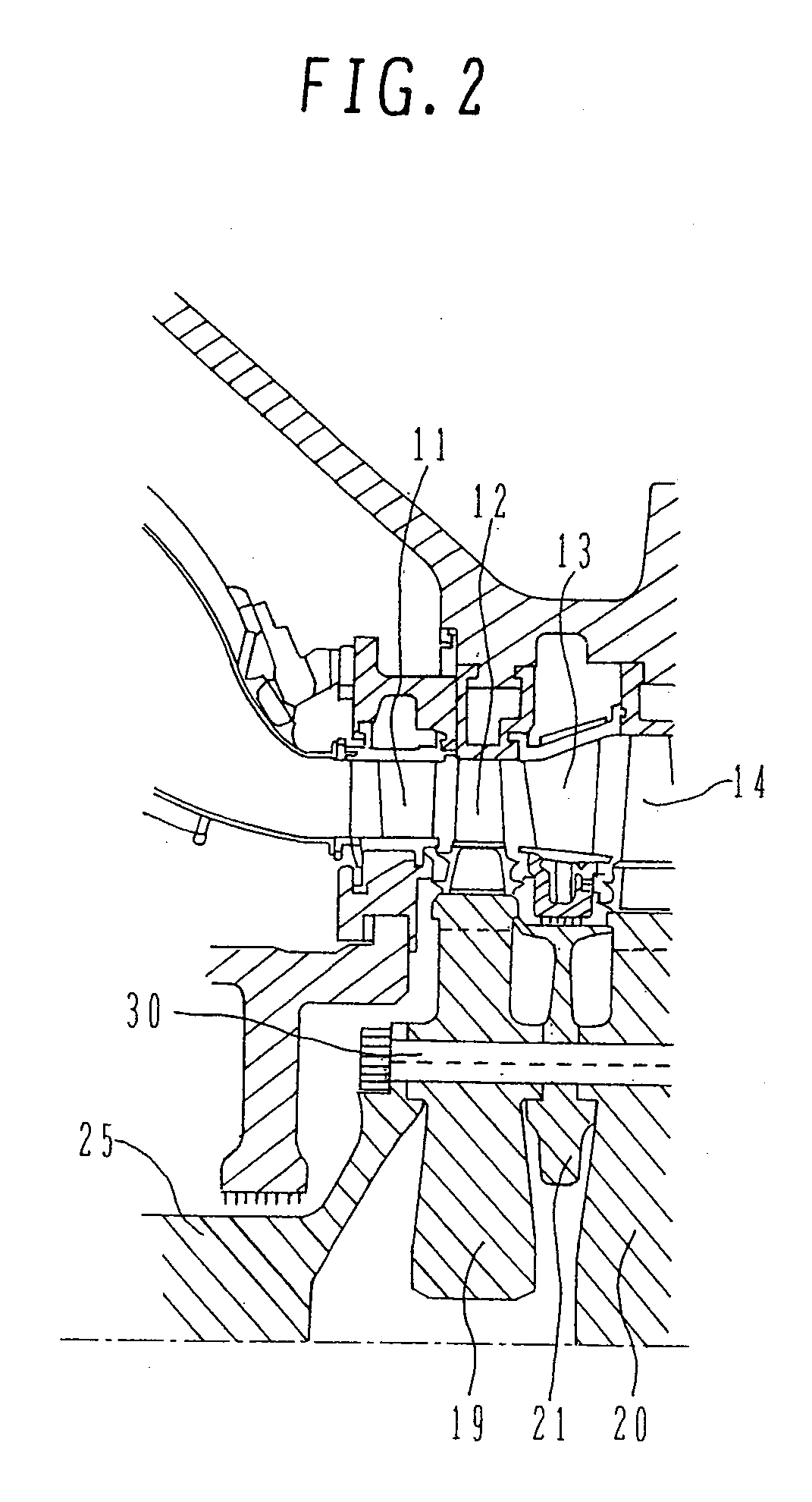

ActiveUS7305877B2Inhibition of flow separationElectrical controlVolume/mass flow by thermal effectsLine tubingEngineering

A device for determining at least one parameter of a medium flowing in a line, in particular for determining the air mass flow rate in the intake manifold of an internal combustion engine, which include a line component 3 and a sensor device 1 having a bypass part 6, are known. To prevent separation of the flow at the sidewalls of the bypass part, it is provided that a flow diversion element 2 be positioned in the line component 3 upstream from the bypass part 6 with respect to the main flow direction 18 and have at least one diversion surface 20 facing the main flow direction 18, which, starting from an apex line 25 located at a distance from the bypass part 6, curves evenly on both sides toward the two sidewalls 16, 17 so that the ends 38 of the diversion surface 20 facing away from the apex line are aligned with the sidewalls 16, 17.

Owner:ROBERT BOSCH GMBH

Diffuser arrangement

InactiveUS20100226767A1Produced cost-effectivelyLower overall flow resistanceEngine manufacturePump componentsEngineeringCell separation

A diffuser arrangement through which a fluid may flow is provided. The diffuser includes an outer diffuser comprising an inner surface, and a flow-guiding device, which is configured such that at least part of the boundary layer flow forming on the inner surface of the outer diffuser can be accelerated in the main flow direction, so that a flow separation is prevented on the inner surface of the outer diffuser. Also provided are an exhaust steam plenum of a steam turbine and an exhaust gas plenum of a gas turbine, both including a diffuser arrangement.

Owner:SIEMENS AG

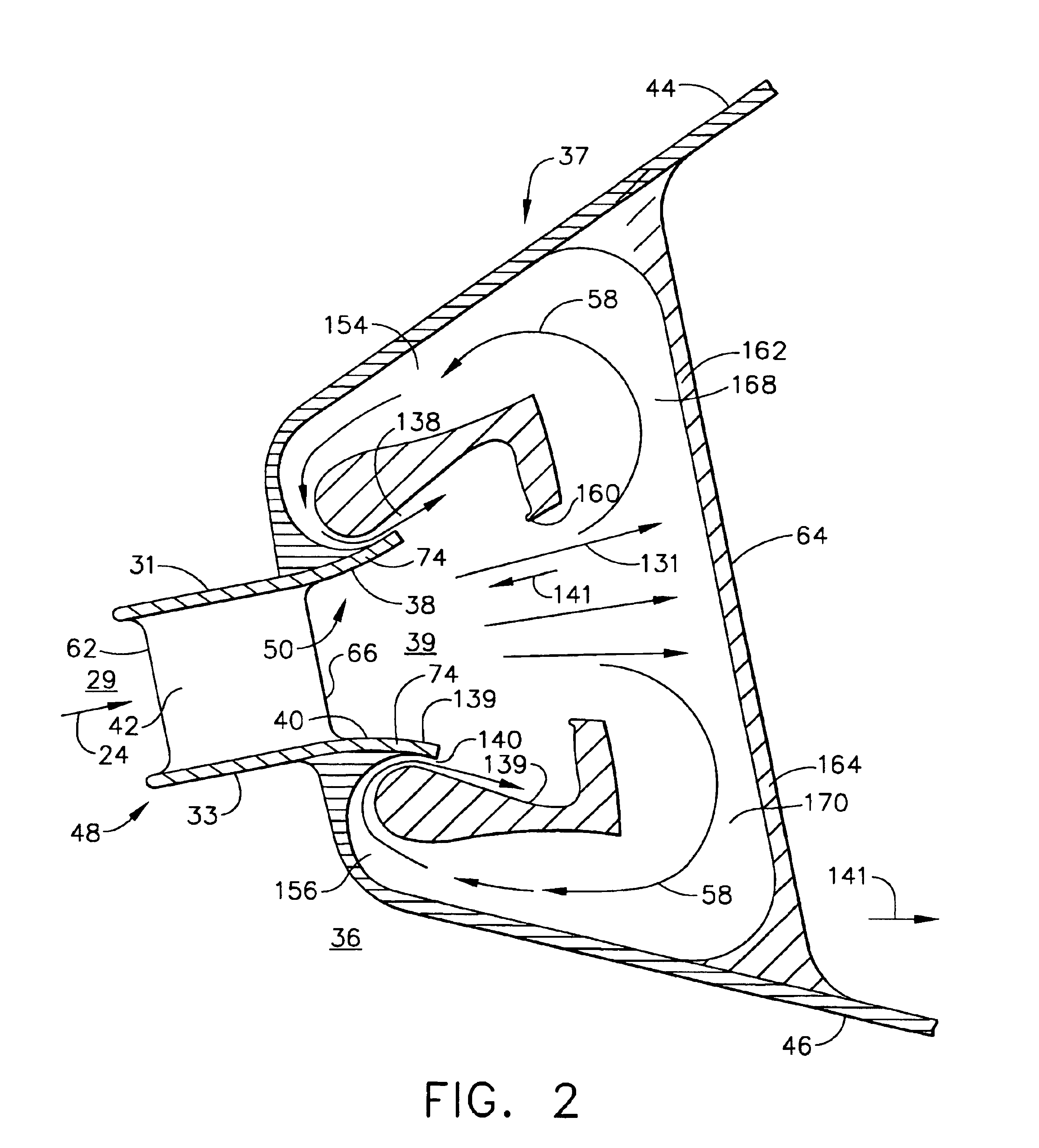

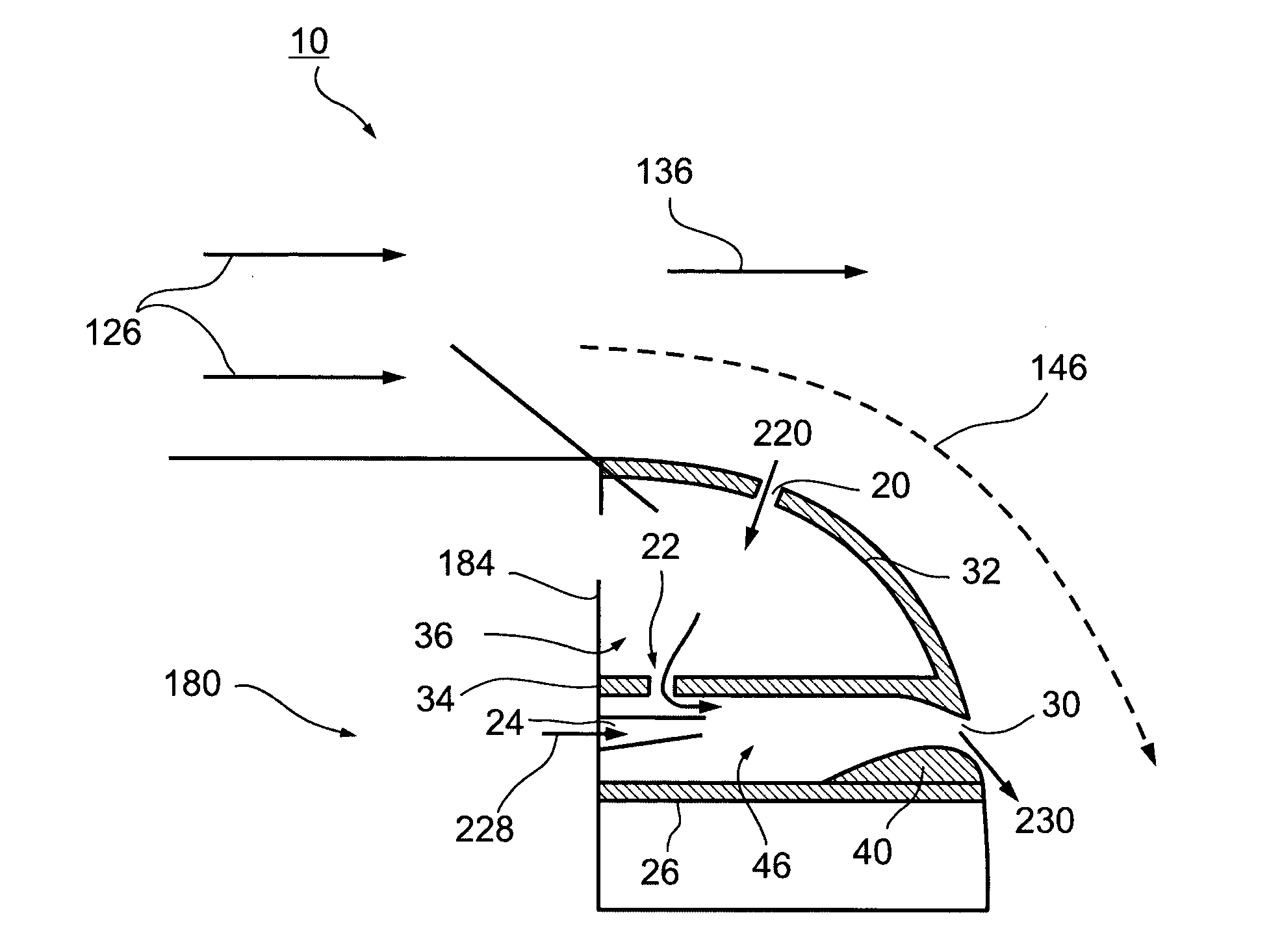

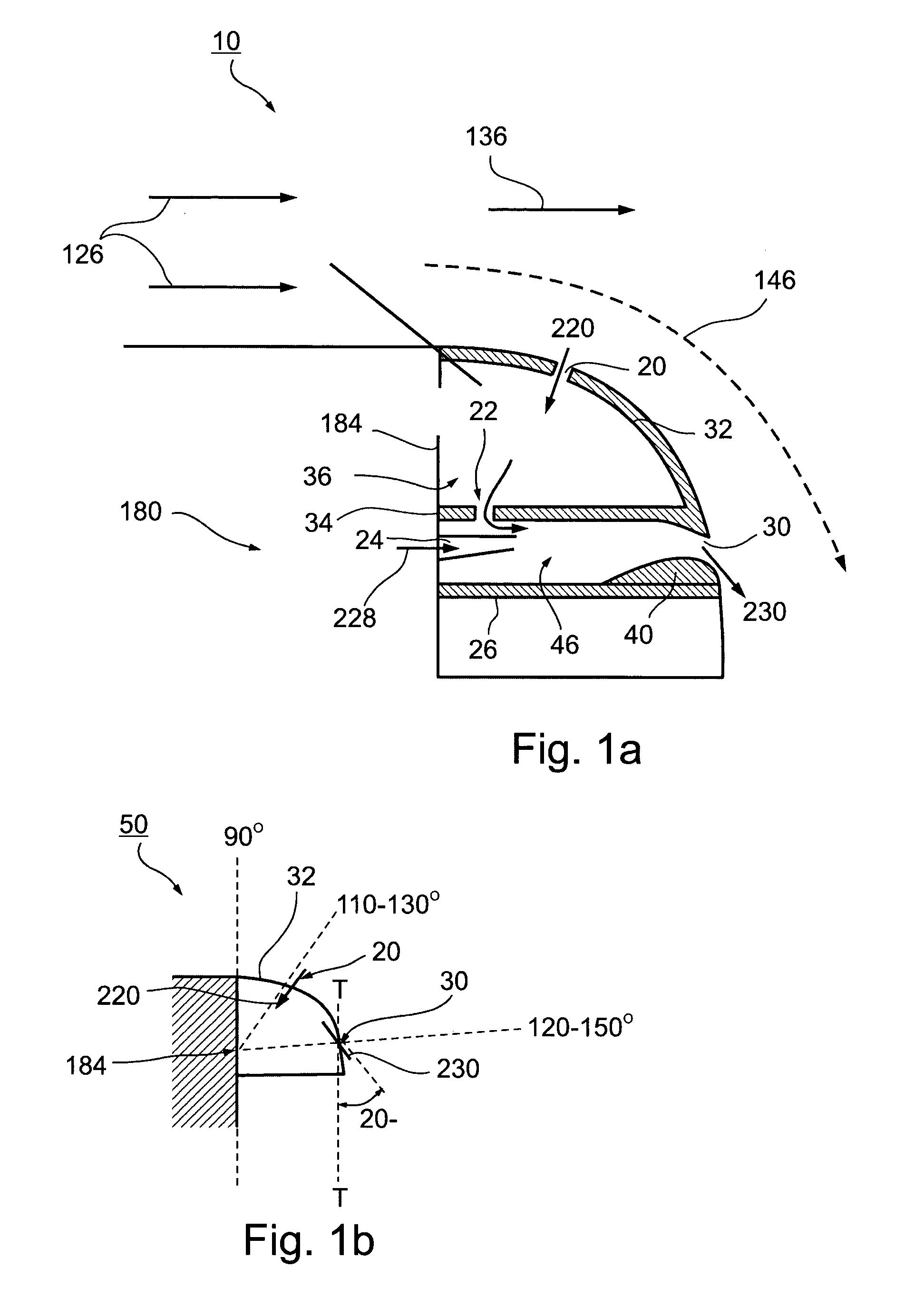

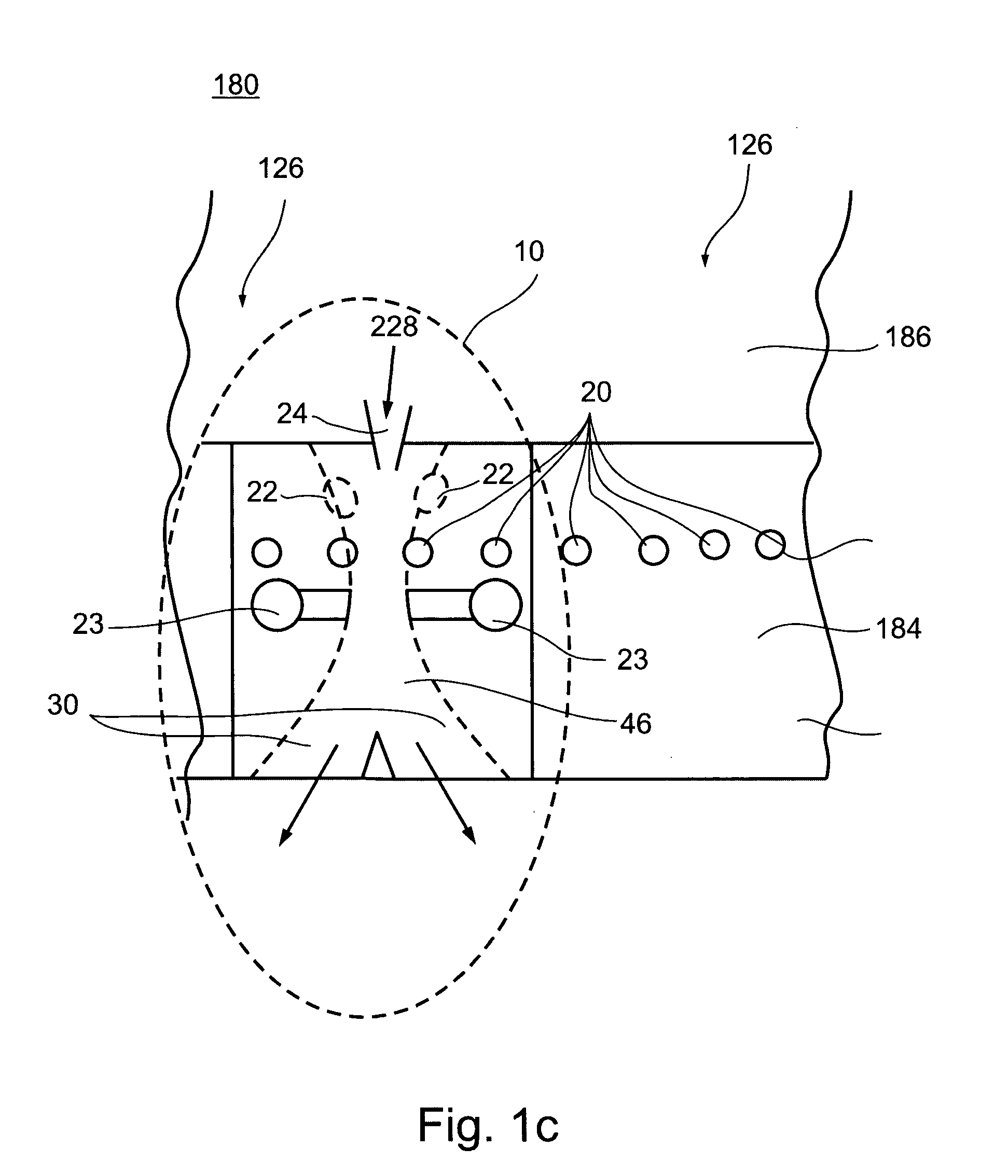

Combustor inlet diffuser with boundary layer blowing

InactiveUS6843059B2Shorten the axial lengthInhibition of flow separationPump componentsGas turbine plantsCombustorCombustion chamber

