High-efficiency pneumatic layout structure of synergistic jet for high-altitude propeller and control method

A technology of coordinated jet flow and aerodynamic layout, applied in propellers, aircraft parts, transportation and packaging, etc., can solve the problems of difficult to effectively improve the working efficiency of the propeller propulsion system, low working efficiency, low controllable flow rate, etc., and achieve the expansion of working conditions range, improved aerodynamic efficiency, and increased stall angle of attack effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a high-altitude propeller cooperative jet aerodynamic layout configuration installed on the propulsion system of a 20km high-altitude aircraft.

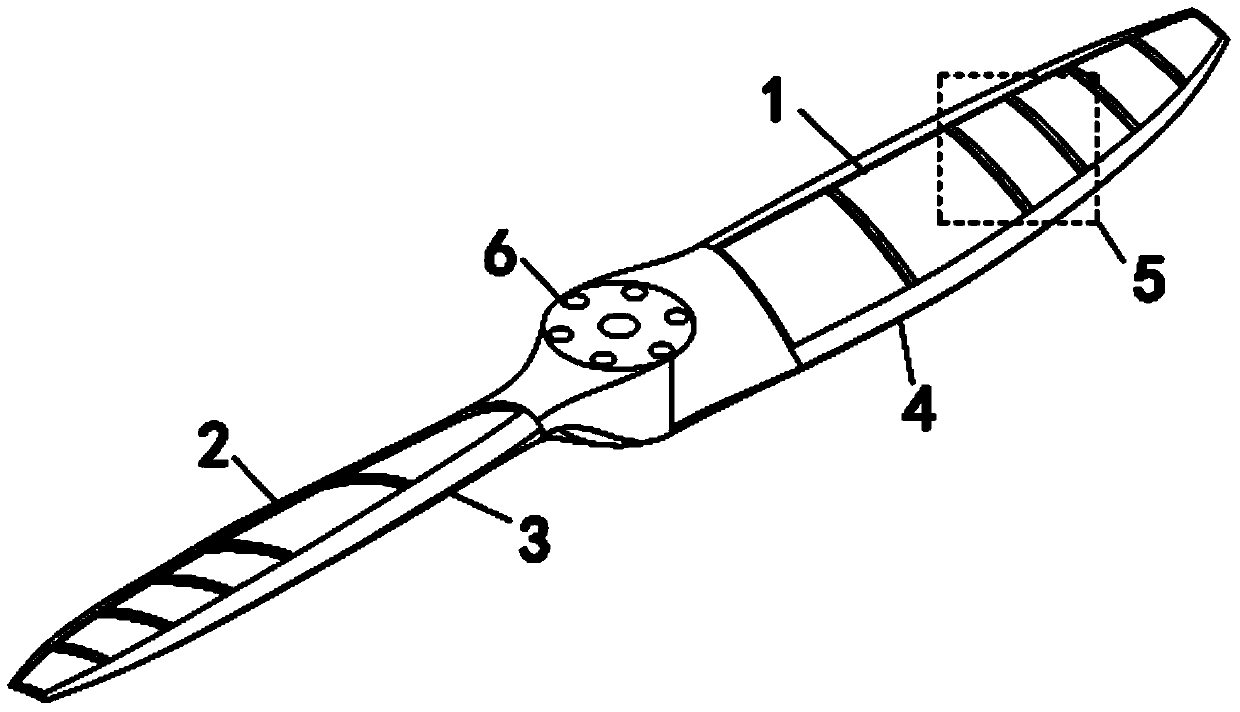

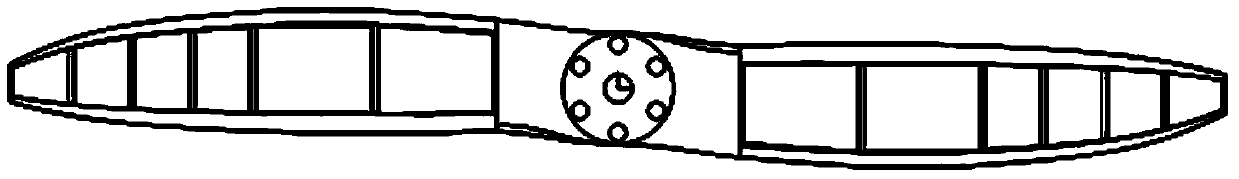

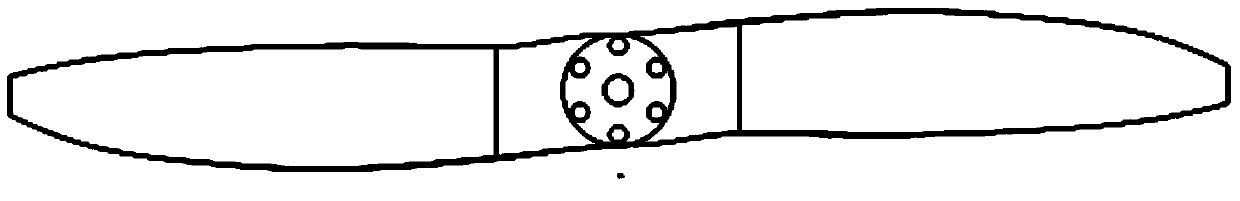

[0061] like figure 1 As shown, it is a three-dimensional view of high-altitude propeller cooperative jet efficient aerodynamic layout configuration; as figure 2 As shown, it is the main figure of high-altitude propeller cooperative jet efficient aerodynamic layout configuration; image 3 As shown, it is the rear body diagram of the high-altitude propeller cooperative jet efficient aerodynamic layout configuration; Figure 4 for figure 1 A partial enlarged view of the middle 5 area; Figure 5 for figure 2 Sectional view of the internal structure and schematic diagram of airflow circulation; the propeller includes blades, blade leading edge 3, blade trailing edge 4, hub and mounting holes 6; the coordinated jet device includes a coordinated jet blowing port 1 and a coordinated jet suction port 2 ,...

Embodiment 2

[0069] This embodiment provides a high-altitude propeller cooperative jet aerodynamic layout configuration installed on the propulsion system of a 28km high-altitude aircraft. Among them, the propeller includes a blade, a blade leading edge 3, a blade trailing edge 4, a hub and a mounting hole 6; the coordinated jet device includes a coordinated jet blowing port 1, a coordinated jet suction port 2, a coordinated jet internal pipe 8, and a coordinated jet flow device. Jet internal air pump7.

[0070] The blade diameter of the high-altitude propeller coordinated jet aerodynamic layout configuration in this embodiment is 2.2 m, and the number of blades is 2. Considering the structural weight, aerodynamic efficiency and aerodynamic requirements, the arrangement interval of the cooperative jet device along the span of the blade is 30% R-90% R (R is the radius of the blade), in order to obtain the best comprehensive performance.

[0071] like figure 1 As shown in Fig. 1, the coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com