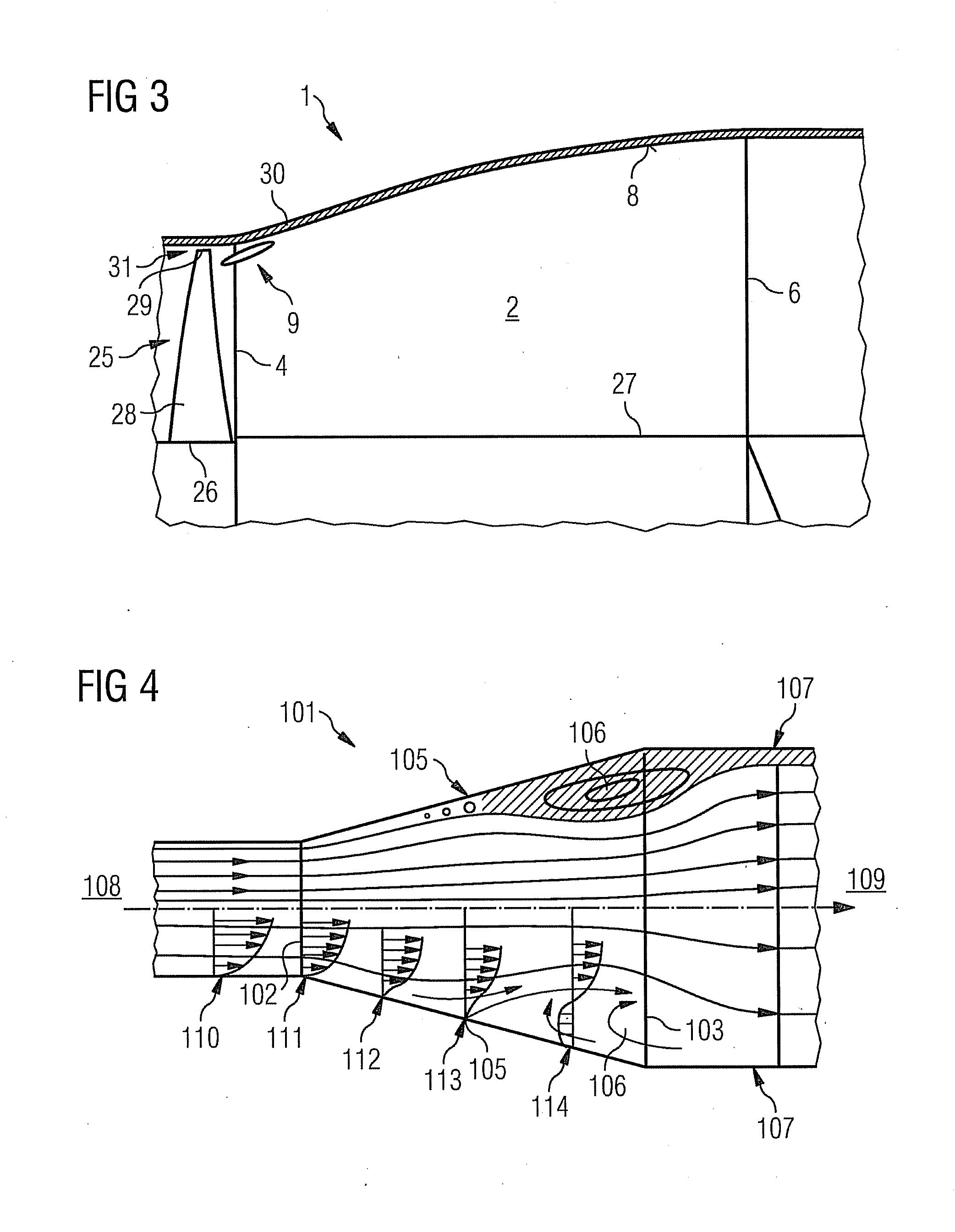

A gas turbine engine combustor inlet diffuser assembly has at least one diverging annular wall including a flowpath surface bounding a diffuser flowpath. An annular blowing slot is axially located along the annular wall and an annular blowing air flowpath leads to and is in fluid communication with the blowing slot. An annular array of scoops disposed in the diffuser flowpath downstream of the blowing slot have upstream facing openings and are in fluid communication with the blowing air flowpath. The annular scoops are supported on hollow struts. Each of the hollow struts has at least one radially extending flow passage for directing blowing air from the scoop to the blowing air flowpath. The blowing slot opens in a downstream direction with respect to the diffuser flowpath. A row of blowing air compressor blades disposed across the blowing air flowpath may be used to pump up the pressure of the blowing air.

Owner:GENERAL ELECTRIC CO

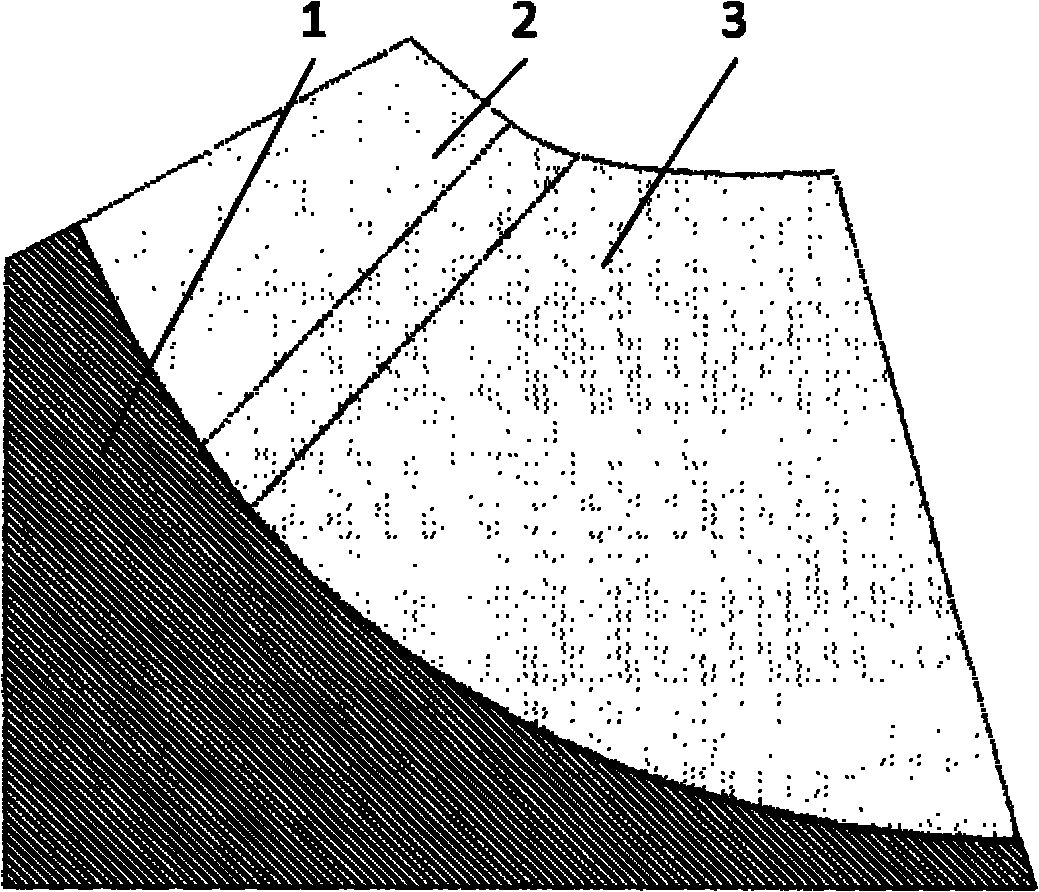

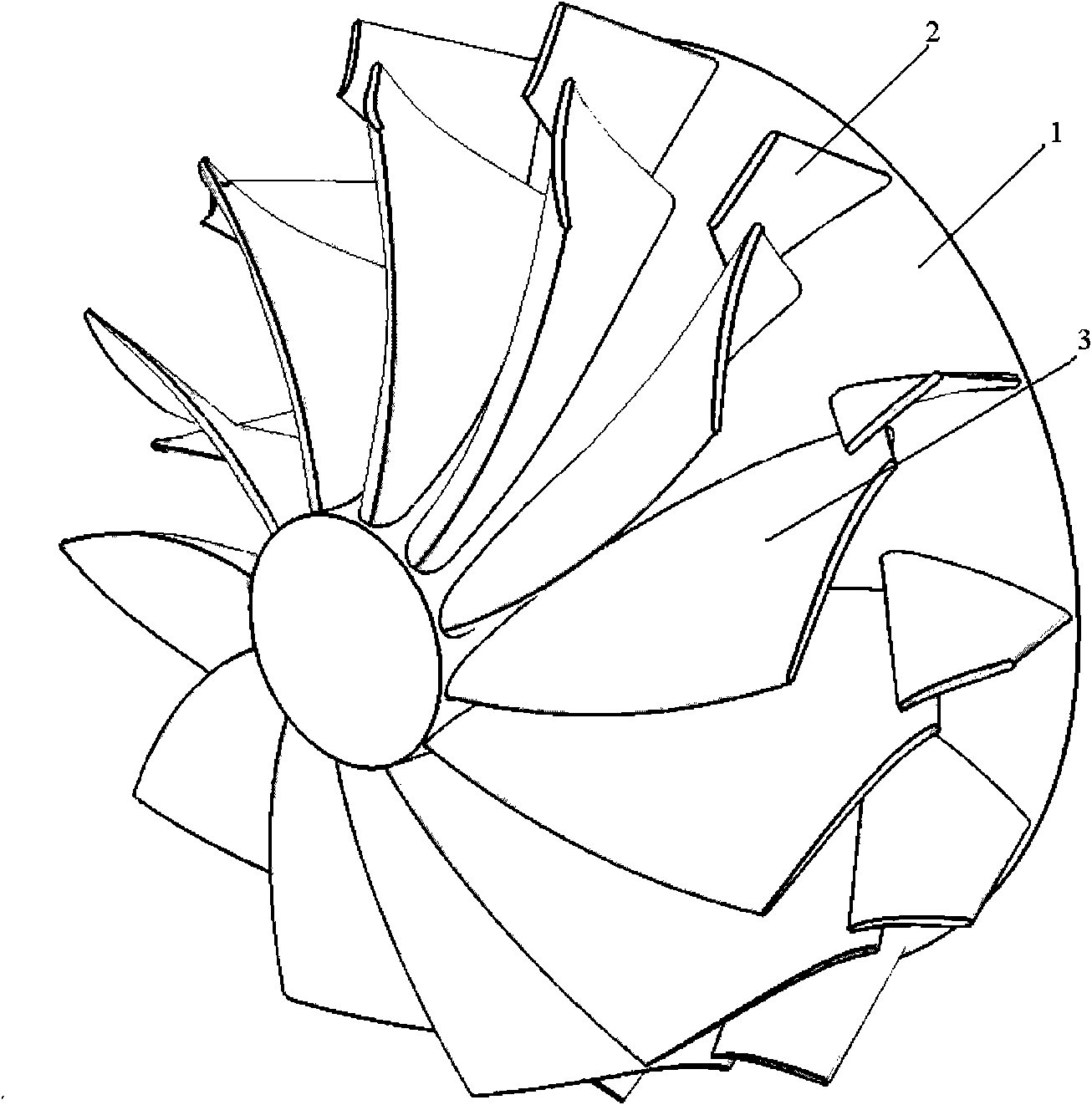

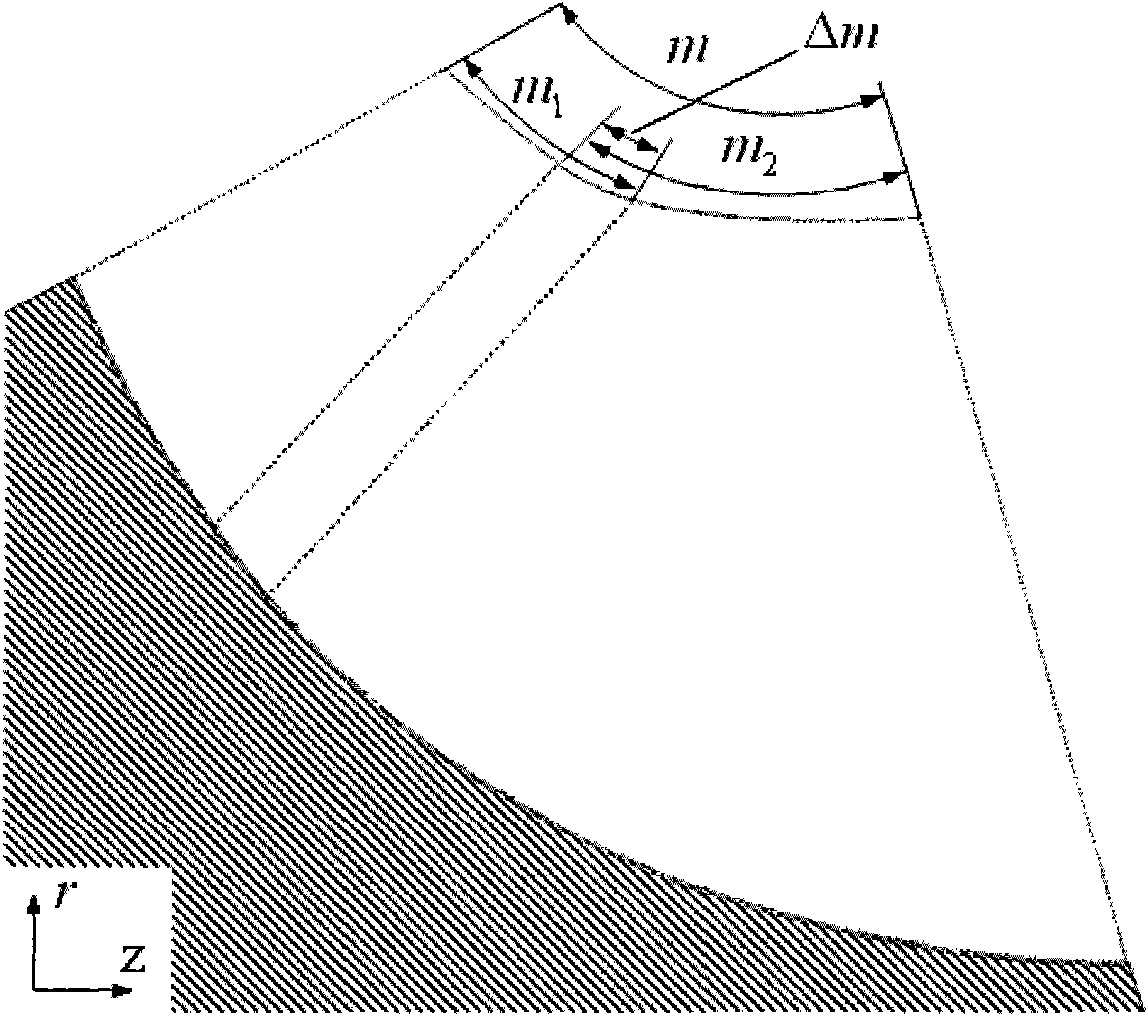

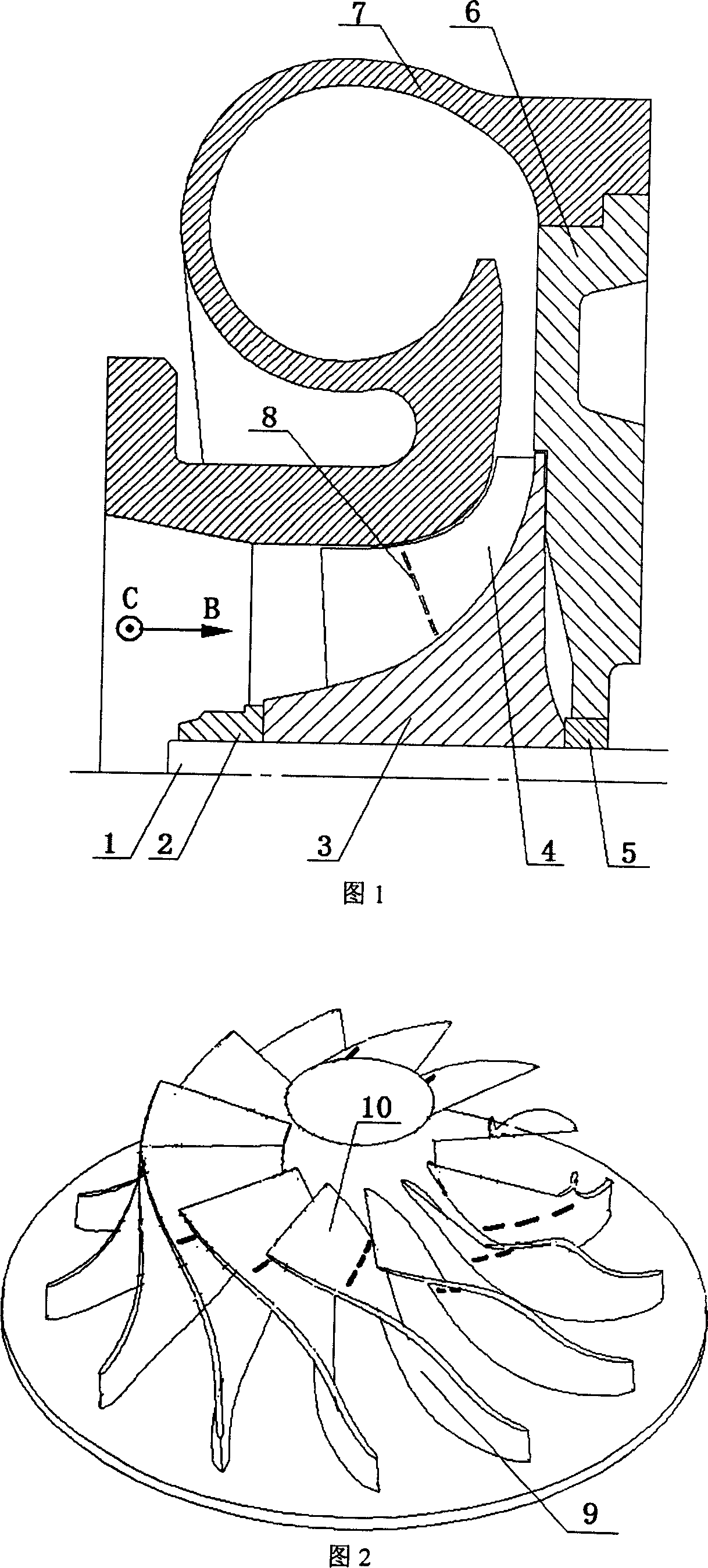

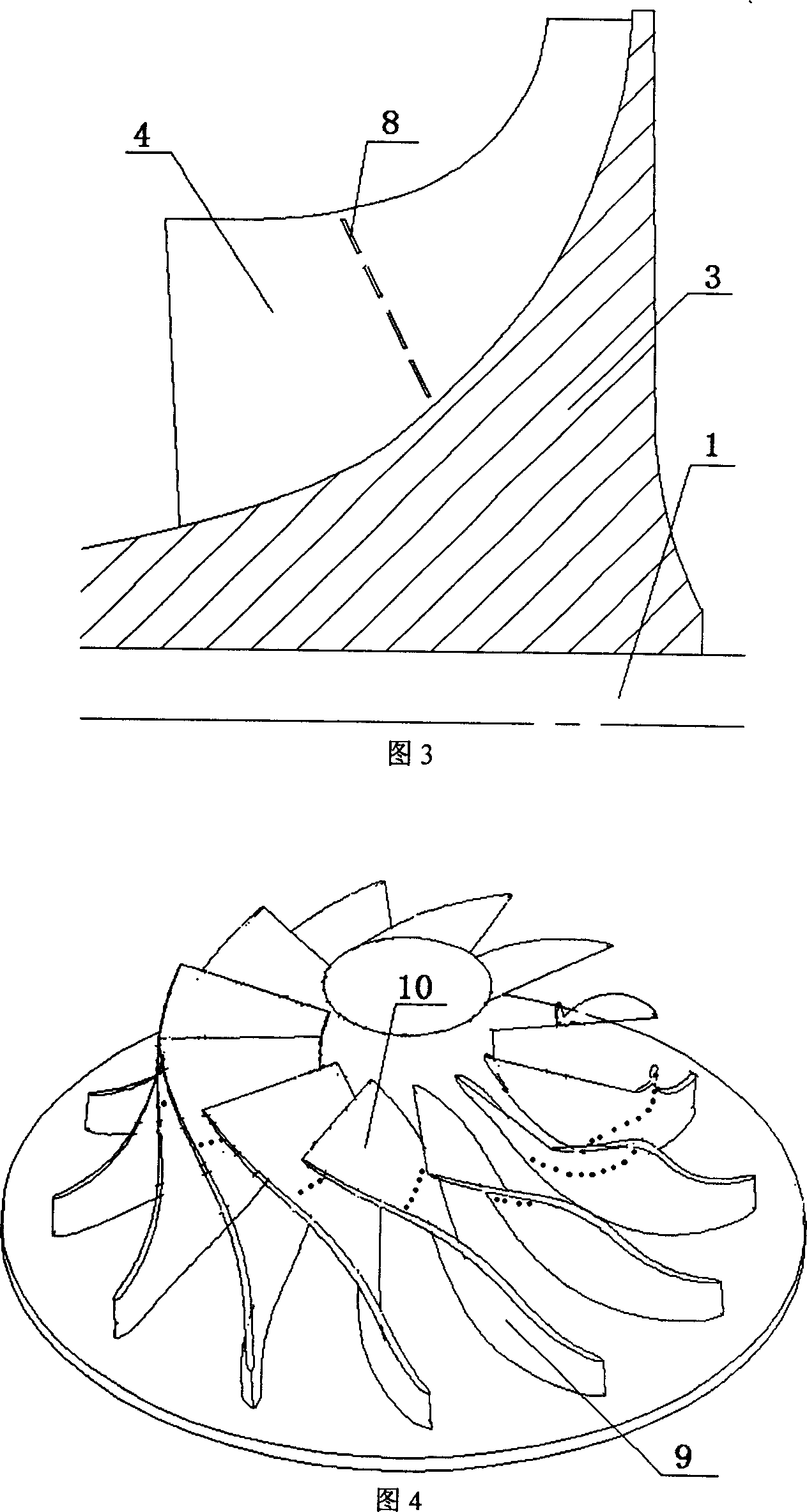

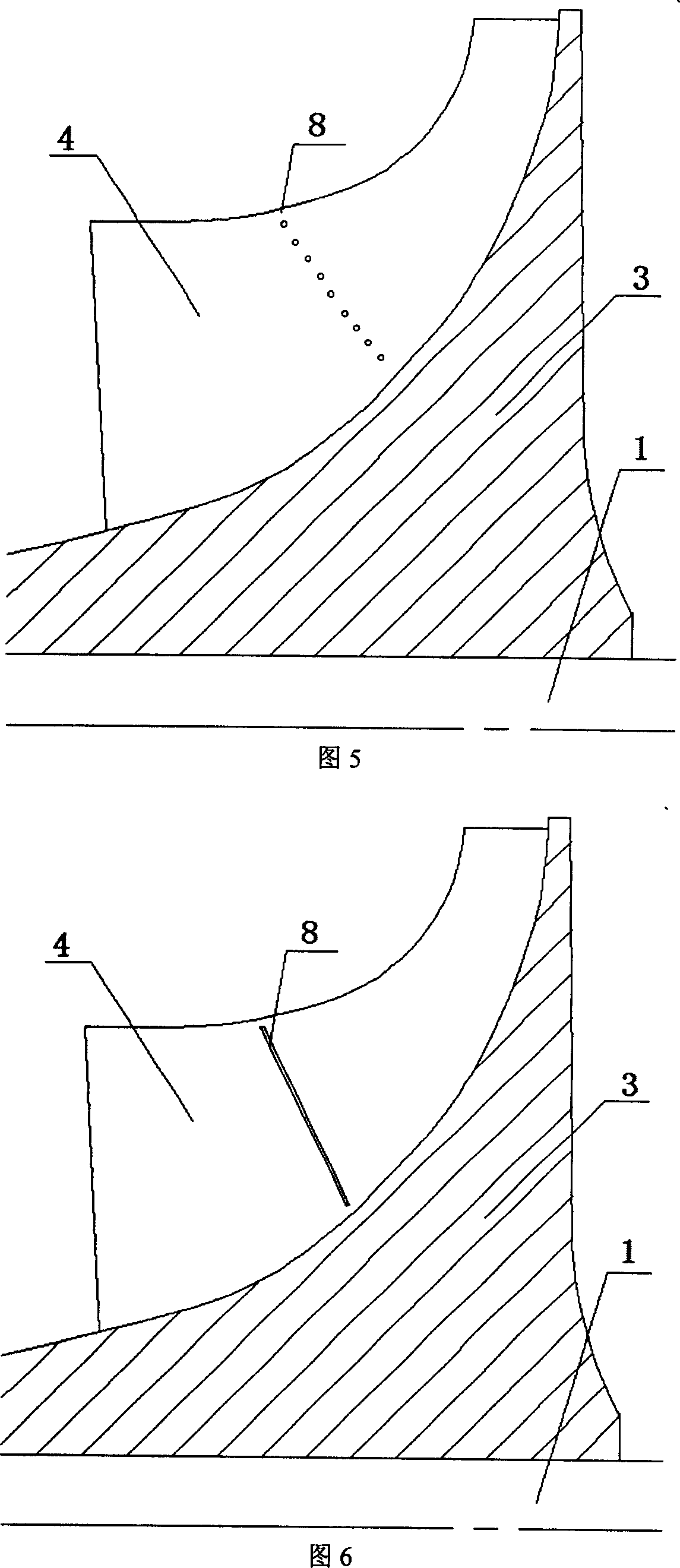

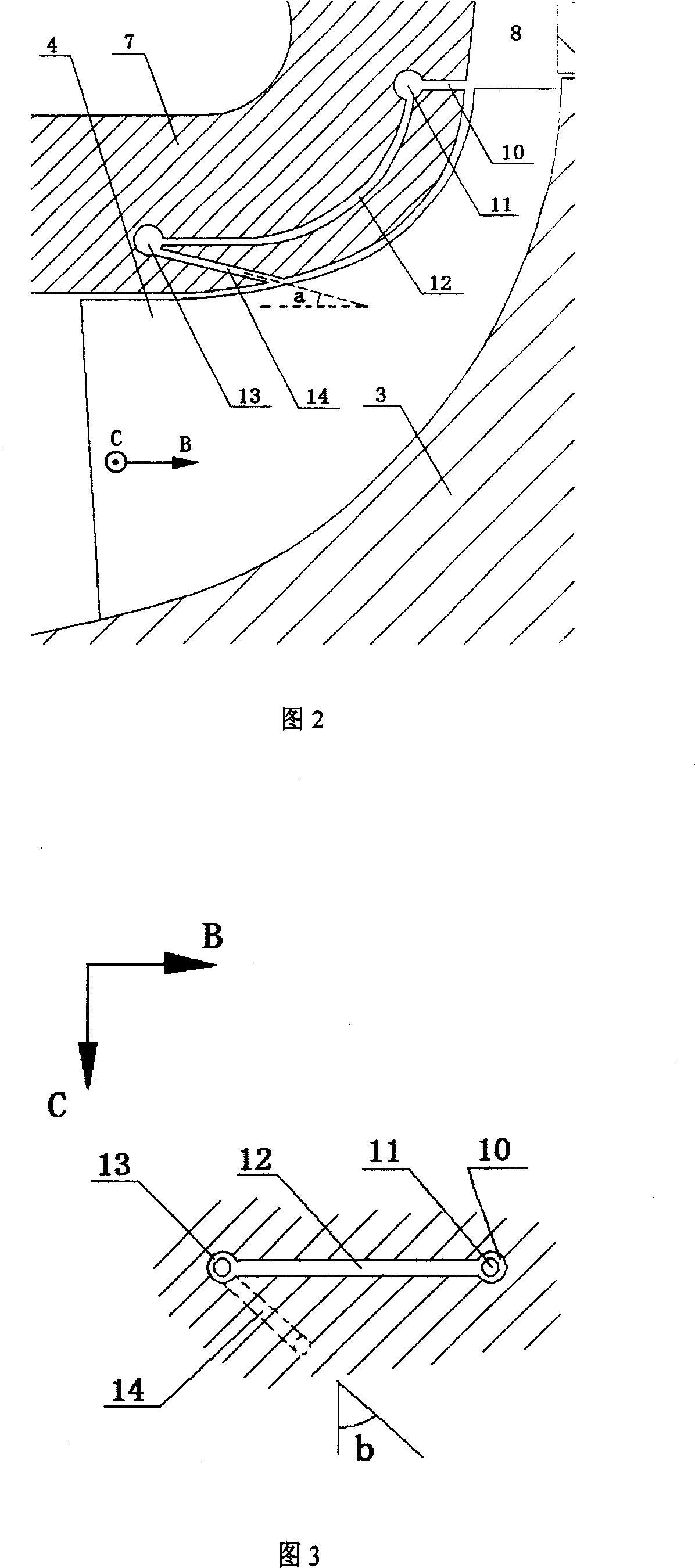

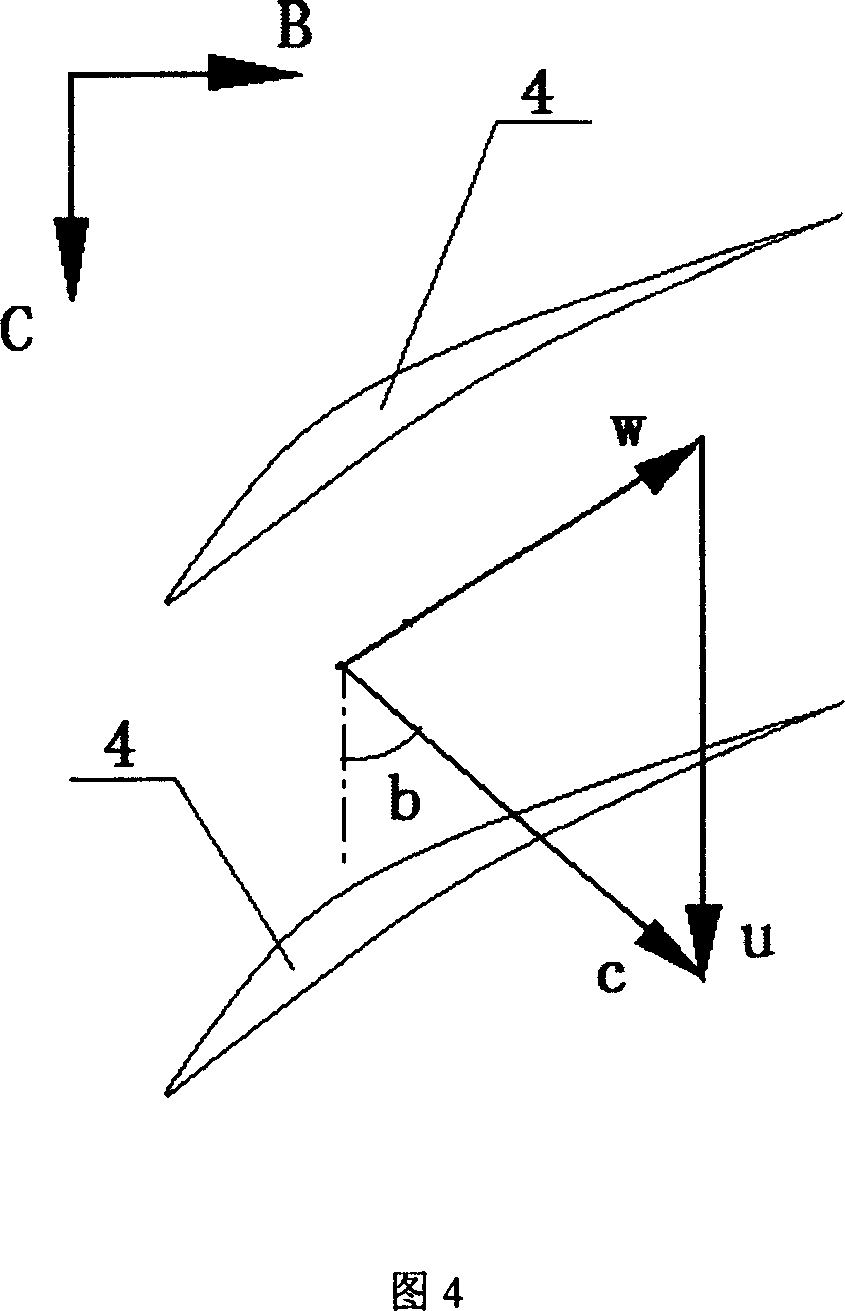

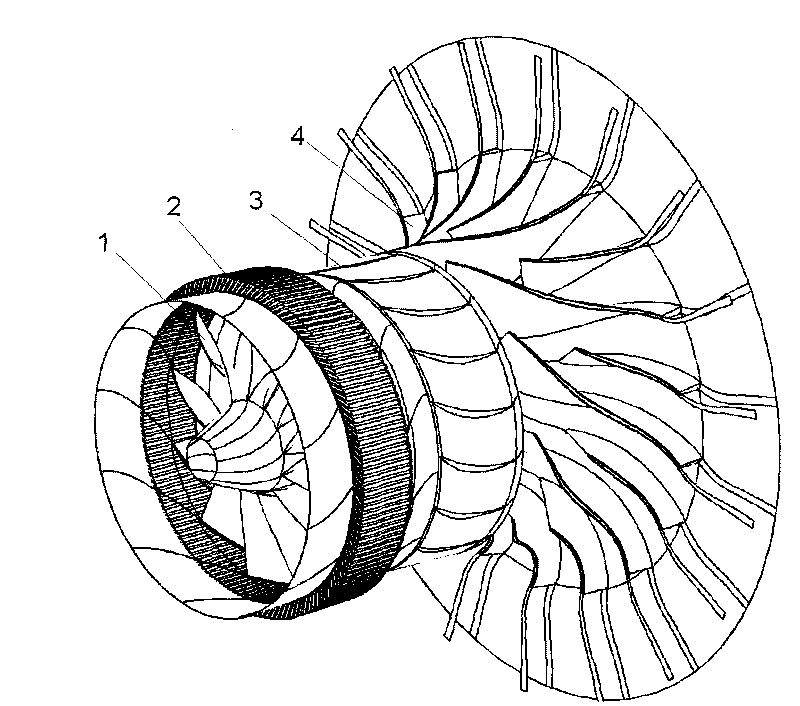

Tandem blade type mixed-flow or radial-flow turbine

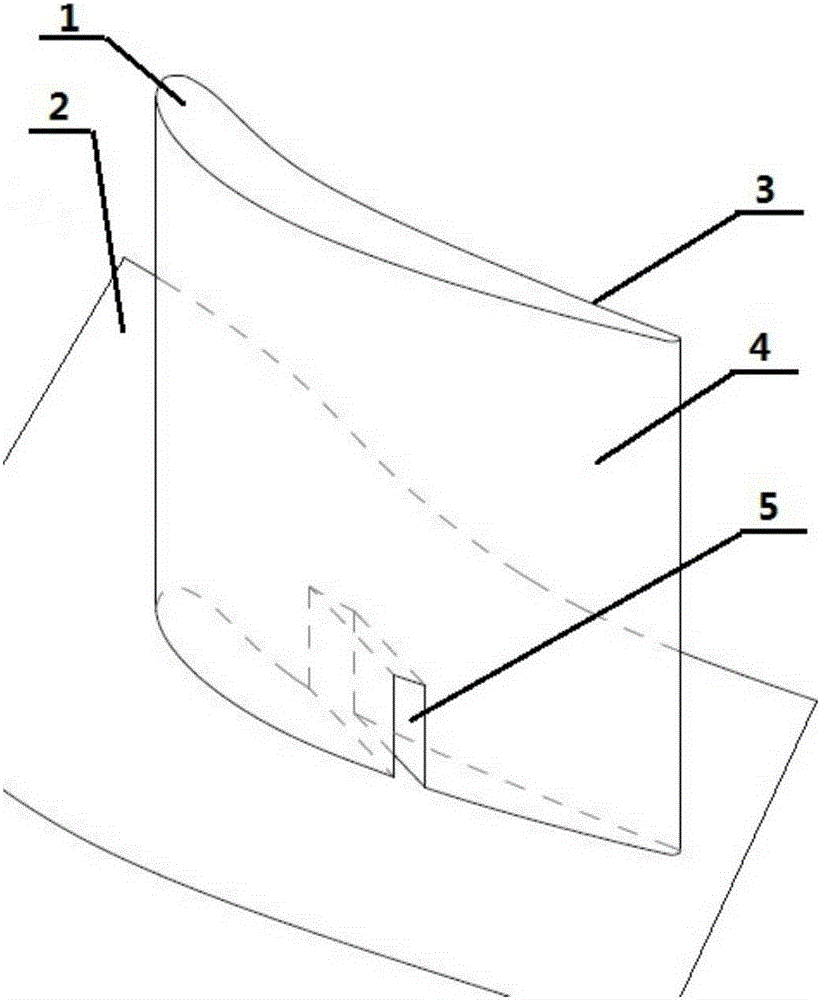

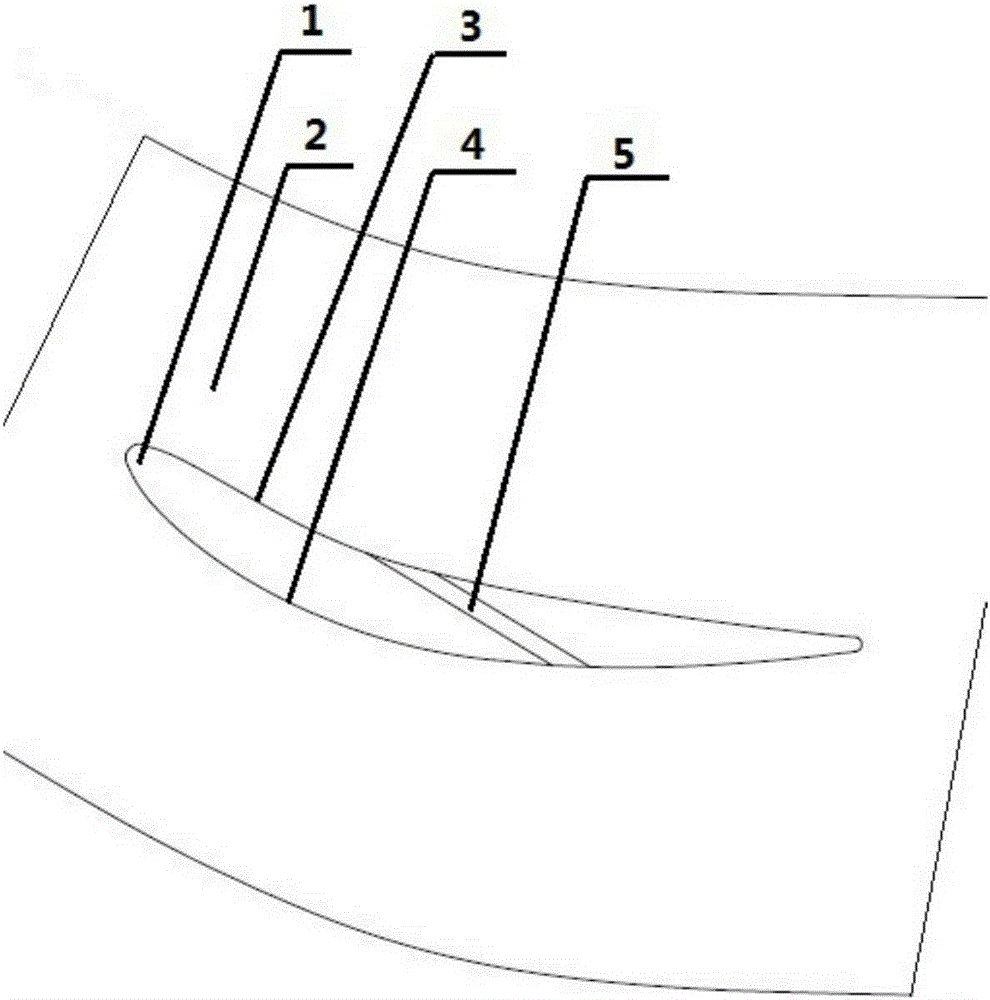

InactiveCN101915126AImprove performanceInhibition of flow separationInternal combustion piston enginesBlade accessoriesMixed flowPulse charge

The invention relates to the technical field of blade type fluid machines, in particular to a tandem blade type mixed-flow or radial-flow turbine comprising a hub, front-row blades and back-row blades, wherein the ratio of the numbers of the tandem blade type front-row Z1 and the numbers of the back-row blades Z2 is 1:1 or 1:2, the ratio variation range of the lengths of the front-row and back-row blades is 0.1-0.5, the variation range of relative circumferential angles between the front edges of the back-row blades and the tail edges of the front-row blades is 0-2 pi / Z1, and the variation range of the distances between the tail edges of the front-row blades and the front edges of the back-row blades is -0.3 to 0.3 of the total blade chord length. By the airflow blowing-down function generated by a gap between the front-row blades and the back-row blades, the flow separation close to the front edges of the blades is restrained, the secondary flow is weakened, the efficient running range is enlarged, and the whole performance of the turbine under undersign conditions and pulse charging conditions is improved.

Owner:TSINGHUA UNIV

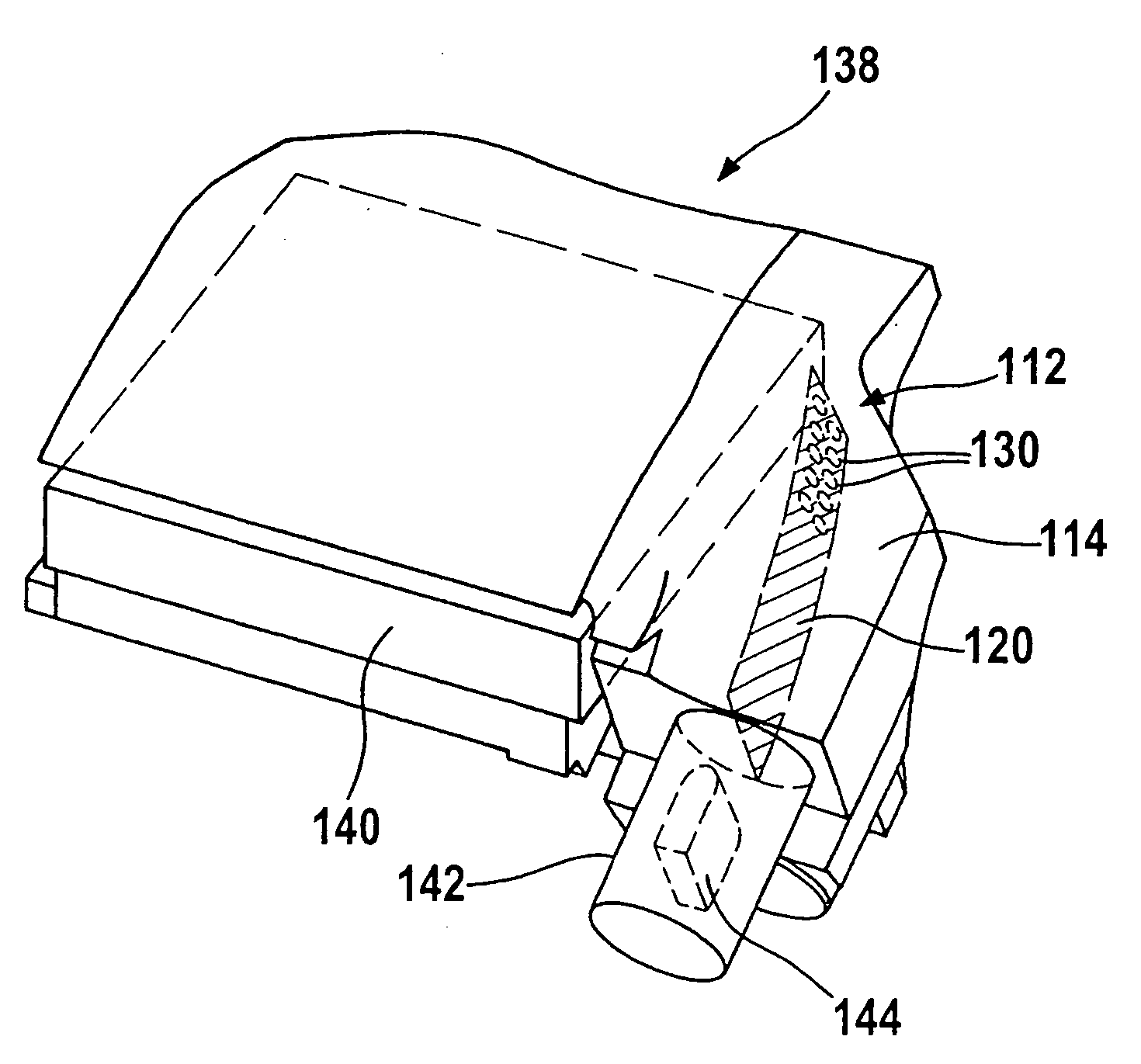

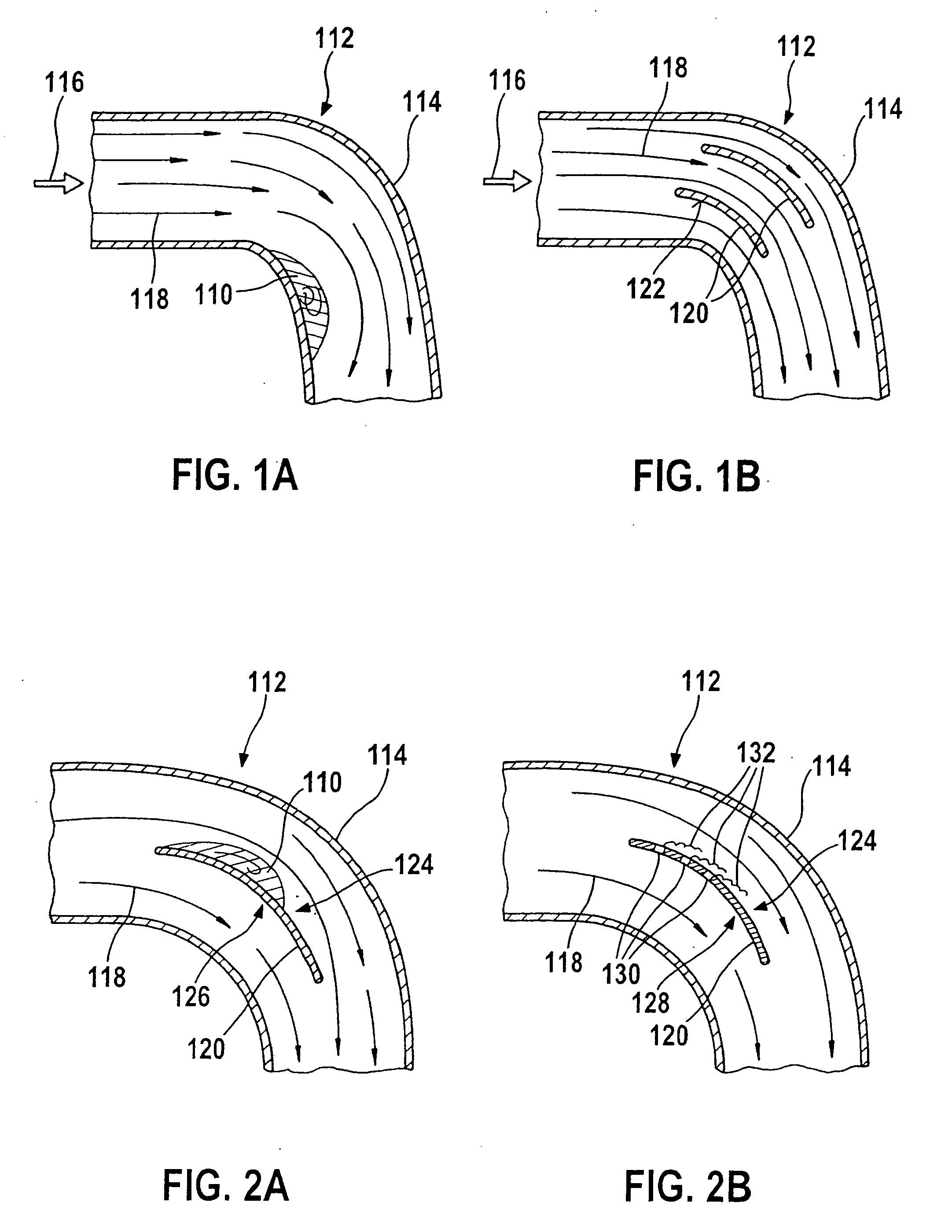

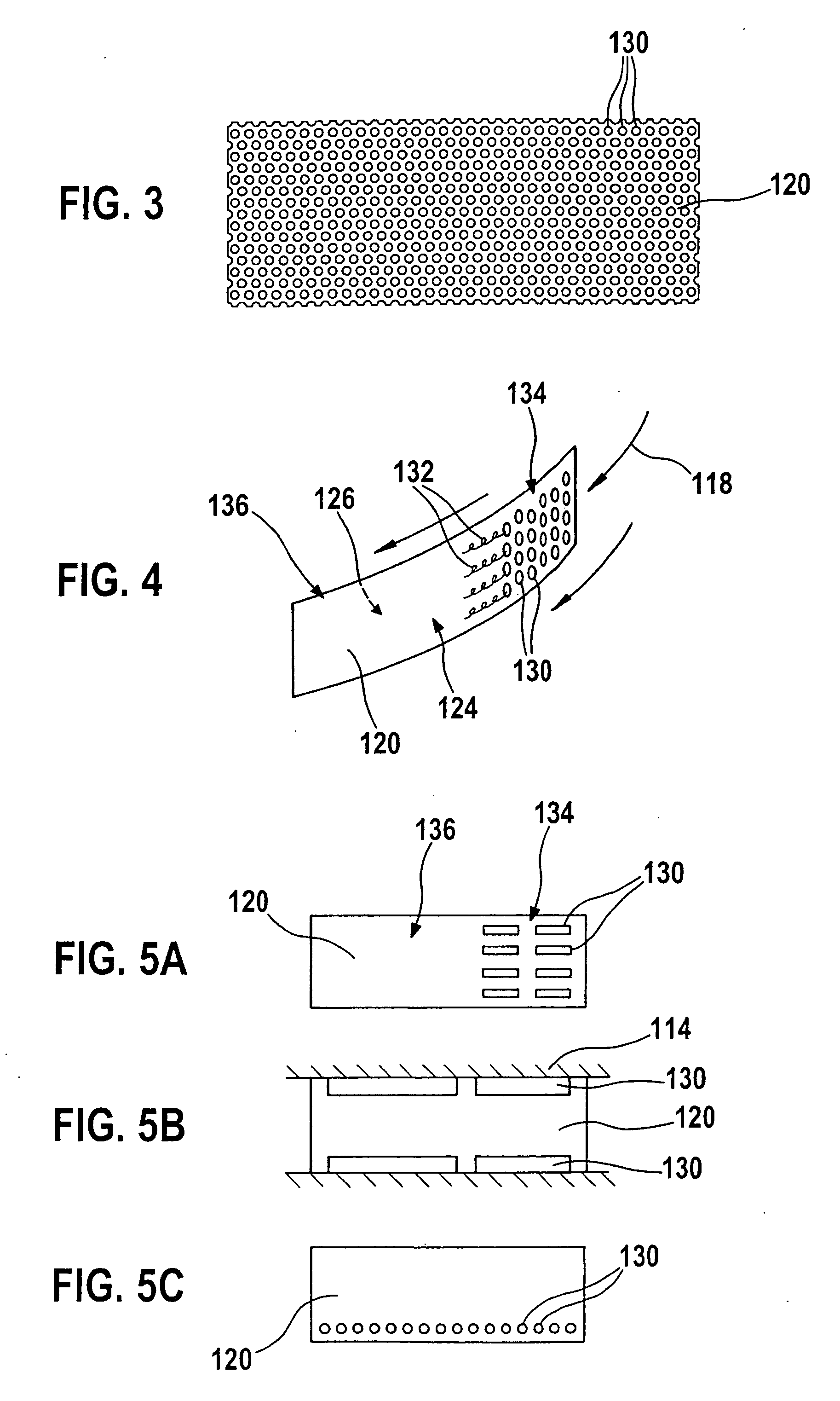

Flow guide element for guiding the flow of a fluid medium

ActiveUS20080283014A1Avoid disadvantagesSuitable for useElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

A flow guide element is provided for guiding a flow of a fluid medium which is particularly suitable for use in an intake tract of an internal combustion engine. The flow guide element includes a flow tube having an elbow for diverting the flow. In the region of the elbow there is situated, in this case, at least one flow baffle having at least one deflector. The deflector is penetrated by an opening, going right through the flow baffle, in at least one area.

Owner:ROBERT BOSCH GMBH

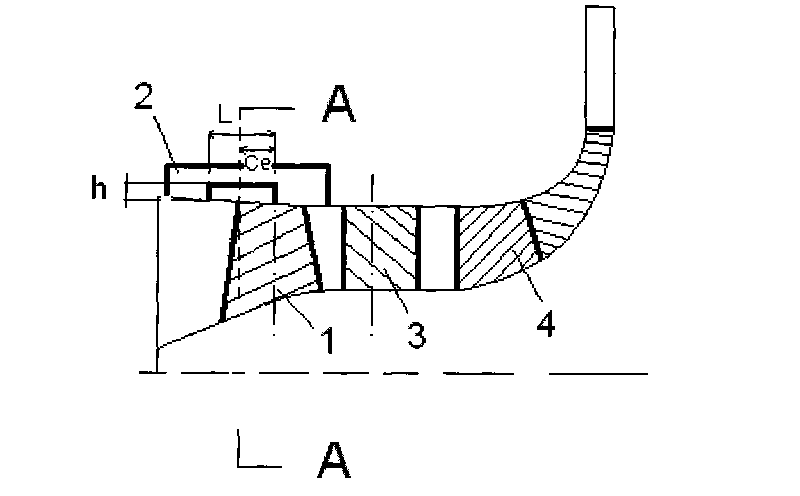

Centrifugal compressor having vane jet orifice

InactiveCN101012838AIncrease stall marginInhibition of flow separationPump componentsPumpsAviationJet flow

A centrifugal compressor with a jet orifice belonged to the turbo-machine field relates to the improvement of the booster centrifugal compressor used for vehicle and ships and aviation centrifugal compressor all the like turbo-machine box. It is characterized that a jet orifice set on the principal flow direction maximal curvature of the blade. Said jet orifice can be a narrow slit or two series-wound narrow slits along blade-high direction or a line of through-hole. The invention makes the suction surface of the impeller blade injected high energy jet flow when the centrifugal compressor operates via setting jet orifice on the blades, to activate the liquid in the boundary layer of the suction surface, thereby improving the ability for opposing adverse pressure gradient, to avoid impeller blade suction surface flow breakaway and improve the stalling allowance of the centrifugal compressor.

Owner:TSINGHUA UNIV

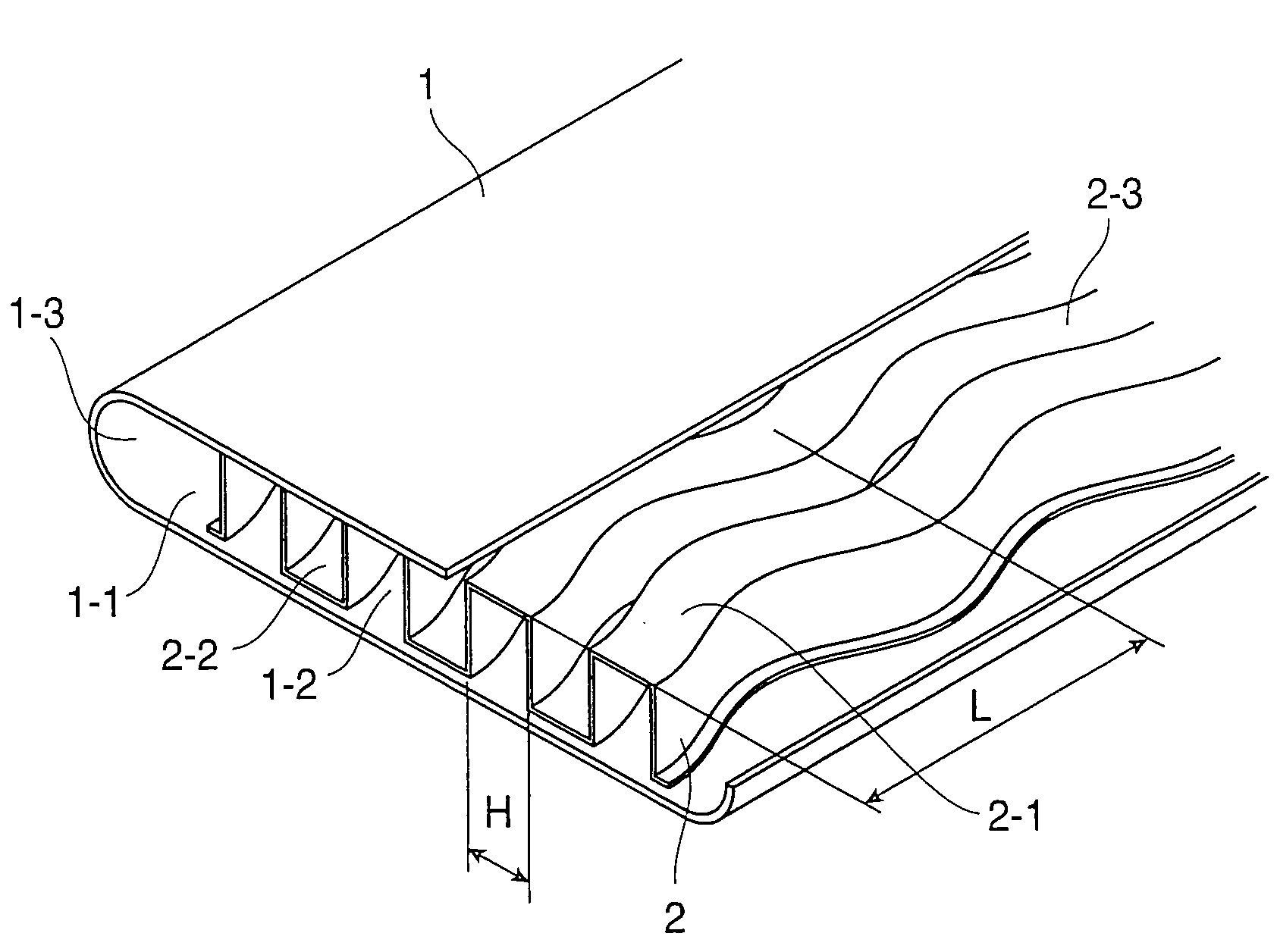

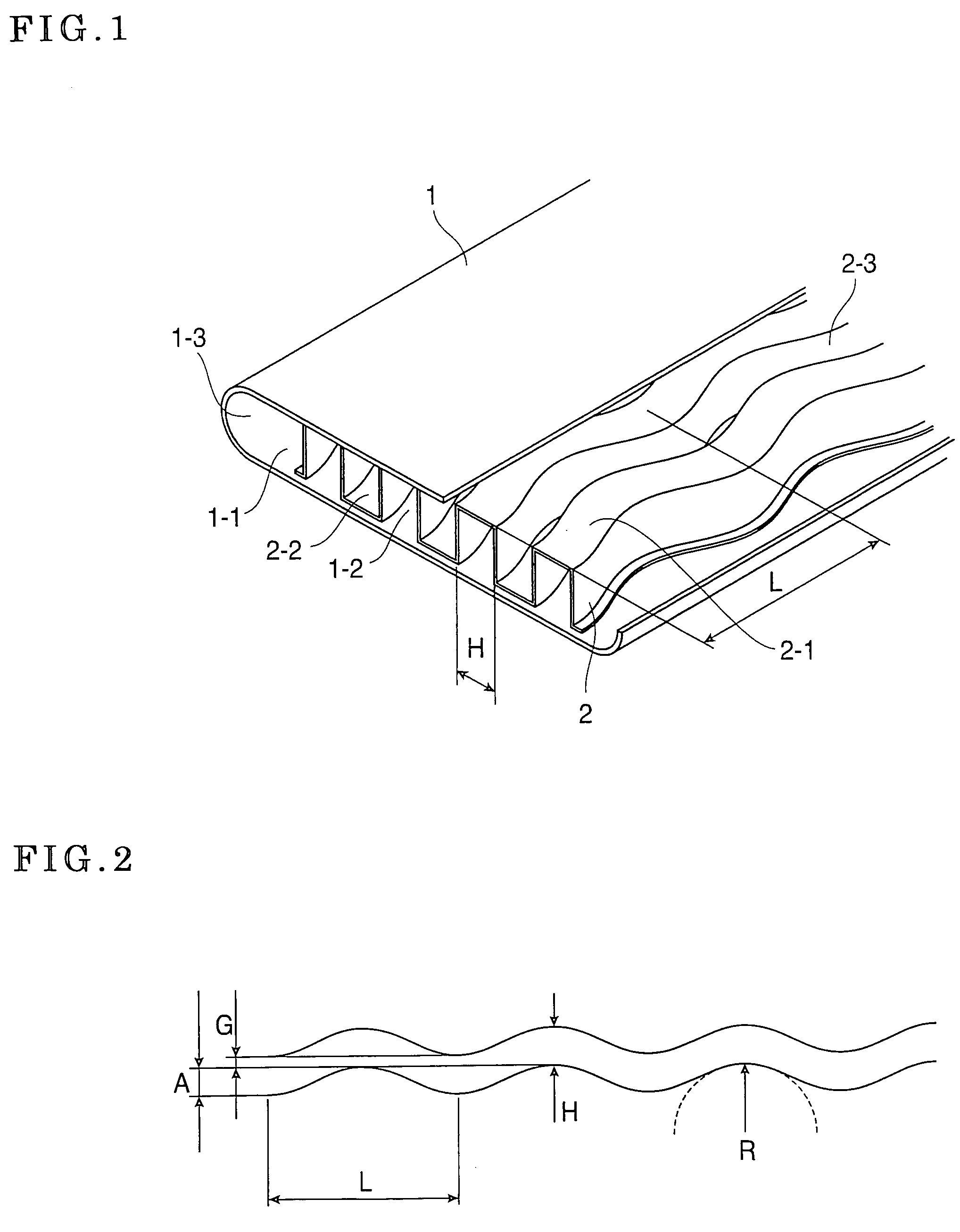

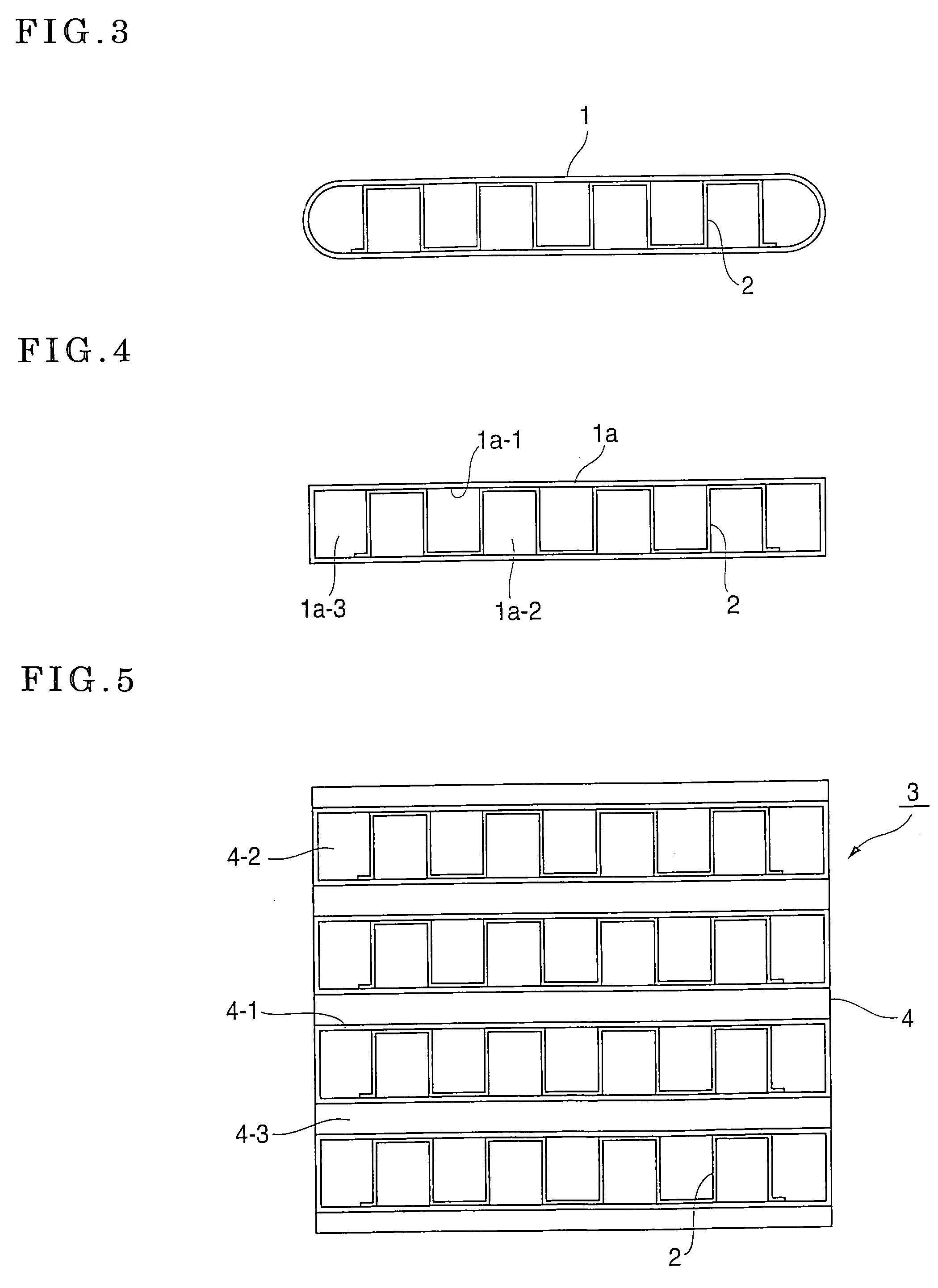

Heat exchanger tube

InactiveUS7614443B2Improve cooling effectImprove heat transfer performanceInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringLength wave

A heat exchanger tube has an inner peripheral surface serving as an exhaust gas flow path with a flat cross-sectional shape. A thin structure is incorporated in the heat exchanger tube and has a substantially rectangular channel-shaped waveform in cross section. The corrugated fin structure has a curved surface forming waveform meandering with a predetermined wavelength in the lengthwise direction. The wave width of the channel-shaped waveform is H, the wavelength of the waveform meandering in the lengthwise direction is L and the amplitude of the waveform meandering in the lengthwise direction is A. The heat exchanger tube is formed so that H / L is set at 0.17 to 0.20 and the ration (G / H) of a gap G determined by H−A to H is set at −0.21 to 0.19.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

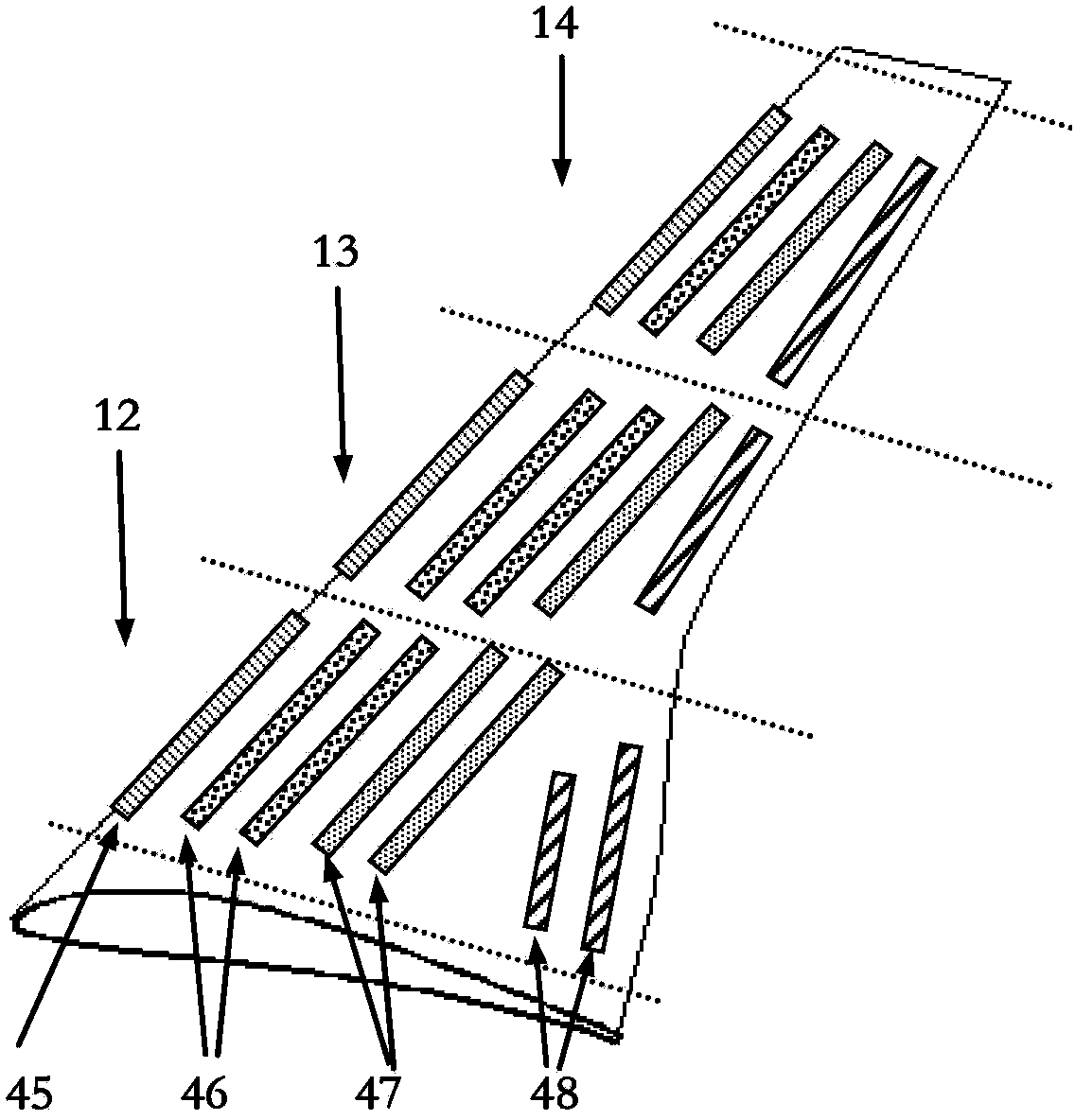

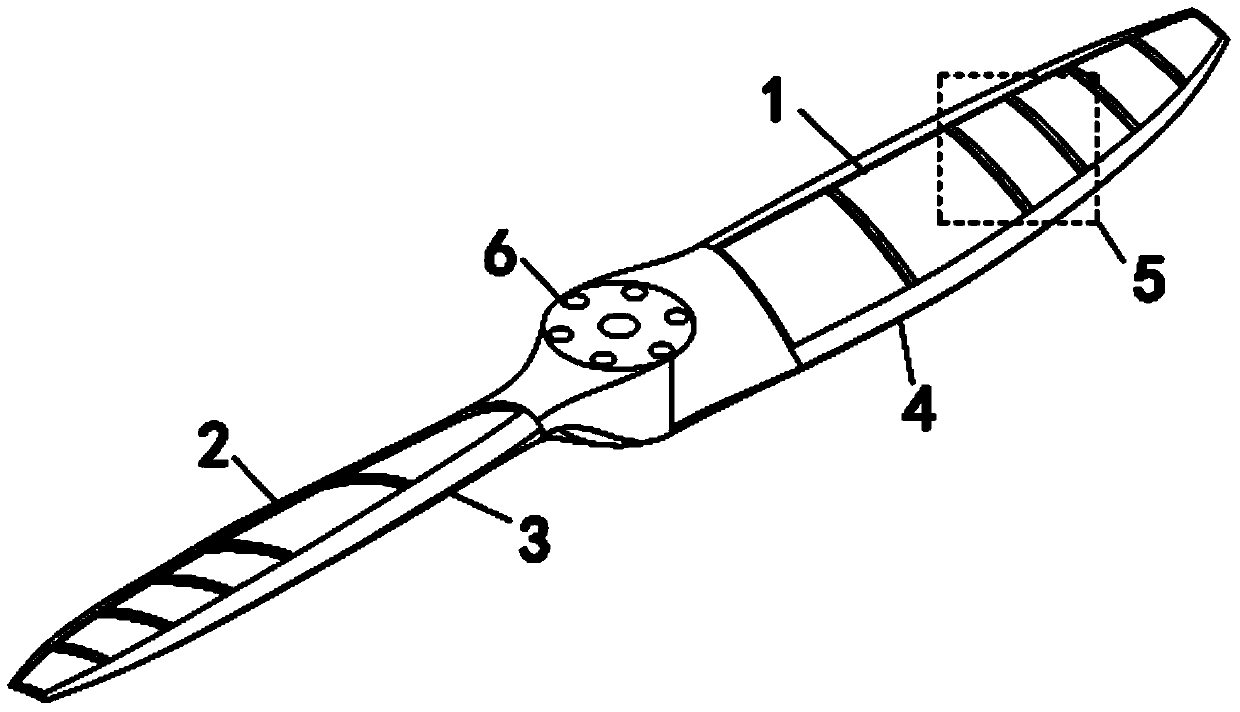

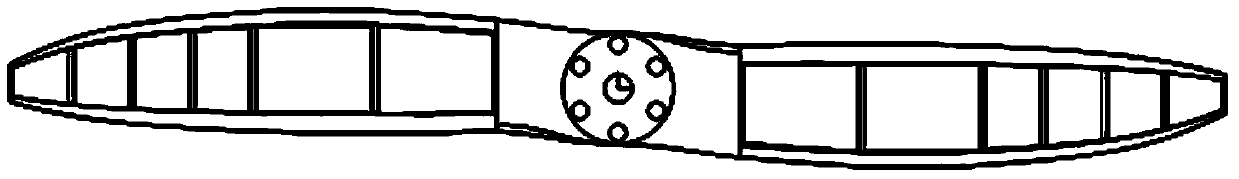

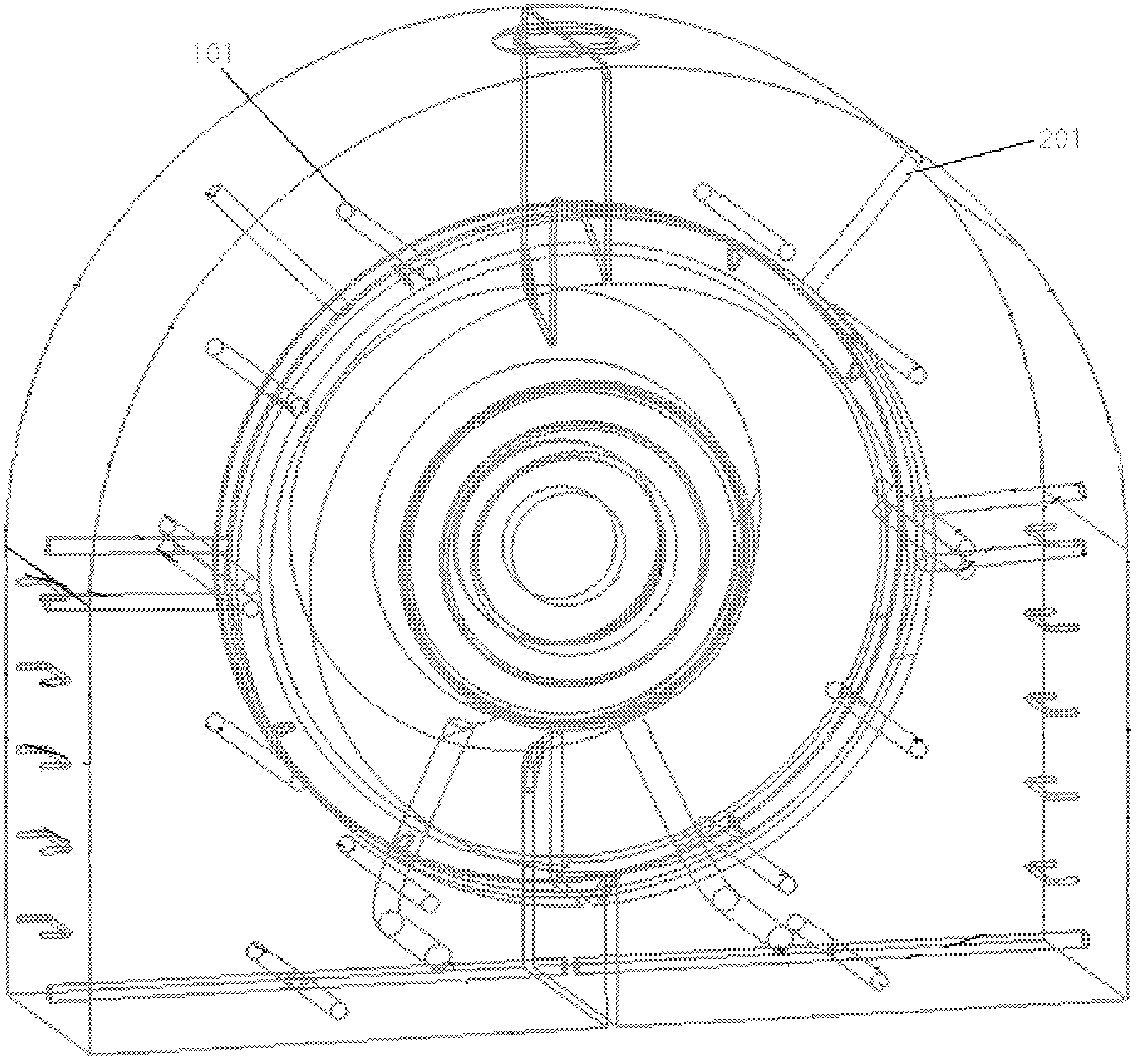

High-efficiency pneumatic layout structure of synergistic jet for high-altitude propeller and control method

ActiveCN104176241AIncrease stall angle of attackImproved stall characteristicsPropellersHigh-pressure areaAir pump

The invention provides a high-efficiency pneumatic layout structure of synergistic jet for a high-altitude propeller and a control method. The high-efficiency pneumatic layout structure is characterized in that a plurality of synergistic jet devices are distributed along propeller blades of the propeller in a spanwise sectional manner; each synergistic jet device comprises an air blowing opening formed in a negative-pressure area of the front edge of the upper surface of the propeller, an air suctioning opening formed in a high-pressure area of the rear edge of the upper surface of the propeller, an airflow pipeline arranged in the paddle and an air pump arranged in the airflow pipeline; the air blowing opening and the air suctioning opening are communicated by the airflow pipeline to form an air-blowing and air-suctioning loop; the air pump is used for driving air suctioning and air spraying to be implemented simultaneously, and by control of the air pump, the air suctioning amount and the air spraying amount are same. The high-efficiency pneumatic layout structure provided by the invention has the advantages that the defects of the traditional propeller layout and the common flow control technology can be made up, and the working efficiency of a propelling system of the high-altitude propeller can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Centrifugal compressor having air removal jet box structure

InactiveCN101012837AIncrease stall marginImprove efficiencyPump componentsRadial flow pumpsHigh energyEngineering

A centrifugal compressor with an air-bleed and a jetting box construction belongs to the turbo-machine field. The invention is characterized in that the wall of the box of worm frame is arranged with at least three exhaust-injection guide channels uniformly arranged around the rotary axle of compressor, while it contains exhaust channels and injection channels. The opening of the exhaust channels is arranged at the wall at the inlet of the non-blade expander channel, and vertical to the wall of inlet box. The opening of the injection channel is at the most torsion of the channel formed by the worm frame and blade, while it is at same direction of main absolute speed of most torsion. The exhaust channel and the injection channel are connected via the guide channel. The inventive exhaust-injection guide channel can exhaust the adhere layer at the wall of expander, restrain the flow separation of expander, and fill high-energy injection into the channel of blade wheel, to restrain the flow separation of adsorption face and restrain the flow separation at small flux, to improve the speed-lost allowance and efficiency.

Owner:TSINGHUA UNIV

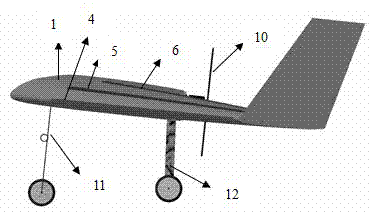

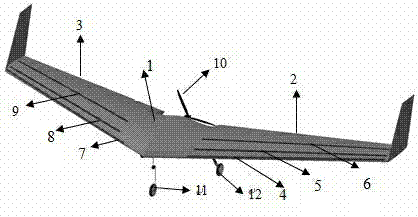

Plasma unmanned aerial vehicle

InactiveCN103661929AInhibition of flow separationEnhance the ability to withstand adverse pressure gradientsAir-flow influencersLeading edgePlasma jet

The invention discloses a plasma unmanned aerial vehicle. First plasma exciters are distributed on the leading edges of a left wing and a right wing of the aerial vehicle; second plasma exciters are distributed in the one fourth positions of chord lines; and third plasma exciters are distributed in the maximum thickness positions. Meanwhile, a miniaturized plasma power supply is designed and integrated into the aerial vehicle, and a switch and relevant discharge parameters of the plasma power supply can be controlled through a program or in a remote control manner. When the plasma exciters start to work, the adverse pressure gradient resistance of a boundary layer is enhanced by means of plasma jet generated by the exciters, a flow field of the upper wing surface of the aerial vehicle can be controlled, and the aerodynamic characteristics of the aerial vehicle are improved; starting of the plasma exciters in the different positions is appropriately adjusted, and aerodynamic moment can be produced, so that the flight attitude of the aerial vehicle can be controlled; and the plasma aerial vehicle has the characteristics that the aerodynamic characteristics are improved, control plane flight controlling is not required, the invisibility is good and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

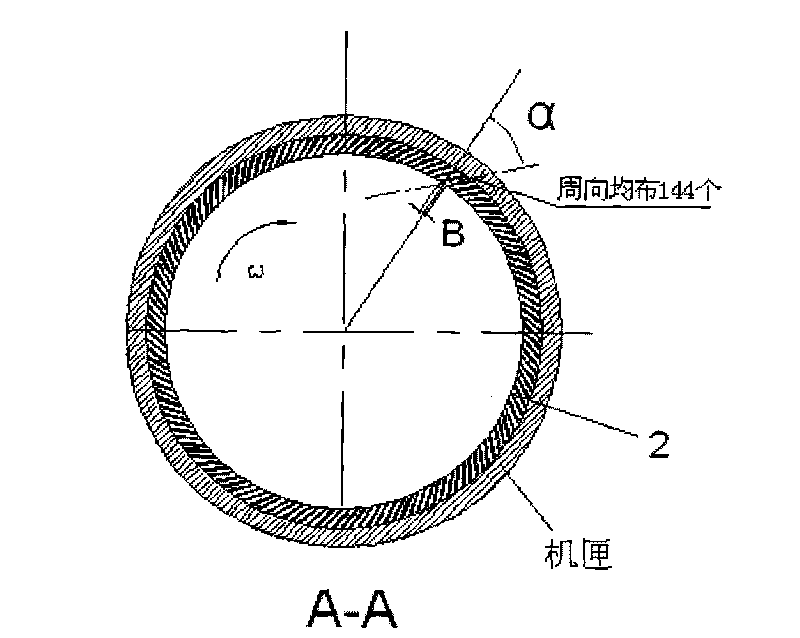

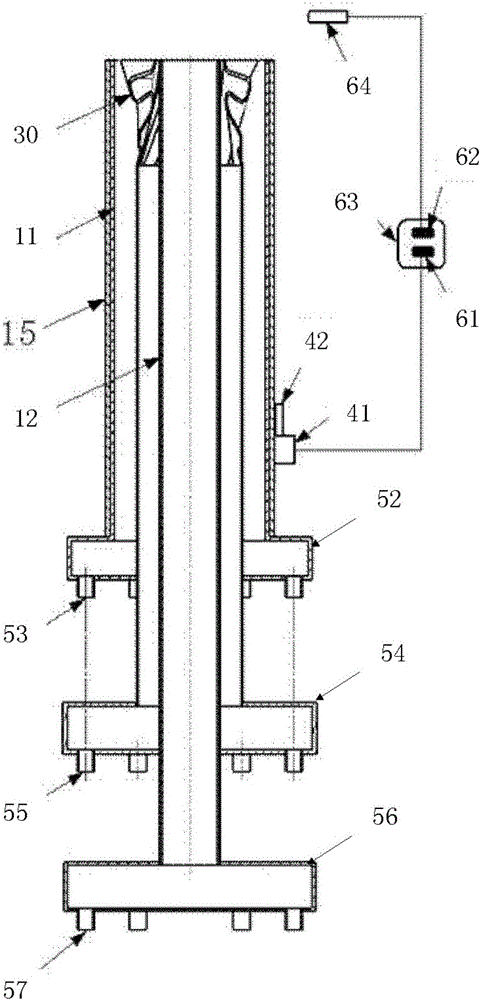

Axial and radial flowing compressor with axial chute processor casing structure

InactiveCN101691869AIncrease stall marginControl of low energy gap vorticesPump componentsPump installationsImpellerEngineering

The invention relates to an axial and radial flowing compressor with an axial chute processor casing structure, belonging to the technical field of impeller machinery; the axial and radial flowing compressor comprises an axial flowing rotor, an axial flowing stator and a radial-flowing compressor which are coaxially connected sequentially; axial chutes which are circumferentially distributed uniformly are processed on a casing wall surface of the axial flowing rotor of the axial and radial flowing compressor, the axial chute is radially inclined with 30-60 degrees along the rotating direction of the rotor. In the axial and radial flowing compressor with the axial chute processor casing structure, the low-energy tip clearance vortex of axial-flowing grade blade tip can be effectively controlled under the pumping action of the axial chute processor casing on the axial flowing rotor, flow separation is inhibited under a low flow-rate condition, the entrance condition of the radial flowing compressor is improved, so as to improve surge-to-stall margin of the axial and radial flowing compressor greatly on the premise of ensuring the little change of pressure ratio and efficiency.

Owner:TSINGHUA UNIV

Methods and apparatus for reduction of aerodynamic drag

ActiveUS20100194142A1Reduce aerodynamic dragReduce air resistanceVehicle seatsWindowsAerospace engineeringAerodynamic drag

A method of reducing aerodynamic drag on a moving blunt-edged body, the method comprising actively generating a flow of air at a blunt edge of a body and using the generated flow of air to control an external flow of air moving relative to an edge of a moving blunt-body.

Owner:RAMOT AT TEL AVIV UNIV LTD

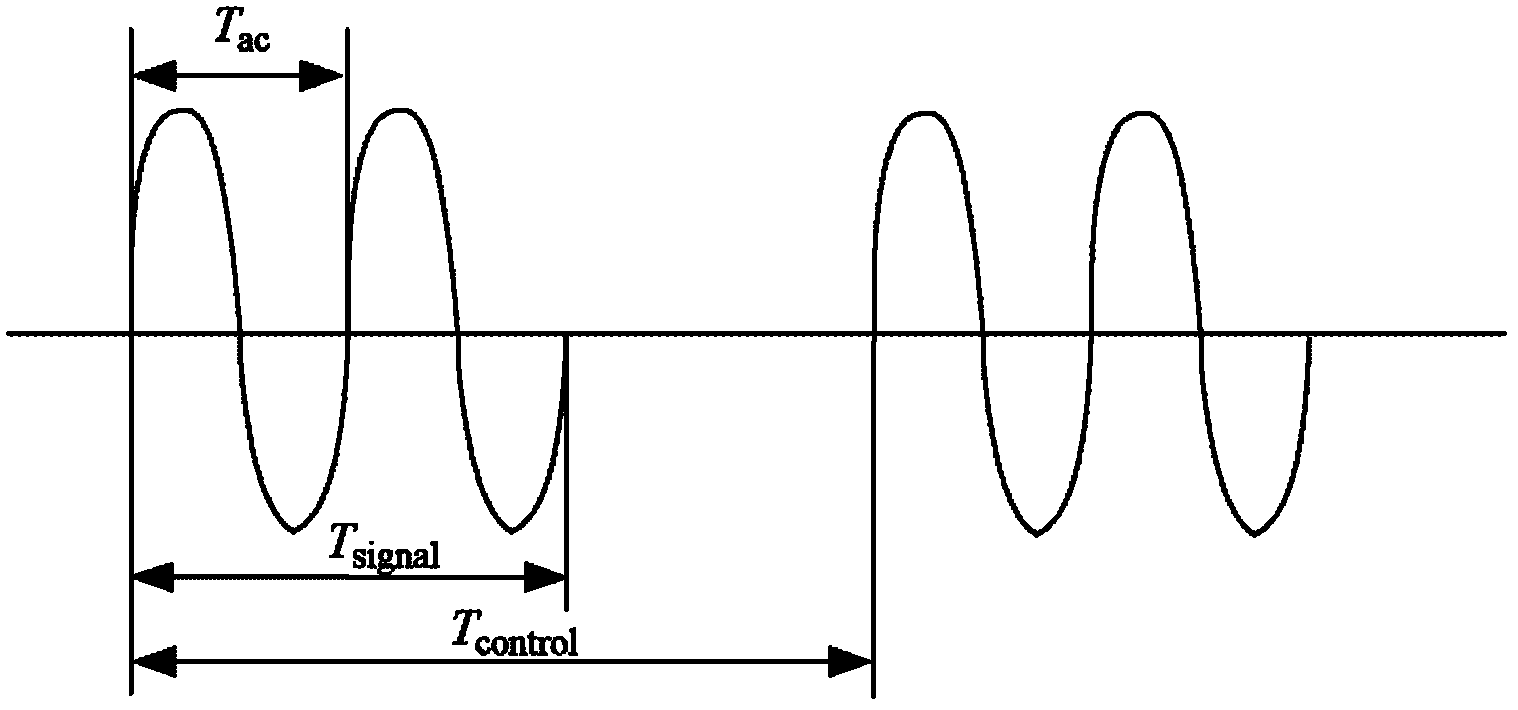

Method for controlling plasma flow of wing lift-rising apparatus

InactiveCN103523208AImprove the lift-to-drag ratioIncrease lift coefficientAir-flow influencersLeading edgeTrailing edge

The invention relates to a method for controlling plasma flow of wing lift-rising apparatus, and the technical scheme is characterized in that: plasma exciters are laid on the suction face of the leading edge slat, the suction face of the main wing trailing edge and the suction face of the trailing edge flap. The plasma exciter is composed of electrodes in asymmetric layout and separated by an insulating material, the electrode on the upper surface of the insulating material is connected with the high-voltage terminal of a pulse plasma power supply, and the electrode on lower surface is earthed. The laying positions of the plasma exciters are at the leading edge and the trailing edge of a separation point. When the leading edge slat and the trailing edge flat are deployed during the launching and the landing of an airplane, a signal of 'on' is emitted and the plasma exciters are turned on; and when the leading edge slat and the trailing edge flat are fold by the airplane, a signal of 'off' is emitted and the plasma exciters are turned off. The method helps to effectively control the flow separation of the suction faces of the leading edge slat, the main wing trailing edge and the trailing edge flap when the airplane is in a launching or landing state, substantially improving wing lift-drag ratio and maximum lift coefficient, and further improve the launching and landing weight of the airplane and shorten the running distance.

Owner:AIR FORCE UNIV PLA

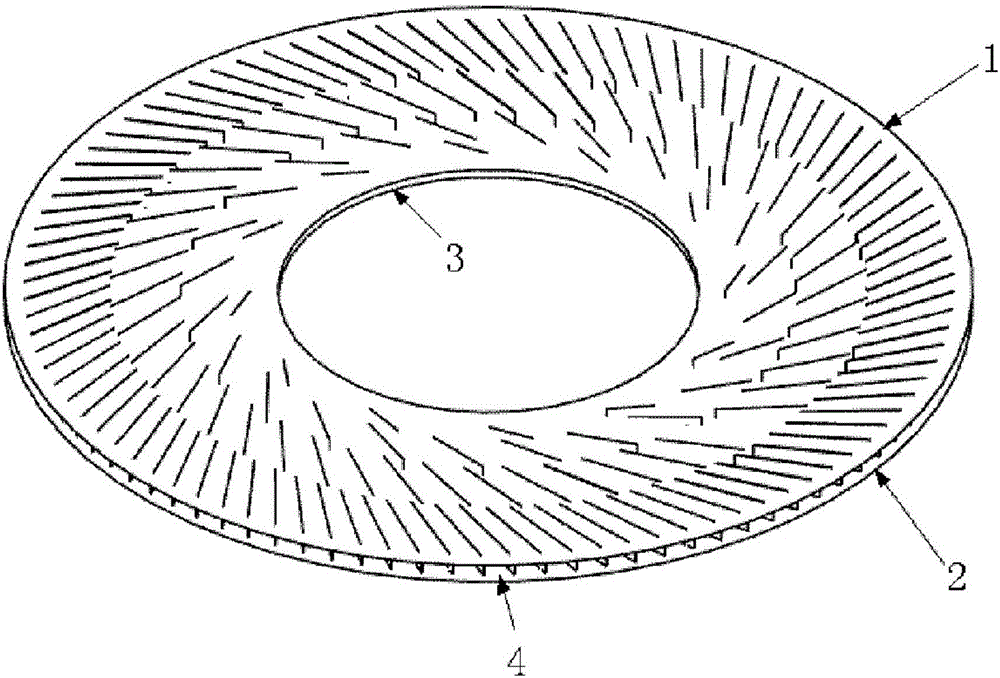

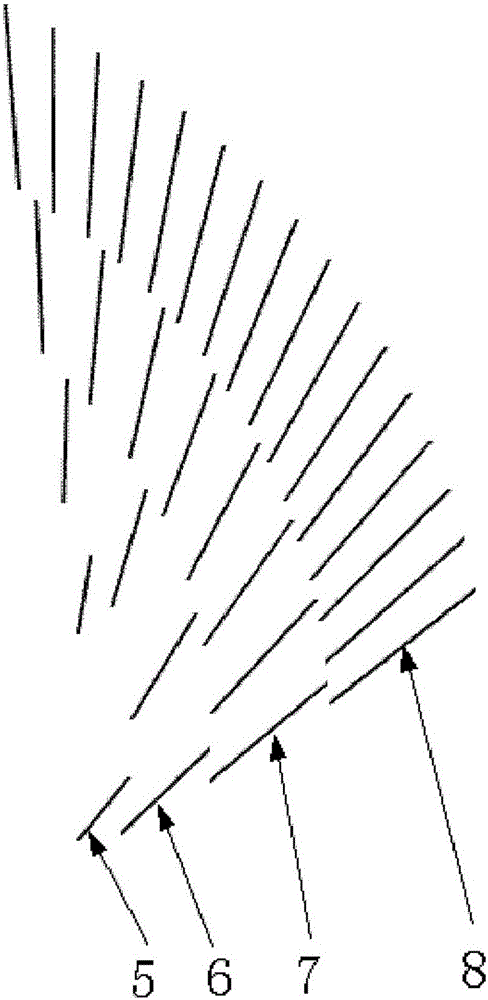

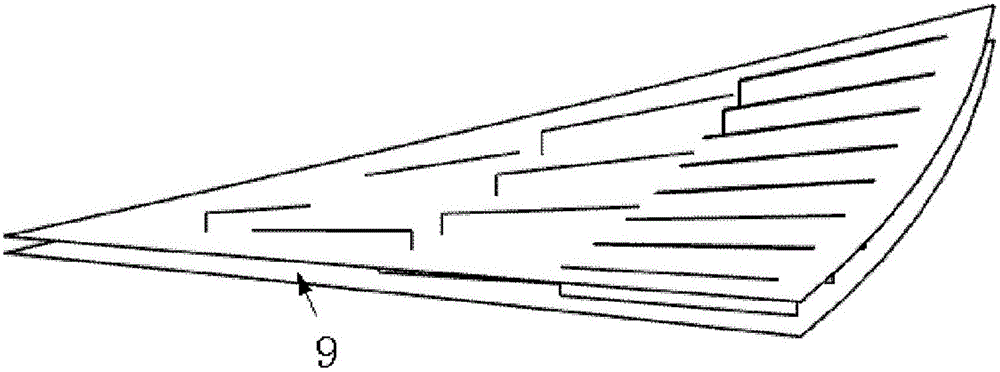

Pressure expander based on fractal blades

InactiveCN106089807AImprove the diffusion capacityImprove efficiencyPump componentsPumpsEngineeringCentrifugal compressor

The invention provides a pressure expander based on fractal blades. The pressure expander comprises an upper cover plate, a lower cover plate and a fractal blade group, wherein the fractal blade group is arranged between the upper cover plate and the lower cover plate in a clamping manner; a gas flow channel is formed among the upper cover plate, the lower cover plate and the fractal blade group; and after passing through the gas flow channel, the pressure of a gas flow is enlarged. The multi-stage fractal blades of the pressure expander disclosed by the invention can restrain flow separation, reduce flow blockage and flow loss, and improve the pressure expanding capacity and the pressure expanding efficiency of the pressure expander are improved, so that improvement of the efficiency of the whole machine, the reduction of the size of the whole machine and increase of the thrust-weight ratio / power-weight ratio are facilitated, the pressure expander disclosed by the invention is convenient to process and low in manufacturing cost, and can be directly mounted on a pressure expanding section of a centrifugal compressor, and the modifying and the upgrading of the compressor are facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

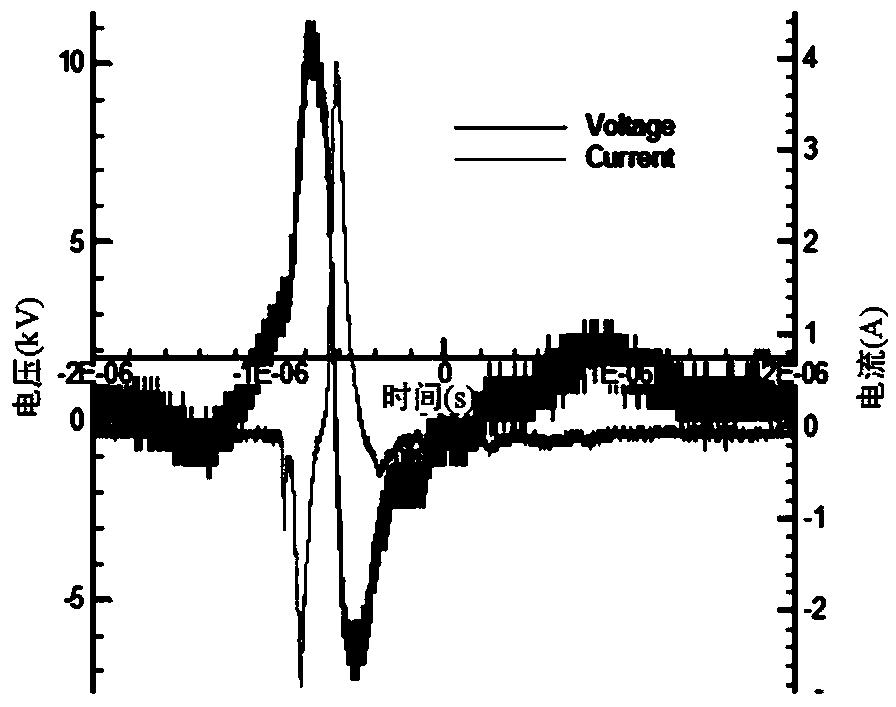

Plasma flow control method for suppressing flow separation of suction surface of wind turbine blade

InactiveCN102913386ASimple structureReduce power consumptionWind motor controlMachines/enginesEngineeringCell separation

The invention relates to a plasma flow control method for suppressing the flow separation of a suction surface of a wind turbine blade. The plasma flow control method comprises the following steps of: asymmetrically distributing two metal electrodes at both sides of an insulating material to form a group of plasma exciter, wherein one metal electrode is exposed in the air, while the other metal electrode is embedded in the insulating material; arranging at least one group of plasma exciter on the suction surface of the wind turbine blade in a mounting mode capable of ensuring that a plasma induced flow direction is the same as a main flow direction; applying plasma excitation voltage on the two metal electrodes of the plasma exciters, and generating low-temperature plasma above the metal electrodes embedded in the insulating material; and transferring energy to a boundary layer through the collision of ions and neutral gas molecules to ensure that a horizontal direction jet flow with a static flow of zero is formed by surrounding air so as to accelerate air flows in the boundary layer. The plasma flow control method has the advantages of simple and compact structure, quick reaction, low energy consumption and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

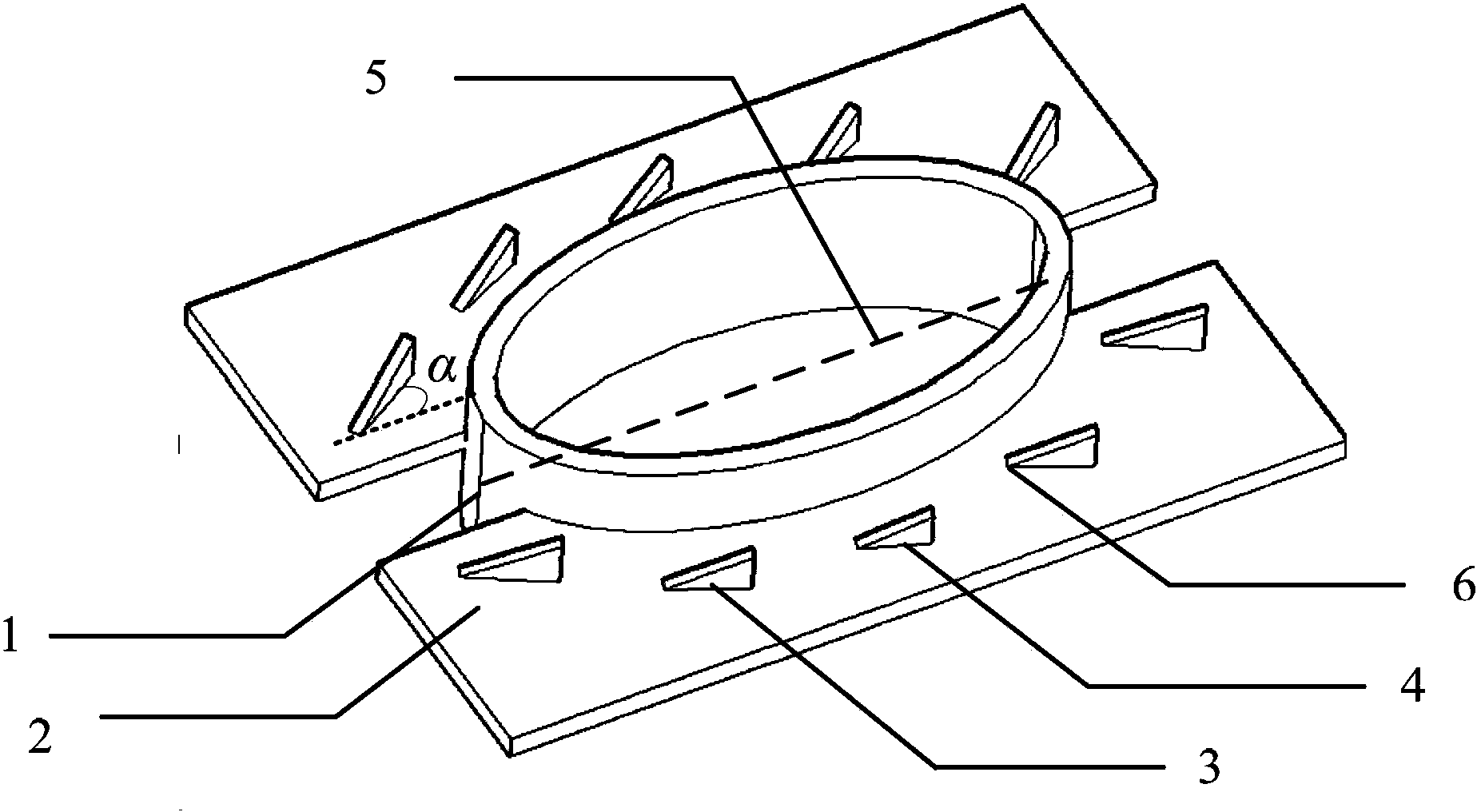

Elliptical tube H-shaped fin heat exchanger for waste heat recovery

ActiveCN103438746AIncrease disturbanceIncrease the thermal resistance of heat transfer, reduce the wake zone" enhanced heat transfer principleTubular elementsParticle adhesionWaste heat recovery unit

The invention discloses an elliptical tube H-shaped fin heat exchanger for waste heat recovery. The elliptical tube H-shaped fin heat exchanger comprises an elliptical heat exchange tube, a plurality of groups of H-shaped fins and a heat exchanger surface, wherein the H-shaped fins are sleeved on the surface of the heat exchange tube; the heat exchanger surface consists of non-uniform triangular small wings, which are elliptically arranged, on the surfaces of the H-shaped fins around the elliptical heat exchange tube. When dusty flue gas flows through the surfaces of the H-shaped fins, the small wings disturb the fluid to enhance the heat exchange on the tube wall and the downstream side, and meanwhile, the deposition of particles on the tube wall is reduced; the pressure drop can be reduced by the elliptical tube while the particle adhesion is reduced. A plurality of longitudinal vortexes are arranged in a non-uniform manner; at the front and rear edges of the wing, the size of the small wings and the windward attack angle are larger; on the middle parts of the H-shaped fins, the size of the small wings and the attack angle are smaller; by using the device, the heat exchange surface in different flow states can be enhanced respectively, the heat exchange of the fins are effectively enhanced, the pressure drop is reduced, and the deposition of dust particles in the flue gas on the heat exchange surface is reduced, so that the heat exchanger can operate efficiently for a long time in the dusty flue gas.

Owner:XI AN JIAOTONG UNIV

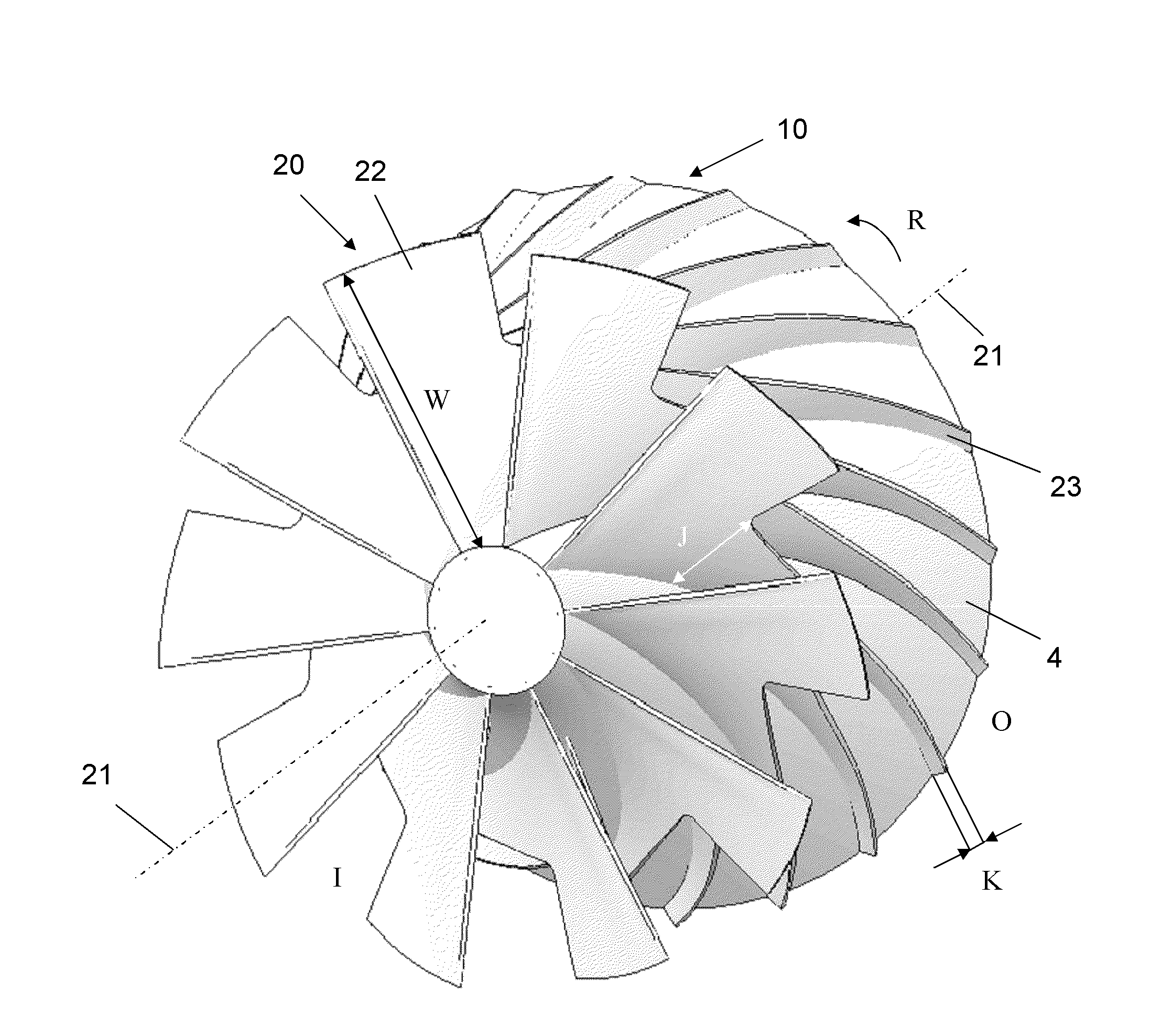

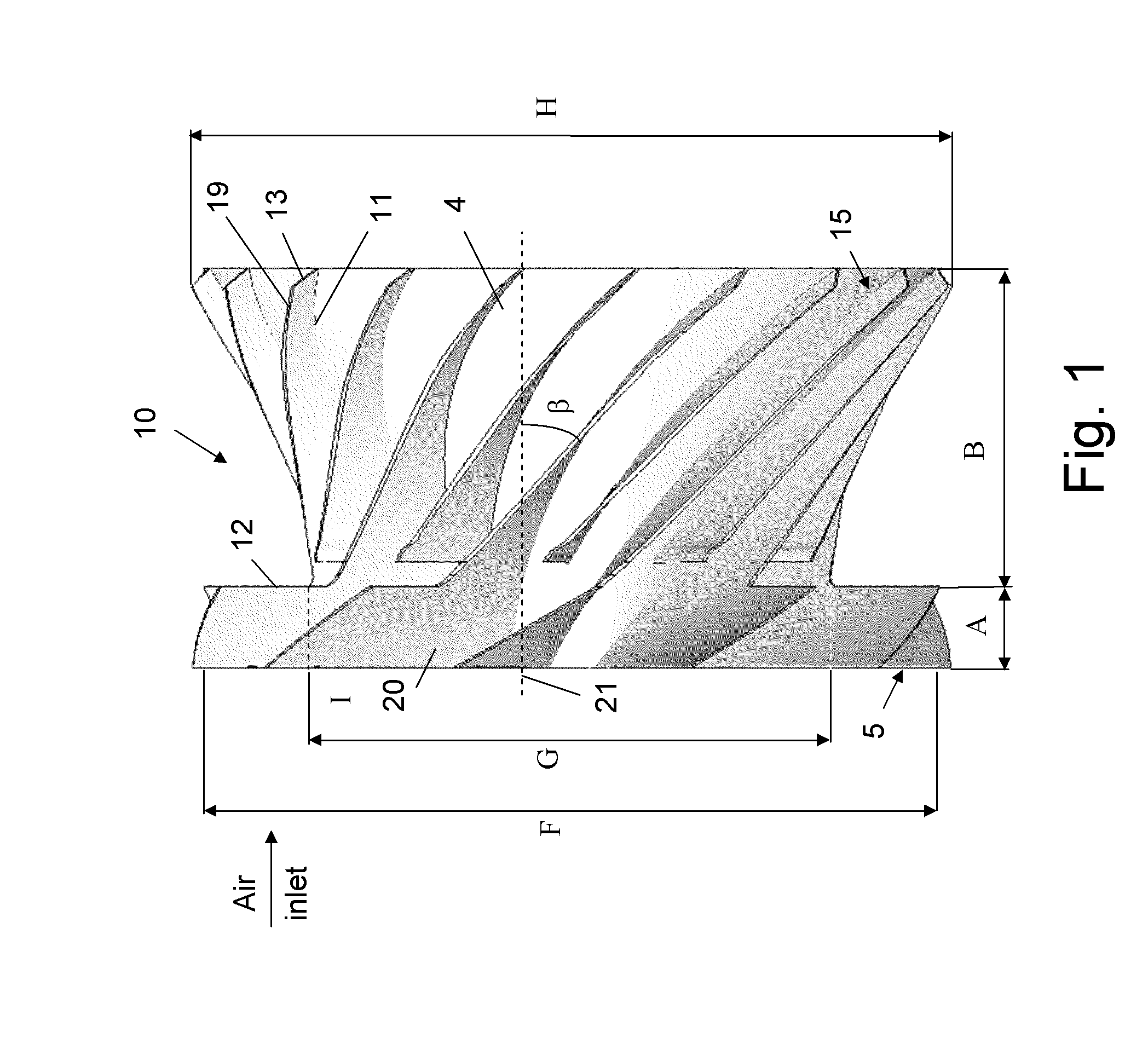

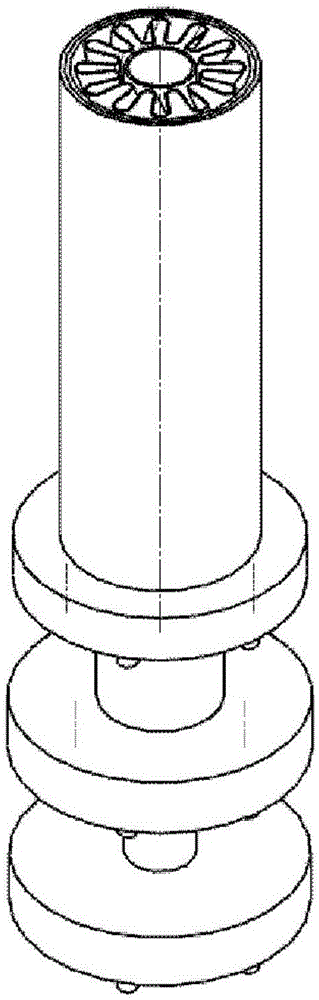

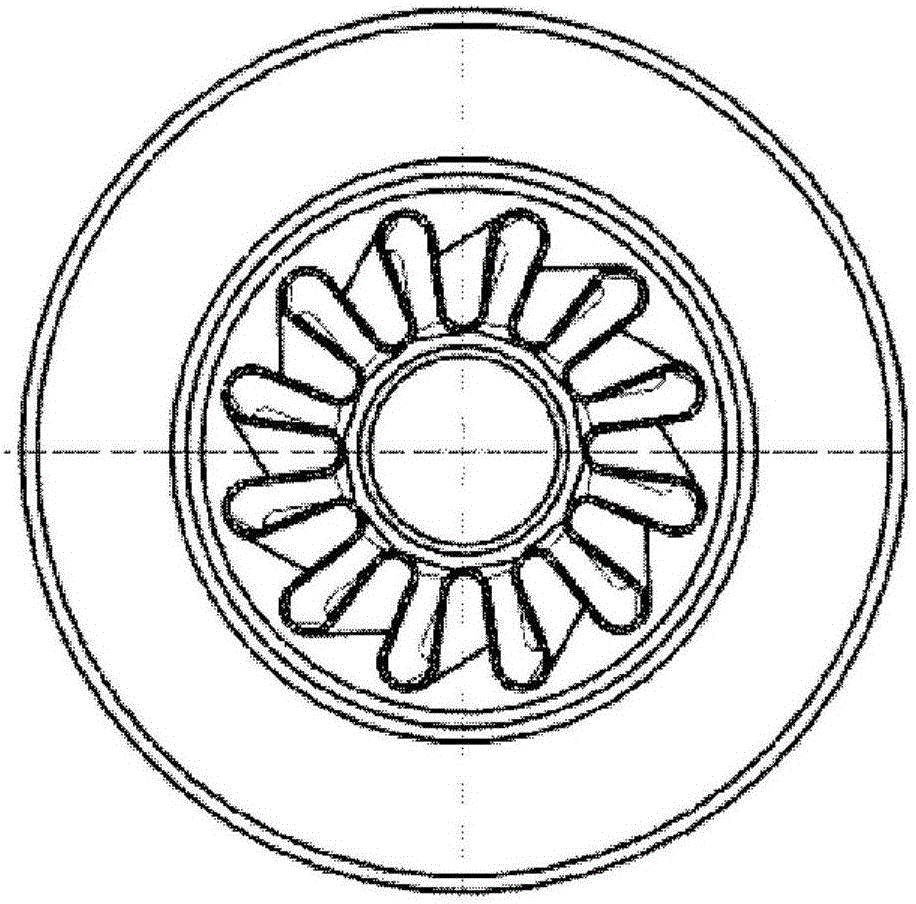

Impeller

ActiveUS20130115067A1Inhibition of flow separationAvoid eddy currentsEngine manufacturePump componentsImpellerMixed flow

A combined fan-compressor impeller comprises a single hub and a plurality of spaced main blades extending outwardly from the hub such that an air passage channel is defined between two of the main blades. Each of the main blades is a mixed flow blade which continuously extends from a fan section at an inlet end of a channel to a compressor section at an outlet end of the channel without any axial clearance between the fan section and the compressor section, providing aerodynamic matching of pressurized air flowing through the channel from the fan section to the compressor section.

Owner:RAFAEL ADVANCED DEFENSE SYSTEMS

Adjustable nozzle, nozzle array and combustor

ActiveCN105910136ATake advantage ofImprove combustion effectContinuous combustion chamberWave structureCombustor

The invention provides an adjustable nozzle comprising an inner cylinder, an outer cylinder, an outer cylinder sleeve and N layers of outer wave structures clamped between the inner cylinder and the outer cylinder; the outer wave structures are radially arranged in sequence along the periphery; gas channels are formed between adjacent outer wave structures, and between the outer wave structures and the inner and outer cylinders; the outer cylinder sleeve is sleeved outside the outer cylinder, and can axially move along the cylinder shaft, thus switching work modes and adjusting flame positions.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for exciting and controlling gas flow of stator blade end wall of axial-flow compressor by aid of plasmas

InactiveCN102606502AInhibition of flow separationImprove stabilityPump controlNon-positive displacement fluid enginesControl signalEngineering

The invention relates to a method for exciting and controlling gas flow of the stator blade end wall of an axial-flow compressor by the aid of plasmas, which is characterized by including the steps: laying a plasma pneumatic exciter on the stator blade passage end wall of the axial-flow compressor, wherein the front edge and the tail edge of an electrode of the plasma pneumatic exciter are level to the front edge and the tail edge of a stator blade respectively, and the direction of the electrode is parallel to a mean camber line of the stator blade; when an engine controller detects flow instability indication, loading electric signals to the electrode of the plasma pneumatic exciter by employing a pulse plasma power source; and when the engine controller detects disappearance of flow instability indication, sending out control signals, and closing the plasma pneumatic exciter. The control method is capable of effectively suppressing stator blade angle area flow separation of the axial-flow compressor, short in exciting response time and wide in bandwidth, and has an important role in reduction of stator blade wake pitot loss and improvement on stability and efficiency of the compressor.

Owner:AIR FORCE UNIV PLA

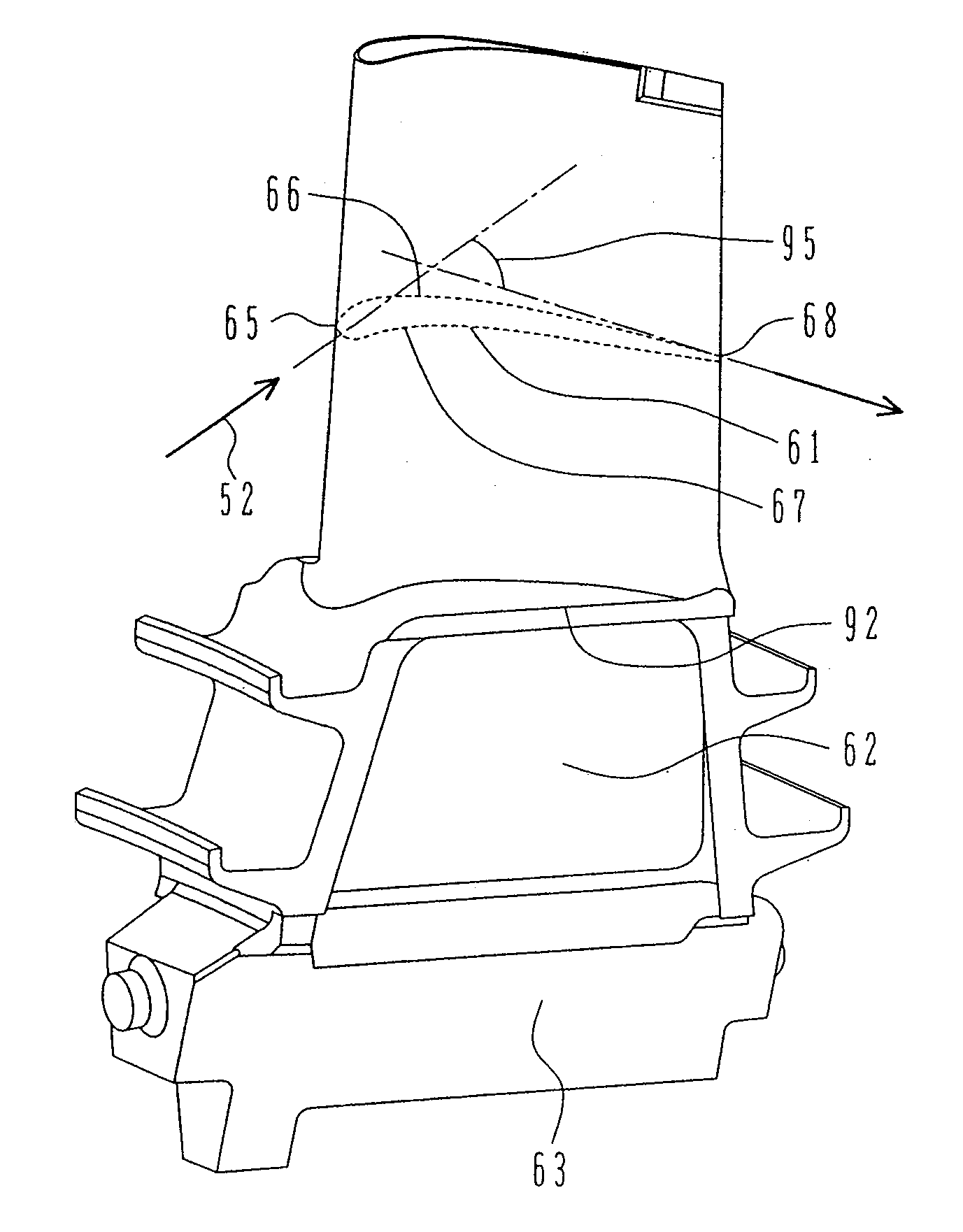

Turbine blade

ActiveUS20080240924A1Improve performanceInhibition of flow separationPropellersEngine manufactureTurbine bladeEngineering

An airfoil profile is formed such that a passage width ratio, represented in a dimensionless manner, of an inter-blade passage width of vain root cross-section to an outlet throat width substantially monotonously decreases from a blade inlet toward a blade outlet. The blade has a blade airfoil profile shape in an envelope within a range of ±2.0 mm in a direction normal to any surface location of an airfoil profile portion. The airfoil profile portion has a reference airfoil contour represented in Cartesian coordinates wherein Z is a distance representing a sectional height from a root of the airfoil profile portion. The contours represented by X and Y at each section Z are joined smoothly with one another in a blade height direction to form a complete shape of the airfoil profile portion.

Owner:MITSUBISHI POWER LTD

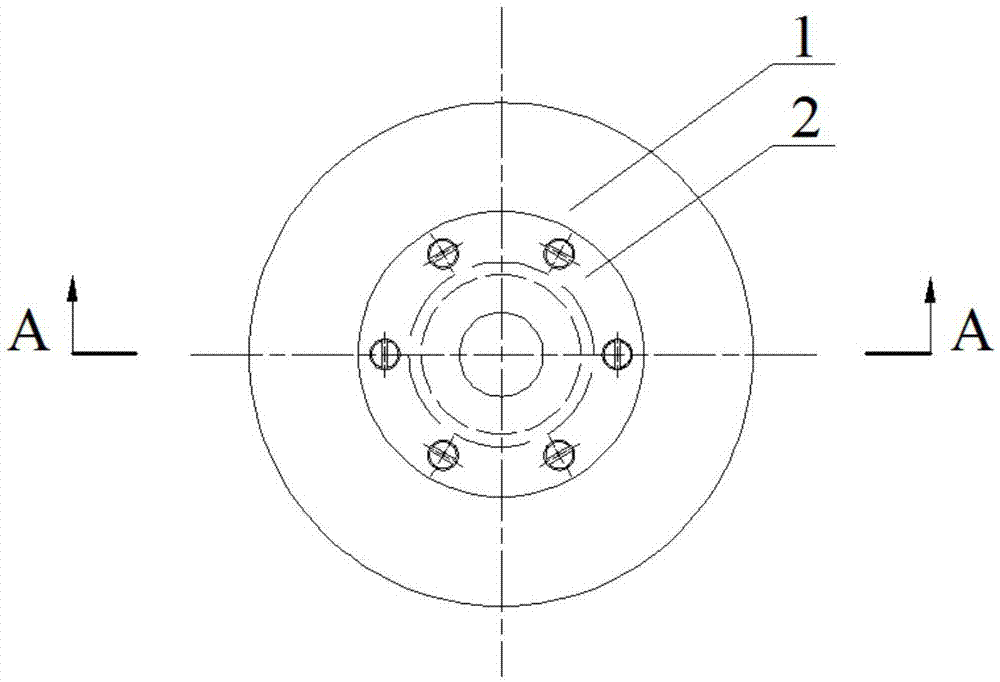

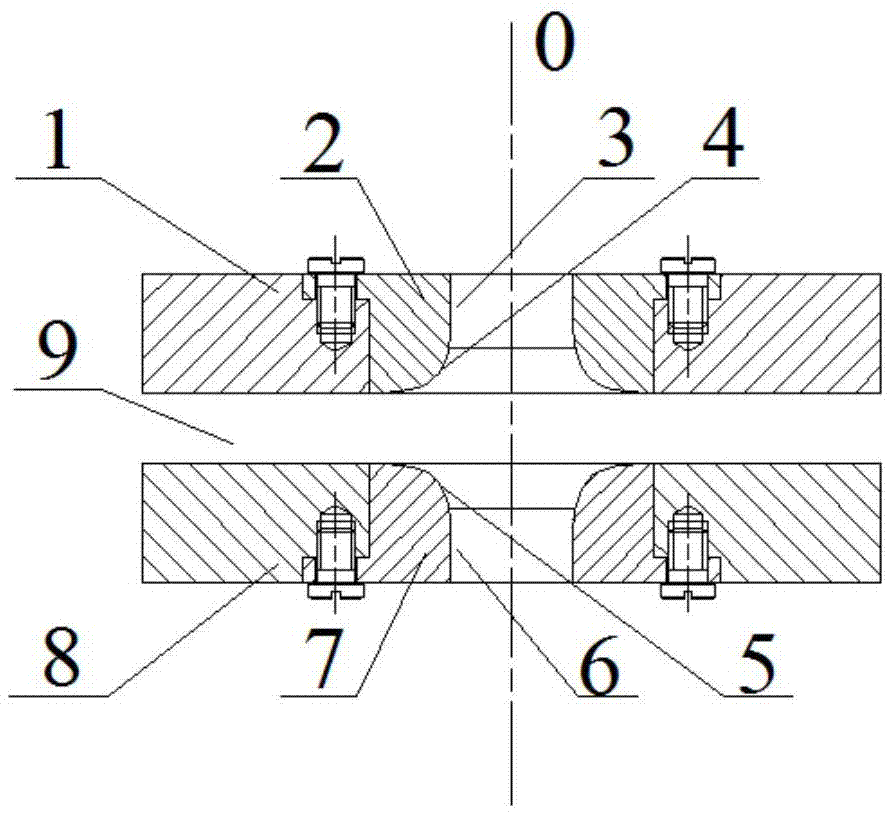

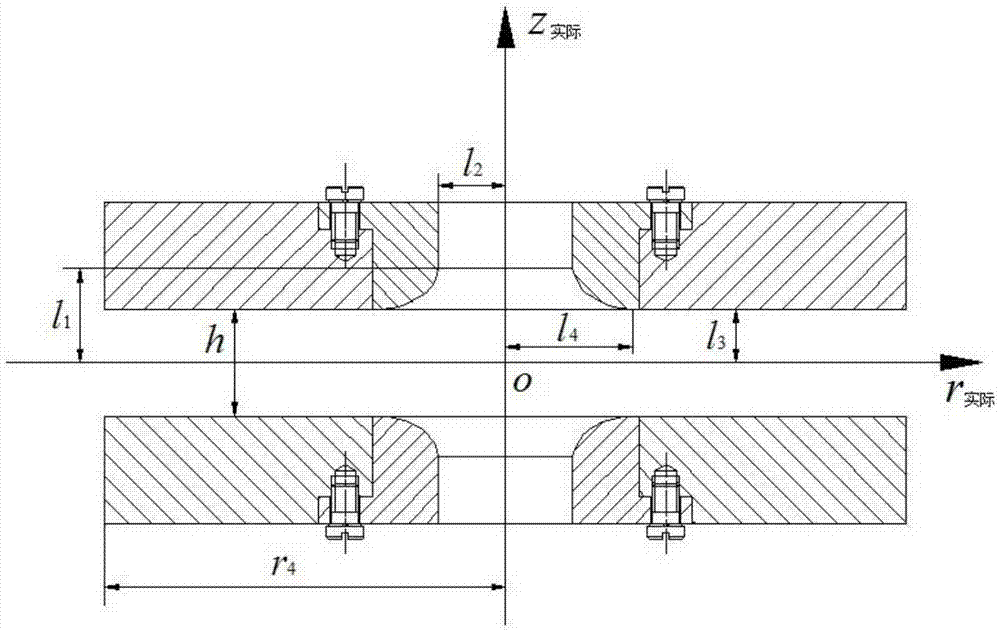

High-pressure disc thrust gas bearing adopting double symmetrical contraction sections for gas supply and design method

ActiveCN105443579AReduce distractionsImprove flow field structureGas cushion bearingsGas lubricationProcess engineering

A high-pressure disc thrust gas bearing adopting double symmetrical contraction sections for gas supply comprises an upper working disc (1) and a lower working disc (8) which are arranged in parallel, a gas lubricating film (9) is formed between the upper working disc (1) and the lower working disc (8), and a gas supply component (2) is arranged in the center of the upper working disc (1) and is further connected with an upstream pressure stabilizing cavity. A gas supply hole (3) is formed in the center of the gas supply component (2) and used for introducing gas flow. The double symmetrical contraction sections (4) in a curved surface form are arranged on the downstream of the gas supply hole (3) and are used for smoothly accelerating axial low-speed incoming flow into radial subsonic speed gas flow. According to the high-pressure disc thrust gas bearing, the axial low-speed incoming flow at inlets of the contraction sections is smoothly accelerated into the uniform radial subsonic speed gas flow at outlets of the contraction sections, serious flow separation is avoided at the same time, and the gas flow is further accelerated to the supersonic speed at a gas film outlet. After the gas supply pressure exceeds a certain specific value, the bearing capability of the bearing can be linearly increased along with the increase of the gas supply pressure, and the high-pressure disc thrust gas bearing is suitable for working under high-pressure, heavy-load and large-gap working conditions.

Owner:WUHAN UNIV OF SCI & TECH

Cooled turbine guide vane or blade for a turbomachine

InactiveUS9896942B2Improve heat transfer performanceReduce the amount requiredEngine fuctionsBlade accessoriesSuction stressEngineering

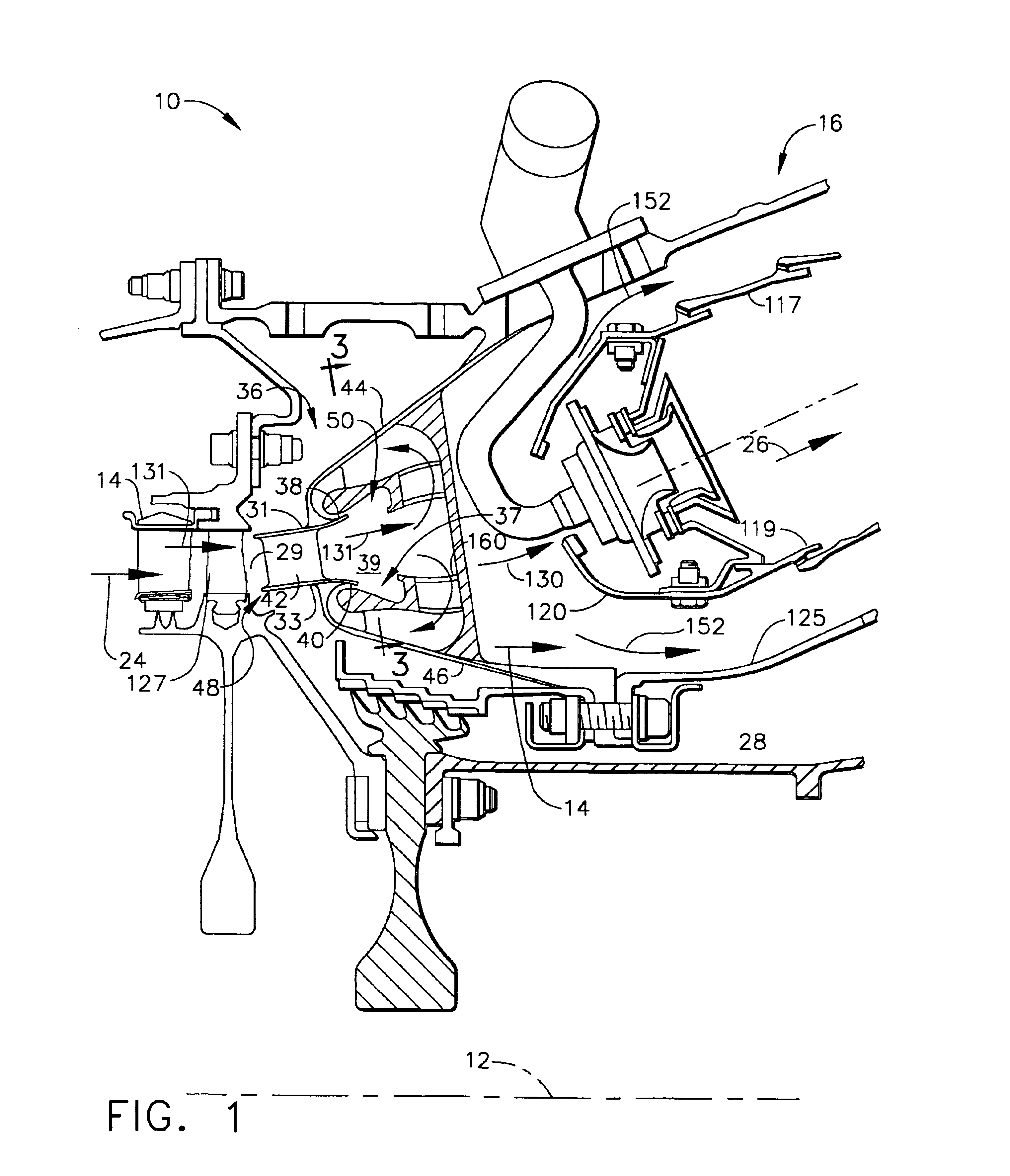

A turbine airfoil has a suction side wall and a pressure side wall of an airfoil cavity, through which a cooling fluid flows for cooling of the side walls. The suction side wall has one or more protrusions extending therefrom into the airfoil cavity. The protrusions are arranged such that: a number of the one or more protrusions on the suction side wall is higher than a number of protrusions on the pressure side wall; and / or a protrusion density on the suction side wall is higher than a protrusion density on the pressure side wall, and / or a total protrusion surface area on the suction side wall is larger than a total protrusion surface area on the pressure side wall, so that the heat transfer from the suction side wall to the cooling fluid is higher compared to that of the pressure side wall during operation of the turbomachine.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

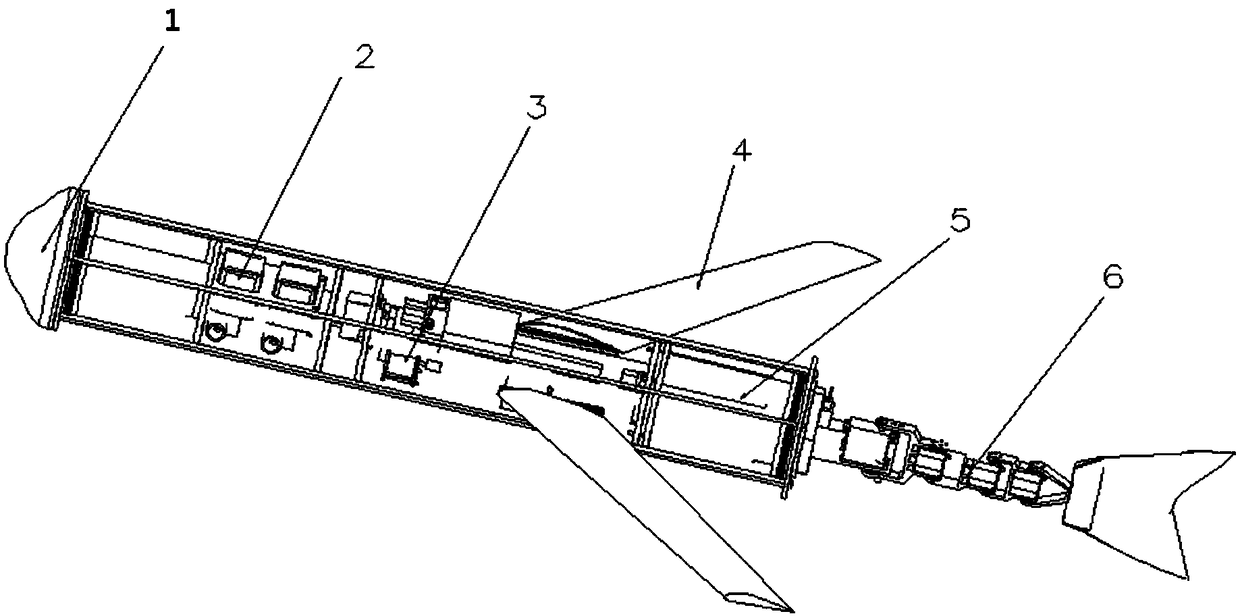

Underwater robot of bionic and gliding hybrid propulsion mode

InactiveCN108241179ARealize monitoringIncrease the voyageGeological measurementsPosition/course control in three dimensionsFiberCarbon fibers

The invention discloses an underwater robot of a bionic and gliding hybrid propulsion mode. The underwater robot comprises a head part, a sinking and floating adjustment mechanism, a center of gravityadjustment mechanism, a circuit compartment, a gliding wing and a tail part. The head part is composed of an image collection compartment. The sinking and floating adjustment mechanism includes an inner oil sac, a reversing valve, a hydraulic pump, a relief valve and an outer oil sac. The center of gravity adjustment mechanism includes a stepping motor driver, a stepping motor, a steering gear drive, a left and right center of gravity steering gear, a screw rod, a guide rail and a heavy block. The circuit compartment consists of a control system, including a moving layer, a sensing layer, a control layer, a communication layer and a monitoring layer. The gliding wing is made of epoxy carbon fiber material, with the advantages of high strength, light weight and so on. The tail part includes a four-joint bionic fishtail steering gear and a fishtail skeleton. The underwater robot of the bionic and gliding hybrid propulsion mode in the invention has the characteristics of large range, lownoise, low energy consumption, high concealment, small turning radius and so forth, and can improve the accuracy of measurement data and improve the working efficiency of measurement.

Owner:NANJING INST OF TECH

Gas compressor stationary blade cascade with equal-width linear groove formed in blade root

ActiveCN105179322AStrong ability to resist reverse pressure gradientInhibition of flow separationPump componentsPumpsEngineeringGas compressor

The invention provides a gas compressor stationary blade cascade with an equal-width linear groove formed in a blade root and relates to the passive flow control technology in the technical field of turbomachinery. By means of the gas compressor stationary blade cascade, the equal-width linear groove is formed in the blade root end wall of the gas compressor stationary blade cascade from the pressure face to suction face, and jet flow is formed through detour flow pressure differentials of a blade, so that flow separation is restrained and delayed. The groove is located in the blade root end wall of the gas compressor stationary blade cascade. The spanwise height is a constant value. The inlet of the groove is located in the pressure face of the stationary blade cascade. The outlet of the groove is located in the suction face of the blade cascade. The center line of the groove is a straight line and equidistant from the two side walls of the groove. The gas compressor stationary blade cascade has the beneficial effects that corner separation is restrained; the flow capacity of the blade cascade is increased; the total pressure loss is reduced; the diffusion capacity is improved.

Owner:BEIHANG UNIV

Exhaust steam cylinder of miniature steam turbine

ActiveCN102434233AEliminate the impact of workmanshipAvoid problemsMachines/enginesEngine componentsSteam pressureEngineering

The invention discloses an exhaust steam cylinder of a miniature steam turbine, which comprises a volute and a diffuser, wherein the diffuser comprises an inner deflector and an outer deflector; the volute is arranged on the circumference of the diffuser and comprises an upper wall and a side wall; the width of the volute along the axial direction of the exhaust steam cylinder is bigger than that of the diffuser; the outer deflector is connected with the side wall, and the inner deflector is arranged in the volute; inner wall corners at the connecting part of the upper wall and the side wall and the connecting part of the outer deflector and the side wall are both arc-shaped wall corners; the side face of the inner deflector is a side face consisting of first non-uniform rational spline curves; and the side face of the inner deflector consists of second non-uniform rational spline curves. The exhaust steam cylinder of the miniature steam turbine, provided by the invention, can prevent vortex secondary flow from occurring at the wall corners and eliminate the influence of the vortex secondary flow on steam pressure at the final blade cascade outlet of the miniature steam turbine.

Owner:QINGDAO JIENENG STEAM TURBINE GROUP CO LTD

Pit-type compressor blade and control method for flow separation in cascade

InactiveCN109058173AIncrease momentum levelInhibition of flow separationPump componentsPumpsImpellerEngineering

The invention relates to the technical field of turbomachines, in particular to a pit-type compressor blade and a control method for flow separation in a cascade, wherein the compressor blade is provided with a pit. The pit is used as a kind of vortex generator, when the boundary layer fluid flows through the suction surface of the blade, a different form of vortex structure will be formed inside,and the generated vortex will promote the mixing of low-energy and high-entropy fluid and extra-layer fluid in the boundary layer, thereby increasing the kinetic energy level of the boundary layer and suppressing the flow separation, it is mainly used to control the flow separation in a stationary cascade of a compressor and reduce the flow loss, thereby improving the flow condition and the aerodynamic performance of the stationary cascade of the compressor.

Owner:大连凌海华威科技服务有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com